A high-power current stripping tooling and a use method thereof

A high-power, high-current technology, applied in the installation of cables, cable installation devices, electrical components, etc., can solve the problems of difficult removal of the enameled wire paint layer, increase the fatigue of the staff, and the efficiency of stripping is not very high, so as to reduce the workload. , Novel design concept, fast and accurate peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

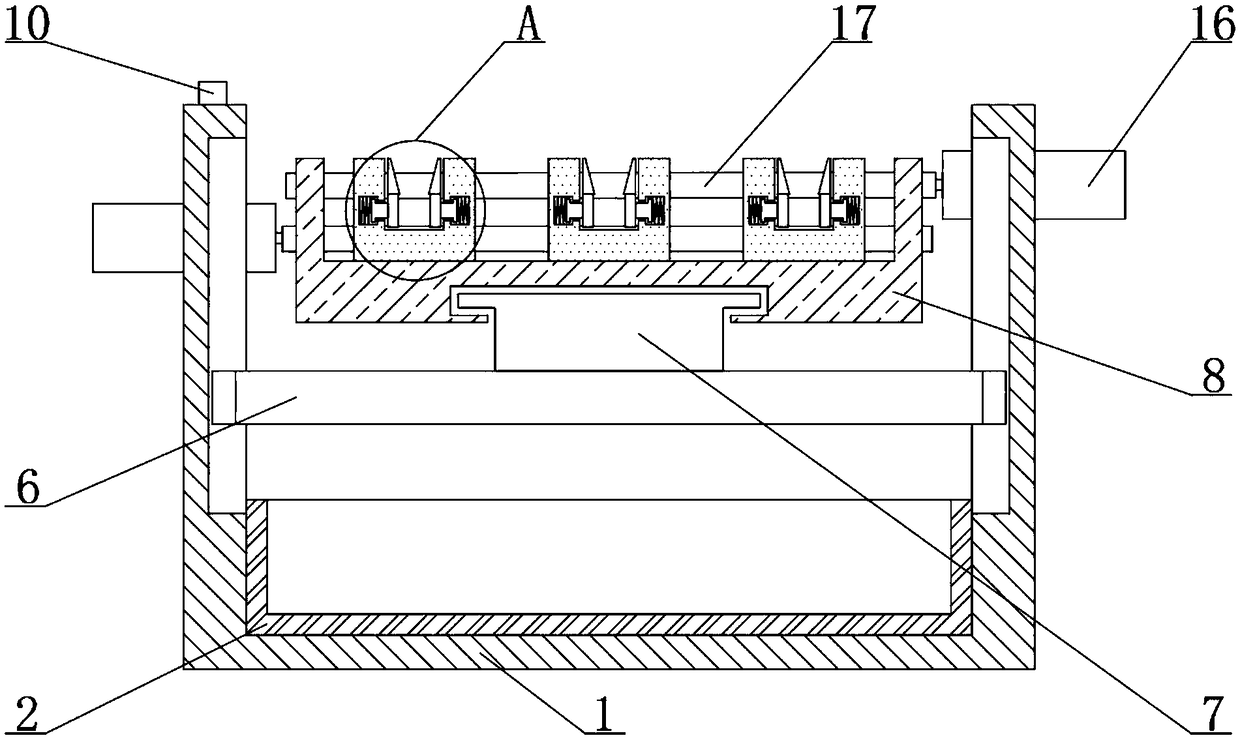

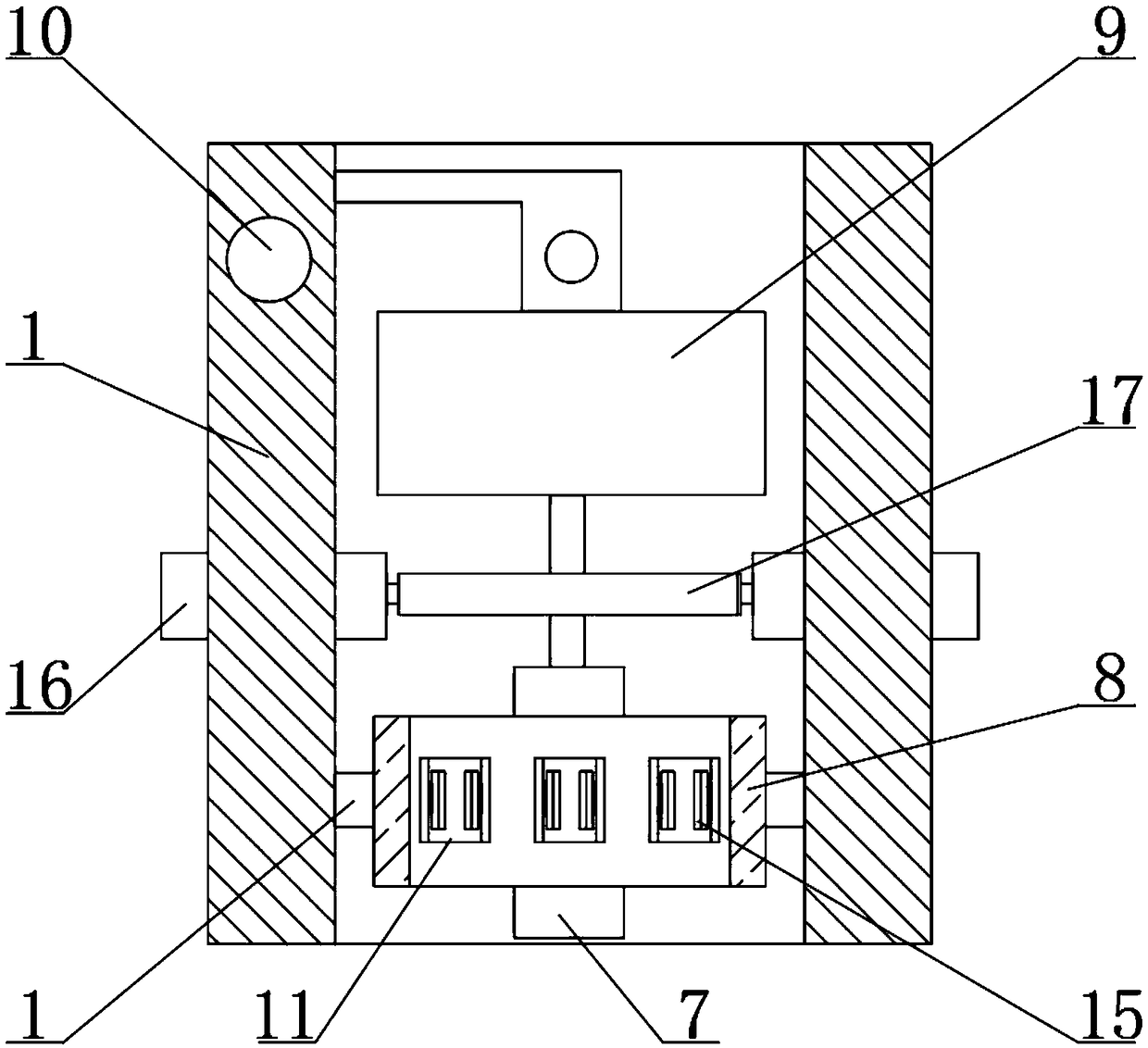

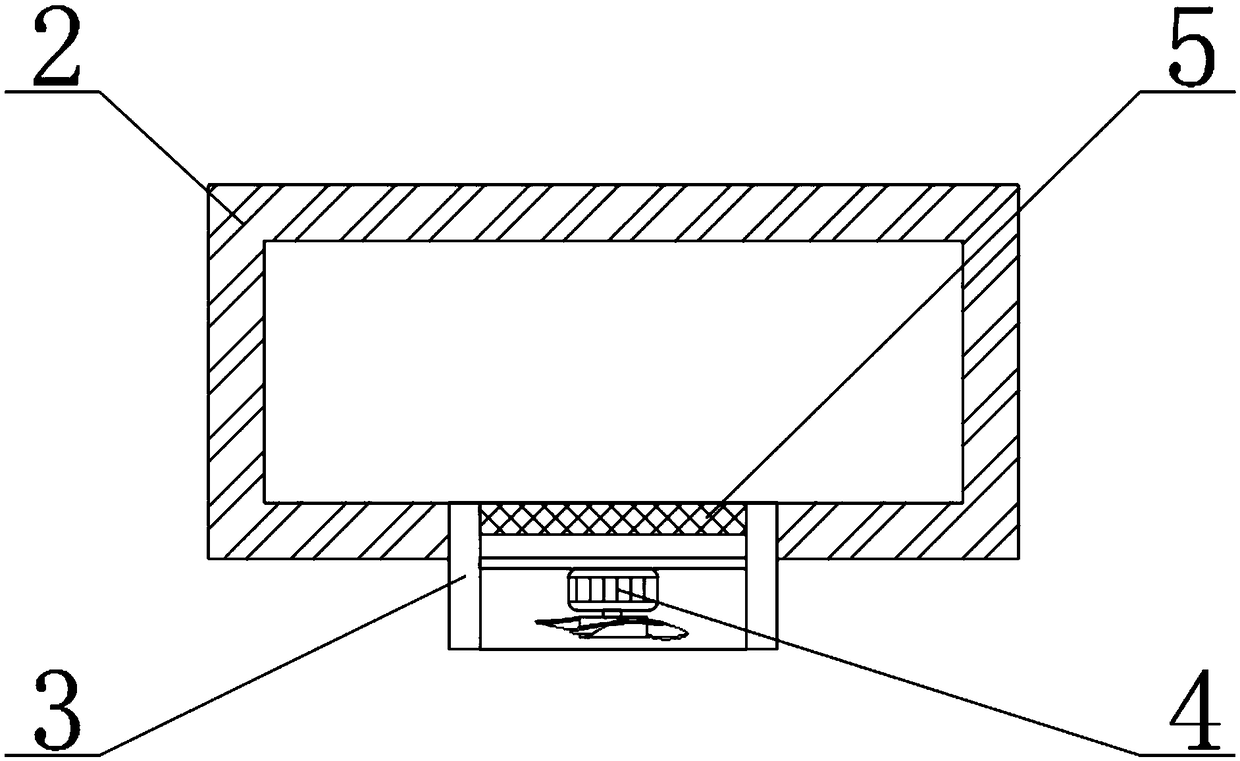

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the high-power current stripping tool of this embodiment includes a fixed frame 1 and a motor 16, the bottom end surface of the fixed frame 1 is slidingly connected to the inside of the collection box 2, the front surface of the collection box 2 is connected to the bellows 3, and the inside of the bellows 3 is provided with a The fan 4 and the filter screen 5 are arranged front and back, and the fan 4 is fixedly connected with the bellows 3 through the connecting rod, the filter screen 5 is fixedly connected with the bellows 3, the inside of the fixed frame 1 is slidably connected with a slide bar 6, and the top surface of the slide bar 6 is fixedly connected with a The first slide block 7, the outside of the first slide block 7 is slidably connected with the limit f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com