Patents

Literature

43results about How to "Avoid underreaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly water-soluble carbon nanometer tube preparation method

The invention relates to preparation method for high water-soluble nano carbon tube, which comprises acidifying purifying treatment, acylchloridization and grafting. Wherein, based on not destroying its high length-diameter ratio and electron valence band structure, using chemical modification to graft lycine on wall and end of the tube to endow its high water-solubility of 30mg / ml and biocompatibility; reflowing the tube in HNO3 to remove the impurity metal catalyst particle and carboxylate the tube; then, reflowing tube in SOCl2 for completed acylchloridization; finally, acyl chloride group and amido in grafted lycine react to obtain the product.

Owner:JILIN UNIV

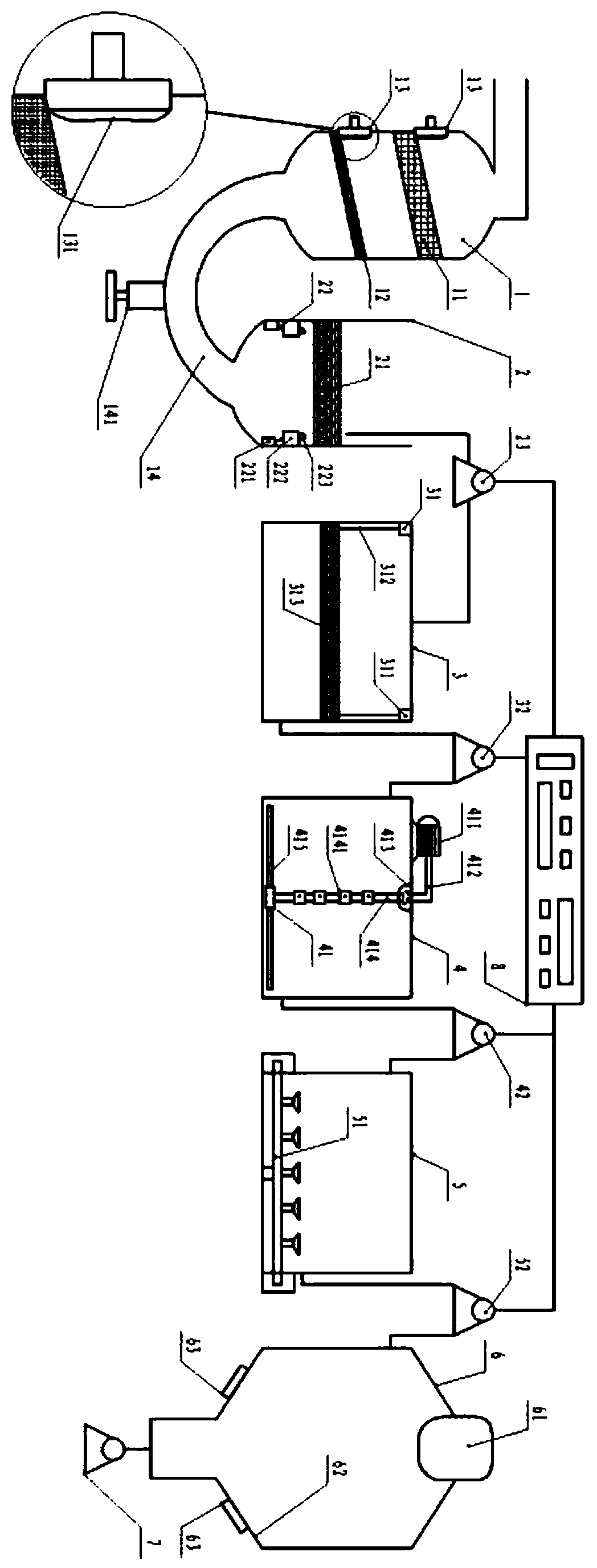

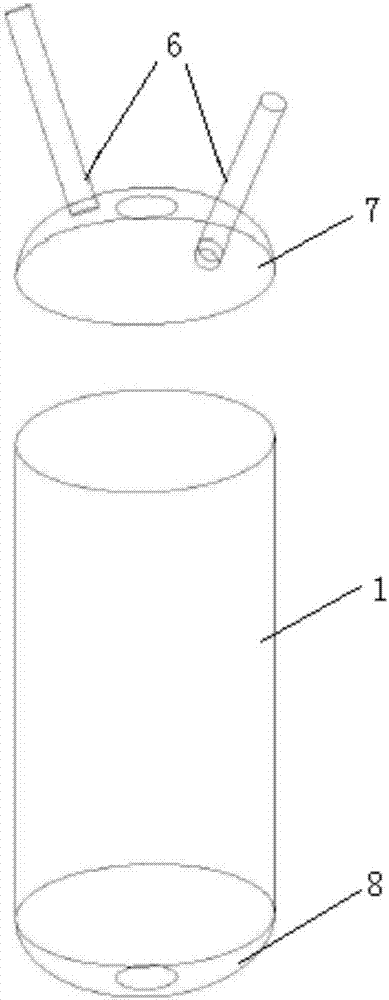

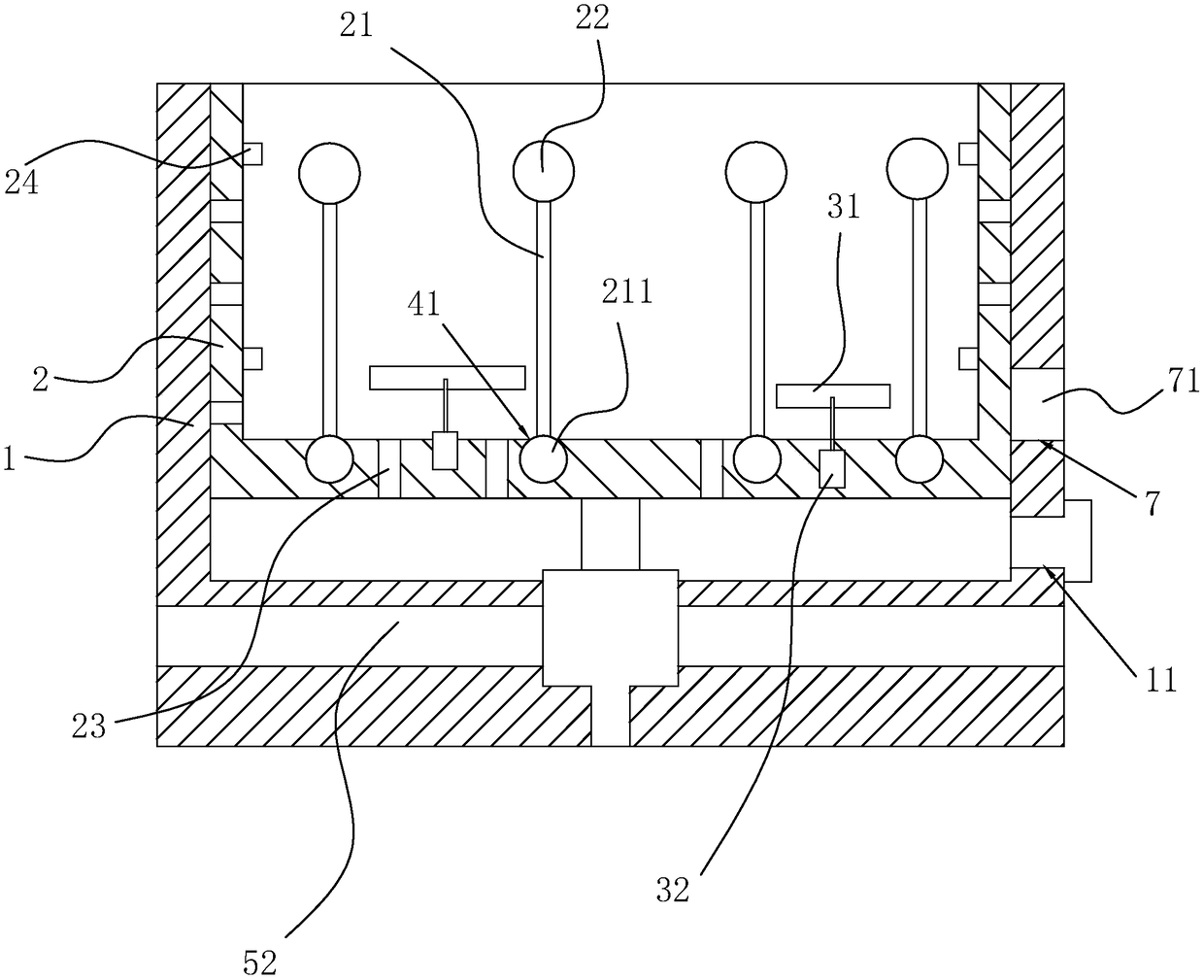

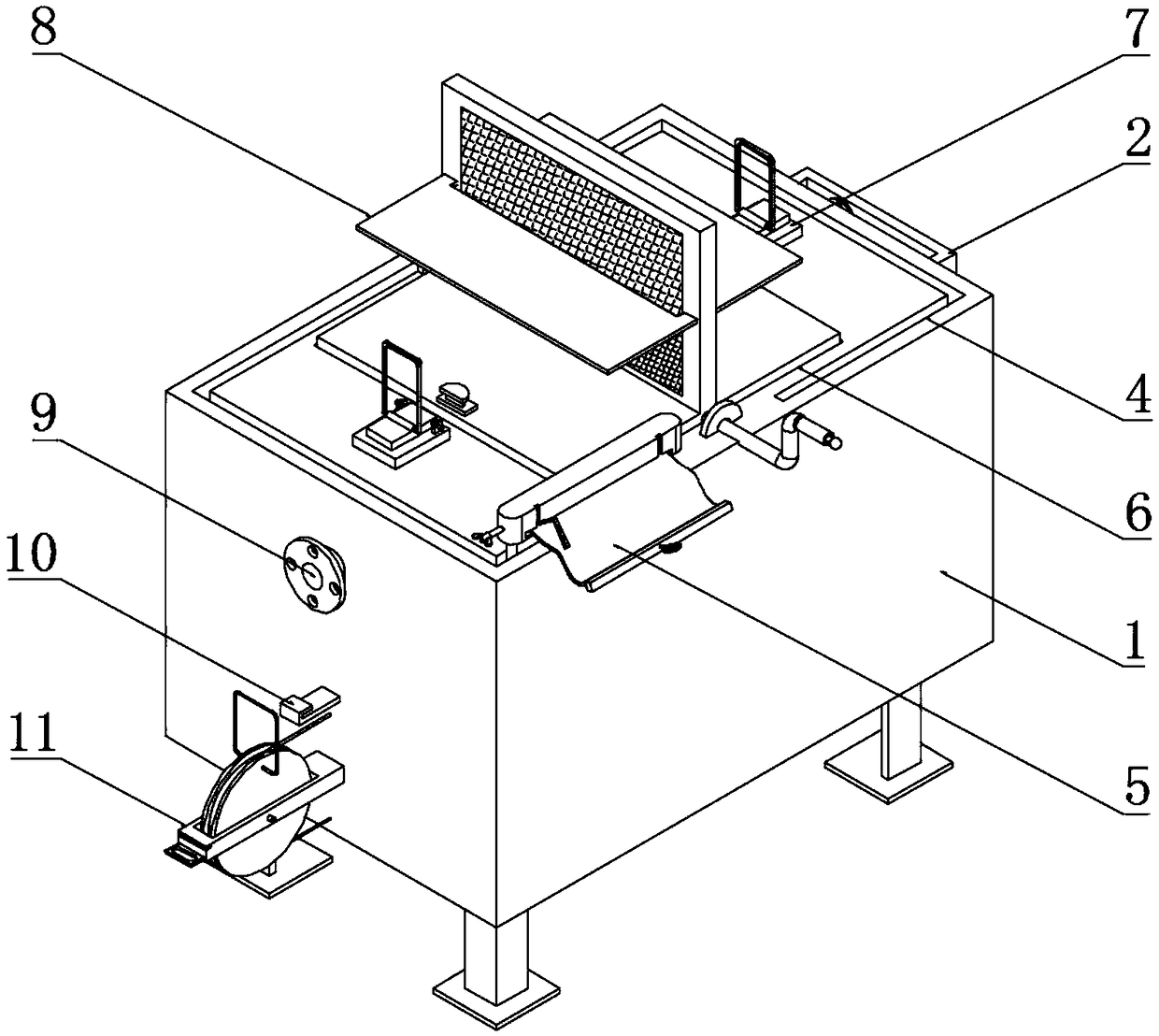

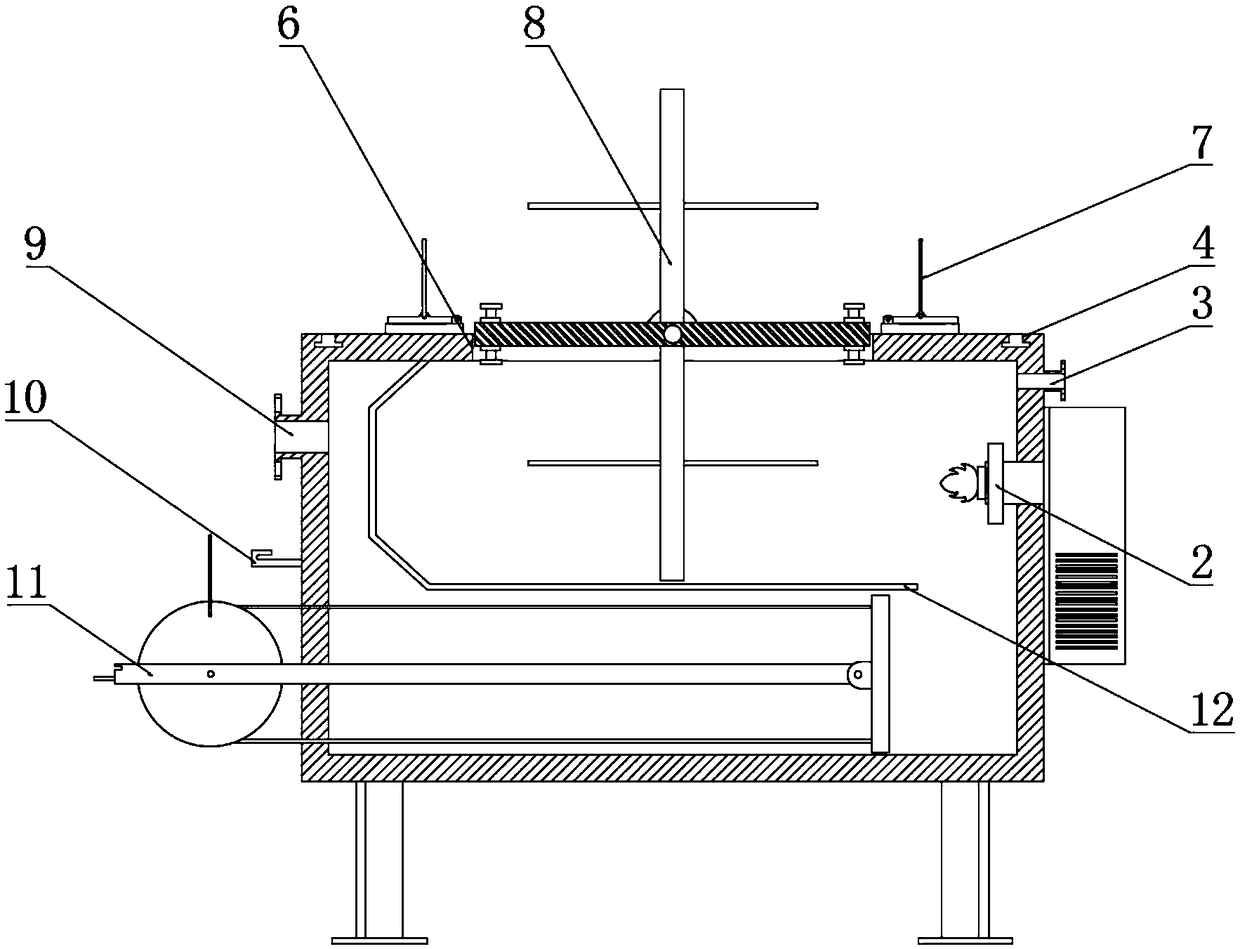

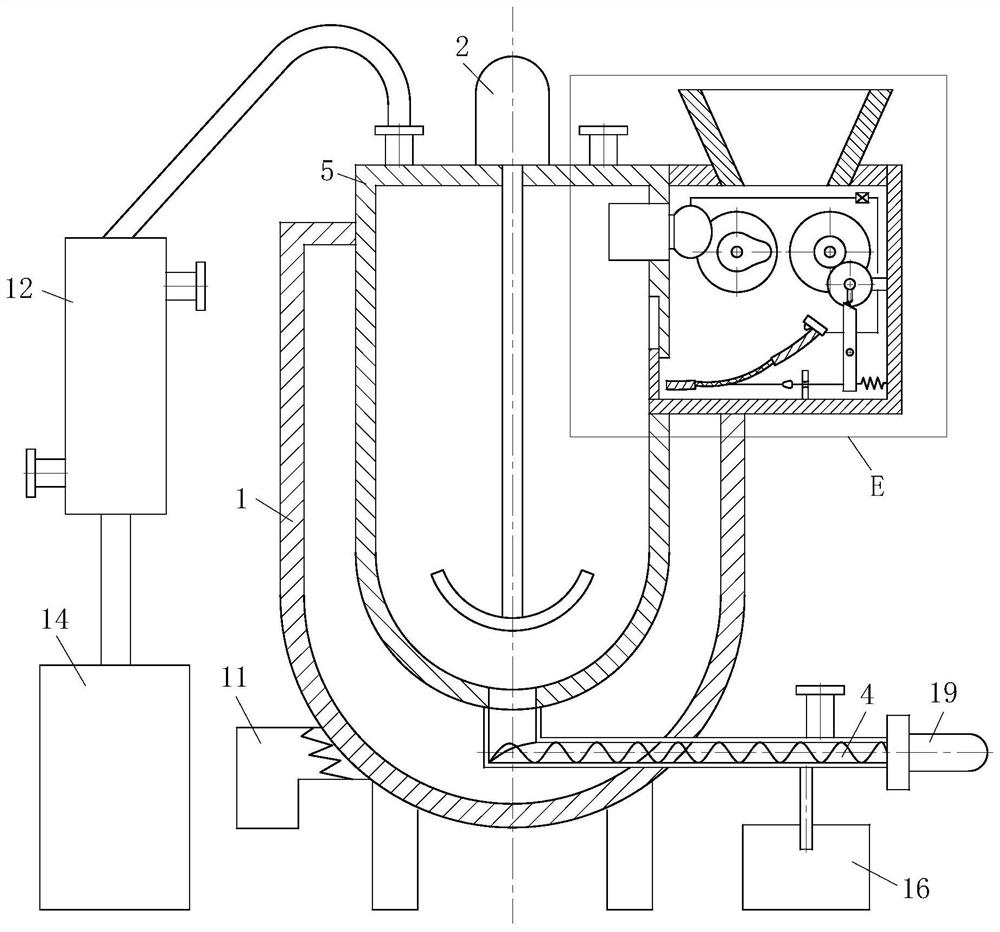

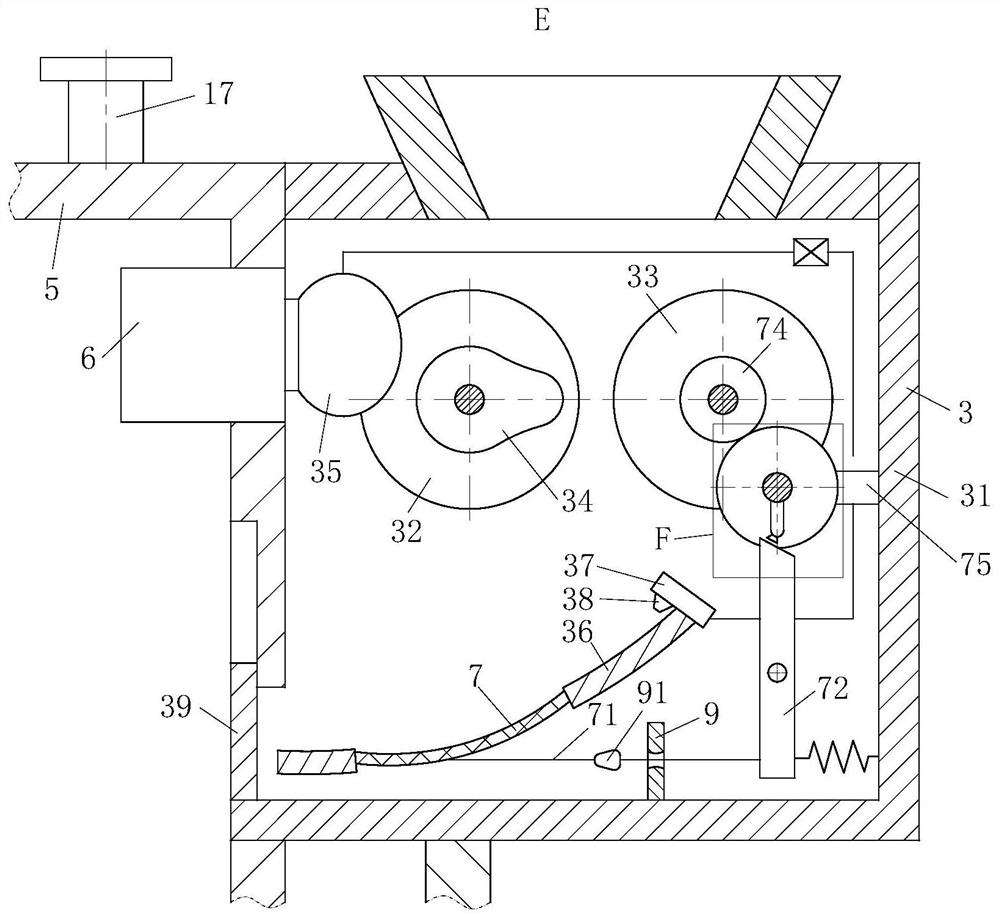

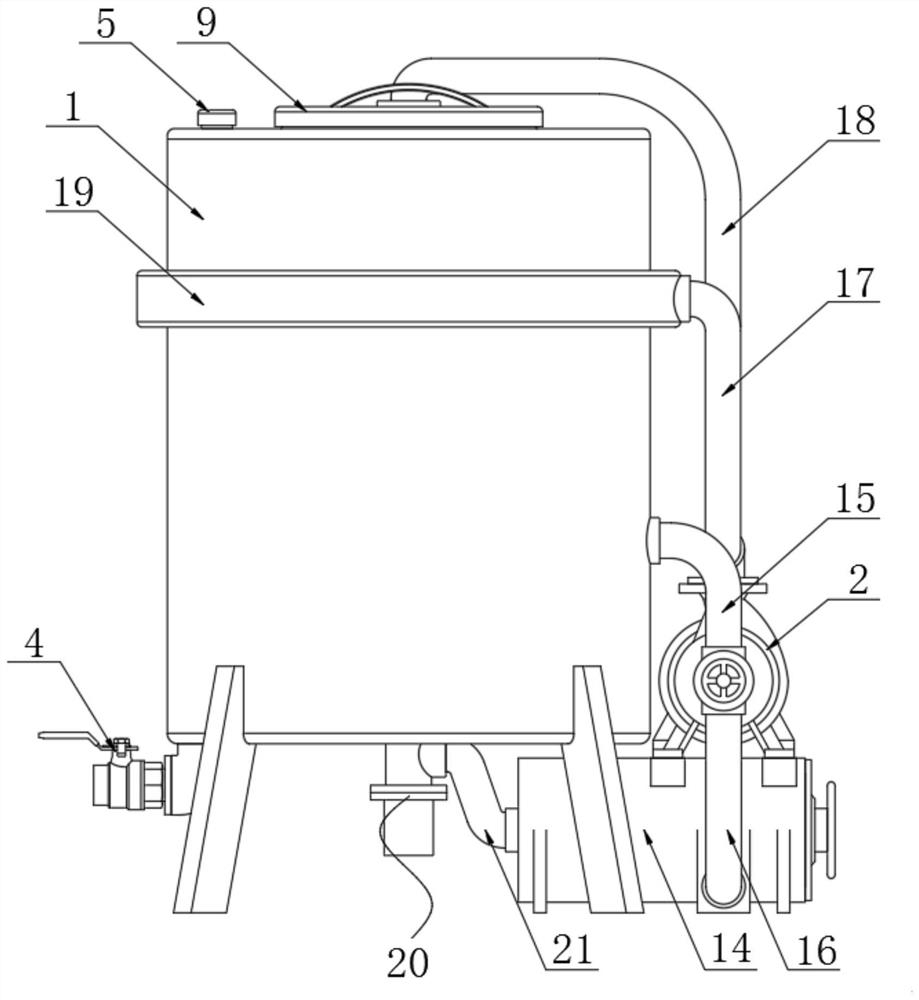

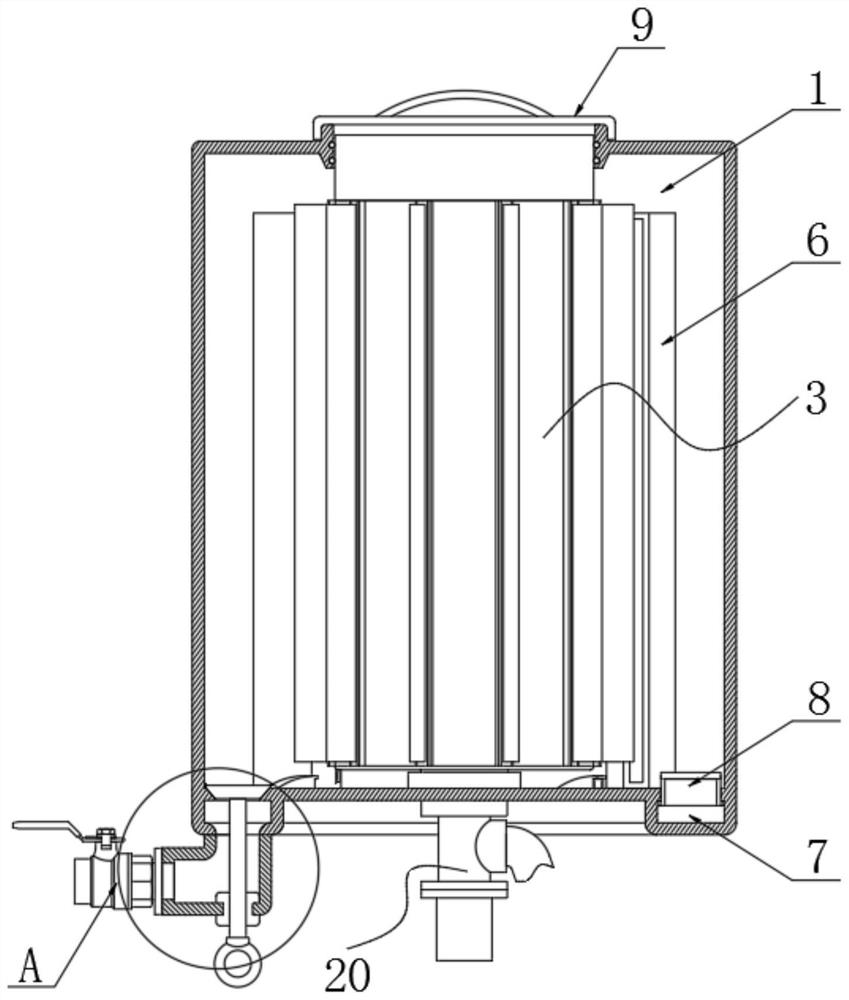

Municipal sewage integrated treatment device

PendingCN110697993ASmall footprintLow costFatty/oily/floating substances removal devicesTreatment using aerobic processesMunicipal sewageEnvironmental geology

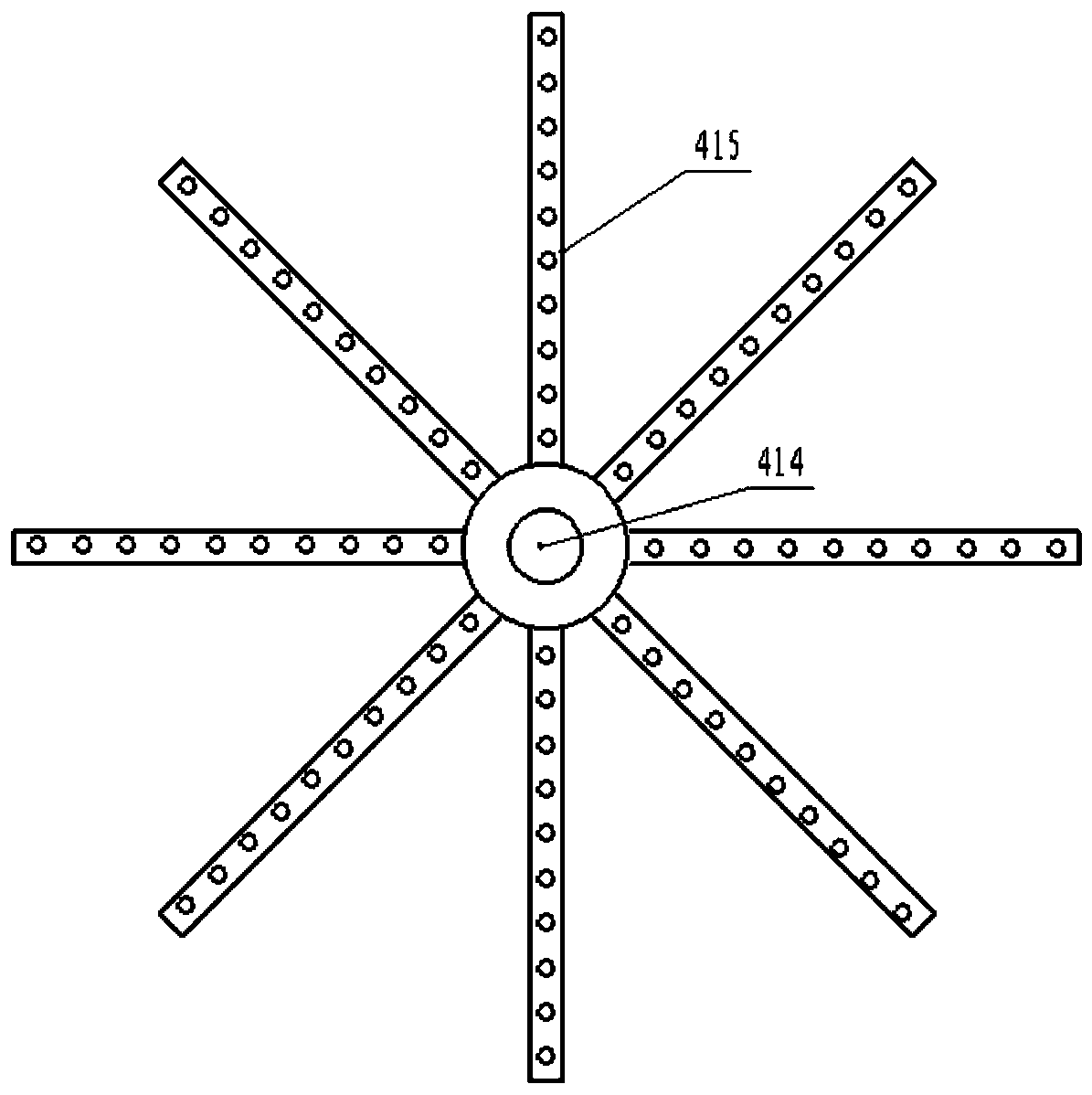

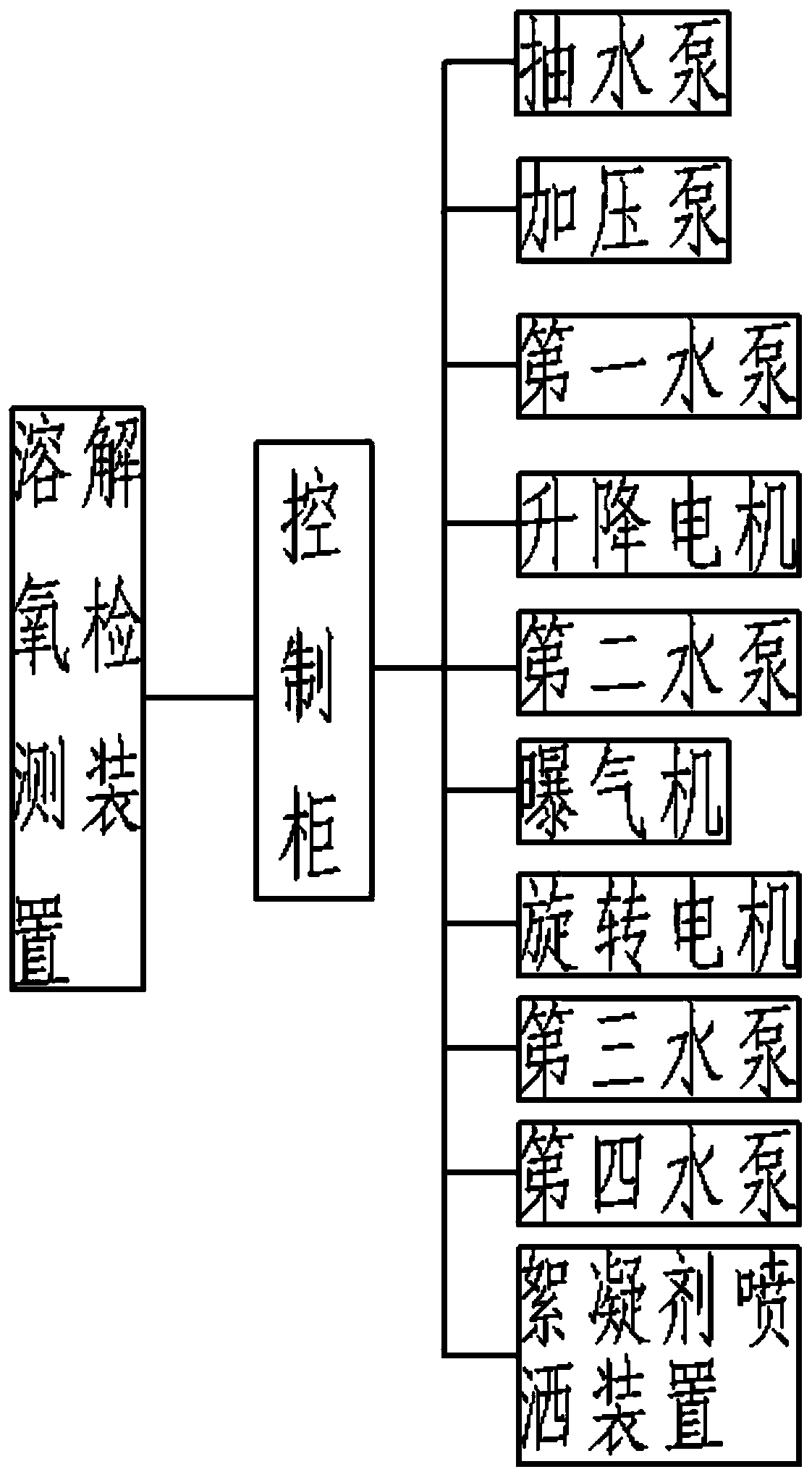

The invention discloses a municipal sewage integrated treatment device, which comprises a filtering tank, an oil removal groove, an anaerobic tank, an anoxic tank, an aerobic tank, a precipitation tank, a sludge pump and a control cabinet, wherein the bottom end of the oil removal groove is communicated to the bottom end of the filtering tank through a U-shaped pipe, the oil removal groove comprises an oil-water separation membrane and a backwashing device, the anaerobic tank is communicated to the oil removal groove and comprises a lifting type filler groove, the anoxic tank is connected to the anaerobic tank, and comprises a rotary aeration device, the aerobic tank is connected to the anoxic tank, a cyclone aerator is arranged at the bottom of the aerobic tank, the precipitation tank isconnected to the aerobic tank, and the sludge pump is connected to the bottom end of the precipitation tank, and the control cabinet is respectively connected to the backwashing device, a first waterpump, a lifting motor, a second water pump, an aerator, a rotating motor, a third water pump, the cyclone aerator and the sludge pump. According to the invention, the device has advantages of novel structure, convenience use, good treatment effect and the like.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

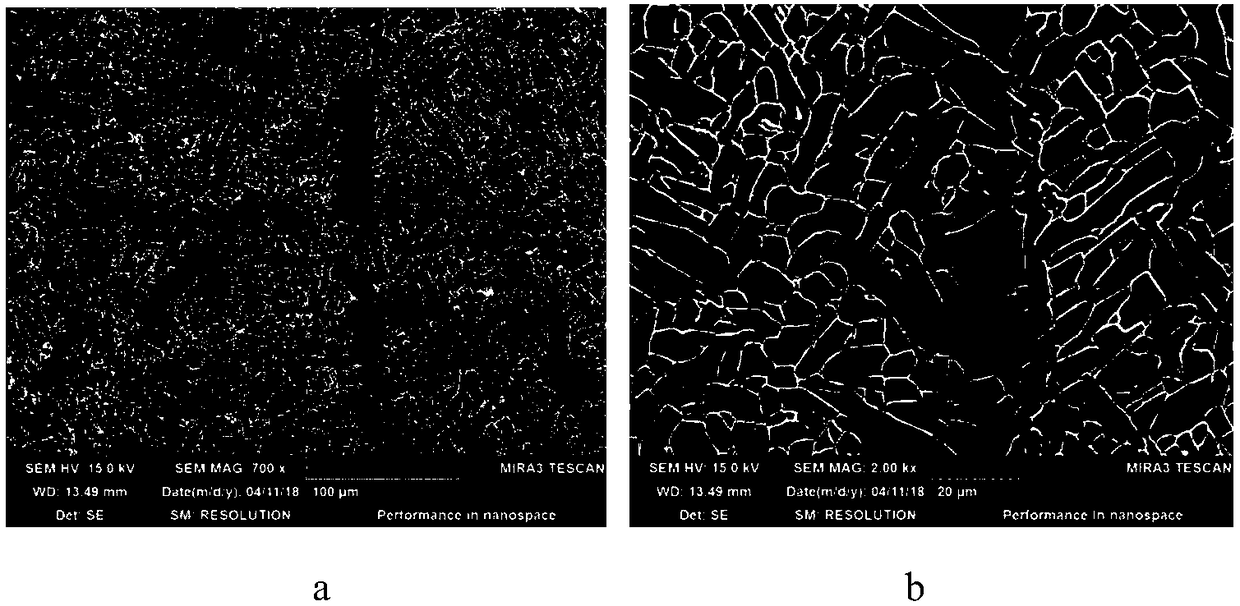

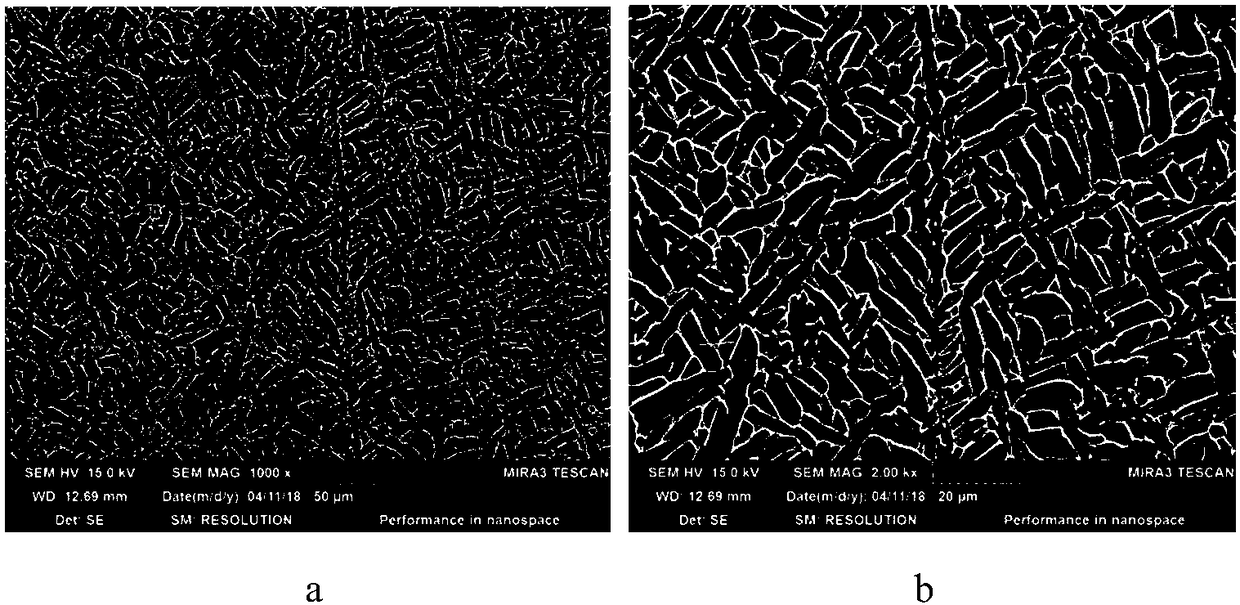

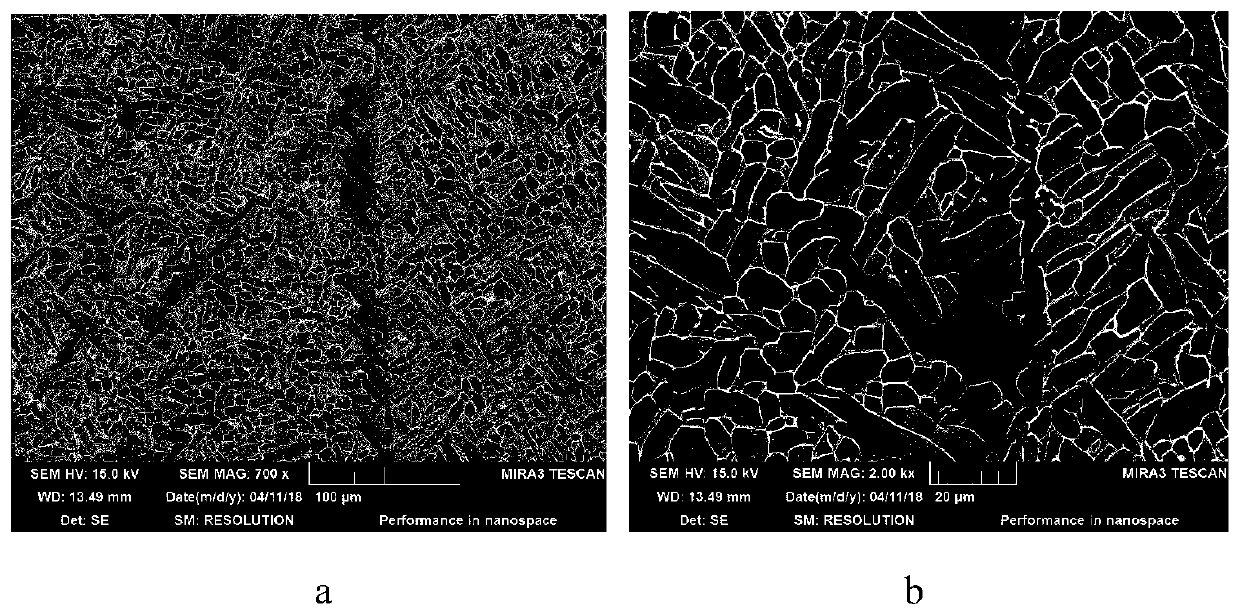

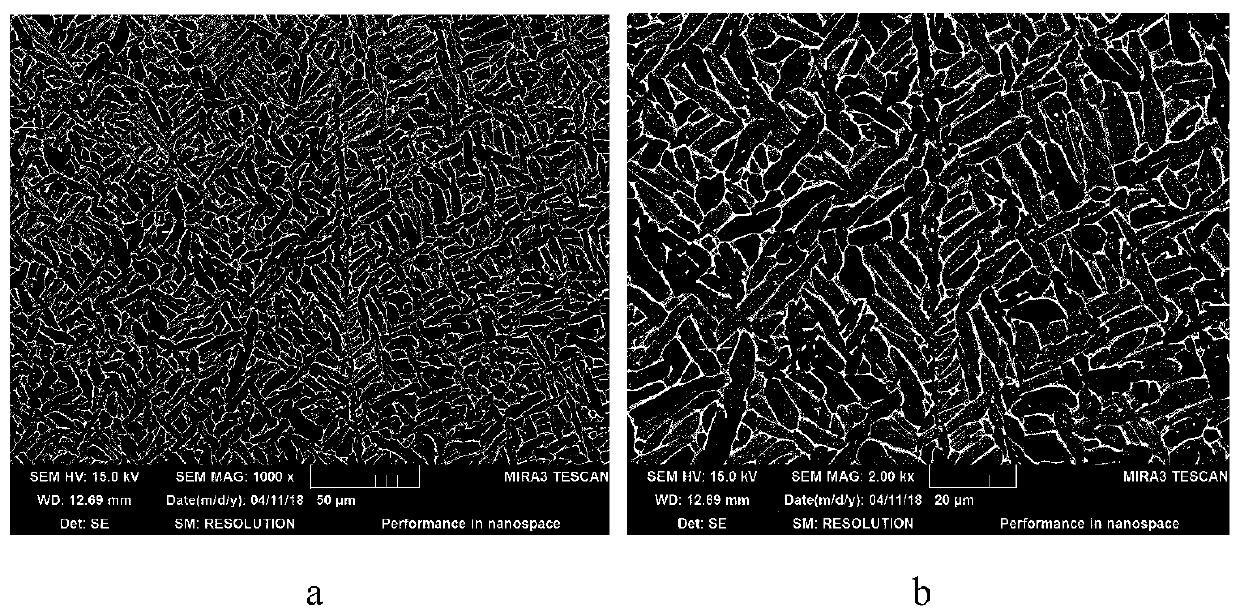

Method to eliminate primary Beta grain boundary in laser additive manufacturing TC4 alloy by induction heating of added B

InactiveCN108555297AEliminate beta grainsImprove microstructureAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingTitanium alloy

The invention discloses a method to eliminate primary Beta grain boundary in laser additive manufacturing TC4 alloy by induction heating of added B; the method comprises the steps of S1, drying B powder and titanium alloy powder in vacuum, wherein the B power accounts for 0.01-0.2% by mass; S2, mixing well the dried B powder of step S1 and titanium alloy powder to obtain mixed powder; S3, heatinga base material to 900-1100 DEG C, and forming a sample on the base material by a laser additive manufacturing apparatus. The method has the advantages that primary Beta grain boundary of laser additive manufacturing TC4 can be eliminated, grain is fined, and microstructure of TC4 alloy is improved.

Owner:XI AN JIAOTONG UNIV

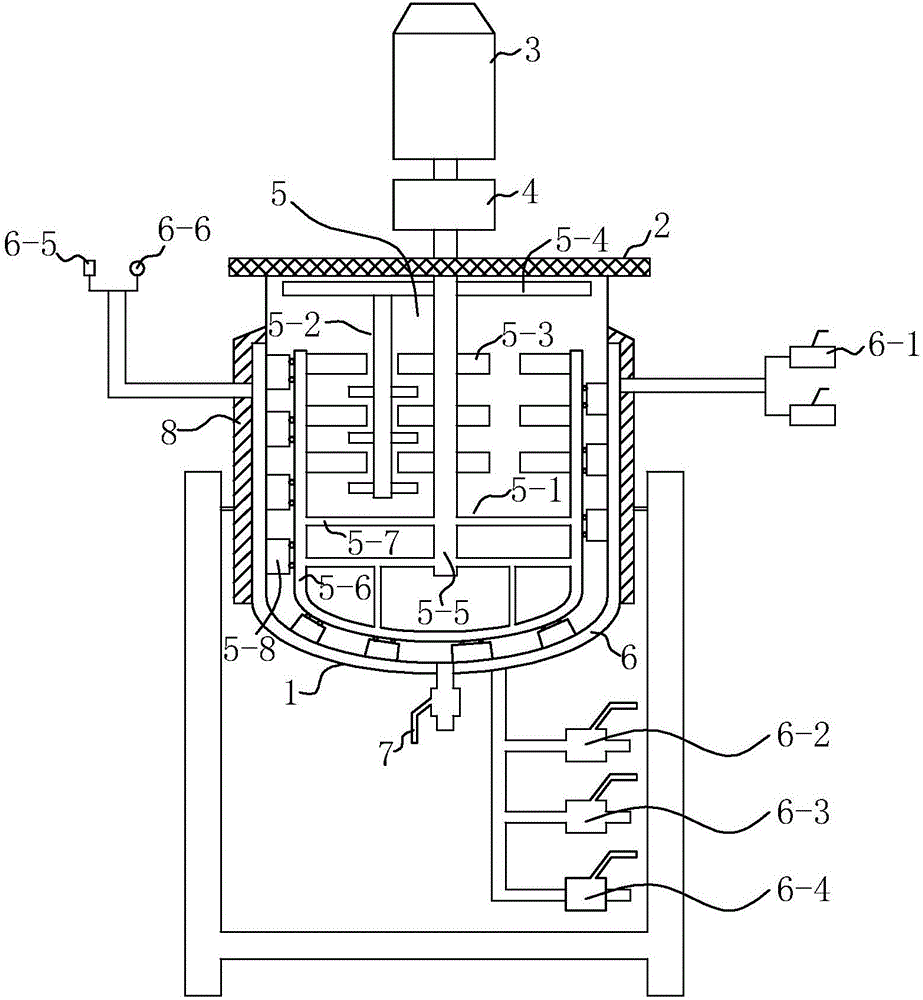

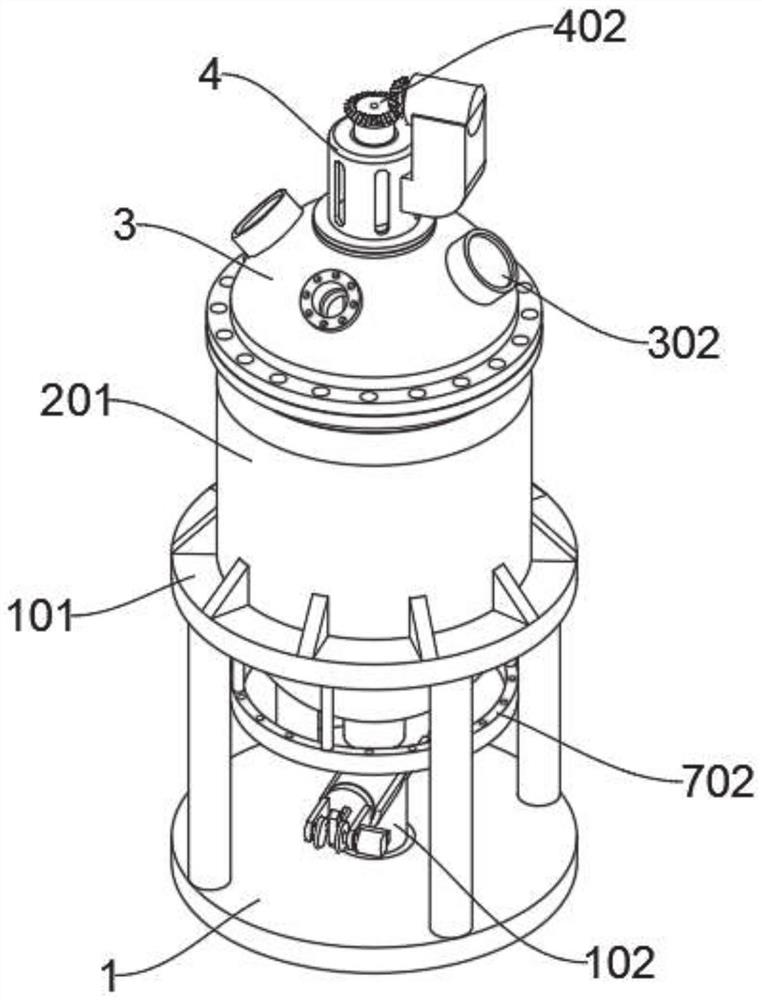

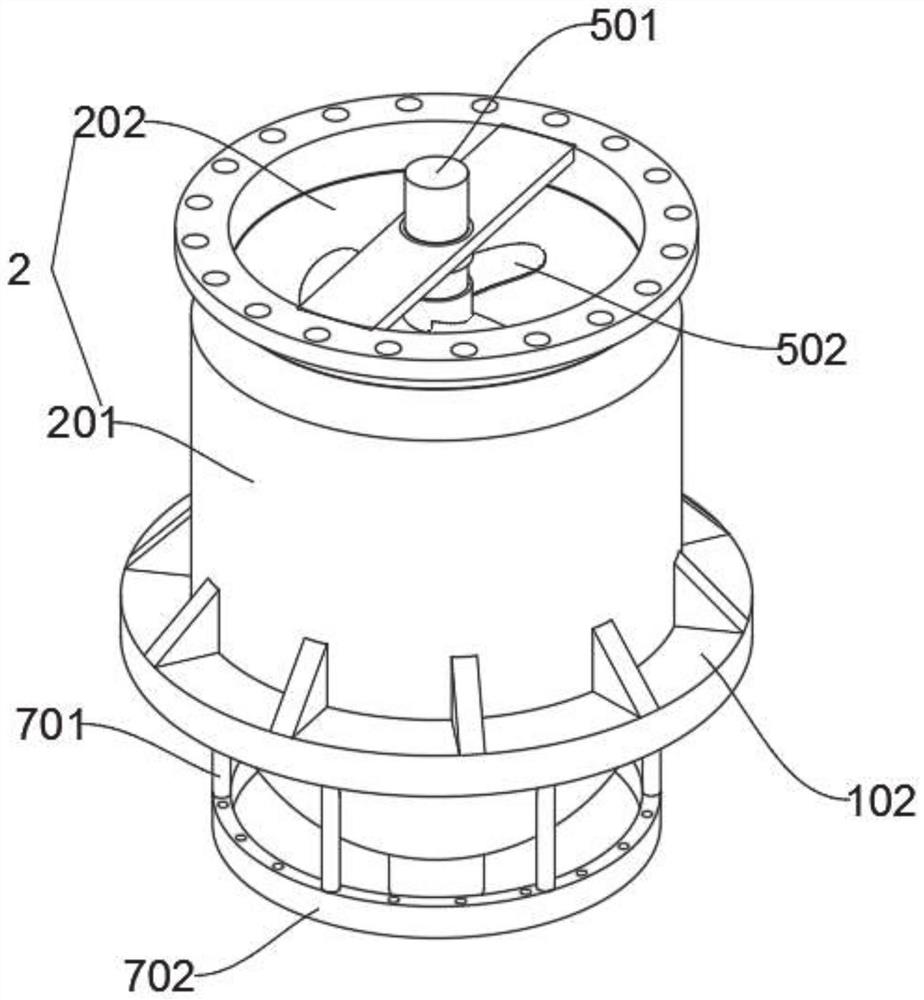

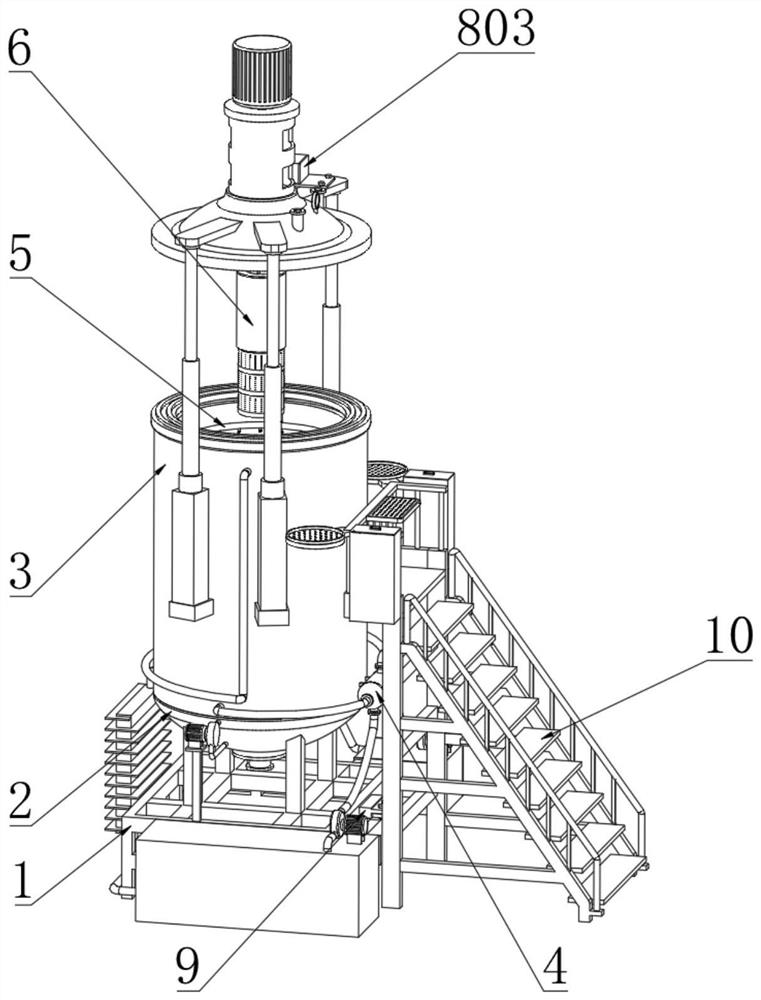

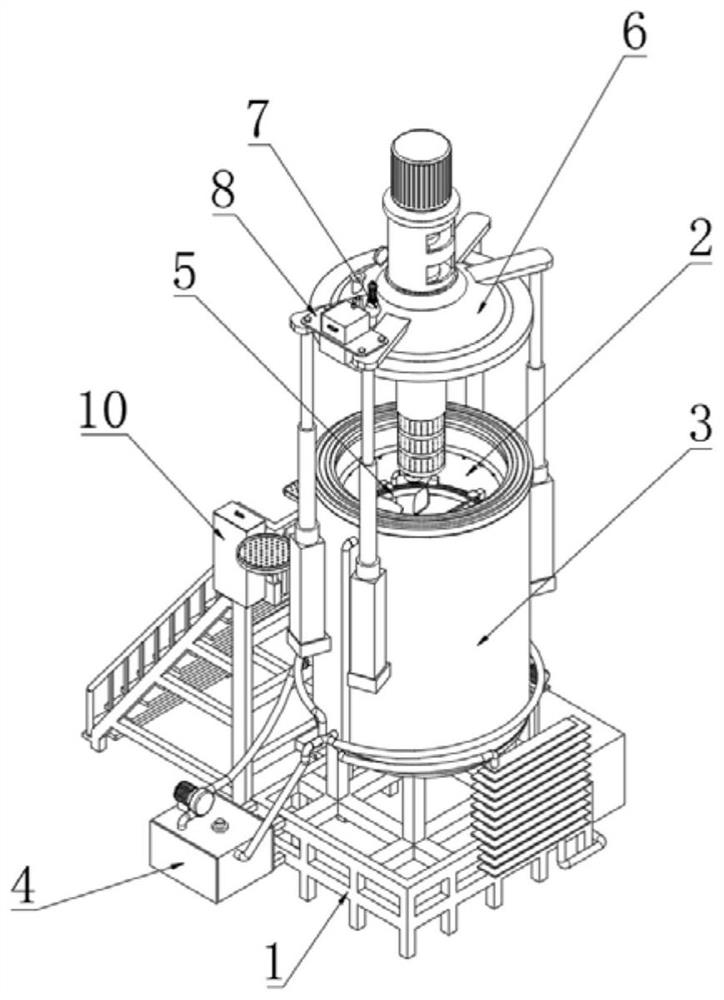

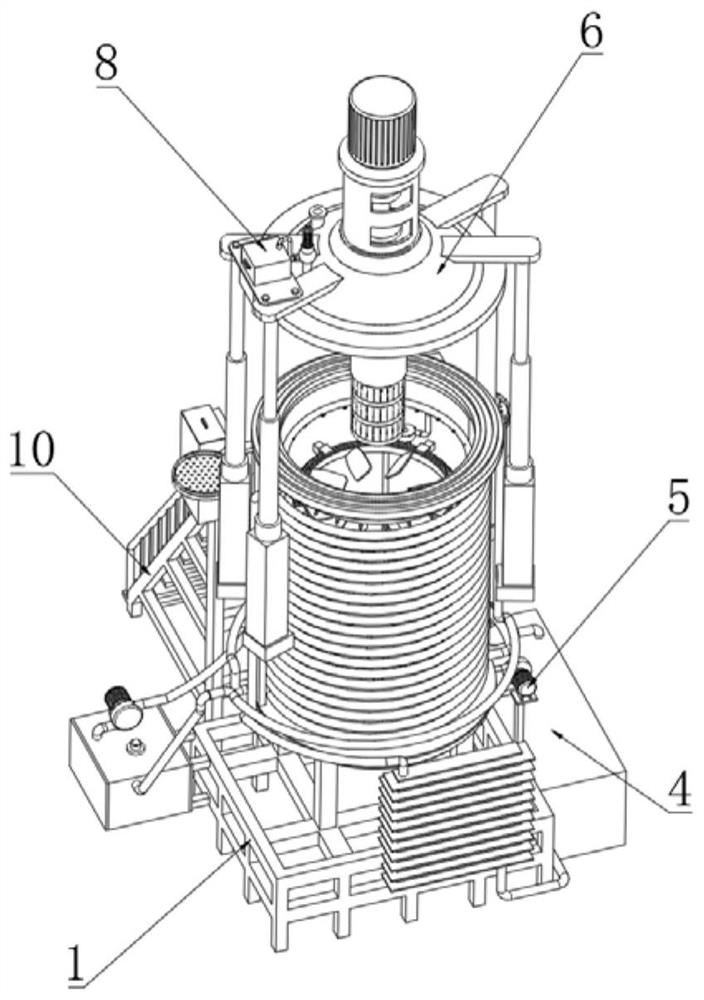

Environment-friendly cooling reaction kettle for chemical production

ActiveCN111530400AScientific and reasonable structureEasy to useChemical/physical/physico-chemical stationary reactorsFeed devicesProcess engineeringChemical agent

The invention discloses an environment-friendly cooling reaction kettle for chemical production. The environment-friendly cooling reaction kettle includes a supporting underframe, a reaction kettle main body is fixedly connected to the middle of the top end of the supporting underframe; a protective shell is fixedly connected to the middle of the outer side of the reaction kettle main body; one side of the supporting underframe is fixedly connected with a cooling oil tank. The top of the cooling oil tank is fixedly connected with a cold oil pump through an oil pipe; the input end of the cold oil pump is electrically connected with the output end of mains supply; one end of the cold oil pump is fixedly connected with a lower cooling oil pipe; a heat exchanger is fixedly connected to the bottom of one side, corresponding to the protective shell, of the top of the lower cooling oil pipe; according to the reaction kettle, the temperature of the reaction kettle can be slowly and quickly reduced through a temperature conversion mechanism, damage to the reaction kettle due to sudden temperature drop is prevented, the production safety of the reaction kettle is improved, the phenomenon ofenvironmental pollution caused by chemical agent leakage due to explosion of the reaction kettle is prevented, and the environmental protection performance of the reaction kettle is improved.

Owner:宁夏宏民生物科技有限公司

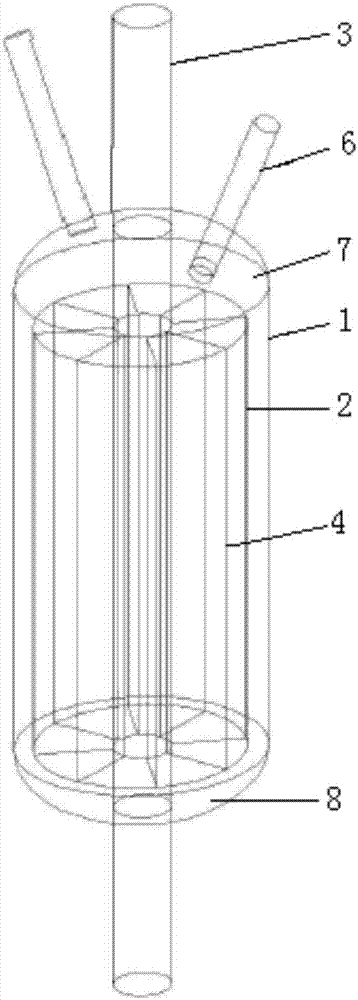

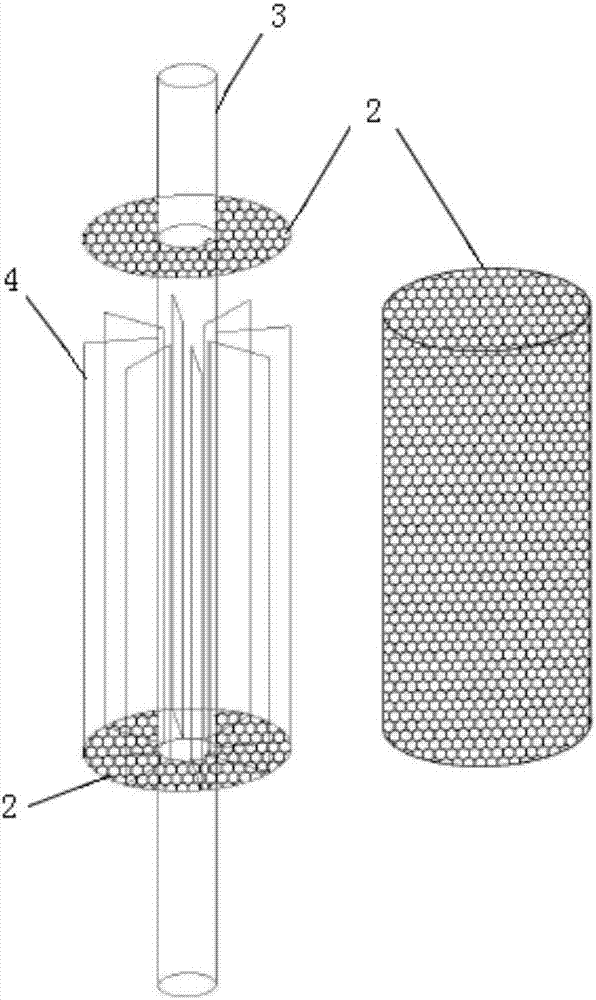

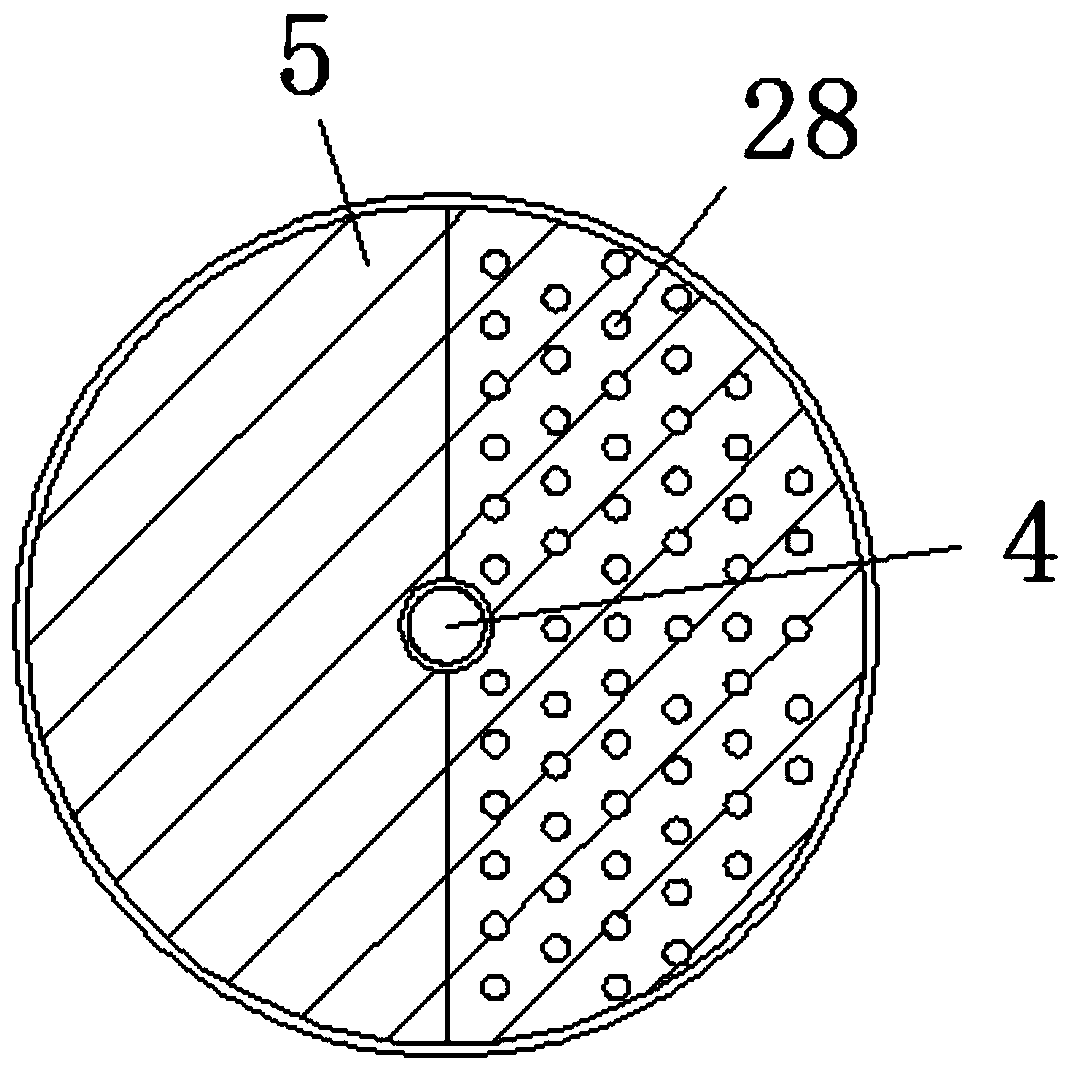

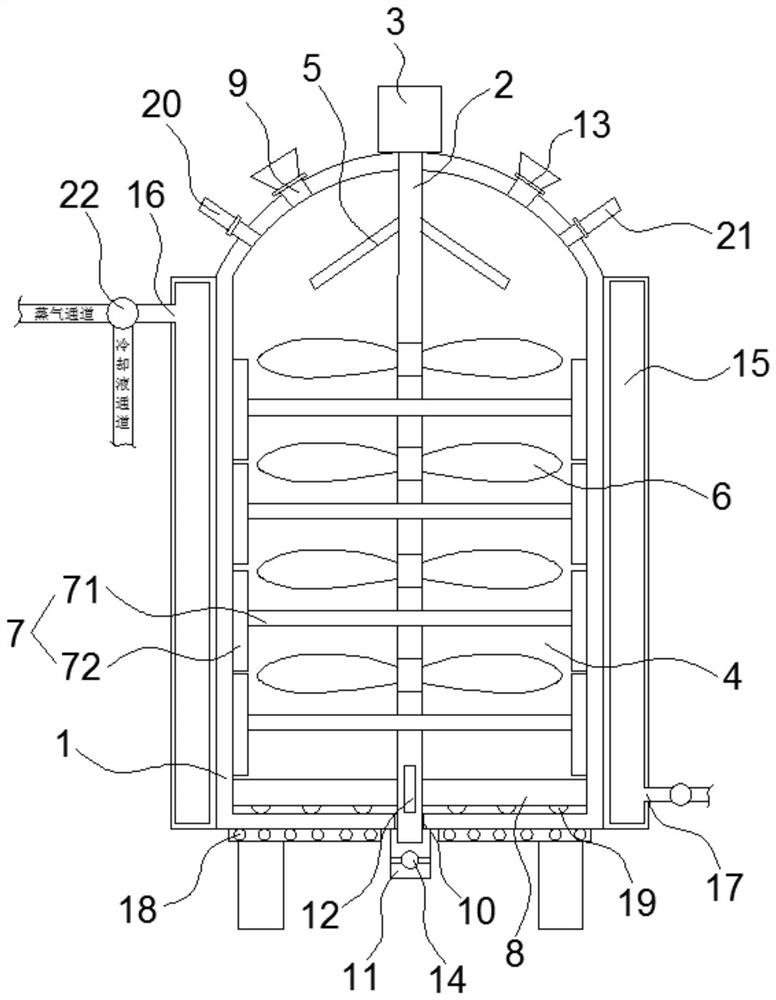

High-efficiency reactor for hydrated salt chemical energy storage

InactiveCN107289803AHigh reaction conversion rateHigh energy storage densityHeat storage plantsHydration reactionEngineering

The invention discloses a high-efficiency reactor for hydrated salt chemical energy storage. The high-efficiency reactor comprises a heat insulation container, a column body for wrapping hydrated salt, a heat exchange pipe, fins, hydrated salt and pipelines, wherein the column body is arranged in the heat insulation container; the heat exchange pipe is arranged at the center of the column body; the multiple fins are uniformly arranged between the heat exchange pipe and the column body; one end of each fin is connected with the outer wall of the heat exchange pipe, and the other end of the fin is connected with the inner wall of the column body; a space between the heat exchange pipe and the column body is filled with the hydrated salt; and the two pipelines are arranged on an upper end cover of the heat insulation container. The high-efficiency reactor for hydrated salt chemical energy storage disclosed by the invention can well enable reaction salt to react with steam; the reaction is faster and more thorough, and the heat transfer and mass transfer effect in a reaction process is obviously enhanced; irreversible loss caused by liquefaction of the hydrated salt due to excessive water absorption can be further effectively avoided, so that the number of times of recycling of an energy storage material is increased, and the service life of the material is prolonged; and meanwhile, the corrosion effect of the liquefied hydrated salt on the reactor is also avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

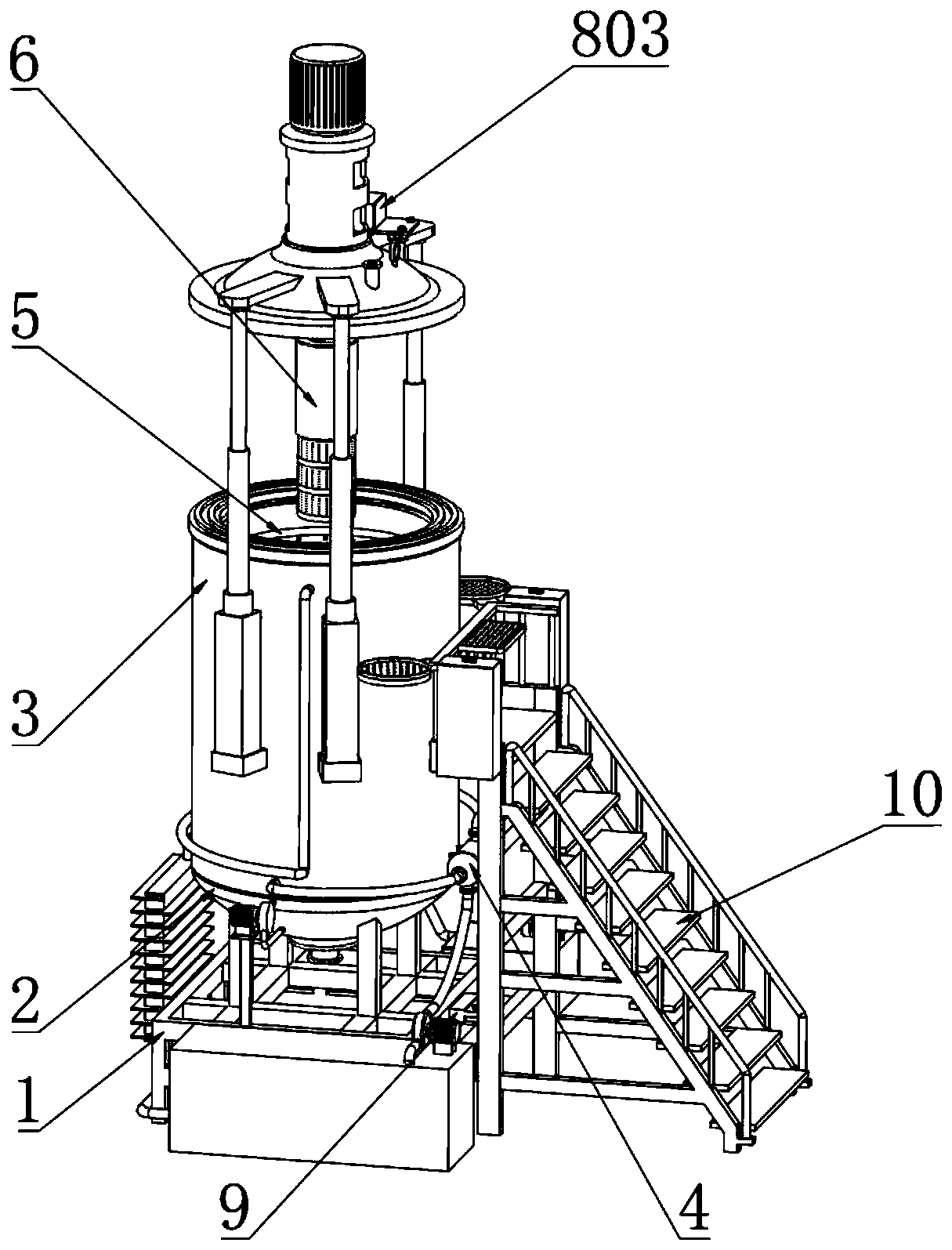

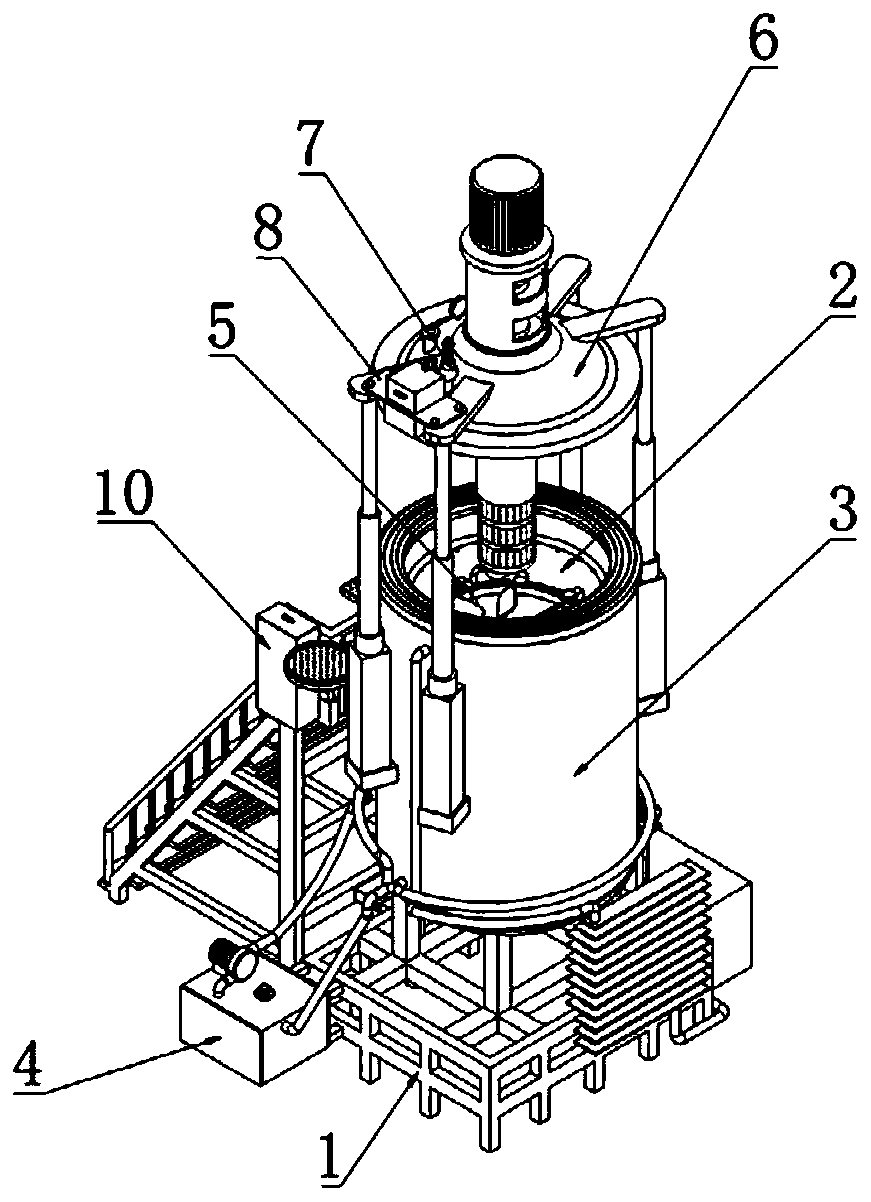

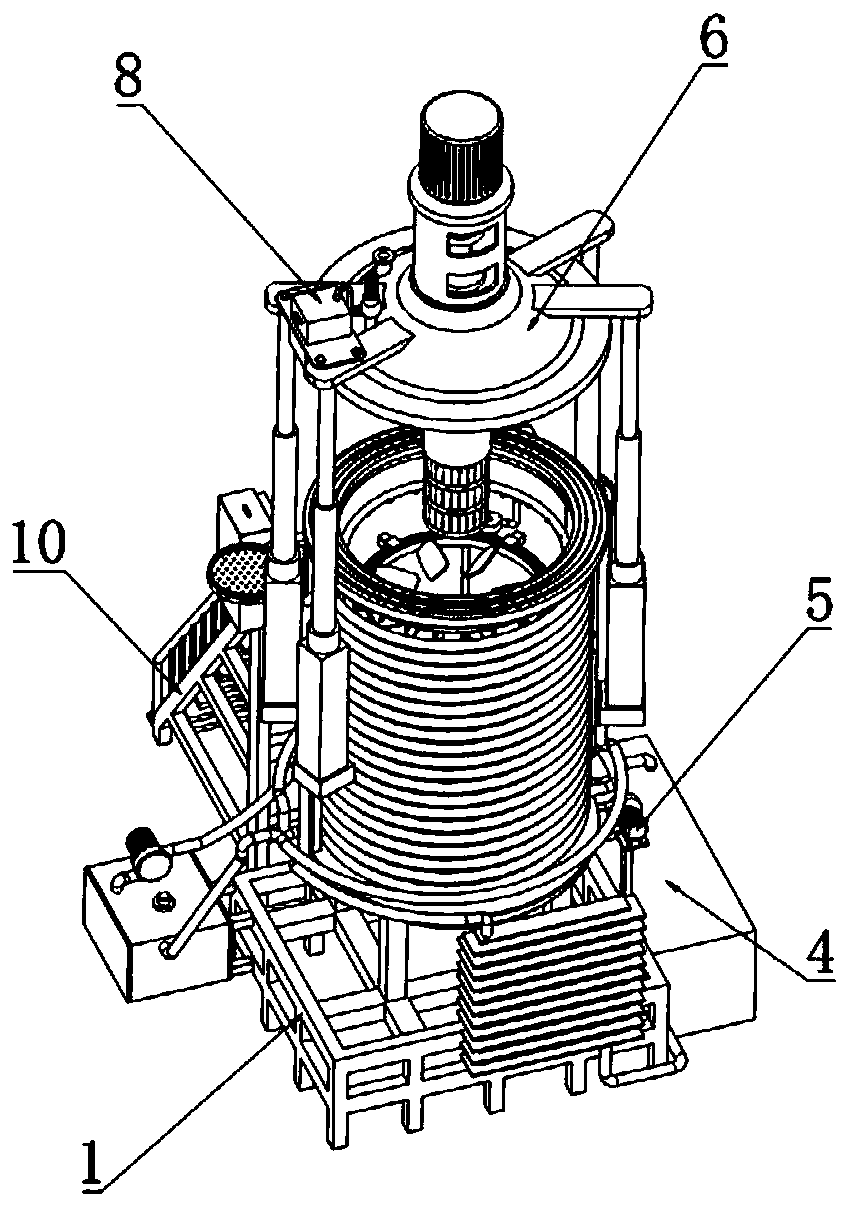

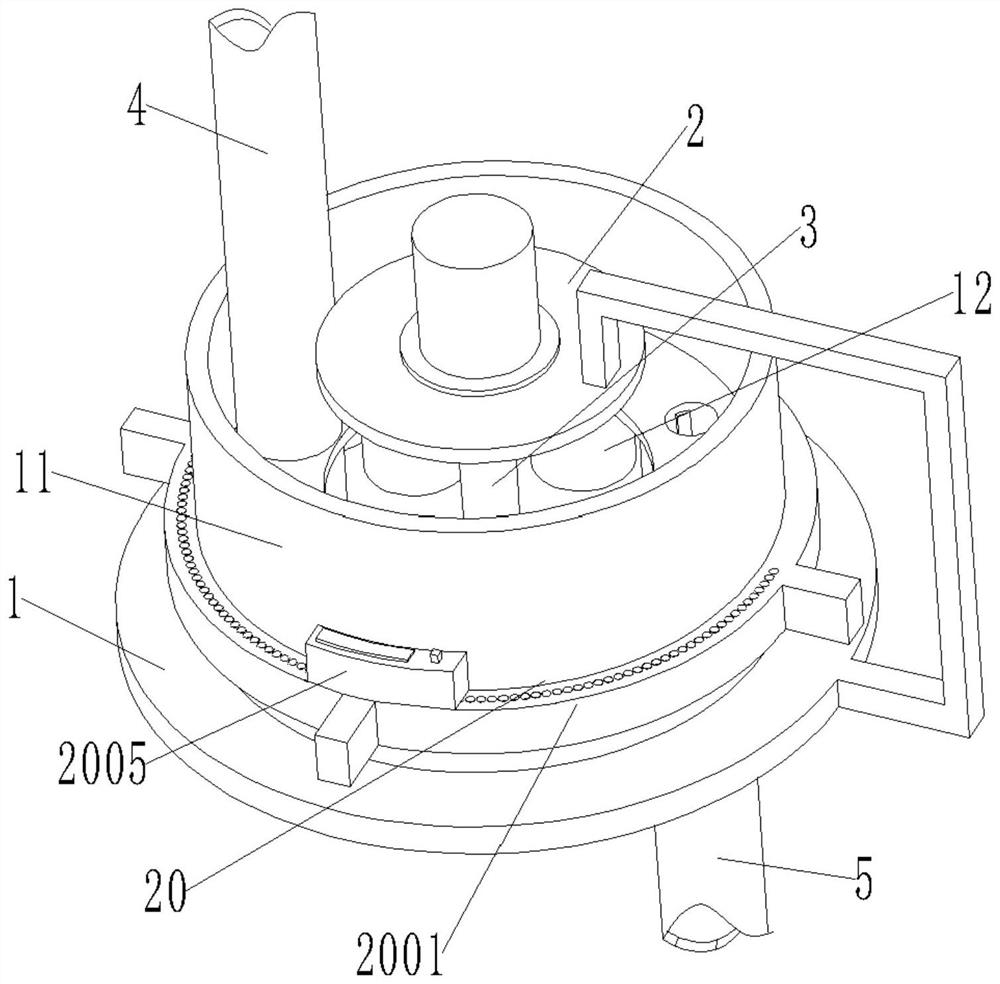

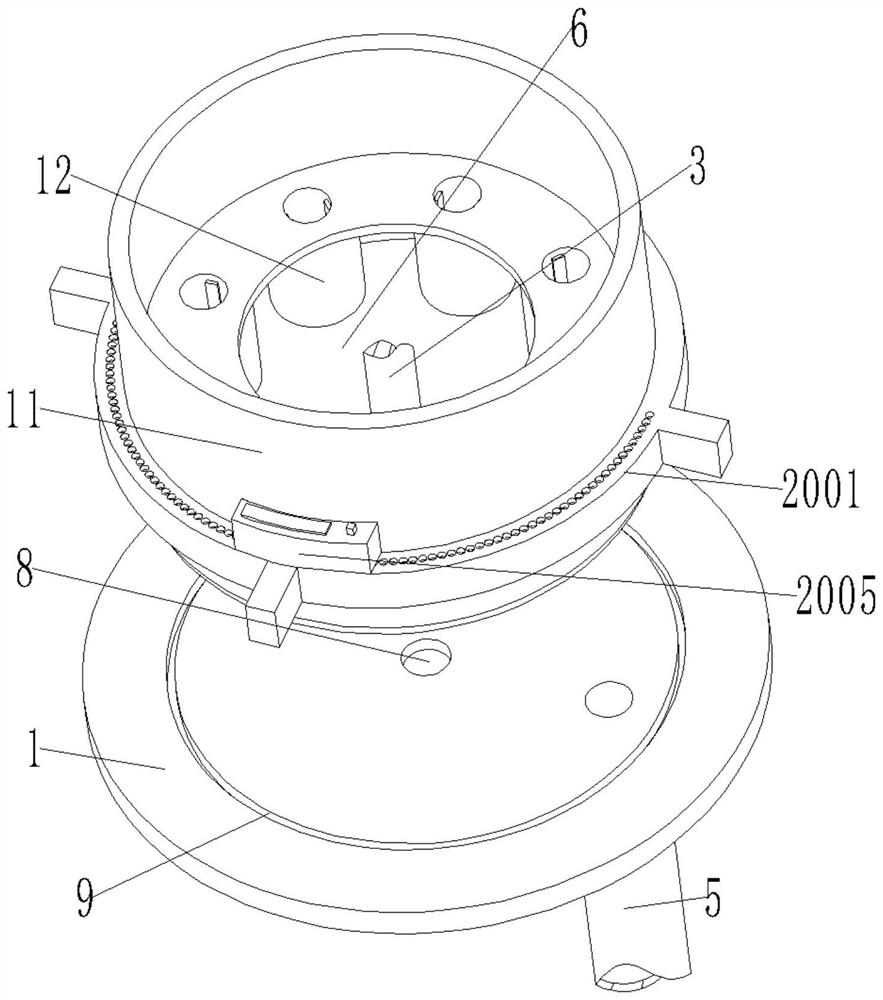

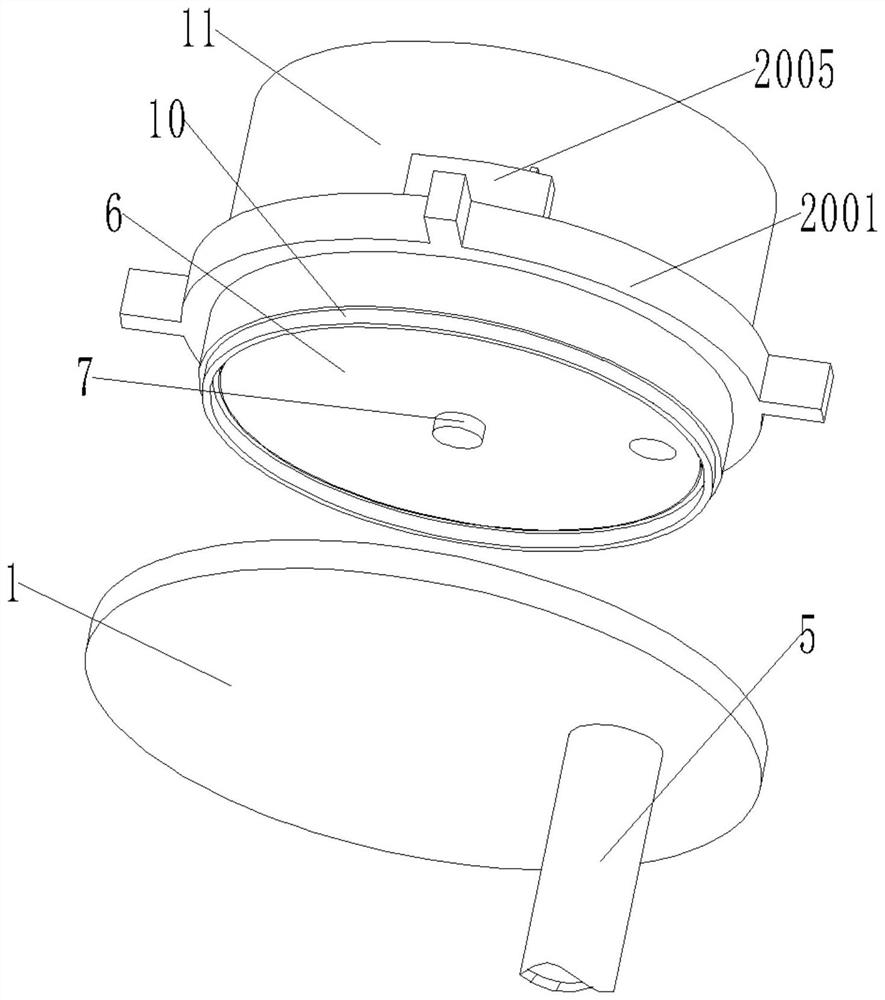

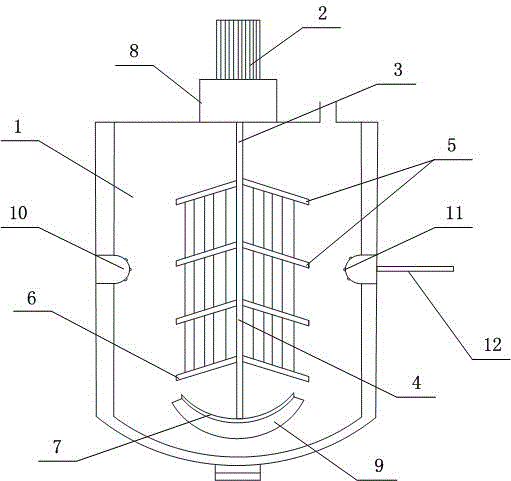

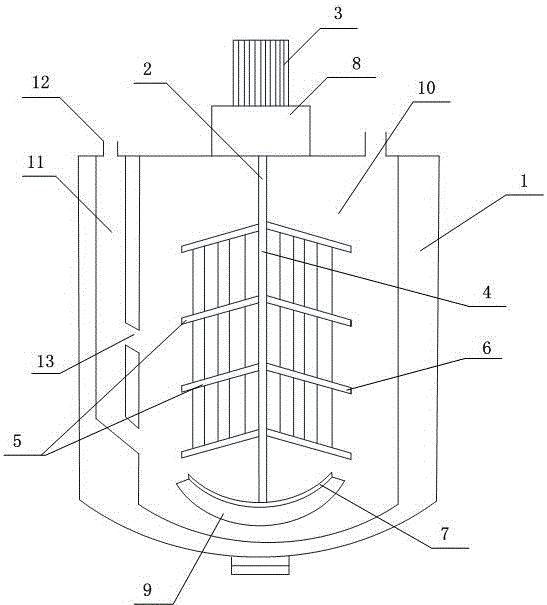

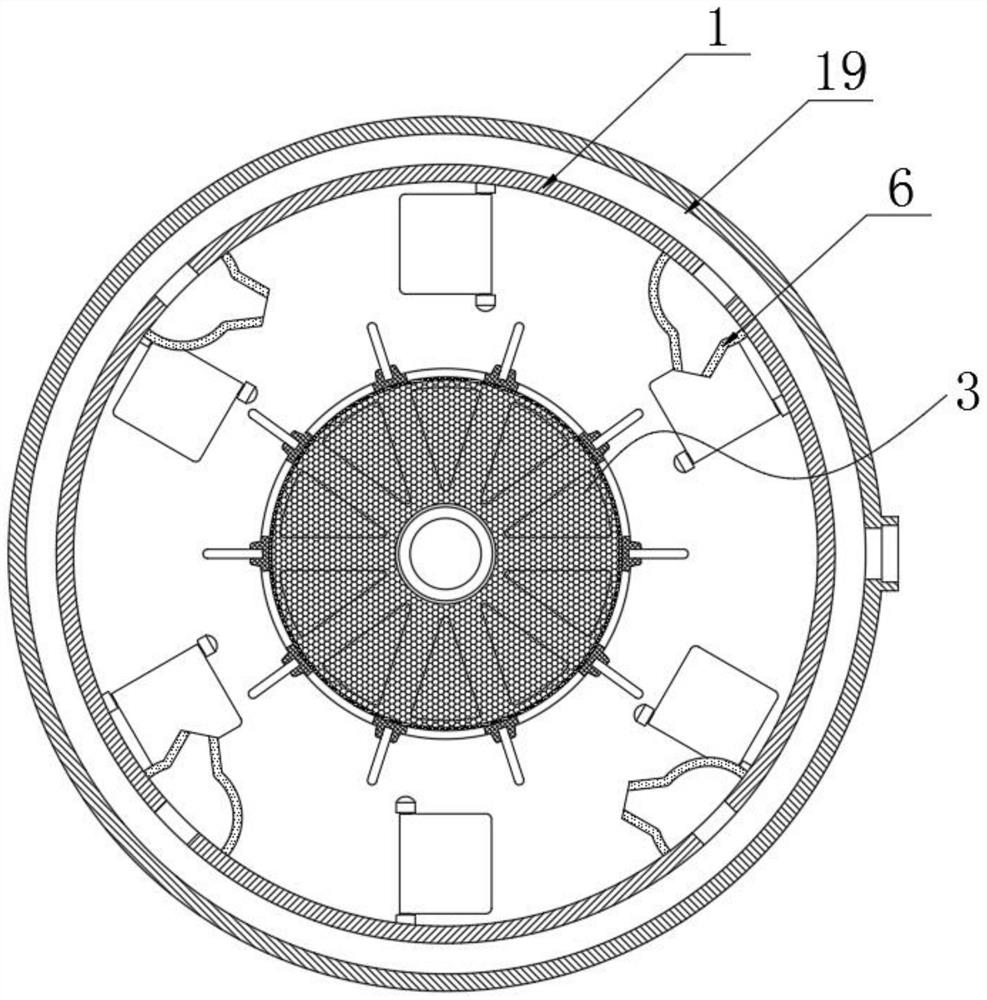

Reaction kettle

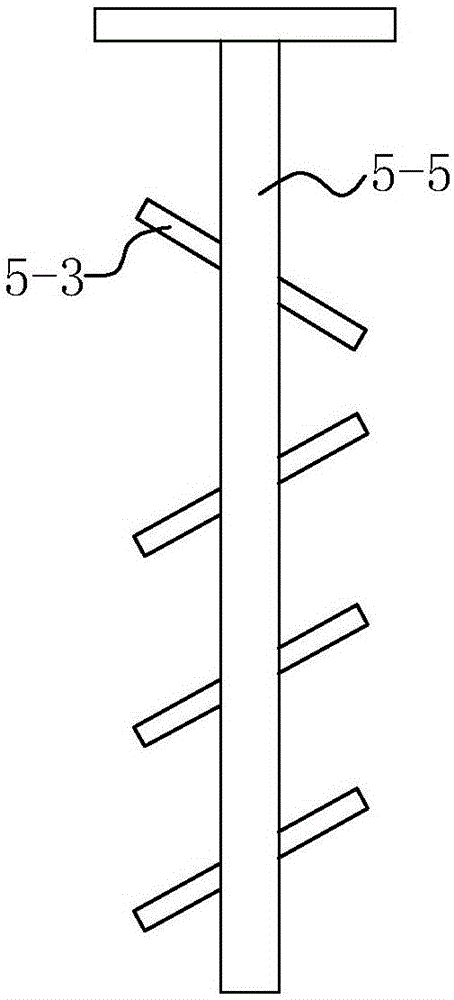

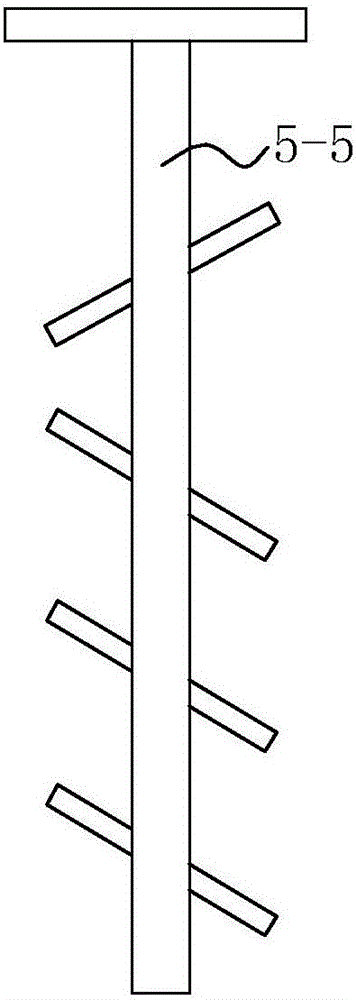

InactiveCN106732260AStir wellAvoid underreactionChemical/physical/physico-chemical stationary reactorsControl engineeringReaction rate

The invention discloses a reaction kettle which comprises a kettle body and a kettle cover, wherein a motor is arranged on the kettle cover; the lower part of the motor is connected with a speed reducer; the speed reducer is provided with an output shaft; the lower part of the output shaft of the speed reducer is connected with a reaction paddle; the kettle body comprises a closed jacket composed of an outer wall and an inner wall; the reaction paddle comprises a first reaction paddle and a second reaction paddle which is perpendicular to the first reaction paddle; the first reaction paddle and second reaction paddle are respectively provided with multilayer blades in the vertical direction; and the inclination directions of the blades of the first reaction paddle are not completely consistent. The reaction kettle can implement large-amplitude stirring in the horizontal direction, stirring on various levels in the vertical direction and impact fusion in different stirring directions, so that the stirring is more sufficiently and uniformly, thereby greatly enhancing the reaction rate and reaction quality.

Owner:鹤山市知墨印刷粘合材料有限公司

Method for preparing self-repaired polymer composite material

The invention discloses a method for preparing a self-repaired polymer composite material and belongs to the technical field of self-repairing material preparation. To solve the problems that a conventional self-repaired polymer material is poor in mechanical property, and insufficient reactions can be caused since urea for providing N-H groups is liable to sublimate in the reaction process, the method comprises the following steps: firstly, performing grafting modification on hydroxylation multiwalled carbon nanotubes with urea propyl trimethoxy silane, secondly, performing cross-linking polymerization with dimer acid and diethylenetriamine so as to generate a polymer, and finally enabling the surface grafted carbon nanotubes as a reactant to react with the polymer, thereby obtaining theself-repaired polymer composite material with dynamic hydrogen bonds. The method has the advantages that due to the nano-grade reinforcement properties of the carbon nanotubes, the mechanical properties of the material are improved, and the practicability of the material is improved; due to cross-linking polymerization reactions of the amidate carbon nanotubes, and due to a nano dimension effect of a nano material, reactions can be carried out relatively sufficiently.

Owner:NORTHEAST FORESTRY UNIVERSITY

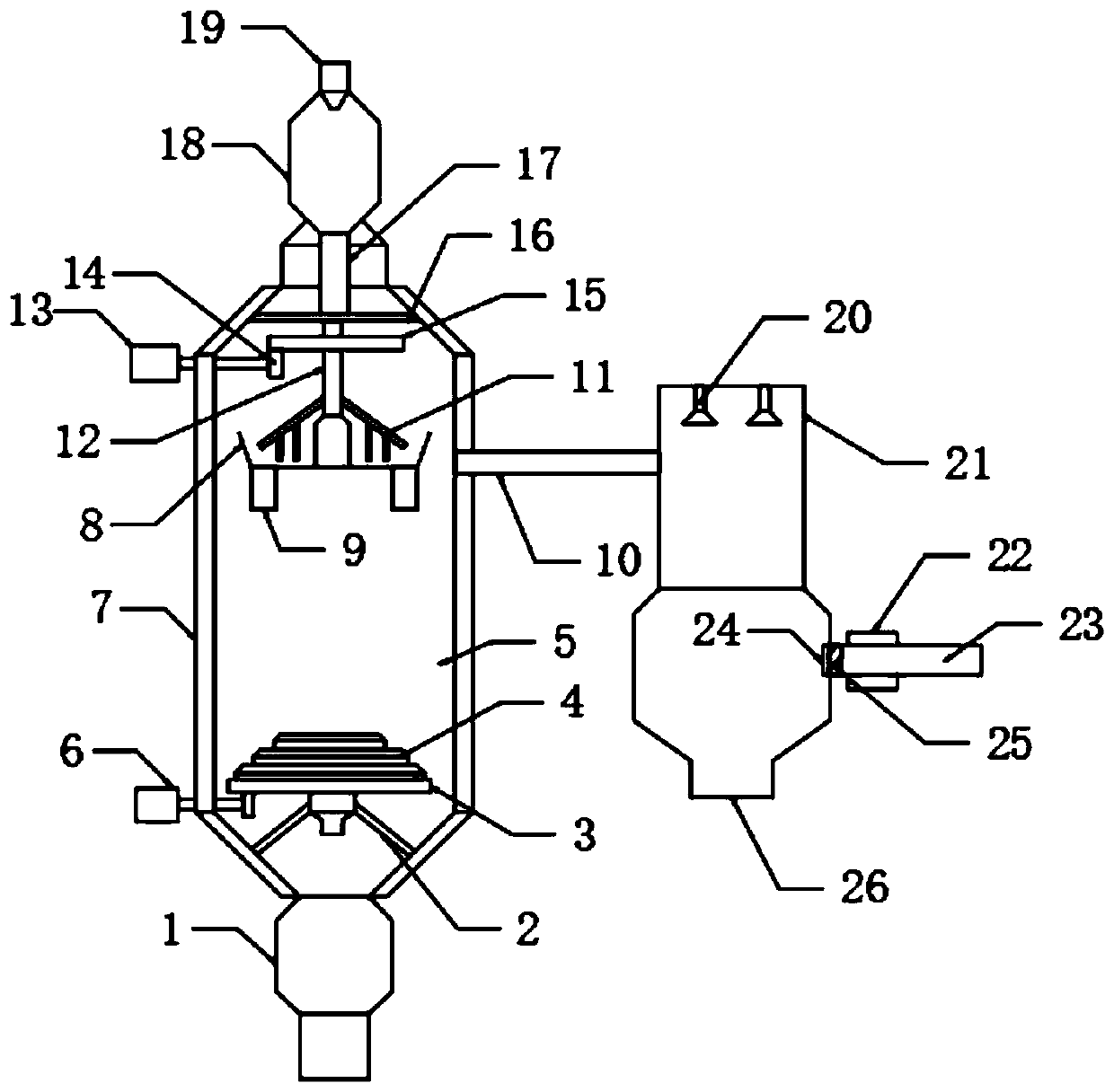

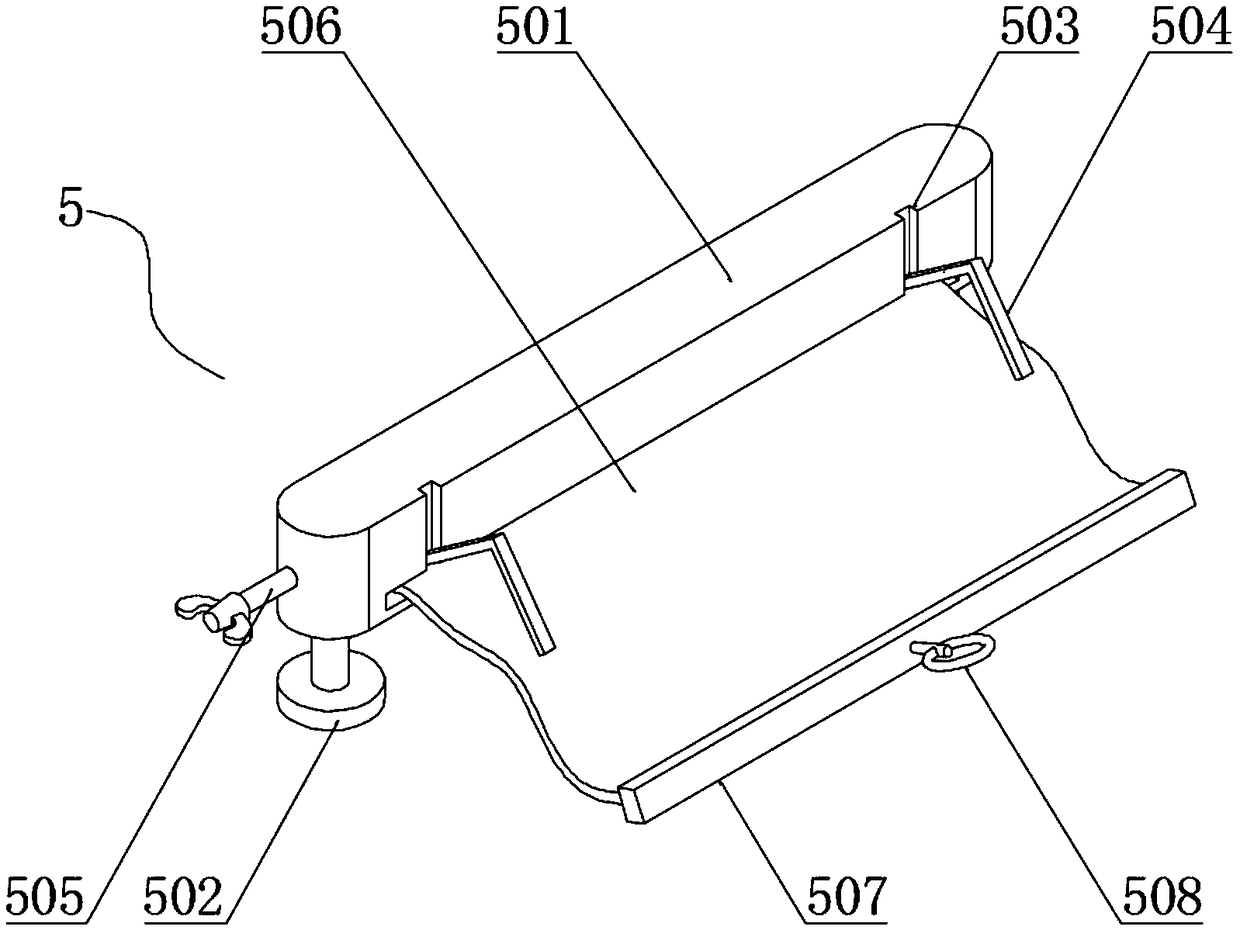

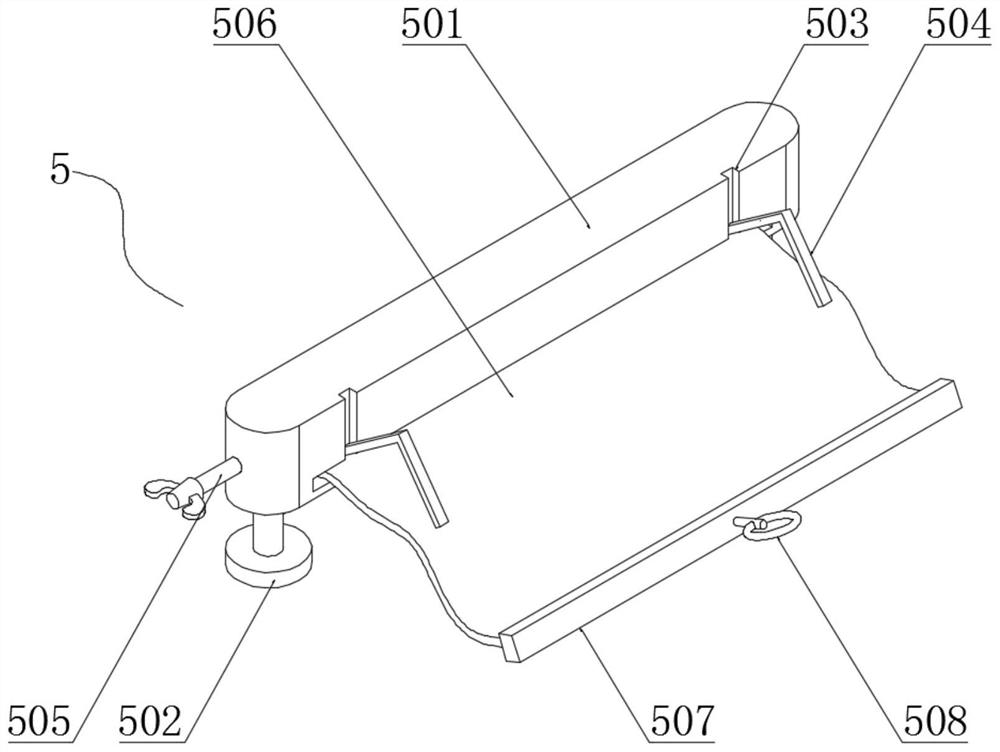

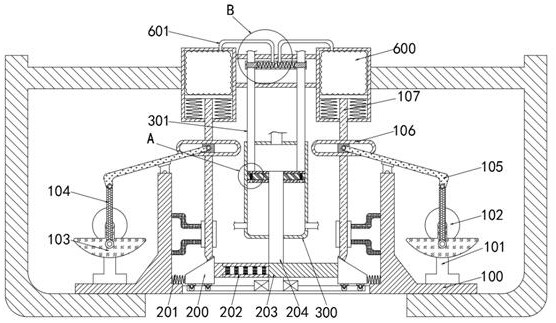

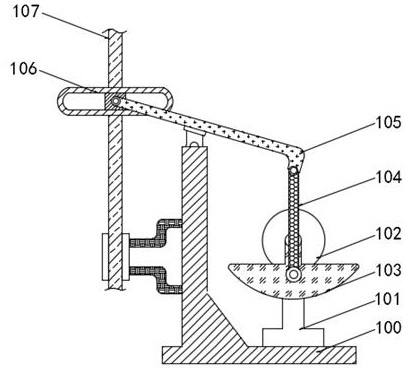

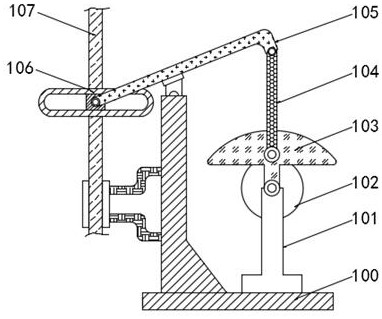

Quantitative feeding device for chemical production

InactiveCN112569867AImprove work efficiencyRealize equal feeding functionFeed devicesChemical industryChemical reaction

The invention discloses a quantitative feeding device for chemical production. The quantitative feeding device can realize an equivalent feeding function in chemical production work through a rotatingchassis and a material containing barrel, so the feeding work of chemical raw materials is more accurate, and the waste caused by excess chemical reaction and influence on product quality due to insufficient reaction are prevented; the quantity of the raw materials can be quantitatively controlled according to the actual requirements of a chemical reaction through an arranged regulation and control block and an arranged quantitative regulation and control mechanism, so the actual production requirements of the chemical industry can be better met, unnecessary waste is prevented, the problem ofinsufficient reaction is avoided, the working efficiency of the chemical reaction is improved, product quality is guaranteed, and the economic benefits of work are improved.

Owner:龚敬安

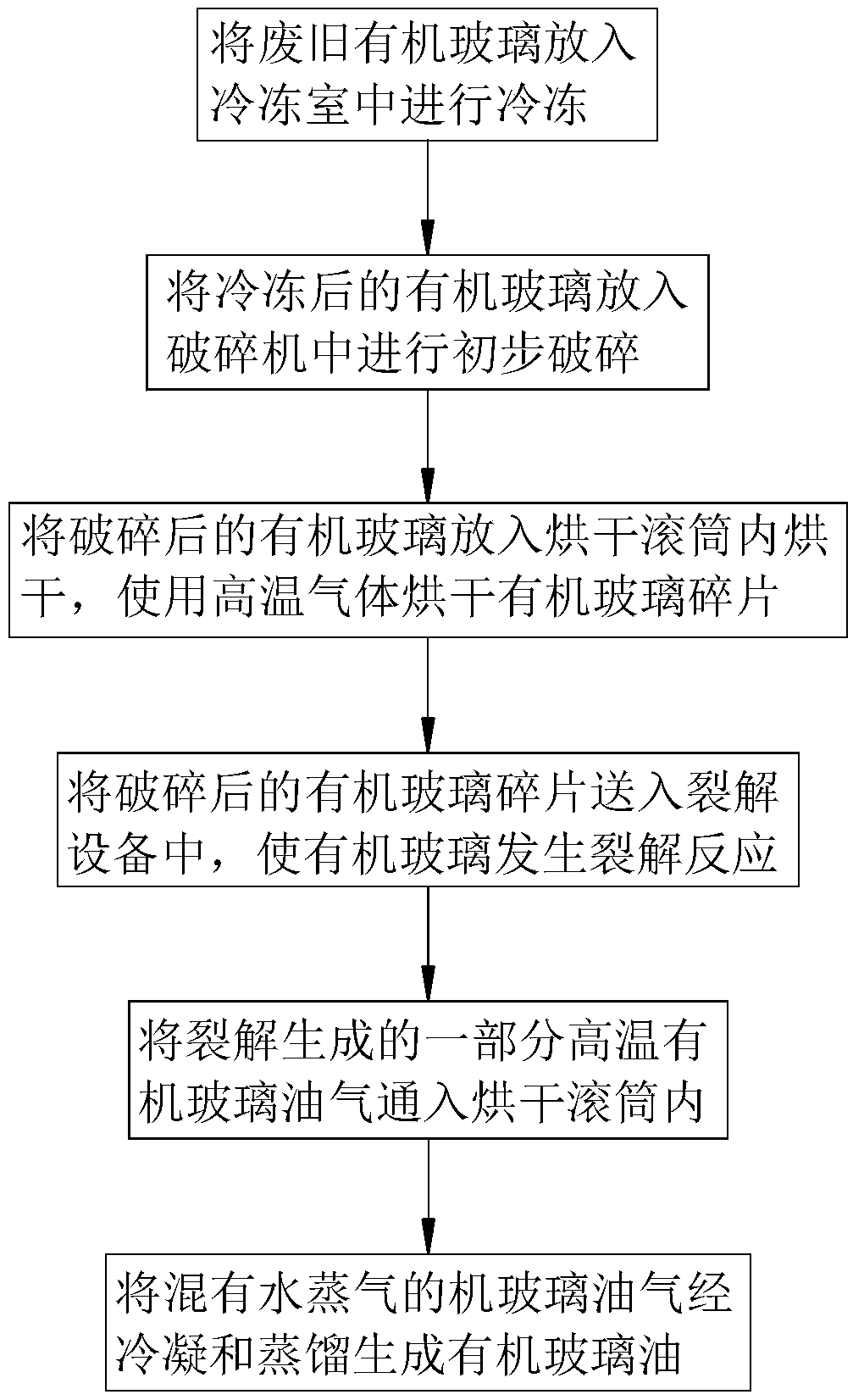

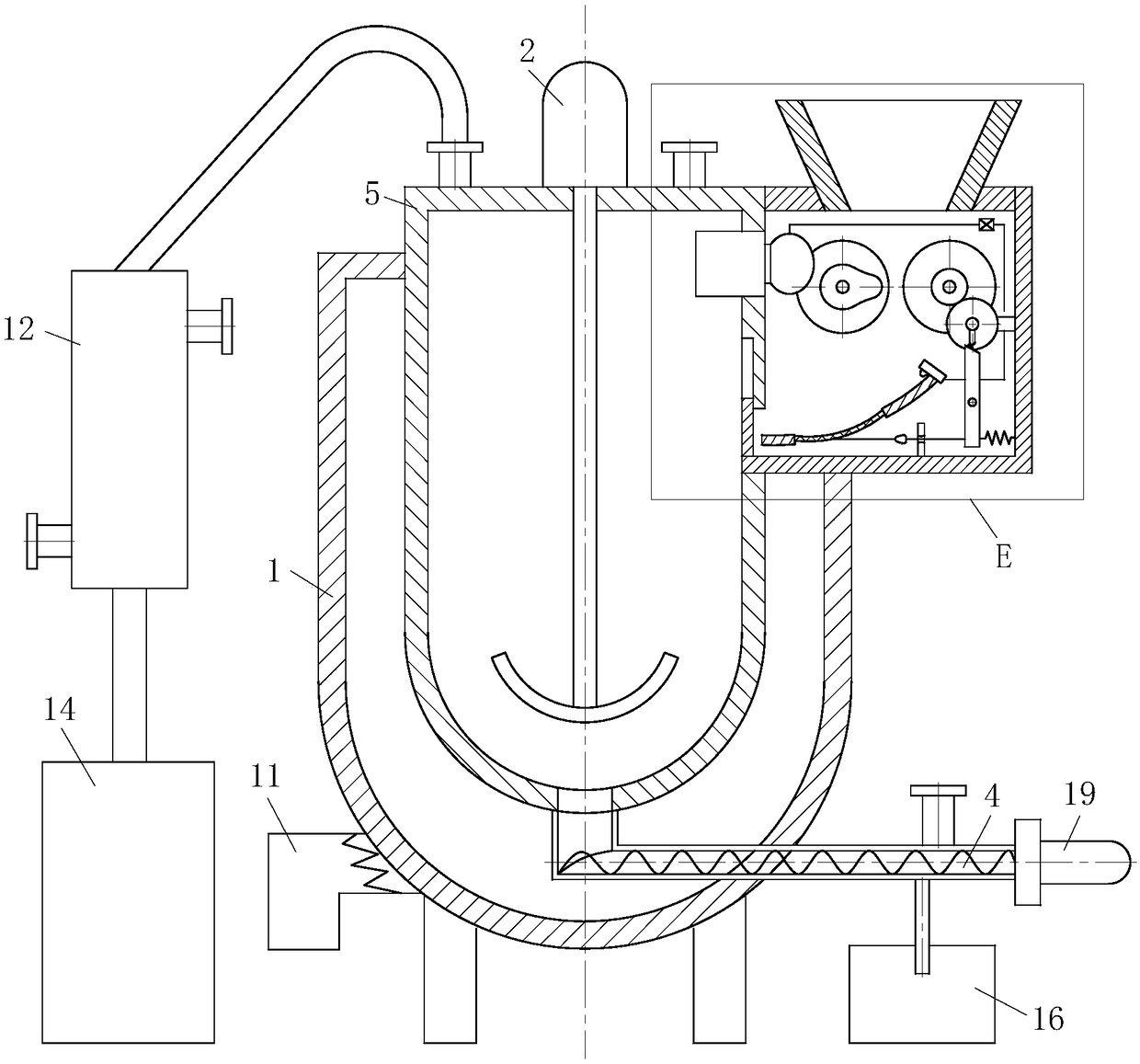

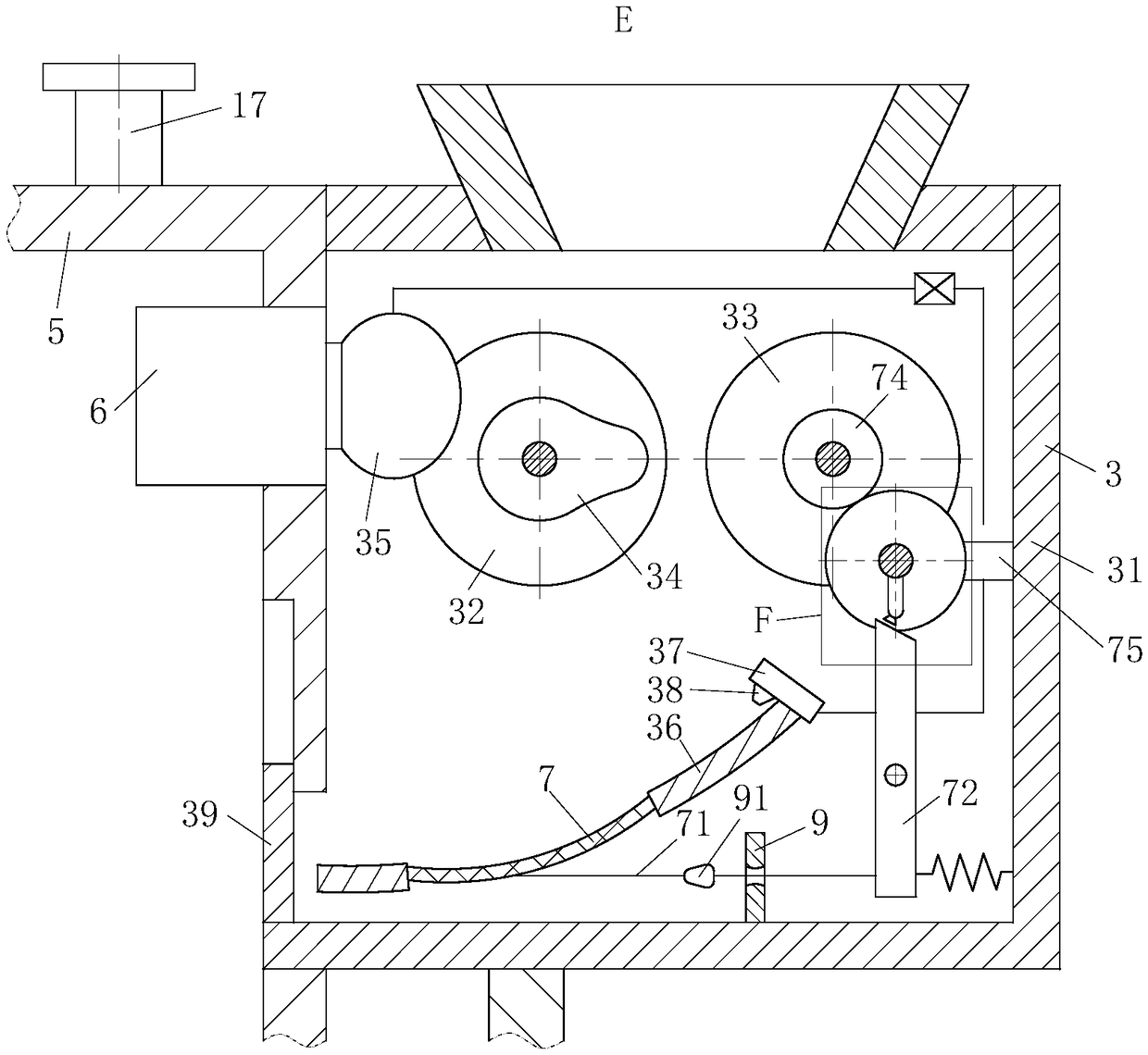

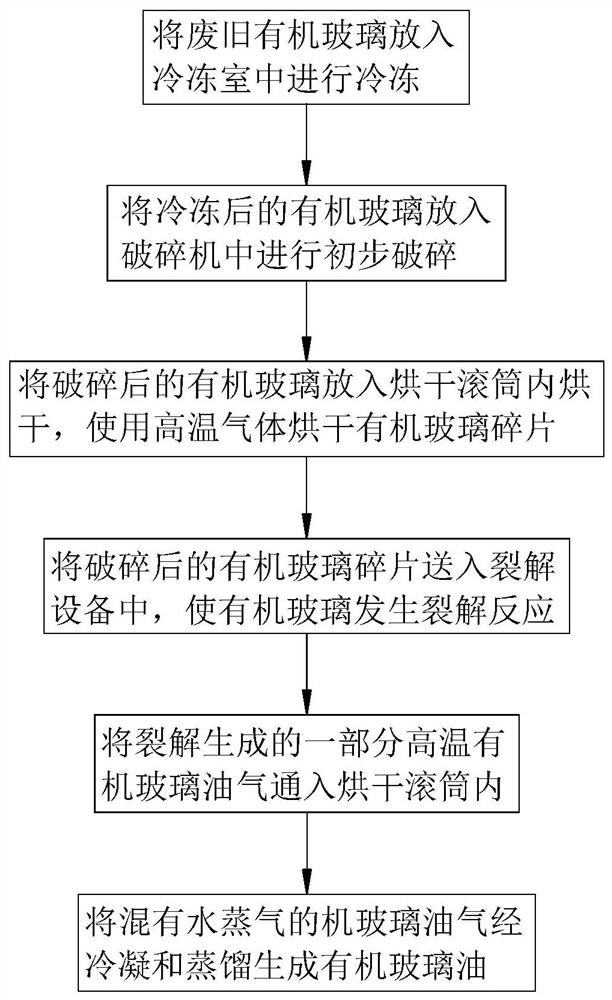

Waste plexiglass recycling method

ActiveCN109021284AEvenly dispersedAvoid affecting productivityPlastic recyclingElectricityCombustion

The invention belongs to the technical field of plexiglass recycling, and in particular relates to a waste plexiglass recycling method. The method uses a cracking device; the cracking device comprisesa furnace body, a stirring motor, a feeding module and a deslagging device, wherein an electric combustion machine is arranged at the bottom of one side of the furnace body; the furnace body is internally provided with a hearth; the stirring motor is fixedly connected with a stirring shaft by means of a gearbox; the stirring motor is arranged on the top of the hearth; the stirring shaft passes through the hearth and enters the hearth; the hearth is communicated with a condenser by means of a hose pipe; a storage tank is arranged under the condenser; the bottom of the deslagging device is communicated with a water tank by means of a pipeline; the feeding module is installed at the right upper corner of the furnace body; the feeding module comprises a feeding box, a driving motor, a drivinggrinding roller, a driven grinding roller, a cam, an air bag, an arc-shaped guide plate, a mounting plate, a blow head and an automatic door. Plexiglass particles are thrown to the middle upper partof the hearth by means of the air bag, thus being evenly dispersed, and avoiding the phenomenon that the production efficiency is affected due to the insufficient reaction caused by raw material accumulation in the hearth.

Owner:台州佑辅机械实业有限公司

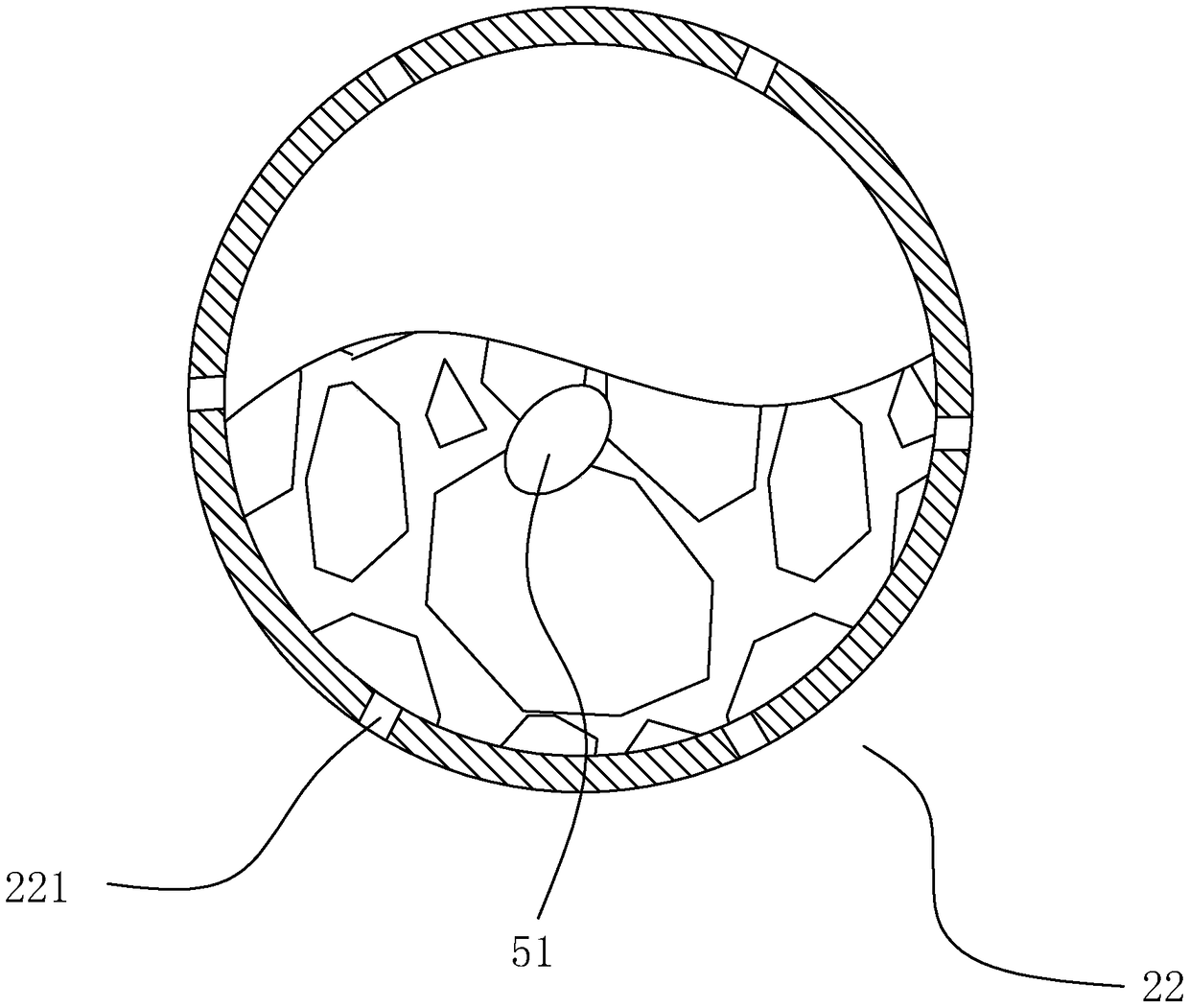

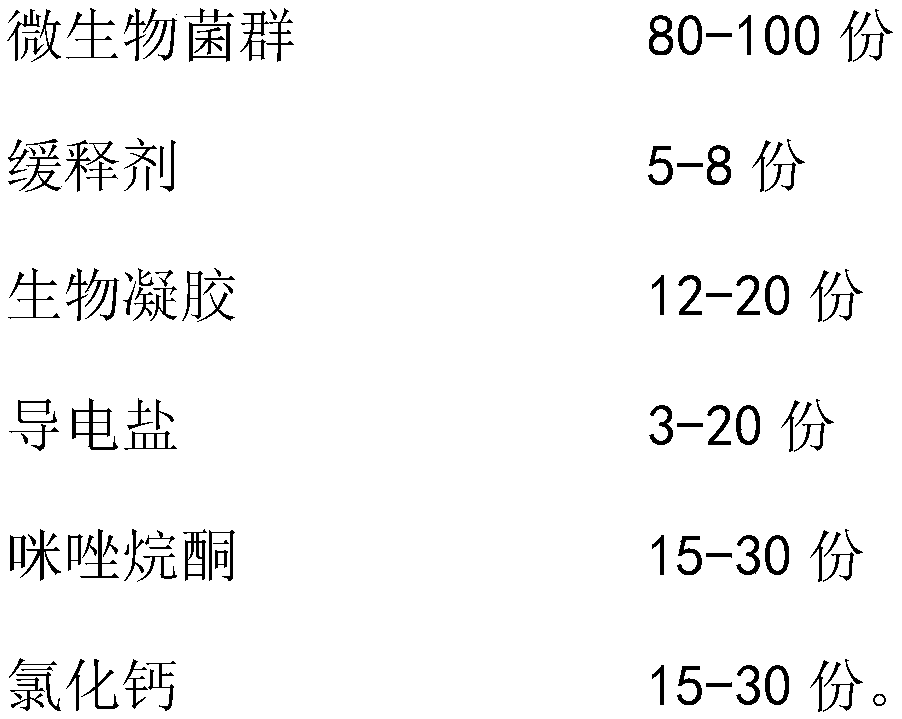

Rotary biofilm reactor

PendingCN109354164AAvoid underreactionEasy to handleBiological treatment apparatusSustainable biological treatmentBiofilmWater flow

The invention relates to a rotary biofilm reactor. The reactor comprises an outer frame and a reaction cavity which are arranged through mutual sleeving; multiple fixed rods are arranged in the reaction cavity, each fixed rod is provided with a biological packing cage, and multiple through holes running through the thickness of the reaction cavity are formed in the reaction cavity; the reactor further comprises a connecting device capable of making the biological packing cages move in all directions. When the device is utilized for conducting sewage treatment, the reaction cavity can be liftedto be separated from the outer frame through a lifting device, then water is injected inside by means of a water inlet, and then the reaction cavity is put into the outer frame through the lifting device; in the putting process, water flows into the reaction cavity through the through holes; then a driving motor is turned on, a stirring paddle rotates, the positions of all the biological packingcages are adjusted, the biological packing cages are uniformly located in the reaction cavity, and then the problem that in the background technology, a reaction of partial water areas is insufficientis avoided.

Owner:CLEAR SUZHOU ENVIRONMENTAL TECH CO LTD

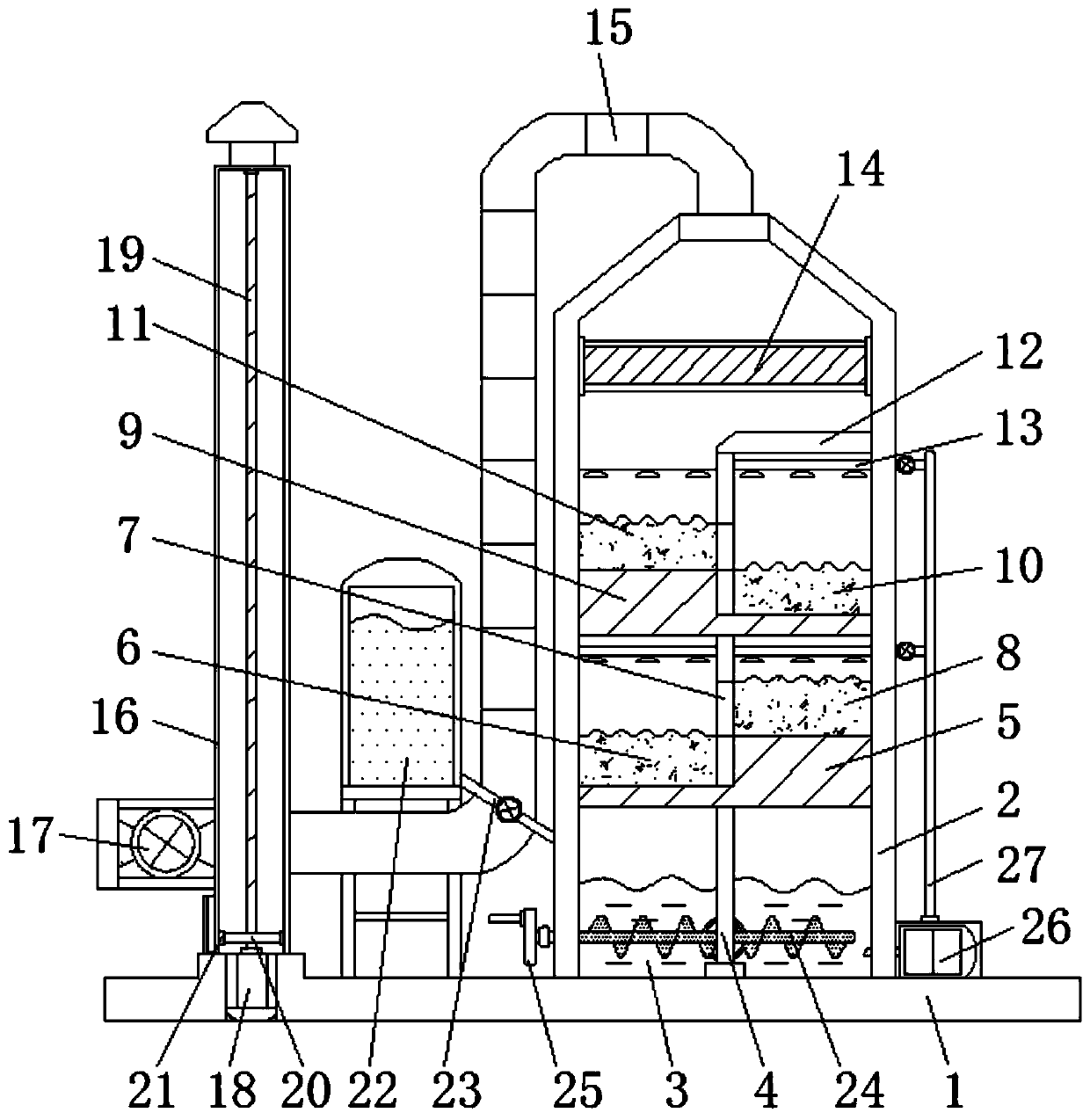

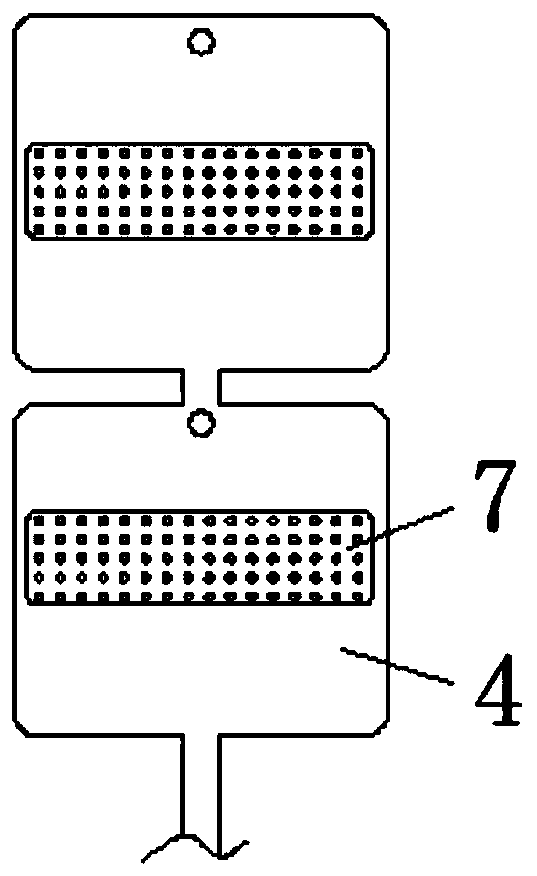

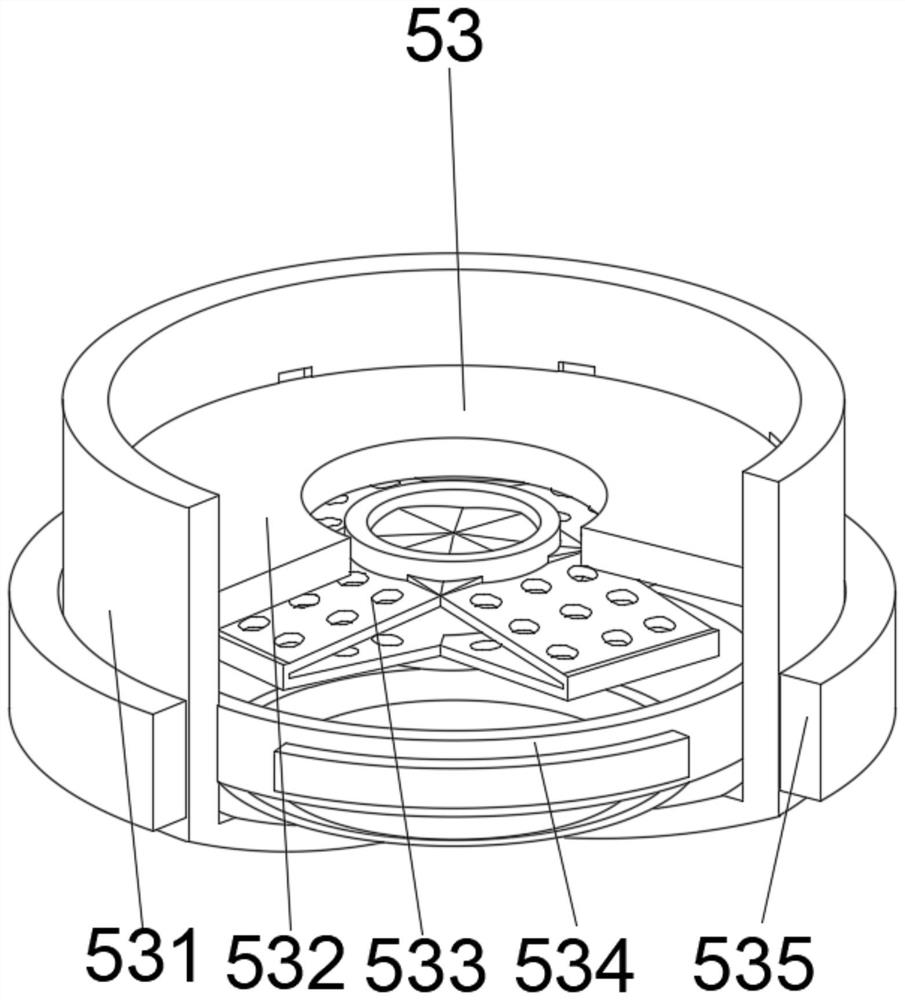

Negative pressure type purification tower for combustion waste gas treatment of multistage spraying contact reaction

ActiveCN111298622AImprove responseAvoid underreactionDispersed particle filtrationLighting and heating apparatusActivated carbonExhaust fumes

The invention discloses a negative pressure type purification tower for combustion waste gas treatment of a multi-stage spraying contact reaction. The negative pressure type purification tower comprises a bottom plate, a purification tower, a negative-pressure fan, a driving motor and a circulating water pump. The purification tower is fixedly mounted on the right side of the upper part of the bottom plate, a water storage chamber is arranged at the bottom of the purification tower, and a partition plate is fixedly installed in the middle of the water storage chamber. A chemical adding barrelis installed between the purification tower and an exhaust smoke pipe, and the lower end of the chemical adding barrel is connected with the upper portion of the water storage chamber through a chemical guide pipe. A stirring shaft is rotationally installed in the water storage chamber, and a rotary disc is fixedly connected to the left end of the stirring shaft. According to the negative pressuretype purification tower for combustion waste gas treatment of the multi-stage spraying contact reaction, a first filter plate, a second filter plate, a first connecting pad and a second connecting pad which are symmetrically distributed are arranged in a purification layer, and the purification effect of waste gas and the purity of the waste gas can be improved through the filtering effect of thefilter plates in cooperation with the sponge connecting pads and an activated carbon layer.

Owner:东营市广利临港产业园有限公司 +1

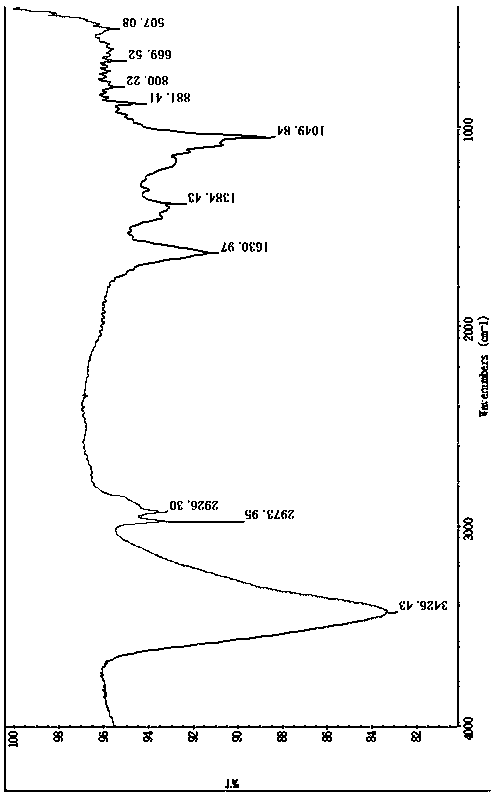

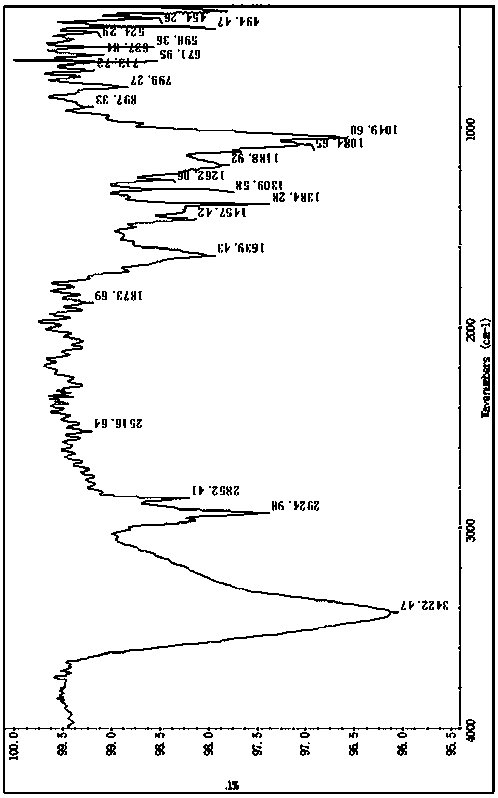

Highly water-soluble carbon nanometer tube preparation method

InactiveCN1308230CAvoid damageAvoid underreactionNanostructure manufacturePtru catalystBiocompatibility

The invention relates to preparation method for high water-soluble nano carbon tube, which comprises acidifying purifying treatment, acylchloridization and grafting. Wherein, based on not destroying its high length-diameter ratio and electron valence band structure, using chemical modification to graft lycine on wall and end of the tube to endow its high water-solubility of 30mg / ml and biocompatibility; reflowing the tube in HNO3 to remove the impurity metal catalyst particle and carboxylate the tube; then, reflowing tube in SOCl2 for completed acylchloridization; finally, acyl chloride group and amido in grafted lycine react to obtain the product.

Owner:JILIN UNIV

Coal gasifier for coal gasification production

InactiveCN110616088AAvoid corrosionAvoid underreactionDispersed particle filtrationTransportation and packagingCoal gasifierProcess engineering

The invention discloses a coal gasifier for coal gasification production. The furnace comprises a furnace body, an ash locking bin is arranged at the bottom of the furnace body; a water jacket is sleeved outside the furnace body. In the coal gasifier, the movable frame and the rolling wheels are arranged, therefore, the coal can intermittently fall into the coal separator, and excessive coal carried in the coal separator due to the fact that a large amount of coal enters the furnace body in a short time is avoided; the phenomenon that a large amount of coal cannot fully react after entering the furnace body is avoided; by means of the filter screen, coal gas mingled with residual coal ash enters the gas outlet pipe; the residual coal ash is blocked by the filter screen; coal ash is prevented from entering the air outlet pipe; meanwhile, the filter screen can block water drops mixed in coal gas, so that the gas outlet pipe is prevented from being corroded; and by arranging a brush, after the filter screen is blocked after being used for a long time, a cam is driven by a third motor to rotate, so that the cam drives a pull rod to move back and forth through a movable rod, and then the brush cleans the filter screen.

Owner:FOSHAN FENGHUI MACHINERY

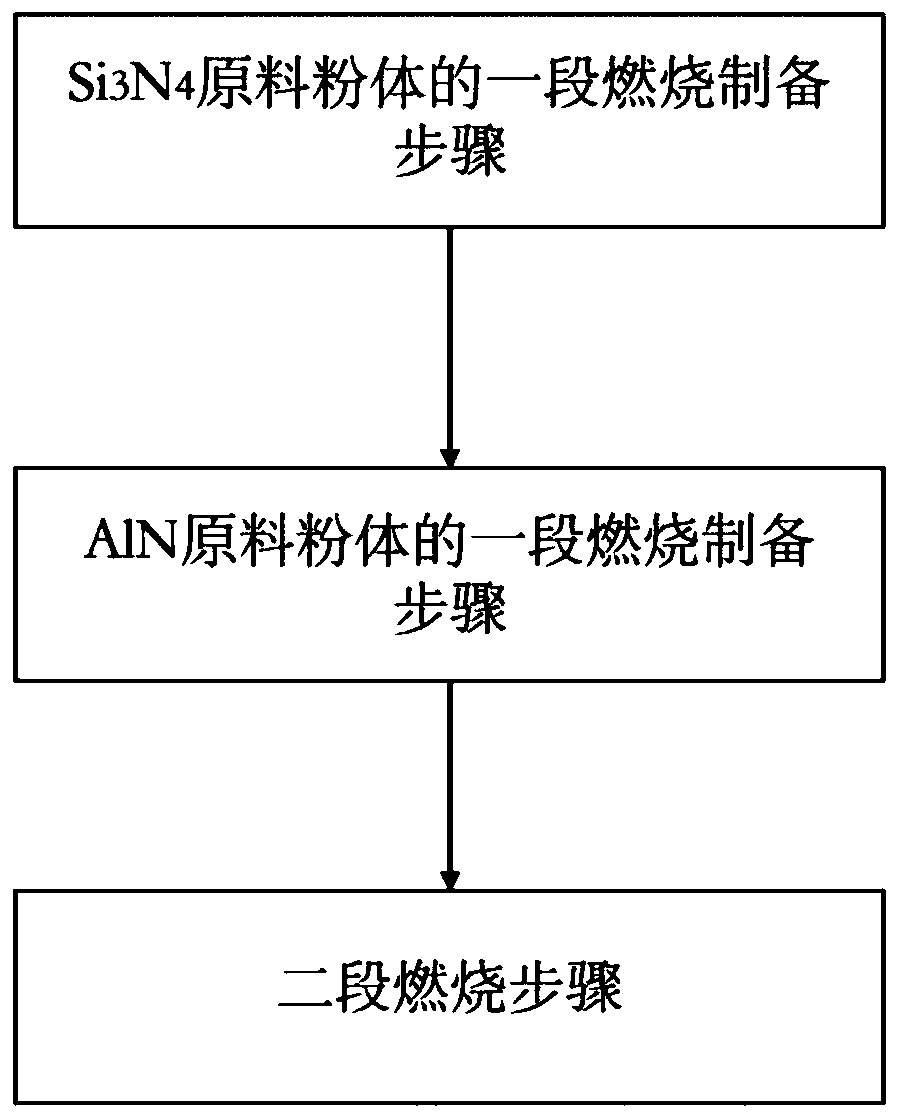

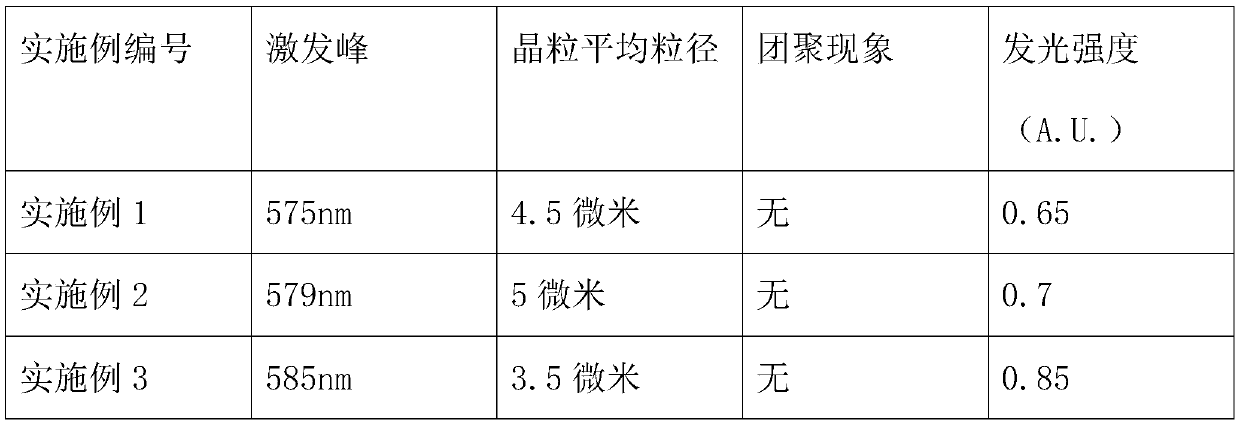

Phosphor powder material for LED lighting and preparation method thereof

ActiveCN108485657BReduce usageIncrease composition contentLuminescent compositionsNitrogen oxidesPhysical chemistry

The invention relates to a fluorescent powder material for light-emitting diode (LED) lighting and a preparation method thereof. A two-stage burning synthesis new technology is adopted for nitride andnitric oxide fluorescent powder for LED, so that two types of high-quality raw material powder, i.e., Si3N4 and AlN are prepared, and the nitride and nitric oxide fluorescent powder is further prepared. According to the fluorescent powder material for LED lighting and the preparation method provided by the invention, the influence rule of formula and process parameters on ingredients, structuresand performance of the prepared raw material powder and the fluorescent powder is systematically researched, and on the basis, through the process optimization, the Si3N4 and AlN raw material powder with low oxygen content and high activity, and the nitride and nitric oxide fluorescent powder with a complete crystal form and excellent light-emitting performance are prepared.

Owner:SHANDONG YICHANG LIGHTING TECH

Flame retardant stirring reactor with brush

InactiveCN106076235AStir wellStirring effect is evenTransportation and packagingMixer accessoriesEngineeringHigh pressure

The invention discloses a flame retardant stirring reactor with a brush. The flame retardant stirring reactor with the brush comprises a reactor body, a stirring device and a motor. A semispherical protruding block is arranged on the inner wall of the reactor body and is uniformly distributed by one circle around the inner wall of the reactor body. The part, where the protruding block is located, of the inner wall and the protruding block are hollow and are communicated with each other. Gas heads are arranged on the surface of the protruding block, and a high-pressure gas source is connected to the part, where the protruding block is located, of the inner wall. The stirring device comprises a stirring shaft and stirring blades connected to the stirring shaft. The stirring blades comprise four pairs of stirring rods connected to the stirring shaft, and the lengths of the stirring rods are different and are sequentially increased from top to bottom. Vertical steel wires are arranged between every two vertically-adjacent stirring rods. A transverse plate is connected to the end of the stirring shaft, and the brush is connected to the transverse plate. According to the reactor, through the coordinative stirring of the stirring shaft and gas flow on the inner wall of the reactor, the effect of evenly stirring materials can be achieved, and materials can be prevented from sticking to the inner wall.

Owner:成都米特瑞新材料科技有限公司

Polyurethane reaction kettle

PendingCN111686672AIncrease the degree of mixingReduce wasteHollow article cleaningChemical/physical/physico-chemical stationary reactorsTemperature controlElectric machine

The invention relates to the technical field of reaction kettles, and discloses a polyurethane reaction kettle. The reaction kettle comprises a kettle body, a rotating shaft, a motor and a controller,a cavity is arranged in the kettle body, the motor is arranged in kettle body, the motor and rotating shaft are in connection, the rotating shaft is provided with a material dispersing annular plate,the rotating shaft is provided with stirring blades and scraping plates alternately at intervals, a stirring rod in contact with the bottom of the cavity is arranged at the lower part of the rotatingshaft, the top of the kettle body is provided with a feeding hole positioned above the material dispersing annular plate, a discharge hole is formed in the bottom of the kettle body, a discharge pipeis connected to the discharge hole, the bottom end of the rotating shaft extends into the discharge pipe, the rotating shaft is of a hollow structure, a material passing port for communicating the cavity with the discharge pipe is formed in the lower portion of the rotating shaft, a temperature control mechanism is arranged on the kettle body, a temperature sensor is arranged on the cavity, and the controller is electrically connected to the motor, a feed valve, a discharge valve, the temperature control mechanism and the temperature sensor respectively. The reaction kettle has the advantagesthat reaction raw materials can be fully mixed, the reaction temperature can be automatically controlled, the reaction efficiency is high, and the finished product quality is high.

Owner:QINGYUAN FANYI POLYURETHANE CO LTD

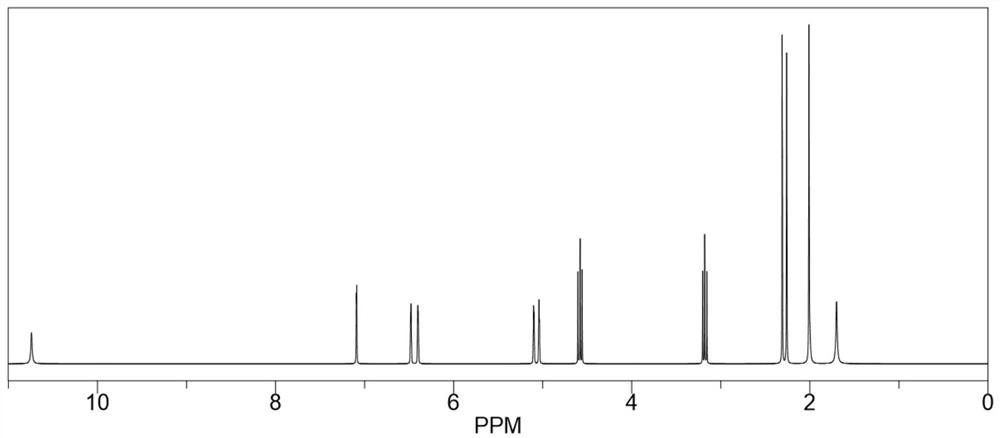

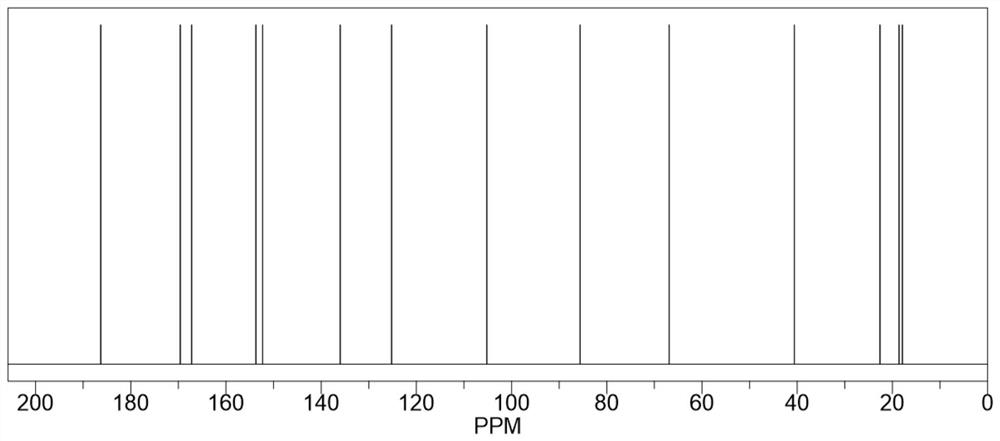

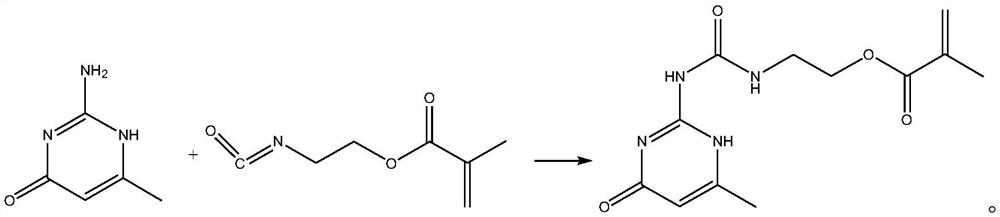

Synthesis method of pyrimidine aminoethyl methacrylate compound

InactiveCN113717108AHigh yieldAvoid underreactionOrganic chemistrySecondary cellsComposite materialPyrimidine

The invention discloses a synthesis method of a pyrimidine aminoethyl methacrylate compound, and relates to the technical field of lithium batteries. The synthesis method is characterized in that an aminopyrimidine compound and isocyano ethyl methacrylate are subjected to an addition reaction to obtain the pyrimidine aminoethyl methacrylate compound. According to the method, by-products generated by a violent polymerization phenomenon after isocyano ethyl methacrylate is added can be effectively inhibited, and the yield of the product is further improved; and according to the synthesis method, the yield reaches 97.89% or above, and the purity reaches 99.5% or above.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

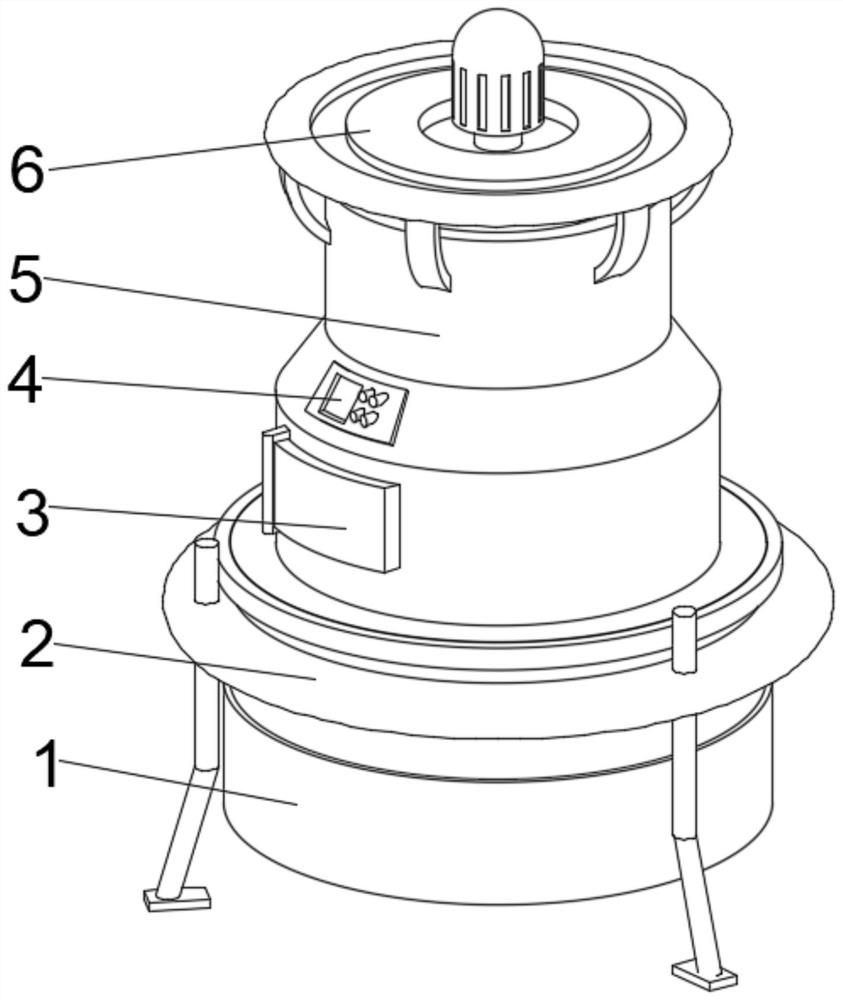

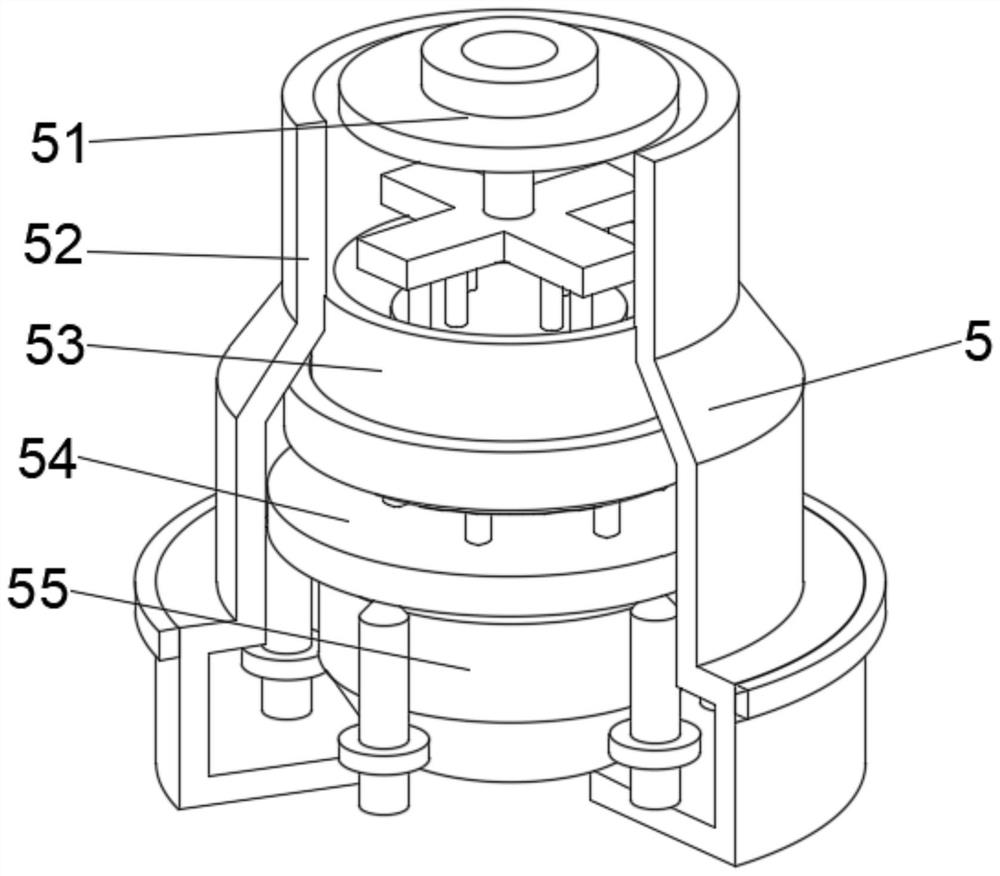

Biological medicine extraction device

PendingCN114344937AAvoid underreactionEasy to handleSolid solvent extractionMedicinal herbsBiochemical engineering

The invention discloses a biological medicine extraction device which comprises a protective base, a purification device is fixedly connected to the top of the protective base, fixing supports are fixedly connected to the bottoms of the outer walls of the two sides of the purification device, and mounting frames are arranged on the tops of the outer walls of the two sides of the purification device; a closing plate is arranged in the middle of the front face of the purification device, and a control panel is fixedly connected to the position, located above the closing plate, of the front face of the purification device. According to the biological medicine extraction device, the temperature is kept constant in the internal purification process, the situation that in the process that internal medicinal materials are stirred through a linkage disc, the medicinal materials adhere together, and consequently the reaction is insufficient is avoided, meanwhile, the internal mixing uniformity is effectively improved, internal purified medicine residues can be conveniently treated, and the practicability is high. And the processing time of medicine liquid purification is shortened, and the collecting mechanism facilitates separation and collection of liquid while medicine residues are collected.

Owner:潘田田

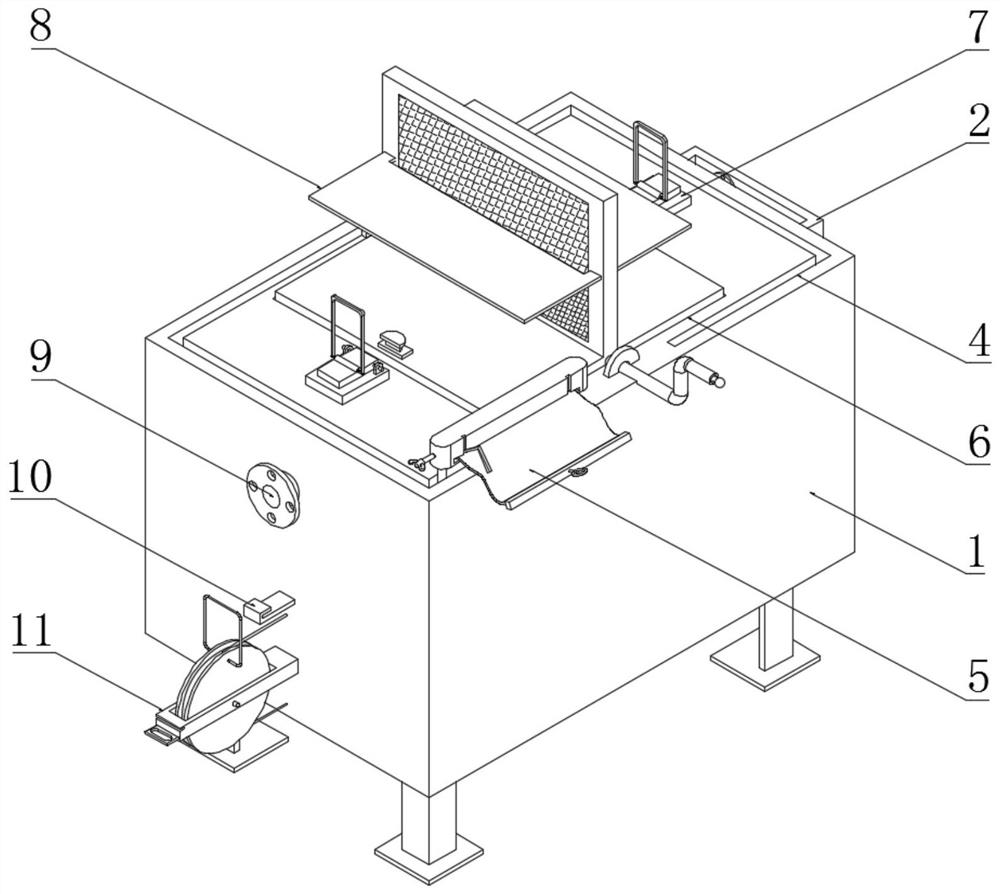

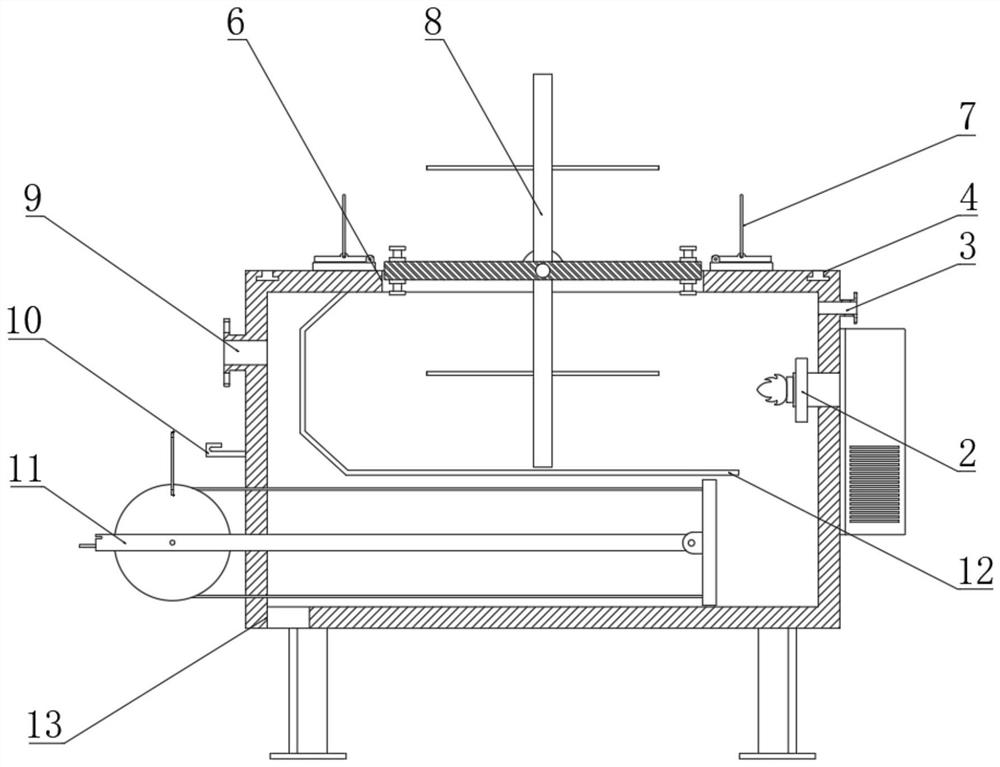

Waste gas treatment equipment for environmental engineering

ActiveCN108644795AScientific and reasonable structureEasy to useIncinerator apparatusAir quality improvementEngineeringPlastic film

The invention discloses waste gas treatment equipment for environmental engineering. The waste gas treatment equipment comprises a reaction box body; a sliding groove is formed in the outer ring of the upper surface of the reaction box body; a detection mechanism is arranged above the sliding groove; the two ends of an adjusting rope are connected to a compressed gas cleaning plate; a flow baffleis arranged in the reaction box body; a sliding column is arranged at the bottom of a storage box; and partition plates are arranged on the two sides of the middle of a catalytic bed. The waste gas treatment equipment has the advantages of being scientific and reasonable in structure and safe and convenient to use, a plastic film is fixed to the edges of the reaction box body through sealing rods,so that whether cracks exist at the edge position can be effectively known, the generation of the cracks of the reaction box body can be conveniently found in time, and the hidden danger in installation, the escape of pollution waste gas and the waste of heat energy can be avoided; and a rocking handle is rotated to enable sealing plates to drive the catalytic bed to rotate, the operation is simple and easy to carry out, workers can conveniently and quickly replace the catalytic bed inside the reaction box body, so that the situation that the environment pollution is caused due to the fact that the waste gas in the reaction box body escapes can be avoided.

Owner:安徽中疆数字科技有限公司

Method of eliminating primary β grain boundary of tc4 alloy by adding b induction heating in laser additive manufacturing

InactiveCN108555297BEliminate beta grainsImprove microstructureAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingTitanium alloy

The invention discloses a method of adding B induction heating to eliminate the primary β grain boundary of TC4 alloy produced by laser additive material, comprising the following steps: step S1, drying B powder and titanium alloy powder in a vacuum environment, wherein the mass ratio of B powder is 0.01-0.2%; step S2, uniformly mix the dry B powder and titanium alloy powder obtained in step S1 to obtain a mixed powder; step S3, heat the base material to 900-1100°C, and use a laser additive manufacturing device on the base Formed samples on the material. The laser additive manufacturing TC4 primary β grain boundary can be eliminated, thereby refining its grains and improving the microstructure of the TC4 alloy.

Owner:XI AN JIAOTONG UNIV

A kind of recycling method of waste organic glass

The invention belongs to the technical field of plexiglass recovery, and specifically relates to a method for recycling waste plexiglass. The method uses cracking equipment, and the cracking equipment includes a furnace body, a stirring motor, a feeding module and a slag extractor. One side of the furnace body is There is an electric burner at the bottom, and a furnace in the furnace body. The stirring motor is fixedly connected to the stirring shaft through the gearbox; the stirring motor is set on the top of the furnace; the stirring shaft runs through the furnace and enters the furnace; Connected; there is a storage tank under the condenser; the bottom of the slag discharger is connected to the water tank through a pipe; the feeding module is installed in the upper right corner of the furnace body; the feeding module includes a feeding box, a driving motor, a driving roller, and a driven roller , cams, airbags, curved guides, mounting plates, blowing heads and automatic doors. In the present invention, the organic glass particles are projected to the middle and upper part of the furnace through the air bag, so that the organic glass particles are evenly dispersed, and the raw materials are not piled up in the furnace to cause insufficient reaction and affect the production efficiency.

Owner:台州佑辅机械实业有限公司

Reaction kettle capable of enabling reaction rate to reach expected value for dangerous chemical production

PendingCN114471435AAchieve stirring effectEffective mixing effectProcess control/regulationRotary stirring mixersChemical reactionReaction rate

The invention provides a reaction kettle capable of enabling a reaction rate to reach an expected value for dangerous chemical production, relates to the technical field of chemical production, and aims to solve the problems that the reaction rate cannot reach the expected value due to the fact that an existing chemical reaction kettle cannot perform stirring in multiple directions, and the discharging direction cannot be adjusted according to actual conditions, so that the production cost is reduced. Most of the materials are discharged in a fixed manner; the chemical reaction kettle comprises a supporting device, a feeding device and a discharging device, wherein the supporting device is arranged on the feeding device; a reaction kettle main body is fixedly arranged at the top of the supporting device; a discharging device is fixedly arranged at the top of the supporting device; a reaction kettle cover body is fixedly arranged at the top of the reaction kettle main body, and a first stirring device is rotationally arranged in the reaction kettle main body; an adjusting device is fixedly arranged on the outer side of the bottom of the reaction kettle main body; a control device is fixedly arranged at the top of the reaction kettle cover body; a second stirring device is rotationally arranged in the first stirring device; and an auxiliary device is fixedly arranged on the rear side of the discharging device.

Owner:李和勇

Stirring reactor for feeding material uniformly in reaction

InactiveCN106268590AAchieving stirringWell mixedChemical/physical/physico-chemical stationary reactorsNuclear engineeringReaction chamber

The invention discloses a stirring reactor for feeding a material uniformly in reaction, comprising a reactor body, a stirring device and a motor; the top end of the reactor body is provided with a charge port, with the bottom end provided with a discharge port; the reactor body comprises a reaction chamber and a feed cavity; the feed cavity is provided with a feed port positioned in the reactor body; the feed cavity and the reaction chamber are communicated through at least one connection pipe; the connection pipes are arranged in the middle of the reaction chamber; the stirring device comprises a stirring shaft and stirring blades connected to the stirring shaft; the reactor is provided with the feed cavity that is communicated with the reaction chamber through at least one connection pipe, reaction material can be fed to the center of the reaction chamber, and it is possible to feed the material to the reaction chamber from different directions and positions in the case that there are a plurality of connection pipes; the stirring device of the reactor enables stirring for the whole reactor such that materials in the reactor are fully mixed and reacted.

Owner:成都米特瑞新材料科技有限公司

A waste gas treatment equipment for environmental engineering

ActiveCN108644795BScientific and reasonable structureEasy to useIncinerator apparatusAir quality improvementEnvironmental engineeringPlastic film

The invention discloses waste gas treatment equipment for environmental engineering. The waste gas treatment equipment comprises a reaction box body; a sliding groove is formed in the outer ring of the upper surface of the reaction box body; a detection mechanism is arranged above the sliding groove; the two ends of an adjusting rope are connected to a compressed gas cleaning plate; a flow baffleis arranged in the reaction box body; a sliding column is arranged at the bottom of a storage box; and partition plates are arranged on the two sides of the middle of a catalytic bed. The waste gas treatment equipment has the advantages of being scientific and reasonable in structure and safe and convenient to use, a plastic film is fixed to the edges of the reaction box body through sealing rods,so that whether cracks exist at the edge position can be effectively known, the generation of the cracks of the reaction box body can be conveniently found in time, and the hidden danger in installation, the escape of pollution waste gas and the waste of heat energy can be avoided; and a rocking handle is rotated to enable sealing plates to drive the catalytic bed to rotate, the operation is simple and easy to carry out, workers can conveniently and quickly replace the catalytic bed inside the reaction box body, so that the situation that the environment pollution is caused due to the fact that the waste gas in the reaction box body escapes can be avoided.

Owner:东营金辉环保科技有限公司

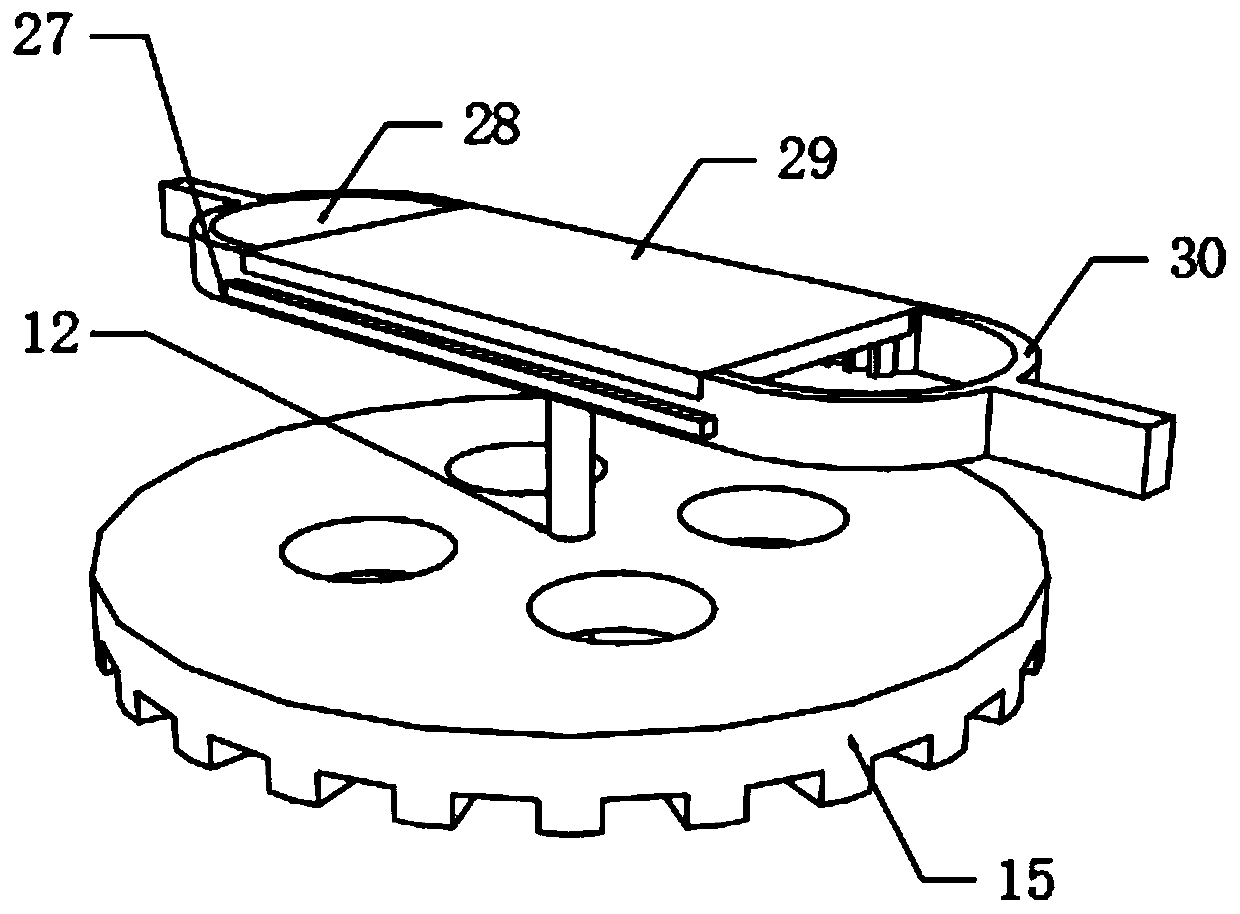

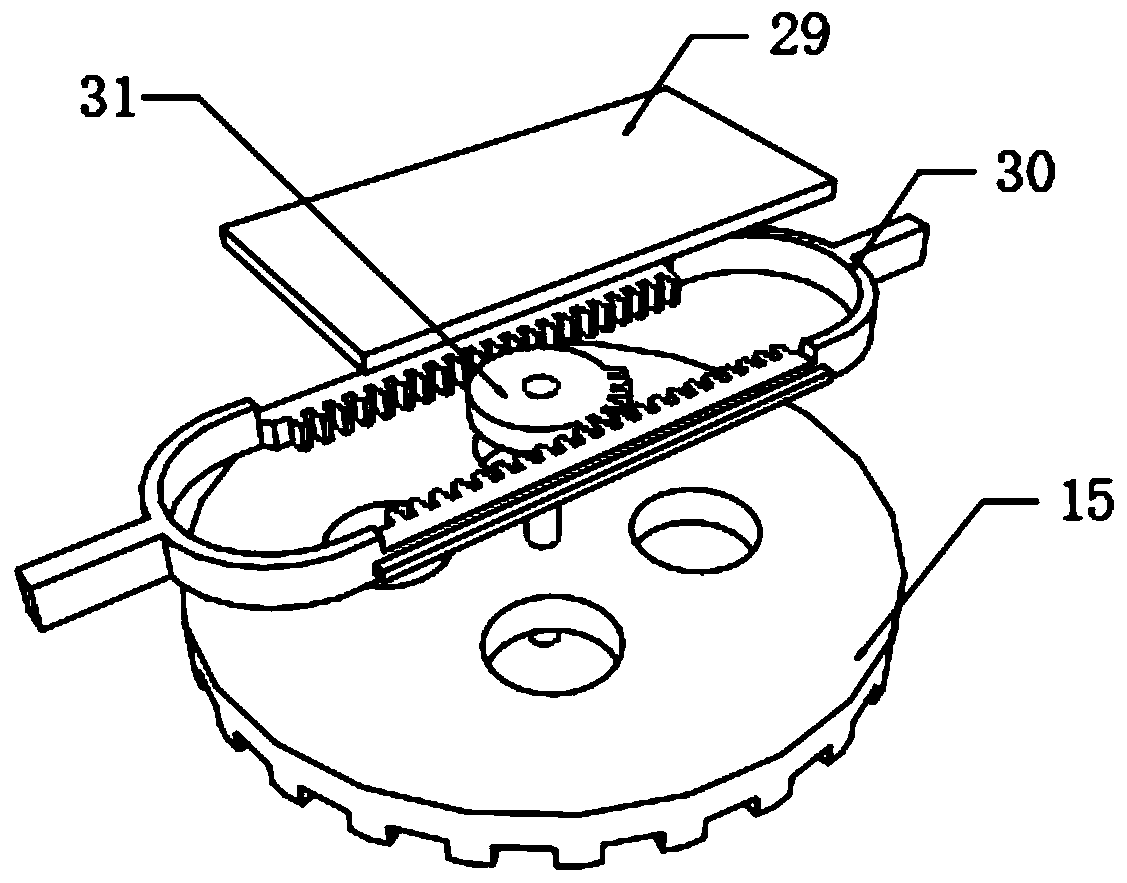

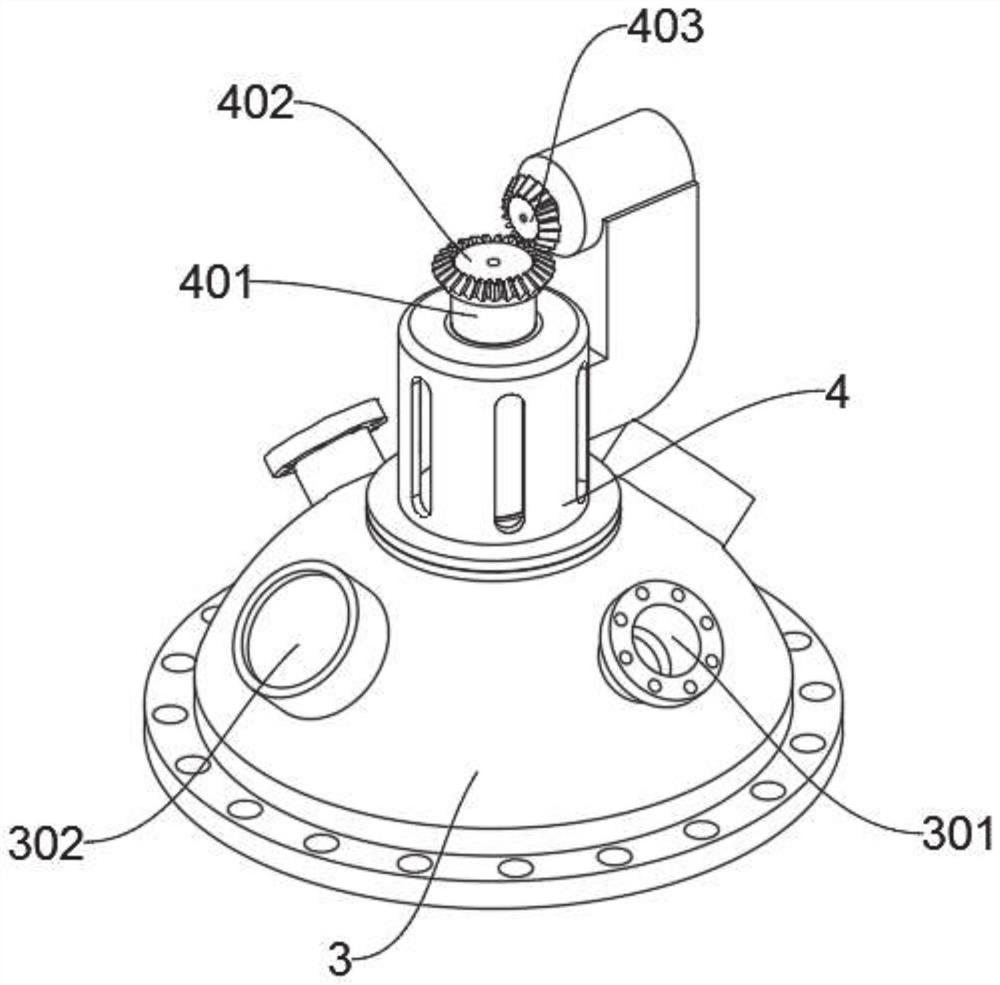

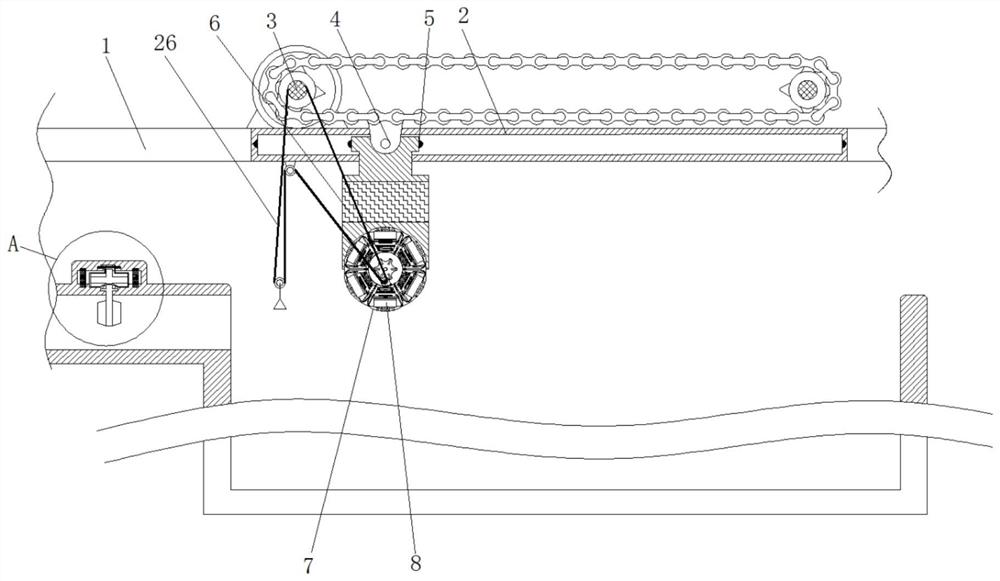

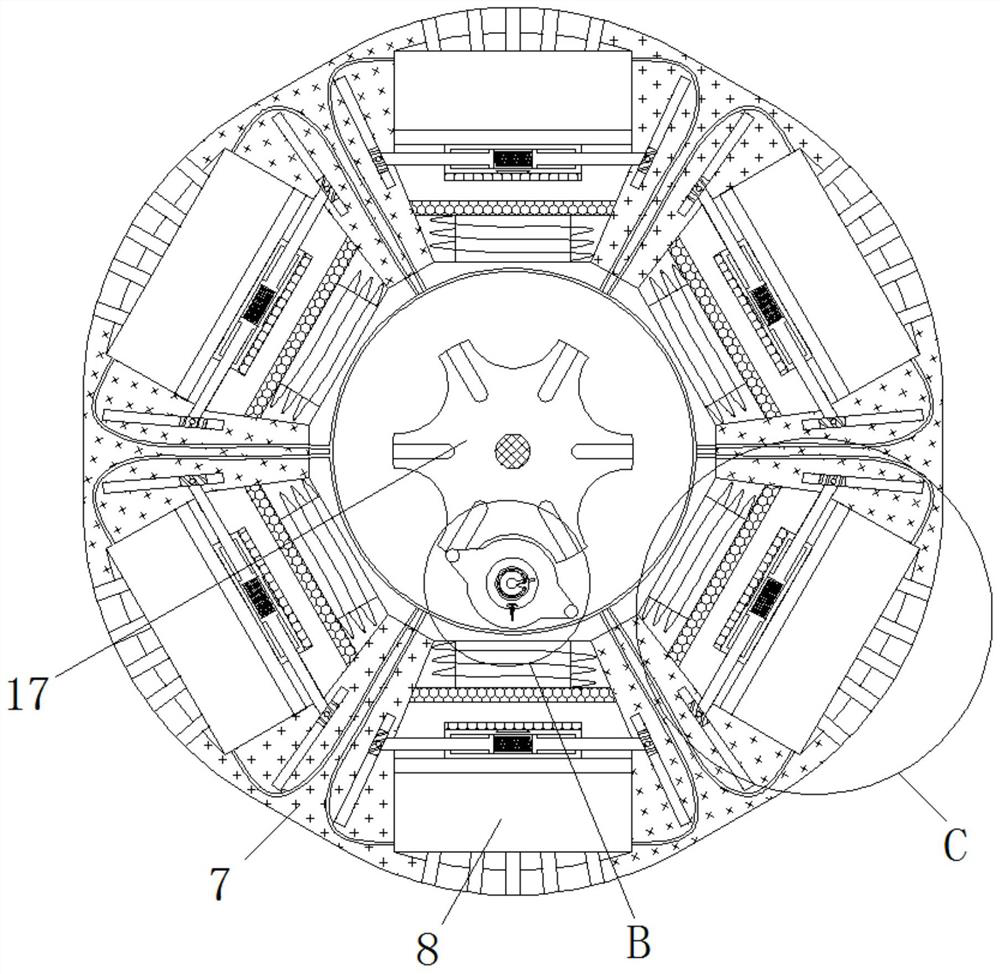

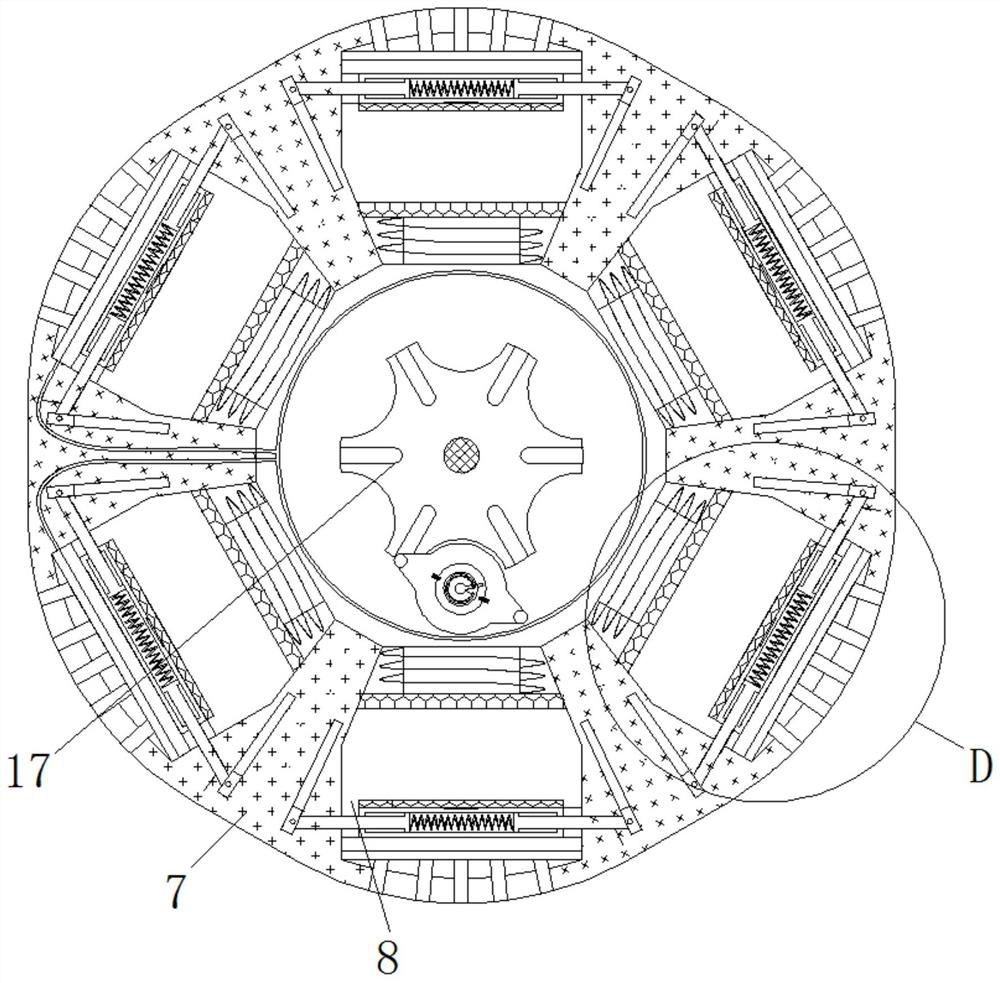

Sewage treatment automatic dosing equipment based on environmental protection

InactiveCN112047407AAvoid underreactionEven doseWater/sewage treatment apparatusGear driveDosing Frequency

The invention relates to the technical field of sewage treatment equipment, and discloses sewage treatment automatic dosing equipment based on environmental protection. The equipment comprises a tankbody, a limiting groove is fixedly connected to the top of the tank body, a chain gear transmission is fixedly connected to the top of the limiting groove, and a movable support is fixedly connected to the bottom of the chain gear transmission. The left end and the right end of the movable support are fixedly connected with contacts, the bottom of the movable support is fixedly connected with a liquid medicine supply device, and the bottom of the liquid medicine supply device is rotationally connected with a feeding disc. According to the sewage treatment automatic dosing equipment based on environmental protection, the movable support moves back and forth for dosing, so that the effect of uniform dosing is achieved, and the problems that liquid medicine and sewage are not fully reacted due to uneven dosing of the liquid medicine; the larger the sewage discharge capacity is, the higher the rotating speed of the cam rotating block is, and the higher the rotating dosing frequency of a fluted disc in transmission connection with the cam rotating block is are solved; and the effect of automatically adjusting the liquid medicine spraying frequency according to the sewage discharge amount is achieved, and the purification efficiency is improved.

Owner:黄明

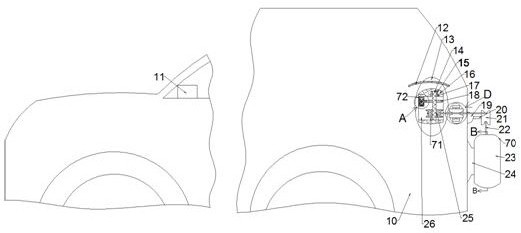

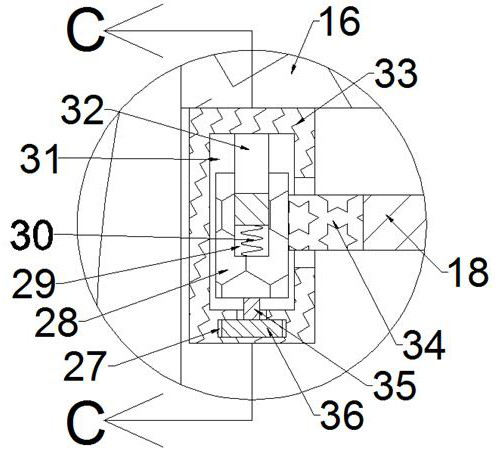

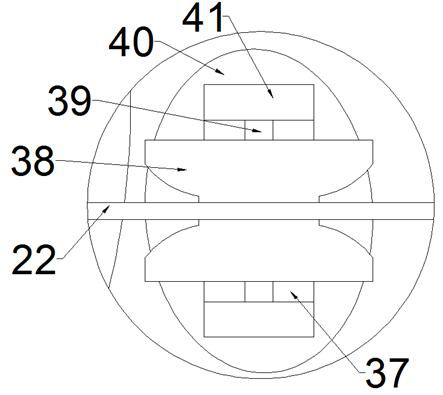

A Self-adjusting Ultrasonic Detector for Anti-Side Collision of Automobiles

ActiveCN110780304BAvoid underreactionSave energyAcoustic wave reradiationDriver/operatorMechanical engineering

The invention discloses a self-adjusting type automobile side collision prevention ultrasonic detector. The self-adjusting type automobile side collision prevention ultrasonic detector comprises an automobile, an air pressure mechanism is arranged on the right side of the automobile, the air pressure mechanism comprises a storage box, an air pressure cavity with an upward opening is formed in thestorage box, an air pressure plate is arranged in the air pressure cavity in a sliding manner, the air pressure plate can slide up and down according to external atmospheric pressure, and a transmission mechanism is arranged on the front side of the automobile. According to the detector, the speed of the automobile is determined by turbulent flow generated at the rear part of the automobile in theautomobile driving process to determine whether an ultrasonic ranging part device on the side of the automobile needs to be started or not, utilize useless turbulent flow and save energy; and moreover, along with increase of the turbulent flow on the rear portion of the automobile, the ultrasonic ranging alarm part can start alarm prompt at a far position, a good side collision prevention effectis achieved, and under the condition that the automobile speed is higher, the alarm distance is longer, and the situation that a driver cannot respond well due to the fact that the automobile speed istoo high is avoided.

Owner:WM MOTOR TECH GRP CO LTD

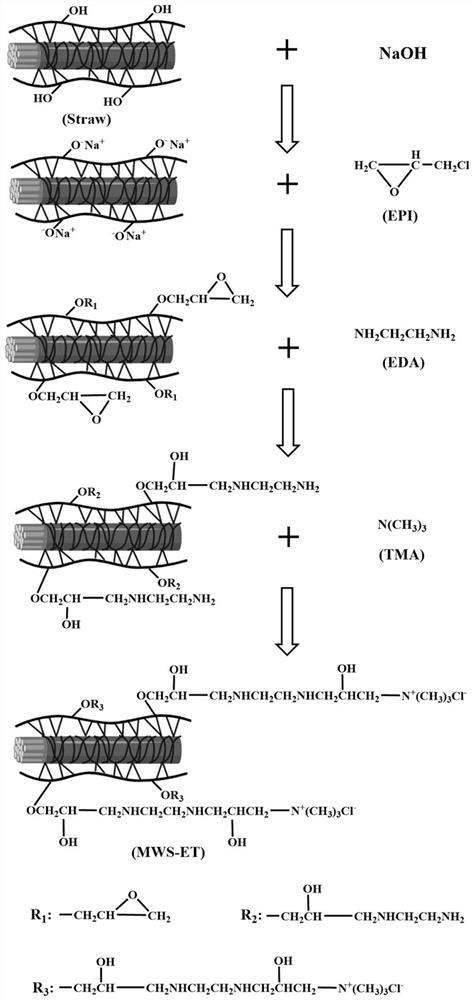

Quaternary amine modified straw material for removing nitrate in water body, preparation method and application

ActiveCN114570335BReduce usageReduce manufacturing costOther chemical processesWater contaminantsEpichlorohydrinEthylenediamines

The invention belongs to the technical field of water treatment materials, and discloses a quaternary amine modified straw material for removing nitrate in water body, a preparation method and application thereof. Dry at 60 °C for 24 h, pack in a sealed bag, and store in a glass desiccator; take the obtained straw, add 10% NaOH solution by mass, and carry out alkali pretreatment at room temperature for 2 h to obtain a treatment solution, which is dehydrated; Then add epichlorohydrin to the straw sample; slowly add ethylenediamine to obtain ethylenediamine-treated straw; add 30% trimethylamine solution by volume and react at 90 °C for 3 h; the product is adjusted with sodium hydroxide and hydrochloric acid to neutral, washed with ethanol and deionized water, and dried in an oven at 60° C. to obtain a quaternary amine modified straw material. The invention uses NaOH and ethylenediamine as main reagents, reduces the use of highly toxic reagents, and reduces the preparation cost of quaternary amine modified straw.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

Extraction process based on novel graphene material

InactiveCN113716554AProblems Affecting Extraction PurityIncrease contactGaseous chemical processesGrapheneGraphene flakeWater flow

The invention discloses an extraction process based on a novel graphene material. A device used in the extraction process comprises an extraction box, wherein the center of the interior of the extraction box is rotatably connected with a separation barrel, and the left side of the top of the extraction box is provided with a material supplementing port. The invention relates to the technical field of graphene processing. According to the extraction process based on the novel graphene material, by arranging a water circulation structure, stripping liquid can circularly flow, and then the stripping liquid can better make contact with graphene flakes; meanwhile, the separation barrel containing the graphene flakes can be indirectly pushed to rotate by means of the pushing force of water circulation, the graphene flakes in the separation barrel can fully roll over through cooperation between the pushing force of water circulation with the pushing force of water flow, so stripping effect is better; and no extra stirring device needs to be arranged, a material blocking structure is arranged in the separation barrel and can block a part of turned graphene flakes, then the situation that the whole graphene flakes completely rotate along with water flow can be avoided, the graphene flakes make full contact with stripping liquid, and better effect is obtained compared with an existing stirring structure.

Owner:刘四保

An environmentally friendly chemical production cooling reaction kettle

ActiveCN111530400BScientific and reasonable structureEasy to useChemical/physical/physico-chemical stationary reactorsFeed devicesProcess engineeringChemical agent

Owner:宁夏宏民生物科技有限公司

A solid phase condensation recovery device for zirconium and hafnium metallurgy

ActiveCN112076621BAvoid hydrolysisFully contactedGas treatmentDispersed particle separationHafniumMaterials science

The invention relates to the technical field of zirconium and hafnium metallurgy, and discloses a solid-phase condensation recovery device for zirconium and hafnium metallurgy, which includes a base and a dehydration chamber. The upper part of the dehydration chamber is provided with thin tubes, and the inside of the dehydration chamber is fixedly installed with A fixed plate, the outer side of the fixed plate is provided with fine holes, the inside of the fixed plate is provided with a discharge port, the inside of the fixed plate is provided with a rotating plate, the outer side of the rotating plate is provided with a blocking column, the A second spring is fixedly connected below the blocking post. The solid-phase condensation recovery device for zirconium and hafnium metallurgy, when the rotating plate rotates, when the plugging column moves below the fine hole opened on the fixed plate, the blocking column moves up into the fine hole under the elastic force of the second spring, making the powder The water-absorbing agent will not fall, and as the rotating plate rotates, the plugging column squeezes the second spring and leaves the pores, and the water-absorbing agent falls through the pores and swayes to the lower part of the dehydration chamber, so that the powdery quicklime swayes in the dehydration chamber and is fully mixed with the dehydration chamber. The effect of water contact thereby absorbing water.

Owner:宝钛华神钛业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com