Patents

Literature

70results about How to "Reduce grinding times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denture data processing and three-dimensional printing system

ActiveCN104367389AReduced adjustabilityReduce grinding timesArtificial teethSpecial data processing applicationsPersonalizationDentures

The invention discloses a denture data processing and three-dimensional printing system comprising a data acquisition device, a data processing device and a three-dimensional printing device, wherein the data acquisition device comprises hand-held equipment, data storage equipment and display equipment; the hand-held equipment can be used for performing three-dimensional color scanning and image shooting on the mouth cavity; the data processing device is a computer, is provided with data reading recovery software and CAD design software, can be used for restoring and recovering data transmitted by the data acquisition device and designing and modifying the data, and then can be used for restoring the data to obtain a virtual simulated tooth model, namely, to obtain required virtual model data; and the three-dimensional printing device can be connected with the data processing device, and a required denture manufacturing working model can be obtained according to the obtained virtual model data by virtue of three-dimensional printing and molding. The denture data processing and three-dimensional printing system disclosed by the invention does not need to take tooth models, can also be used for preparing dentures by virtue of three-dimensional printing and rapid molding, is manpower-saving and short in cycle, and can also meet the personalized production requirements.

Owner:SHANGHAI I DENTAL TECH CO LTD

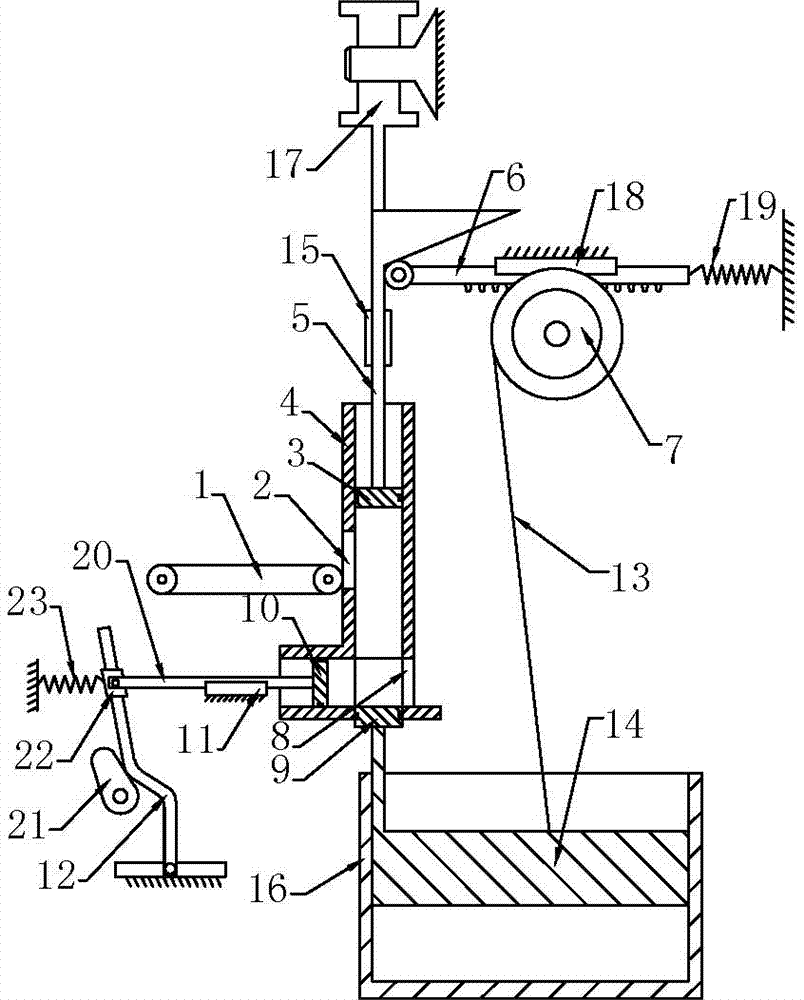

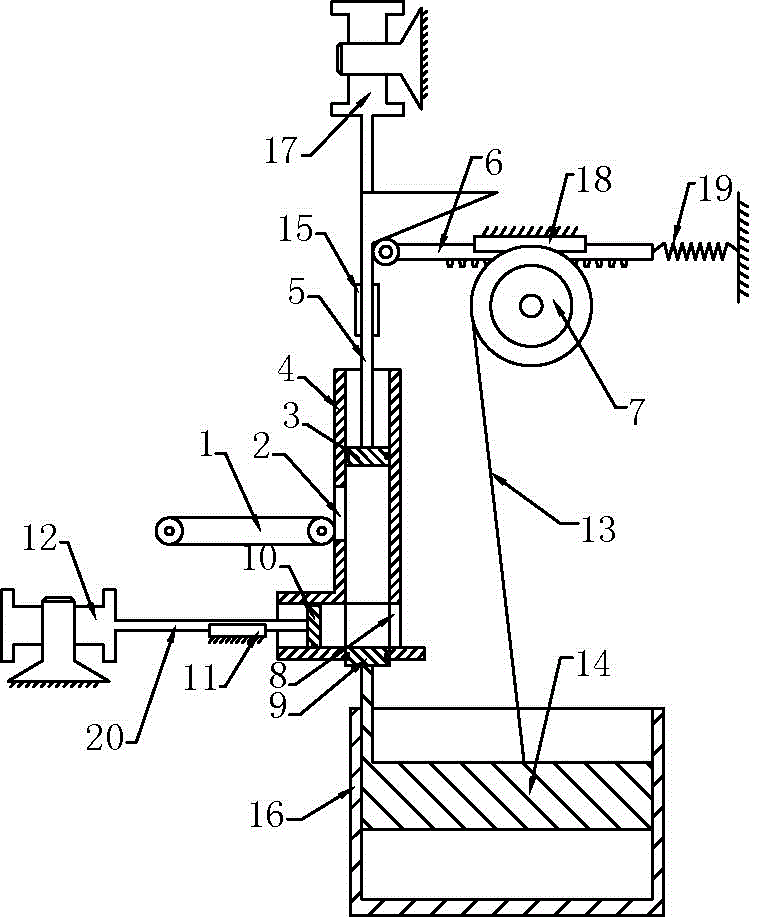

Extruding device for producing organic fertilizers

InactiveCN105435886AEasy to GrindReduce the number of crushingGrain treatmentsAgricultural engineeringCam

The invention discloses an extruding device for producing organic fertilizers. The extruding device comprises a frame; a feed hopper is arranged on the frame; an upper pressing plate and a lower pressing plate are slidingly connected into the feed hopper; the upper pressing plate is connected with an upper connecting rod with the top as a wedge surface; the upper connecting rod is connected with a cylinder, and is butted against a roller; the roller is connected with a rack; the right side of the rack is connected with a first spring; the rack is engaged with a gear; the gear is connected with a drum; the drum is wound with a rope; the lower pressing plate is connected with a lower connecting rod; the rope is wound on the lower connecting rod; a feed port is formed in one side of the feed hopper; the bottom of the feed hopper is communicated with a push pipe; a discharge port is formed in the wall of the feed hopper on one opposite side of the push pipe; a push plate is slidingly connected into the push pipe, and is connected with a push rod; a swing rod is arranged on the left side of the push rod, and is connected with the spring; a cam is butted against the bottom of the swing rod; and the swing rod is slidingly connected with a slide block. The invention provides an extruding device with high crushing efficiency, and solves the problem of low grinding efficiency.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

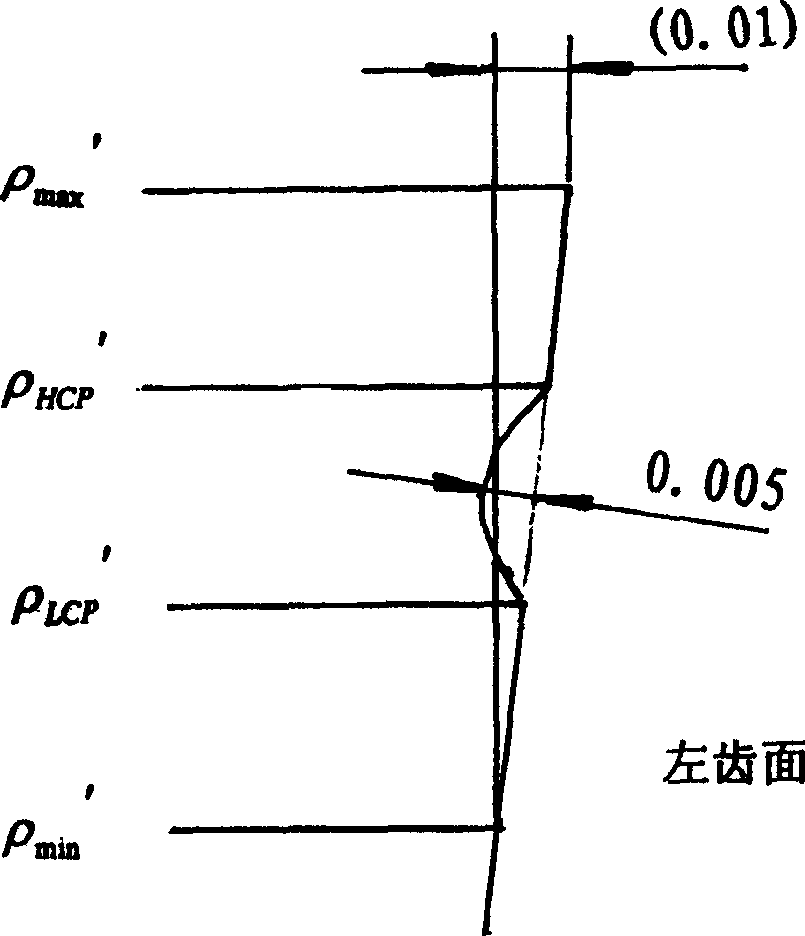

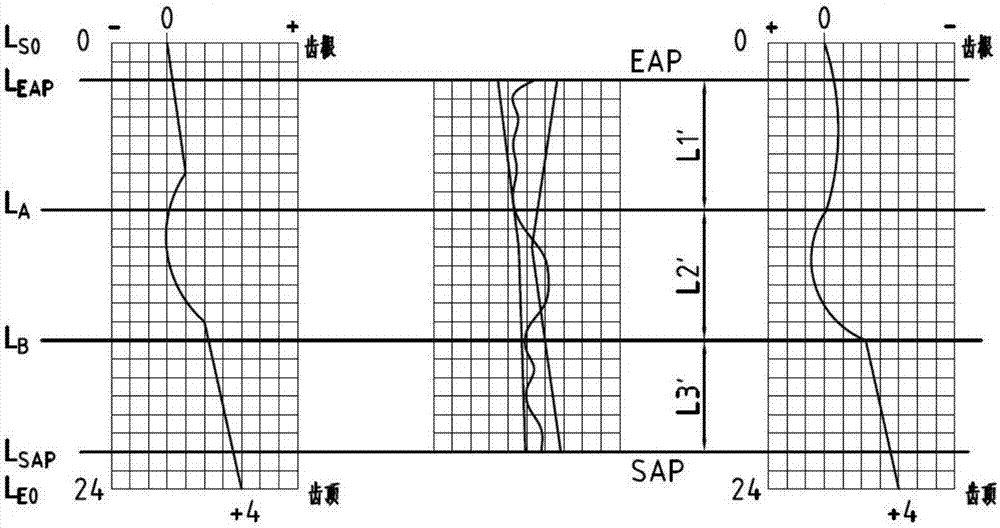

Method for shaping gear shaver

InactiveCN1781637AFew engagement pointsStrong targetingGear teeth manufacturing toolsGear teethEngineeringMechanical engineering

The method of shaping gear shaver includes calculating the curvature values of the practical engagement conversion point based on the curvature values of the machined gear, calculating the corresponding curvature values of the gear shaver in the engagement conversion point based on the no-side gap helical gear engagement formulation, and designing the shape correcting curve of the gear shaver precisely. The method can determine the reverse concave position range of gear shaver fast and accurately and has high shape correcting efficiency and low production cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

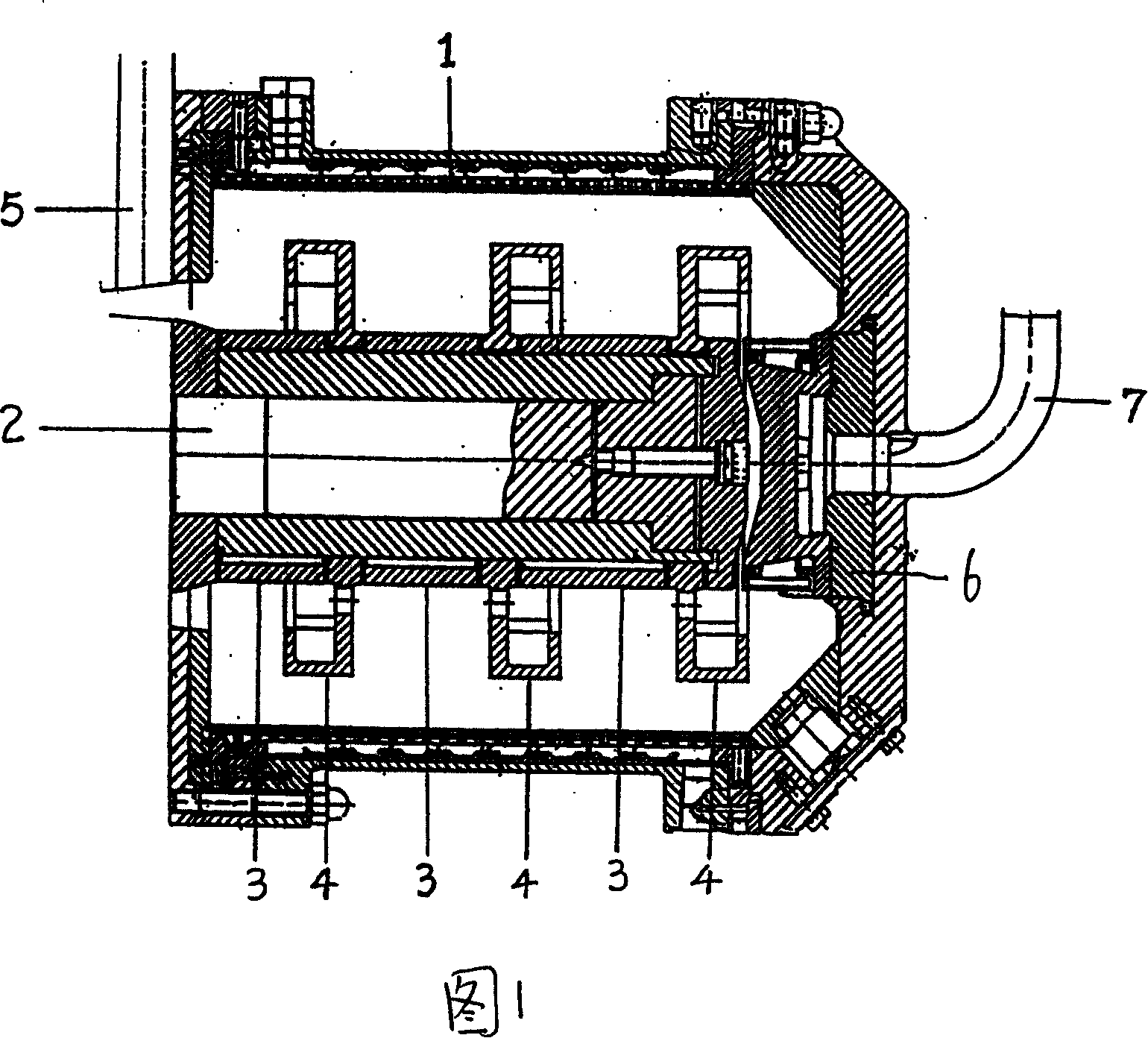

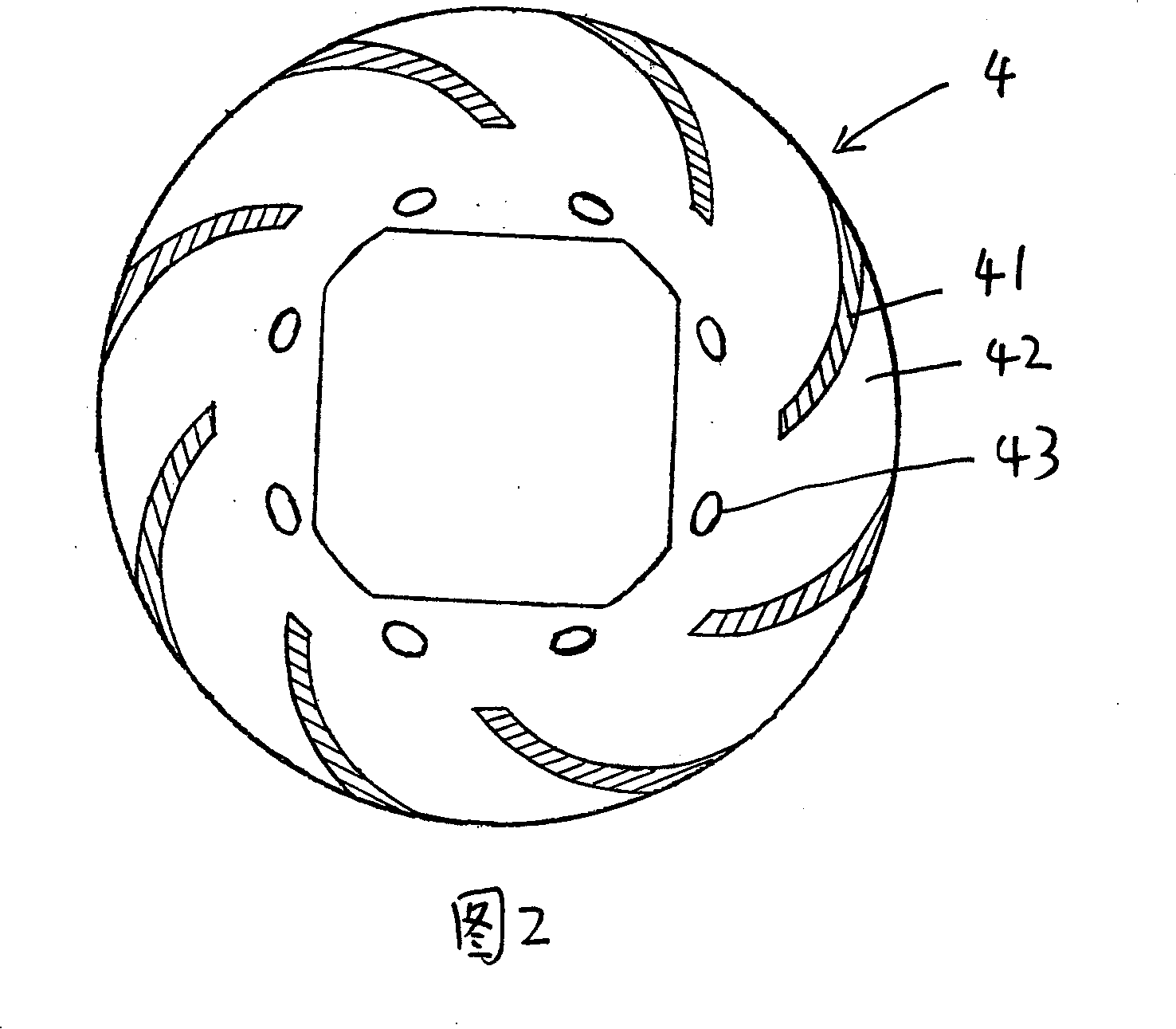

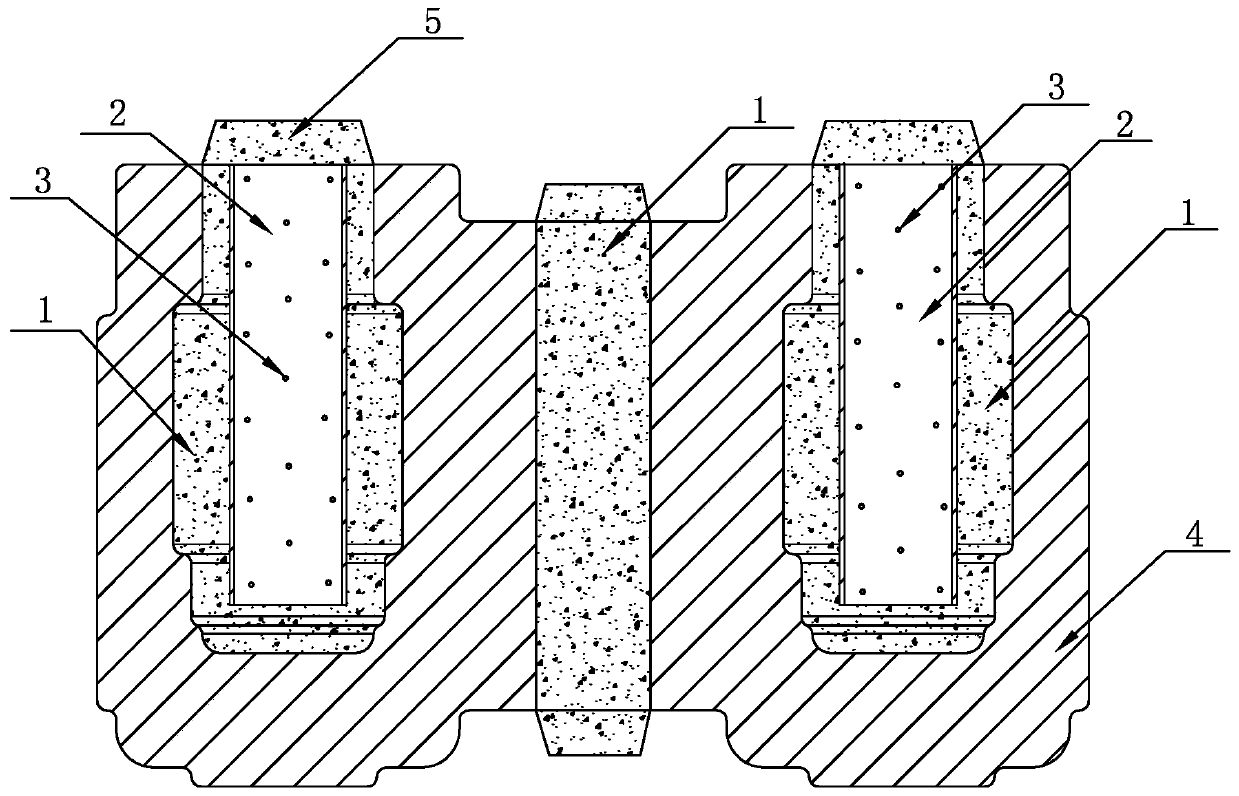

Horizontal sand mill

The present invention relates to a horizontal sand mill for dispersing liquid material. Said horizontal sand mill includes the following several portions: main shaft, barrel body and several dispersion wormwheels which are spaced, extended into the barrel body interior and mounted on the main shaft. Said invention also provides its working principle and its concrete operation method.

Owner:ZHENGDONG INDAL KUSN CITY

Planographic printing ink containing high-concentration kaolin and preparation method thereof

The invention relates to the technical field of planographic printing ink and particularly relates to planographic printing ink containing high-concentration kaolin and a preparation method thereof. The planographic printing ink is formed by mixed base ink, a pigment connecting material, an anti-friction auxiliary agent, and ink oil, wherein the content of kaolin in the mixed base ink is 8-20%. Compared with the prior art, the high-concentration kaolin and a coloring pigment are added to be kneaded to prepare the mixed base ink, so that a production process is simplified and the production efficiency is improved; even if the content of kaolin in the ink is increased, the decline of the qualities of the glossiness, the mobility and the like of the ink can be inhibited, so that high-concentration kaolin with the lower price can be adopted to prepare the planographic printing ink with the good dispersing performance, glossiness and mobility; and furthermore, the production cost is reduced and the planographic printing ink containing the high-concentration kaolin has a better market prospect.

Owner:茂名阪田油墨有限公司

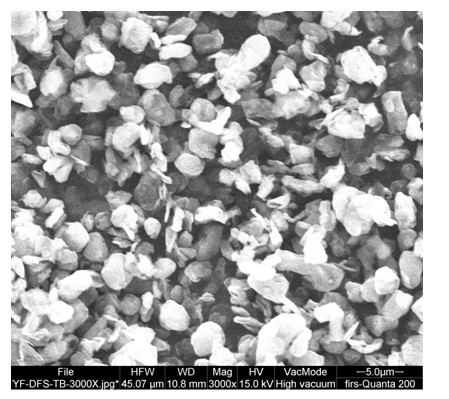

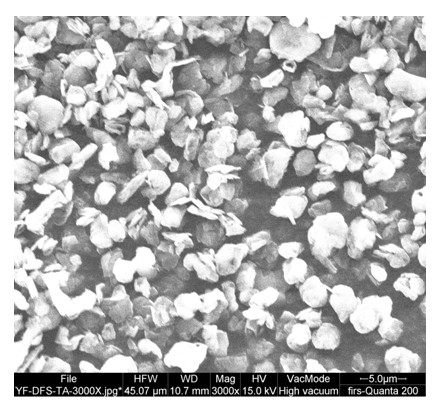

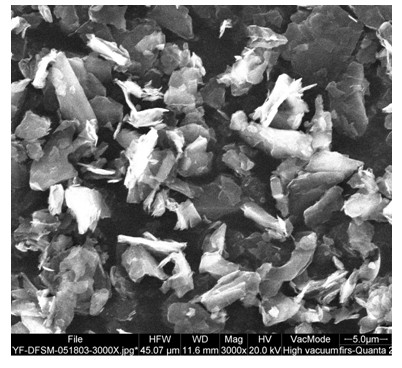

Preparation method and application of high-purity high-fineness graphite powder

ActiveCN102689895AEasy to introduceSimple preparation processCarbon compoundsNanotechnologyFiberElectrical battery

The invention discloses a method for preparing high-purity high-fineness graphite powder, comprising the following steps of: a), irradiating graphite raw materials by rays under a room temperature; and b) grinding and pulverizing the graphite raw materials which are obtained after the treatment of step a) to obtain high-purity graphite powder. The graphite powder can be applied to preparation of coatings, plastics, rubbers, fibers, heat preservation cottons, power supplies and batteries. Because the preparation process is simple, the times for grinding can be greatly reduced, impurities are difficult to enter, and the high-purity graphite powder, of which the grain diameter is less than 1mm, can be prepared. The preparation method and the application can be widely applied to the field of graphite processing.

Owner:王宏晓

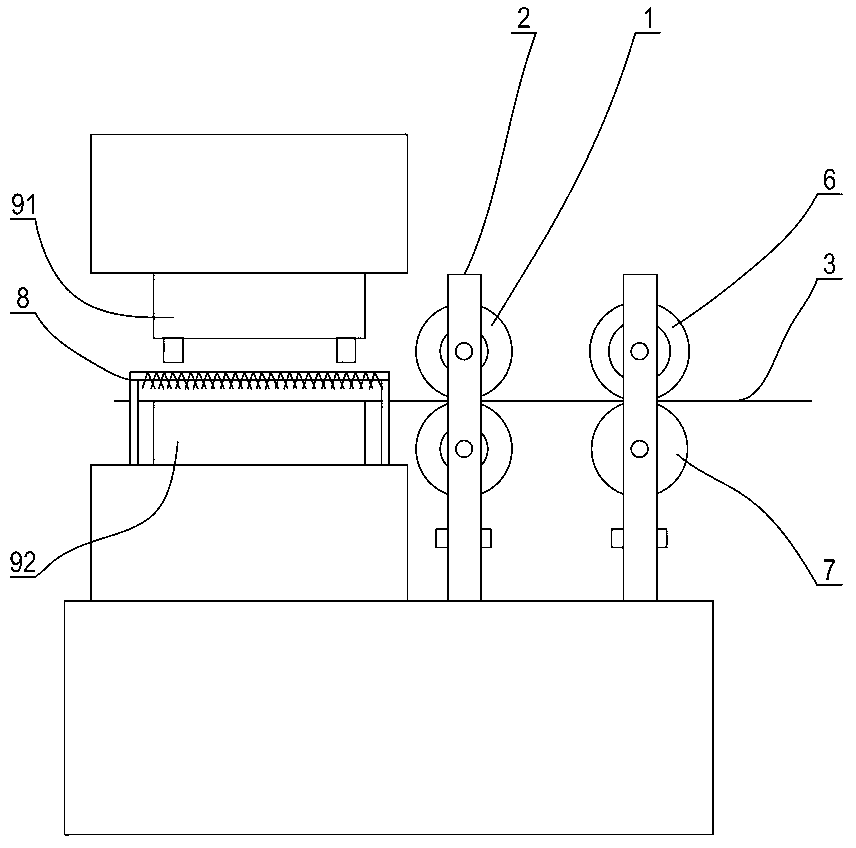

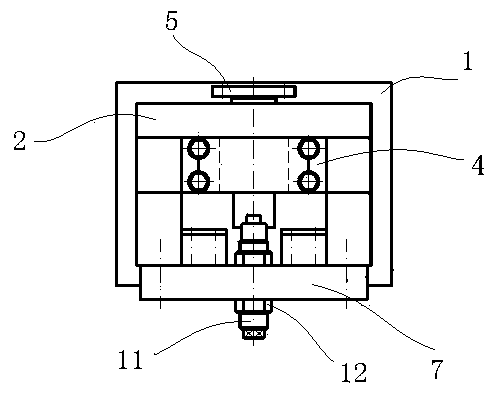

Stampings bonding prevention device for stamping die

ActiveCN103157728AAvoid it happening againAvoid downtime for cleaningShaping toolsCleaning using toolsPunchingTerete

The invention discloses a stampings bonding prevention device for a stamping die and is suitable for punching of coiled materials. The stampings bonding prevention device for the stamp die comprises two rotary cylinders which are located on one side of the die, and the coiled materials go in from the side. The two rotary cylinders are tightly attached to each other and arranged up and down. Each rotary cylinder comprises an oil storage drum with two sealed ends and an oil impregnating layer which is arranged on the outer side of the oil storage cylinder. The oil impregnating layer has elasticity. A plurality of oil impregnating holes are uniformly formed in the circumferential surface of each oil storage cylinder. One ends of the oil storage cylinders are connected with a punching oil conveying system through pipelines. A damping layer with elasticity is arranged between each oil storage cylinder and each oil impregnating layer. A plurality of oil impregnating cylinders are uniformly arranged on the circumferential surface of each damping layer and embedded in each oil impregnating layer. Oil outlet holes which penetrate through the inner surface of each damping layer are formed in each oil impregnating cylinder. Kerfs which are communicated with the oil outlet holes are uniformly arranged on the circumferential surface of each oil impregnating cylinder. The stampings bonding prevention device for the stamp die can prevent stampings from bonding with the die, and therefore continuous punching can be achieved, and influence of machine halt on production efficiency is avoided. Besides, the stampings bonding prevention device for the stamp die is beneficial for prolonging service life of the die and improving punching quality of products.

Owner:WANXIANG 123 CO LTD

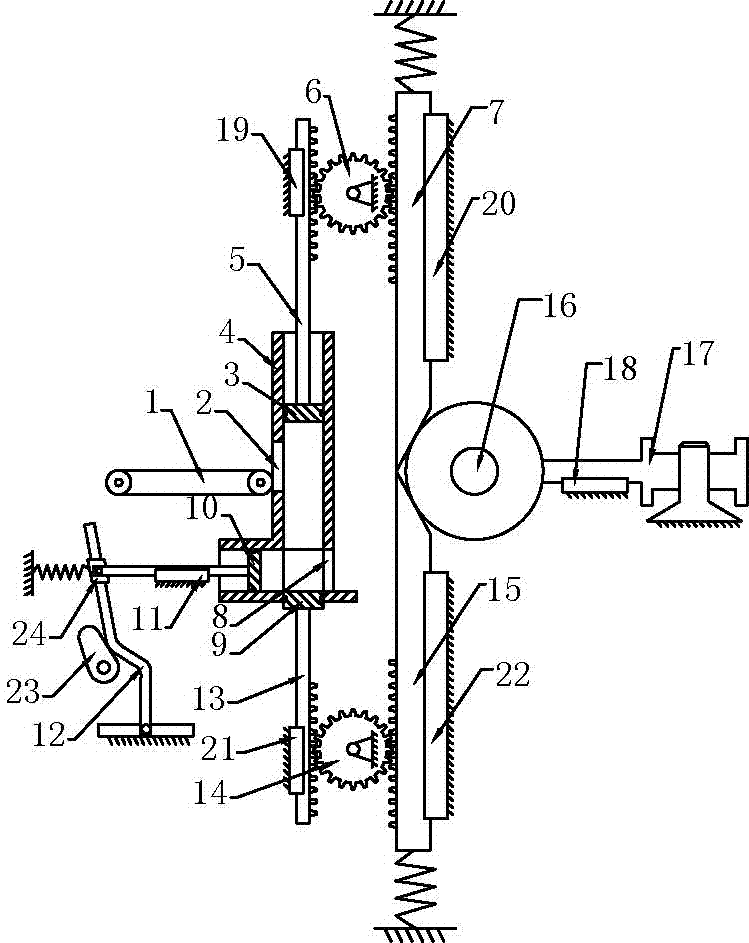

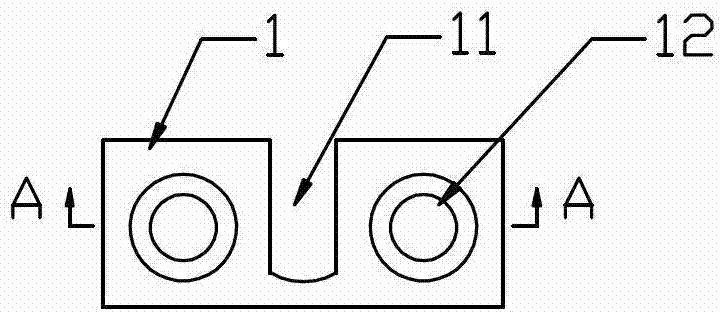

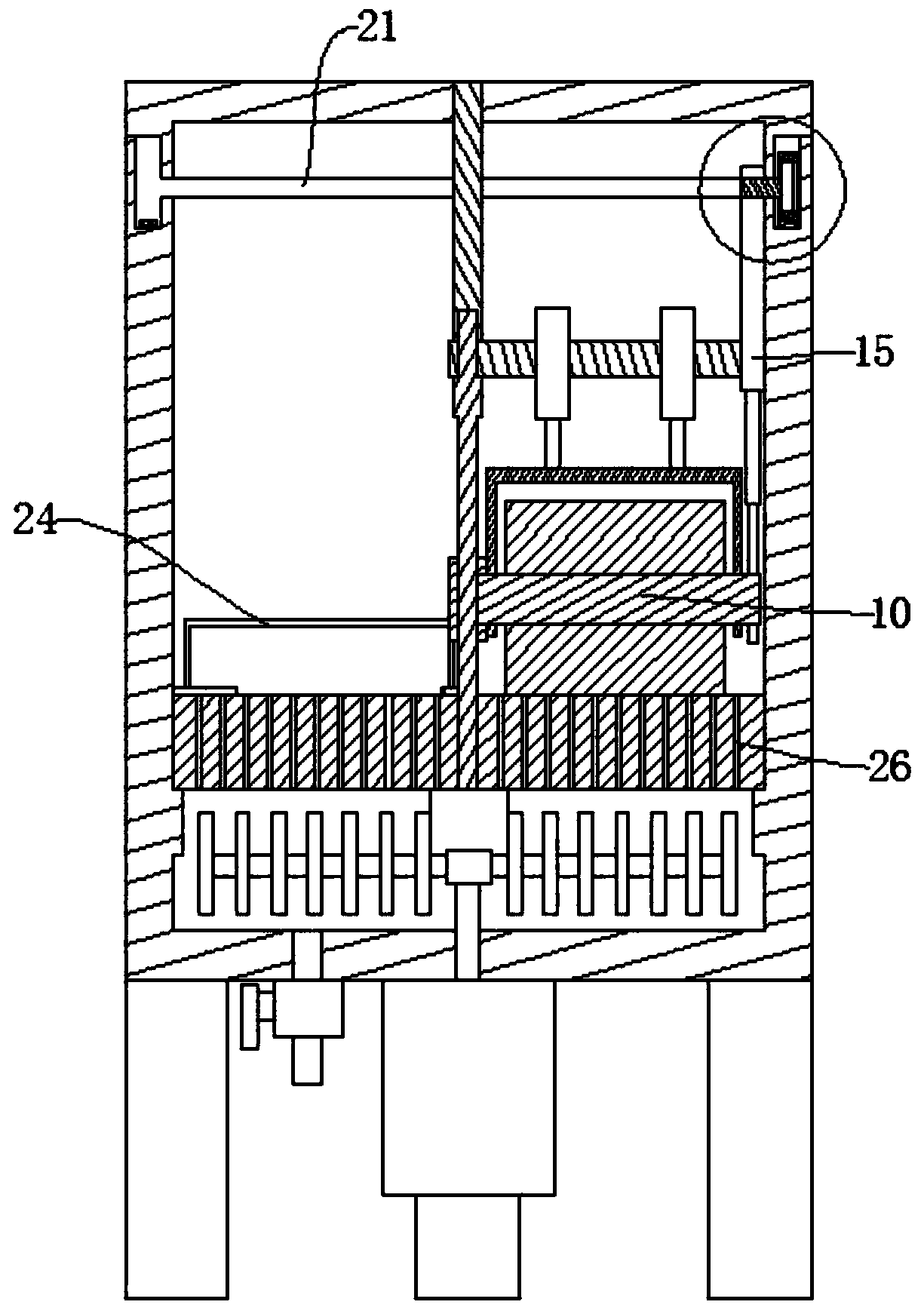

Extruding device for producing organic fertilizers

InactiveCN105435885AEasy to GrindReduce grinding timesClimate change adaptationExcrement fertilisersEngineeringOrganic fertilizer

The invention discloses an extruding device for producing organic fertilizers. The extruding device comprises an upper pressing plate; a lower pressing plate is arranged below the upper pressing plate; the upper pressing plate is connected with a first rack; the first rack is engaged with a first gear; the first gear is engaged with a second rack; the lower pressing plate is connected with a third rack; the third rack is engaged with a second gear; the second gear is engaged with a fourth rack; the second rack and the fourth rack are both connected with first springs; the second rack and the fourth rack are both provided with wedge surfaces; the two wedge surfaces are butted against with the same turntable; the upper pressing plate and the lower pressing plate are slidingly connected with a feed hopper; the feed hopper is provided with a feed port and a discharge port; the feed hopper is communicated with a push pipe; a push plate is slidingly connected into the push pipe; the push plate is connected with a push rod; a swing rod is arranged on the left side of the push rod, and is connected with a spring; the bottom of the swing rod is butted against a cam; the swing rod is slidingly connected with a slide block; and the push rod is hinged to the slide block. The extruding device is high in crushing efficiency, and solves the problem of low grinding efficiency.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

Preparation method for producing calcium-carbonate-containing lithographic ink through one-step kneading method

ActiveCN103087587AGood dispersionDecrease and increase stirring timeInksPhysical chemistryHigh calcium

The invention relates to the technical field of lithographic ink, and particularly relates to a preparation method for producing calcium-carbonate-containing lithographic ink through a one-step kneading method. The preparation method comprises the following step: simultaneously adding 15-30% of calcium carbonate filter cake, 10-30% of tinting pigment and 20-40% of pigment binder into a kneading machine, thus preparing the mixed base ink having a high calcium carbonate concentration through a one-step kneading method. Compared with the prior art, the invention simplifies the production process, improves the production efficiency, lowers the production cost, increases the calcium carbonate content in the ink and can obtain lithographic ink having favorable ink gloss and flowability, thus having broad market prospects.

Owner:茂名阪田油墨有限公司

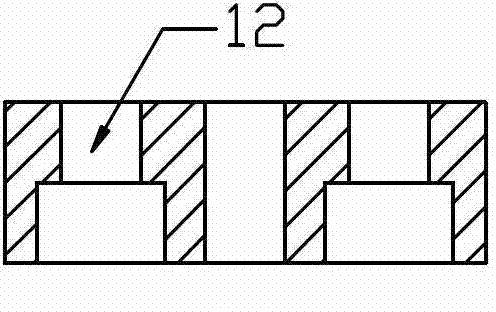

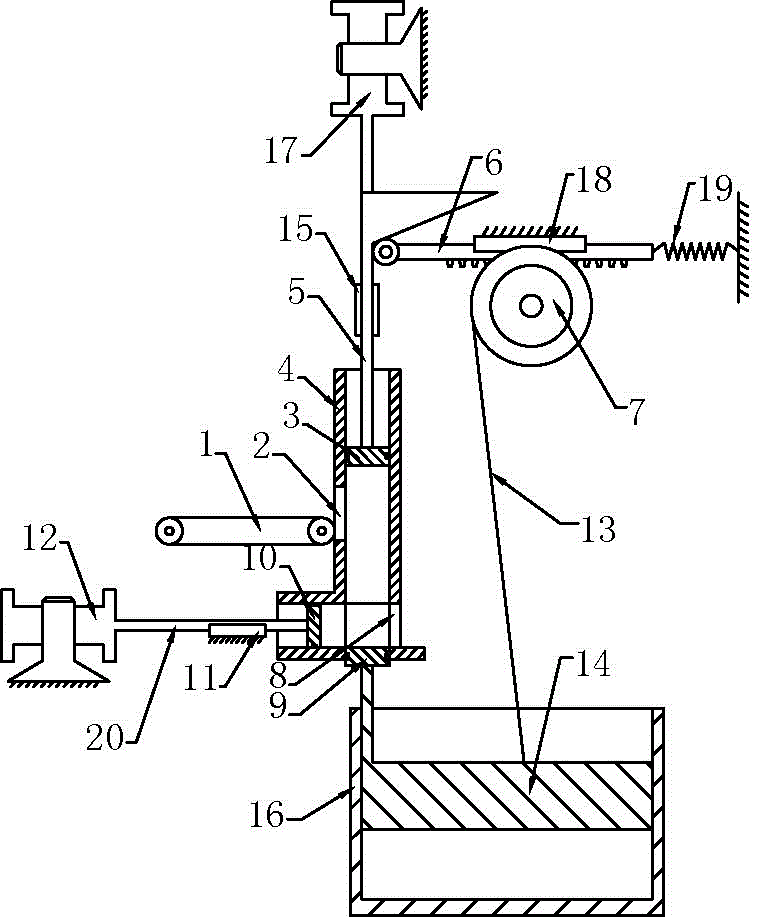

Extrusion device for fertilizer manufacturing

InactiveCN105498891AEasy to GrindReduce grinding timesClimate change adaptationExcrement fertilisersAgricultural engineeringCam

The invention discloses an extrusion device for fertilizer manufacturing. The extrusion device comprises a machine frame, a feed hopper is arranged on the machine frame, an upper pressing plate and a lower pressing plate are connected in the feed hopper in a sliding mode, the upper pressing plate is connected to an upper connecting rod with the top being a wedge surface, the upper connecting rod is connected to an air cylinder and abuts against a first idler wheel, the first idler wheel is connected to a rack, a spring is connected to the side, away from the first idler wheel, of the rack, the rack is meshed with a gear, the gear is connected to a roller, a rope winds around the roller, the lower pressing plate is connected to a lower connecting rod, and the free end of the rope winds around the lower connecting rod; a feed hole is formed in one side of the feed hopper, the bottom of the feed hopper is communicated with a pushing pipe, a discharge hole is formed in the wall of the side, opposite to the pushing pipe, of the feed hopper, a pushing plate is connected in the pushing pipe in a sliding mode and is connected to a pushing rod, and the pushing rod abuts against a cam and is connected to a second spring. The extrusion device for fertilizer manufacturing can improve the crushing efficiency and solve the problem that existing grinding devices are low in grinding efficiency.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

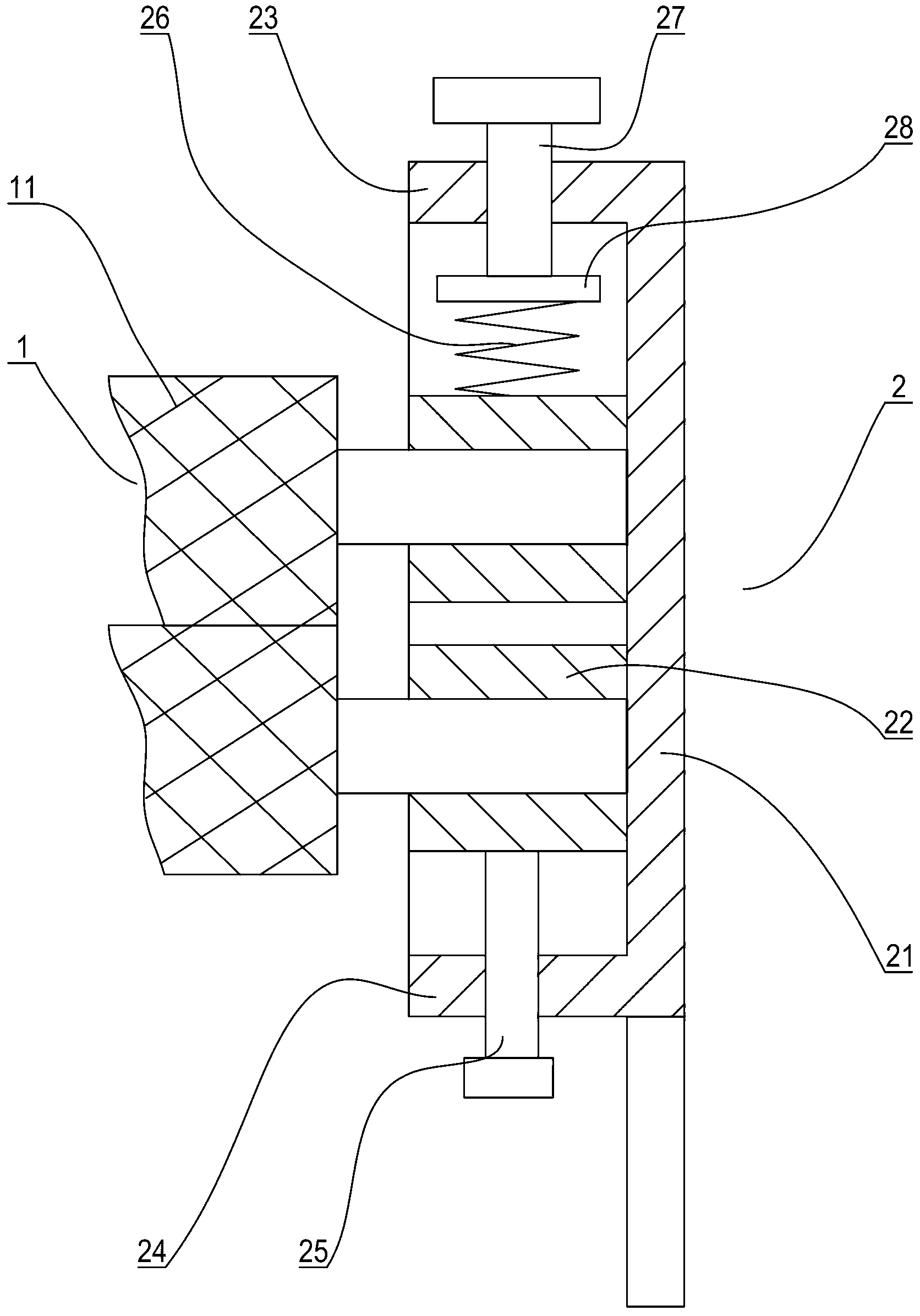

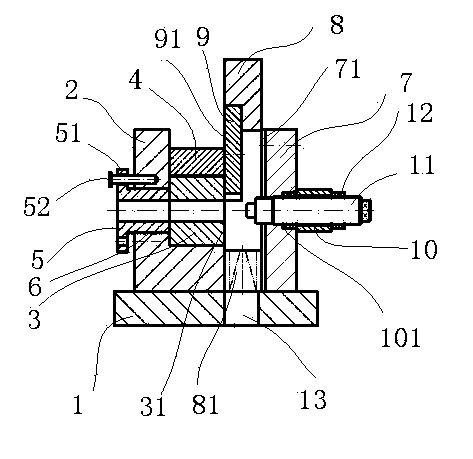

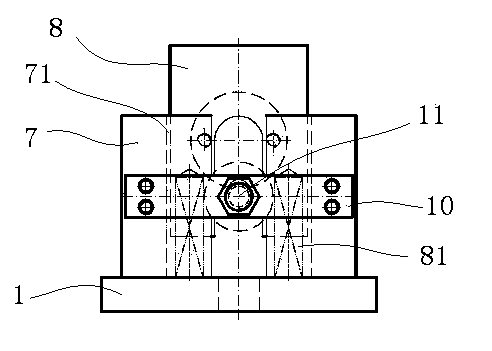

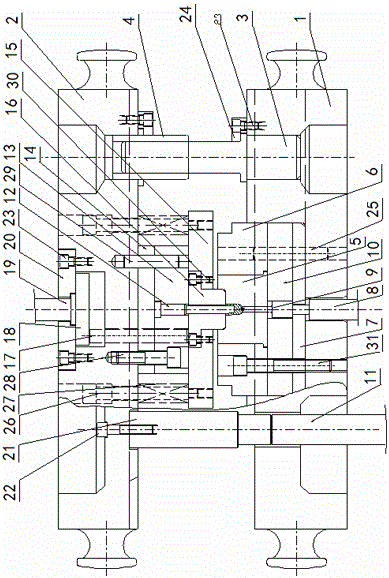

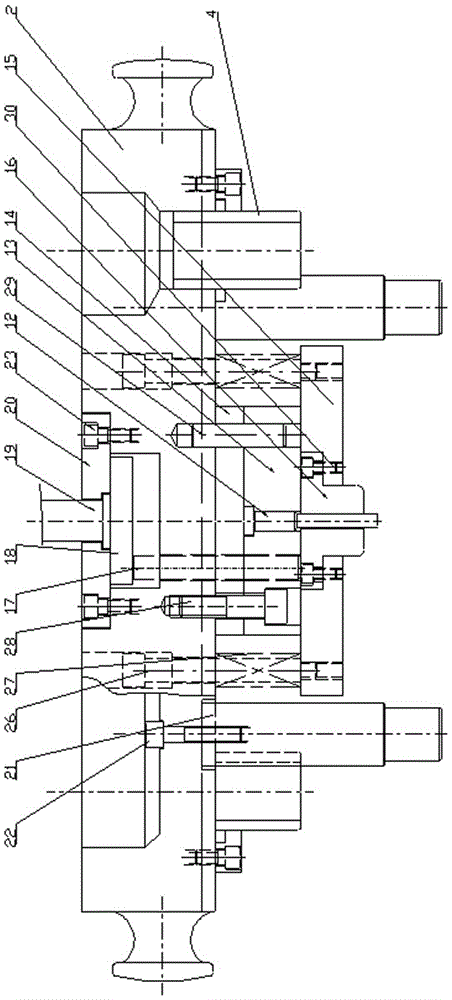

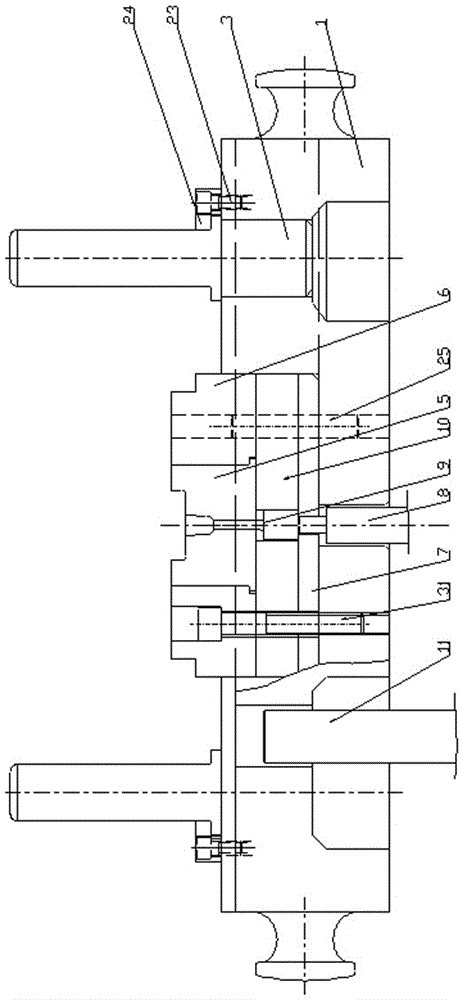

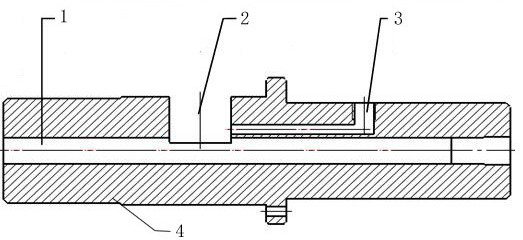

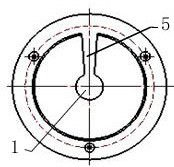

Cold extrusion blanking die for cross shaft blanks

The invention discloses a cold extrusion blanking die for cross shaft blanks. The cold extrusion blanking die comprises a base plate. A die holder is fixed onto the base plate, a lower cutting board is arranged on the die holder and is connected with the die holder by a gland, an adjusting screw tube is abutted to the rear end of the lower cutting board and is matched with an adjusting screw hole in the die holder, and a shoulder of the rear end of the adjusting screw tube is locked by a pin; a guide rail seat is arranged at the front end of the die holder and is fixedly connected with the base plate, guide rails are arranged on the back of the guide rail seat, an upper cutting board is embedded in a movable die plate which is arranged in the guide rails in a sliding fit manner, the outer end of the upper cutting board is in sliding fit with the front end of the lower cutting board, two compression springs are arranged at the lower end of the movable die plate, and the other end of each compression spring is abutted onto the base plate; a back plate is fixedly connected to the front end of the guide rail seat, a regulating screw hole is formed in the middle of the back plate, a blank length control screw is arranged in the regulating screw hole and is locked with the back plate by two locking nuts, and the tail end of the blank length control screw is opposite to the lower cutting board. The cold extrusion blanking die has the advantages that a gap between the upper cutting board and the lower cutting board can be accurately adjusted; a slider of a press machine is prevented from being directly impacted with the upper cutting board, and a vertex position of a bar can be instantly broken; materials can be discharge conveniently, and each cutter of the cold extrusion blanking die is provided with multiple blades.

Owner:WANXIANGQIANCHAO CO LTD +1

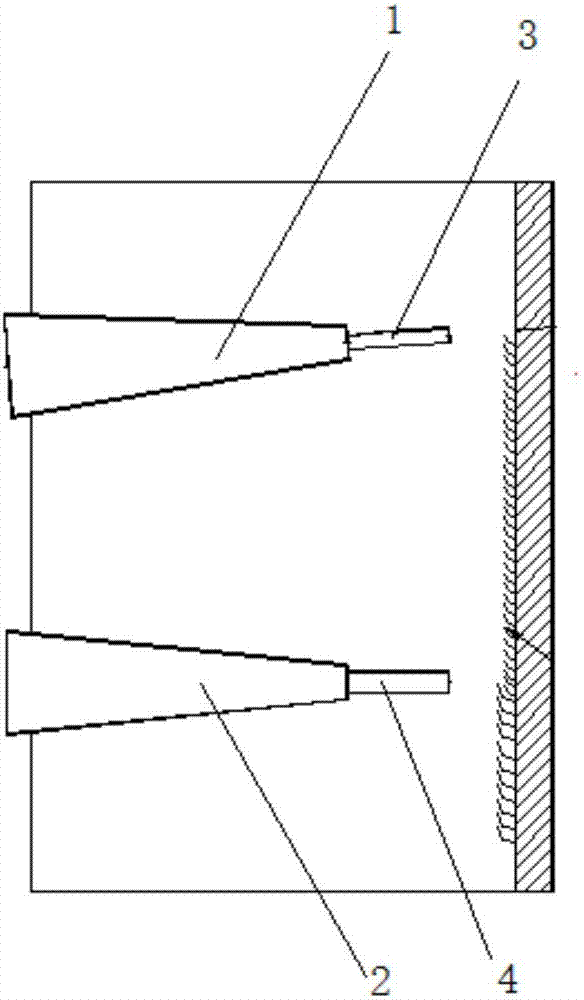

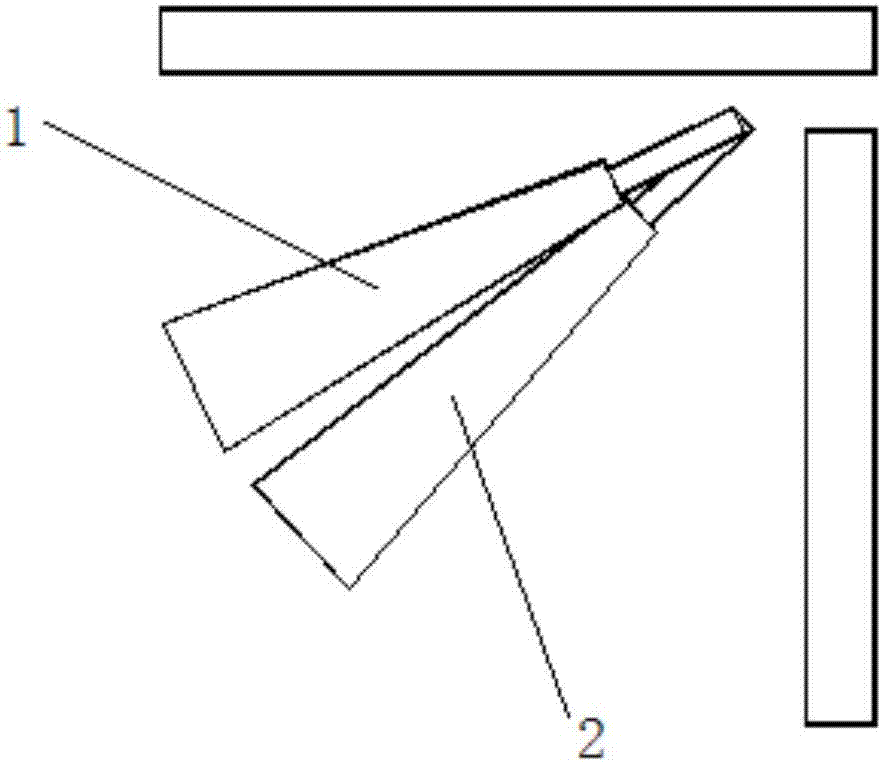

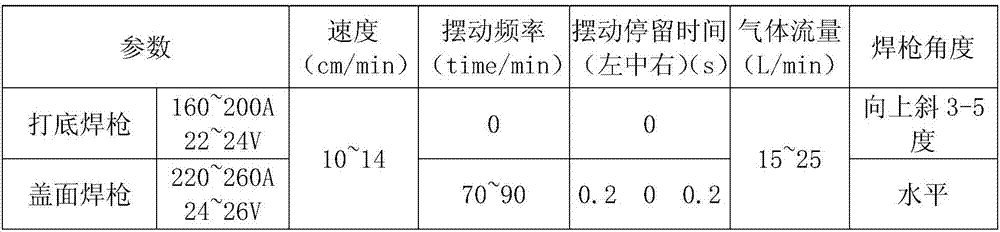

Method for automatically welding double wires through vertical-position fillet welding

InactiveCN106891081AImprove welding efficiencyImprove welding qualityArc welding apparatusFillet weldManufacturing technology

The invention relates to the technical field of shipbuilding, in particular to a method for automatically welding double wires through vertical-position fillet welding. The method is mainly applied to welding through a vertical-position fillet welding joint in the shipbuilding industry (and other steel structure industries), and the middle plate thickness range and the assembly clearance of the vertical-position fillet welding joint reach 10-20 mm and 0-5 mm correspondingly. In the welding process, one vertical-position fillet weld is welded by adopting two welding guns simultaneously; the two welding guns are arranged in an upper-lower manner; the upper welding gun is responsible for backing welding, thereby guaranteeing the fusion of weld base points; the lower welding gun is responsible for swing and cosmetic welding, thereby guaranteeing the weld size and the good formation; and accordingly, a ship-structure vertical-position fillet weld of which the welding foot size is 10-14 mm can be welded efficiently and automatically, the man-hours for welding and grinding of the vertical-position fillet weld in the shipbuilding process as well as the labor intensity can be effectively reduced; and the welding efficiency and quality of the vertical-position fillet weld can be improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

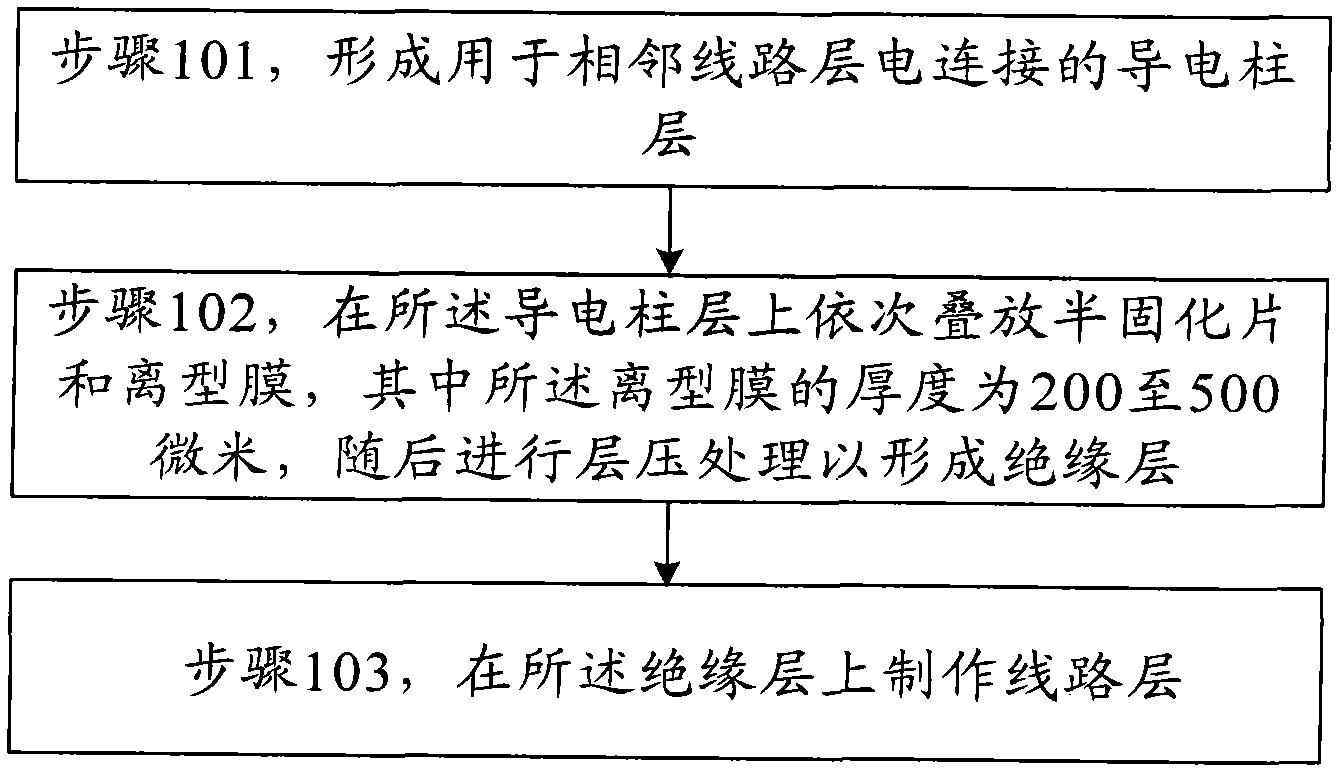

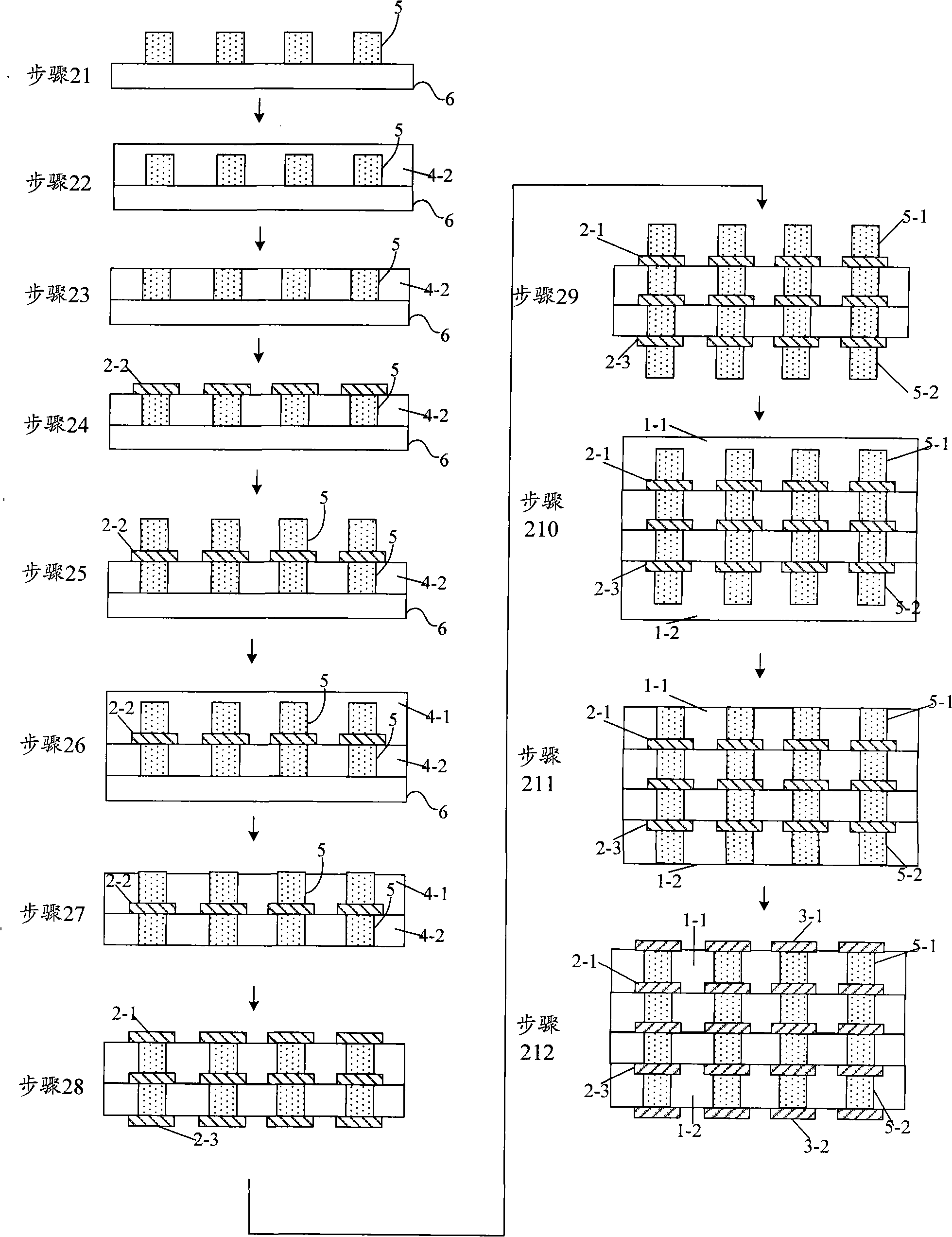

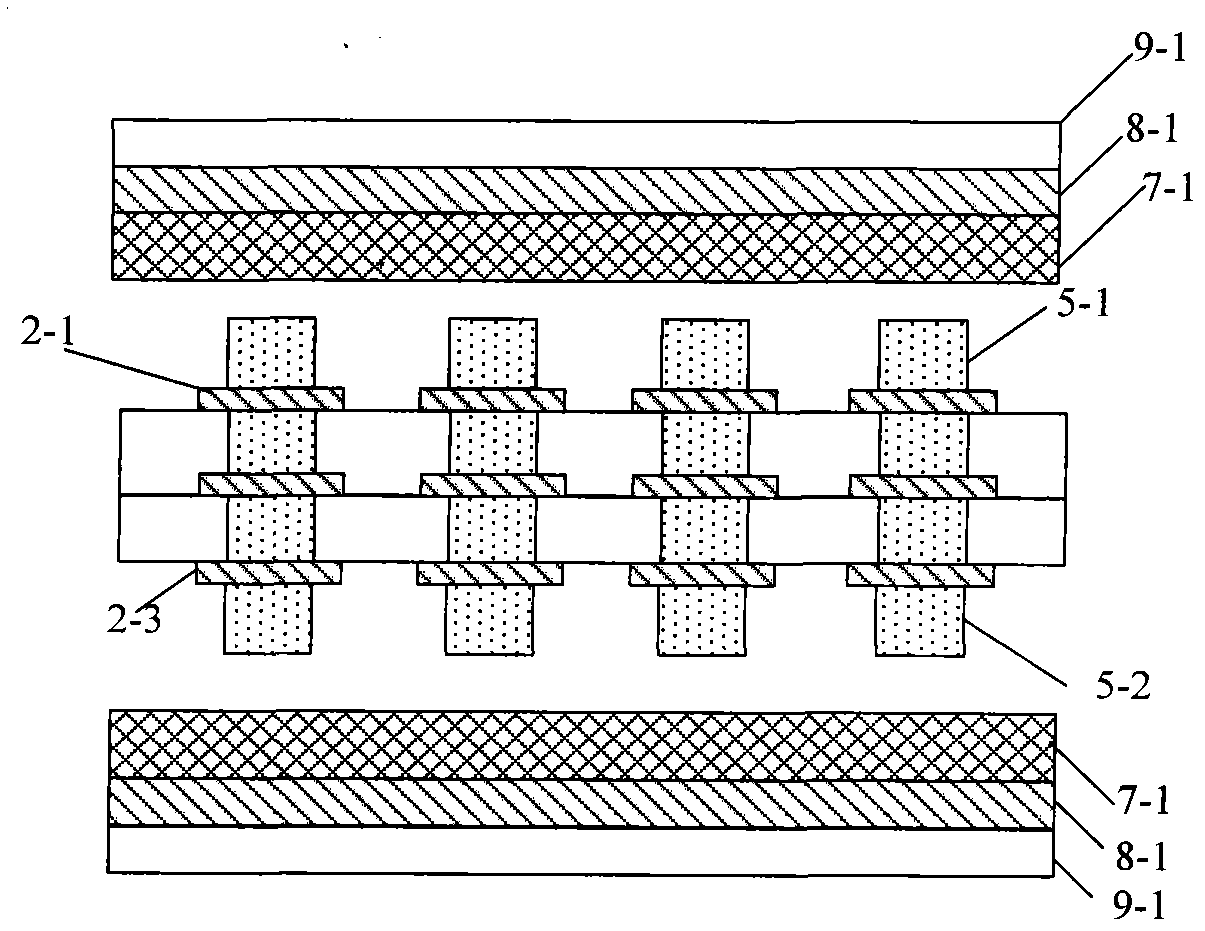

Manufacturing method of multilayer circuit board and laminated structure for multilayer circuit board

ActiveCN102573336AImprove uniformityReduce the number of grindingMultilayer circuit manufactureEngineeringElectrical and Electronics engineering

The embodiment of the invention discloses a manufacturing method of a multilayer circuit board and a laminated structure for the multilayer circuit board, relating to the field of circuit board manufacturing, and being capable of effectively improving the uniformity of the thickness of an insulating layer. The manufacturing method of the multilayer circuit board comprises the following steps of: forming a conductive column layer for electrically connecting adjacent circuit layers; stacking a prepreg and a release film on the conductive column layer in turn, and laminating to form the insulating layer, wherein the thickness of the release film is 200 to 500 microns; and manufacturing a circuit layer on the insulating layer. The manufacturing method can be used for manufacturing the multilayer circuit board.

Owner:新方正控股发展有限责任公司

Extruding device for producing organic fertilizer

InactiveCN105461363AEasy to GrindReduce grinding timesClimate change adaptationExcrement fertilisersEngineeringOrganic fertilizer

The invention discloses an extruding device for producing organic fertilizer. The extruding device comprises a machine frame. A feeding hopper is arranged on the machine frame, an upper pressure plate and a lower pressure plate are connected into the feeding hopper in a slidable mode. An upper connection rod with the top being a wedge face is connected to the upper pressure plate and is connected with a first air cylinder. A rolling wheel abuts against the upper connection rod and is connected with a rack. A spring is connected with one side, away from the rolling wheel, of the rack which is engaged with a gear. The gear is connected with a roller, a rope is wound around the roller, a lower connection rod is connected to the lower pressure plate, and the free end of the rope is wound around the lower connection rod. A feeding opening is formed in one side of the feeding hopper, the bottom of the feeding hopper is communicated with a pushing tube, a discharging opening is formed in the wall of the feeding hopper in one side opposite to the pushing tube, a pushing plate is connected into the pushing tube in a slidable mode, a pushing rod is connected with the pushing plate, and a second air cylinder is connected with one side, away from the pushing plate, of the pushing rod. The extruding device for producing the organic fertilizer can improve the crushing efficiency, so that the problem of low grinding efficiency of existing grinding devices is solved.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

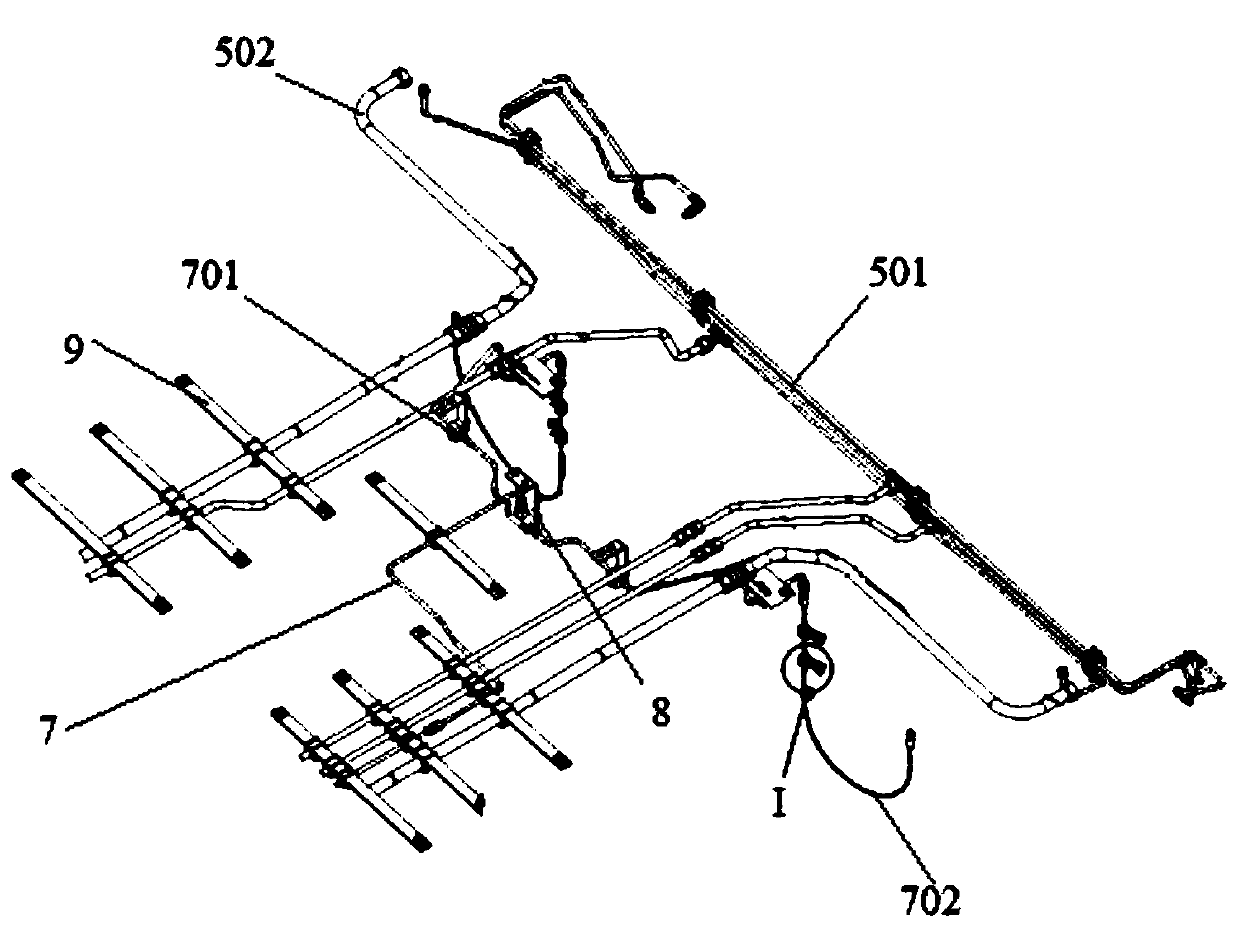

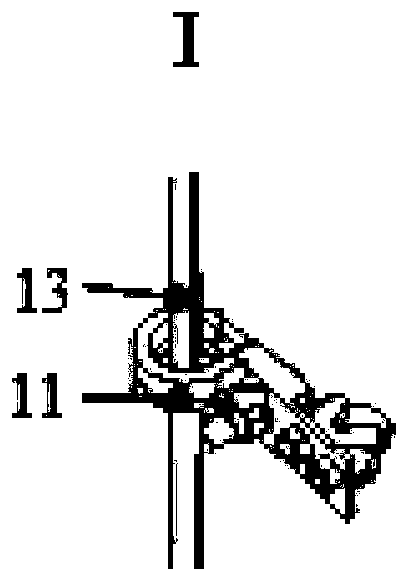

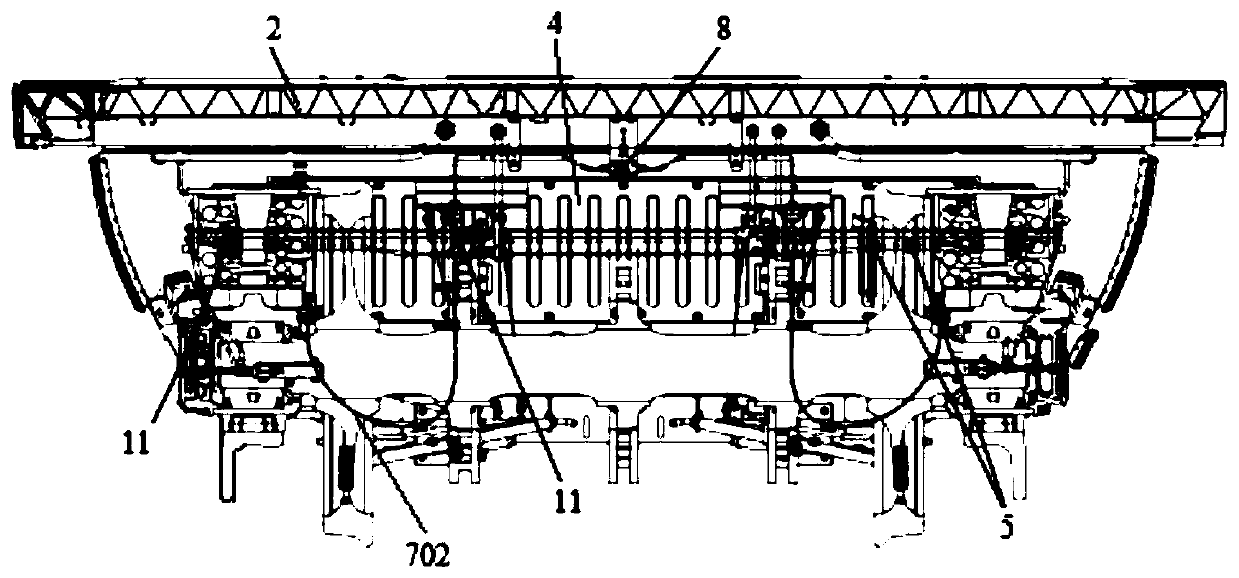

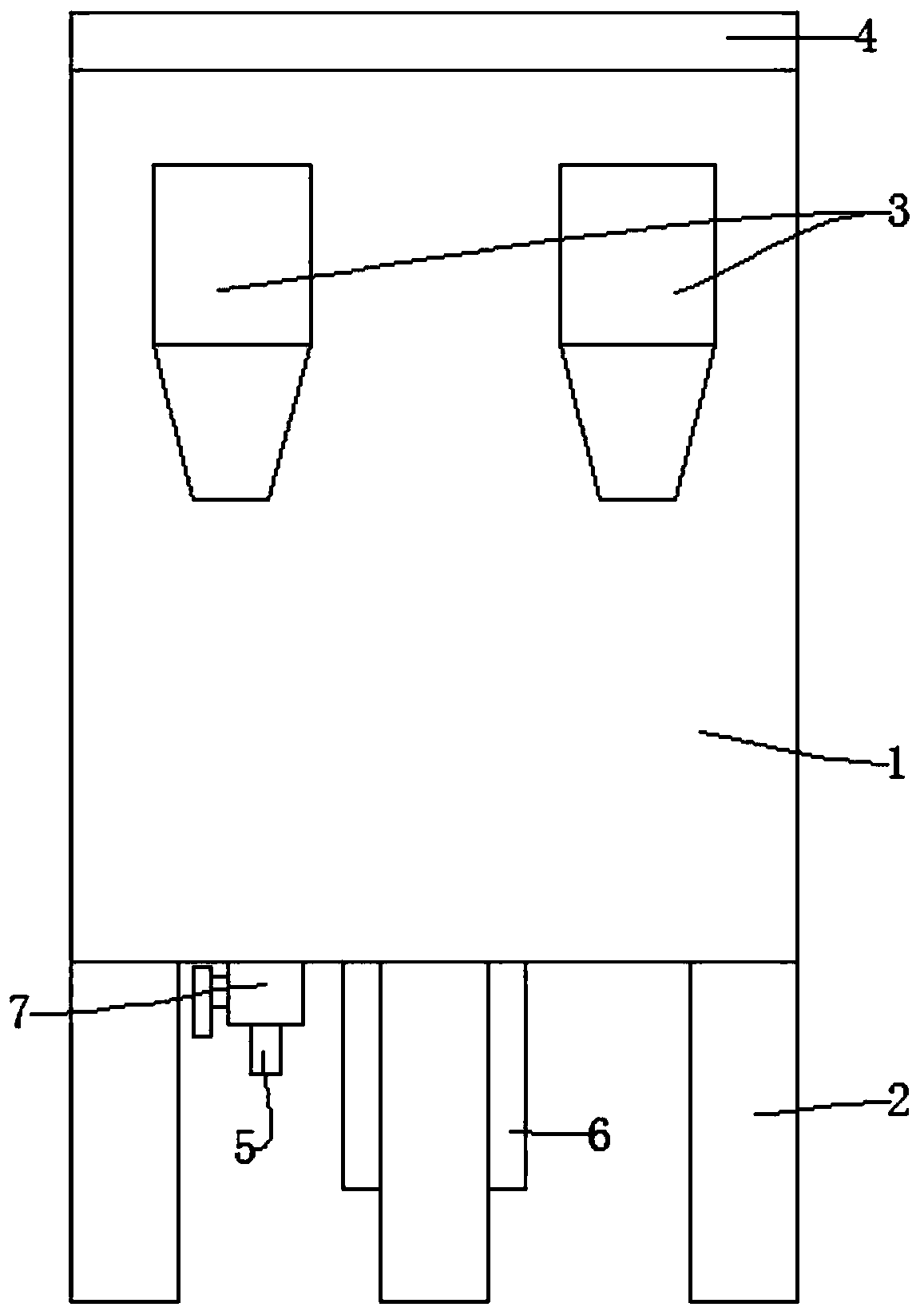

D-series high-speed train and sanding lubrication system

PendingCN109849962AReduce noiseReduce grinding timesRail lubricationRail wetting/lubricationAdhesion coefficientSand blasting

The invention discloses a d-series high-speed train and a sanding lubrication system. The sanding lubrication system is used in the d-series high-speed train, the sanding lubrication system comprisesa sand box, a sanding pipe, a sand blasting nozzle, a lubricant supply device, a lubrication pipe and an oil nozzle. When the d-series high-speed train needs to be braked, materials in the sand box are transferred to the sand blasting nozzle through the sanding pipe and scattered to a wheel through the sand blasting nozzle, and the adhesion coefficient between wheeltracks is improved. When the abrasion of a wheel rim needs to be reduced, the lubricant supply device transports a lubricant to the oil nozzle through the lubrication pipe, and the lubricant is sprayed to the wheel rim through the oil nozzle, the abrasion of the wheel rim is reduced, the number of times of grinding of the wheel is reduced, the maintenance cost is reduced, meanwhile, noise of the d-series high-speed train in curves and tunnels is reduced, and the risk of the wheel disengaging from tracks is reduced. In conclusion, according to the d-series high-speed train and the sanding lubrication system, the wheel abrasion of the d-series high-speed train is reduced, and the sliding probability of the d-series high-speed train during braking is reduced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Machining method for toothed long cutter applicable to glasses cloth cutting

The invention discloses a machining method for a toothed long cutter applicable to glasses cloth cutting and belongs to the technical field of mechanical blades. The machining method comprises the steps that (1) raw materials are prepared; (2) annealing is conducted, specifically, the temperature of annealing is 830-860 DEG C, a heat preserving furnace is cooled to 720-740 DEG C, heat preserving is conducted, cooling with a furnace is conducted again till the temperature reaches 500-530 DEG C, and the raw materials are taken out from the furnace and subjected to air cooling; (3) blank forging and rough machining are conducted; (4) heat treatment is conducted, specifically, annealing is conducted, that is, the long cutter is subjected to annealing again before quenching and heated to the temperature of 600-630 DEG C, after heat preserving, cooling with the furnace is conducted till the temperature reaches 500 DEG C, and the long cutter is taken out from the furnace and subjected to air cooling; quenching is conducted, that is, the toothed long cutter is heated to the temperature of 620-660 DEG C for the first time, subjected to heat preserving for 0.5-1 h, then preheated for the second time, heated up to 820-860 DEG C, subjected to heat preserving again for 0.5-1.5 h, finally heated up to 1000-1050 DEG C, taken out from the furnace and subjected to oil quenching; and tempering is conducted, that is, the toothed long cutter is subjected to tempering at the temperature of 550-560 DEG C for the first time, heat preserving is conducted, then tempering is conducted at the temperature of 560-570 DEG C for the second time, and the toothed long cutter is cooled and taken from the furnace after heat preserving; and (5) finish machining is conducted. The properties of the prepared toothed long cutter can meet the cutting requirement of a glasses cloth, and the obtained glass cloth is good in appearance quality.

Owner:MAANSHAN WEIMA MACHINERY EQUIP

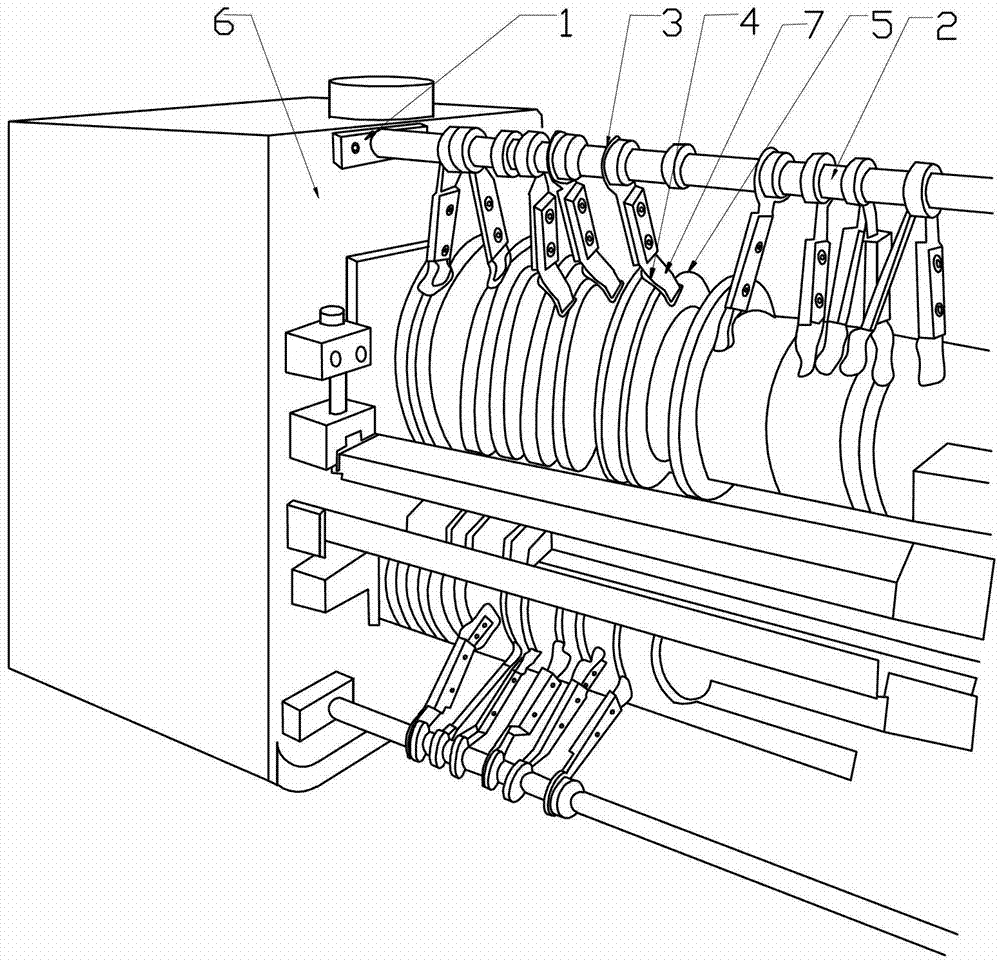

Auxiliary mechanism on disk slitting machine

ActiveCN102825332AExtended service lifeEasy to makeShearing machinesShearing machine accessoriesCircular discEngineering

The invention discloses an auxiliary mechanism on a disk slitting machine. A bracket with a plurality of blades extending to a disk blade group is mounted on a tool apron of the disk slitting machine; an elastic element and a flexible hygroscopic material are arranged on the bracket; and an elasticity direction of the elastic element enables the flexible hygroscopic material to lean against the cutting end faces of the blades. With the adoption of the auxiliary mechanism on the disk slitting machine, the quality of edges of copper and copper alloy strips in a slitting procedure is improved, the service life of the blades of the disk slitting machine is prolonged, and the color changing problem of the end face of a product is improved, and so on.

Owner:北京金鹏振兴铜业有限公司

Production method for violet offset ink

The invention relates to the technical field of printing ink, in particular to a production method for violet offset ink. The production method comprises the following steps: 1, wetting; 2, displacing; 3, dehydrating; 4, thinning; 5, filling; 6, adjusting viscosity. According to the production method, a permanent violet pigment is wet through water to reduce the surface tension of the pigment, so as to realize a better wetting effect. In addition, through the better wetting effect, the dispersion of the pigment in a binder can be improved, and the milling time of the violet offset ink is greatly shortened. In the production method, tap water is used as a pigment wetting agent, compared with a method adopting soft water, the acquired effects are the same, while tap water is easy to obtain and low in cost, so that the production cost is reduced by using the tap water as the wetting agent. The production method has the characteristics of being simple to operate, low in cost and high in production efficiency.

Owner:茂名阪田油墨有限公司

Device and method for mixing silicon monoxide composite negative electrode materials

InactiveCN109126598AVersatileReduce the number of grindingTransportation and packagingMixersMixed approachEngineering

The invention discloses a device for mixing silicon monoxide composite negative electrode materials. The device comprises a mixing barrel and a plurality of legs. The legs are fixedly mounted at the lower end of the mixing barrel, a cover is detachably mounted at the upper end of the mixing barrel, feed hoppers are fixedly mounted on the side walls of the mixing barrel, a liquid outlet pipe and astirring motor are fixedly mounted on the lower surface of the mixing barrel, and a control valve is mounted on the liquid outlet pipe. The device and a method for mixing the silicon monoxide composite negative electrode materials have the advantages that mixed raw materials can be ground by the aid of the device and the method in procedures for mixing the mixed raw materials for the silicon monoxide composite negative electrode materials, and the device has abundant functions; the frequencies for individually grinding the mixed raw materials in follow-up procedures can be reduced, accordingly, the integral silicon monoxide composite negative electrode material production cycle can be shortened, the production cost can be reduced, and the device and the method are good in practicality.

Owner:于珊

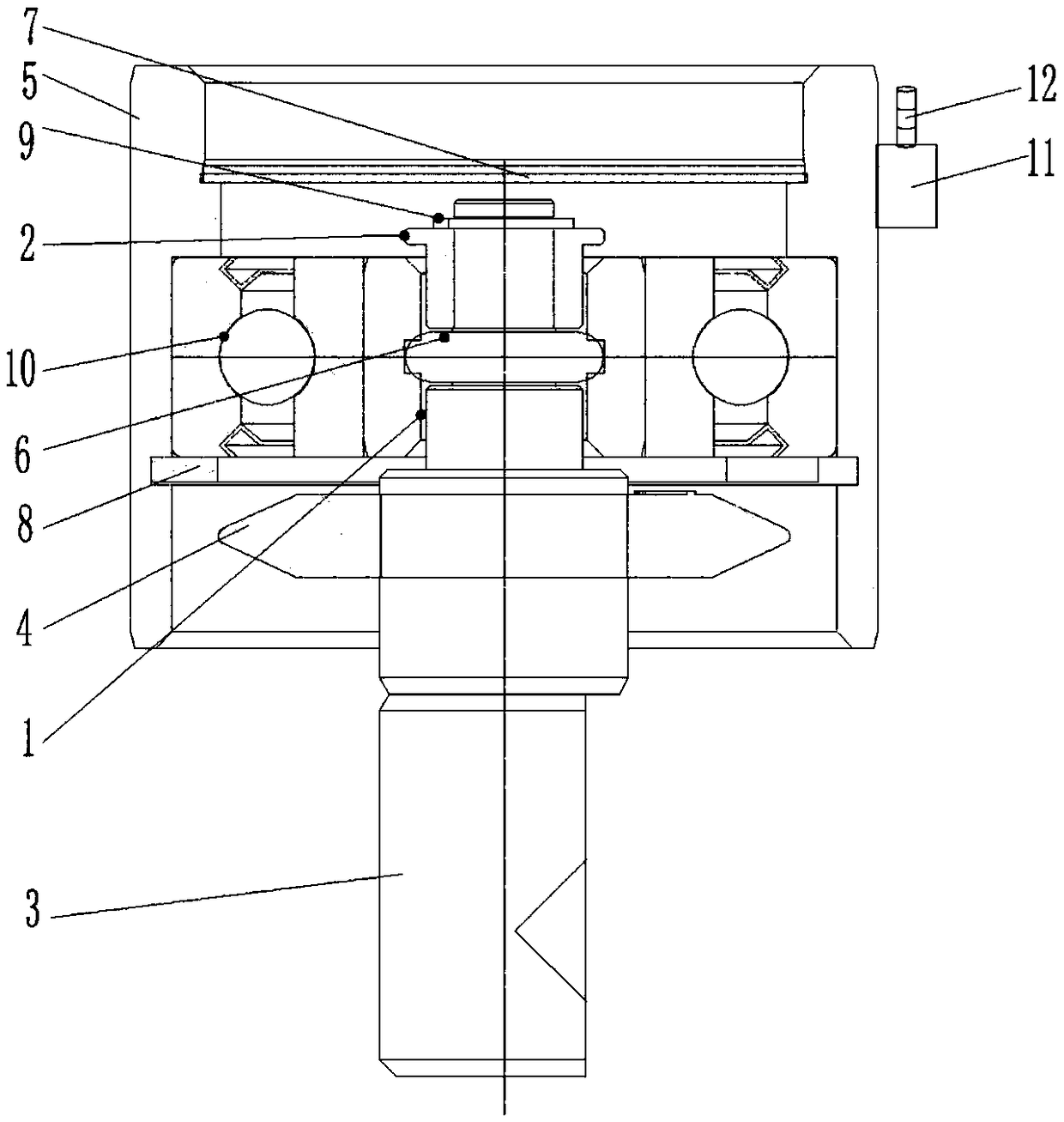

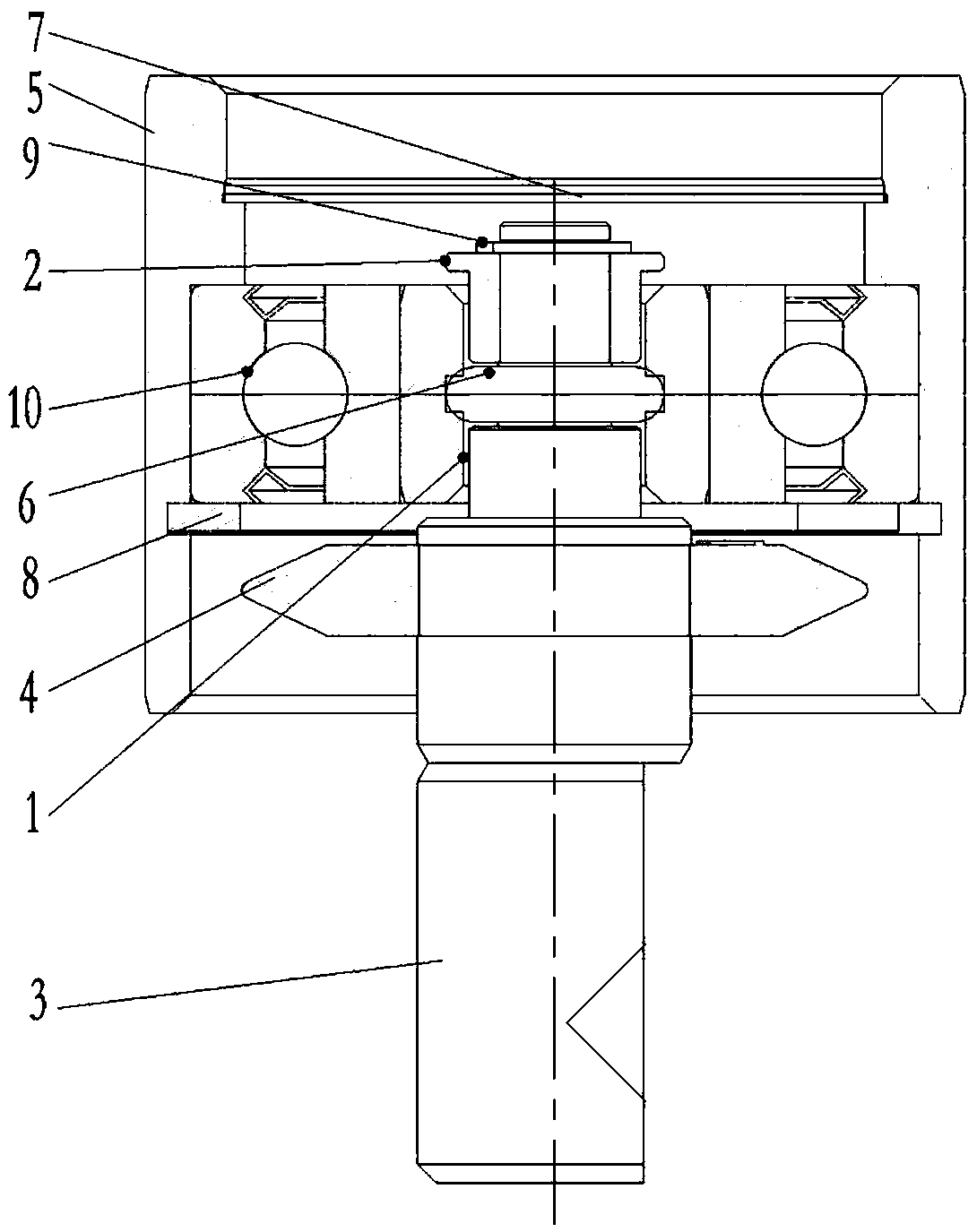

Safety roller for spinning machine drafting mechanism

The invention discloses a safety roller for a spinning machine drafting mechanism, and mainly relates to the technical field of textile machinery. A bearing inner sleeve is integrally nested in an outer sleeve, a bearing is nested in the outer sleeve, and the two ends of the bearing abut against the outer sleeve and a first check ring respectively; a dust cover is clamped in the outer sleeve; a detection mechanism is arranged on one side of the outer sleeve, the detection mechanism comprises a temperature sensor, a humidity sensor and a smoke sensor; an automatic alerter is connected to the top of the detection mechanism; a protection layer is arranged on the surface of a shaft and composed of an acid-base corrosion resistance layer, a high temperature resistance layer and a wear resistance layer. The roller can perform enough compensation, the sealing property is good, the service life is long, the application arrange is wide, the safety is good, and it is guaranteed that spinning isperformed with high quality for a long time.

Owner:苏州益垚精密机械有限公司

Use method of extrusion device used for manufacturing organic fertilizer

The invention relates to the field of extrusion devices, and discloses a use method of an extrusion device used for manufacturing organic fertilizer. The method includes the following use steps that A, the position is adjusted; B, materials are put in; C, the materials are extruded; D, the materials are transferred; E, the materials are pushed; and F, a material pushing plate resets. The invention aims at providing the use method which can improve crushing efficiency and is used for the extrusion device used for manufacturing the organic fertilizer, and therefore the problem that an existing grinding device is low in grinding efficiency is solved.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

Preparation method of producing high-concentration kaolin planographic printing ink by adopting secondary kneading method

The invention relates to the technical field of planographic printing ink, in particular to a preparation method of producing high-concentration kaolin planographic printing ink by adopting a secondary kneading method. The preparation method comprises the following specific steps: mixing mixed base ink, pigment connecting materials, friction-proof auxiliaries and ink oil, wherein the mixed base ink adopts secondary kneading technique, high-concentration kaolin and moisture-containing tinting pigment are added for first-time kneading, and soft water is added for secondary kneading after the replacement and dewatering are conducted. Compared with the prior art, according to the preparation method, the production technique is simplified, the production efficiency can be improved, the problems of declining qualities such as the brightness, flowability of the ink, and the like can also be stopped even if the content of the kaolin in the ink is increased, so that the addition amount of the kaolin with lower cost can be increased, the planographic printing ink with good dispersity and excellent brightness and flowability properties can be prepared, the production cost can be further lowered, thereby having better market prospects.

Owner:茂名阪田油墨有限公司

Shaving cutter profile modifying method based on involute key point

ActiveCN107378646AHigh shaping efficiencyKeep the correct and valid partGeometric CADPlaning/slotting toolsEngineeringGear tooth

The invention discloses a shaving cutter profile modifying method based on an involute key point. The method comprises the steps of determining key points in a gear tooth form to be profile-modified, and obtaining the developed length of each key point and the drum-shaped size between a tooth-formed inclined angle and the adjacent key point; calculating vertical coordinates and horizontal coordinates of the key points of a shaving cutter to be profile-modified; determining the profile-modified length, the tooth-formed inclined angle and the profile-modified drum-shaped size between each two adjacent key points; and finally using a shaving cutter grinding machine tool for polishing the shaving cutter. According to the method, profile modifying parameters can be calculated aiming at the practical situations of the shaving cutter, a correct part in the shaving cutter is effectively remained, and only part of meshed teeth to be profile-modified needs to be profile-modified, so that the profile modifying efficiency and the accurate rate of the shaving cutter are improved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

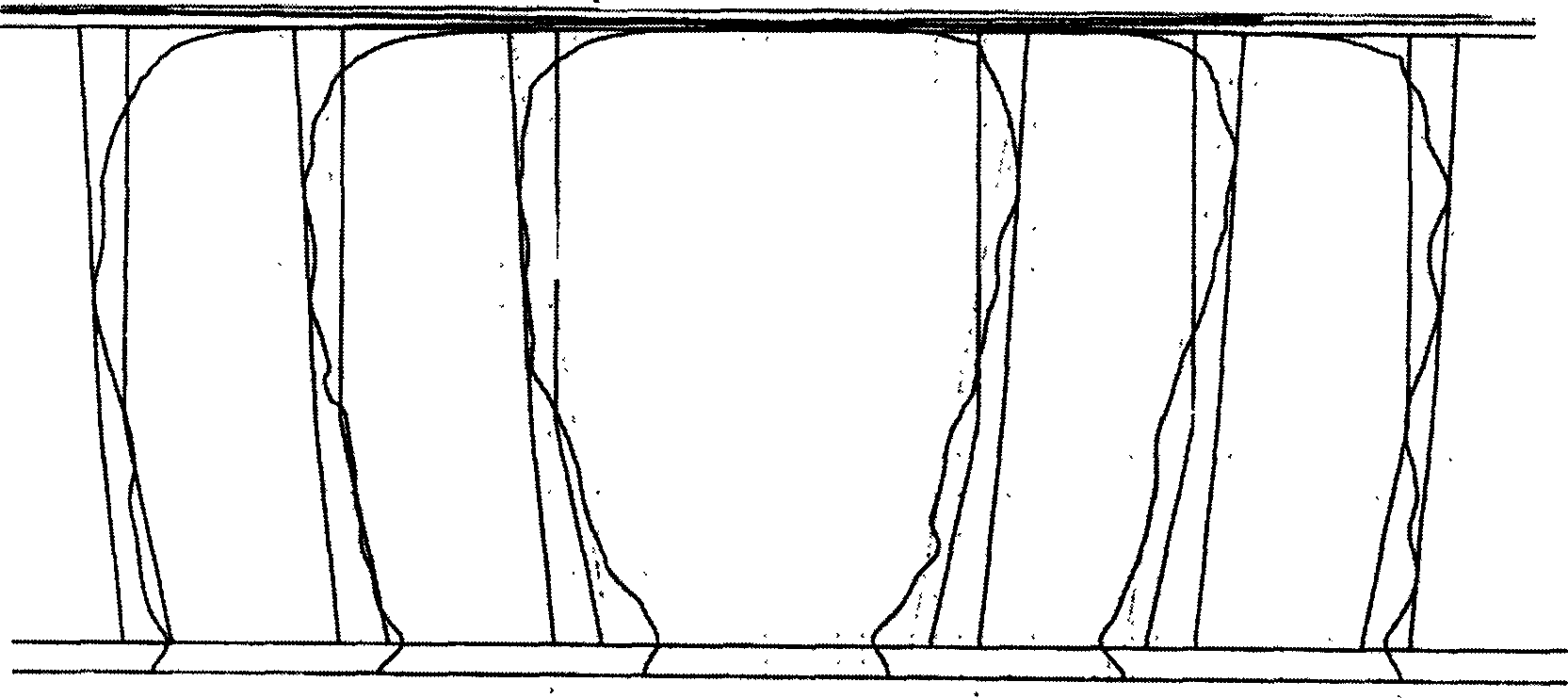

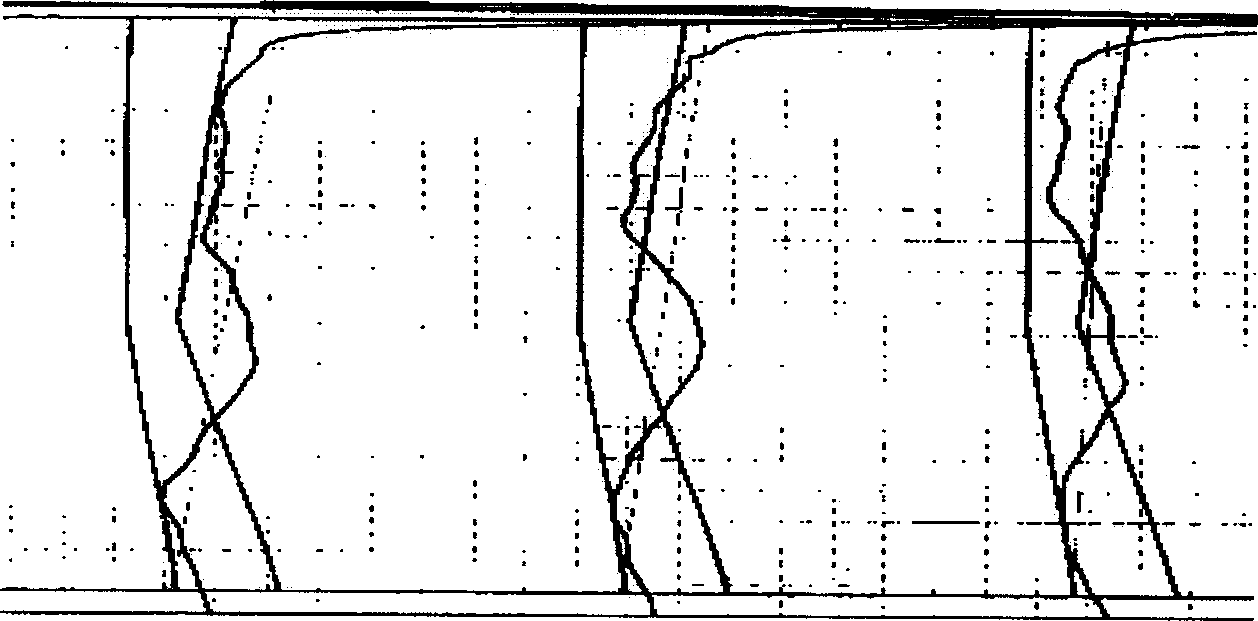

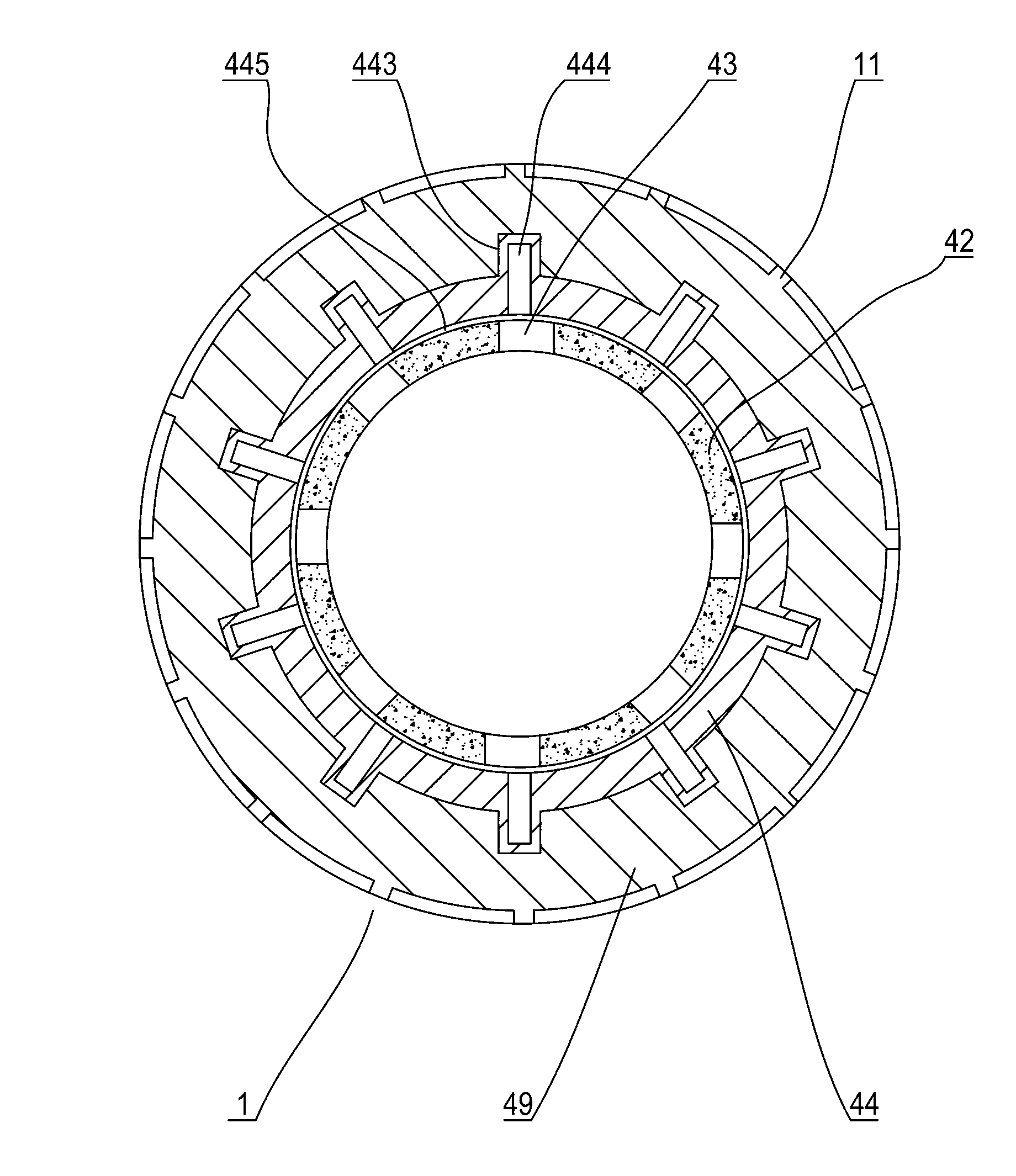

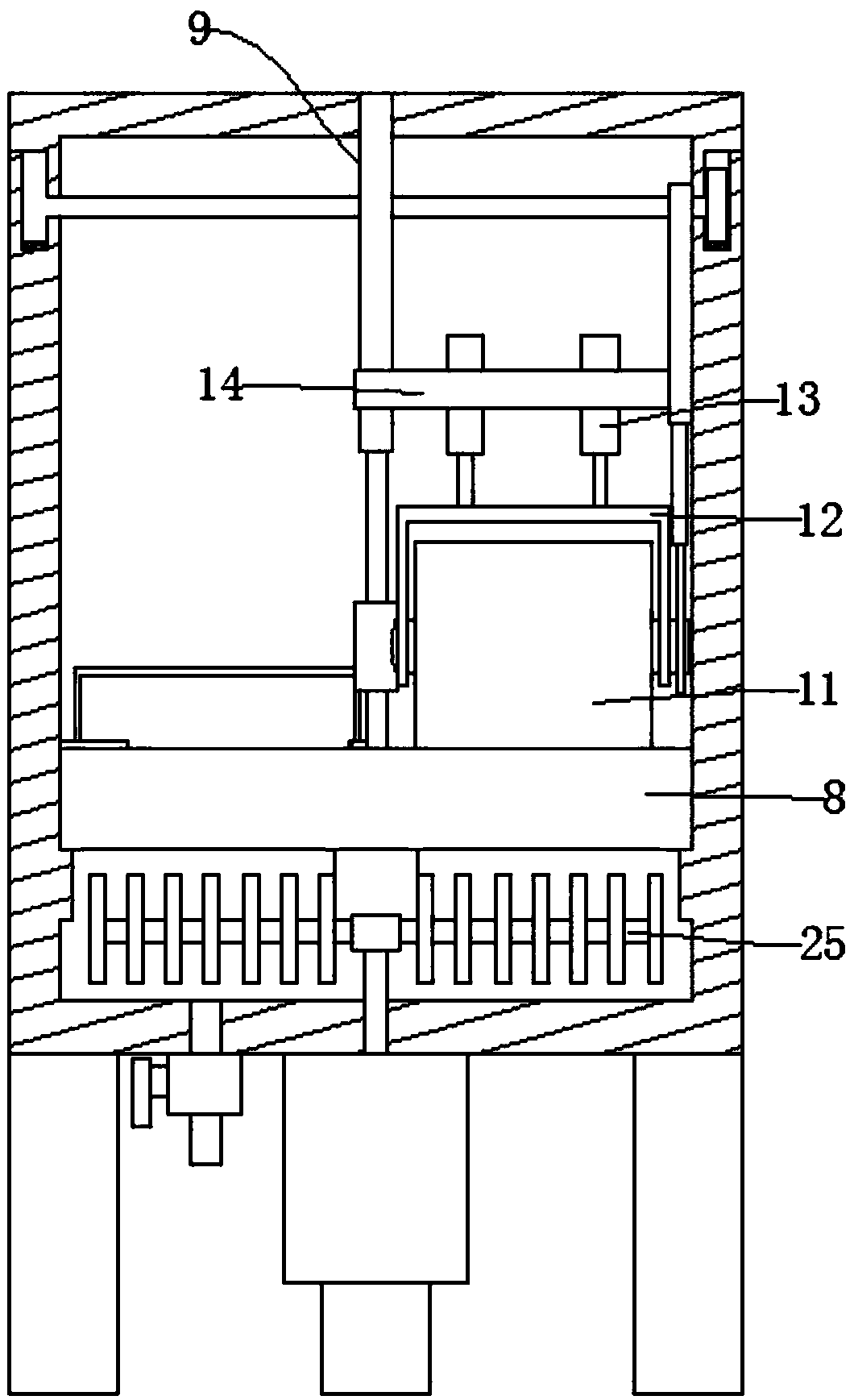

Grinder for automobile transmission gears

InactiveCN107662031AReduce grinding timesGuaranteed identityGrinding carriagesGrinding bedsBristleEngineering

The invention discloses a grinder for automobile transmission gears, which comprises a frame, a connecting rod, a main grinding head, two pressure plates and a motor. A central shaft is fixed on the frame, and an annular groove is opened on the central shaft. A spacer and a plurality of side grinding heads are alternately set in the annular groove, and two nuts are set in the annular groove and matched with the thread. There are a plurality of screw holes on the inner walls of the two sides of the frame, and the pressure plate is connected with the screw through the screw. The fit of the screw holes is fixed on the frame, and the two ends of the connecting rod are respectively rotated and set on the pressure plate. The side grinding head is composed of an interconnected connecting plate and a circular brush plate. There are adjustment holes, steel bristles are provided on the two side walls of the brush plate, multiple gears are sleeved on the central shaft, and a single gear is located between two adjacent brush plates. The inventor improves the grinding structure so that multiple gears can be ground at the same time, and the tooth surface and two end surfaces of the gear can be polished at the same time, which shortens the grinding time of the gear.

Owner:CHONGQING ZHANRUI AUTOMOBILE FITTING FACTORY

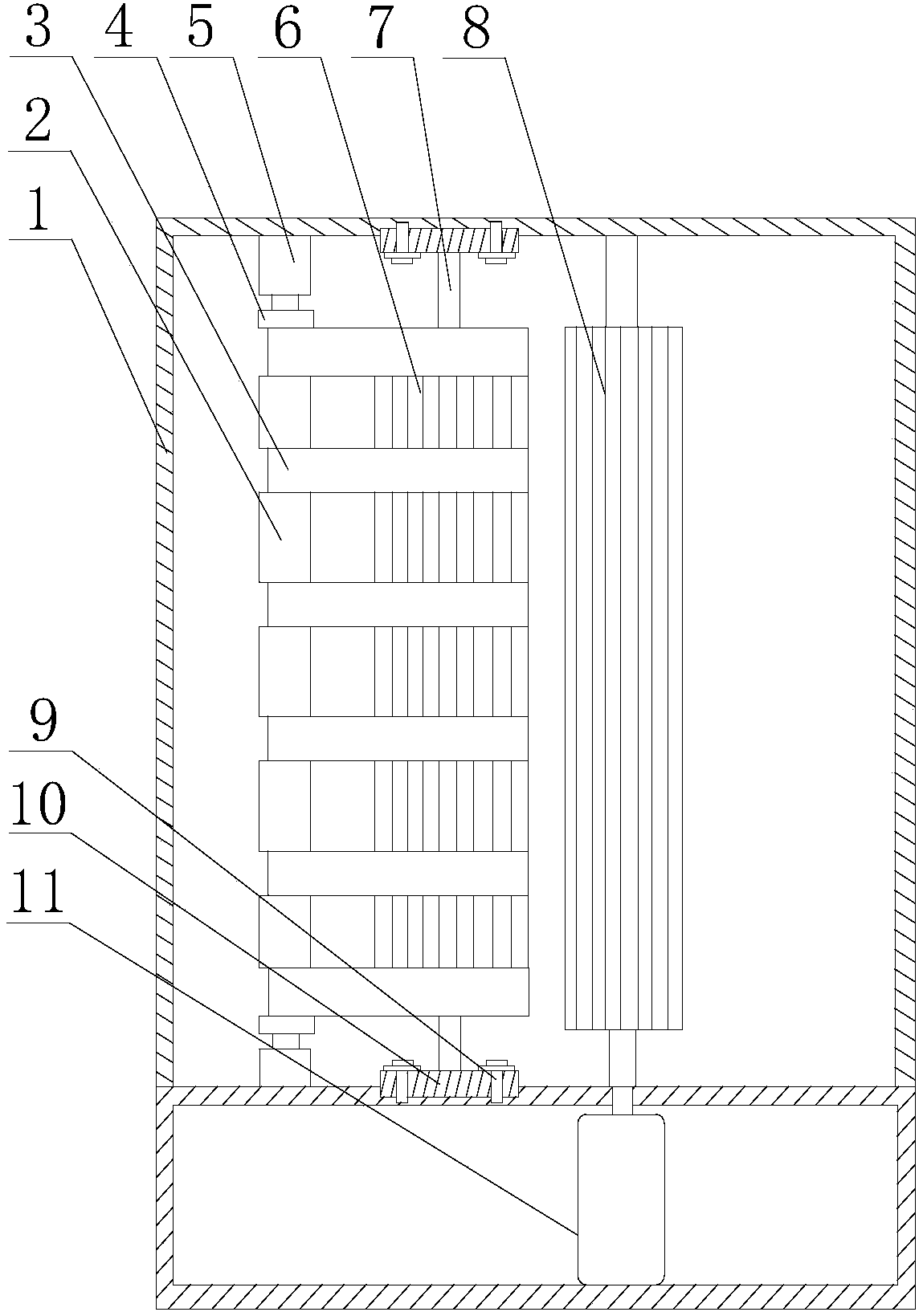

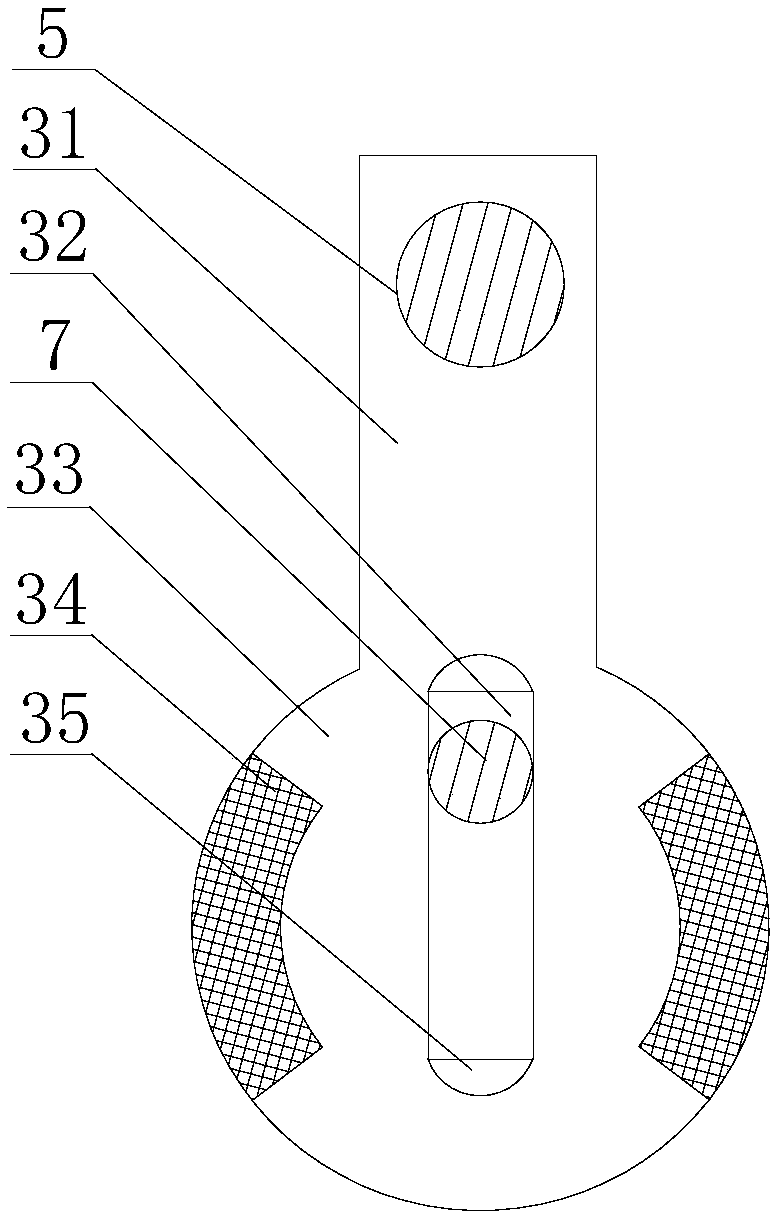

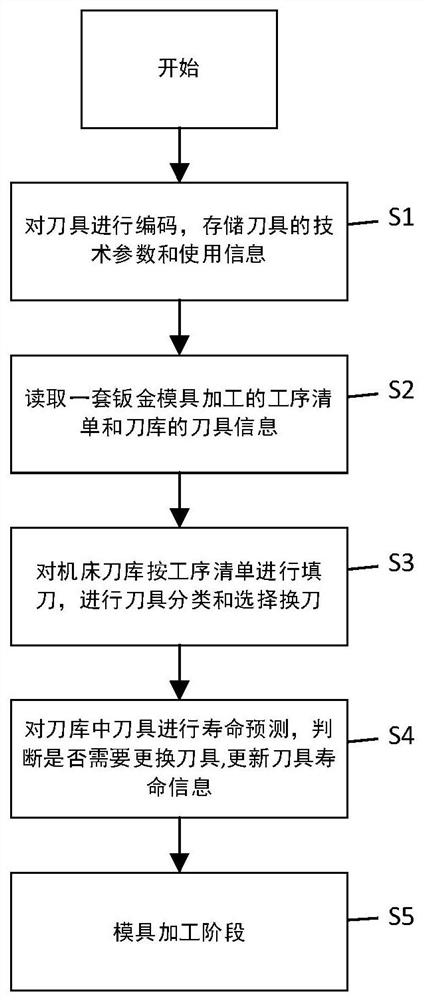

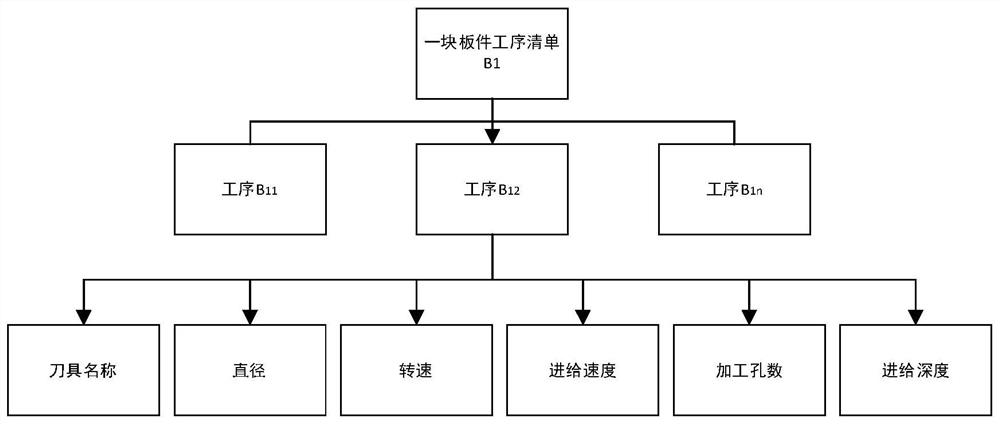

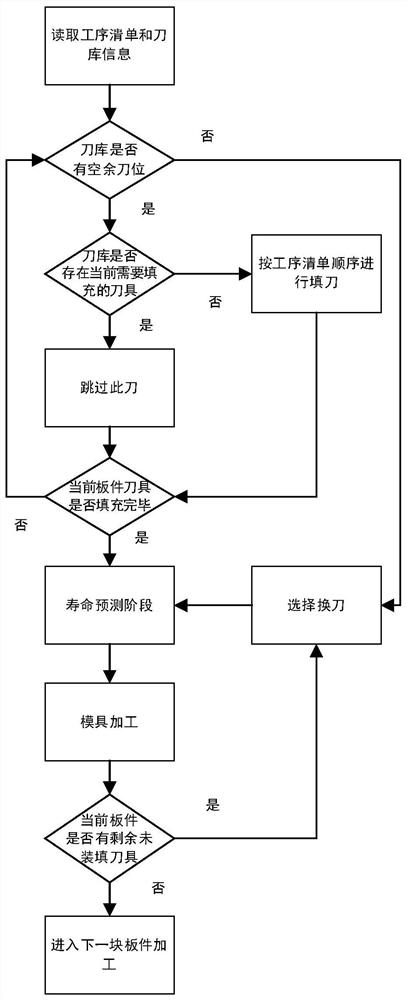

Tool management method for drilling machining of complete set of sheet metal mold

ActiveCN112536457AReduce tool change timeImprove processing efficiencyPositioning apparatusBoring/drilling componentsMetal moldMachine tool

The invention discloses a tool management method for drilling machining of a complete set of sheet metal mold. Tool filling is carried out on a tool magazine of a machine tool according to a process list, tool filling is finished if the tool magazine tool position is full or the tools required by a current plate are completely filled, after tool filling, if the tools which do not fill exist in thecurrent plate, grading is carried out on the tool magazine and the residual tools, then selective tool changing for the tool magazine is completed; service life predicting is carried out on the toolsaccording to the tool use information in the processing list, whether the tools has the service life or not is judged, whether the tools need to be replaced or not is judged, then the service life information of the tools is updated; entering a mold machining stage is carried out, and if the tools which do not fill exist in the current plate, returning is carried out for selective tool changing;and if the current plate is not provided with the residual tools which do not fill, the machining of the current plate is finished, and entering the machining of the next plate is carried out. According to the tool management method for drilling machining of the complete set of sheet metal mold, the tool management method is constructed, efficient and reasonable configuring is carried out on the drilling tools, and therefore during mold machining, the preparation time of CNC tool changing is shortened, the CNC drilling efficiency is improved, and the production cost of mold machining is reduced.

Owner:绍兴市上虞区武汉理工大学高等研究院 +1

Stamping die for welded electrode cap manufacturing

InactiveCN106216525AHigh dimensional accuracyImprove consistencyShaping toolsMachining processCushion

The invention relates to a stamping die for welded electrode cap manufacturing. The die comprises an upper die body and a lower die body. The upper die body comprises an upper baseplate, a guiding sleeve, a male die body, a male die body fixing plate, a male die body bolster, an upper stripper fixing plate, an upper stripper, an upper stripping rod, an upper stripping plate, an upper knockout rod, an upper cover plate, an upper pushing rod, a first screw, a second screw, a stripping screw, a high-strength spring, a third screw, a pin and a fourth screw. The low die body comprises a lower baseplate, a guiding post, an inner female die, an inner female die fixing block, a female die bolster, a lower pushing rod, a lower ejecting rod, a female die cushion block, a lower mandril, a pressing plate, a pin and a screw. According to the die, the flaws that materials are wasted, dimension consistency is bad, and production efficiency is low in the machining process of a traditional production technology are overcome.

Owner:长春吉文汽车零部件有限公司

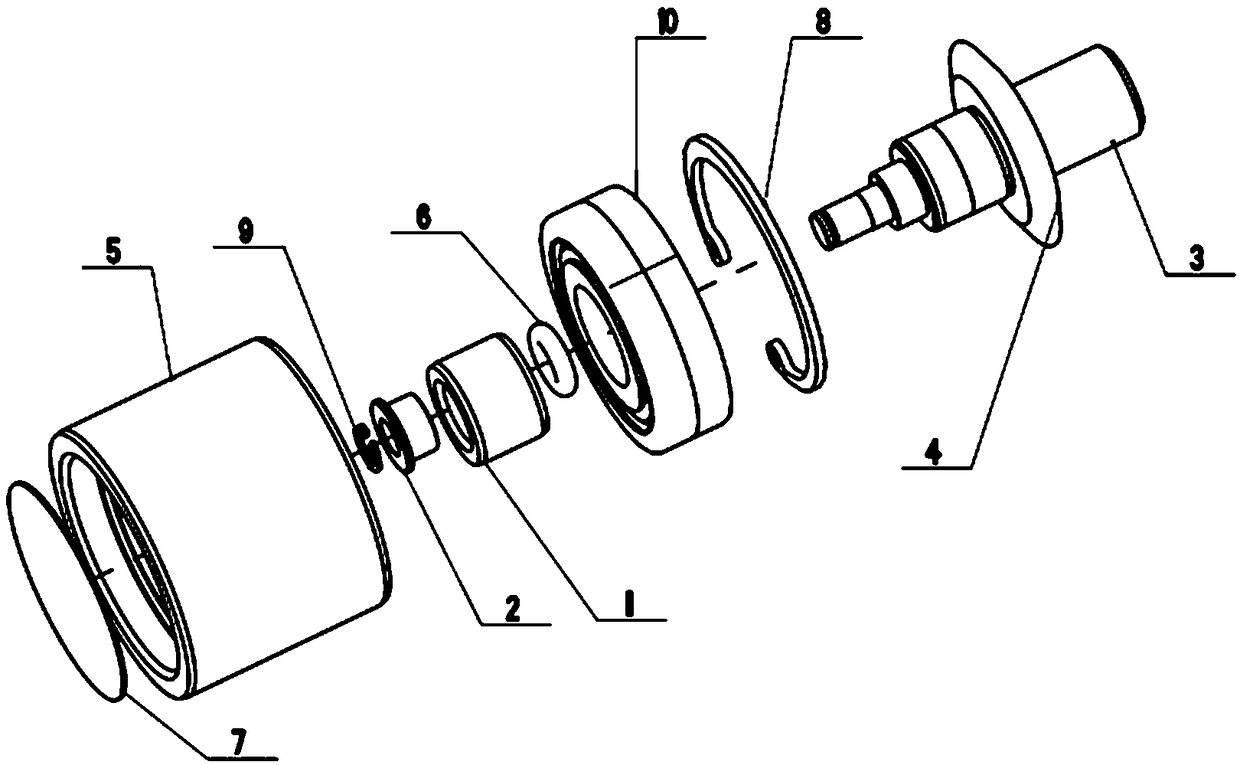

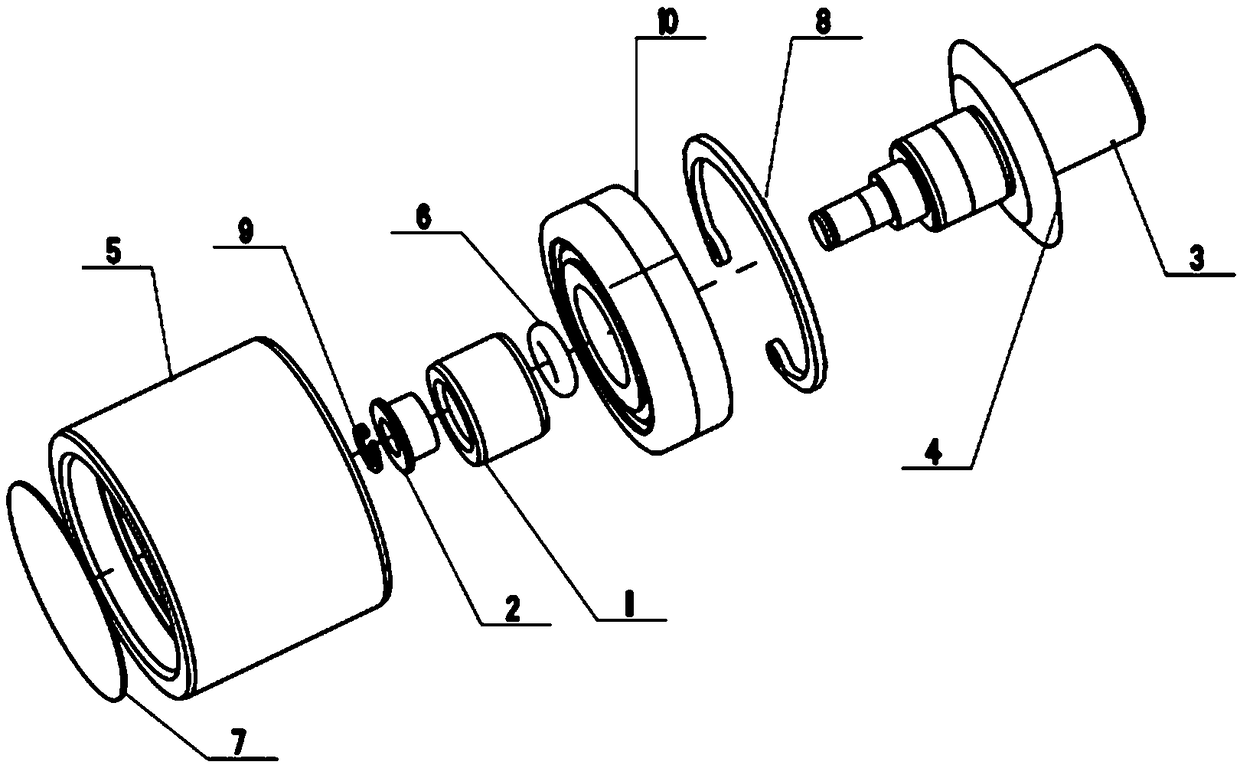

Combined type roller for spinning machine drafting mechanism

InactiveCN108796693AQuality assuranceIncrease contactDrafting machinesRubber ringAgricultural engineering

The invention discloses a combined type roller for spinning machine drafting mechanism, and mainly relates to the technical field of textile machinery. The roller comprises a bearing inner sleeve, a shaft sleeve, a shaft, an outer sleeve and a bearing; the shaft penetrates through a rubber ring to be cooperatively connected with the bearing inner sleeve and the bearing sleeve in sequence, a secondcheck ring sleeves the end of the shaft, and a second gasket abuts against the shaft sleeve; a nylon ring sleeves the middle of the shaft, and the lower portion of a shaft sleeve is sleeved with theinner side of a bearing inner sleeve; the bearing inner sleeve is integrally nested in the bearing, the bearing is nested in the outer sleeve, and the two ends of the bearing abut against the outer sleeve and a first check ring respectively; a dust cover is clamped in the outer sleeve. The roller can perform enough compensation, the spinning quality is greatly guaranteed, the sealing property is good, the service life is long, and the application range is wide.

Owner:苏州益垚精密机械有限公司

Casting core making material and core making method

InactiveCN110252940ASave saveOmit operabilityFoundry mouldsFoundry coresCasting defectCompressive strength

The invention discloses a casting core making material. The casting core making material comprises, by weight percentage, 55%-65% of steel shots, 15%-25% of carbon granules and the balance silica sand. The particle size of each steel shot ranges from 0.5 mm to 1.5 mm, and the granule size of each carbon granule is smaller than 1.0 mm. The casting core making material can be used instead of conventional formed direct or indirect chill iron, the casting defects such as shrinkage cavities and shrinkage porosity of castings are effectively overcome, the molding difficulty is reduced, the cleaning and polishing labor time of the castings is shortened, the production efficiency of the castings is obviously improved, and the product quality of the castings is guaranteed. The casting core making material is particularly suitable for the castings with the high quality requirements and the regions where the chill iron is difficult to place or clean, such as pressure vessel or oil cylinder parts with guide pillar holes and the castings with long and thin holes formed in the side walls, the number of the casting defects is effectively reduced, or the casting defects are effectively overcome, and the product percent of pass is improved. The compressive strength of a sand core which is obtained according to a core making method is 2.9 MPa or above, and the pouring requirements of the castings are completely met.

Owner:NINGBO YONGXIANG CASTING

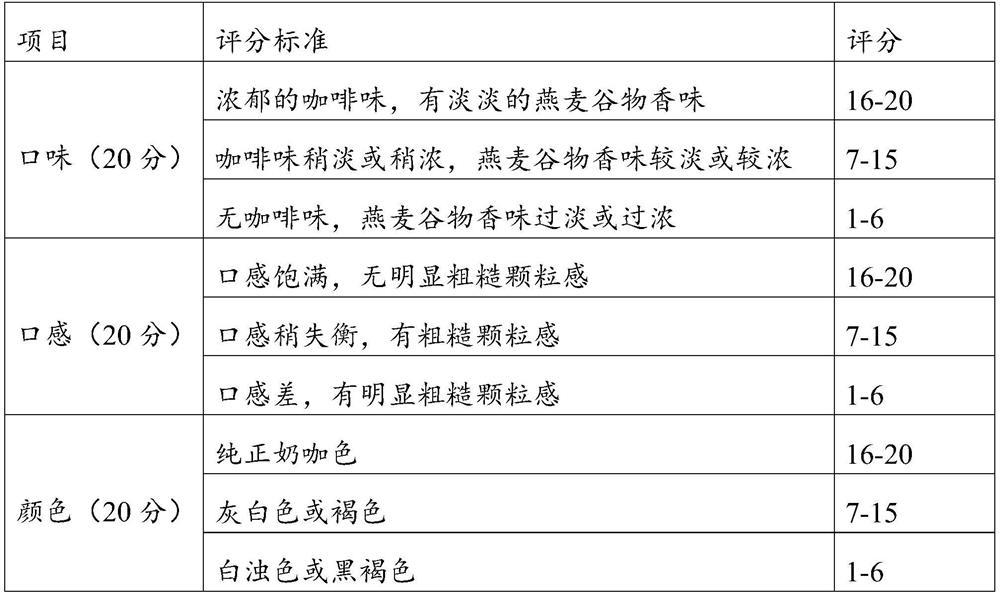

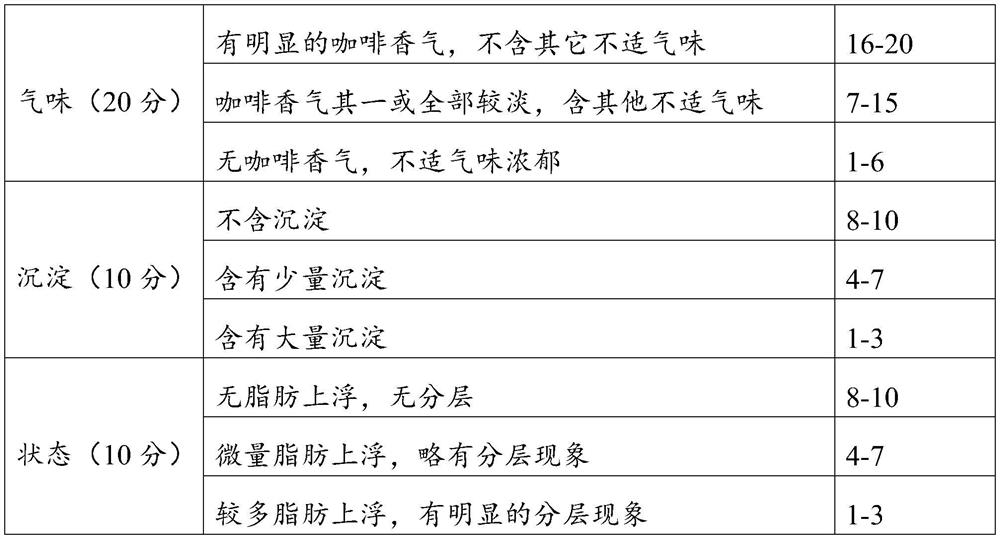

Oat latte coffee and preparation method thereof

PendingCN114027380ASolve insolubleSimple processFood dryingFood ingredient functionsBiotechnologyNutrition

The invention discloses oat latte coffee. The oat latte coffee is prepared from enzymolysis oat flour, sunflower seed oil powder, maltodextrin, erythritol and instant coffee powder. According to the three-in-one coffee, the enzymolysis oat powder is used as a milk base of the three-in-one coffee, traditional non-dairy creamer is completely replaced, and oat has the highest content of water-soluble dietary fibers in all grains and contains rich B vitamins and minerals, so that the three-in-one coffee is a green food which is nutritional and healthy. The oat latte coffee disclosed by the invention is pure and healthy in components, full in mouth feel, free from obvious rough granular sensation and light in oat fragrance. The product is novel in form and conforms to the prey psychology of young consumers. Moreover, equipment and a process for producing the oat latte are simple, the cost is low, and the oat latte is suitable for industrial production.

Owner:广西创泰食品科技有限公司

Hole milling device and method for corrugated copper pipe outer conductor coupling type leaky coaxial cable

PendingCN114769683AImpact of electrical indicatorsGuaranteed lubrication effectMilling equipment detailsMaintainance and safety accessoriesCoaxial cableElectrical conductor

The invention discloses a hole milling device and method for a corrugated copper pipe outer conductor coupling type leaky coaxial cable, and the device comprises a milling cutter, a groove milling die, and a lubricating oil atomizer. The groove milling die comprises a die body, and a through hole is formed in the axis direction of the die body. A milling cutter groove hole is formed in the upper section of the die body, an oil mist channel is further formed in the die body, an inlet of the oil mist channel is communicated with an air outlet of the lubricating oil atomizer, and an outlet of the oil mist channel is formed in one side of the milling cutter groove hole. According to the invention, the FRL air source is adopted to process the atomized lubricator, so that the liquid cutting fluid is atomized, and the atomized cutting fluid is blown to the cutting edge of the cutter to lubricate and cool by connecting the cable groove milling die with the oil mist hole channel through the pipeline, so that the groove opening of the cable outer conductor groove milling is smooth and burr-free, the electrical index of the cable is not influenced, and the service life of the cable is prolonged. The product quality is improved.

Owner:JIAOZUO RAILWAY CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com