Paper cigarette filter rod filter media and processing method thereof

A cigarette filter tip and filter material technology, which is applied to e-liquid filter cartridges, tobacco, textiles and papermaking, etc., can solve the problems affecting the stability of the filter rod quality, the shedding of tobacco stem particles, and the impact of cigarette smoking taste, etc., and achieve the quality of the filter tip. Stable, stable quality, stable and favorable effect of filter quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

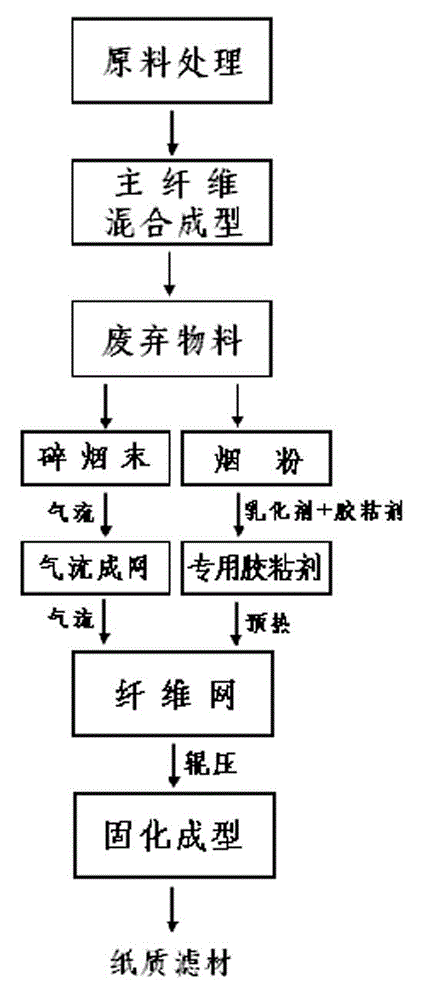

Method used

Image

Examples

Embodiment 1

[0035] First, crush and sieve waste tobacco raw materials, select 10kg of tobacco powder with a specification of 80-500 mesh, mix and stir evenly with 15kg of polyvinyl acetate emulsion, and 0.5kg of sucrose fatty ester to prepare the special adhesive for air-laid paper. Take 40kg of tobacco rod fibers and 35kg of hemp fibers, mix them, and then disperse them. After they are fully dispersed, they are transported to the forming section by a fan for laying and forming, and a fluffy and uniform fiber web is formed on the forming belt. Then it enters the sizing section, and evenly coats the prepared special adhesive on the fiber net, and finally preheats, rolls, solidifies, shapes, and dries to obtain cigarette filter rod filter material paper. The paper filter material is formed into a filter rod, and combined with the cigarette, and then compared and smoked according to "YC / T 138-1998 Tobacco and Tobacco Products Sensory Evaluation Method". Compared with other samples, the stimu...

Embodiment 2

[0037] Firstly, crush and sieve waste tobacco raw materials, and select 5 kg of shredded tobacco powder with a specification of 0.5-1 mm. Take 40kg of tobacco stem fiber, 20kg of flax fiber, 15kg of jute fiber, and 10kg of sisal fiber, mix them, and then disperse them. After they are fully dispersed, they are transported to the forming section by a fan for laying and forming, and a fluffy and uniform fiber net is formed on the forming belt. The crushed tobacco powder is conveyed by a fan and evenly added to the fiber web, and then enters the sizing section, and 10kg of polyacrylate emulsion is evenly coated on the fiber web, and finally preheated, rolled, cured, formed, and dried to obtain a cigarette filter. Rod filter paper. The paper filter material is formed into a filter rod, and combined with the cigarette, and then compared and smoked according to "YC / T 138-1998 Tobacco and Tobacco Products Sensory Evaluation Method". Compared with other samples, the stimulation is red...

Embodiment 3

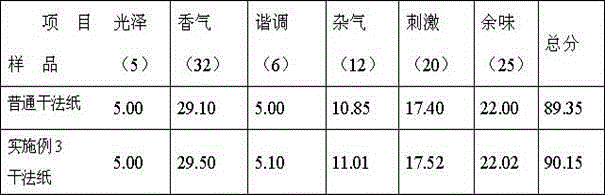

[0039] First, crush and sieve the waste tobacco raw materials, select 2kg of shredded tobacco powder with a specification of 0.5-1mm and 6kg of tobacco powder with a size of 80-500, mix 6kg of tobacco powder with 3kg of polyacrylate copolymer emulsion, 1kg of modified starch adhesive, 0.18 kg polyglycerin fatty acid ester was mixed and stirred evenly to make the special adhesive for air-laid paper. Take 20kg of tobacco stem fiber, 28kg of tobacco rod fiber, 5kg of hemp fiber, 10kg of flax fiber, 10kg of ramie fiber, 5kg of jute fiber, 5kg of kenaf fiber, and 5kg of sisal fiber, mix them and then disperse them, and then transport them to the molding section through a fan after they are fully dispersed. Laying and forming, forming a fluffy and uniform fiber web on the forming belt. 2kg of shredded tobacco is conveyed by a fan and evenly added to the fiber web, then enters the sizing section, and the prepared special adhesive is evenly coated on the fiber web, and finally preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com