Patents

Literature

74 results about "Chemical quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process and sterilization method for instant flavor fish

InactiveCN102669248AHigh hardnessImprove chewinessFood preparationMeat/fish preservation by irradiation/electric treatmentChemical qualityHigh pressure

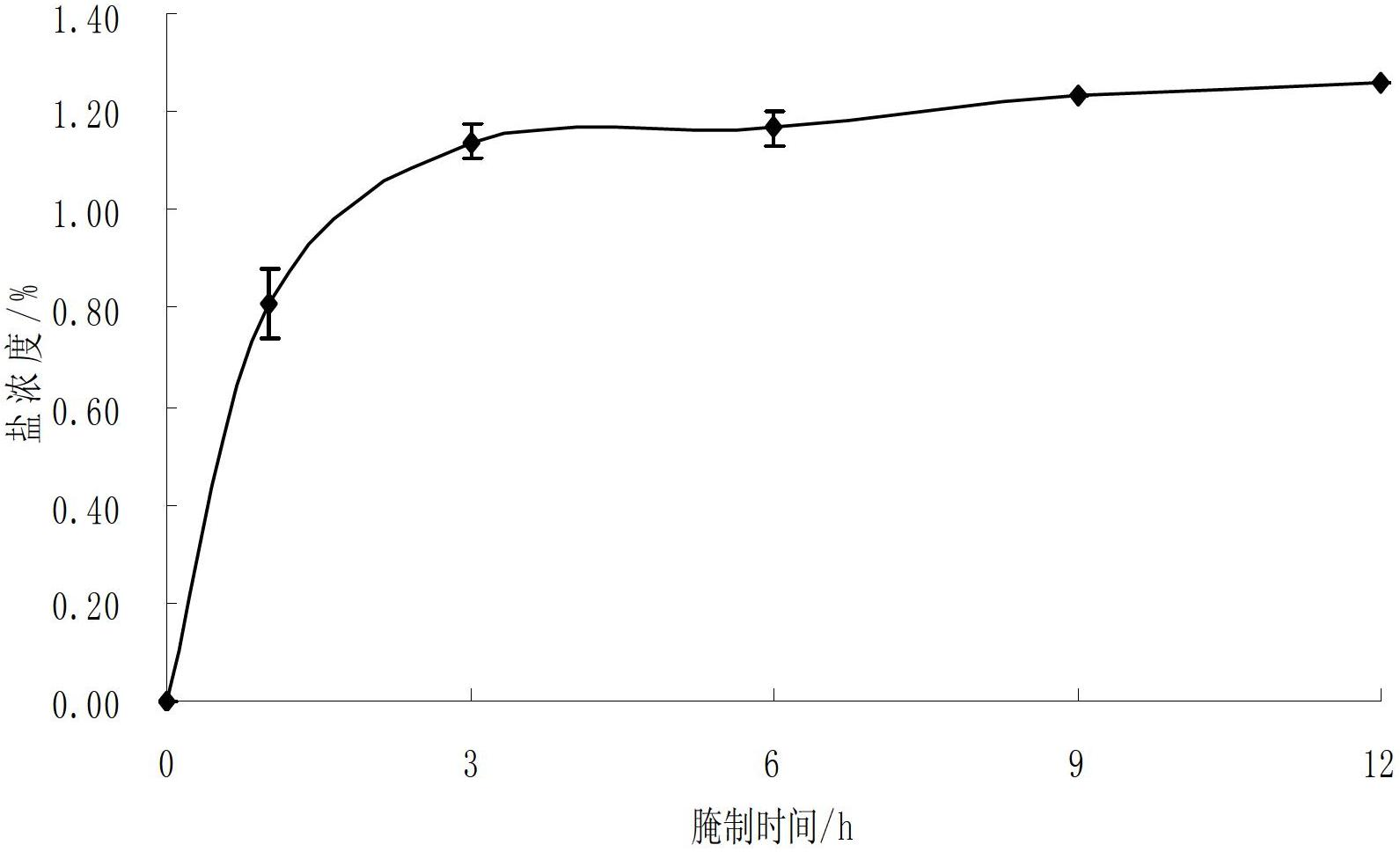

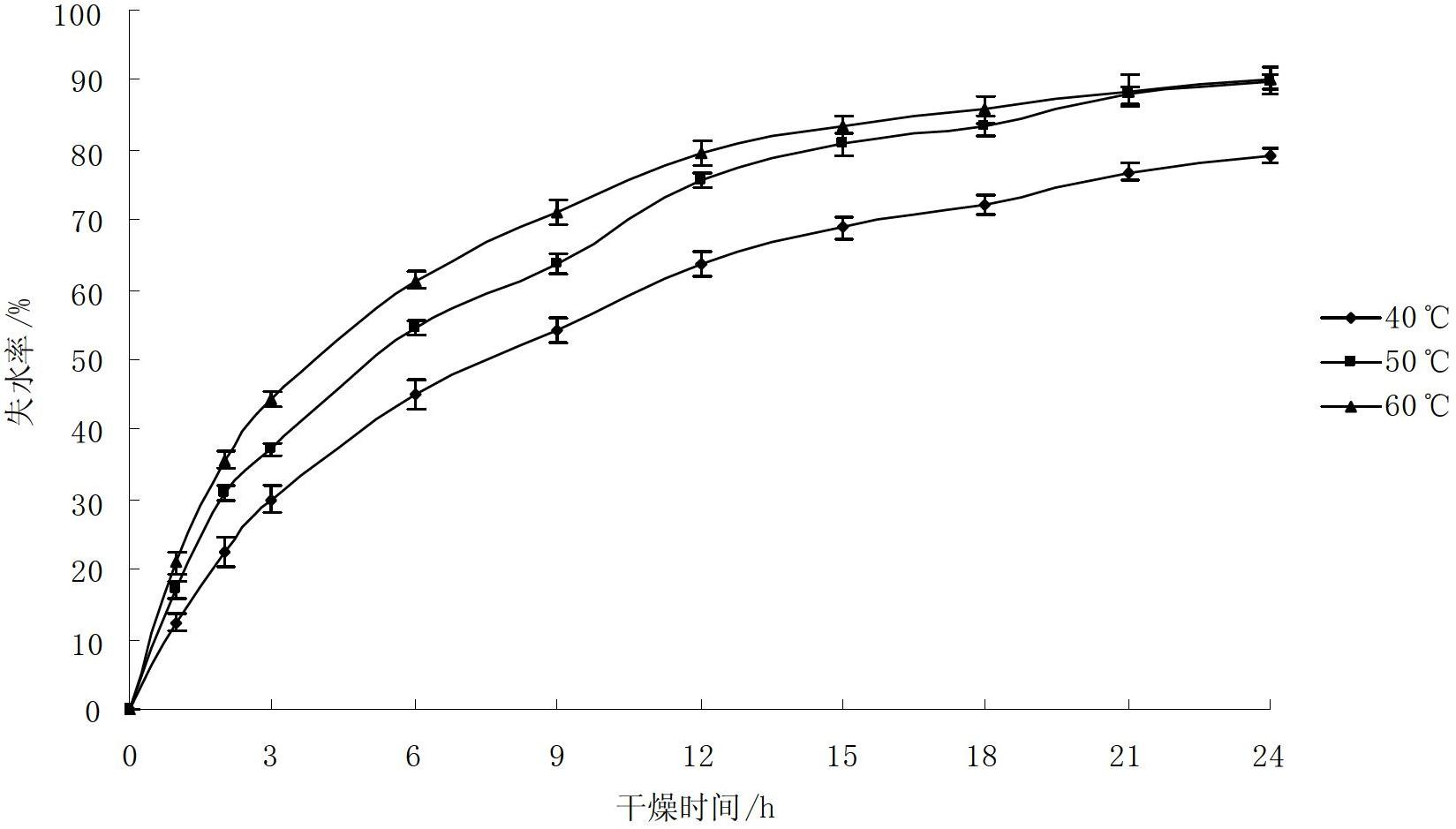

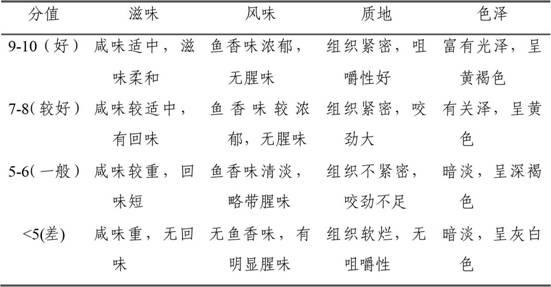

The invention relates to a preparation process and a sterilization method for instant flavor fish. The preparation steps are as follows: removing scale, viscera, the head, the tail and fishbone from a 1.5 to 2kg fresh grass carp, and cleaning, draining and dividing the grass carp into fish blocks of about 2cm in width; salting the fish blocks with 2%(w / w) salt, 1%(w / w) white spirit and 1%(w / w) white vinegar at the temperature of 5 DEG C for 3h by using a low-temperature dry salting method; drying the fish blocks with hot air at the temperature of 50 DEG C for 18-24h; seasoning with 2%(w / w) plant oil, 1%(w / w) horseradish, 5%(w / w) pickled pepper and natural flavor (including cassia, star anise, fennel, amomum tsao-ko, radix glycyrrhizae and Chinese red pepper) in an appropriate amount; performing vacuum packing; and irradiating the fish blocks with a 1.11*106Bq cobalt source for sterilization, wherein the irradiation dose is 3kGy and the irradiation temperature is normal temperature. Compared with the traditional high-temperature and high-pressure sterilization, and the product irradiated for sterilization is reduced in color and increased in hardness and chewiness, the content of hydrolysis amino acid is basically the same, and the quantity of each microbe is less than 10cfu / g, this shows that the fish product irradiated for sterilization is better in sensory quality and physical and chemical quality, and more suitable for sterilization of the flavor fish.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

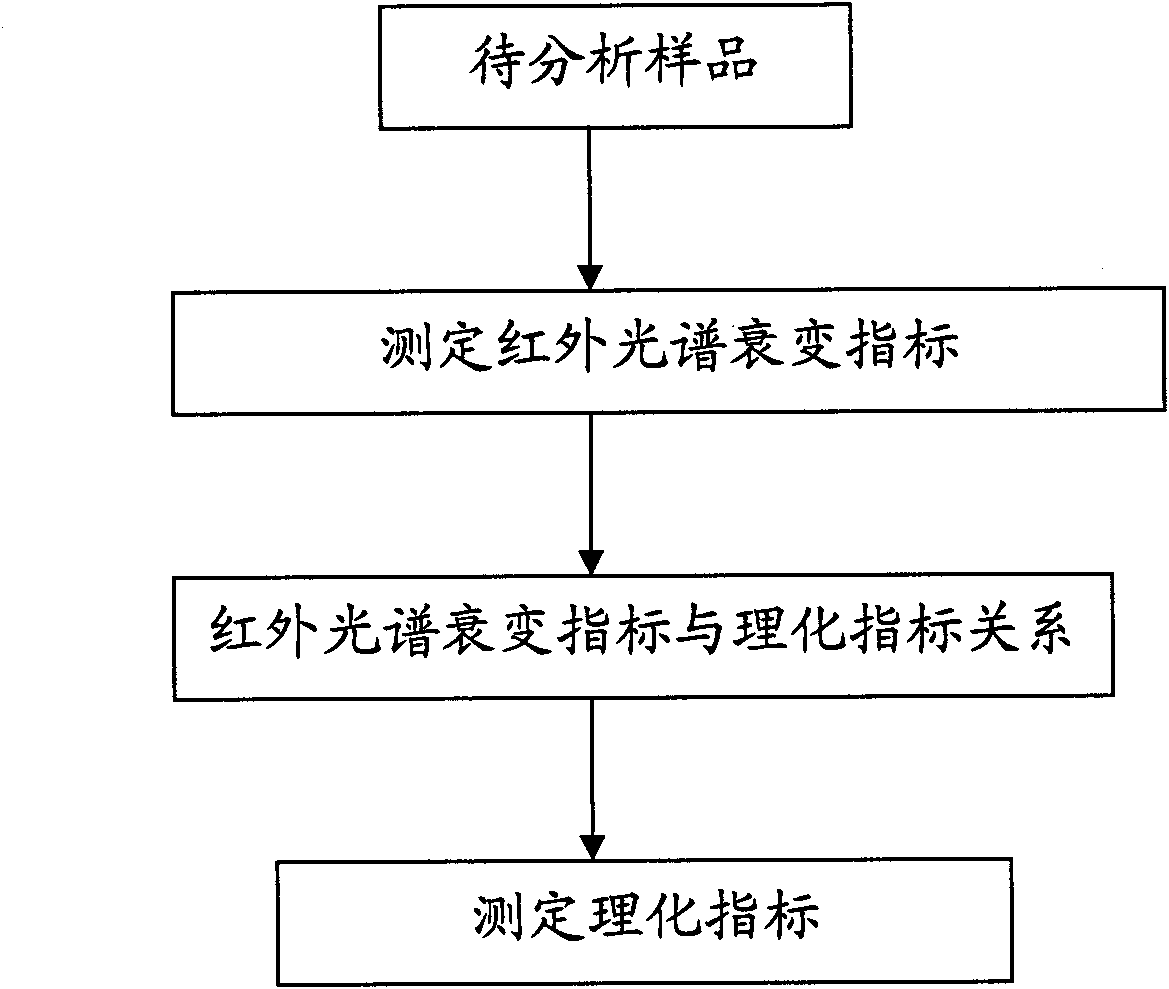

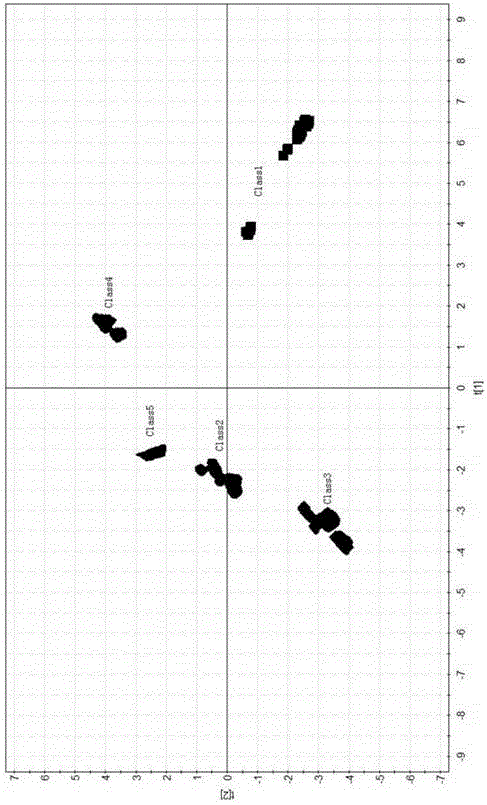

Method for rapidly measuring physical and chemical quality indexes of in-use lubricating oil

InactiveCN101782512AAccurate measurementSave human effortColor/spectral properties measurementsTotal Base NumberChemical quality

The invention discloses a method for rapidly measuring physical and chemical quality indexes of in-use lubricating oil, which comprises the following steps: in a first step, collecting representative samples as a training set; in a second step, measuring an infrared spectrum decay index of the in-use lubricating oil; in a third step, measuring in-use oil physical and chemical quality indexes; in a fourth step, adopting a gradual linear regression method to carry out optimization on the infrared spectrum decay index and establishing a multiple linear regression equation of the physical and chemical indexes and the infrared spectrum decay index; and in a fifth step, for an in-use oil sample, firstly measuring the infrared spectrum decay index and then utilizing the regression equation established in the fourth step to calculate the physical and chemical quality indexes. The method of the invention can rapidly measure seven physical and chemical quality indexes of the in-use lubricating oil, i.e. a kinematic viscosity at the temperature of 40 DEG C, a kinematic viscosity at the temperature of 100 DEG C, water content, a total acid number (TAN), a total base number (TBN), a flash point and a pour point, monitor the quality decay of the lubricating oil, guide to change the oil and guarantee the normal operation of the engine.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

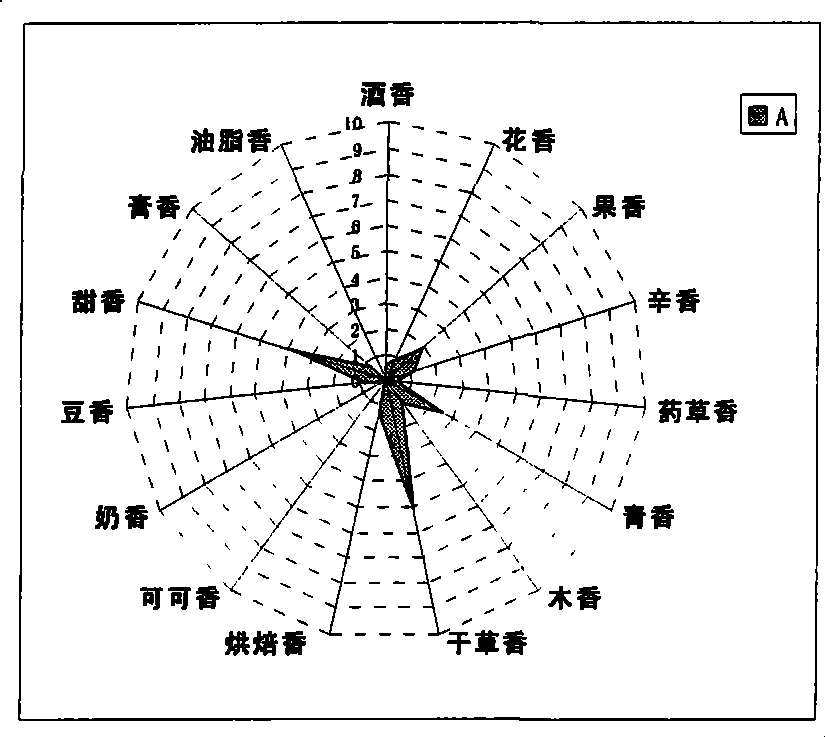

Method for determining and reviewing aroma style of cigarette

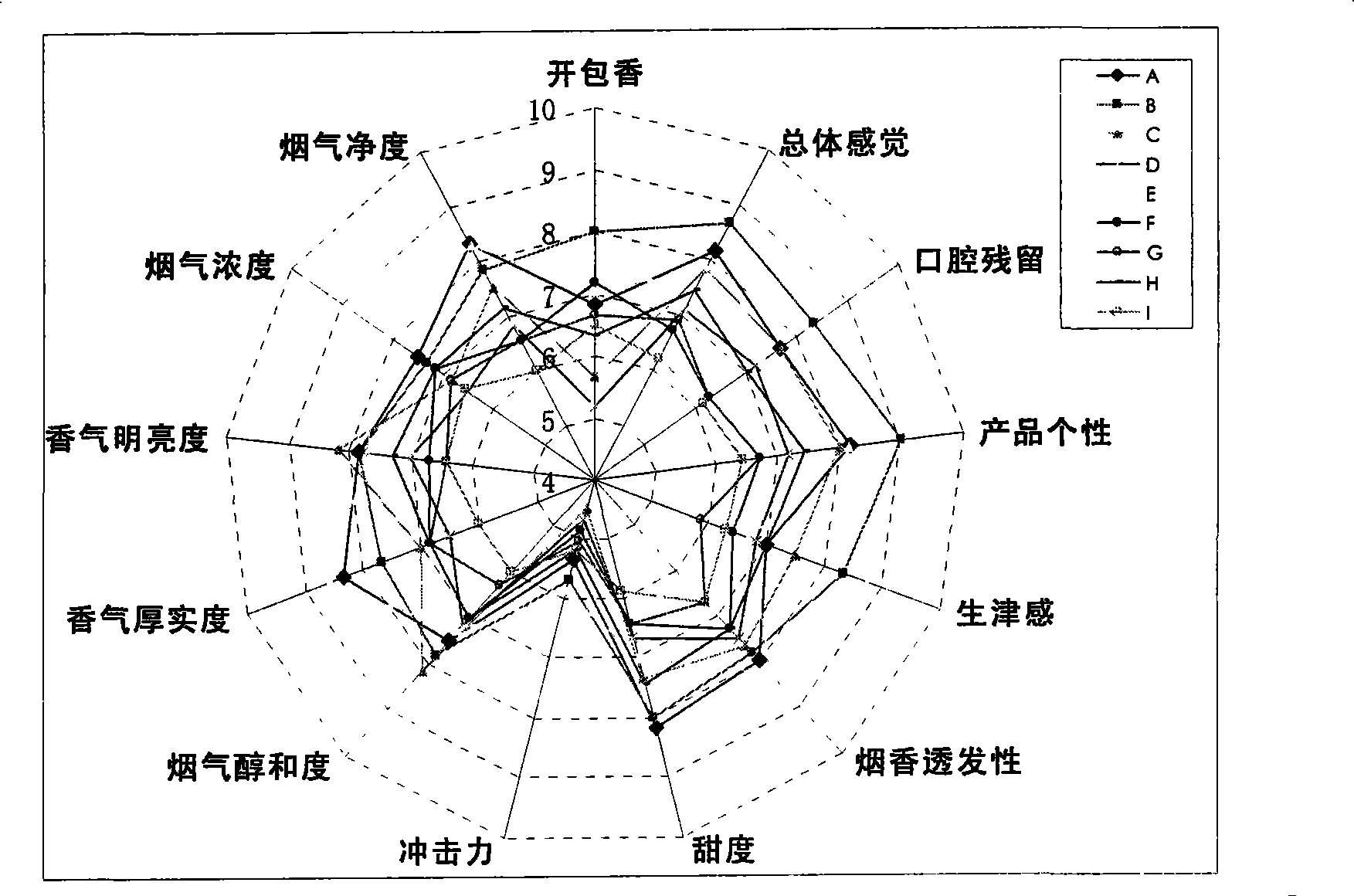

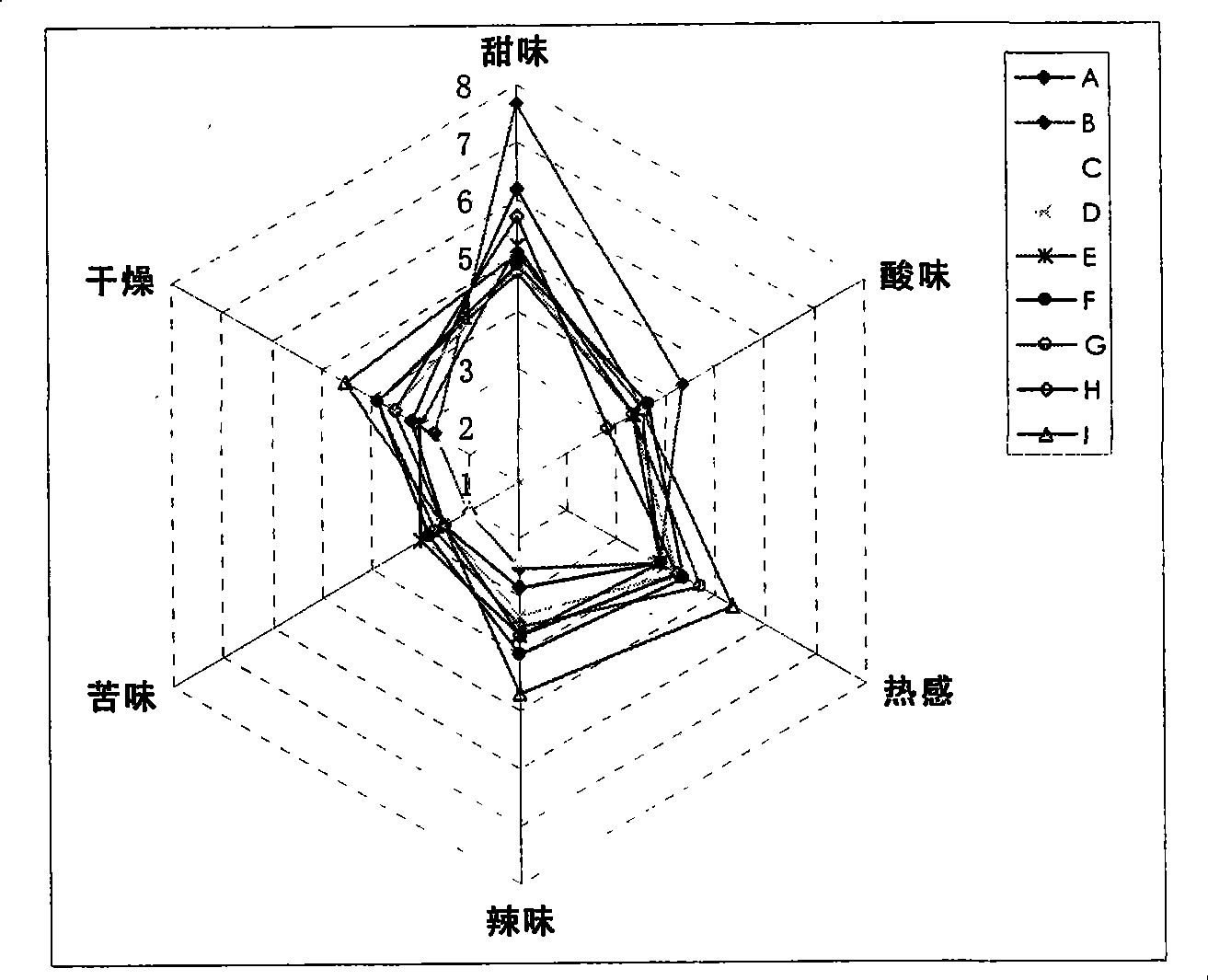

The invention discloses a method for evaluating the perfume style of cigarettes, which relates to the measuring method of cigarette qualities. The invention uses a contour evaluating method, and establishes multi-dimension cigarette style characteristic contour evaluation from the two aspects of a quality index and a characteristic index, the five contours of basic feeling, fragrance characteristics, perfume characteristics, chemical quality indexes, chemical characteristic indexes, etc., and 46 basic factors. The establishment of the method provides an evaluating method of direct image and convenient operation for determining the perfume style of the cigarettes.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

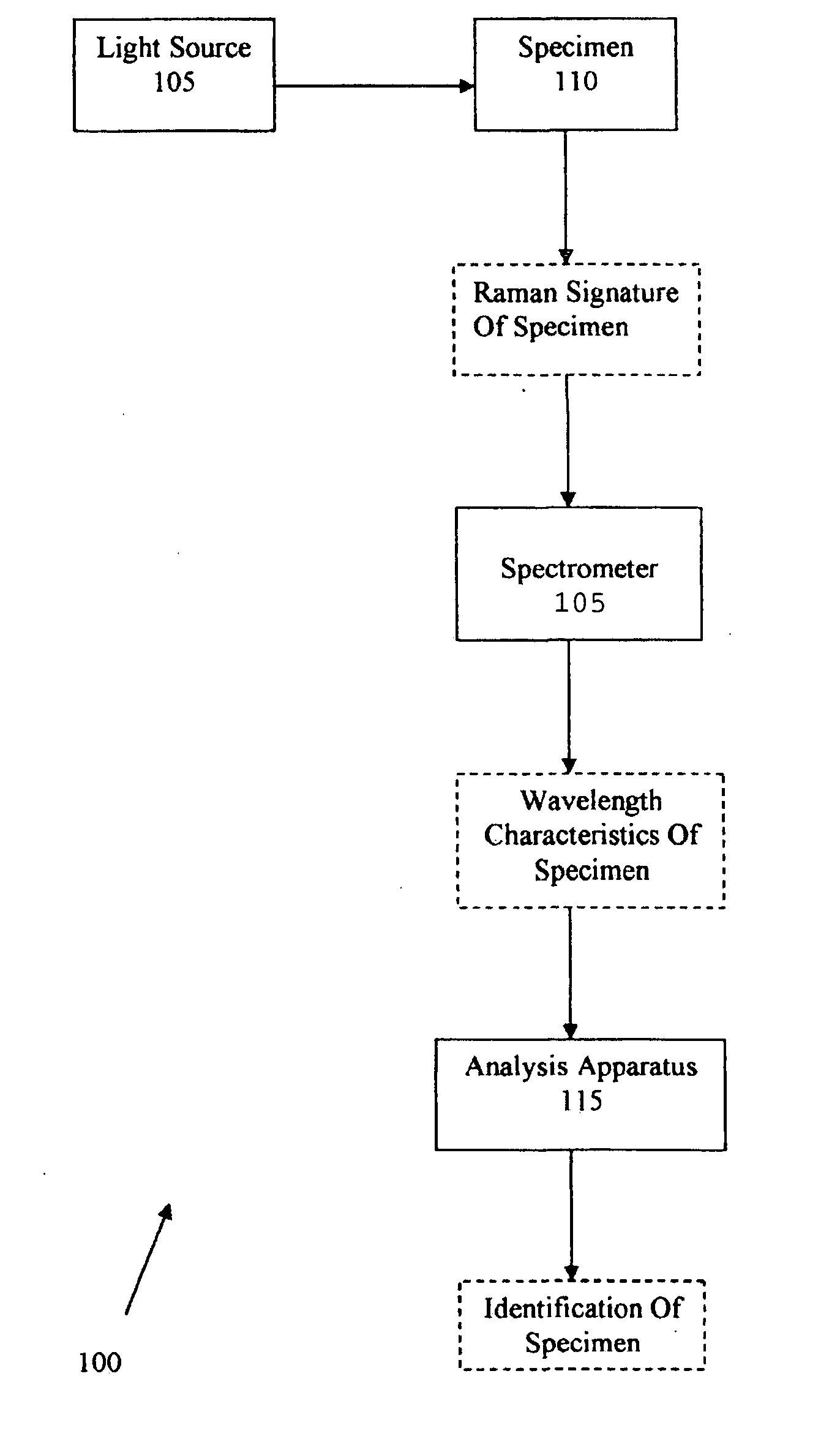

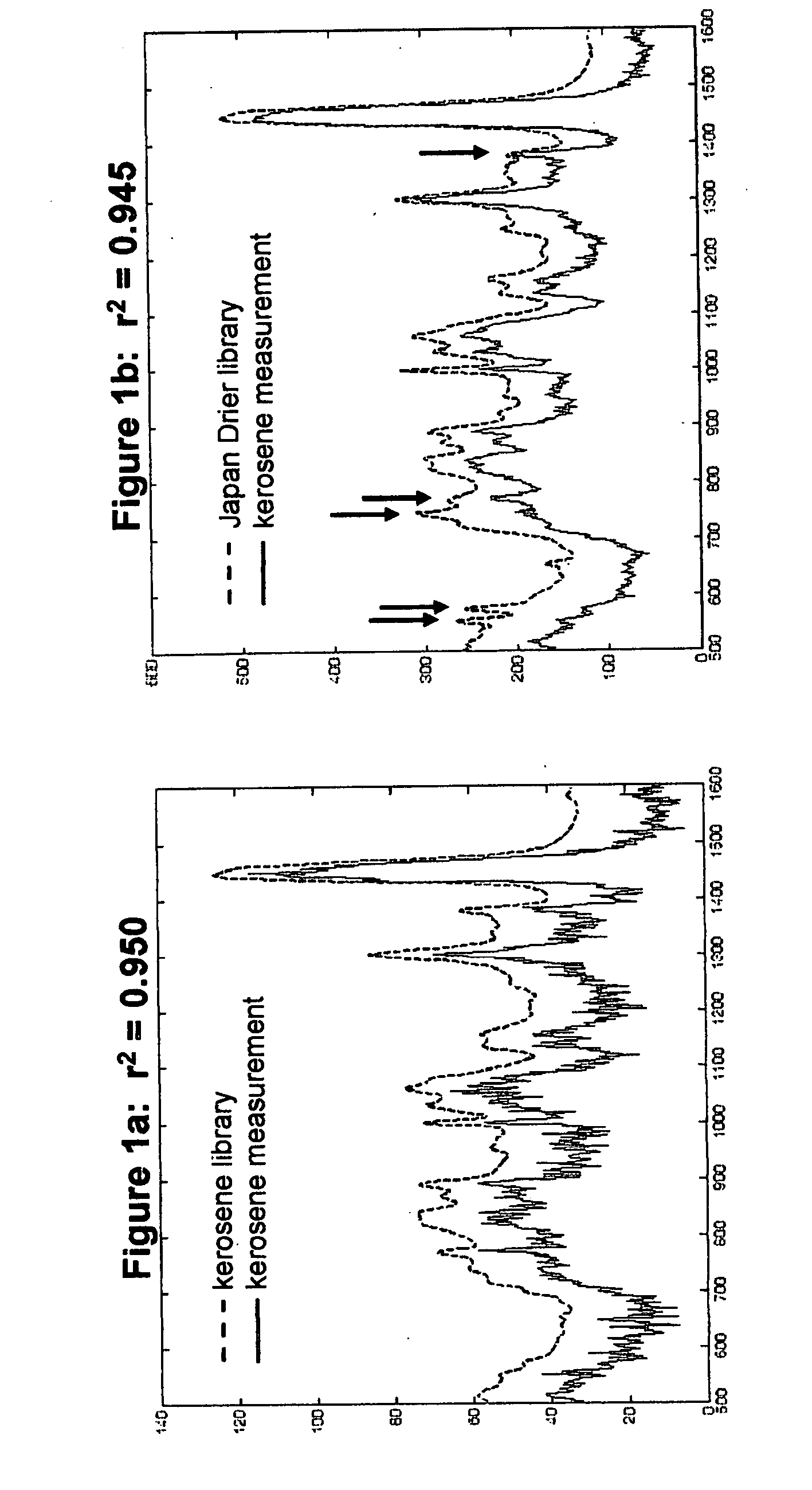

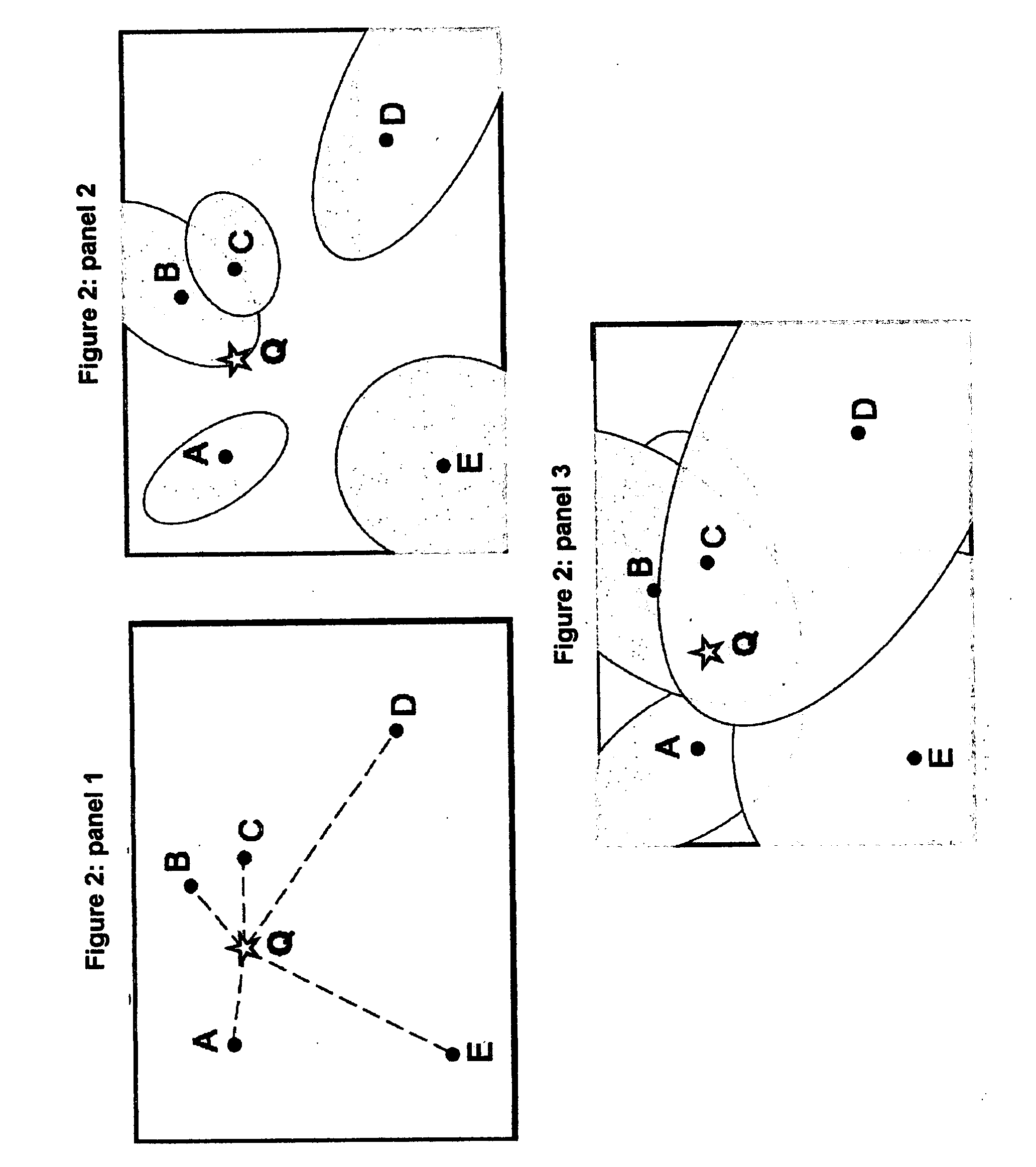

Spectrum searching method that uses non-chemical qualities of the measurement

ActiveUS20080033663A1Spectral/fourier analysisSpectrum investigationFrequency spectrumChemical quality

In one form of the invention, there is provided a method for determining the most likely composition of a sample, comprising: obtaining data from a sample, wherein the data comprises a representation of a measured spectrum; determining the precision state of the representation of the measured spectrum; providing a plurality of library candidates and, for each library candidate, providing data representing the same, wherein the data comprises a representation of a library spectrum; determining a representation of the similarity of the sample to each library candidate using (i) the representation of the measured spectrum; (ii) the precision state of the representation of the measured spectrum; and (iii) the representation of the library spectrum for that library candidate; and determining the most likely composition of the sample based upon the determined representations of similarity of the sample to each library—candidate. In another form of the invention, there is provided a method for determining the most likely composition of a sample, comprising:

Owner:AHURA CORP

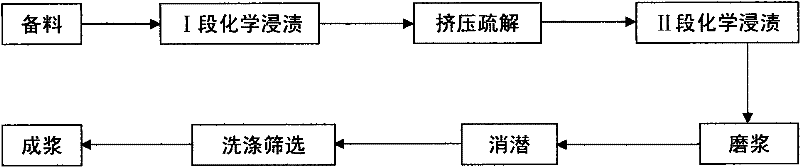

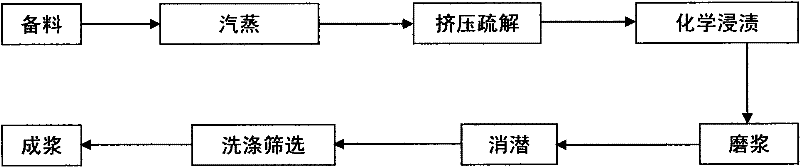

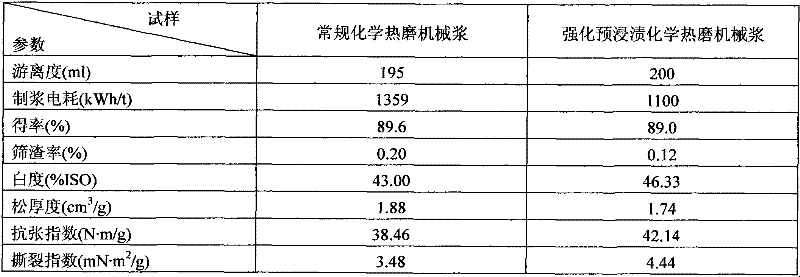

A method for strengthening pre-impregnation of chemical thermomechanical pulp

InactiveCN102268825AEnhanced chemical pre-impregnation effectEnhance swellingPulping with inorganic basesPulping with organic solventsChemical qualityFiber bundle

The invention discloses a method for intensified pre-impregnation of chemical thermomechanical pulp, which is an improvement to the pulping process of chemical thermomechanical pulp, mainly improving the swelling and softening of wood through two-stage impregnation and adding chemical additives The effect is to reduce the forced tearing of fibers in the process of extrusion, defrosting and refining, and reduce the residual rate of fiber bundles. At the same time, it can strengthen the cleaning of colored substances in the slurry, so as to obtain more uniform fiber length and better quality. Thermomechanical pulp, and can reduce pulping power consumption. Although the present invention adopts two stages of chemical impregnation, its effect is mainly achieved by rationally distributing chemical impregnated drugs and improving drug utilization efficiency, rather than greatly increasing the amount of chemicals used, so the pollution load will not be significantly increased.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

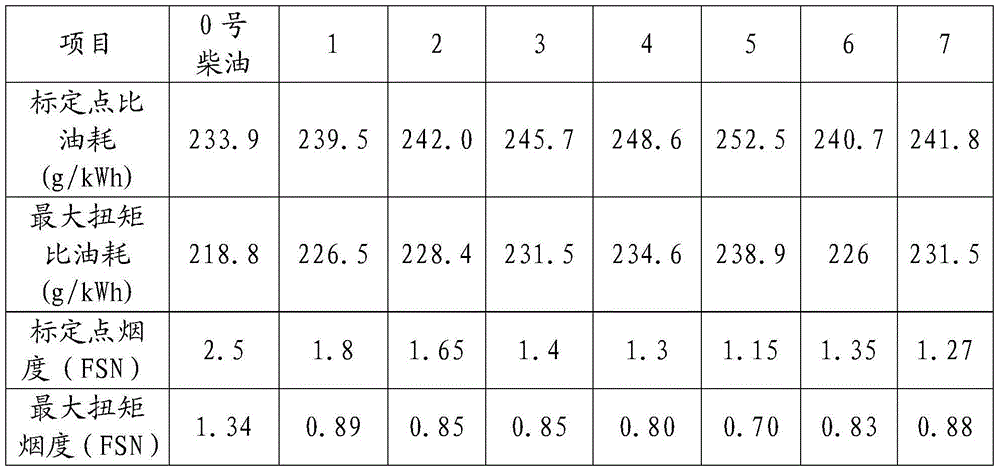

Clean fuel oil and preparation method thereof

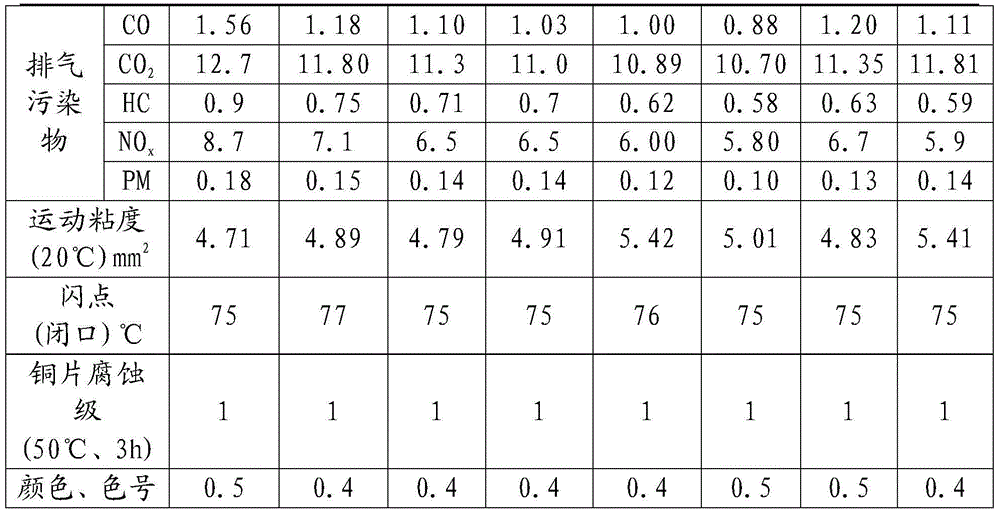

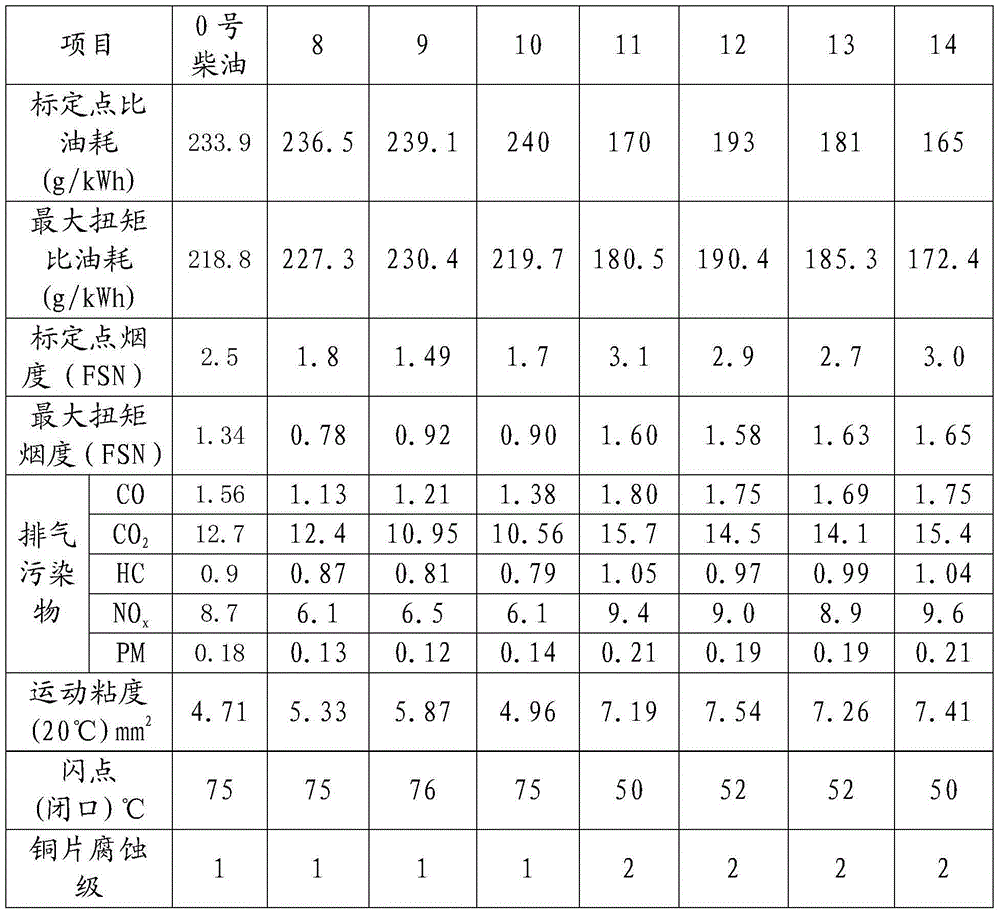

InactiveCN105296020AHigh methanol contentImprove stabilityLiquid carbonaceous fuelsChemical qualityHazardous substance

The invention relates to the technical field of clean energy, in particular to clean fuel oil. The clean fuel oil is prepared from methanol, vacuum one-line heavy diesel oil, a combustion improver, sebate, 2-hydroxy-4-n-octyl-oxy-diphenyl ketone, a metal deactivator, pentaerythritol ester, biodiesel, benzyl alcohol, C4-12 fatty alcohol, a solubilizing surfactant and a cetane number improver according to a certain proportion. As various additives of certain quantities are added into methanol and vacuum one-line heavy diesel oil, the clean fuel oil is excellent in stability while the methanol content is high, and is low in corrosivity and swelling property, is as good as 0# diesel oil in energy consumption and power performance, and meets the national standards of physical and chemical quality indexes of 0# diesel oil. As the clean fuel oil contains large quantities of methanol and biodiesel, not only is the consumption of mineral diesel oil reduced, but also emission of hazardous substances and smoke is effectively reduced, the environmental protection performance is excellent, and the exhaust emission index meets the European No. VI emission standard.

Owner:EMANUEL RESOURCES GRP LTD

Cathode gold electrolytic refining process

InactiveCN102978658ASolving Corrosion ProblemsSolve layeringPhotography auxillary processesElectrodesSolubilityConcentration polarization

The invention provides a cathode gold electrolytic refining process. According to the invention, an electrolyte formula is changed, and electrolytic refining is carried out in a hydrochloric acid system with low gold ion solubility (Au<3+> 80-120g / L) and low acid (60-90g / L) with a titanium motherboard used for replacing a traditional gold starting sheet as a cathode. During the electrolysis process, with a quantitative dosing device, an inhibiting agent is automatically added online according to the variation of the components of the electrolyte, such that interferences of impurities such as lead and silver upon electric gold quality and an anode passivation problem are solved. Also, an automatic thermal insulation measure is provided for the electrolyte, such that a phenomenon of easy stratification and concentration polarization is eliminated. Higher than 99.995% electric gold products with qualified physical specifications and chemical qualities can be produced through one-step direct electrolysis. Aiming at a workplace environment ventilation problem, inner-ring and outer-ring skilful isolation is adopted, such that process exhaust problems of product pollution, environment pollution and equipment corrosion are solved. With the process provided by the invention, purposes of high efficiency, environment protection, and energy saving are realized. The process has a high popularization value in the field of precious metal refining.

Owner:JIANGXI COPPER

Pigments treated with organo-phosphoric acids and their salts

InactiveUS7259195B2Easy to prepareCost-effectiveLiquid surface applicatorsMixingChemical reactionChemical quality

Owner:TRONOX LLC

Method for synthesizing benzoyl peroxide and benzoyl peroxide synthesized with method

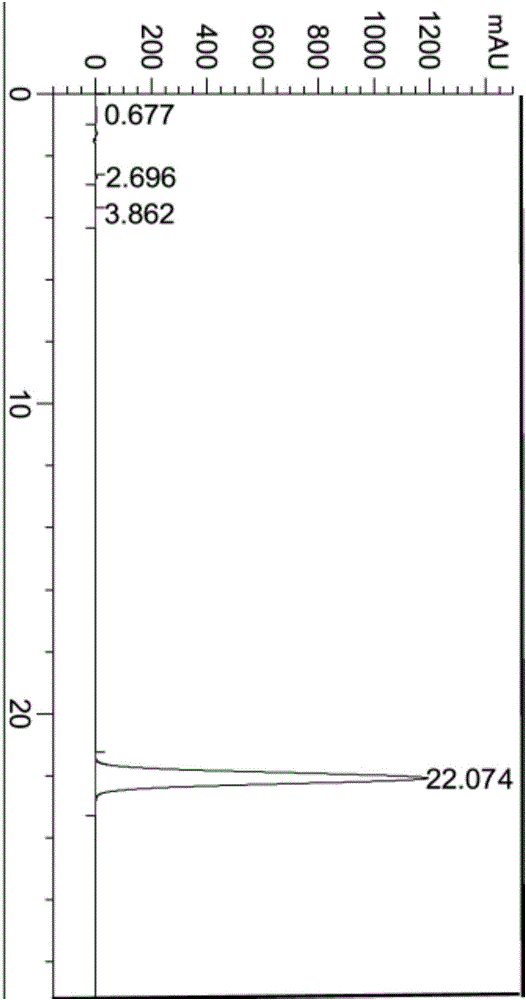

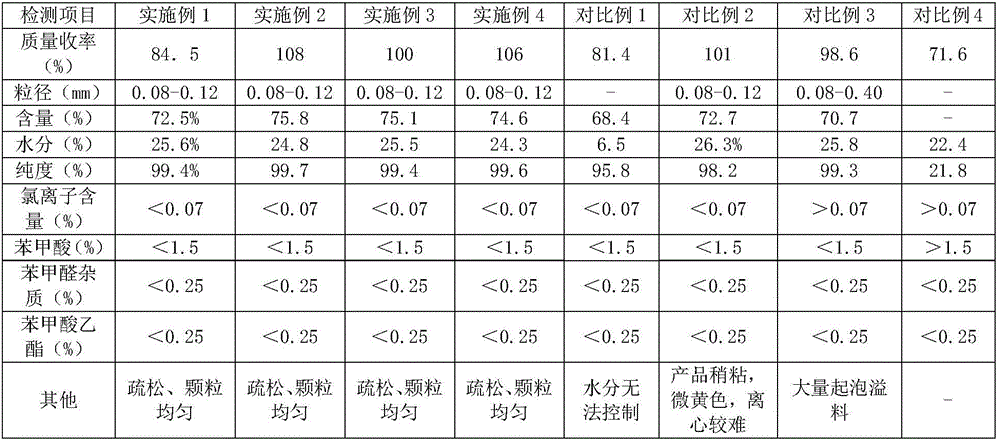

ActiveCN105924378ASimple processOperational securityOrganic compound preparationPeroxy compound preparationChemical qualityBenzoyl peroxide

The invention provides a method for synthesizing benzoyl peroxide. According to the method for synthesizing benzoyl peroxide, benzoyl chloride, hydrogen peroxide, sodium hydroxide and a surfactant serve as raw materials, the raw materials are subjected to a one step reaction to obtain the product, the method is simple in technology, safe in operation, low in production cost, high in yield and the like, and is suitable for industrial production and wide application. According to the method, in the feeding process, the surfactant is dissolved into a reaction solvent before the sodium hydroxide is added, and therefore the solution overflowing phenomenon when the surfactant is dissolved is effectively avoided. The benzoyl peroxide synthesized with the method has the advantages of being free of blocking, even in granularity, easy to wash and the like, and meets the bulk-pharmaceutical-chemical quality standard recorded by the Chinese pharmacopoeia and the European pharmacopoeia.

Owner:SHANGHAI MEDICILON INC

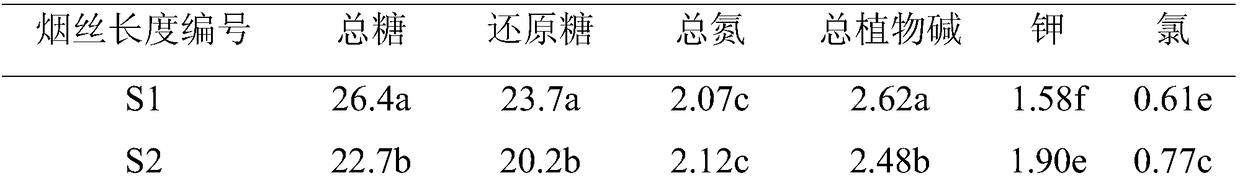

Method for characterizing distribution stability of finished product cut tobacco structure by using conventional chemical compositions

InactiveCN108645968AAvoid errorsCharacterize stabilityTesting plants/treesChemical qualityChemical composition

The invention provides a method for characterizing distribution stability of a finished product cut tobacco structure by using conventional chemical compositions. The method comprises the following steps: sampling the finished product cut tobacco; performing determination of conventional chemical components, such as total sugar, reducing sugar, total nitrogen, total plant alkali, potassium, and chlorine; calculating average, standard deviation, coefficient of variation and stability factor of the six conventional chemical components of the cut tobacco sample; finally, the average value of thestability coefficients of the six conventional chemical components is calculated. The larger the average value is, the closer to 100%, the better the distribution stability of the cut tobacco structure is. The conventional chemical components with high contents in the cut tobacco are used as evaluation indices, in order to quantitatively, scientifically and reasonably evaluate the distribution stability of the tobacco structure; and the inherent chemical quality stability of the finished product cut tobacco and the blending uniformity of the 'three kinds of cut tobaccos' are objectively reflected, in order to provide reference basis for improving cigarette quality and optimal control.

Owner:云南熏爵生物科技有限公司

Culturing method of high-zinc nutrient high-grade rice

InactiveCN101530061AIncrease added valuePromote new rural constructionPlant genotype modificationChemical qualityZinc

The invention discloses a culturing method of high-zinc nutrient high-grade rice, including: collecting rice material, planting and managing in a normal method, selecting beefy and plump rice material, originally screening by using the seed diphenylthiocarbazone staining method to obtain the material with red incision, preparing fine rice powder, determining the content of zinc in the rice, selecting the rice with the zinc content of over 25 mg / kg; shelling by a sheller, selecting the rice with transparency appearance and little chalkiness, testing the physical and chemical quality, selecting the rice with the amylase content of 15% to 25% , the jelly consistency of over 60 mm and the alkali spreading value of over 5 grade, continuing to plant and reproduce, evaluating the stability of high-zinc nutrition and high-grade inherited characteristic to obtain the high-zinc nutrient high-grade rice. The rice cultured according to the invention is nutrient and high-grade, has simple method and lower cost, and is convenient for the screening use in the breeding of large group.

Owner:ZHEJIANG UNIV

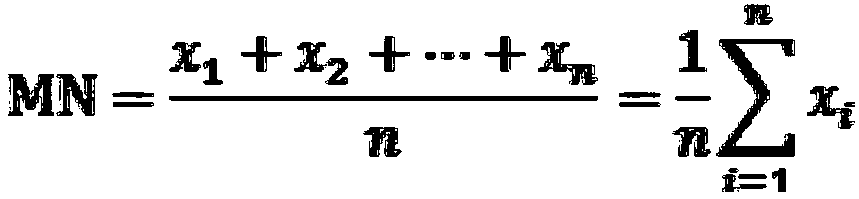

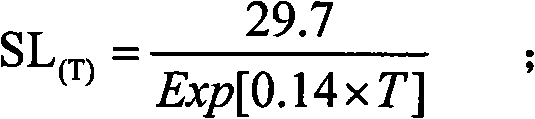

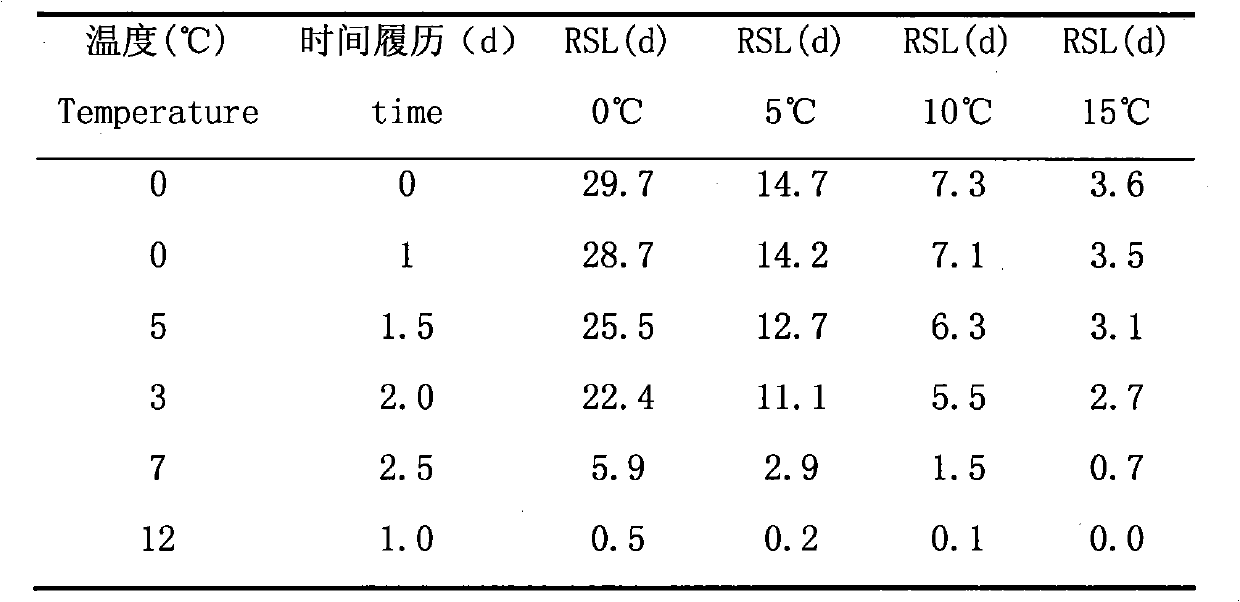

Method for predicting refrigerated carp freshness quality

InactiveCN101949870AAvoid hysteresisReduce in quantityMaterial heat developmentRate equationChemical quality

The invention relates to a method for predicting refrigerated carp freshness quality. The method comprises the following steps of: determining the shelf life of a product by researching the sense organ quality, chemical quality and microbiologic quality of refrigerated bred carp; describing a relationship between temperature and the carp freshness quality by adopting an index relative corruption rate equation model, wherein the relative corruption rate equation is LN(RRS)=0.14*T-0.0314; RRS is a relative corruption rate; and T is temperature (DEG C); and further building a carp freshness quality predicting equation in the temperature range (0 to 15 DEG C), wherein RSL is residual shelf life (day), SL(Tn) is the time (day) at the temperature of Tn, Tn is the temperature (DEG C), and RRS (Tn) is the relative corruption rate at the temperature of Tn. The quality predicting model is applied to monitoring the environmental condition of packaged foods, the food quality and safety information of the product during transportation and storage is provided, the production efficiency and product quality are effectively improved and a quantized basis is provided for reducing complaints from shopkeepers and consumers.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

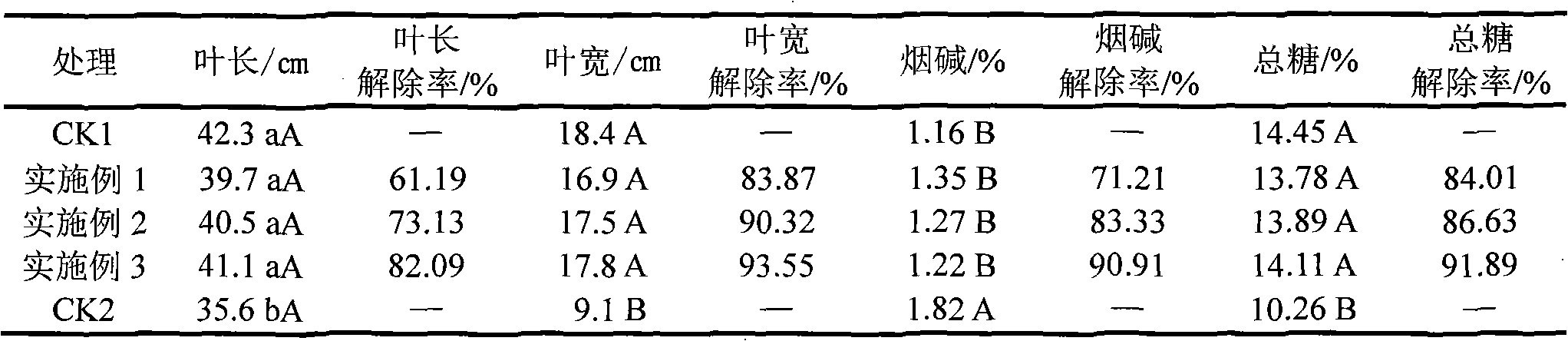

Detoxicating agent on tobacco deformity induced by quinclorac and applying method thereof

ActiveCN101773119APromote growth and developmentIncreases Nutrient ResistanceBiocideAnimal repellantsEarly generationChemical quality

The invention relates to a detoxicating agent on tobacco deformity induced by quinclorac and an applying method thereof. The detoxicating agent is prepared from the following materials: 0.4%-0.6% of natural plant growth regulator, 3.6%-9.0% of plant microecology agent, 13.3%-31.6% of tobacco leaf nutrient and 61.3%-81.9% of efficiency enhancer. The applying method of the detoxicating agent comprises the following steps of: using 35-75 times of clean water to dilute 500g-900g of detoxicating agent for every 1000 tobacco plants, and uniformly spraying onto the tobacco plants and the positive and reverse surfaces of the tobacco leaves until the wet dew on the leaf surface has no water dripping in the early generation period of tobacco deformity induced by quinclorac. The invention obviously increases the leaf length of the tobacco leaf deformity induced by quinclorac, obviously increases the leaf width and total sugar, obviously decreases the nicotine, effectively removes the symptom of the tobacco leaf deformity induced by quinclorac, enables the tobaccom leaf to obviously recover the normal botany property and internal chemical quality, and has the advantages of strong compounding property of raw materials, simple preparation, high safety, strong point and high practical value in the tobacco leaf production.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

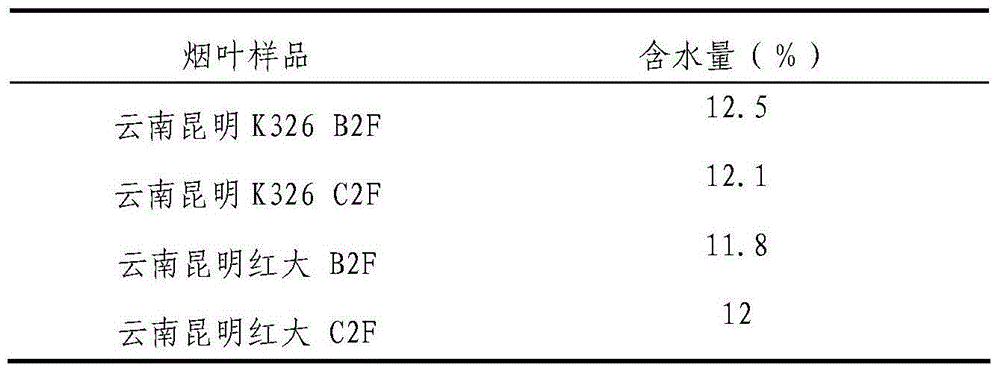

Lodderomyces elongisporus and application thereof

ActiveCN104164372AIncrease aromaImprove the quality of flue-cured tobaccoFungiTobacco treatmentBase RatioMicroorganism

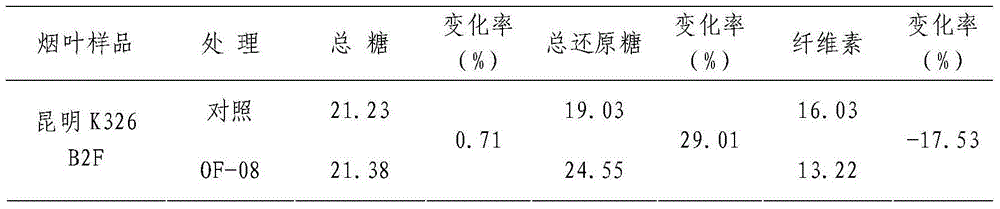

The invention discloses a Lodderomyces elongisporus and application thereof, belonging to the technical field of application of microbes. The classification designation of the strain is Lodderomyces elongisporus OF-08. The strain is collected at General Microorganisms Center in China Committee for Culture Collection of Microorganisms on October 8th, 2012, and the collection number is CGMCC No.6645. The physiological-biochemical characteristics of the OF-08 strain and 26S rDNA gene sequence (the sequence number in GeneBank database is JQ916053) are primary characteristic references for identifying the strain. The strain preparation can be sprayed to enhance the aroma quality of tobacco, increase the reducing sugar content and lower the contents of proteins, cellulose, total nitrogen and nicotine. Therefore, the sugar / nitrogen ratio, sugar / base ratio and nitrogen / base ratio tend to increase, so that the chemical quality is more harmonious, and the tobacco smoking quality is improved.

Owner:CHINA TOBACCO YUNNAN IND

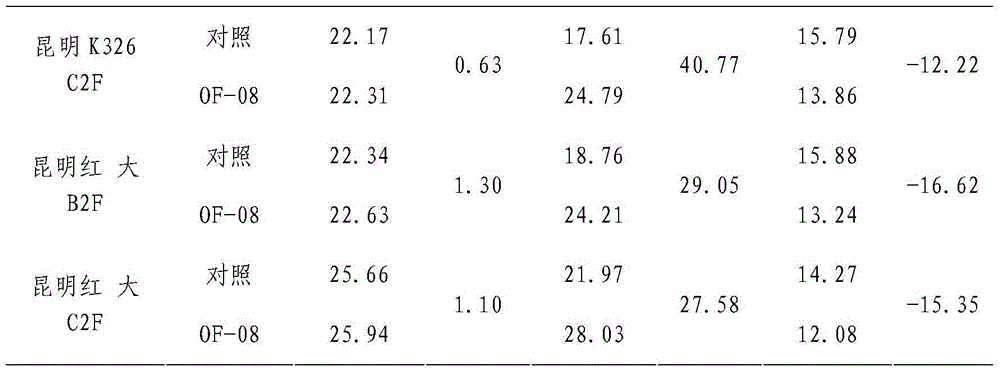

Production method for honey tea

InactiveCN103564076APure tastePromote digestionPre-extraction tea treatmentChemical qualitySunstrokes

The invention discloses a production method for honey tea. The production method comprises the following steps of: stacking strong-flavour Tieguanyin, high-mountain wide tea and winter honey in a storage vat in a mixing ratio of 1: 0.2: 1.6, and adequately and completely mixing and stirring to be uniform, storing for a few of days, stirring and turning the honey tea in the storage vat, performing chemical quality detection on the honey tea at a fixed period, forming the honey tea after the honey is organically integrated with the tea, and performing precise packaging. Compared with the prior art, according to the production method disclosed by the invention, the honey tea is prepared by storing and fermenting the natural strong-flavour Tieguanyin, high-mountain wide tea and winter honey in the sealed vat in a mixing ratio of 1: 0.2: 1.6, and the honey tea integrates honey and tea as the combination of honey and tea, can improve the conditions of digestion and metabolism, moisten lung and tonify kidney, and prevent constipation, and has the effects of preventing sunstroke, reducing internal heat, sterilizing and stopping dysentery, and the like.

Owner:FUJIAN RICHUN IND

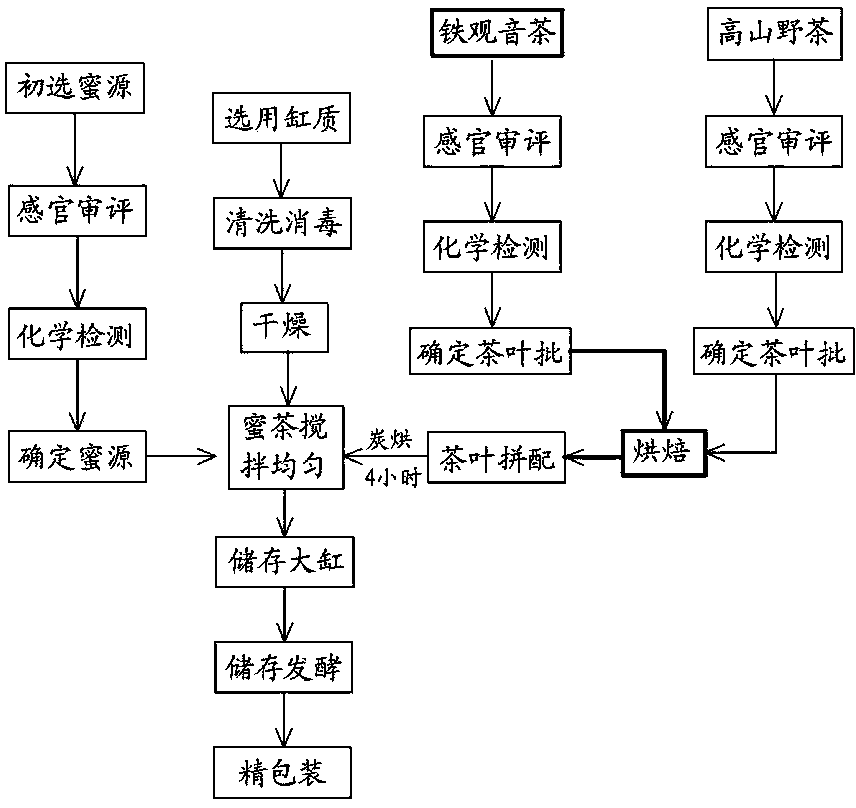

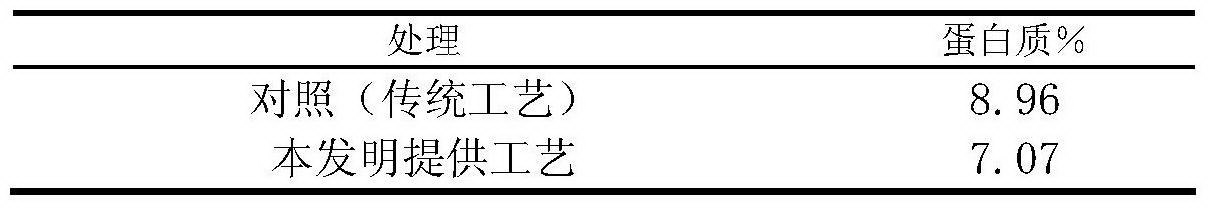

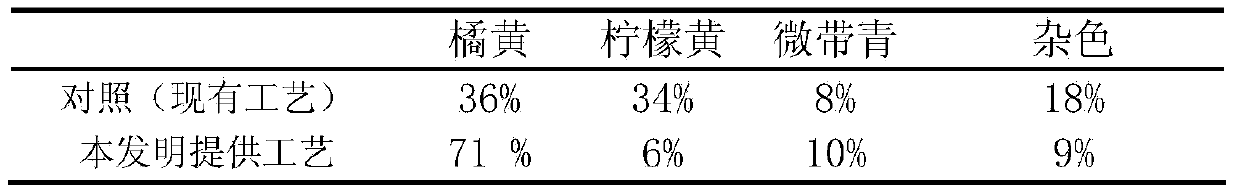

Flue-curing process method capable of reducing protein content in flue-cured tobacco

InactiveCN103798945AIncrease hierarchyImprove sensory qualityTobacco preparationChemical qualityNitrogen

The invention discloses a flue-curing process method capable of reducing protein content in the flue-cured tobacco. The process method disclosed by the invention is implemented according to the following steps of: A, preparing the flue-cured tobacco and placing the flue-cured tobacco into flue-curing equipment; B, sequentially carrying out six continuous flue-curing stages comprising four short-time flue-curing stages and two long-time flue-curing stages in the flue-curing process of the flue-cured tobacco; C, after flue-curing, obtaining the flue-cured tobacco with low protein content. According to the invention, on the premise of ensuring quality of the flue-cured tobacco, the step of controlling the content of a protein which is an important nitrogen-containing compound is migrated to the tobacco leave modulating stage, so that the flue-curing process method is helpful for improving chemical quality of tobacco leaves, and thus, damage of smoking to health of human bodies is further reduced. By the process conditions of the flue-curing process method, compared with a flue-cured sample in a conventional method, the flue-cured tobacco leaves has the advantages that the appearance quality, the proportion of medium-class and first-class tobacco and the smoking quality are all improved and the release amount of the protein is reduced by 15 percent to 25 percent.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Processing process for special ginger garlic aromatic vinegar

The invention relates to a processing process for special ginger garlic aromatic vinegar, and belongs to the production processing field. The ginger garlic aromatic vinegar produced by the processing process not only retains flavor and physical and chemical quality of original vinegar but also fuses the original taste of ginger-garlic, so that the product has strong fermented vinegar fragrance and ginger garlic fragrance and is agreeable to taste with the mouthfeel being fragrant, sour, fresh and sweet, and at the same time, turbidity and precipitate of the ginger garlic aromatic vinegar / dumpling vinegar caused by colloid substances of the garlic and starch in the ginger.

Owner:GUIYANG WEICHUNYUAN FOODS

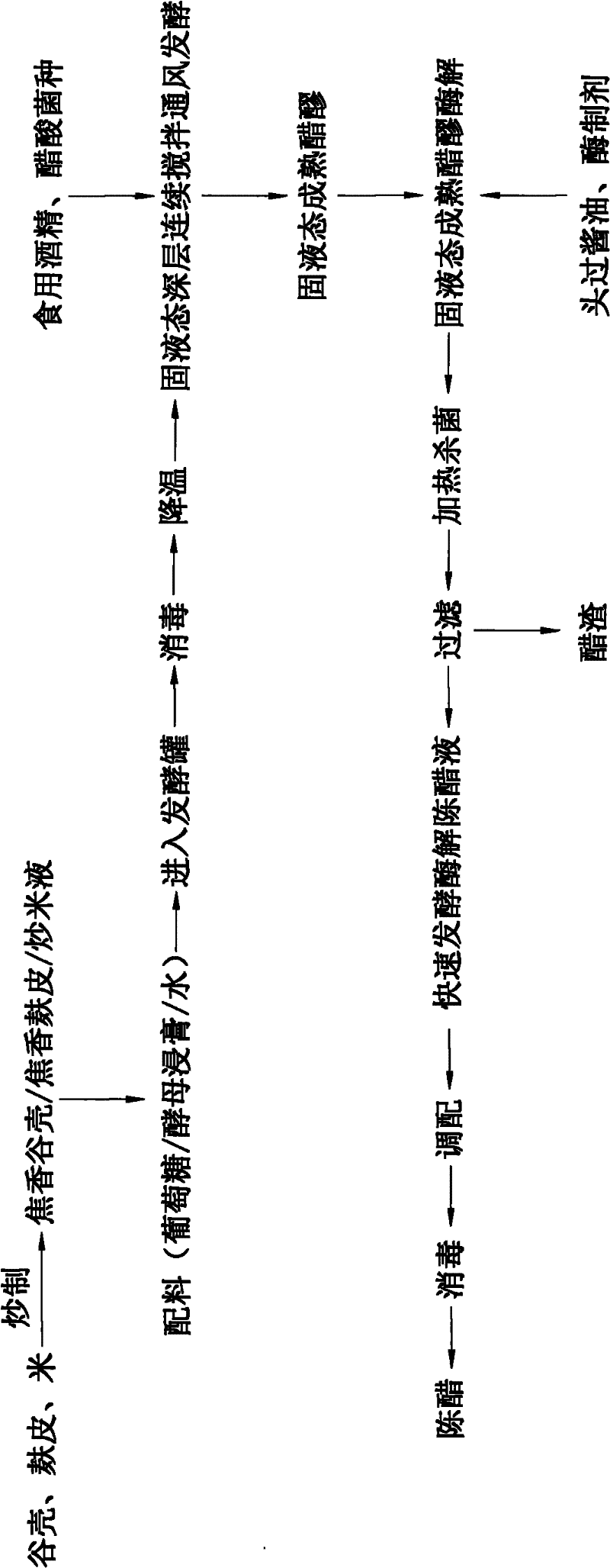

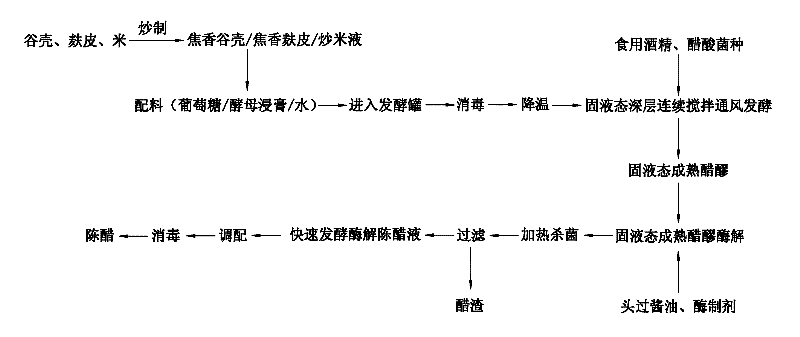

Preparation method for mature vinegar

ActiveCN102206569ARaw materials are easy to getShort fermentation cycleMicroorganism based processesVinegar preparationChemical qualityAlcohol

The invention discloses a preparation method for a mature vinegar. The method comprises the following steps: A, preparing raw materials: mixing fried hulls, fried wheat bran, liquid of fried rice, water, glucose powders and yeast extract, followed by a sterilizing, then adding edible alcohol and acetic acid bacteria to obtain the mixed raw materials; B, carrying out a fermenting: carrying out a fermenting for the mixed raw materials through a continuous ventilation stirring of deep solid-liquid state substance to obtain a solid-liquid state mature vinegar mash; C, carrying out a enzymolysis: adding first soy and a enzyme preparation to the solid-liquid state mature vinegar mash, and carrying out a solid-liquid state enzymolysis to obtain a enzymolysis vinegar mash; D, carrying out a post processing: sequential carrying out a heating for sterilize, a storing, a rough filtering, a fine filtering, a blending, a disinfecting and a sterilizing for the enzymolysis vinegar mash to obtain a finished product of the mature vinegar. The preparation method provided by the present invention has advantages of available raw materials, short fermentation period, easy realization of mechanized operation, high labour efficiency, low work intensity, and is suitable for a large-scale production. In addition, physical and chemical quality indexes of the mature vinegar provided by the present invention can reach the national quality standard of the vinegar.

Owner:FOODSTAR CHINA INVESTMENTS

Powder mixing technology for compound antibiotic

ActiveCN103040768AReduce pollutionStable chemical qualityPowder deliveryAntiinfectivesChemical qualityOrganic solvent

The invention relates to a powder mixing technology for a compound antibiotic. The compound antibiotic is obtained by cold drying after uniform mixing of antibiotic A and antibiotic B in advance, wherein the antibiotic A is mezlocillin sodium, amoxicillin sodium, cefoperazone sodium, and piperacillin sodium, and the antibiotic B is sulbactam sodium. According to the powder mixing technology, organic solvent is omitted, the environment is less polluted, the freeze-drying technology has stable yield, and the cost is low; the freeze-drying mixed powder has good uniformity, fast dissolution rate, and stable chemical quality, so that the powder mixing technology is applicable to preparation of various of compound antibiotics, and is suitable for mass production.

Owner:山东二叶制药有限公司

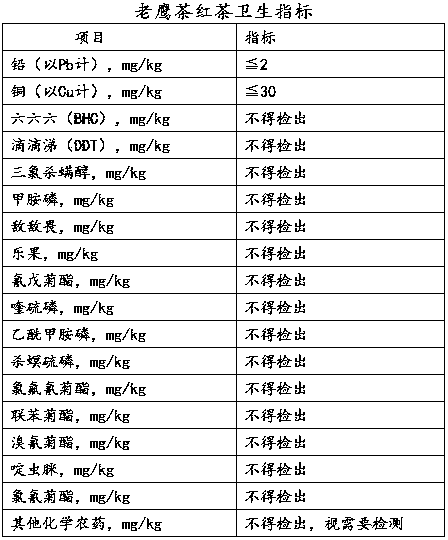

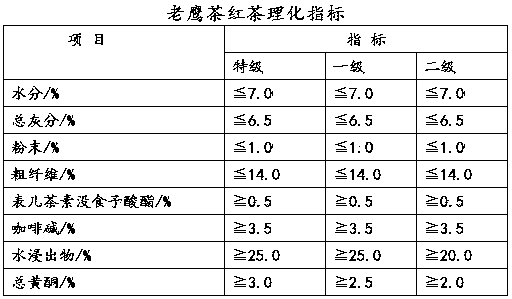

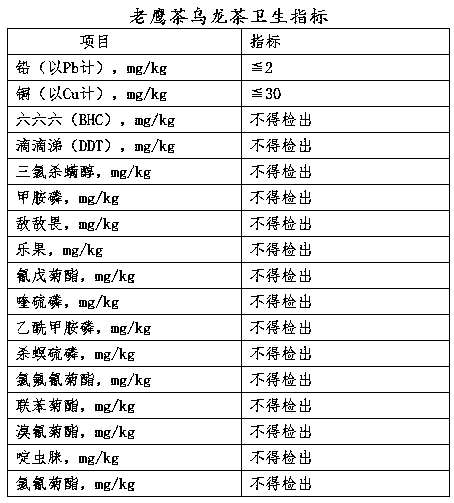

Processing method for eagle tea oolong tea

PendingCN108402242AReduce accumulationImprove physical and chemical qualityTea substituesActinodaphne cupularisChemical quality

The invention relates to a processing method of eagle tea oolong tea. The processing method comprises 6 technique links of (1) picking fresh leaves; (2) performing withering; (3) performing rolling; (4) performing fermenting; (5) performing drying; and (6) performing sieving and packing. According to the physical and chemical index detection and organoleptic review results of products processed according to different technologies of plant actinodaphne cupularis of eagle tea raw materials, and according to unique physical and chemical quality and organoleptic quality evaluation standards of excellent high-quality black tea, a black tea technology suitable for scaleable processing of actinodaphne cupularis is optimized and established. The technical parameters of picking fresh leaves, withering, rolling, fermenting, drying and the like are reported for the first time. The product pollutants, residues and the likes of products are lower than relevant limit values of hygienic indexes of NY5196-2002 organic tea, and the eagle tea oolong tea has the quality characteristics of being high in contents of caffeine and epicatechin gallate, having black, moistening and golden hairs, being orange and bright in soup color, being rich in fruity flavor, having cinnamomum longepaniculatum fragrance, and being rich and mellow in sweet after taste.

Owner:GUIZHOU INST OF BIOLOGY

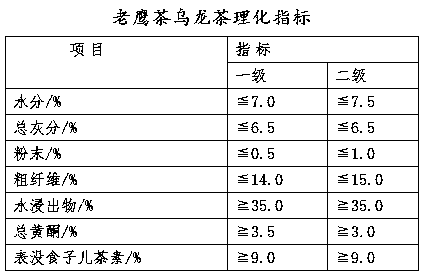

Processing method for eagle tea oolong tea

The invention relates to a processing method of eagle tea oolong tea. The processing method comprises the following steps of (1) picking fresh leaves; (2) performing withering including 2 steps of smoking tea leaves and sunning tea leaves by air; (3) performing rocking of tea leaves; (4) performing fixation; (5) performing rolling and baking including 6 steps of rolling for the first time, bakingfor the first time, wrapping-twisting for the first time, baking for the second time, wrapping-twisting for the second time and baking for the second time; and (6) performing sieving and packing. According to physical and chemical index detection and organoleptic review results of products processed according to different technologies of plant lisea coreana of eagle tea raw materials, and according to unique physical and chemical quality and organoleptic quality evaluation standards of excellent high-quality oolong tea, an oolong tea technology for scaleable processing of young, tender and spring tips of the lisea coreana is optimized and established. The technical parameters of the oolong tea processing technology are reported for the first time. The hygienic indexes of the eagle tea oolong tea products produced by the method conform to the relevant limit, of NY5196-2002 organic tea, and the eagle tea oolong tea has the quality characteristics of being high in contents of selenium, zinc, total flavonoids and epigallocatechin, and orange and clear in soup color, and having fresh and refreshing fruity fragrance mixed with cinnamomum longepaniculatum fragrance.

Owner:GUIZHOU INST OF BIOLOGY

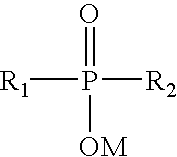

Particulate inorganic solids treated with organophosphinic compounds

ActiveUS20050027038A1Good dispersionImprove dispersion qualityPigmenting treatmentOther chemical processesCompound aParticulates

A treatment for particulate inorganic solids is provided. This treatment, which uses certain organophosphinic compounds, imparts improved physical and chemical qualities including lacing resistance, improved dispersion and decreased chemical reactivity when these treated particulate inorganic solids are incorporated into polymeric matrices. The addition of the organophosphinic compounds of the present invention may flexibly be incorporated into known processes at varying points, and are preferably added downstream of any filtering steps or to a dry particulate inorganic solid.

Owner:TRONOX LLC

Method for establishing rapid monitoring and processing of orchard data

ActiveCN109827910ALarge capacityLow costColor/spectral properties measurementsChemical qualityData system

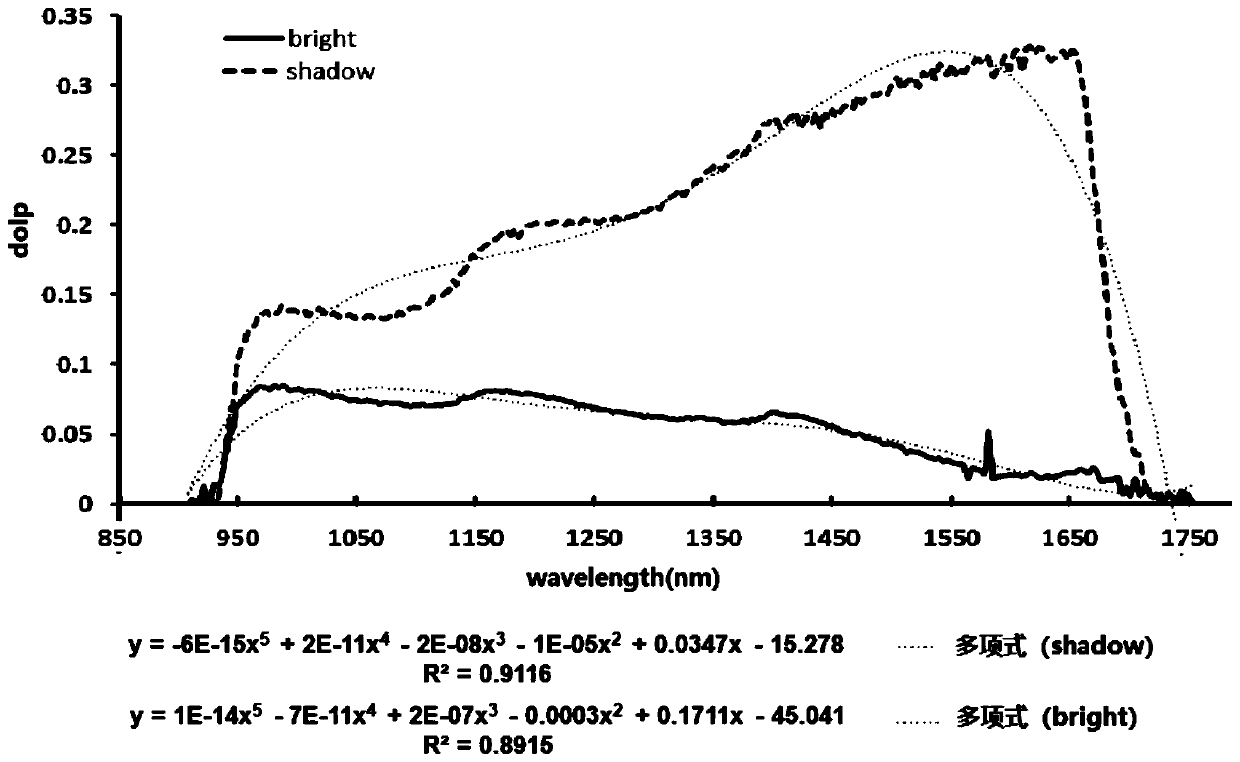

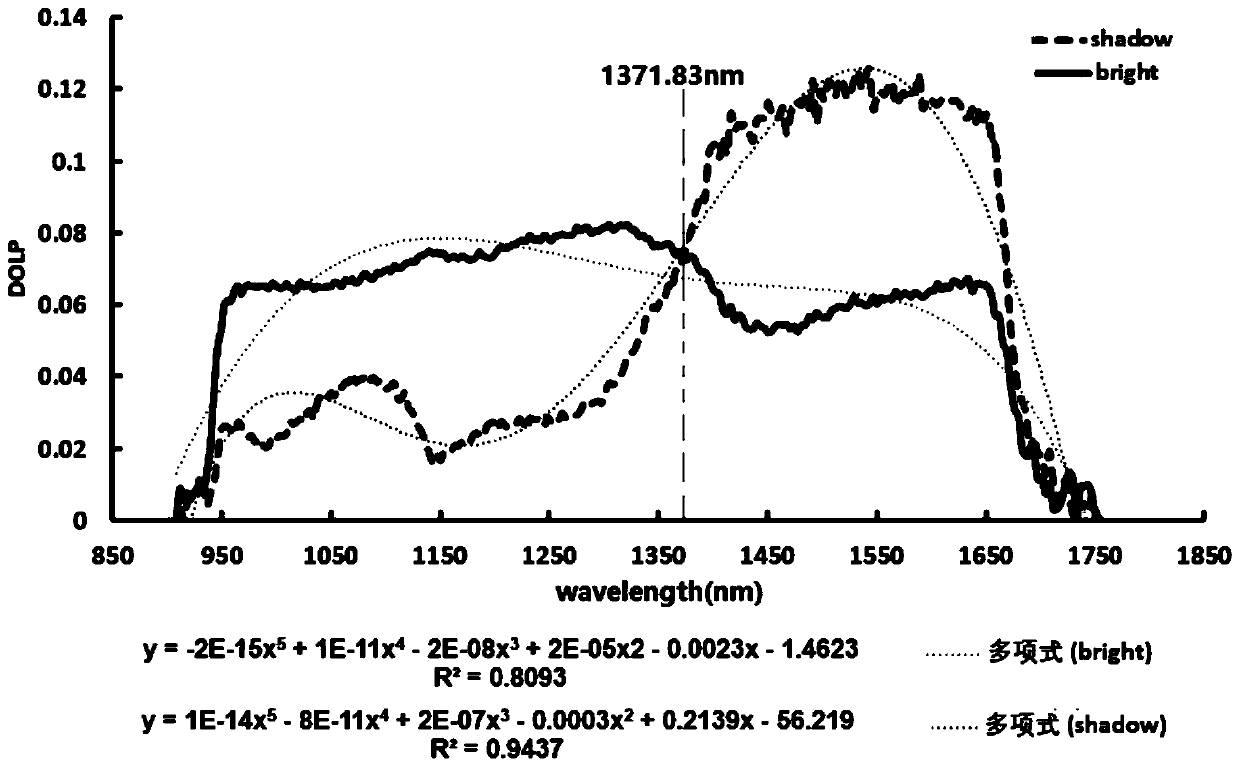

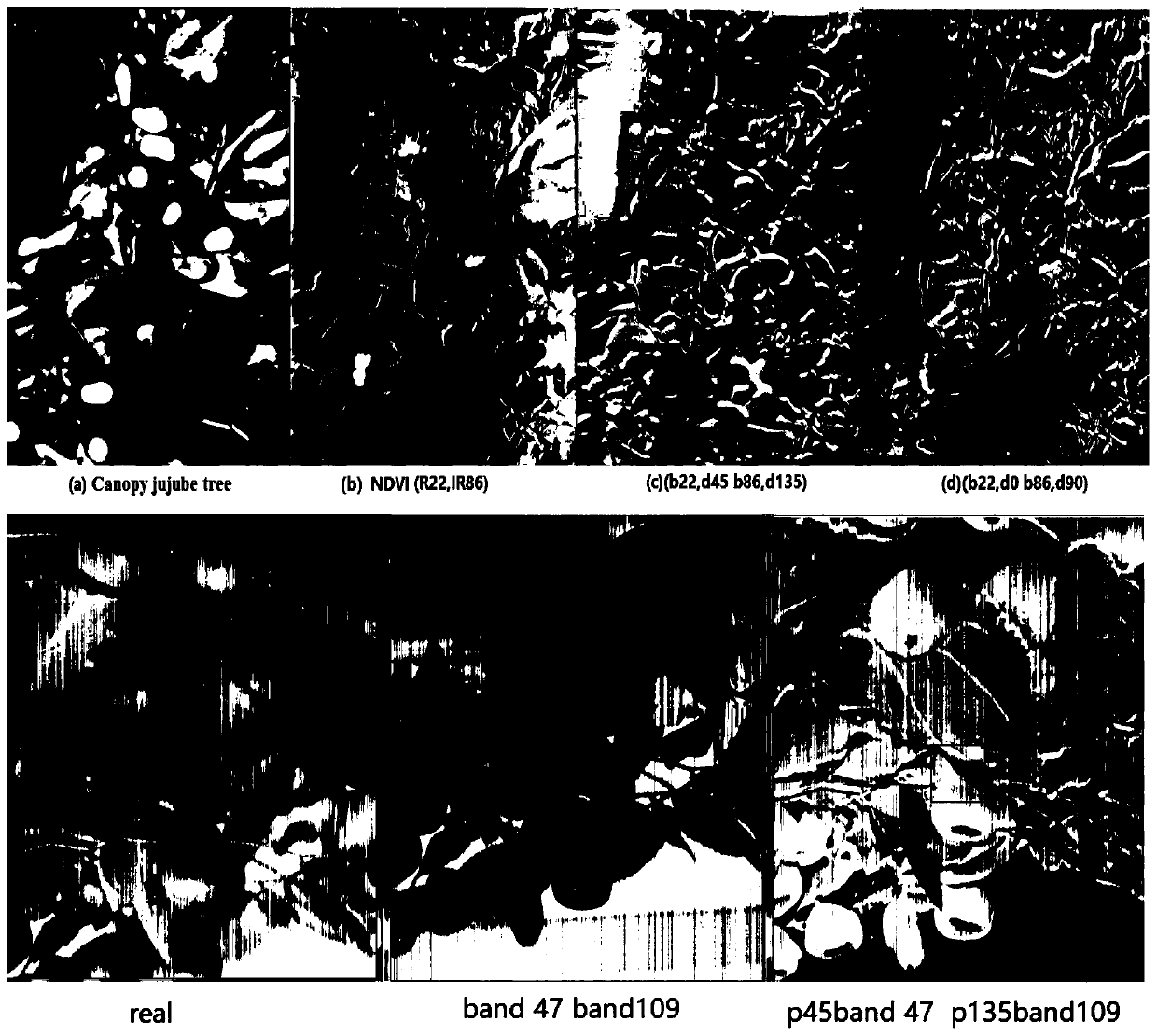

The invention discloses a method for establishing rapid monitoring and processing of orchard data. The method comprises the steps of: detecting the physical and chemical qualities of fruits and collecting the physical and chemical data; obtaining hyperspectral images of the fruits; using processing software related to the hyperspectral images to analyze the massive hyperspectral images and the physical and chemical data, extracting the features, and establishing a corresponding standard model of the fruit quality feature factors and multi-dimensional optical parameters; employing a neural network algorithm to obtain different feature weights; extracting hyperspectral images of the quality feature wave band, and employing the spectral partial correlation to perform feature enhancement; employing the standard model to perform physical and chemical quality classification of other fruits to be detected to obtain reference classification images with different components and concentrations,and establishing a feature classification image library; employing a holographic related identification technology to perform feature storage and identification for the reference classification images, and comparing the identification result to correct the reference image features and the weight factors; and establishing a fruit big data system to achieve rapid monitoring and processing of the massive information of the orchard.

Owner:TARIM UNIV

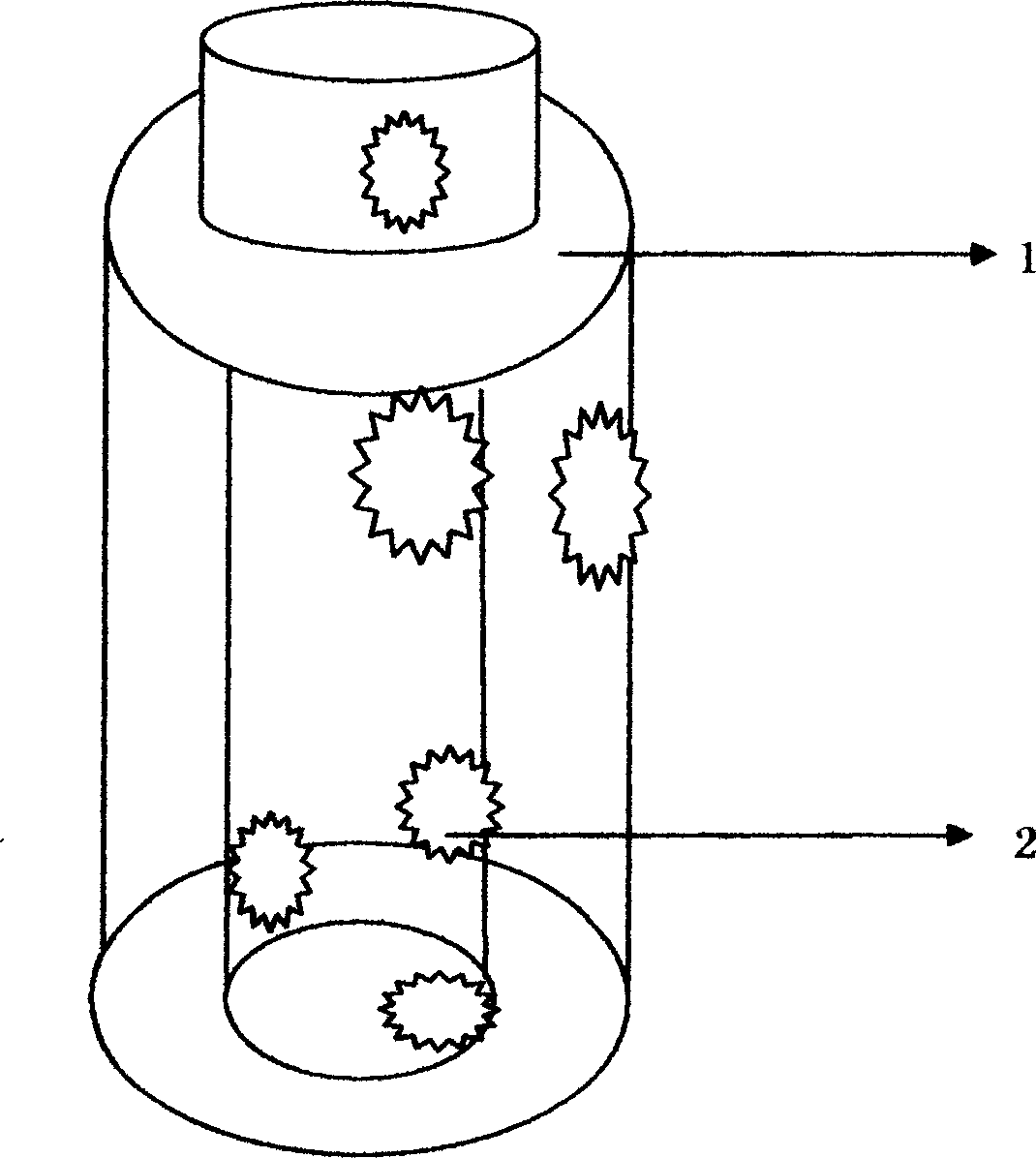

Chemical quality detector

The present invention relates to a chemicals quality detection device, belonging to the field of wireless label sensor and detection device technology. Said invention is characterized by that several wireless label sensors are mounted in the interior of chemicals bottle, so that various quality indexes of chemicals can be read by using external reader-writer (equipment) at all times.

Owner:SHANGHAI ZHONGCE IND & TRADING +1

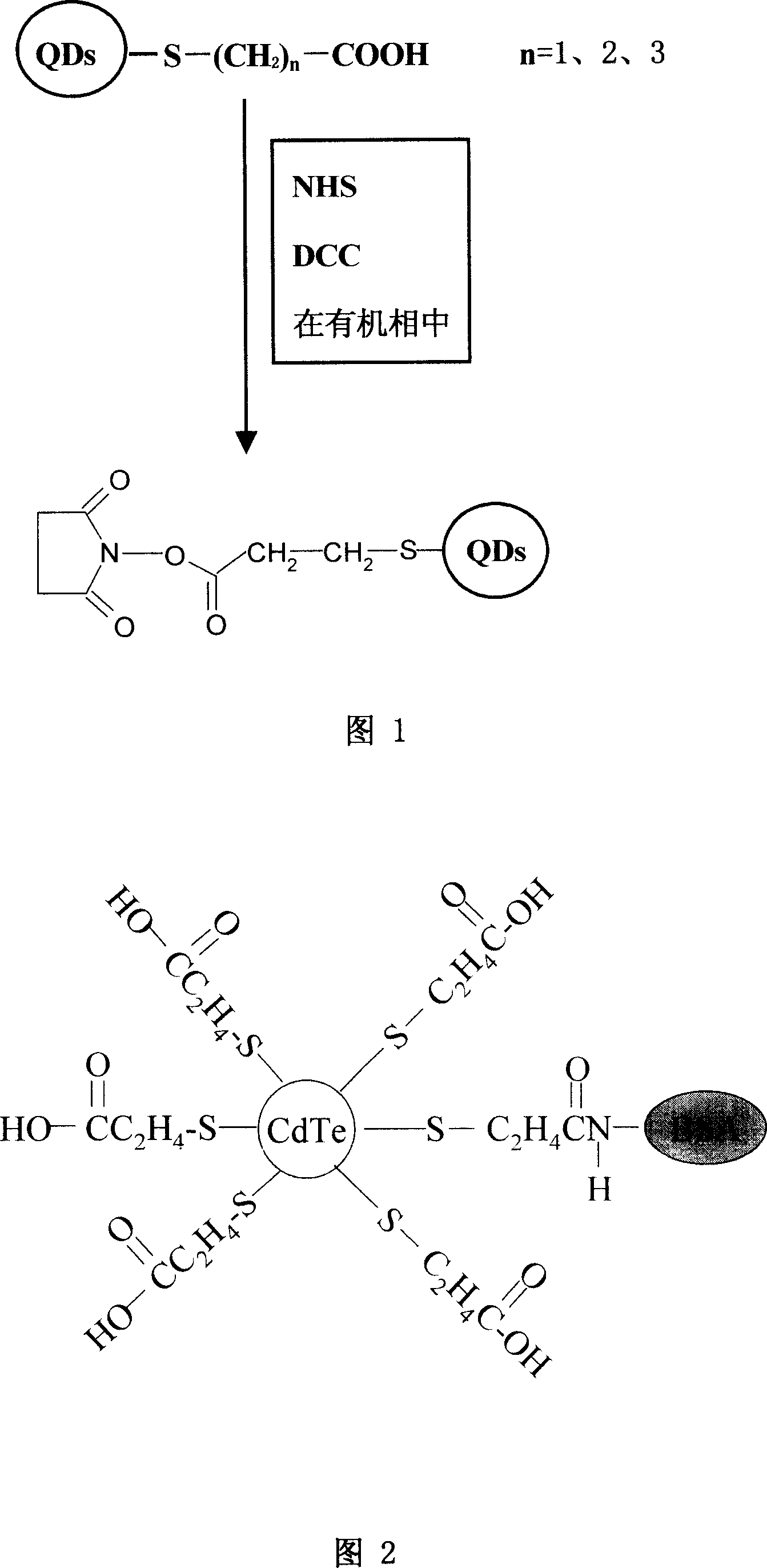

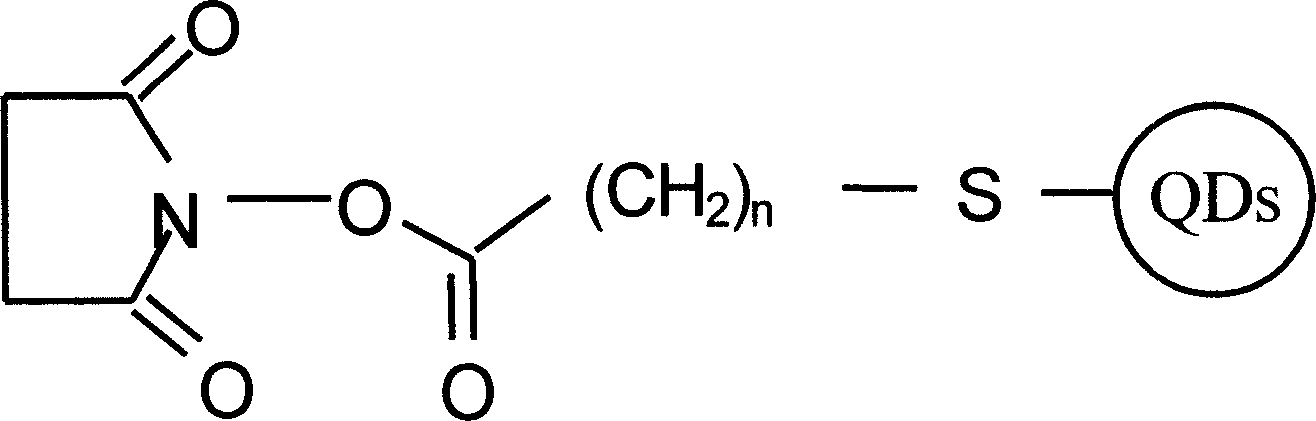

Functionalized quantum dot, process for preparation and use thereof

InactiveCN1952037AFor long-term storageChemical properties are not affectedLuminescent compositionsMaterial analysisChemical qualityQuantum dot

The invention relates to a kind of functional quanta spot. The producing procedure comprises the following steps: pretreating the quanta spot synthesized in stablizing agent; adding pretreated quanta spot to the dissolved N-hydroxyl succinimide then adding the dissolved cicyclohexylcarbodiimide to get the reacting solution; wrapping the solution with paper which can protect the solution from light and making the solution react on the shaker for at least 125h; packaging; evacuating and drying in freeze-vacuum concentrator to get the esterified quanta spot by N- hydroxyl succinimide. The invention has solved many technological problems in background skills such as low labeling rate, unable to keep the quanta for a long time and unable to extend the practical use. The product disclosed in the invention has many advantages: it's water-soluble so it's easier and more efficient to label the biomacromolecule; it has good stability and versatility; it can be preserved for a long time while keeping its physical and chemical qualities.

Owner:SHANXI LIFEGEN

Tobacco flavor and perfume quality analysis method

The invention discloses a tobacco flavor and perfume quality analysis method. The tobacco flavor and perfume quality analysis method comprises the following steps: 1) preparing a sample; 2) acquiring a fingerprint spectrum; 3) building a model; 4) verifying the model; 5) analyzing the quality. The tobacco flavor and perfume quality analysis method can comprehensively detect the interior quality of the tobacco flavor and perfume, and combines with a chemometric method to reflect the interior chemical quality and the quality fluctuation situation of the flavor and perfume.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Particulate inorganic solids treated with organophosphinic compounds

ActiveUS7091262B2Good dispersionExcellent lacingPigmenting treatmentGroup 5/15 element organic compoundsCompound aParticulates

A treatment for particulate inorganic solids is provided. This treatment, which uses certain organophosphinic compounds, imparts improved physical and chemical qualities including lacing resistance, improved dispersion and decreased chemical reactivity when these treated particulate inorganic solids are incorporated into polymeric matrices. The addition of the organophosphinic compounds of the present invention may flexibly be incorporated into known processes at varying points, and are preferably added downstream of any filtering steps or to a dry particulate inorganic solid.

Owner:TRONOX LLC

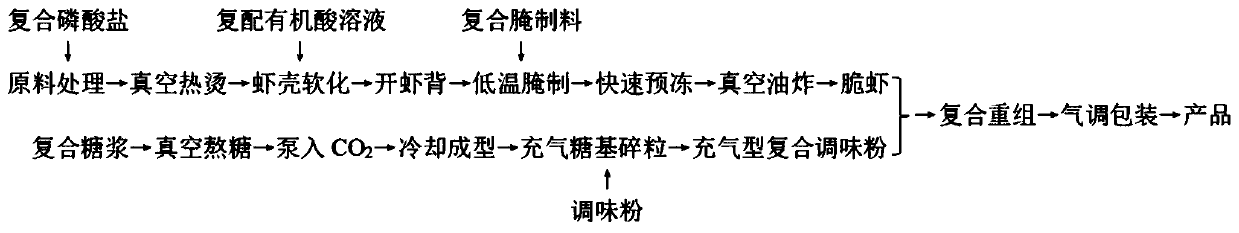

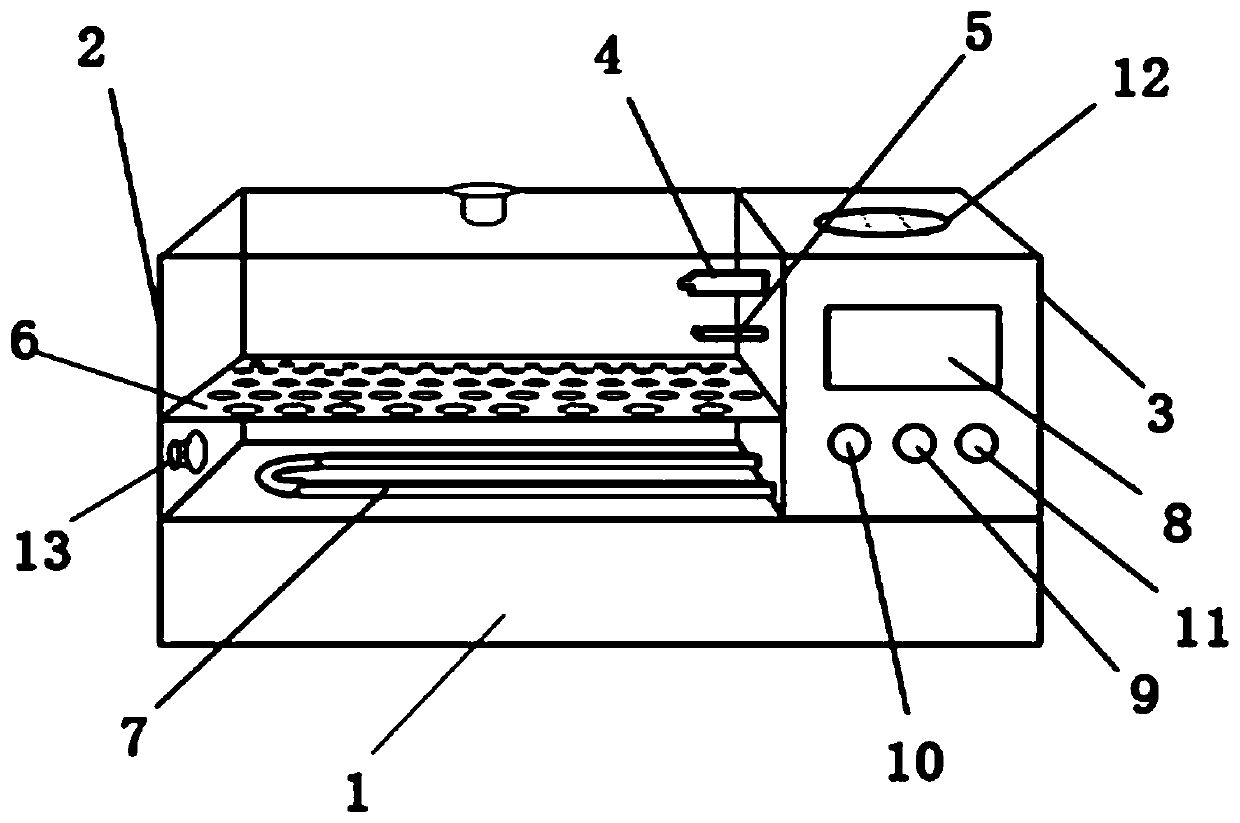

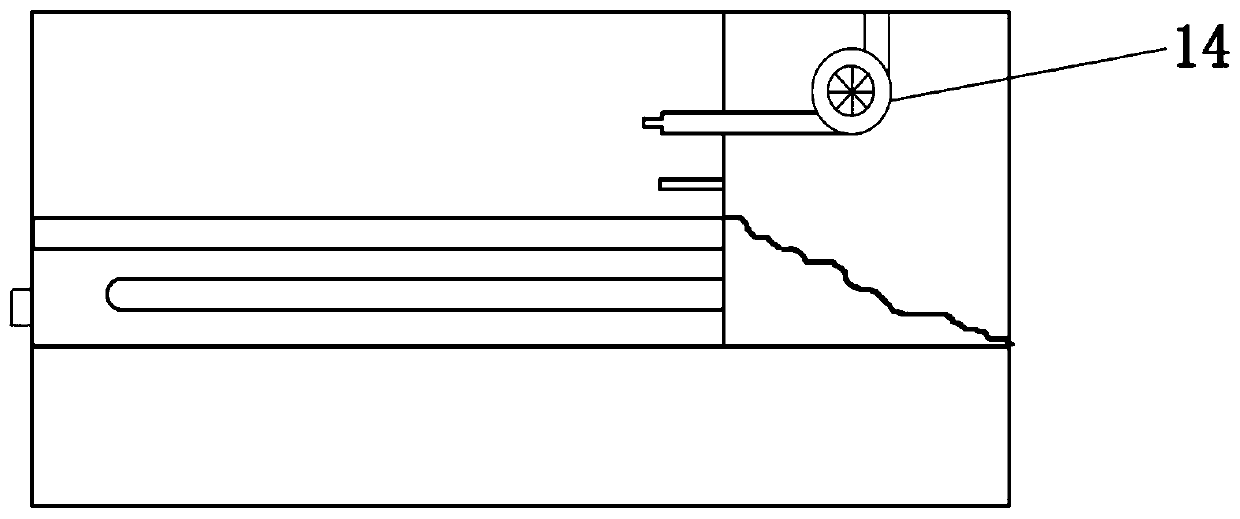

Production method of interesting ready-to-eat leisure jumping shrimps

PendingCN110604272AImprove physical and chemical qualityOrganizational structure is completeFood scienceFlavorReady to eat

The invention discloses a production method of interesting ready-to-eat leisure jumping shrimps. Through soft green processing techniques of performing vacuum low-heat blanching, softening shrimp shells, performing vacuum low-temperature preserving, performing quick pre-freezing, performing vacuum deep-frying and the like, crisp type dehydrated dried shrimps are prepared; through a high-pressure shaping technique and a three-dimensional uniform mixing technique, inflation type composite seasoning powder is prepared; and then recombination and shaping are performed, so that the inflation type composite seasoning powder is inlaid into crisp shrimps of which the backs are split, and the interesting ready-to-eat jump shrimp leisure foods are produced. According to the production method disclosed by the invention, running off of nutritive components of the prawns can be effectively reduced, and physical and chemical quality of products are improved; deep-frying dehydrating treatment is performed under vacuum low-heat condition, so that the flavor and the nutritional quality of the products are better; a plurality of treatment processes are all performed under the vacuum condition, so that the organoleptic quality and nutrients of the products are reserved better; and the production method disclosed by the invention has the characteristics that the technique is green and friendly, nutrients are efficiently reserved, the mouth feel experience is unique, and the production cost is controllable, and consumption hobby of nutritive healthy leisure interesting modern foods can be met.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Separation and purification method of beta-glucan

The invention discloses a separation and purification method of beta-glucan, and the method comprises the following steps: (1) extraction of a beta-glucan solution; (2) filtration; (3) defatting and enzyme deactivation; (4) refiltration; and (5) pressure filtration. When the method is used for separation and purification of the beta-glucan, the molecular structure and chemical quality of the beta-glucan cannot be destroyed, the purity and yield of the beta-glucan can be effectively improved, and the whole separation process is pollution-free, green, environment-friendly and easy to realize industrial popularization.

Owner:SICHUAN HUI TAI AGRI TECH CO LTD

Method for culturing temperature-sensitive high-grade early rice

InactiveCN101530059AChange the traditional concept of poor qualityImprove planting efficiencyPlant genotype modificationAgricultural scienceChemical quality

The invention discloses a method for culturing temperature-sensitive high-grade early rice with the characteristic of high-grade late non-glutinous rice, including: collectingthe non-glutinous rice material, planting according to the early rice, selecting the premature rice material sensitive to the temperature, observing the appearance quality, determining the physical and chemical quality, selecting the rice material with transparency appearance, no chalkiness, good physical and chemical quality, performing stage planting, selecting the temperature non-sensitive rice material, evaluating the stability of transmissibility, obtaining the temperature non-sensitive type rice sensitive to the temperature in the generational period. The rice cultured according to the invention has the characteristic of high-grade late non-glutinous rice, is basically different from the traditional poor-quality early rice, has good quality and lower price; the planting efficiency is improved and a new way for the breeding of the high-grade early rice is provided in the breeding method.

Owner:ZHEJIANG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com