Variable-cross-section large part forming process method

A technology of large parts and molding process, applied in the field of parts manufacturing, can solve the problems of low utilization rate of raw materials, waste of raw materials, high processing cost, etc., and achieve the effect of reducing the time cost of material selection, reducing material cost and improving material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solution of the application will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

[0030] In order to solve the problems of low utilization rate of raw materials and high time and high processing costs in traditional overall processing, the present invention provides a forming process for large parts with variable cross-section. The basic inventive concept is as follows:

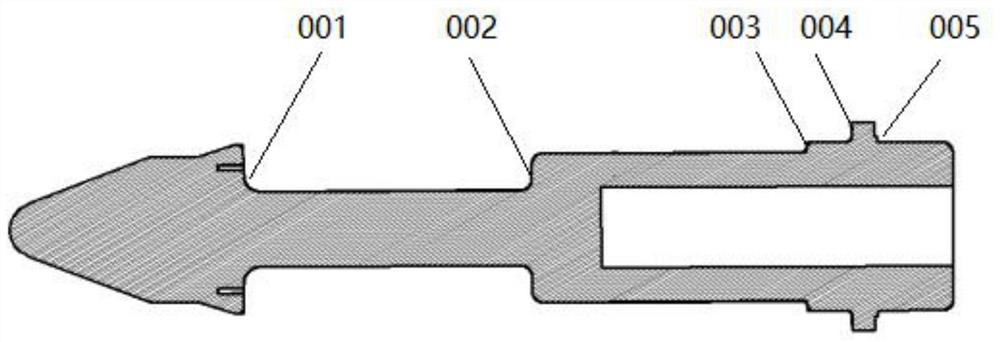

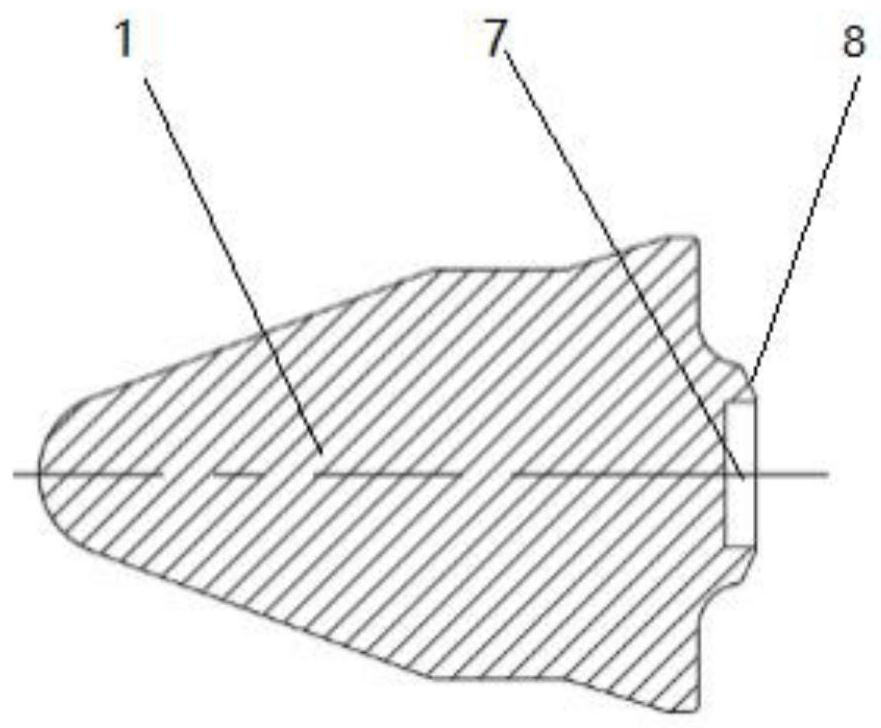

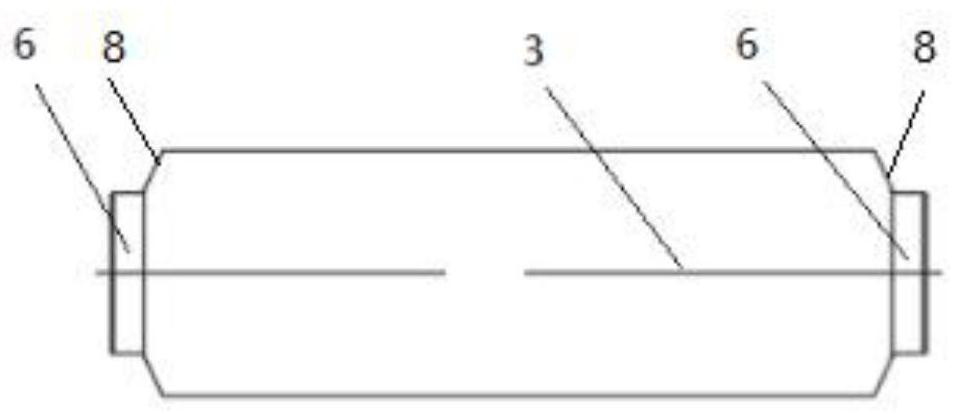

[0031] A process method for forming large parts with variable cross-sections, the process steps comprising:

[0032] Segmenting the part model, classifying the design model of the variable-section large-scale part according to the shape and / or size, determining the interface, and segmenting the design model according to the interface to obtain a segment model;

[0033] Blanking and rough machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com