Patents

Literature

119results about How to "High recovery purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

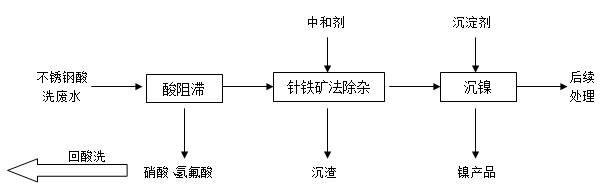

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

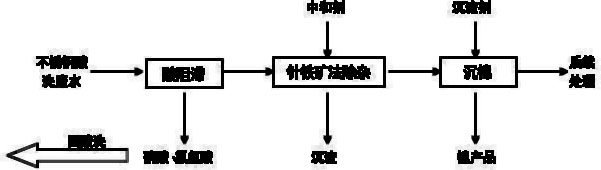

Treatment method for waste lithium-ion battery

InactiveCN105789724AHigh recovery rateHigh recovery purityWaste accumulators reclaimingBattery recyclingChemical synthesisAluminium

The invention relates to the technical field of comprehensive utilization of resources and discloses a treatment method for a waste lithium-ion battery. The method comprises the following steps: carrying out disassembling, discharging, breaking, crushing and sorting; carrying out alkaline transfer, acid dissolution and impurity removal on the sorted electrode material; and then carrying out chemical separation through pretreatment on the waste lithium-ion battery, wherein extraction and separation are a key step; partial cobalt is separated from lithium to obtain a nickel-cobalt-lithium, nickel-cobalt or nickel-cobalt-manganese mixed salt, a lithium salt and a cobalt salt; mixed sulfate regenerates a cathode material through chemical synthesis; an electrolyte and the cathode material can be obtained in the overall treatment process; the recovery rate of the cathode material is improved; and the recovery purity of copper, aluminum and the like are improved. In addition, the cathode material is directly produced; the production process is shortened; and construction of the circulating industry chain of battery production, battery recovery treatment and battery production is increased.

Owner:CHINA ELECTRONICS ENG DESIGN INST

Method for reclaiming nitrogen and phosphorus in nitrogen and phosphorus-containing wastewater by using bittern as magnesium source

InactiveCN102092871AHigh recovery purityMultistage water/sewage treatmentWater/sewage treatment by neutralisationResource recoveryNitrogen

The invention discloses a method for reclaiming nitrogen and phosphorus in nitrogen and phosphorus-containing wastewater by using bittern as a magnesium source, and belongs to the technical field of environmental engineering water treatment. The method comprises the following steps of: regulating the initial pH value of the nitrogen and phosphorus-containing wastewater, fully stirring the wastewater, adding a certain amount of bittern, controlling the reaction time and the reaction pH value, then standing, performing solid-liquid separation, and reclaiming struvite sediment. Compared with the prior art, the waste can be treated by using the other waste, the wastewater treatment cost is saved, the struvite serving as a reaction product can be used as a fertilizer, and the method lays a foundation for practical application and can fulfill the purpose of recycling the resources.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

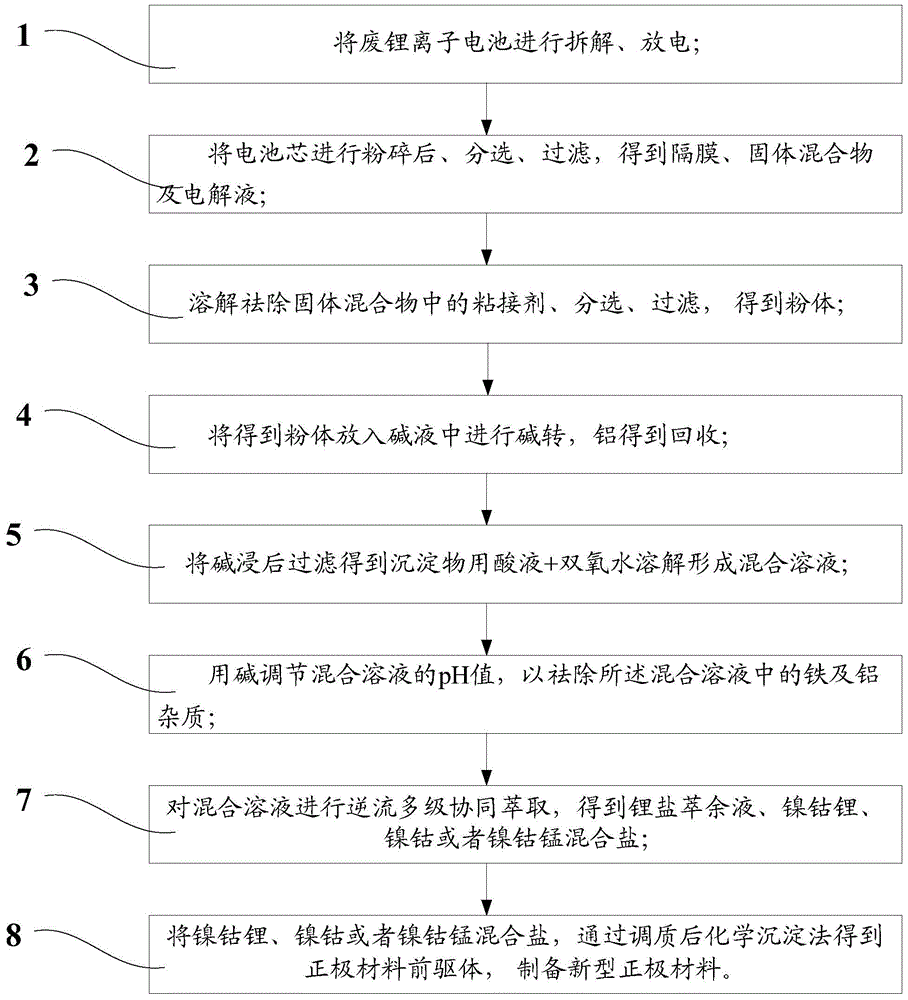

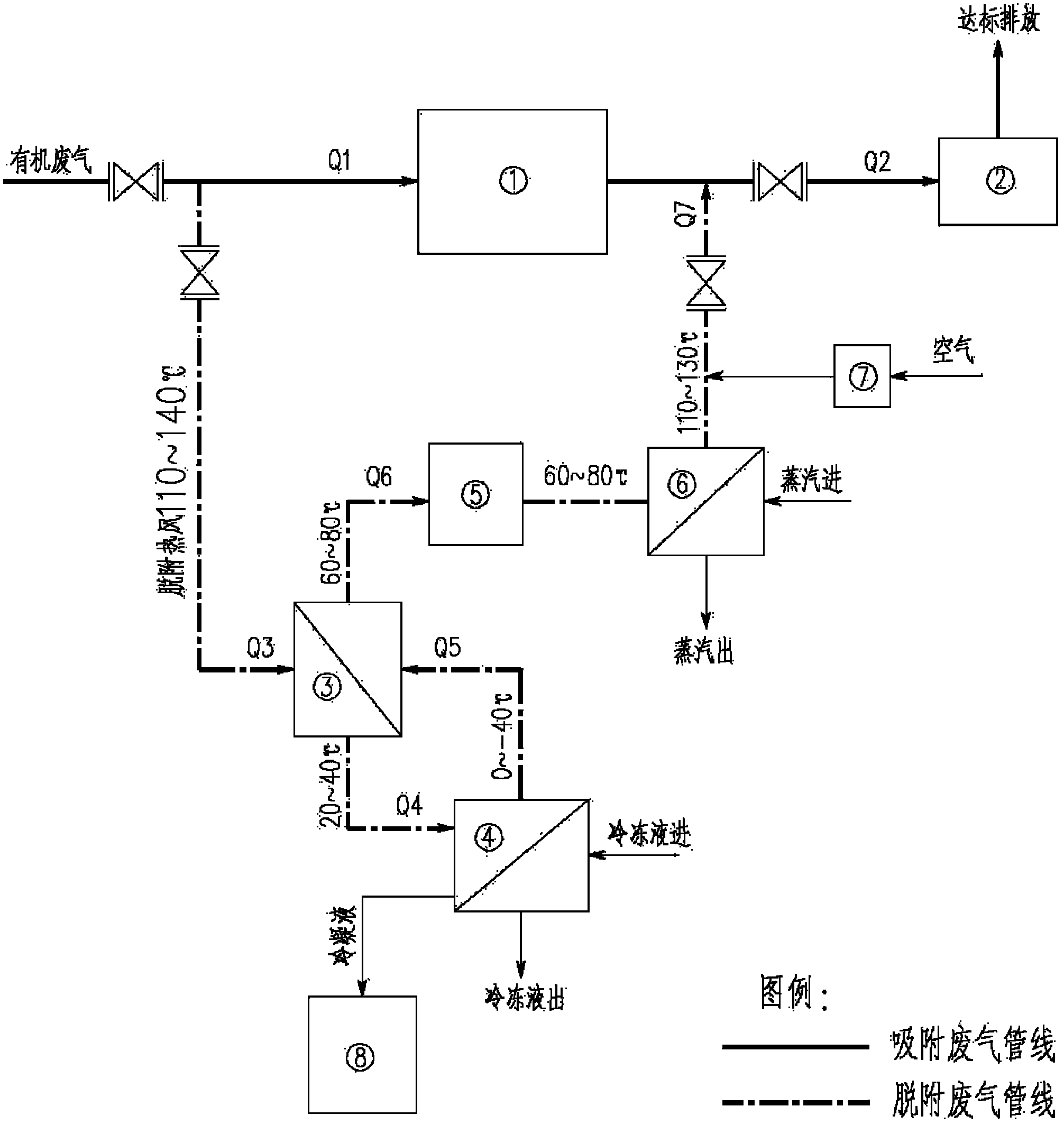

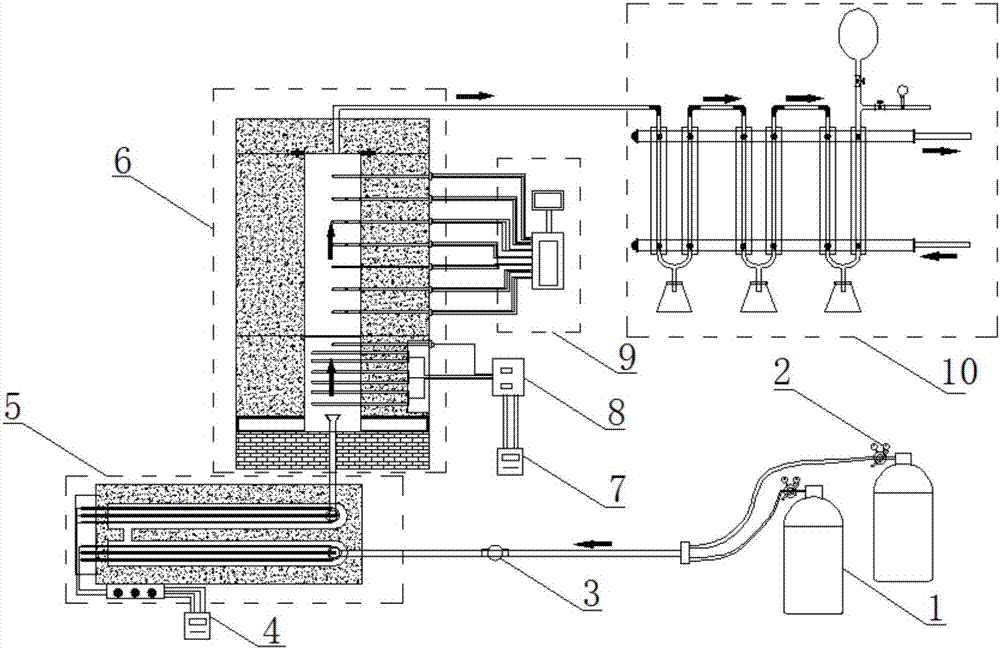

Method for recovering organic solvent from organic water gas

InactiveCN102489113ANo emissionsNo secondary pollutionDispersed particle separationVapor condensationEnvironmental resistanceDesorption

The invention belongs to the technical field of treatment of organic waste gas, and relates to a method for recovering an organic solvent from organic waste gas. The method comprises the following steps of: adsorbing the organic solvent in the organic waste gas into active carbon, purifying, and discharge within controlling indexes of a national standard; when the active carbon is saturated by adsorbing, heating the residual organic waste gas in a pipeline, desorbing the organic solvent which is absorbed by the active carbon, and regenerating the active carbon; performing heat exchange on thedesorbed organic solvent gas, condensing into liquid, and recovering; and heating condensed waste gas, reentering the desorbed saturated active carbon again, circulating, and finishing one-time desorption. The method has the advantages of simple process flow, convenience for operating, saving in energy, reduction in production cost, lowering of the organic substance content of the waste gas to reach an environmentally-friendly emission standard, capability of recycling organic substances in the waste gas as resources, regeneration of active carbon, no emission of secondary pollutants, remarkable economic benefit and wide application field.

Owner:SHANGHAI TONGJI CLEARON ENVIRONMENTAL PROTECTION EQUIP ENG CO LTD +1

Method for recycling aluminum ash

InactiveCN103695656AImprove recycling efficiencyReduce productionProcess efficiency improvementSlagAluminium

The invention provides a method for recycling aluminum ash. The method comprises the following steps: (1) digging out hot aluminum ash positioned on the surface of a smelting furnace, and conveying the hot aluminum ash into an aluminum ash frying pot within 5 minutes for stirring; (2) controlling the temperature of the aluminum ash inside the aluminum ash frying pot to 720-760 so that aluminum contained in the aluminum ash is melted into molten aluminum and layered with slag; (3) draining the molten aluminum from an open pore formed in the bottom of the aluminum ash frying pot till no molten aluminum is drained from the open pore formed in the bottom of the aluminum ash frying pot; and (4) discharging the slag from the aluminum ash frying pot, and conveying into a cooling barrel provided with cooling equipment for cooling, cooling the slag to 60-100 DEG C within 30 minutes, continuously crushing and grinding the slag in a cooling process, conveying the crushed and ground slag into a screening barrel for screening, and screening to obtain fine ash, medium screened ash and coarse ash. According to the method for recycling the aluminum ash, which is provided by the invention, the oxidation of the aluminum ash in a recovery process can be effectively reduced and the recovery rate of aluminum contained in the aluminum ash is increased.

Owner:台澳铝业(台山)有限公司

Method for recycling metal bismuth from anode slime

ActiveCN105821215ASimple methodEasy to operateProcess efficiency improvementSelenium/tellurium oxides/hydroxidesLiquid temperatureSulfite salt

A method for recycling metal bismuth from anode slime includes the following steps that a, sintering is performed; b, copper separation is performed so that a sulfate solution and copper separation slag can be obtained; c, gold separation is performed so that gold separation mother liquor can be obtained, wherein the concentration of sulfuric acid is 100 g / L to 120 g / L, the concentration of hydrochloric acid is 10 g / L to 15 g / L, the concentration of chloride ions is 25 g / L to 35 g / L, temperature is raised to 75 DEG C to 85 DEG C, excessive sodium chlorate is added, after a reaction, gold metal, platinum metal, palladium metal, tellurium metal and bismuth metal are dissolved in the gold separation mother liquor, then sodium sulfite is added in the gold separation mother liquor to separate gold so that gold separation liquid can be obtained; d, sodium chloride and sodium sulfite are added in the gold separation liquid obtained in the step c, the concentration of sodium chloride is controlled to be 250 g / L to 300 g / L, liquid temperature is controlled to be 75 DEG C to 85 DEG C, precious metal, tellurium and selenium in the liquid are reduced into suspended matter, and after filtration, bismuth separation liquid is obtained; and e, sodium hydroxide is added into the bismuth separation liquid obtained in the step d, PH is adjusted to be 10 to 11, bismuth in the liquid is hydrolyzed, bismuth slag is obtained after filtration, and metal bismuth is obtained after reduction. The method has the following beneficial effects that the method is simple, operation is convenient, and the bismuth recycling rate and the bismuth recycling purity are high.

Owner:ZHEJIANG YADONG IND CO LTD

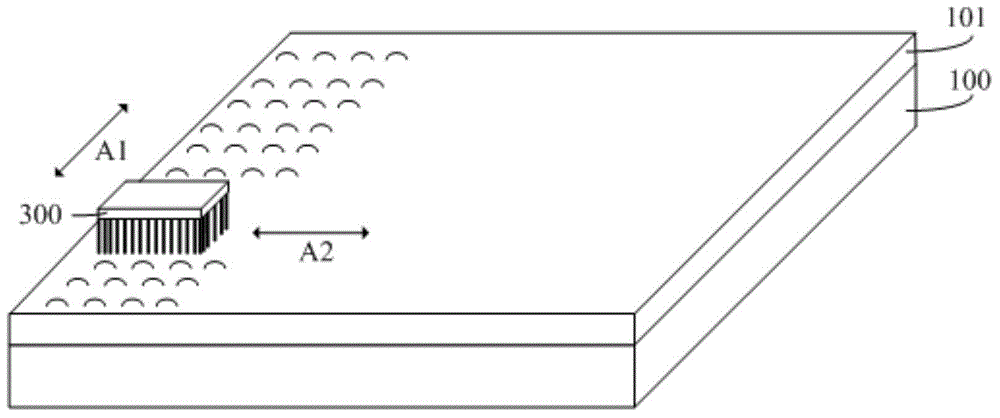

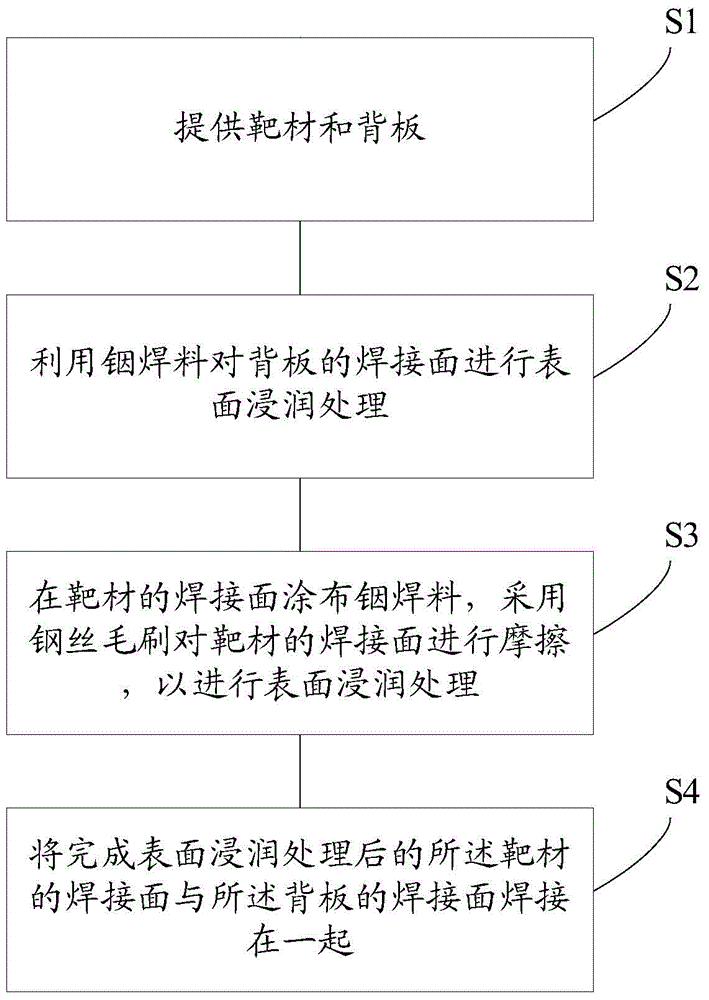

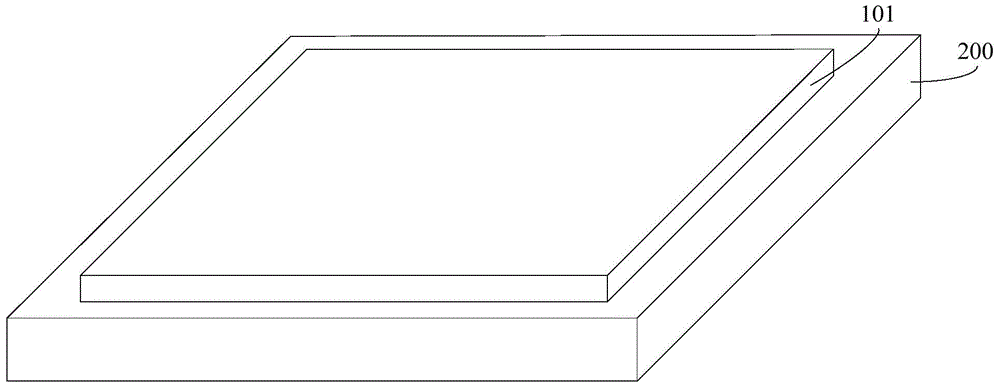

Manufacturing method for target material assembly

InactiveCN105618886AManufacturing Method AdvantagesHigh recovery puritySoldering apparatusIndiumOxide

The invention provides a manufacturing method for a target material assembly. The manufacturing method for the target material assembly includes the steps that surface infiltration treatment is carried out on a welding surface of a back plate through indium solder; a welding surface of a target material is coated with indium solder and is rubbed through a steel wire hairbrush, so that surface infiltration treatment is carried out; and the welding surface, subjected to surface infiltration treatment, of the target material and the welding surface of the back plate are welded together. Through the step of rubbing the welding surface of the target material through the steel wire hairbrush, metal oxide on the welding surface of the target material can be removed, the roughness of the welding surface of the target material is increased, and accordingly the indium solder can fully infiltrate the welding surface of the target material. After the welding surfaces of the target material and the back plate are welded, the bonding performance of the welding surfaces of the target material and the back plate is high, and defects are not prone to occurrence. The target material and the back plate are both infiltrated through the indium solder, the bonding performance of the indium solder is high, the total use amount of the indium solder is smaller compared with that in the prior art, and the recycling purity of the indium solder is improved.

Owner:合肥江丰电子材料有限公司

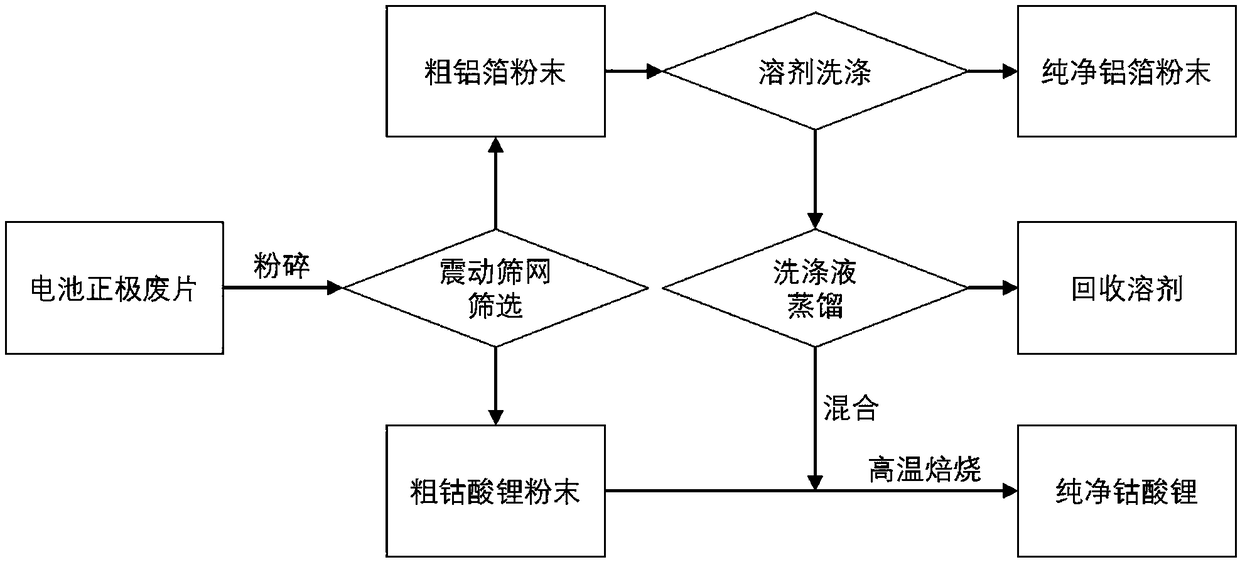

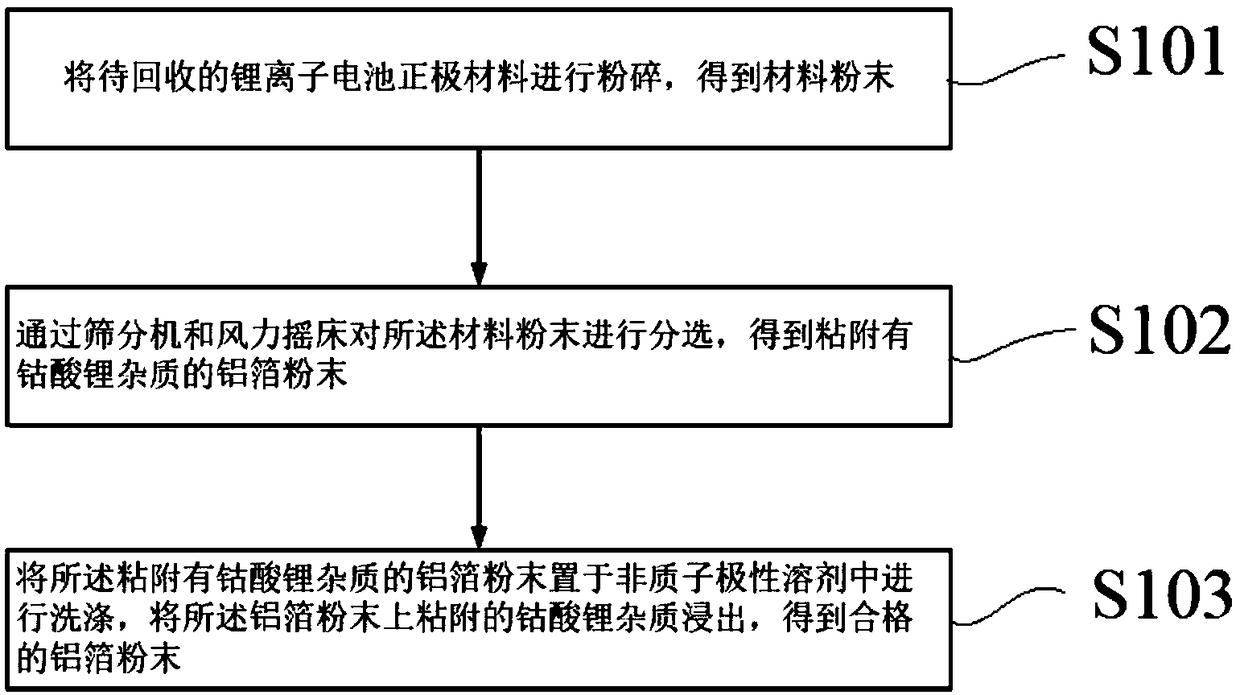

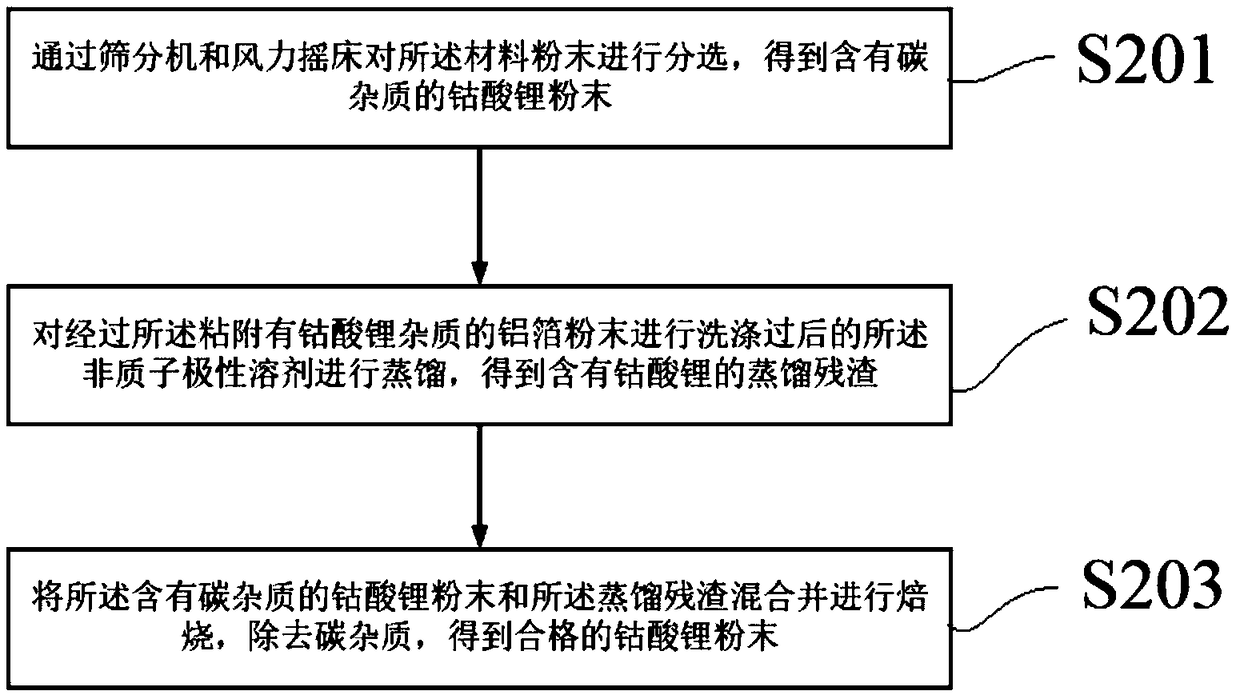

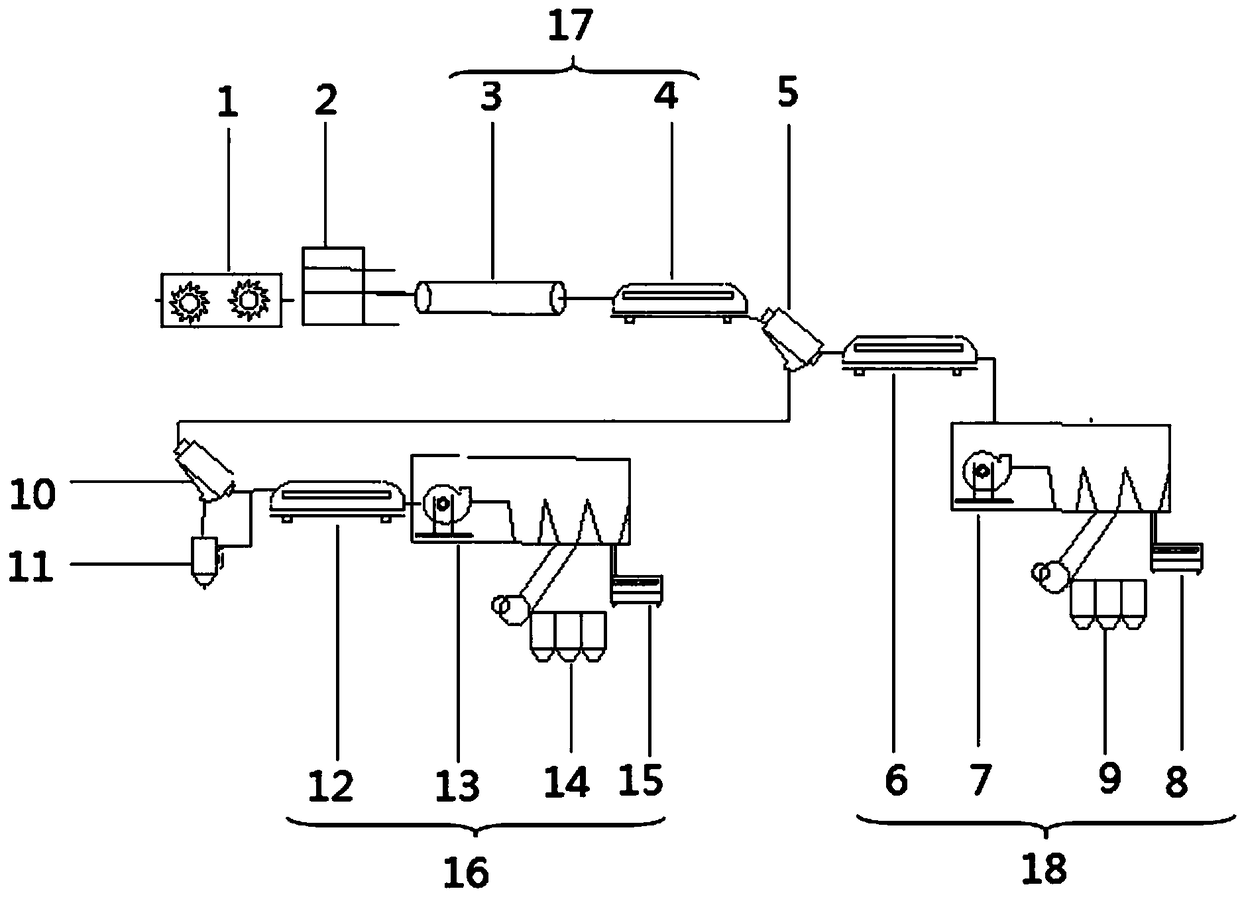

Recycling method and device of lithium ion battery positive electrode material

InactiveCN108666643AHigh recovery puritySave resourcesSolid waste disposalWaste accumulators reclaimingSolventAir separation

The invention discloses a recycling method and device of a lithium ion battery positive electrode material. The recycling method of the lithium ion battery positive electrode material comprises the steps of smashing the lithium ion battery positive electrode material to be recycled to obtain material powder; sorting the material powder by a screening machine and a wind shaking table to obtain aluminum foil powder attached with lithium cobaltate impurity; and placing the aluminum foil powder attached with the lithium cobaltate impurity in an aprotic polar solvent for washing, and leaching the aluminum foil powder attached with the lithium cobaltate impurity to obtain qualified aluminum foil powder. The recycling device of the lithium ion battery positive electrode material comprises a smashing device, a screening device, an air separation device, a washing device, a distillation device and a roasting device. By the recycling method and the recycling device, the problem that lithium cobaltate can be attached onto mechanically-processed fine aluminum foils in a mechanical smashing and separation method in the prior art to cause insufficient aluminum recycling purity and resource lossis solved.

Owner:祝融峰

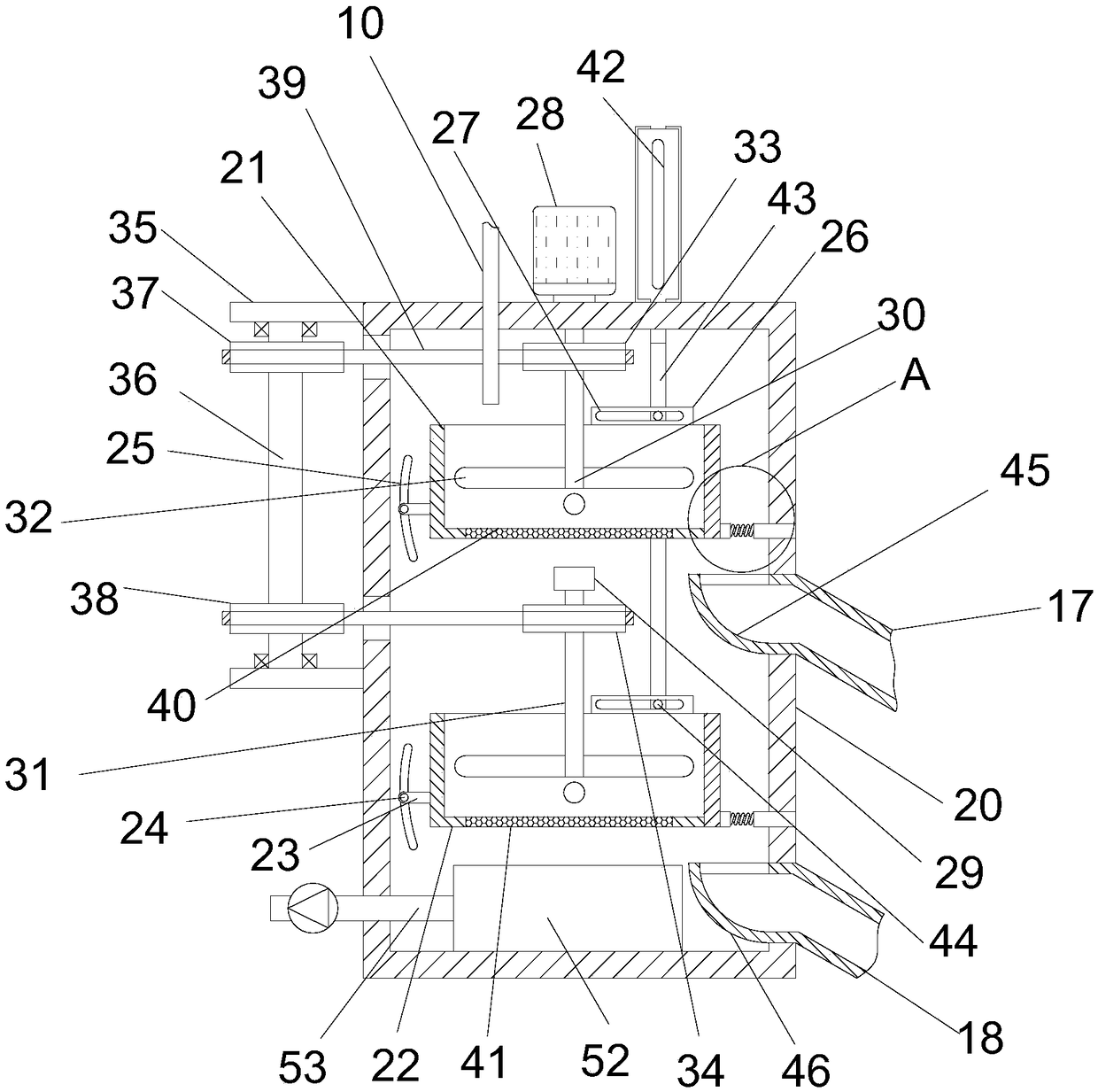

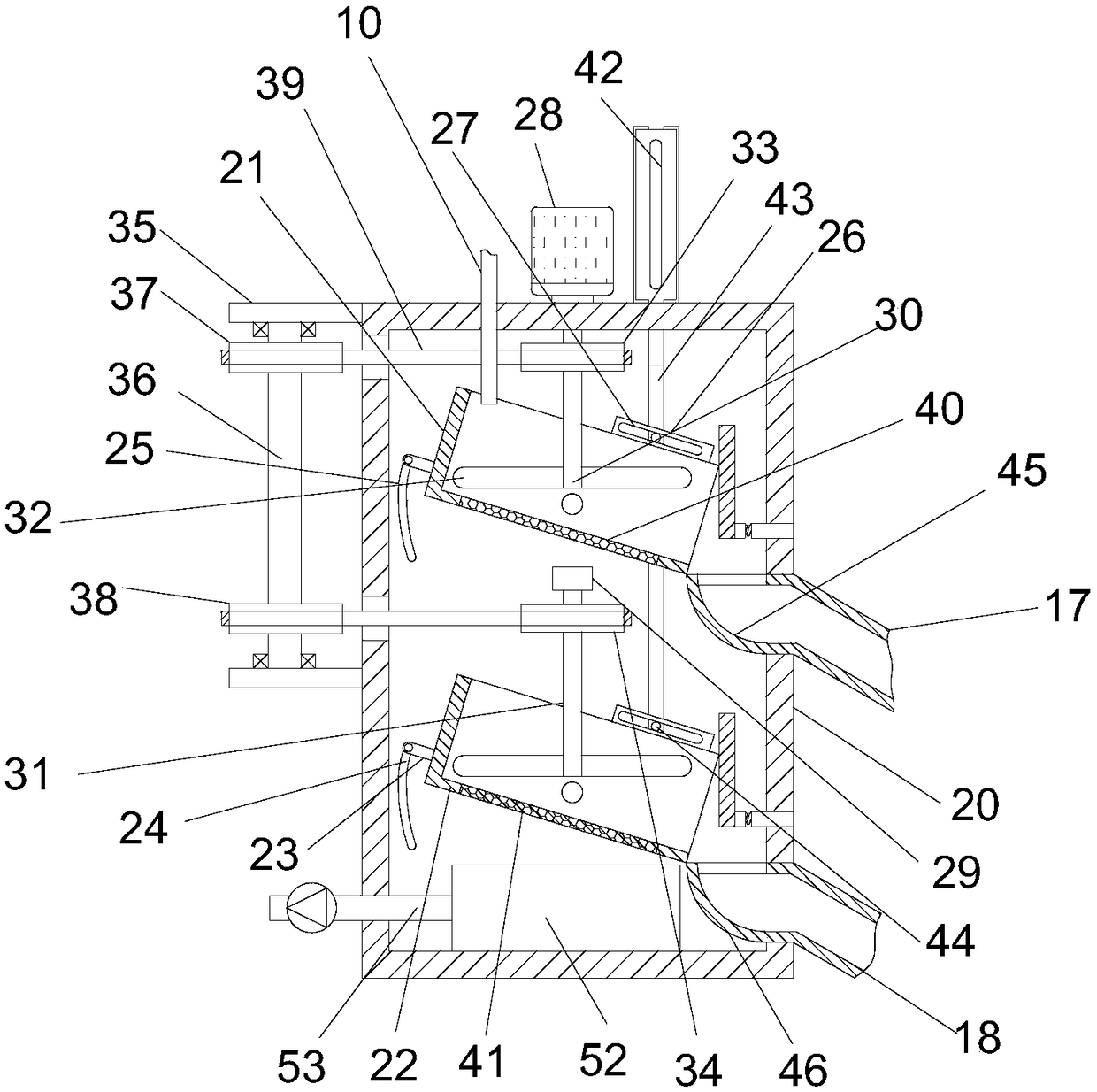

Small and medium-sized city household garbage sorting treatment system and method

ActiveCN108580520AImprove sorting efficiencyAchieving precision and efficiencySolid waste disposalClimate change adaptationBiogasEnvironmentally friendly

The invention discloses a small and medium-sized city household garbage sorting treatment system. The sorting treatment system comprises a household garbage sorting system and a household garbage treatment system; the household garbage treatment system is disposed on the downstream of the household garbage sorting system; the household garbage treatment system comprises an organic matter treatmentsystem, a sewage and waste treatment system and a non-organic regenerant treatment system; and the organic matter treatment system is a pyrohydrolysis-anaerobic fermentation combined system. The small and medium-sized city household garbage sorting treatment system is high in sorting efficiency, low in household garbage treatment cost, high in household garbage recycling ratio, free of secondarypollution and environmentally friendly, the biodegradability of organic wastes is effectively improved, the fertilizing effect and utilization value of fermented biogas residues are improved, and quantity reduction, harmless effect and reclamation of household garbage treatment are achieved.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

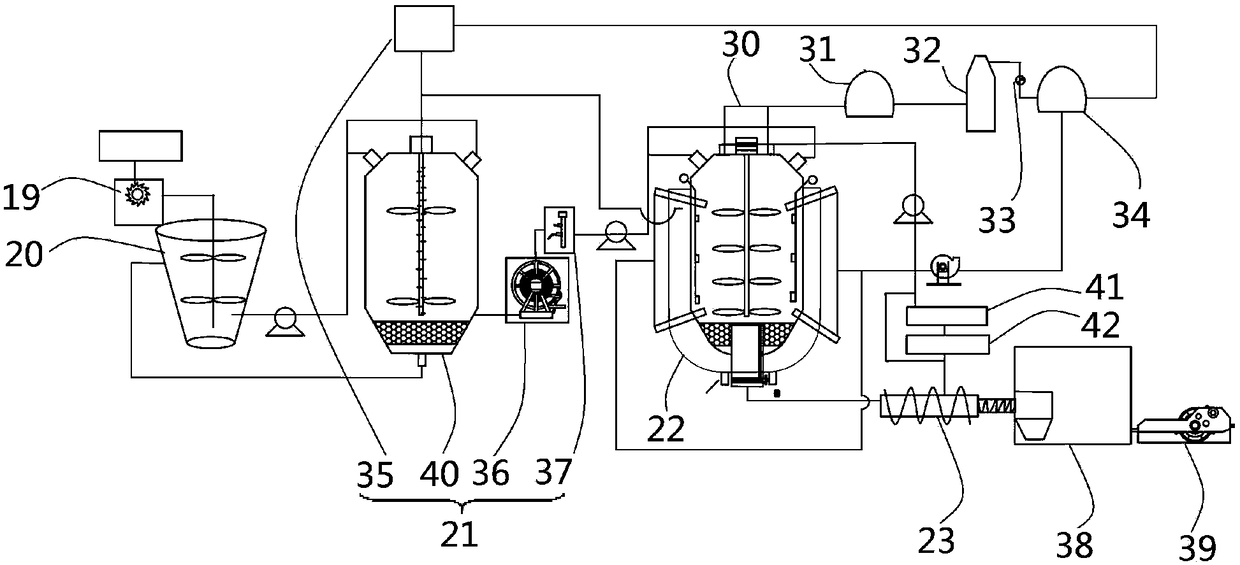

Method for recovering copper from acidic waste water containing copper

ActiveCN101974695AEasy to replacePrevent direct attachmentRotary drum furnacesCrucible furnacesResource recoveryWastewater

The invention discloses a method for recovering copper from acidic waste water containing copper, which belongs to the technical field of resource recovery. The method comprises the following steps: regulating the pH value of the waste water containing copper to 0.5-1.5; and adding a fixed quantity of additives, evenly mixing, adding iron, and carrying out replacement reaction to obtain the copper powder of which the copper content is higher than 99%. The obtained copper powder does not need high-temperature smelting purification, and can naturally shed without continuous knocking; and the purity and recovery rate can reach more than 99%.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

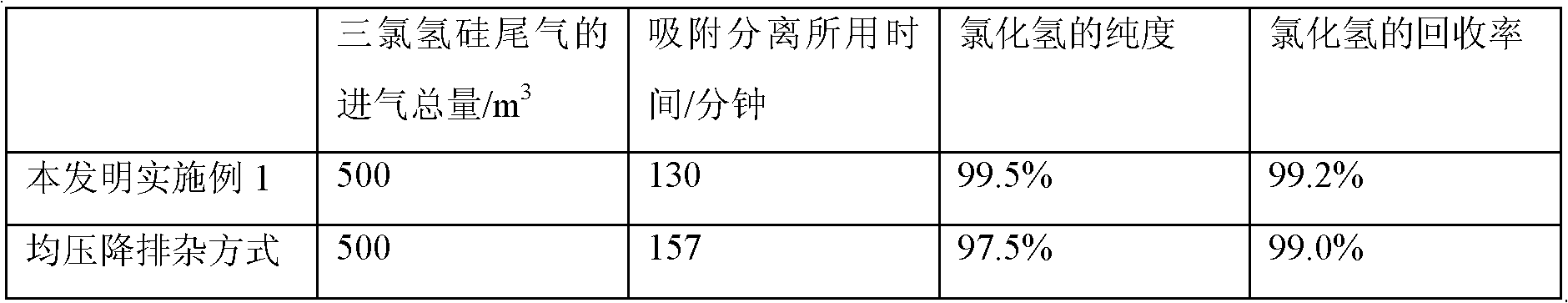

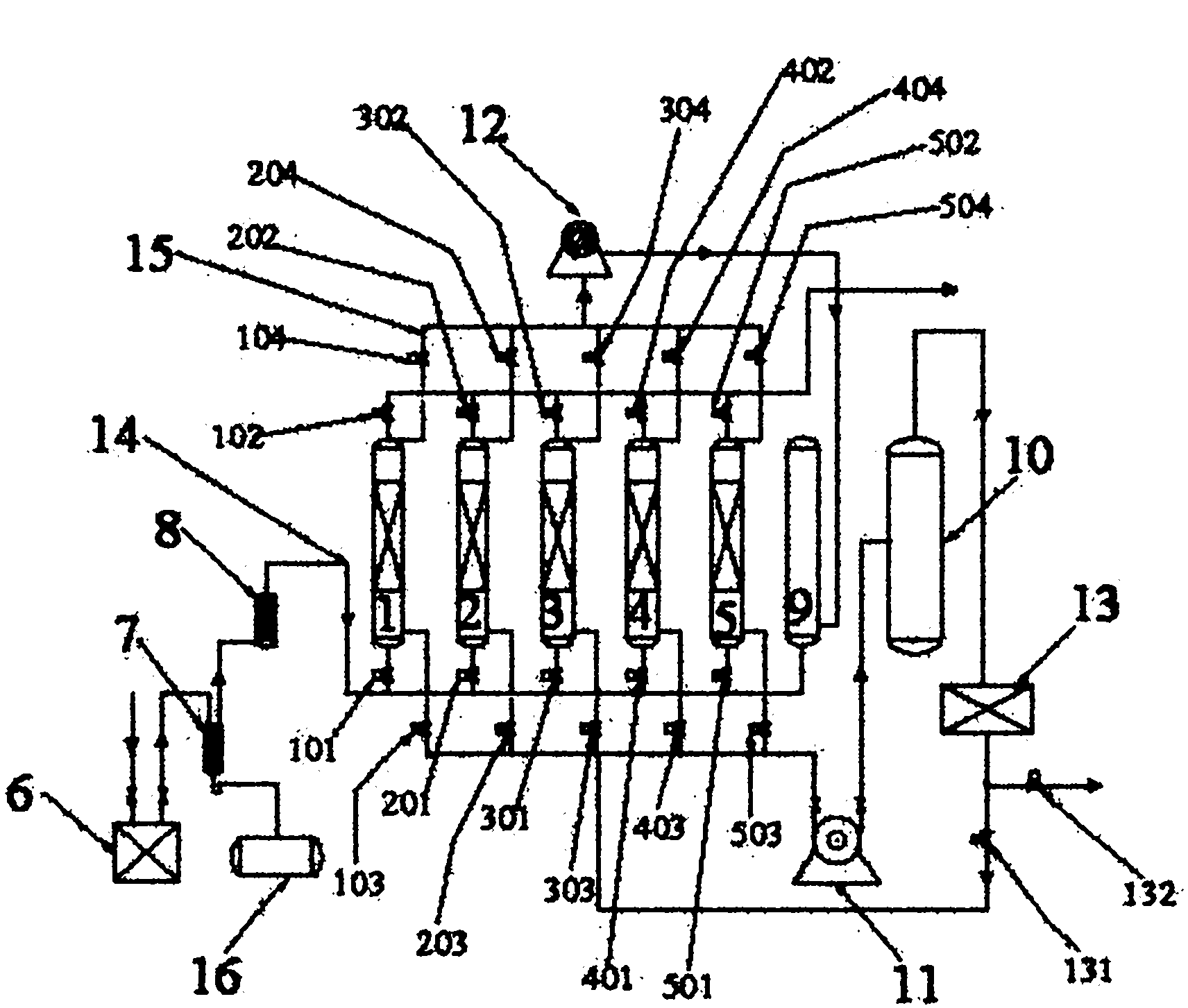

Method for recovering hydrogen chloride from trichlorosilane tail gas

ActiveCN102009955AWon't affect conversion rateEasy to recycleChlorine/hydrogen-chloride purificationDispersed particle separationSorbentDesorption

The invention relates to separation of gases, in particular to a method for recovering hydrogen chloride from trichlorosilane tail gas. The method comprises the following steps that: the trichlorosilane tail gas enters a compressor, is compressed, and enters a recovery condenser; the trichlorosilane, dichlorosilane and silicon tetrachloride in the tail gas are condensed to a liquid state from a gaseous state, and are recovered; noncondensable gas in the tail gas is heated and enters an adsorption system; the hydrogen chloride is adsorbed by adsorbent in a packed tower, and is separated from the tail gas after impurity removal and desorption; and the separated hydrogen chloride is delivered to a trichlorosilane synthetic furnace to be recycled. The method has the advantages of small investment, lower operation cost, simplicity, high recovery rate of the hydrogen chloride in the trichlorosilane tail gas, and high purity of the recovered hydrogen chloride.

Owner:江西宏柏新材料股份有限公司

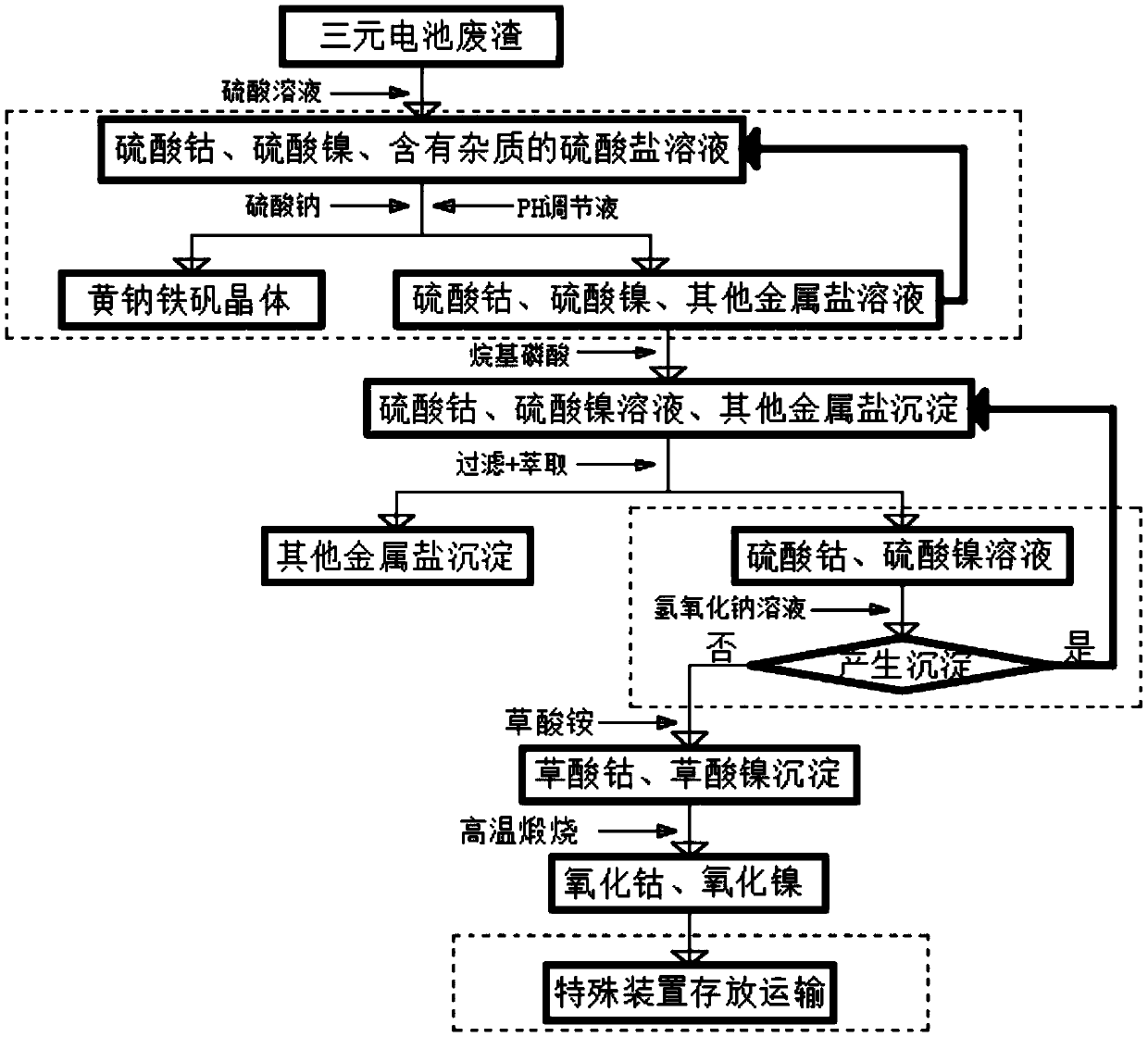

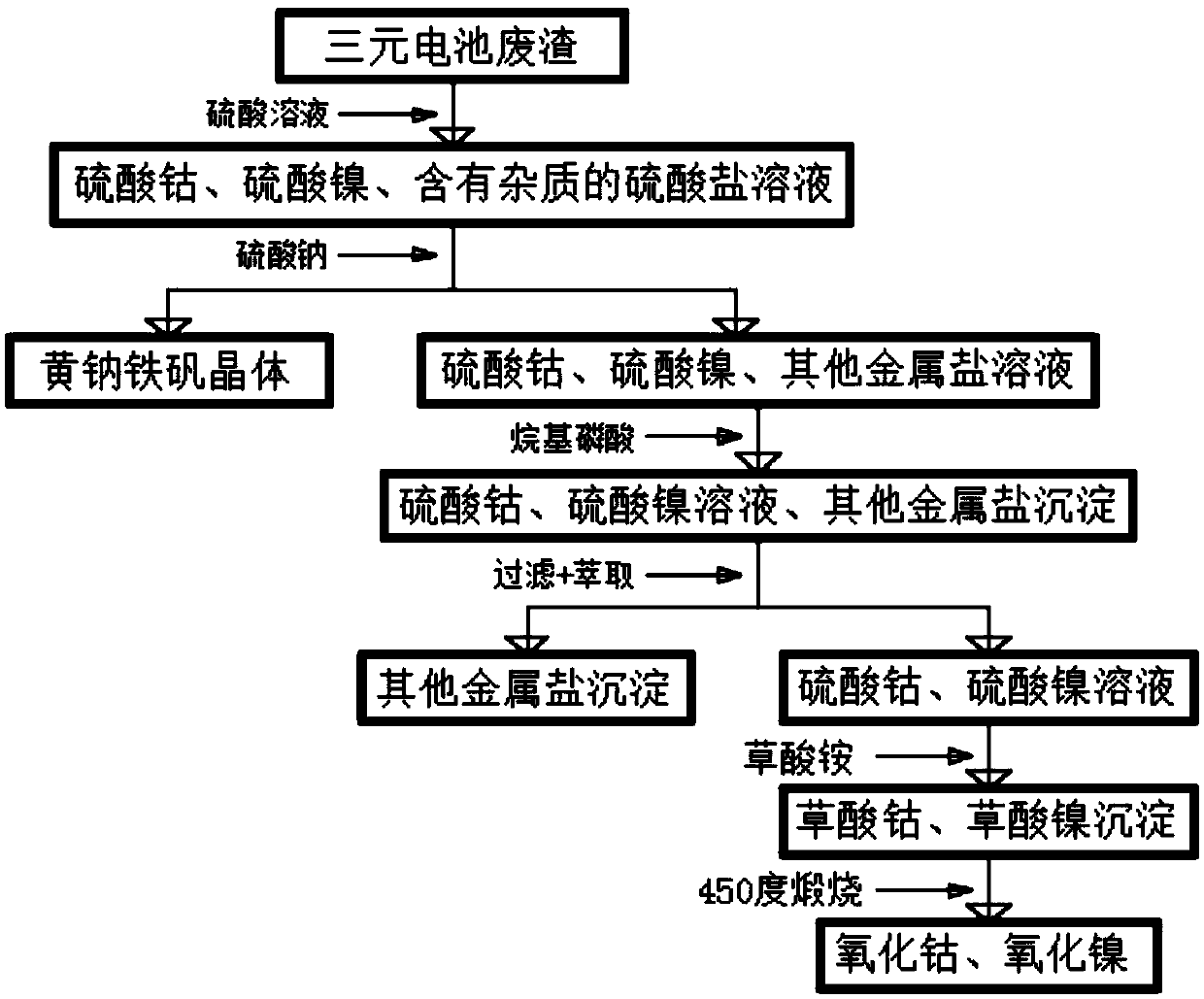

Cobalt and nickel purifying method based on waste battery metal recovery technology

InactiveCN109536724AHigh impurity removal rateImprove the efficiency of impurity removalProcess control/regulationChemical/physical/physico-chemical stationary reactorsFeedback effectMetal impurities

The invention discloses a cobalt and nickel purifying method based on a waste battery metal recovery technology, and belongs to the field of waste battery recovery. The cobalt and nickel purifying method based on the waste battery metal recovery technology comprises the step of recovery of ternary battery waste residues, the original waste battery metal recovery technology is improved, on the onehand, the impurity removal rate for iron ions can be higher than an impurity removal technology for the iron ions in the prior art, meanwhile, the impurity removal efficiency for the iron ions can beimproved, the recovery purity of cobalt and nickel is increased, the progress of the whole technology is accelerated, and the recovery efficiency is improved; on the other hand, compared with the prior art, the method has the advantages that detection of metal impurities in a solution after impurity removal operation is increased, the reaction phenomenon produced in the solution has the feedback effect, impurities can be removed more thoroughly, and the recovery purity of the metal cobalt and the metal nickel is further improved.

Owner:南通北新新能科技股份有限公司

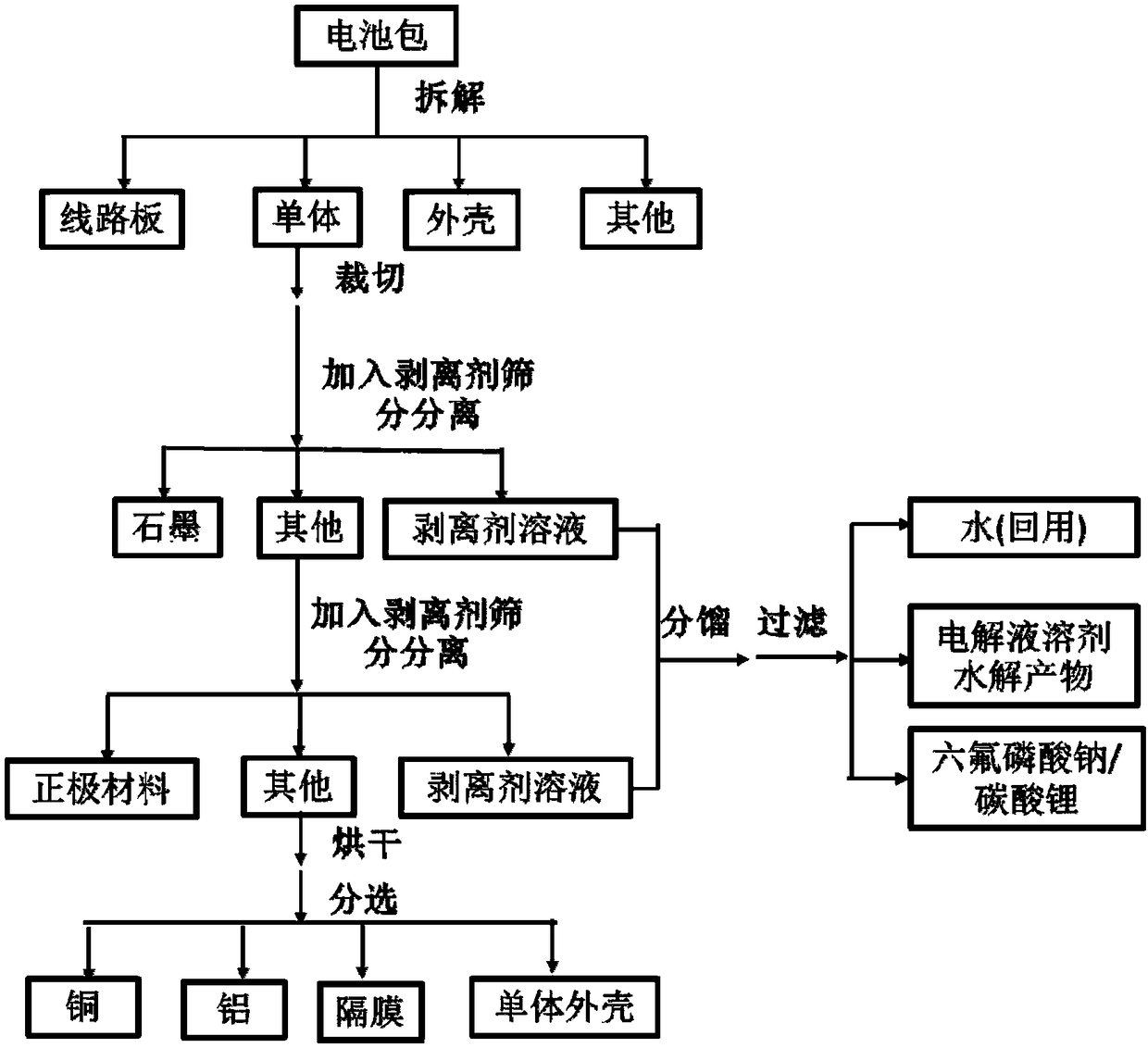

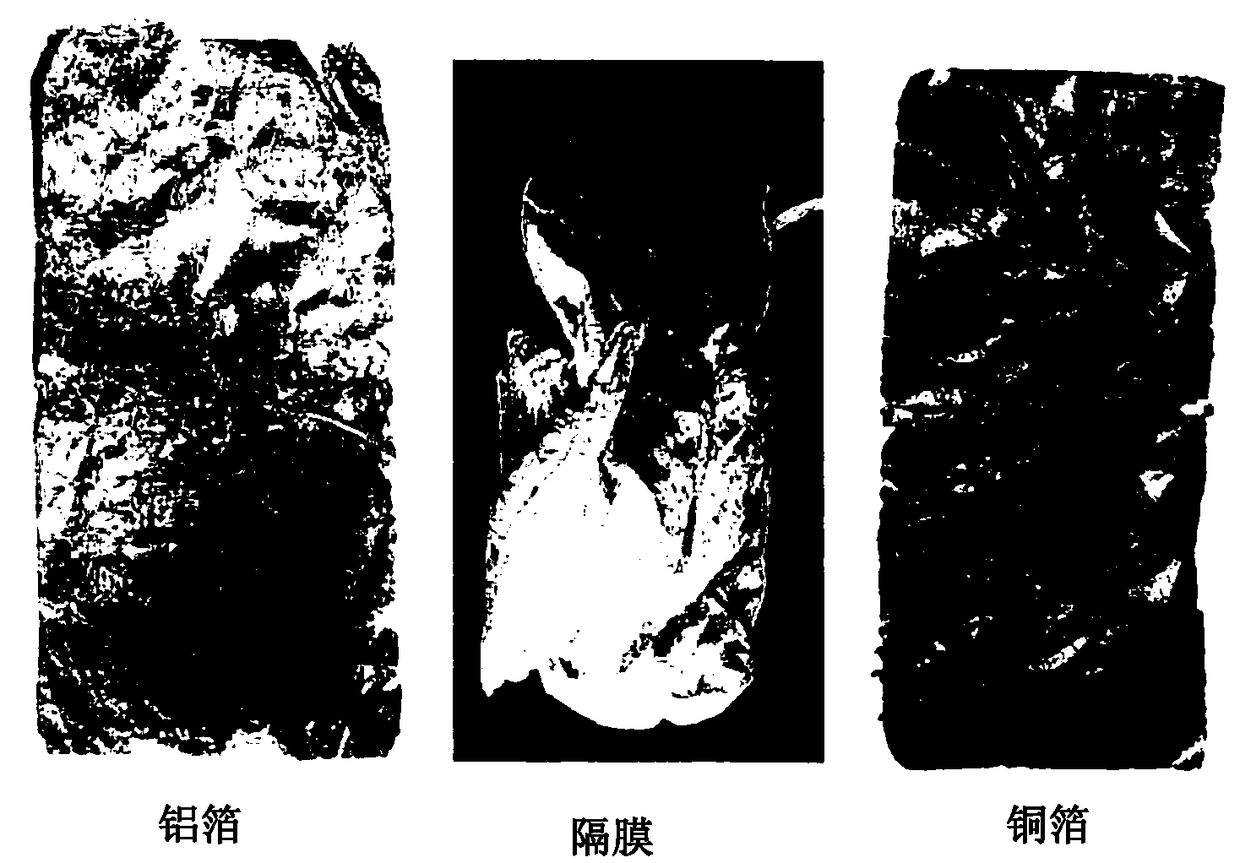

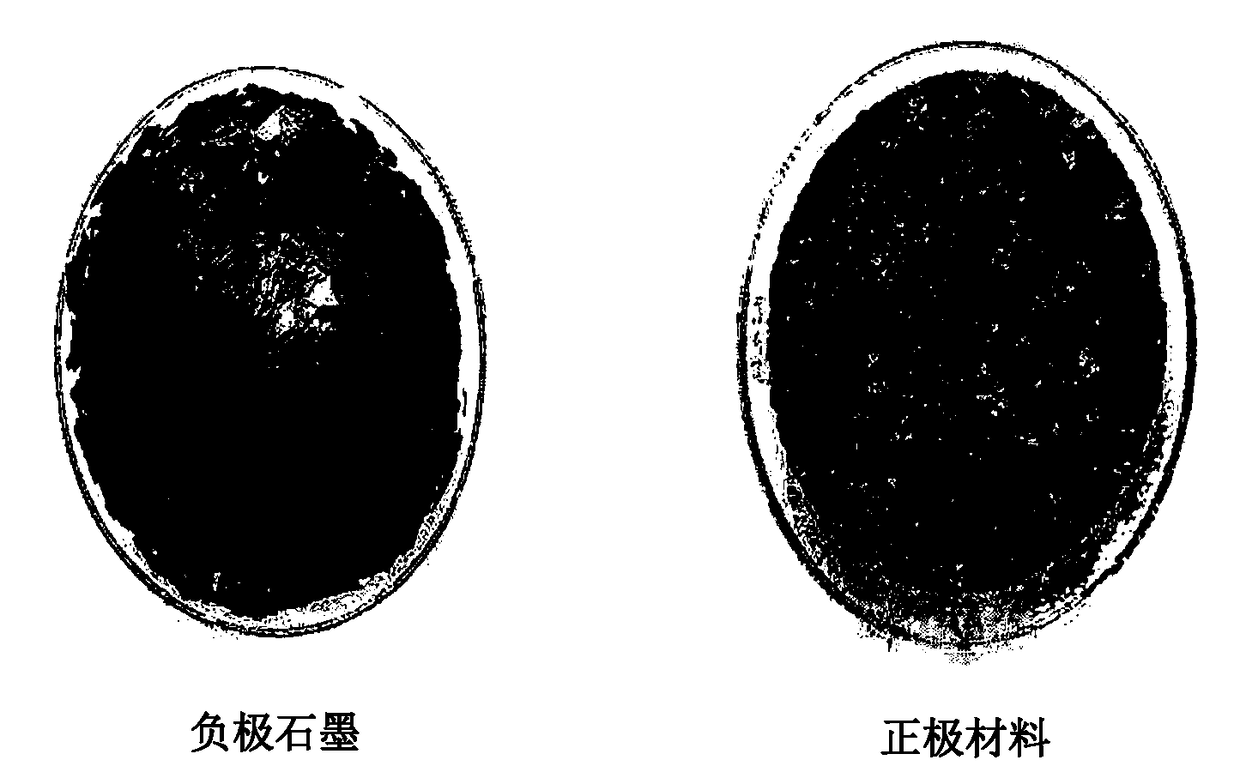

Green peeling method for electrode material of waste lithium ion power battery

ActiveCN108666645ASimple processLow costSolid waste disposalWaste accumulators reclaimingStrong acidsCopper foil

The invention provides an overall peeling method for a cathode material and an anode material based on the characteristics of compact structure, complicated composition, harmful electrolyte containingand the like of a waste lithium ion battery, wherein aluminum foil is effectively separated from the cathode material in controllable conditions, and then cathode graphite is effectively separated from copper coil while the electrolyte is effectively recycle; the whole technology does not apply corrosive solutions such as strong base, strong acid and strong oxidant, the peeling process is fast and efficient, the composite solvent is low in cost, all sub-systems are linked with each other, thus the method is a green and environment-friendly method for circularly utilizing a waste lithium ion power battery.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

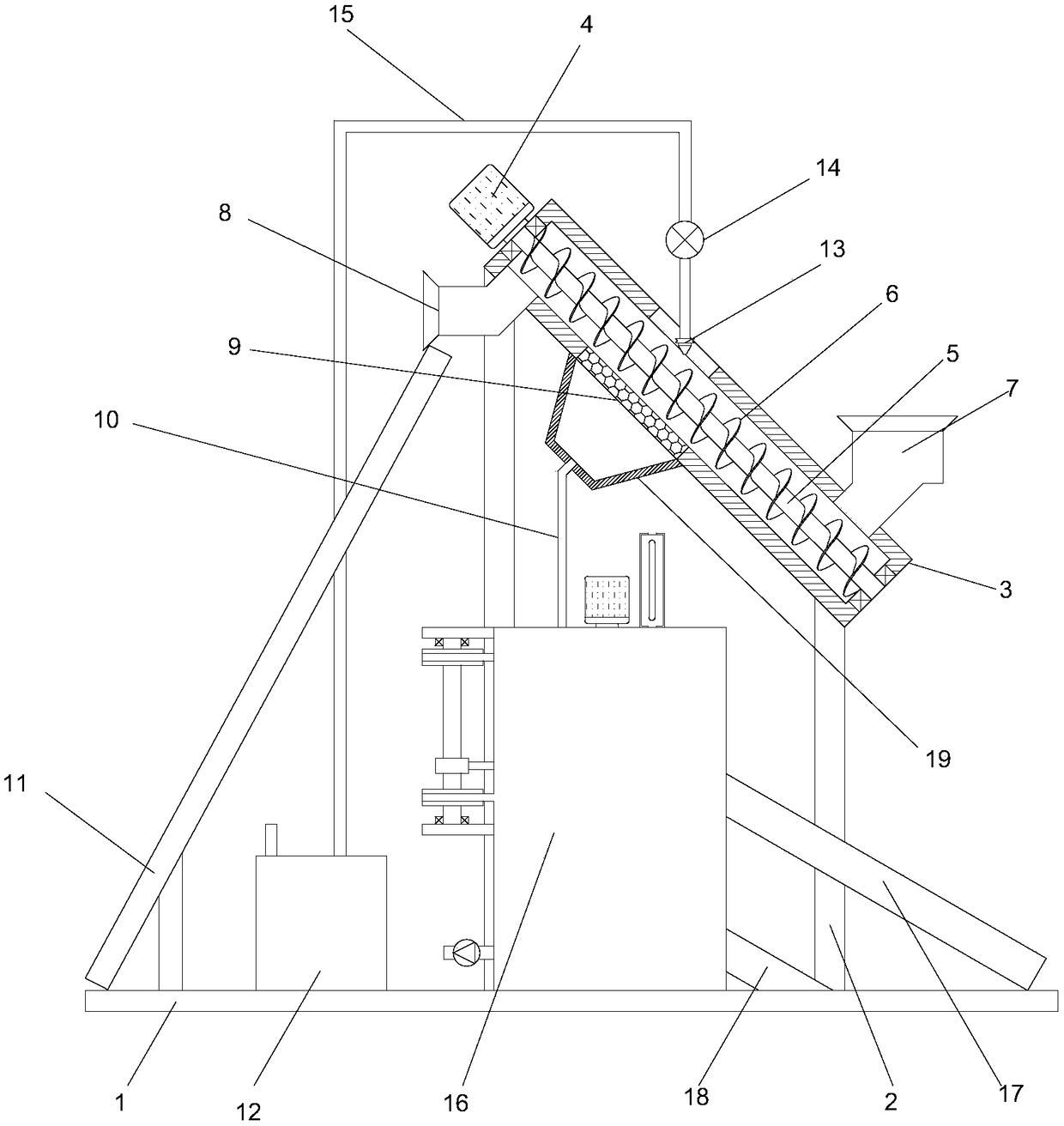

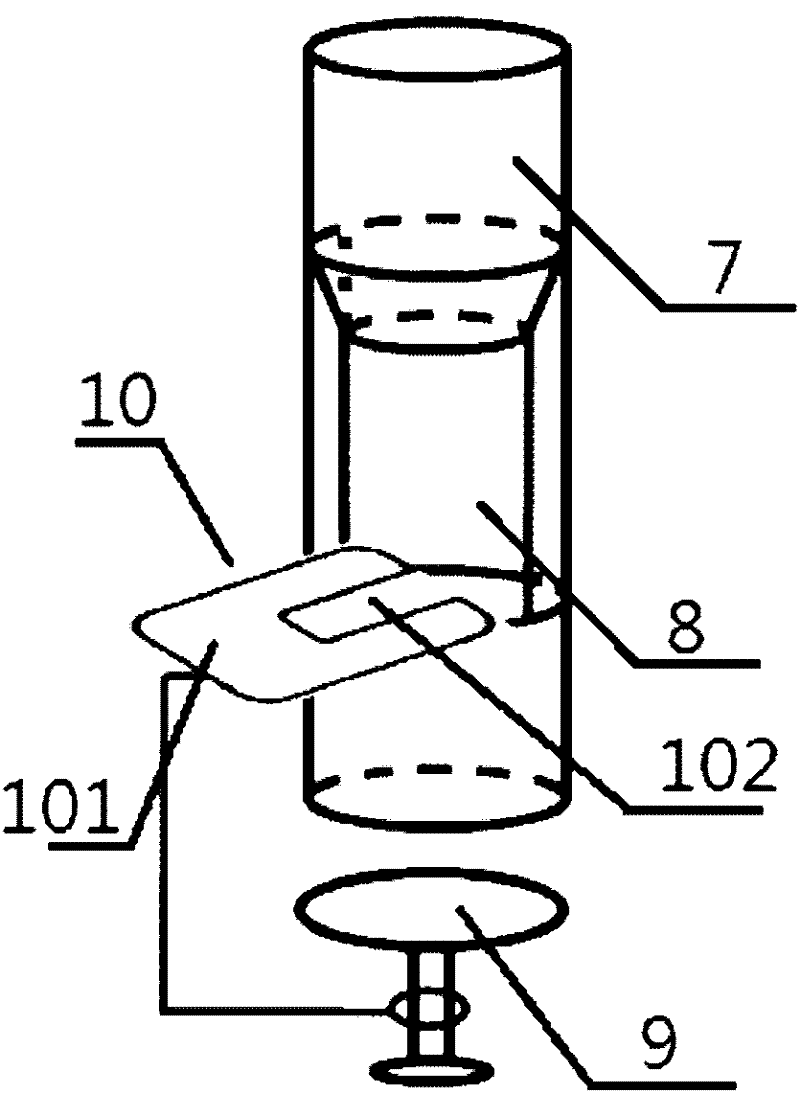

Sandstone separator with fine sand separating device

PendingCN108421711AEasy to separateHigh recovery puritySievingGas current separationFiltrationEngineering

The invention discloses a sandstone separator with a fine sand separating device. The sandstone separator comprises a bottom plate, a supporting column, a sandstone separation module, a fine sand separating device and a cleaning module, wherein the sandstone separation module is used for separating stones and cleaning and recycling the stones by the cleaning module; the fine sand separating deviceis used for separating mortar to obtain coarse sand and fine sand, so that the mortar is completely separated, the fine sand recycling purity is improved, and the fine sand is reutilized; a second motor is started to drive a first stirring shaft to rotate, so that the second stirring shaft is driven to rotate under the actions of a driving guide wheel, a driven guide wheel, a transmission shaft,a first transmission wheel, a second transmission wheel and a belt. The filtered mortar can be stirred under the effects of stirring blades, the filtration is accelerated, the production efficiency isimproved, the automatic sand discharging function is realized under the effects of a cylinder, a push rod, a second pin shaft, a second chute, a baffle, a spring, a sliding column and a sliding sleeve, the manual cost is reduced, and the production efficiency is improved.

Owner:广州臻太机械制造有限公司

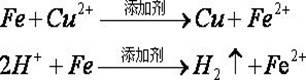

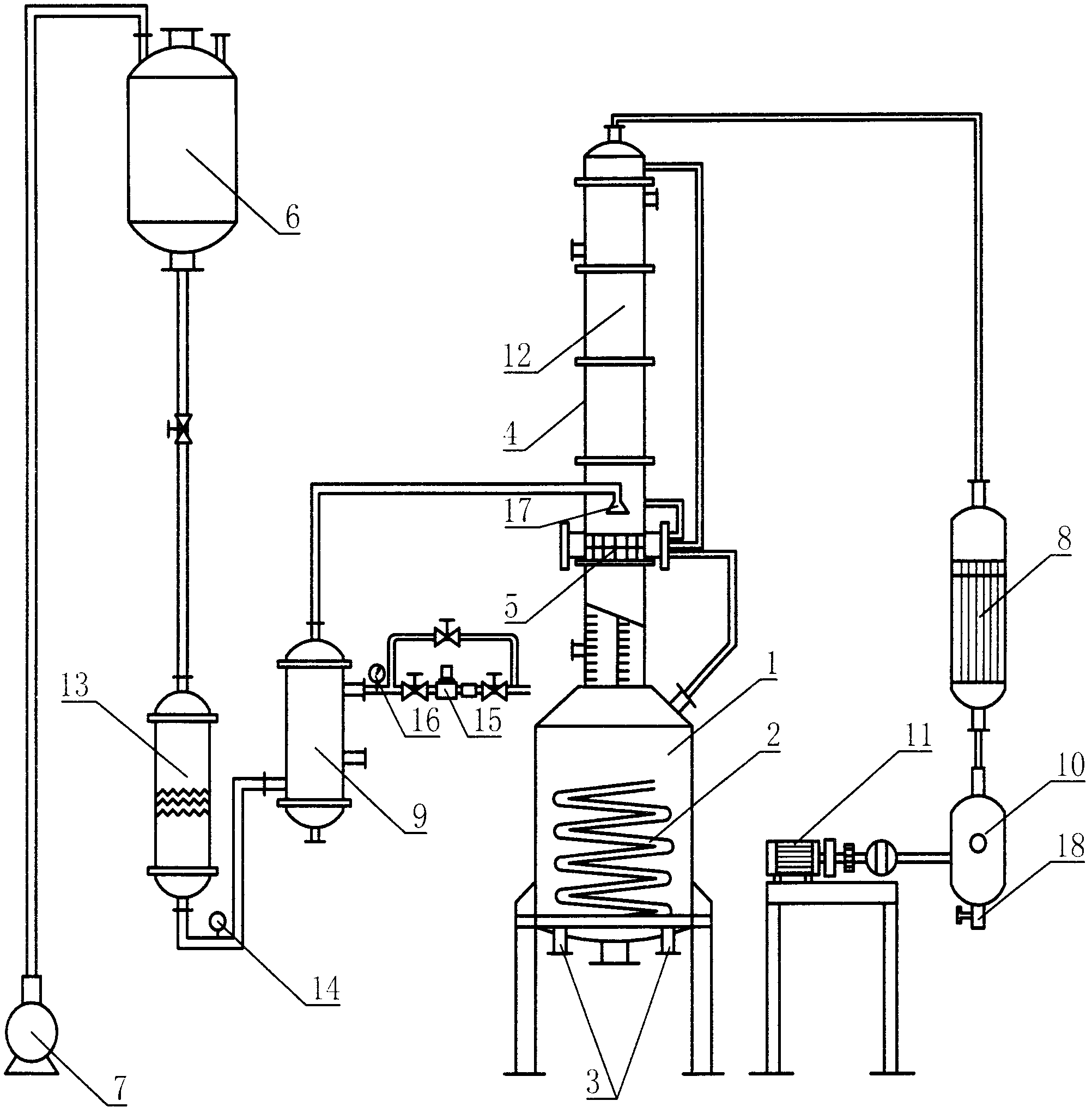

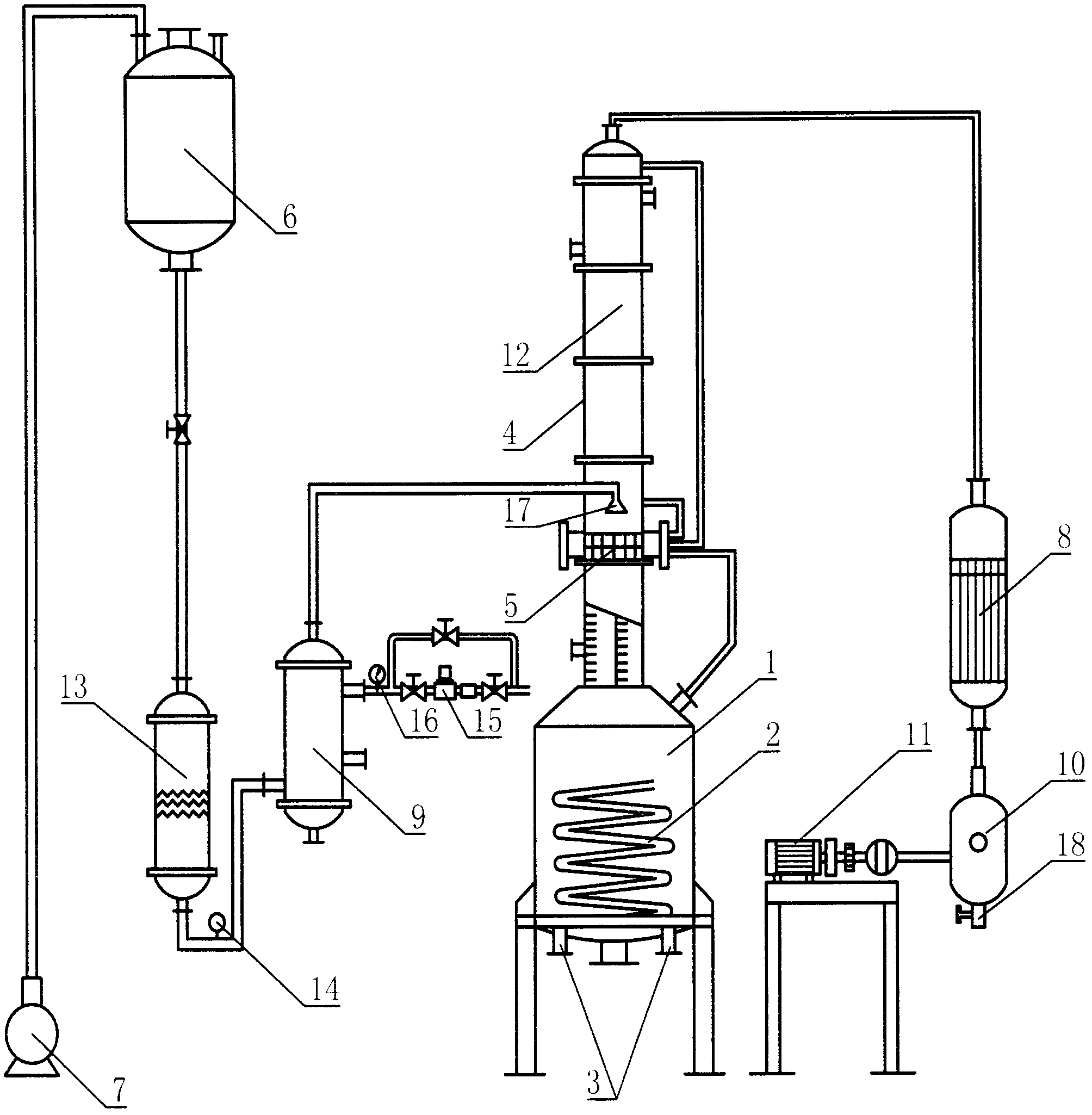

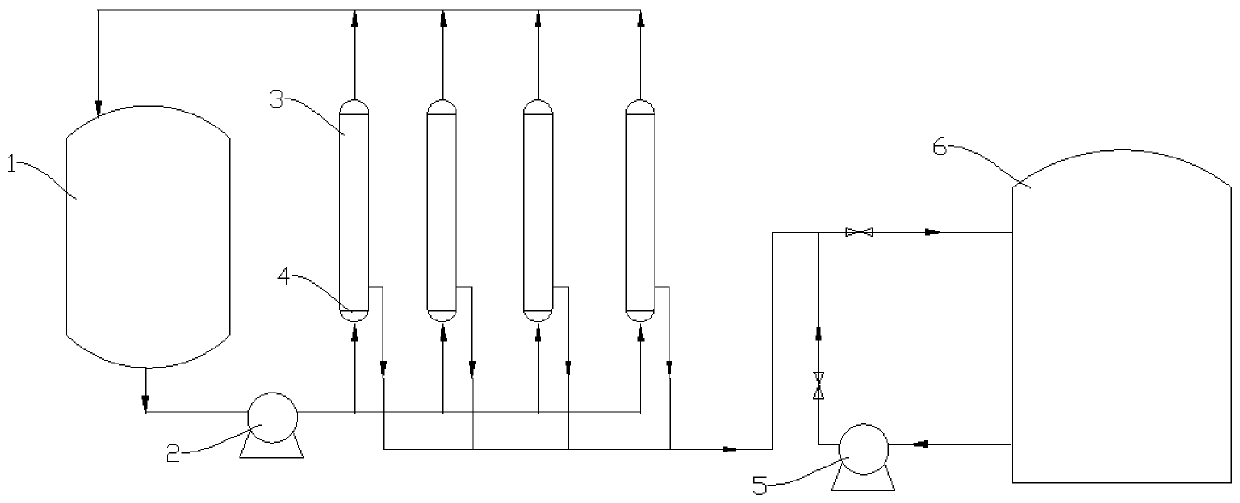

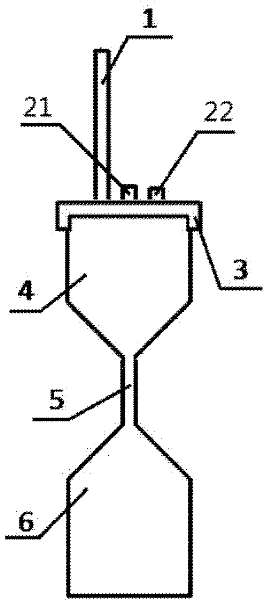

Alcohol recovery tower

InactiveCN102584524AEffective primary filtrationHigh recovery purityOrganic compound preparationHydroxy compound preparationAqueous alcoholDistillation

The invention relates to an alcohol recovery device, in particular to an alcohol recovery tower, which has a high recovery speed and high recovery purity and is economical and durable. The alcohol recovery tower comprises a distillation tower kettle (1), a distillation tower body (4), a high-level storage tank (6), a centrifugal pump (7), a condensation cooler (8), a filter (13), a preheater (9) and a vacuum storage tank (10), wherein the distillation tower body (4) is arranged above the distillation tower kettle (1); a heating pipe (2) is arranged inside the distillation tower kettle (1); two steam inlets (3) are symmetrically formed at the bottom of the distillation tower kettle (1); a filler (5) is arranged in the distillation tower body (4); one side of the distillation tower body (4) is connected with the high-level storage tank (6) provided with the centrifugal pump (7) through a pipeline; the other side of the distillation tower body (4) is connected with the condensation cooler (8) through a pipeline; the preheater (9) is arranged between the high-level storage tank (6) and the distillation tower body (4), and a steam heating way is adopted for the preheater (9); the vacuum storage tank (10) is arranged below the condensation cooler (8); one side of the vacuum storage tank (10) is provided with a vacuum pump (11); and the bottom of the vacuum storage tank (10) is provided with an alcohol outlet (18).

Owner:付顺林

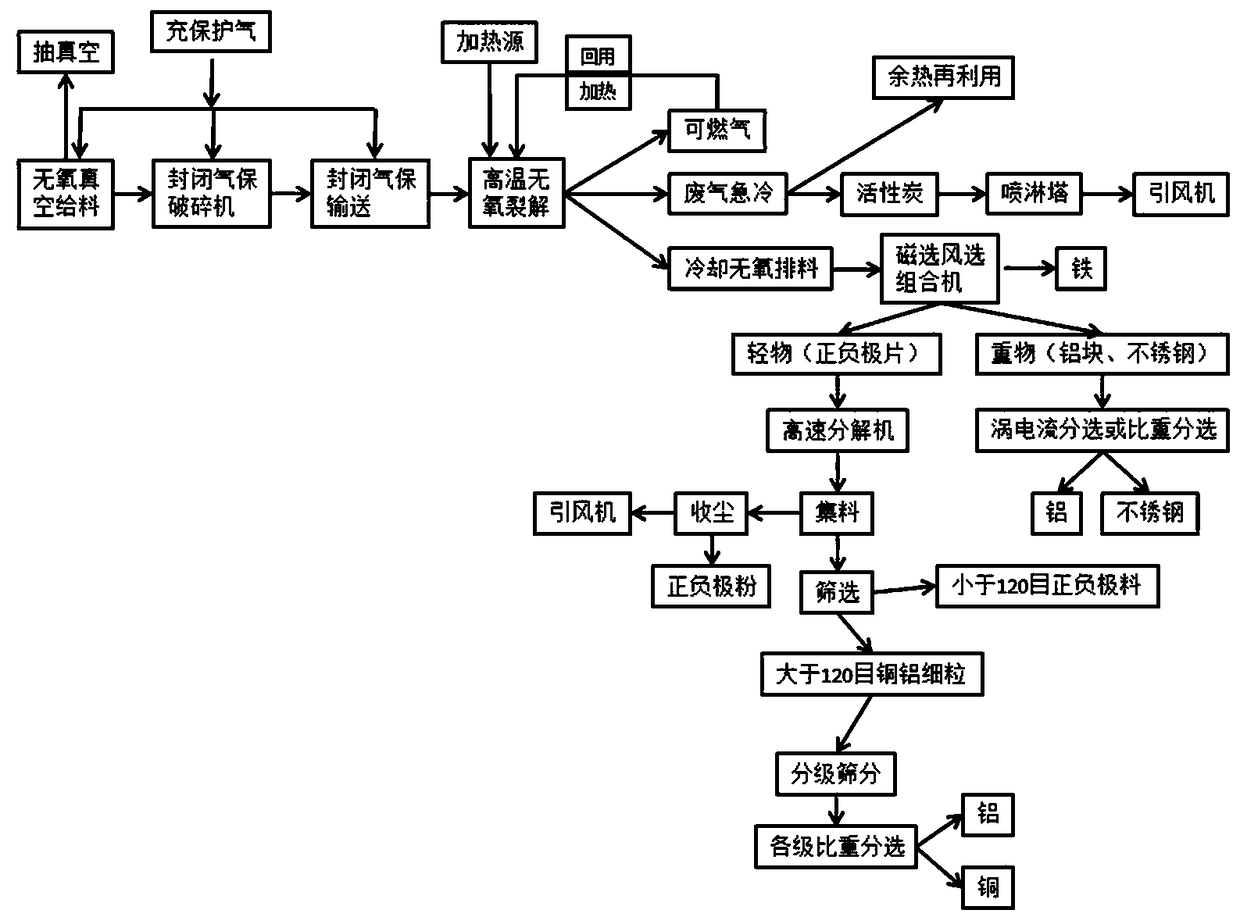

Crushing and recycling process of lithium battery after anaerobic cracking

ActiveCN108927401AReduce adhesionHigh recovery purityTransportation and packagingSolid waste disposalForming gasCombustible gas

Owner:河南巨峰环保科技有限公司

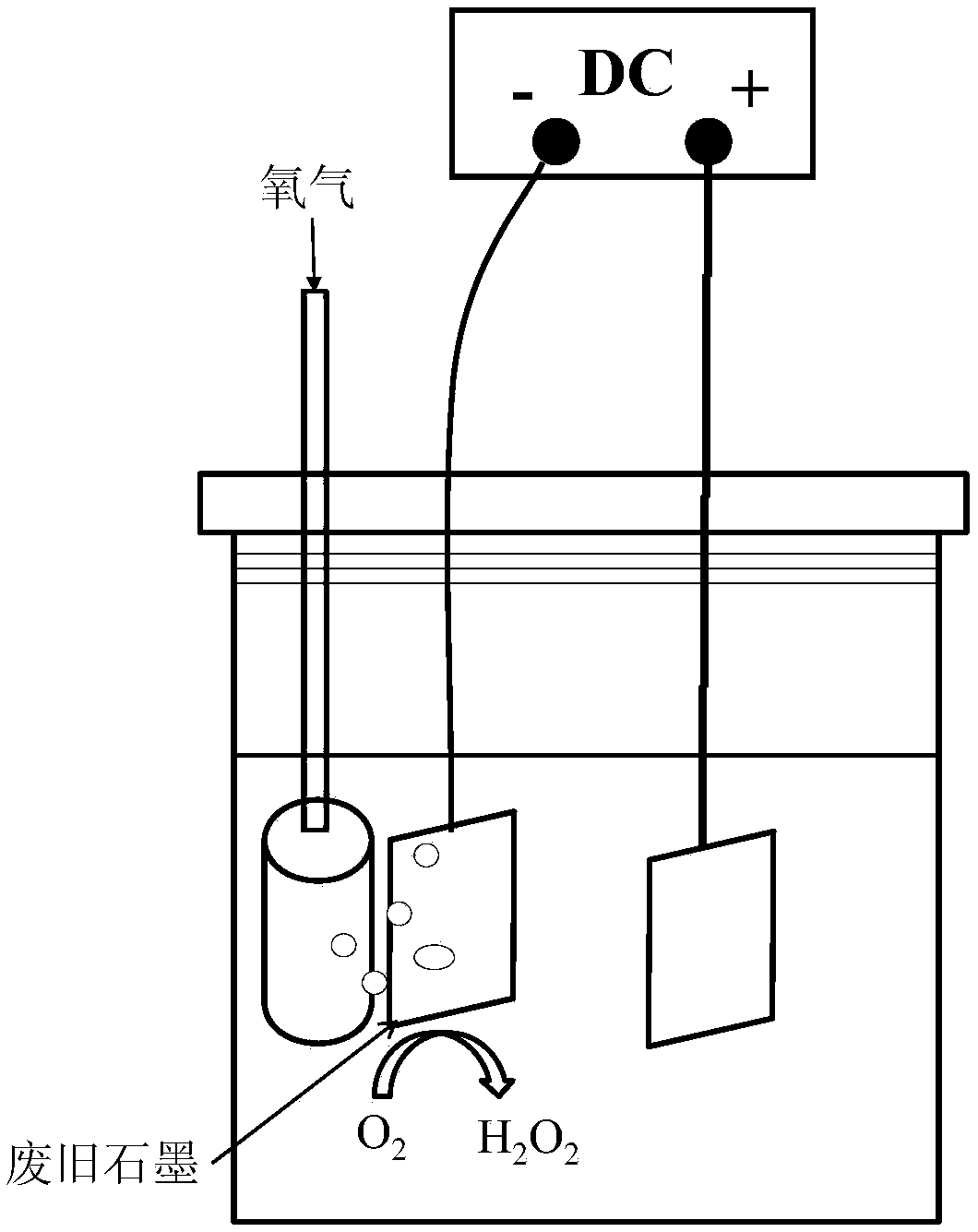

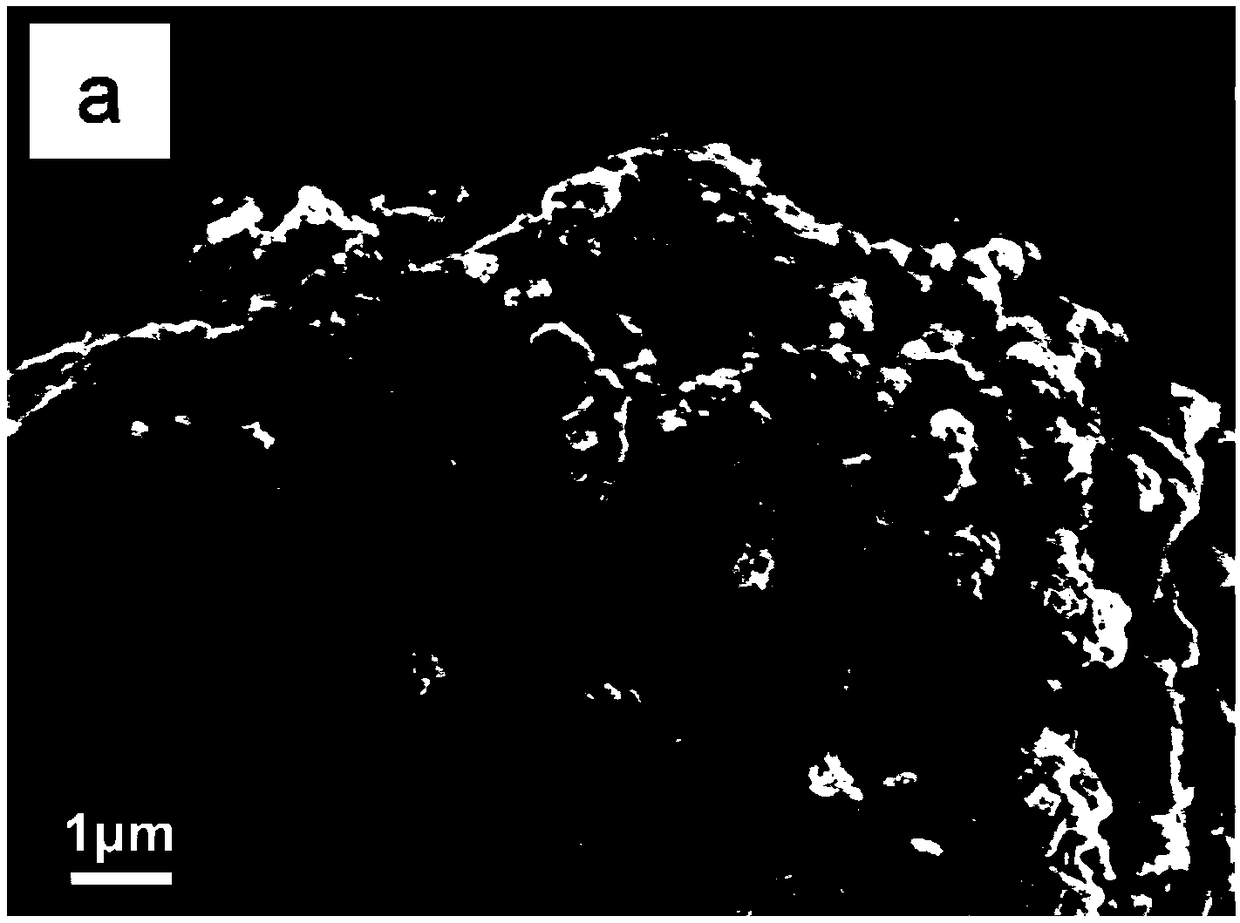

Method for preparing electric Fenton cathode by recycling graphite from negative electrode of lithium ion battery

ActiveCN108123186AHigh purityThe purity is greatly improvedWaste accumulators reclaimingBattery recyclingEconomic benefitsSlurry

The invention provides a method for preparing an electric Fenton cathode by recycling graphite from a negative electrode of a lithium ion battery. The method comprises the following steps: (1), takinga negative electrode sheet of the lithium ion battery; (2), performing ultrasonic stripping on the negative electrode sheet obtained in the step (1), and collecting to obtain stripped graphite powder; (3), leaching the stripped graphite powder obtained in the step (2), filtering, and collecting a filter residue to obtain treated graphite powder; and (4), preparing the treated graphite powder obtained in the step (3) into an electrode slurry, stirring, and laminating onto a base electrode to obtain the electric Fenton cathode. The electric Fenton cathode prepared by the method provided by theinvention has relatively high hydrogen peroxide yield and can efficiently degrade pollutants during pollutant treatment. By the method provided by the invention, environment pollution can be relievedand maximization of the economic benefit is achieved. By the method, the graphite recycling purity can be as high as 99%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

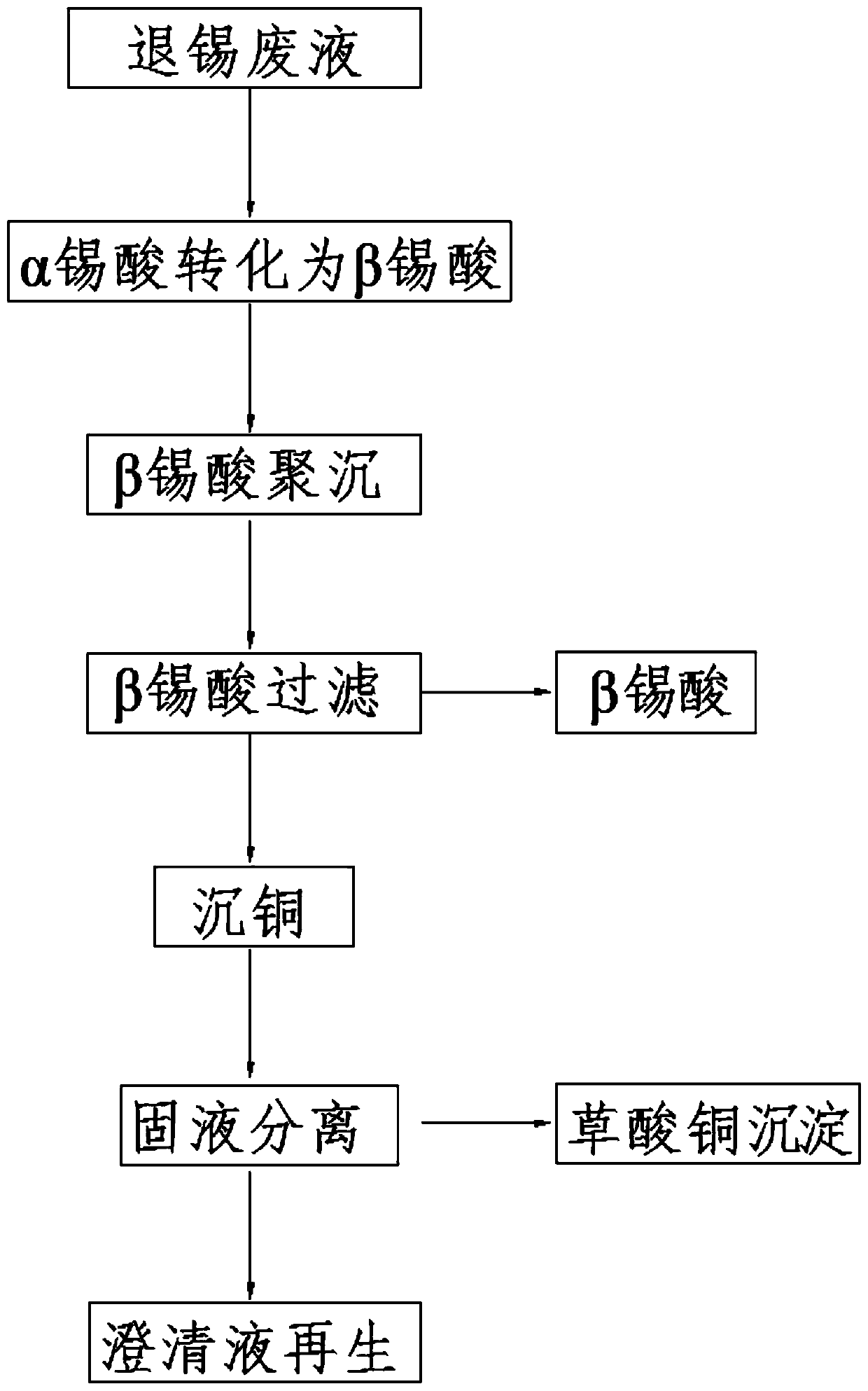

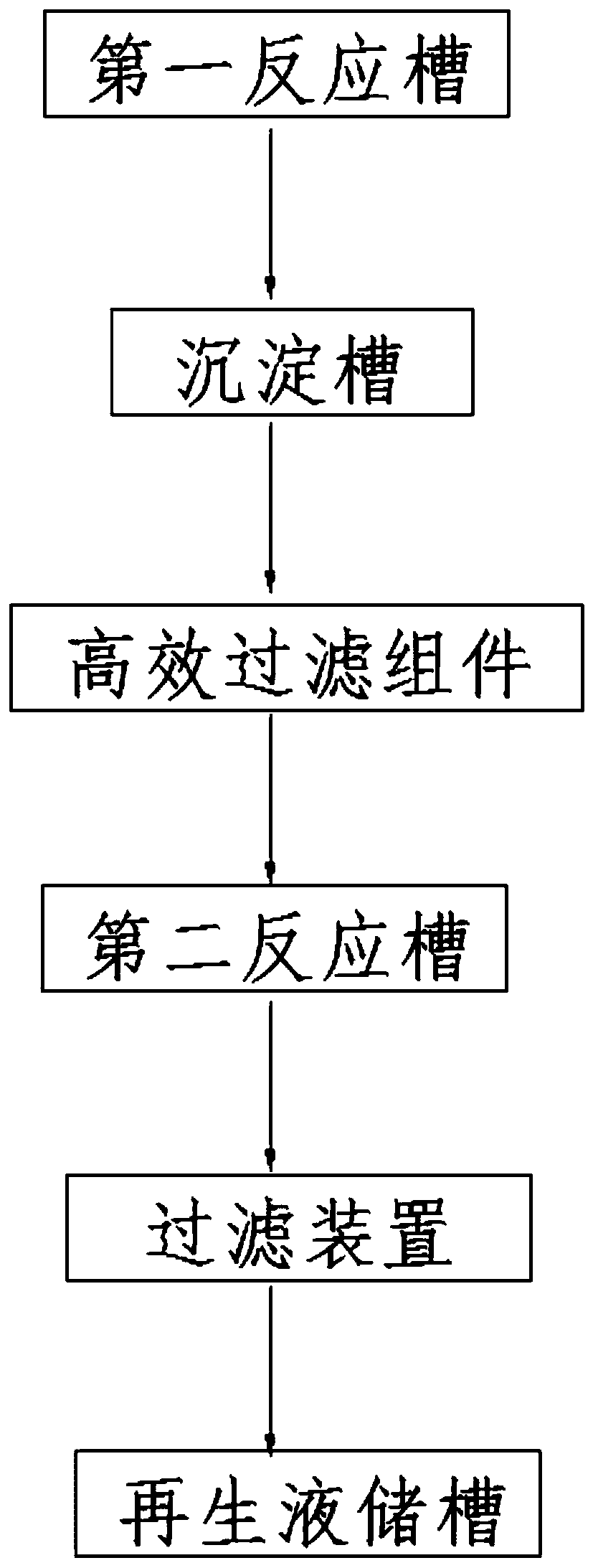

Regeneration system and method of solder stripping waste water

ActiveCN111424280AHigh purityHigh recovery rateProcess efficiency improvementFiltrationLiquid storage tank

The invention relates to the field of production waste treatment in printed circuit manufacturing, and discloses a regeneration method of solder stripping waste water. The regeneration method comprises the following steps of completely converting alpha stannic acid into beta stannic acid; coagulating the beta stannic acid; filtering the beta stannic acid; precipitating copper from the filtrate; carrying out solid-liquid separation; and regenerating clarified liquid; wherein the regeneration system comprises a waste liquid storage tank, a first reaction tank, a precipitation tank, an efficientfiltering assembly, a second reaction tank, a filtering device and a regeneration liquid storage tank which are sequentially connected. According to the method, firstly, the solder stripping waste water is innovatively pretreated to convert alpha stannic acid into beta stannic acid, then the beta stannic acid is subjected to coagulation, filtration, filtrate re-copper deposition, filtration and sub-liquid regeneration, and copper and tin are separated step by step, so that the use amount of a copper deposition agent is reduced, the treatment cost is reduced, meanwhile, an alkaline solution isnot required to be used in the treatment process, the raw material cost of the regeneration treatment process of the solder stripping waste water is greatly reduced, the treatment process is simplified, meanwhile, the recovery purity of copper and tin products is improved, and the profit of the recovered products is improved.

Owner:遂宁市瑞思科环保科技有限公司

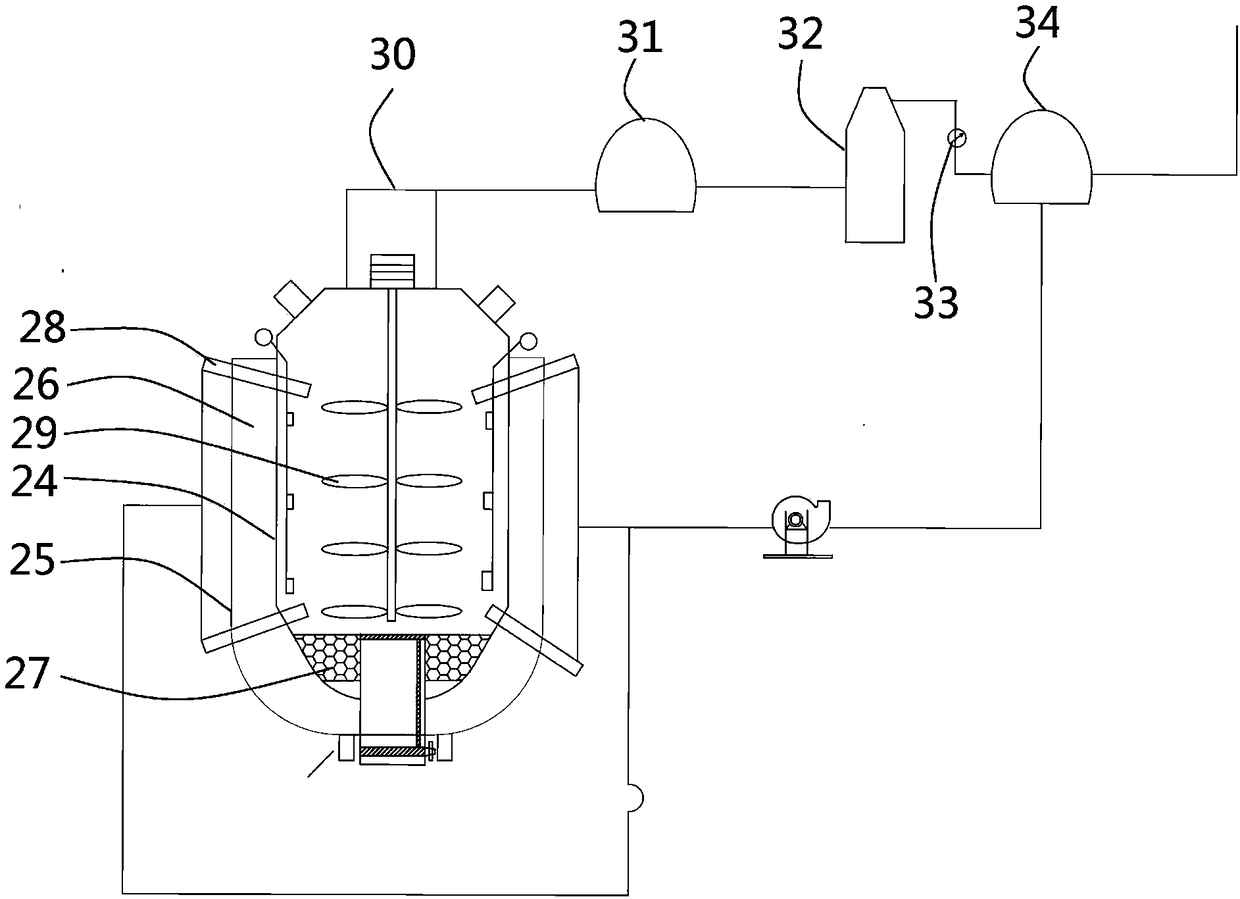

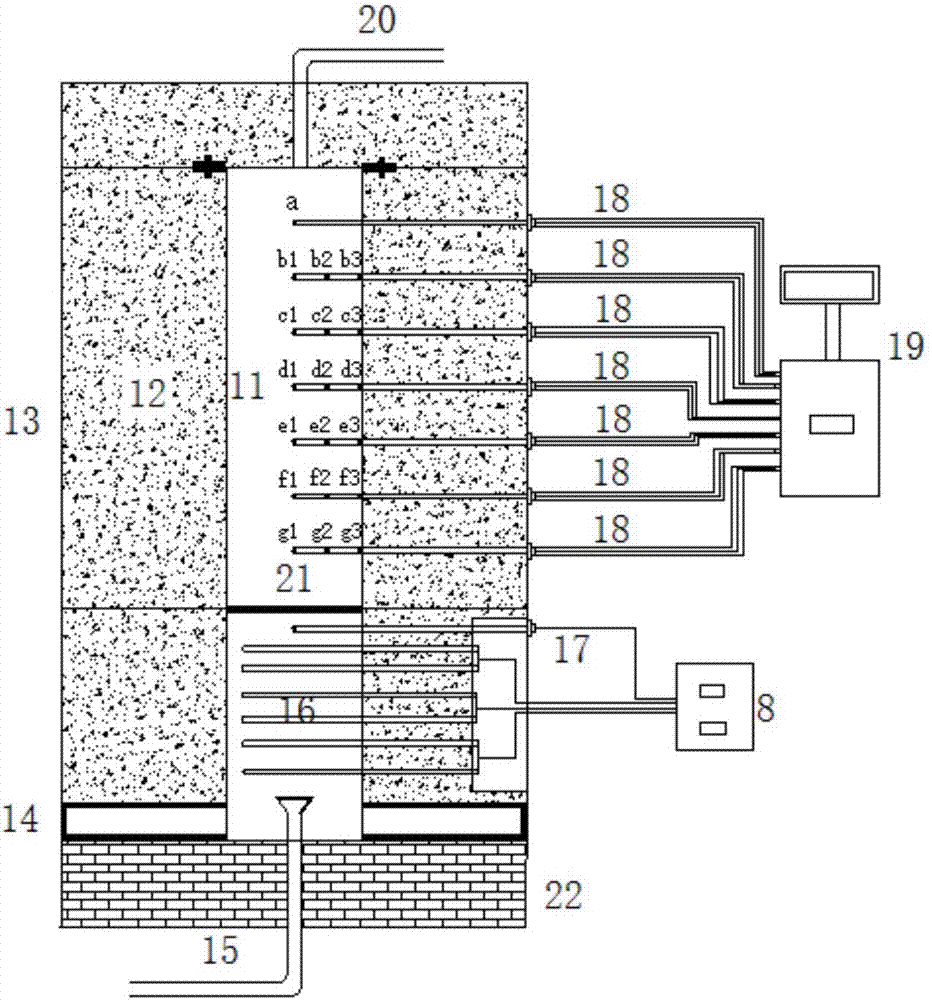

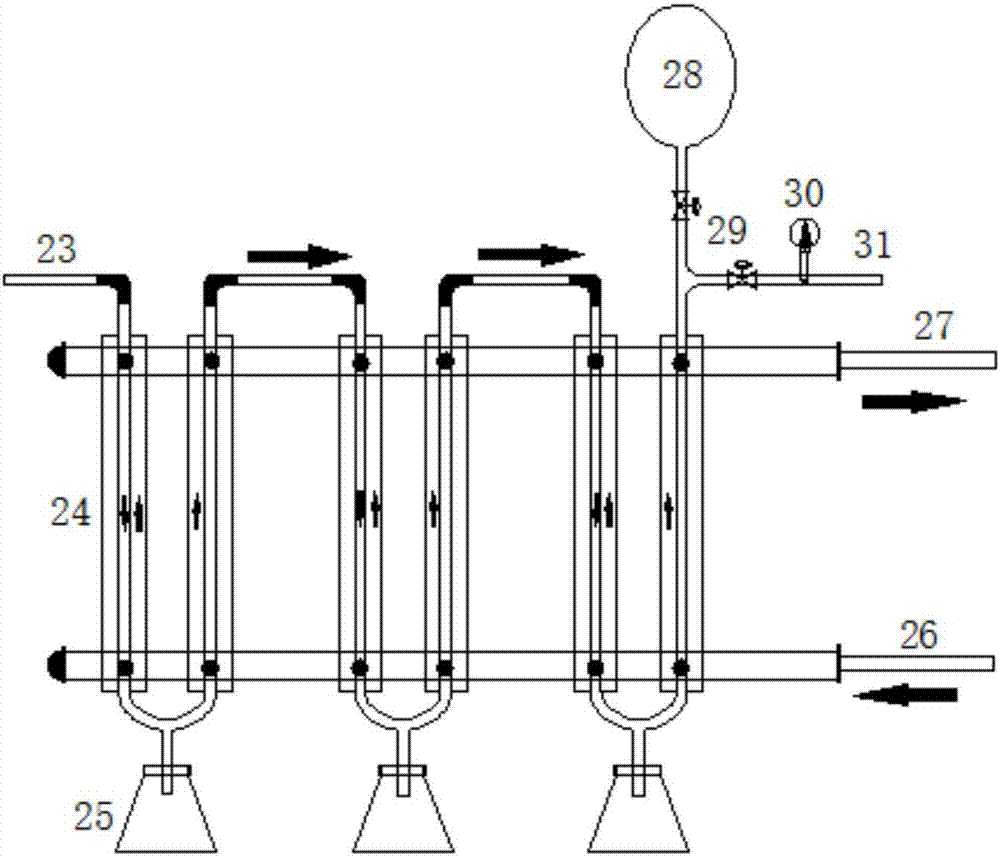

Waste circuit board fixed bed pyrolyzing system heated through high-temperature gas seepage

PendingCN106944455AHigh recovery rateHigh recovery purityTransportation and packagingSolid waste disposalFixed bedHearth

The invention discloses a waste circuit board fixed bed pyrolyzing system heated through high-temperature gas seepage. A porous plate is mounted at the bottom of a hearth of the pyrolyzing furnace in the horizontal direction. A control box side thermocouple and an auxiliary heater are arranged in the interior, on the lower portion of the porous plate, of the hearth of the pyrolyzing furnace. A plurality of mounting holes leading to the hearth of the pyrolyzing furnace are formed in the position, on the upper portion of the porous plate, of a furnace body. A pyrolyzing furnace thermocouple is mounted in each mounting hole. A pyrolysis gas outlet pipe communicating with the hearth of the pyrolysis furnace is arranged on a furnace cover. An outlet of the pyrolysis gas outlet pipe is connected with a pyrolysis gas condensation collecting system. The bottom of the hearth of the pyrolysis furnace communicates with a pipeline and a self-pressurization nitrogen tank in the heater in sequence through a high-temperature nitrogen inlet pipe. By adopting the device, pyrolysis efficiency can be improved, and pollution to the environment is reduced.

Owner:TIANJIN UNIV

Method for recycling copper from copper nitrate waste water

ActiveCN101906644AHigh recovery rateSimple production processPhotography auxillary processesProcess efficiency improvementCopper nitrateWastewater

The invention discloses a method for recycling copper from copper nitrate waste water. The technical key points of the invention are that: an iron rod is taken as an insoluble anode; a copper plate is taken as a cathode; and gas stirring is performed on the copper nitrate waste water in an electrolytic bath, so that an electrolytic process can be operated continuously. The purity of the copper recycled by the method is over 99.97 percent, and the recovery rate of the copper is over 99.5 percent. The method has the advantages of short process flow, simple operation, simple equipment, low equipment requirement, low investment and particular suitability for the realization of the recycling of the copper from the copper nitrate waste water in small and medium-sized enterprises.

Owner:温州伟达贵金属粉体材料有限公司

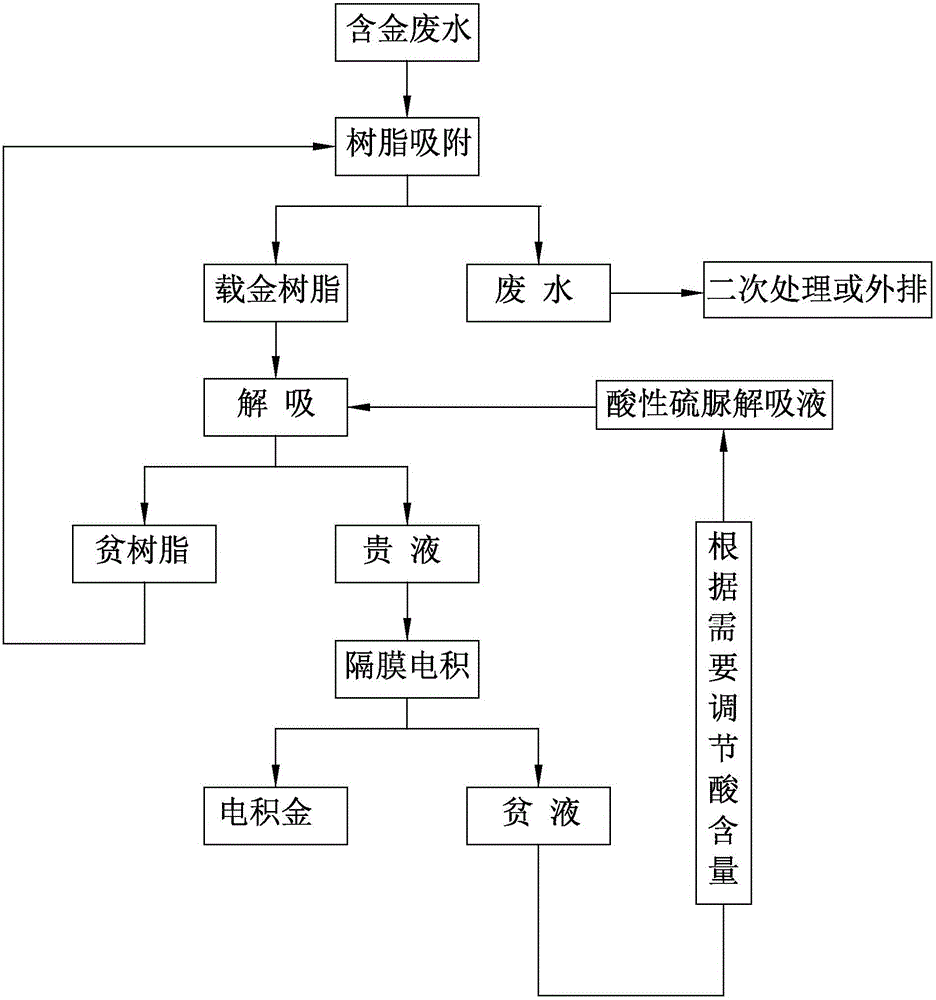

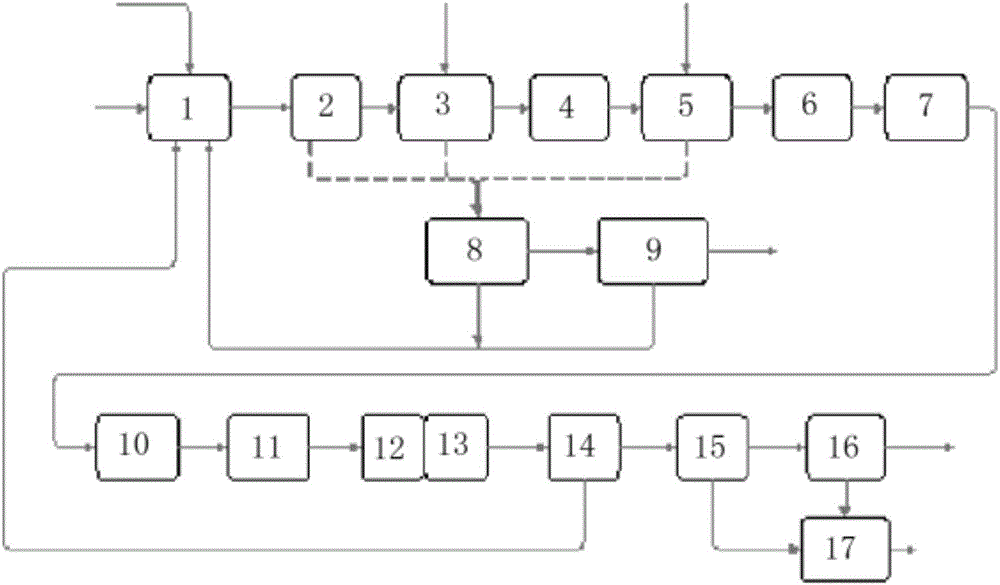

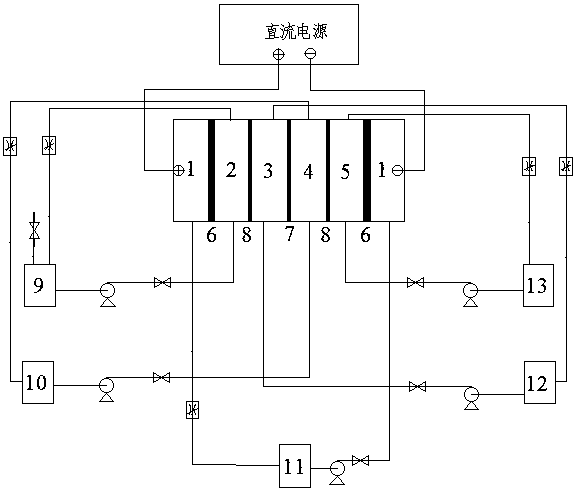

Method for recycling gold in situ from gold-containing wastewater

InactiveCN105819595AIncrease productivityReduce manufacturing costPhotography auxillary processesWater contaminantsChelating resinElution

The invention discloses a method for recycling gold in situ from gold-containing wastewater. The method is free of pollution, simple in process and convenient and rapid to implement, and intermediate consumables can be reutilized. The technological method of resin adsorption, gold-loaded resin desorption, diaphragm electrodeposition and barren resin gold adsorption is adopted, so that the process has the advantages of being high in production efficiency, low in production cost, free of wastewater transfer cost, thorough in gold recycling and the like; enrichment, elution desorption and electrolysis are carried out in situ, gold recycling is achieved, and the risk of wastewater transfer is avoided. According to the method, chelate resin is adopted to adsorb gold, an acidic thiourea system is adopted to carry out elution desorption on gold-loaded resin, barren resin obtained after desorption is returned to adsorb gold, gold in a pregnant solution obtained after desorption is extracted with a diaphragm electrodeposition method, a barren solution obtained after electrolysis is returned and used for desorbing the gold-loaded resin, and thus the technological process with the gold adsorption resin and the desorption solution reused is formed. When the method is applied to wastewater containing minor gold or trace gold, gold can be thoroughly recycled, and the gold residual in the barren solution can be reduced to 0.001 ppm and is almost zero.

Owner:深圳市世清环保科技有限公司 +1

Treating method and treating device for zero discharging of desulfurization wastewater

PendingCN106517598AReduce hardnessAvoid pollutionWater treatment compoundsWater contaminantsFiltrationIon exchange

The invention discloses a treating method and a treating device for zero discharging of desulfurization wastewater. The treating method comprises the following steps: (1) performing aeration treatment and pre-sedimentation treatment on the desulfurization wastewater and collecting a first effluent; (2) performing coagulation treatment and softening treatment on the first effluent in turn, thereby obtaining a second effluent; (3) performing ultra-filtration treatment and ion exchange treatment on the second effluent in turn and collecting a third effluent; (4) performing nano-filtration treatment on the third effluent and collecting clean water; (5) performing reverse osmosis treatment on the clean water, thereby obtaining second concentrated water; (6) performing crystallizing treatment on the second concentrated water, thereby obtaining a crystal salt, and meanwhile, collecting the water generated in the steps (5) and (6), thereby obtaining water meeting standard. The device comprises an aeration adjusting device, a pre-sedimentation device, a coagulation treatment device, a softening treatment device, an ultra-filtration device, an ion exchange device, a nano-filtration device, a reverse osmosis device and a crystallizing device. The device has the advantages of running stability, good wastewater treatment effect and high recycling purity of sodium chloride.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

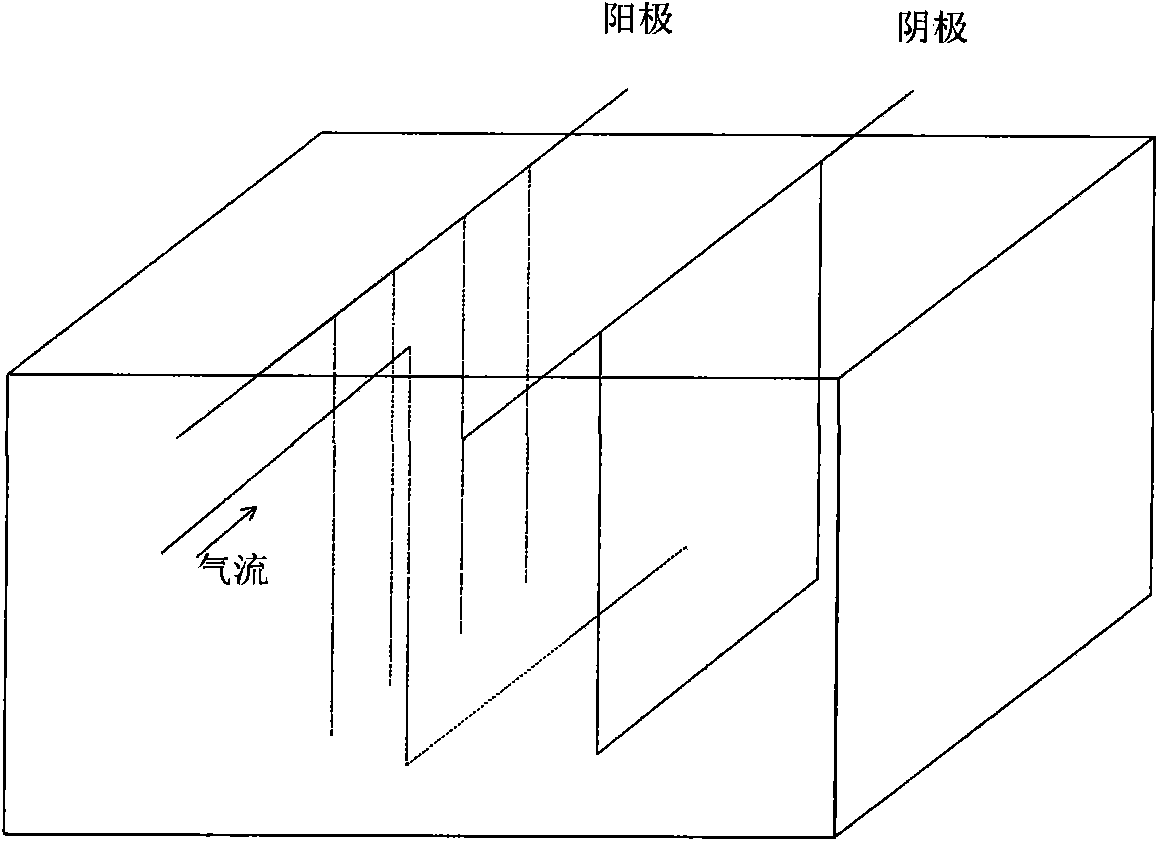

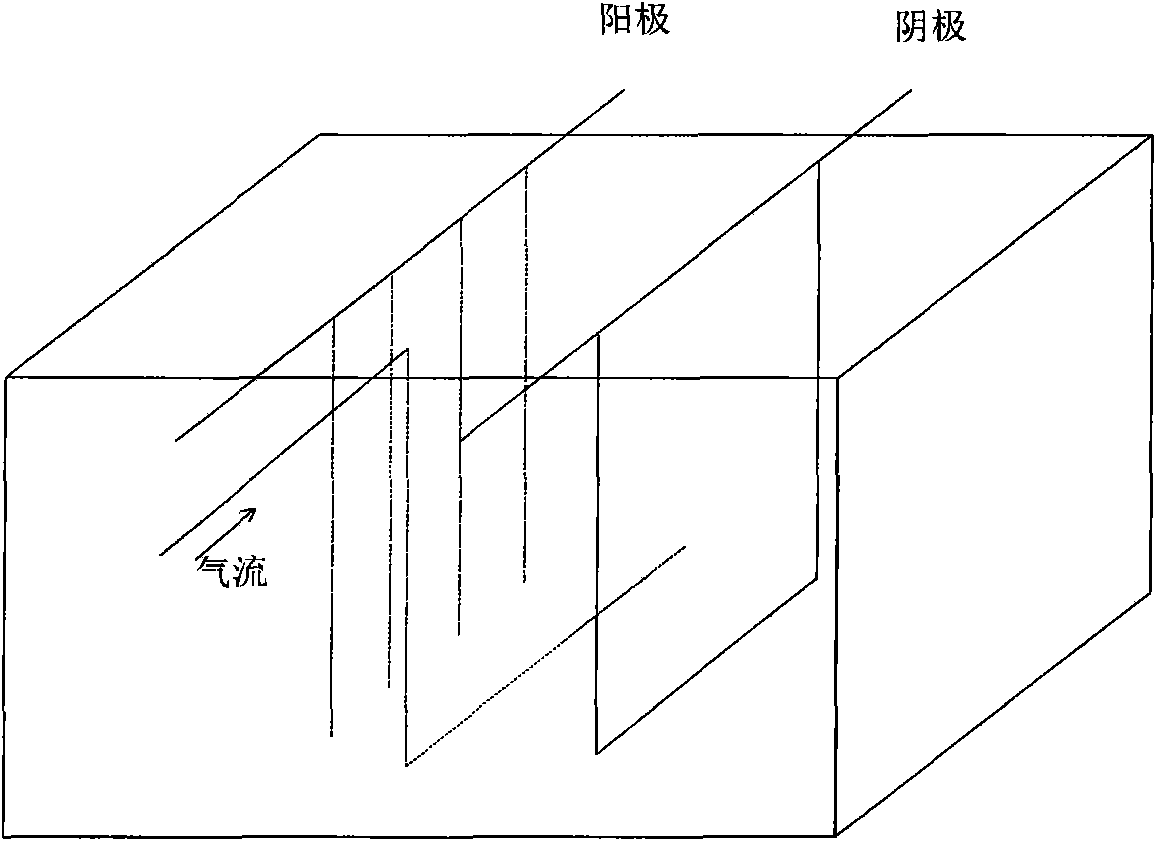

Method for recovering tetrabutylammonium hydroxide by electrolysis of tetrabutylammonium sulfate solution

InactiveCN108467347AHigh recovery purityHigh purityAmino compound purification/separationOrganic compound preparationElectrolysisTetrabutylammonium sulfate

The invention discloses a method for recovering tetrabutylammonium hydroxide by electrolysis of a tetrabutylammonium sulfate solution, and belongs to the technical field of recovery of tetrabutylammonium hydroxide by bipolar membrane electrodialysis. According to the key points of the technical scheme, the tetrabutylammonium sulfate solution is subjected to bipolar membrane electrodialysis in a four-compartment electrodialysis device with an intermediate liquid chamber, and the four-compartment electrodialysis device with the intermediate liquid chamber comprises polar liquid chambers at bothsides and an electrodialysis compartment sandwiched between the polar liquid chambers at two sides, and the electrodialysis compartment is of a four-compartment structure and is composed of the intermediate liquid chamber, an acid liquid chamber, a material liquid chamber and an alkaline liquid chamber which are formed by alternately and separately arraying a bipolar membrane, a cationic exchangemembrane, an anionic exchange membrane, a cationic exchange membrane and a bipolar membrane; a tetrabutylammonium hydroxide solution is obtained in the alkaline liquid chamber, and a sulfuric acid solution is obtained in the acid liquid chamber. The method can remarkably improve the purity and the recovery rate of the recovered product tetrabutylammonium hydroxide.

Owner:XINXIANG CHEM FIBER

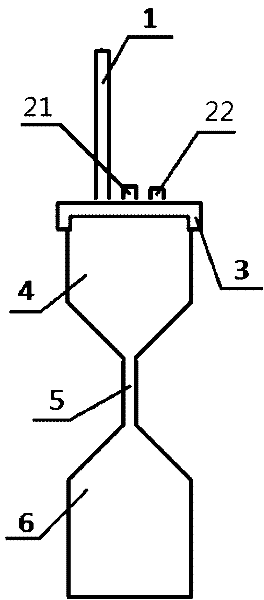

Totally-enclosed cell and cell factor preparation device and preparation method thereof

ActiveCN102242054AShorten the flow distanceReduce lossesBioreactor/fermenter combinationsBiological substance pretreatmentsCord blood stem cellMedicine

The invention discloses a totally-enclosed cell and cell factor preparation device which comprises an upper blood bag, a lower blood bag and a thin connecting pipe, wherein the upper blood bag is provided with an anti-coagulation inlet, a plasma sucking port for sucking plasma and an output port for outputting cells and cell factors; the bottom of the upper blood bag is conical; the top of the lower blood bag is conical; and the upper blood bag, the thin connecting pipe and the lower blood bag are formed into a dumbbell-shaped blood collecting bag. The cell and cell factor preparation method comprises the following steps of: introducing anti-coagulation blood, marrow and cord blood into the blood collecting bag, erecting the blood collecting bag on a hard sleeve, putting the hard sleeve into a centrifuge, and starting the centrifuge; separating the lower blood bag from the thin connecting pipe; fully mixing the plasma in the upper blood bag, and extracting the plasma in the upper blood bag for testing platelet concentration; reserving the plasma in the upper blood bag for later use; or centrifuging again to extract a plasma layer, and reserving centrifugally precipitated cells. The invention has the advantages of simplicity and convenience in operation, low loss of platelets, mononuclear cells and cell factors and high enrichment ratio, and obviously improves the safety and practicality.

Owner:ZHEJIANG XINGYUE BIOTECH

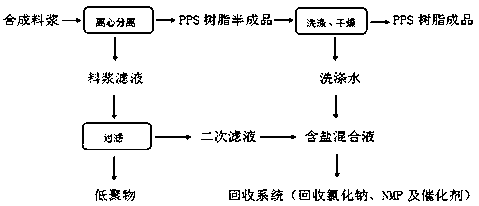

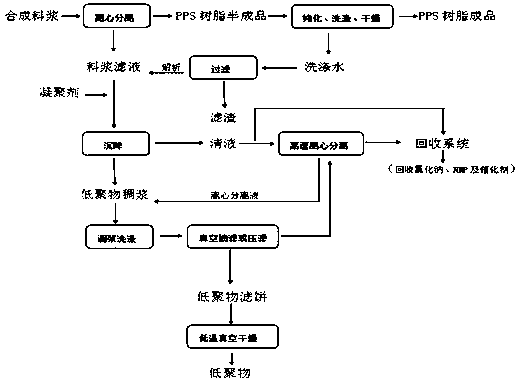

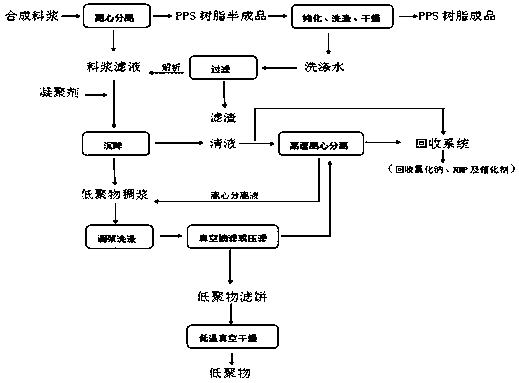

Method for separating oligomers from polyphenylene sulfide resin synthesis slurry

The invention discloses a method for separating oligomers from a polyphenylene sulfide resin synthesis slurry. The method comprises the following steps: (1) synthesizing polyphenylene sulfide resin; (2) washing the polyphenylene sulfide resin, separated from the synthesis slurry, with water; (3) filtering obtained washing water, and adding the filtered washing water to the synthesis slurry remaining after the separation in order to form a mixed slurry; and (4) adding a first reagent to the mixed slurry, carrying out standing settlement for 2-8 h, and separating and collecting the oligomers obtained after the settlement, wherein the first reagent is one or more selected from nitric acid, sulfuric acid, hydrochloric acid and phosphoric acid. The method can fully desorb and agglomerate the oligomers in the polyphenylene sulfide synthesis slurry, so the recovery rate and the recovery purity of raw materials, solvents, byproducts and catalysts remaining in the synthesis slurry are greatly improved.

Owner:YIBIN UNIV

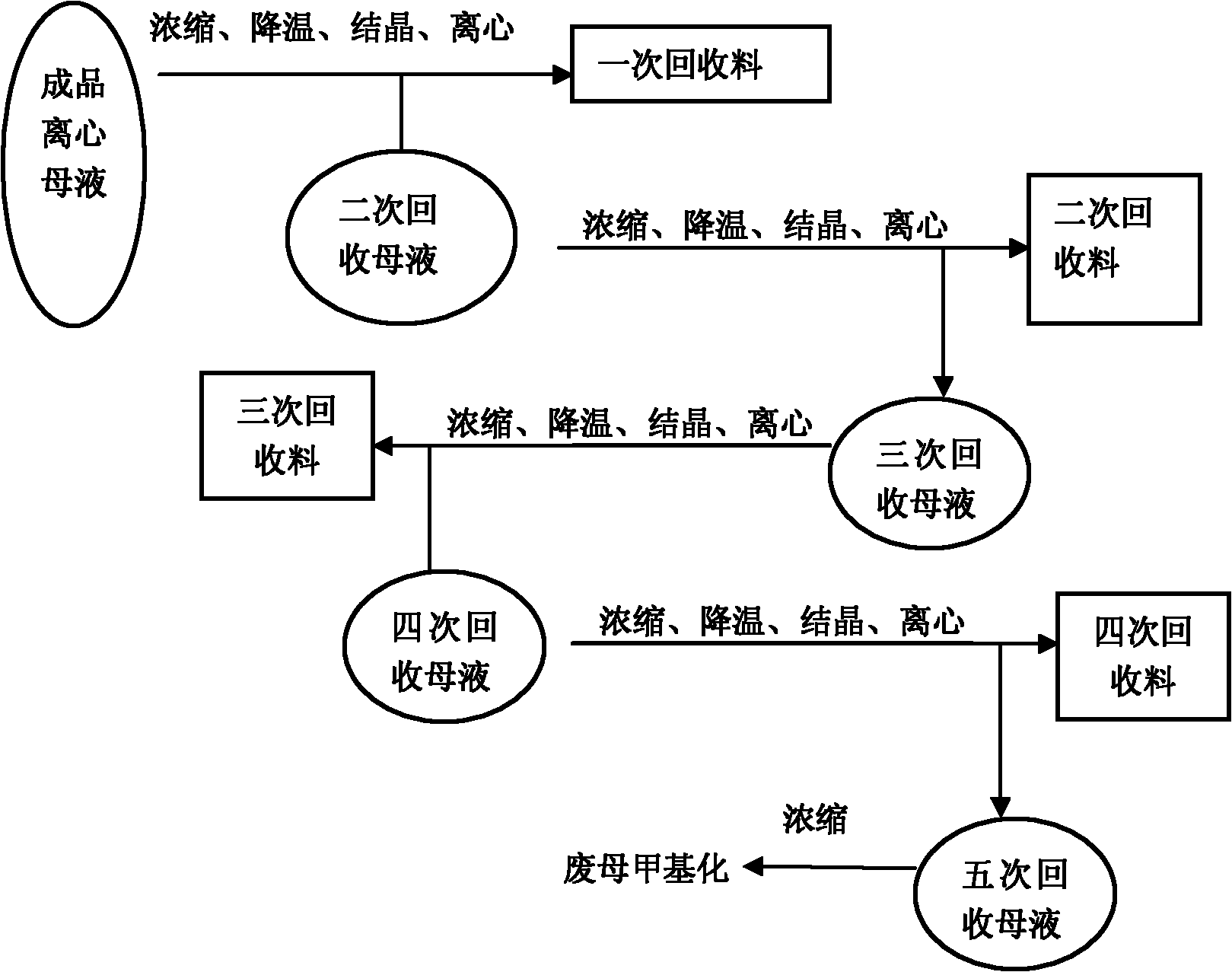

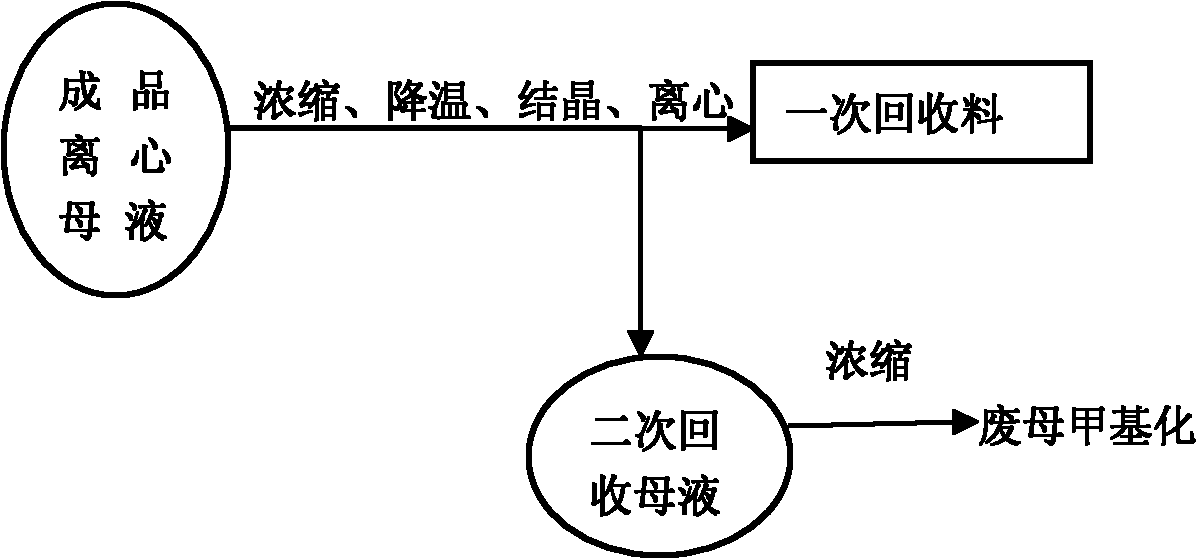

Recovery process of analginum finished product centrifugal mother liquid

ActiveCN102584706ASimple processIncrease crystallization rateOrganic chemistryOrganic solventCentrifugation

The invention belongs to the field of medicine chemical and particularly relates to a recovery process of analginum finished product centrifugal mother liquid. Firstly, the analginum finished product centrifugal mother liquid is concentrated, then, organic solvents are added into concretes for dissolution, and analginum primary recovery materials and secondary recovery mother liquid are prepared through temperature reduction, crystallization and centrifugation. The recovery process provided by the invention has the advantages that the process is simple, the content in the analginum primary recovery materials can reach 77 to 80 percent, and the crystallization rate of the finished product centrifugation mother liquid reaches 84 to 92 percent. The centrifugation rate is improved, the analginum content in the secondary recovery mother liquid only accounts for 3 to 5 percent of the total theoretical quantity of the analginum, and the secondary recovery mother liquid can be directly delivered to aminopyrine waste mother liquid methylation posts. The recovery temperature reduction problem of secondary recovery mother liquid to quartic recovery mother liquid is avoided. An open type stainless steel groove can be directly removed, the in-site environment is obviously improved, and the recovery process more perfectly conforms to the environment-protection and audit requirement. The analginum recovery purity is high, the crystallization rate is high, the pollution is avoided, and the industrial production is easily realized.

Owner:SHANDONG XINHUA PHARMA CO LTD

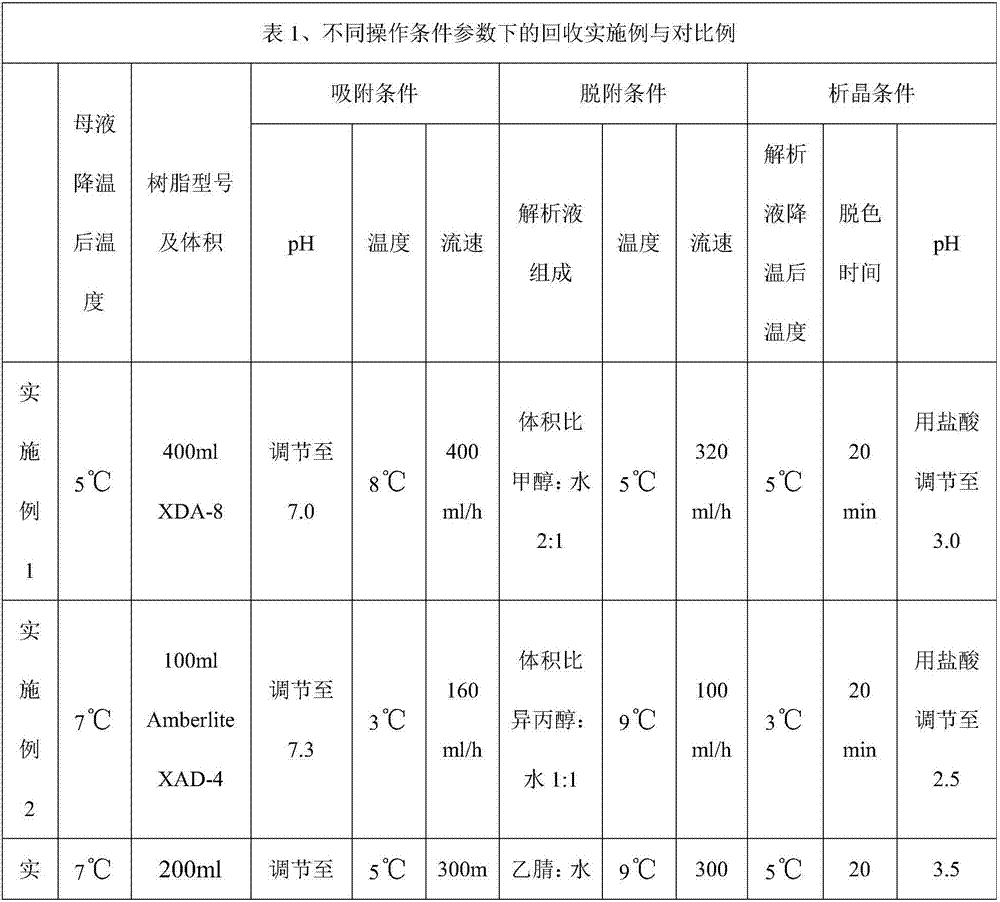

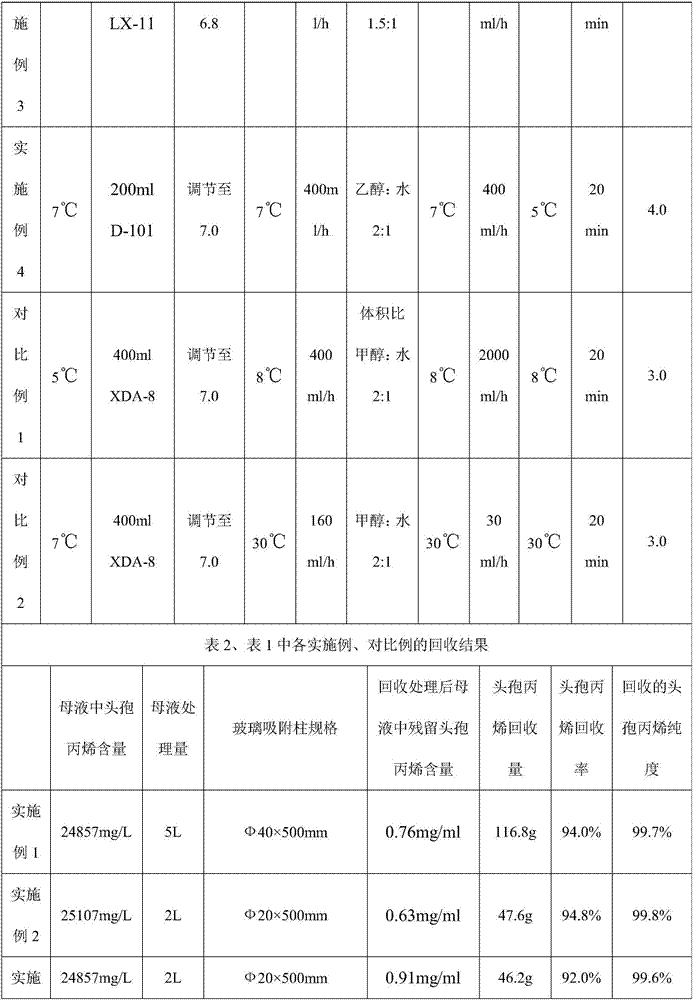

Method for recovering cefprozil from cefprozil crystallization mother liquor

The invention discloses a method for recovering cefprozil from cefprozil crystallization mother liquor. The method is characterized in that the absorption, desorption and crystallization treatment is performed on the cooled cefprozil crystallization mother liquor by adopting macro-porous resin, and the purified cefprozil is recovered. The method comprises the following steps: by utilizing the macro-porous resin, in combination with the cooperation of the adsorption conditions of specific pH, temperature and flow rate and the desorption conditions of certain pH, temperature and flow rate of a specific analytical solution, effectively absorbing and efficiently desorbing the cefprozil remaining in the efprozil crystallization mother liquor through the macro-porous resin and recovering; finally de-coloring, crystallizing, filtering and drying the analytical solution to obtain a high-purity cefprozil product conforming to qualified product standard requirements. The method disclosed by the invention is high in recovery rate, simple and convenient to cooperate, low in cost, green and safe; and the residue of the cefprozil in the cefprozil crystallization mother liquor after recovery treatment is less than or equal to 1 mg / ml, so that the COD value of wastewater can be effectively reduced, and the environmental protection pressure and the wastewater treatment cost are reduced, and therefore, the economic and social benefits are significant.

Owner:TIANJUSHI ENG TECH GROUP

Organic amine desulfurizer for cyclically absorbing and removing SO2 from flue gas and application of organic amine desulfurizer

InactiveCN103894043AEfficient Absorptive CapacityStrong absorption capacityDispersed particle separationAbsorption capacityAntioxidant

The invention relates to an organic amine desulfurizer for cyclically absorbing and removing SO2 from flue gas. The organic amine desulfurizer comprises an absorbent and a solvent, wherein the absorbent is a water-soluble organic amine compound with the boiling point higher than 120 DEG C; the organic amine compound is selected from one of pyridylamine, N,N-dimethylacetamide, N,N-dimethyl-p-phenylenediamine, butyrolactam, polyacrylamide, hexamethylene tetramine, 2-aminoacetamide, 2-hydroxy-4-nitroaniline, or phenylenediamine, and also comprises an antioxidant, a corrosion inhibitor and an activator. The invention also relates to a regeneration application of the organic amine desulfurizer. The organic amine desulfurizer has a wide material resource; a processing method is simple; the organic amine desulfurizer disclosed by the invention has an efficient and high-specificity absorption capacity on sulfur dioxide when the organic amine desulfurizer is used for desulfurization; the influence of carbon dioxide in late-period sulphur dioxide recycle is eliminated; the recovery purity of the sulfur dioxide is improved. The desulfurizer can be recycled; the recycling and the low-energy-consumption regeneration of the desulfurizer are realized; the desulfurization cost is reduced; the desulfurization efficiency is improved.

Owner:山东金瑞达环保科技股份有限公司 +1

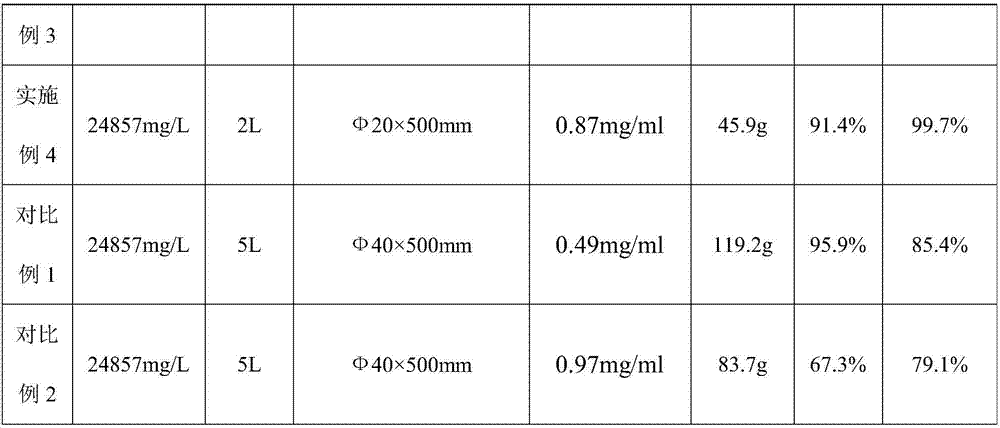

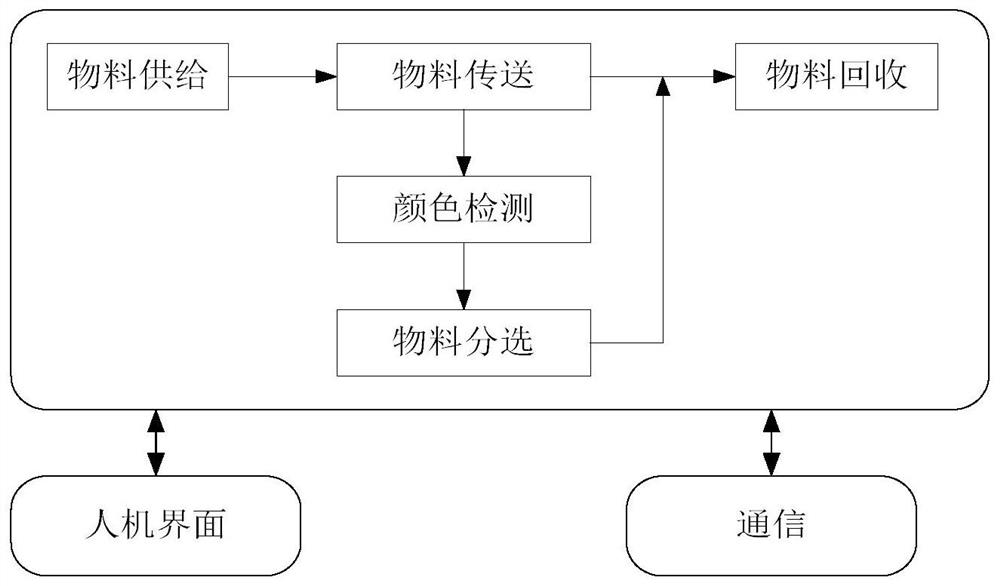

High-precision material color-sorting device

The invention relates to a high-precision material color-sorting device which comprises a material supply part, a material transfer part, a color detecting part, a material sorting part and a materialrecycling part, wherein the material supply part, the color detecting part, the material sorting part and the material recycling part are sequentially arranged in a material transfer direction of thematerial transfer part. According to the material color-sorting device provided by the embodiment of the invention, material adhesion is overcome by mechanical force, the materials are favorably prevented from being pressed, collected and adhered, and the materials are effectively dispersed, so that recycling purity is effectively improved and a recovery rate is effectively increased.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI +1

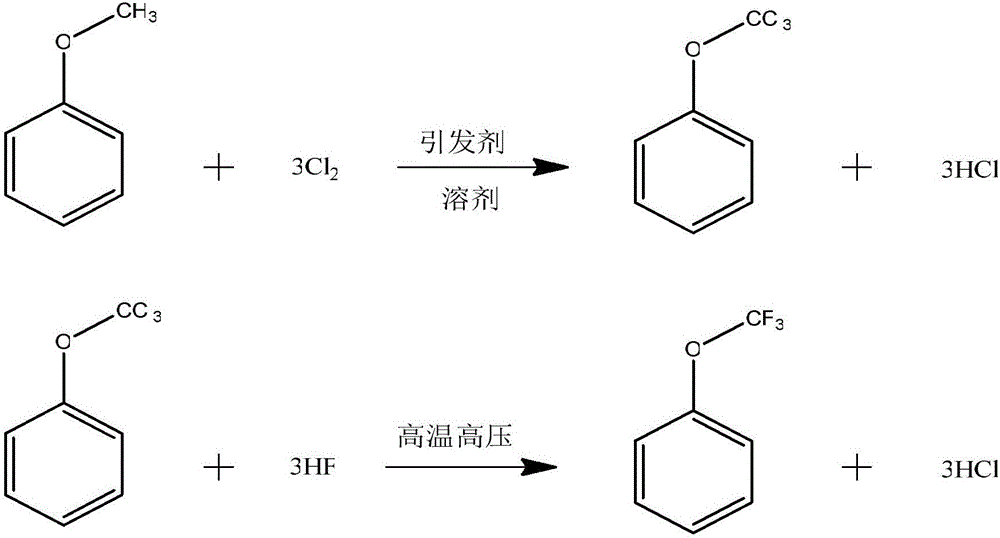

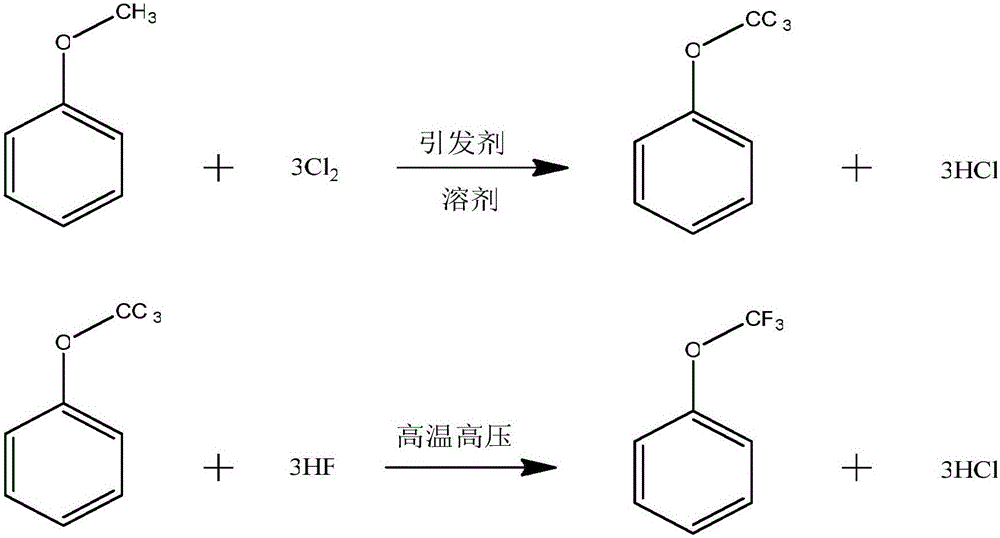

Production method of trifluoromethoxybenzene

ActiveCN106008175AHigh recovery purityHigh recovery rateOrganic chemistryOrganic compound preparationChemical reactionOil phase

The invention relates to a production method of an aromatic compound, in particular to a production method of trifluoromethoxybenzene. The production method includes chlorination reaction, fluoridation reaction and product separation and is characterized in that anisole is used as the initial raw material, the chlorination reaction uses aromatic hydrocarbon containing fluorine as the solvent, the solvent cannot be separated after the reaction, the fluoridation reaction of the solvent and HF is performed under proper conditions, the reaction products of the fluoridation reaction are subjected to washing and layering, the lower oil phase is subjected to rectification to obtain the trifluoromethoxybenzene, and the solvent is recycled. The purity of the obtained trifluoromethoxybenzene is larger than 99%, and the yield of the trifluoromethoxybenzene is larger than 95%. The chemical reaction formula is shown as follows.

Owner:SHANDONG DOCRIS CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com