Patents

Literature

2120results about How to "Improve sensory quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

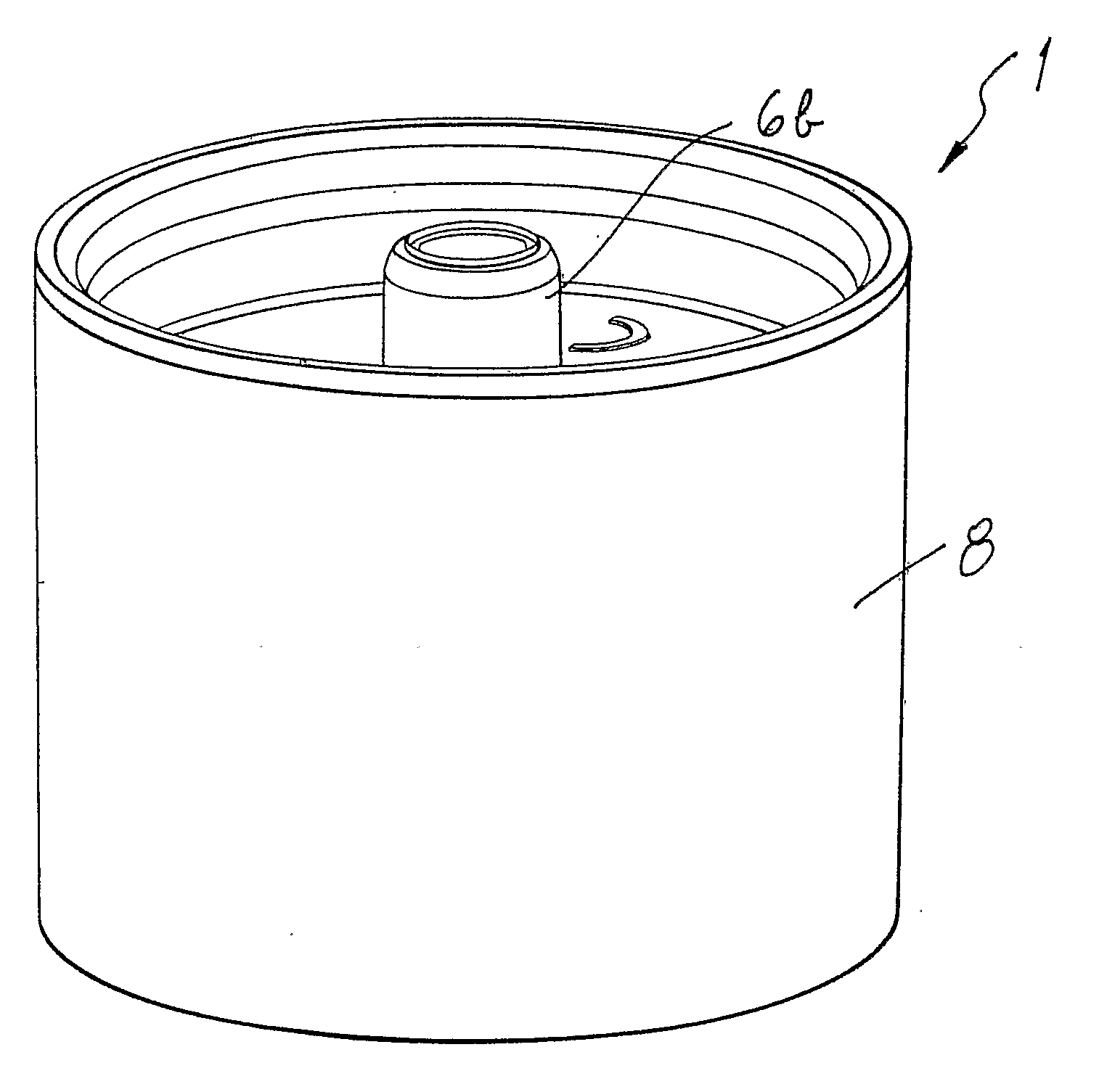

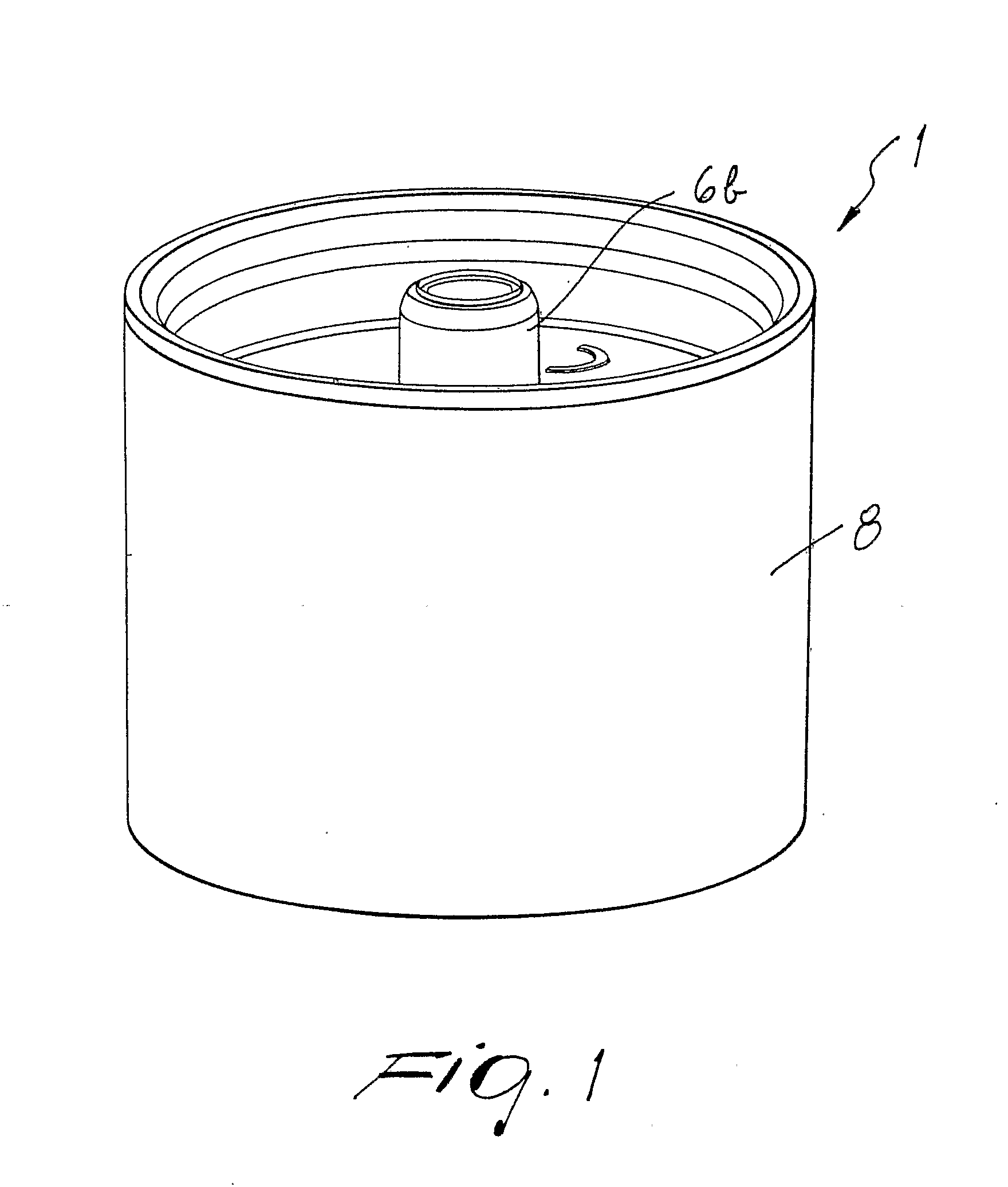

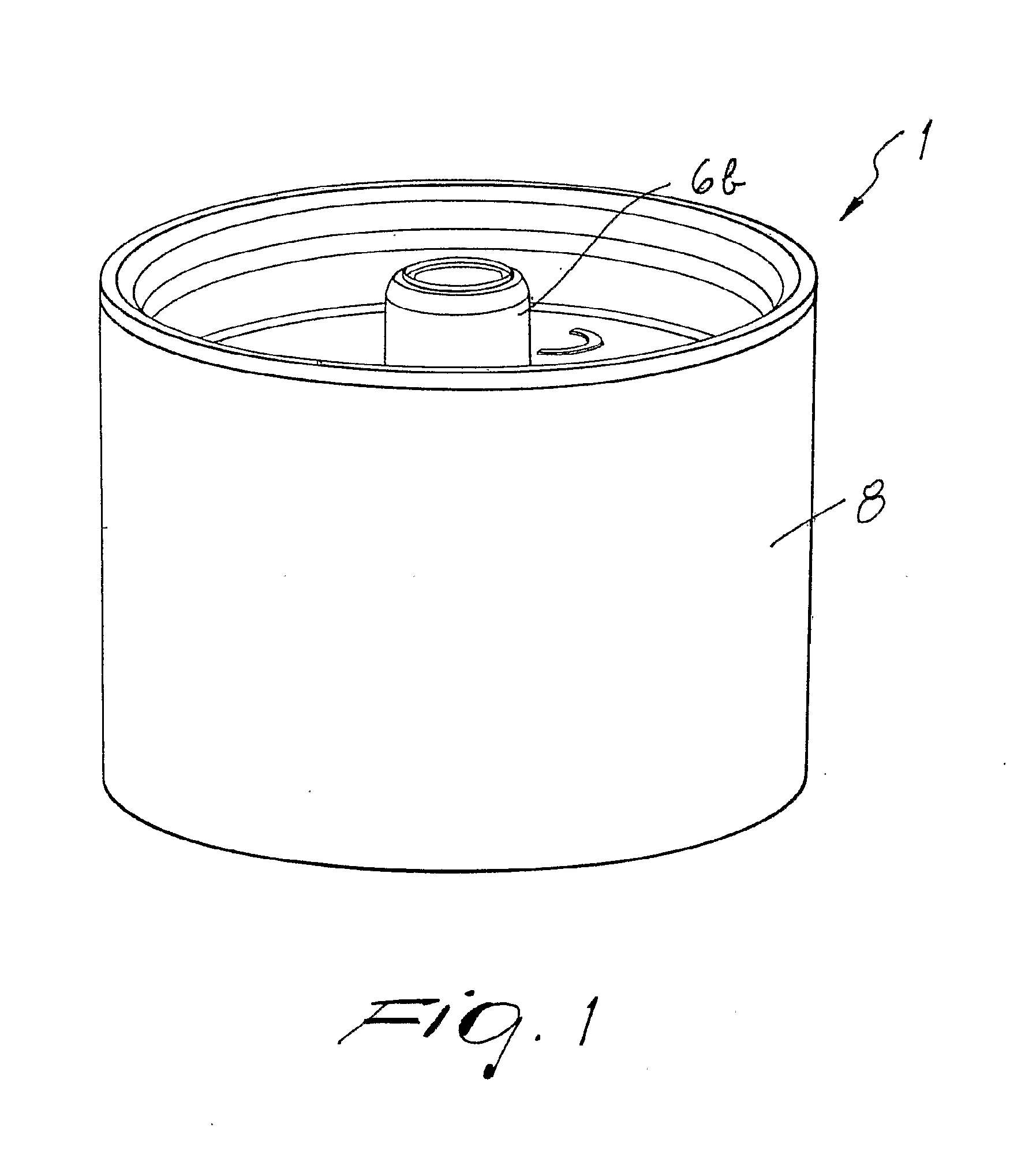

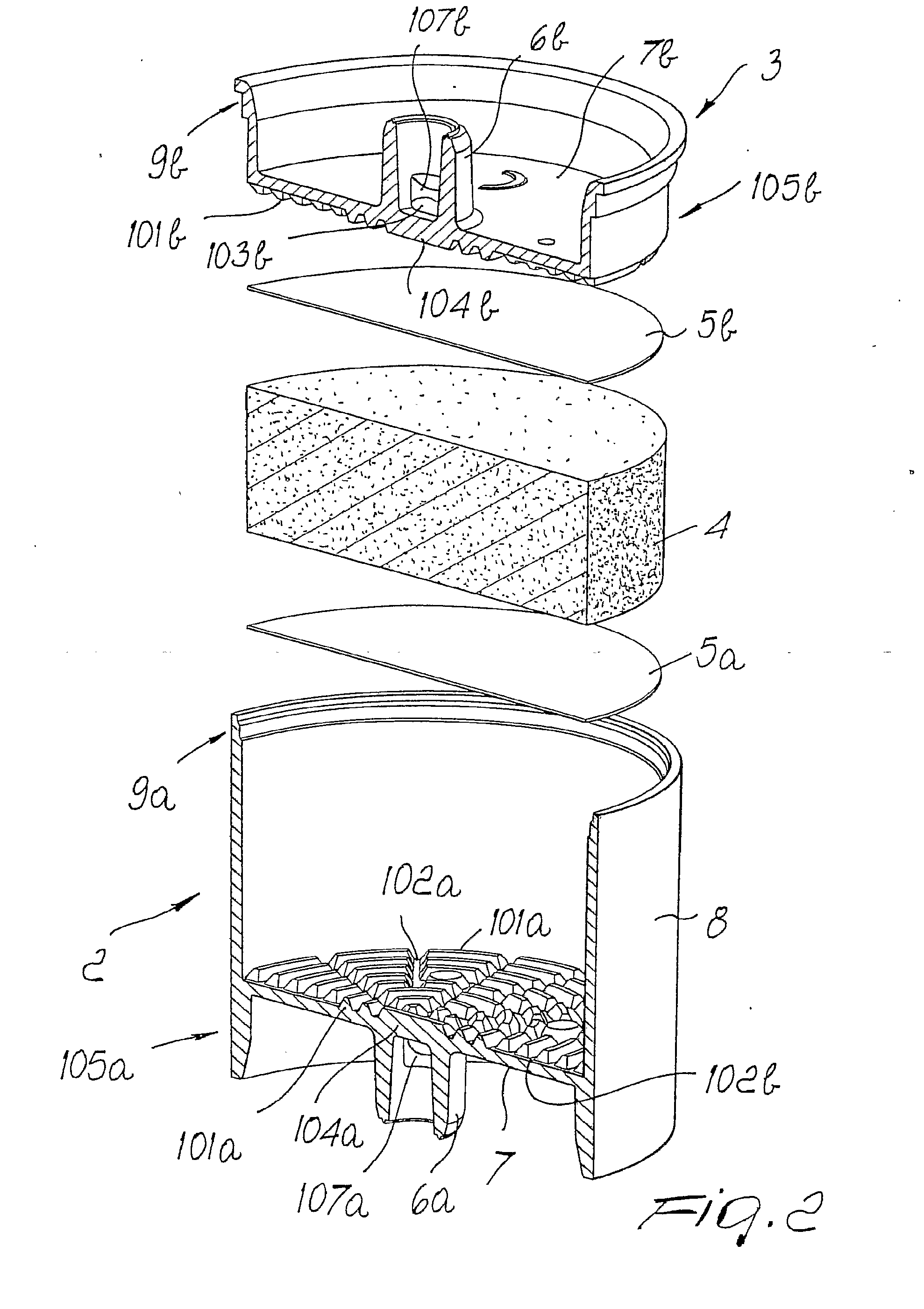

Beverage extraction assembly for extracting a beverage from a particulate substance contained in a cartridge

ActiveUS20070186784A1High level of preservationReduce pollutionBeverage vesselsPackaging foodstuffsFluid - substanceBiomedical engineering

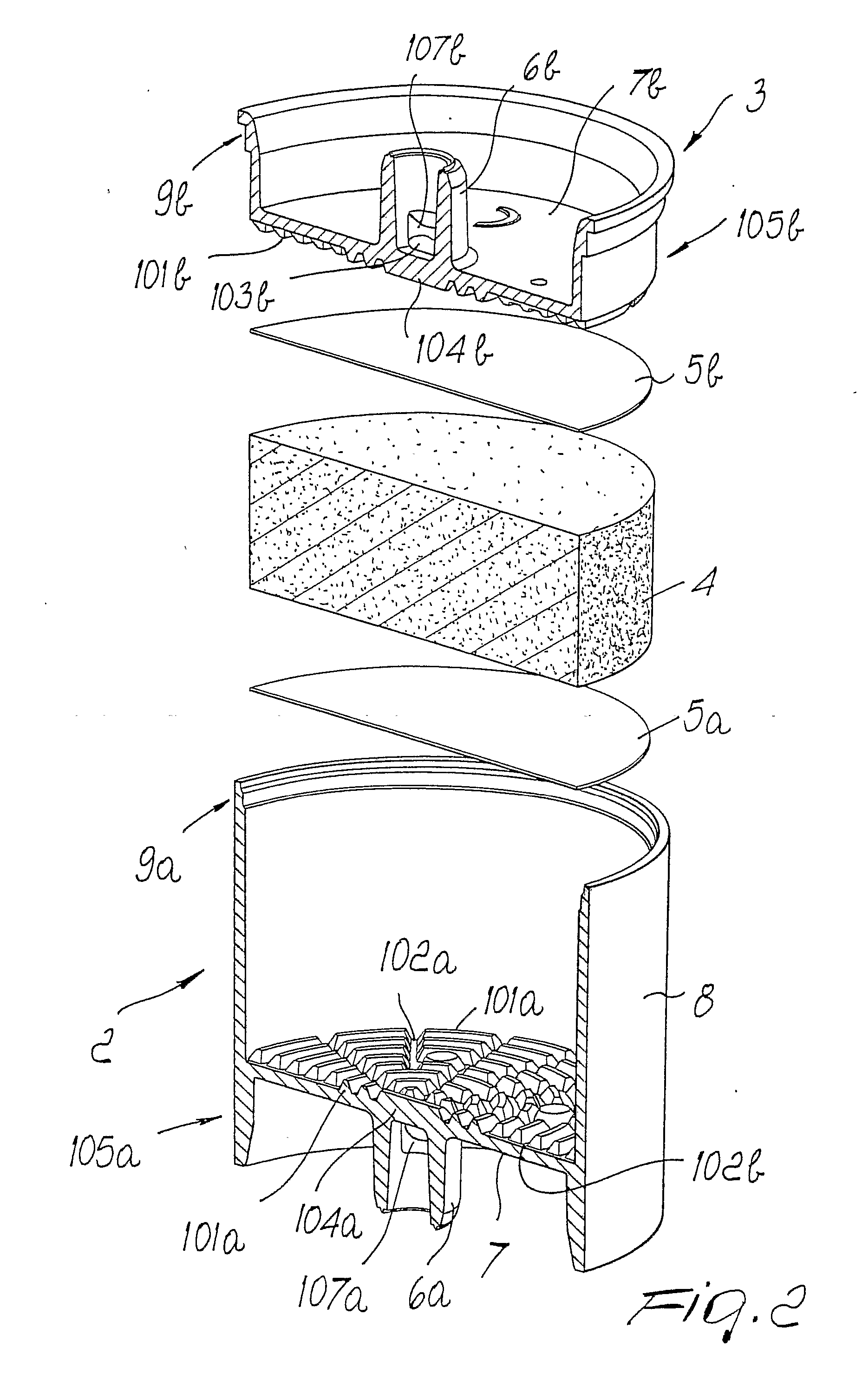

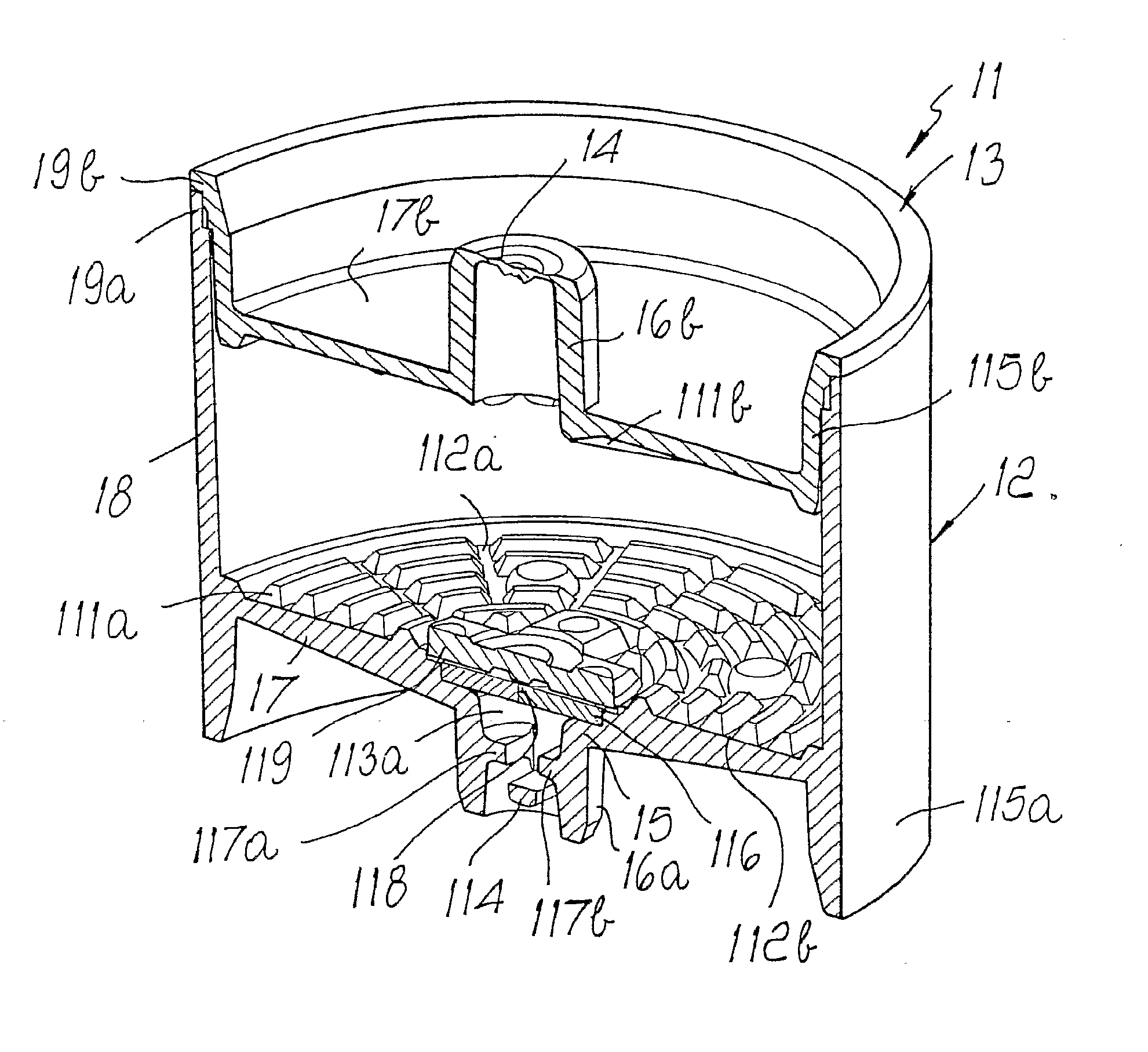

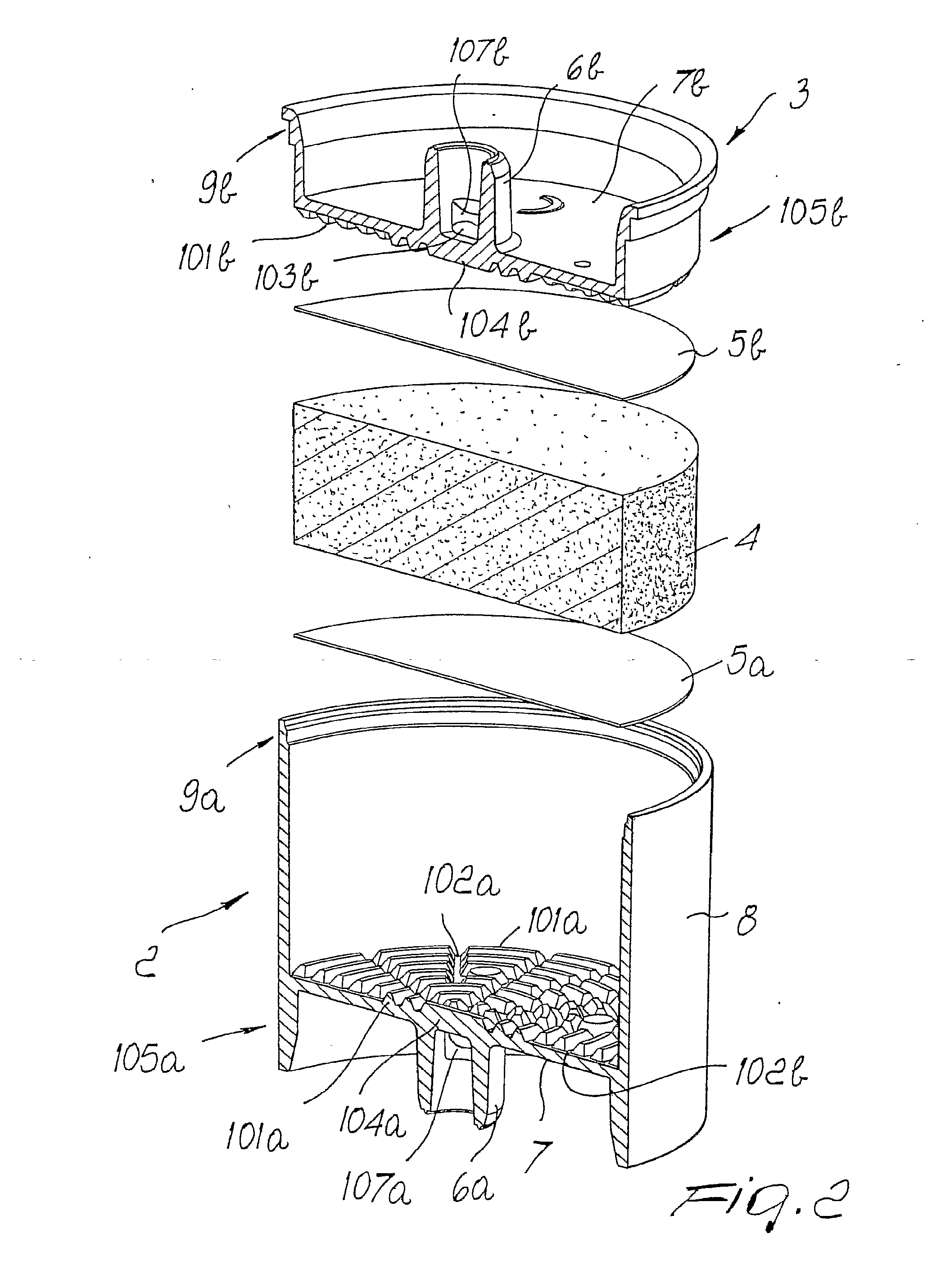

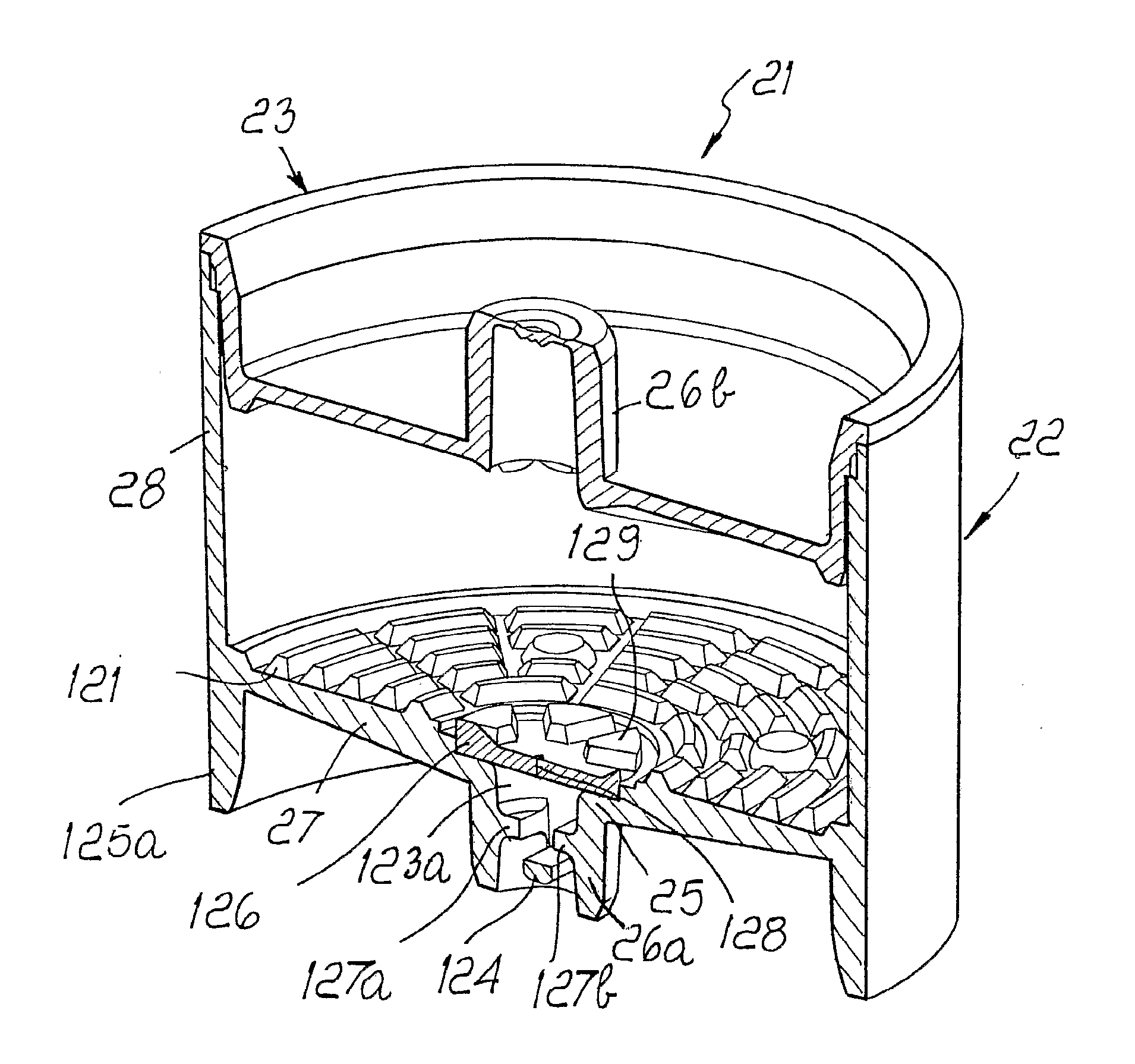

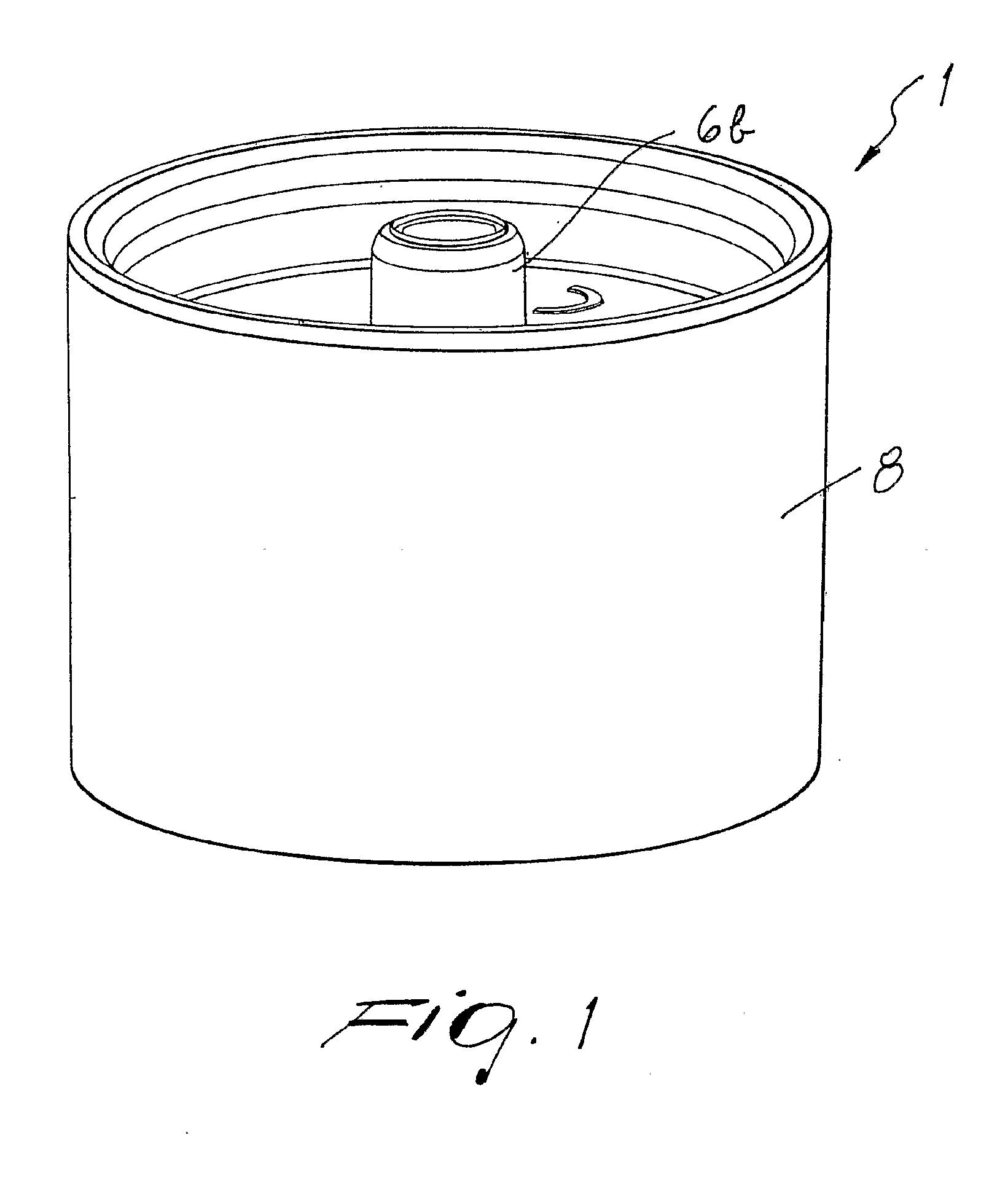

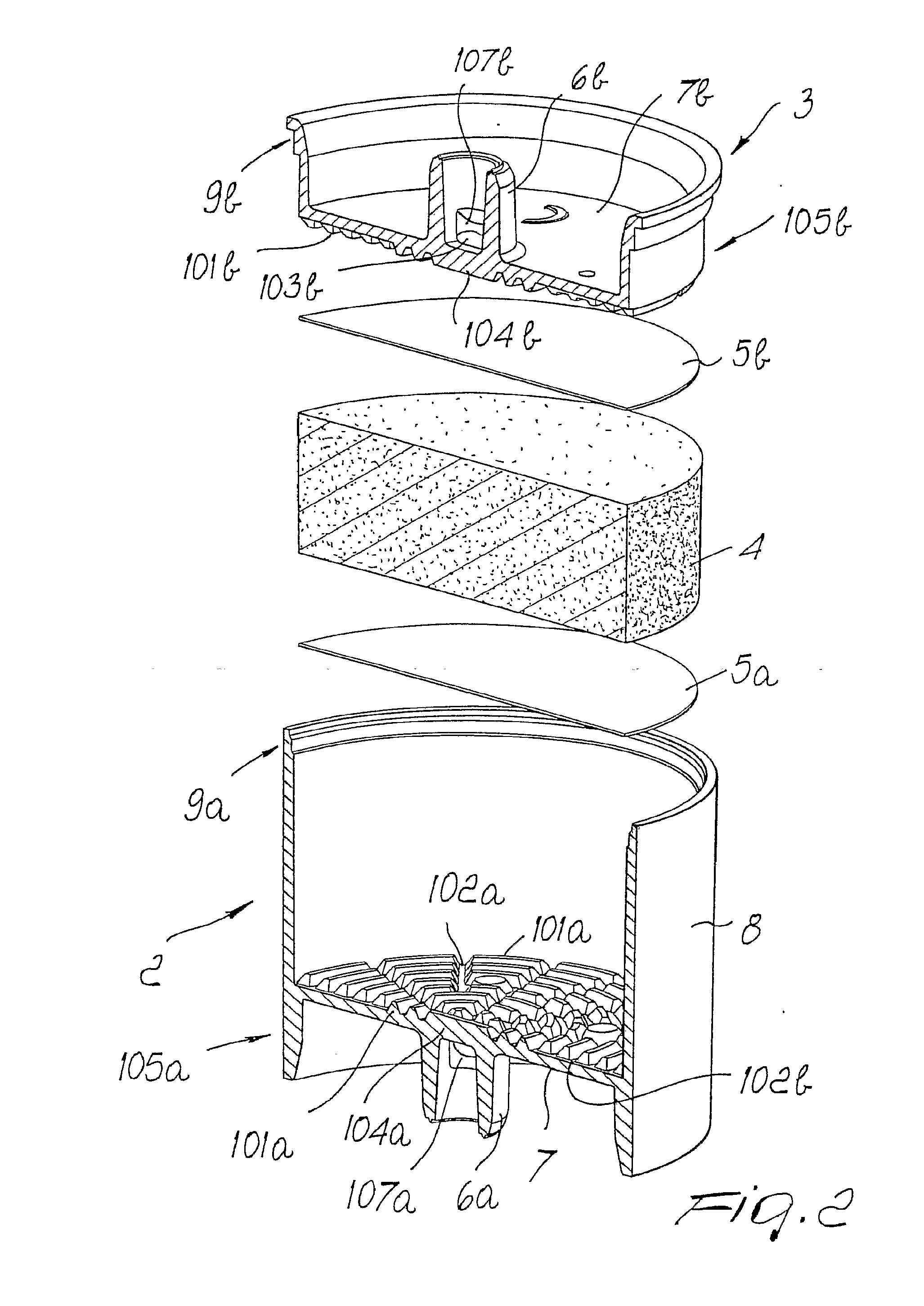

A cartridge for extracting a beverage from a particulate substance contained therein by means of water under pressure, the cartridge comprising: a main body comprising a cup portion and a lid portion, the cup portion comprising a base, a sidewall and a rim opposed to the base, the lid portion being fixedly attached to the rim of the cup portion so as to define an internal volume of the cartridge, the internal volume of the cartridge housing the particulate substance comprised within filtering means for retaining the particulate substance and for percolating fluid substances therethrough, the lid portion comprising a lid port defining a first passage for percolation fluid substances, the base of the cup portion comprising a cup port defining a second passage for percolation fluid substances, wherein the base comprises a plurality of ridges directly formed thereon and protruding towards the internal volume of the cartridge, so as to support the filtering means and the particulate substance and to define a fine canalization between the filtering means and the cup port.

Owner:ILLYCAFFE SPA

Integrated cartridge for extracting a beverage from a particulate substance

InactiveUS20100043646A1Improve sensory qualityQuality improvementSmall article dispensingReady-for-oven doughsEspresso coffeeFluid - substance

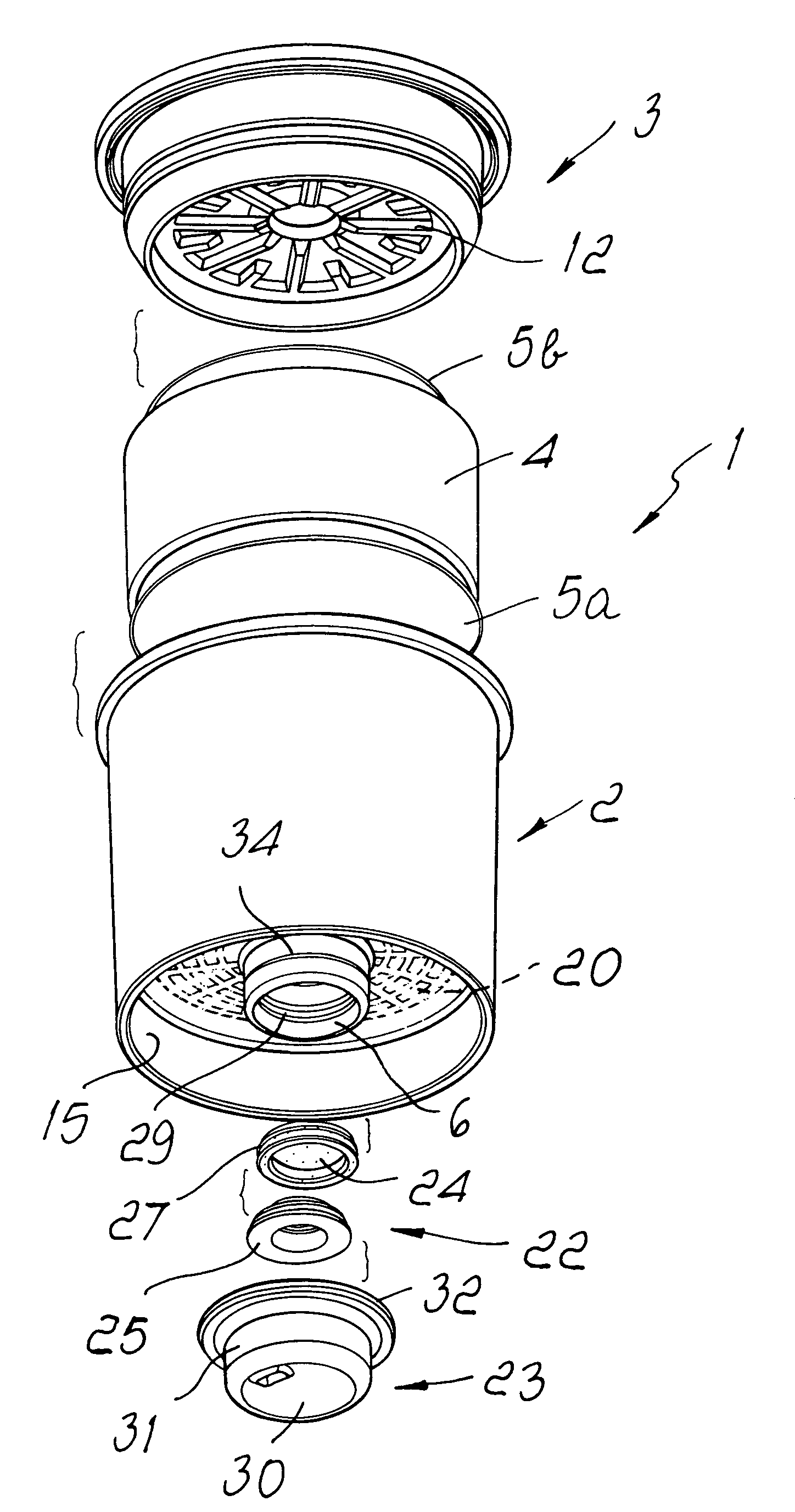

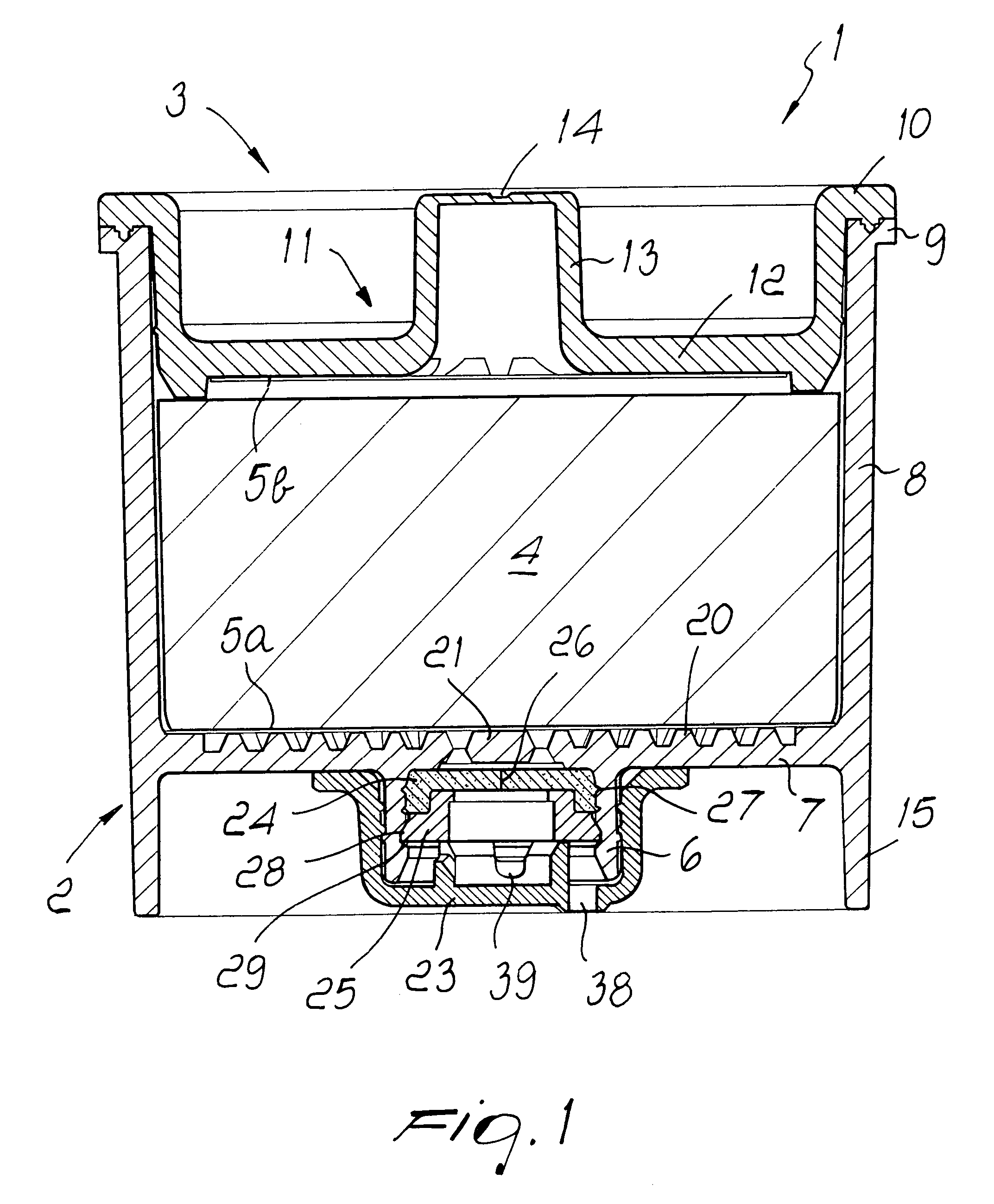

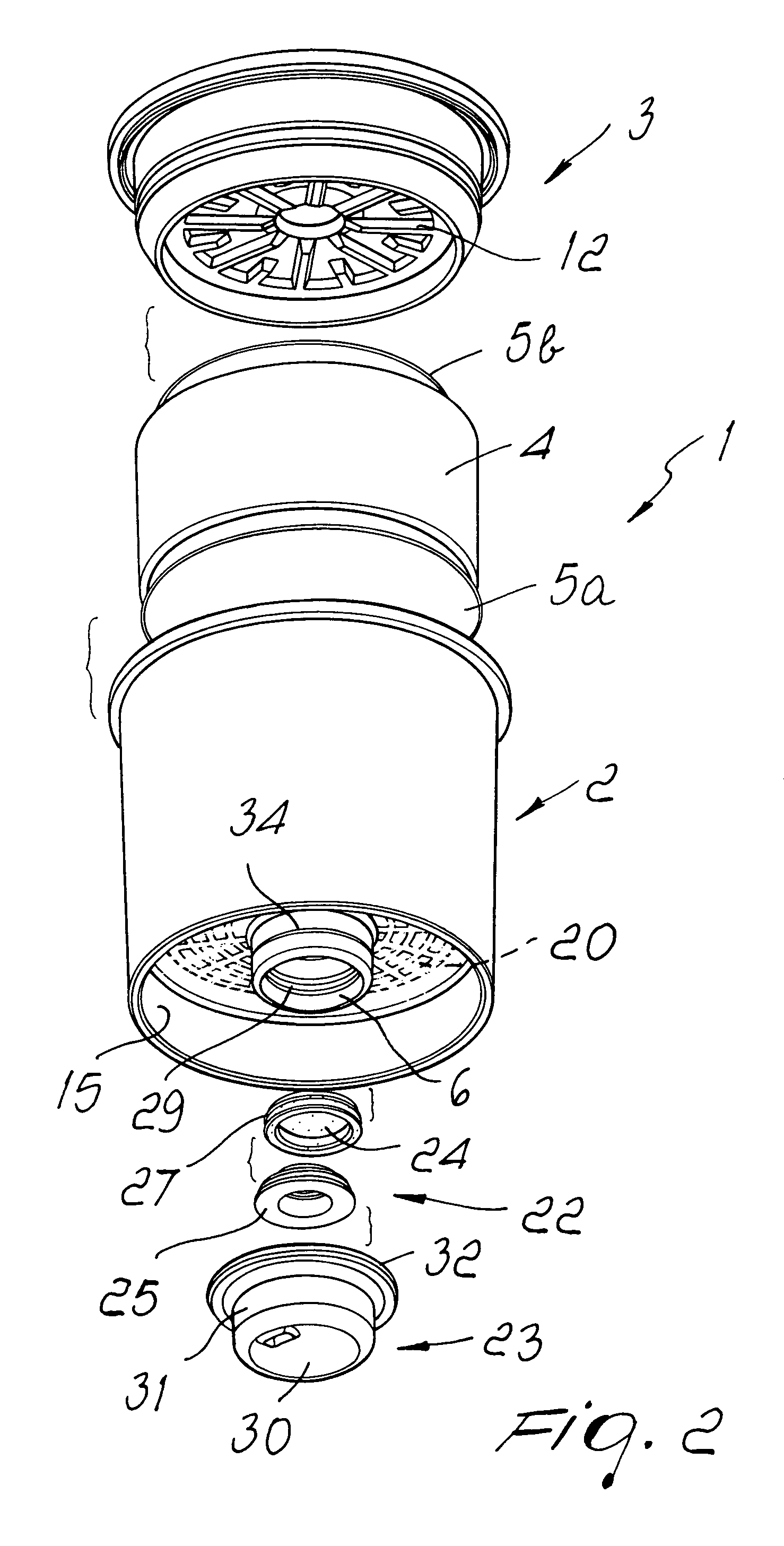

A cartridge, particularly for espresso coffee machines, for extracting a beverage from a particulate substance contained therein by means of water under pressure is provided. The cartridge comprises a main body with a cup portion and a lid portion. The cup portion comprises a base, a sidewall and a rim opposed to the base, while the lid portion is fixedly attached to the rim of the cup portion so as to define an internal volume of the cartridge. The internal volume of the cartridge houses the particulate substance comprised within filtering means for retaining the particulate substance and for percolating fluid substances therethrough. The lid portion comprises a normally closed lid port defining a first passage for percolation fluid substances when it is opened. The cartridge further comprises a tappet arranged inside the internal volume so as to pierce the base when a pressure is applied to the base towards the internal volume, thus opening a normally closed cup port.

Owner:ILLYCAFFE SPA

Integrated cartridge for extracting a beverage from a particulate substance

InactiveUS20100043645A1Improve sensory qualityQuality improvementSmall article dispensingOther accessoriesParticulate (substance)Fluid - substance

Owner:ILLYCAFFE SPA

Integrated cartridge for extracting a beverage from a particulate substance

InactiveUS20100043644A1Improve sensory qualityQuality improvementSmall article dispensingOther accessoriesEngineeringFluid - substance

A cartridge for extracting a beverage from a particulate substance contained therein by means of water under pressure, the cartridge comprising: a main body comprising a cup portion and a lid portion, the cup portion comprising a base, a sidewall and a rim opposed to the base, the lid portion being fixedly attached to the rim of the cup portion so as to define an internal volume of the cartridge, the internal volume of the cartridge housing the particulate substance comprised within filtering means for retaining the particulate substance and for percolating fluid substances therethrough, the lid portion comprising a lid port defining a first passage for percolation fluid substances, the base of the cup portion comprising a cup port defining a second passage for percolation fluid substances, wherein the base comprises a plurality of ridges directly formed thereon and protruding towards the internal volume of the cartridge, so as to support the filtering means and the particulate substance and to define a fine canalization between the filtering means and the cup port.

Owner:ILLYCAFFE SPA

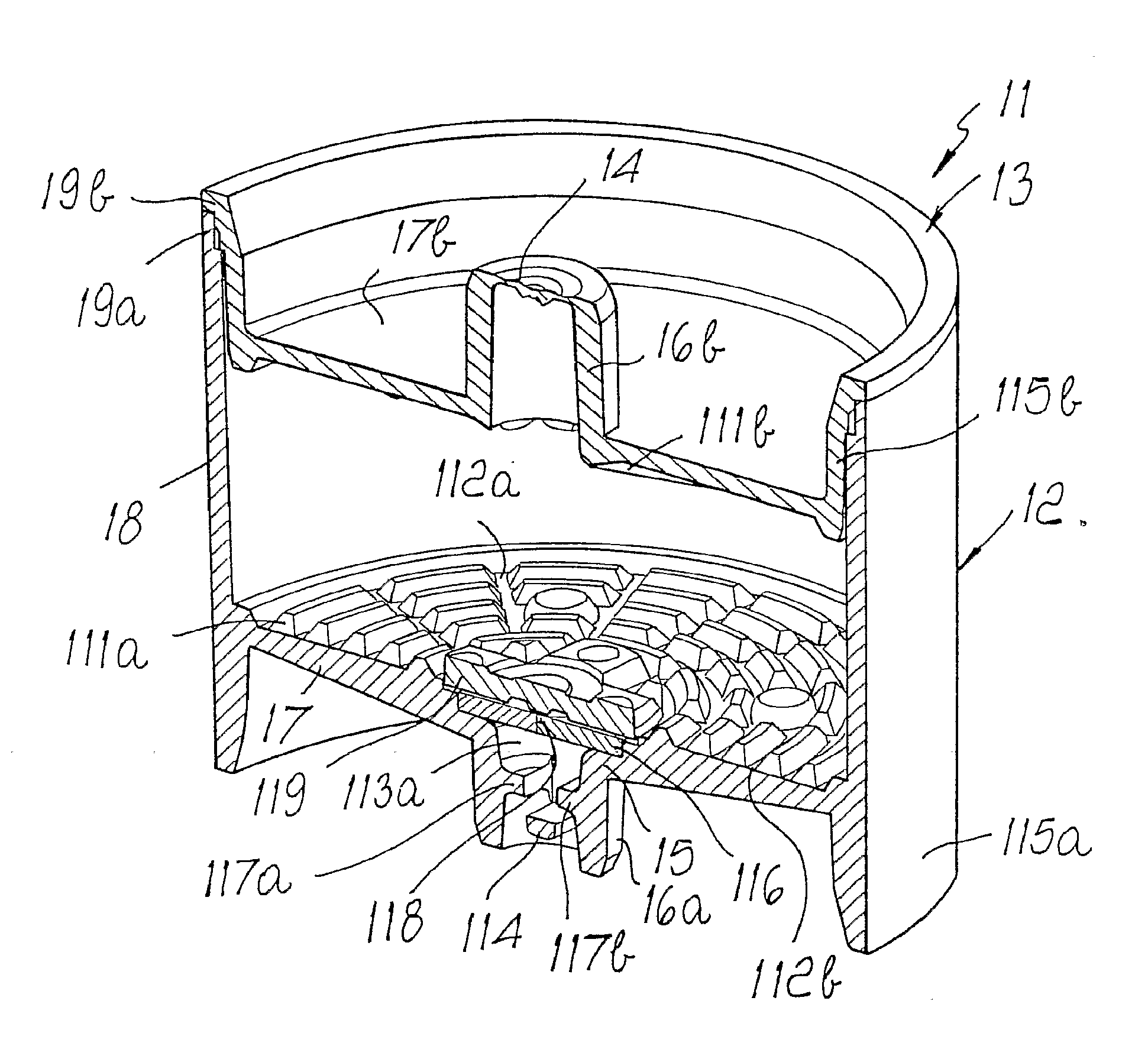

Integrated cartridge containing a substance for extracting a beverage

ActiveUS7681492B2Improve sensory qualityQuality improvementReady-for-oven doughsBeverage vesselsBiomedical engineering

A cartridge for extracting a beverage from an edible substance contained therein by means of a liquid under pressure, the cartridge comprising a main body having a cup portion and a lid portion. The base of said cup portion comprises a cup port defining a passage for the extracted beverage and protruding from the base outwardly with respect to the internal volume of the cartridge. Valve means are fixedly mounted on the internal surface of the cup port and are resiliently openable under pressure of the extracted beverage during a beverage extraction phase. The diameter of the open end of said cup port that is opposite to said cup base is sized so as to allow insertion of the valve means within the cup port. A safety cap is mounted on the external surface of the cup port and partially closes the external open end thereof.

Owner:ILLYCAFFE SPA

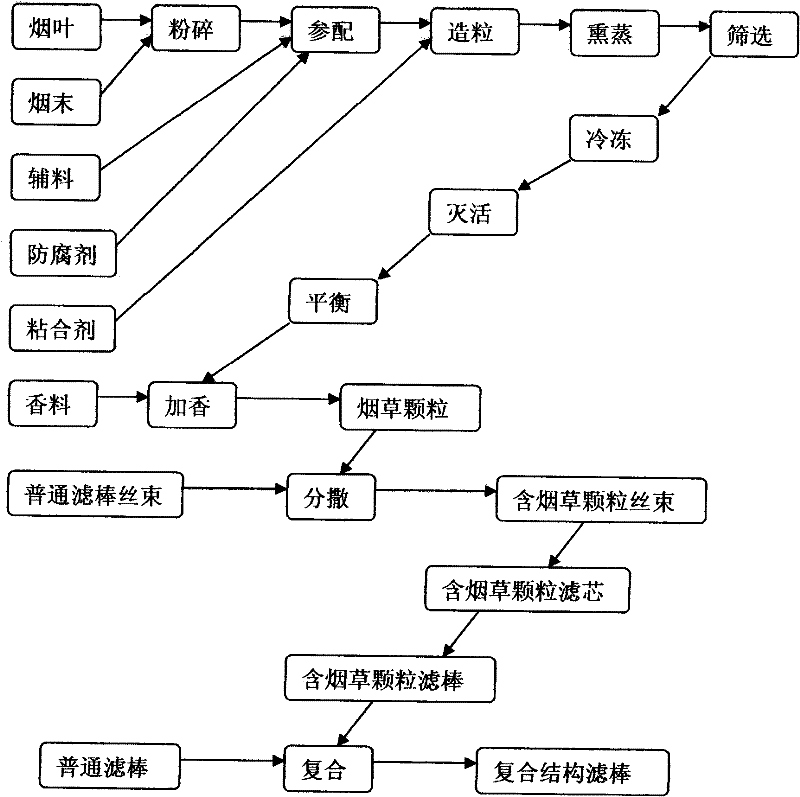

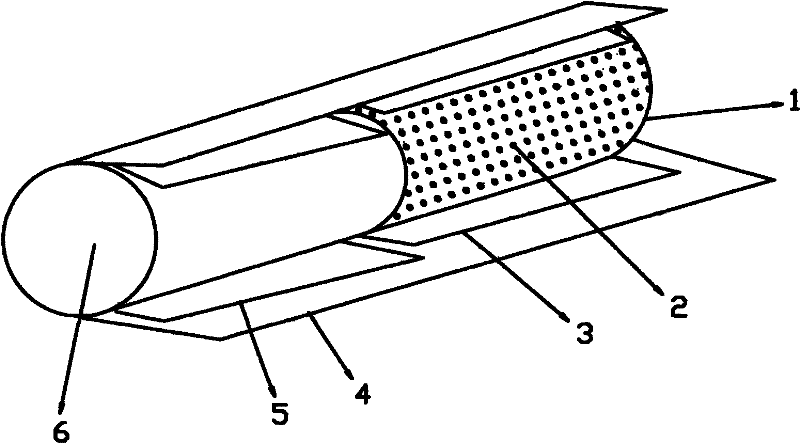

Filter stick containing tobacco particles and preparation method thereof

The invention provides a novel filter stick for cigarettes and a preparation method thereof. Tobacco particles are added in a filter core of the filter stick, tobacco leaves and tobacco smalls are adopted as main raw materials of the tobacco particles and are used as additives after the technical processing such as pulverizing, rotten prevention, granulating, fumigating, perfuming and the like tobe thrown into tows of the filter stick, and then the filter stick containing the tobacco particles or the filter stick with a composite structure can be prepared by adopting a filter stick forming machine. The filter stick can strengthen the adsorption function, can reduce the tar and alleviating the harm, and fragrance of the tobacco particles also can effectively compensate the decreased fragrance of the cigarette caused by the filtering of the filter stick. At the same time, the filter stick is easy to cut and is friendly to the environment.

Owner:NANTONG CIGARETTE FILTER

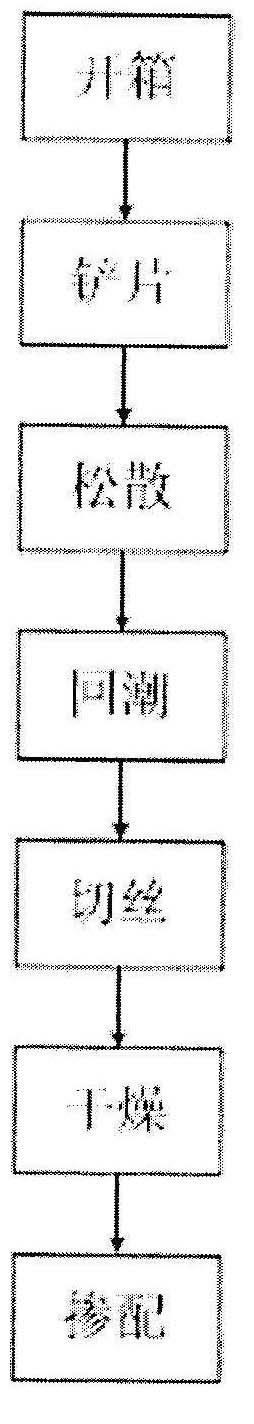

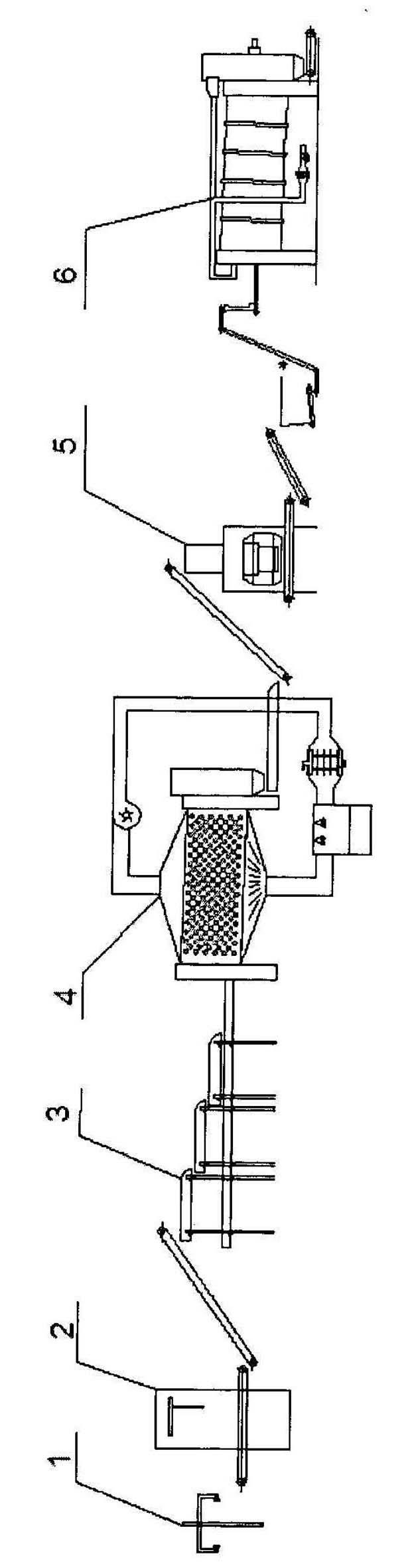

Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

ActiveCN102178337ASolve the strength problemAvoid pulling forceTobacco preparationPulp and paper industryMoisture regain

The invention discloses an independent tobacco cutting process and independent tobacco cutting equipment based on paper making method regenerated tobacco leaf processing characteristics. The process comprises the following process steps: opening a box, shoving tobacco leaves, loosening, regaining moisture, cutting, drying and mixing. The equipment comprises a box opening machine, a tobacco leaf shoving machine, a high-frequency-vibrating loosening machine, a moisture regaining machine, a cutting machine and a roller cut tobacco drying machine, wherein the mechanisms can be arranged and can operate alone or in combination through the connection by a material conveying and feeding mechanism. The process and the equipment can cut the boxed regenerated tobacco leaves independently according to the processing characteristics of the boxed regenerated tobacco leaves, thereby improving the effective utilization rate of the paper making method regenerated tobacco leaves, effectively retaining fragrance, improving visual quality, and making the prepared regenerated cut tobacco uniform in length and good in looseness so that the cut tobacco can be blended with other cut tobacco uniformly. The process and the equipment have high adaptability; meanwhile, according to the change in the form of supplied materials, 'three-step method' tobacco cutting adopted in the prior art is changed into one-step cutting with the same effect, the production efficiency is improved and the production cost is lowered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

Technology for processing tobacco stalk into shreds

ActiveCN102631016AUniform expansionSimilar expansion rateTobacco preparationTobacco treatmentMicrowaveTar

The invention provides a technology for processing tobacco stalk into shreds, and belongs to the technical field of tobacco processing. The technology disclosed by the invention has the following steps of: pretreating tobacco stalk, expanding the tobacco stalk with microwave, washing the tobacco with water, storing the tobacco stalk, straightening out the tobacco stalk, slicing the tobacco stalk, charging and storing stalk slices, shredding the stalk slices, drying and shaping the stalk shreds, and perfuming the stalk shreds and storing the stalk shreds. Equipment used in the technology is purchased from the market, wherein the equipment which is purchased from the market, adopts a low-frequency (915MHz) high-power (more than 10kW) microwave magnetron, and transports the tobacco stalk by a belt is improved into equipment which adopts an ultrahigh-frequency (2450MHz) single-pipe low-power (1.5kW) microwave magnetron, performs group control on the microwave magnetron and transports tobacco stalk by a drum. The technology has the characteristics that the tobacco stalk shreds are good in quality consistency and more similar to tobacco leaf shreds in the physical property, and have high sensory quality and filling value; and uniformity, stability and mixing proportion of the tobacco stalk shreds are improved when the tobacco stalk shreds are mixed with the tobacco leaf shreds, the quality of cigarette is improved, the application range and use ratio of the tobacco stalk shreds in the cigarette are improved, and the aims of tar reducing, harm reducing, cost reducing and efficacy enhancing are achieved.

Owner:YUNNAN RES INST OF TOBACCO SCI

Stage method for improving uniform expansion effect of granular fruits and vegetables during microwave spouted drying

The invention discloses a stage method for improving the uniform expansion effect of granular fruits and vegetables during microwave spouted drying, which belongs to the technical field of the processing of fruit and vegetable foods. The method mainly comprises the steps of: performing selection, washing, dicing, enzyme killing by blanching, and color protection treatment on fruit and vegetable raw materials; placing the pretreated fruit and vegetable cubes into a microwave spouted drying bed; setting the microwave power and the air inlet heating temperature; then performing the combined drying of stage hot air drying and microwave drying; and controlling different spouted air intakes at different drying stages, wherein the uniform expansion effect of products is improved during the quick microwave drying. The method has the advantages that the method ensures that the granular fruits and vegetables are evenly heated in a microwave field through a hot air and microwave spouted drying stage method, has quick moisture evaporation, ensures that the fruits and vegetables have porous structures after the drying, effectively improves the expansion degree of the products, also improves the expansion effect of the products and ensures the uniform expansion of the products while the granular fruits and vegetables are quickly dried, and has the characteristics of good preservation of nutrient content and good qualities of color luster, sense and the like.

Owner:JIANGNAN UNIV +1

Processing method of tobacco raw materials for heating non-combustion tobacco products

ActiveCN103445283AIncrease contentGood release effectTobacco preparationTobacco treatmentGlycosideCombustion

A processing method of tobacco raw materials for heating non-combustion tobacco products sequentially includes: adjusting moisture of the tobacco raw materials, heating at 100-300 DEG C for 0.5-8 hours; cooling at room temperature; balancing at 22 DEG C and 60% of moisture for 24-120 hours, applying glycoside aroma precursors, and standing for 48-120 hours to guarantee that the aroma precursors are fully absorbed by the raw materials; applying polyol to the raw materials after perfuming, and standing for 48-120 hours under a seal state to guarantee that the polyol is fully absorbed by the raw materials; balancing for 24-120 hours to obtain the tobacco raw materials for heating the non-combustion tobacco products. The tobacco raw materials processed by the method has the advantages that smoke releasing performance of the tobacco raw materials during heating of the non-combustion tobacco products is increased evidently, sensory quality of the released smoke is improved evidently, and good satisfaction and comfortableness are achieved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

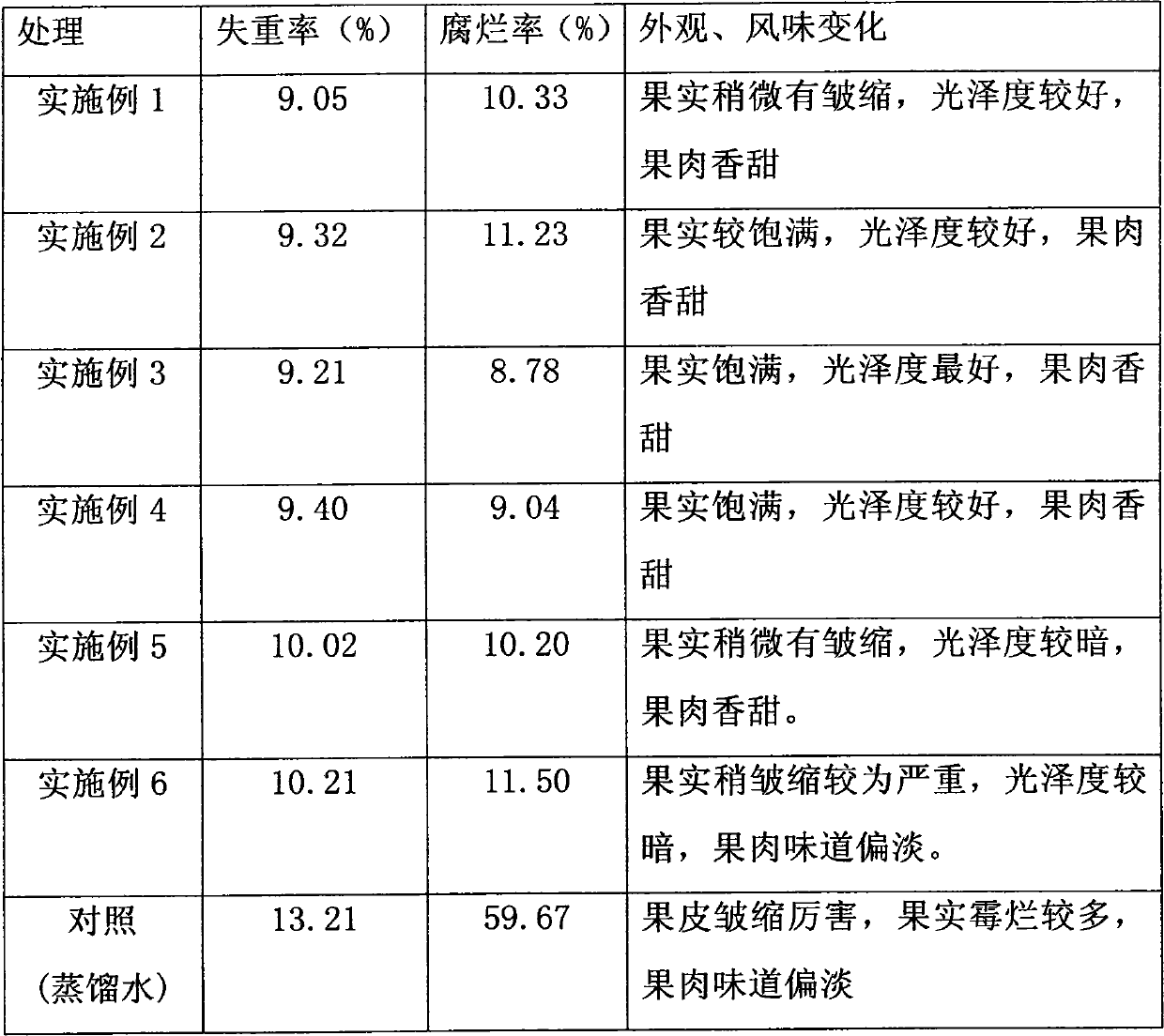

All-natural plant composite preservative and preparation method and preservation method thereof

The present invention discloses an all-natural plant composite preservative and preparation method and preservation method thereof. The preservative comprises, by weight percentages, the following ingredients: 0.02%-4% of star anise extract, 0.01%-3% of thyme extract, 0.01%-2% of origanum vulgare extract, 0.02%-5% of litsea cubeba extract, 0.5%-3% of chitosan, 0.05%-12% of emulsifier, and the balance of distilled water. The preservative prepared by the present invention has excellent effect for inhibiting the rot-causing pathogens appeared during the storage of fruits such as cherry; is easy used; can be used to soak fruits or sprayed directly onto fruits; can reduce the rot rate of cherry by more than 50% after room temperature storage for 7 days, compared with a blank group; can also slowdown the water loss of the cherry, maintain the quality of the cherry, and improve the marketability of the cherry.

Owner:TIANJIN UNIV OF SCI & TECH

Multi-enzyme and multi-steps type method for producing diet cellulose flour from wheat bran

ActiveCN1718107ACompletely hydrolyzedReduce lossesVegetable proteins working-upFood preparationPhytaseCELLULOSE FLOUR

A process for preparing the edible fibre powder from wheat bran by multi-enzyme step treating method includes such steps as treating wheat bran sequentially by endogenous phytase, amylase, proteinase and lipase to obtain high-purity edible fibres, decoloring by sodium hypochlorite and hydrogen peroxide, squeezing, laying aside and superfine pulverizing.

Owner:江苏江南上一道科技股份有限公司

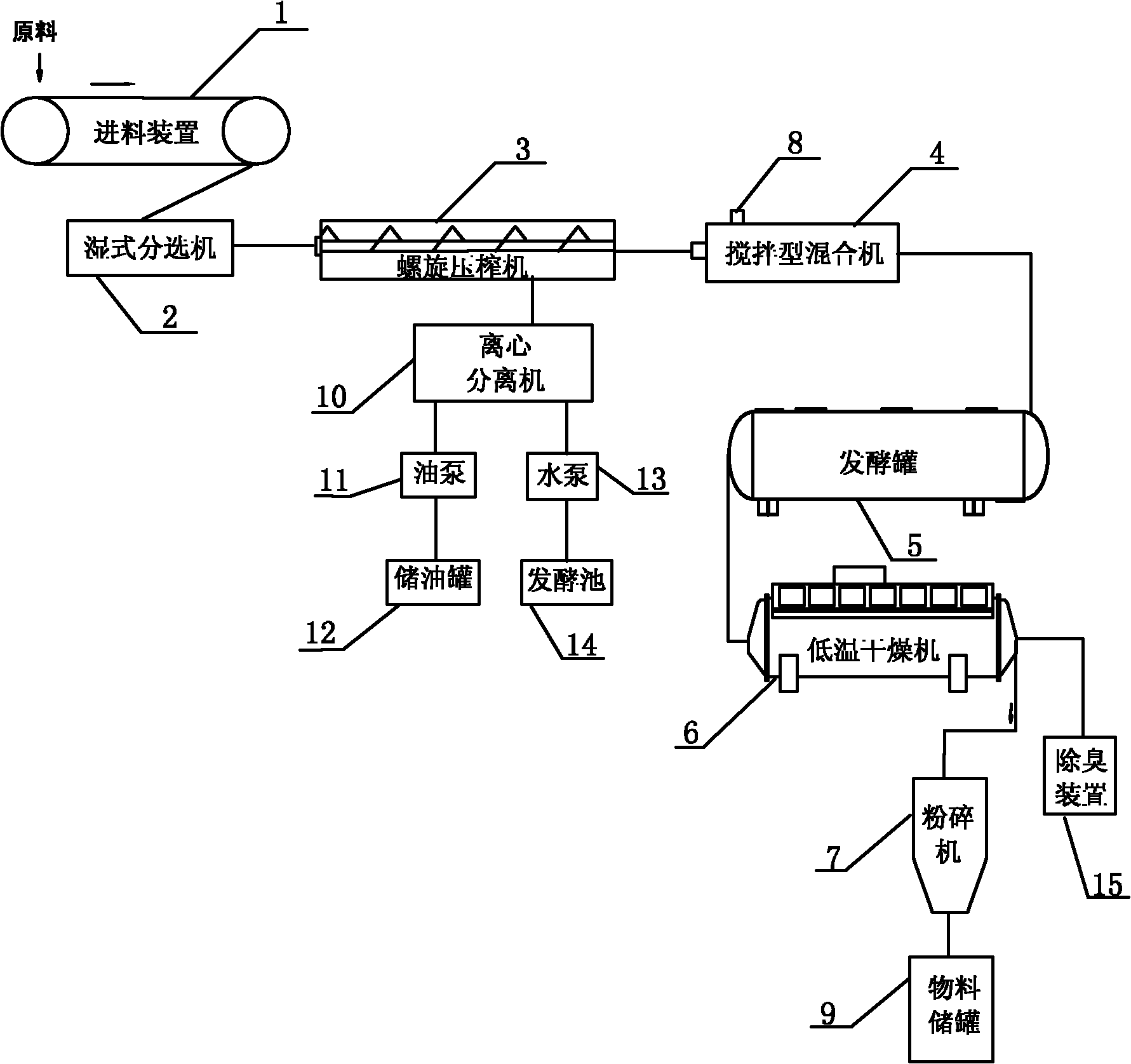

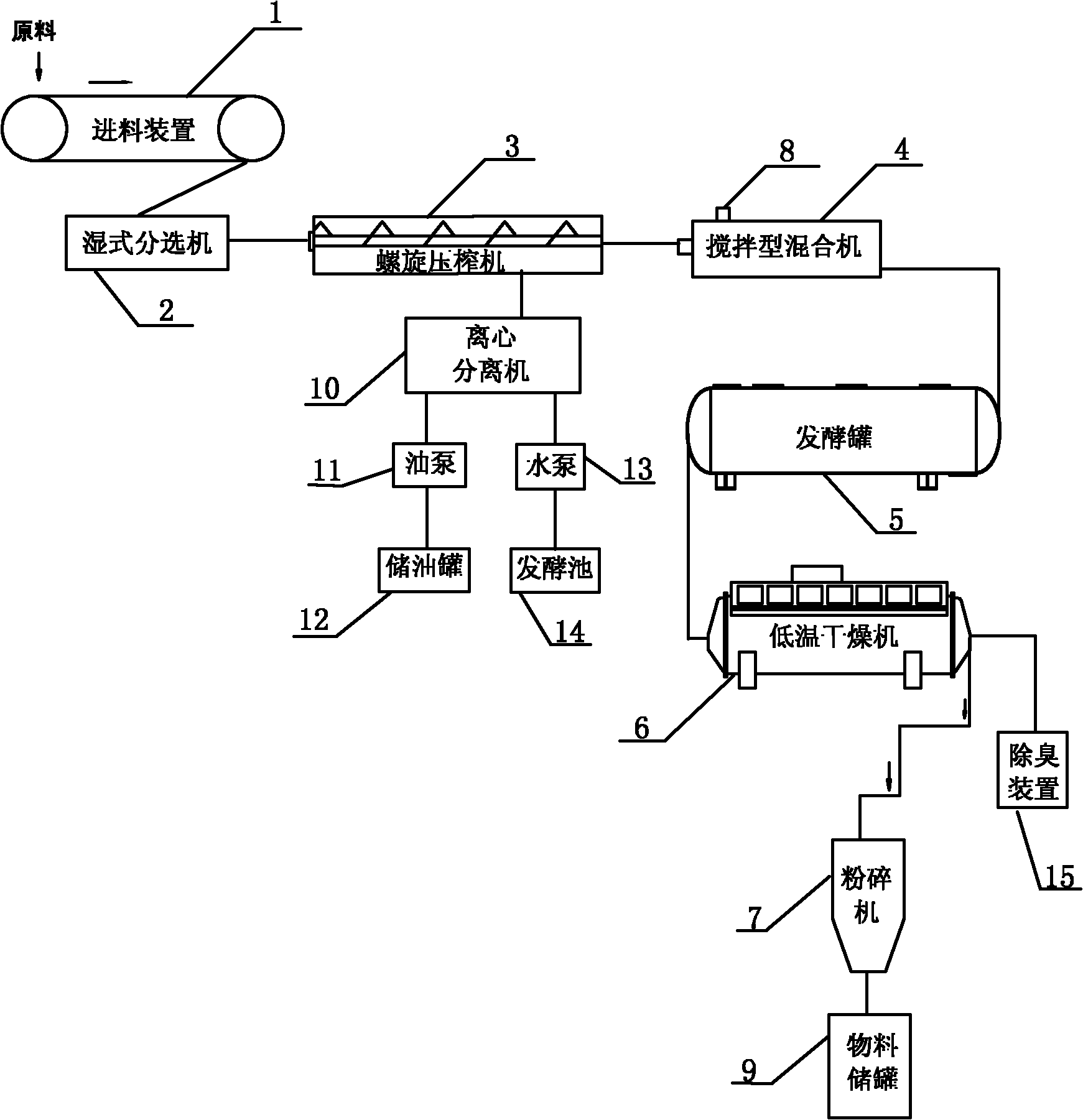

Method and system for preparing restaurant-kitchen wastes into livestock and poultry feed

InactiveCN102125166AGood flavor and colorImprove fermentation effectFeeding-stuffFood processingMixed materialsCrusher

The invention discloses a method and a system for preparing restaurant-kitchen wastes into a livestock and poultry feed, wherein the method comprises the following steps: carrying out sorting preprocessing on restaurant-kitchen wastes so as to obtain biodegradable restaurant-kitchen wastes; carrying out solid-liquid separation on the obtained biodegradable restaurant-kitchen wastes; adding bran, corn flour and coarse meal into the obtained product so as to obtain a mixed material; adding composite fungicides into the mixed material according to the inoculum concentration (8-20 wt%) so as to ferment the mixed material; and finally, drying and cooling the fermented mixture, then packing the obtained object so as to obtain a livestock and poultry feed product. The system comprises a feed device, a wet sorting machine, a pressafiner, an agitated mixer, a fermentation tank, a low-temperature drying machine, a crusher and a finished product material storage tank which are sequentially connected; and the system has the advantages that the growth of putrefying bacterias and the reproduction of pathogenic microorganisms in restaurant-kitchen wastes can be inhibited, and the freshness retaining effect and organoleptic quality of the livestock and poultry feed are good; meanwhile, the protein content of the livestock and poultry feed can be improved; in addition, the system is low in used equipment cost, small in energy consumption, high in production efficiency and beneficial to environmental protection.

Owner:张荣尚

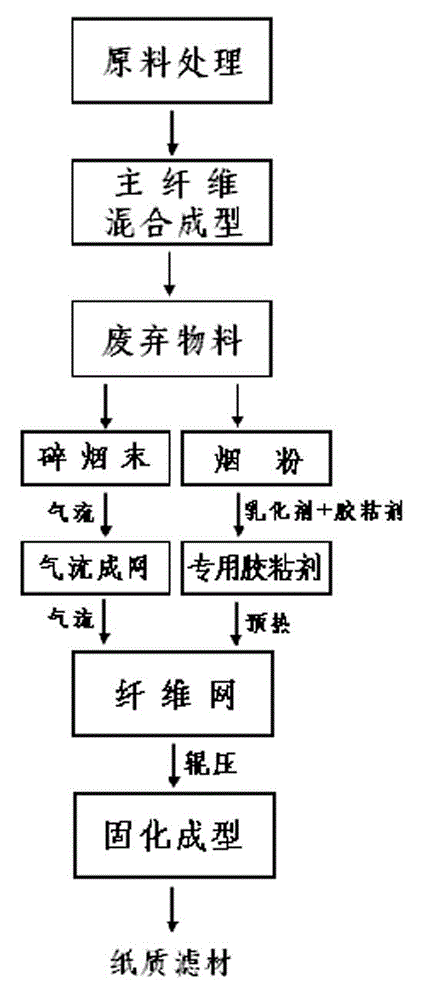

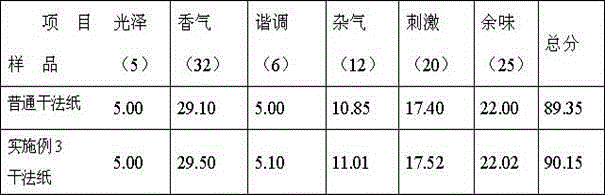

Paper cigarette filter rod filter media and processing method thereof

ActiveCN102747647AImprove sensory qualityEvenly distributedTobacco smoke filtersTextiles and paperFiberFilter media

The present invention discloses a paper cigarette filter rod filter media and a processing method thereof, wherein the paper filter media is obtained through performing a dry process on the following components: 40-74% of natural cigarette fiber, 4-40% of bast fiber, 1-12% of natural tobacco waste raw material, and 4-20% of adhesive. The method comprises the following steps: raw material processing, main fiber mixing shaping, waste material adding and prepared paper shaping process. After the natural tobacco fiber is mixed with the bast fiber, discongestion is performed. After sufficient dispersion, the mixed material is conveyed to a shaping section through a blower for being laid on a net and shaped. A fluffy and uniform fiber net is formed on a shaping net belt. The cigarette filter media paper is obtained through adhesive applying, preheating, roller pressing, solidifying and shaping. As the cigarette fiber is used as the main fiber raw material, the paper cigarette filter rod filter media according to the invention has reduced foreign gas of wood and settles a problem that the fragrance quality is reduced by the foreign gas of wood in the prior-art paper filter rod. The natural tobacco waste raw material is added in the paper shaping process. Not only is whole aesthetic quality of the cigarette improved, but also the tobacco raw material is uniformly distributed in the dry process paper and does not easily drop off. The quality of the filter rod is more stable.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

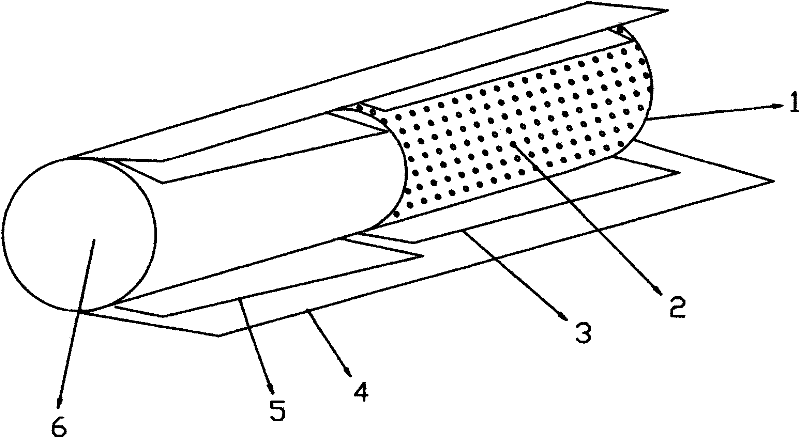

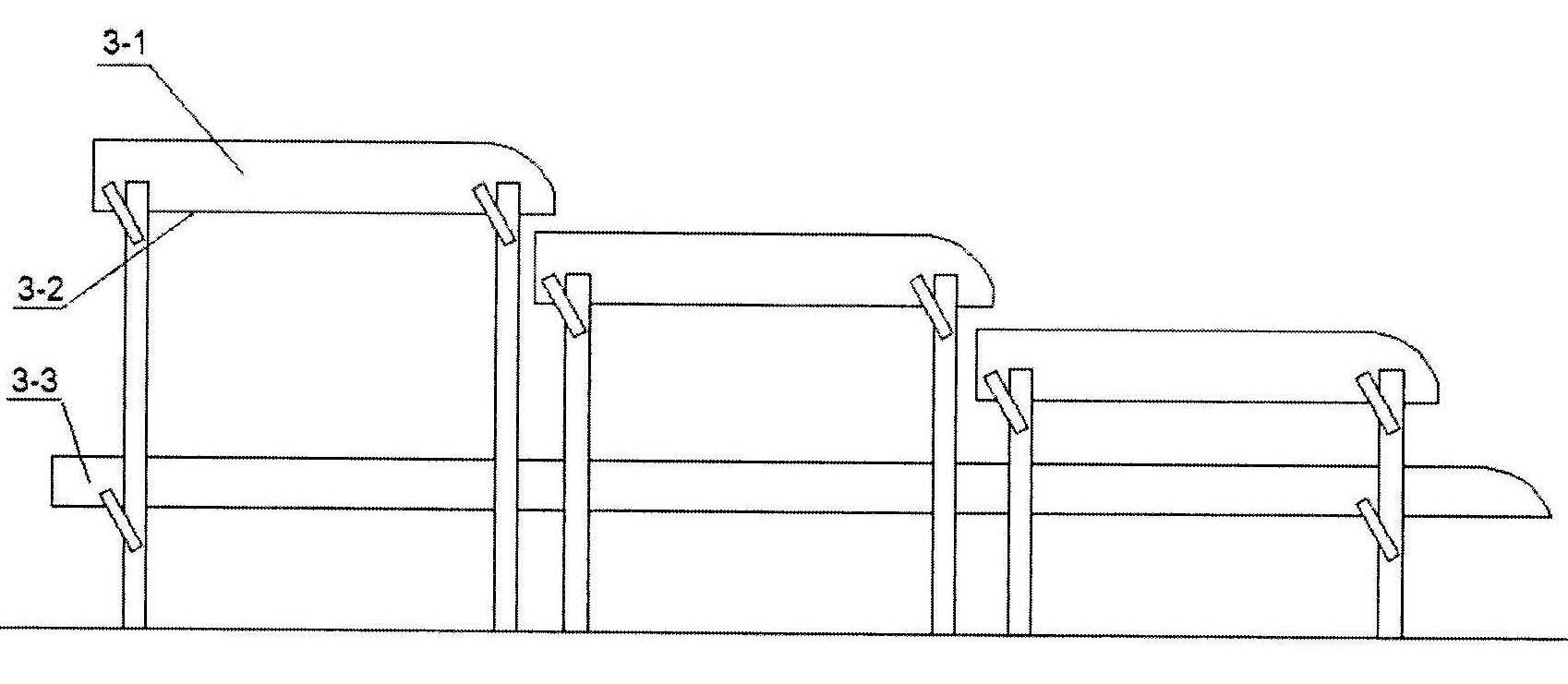

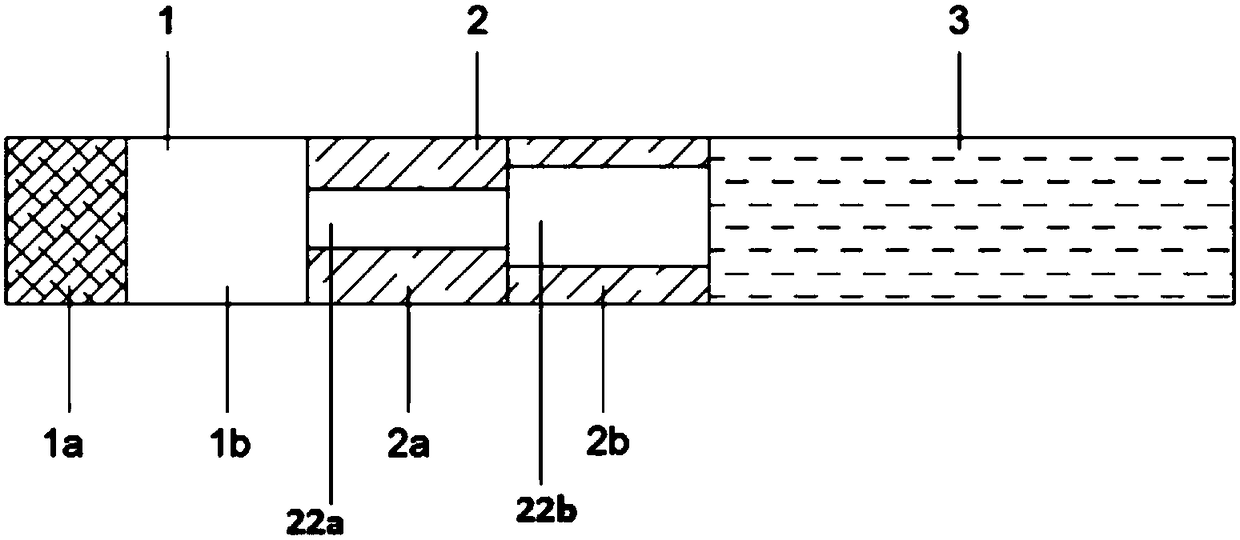

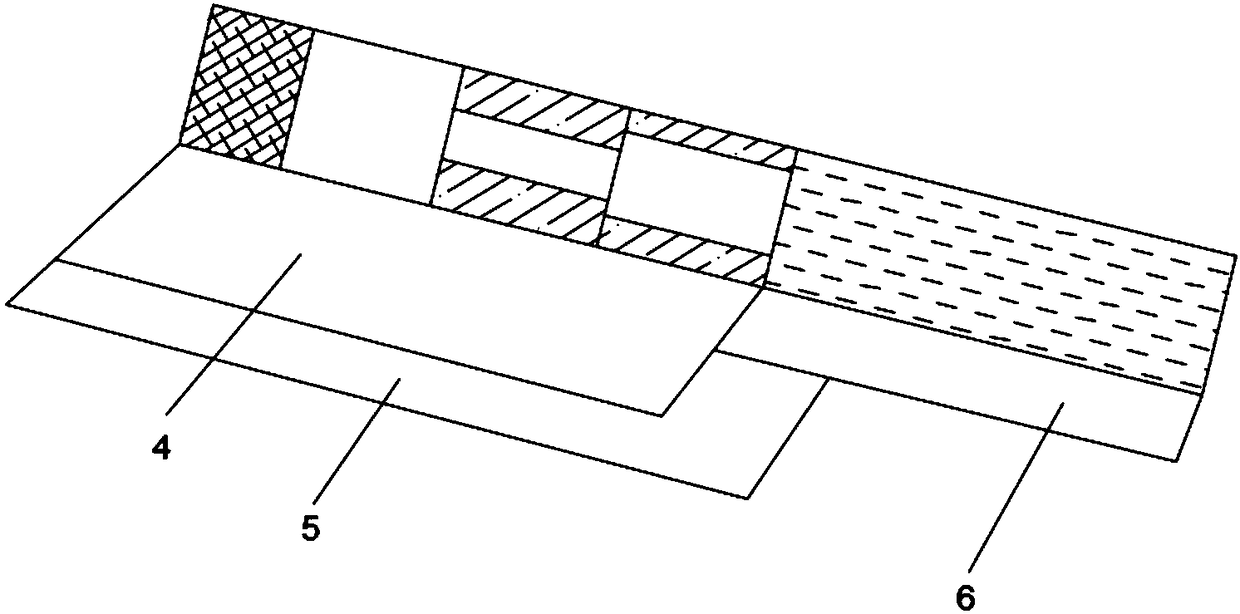

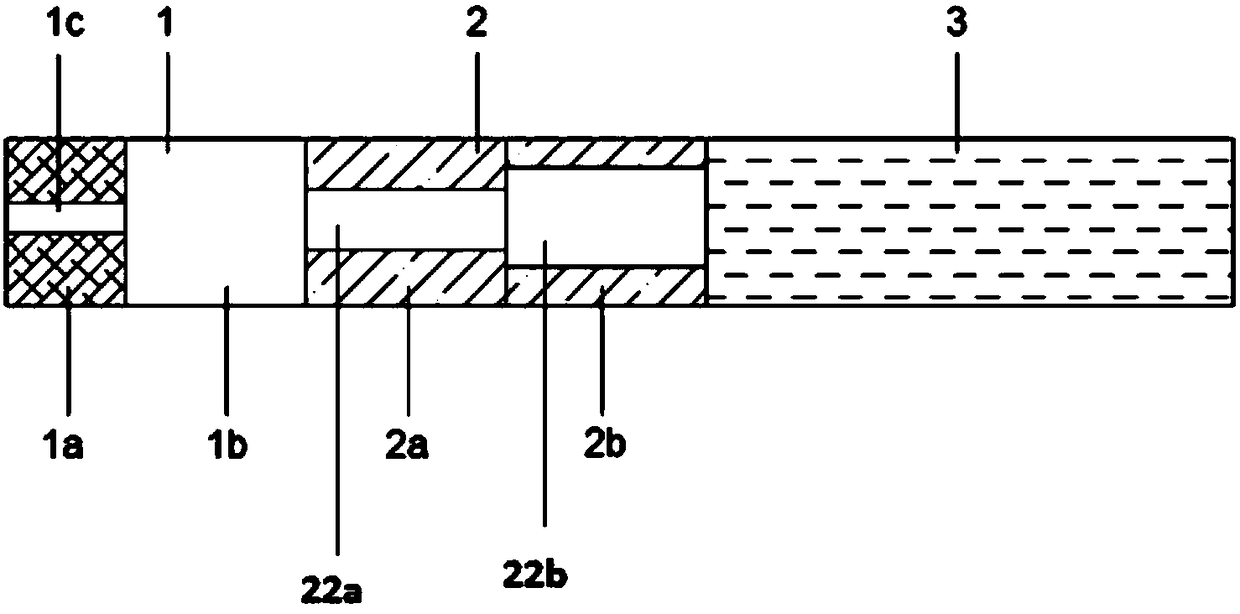

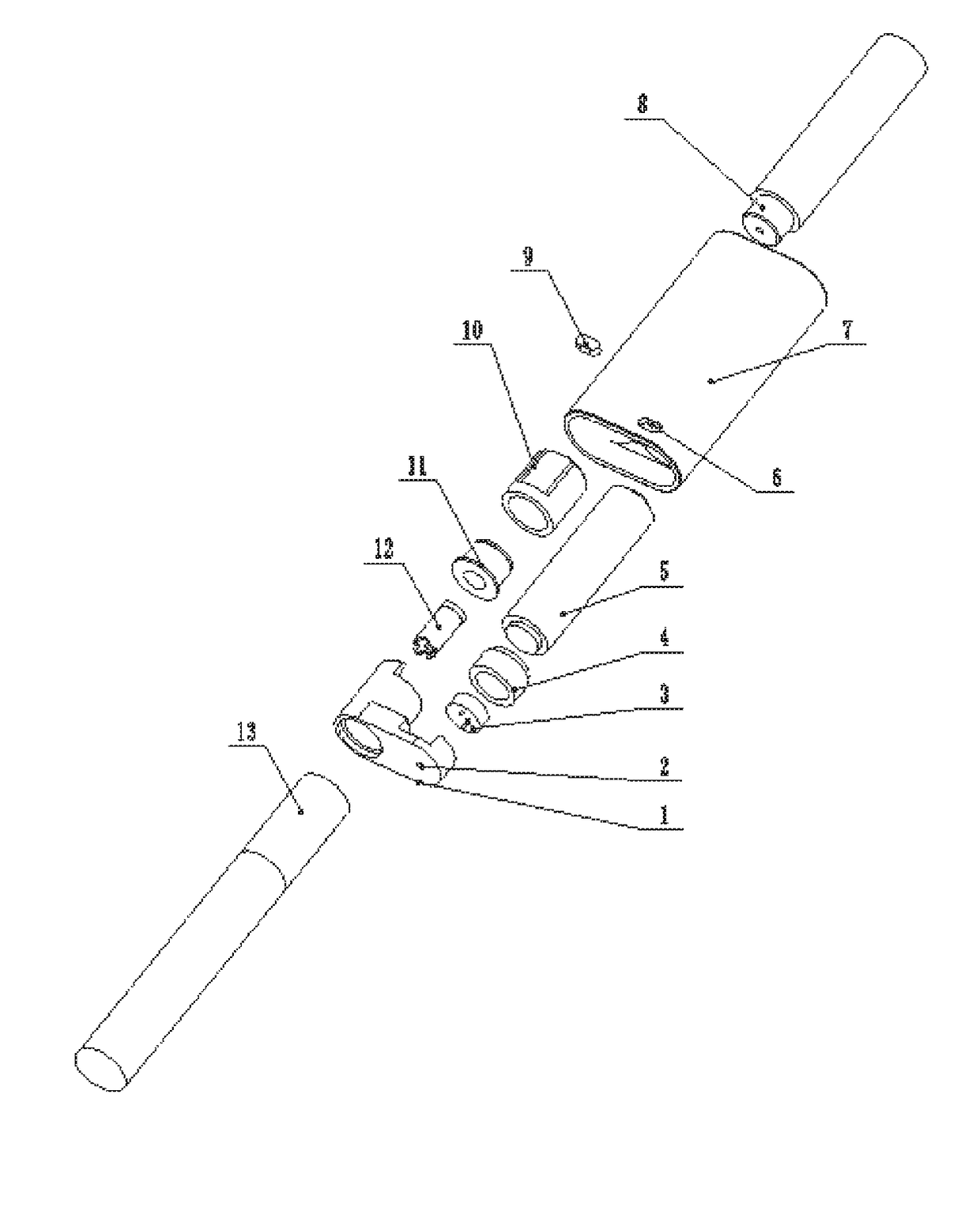

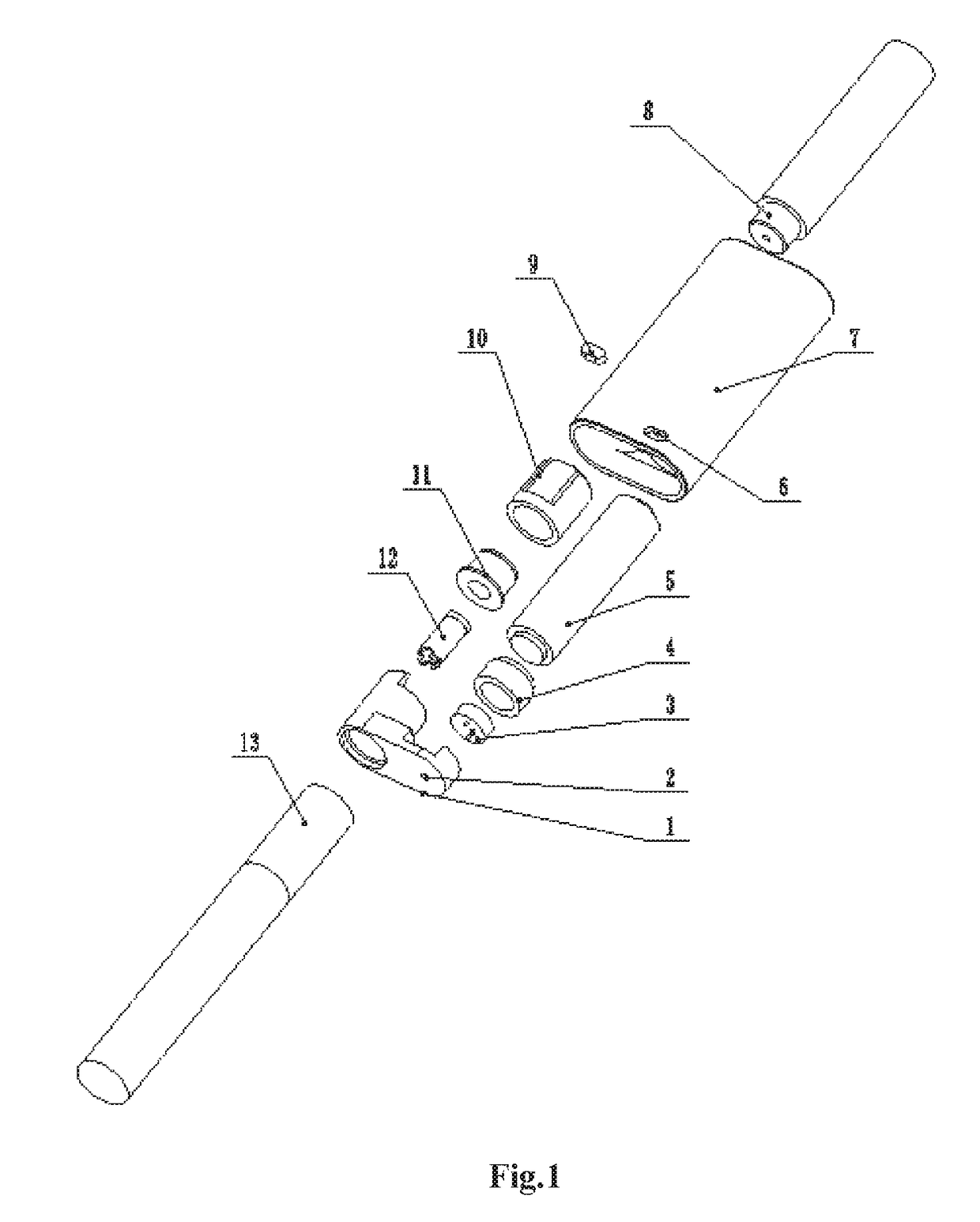

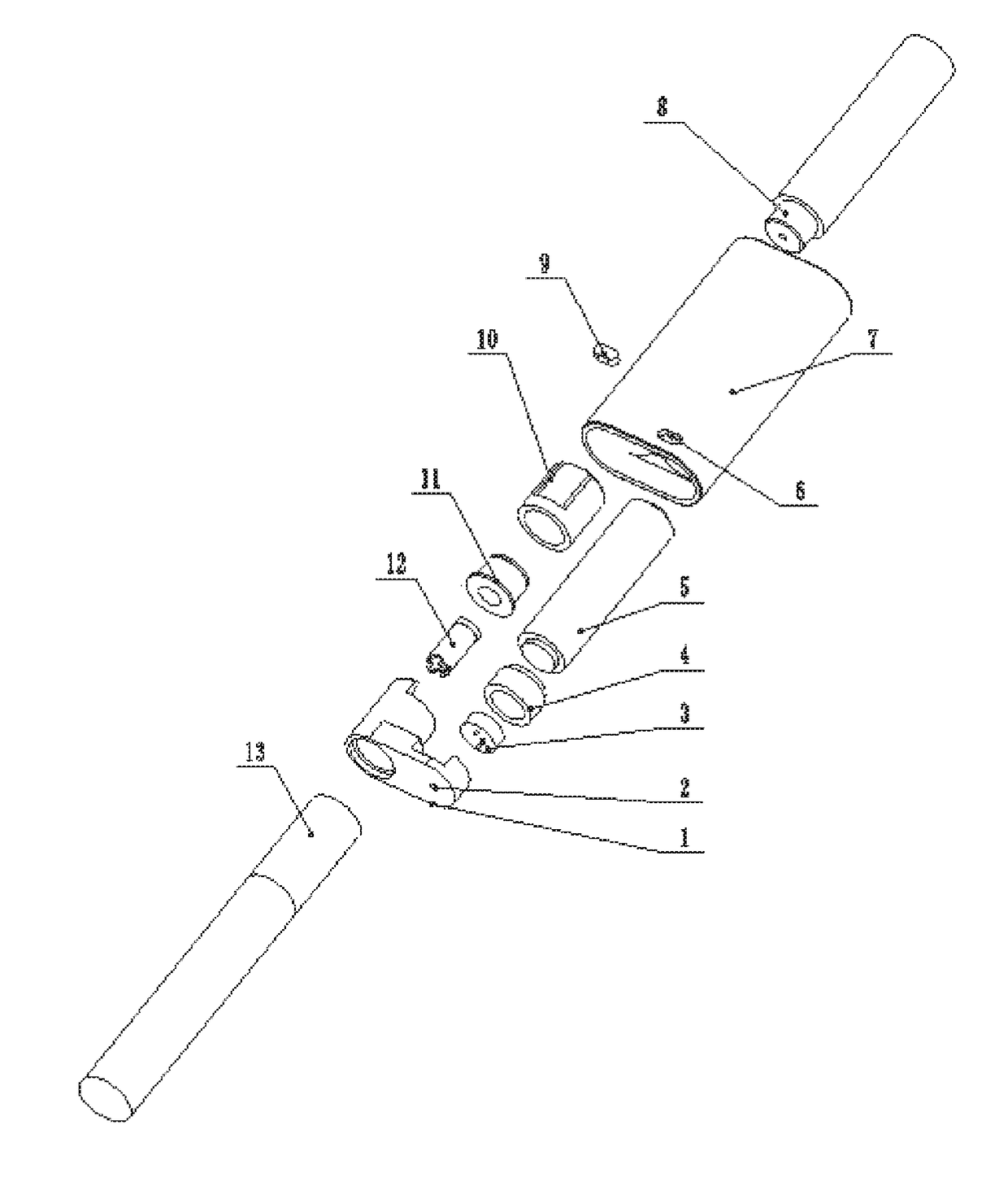

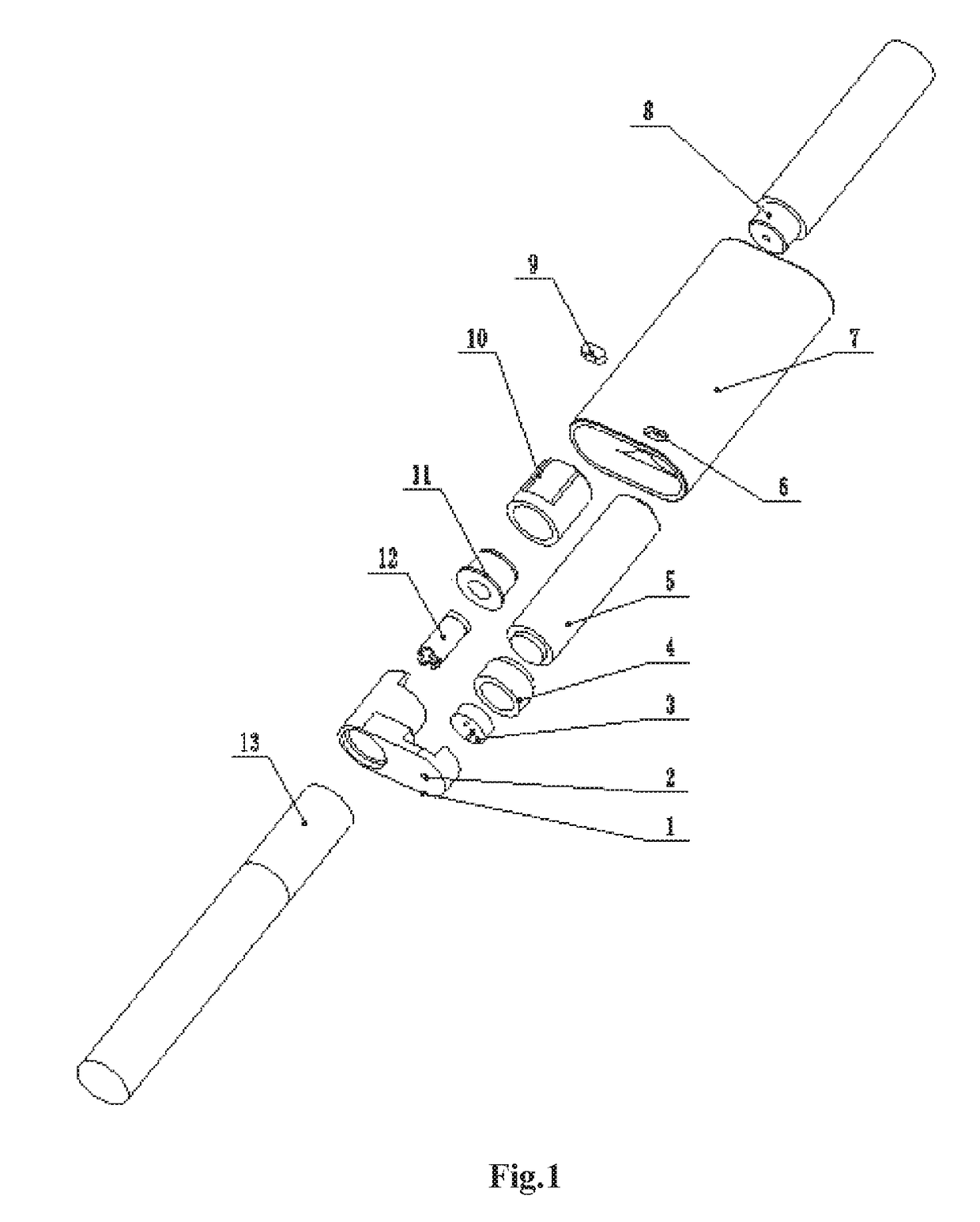

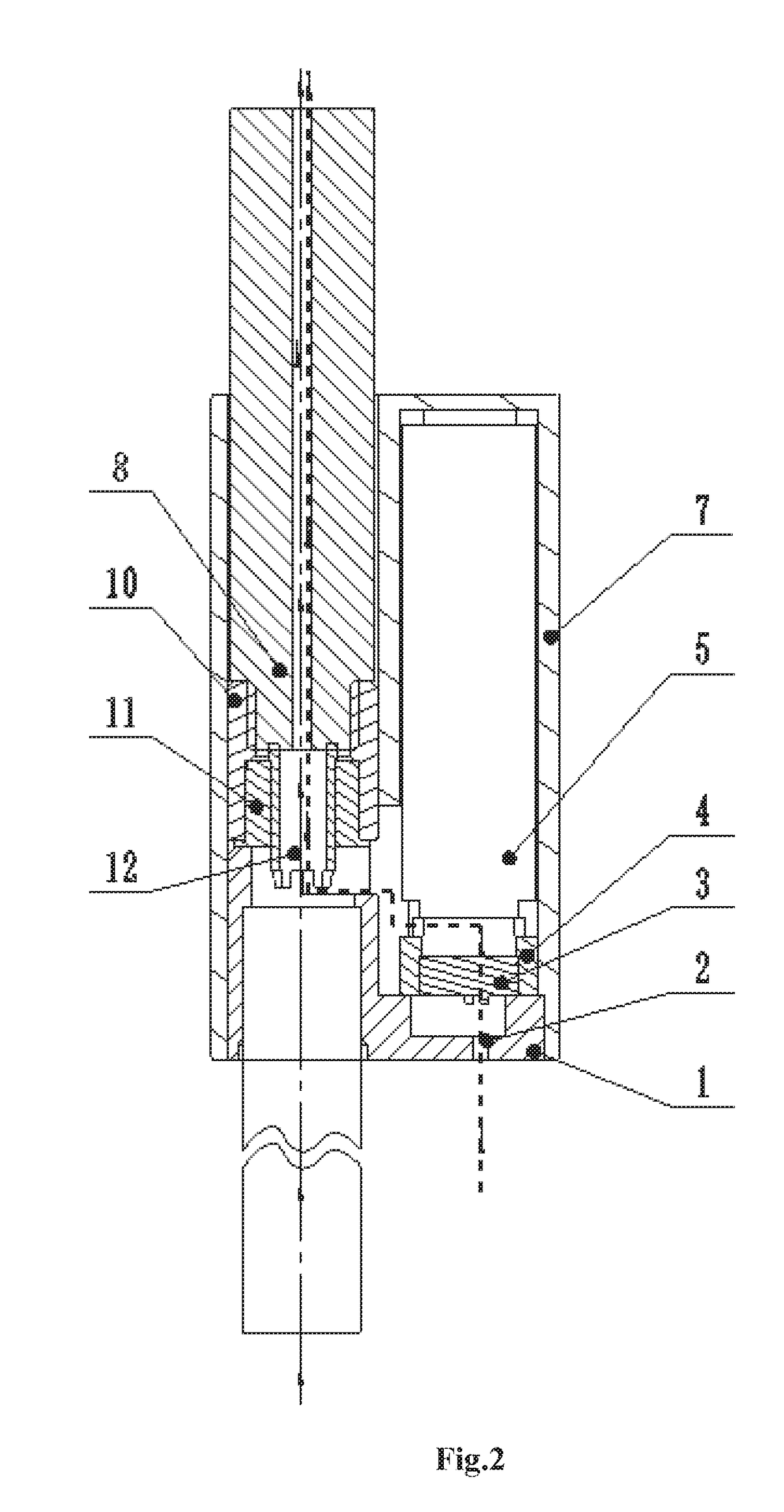

Novel cigarette for heating non-combustible tobacco

PendingCN108185517AReduce the temperatureReduce usageTobacco smoke filtersBiomedical engineeringVenturi effect

The invention discloses a novel cigarette for heating a non-combustible tobacco. The cigarette comprises a reversal counter-sunk filter stick (1), a first hollow filter stick (2a), a second hollow filter stick (2b) and a tobacco stick (3), wherein the reversal counter-sunk filter stick (1) comprises a filter section (1a) and a hollow section (1b); the first hollow filter stick (2a) is provided with a first axial cavity (22a); the second hollow filter stick (2b) is provided with a second axial cavity (22b); the equivalent diameter of the second axial cavity (22b) is greater than equivalent diameter of the first axial cavity (22a); and the equivalent diameter of the second axial cavity (22b) is less than the diameter of the hollow section (1b). The novel cigarette provided by the invention can be used for reducing smoke temperature on the basis of a Venturi effect; and the cigarette is sufficient in smodke amount, high in smoke release speed and high in smoking times.

Owner:CHINA TOBACCO YUNNAN IND

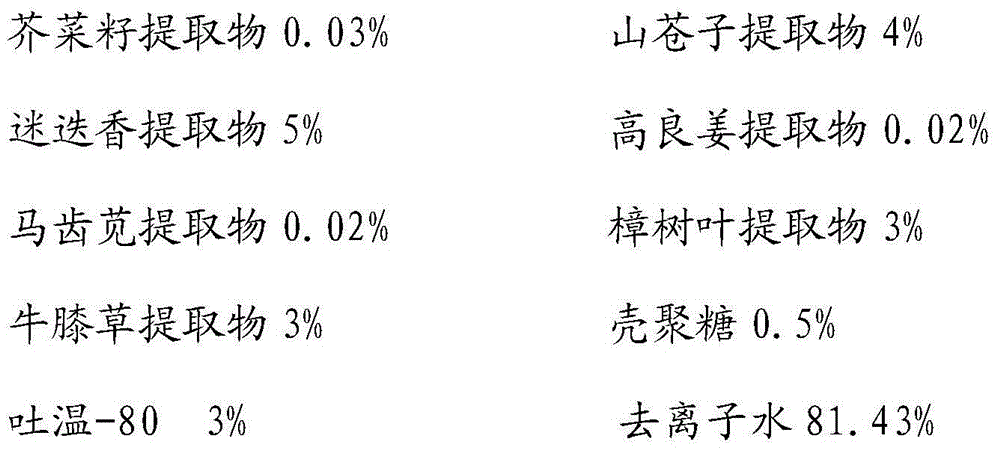

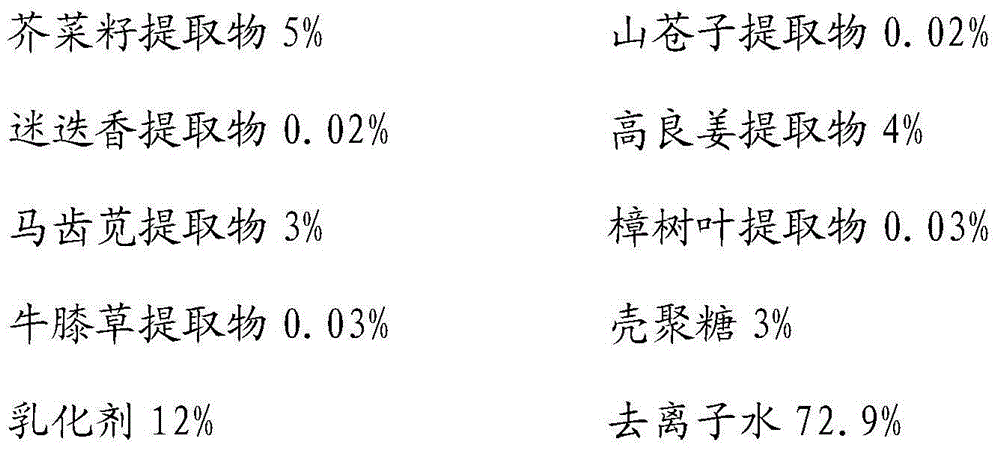

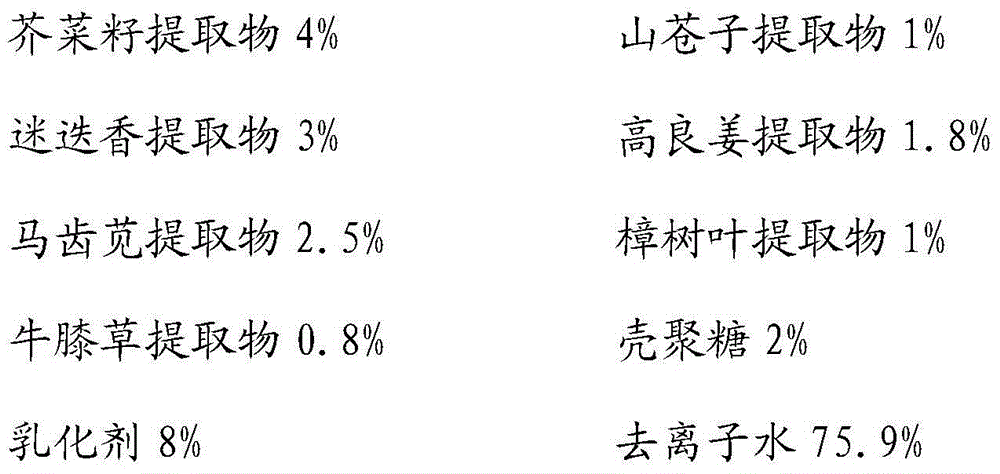

Plant source fruit and vegetable preservative

InactiveCN104146055AReduce rotEnhanced inhibitory effectFruit and vegetables preservationChemical synthesisHyssopus officinalis extract

The invention discloses a plant source fruit and vegetable preservative, belonging to the technical field of fruit and vegetable preservation. The plant source fruit and vegetable preservative is characterized by being composed of following components in percentage by weight: 0.03-5% of mustard seed extract, 0.02-4% of litsea cubeba extract, 0.02-5% of rosemary extract, 0.02-4% of alpinia officinarum hance extract, 0.02-3% of portulaca oleracea extract, 0.03-3% of camphortree leaf extract, 0.03-3% of hyssopus officinalis extract, 0.5-3% of chitosan, 3-12% of emulsifying agent and the balance of de-ionized water. The main antibacterial components of the plant source fruit and vegetable preservative are extracted from medicine and food homology plants; raw materials are natural and non-toxic and do not contain common chemically-synthesized preservatives including sodium benzoate and the like, thus the plant source fruit and vegetable preservative is very safe to a human body; and the synergic antibacterial effect of plant extracts with good antibacterial effect is utilized so that the preservation effect is good and the shelf life of fruits and vegetables can be prolonged.

Owner:GUANGXI UNIV

Water-soluble chitosan and shrimp antistaling agent prepared by ginger extract as well as using method

InactiveCN101496535AImprove sensory qualityStay hydratedMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsAntioxidantPhytic acid

The invention provides a shrimp preservative prepared from water-soluble chitosan and ginger extract, and a using method thereof. The shrimp preservative is a composite preservative which is formed by taking water-soluble chitosan and ginger extract as main raw materials and compounding the main raw materials with antioxidant, phytic acid, sodium citrate and dextrin. Fresh shrimps or shrimp meat with no head and shell are soaked in seawater or clear water in which the shrimp preservative is dissolved at a temperature of between 0 and 10 DEG C, and then the aims of preventing decay, stopping shrimp heads from blackening, preventing fishy smell from increasing and the like can be achieved. The shrimp preservative has broad application prospects. As the shrimps subjected to freshness-keeping treatment seldom change color or decay in a processing course, are bright in body, pure in taste, strong and elastic in meat, the sensory quality of the shrimps is remarkably improved. The shrimp preservative has the advantages that the shrimp preservative is simple in production method, convenient to use, capable of applying to various types of food processing taking the shrimps as raw materials, remarkable in freshness-keeping effects and capable of keeping the moisture of the shrimps, raising product yield, improving product quality and increasing economic benefit.

Owner:GUANGDONG OCEAN UNIVERSITY

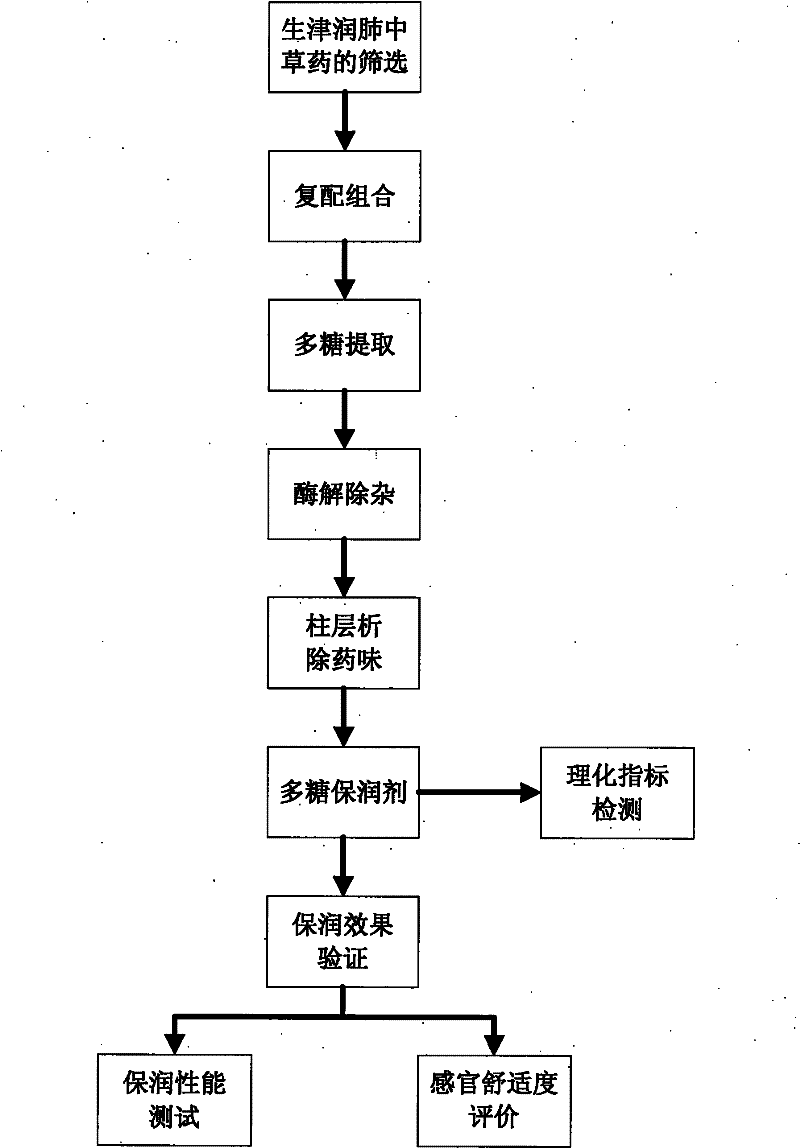

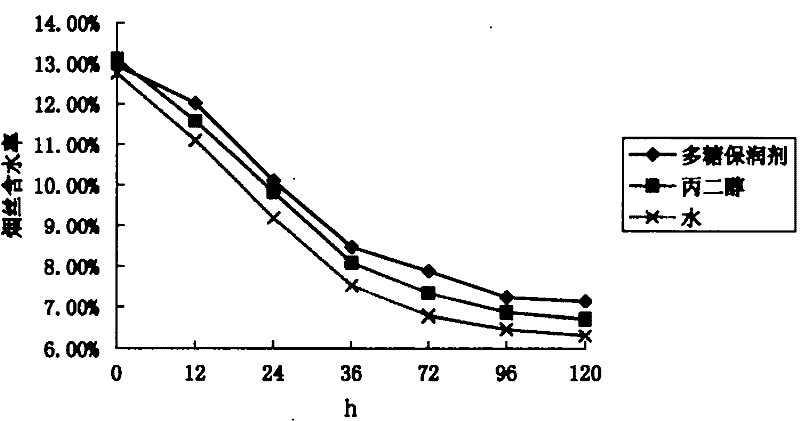

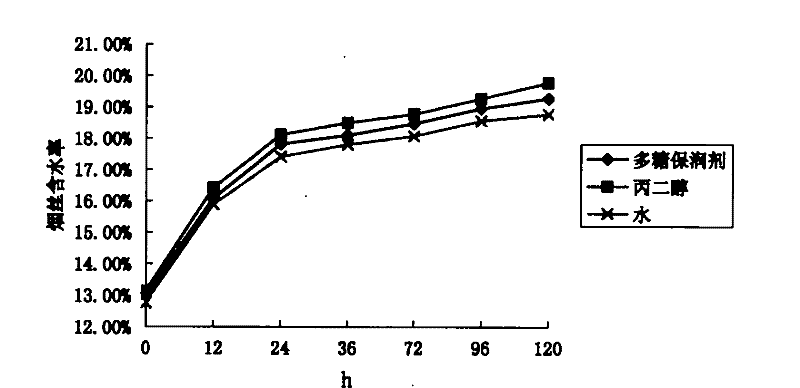

Preparation of compound polysaccharide humectant and application of compound polysaccharide humectant to cigarettes

InactiveCN102217796AImprove sensory qualityReduce drynessTobacco treatmentRotary evaporatorMacroporous resin

The invention discloses the preparation of a compound polysaccharide humectant and application of the compound polysaccharide humectant to cigarettes. The preparation method comprises the following steps of: (1) crushing compound Chinese medicines such as Adenophora elata, dwarf lilyturf tuber, and platycodon grandiflorus, adding water, slightly boiling, performing reflux extraction, mixing extracting solution, and filtering; (2) adding protamex and high-temperature amylase into the extracting solution, and performing enzymolysis; (3) absorbing naturally cooled enzymolysis extracting solution by using a macroporous resin column, and collecting flow-through liquid; (4) concentrating the flow-through liquid in a rotary evaporator until the moisture is not evaporated to obtain the polysaccharide humectant; and (5) dissolving the polysaccharide humectant in water and adding into cut tobacco, wherein the humidification effect of cigarettes is remarkably improved, and the dry sensation of the cigarettes is reduced and the sweet degree of the cigarettes is strengthened when the cigarettes are smoked. The invention has the outstanding advantages that: the compound polysaccharide humectant can improve the aesthetic quality of the cigarettes, reduce the dry sensation of smoke, improve the sweet degree and comfort degree, and has remarkable effects of promoting the secretion of saliva or body fluid and humidifying; and the application of the technology cannot change the conventional cigarette processing technology, and the technology has actual application value.

Owner:广州华芳烟用香精有限公司

Low-sugar banana-pineapple compound jam and manufacture method thereof

The invention belongs to the food processing field, in particular to a low-sugar banana-pineapple compound jam and a manufacture method thereof. The low-sugar banana-pineapple compound jam is prepared from the following raw materials: bananas, pineapples, xylitol, Xanthan gum, citric acid and ascorbic acid through the steps of selecting, protecting colors, pulping, concentrating, homogenating, canning and sterilizing, the content of soluble solids is between 25 percent and 40 percent, and the total sugar content is lower than 65 percent. The invention has wide resources and low cost because defective bananas and pineapples are used as main raw materials, effectively and remarkably lowers the sweetness of the jam because the xylitol is adopted as a sweetener, greatly improves the jam flavor without adding any essence, has the advantages of low sugar, white color, rich nutrition, good taste, simple process, simple and convenient operation, easy control, low cost, environmental protection, easy industrialized production, and the like.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

Method for producing instant straight rice vermicelli

The invention discloses a method for producing instant straight rice vermicelli, and belongs to the technical field of food processing. The rehydration property and eating quality of the instant straight rice vermicelli are improved on the basis of a one-step aging method, as well as strong cavatition and a uniform inner-outer drying effect during cooperative drying of ultrasonic wave and medium-short wave infrared rays. The method mainly comprises the following steps: by selecting early indica rice as raw materials, performing immersing, crushing, flour stirring, dual-screw extrusion, aging, re-steaming and washing, and then performing cooperative drying through the ultrasonic wave and medium-short wave infrared rays to obtain the instant straight rice vermicelli which is low in breakage rate, excellent in rehydration property and good eating quality.

Owner:XUZHOU NAILI MACROMOLECULE TECH CO LTD

Production technique for chicken powder with great freshness flavor

ActiveCN103689522AIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

Method of preparing transparent sodium protonate from transparent protonic acid fermentation liquid

A process for preparing the sodium hyaluronate from the flermented liquid of hyaluronic acid incldues such steps as removing bacteria from said fermented liquid, enzymolyzing, depositing in alcohol, complexing, cleavaging, depositing in alcohol, ultrafiltering, depositing in alcohol, washing, dewatering and dryin. It has high molecular weight and low content of protein.

Owner:JIANGNAN UNIV

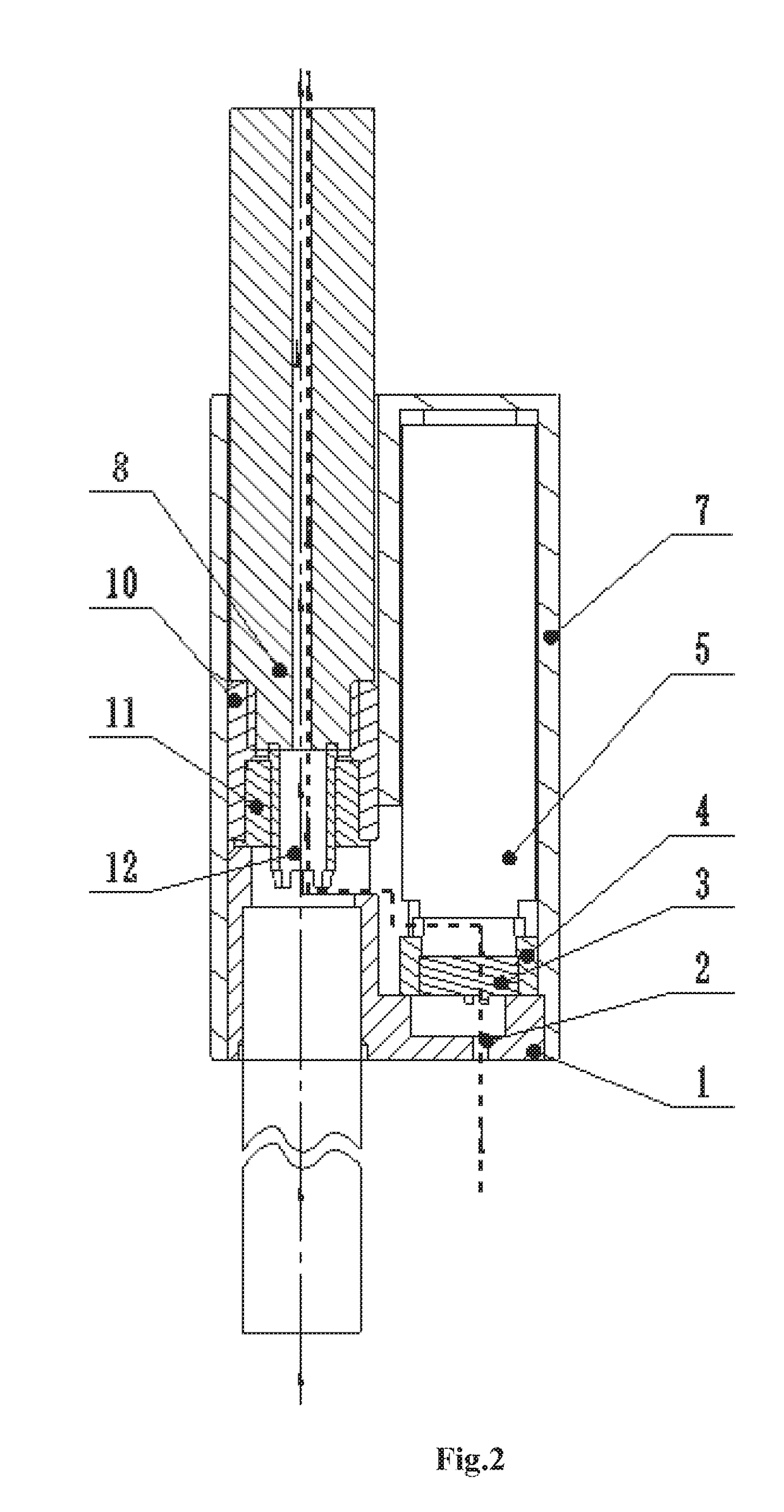

Cigarette smoking device having electronic atomization function and method for improving cigarette smoking quality

ActiveUS10104909B2Increasing smoking numberHarmful to environmentTobacco pipesTobacco devicesEngineeringAirflow

The present invention relates to a cigarette smoking device having an electronic atomization function, including a cigarette holder and an electronic atomization component cooperatively assembled with one another, wherein the cigarette holder includes a cigarette holding cavity and an optional end cap for closing the open end of a shell; the electronic atomization component includes the shell and the following components located in the shell: a power supply, an airflow sensor switch and an atomizer provided with a central airflow channel; the cigarette holding cavity is in air communication with the central airflow channel of the atomizer; the cigarette smoking device further includes an airflow sensor switch air inlet penetrating the shell and / or the end cap of the cigarette holder. Also provided is a method for improving cigarette smoking quality, the method includes smoking after mainstream smoke generated by an end-lighting cigarette, dilution air and atomization vapor are mixed.

Owner:CHINA TOBACCO YUNNAN IND

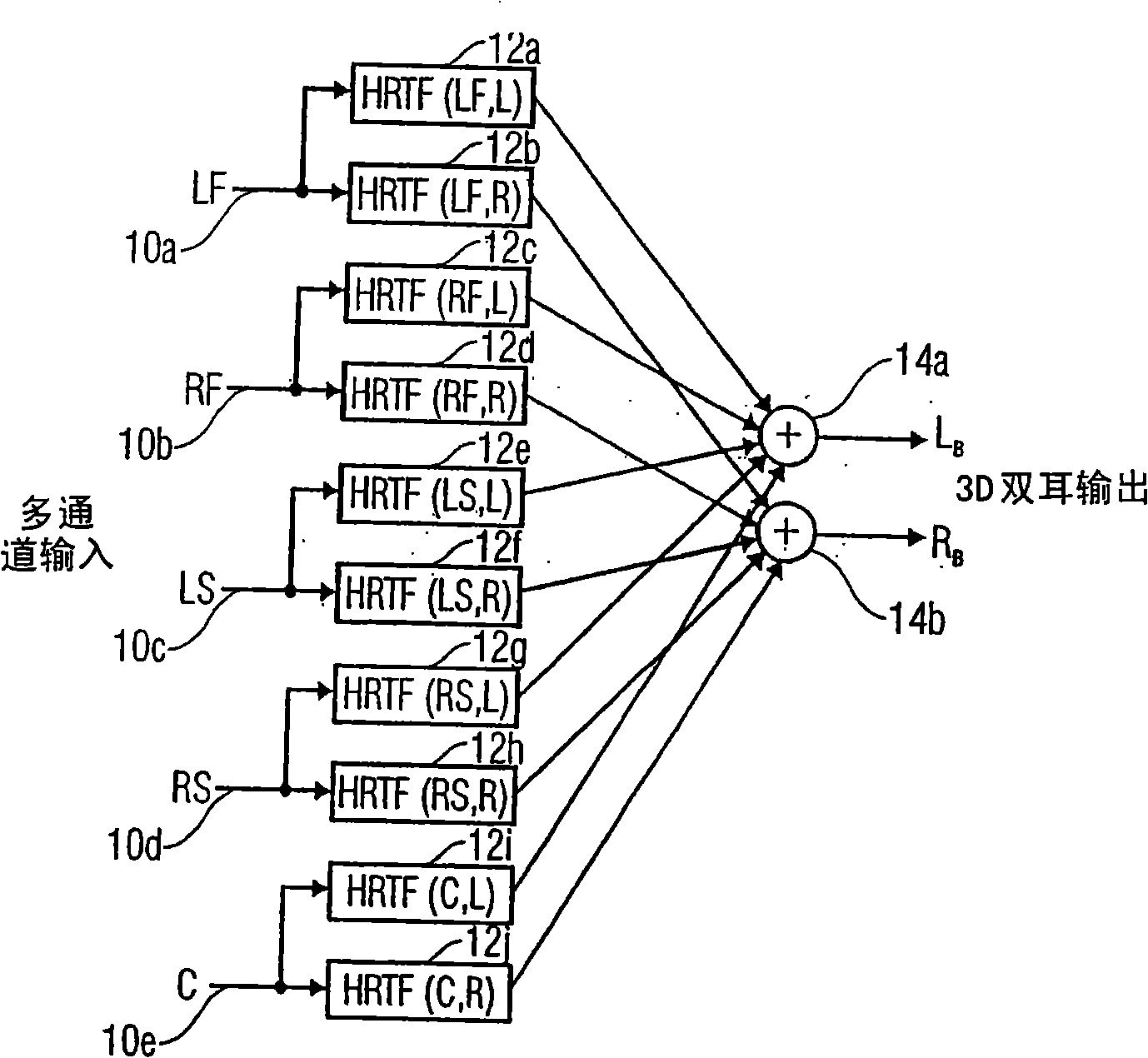

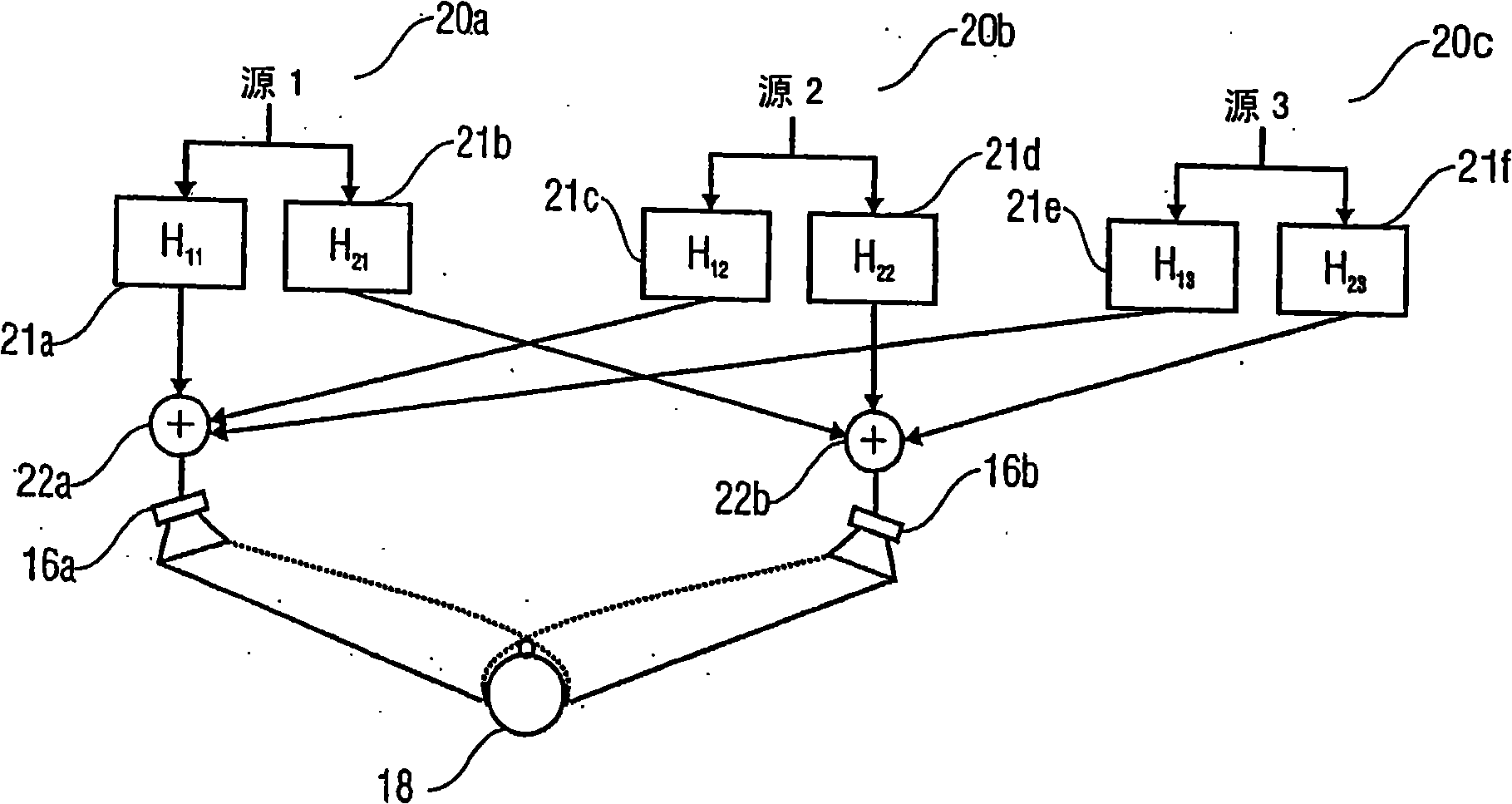

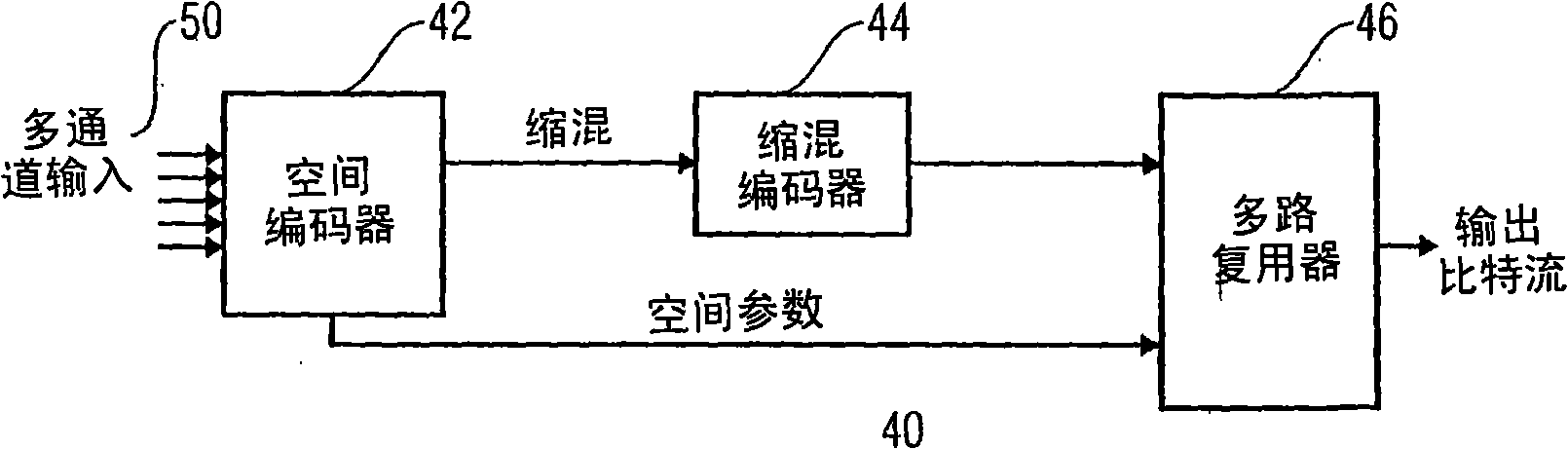

Generation of spatial downmixes from parametric representations of multi channel signals

ActiveCN101406074AExtend playback lengthReduce computational complexityStereophonic systemsEngineeringHeadset

A headphone down mix signal (314) can be efficiently derived from a parametric down mix of a multi-channel signal (312), when modified HRTFs (310) (head related transfer functions) are derived from HRTFs (308) of a multi-channel signal using a level parameter (306) having information on a level relation between two channels of the multi-channel signals such that a modified HRTF (310) is stronger influenced by the HRTF (308) of a channel having a higher level than by the HRTF (308) of a channel having a lower level. Modified HRTFs (310) are derived within the decoding process taking into account the relative strength of the channels associated to the HRTFs (308). The HRTFs (308) are thus modified such that a down mix signal (314) of a parametric representation of a multi-channel signal can directly be used to synthesize the headphone down mix signal (314) without the need of an intermediate full parametric multi-channel reconstruction of the parametric down mix.

Owner:DOLBY INT AB +1

Cigarette smoking device having electronic atomization function and method for improving cigarette smoking quality

ActiveUS20180042299A1Reduce harmComplex extraction processTobacco pipesTobacco devicesEngineeringAirflow

The present invention relates to a cigarette smoking device having an electronic atomization function, including a cigarette holder and an electronic atomization component cooperatively assembled with one another, wherein the cigarette holder includes a cigarette holding cavity and an optional end cap for closing the open end of a shell; the electronic atomization component includes the shell and the following components located in the shell: a power supply, an airflow sensor switch and an atomizer provided with a central airflow channel; the cigarette holding cavity is in air communication with the central airflow channel of the atomizer; the cigarette smoking device further includes an airflow sensor switch air inlet penetrating the shell and / or the end cap of the cigarette holder. Also provided is a method for improving cigarette smoking quality, the method includes smoking after mainstream smoke generated by an end-lighting cigarette, dilution air and atomization vapor are mixed.

Owner:CHINA TOBACCO YUNNAN IND

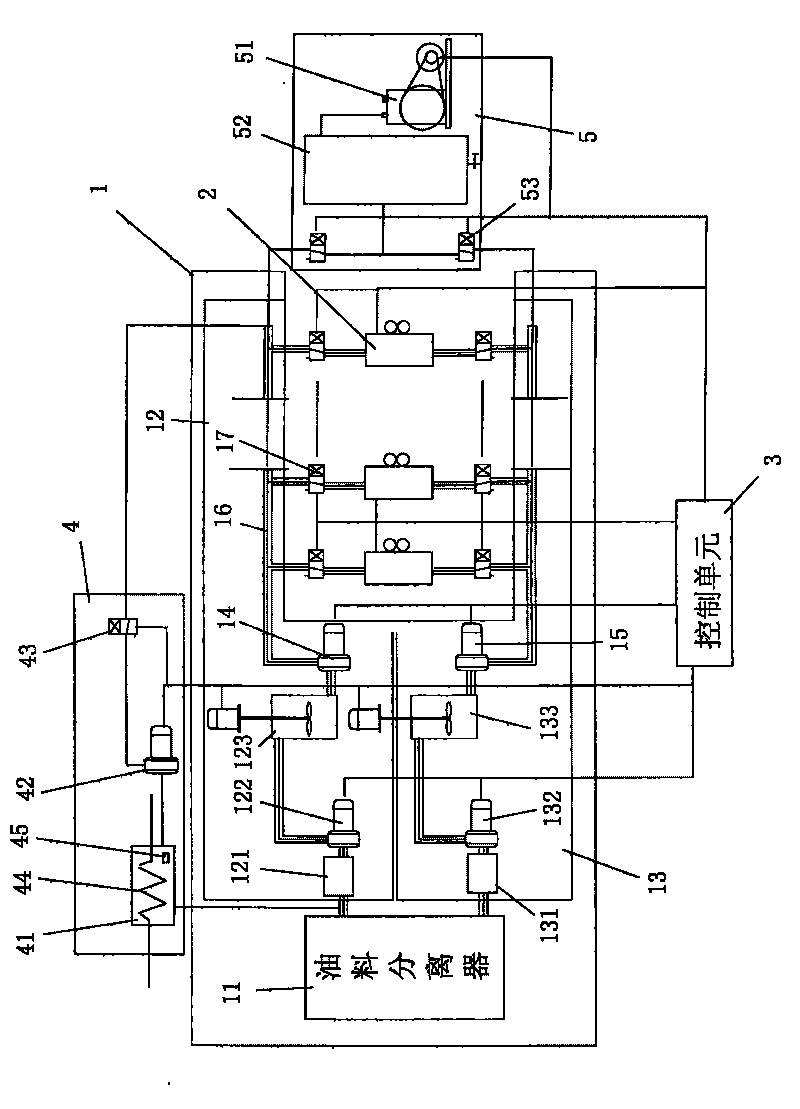

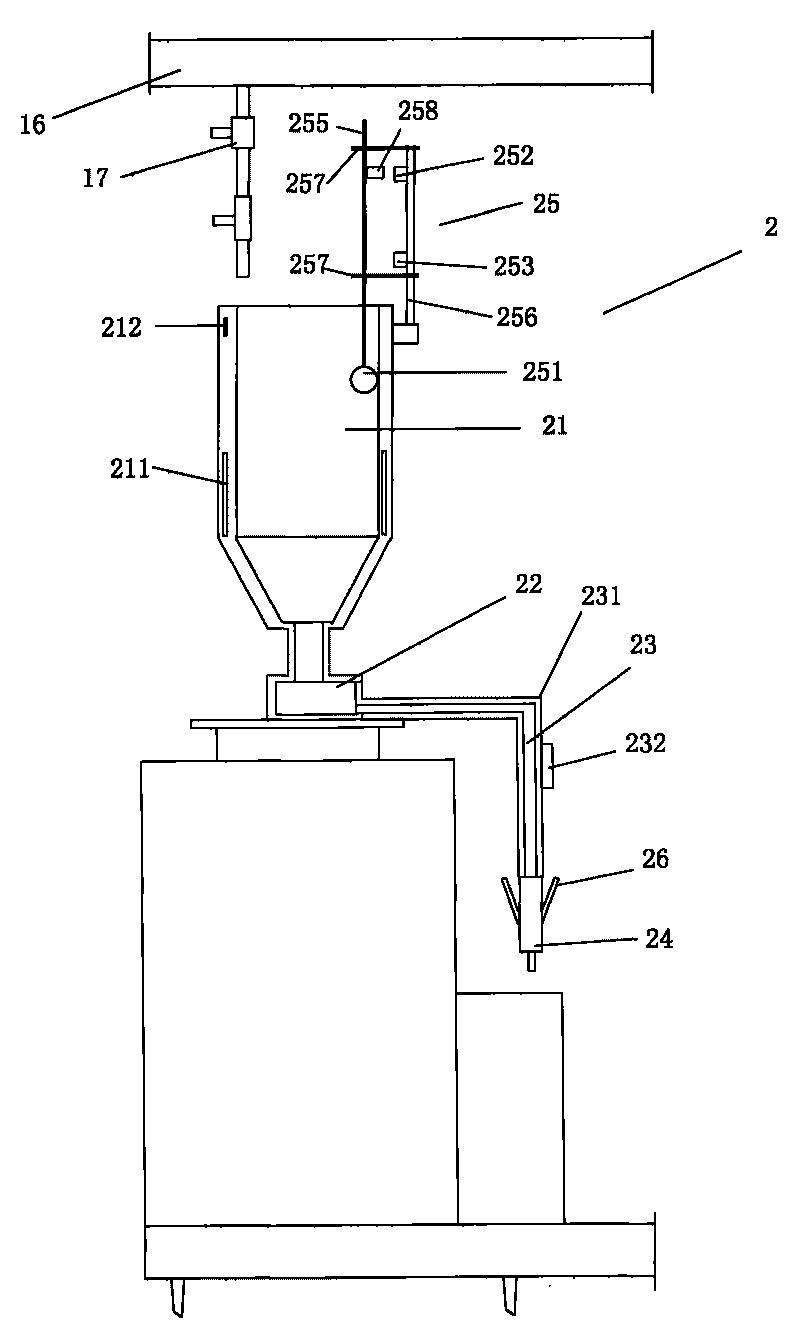

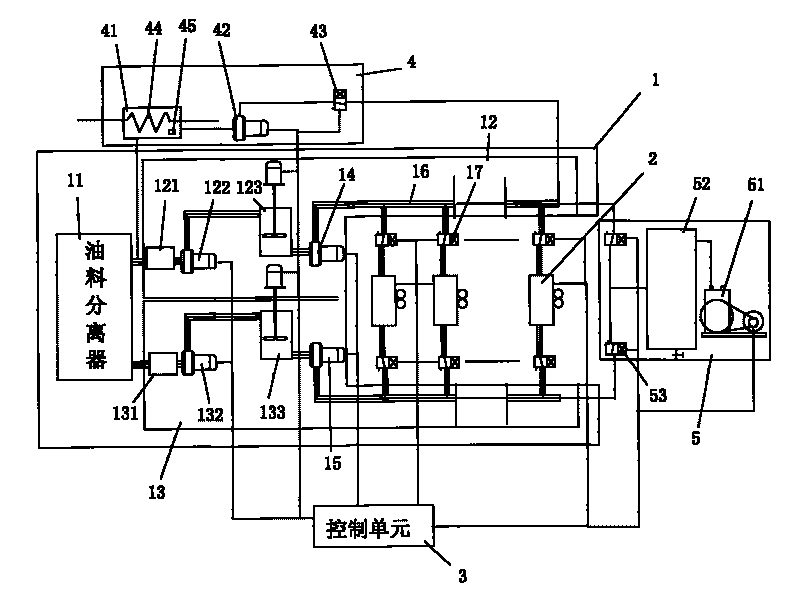

Fully-automatic packaging production line of beef tallow hot pot seasoning

ActiveCN101734382AAutomate the packaging processTake the time easilyPackaging automatic controlLiquid materialFully automaticBeef Tallow

The invention relates to an automatic packaging production line, in particular to a fully-automatic packaging production line of a beef tallow hot pot seasoning. The production line comprises a feeding and conveying device, a packaging machine and a control unit, wherein the packaging machine is a horizontal type fully-automatic constant temperature packaging machine; the feeding and conveying device comprises a tallow separator, a material feeding device and a tallow feeding device connected with the tallow separator, a booster pump respectively connected with the material feeding device and the tallow feeding device and an insulating conveying pipe provided with an insulating interlayer; the insulating conveying pipe is connected with the packaging machine through an electromagnetic valve; a heating device is arranged and connected with the feeding and conveying device; and the control unit is electrically connected with the horizontal type fully-automatic constant temperature packaging machine, the feeding and conveying device and the heating device so as to control the feed, the temperature, the quantitative loading and the packaging of materials and the cleanness of production line equipment. The production line realizes the packaging automation of the beef tallow hot pot seasoning, improves the productivity and avoids pollutions to products by manual operations.

Owner:四川天味食品集团股份有限公司

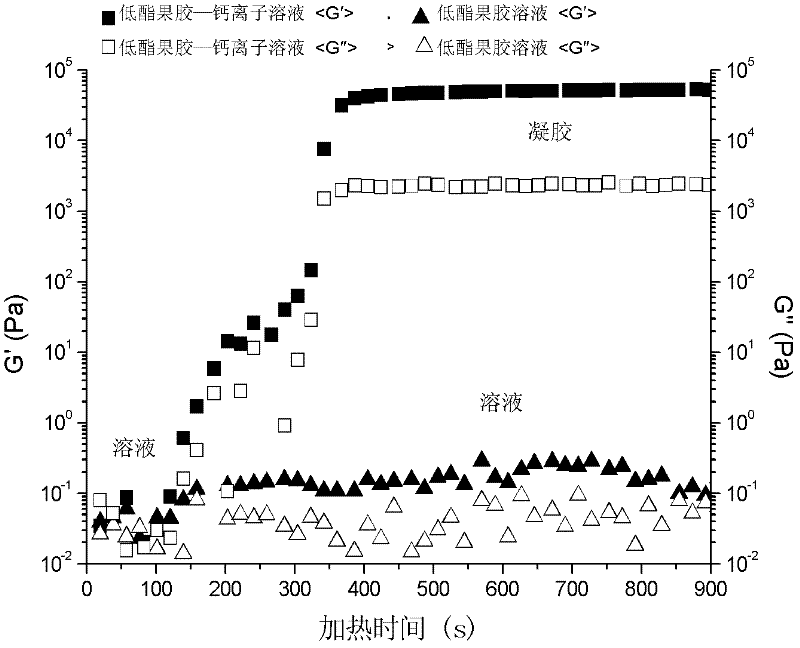

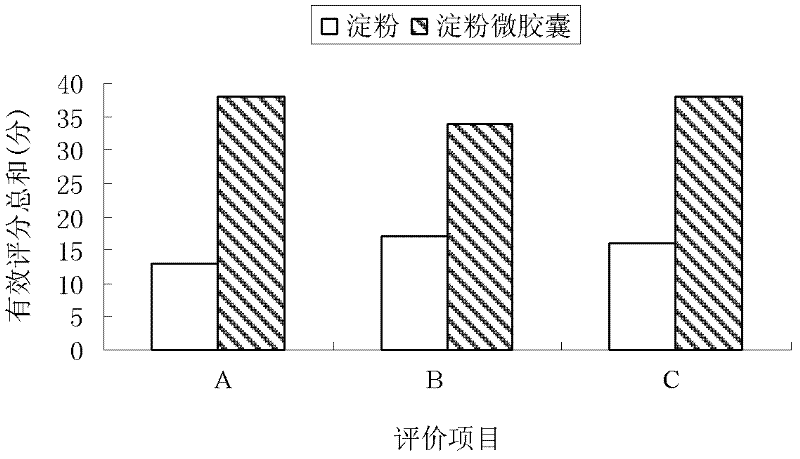

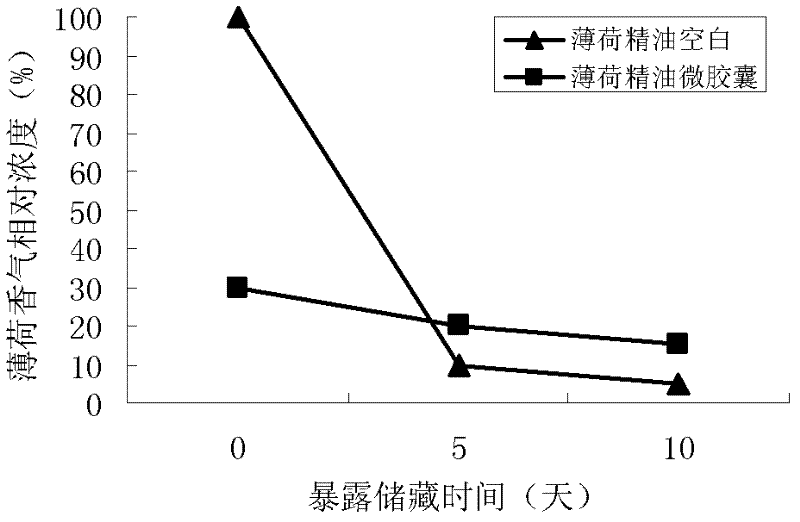

Method for preparing microcapsules based on low-ester pectin and calcium ion gelatinization and application of microcapsules

ActiveCN102553499ARich applicabilityHigh-quality and efficient application effectsPharmaceutical non-active ingredientsMicroballoon preparationFood ComponentBULK ACTIVE INGREDIENT

The invention discloses a method for preparing microcapsules based on low-ester pectin and calcium ion gelatinization and application of the microcapsules and belongs to the field of food and medicament microencapsulation. According to the microencapsulation method, water is evaporated in an atomized drying way, so that a low-ester pectin solution containing low-concentration calcium ions forms a gel with the increase of the concentration of the calcium ions, and the gel coated on the surface of a granular material or agglutinates micro materials into particles. The method for preparing the microcapsules based on low-ester pectin and calcium ion gelatinization has good effect of coating or embedding ordinary food components, physiological active substances and medicaments, and can be widely applied to the promotion of the sensory quality of the food components, the quality of food products and the active ingredients of controlled-release functional foods and medicaments.

Owner:JIANGNAN UNIV

Wine of low or free alcohol and its brewing method

The invention disclosed the method of brewing the non-low alcohol grape wine, which is enzyme treatment and penetration vaporzatioin method. The characteristics of the invention is the alcohol ranging from 0.5% to 7%, the sugar content which is the glucose below 12g / L in baked mold and below 120g / L in sweet mold, the total acid ranging from 4.5 to 8.0g / L measured by dihydroxysuccinic acid, the extract above 15g / L, free sulfur dioxide below 50mg / L, and total sulfur dioxide below 250mg / L. The said non-low alcohol grape wine is harmonization, delicate fragrance, suitable for the particular group and occasion,

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Processing method for improving cut stem quality

The invention belongs to the field of tobacco processing, in particular to a processing method for improving cut stem quality. The processing method for improving the cut stem quality is characterized in that tobacco stems and stem pieces are extracted by using an alcoholic solution, and then the alcoholic solution is added back into the produced cut stems made from the tobacco stems or the stem pieces. Compared with the prior art, the processing method for improving the cut stem quality has the advantages that substances with active functions on tobacco smoking smell such as sugar, nicotine, pigment ingredients and the like of the tobacco stems are extracted by using the alcoholic solution and are added back into the cut stems later, compounds harmful to the tobacco smoking smell such as macromolecules (like pectin, protein and the like) in the tobacco stems are removed by combining water washing with acidolysis and enzymolysis, and therefore improvement of sensory quality of the cut stems is achieved, and smoke panel tests demonstrate that the cut stems prepared have the advantages that the offensive odors are reduced, the irritation is lowered, and the flavor remaining smell is improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Production method for high-quality instant lentinus edodes crisp chips

InactiveCN103652833AComplete shapeFlat surfaceFood freezingFood coatingAdditive ingredientAdditional values

The invention relates to a production method for high-quality instant lentinus edodes crisp chips and belongs to the technical field of deep processing of agricultural products. A main process for producing the instant lentinus edodes crisp chips comprises the following steps: harvesting fresh lentinus edodes with good quality; removing pedicles; washing; immersing; freezing; freezing and drying in vacuum; and seasoning and carrying out nitrogen-filled packing. The production method adopts a novel vacuum freezing and drying process to produce the lentinus edodes crisp chips. Compared with the prior art, the process adopts a low-temperature dehydration manner of freezing and drying in vacuum to keep the nutrition and the flavor components of the lentinus edodes to the greatest extent; the sensory quality of the product is improved and the defects of traditional oil fried crisp chips that the oil content is high, the color and luster are poor, the mouth feel is hard and the like are avoided. The product obtained by the process has the characteristics of rich flavor, crispy mouth feel, low oil content, high additional value, good sensory quality and the like; the invention provides a feasible new way for deeply processing the lentinus edodes.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com