Electric vibration discharging control method and system

A control method and technology for a control system, which are applied in the field of electro-vibration blanking control methods and systems, can solve problems such as low blanking hit rate, and achieve the effects of improving production efficiency, improving blanking control accuracy, and improving regulation capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

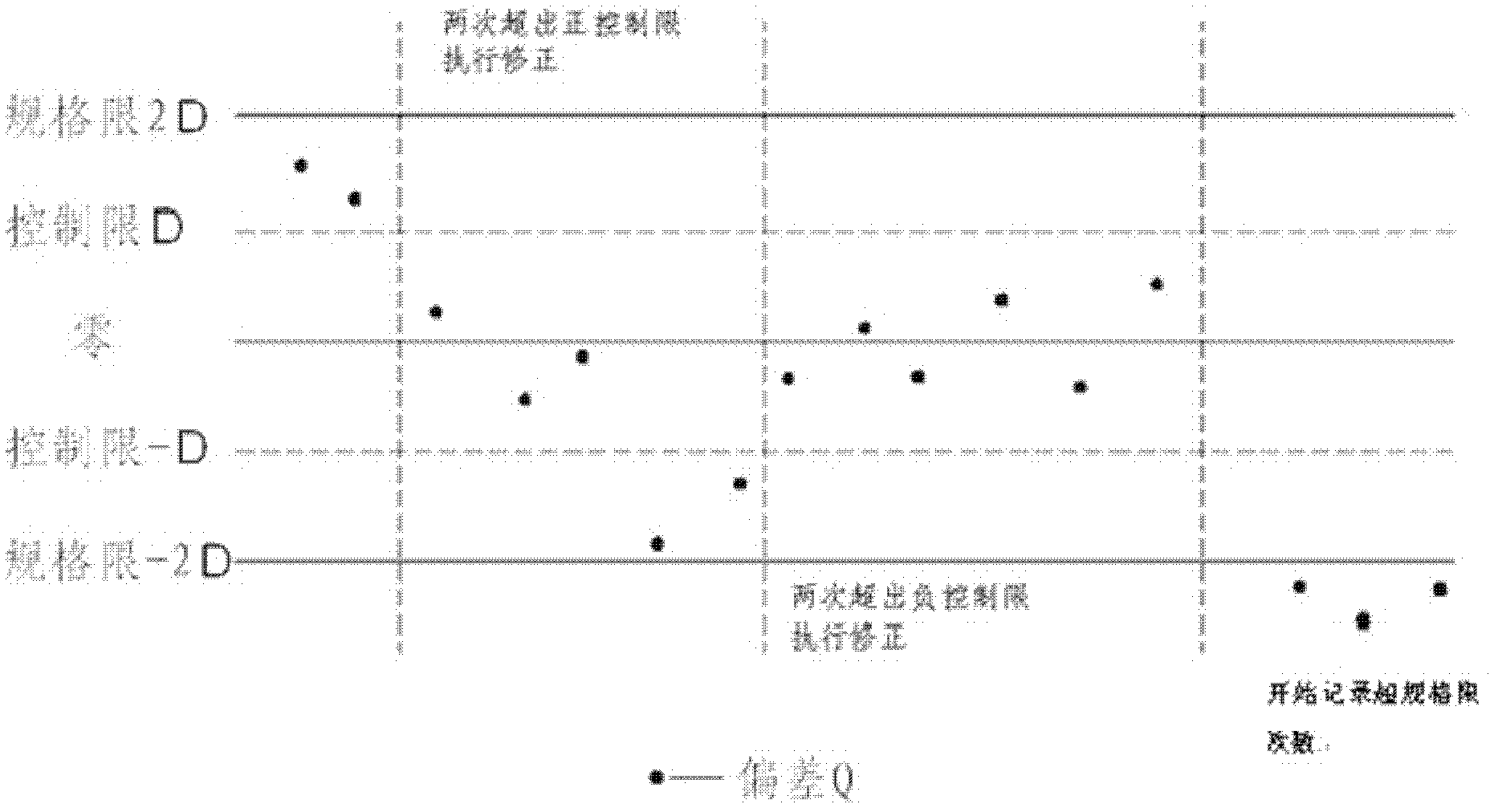

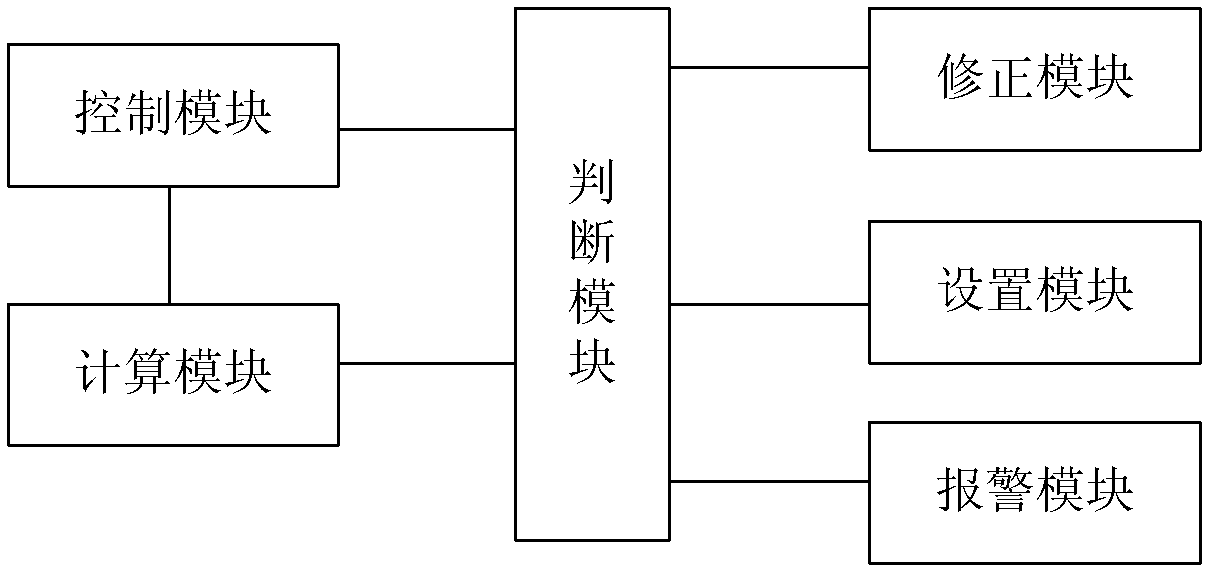

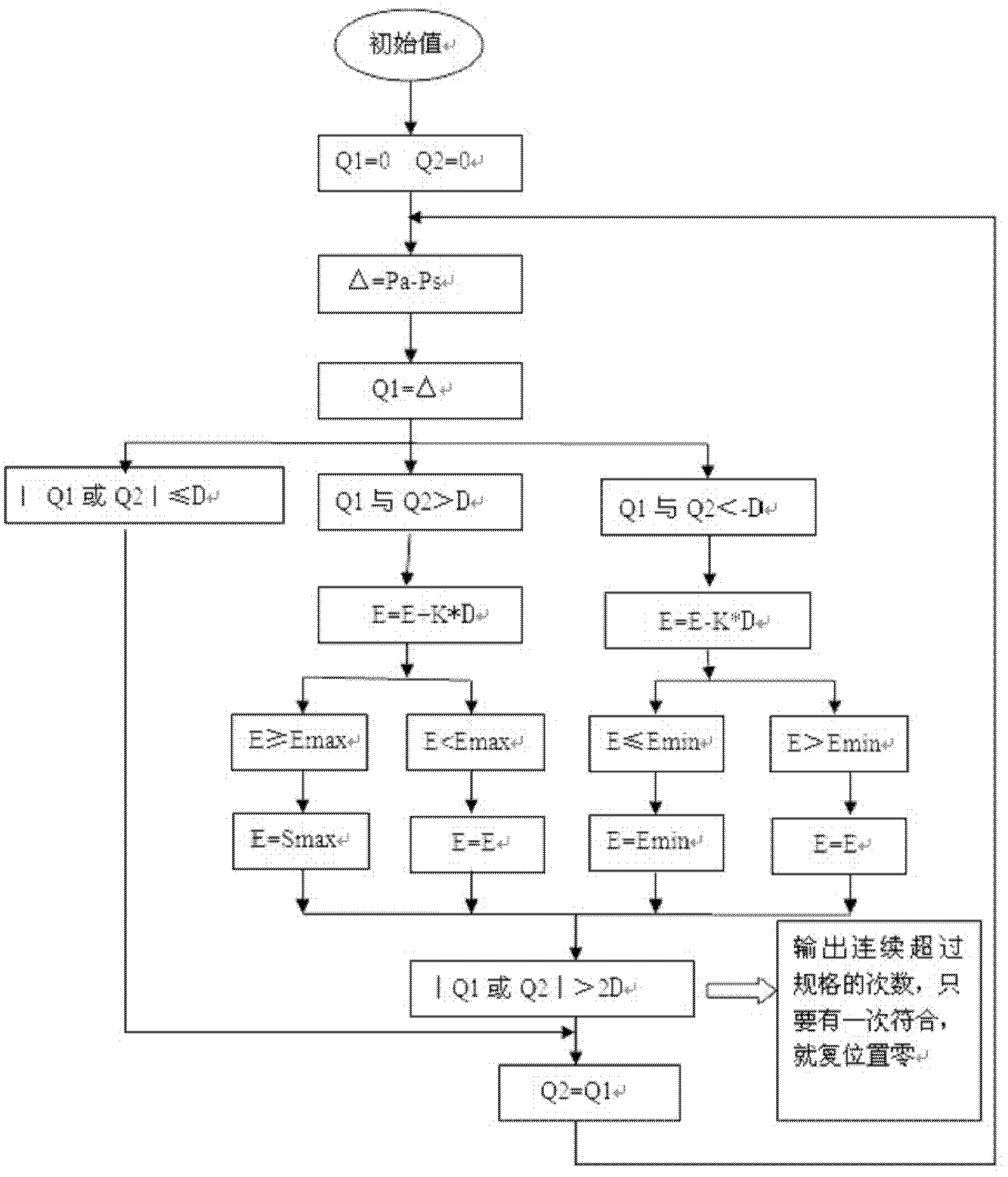

[0023] Such as figure 1 As shown, an electric vibration cutting control method provided by the present invention includes:

[0024] Step 1: Pre-set E1 value, K value, control limit D and specification limit 2D. Among them, the blanking advance E1 is obtained through experimental statistics. The initial value of E1 is determined, which is related to the angle adjustment of the electric vibration equipment and the particle fluidity of the material. For example, the set value of the blanking is in Kg. The general setting is The material drop value E is a value of 2-6Kg. After the blanking test, observe the deviation value Q. The E value where Q is close to 0 is a relatively suitable drop value. After the control method is put into use, the system will automatically adjust the E value. Make Q stable within the control limit. K is the correction coefficient, and the value range of K is controlled within 0.5-1.

[0025] Step 2: When the difference between the displayed value PI of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com