Patents

Literature

636 results about "Control limits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control limits, also known as natural process limits, are horizontal lines drawn on a statistical process control chart, usually at a distance of ±3 standard deviations of the plotted statistic from the statistic's mean.

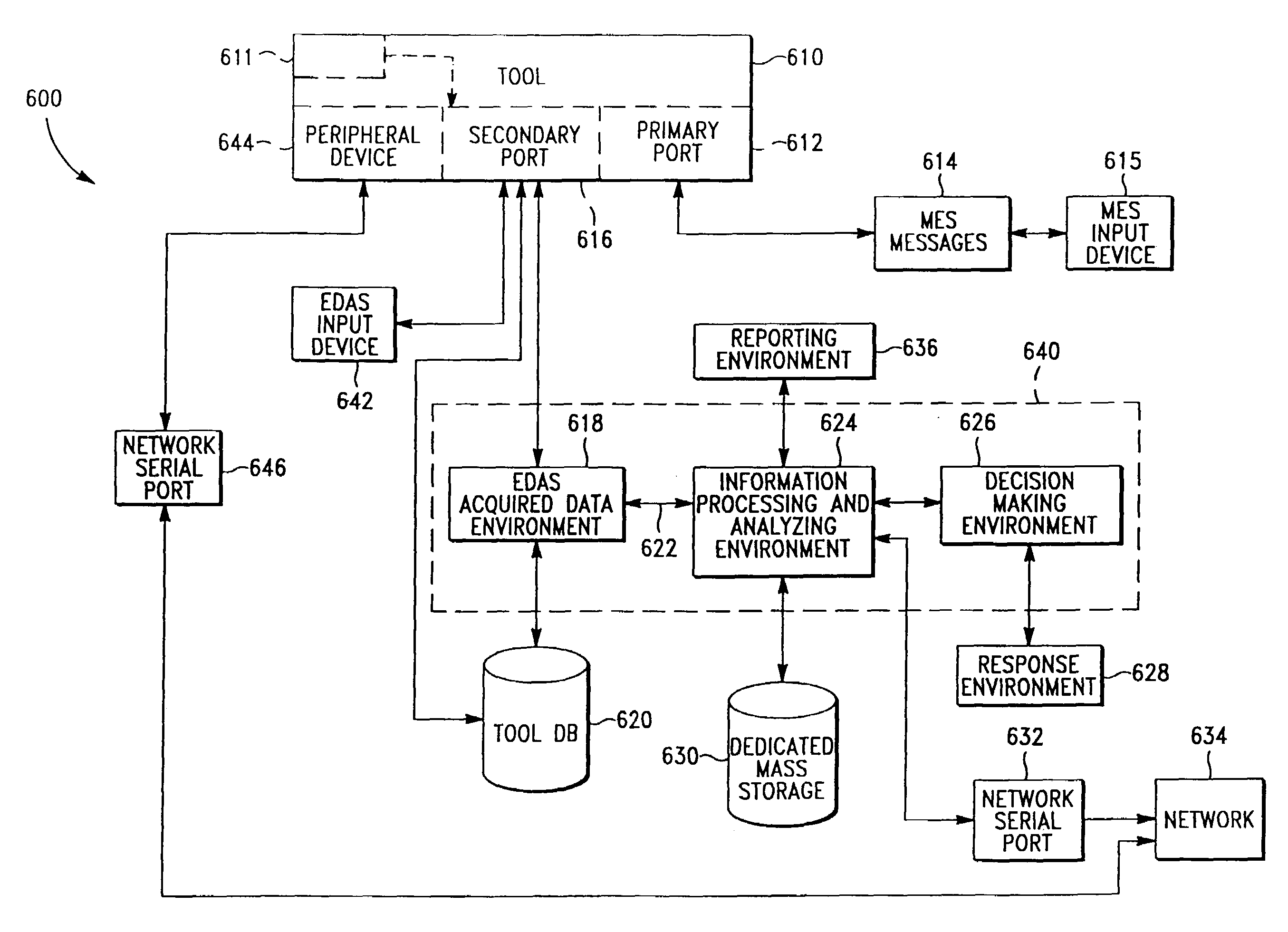

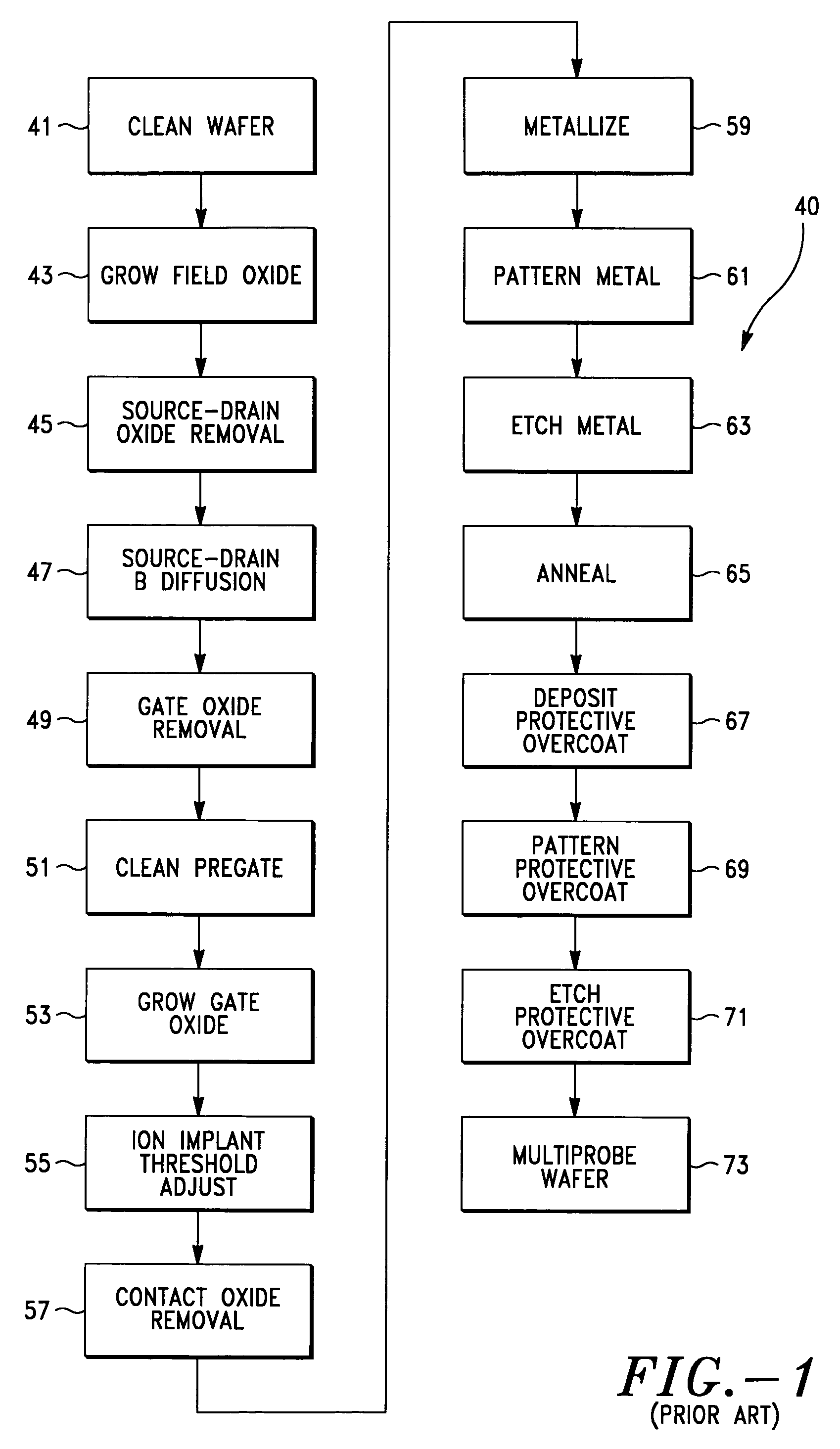

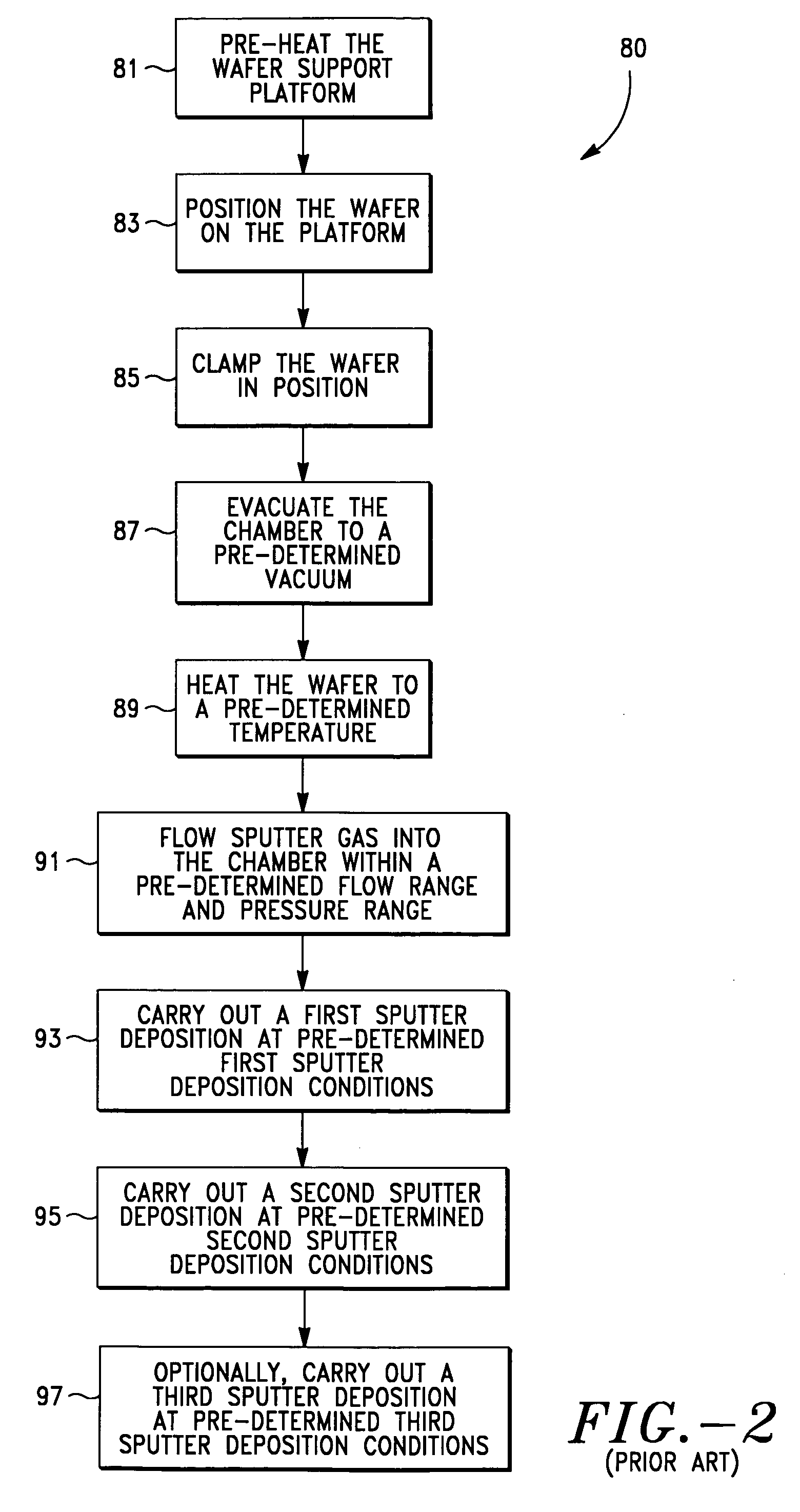

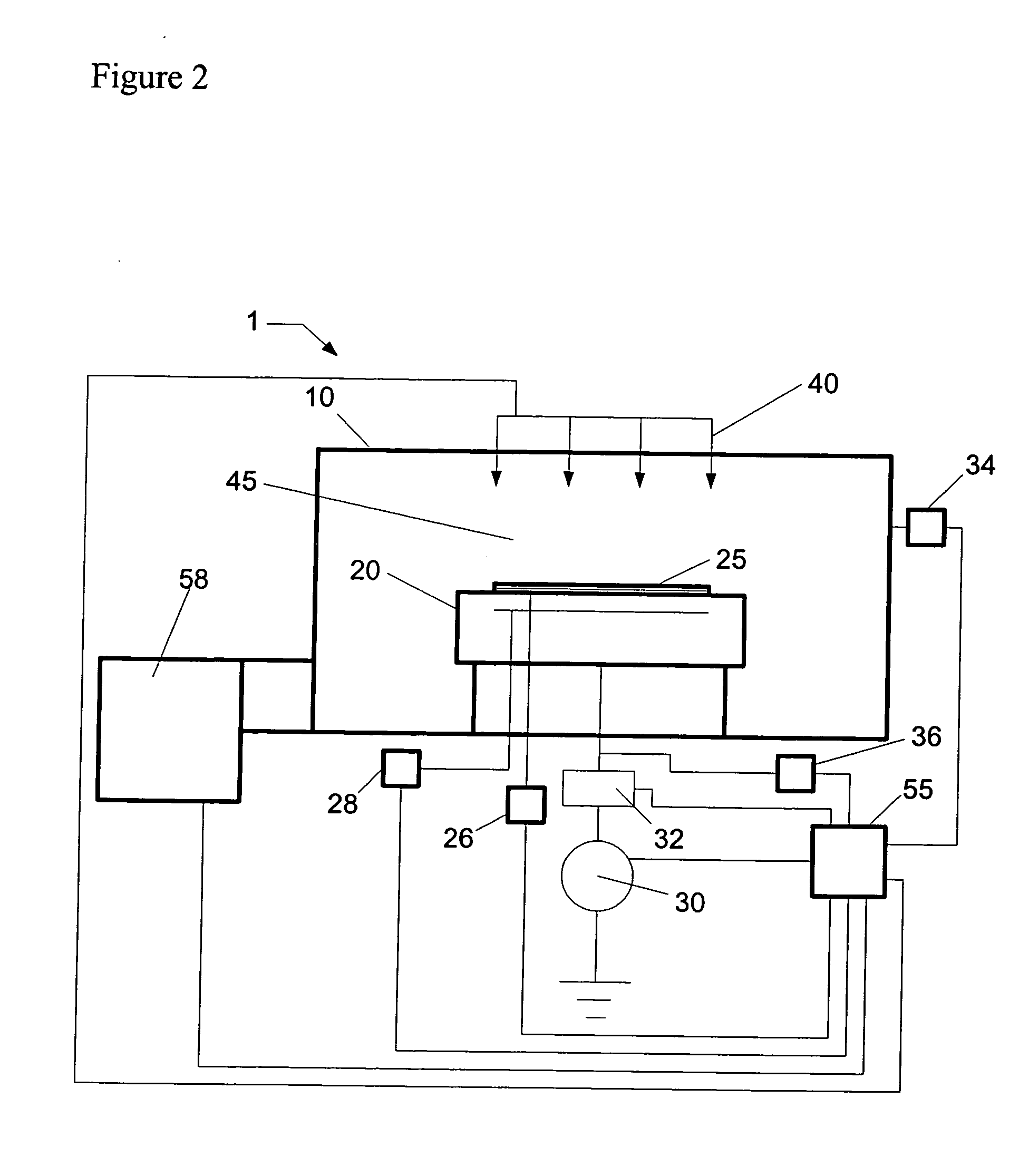

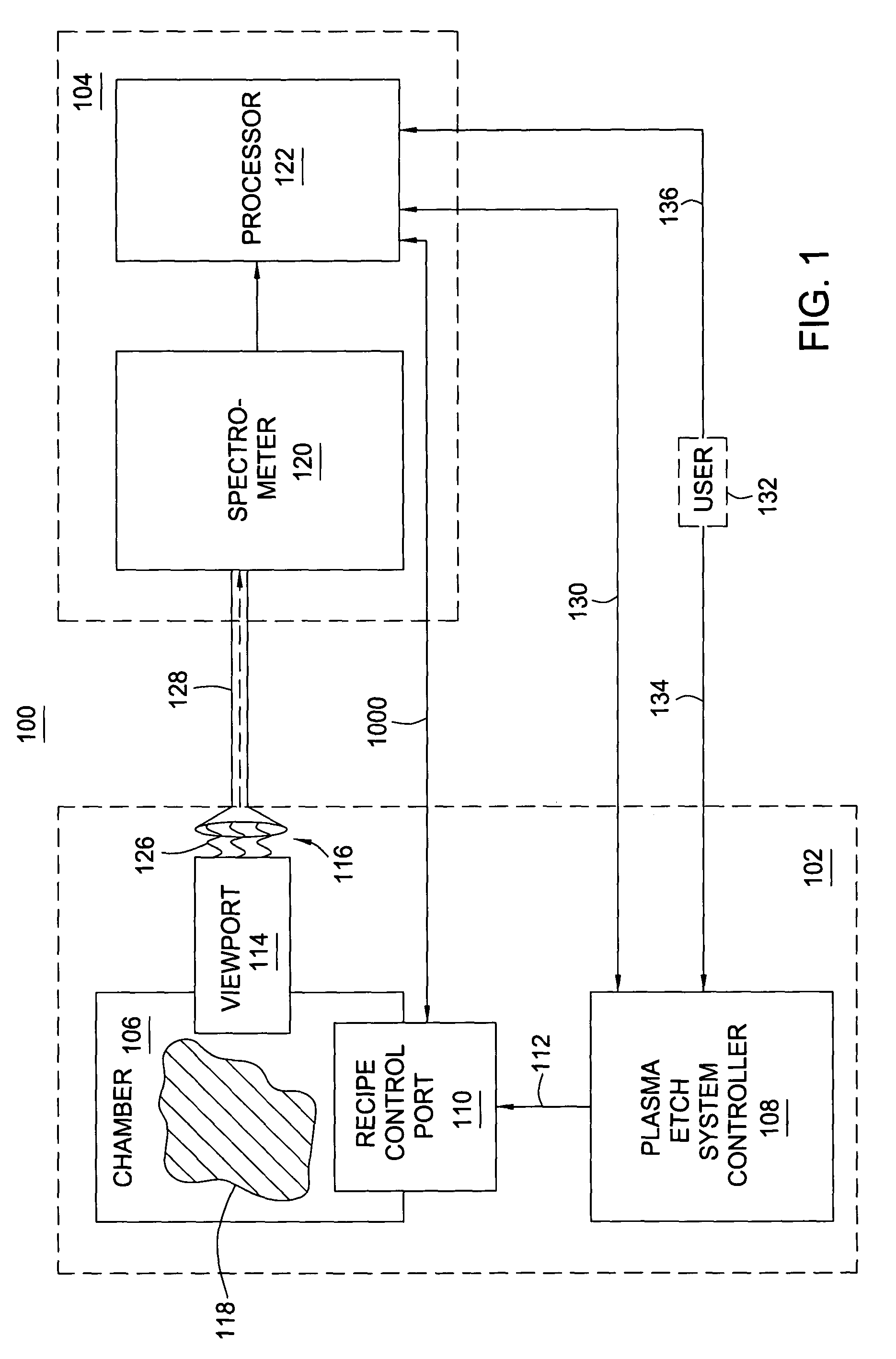

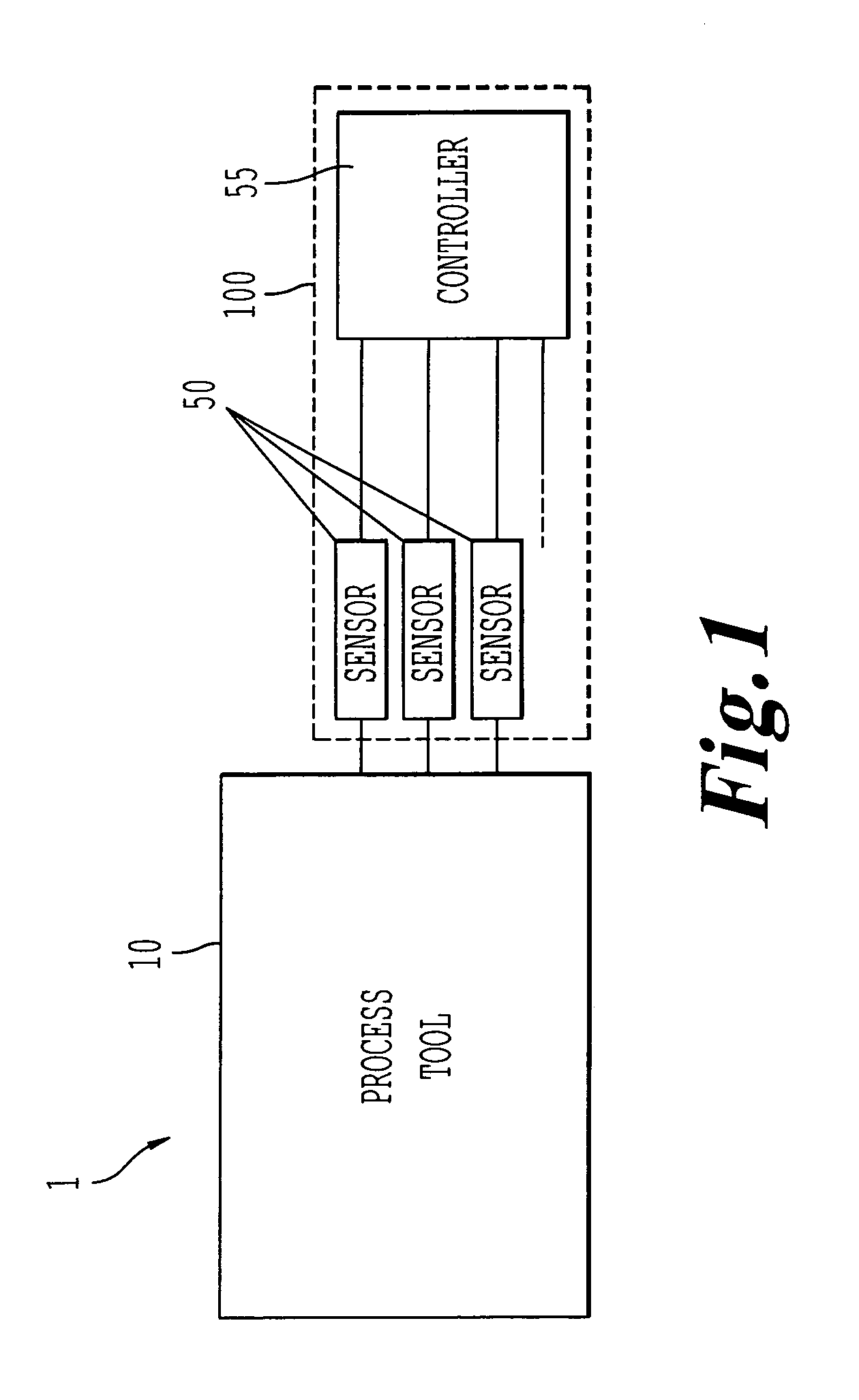

Wafer fabrication data acquisition and management systems

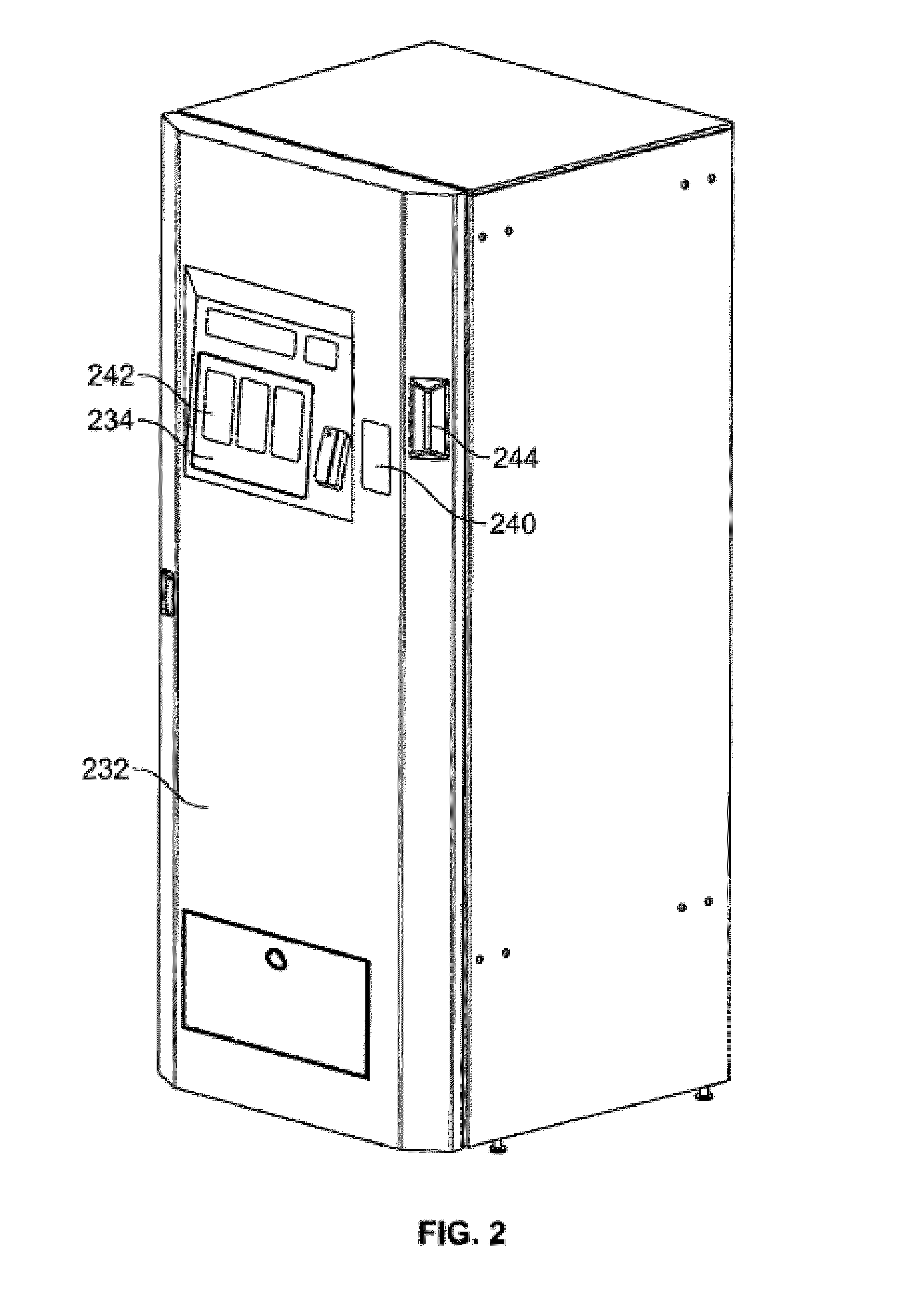

InactiveUS6952656B1Improve data transfer performanceIncrease costResistance/reactance/impedenceComputer controlWafer fabricationData acquisition

The present invention provides a semiconductor processing device (800) including a tool (802) having one or more sensors, a primary data communication port (804) and a secondary data communication port (806). A sensor data acquisition subsystem (808) acquires sensor data from the tool via the secondary port (806). The data acquisition subsystem (808) acquires MES operation messages via the primary port (804). Sensor data are communicated to a sensor processing unit (828) of a sensor data processing subsystem (810). The sensor processing unit (828) processes and analyzes the sensor data. Additionally, the processing unit (828) can be adapted for making product or processing related decisions, for example activating an alarm if the process is not operating within control limits. In another embodiment, the present invention provides a method and apparatus for processing data from a wafer fab facility (1000) including a plurality of tools (1004–1010) each having a primary data communication port (1012–1018) and a secondary data communication port (1042–1048).

Owner:APPLIED MATERIALS INC

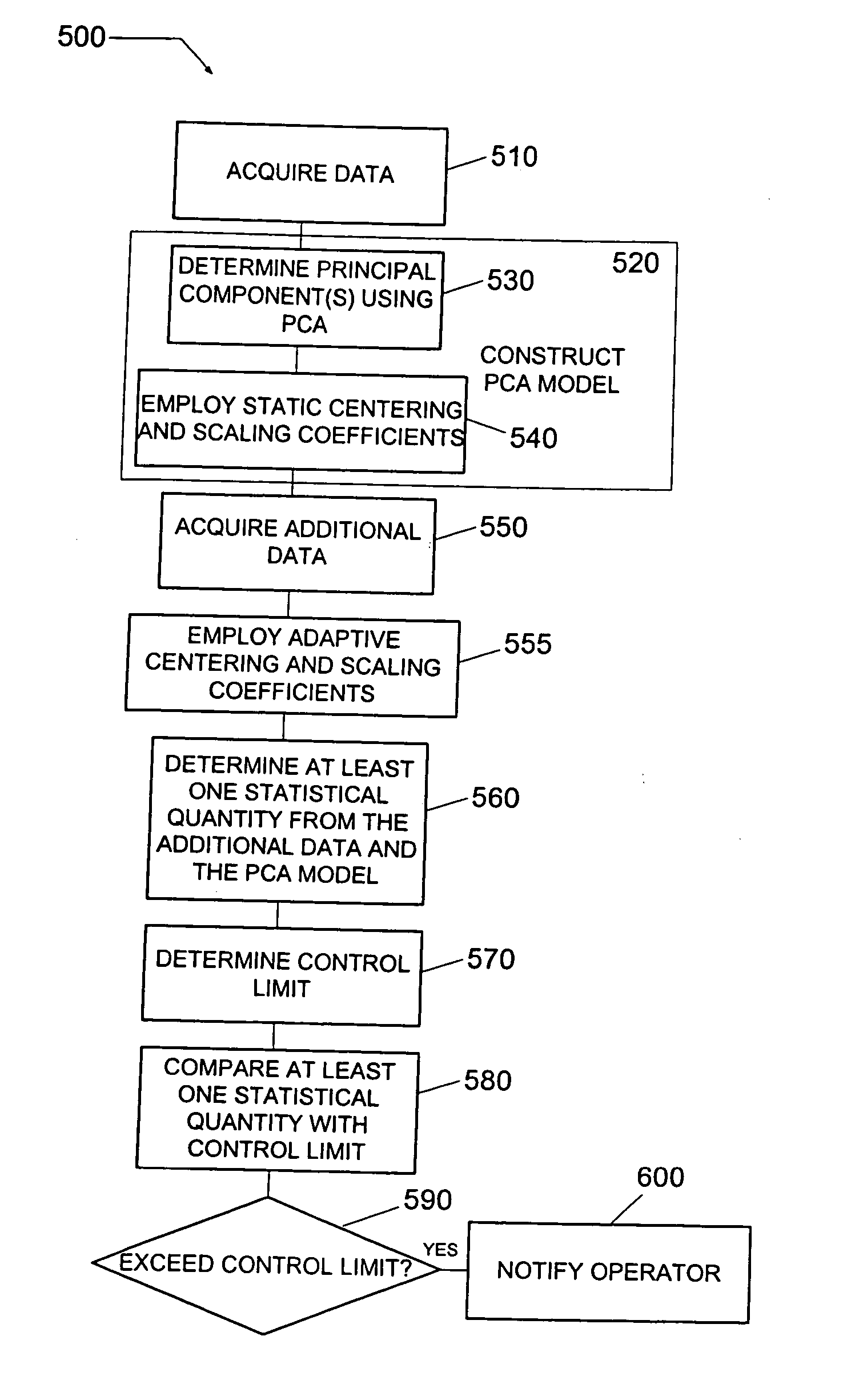

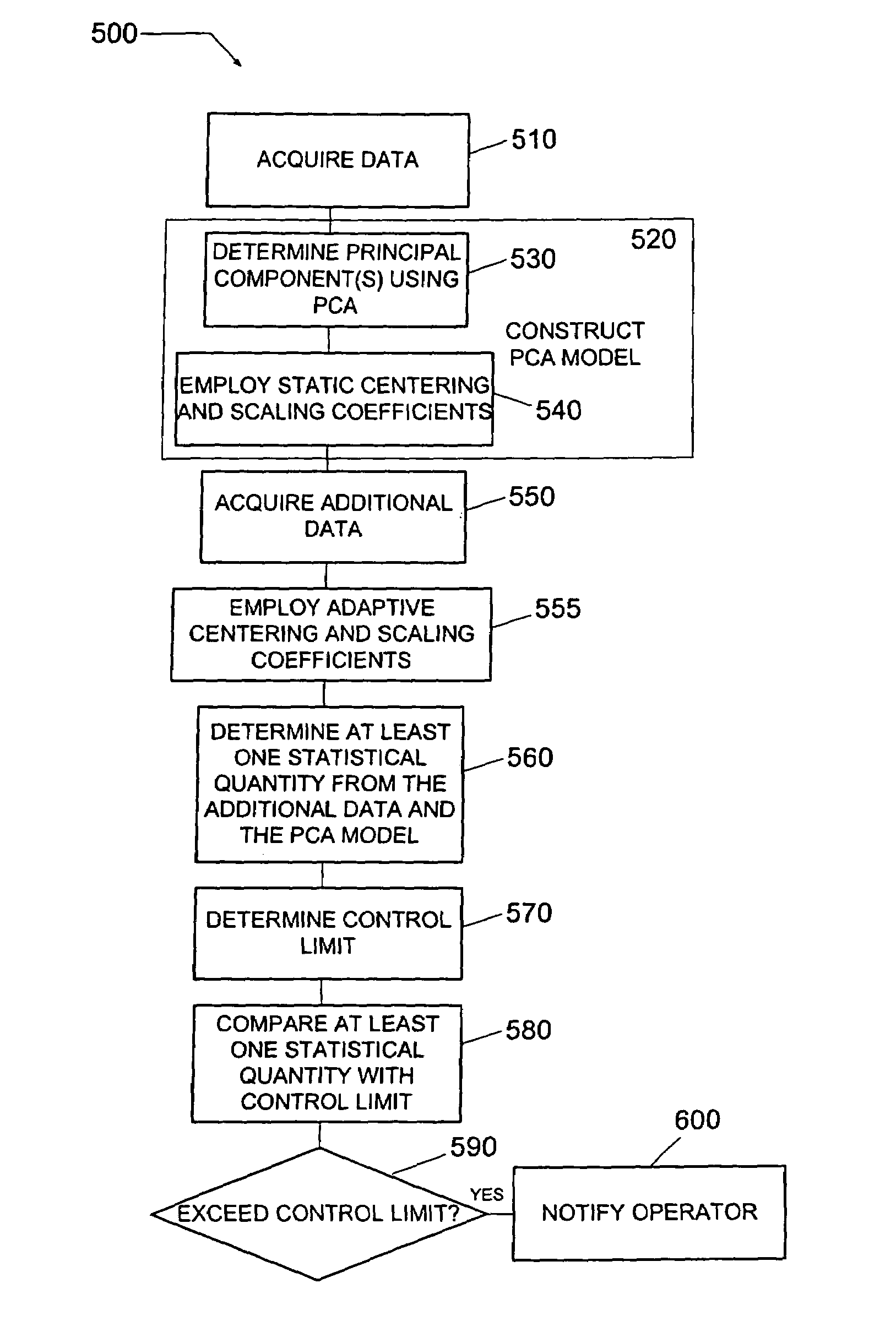

Method and system of diagnosing a processing system using adaptive multivariate analysis

ActiveUS20050060103A1Useful applicationAmplifier modifications to reduce noise influenceDigital computer detailsPrincipal component analysisControl limits

A method and system of monitoring a processing system and for processing a substrate during the course of semiconductor manufacturing. As such, data is acquired from the processing system for a plurality of observations, the data including a plurality of data parameters. A principal components analysis (PCA) model is constructed from the data and includes centering coefficients. Additional data is acquired from the processing system, the additional data including an additional observation of the plurality of data parameters. The centering coefficients are adjusted to produce updated adaptive centering coefficients for each of the data parameters in the PCA model. The updated adaptive centering coefficients are applied to each of the data parameters in the PCA model. At least one statistical quantity is determined from the additional data using the PCA model. A control limit is set for the statistical quantity and compared to the statistical quantity.

Owner:TOKYO ELECTRON LTD

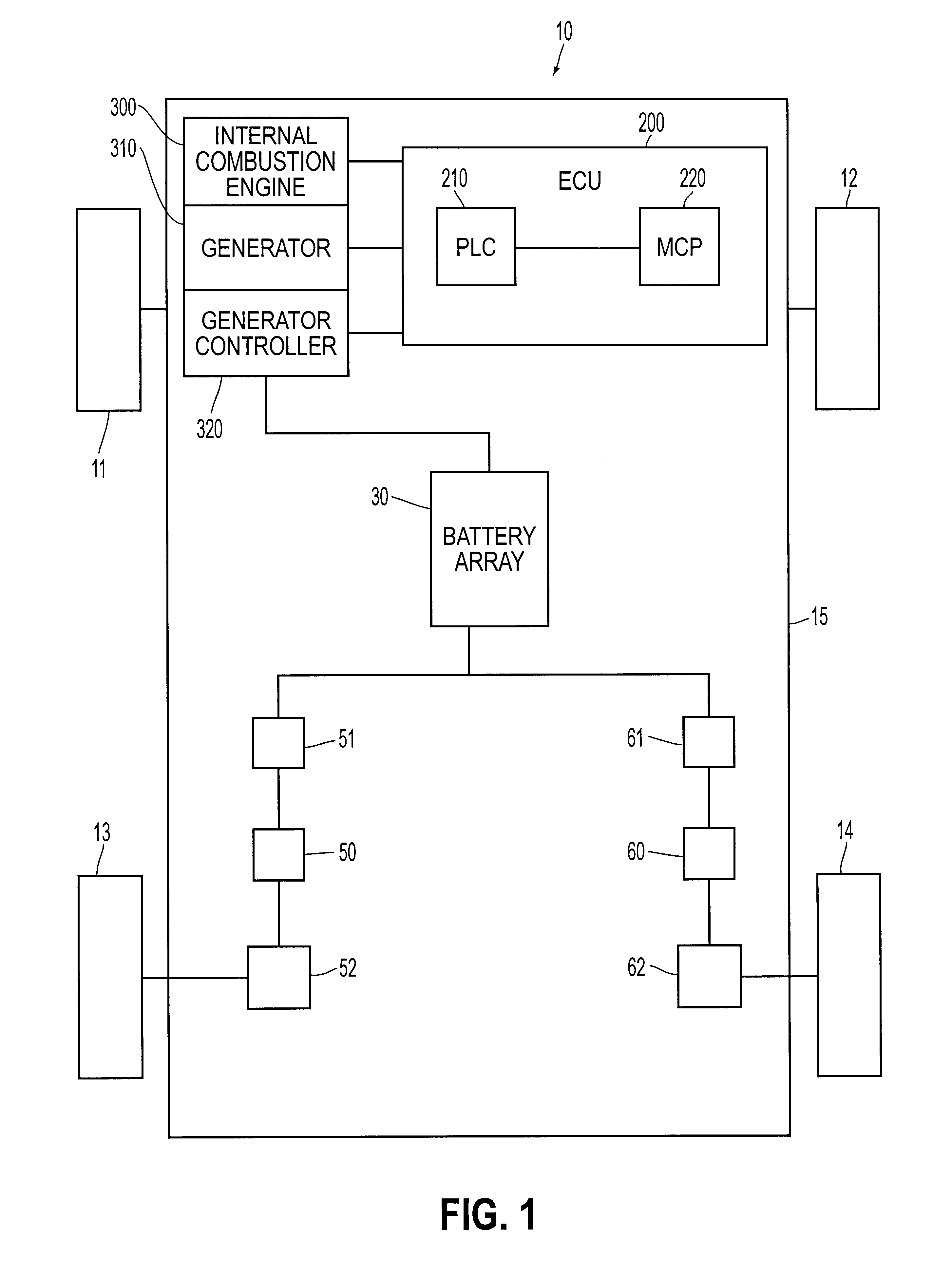

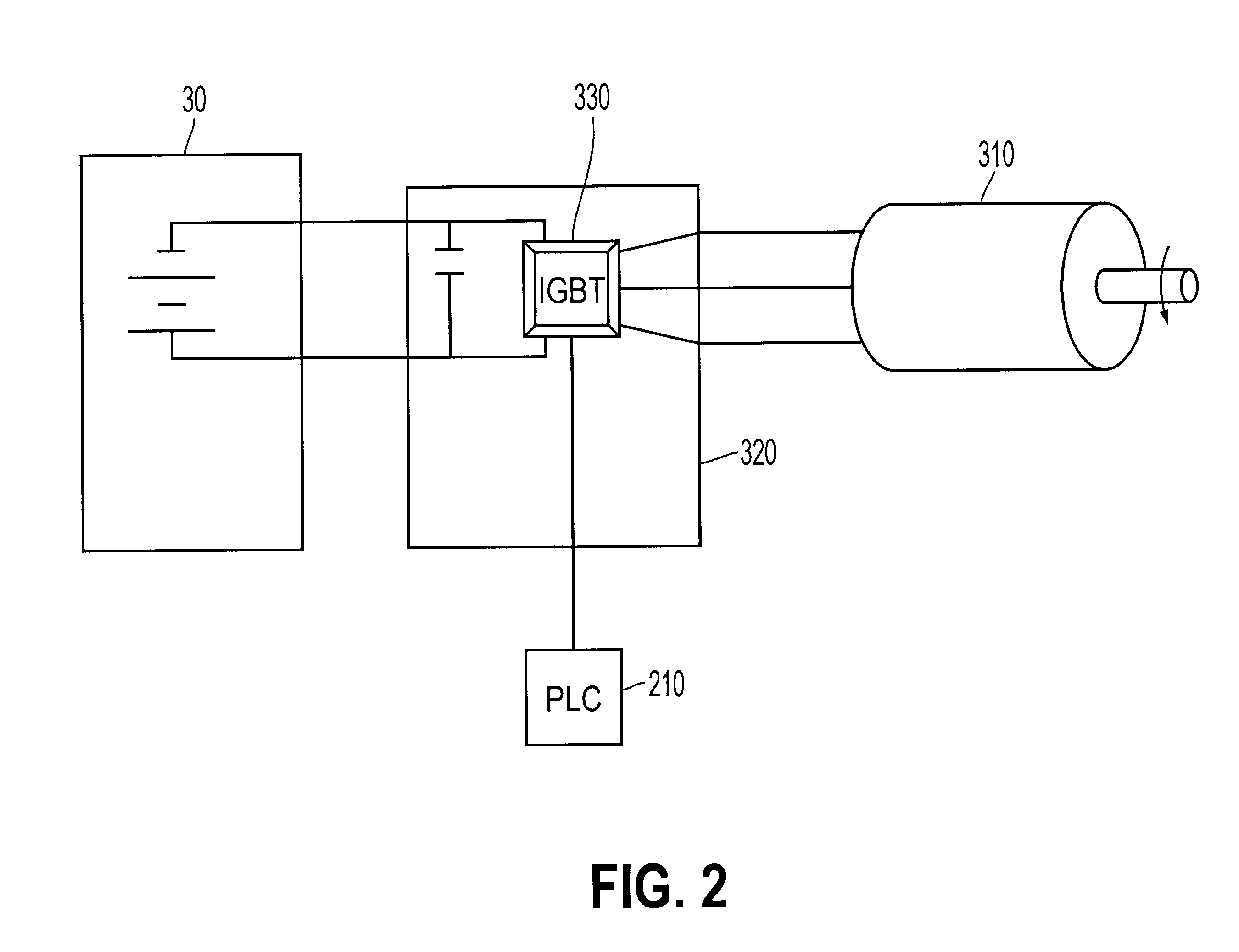

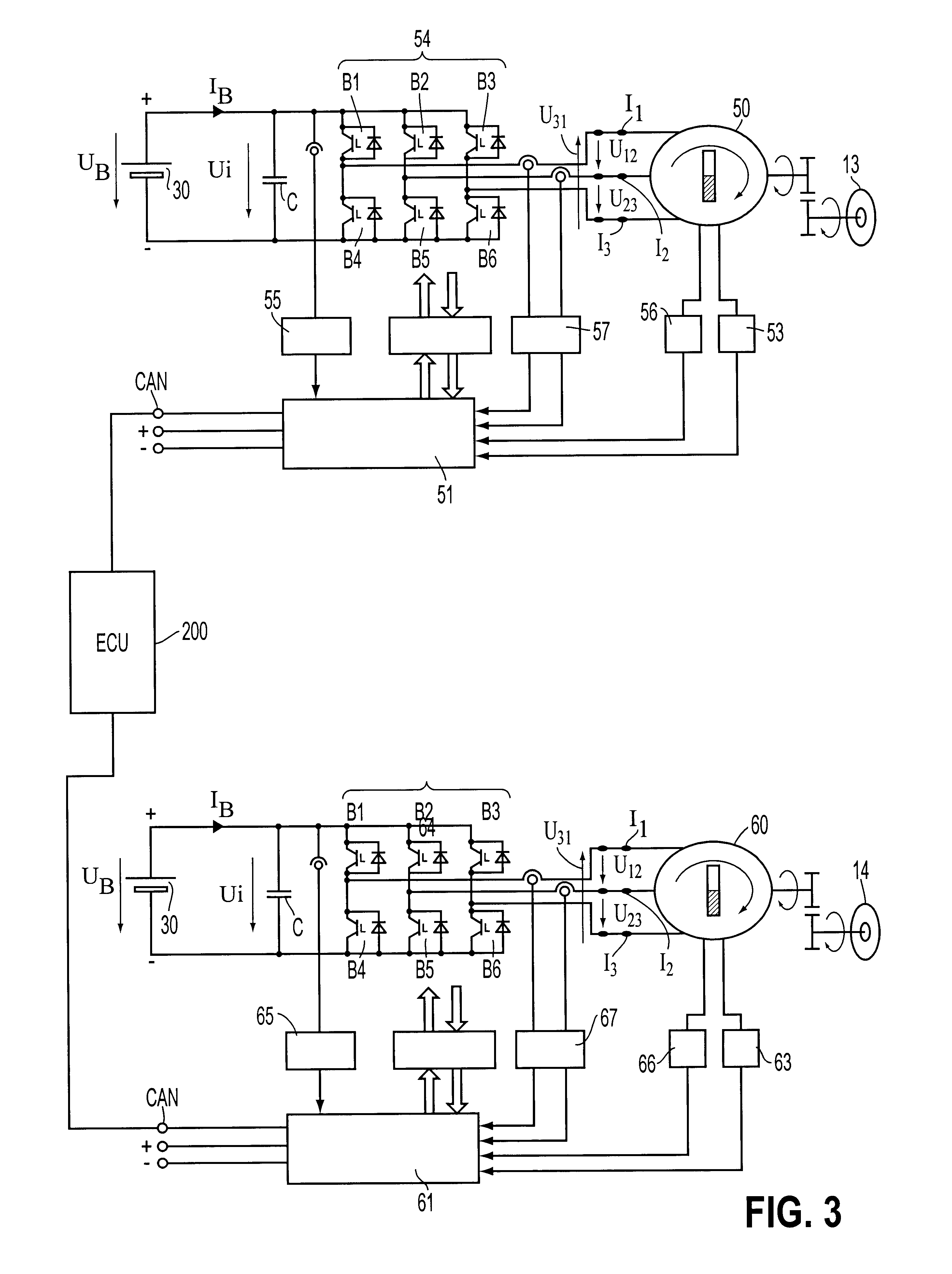

Method and apparatus for adaptively controlling a state of charge of a battery array of a series type hybrid electric vehicle

InactiveUS6333620B1Batteries circuit arrangementsSecondary cells charging/dischargingElectrical batteryElectric vehicle

A series type hybrid electric vehicle including a generator set having an internal combustion engine and a generator, a battery array and at least one electric motor includes a controller for maintaining a state of charge of the battery array within a control limit. A controller of the vehicle determines if the vehicle is in one of a plurality of forward driving modes, compares a state of charge of the battery array to an upper control limit associated with a forward driving mode, decreases generated by the generator, if the state of charge is equal to or greater than the associated upper control limit, and increases the power generated by the generator, if the state of charge is less than the associated upper control limit. A method of controlling the state of charge of the battery array includes determining if the vehicle is in one of a plurality of forward driving modes, comparing a state of charge of the battery array to an upper control limit associated with a forward driving mode, decreasing the power generatred by the generator, if the state of charge is equal to or greater than the associated upper control limit, and increasing the power generated by the generator, if the state of charge is less than the associated upper control limit.

Owner:TRANSPORTATION TECH

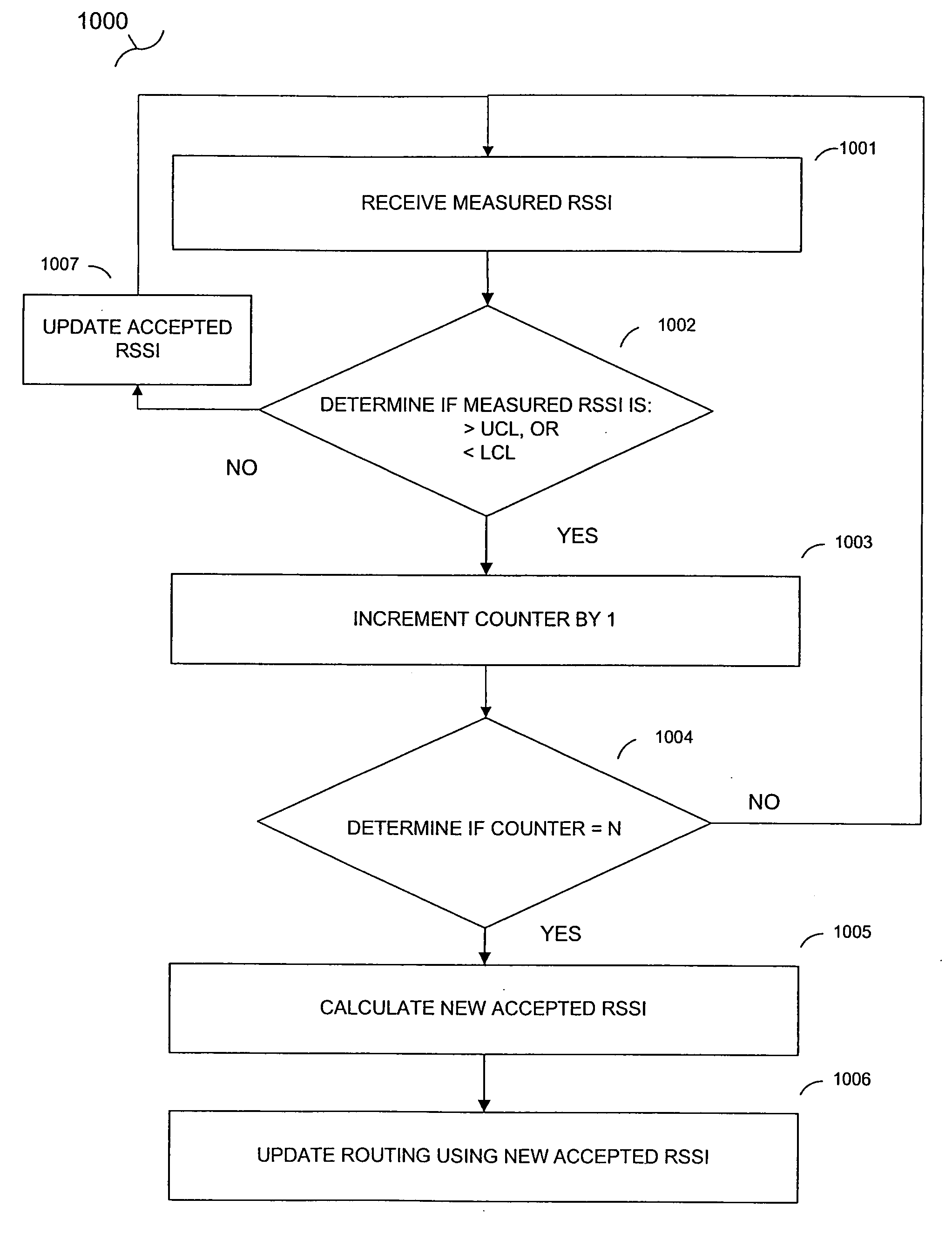

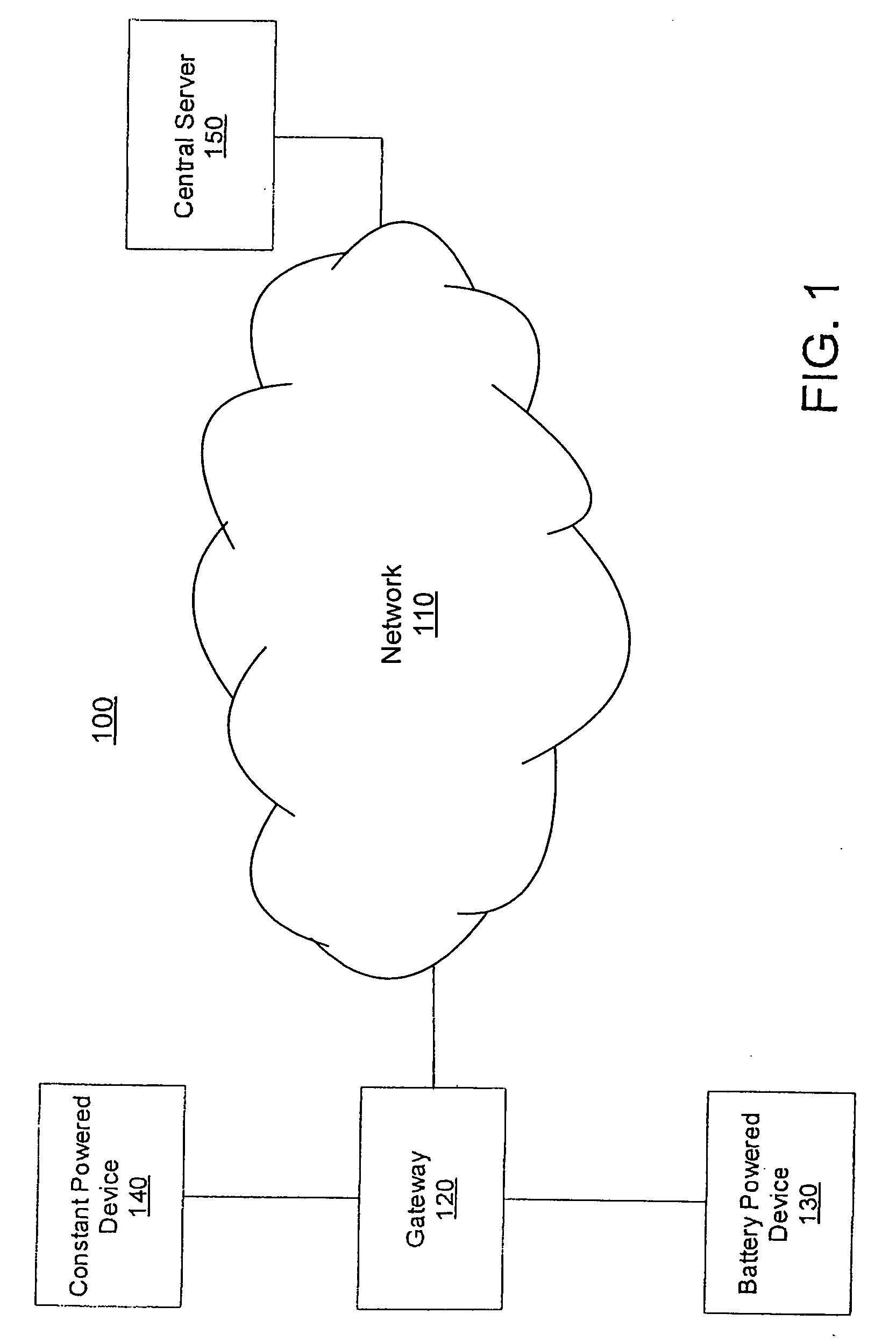

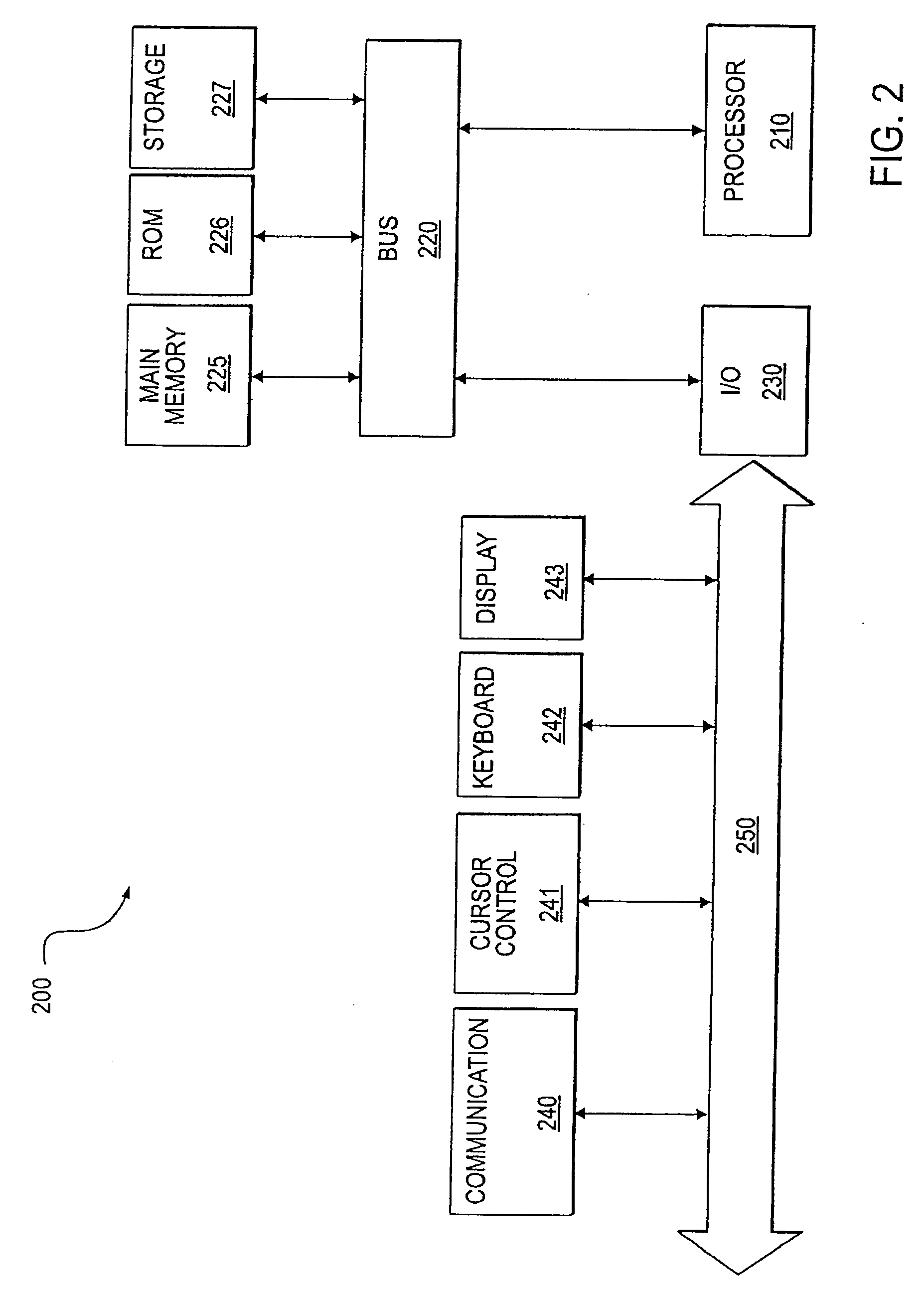

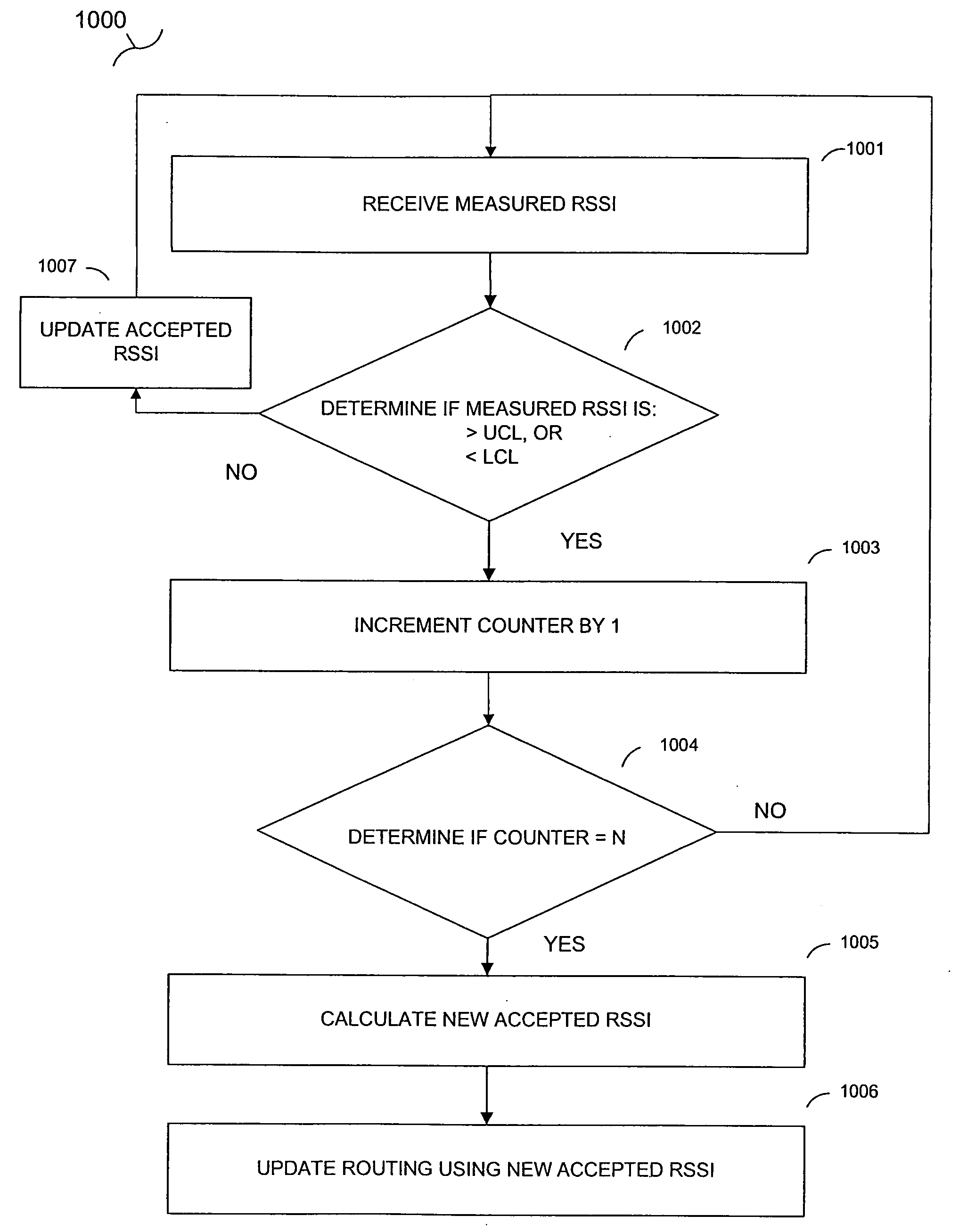

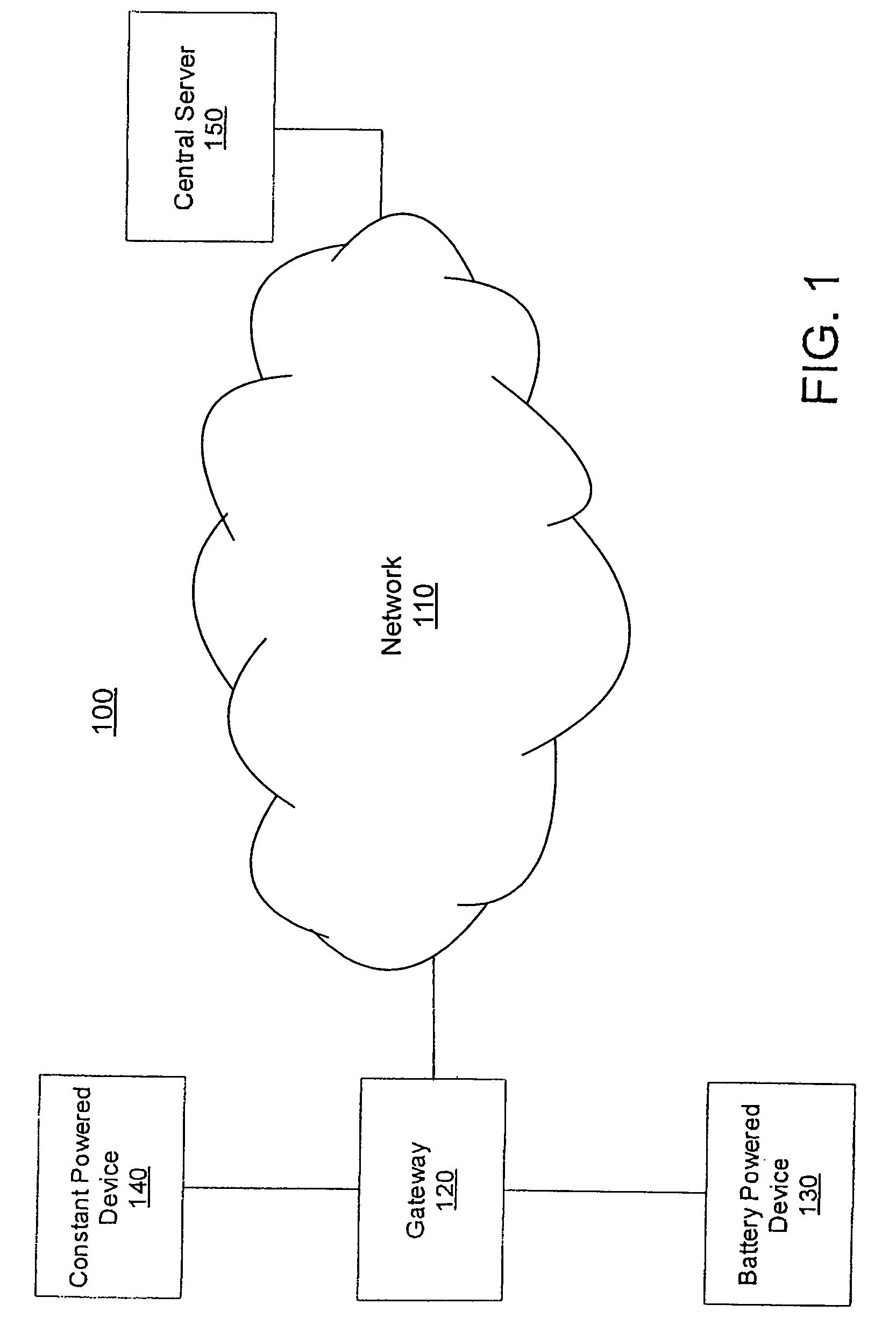

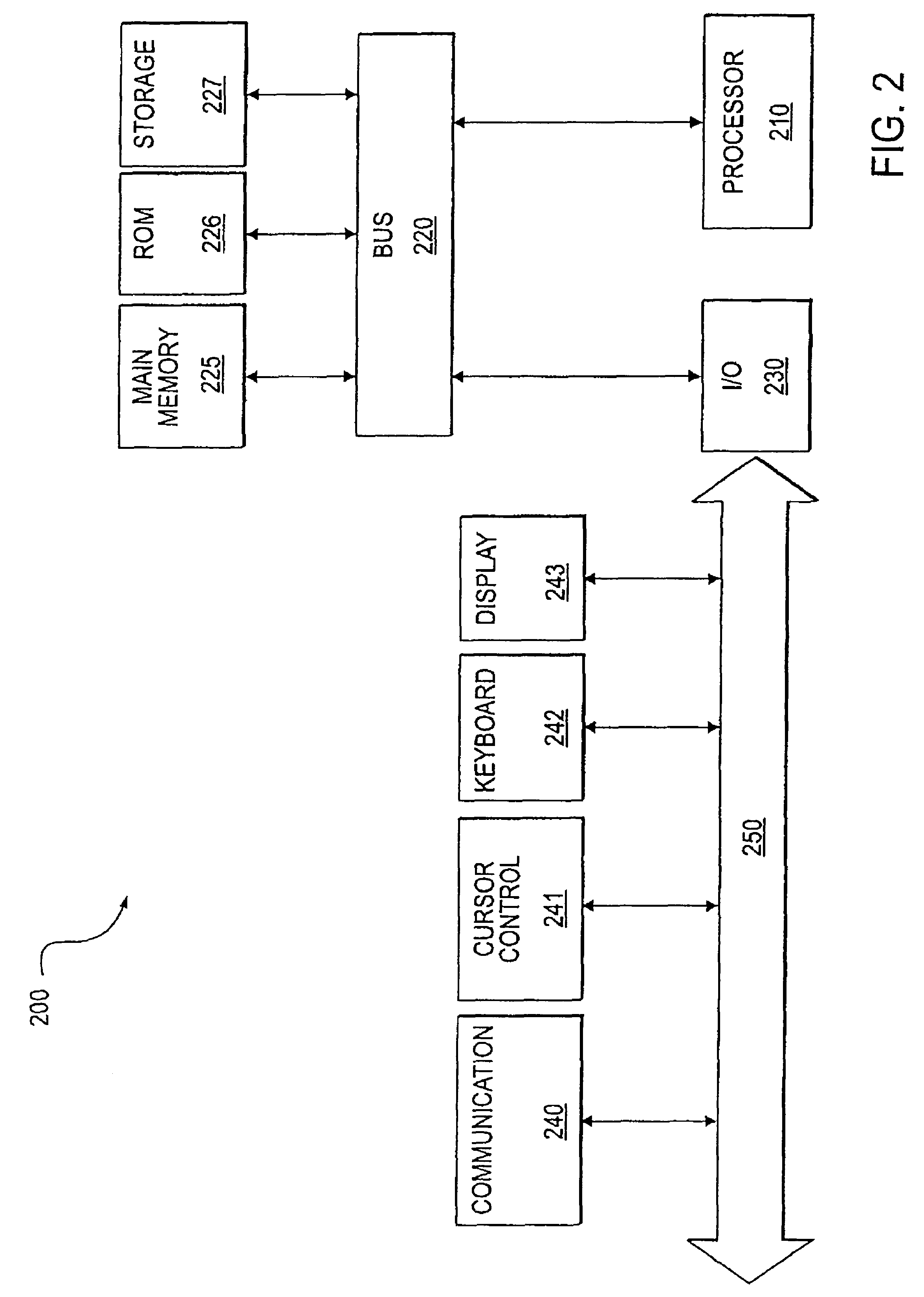

Method and system for providing a routing protcol for wireless networks

A method and system for providing a network protocol for utility services are disclosed are disclosed. In one embodiment, a computer-implemented method determines whether a measured real signal strength differs from a an accepted real signal strength by a configurable control limit parameter. In the event the measured real signal strength exceeds either an upper or lower bound based upon the configurable control limit parameter a determination is made whether there has been an unacceptable number of measured real signal strengths that exceed either an upper or lower bound based upon the configurable control limit parameter. In the event there has been an unacceptable number of measured real signal strengths that exceed either an upper or lower bound, which may include reaching or exceeding a configurable out of bound incidence limit, then a determination is made to calculate a new accepted real signal strength.

Owner:ITRON NETWORKED SOLUTIONS INC

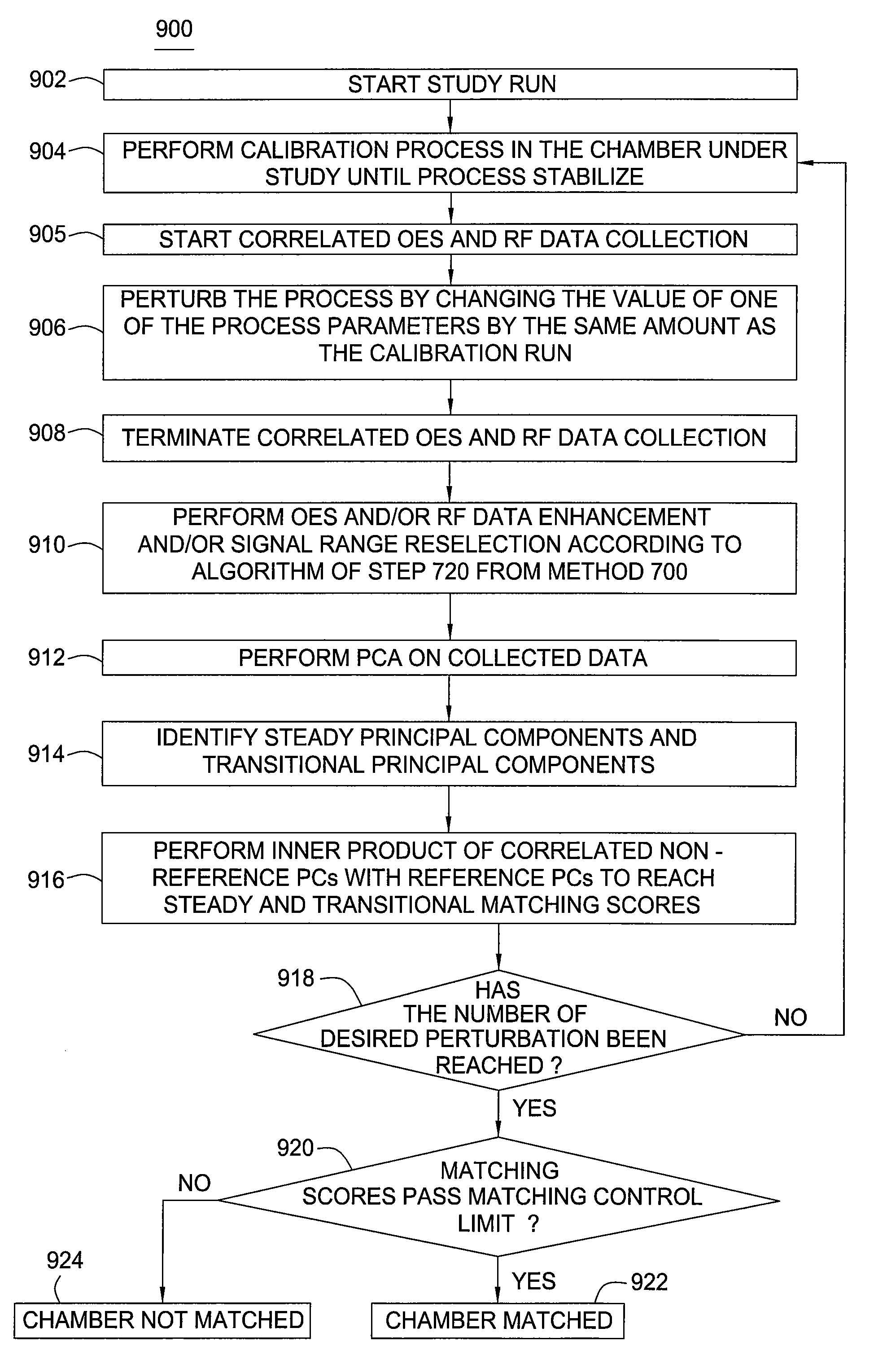

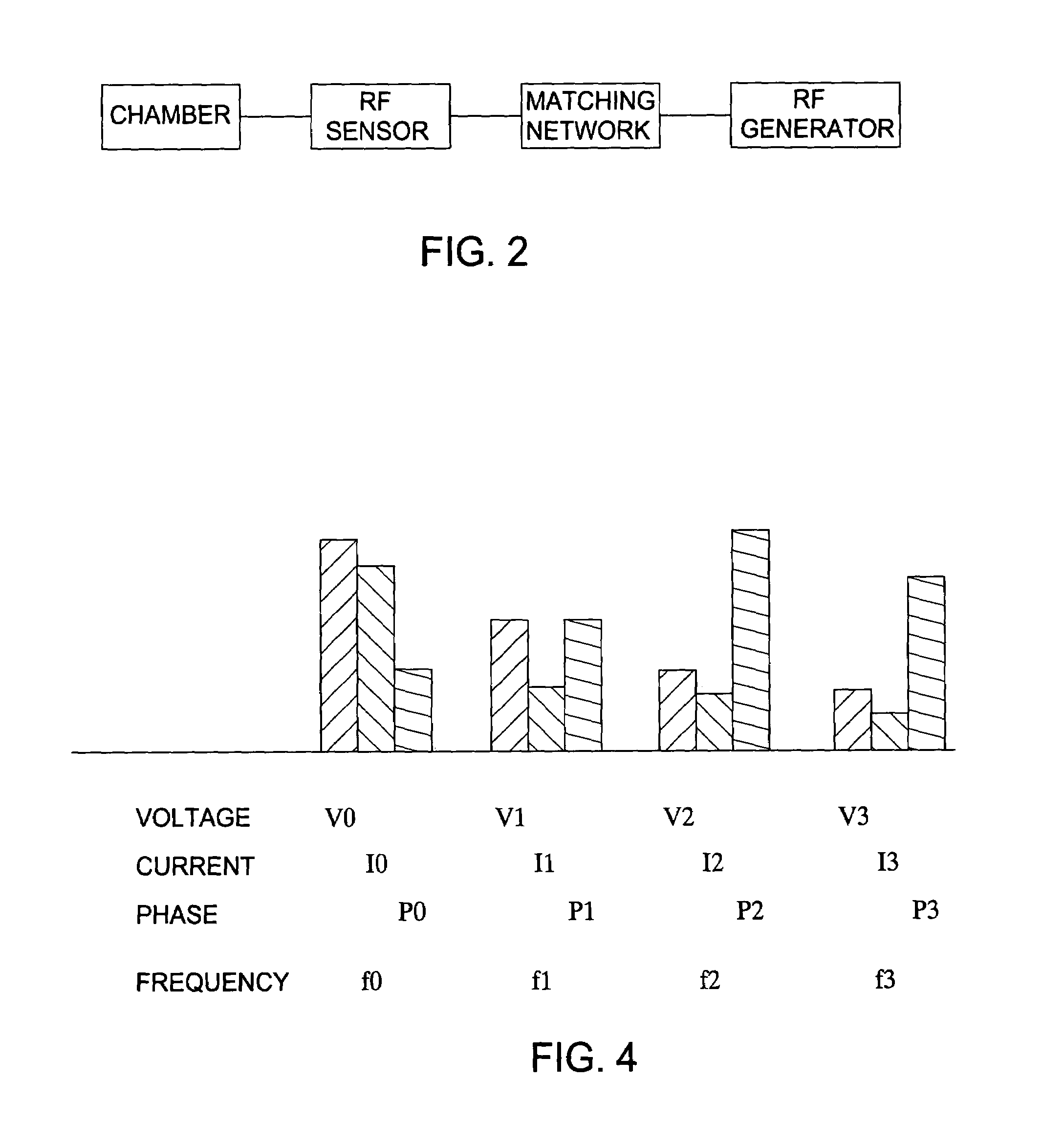

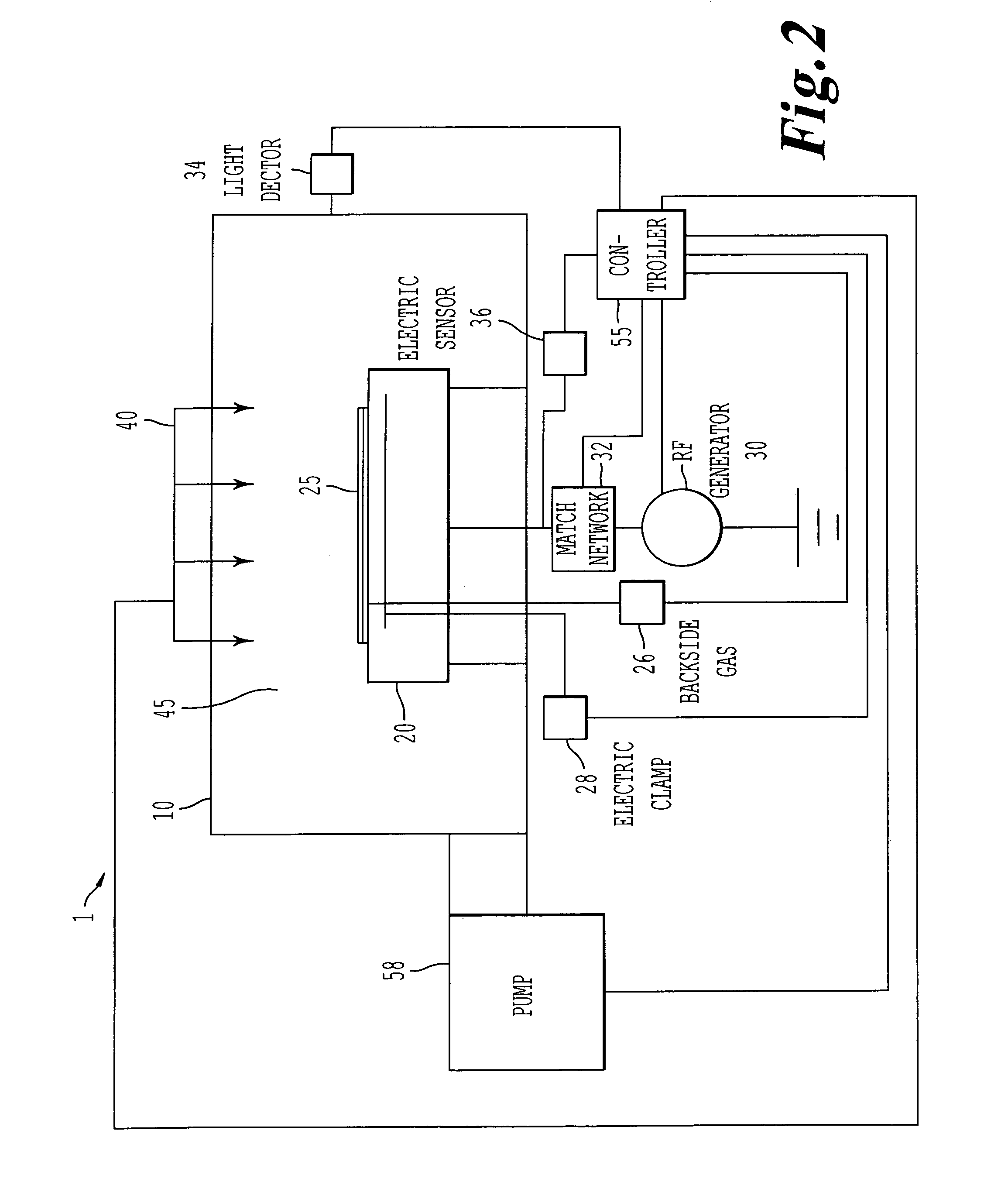

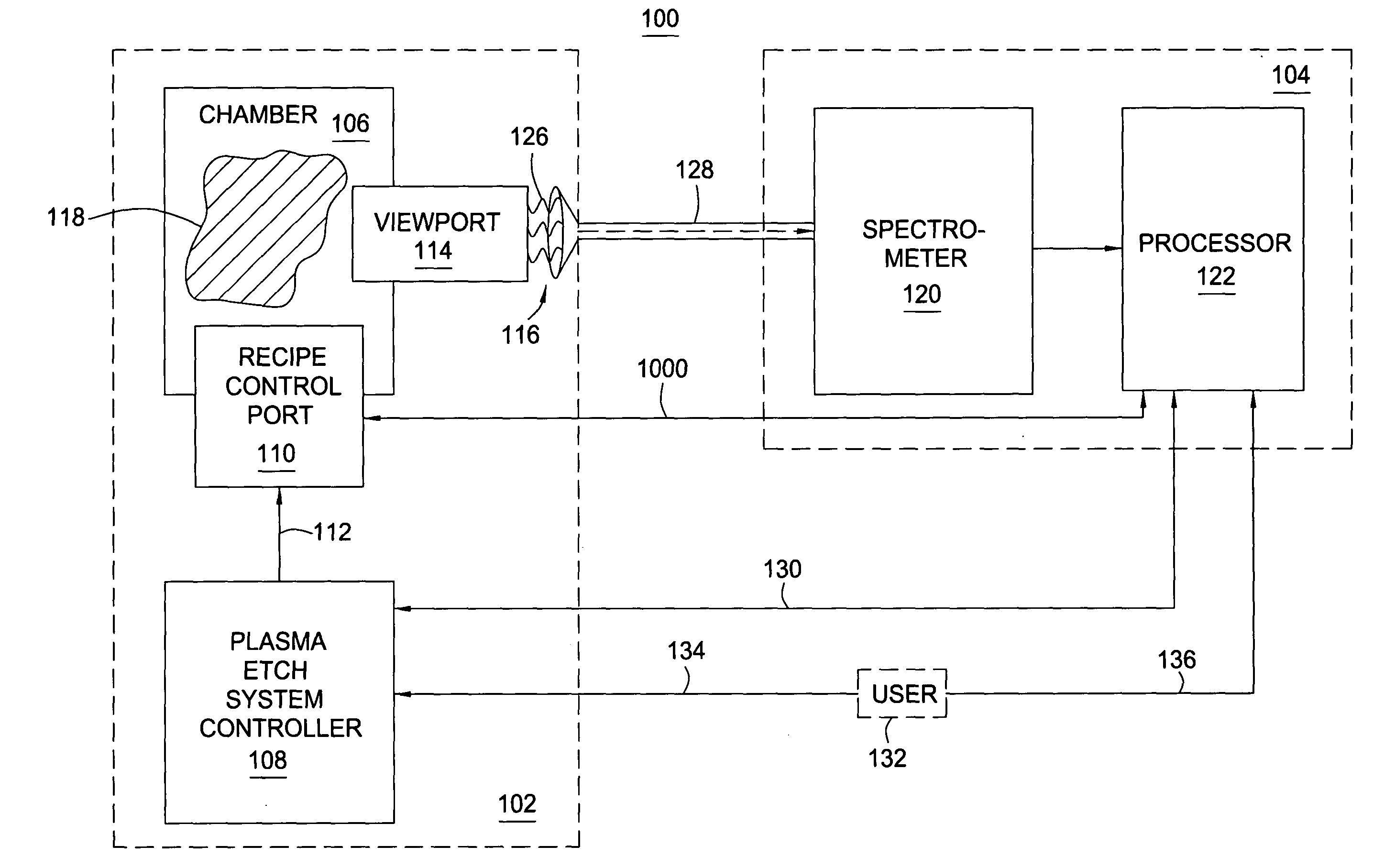

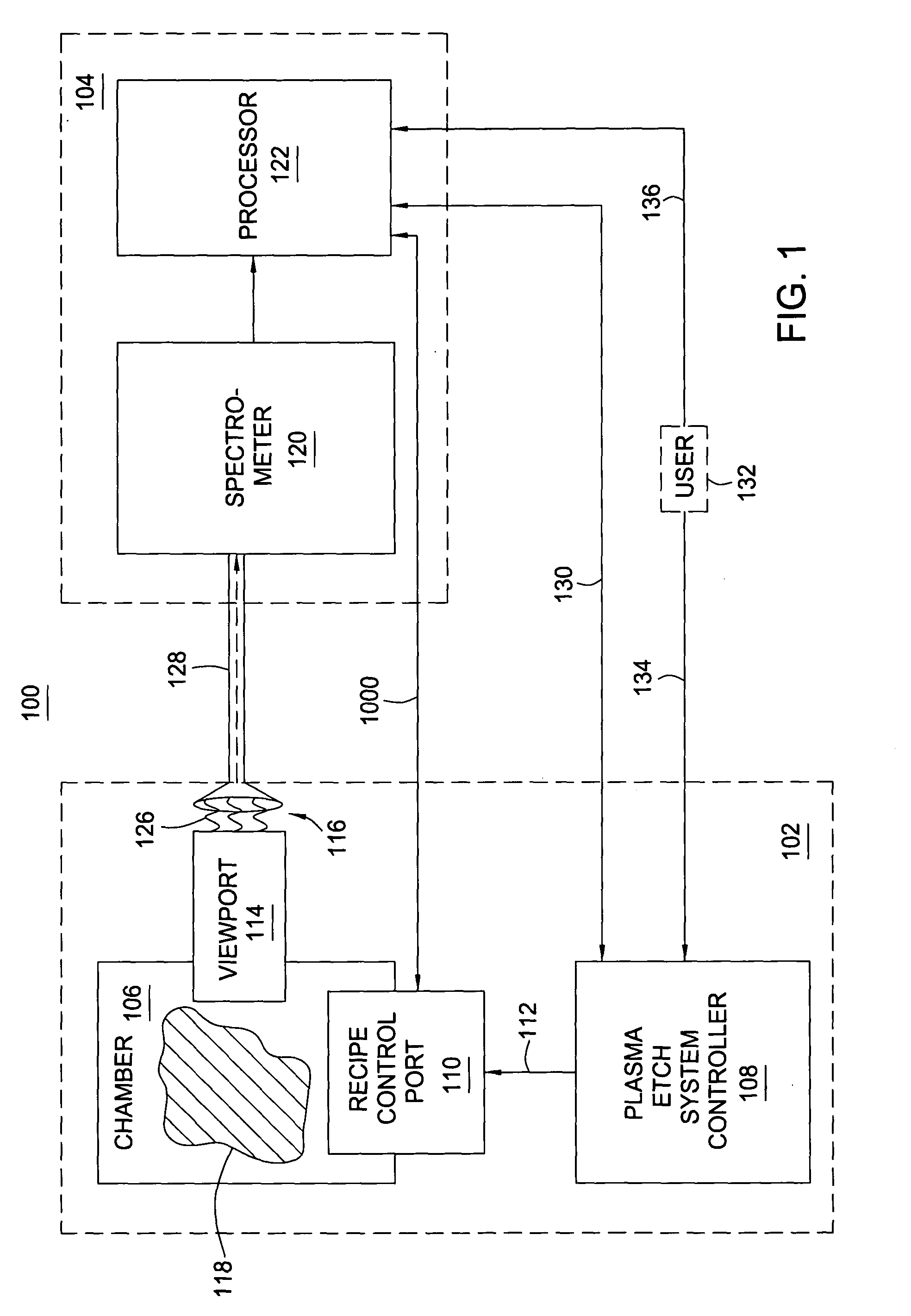

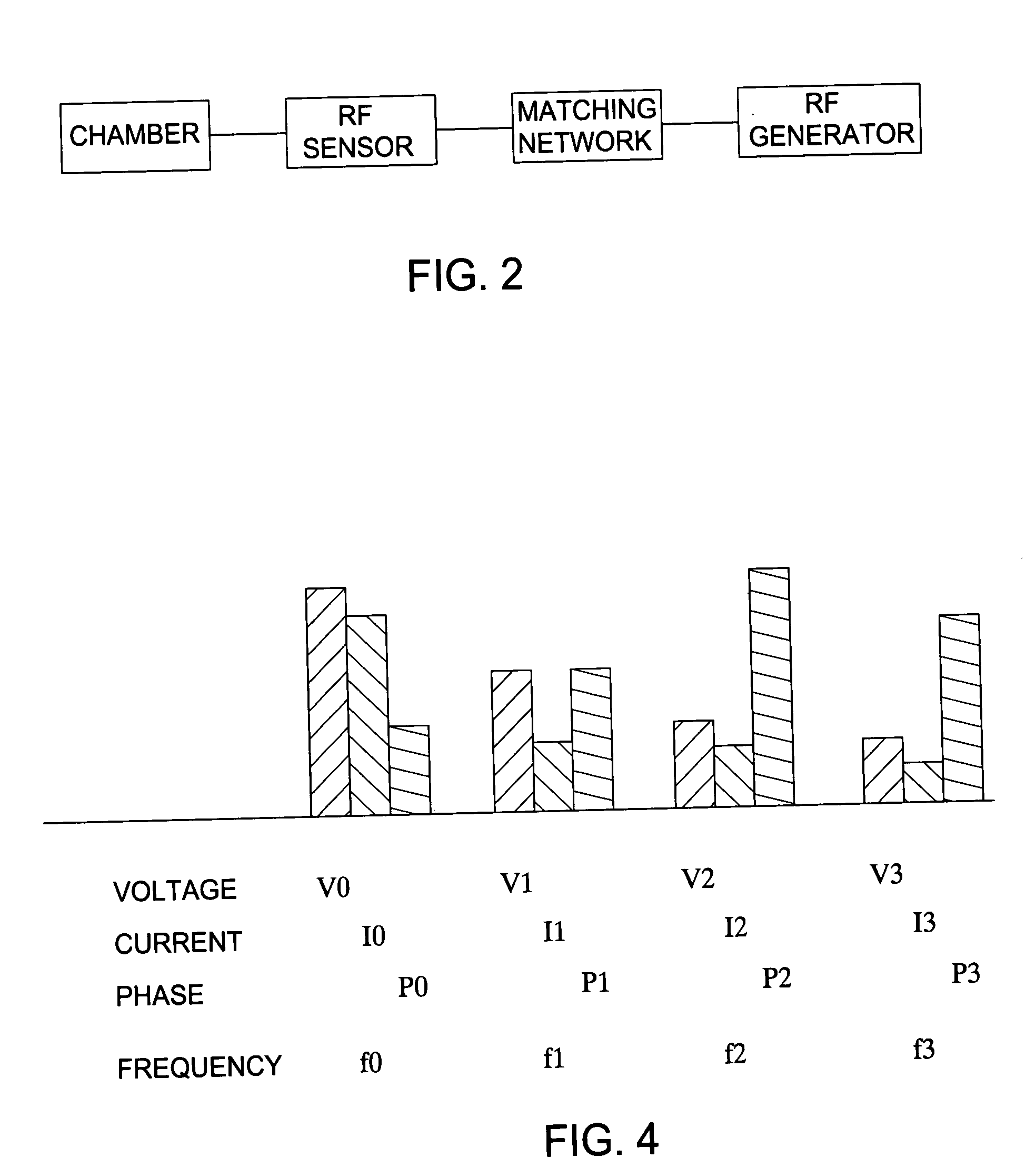

Method for automatic determination of semiconductor plasma chamber matching and source of fault by comprehensive plasma monitoring

InactiveUS7169625B2Electric discharge tubesSemiconductor/solid-state device manufacturingSemiconductor plasmaProcedural parameter

A method and apparatus for automatic determination of semiconductor plasma chamber matching a source of fault are provided. Correlated plasma attributes are measured for process used for calibration both in a chamber under study and in a reference chamber. Principal component analysis then is performed on the measured correlated attributes so as to generate steady principal components and transitional principal components; and these principal components are compared to reference principal components associated with a reference chamber. The process used for calibration includes a regular plasma process followed by a process perturbation of one process parameter. Similar process perturbation runs are conducted several times to include different perturbation parameters. By performing inner products of the principal components of chamber under study and the reference chamber, matching scores can be reached. Automatic chamber matching can be determined by comparing these scores with preset control limits. The potential source(s) of chamber fault can also be identified by the lowest matching score(s).

Owner:APPLIED MATERIALS INC

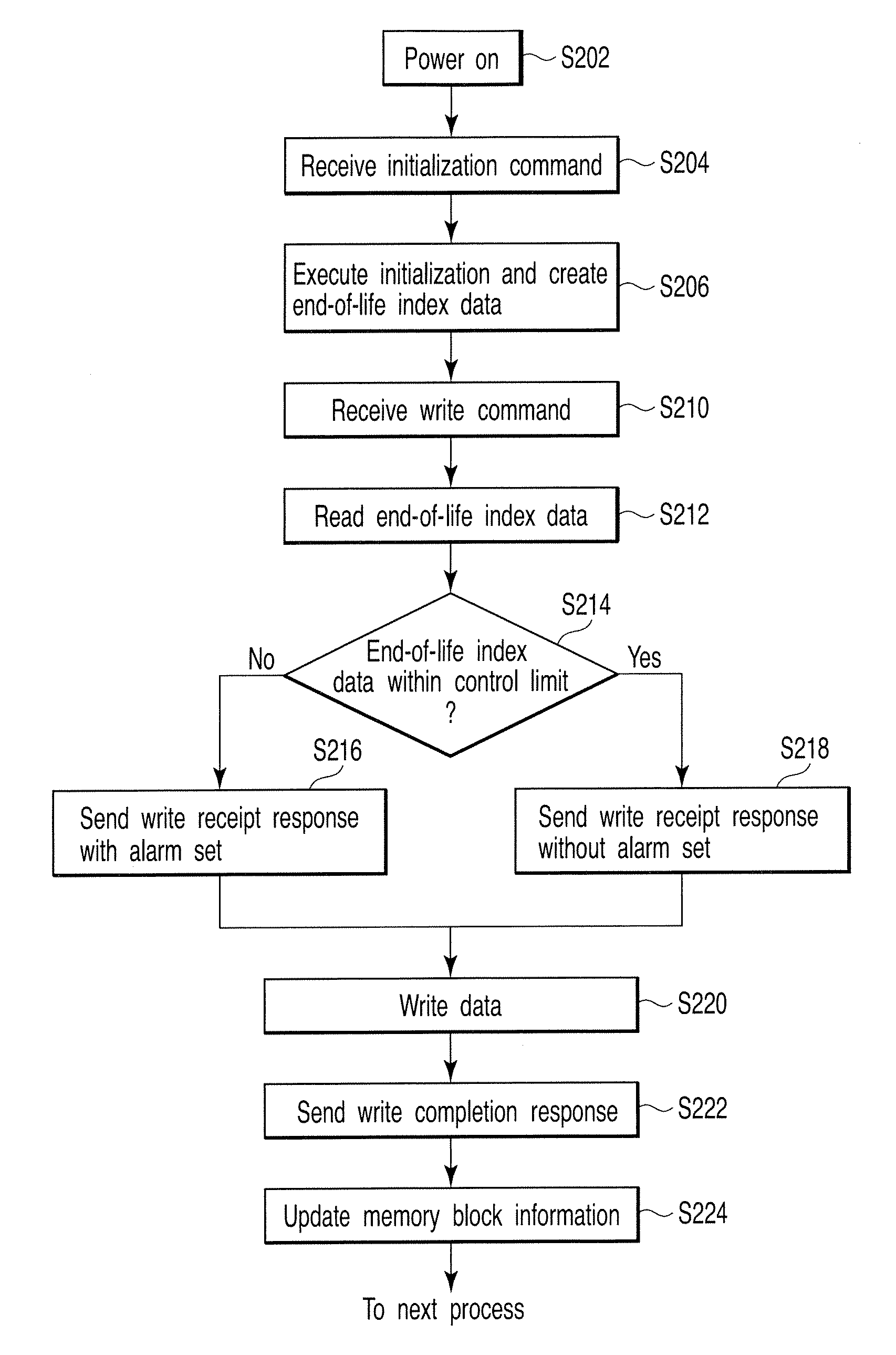

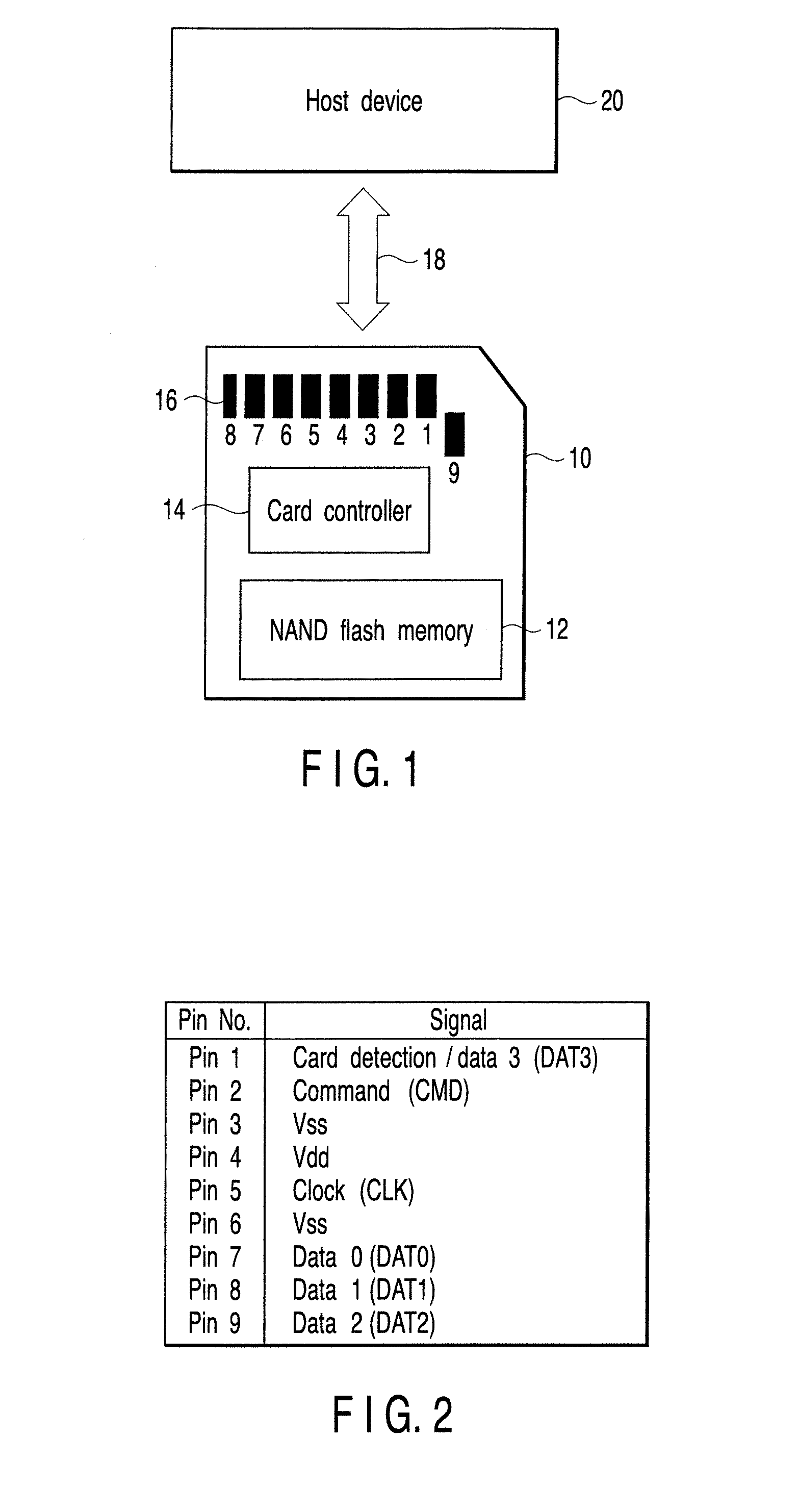

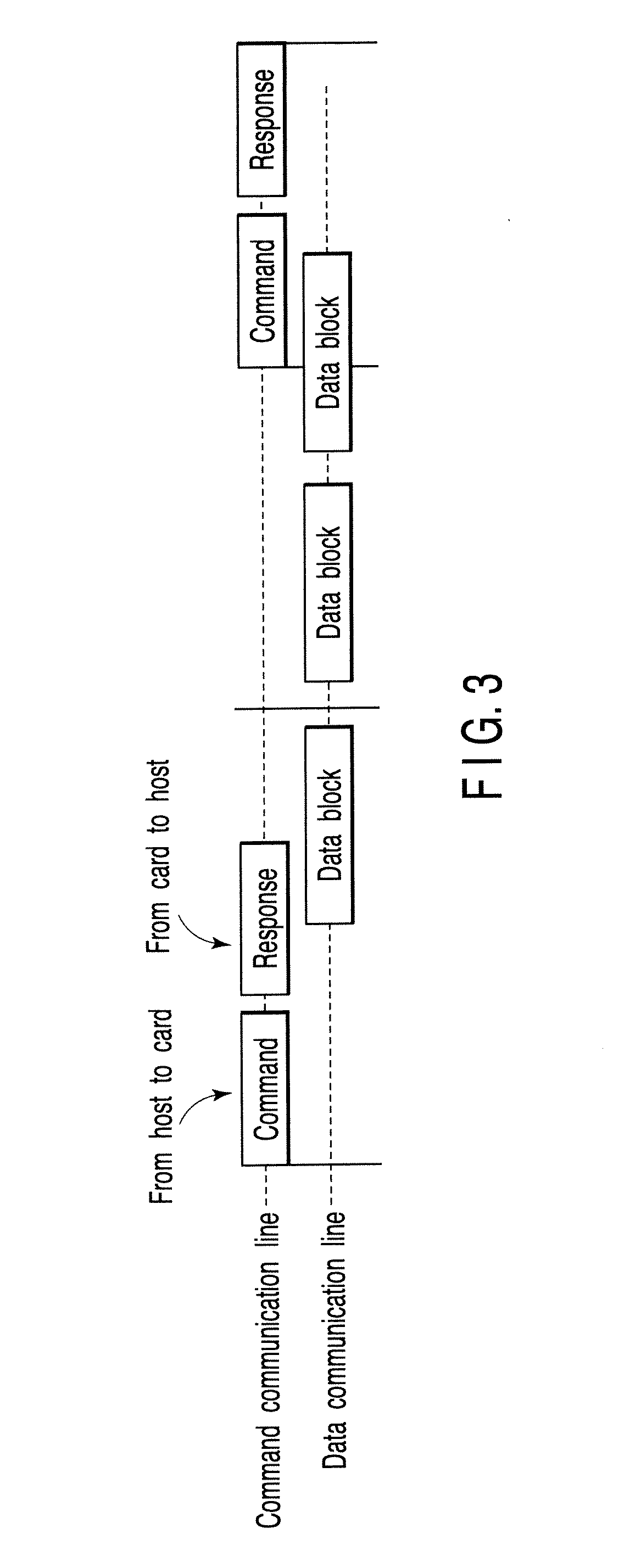

Method of controlling semiconductor memory card system

A method of controlling a semiconductor memory card system including a host device incorporating a semiconductor memory card and communicating information with a user of the host device to warn the imminent end of the life of the memory card in the system is provided. According to one aspect, there is provided a method of controlling a semiconductor memory card, the method comprising creating end-of-life index data of the semiconductor memory card, reading the end-of-life index data in response to a command from a host device to the semiconductor memory card, creating an end-of-life warning status of the semiconductor memory card from the end-of-life index data based on a life control limit value, and sending a response containing the end-of-life warning status to the host device as a response to the command through the same communication line as that for the command.

Owner:KK TOSHIBA

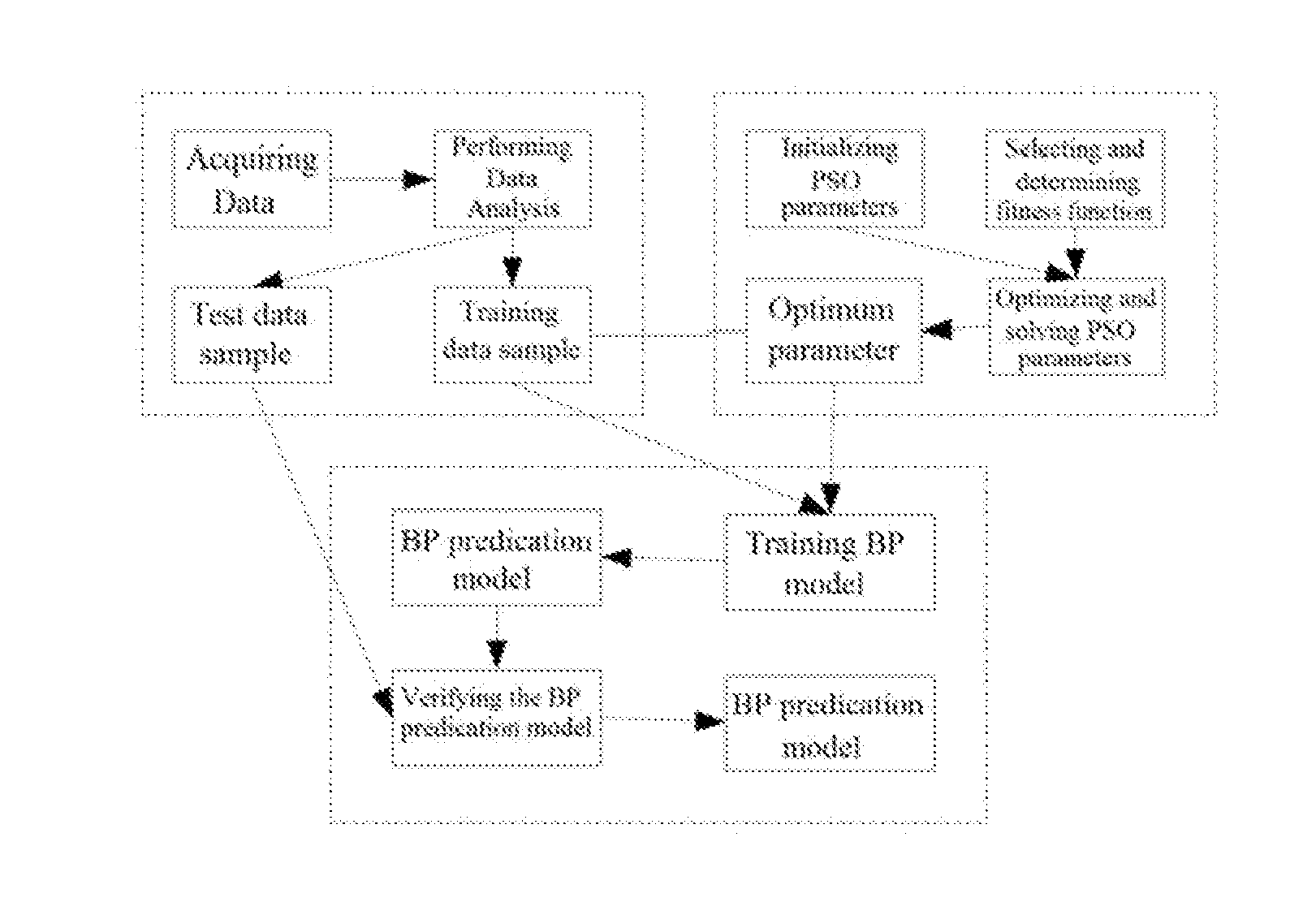

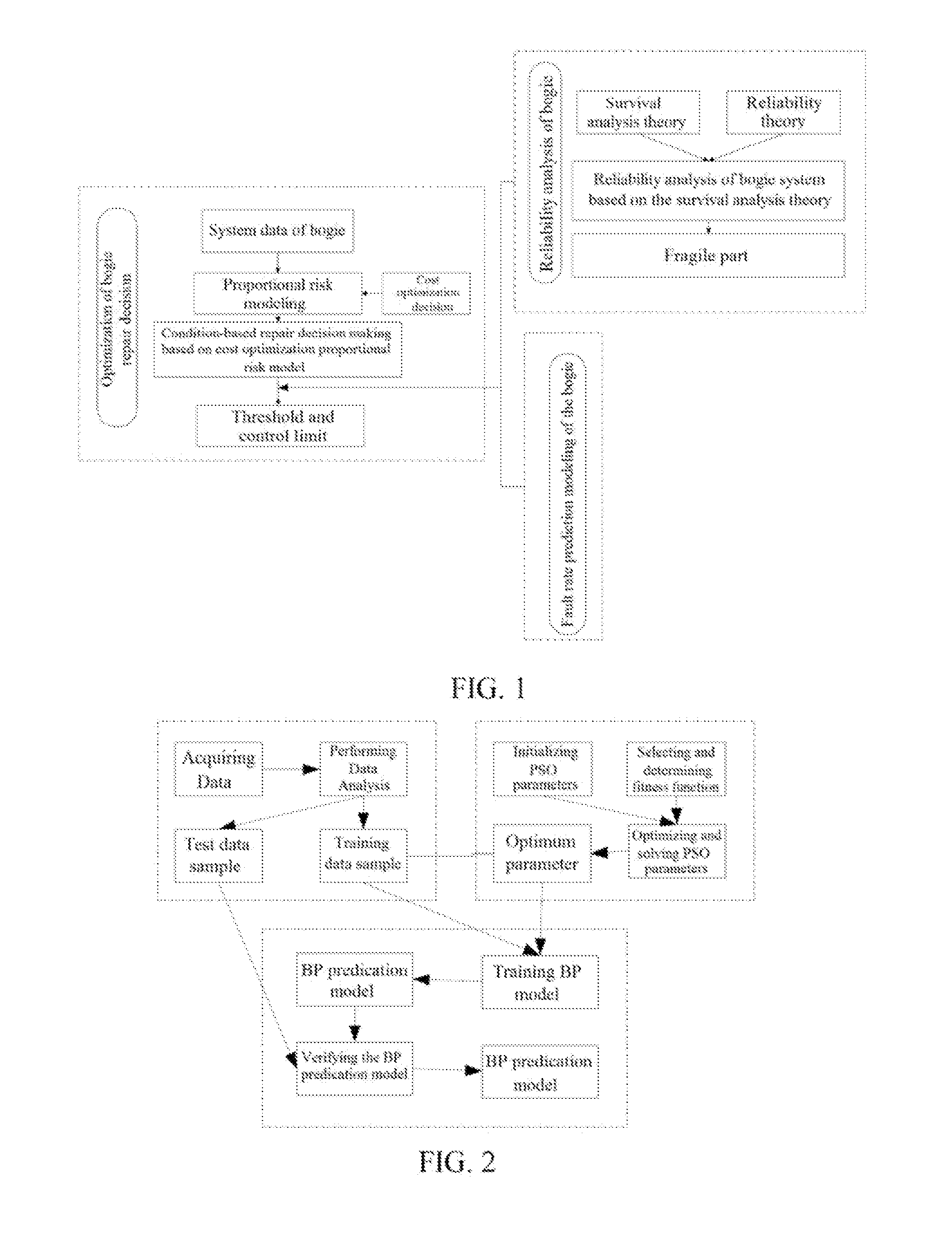

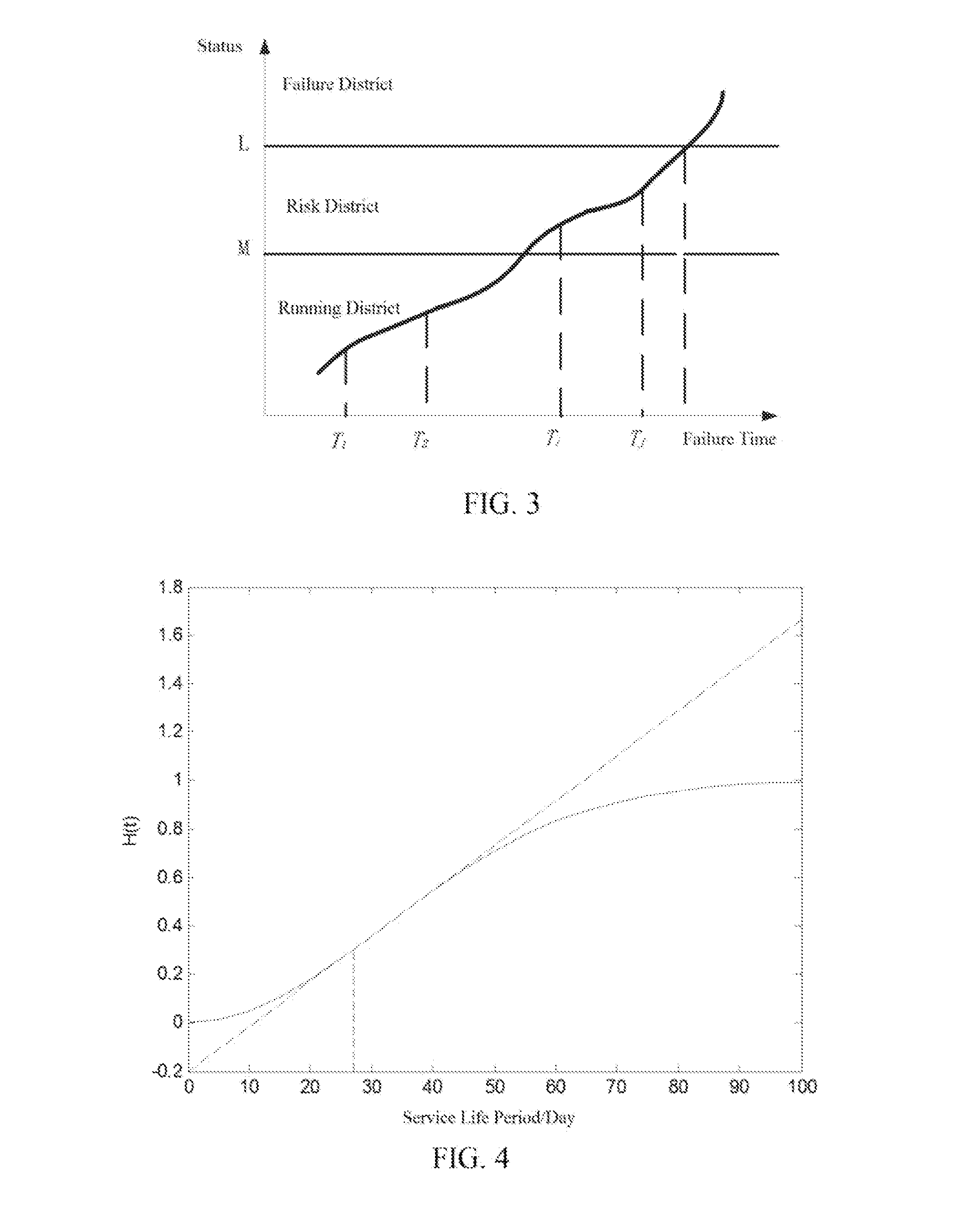

Fault Prediction and Condition-based Repair Method of Urban Rail Train Bogie

ActiveUS20160282229A1Failure rateAvoid waste of repair costArtificial lifeRailway vehicle testingFailure rateBogie

The present invention provides a fault prediction and condition-based repair method of an urban rail train bogie. An optimum service life distribution model of a framework, a spring device, a connecting device, a wheel set and axle box, a driving mechanism, and a basic brake device of a bogie is determined by adopting a method based on survival analysis; a reliability characteristic function of each subsystem is obtained; then, a failure rate of each subsystem of the bogie is calculated by adopting a neural network model optimized by an evolutionary algorithm; and finally, proportional risk modelling is conducted by taking the failure rate and safe operation days of each subsystem of the bogie as concomitant variables; and on the basis of cost optimization, thresholds and control limits for condition-based repair of a bogie system are obtained.

Owner:BEIJING JIAOTONG UNIV

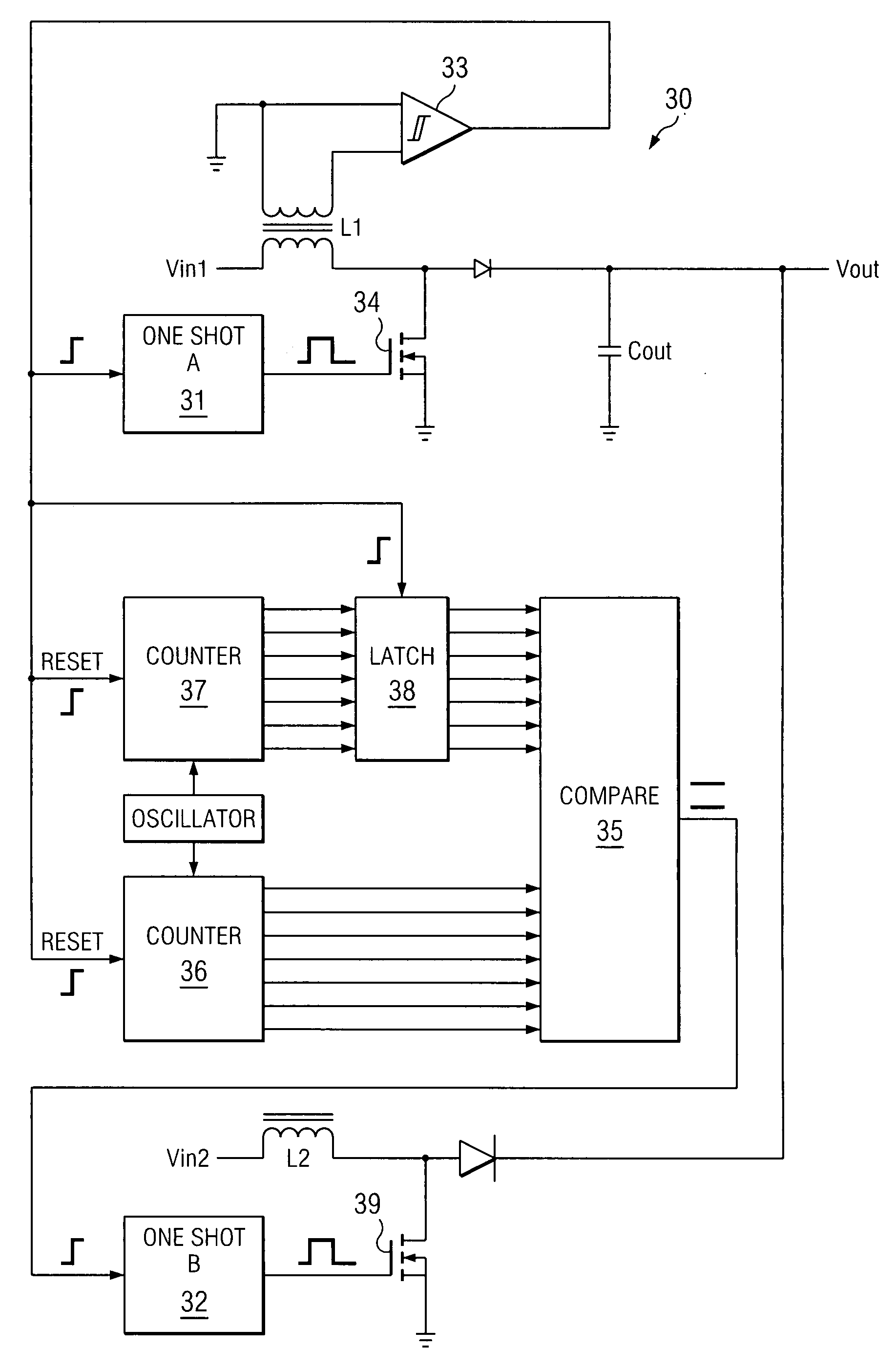

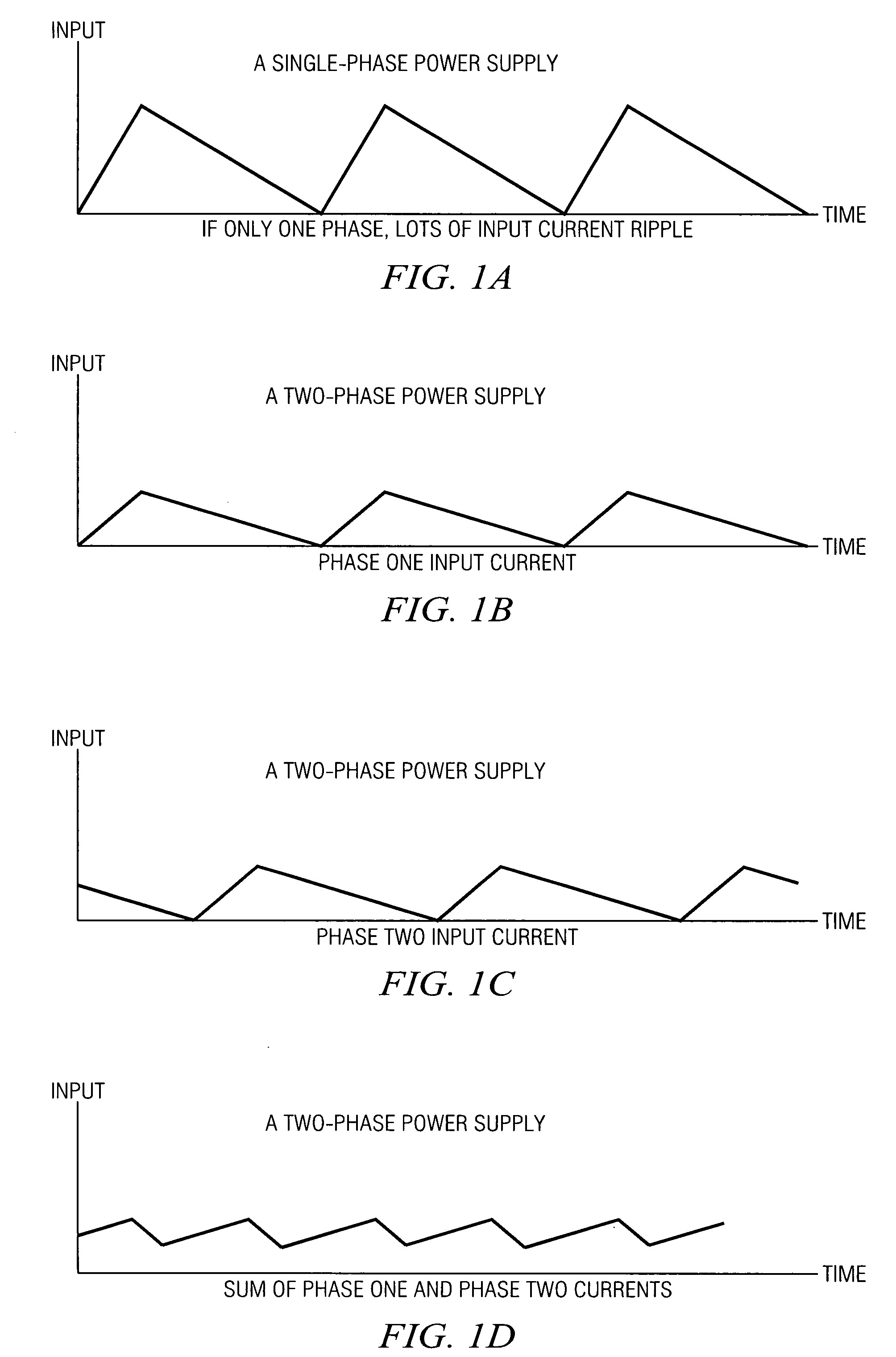

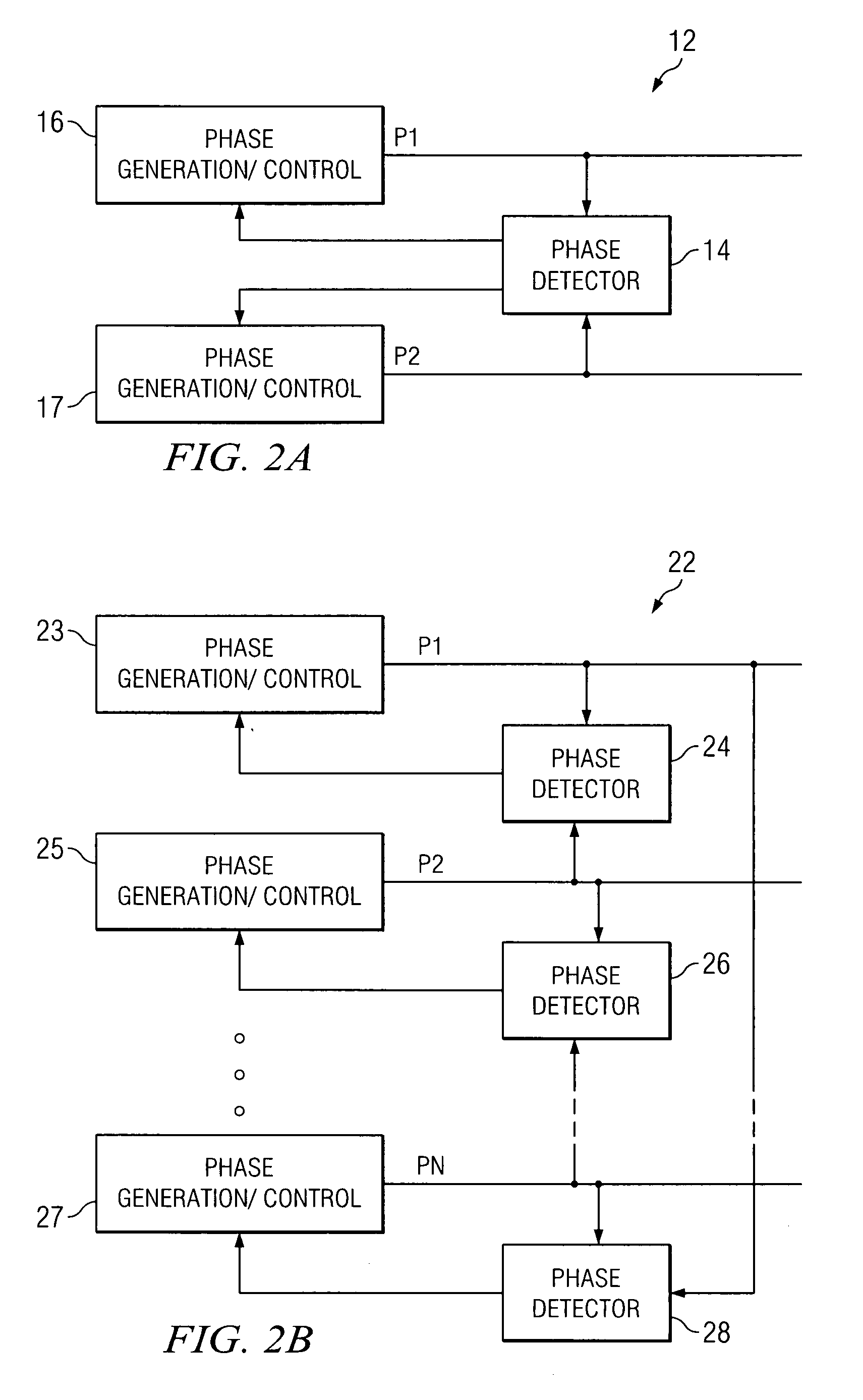

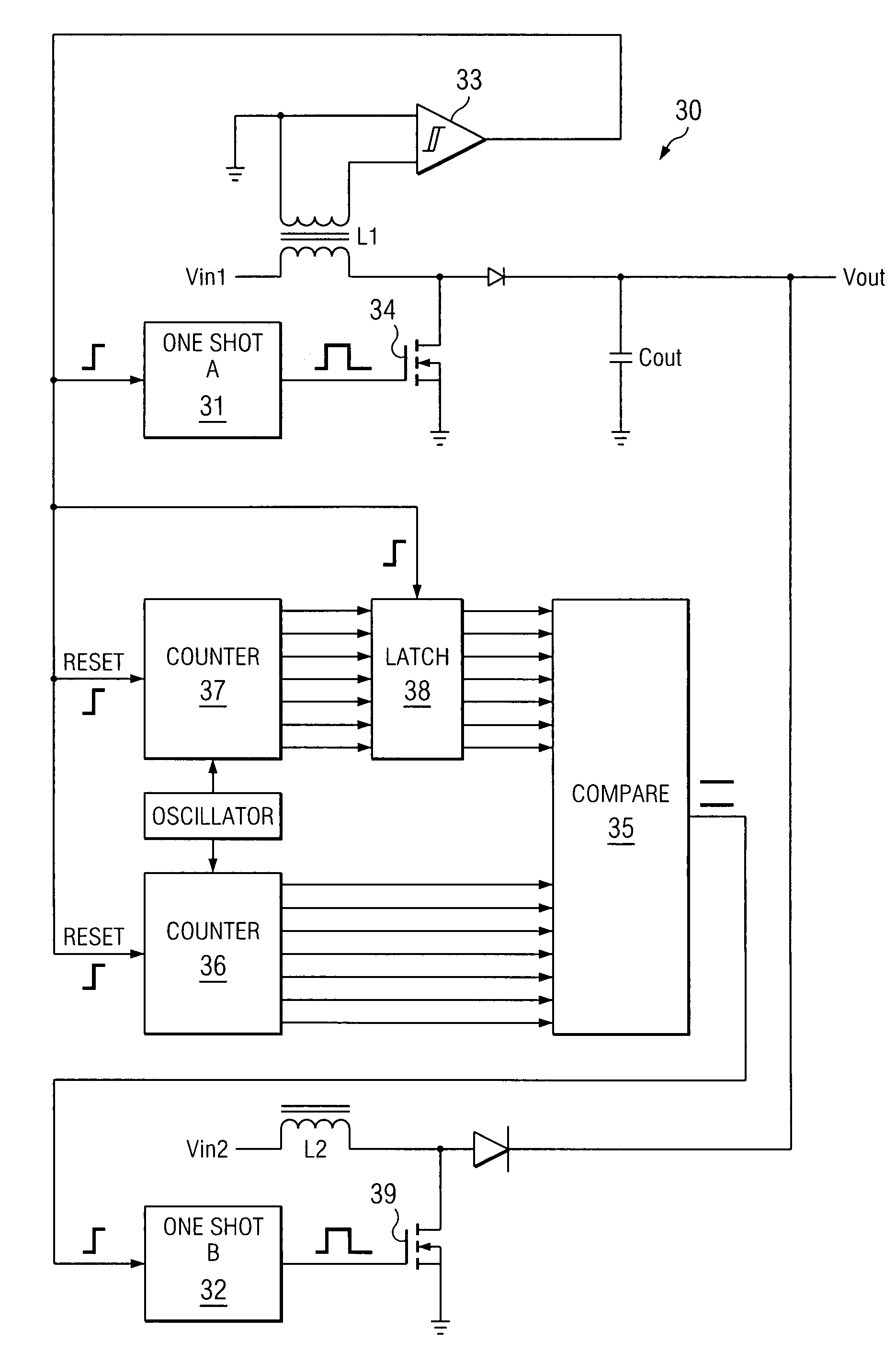

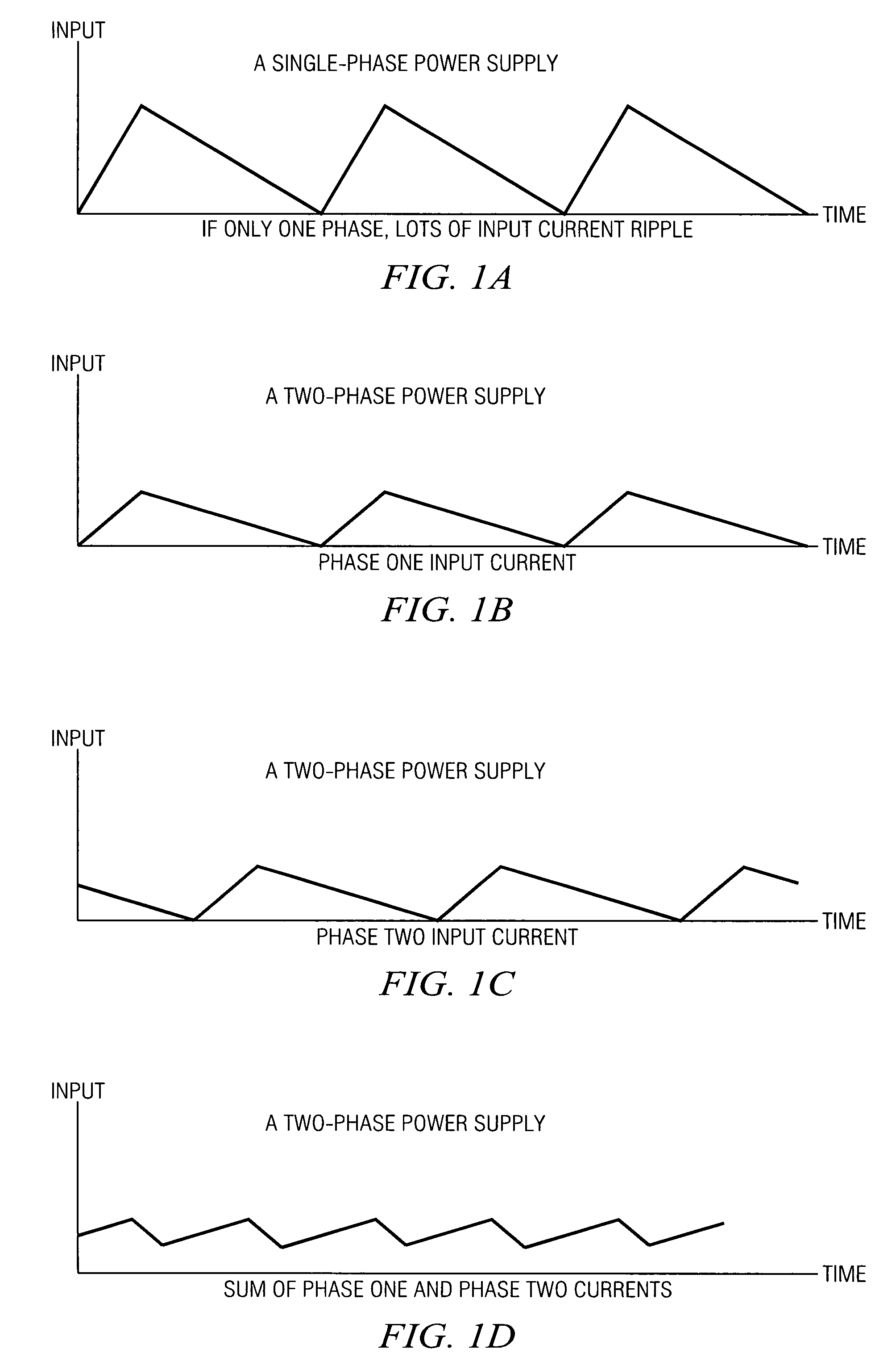

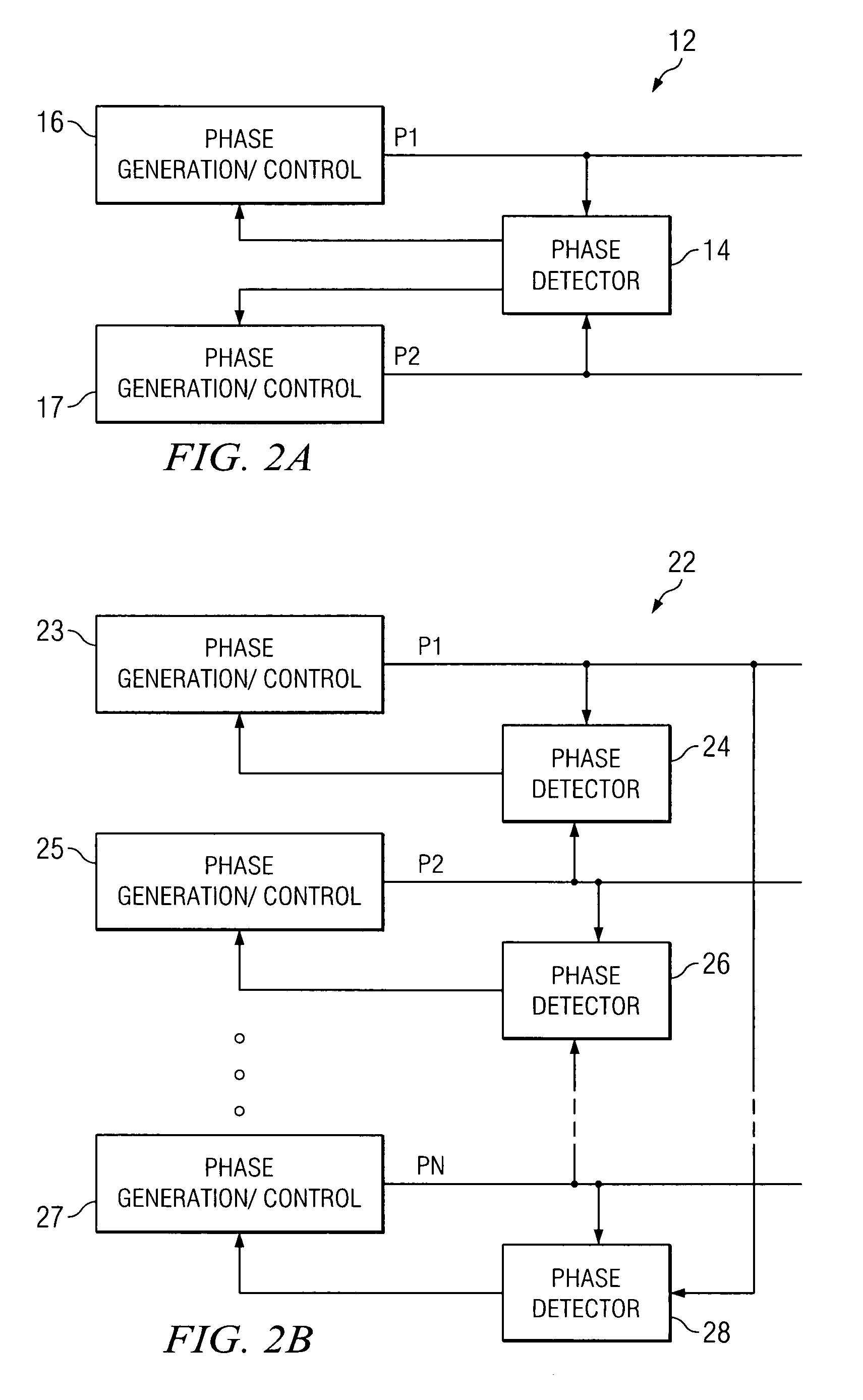

Method and apparatus for multi-phase power conversion

ActiveUS20070253223A1Improve circuit efficiencyReduce and eliminate impactEfficient power electronics conversionAc-dc conversionEngineeringSwitching frequency

A system and method for power conversion synchronizes multiple phases at a desired phase angle difference. The power conversion involves variable frequency switching, fixed on-time and provides power factor correction. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The power conversion involves transition mode switching to help reduce switching losses. A phase angle difference detector may be provided for each phase. The various phases may have different inherent frequencies that vary with switching frequency, and are synchronized to an average frequency. Current measures can be taken with a single component, such as a resistor. A maximum frequency control limits period width to avoid high frequency switching. An added switch on time improves input voltage crossover distortion. One or more phases can be deactivated in light load conditions.

Owner:TEXAS INSTR INC

Method and system for providing a routing protocol for wireless networks

A method and system for providing a network protocol for utility services are disclosed are disclosed. In one embodiment, a computer-implemented method determines whether a measured real signal strength differs from a an accepted real signal strength by a configurable control limit parameter. In the event the measured real signal strength exceeds either an upper or lower bound based upon the configurable control limit parameter a determination is made whether there has been an unacceptable number of measured real signal strengths that exceed either an upper or lower bound based upon the configurable control limit parameter. In the event there has been an unacceptable number of measured real signal strengths that exceed either an upper or lower bound, which may include reaching or exceeding a configurable out of bound incidence limit, then a determination is made to calculate a new accepted real signal strength.

Owner:ITRON NETWORKED SOLUTIONS INC

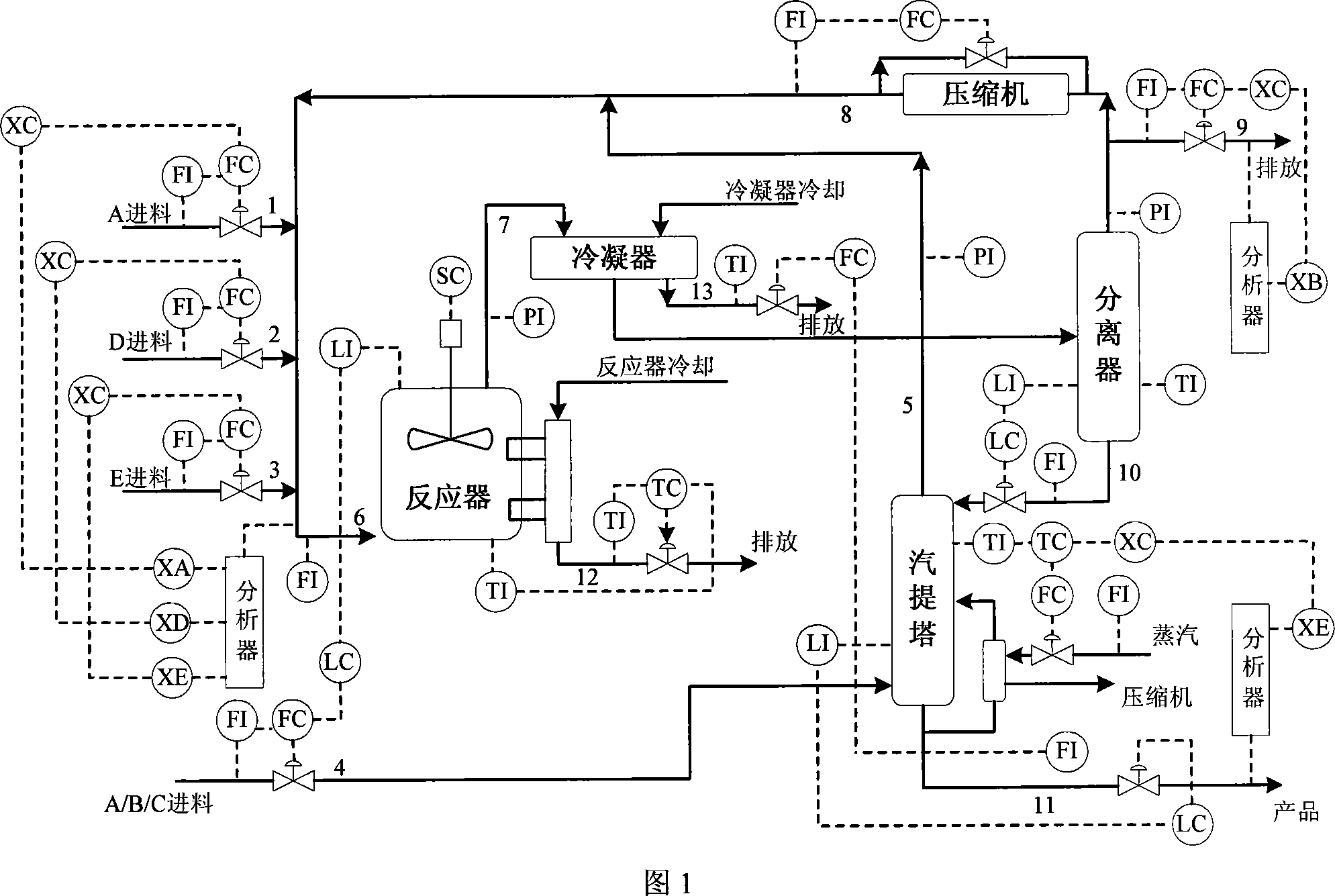

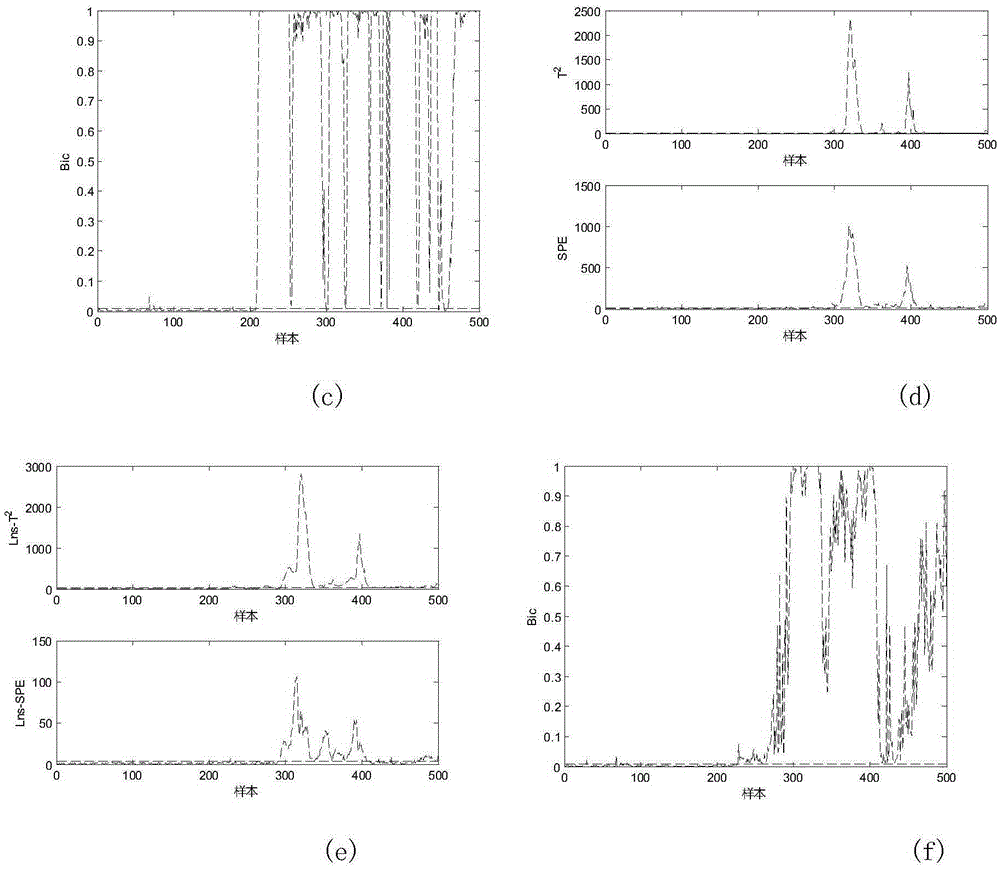

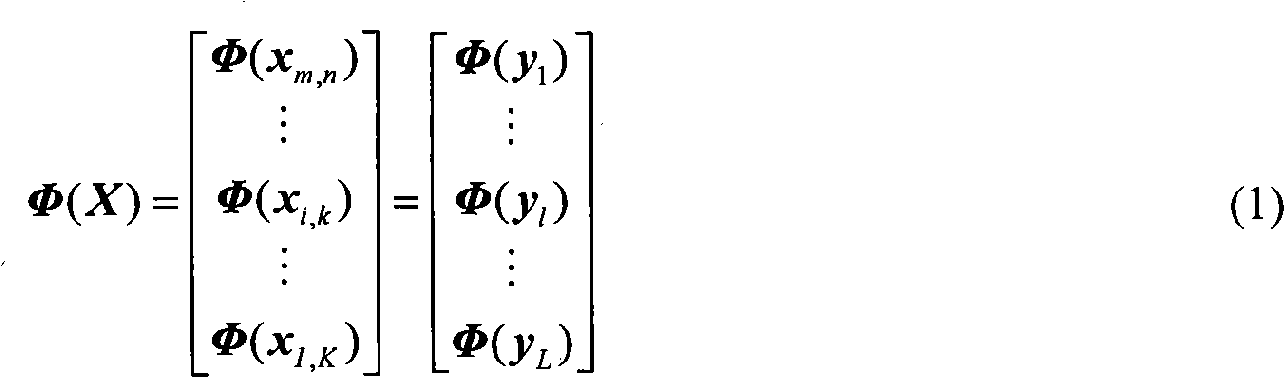

Non-linear procedure fault identification method based on kernel principal component analysis contribution plot

InactiveCN101169623AOvercoming Difficulties in Fault IdentificationCharacter and pattern recognitionAdaptive controlKernel principal component analysisAlgorithm

The invention relates to a non-linear fault identifying method based on a PCA (principal component analysis) contribution diagram, and includes five steps, namely, collecting data, extracting the base of the feature space, extracting the non-linear principal component, detecting faults and identifying faults. The invention puts forward a new method for extracting the base of the feature space, reduces the linear redundancy after the data are mapped to the feature space by extracting the base and decreases the calculation amount of KPCA when training samples are large in quantity. The invention adopts the contribution diagram to identify faults, calculates out the contribution diagram and the control limit for each variant in the process and determines the responsibility for the occurrenceof faults that each variant should shoulder when each variant is out of control through the relationship between the contribution diagram and the control limit. The identifying method overcomes the trouble in identifying faults due to the fact that the input space and the feature space cannot be converted freely.

Owner:NORTHEASTERN UNIV

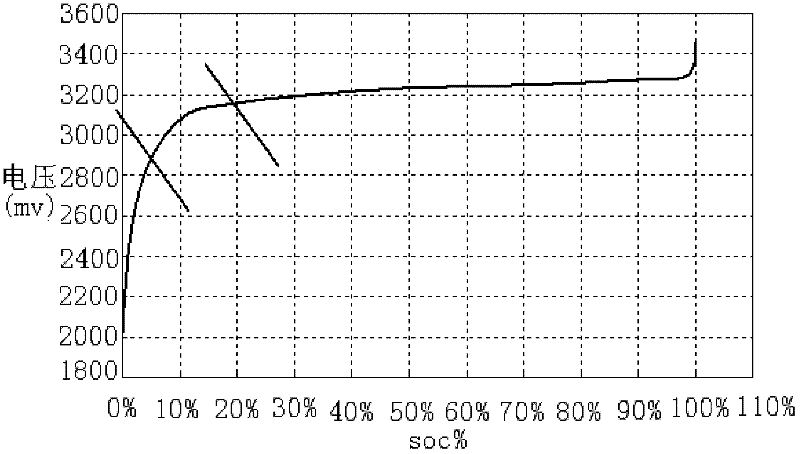

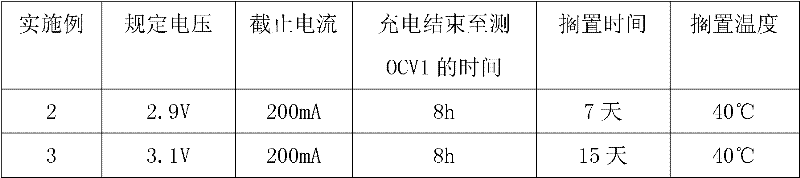

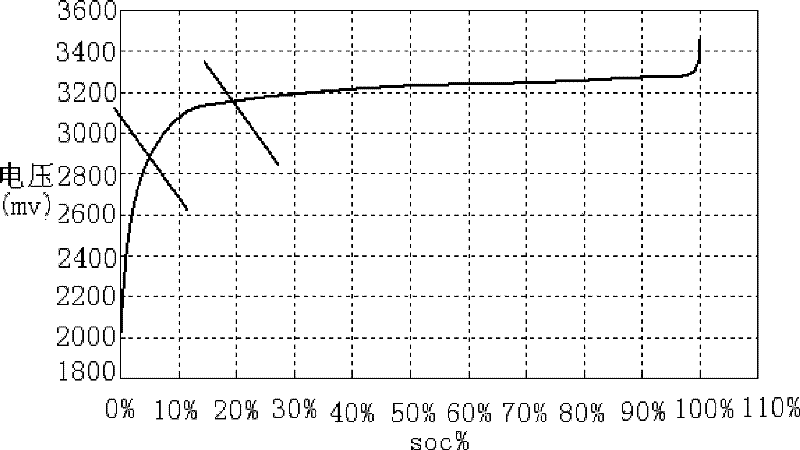

Method for evaluating self-discharge consistency of lithium iron phosphate battery

ActiveCN102508165AGood voltage consistencyImprove self-discharge rateElectrical testingLithium iron phosphateElectrical battery

The invention discloses a method for evaluating self-discharge consistency of a lithium iron phosphate battery. The method mainly comprises the following steps of: measuring open circuit voltage after the battery is charged and open circuit voltage after the battery is laid at high temperature under the conditions of constant voltage and constant current; calculating the voltage drop of the battery, a mean value and a standard difference; and determining the upper control limit of the voltage drop to determine that the battery has high self-discharge consistency under the condition that the voltage drop does not surpass an upper specification limit. By the method for evaluating the self-discharge consistency of the lithium iron phosphate battery, evaluation accuracy, high production operability and obvious practical meaning are achieved, and the grouping consistency of the lithium iron phosphate battery is effectively improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

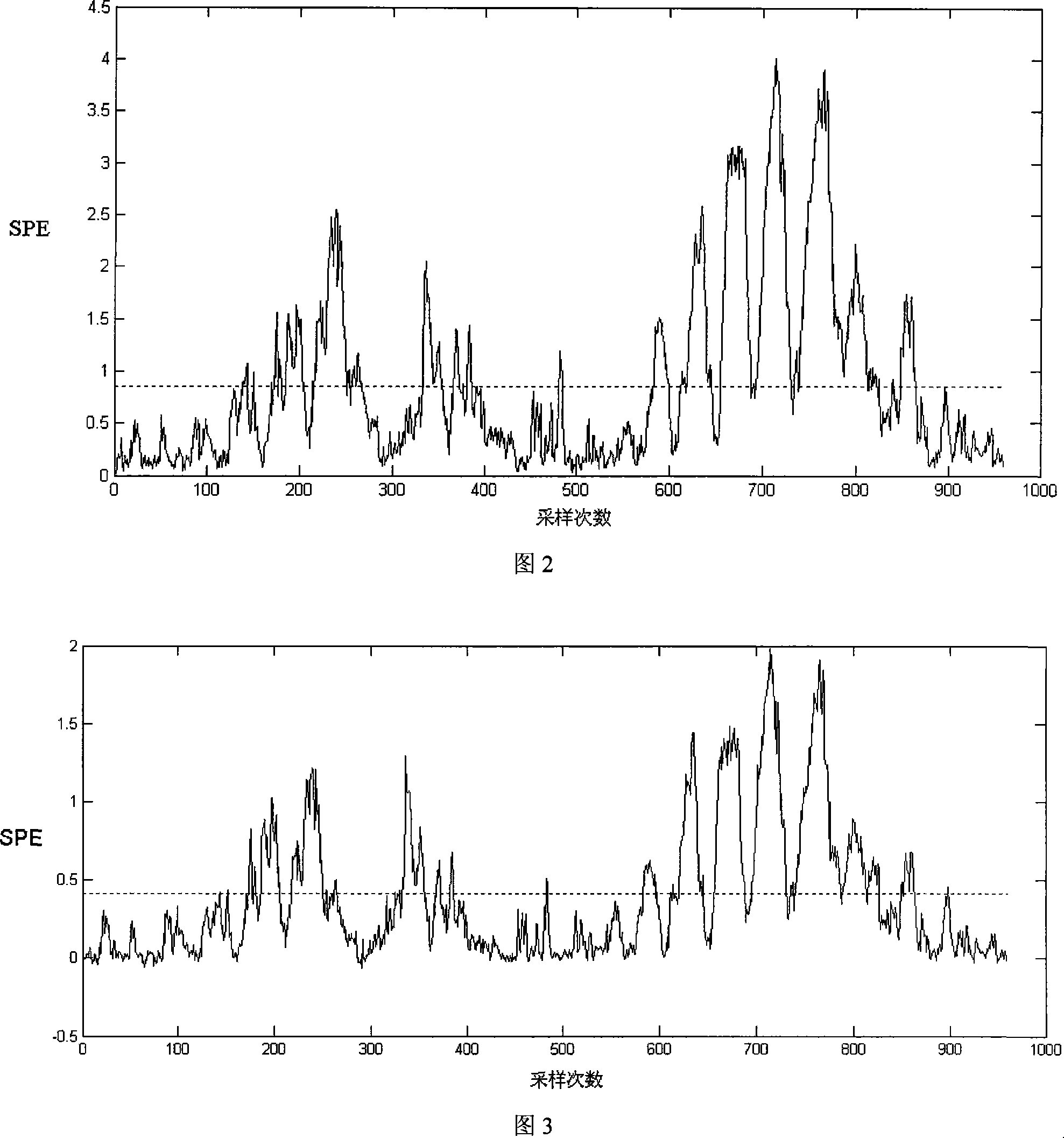

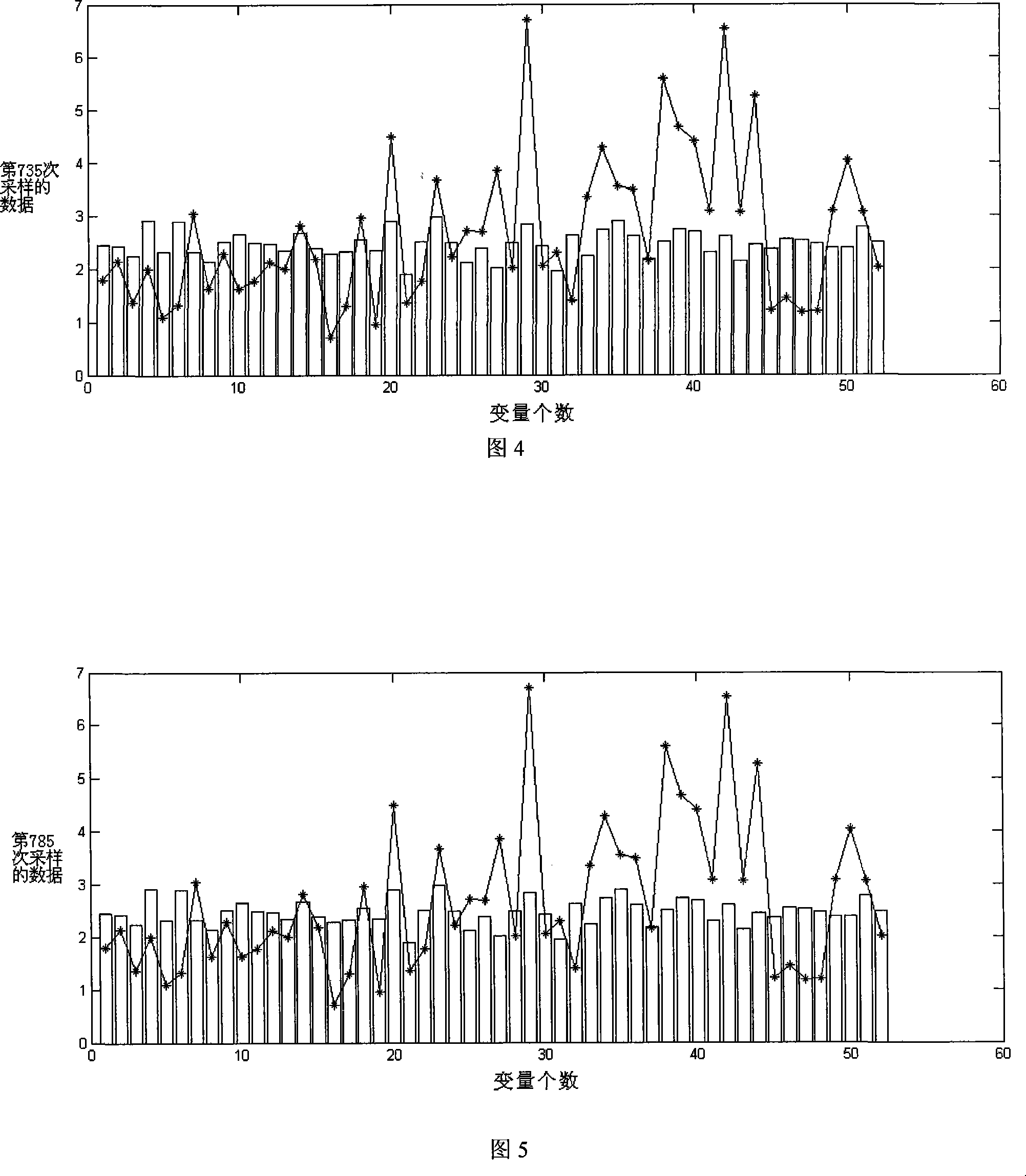

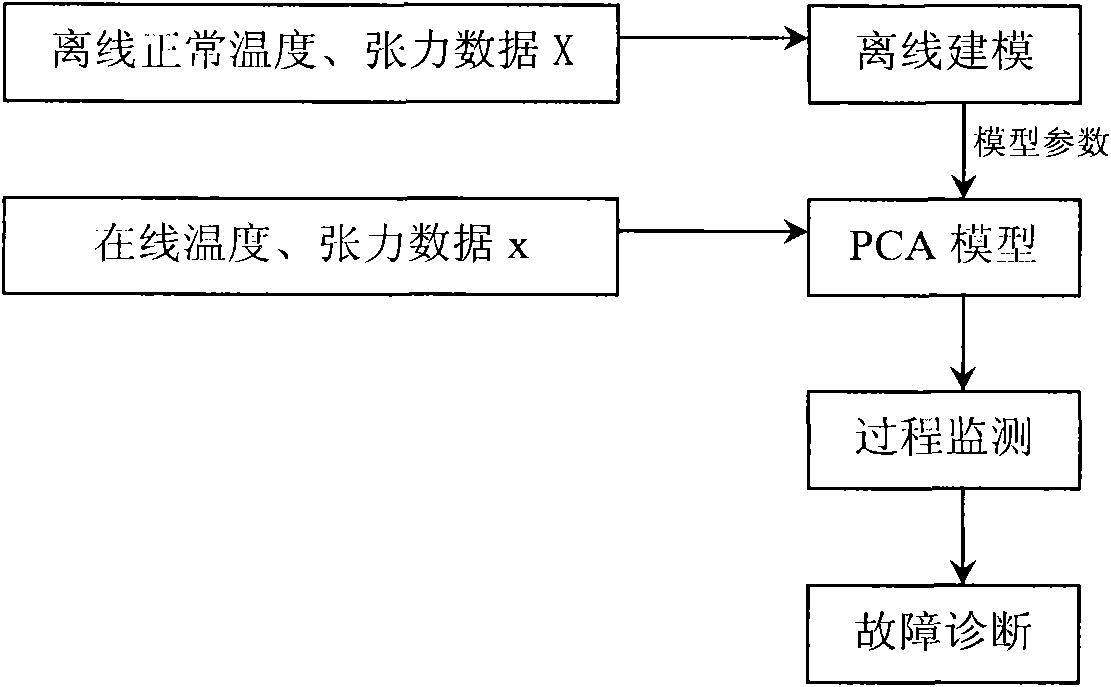

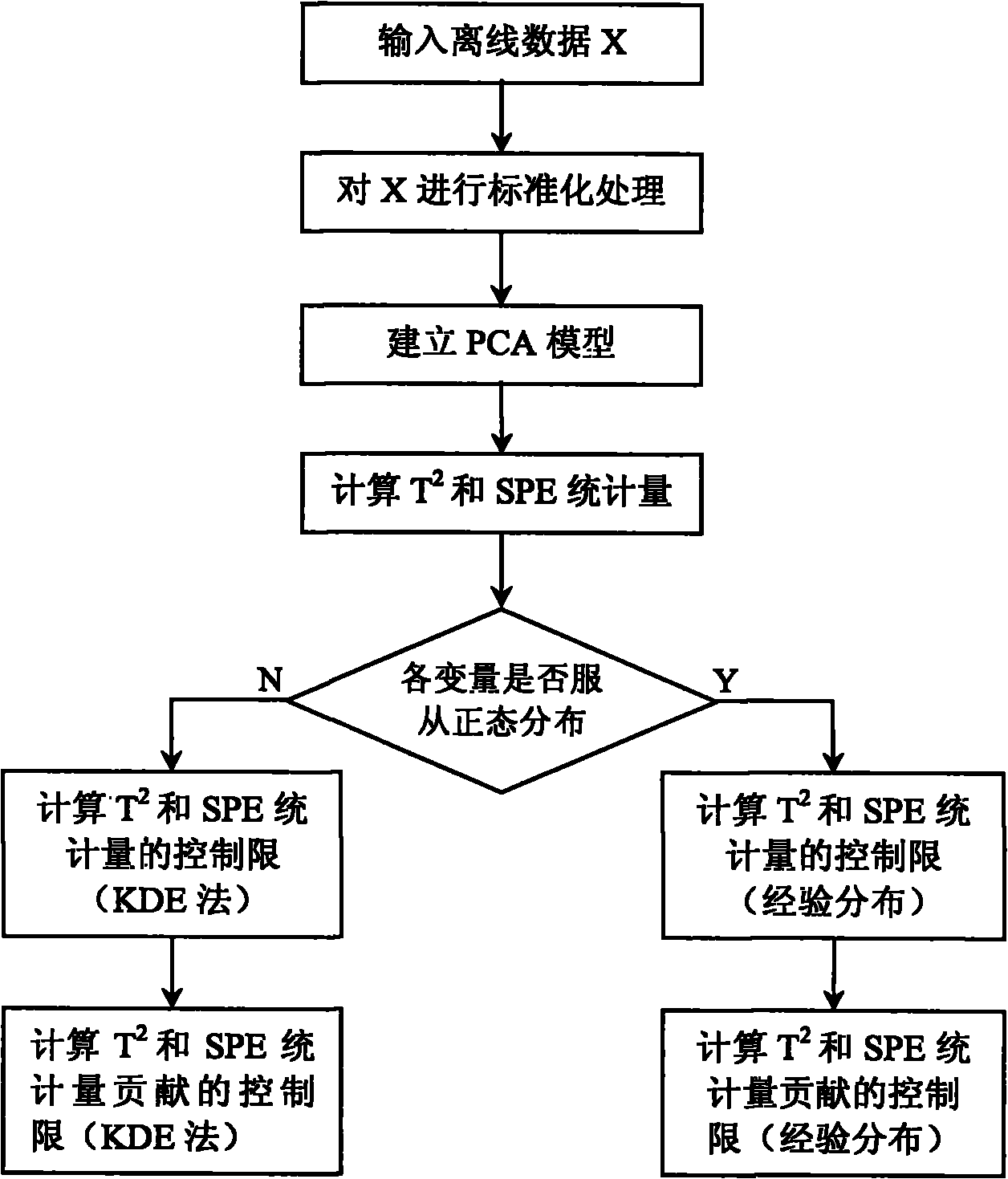

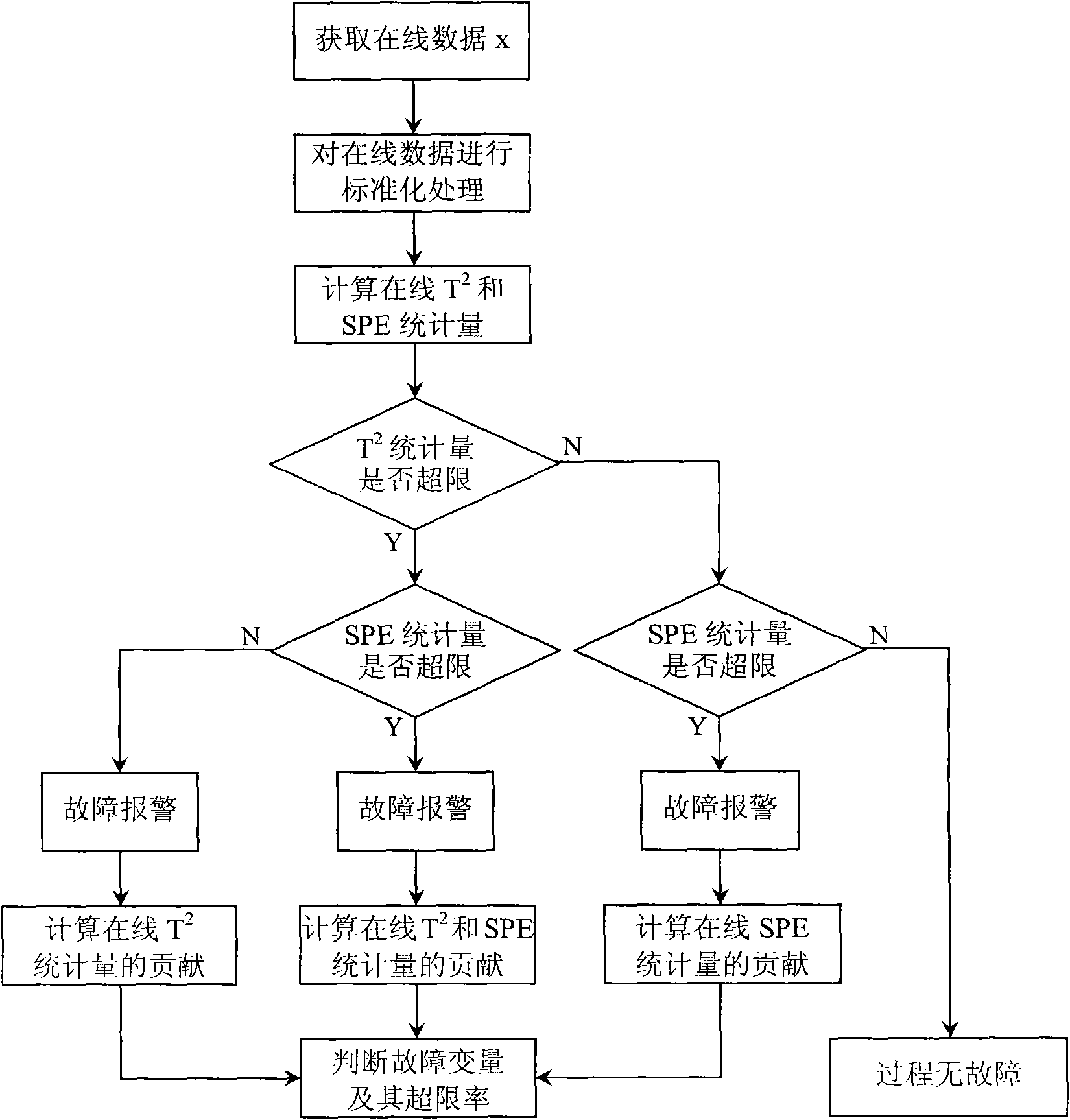

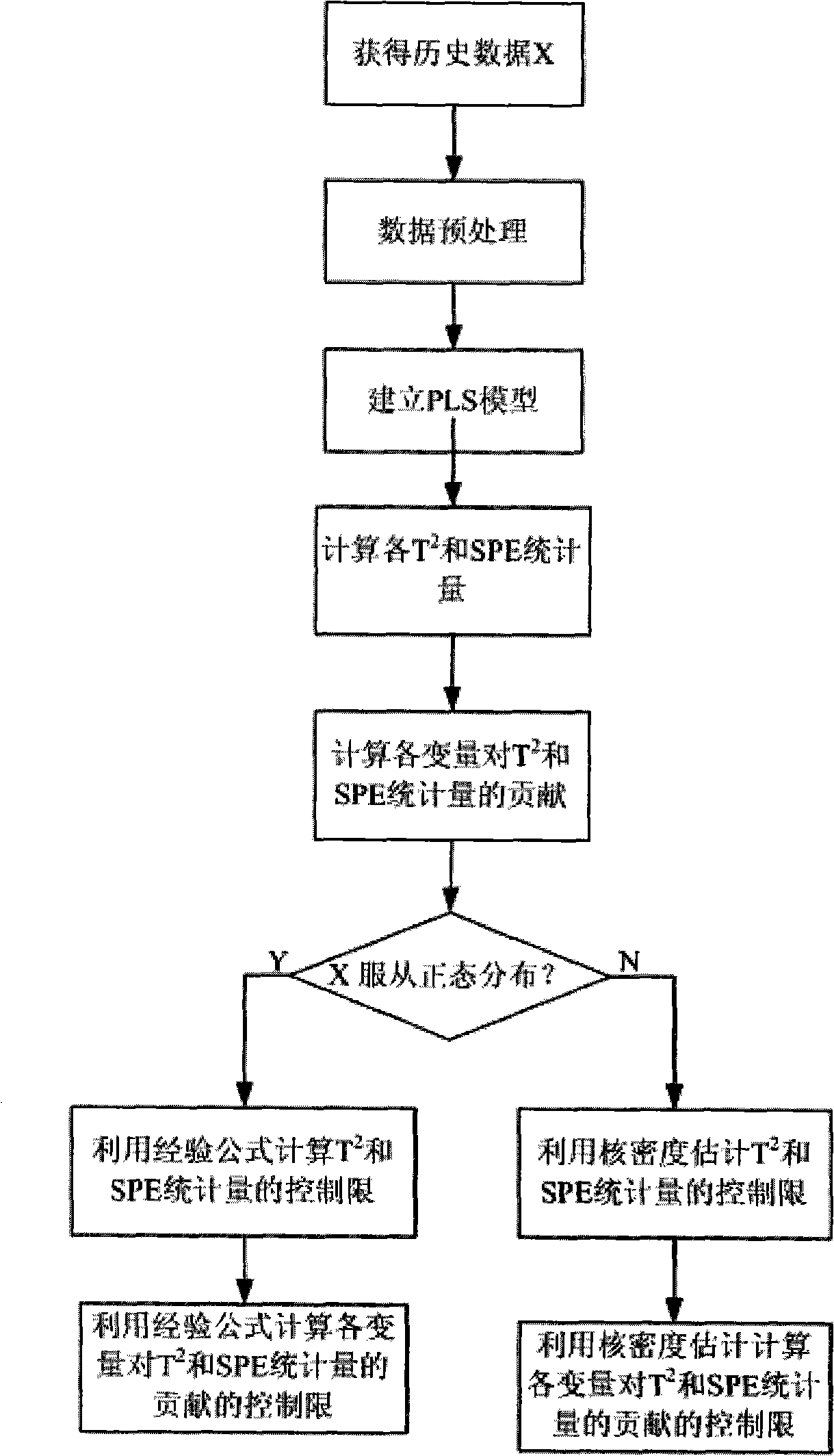

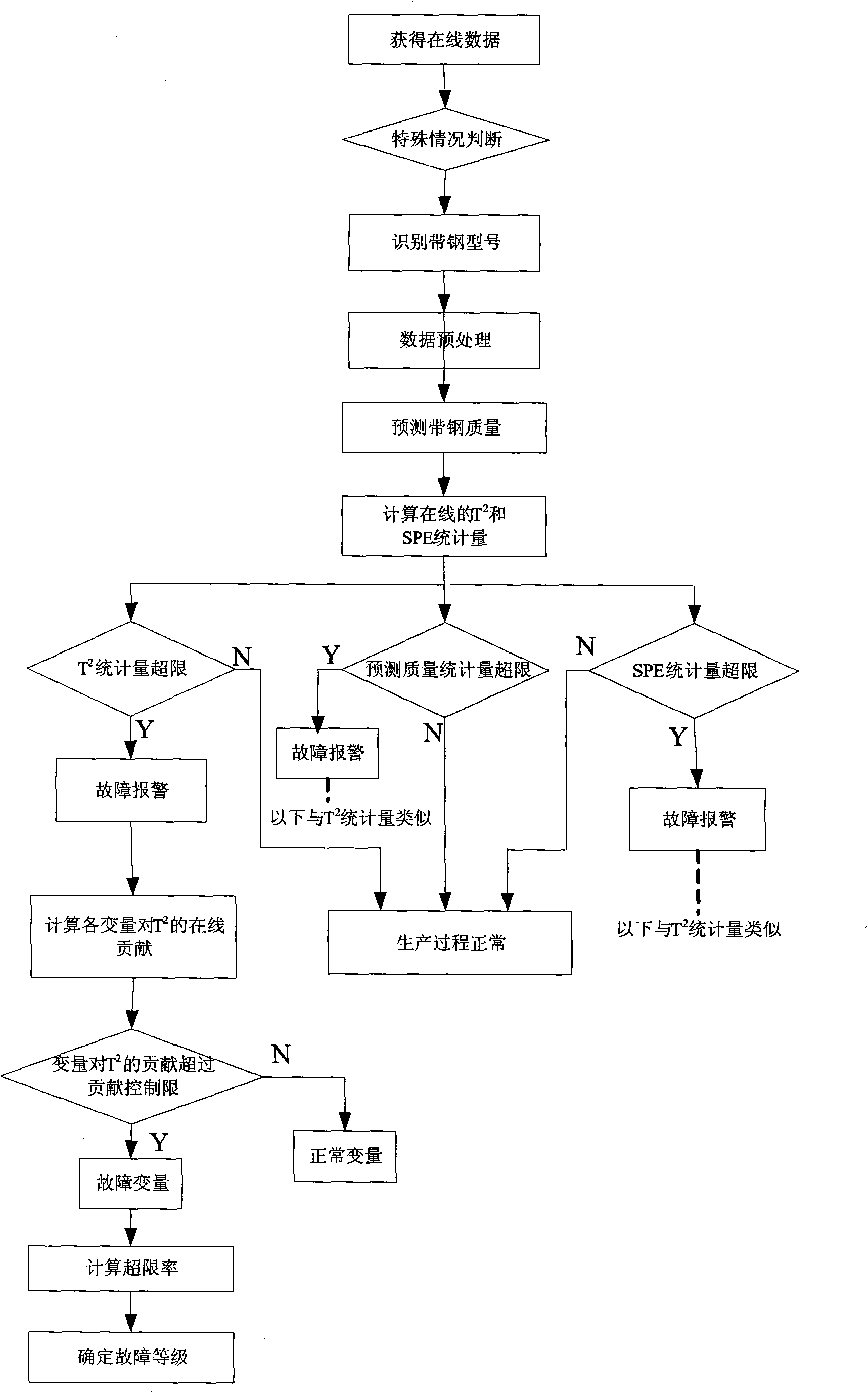

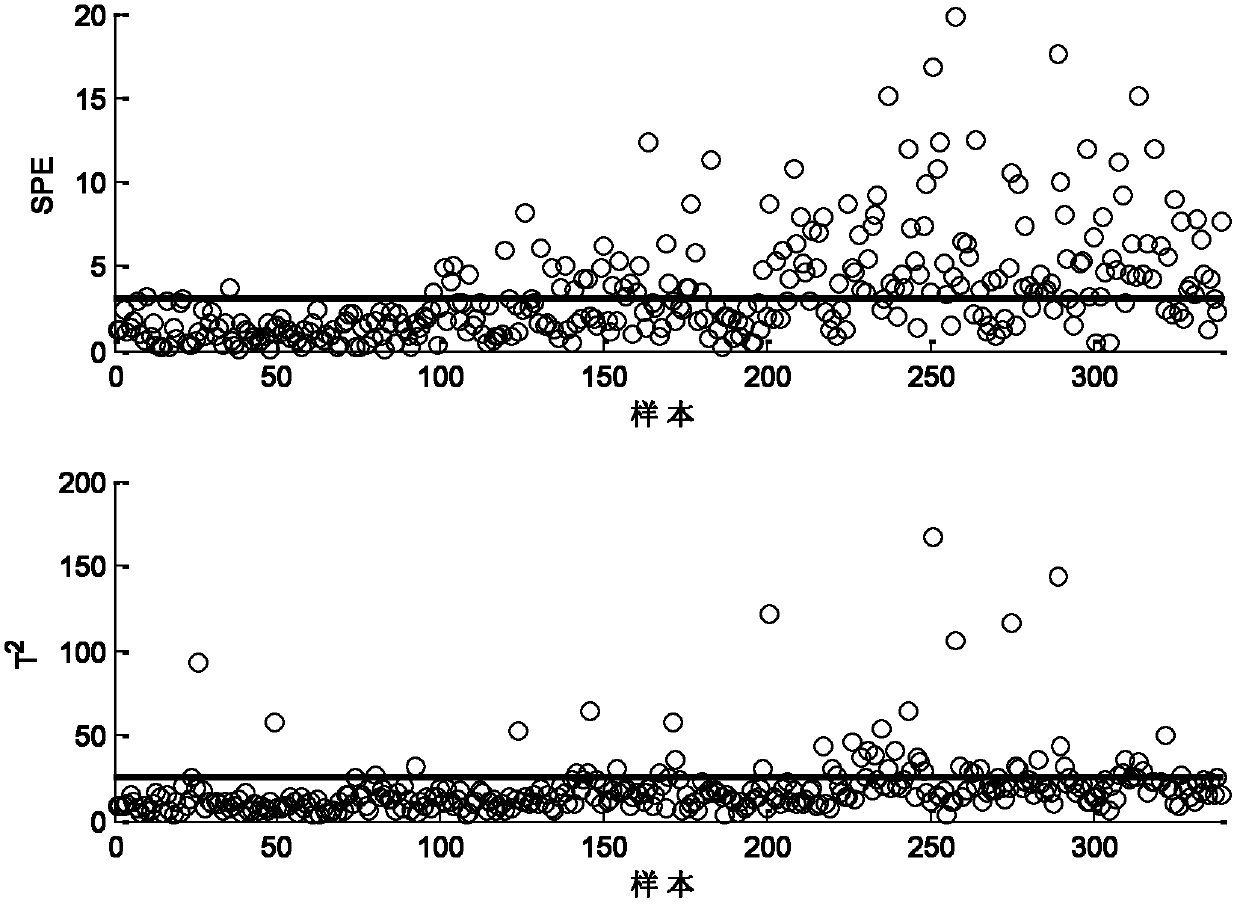

PCA (Principle Component Analysis) model based furnace temperature and tension monitoring and fault tracing method of continuous annealing unit

InactiveCN101899563AClear structureClear relationshipHeat treatment process controlFurnace temperatureOnline model

The invention relates to a fault monitor and diagnosis method of a continuous annealing unit, in particular to a PCA (Principle Component Analysis) model based furnace temperature and tension monitoring of a continuous annealing unit, mainly comprising the following steps of firstly, according to process variable data obtained in the field, and establishing a temperature and tension monitor modelby utilizing a principle component analysis PCA method; secondly, establishing an off-line model and calculating the T2 statistics quantity and the SPE statistics quantity as well as contributed control limits thereof by utilizing the data, obtained in step one, when process variable is in a normal work condition; thirdly, applying an on-line model, calculating the T2 statistics quantity and the SPE statistics quantity of current data, monitoring whether a current state is normal or not according to information supplied by the off-line model, and giving alarm signals if abnormal; fourthly, determining a leading variable which causes a fault by utilizing contribution of the T2 statistics quantity and contribution of the SPE statistics quantity. The invention monitors the furnace temperature and tension in real time in the production process and traces back a fault reason for leading to system abnormality when the abnormality occurs.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

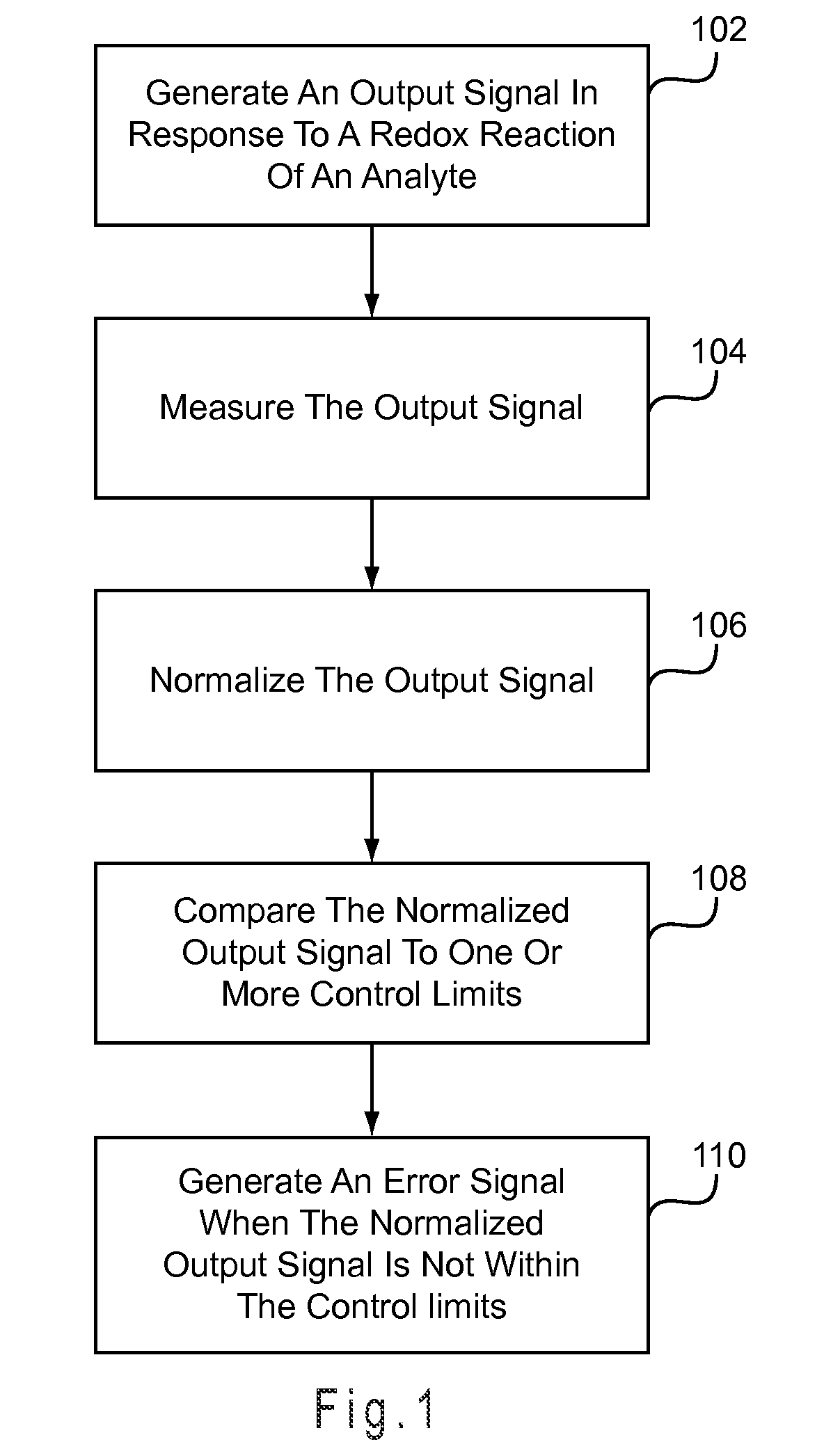

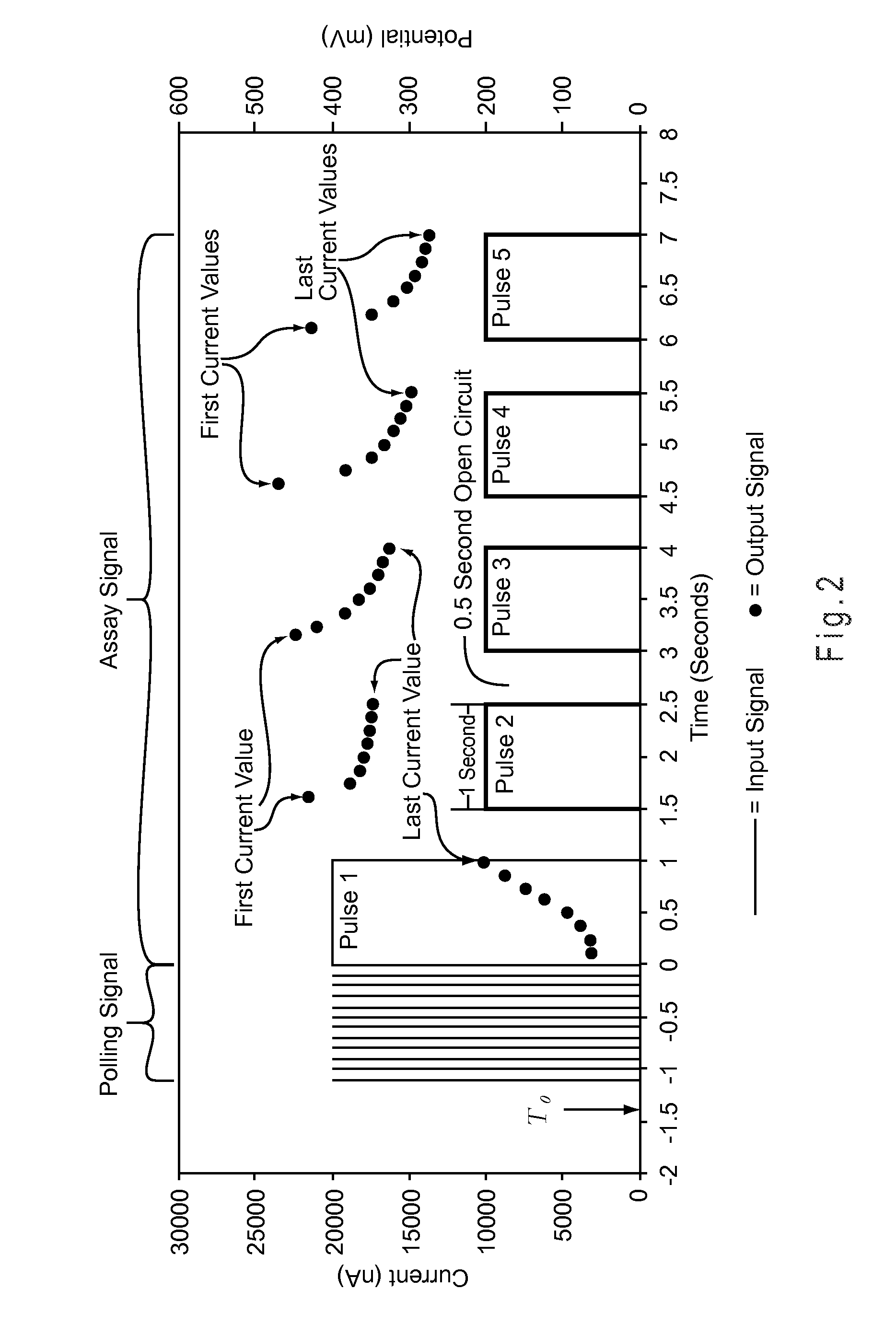

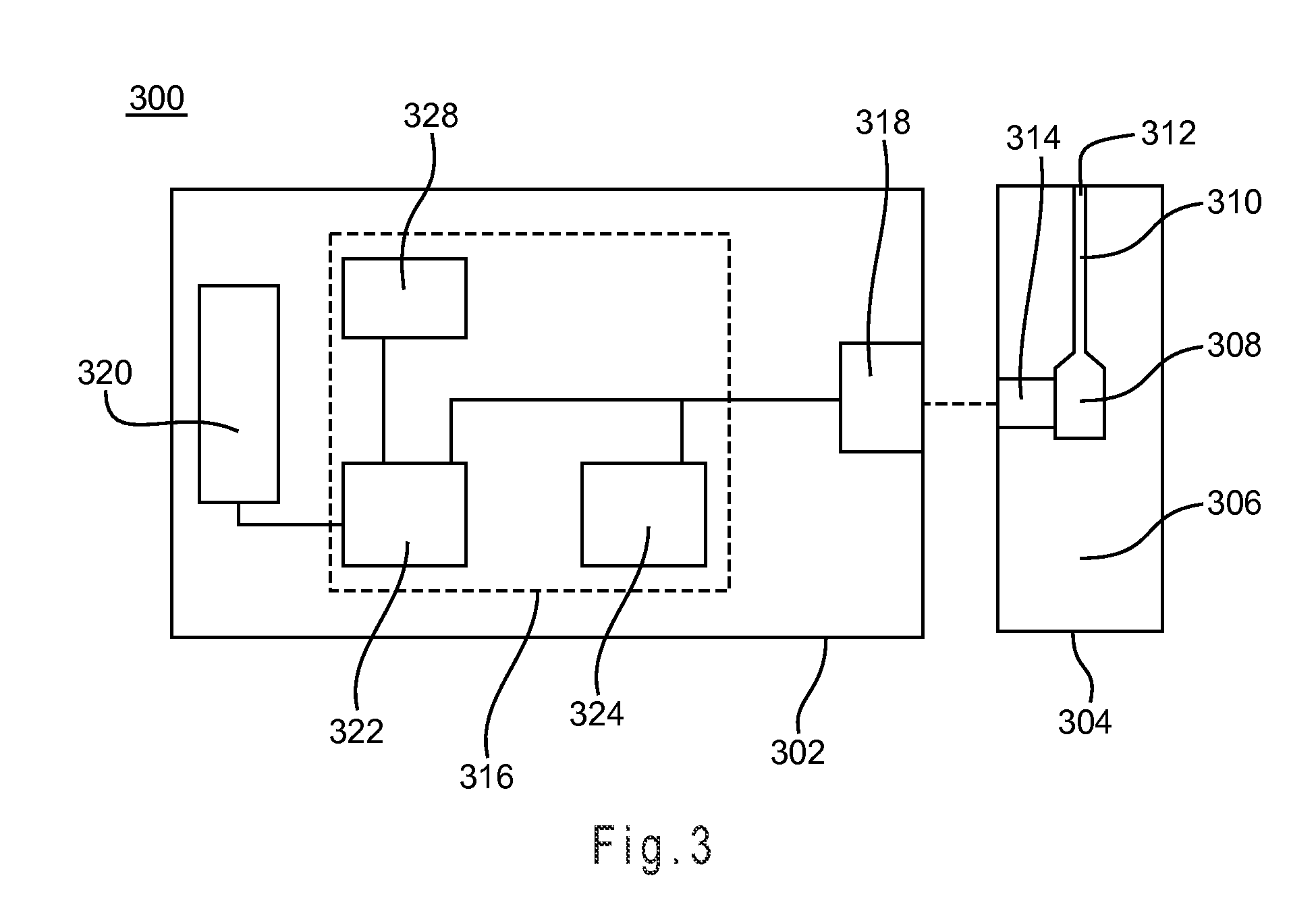

Abnormal Output Detection System For A Biosensor

ActiveUS20090099787A1Accurate and precise analysisMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalyteRedox

A biosensor has an abnormal output detection system that determines whether an output signal from the redox reaction of an analyte has a normal or abnormal shape or configuration. The abnormal output detection system improves the accuracy and precision of the biosensor in determining whether an output signal has a shape or configuration that may not provide an accurate and / or precise analysis of a biological fluid. The biosensor generates an output signal in response to the redox reaction of the analyte. The biosensor normalizes the output signal and compares the normalized output signal with one or more control limits. The biosensor may generate an error signal when the normalized output signal is not within the control limits.

Owner:ASCENSIA DIABETES CARE HLDG AG

Method and system of diagnosing a processing system using adaptive multivariate analysis

InactiveUS7328126B2Useful applicationAmplifier modifications to reduce noise influenceDigital computer detailsPrincipal component analysisHandling system

A method and system of monitoring a processing system and for processing a substrate during the course of semiconductor manufacturing. As such, data is acquired from the processing system for a plurality of observations, the data including a plurality of data parameters. A principal components analysis (PCA) model is constructed from the data and includes centering coefficients. Additional data is acquired from the processing system, the additional data including an additional observation of the plurality of data parameters. The centering coefficients are adjusted to produce updated adaptive centering coefficients for each of the data parameters in the PCA model. The updated adaptive centering coefficients are applied to each of the data parameters in the PCA model. At least one statistical quantity is determined from the additional data using the PCA model. A control limit is set for the statistical quantity and compared to the statistical quantity.

Owner:TOKYO ELECTRON LTD

Method and apparatus for multi-phase power conversion

ActiveUS7706151B2Reduce switching lossesTempo syncEfficient power electronics conversionAc-dc conversionSwitching frequencyEngineering

A system and method for power conversion synchronizes multiple phases at a desired phase angle difference. The power conversion involves variable frequency switching, fixed on-time and provides power factor correction. A relative measure of a phase angle difference between two phases permits each phase to be controlled to obtain the desired phase angle difference. The power conversion involves transition mode switching to help reduce switching losses. A phase angle difference detector may be provided for each phase. The various phases may have different inherent frequencies that vary with switching frequency, and are synchronized to an average frequency. Current measures can be taken with a single component, such as a resistor. A maximum frequency control limits period width to avoid high frequency switching. An added switch on time improves input voltage crossover distortion. One or more phases can be deactivated in light load conditions.

Owner:TEXAS INSTR INC

Method for automatic determination of semiconductor plasma chamber matching and source of fault by comprehensive plasma monitoring

InactiveUS20050019961A1Electric discharge tubesSemiconductor/solid-state device manufacturingPrincipal component analysisSemiconductor plasma

A method and apparatus for automatic determination of semiconductor plasma chamber matching a source of fault are provided. Correlated plasma attributes are measured for process used for calibration both in a chamber under study and in a reference chamber. Principal component analysis then is performed on the measured correlated attributes so as to generate steady principle components and transitional principle components; and these principal components are compared to reference principal components associated with a reference chamber. The process used for calibration includes a regular plasma process followed by a process perturbation of one process parameter. Similar process perturbation runs are conducted several times to include different perturbation parameters. By performing inner products of the principle components of chamber under study and the reference chamber, matching scores can be reached. Automatic chamber matching can be determined by comparing these scores with preset control limits. The potential source(s) of chamber fault can also be identified by the lowest matching score(s).

Owner:APPLIED MATERIALS INC

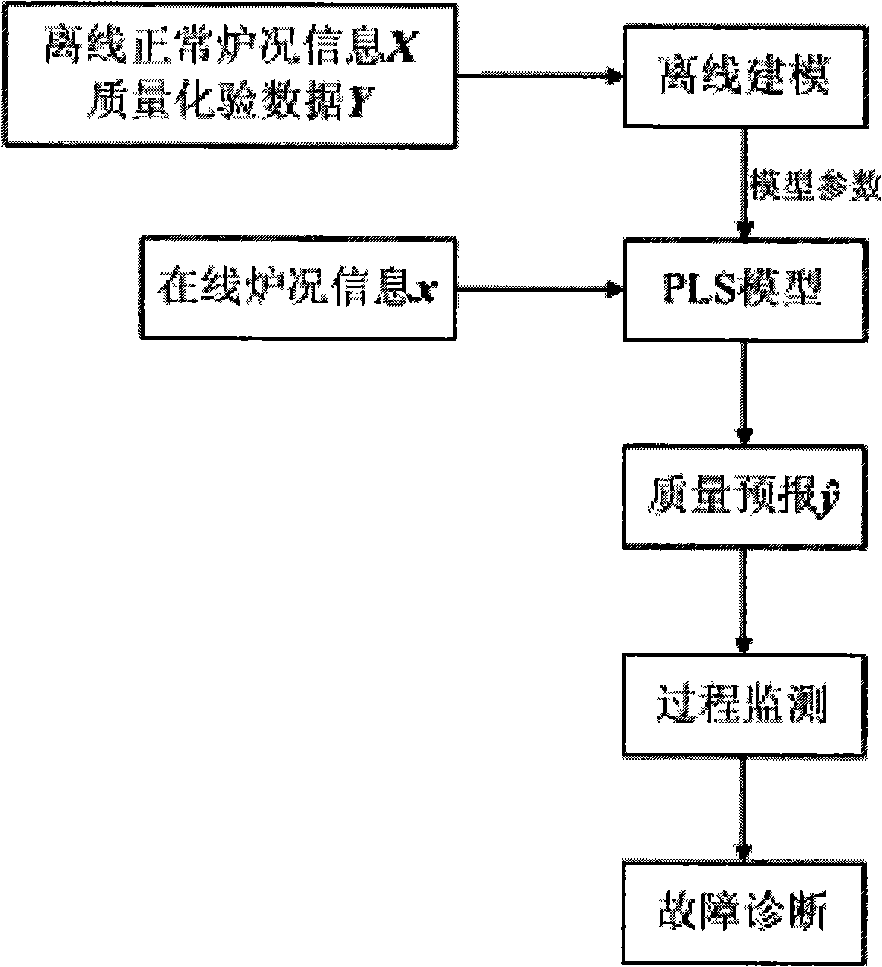

Strip steel quality forecasting, furnace condition early-warning and fault diagnosis method based on partial least square

ActiveCN102033523AClear structureClear relationshipFurnace typesHeat treatment furnacesModel selectionData pre-processing

The invention relates to a strip steel quality forecasting, furnace condition early-warning and fault diagnosis method, in particular to a strip steel quality forecasting, furnace condition early-warning and fault diagnosis method based on partial least square, comprising the following steps: model selection: multiple models are adopted to describe the process characteristics of corresponding steel types; data preprocessing: data alignment based on the model is carried out, synchronization relation of process input and quality output is built and data dimensionless treatment is carried out to eliminate effect of process data on modeling precision owning to non-unity of physical units; an off-line model building; a PLS (partial least square) model for strip steel quality and process variable is built by utilizing a great amount of historical data in normal working conditions; determining control limit of an monitor-control index; determining variable quantity control limit; and on-line forecasting and on-line detection and fault diagnosis. In the invention, the model for the strip steel quality and the process variable is built by PLS algorithm, so as to realize real-time quality forecasting, process monitoring and fault diagnosis.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

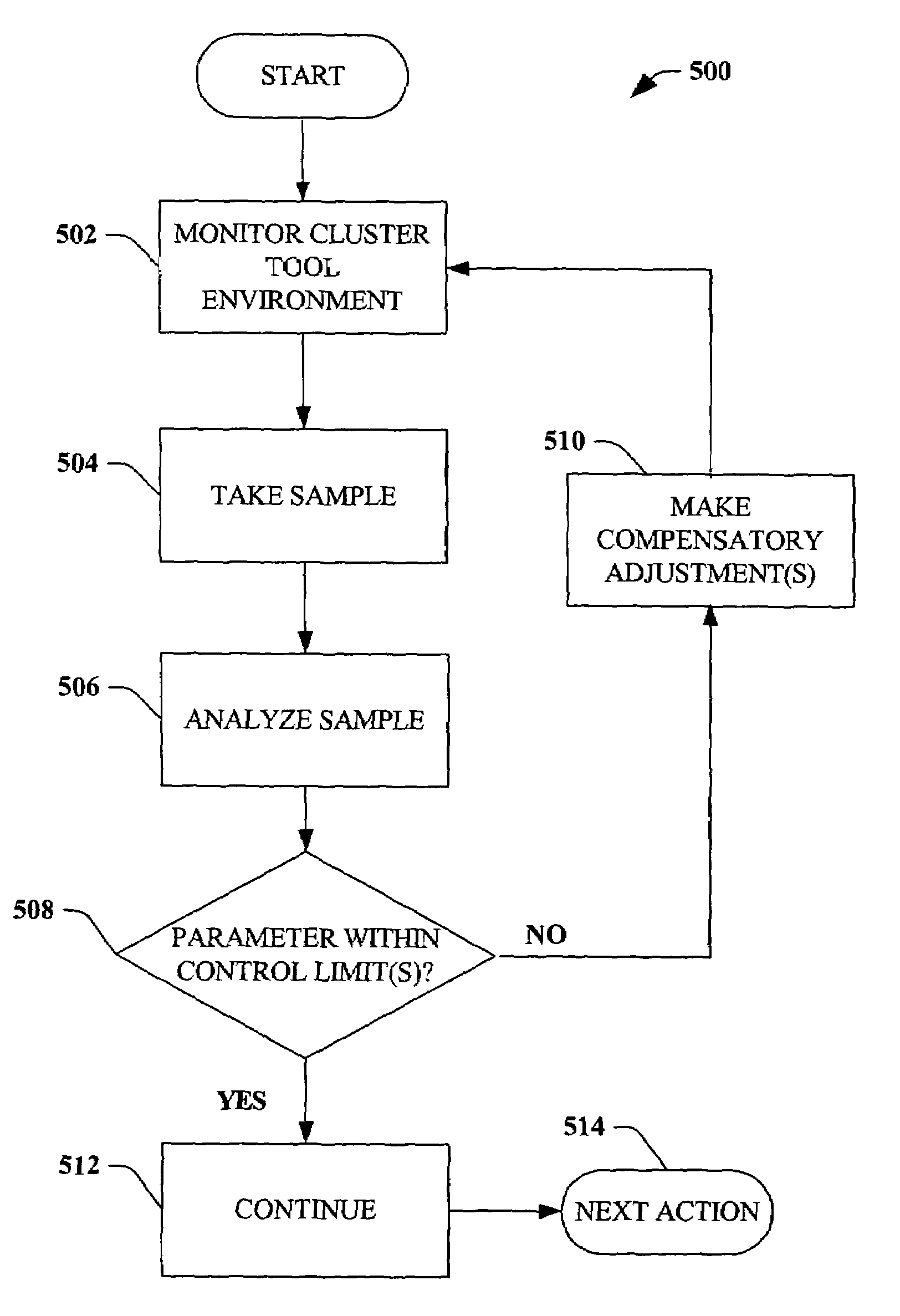

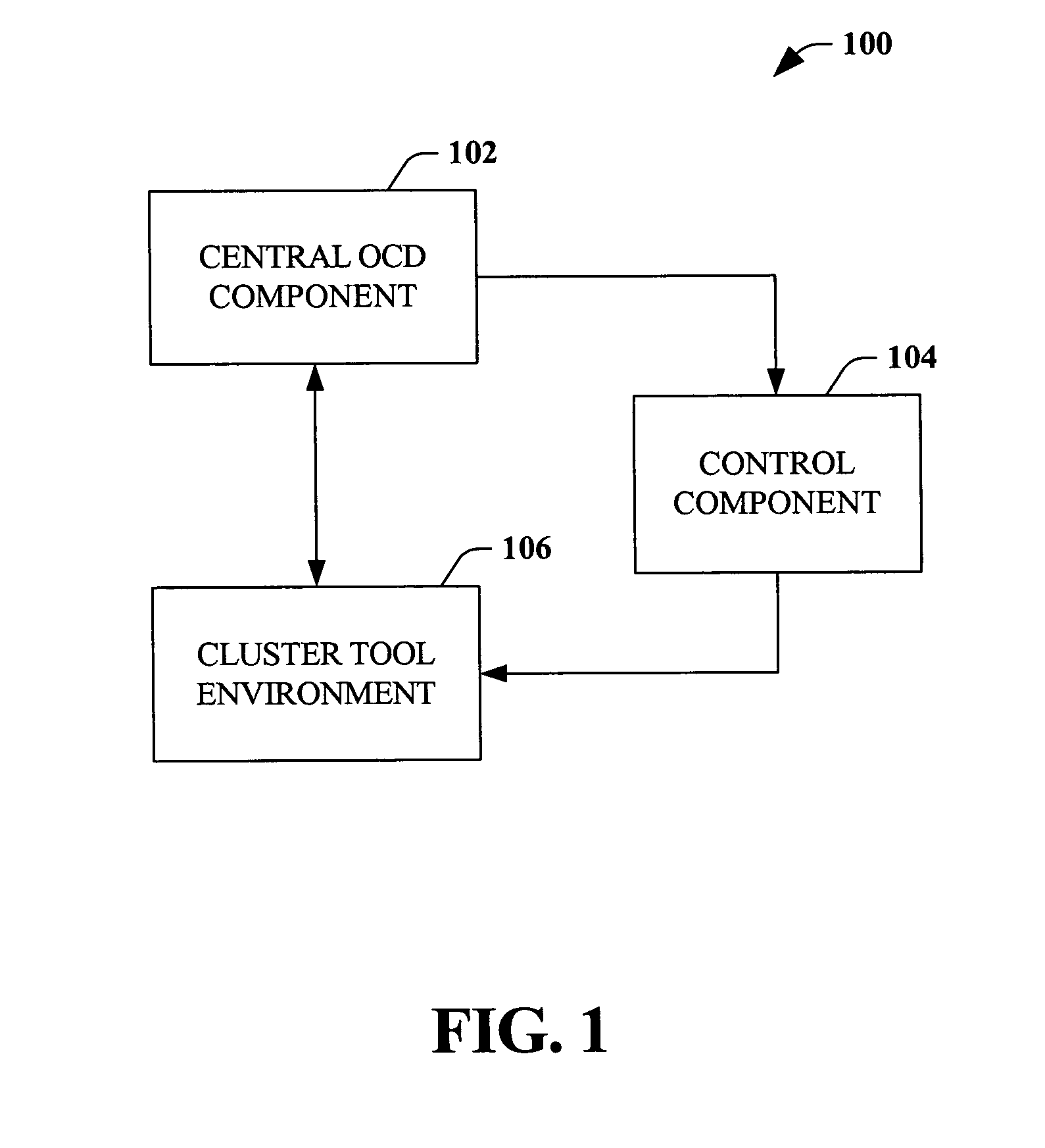

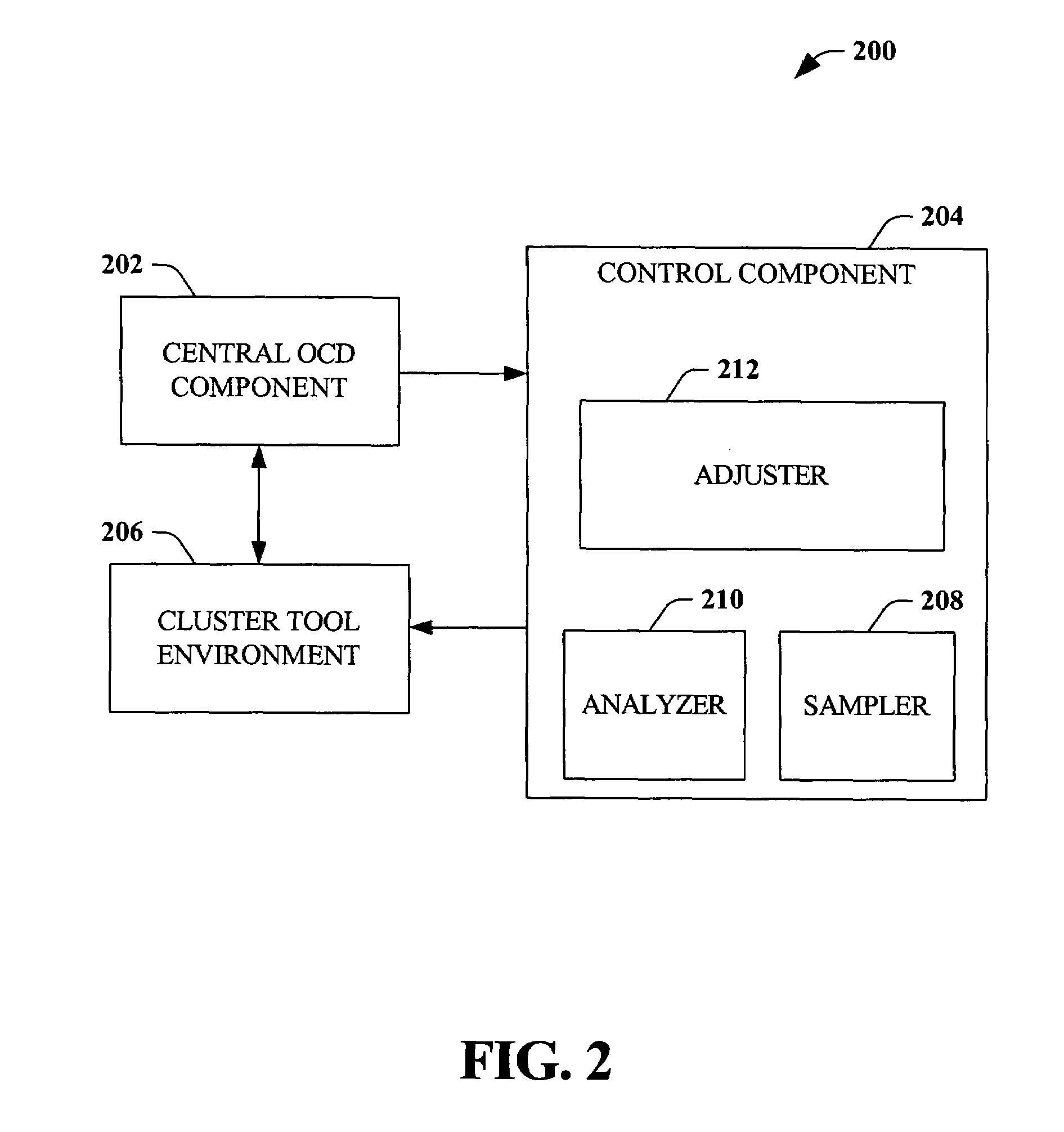

Scatterometry monitor in cluster process tool environment for advanced process control (APC)

ActiveUS7076320B1Strengthen process controlIncrease productivityFeeler-pin gaugesPhotomechanical apparatusControl limitsPlasma etcher

Systems and methods that improve process control in semiconductor manufacturing are disclosed. According to an aspect of the invention, conditions in a cluster tool environment and / or a wafer therein can be monitored in-situ via, for example, a scatterometry system, to determine whether parameters associated with wafer production are within control limits. A cluster tool environment can include, for example, a lithography track, a stepper, a plasma etcher, a cleaning tool, a chemical bath, etc. If an out-of-control condition is detected, either associated with a tool in the cluster tool environment or with the wafer itself, compensatory measures can be taken to correct the out-of-control condition. The invention can further employ feedback / feed-forward loop(s) to facilitate compensatory action in order to improve process control.

Owner:ADVANCED MICRO DEVICES INC

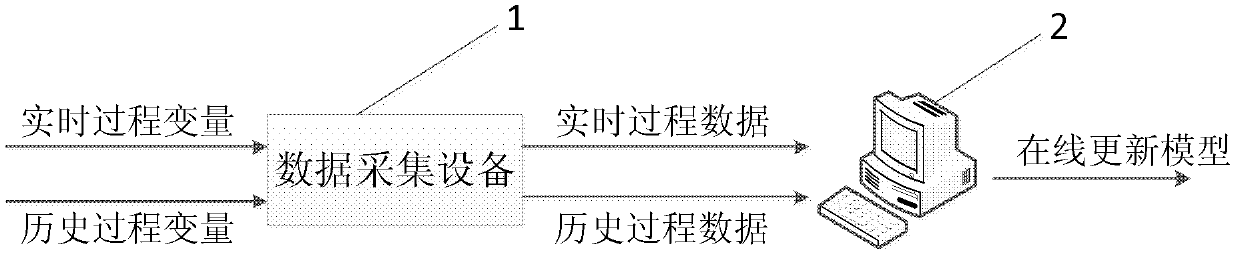

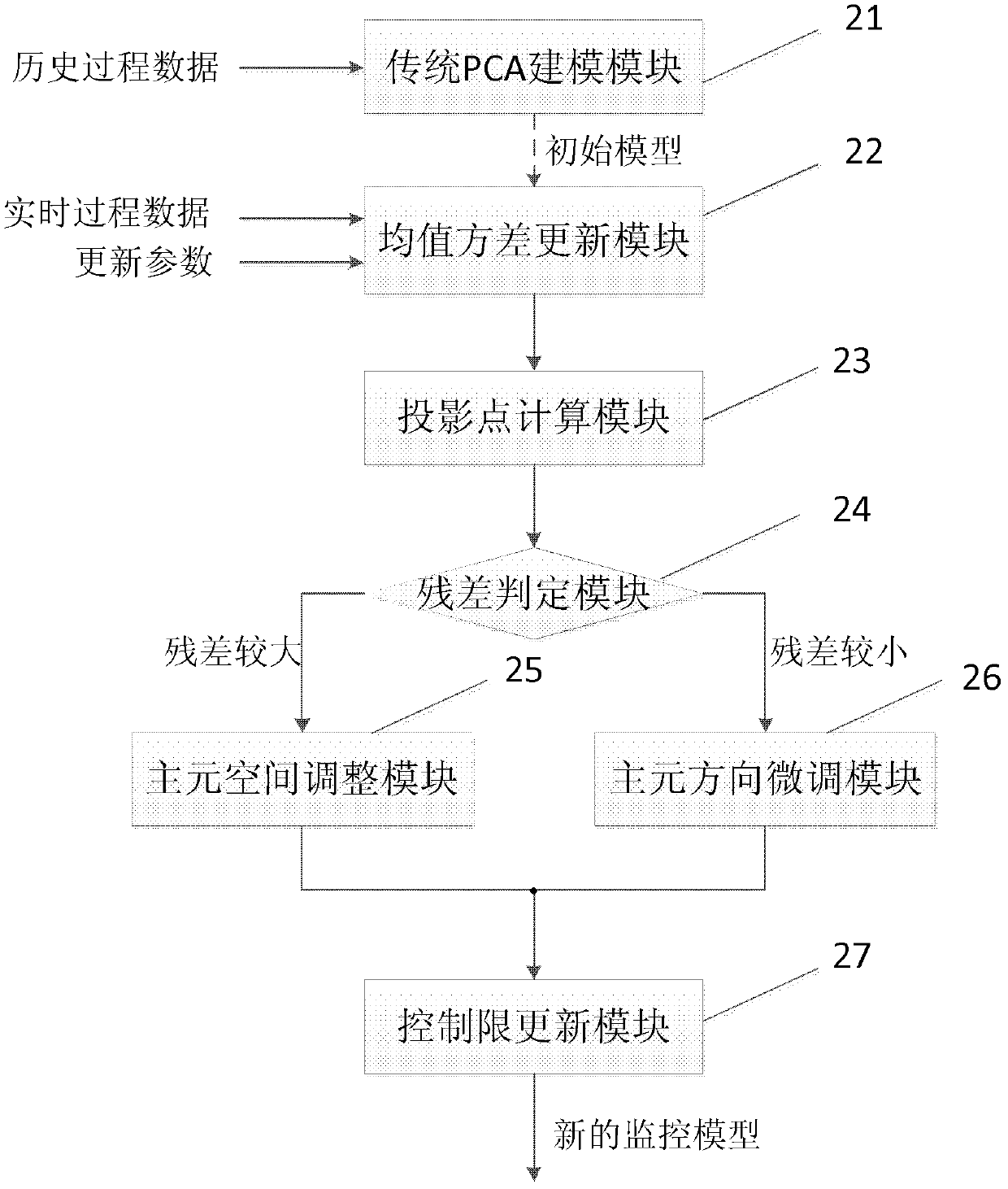

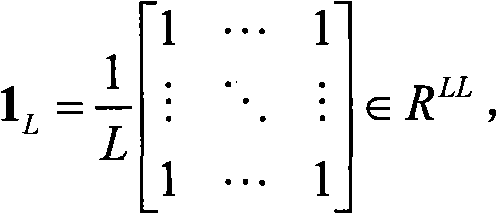

Online updating method of principal component analysis monitoring model

ActiveCN102662321AEnsure consistencyReduce false alarm rateAdaptive controlKernel principal component analysisPrincipal component analysis

The invention relates to an online updating method of a principal component analysis monitoring model. The method comprises the following steps that: 1) A model online updating system comprising data acquisition equipment and a monitoring computer is arranged in industry field; 2) A traditional principal component analysis (PCA) modeling module uses historical data to establish a PCA initial monitoring model; 3) After the monitoring begins, a mean value variance updating module calculates a mean value and a standard deviation sigma' of a new model according to real-time process data and the current PCA model; 4) A projection point calculation module calculates a residual vector of a new sample and transmits to a residual determination module; 5) The residual determination module determines an updating method of a projection direction according to a size of a residual vector die; if the residual is large, a principal component space adjusting module is called; if the residual value is small, a principal component direction fine adjusting module is called; finally a load vector P' nk and a characteristic value matrix lambda' kk of the new model is obtained; 6) A control limit updating module carries out control limit and updating on statistical magnitude of the model; the system finally outputs the new model omega' which is used for online monitoring and fault diagnosis during an industrial process.

Owner:TSINGHUA UNIV

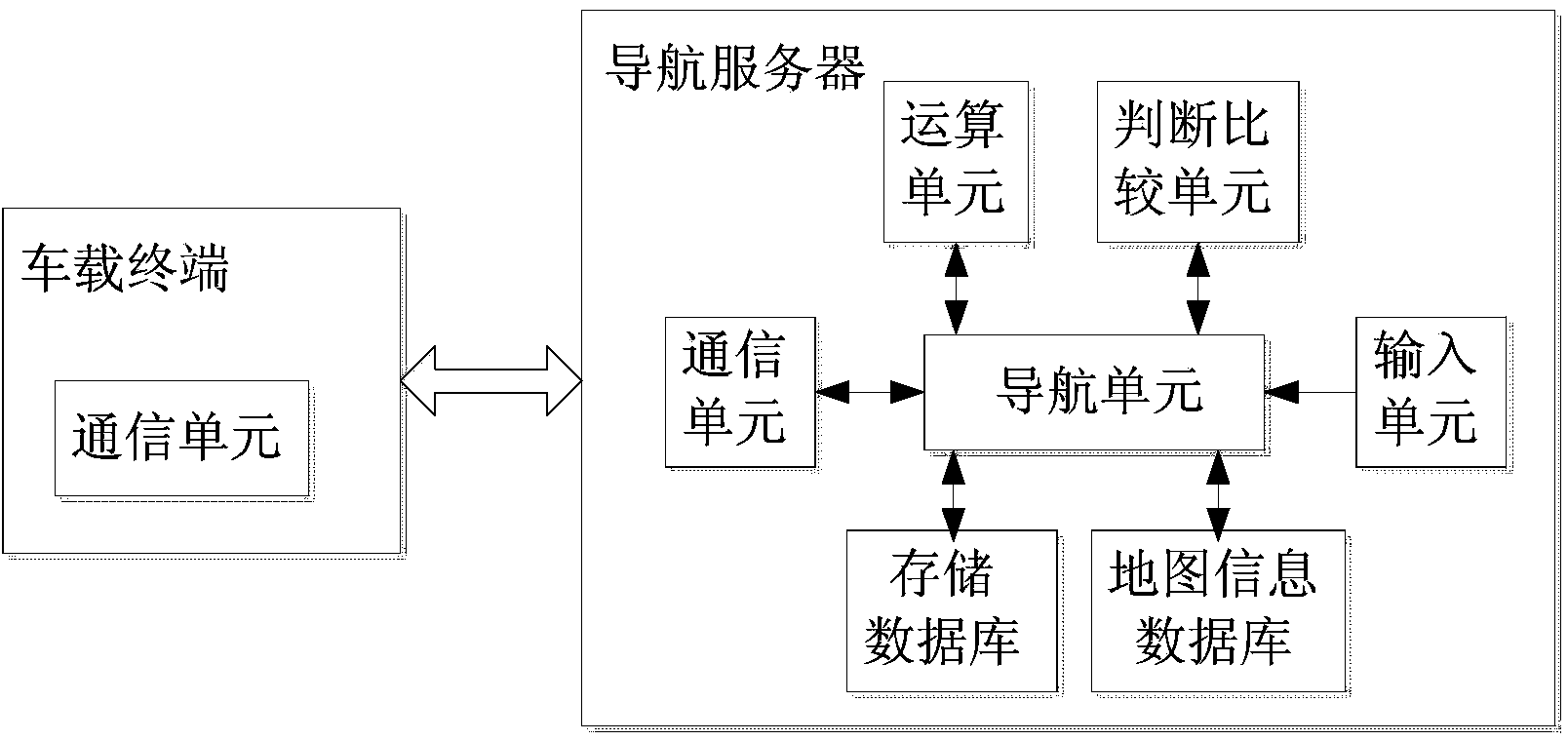

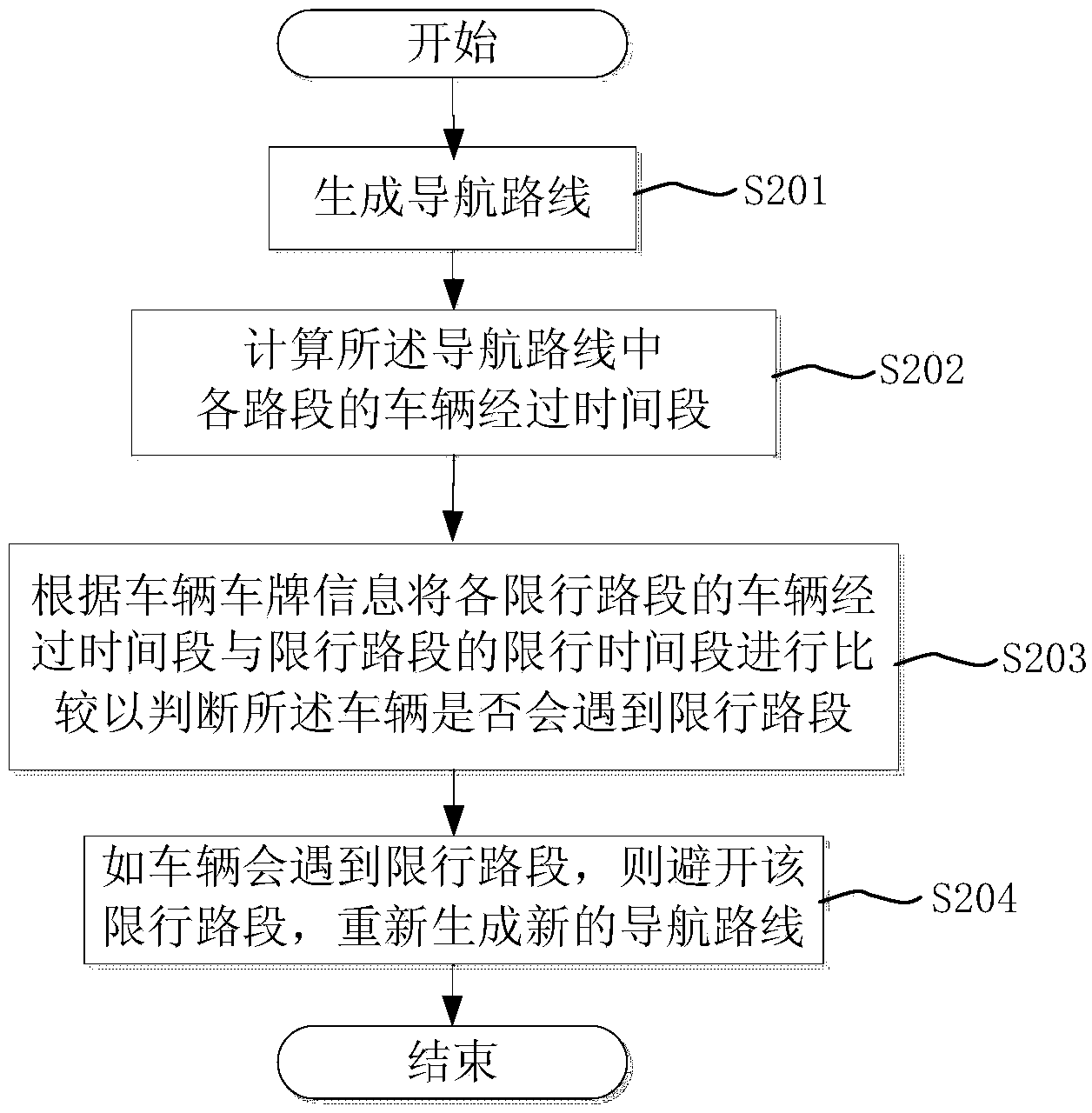

Vehicle navigation system and vehicle navigation method

InactiveCN103712630AReasonable planningSave driving timeInstruments for road network navigationEngineeringControl limits

The invention discloses a vehicle navigation system and a vehicle navigation method. The vehicle navigation method comprises the following steps: generating a navigation route; calculating vehicle passing time periods of all road sections in the navigation route; according to vehicle license information, comparing the vehicle passing time periods of vehicles at traffic control roads with the traffic control time periods of the traffic control roads so as to judge whether the vehicles can encounter the traffic control roads; if yes, keeping off the traffic control road and regenerating a new navigation route; when judging whether the vehicles can encounter the traffic control roads, combining the departure time point, a preset city traffic control time period and a preset city traffic control road of the navigation route, so as to judge whether the route in the current time can encounter the traffic control limit. According to the vehicle navigation system and the vehicle navigation method, the traffic control roads can be timely kept off according to the traffic control information of the roads, route planning can be aided more reasonably and effectively so as to save the traveling time of a user, and reduce the energy consumption of an automobile.

Owner:SHANGHAI ONSTAR TELEMATICS

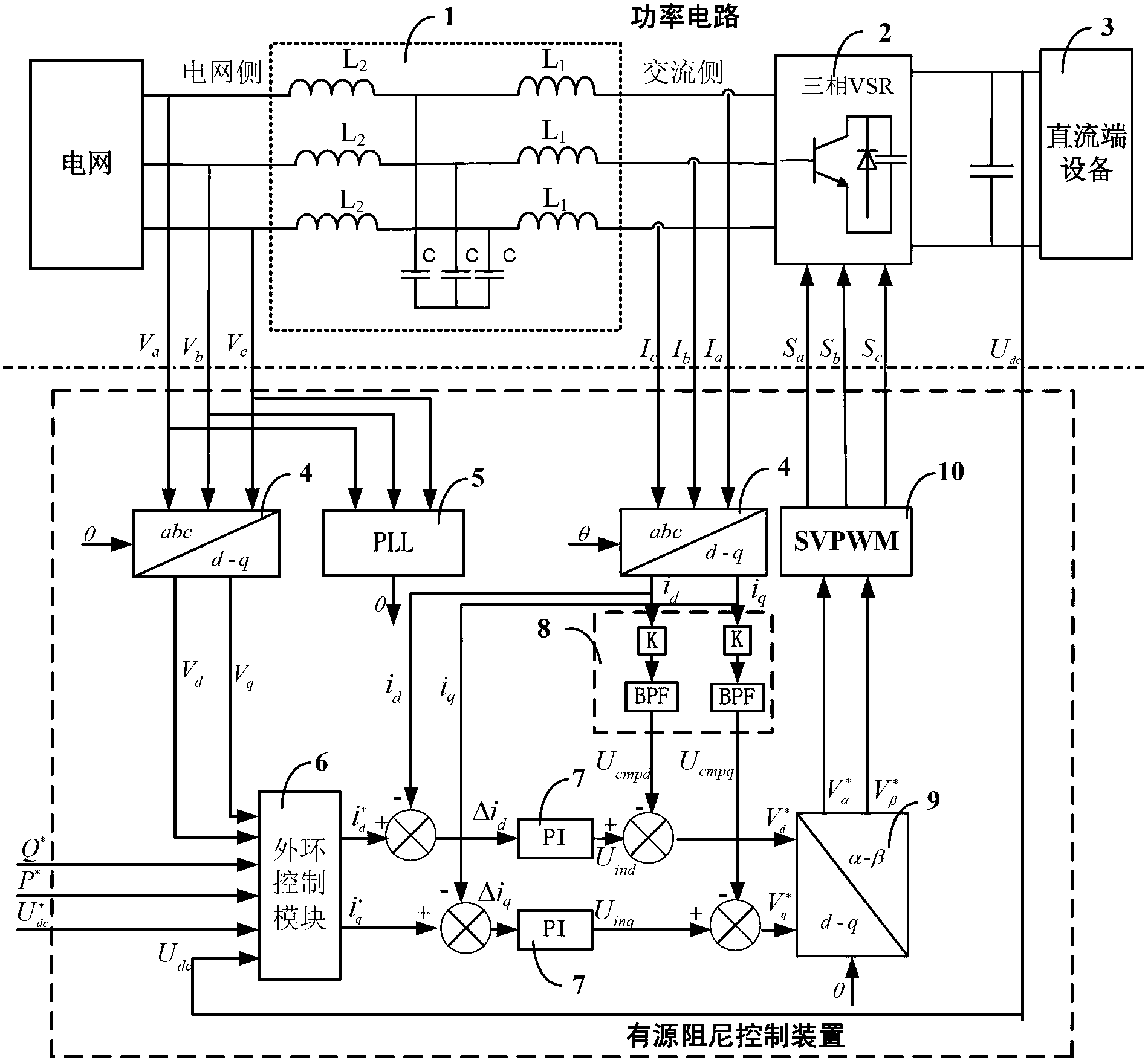

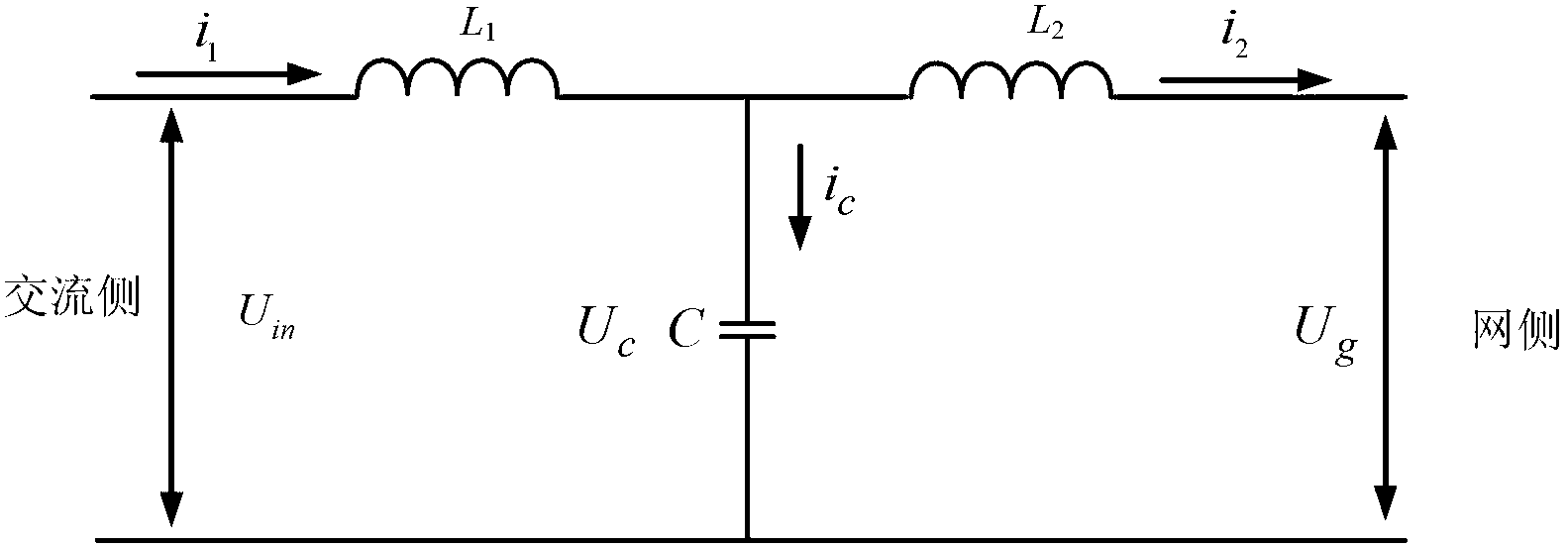

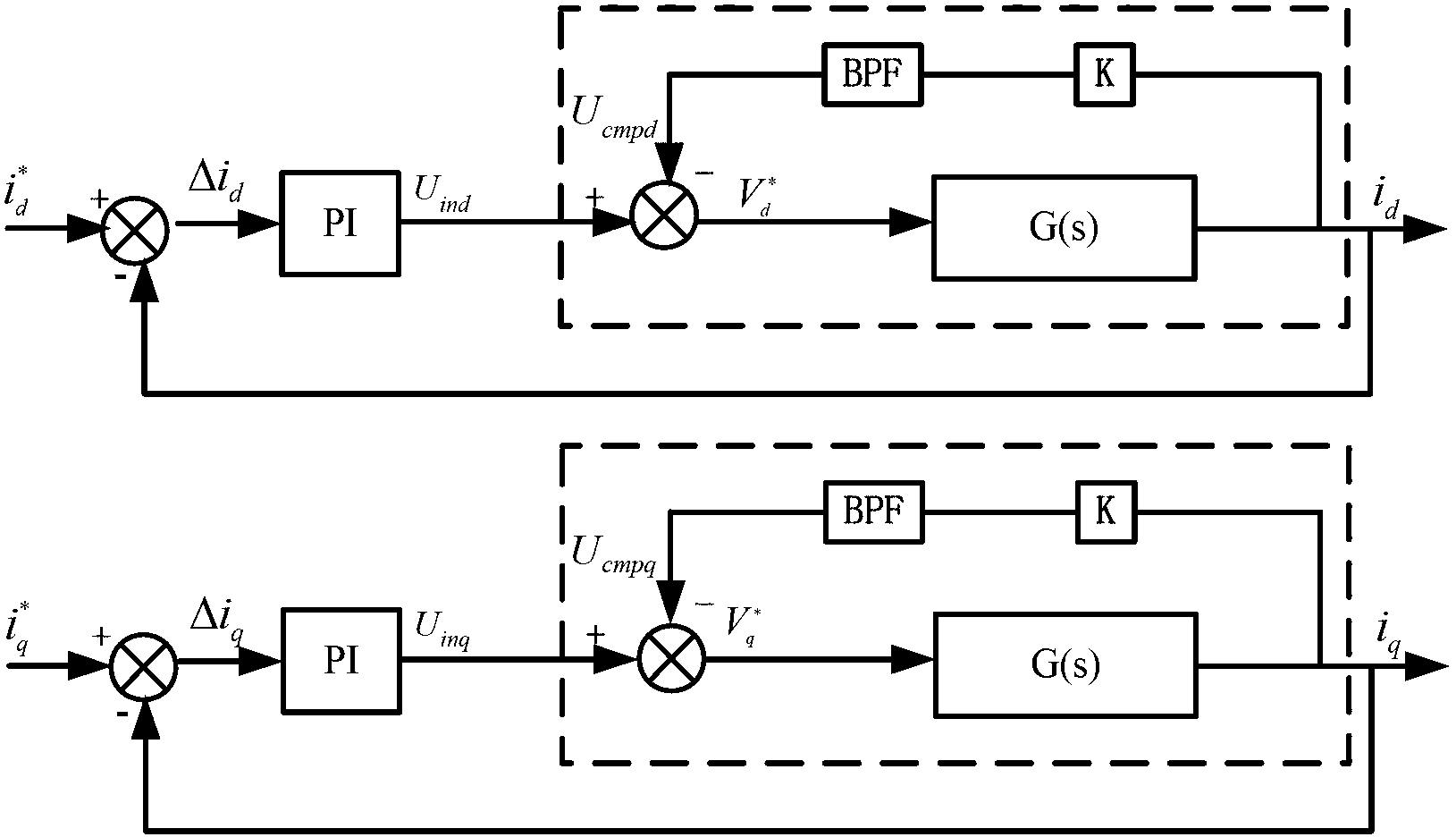

Active damping control device for LCL filtering PWM current converter

InactiveCN102710105AImprove efficiencyLow costPower conversion systemsElectrical resistance and conductanceProportional control

The invention discloses an active damping control device for an LCL (Lower Control Limit) filtering PWM (Pulse-Width Modulation) current converter, which is improved to solve the problem that an additional sensor is required to be introduced for active damping control, and a current control structure is innovated. The invention designs a novel AC-side current feedback compensation damping control mode based on a double proportional control module and a band-pass filter. Through current on the AC side, the controlled quantity of the active damping control device is compensated. Firstly, the method is taken as active damping control without additionally arranging a damping resistor and then directly compensates through the current on the AC side, so that the additional sensor is not required to be arranged. The active damping control device has the benefits that on the basis of resonance problem that an LCL filter is restrained to be introduced, the practical damping resistor and the additional sensor are not required to be additionally arranged, so that both the efficiency and the cost of systems can be improved to a certain degree.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

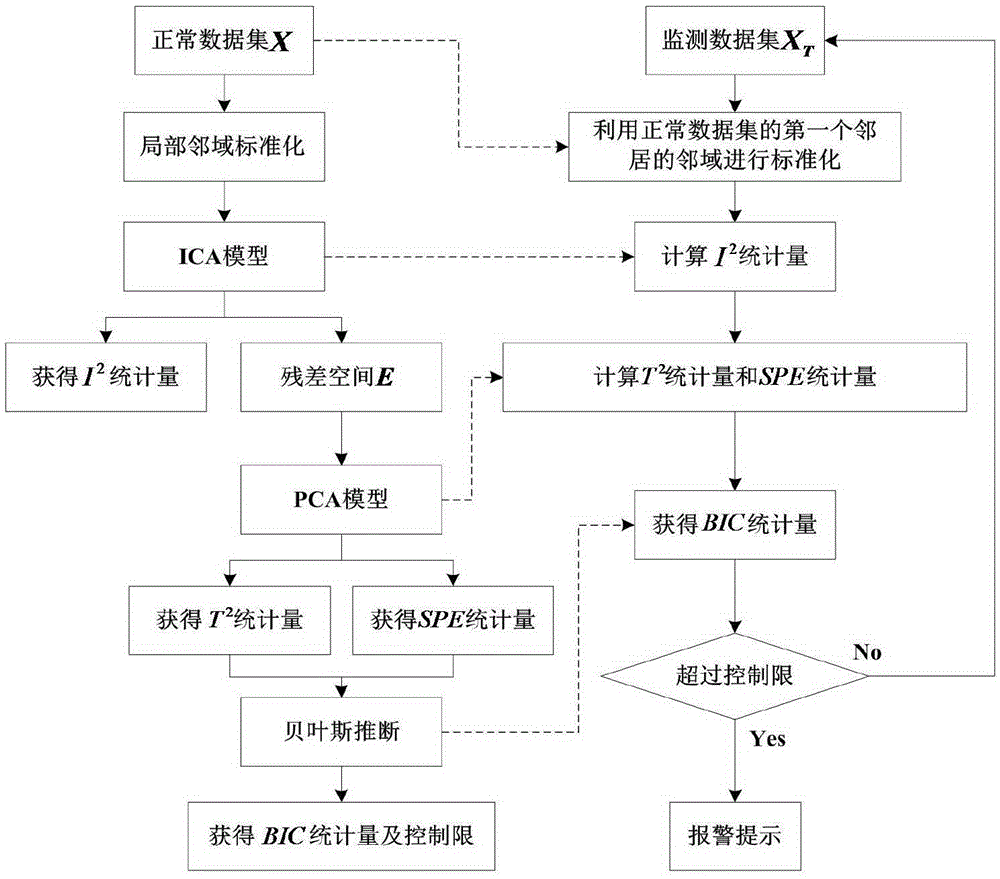

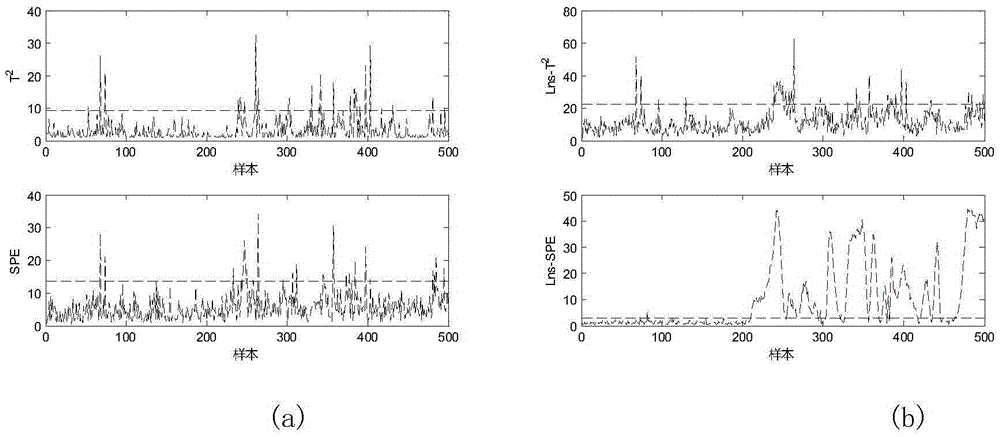

ICA-PCA multi-working condition fault diagnosis method based on local neighborhood standardization and Bayesian inference

ActiveCN105425779AEasy to observe and monitorEasy to handleProgramme controlElectric testing/monitoringData setDiagnosis methods

The invention discloses an ICA-PCA multi-working condition fault diagnosis method based on local neighborhood standardization and Bayesian inference. The method firstly carries out independent sampling of each normal working condition during an industrial course to obtain a training dataset, carries out the local neighborhood standardization of the training dataset to obtain a dataset which follows single distribution, and then uses an ICA-PCA method to respectively analyze and process Gaussian features and non-Gaussian features of the dataset so as to obtain an overall model. At an online monitoring stage, independent and repeated sampling is carried out to industrial course data, a plurality of statistical quantities are acquired by applying the model to carry out analysis and processing after the local neighborhood standardization processing, then the multiple statistical quantities are combined into one statistical quantity by the Bayesian inference, and a fault diagnosis result is acquired by comparing control limits. In comparison with traditional fault diagnosis methods, the ICA-PCA multi-working condition fault diagnosis method based on the local neighborhood standardization and the Bayesian inference disclosed by the invention can simplify processing courses, improve diagnosis effects and improve course monitoring performance, and can also make workers' monitoring and observation convenient, make for avoiding safety hidden dangers and guarantee normal running of the industrial course.

Owner:JIANGNAN UNIV

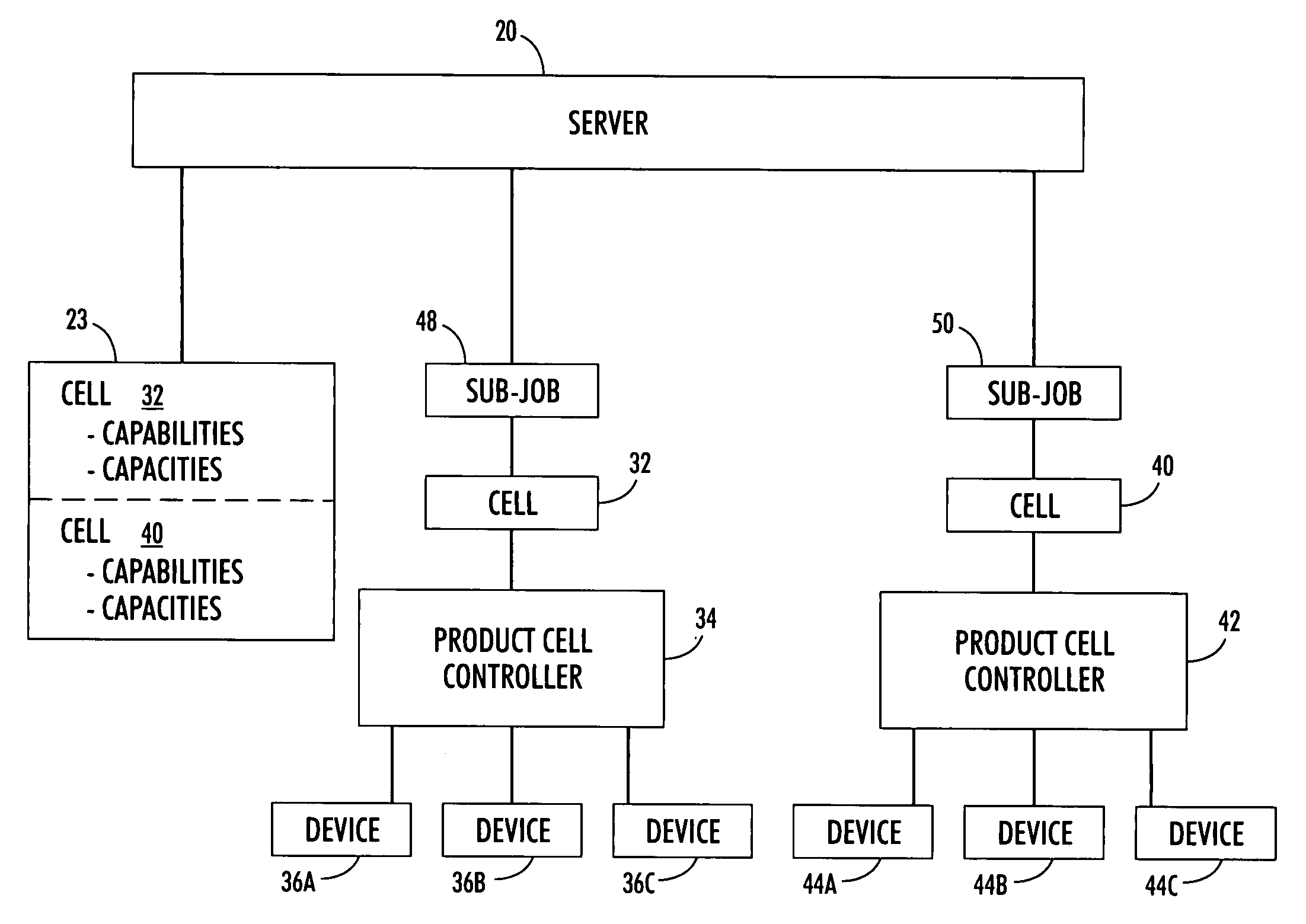

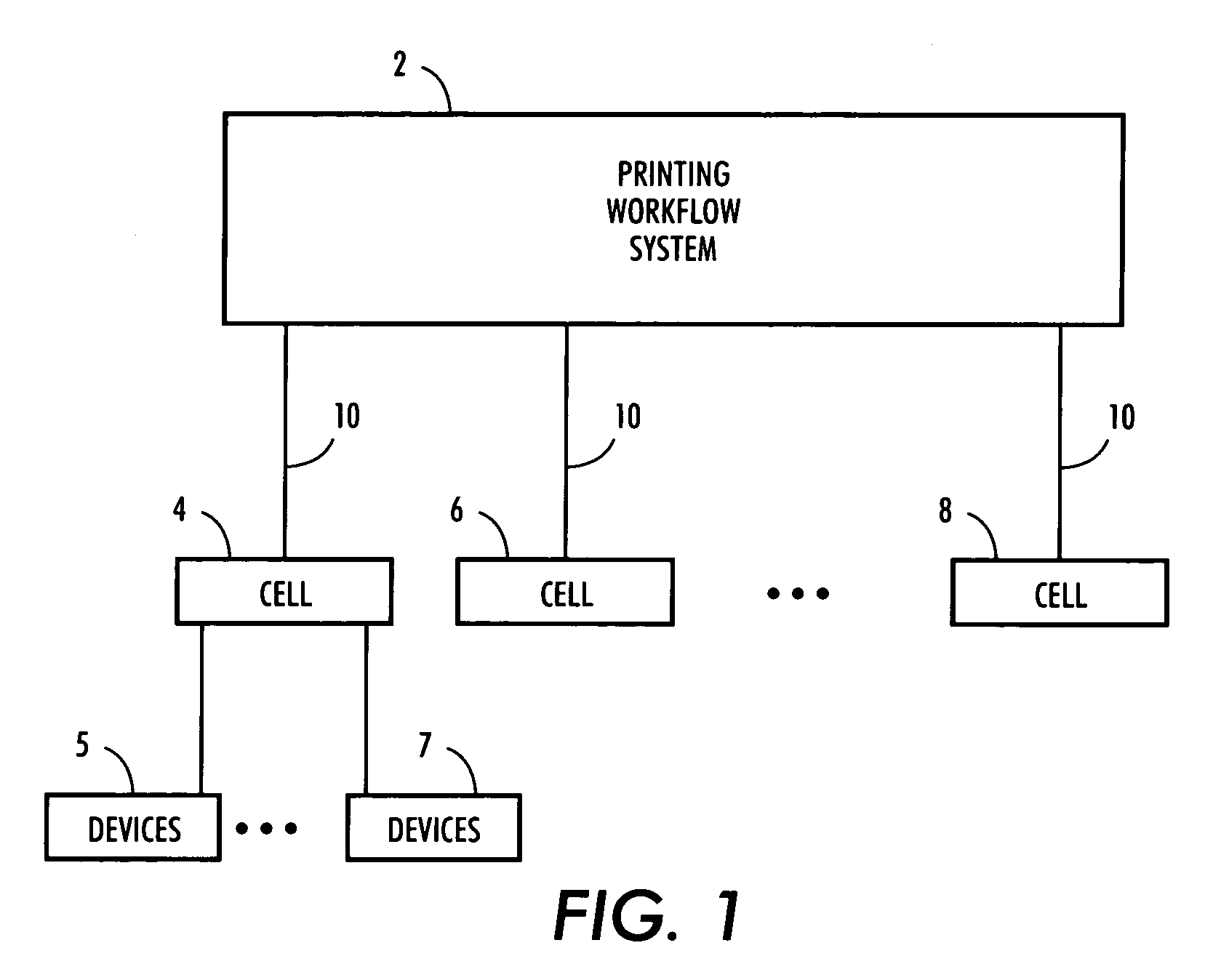

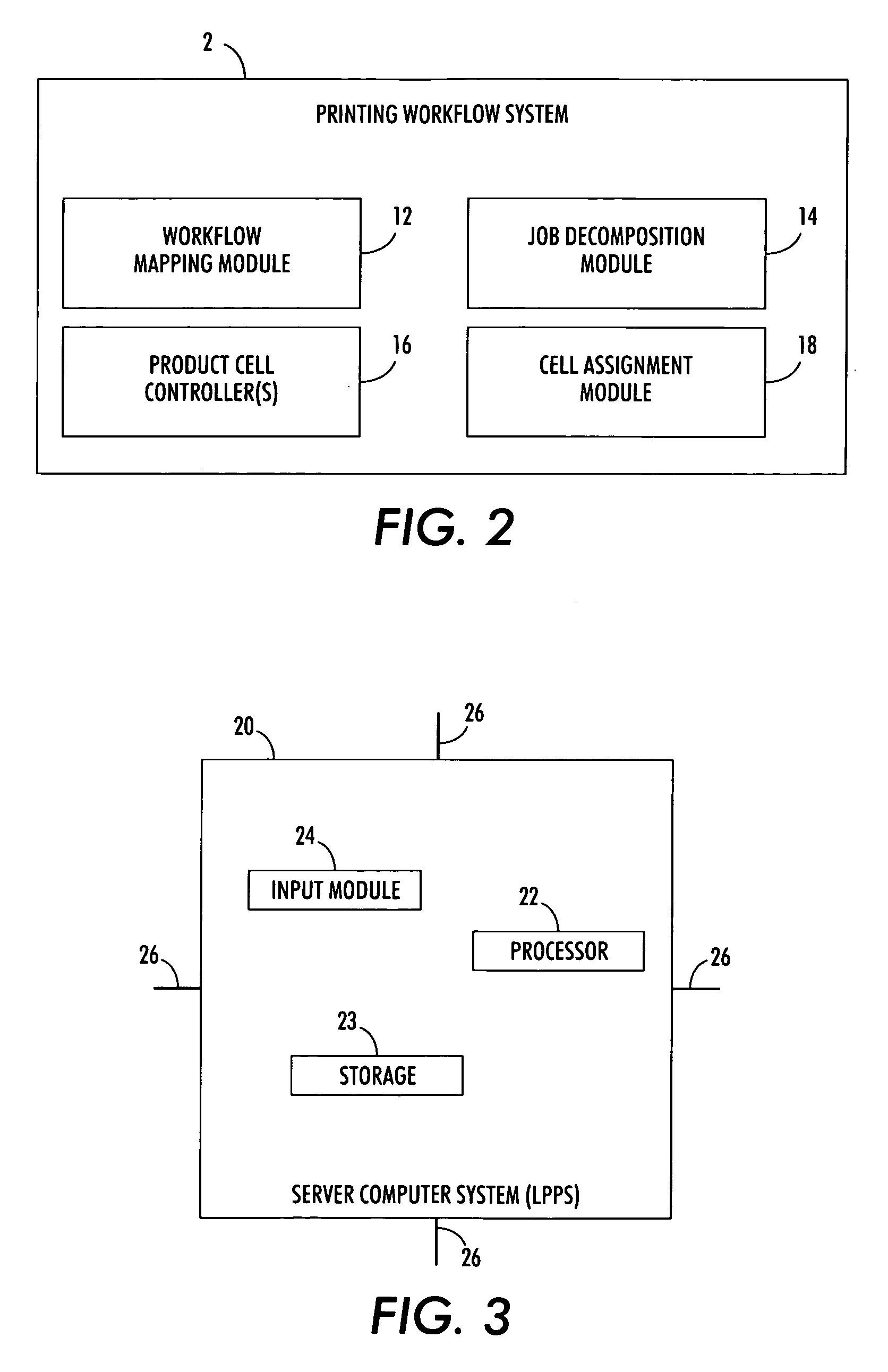

Print job management system

InactiveUS20070236724A1Significant time delayReduce turnaround timeDigitally marking record carriersDigital computer detailsControl limitsComputer science

A system for managing the size of a print job to be processed in a print shop is provided. The print shop includes a plurality of autonomous cells and the job size management system includes a scheduling tool for generating a list including a plurality of jobs. A processor is used to (a) assign a job size related value to each one of the plurality of jobs so that the plurality of jobs are corresponded respectively with a set of job size related values, (b) use the set of job size related values to calculate a control limit, and (c) for each job size related value exceeding the control limit, splitting the job corresponding with the job size related value exceeding the control limit into n number of sub-jobs for processing at the plurality of autonomous cells.

Owner:XEROX CORP

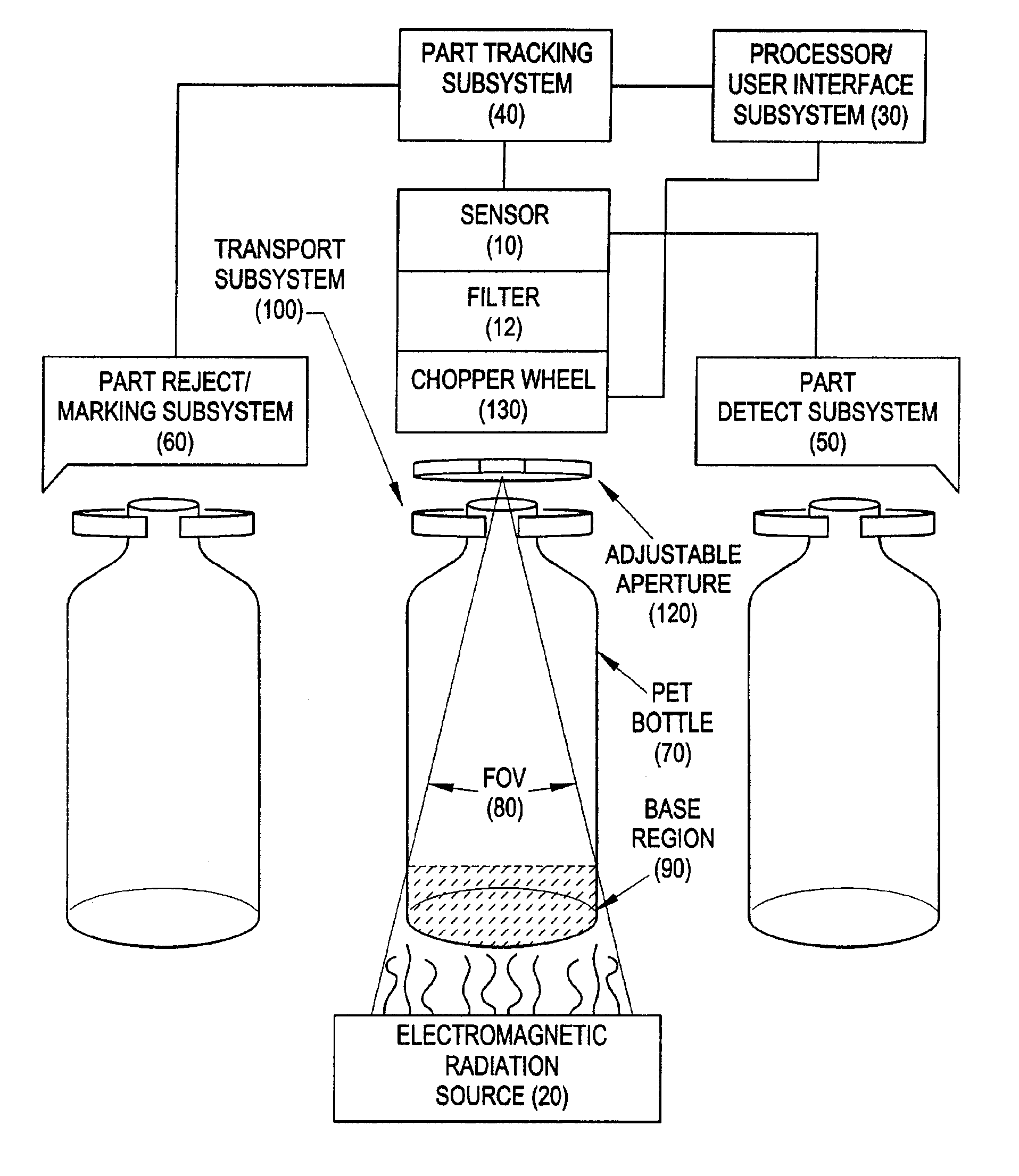

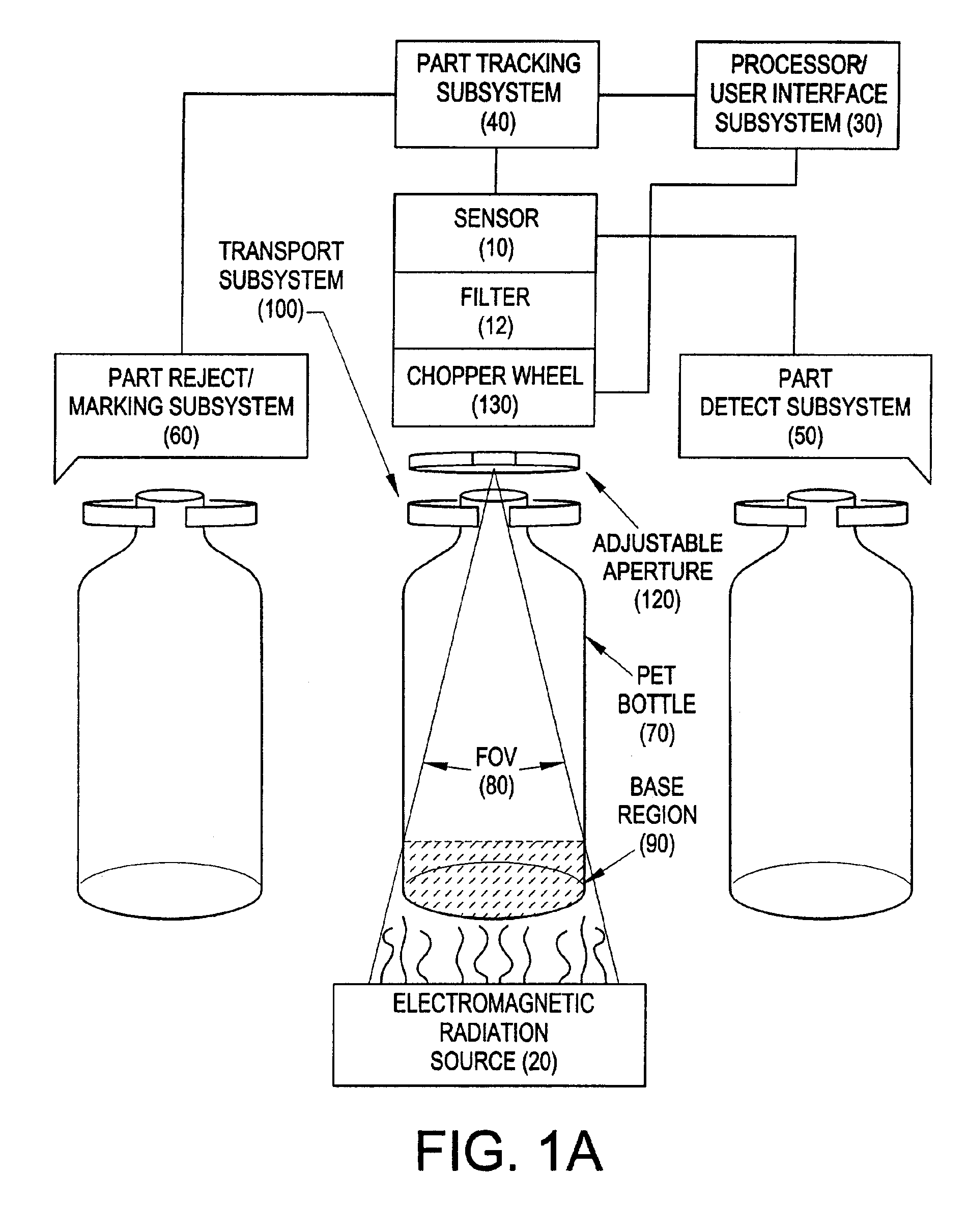

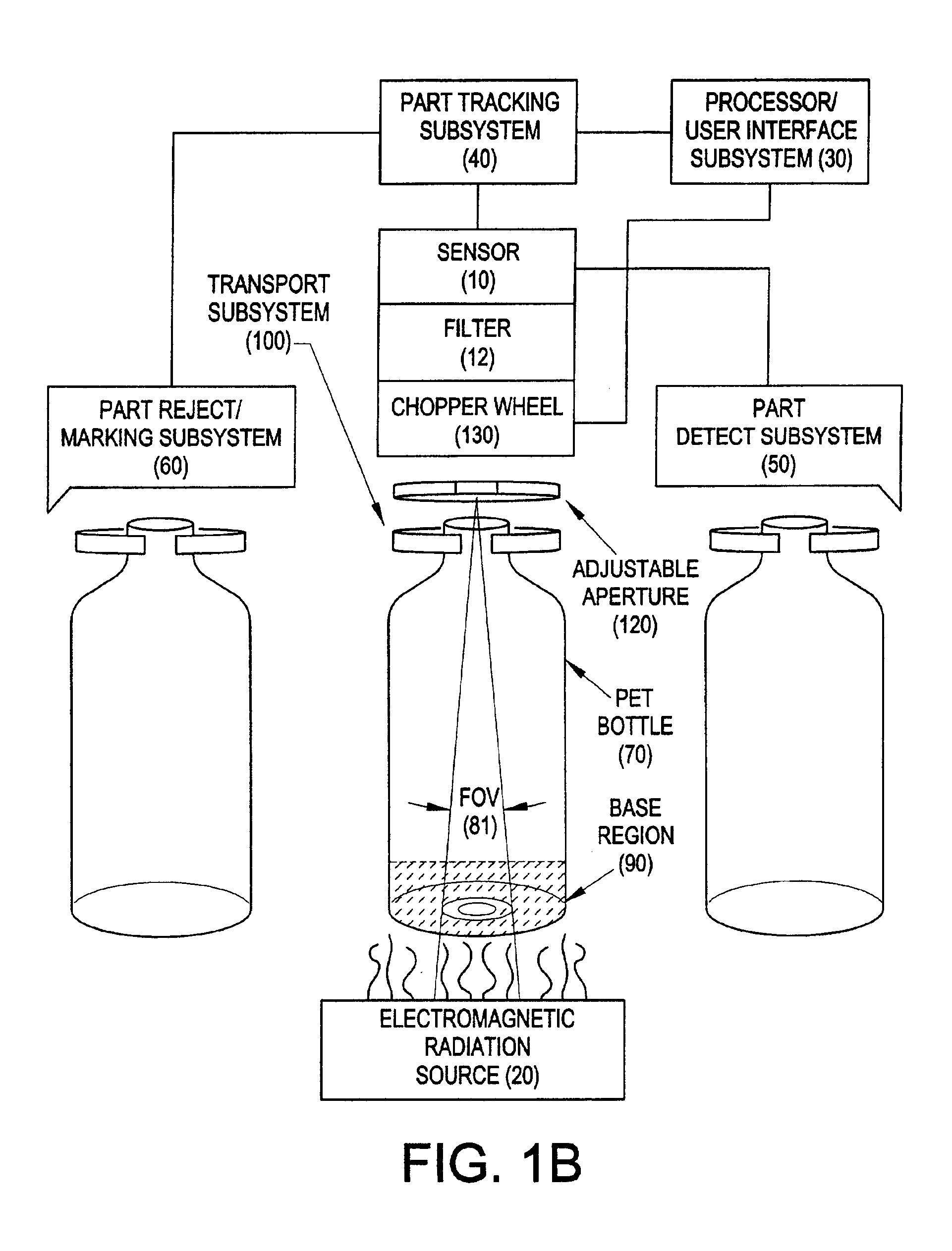

Apparatus and method for providing spatially-selective on-line mass or volume measurements of manufactured articles

InactiveUS6872895B2Material analysis by optical meansMaterial check-weighingVolume measurementsQuality control

This invention relates to a method and apparatus for mass and / or volume measurements of manufactured articles. More particularly, this invention relates to a method and apparatus for mass and / or volume measurements that can be performed on-line in a part manufacturing process. On-line measurement of the mass or volume of material contained in a specific region of interest of the manufactured items is performed 100% on-line. Real-time process control information is based on real-time measurement of the mass or volume of material contained in a specific region of interest of a manufactured item. Automated quality control inspection for manufactured articles is based on real-time measurement of the mass or volume of material contained in a specific region of interest of manufactured items. A manufacturing closed-loop process is directly corrected to keep it within control limits based on real-time measurement of the mass or volume of material contained in a specific region of interest of manufactured items soon after these items are manufactured.

Owner:PRESSCO TECH INC

Method of monitoring faults in sections for intermittent control system

InactiveCN103279123AThe phase division complies withThe phase division is more in line with the batch process actually in line withElectric testing/monitoringFuzzy clustering analysisPrincipal component analysis

The invention discloses a method of monitoring faults in sections for an intermittent control system and relates to a fault monitoring method. Firstly, a plurality of batches of collected intermittent process data are standardized in a way of expanding variables, and a data matrix on each sampling time is subjected to principal component analysis; secondly, a fuzzy C-means clustering is a fuzzy clustering analysis method which is suitable for soft partition and is generated through combining a fuzzy set theory and a k-means clustering; and thirdly, after segmentation is finished, an improved MPCA (Multiway Principal Component Analysis) model with a time varying principal element covariance on the basis of expanding variables is established on each subphase, then when on-line monitoring is carried out, which phase a new batch of data belongs to is judged, whether the data exceeds the fault monitoring control limit or not is calculated and judged, if so, a fault occurs, and the fault monitoring in sections ends. According to the invention, process multi-phase partition is more accurate, misinformation and missing report rates in monitoring are reduced, and the practical application and operability are strong.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

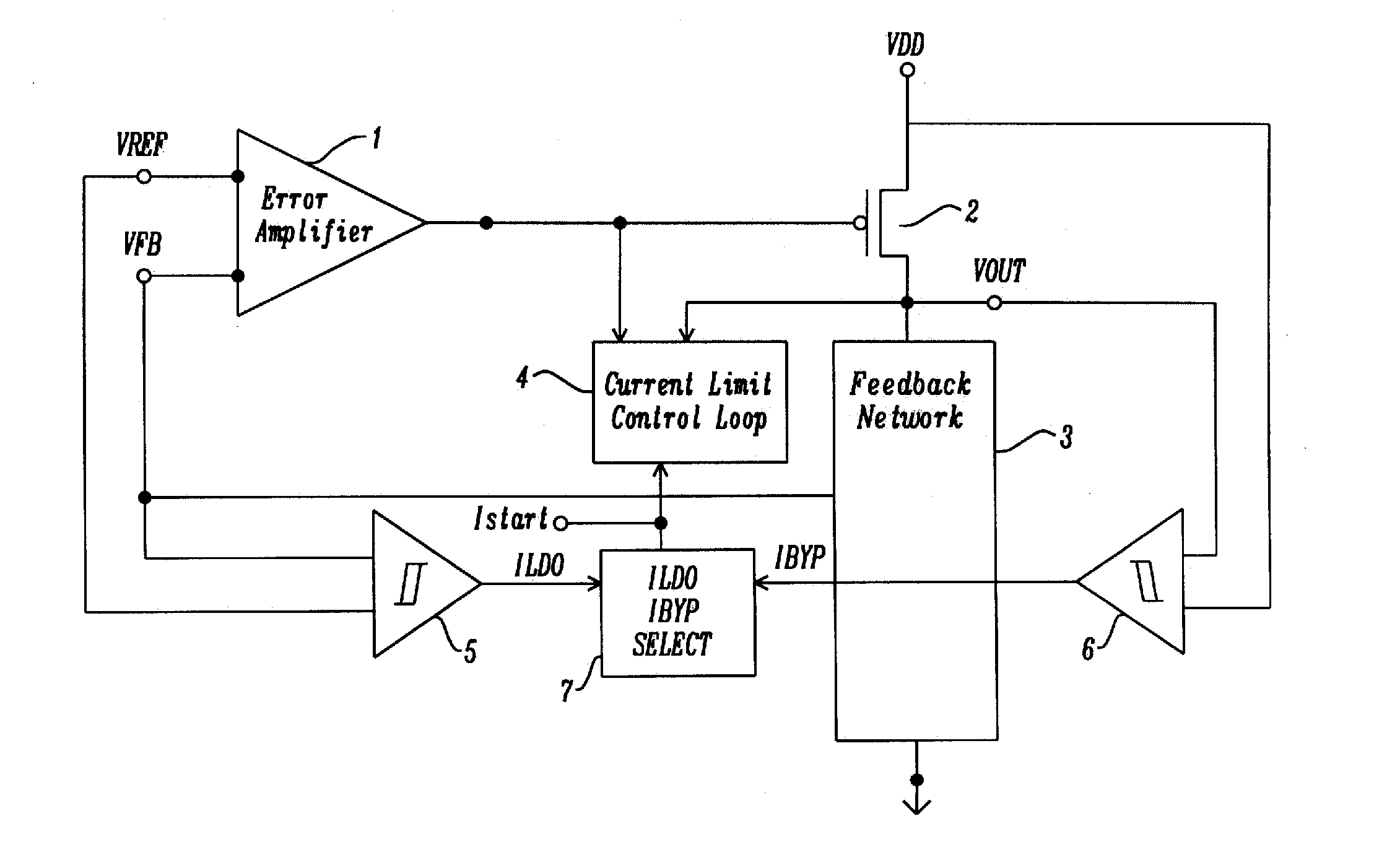

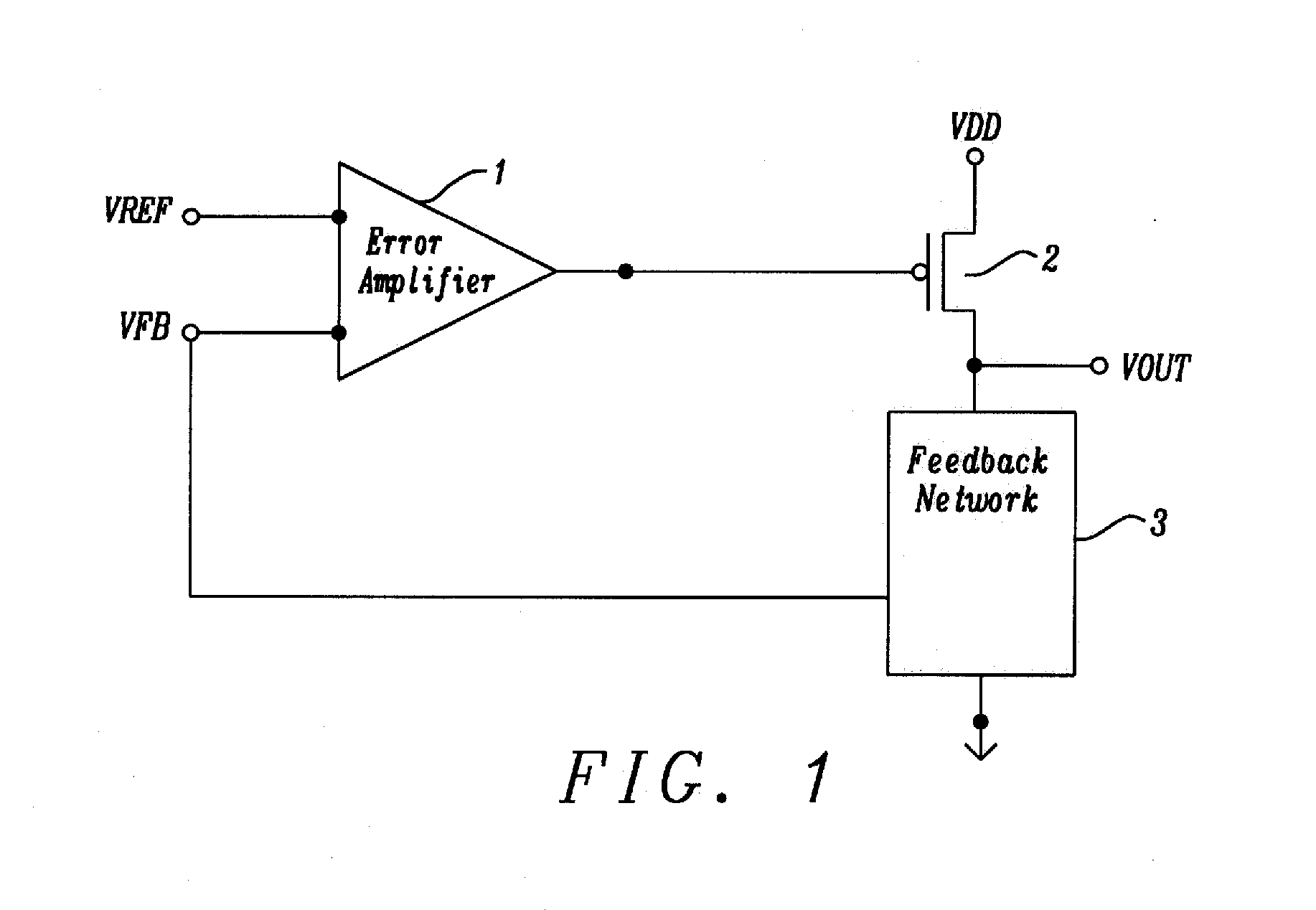

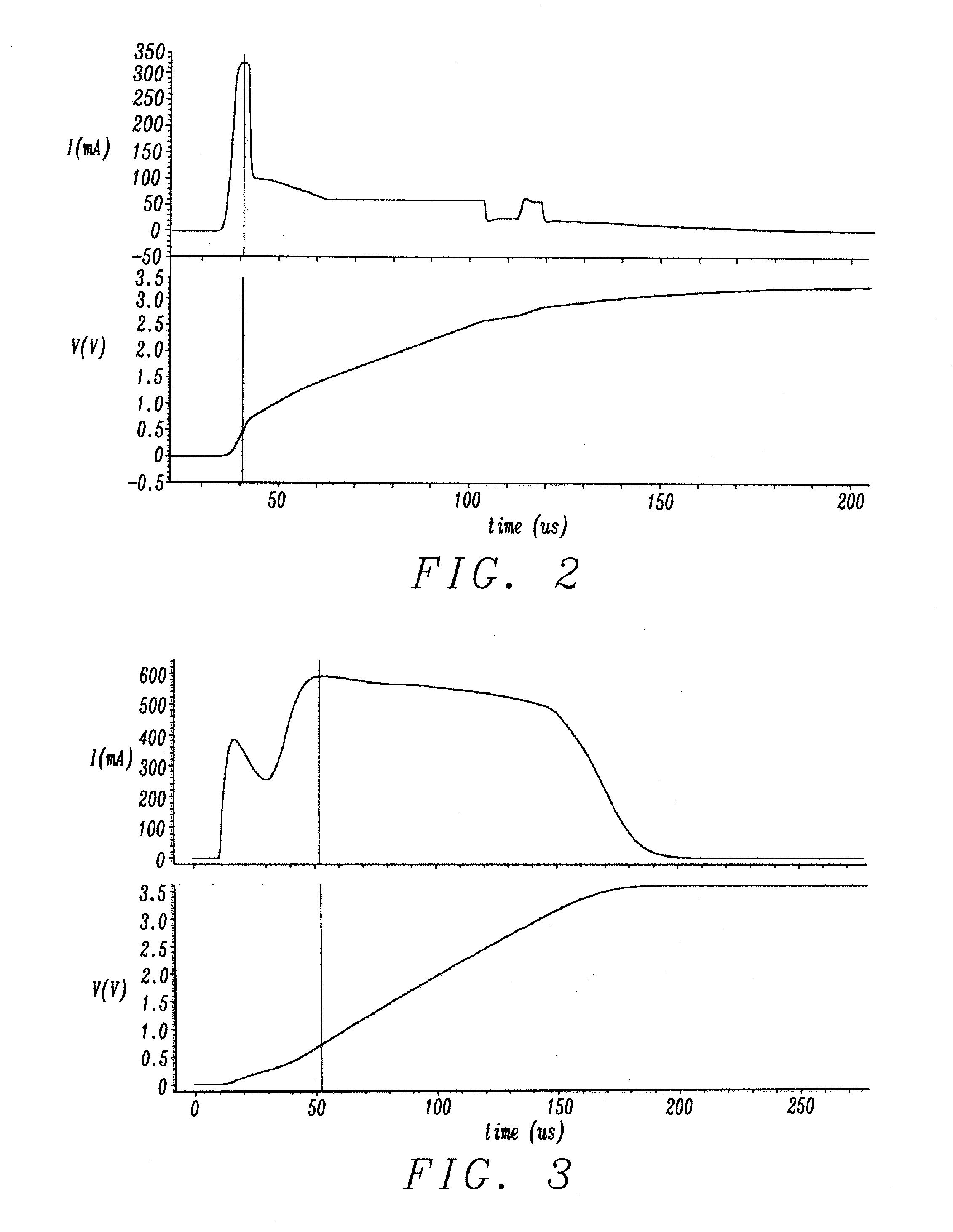

Method and Apparatus for Limiting Startup Inrush Current for Low Dropout Regulator

ActiveUS20150061622A1Reduce differential pressureAvoid adjustmentElectric variable regulationElectricityPower flow

A low dropout (LDO) regulator with a limited startup inrush current is disclosed. The LDO includes a power source, error amplifier, pass transistor, feedback network, and a current limit control whose input is electrically connected to the pass transistor and the electrical output of the error amplifier and whose output limits current during startup. The LDO can include a current control limit comparator including a power source, and output of the pass transistor. The LDO can also include a bypass mode current control limit comparator having a first input voltage of the error amplifier, and a second input voltage from the error amplifier.

Owner:DIALOG SEMICONDUCTOR GMBH

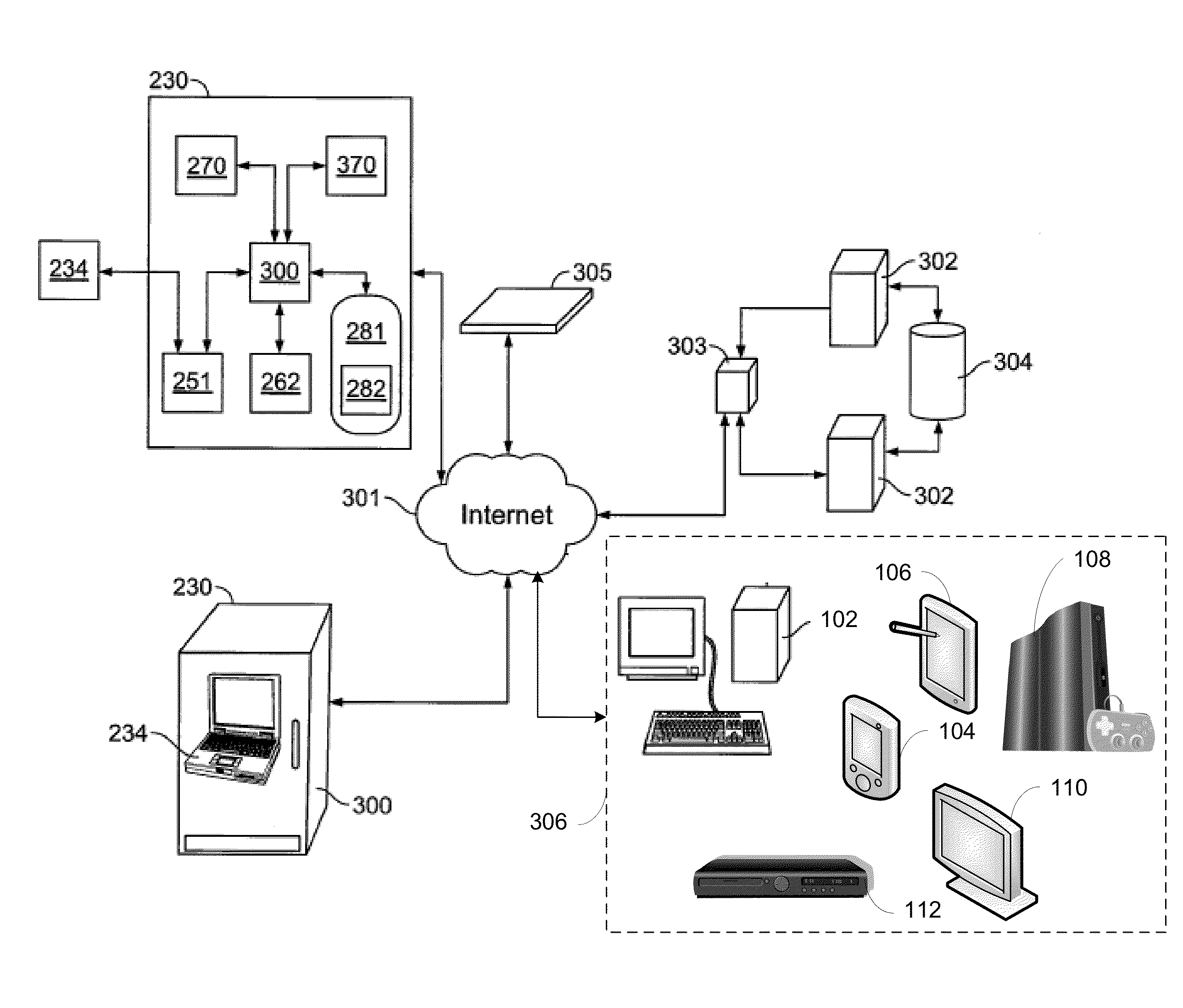

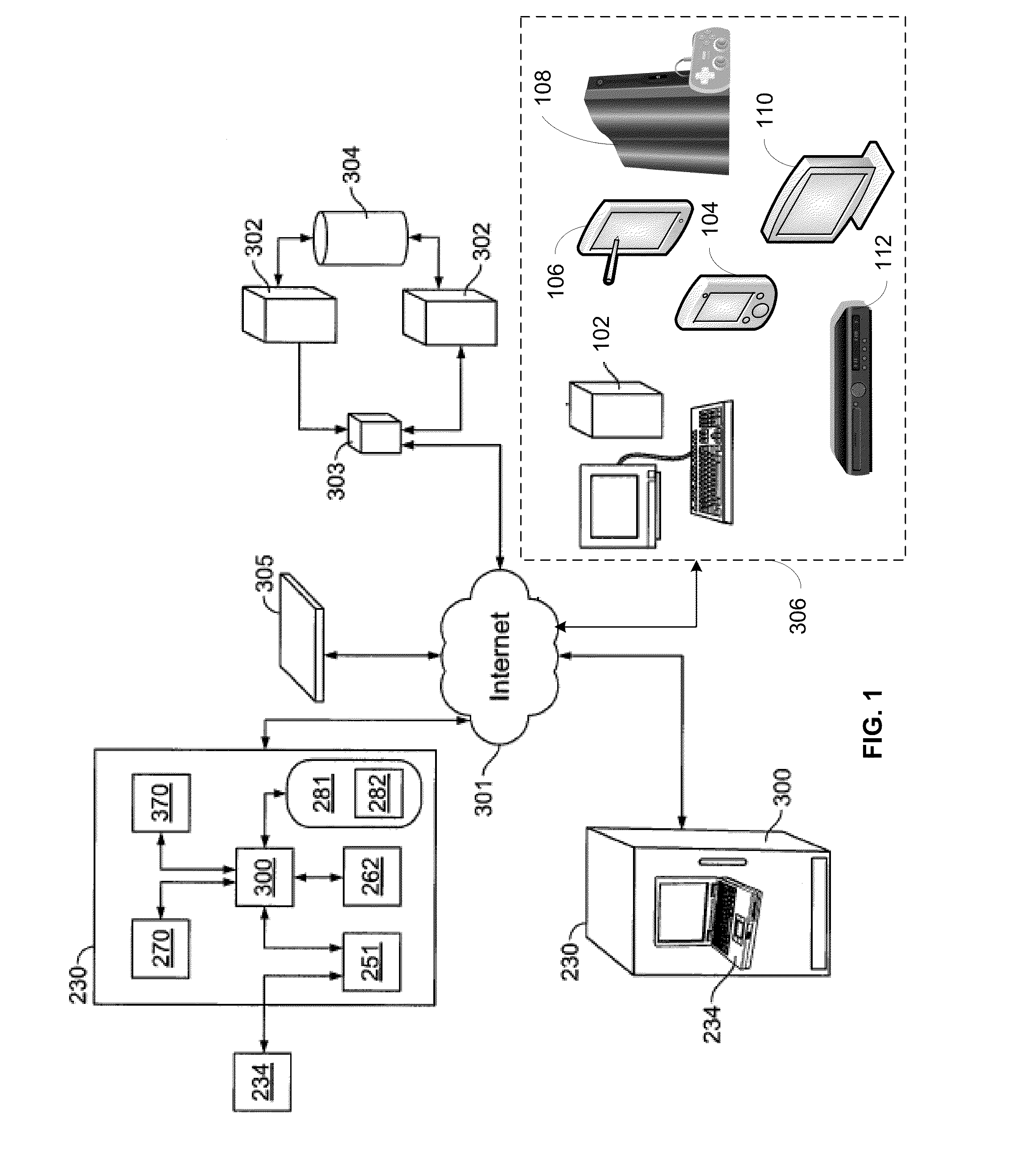

System and method for applying parental control limits from content providers to media content

ActiveUS20130061260A1Overcome disadvantagesFacilitate communicationAcutation objectsAnalogue secracy/subscription systemsComputer networkControl limits

Methods of filtering and modifying access to media content based on parental control limits are provided. The method for filtering media content includes receiving authentication information for a content provider, authenticating to the content provider, importing parental control limits from the content provider, storing the received parental control limits in a customer profile, and filtering the media content based on the parental control limits to produce a filtered list of the media content. The method for modifying access to media content includes authenticating to a customer profile with a unique customer identifier, retrieving parental control limits from the customer profile, and modifying access to the media content based on the retrieved parental control limits. Changes in the parental control limits at a content provider may be detected and updated in the customer profile.

Owner:REDBOX AUTOMATED RETAIL

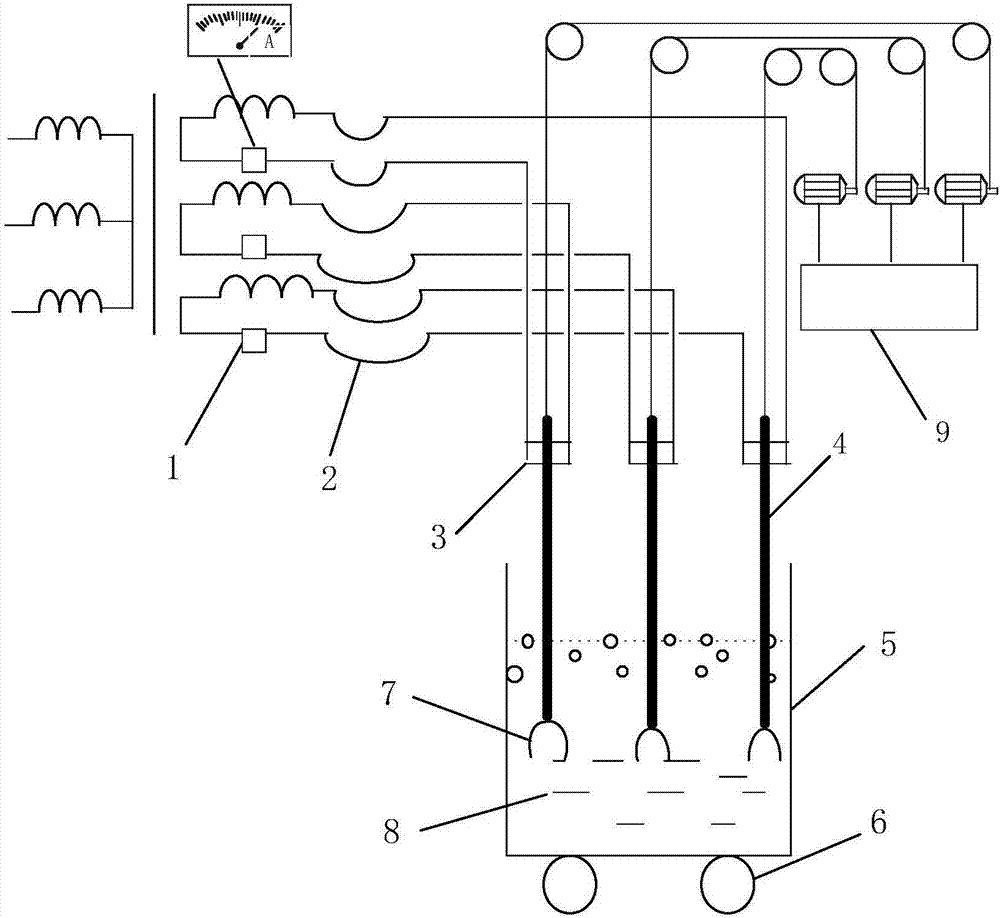

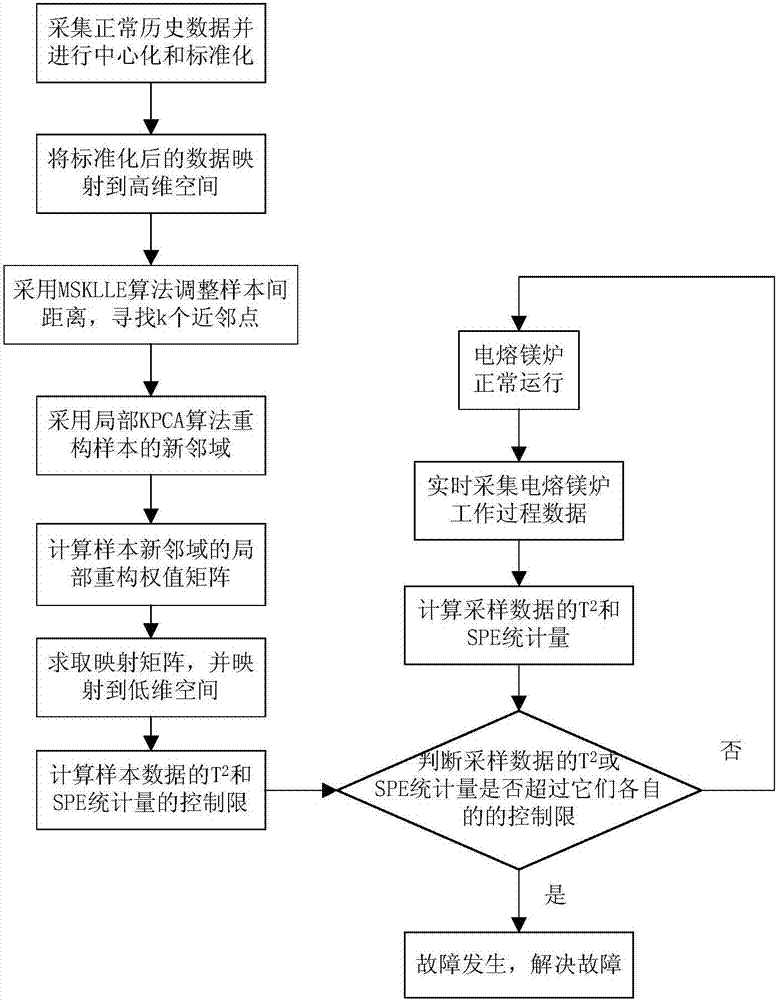

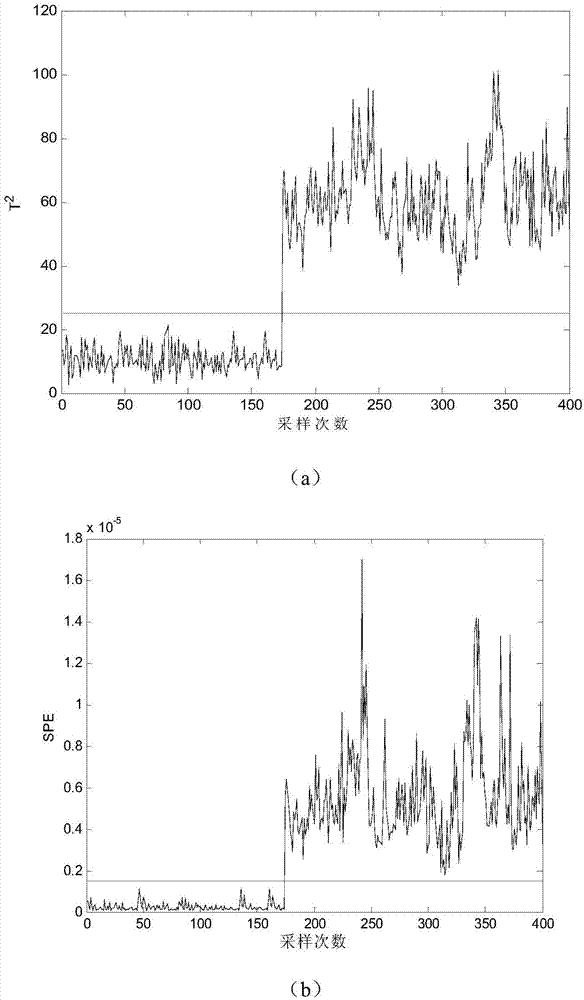

Method for monitoring process of fused magnesium furnace based on improved supervised kernel locally linear embedding method

ActiveCN107092923AEffective real-time online detectionImprove life safetyElectric testing/monitoringCharacter and pattern recognitionAlgorithmData space

The invention provides a method for monitoring the process of a fused magnesium furnace based on an improved supervised kernel locally linear embedding method, and relates to the technical field of fault monitoring and diagnosis. The method includes the steps of mapping sample data X to a high dimensional feature space [phi](X) by using a kernel function; selecting the number of k neighbor points through a MKSLLE (Modified supervised kernel locally linear embedding) algorithm, and adding a regular term when constructing a reconstruction weight matrix; performing dimensionality reduction for an objective function composed of a KPCA-combined global preserving features and local preserving features, and obtaining a mapping matrix from a high dimensional data space to a low dimensional feature space and a coefficient matrix through approximate calculation; and constructing a Hotelling T2 statistic and an SPE statistic and determining control limits thereof. According to the invention, abnormalities and faults can be monitored online in real time in the working process of a fused magnesium furnace, the accuracy of fault monitoring is effectively improved, the occurrence of false alarms and false negatives is reduced, the property loss is reduced, and the personal safety of working staff is guaranteed.

Owner:NORTHEASTERN UNIV

Non-linear procedure failure testing method based on two-dimensional dynamic kernel principal component analysis

InactiveCN101308385ACapture comprehensiveMonitor the production processElectric testing/monitoringCharacter and pattern recognitionKernel principal component analysisObservation data

Disclosed is a non-linear process fault detection method based on two-dimensional dynamic kernel principal component analysis, belonging to the fault detection technical field; the method comprises the following steps: the first step is to determine the sampling parameters, namely, to judge the execution process, determine the sampling parameters, select the data parameters which affect the fault, and then judge whether to carry through training or testing; the second step is training, that is, to collect the data of normal work, pick up the non-linear principal component of the training data through two-dimensional dynamic kernel principal component analysis, calculate the square prediction error of the training data and determine the control limit; the third step is testing, that is, to collect the online observation data, pick up the non-linear principal component of the online observation data through two-dimensional dynamic kernel principal component analysis, calculate the square prediction error of the real-time online observation data, compare the control limit of the square prediction error of the real-time online observation data with the control limit of the square prediction error of the training data, display and gives an alarm if the control limit of the former exceeds that of the latter. The invention can timely detect the fault in the production process and reduce losses in the industrial production process.

Owner:NORTHEASTERN UNIV

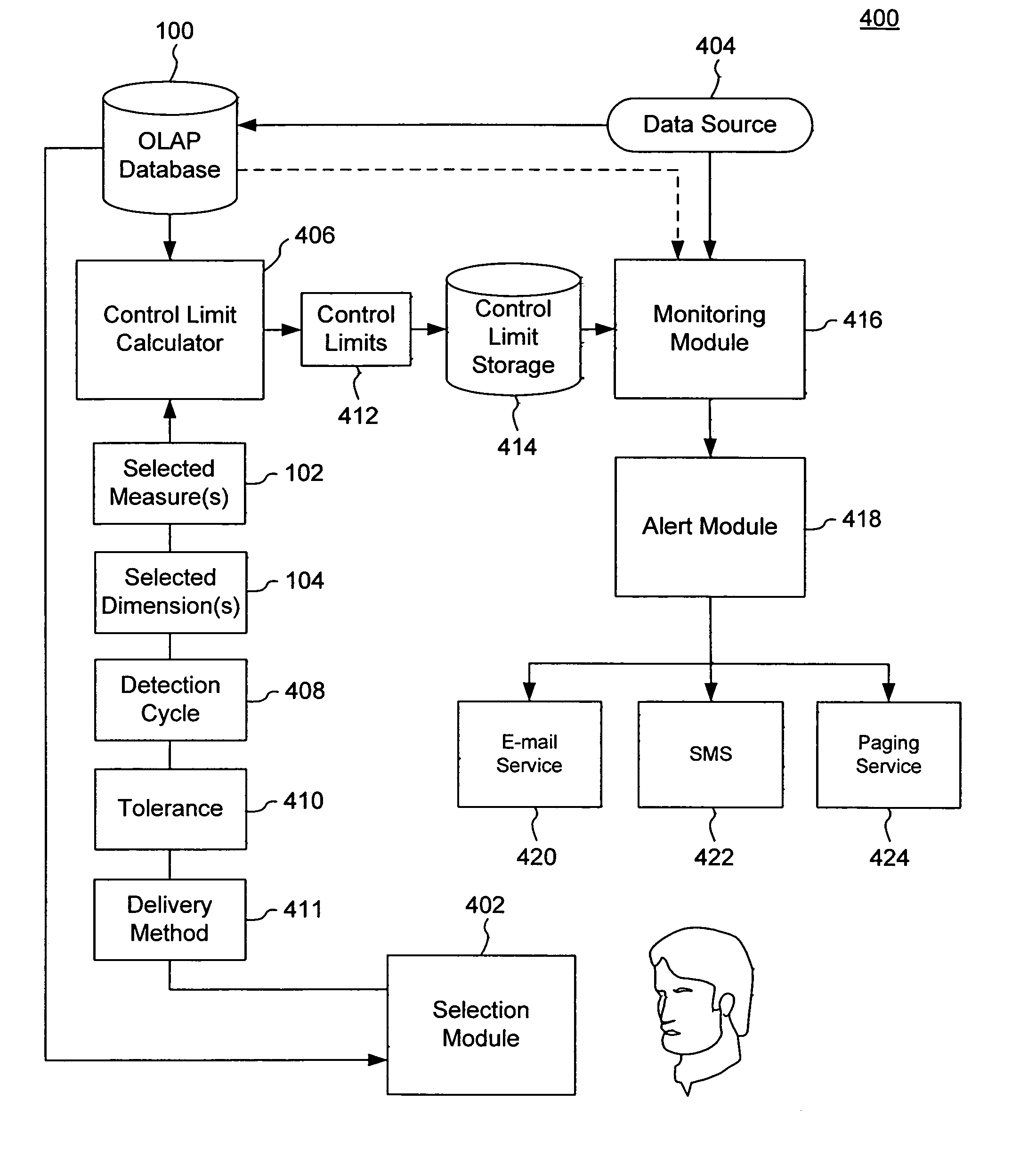

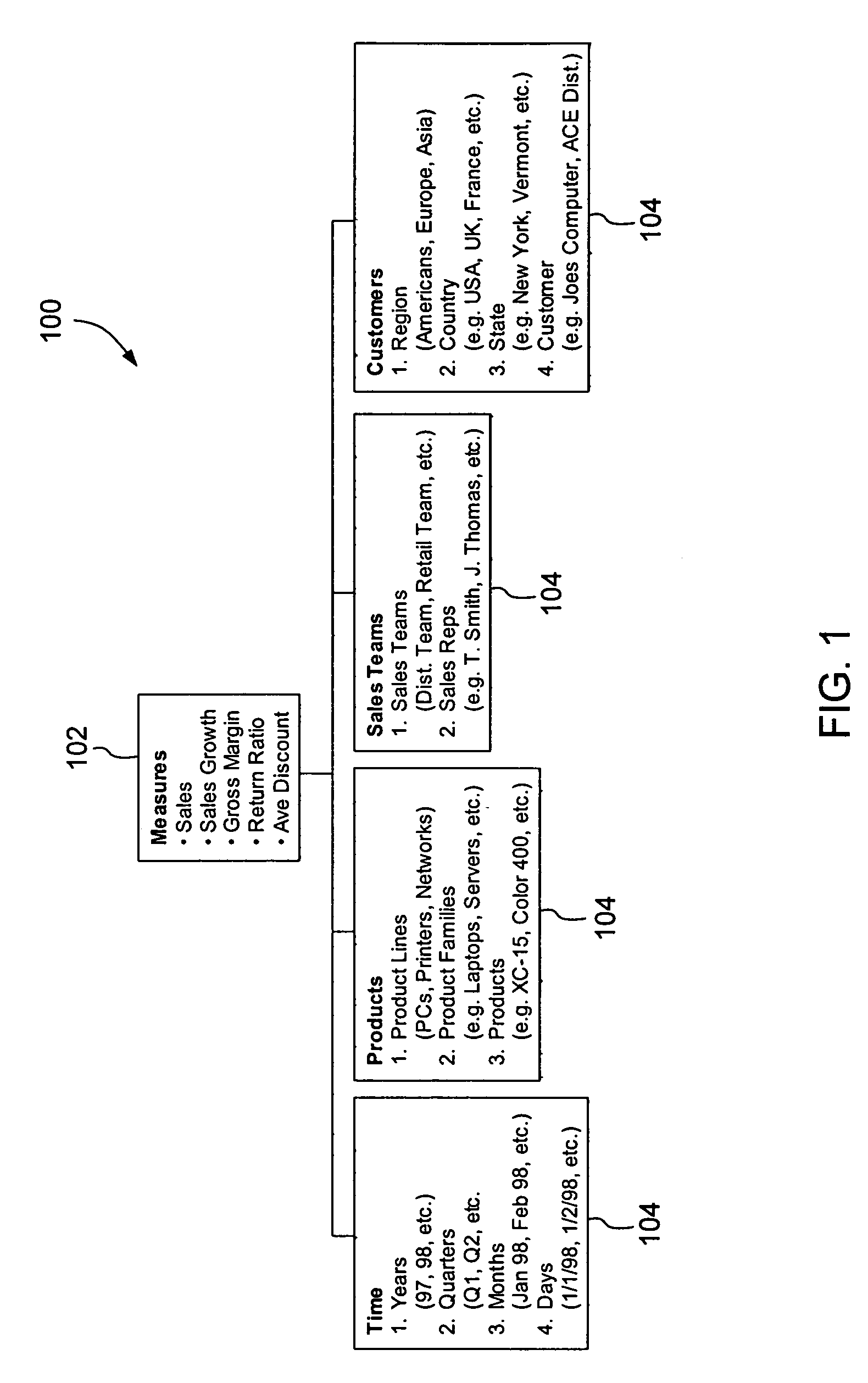

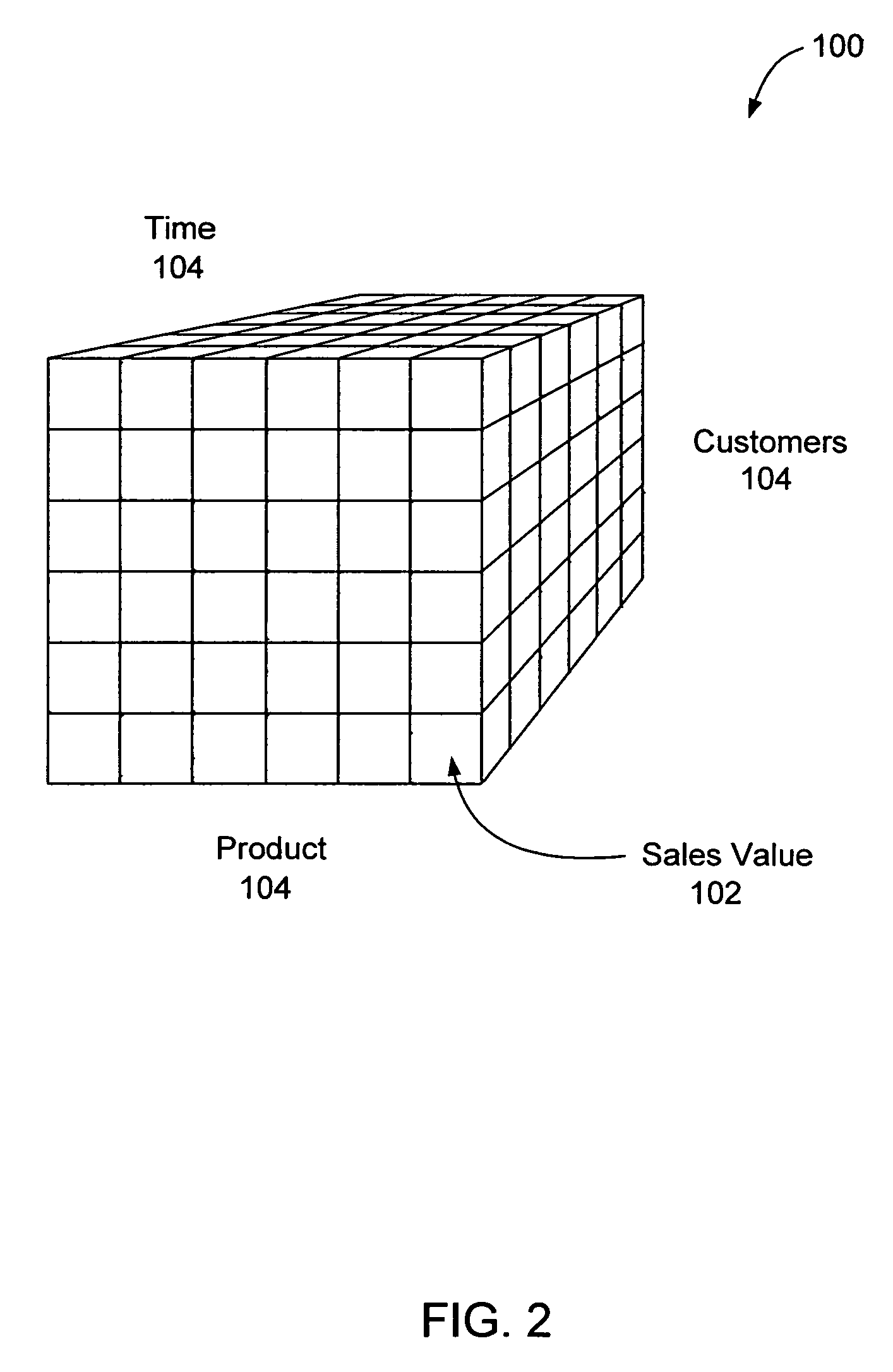

Automatic monitoring and statistical analysis of dynamic process metrics to expose meaningful changes

InactiveUS7072899B2Data processing applicationsDigital data processing detailsStatistical analysisMultidimensional data

A selection module allows a user to specify at least one measure to be monitored in at least one dimension of a dimensional hierarchy. A control limit calculator extracts, for each specified measure and for each specified dimension, a time series from a multidimensional database for the specified measure in the specified dimension and automatically calculates one or more control limits for the specified measure in the specified dimension based on the extracted time series using a Statistical Process Control (SPC) technique. Thereafter, a monitoring module monitors newly acquired data including each specified measure in each specified dimension for an out-of-limits condition based on one or more automatically-calculated control limits. An alert module triggers an alert in response to an out-of-limits condition being detected.

Owner:MICROSOFT TECH LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com