On-line real-time failure monitoring and diagnosing system device for industrial processing of residual oil

A system device, real-time fault technology, applied in the direction of total factory control, total factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

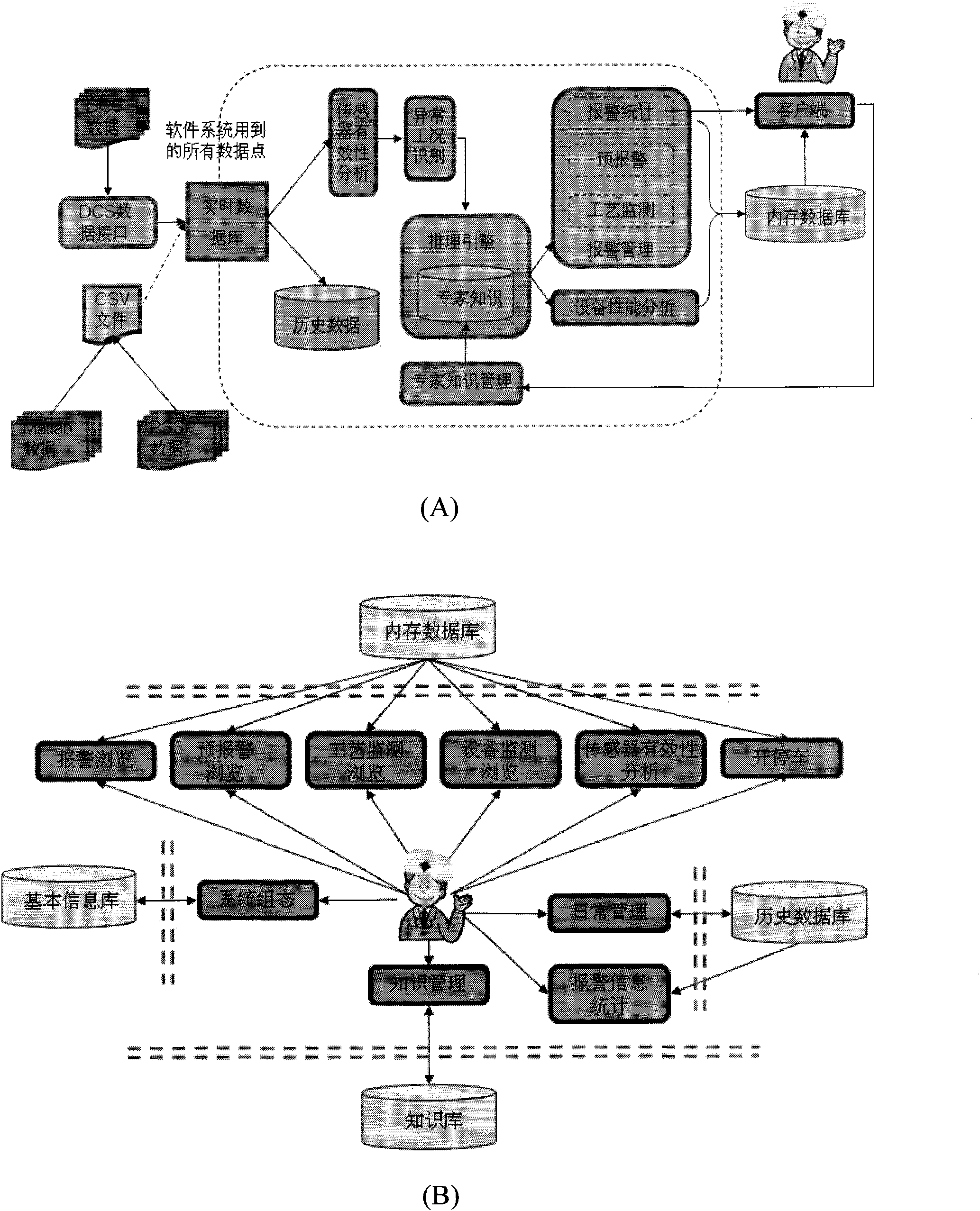

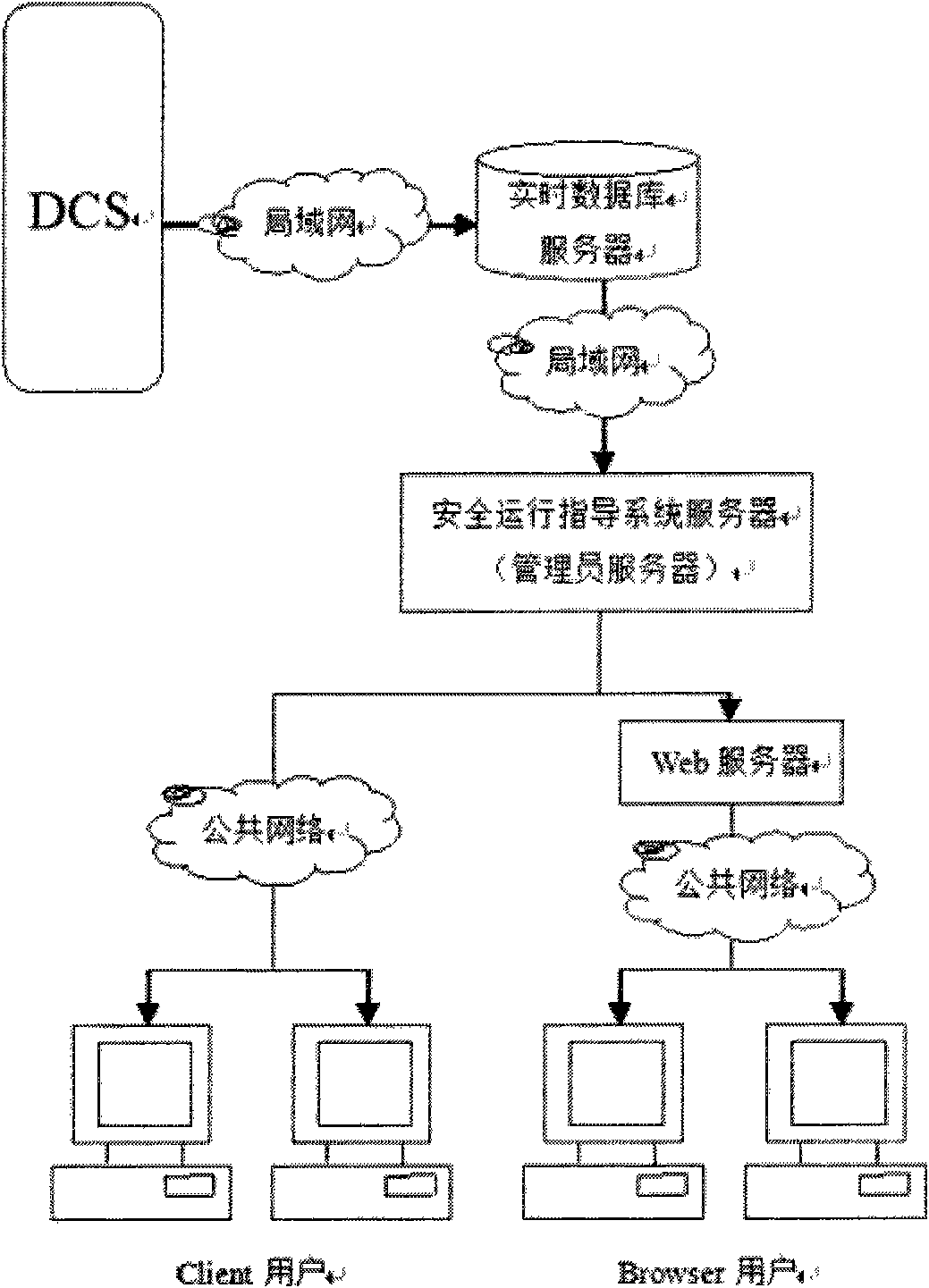

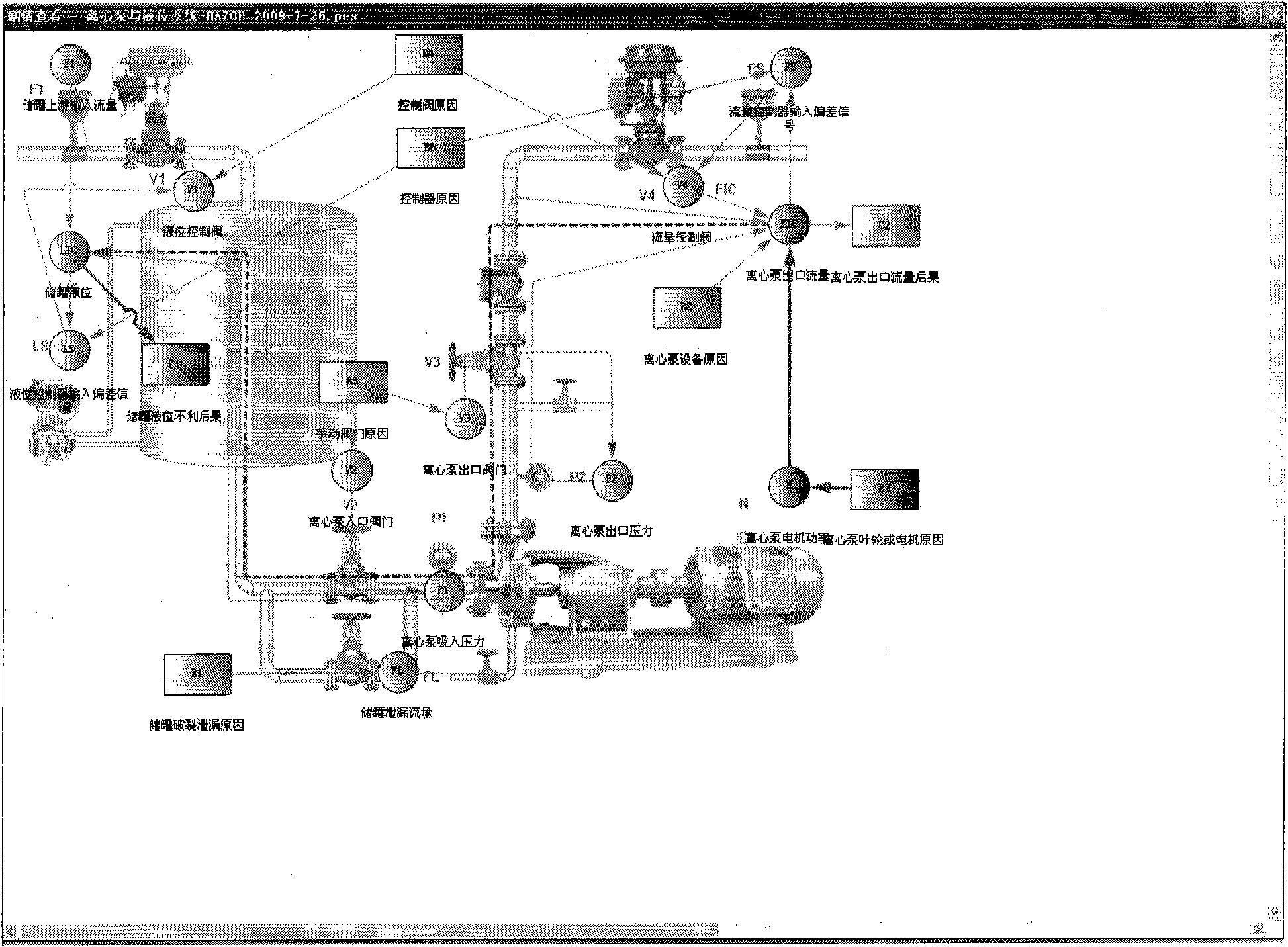

[0022] A system device for on-line real-time fault monitoring and diagnosis of industrialized residual oil processing, using a delayed coking unit for oil refining, and installing a DCS system on the delayed coking unit to connect to the actual process and collect real-time data from the production site. Configure the server in the central control room, install and run the real-time database and the delayed coking safety operation guidance system, wherein the DCS system, the real-time database server and the safety operation guidance system are connected in sequence through the local area network, and the safe operation guidance system communicates with customers through the public network The core of the delayed coking safety operation guidance system is the inference engine subsystem, the engine subsystem includes a process monitoring module and an equipment monitoring module, which is responsible for the reasoning and analysis of online faults, composed of SDG, principal comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com