Patents

Literature

30results about How to "Easy to process separately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining lathe for bearing rings

ActiveCN110076352AEasy to process separatelyReduce workloadTurning machinesMetal working apparatusEngineeringMechanical engineering

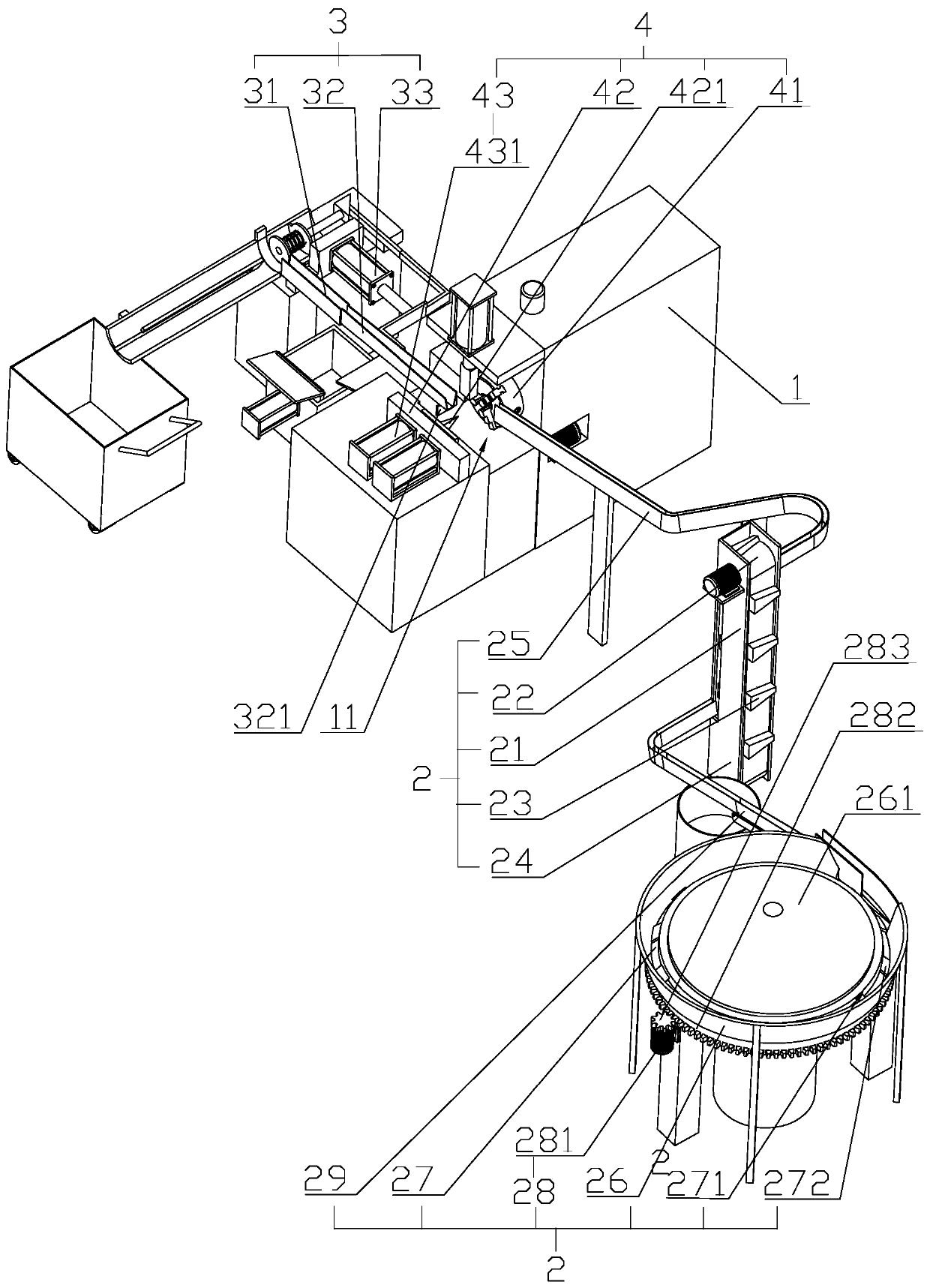

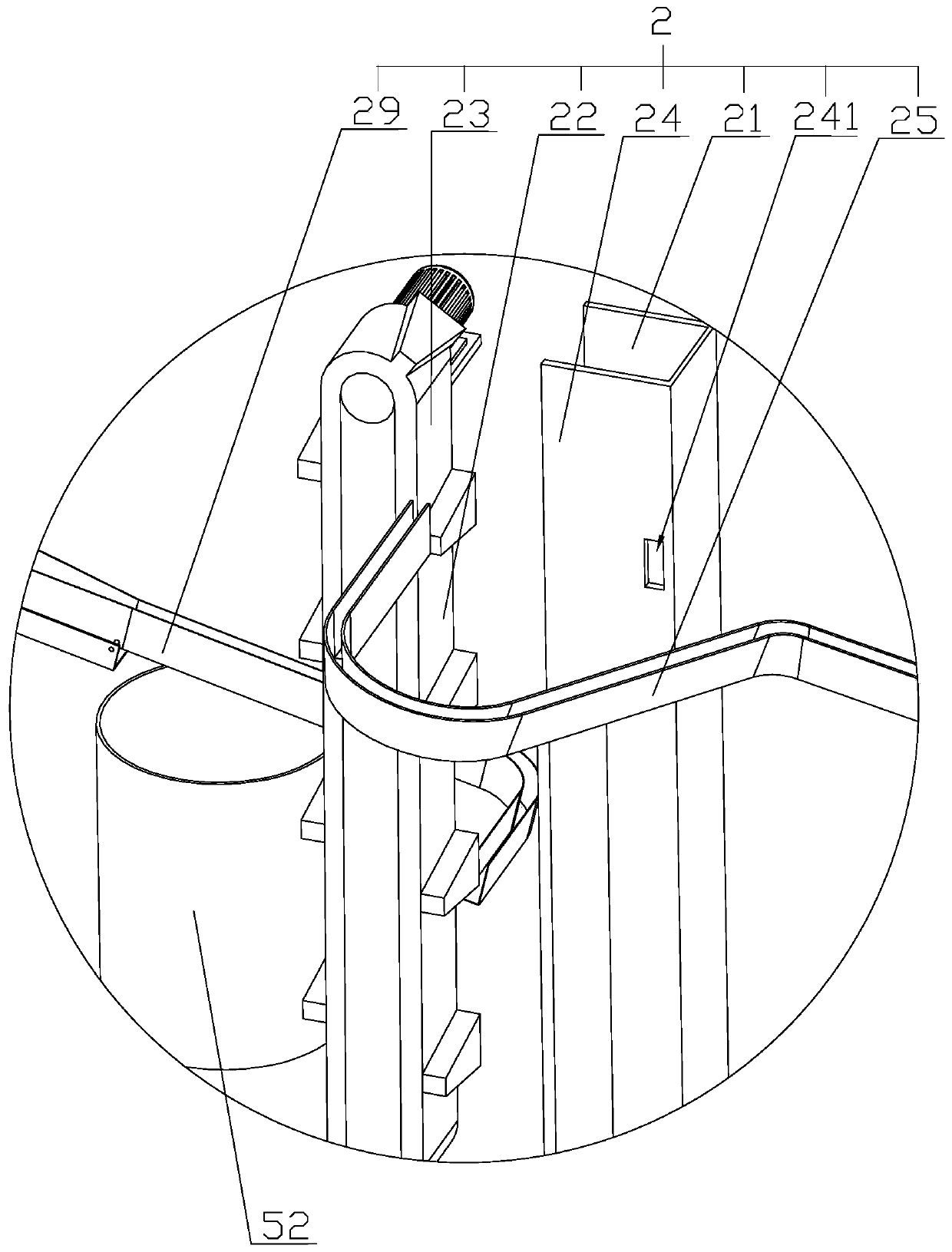

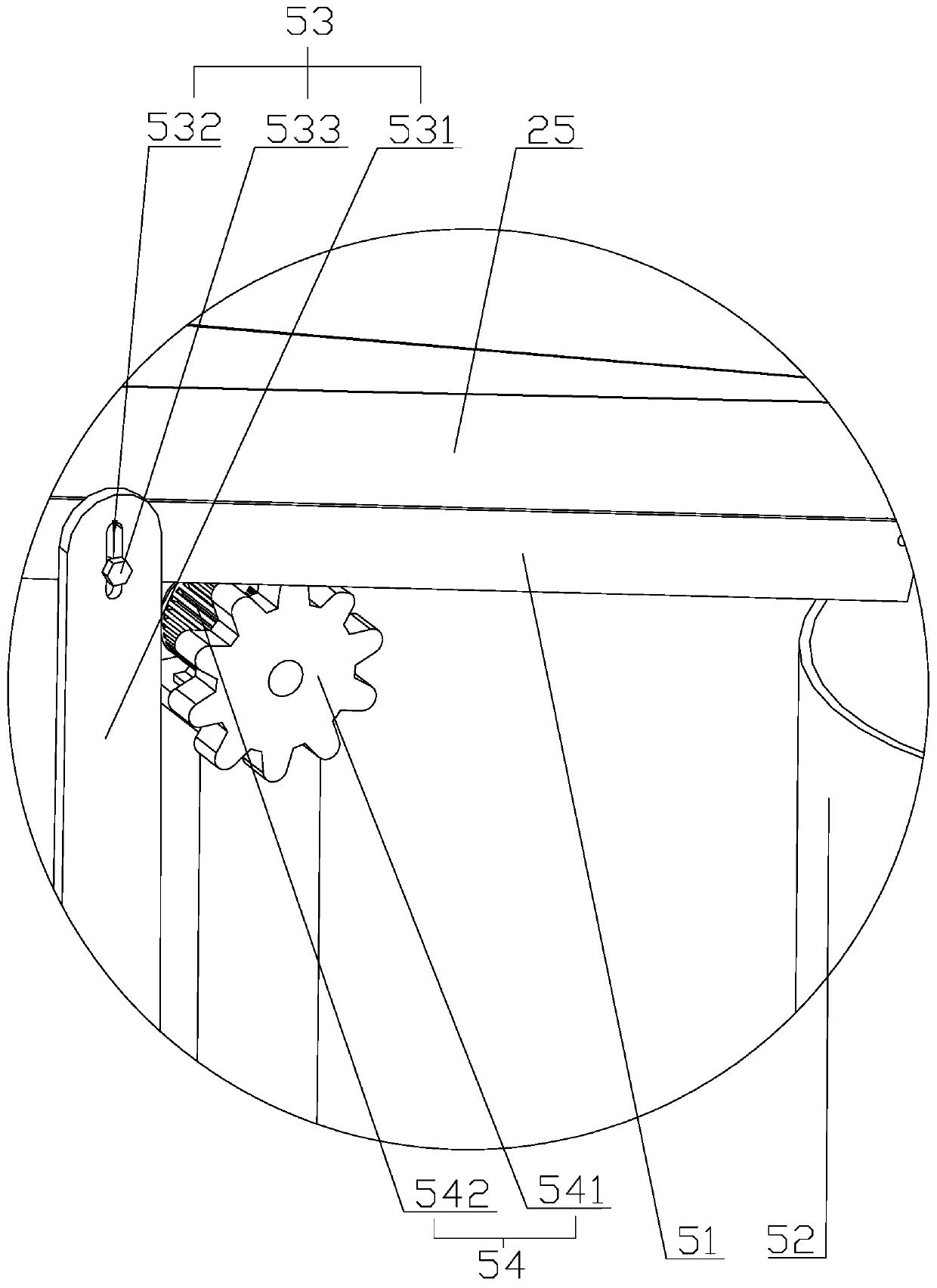

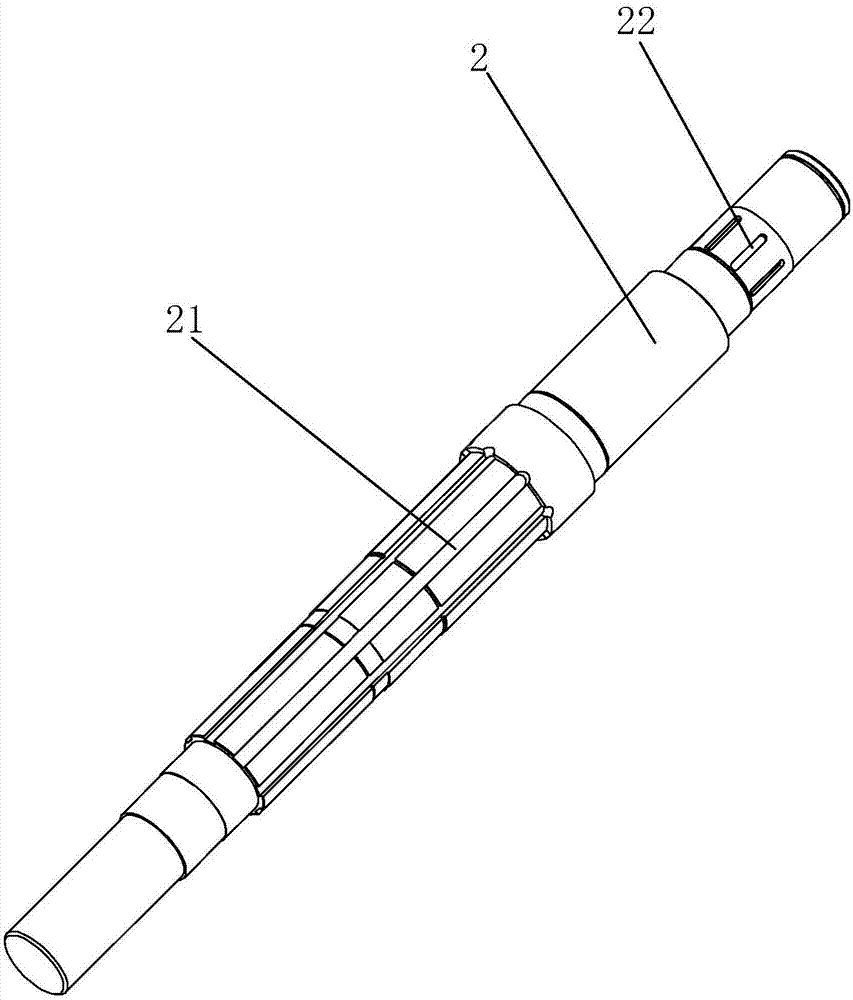

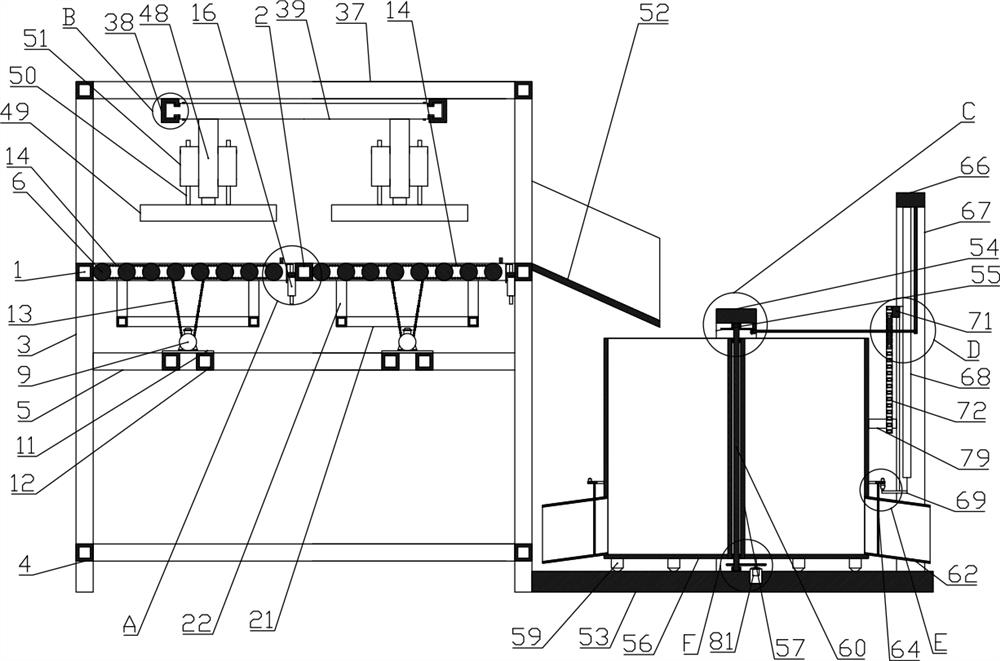

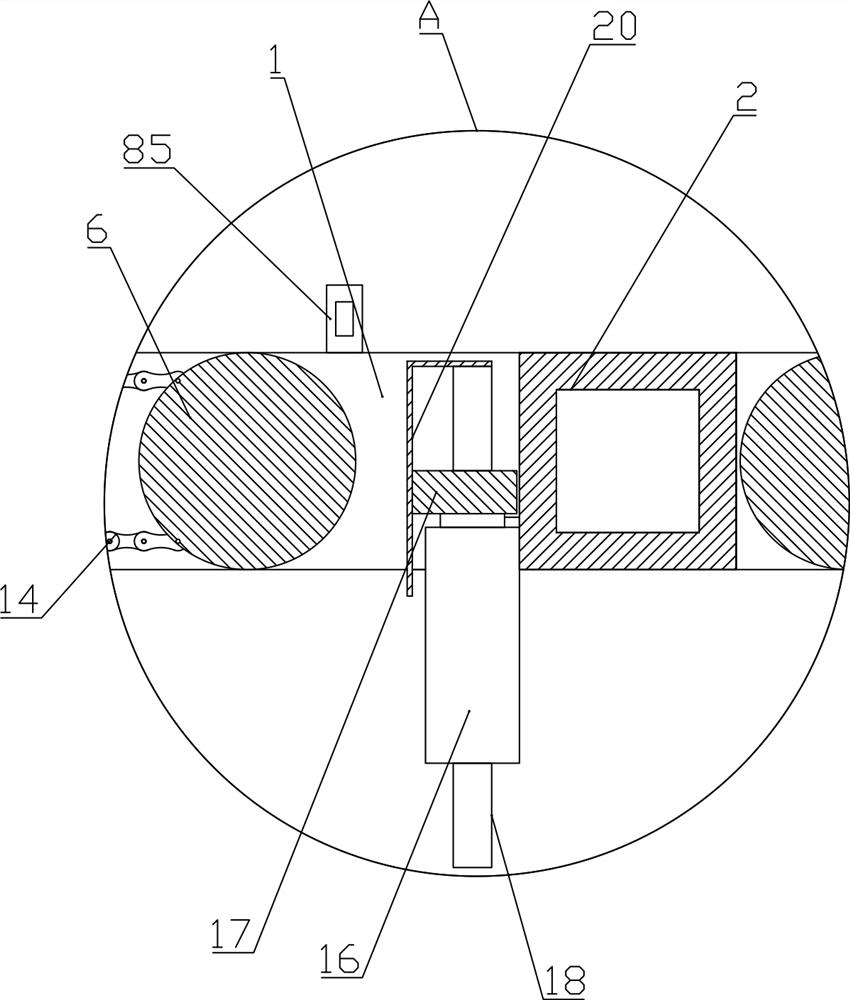

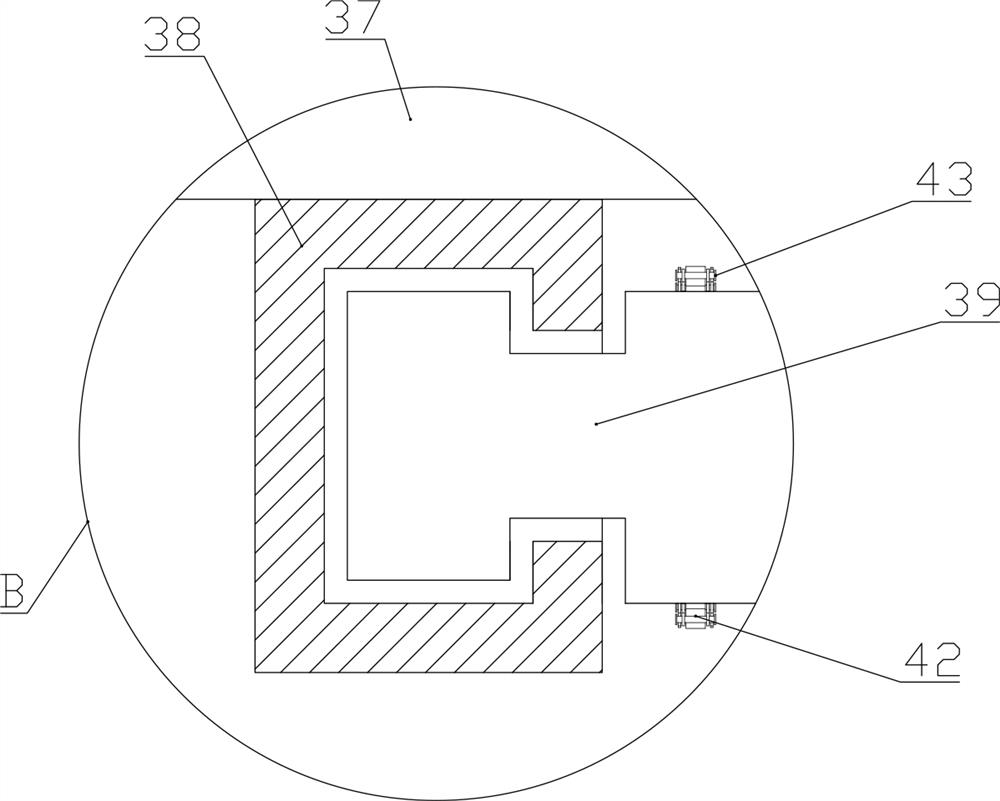

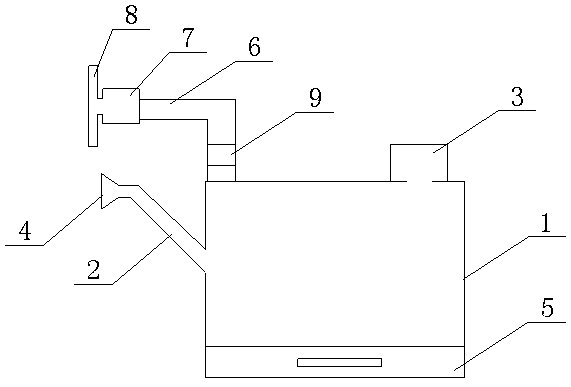

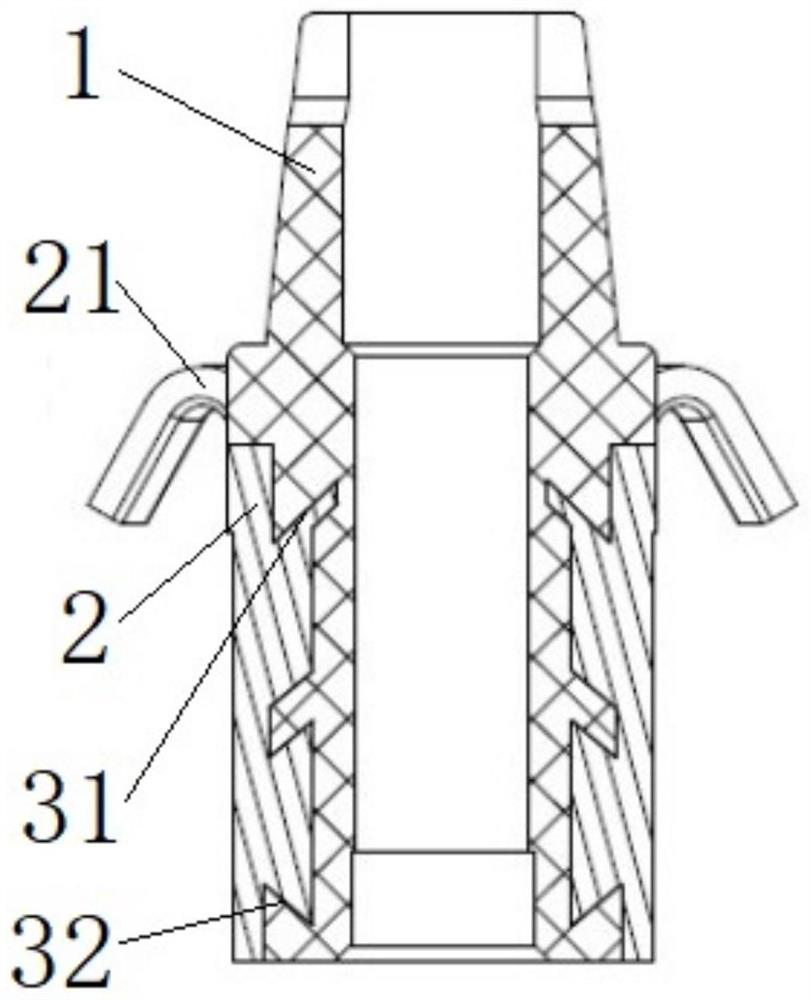

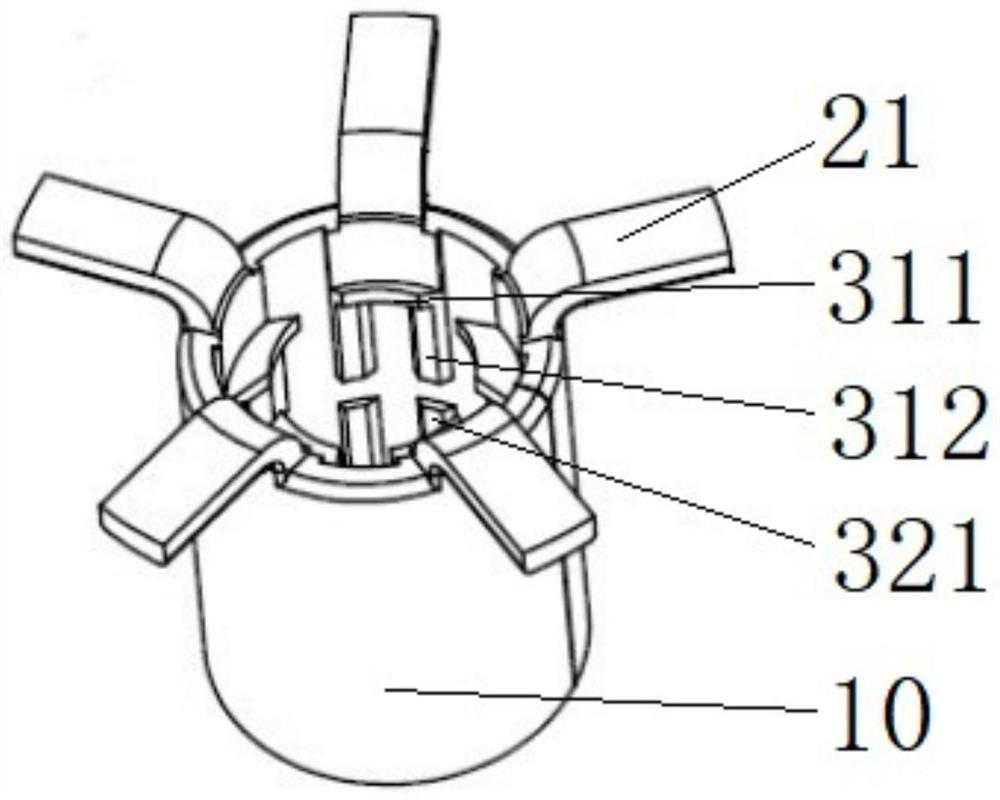

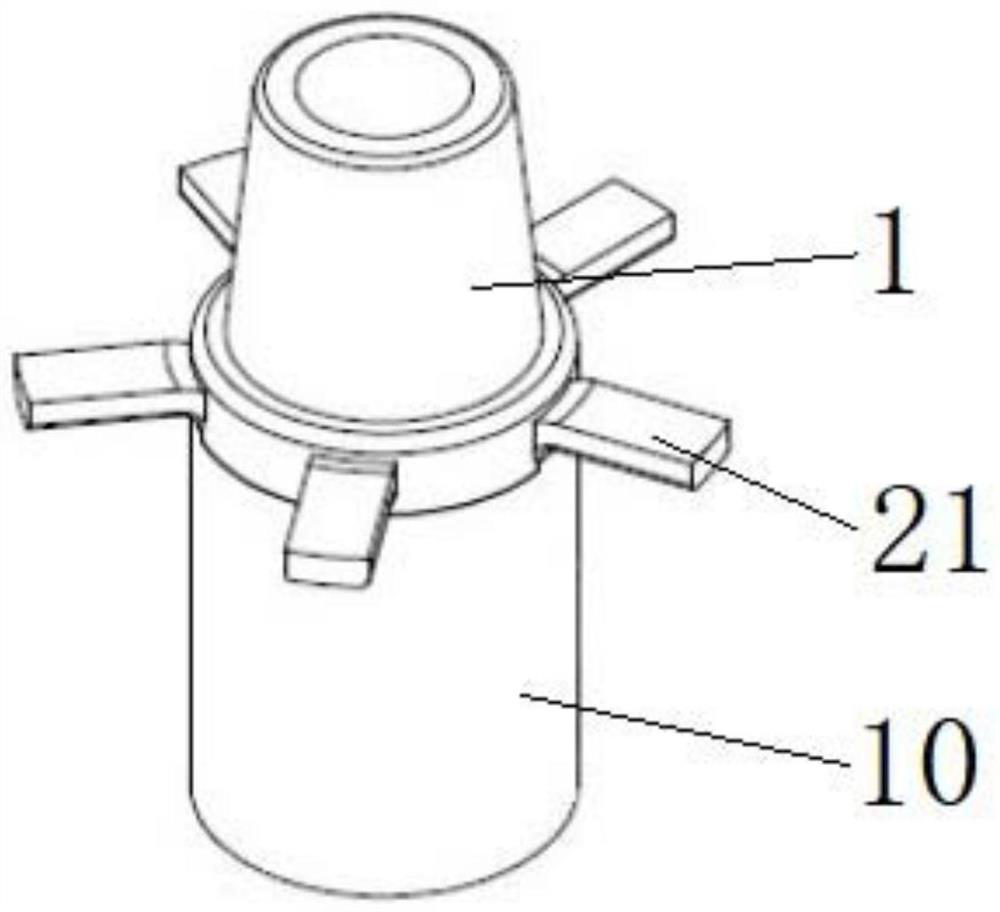

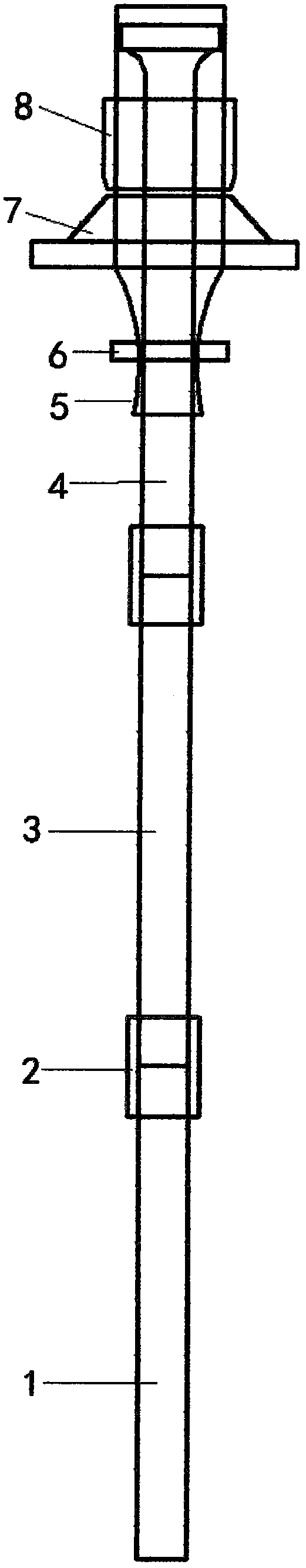

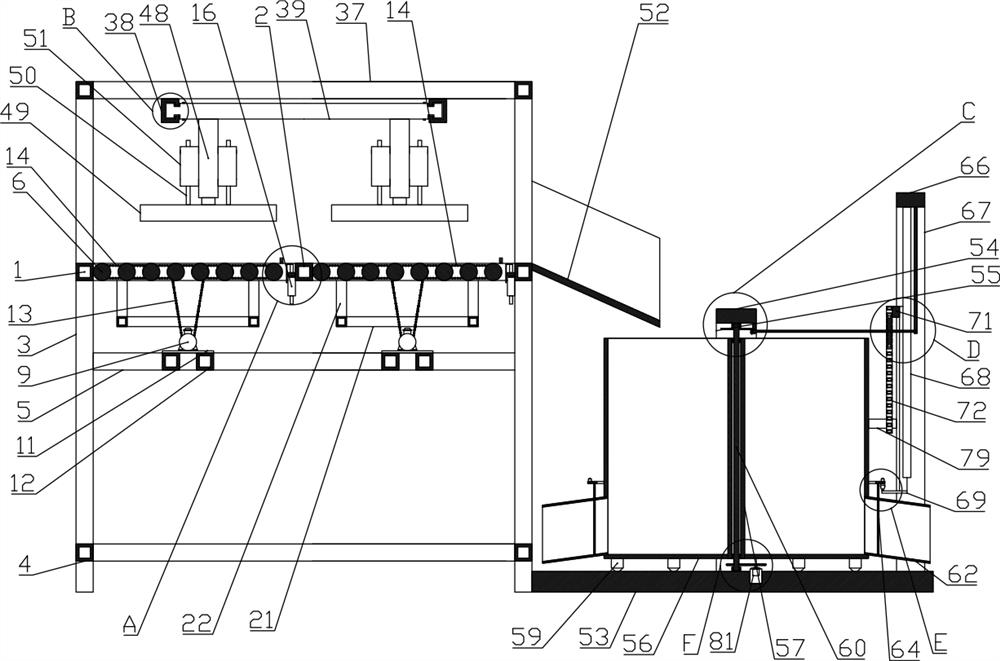

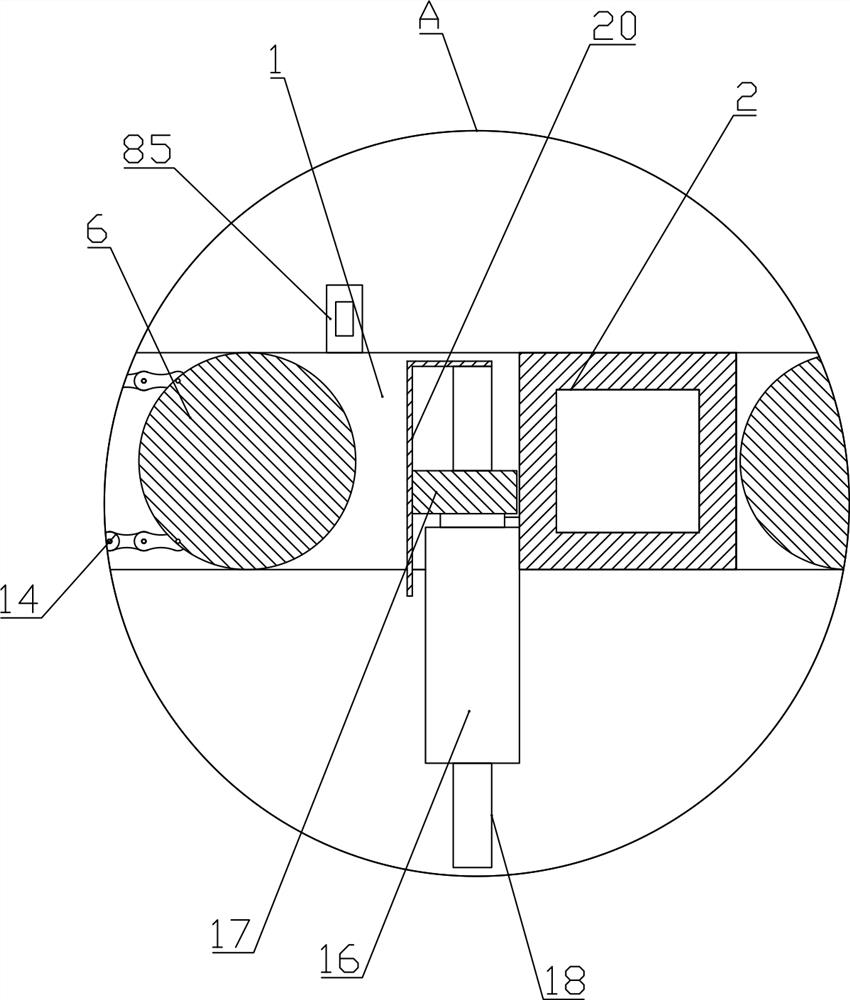

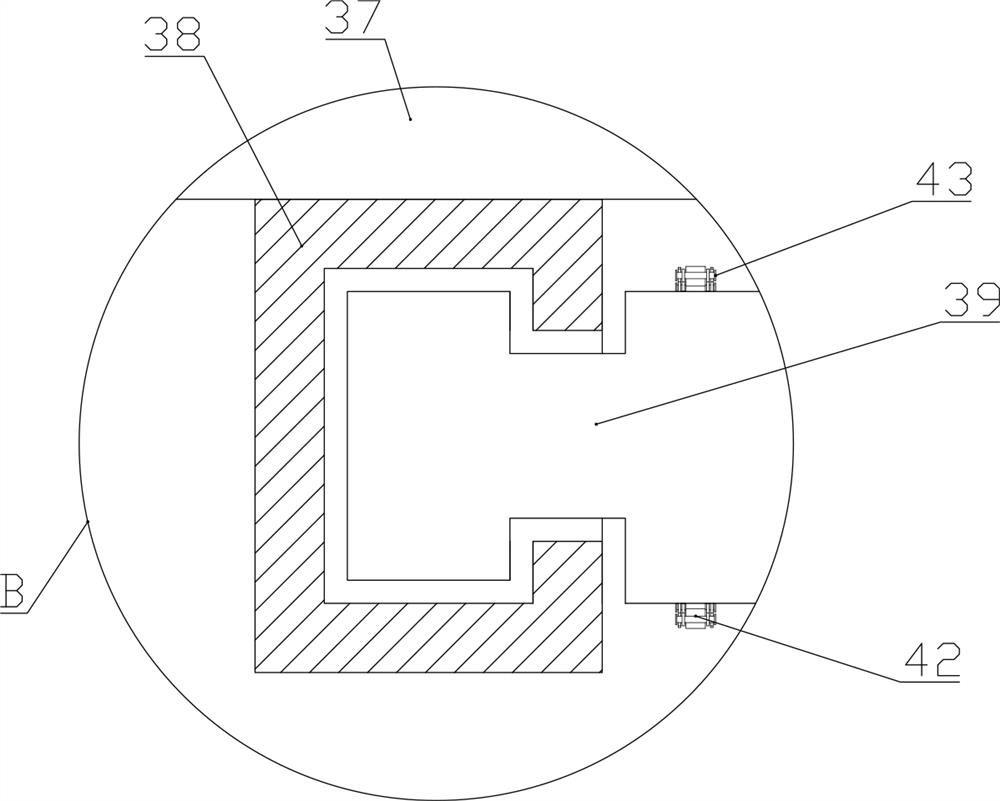

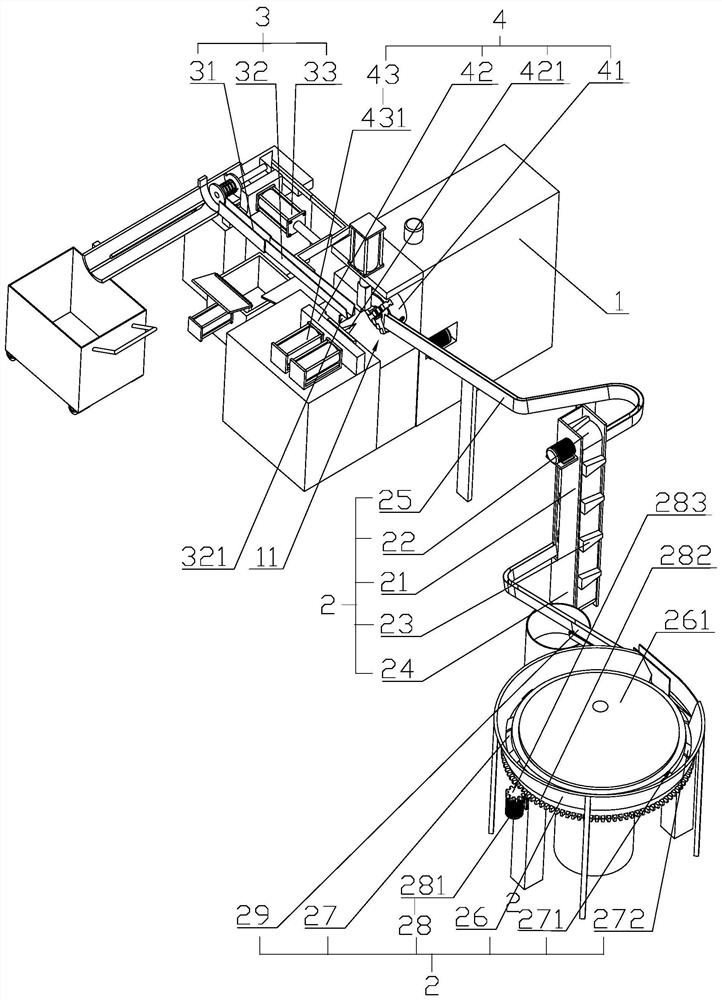

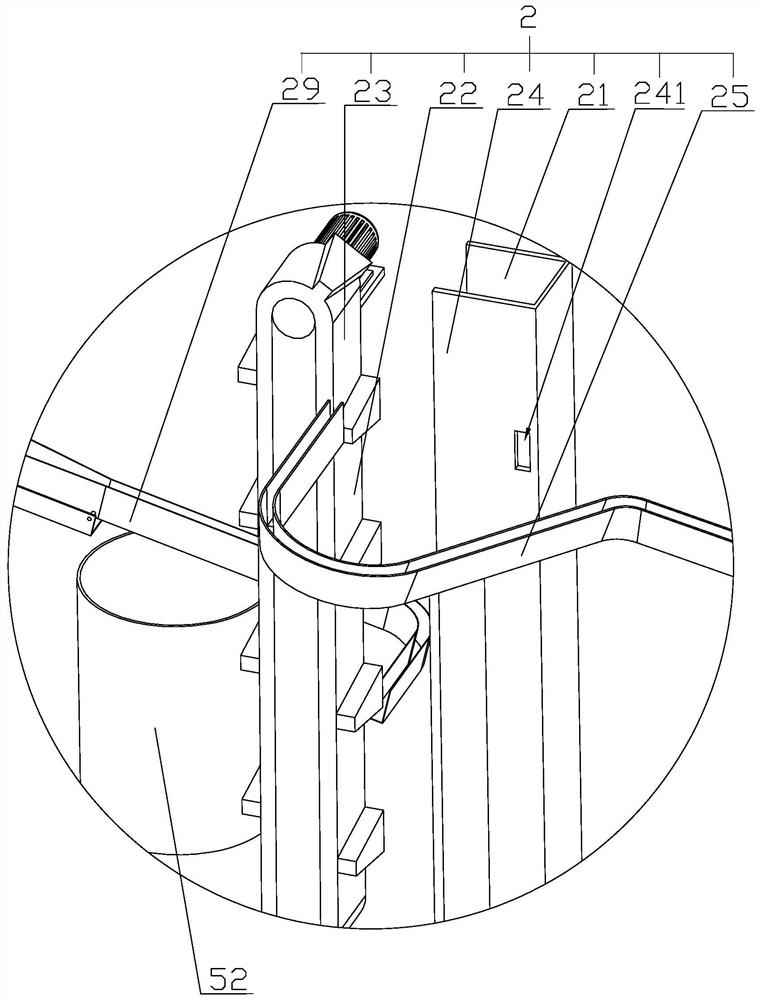

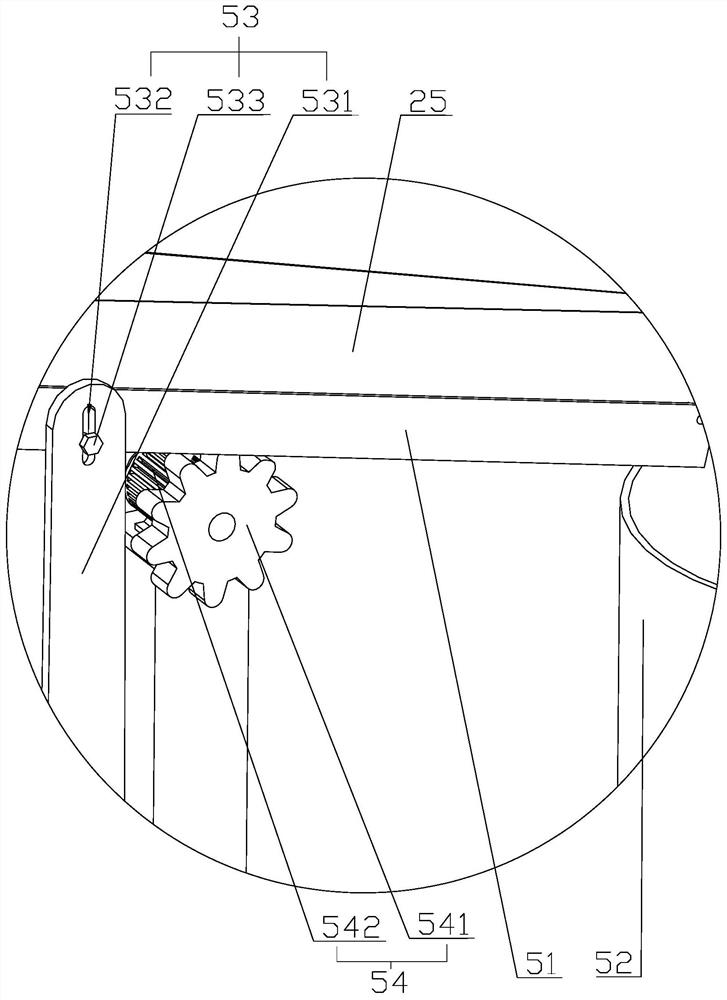

The invention relates to a machining lathe for bearing rings, and relates to the technical field of bearing machining equipment. The machining lathe comprises a machine body and further comprises a feeding mechanism, a cutting mechanism and a discharging mechanism. The feeding mechanism, the cutting equipment and the discharging mechanism are sequentially arranged on the machine body in the conveying direction of the bearing rings. The feeding mechanism comprises a screening basin, a conical unloading plate arranged on the screening disc, boosting rings distributed in the circumferential direction of the unloading plate and rotationally connected with the screening basin, a drive part arranged on the machine body and used for driving the boosting rings to rotate, and a feeding pipe tangentto the peripheral side walls of the boosting rings and communicating with the boosting rings. One end of the feeding pipe communicates with a cutting lathe, the width of the feeding pipe is consistent with the heights of the bearing rings, ring slots communicating with the peripheral side walls are formed in the top faces of the boosting rings in the circumferential directions of the boosting rings, the bottom walls of the ring slots are inclined, and the inclined surfaces face the side away from the unloading plate. The machining lathe has the effect that feeding of the bearing rings is facilitated in order to improve the production efficiency.

Owner:XINCHANG COUNTY XINXIANGYU BEARING

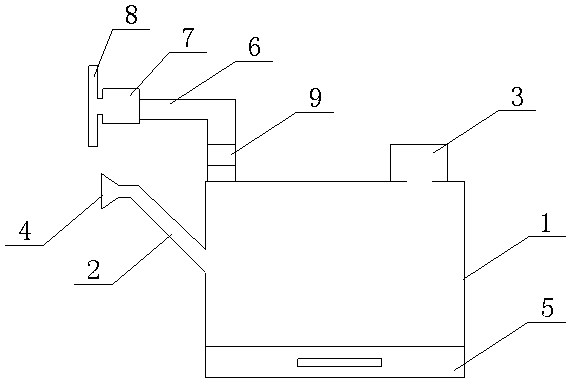

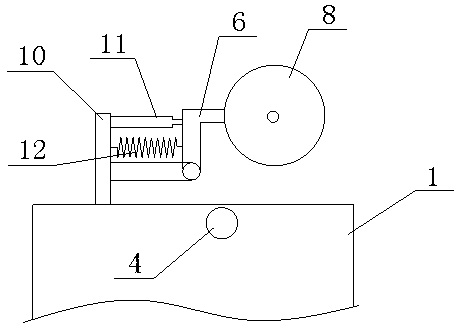

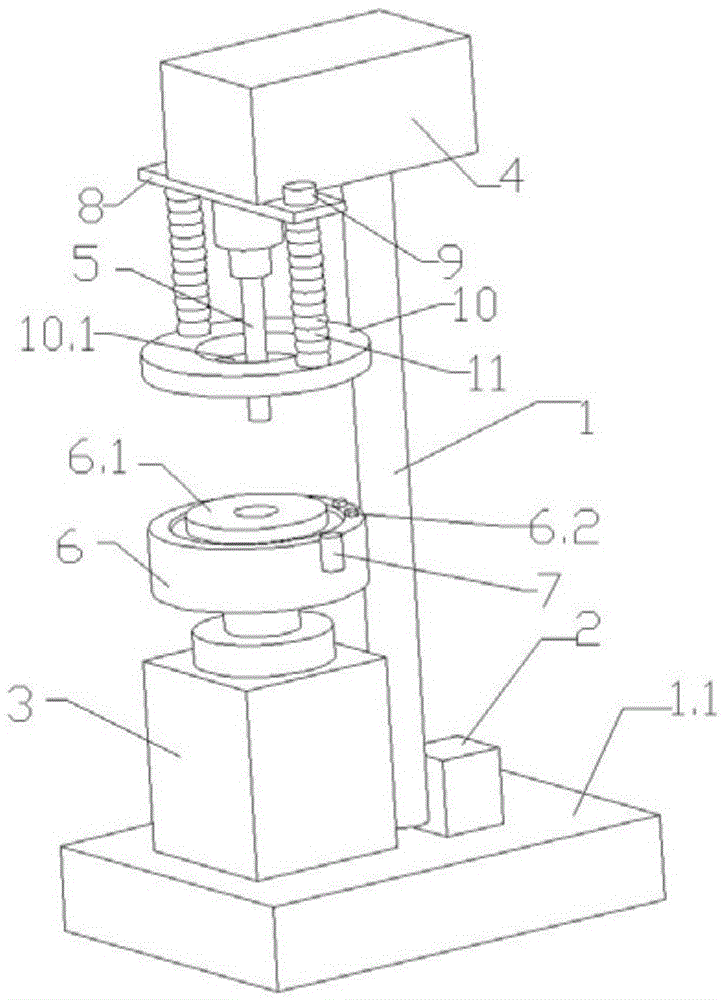

Automatic reaming machine

InactiveCN104070234ANo wasteAvoid compromising reaming qualityFeeding apparatusReaming devicesInductorEngineering

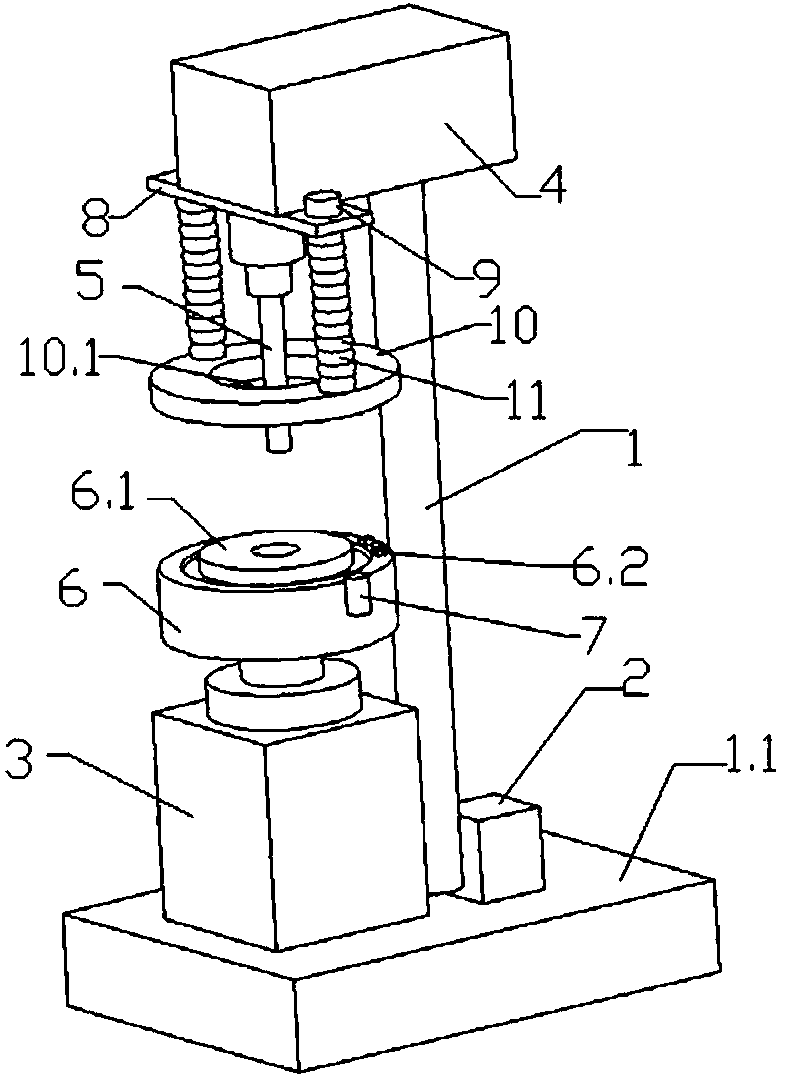

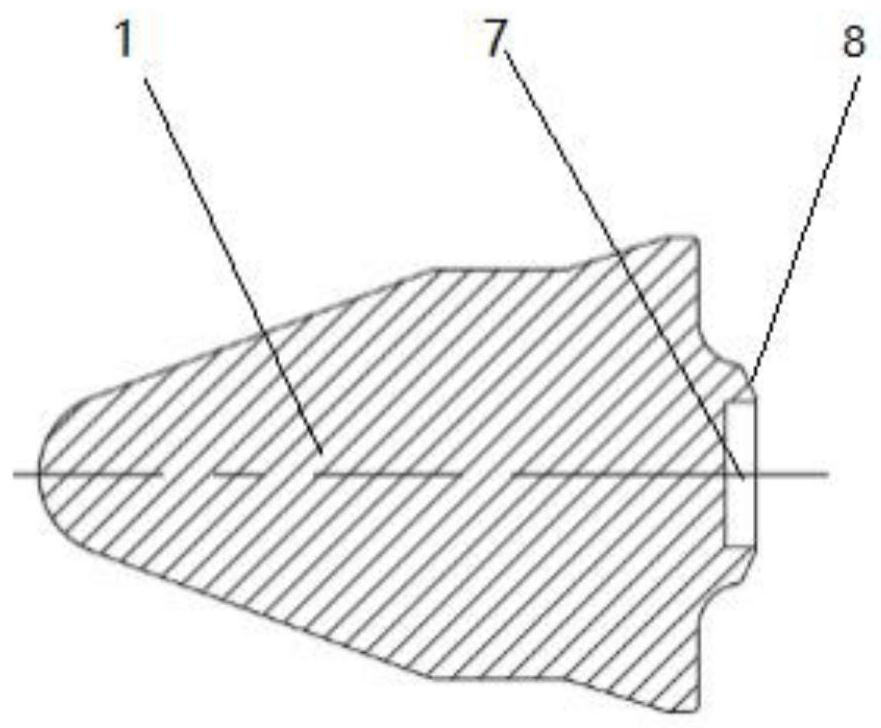

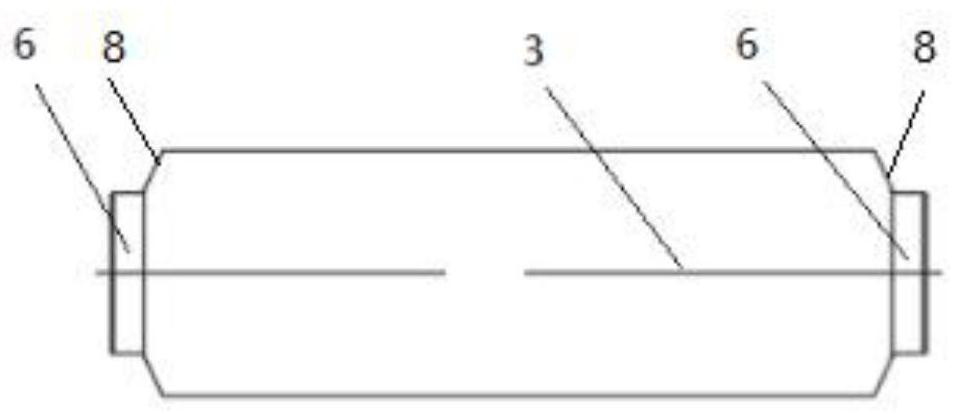

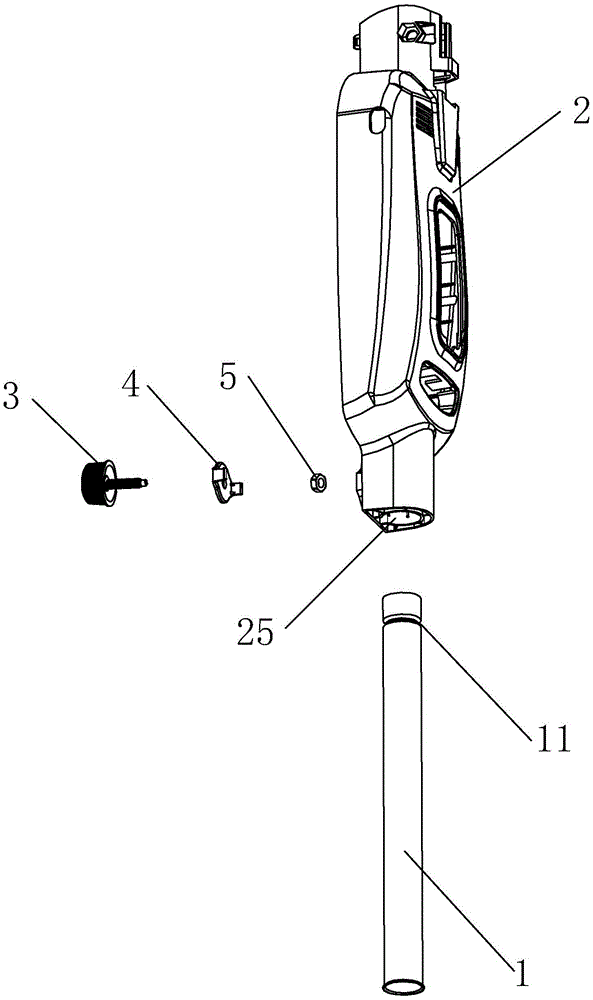

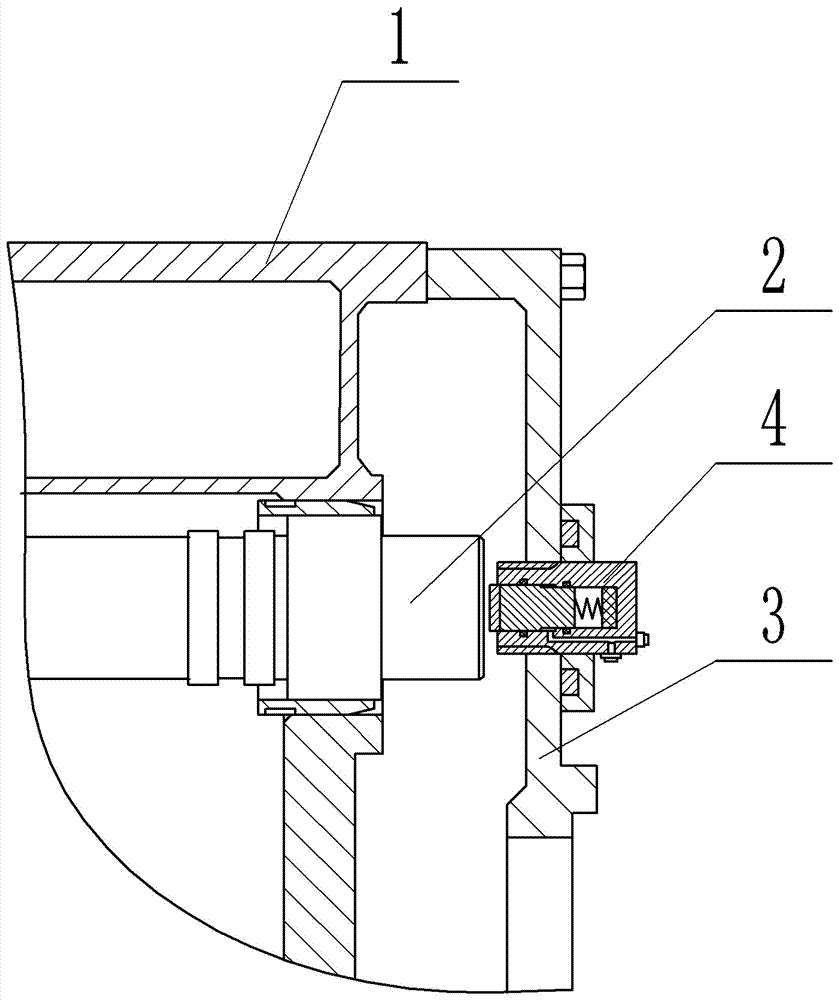

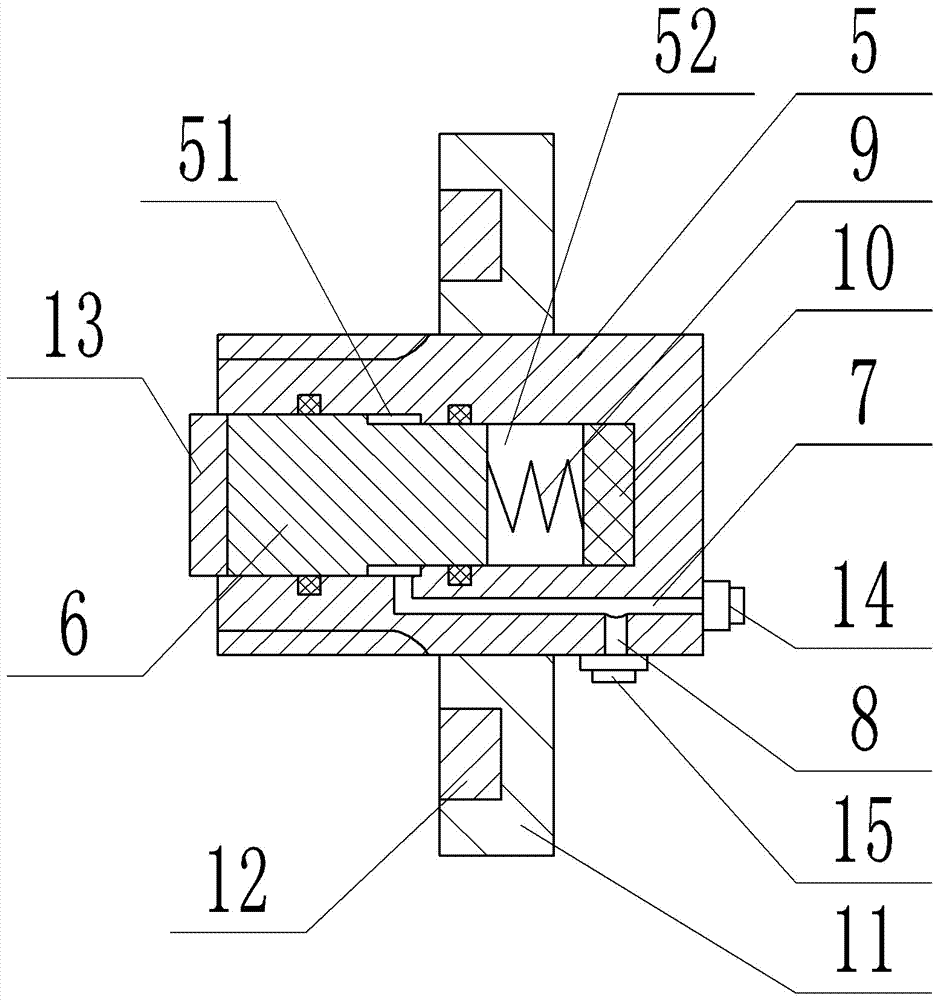

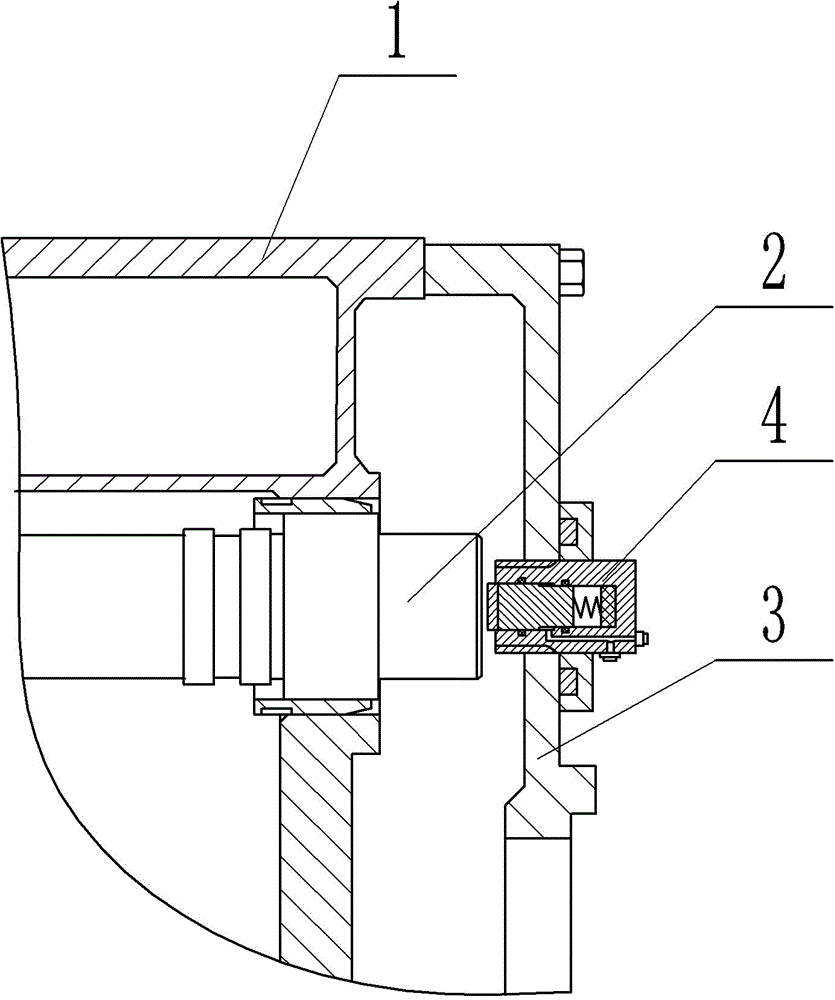

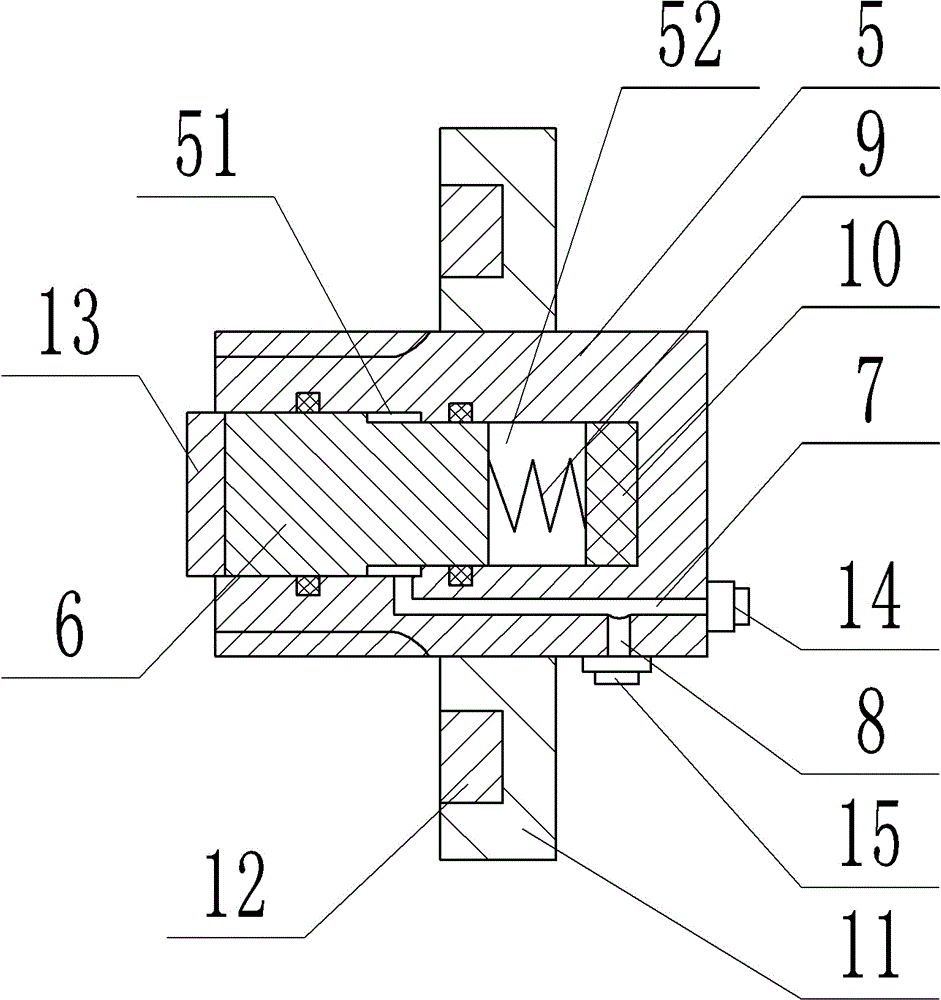

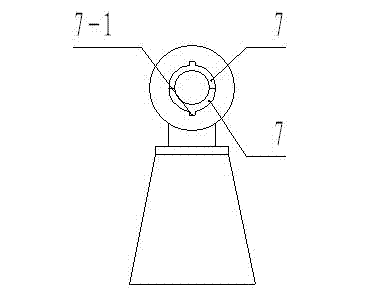

The invention discloses an automatic reaming machine. The automatic reaming machine comprises a rack (1), a controller (2), a cylinder (3) and a motor (4), wherein a reamer (5) is installed on a motor output shaft; a location seat (6) is installed on a cylinder piston rod; a location boss (6.1) is formed on the location seat (6); a limit block (6.2) is further arranged on the location seat (6); an inductor (7) used for inducting an aluminium freezing motor shell, and clamped and located on the location seat (6) is further installed on the location seat (6); the cylinder piston rod, the location seat (6), the motor output shaft and the reamer (5) are coaxially arranged; the cylinder (3), the motor (4) and the inductor (7) are electrically connected with the controller (2). The automatic reaming machine is high in automation degree, fast in reaming speed, high in efficiency, high in reaming quality, and relatively low in cost.

Owner:NINGBO LIONBALL VENTILATOR

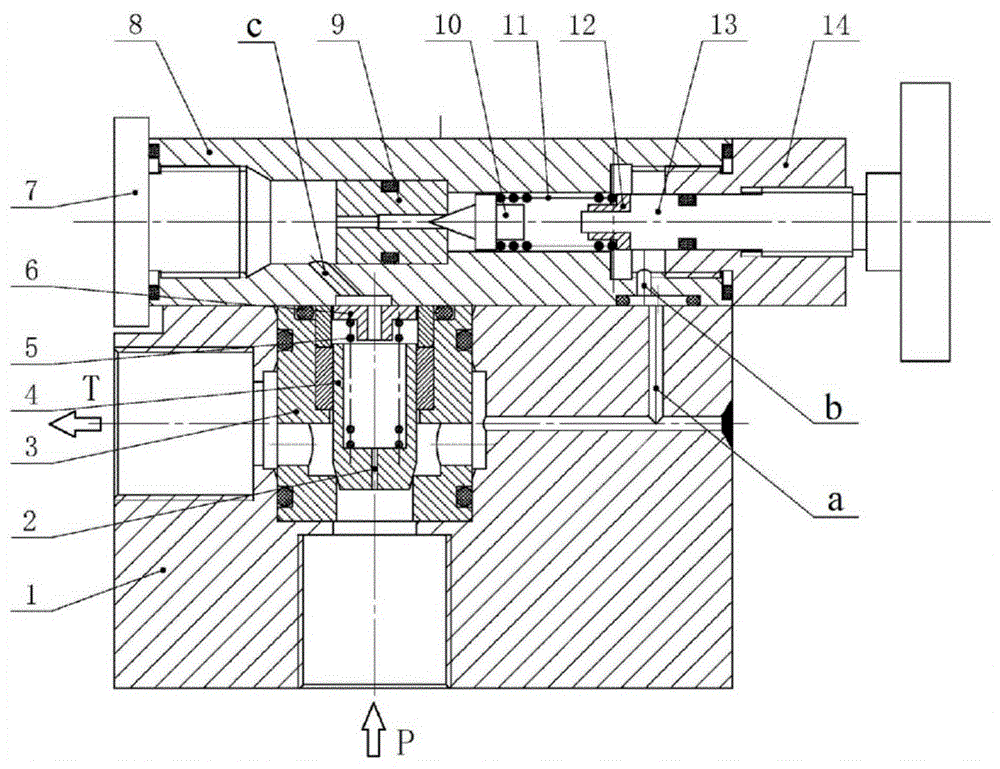

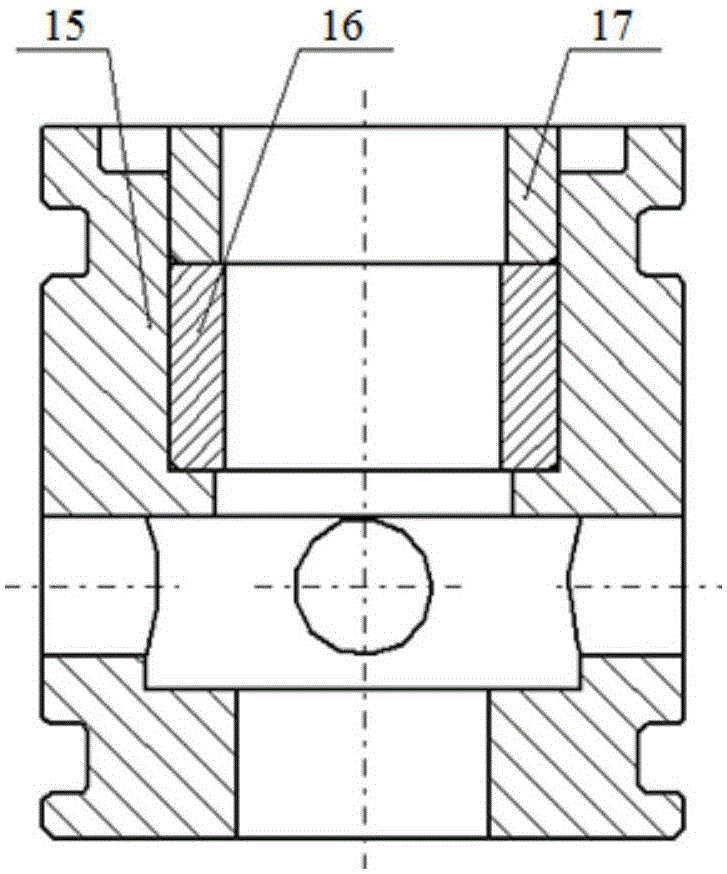

Pilot operated type overflow valve

The invention discloses a pilot operated type overflow valve which comprises a main valve and a pilot valve, wherein the main valve comprises a main valve body, a main valve sleeve assembly and a main valve core; the main valve sleeve assembly comprises a main valve seat, a main valve sleeve and a main valve spacer sleeve, which are arranged in the main valve body; the main valve sleeve and the main valve spacer sleeve are arranged in the inner hole of the main valve seat and are in interference fit with the inner hole of the main valve seat; the main valve sleeve is axially positioned through a step surface on the main valve seat and the lower end surface of the main valve spacer sleeve; and the main valve core is arranged in the main valve sleeve and in clearance fit with the inner hole of the main valve sleeve. According to the pilot operated type overflow valve disclosed by the invention, separate processing of the main valve sleeve and the main valve seat is facilitated, the processing difficulty is reduced, and the overflow valve is enabled to have good whole processability and is low in cost; the main valve sleeve is made of natural bone material through machining and matched with the main valve core, and by using good water lubrication capability and impact resistance of the bone material, leakage is reduced while friction between the main valve core and the main valve sleeve is reduced, so that the purposes of improving static and dynamic properties of the overflow valve are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

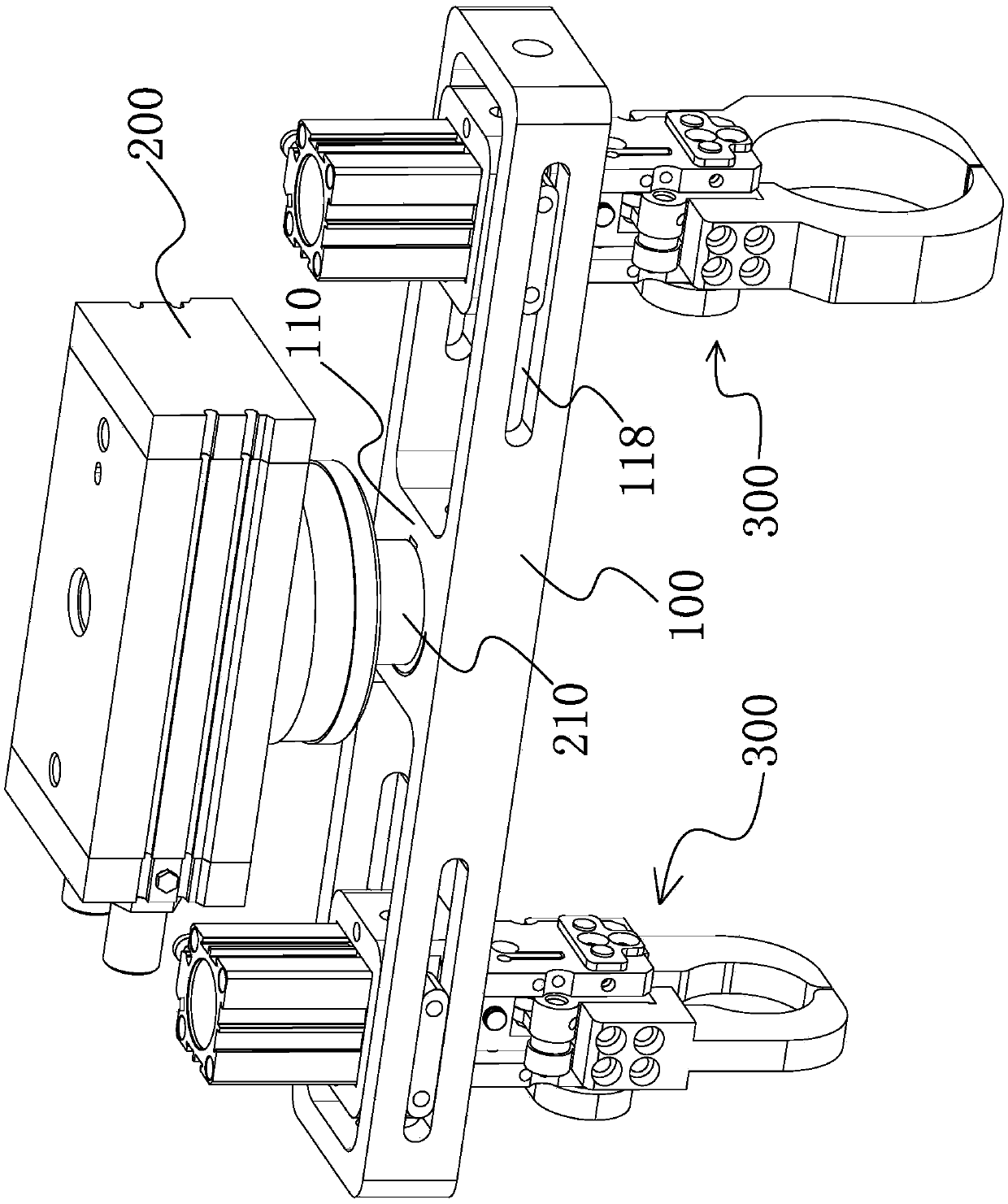

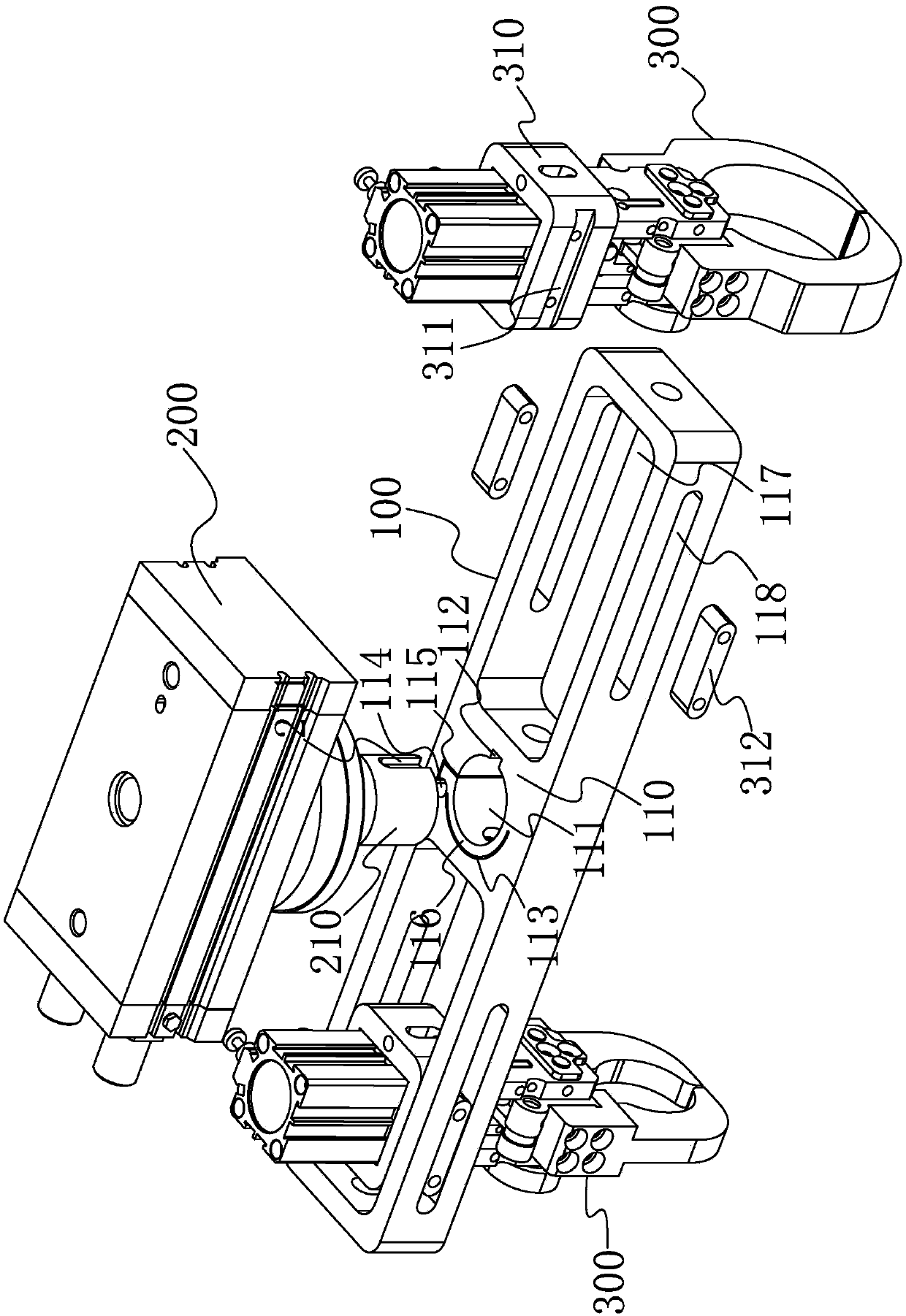

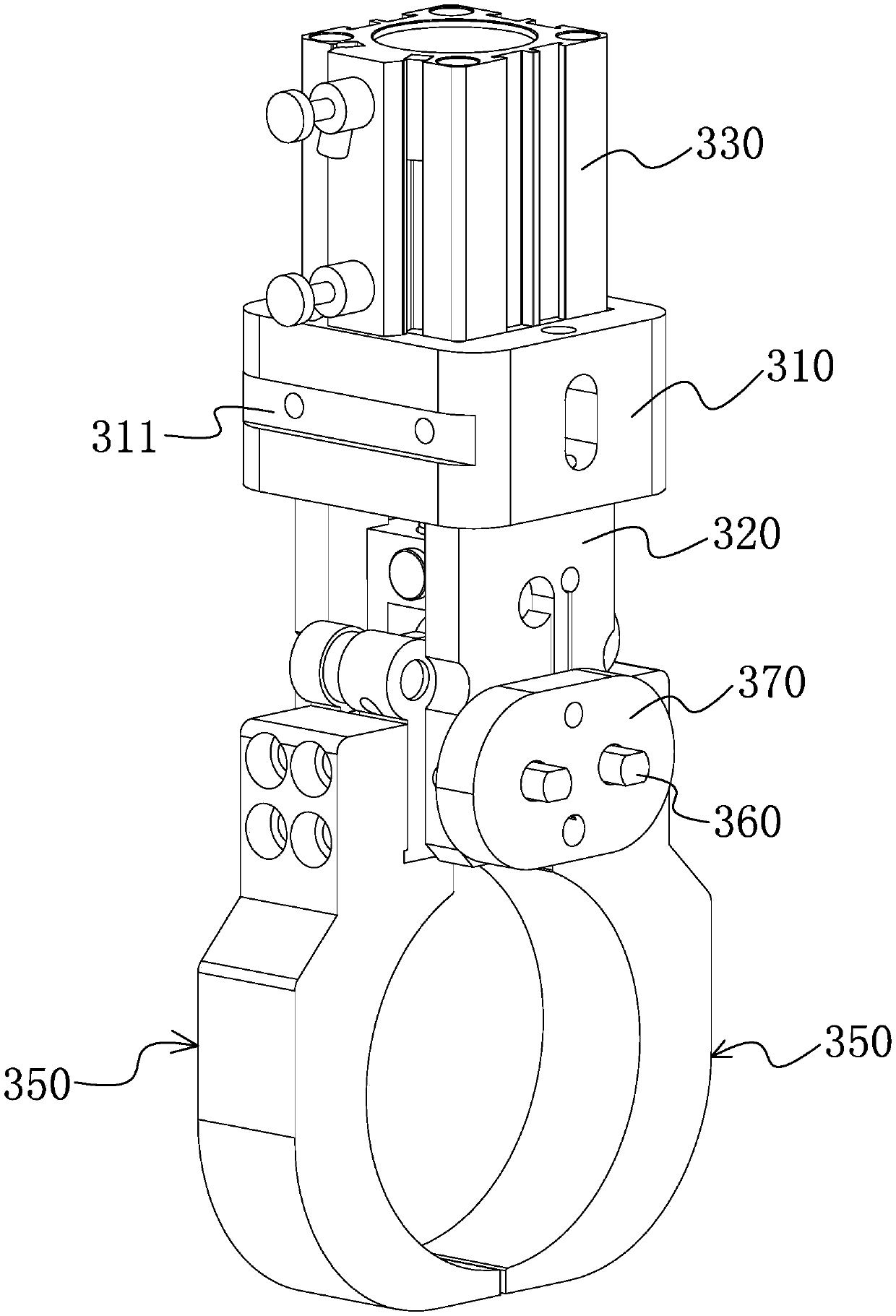

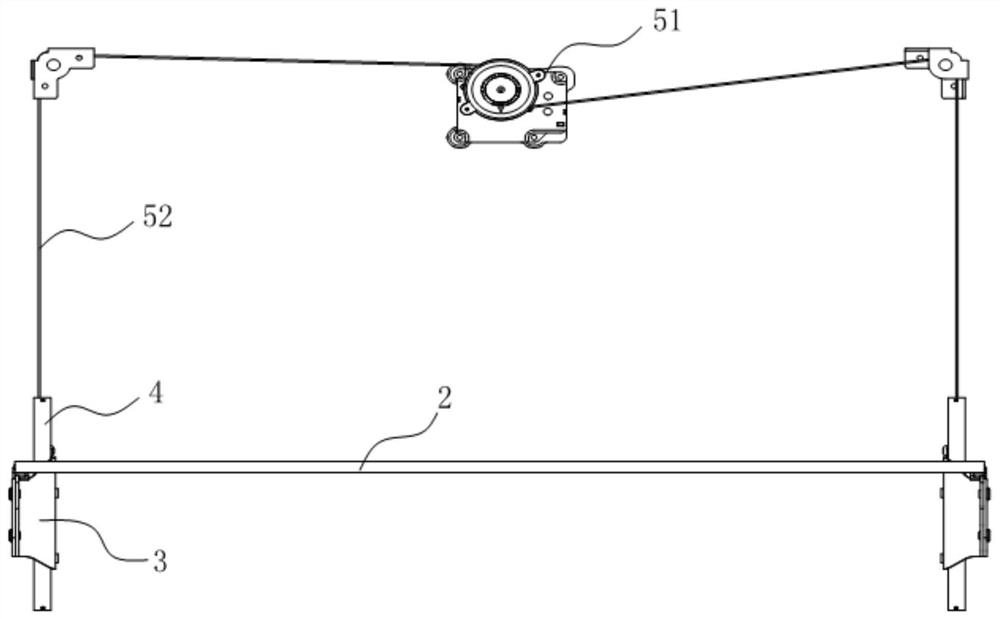

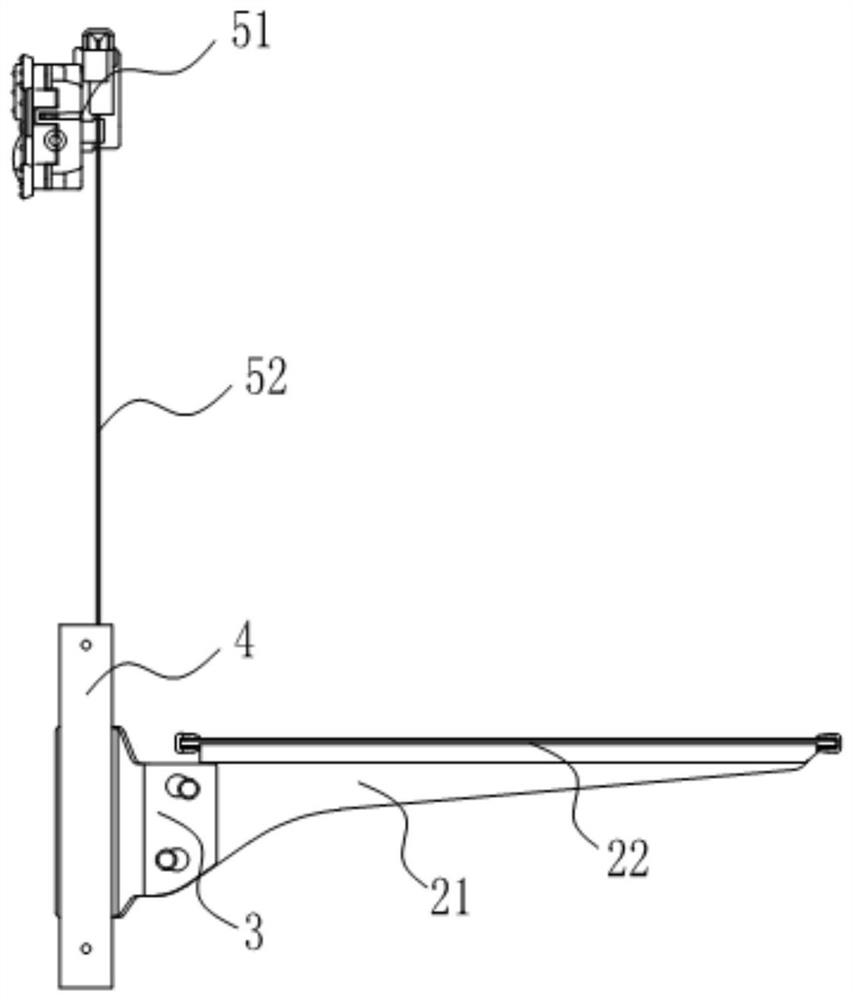

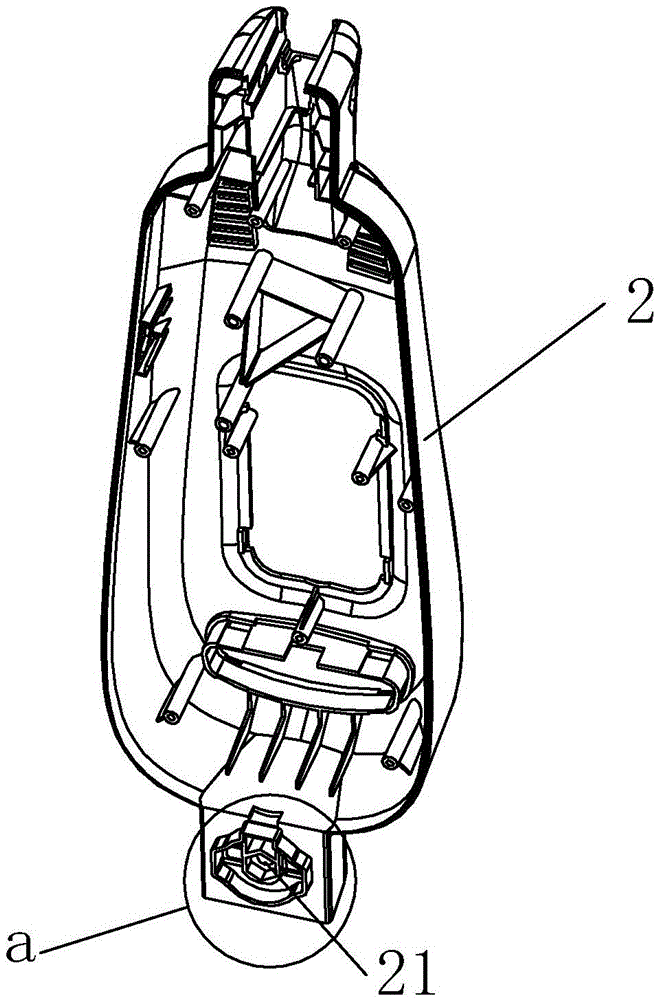

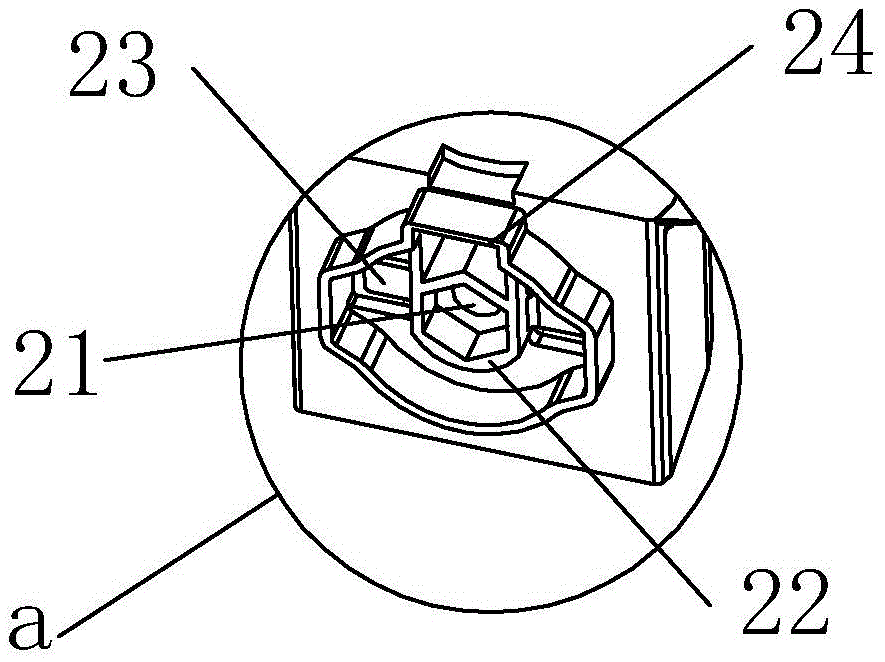

Rotatable mechanical gripper device

The invention provides a rotatable mechanical gripper device, and belongs to the technical field of mechanical grippers. The technical problem that an existing pneumatic gripper device cannot achievethe effect that two grippers are switched in the horizontal plane is solved. The rotatable mechanical gripper device comprises a machine frame, a rotation air cylinder and two mechanical grippers, wherein the machine frame is horizontally arranged; an output shaft of the rotation air cylinder is fixedly connected with the middle of the machine frame; the two mechanical grippers are movably connected with the two ends of the machine frame, are coaxially arranged and can clamp and place workpieces; the rotation air cylinder can drive the machine frame to horizontally rotate within the preset angle, and the two mechanical grippers can synchronously move along with rotation of the machine frame; and the two mechanical grippers are simultaneously installed on the horizontally-arranged machine frame, the machine frame is driven to rotate through the rotation air cylinder, then, switching of the two mechanical grippers in the horizontal direction can be achieved, and accordingly, workpieces can be rotated in the horizontal direction.

Owner:宁波开浦智能科技有限公司

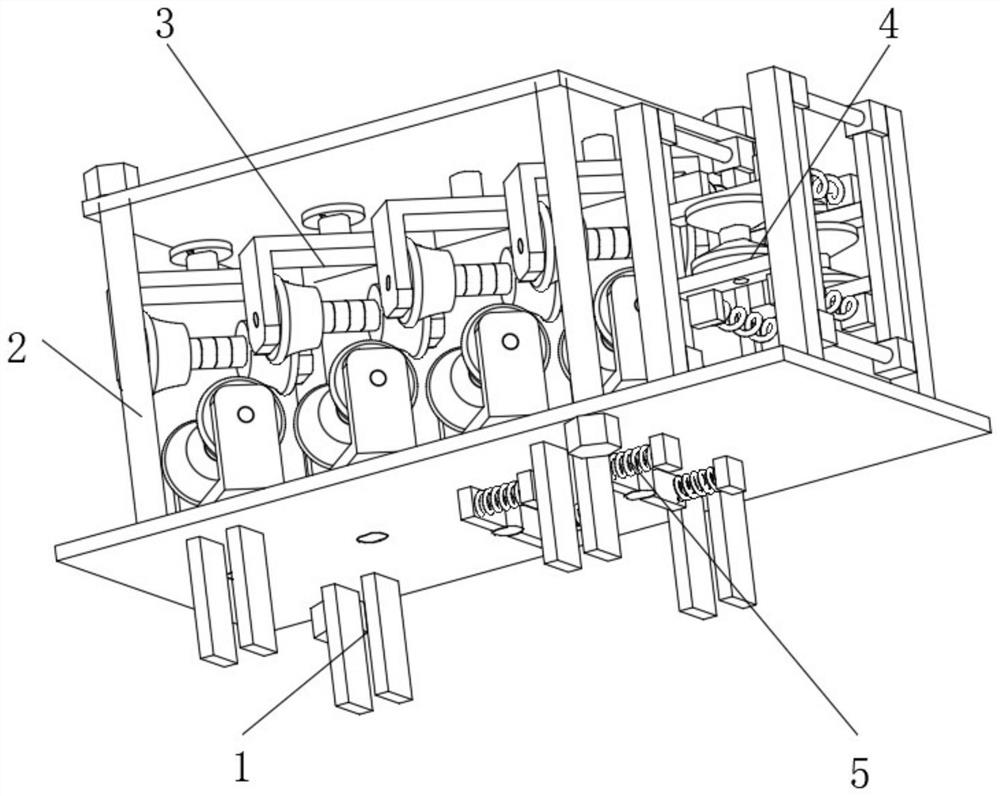

Combined steel pipe straightening roller and straightening device thereof

InactiveCN112090997AExpand the scope ofEasy to process separatelyMetal-working feeding devicesPositioning devicesSteel tubePipe

The invention discloses a combined steel pipe straightening roller and a straightening device thereof, and relates to the technical field of steel pipe straightening. The invention aims to solve the problem of range adjustability. The combined type steel pipe straightening roller specifically comprises an adjustable frame structure fixed to the ground through supporting legs, the adjustable framestructure comprises a base and a top plate, first screws are connected to the inner walls of the opposite corners of the top plate through threads, and second screws are rotatably connected to the inner walls of the other opposite corners of the top plate; and the inner walls of the bottoms of the first screws make contact with the outer portion of the top of the base. According to the combined steel pipe straightening roller and the straightening device thereof, by hyperbolic surface structures of first roller blocks and second roller blocks, the range of the pipe diameter of a straightened steel pipe can be guaranteed; and adjusting cushion blocks are arranged between the first roller blocks and the second roller blocks, and the distances between the first roller blocks and the second roller blocks can be adjusted by adjusting the number of the adjusting cushion blocks between the first roller blocks and the second roller blocks, so that the pipe diameter range of the straightened steel pipe is changed, and the range of the straightened steel pipe is expanded.

Owner:杭州嘉威机械配件有限公司

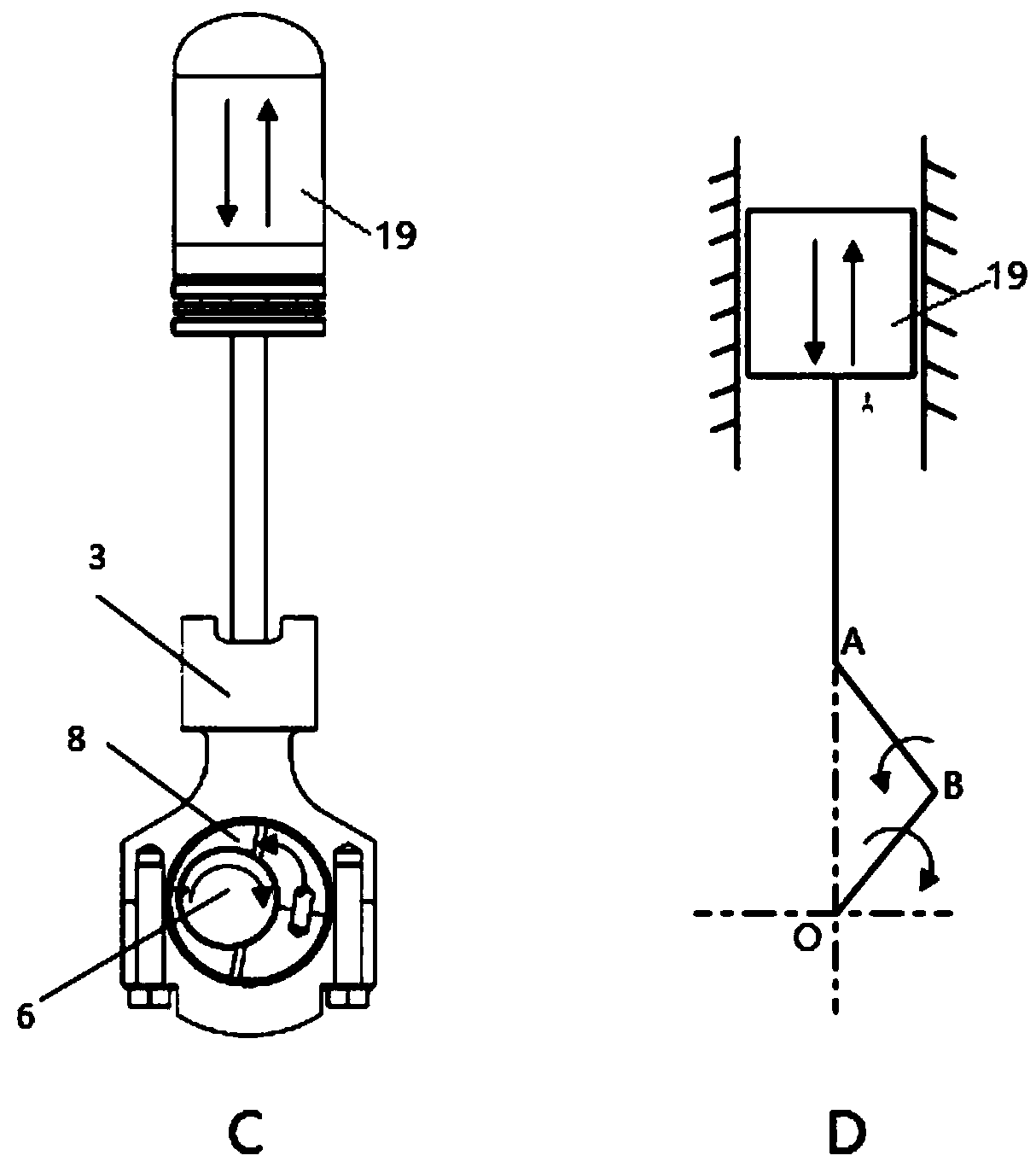

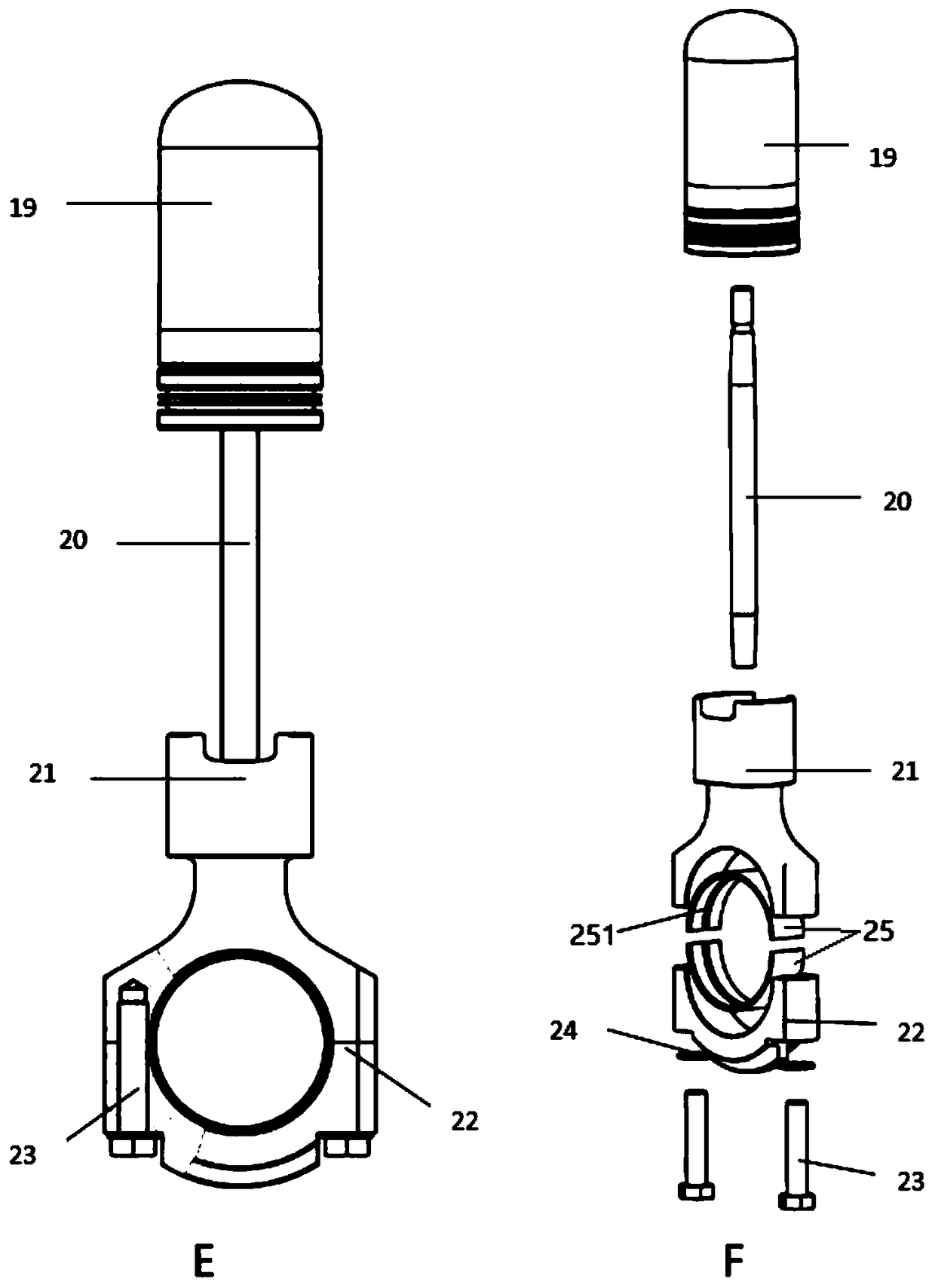

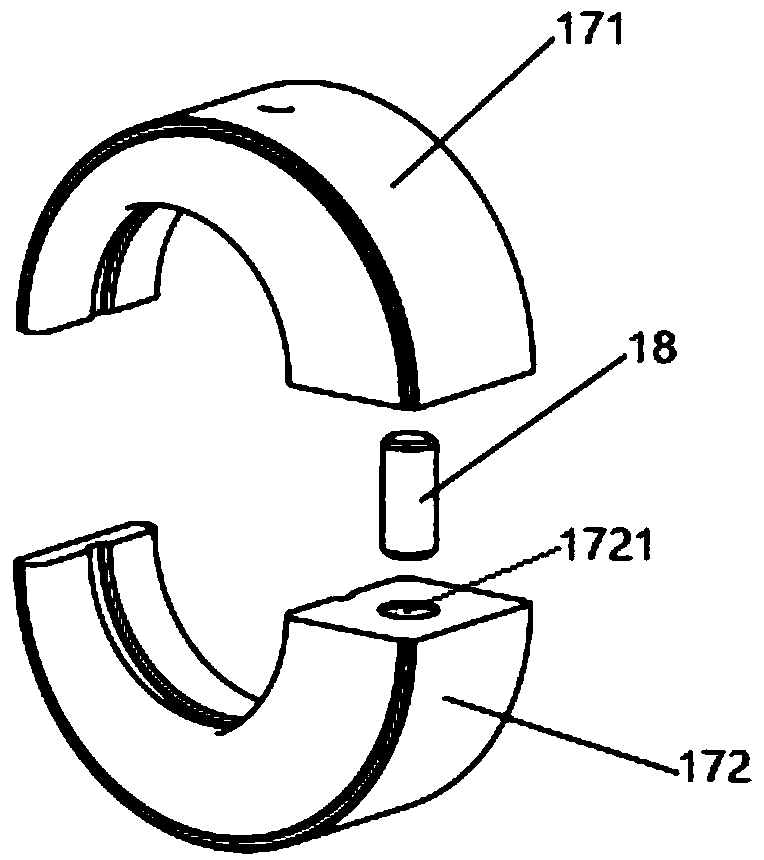

Connecting-rod-free hot air engine transmission mechanism and connecting-rod-free hot air engine transmission system

ActiveCN109488388ACompact structureReduce weightInternal combustion piston enginesEngine componentsInertia forceEnergy loss

The invention discloses a connecting-rod-free hot air engine transmission mechanism and a connecting-rod-free hot air engine transmission system. The connecting-rod-free hot air engine transmission mechanism comprises a piston assembly and an eccentric wheel sliding block. The eccentric wheel sliding block comprises a first moon-shaped sliding block and a second moon-shaped sliding block oppositeto the first moon-shaped sliding block. A shaft neck hole for sleeving a crankshaft is formed by the inner side walls of the first moon-shaped sliding block and the second moon-shaped sliding block. The outer side wall of the eccentric wheel sliding block is formed by the outer side walls of the first moon-shaped sliding block and the second moon-shaped sliding block. The distance between the circle centers of the shaft neck hole and the eccentric wheel sliding block is equal to the crank throw eccentric distance of the crankshaft. The piston assembly is connected with the eccentric wheel sliding block, the rotating direction of the eccentric wheel sliding block is opposite to that of the crankshaft, and the rotating speed of the eccentric wheel sliding block is equal to that of the crankshaft. Under certain displacement of a hot air engine, the turning radius of a crank is reduced to be half of the turning radius of a crank connecting rod structure, the rotating inertia force of the crank is small, the side thrust of a piston, crankshaft stress and bearing loads are reduced, energy losses are reduced, the service life of parts of the hot air engine is prolonged, and the efficiencyand the reliability of the hot air engine are improved.

Owner:SHANGHAI MICROPOWERS

Variable-cross-section large part forming process method

PendingCN112643235AIncrease profitAvoid the problem of wasting raw materialsWelding/cutting auxillary devicesAuxillary welding devicesMachine partsButt joint

The invention discloses a variable cross-section large part forming process method which comprises the following process steps of: segmenting a part model: classifying a design model of a variable-cross-section large part according to the shape and / or size, determining a division surface, and segmenting the design model according to the division surface to obtain a segmented model; conducting blanking and rough machining: selecting a blank for blanking, conducting rough machining on the blank, and obtaining rough-machined parts; splicing and installing rough-machined parts: conducting butt joint on the butt-joint faces of the two rough-machined parts to be connected, connecting and fixing the two rough-machined parts, and obtaining splicing pieces; welding the splicing pieces: welding the butt-joint faces of the splicing pieces, and obtaining welding pieces; and conducting finish machining on the welding pieces: conducting finish machining on the welding pieces, and completing part machining. According to the variable-cross-section large part forming process method provided by the invention, the variable-cross-section large part is divided into parts with different cross sections, so that the machining cost is reduced to a certain extent, and the raw material utilization rate is increased.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

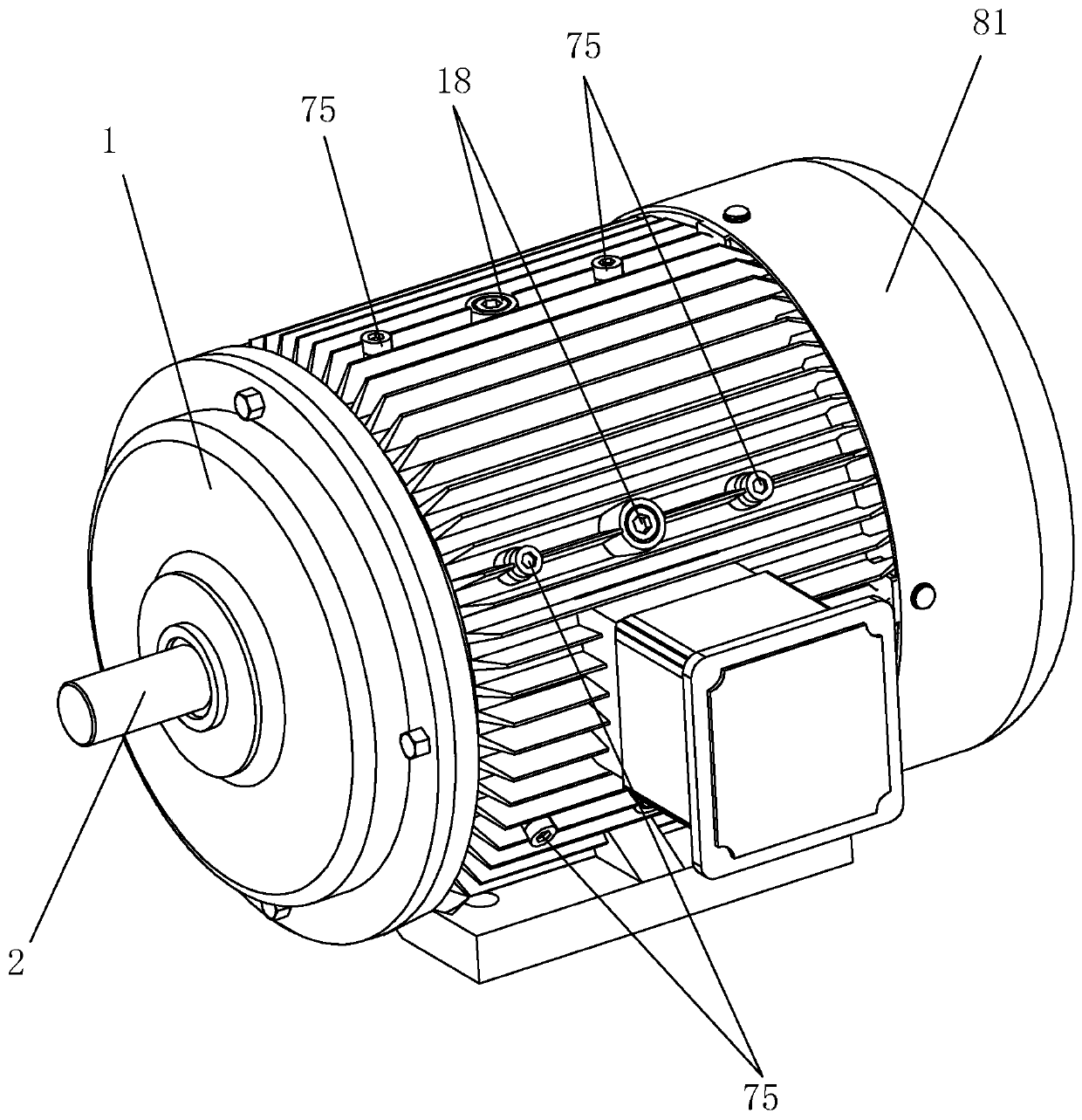

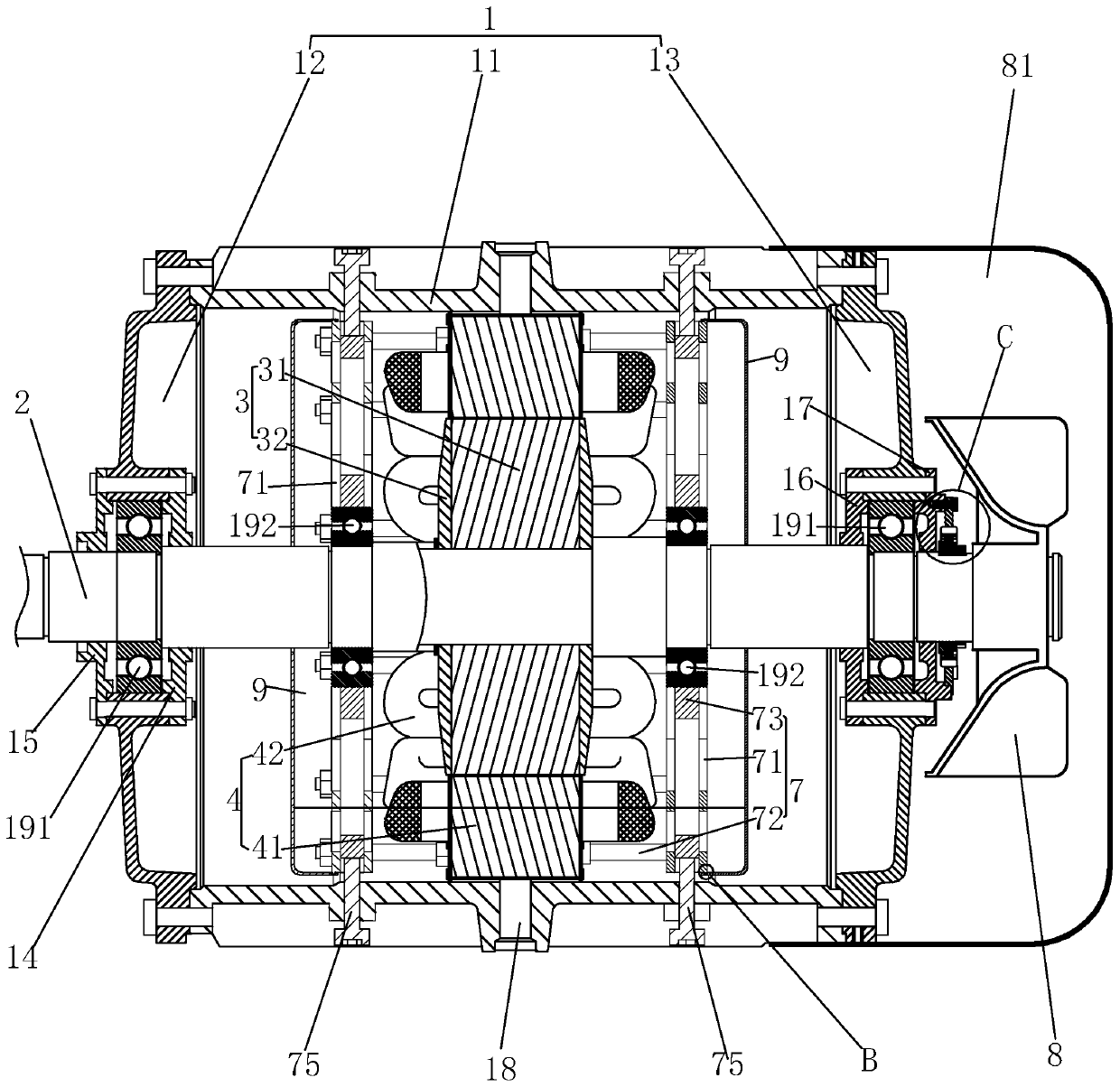

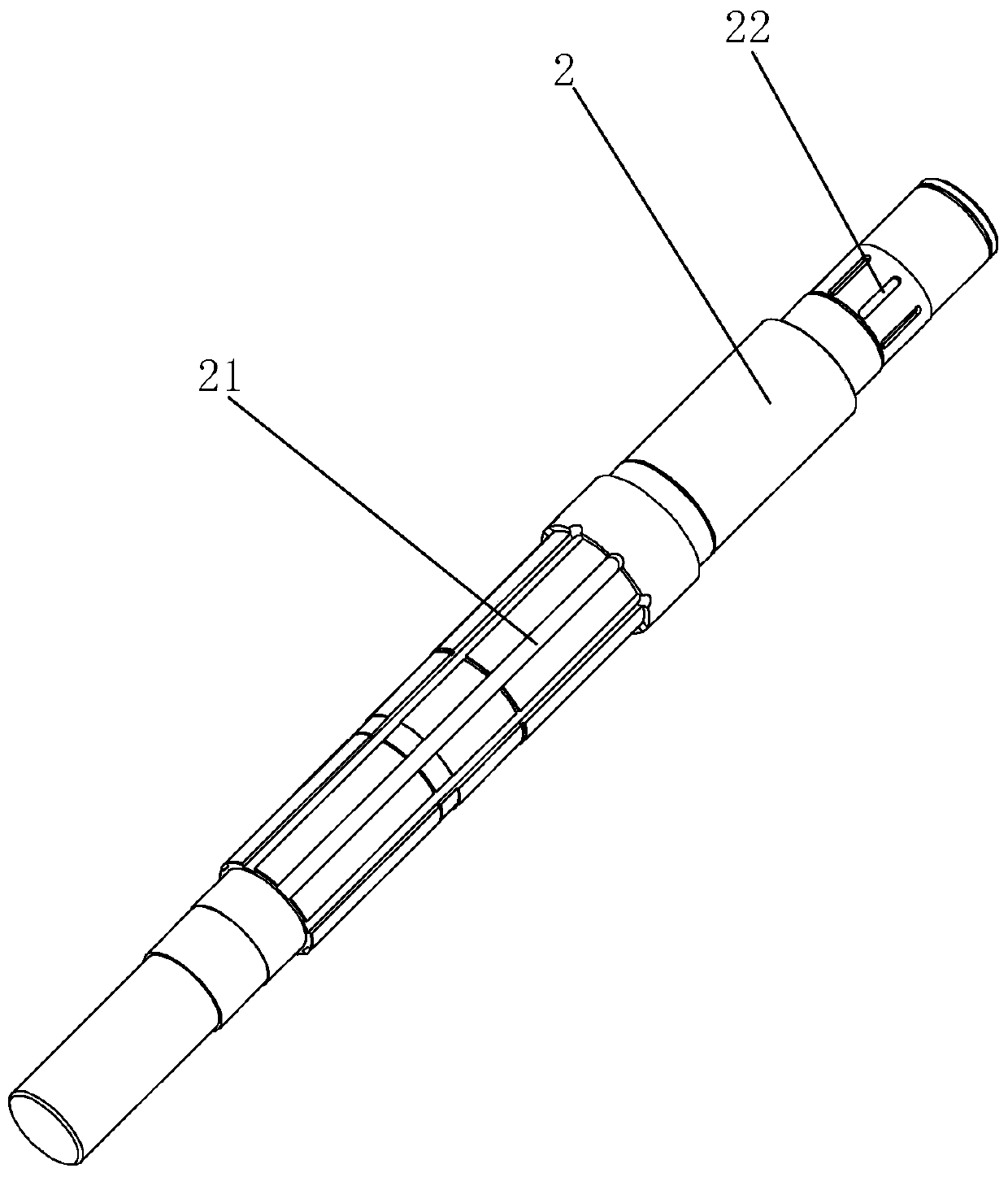

Switch reluctance motor

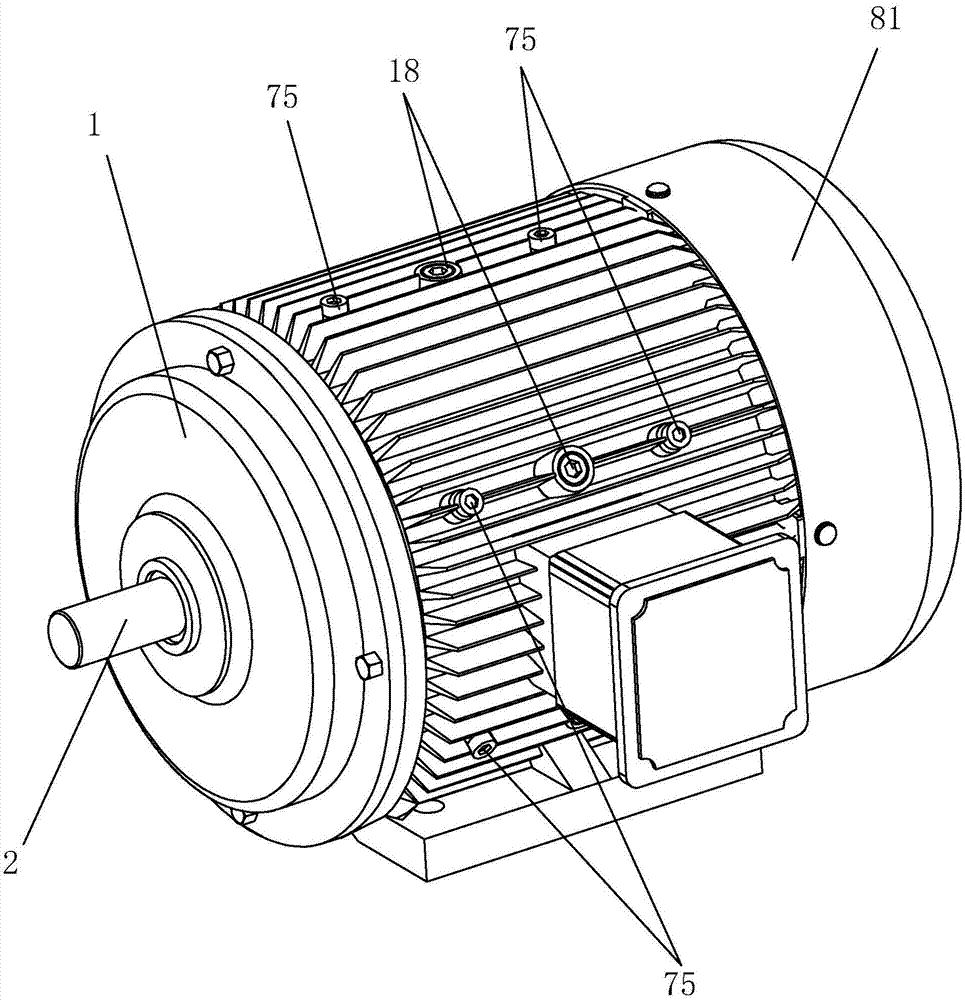

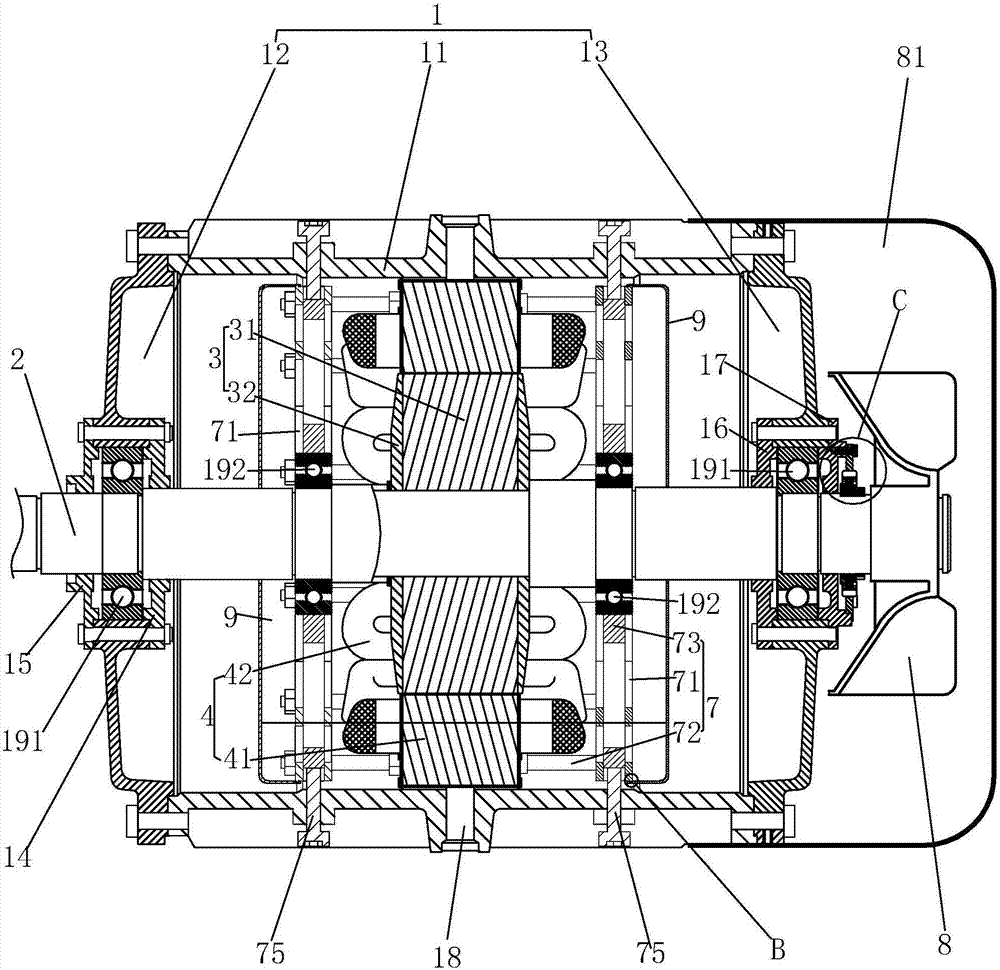

ActiveCN107968498AImprove dynamic balanceRotation stabilizationMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronismStator

The invention discloses a switch reluctance motor. The switch reluctance motor is technically characterized in that the switch reluctance motor comprises a casing, a main shaft rotationally connectedwith the casing, a motor rotor which is fixedly connected with the main shaft, a motor stator which is fixedly connected with the inside casing, and a position detector. The motor rotor comprises a rotor piece and end plates arranged on both ends of the motor rotor. A number of motor rotor salient poles are evenly arranged on the rotor piece. A shaft hole is arranged in the center of the rotor piece. Rotor key tables are integrally fixedly arranged on the circumference of the shaft hole. The number of the rotor key tables is consistent with the number of the motor rotor salient poles, and the rotor key tables are evenly distributed on the circumferential surface of the shaft hole. Rotor key slots matching the rotor key tables are arranged on the main shaft, which can reduce the degree ofinfluence of the rotor on the rotation synchronism of the main shaft.

Owner:CHUANGYUAN YIDE TIANJIN GRP CO LTD

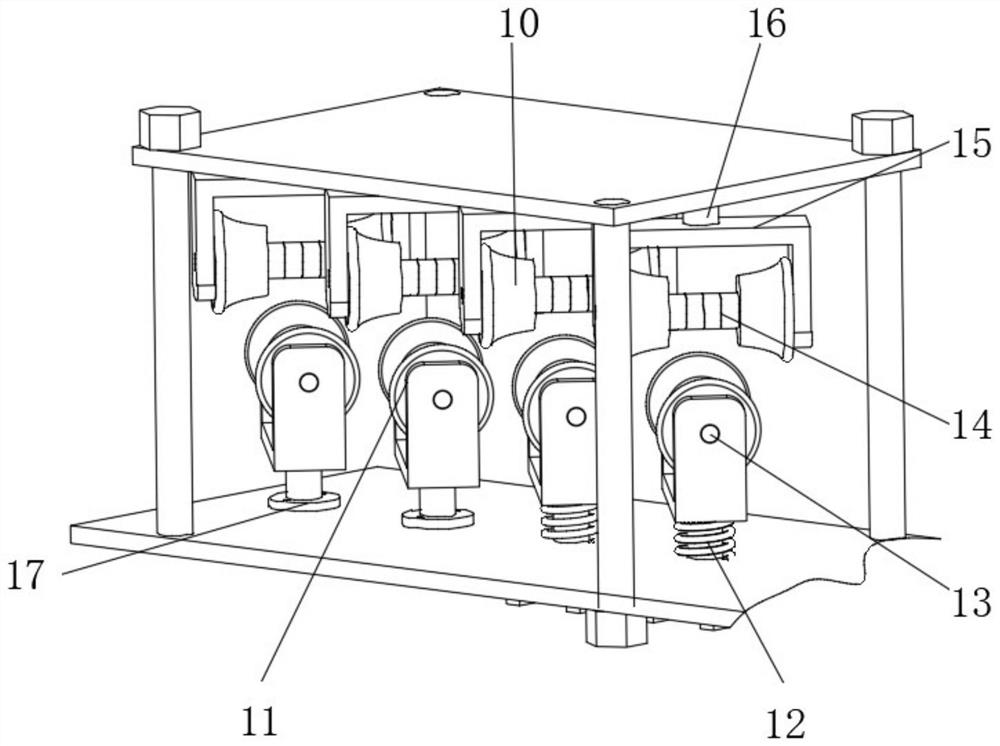

High-speed precise rock wool push plate mechanism

ActiveCN112811077AEasy to process separatelyPrecise positioningLoading/unloadingConveyor partsWoolGeotechnical engineering

The invention discloses a high-speed precise rock wool push plate mechanism which comprises a square frame, a positioning and feeding mechanism is arranged on the square frame, a pushing mechanism is arranged on one side of the positioning and feeding mechanism, and a discharging mechanism is arranged on one side of the positioning and feeding mechanism. The high-speed precise rock wool push plate mechanism has the beneficial effects that a second lifting block can be lifted and lowered through stretching out and drawing back of a second air cylinder, rock wool boards and rock wool strips can be conveniently positioned, the positioning precision is high, after positioning is completed, through lifting of a third lifting block and moving of a moving table, the rock wool boards and the rock wool strips can be conveniently pushed to one side, stacking is convenient, and when waste exists, a first lifting block can be lowered, waste materials can be pushed into a discharging barrel, the waste materials can be conveniently guided out, after the waste materials are guided out, the end, filled with the waste materials, in the discharging barrel can be rotated away through rotation of the discharging barrel, the waste materials can be conveniently taken away, the device can machine multiple sets of rock wool boards or rock wool strips at a time, and the working efficiency is improved.

Owner:邯郸理想包装机械有限公司

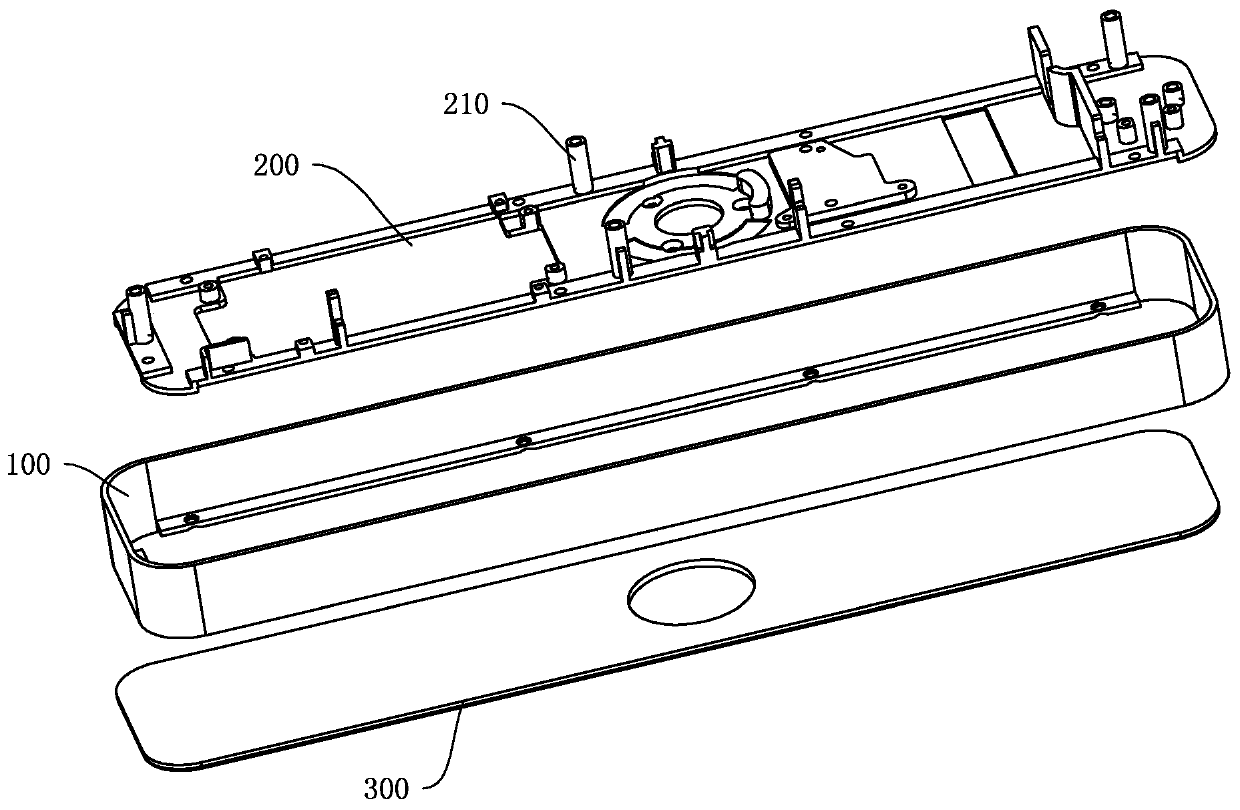

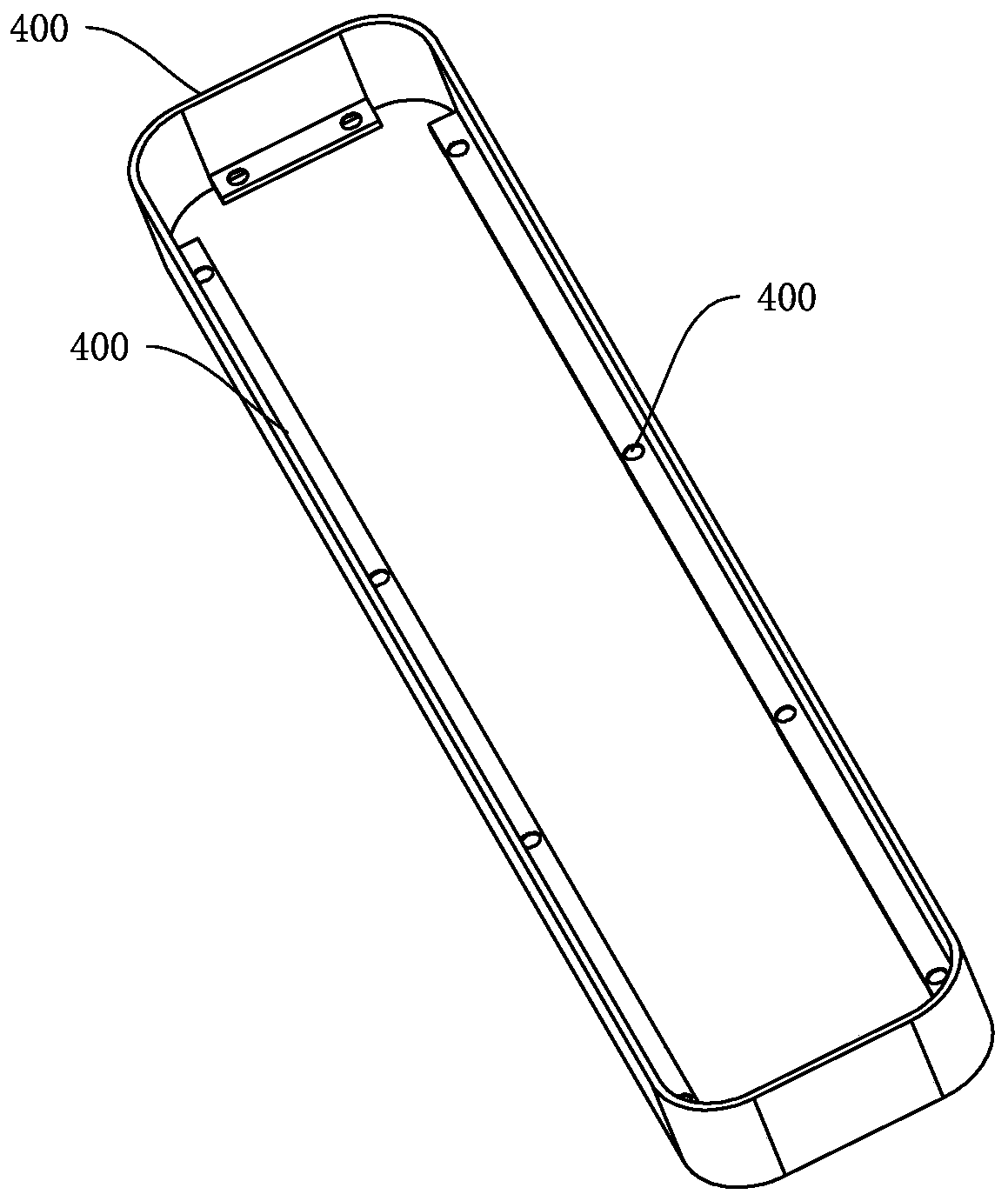

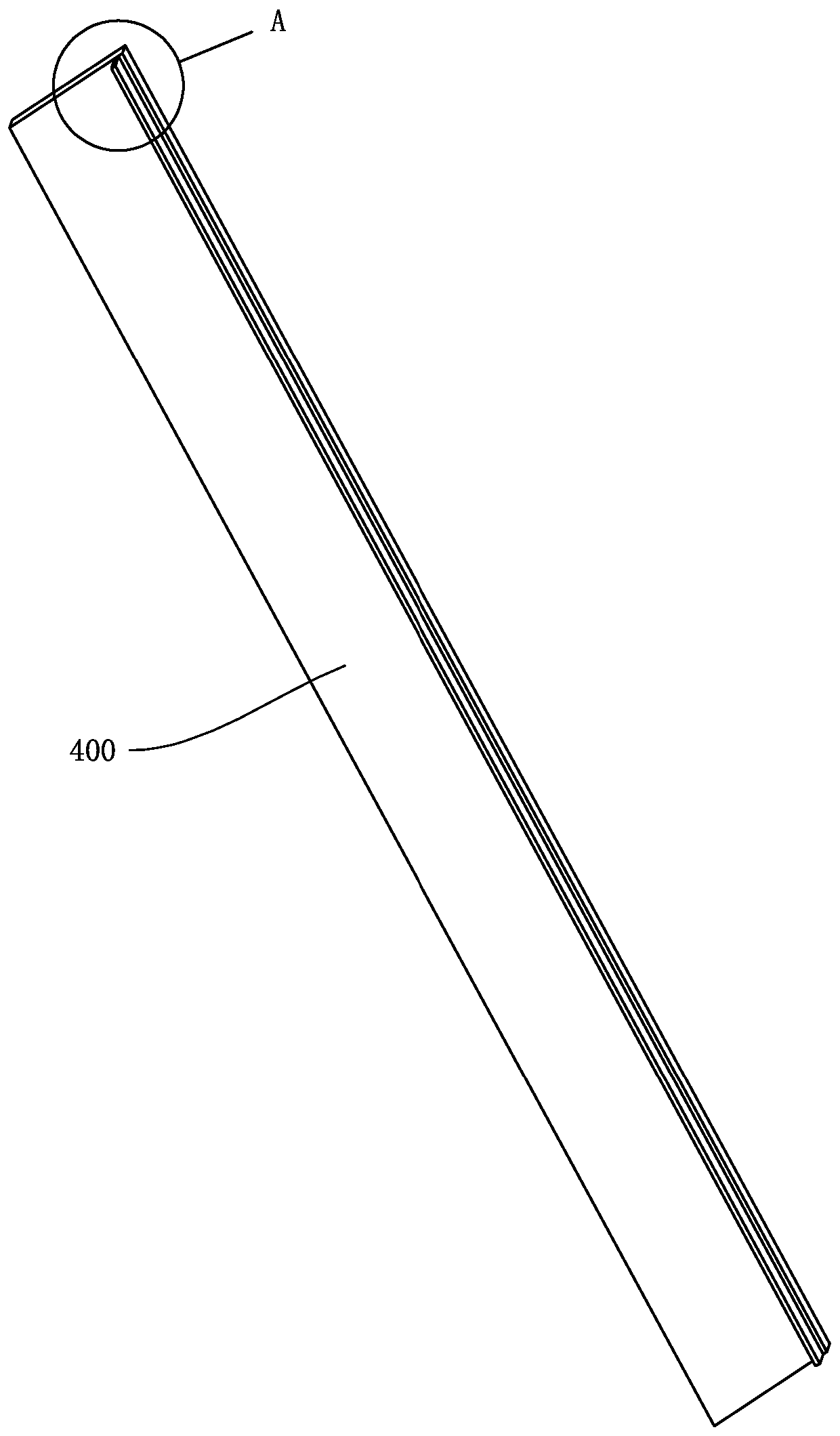

A processing method for split lock cover and lock cover frame

The invention discloses a split type lock cover, and discloses a processing method of the lock cover frame, wherein the processing method of the lock cover frame includes: step a, selecting a square aluminum ingot, extruding and forming a square frame strip, the square frame The position of the frame strip close to the bottom side of the square frame strip is provided with a convex strip that is parallel to the long side of the direction frame strip; step b, part of the convex strip is cut off, and a plurality of mutually disconnected convex edges are formed on the square frame strip; step c, bending the square frame strip to form a rounded rectangular frame, and the rounded corner of the rounded rectangular frame is located at the disconnection of the convex edge; step d, welding the head and tail of the original square frame strip on the rounded rectangular frame; In step e, anodizing treatment is performed on the outer surface of the entire rounded rectangular frame. The present invention reasonably designs the processing method of the lock cover frame, greatly shortens the manufacturing process of the lock cover, improves the production efficiency, and manufactures the lock cover frame with stable structure and beautiful appearance.

Owner:珠海东荣金属制品有限公司

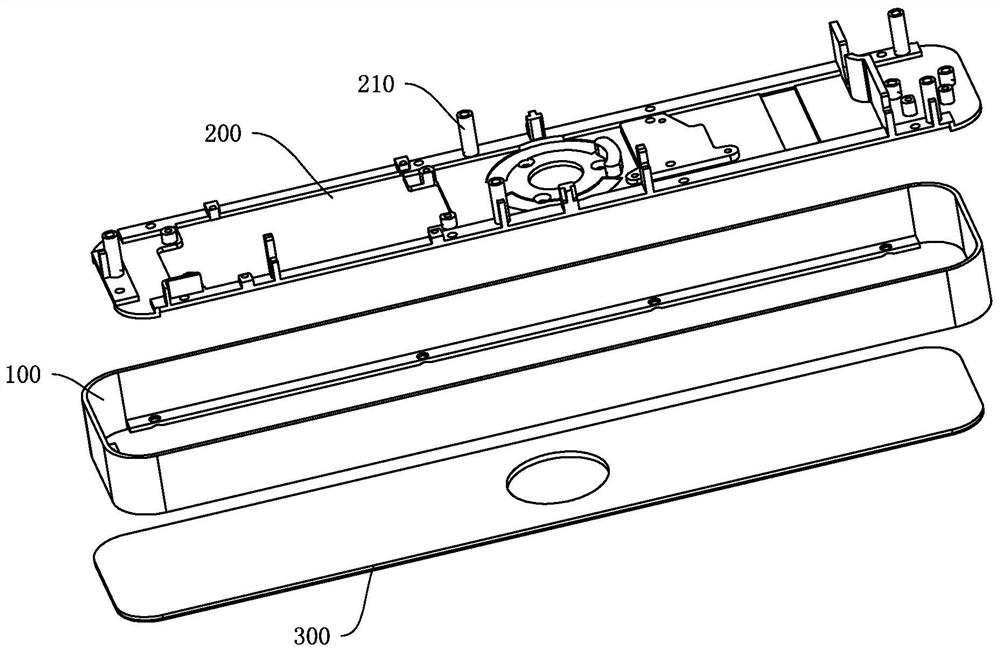

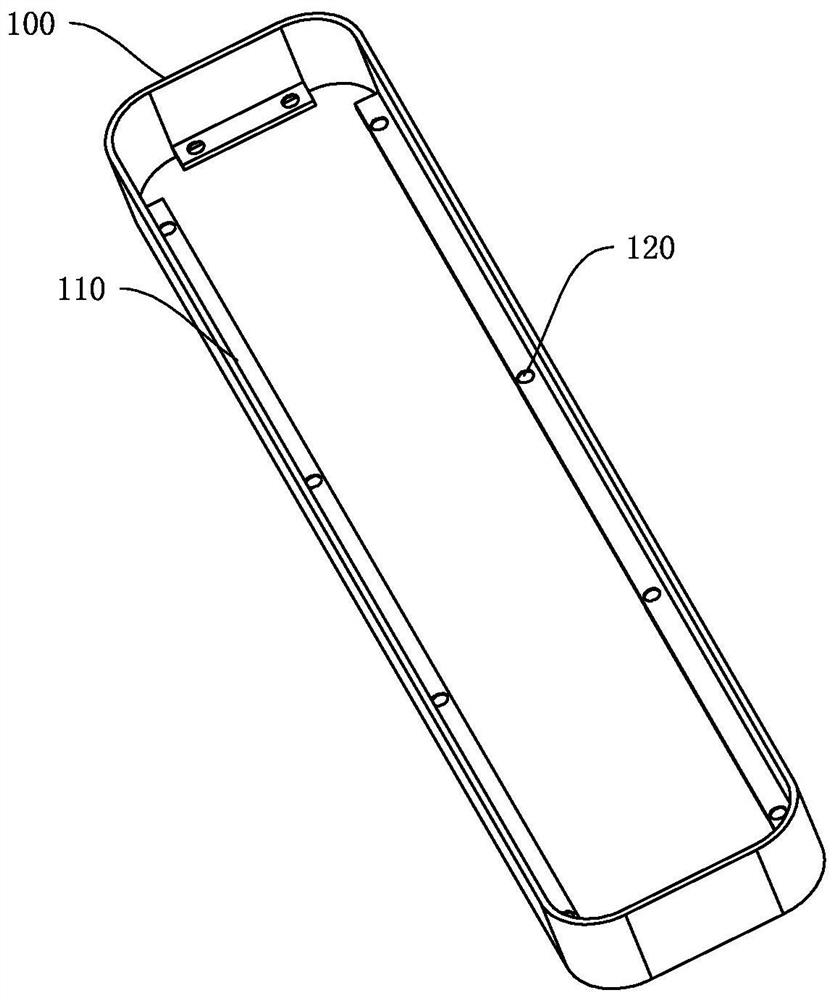

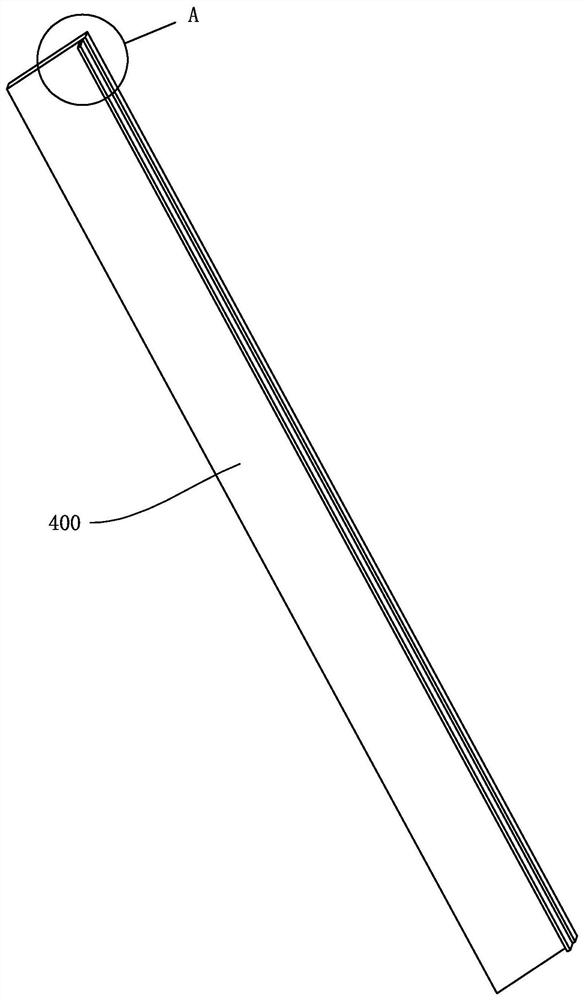

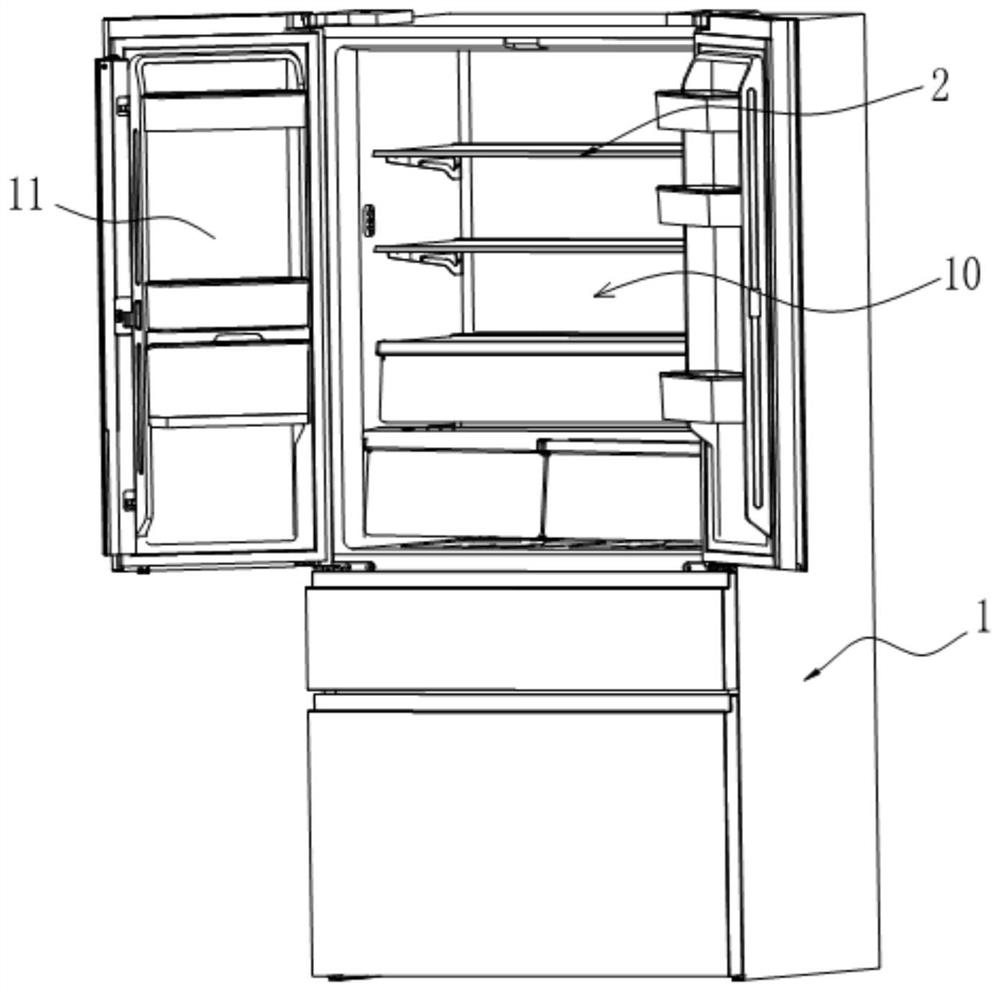

Refrigerator

ActiveCN113959138ASimple structureEasy to process separatelyLighting and heating apparatusDomestic refrigeratorsIceboxEngineering

The invention relates to a refrigerator. The refrigerator comprises a refrigerator body and a shelf, the shelf comprises cantilevers, a shelving plate and side decoration strips, and the cantilevers extend in the front-back direction; ribs extending in the front-back direction are convexly arranged on the side wall, facing the other cantilever, of one cantilever; the shelving plate is transversely arranged between the two cantilevers; and the two side decoration strips are arranged at the transverse left side edge and the transverse right side edge of the shelving plate respectively, and the bottom faces of the side decoration strips are downwards arranged in a protruding manner to form buckles. The buckles are connected to the ribs in a buckled manner, the ribs are clamped between the buckles and the bottom faces of the side decoration strips, and the buckles can slide along the ribs. The shelf is assembled and disassembled through cooperation of the cantilevers, the shelving plate and the side decoration strips, meanwhile, the buckles at the bottoms of the side decoration strips are matched with the ribs at the side portions of the cantilevers, the shelving plate can be connected to the cantilevers in a sliding manner along with the side decoration strips, a detachable sliding and buckling structure is formed, the structure of the shelf is simplified, separate machining of all parts is facilitated, a user can conveniently assemble, disassemble and maintain the refrigerator, and the user experience is improved.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Apple snail processing device

InactiveCN106509052BImprove overall utilizationLow costShrimp/lobster processingEngineeringUtilization rate

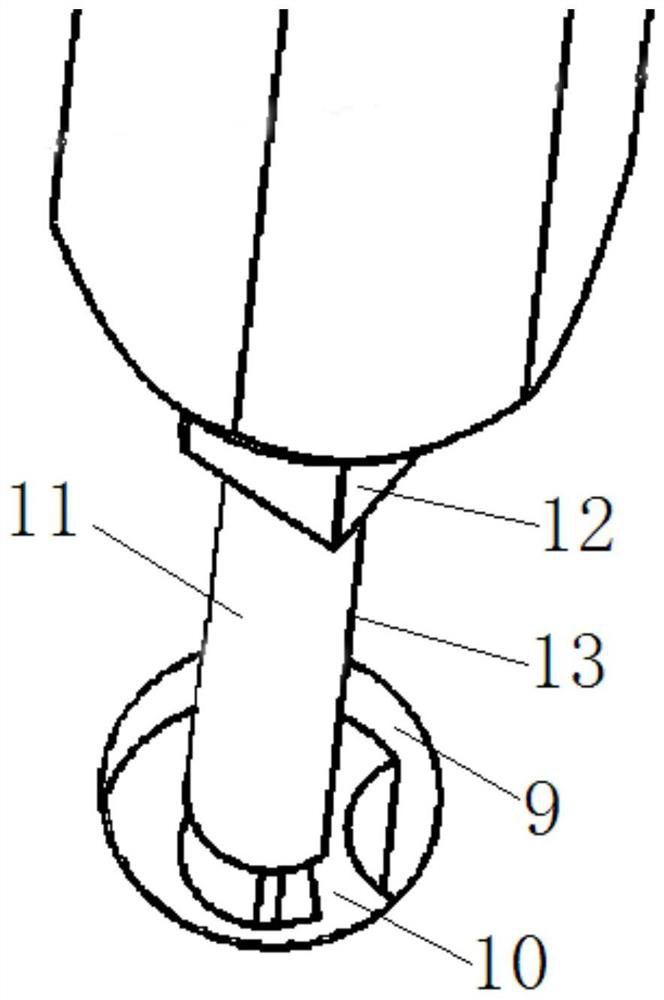

The purpose of the invention is to provide an ampullaria gigas spix processing device which is capable of rapidly separating the meat of the ampullaria gigas spix from the shells so as to facilitate subsequent processing and raise the utilization rate of the ampullaria gigas spix. The ampullaria gigas spix processing device disclosed by the invention comprises a meat collecting box; a meat collecting tube is arranged at the upper part of one side of the meat collecting box; the upper part of the other side of the meat collecting box is connected with a negative pressure generating device; an elastic hopper-shaped compression ring is arranged at the end part of the meat collecting tube; an extractable meat collecting plate is arranged at the bottom of the meat collecting box; and the meat collecting plate and the meat collecting box are connected in sealed connection. Being used, the head end of the ampullaria gigas spix is pressed on the compression ring, the negative pressure generating device is started so as to suck the meat of the ampullaria gigas spix into the meat collecting tube by utilizing the negative pressure generated by the negative pressure generating device, and finally, the sucked meat drops onto the meat collecting plate through the meat collecting tube. The meat collecting plate is extracted from the meat collecting box when the meat on the meat collecting plate reaches a certain amount. The ampullaria gigas spix processing device is capable of adapting to ampullaria gigas spix of different sizes for the compression ring is elastic and hopper-shaped.

Owner:茂名市茂南区生产力促进中心

Low-temperature-rise micro heat dissipation flow channel magnetic core

ActiveCN111933407ADoes not affect strengthEasy to exportTransformers/inductances coolingTransformers/inductances magnetic coresEngineeringMagnetic flux

The invention discloses a low-temperature-rise micro heat dissipation flow channel magnetic core. The magnetic core comprises a base, side columns and a middle column, a non-through middle column groove corresponding to the middle column is formed in the top of the middle of the base; the middle column groove is a horn mouth groove; a through connecting column hole is downwards formed in the middle of the middle column groove; a through connecting column hole corresponding to the connecting column hole is also formed in the middle of the middle column; matched connecting columns are inserted into the two connecting column holes, three-way heat conduction grooves which are communicated with the middle column groove and penetrate through the base are formed in the inner sides of the two sidecolumns on the base, a plurality of heat dissipation micro grooves are formed in the bottom of the middle column groove, one end of each heat dissipation micro groove is communicated with the corresponding connecting column hole, and the other end of each heat dissipation micro groove extends to the position below the corresponding three-way heat conduction groove. According to the low-temperature-rise micro heat dissipation flow channel magnetic core, the middle column is detachably arranged, the uniformity of the density of the machined core column can be guaranteed, and winding is facilitated; the micro-channels are formed in the middle column and the base, and heat dissipation can be well achieved under the condition that winding and magnetic flux of the magnetic core are not affected.

Owner:海宁市康明电子有限公司

Commutator, motor and cutter

PendingCN114171997AExtend your lifeAvailable for mass productionRotary current collectorTurning toolsElectric machineryEngineering

The invention discloses a commutator, a motor and a cutter. The commutator comprises: an insulating substrate; the commutator comprises an insulating substrate, commutator segments, the commutator segments are arranged on the periphery of the insulating substrate, the commutator segments are provided with a plurality of K-shaped inner hooks so as to be connected to the insulating substrate, and the diameter of the commutator is greater than or equal to 7.8 mm and less than 8.8 mm. According to the commutator with the structure, the situation that a plurality of coulter teeth are arranged along the circumferential direction of the same height in the prior art is avoided by changing the arrangement of the cutter, so that the situation that the distance between adjacent coulter teeth is limited by the size of the commutator and the coulter teeth are too small is avoided; the service life of a cutter can be prolonged, the economic cost is reduced, and mass production can be achieved, so that the commutator with the diameter smaller than 8.8 mm and the K-shaped inner hook can be machined in a mass production mode.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

An easy-to-disassemble bracket fixing structure

ActiveCN103542238BEasy to useFirmly connectedPump componentsStands/trestlesEngineeringTransportation cost

The invention discloses a bracket fixing structure easy to mount and demount. The bracket fixing structure comprises a tubular bracket, a shell and a screw, the tubular bracket serves as a bearing part, the shell is sleeved on the tubular bracket, the screw is used for fastening the tubular bracket and the shell, an annular groove is formed in the upper end portion of the tubular bracket, a sleeve hole capable of having the tubular bracket sleeved is formed in the lower end of the shell, a piercing hole horizontally penetrating to a position of the sleeve hole is formed in the lower end of the shell, and under a fixed condition, the screw penetrates the piercing hole to be screwed in the sleeve hole and clamped in the annular groove of the tubular bracket. The bracket fixing fixture easy to mount and demount has the advantages that after being connected in a sleeved manner, the bracket fixing structure is fastened through a bolt, so that the structure is connected stably without offsetting, turning over or rotating; an angle range can be rapidly and conveniently regulated by releasing the bolt; the structure can be rapidly demounted, separate processing, packaging and transporting are facilitated, and accordingly transportation cost is lowered; special demounting tools are not needed, demounting difficulty of demounting is lowered, and accordingly customers can use the structure conveniently; the bracket fixing structure easy to mount and demount is simple in structure and low in production and processing costs.

Owner:KENNEDE ELECTRIONICS MFG CO LTD

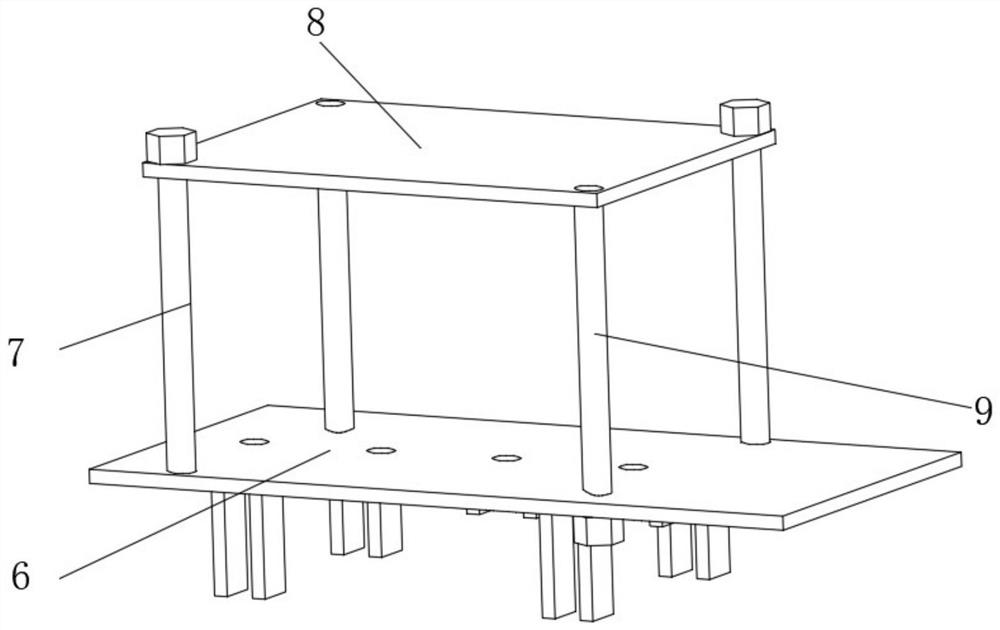

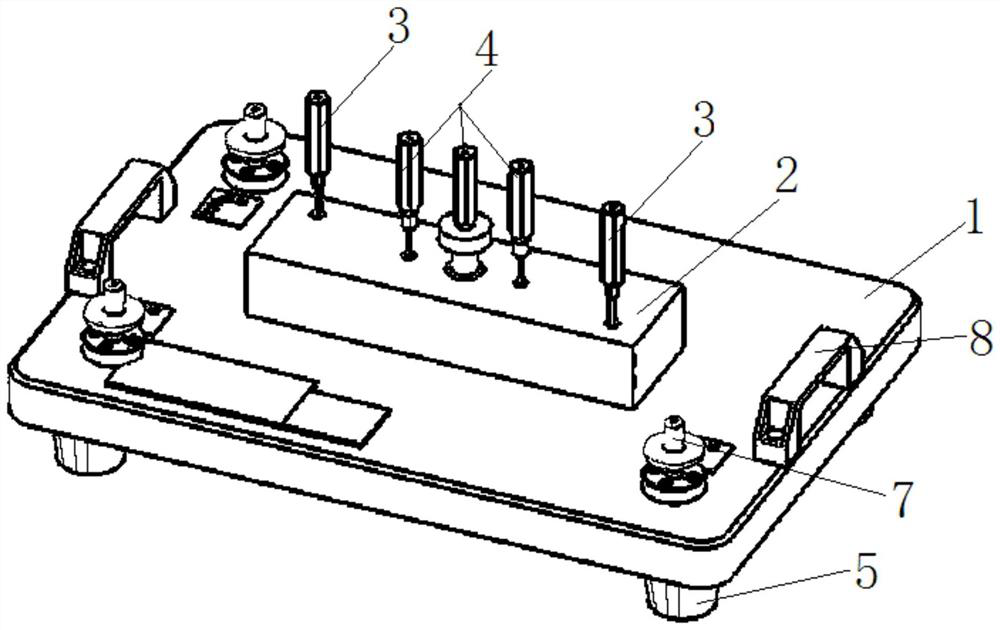

Workpiece hole site detection device

InactiveCN113310382ASimple structureImprove detection accuracyMechanical measuring arrangementsEngineeringSynchronous detection

The invention provides a workpiece hole site detection device. The workpiece hole site detection device comprises a base; a detection table is arranged on the base, wherein the top surface of the detection table is provided with a standard hole position matched with a to-be-detected hole; a positioning pin which is provided with a positioning end and a detection end which are coaxially arranged, wherein the size of the cross section of the positioning end is consistent with that of the cross section of a standard hole, the positioning end is used for passing through the to-be-detected hole and being inserted into the standard hole position, and the detection end is used for stretching into the to-be-detected hole. The workpiece hole site detection device is simple in structure and relatively high in detection precision, can realize synchronous detection of each hole site of the workpiece, and improves the detection efficiency.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

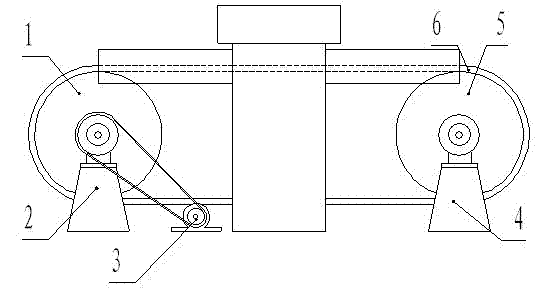

Graphite separation equipment with insulating supports

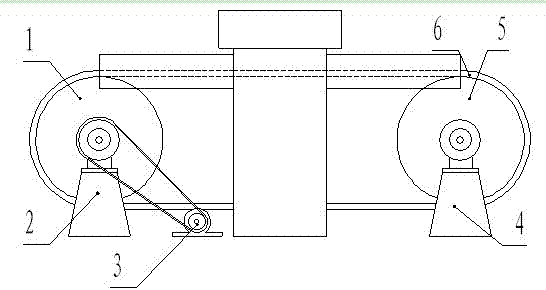

The invention discloses graphite separation equipment with insulating supports. The graphite separation equipment with the insulating supports comprises a driving wheel (1), a driving wheel support (2), a driving motor (3), a driven wheel support (4), a driven wheel (5) and a conveying belt (6). The driving wheel (1) is connected with the driving motor (3) through a transmission belt and is hinged with the driving wheel support (2), the driven wheel (5) is hinged with the driven wheel support (4), the driving wheel (1) is connected with the driven wheel (5) through the conveying belt (6), and ceramic shaft sleeves are respectively arranged on a mounting shaft of the driving wheel support and a mounting shaft of the driven wheel support. According to the technical scheme, the graphite separation equipment with the insulating supports has the advantages that the operational requirement can be met since the driving wheel support and the driven wheel support are made of materials with high mechanical strength, the insulating requirement can be met due to the ceramic shaft sleeves, the manufacturing process is simple, and the service life of the graphite separation equipment is prolonged.

Owner:NANTONG SANXIN CARBON GRAPHITE EQUIP

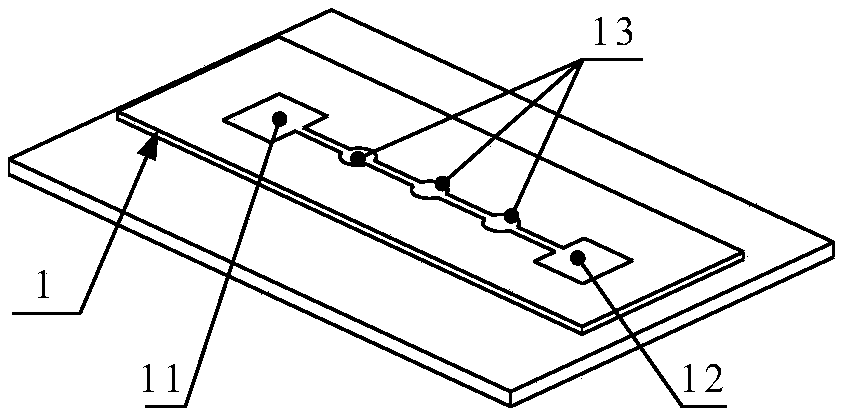

Microfluidic device

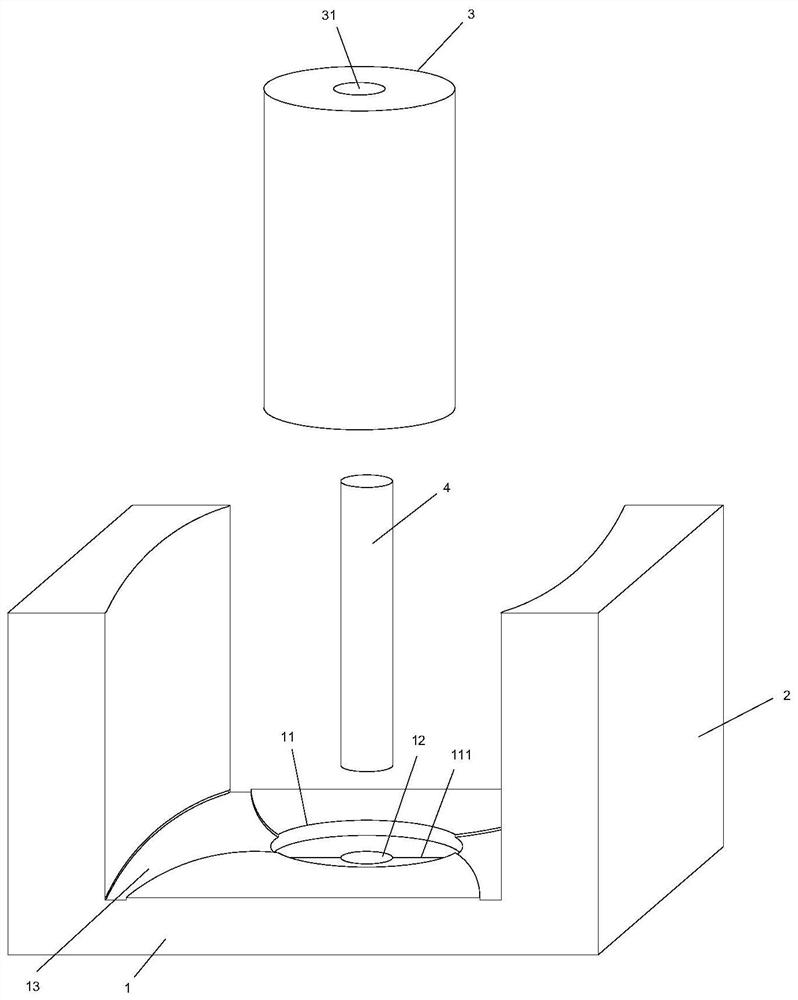

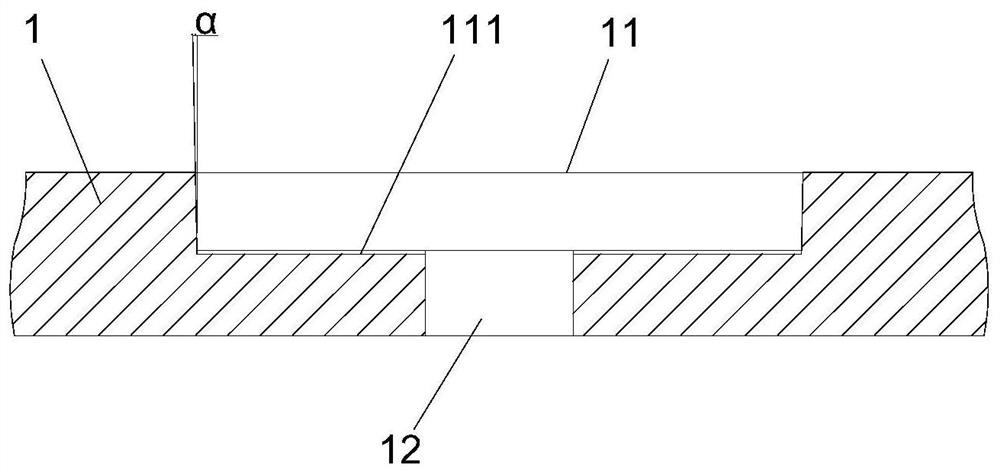

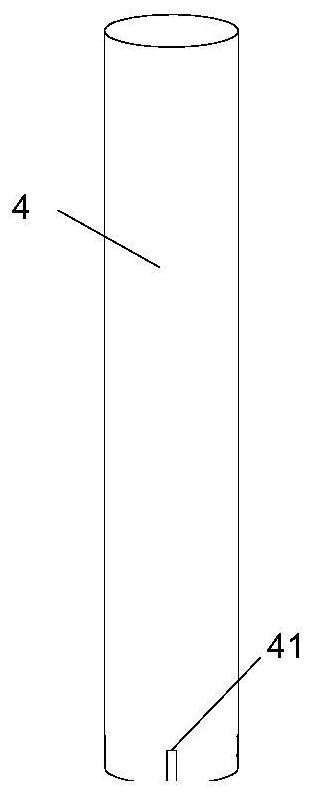

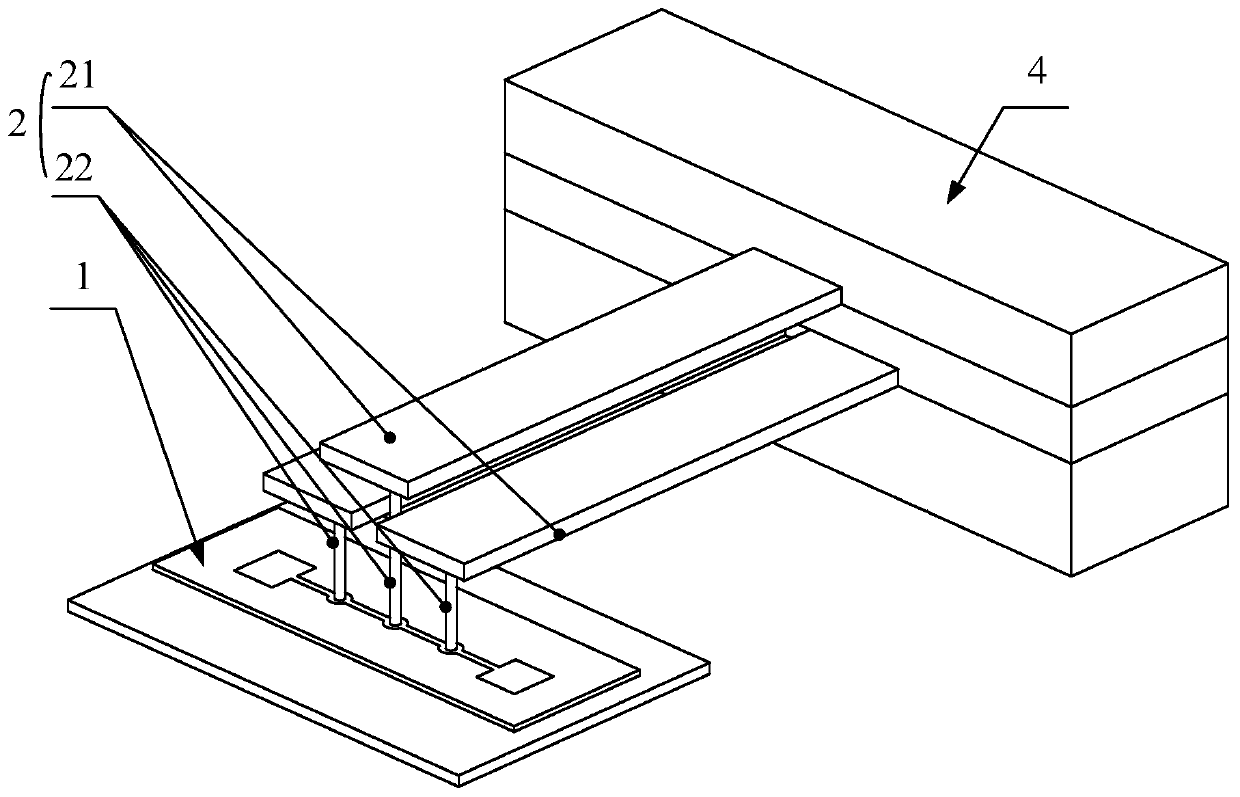

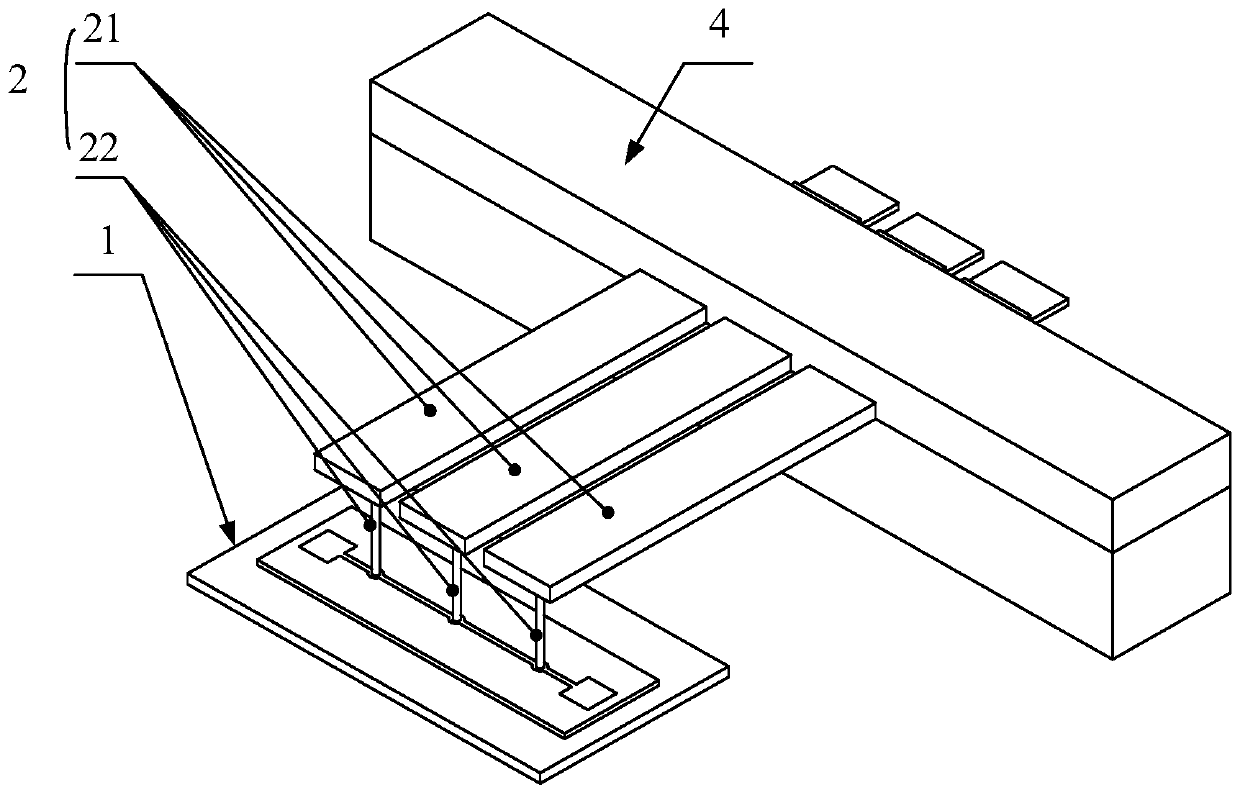

ActiveCN108626102BAchieve flowEasy to control flow areaFlexible member pumpsPositive-displacement liquid enginesEngineeringActuator

The invention discloses a micro-fluidic device. The micro-fluidic device comprises a displacement actuator (2) and a micro-fluidic chip (1); the displacement actuator (2) and the micro-fluidic chip (1) are mutually independent; the micro-fluidic chip (1) is provided with a micro-pipeline; the micro-pipeline is provided with an input end (11) and an output end (12); an extruding part (13) is arranged between the input end (11) and the output end (12) of the micro-pipeline; and the displacement actuator (2) is provided with a brake part for extruding the micro-pipeline of the extruding part (13). According to the micro-fluidic device provided by the invention, the displacement actuator and the micro-fluidic chip are mutually independent, so that separate processing of the displacement actuator and the micro-fluidic chip is facilitated and the processing difficulty of the overall manufacturing process is reduced; and the condition that fluid is directly contacted with the displacement actuator is effectively avoided, the fluid flows only through the micro-pipeline, the flow area of the fluid is controlled conveniently and the control precision is improved.

Owner:UNIV OF SCI & TECH OF CHINA

A switched reluctance motor

ActiveCN107968498BHigh measurement accuracyImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic reluctance

The invention discloses a switched reluctance motor. The key points of its technical scheme include a casing, a main shaft rotatably connected to the casing, a motor rotor fixedly connected to the main shaft, a motor stator fixedly connected in the casing, and a position detection motor. The motor rotor includes a rotor piece and end plates arranged at both ends of the motor rotor. A plurality of motor rotor salient poles are evenly arranged on the rotor piece. A shaft hole is opened in the center of the rotor piece. The circumference of the shaft hole is integrally fixed with Rotor key table, the number of rotor key table is consistent with the number of salient poles of the motor rotor and evenly distributed on the circumferential surface of the shaft hole. There is a rotor keyway on the main shaft that matches the rotor key table, which can reduce the installation of the rotor. The degree of influence on the synchronization with the spindle rotation.

Owner:CHUANGYUAN YIDE TIANJIN GRP CO LTD

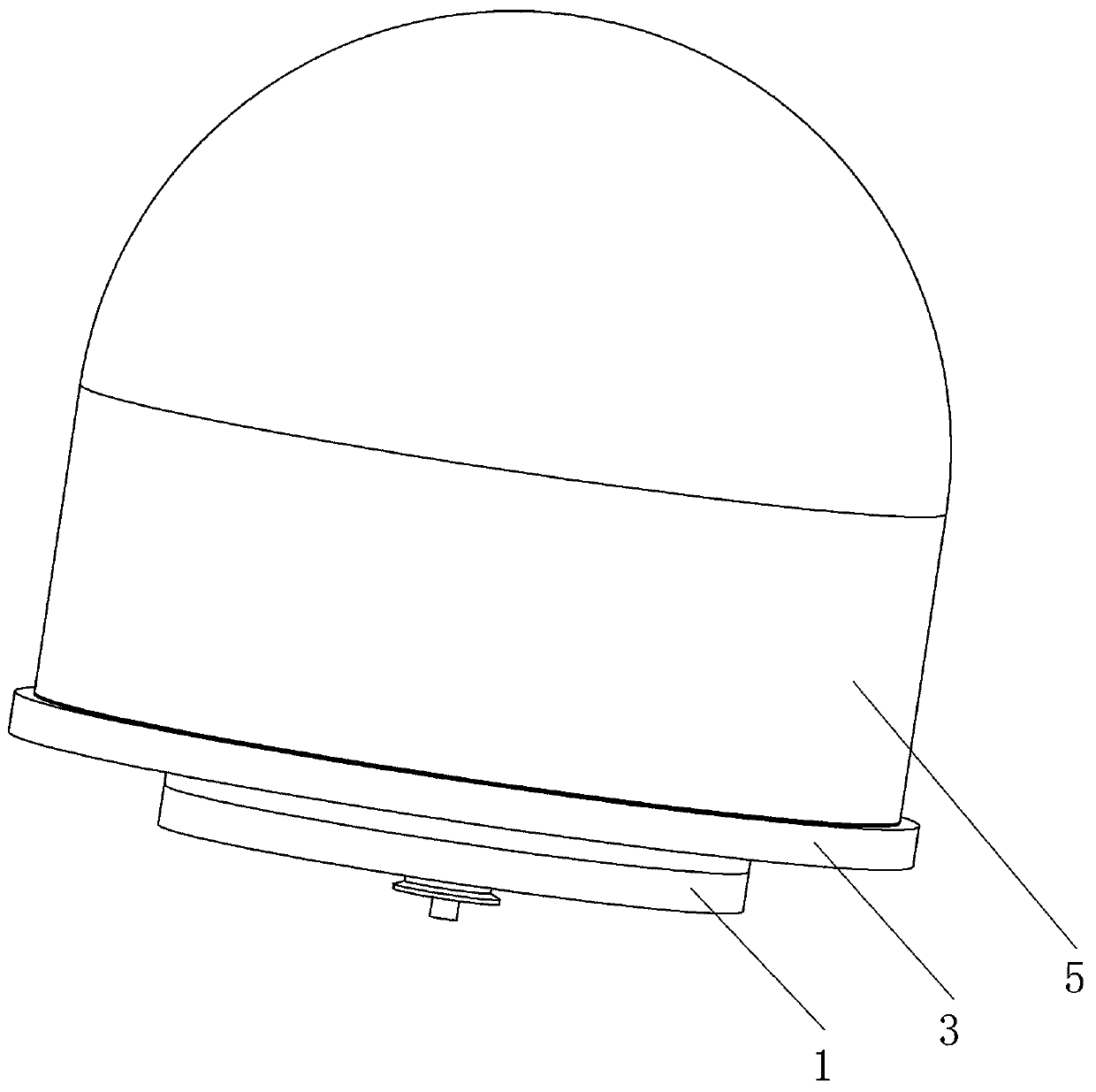

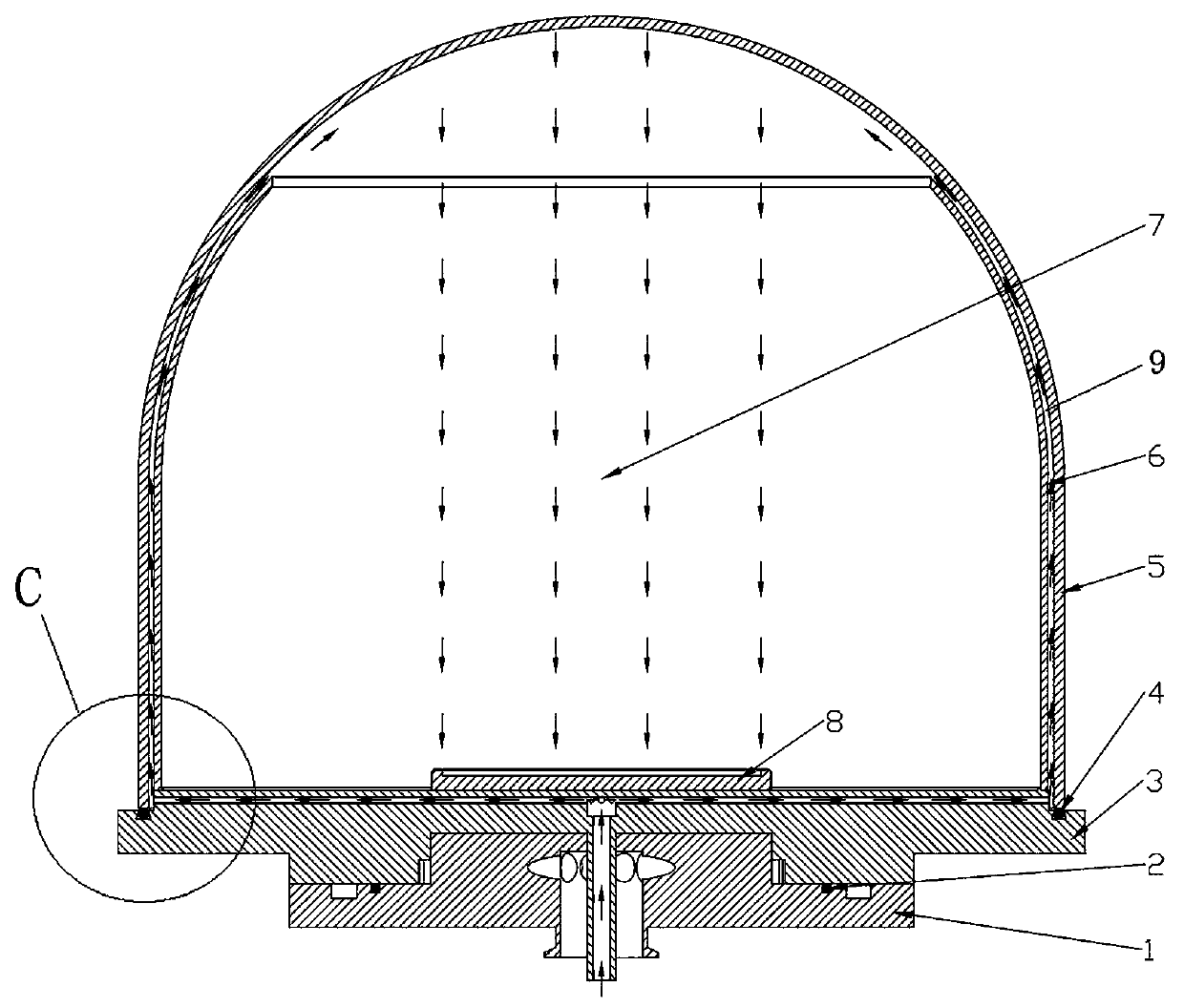

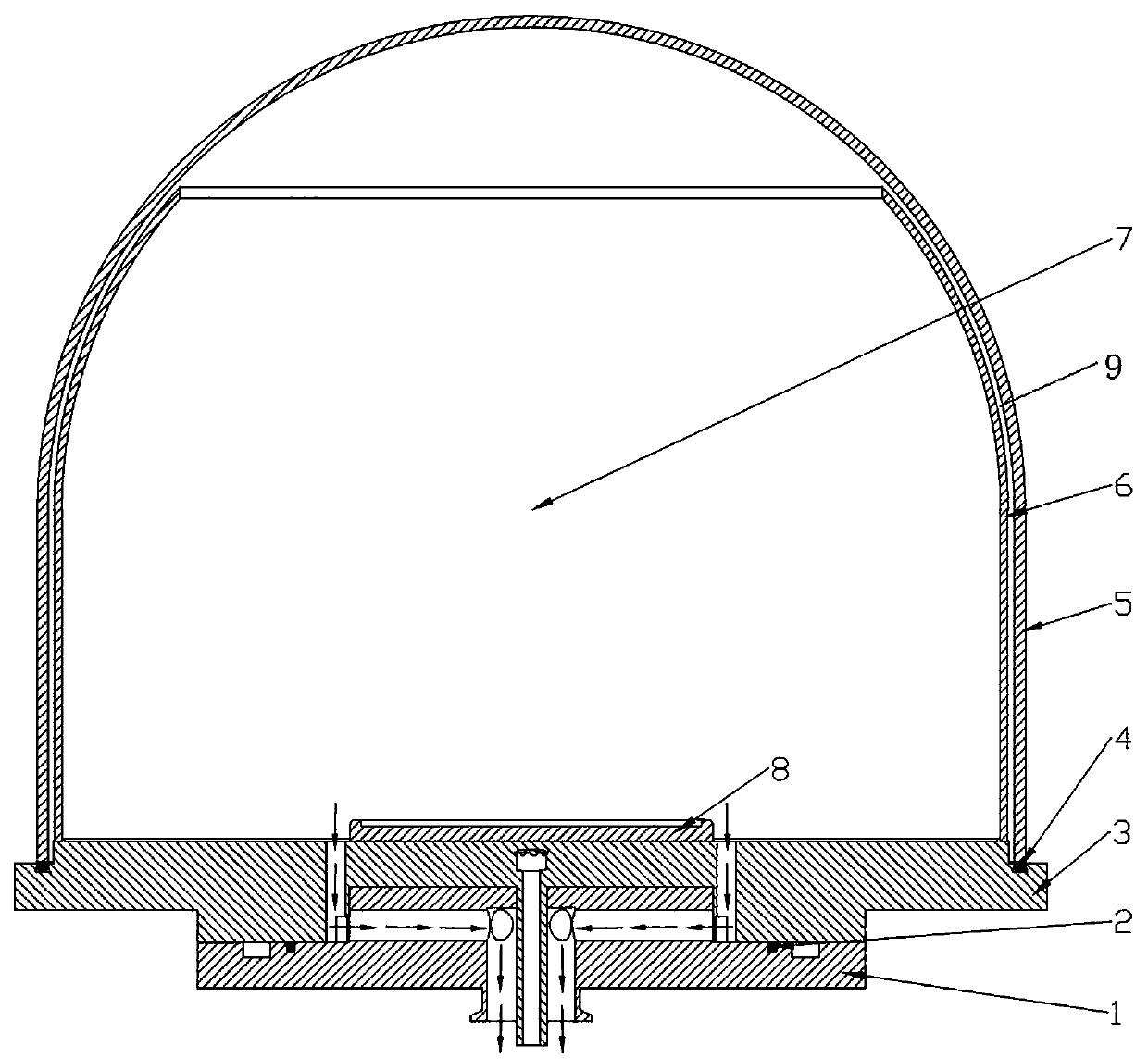

Deposition chamber for improving gas distribution and MPCVD device

ActiveCN110306171AIncrease profitAvoid underreactionFinal product manufactureChemical vapor deposition coatingInlet channelButt joint

The invention belongs to the technical field of microwave plasma chemical vapor deposition, and particularly relates to a deposition chamber for improving gas distribution and an MPCVD device. The deposition chamber comprises a base part, an outer cover body and a deposition table, wherein the outer cover body is hermetically mounted on the base part so as to form a reaction cavity with the base part; the deposition table is arranged on the side, facing the reaction cavity, of the base part, and the base part is provided with an gas inlet channel and an exhaust channel which both communicate with the reaction cavity; the deposition chamber for improving the gas distribution further comprises an air guide channel which is located on the inner side of the outer cover body and extends towardsthe upper part of the reaction cavity, the air guide channel is in butt joint communication with the gas inlet channel, the upper part of the air guide channel communicates with the reaction cavity so as to guide gas input by the gas inlet channel to the upper part of the reaction cavity. The gas guide channel guides upwards the gas entering the deposition chamber, so that the gas can pass through the deposition station before being discharged from the exhaust channel, the utilization rate of the gas is improved, and the reaction efficiency of a deposition device is improved at the same time.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

Automatic reaming machine

InactiveCN104070234BNo wasteAvoid compromising reaming qualityFeeding apparatusReaming devicesEngineeringInductor

The invention discloses an automatic reaming machine. The automatic reaming machine comprises a rack (1), a controller (2), a cylinder (3) and a motor (4), wherein a reamer (5) is installed on a motor output shaft; a location seat (6) is installed on a cylinder piston rod; a location boss (6.1) is formed on the location seat (6); a limit block (6.2) is further arranged on the location seat (6); an inductor (7) used for inducting an aluminium freezing motor shell, and clamped and located on the location seat (6) is further installed on the location seat (6); the cylinder piston rod, the location seat (6), the motor output shaft and the reamer (5) are coaxially arranged; the cylinder (3), the motor (4) and the inductor (7) are electrically connected with the controller (2). The automatic reaming machine is high in automation degree, fast in reaming speed, high in efficiency, high in reaming quality, and relatively low in cost.

Owner:NINGBO LIONBALL VENTILATOR

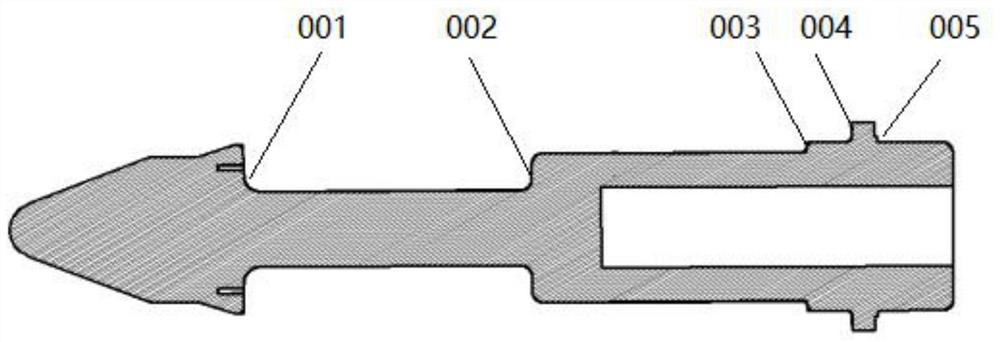

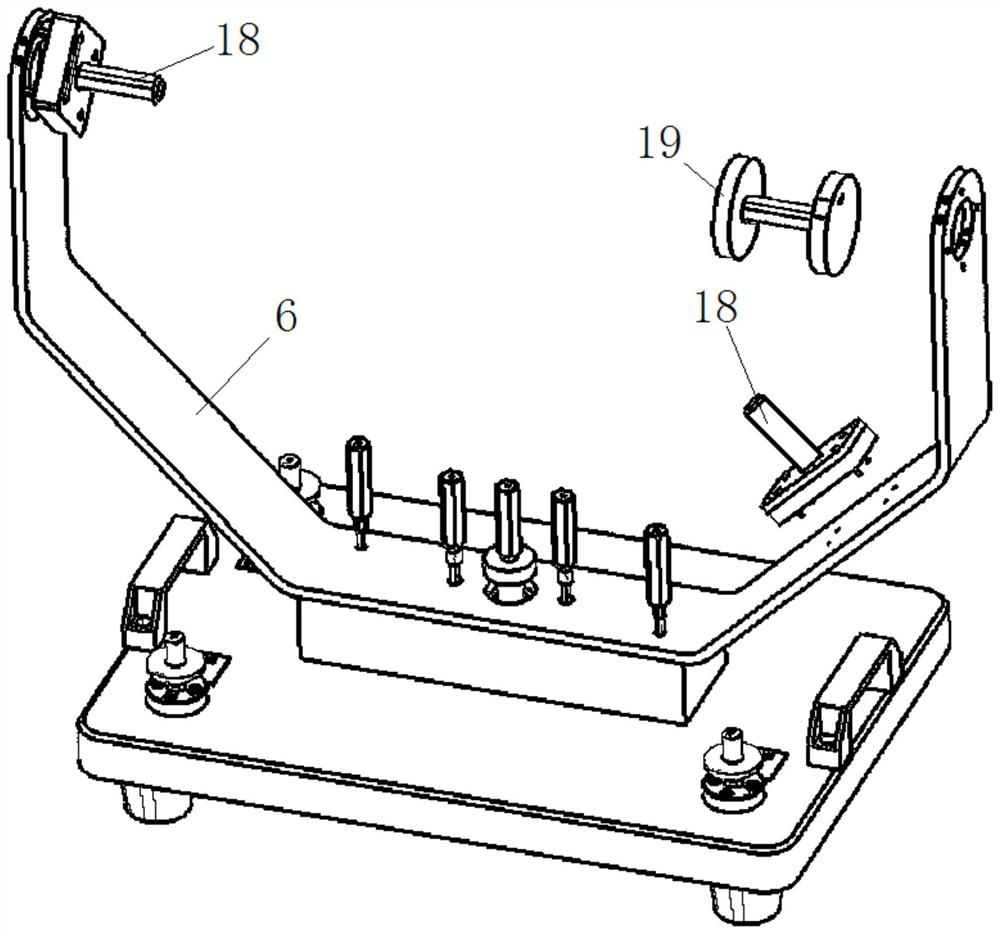

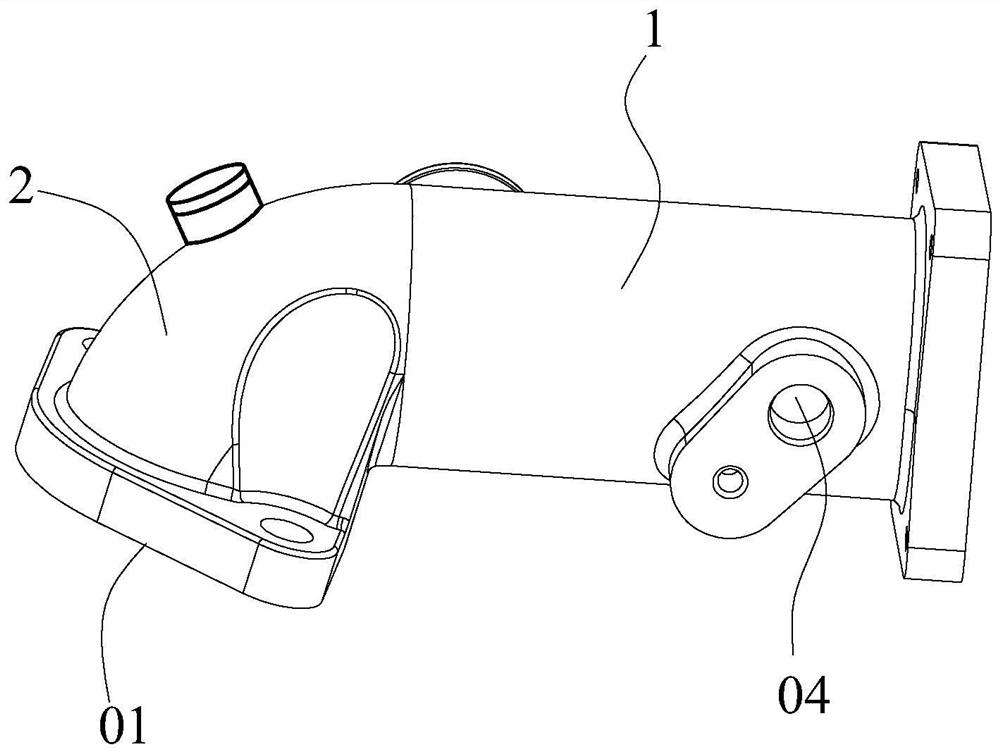

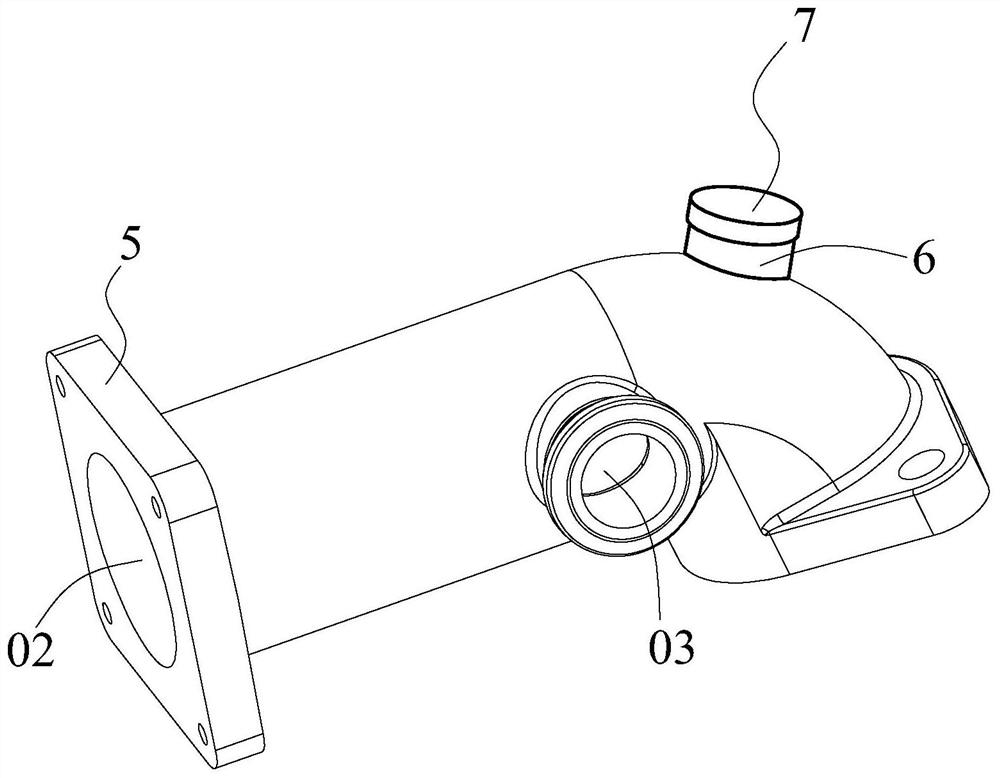

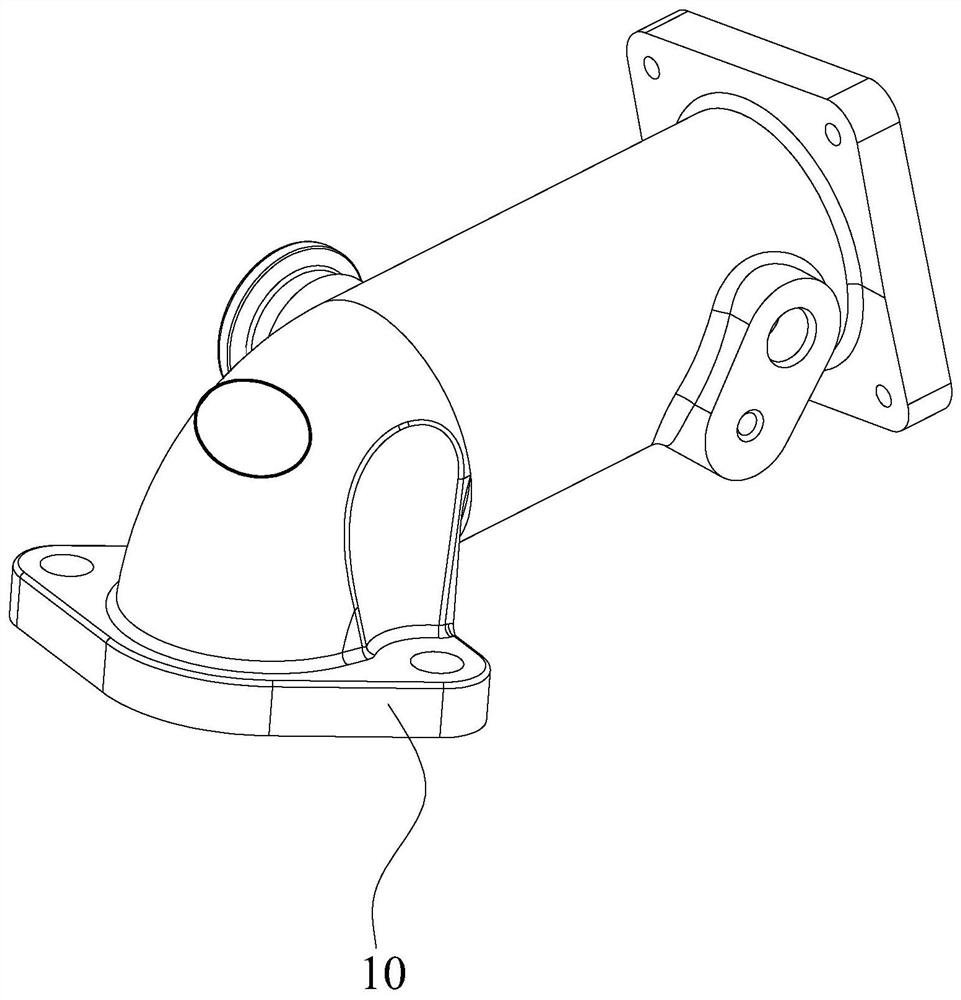

Engine intake pipe and its processing and positioning tooling

ActiveCN112727645BEasy to process separatelyAchieve reuseWork clamping meansExhaust gas recirculationSpiral bladeFresh air

Owner:宁波裕隆汽车制泵有限公司

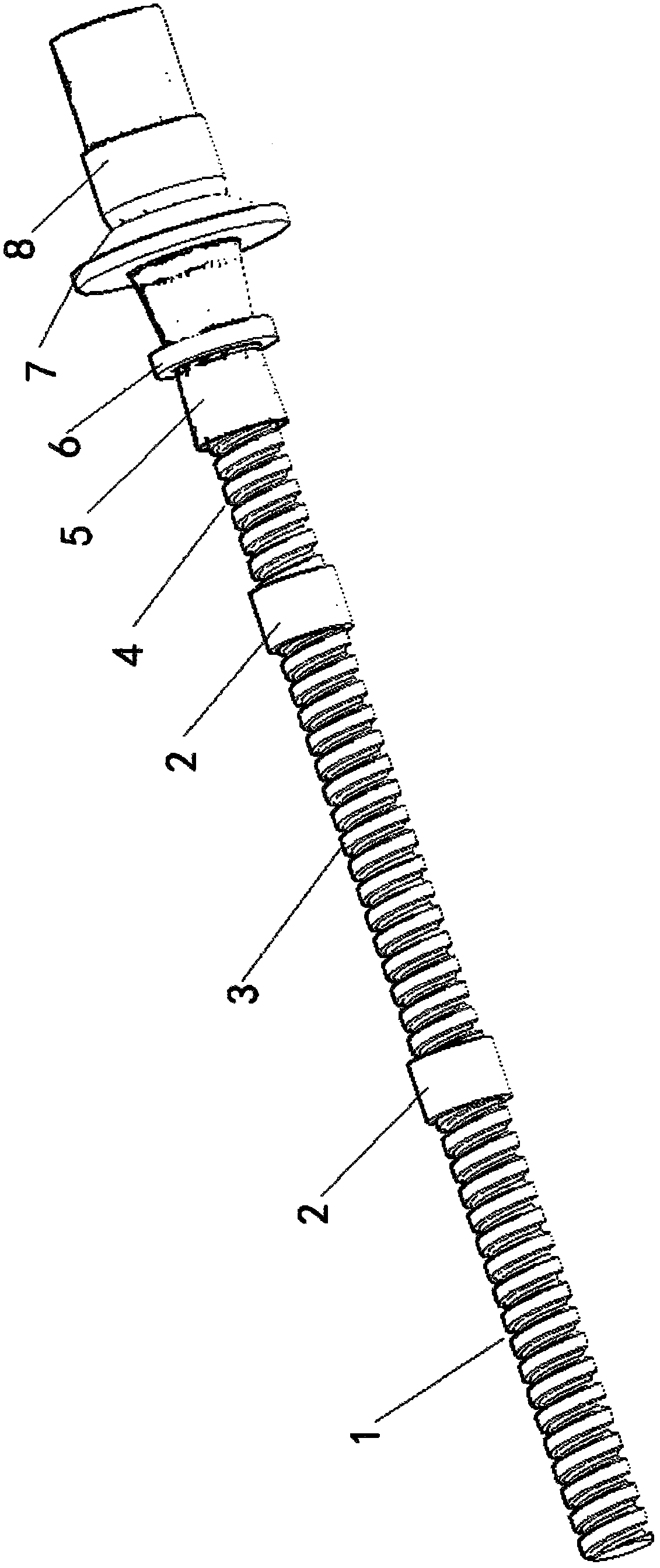

Anti-shock ground pressure extension bolt

The invention relates to an anti-shock ground pressure extension rock bolt, which includes a front bolt body and a middle bolt body, the front bolt body and the middle bolt body are connected through a connecting sleeve, and also includes a relief rod, a thin-walled round pipe, a clip hoop, dish-shaped tray, and lock nut, and the relief rod, thin-walled round pipe, clamp, dish-shaped tray and lock nut constitute the anchor rod relief anti-shock device, and the lower end of the relief rod is provided with a thread, which passes through The connecting sleeve is connected with the middle anchor rod body, the upper end of the relief rod is wedge-shaped; the upper end of the thin-walled circular tube is provided with external threads, the relief rod is inserted into the thin-walled circular pipe, and the lower end of the thin-walled circular pipe is pressed against the relief rod. Tight, a hoop is installed on the pressing position; a dish-shaped tray is set on the threaded end of the thin-walled round pipe, and a lock nut is used to connect and fix the thin-walled round pipe on the top of the dish-shaped tray. The invention increases the elongation rate of the anchor rod while increasing the length of the anchor rod, and has simple structure, safety and reliability.

Owner:LIAONING TECHNICAL UNIVERSITY +1

Camshaft axial limit structure

ActiveCN104832240BEliminate vibrationAffect stabilityValve arrangementsMachines/enginesHydraulic cylinderElastic component

The invention relates to an axial limiting structure for a cam shaft. The axial limiting structure for the cam shaft overcomes the defect that the axial limiting of an existing cam shaft is rigid limiting, so that shaking of the cam shaft is transmitted to a machine body, and an impact force subjected by the machine body from the cam shaft leads the machine body to shake when a thrust plate or a thrust bolt conducts liming on the cam shaft. The provided axial limiting structure for the cam shaft comprises a machine body, the cam shaft and an end cover. A position, corresponding to the end face of the cam shaft, on the end cover is provided with a limiting seat. The limiting seat comprises a hydraulic cylinder barrel and a limiting column. The hydraulic cylinder barrel is provided with a first cavity, a second cavity, a main oil circuit and a branch oil circuit. The bore diameter of the first cavity is greater than that of the second cavity. The main oil circuit is communicated with the first cavity. The branch oil circuit is communicated with the main oil circuit. A liquid inlet valve is arranged at an outlet of the main oil circuit. A safe valve is arranged at an outlet of the branch oil circuit. The limiting column comprises a first piston part and a second piston part from left to right. The end portion of the second piston part is provided with an elastic component. The bottom of the second cavity is provided with a shock absorption component.

Owner:遵义市文杰机电有限责任公司

High-speed and precise rock wool push plate mechanism

ActiveCN112811077BEasy to process separatelyPrecise positioningLoading/unloadingConveyor partsMechanical engineeringWaste material

The invention discloses a high-speed and precise rock wool push plate mechanism, which comprises a square frame, a positioning feeding mechanism is arranged on the square frame, a pushing mechanism is arranged on one side of the positioning feeding mechanism, and a lower material organization. The beneficial effect of the present invention is that, through the expansion and contraction of the second cylinder, the second lifting block can be raised and lowered, which facilitates the positioning of rock wool boards and rock wool strips, and the positioning accuracy is high. After the positioning is completed, the third lifting block The lifting of the block and the movement of the mobile table can facilitate the rock wool board and rock wool strips to be pushed to one side, which is convenient for stacking. When there is waste, the first lifting block can be lowered, and the waste can be pushed into the lower barrel. , to facilitate the export of waste materials, after the waste materials are exported, through the rotation of the lower material cylinder, the end of the lower material cylinder containing the waste materials can be rotated away to facilitate the removal of waste materials, and this device can process multiple groups of rock wool boards at one time Or rock wool strips, which improve work efficiency.

Owner:邯郸理想包装机械有限公司

Axial limiting structure for cam shaft

The invention relates to an axial limiting structure for a cam shaft. The axial limiting structure for the cam shaft overcomes the defect that the axial limiting of an existing cam shaft is rigid limiting, so that shaking of the cam shaft is transmitted to a machine body, and an impact force subjected by the machine body from the cam shaft leads the machine body to shake when a thrust plate or a thrust bolt conducts liming on the cam shaft. The provided axial limiting structure for the cam shaft comprises a machine body, the cam shaft and an end cover. A position, corresponding to the end face of the cam shaft, on the end cover is provided with a limiting seat. The limiting seat comprises a hydraulic cylinder barrel and a limiting column. The hydraulic cylinder barrel is provided with a first cavity, a second cavity, a main oil circuit and a branch oil circuit. The bore diameter of the first cavity is greater than that of the second cavity. The main oil circuit is communicated with the first cavity. The branch oil circuit is communicated with the main oil circuit. A liquid inlet valve is arranged at an outlet of the main oil circuit. A safe valve is arranged at an outlet of the branch oil circuit. The limiting column comprises a first piston part and a second piston part from left to right. The end portion of the second piston part is provided with an elastic component. The bottom of the second cavity is provided with a shock absorption component.

Owner:遵义市文杰机电有限责任公司

Split type lock cover and processing method of lock cover frame of split type lock cover

The invention discloses a split type lock cover, and discloses a processing method of a lock cover frame of the split type lock cover. The processing method of the lock cover frame comprises the stepsthat step a, a square aluminum ingot is selected and extruded and molded to form square frame bars, and convex bars parallel to the long sides of the square frame bars are arranged at the positions,near the bottom sides of the square frame bars, of the square frame bars; step b, the partial convex bars are removed, and a plurality of disconnected convex edges are formed on the square frame bars;step c, the square frame bars are bent and molded to form rounded rectangular frames, and the rounded corners of the rounded rectangular frames are located at the disconnection of the convex edges; step d, heads and tails of the original square frame bars on the rounded rectangular frames are welded; and step e, anodic oxidation treatment is carried out on the outer surfaces of the whole roundedrectangular frames. The processing method of the lock cover frame is reasonably designed, the manufacturing process of the lock cover is greatly shortened, the production efficiency is improved, and the stable and beautiful lock cover frame is prepared.

Owner:珠海东荣金属制品有限公司

Structural-insulation graphite separation equipment

InactiveCN102814287AMeet insulation requirementsEasy to process separatelyGradingDrive wheelTransmission belt

The invention discloses structural-insulation graphite separation equipment which comprises a driving wheel (1), a driving wheel support (2), a driving motor (3), a driven wheel support (4), a driven wheel (5) and a conveying belt (6). The driving wheel (1) is connected with the driving motor (3) through a transmission belt and is hinged with the driving wheel support (2), the driven wheel (5) is hinged with the driven wheel support (4), the driving wheel (1) is connected with the driven wheel (5) through the conveying belt (6), and two ceramic bearing bushes (7) are respectively arranged on a mounting shaft of the driving wheel support and a mounting shaft of the driven wheel support. According to the technical scheme, the structural-insulation graphite separation equipment has the advantages that the operational requirement can be met since the driving wheel support and the driven wheel support are made of materials with high mechanical strength, the insulating requirement can be met due to the ceramic bearing bushes, the manufacturing process is simple, and the service life of the graphite separation equipment is prolonged.

Owner:NANTONG SANXIN CARBON GRAPHITE EQUIP

A bearing ring processing lathe

ActiveCN110076352BEasy to process separatelyReduce workloadMetal working apparatusTurning machinesClassical mechanicsEngineering

The invention relates to a machining lathe for bearing rings, and relates to the technical field of bearing machining equipment. The machining lathe comprises a machine body and further comprises a feeding mechanism, a cutting mechanism and a discharging mechanism. The feeding mechanism, the cutting equipment and the discharging mechanism are sequentially arranged on the machine body in the conveying direction of the bearing rings. The feeding mechanism comprises a screening basin, a conical unloading plate arranged on the screening disc, boosting rings distributed in the circumferential direction of the unloading plate and rotationally connected with the screening basin, a drive part arranged on the machine body and used for driving the boosting rings to rotate, and a feeding pipe tangentto the peripheral side walls of the boosting rings and communicating with the boosting rings. One end of the feeding pipe communicates with a cutting lathe, the width of the feeding pipe is consistent with the heights of the bearing rings, ring slots communicating with the peripheral side walls are formed in the top faces of the boosting rings in the circumferential directions of the boosting rings, the bottom walls of the ring slots are inclined, and the inclined surfaces face the side away from the unloading plate. The machining lathe has the effect that feeding of the bearing rings is facilitated in order to improve the production efficiency.

Owner:XINCHANG COUNTY XINXIANGYU BEARING

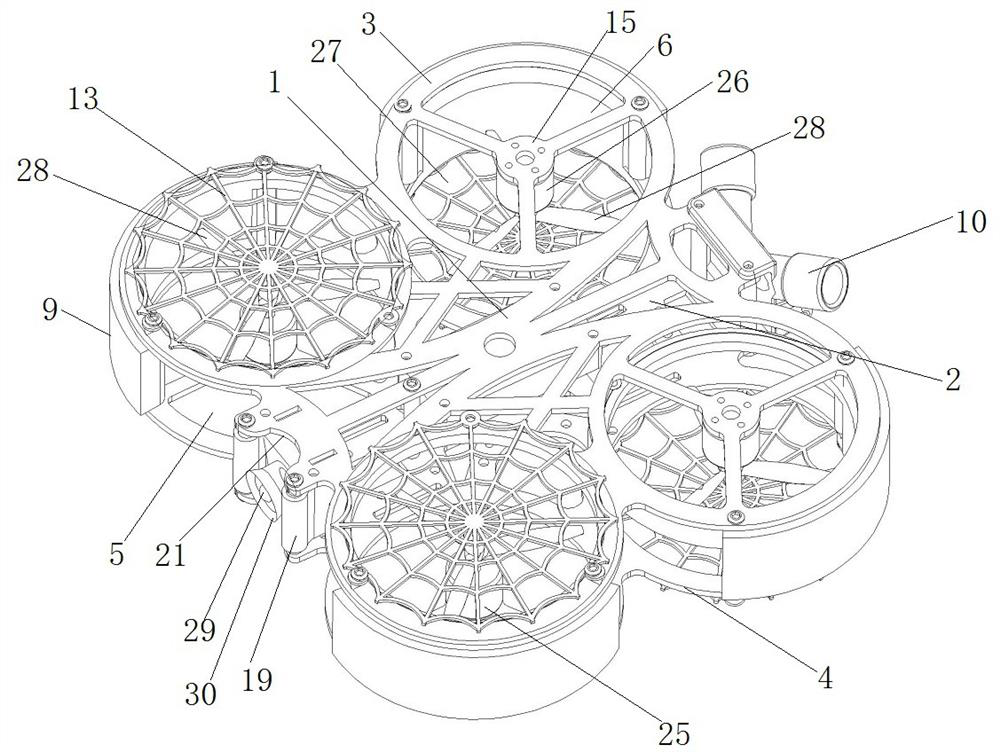

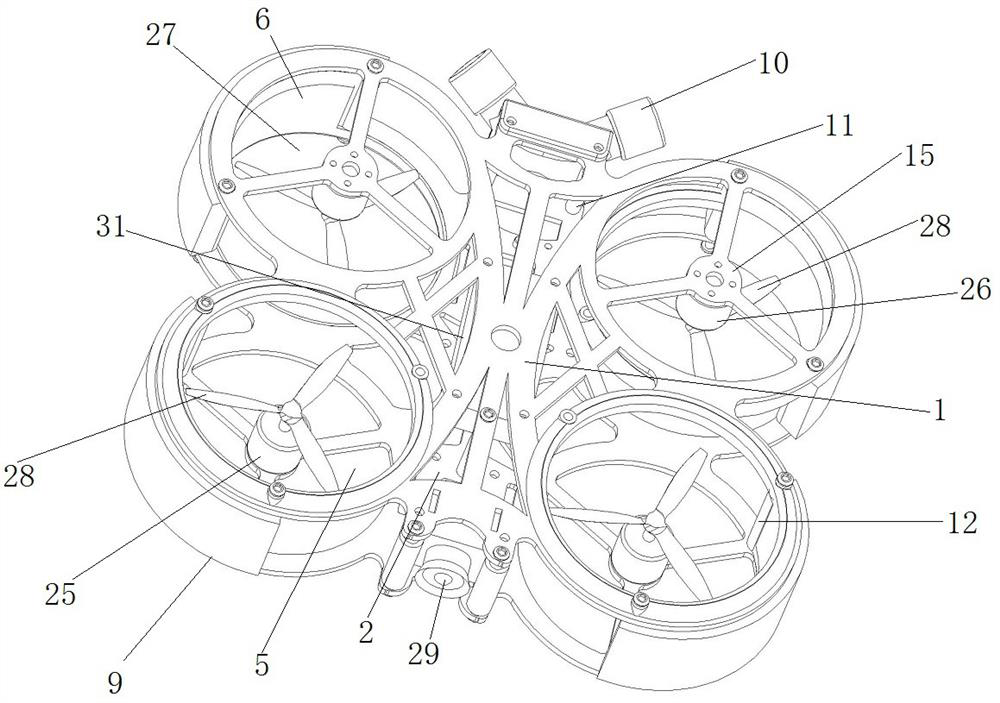

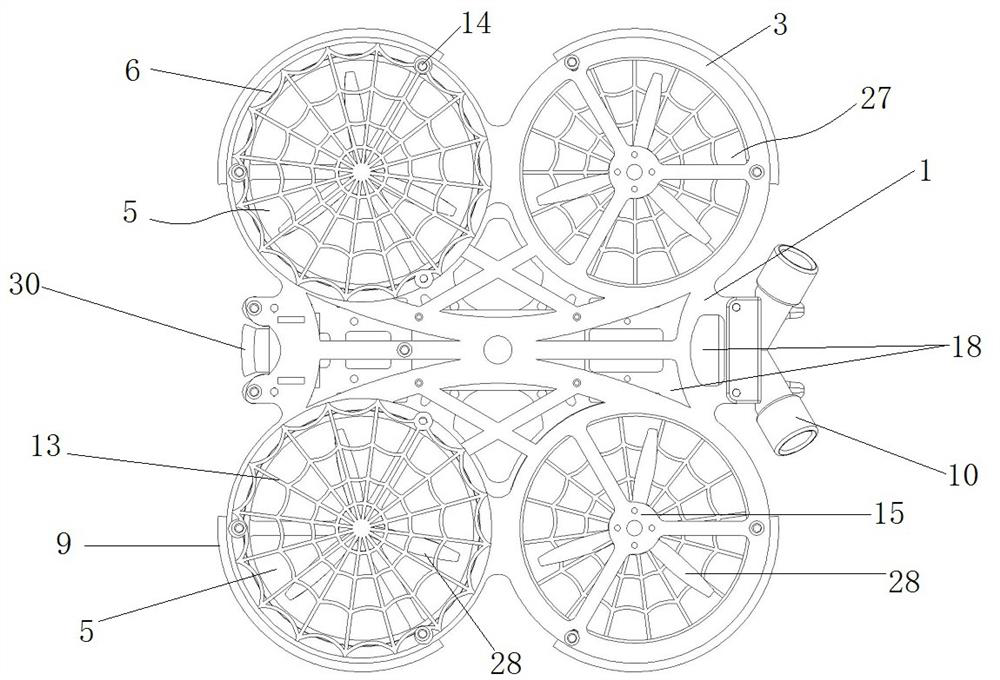

Crossing machine

PendingCN111942579AImprove flight efficiencyEasy to reinforceFuselagesRotocraftElectric machineryPropeller

The invention relates to a crossing machine. The crossing machine comprises a rack and a power device arranged on the rack, the rack is provided with ducts for airflow to pass through, and the ducts comprise a front duct and a rear duct. The power device comprises a front motor arranged in the front duct and a rear motor arranged in the rear duct, propellers are assembled on the front motor and the rear motor, and the front motor and the rear motor are arranged below the corresponding motor fixing seats; the propeller on the front motor and the propeller on the rear motor are located in the same horizontal plane, or one of the front motor and the rear motor is arranged above the corresponding motor fixing seat, and the other one is arranged below the corresponding motor fixing seat; therefore, a height difference exists between the propeller installed on the front motor and the propeller installed on the rear motor in the vertical direction. The weight of the crossing machine is reduced, meanwhile, the flight safety and stability are improved, meanwhile, aerodynamic optimization design is adopted in the duct, and the flight efficiency of the crossing machine is improved.

Owner:河南鲲之腾教育科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com