Patents

Literature

190 results about "Principal element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

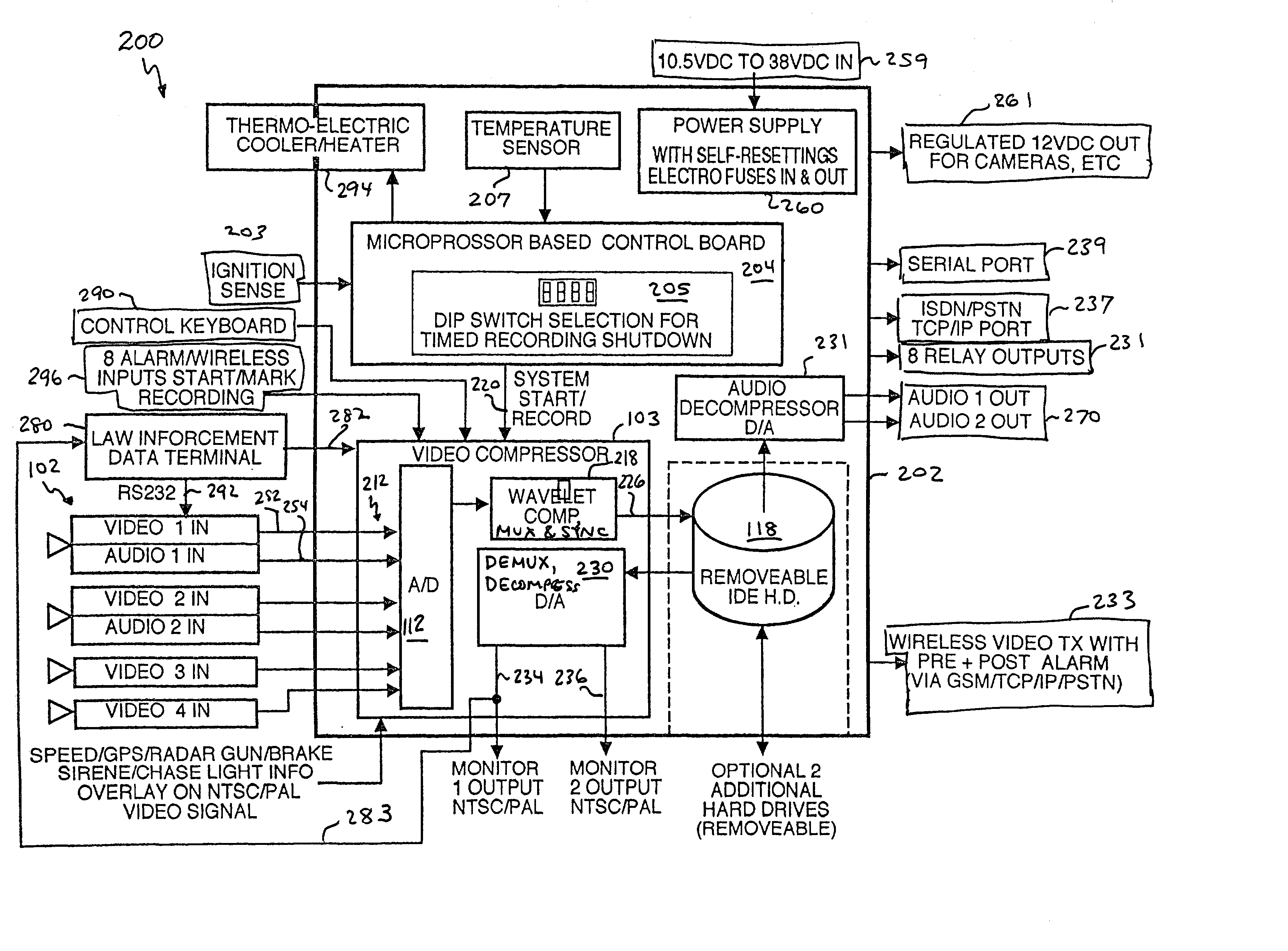

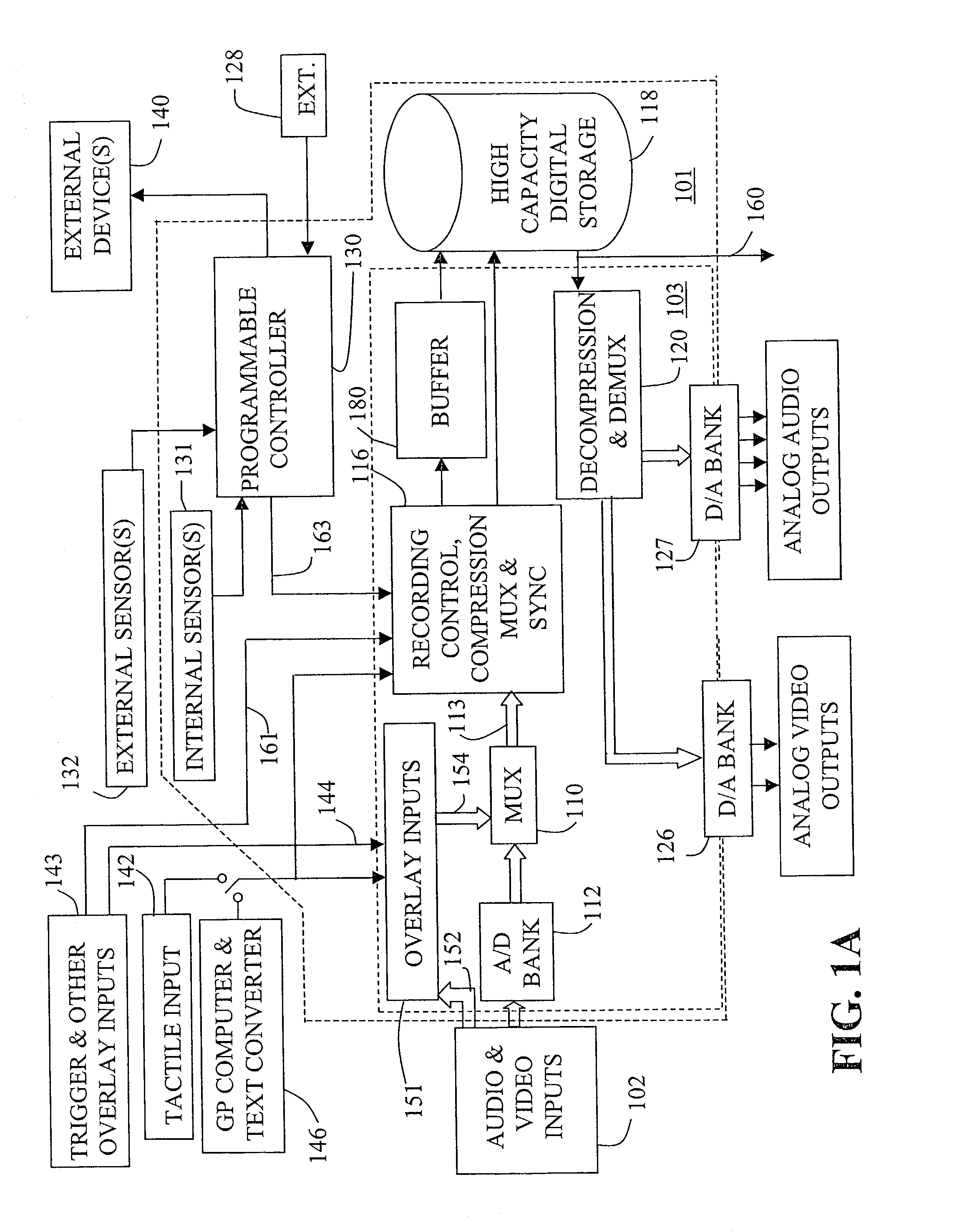

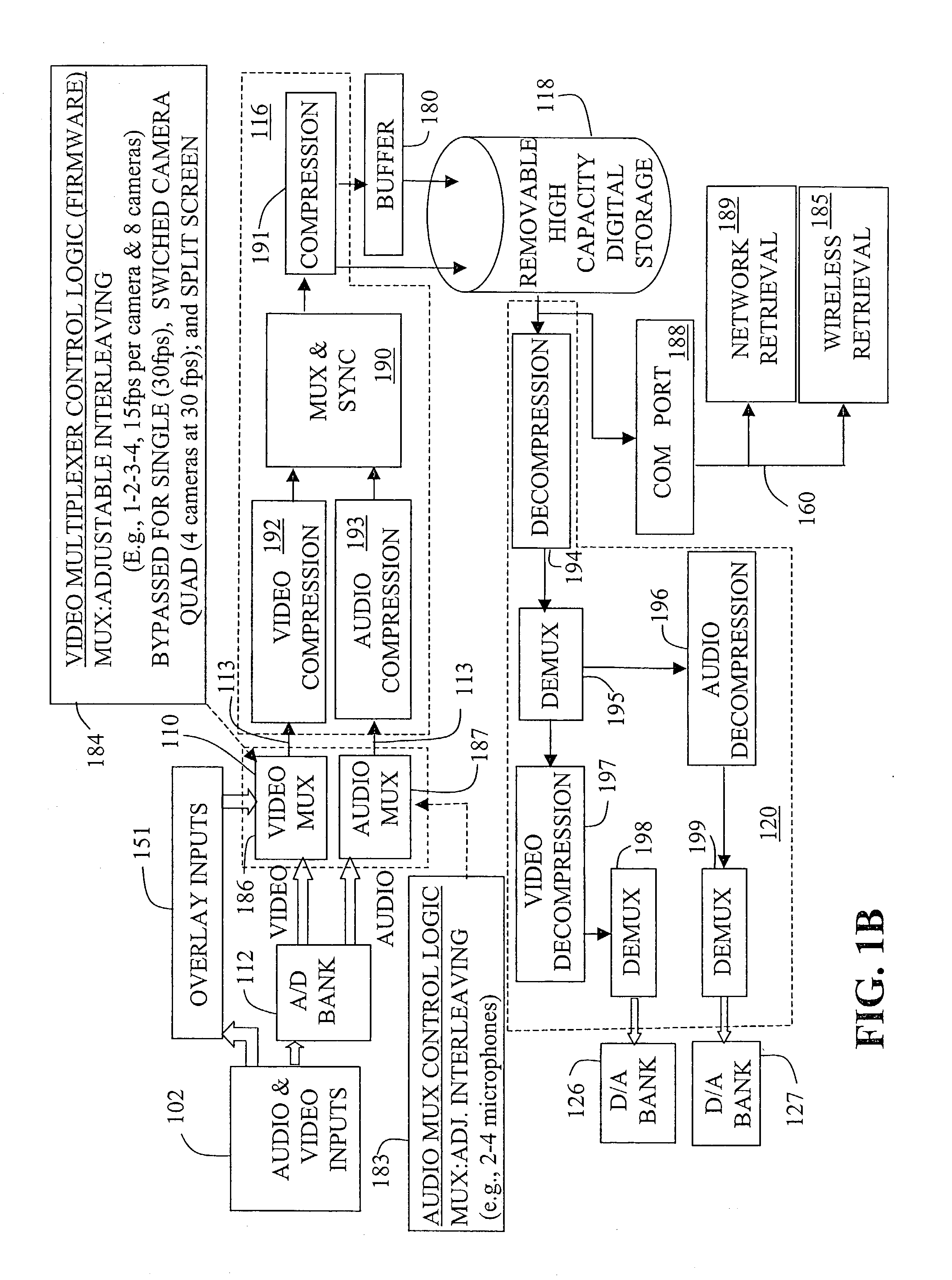

Mobile digital video recording with pre-event recording

InactiveUS20030081127A1Quick analysisSimple processTelevision system detailsDisc-shaped record carriersMobile vehicleDigital video

Provided is a mobile event-recording device that includes distributed elements within, attached to or otherwise mounted to a mobile vehicle, with the principal elements being: a first camera providing a real-time video signal that corresponds to an observed outboard live-motion scene; and a digital video recorder receiving the video signal provided by the camera and recording the video signal in response to a trigger signal (e.g., an activation switch for a light bar or siren, an air bag sensor signal indicating air bag deployment, or depression of an emergency button or a dedicated recording activation switch). The video recorder uses a buffer to receive and store the video signal so as to preserve the video signal during a programmable sliding (or rolling) time interval prior to the triggering event. Thus, in response to provision of the trigger signal, at least a portion of the video signal stored in the buffer is preserved for recording by the video recorder on a hard disk (or other long-term storage medium) and thereafter, the video recorder records directly on the hard disk (or other long-term storage medium).

Owner:HUBB SYST

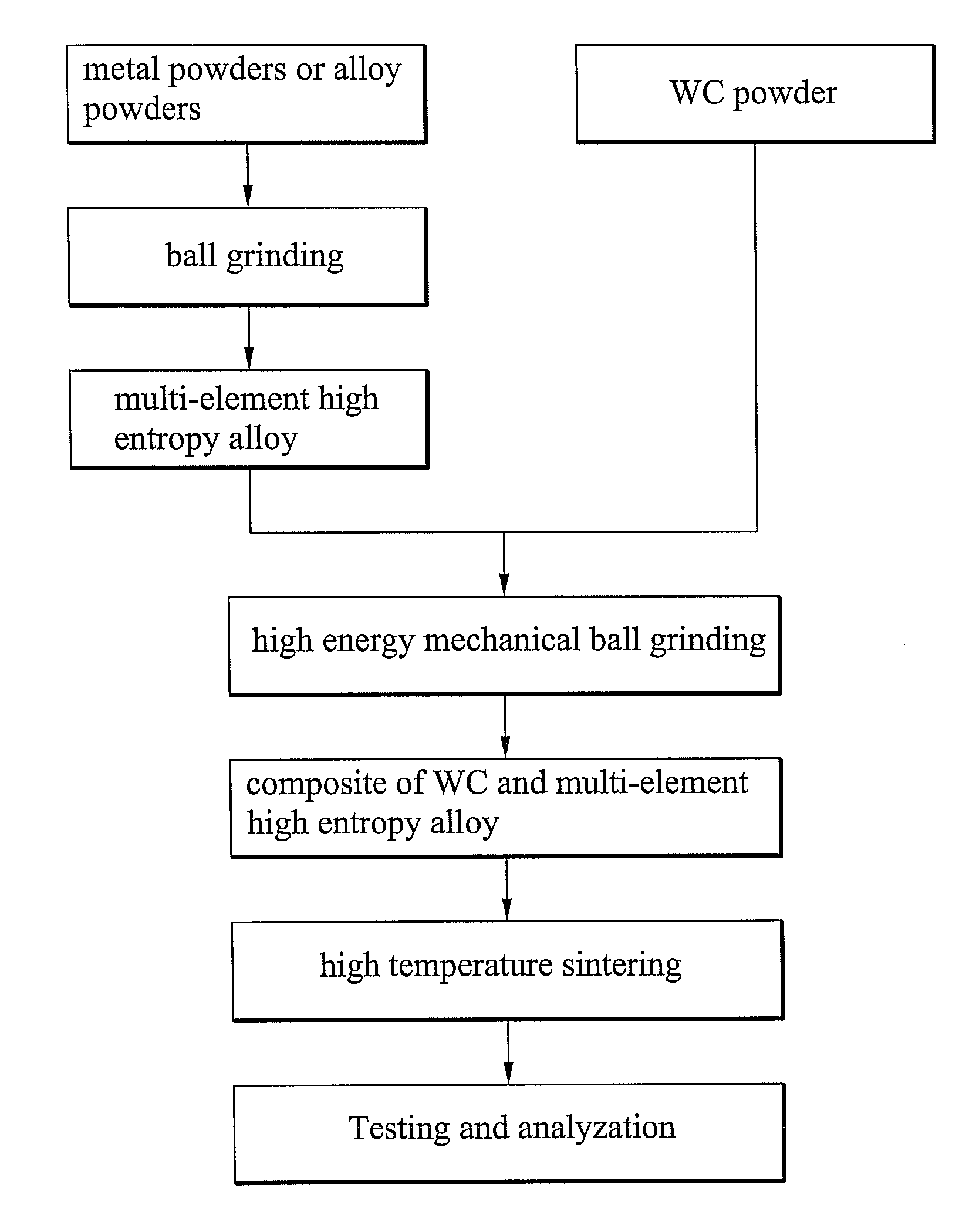

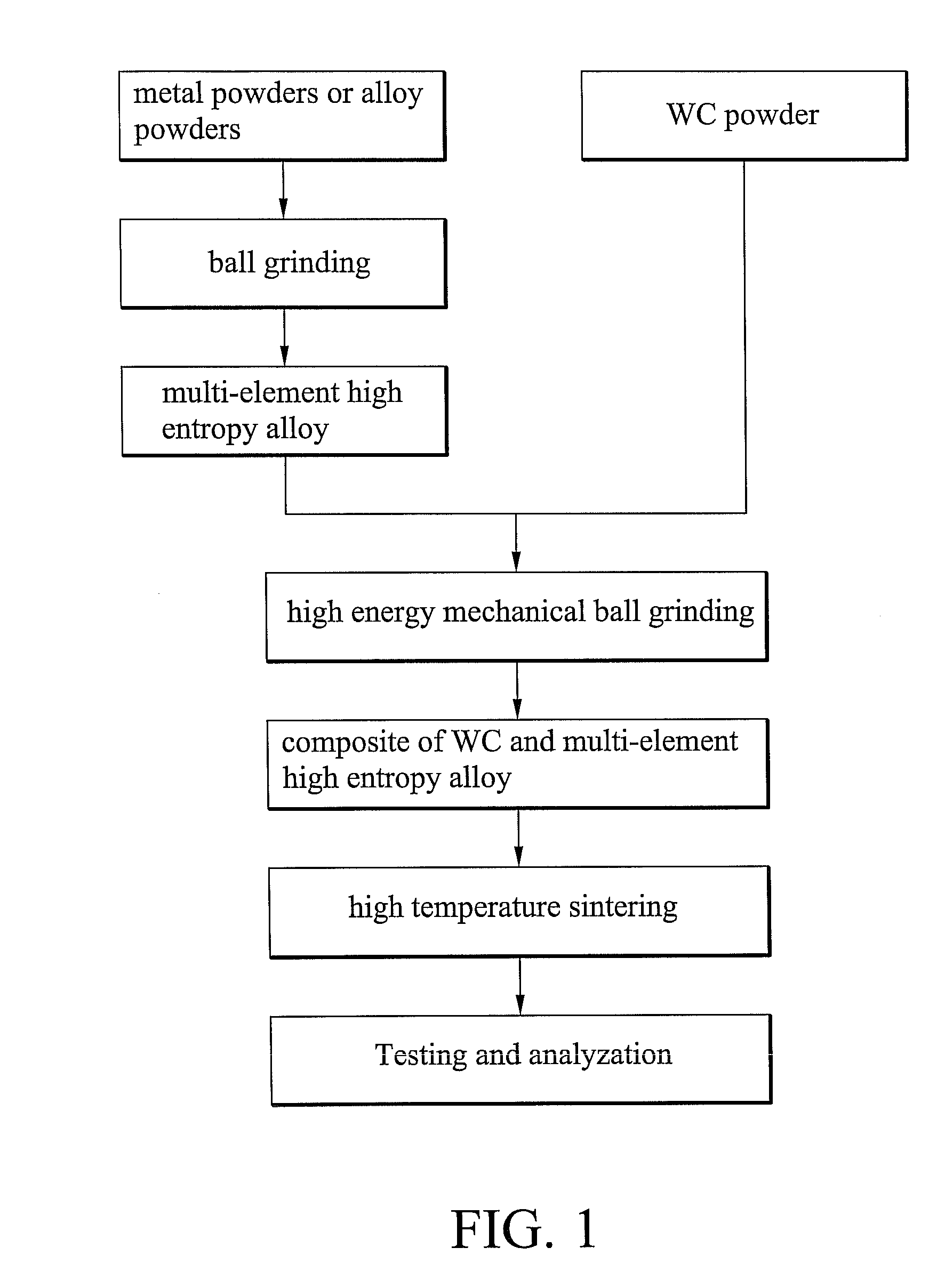

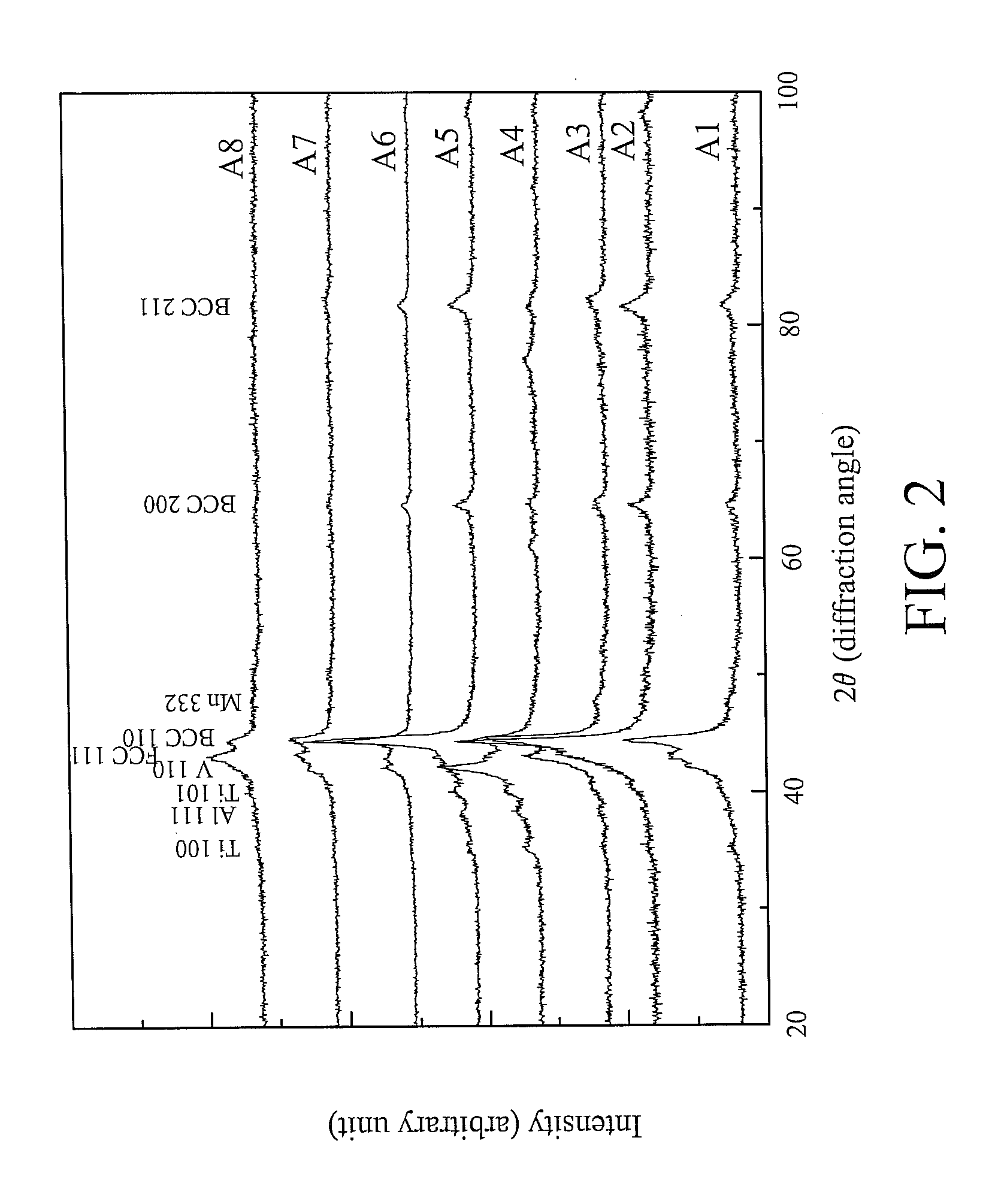

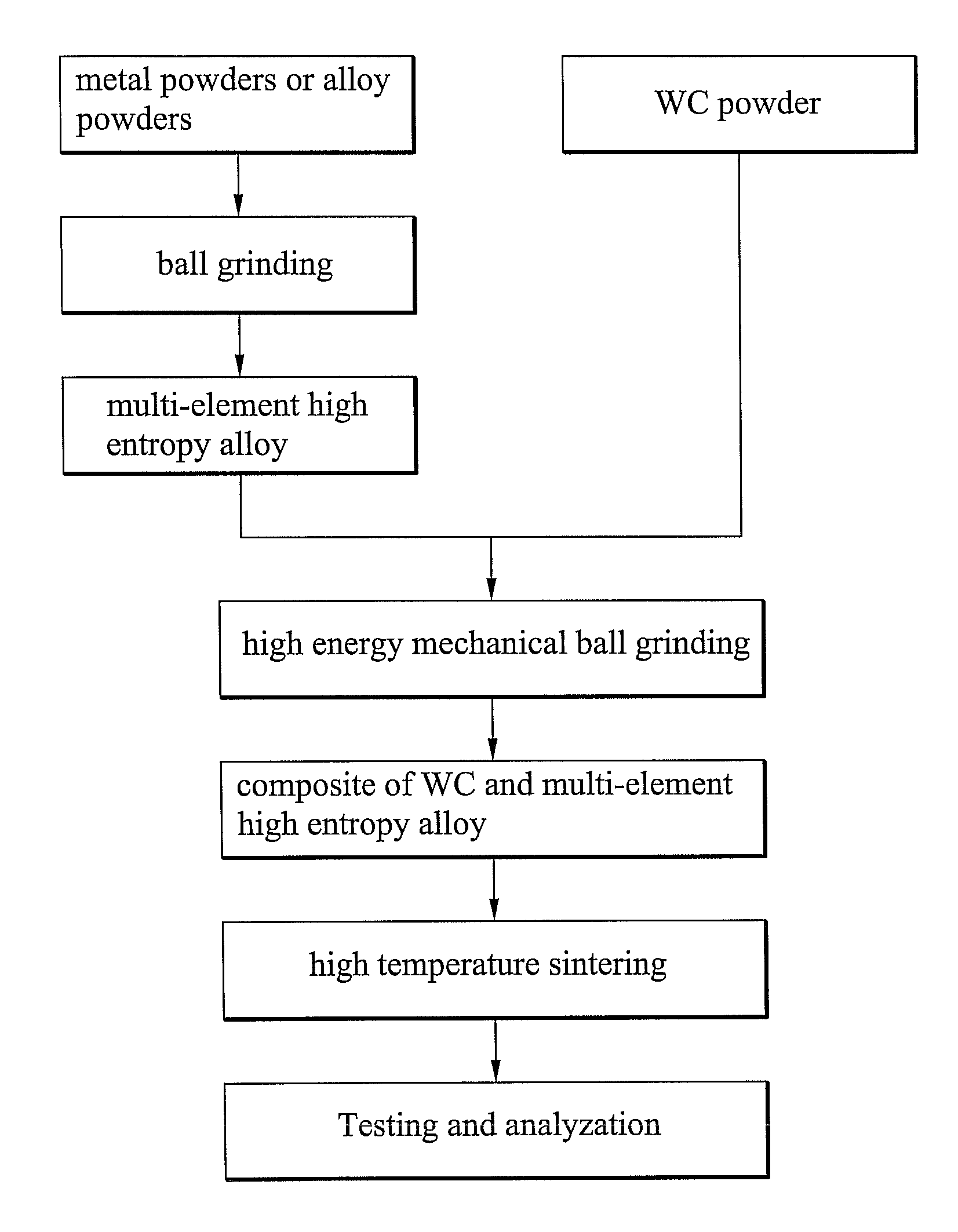

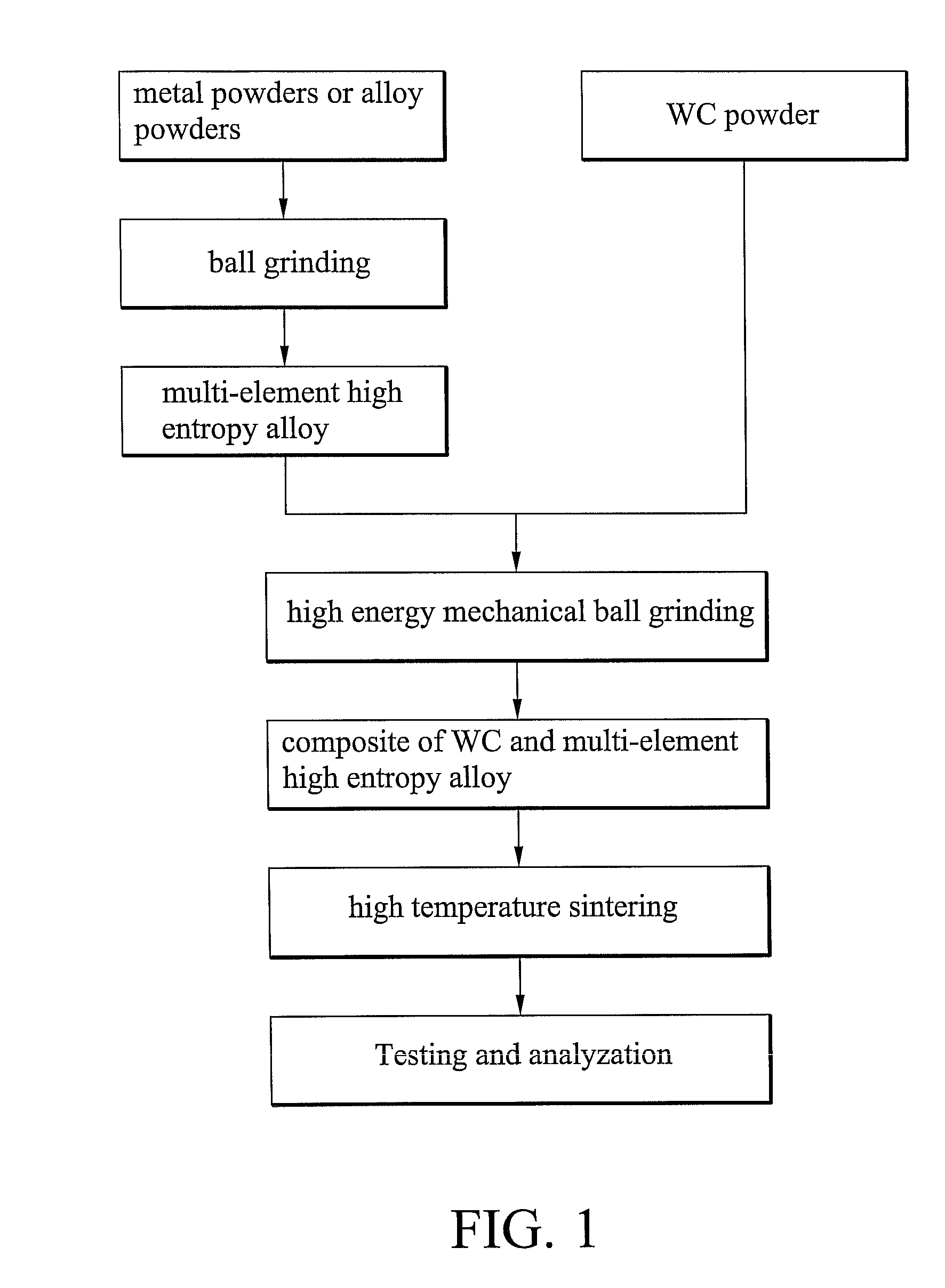

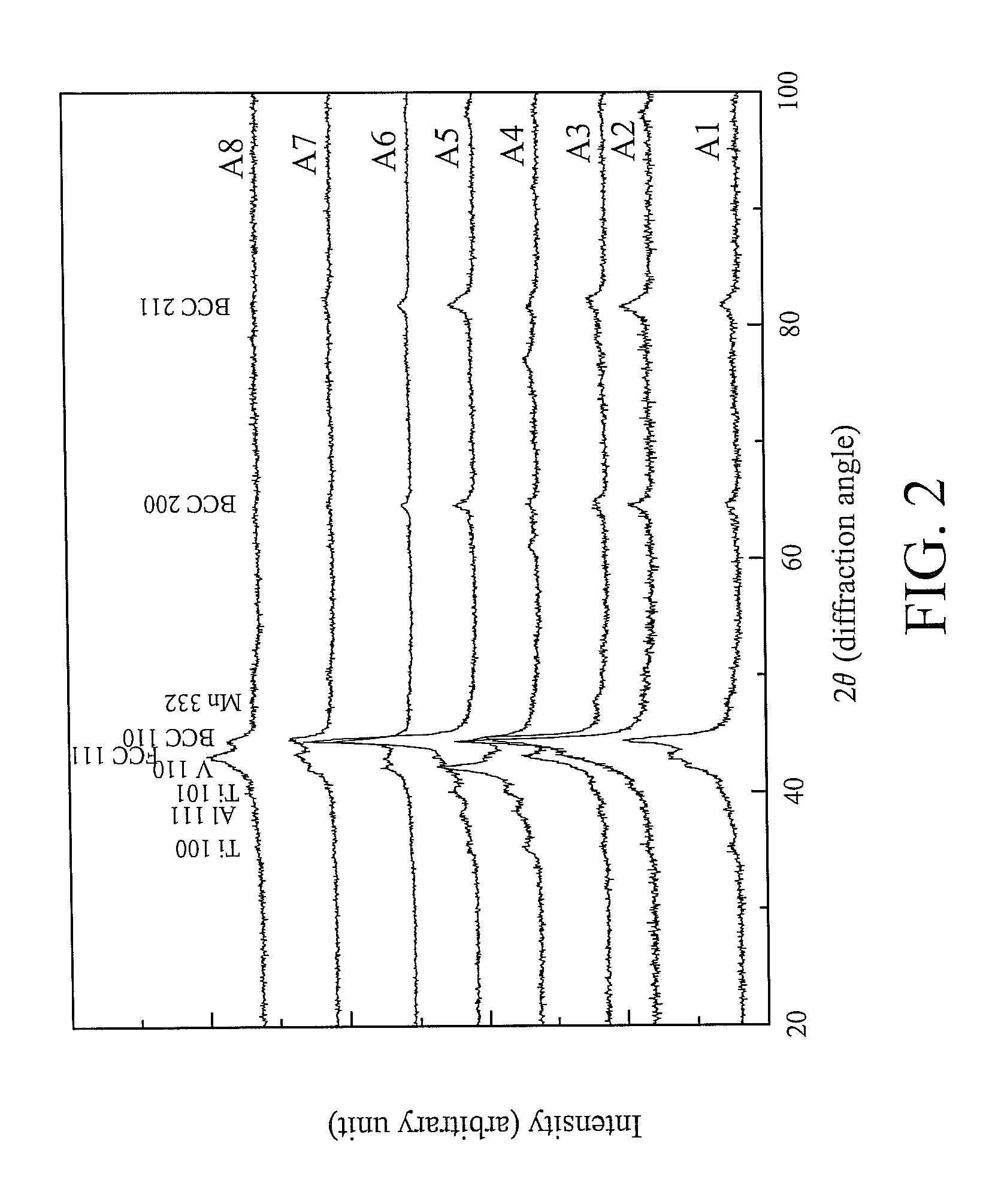

Ultra-hard composite material and method for manufacturing the same

The disclosed is an ultra-hard composite material. The method for manufacturing the ultra-hard composite material includes mixing a metal carbide powder and a multi-element high-entropy alloy powder to form a mixture, green compacting the mixture, and sintering the mixture to form the ultra-hard composite material. The described multi-element high-entropy alloy consists of five to eleven principal elements, with every principal element occupying a 5 to 35 molar percentage of the alloy.

Owner:IND TECH RES INST

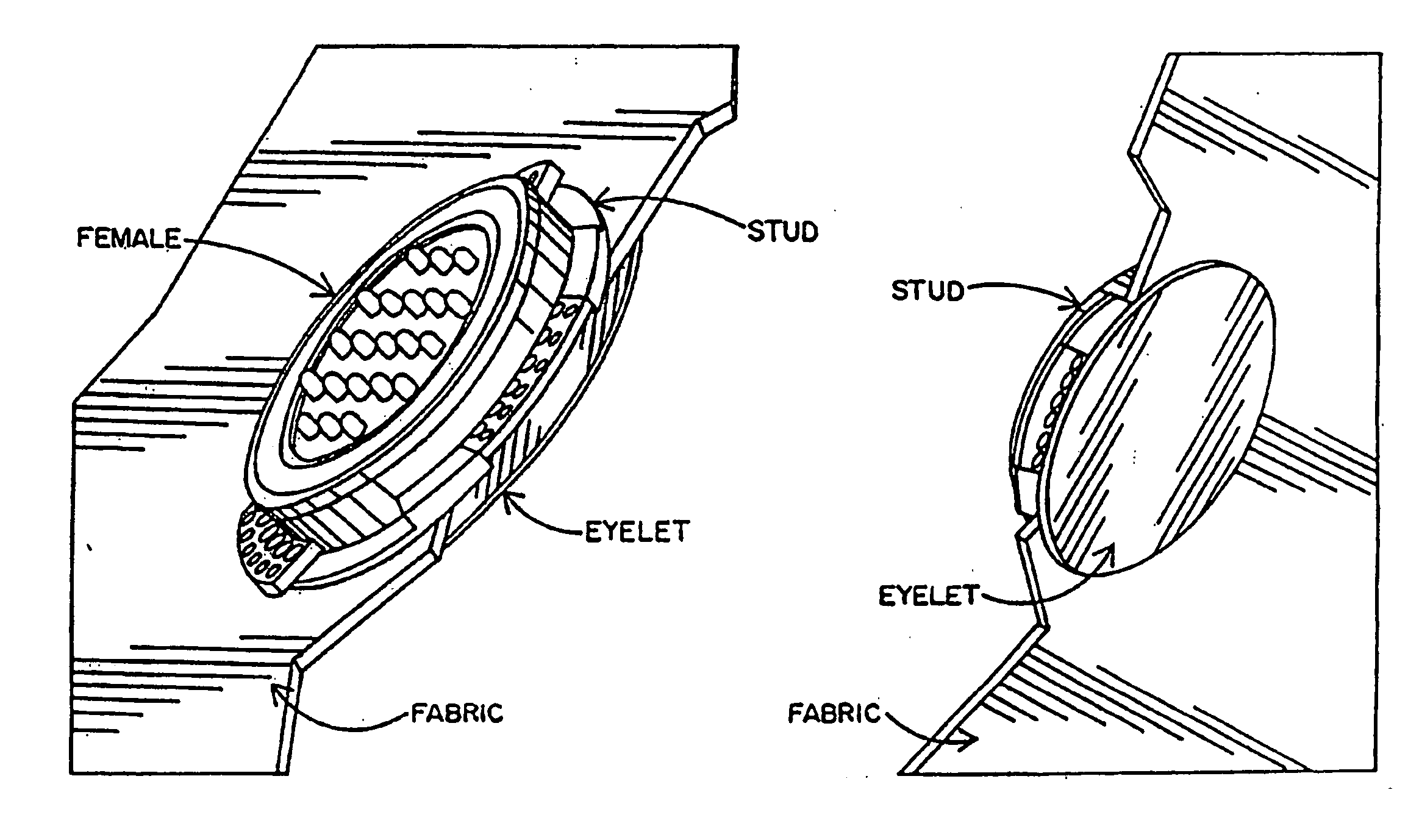

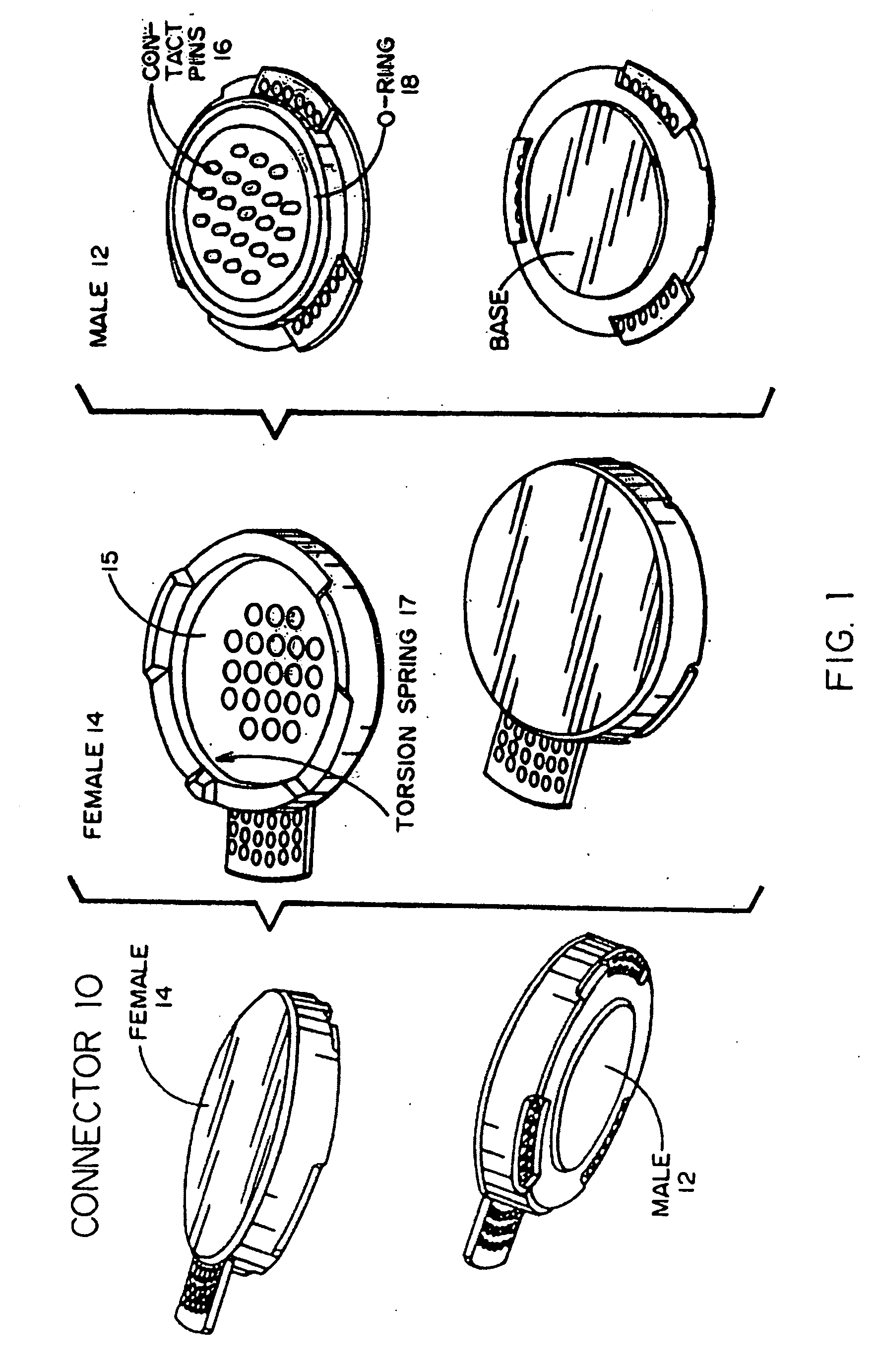

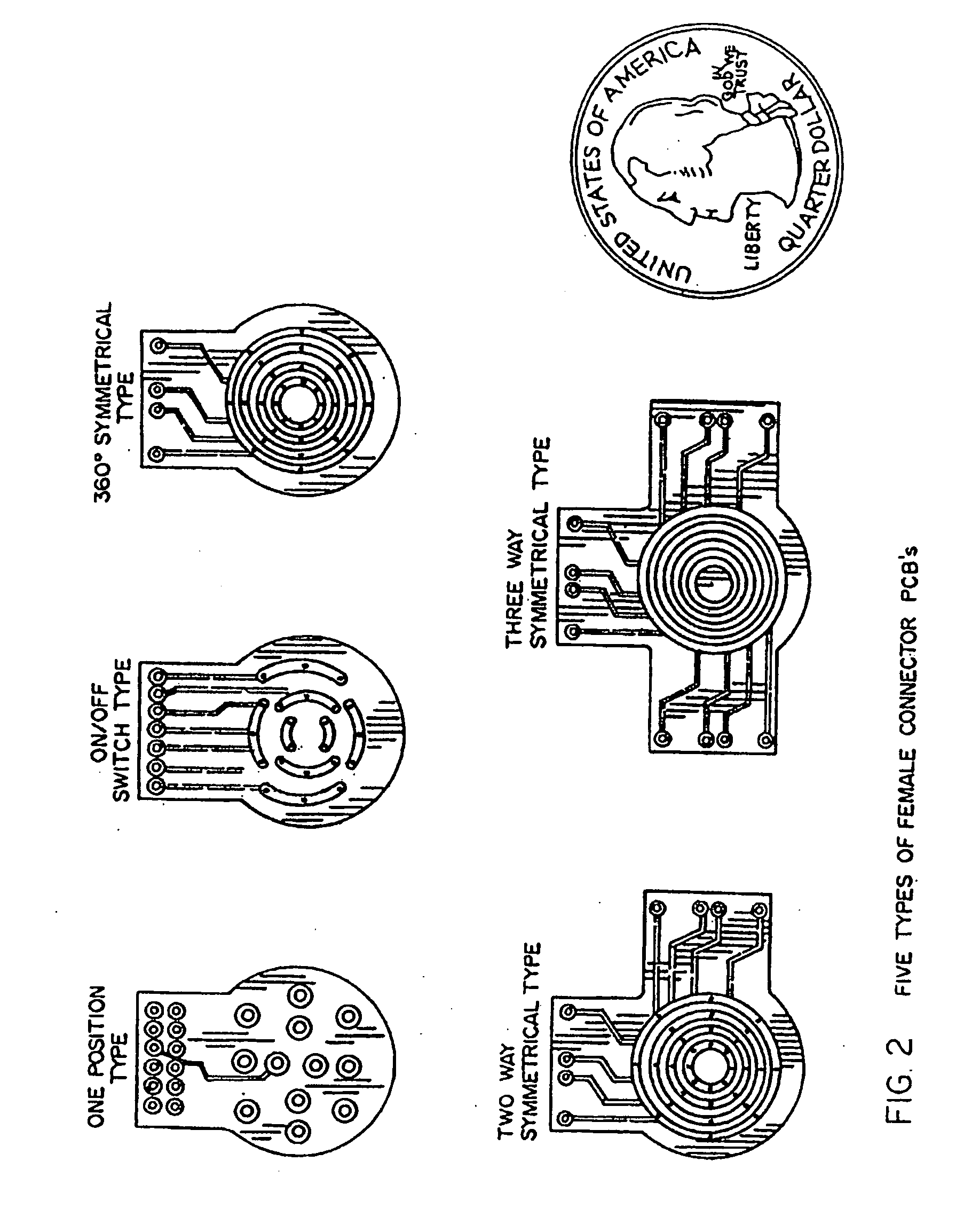

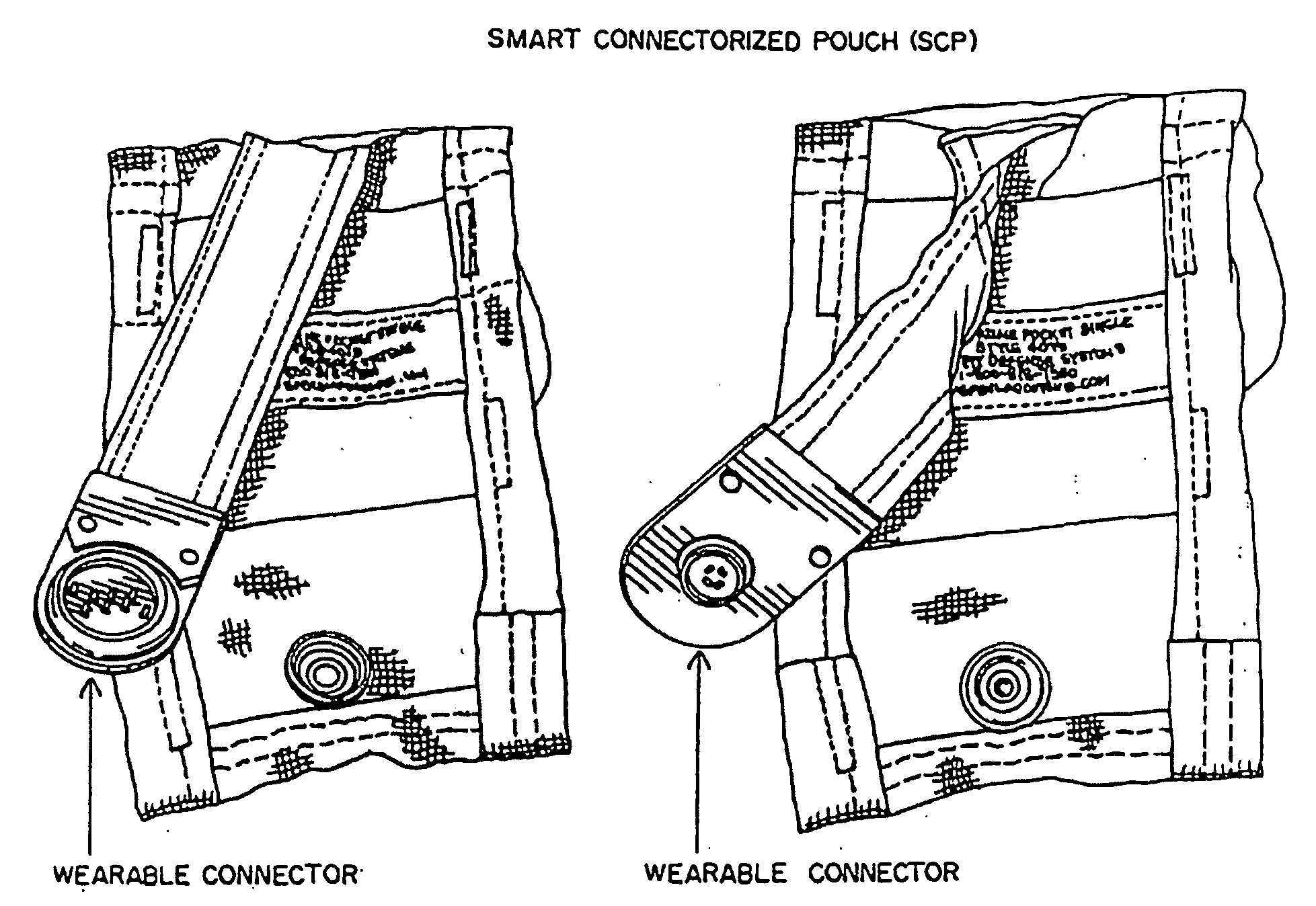

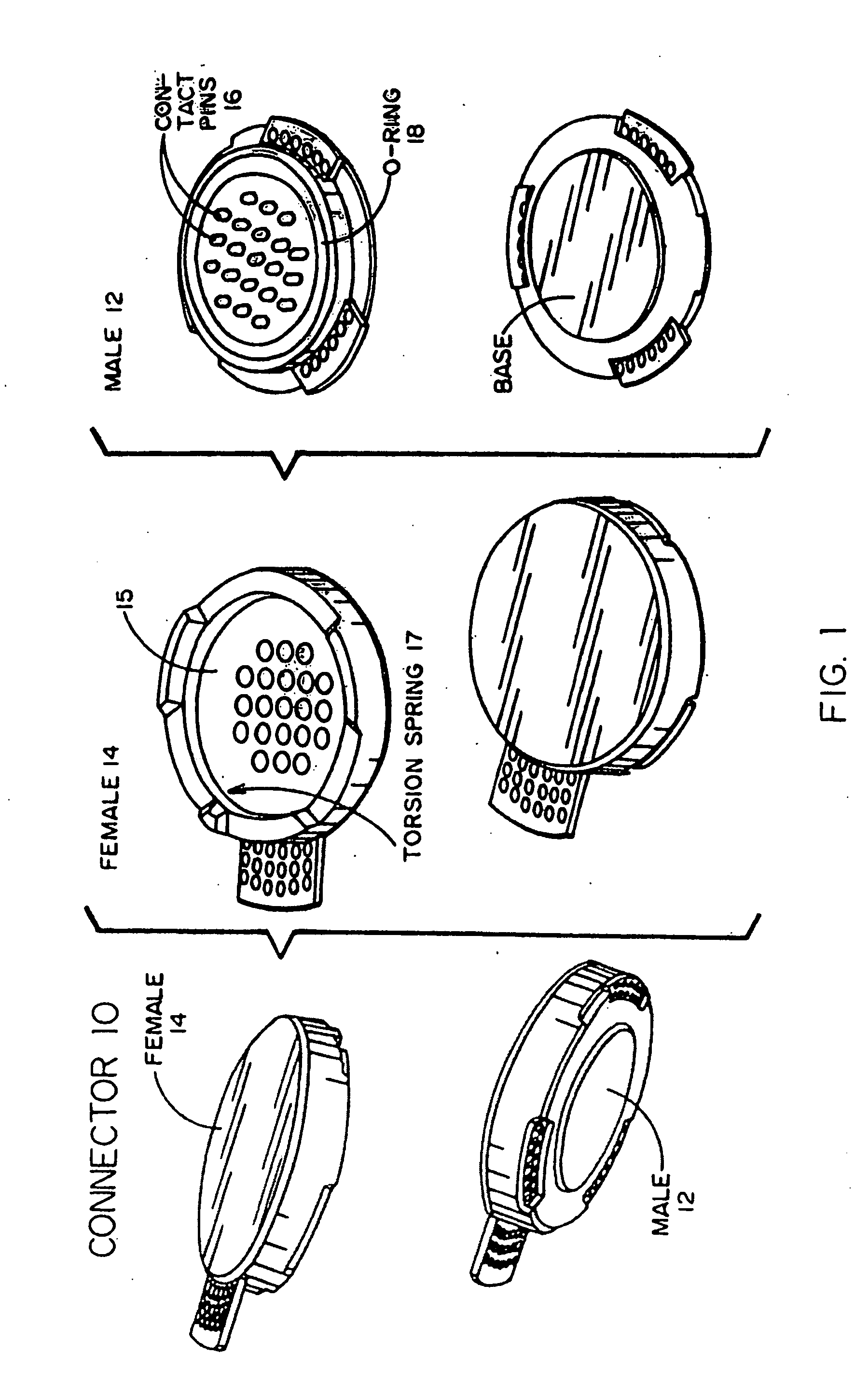

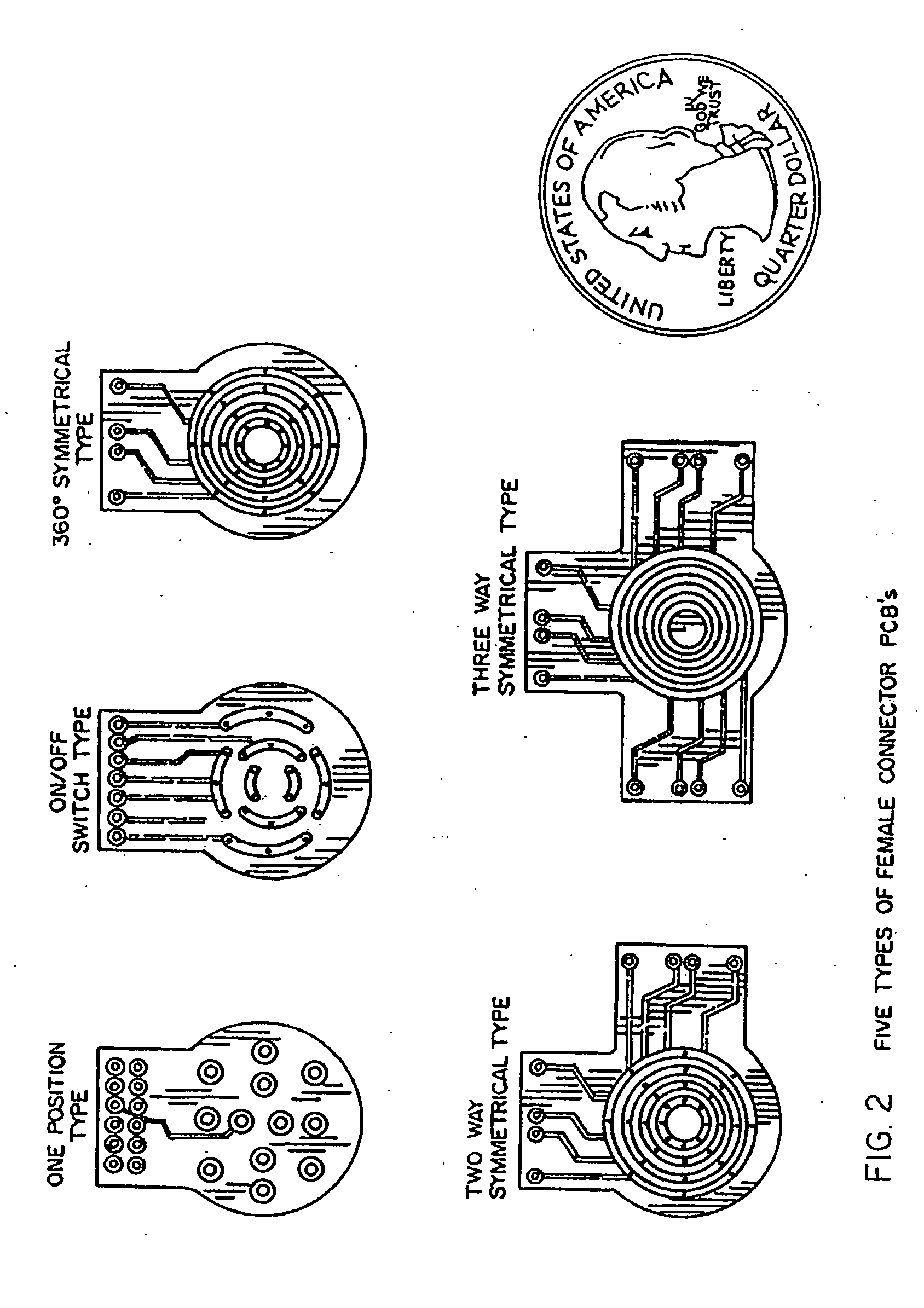

Inherently sealed electrical connector

ActiveUS20090149036A1Easy to operateRotary current collectorNon-rotary current collectorElectricityModularity

An entirely wearable electrical connector for power / data connectivity. The principal element of a modular network is the wearable electrical connector, which is integrated into a personal area network with USB compatibility. An embodiment comprises a non-conductive elastomeric environmental seal.

Owner:INTELLISENSE SYST INC

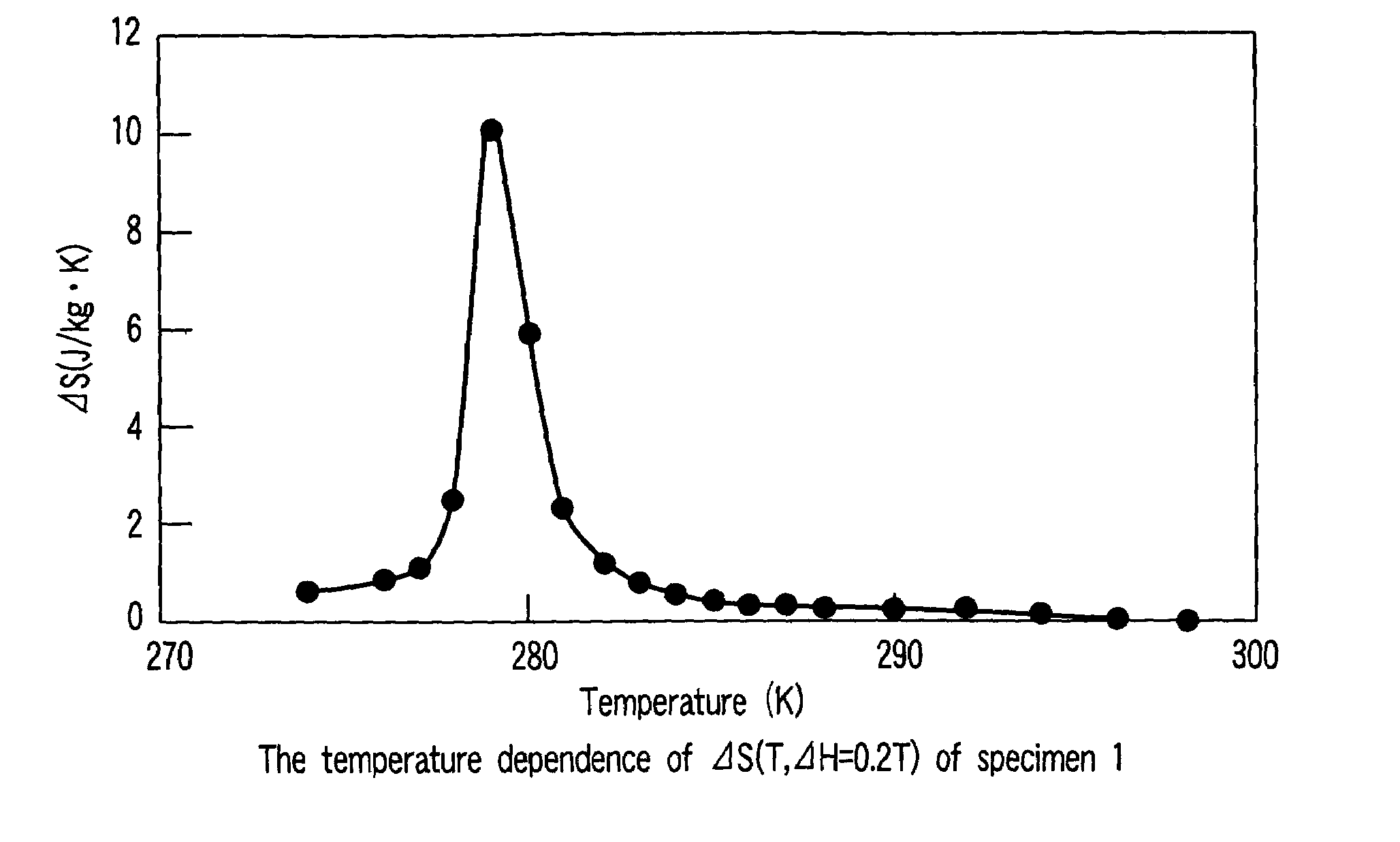

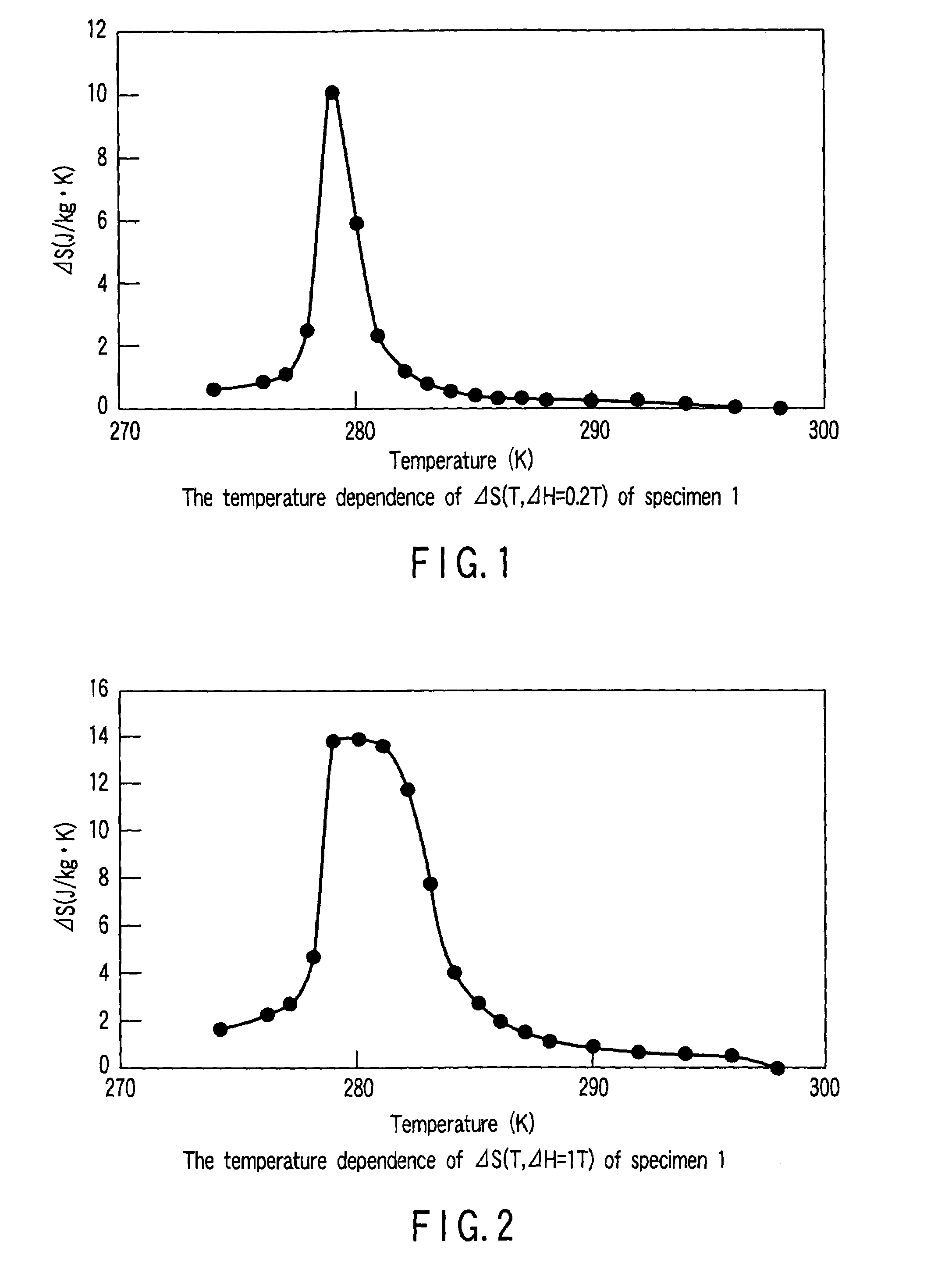

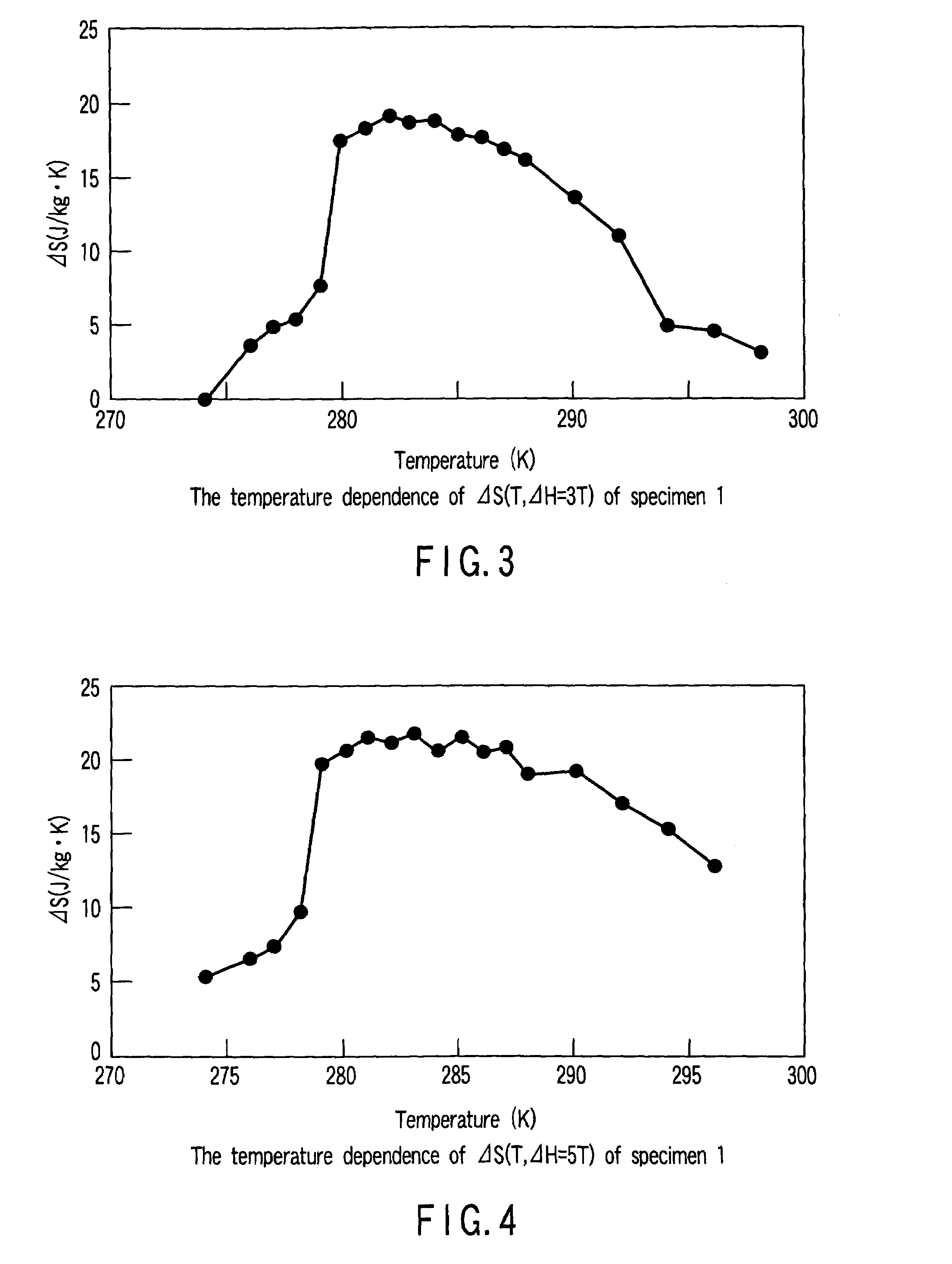

Magnetic material for magnetic refrigeration and method for producing thereof

ActiveUS7063754B2Stable magnetic refrigeration cycleLow costCompression machinesInorganic material magnetismHydrogenRoom temperature

The magnetic material for magnetic refrigeration according to the present invention has an NaZn13-type crystalline structure and comprises iron (Fe) as a principal element (more specifically, Fe is substituted for the position of “Zn”) and hydrogen (H) in an amount of 2 to 18 atomic % based on all constitutional elements. Preferably, the magnetic material for magnetic refrigeration preferably contains 61 to 87 atomic % of Fe, 4 to 18 atomic % of a total amount of Si and Al, 5 to 7 atomic % of La. The magnetic material for magnetic refrigeration exhibits a large entropy change in a room temperature region and no thermal hysteresis in a magnetic phase transition. Therefore, when a magnetic refrigeration cycle is configured using the magnetic material for magnetic refrigeration, a stable operation can be performed.

Owner:KK TOSHIBA

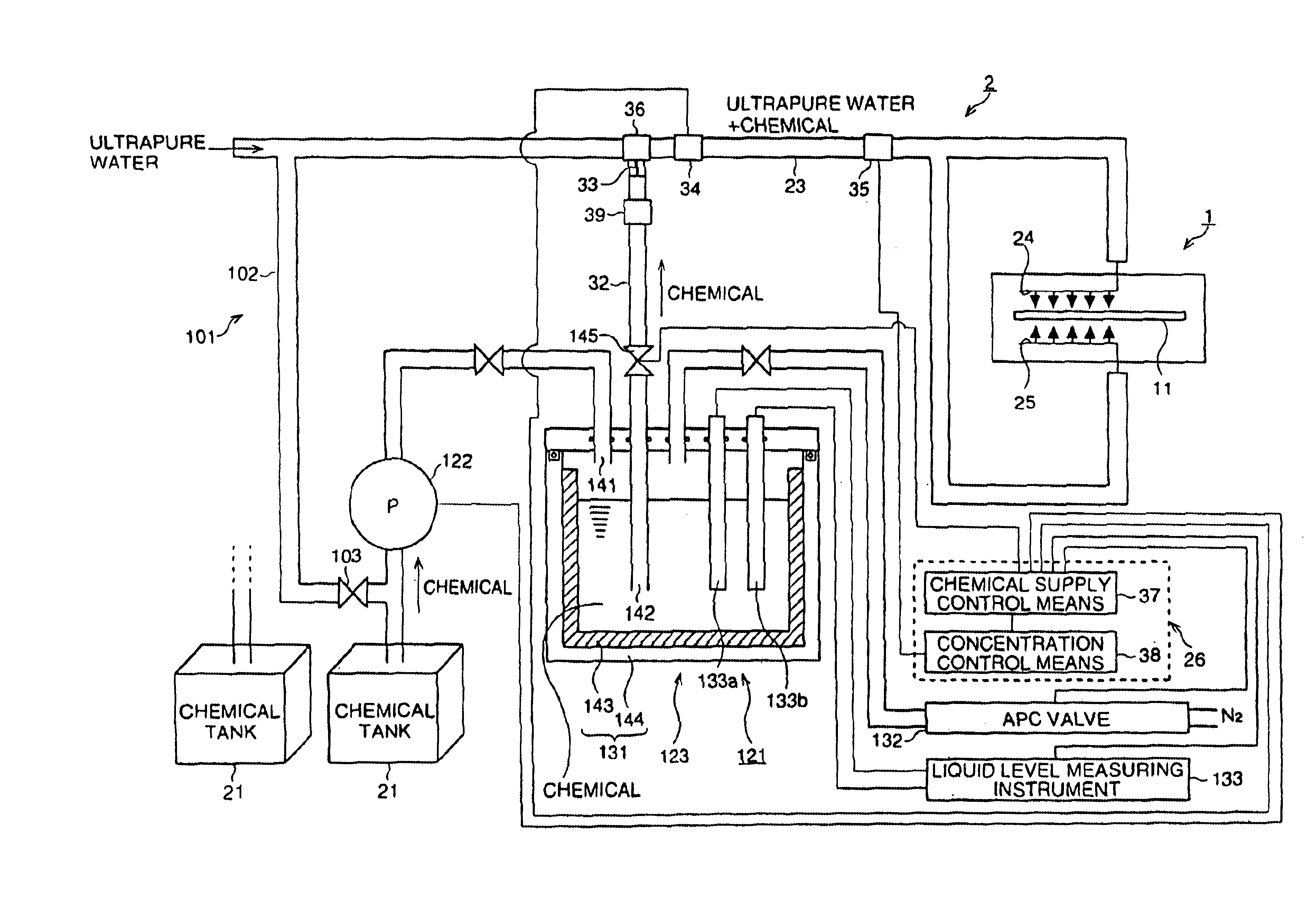

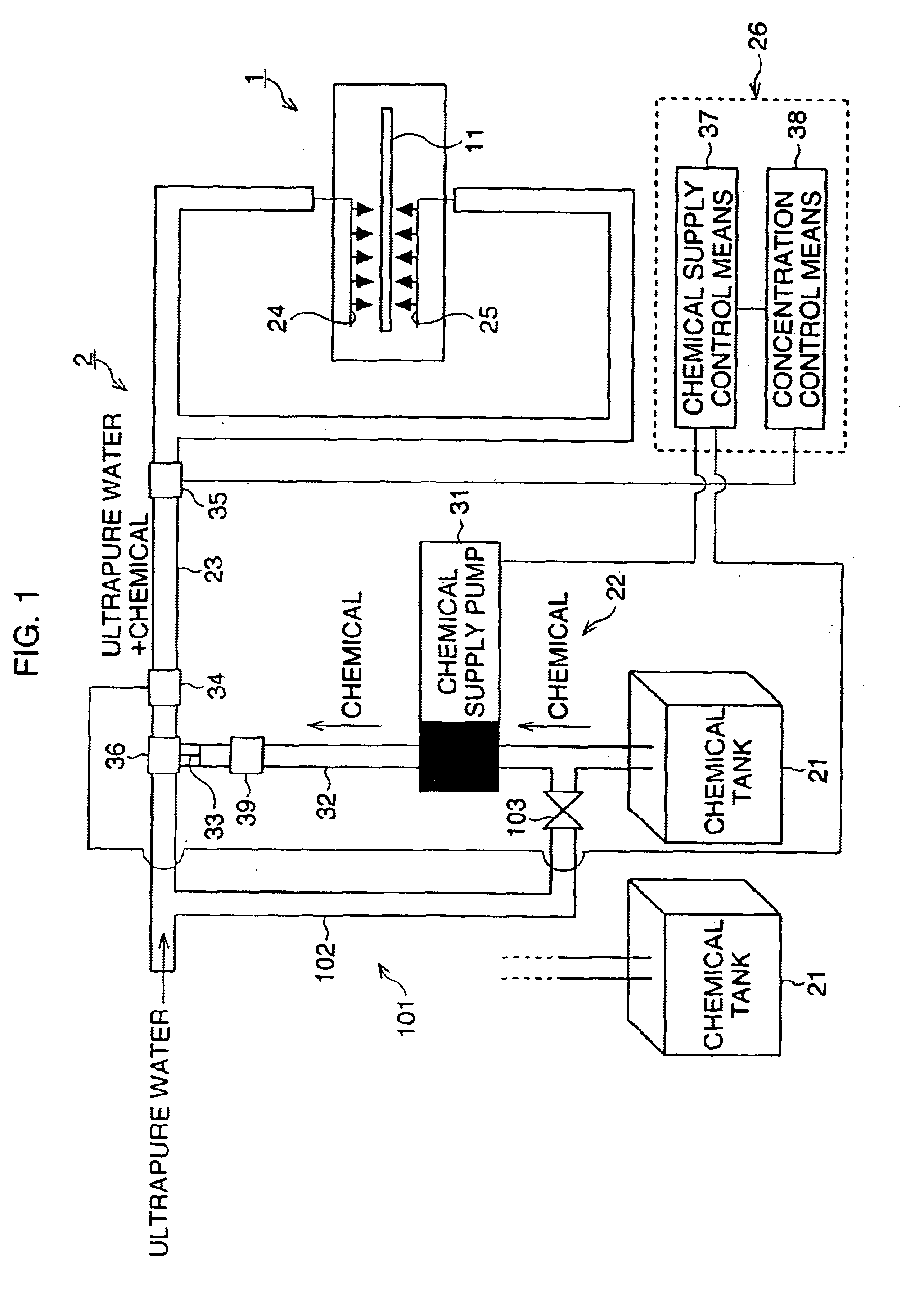

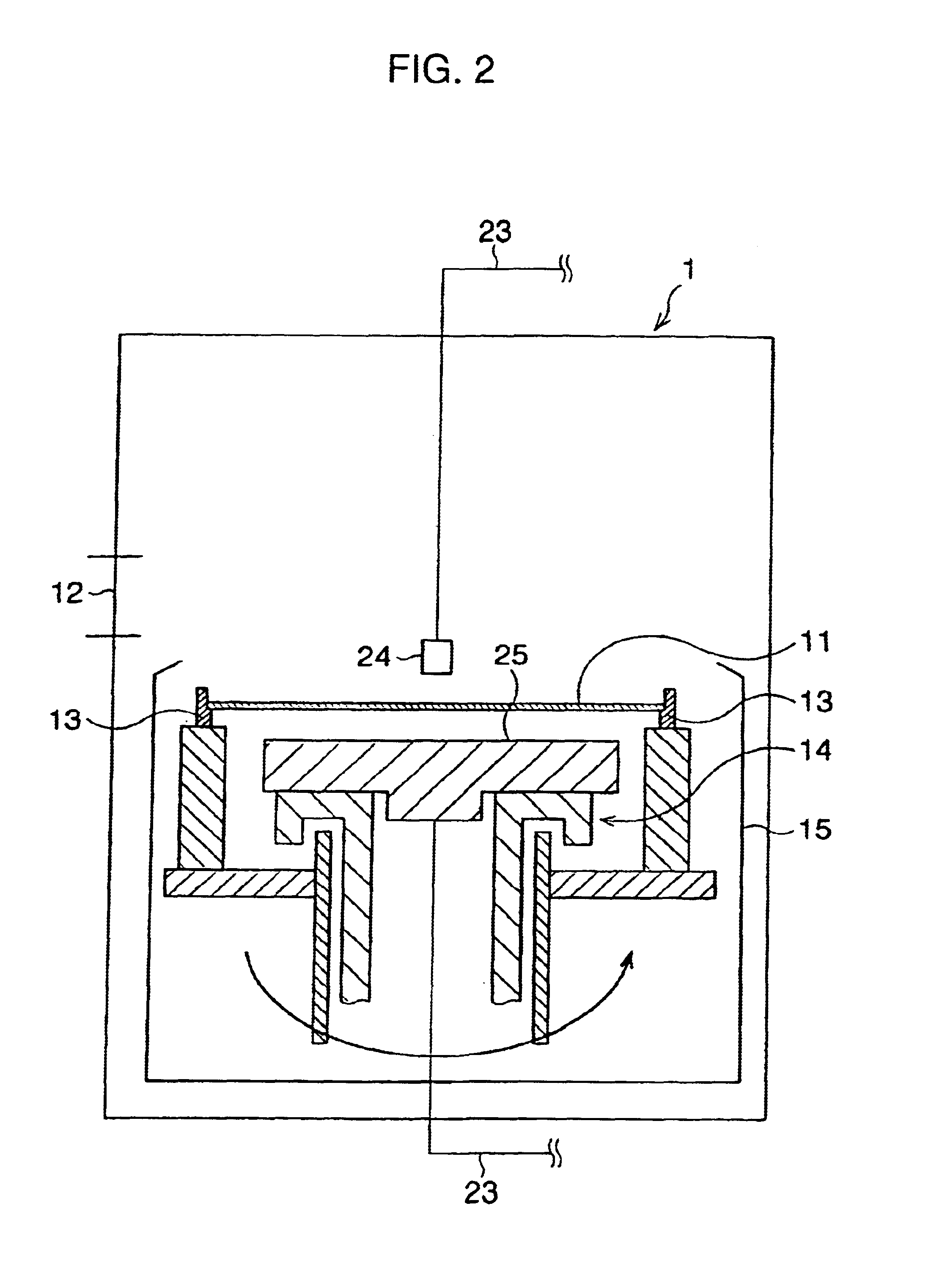

Chemical supply system

InactiveUS6764212B1Improve anti-corrosion performanceEasy to control its porosityDiaphragm valvesShaking/oscillating/vibrating mixersChemical storageMiniaturization

A chemical supply system comprises, as principal elements, a chemical storage tank in which a liquid chemical for cleaning is stored in the state of its formulated concentrate, a chemical supply apparatus connected to the chemical storage tank for positively performing chemical supply, a piping system connected to the chemical supply apparatus to form a supply flow passage that is a passage for ultrapure water which the liquid chemical is to be mixed with, a pair of discharge nozzles disposed at end portions of the piping system so as to oppose surfaces of a wafer set in a cleaning chamber to supply a cleaning liquid onto the surfaces. Thereby, remarkable miniaturization / simplification of a cleaning liquid supply system including chemical tanks is intended, it is made possible easily and rapidly to compound and supply a cleaning liquid at an accurate chemical concentration, and particles or the like being generated and mixing in a cleaning liquid, are suppressed to the extremity.

Owner:ULTRACLEAN TECH RES INST

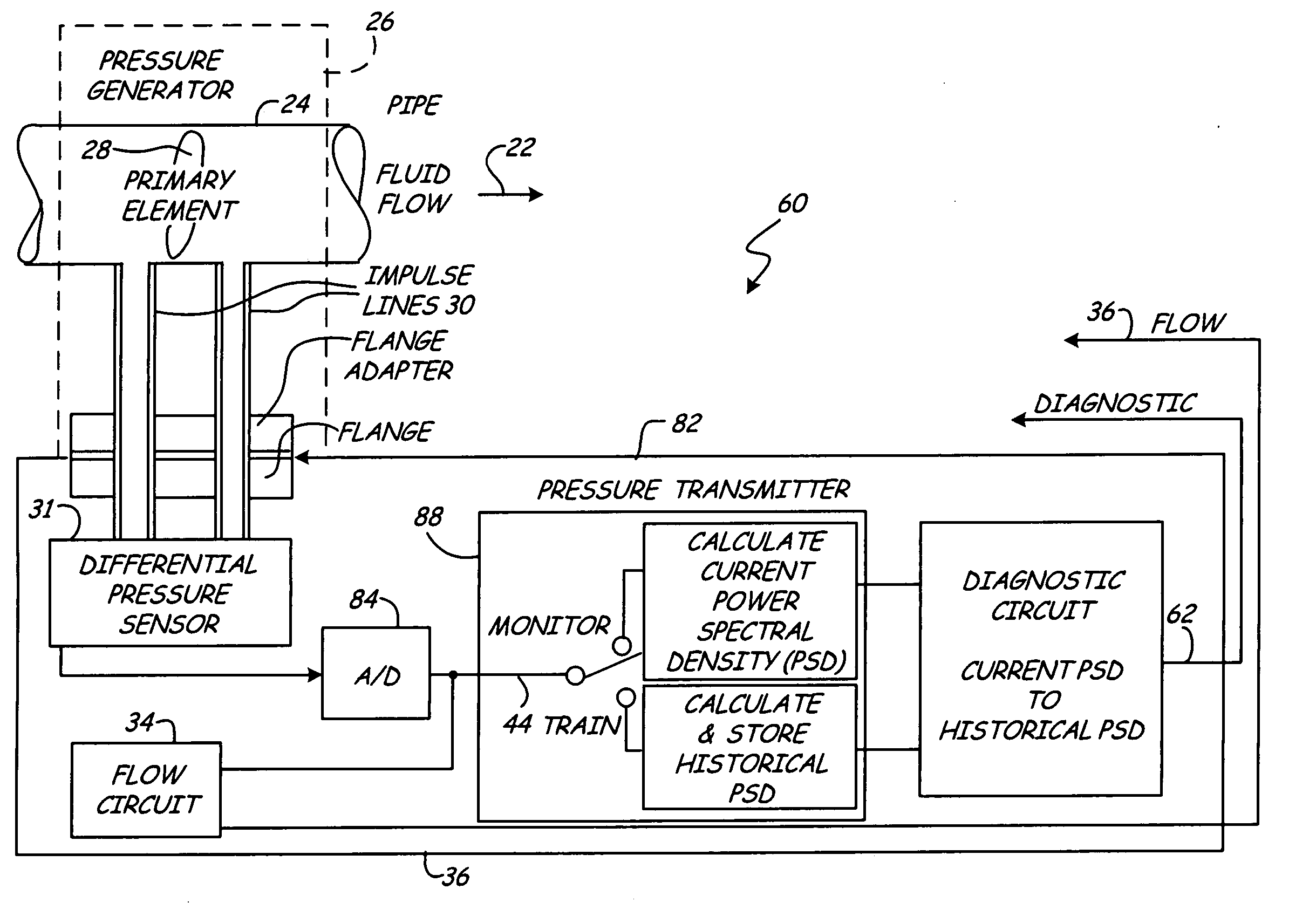

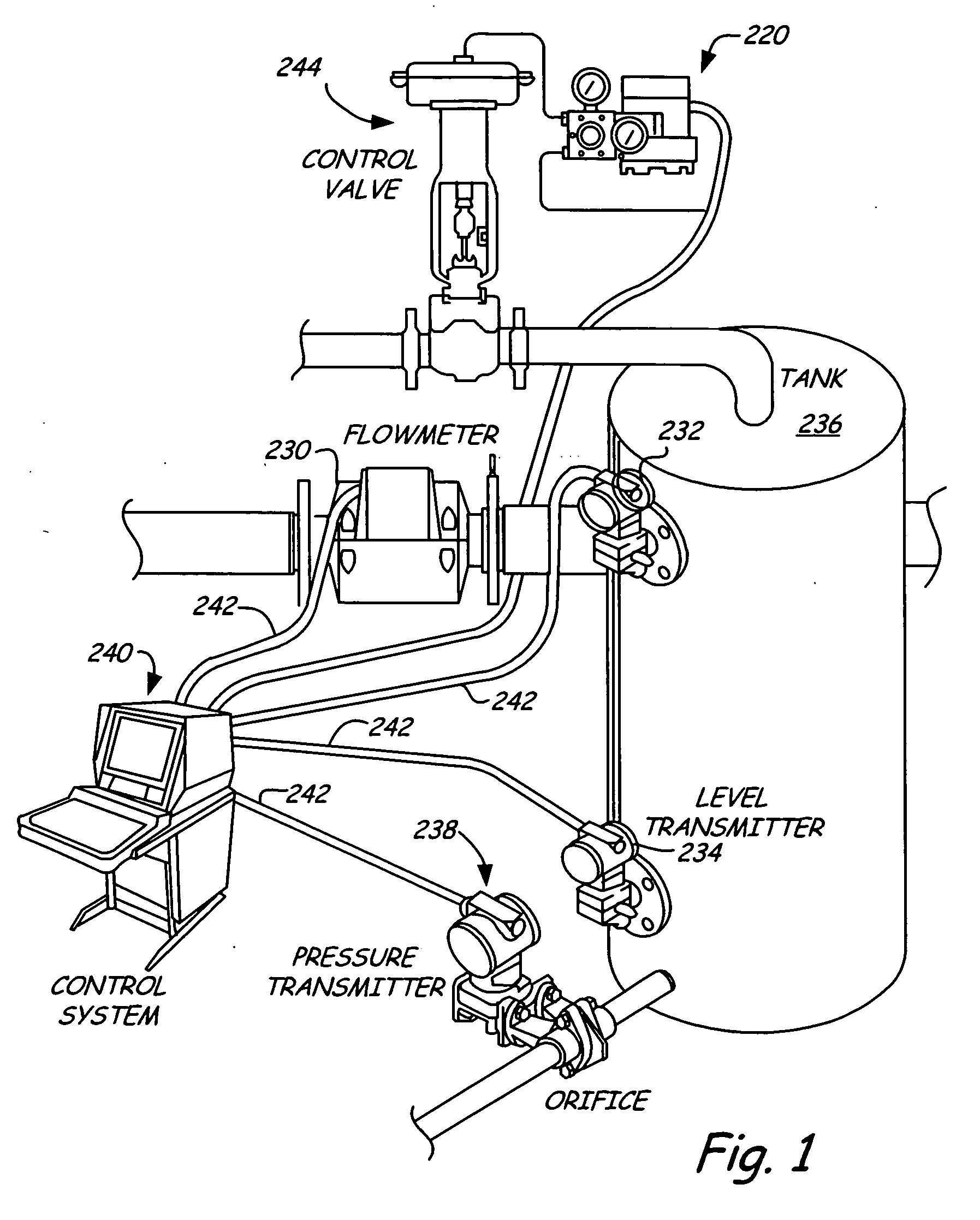

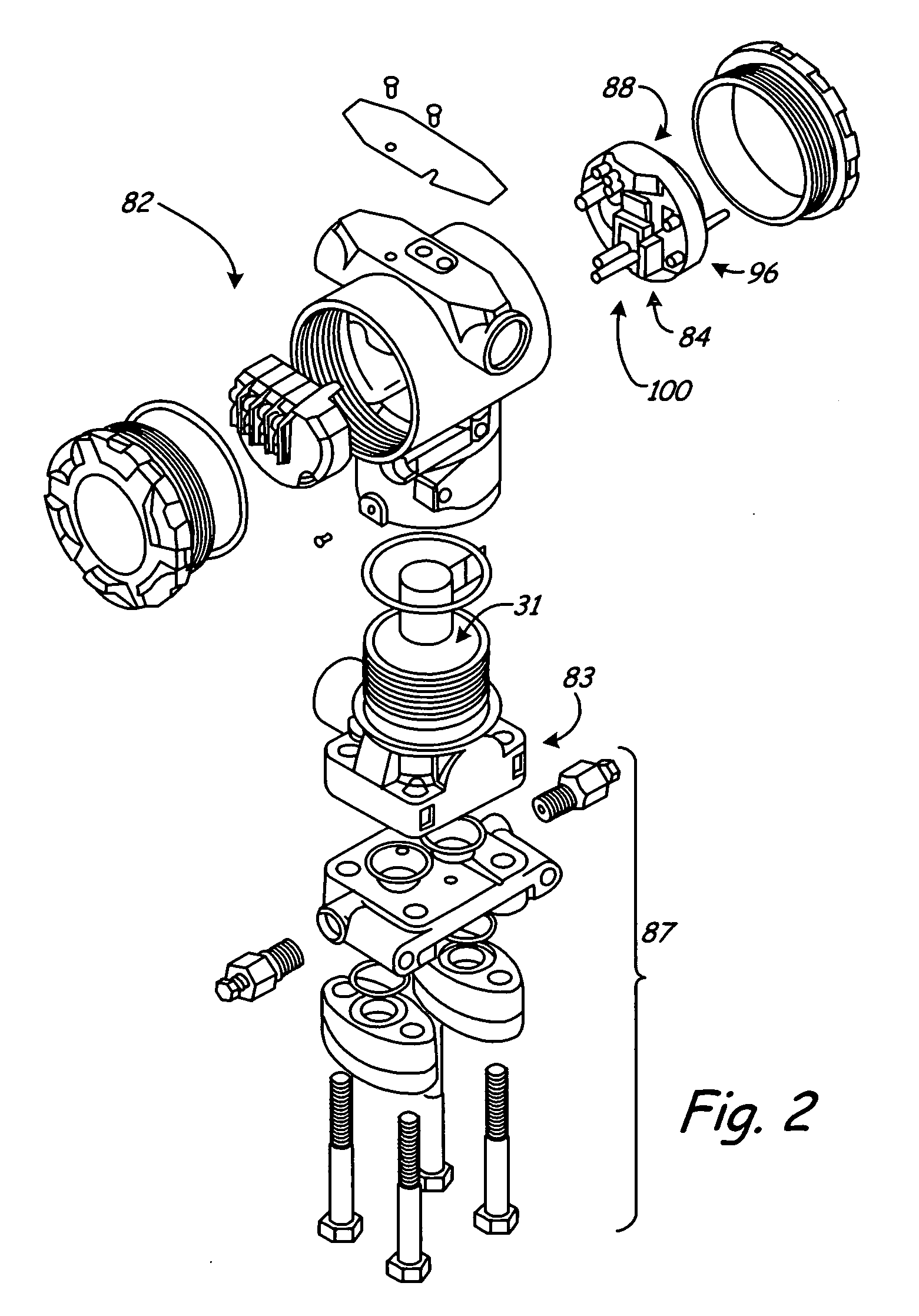

Process variable transmitter with diagnostics

InactiveUS20060036404A1Easy diagnosisSpectral/fourier analysisSampled-variable control systemsDigitizationPrincipal element

A process variable transmitter with diagnostics based on power spectral density (PSD) analysis of a process variable sensor signal is provided. In one embodiment, the process variable transmitter is a pressure transmitter and the diagnostics are used to diagnose impulse line obstruction or impending obstruction. Other diagnostics are also useful such as diagnosing primary element degradation. The sensor signal is digitized and the digitized signal is transferred into the frequency domain. The power of the frequencies on the sensor signal is examined to provide the enhanced diagnostics. In one aspect diagnostics are generated directly with the sensor PSD data. In another aspect, the PSD analysis is used to tune a filter in order to enhance traditional diagnostic algorithms.

Owner:ROSEMOUNT INC

Aluminum alloy material and heat treatment technique thereof

ActiveCN103131904AOptimize heat treatment processIntense organic combinationUltimate tensile strengthToughness

The invention discloses an aluminum alloy material and a heat treatment technique thereof. The aluminum alloy material comprises the following components in percentage by mass: 0.8-1.3% of Si, 0.3-0.7% of Cu, 0.20-0.60% of Mn, 0.8-1.4% of Mg, 0.05-0.25% of Cr, 0.05-0.2% of Zr, at most 0.5% of Fe, at most 0.2% of Zn, at most 0.1% of Ti, and the balance of Al and impurities. According to the aluminum alloy material aluminum alloy and the heat treatment technique thereof, on the basis of the traditional 6xxx alloy, microelements are added to optimize the content of principal elements; meanwhile, the heat treatment technique is optimized to further enhance the strength and toughness of the aluminum alloy material, thereby implementing organic combination of strength, toughness and corrosion resistance; and the aluminum alloy material can be used instead of 2xxx and 7xxx aluminum alloys in some fields. Thus, the product has favorable application prospects in the fields of aerospace, civil automobiles and the like.

Owner:佛山市三水凤铝铝业有限公司 +1

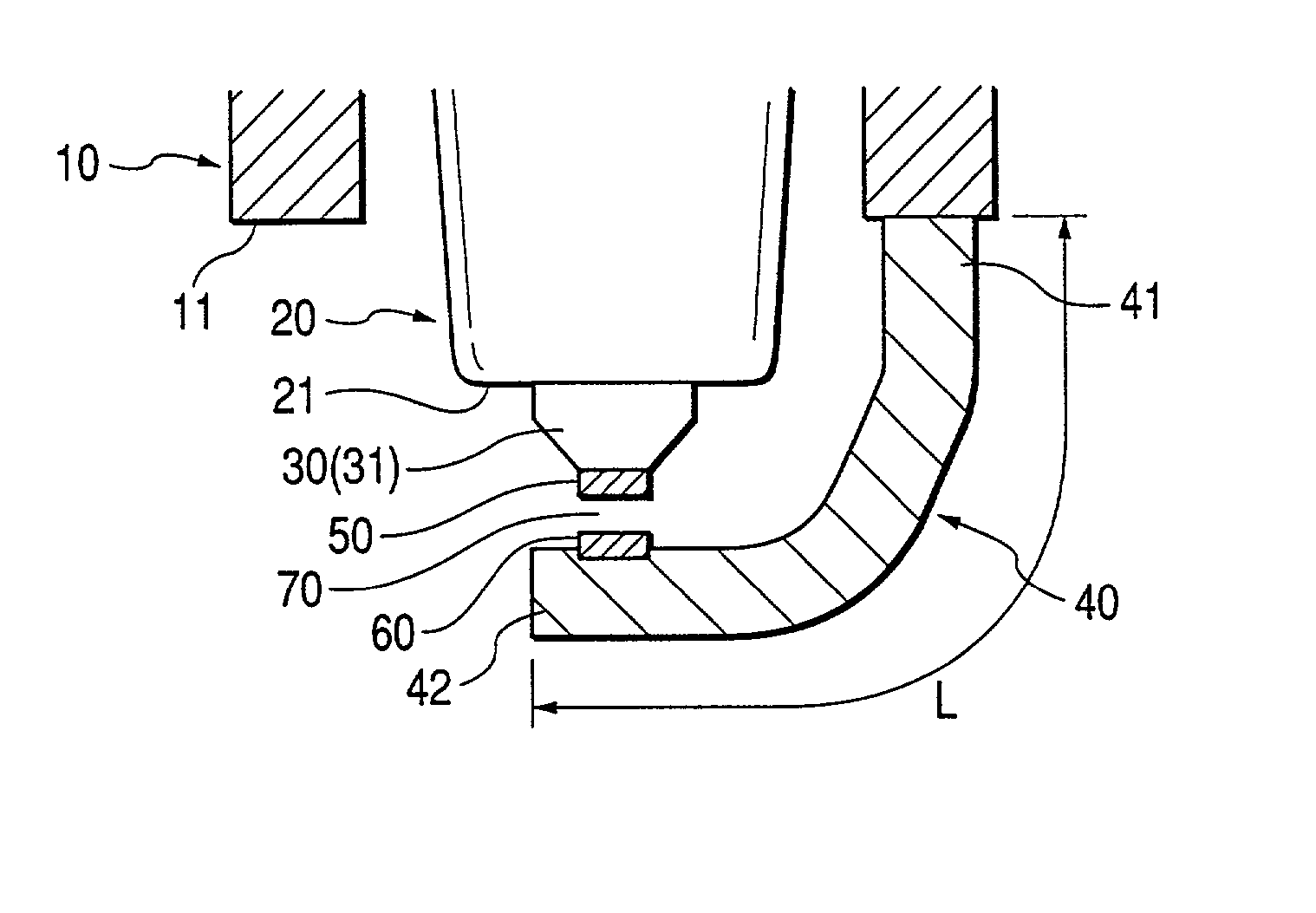

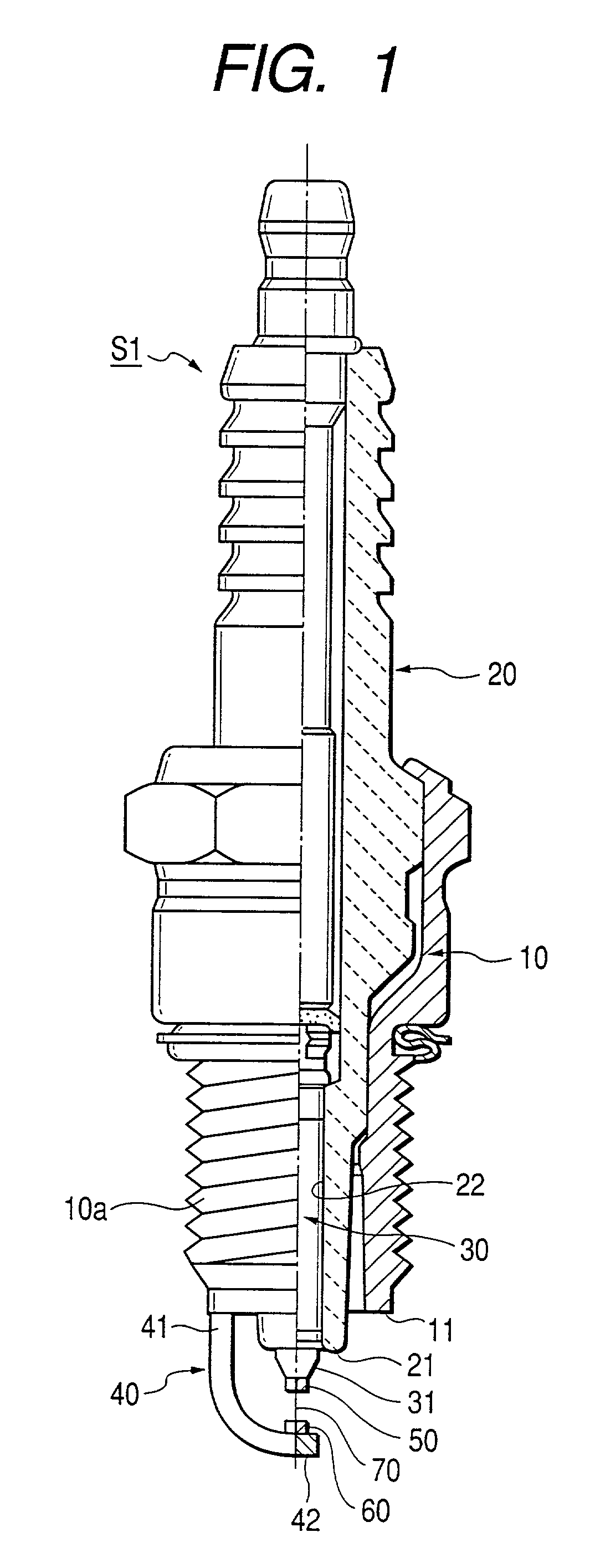

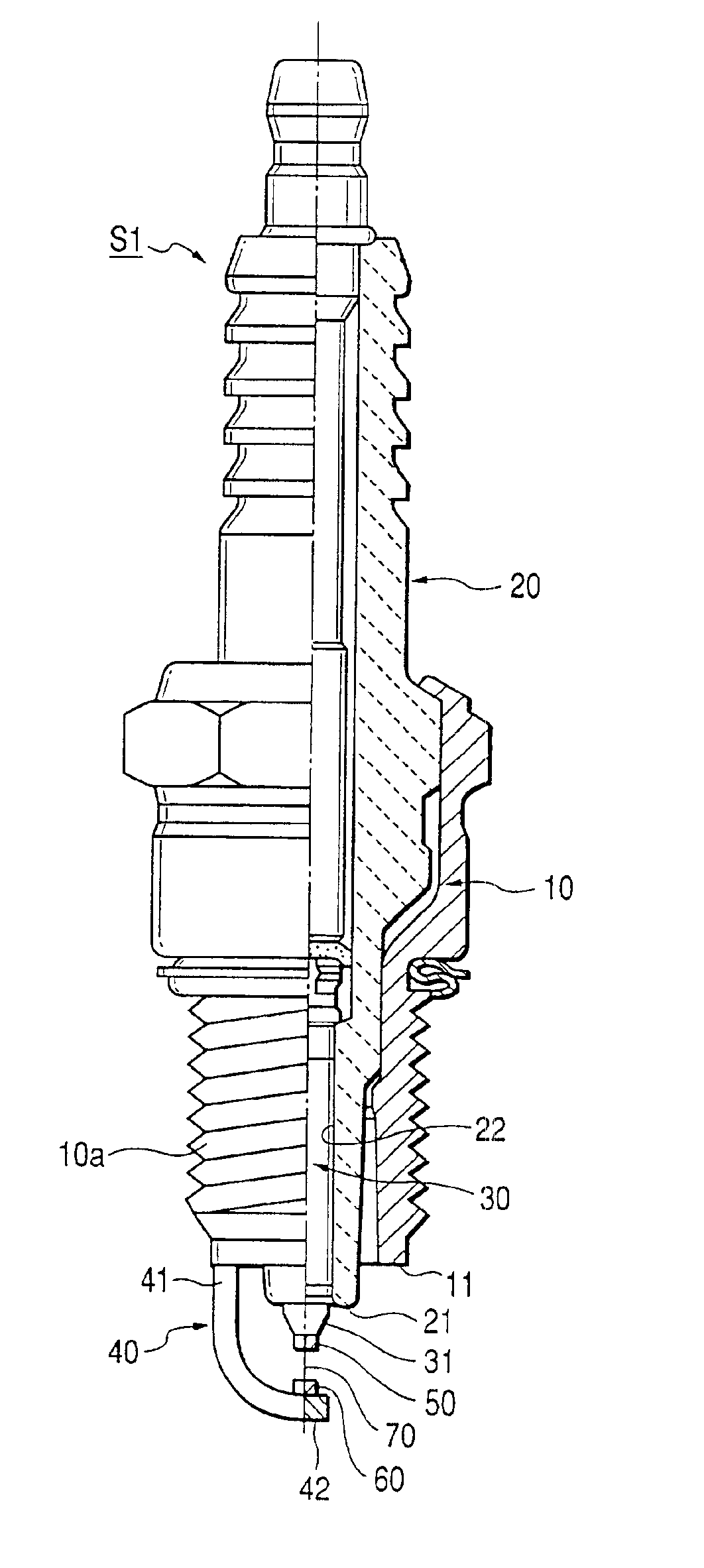

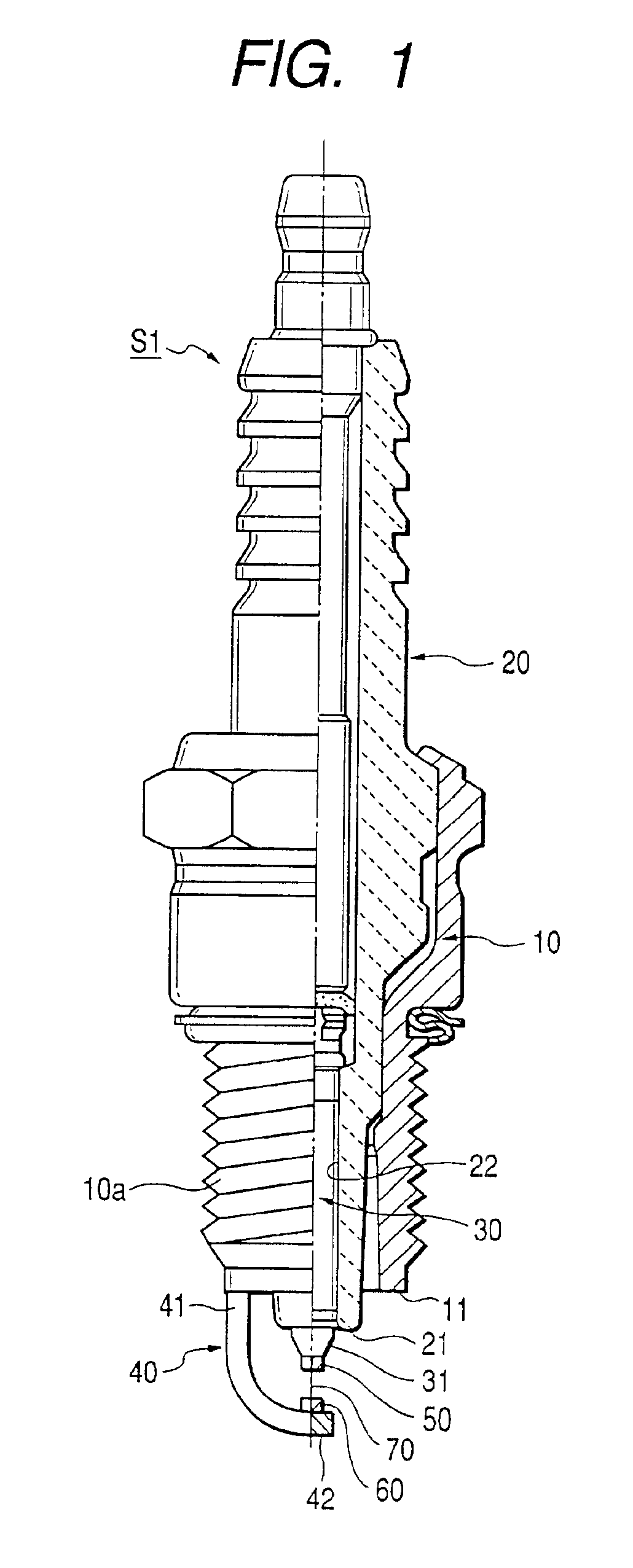

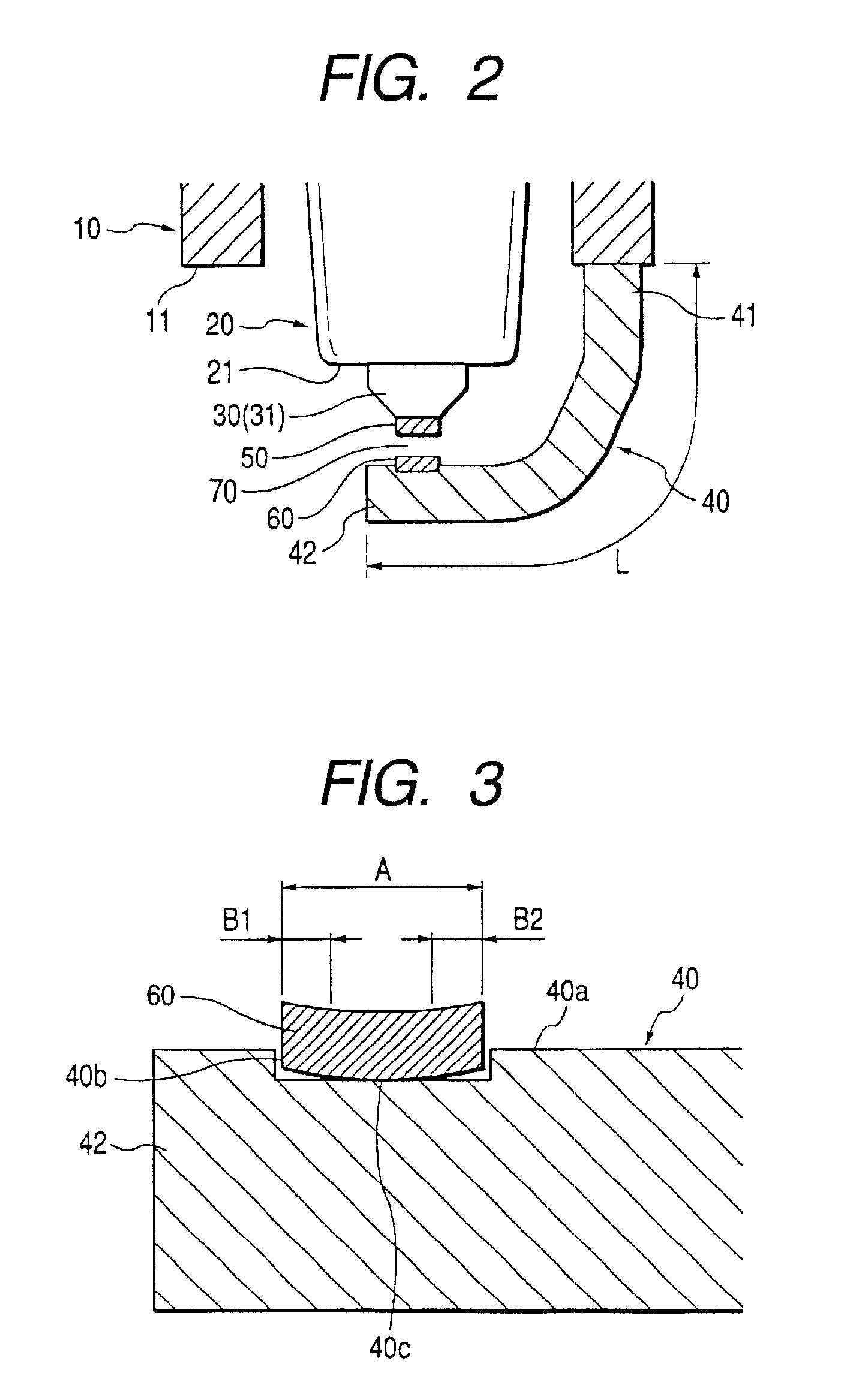

Spark plug and its manufacturing method

InactiveUS20020130602A1Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

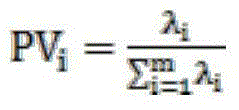

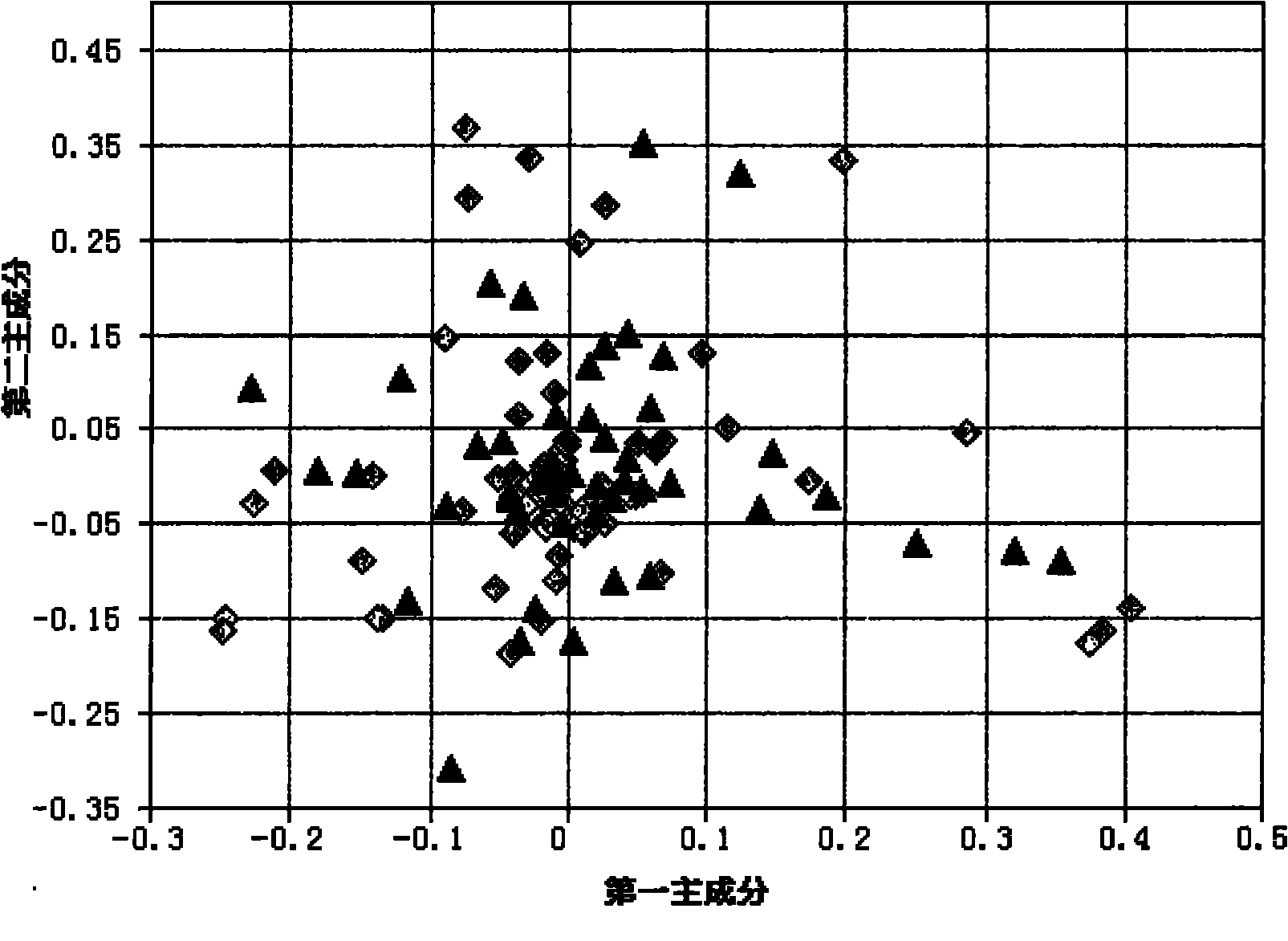

Wind turbine gear box fault recognition method

InactiveCN105136454AEasy to handleImprove fault recognition rateMachine gearing/transmission testingSpecial data processing applicationsPrincipal component analysisFourier transform on finite groups

The invention discloses a wind turbine gear box fault recognition method. The method comprises the following steps: historical wind turbine gear box operation data in a certain time range are acquired; autocorrelation analysis is adopted for carrying out wavelet de-noising processing on the historical data; through fast Fourier transform, time domain and frequency domain characteristic parameters in the historical data after de-noising are extracted; a kernel principal component analysis method is adopted to carry out dimensionality reduction on the characteristic parameters, and several nonlinear principal elements with the maximum variance cumulative contribution rate are extracted; the nonlinear principal elements extracted by the historical gear box normal operation data are used for building a normal model, a support vector machine is used for training to guide the nonlinear principal elements extracted by later gear box operation historical data to the model after training, and thus, the gear box fault is recognized. The vibration signal processing ability is improved, and an important role is played in gear box fault recognition.

Owner:SHANGHAI DIANJI UNIV

Spark plug and its manufacturing method

InactiveUS6885135B2Satisfactory propertyImprove adhesion strengthSpark gapsSparking plugs manufactureFree energiesAlloy

Noble metallic tips, made of a Pt alloy or an Ir alloy, are fixed to electrode base materials. The electrode base materials are an alloy containing a chief element selected from the group consisting of Ni, Fe, and Co and a plurality of additive elements. At least two kinds of additive elements contained in this alloy have a standard free energy of formation smaller than that of the chief element.

Owner:DENSO CORP

Self-identifying electrical connector

ActiveUS20090149037A1Easy to operateRotary current collectorElectric discharge tubesElectricityEngineering

An entirely wearable electrical connector for power / data connectivity. The principal element of a modular network is the wearable electrical connector, which is integrated into a personal area network with USB compatibility. Several wearable connector embodiments are disclosed. An enhancement to the wearable connector includes OSI Layer 2 (and potentially Layer 3) functionality. Data Link layer functionality is supported by including electronic serial numbers at wearable snap-connector points.

Owner:INTELLISENSE SYST INC

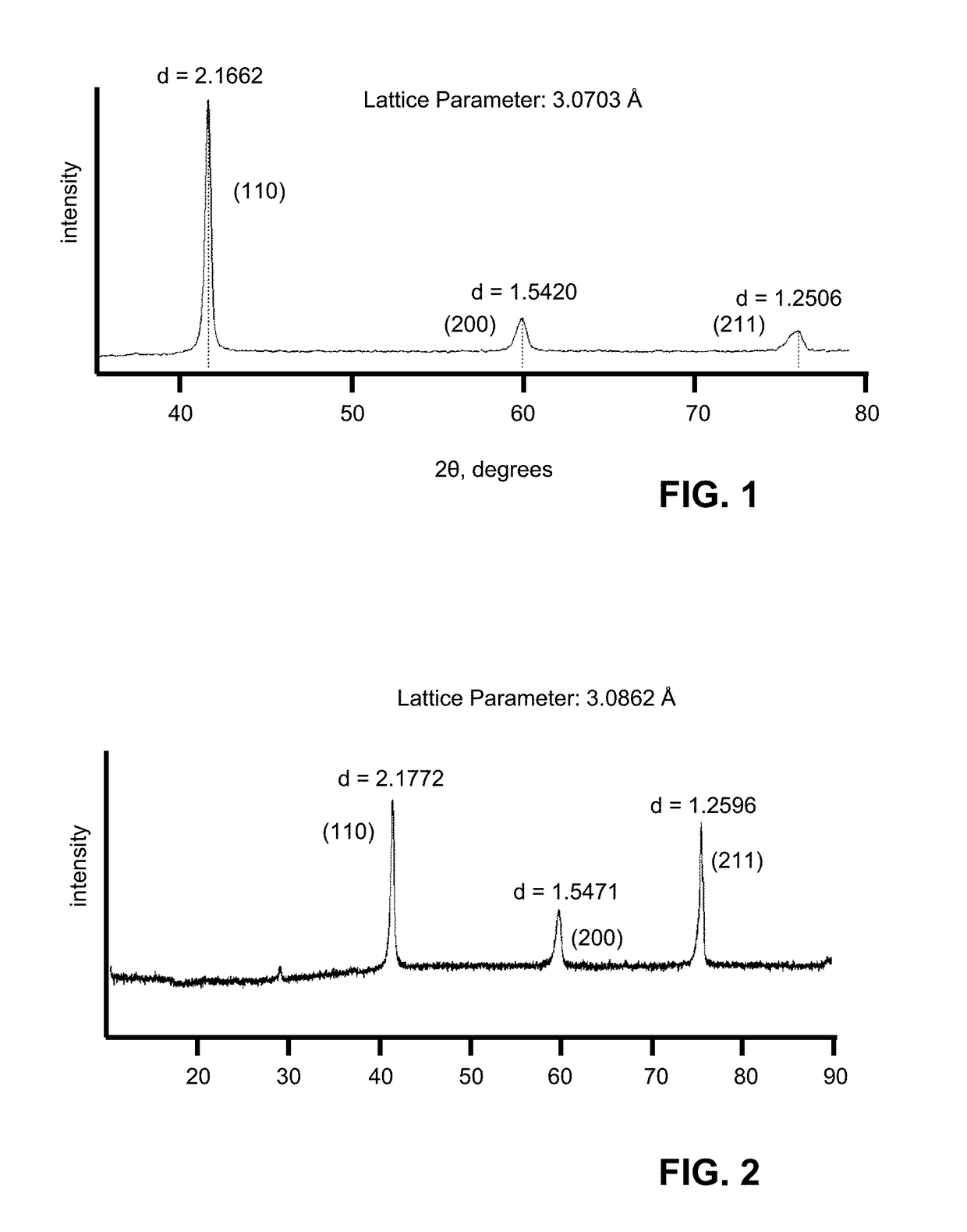

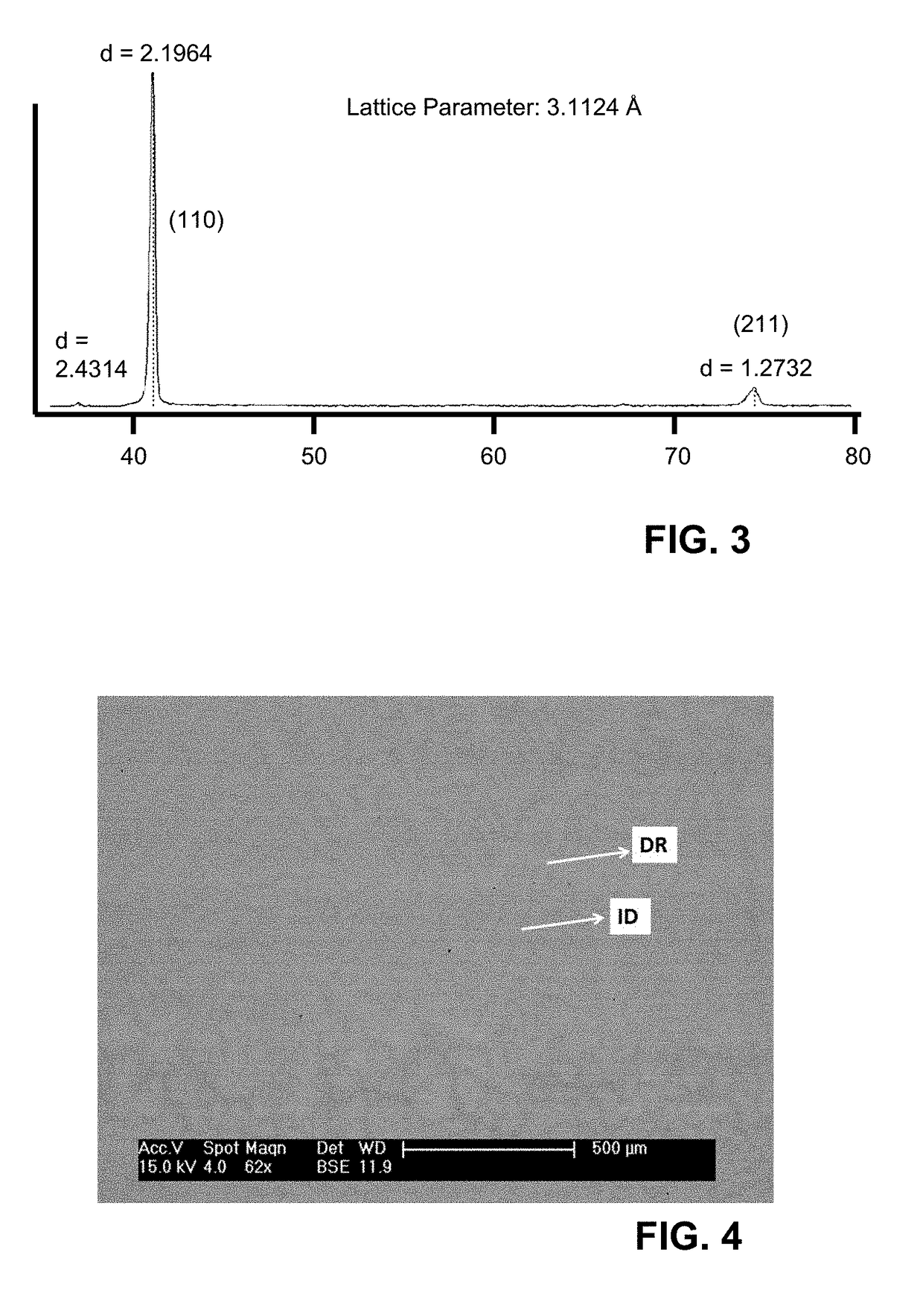

HIGH-ENTROPY AlCrTiV ALLOYS

The present disclosure relates to relates generally to metal alloys. The present disclosure relates more particularly to High Entropy Alloys having relatively high strength and relatively low weight. In one aspect, the present disclosure provides a multiple-principal-element high-entropy AlCrTiV metal alloy comprising Al in an amount of 5-50 at %; Cr in an amount of 5-50 at %; Ti in an amount of 5-60 at %; and V in an amount of 5-50 at %, wherein the total amount of Al, Cr, Ti and V is at least 80 at %.

Owner:OHIO STATE INNOVATION FOUND

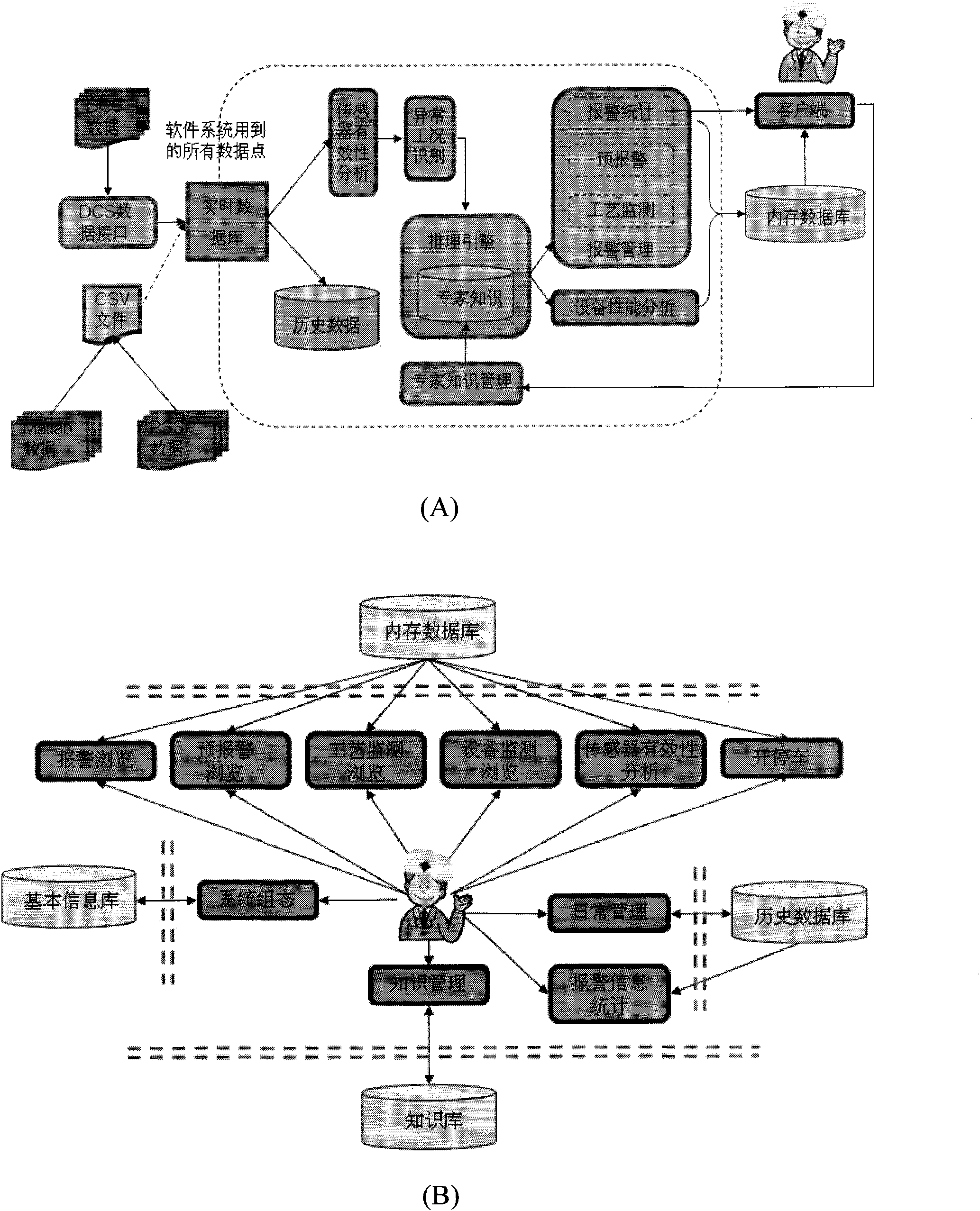

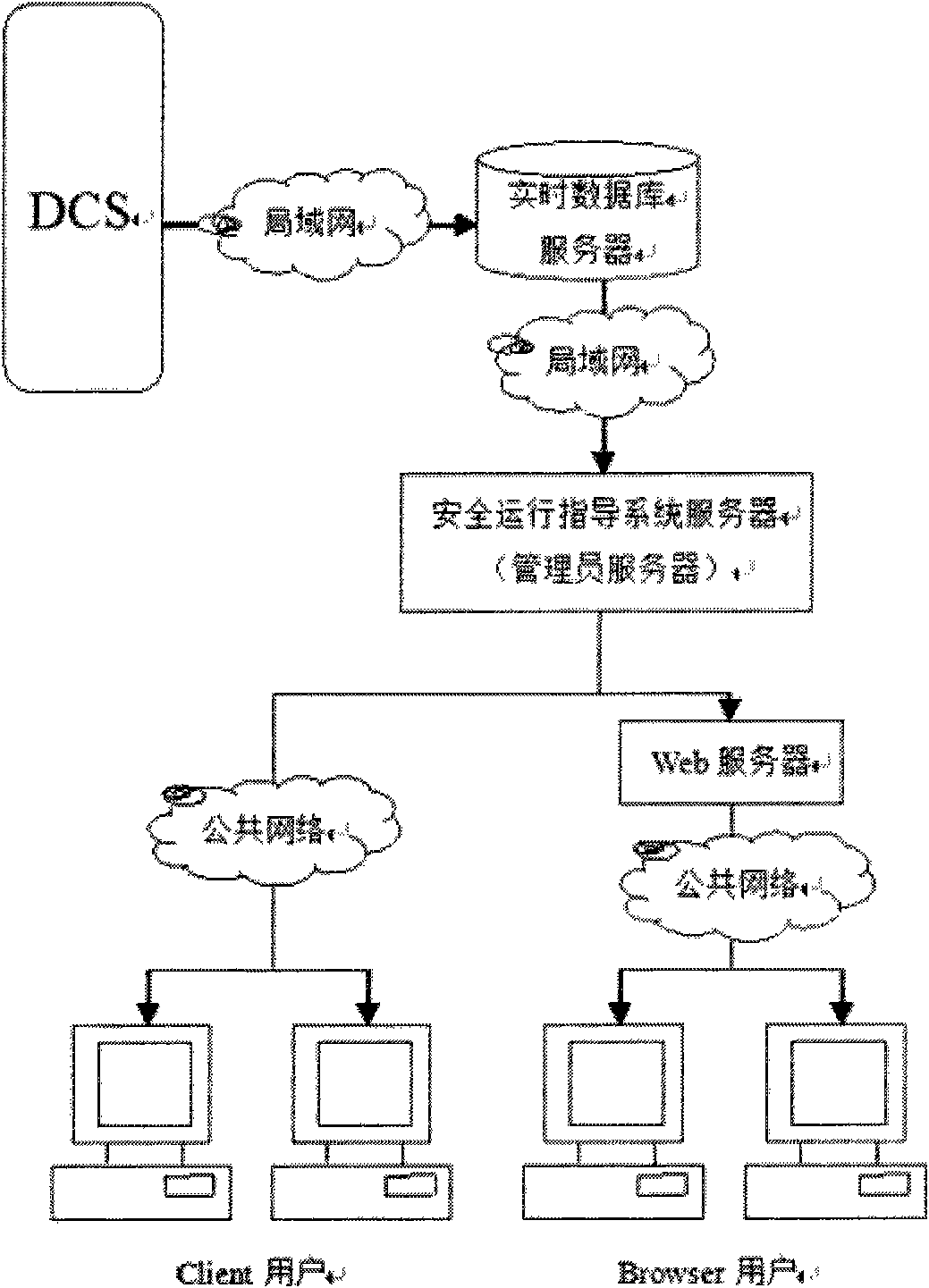

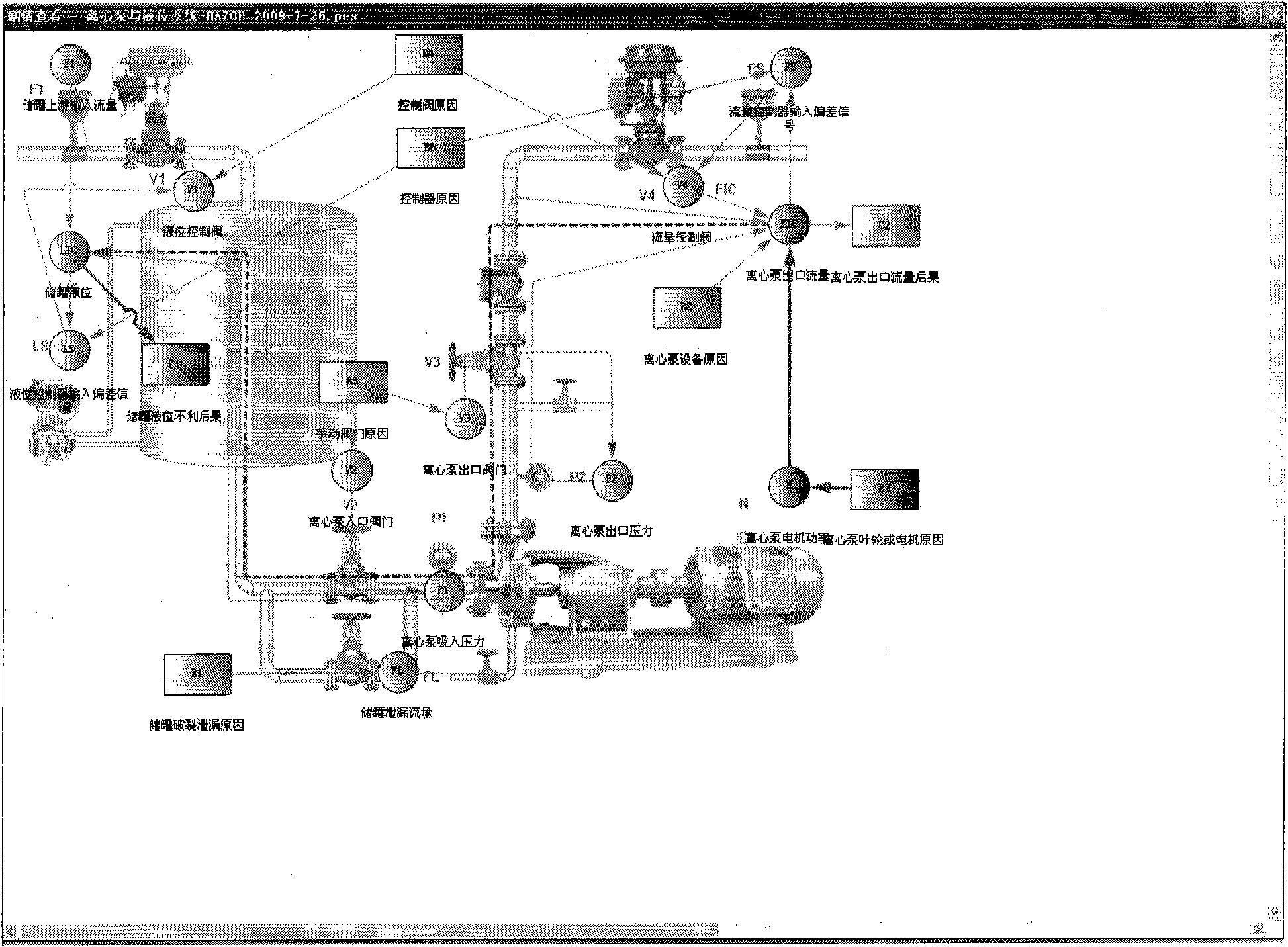

On-line real-time failure monitoring and diagnosing system device for industrial processing of residual oil

ActiveCN101989087ALong period of delayDelay full loadTotal factory controlProgramme total factory controlData acquisitionFilter effect

The invention relates to an on-line real-time failure monitoring and diagnosing system device for industrial processing of residual oil. The device has the functions of data acquisition, data filtering, sensor efficiency analysis, alarm management (process monitoring, pre-alarm and alarm counting), equipment monitoring, expert knowledge management, intelligent self-explanation of failure scenario, visualization display and the like, and can provide the daily management functions of shifting of duty, operation log, working calendar, process chart and the like. An inference engine subsystem is a core part, comprises a process monitoring engine and an equipment monitoring engine, is in charge of most inference work, and mainly comprises a signed directed graph (SDG), principal element analysis, fuzzy logic, mathematical analytical model and expert rule base. A process monitoring module uses a hybrid algorithm engine with various fused inference algorithms to obtain compatible paths of failure propagation, and removes false compatible paths by the filtering effect of expert rules to obtain the final diagnostic result.

Owner:CHINA PETROLEUM & CHEM CORP +1

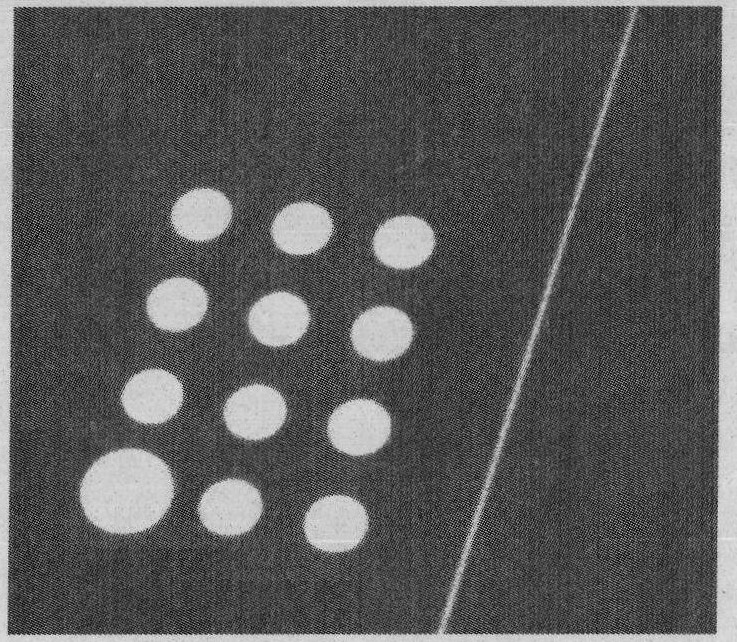

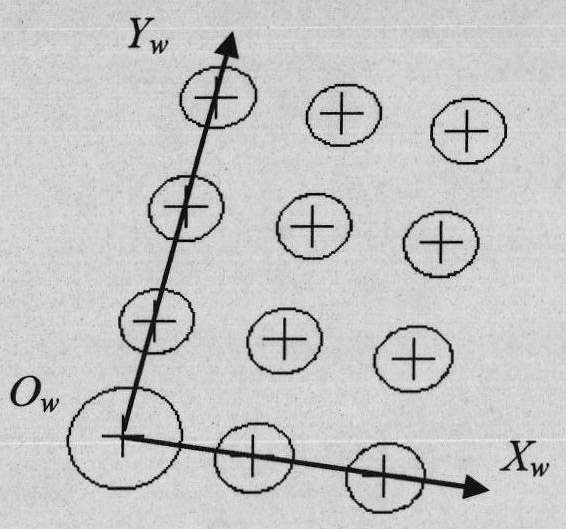

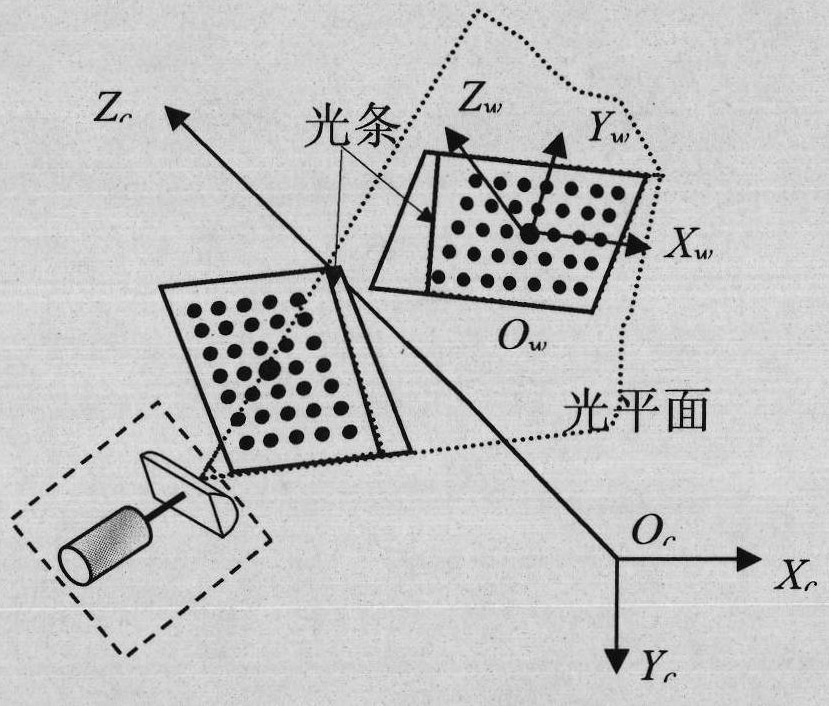

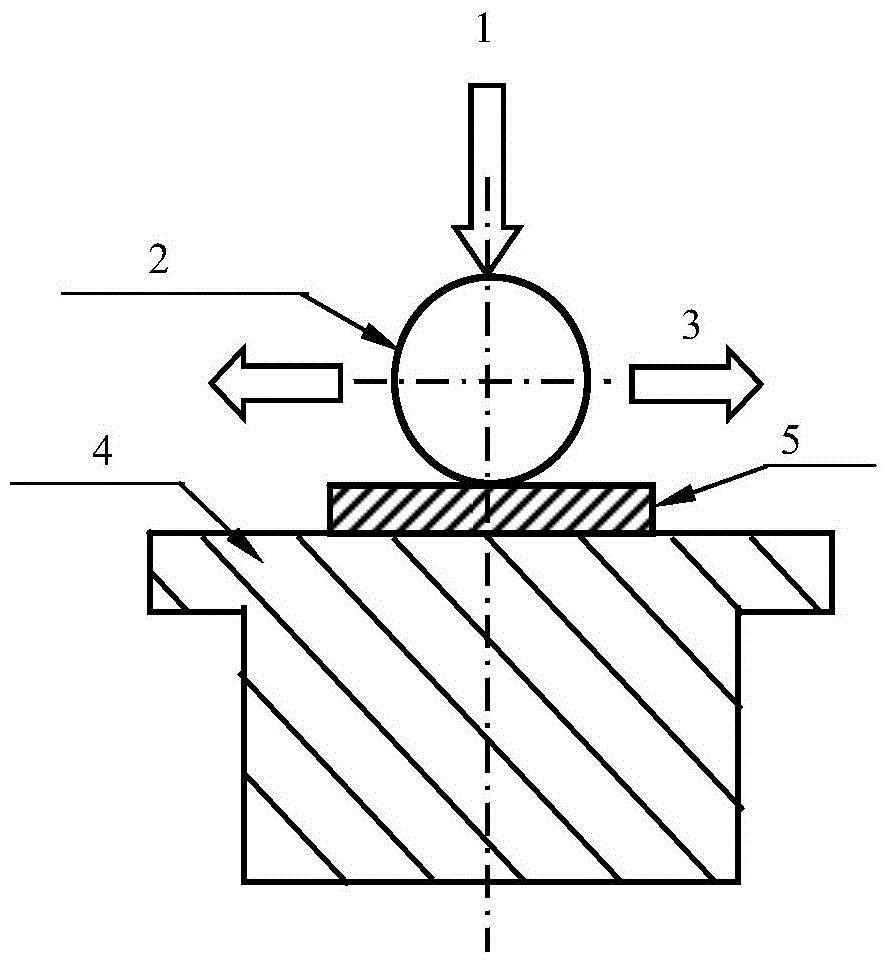

Rapid calibration method of line-structured light vision sensor based on space plane restriction

InactiveCN101943563AMeet the needs of high-precision detection tasksEasy extractionUsing optical meansVision sensorAnalysis method

The invention discloses a calibration method of a line-structured light vision measuring sensor based on the space plane restriction, comprising the following calibrating steps: placing a two-dimensional planar target in a camera field range; collecting a group of images of multiple characteristic circles at the different positions on a two-dimensional target panel; determining the target topological relation; and synchronously completing the internal parameter calibration and the light planar calibration of a camera. In the process of the light planar calibration, substantial quantity of line-structured light planar three-dimensional points can be easily extracted by utilizing a camera imaging model and the restraining provided by the space plane formed by each position target; and planar fitting is carried out on the three-dimensional point set based on a principal element analytical method, so as to obtain an equation of the light plane in the coordinate system. The calibration method of the invention has simple operation and reliable result, is suitable for field calibration, and can satisfy the requirements of the line-structured light vision high-precision detecting tasks.

Owner:TIANJIN UNIV

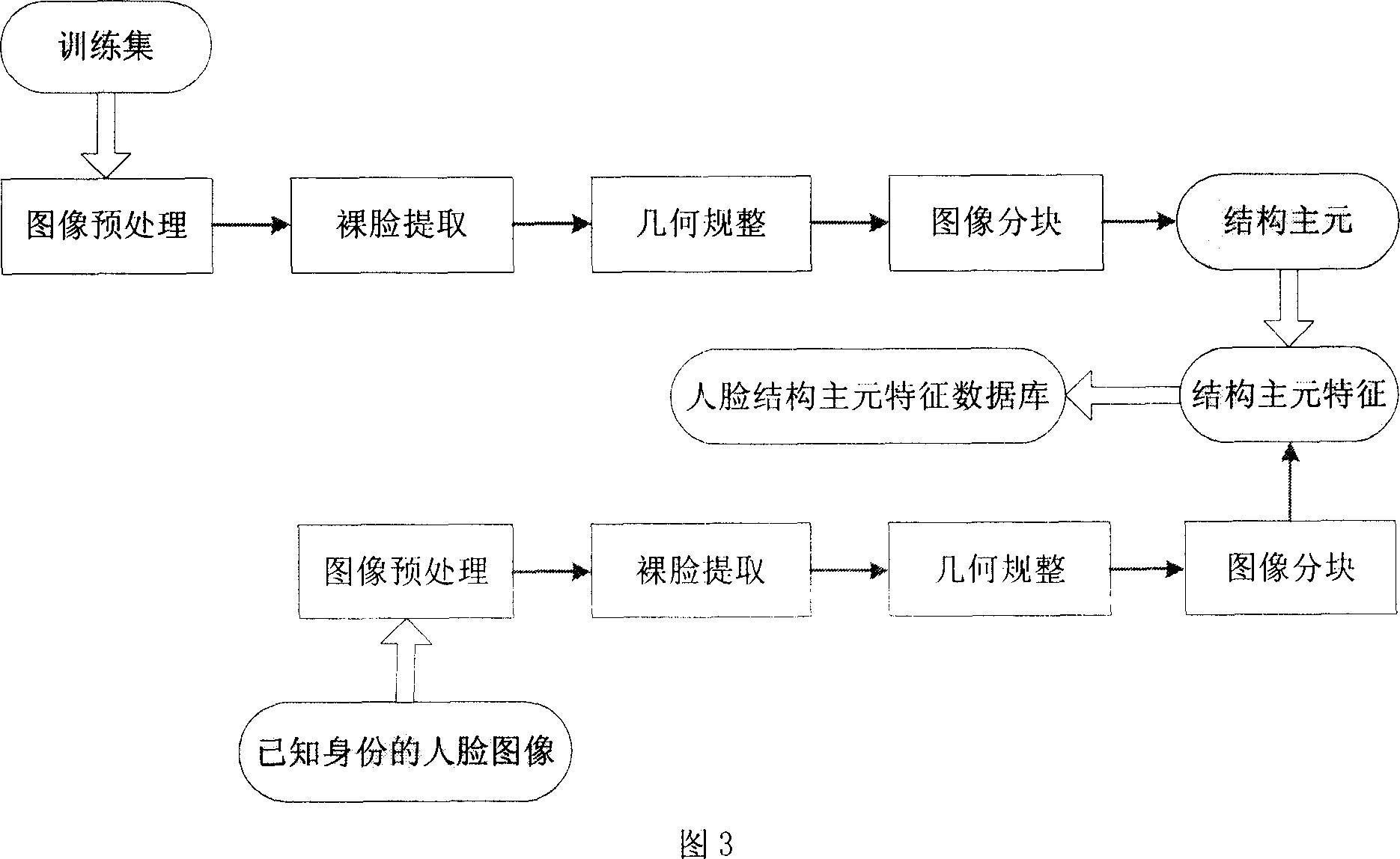

Human face identifying method based on structural principal element analysis

InactiveCN1975759AIncrease or decrease of data volumeReduce data volumeCharacter and pattern recognitionWeight coefficientWeight adjustment

The invention belongs to pattern recognition technology area. The invention consists of following key steps: geometric warping, image block, two-dimensional principal component analysis (2DPCA) and similarity coefficient weighted adjustment. The invention performs geometric warping with eyes and mouse as benchmark. After the geometric warping, all face images are the same size, the positions of face various parts in the facial image are fixed, and after the image blocking, the human face local area contained in each block is fixed. The invention uses 2DPCA method to calculate main element and main feature of each image block. The similarity of two images is the distance between their main features, and the similarity is the weighted sum of the similarities of total image blocks. By adjusting the number of main elements and weighted coefficients of similarity of each image block, one can highlight or suppress roles of some pieces in the human image in face recognition.

Owner:SUN YAT SEN UNIV

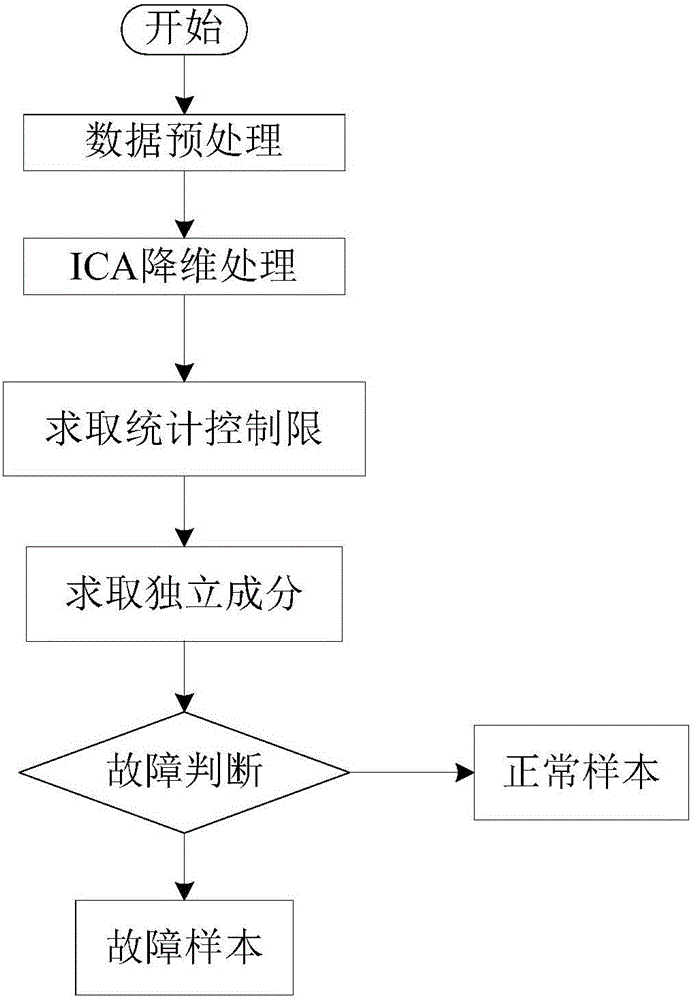

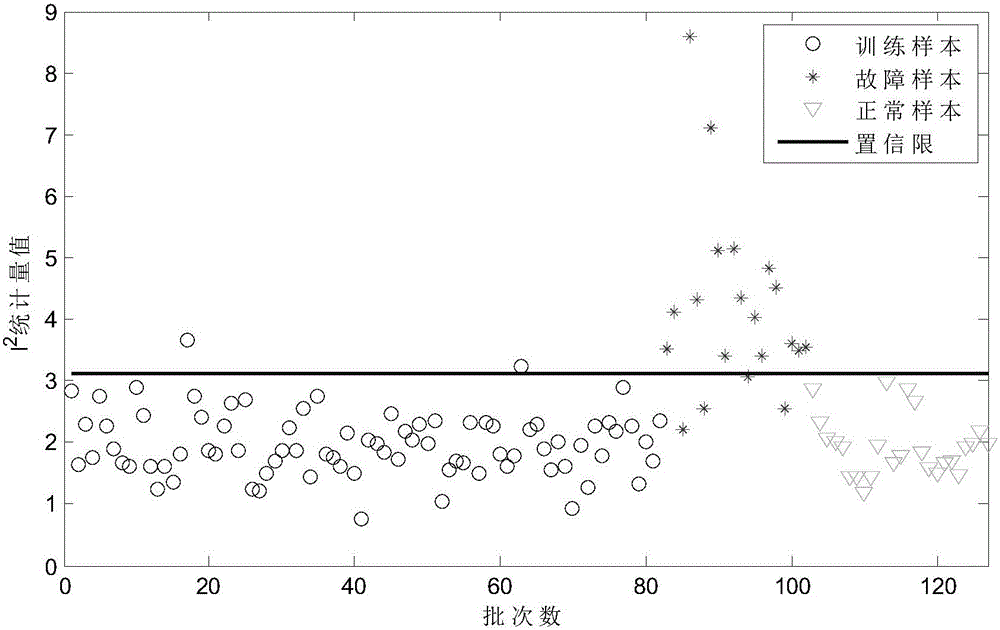

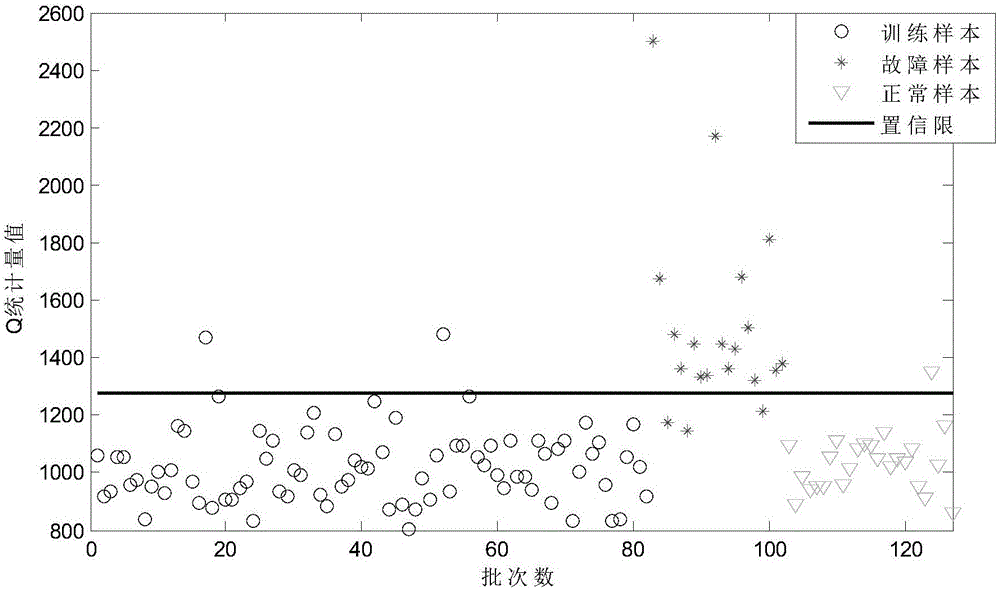

Method of monitoring faults in sections for intermittent control system

InactiveCN103279123AThe phase division complies withThe phase division is more in line with the batch process actually in line withElectric testing/monitoringFuzzy clustering analysisPrincipal component analysis

The invention discloses a method of monitoring faults in sections for an intermittent control system and relates to a fault monitoring method. Firstly, a plurality of batches of collected intermittent process data are standardized in a way of expanding variables, and a data matrix on each sampling time is subjected to principal component analysis; secondly, a fuzzy C-means clustering is a fuzzy clustering analysis method which is suitable for soft partition and is generated through combining a fuzzy set theory and a k-means clustering; and thirdly, after segmentation is finished, an improved MPCA (Multiway Principal Component Analysis) model with a time varying principal element covariance on the basis of expanding variables is established on each subphase, then when on-line monitoring is carried out, which phase a new batch of data belongs to is judged, whether the data exceeds the fault monitoring control limit or not is calculated and judged, if so, a fault occurs, and the fault monitoring in sections ends. According to the invention, process multi-phase partition is more accurate, misinformation and missing report rates in monitoring are reduced, and the practical application and operability are strong.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

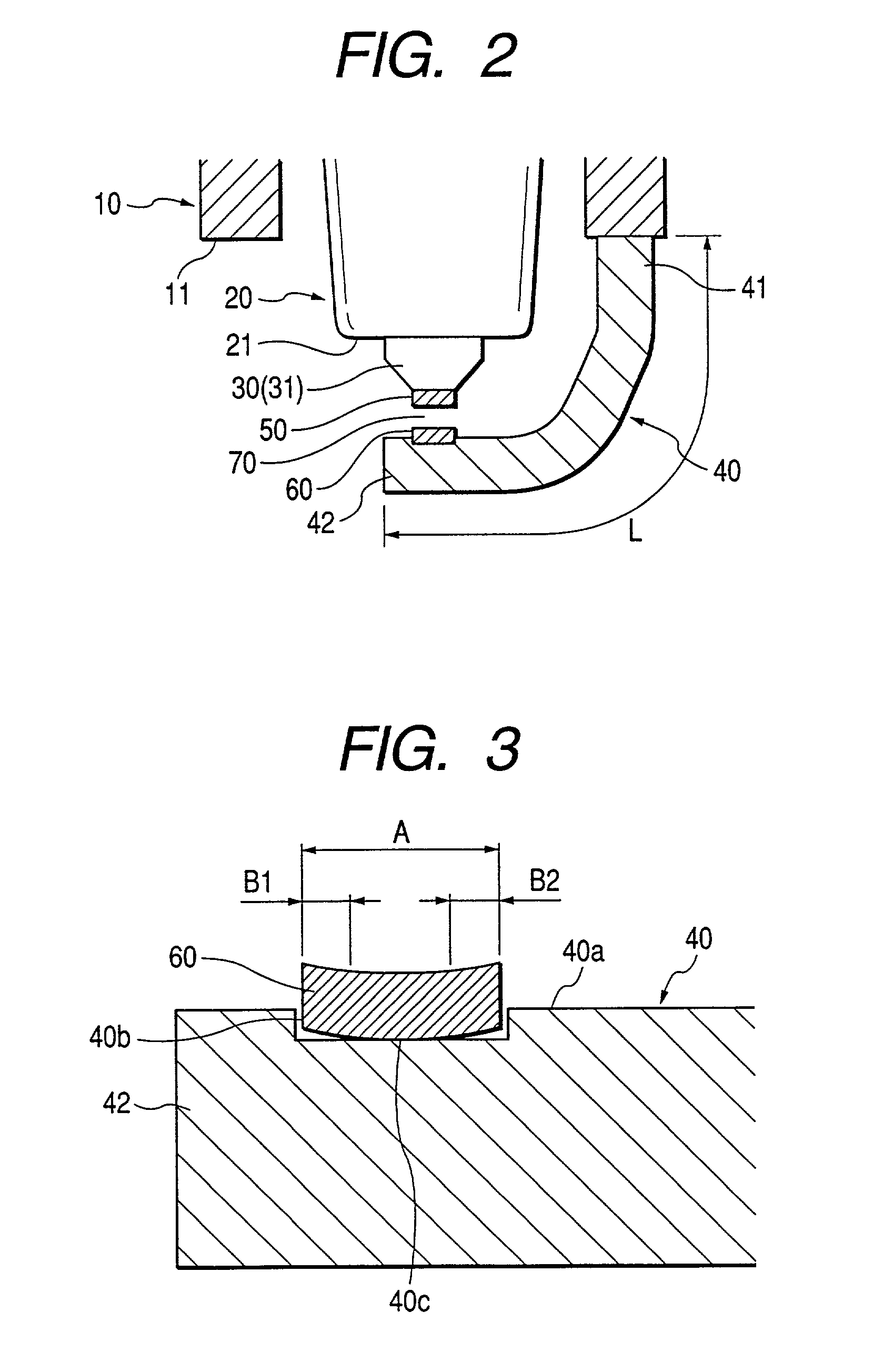

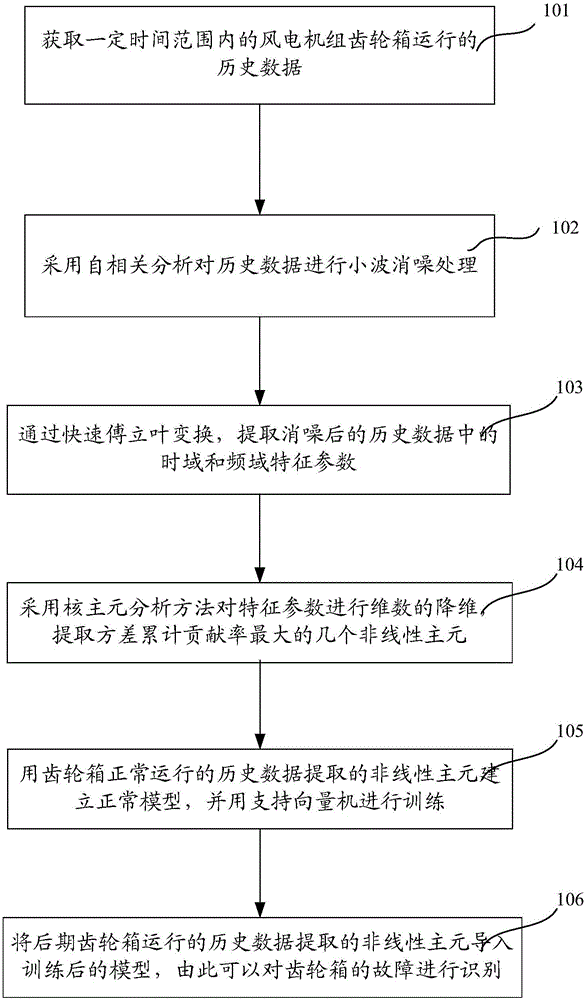

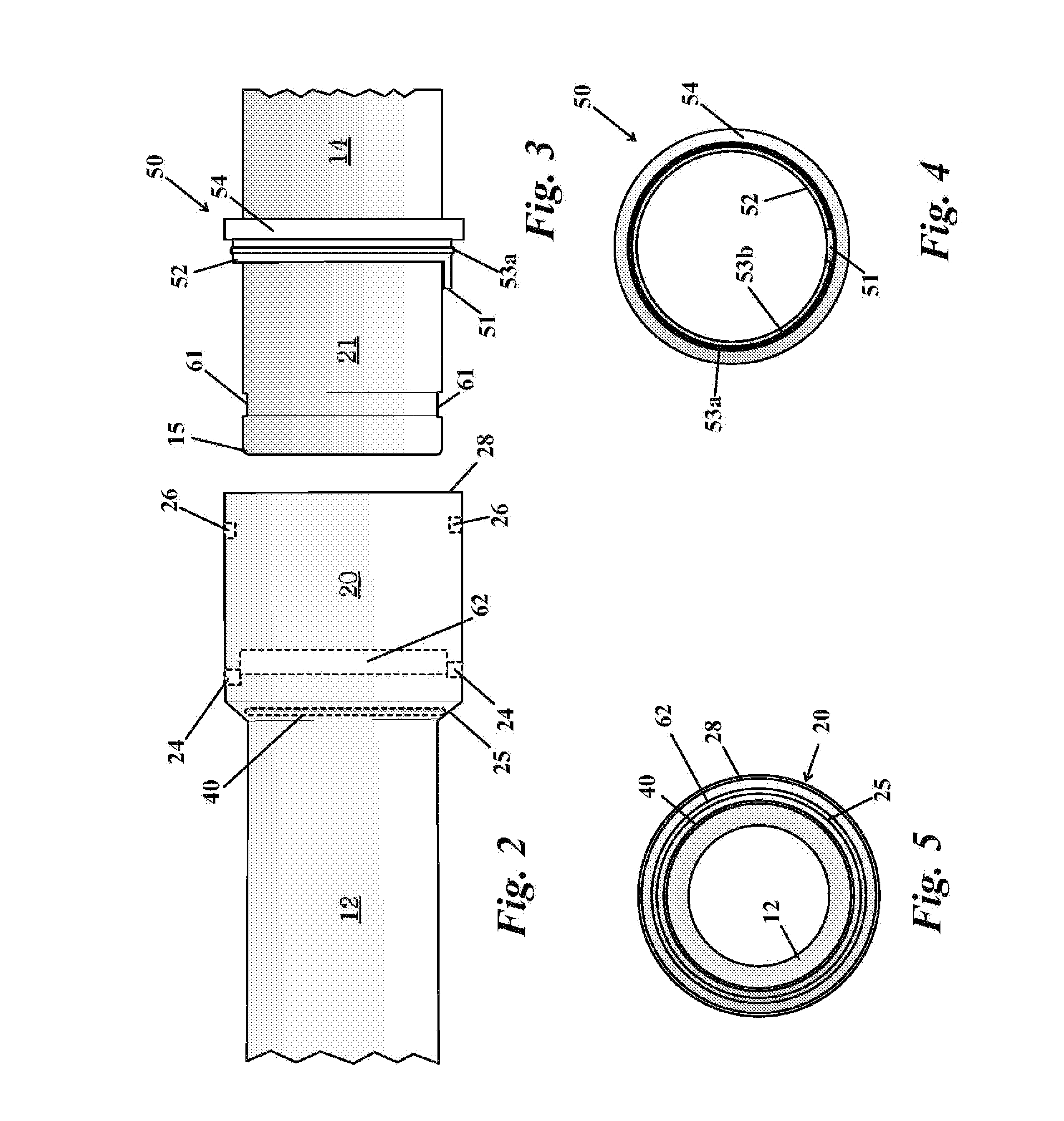

Pipe joints

The invention is a pipe joint for joining pipes composed of materials that are difficult to adhere. The major elements are an extrudable adhesive; a first pipe having a socket with an inside diameter, where said socket has a mouth, a self-centering bottom with a gasket, a cylindrical wall with a plurality of ports, and an inner annular channel. A second pipe has an insertion section with an squared-off end and a rolled groove. The second pipe having an outside diameter that is less than the inside diameter of the socket, where the difference defines a coaxial cavity with a width. The rolled groove serves as a distribution channel while the adhesive is a liquid, and upon curing the solid adhesive functions as a retaining ring. A flanged annular ring, potentially aided by a compression apparatus, caps the cavity, centers the insertion section, and maintains compression. The adhesive includes alkyl-borane-adhesives.

Owner:IPS WELD ON DIV

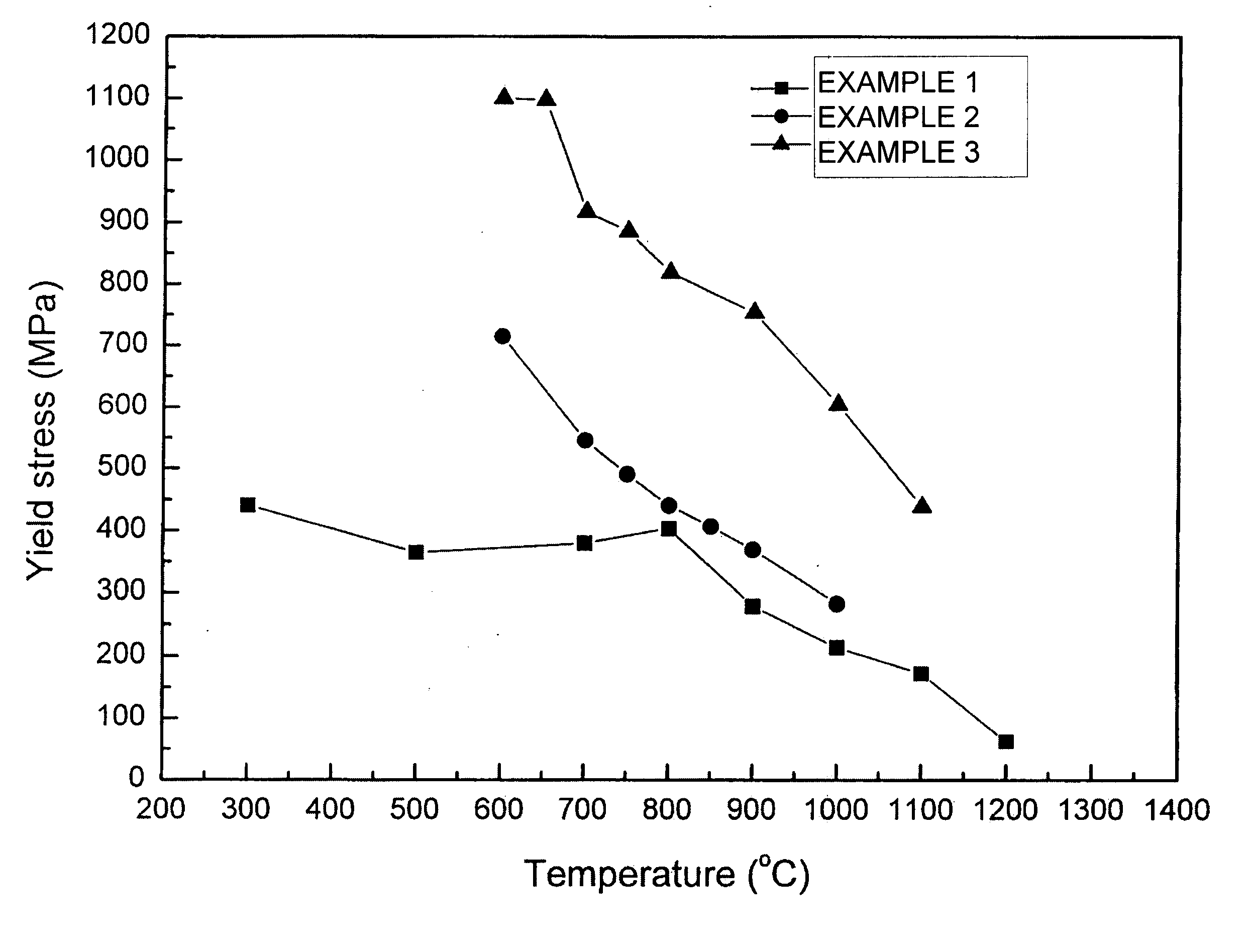

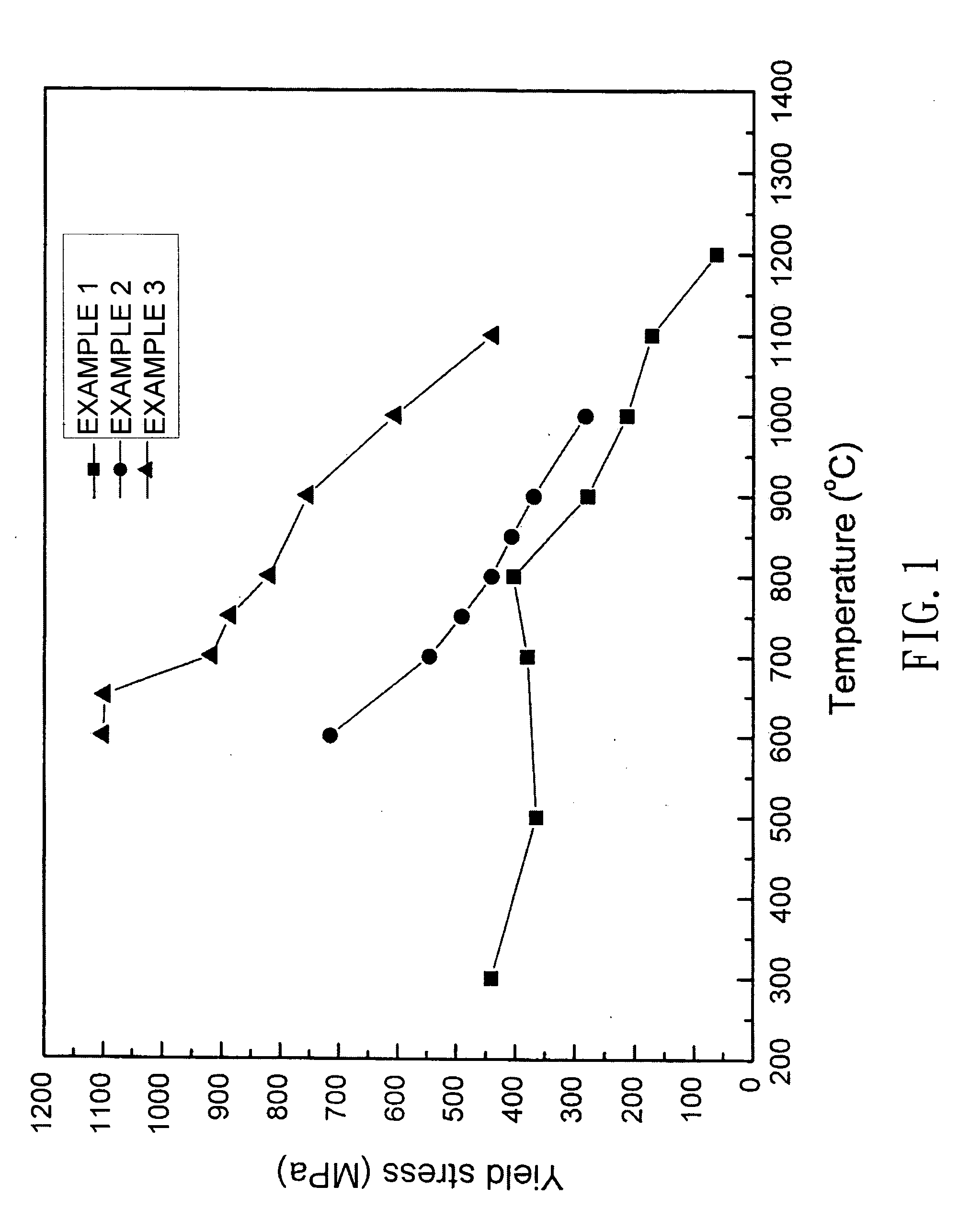

High strength multi-component alloy

A high strength multi-component alloy contains multi-principal elements and is formulated under a design concept different from the prior art. The multi-component alloy contains Fe, Co, Ni, Cr, Cu and Al as main elements. Each main element of the multi-component alloy is in the range of about 5 to about 35 atom % based on the total number of atoms of the alloy. The multi-component alloy has high strength at high temperature.

Owner:IND TECH RES INST +1

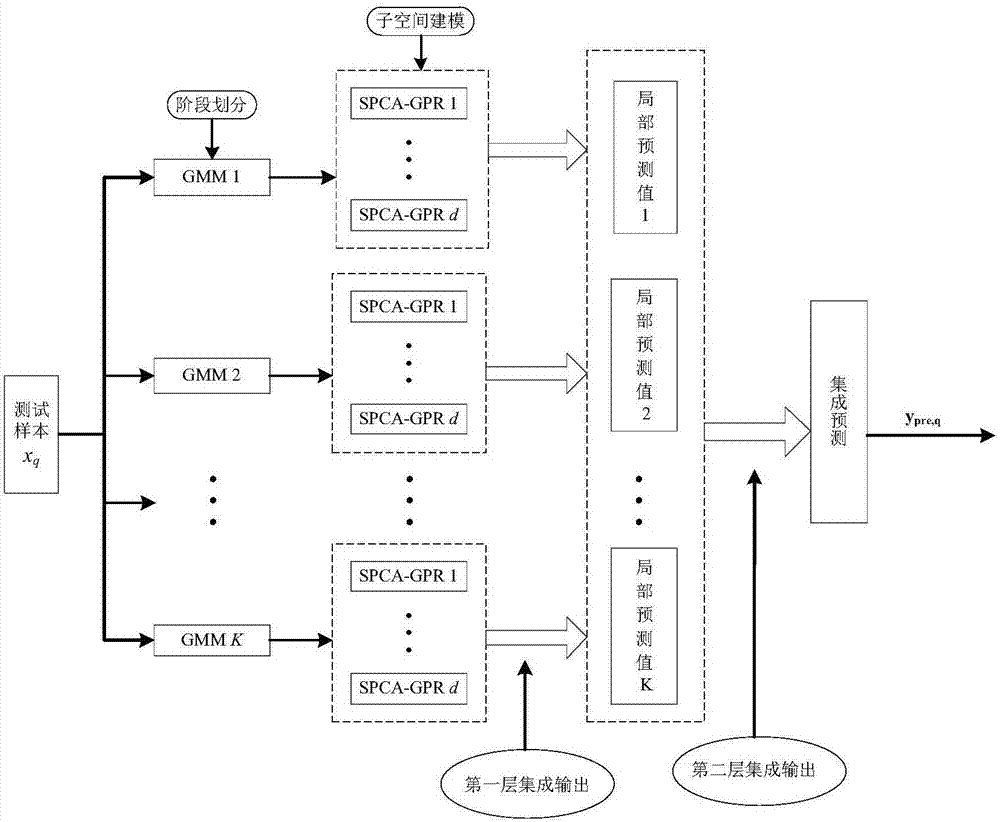

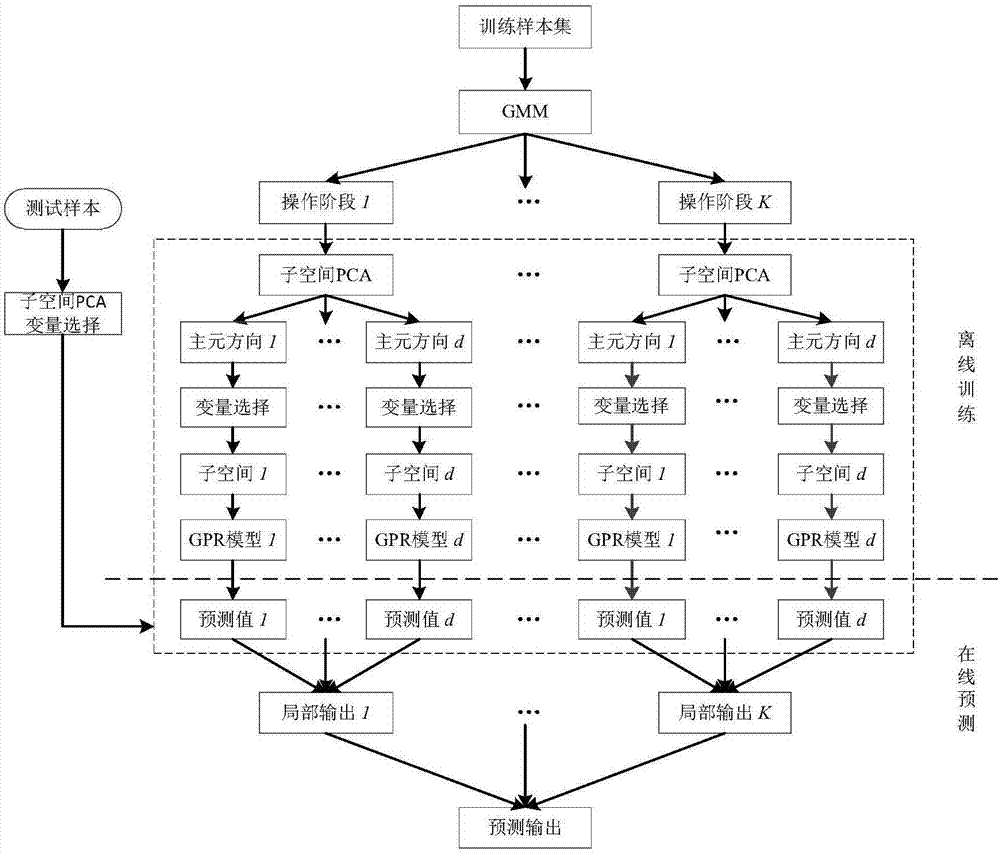

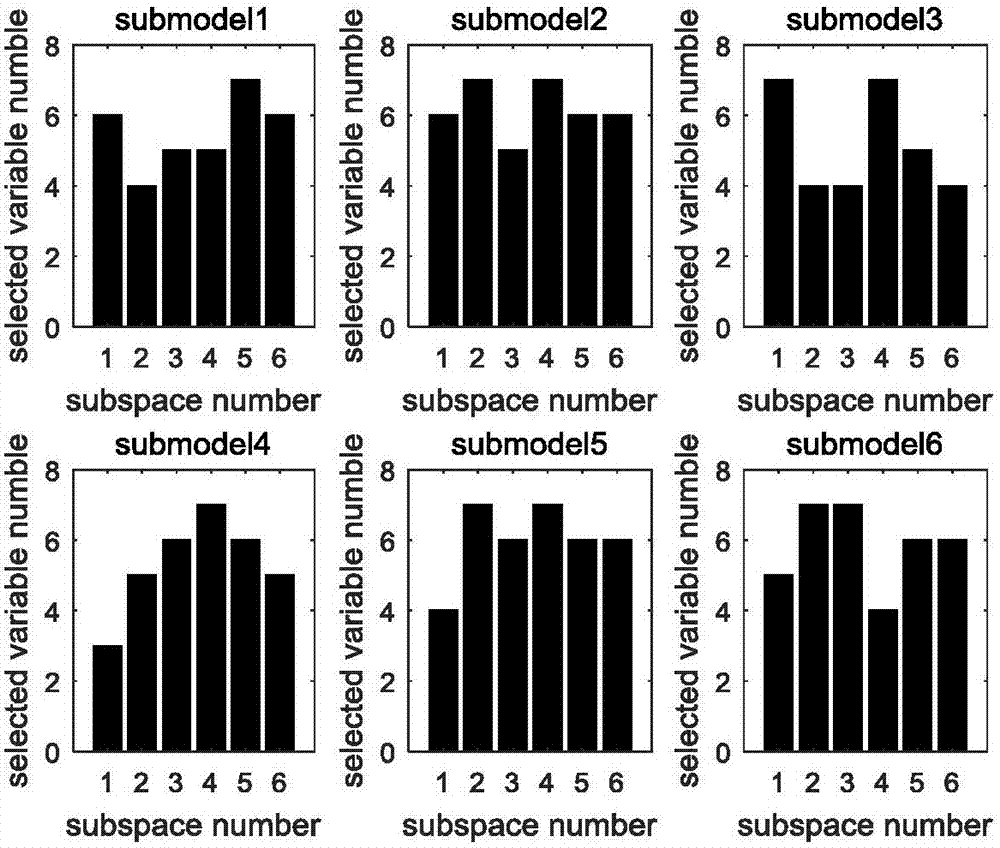

Layered integrated Gaussian process regression soft measurement modeling method

ActiveCN107451101AStrong generalizationRealize online estimationCharacter and pattern recognitionComplex mathematical operationsSubspace modelPrincipal component analysis

The invention discloses a layered integrated Gaussian process regression soft measurement modeling method used for a complex changeable multi-stage chemical process. The layered integrated Gaussian process regression soft measurement modeling method is an on-line multi-model strategy. A Gaussian mixture model is employed to identify different stages of the process, principal component analysis is carried out on data in each stage, on the basis of the contribution degree of each auxiliary variable in the principal element space, data in each mode is divided into several subspaces, and a corresponding Gaussian process regression soft measurement model is established. When new data comes around, variable selection is carried out by means of subspace PCA, and on the basis of the soft measurement model which is established off line, the prediction output of each model can be obtained. By carrying out mean value fusion on outputs of subspace models, first layer integrated output, i.e., local prediction output in each mode can be obtained, finally new data obtained according to calculation is attached to the posterior probability of each different stage, and local prediction in each mode is fused by means of the posterior probability to obtain second layer integrated output. Key variables can be accurately predicted, and therefore the product quality is improved, and the production cost is reduced.

Owner:JIANGNAN UNIV

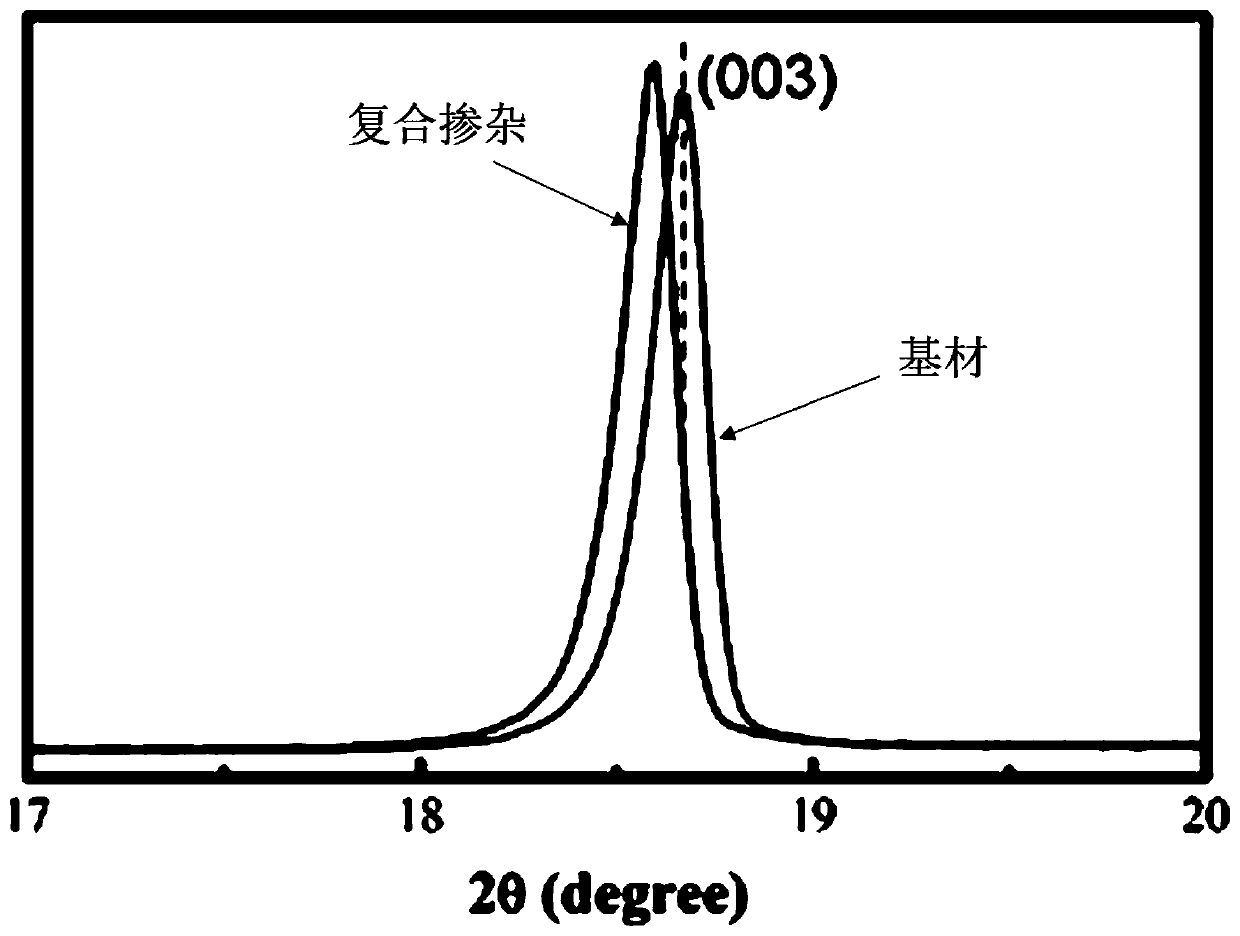

Multiphase-doped nickel-cobalt-manganese ternary anode material and preparation method and application thereof

InactiveCN109768232AEasy to useEnhanced mass transferCell electrodesSecondary cellsChemical LinkageManganese

The invention discloses a multiphase-doped nickel-cobalt-manganese ternary anode material and a preparation method and application thereof. The chemical expression of the multiphase-doped nickel-cobalt-manganese ternary anode material is Li<delta>Ni<x>Co<y>Mn<z>MNO<2>, wherein the following relations are met: 0.9<=delta<=1.3; 0.33<=x<=0.98; 0.02<=y<=0.4; 0.02<=z<=0.4; x+y+z=1; a>0, b>0, and0.0024<=a+b<=0.042; M is a principal element in a melting additive; and N is a principal element in a strong chemical-bond energy additive. Meanwhile, the invention discloses the preparation method ofthe multiphase-doped nickel-cobalt-manganese ternary anode material and also discloses application of the multiphase-doped nickel-cobalt-manganese ternary anode material. According to the prepared multiphase-doped nickel-cobalt-manganese ternary anode material, the use effectiveness of the anode material is improved multi-dimensionally by use of the synergistic effect among doped elements.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Batch process fault detecting method based on ICA-KNN

InactiveCN105739489AImprove fault detection rateReduce computational complexityElectric testing/monitoringComputation complexityData set

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

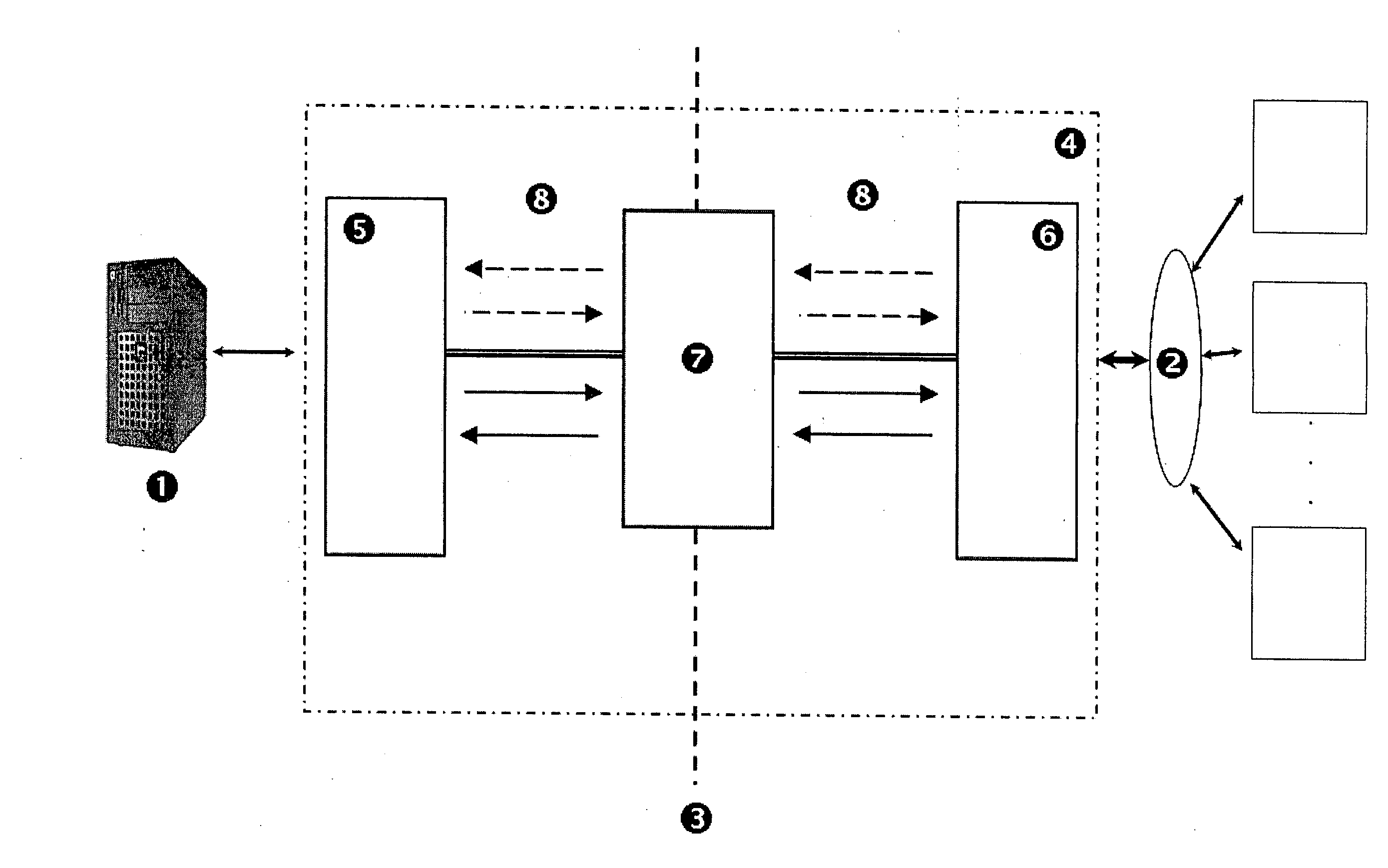

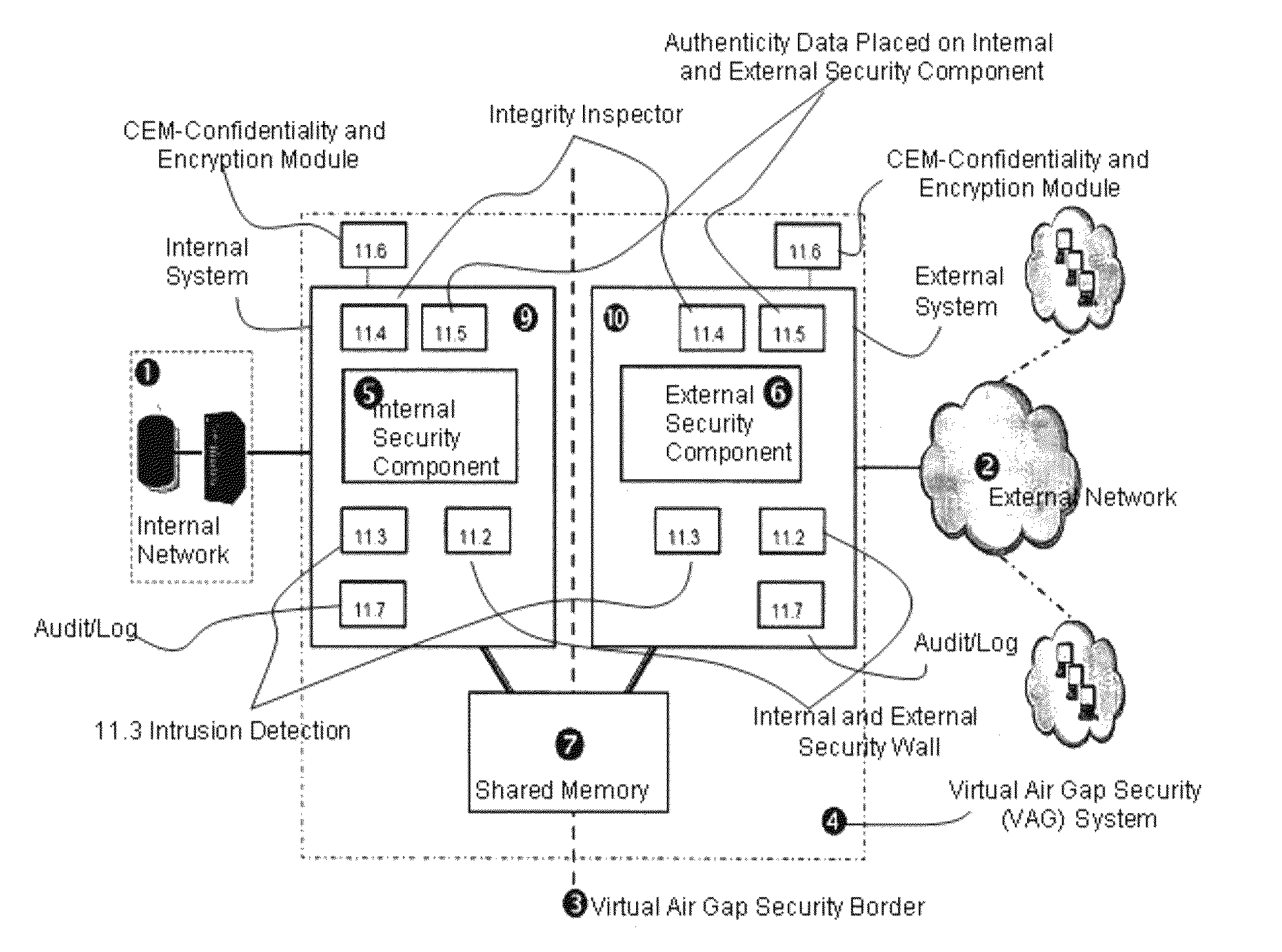

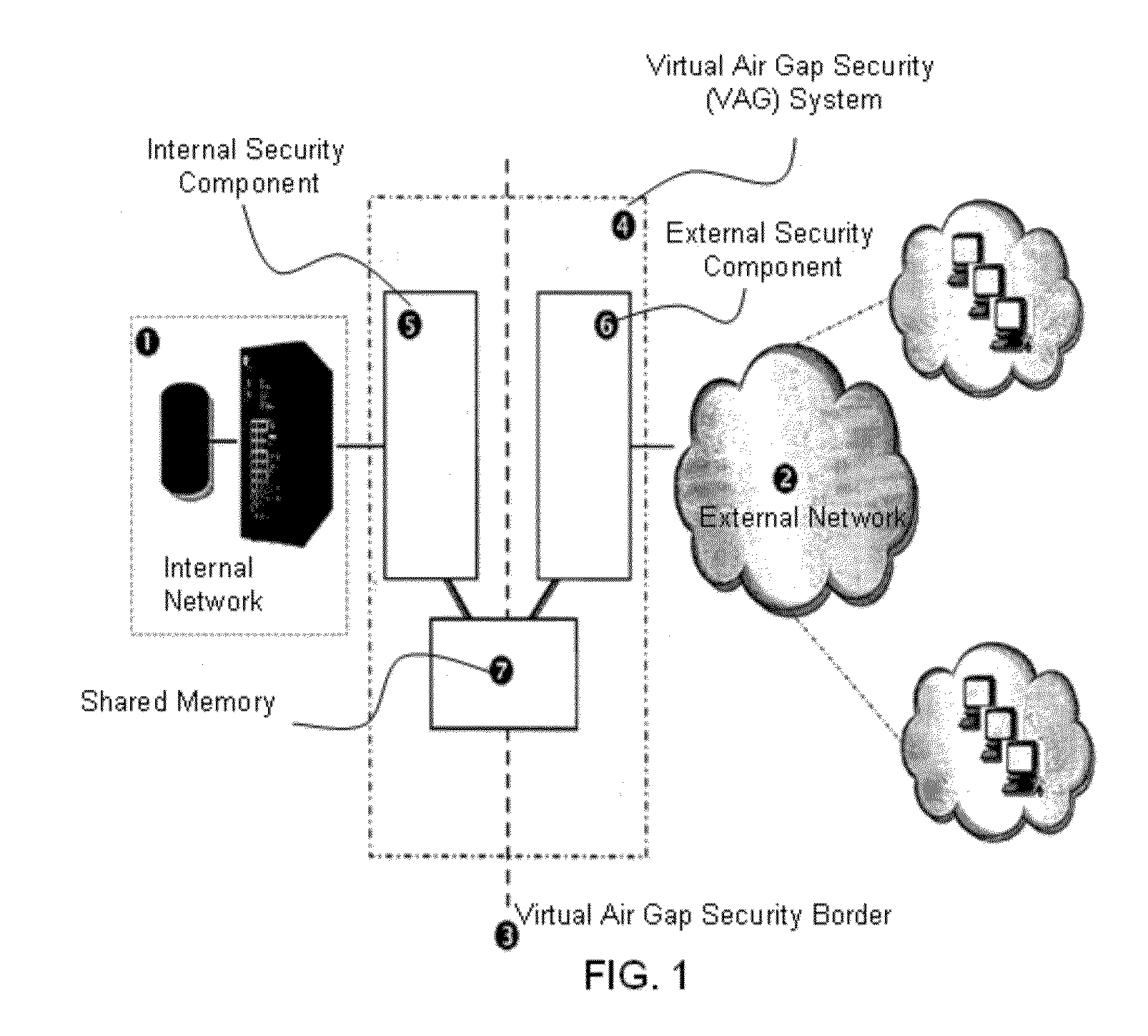

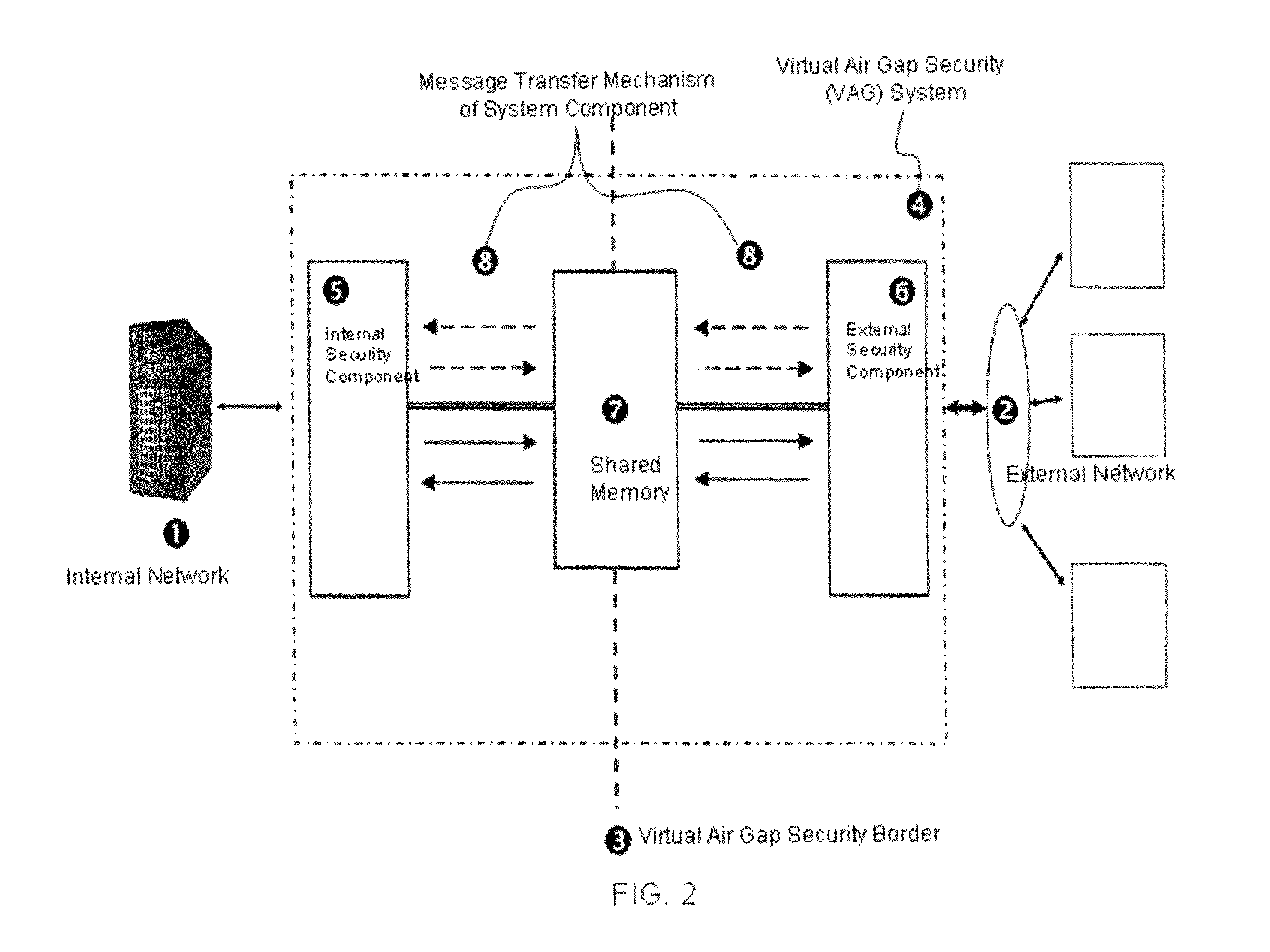

Virtual air gap - vag system

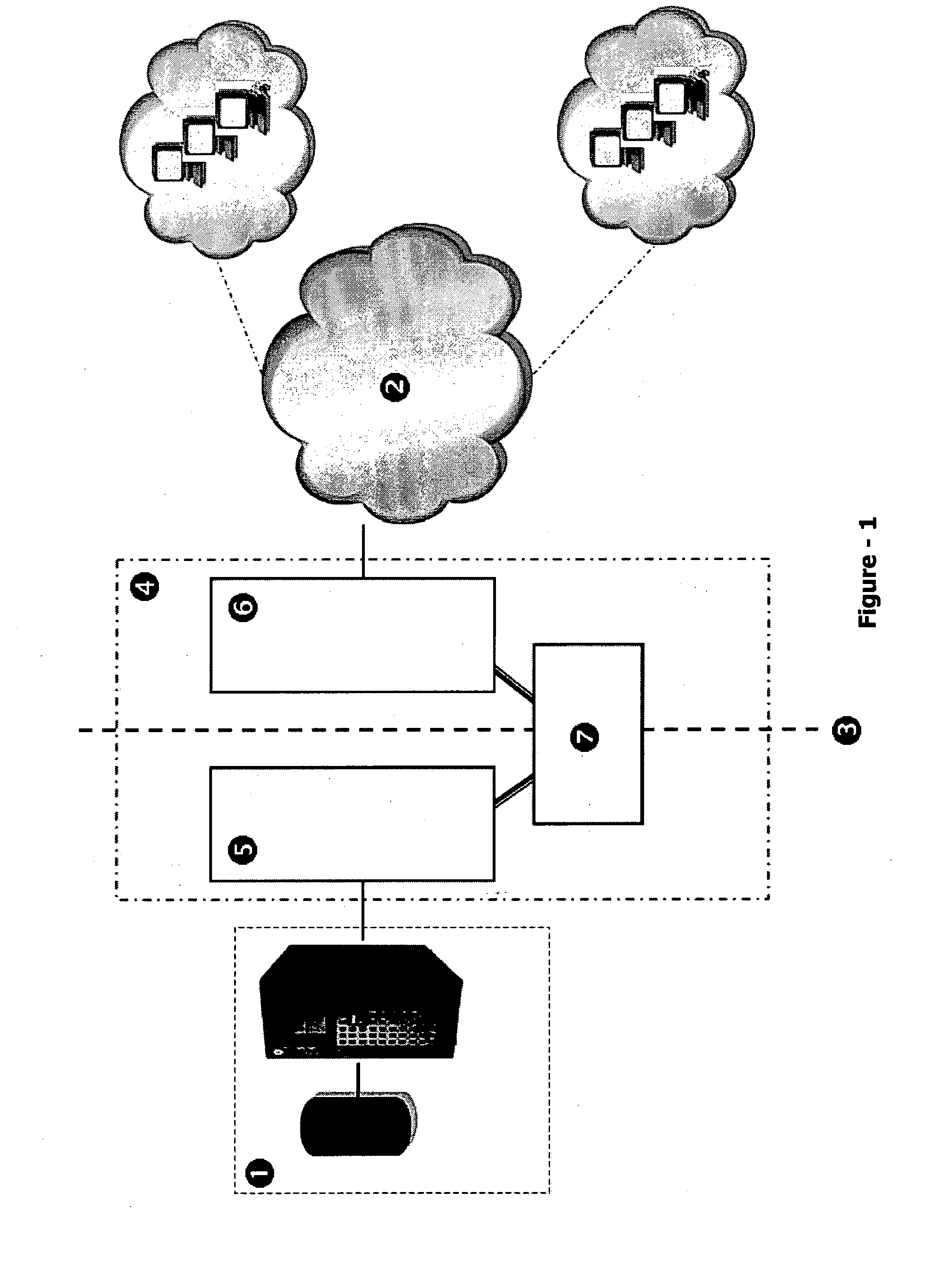

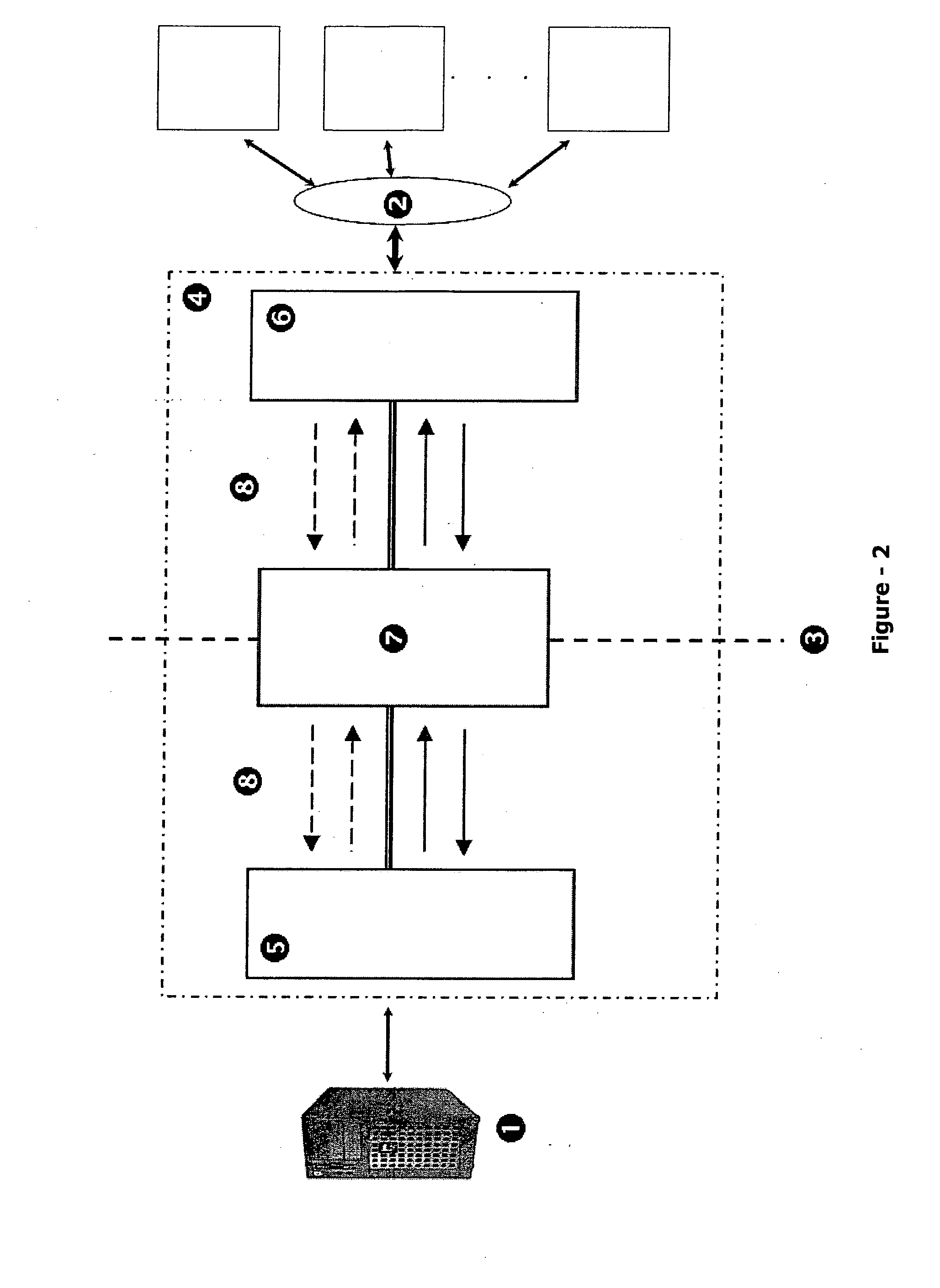

This invention consists of a virtual air gap—VAG system developed in order to provide Internet and computer security. The virtual air gap system developed in this invention is characterized by the principal elements of: “Virtual air gap (14),” Internal security component (15), “External security component (16),” Message transfer mechanism of the system components positioned between internal and external security components (5, 6) and a shared memory (7), “Internal system (9) consisting of the internal security component and such other components (11) contained in the system, and connecting the same to the internal network (1),” External system (10) consisting of the external security component and such other components contained in the system, and connecting the same to the external network (2), and “Shared memory (7).

Owner:OZGIT ATTILA

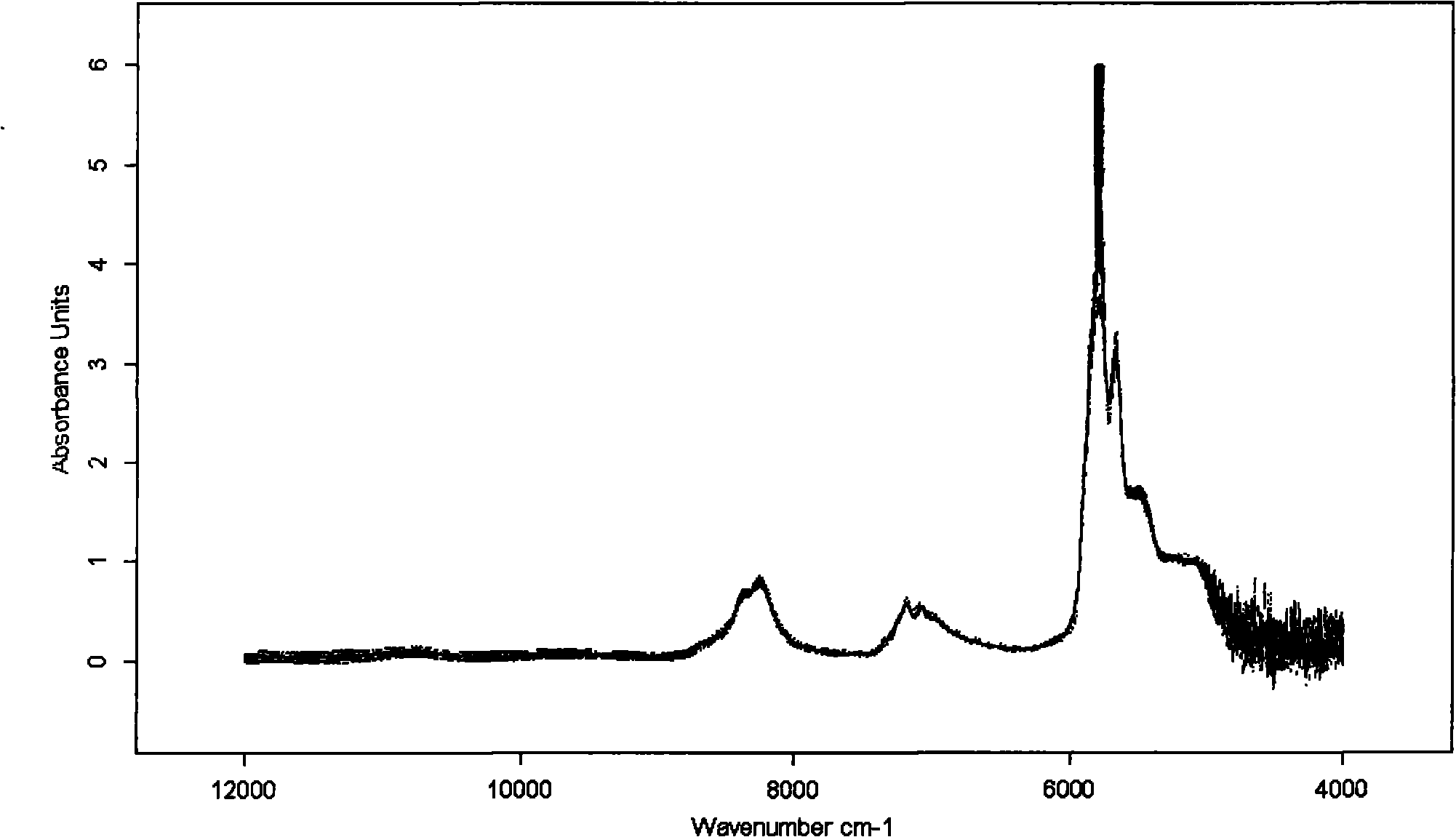

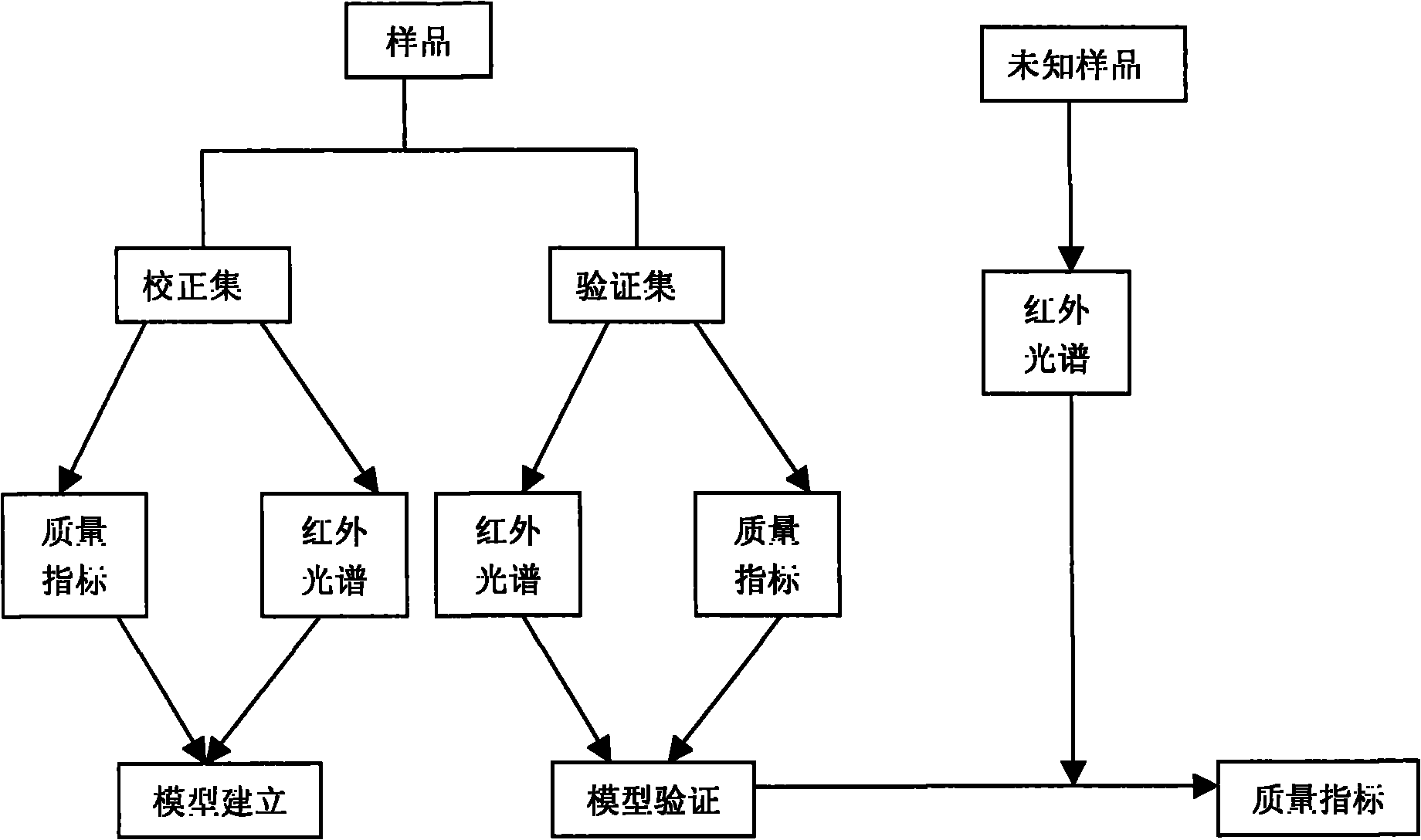

Near infrared spectrum quick test method of new oil quality of lubricating oil

InactiveCN101893561AColor/spectral properties measurementsSpecial data processing applicationsInfraredOil quality

The invention discloses a near infrared spectrum quick test method of new oil quality of lubricating oil. The method comprises the following steps of: 1, collecting a representative sample of the lubricating oil as a training set; 2, measuring the near infrared spectrum of the lubricating oil sample of the training set, performing the corresponding pretreatment of the near infrared spectrum, and using the pretreated spectrum data as a variable; 3, selecting a proper multivariate calibration method to establish a model of the relationship between an new oil quality index of the lubricating oil and the spectrum; and 4, for the quality measurement of the unknown lubricating oil sample, measuring the near infrared spectrum of the lubricating oil sample, performing the same pretreatment, and measuring the quality index of the lubricating oil by the quality analysis model of the lubricating oil. The method can quickly measure 18 quality parameters such as chemical composition content, physical-chemical properties, main elements and additive elements by the near infrared spectrum and has the advantages of high analytic speed, easy operation and high quality monitoring capability of the lubricating oil.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

Ultra-hard composite material and method for manufacturing the same

An ultra-hard composite material and a method for manufacturing the same, including mixing a metal carbide powder and a multi-element high-entropy alloy powder to form a mixture, green compacting the mixture, and sintering the mixture to form the ultra-hard composite material. The described multi-element high-entropy alloy consists of five to eleven principal elements, with every principal element occupying a 5 to 35 molar percentage of the alloy.

Owner:IND TECH RES INST

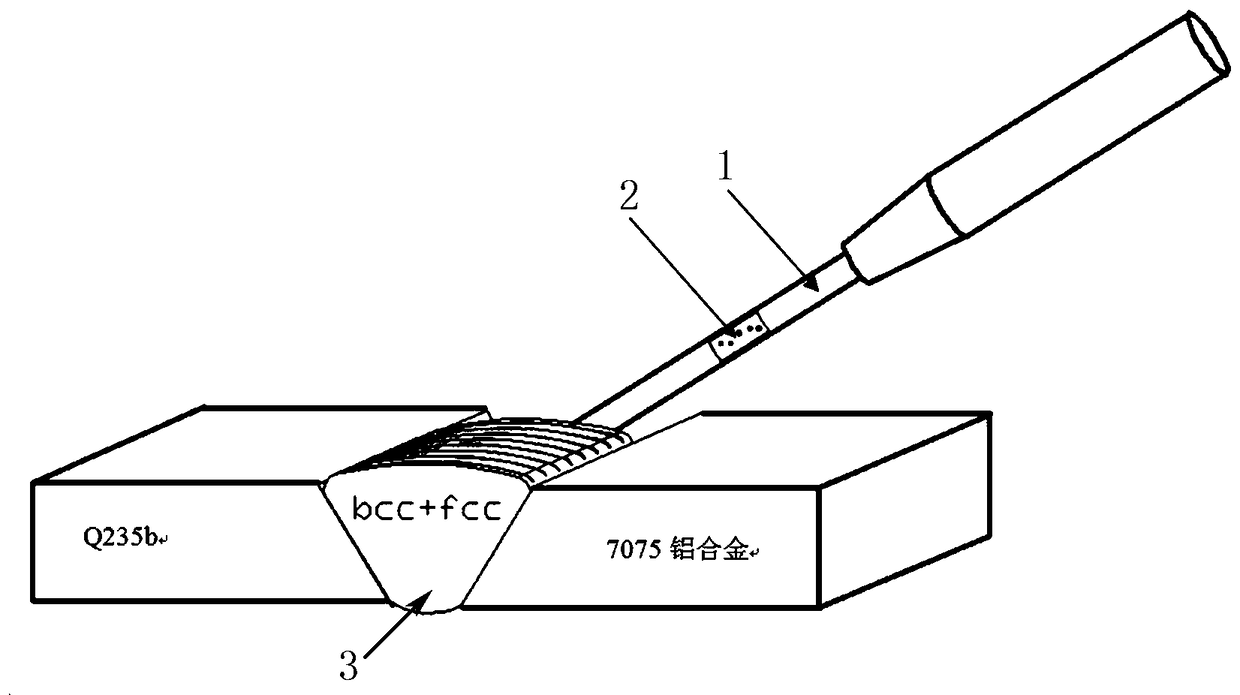

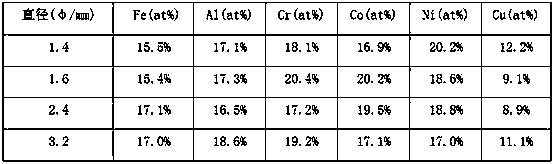

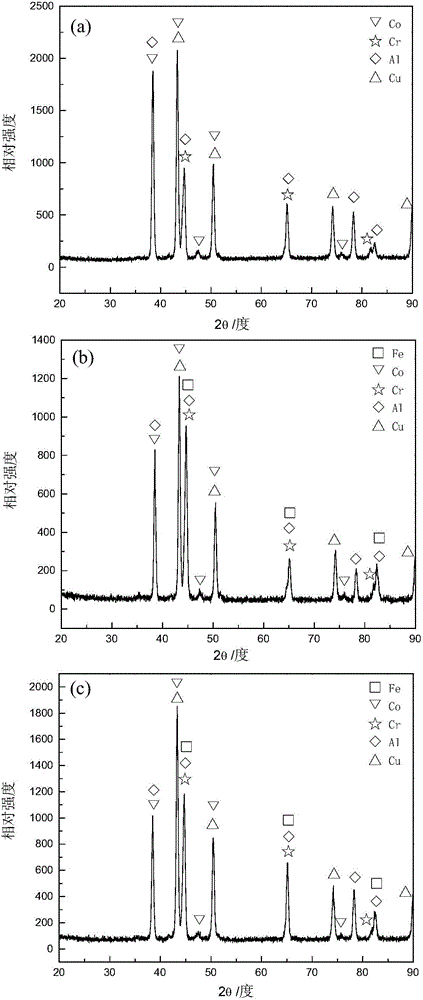

High-entropy flux cored wire for aluminum-steel MIG welding and preparation method of high-entropy flux cored wire

InactiveCN108161278AGood compatibilityAvoid it happening againWelding/cutting media/materialsSoldering mediaEntropy fluxHigh entropy alloys

The invention discloses a high-entropy flux cored wire for aluminum-steel MIG welding. Powder is prepared from, by atomic percentage, 5%-15% of Fe, 10%-20% of Al, 20%-30% of Co, 18%-35% of Cr, 20%-35%of Ni and 5%-13% of Cu, and the total percentage is 100%. Industrial high-purity copper tape is adopted for an outer skin material. A preparation method comprises the steps that firstly, a mother alloy is melted; secondly, atomized power is prepared by applying a vacuum gas atomization powdering technology; and thirdly, the high-entropy flux cored wire is prepared by the adoption of flux cored wire forming unit equipment. The high-entropy flux cored welding wire is used for aluminum-steel MIG welding, a high-quality aluminum-steel welded joint is obtained, the chemical compositions of weld metal are within a principal element range of a high-entropy alloy, and the high entropy of a weld is achieved. The weld has excellent strength and toughness, brittle intermetallic compound phases are eliminated effectively, and the good synthesized mechanical properties are provided.

Owner:TAIYUAN UNIV OF TECH

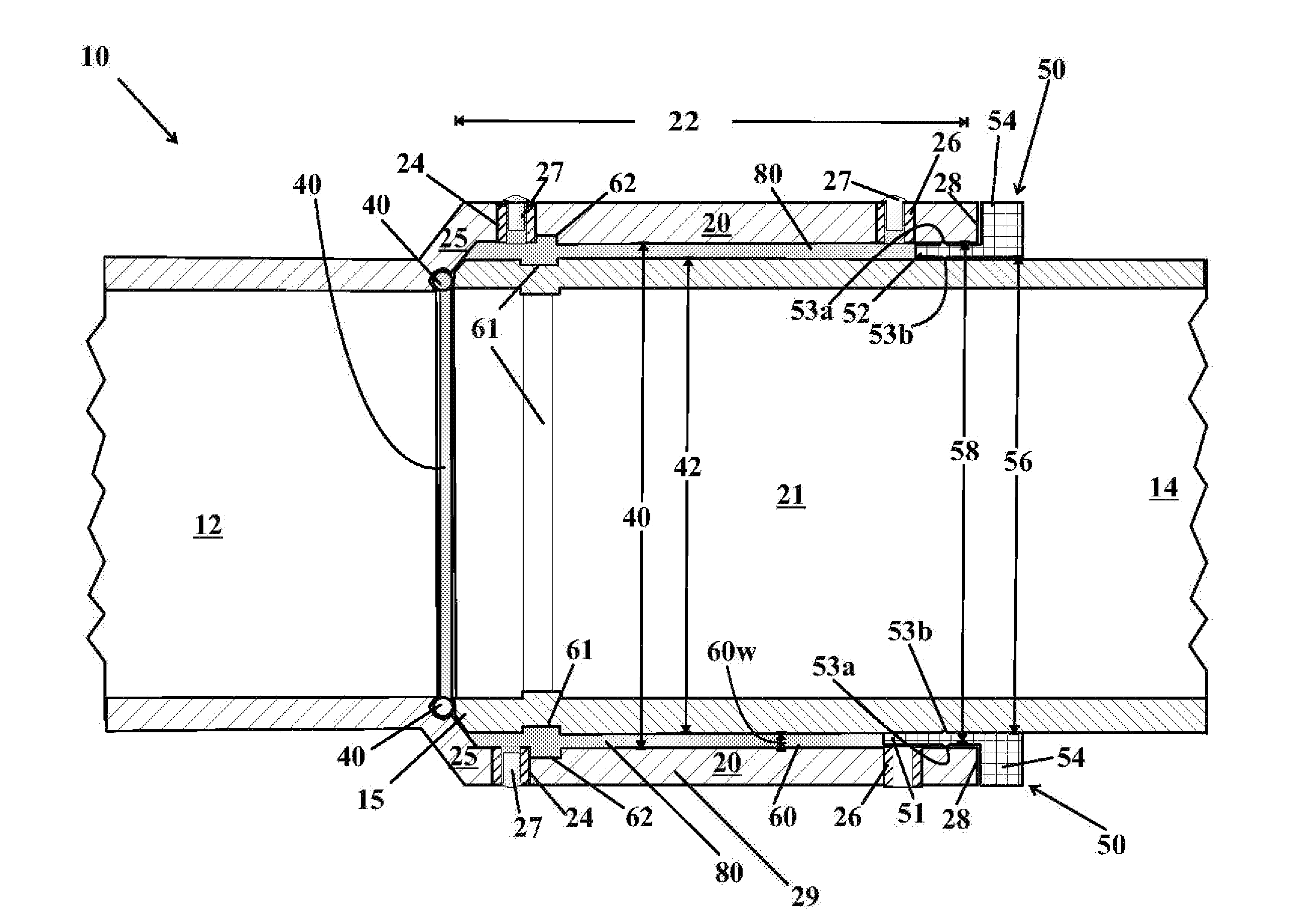

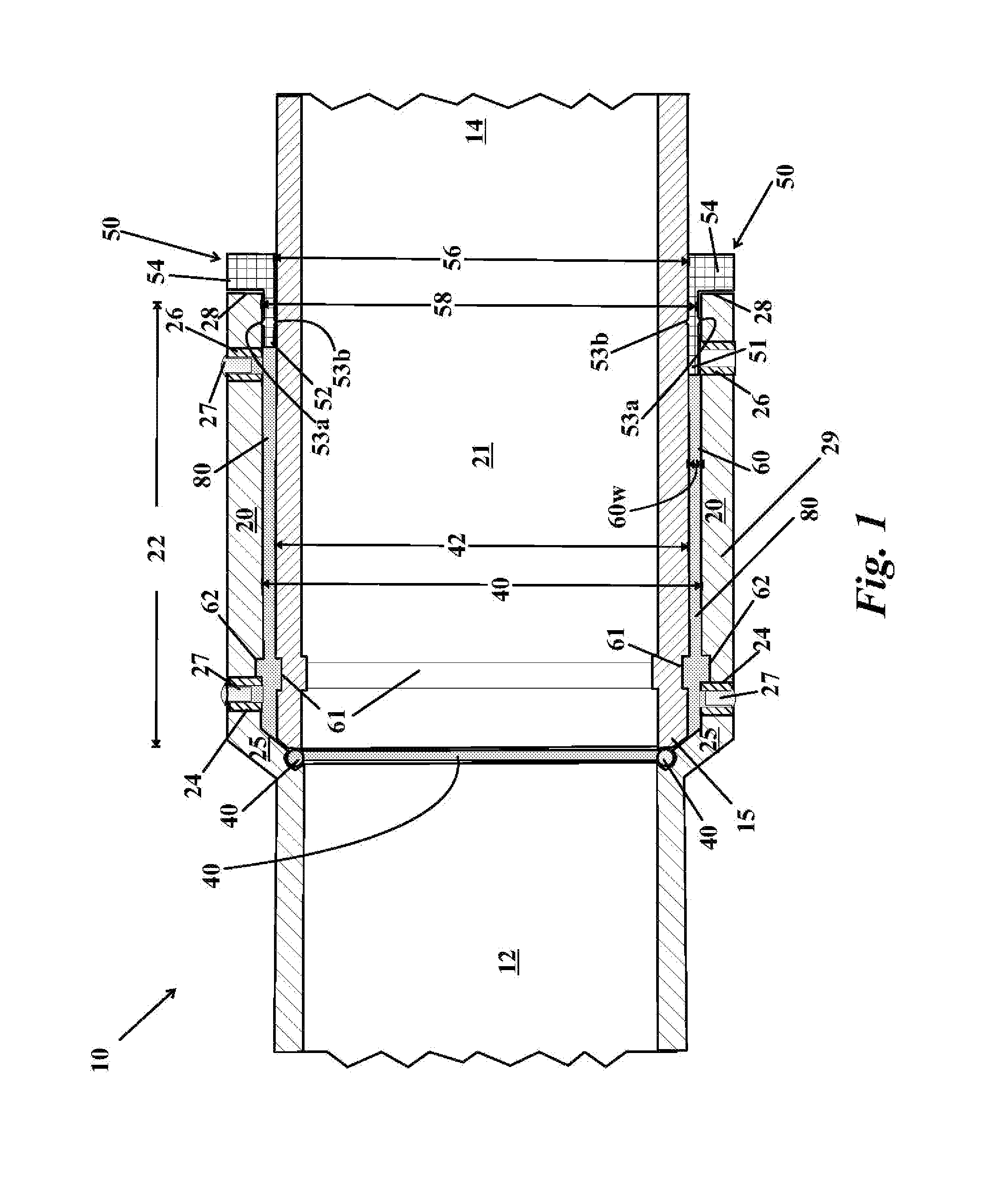

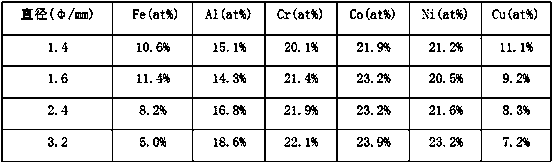

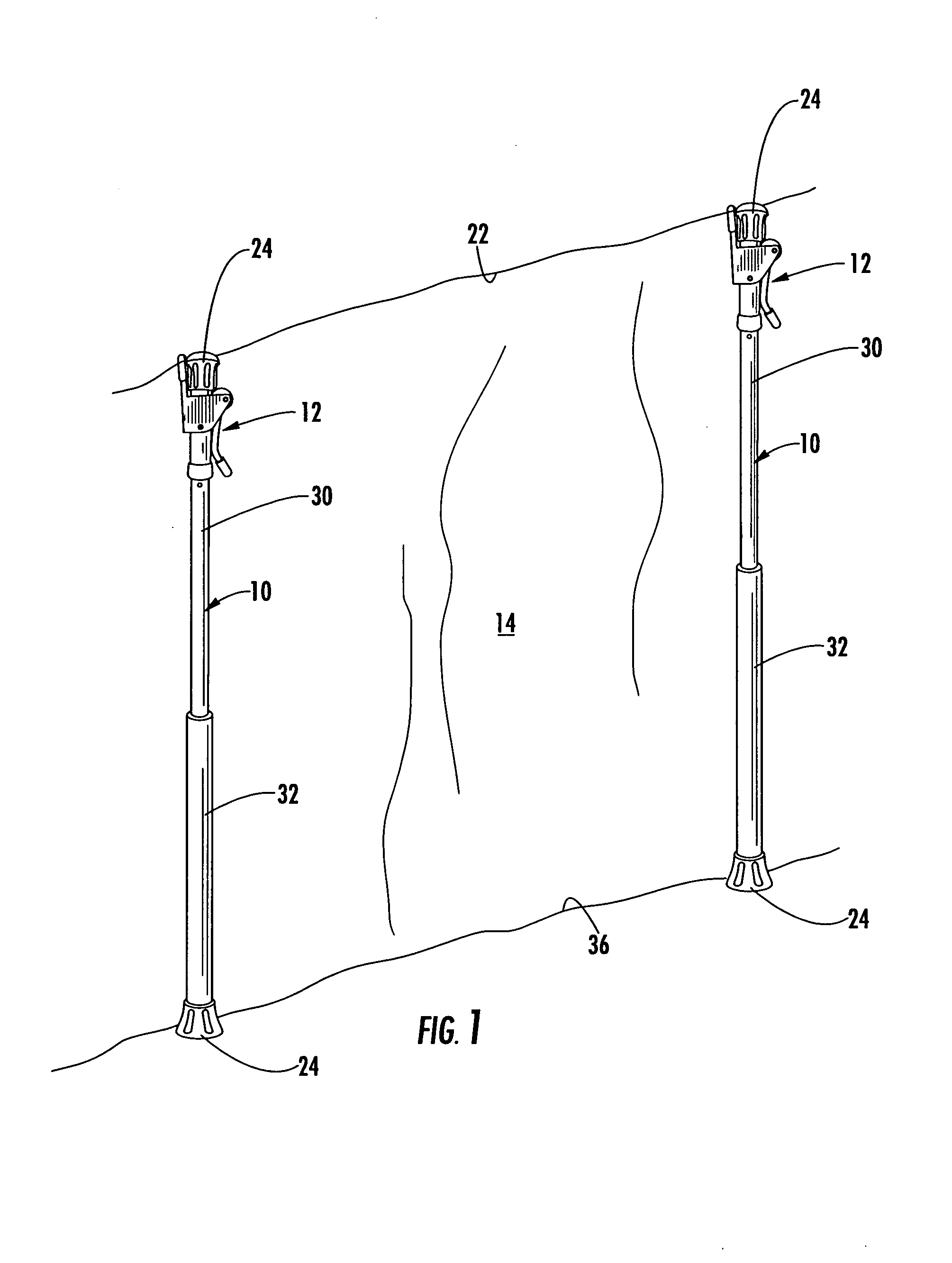

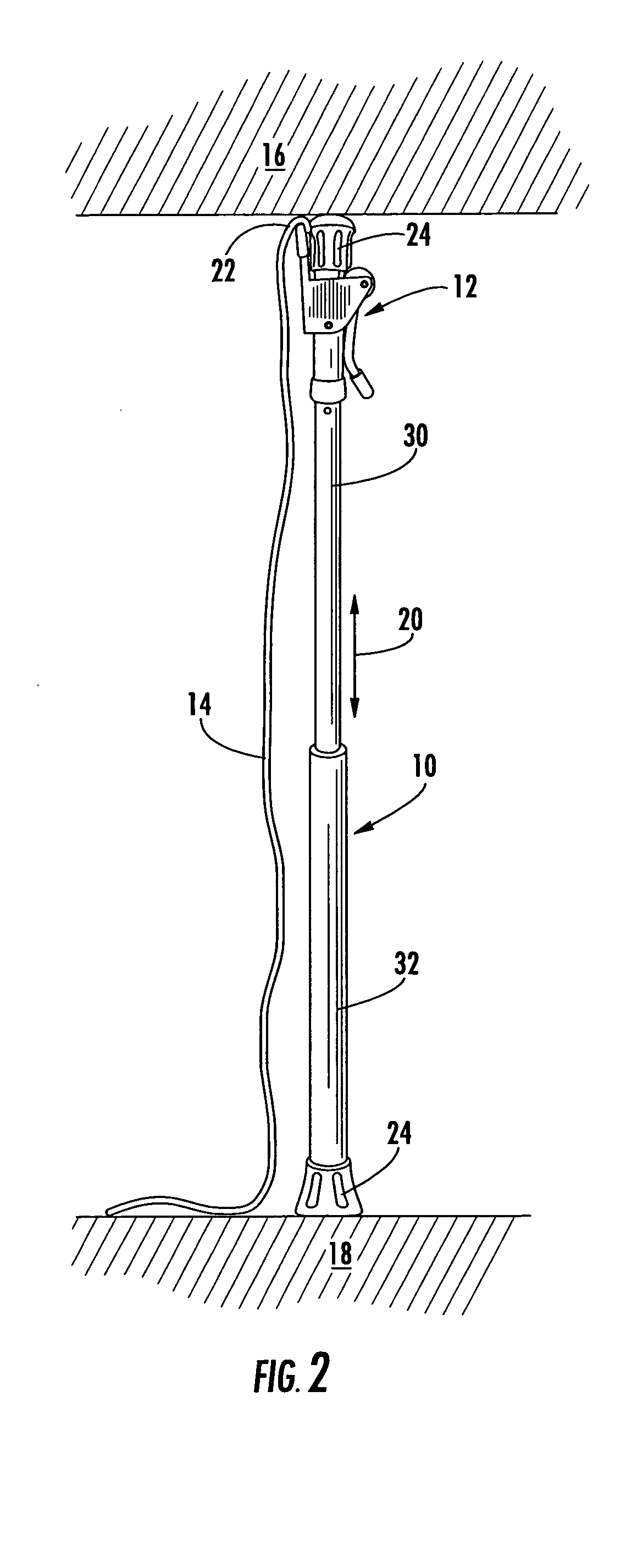

Temporary partition system

A novel clamping device for use in conjunction with a temporary partition system is provided. The present invention is a telescoping pole system having a unique clamping end that retains a sheet of plastic or other sheeting material for the establishment of temporary partitions such as the type typically used in connection with dust control. The principal elements of the system include an adjustable, telescoping pole, a clamping end with a mechanism thereon for retaining sheeting material and the sheeting material itself. In conjunction, the elements of the system are installed in the desired location between supporting structure to provide a temporary partition as necessary.

Owner:EZ WALL LLC

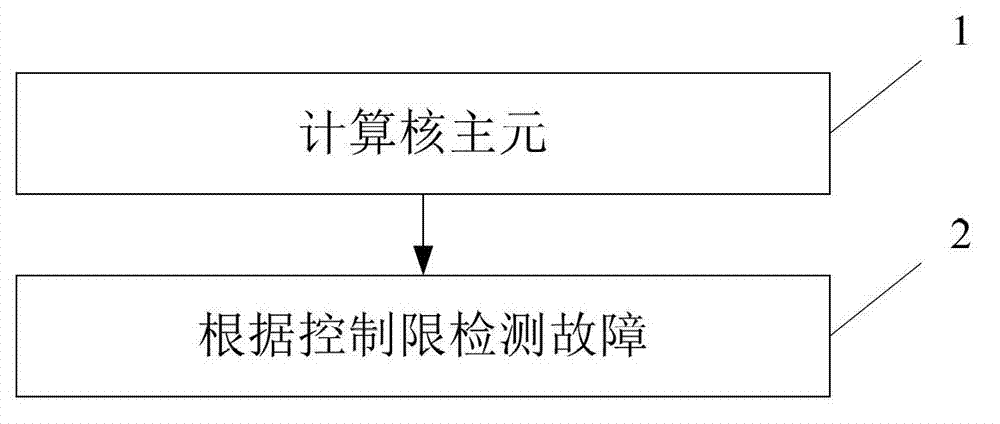

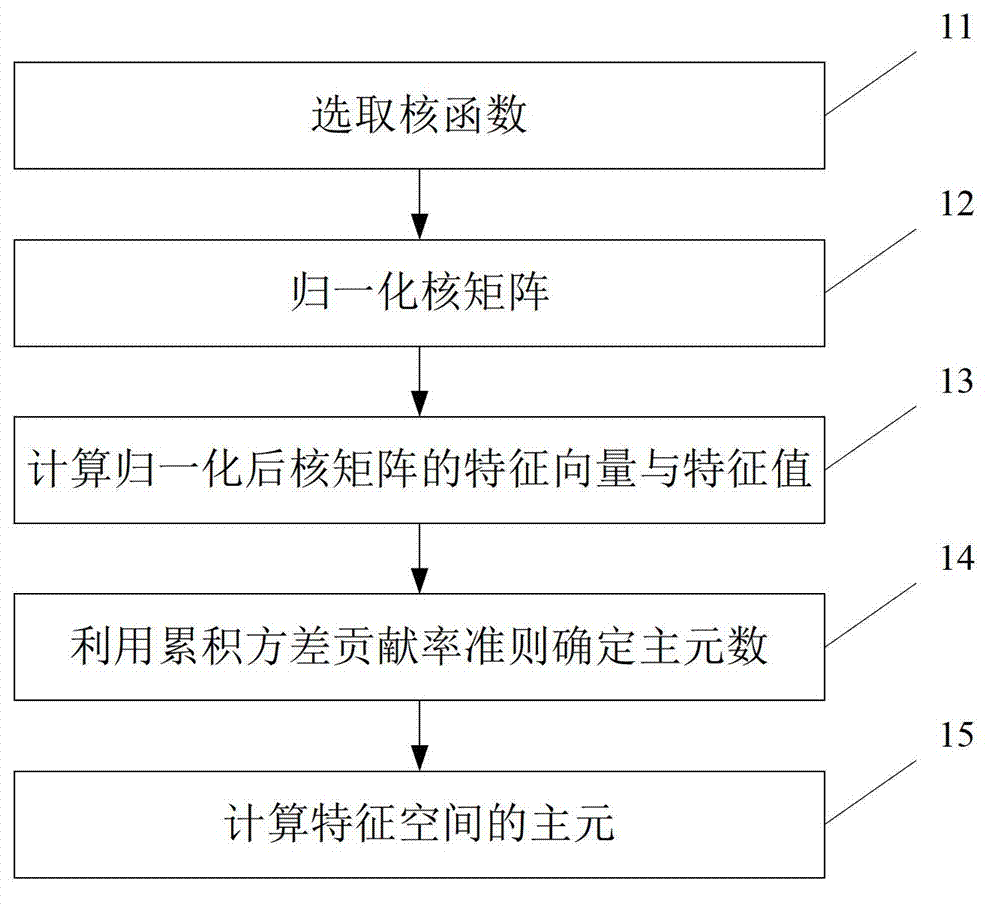

Method and system of failure prediction

ActiveCN103197663ASolve nonlinear problemsAccurate Failure Prediction ResultsElectric testing/monitoringKernel principal component analysisPredictive methods

The invention relates to a method and a system of failure prediction. The method of the failure prediction comprises calculating a kernel principal element, and detecting a failure according to control limits. A method based on kernel principal component analysis (KPCA) reconfiguration is adopted in the failure prediction aiming at rotating machinery, the nonlinear problem of process data can be solved well, a failure direction is obtained from the data implying failures, a failure amplitude value is estimated, the multi-dimensional character of the failures is considered, and an accurate failure prediction result can be obtained.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Virtual air gap—VAG system

Owner:OZGIT ATTILA

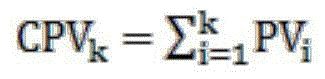

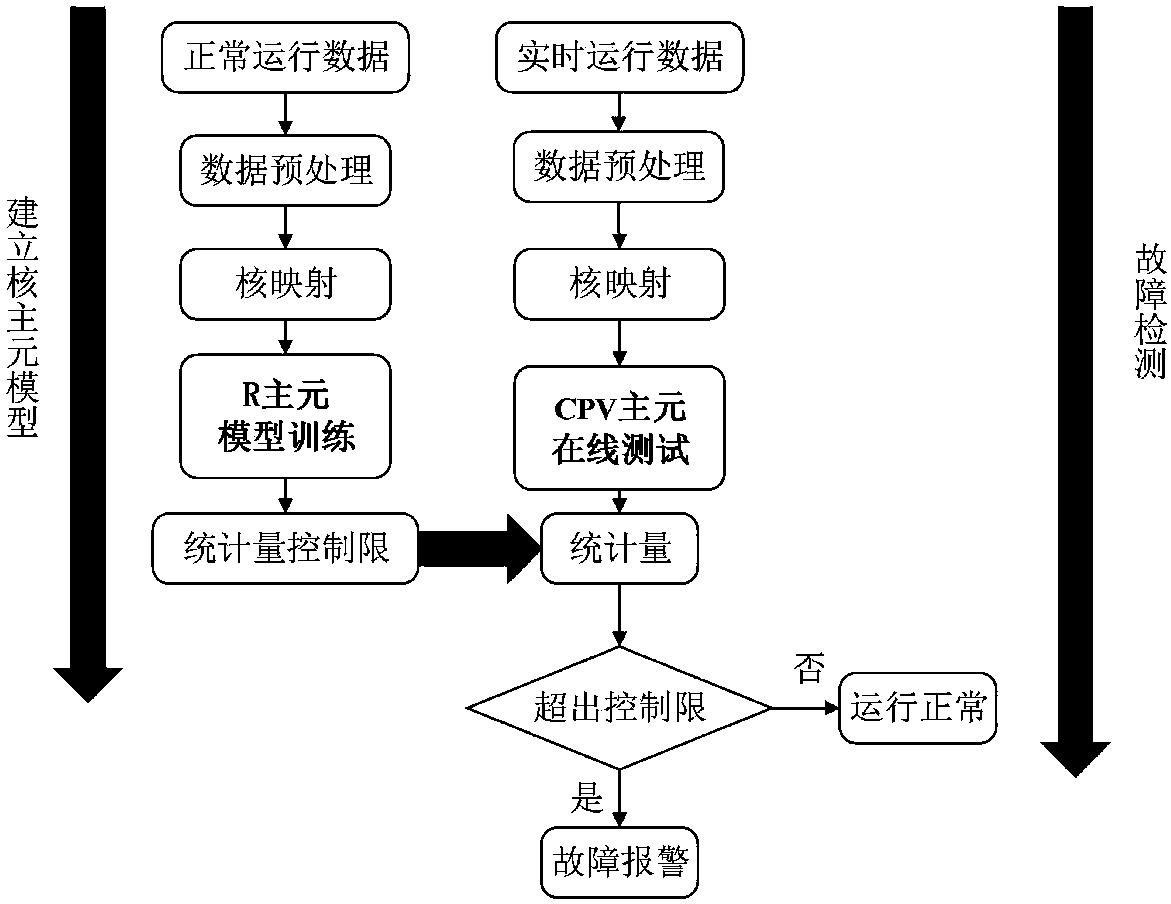

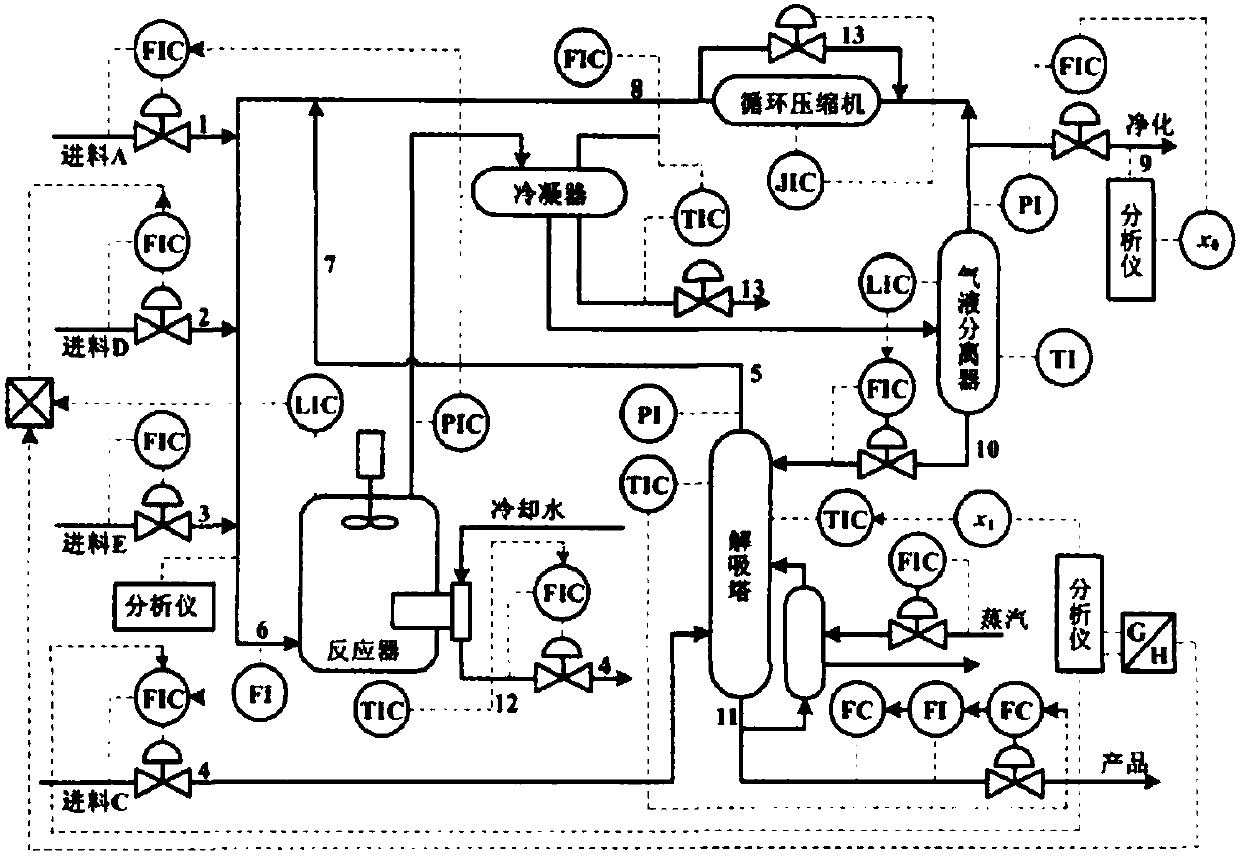

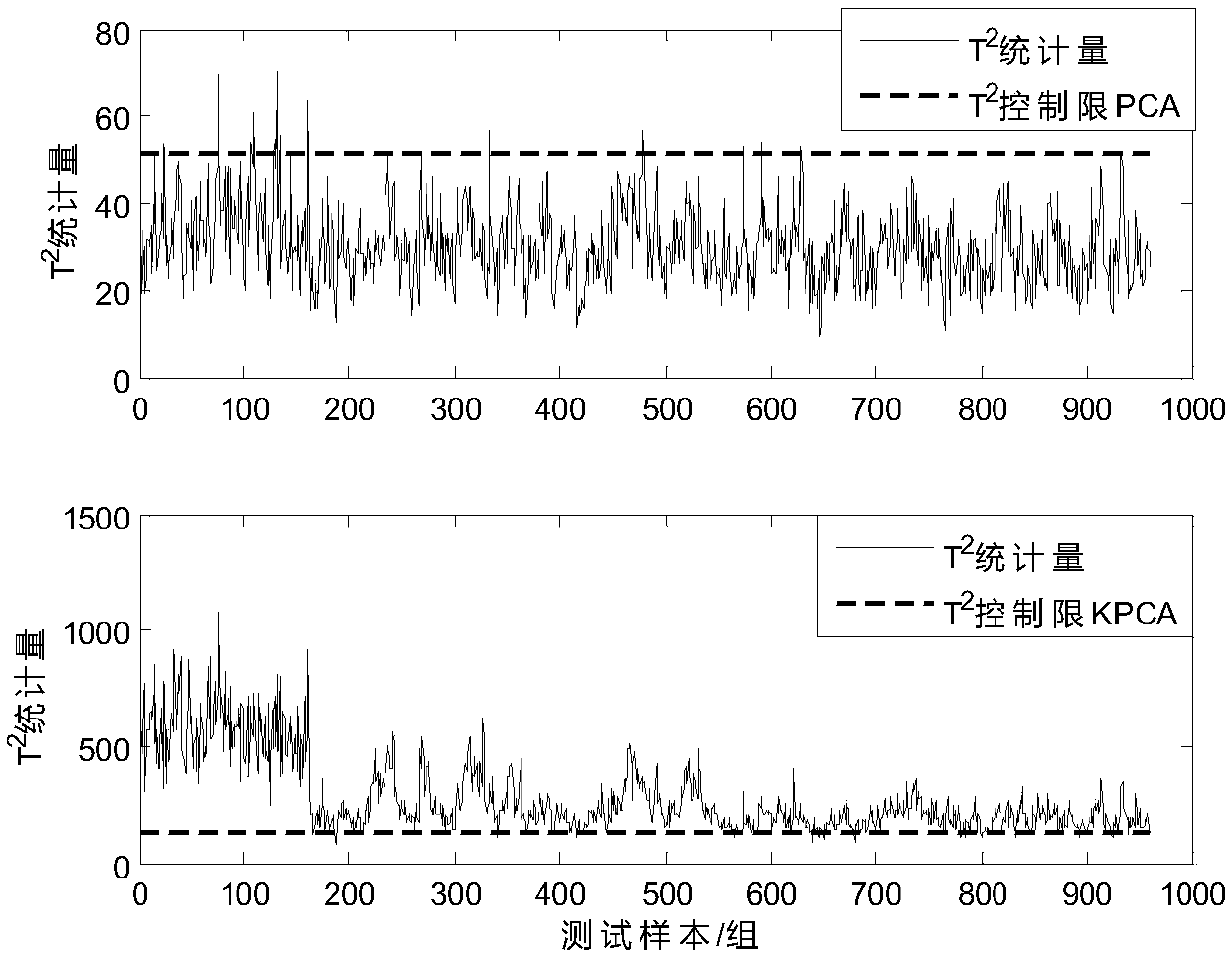

Double main element-dynamic kernel principal component analysis fault diagnosis method based on chemical TE process

ActiveCN108062565AImprove recognition rateImprove modeling accuracyCharacter and pattern recognitionDesign optimisation/simulationKernel principal component analysisPrincipal component method

The invention discloses a double main element-dynamic kernel principal component analysis (DME-DKPCA) fault diagnosis method based on a chemical TE process. According to the method, a DOD algorithm isused to determine an optimal parameter order of process data, after a generated dynamic matrix projects in a kernel principal element space, the suppression ability of an R principal component method to high-dimensional noise is used to effectively determine the number of principal components of normal state data in a kernel feature space, and T2 and SPE control limits of a fault detection high-dimensional space are generated; then a CPV method is used to retains fault information to the maximum extent, the number of new principle components is determined from data to be detected, and T2 and SPE statistics are recalculated to monitor and detect a fault. According to DME-DKPCA method, the recognition rate of fault detection is effectively improved, and the method has better model accuracy than a DKPCA method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

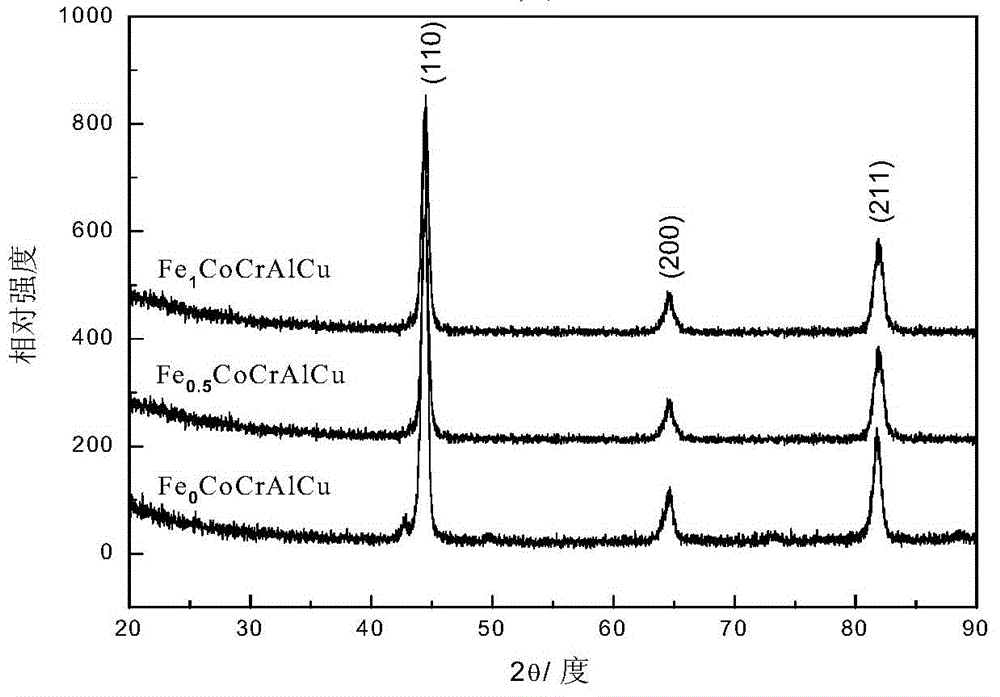

Powder material for laser high entropy alloying of iron single element base alloy surface

ActiveCN104646660ASolve the disadvantages of poor combinationSolve crackingMetallic material coating processesSurface engineeringHigh entropy alloys

The invention discloses a powder material for laser high entropy alloying of an iron single element base alloy surface, belongs to the surface engineering technology field, and provides a new power material for preparation of a high entropy alloy coating. The powder material for the laser high entropy alloying of the iron single element base alloy surface consists of five types or more than five types of metallic elements. Constituent elements of the powder material for the laser high entropy alloying of the iron single element base alloy surface contain single element base alloy base material principal element iron, wherein content of the confirmed single element base alloy base material principal element iron is 0-30% of the total molar fraction of the coating alloy power material, and adding content of other types of the constituent elements in the coating alloy power material is 5-35% 0f the total molar fraction of the coating alloy power material. The powder material for the laser high entropy alloying of the iron single element base alloy surface is prepared by using appropriate laser irradiation technological parameters, and can prepare the high entropy alloy coating in metallurgical bonding with an iron base alloy base material, uniform and fine in texture, flawless and excellent in performance.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com