Patents

Literature

56results about How to "Accurate peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

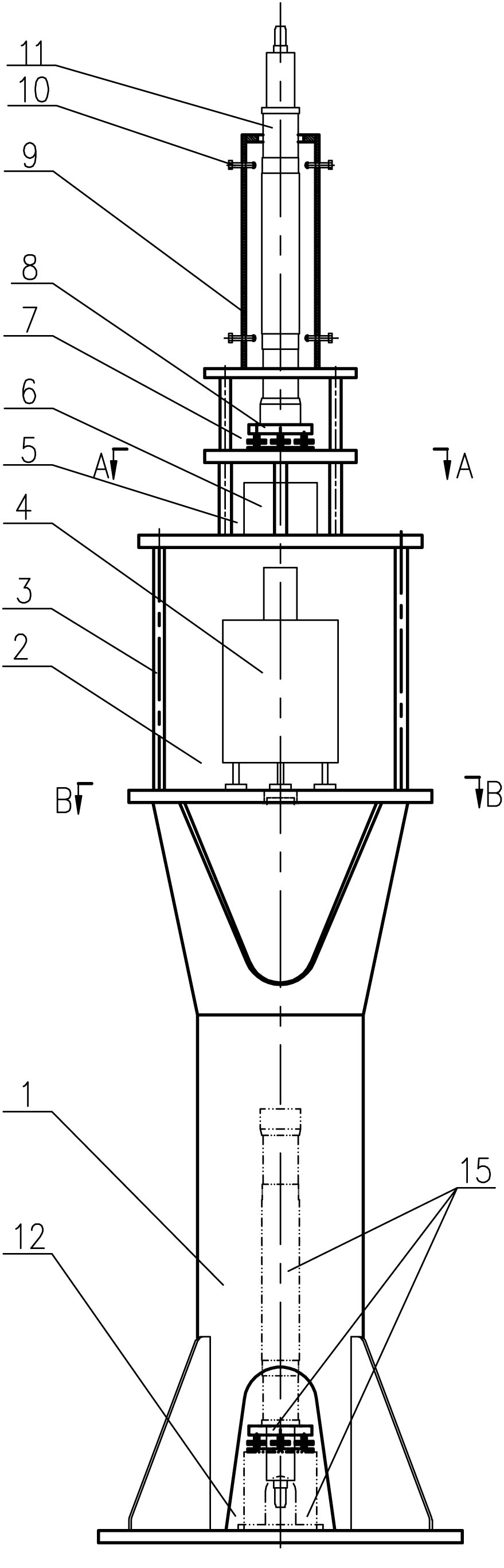

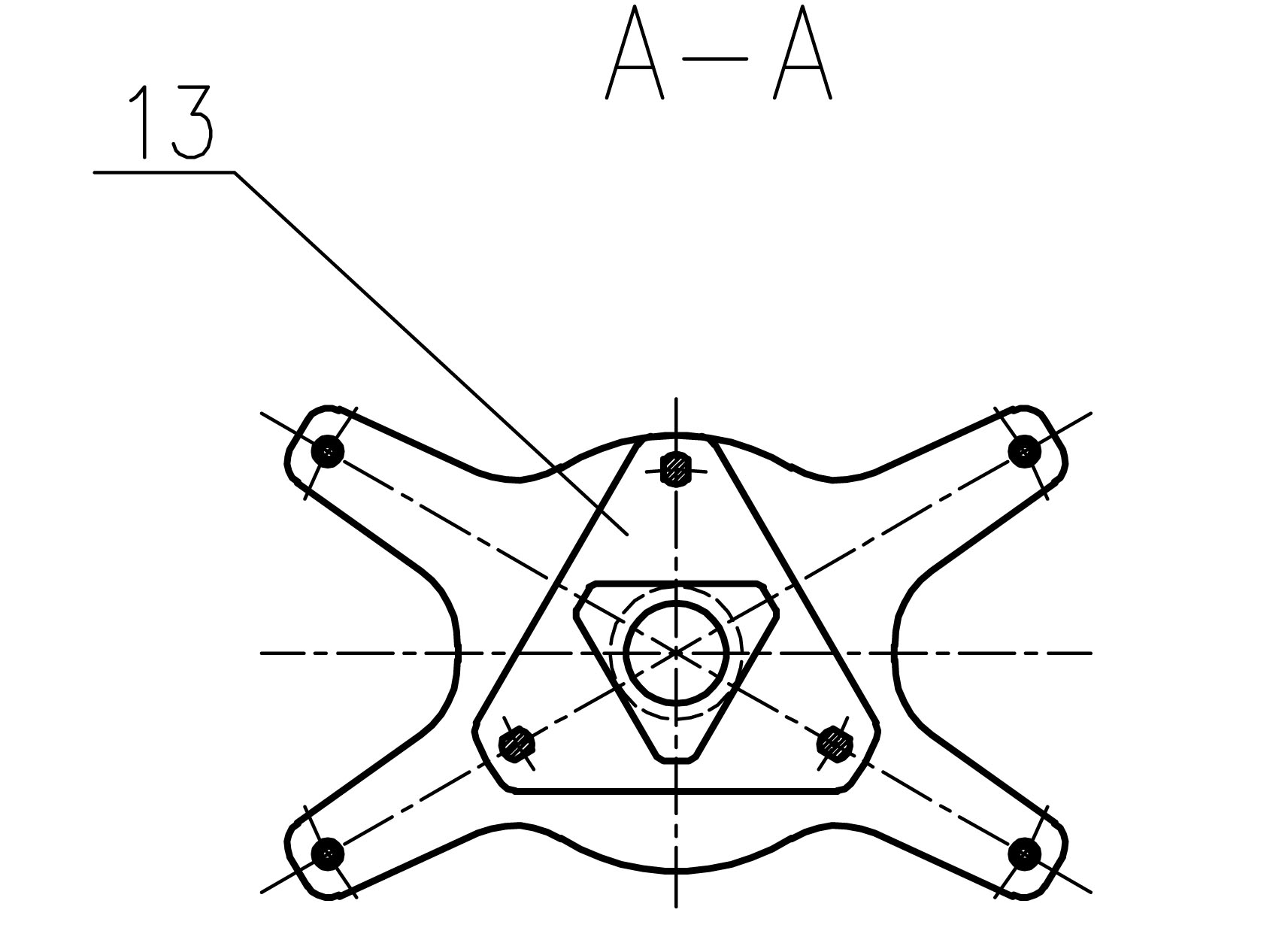

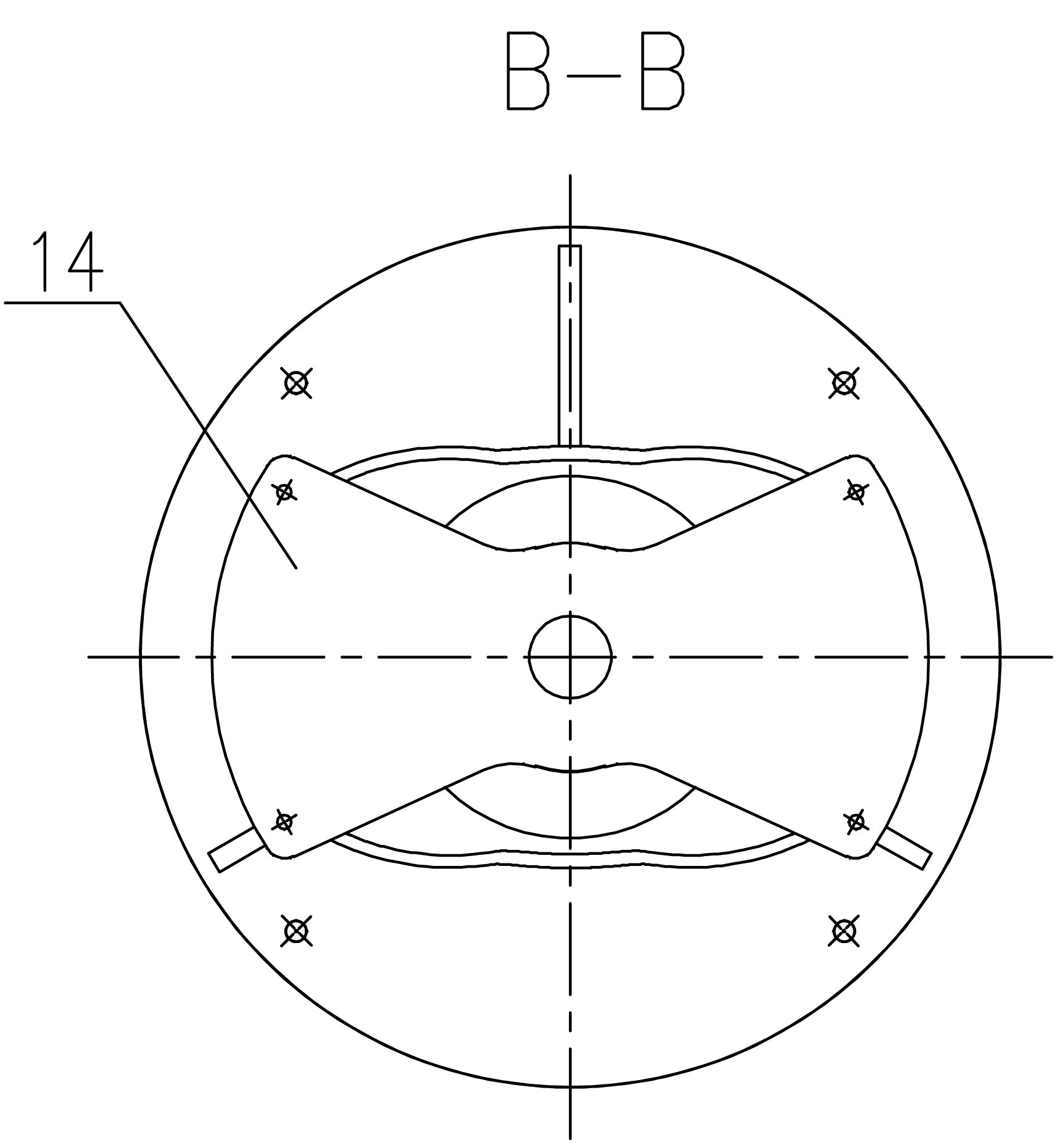

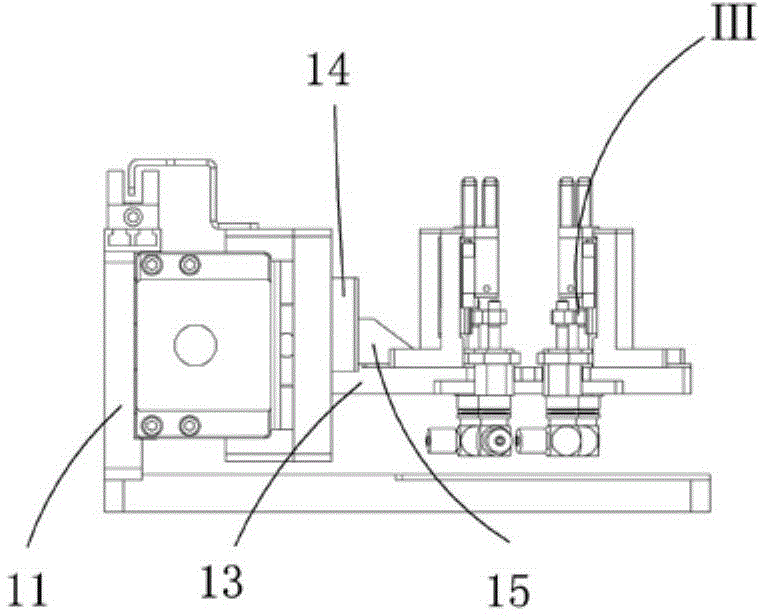

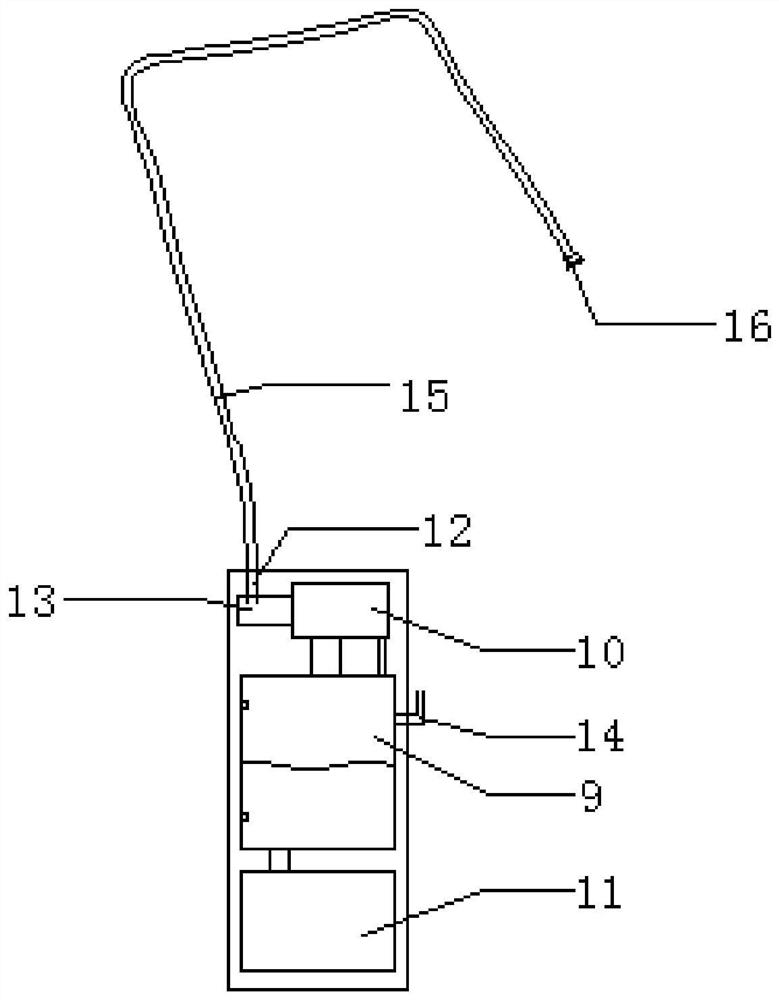

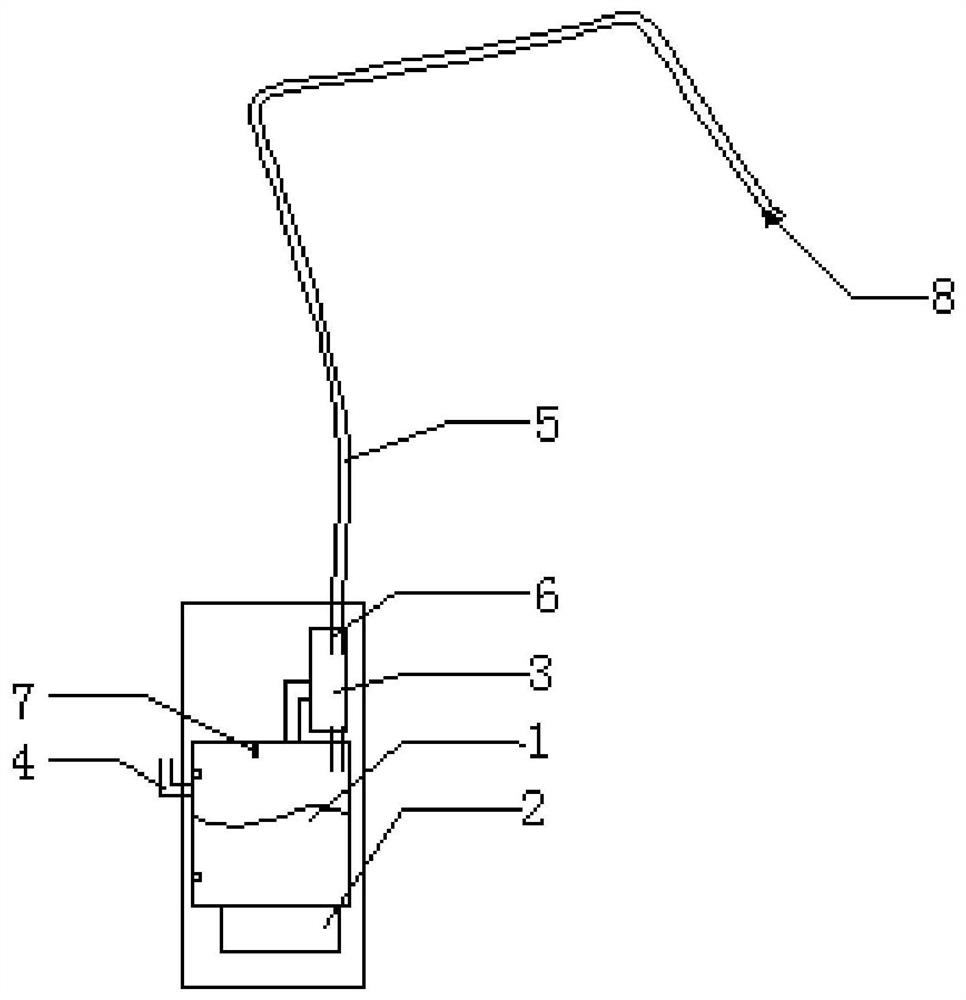

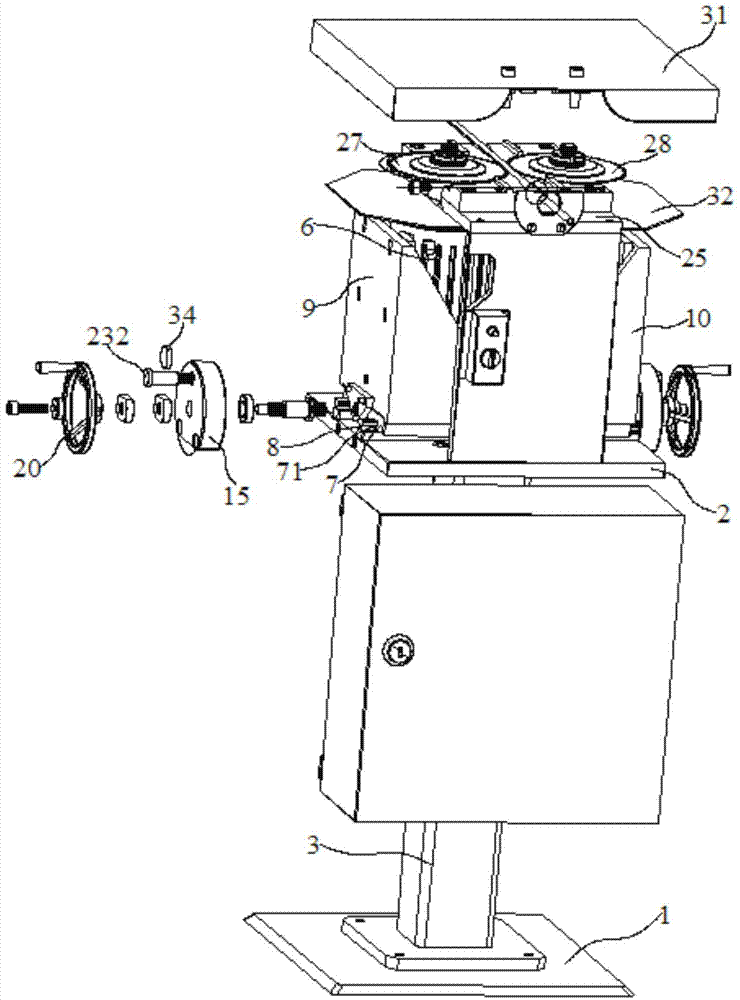

Device and method for calibrating plumb aligner

The invention discloses a device for calibrating a plumb aligner. An upright column is provided with a plumb aligner holding cabin and an operating platform which are connected with a laser mirror cabin through a supporting column; the laser mirror cabin is connected with a fine adjusting cabin through a supporting column; the fine adjusting cabin is provided with a rough adjusting head; and the rough adjusting head is provided with a plurality of rough adjusting bolts. The invention provides the device and a method for calibrating the plumb aligner, which are used for calibrating a sight axis and a laser optical axis by taking a vertical axis and a zenith / nadir sighting mark (or remote fixed sighting mark) of the plumb aligner calibrated by a water level as dynamic bench marks. In the calibration process, the calibrated plumb aligner always keeps the leveling state during use, the target seeking task is completely finished by the zenith / nadir sighting mark, and therefore, the influence of included target seeking of the plumb aligner in the traditional method on the indeterminacy of a calibration result is greatly reduced. In addition, fewer adjustment times, shorter adjustment time, higher correction precision and more convenience for operation are realized.

Owner:宜昌市计量检定测试所 +1

Method of thermal adherend release and apparatus for thermal adherend release

InactiveCN1787169AWill not cause sheddingStripping does not causeSolid-state devicesSemiconductor/solid-state device manufacturingFoaming agentSwelling pressure

A heat-adherent peeling method, wherein a part of an adherend adhered to a heat-peelable pressure-sensitive adhesive sheet having a heat-expandable layer containing a foaming agent is partially heated by partially heating the heat-peelable pressure-sensitive adhesive The adhesive sheet is selectively peeled from the pressure-sensitive adhesive sheet, wherein the method comprises preheating the adherend to be peeled off at a temperature at which the heat-expandable layer of the heat-peelable pressure-sensitive adhesive sheet does not expand. The adherend is then heated at the temperature at which the heat-expandable layer expands, thereby selectively peeling the adherend.

Owner:NITTO DENKO CORP

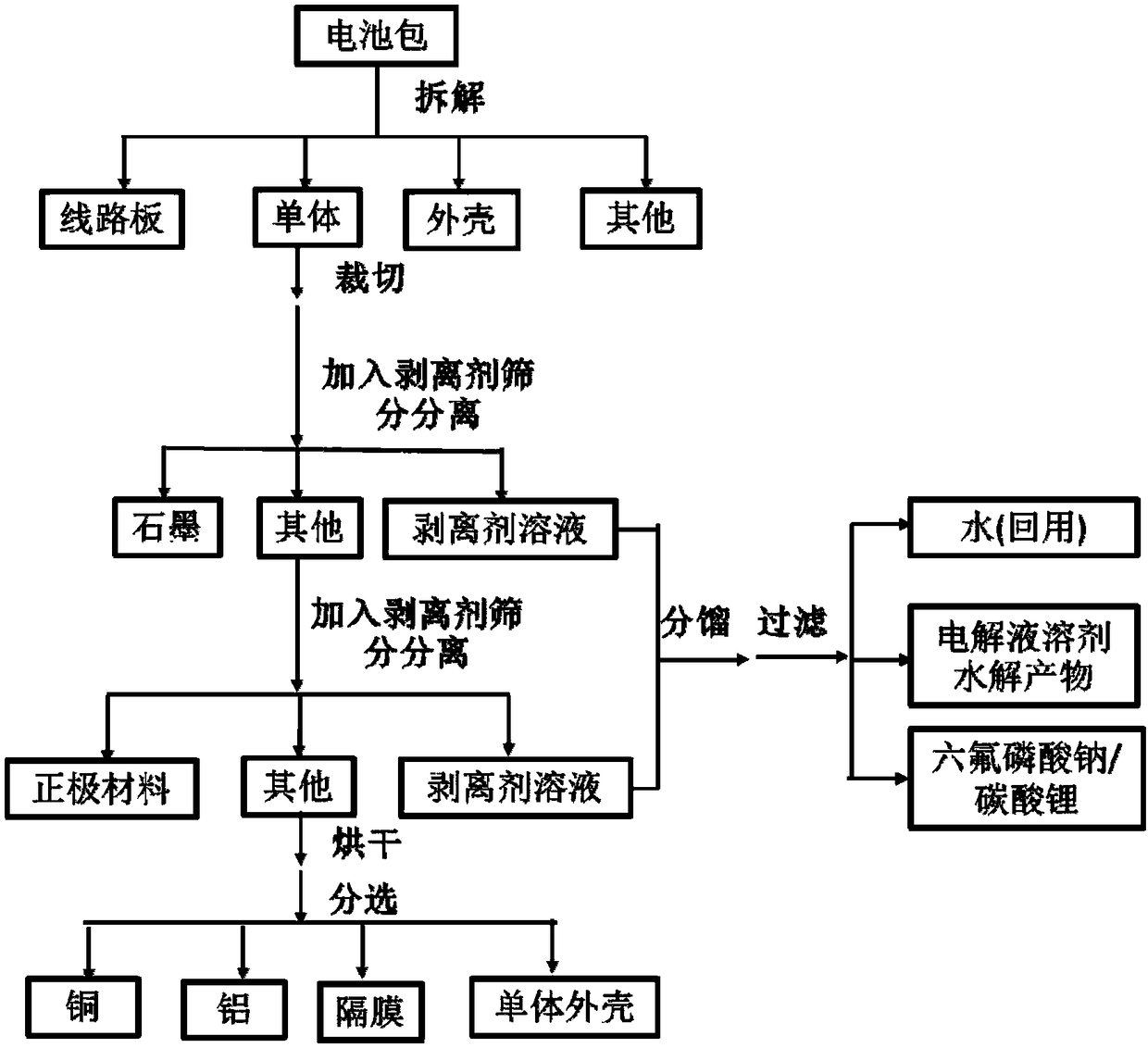

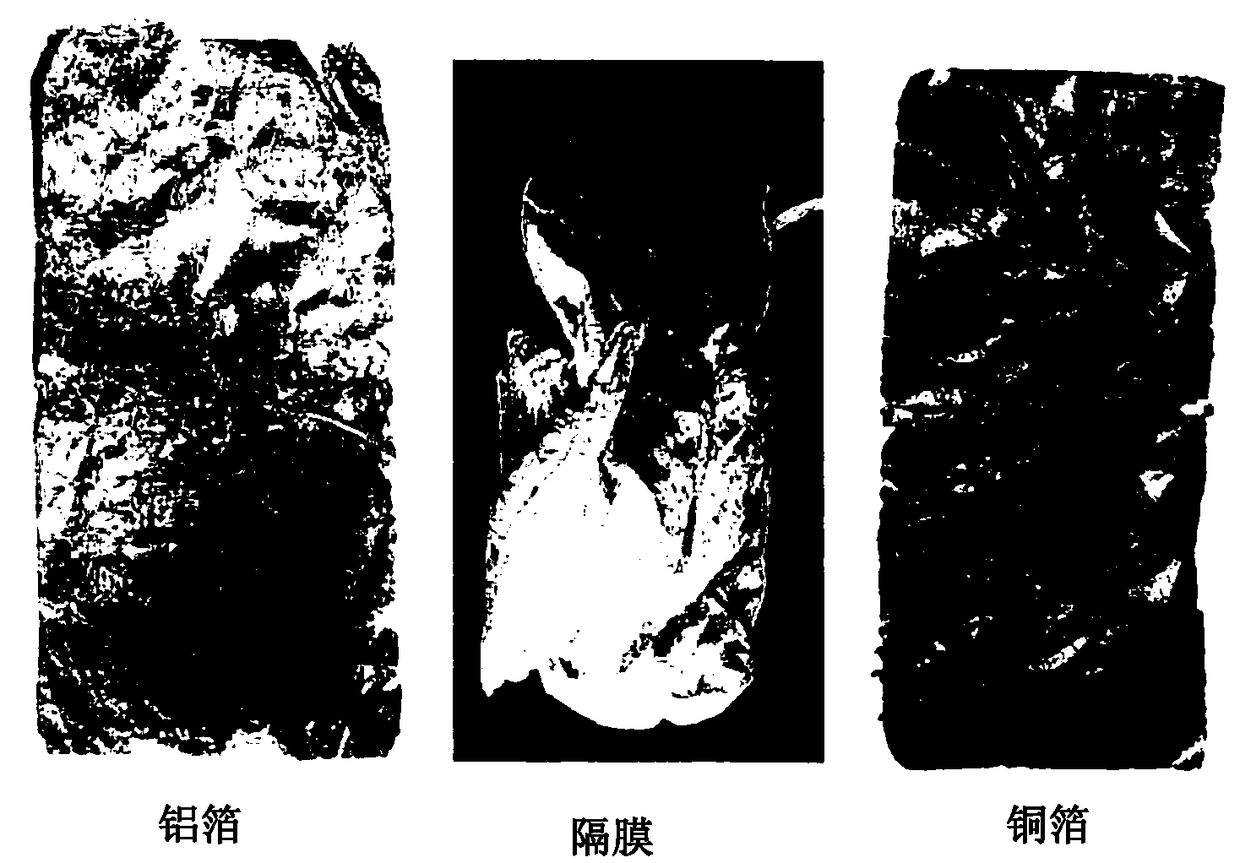

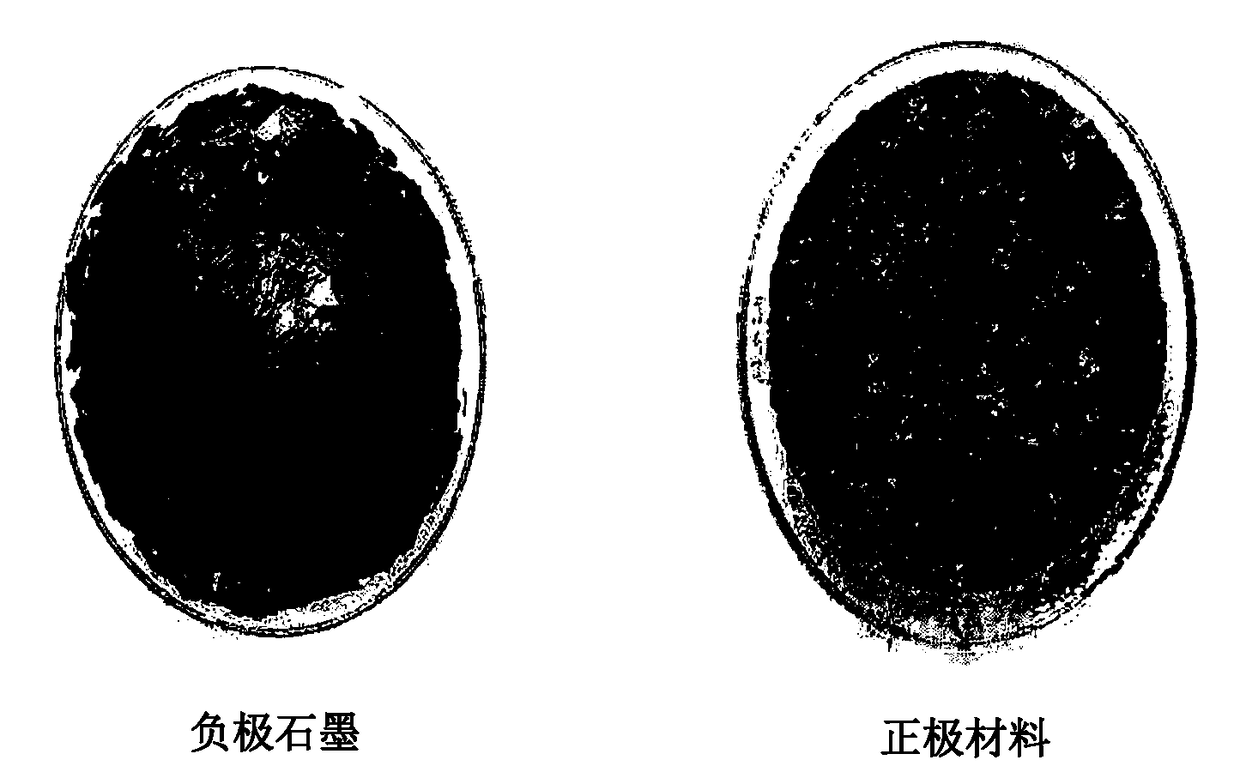

Green peeling method for electrode material of waste lithium ion power battery

ActiveCN108666645ASimple processLow costSolid waste disposalWaste accumulators reclaimingStrong acidsCopper foil

The invention provides an overall peeling method for a cathode material and an anode material based on the characteristics of compact structure, complicated composition, harmful electrolyte containingand the like of a waste lithium ion battery, wherein aluminum foil is effectively separated from the cathode material in controllable conditions, and then cathode graphite is effectively separated from copper coil while the electrolyte is effectively recycle; the whole technology does not apply corrosive solutions such as strong base, strong acid and strong oxidant, the peeling process is fast and efficient, the composite solvent is low in cost, all sub-systems are linked with each other, thus the method is a green and environment-friendly method for circularly utilizing a waste lithium ion power battery.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

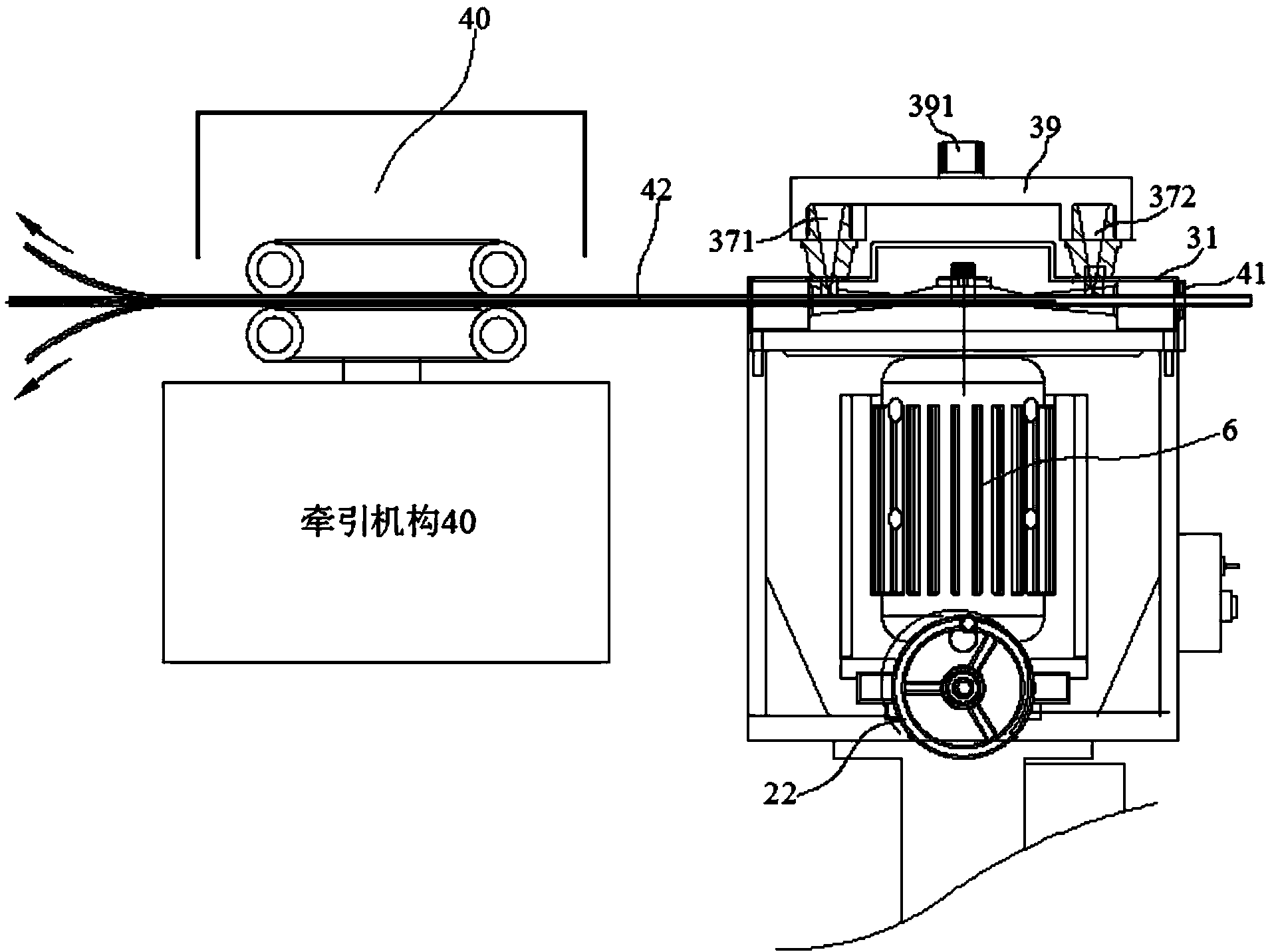

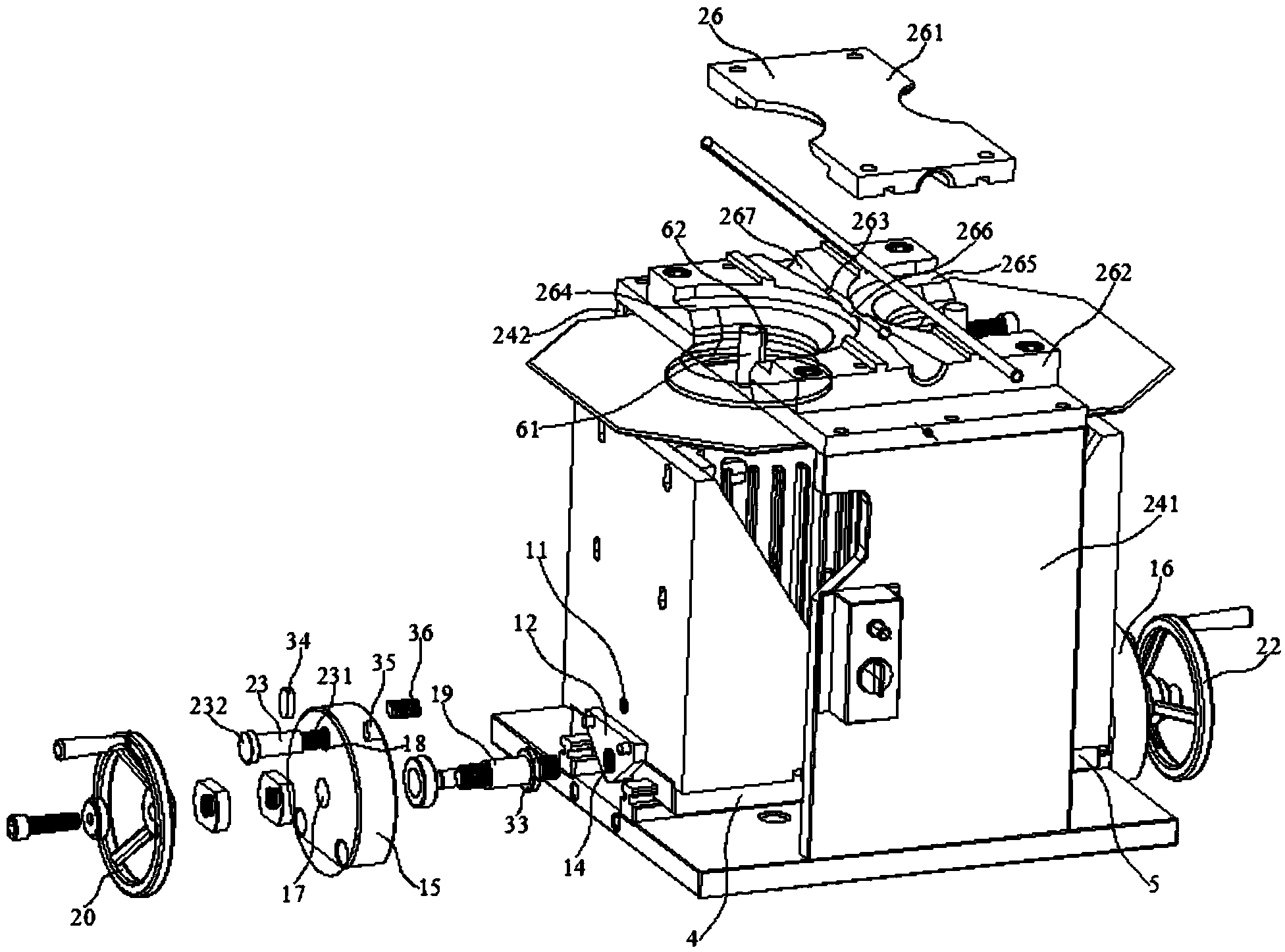

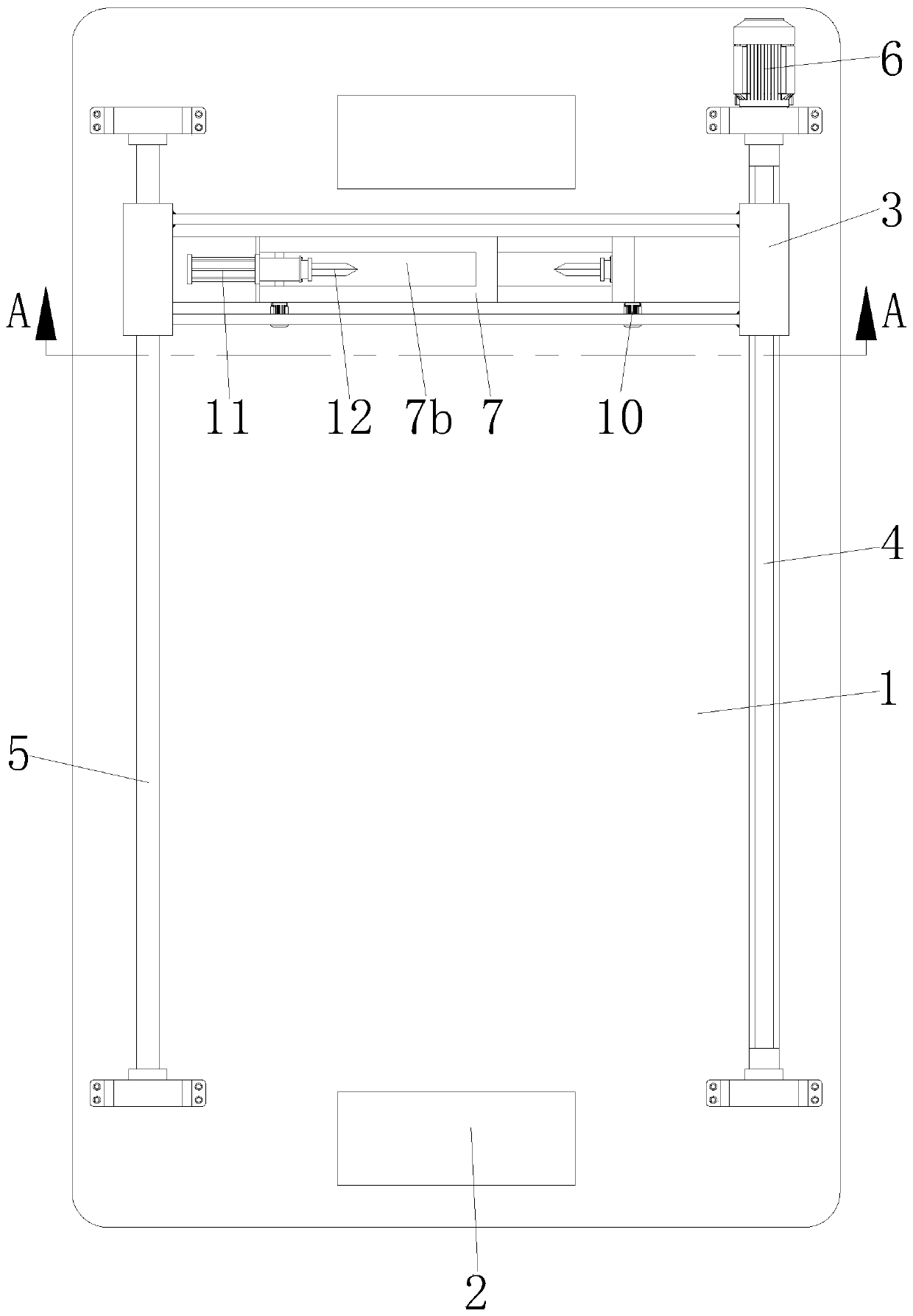

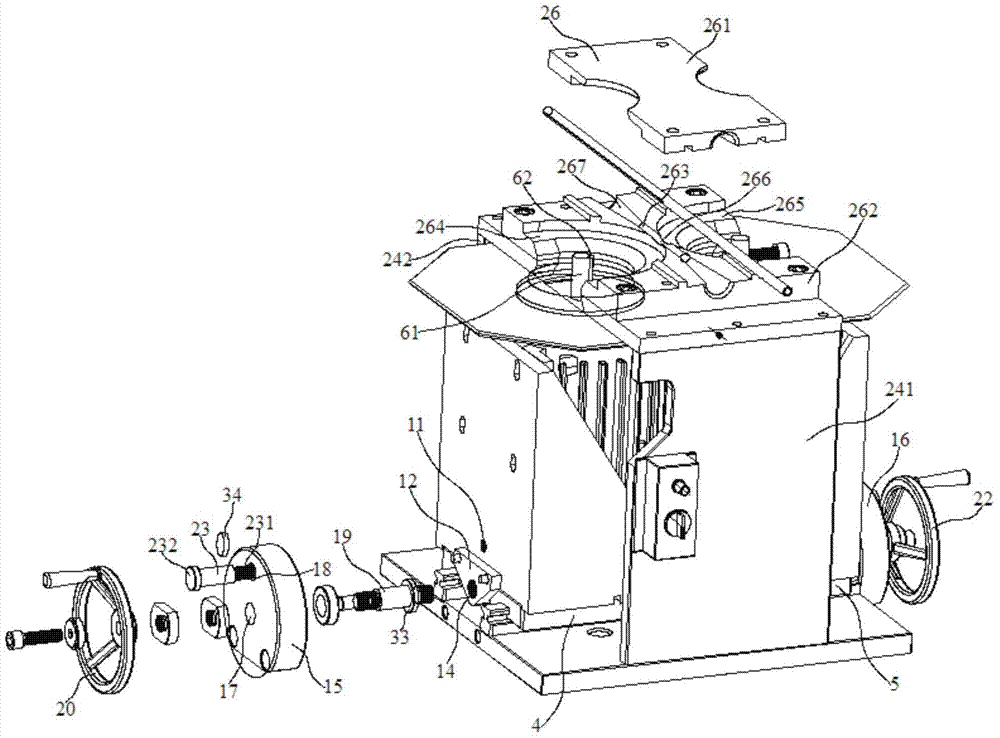

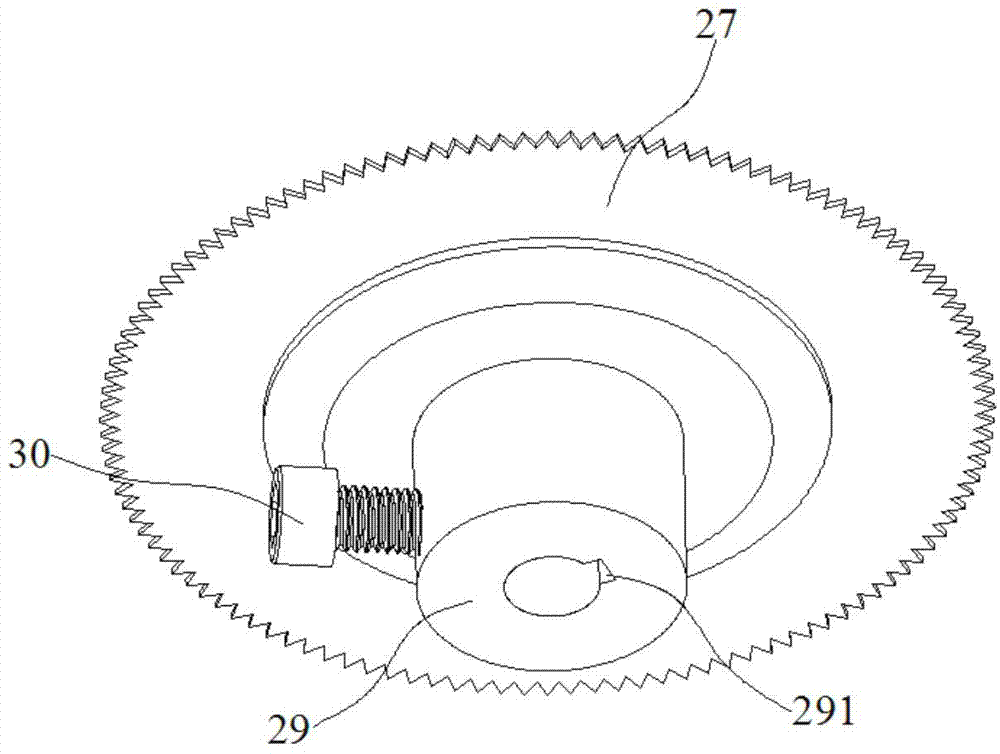

Elevator cable stripping device and stripping process

ActiveCN103414127AQuick peelLabor-saving strippingLine/current collector detailsApparatus for removing/armouring cablesEdge matchingMechanical engineering

The invention discloses an elevator cable stripping device which comprises a clamping mechanism and a stripping mechanism. The clamping mechanism is used for tightly clamping an elevator cable to be stripped. The stripping mechanism is used for stripping the elevator cable to be stripped. The stripping mechanism comprises a fixed tool set and a movable tool set, wherein the movable tool set can move in the axis direction of the elevator cable or in the direction perpendicular to the axis of the elevator cable. A channel for the elevator cable to pass through is arranged between the fixed tool set and the movable tool set. The fixed tool set and the movable tool set are respectively provided with a blade set with a tool edge matched with the elevator cable in shape. The invention further provides a stripping process using the elevator cable stripping device. The elevator cable stripping device and the stripping process enable an elevator cable sheath to be stripped quickly and accurately in an effort saving mode.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

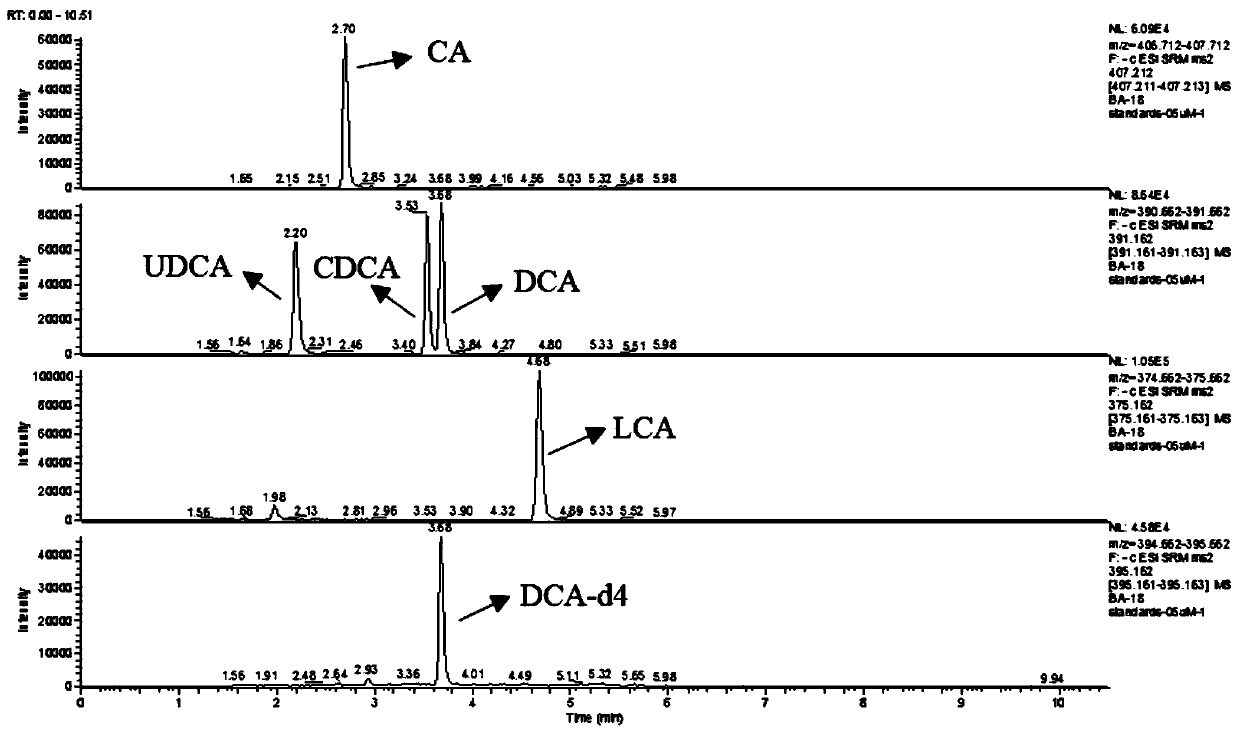

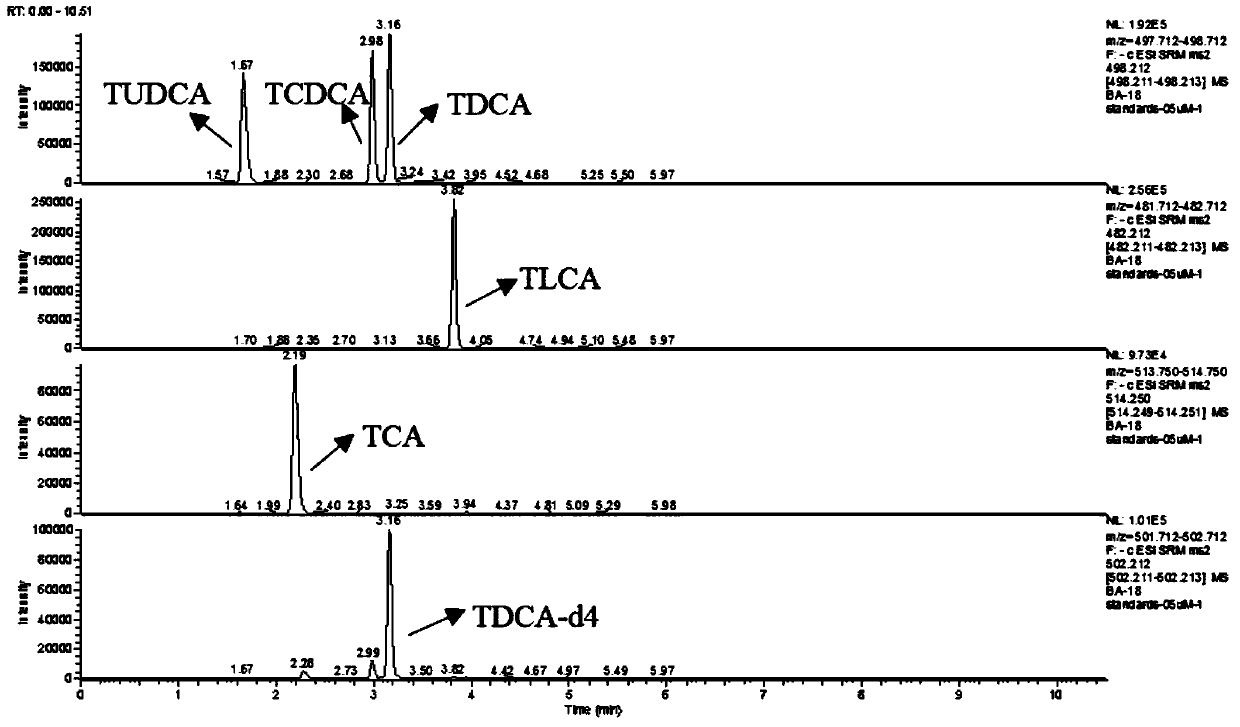

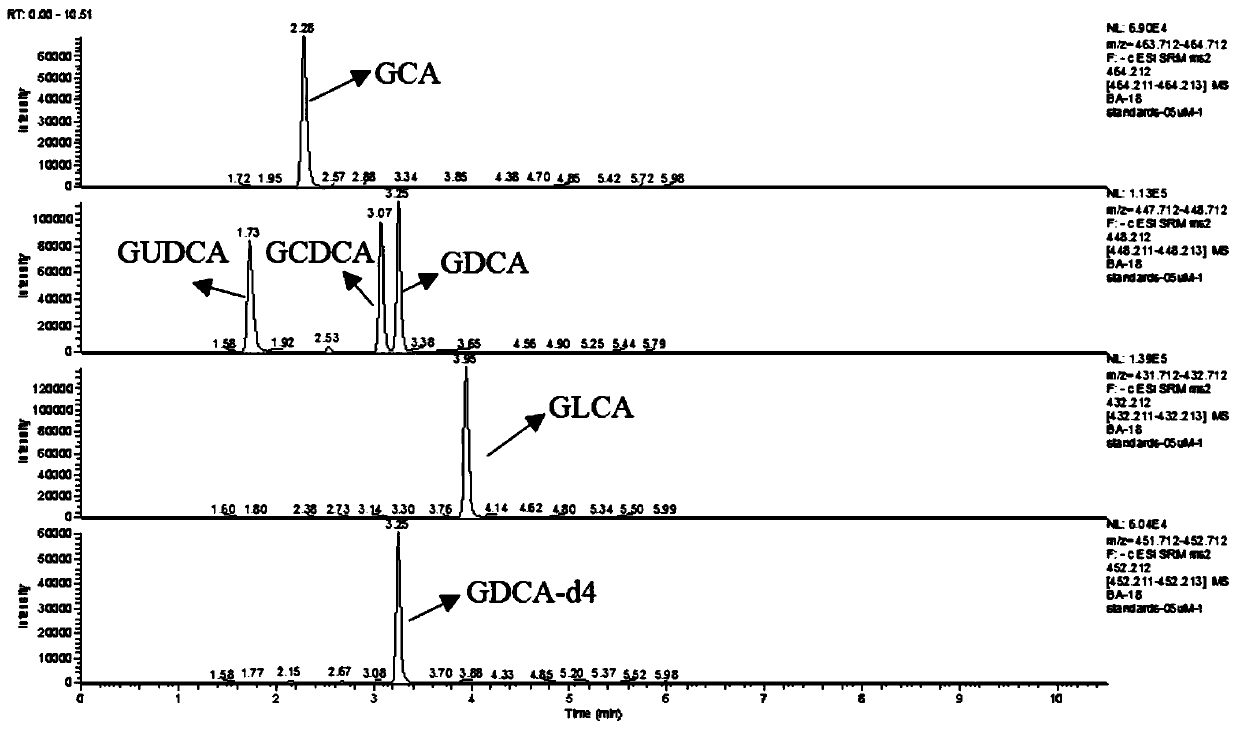

Mass spectrum kit for accurately determining concentration of bile acid in serum

InactiveCN111474288ASmall sample sizeHigh detection specificityComponent separationInternal standardMass analyzer

The invention discloses a mass spectrum kit for accurately determining the concentration of bile acid in serum. The mass spectrum kit is characterized by comprising a calibrator containing 15 kinds ofbile acid, an internal standard of deoxycholic acid-d4, glycodeoxycholic acid-d4 and taurodeoxycholic acid-d4, a quality control material of the 15 kinds of bile acid, an extracting solution, a mobile phase and a reconstitution fluid. The method has the advantages that complex purification steps are not needed, the required sample size is small, and the method can be matched with a liquid chromatograph tandem mass spectrometer for use and is applied to inspection of clinical samples. Meanwhile, the product can detect 15 bile acids with different structures at the same time, achieves a single-sample multi-index synchronous detection function, and has the characteristics of high accuracy, short detection time, low reagent consumption, convenience in operation and the like. In addition, themeasurement result can be directly traced back to the reference system, thereby guaranteeing the accuracy of the measurement result.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

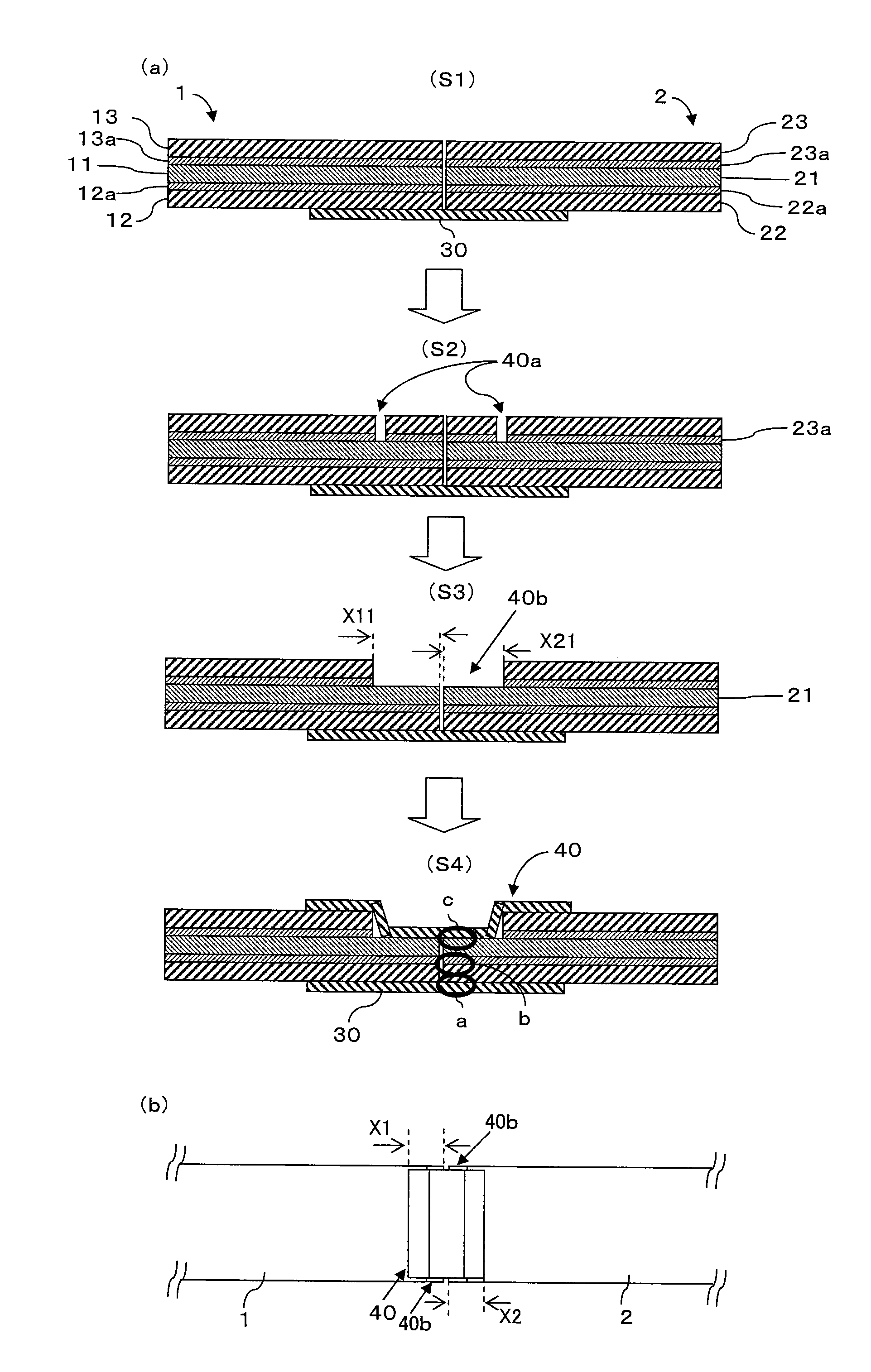

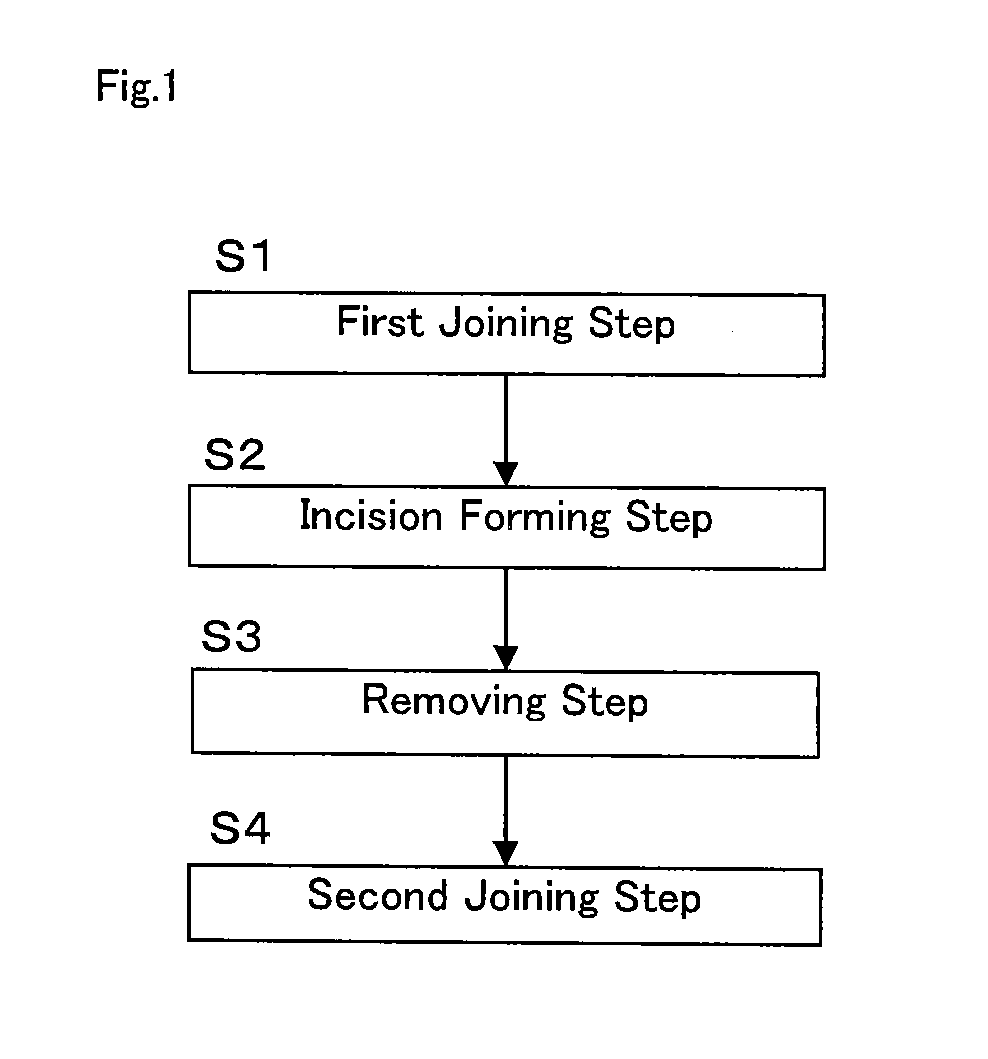

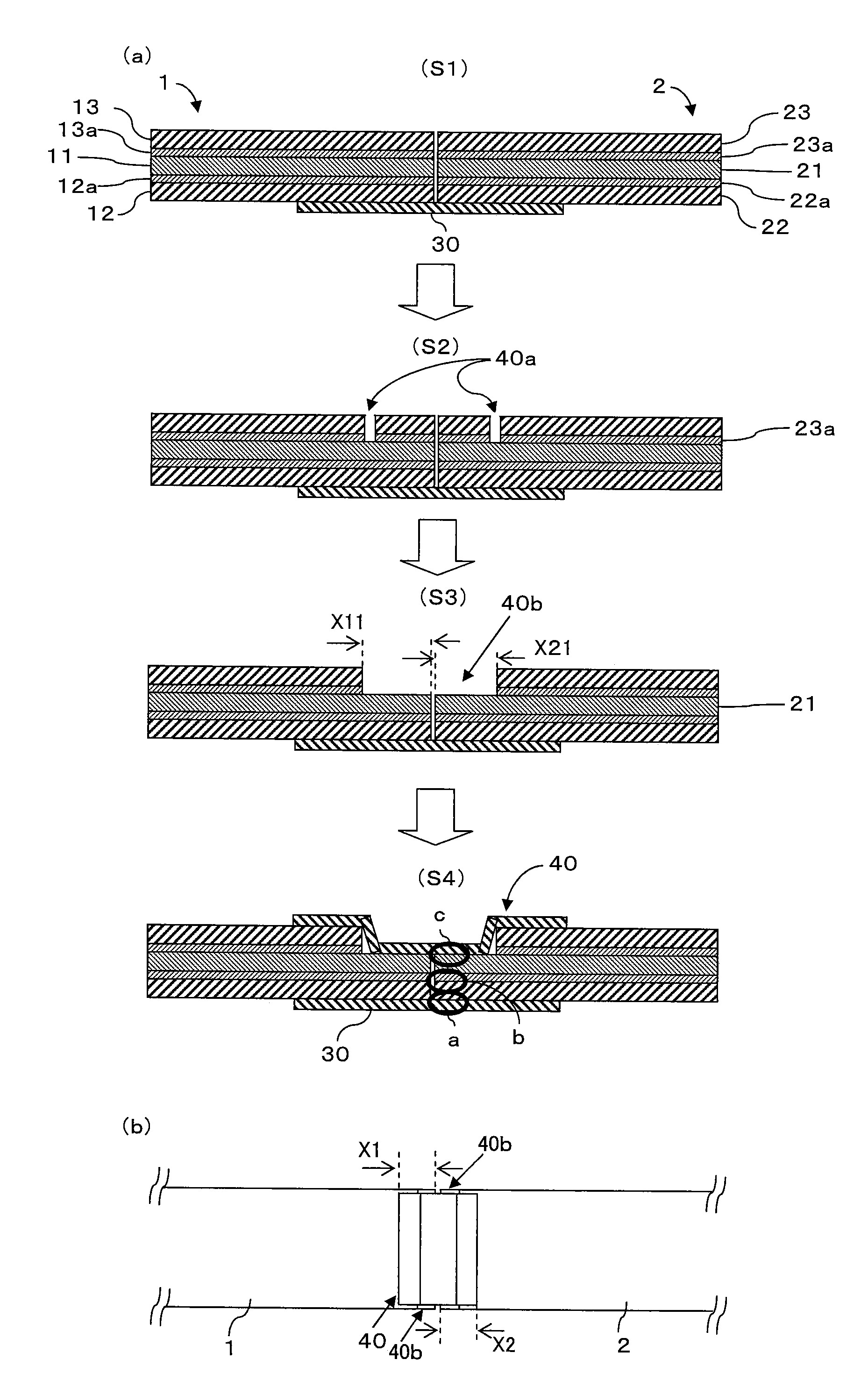

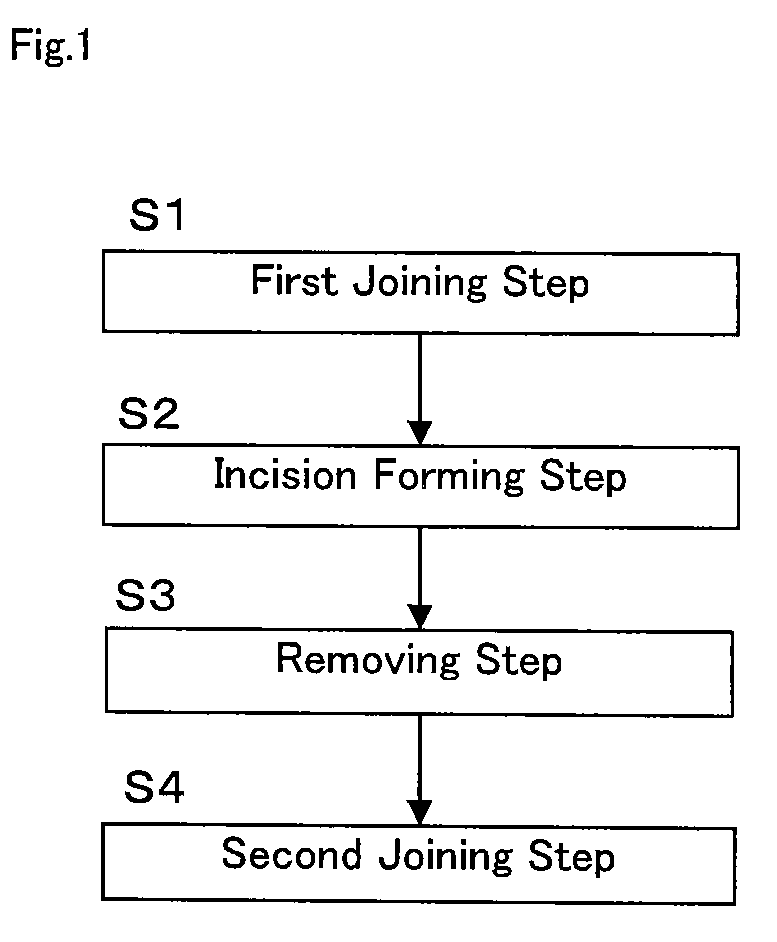

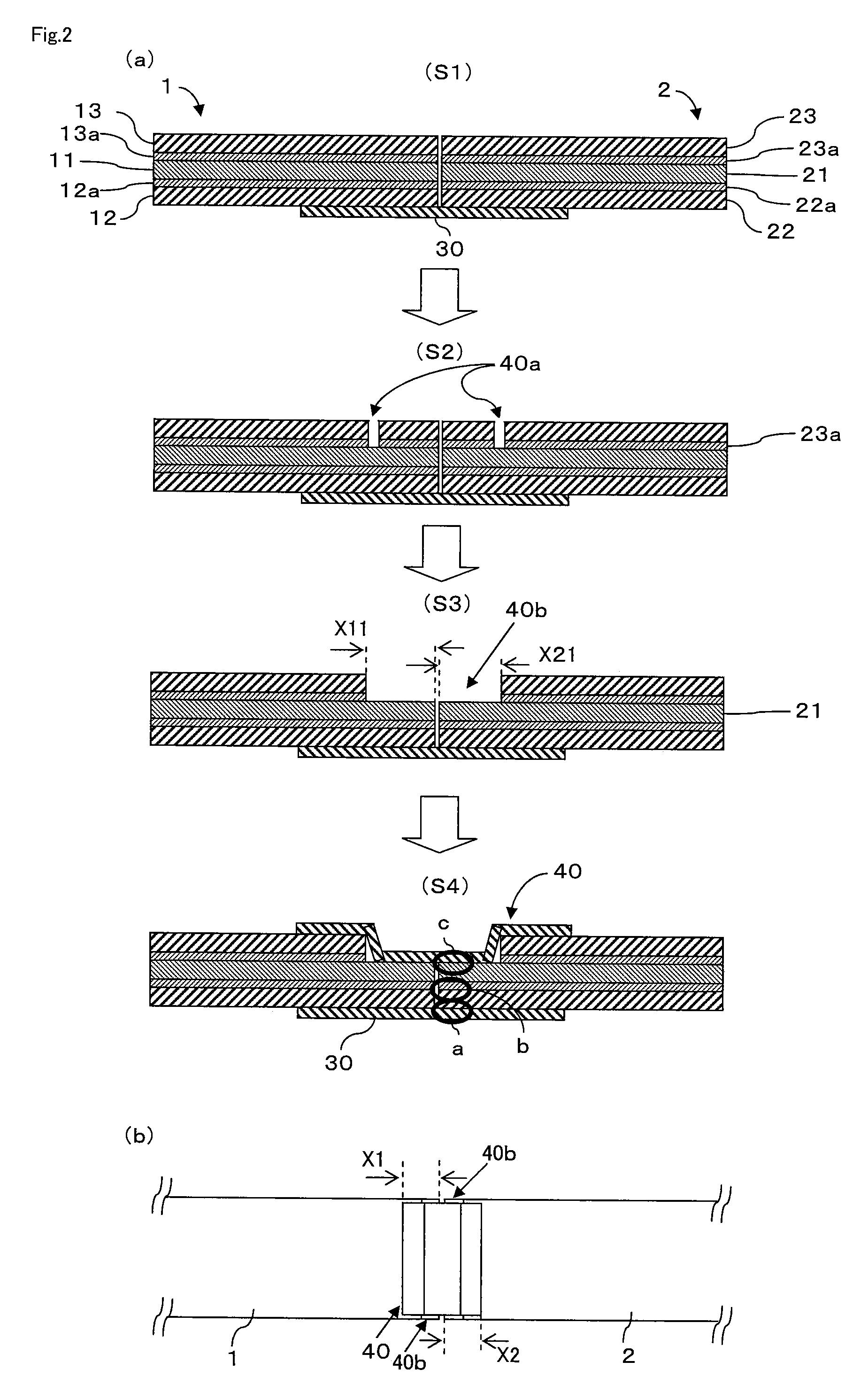

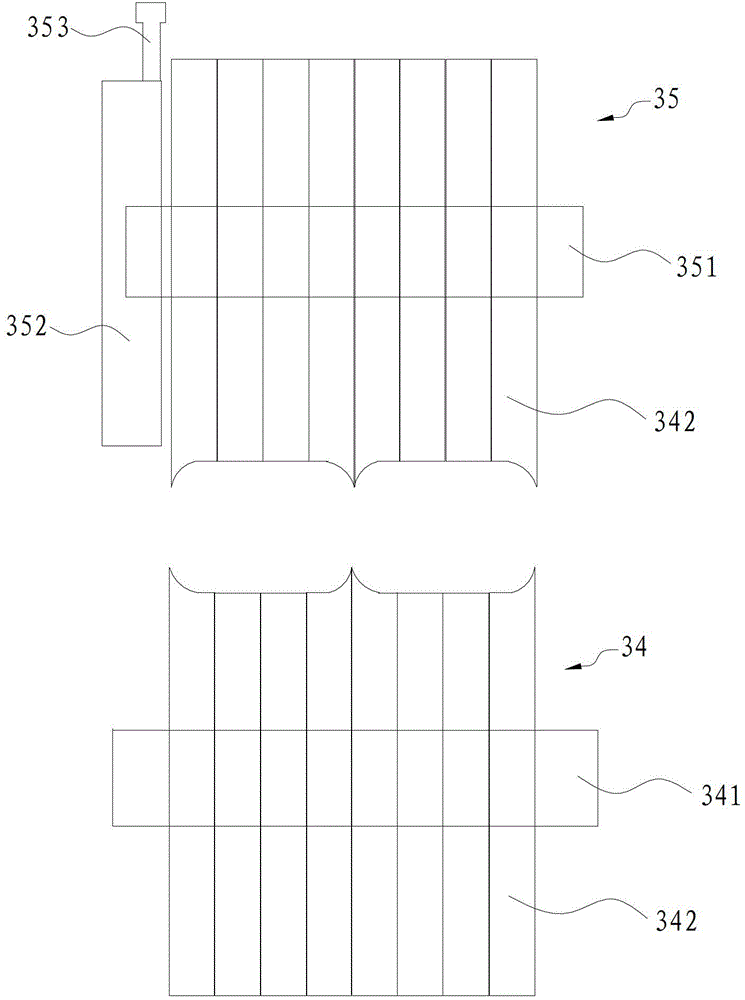

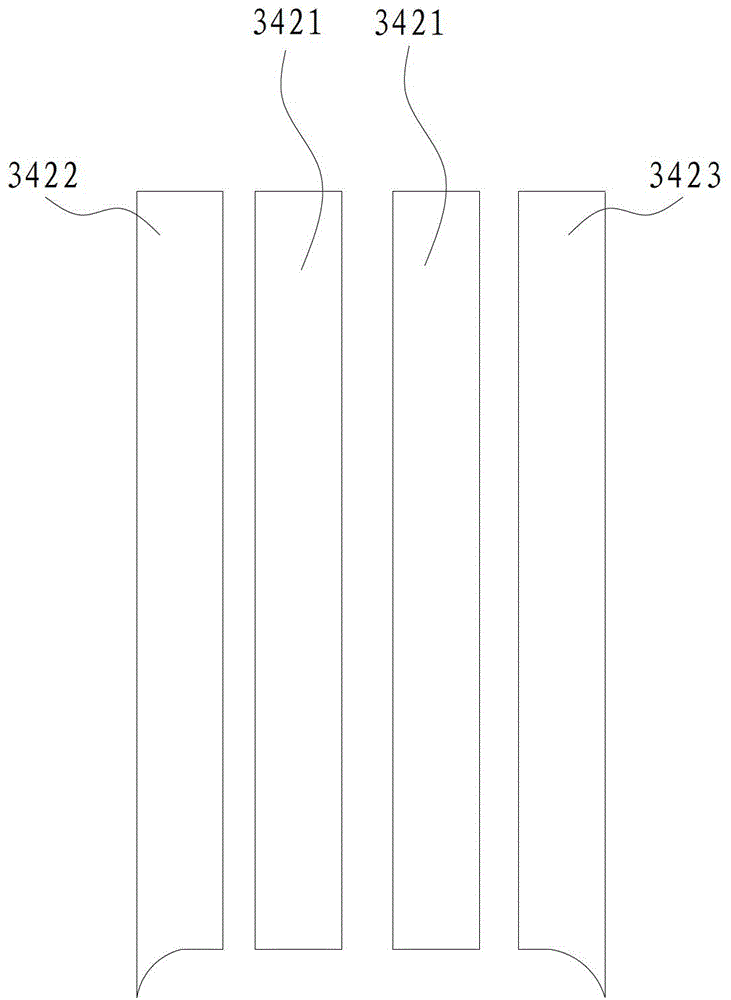

Method for manufacturing joined sheet material, joined sheet material and method for manufacturing optical display unit

InactiveUS20100227104A1Short processLarge widthMechanical working/deformationLamination ancillary operationsBiomedical engineeringPressure sensitive

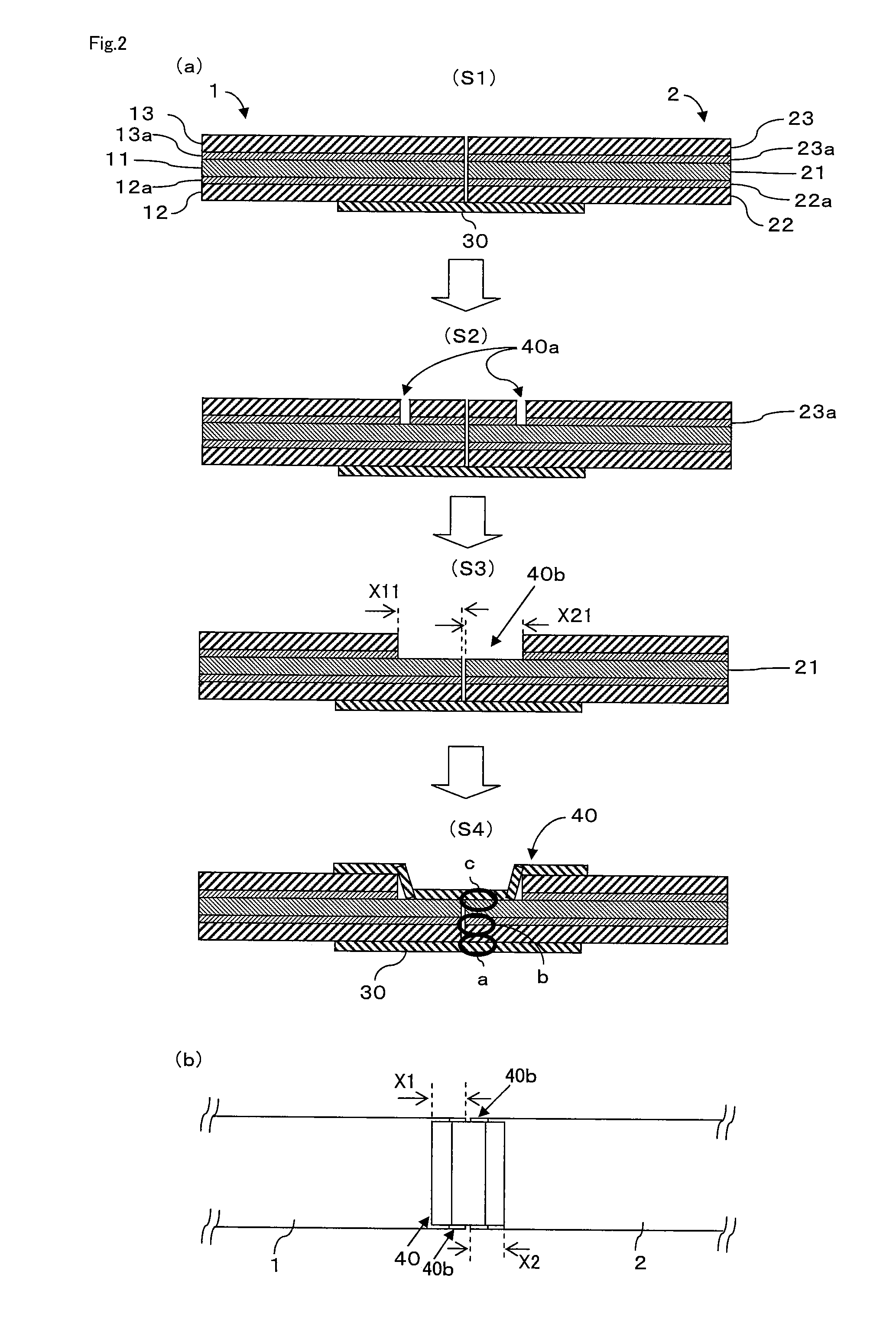

The invention is to provide a method for manufacturing a joined sheet product. The method comprising a first joining step including opposing a transverse end face of a first sheet product(1) to a transverse end face of a second sheet product(2) and joining release films of the first and second sheet products with a first joining member(30); a removing step including removing a portion of an intended member including at least a surface protecting member so as to leave at least the release film and a pressure-sensitive adhesive provided on the release film among the constituent members of both or any one of the first and second sheet products(1, 2), wherein the portion has a predetermined length from the transverse end face of the intended member; and a second joining step including providing a second joining member(40) on at least an exposed portion(40b) resulting from the removal of the intended member to join the surface protecting member sides of the first and second sheet products(1, 2).

Owner:NITTO DENKO CORP

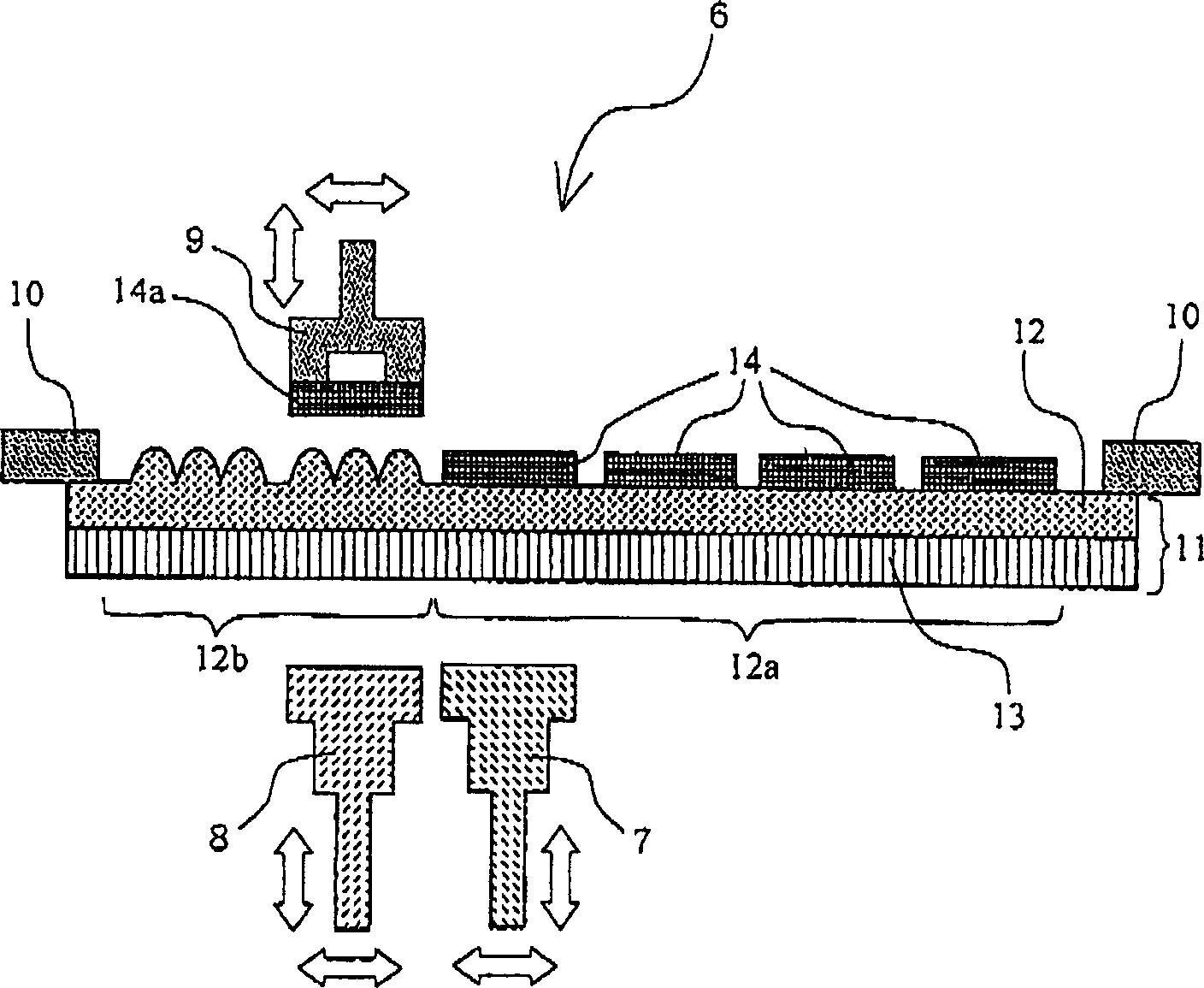

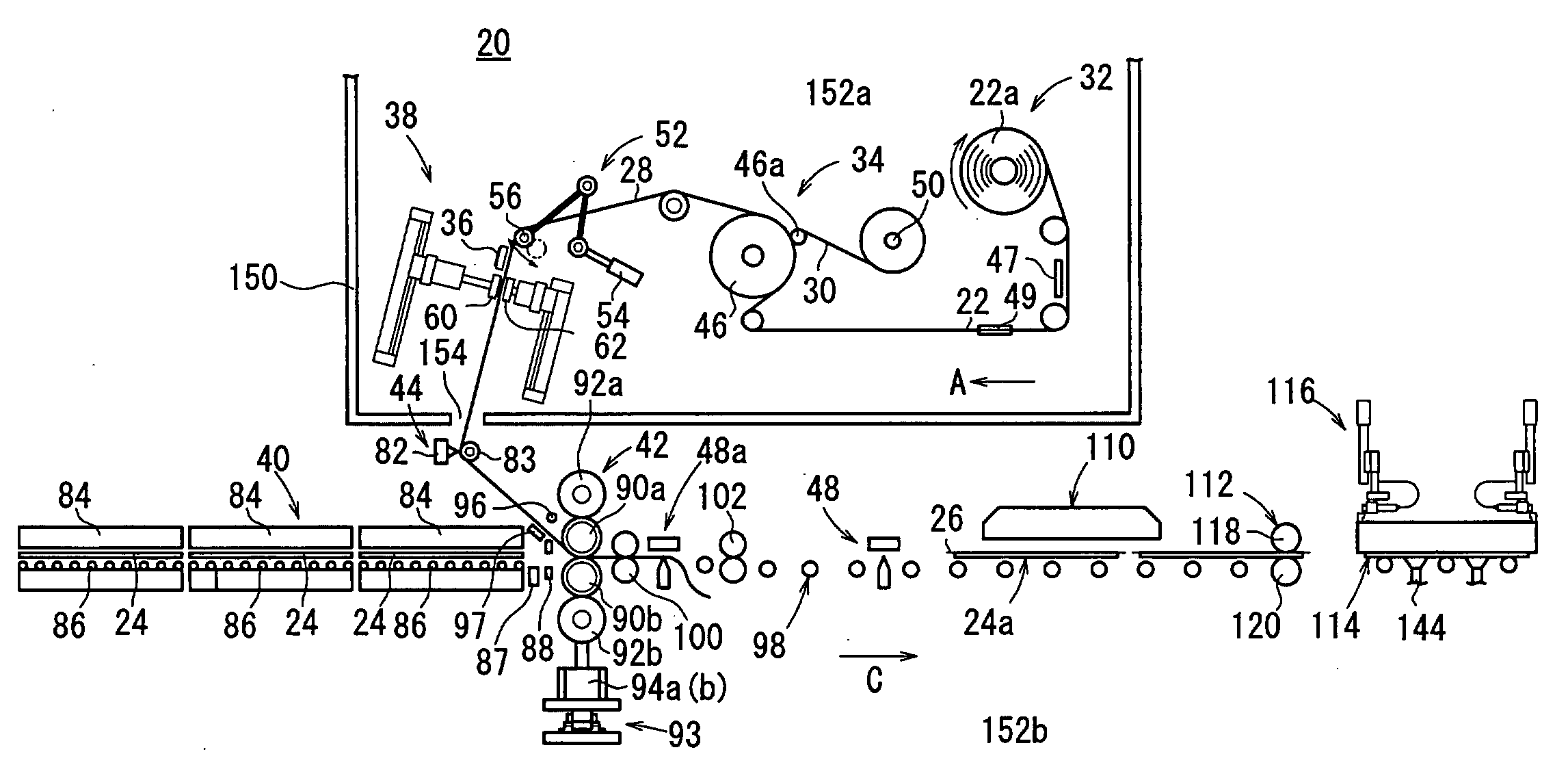

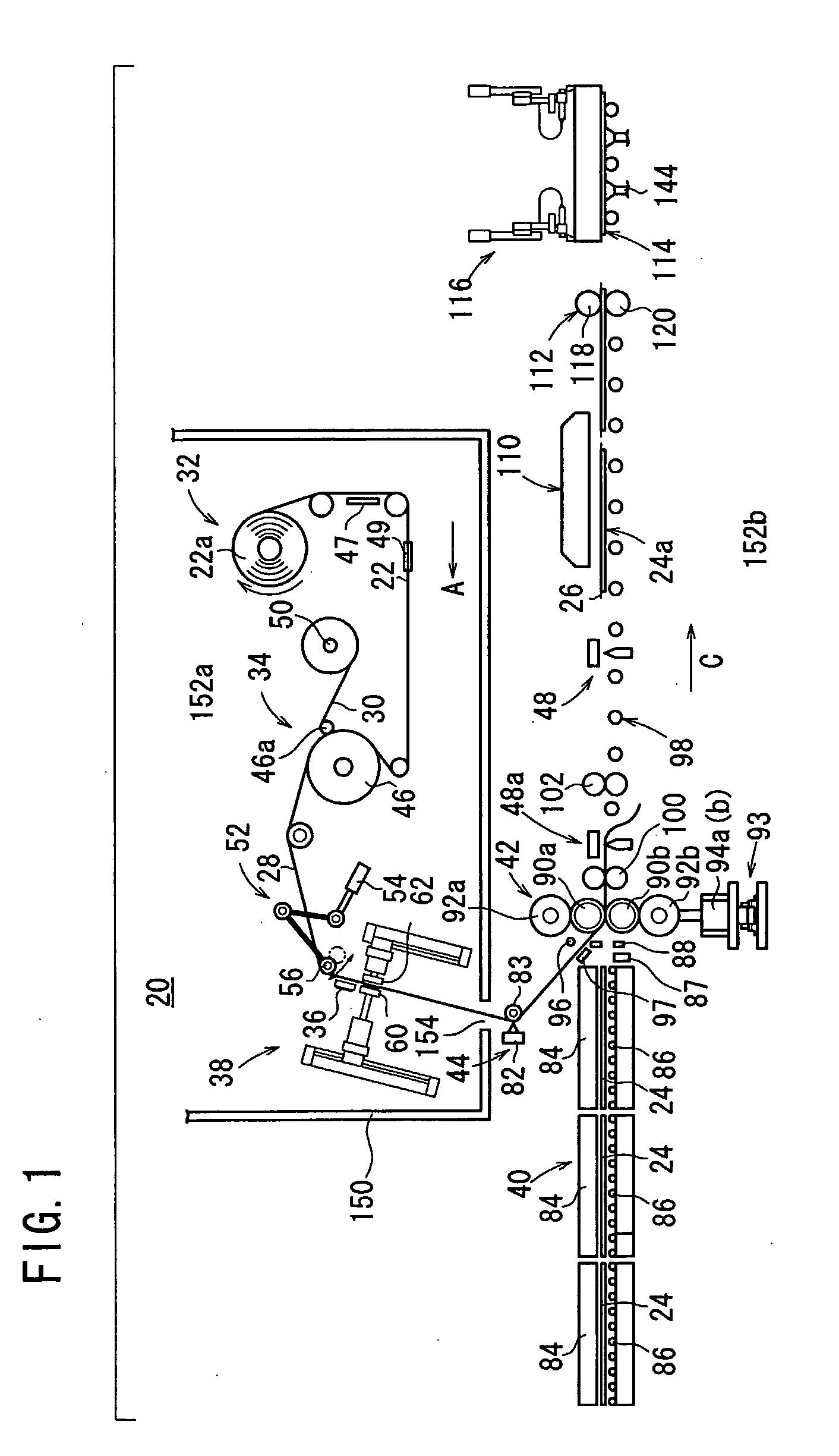

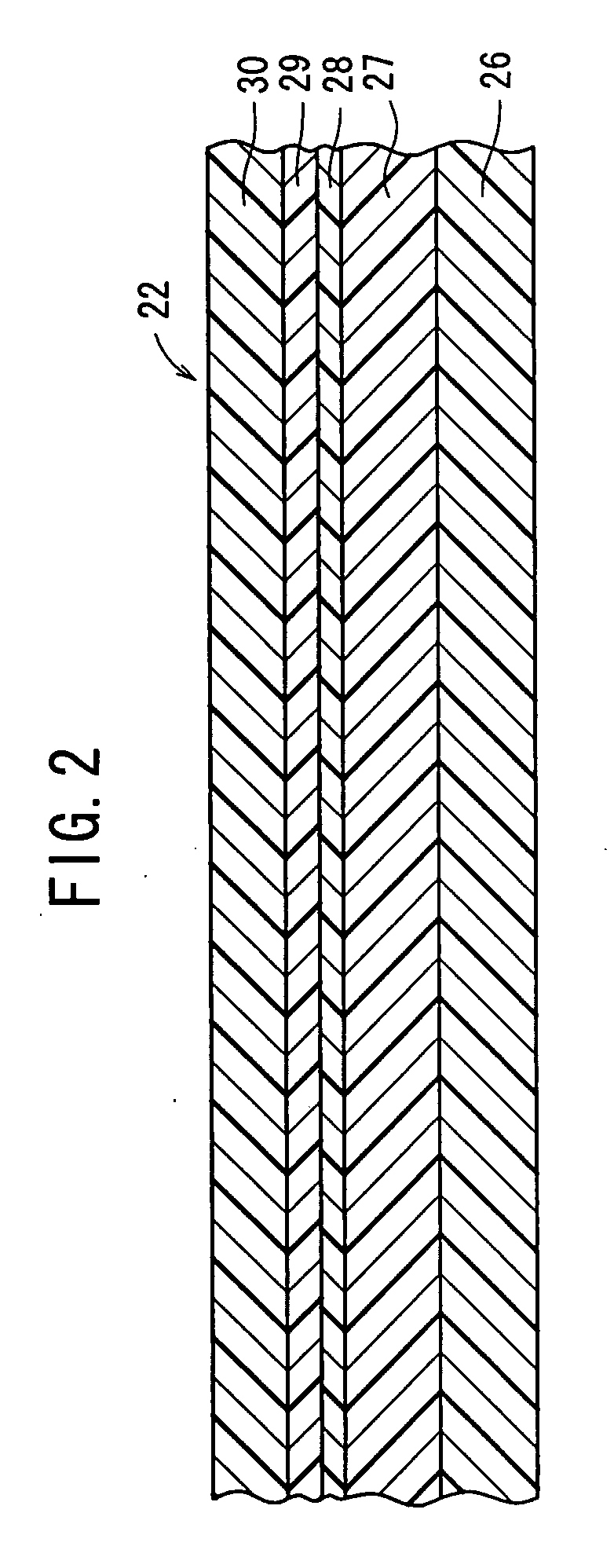

Method of and apparatus for laminated substrate assembly

InactiveUS20090044900A1Easy to assembleSimple processLamination ancillary operationsDecorative surface effectsVitrificationGlass transition

A manufacturing apparatus has a joining mechanism for bonding a photosensitive web to a glass substrate such that a cushion layer thereof faces the glass substrate, thereby to produce a joined substrate. The manufacturing apparatus also has a cooling mechanism for forcibly cooling the joined substrate with cooling air, a heating mechanism for heating the cushion layer to a temperature in a predetermined temperature range up to a glass transition temperature thereof, and a peeling mechanism for peeling off a base film of the photosensitive web from the heated joined substrate. The cooling mechanism, the heating mechanism, and the peeling mechanism are successively arranged in the direction in which the joined substrate is fed along.

Owner:FUJIFILM CORP

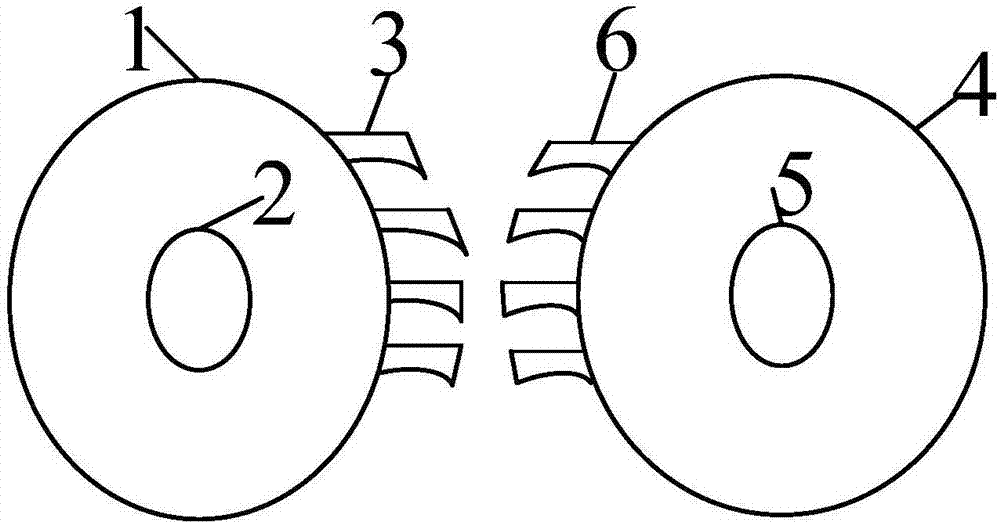

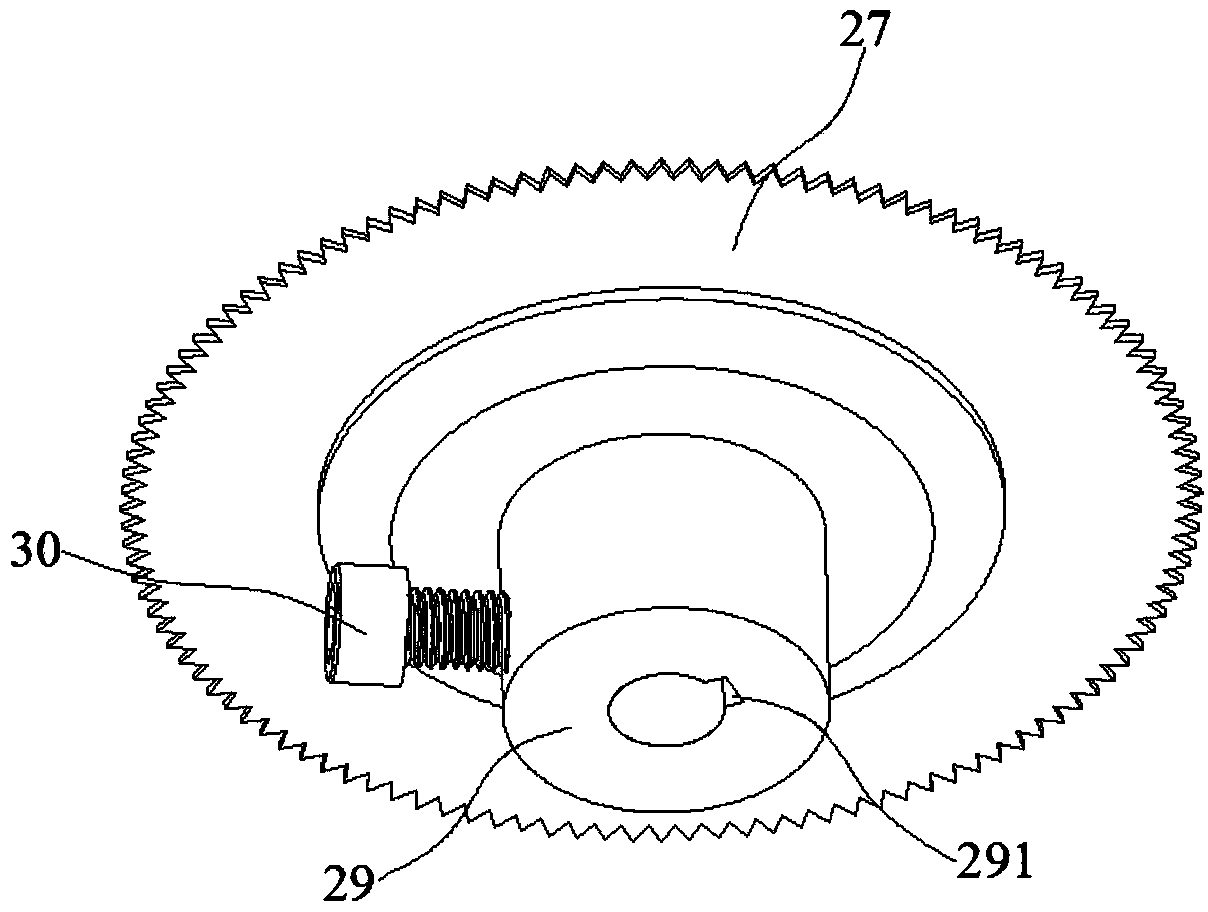

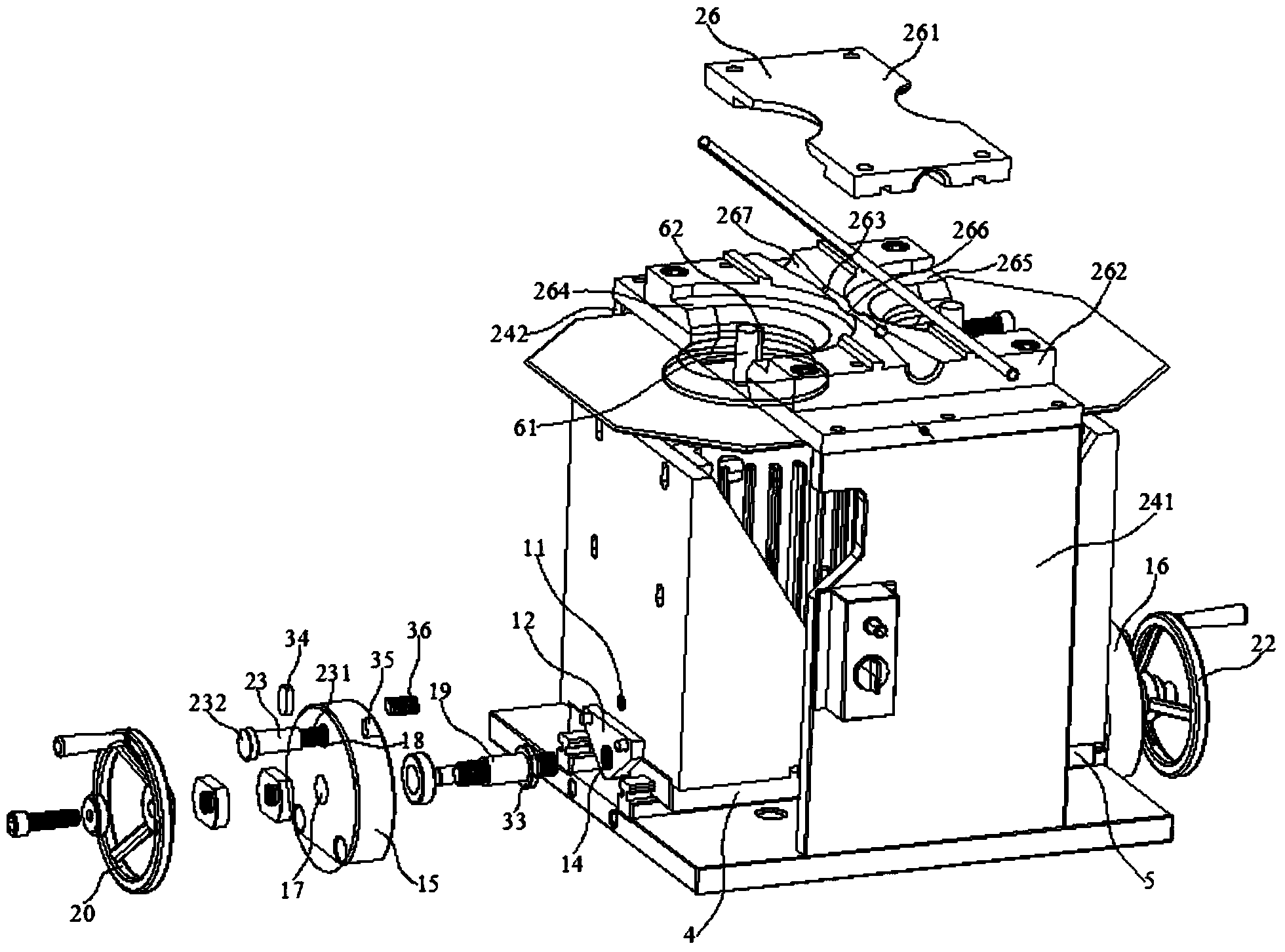

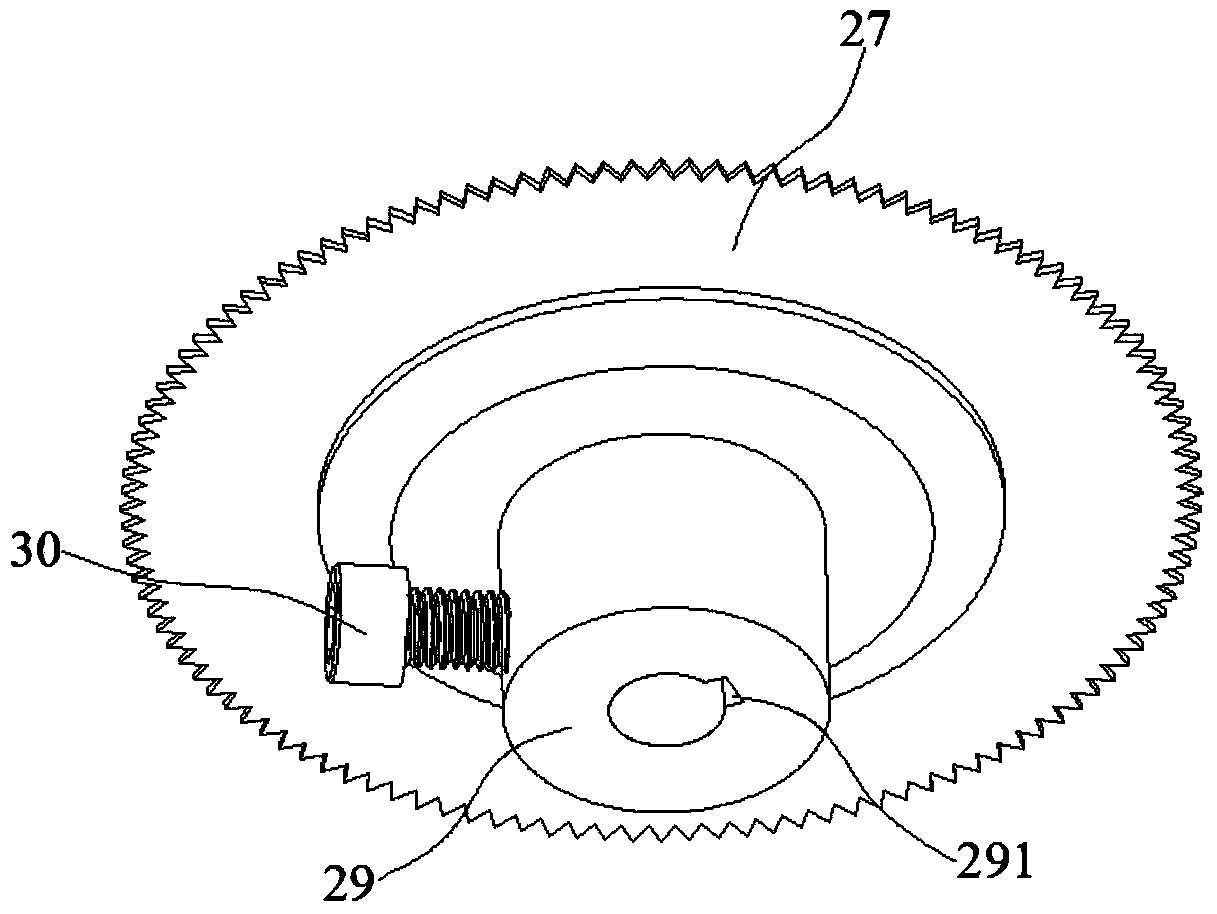

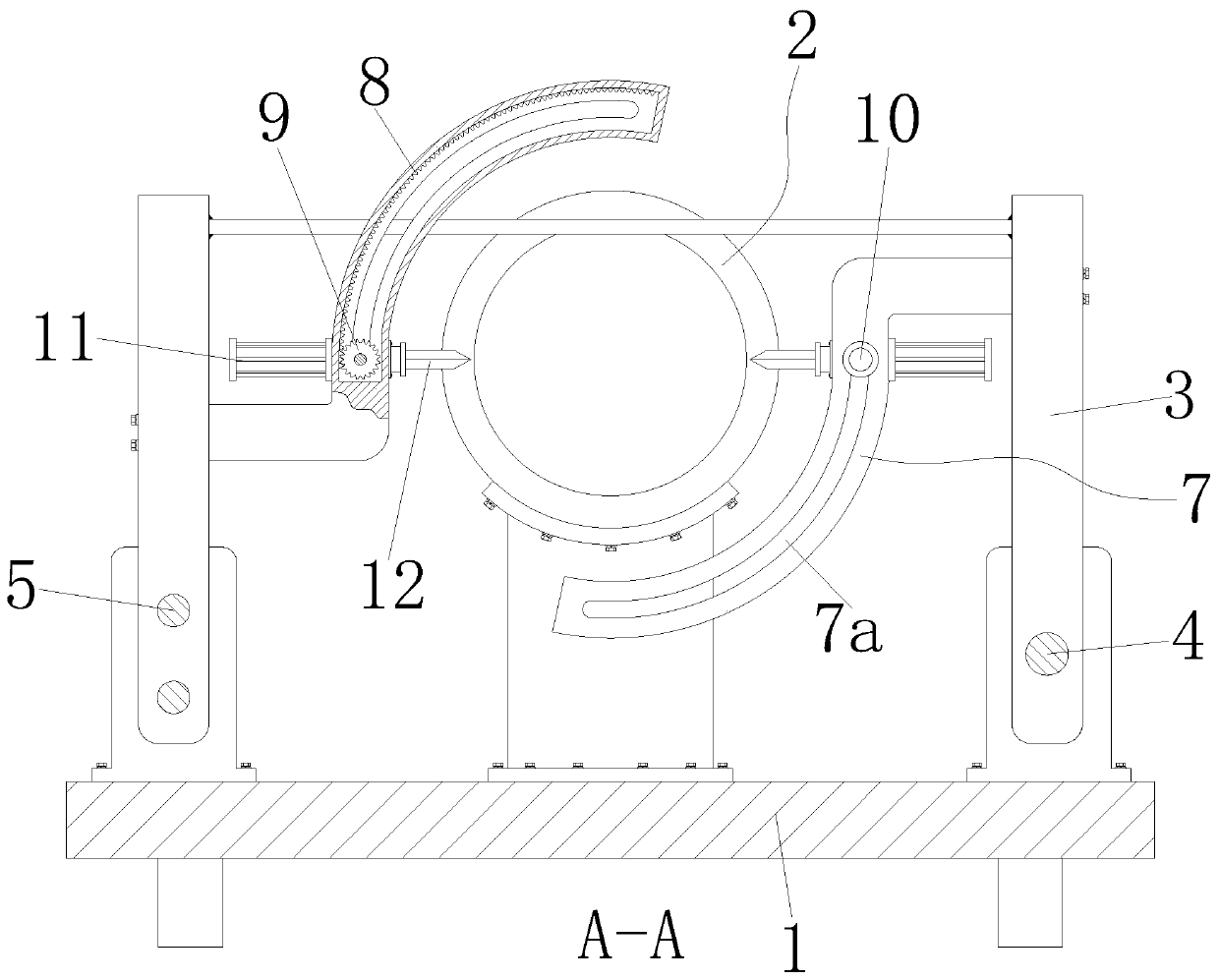

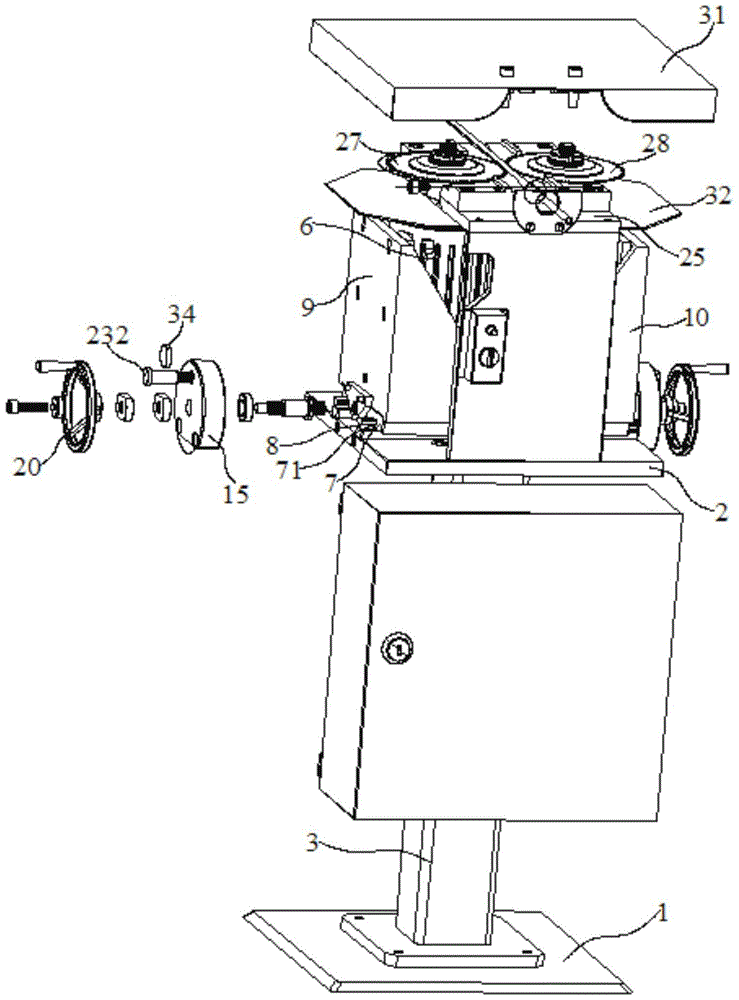

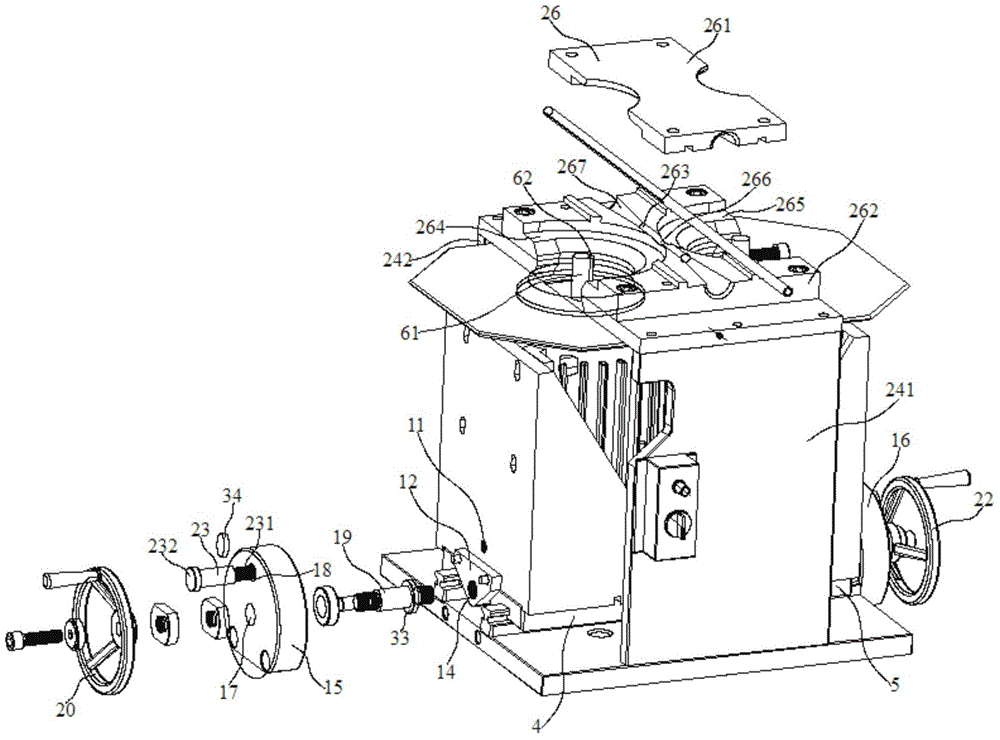

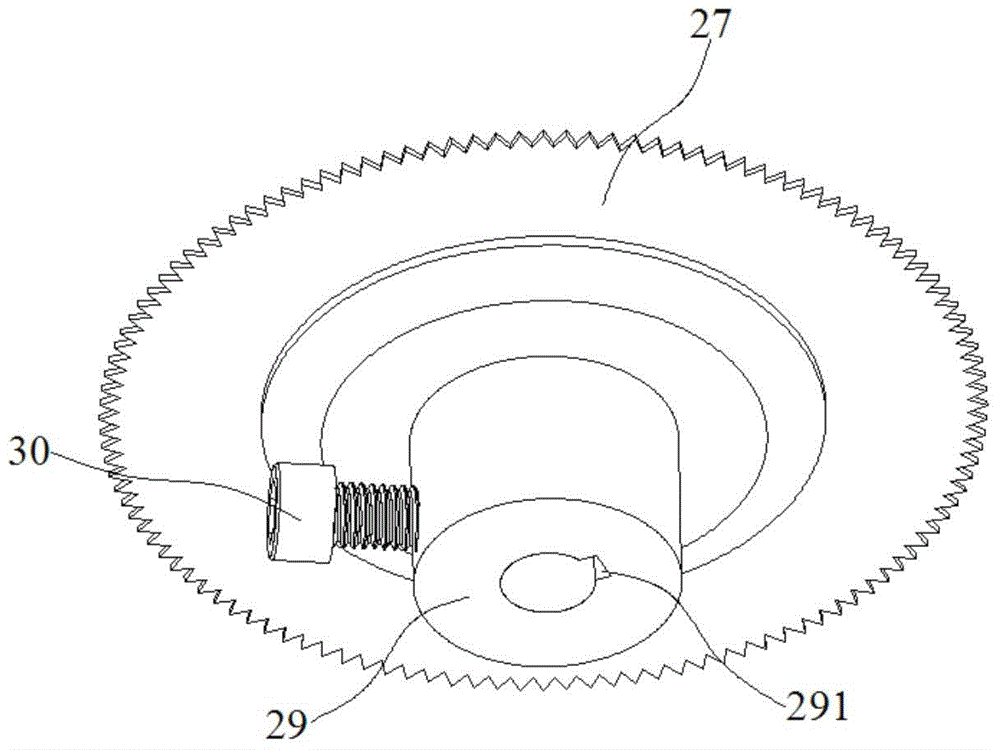

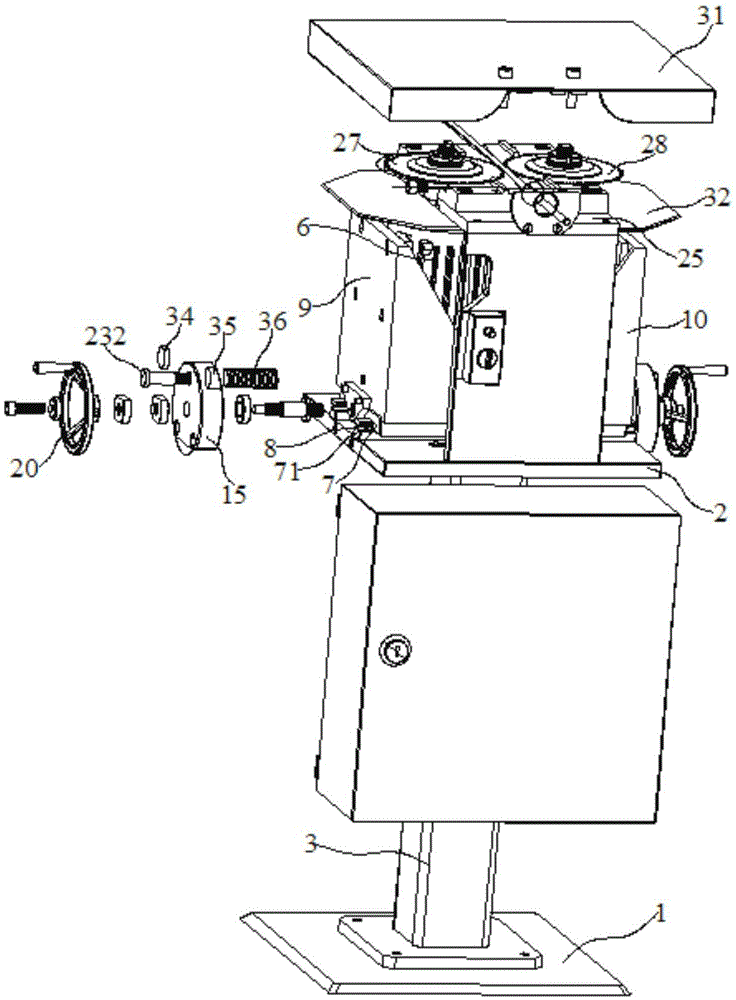

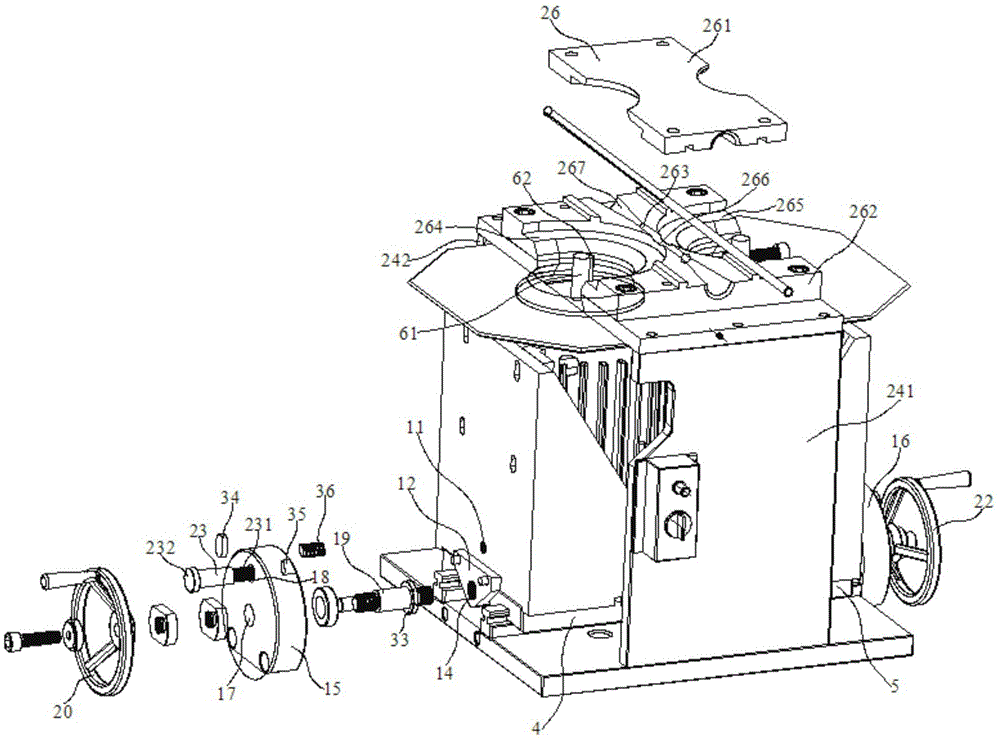

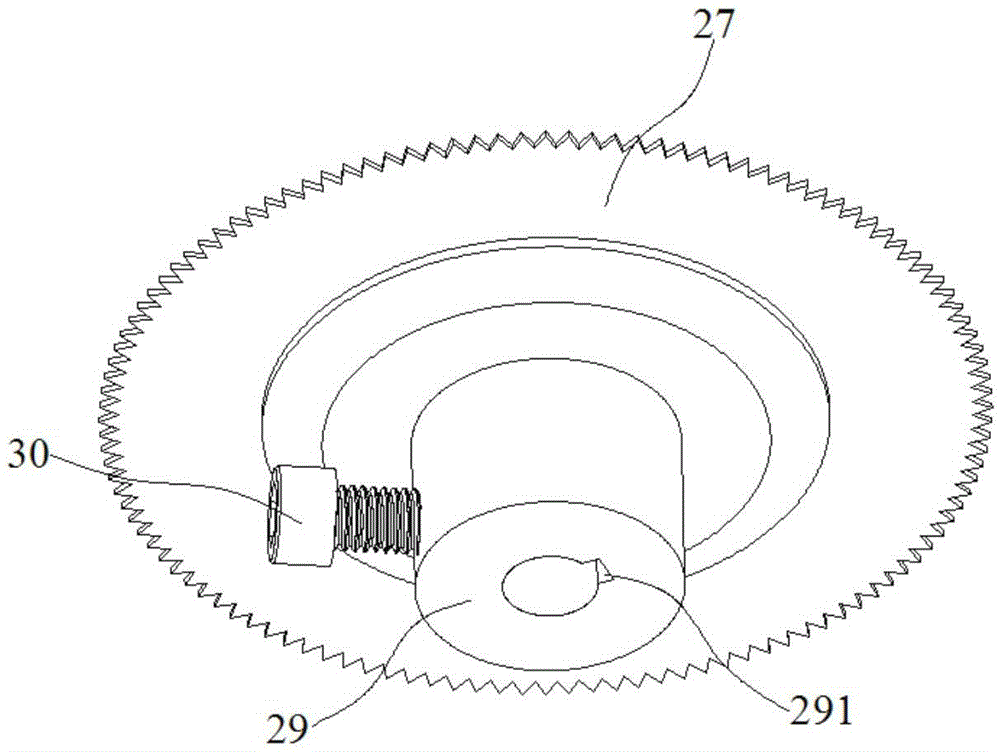

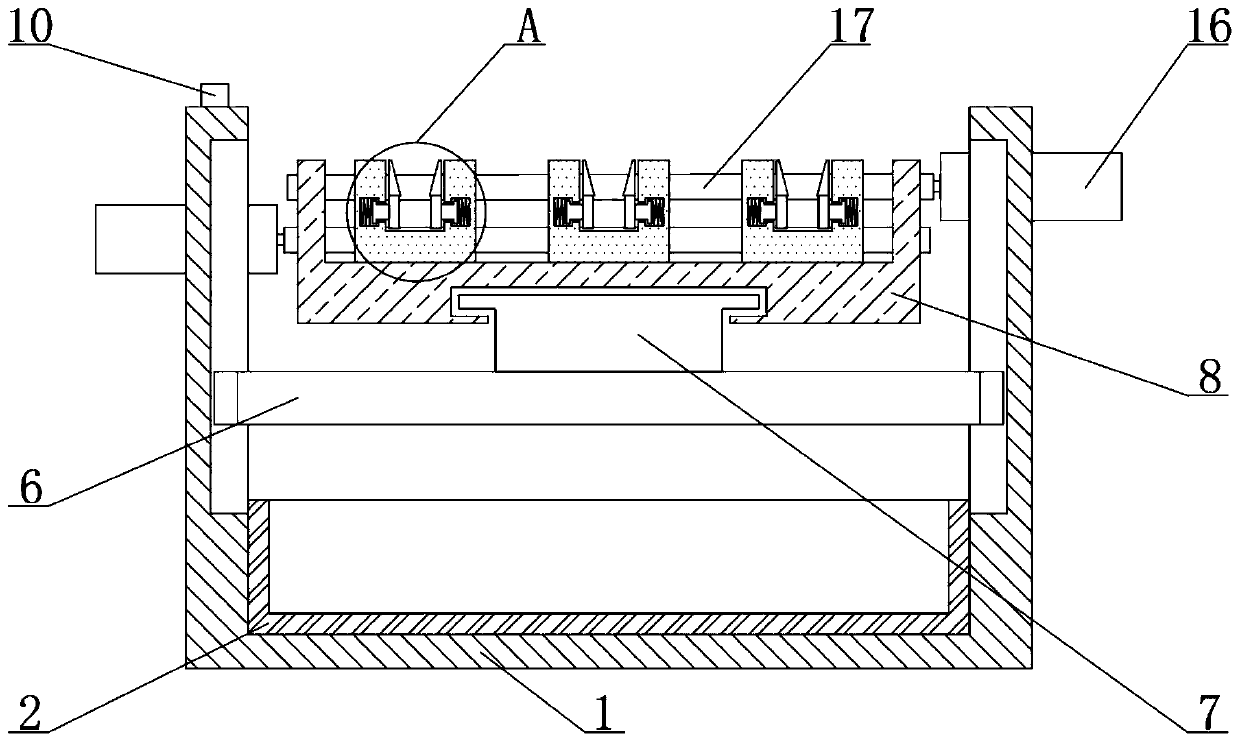

Precise separation device and method for down and hair fibers of animals

The invention provides a precise separation device and method for down and hair fibers of animals. The device comprises an original down winding roller and a down fiber stripping roller, wherein first card clothing and second card clothing which have the same structure are arranged on surface circumferences of the original down winding roller and the down fiber stripping roller at equal angles, the first card clothing and the second card clothing are flat-head card clothing with arc bottoms, the rotating speed of the original down winding roller is smaller than that of the down fiber stripping roller, and the rotating directions of the original down winding roller and the down fiber stripping roller are identical. During usage, original down fiber containing down fiber and hair fiber winds around the original down winding roller, the original down fiber is gradually transferred to the down fiber stripping roller by the aid of negative pressure difference produced during rotation of the original down winding roller and the down fiber stripping roller, meanwhile, the hair fiber falls off during transferring as the rigidity and weight of the hair fiber are larger than those of the down fiber, so that precise separation of down and hair in the original down fiber flexibly carded on the basis of small distance and large space is realized, the carding times are reduced, and low-damage carding is realized.

Owner:新疆天羚绒业科技股份有限公司

Method for manufacturing joined sheet material, joined sheet material and method for manufacturing optical display unit

InactiveUS8398806B2Short processLarge widthMechanical working/deformationLamination ancillary operationsBiomedical engineeringPressure sensitive

The invention is to provide a method for manufacturing a joined sheet product. The method comprising a first joining step including opposing a transverse end face of a first sheet product(1) to a transverse end face of a second sheet product(2) and joining release films of the first and second sheet products with a first joining member(30); a removing step including removing a portion of an intended member including at least a surface protecting member so as to leave at least the release film and a pressure-sensitive adhesive provided on the release film among the constituent members of both or any one of the first and second sheet products(1, 2), wherein the portion has a predetermined length from the transverse end face of the intended member; and a second joining step including providing a second joining member(40) on at least an exposed portion(40b) resulting from the removal of the intended member to join the surface protecting member sides of the first and second sheet products(1, 2).

Owner:NITTO DENKO CORP

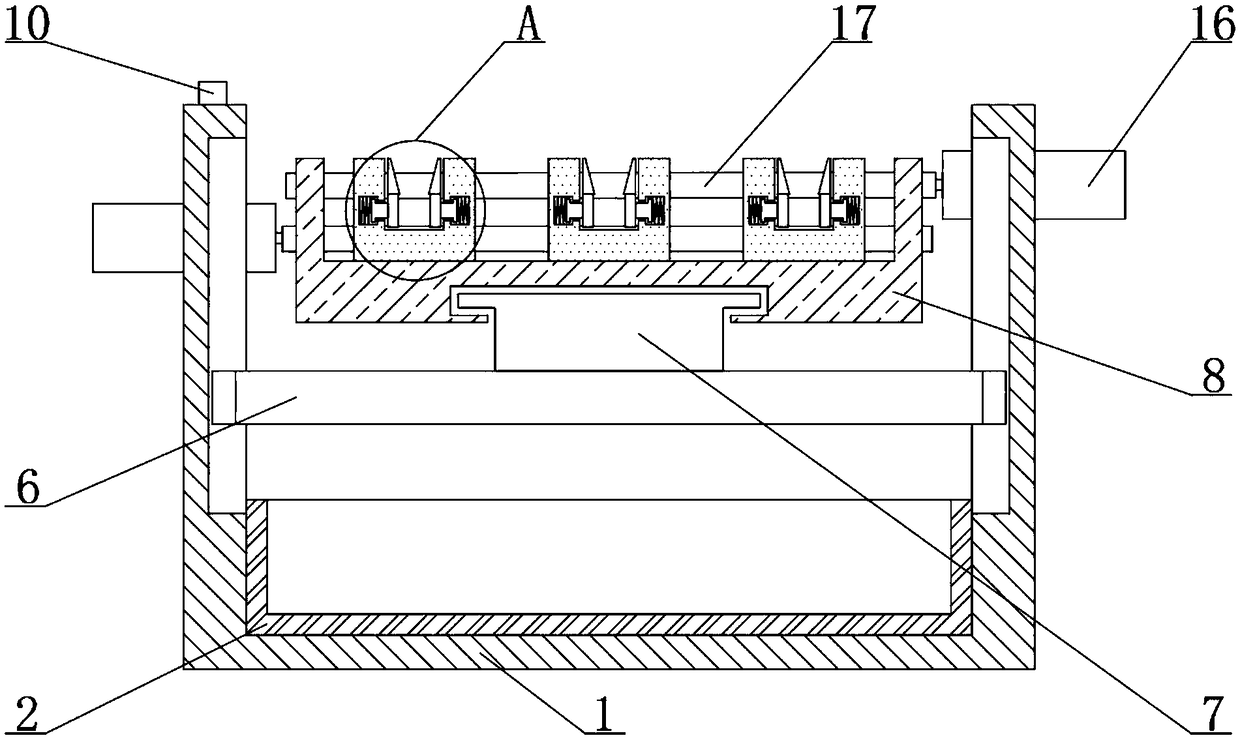

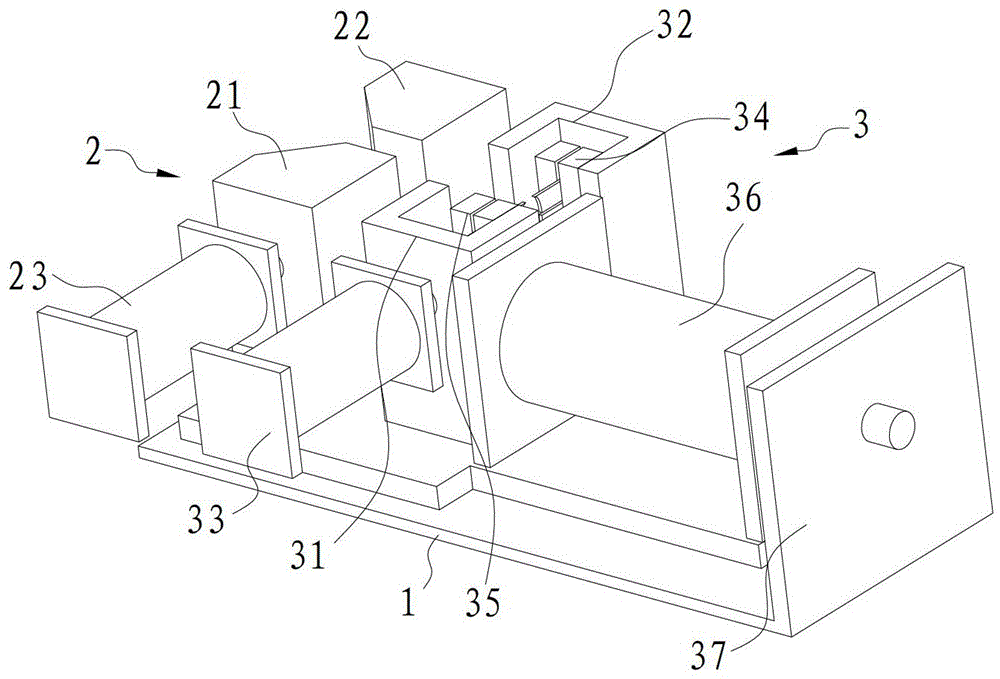

Automatic rail cable machining device

ActiveCN103683127ASolve the difficulty of cutting and peelingImprove reliabilityApparatus for removing/armouring cablesCable machineEngineering

The invention discloses an automatic rail cable machining device which comprises a fixed base plate, a left motor support, a right motor support, two motors and a hauling mechanism, wherein a left baffle provided with an adjusting threaded hole is fixed on the outer side of the left motor support, a right baffle provided with an adjusting threaded hole is fixed on the outer side of the right motor support, a left connecting plate provided with a driving threaded hole is fixed on the outer side of the left baffle, a right connecting plate provided with a driving threaded hole is fixed on the outer side of the right baffle, the left connecting plate and the right connecting plate are located between two linear guide rails, a ground groove is formed in the end face, opposite to the left baffle, of a left fixed base, a ground groove is formed in the end face, opposite to the right baffle, of a right fixed base, two springs are mounted on screws of two limiting bolts in a sleeved mode respectively and located between the left fixed base and the left baffle and between the right fixed base and the right baffle respectively, a left oiling groove and a right oiling groove are formed in a shield, and the left oiling groove and the right oiling groove are located over a left round cutting piece and a right round cutting piece respectively. According to the automatic rail cable machining device, cutting depth can be adjusted dynamically, parameters can be adjusted flexibly by operators according to the characteristics of products and working conditions, generality is high, a cable core is further effectively protected, and danger factors existing in manual or mechanical cutting are also avoided.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

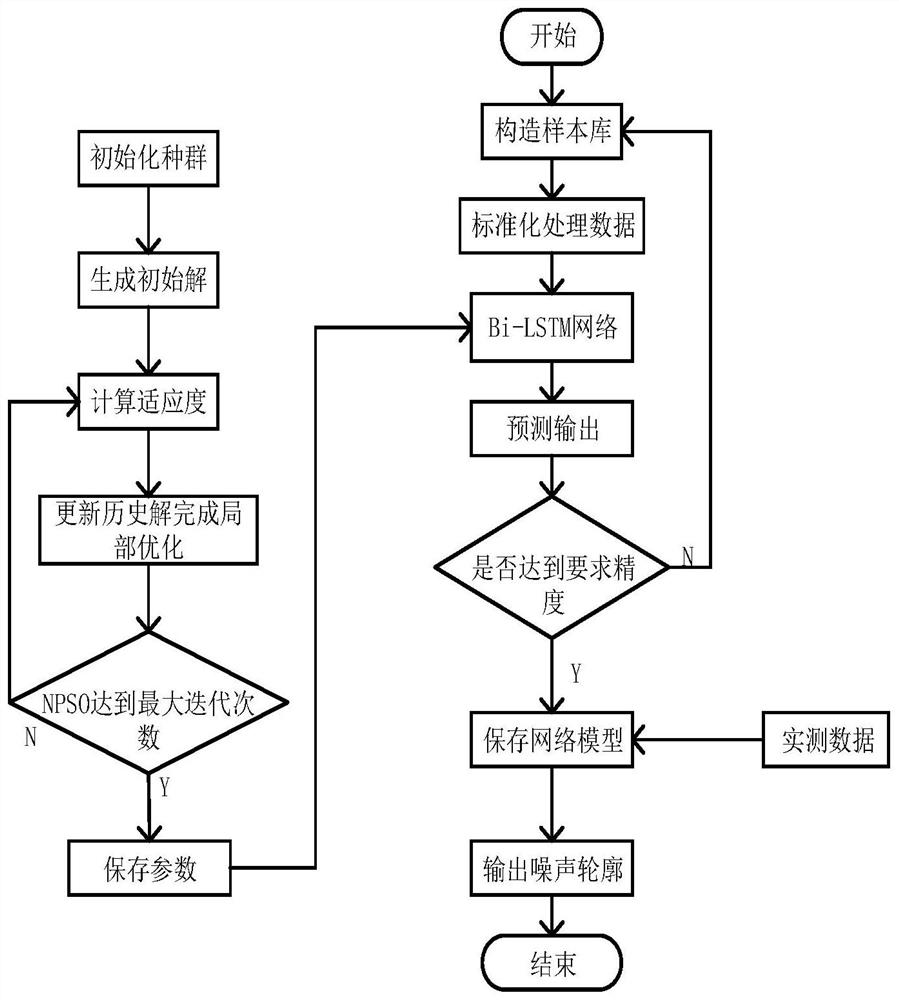

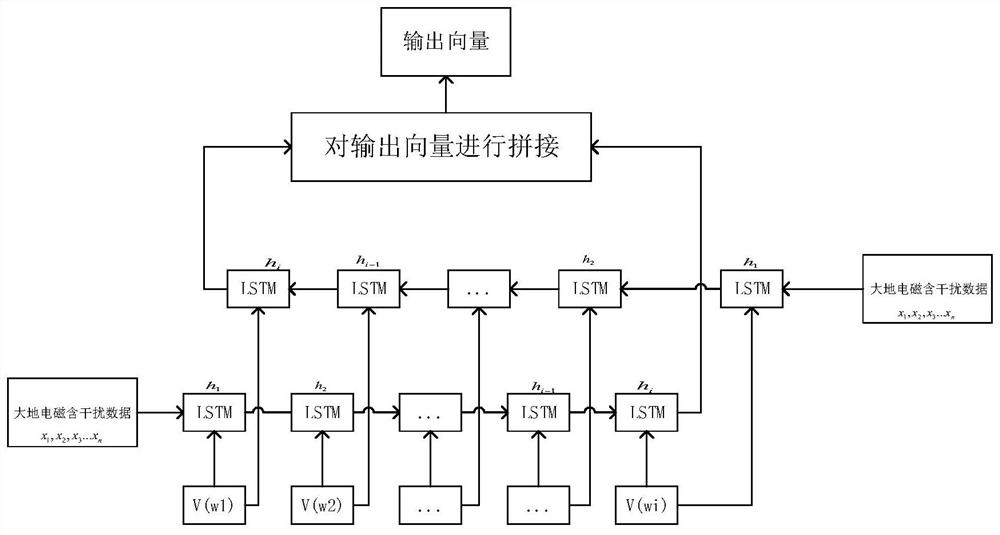

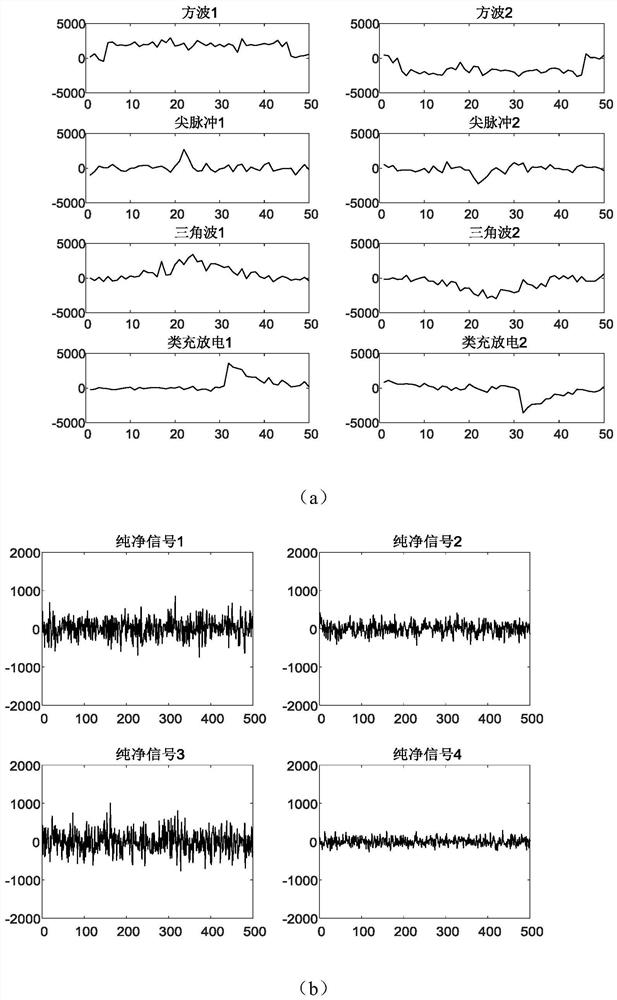

Bi-LSTM-based magnetotelluric signal denoising method and system

ActiveCN113687433AImprove signal-to-noise separation efficiencyOptimize network parametersElectric/magnetic detectionAcoustic wave reradiationLong short term memoryTest set

The invention discloses a Bi-LSTM-based magnetotelluric signal denoising method and system, the method comprises the steps: constructing a large number of noise contours conforming to magnetotelluric weak signals and containing strong interference characteristics, and adding the noise contours to obtain noisy signals; dividing the noisy signals into a corresponding training set and a test set according to a proportion, defining input and output corresponding to the network, preferably selecting related parameters of an optimal bidirectional long-short-term memory neural network by using NPSO, and then sending the training set into the neural network for training to obtain a prediction model; predicting the actually measured magnetotelluric data by using the prediction model to obtain the noise contour; and finally, subtracting the predicted noise contour from the actually measured magnetotelluric data to obtain useful magnetotelluric signals. According to the method, the noise contours can be effectively and accurately predicted, so that the noise in the noisy signals is eliminated, and more useful magnetotelluric signals are reserved.

Owner:HUNAN NORMAL UNIVERSITY

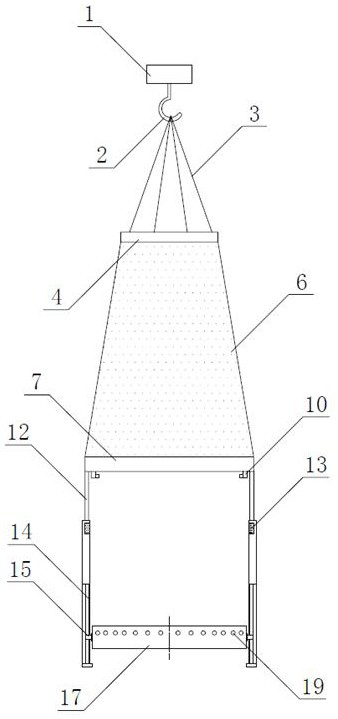

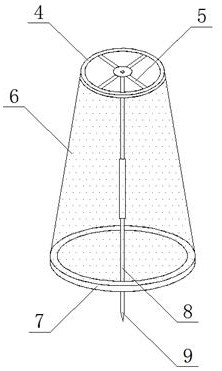

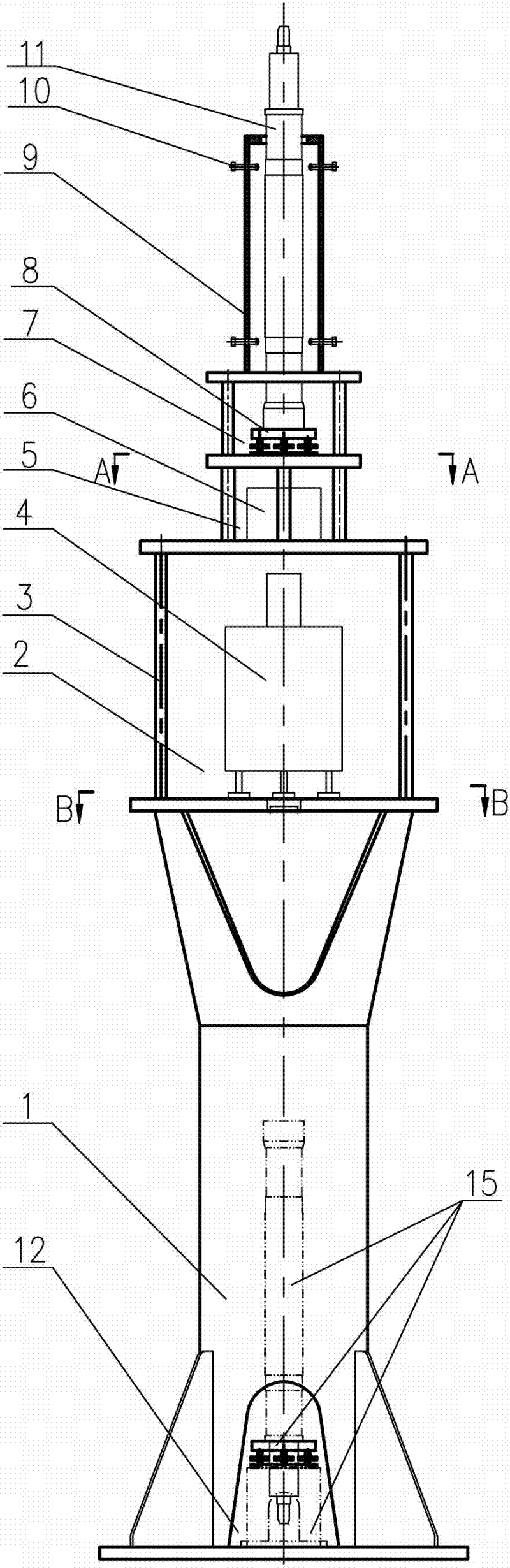

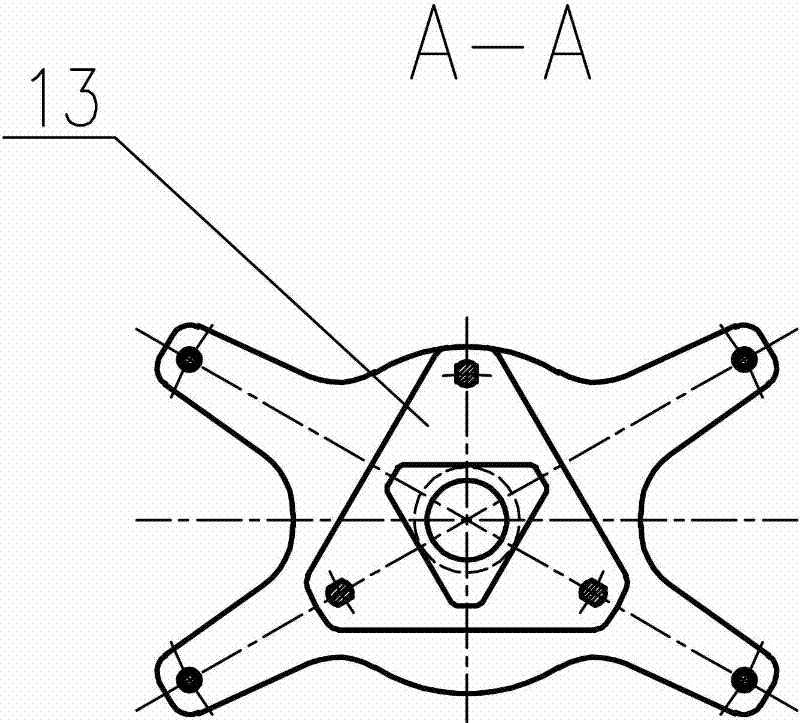

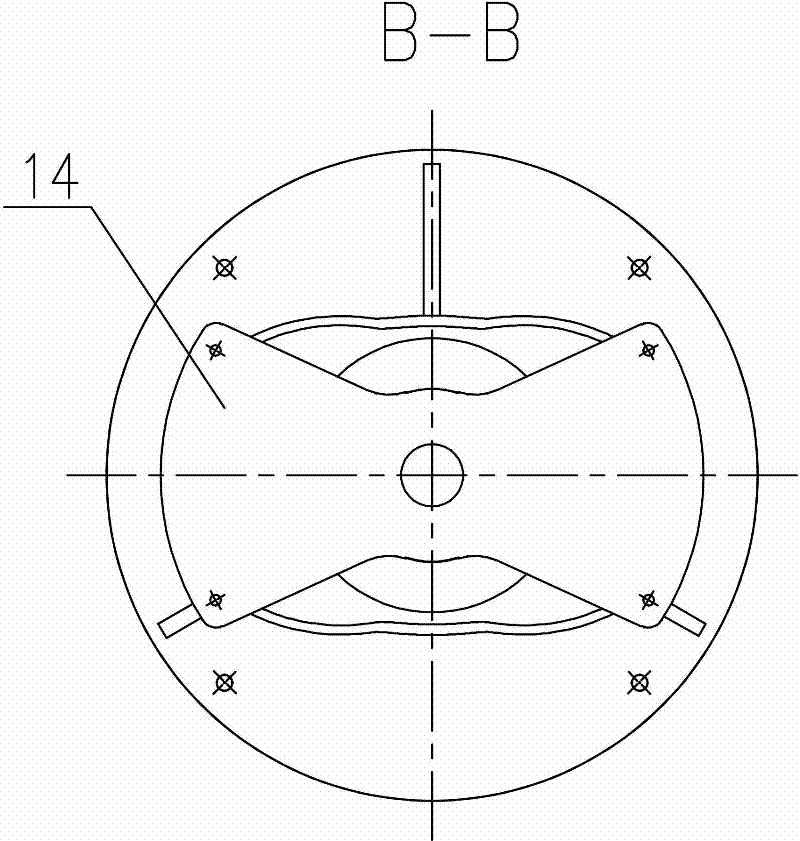

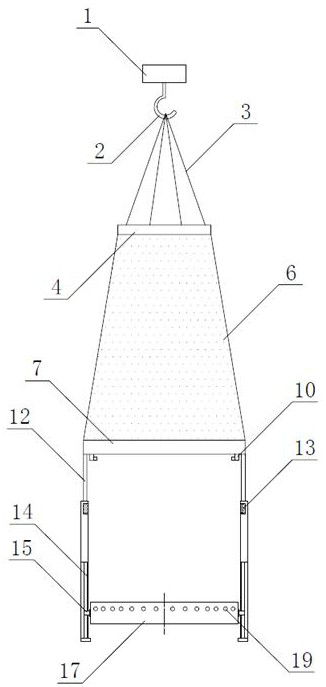

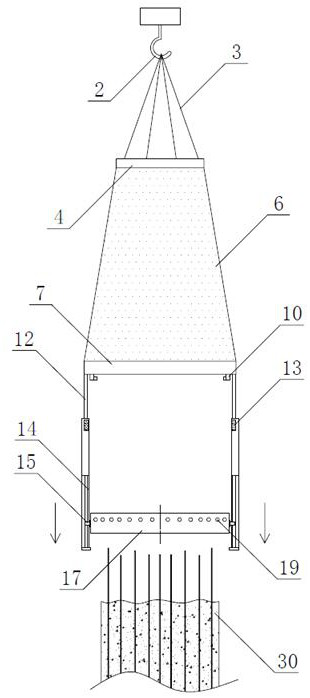

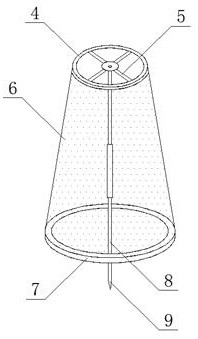

Automatic butt-joint positioning and cutting-off structure for concrete pile head

ActiveCN113199639AFast and accurate dockingFast and accurate positioningWorking accessoriesGrain treatmentsButt jointClassical mechanics

The invention discloses an automatic butt-joint positioning and cutting-off structure for a concrete pile head. The automatic butt-joint positioning and cutting structure for the concrete pile head comprises a lifting appliance (1) and a hanging ring (4) and is characterized in that the lower end of the hanging ring (4) is fixed to the small opening end of a positioning conical cylinder (6), a fixing ring (7) is fixed to the lower portion of the large opening end of the positioning conical cylinder (6), a connecting piece (5) is fixed in the hanging ring (4), the lower end of the connecting piece (5) is located on the axial lead of the positioning conical cylinder (6) and connected with the top end of a vertical supporting rod (8) through a ball-head-shaped hinge shaft, the bottom of the fixing ring (7) is fixed to the upper end of a vertical fixing arm (12), a lifting mechanism is installed at the lower end of the vertical fixing arm (12), and the lifting connecting end of the lifting mechanism is connected with a cutting, stripping and chiseling-away assembly. The structure is reasonable, automatic butt joint positioning can be achieved, the position of a broken cut-off surface can be accurately controlled, the situation that the cut-off length is too large or insufficient is avoided, and the construction efficiency is greatly improved.

Owner:湖北远大建设集团有限公司

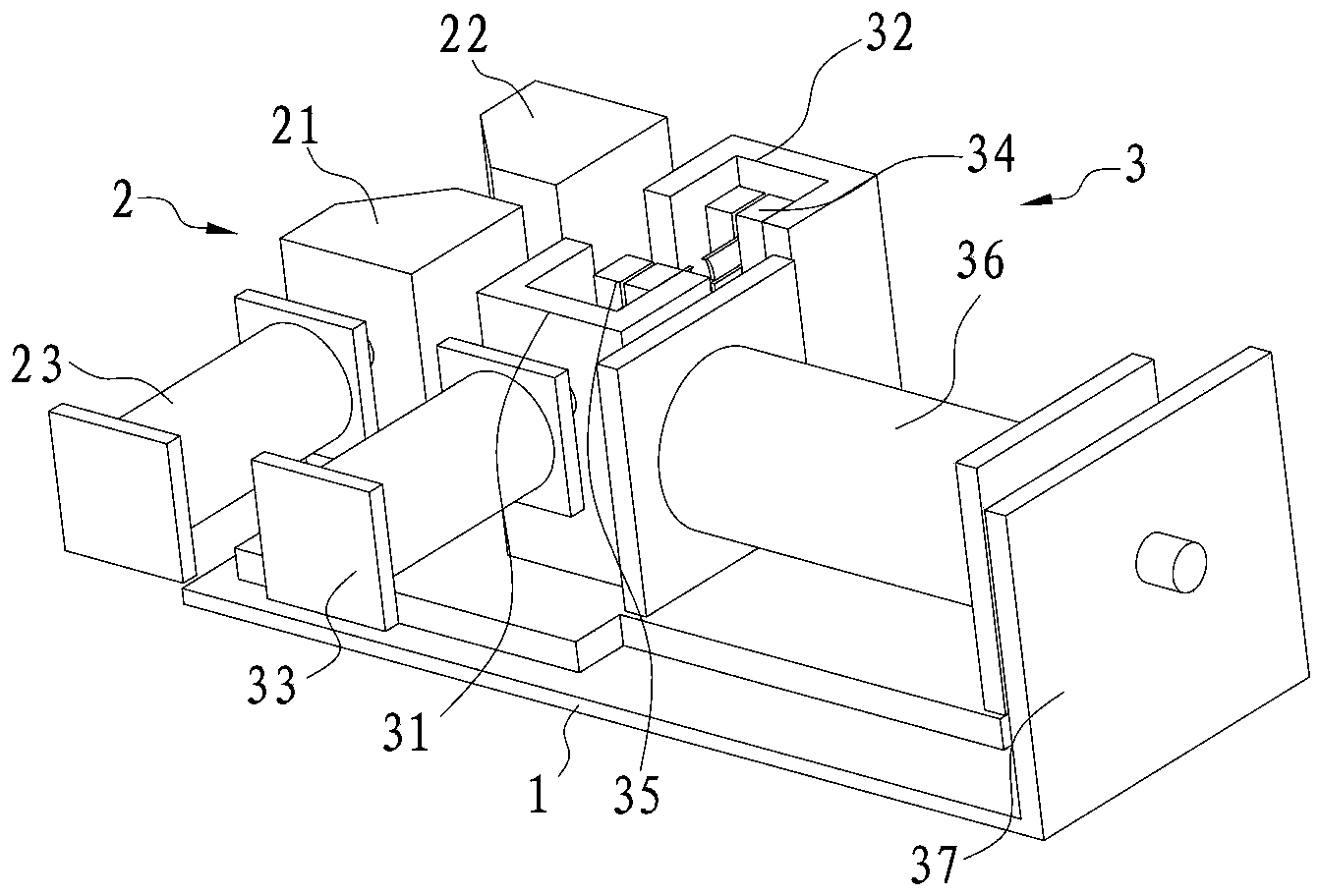

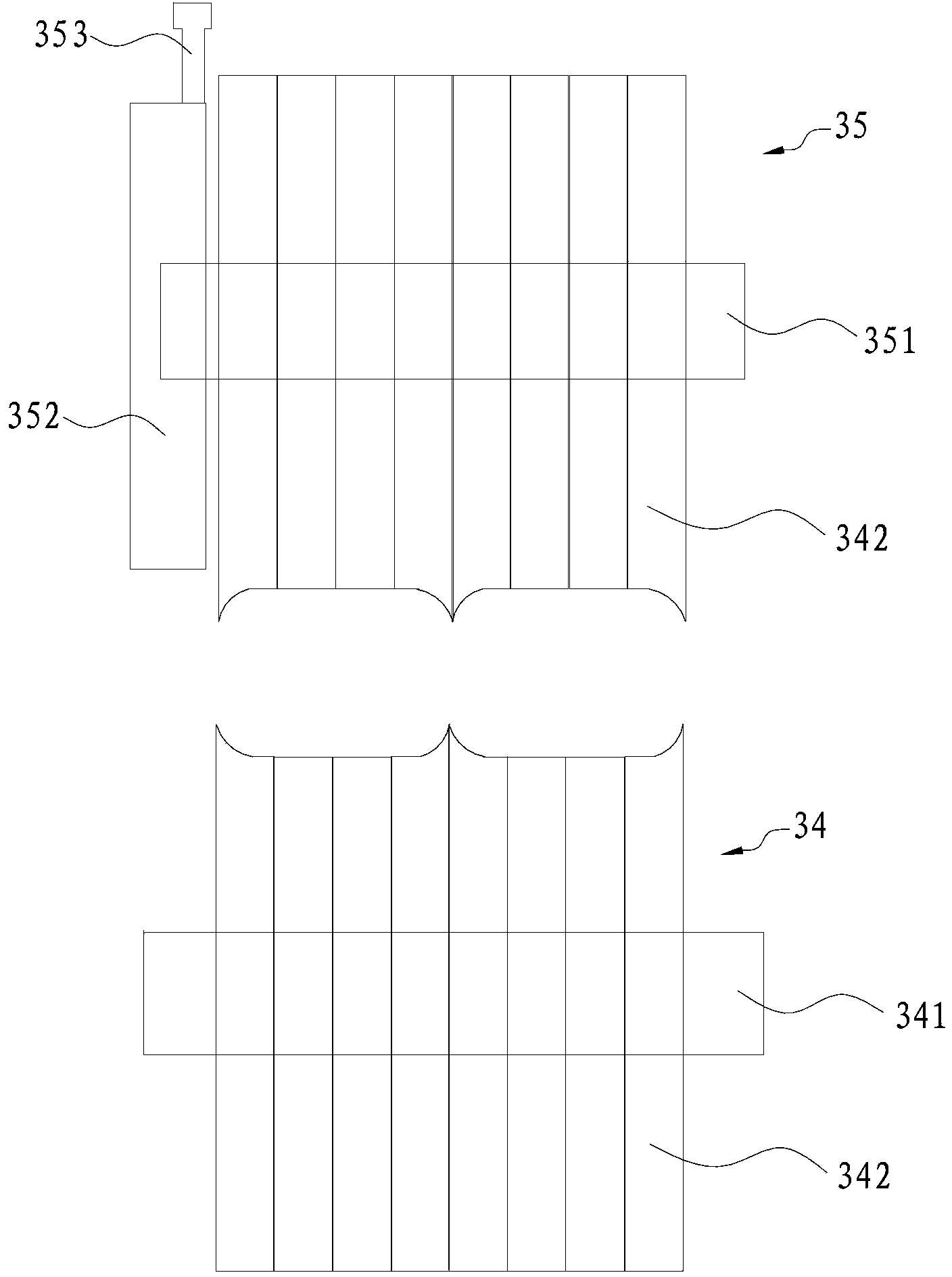

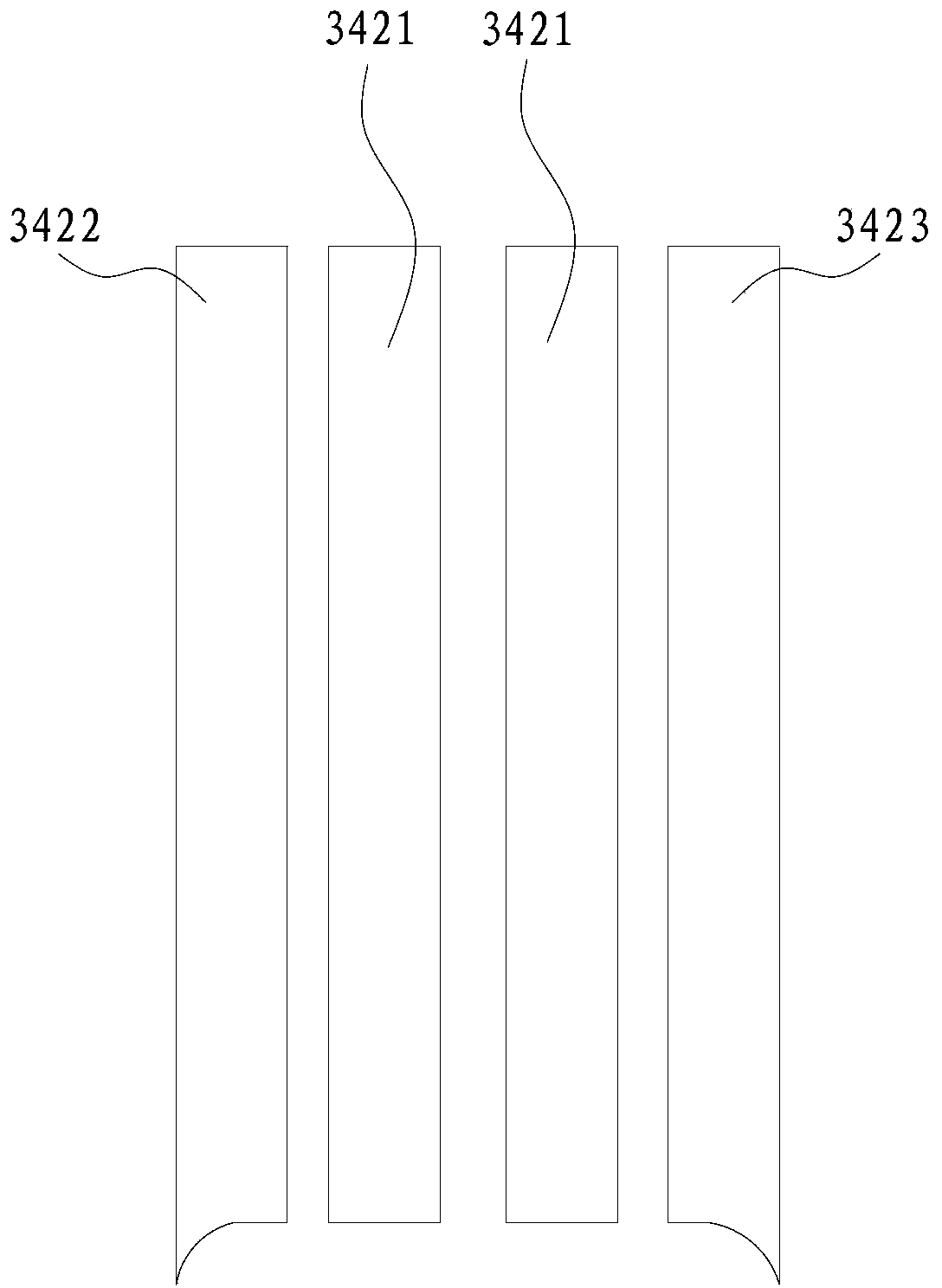

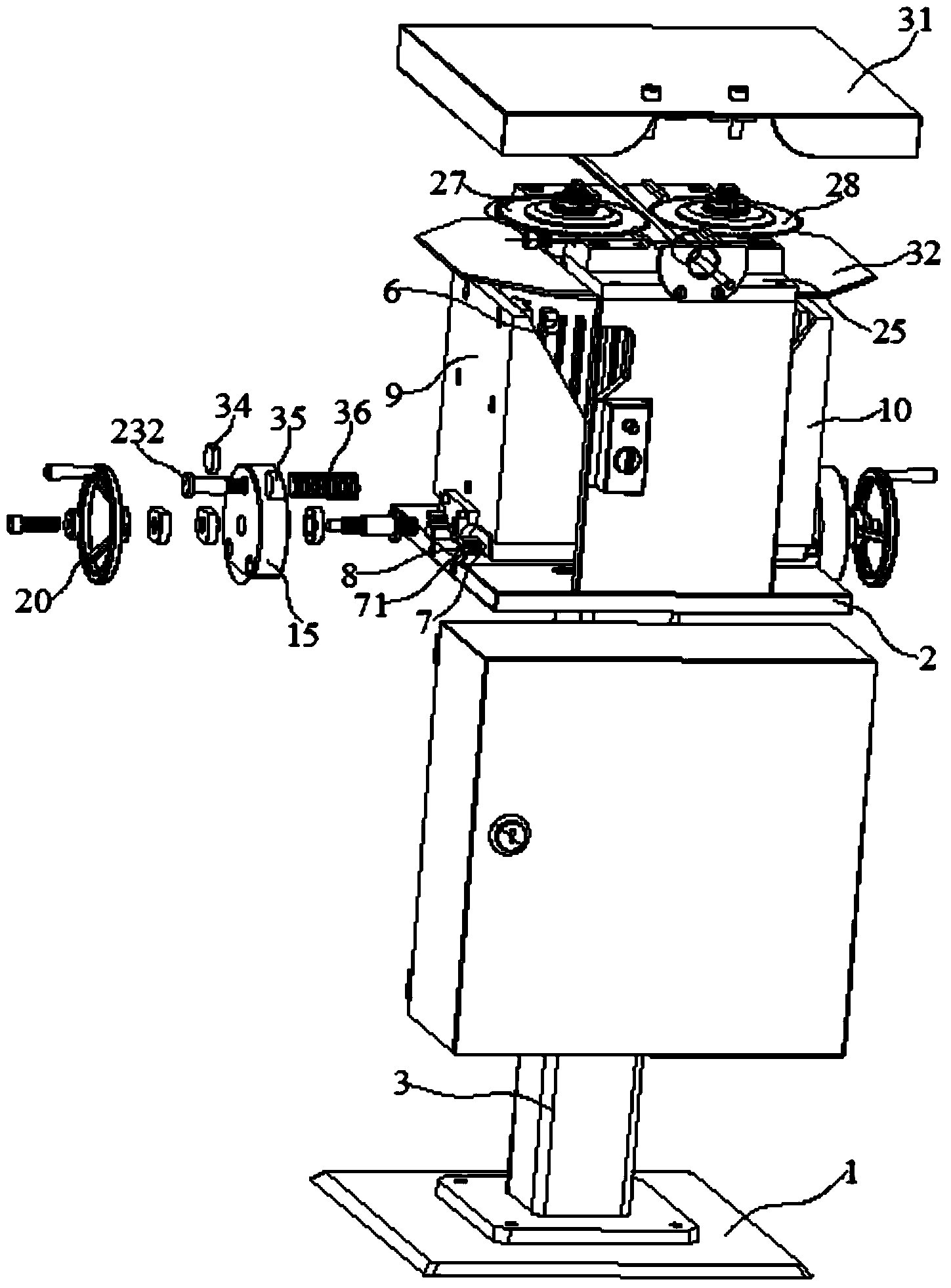

Metal sheath stripping device for rail transit cable

ActiveCN103683129ASolve the difficulty of cutting and peelingImprove stripping efficiencyApparatus for removing/armouring cablesEngineeringRail transit

The invention discloses a metal sheath stripping device for a rail transit cable. The device comprises a base, a fixed base plate, a stand column fixed between the base and the fixed base plate, a left motor support, a right motor support and two motors, wherein one of the two motors is mounted on the left motor support, the other motor is mounted on the right motor support, two sliding blocks are fixed on the lower surface of the left motor support in parallel, two sliding blocks are fixed on the lower surface of the right motor support in parallel, two linear guide rails are arranged on the fixed base plate in parallel and are embedded into grooves of the sliding blocks of the left motor support and grooves of the sliding blocks of the right motor support in sequence, a left baffle provided with an adjusting threaded hole is fixed on the outer side of the left motor support, a right baffle provided with an adjusting threaded hole is fixed on the outer side of the right motor support, a left connecting plate provided with a driving threaded hole is fixed on the outer side of the left baffle, a right connecting plate provided with a driving threaded hole is fixed on the outer side of the right baffle, the left connecting plate and the right connecting plate are located between the two linear guide rails, and the driving threaded holes are located below the left motor support and the right motor support. The metal sheath stripping device for the rail transit cable overcomes the difficulty in cutting and stripping of a metal sheath during detection, connection and installation of metal sheath cables, stripping efficiency is improved, and stripping of long metal sheaths is achieved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

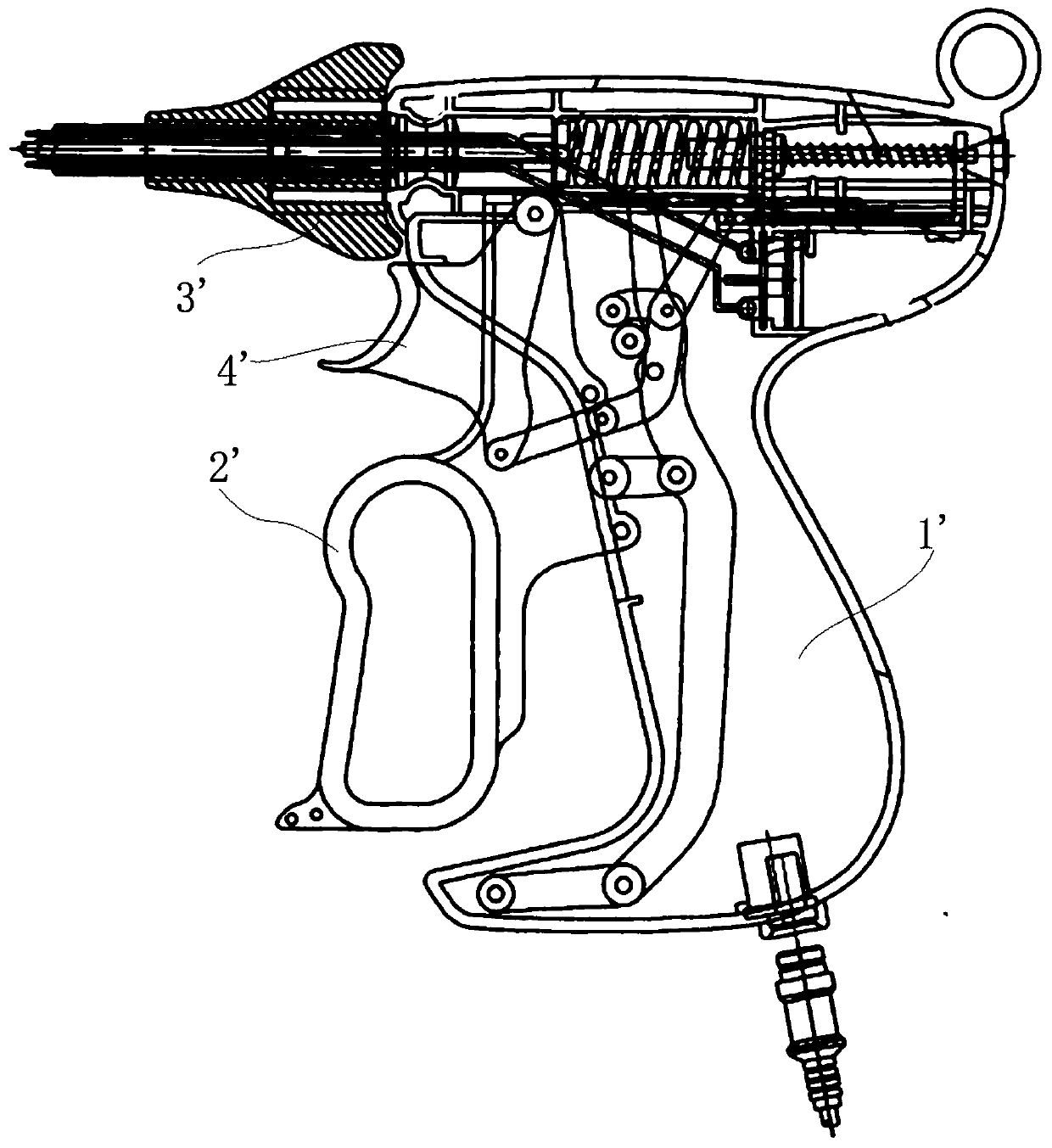

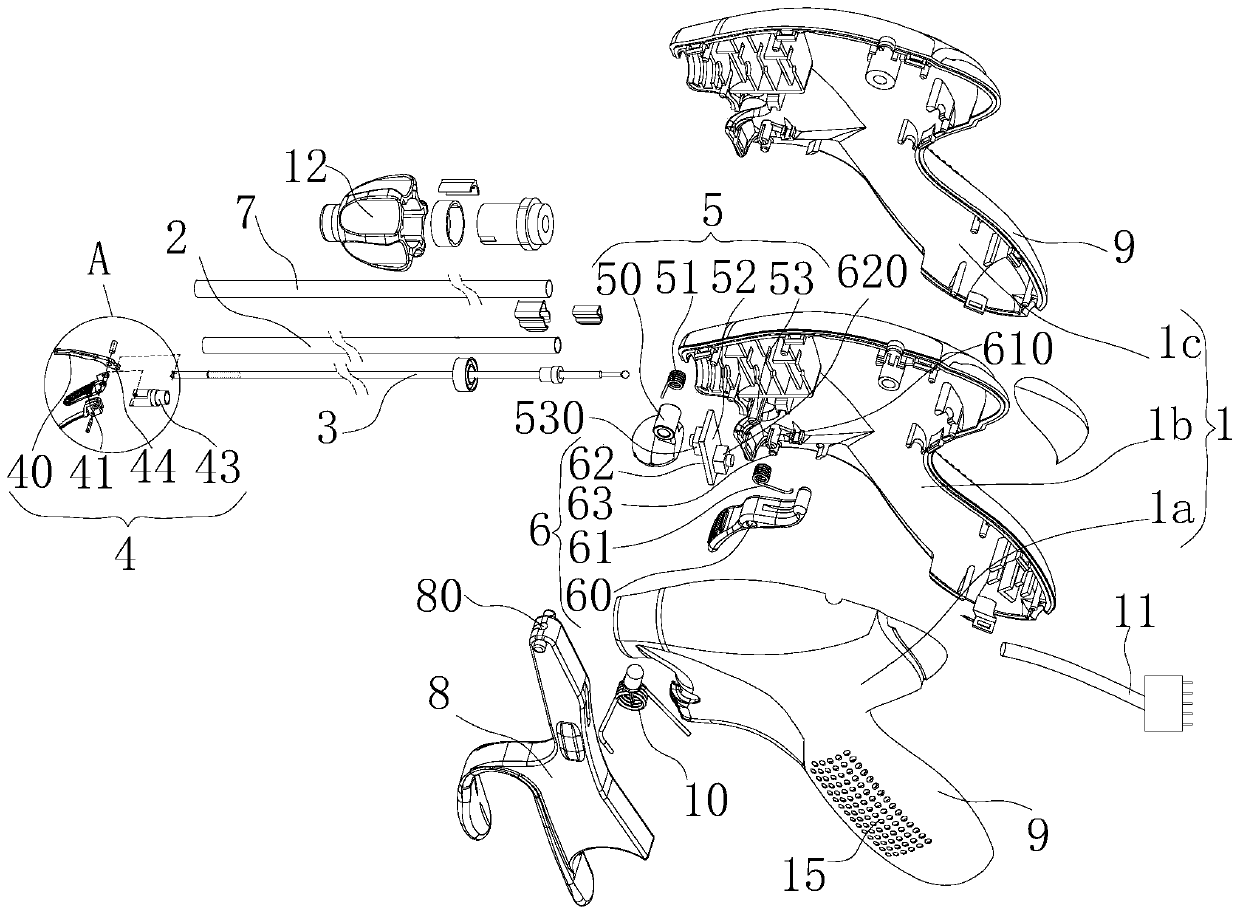

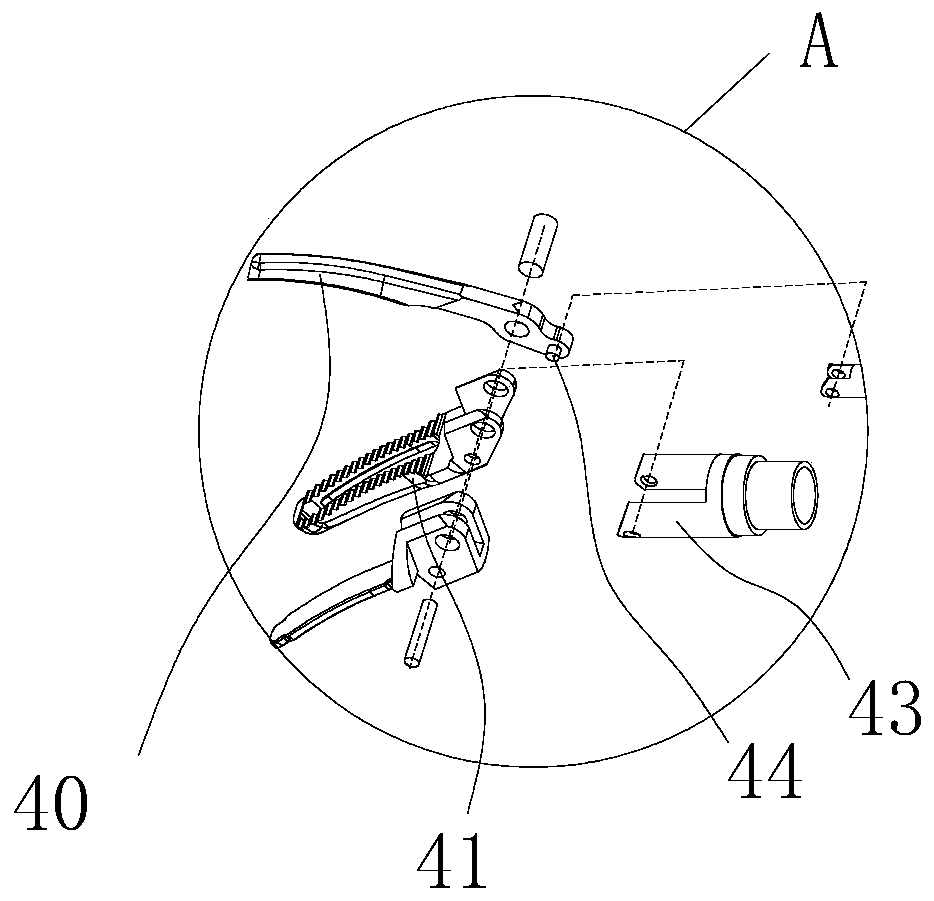

Multifunctional minimally invasive surgical forceps and operation method thereof

PendingCN111407401APrecise positioningStructure labor savingInstrument handpiecesSurgical instruments for heatingForcepsBlood coagulations

The invention discloses a pair of multifunctional minimally invasive surgical forceps and an operation method thereof. The pair of multifunctional minimally invasive surgical forceps comprises a shell, a hollow pipe, a driving rod, an end effector component, a cutting control component and a blood coagulation control component, wherein the end effector component comprises a first jaw component anda second jaw component for touching and grabbing tissues between the jaw components; the cutting control component conducts plasma blood cutting energy to clamped and held tissues between the first jaw component and the second jaw component to carry out a cutting operation; the blood coagulation control component conducts plasma blood coagulation energy to the clamped and held tissues between thefirst jaw component and the second jaw component to carry out a blood coagulation operation; and a finger placing position is also arranged between the cutting button of the cutting control componentand the deflection manipulation handle of the blood coagulation control component, an operator can more stable hold the forceps, tissues can be accurately and easily broken and peeled, the handle ofthe shell can be stably and reliably held through the cooperation of five fingers, the thumb and the palm, and cutting and blood coagulation can be more conveniently and easily carried out due to handcontrol.

Owner:SCANMED CHINA

A high-power current stripping tooling and a use method thereof

ActiveCN109193477ACompact structureReasonable structureApparatus for removing/armouring cablesPower flowFixed frame

The invention relates to a high-power current stripping tooling and a use method thereof, including a mount and motor, a collection box is slidably connected to the inner side of the bottom end face of the fixing frame, a wind box is communicated with the front end surface of the collection box, a fan and a filter screen arranged in front and back are arranged on the inner side of the bellows, andthe fan is fixedly connected with the bellows through a connecting rod, the filter screen is fixedly connected with the bellows, a slide bar is slidably connected to the inside of the fixing frame, afirst slider is fixedly connected to the top end surface of the slide bar, a limit frame is slidably connected to that out side of the first slider, a location block with a stripping length is slidably connected to that inner side of the fix frame through a connecting rod, In the invention, the collection box is arranged, and the arrangement cooperates with the storage function of the collectionbox and the wind guidance of the fan, so as to collect the stripped debris centrally to the maximum extent, thus avoiding the waste of resources and lightening the workload of the cleaning work of thesubsequent tooling.

Owner:WUXI JINGLEI ELECTRONICS

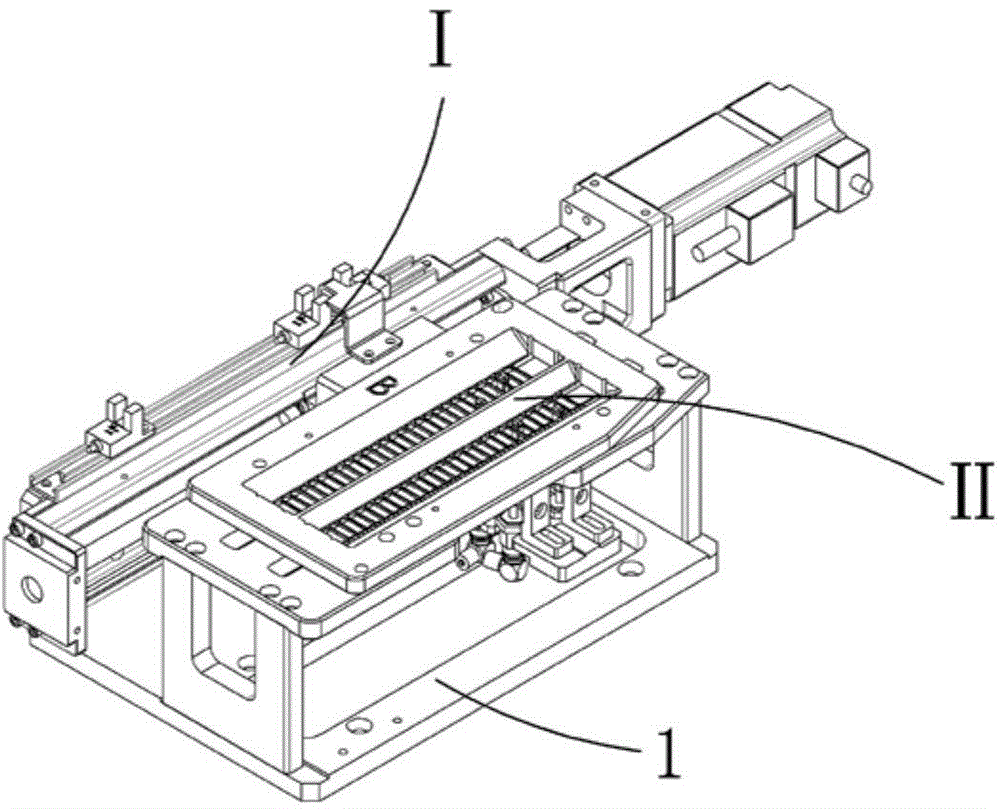

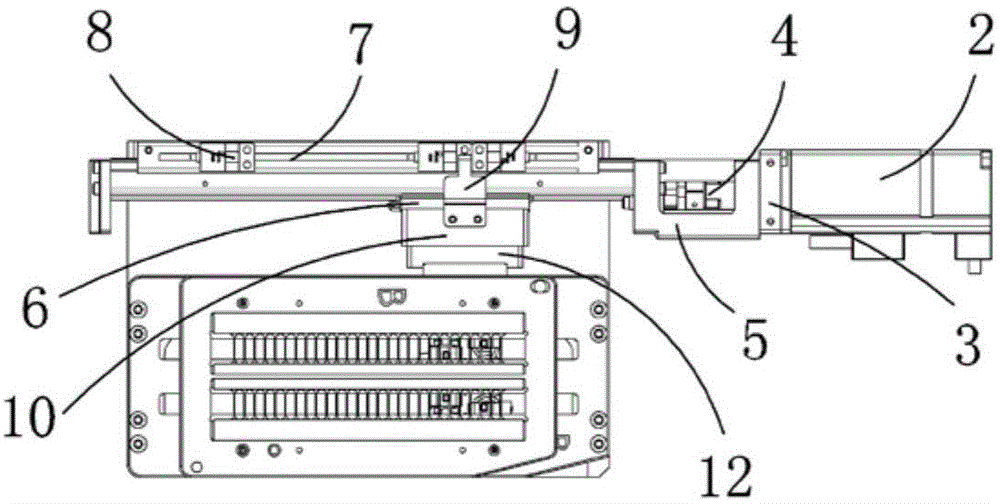

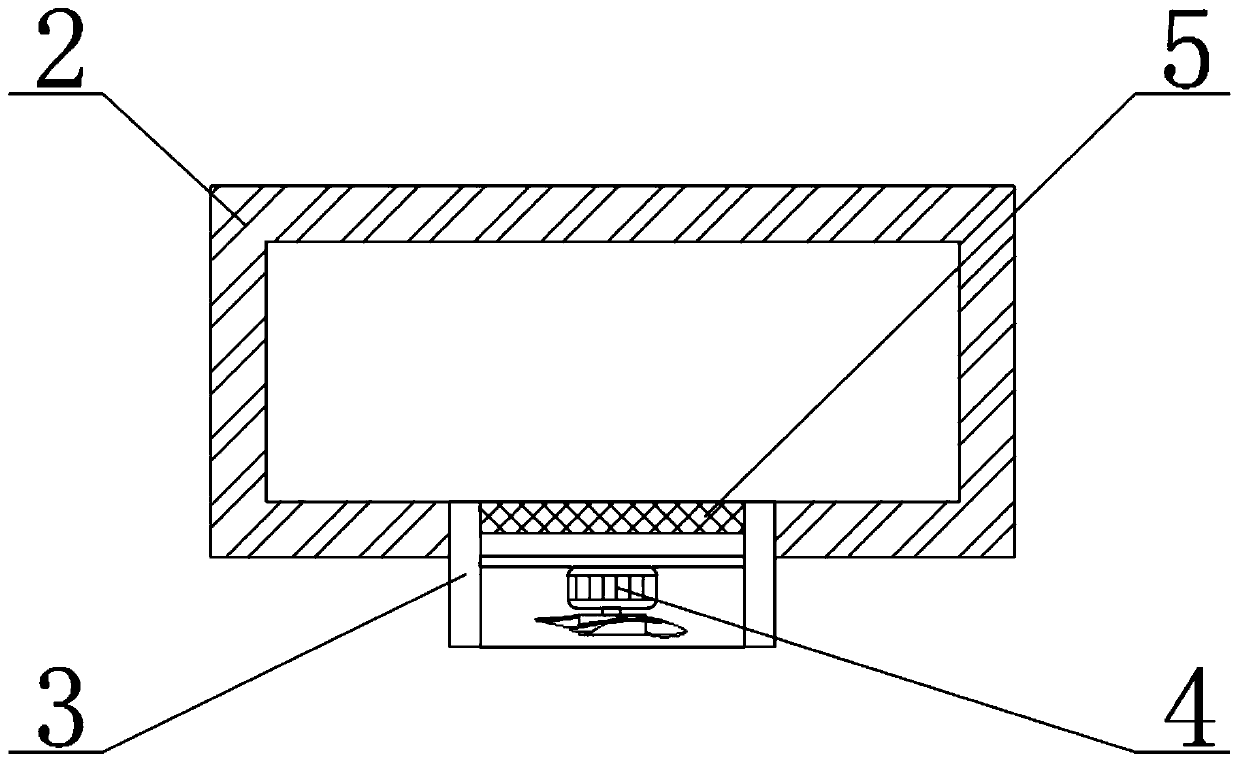

Automatic stripping mechanism

ActiveCN104441924AReduce labor intensityImprove work efficiencyLamination ancillary operationsLaminationCouplingEngineering

The invention relates to an automatic stripping mechanism, wherein a module fixing plate is vertically installed on a bottom plate, a linear module is fixedly arranged on the module fixing plate and a motor is connected with the liner module by virtue of a coupler; an installation bar is installed at the top end of the module fixing plate and is provided with a photoelectric sensor; the linear module is provided with a linear module slide block; a module connecting plate is fixedly arranged on the linear module slide block, and an induction sheet is installed at the top of the module connecting plate; an air cylinder installation plate is fixedly connected to the module connecting plate and an air cylinder adjusting plate is fixedly connected to the air cylinder installation plate; the air cylinder fixing plate is vertically installed at the lower end of the air cylinder adjusting plate; four slide rail permanent seats are respectively provided with slide rails which are provided with slide blocks, each slide block is fixedly connected with a jacking rod, and the jacking rod is provided with a silica gel sleeve; four jacking air cylinders are respectively installed on the air cylinder fixing plate and drive the jacking rods to raise so as to peel materials from material sheets. According to the automatic stripping mechanism provided by the invention, the work efficiency is improved, the production cost is effectively lowered, and the labor intensity of operators is effectively reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

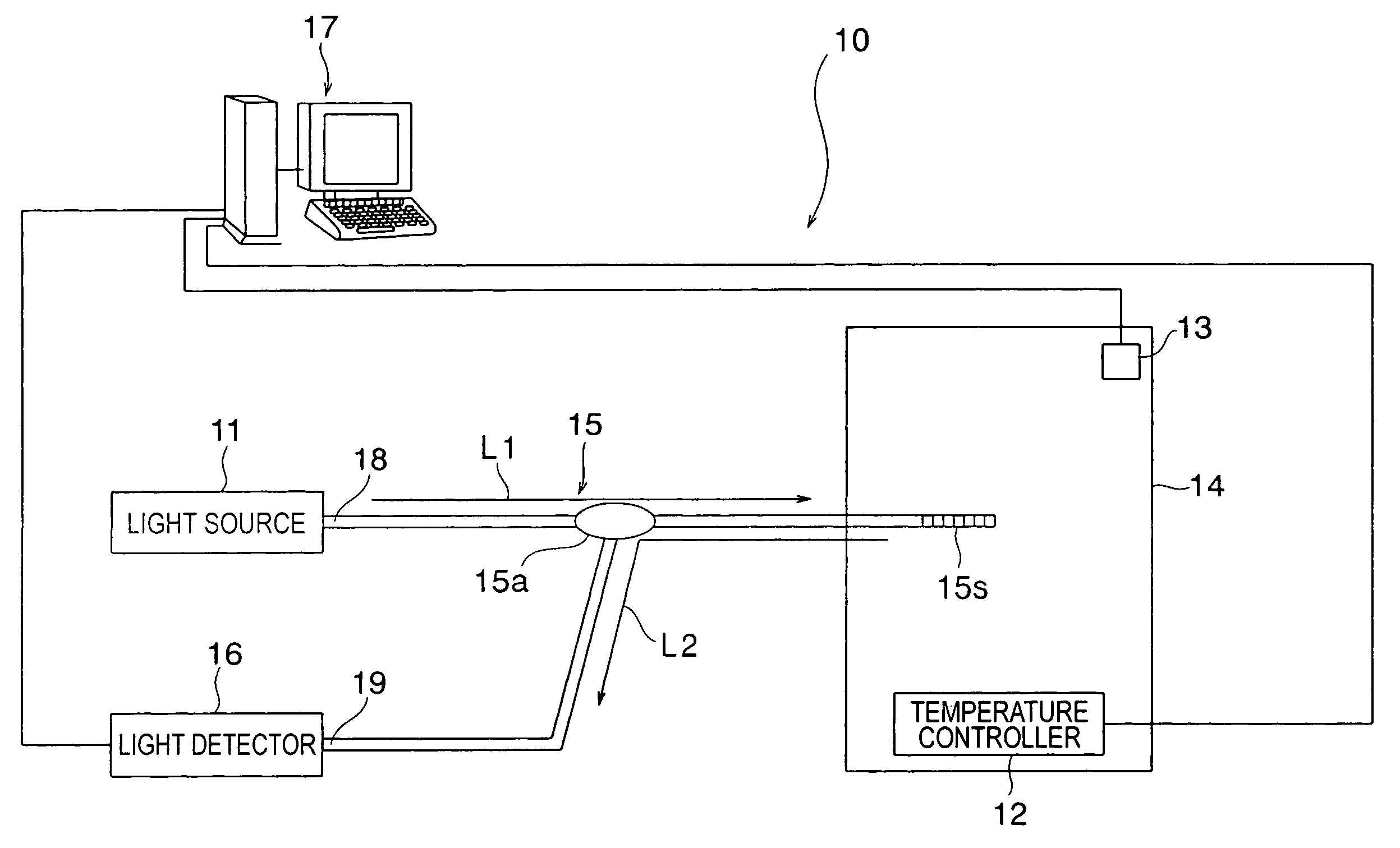

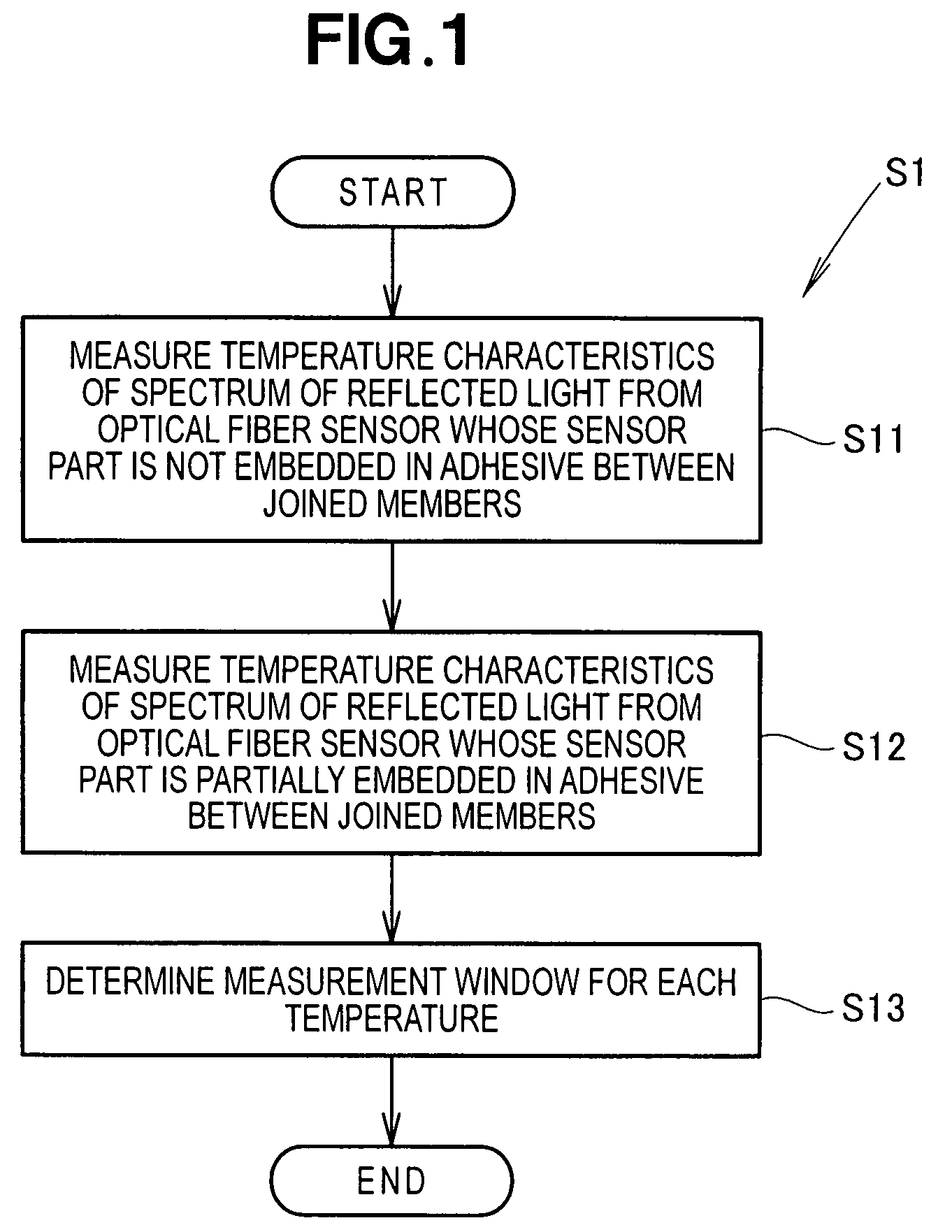

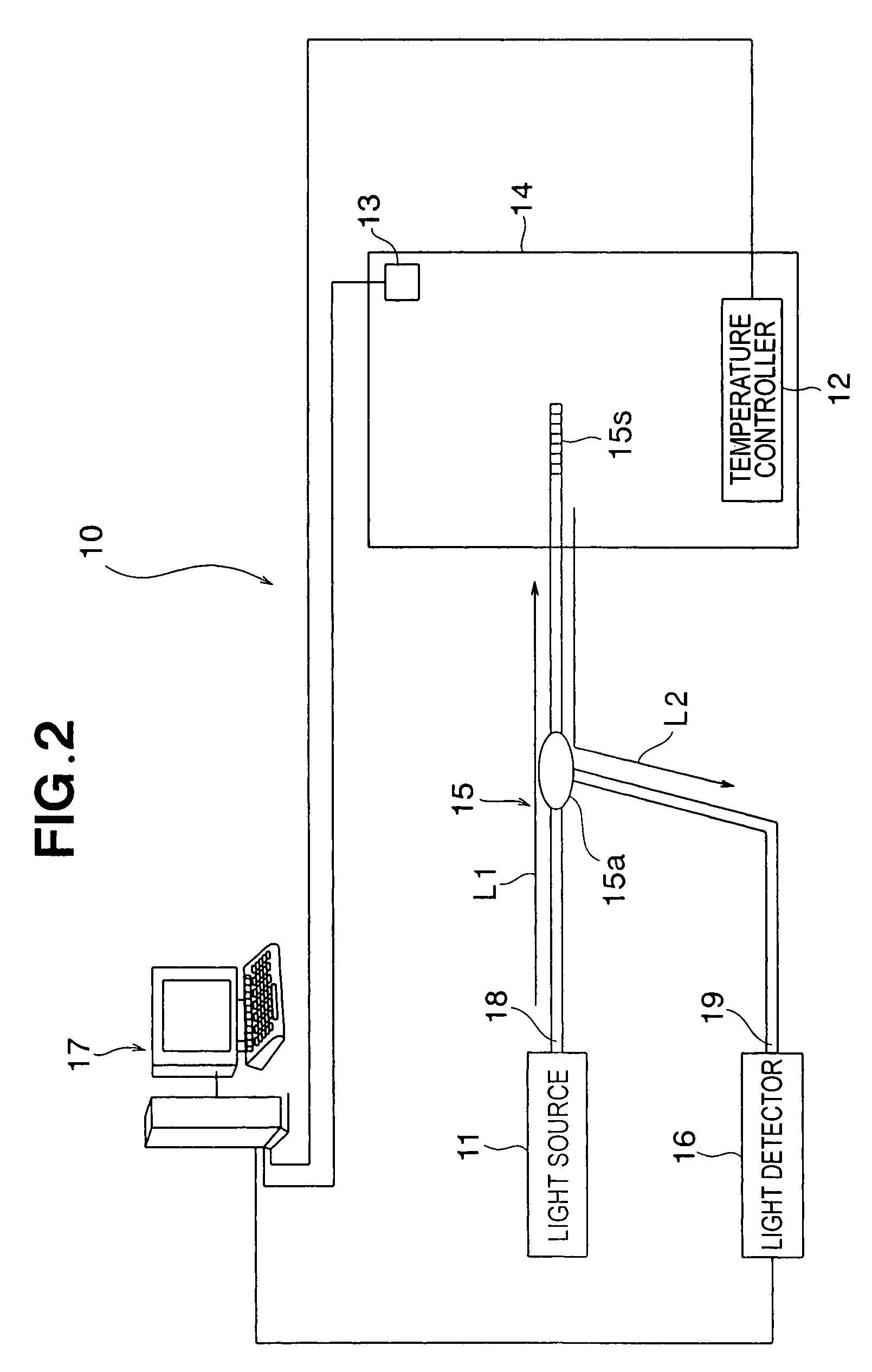

Method for inspecting peeling in adhesive joint

InactiveUS7549337B2Easy to measureAccurate peelingAnalysing solids using sonic/ultrasonic/infrasonic wavesForce measurement by measuring optical property variationOptical propertyAdhesive

Owner:HONDA PATENTS & TECH NORTH AMERICA

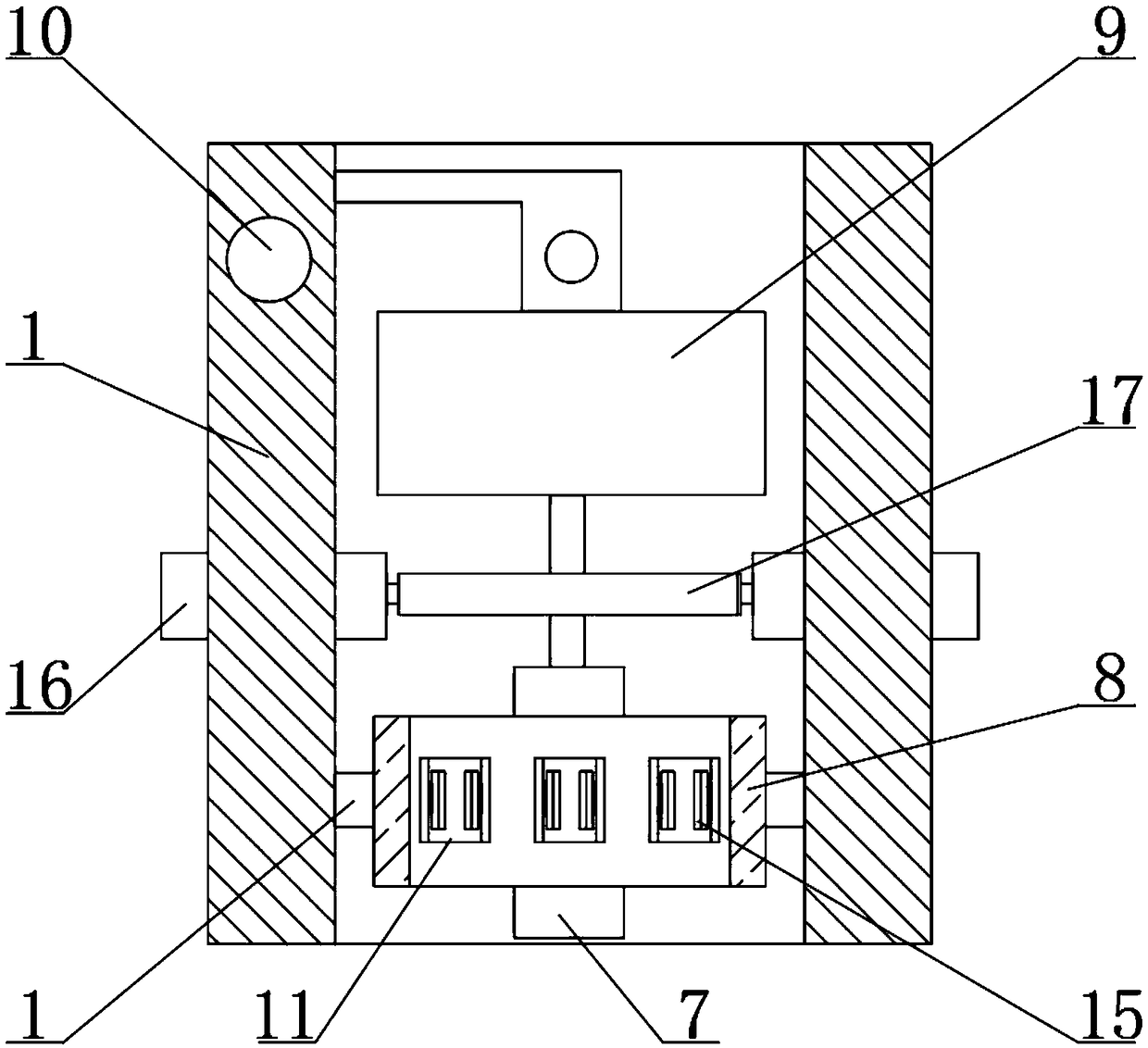

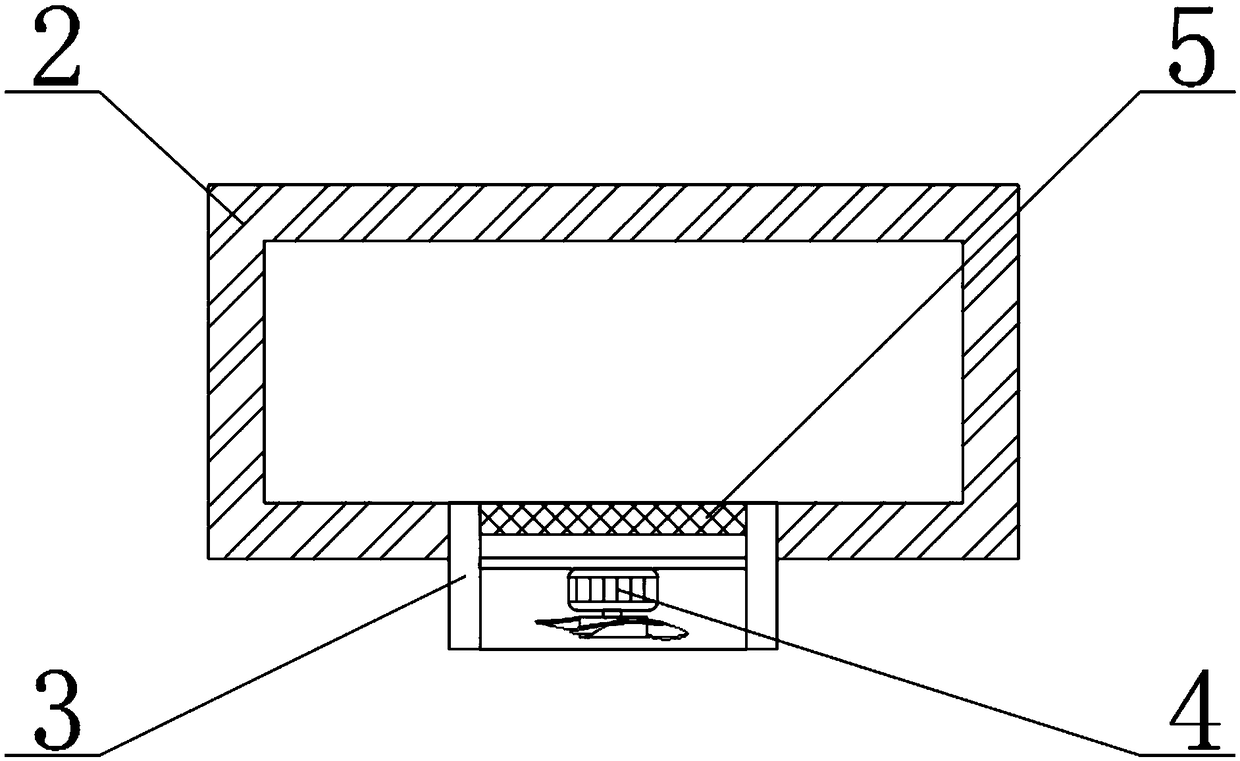

Device and method for calibrating plumb aligner

The invention discloses a device for calibrating a plumb aligner. An upright column is provided with a plumb aligner holding cabin and an operating platform which are connected with a laser mirror cabin through a supporting column; the laser mirror cabin is connected with a fine adjusting cabin through a supporting column; the fine adjusting cabin is provided with a rough adjusting head; and the rough adjusting head is provided with a plurality of rough adjusting bolts. The invention provides the device and a method for calibrating the plumb aligner, which are used for calibrating a sight axis and a laser optical axis by taking a vertical axis and a zenith / nadir sighting mark (or remote fixed sighting mark) of the plumb aligner calibrated by a water level as dynamic bench marks. In the calibration process, the calibrated plumb aligner always keeps the leveling state during use, the target seeking task is completely finished by the zenith / nadir sighting mark, and therefore, the influence of included target seeking of the plumb aligner in the traditional method on the indeterminacy of a calibration result is greatly reduced. In addition, fewer adjustment times, shorter adjustment time, higher correction precision and more convenience for operation are realized.

Owner:宜昌市计量检定测试所 +1

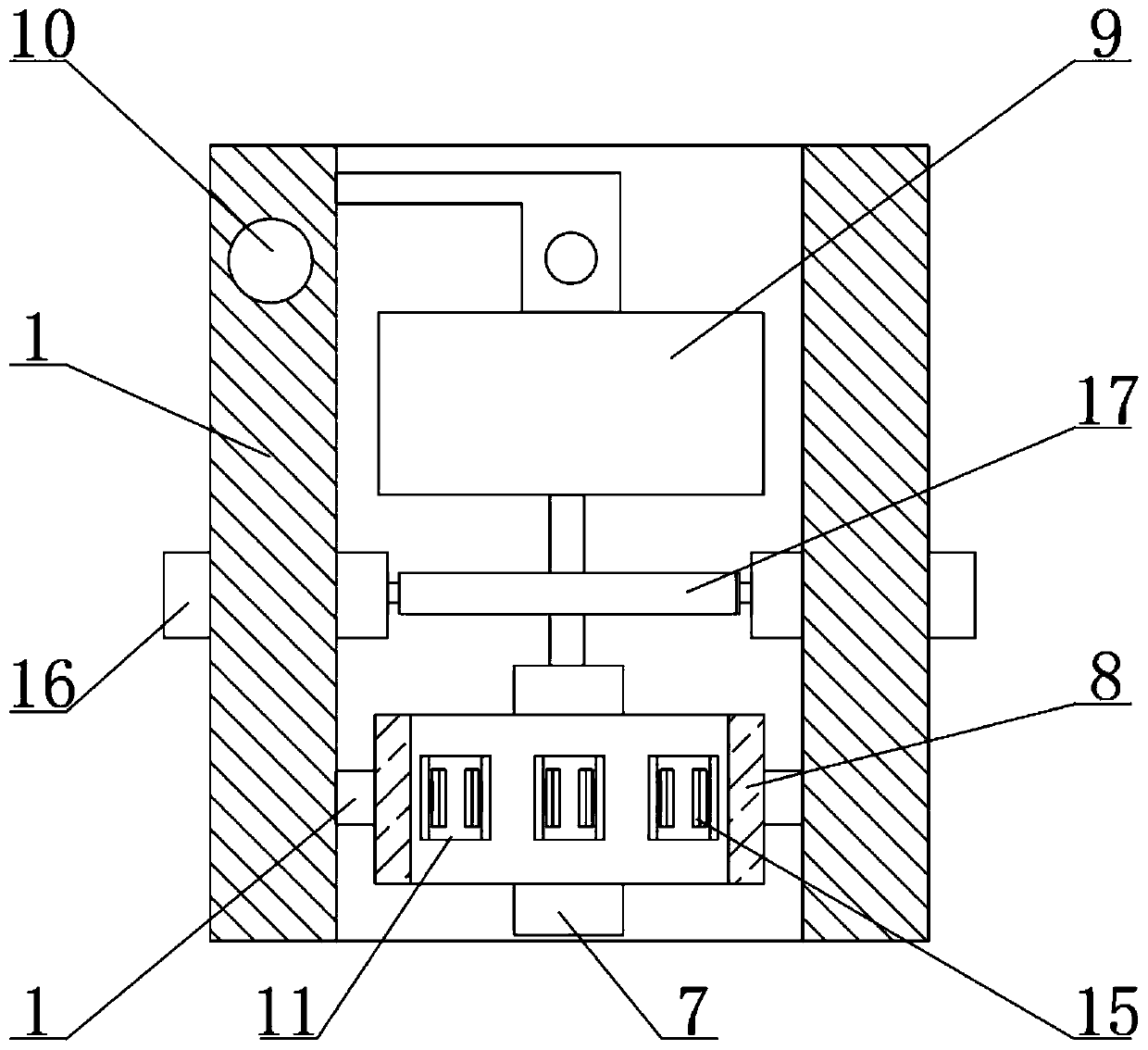

Cable skin rapid stripping equipment for cable

ActiveCN110994478AAchieve strippingAccurate peelingApparatus for removing/armouring cablesStructural engineeringElectric cables

The invention relates to cable skin rapid stripping equipment for a cable, and the equipment comprises a workbench, two guide cable cylinders which are distributed along the same straight line, and astripping frame which is distributed between the two guide cable cylinders and moves back and forth, and the stripping frame is provided with stripping mechanisms which are symmetrically distributed and are used for achieving the rapid stripping of the cable skin. According to the stripping equipment, rectangular stripping of the cable skin is achieved through the stripping frame moving back and forth, the arc-shaped track plate arranged on the stripping frame and the stripping component installed on the arc-shaped track plate in a sliding mode and capable of moving in a reciprocating mode; compared with the prior art, the equipment is high in efficiency, low in labor intensity of workers and free of harm to personal safety of the workers; in addition, stripping is accurate, the effect isgood, the stripped cable skin is complete, and recycling of the cable skin is facilitated.

Owner:安徽国电电缆股份有限公司

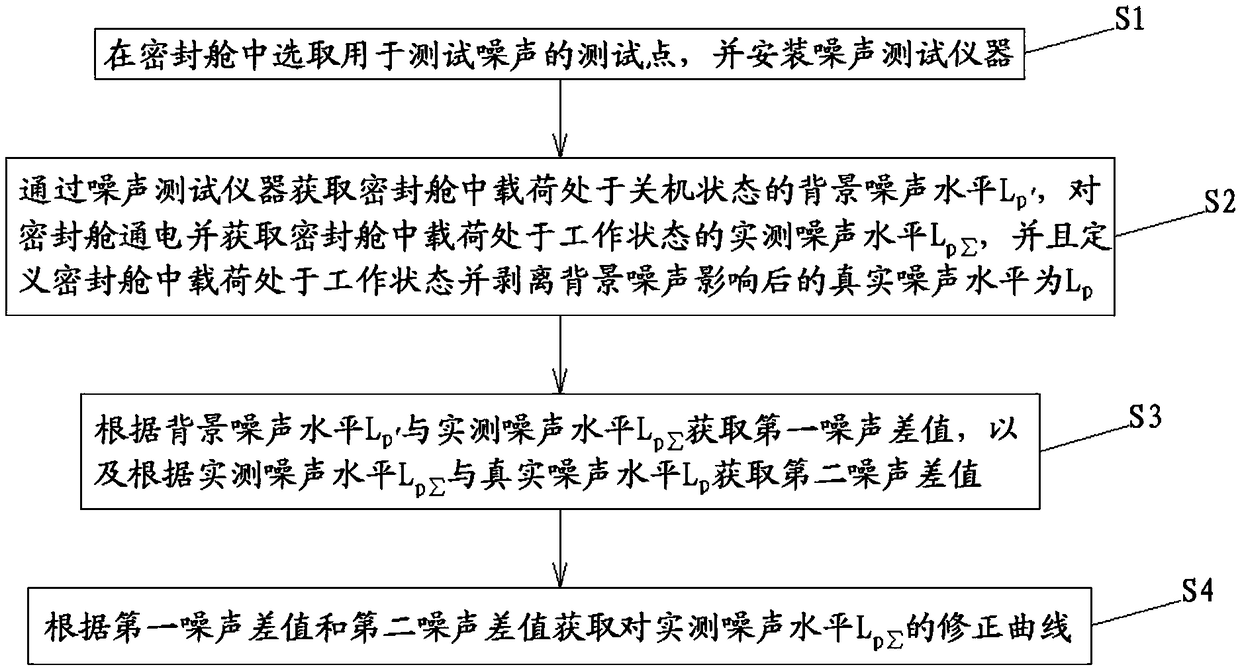

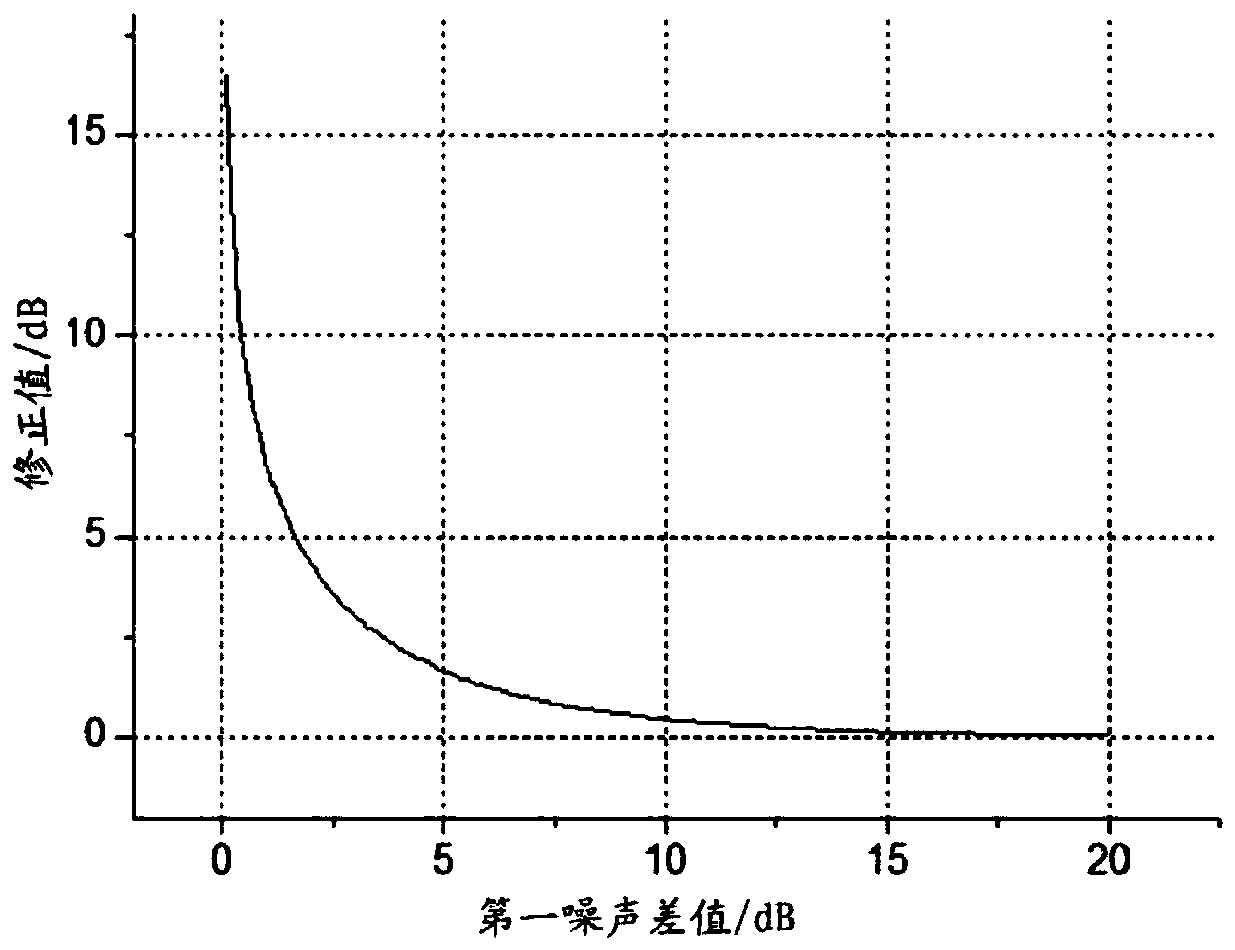

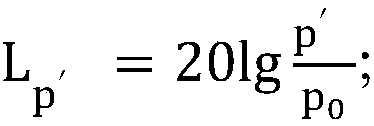

Method used for stripping influence of background noise in sealed cabin noise testing process

InactiveCN109060116AAccurate peelingAccurate True Noise Test ResultsSubsonic/sonic/ultrasonic wave measurementNoise levelEngineering

The invention relates to a method used for stripping influence of a background noise in a sealed cabin noise testing process, comprising the following steps: S1, selecting a test point used for testing a noise in a sealed cabin, and mounting a noise test instrument; S2, acquiring a background noise level Lp' when a load in the sealed cabin is in a shutdown state by virtue of the noise test instrument, electrifying the sealed cabin and acquiring the actually measured noise level LpSigma when the load in the sealed cabin is in an operating state, and defining a real noise level when the load inthe sealed cabin is in the operating state and after the influence of the background noise is stripped as Lp; S3, obtaining a first noise difference value according to the background noise level Lp' and the actually measured noise level LpSigma, and obtaining a second noise difference value according to the actually measured noise level LpSigma and the real noise level Lp; and S4, acquiring a correction curve of the actually measured noise level LpSigma according to the first noise different value and the second noise difference value. The method provided by the invention realizes precise stripping on the background noise and obtains a more accurate real noise test result.

Owner:BEIJING SPACE TECH RES & TEST CENT

Processing device for cables with metal sheath construction

ActiveCN103701072BSolve the difficulty of cutting and peelingImprove reliabilityApparatus for removing/armouring cablesEngineeringMetal

The invention discloses a machining device for a cable with a metal sheath structure. The machining device comprises a base, a fixing bottom plate and two motors, wherein two sliding blocks are fixed in parallel on the lower surfaces of left and right motor brackets; left and right baffles with adjusting screw holes are respectively fixed on the outer sides of the left and right motor brackets; left and right connecting plates with driving screw holes are respectively fixed on the outer sides of the left and right baffles; the left and right connecting plates are positioned between two line tracks and the driving screw holes are formed below the left and right motor brackets; round grooves are formed in end surfaces, opposite to the left and right baffles, of the left and right fixing bases; two springs are respectively sleeved upon screw rods of two limiting bolts and are positioned between corresponding left and right fixing bases and left and right baffles; scrap removing mechanisms are fixed on both sides of a guide base; the scrap removing mechanisms consist of fixing blocks and brushing hair. By adopting the machining device, the difficulties in cutting and peeling off a metal protecting layer of the metal sheath cable in the detection, combination and mounting process are solved, the peeling efficiency is improved, and metal layer peeling off of large length is achieved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

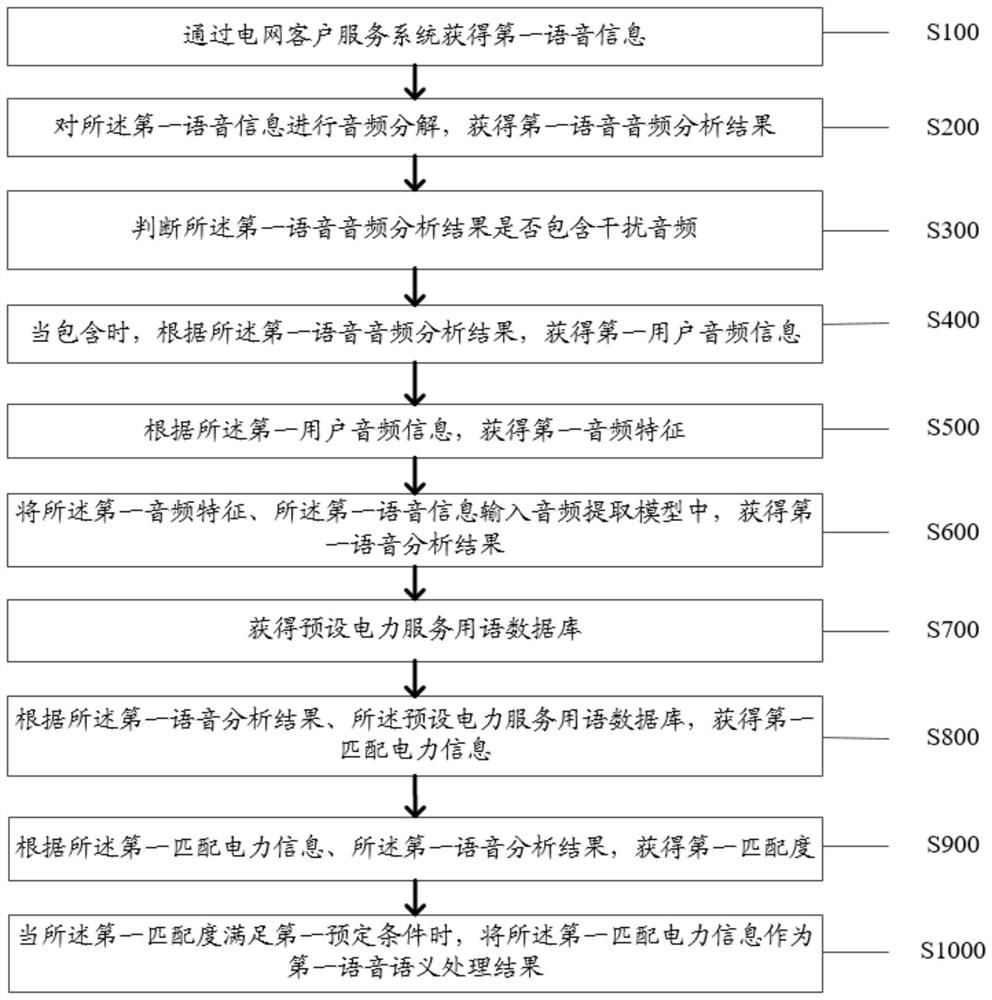

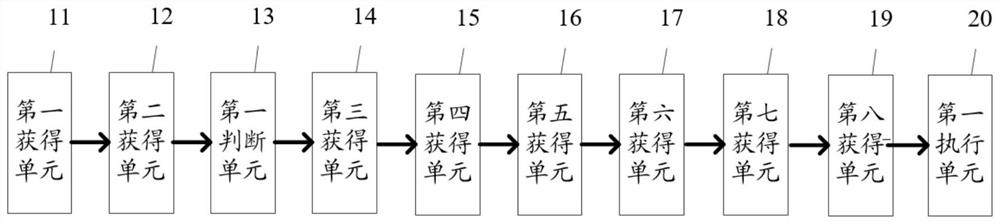

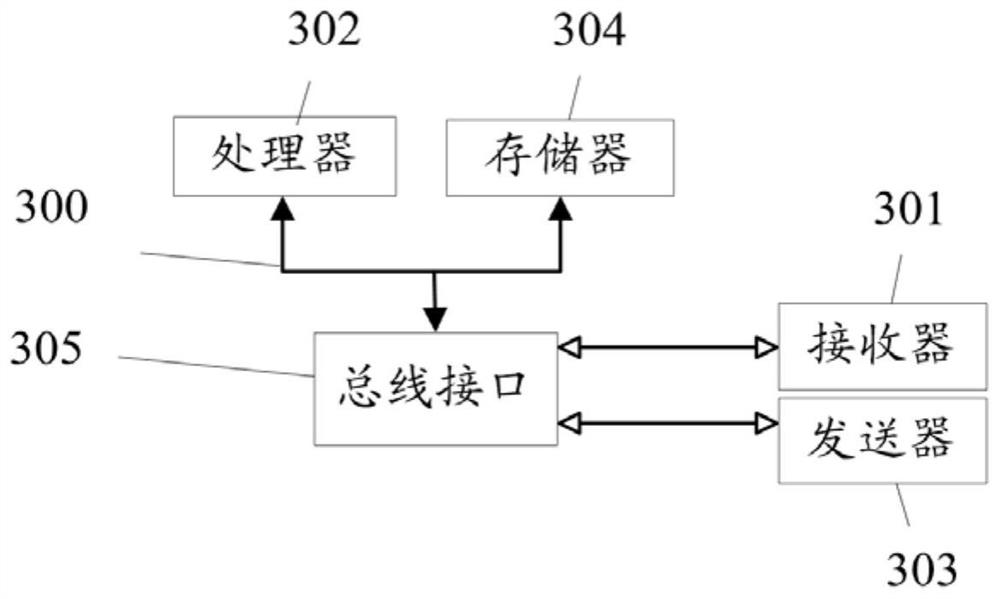

Semantic analysis method and system based on complex scene

ActiveCN113345429AAccurate peelingAccurate extractionSemantic analysisSpeech recognitionVoice analysisService information

The invention discloses a semantic analysis method and system based on a complex scene, and the method comprises the steps: carrying out audio decomposition of first voice information to obtain a first voice audio analysis result; judging whether interference information is included; if yes, obtaining first user audio information according to the first voice audio analysis result; obtaining a first audio feature according to the first user audio information; inputting the first audio feature and the first voice information into an audio extraction model to obtain a first voice analysis result; obtaining a preset power service term database; according to the first voice analysis result and a preset power service term database, obtaining first matched power information; and when the matching degree of the first matching power information and the first voice analysis result meets a condition, taking as a first voice semantic processing result. The technical problems that intelligent customer service information distinguishing and processing capacity of electric power service is insufficient, and particularly, customer consultation content in a complex scene is affected by other interference information, and data processing has deviation are solved.

Owner:图观(天津)数字科技有限公司

Metal sheath stripping device for rail transit cables

ActiveCN103683129BSolve the difficulty of cutting and peelingAchieve strippingApparatus for removing/armouring cablesEngineeringRail transit

The invention discloses a metal sheath stripping device for a rail transit cable. The device comprises a base, a fixed base plate, a stand column fixed between the base and the fixed base plate, a left motor support, a right motor support and two motors, wherein one of the two motors is mounted on the left motor support, the other motor is mounted on the right motor support, two sliding blocks are fixed on the lower surface of the left motor support in parallel, two sliding blocks are fixed on the lower surface of the right motor support in parallel, two linear guide rails are arranged on the fixed base plate in parallel and are embedded into grooves of the sliding blocks of the left motor support and grooves of the sliding blocks of the right motor support in sequence, a left baffle provided with an adjusting threaded hole is fixed on the outer side of the left motor support, a right baffle provided with an adjusting threaded hole is fixed on the outer side of the right motor support, a left connecting plate provided with a driving threaded hole is fixed on the outer side of the left baffle, a right connecting plate provided with a driving threaded hole is fixed on the outer side of the right baffle, the left connecting plate and the right connecting plate are located between the two linear guide rails, and the driving threaded holes are located below the left motor support and the right motor support. The metal sheath stripping device for the rail transit cable overcomes the difficulty in cutting and stripping of a metal sheath during detection, connection and installation of metal sheath cables, stripping efficiency is improved, and stripping of long metal sheaths is achieved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Elevator cable stripping device and stripping process

ActiveCN103414127BQuick peelLabor-saving strippingLine/current collector detailsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses an elevator cable stripping device which comprises a clamping mechanism and a stripping mechanism. The clamping mechanism is used for tightly clamping an elevator cable to be stripped. The stripping mechanism is used for stripping the elevator cable to be stripped. The stripping mechanism comprises a fixed tool set and a movable tool set, wherein the movable tool set can move in the axis direction of the elevator cable or in the direction perpendicular to the axis of the elevator cable. A channel for the elevator cable to pass through is arranged between the fixed tool set and the movable tool set. The fixed tool set and the movable tool set are respectively provided with a blade set with a tool edge matched with the elevator cable in shape. The invention further provides a stripping process using the elevator cable stripping device. The elevator cable stripping device and the stripping process enable an elevator cable sheath to be stripped quickly and accurately in an effort saving mode.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

A high-power current stripping tool and its application method

ActiveCN109193477BCompact structureReasonable structureApparatus for removing/armouring cablesElectric machineFixed frame

Owner:WUXI JINGLEI ELECTRONICS

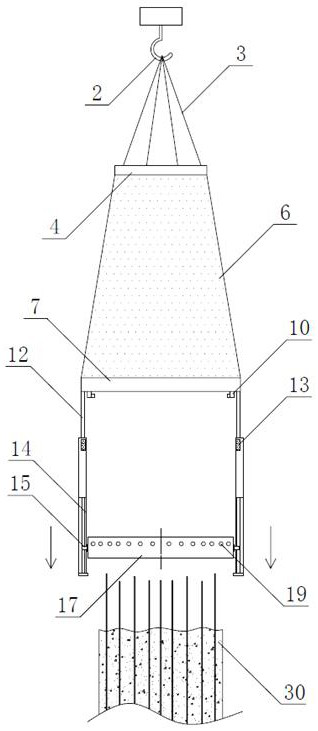

Cast-in-place pile head concrete stripping and chiseling device

ActiveCN113513022AFast and accurate dockingSolve the quick positioningBulkheads/pilesMechanicsWire rope

The invention discloses a cast-in-place pile head concrete stripping and chiseling device. The cast-in-place pile head concrete stripping and chiseling device comprises a lifting appliance (1), a lifting hook (2), a steel wire rope (3) and a hanging ring (4), and is characterized in that the lower end of the hanging ring (4) is fixed to the small opening end of a positioning conical barrel (6), a fixing ring (7) is fixed to the lower portion of the large opening end of the positioning conical barrel (6), a connecting piece (5) is fixed in a ring body of the hanging ring (4), a vertical supporting rod (8) is fixed to the position, located on the axis of the positioning conical barrel (6), of the lower end of the connecting piece (5), the bottom of the fixing ring (7) is fixed to the upper end of a vertical fixing arm (12), a lifting mechanism is installed at the lower end of the vertical fixing arm (12), and the lifting connecting end of the lifting mechanism is fixedly connected with an annular outer frame (17). The device is reasonable in structure, mechanical automatic construction is adopted, the construction efficiency is greatly improved, the position of a broken cut-off plane can be accurately controlled, the overall stripping and chiseling quality is good, and the cut-off plane is regular.

Owner:湖北远大建设集团有限公司

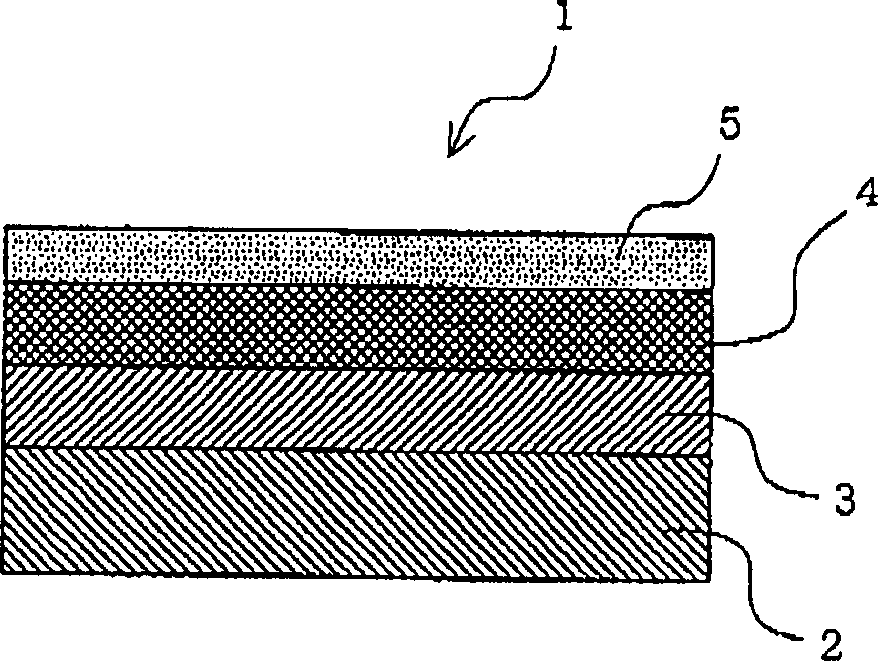

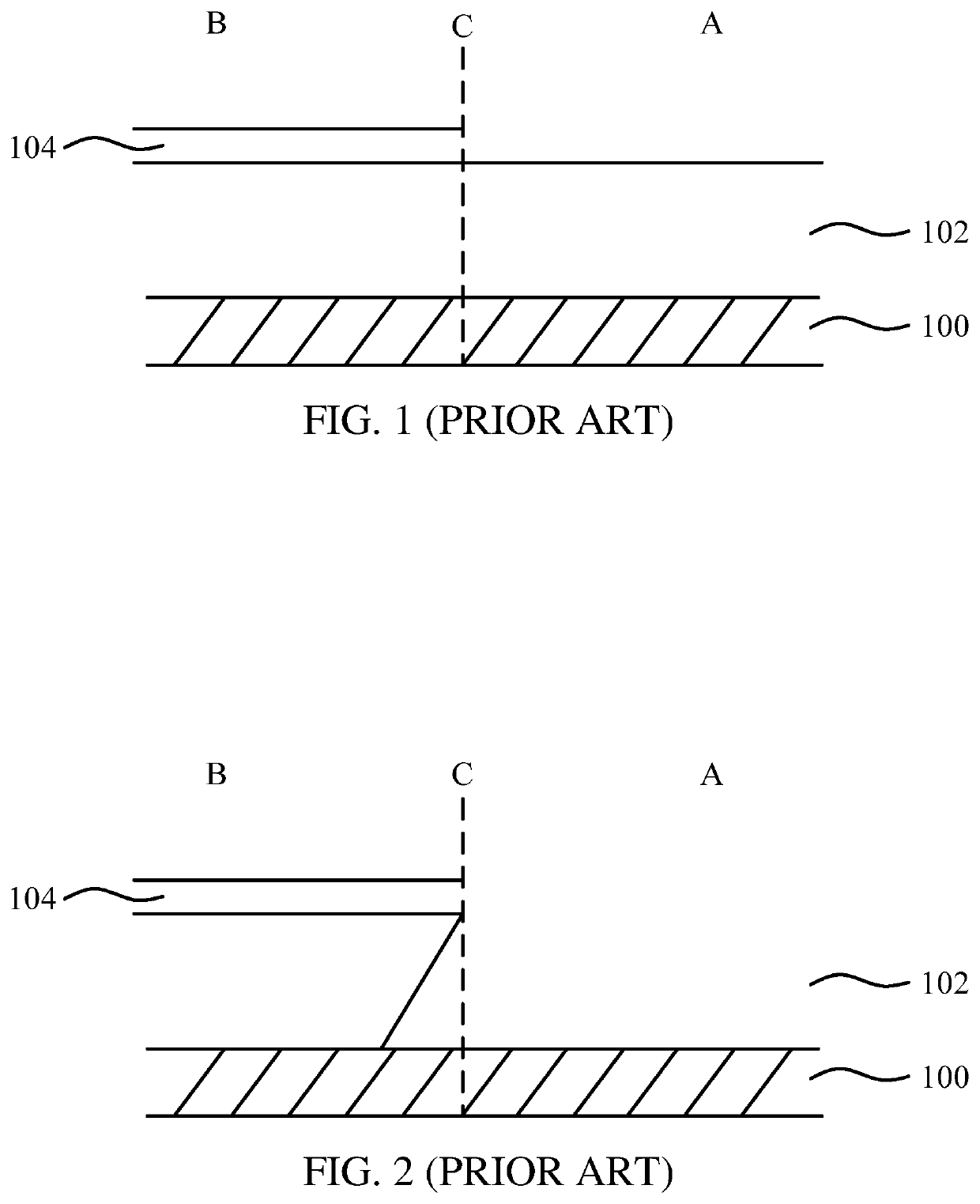

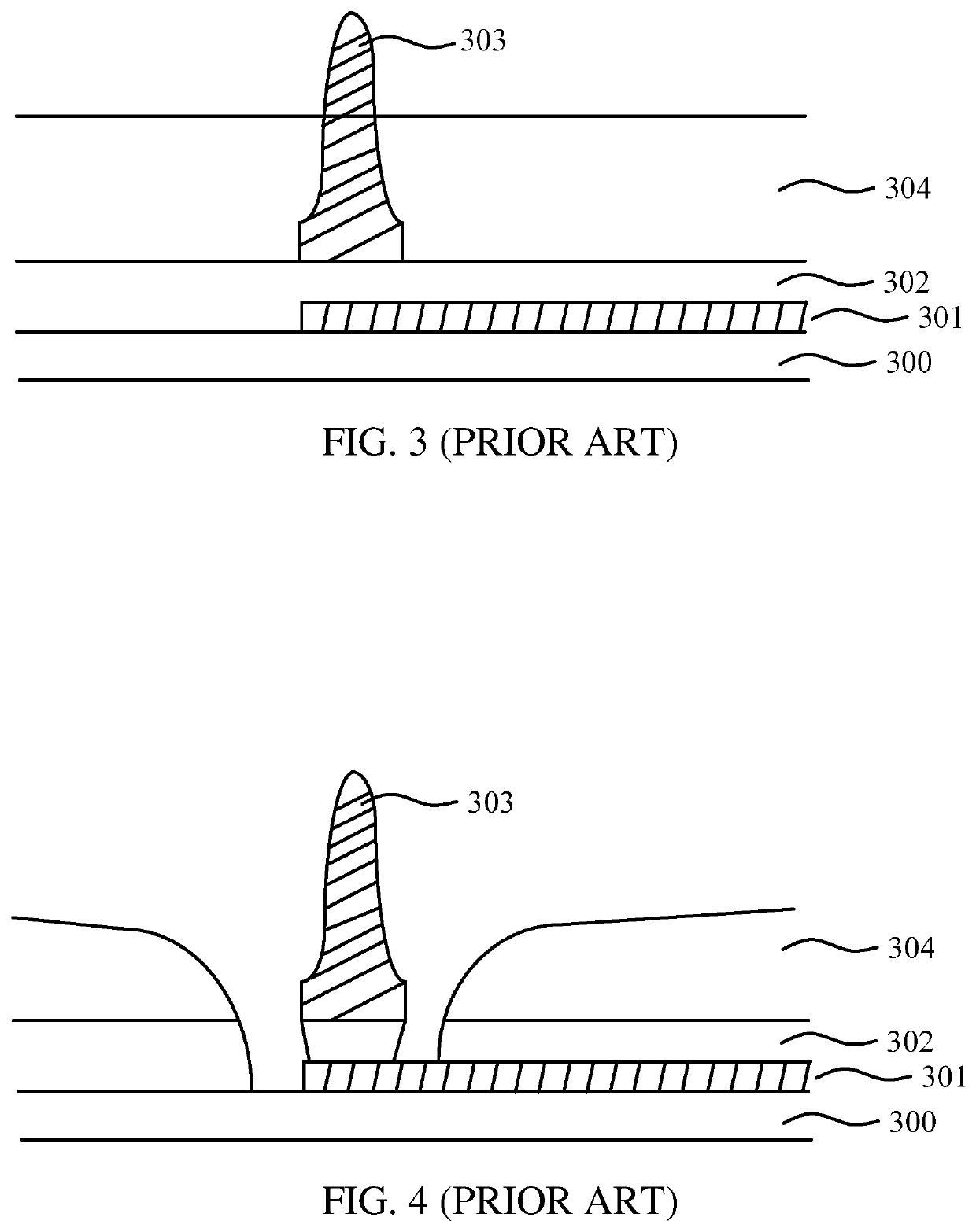

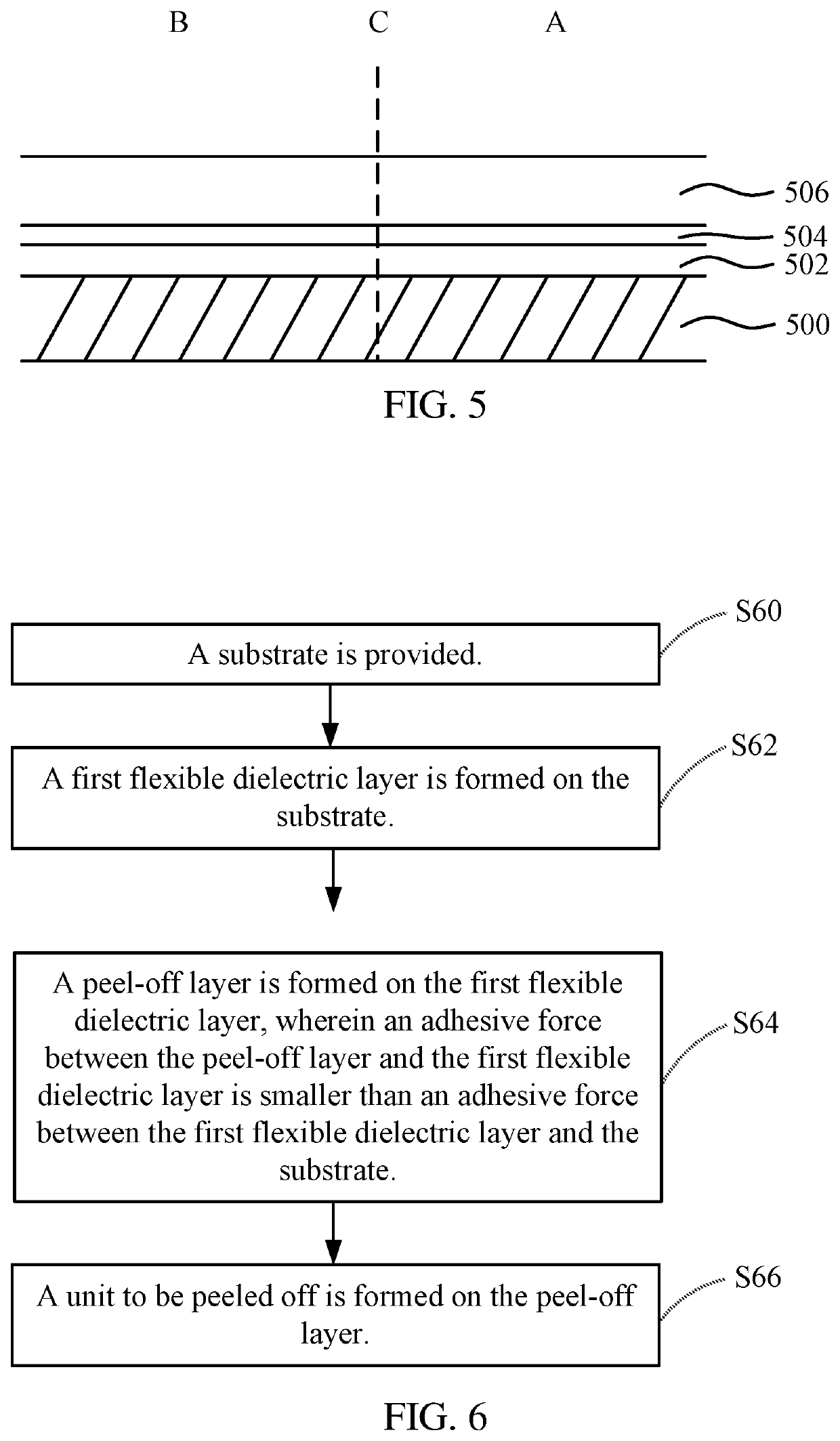

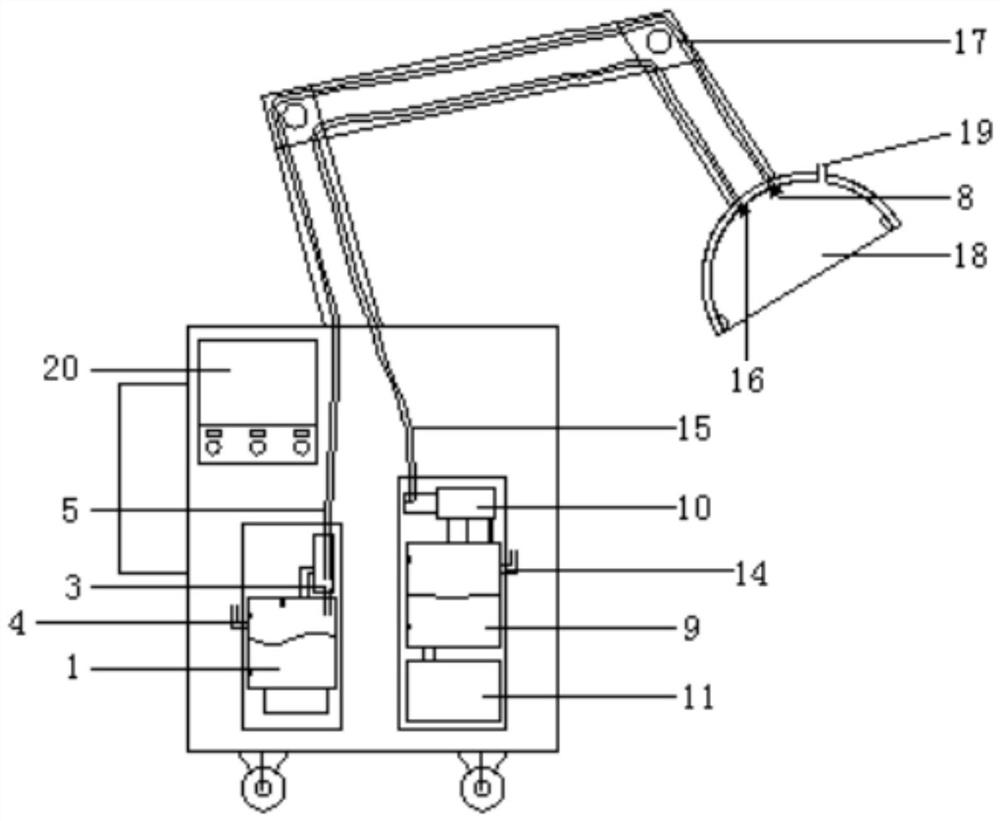

Multi-layer substrate structure which can be peeled off precisely and a method for manufacturing the same

InactiveUS20220087027A1Accurate removalSmall adhesion forceSemiconductor/solid-state device detailsPrinted circuit aspectsDielectric layerComposite material

A multi-layer substrate structure which can be peeled off precisely includes: a substrate; a first flexible dielectric layer formed on the substrate; a peel-off layer formed on the first flexible dielectric layer; and a unit to be peeled off formed on the peel-off layer; wherein an adhesive force between the peel-off layer and the first flexible dielectric layer is smaller than an adhesive force between the first flexible dielectric layer and the substrate, and the substrate, the first flexible dielectric layer, the peel-off layer, and the unit to be peeled off together form the multi-layer substrate structure. A method for manufacturing a multi-layer substrate structure which can be peeled off precisely is also provided.

Owner:PRINCO CORP

Skin thermal stripping device

The invention provides a skin thermal stripping device. The skin thermal stripping device comprises a thermal action unit, a cold action unit, a treatment unit, a control unit and a power supply unit. The thermal action unit comprises a steam box, a steam generator, a steam ejector and a steam outlet. The cold acting unit comprises a cold water tank, an air pump and a cold air outlet. The treatment unit is used for spraying the steam and the cold air out of a set skin area, comprises a mechanical arm, a steam transmission pipe, a cold air transmission pipe, a steam spray head and a cold air spray head, and is used for spraying the steam and the cold air out respectively. a control unit comprises an adjusting device, a monitoring device and a display screen. a power supply unit is used for supplying power to each electrical device. The epidermis of an affected part is stripped under the thermal action of water vapor, heat can selectively act on the epidermis layer of the skin by controlling the thermal duration time, low-temperature cold air is sprayed out in time, expansion of thermal damage of the water vapor in the skin layer and range is avoided, and the effect of accurately stripping the epidermis is achieved.

Owner:贵阳德漫多医疗科技有限公司

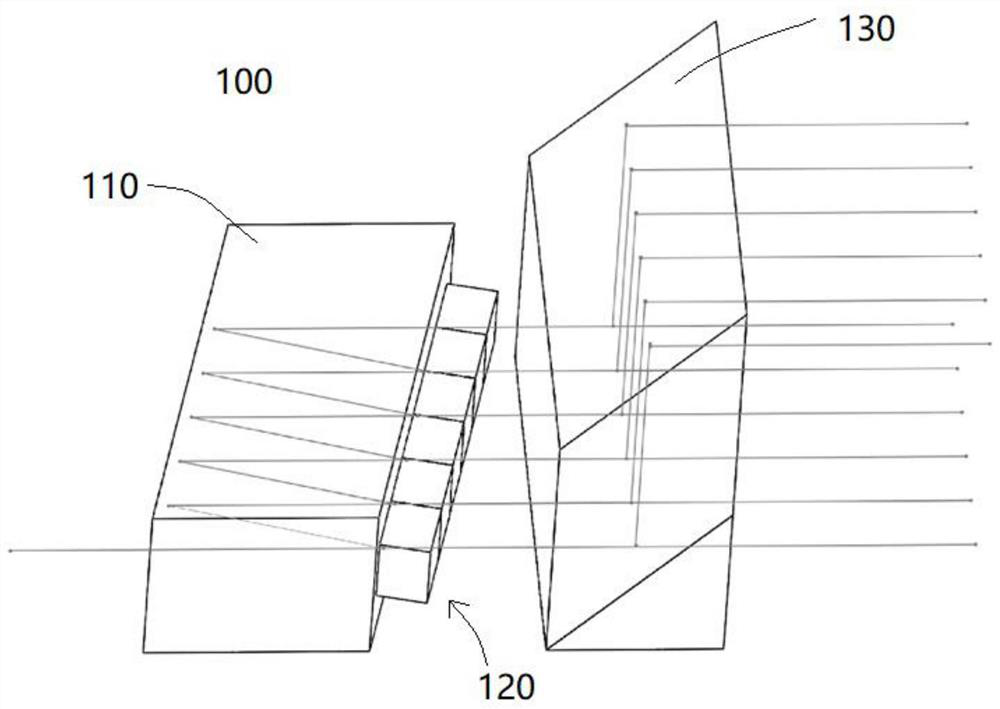

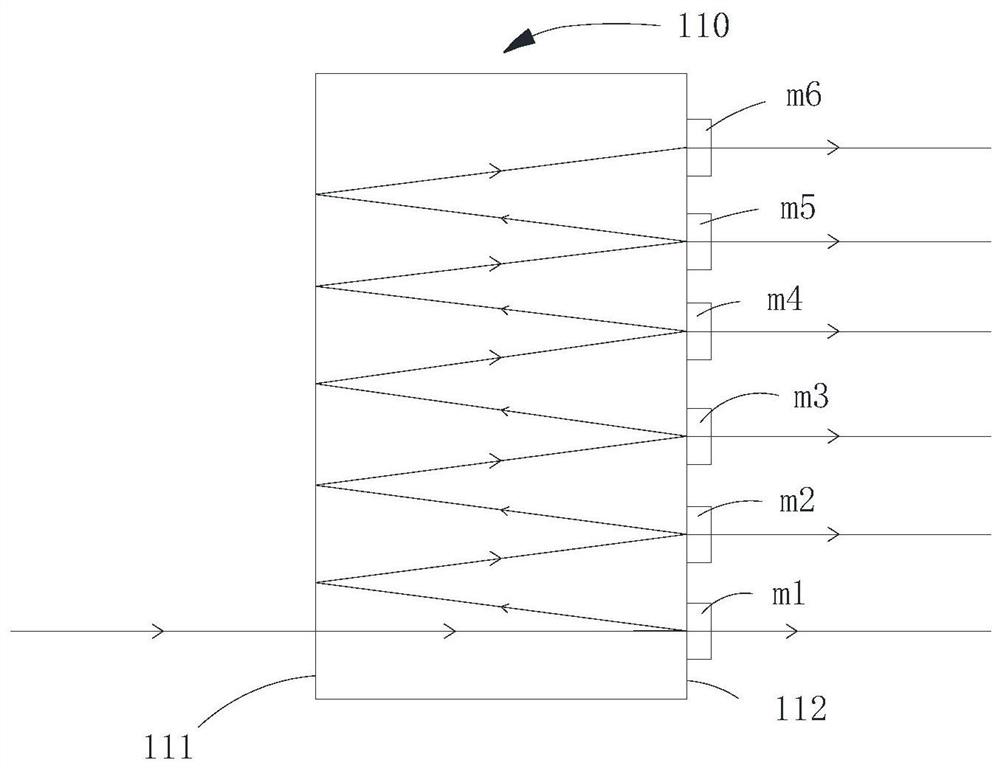

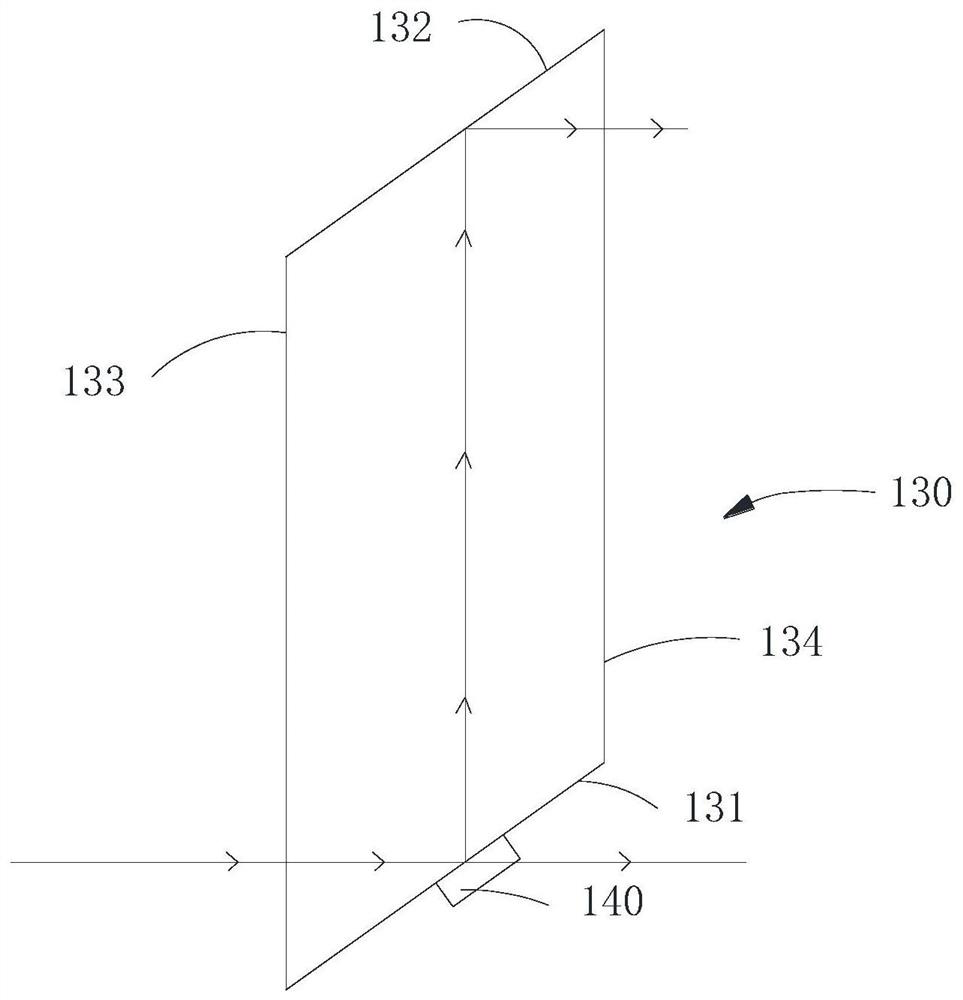

Wavelength division multiplexing device

The invention relates to a wavelength division multiplexing device, which comprises a primary wavelength division component, a primary optical filter group, a secondary wavelength division component and a secondary optical filter group. The primary wavelength division component is provided with a first light entering surface and a first light emitting surface; the primary optical filter group is provided with a plurality of primary optical filters capable of transmitting light with corresponding wavelengths, and pretreated light enters the primary wavelength division component through the first light entering surface and is partially transmitted through the primary optical filter group arranged on the first light emitting surface; the secondary wavelength division component is provided with a second light emitting surface and a second reflecting surface opposite to the second light emitting surface; and the secondary optical filter group is provided with secondary optical filters corresponding to the primary optical filters in number, and light transmitted by the primary wavelength division component enters the secondary wavelength division component, is partially transmitted and partially reflected by the corresponding secondary optical filters and is reflected out of the secondary wavelength division component through the second reflecting surface. A multi-stage wavelength division structure is adopted, light of different wavelengths in the pretreated light can be accurately stripped without using an MWDM film with higher cost, so that the production and use costs are reduced.

Owner:易锐光电科技(安徽)有限公司 +1

Machining device for cable with metal sheath structure

ActiveCN103701072AProtective coreSolve the difficulty of cutting and peelingApparatus for removing/armouring cablesEngineeringMetal

The invention discloses a machining device for a cable with a metal sheath structure. The machining device comprises a base, a fixing bottom plate and two motors, wherein two sliding blocks are fixed in parallel on the lower surfaces of left and right motor brackets; left and right baffles with adjusting screw holes are respectively fixed on the outer sides of the left and right motor brackets; left and right connecting plates with driving screw holes are respectively fixed on the outer sides of the left and right baffles; the left and right connecting plates are positioned between two line tracks and the driving screw holes are formed below the left and right motor brackets; round grooves are formed in end surfaces, opposite to the left and right baffles, of the left and right fixing bases; two springs are respectively sleeved upon screw rods of two limiting bolts and are positioned between corresponding left and right fixing bases and left and right baffles; scrap removing mechanisms are fixed on both sides of a guide base; the scrap removing mechanisms consist of fixing blocks and brushing hair. By adopting the machining device, the difficulties in cutting and peeling off a metal protecting layer of the metal sheath cable in the detection, combination and mounting process are solved, the peeling efficiency is improved, and metal layer peeling off of large length is achieved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com