Preparation process and sterilization method for instant flavor fish

A technology for flavored fish and grass carp, applied in food preparation, food science, preservation of meat/fish by radiation/electrical treatment, etc., can solve the problems of product texture damage, surface shrinkage, lack of chewiness, etc., and achieve increased chewiness , good texture, good chewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

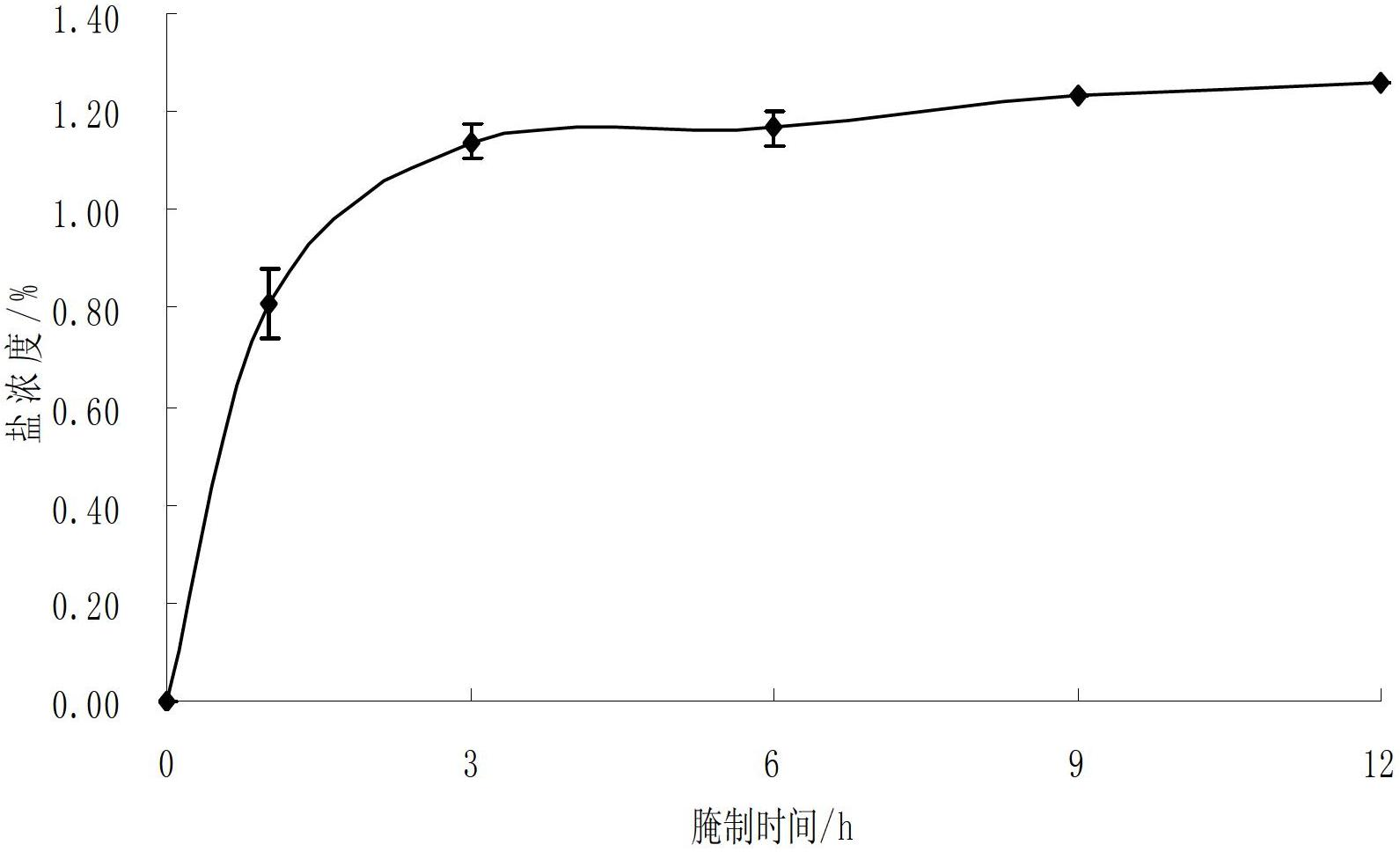

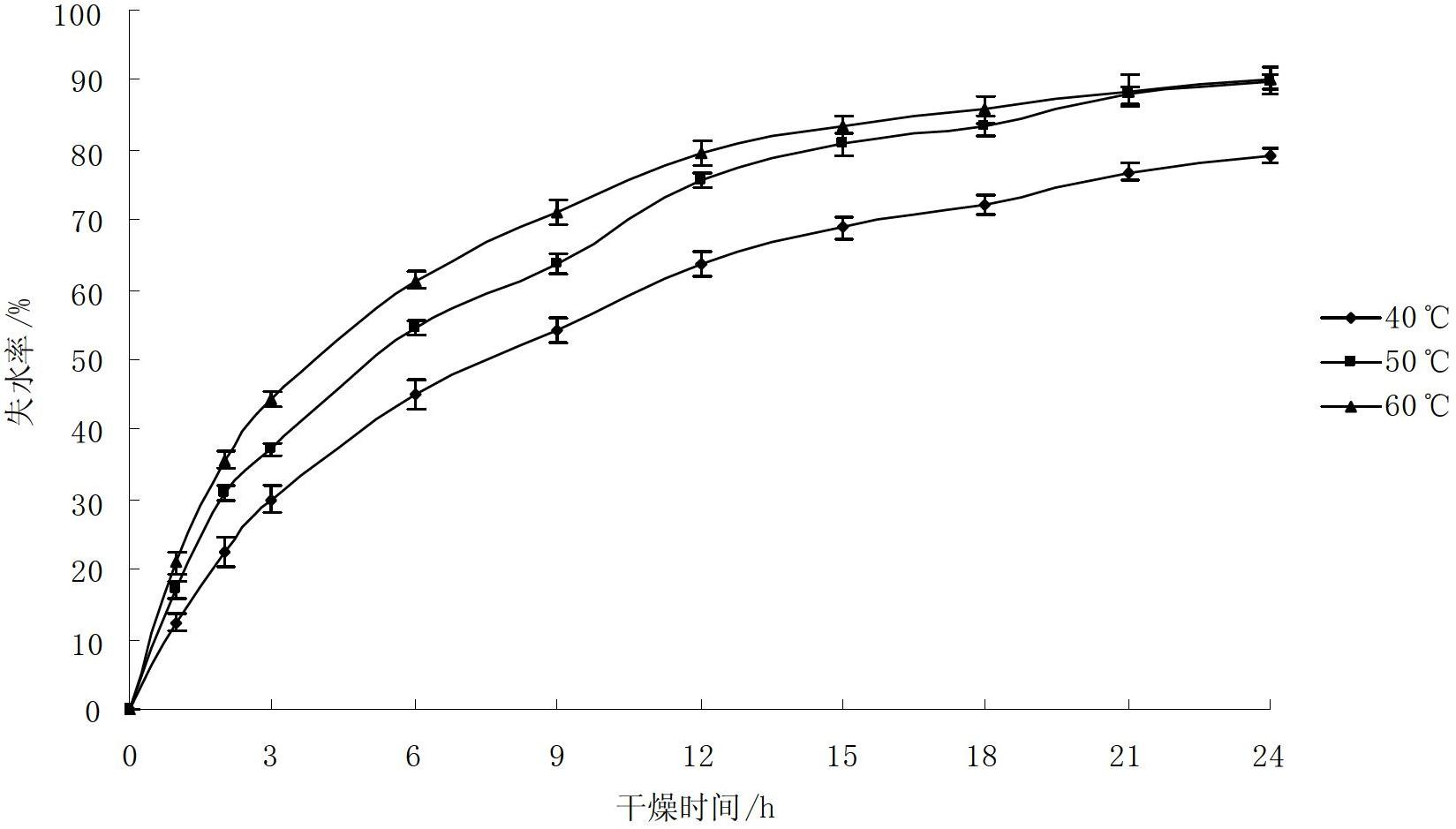

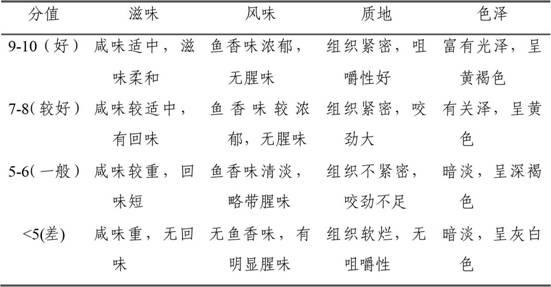

[0032] Effects of Salt Concentration, Drying Temperature and Sterilization Methods on Sensory Quality of Products

[0033] 1.5-2kg fresh grass carp, remove scales, internal organs, fish head, fish tail and fish bone spurs, wash, drain, cut into fish pieces with a width of about 2cm, under the condition of 5℃, the salt concentration of 2%, 3%, 5% respectively Pickled by dry pickling, dried at 40°C, 50°C, and 60°C after pickling, seasoned the dried fish pieces, passed the sensory evaluation test, and optimized the formula as follows: vegetable oil 2% (w / w), horseradish 1%, 5% pickled pepper (w / w), appropriate amount of natural spices (including cinnamon, anise, cumin, grass fruit, licorice, and peppercorns), the product taste and flavor sensory quality is good. Seasoned fish nuggets were vacuum-packed, sterilized by irradiation at a dose of 3 kGy or sterilized under high temperature and high pressure at 121°C for 20 minutes, and compared the effects of pickling salt concentratio...

Embodiment 2

[0040] Effects of High Temperature and High Pressure Sterilization and Irradiation Sterilization on Product Color, Texture and Hydrolyzed Amino Acid Content

[0041] The fish pieces were processed by Example 1, marinated with 2% salt for 3 hours, dried at 50°C for 18-24 hours, seasoned, vacuum-packed, and the effects of high-temperature, high-pressure sterilization and radiation sterilization on product color, texture, and hydrolyzed amino acid content were compared. , so as to determine the effect of irradiation sterilization on maintaining the quality of ready-to-eat flavor fish.

[0042] Table 3 Differences in product color between the two sterilization methods

[0043]

[0044] The difference in color of the products obtained by the two sterilization methods is shown in Table 3. The L* value and Hunter whiteness of the irradiation sterilization products are higher than those of the high temperature and high pressure sterilization products, while the a* value and b* valu...

Embodiment 3

[0054] Changes in microbial indicators during product processing

[0055] The fish pieces were processed by Example 1, 2% salt dry-cured for 3 hours, dried at 50°C for 18-24 hours, seasoned, vacuum-packed, observed the changes in microbial indicators during product processing, and determined the effect of irradiation on the sterilization of ready-to-eat flavored fish. Effect.

[0056] Table 6 Changes in microbial indicators during product processing

[0057]

[0058] Table 6 shows that the total number of bacteria in fresh fish is higher. This is because the raw fish itself carries a large number of microorganisms, and the secondary pollution in the processing process leads to a higher initial bacterial count in fresh fish. During the pickling process, the salt osmotic pressure is high, which dehydrates the microorganisms, which is not conducive to the survival of bacteria, resulting in a decrease in the total number of bacteria and mold. Under hot air drying conditions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com