Near infrared spectrum quick test method of new oil quality of lubricating oil

A technology of near-infrared spectroscopy and rapid determination, which is used in the measurement of color/spectral properties, measuring devices, and material analysis by optical means, etc., to achieve the effects of cheap instruments, strong environmental adaptability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0066] Example 1: Determination of lubricating oil quality indicators by FT-NIR method

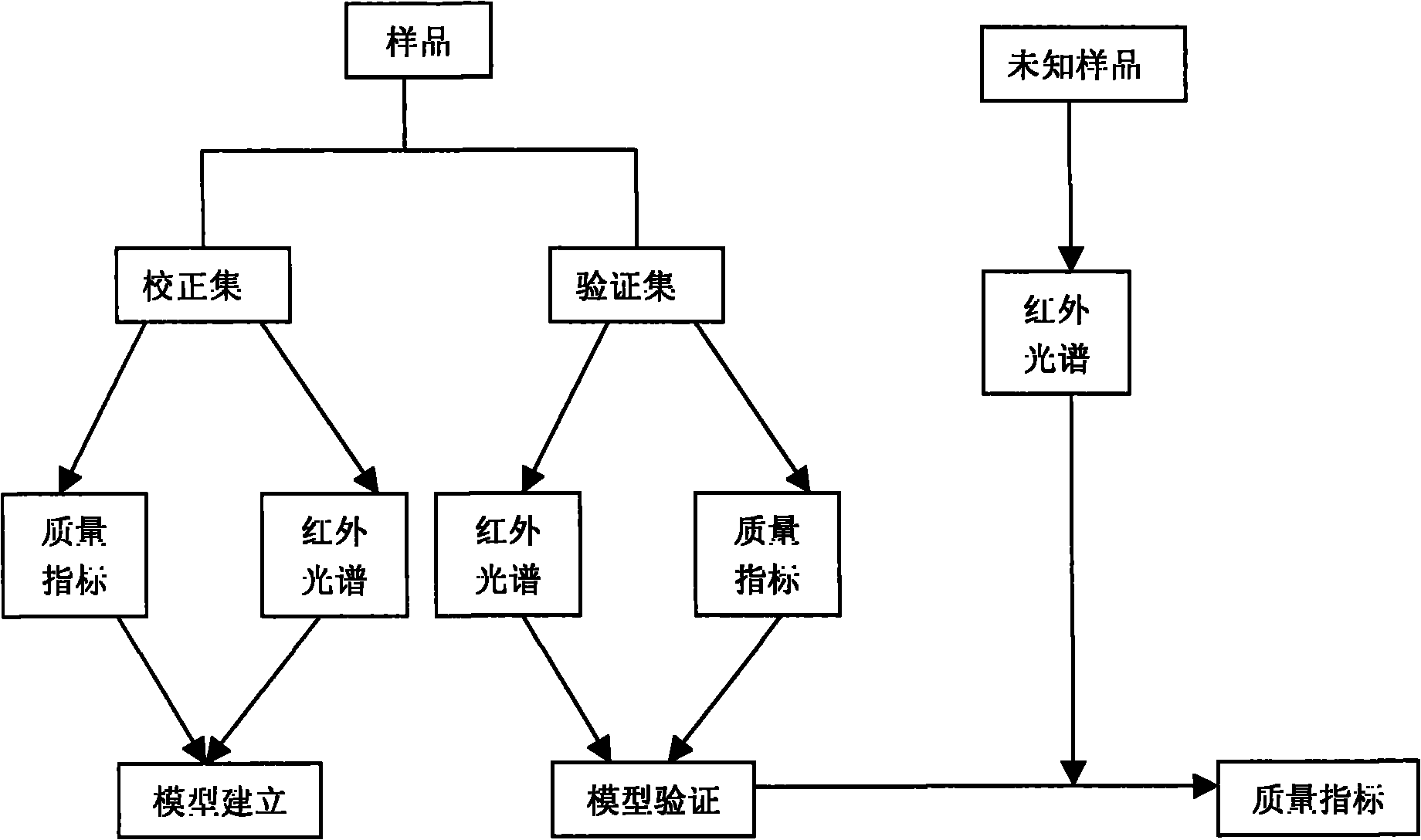

[0067] 1) Collect training set samples

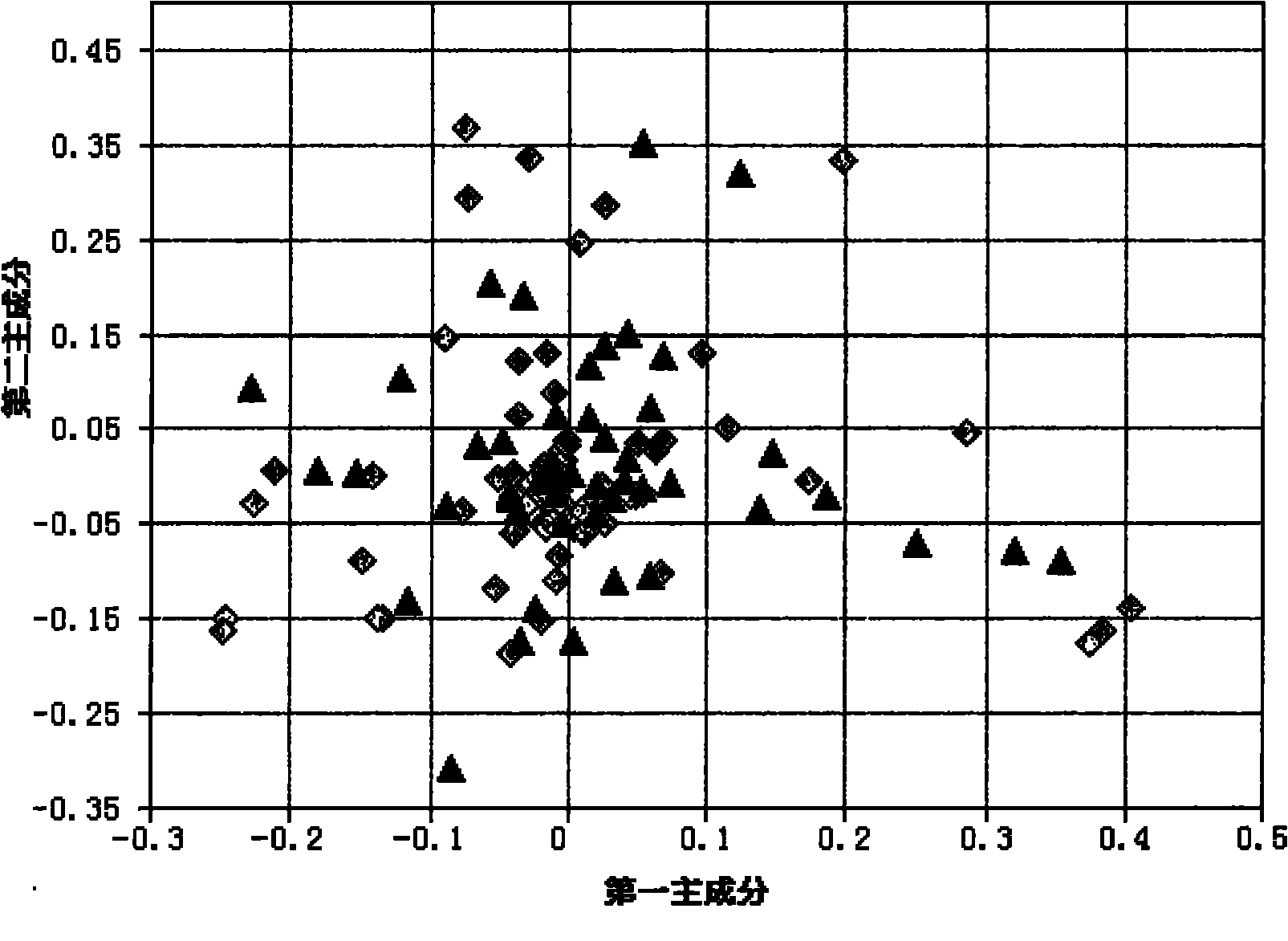

[0068] 125 lubricating oil samples were collected, including 86 internal combustion engine oils, 26 hydraulic oils, and 13 gear oils, whose manufacturers include Shell, ESSO, Mobil, MOBIL, Great Wall and Kunlun, etc. The training set is further divided into a correction set and a verification set. The ratio of the number of samples in the correction set to the verification set is 6 / 4. The distribution is shown in image 3 .

[0069] 2) Determination of the near-infrared spectrum of the training set samples

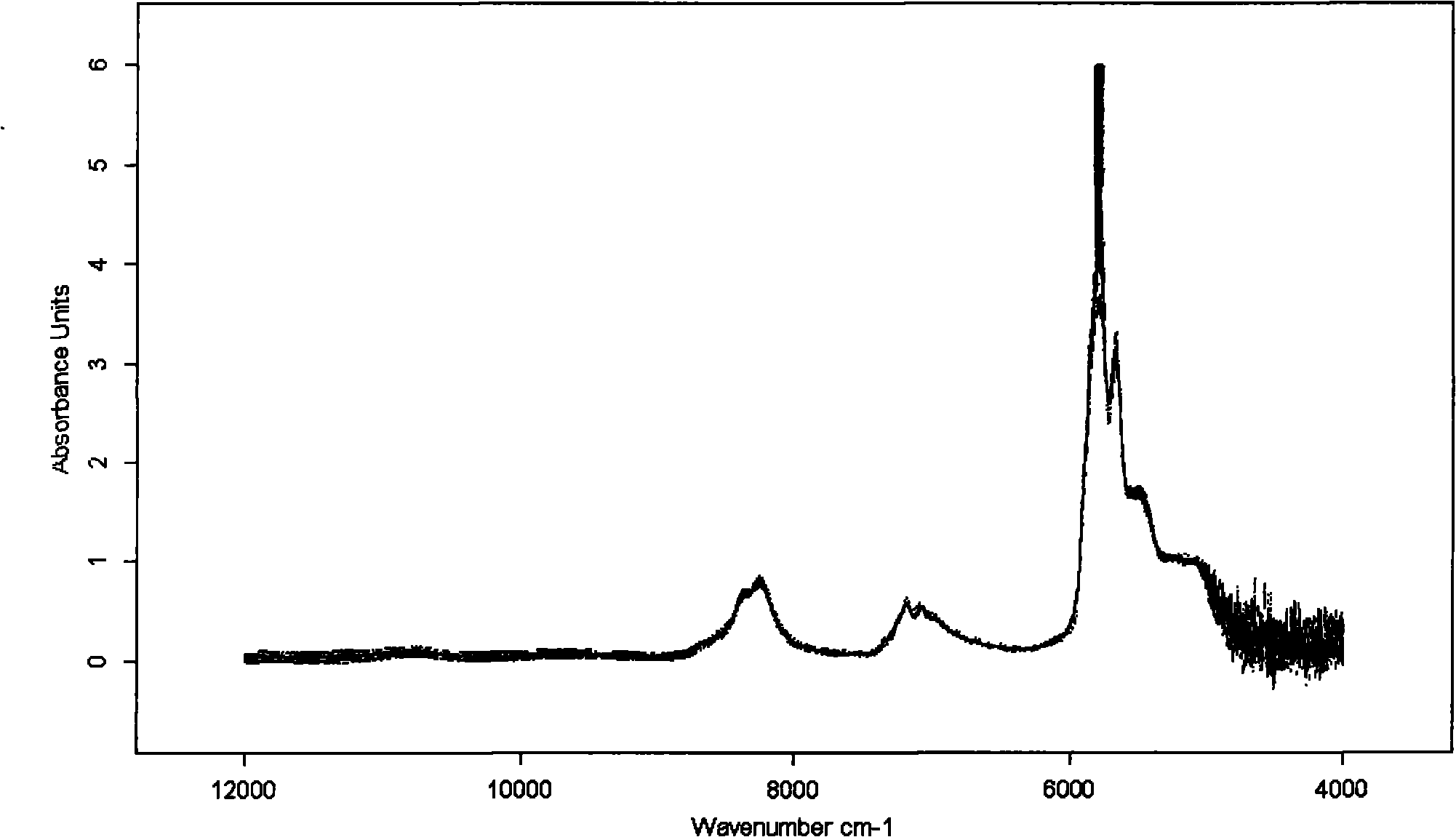

[0070] The transmission absorbance spectra of the samples in the training set were measured by FT-NIR spectrometer. The instrument is VECTOR 22 / N, produced by Bruker. The measurement conditions are: resolution 4cm -1 , scan 32 times, wavelength range: 4000~12000cm -1 (833nm-2500nm), quartz cuvette, the optical path is 0.5cm. The measured ...

example 2

[0087] Example 2: Determination of lubricating oil quality indicators by CCD-NIR method

[0088] 1) Collect new oil samples

[0089] The samples were the same as in Example 1.

[0090] 2) Determination of near-infrared spectrum of lubricating oil

[0091] The near-infrared absorption and transmission spectra of lubricating oil samples were measured by CCD-NIR spectrometer. The instrument is a portable mass analyzer produced by the Oil Plant Research Institute of the General Logistics Department. The detector is a CCD with 2048 pixels, a wavelength range of 700-1100nm, and a resolution of 0.2nm. Spectral measurement conditions: the instrument temperature is 37°C, and the sample temperature is 25°C. When the temperature reaches the set value, put the sample into a 5cm closed color dish, scan automatically, and record the last spectrum as the final spectrum. Determination spectrum see Figure 22 .

[0092] 3) The quality index of the lubricating oil sample was measured by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com