Steel pipe grinding device for machining

A technology for mechanical processing and steel pipes, which is applied in the field of steel pipe grinding devices for mechanical processing, can solve the problems of inability to guarantee the uniformity of grinding, poor grinding effect, and low grinding efficiency, and achieve consistent grinding strength, convenient grinding, and uniform grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

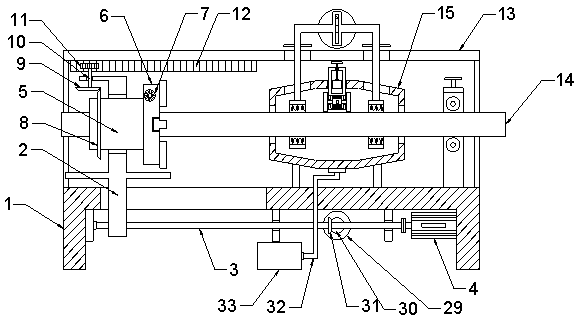

[0022] see Figure 1~3 , in an embodiment of the present invention, a steel pipe grinding device for mechanical processing, comprising a base 1, a steel pipe 14, and a derusting cylinder 15 fixedly connected to the base 1; There is a rotating cylinder 5, and a three-jaw chuck 6 is fixedly connected to one side of the rotating cylinder 5. The outer wall of the three-jaw chuck 6 is provided with a manual adjustment handle 7. By rotating the manual adjustment handle 7, the claws move to the inside, and the steel pipe 14 is adjusted. Clamping and fixing, the fixing of steel pipes with different diameters and specifications is realized by being provided with a three-jaw chuck 6, which is convenient for moving the steel pipes.

[0023] The lower end of the mobile frame 2 extends to the bottom of the base 1, and the base 1 is provided with a first sliding groove for the lateral sliding of the mobile frame 2, and the lower part of the mobile frame 2 moves in the first sliding groove; ...

Embodiment 2

[0027]The lower end of the derusting cylinder 15 is connected with a dust suction pipe 32, and the dust suction pipe 32 is connected with an industrial vacuum cleaner 33. The industrial vacuum cleaner 33 is a common industrial dust collection equipment in this field, and will not be described in detail here. The industrial vacuum cleaner 33 is electrically connected to an external power supply , Efficiently collect the iron filings and dust from grinding, avoid the random scattering of iron filings, prevent the iron filings from polluting the working environment and endangering the health of workers.

[0028] Industrial dust collection equipment can be replaced by electrostatic precipitators or electromagnetic precipitators.

Embodiment 3

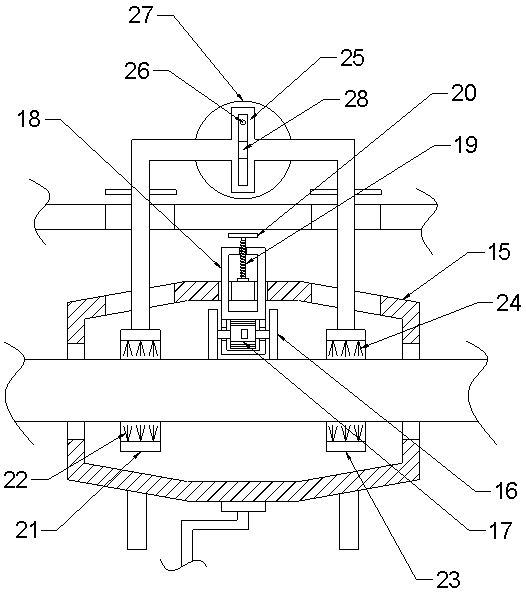

[0030] see image 3 and Figure 4 The difference between this embodiment and Embodiment 2 is that: the grinding wheel 16 is provided with a first derusting cylinder brush 21 near the feeding side of the steel pipe, and the grinding wheel 16 is provided with a second derusting cylinder near the discharging side of the steel pipe 14 Brush 23, the first derusting tube brush 21 is in a cylindrical structure and the inner wall surface is evenly bonded with steel wire bristles 22, the second derusting tube brush 23 is in a cylindrical structure and the inner wall is bonded with soft bristles 24, steel wire bristles 22 Pretreat the surface of the steel pipe 14 so that the iron filings are more likely to peel and warp, which is convenient for subsequent grinding with the grinding wheel 16 to improve the quality and efficiency of grinding; the soft bristles 24 clean the polished steel pipe surface to avoid sticking of the iron filings, or After steel pipe 14 is taken out of derusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com