Patents

Literature

350 results about "Paper filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

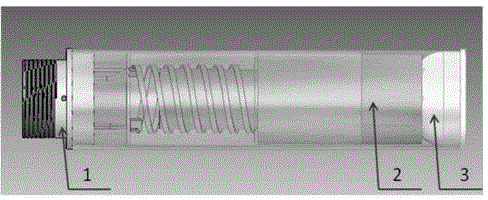

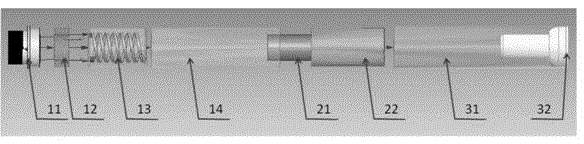

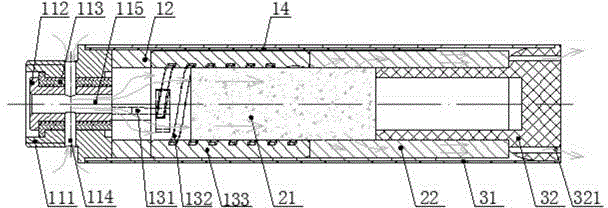

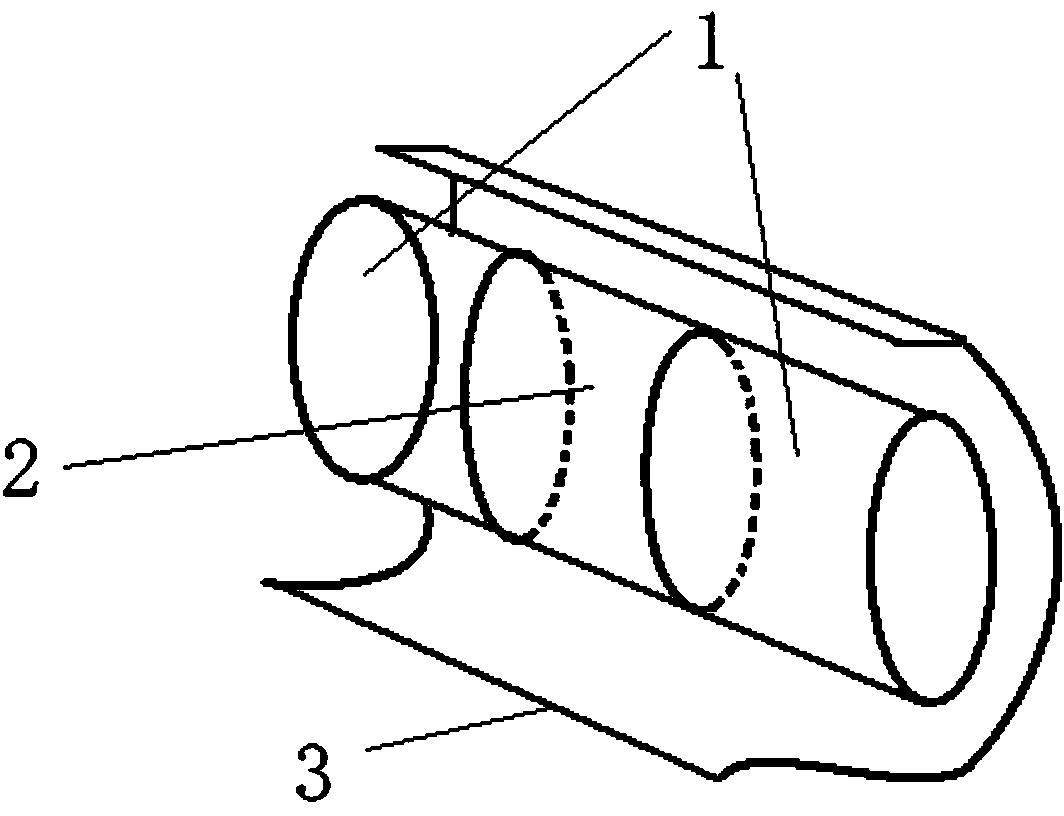

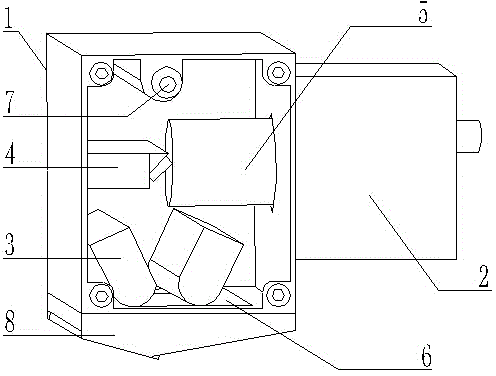

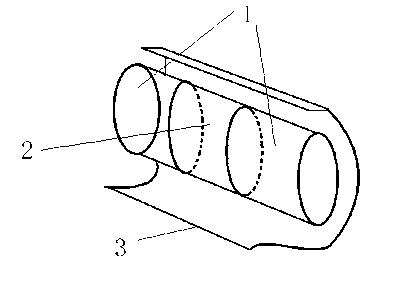

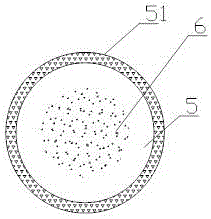

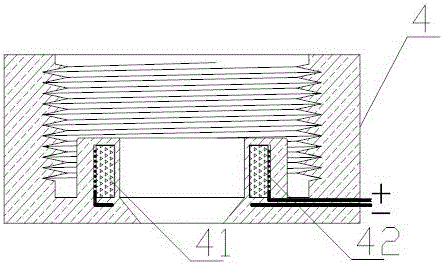

Low-temperature heating type electronic cigarette heater

A low-temperature heating type electronic cigarette heater comprises a heater component, a composite cigarette core and a cigarette holder portion. The composite cigarette core is consumable and cannot be reused, and the other portions are reusable; the composite cigarette core is composed of a core body and a filtering core in a combined manner and fills the heater component, the core body adopts natural plant fibers as the base material and is provided with tobacco aroma substances in an absorbed manner and tea polyphenol microcapsules, and the filtering core is tobacco paper filtering core compounded with bamboo fibers and is prevented from being carbonized during heating; a cigarette holder is connected to the heater component in a sleeved manner; the heater component comprises a connecting component, a supporting seat, a ceramic heating ring and a heat insulating sleeve. The composite cigarette core contacts with the ceramic heating ring in a cylindrical surface manner, the heating area is large, three ways, namely conduction, convection and radiation, of heat transfer during heating are provided, and the heating efficiency is high; the cigarette core releases contained tobacco ingredients through low-temperature heating, the taste is similar to that of a traditional cigarette, and toxics produced in the burning process can be avoided.

Owner:POWERTHINK (BEIJING) TECH CO LTD +2

Ethylene-vinylacetate copolymer resin hot melt adhesive with high melting point, fast curing and low viscosity

InactiveCN102108269AShort opening hoursMeet the needs of the above purposesMineral oil hydrocarbon copolymer adhesivesWaxPaper filter

The invention relates to an ethylene-vinylacetate (EVA) copolymer resin hot melt adhesive with high melting point, fast curing and low melting viscosity. The hot melt adhesive comprises the following components in parts by weight: 40-60 parts of ethylene-EVA copolymer resin, 20-40 parts of tackifying resin and 10-30 parts of synthetic wax. The hot melt adhesive is especially suitable for splicing the paper filter element of the air cleaner.

Owner:上海理日化工新材料有限公司

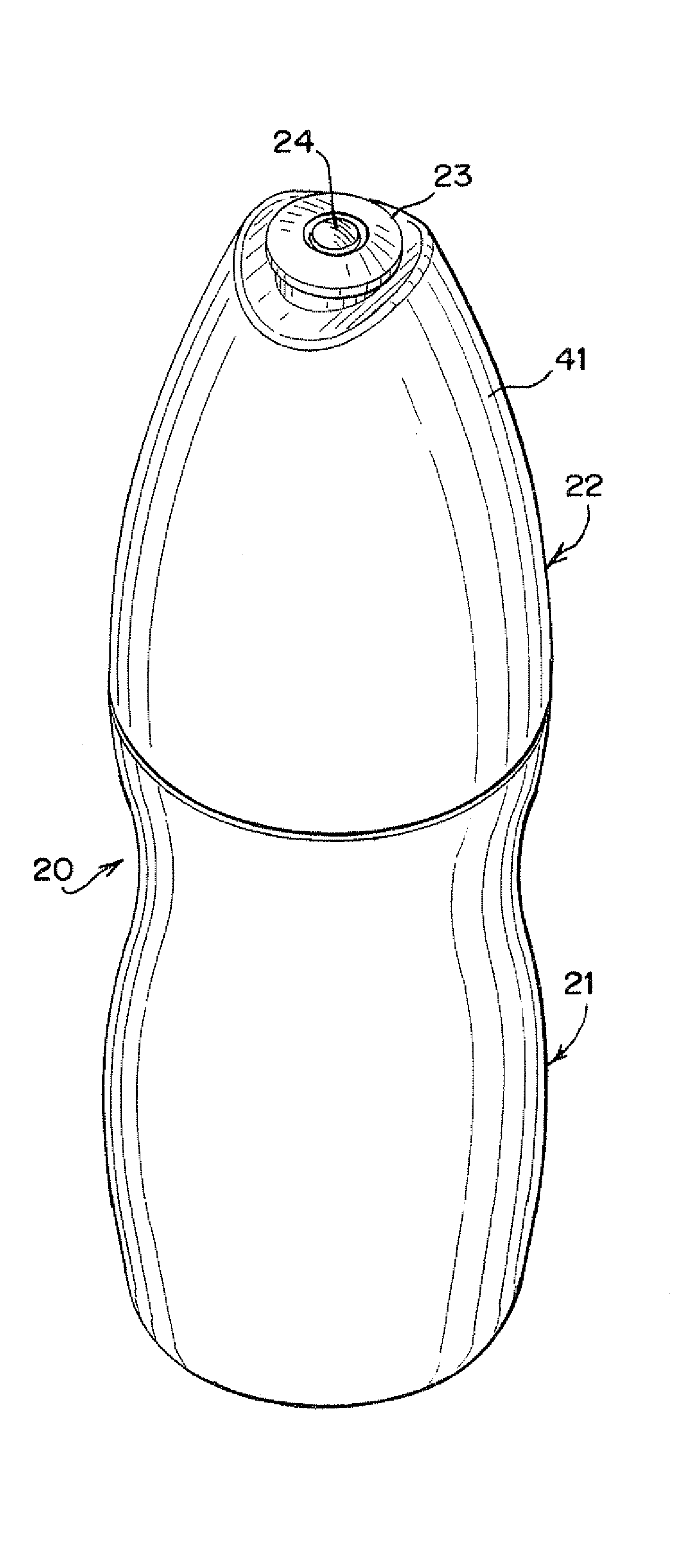

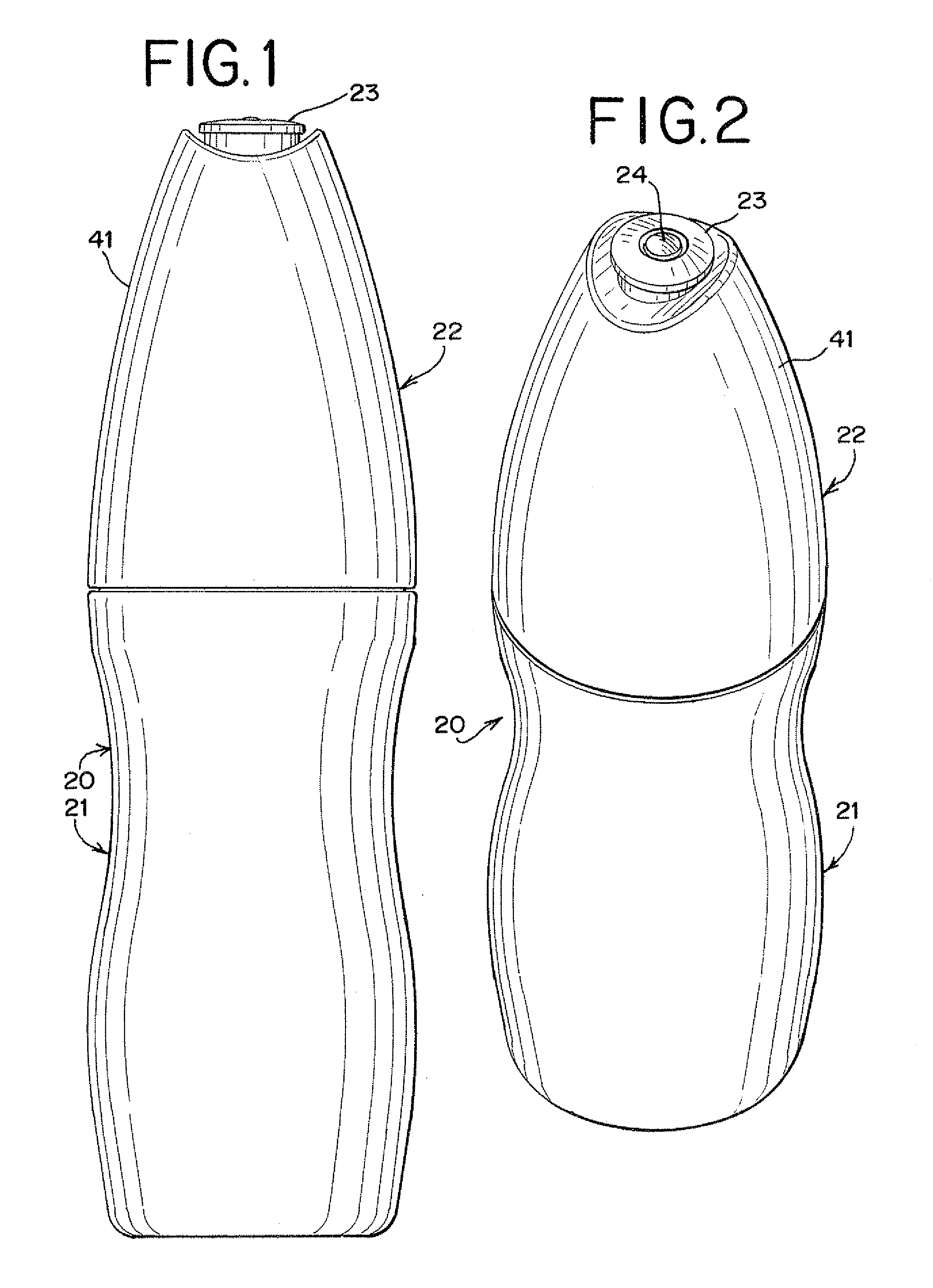

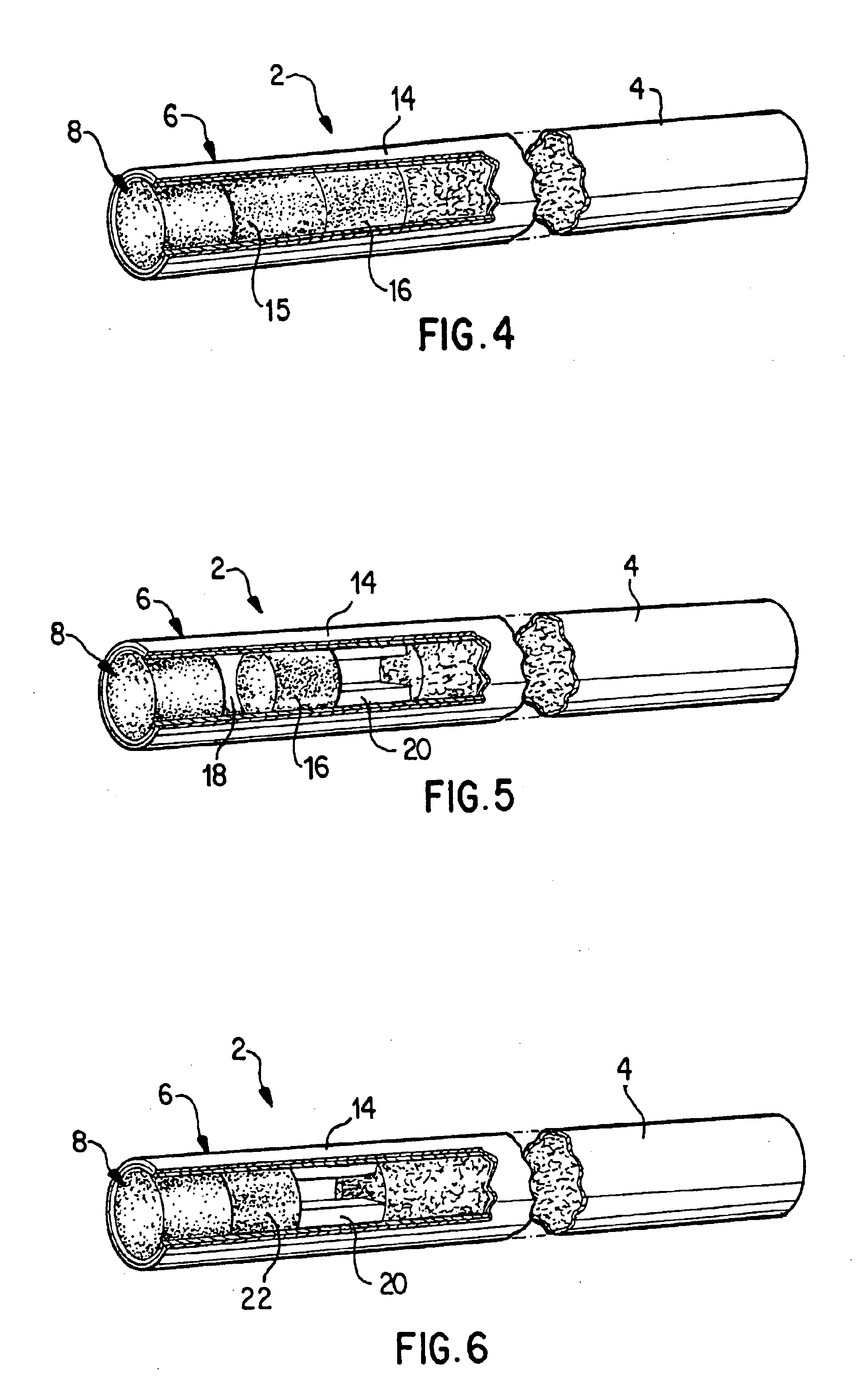

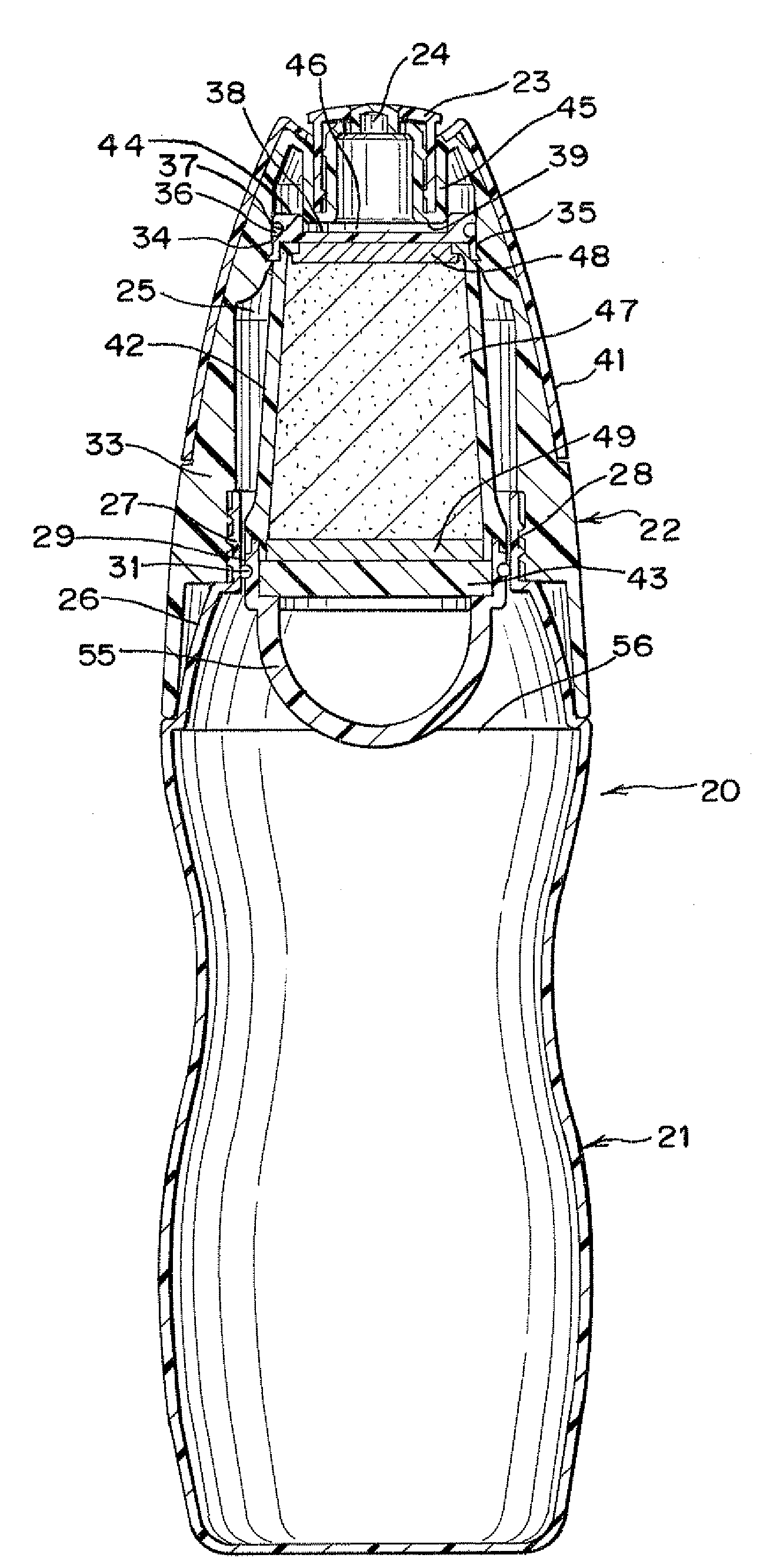

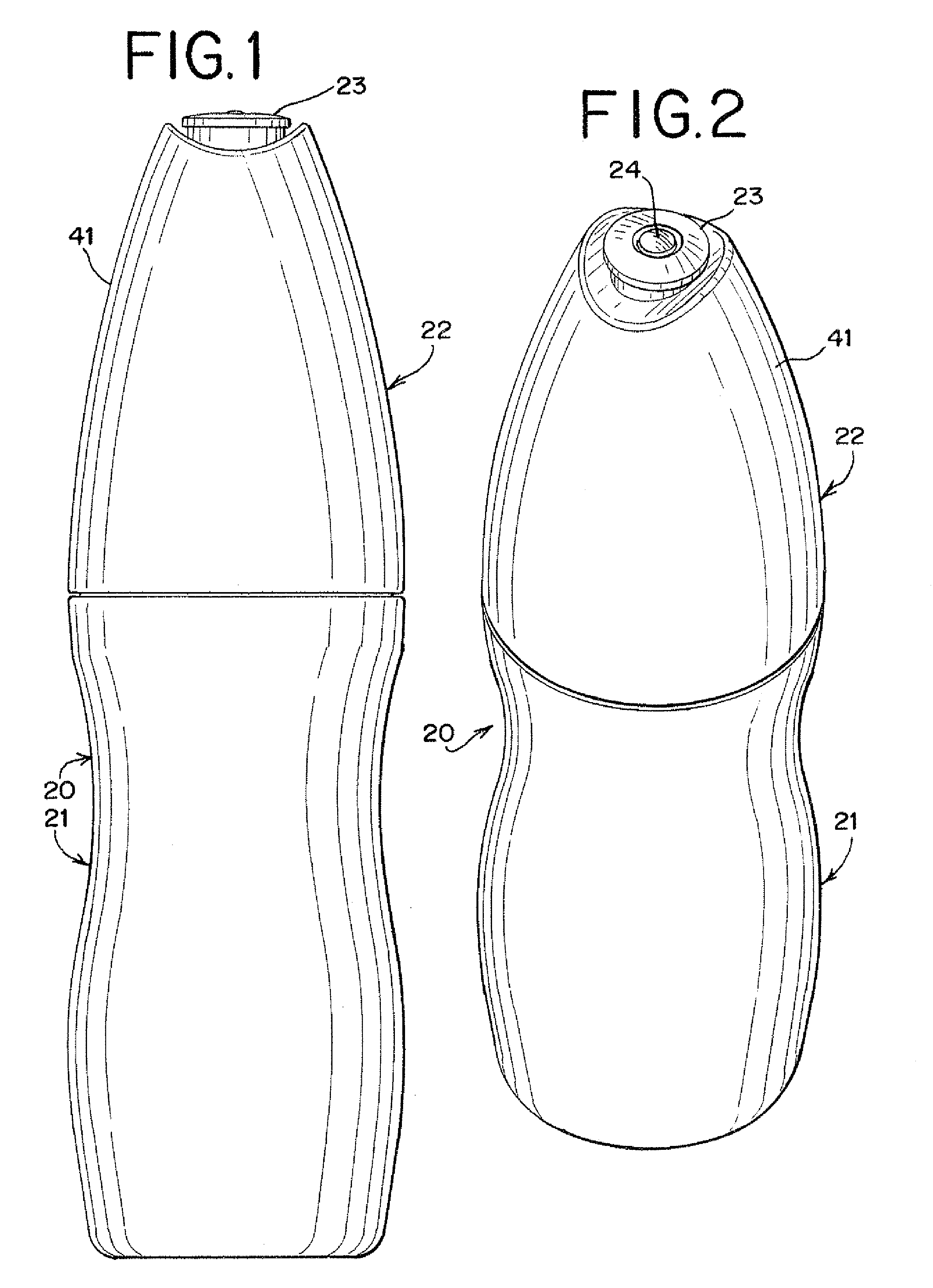

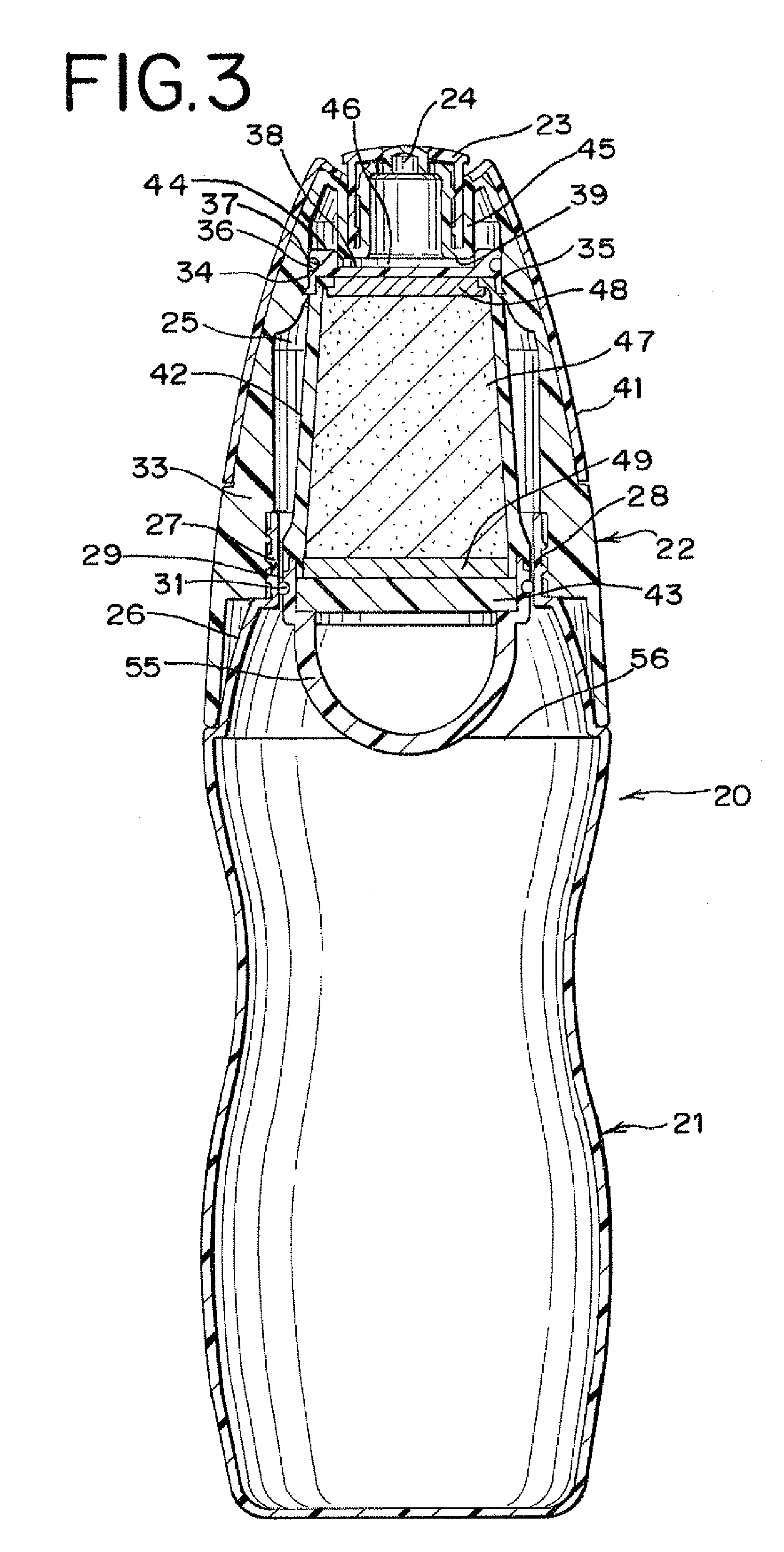

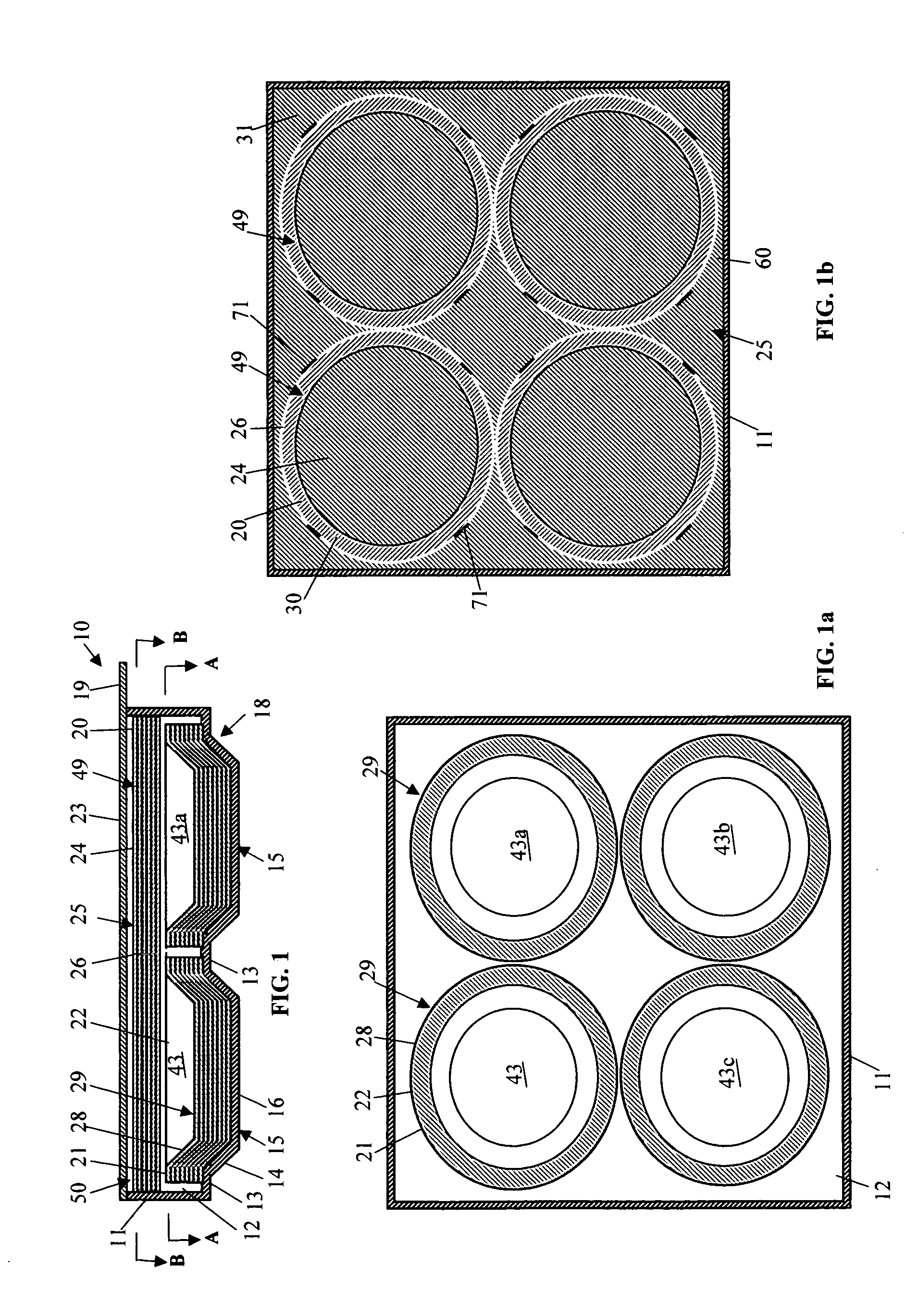

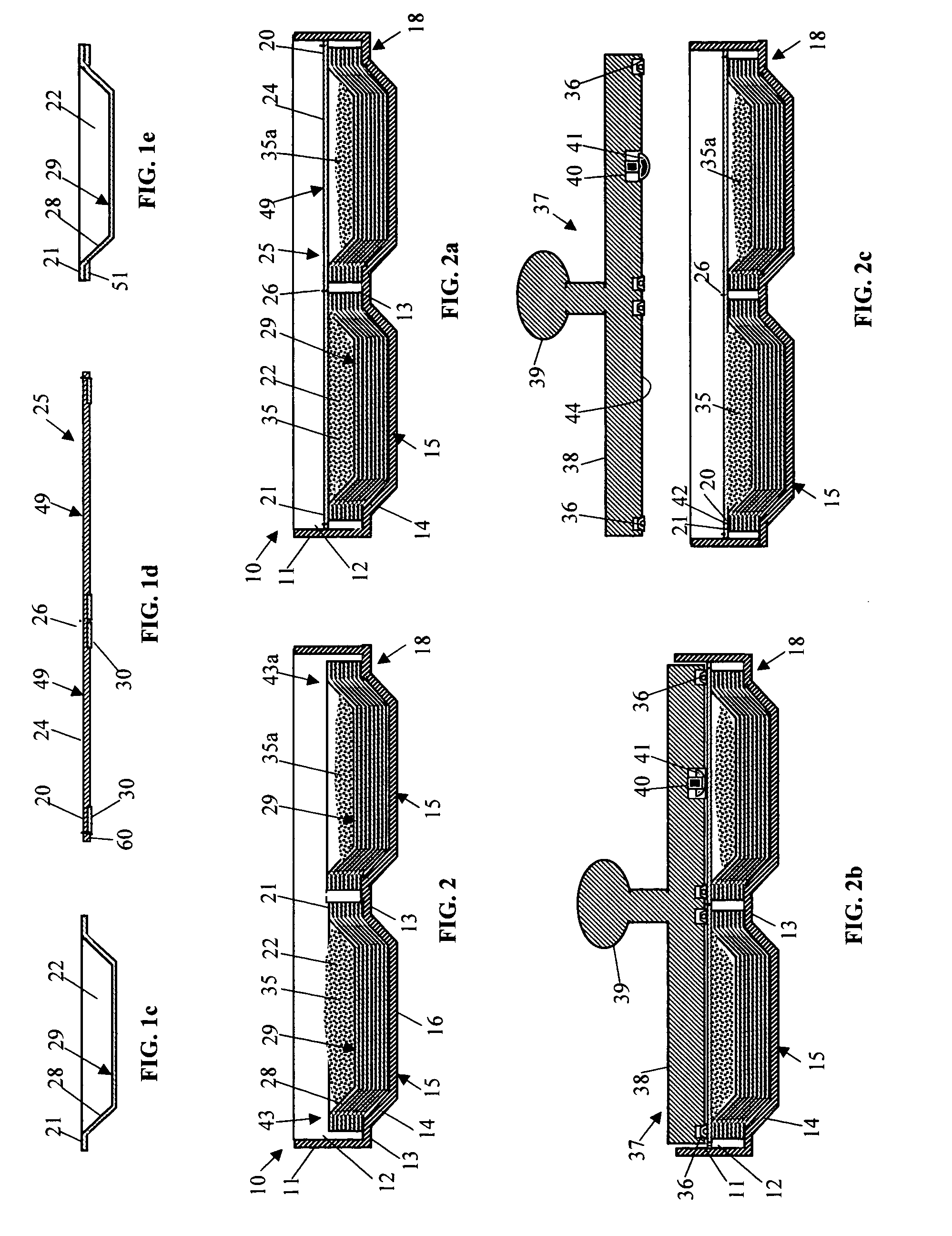

Water Bottle with Filtration Feature

InactiveUS20090145839A1Easily removableEasily replaceableTreatment involving filtrationWater treatment locationFiltrationActivated carbon filtration

A flexible water bottle is provided that includes an approach for filtering unfiltered water within the bottle. The bottle includes a filter assembly located within the cap of the bottle such that the filter assembly need not descend into the bottle cavity when the cap is screwed on, thereby not displacing water while screwing on the cap. The filter assembly has an axial flow orientation. An illustrated filter assembly includes paper filters covering the upper and lower ends and can include an activated charcoal filter in between the paper filters. Water is filtered when pressure generated by squeezing the bottle forces water from the bottle cavity through the filter along an axial flow path and out through a spout.

Owner:MEDPORT

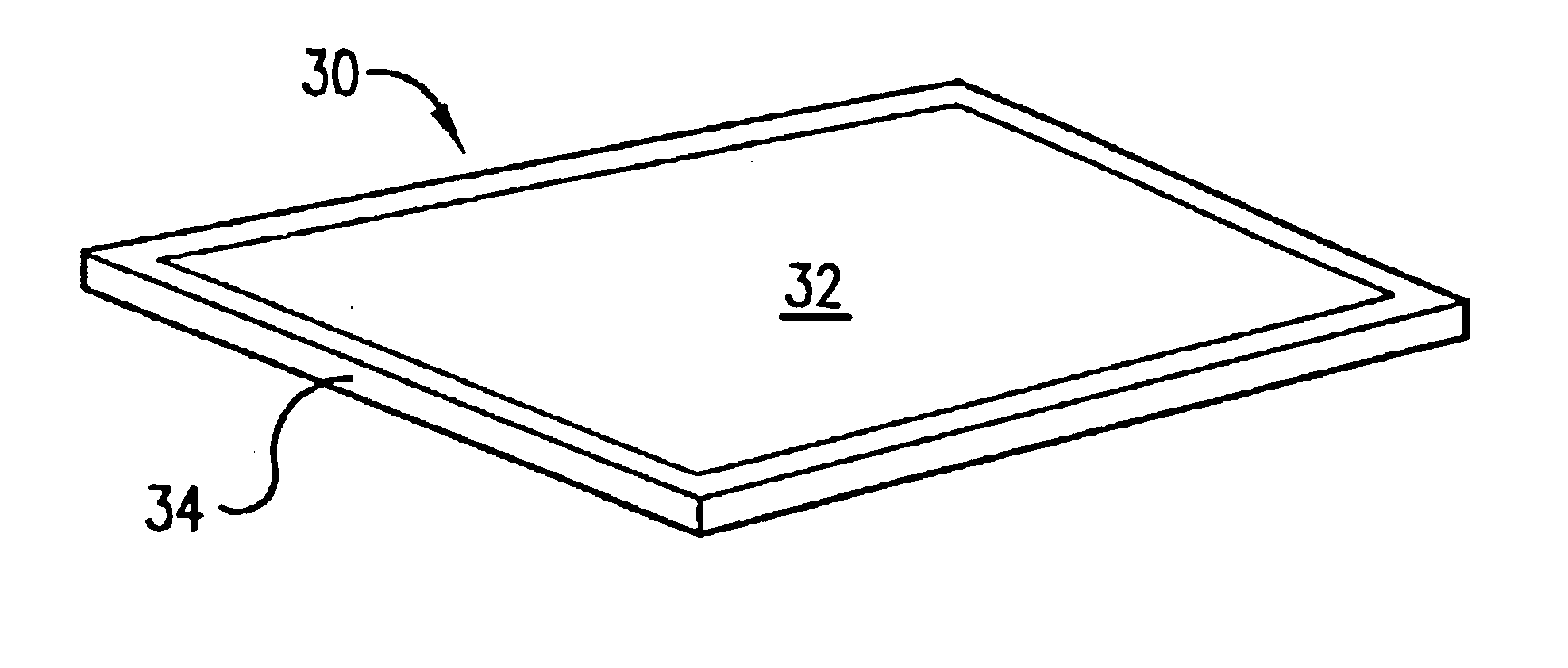

Filter for selective removal of a gaseous component

A filter such as an air having a reagent which chemically reacts with and removes a gaseous component of an air stream. The reagent contains functional groups covalently bonded to a non-volatile inorganic substrate which is incorporated in the filter. The filter can remove gaseous components such as aldehydes. Preferred functional groups are 3-aminopropylsilyl groups covalently bonded to silica gel (APS silica gel). The reagent can be contained in a space in the filter or incorporated in one or more filter elements. The reagent can be part of or coated on paper such as filter paper or incorporated in non-paper filter elements formed from fibrous materials such as cellulose acetate or polypropylene fibers. Other preferred reagents include aminoethylaminopropylsilyl silica gel (AEAPS) and aminoethylaminoethylaminopropylsilyl silica gel (AEAEAPS).

Owner:FILIP MORRIS PRODAKTS INK

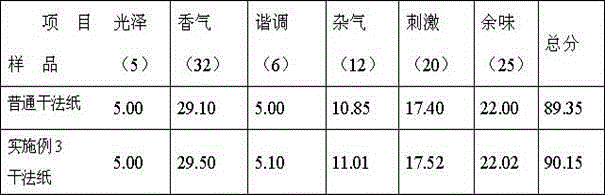

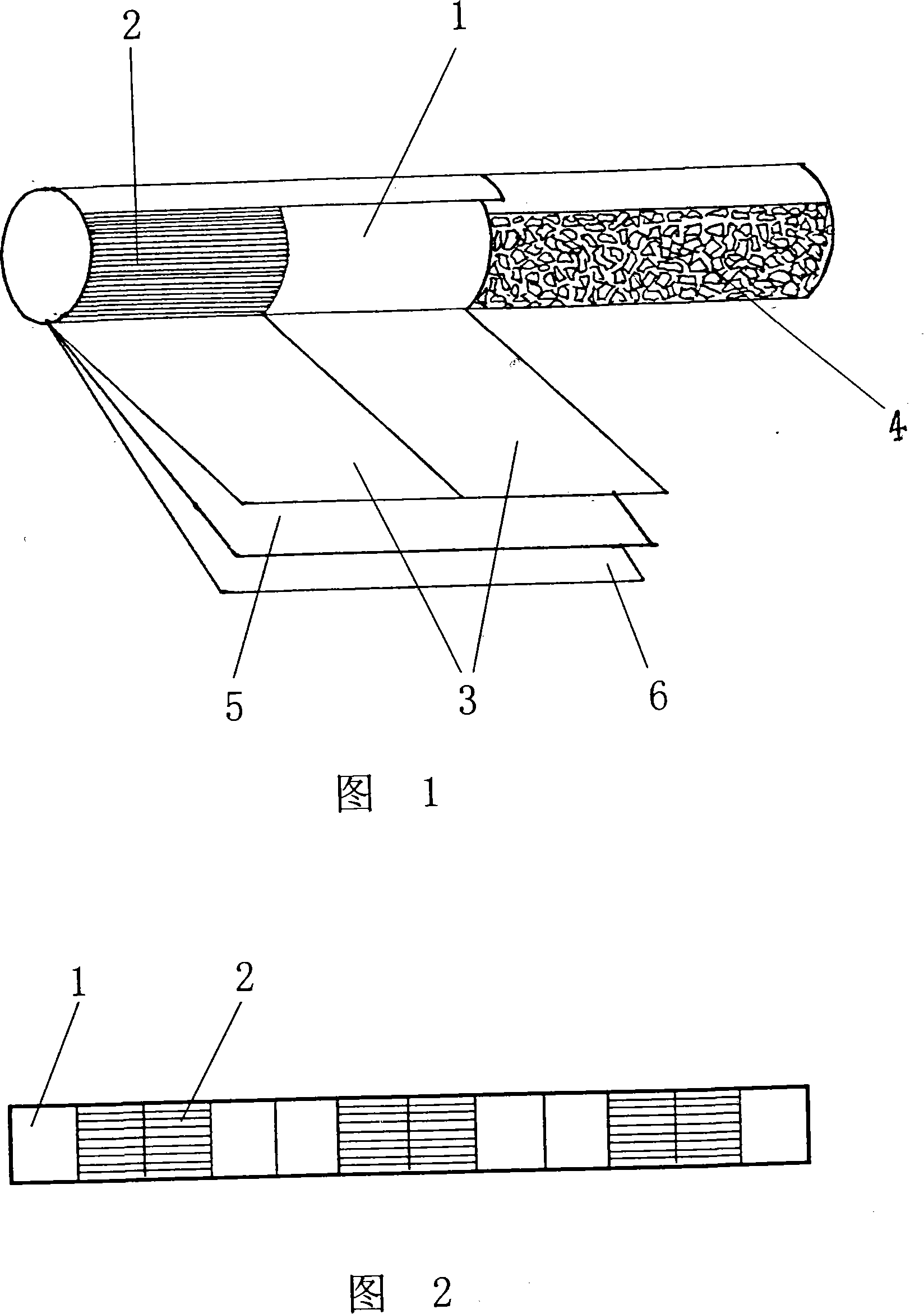

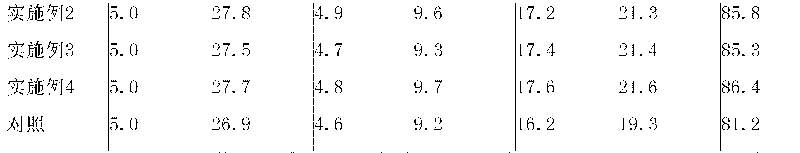

Application of acetate fiber paper added with adsorptive filling material in paper filter rod

InactiveCN102247012ALarge specific surface areaImprove functional adsorption capacityTobacco smoke filtersFiberFilling materials

The invention discloses an application of acetate fiber paper added with an adsorptive filling material in a paper filter rod. Through the invention, smoke can sufficiently contact with the adsorptive filling material when flowing in the filter tip so that the adsorptive filling material catches harmful components such as tar, nicotine and the like in smoke and the filtering effect of the paper filtering material is improved. The cigarette filter made from the acetate fiber paper filtering material added with the adsorptive filling material has a remarkably obvious effect in adsorbing solid grain phase matters, tar, nicotine and other harmful components in smoke. Through the invention, the suction volume of people for harmful components in cigarette smoke can be greatly reduced to improve the cigarette safety.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

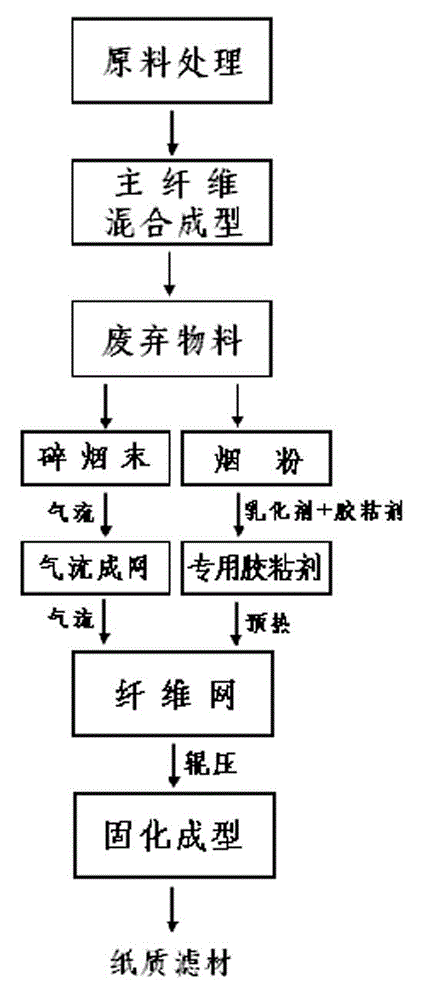

Paper cigarette filter rod filter media and processing method thereof

ActiveCN102747647AImprove sensory qualityEvenly distributedTobacco smoke filtersTextiles and paperFiberFilter media

The present invention discloses a paper cigarette filter rod filter media and a processing method thereof, wherein the paper filter media is obtained through performing a dry process on the following components: 40-74% of natural cigarette fiber, 4-40% of bast fiber, 1-12% of natural tobacco waste raw material, and 4-20% of adhesive. The method comprises the following steps: raw material processing, main fiber mixing shaping, waste material adding and prepared paper shaping process. After the natural tobacco fiber is mixed with the bast fiber, discongestion is performed. After sufficient dispersion, the mixed material is conveyed to a shaping section through a blower for being laid on a net and shaped. A fluffy and uniform fiber net is formed on a shaping net belt. The cigarette filter media paper is obtained through adhesive applying, preheating, roller pressing, solidifying and shaping. As the cigarette fiber is used as the main fiber raw material, the paper cigarette filter rod filter media according to the invention has reduced foreign gas of wood and settles a problem that the fragrance quality is reduced by the foreign gas of wood in the prior-art paper filter rod. The natural tobacco waste raw material is added in the paper shaping process. Not only is whole aesthetic quality of the cigarette improved, but also the tobacco raw material is uniformly distributed in the dry process paper and does not easily drop off. The quality of the filter rod is more stable.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

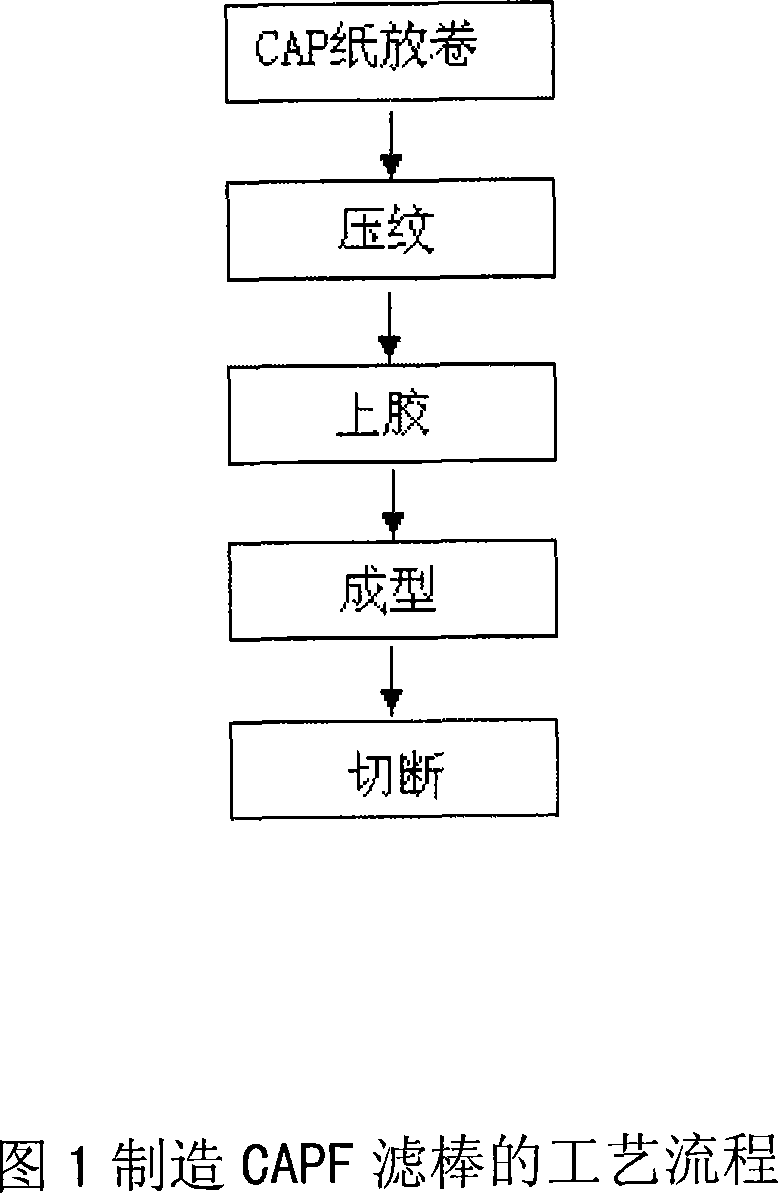

Producing technique of filter tip bar for filling material including acetate fibre paper to cigarette

The present invention relates to cigarette filter tip making technology, and is especially one kind of cigarette filter tip with cellulose acetate paper as the filling and filtering material. The cellulose acetate paper filter tip may be filter tip made of cellulose acetate paper or composite filter tip made of composite material with cellulose acetate paper. During the formation of the cellulose acetate paper filter tip, triglycreyl acetate or other cellulose acetate is applied as the plasticizer, and the filter tip may be 'cured' or 'non-cured'.

Owner:NANTONG CIGARETTE FILTER +1

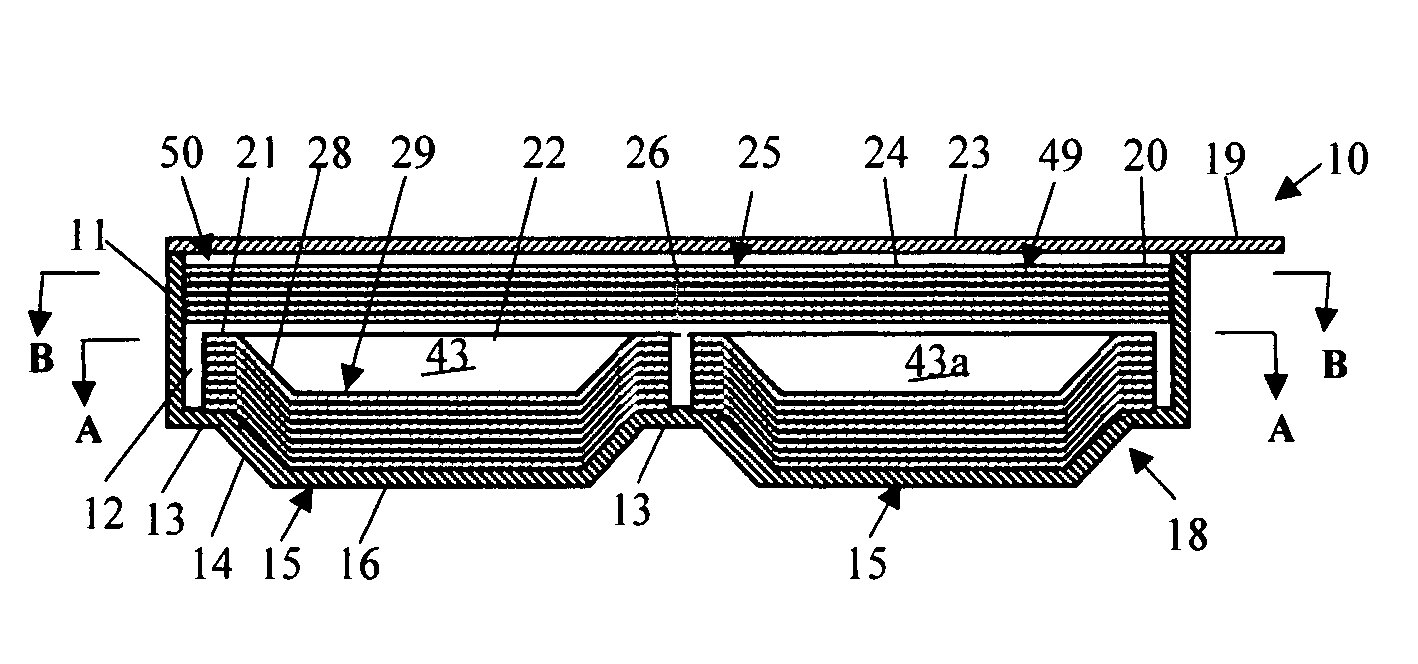

Water bottle with filtration feature

InactiveUS7810651B2Easily removableEasily replaceableTreatment involving filtrationLiquid transferring devicesActivated carbon filtrationFiltration

A flexible water bottle is provided that includes an approach for filtering unfiltered water within the bottle. The bottle includes a filter assembly located within the cap of the bottle such that the filter assembly need not descend into the bottle cavity when the cap is screwed on, thereby not displacing water while screwing on the cap. The filter assembly has an axial flow orientation. An illustrated filter assembly includes paper filters covering the upper and lower ends and can include an activated charcoal filter in between the paper filters. Water is filtered when pressure generated by squeezing the bottle forces water from the bottle cavity through the filter along an axial flow path and out through a spout.

Owner:MEDPORT

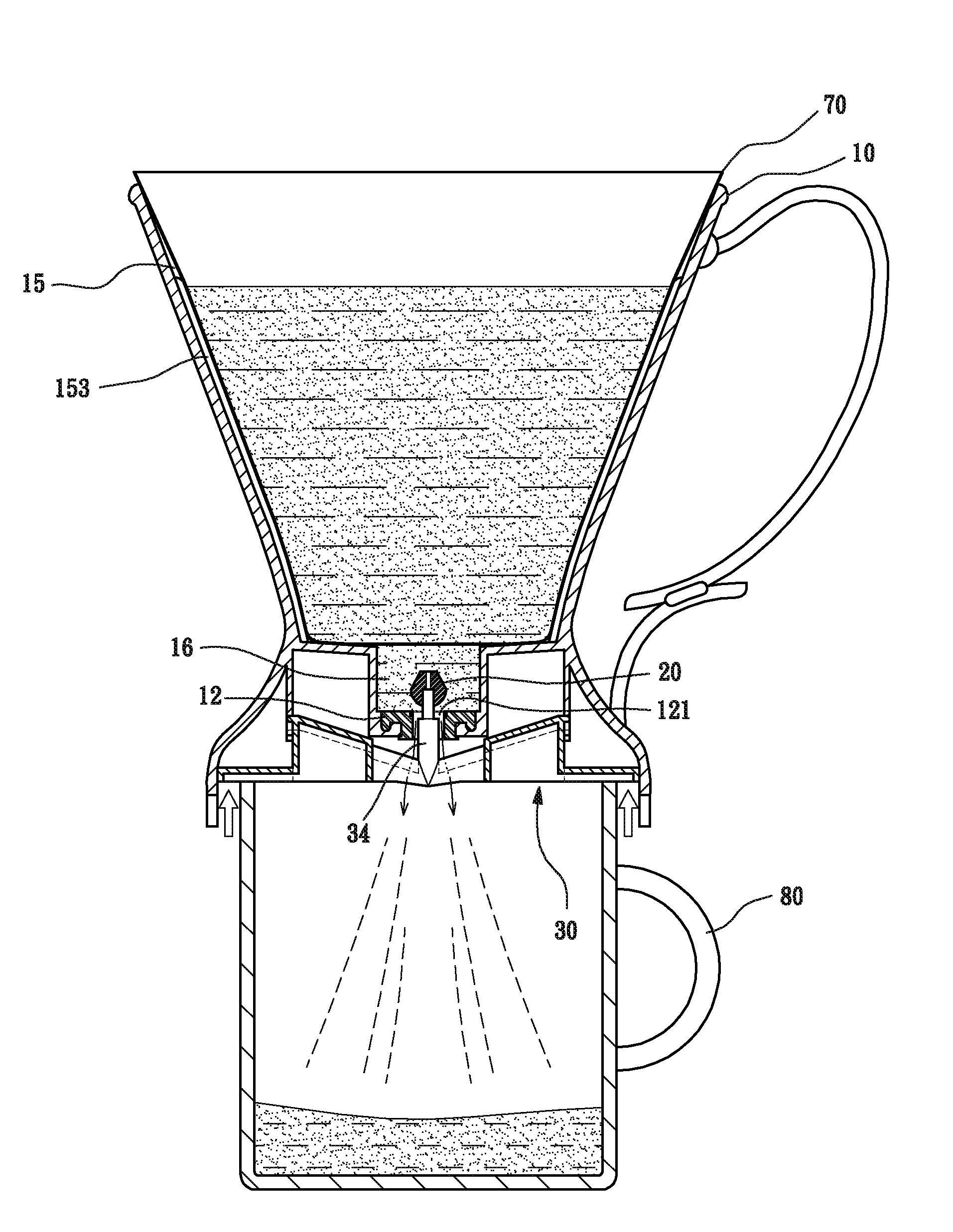

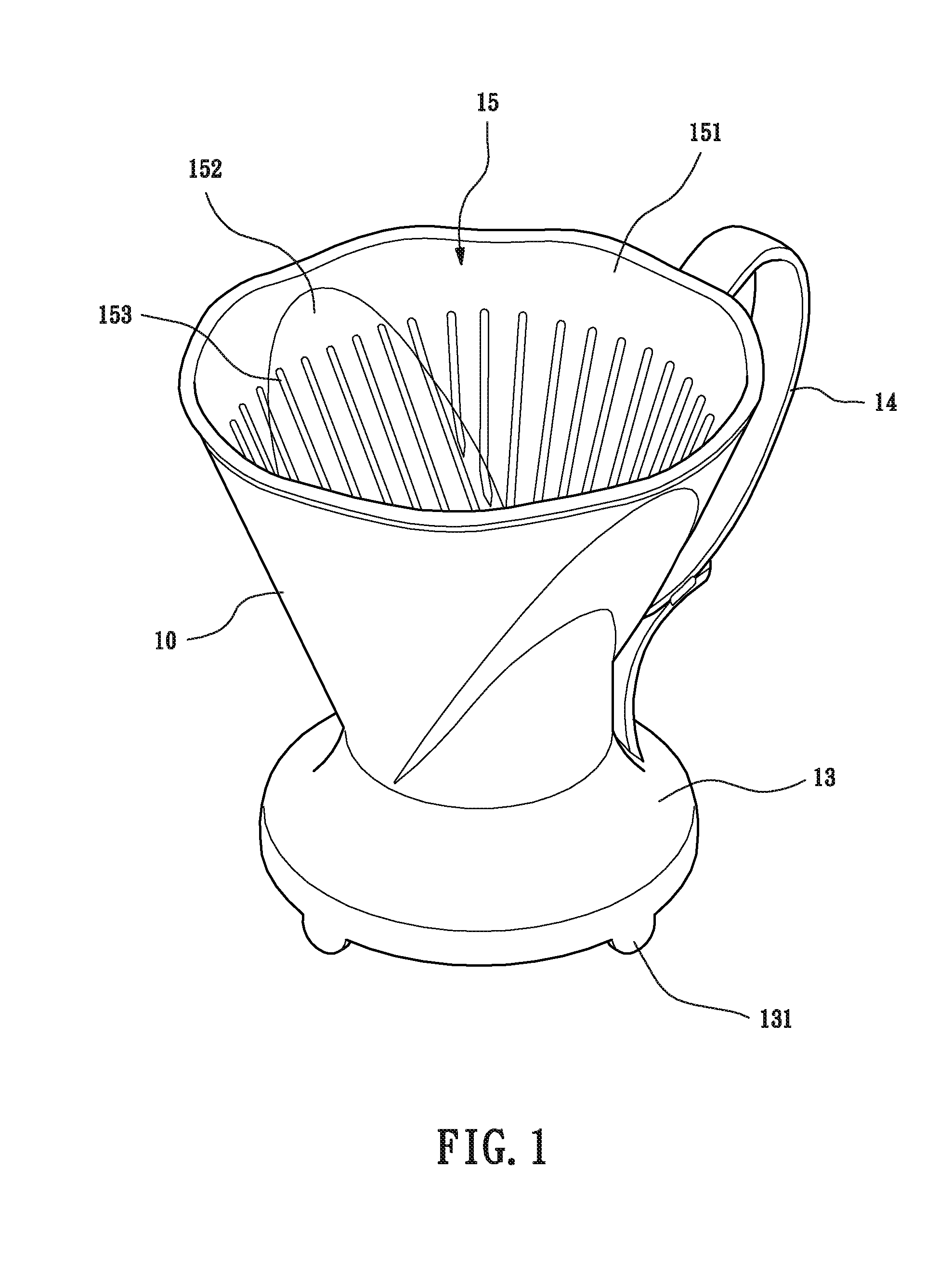

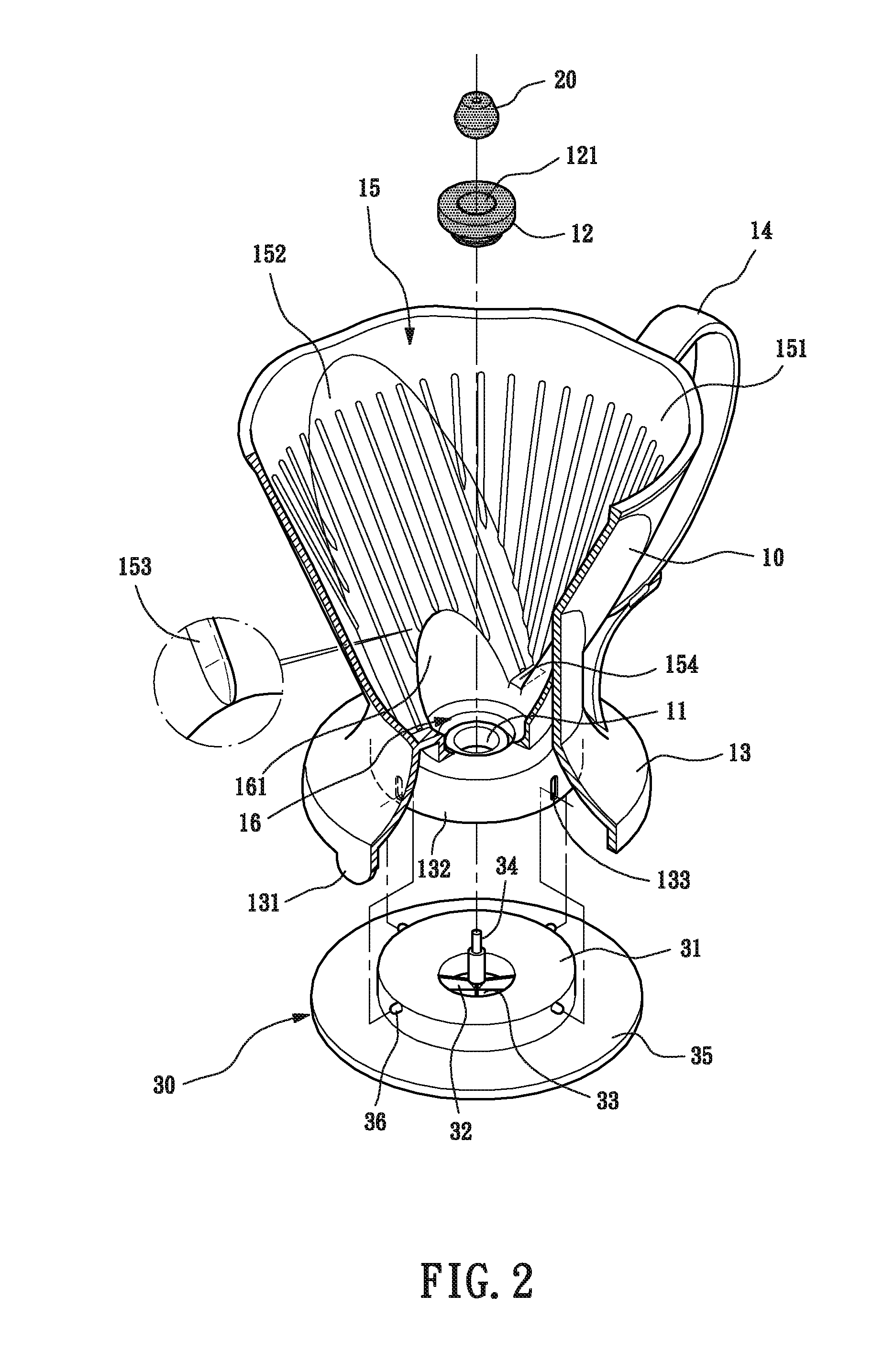

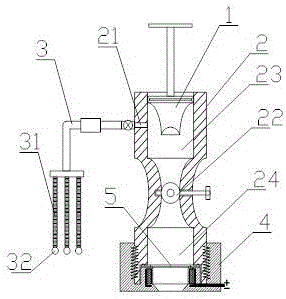

Coffee making kettle using venturi

Provided is a coffee making kettle using Venturi, including a kettle body having a bottom forming a through opening and defining a first chamber and a second chamber. The opening has an upper circumference from which two opposite inclined surfaces extend upward. Top edges of the inclined surfaces form a circular opening. The first chamber is located above the second chamber and is greater in volume than the second chamber. The second chamber is in communication with the through opening. When a paper filter that contains an object-to-be-brewed (such as coffee powders) is positioned in the kettle body and liquid (such as hot water) is added, the liquid is filtered by the paper filter and is guided by the inclined surfaces into the second chamber, so that the brewing liquid is subjected to the effect of Venturi to induce a pressure difference and increase of flowing speed.

Owner:TIEN JUNG JUNG

Binary composite cigarette filter stick

InactiveCN101171981AImprove adsorption capacitySimple manufacturing processTobacco smoke filtersFiberHazardous substance

The invention relates to a binary combined type cigarette filter tip rod manufactured in the technical field of the cigarette. The filter tip rod is characterized in that the monad adjacent to the tobacco shred in the binary comprises a filter core made by expanding and dying paper and molded package paper, and the monad adjacent to the sucking end comprises a filter core made of acetate fiber and the molded package paper. The expanding and dying paper is pure wood pulp or 50 to 95 percent of wood pulp mixed with 5 to 50 percent of complex fiber, and 1 to 12 percent of active carbon grain or paligorskite grian can be added into the expanding and dying paper filter core of the monad adjacent to the tobacco shred. The invention has the advantages that the wood pulp fiber is natural environmental protection material, the absorption affinity is high, the absorption to coke tar and other hazardous substances is favored, the wood pulp fiber is not required to be shredded during the manufacturing, no cellosolve and adhesive composition is added, the technology is simplified, at the same time, the prior normal equipment can be utilized, and the manufacturing cost is low.

Owner:梅建华

Application of humectant in cigarette paper filtering materials

ActiveCN101731757AImprove moisture balanceReduce drynessTobacco smoke filtersPulp and paper industryPaper filter

The invention relates to an application of a humectant in cigarette paper filtering materials, belonging to the technical field of cigarette preparation. A solution containing the humectant is coated or sprayed on the paper filtering materials, and then, the paper filtering materials are embossed, dried and split to form cigarette paper filtering bars. The invention has the advantage of simple method, can obviously reduce the paper taste, the pungency and the foreign taste of paper filtering material cigarettes, and can obviously improve the smoking taste of the cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

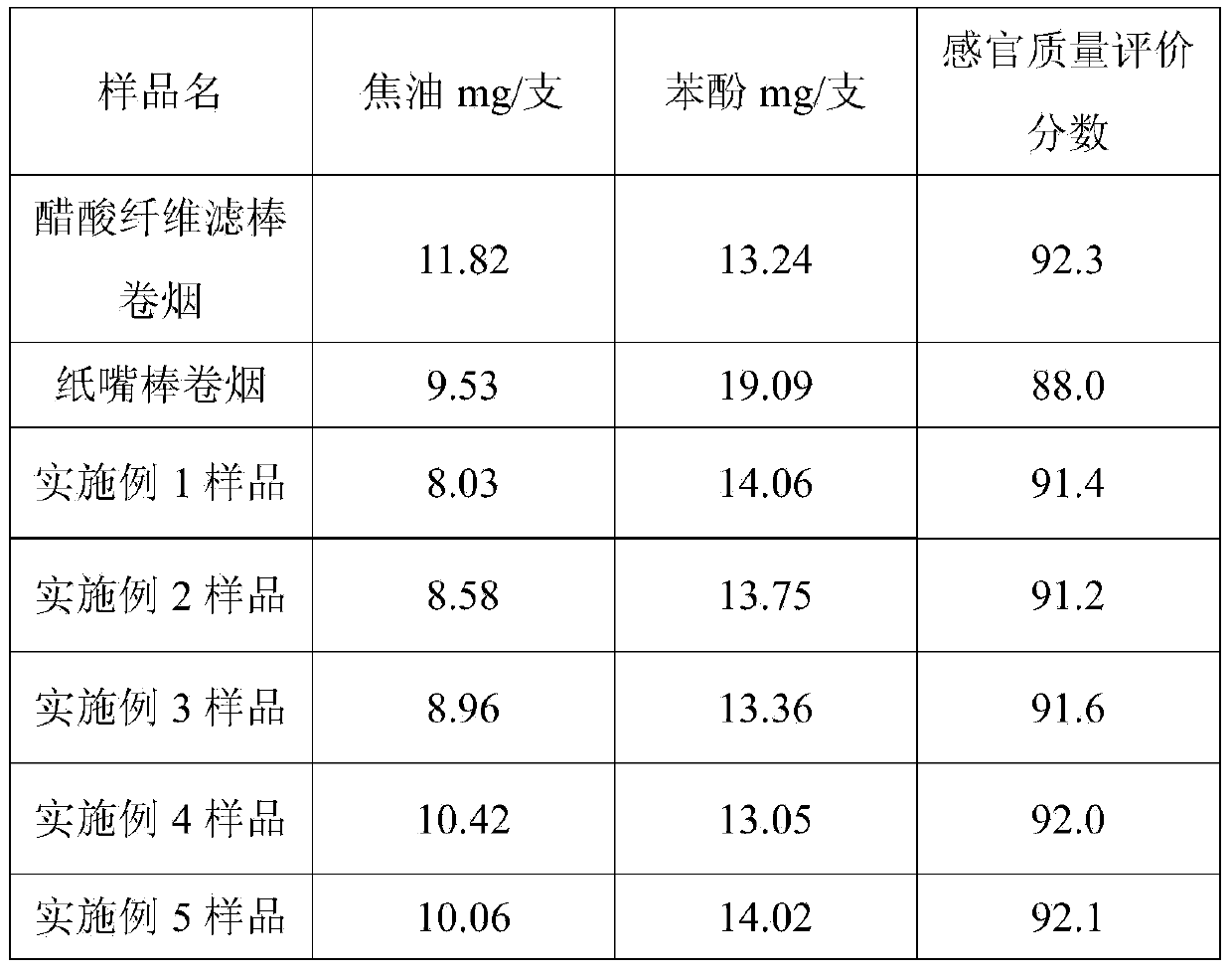

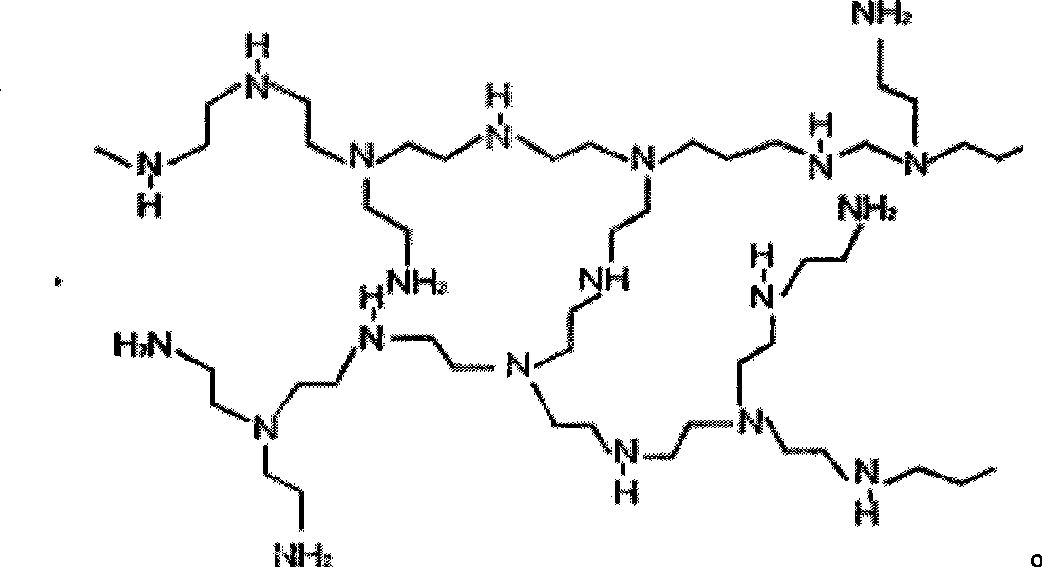

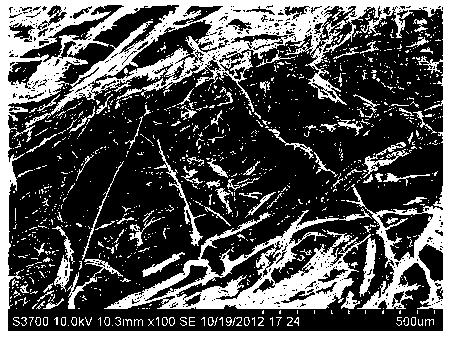

Method for preparing nanofiber membrane modified paper base material based on electrostatic spinning and application of nanofiber membrane modified paper base material

ActiveCN103625090AUniform thicknessSpecial pore structureSynthetic resin layered productsTobacco smoke filtersSolventPhenol

The invention discloses a method for preparing a nanofiber membrane modified paper base material based on electrostatic spinning and an application of the nanofiber membrane modified paper base material. The method for preparing the nanofiber membrane modified paper base material based on the electrostatic spinning comprises the following steps: after dissolving a polymer raw material into a solvent to prepare a spinning solution, putting the spinning solution into a liquid storage device; after adjusting the voltage of the electrostatic spinning, continuously feeding the spinning solution in the liquid storage device into a spinning head connected with the liquid storage device through a micro pump; and spraying the spinning solution by the spinning head to the surface of a raw paper base body which moves continuously to form a nanofiber membrane, thereby obtaining the nanofiber membrane modified paper base material. The preparation method is simple and can realize continuous industrial production; the prepared nanofiber membrane modified paper base material is applied to preparation of a cigarette paper filter stick which can be used for improving the smoking quality of cigarettes and effectively reducing tar and phenol releasing amount in main stream smoke of the cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

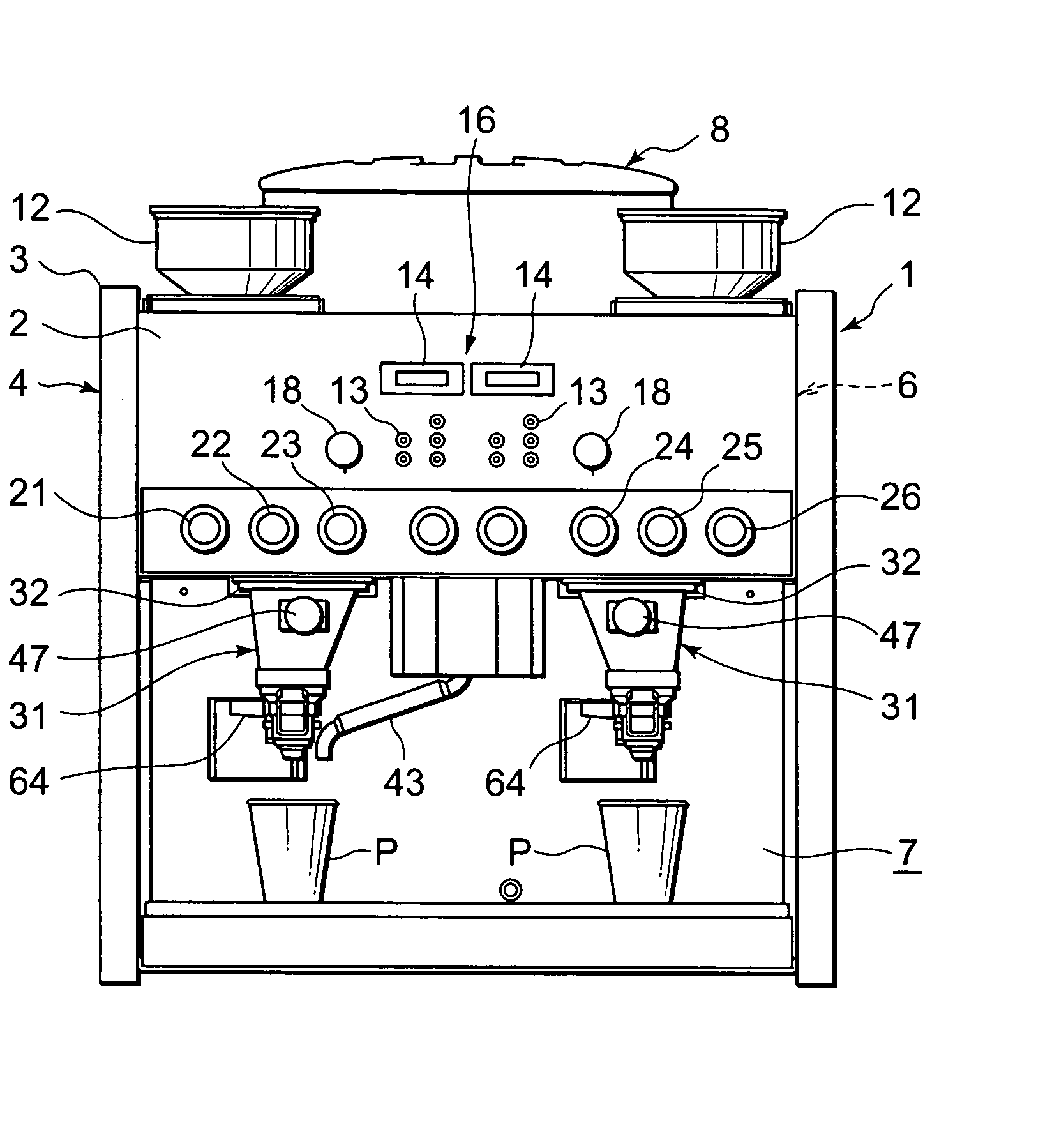

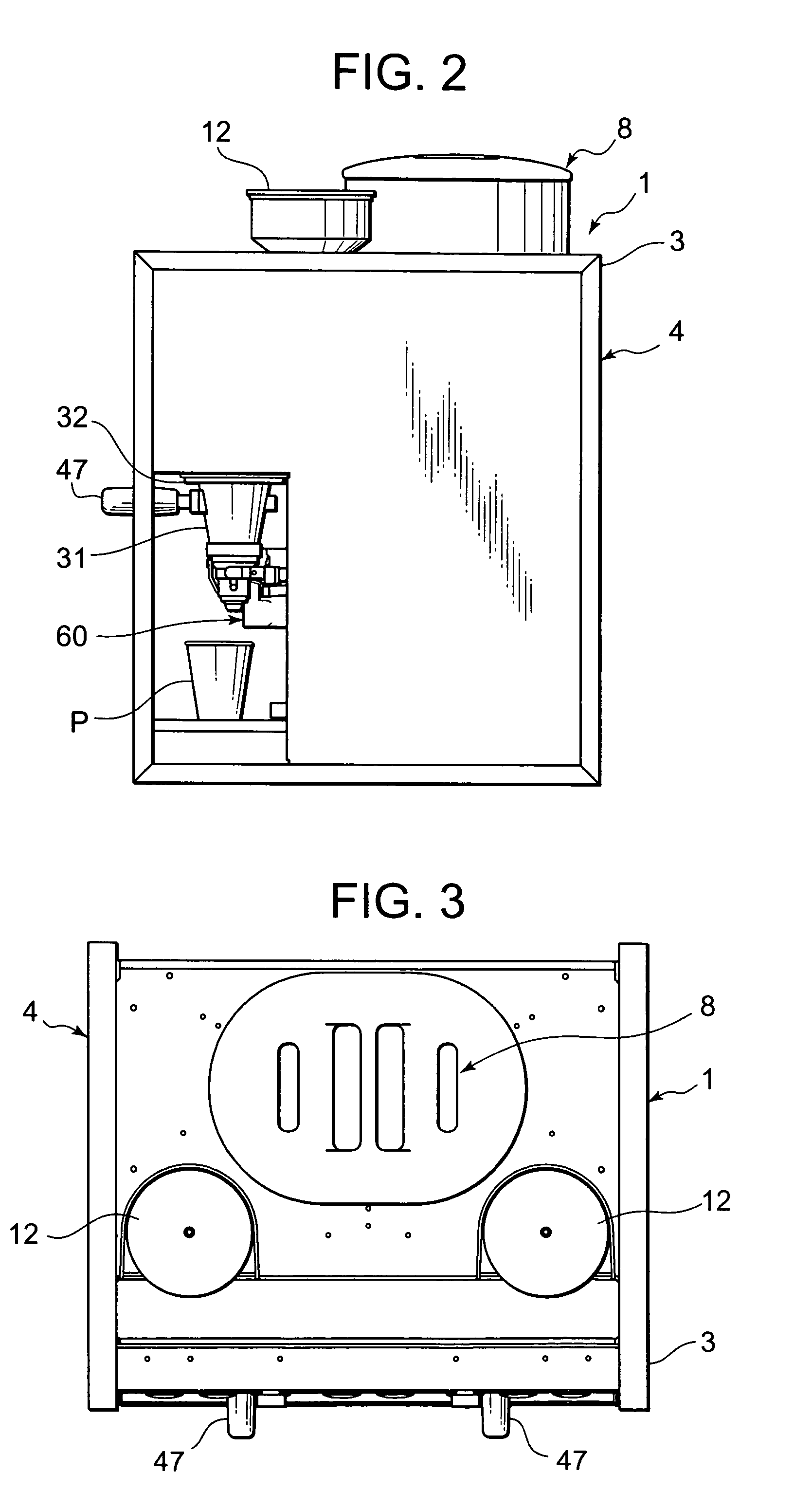

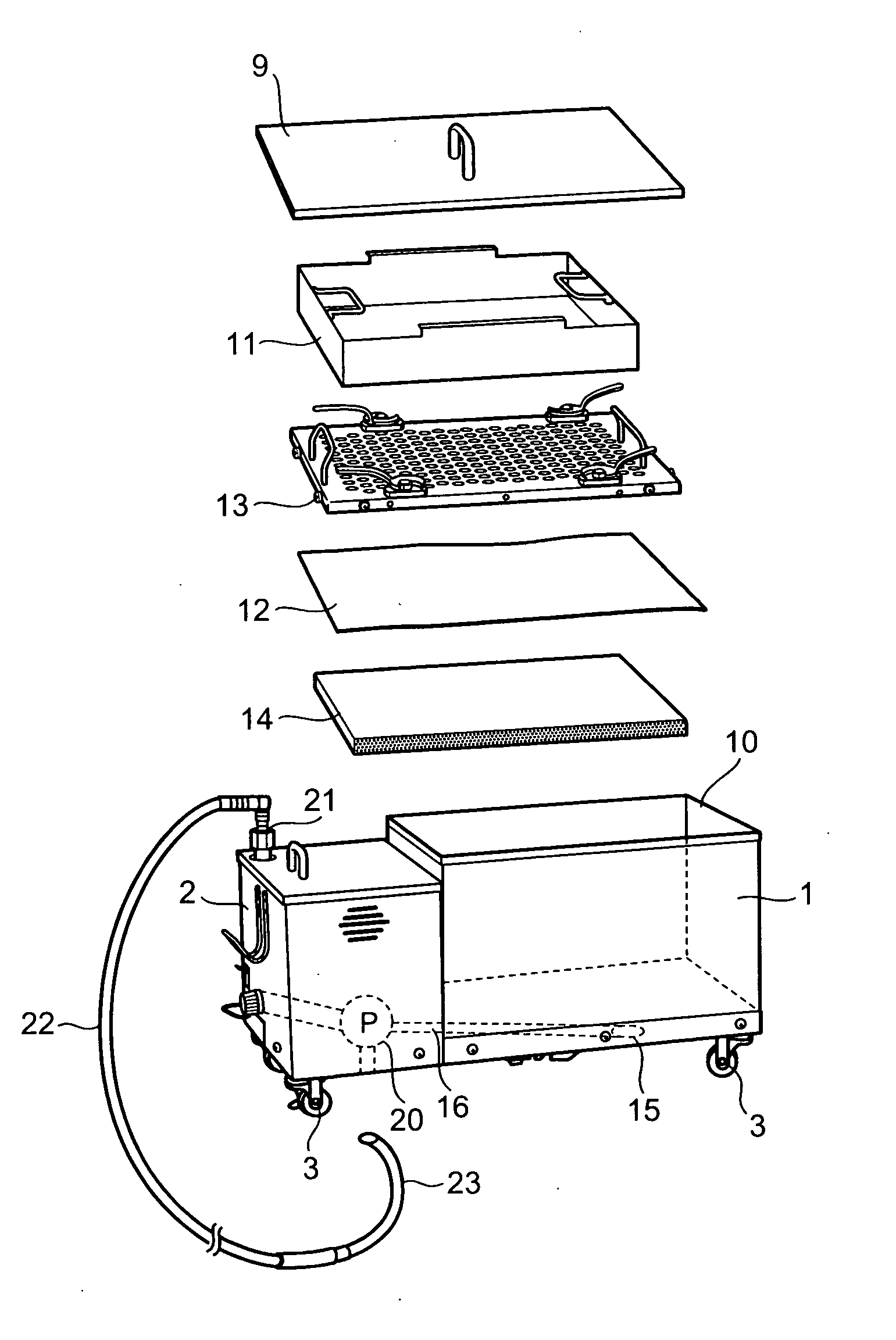

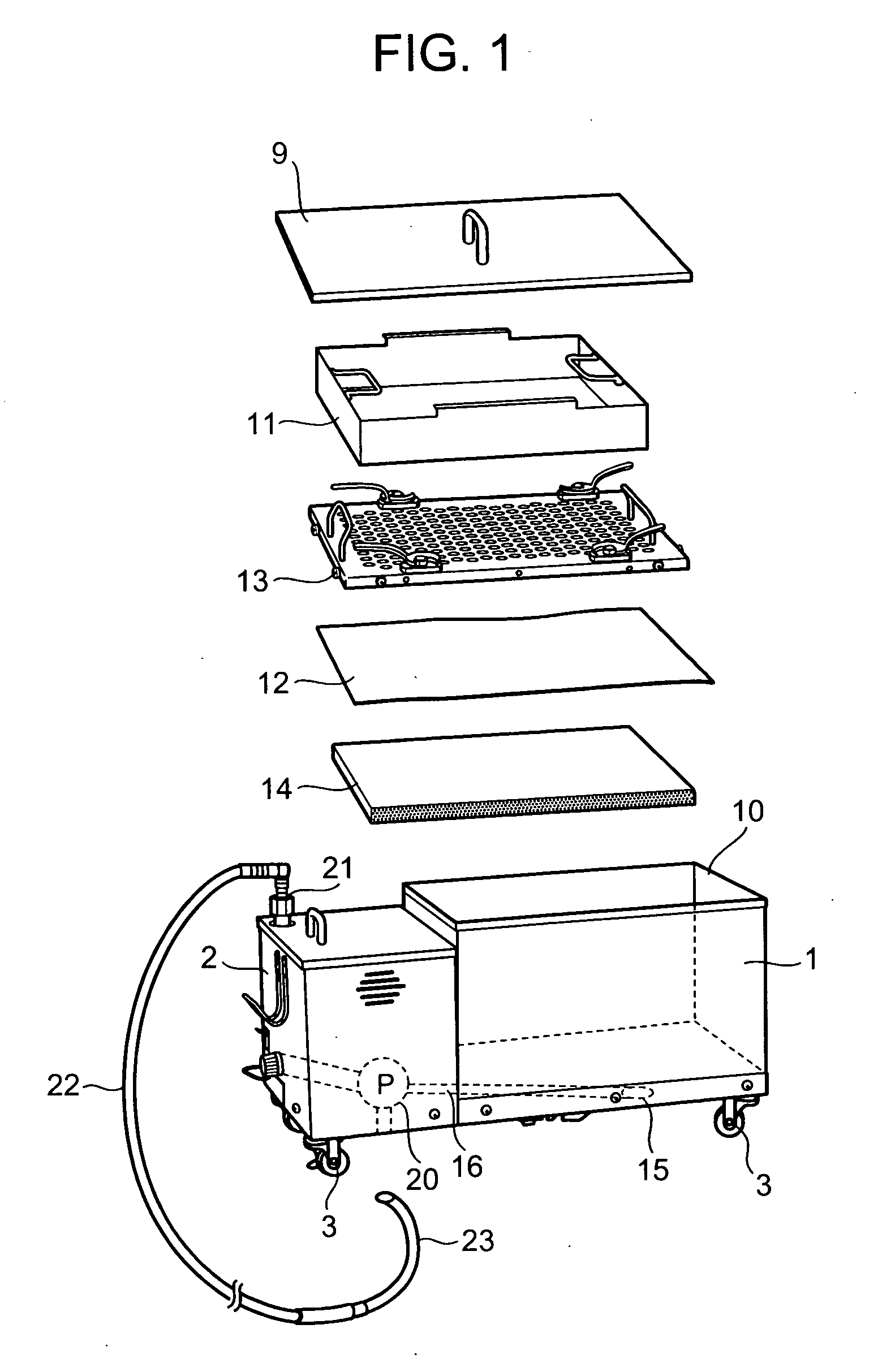

Beverage manufacturing apparatus

InactiveUS20050193890A1Quick serviceImprove versatilityTea extractionBeverage vesselsMicrocomputerManufactured apparatus

For a purpose of providing a beverage manufacturing apparatus capable of quickly serving high-quality tea beverage which suits user's palate and enhancing versatility, the beverage manufacturing apparatus comprises: a tea mill for crushing leaf tea to produce crushed leaf tea; a hot water tank unit for producing hot water; an extraction container for extracting tea beverage using the crushed leaf tea and the hot water; and a microcomputer for controlling supply of the crushed leaf tea from the tea mill to the extraction container and supply of the hot water from the hot water tank unit to the extraction container based on arbitrary setting, and the extraction unit is capable of being charged with a dripper and a paper filter.

Owner:SANYO ELECTRIC CO LTD

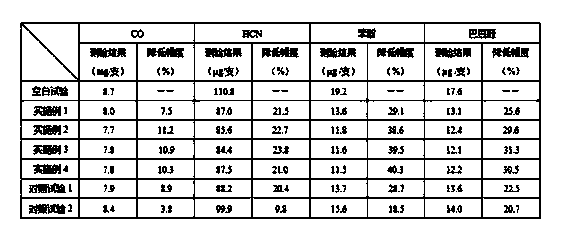

Cigarette filter tip added with chitosan-graphene oxide composite material

ActiveCN104389234AGood biocompatibilityGood dispersionCigarette manufacturePaper coatingOxide compositeKetone

Belonging to the technical field of cigarette filter tip production, the invention relates to a chitosan-graphene oxide composite material with efficient adsorption capacity on harmful ingredients of cigarette main stream smoke and a cigarette filter tip prepared from the material. The cigarette filter tip is prepared from the chitosan-graphene oxide composite material by a solution miscibility technique. Firstly the chitosan-graphene oxide composite material is prepared into a cigarette paper filter tip unit, and then the cigarette paper filter tip unit is prepared into a binary composite filter tip. Under the circumstance of a very small adding amount into the cigarette filter tip, the chitosan-graphene oxide composite material for cigarette filter tips provided by the invention can realize efficient adsorption of volatile aldehyde and ketone promoting molecules, phenol, HCN and the like. Also, the composite material is green, environment-friendly, and free of additional toxicity. At the same time, the preparation method has the characteristics of simplicity, easily available raw materials, easy scale production and low production cost. Thus, the cigarette filter tip added with the chitosan-graphene oxide composite material has broad application prospects in the harm and tar reduction field of cigarettes.

Owner:CHINA TOBACCO HENAN IND

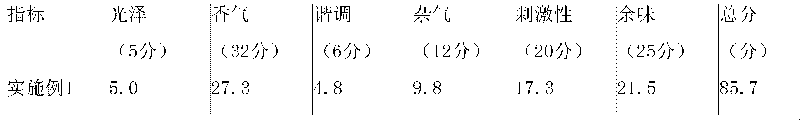

Preparation and application of cigarette paper filter material containing Chinese herbal components

ActiveCN101736654ALess irritatingReduce mistTobacco smoke filtersFiltration separationMedicineLicorice roots

The invention discloses preparation and application of cigarette paper filter material containing Chinese herbal components, which belongs to the technical field of cigarette preparation. The preparation and the application comprise: crushing one or more of common coltsfoot flowers, aster, fineleaf schizonepeta herbs, ballonflower, reed rhizome, Japanese ardisia herbs, sessile stemona roots, cynanchum stauntoni, mint, licorice roots and the like and then performing beating and papermaking on the obtained product together with wood pulp, cotton pulp or bamboo pulp for papermaking; or extracting raw materials through water or ethanol and then smearing or spraying extract on cigarette paper filter material; embossing and cutting the cigarette paper filter material; molding the obtained product to be cigarette filter rods; and preparing cigarettes from the filter rods separately or preparing the filter rods into composite filter rod rolls and then preparing the cigarettes. The method has the advantages of significantly reducing the irritation and mixed smell of the cigarettes with paper filter tips, improving the smoking odor of the cigarettes and improving the applicability of paper filter material in the cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Ternary tobacco fiber paper filter rod made from composite aroma-enhancing plants and preparation method of filter rod

The invention relates to the technical field of tobacco filter rods, and discloses a ternary tobacco fiber paper filter rod made from composite aroma-enhancing plants. The filter rod is composed of filter elements and forming paper wrapping the filter elements, the filter elements include two sections of tobacco fiber paper filter elements and a natural aromatic plant filter between the two sections of tobacco fiber paper filter elements, and the tobacco fiber paper filter elements are formed by rolling of paper fibers. The paper filter element has higher capabilities of removing tar and nicotine than an acetate fiber filter rod, raw materials are from tobacco or other natural plants, color, seen by consumers, of the filter rod is identical to that of cigarette tobacco shreds, strong natural tobacco material quality is provided, reasonable addition of the aroma-enhancing plants adds rich flavors to tar and harm reduced cigarette smoke, and a new research direction is guided to the technical field of the filter rods.

Owner:CHINA TOBACCO GUANGDONG IND

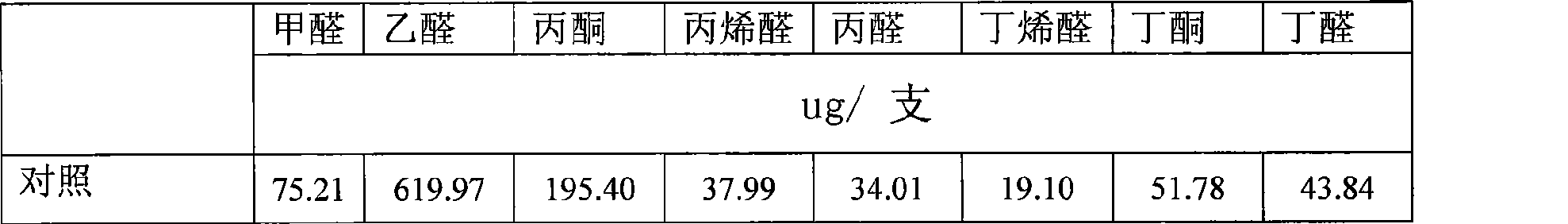

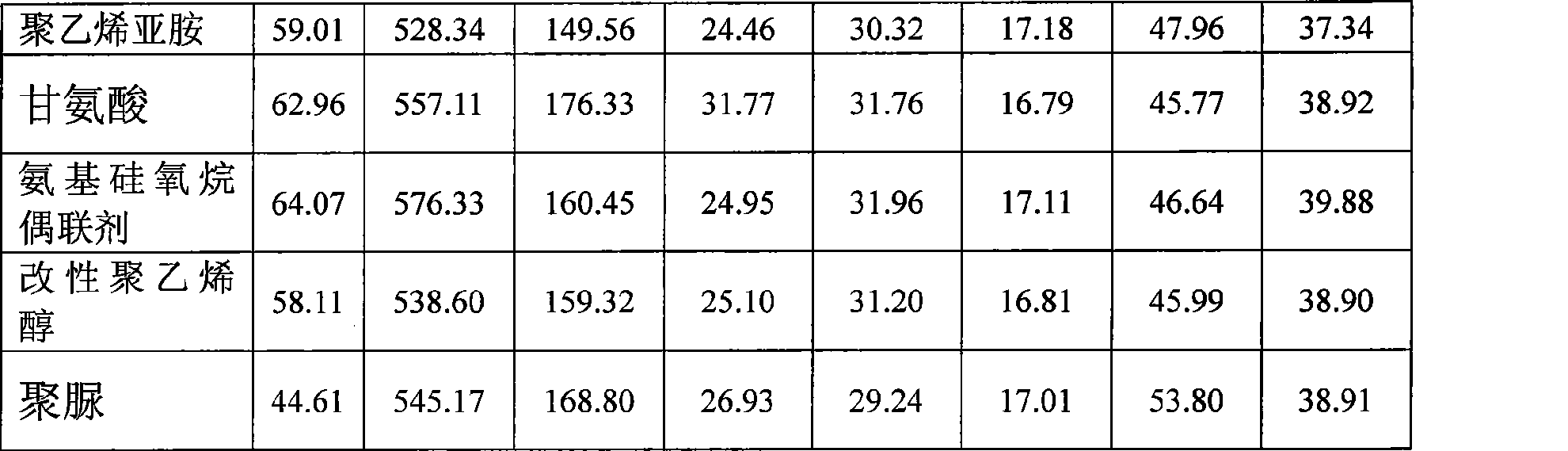

Papery filter tip for reducing aldehydes material in smoke of cigarette and preparation method thereof

The invention relates to a paper filter tip capable of reducing aldehydes in cigarette smoke gas and a preparation method thereof. The paper filter tip capable of reducing aldehydes in cigarette smoke gas adopts the paper containing one or a plurality of wood pulp fibers or jute pulp fibers. The paper undergoes a coating process. Through the high water absorption of the paper, compound solution containing amino groups are coated onto the paper; and after drying, cutting and embossing, the paper filter tip is prepared by the paper through a filter tip forming machine. The paper filter tip can effectively reduce formaldehyde by 15 to 40 percent, acetaldehyde by 10 to 25 percent, acrolein by 15 to 30 percent and crotonaldehyde by 10 to 20 percent in cigarette smoke gas.

Owner:CHINA TOBACCO HUNAN INDAL CORP

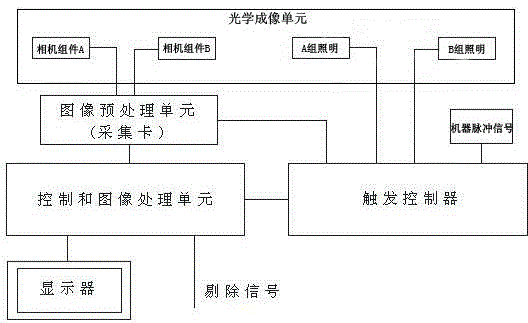

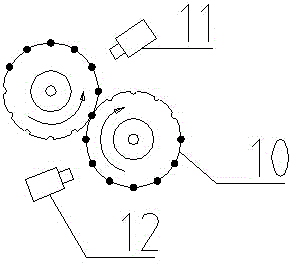

Machine-vision-based visual cigarette appearance inspection device of cigarette making machine

The invention discloses a machine-vision-based visual cigarette appearance inspection device of a cigarette making machine. The machine-vision-based visual cigarette appearance inspection device comprises an optical image-forming unit, an image pre-processing unit, a control and image analyzing unit and a trigger signal unit, wherein the optical image-forming unit comprises a camera component A and a camera component B which are respectively positioned on the two side surfaces of a transmission drum wheel of the cigarette making machine; the image pre-processing unit comprises a PCI image acquisition card with a CAMLINK interface; the control and image analyzing unit mainly comprises an industrial computer; the trigger signal unit mainly comprises FPGAs; the optical image-forming unit, the image pre-processing unit, and the control and image analyzing are connected one by one; and the trigger signal unit is simultaneously connected to the optical image-forming unit, the image pre-processing unit, and the control and image analyzing unit. Cigarette images acquired by the device include images of a tipping paper filter tip part, so that complete finished product cigarettes can be inspected.

Owner:云南远足科技有限公司

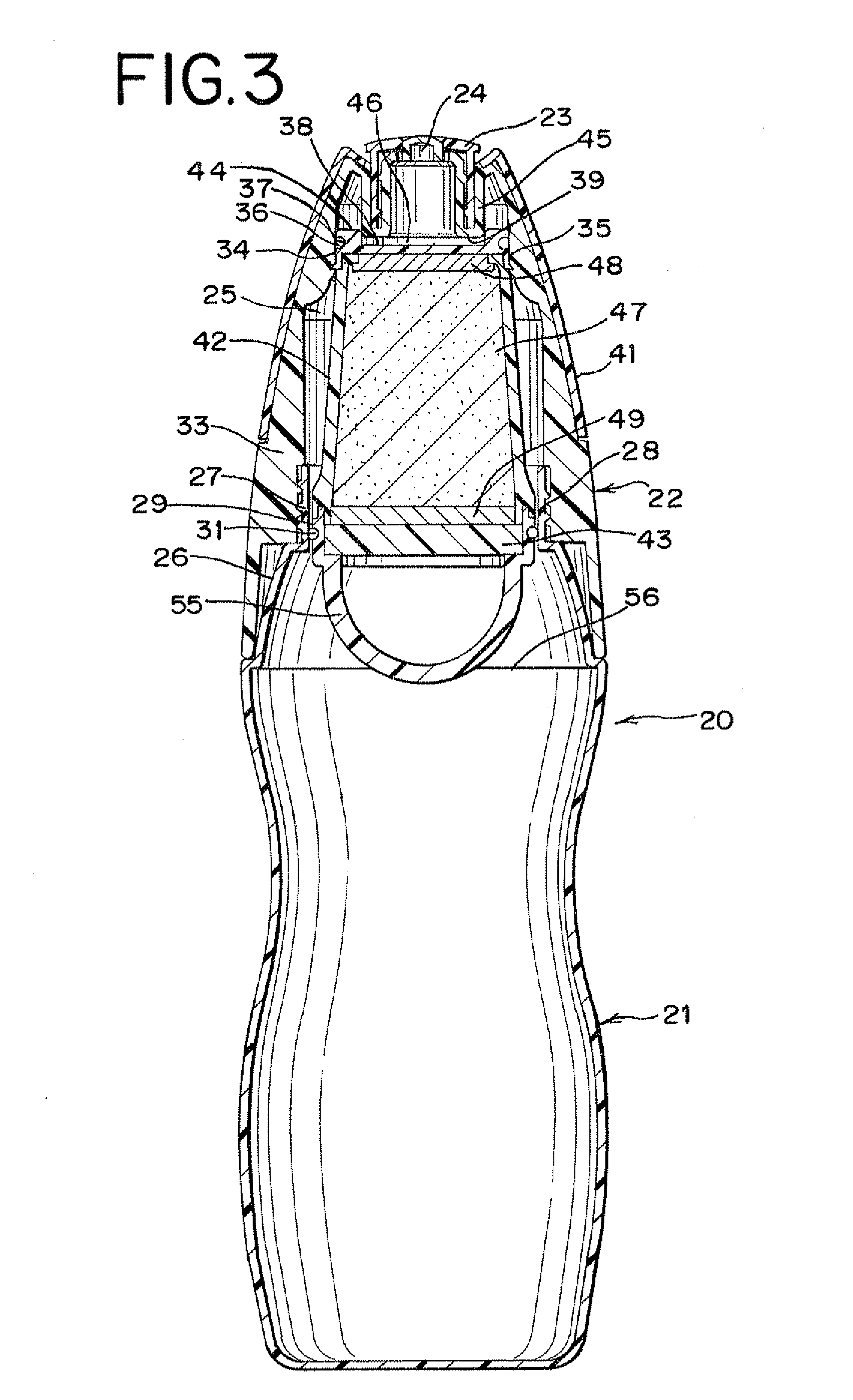

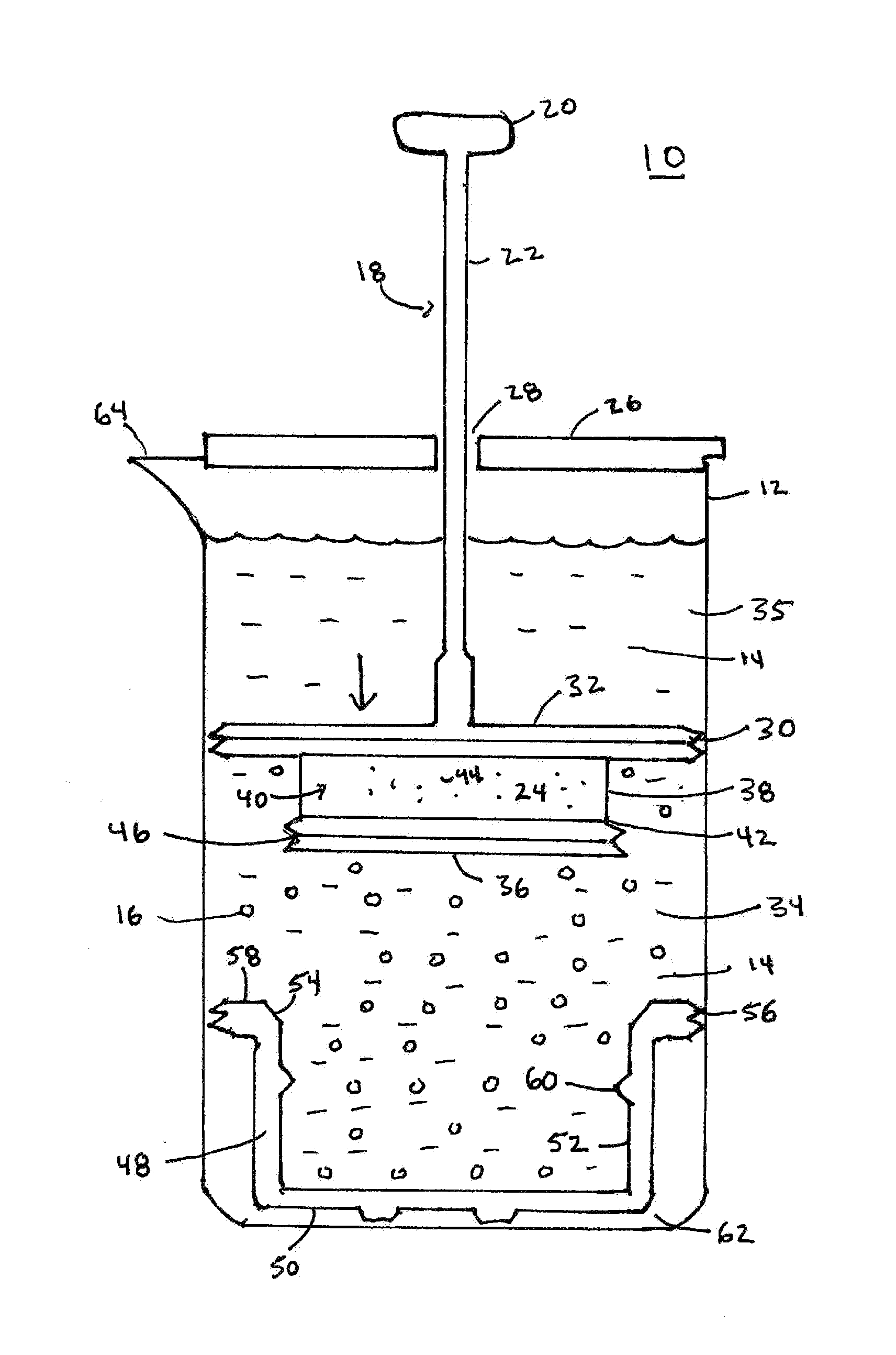

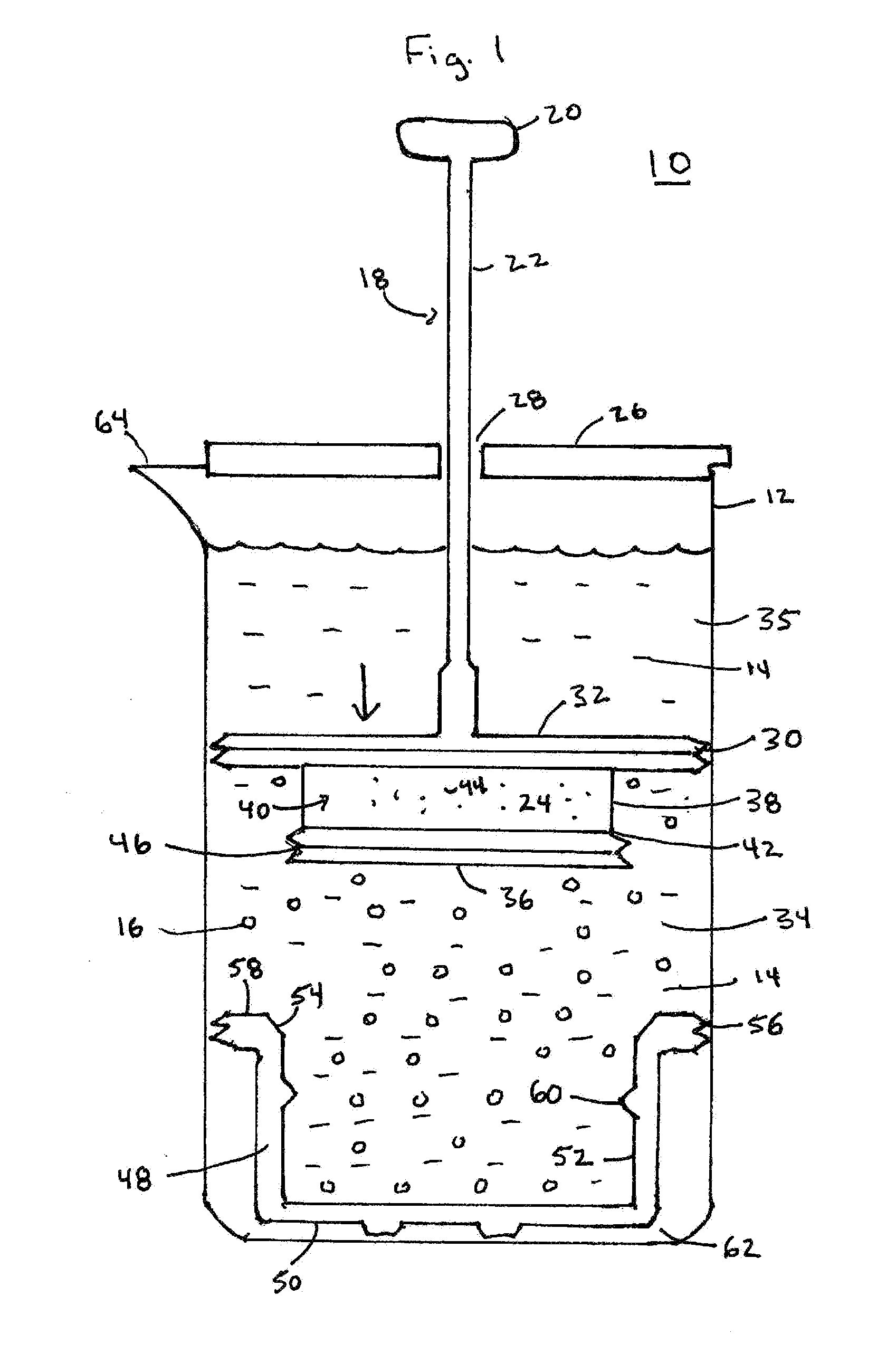

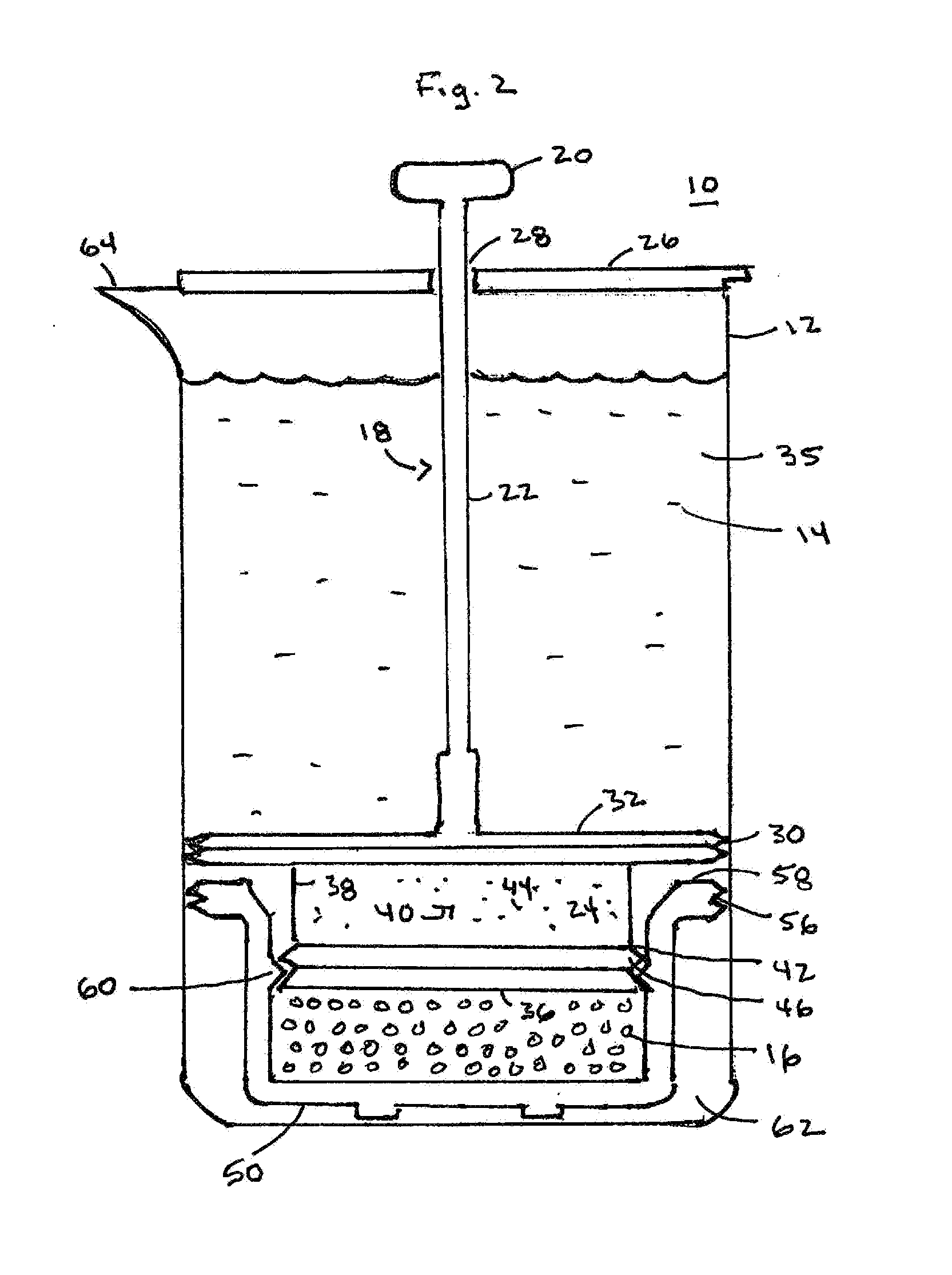

Infusion extracting apparatus and method

ActiveUS20150196158A1Easy extractionEasy to insertBeverage vesselsDomestic vesselsFiltrationEngineering

A piston-type extraction apparatus and methods for making and using the same are disclosed. The apparatus includes a cylindrical container with lid and pour spout, a container insert, and plunger element including piston, rod, handle, and filtration chamber. The container insert is designed to catch coffee grounds or other infusible material which may be easily removed from the container when the container is empty or when the extract fluid remains in the container. The filtration chamber is adapted for use with a paper filter. The plunger element may temporarily couple with the insert to allow the insert to be pulled up through the container with the grounds of other infusible material captured between the insert and the plunger element allowing for quick and easy cleanup. The extraction apparatus is adapted for a use in a variety of sizes and may be adapted for manufactured at low cost.

Owner:MADE SIMPLI

Ternary tobacco fiber paper filter stick of composite moistening plants and preparation method thereof

ActiveCN103054189AImprove adsorption capacityPromote absorptionCigarette manufactureTobacco smoke filtersFiberCellulose acetate

The invention relates to the technical field of tobacco filter sticks and discloses a ternary tobacco fiber paper filter stick of composite moistening plants. The ternary tobacco fiber paper filter stick is composed of a filter element and a molding paper wrapped on the filter element, the filter element comprises two sections of tobacco fiber paper filter elements and a moistening plant filter element arranged between the two sections of tobacco fiber paper filter elements, the tobacco fiber paper filter element is reeled by paper fibers, and the moistening plant filter element is pressed by throat moistening plant particle. The ternary tobacco fiber paper filter stick is based on wet-method papermaking and enables tobacco fiber slurry and long fiber slurry to be mixed according to appropriate proportion in a papermaking slurry mixing stage, and the prepared paper filter stick has stronger tar and nicotine removal capability than cellulose acetate fibers, does not bring in miscellaneous gas, wet whistles and returns sweet. Raw material resources are natural plants, the ternary tobacco fiber paper filter stick has no paper or chemical fiber taste, the color of the ternary tobacco fiber paper filter stick is same with that of cigarette scraps, the ternary tobacco fiber paper filter stick has strong natural material texture of tobaccos, and guides a new research direction for the technical field of cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND

Preparation method of natural plant carbonated material and application thereof to cigarette filter rod

ActiveCN101757891AImprove permeabilityImprove filtering effectOther chemical processesTobacco smoke filtersCarbonizationEngineering

The invention discloses a preparation method of a natural plant carbonated material and application thereof to a cigarette filter rod. The carbonated material is obtained by pretreating a natural plant raw material and then carrying out carbonization treatment. The application of the natural plant carbonated material is realized by the following steps: adjusting the water content of granulate carbonated material the grain diameter of which is 20-60 meshes to the water content of 6-8 percent; then evenly spreading the carbonated material on a filter rod tow; processing the carbonated material into a cigarette filter rod by using cigarette filter rod forming equipment; or crushing the carbonated material to a powdery carbonated material with less than 100 meshes; evenly coating the powdery carbonated material on paper filter rod core paper on which a paper filter rod can be coated or evenly spreading the powdery carbonated material on the paper filter rod core paper or corrugated filter rod paper for cigarettes; and processing the powdery carbonated material into the cigarette filter rod by using the cigarette filter rod forming equipment. The invention can be used for applying the carbonated material taking a natural plant as the resource to the cigarette filter rod, can effectively reduce harmful components in smoke gas of the cigarettes and cannot influence the smoking quality and the style character of Chinese cigarette products.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Cleaning and sterilizing apparatus combined with an ultra-violet lamp

InactiveCN101026987APrevent fallingPrevent falling and stackingSuction filtersCarpet cleanersImpellerGrating

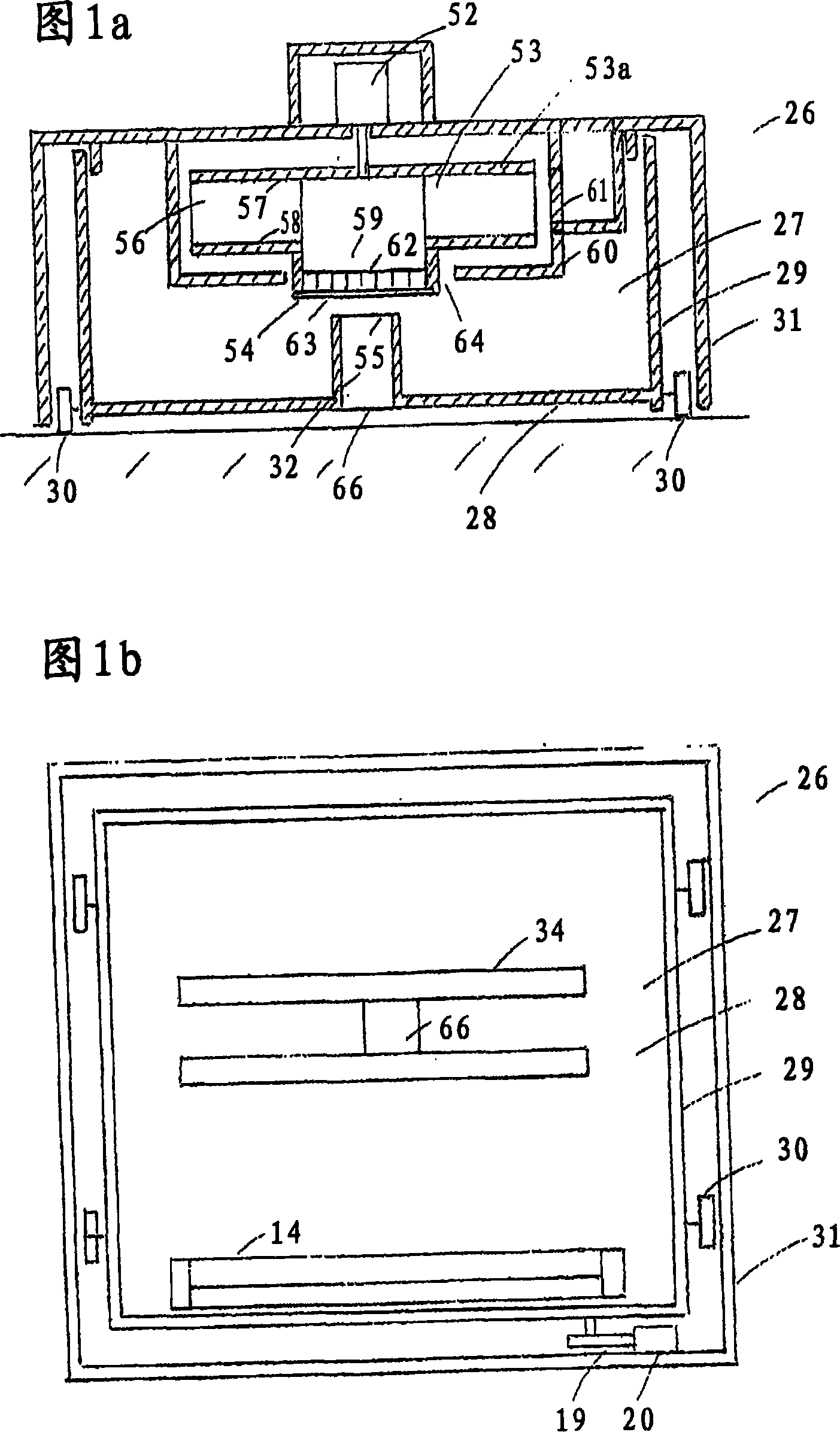

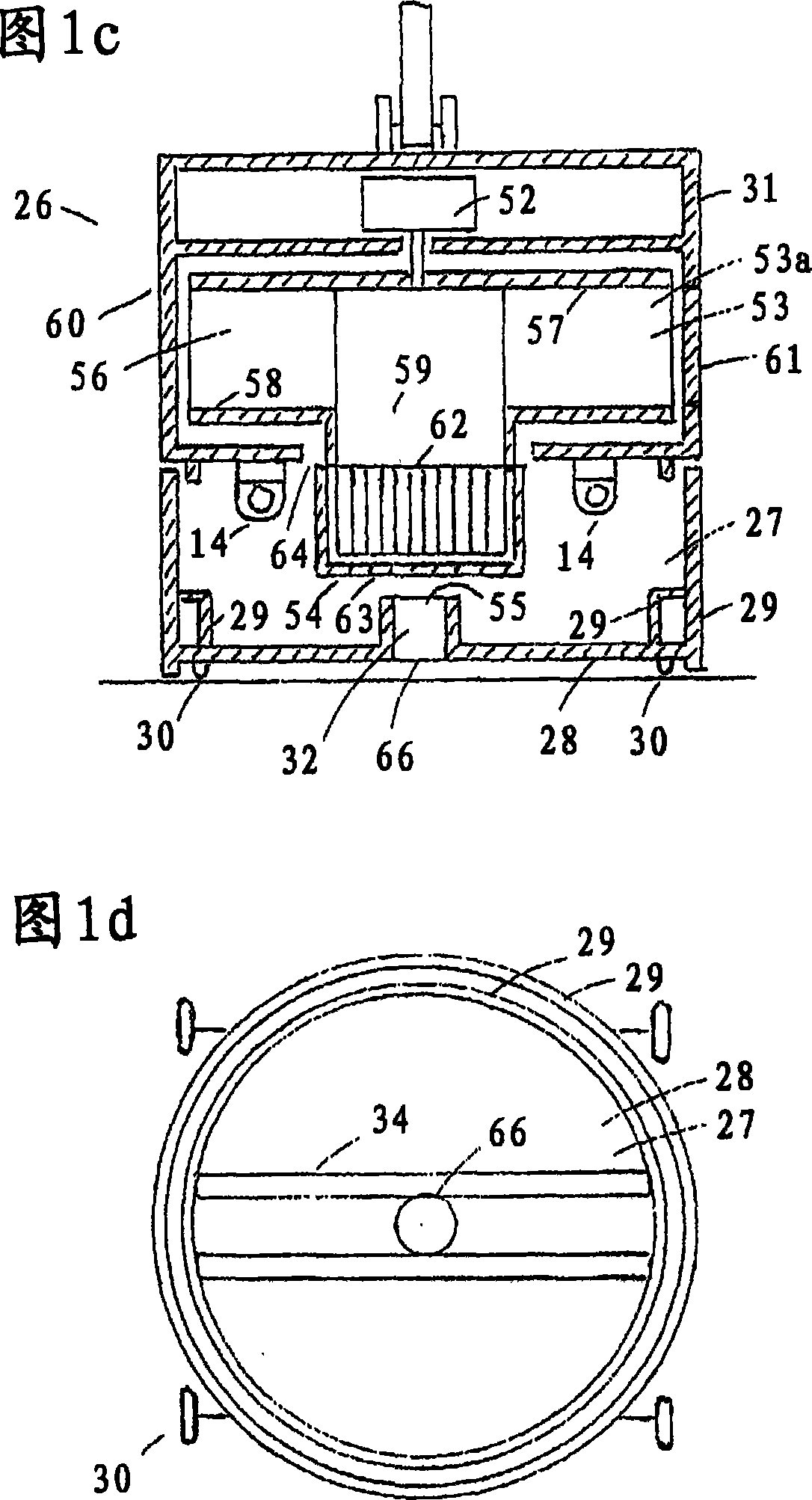

A cleaning or sterilizing apparatus combined with UV lamp consisting of an upright compact vacuum cleaner (26) comprising a dust container (27) with a transparent bottom (28) and a suction nozzle (34) incorporated in the bottom (28) and a protective housing (31) which covers the dust container (27) and which incorporates a fan (53) with a centrifugal dust filter (54) and UV germicidal lamp fixture (14) for destroying micro-organisms on cleaning surface and inside the dust container (27). The dust filter (54), which consists of a cylindrical grating (62) with or without a cylindrical paper filter (63), is mounted to the cylindrical opening (59) of the fan's impeller (53a) and located partly outside of the fan's casing (60) but inside the dust container (27). Rotating at high speed, the fan's impeller (53a) sucks in the air through the dust filter (54), which throws of dust particles outward toward the space inside the dust container (27) preventing clogging, separating particles from the air and obtaining purification of the air.

Owner:德拉高尔尤伯·佩鲁尼希克

Paper and filter stick of paper filter stick for reducing phenols material in cigarette smoke and preparing method thereof

InactiveCN101408012AOvercoming thermal collapseOvercome the dryness of smokeTobacco smoke filtersSynthetic cellulose/non-cellulose material pulp/paperFiberPhenol

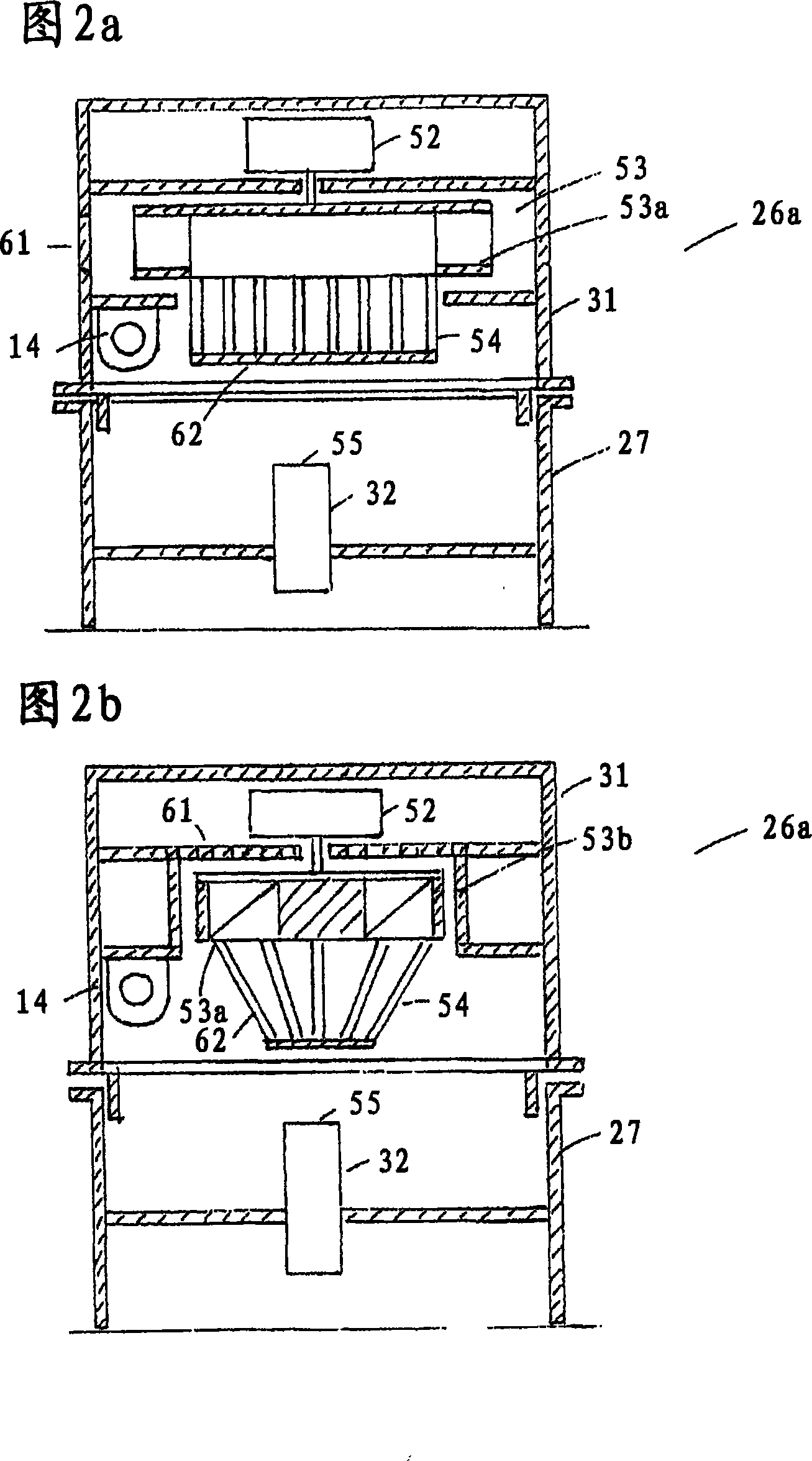

The invention relates to paper and paper filter sticks containing secondary acetate functionalized by amine compounds, and a preparation method thereof, belonging to the preparation technical field of cigarette filter sticks. The weight content of the secondary acetate functionalized by amine compounds in the paper filter stick is 10 to 60 percent, and the rest is one or a plurality of wood pulp fiber or jute pulp fiber. The invention has the advantages that: the cigarette-used paper filter stick containing the secondary acetate functionalized by amine compounds overcomes the defects that the adoption of pure plant fiber paper filter sticks causes the dry feeling of the smoke and the estimation reduction of aesthetic quality, and under the condition of keeping the estimation of the cigarette aesthetic quality to be basically unchanged, the amount of tar can be reduced to 3 to 5mg per unit, and the removing rate of phenol, pyrocatechol, hydroxyphenol, hydroquinone and paracresol reaches the best, which respectively reaches 36.04 percent, 18.03 percent, 36.81 percent, 22.04 percent and 29.83 percent.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Coffee paper filters and method of use

InactiveUS20060021930A1Avoid layeringPrecise alignmentBeverage vesselsMachines/enginesPaper filterGround coffee

A pack of coffee paper filters to enable consumers to use freshly ground coffee beans to brew coffee in coffeemakers designed to use pre-packaged coffee pods comprises a stack of pan-shaped paper filters having a rim and a chamber adapted to receive various amounts of coffee beans to achieve the desired brew strength, a stack of overflow prevention sheets having a plurality of overflow stoppers connected to the sheet by bridges, and a container having a chamber to position the stack of pan-shaped filters, a guide chamber for guiding and aligning a seal presser with the rim of the pan-shaped filter and a seal platform for supporting the rim. The overflow stopper has a water permeable center portion, a sufficiently soft rim larger than rim of the pan-shaped filter and an adhesive ring at the rim on the rim. Another aspect of the invention is a method of using the pack of coffee filters to make a pod directly in the holder of the coffeemaker during a brewing process, which includes placing a pan-shaped filter into the holder, adding to the pan-shaped filter a desired amount of freshly ground coffee beans for a desired coffee strength, placing an overflow stopper into the holder, closing the brew head of the coffeemaker to cause the overflow stopper to seal to the pan-shaped filter to form the pod.

Owner:CAI EDWARD Z +1

Filter apparatus and count method for counting porphyra spores

PendingCN106644663ASuck out easilyReduce the number of calculationsInvestigation of vegetal materialPreparing sample for investigationSporeWater storage

The invention relates to a filter apparatus and a count method for counting porphyra spores. The apparatus comprises a piston rod and a piston cylinder, wherein the piston rod enters the piston cylinder from one end of the piston cylinder and is arranged in the piston cylinder in a reciprocating manner, a water inlet hole is formed in the upper side wall of the piston cylinder, the water inlet hole is communicated with a sampling tube by virtue of an electromagnetic valve, and the sampling tube is internally and serially connected with a water pump; the middle portion of the piston cylinder is converged, a manual valve is arranged at a converged position, the piston cylinder forms a water storage cavity at the upper portion of the manual valve and forms a paper filter cavity at the lower portion of the manual valve; and a lower opening of the paper filter cavity, i.e. an opening of the piston cylinder is connected with a pressure block with a filter water outlet in the middle portion, the pressure block presses a piece of filter paper at the opening of the paper filter cavity, the filter paper is white, and pores of the filter paper are smaller than porphyra spores. Sample spore fluid with sufficient water is filtered by the filter paper, so that the spores are intercepted on the filter paper, the number of the spores on the filter paper is observed by a microscope, and then the spore concentration in an entire culture pond is then calculated.

Owner:INST OF OCEANOLOGY & MARINE FISHERIES JIANGSU

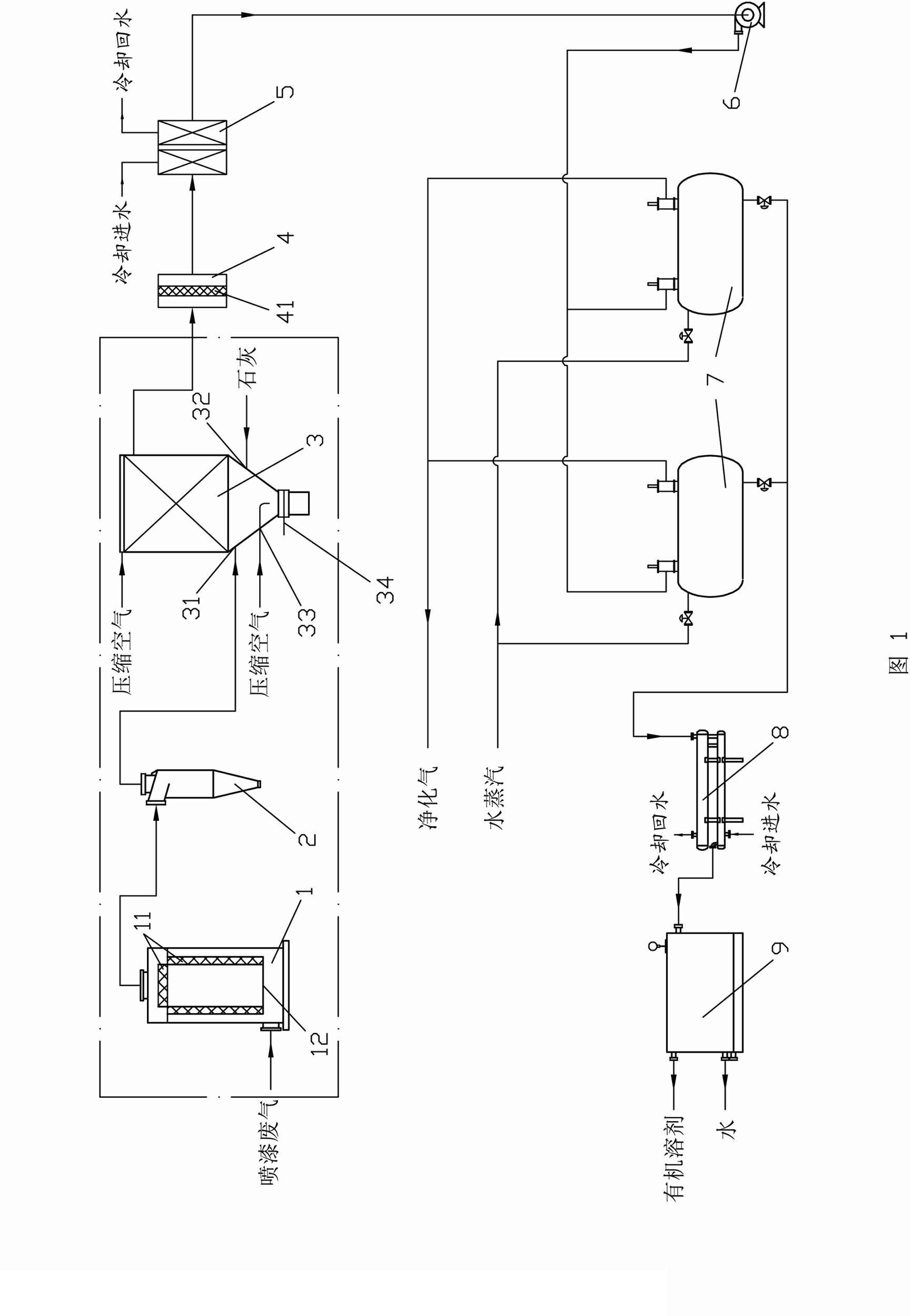

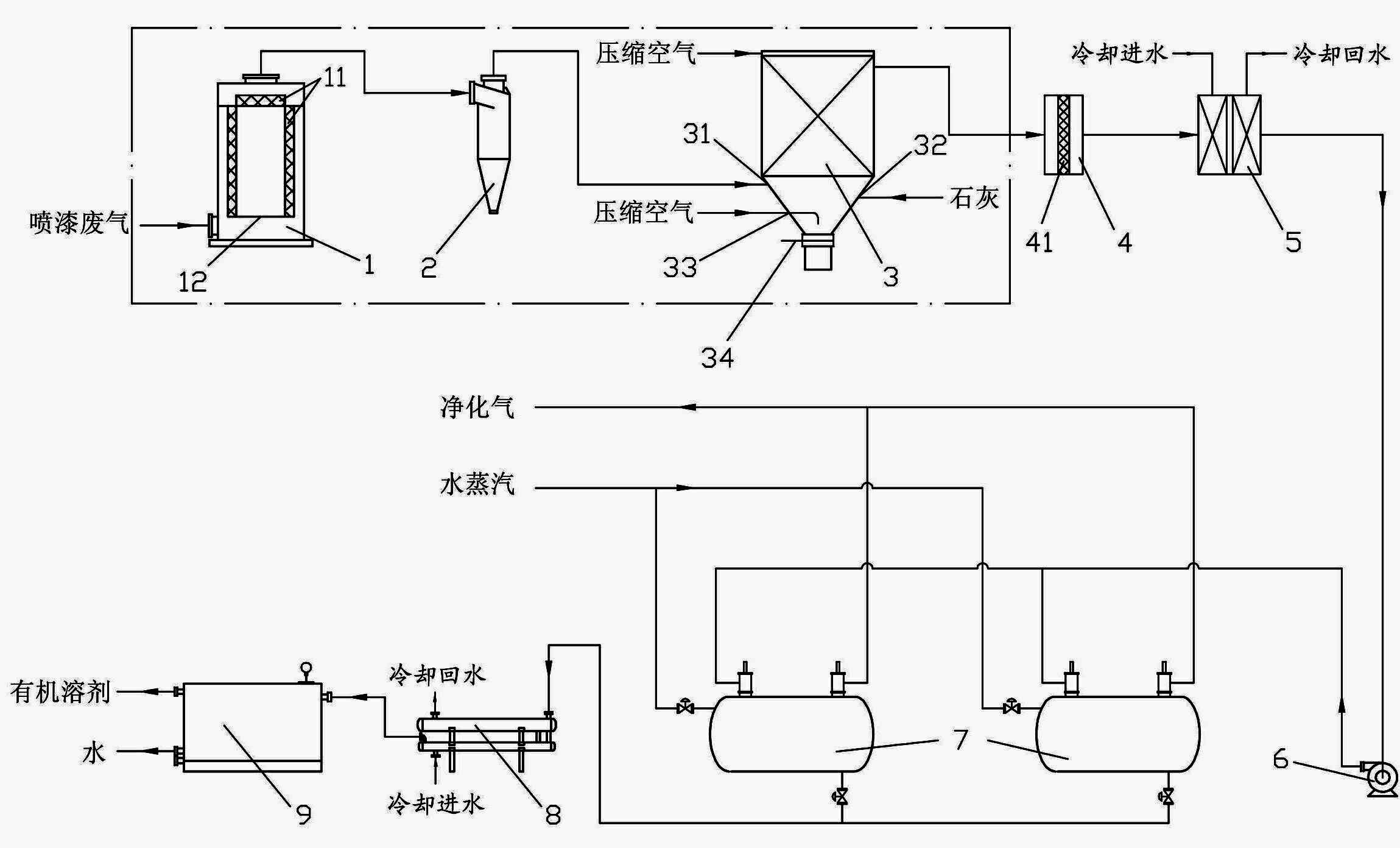

Purifying device for paint spraying organic waste gas and solvent recovering method thereof

ActiveCN102614731AHigh recovery purityNot pollutedCombination devicesVapor condensationActivated carbonOrganic solvent

The invention discloses a purifying device for paint spraying organic waste gas. The purifying device comprises a paint mist removing device, an oil stain filter, a cooler, a fan, a purifying tank, a condenser and an oil-water separator connected in sequence, wherein the paint mist removing device comprises a paper filter, a cyclone dust collector and a bag-type dust collector; the inlet of the paper filter is connected with an organic solvent waste gas pipe of a paint room; the outlet of the paper filter is connected with the inlet of the cyclone dust collector; the outlet of the cyclone dust collector is connected with the inlet of the bag-type dust collector; and the outlet of the bag-type dust collector is connected the oil stain filter. Due to the adoption of the device, the paint mist removing capability is greatly improved, active carbon is prevented from being polluted, and the recovering purity of an organic solvent is increased simultaneously. The invention further discloses a method for recovering an organic solvent by using the purifying device. The method comprises the following steps of: removing paint mist and oil stains; cooling and absorbing organic solvent waste gas; desorbing with water steam; condensing; and separating oil and water, wherein in the step for removing the paint mist, paint mist is effectively removed after being turned into paint powder; and the process of the method is reasonable, and contributes to saving energy and labor sources.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

Cool additive for mint type cigarettes, preparation thereof and application thereof

The invention relates to a cool additive for mint type cigarettes, preparation thereof and application thereof, which belong to the technical field of cigarette preparation. The cool additive is obtained by dissolving and refluxing menthol and soluble calcium salt together, then adding alkali solution into the mixture, settling and standing the solution, filtering and washing the sediment and drying the sediment in vacuum. The cool additive serving as a filter is added in the preparation of cigarette paper and paper filter materials for the cigarettes, or coated to the cigarette paper, filter stick forming paper or paper filter materials for the cigarettes, or added to shreds of cigarette filter sticks. The method adopted by the invention is simple and has low cost; and the prepared cool additive is applied to the cigarette accessory so as to avoid the pollution to the cigarette production line. The cool additive prepared by the method is applied to the cigarette paper filter material, the produced cigarettes have no impurity gas and peculiar smell, and the smoking taste of the paper filter tip cigarettes can be obviously improved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

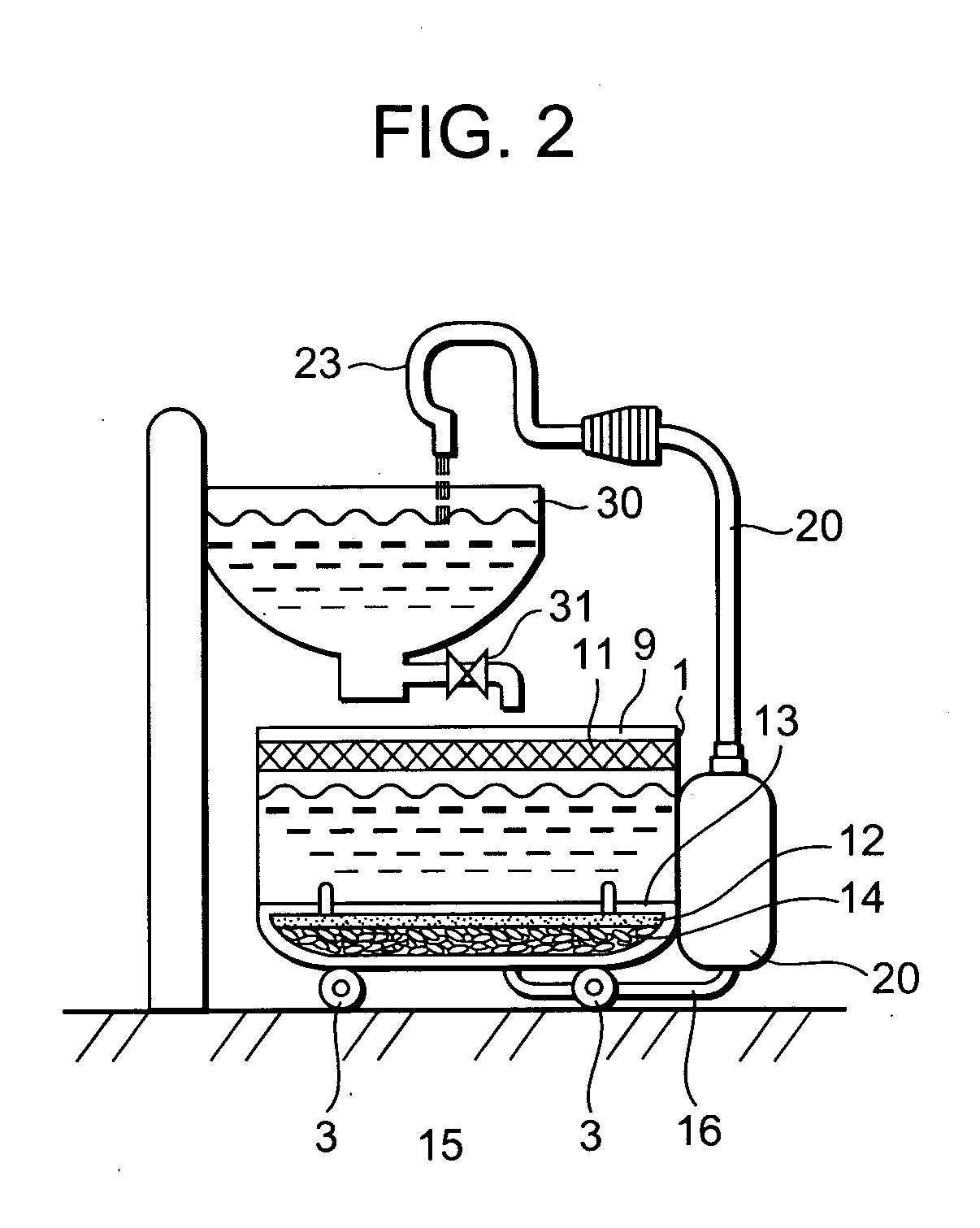

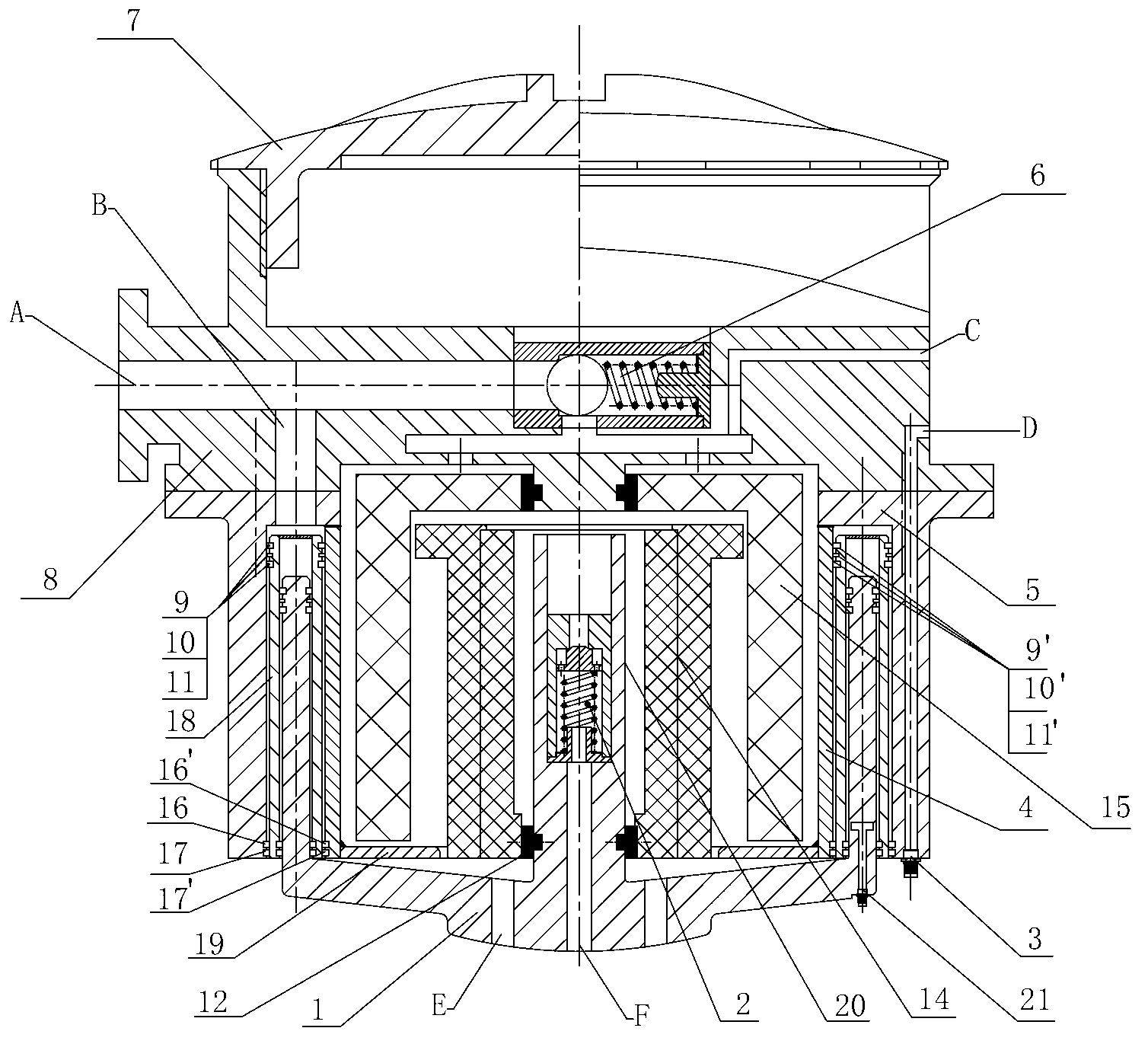

Method for purifying cooking oil and cooking oil filter apparatus

InactiveUS20050223909A1Prevent degradationSuitable materialFatty substance recovery/refiningFiltration separationOxidation resistantFilter material

To use cooking oil repeatedly for a long time while maintaining quality of the cooking oil in a good condition, a cooking oil filter apparatus according to this invention filters the cooking oil collected from a fryer in using a filtering material. A fragment of granite porphyry containing amphibole is used as the filtering material. The granite porphyry containing the amphibole indicates a good antioxidant effect against the cooking oil, and the cooking oil is recycled upon contact with the granite porphyry, thereby prevented from degrading. As a structure, for example, the apparatus has a filter cartridge containing the fragment of the granite porphyry containing the amphibole, in which a basket and a paper filter respectively in a mesh form are disposed on the filter cartridge.

Owner:KURATA KATSUHIKO

Telescopic filter

InactiveCN103286003AGuaranteed Compactness RequirementsMeet the requirements of special installation environmentMagnetic separationThree stageEngineering

The invention discloses a telescopic filter which consists of a plurality of telescopic stages, and comprises a first stage of filter, a second stage of filter and a third stage of filter; a three-stage filtering way is formed by net type filter cores, paper filter cores and magnetic bars which are respectively arranged in the multiple stages of filters; internal hydraulic oil entering the filters or an external hydraulic oil source is adopted to control the extension of the stages of filters; the stages of filters can slide in a cylinder barrel between a shell of the first stage of filter and a welding steel cylinder, so that the filter cores of the filters can fully stretch for filtering; the filters can filter in the manner that hydraulic oil enters the filters through an oil hole of a one-way valve, and then the stretching filter cores are used for fully filtering. The pressure alarm and signal transmission can be carried out by a pressure relay of the system. When outlets of the filters are blocked and the filter cores need to be replaced, the stages of filters can retract into a first stage of cylinder barrel by virtue of the external hydraulic oil source so as to be disassembled. The filter is compact in structure, good in effect of three-stage filtering, simple to install and convenient to disassemble.

Owner:YANSHAN UNIV

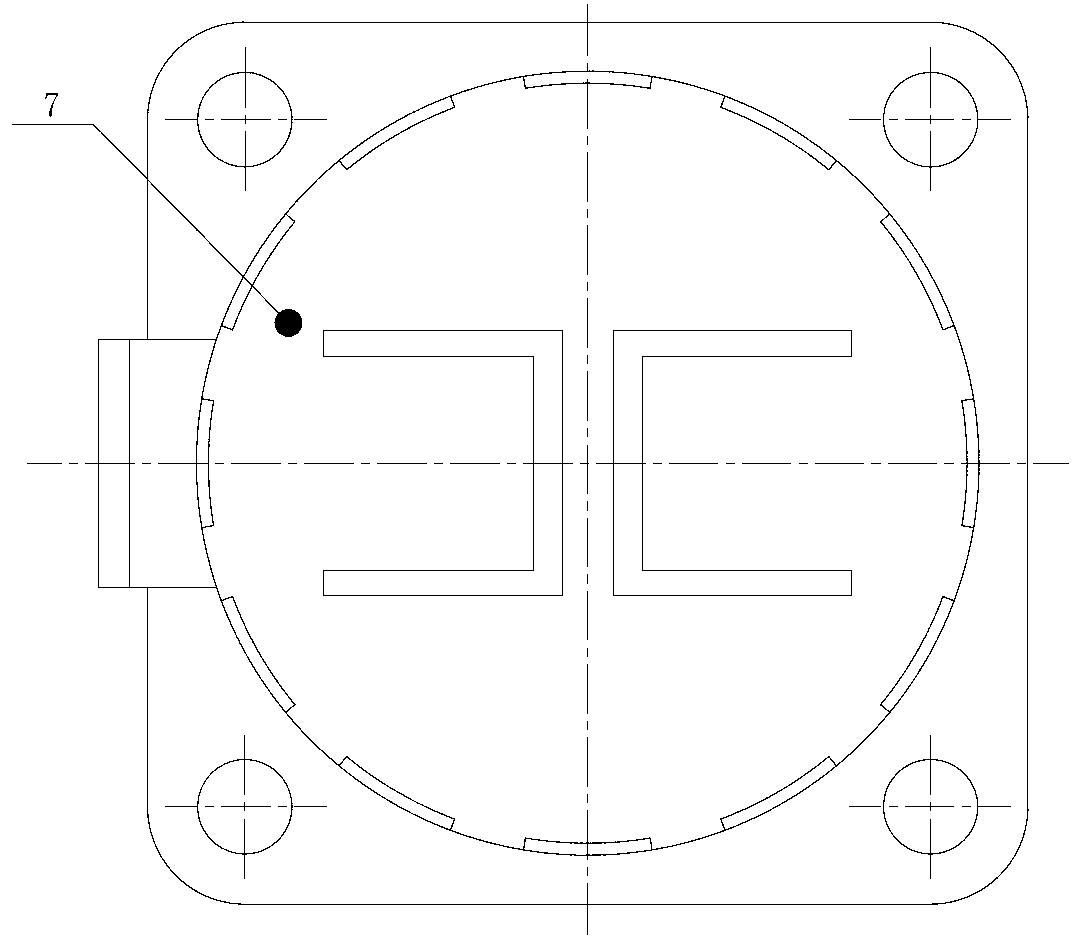

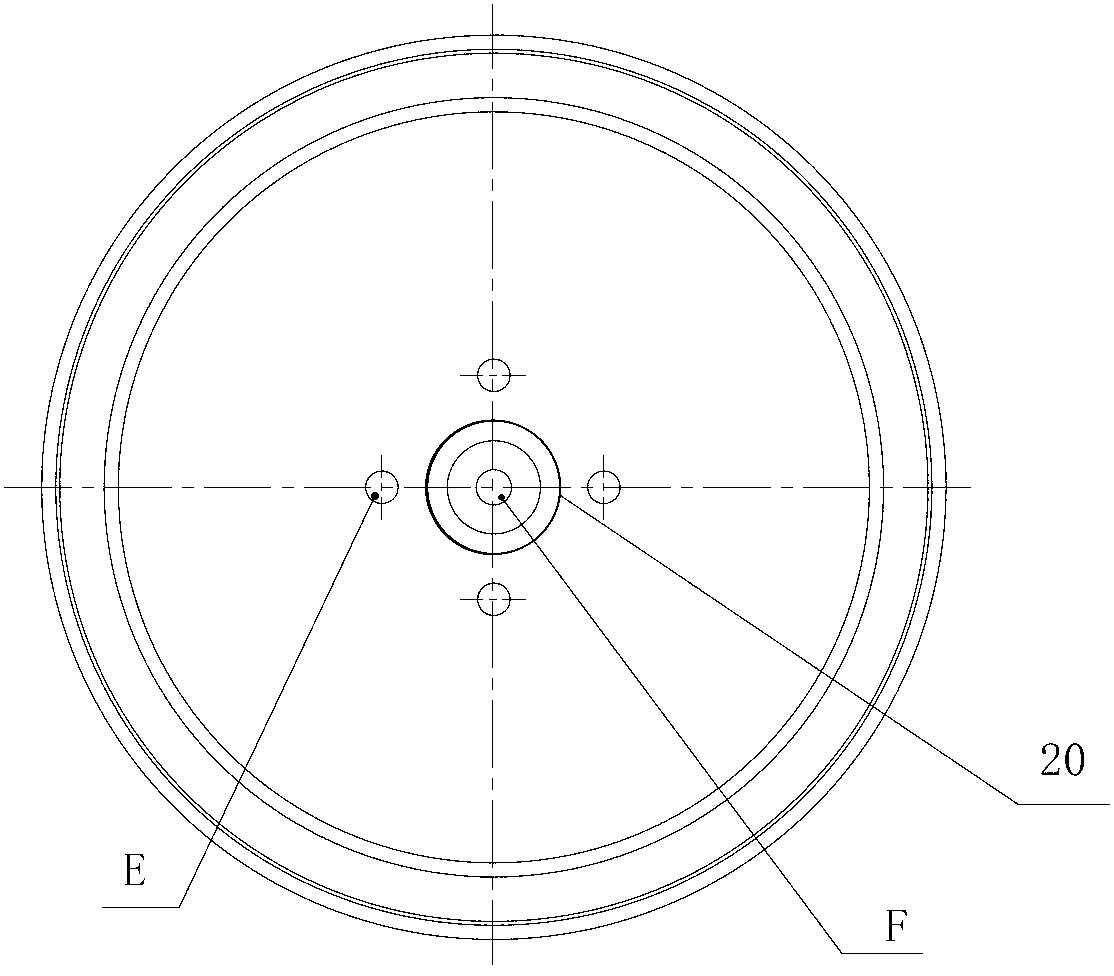

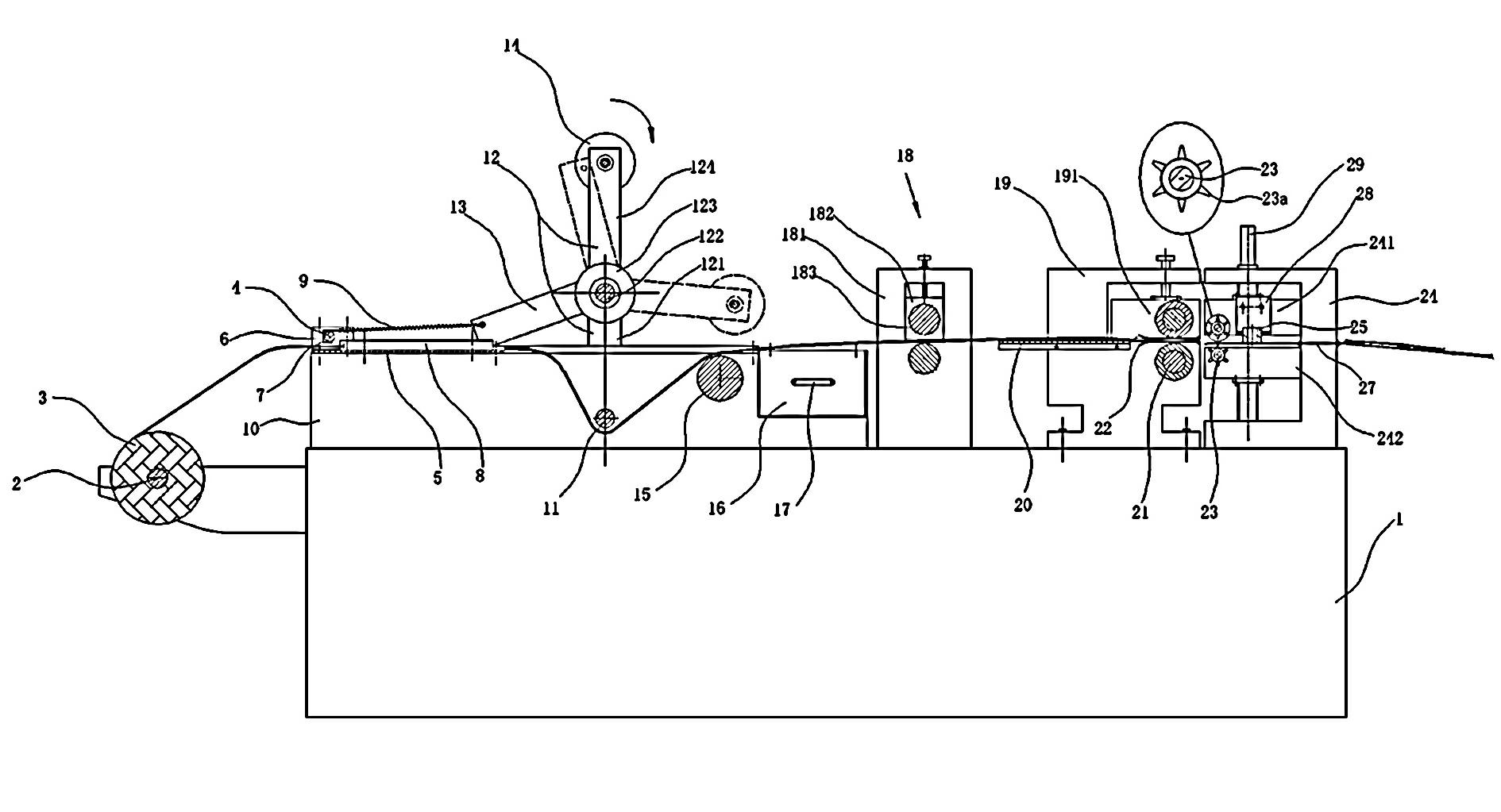

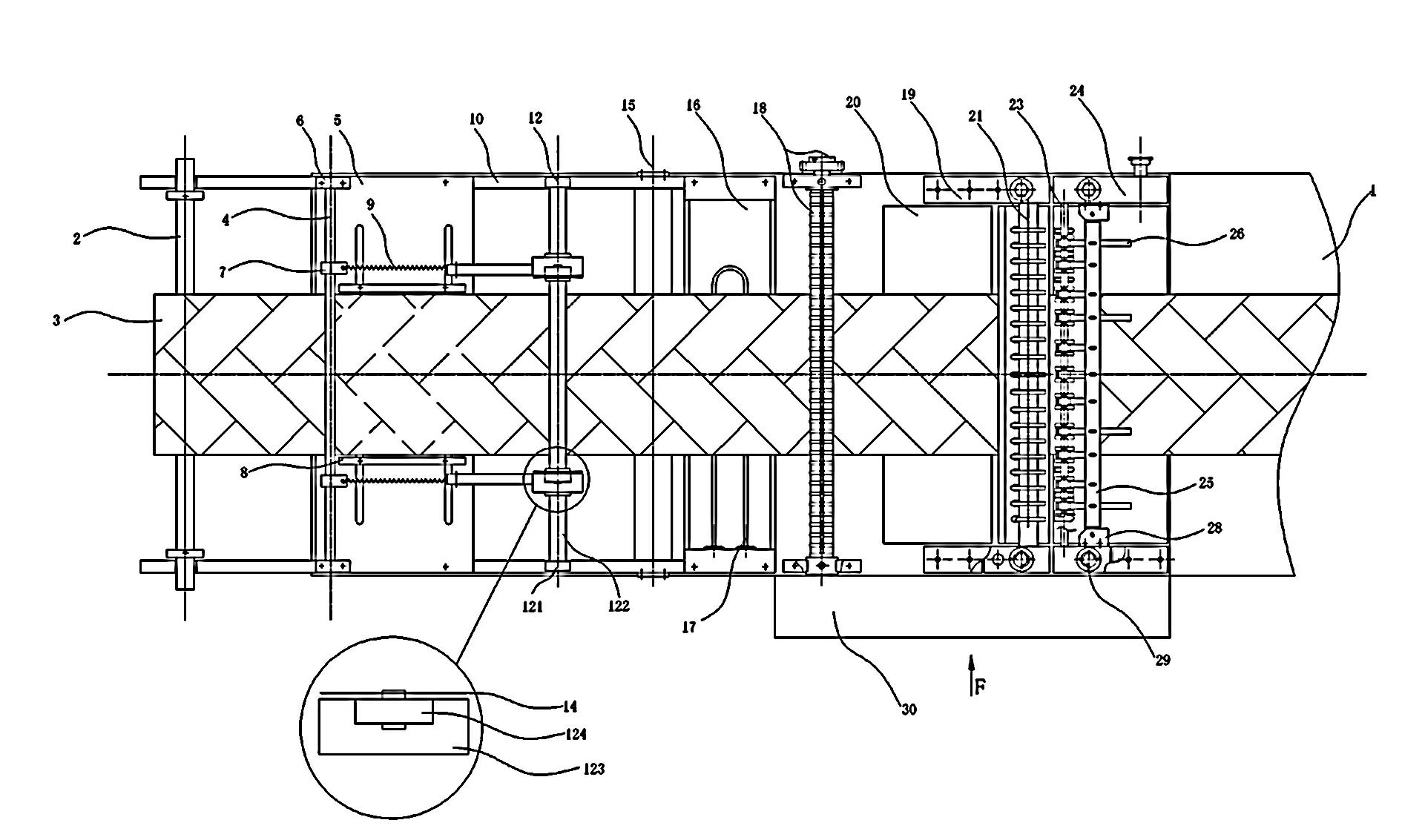

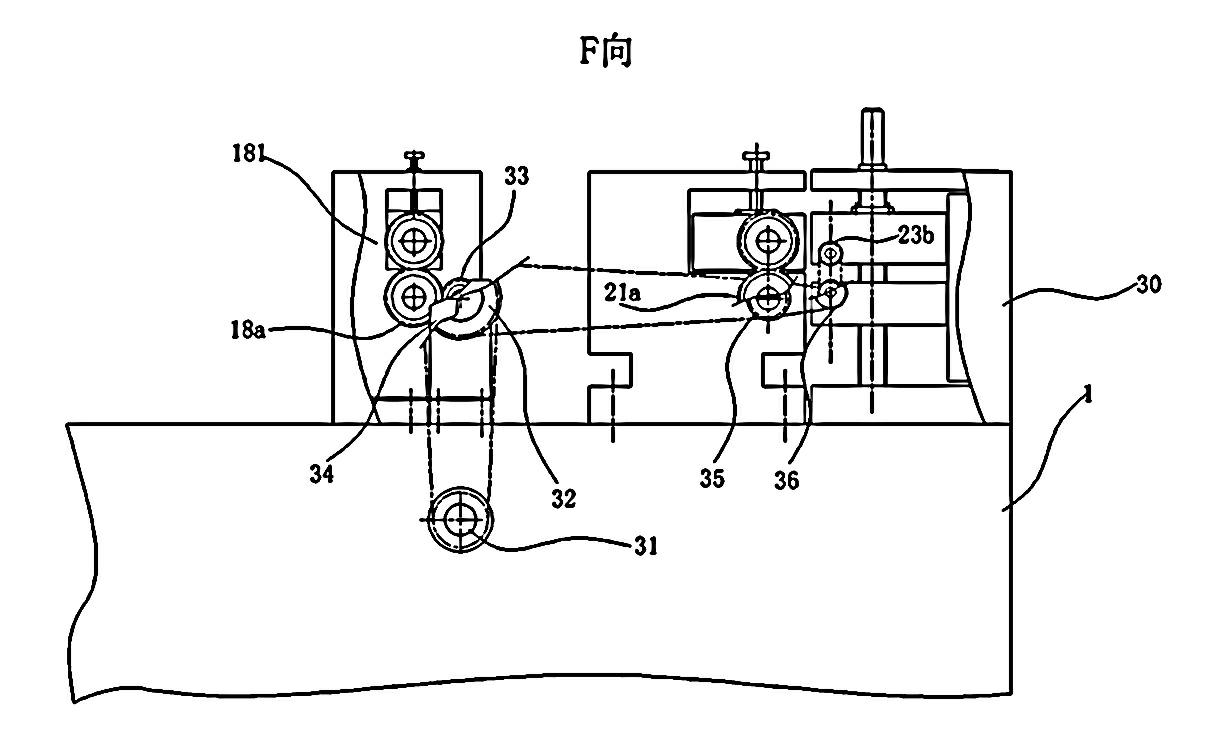

Paper filtering and folding machine of full-automatic filter

InactiveCN102320162AProduction without manual assistanceNo need to save paper costsMechanical working/deformationPulp and paper industryPaper filter

The invention relates to a paper filtering and folding machine of a full-automatic filter. A rectangular heating water tank (16) is additionally arranged on a normal paper folding machine; a U-shaped heater (17) is arranged in the water tank in a connection manner; furthermore, a pair of folding rollers (23) is also additionally arranged; the two rollers are in parallel vertically to form the opposite roller motion; the two rollers are respectively provided with a set of hexagonal nylon ratchet wheels (23a); and upper and lower sets of ratchet wheels are arranged in a staggered manner to form grabbing folds so as to fold, fix and form a piece of filter paper. The paper filtering and folding machine of the full-automatic filter disclosed by the invention has the advantages that: the filter paper is in a wet processing state and convenient to process and form; furthermore, an automatic folding device is additionally arranged; the artificial auxiliary production link is avoided; the production cost is saved; and the production efficiency is increased.

Owner:蚌埠银丰滤清器科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com