Green peeling method for electrode material of waste lithium ion power battery

A power battery and electrode material technology, which is applied in the field of green stripping of waste lithium-ion power battery electrode materials, can solve the problem of lithium battery electrolyte treatment technology and component separation immaturity, the complexity and cost increase of positive electrode material recovery process, and the environment The health hazards of operating workers and other problems are achieved, and the effect of convenient operation, low cost and less usage is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention specifically comprises the following steps:

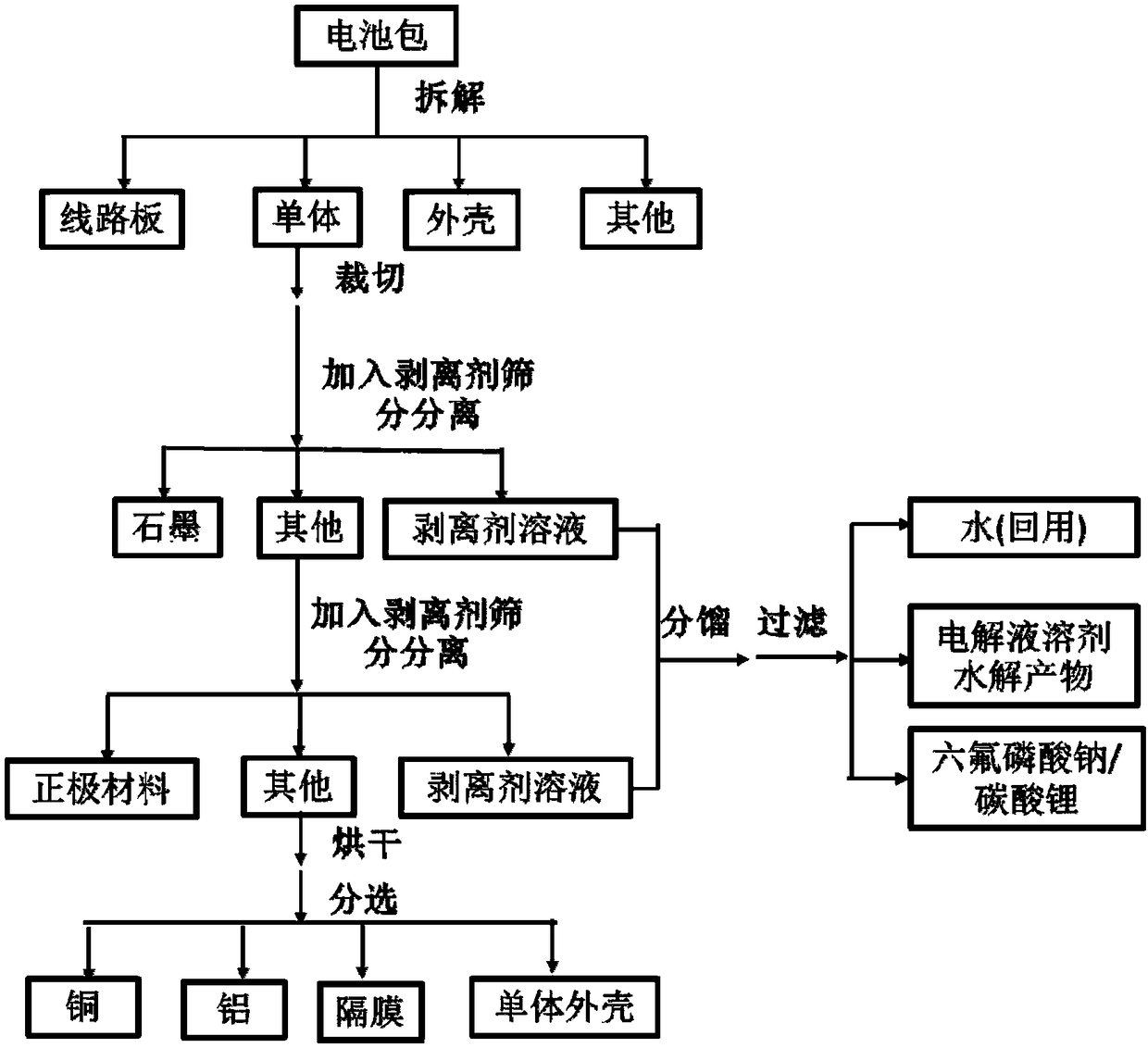

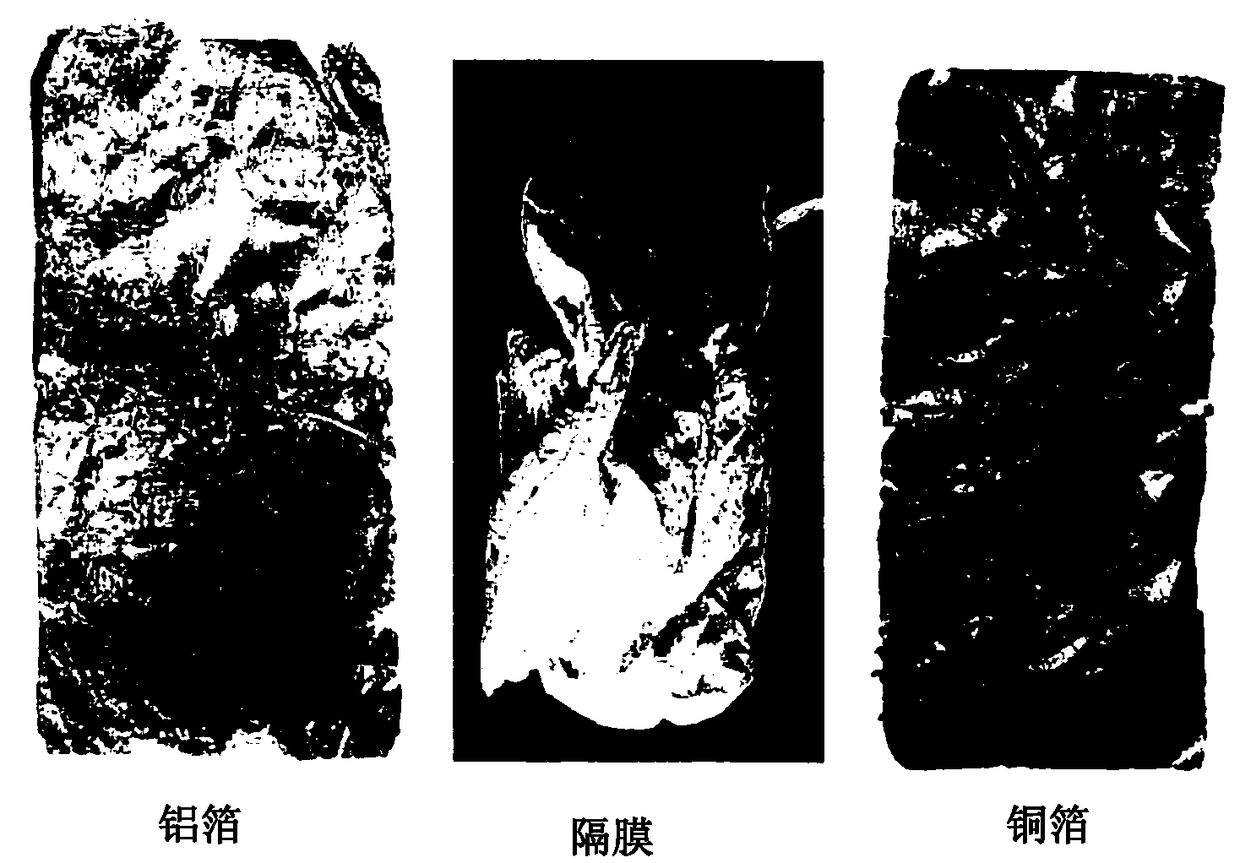

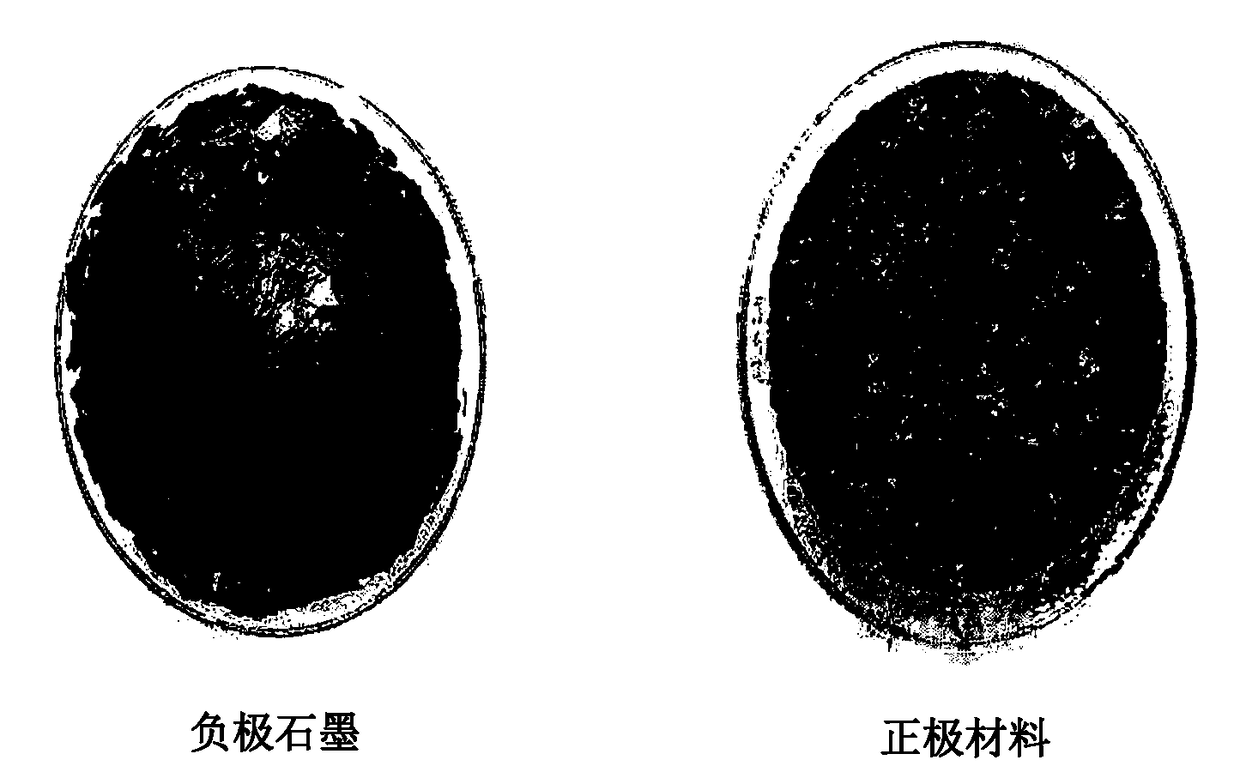

[0025] according to figure 1 Flow chart, after the waste lithium-ion battery pack is discharged as a whole, it is disassembled to obtain battery cells, metal casings, wires, pipelines and circuit boards. After the dismantled battery cells were cut into strips, they were transferred to immerse in a negative electrode stripper with a concentration of 0.1 mol / L, and stayed for 2 minutes. After sieving, the undersieves were collected and dried to obtain graphite. The oversize material was immersed in the positive electrode material with a concentration of 2 mol / L, stayed for 15 minutes, and was sieved to obtain the undersize material, which was collected and dried as the positive electrode material. After drying the sieved material after the second sieving, after sorting, the diaphragm, shell and copper / aluminum are separated to obtain the product. When the concentration of organic matter in the leaching ...

Embodiment 2

[0027] The present invention specifically comprises the following steps:

[0028] according to figure 1 Flow chart, after the waste lithium-ion battery pack is discharged as a whole, it is disassembled to obtain battery cells, metal casings, wires, pipelines and circuit boards. After the dismantled battery cells were cut into strips, they were transferred and immersed in a negative electrode stripping agent with a concentration of 0.2 mol / L, and stayed for 2 minutes. After sieving, the undersize was obtained, which was graphite after drying. The oversize material was immersed in a positive electrode stripper with a concentration of 1.0 mol / L, and stayed for 20 minutes. After sieving, the undersize material was collected and dried to obtain the positive electrode material. After the oversize is dried, it is sorted to separate the diaphragm, casing and copper / aluminum to obtain the product. When the concentration of organic matter in the leaching solution reaches 20wt.%, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com