Active damping control device for LCL filtering PWM current converter

A technology of damping control and converters, which is applied in the field of converters, can solve problems such as increased cost, difficulty in packaging LCL filters, and increased failure rate of PWM converters, and achieves the effect of improving efficiency and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

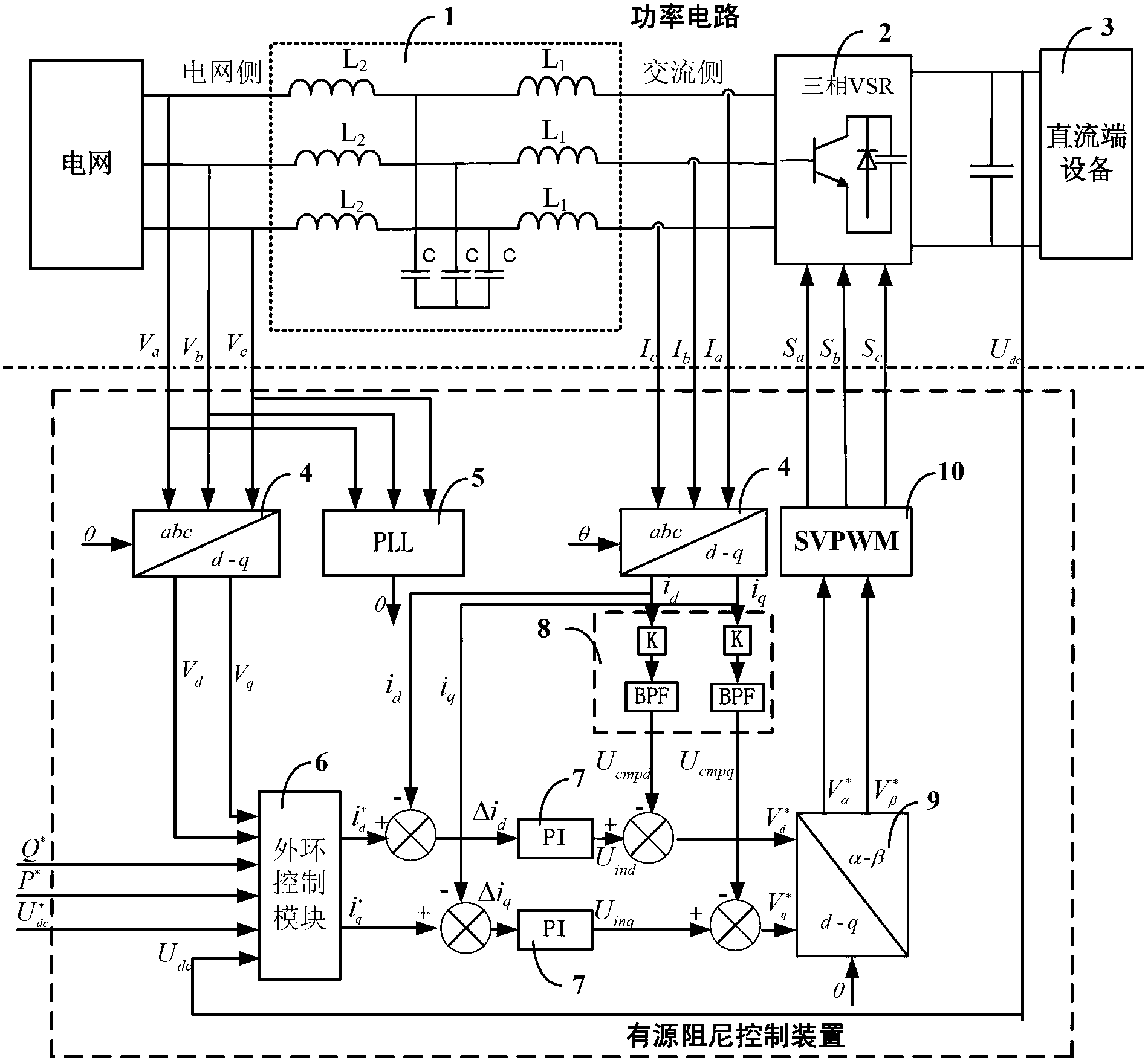

[0031] figure 1 It is a control block diagram of a specific embodiment of the active damping control device applied to the LCL filter PWM converter of the present invention.

[0032] In this example, if figure 1 As shown, the LCL filter PWM converter includes two parts: a power circuit and an active damping control device, wherein the dotted line below is the active damping control device applied to the LCL filter PWM converter of the present invention.

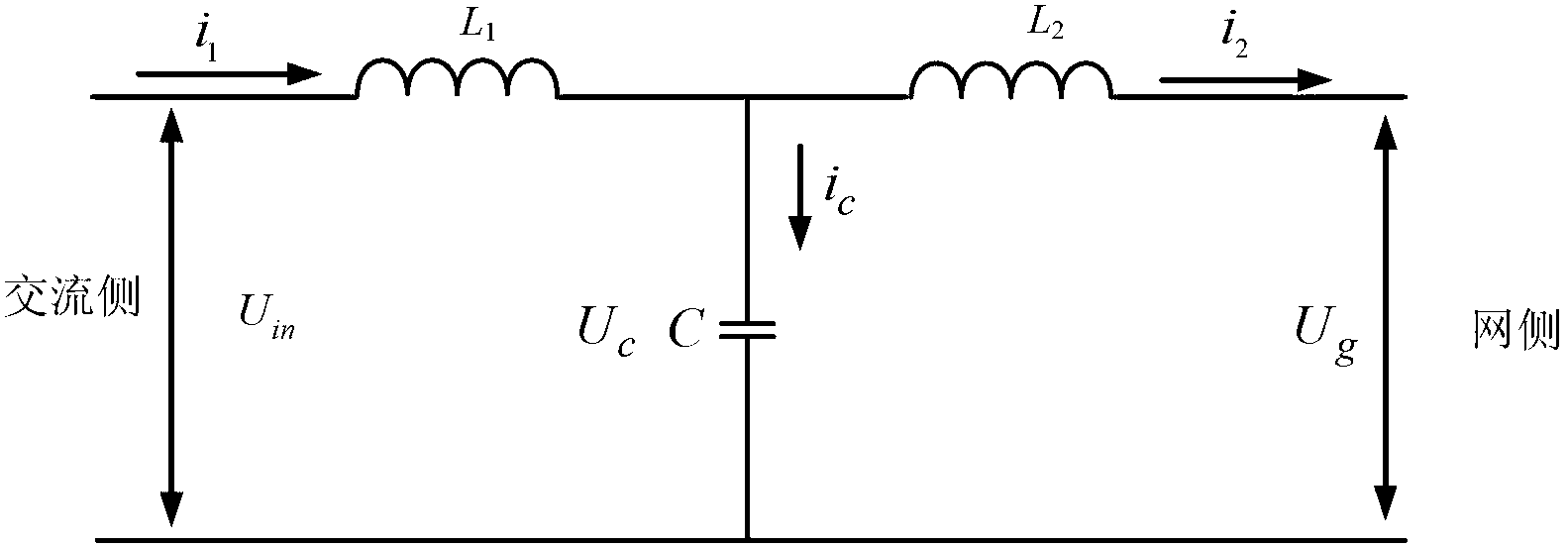

[0033] The power circuit part is composed of LCL filter 1, three-phase VSR 2, and DC terminal equipment 3. Firstly, the power grid is connected to the LCL filter 1 and then connected to the three-phase VSR 2 through the other end of the LCL filter 1, and then the three-phase VSR 2 is connected to the DC terminal device 3, thus forming a complete power circuit of the PWM converter.

[0034] The active damping control device includes a PLL phase-locked loop module 5 for a , V b , V c Get the phase angle θ.

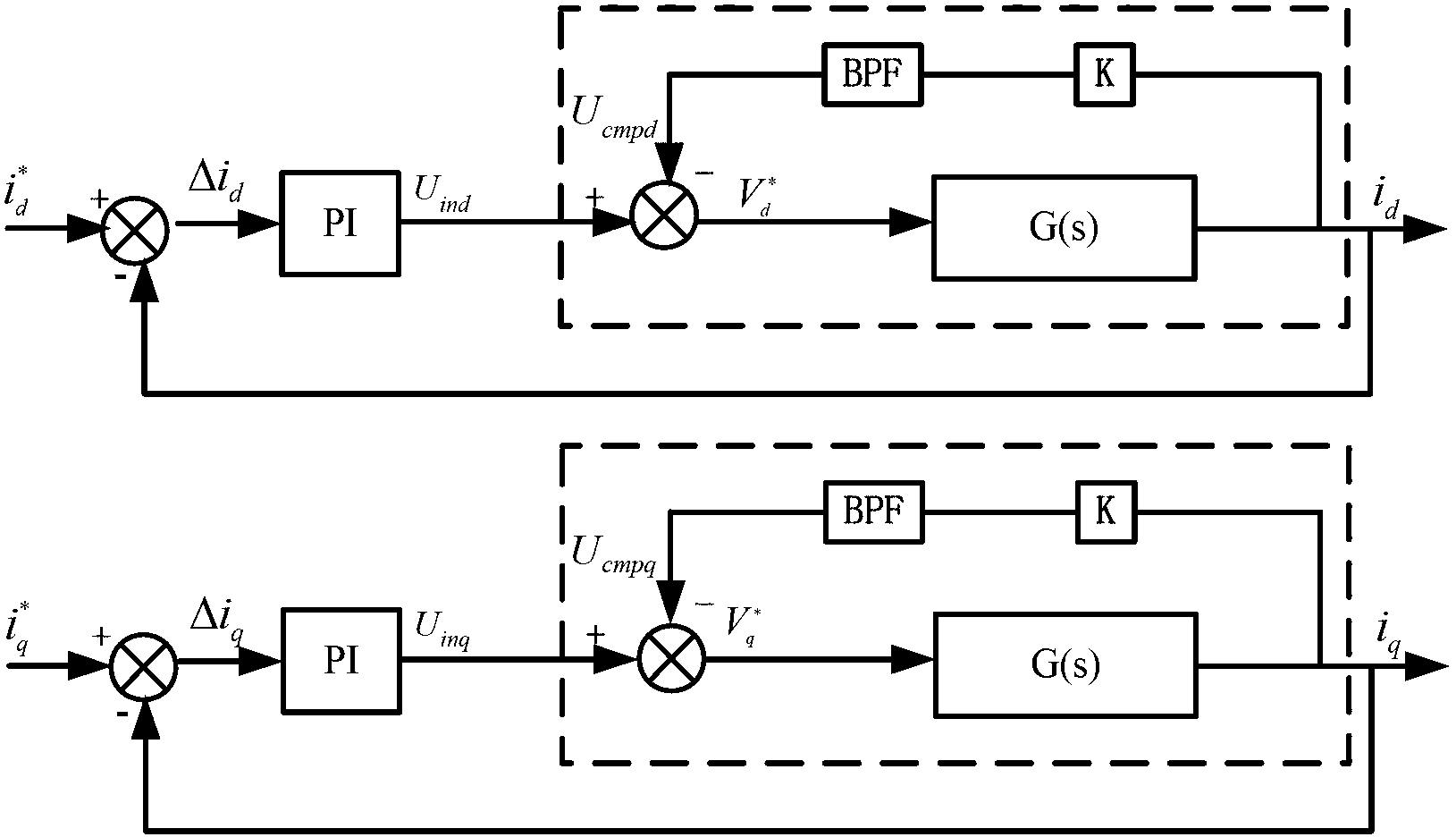

[0035] The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com