Patents

Literature

56results about How to "Improve blanking accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

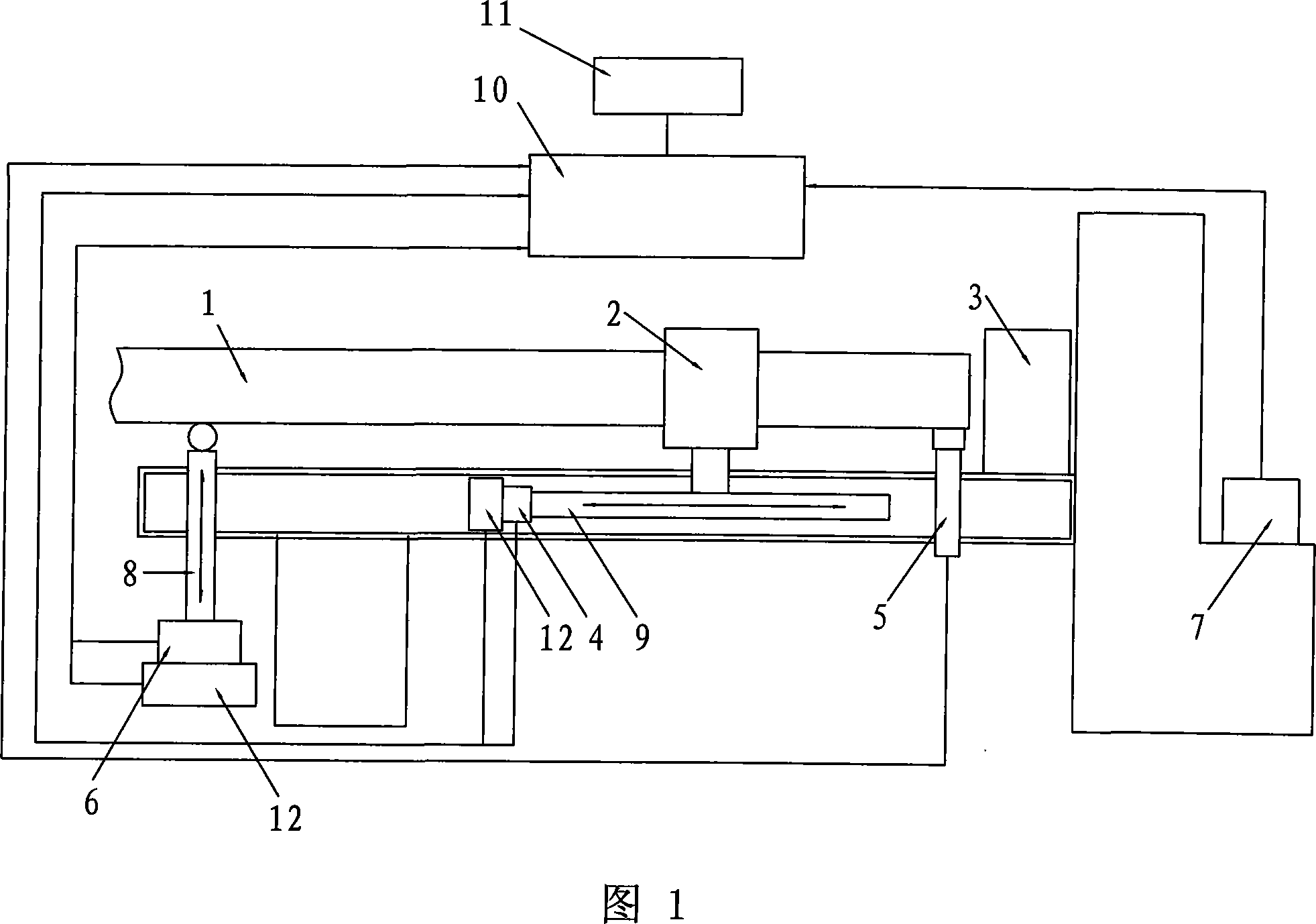

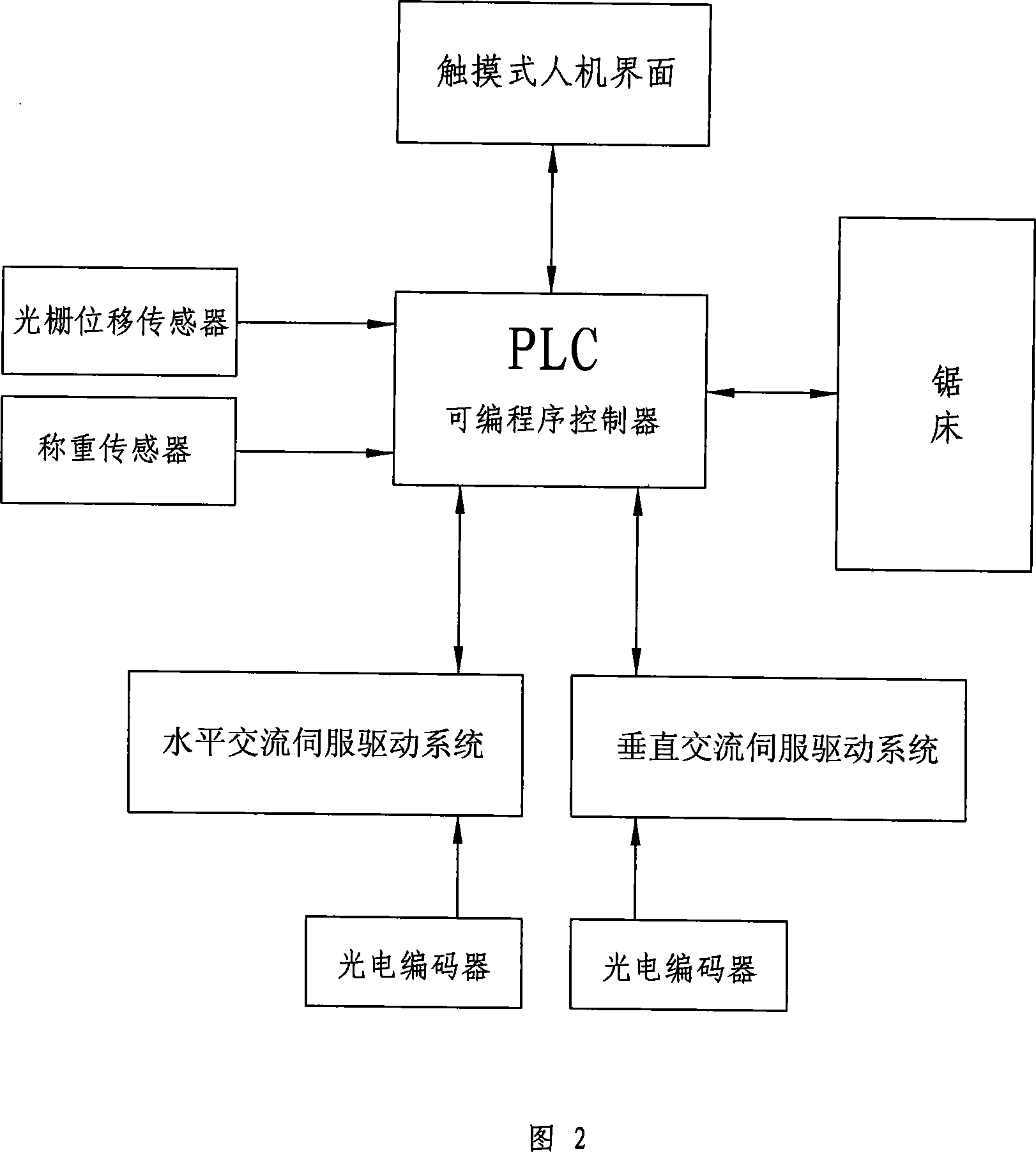

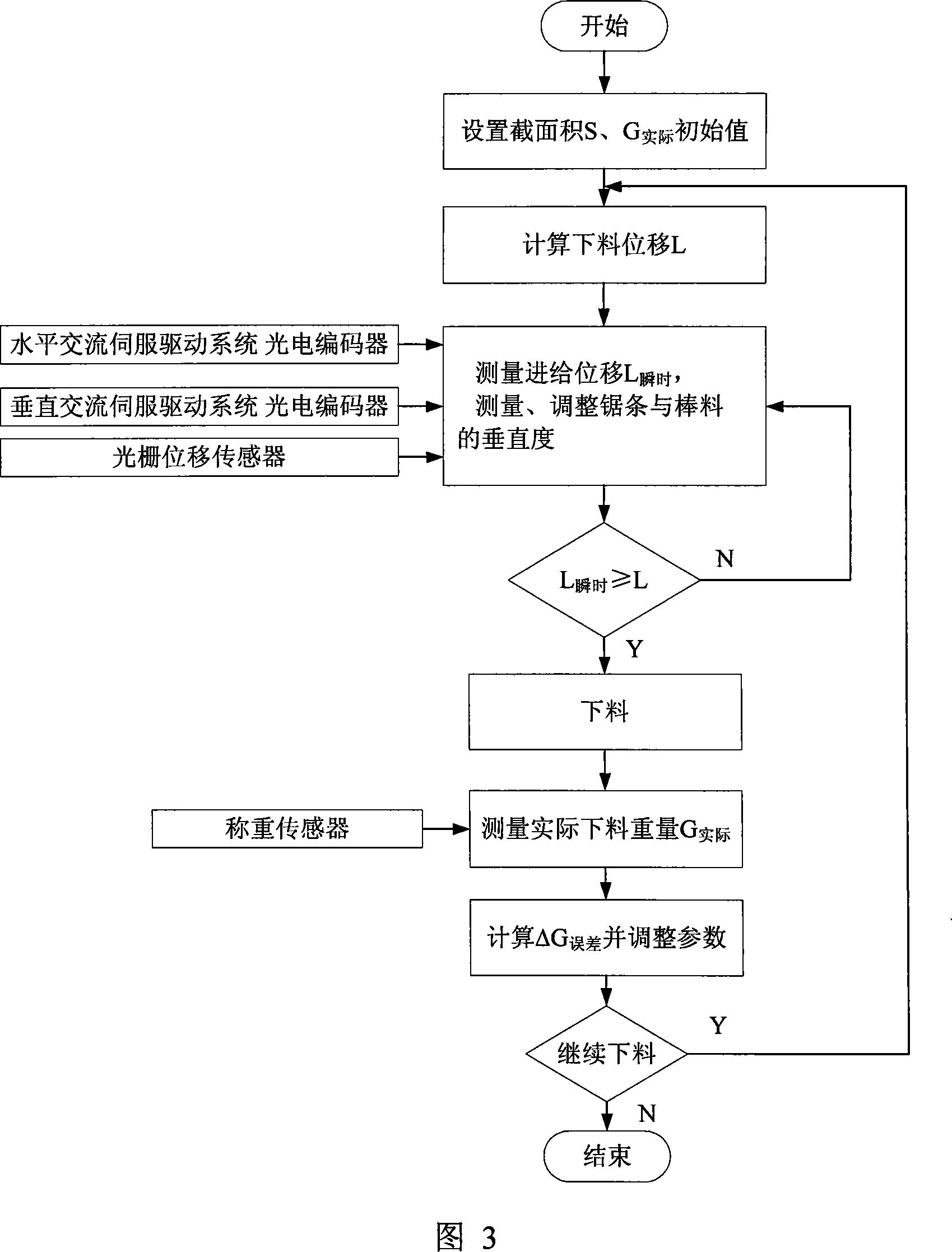

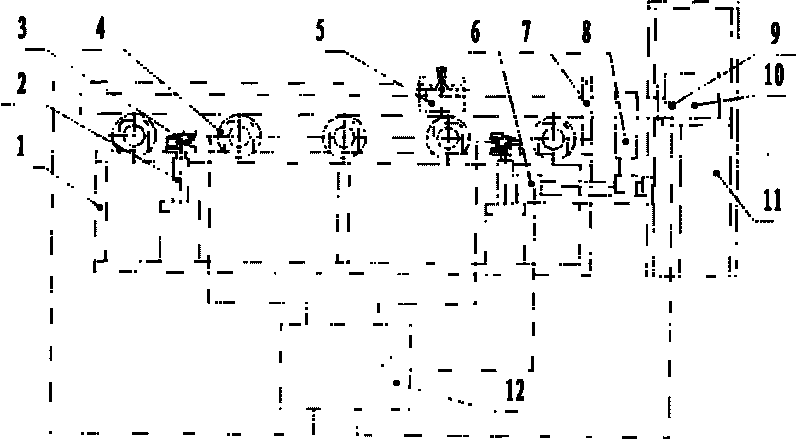

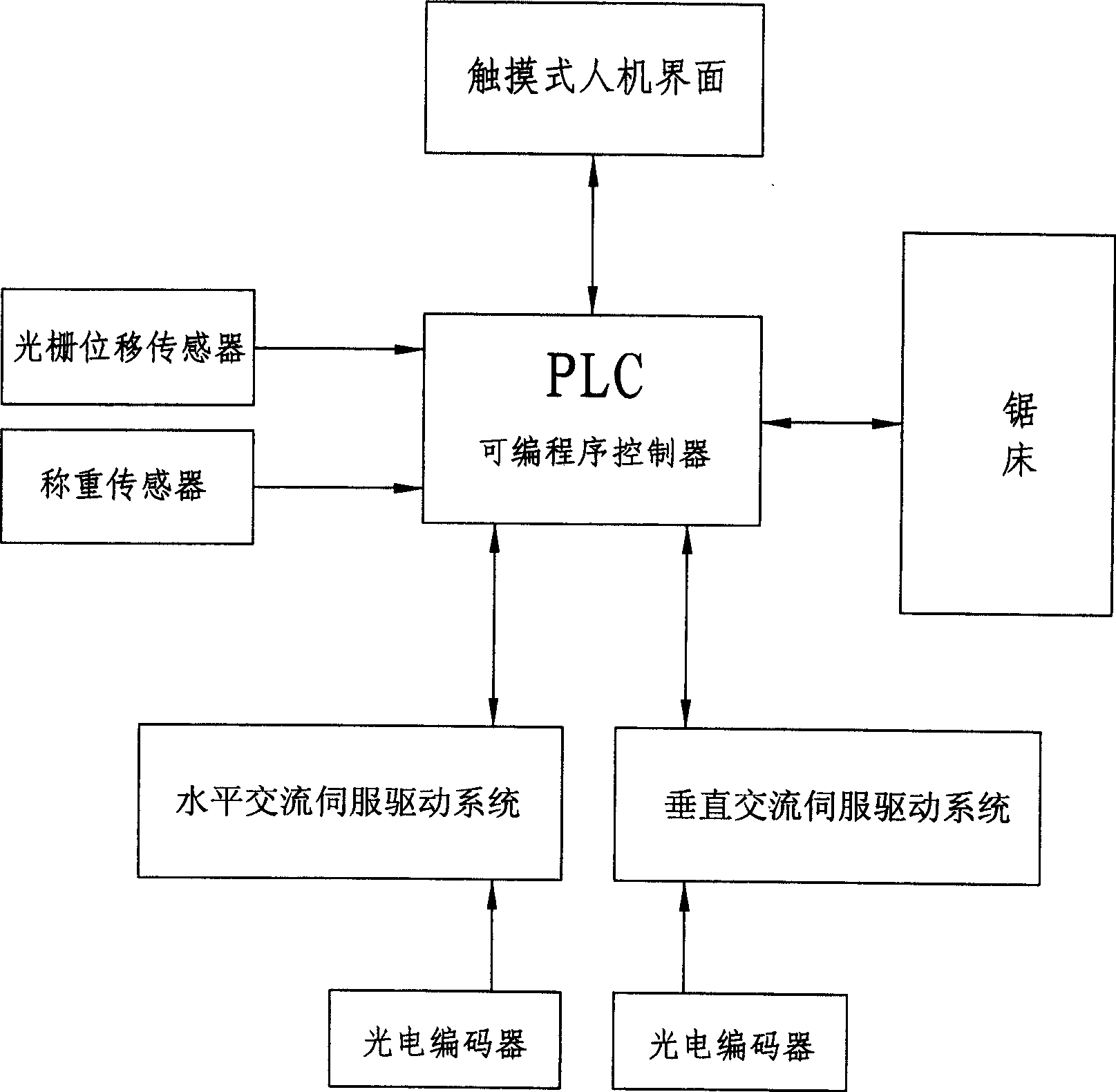

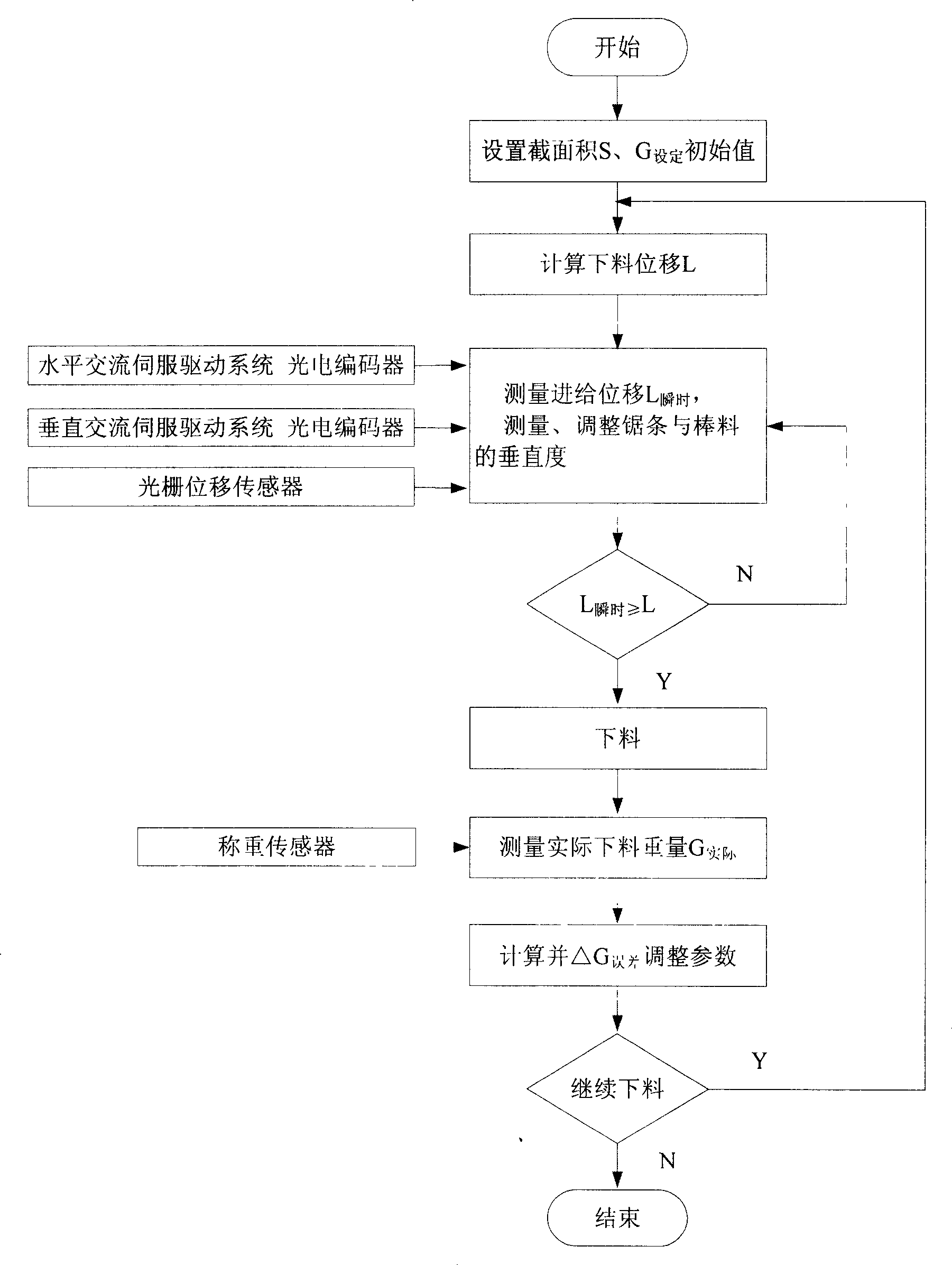

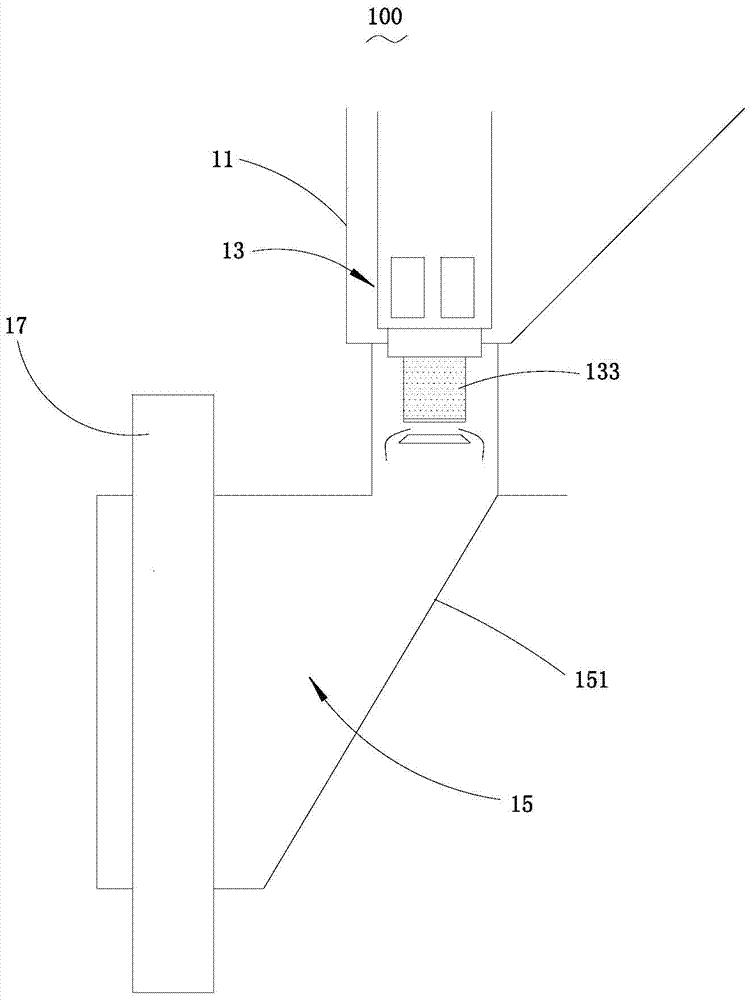

Control method for bar stock saw cutting self-adapting precision baiting

InactiveCN101135895AAccurately control the actual length accuracyRealize adaptive control of precision sawingProgramme control in sequence/logic controllersEngineeringSelf adaptive

The method comprises: using a bar stock saw automatically-adaptive lay- off system. The method comprises: a horizontal AC servo drive system is used for realizing the rod feed; a highly-accurate photoelectric encoder is used to detect the amount of fed rod; a grating shifting sensor is used to detect the height value of front end of the rod; a vertical AC servo drive system is used to adjust the height of the rear end of the rod to keep the consistency between the front end and the rear end of the rod; a highly-accurate weight sensor is used to weigh the actual weight G of the rod and to compare the actual weight of rod with the reset value, and according to the difference Delta G to adjust the cutting length.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

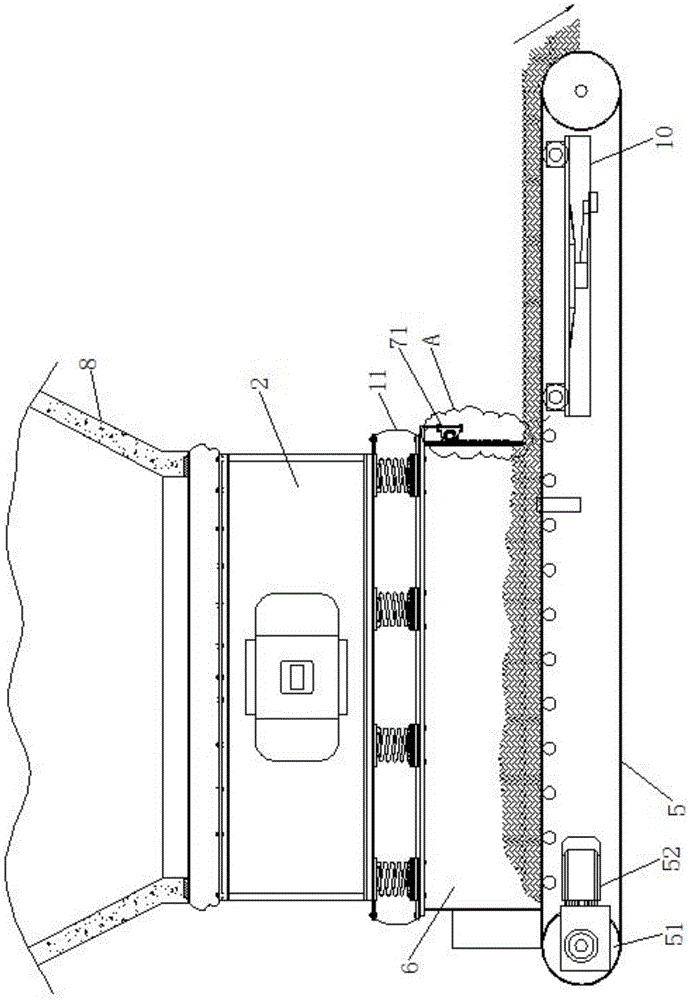

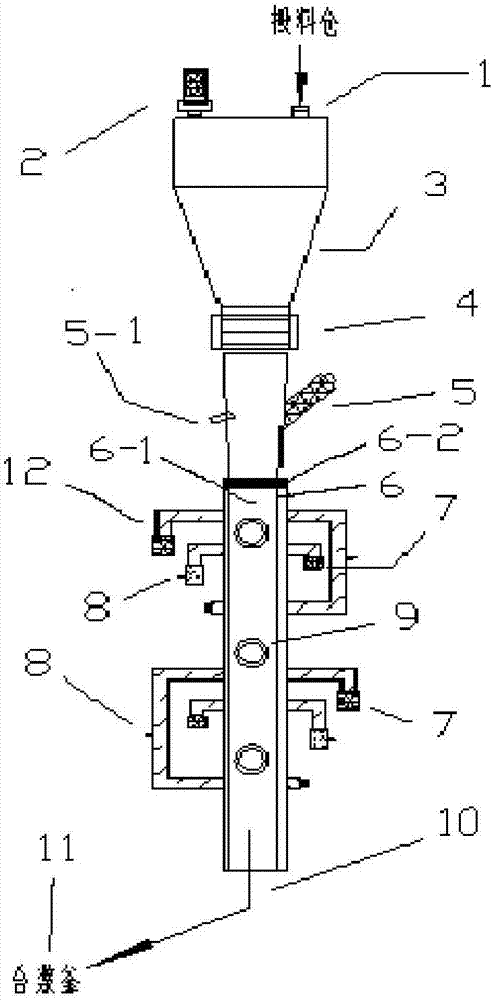

Precise ingredient activation feeder

ActiveCN105417097AStable outputAvoid affecting subsequent processing and productionConveyorsLoading/unloadingAdditive ingredientEngineering

The invention discloses a precise ingredient activation feeder. The precise ingredient activation feeder comprises a frame, a feed excitation bin, a vibration motor and a conveying belt mechanism, and further comprises a buffer bin and a gate plate; the bottom of the feed excitation bin is mounted on the top table surface of the frame through an elastic connecting piece; a vibration end of the vibration motor is connected to the side surface of the feed excitation bin through an elastic connecting piece; a feed port communicated with the internal is formed in the top of the feed excitation bin; a discharge port communicated to the internal of the feed excitation bin is formed in the bottom of the feed excitation bin; a feed channel penetrating through the table surface of the frame up and down is formed in the table surface of the frame; the conveying belt mechanism is transversely arranged below the feed channel; the buffer bin is fixed at the bottom of the table surface of the frame; the bottom of the buffer bin is contacted with a belt; the buffer bin is provided with a discharge gap along the lower end edge of the front side of the advancing direction of the belt; and the gate plate is mounted outside the front side bin wall of the buffer bin. The precise ingredient activation feeder has the advantages of simple structure, convenience for use, capability of activating upper logistics, prevention of arching, capability of adjusting the material discharge quantity, guarantee of the supply quantity of materials in the buffer bin satisfying the requirement and guarantee of stable material conveying.

Owner:WUHAN XIN HUAYUAN ELECTRIC POWER EQUIP

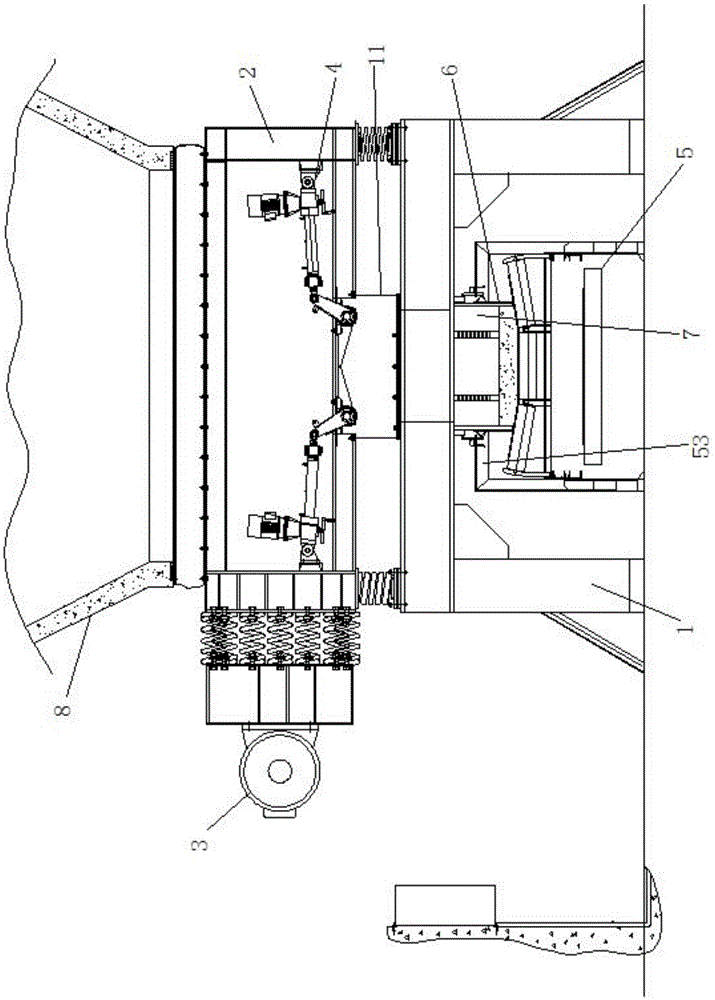

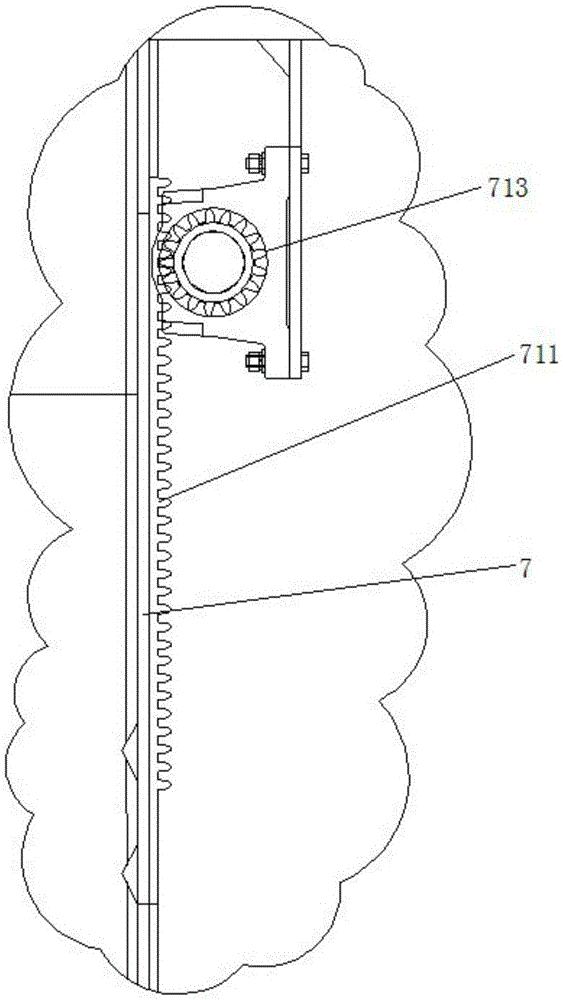

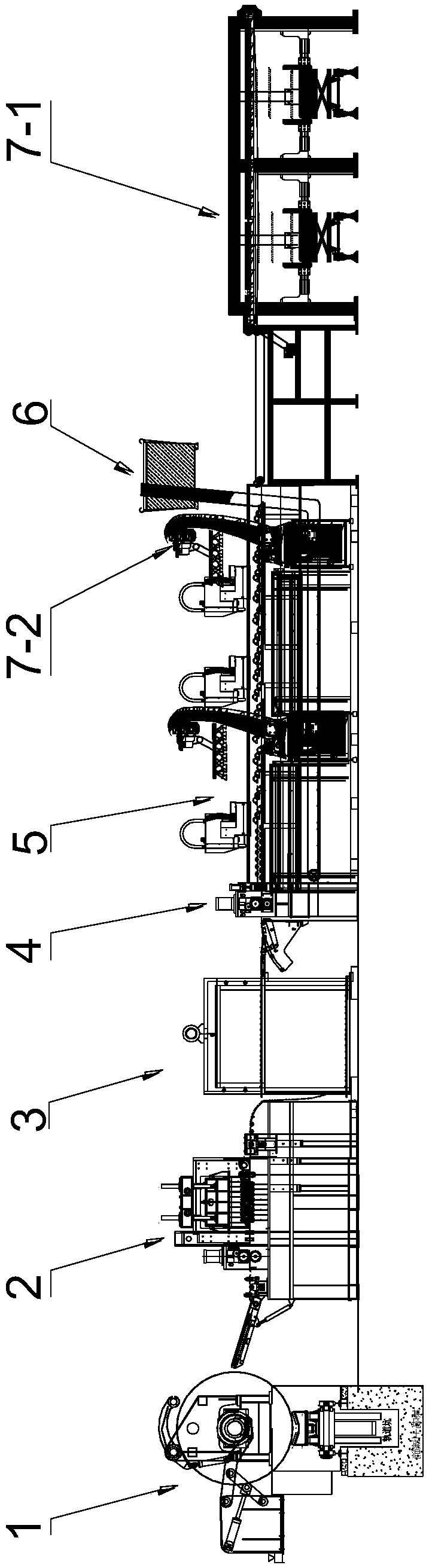

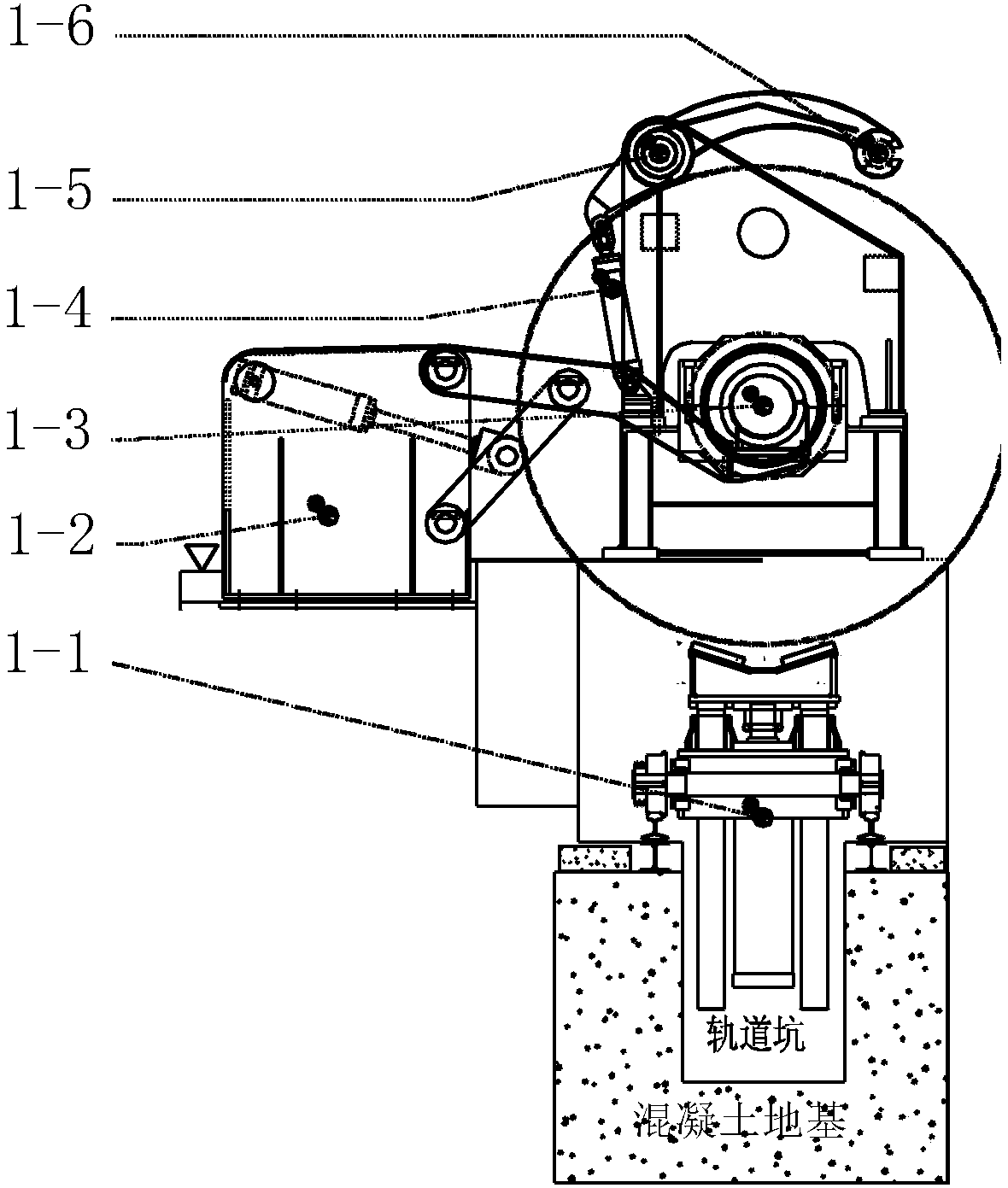

Fully-automatic uncoiling leveling laser cutting blank automatic stacking intelligent manufacturing production line

PendingCN108481000AImprove blanking accuracyReduce upfront investmentOther manufacturing equipments/toolsProduction linePunching

The present invention discloses a fully-automatic uncoiling leveling laser cutting blank automatic stacking intelligent manufacturing production line, comprising an unreeling machine, a leveler, a buffering device, a finishing mechanism and a stacking system sequentially arranged on the moving track of a slab to be processed, further comprising a laser cutting system; and the laser cutting systemis arranged behind the finishing mechanism. The fully-automatic uncoiling leveling laser cutting blank automatic stacking intelligent manufacturing production line is applicable to the intelligent manufacturing of steel and steel panels required in the industries of automobiles, electric appliances and the like, the traditional large plate metal processing equipment performs machining by taking punching as power, a new die needs to be designed when a new product is developed, the development cost is high and the development period is long, the manufacturing of a new product can be completed ina short period of time by introducing the intelligent laser cutting system into the production line, thus only product data are required to be provided when the new product is developed, and the fully-automatic uncoiling leveling laser cutting blank automatic stacking intelligent manufacturing production line has the advantages of low early-state investment, low maintenance and operation costs, high laying-off accuracy, good product quality, green energy conservation and the like.

Owner:武汉诚兴和汽车零部件有限公司

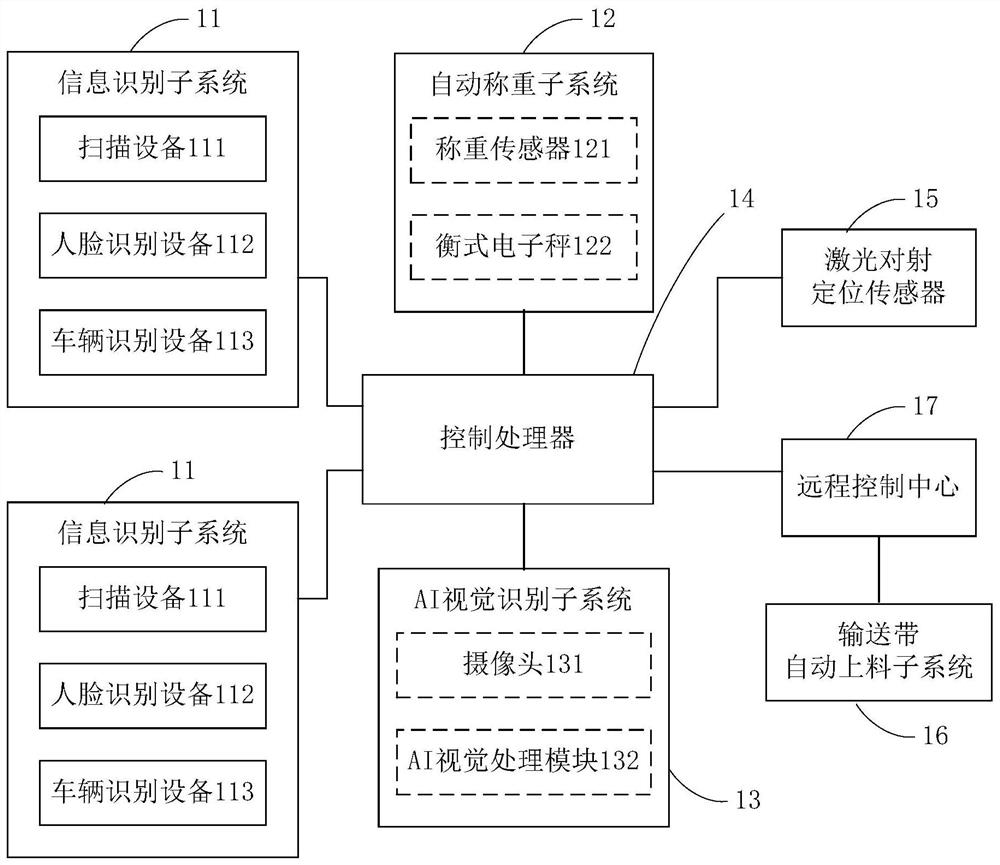

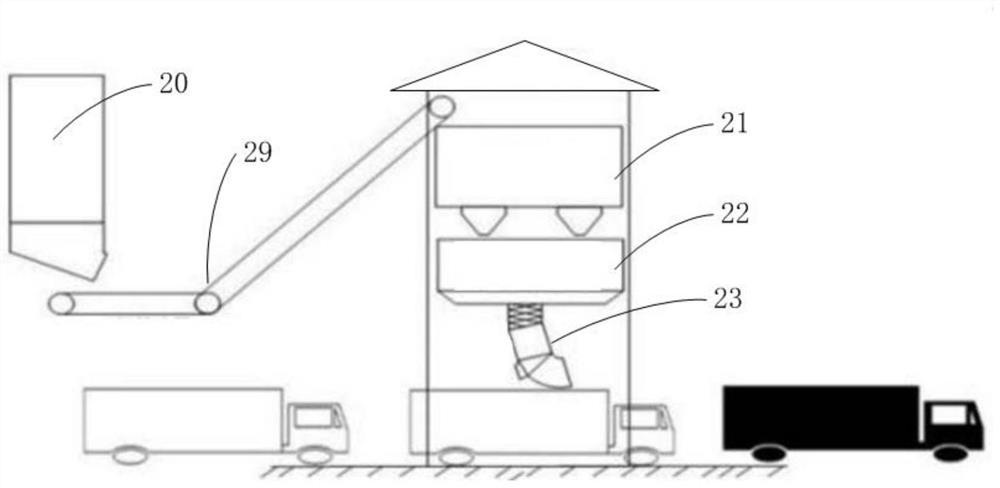

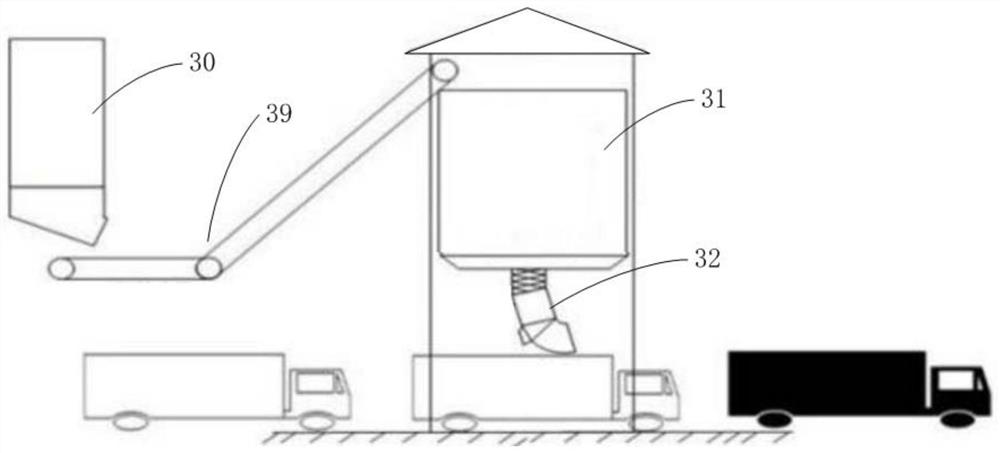

Intelligent loading control system and method

InactiveCN112299049ARealize the whole process automationGo onlineLoading/unloadingControl systemControl engineering

The invention discloses an intelligent loading control system and method. The system comprises a plurality of information identification subsystems, an automatic weighing subsystem, an AI visual identification subsystem and a control processor. Accurate positioning of a parking position and an unloading position of a transport vehicle and accurate measurement of a unloading weight can be achieved,unmanned, intelligent and scenarized loading is achieved, an unloading speed can be increased, the continuity of automatic unloading is ensured, the unloading time is controllable, and the unloadingprecision and a loading full load rate are improved.

Owner:上海平奥供应链管理有限公司

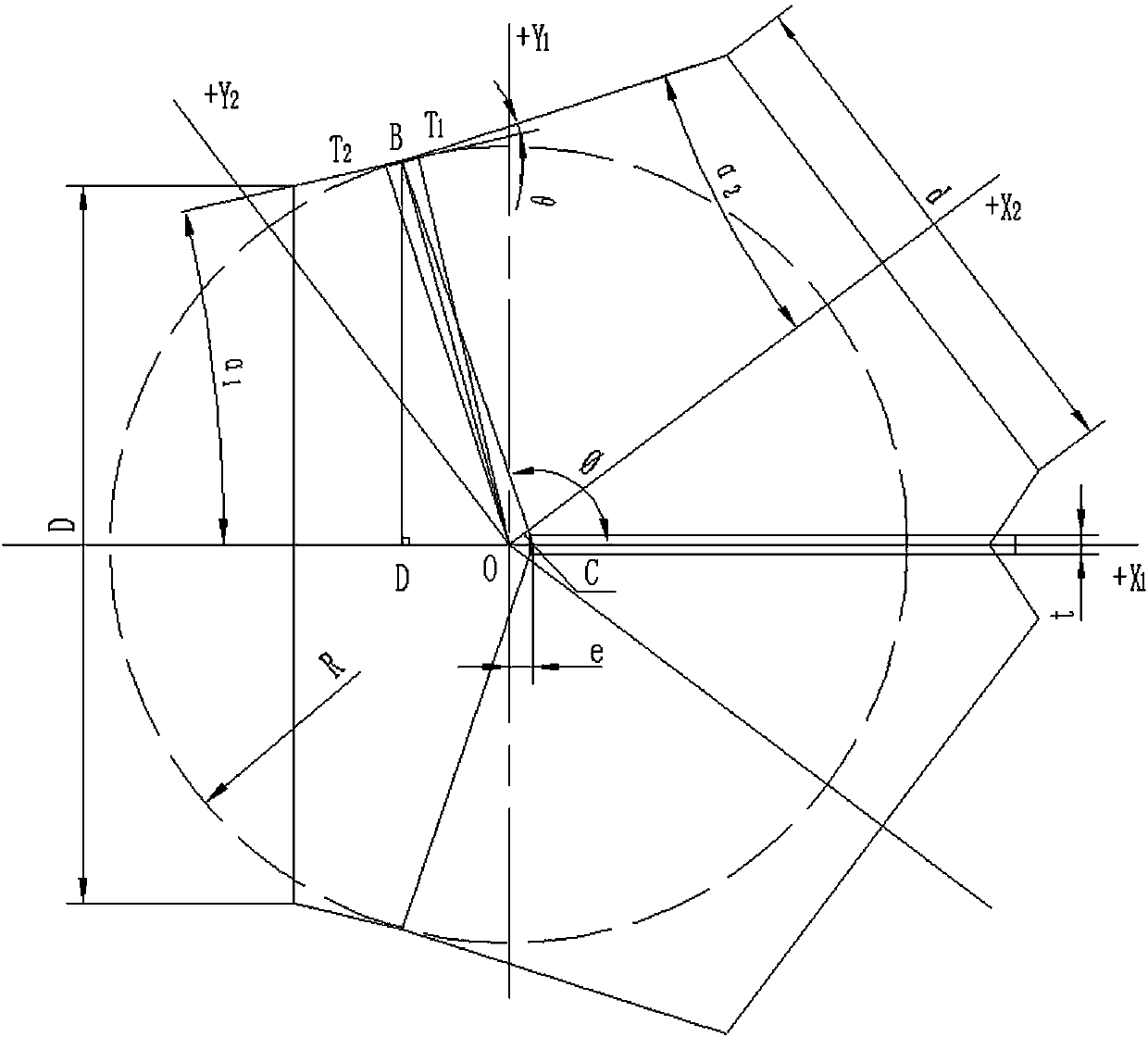

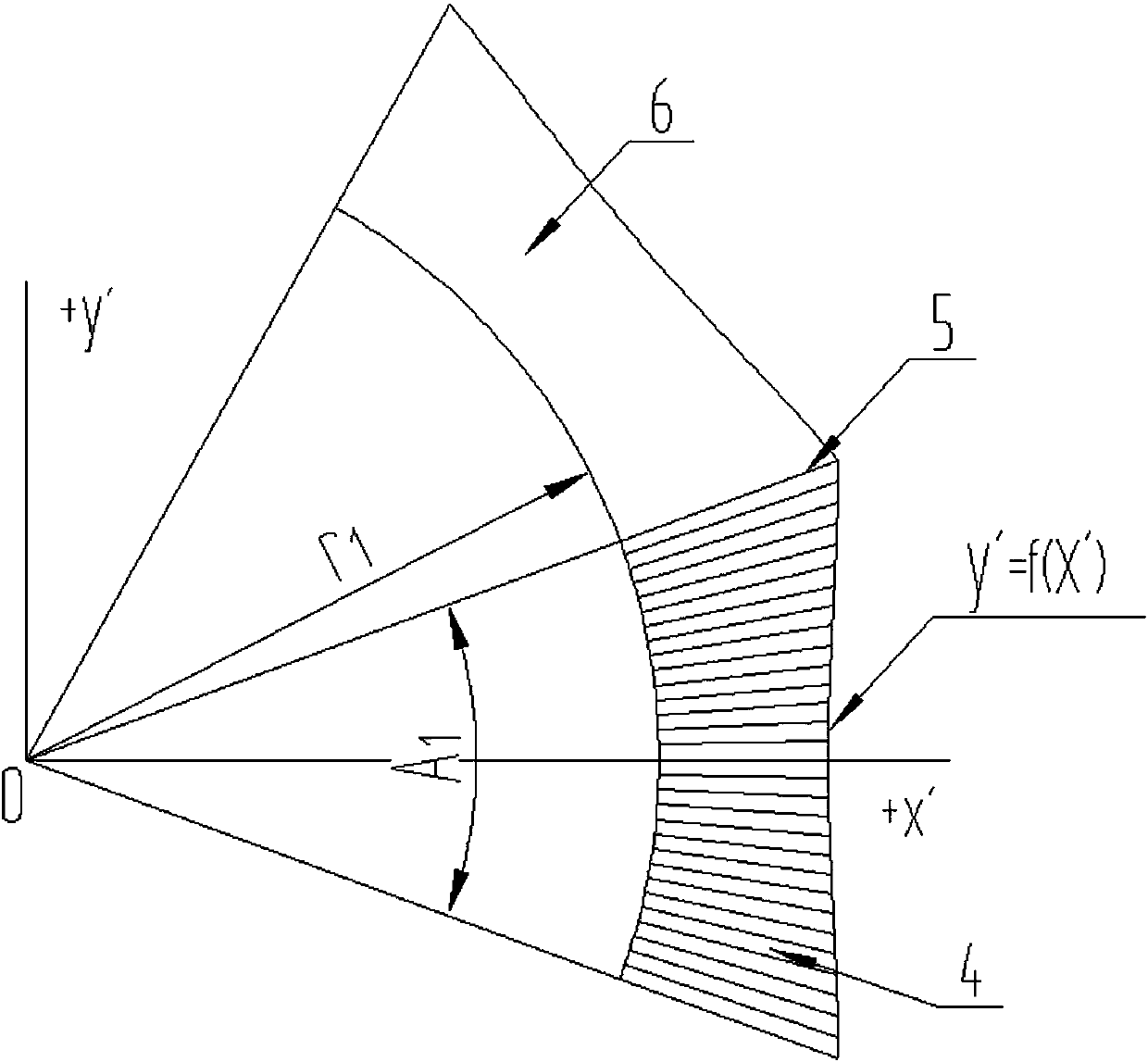

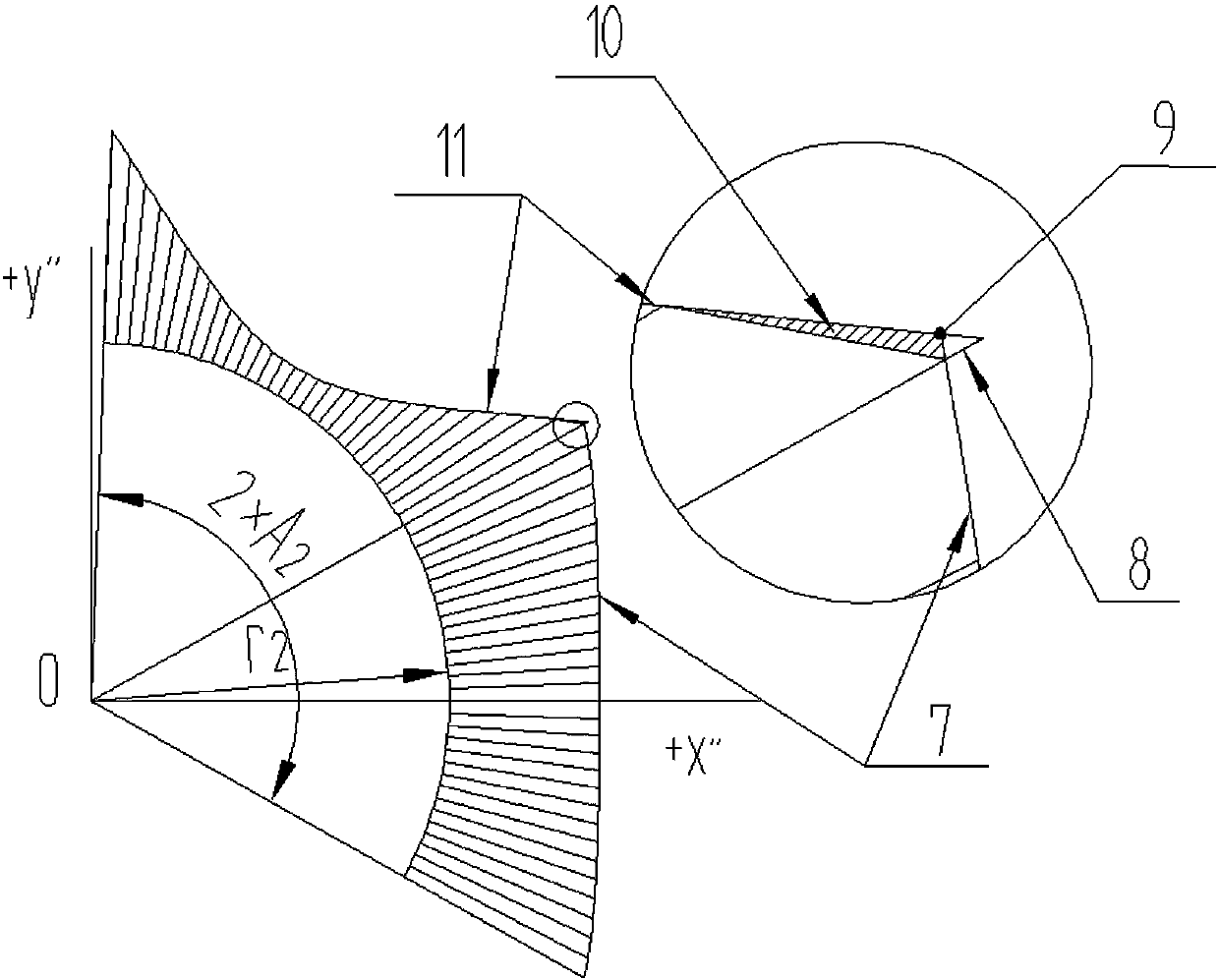

Calculation method for unfolding and unloading of Y-shaped symmetric crescent rib steel branch tube

ActiveCN108229036AAvoid repeated transformation of the calculation processAvoid the risk of shortageGeometric CADComplex mathematical operationsEngineeringCalculation methods

The invention provides a calculation method for unfolding and unloading of a Y-shaped symmetric crescent rib steel branch tube. The method comprises the steps of establishing a coordinate system; establishing a cone surface equation of a main cone tube in a main cone tube coordinate system and a cone surface equation of a branch cone tube in the branch cone tube coordinate system of the cone tube;obtaining the coordinates of the intersecting line intersection point of the main cone tube and the branch cone tube in the main cone tube coordinate system and the branch cone tube coordinate systemrespectively; obtaining an intersection line equation of a plane of the main cone tube and the intersecting line; obtaining an intersection line equation of the plane of the branch cone tube and theintersecting line; obtaining the equation of a crescent plate plane in the branch cone tube coordinate system; solving the unloading of the main cone tube, and calculating a cone tessellation line family equation of the main cone tube; solving the unloading of the branch cone tube, and calculating a cone tessellation line family equation of the branch cone tube; deficiency error analysis and compensation of a cusp of the unloading of the branch cone tube are conducted; the method has the advantages that a complicated coordinate iterative transformation process is avoided, the calculation process is simple, the unloading precision is high, the unloading errors are compensated, and the risk of material shortage is avoided.

Owner:DONGFANG ELECTRIC MACHINERY

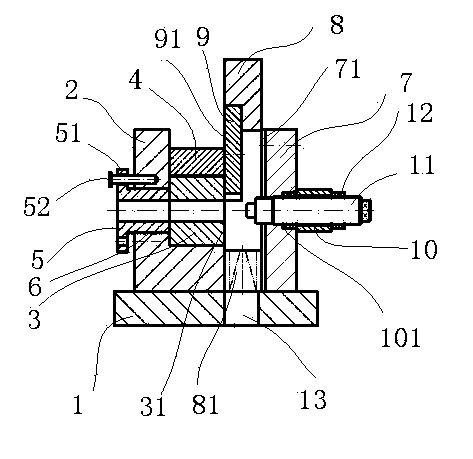

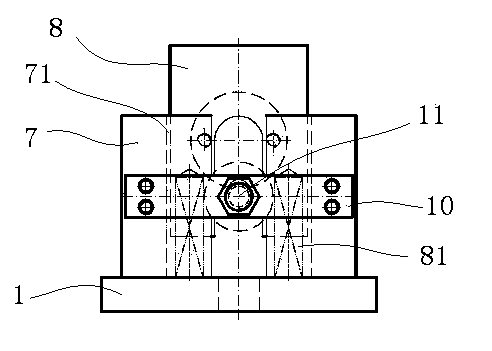

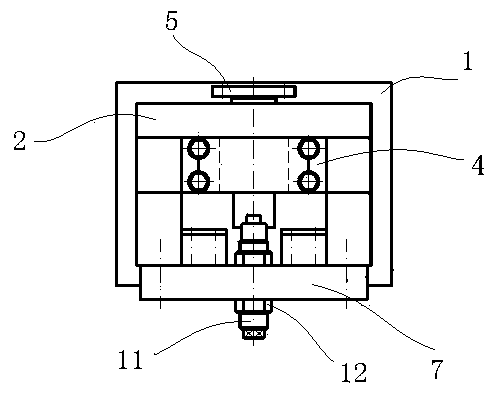

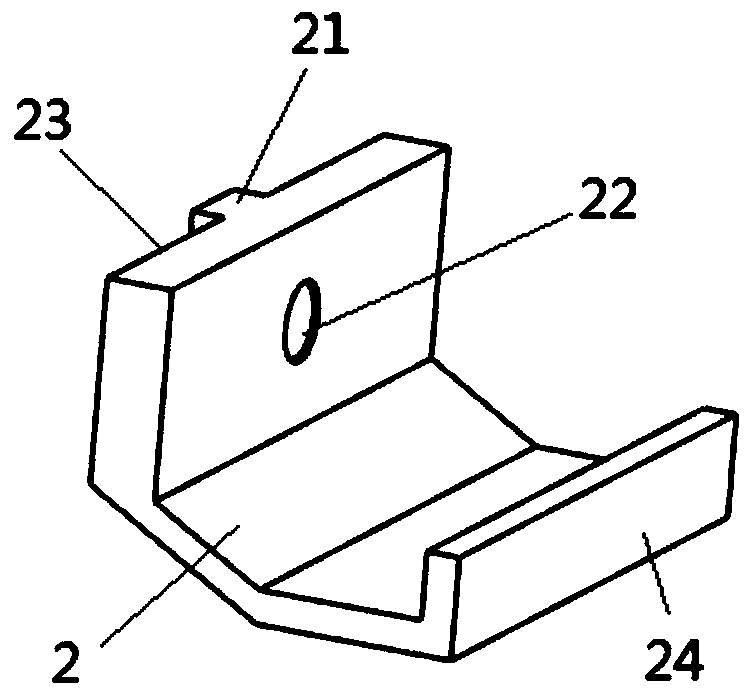

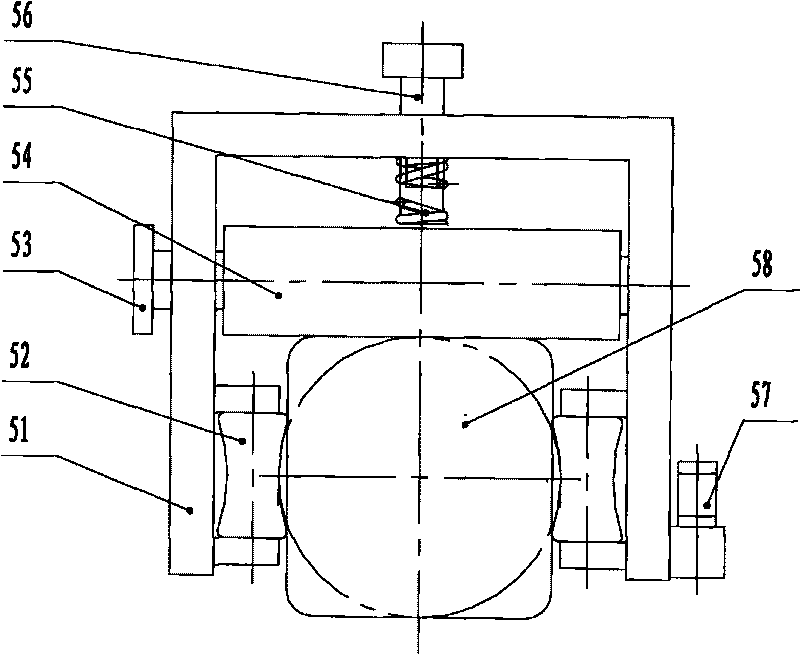

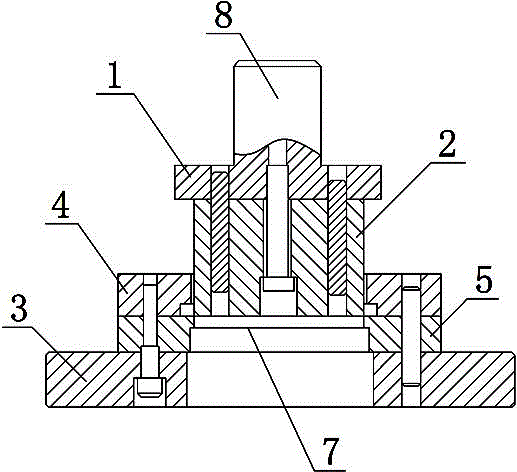

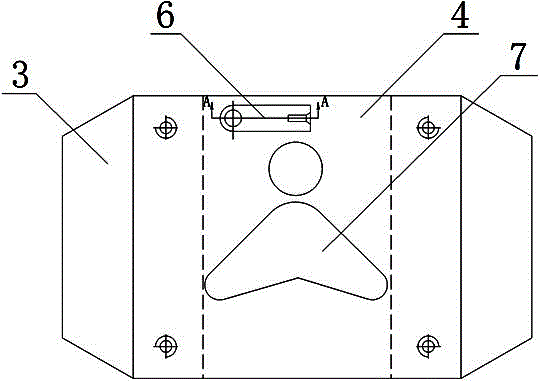

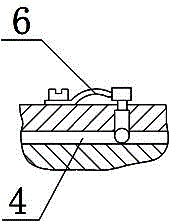

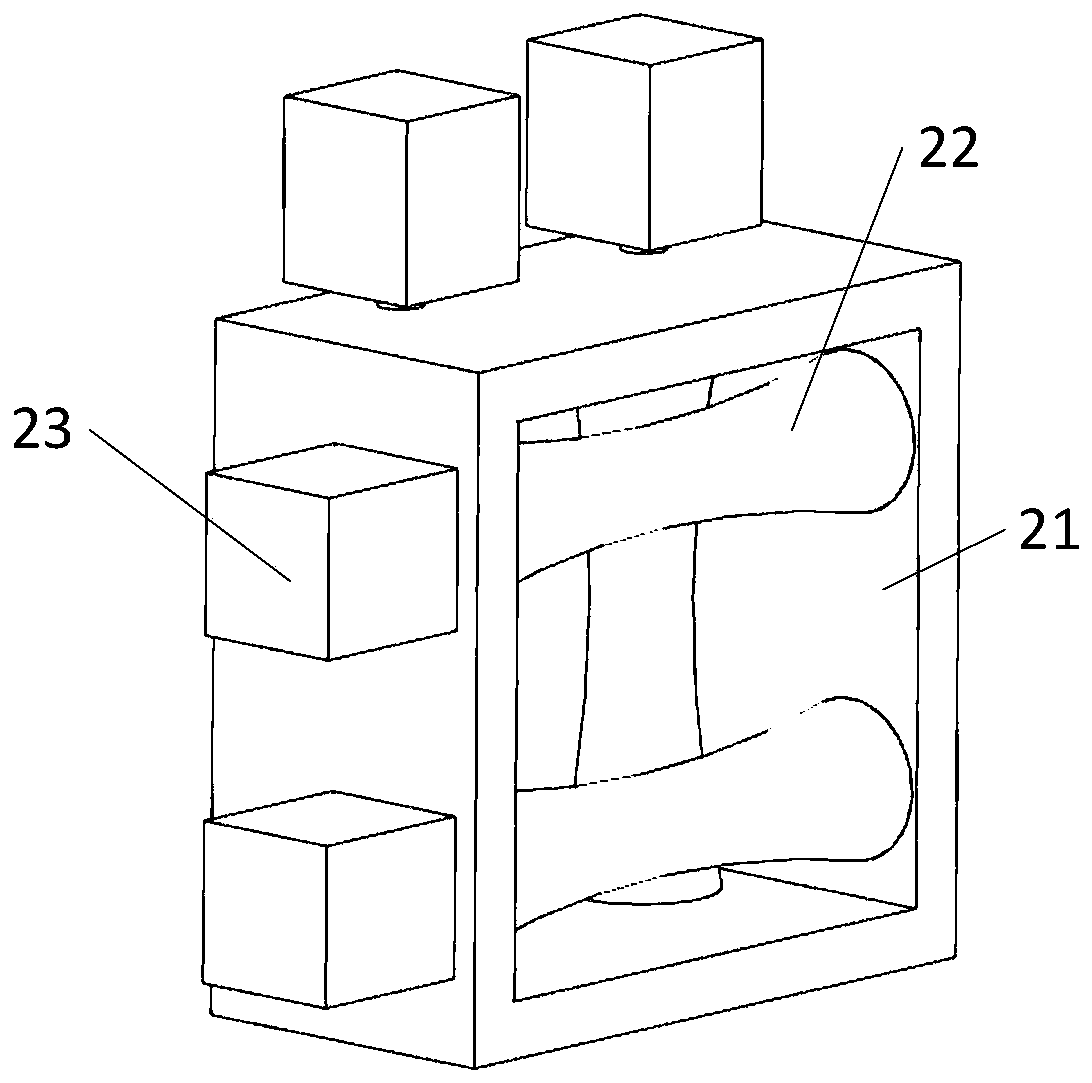

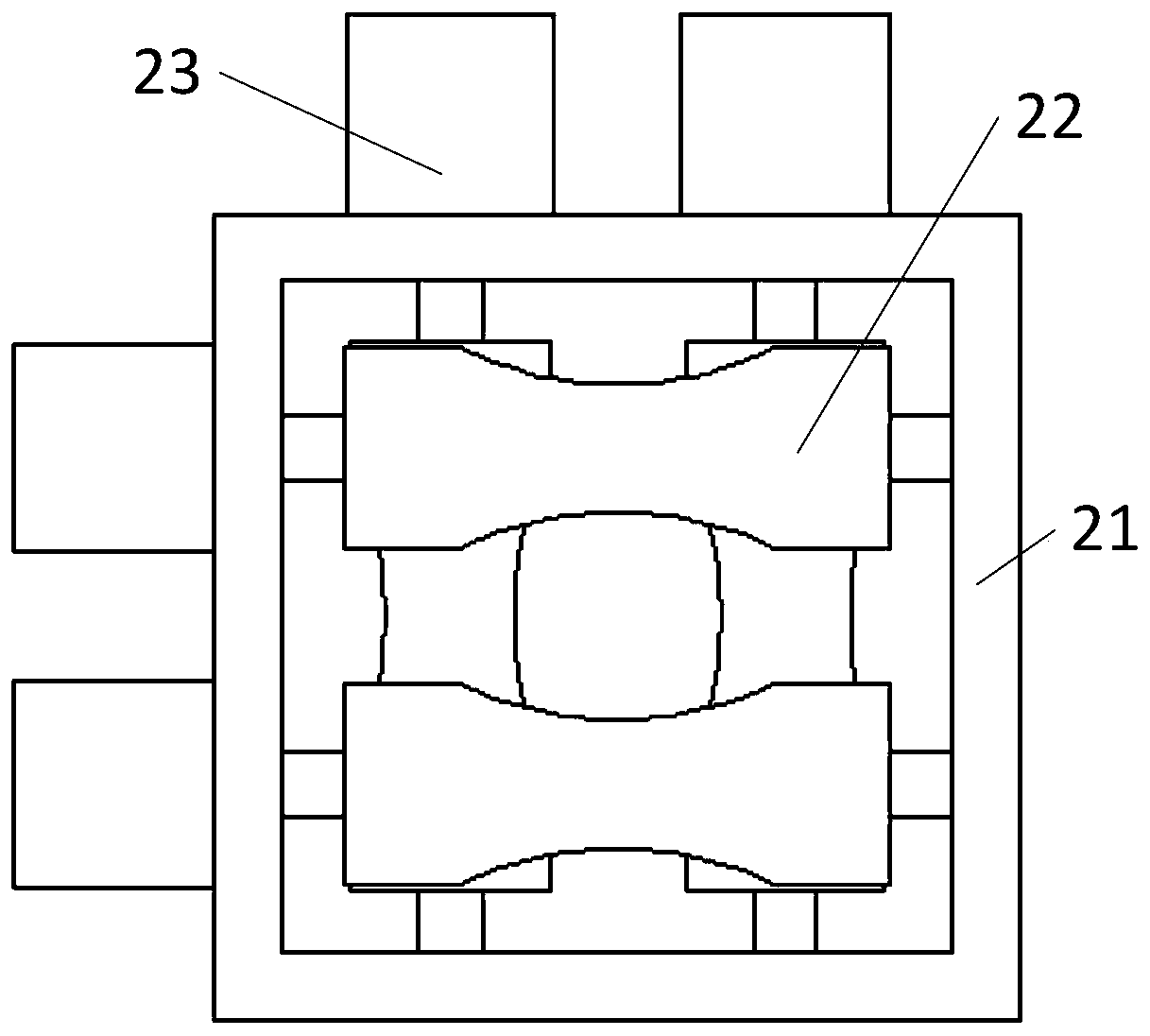

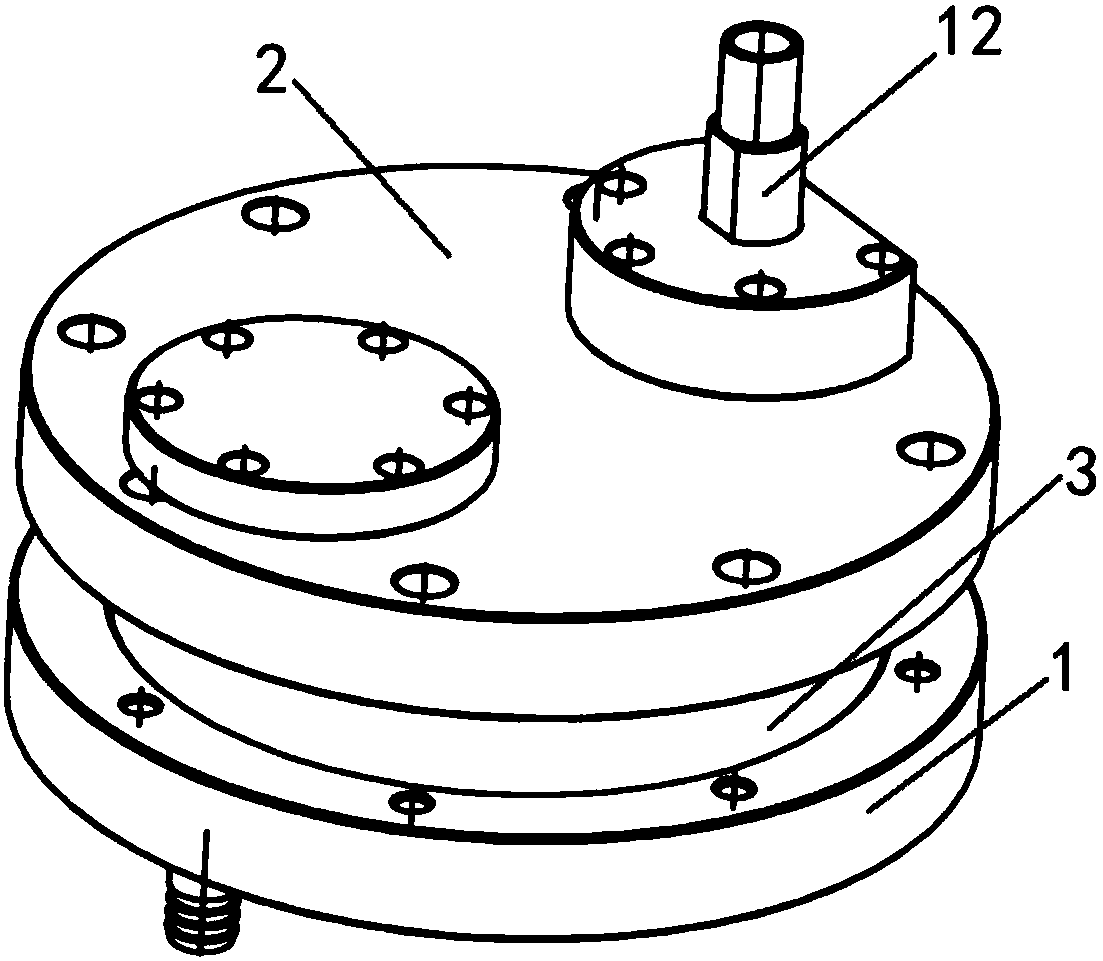

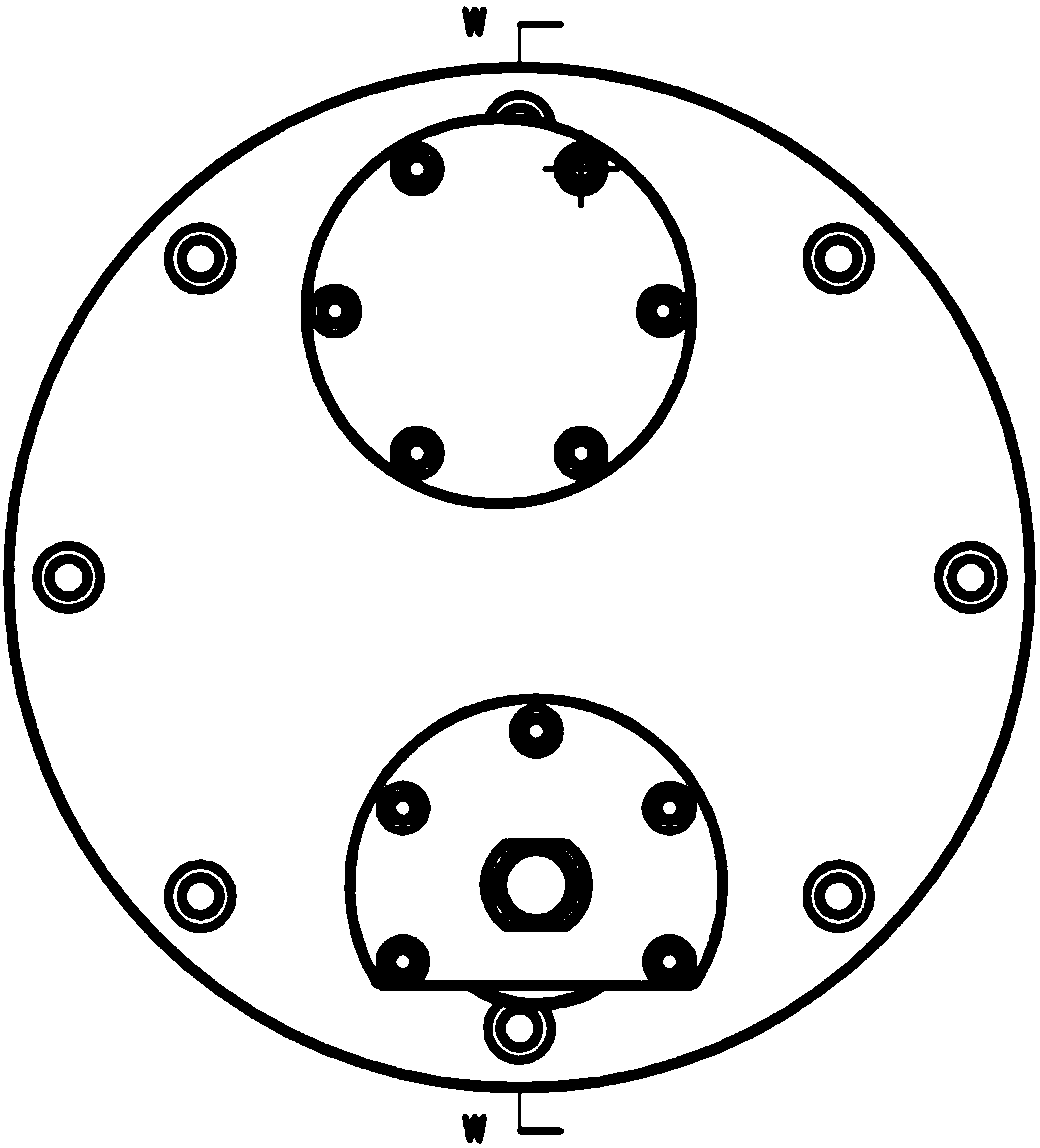

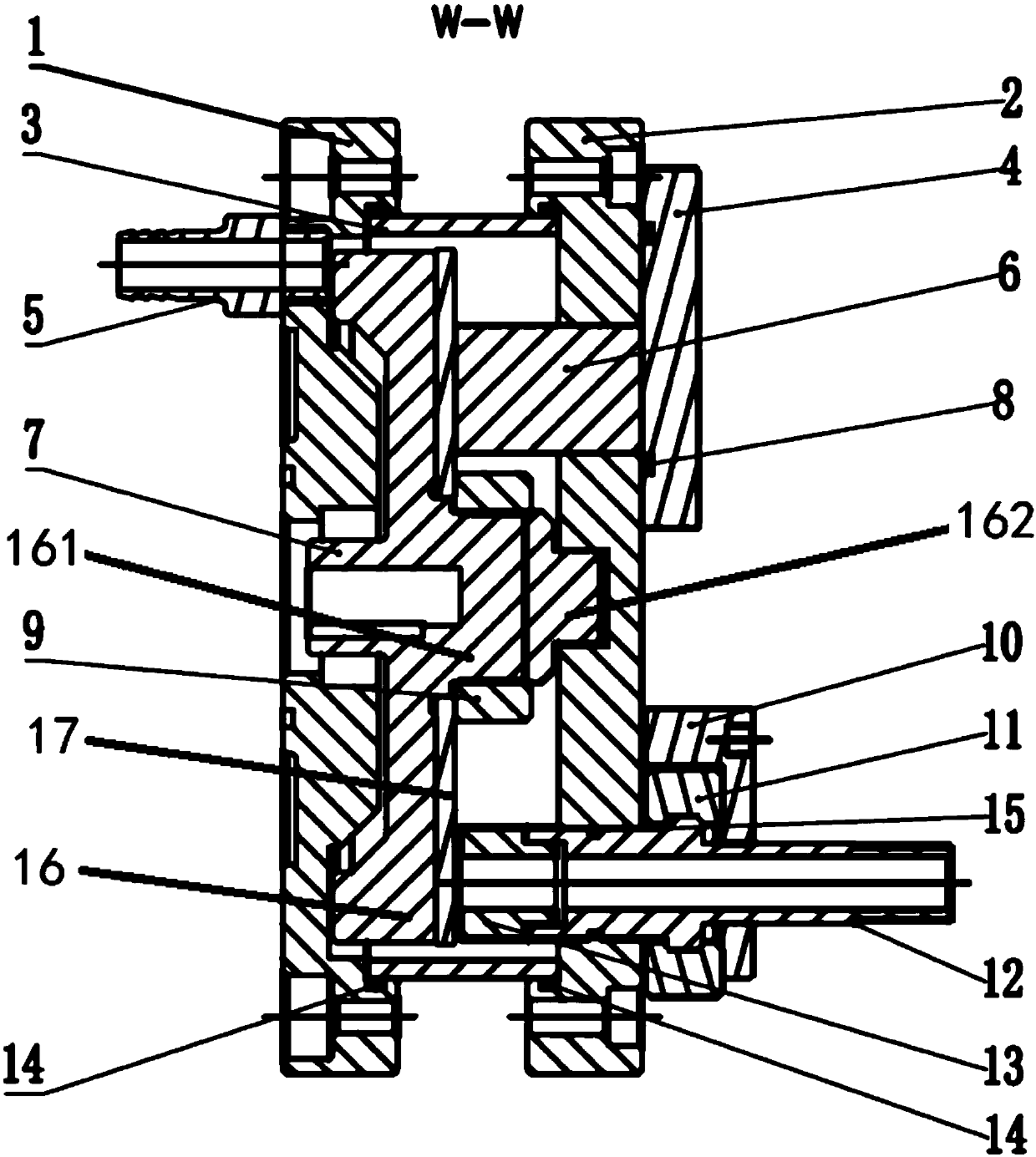

Cold extrusion blanking die for cross shaft blanks

The invention discloses a cold extrusion blanking die for cross shaft blanks. The cold extrusion blanking die comprises a base plate. A die holder is fixed onto the base plate, a lower cutting board is arranged on the die holder and is connected with the die holder by a gland, an adjusting screw tube is abutted to the rear end of the lower cutting board and is matched with an adjusting screw hole in the die holder, and a shoulder of the rear end of the adjusting screw tube is locked by a pin; a guide rail seat is arranged at the front end of the die holder and is fixedly connected with the base plate, guide rails are arranged on the back of the guide rail seat, an upper cutting board is embedded in a movable die plate which is arranged in the guide rails in a sliding fit manner, the outer end of the upper cutting board is in sliding fit with the front end of the lower cutting board, two compression springs are arranged at the lower end of the movable die plate, and the other end of each compression spring is abutted onto the base plate; a back plate is fixedly connected to the front end of the guide rail seat, a regulating screw hole is formed in the middle of the back plate, a blank length control screw is arranged in the regulating screw hole and is locked with the back plate by two locking nuts, and the tail end of the blank length control screw is opposite to the lower cutting board. The cold extrusion blanking die has the advantages that a gap between the upper cutting board and the lower cutting board can be accurately adjusted; a slider of a press machine is prevented from being directly impacted with the upper cutting board, and a vertex position of a bar can be instantly broken; materials can be discharge conveniently, and each cutter of the cold extrusion blanking die is provided with multiple blades.

Owner:WANXIANGQIANCHAO CO LTD +1

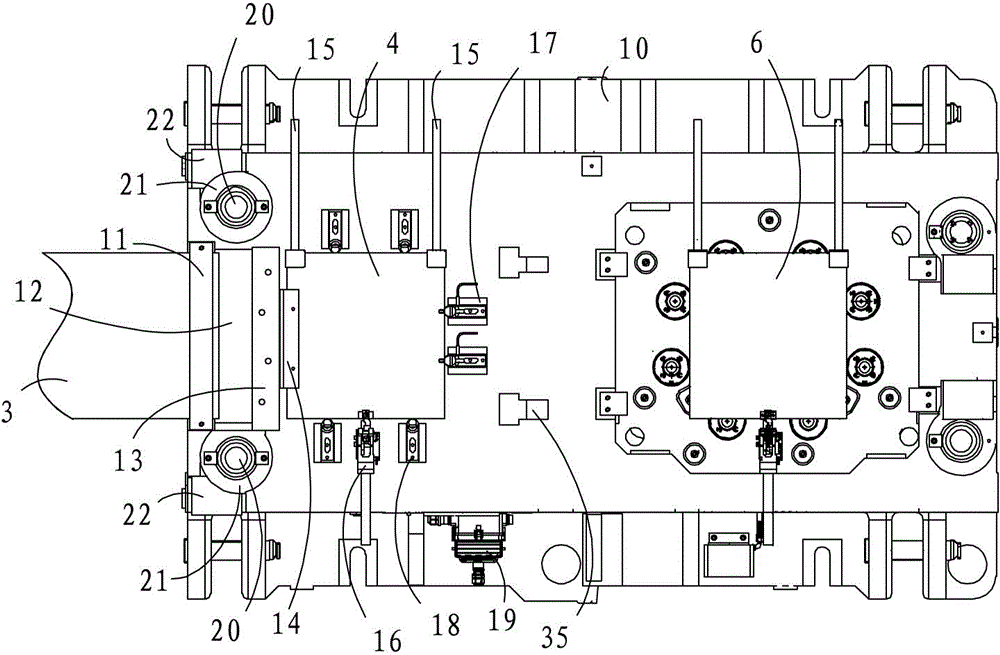

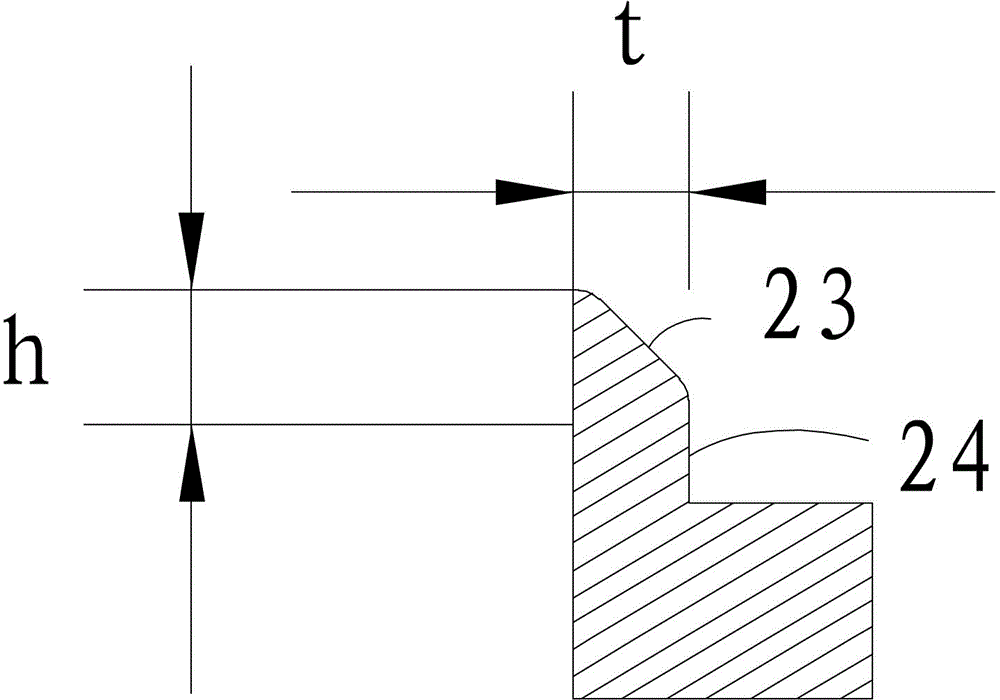

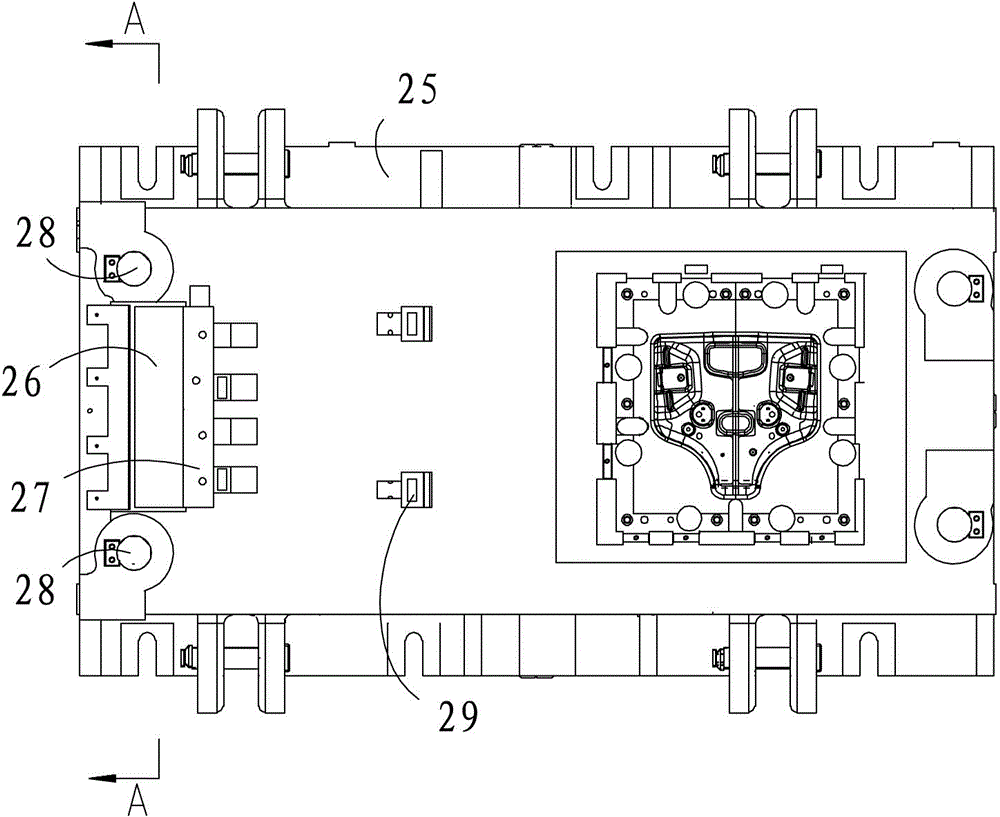

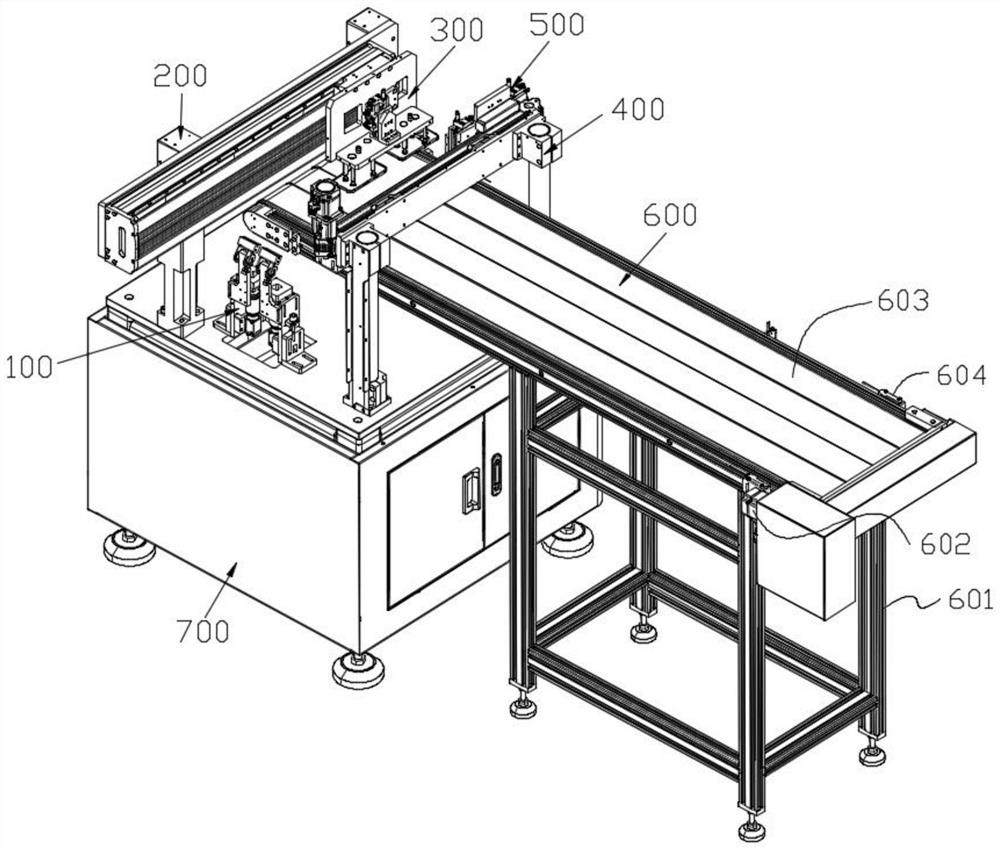

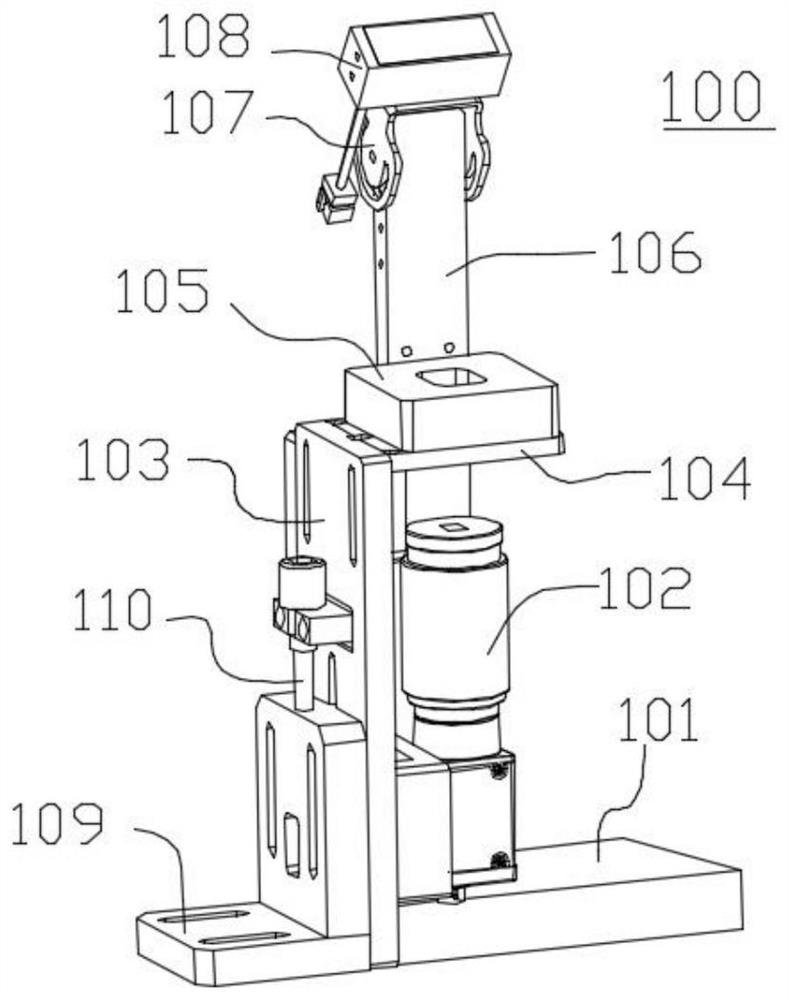

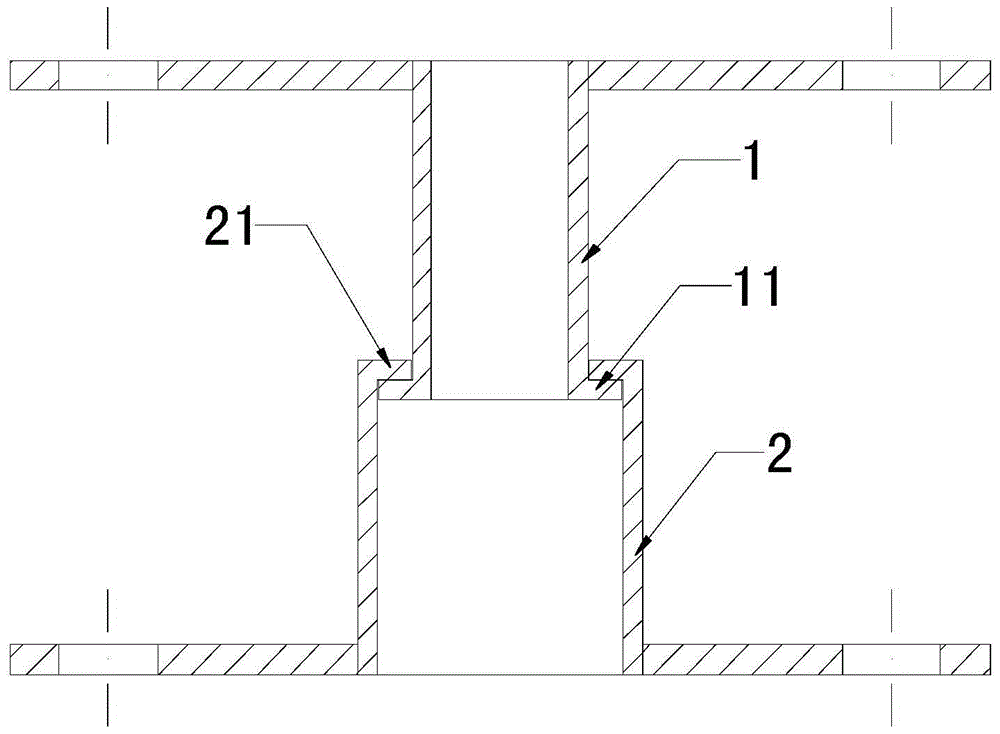

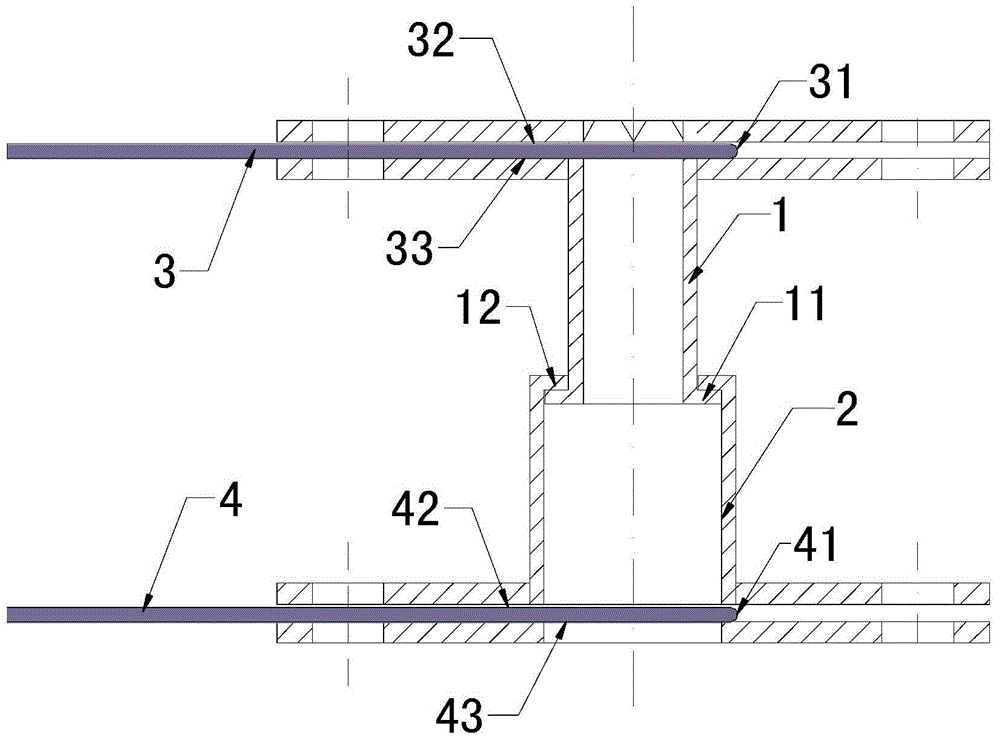

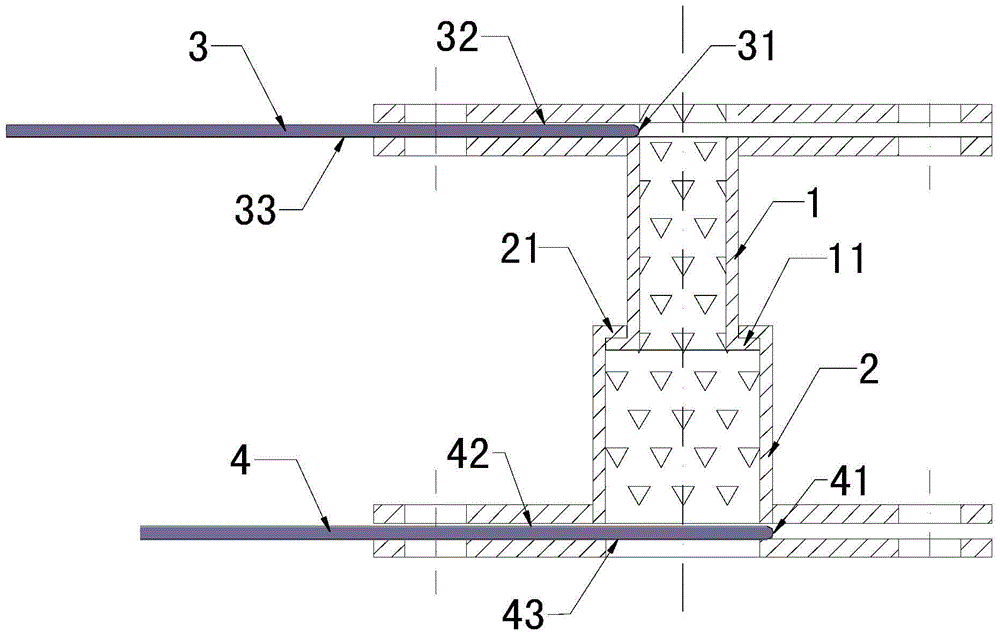

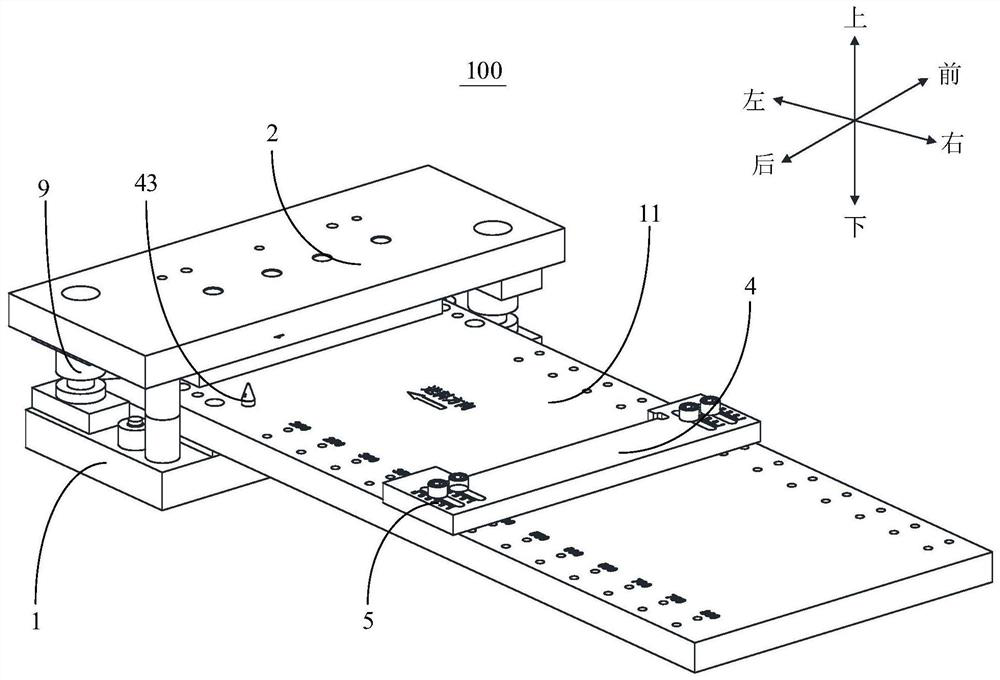

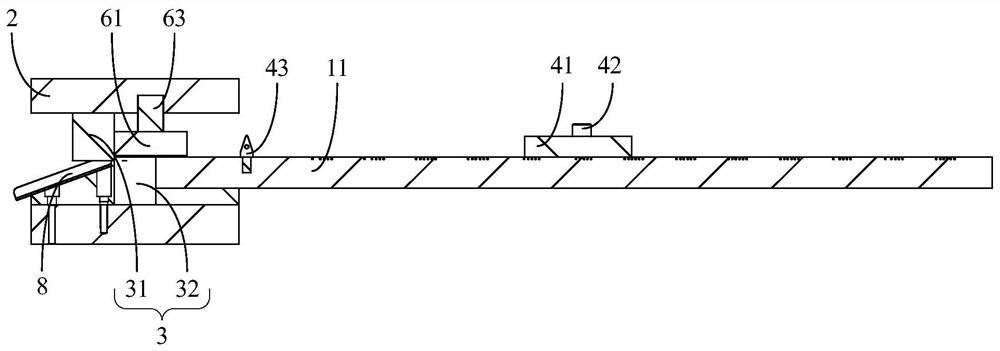

Uncoiling and blanking die and multi-station machining device

ActiveCN106140933AConvenient pick-up operationPrecise positioningShaping toolsMetal-working feeding devicesPunchingEngineering

The invention provides an uncoiling and blanking die. The uncoiling and blanking die comprises a lower die base and an upper die base which is located above the lower die base and matched with the lower die base for punching. A lower die deburring insert and a supporting plate located on one side of the lower die deburring insert are arranged on the lower die base. A pressing core is arranged on the portion, corresponding to the lower die deburring insert, of the upper die base. An upper die deburing insert is arranged on one side of the pressing core in an attached mode. A guide positioning plate is arranged on the lower die base and located between the lower die deburring insert and the supporting plate. An oblique guiding plane which is in smooth connection with the top end face of the lower die deburring insert, and a vertical positioning plate which is in smooth connection with the bottom of the guiding plane are formed at the top of the guide positioning plate. The bottom of the positioning plane intersects with the horizontal top end face of the guide positioning plate. The invention further provides a multi-station machining device provided with the uncoiling and blanking die. According to the uncoiling and blanking die, accurate positioning can be conducted during coil stock blanking, and workpieces can be taken conveniently after being blanked.

Owner:GREAT WALL MOTOR CO LTD

Pharmaceutical quantitative feeding metering device

InactiveCN112027132AImprove blanking accuracyIncrease productivitySolid materialGrain treatmentsPharmaceutical drugEngineering

The invention discloses a pharmaceutical quantitative feeding metering device, and relates to the technical field of pharmaceutical auxiliary equipment. The pharmaceutical quantitative feeding metering device comprises a pharmaceutical storage bin and a supporting base, wherein blanking pipes are arranged on the bottom wall of the pharmaceutical storage bin at equal intervals, metering rotating rollers are arranged in the blanking pipes, four medicine storage grooves are formed in the surfaces of the metering rotating rollers at equal angles, metering cylinders are arranged below the blankingpipes, rotating rods are symmetrically arranged on the upper side and the lower side in the pharmaceutical storage bin, and stirring rods are symmetrically arranged on the surfaces of the rotating rods up and down. Medicines in the pharmaceutical storage bin fall into the medicine storage grooves in the surfaces of the metering rotating rollers through the blanking pipes due to the gravity effect,the medicines in the medicine storage grooves fall into the metering cylinders due to the gravity effect, and when normal blanking is carried out, electromagnetic valves are all in an open state, andafter blanking is completed, if the numerical value of a pressure sensor exceeds or is smaller than a normal range, a worker can immediately press a control button, so that the electromagnetic valvesare closed, a controller controls the metering rotating rollers to stop rotating, the blanking precision is higher, and the production efficiency is effectively improved.

Owner:ANHUI YONSENT PHARMA

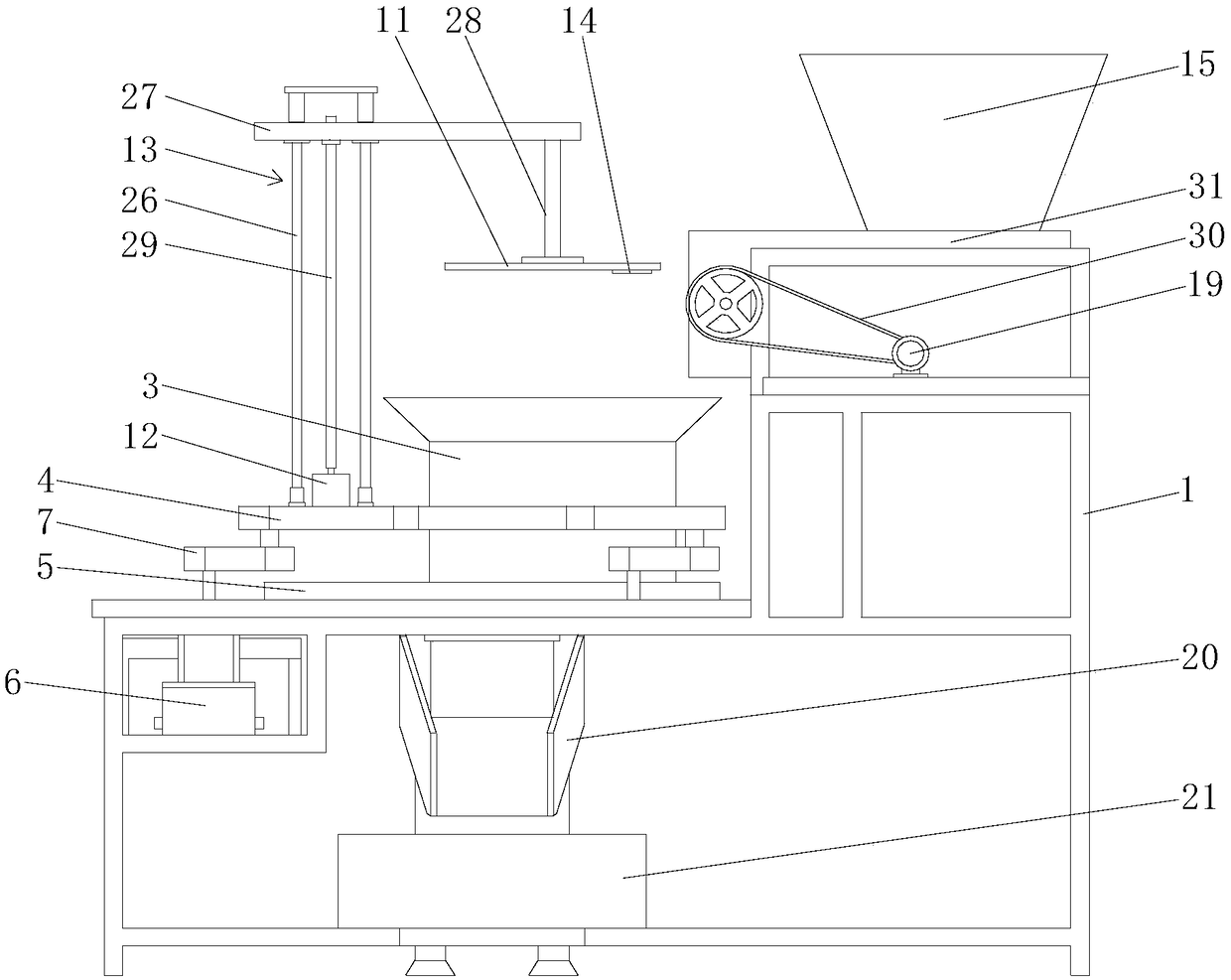

Batching machine

ActiveCN106861549AImprove blanking accuracyAvoid accumulationRotary stirring mixersTransportation and packagingBatch machineSieve

The invention relates to a batching machine. The batching machine comprises a base, a stirring rod, a charging assembly and a feeding part, wherein the feeding part is connected to the base; the base comprises a containing cavity and a charging hole communicated with the containing cavity; the charging hole is located at a connecting part of the feeding part and the base; the charging assembly is arranged at the charging hole; the charging assembly comprises a movable sieve, a fixed sieve fixed relative to the base and a resetting part; the movable sieve can move relative to the fixed sieve to be at a first state and a second state respectively; under the first state and the second state, the movable sieve and the fixed sieve are matched to stop a material from entering the base from the feeding part or allow the material to enter the base from the feeding part respectively; the stirring rod can contact the movable sieve to drive the movable sieve to move through the movement of the stirring rod; the resetting part is used for applying a restoring force for restoring the second state to the first state to the movable sieve. By adopting the batching machine, the material can be prevented from being accumulated at the charging hole and an arch is not formed; the material can smoothly fall into the containing cavity and is not accumulated in the containing cavity so that the discharging precision of the batching machine is improved.

Owner:珠海优特智厨科技有限公司

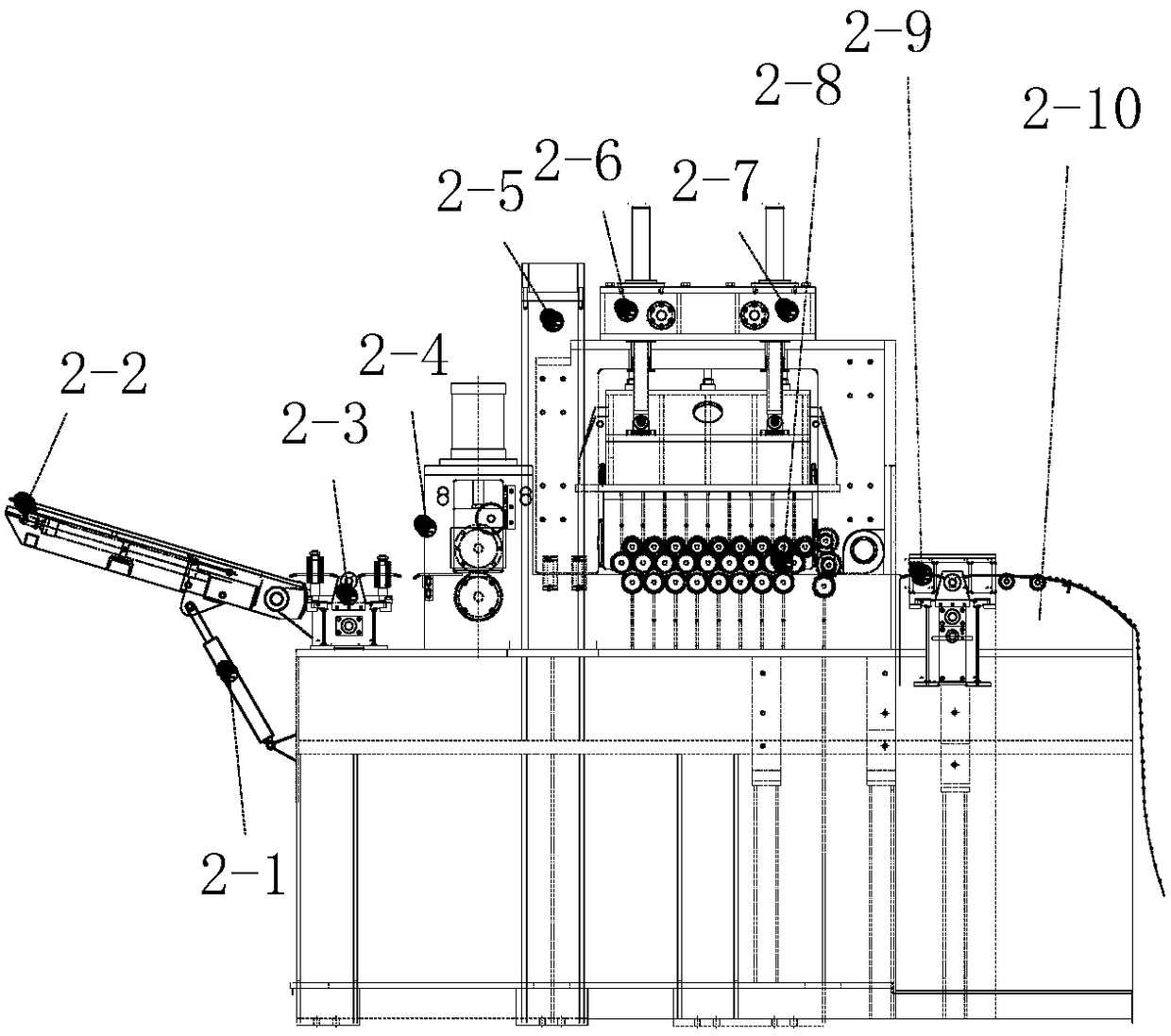

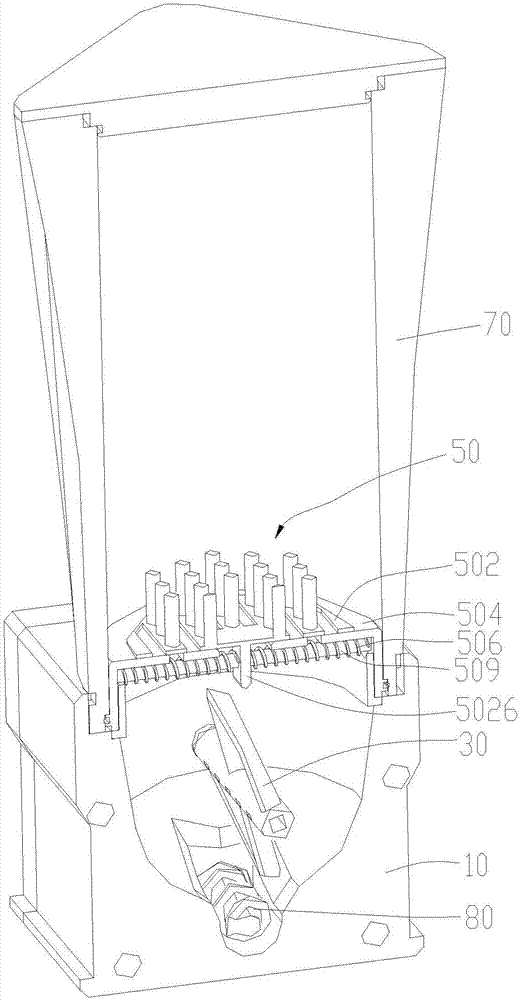

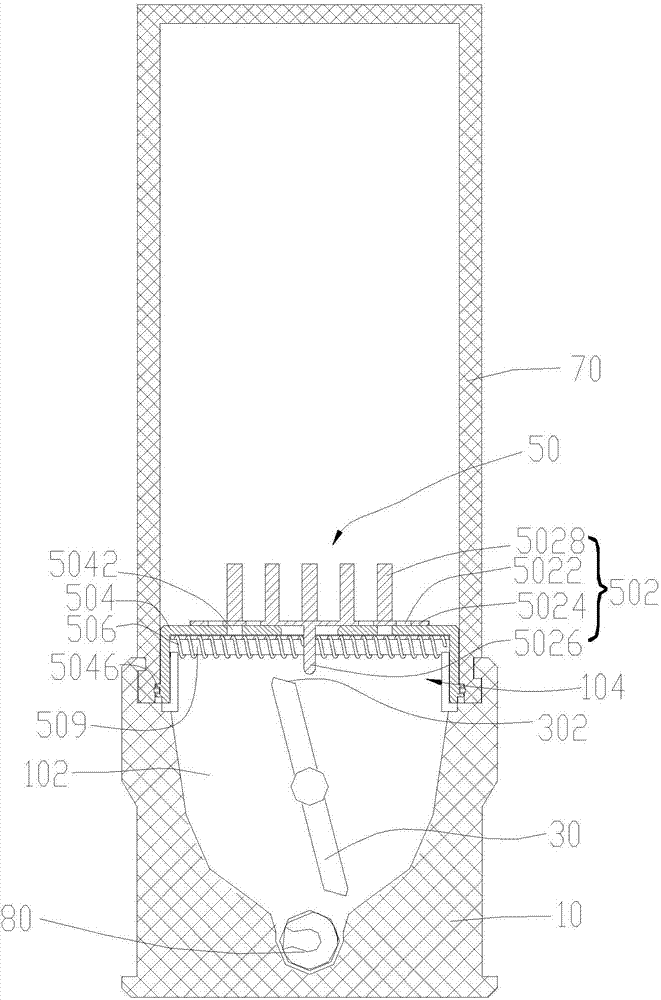

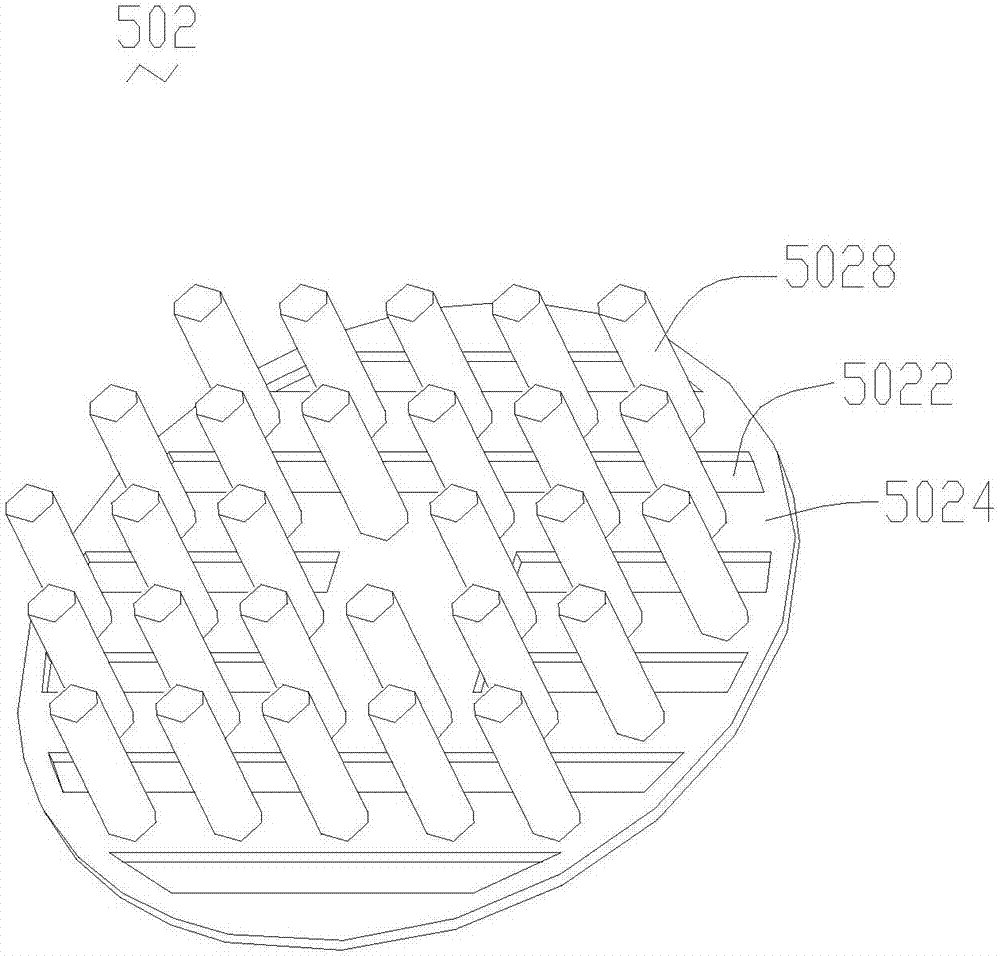

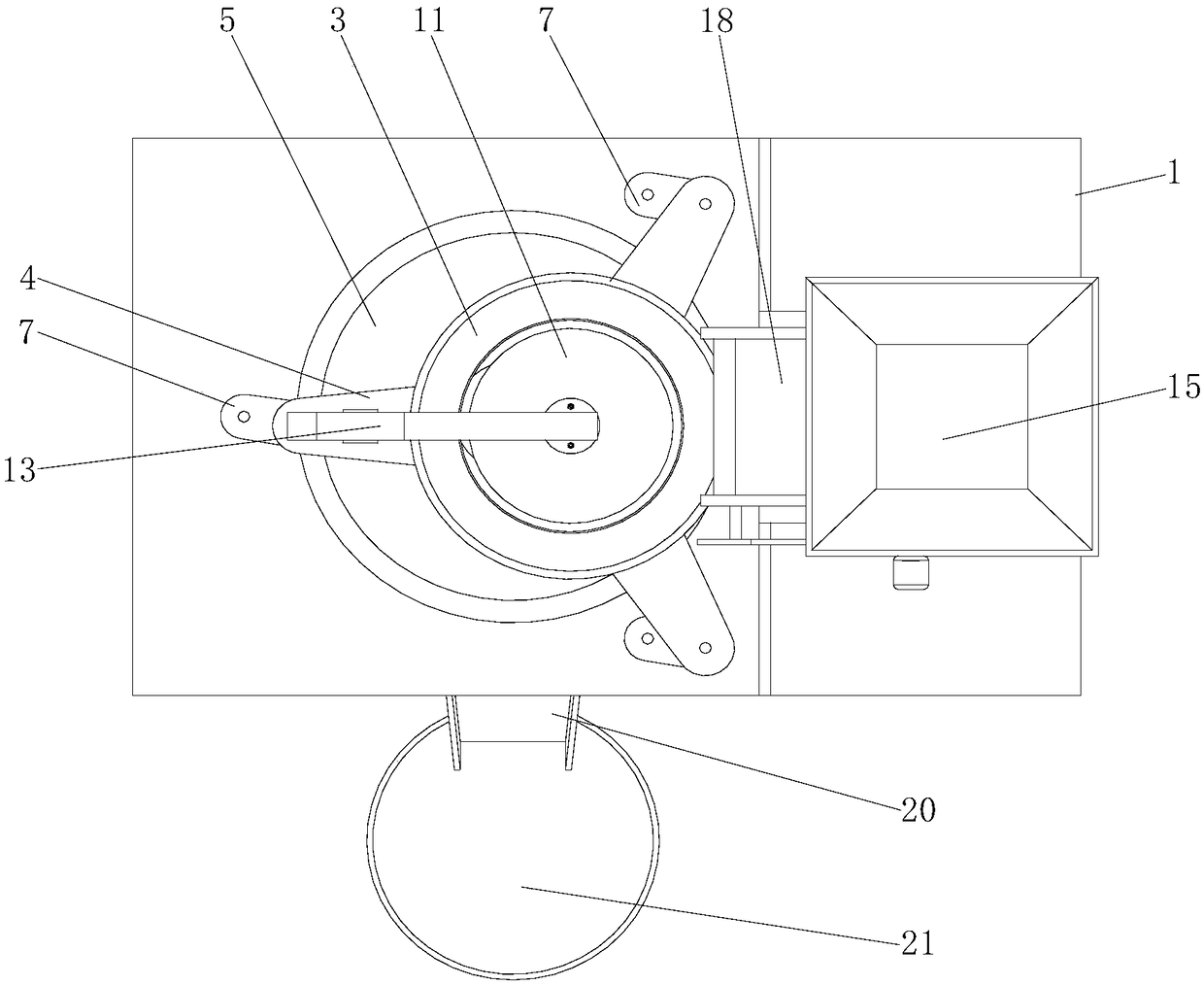

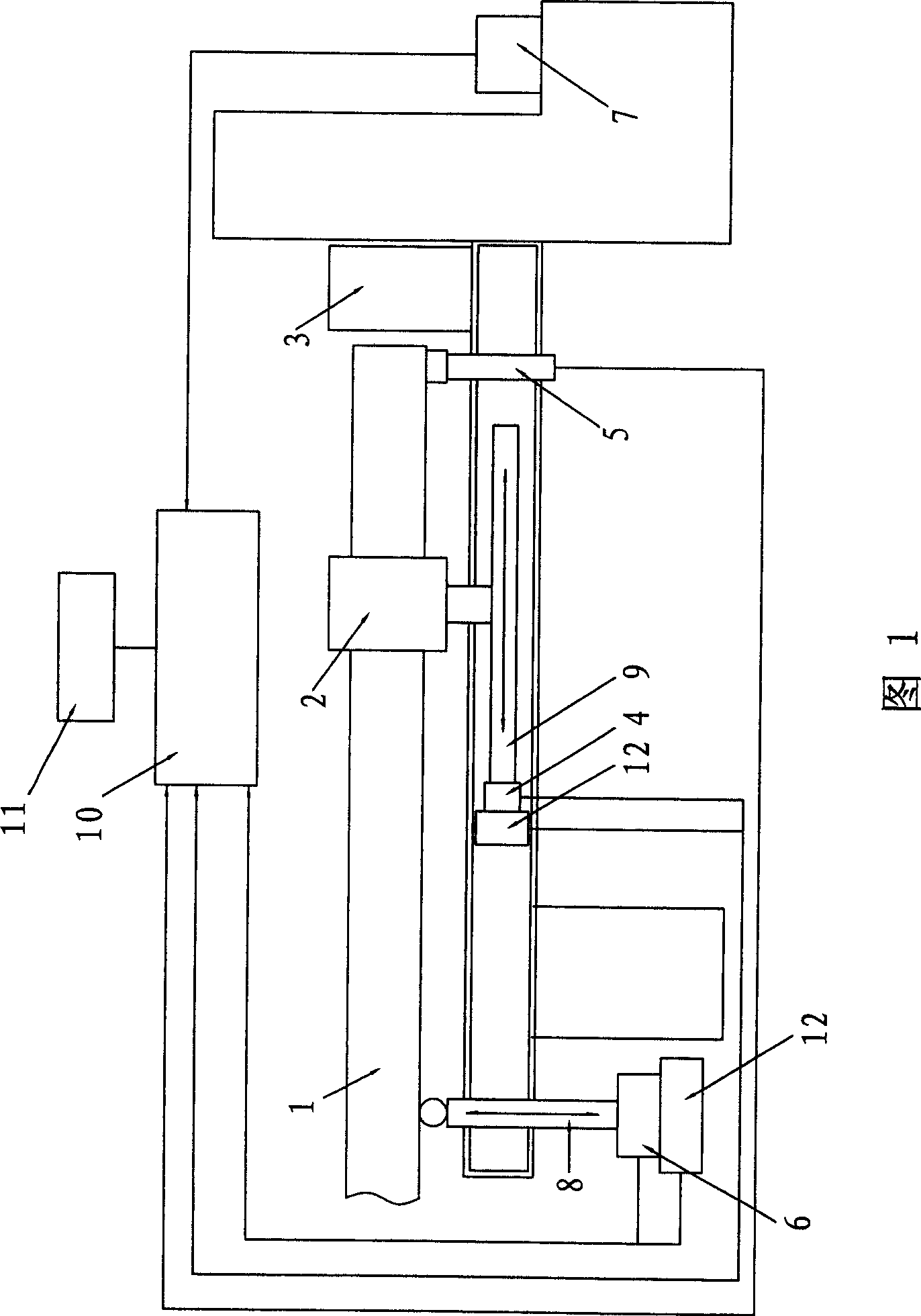

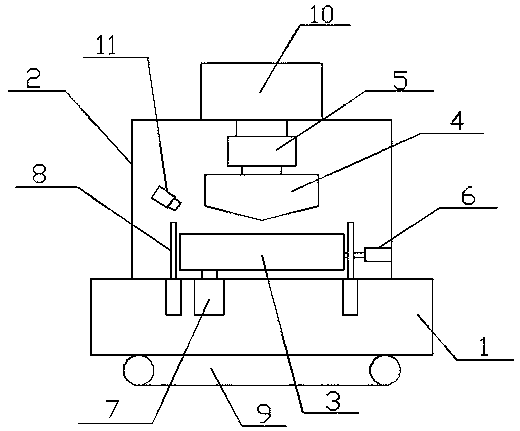

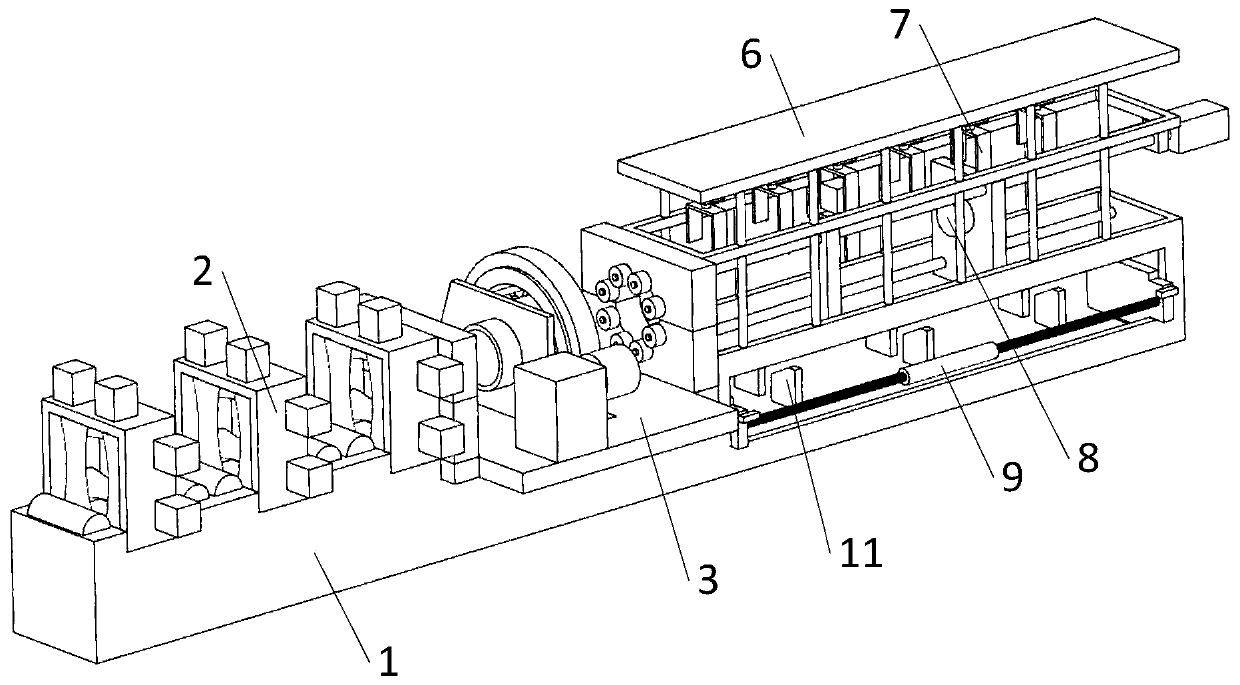

Tea leaf twisting machine

PendingCN108887423AReduce manufacturing costImprove product qualityPre-extraction tea treatmentProduction rateEngineering

The invention discloses a tea leaf twisting machine. The tea leaf twisting machine comprises a stander and a controller, wherein a material storage mechanism, a feeding mechanism, a pressurizing mechanism, a twisting mechanism and an unloading mechanism are respectively arranged on the stander, one end of the feeding mechanism is linked with an input hole of the storage mechanism, the other end ofthe twisting mechanism linked with the twisting mechanism, the pressurizing mechanism is mounted on the twisting mechanism, and the unloading mechanism is linked with the output hole of the twistingmechanism; and the controller is connected with the material storage mechanism, the feeding mechanism, the pressurizing mechanism and the twisting mechanism respectively so as to be used for controlling the mechanisms to work. The tea leaf twisting machine has the beneficial effects that the pressure in the twisting process of tea leaves can be changed, automatic loading and unloading can be realized, the operation is simple, the production rate is high, and the production quality of tea is good.

Owner:WUZHOU UNIV

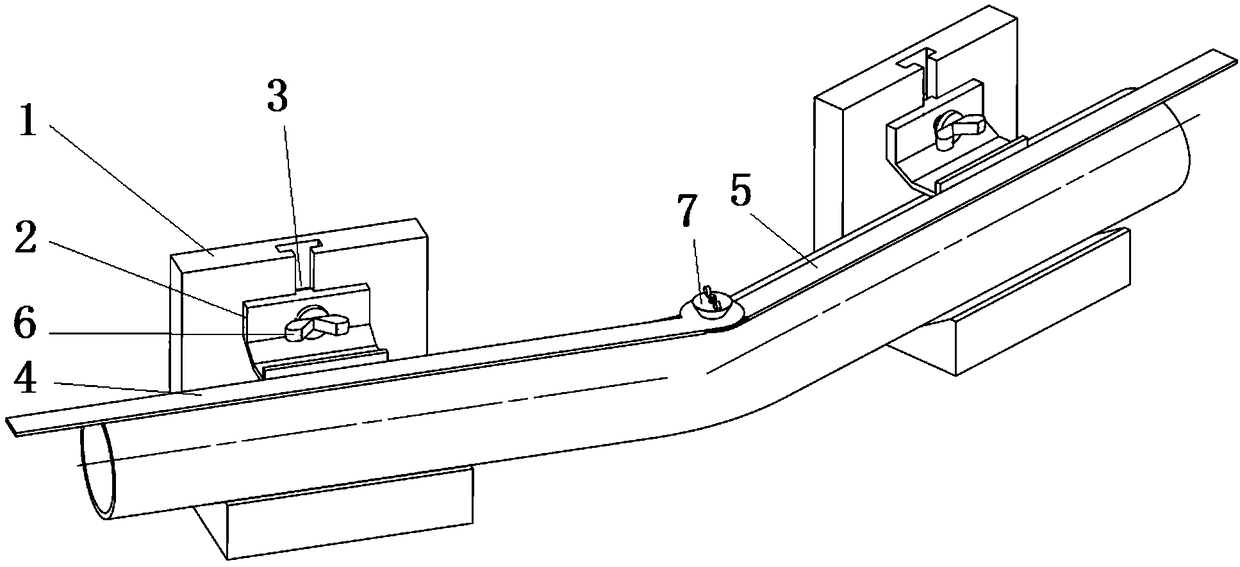

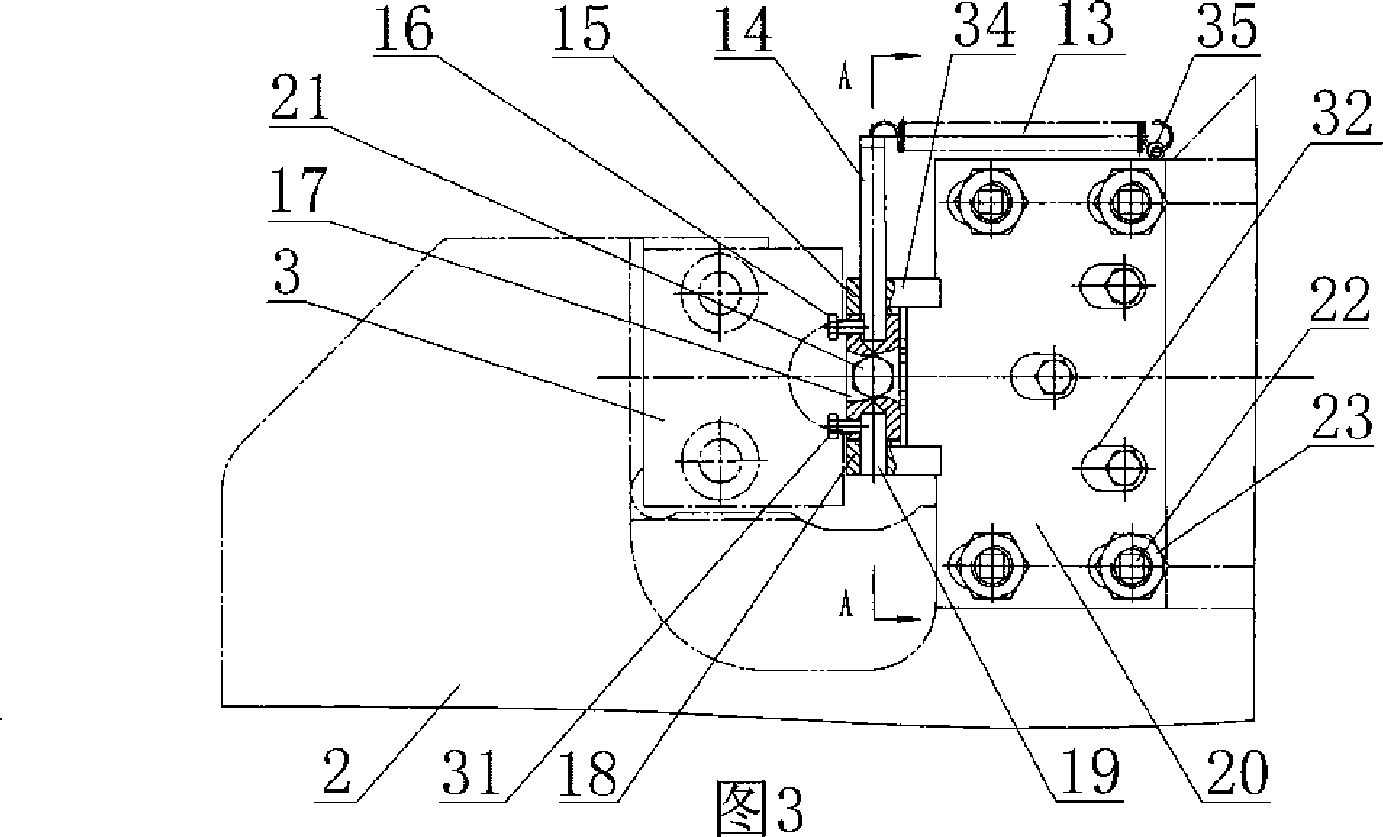

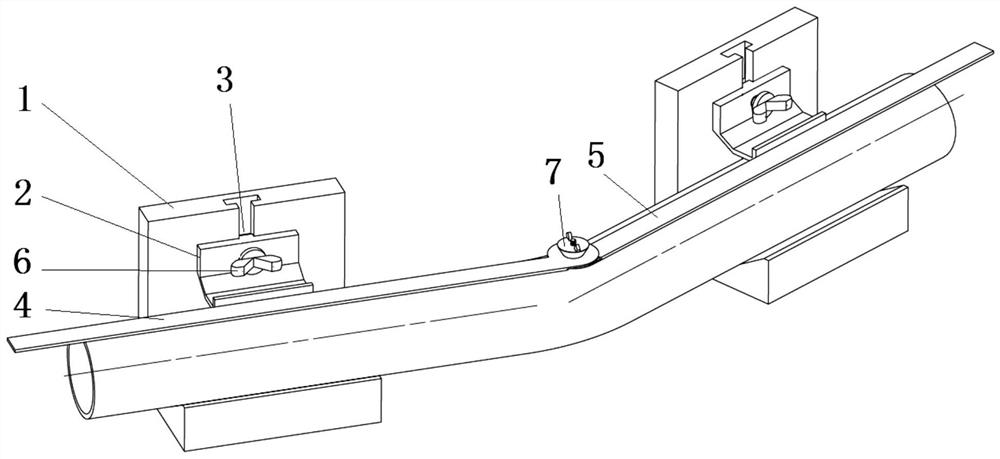

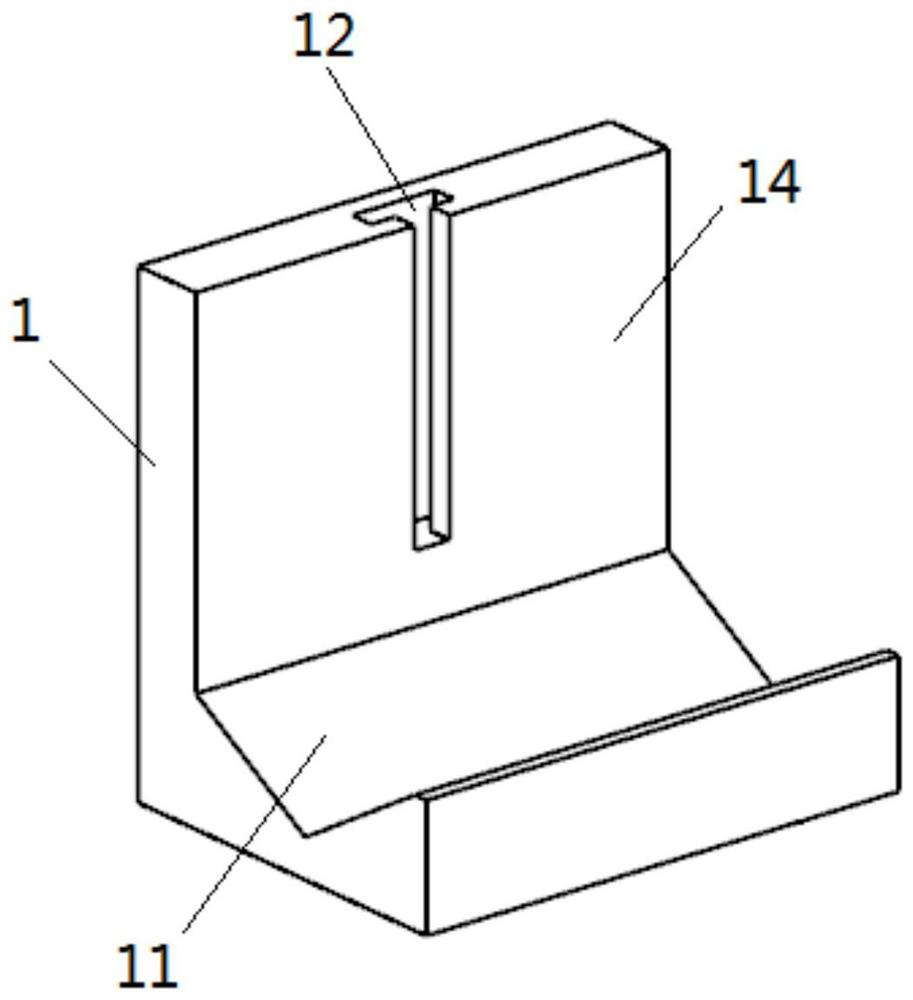

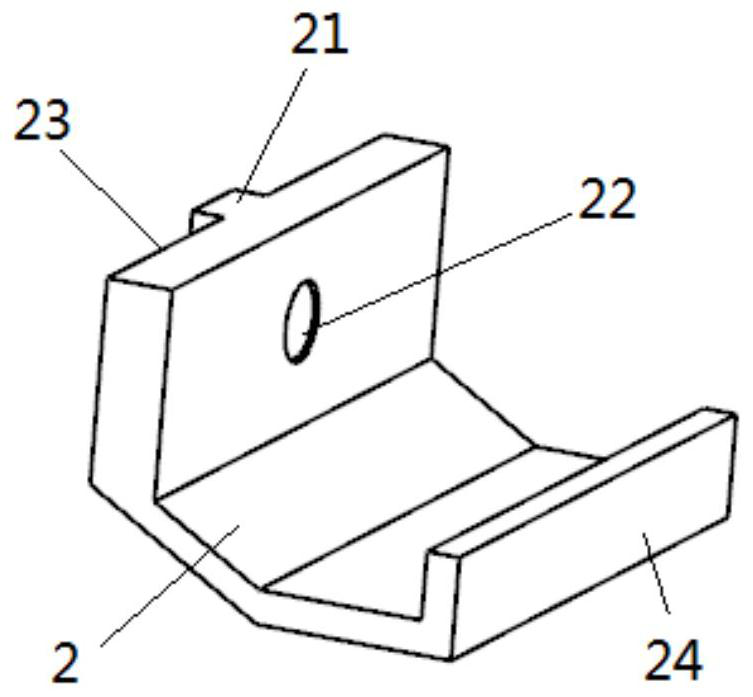

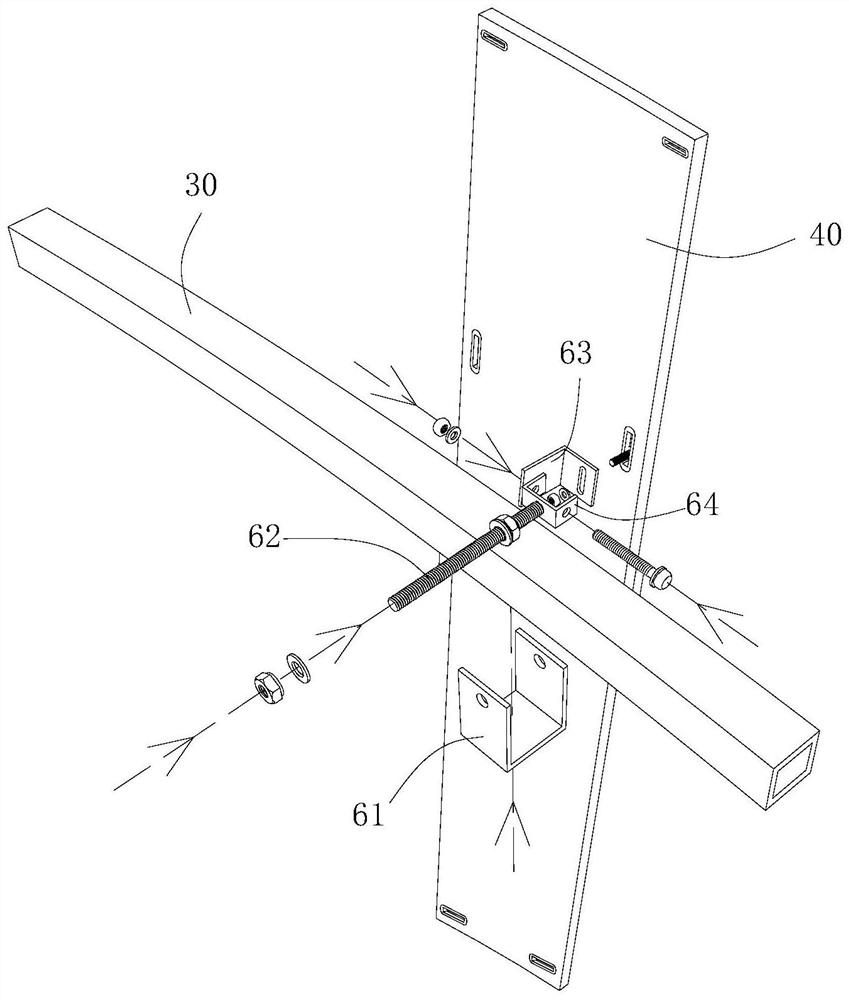

Marking device and method used for steel tube elbow

ActiveCN108724139AHigh marking accuracyImprove blanking accuracyOther workshop equipmentArchitectural engineeringPerpendicular direction

The invention discloses a marking device and method used for a steel tube elbow. The marking device comprises two positioning base assemblies and a marking ruler, wherein each positioning base assembly comprises a base cushion block, a limiting plate, a T-shaped block and a fastening bolt, the base cushion block is equipped with a V-shaped slot for placing a steel tube and a T-shaped slot in the perpendicular direction, the limiting plate is connected with the T-shaped block and is mounted in the T-shaped slot, and can move up and down along the T-shaped slot; the marking ruler comprises a fastening screw cap, a left ruler and a right ruler, the left end of the right ruler is connected with the right end of the left ruler, the fastening screw cap is used for fixing an angle position formedby the left ruler and the right ruler, and length scales for measuring a marking distance are arranged on the ruler edge of the marking ruler; during marking operation, the steel tube elbow is horizontally placed in the V-shaped slots of the two base cushion blocks, so that the limiting plates move along the T-shaped slots until the limiting plates are in contact with the steel tube elbow and arefixed; and the marking ruler is adjacent to the limiting plates, the fastening screw cap is screwed up, scales on the marking ruler are read, and blanking dimensions are marked. The marking device has the advantages of being simple in structure, convenient to use, high in reliability, wide in range of application and the like.

Owner:CSSC MES DIESEL

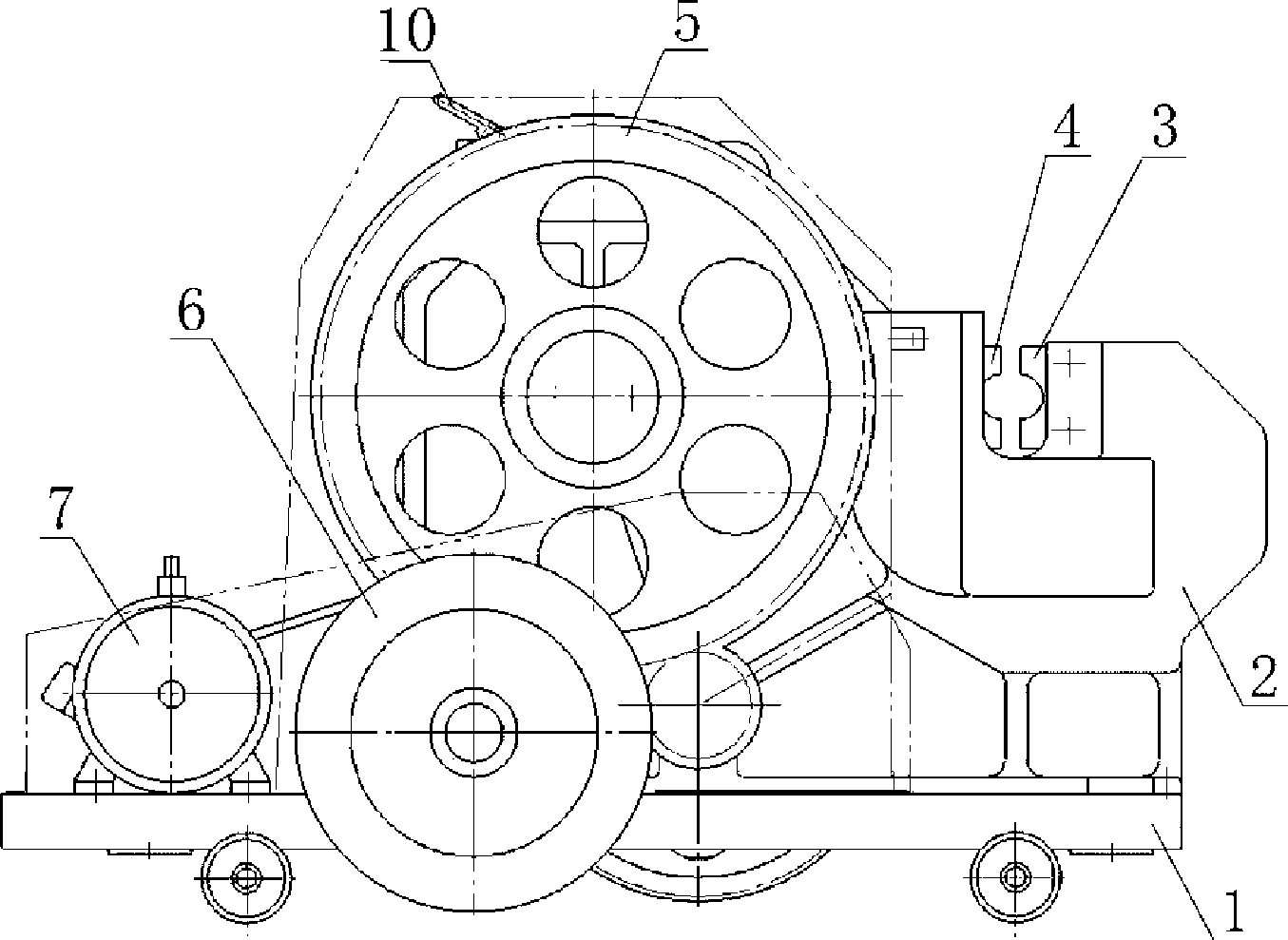

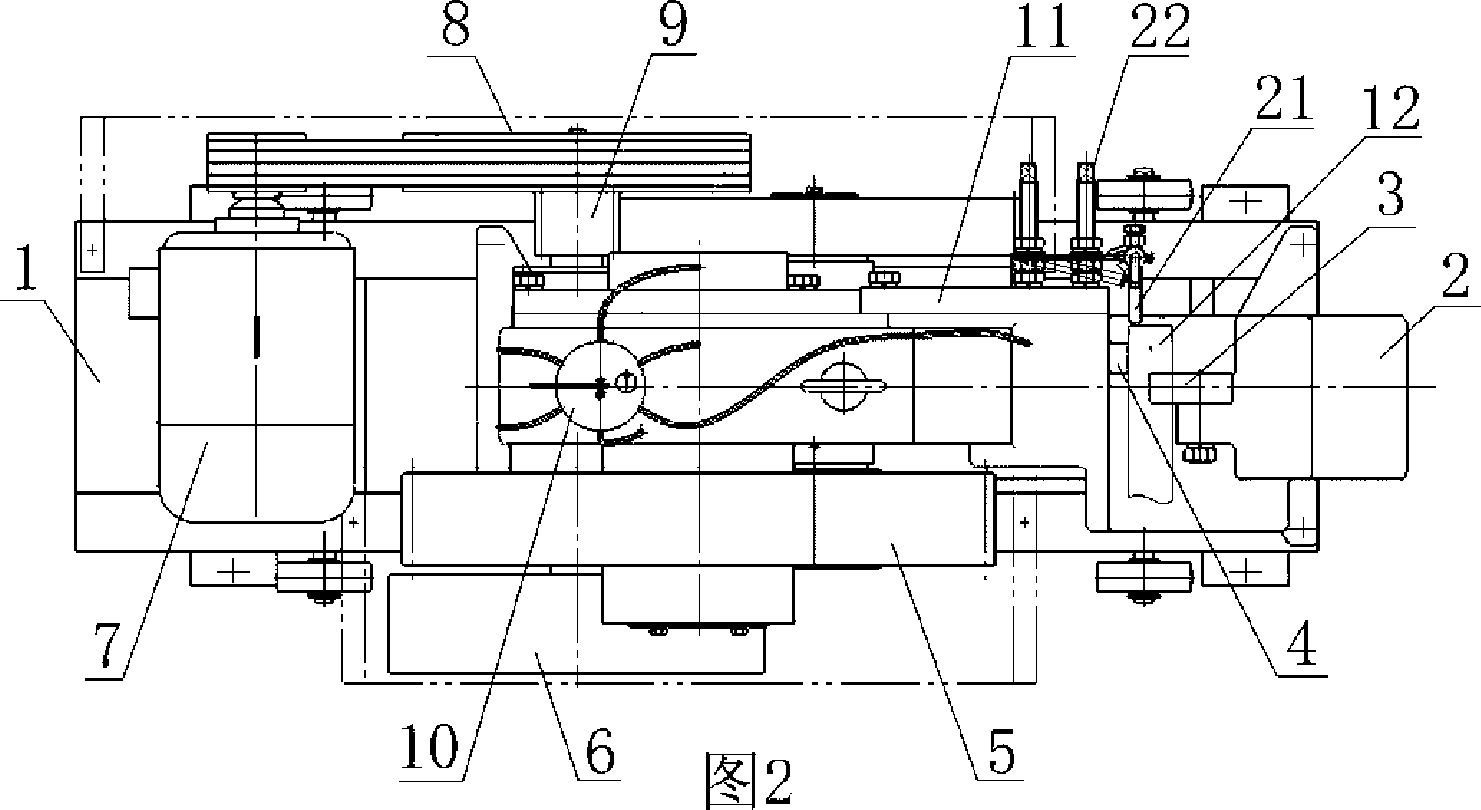

Horizontal type billet shearing machine

InactiveCN101386084AImprove blanking accuracyEnsure consistencyShearing machinesShearing machine accessoriesBlade plateHigh energy

The invention provides a horizontal rod cutting machine; a machine body is fixed on a machine seat; one end of the machine body is fixed with a fixed cutter plate; the edge of the fixed cutter plate is corresponding to a movable cutter plate transversely; the movable cutter plate is fixed at the end of the sliding block of the crankshaft sliding mechanism; the wearable slideway of the sliding block is pressed on the machine body by a pressing plate; the crankshaft of the crankshaft sliding block mechanism is connected with the motor by a dual-flywheel transmission system in a driving way; rod blank to be cut is vertical to the slideway; the edge on the top of the rod blank to be cut is provided with a flexible fixed-pitch adjusting device; the fixed-pitch screw of the flexible fixed-pitch adjusting device is connected with a locking nut. The horizontal rod cutting machine solves the technical problems such as large error of blanking length, easily damageable machine body, huge structure and high energy dissipation and can be applied to the blanking of round steels in the industries such as motorcycles, automobile fittings, building tennis balls, etc.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

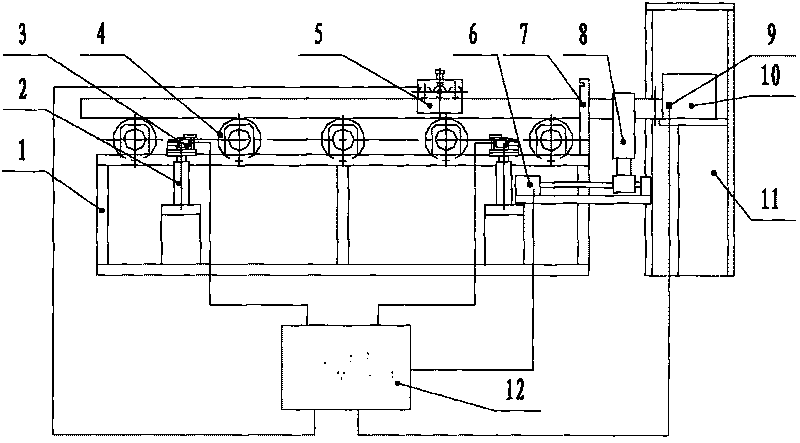

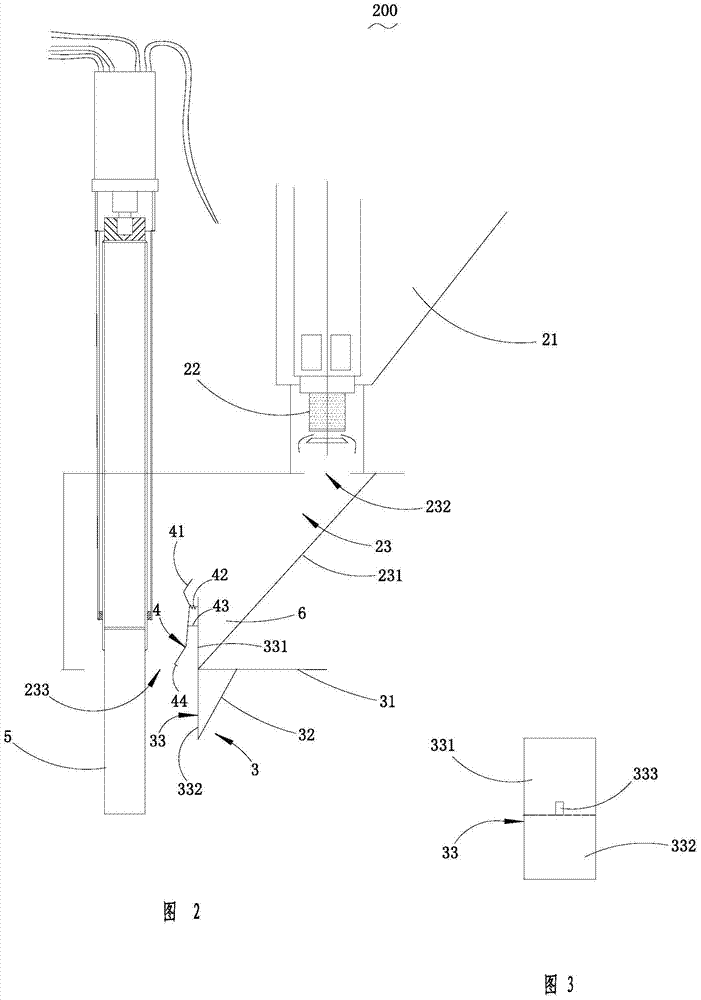

Blanking method and system thereof

InactiveCN101700633AAvoid measuringImprove blanking accuracyMetal sawing accessoriesMetal working apparatusCycle controlVolumetric Mass Density

The invention discloses a blanking method and a system thereof. The method comprises the following steps of: A. weighing a raw material and measuring the length of the raw material in advance; and figuring out the actually linear density of the material and the length of the needed blanking; B. controlling the feeding stroke according to the blanking length and blanking. The invention avoids the measurement on the section geometric dimension of the raw material, only needs to measure the weight and the length of each material on line so as to obtain the actually linear density and forms the closed cycle control of the blanking length in the terms of length control; therefore, the method is suitable for blanking solid or hollow materials with any section shapes. The invention overcomes the shortcoming of the traditional blanking method, is suitable for production field and increases the blanking precision.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Control method for bar stock saw cutting self-adapting precision baiting

InactiveCN100465835CImprove blanking accuracyFacilitate industrialized mass productionProgramme control in sequence/logic controllersEngineeringSelf adaptive

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

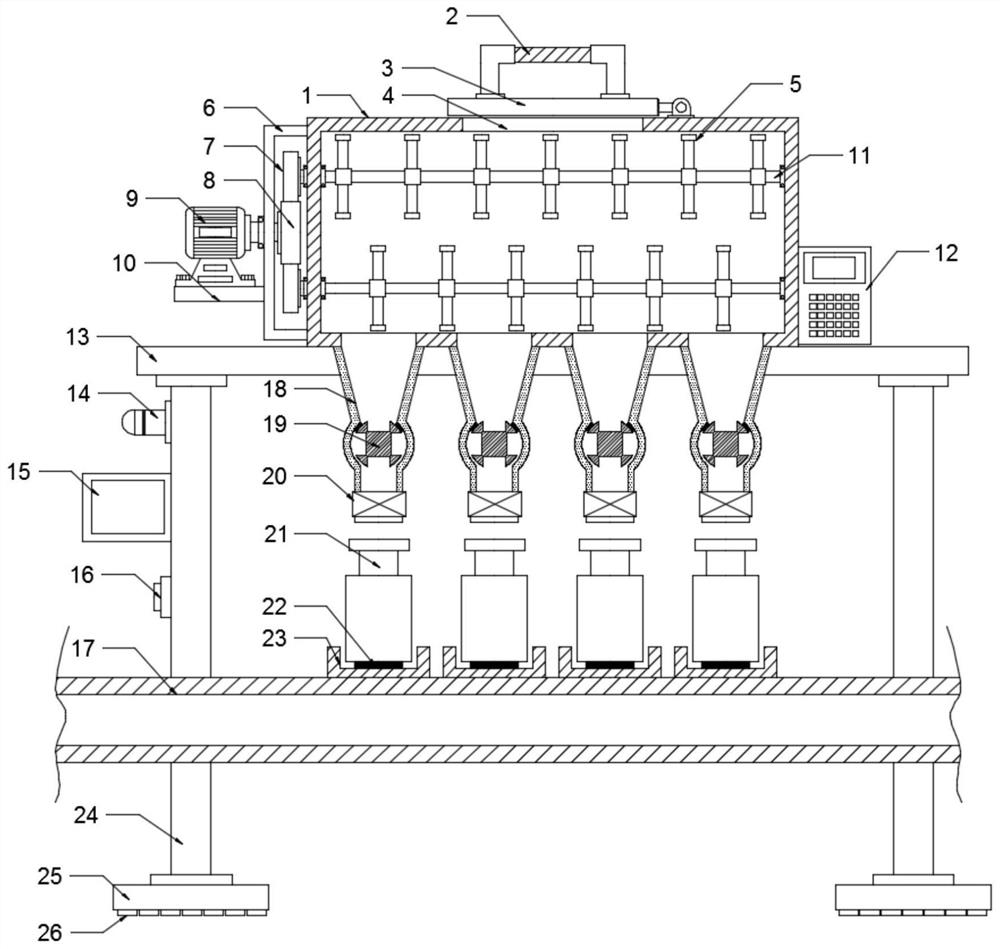

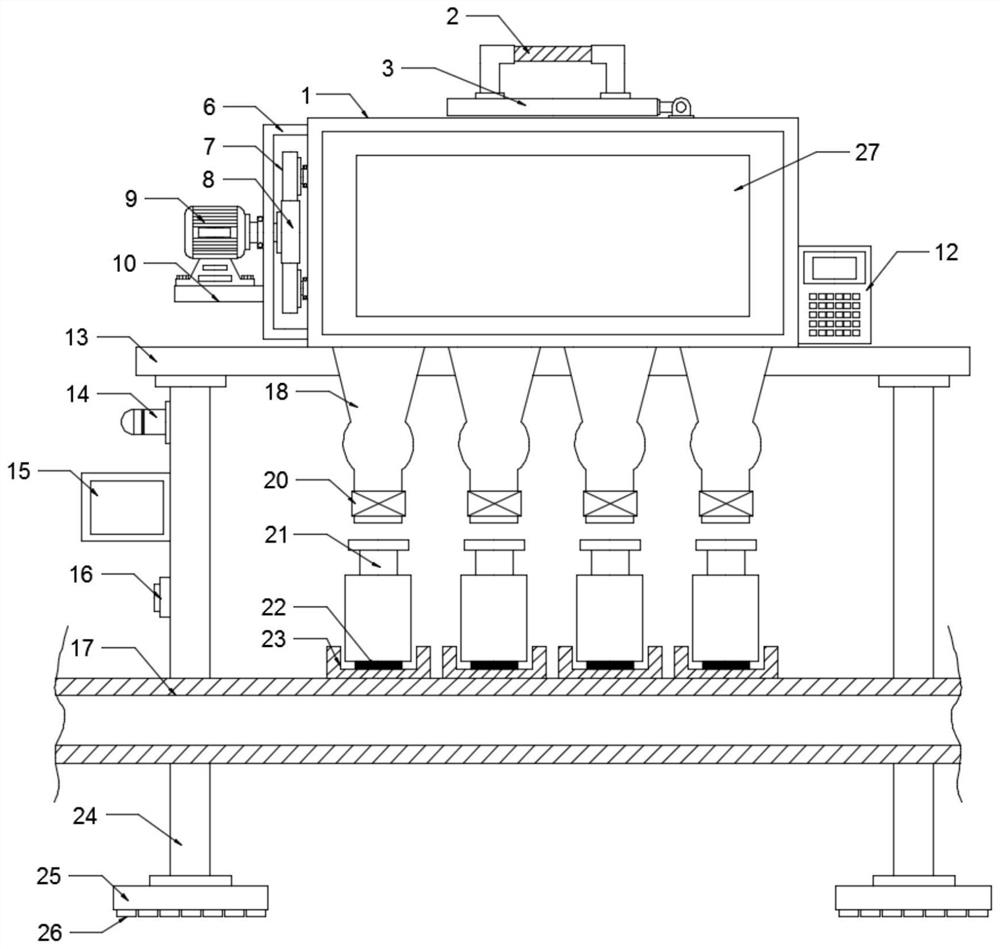

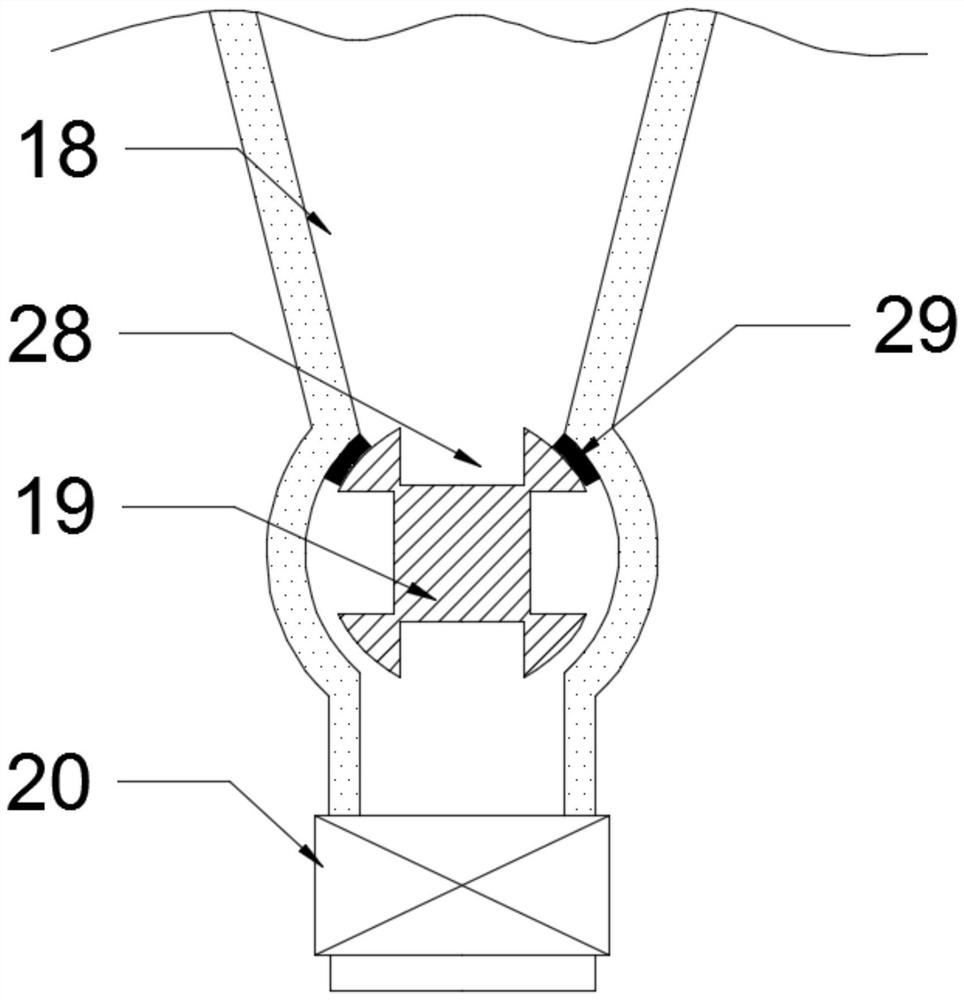

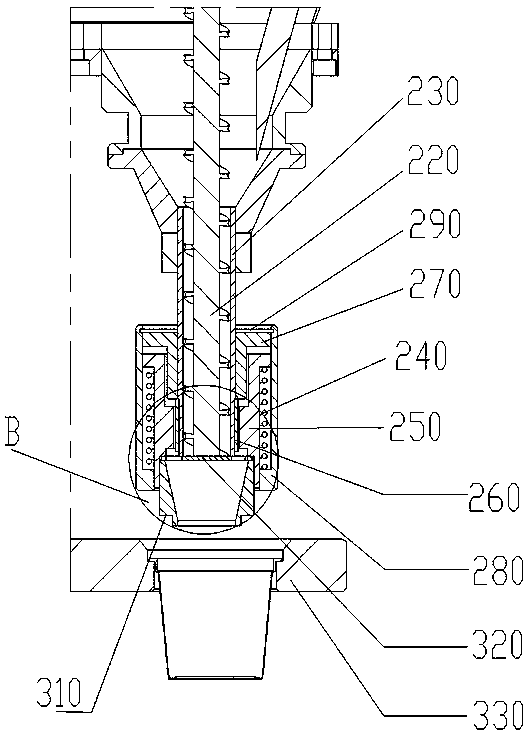

Blanking device of capsule cup filling machine

PendingCN108438268AImprove blanking accuracyImprove sealingSolid materialEngineeringMechanical engineering

The invention discloses a blanking device of a capsule cup filling machine. The blanking device of the capsule cup filling machine comprises a storage mechanism, a blanking control mechanism and a discharging mechanism. The blanking control mechanism comprises a motor. The motor is connected with a blanking screw and used for driving the blanking screw to rotate. The blanking screw is sleeved witha screw casing. The upper end of the screw casing is connected with the lower end of a hopper. The lower end of the screw casing is connected with an end cover through a screw casing lock sleeve. Theend cover is mounted on an outer shell and fixed by a retainer ring. A spring seat is slidably arranged outside the screw casing and slidably mounted in the shell. A spring is arranged between the spring seat and the shell. The discharging mechanism comprises a discharging head, a stop piece and a main device template. The discharging head is fixedly connected with the spring seat, presses and fixes the stop piece in the spring seat and makes the upper end face of the stop piece in close contact with the lower end face of the screw casing under the effect of the spring. The main device template is arranged below the discharging head and used for fixing an external cup. The blanking device has the advantages that the metering precision of material blanking is high, and powder leakage and powder dropping are avoided.

Owner:温州市途麦机械有限公司

A marking device and method for steel pipe bending

ActiveCN108724139BHigh marking accuracyImprove blanking accuracyOther workshop equipmentStraightedgeScrew cap

A marking device and method for steel pipe bending, including two positioning seat assemblies and a marking ruler; wherein, the positioning seat assembly includes a base pad, a limit plate, a T-shaped block and fastening bolts, and the base pad The block is provided with a V-shaped groove for placing steel pipes and a T-shaped groove along the vertical direction. The limit plate is connected with the T-shaped block and installed in the T-shaped groove, and can move up and down along the T-shaped groove. The marking ruler includes fastening Nut, left ruler and right ruler, the left end of the right ruler is connected with the right end of the left ruler. There is a length scale for measuring the marking distance; during the marking operation, place the steel pipe elbow horizontally in the V-shaped groove of the two base blocks, and make the limit plate move along the T-shaped groove until it touches the steel pipe elbow And fix the limit plate, close the marking ruler to the limit plate, tighten the fastening nut, read the scale on the marking ruler, and mark the blanking size by marking. The invention has the advantages of simple structure, convenient use, high reliability, wide application range and the like.

Owner:CSSC MES DIESEL

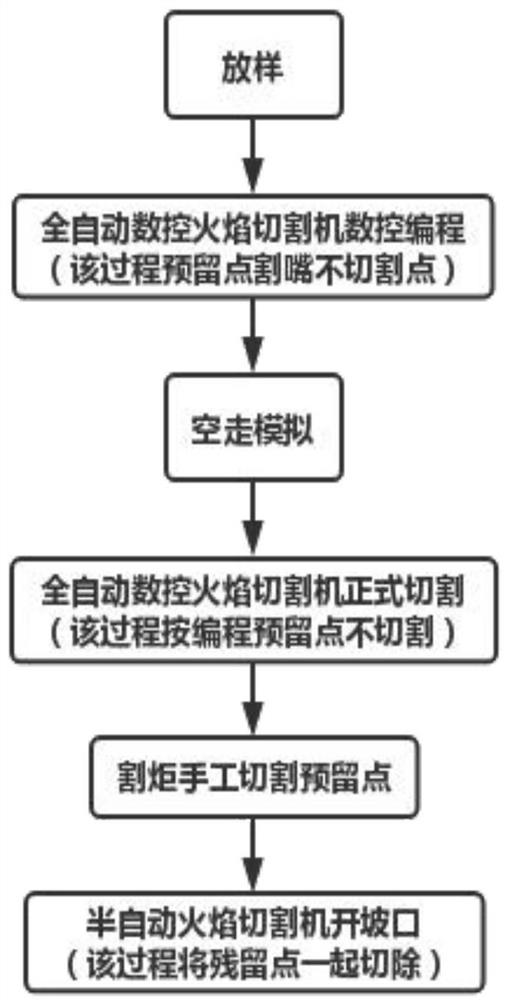

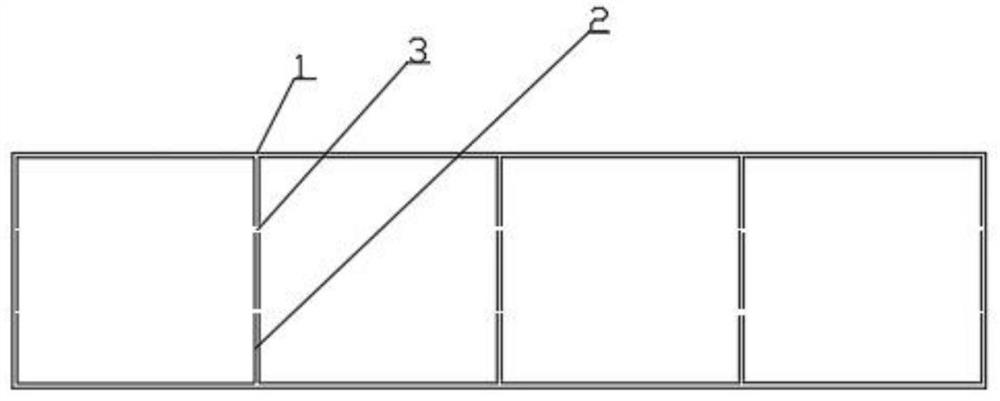

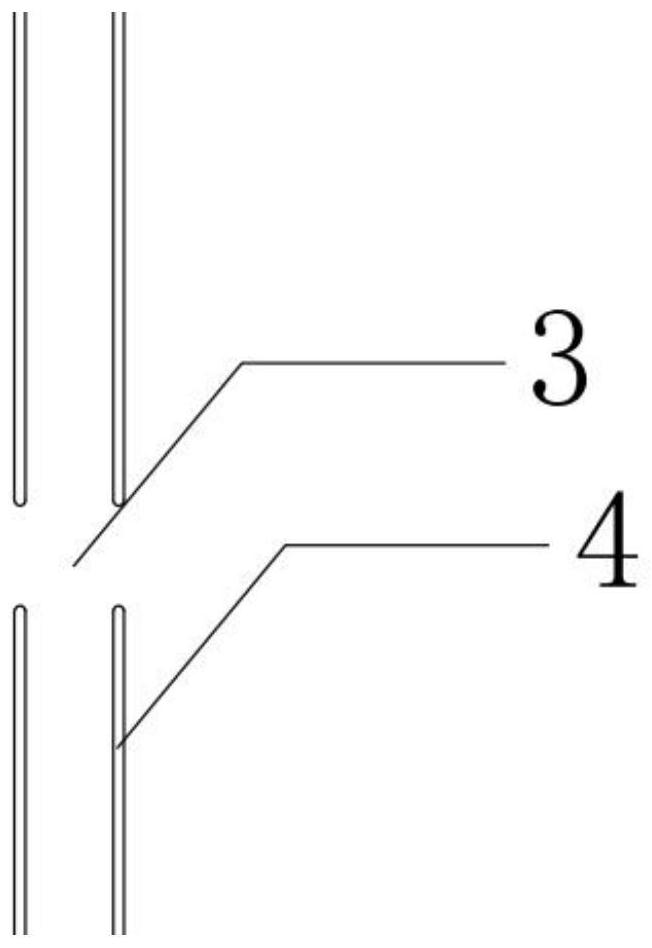

Method for improving flame cutting blanking precision of steel tube arch rib shell section base metal steel plate

PendingCN114523174AEnsure accuracy andQuality assuranceTotal factory controlGas flame welding apparatusNumerical controlFlame cutting

The invention discloses a method for improving flame cutting and blanking precision of a steel tube arch rib shell section base metal steel plate, which comprises the following specific blanking steps: step 1, selecting raw materials, determining the steps of the steel tube arch rib shell section base metal cutting and blanking method and corresponding raw material production equipment, and carrying out trial operation on the production equipment; step 2, lofting a steel plate, performing numerical control programming on a full-automatic numerical control flame cutting machine, compiling a running track of a cutting nozzle in a computer, and debugging related parameters; thirdly, before formal cutting, the cutting torch is made to run for one round in an idle mode according to numerical control programming, and the cutting running track is simulated; fourthly, the full-automatic numerical control flame cutting machine begins to conduct formal cutting, and after cutting is finished, four points of the shell section base metal steel plate are still not cut; the blanking and cutting precision of the steel pipe arch rib shell section base metal steel plate is improved, it is ensured that the blanking precision and quality of the steel plate are within the controllable range, and a foundation is laid for a series of subsequent machining and manufacturing of the steel pipe arch rib with the high precision requirement.

Owner:广西桂通工程管理集团有限公司

Undirected fixed-discharging type blanking die

Owner:LEACREE CHENGDU

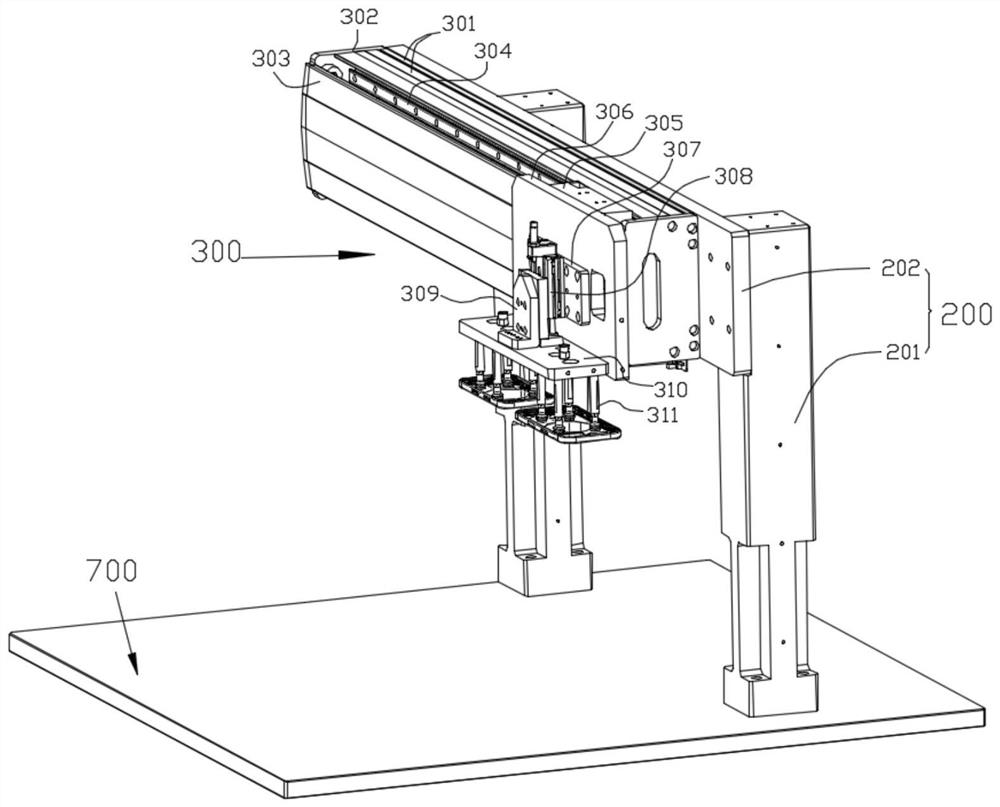

Back inspection sorting blanking device and blanking method

ActiveCN114535107AImplement backside detectionRealize quality judgmentSortingPhotovoltaic energy generationFace detectionEngineering

The invention provides a back detecting, sorting and discharging device and method, and belongs to the technical field of discharging of intelligent detecting and machining equipment.The device comprises a back detecting module, a back detecting side hanging assembly, a detecting and carrying module, a translation side hanging assembly, a sorting translation steering assembly, a multi-column belt conveying unit, a bottom frame and a controller; the controller is in telecommunication connection with the back face detection module, the detection carrying module, the sorting translation steering assembly and the multiple rows of belt conveying units, and feeding, back face detection, quality judgment and screening, steering, transferring and discharging of materials are achieved through control. By means of the back detection, sorting and discharging device and method, back detection, quality judgment, sorting and precise discharging of the materials can be achieved, the discharging precision and efficiency are improved, and the device and method can be conveniently applied and popularized in the field of detection and discharging of plate-shaped materials such as 3C products, semiconductor wafers and photovoltaic silicon wafers.

Owner:TZTEK TECH

Pipeline factory prefabrication construction method

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

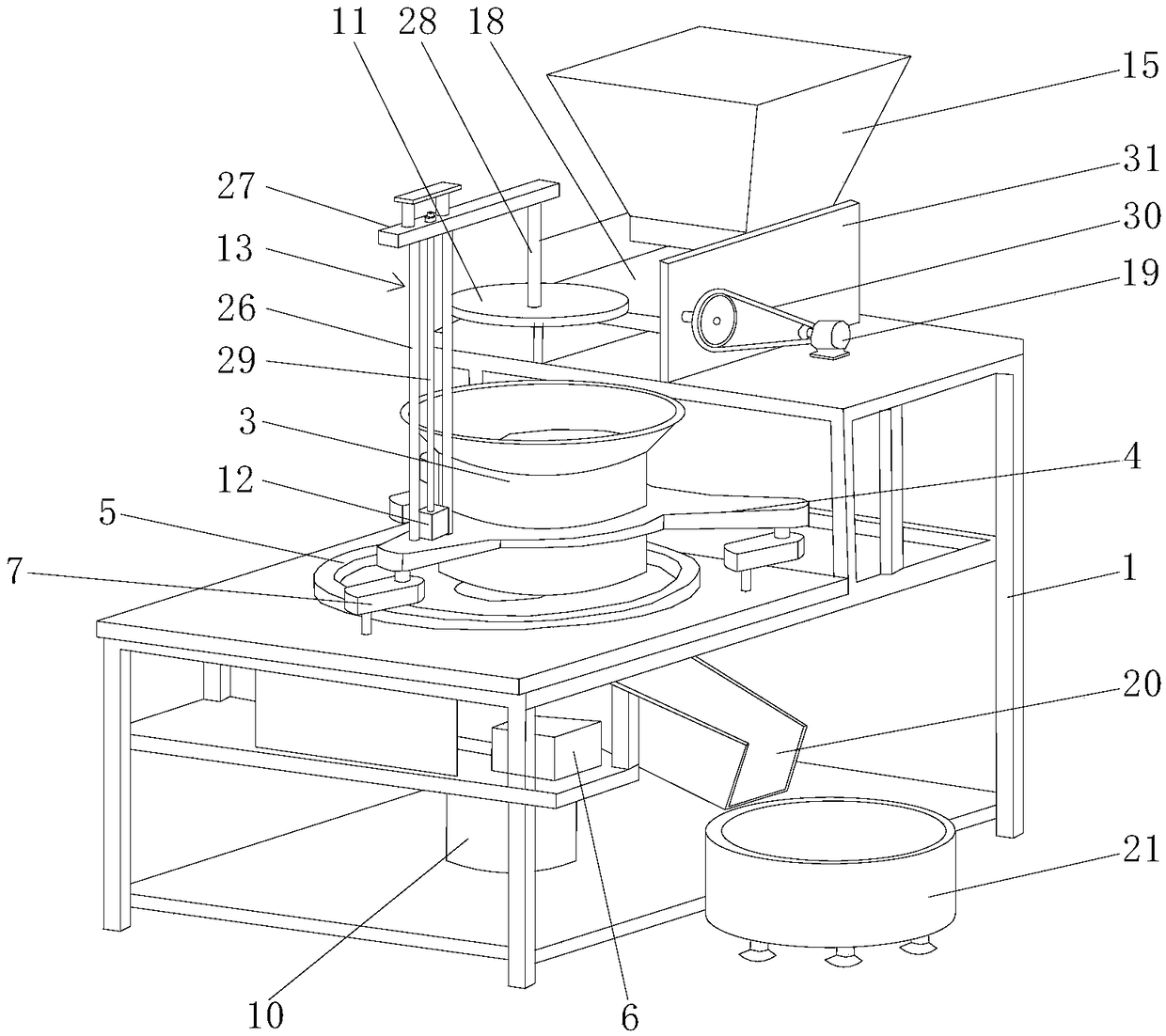

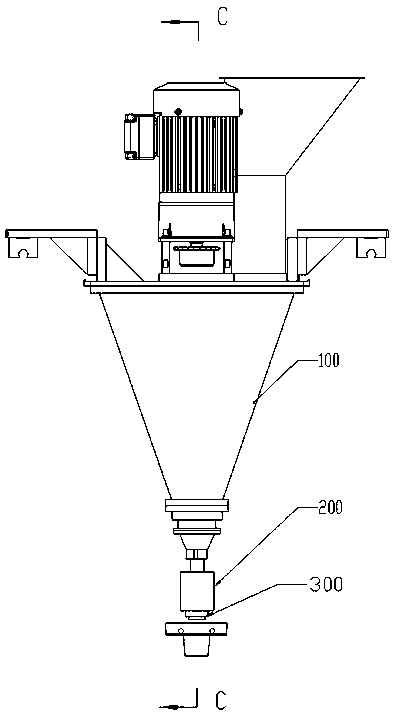

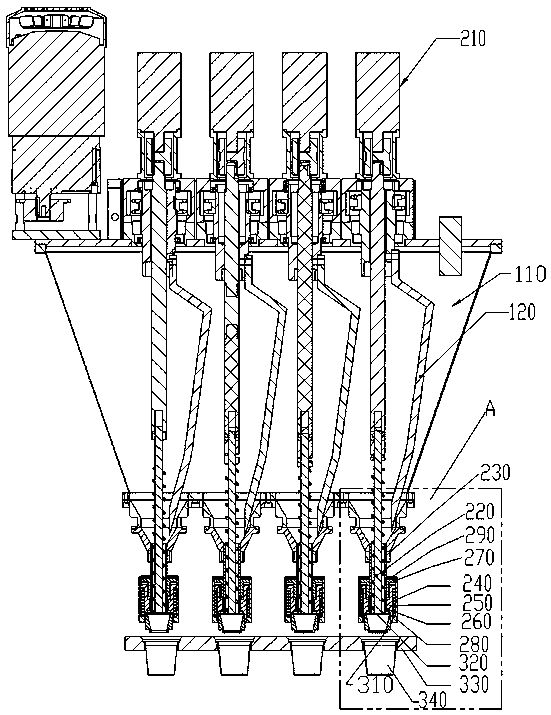

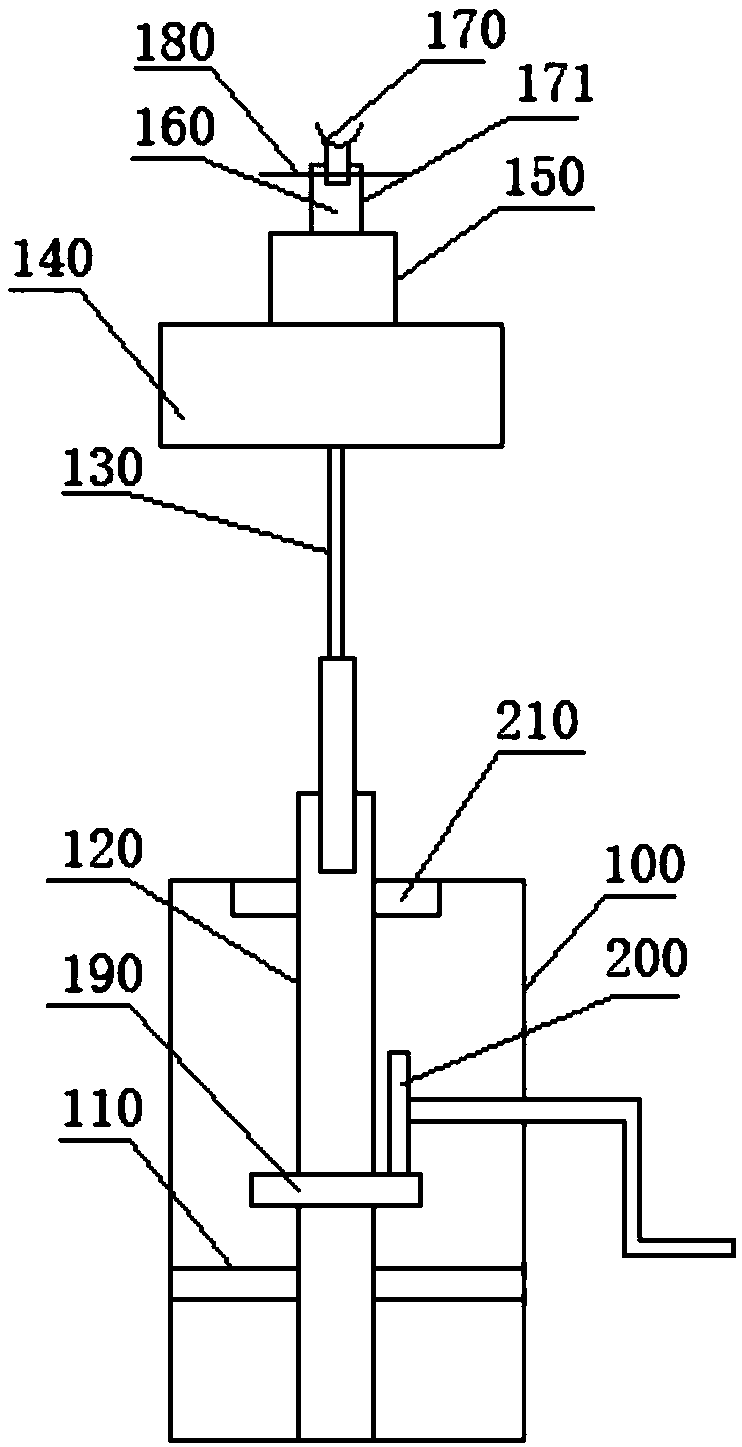

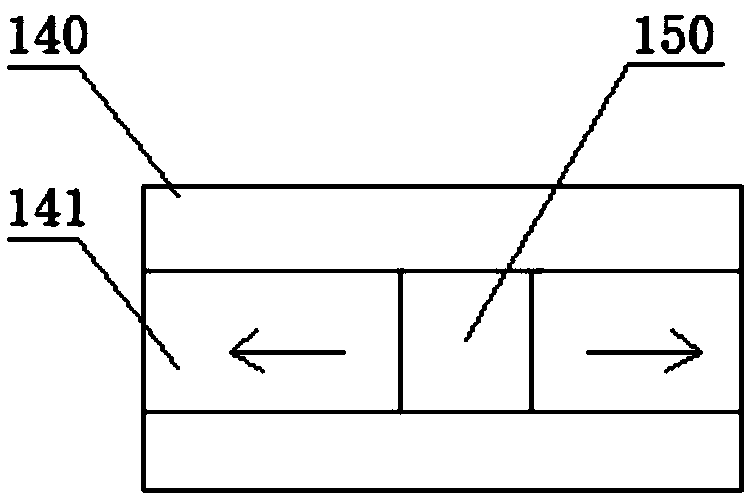

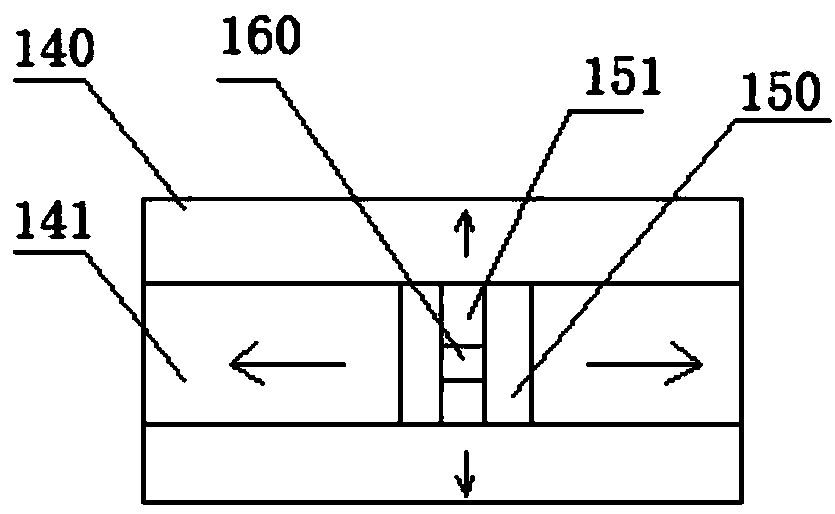

A quantitative feeding device and a feeding machine using the quantitative feeding device

ActiveCN104813973BReduce deliveryThe delivery volume can be adjusted in a large rangeClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention discloses a quantified blanking apparatus and a bait casting machine employing same. The quantified blanking apparatus comprises a first material canister, a second material canister, a first control gate and a second control gate, wherein the first material canister and the second material canister are coaxially arranged, the first control gate closes or opens the opening in the first material canister, the second control gate closes or opens the opening in the second material canister, and the axial relative position of the first material canister and the second material canister are adjustable. The blanking volume is determined according to the proportion of different baits. The axial positions of the first material canister and the second material canister are adjusted to change the volumes of the material canisters for receiving baits and to match with the blanking mass. The adjusting scope of bait blanking volume is large. The quantified blanking apparatus and the bait casting machine are easy to operate, and the blanking quantity can be accurately measured in gram. The automatic level and blanking precision of fishery facilities are improved, the labor intensity is lowered, the utilization rate of baits is improved, and the influence of artificial factors on culture effect is minimized.

Owner:SHANGHAI QINGMIAO OPTOELECTRONICS TECH

Vertical grinding equipment convenient to discharge

The invention provides a vertical grinding equipment convenient to discharge. The vertical grinding equipment comprises a equipment base, wherein a grinding box is arranged on the equipment base, a grinding disc is arranged in the grinding box, a grinding head is arranged above the grinding disc; the grinding head is driven by a grinding motor arranged at the upper end to rotate, so that materialson the grinding disc are ground; the grinding disc is conical, and the periphery of the grinding disc is high and the center of the grinding disc is low; telescopic air cylinders are arranged at thetwo ends of the grinding disc, the grinding disc is driven by the telescopic air cylinders to shake left and right, so that the center of a material box slides; and a jacking air cylinder is arrangedon one side of the lower end of the grinding disc, and the grinding disc is jacked up by the jacking air cylinder for discharging. One end of the grinding disc is jacked up by the jacking air cylinderfor discharging, so that the discharging work is completed without manual work, the discharging precision and the working efficiency are improved, and the personnel cost is reduced; the powder grinding disc is specially designed, so that the materials can be gathered conveniently, and the grinding efficiency is improved; and the materials are blown by a material blowing nozzle, so that the discharging speed is increased.

Owner:JIANGSU XINYE HEAVY IND

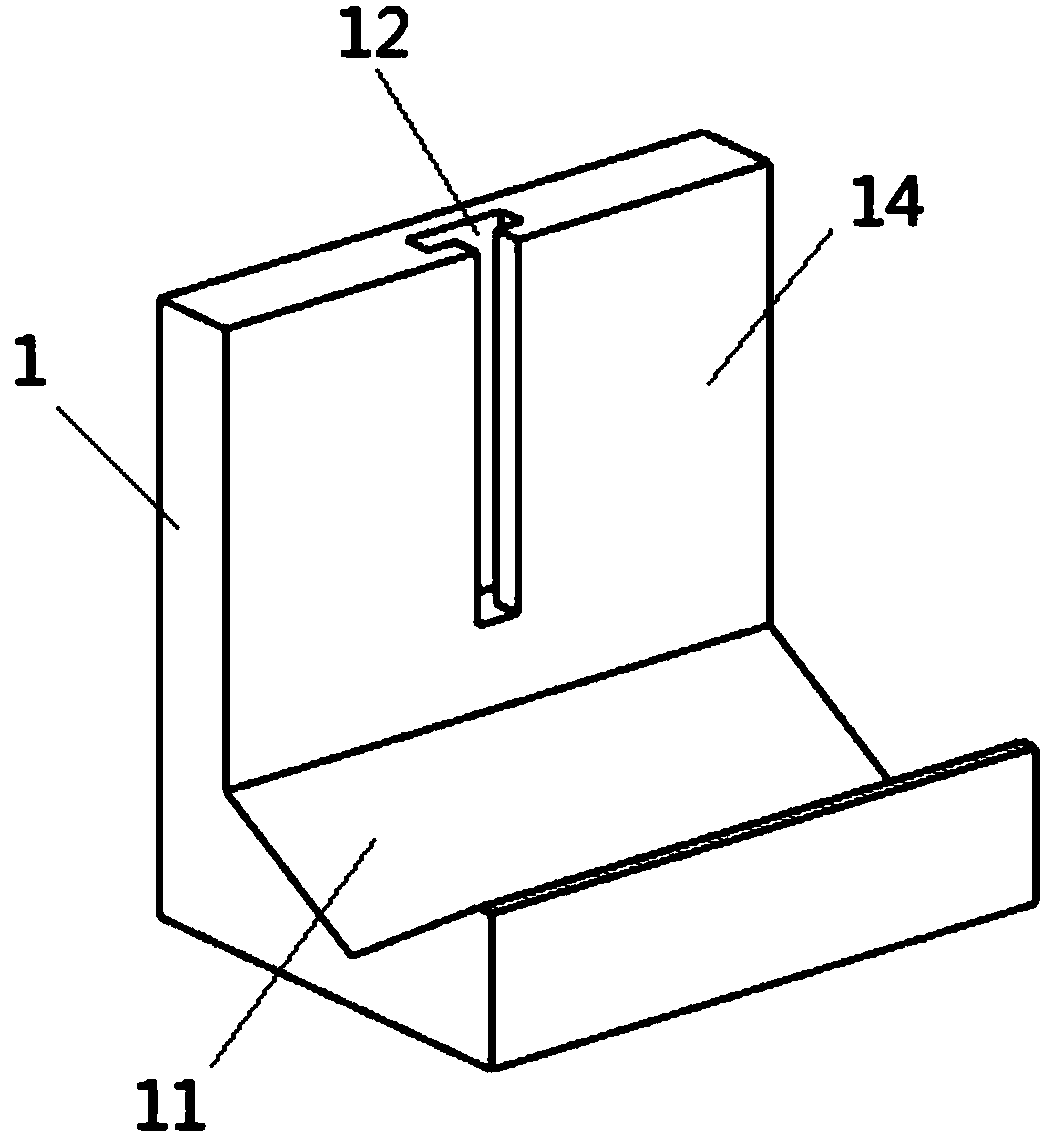

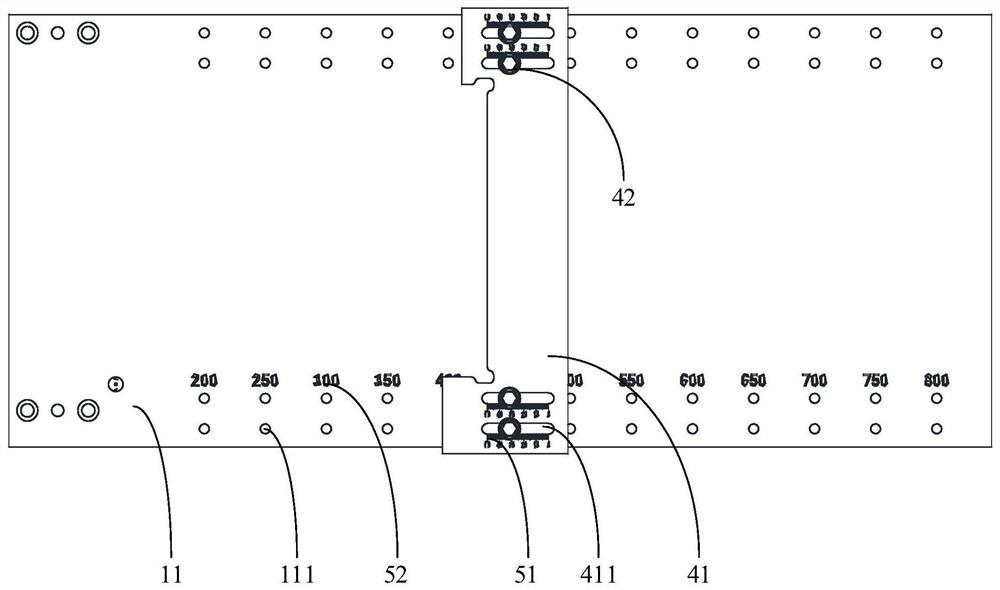

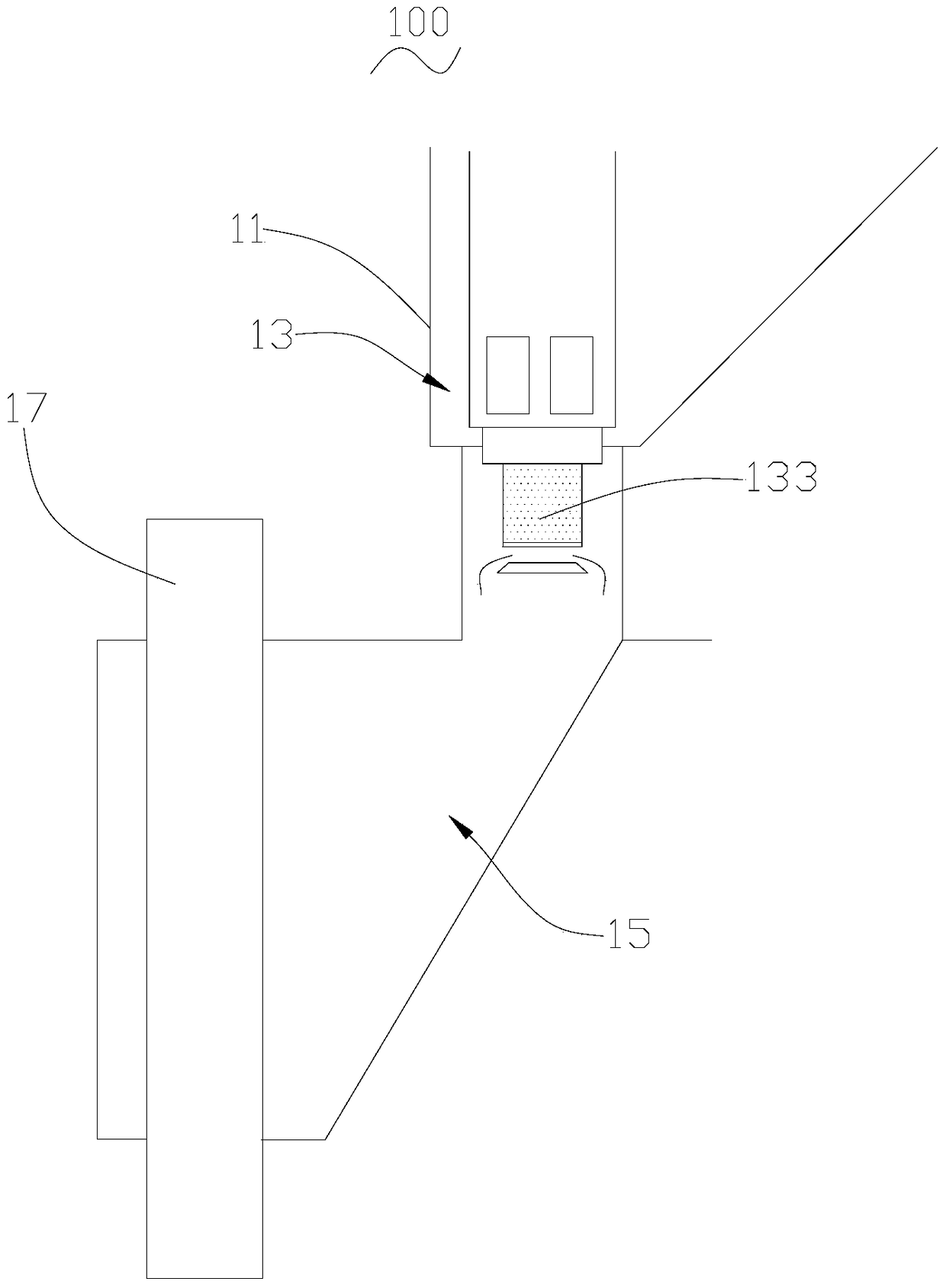

Blanking die

InactiveCN112692154AImprove blanking accuracyIncrease productivityDirt cleaningVehicle componentsStructural engineeringWaste material

The invention discloses a blanking die which comprises a lower die base, an upper die base, a blanking device, a positioning and length taking structure and a length indicating structure, the lower die base comprises a bearing plate extending in the left-right direction, the bearing plate is provided with a first end and a second end which are opposite, the upper die base can be movably installed on the lower die base in the up-down direction, the blanking device is provided with a blanking position formed on one side of the first end, the positioning and length taking structure comprises a positioning plate and an alignment part which are arranged at the second end, the positioning plate can move left and right relative to the alignment part, the length indicating structure comprises a plurality of first length scale marks arranged on the positioning plate, the first length scale marks extend left and right, the alignment part is selected to be aligned with one of the first length scale marks, the positioning plate is fixed to an alignment installation position, one end of a material plate is positioned and abuts against the positioning plate, the other end of the material plate protrudes out of the blanking position to form a waste section, the blanking device cuts off the waste section, and the blanking die accurately performs blanking through the positioning and length taking structure and the length indicating structure.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

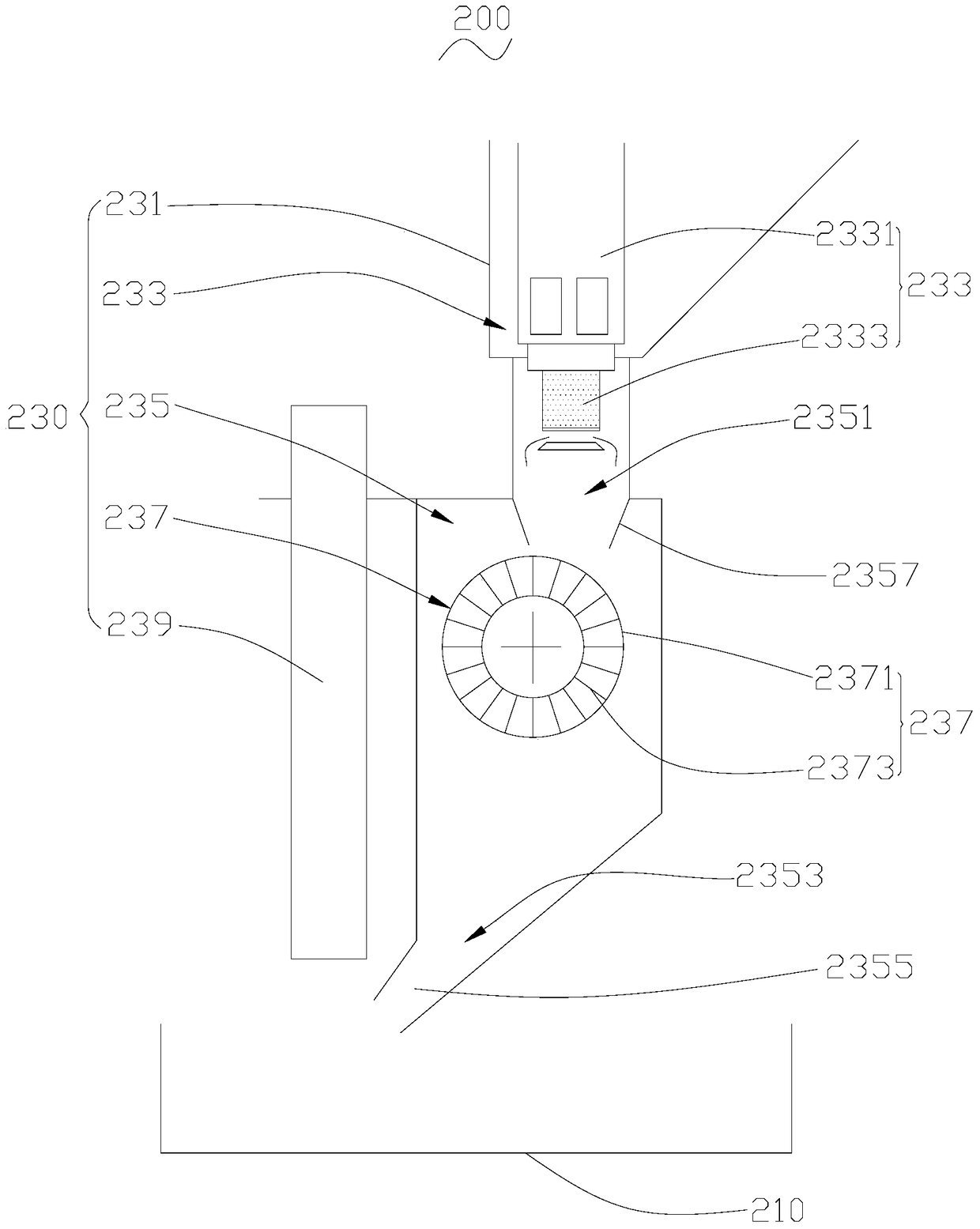

Electrolyzer feeding system and electrolyzer system

The invention provides an electrolytic cell feeding system and an electrolytic cell system. The electrolytic cell feeding system comprises a material box, a constant-volume feeder and a feeding chute. The material box contains electrolyte raw materials. The constant-volume feeder is partially contained in the material box and outputs the electrolyte raw materials contained in the material box to the feeding chute. The feeding chute is arranged below the material box and comprises an upper material opening and a lower material opening. The upper material opening is located below the constant-volume feeder and receives the electrolyte raw materials provided by the constant-volume feeder. A rotary drum is arranged in the feeding chute and located between the upper material opening and the lower material opening. A groove structure is formed in the surface of the rotary drum. The electrolyte raw materials fall into the groove structure of the rotary drum through the upper material opening. The electrolytic cell system is provided with the electrolytic cell feeding system.

Owner:SNTO TECH GRP

Efficient powder discharging device for lithium ion battery pulp combining

PendingCN107265136ASimple structureAccurate measurementLarge containersLoading/unloadingDischarge efficiencyElectrical battery

The invention relates to an efficient powder discharging device for lithium ion battery pulp combining. The efficient powder discharging device comprises a metering bin, a discharging funnel and a discharging pipeline, all of which are sequentially arranged and combined from top to bottom. A vent valve and a metering bin feeding port are formed in the top end of the metering bin, the lower end of the metering bin is connected with the discharging funnel in a penetration manner, the lower end of the discharging funnel is connected with the discharging pipeline in a penetration manner, and a port in the lower end of the discharging pipeline is connected with a pulp combining kettle. After the above structure is adopted, compared with the prior art, according to the efficient powder discharging manner for lithium ion battery pulp combining and a discharging system of the efficient powder discharging manner, the structure is simple, metering is accurate, reliability is high, and continuous production can be achieved; and meanwhile, through the arrangement of an air hammer and a crossed concentric-square-shaped air blowing structure, the discharging efficiency and the discharging precision are effectively improved.

Owner:CALB CO LTD

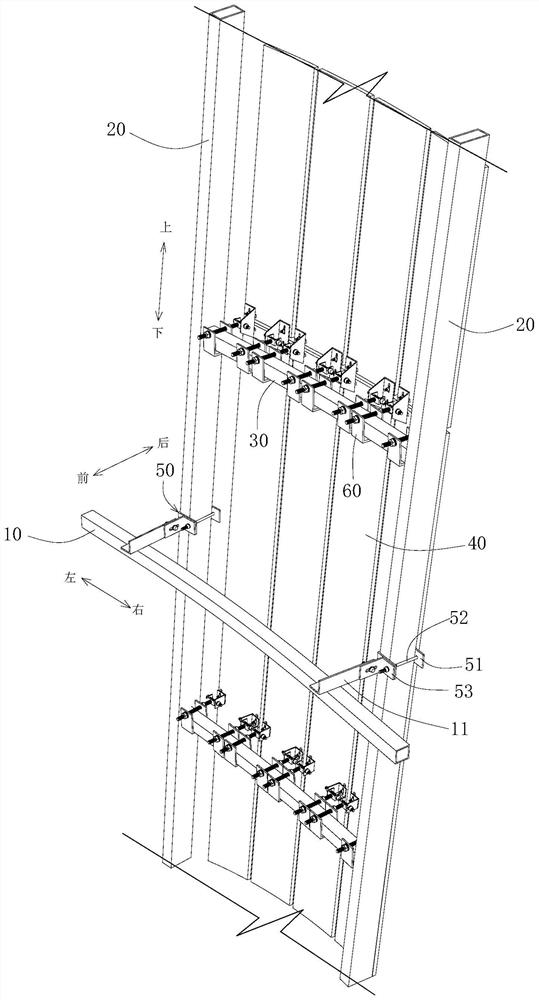

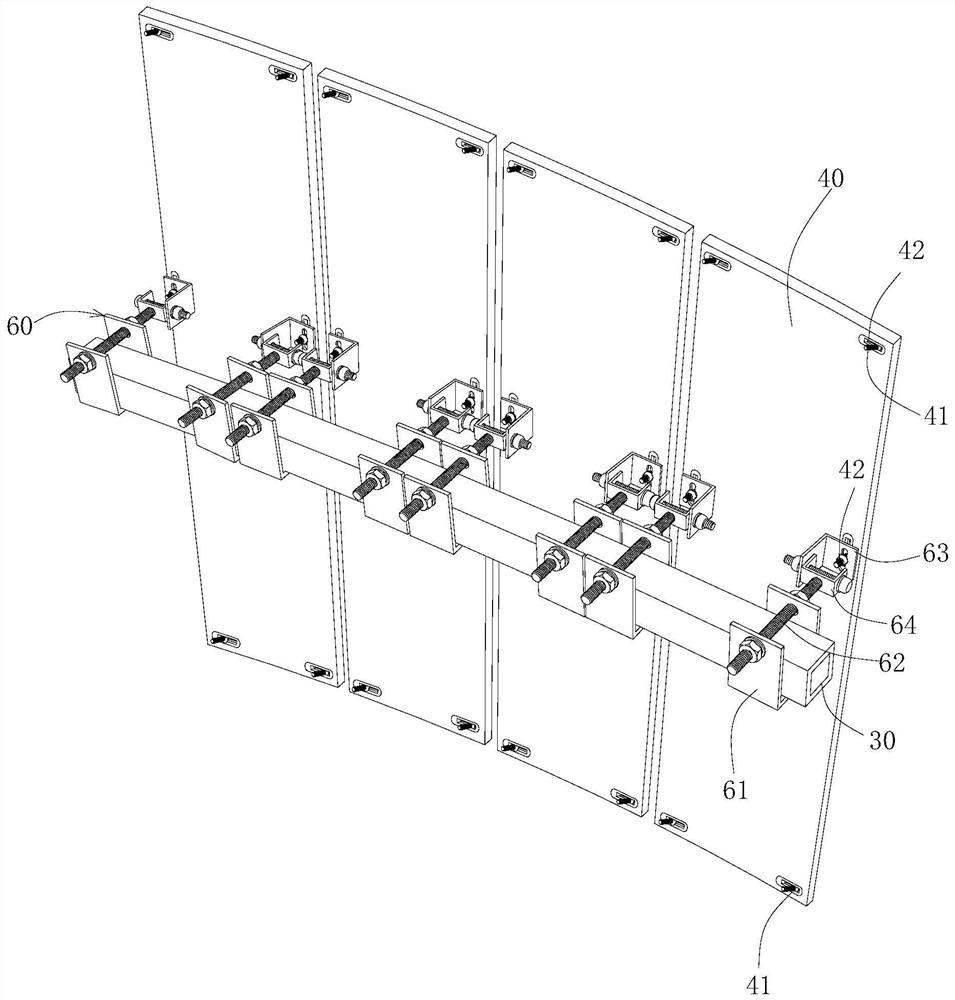

Construction method for cylindrical surface decoration of hyperbolic C-shaped column with variable cross-section

Owner:SHENZHEN BAUING CONSTR GRP

A pipe cutting device for self-positioning pipes

InactiveCN109590758BHigh precisionReduce vibrationOther manufacturing equipments/toolsMachinePiston rod

The invention discloses a pipe cutting device for a self-positioning pipeline. The device comprises a rack, and further comprises multiple straightening devices, a cutting machine and a positioning device which are sequentially arranged on the top of the rack in the machining direction; the cutting machine comprises a cutting table, two clamping tables and a cutting disc; the cutting table is fixed to the rack, the two clamping tables are symmetrically mounted on the two ends of the cutting table, the cutting disc is arranged on the cutting table through a supporting frame, the positioning device comprises a support, a screw, a servo motor, a baffle and automatic clamping claws, the support is fixed to the rack, multiple air cylinders which are arranged in a hanging manner are arranged onthe support, the automatic clamping claws are arranged on piston rods of the air cylinders, and a material accumulating groove is formed in the position, below the support, of the rack. The cutting machine and the positioning device are arranged, the long pipeline can be precisely positioned and cut, machining efficiency is improved, the process of cutting the pipeline again on the later is removed, and raw material waste is reduced.

Owner:自贡东光汽车配件有限公司

Aluminum electrolytic cell blanking system and aluminum electrolytic cell system

ActiveCN105420759BReduce the probability of blockingDissolve evenly and stablyElectrolysisCell system

The invention provides an aluminum electrolysis cell feeding system which comprises a material box, a constant-volume feeding device and a feeding chute. The material box contains aluminum oxide raw materials, the constant-volume feeding device is partially contained in the material box, the constant-volume feeding device outputs the aluminum oxide raw materials contained in the material box to the feeding chute, and the feeding chute is arranged below the material box and comprises a material inlet, a feeding opening and a material guide inclined wall; the material inlet is located below the constant-volume feeding device and receives the aluminum oxide raw materials provided by the constant-volume feeding device, the upper end face of the material guide inclined wall is flush with the material inlet, the lower end face of the material guide inclined wall is flush with the feeding opening, and the aluminum electrolysis cell feeding system further comprises a buffer and an automatic dredging device. Compared with the prior art, the aluminum electrolysis cell feeding system has the advantages that an aluminum electrolysis cell is good in stability, high in current efficiency, low in energy consumption, long in service life and good in aluminum oxide feeding effect.

Owner:内蒙古创源金属有限公司

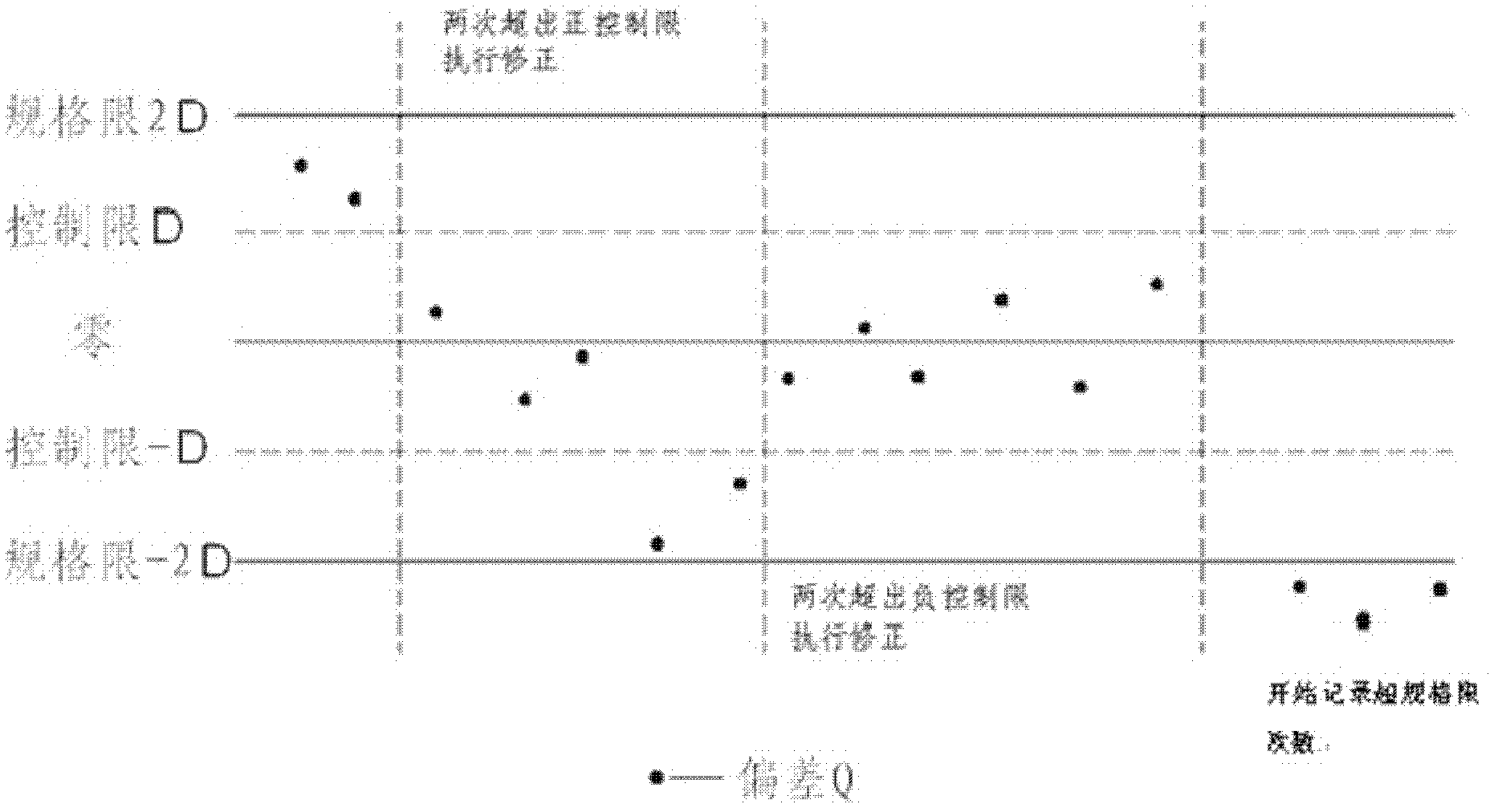

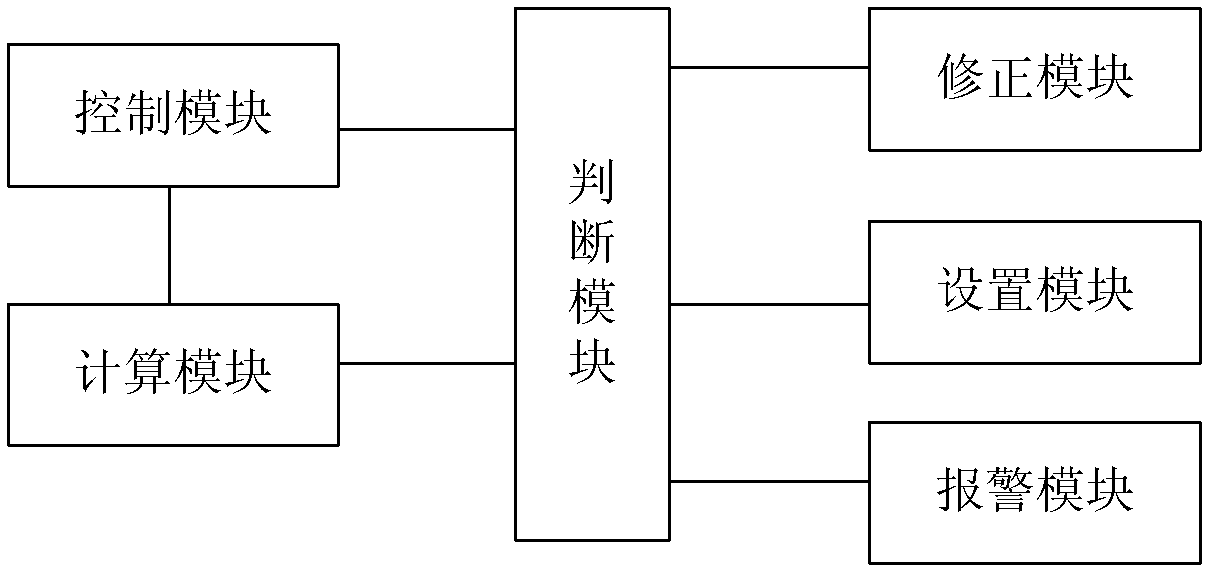

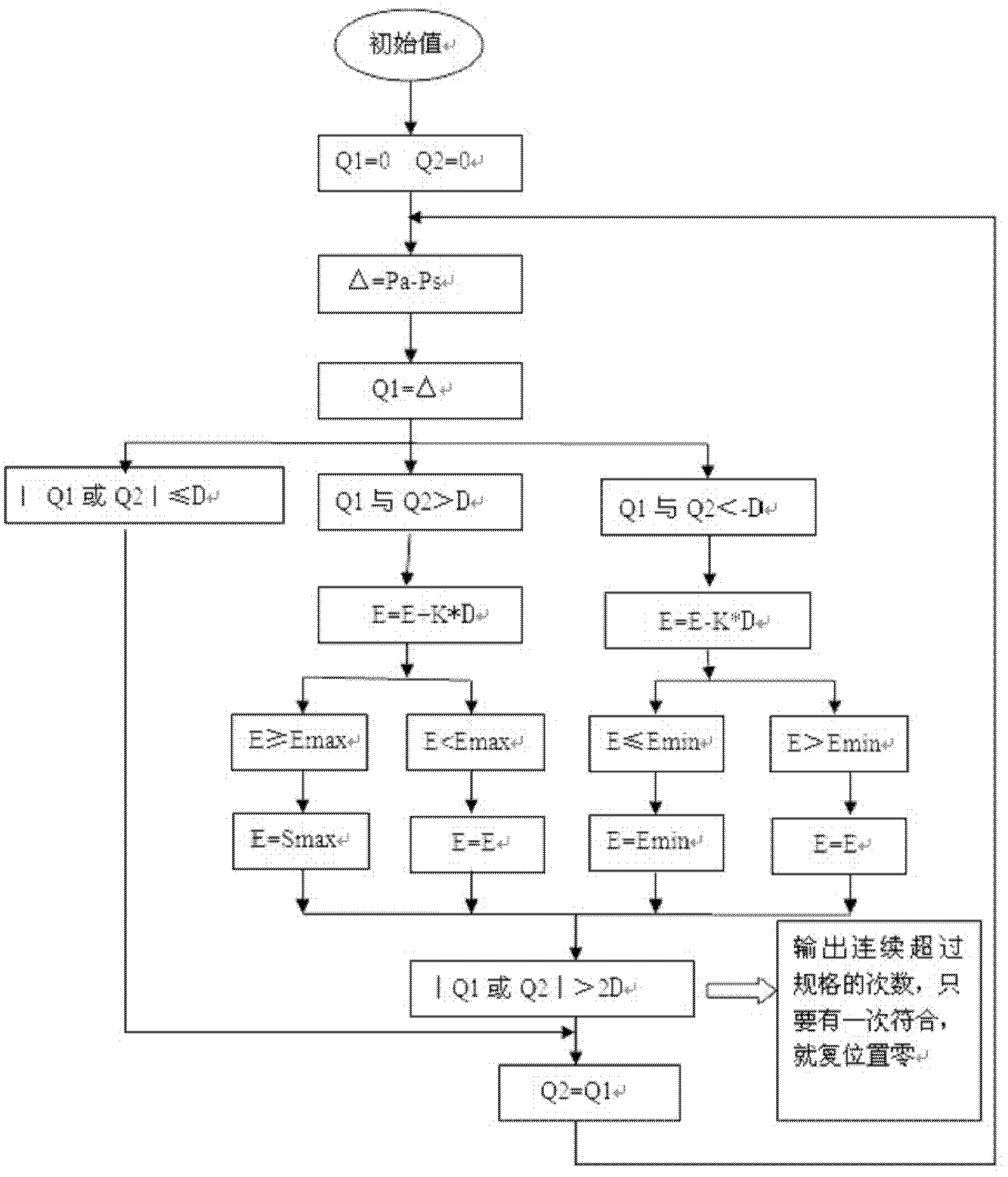

Electric vibration discharging control method and system

ActiveCN102402231BImprove control abilityImprove blanking accuracyControlling ratio of multiple fluid flowsEngineeringControl limits

The invention discloses an electric vibration discharging control method and a corresponding system. The method comprises the following steps of: correcting the discharging fall value E2 according to an equation of E2=E1+ / -K when absolute value of offset value Q1 between the final discharging quantity Pa and the defined discharging quantity Ps at first time, and absolute value of offset value Q2 between the both at second time are greater than predefined control limit D; the E1 is the discharging predefined quantity; and the K is the repair coefficient and is controlled to be 0.5-1. The system comprises a calculation module, a judgment module, a correction module, a control module, an alarm module and a setting module. The method and the system can greatly improve discharging control accuracy in the steel making process so as to effectively improve regulation and control capability on liquid steel components.

Owner:BEIJING SHOUGANG CO LTD

Quartz sand feeding device and method

The invention relates to a quartz sand feeding device and method. The quartz sand feeding device comprises a cover plate, an observation window and a bottom plate, wherein the observation window has ahollow structure; the cover plate, the observation window and the bottom plate are successively connected to form a closed cavity; the inside of the cavity is rotatably connected with a rotating plate; the bottom plate is connected with a driving source which drives the rotating plate to rotate; the bottom plate is connected with a discharging connector which communicates with the cavity and is provided with a discharging channel; a feeding opening of the discharging connector is positioned between the inner wall of the observation window and the side wall of the rotating plate; a feeding adjusting tube with a feeding channel is arranged on the cover plate; a feeding opening of the feeding adjusting tube is positioned on the upper part of the rotating plate; a scraper blade is arranged onan end surface, which faces the rotating plate, of the cover plate; the lower end surface of the scraper blade is attached to the upper end surface of the rotating plate; and the discharging direction of the scraper blade corresponds to the feeding opening of the discharging connector. The quartz sand feeding device has the advantages that the quartz sand feeding amount is controlled, the quartzsand feeding accuracy is improved, and the follow-up quartz sand processing procedures are ensured.

Owner:中建材衢州金格兰石英有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com