Rotatable mechanical gripper device

A technology of rotating manipulators and manipulators, applied in metal processing and other directions, can solve the problems of workpiece clamping, inability to realize, and inability to realize the horizontal exchange of two claws, etc., to achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

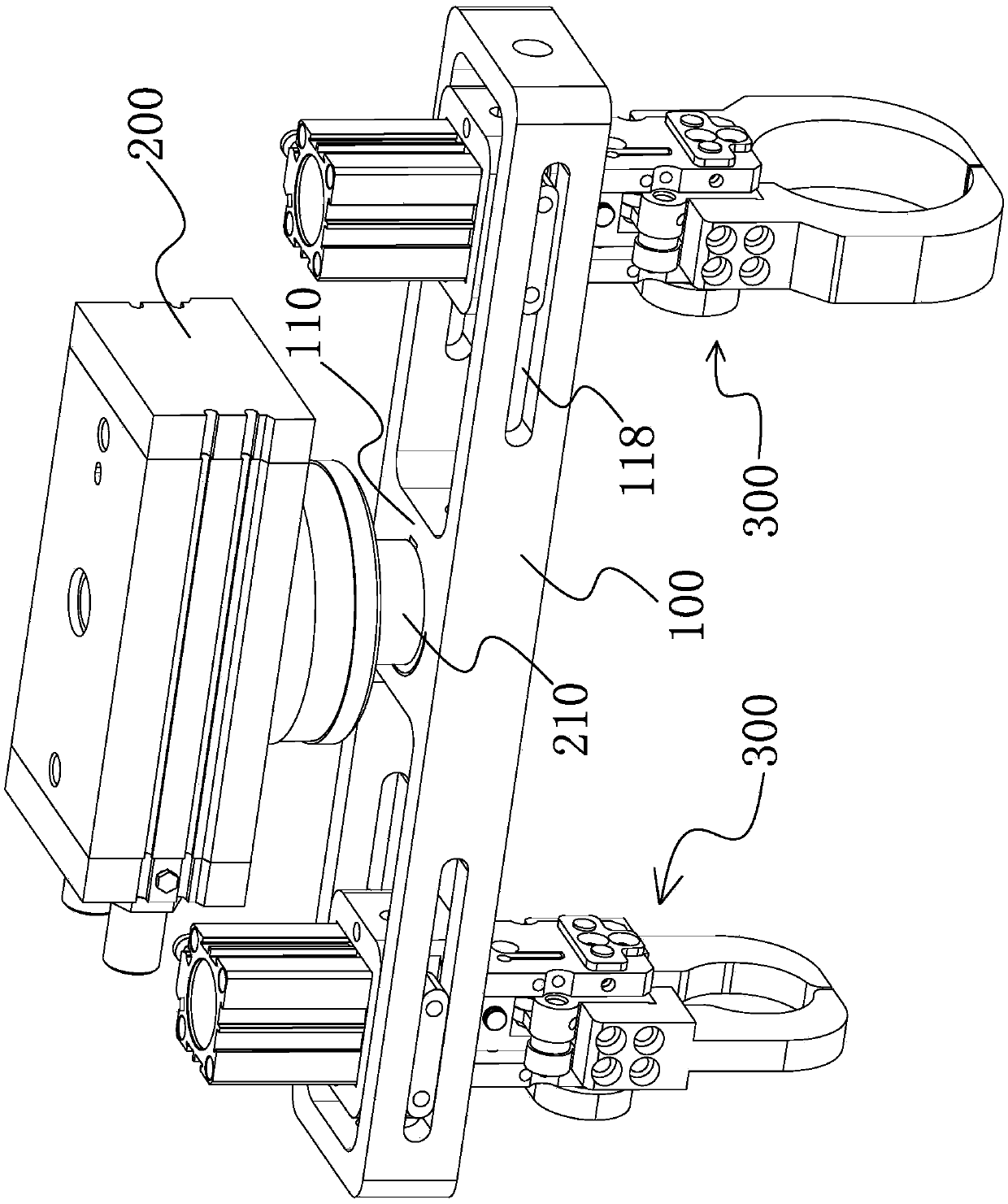

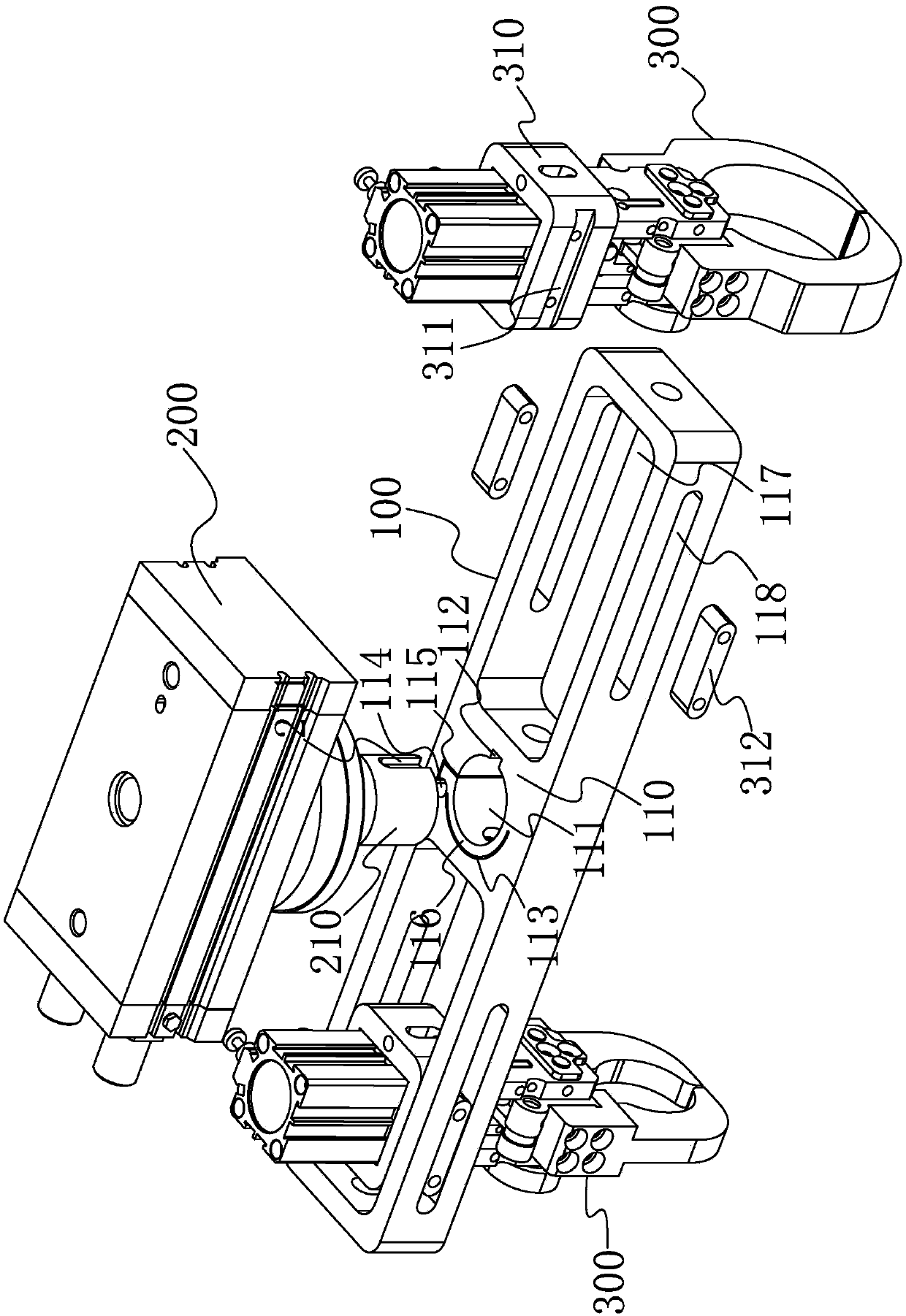

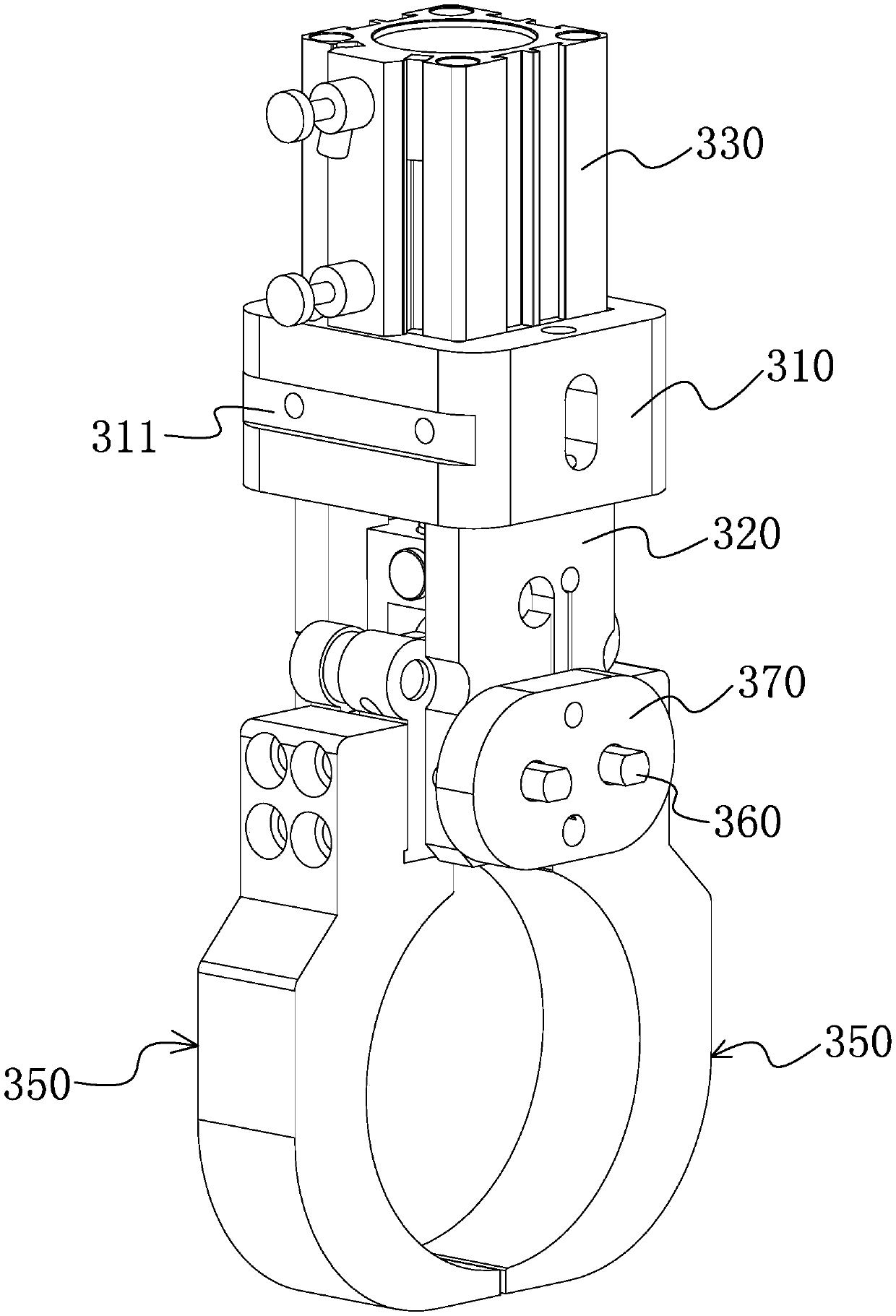

[0051] Such as figure 1 , figure 2 As shown, a rotatable manipulator 300 device of the present invention includes a frame 100 , a rotary cylinder 200 and a manipulator 300 .

[0052] The frame 100 is axially and horizontally arranged, the middle part of the frame 100 has a mounting plate 110, the output shaft 210 of the rotary cylinder 200 is fixedly connected with the mounting plate 110, and there are two groups of mechanical claws 300, preferably, each group has a mechanical claw 300 , the two manipulator claws 300 are respectively movably connected with the two ends of the frame 100, and the two sets of manipulator claws 300 are coaxially arranged and can hold workpieces. When working, the rotary cylinder 200 can drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com