Patents

Literature

214results about How to "Avoid affecting productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

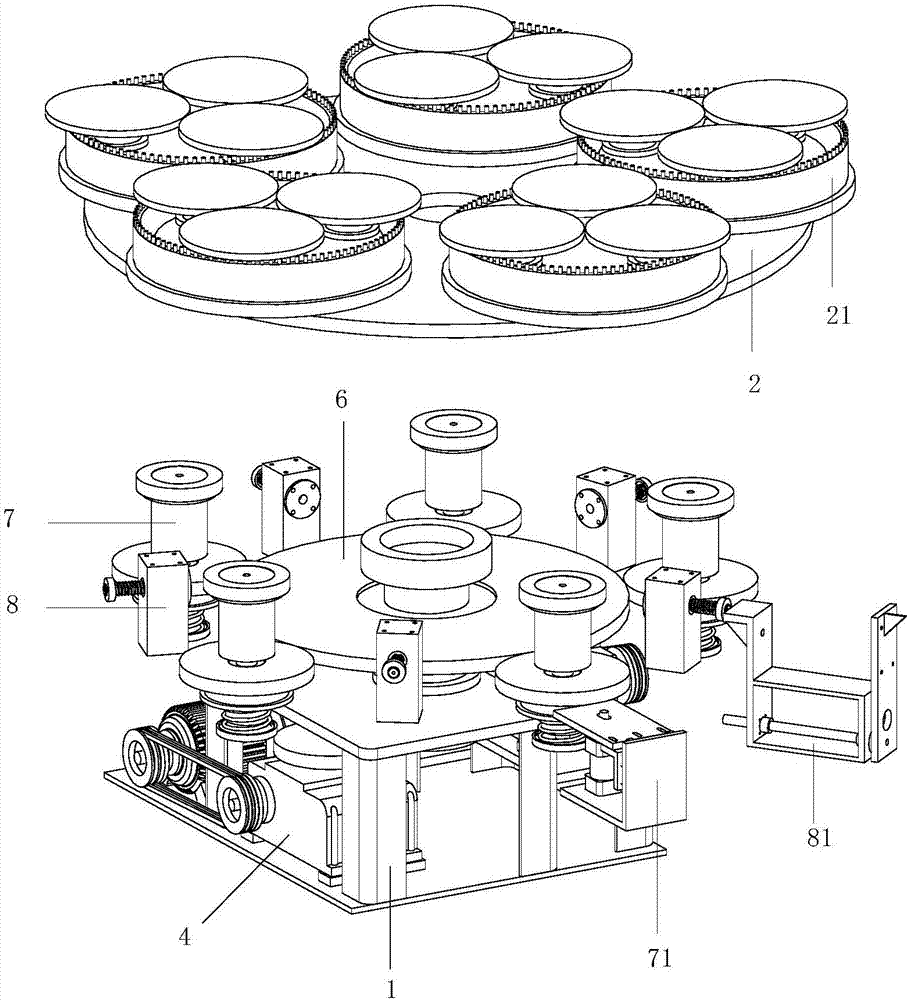

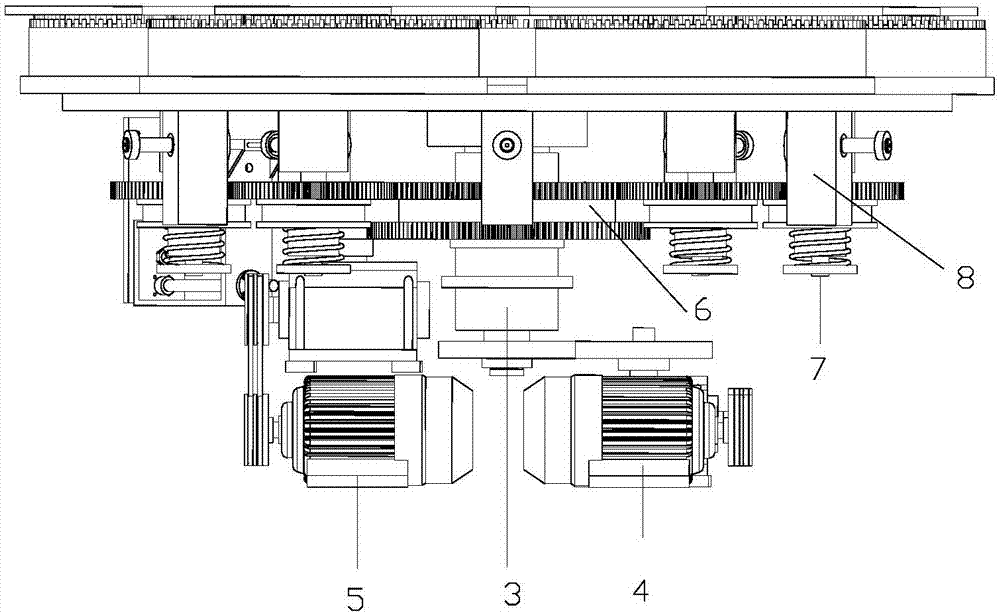

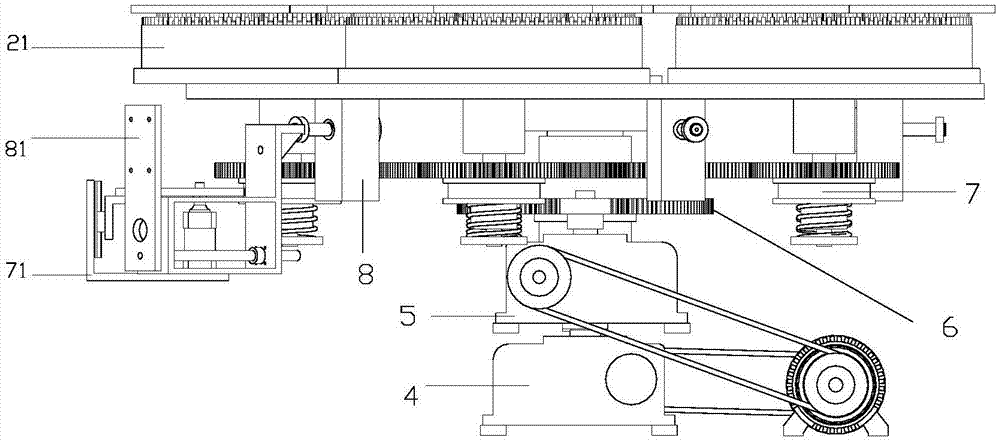

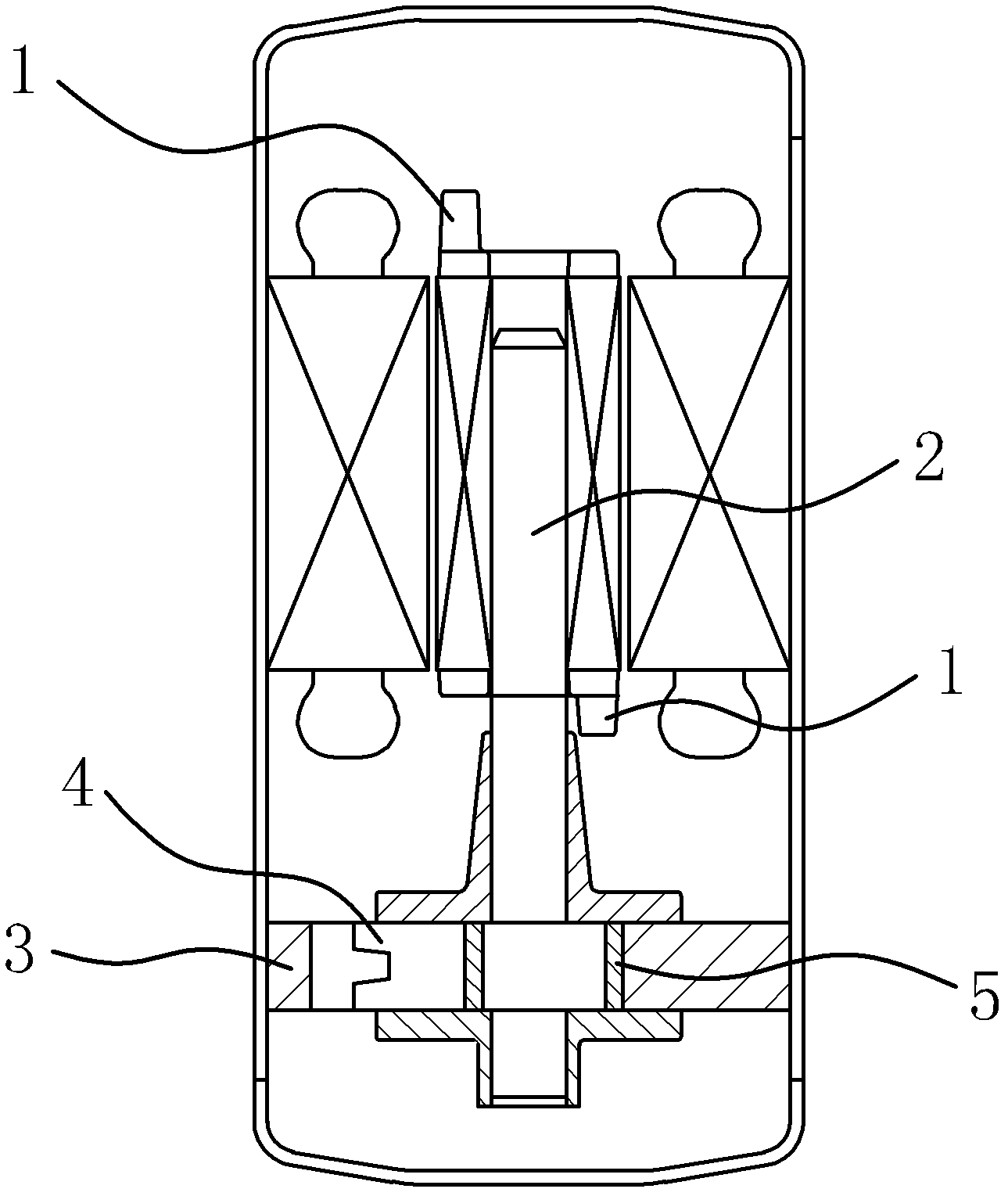

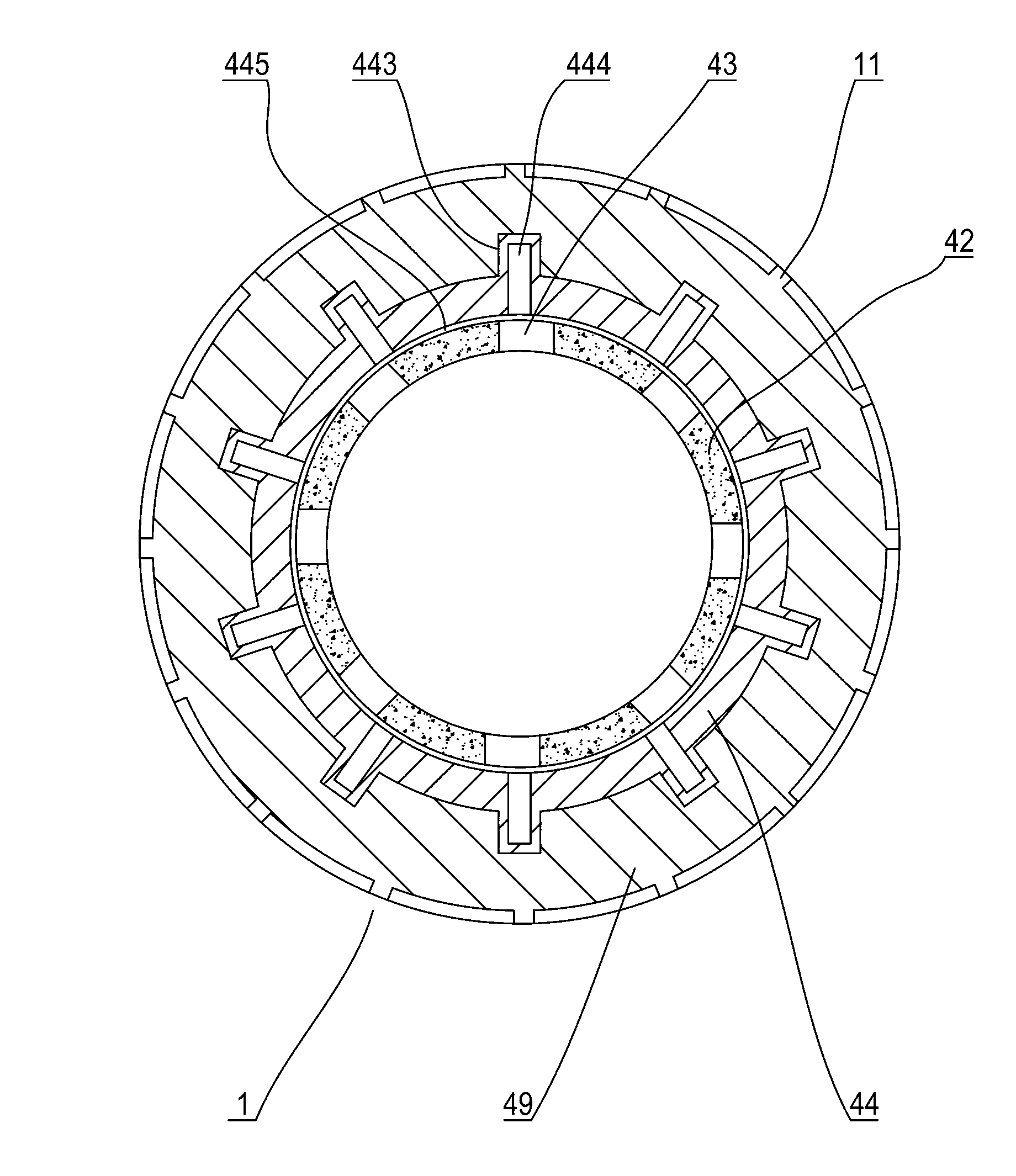

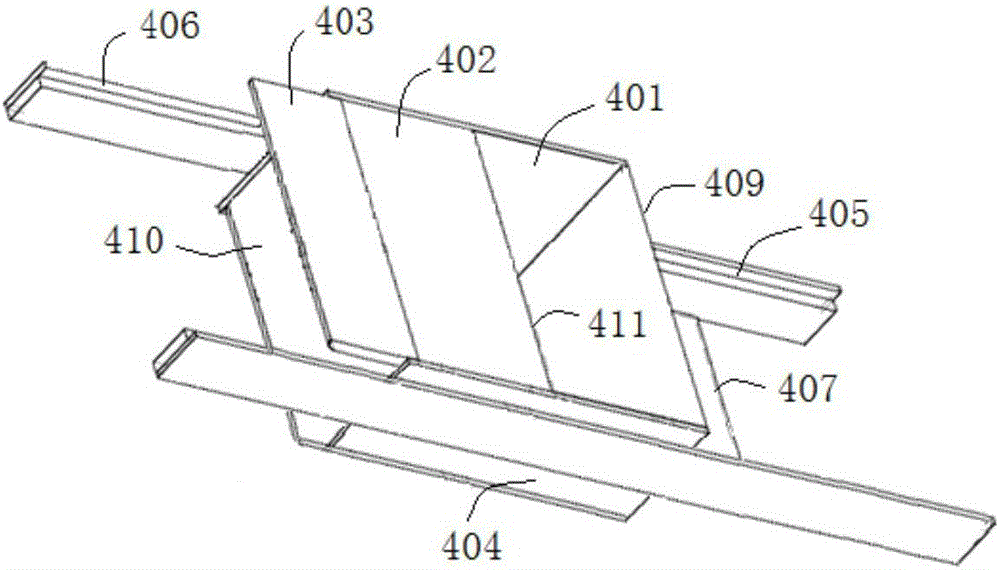

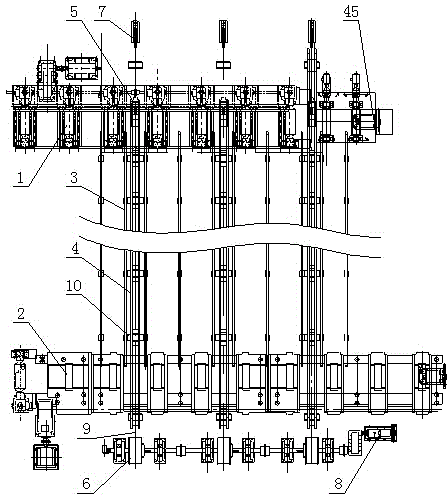

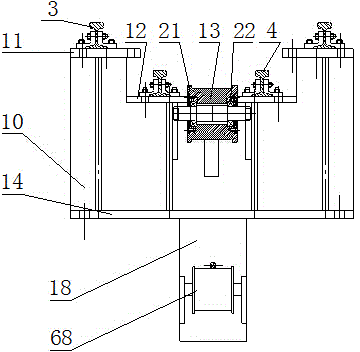

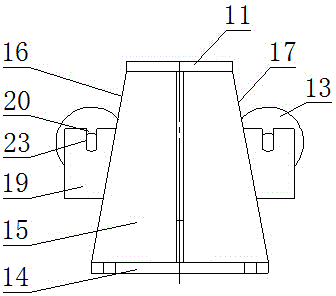

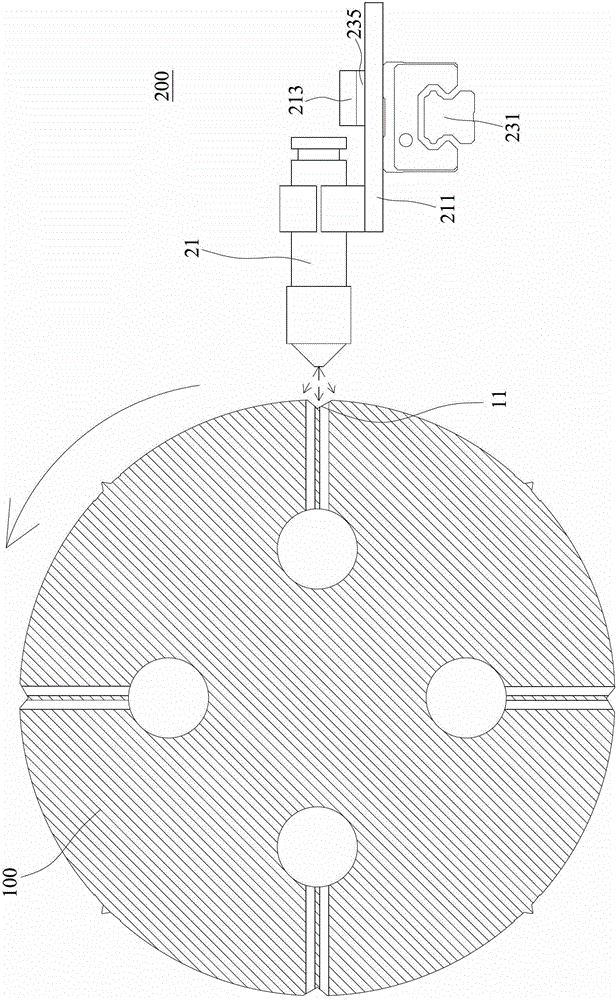

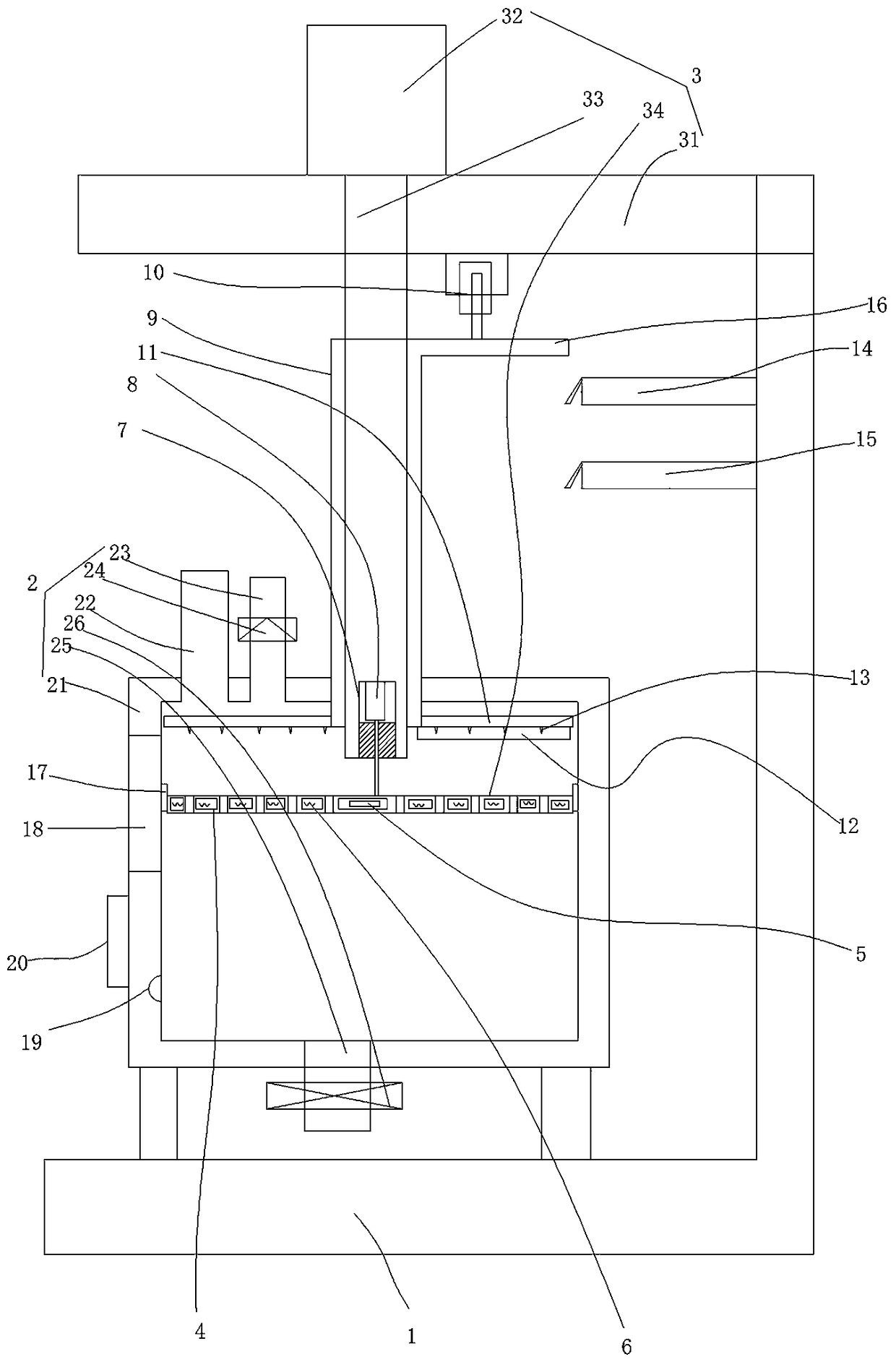

Intelligent multi-work-section hook face polishing machine

ActiveCN107322452AIncrease the number ofImprove processing efficiencyPolishing machinesGrinding drivesEngineeringMachining

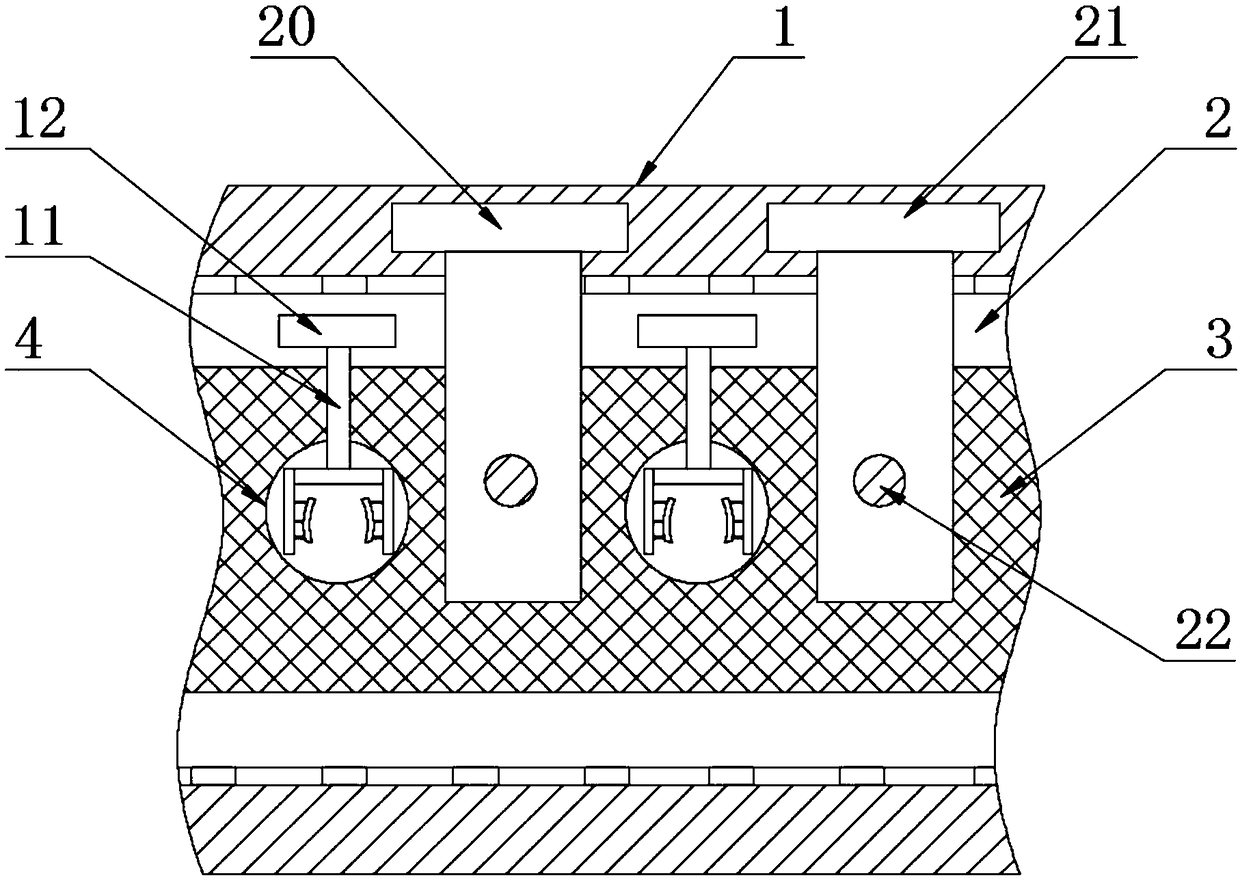

The invention discloses an intelligent multi-work-section hook face polishing machine. The intelligent multi-work-section hook face polishing machine comprises a work disc, a first transmission assembly, a second transmission assembly and a plurality of rotation stop control devices. The first transmission assembly is arranged at the bottom of the work disc and drives the work disc to rotate around the axis of the work disc. A plurality of self-rotation assemblies are arranged on the periphery of the upper surface of the work disc. The second transmission assembly penetrates the work disc and is connected with the self-rotation assemblies, and the second transmission assembly drives the self-rotation assemblies to rotate around the axes of the self-rotation assemblies. The multiple rotation stop control devices are arranged on the second transmission assembly and control the target self-rotation assembly to stop rotating. According to the intelligent multi-work-section hook face polishing machine, through the manner of self-rotation and revolution, multi-level rotation and simultaneous multi-work-section machining of products are achieved. When workpieces are matched, the intelligent multi-work-section hook face polishing machine can firmly adsorb the workpieces, stop control can be conducted on the target self-rotation assembly without influencing machining of other self-rotation assemblies, and the workpiece machining efficiency is improved.

Owner:SHENZHEN XIKEO IND CO LTD

Hydrogen peroxide working solution and its application in preparation of hydrogen peroxide

ActiveCN103588177AReduce solubilityImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention belongs to the technical field of hydrogen peroxide, and especially relates to a hydrogen peroxide working solution and its application in the preparation of hydrogen peroxide. The hydrogen peroxide working solution comprises 2-ethylanthraquinone having a mass concentration of 120-200g / L and an organic solvent, and the organic solvent comprises, by volume, 70-80% of a C9-C10 aromatic hydrocarbon, 14-20% of trioctyl phosphate, 4-10% of 2-methylcyclohexyl acetate and 0.4-0.9% of tertiary amine When the hydrogen peroxide working solution is used in the preparation of hydrogen peroxide, the hydrogen peroxide working solution can greatly improve the hydrogenation efficiency and the oxidation efficiency of 2-ethylanthraquinone, and has the advantages of low production cost, no peculiar smell and product yield improvement.

Owner:WEIFANG MENJIE CHEM

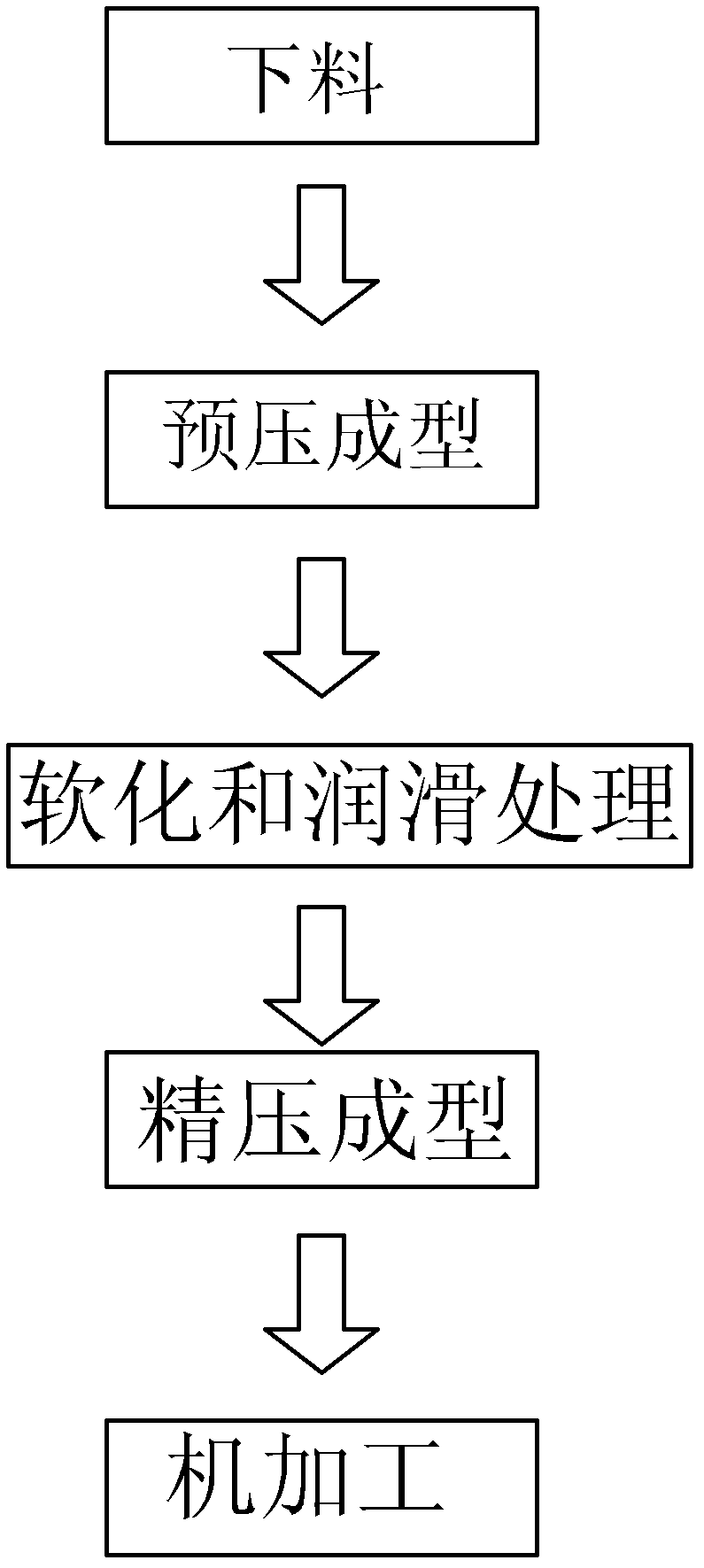

Method for manufacturing air condition compressor balance block

ActiveCN102248373ALow costIncreased production flexibilityMechanical engineering technologyWork in process

The invention provides a method for manufacturing an air condition compressor balance block, belonging to the technical field of mechanical engineering. By means of the method, the technical problems that the production efficiency is low, the reject rate is high and the like when high manganese steel is adopted to manufacture the air condition compressor balance block in a conventional method for manufacturing the air condition compressor balance block are solved. The method for manufacturing the air condition compressor balance block comprises the following steps of: A, blanking: cutting a section made from high manganese steel materials into blanks with a length corresponding to a required length; B, pre-pressing forming: putting the blanks in a mould and extruding into process products with shapes similar to the shapes of finished products; C, softening and lubricating treatments: carrying out the softening treatment and the phosphorization and saponification lubricating treatment on the process products; D, coining forming: putting the process products subjected to softening and the lubricating treatments in the mould to carry out extrusion forming to obtain semi-finished products; and E, machining: clamping the semi-finished products on a machine tool and machining to obtain the finished products. The method provided by the invention has the advantages of low production cost, high production efficiency and the like.

Owner:浙江百达精工股份有限公司

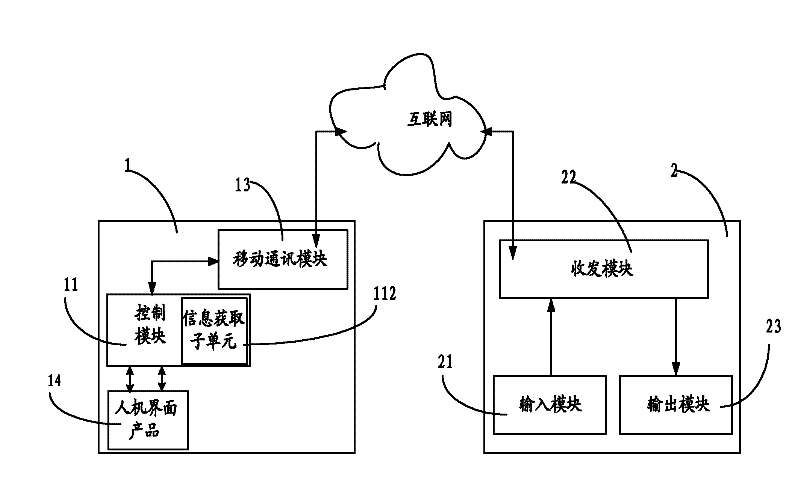

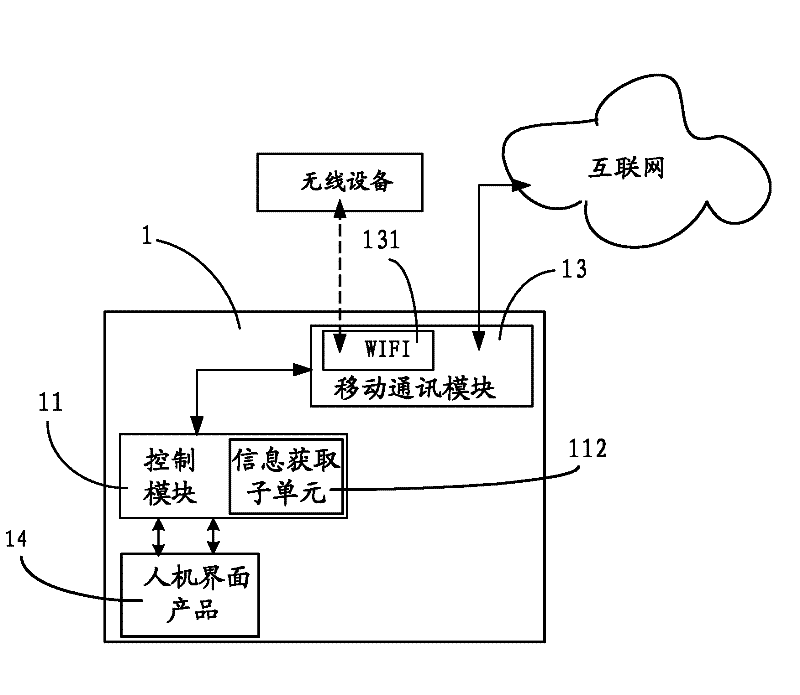

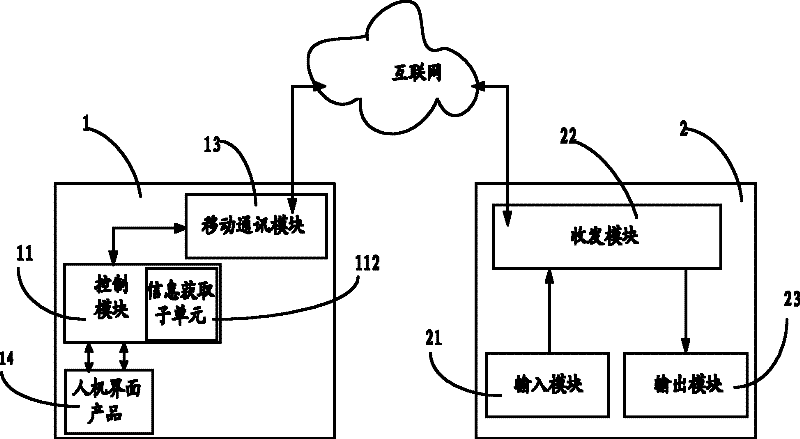

Industrial equipment maintenance and service system

InactiveCN102195976AAvoid affecting productivityReduce labor intensityTransmissionHuman–machine interfaceMan machine

The embodiment discloses an industrial equipment maintenance and service system. The system comprises an equipment terminal and a server terminal, wherein the equipment terminal comprises a man-machine interface product, a control module, a mobile communication module and an information acquisition subunit; the information acquisition unit is used for acquiring information data stored in the control module and transmitting the information data through the mobile communication module; the control module is used for exchanging data with the mobile communication module, and controlling the industrial equipment according to a control instruction received by the mobile communication module; the man-machine interface product is an input / output interface for realizing the operation and application of the control module; and the server terminal comprises an input module for inputting the control instruction, a transceiving module for receiving the information data and transmitting the control instruction, and an output module for outputting the information data. In the embodiment, the industrial equipment maintenance and service system can be used for maintaining the industrial equipment without the field operation of maintenance personnel, thereby improving the working efficiency.

Owner:NINGBO TECHMATION

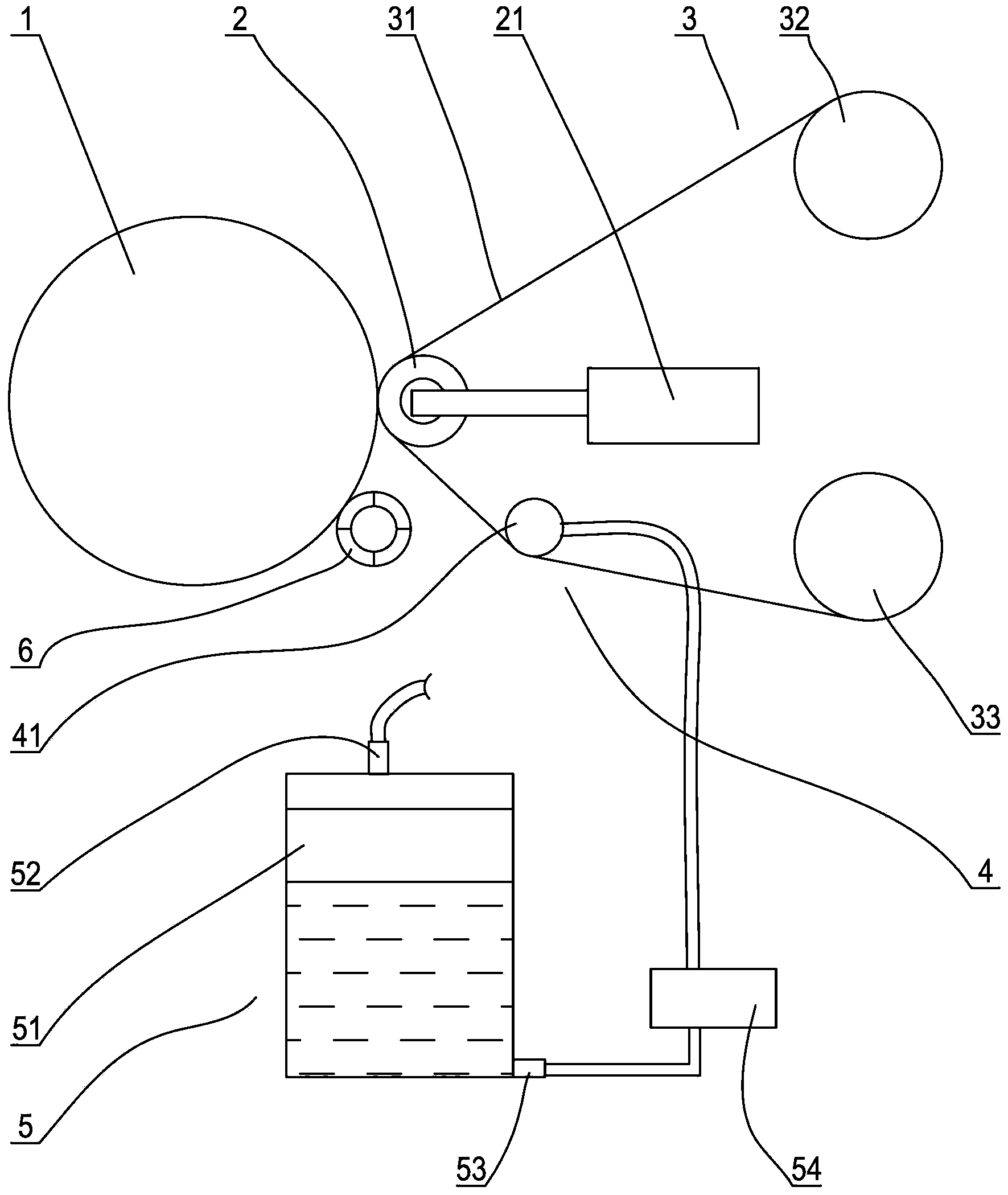

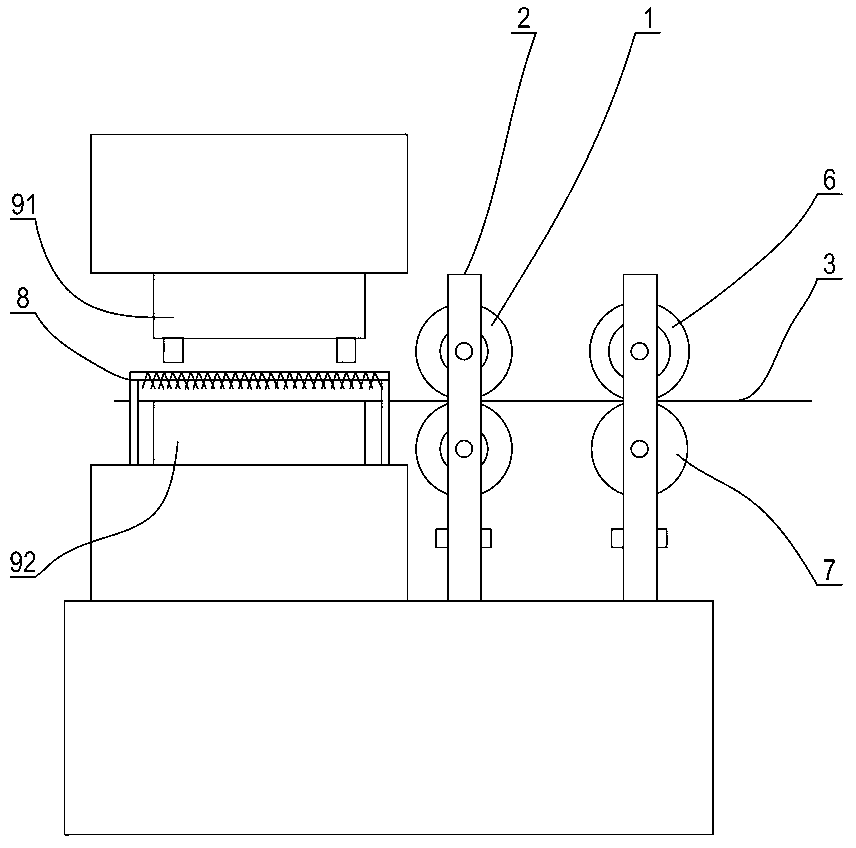

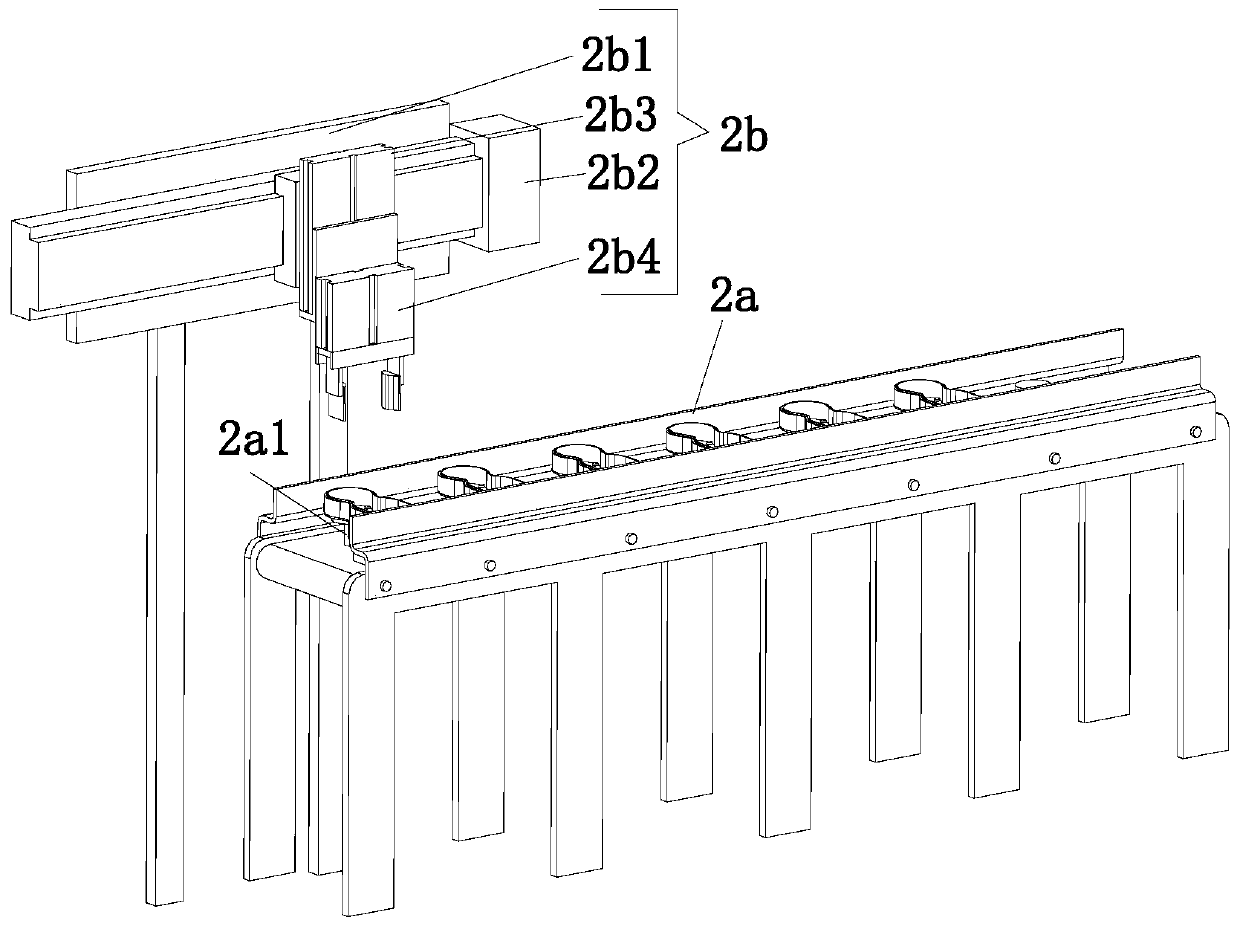

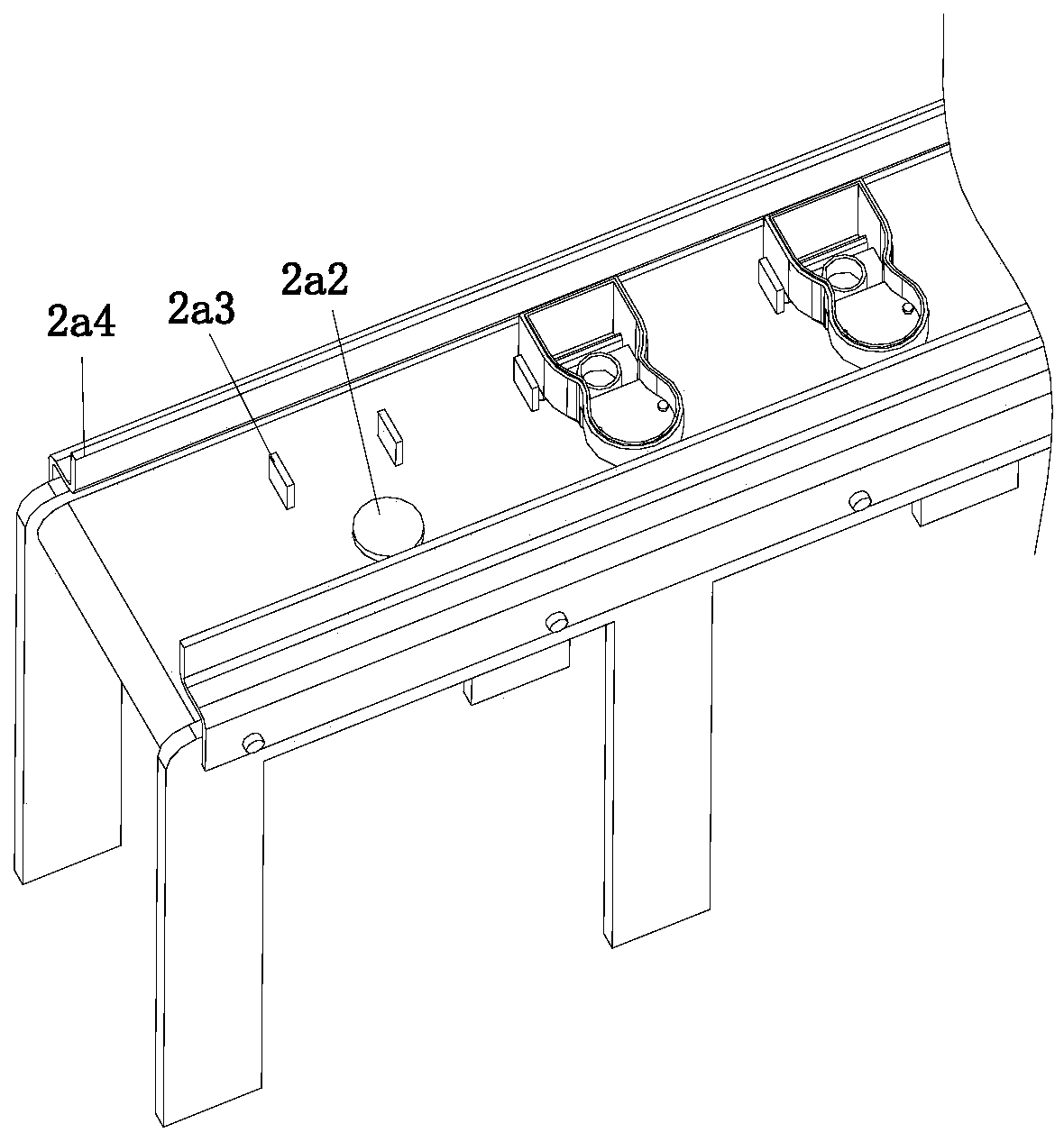

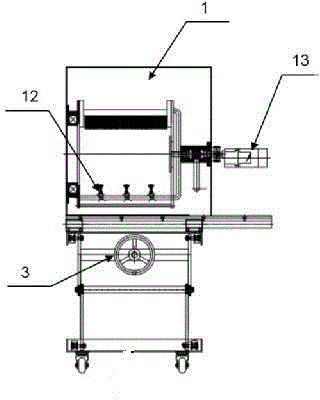

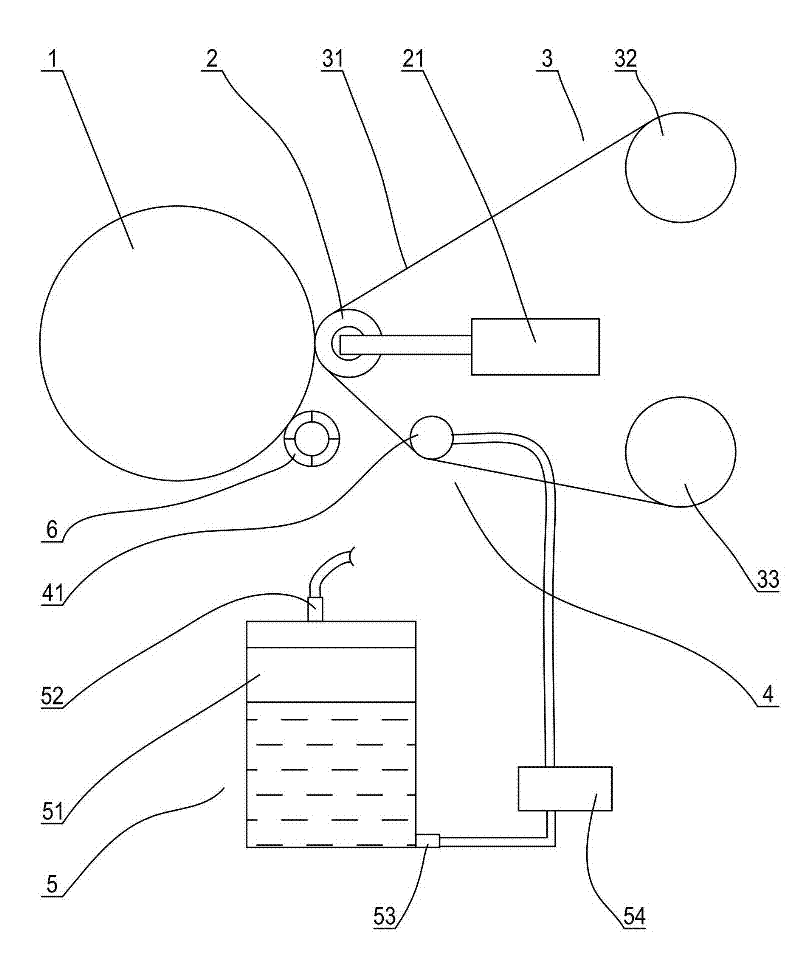

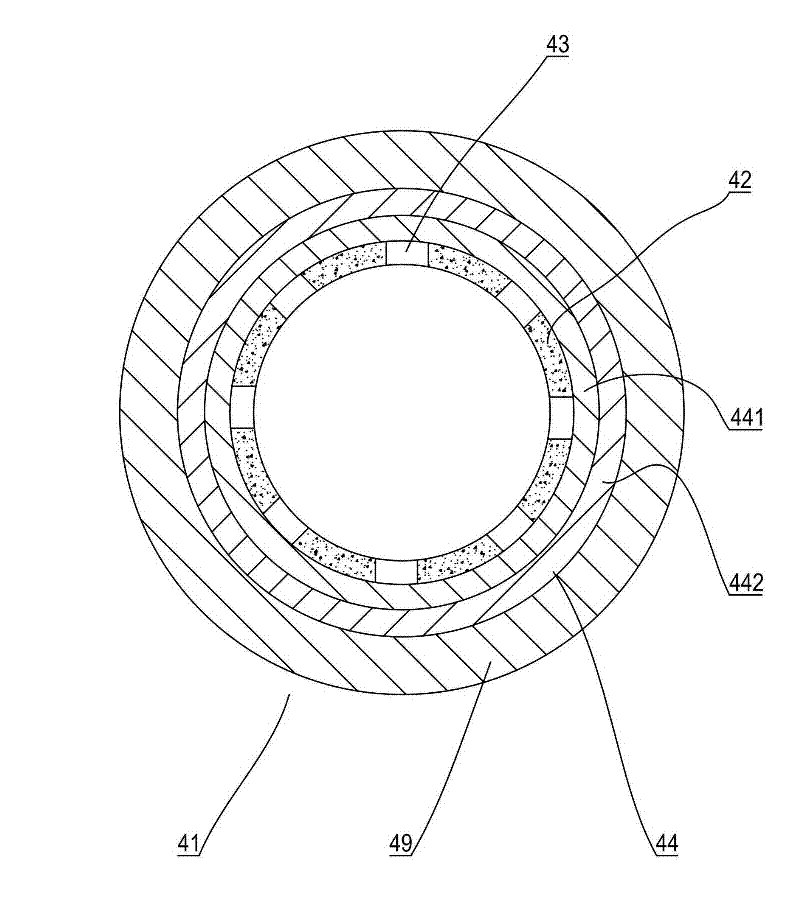

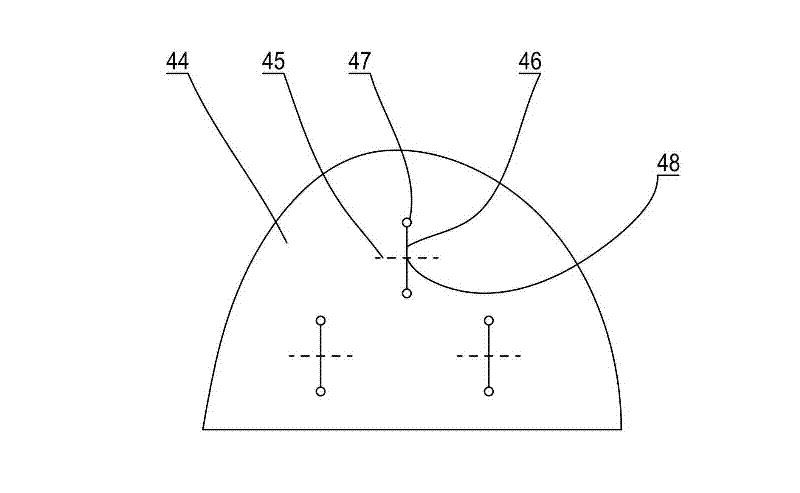

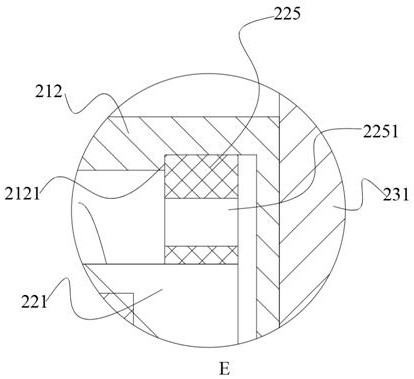

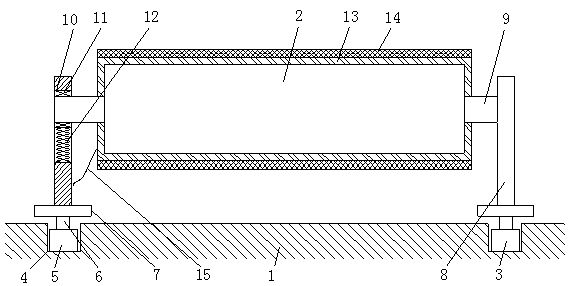

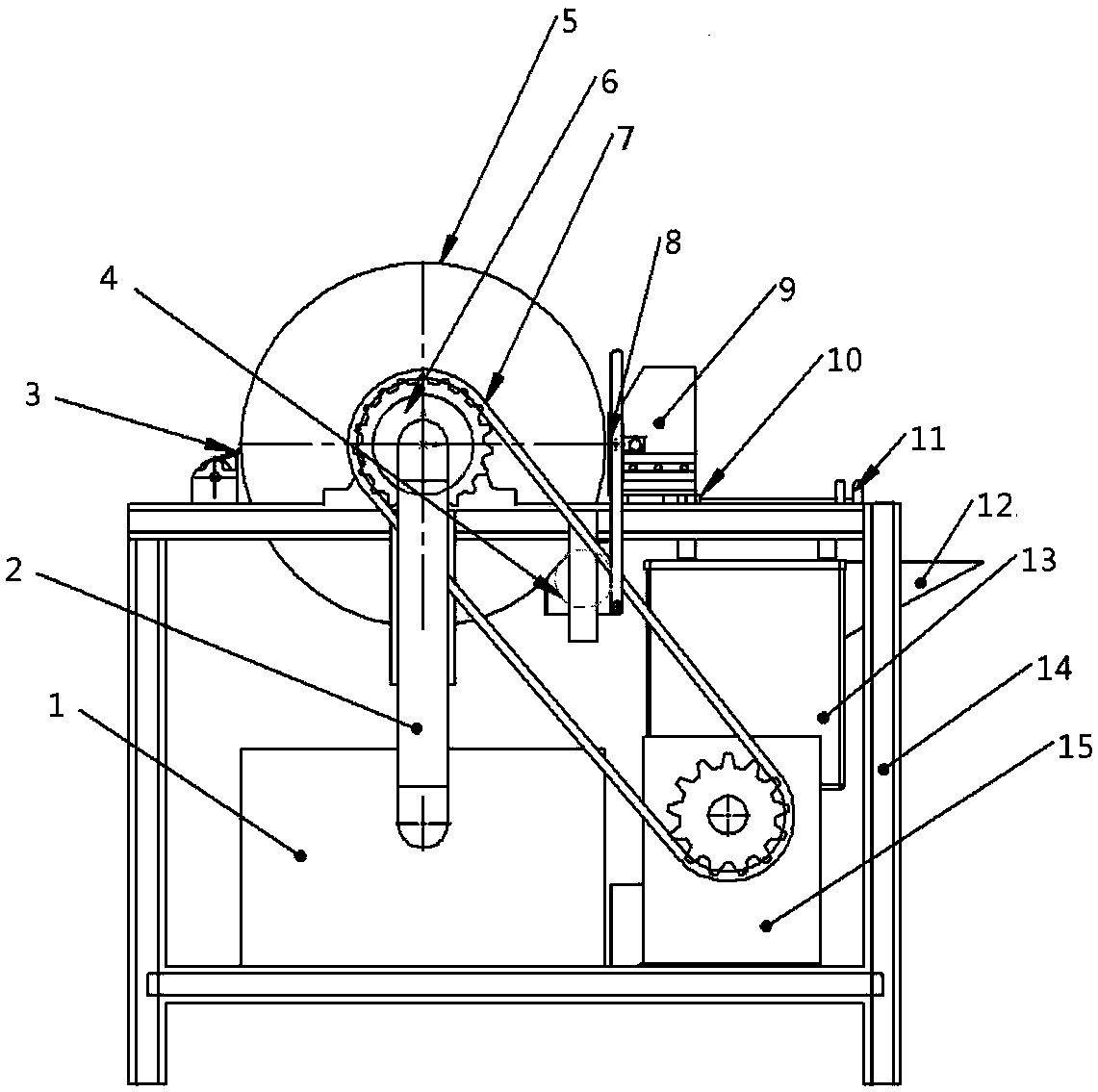

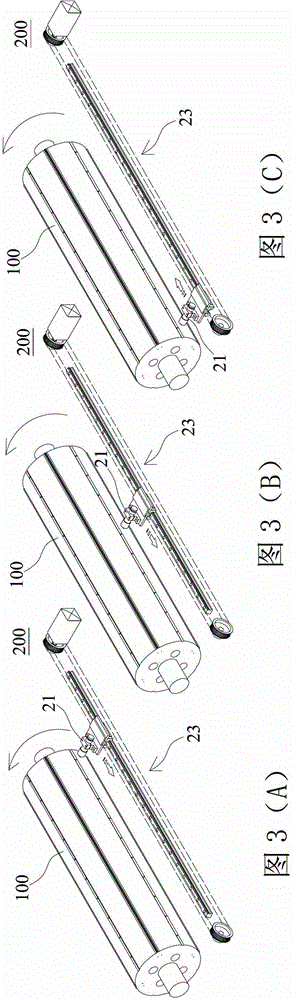

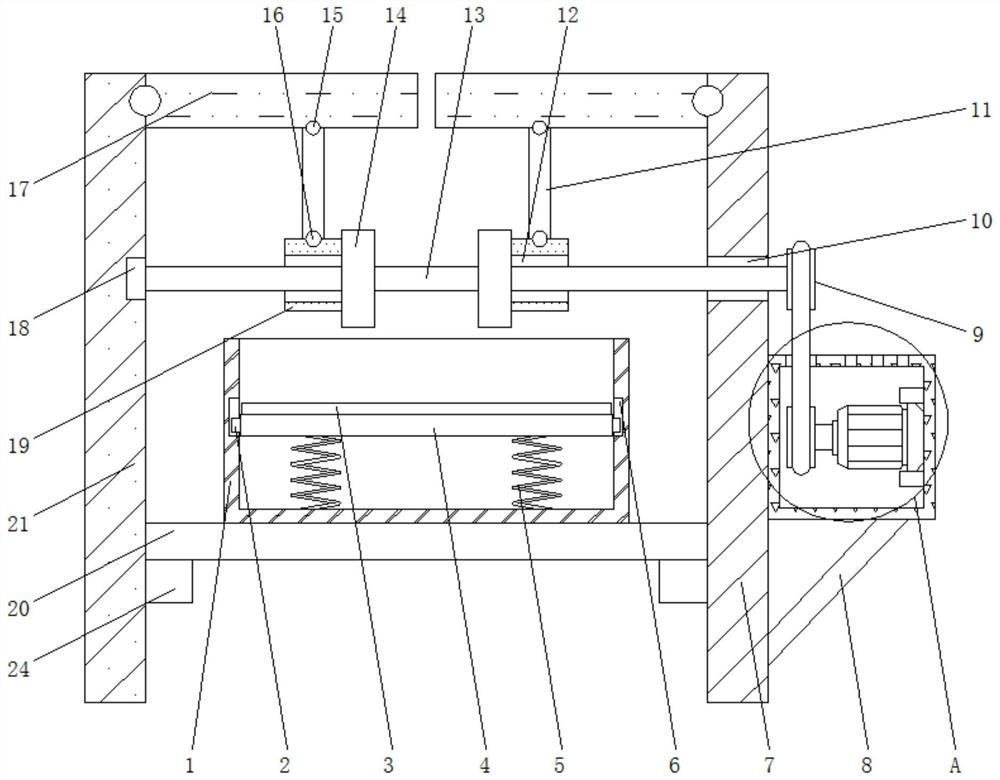

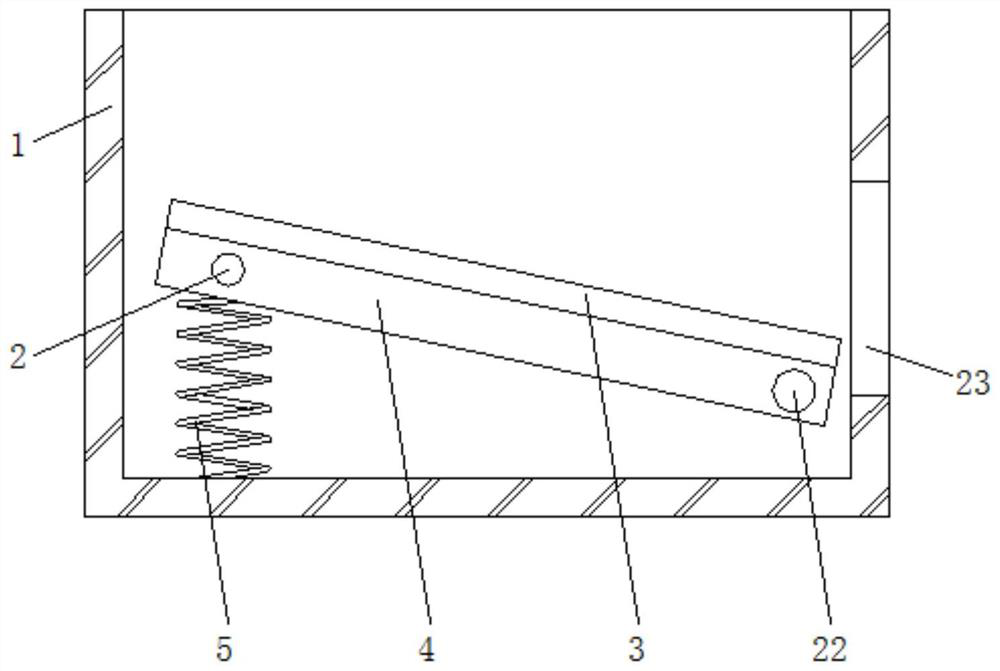

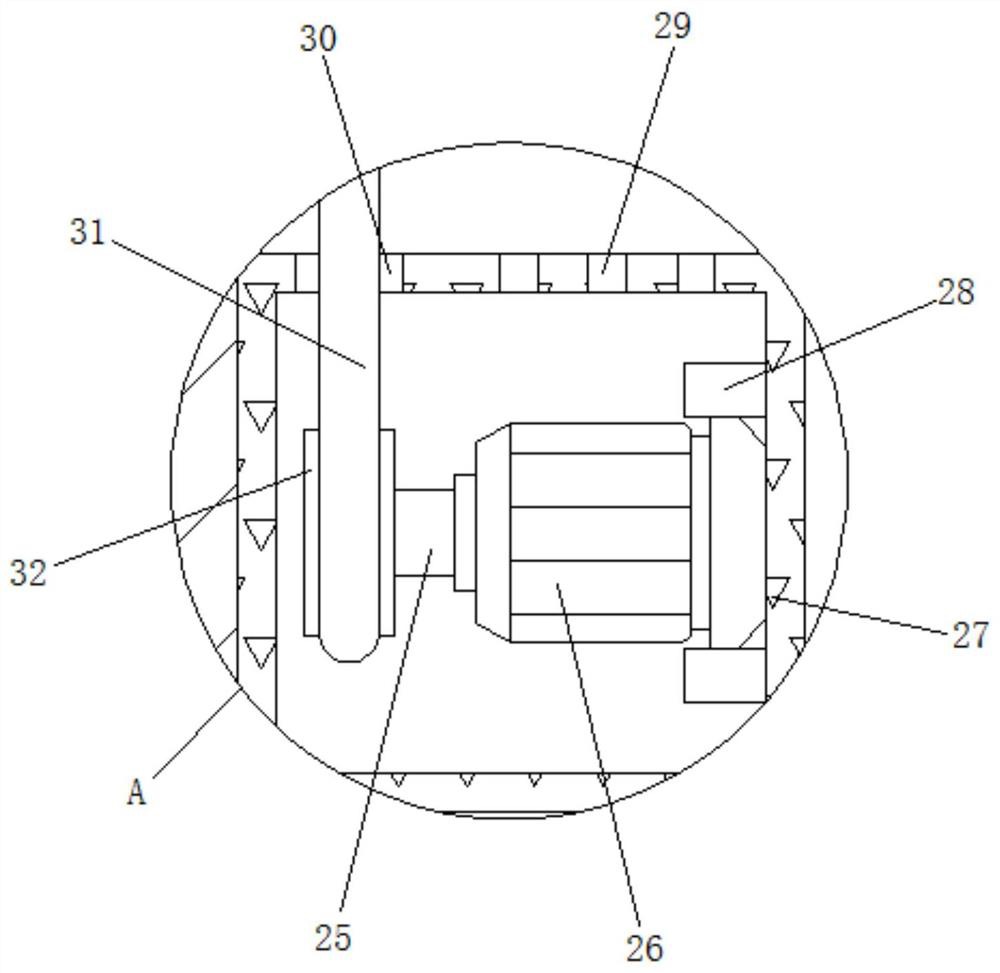

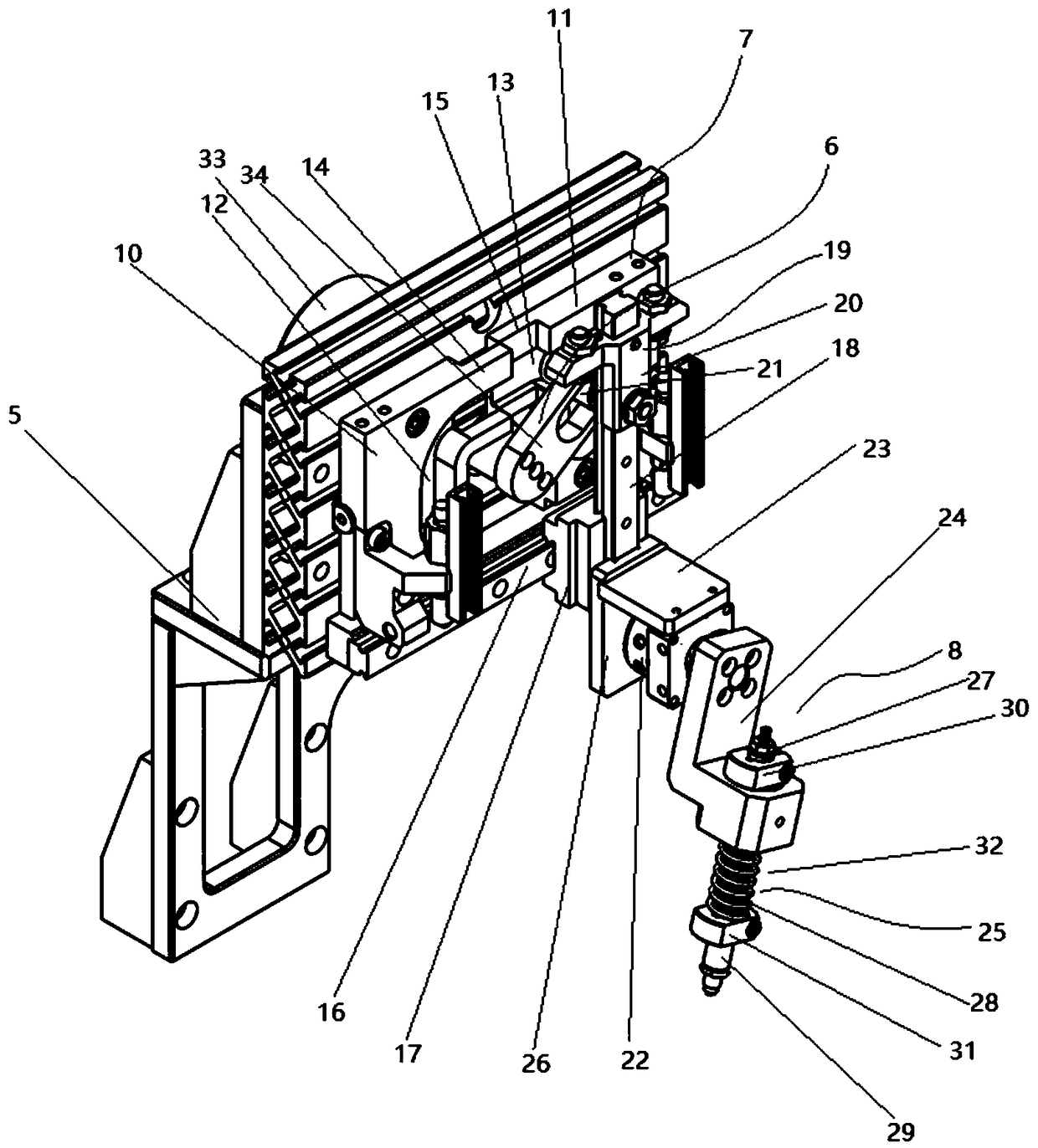

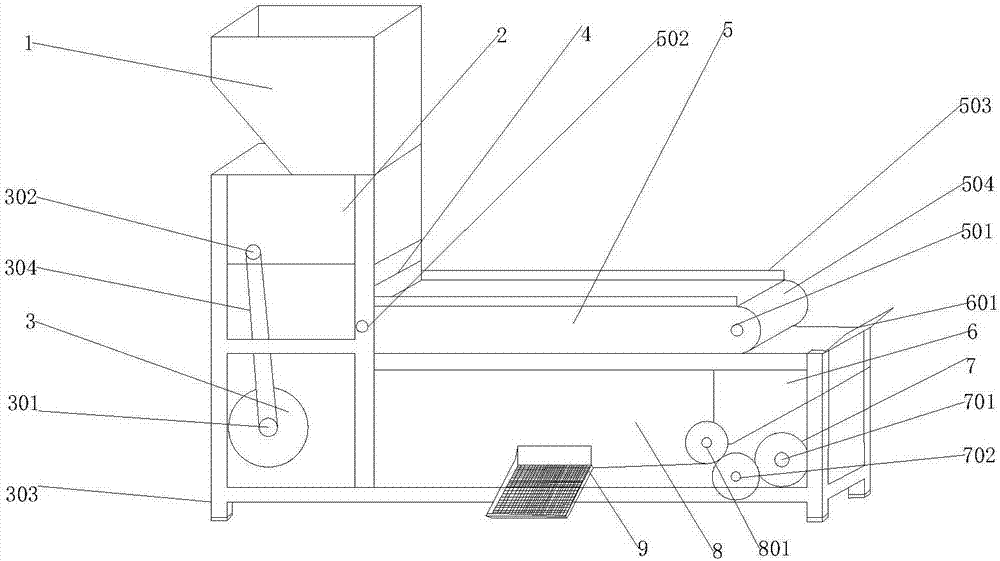

Press roller cleaning mechanism of lithium battery pole piece rolling machine

InactiveCN103658073AAvoid affecting productivityFacilitates self-cleaningCleaning using toolsCleaning using liquidsPole pieceMechanical engineering

The invention discloses a press roller cleaning mechanism of a lithium battery pole piece rolling machine. The press roller cleaning mechanism comprises two cleaning units which are used for cleaning an upper press roller and a lower press roller respectively. The press roller cleaning mechanism is characterized in that each cleaning unit comprises a movable follow-up roller, a coiled material conveying device and an infiltrating device. The movable follow-up roller is arranged in parallel with the press rollers. The coiled material conveying device is used for collecting and releasing coiled materials, and the infiltrating device is used for infiltrating the cleaned coiled materials. The coiled material conveying device is provided with a coiled material delivering end and a coiled material collecting end, the cleaned coiled materials between the coiled material delivering end and the coiled material collecting end sequentially pass through the infiltrating device and the follow-up roller, and the follow-up roller is provided with a working position for compressing the press rollers and a standby position far away from the press rollers. The press roller cleaning mechanism can perform on-line continuous cleaning, and it is avoided that production efficiency is affected by a machine halt; automatic cleaning is convenient to achieve, and labor cost is reduced; uniformity of cleaning is high and the overall effect is good.

Owner:万向电动汽车有限公司 +1

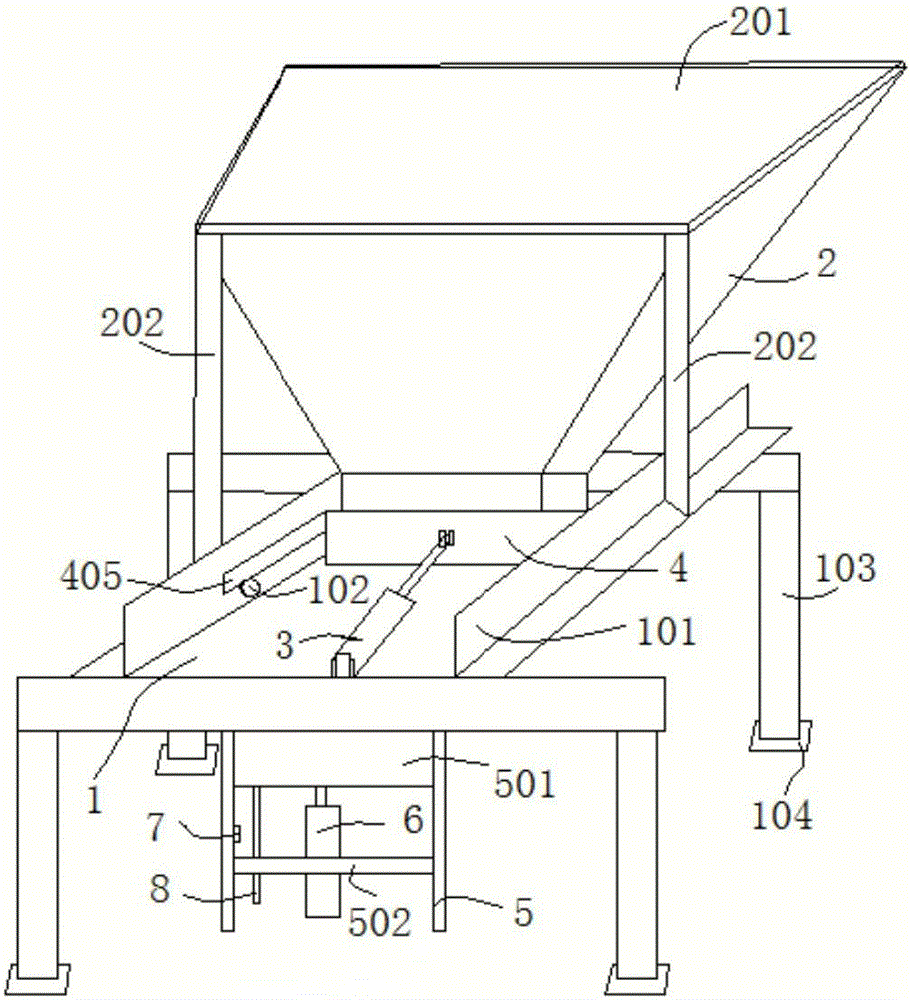

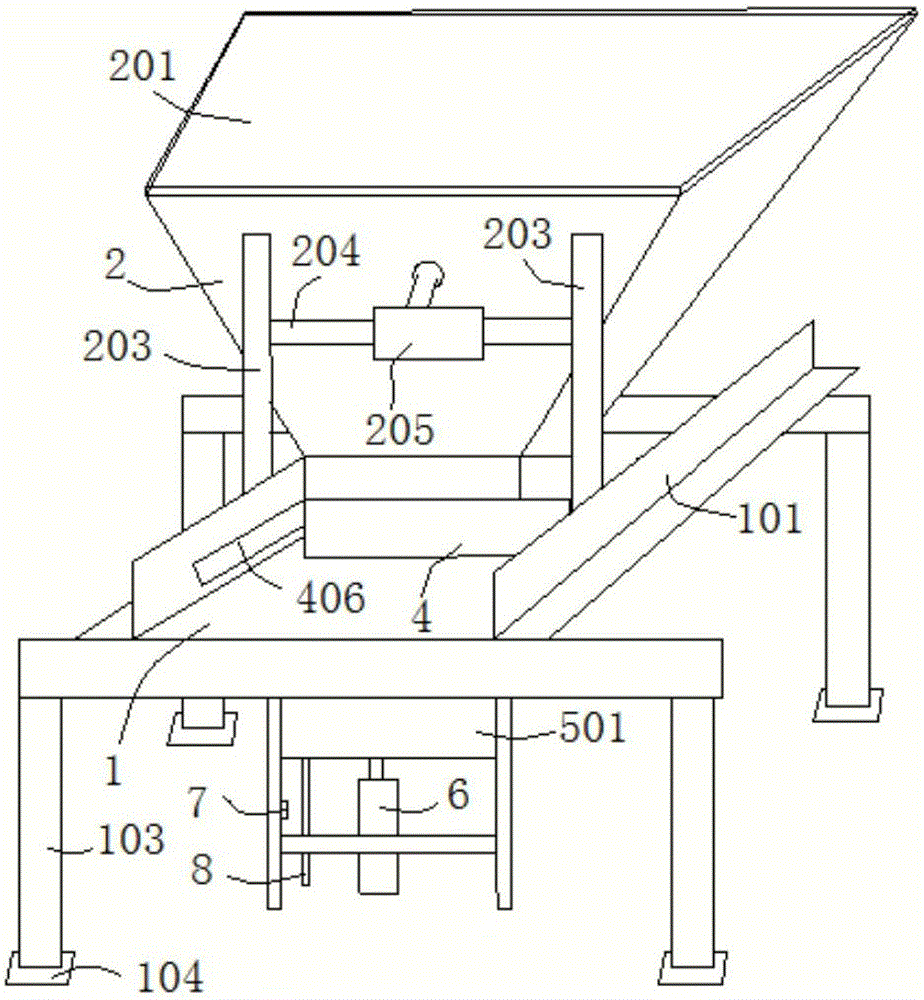

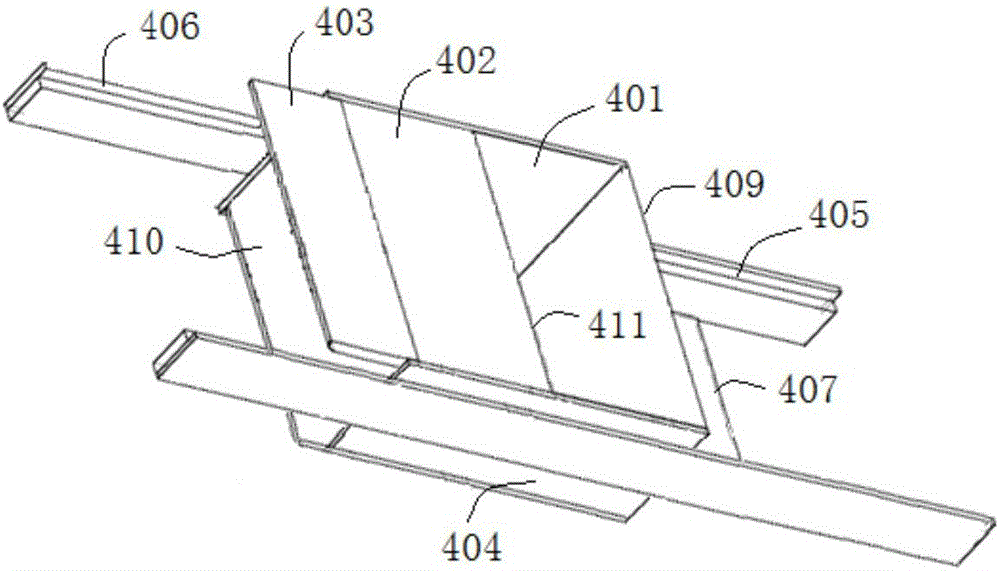

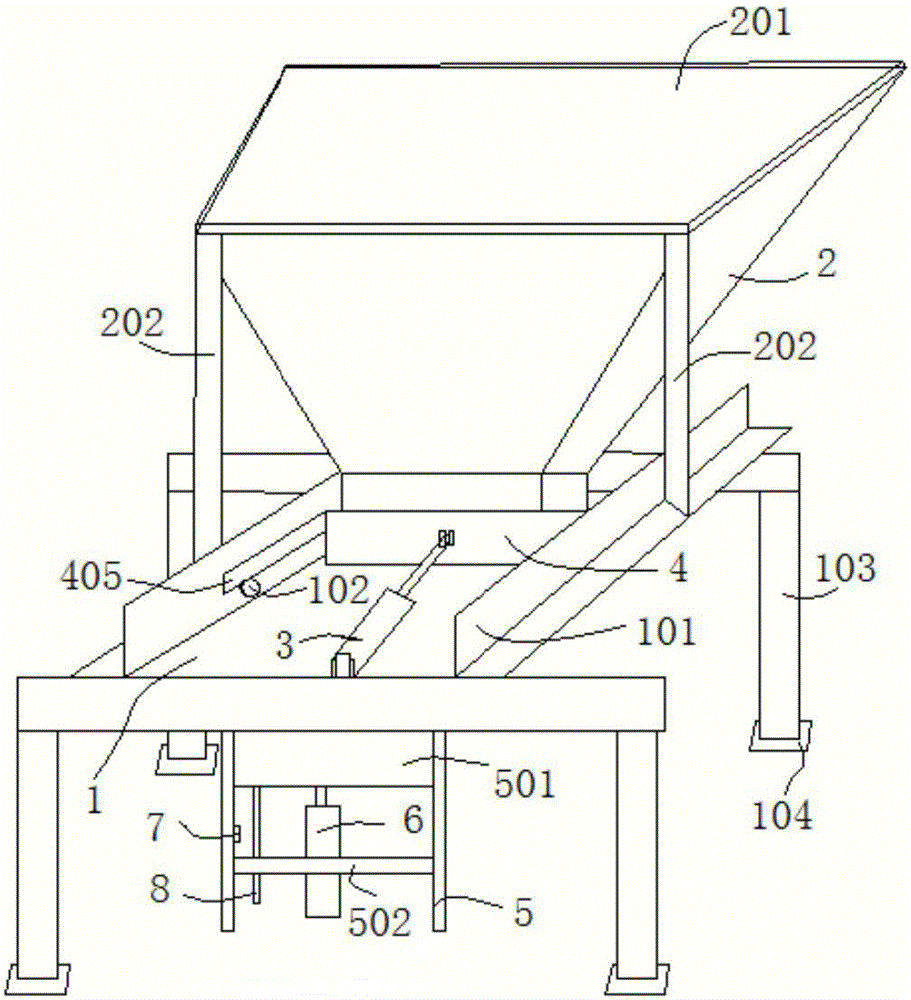

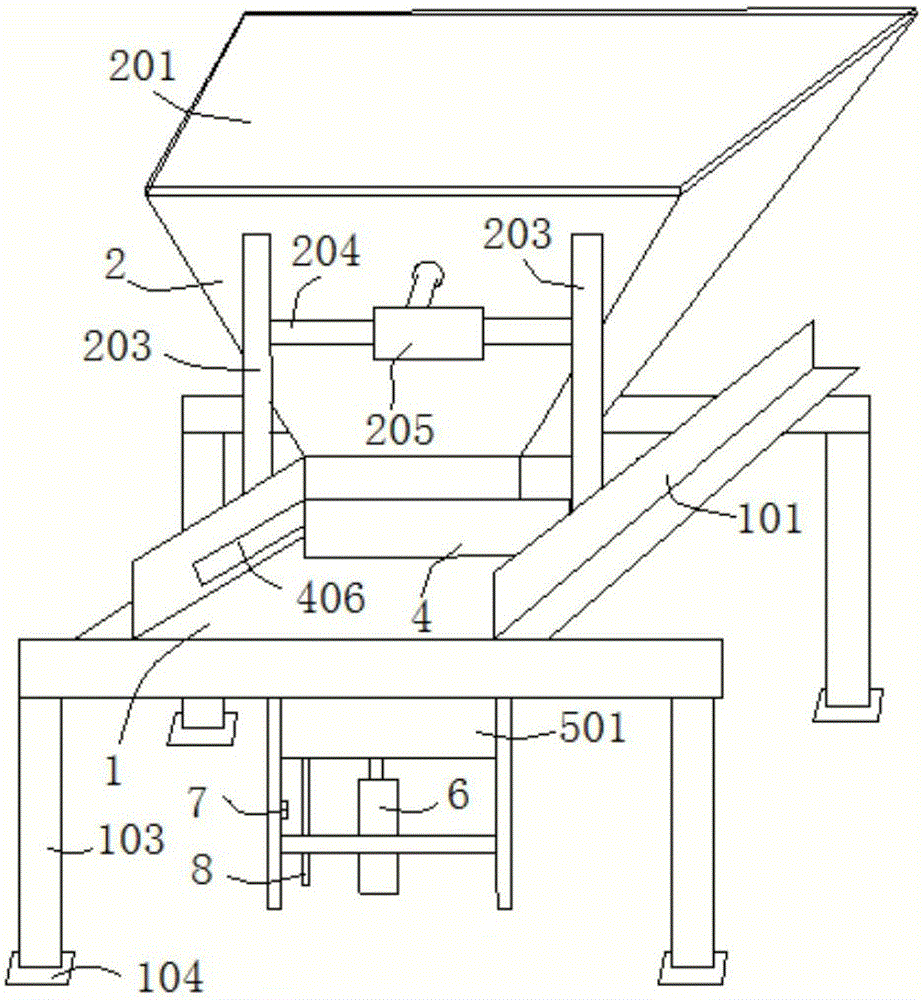

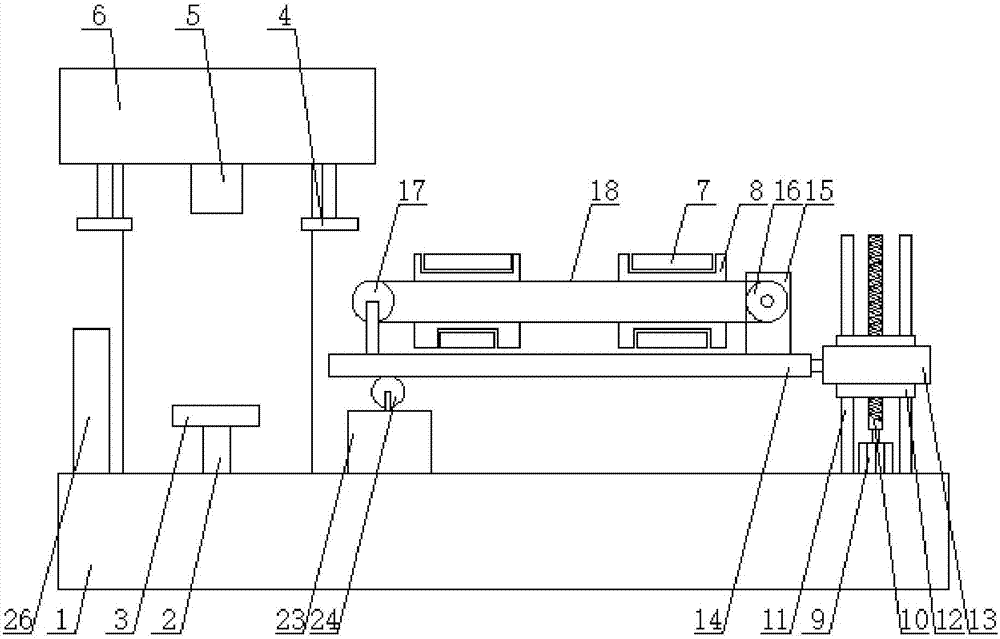

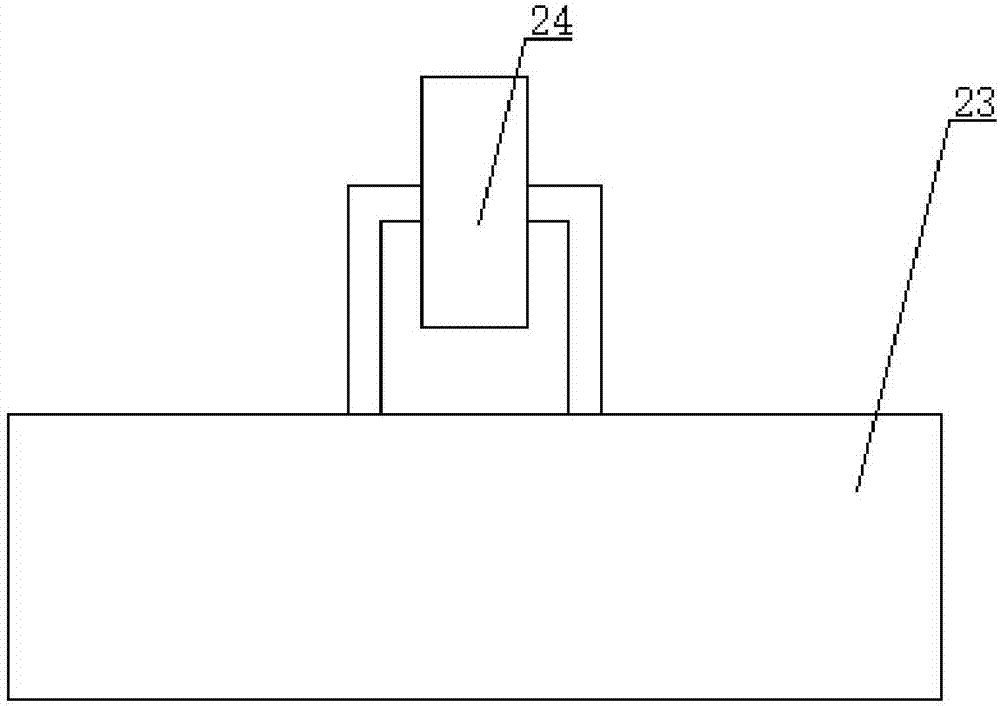

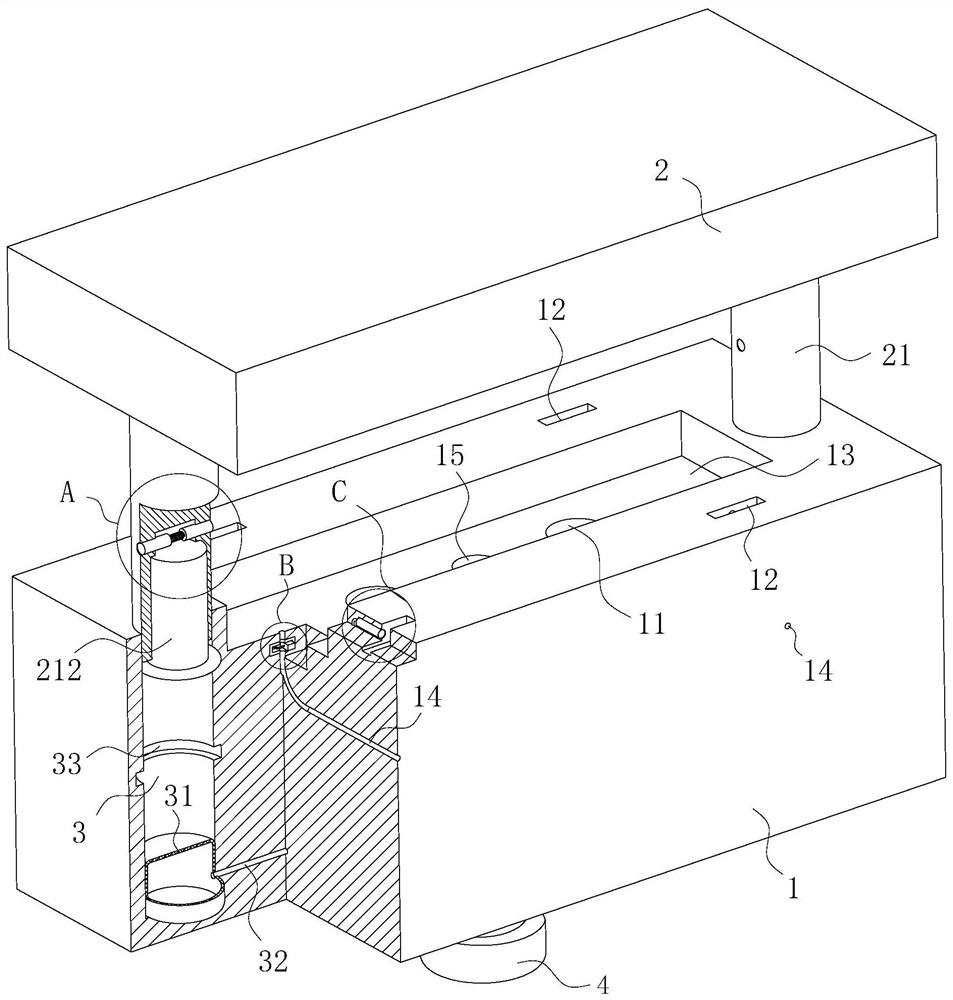

Automatic forming device for producing baking-free bricks

ActiveCN106313297AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

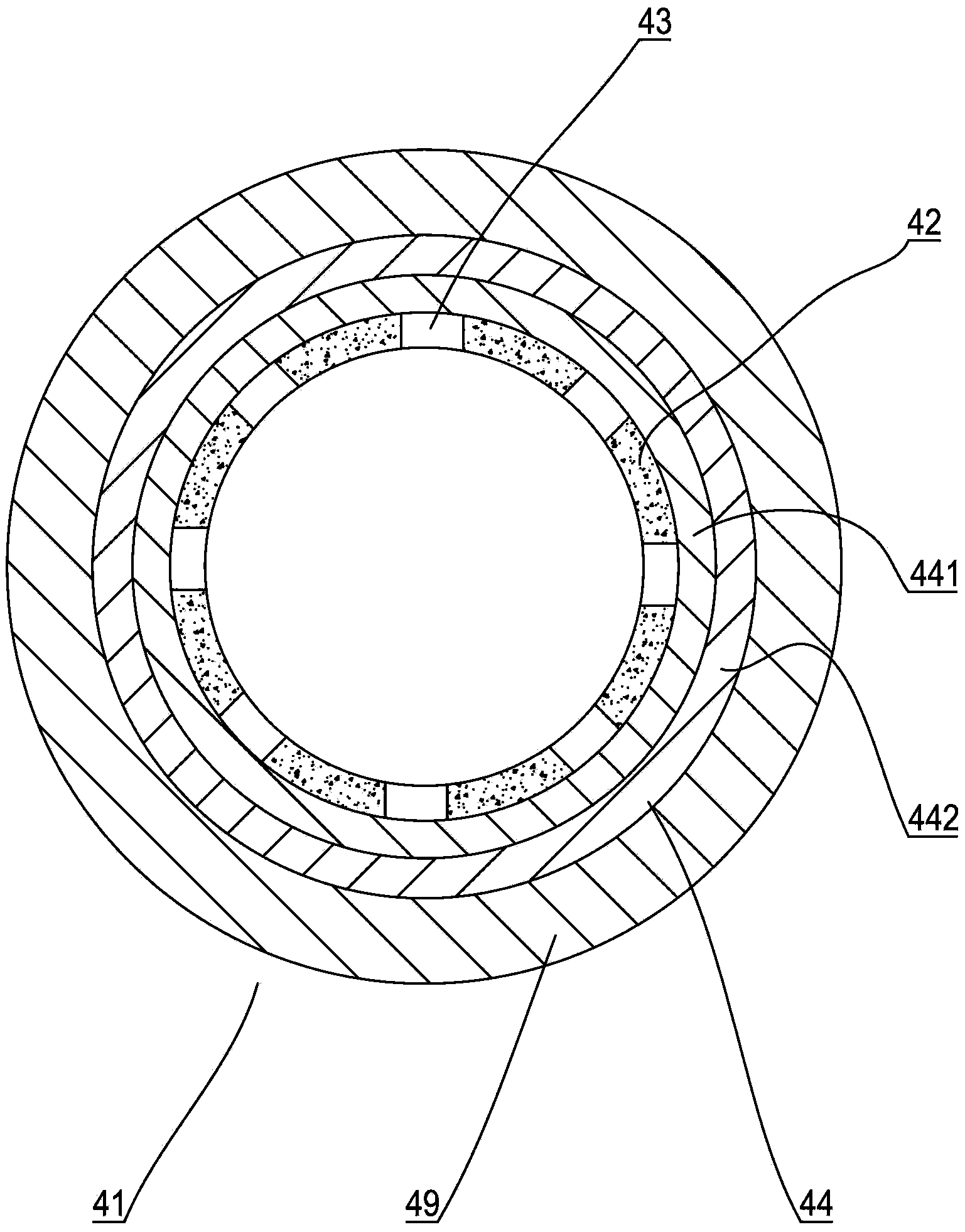

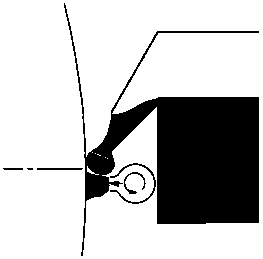

Stampings bonding prevention device for stamping die

ActiveCN103157728AAvoid it happening againAvoid downtime for cleaningShaping toolsCleaning using toolsPunchingTerete

The invention discloses a stampings bonding prevention device for a stamping die and is suitable for punching of coiled materials. The stampings bonding prevention device for the stamp die comprises two rotary cylinders which are located on one side of the die, and the coiled materials go in from the side. The two rotary cylinders are tightly attached to each other and arranged up and down. Each rotary cylinder comprises an oil storage drum with two sealed ends and an oil impregnating layer which is arranged on the outer side of the oil storage cylinder. The oil impregnating layer has elasticity. A plurality of oil impregnating holes are uniformly formed in the circumferential surface of each oil storage cylinder. One ends of the oil storage cylinders are connected with a punching oil conveying system through pipelines. A damping layer with elasticity is arranged between each oil storage cylinder and each oil impregnating layer. A plurality of oil impregnating cylinders are uniformly arranged on the circumferential surface of each damping layer and embedded in each oil impregnating layer. Oil outlet holes which penetrate through the inner surface of each damping layer are formed in each oil impregnating cylinder. Kerfs which are communicated with the oil outlet holes are uniformly arranged on the circumferential surface of each oil impregnating cylinder. The stampings bonding prevention device for the stamp die can prevent stampings from bonding with the die, and therefore continuous punching can be achieved, and influence of machine halt on production efficiency is avoided. Besides, the stampings bonding prevention device for the stamp die is beneficial for prolonging service life of the die and improving punching quality of products.

Owner:WANXIANG 123 CO LTD

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

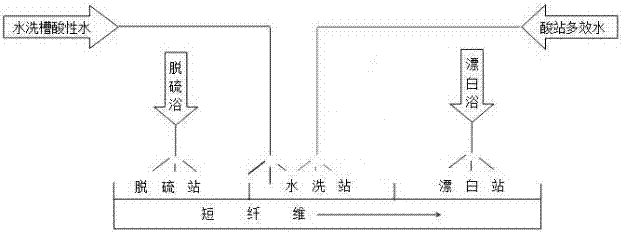

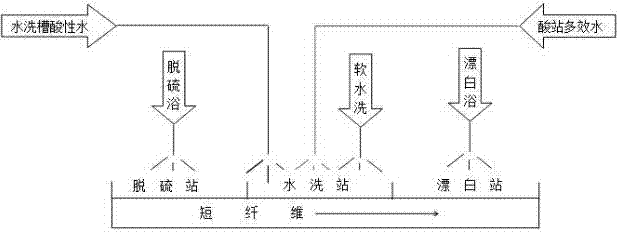

Staple fiber producing acidic water recycling technology

InactiveCN107459122AReduce manufacturing costReduce processing costsWater/sewage treatment by neutralisationWaste water treatment from textile industryFiberWater resources

The invention discloses a staple fiber producing acidic water recycling technology, and belongs to the technical field of viscose staple fiber production. The staple fiber producing acidic water recycling technology comprises the following steps: introducing multi-effect wastewater at an acid station and acidic wastewater in a washing tank into a washing station at the back end of a desulfurizing station, and washing fiber desulfurized by the desulfurizing station, wherein the pH value of the washed fiber is 8.0-11.0. By the staple fiber producing acidic water recycling technology, the technical problems that in the prior art, waste of water resources is caused and a lot of sewage is produced because the fiber after a desulfurizing bath is required to be washed by using soft water are mainly solved. The staple fiber producing acidic water recycling technology has the advantages of reduction in wastewater treatment cost and reduction in pollution.

Owner:YIBIN GRACE +1

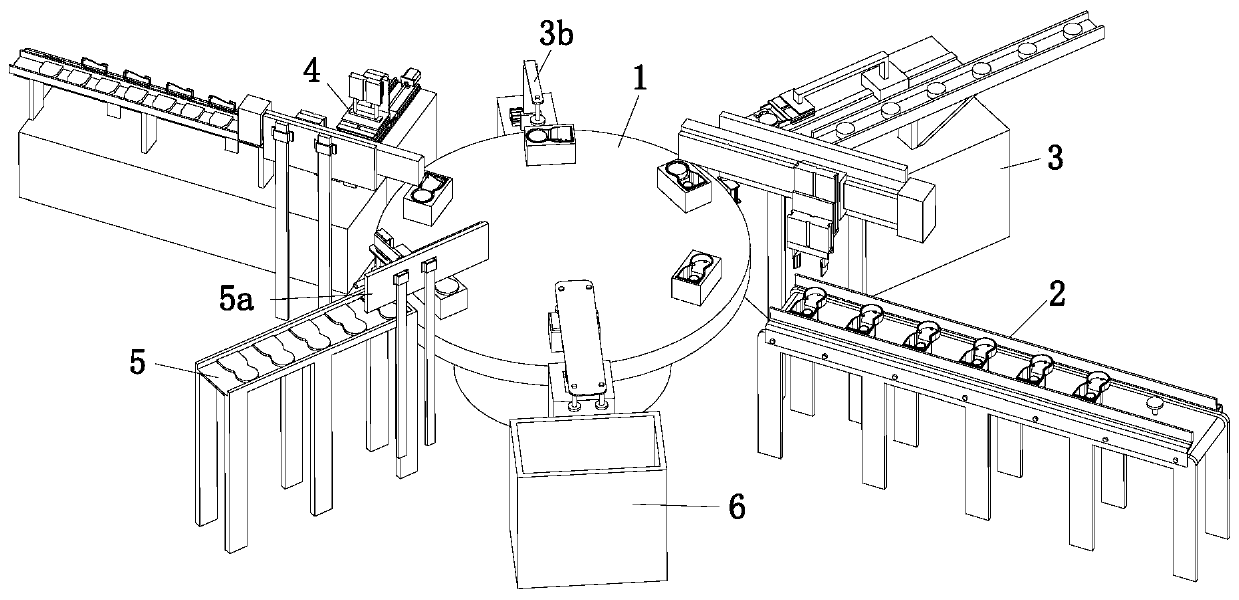

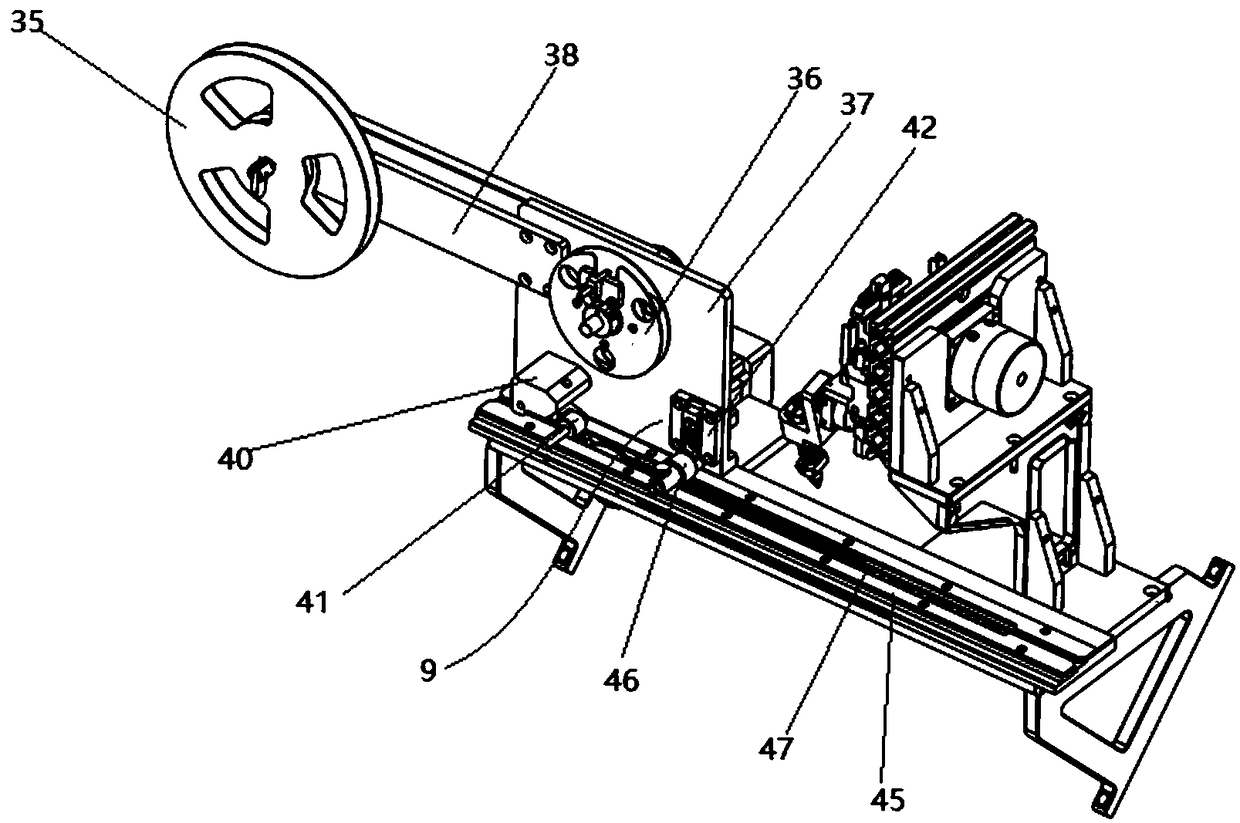

Automatic tire pressure sensor production process

ActiveCN111168384AReduce labor costsEasy to removeLiquid surface applicatorsAssembly machinesProcess engineeringMechanical engineering

The invention relates to the field of tire pressure sensor production processes, in particular to an automatic tire pressure sensor production process. The automatic tire pressure sensor production process comprises the following steps of S1, automatically feeding a bottom shell; S2, automatically feeding a battery pack; S3, compressing the battery pack and the bottom shell; S4, assembling a circuit board and an antenna; S5, assembling a shell cover; and S6, carrying out automatic discharging. The automatic tire pressure sensor production process has the beneficial effects that corresponding parts are sequentially transferred to a rotating device through a feeding device, a conveying device, an assembling device and a mounting device, and after the multiple parts are assembled on the rotating device, workpieces on the rotating device are removed through a discharging device to complete automatic production, so that the expenditure of labor cost is saved, the process is ingenious in design and smooth in procedure connection; and compared with manual assembly, the efficiency is improved by 10-12 times or above, and the yield reaches 99.99%.

Owner:三森电子股份有限公司

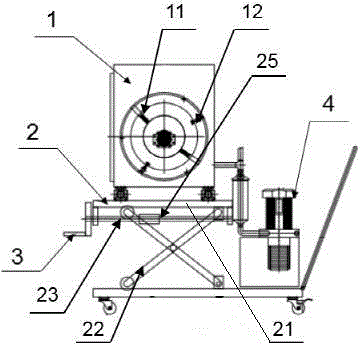

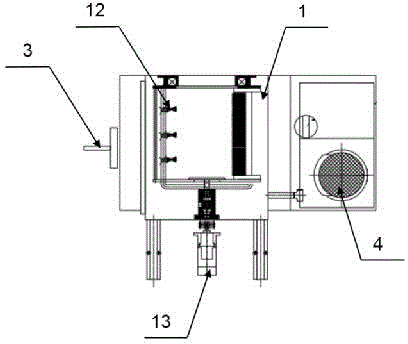

Movable type piston rod head cleaning device

ActiveCN104368544AThe equipment is easy to operateEasy tooling replacementDrying gas arrangementsCleaning using toolsSpray nozzleEngineering

The invention discloses a movable type piston rod head cleaning device. The movable type piston rod head cleaning device comprises a movable trolley. A lifting table and a spraying pump are fixed to the movable trolley. A cleaning chamber is fixed to the lifting table, a plurality of brush heads rotating along the same axis are evenly distributed inside the cleaning chamber, and cleaning spray nozzles are further fixed to the inner wall of the cleaning chamber. A motor used for driving the brush heads is fixed to the outer wall of the cleaning chamber. A water inlet of the spraying pump is connected with a liquid storage box through a pipeline, a water outlet of the spraying pump is connected with a T-shaped filter, and the other end of the T-shaped filter is connected to the cleaning spraying nozzles inside the cleaning chamber through a pipeline. The movable type piston rod head cleaning device can move while workpieces do not move by utilizing the movable trolley, so that influences on production caused by frequent transportation of large parts are avoided. The movable type piston rod head cleaning device is suitable for cleaning piston rod heads of various specifications by replacing a tool. The movable type piston rod head cleaning device is easy and convenient to operate, enables the tool to be replaced conveniently, is low in manufacturing and repairing cost, and is favorable for efficiency work.

Owner:XCMG HYDRAULICS CO LTD

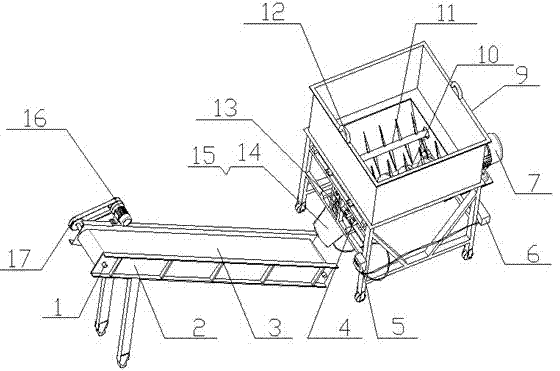

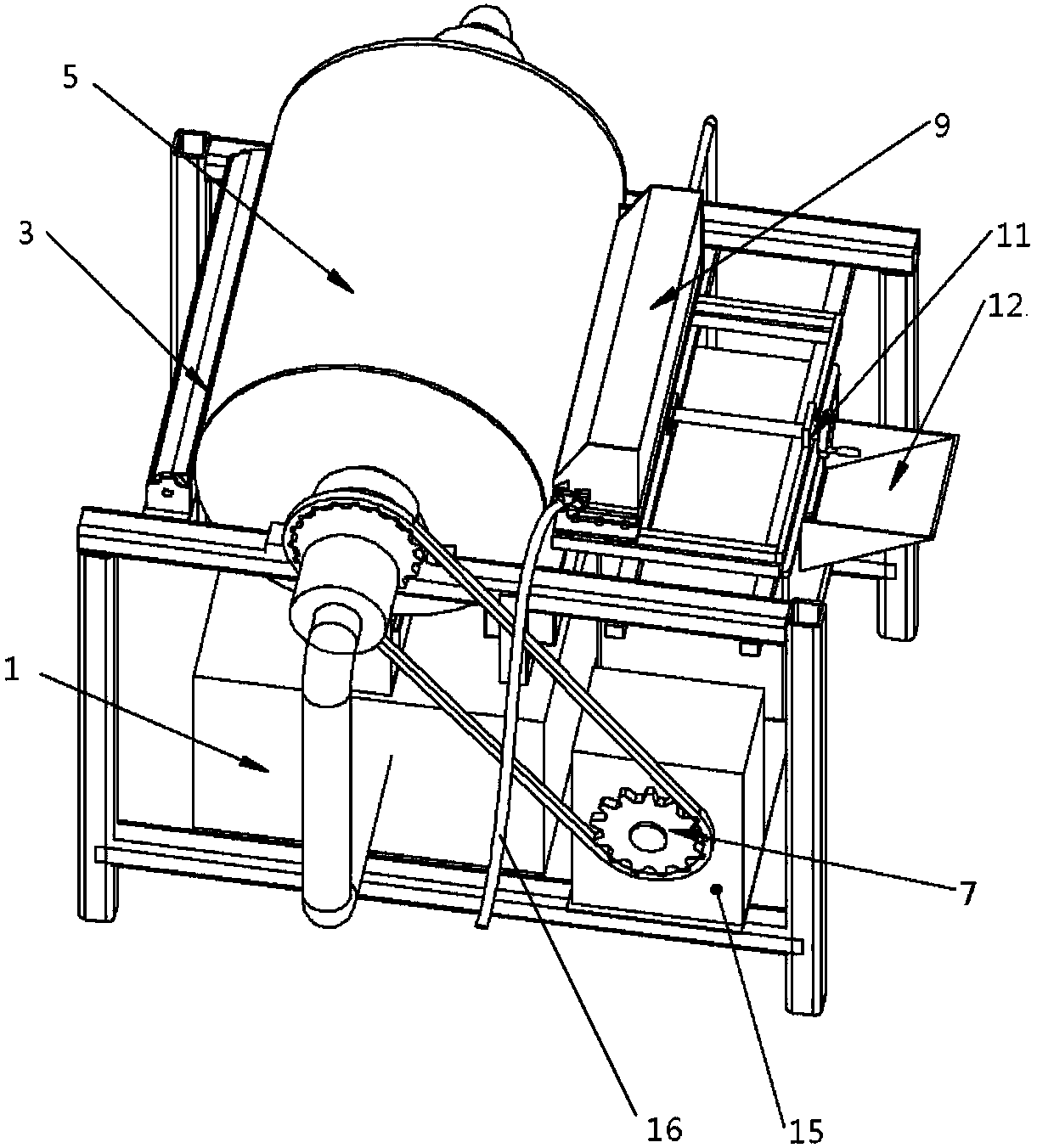

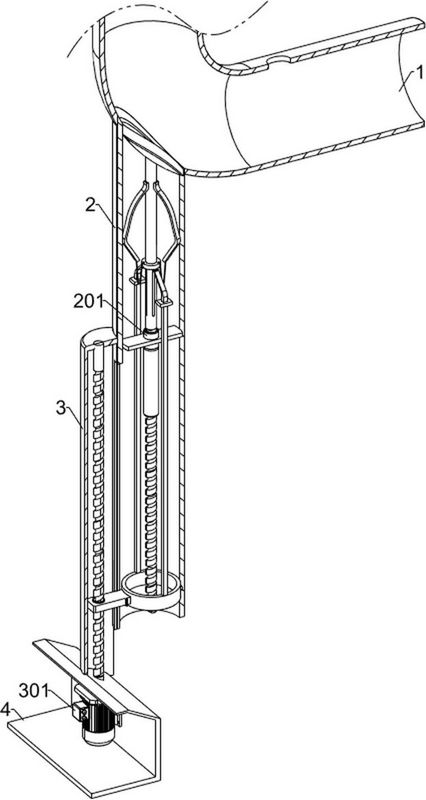

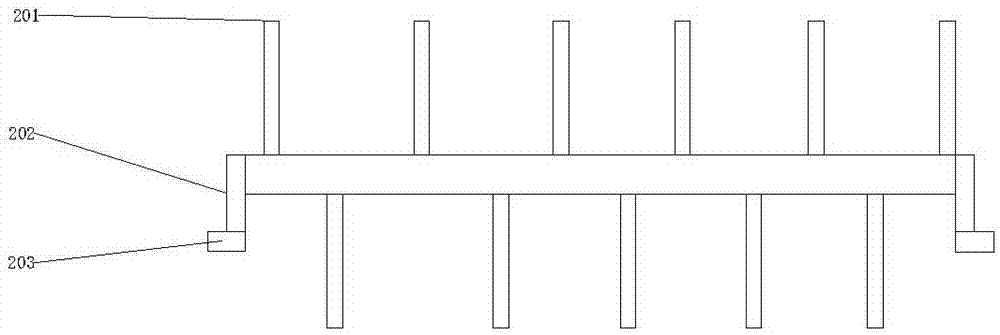

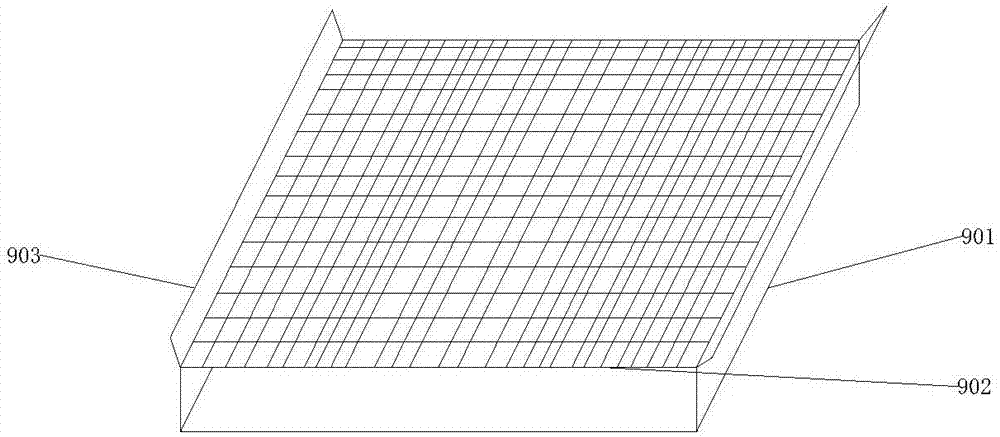

Automatic straw material feeding device of ring die briquetting machine

ActiveCN104192545AGuaranteed uniformityGuaranteed continuityConveyor partsProduction lineAgricultural science

The invention belongs to the field of agricultural machines, and particularly relates to an automatic straw material feeding device of a ring die briquetting machine. The automatic straw material feeding device comprises a feeding device, a material conveying device and a control module. The control module comprises a PLC, a motor driver, a weighing sensor and a motor switch. Mass-shaped materials are grasped into a material storage box through a grass grasping machine, and the materials are dispersed by two spiked shafts in the upper part of the material storage box and then evenly fall on a large screw rod. The large screw rod outputs the materials uniformly through a guide hopper, and the materials fall on a conveying belt of the material conveying device and then are fed into the ring die briquetting machine. The weighing sensor below the material guide hopper transmits information to the PLC in real time, the PLC sends out pulses to the motor driver to perform feedback control of the rotating speed of a large screw rod motor, and therefore the stable feeding amount of straw is ensured. The automatic straw material feeding device is simple in structure and convenient to operate, the feeding end is intelligently controlled, feeding labor of two to three persons is saved, the problems that straw feeding is unstable in a straw briquetting production line and blocking frequently happens are solved, and therefore the straw briquetting quality and the production efficiency are improved.

Owner:万华禾香板业(公安县)有限责任公司

Automatic cleaning device for press rolls

ActiveCN102553846AReduce usageEnsure consistencyCleaning using toolsCleaning using liquidsEngineeringMechanical engineering

Owner:WANXIANG 123 CO LTD

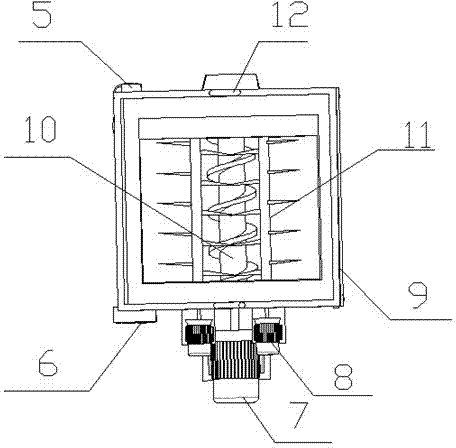

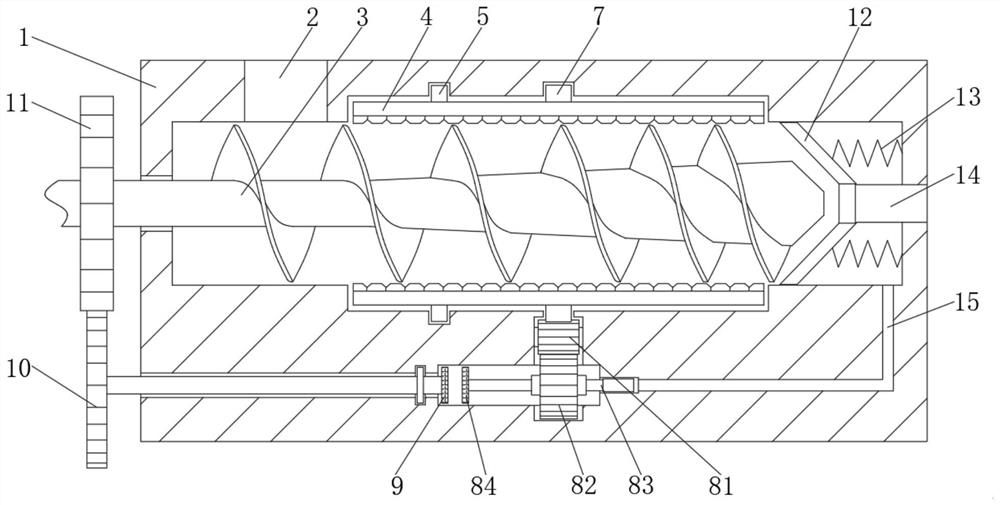

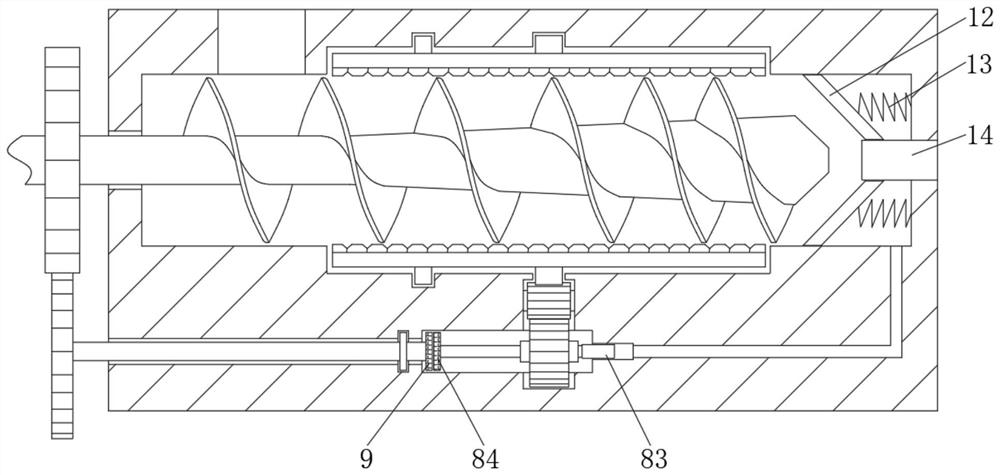

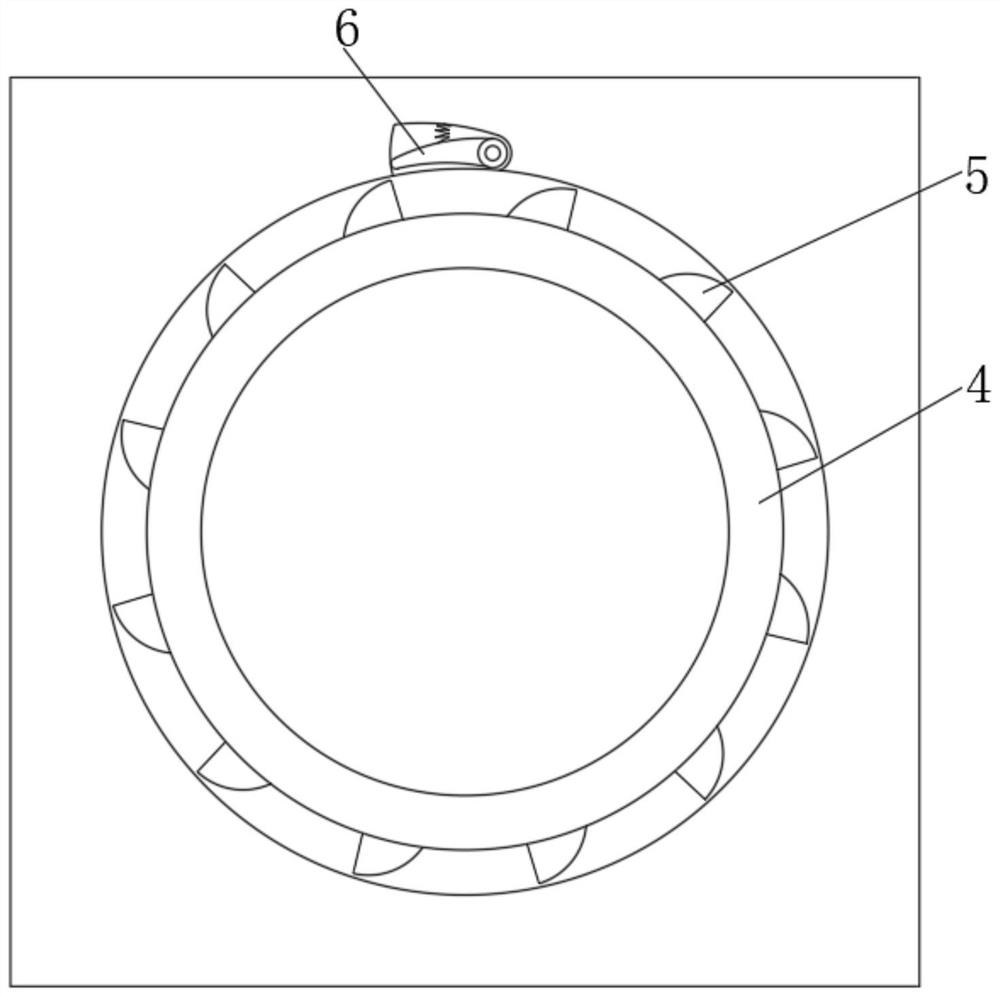

Bulking machine extrusion mechanism capable of reducing damage rate of screw

The invention relates to the technical field of food production and manufacturing, and discloses a bulking machine extrusion mechanism capable of reducing the damage rate of a screw. The bulking machine extrusion mechanism comprises a cavity, the screw is slidably installed in an inner cavity of the cavity, the outer side of the screw is movably sleeved with an inner cylinder, the middle position of the outer side of the inner cylinder is fixedly sleeved with a gear, the gear is engaged with a transmission gear I, the transmission gear I is meshed with a transmission gear II, the transmission gear II is movably connected to the outer side of a sliding rod in a sleeving mode, and a magnetic part I is fixedly installed at the left end of the sliding rod. Through the arrangement of the inner cylinder, materials can rub with threads of the inner cylinder in the process of pushing and extruding the materials by the screw, and compared with a flat inner wall of an original device, the friction force borne by the materials in the moving process is increased, so that the temperature of the materials is increased, water is evaporated, the air pressure in a cavity is increased, therefore, the puffing degree of the materials during discharging is increased, and the puffing effect of the materials is improved.

Owner:淮北市欣然食品有限责任公司

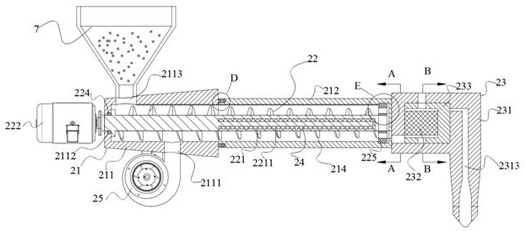

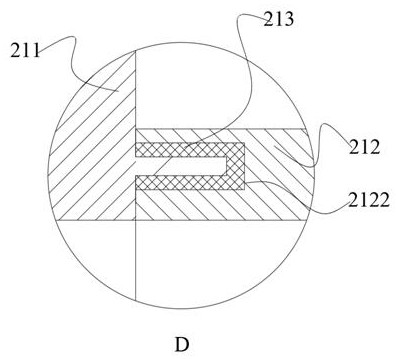

TPU color-changing film production device and production method

The invention discloses a TPU color-changing film production device and a production method. The TPU color-changing film production device comprises a fixing device; the fixing device is sequentially provided with forming devices, a cooling device, a gluing device and an attaching device; the forming devices are fixedly connected with the fixing device, and the two forming devices are arranged in the vertical direction; the cooling device is fixedly connected with the fixing device; the gluing device is connected with the fixing device; the attaching device is connected with the fixing device; the fixing device comprises a frame and a workbench; one side of the frame is fixedly connected with one side of the workbench; and each forming device is located on the upper side of the workbench and comprises a shell, a transmission assembly and a die head assembly, wherein the shell is connected with the transmission assembly, and one side of the shell is connected with the die head assembly. The production method mainly comprises the following steps: raw material crushing, melting and extruding; base film cooling and extrusion forming; gluing and drying; hot melting and double layer base film lamination; and cooling and rolling.

Owner:南通纳科达聚氨酯科技有限公司

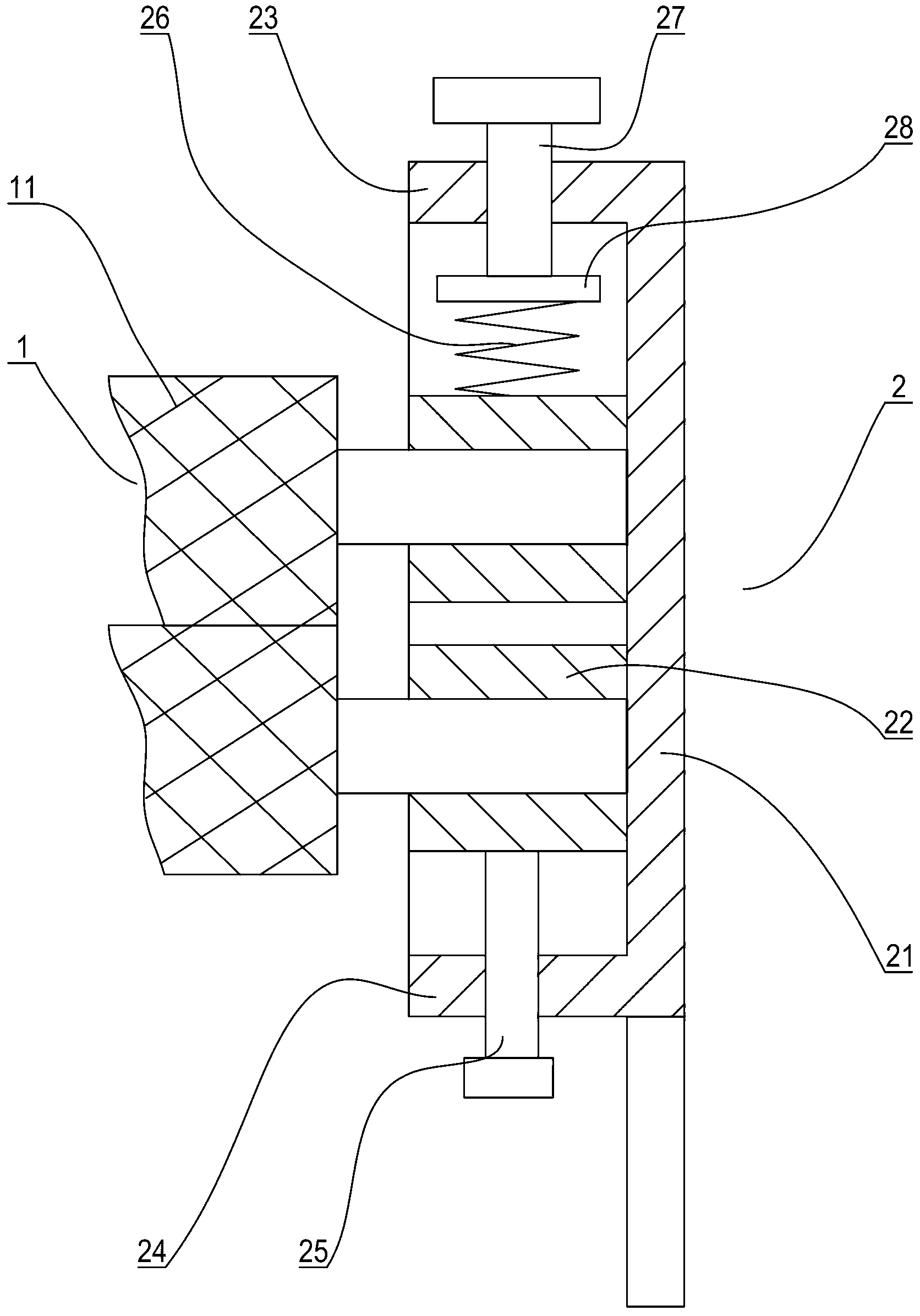

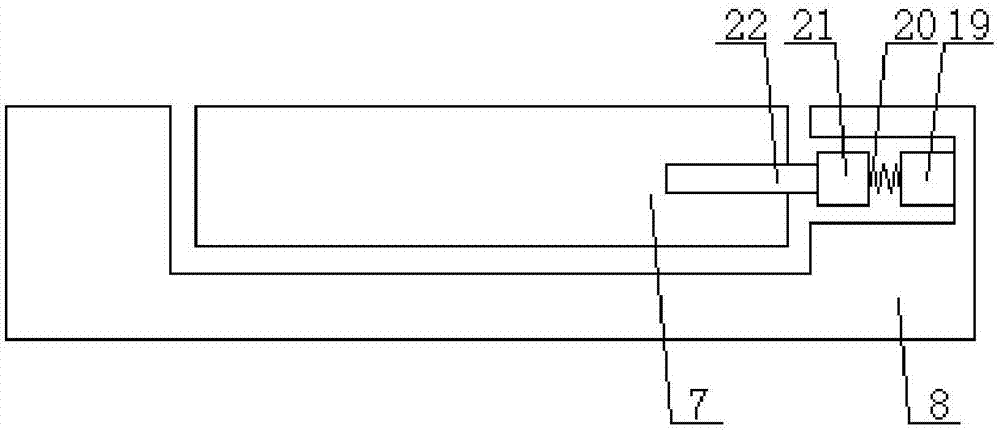

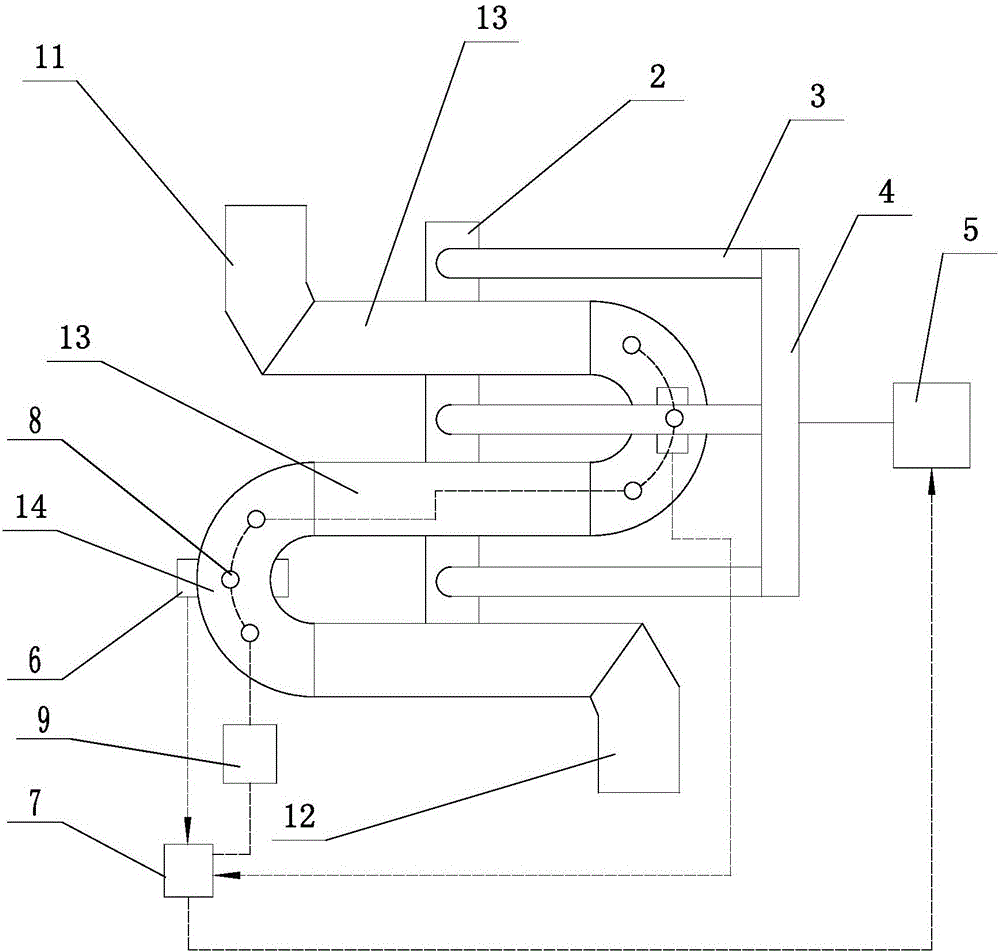

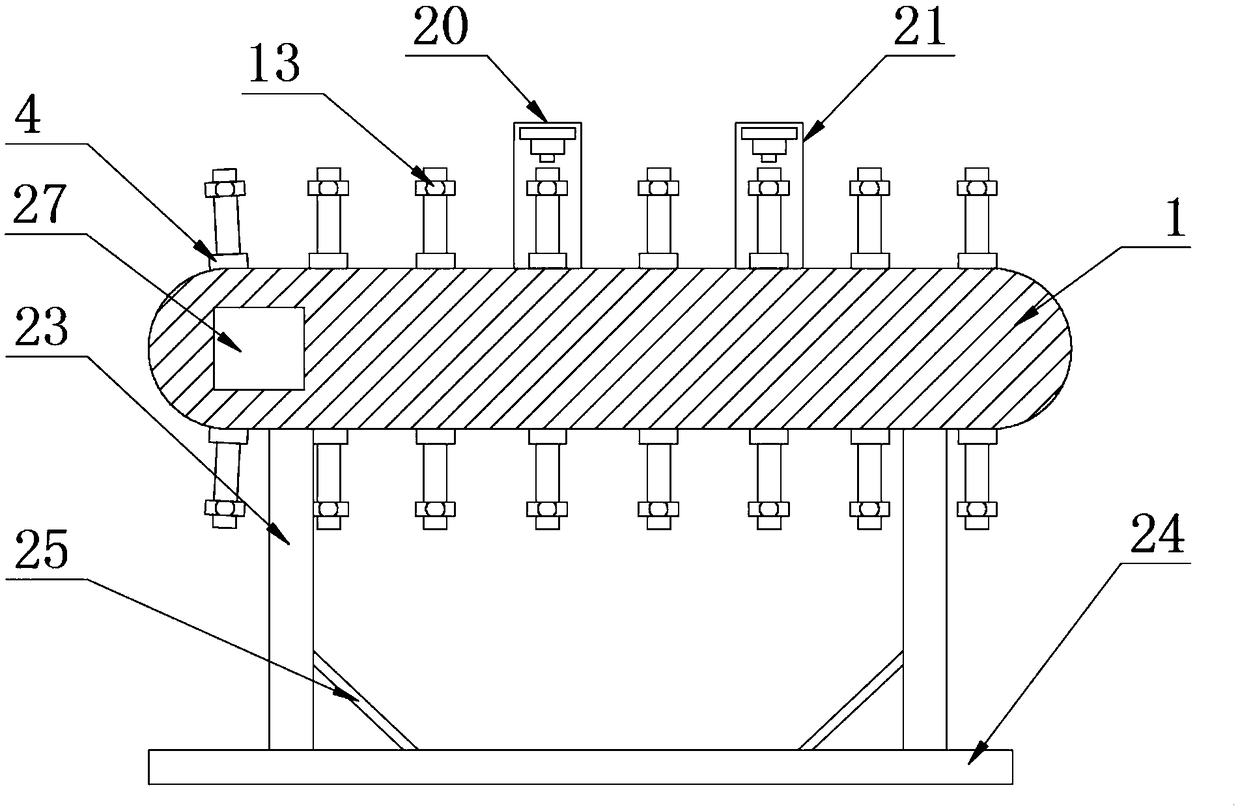

Intelligent sealing equipment

ActiveCN106945888AReduce labor intensityAvoid affecting productivityWrapper twisting/gatheringDrive wheelHobbing

The invention relates to intelligent sealing equipment which comprises a base, a guide rod, a tray, a hobbing cutter, a rotary shaft and a drive device. The base further comprises a pressure head replacing device. The pressure head replacing device comprises a pressing head, a lifting mechanism, a pushing mechanism, a conveying mechanism and a fixing mechanism. The lifting mechanism comprises a first motor, a lead screw, a sliding rod and a sliding block. The pushing mechanism comprises an air cylinder and a pushing plate. The conveying mechanism comprises a second motor, a driving wheel, a driven wheel and a belt. The fixing mechanism comprises a plurality of fixing assemblies. Each fixing assembly comprises an electromagnet, a spring, an iron block and a limiting rod. According to the intelligent sealing equipment, the pressure head replacing device is arranged, a pressure head can be replaced automatically by starting the pressure head replacing device when the intelligent sealing equipment needs to seal packaging containers of other calibers, and compared with manual operation, time and labor are saved, the labor intensity is relieved, and the production efficiency is not affected.

Owner:GUILIN SEAL TECH

Textile guide roll for automatic textile machine

The invention discloses a textile guide roll for an automatic textile machine. The textile guide roll comprises a rack and a roll body, wherein symmetrically-distributed lifting devices are arranged on the rack; a support is arranged at the top ends of the lifting devices; symmetrically-distributed rotary shafts are arranged at the two ends of the roll body; installation holes are formed in the support; the rotary shafts are rotationally connected into the installation holes; a conducting layer wraps the periphery of the roll body; a conducting wire is arranged at the lower side of the left end of the roll body; and one end of the conducting wire is connected with the conducting layer in a contact manner, and the other end of the conducting wire is grounded. The textile guide roll disclosed by the invention is simple in structure, capable of adapting to many textiles with different specifications through adjustment for the roll body, and wide in applicability, effectively prevents theinterference of static electricity on transport for the textiles, and improves the production quality.

Owner:SUZHOU MEILU TEXTILE MASCH ELECTRONICS CO LTD

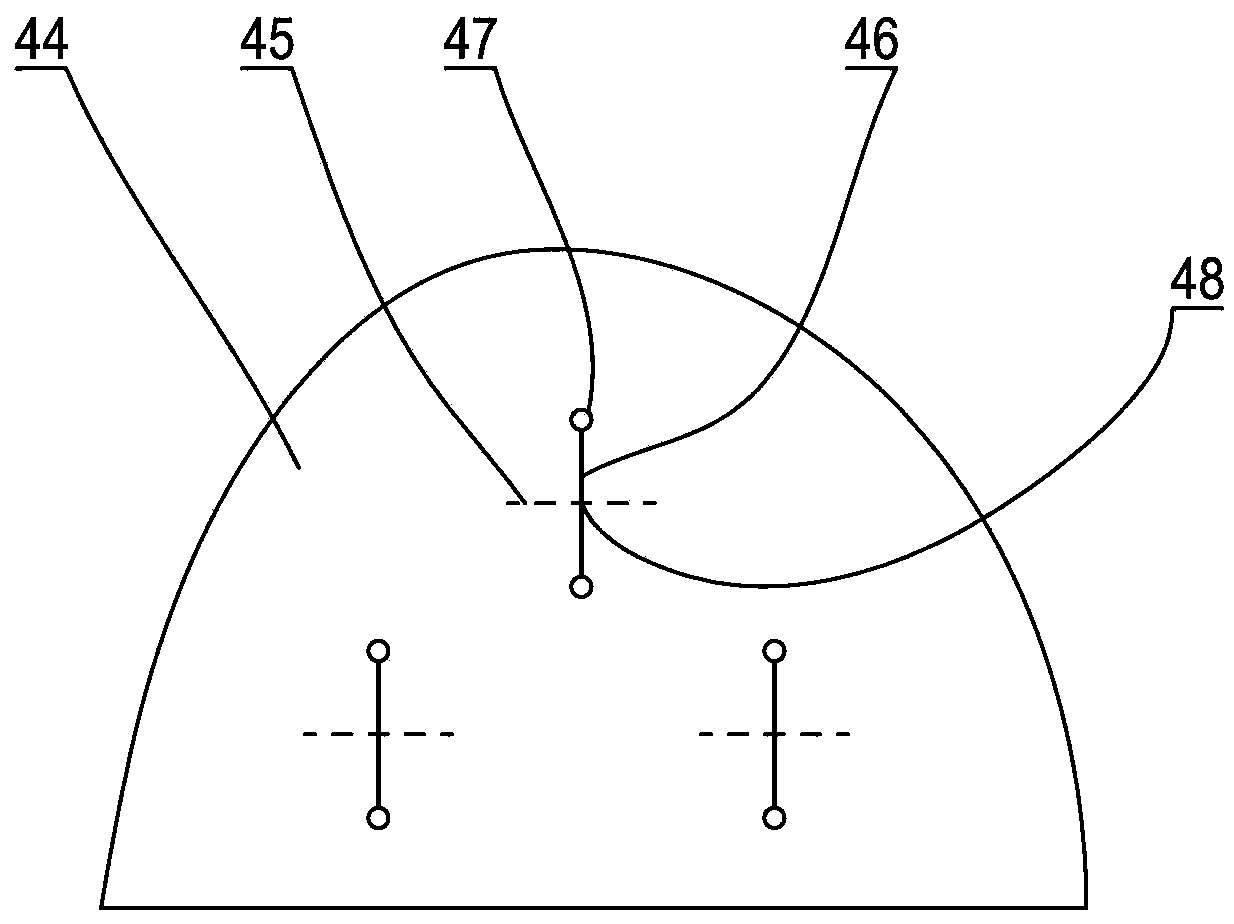

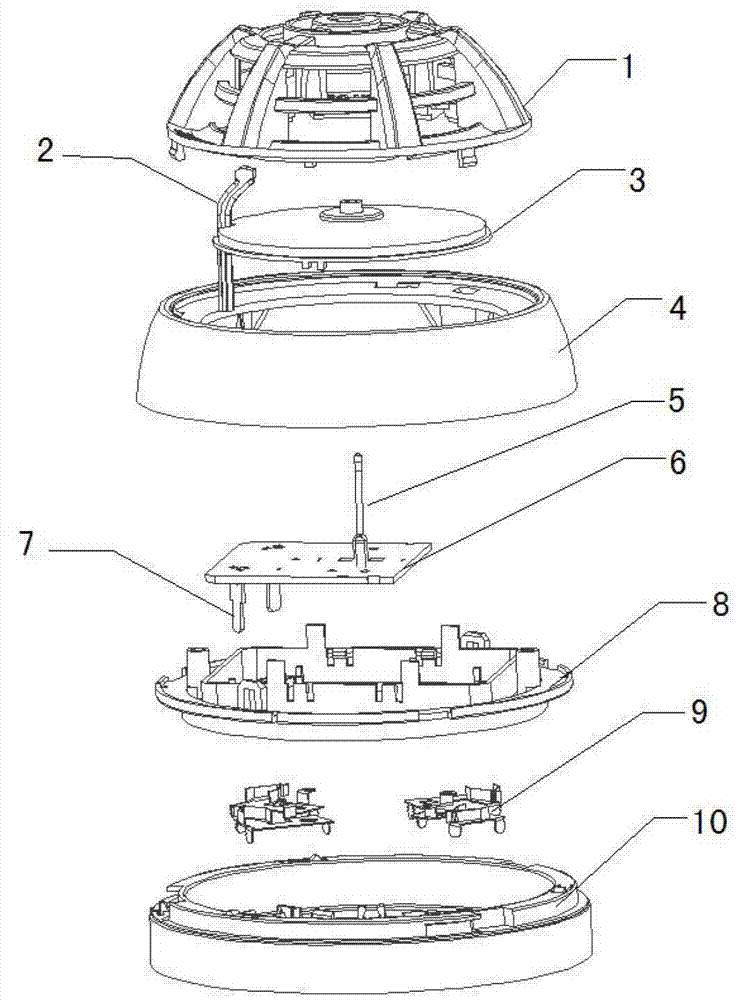

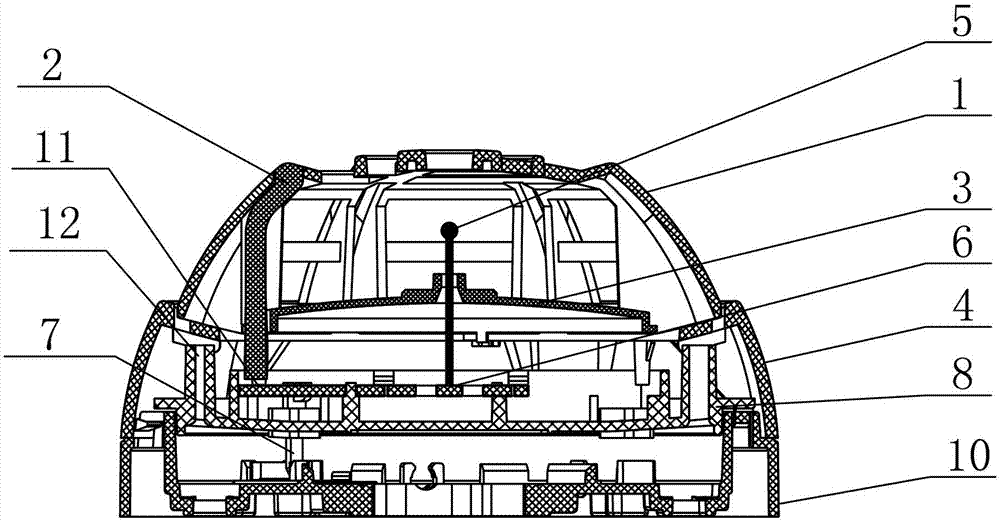

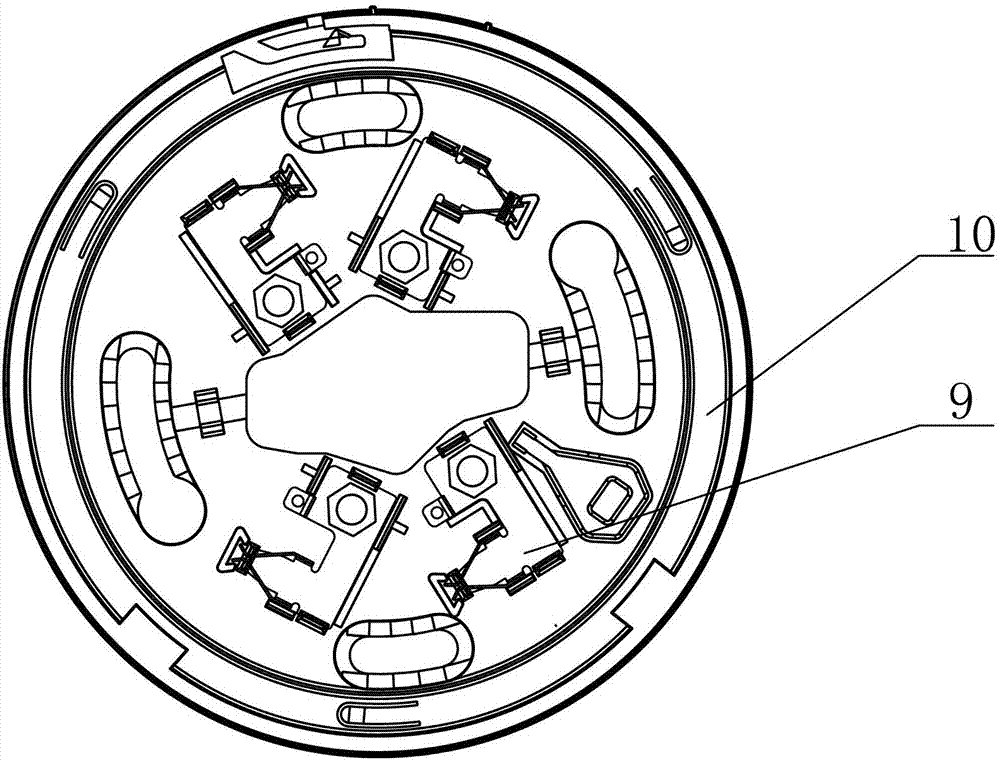

Point-type heat fire detector

InactiveCN102903199ASimple processImprove conduction efficiencyFire alarm electric actuationFire detectorLight guide

The invention relates to a point-type heat fire detector. The point-type heat fire detector comprises a shell and a circuit board in the shell, wherein a thermistor and a light emitting diode are arranged on the circuit board; a light guide column and a plate-like middle fastener are arranged in the shell; the shell comprises a base, an annular middle cover and an upper cover, which are sequentially connected; an outer contour which consists of the base, the annular middle cover and the upper cover is in a shape of a hemispherical table; the upper cover is positioned on the top of the hemispherical table; the middle fastener is clamped in the annular middle cover; the circuit board is clamped on the middle fastener; the surface of a light emitting part of the light emitting diode faces the upper cover; the light guide column has a columnar bending structure; one end of the light guide column faces and approaches the light emitting part of the light emitting diode, and the other end of the light guide column is bent to the top of the upper cover along the radian of the upper cover and corresponds to an annular through structure which is arranged on the upper cover; and one end of the light guide column, which is bent along the radian of the upper cover, is bent back at the end head, so the light conduction directions of the end heads of the two ends of the light guide column are the same. By adoption of the point-type heat fire detector, a light emitting display effect can be improved, an installation process is simplified, and reliability is improved.

Owner:北京福赛尔安全消防设备有限公司

Multi-functional egg pancake processing machine and using method thereof

PendingCN107646921AAvoid wastingAvoid affecting productivitySpecial goods bakingElectricityProcess engineering

Owner:NANJING XIAOZHUANG UNIV

Rack base and profile steel inspection bench

ActiveCN104148411AImprove protectionRuns smoothlyMeasurement apparatus componentsMetal rolling arrangementsStructural engineeringMechanical engineering

The invention discloses a rack base and a profile steel inspection bench. Vertical rotating rolls are arranged in the middles of the two ends, located in the length direction of a steel drawing guide rail in the rack base. The rack base is adopted for the profile steel inspection bench. Meanwhile, a hooking and taking piece provided with a mechanical structure is arranged on a steel drawing trolley for drawing steel, and a lifting steel rolling limiting mechanism is further arranged in gaps, located in the front of the steel drawing guide rail and in the conveying direction in an entry table, of entry rollers to achieve profile steel limiting. By means of the rack base and profile steel inspection bench, the rack base has better protective effect, and the situation that production efficiency is affected because the steel is destroyed in the drawing process and needs to be overhauled is avoided, and the rack base and the profile steel inspection bench further have the advantages of enabling the profile steel to berth precisely on the entry table for facilitating steel drawing and the like.

Owner:CHONGQING IRON & STEEL CO LTD

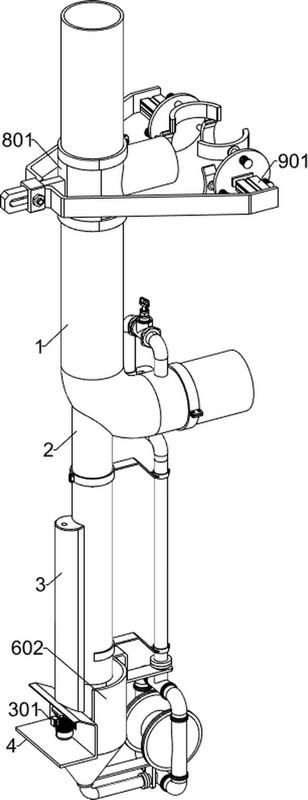

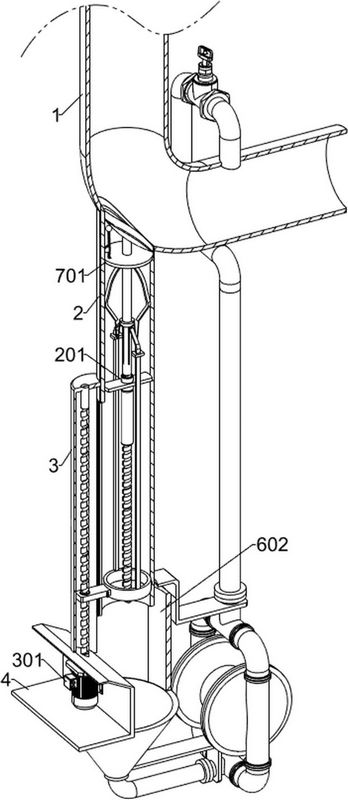

Powder conveying pipeline with automatic blockage removing function

ActiveCN113716262AAvoid affecting productivityAvoid wastingCleaningHollow article cleaningProcess engineeringPipe

The invention relates to the field of powder conveying, in particular to a powder conveying pipeline with an automatic blockage removing function, and aims to solve the technical problems that powder is likely to gather in the vertical part of an L-shaped pipeline in the conveying process, the powder finally cakes and blocks the L-shaped pipeline, and the production efficiency is seriously affected. According to the technical scheme, the powder conveying pipeline with the automatic blockage removing function comprises an L-shaped pipe, a first pipe shell, a second pipe shell and the like; the bent part of the L-shaped pipe is communicated with the first pipe shell; and the lower left portion of the first pipe shell is fixedly connected with the second pipe shell. By means of the powder conveying pipeline, powder blocking the vertical part of the L-shaped pipe can be automatically stirred to be loose and cleaned off, so that the influence on the production efficiency is avoided; meanwhile, the powder which is cleaned off is automatically collected and conveyed into a powder conveying system again, so that waste is avoided, and benefits are increased; and meanwhile the problem that the leakproofness is poor as powder exists at the sealing part of the L-shaped pipe is solved.

Owner:苏州盛曼特新材料有限公司

Electrode dust removal and dust suction combined waste gas conveying pipe

InactiveCN106180090ASolve the blockageSmall footprintHollow article cleaningExternal electric electrostatic seperatorEngineeringExhaust pipe

The invention relates to an electrode dust removal and dust suction combined waste gas conveying pipe. The pipe comprises a pipe body; an intake pipe and an exhaust pipe are respectively mounted at two ends of the pipe body; the pipe body is a continuous bent structure, and includes upper and lower multiple layers of transverse pipes and bent arc pipes connected to the end parts of the connected transverse pipes; dust sucking pipes are mounted between the transverse pipes connected up and down, and are respectively connected with dust guide pipes; the dust guide pipes are connected with a dust sucking main pipe; the dust sucking main pipe is connected with a dust sucker; dust removing electrodes are mounted on the outer walls of the bent arc pipes at intervals, and are serially connected to connect with an electrode control module; capacitance sensors are mounted on the outer walls of the bent arc pipes; output ends of the capacitance sensors are connected with an input end of a controller; the controller is connected with the dust sucker and the electrode control module; and according to capacitance signals detected by the capacitance sensors, the controller starts or closes the dust sucker, and opens the dust removing electrodes through the electrode control module.

Owner:无锡派乐科技有限公司

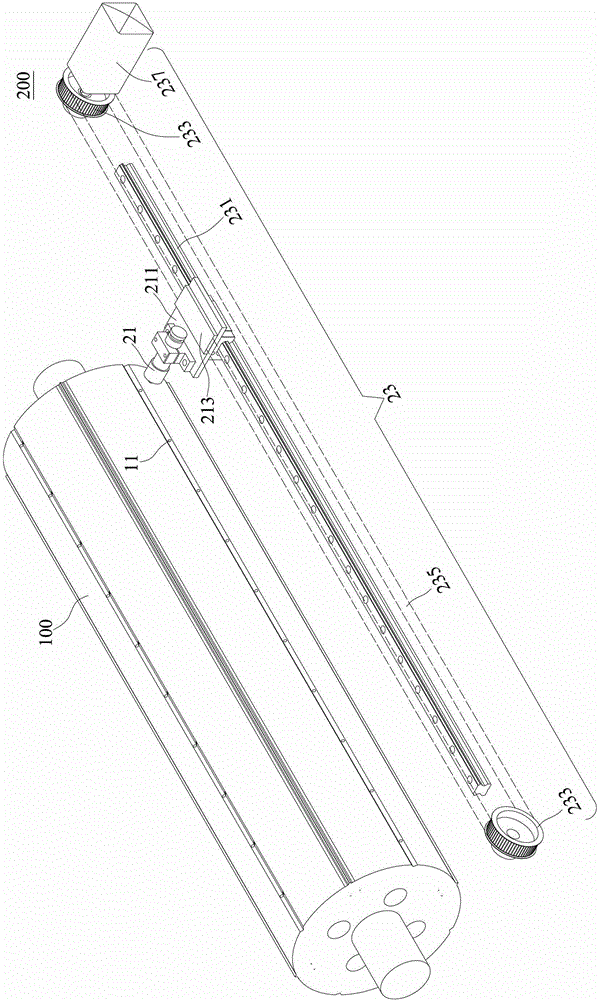

Automatic cleaning device

The invention provides an automatic cleaning device, particularly the automatic cleaning device used for cleaning air sucking holes of an idler wheel. The idler wheel comprises a plurality of air sucking holes; the automatic cleaning device comprises at least one blowing device; and the blowing device is arranged beside the wheel surface of the idler wheel so as to blow toward the air sucking holes of the rolling idler wheel. Due to the adoption of the blowing device, dust or dirt in the air sucking holes of the rolling idler wheel can be blown off, the air sucking holes are always kept clean and ventilating and can be blown and cleaned without stopping the idler wheel, and the production efficiency of a product is prevented from being affected by the stop of the idler wheel.

Owner:CHAN LI MACHINERY

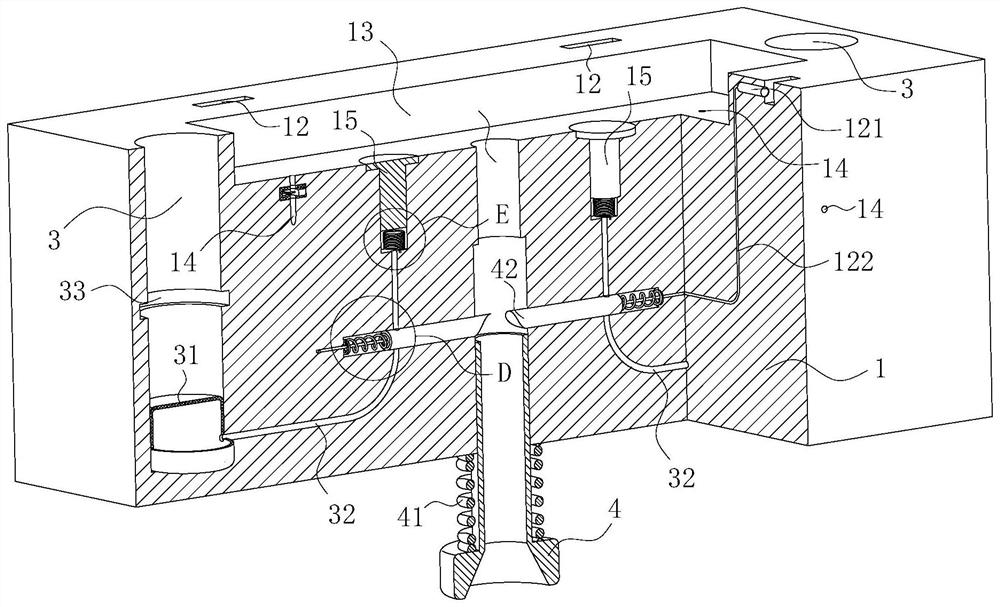

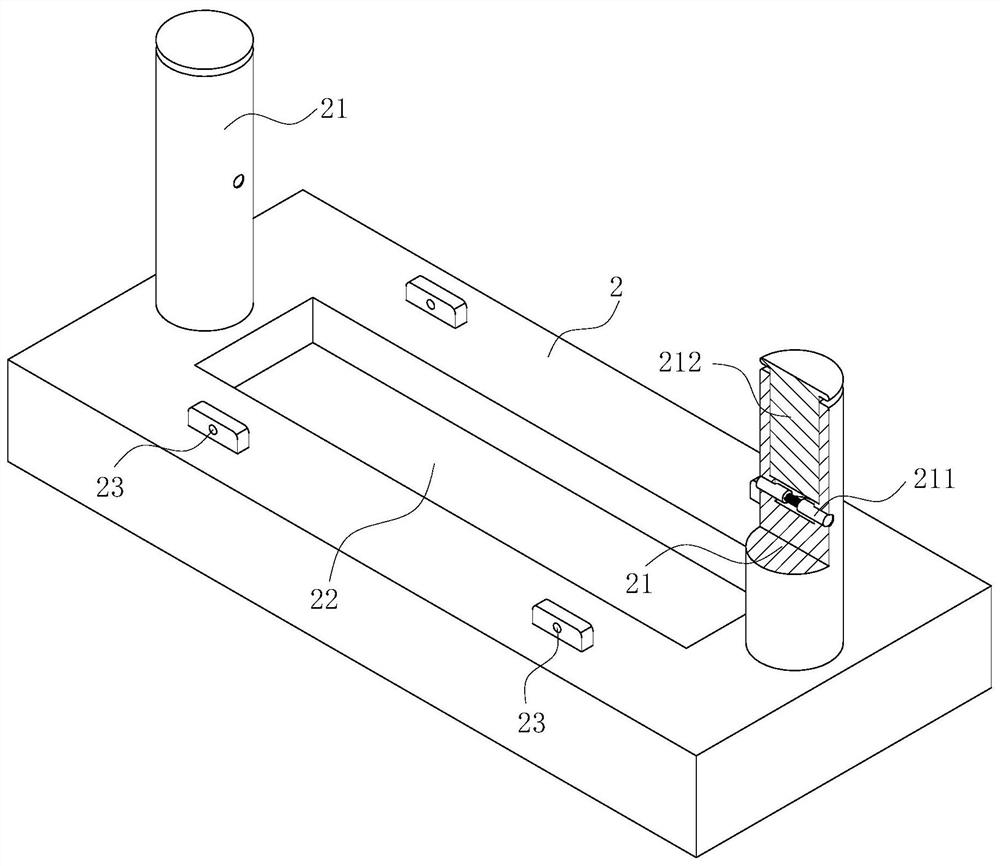

Injection mold

InactiveCN112297357AAvoid damageIncrease the demand for clamping force and increase the difficulty of using the moldEngineeringAirbag

The invention belongs to the technical field of molds, and particularly relates to an injection mold. The injection mold comprises a movable mold and a fixed mold, wherein an upper cavity is formed inthe movable mold; a positioning rod is installed on the movable mold; a lower cavity is formed in the fixed mold; a positioning hole is formed in the fixed mold; the positioning rod is inserted intothe positioning hole; a guide groove is formed in the positioning rod; a positioning protrusion is arranged on the inner wall of the positioning hole and can be inserted into the guide groove; an airbag is installed on the bottom face of the positioning hole; the bottom face of the positioning rod can make contact with the air bag and extrude the air bag; an injection molding hole is formed in the bottom face of the lower cavity in the fixed mold; a lining is installed in the injection molding hole; a first spring is installed on the lining; a third movable cavity is formed in the fixed mold;a buffer rod and a second spring are installed in the third movable cavity; and an air leakage hole is formed in the fixed mold. The injection mold is accurate in positioning, the mold is not prone to loosening after being assembled, and meanwhile air in the mold can be conveniently exhausted.

Owner:陈盈

Lead frame electroplating and discharging device

The invention discloses a lead frame electroplating and discharging device which comprises a first vertical plate. A second vertical plate is arranged on the left side of the first vertical plate; support plates are fixedly connected to one side faces, close to each other, of the first vertical plate and the second vertical plate; sliding plates are fixedly hinged to one side faces, close to eachother, of the first vertical plate and the second vertical plate through two hinges; connecting rods are fixedly hinged to the bottom faces of the two sliding plates through two first pin shafts; andmoving blocks are fixedly hinged to the bottom ends of the two connecting rods through two second pin shafts. According to the lead frame electroplating and discharging device, a spring is arranged, acircuit board fallen from a sloping plate is sprung by utilizing the contractility of the spring, then the spring drives the sloping plate to move up and down and drives a sliding block to slide up and down, and the circuit board is then slid out of a collection box through a discharge hole so as to be protected conveniently during discharging, so that the problems that during discharging, the circuit board is damaged and the production efficiency of the circuit boards is influenced are solved.

Owner:泰兴市龙腾电子有限公司

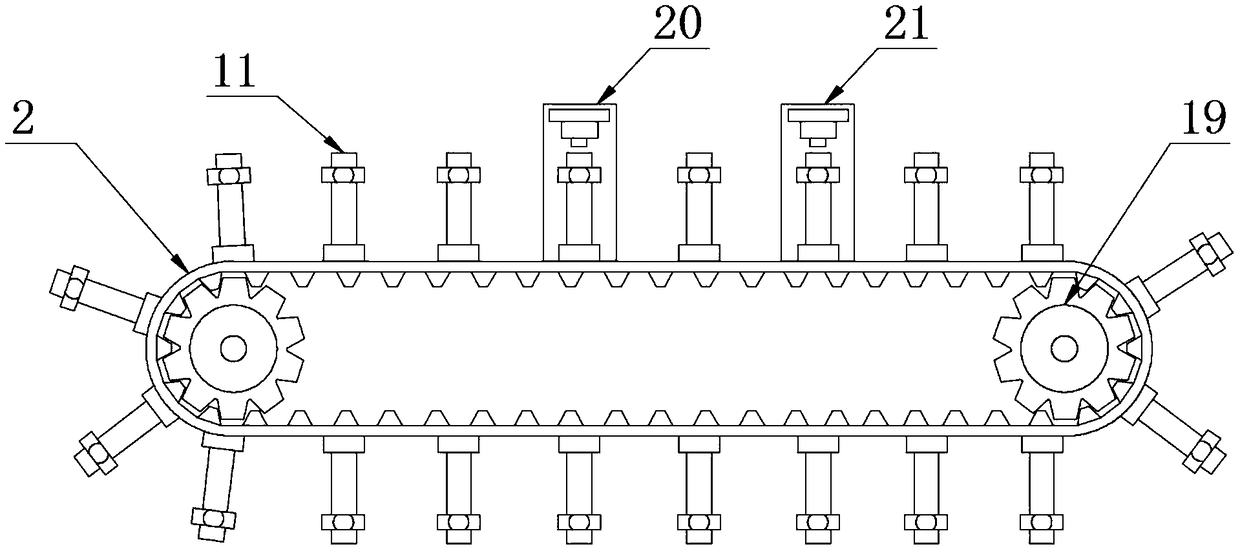

Ribbon knitting machine

PendingCN109353565ASimple mechanical structureReduce manufacturing costPackagingEngineeringMaterial storage

The invention discloses a ribbon knitting machine. The ribbon knitting machine comprises a machine frame, a braid conveying mechanism, a material taking mechanism and a material storage mechanism, thebraid conveying mechanism, the material taking mechanism and the material storage mechanism are fixedly arranged on the machine frame, the material taking mechanism is arranged at one end of the braid conveying mechanism, the material storage mechanism is arranged at the other end of the braid conveying mechanism, the material taking mechanism comprises a material taking and installing plate, a material taking driving mechanism, a material taking track plate and a material taking device, the material taking track plate is fixedly arranged on the material taking and installing plate, the material taking device is movably installed on the material taking track plate, and the material taking driving mechanism is connected with the material taking device; a belt pressing mechanism is fixedlyinstalled on the material storage mechanism, the belt pressing mechanism is connected with the braid conveying mechanism. According to the ribbon knitting machine, the mechanical structure is simple,the production cost is reduced, the control method is simple, the phenomenon that too much alarm occurs in the practical process is avoided, the production efficiency is improved, the belt pressing device is arranged, so that the braiding belt is prevented from being broken in the material storage process, and the production efficiency is influenced.

Owner:平湖市福运包装股份有限公司

Transferring system and method of health care liquor assembly line

InactiveCN109368581AEasy to fixPrevent bevelingSynchronising machinesLiquid bottlingTransfer systemAssembly line

The invention discloses a transferring system and method of a health care liquor assembly line. The transferring system and method of the health care liquor assembly line comprises a machine frame. Fixing rings are both arranged on the two sides of the inner wall of the machine frame. A conveyer belt is arranged between the two fixing rings. The surface of the conveyer belt is evenly provided witha plurality of first fixing devices. Each first fixing device comprises a fixing disk. The top of each fixing plate is provided with a first fixing plate. The two sides of each first fixing plate areboth provided with first clamp plates, wherein the opposite sides of the first clamp plates are both provided with first arc clamp plates. According to the transferring system and method of the health care liquor assembly line, each first fixing device, the corresponding first fixing plate, the two first clamp plates of the corresponding first fixing plate and the corresponding fixing disk can becombined to be used for holding a glass bottle used for containing health care liquor, the two first arc clamp plates of each first fixing plate can fix the glass bottle, corresponding first squeezing springs on the two sides can form a buffering layer between the corresponding first arc clamp plates and the corresponding first fixing plate, and therefore each first fixing device is suitable forglass bottles of different dimensions.

Owner:灵参生物科技(大连)有限公司

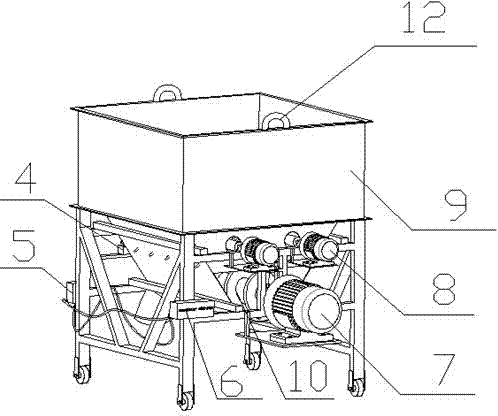

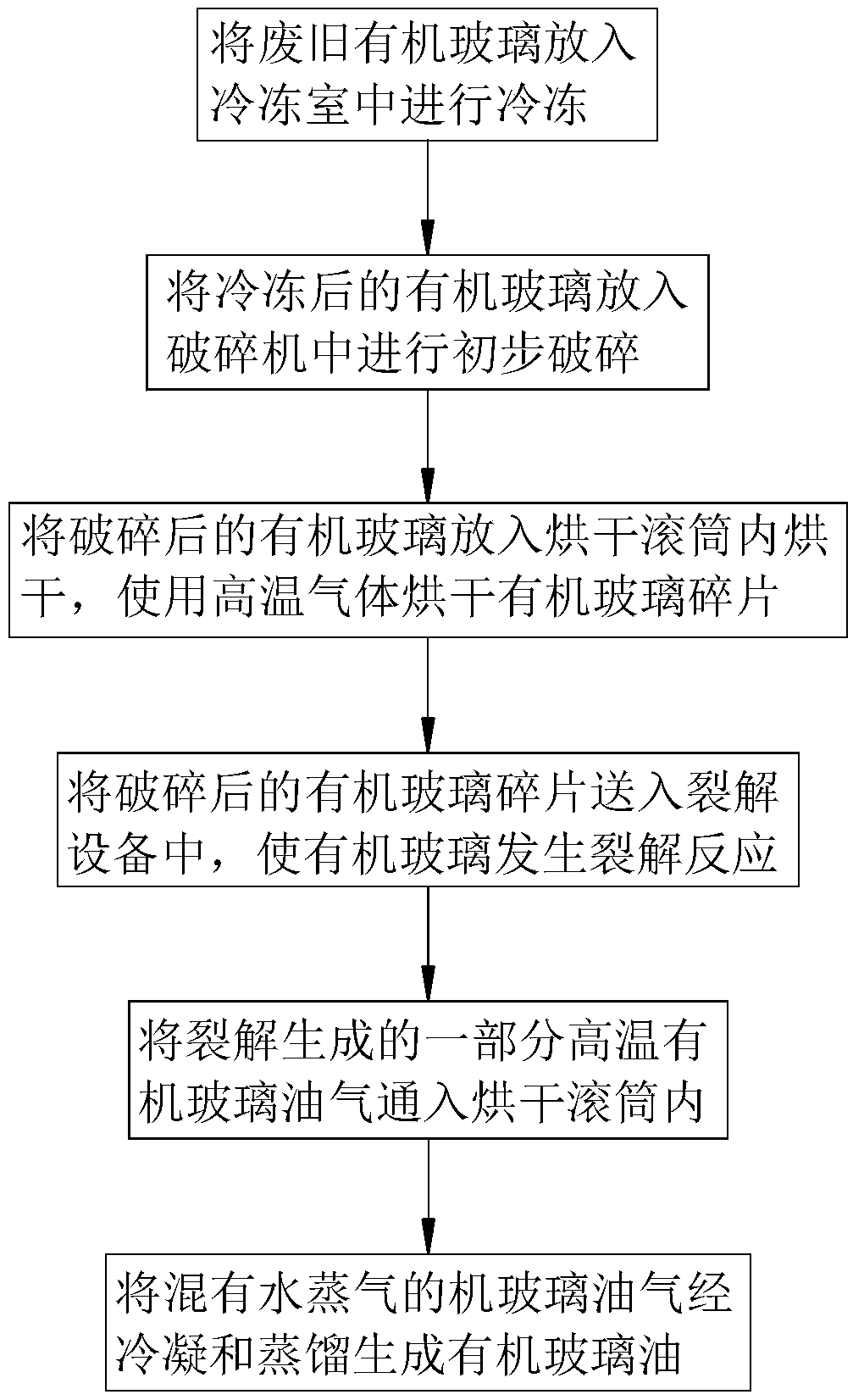

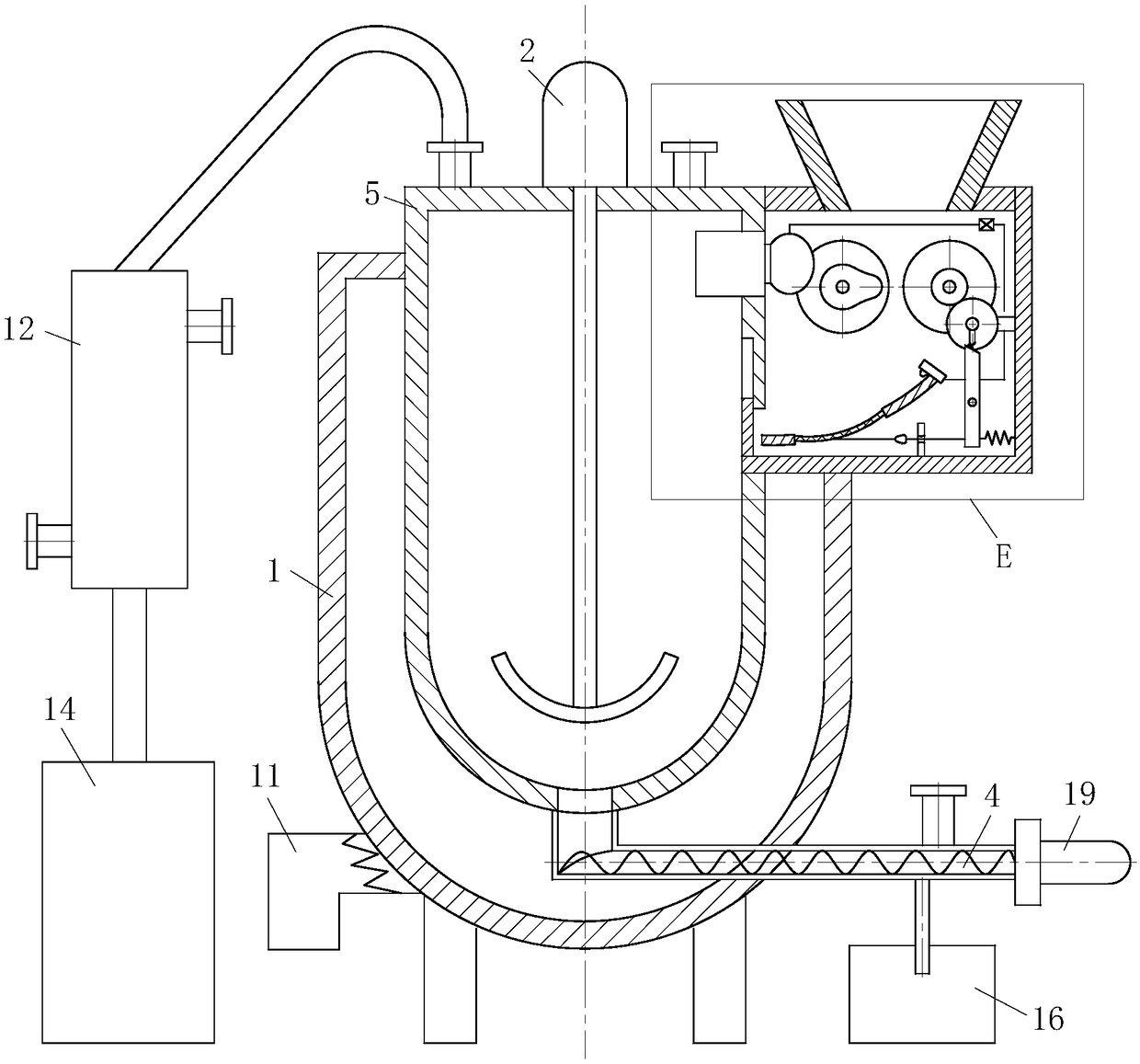

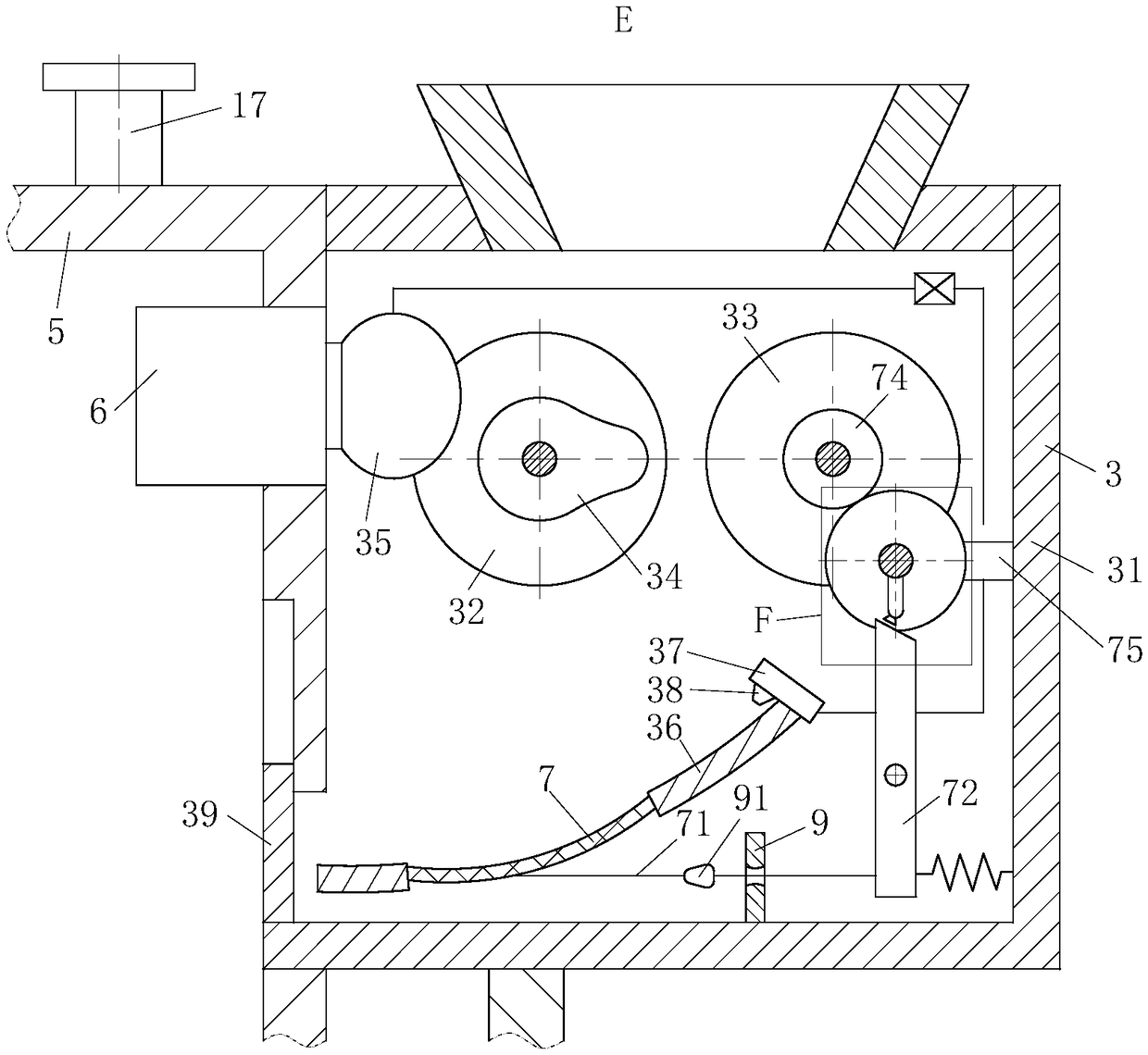

Waste plexiglass recycling method

ActiveCN109021284AEvenly dispersedAvoid affecting productivityPlastic recyclingElectricityCombustion

The invention belongs to the technical field of plexiglass recycling, and in particular relates to a waste plexiglass recycling method. The method uses a cracking device; the cracking device comprisesa furnace body, a stirring motor, a feeding module and a deslagging device, wherein an electric combustion machine is arranged at the bottom of one side of the furnace body; the furnace body is internally provided with a hearth; the stirring motor is fixedly connected with a stirring shaft by means of a gearbox; the stirring motor is arranged on the top of the hearth; the stirring shaft passes through the hearth and enters the hearth; the hearth is communicated with a condenser by means of a hose pipe; a storage tank is arranged under the condenser; the bottom of the deslagging device is communicated with a water tank by means of a pipeline; the feeding module is installed at the right upper corner of the furnace body; the feeding module comprises a feeding box, a driving motor, a drivinggrinding roller, a driven grinding roller, a cam, an air bag, an arc-shaped guide plate, a mounting plate, a blow head and an automatic door. Plexiglass particles are thrown to the middle upper partof the hearth by means of the air bag, thus being evenly dispersed, and avoiding the phenomenon that the production efficiency is affected due to the insufficient reaction caused by raw material accumulation in the hearth.

Owner:台州佑辅机械实业有限公司

LED packaging adhesive anti-precipitation storage device

ActiveCN109078559ARealize stirring and anti-sedimentationAvoid affecting productivityShaking/oscillating/vibrating mixersTransportation and packagingAdhesiveEngineering

The invention discloses an LED packaging adhesive anti-precipitation storage device, which comprises a base, a storage structure and an anti-precipitation structure. The anti-precipitation structure is arranged on the storage structure which is arranged on the base. The storage structure comprises a storage tank, the top of the storage tank is provided with a liquid inlet passage and an exhaust passage, the bottom of the storage tank is provided with a liquid outlet passage, and the liquid outlet passage is provided with a control valve. The anti-precipitation structure comprises a lifting supporting frame, a guide column rod is fixed to a piston shaft of a lifting air cylinder which is arranged on the lifting supporting frame, a mesh plate is fixed to the bottom end of the guide column rod and positioned in the storage tank, the mesh plate is internally provided with a cavity, and a driving power source and an electric heating block connected with the driving power source are fixed inthe cavity. The LED packaging adhesive anti-precipitation storage device is reasonable in structural setting, packaging adhesive stirring and precipitation prevention can be realized effectively while stirring uniformity and heating uniformity can be effectively guaranteed, influences on production efficiency due to local overheating are avoided, and high stability in use and high applicability are realized.

Owner:惠州市浩凌光电科技有限公司

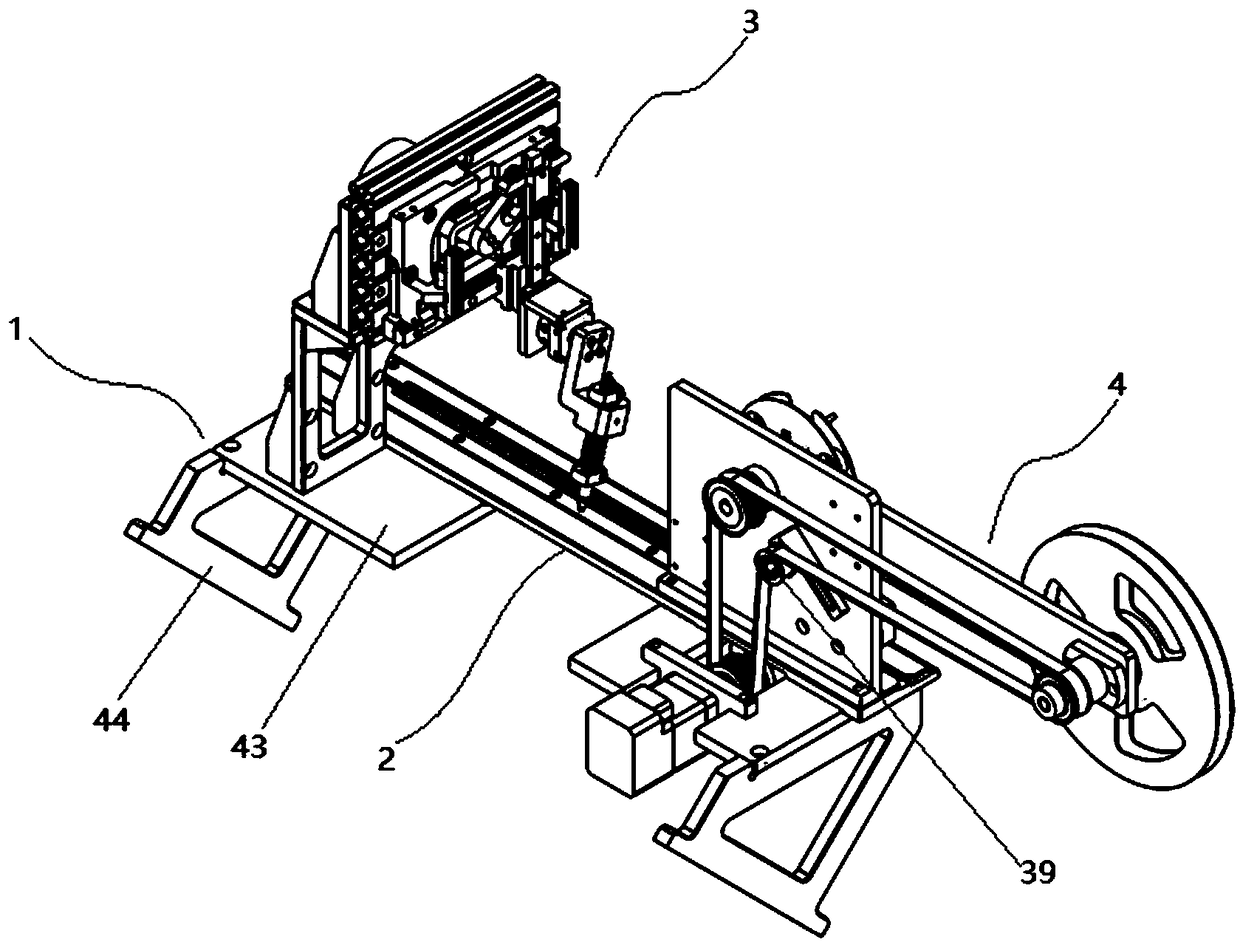

Glass fiber waste filament processing equipment

The invention discloses glass fiber waste filament processing equipment. The glass fiber waste filament processing equipment comprises a material pulling device. A support is arranged at the lower endof the material pulling device and fixedly connected with the material pulling device. A driven belt pulley is arranged at the left side of the material pulling device, and a belt pulley is arrangedin the material pulling device in a penetrating manner. The material pulling device is internally provided with a crank shaft, and the crank shaft is movably connected with the material pulling device. The glass fiber waste filament processing equipment works in order; high efficiency is achieved in the waste filament processing process; a machine body of the equipment is formed by forging an aluminum alloy and is free of rust and good in quality; the equipment is provided with a material sieve, waste filament powder passes through the material sieve, and the waste filament powder which does not reach the standard can be sieved off through vibration generated in the mechanical work process; quality problems are prevented in the reproduction process; meanwhile, the waste filament powder canbe inspected one more time, and thus quality of mechanical work is observed; and the problem that the equipment breaks down due to excessive unqualified powder is prevented.

Owner:WUXI JUNHAO COMPOSITES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com