Stampings bonding prevention device for stamping die

A stamping die and anti-scouring technology, applied in the field of anti-scouring chip bonding devices, can solve the problems of time-consuming mold cleaning, easy bonding of punching chips, low production efficiency, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

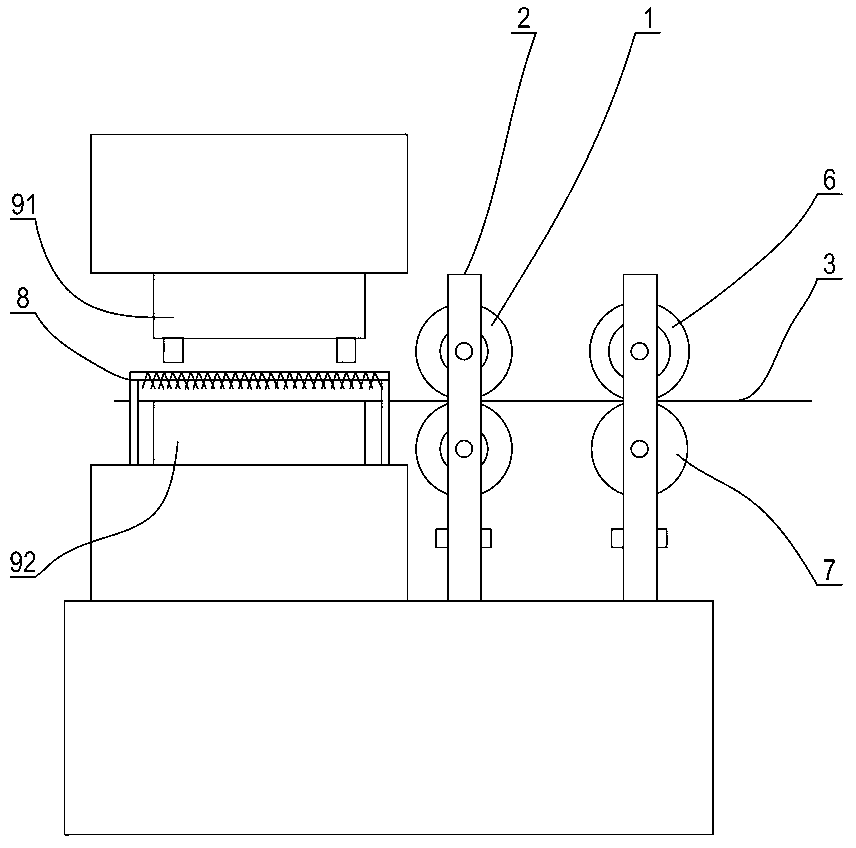

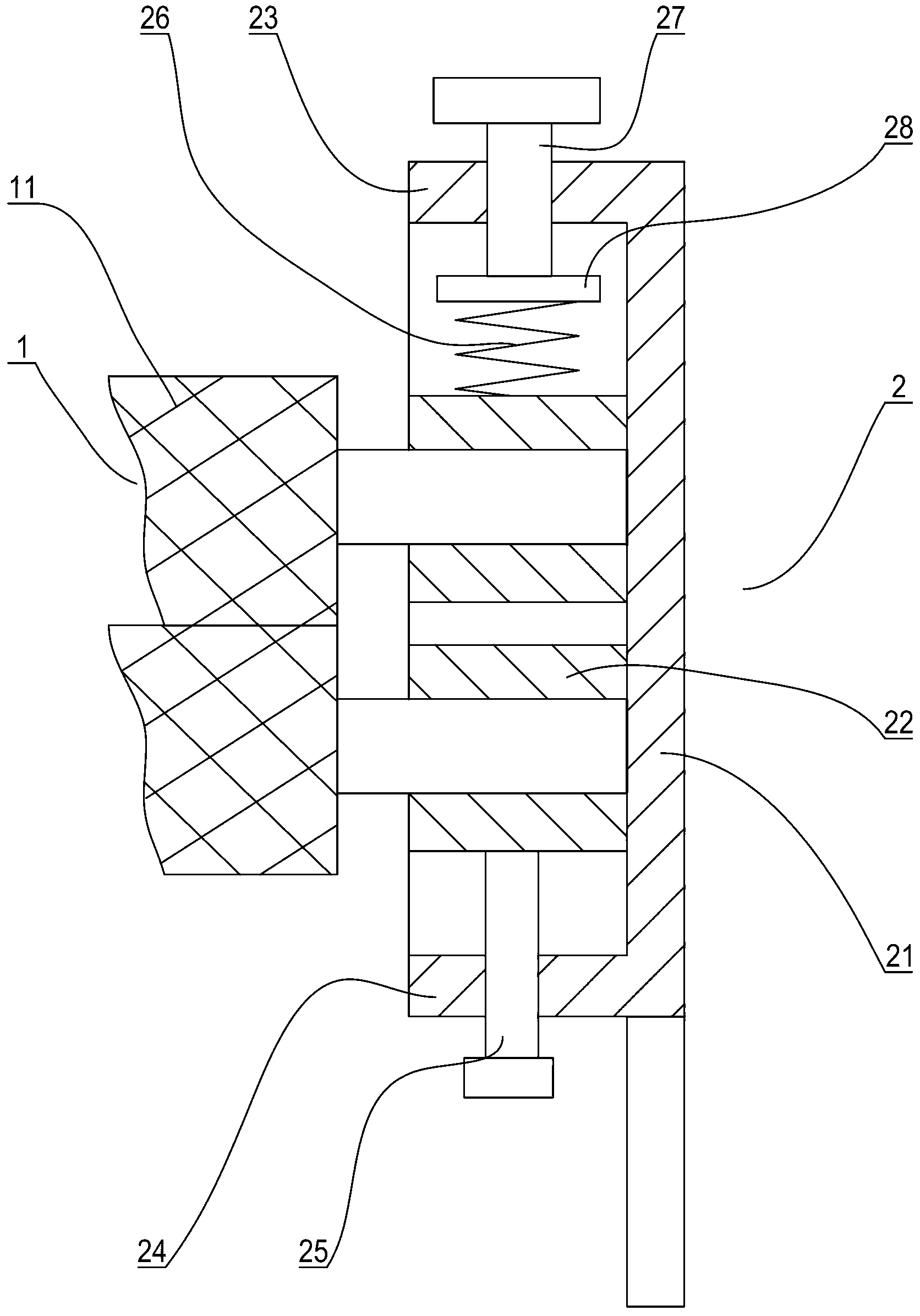

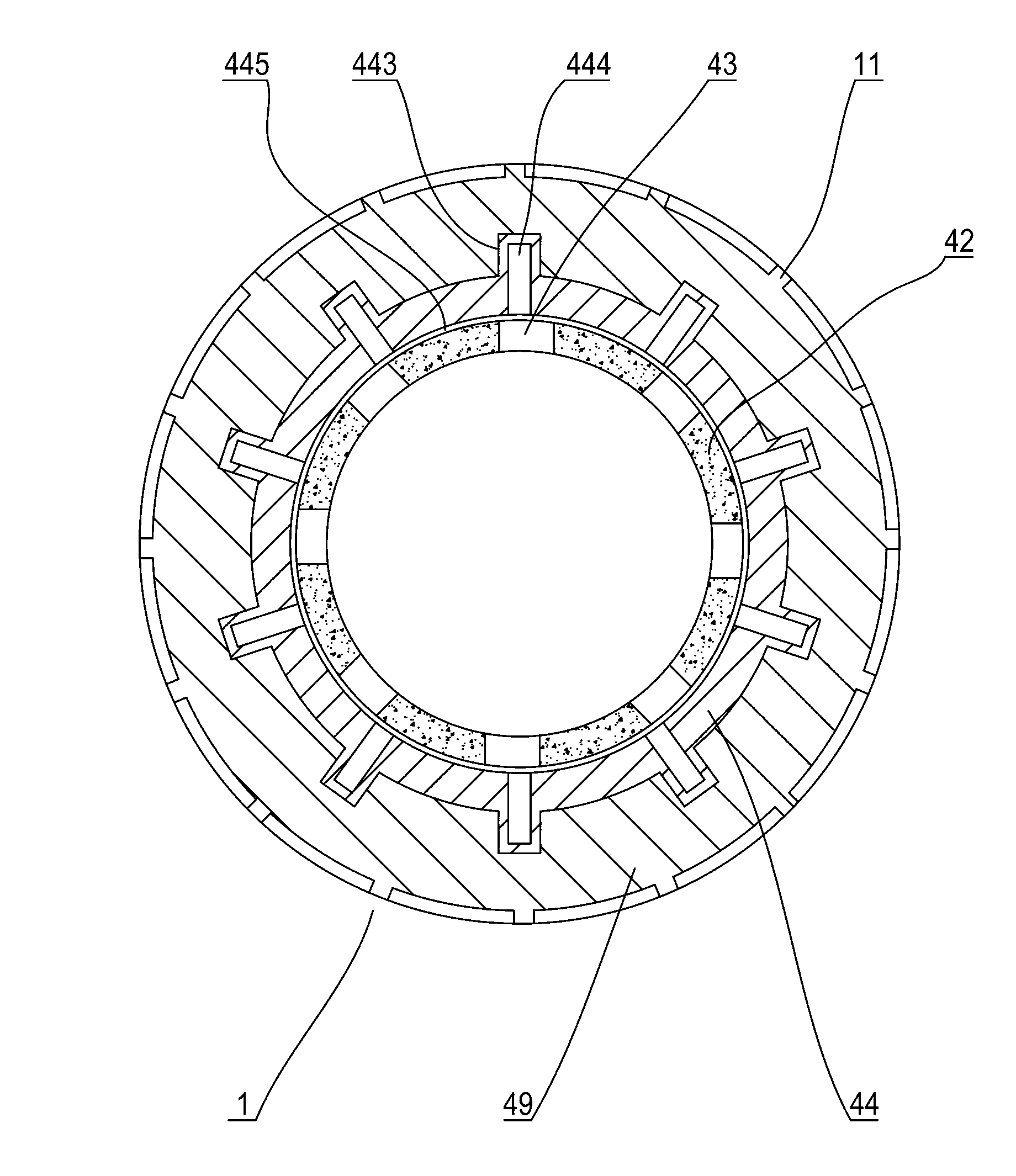

[0026] Such as figure 1 As shown, a device of the present invention for preventing chip sticking in a stamping die, which is suitable for punching coils, includes two horizontal rollers 1 located on the coil feeding side of the mold, and a Ram oil delivery system 5 for delivery of ram oil (see Figure 5 ). The two rollers are close to each other and arranged up and down to apply stamping oil on the upper and lower sides of the coil 3. The two ends of the roller can adopt a height-adjustable lifting support structure 2, such as figure 2 As shown, the lifting support structure includes guide rails 21 vertically arranged at both ends of the drum, and the bearing blocks 22 for supporting the two ends of the drum and the guide rails form a sliding connection up and down. The upper and lower ends of the guide rails are respectively provided with u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com