Patents

Literature

1149 results about "Four-slide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

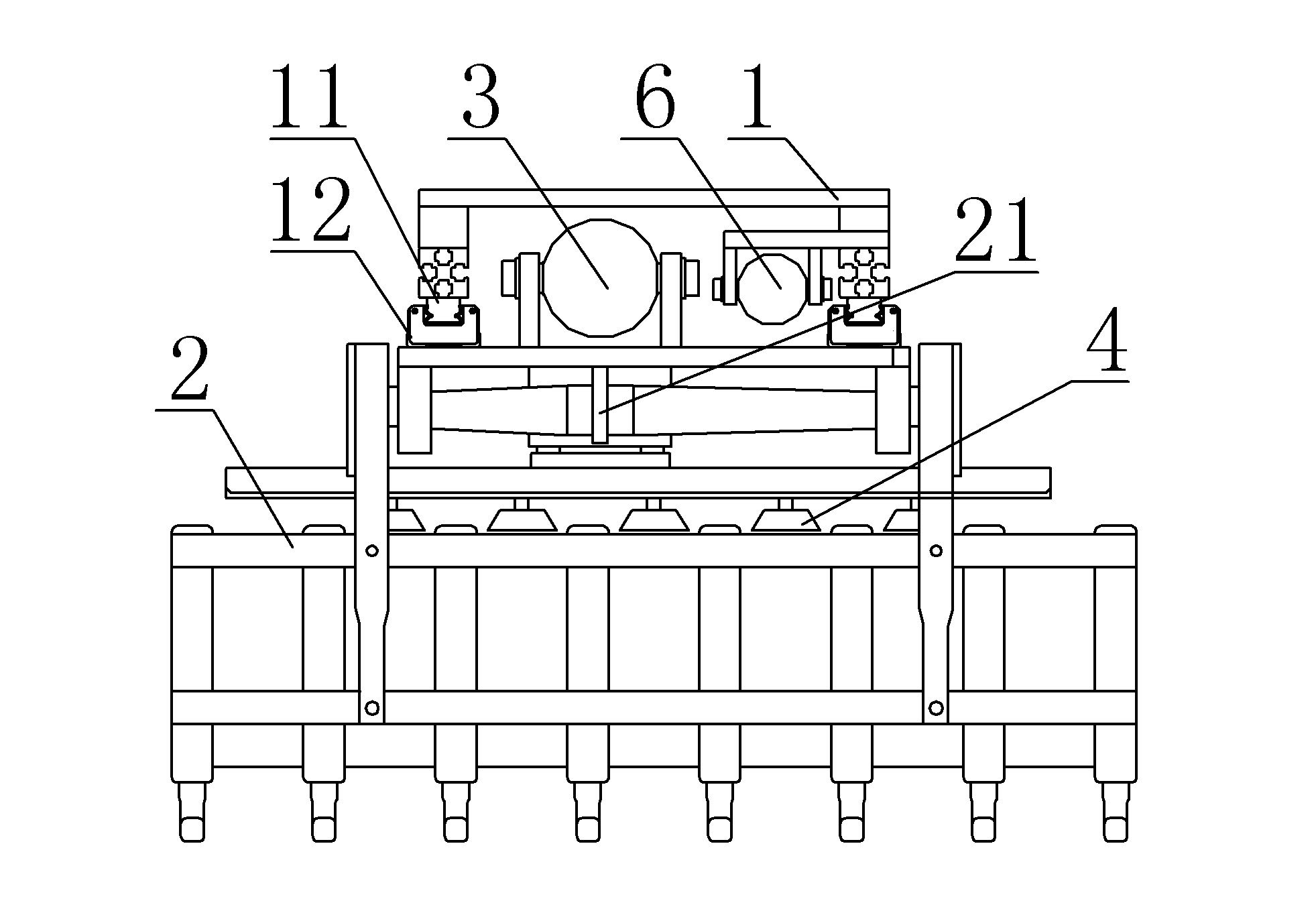

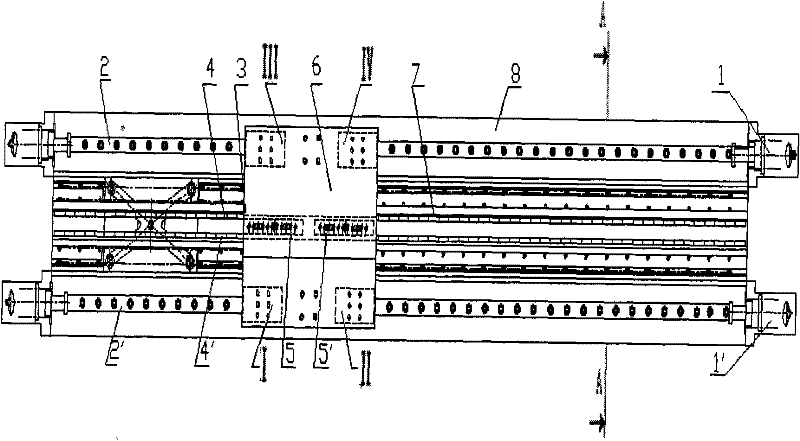

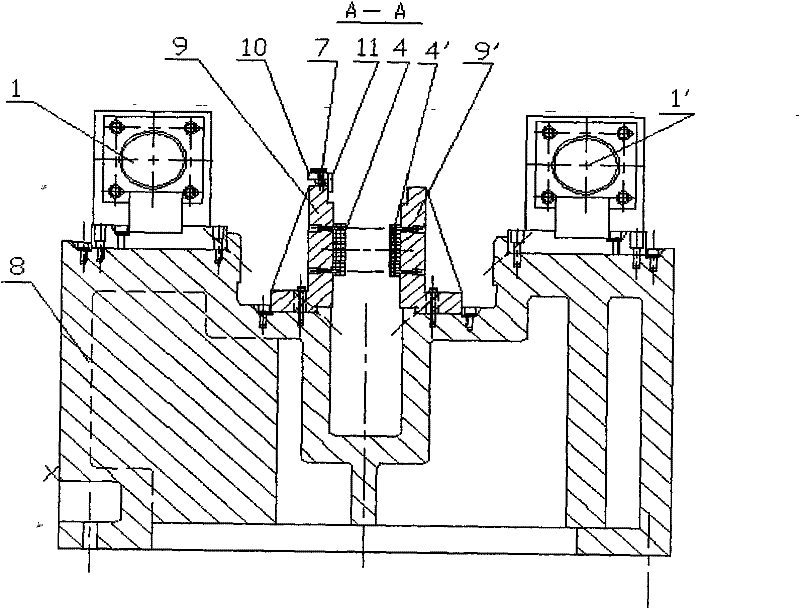

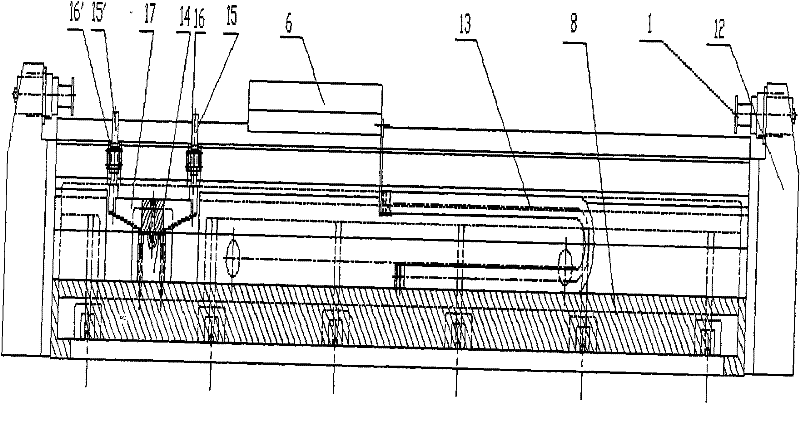

A four-slide, also known as a multislide, multi-slide, or four-way, is a metalworking machine tool used in the high-volume manufacture of small stamped components from bar or wire stock. The press is most simply described as a horizontal stamping press that uses cams to control tools. The machine is used for progressive or transfer stamping operations.

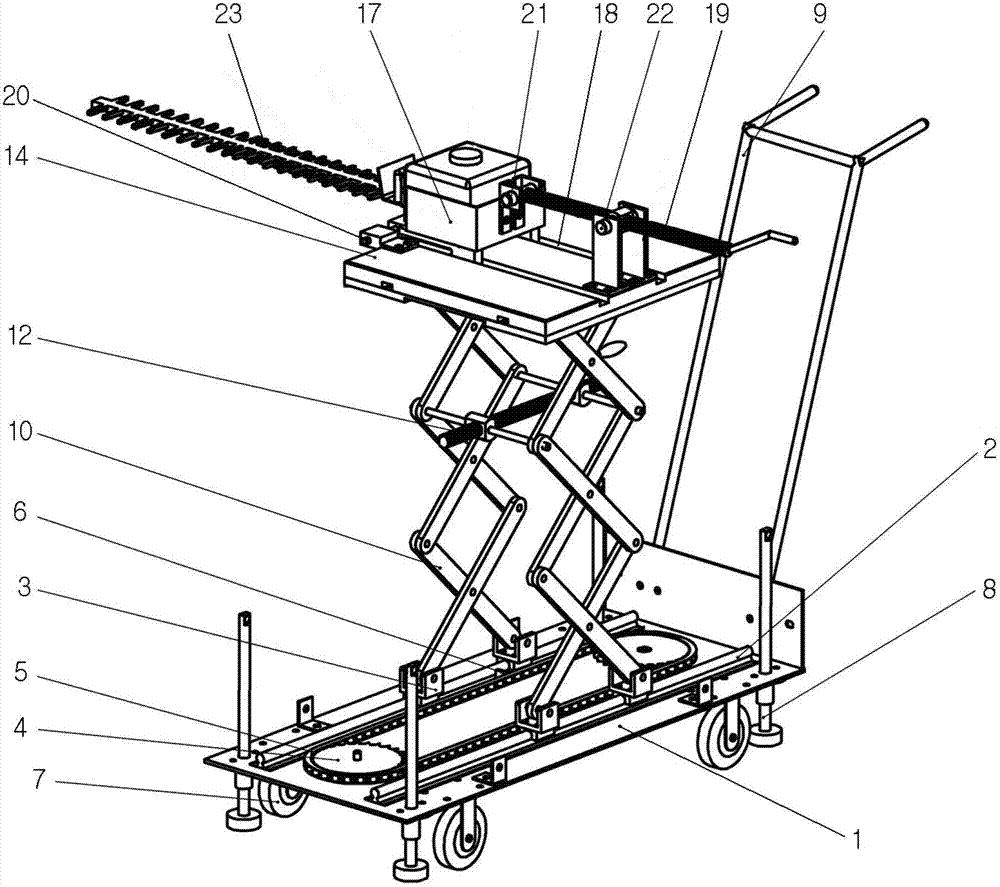

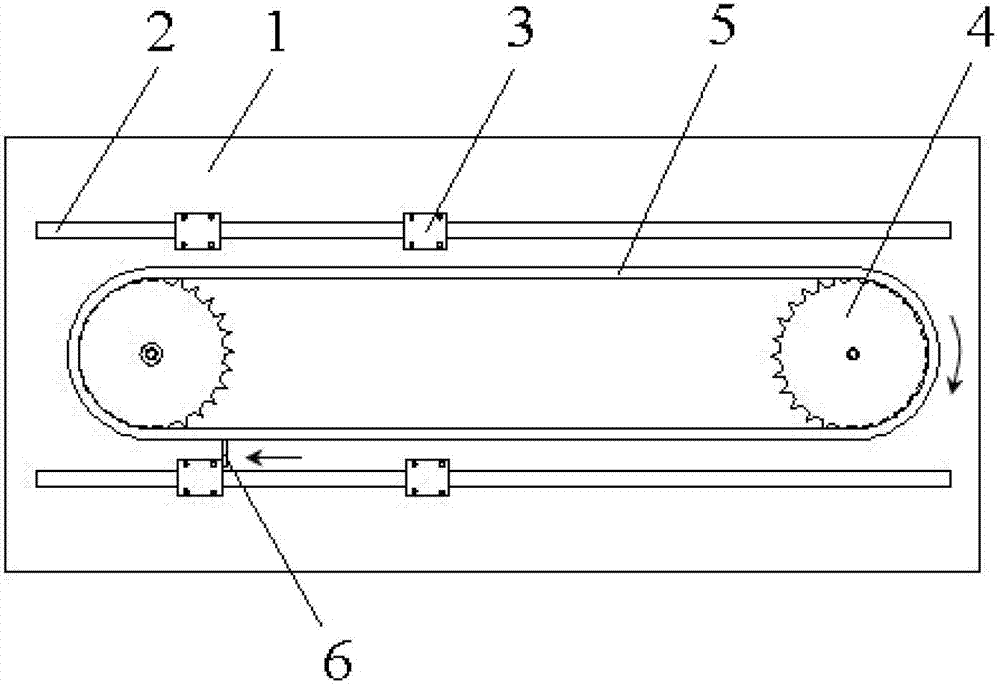

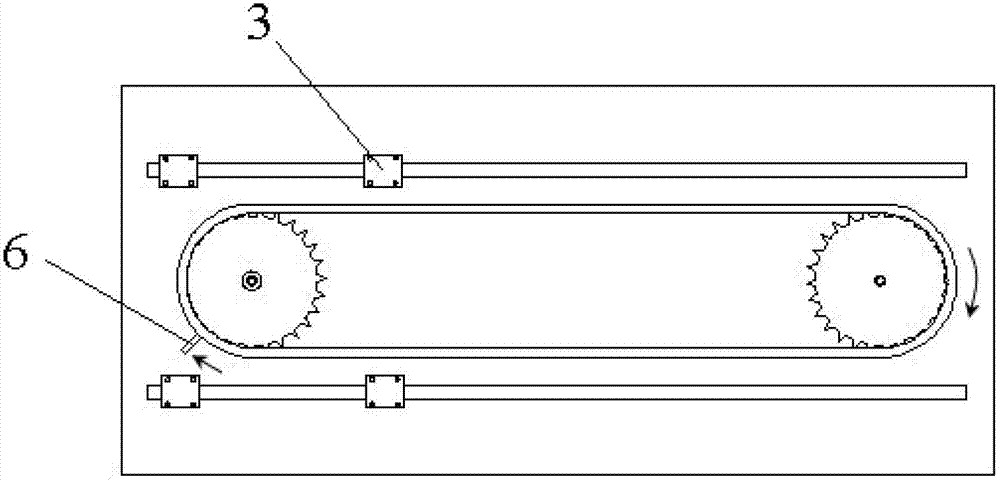

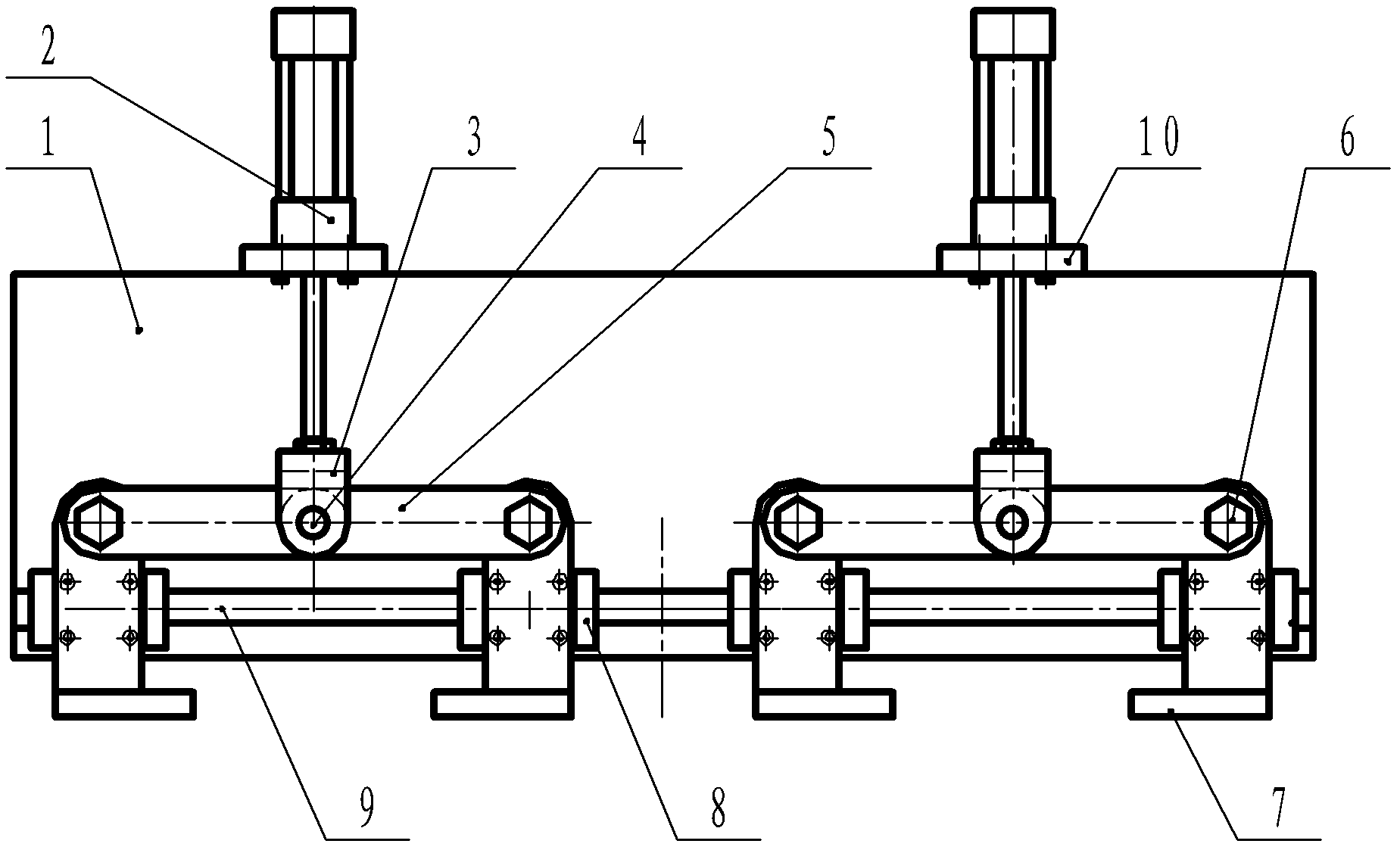

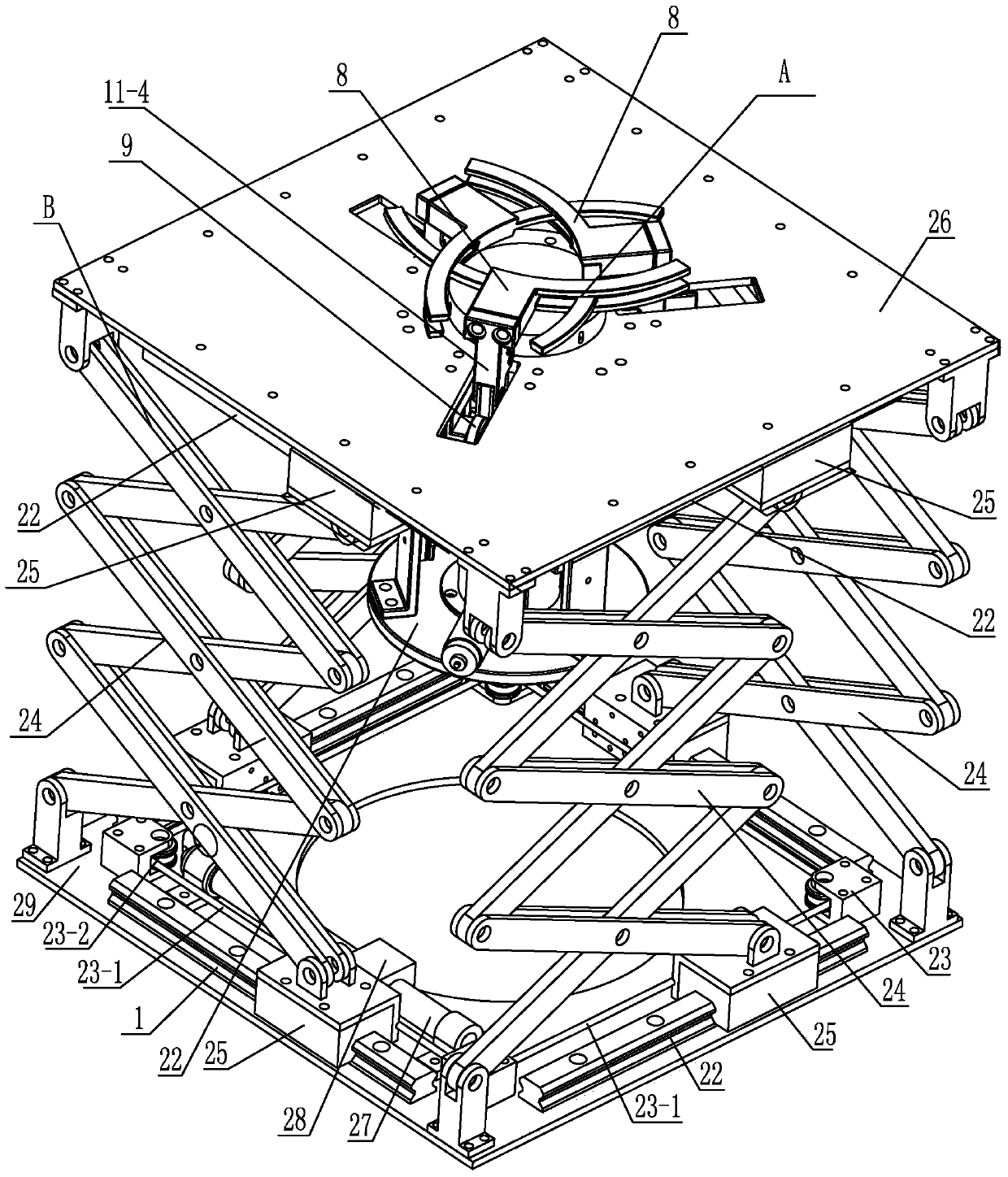

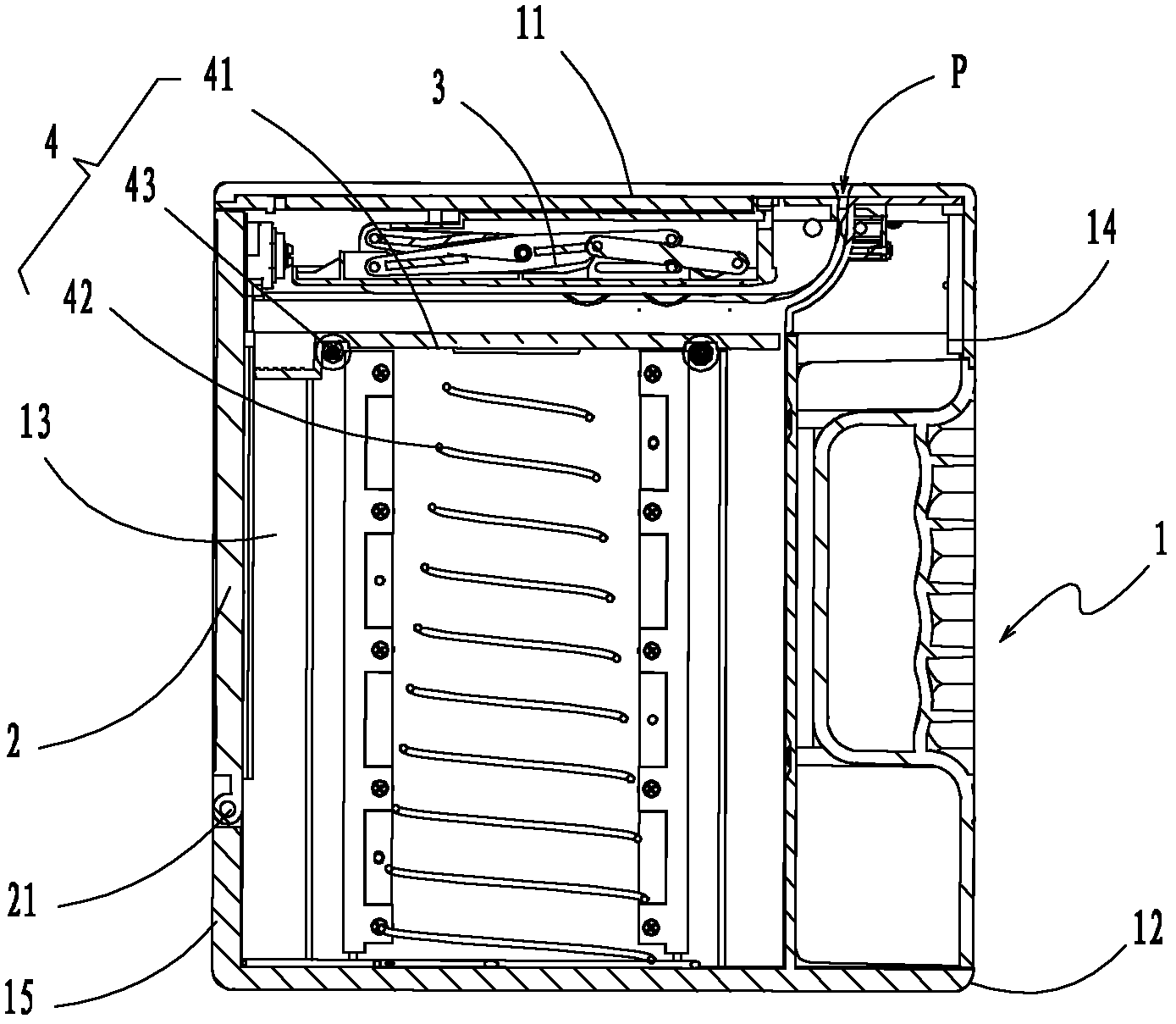

Movable height angle adjustable bracket for hand-held hedge trimmer

The invention discloses a movable height angle adjustable bracket for a hand-held hedge trimmer, belonging to the technical field of landscaping machinery. When an existing hand-held hedge trimmer is used to artificially trim the contour of the plant, the trimming labour intensity is high, and the hedge is difficult to trim flatly and uniformly. The movable height angle adjustable bracket for the hand-held hedge trimmer is composed of a translation mechanism, a lifting mechanism and a replicating mechanism from bottom to top, wherein lower end parts of four connecting rods below two groups of parallelogram four linkages in the lifting mechanism are respectively hinged with four slide blocks in the translation mechanism; and the upper end parts of the four connecting rods above the two groups of the parallelogram four linkages in the lifting mechanism are respectively hinged with a pair of round hole supporting bases and a pair of slot hole supporting bases in the replicating mechanism. The hand-held hedge trimmer is arranged on a blocking base, so that a ring-belt-shaped cutter head of the hand-held hedge trimmer extends forwards. The height of the hand-held hedge trimmer is regulated by the lifting mechanism, and the replicating angle of the blocking base is regulated by the replicating mechanism, so as to be adaptive to trimming different plant contours; and the ring-belt-shaped cutter head translates in a reciprocating manner by the translation mechanism, so as to repeatedly trim.

Owner:CHANGCHUN UNIV OF SCI & TECH

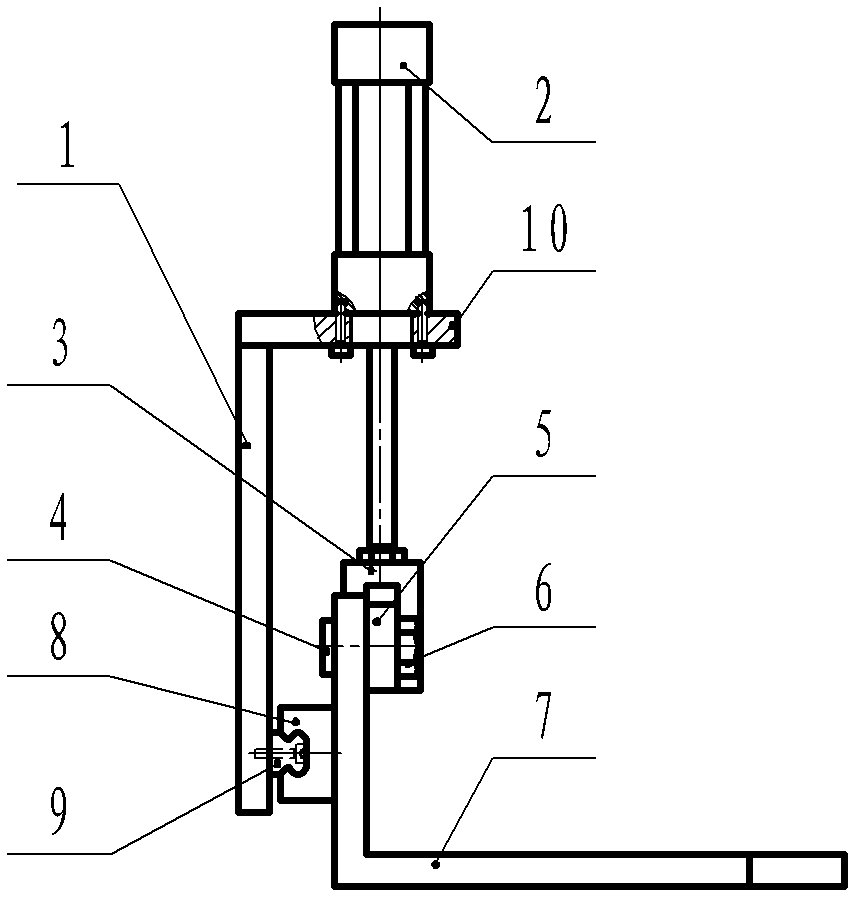

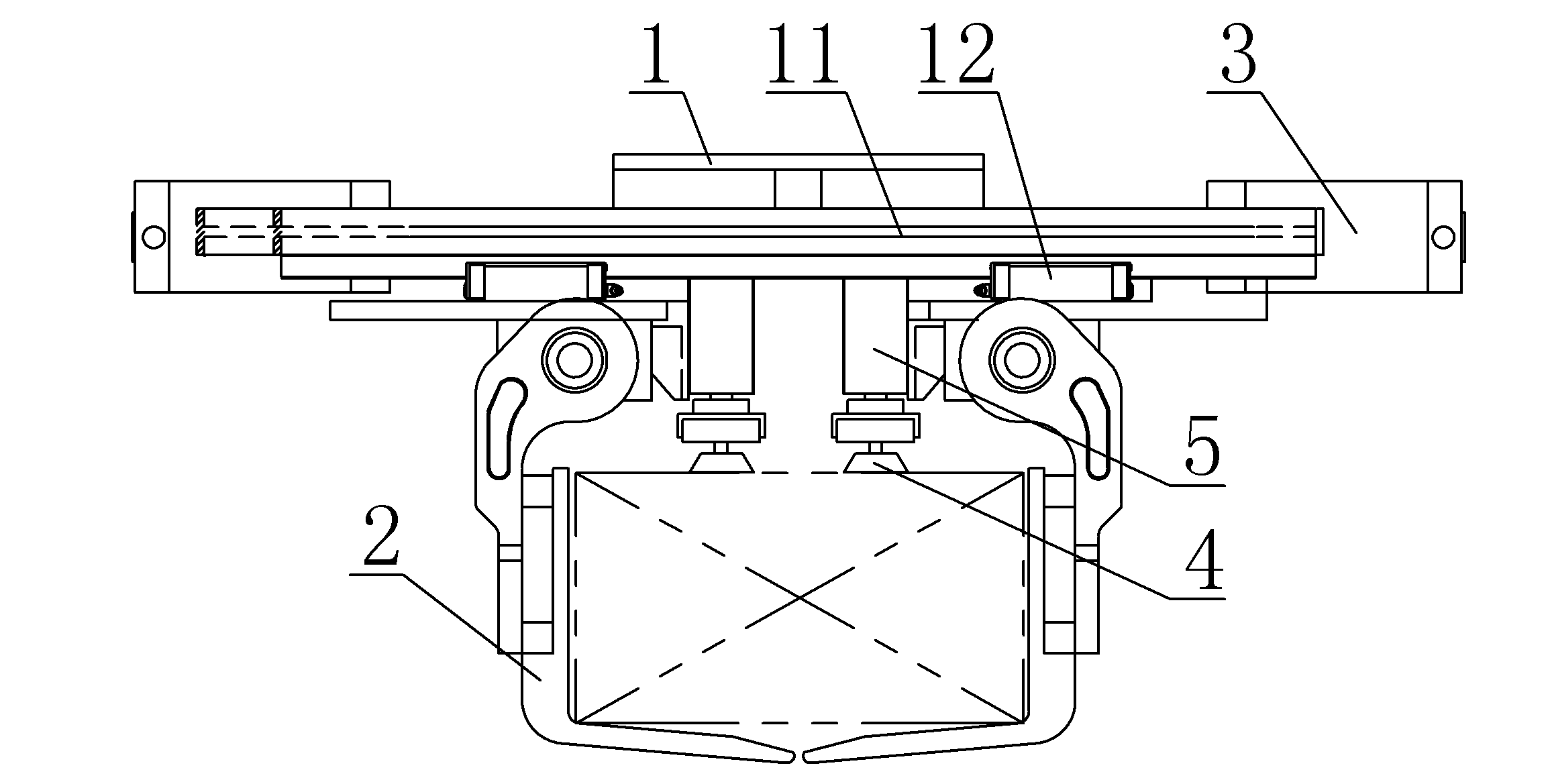

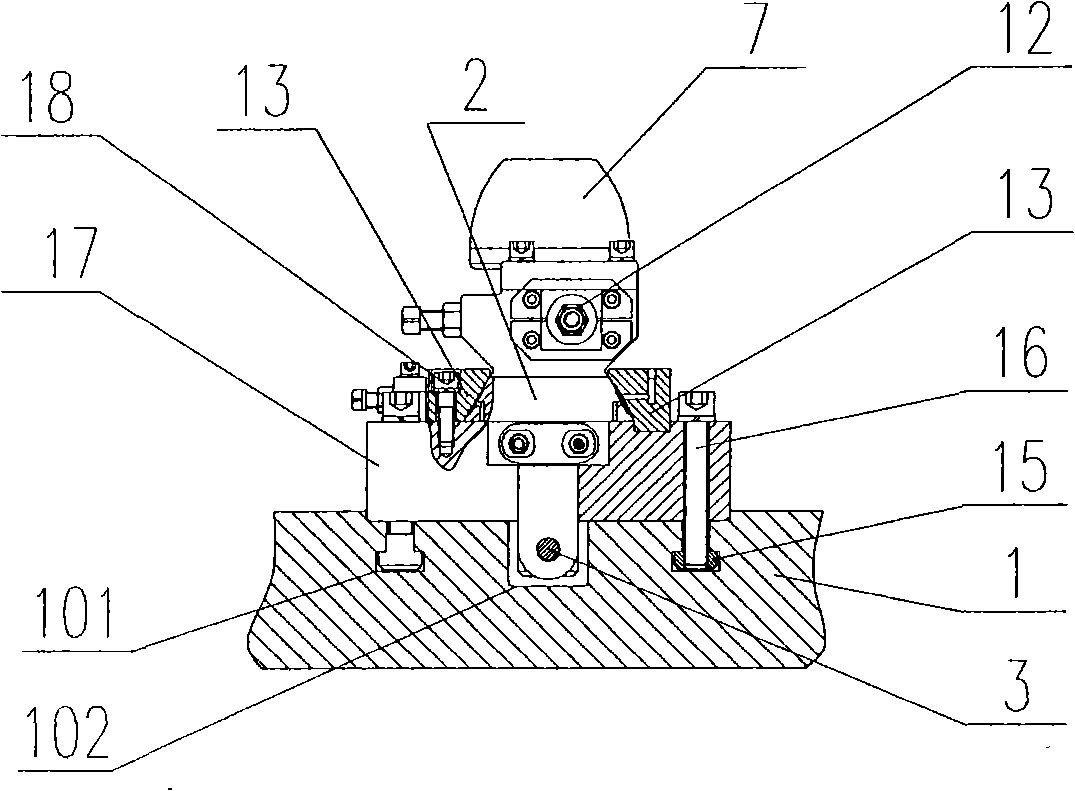

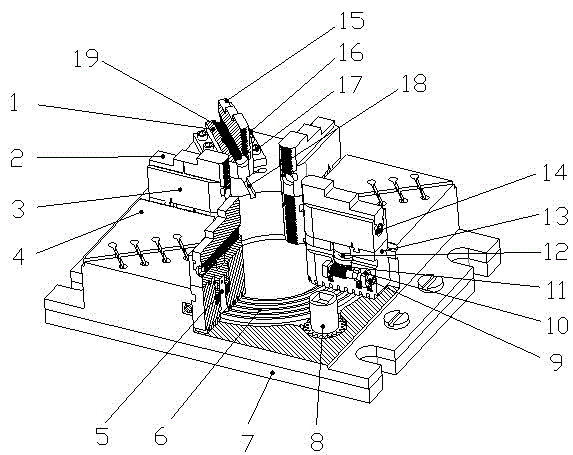

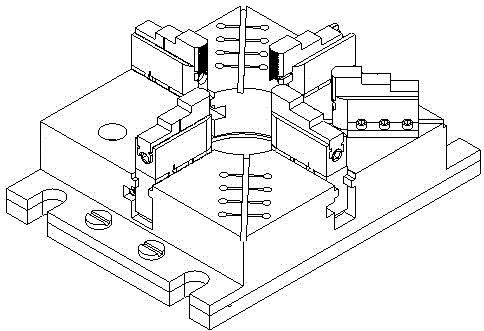

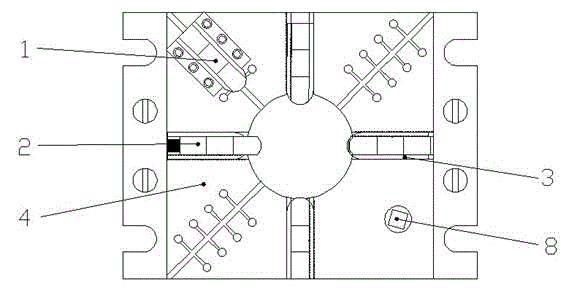

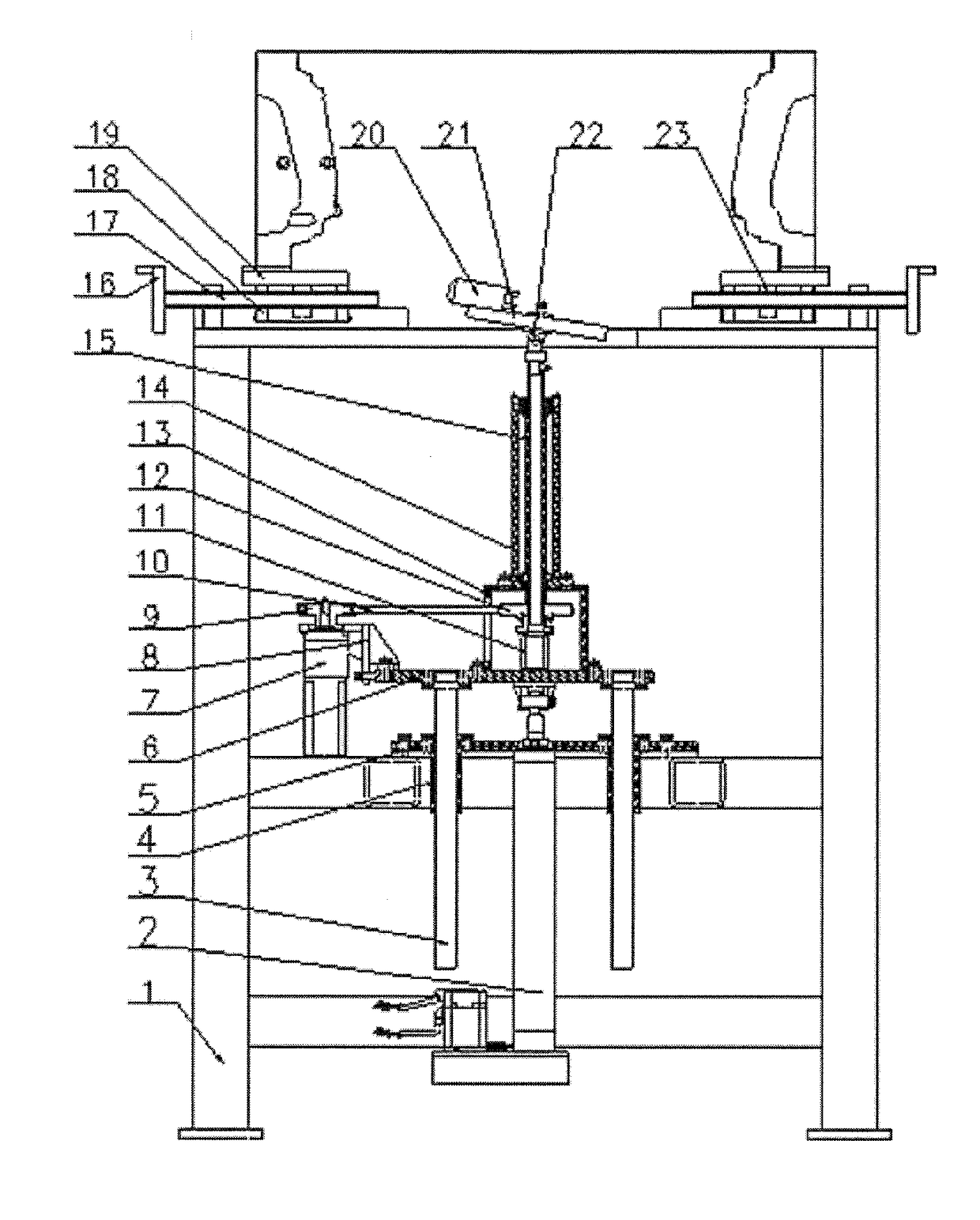

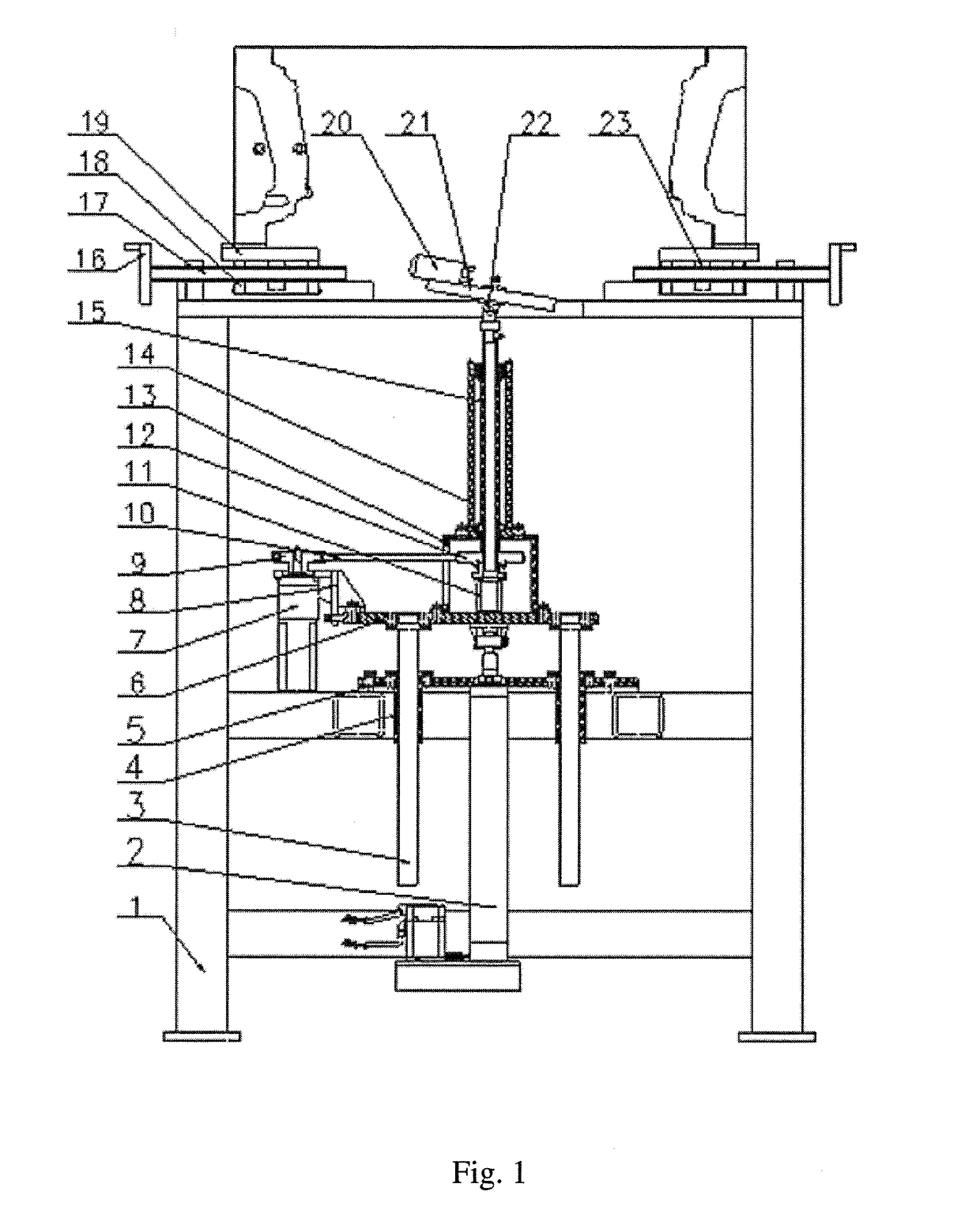

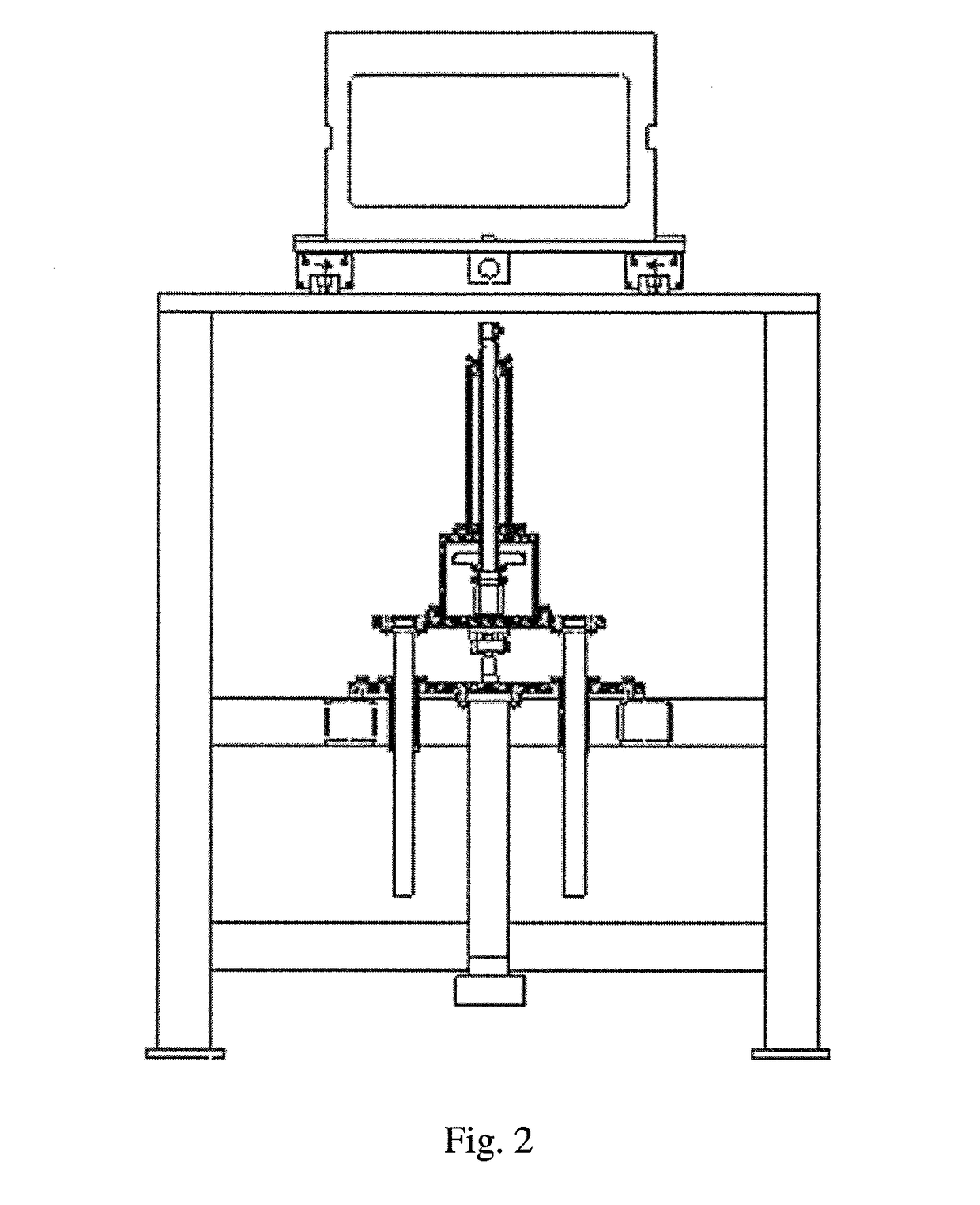

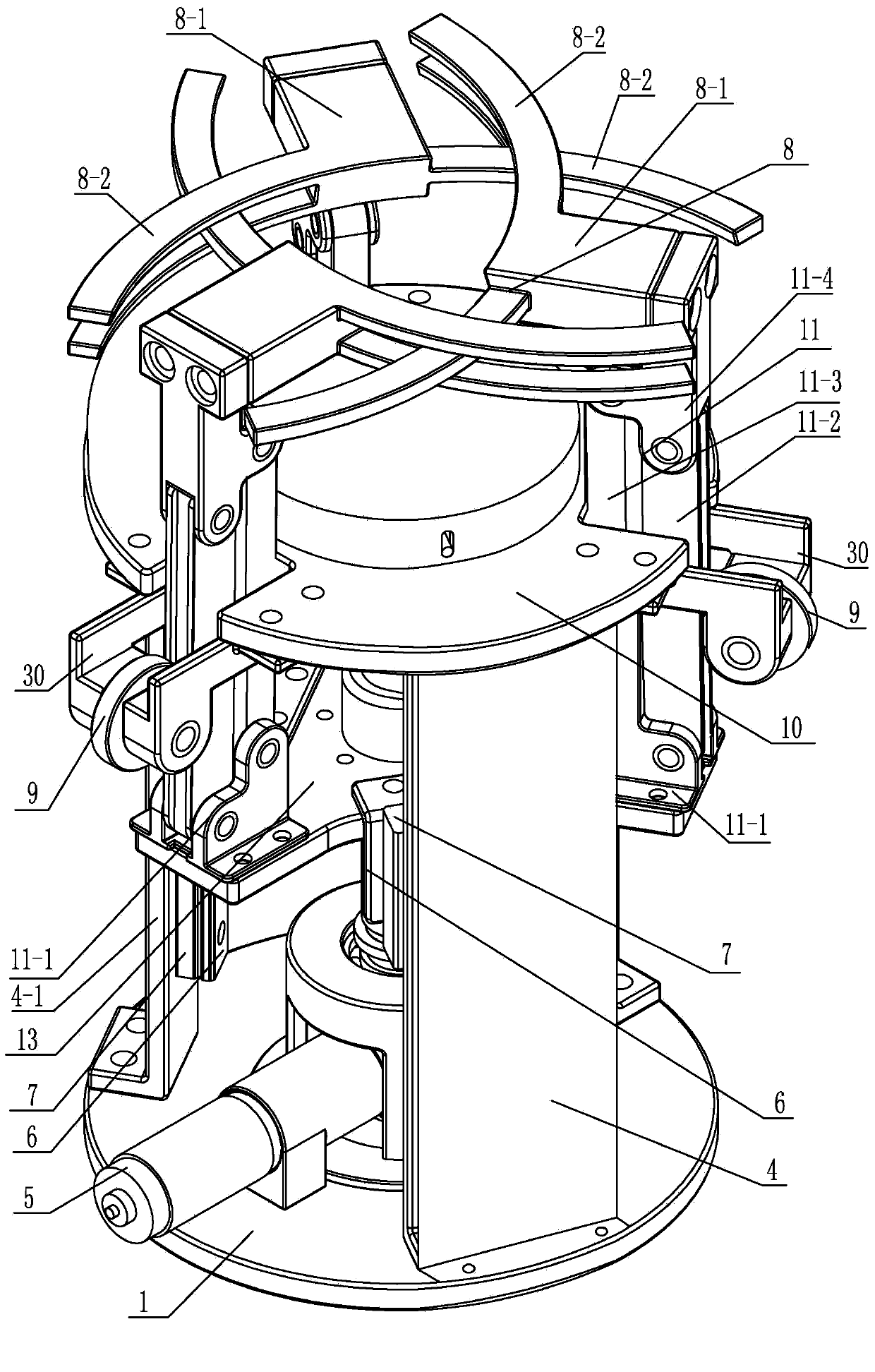

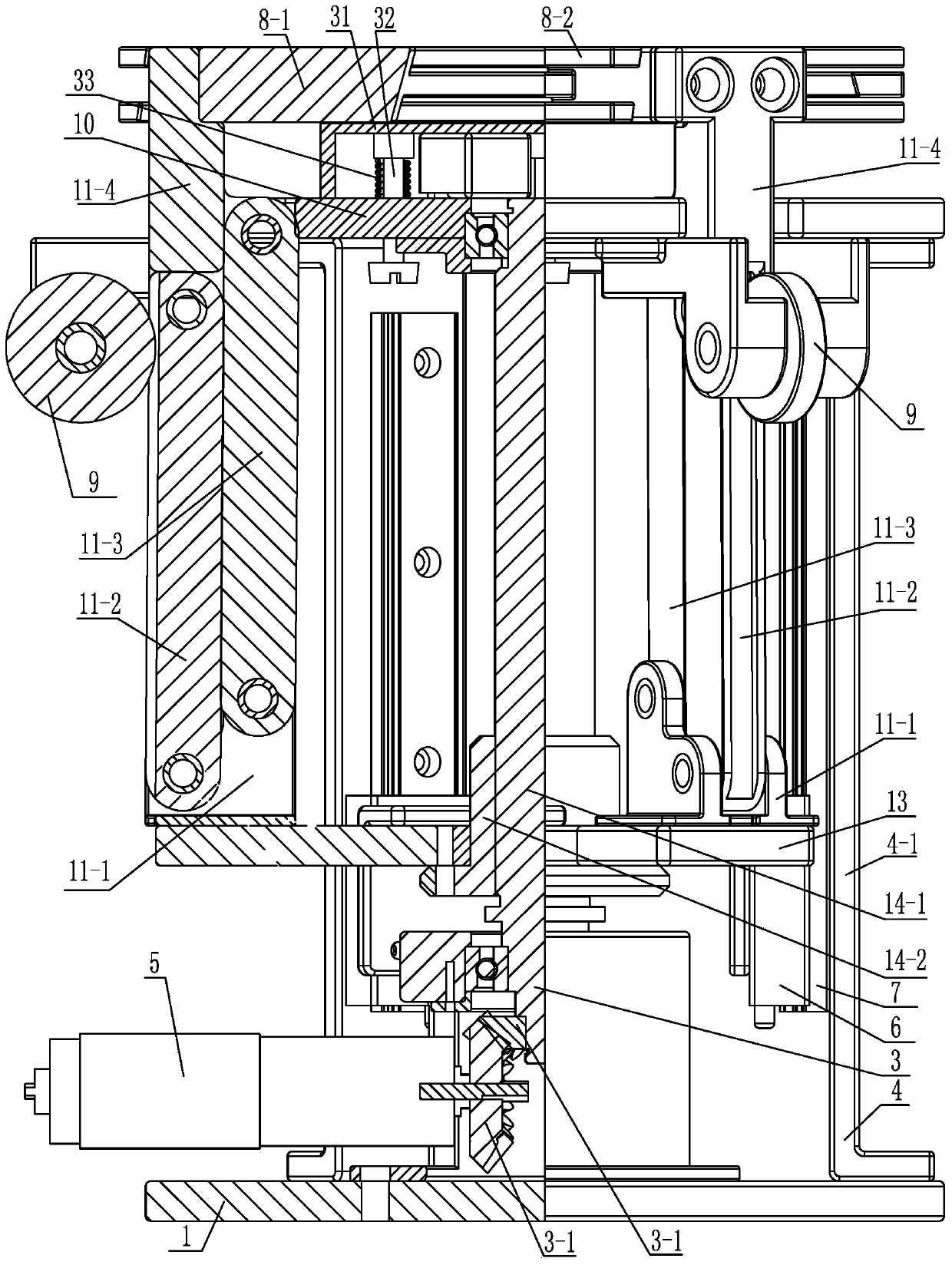

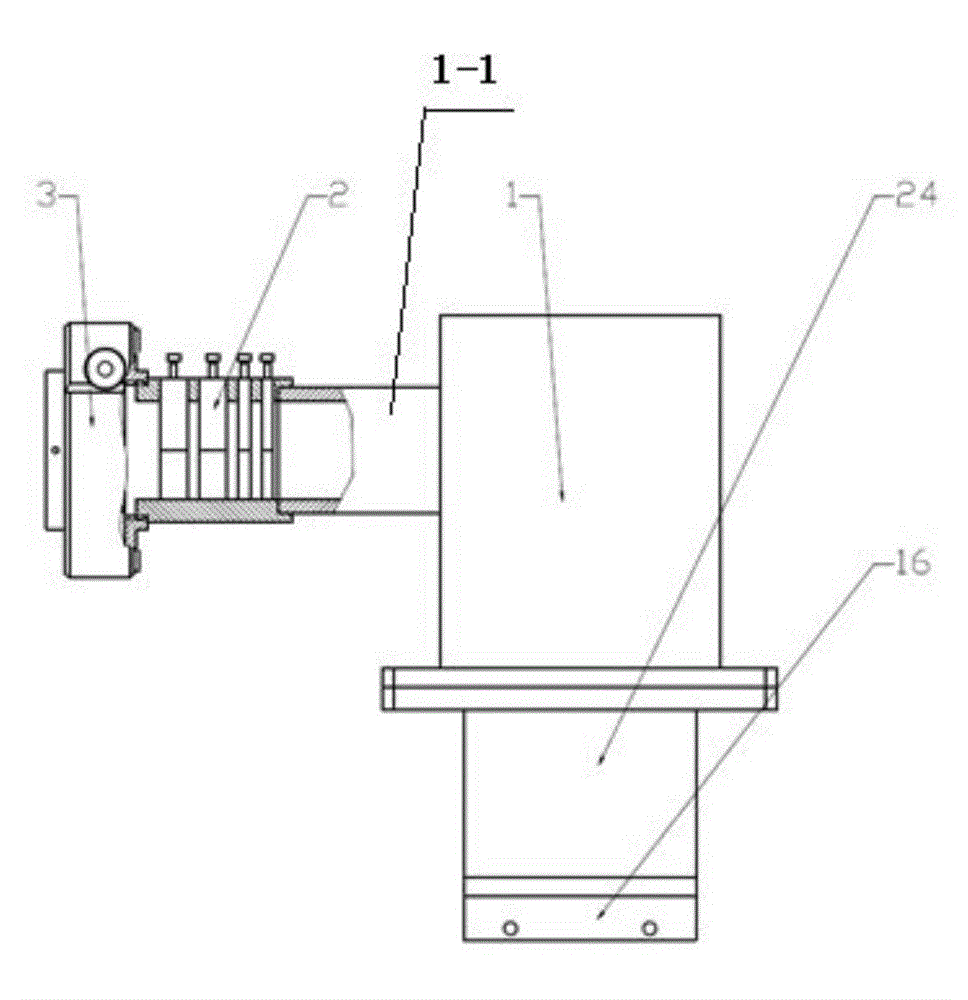

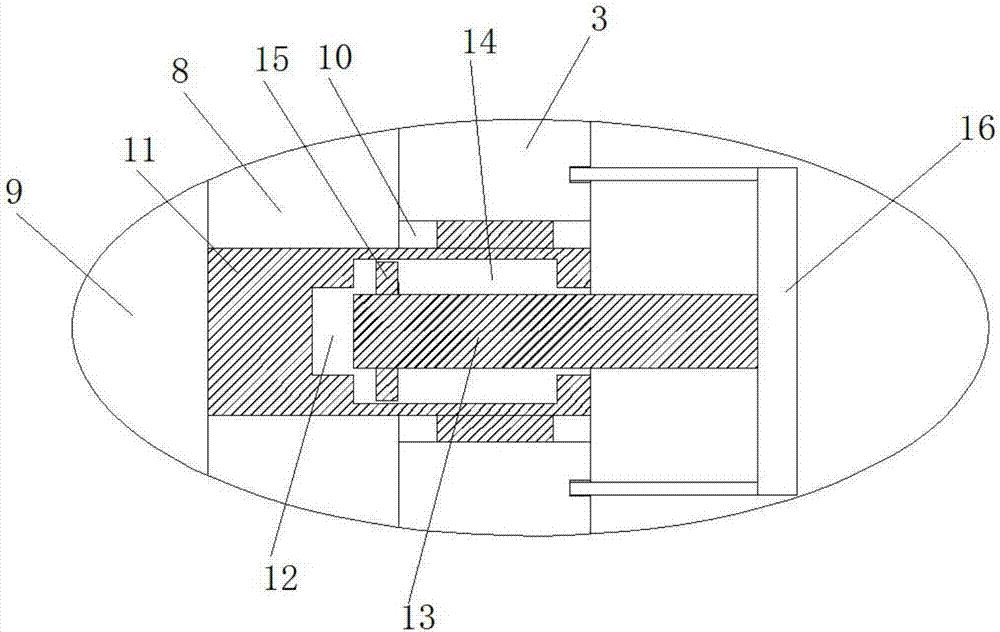

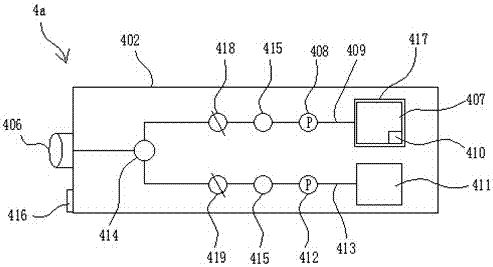

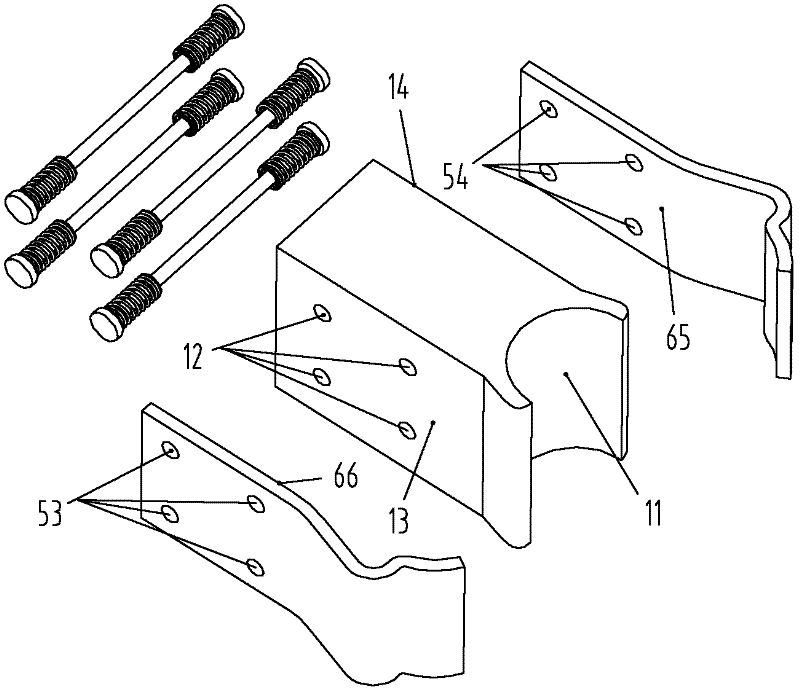

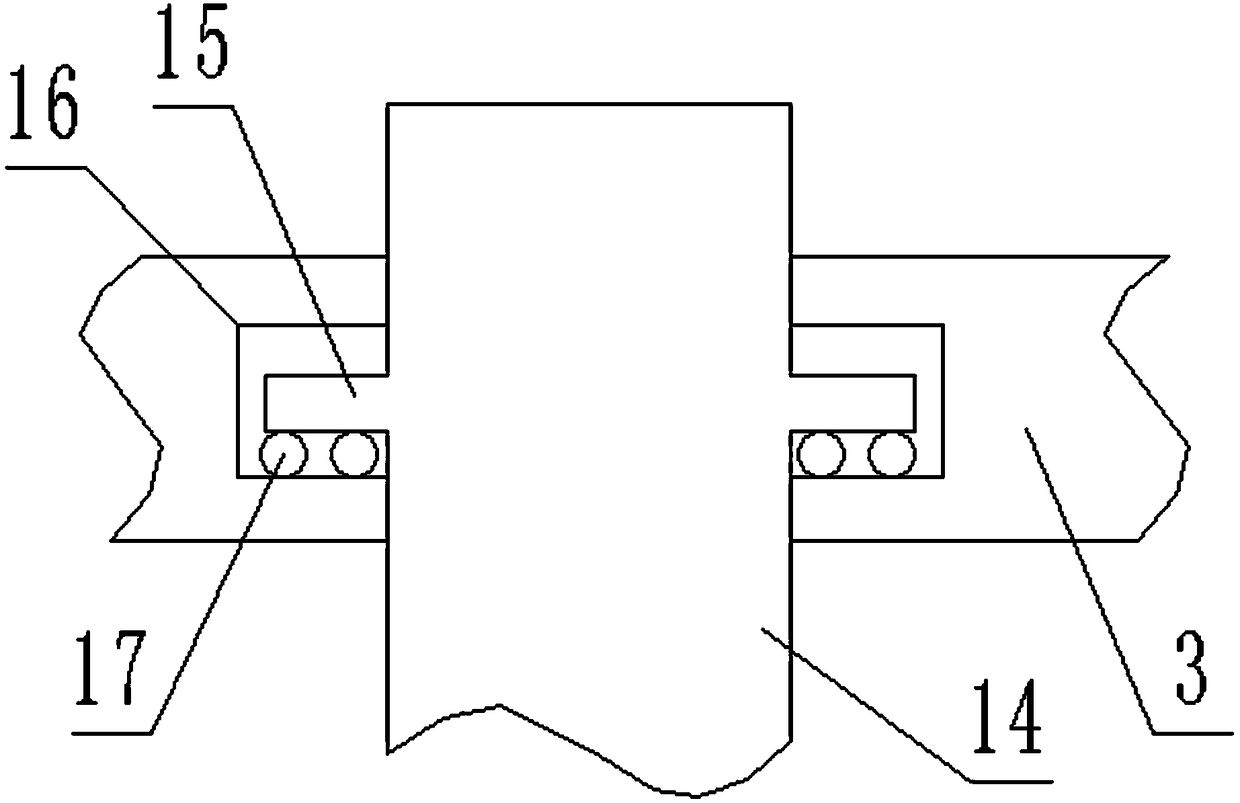

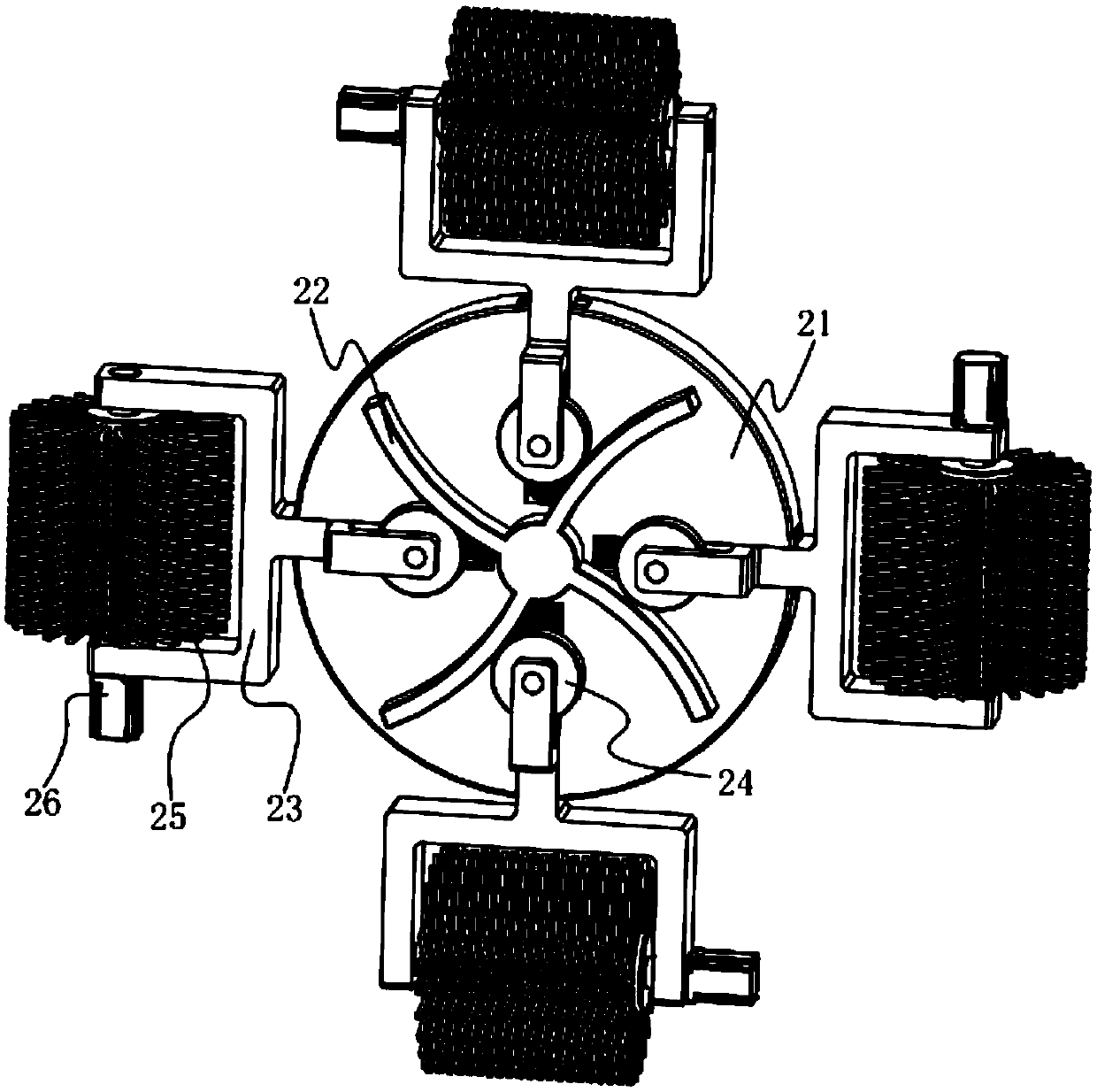

Automatic positioning clamping mechanism for feeding and discharging materials in bell-shaped shell defect-detection/cleaning integrated machine

ActiveCN102608201ASimple structureLow costGripping headsCleaning processes and apparatusEngineeringFour-slide

The invention relates to an automatic positioning clamping mechanism used for feeding and discharging materials in a bell-shaped shell defect-detection / cleaning integrated machine. The mechanism is characterized by fixing a pair of cylinder connecting plates on the top surface of an installing substrate; two pairs of, in other words, four sliding blocks in all, are configured on a straight line guide track at the lower part in front of the installing substrate; a clamping jaw is L-shaped; V-shaped chucks are arranged on the internal side surface at the front parts of a pair of clamping jaw horizontal arms respectively; four clamping jaws are fixed on the four sliding blocks through a perpendicular arm respectively; a cylinder is fixed on the cylinder connecting plate; a movable joint is fixed on a stretching end of a piston rod of the cylinder; the movable joint is U-shaped and the opening thereof faces downwards; each pair of connecting rods are matched in a U-shaped slot of the movable joint rotationally through a hinge pin; and the other ends of each pair of connecting rods are matched on a pair of clamping jaw perpendicular arms rotationally through screws. According to the mechanism, working pieces of different models can be positioned and clamped accurately without adjustment; the adjusting working quantity of the machine can be reduced greatly; the operation is sensitive and reliable; and the production efficiency can be improved greatly.

Owner:SHEYANG HUATONG DETECTOR EQUIP

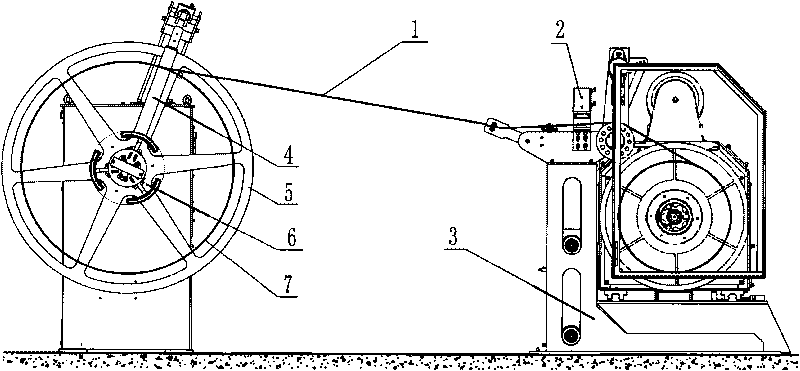

Horizontal moving steel band recoiling device

The invention provides a horizontal moving steel band recoiling device, which comprises a band releasing device and a band take-up device. The band releasing device comprises a steel band roller, a rotating disk, a steel band tensioning device, a steel band disk, a tensioning arc plate, a brake, a brake turnplate, a tensioning cylinder, a push seat, a synchronous belt and an encoder. The band take-up device comprises a groove device, a lifting tray, a synchronous belt, a servomotor, a ball screw pair, linear guide rail pairs, a variable speed reducer, a bobbin and an encoder for counting meters, wherein the synchronous belt is connected with the ball screw pair; a feed screw nut is connected with a sliding case; the sliding case is provided with four slide blocks; on the two linear guide rail pairs, a reciprocating stroke realizes reversing by approaching a positioning switch; the bobbin is connected with a motor with the encoder and the variable frequency speed reducer; the steel band is provided with the encoder for counting meters between the groove device and the bobbin. The device has high automatic degree, reduces labor intensity, and improves safety.

Owner:GUIZHOU AEROSPACE NANHAI ELECTROMECHANICAL

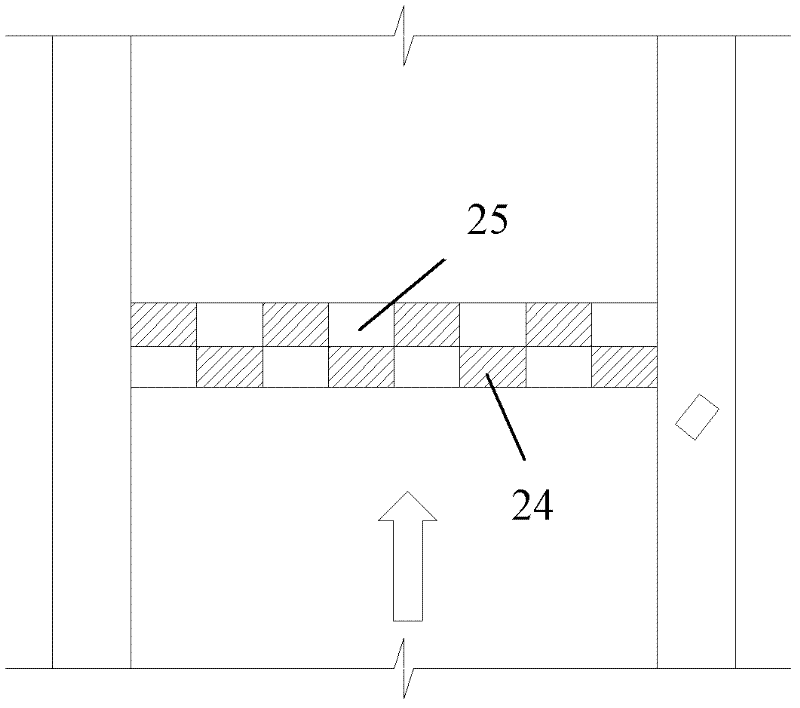

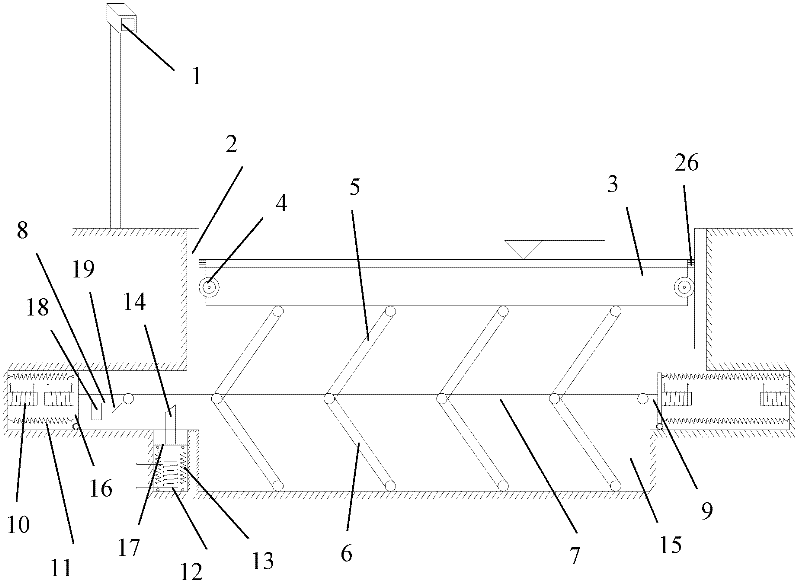

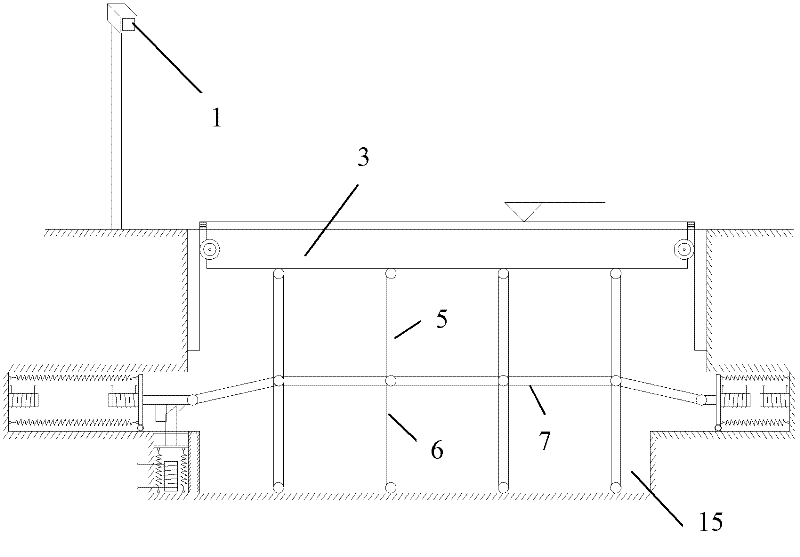

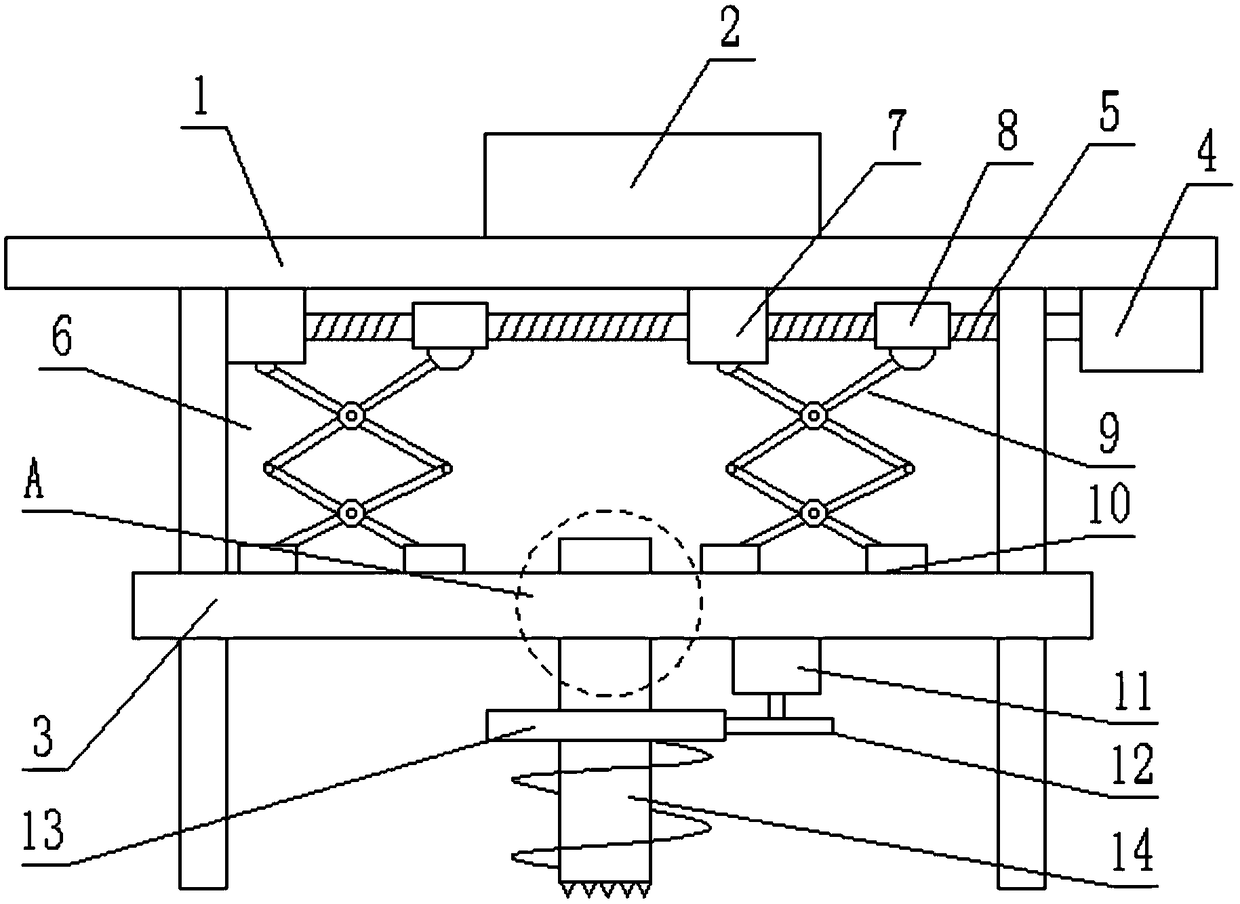

Barrier-free automatic lifting speed bump and control method

The invention discloses a barrier-free automatic lifting speed bump and a control method. The speed bump comprises a radar speed indicator, four guide rails, a speed reducing plate, four sliding wheels, a plurality of upper supporting rods, a plurality of lower supporting rods, a plurality of link rods, a left push-pull rod, a right push-pull rod, two groups of push-pull electromagnets, a plurality of push-pull springs, a thrust electromagnet, a plurality of thrust springs, a thrust rod and a control device. The barrier-free automatic lifting speed bump has no barrier to the normal running vehicles, and can forcibly decelerate the over-speed vehicles, so that the road running comfortableness and the running safety can be improved, the noise is reduced, the service life of a tyre is prolonged and the overhauling expense is reduced. In addition, the control method is simple and convenient.

Owner:CIVIL AVIATION UNIV OF CHINA

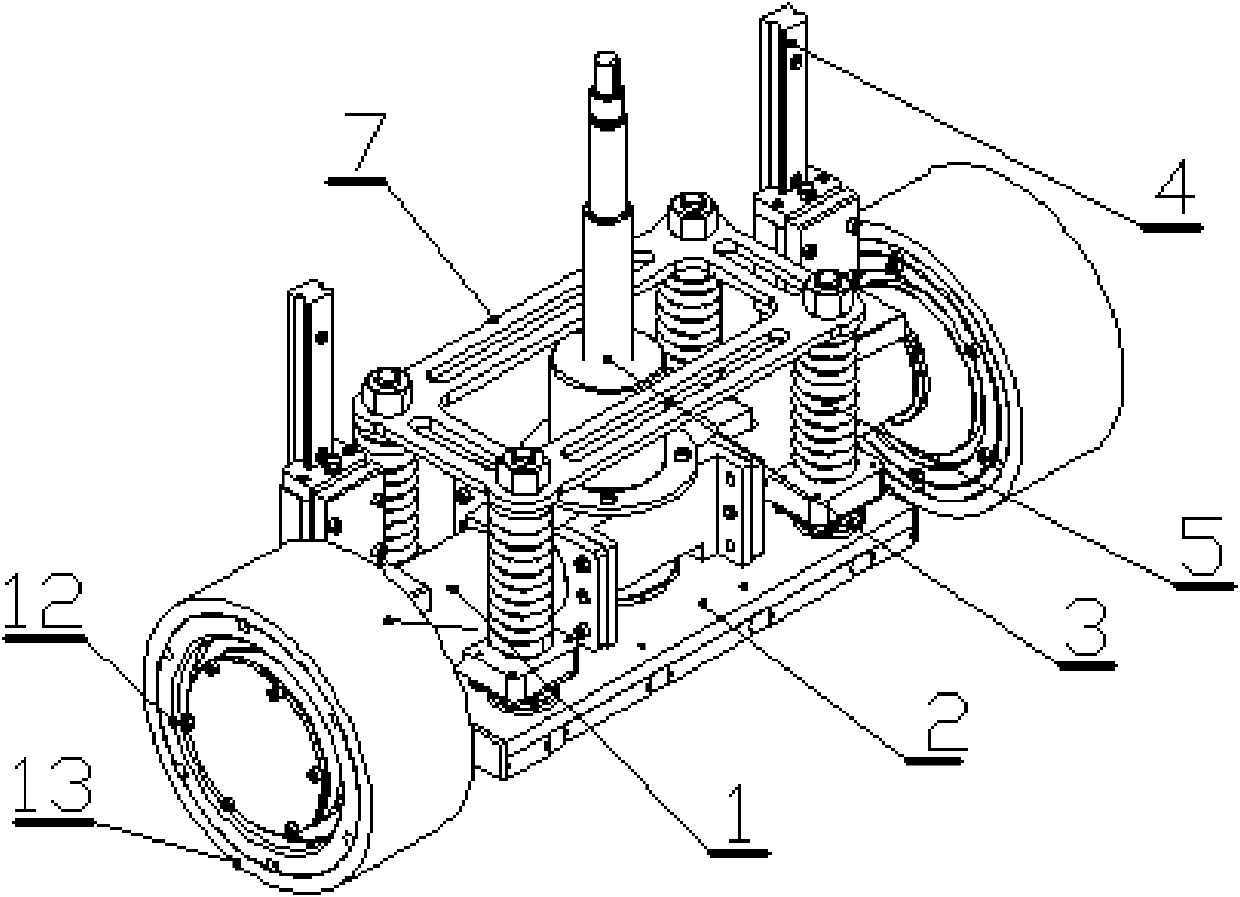

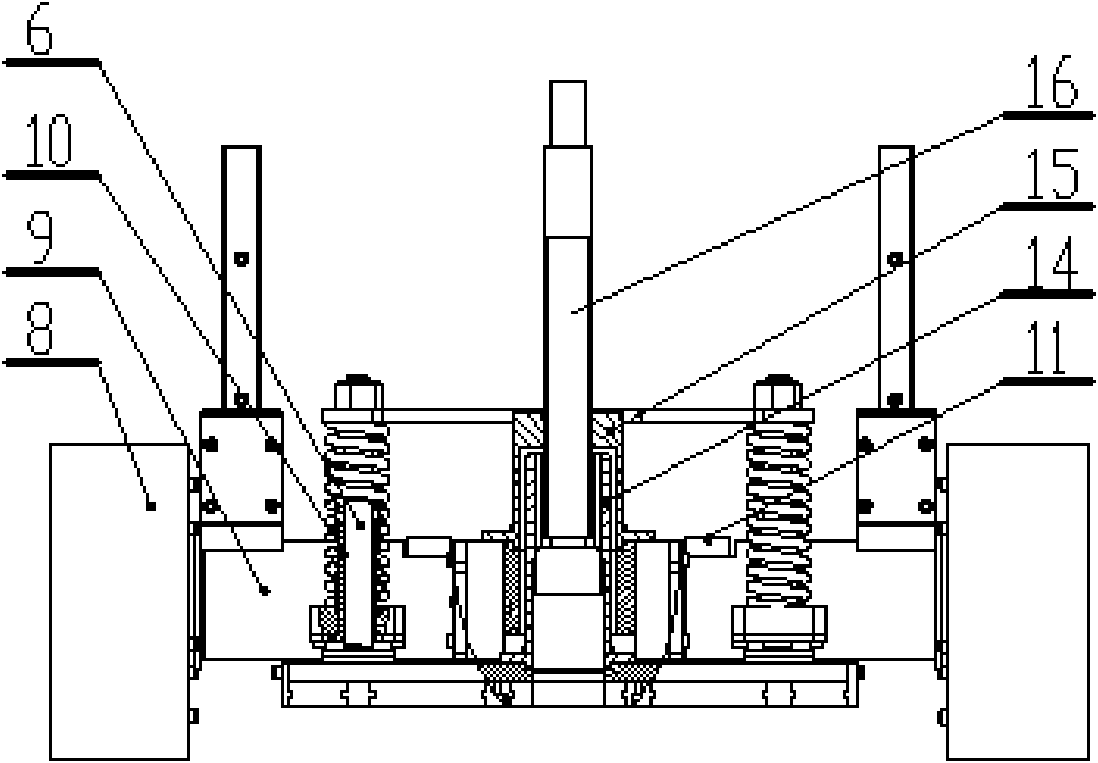

Wheel-type obstacle detouring mechanism for wall climbing robot with adjustable magnetic adsorption force

The invention discloses a wheel-type obstacle detouring mechanism for a wall climbing robot with adjustable magnetic adsorption force in the technical field of robots. The wheel-type obstacle detouring mechanism comprises a moving mechanism, an adsorption mechanism, a lifting mechanism, a linear guide rail, a spring, sliding guide rods and a guide rod connecting frame, wherein the adsorption mechanism is arranged below a driving mechanism and movably connected with four sliding guide rods; the spring is sleeved on the sliding guide rods; the guide rod connecting frame is contacted with the spring and connected with the four sliding guide rods; the lifting mechanism is movably connected with the moving mechanism and the adsorption mechanism; the linear guide rail is connected with the moving mechanism; and the lifting mechanism drives the moving mechanism and the adsorption mechanism to move up and down along the linear guide rail. The non-contact magnetic adsorption wheel-type moving mechanism has the characteristics of flexible movement, high and adjustable adsorption force and lifting capability, and has good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

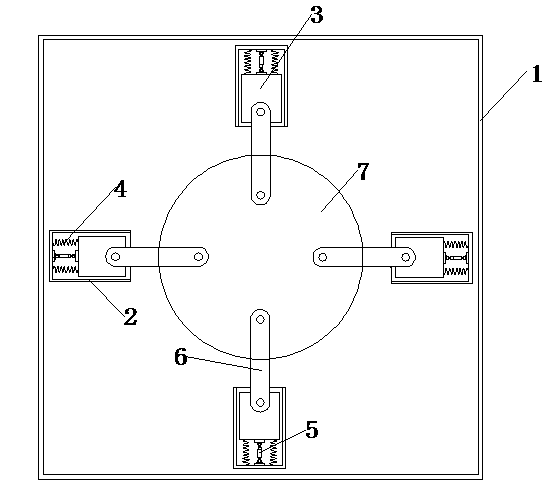

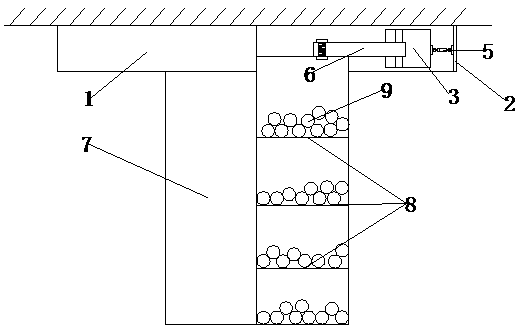

Novel tuned particle mass damper

InactiveCN103541460AEnhance energy dissipation and vibration reduction effectEasy to useBridge structural detailsShock proofingMechanical energyShock resistance

The invention relates to a novel tuned particle mass damper and belongs to the technical field of shock resistance and absorption of structural engineering. The novel tuned particle mass damper comprises a damper fixing plate, mass block sliding cavities, mass blocks, connecting springs, viscous damper units, connecting bars, a damper cavity, damper chamber separating plates, multi-stage damping particle groups. Four sliding cavities are arranged on the damper fixing plate; four mass blocks are arranged inside the four sliding cavities, perform low-damping movement inside the internal tracks of the sliding cavities and are connected with the damper fixing plate through the viscous damper units and the springs and connected with the damper cavity through the connecting bars. The chamber separating plates are arranged inside the damper cavity, a single layer of the multi-stage damping particle groups are uniformly arranged on every chamber separating plate. Under the action of wind and / or earthquakes, the damper cavity moves opposite to a basic structure on the plane and generates control force opposite to that of the basic structure, internal damping particles collide fiercely to rapidly dissipate system mechanical energy and further improve system damping effects.

Owner:TONGJI UNIV

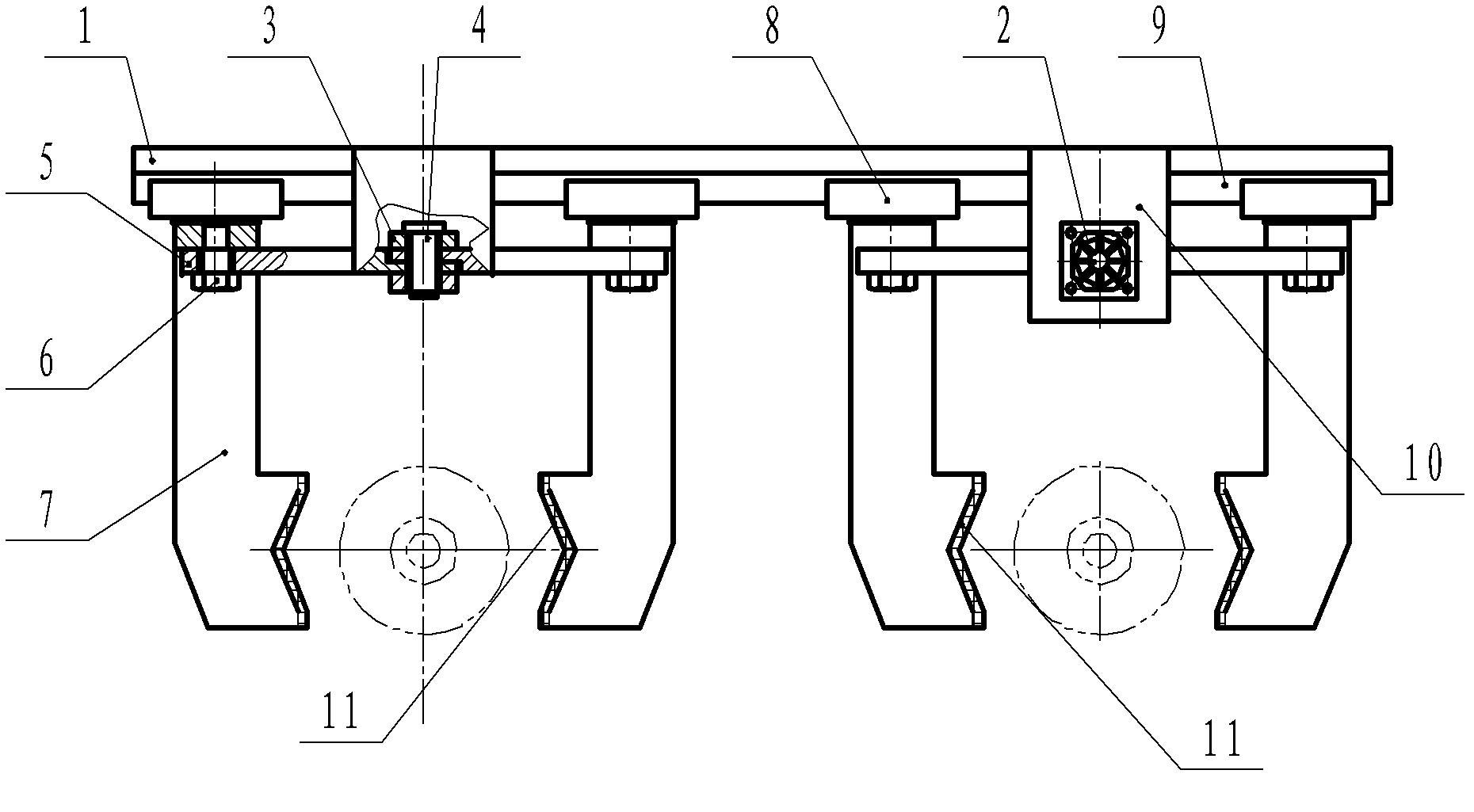

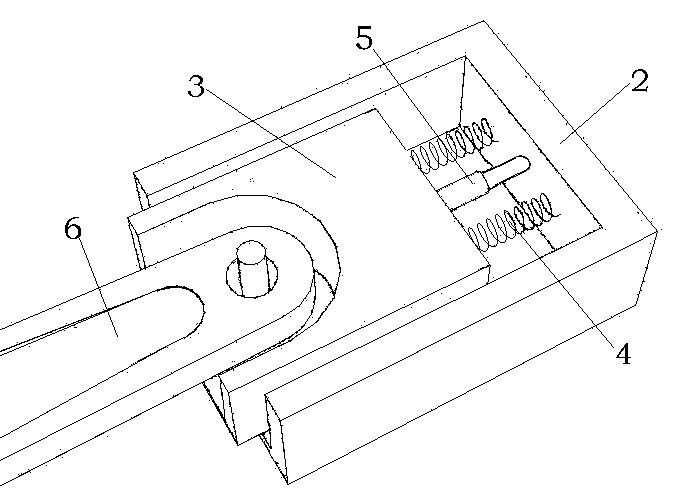

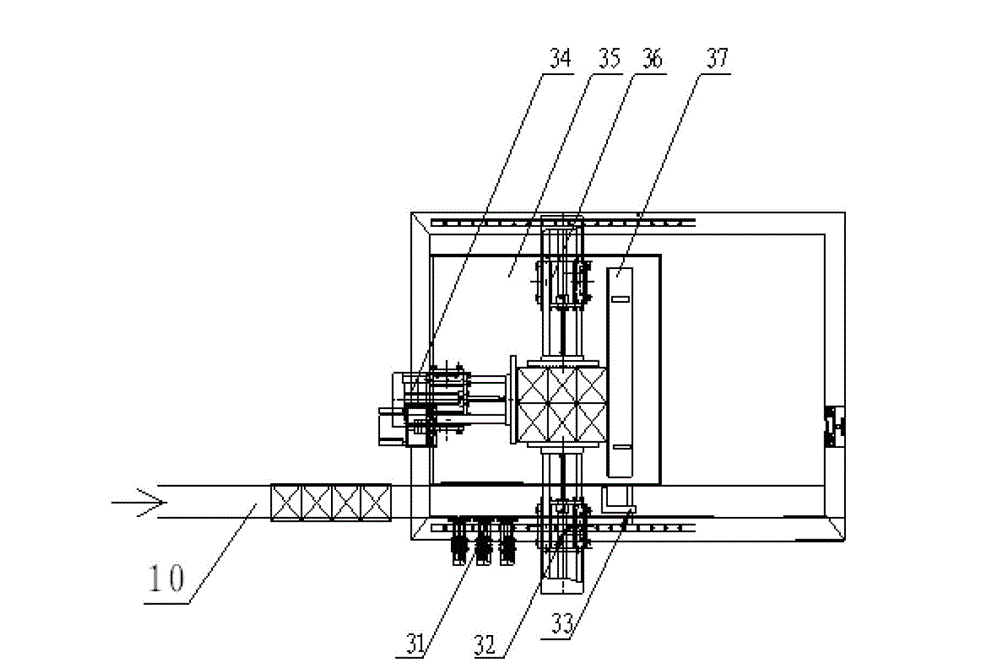

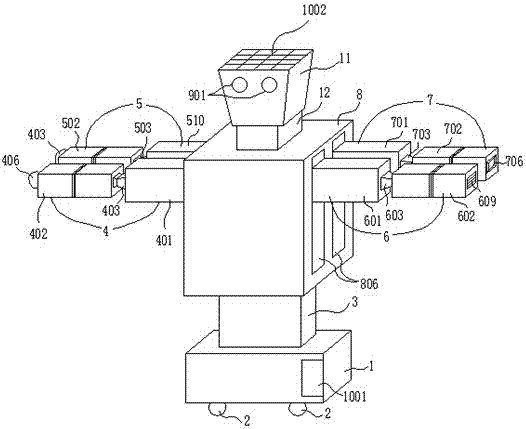

Palletizing robot

InactiveCN102674018ARealize comprehensive crawling functionRealize automatic adjustmentStacking articlesDe-stacking articlesRobotic armEngineering

The invention relates to a palletizing robot which comprises a mechanical arm and a gripper. The mechanical arm and the gripper are connected movably, the gripper comprises a platform, a pair of fingers and a rotary mechanism for driving the fingers to rotate, linear guide rails are installed below the platform, a sliding block group is installed on the linear guide rails and comprises four sliding blocks, two sliding blocks are installed on each linear guide rail, the sliding blocks located on the same sides on the two linear guide rails belong to a group, and two ends of each finger are respectively installed on the same group of sliding blocks in hinged mode. The palletizing robot is further provided with a translation mechanism for driving the fingers to perform translation on the linear guide rails, a plurality of vacuum suckers for absorbing materials and a lifting mechanism for driving the vacuum suckers to move vertically are installed at positions between the pair of fingers on the platform. The rotary mechanism of the palletizing robot drives the gripper to rotate so as to grab objects. The translation mechanism achieves automatic adjustment of appearance of the objects, the vacuum suckers achieve fixation of boxes and cases and facilitate high speed palletizing.

Owner:常州新区中策机械设备有限公司 +1

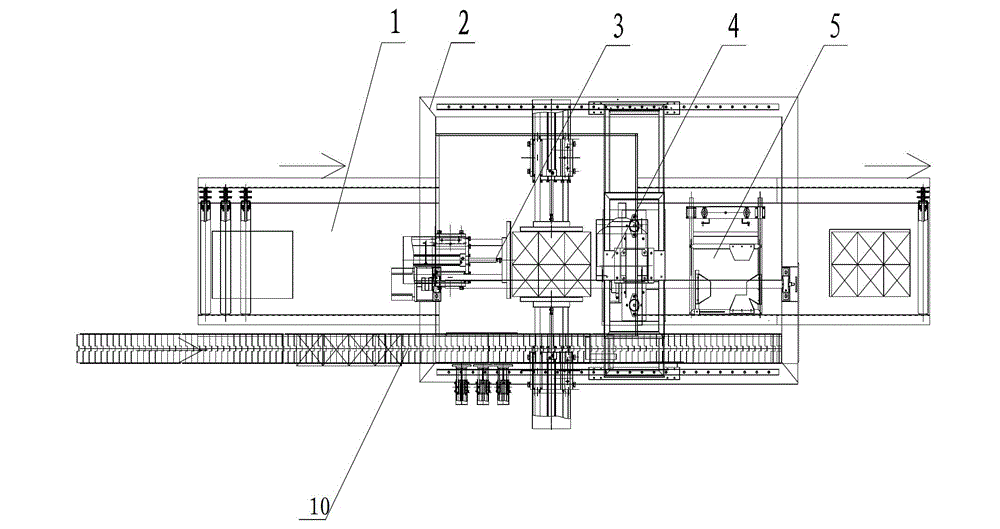

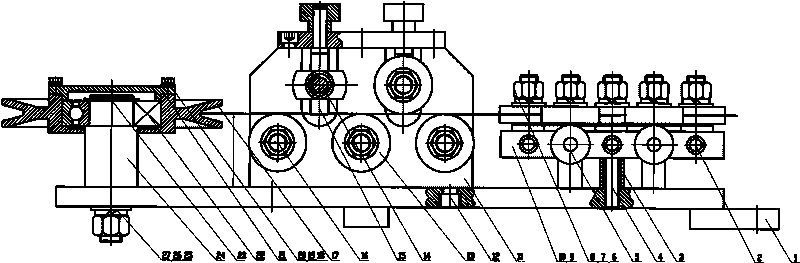

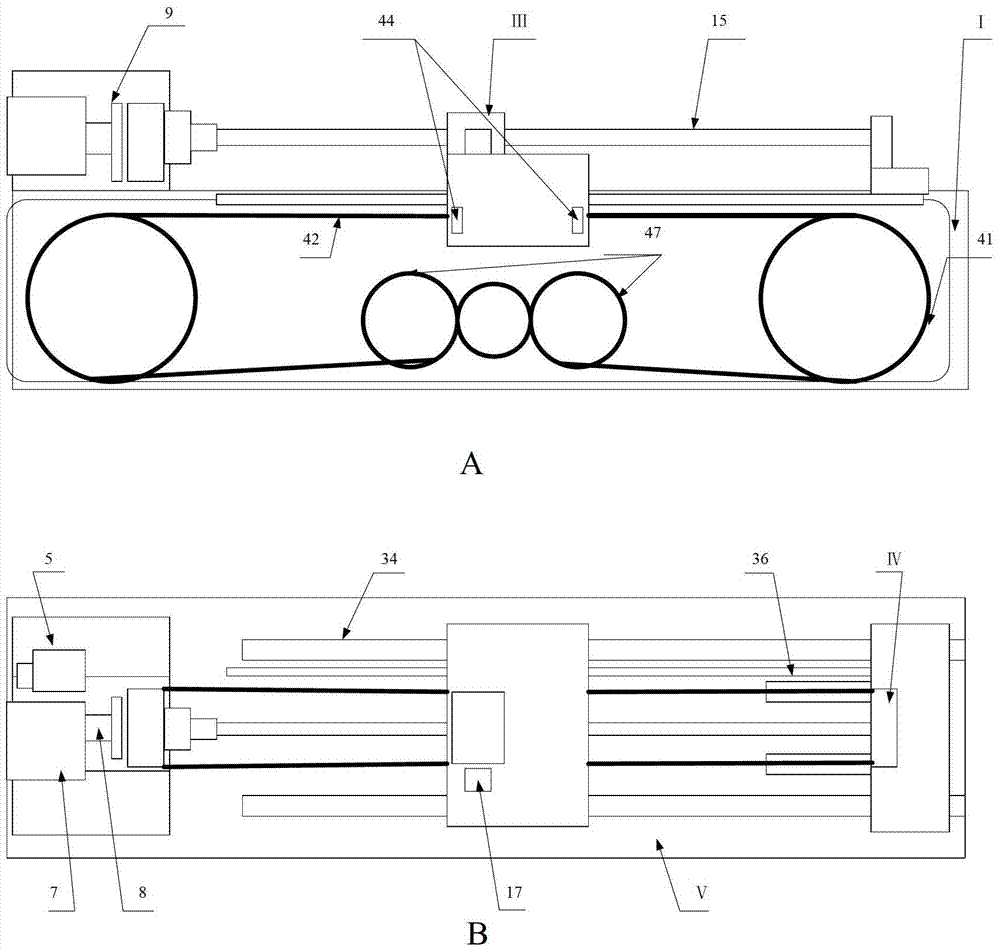

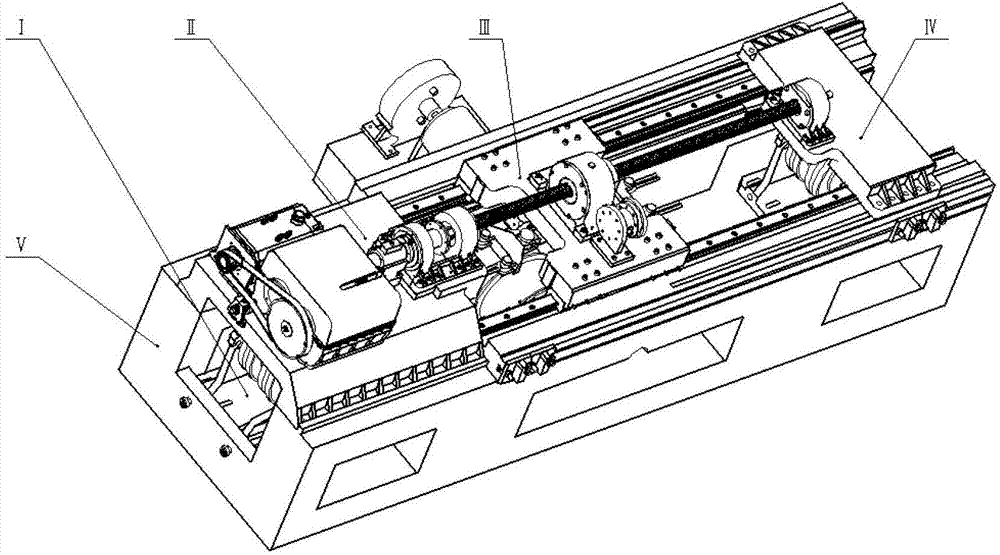

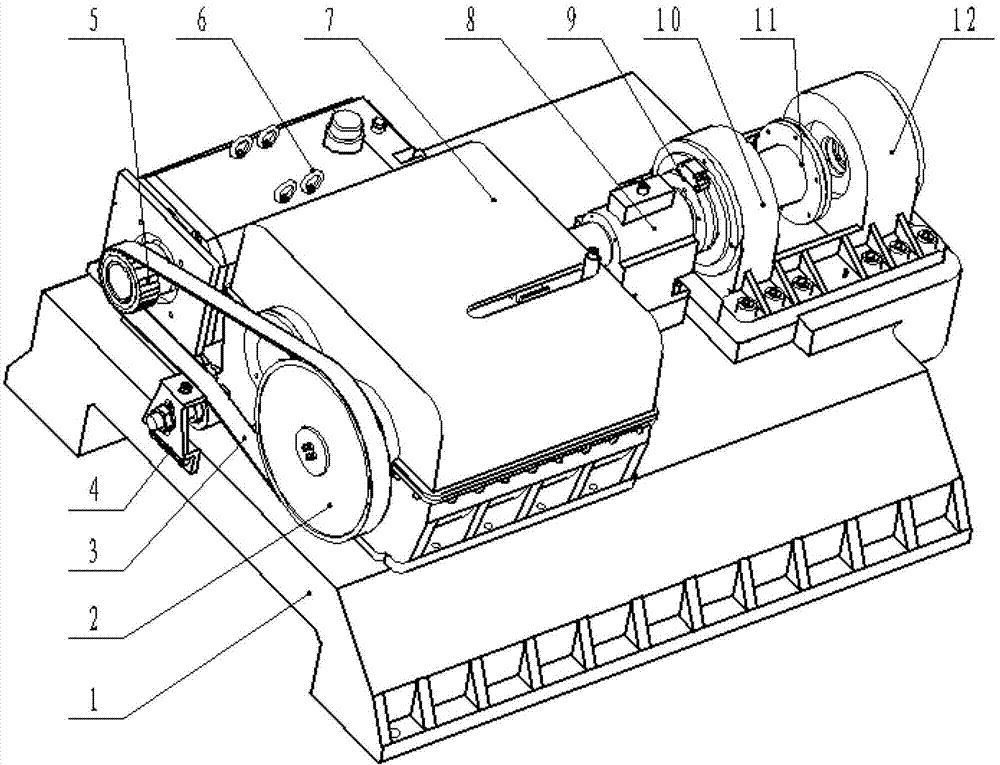

Device for detecting performance of high-speed heavy-load precision roller linear guide rail

InactiveCN102175438AFlexible installationImprove performanceMachine part testingSubsonic/sonic/ultrasonic wave measurementGratingEngineering

Owner:大连高金数控集团有限公司 +1

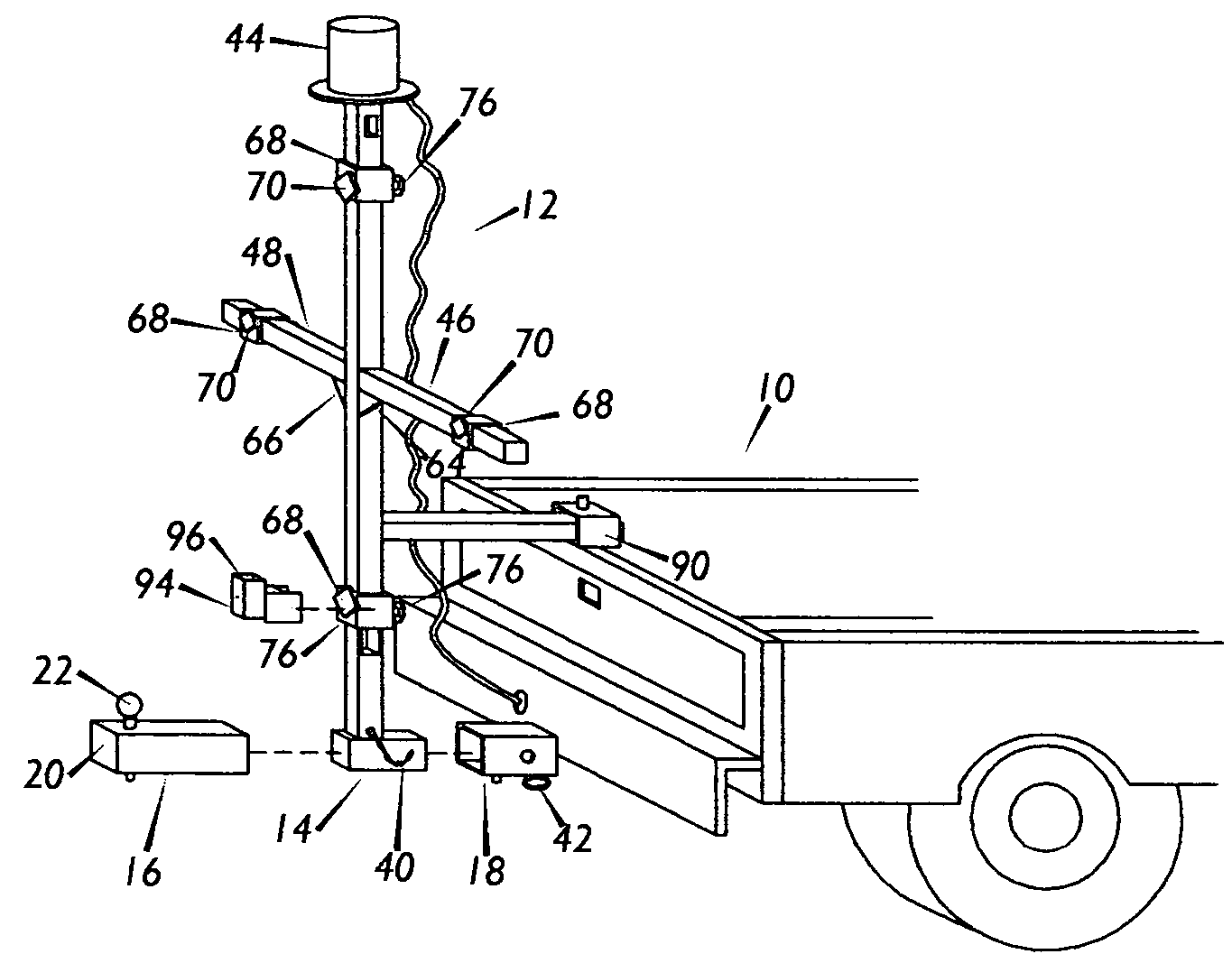

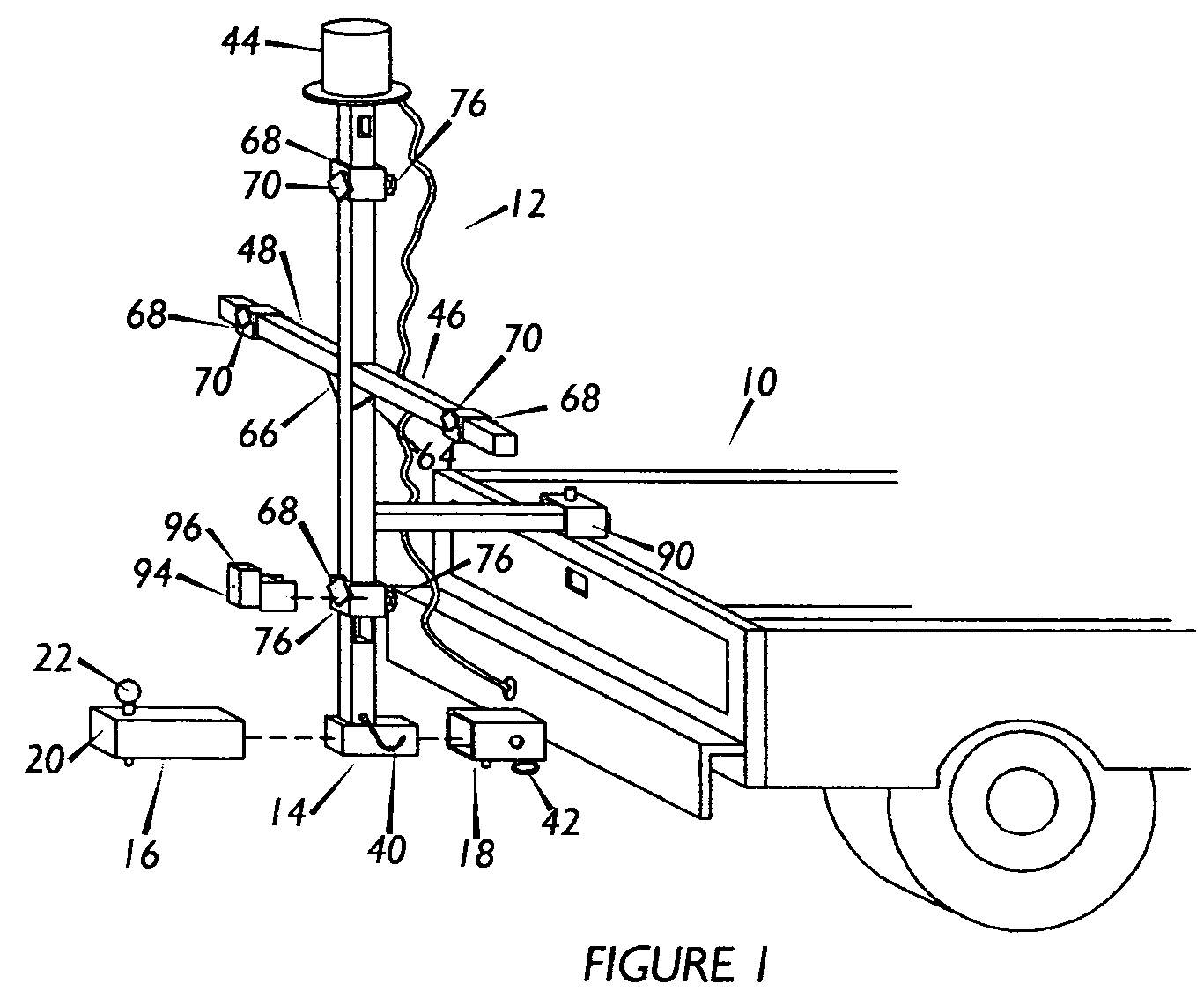

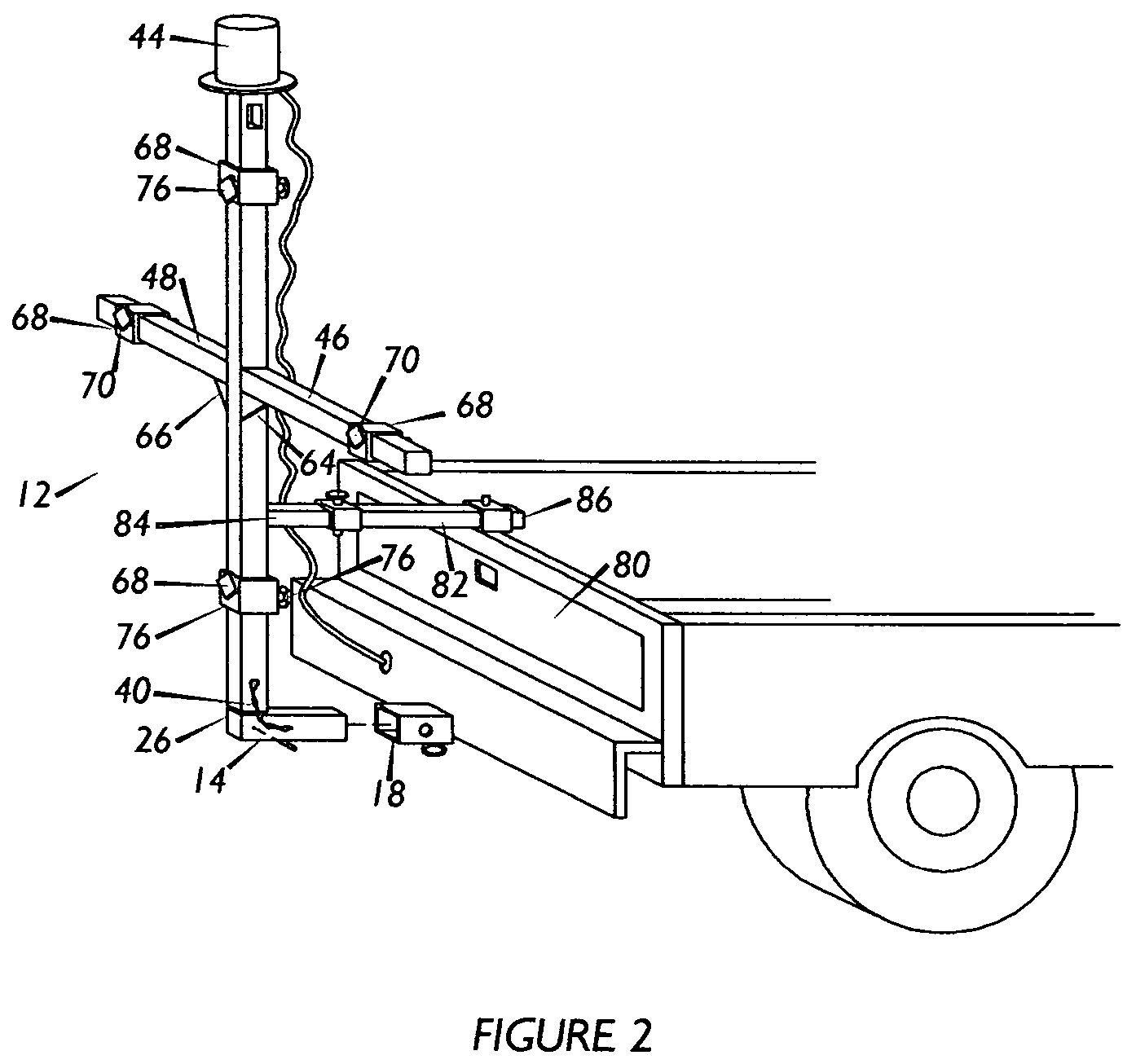

Mobile sign carrier

A mobile sign carrier that mounts on a vehicle receiver hitch and method of use are provided. The mobile sign carrier has a base, a vertical piece and two cross pieces that fold down to form a cross shape. Four sliding brackets are provided, each having permanently attached a square, flat piece, which sliding brackets are mounted one each on each of the cross pieces and one each on the first end and the second end of the vertical piece. The sliding brackets are positioned and secured by means of a fastener to accommodate signs of different sizes. The mobile sign carrier provides a securing device for use on a vehicle with a tailgate. Safety chains further secure the vertical piece to the trailer hitch. A strobe light and night reflective tape are provided.

Owner:CHAFIN WILLIAM ESTILL

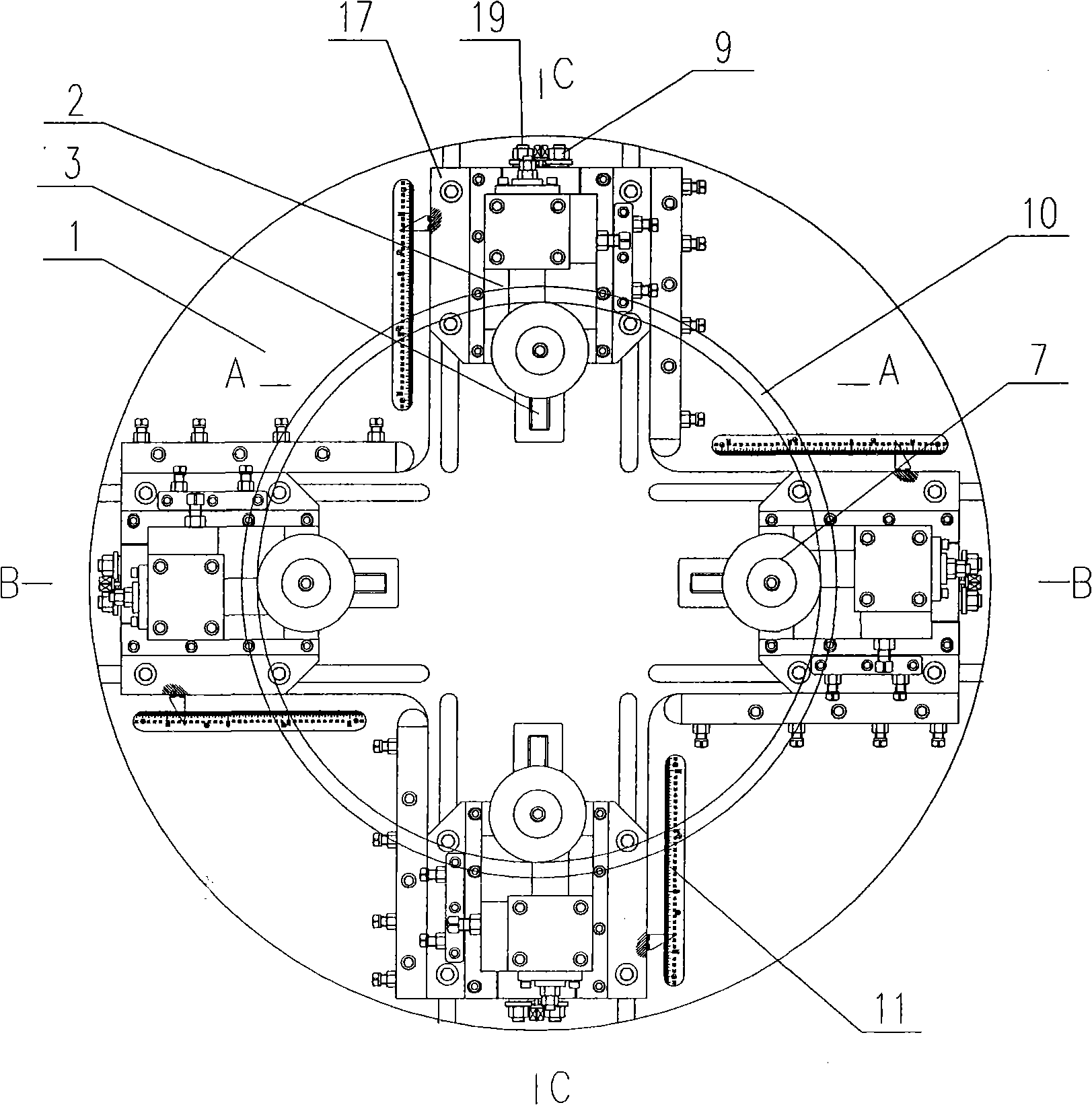

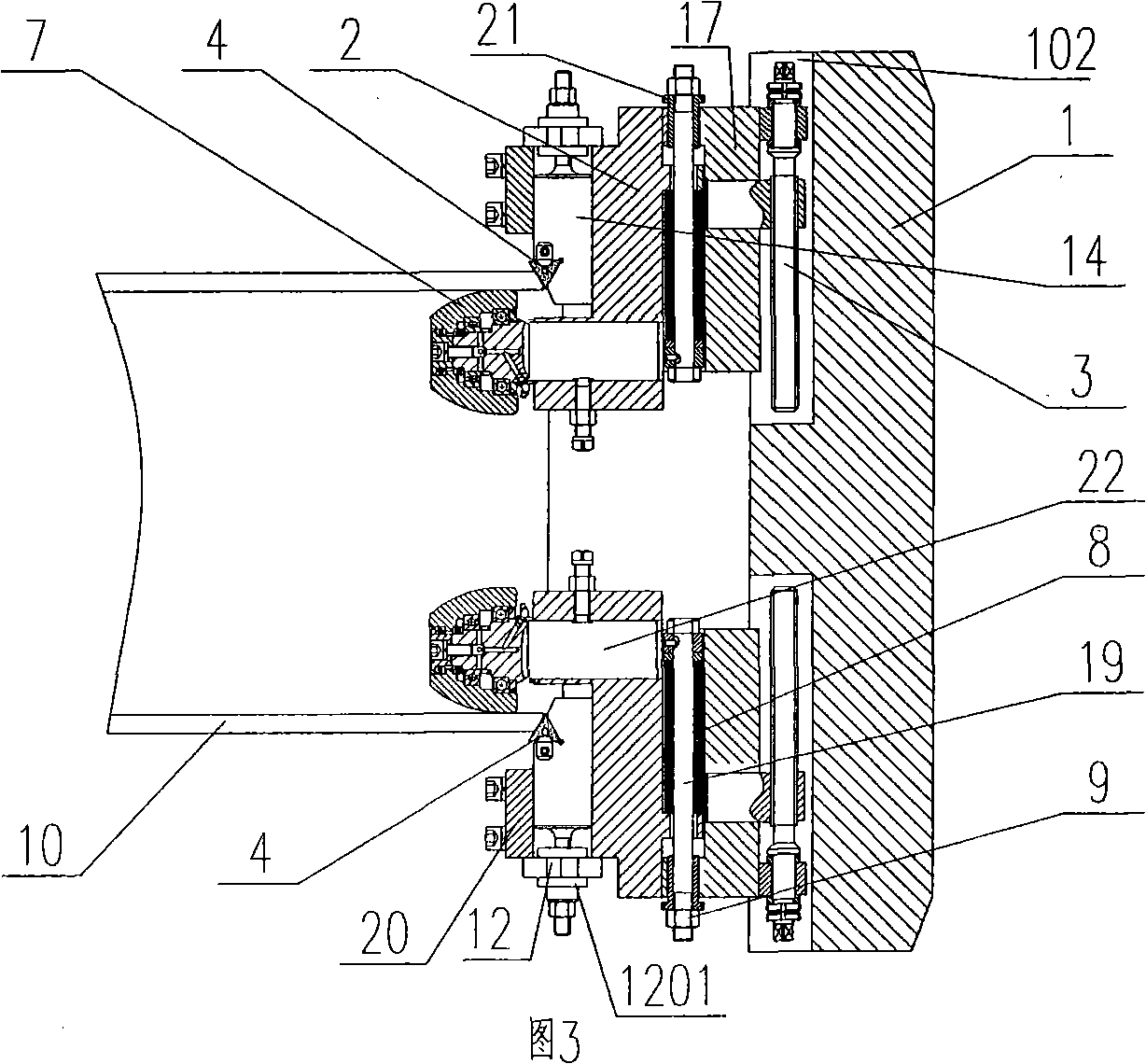

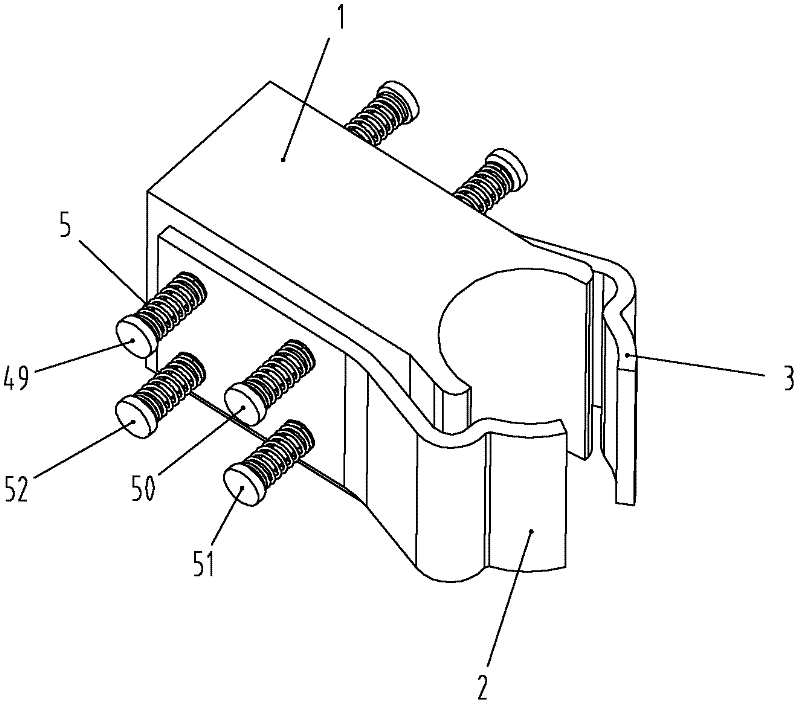

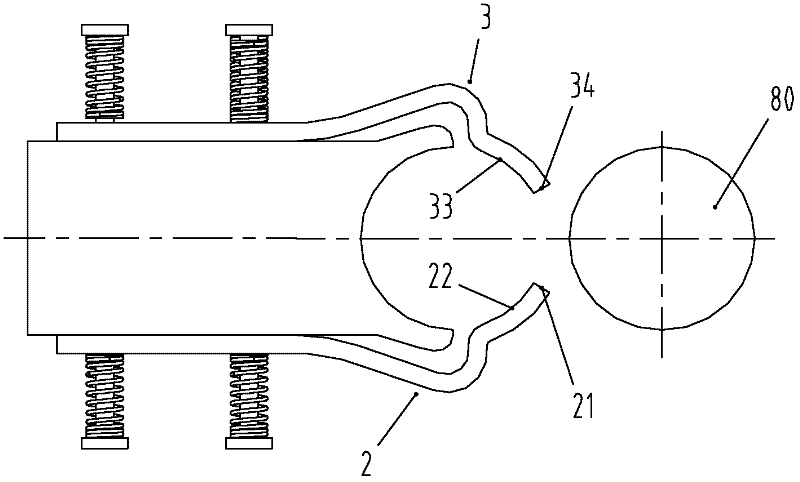

Adjustment method of inner-profile radial floating tool rest and tool

InactiveCN101357404AEat evenlyUniform turningAuxillary equipmentCopying process control systemsProduction lineEngineering

The invention relates to an internal profile modeling tool apron which is used in a steel pipe flat-end-face chamfering device in a large-dimensional and straightly welded seam pipe production line and floats along the radial direction; the tool apron comprises a cutter head, of which the end face are symmetrically provided with four sliding base bodies along the radial direction; each sliding base body is provided with a floating tool apron by a connecting screw rod; a cutter is vertical to the side wall of a steel pipe and arranged on the outer end of the floating tool apron, namely, the end far from an axis; the rear part of the cutter is provided with screw threads which are connected with a cutter adjusting mechanism; the end faces and the middle part of the sliding base bodies are provided with a spring slots; a plurality of dish-shape springs are sheathed on the connecting screw rod and arranged in the spring slots; the outer end of the connecting screw rod is provided with a spring adjusting nut; floating stroke adjusting nuts are arranged on the connecting screw rod and at the inner end of the spring adjusting nut; a profile modeling rolling is arranged at the inner end of the floating tool apron and rolls against the interior wall of the steel pipe; the position of the cutter and the steel pipe wall are relatively fixed, thereby simultaneous penetration of four cutters on the cutter head, even turning, no easy collision of the cutters and high production efficiency are ensured. The invention also relates to an adjusting method of the cutters.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

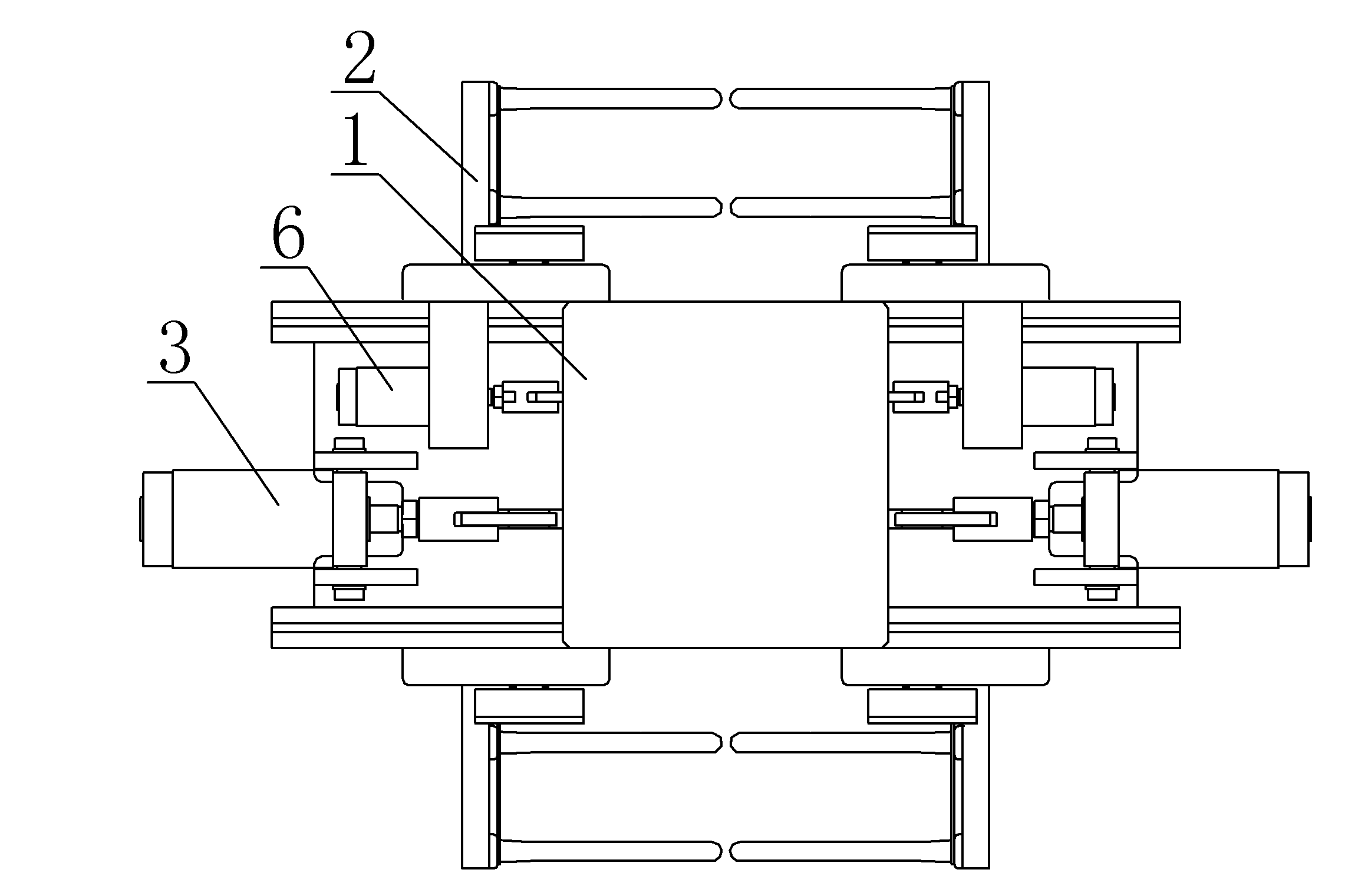

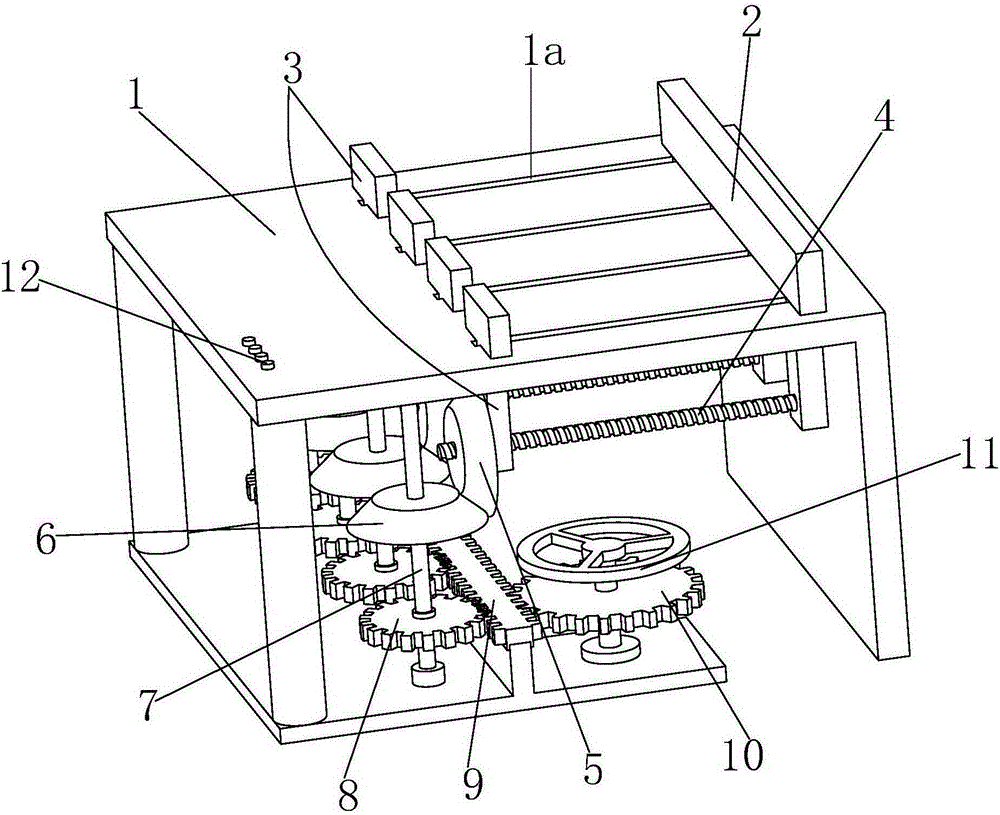

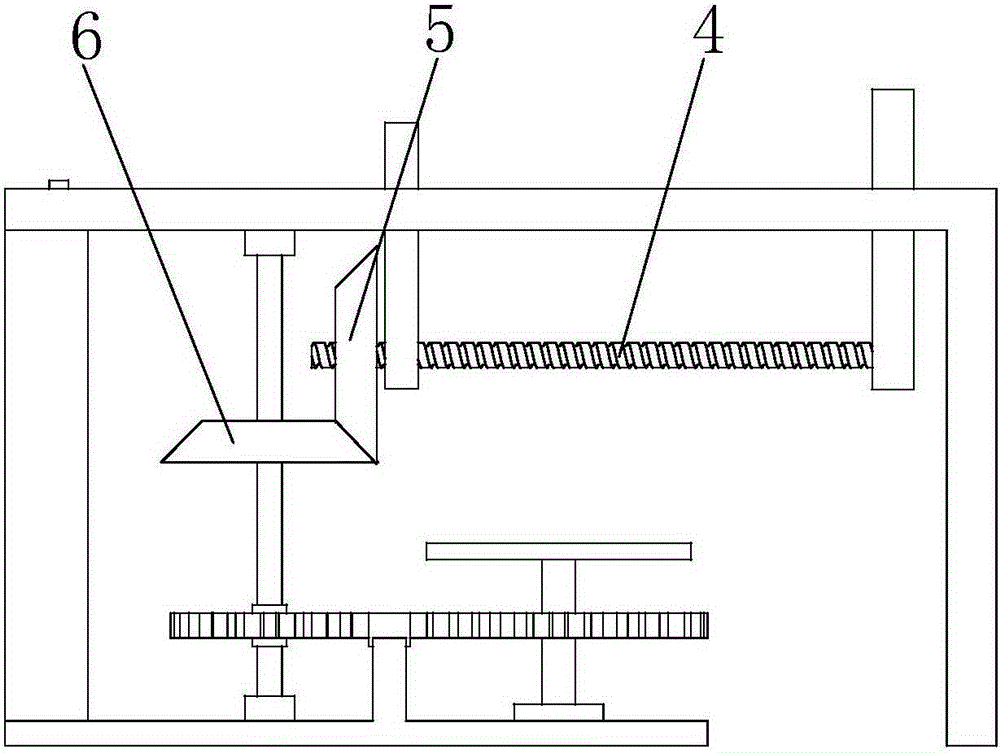

Fixture for milling end faces of workpieces in batches

InactiveCN105269356AEffective control quantityEasy to control the number of milling operationsPositioning apparatusMetal-working holdersBall screwOperation mode

The invention relates to a fixture for milling end faces of workpieces in batches. The fixture mainly comprises a workbench, wherein four sliding grooves are formed in the workbench in front and back; a positioning plate block is arranged at the right ends of the sliding grooves; clamping plates are mounted in the sliding grooves in a sliding manner; the lower ends of the clamping plates are connected with ball screws horizontally arranged; the left ends of the ball screws are connected with bevel gears I; the bevel gears I are meshed with bevel gears II; the bevel gears II are connected with rotating shafts; the lower parts of the rotating shafts are connected with clutch gears; the right ends of the clutch gears are meshed with a double-side rack mounted below the workbench in the manner of sliding front and back; the right end of the double side rack is meshed with a driving gear; and the driving gear is connected with a rotary table. The fixture provided by the invention not only has the function of quickly clamping multiple workpieces at one time in a convenient and rapid operation mode and a gear meshing transmission mode, but also can effectively control the number of clamped workpieces and further can indirectly realize the effects of controlling milling number of workpiecess and increasing the processing speed.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

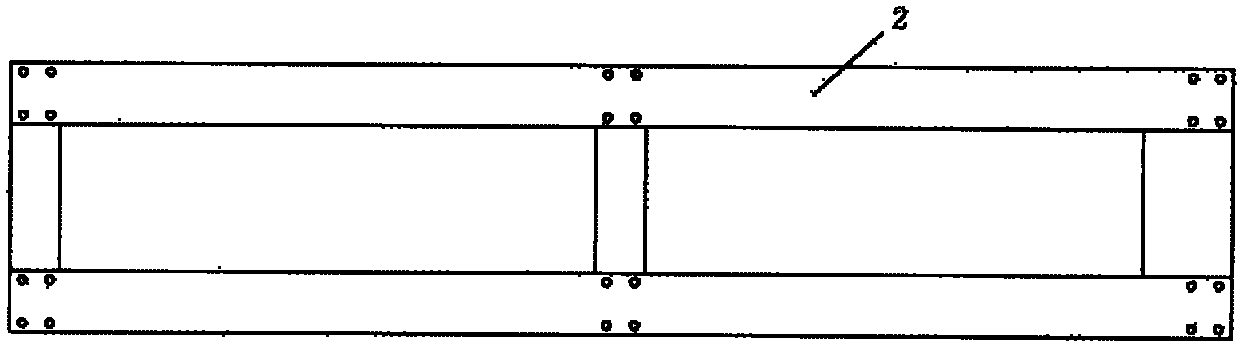

Board centering conveying mechanism

The invention relates to a board conveying mechanism, in particular to a board centering conveying mechanism and a board centering conveyor with the board centering conveying mechanism. The board centering conveying mechanism comprises four guide rail fixing rods, two guide rails, four sliding blocks, four connecting rods, a pull rod, a nut, a screw rod, a motor, centering pulley mounting bases, pulleys and sliding wheel shafts. According to the board centering conveying mechanism and the board centering conveyor with the board centering conveying mechanism, in the board conveying process, centering is carried out directly, the jacking step is omitted, and centering operation and time are effectively reduced.

Owner:HENAN ZHIJIN NETWORK TECH CO LTD

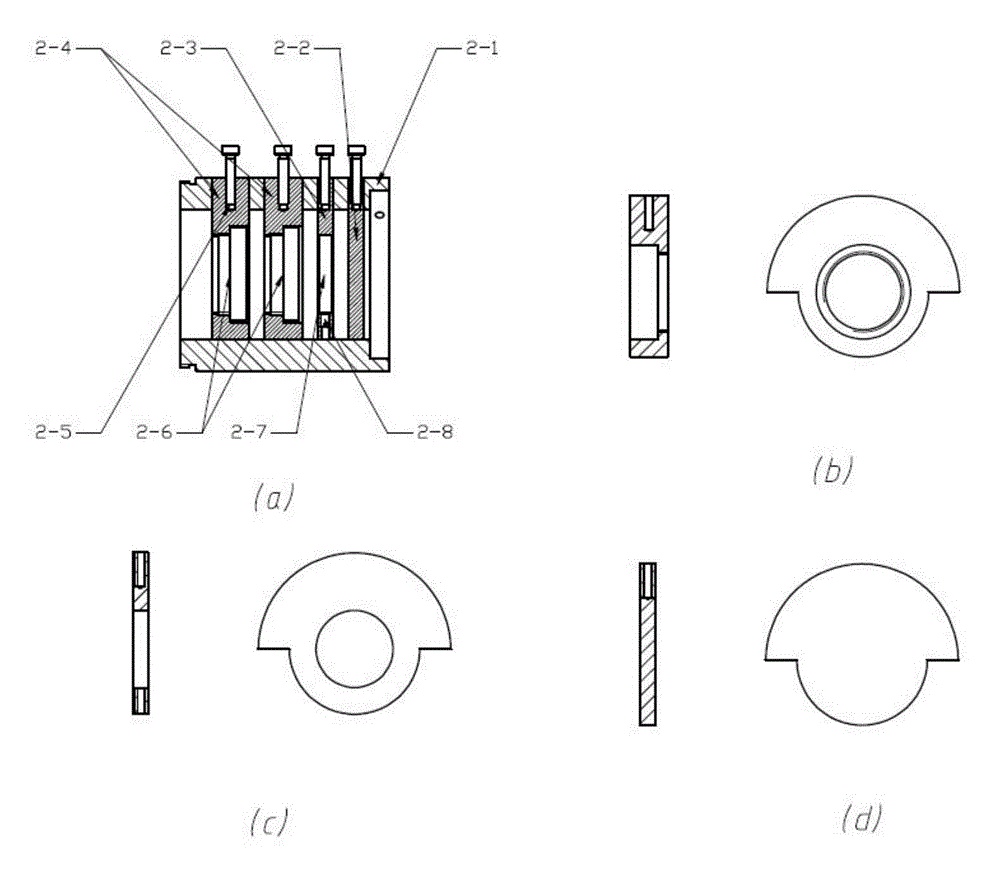

Novel rectangular flexible four-jaw chuck

The invention discloses a novel rectangular flexible four-jaw chuck. The four-jaw chuck comprises a rectangular chuck body, four linkage jaws, four middle steering blocks, four screws and four sliding jaws, wherein the rectangular chuck body is fixedly arranged on a base, the four linkage jaws are distributed on the chuck body by forming a 90-degree angle and are driven by a scroll, the middle steering blocks are movably arranged on the linkage jaws, the sliding jaws are matched with the screw, the screws are arranged in arc grooves at the upper ends of the middle steering blocks, retaining collars fixed on the middle steering blocks limit axial motion of the screws, gear teeth are arranged at the outer edge of the scroll, and a small serrated shaft in driving mesh with the gear teeth is perpendicularly arranged on the chuck body. By adjusting the serrated shaft to realize linkage, the novel rectangular flexible four-jaw chuck is more convenient to operate, the integral height of the chuck is reduced, available height of a Z-axis of a machine tool is increased, and the chuck is higher in practicality. Meanwhile, the chuck enhances reliability in clamping irregular larger workpieces through the additional jaws, and application range thereof is enlarged.

Owner:SOUTH CHINA UNIV OF TECH

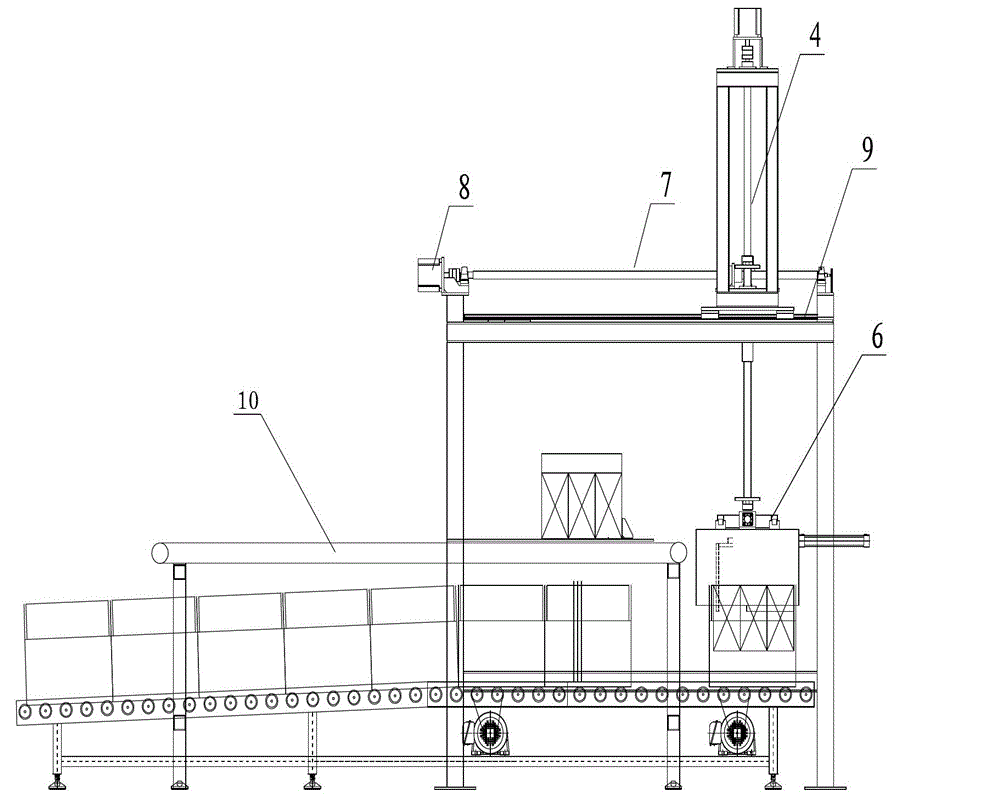

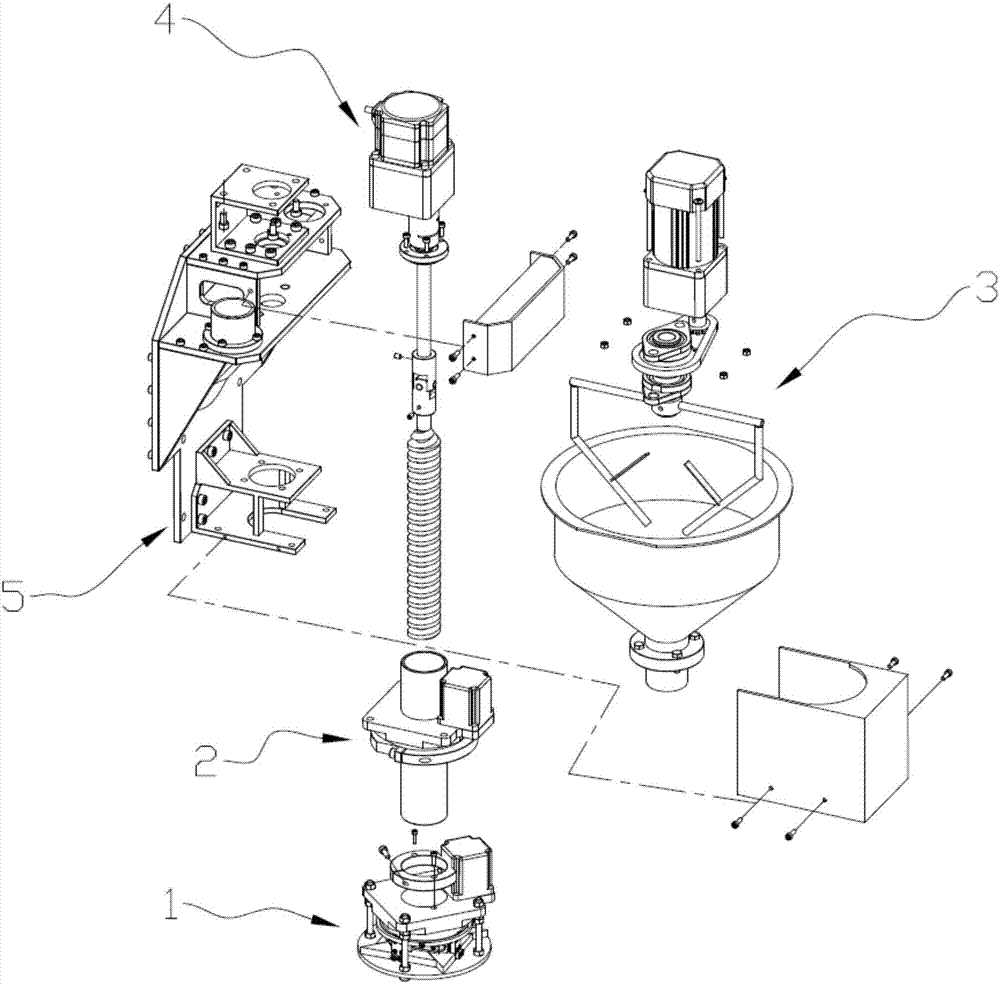

Box-packed white wine automatic incasing machine

InactiveCN103332313AKeep it steadyGuaranteed adaptabilityIndividual articlesOptical axisElectric machinery

The invention relates to a box-packed white wine automatic incasing machine which comprises a case conveying roller way, a machine frame, a box-packed white wine arraying mechanism, a horizontal-moving lifting system, a case propping mechanism, a gripper, a screw rod, a servo motor, two square guide rails and a box-packed white wine conveying chain plate. An incasing platform, the screw rod, the servo motor and the two square guide rails of the box-packed white wine arraying mechanism are respectively arranged on the machine frame. Four sliding blocks of the horizontal-moving lifting system are matched with the two square guide rails arranged at the upper end of the machine frame. One end of screw rod is connected with the servo motor, and a horizontal-moving lifting support of the horizontal-moving lifting system is arranged on the screw rod in a penetrating mode and fixed with the screw rod through a nut. The gripper is connected with the lower ends of two optical shafts of the horizontal-moving lifting system, and the box-packed white wine conveying chain plate and the case conveying roller way are fixed on the ground and matched with the box-packed white wine arraying mechanism, the horizontal-moving lifting system, the gripper and the case propping mechanism to achieve the function of box-packed white wine incasing. The box-packed white wine automatic incasing machine has the advantages of being wide in applicable white wine box type, accurate in incasing positioning, large in transport load, stable in performance and the like, and the difficult incasing problem which troubles the white wine industry for years is solved.

Owner:WUHAN AUTOMATED ELECTROMECHANICAL TECH

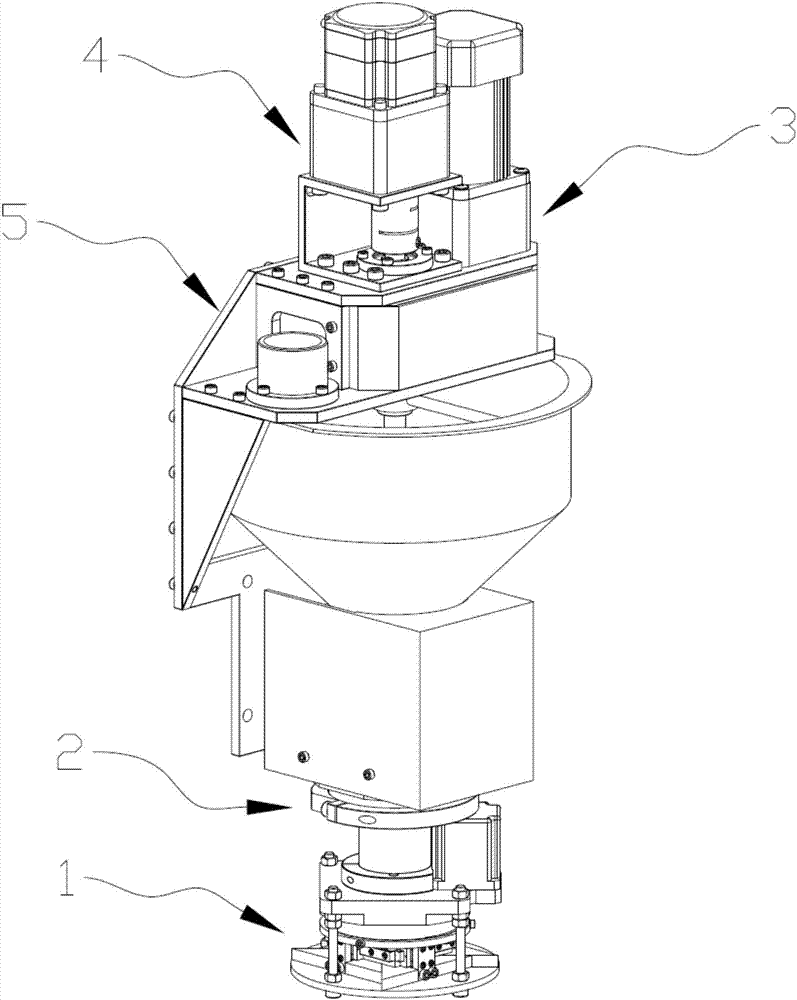

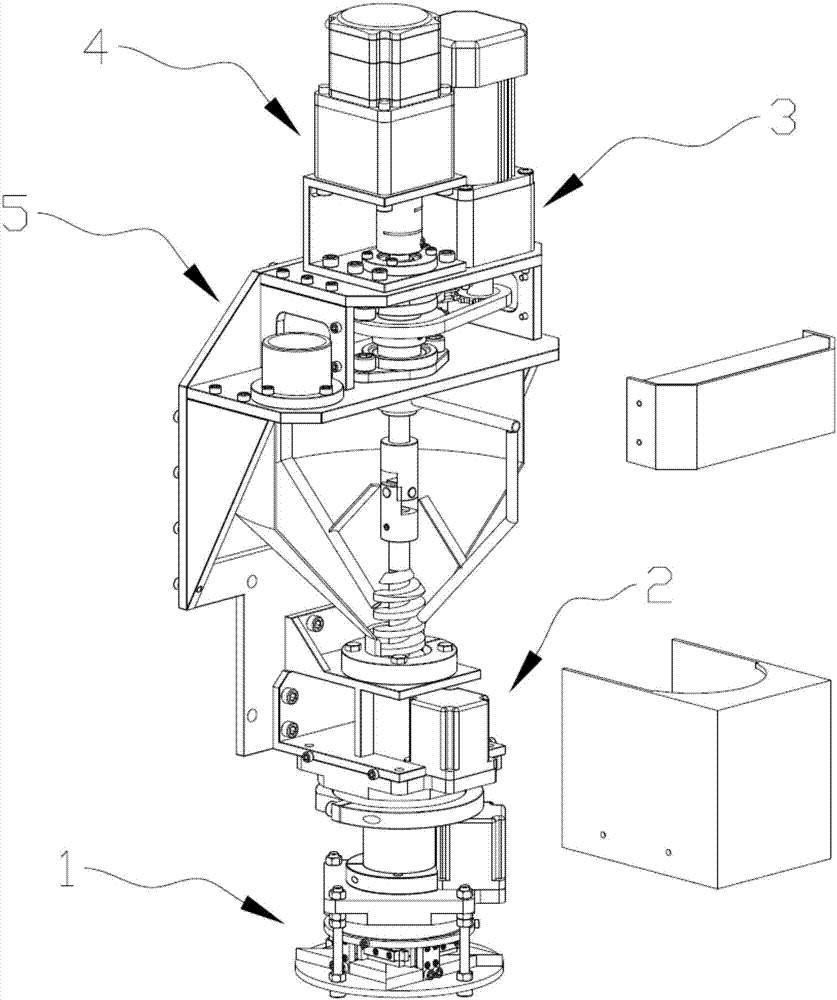

Reducing spray head and extrusion device for building 3D printing

ActiveCN107042632ALarge caliberNo need to extend the stayCeramic shaping apparatusApplying layer meansSpray nozzleEngineering

The invention discloses a reducing spray head for building 3D printing. The reducing spray head comprises a rotary shifting disc, a bottom plate, four linear guide rails, four sliding blocks and four right-angle moving sheets; when relative rotation occurs between the rotary shifting disc and the bottom plate, the rotary shifting disc drives four driving parts to rotate synchronously through four driving grooves, and then drives the four sliding blocks to synchronously slide along the four linear guide rails, and the four sliding blocks drive the four right-angle moving sheets to synchronously make relative movement, thereby changing the size of a square nozzle by changing relative positions of the four right-angle moving sheets in a printing process. A large-area region is printed, the size of the square nozzle can be enlarged and a discharge speed is raised, so that no repeated printing is required, the dwell time of the reducing spray head at such place is not required to be prolonged, and the printing efficiency is improved accordingly.

Owner:HUAZHONG UNIV OF SCI & TECH

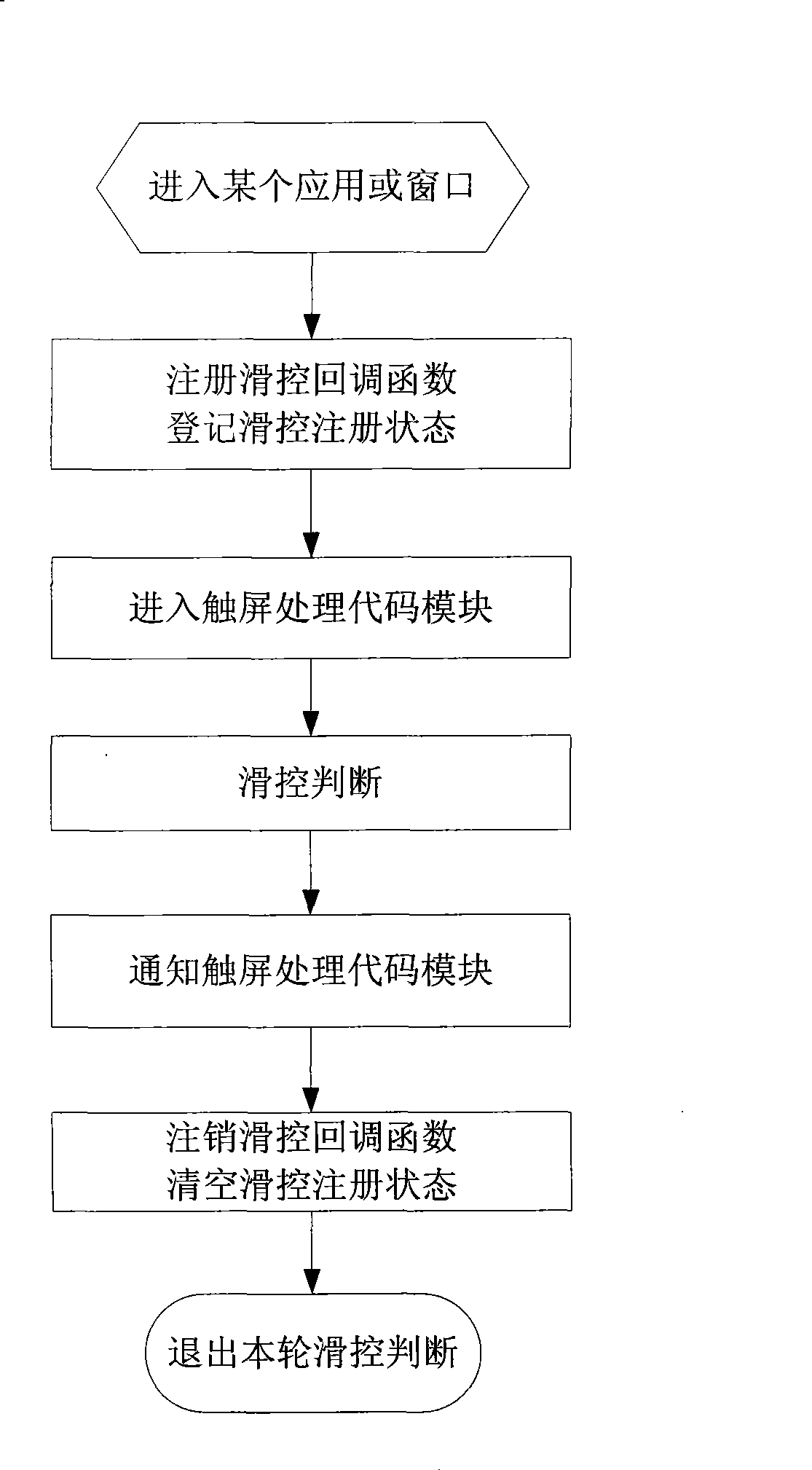

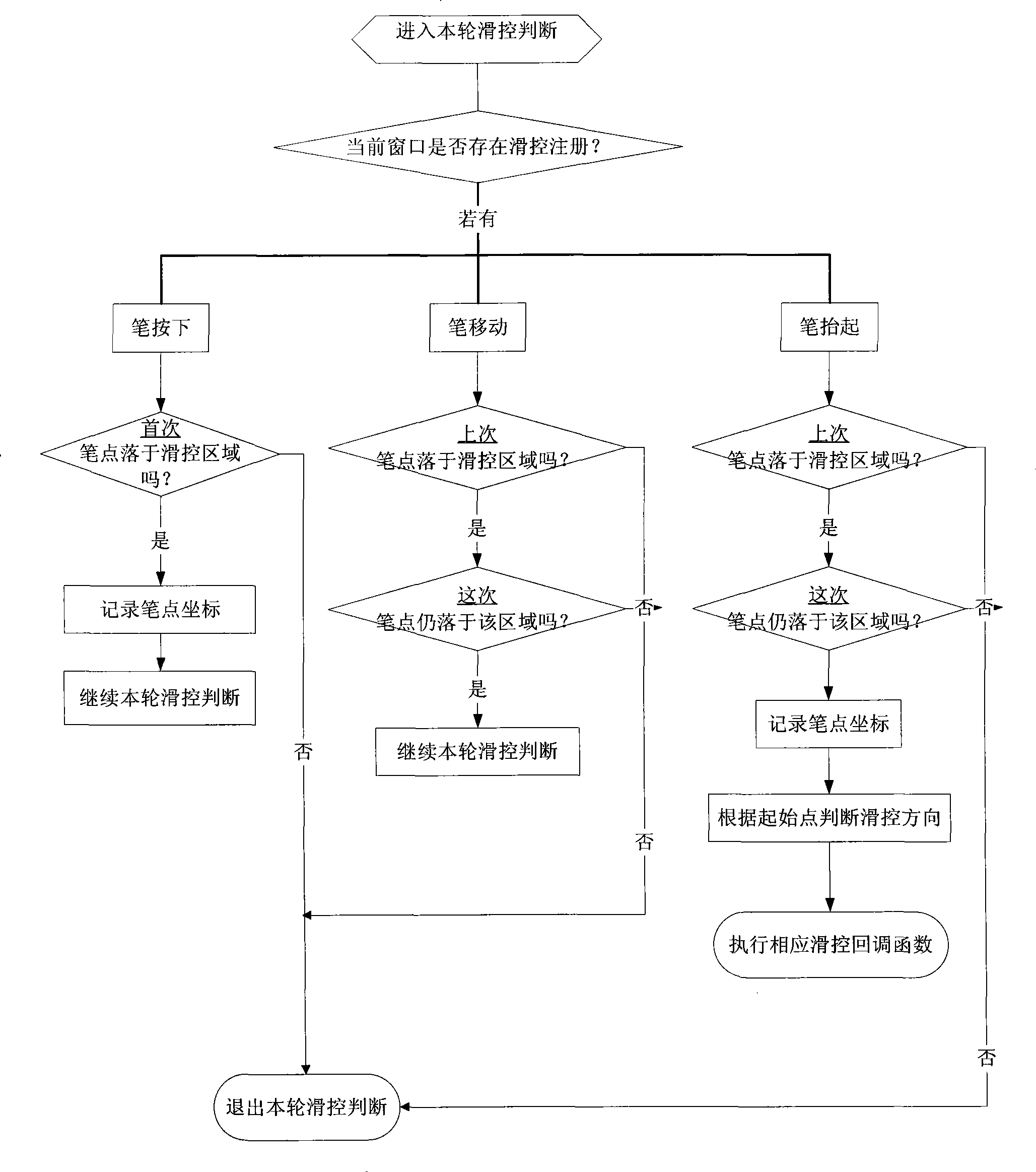

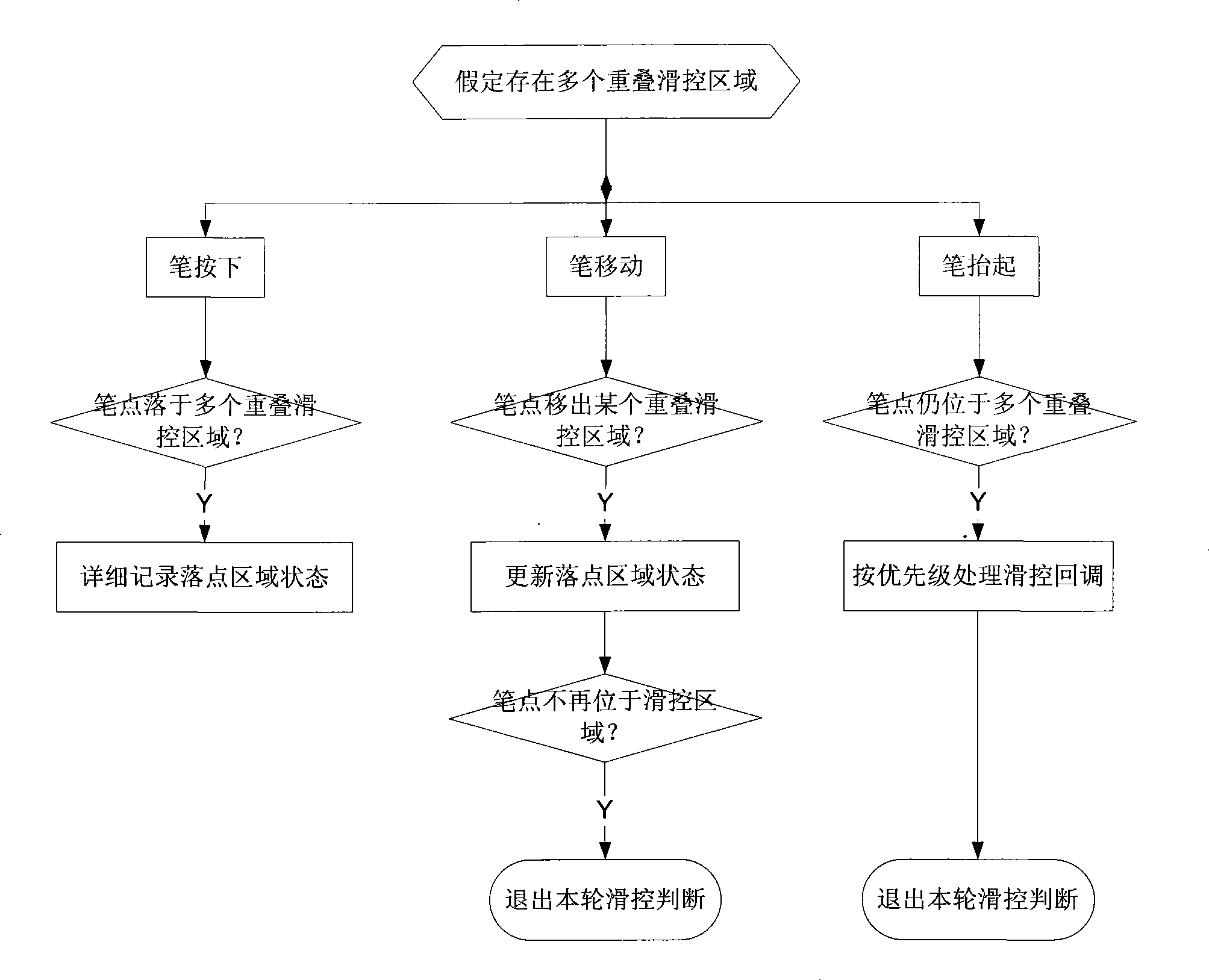

Implementing method of sliding control in terminal human-computer interaction

InactiveCN101398732AEasy to operateAccurate operationInput/output processes for data processingApplication softwareTouchscreen

The invention relates to a method for realizing sliding control in terminal human-machine alternation. A sliding module judges data sent by a touch screen to determine control direction and area, so as to realize corresponding control operation. The control operation is corresponding to four directions including upwards sliding control, downwards sliding control, leftwards sliding control and rightwards sliding control, and the four sliding control operations can be registered to a sliding control module synchronously in each application. The method enriches the touch screen human-machine interaction modes and provides the condition for increasing new functions to terminal application software, and the method provides intuitive and fast effect which point touch operation can not compare with in specific terminal application.

Owner:NUBIA TECHNOLOGY CO LTD

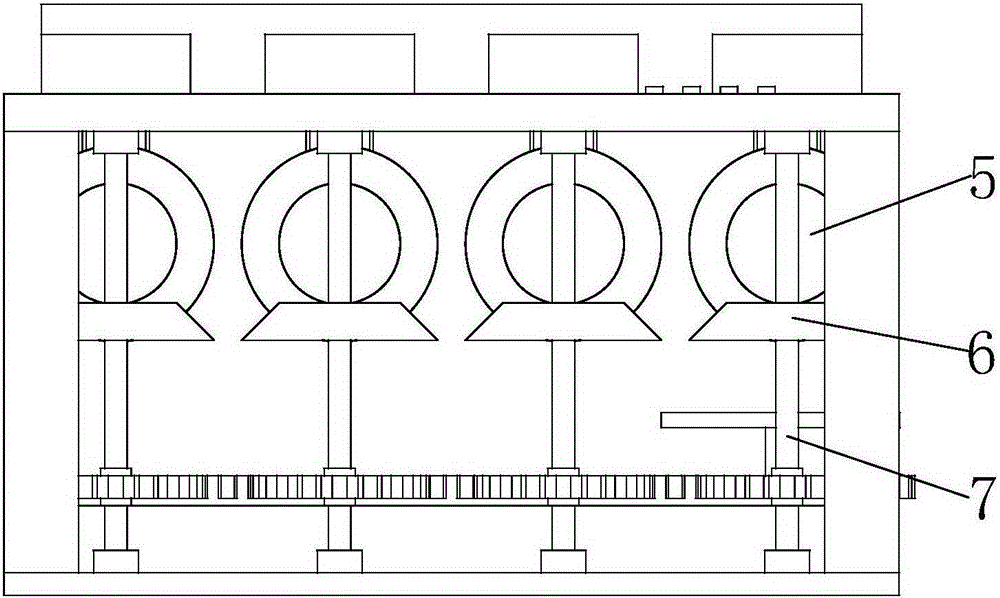

Wheel mold spraying apparatus

ActiveUS20170182551A1Uniform and consistent spraying effectReduce labor intensityLiquid surface applicatorsSpraying apparatusMotor driveSlide plate

The present invention discloses a wheel mold spraying device, which is composed of a frame, a servo motor, a servo electric cylinder, a hollow shaft, a nozzle and the like. Four side molds of a wheel are respectively placed on four slide plates; hand wheels are rotated to adjust the slide plates to proper positions through lead screws and guide rails; the servo motor drives the rotation of the hollow shaft and the nozzle through belt wheels and a synchronous belt, and the nozzle is automatically opened; and through guide posts, the servo electric cylinder lifts the nozzle to the top end while rotating, in which case the process of spraying for the four side molds can be completed.

Owner:CITIC DICASTAL

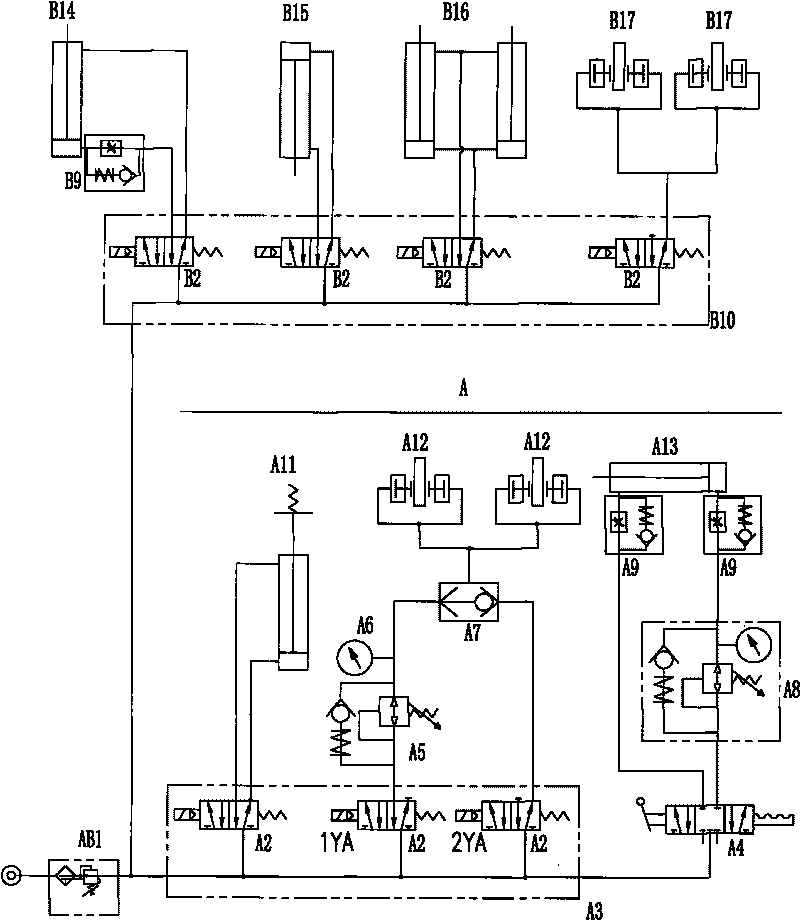

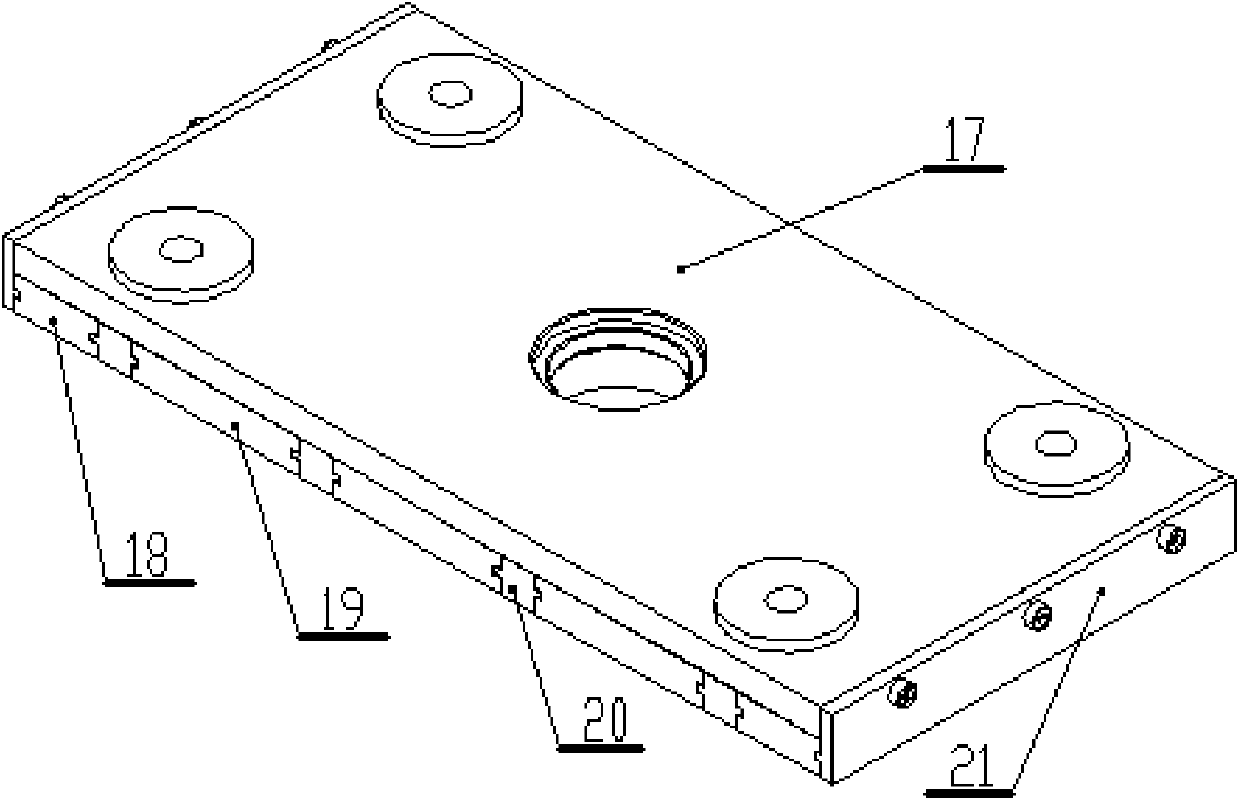

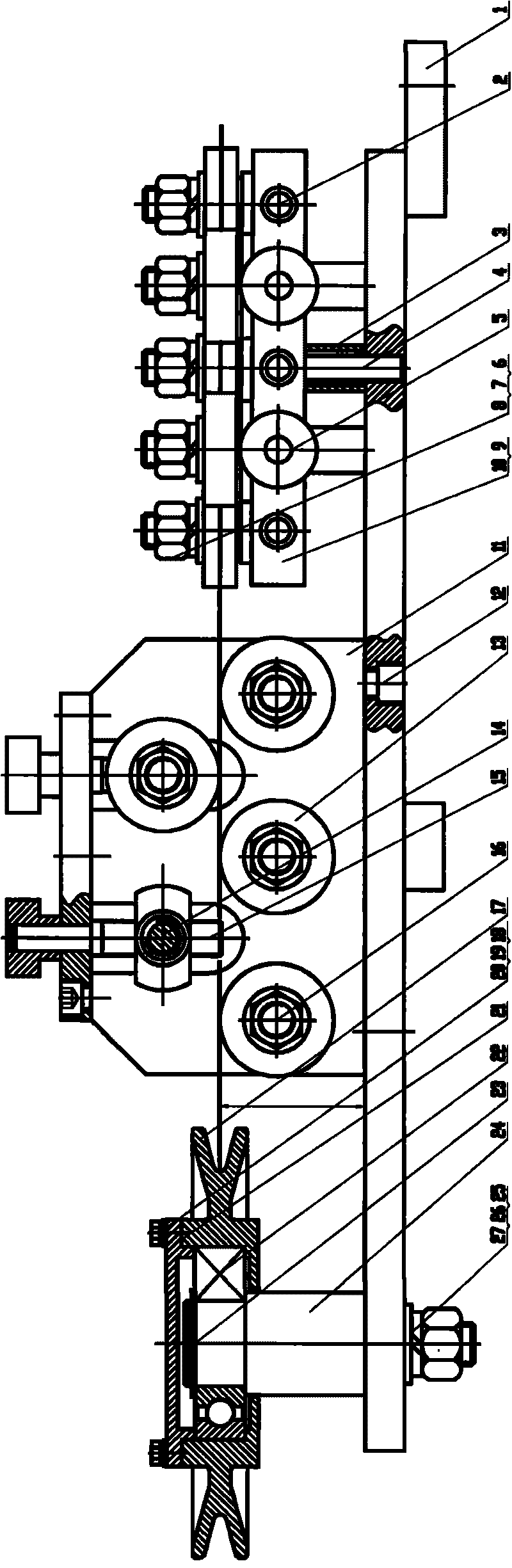

Hydraulic connection operating platform of grounding wires

The invention relates to a hydraulic connection operating platform of grounding wires, belonging to a machine tool for carrying out hydraulic connection on two electric grounding wires by using a crimping pipe. Two rails are erected on a platform base in parallel; two grounding wire support bases are arranged at the left side and the right side of the two rails by sliding blocks; a pair of hydraulic pliers are fixed in a fixed ring through a plurality of fastening bolts; the fixed ring is welded on a mounting plate; the mounting plate is arranged on the two rails through four sliding blocks arranged the lower part of the mounting plate; a stepping motor is arranged on the platform base; a ball screw is connected with the stepping motor through a shaft; the ball screw is arranged below the platform base through two sliding rail supports and spirally connected to a screw nut; and the screw nut is fixed on the bottom surface of the mounting plate. The hydraulic connection operating platform disclosed by the invention has the characteristics of simple structure, safety and reliability, controllable lapping length of the two grounding wires and high crimping efficiency.

Owner:SICHUAN POWER TRANSMISSION & TRANSFORMATION CONSTR +1

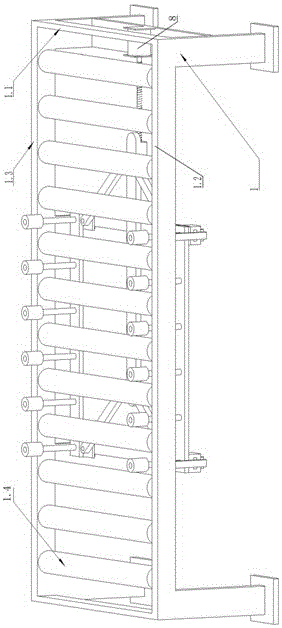

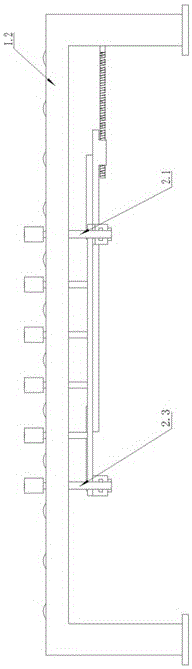

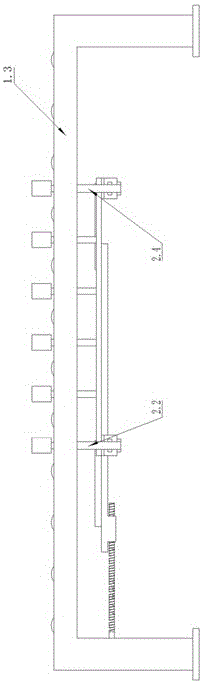

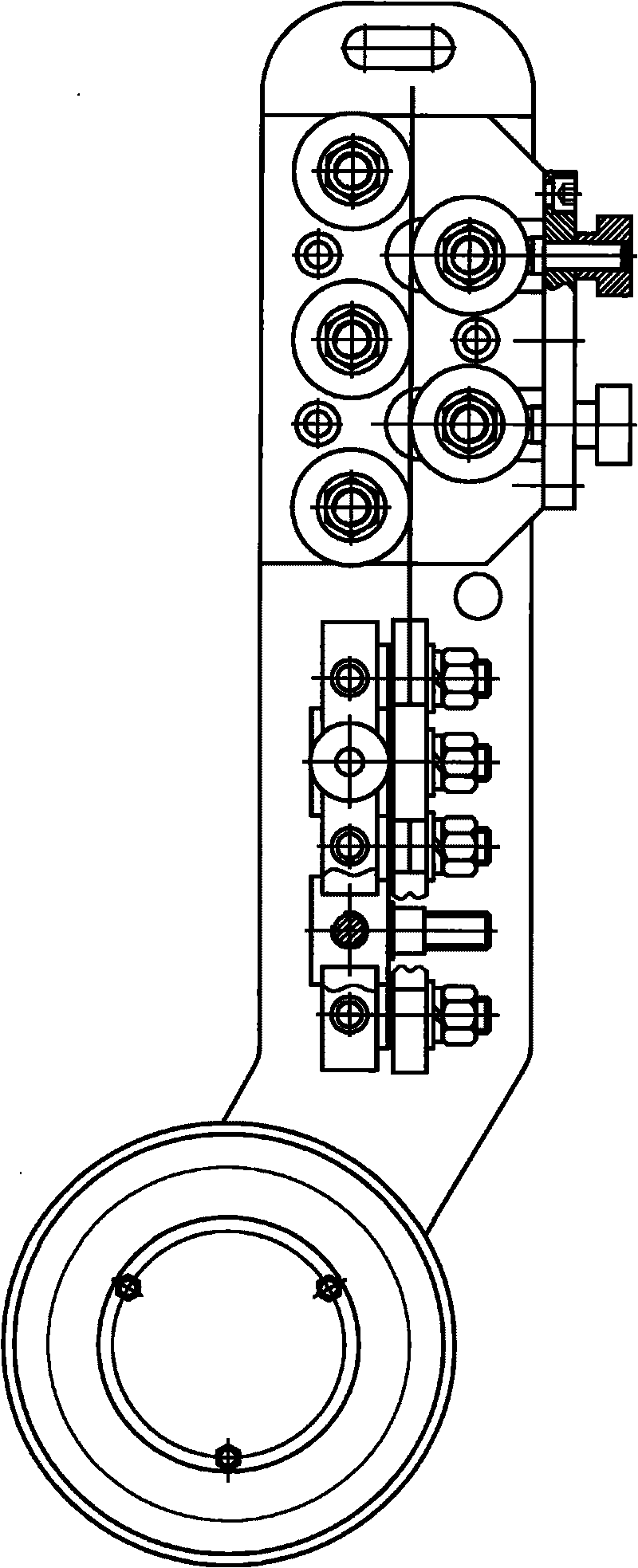

Straightening mechanism on wire drawing machine

The invention relates to a straightening mechanism on a wire drawing machine, particularly used for straightening a steel wire before the wire drawing machine draws the steel wire and belonging to the field of wire drawing in the production of metal products. The straightening mechanism is characterized in that a steering guide wheel shaft is arranged on a straighter baseplate and fixed with a bearing, a steering guide wheel is sleeved outside the bearing, a steering guide wheel cover covers the steering guide wheel, and then a transverse main plate and a vertical main plate are connected to the straighter baseplate by inside hexagonal bolts, ten straightening wheels and ten shafts are respectively arranged on the transverse main plate and the vertical main plate, wherein the ten shafts comprise four sliding shafts and six fixed shafts, the ten straightening wheels are respectively arranged on the four sliding shafts and the six fixed shafts, and a press plate and the transverse main plate are connected by inside hexagonal bolts. The invention is simple, compact and reasonable in structure; the regulation function is designed on the straightening wheels, which is convenient to regulate and straighten, has good straightening effect and can not influence next drawing.

Owner:WUXI PINGSHENG SCI & TECH

Ball screw assembly precision retaining ability testing device

ActiveCN103115770AGuaranteed CompatibilityGuaranteed stabilityMachine gearing/transmission testingValue passingCoupling

The invention discloses a ball screw assembly precision retaining ability testing device. A motor and a gearbox are arranged on a head frame supporting plate. An output shaft of the gearbox is connected with a dynamic torque sensor. The dynamic torque sensor is connected with the tested ball screw assembly through a coupling. A circular magnetic grid is arranged on the coupling. The circular magnetic grid is connected with the tested ball screw assembly. The head portion and tail portion of the tested ball screw assembly are fixed in a supporting mode through a head frame and a tail frame. An eddy current brake is connected with the gearbox and is connected with a load component. The load component comprises two duplex pulley blocks, two duplex coiling blocks and three gears. Steel wire ropes on the coiling blocks transmit damping to the nut of the tested ball screw assembly through a nut supporting board. The supporting board is fixedly connected with the matched nut of the screw assembly. Four sliding blocks are arranged on the lower sides of the two sides of the supporting board and enable the supporting board to slide on a guild rail fixed on a bed body. A tail frame supporting board is arranged on a flat-V guide rail of the tail portion of the bed body. In work, the eddy current brake provides load, through adjusting the current value passing through eddy current brake, simulation of the ball screw assembly working condition can be achieved.

Owner:NANJING UNIV OF SCI & TECH

Non-cooperative target docking mechanism of forked frame

The invention relates to a non-cooperative target docking mechanism of a forked frame and solves the problem that during non-cooperative target docking in the prior art, no docking mechanism is capable of being docked with a spacecraft without standard docking ports. The non-cooperative target docking mechanism comprises a capture mechanism and a telescopic mechanism; the capture mechanism comprises a base, a bevel gear pair, a slide rail support, a first motor, an upper cover, a support, a first lead screw pair, three end gripper jaws, three first sliders, three first slide rails, three rotors and three four-connecting-rod mechanisms; the telescopic mechanism comprises a second motor, a second lead screw pair, an upper base, a lower base, four forked hinge supports and four slide components. The capture mechanism is disposed between the upper base and the lower base, the four-connecting-rod mechanisms penetrate the upper base, the end gripper jaws are arranged on the upper portion of the upper base, and the forked hinge supports and the slide components are circumferentially and uniformly distributed between the upper base and the lower base along the first lead screw pair. The non-cooperative target docking mechanism is applicable to docking of non-cooperative targets.

Owner:HARBIN INST OF TECH

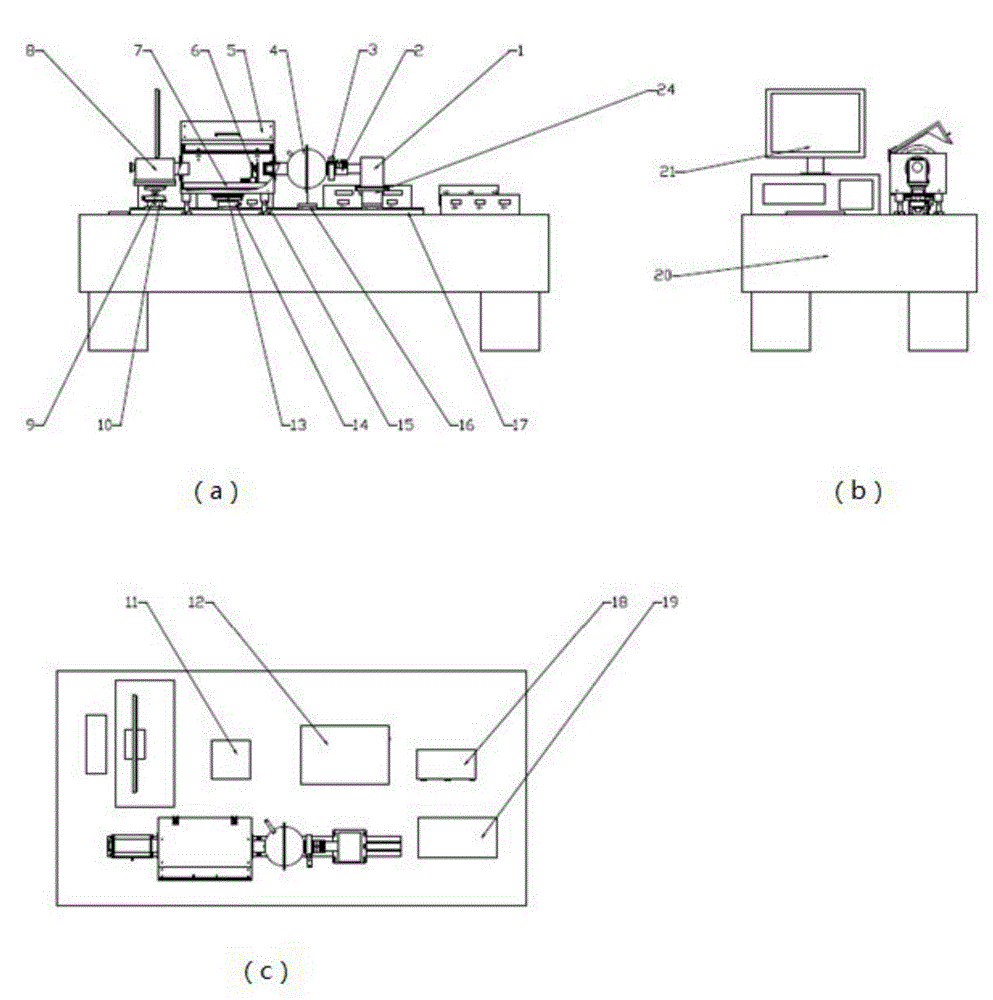

Testing device for radiation luminance gain of ultraviolet image intensifier

InactiveCN104614154AEasy to moveEasy to replaceOptical apparatus testingIndividual semiconductor device testingElectric power systemUltraviolet lights

The invention provides a testing device for the radiation luminance gain of an ultraviolet image intensifier. The testing device comprises an optical platform and a guide rail arranged on the optical platform, wherein four sliding blocks are arranged on the guide rail, and a light source device, an integrating sphere, a testing dark box and a photometer are arranged on the four sliding blocks in sequence. The light source device emits ultraviolet light, the integrating sphere converts the ultraviolet light into uniform light, the tested image intensifier is arranged in the testing dark box, the uniform light irradiates the cathode surface of the image intensifier, and the photometer measures luminance of a fluorescent screen of the image intensifier; the set heights of the integrating sphere, the testing dark box and the photometer enable light in the testing dark box to be located in a straight line; the tested image intensifier is powered by an external power source. The testing device can detect the radiation luminance gain of the ultraviolet image intensifier, is simple in structure, and has significance on providing technical support for development of a novel detection imaging technology and offering help to the fields of power system detection, the space science and environmental protection research.

Owner:NANJING UNIV OF SCI & TECH

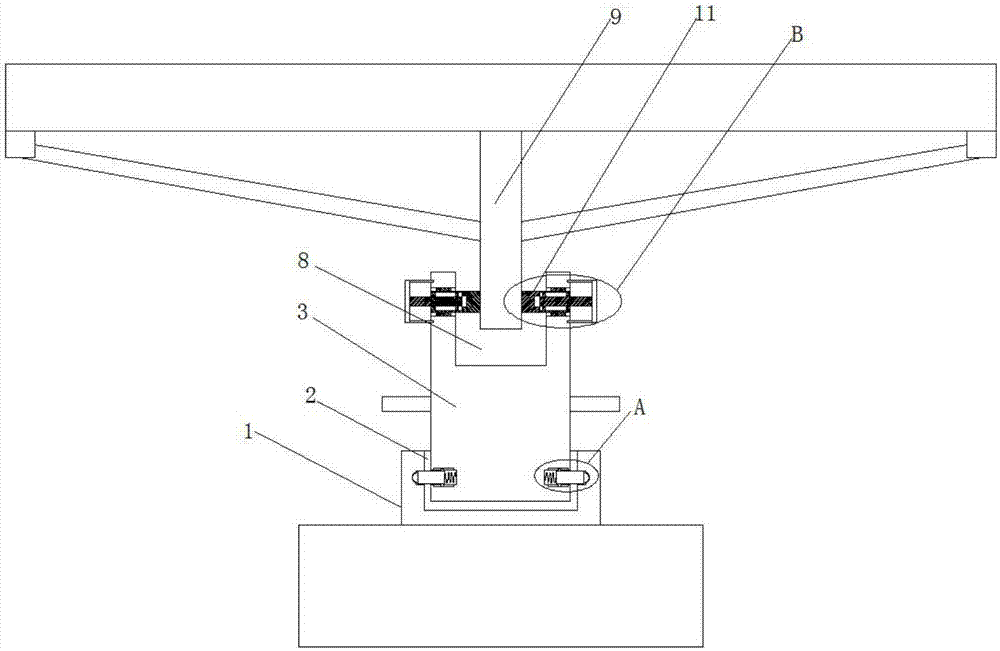

Solar power generation apparatus with multi-angle adjustment function

ActiveCN107294481AFast and accurate multi-angle adjustmentImprove angle adjustment efficiencyPhotovoltaic supportsSolar heat devicesEngineeringSolar power

The invention discloses a solar power generation apparatus with a multi-angle adjustment function. The solar power generation apparatus comprises a fixed base; a first groove is formed in the top of the fixed base; a supporting column is rotationally mounted in the first groove; one end of the supporting column extends to the outside of the first groove; four first circular grooves are formed in the periphery of the supporting column at equal distances; sliding rods are glidingly mounted in the first circular grooves; one ends of the sliding rods extend to the outside of the first circular grooves; a spring is welded on the inner wall on one side, far from the first circular groove opening, of each first circular groove separately; the springs and the corresponding sliding rods are welded and fixed; a sliding groove is formed in the inner wall of the first groove, and the section of the sliding groove is annular; and one ends, positioned outside the four first circular grooves, of the four sliding rods are all glidingly mounted in the sliding groove. By adoption of the solar power generation apparatus, the angles of solar panels in the solar power generation apparatus can be adjusted rapidly and accurately in a multi-angle manner, so that solar panel angle adjusting efficiency by an operator can be improved, and the angle adjustment accuracy is also improved.

Owner:合肥庭鸾能源有限公司

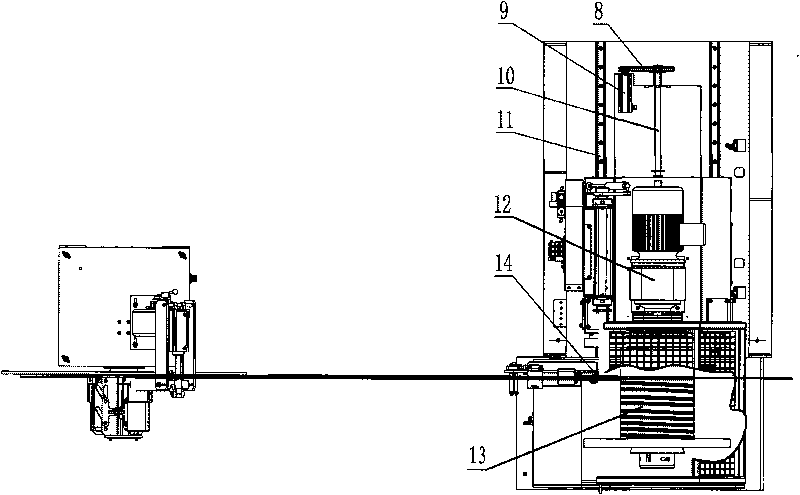

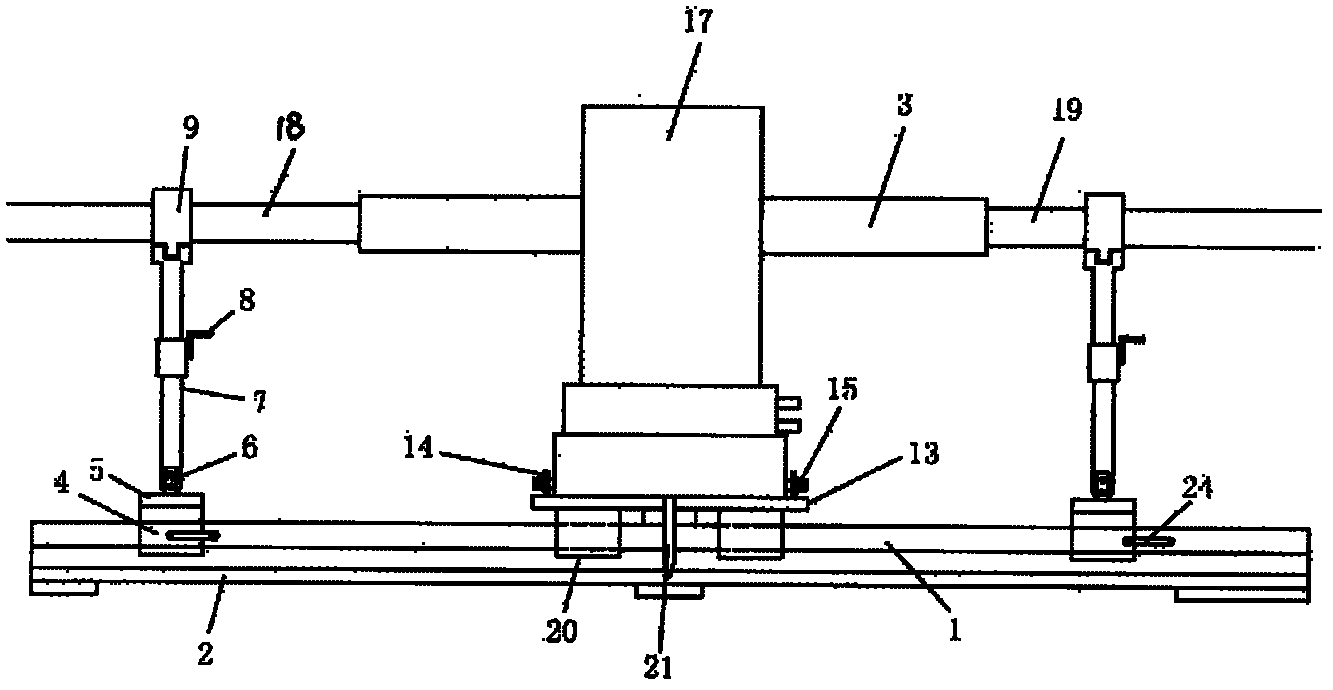

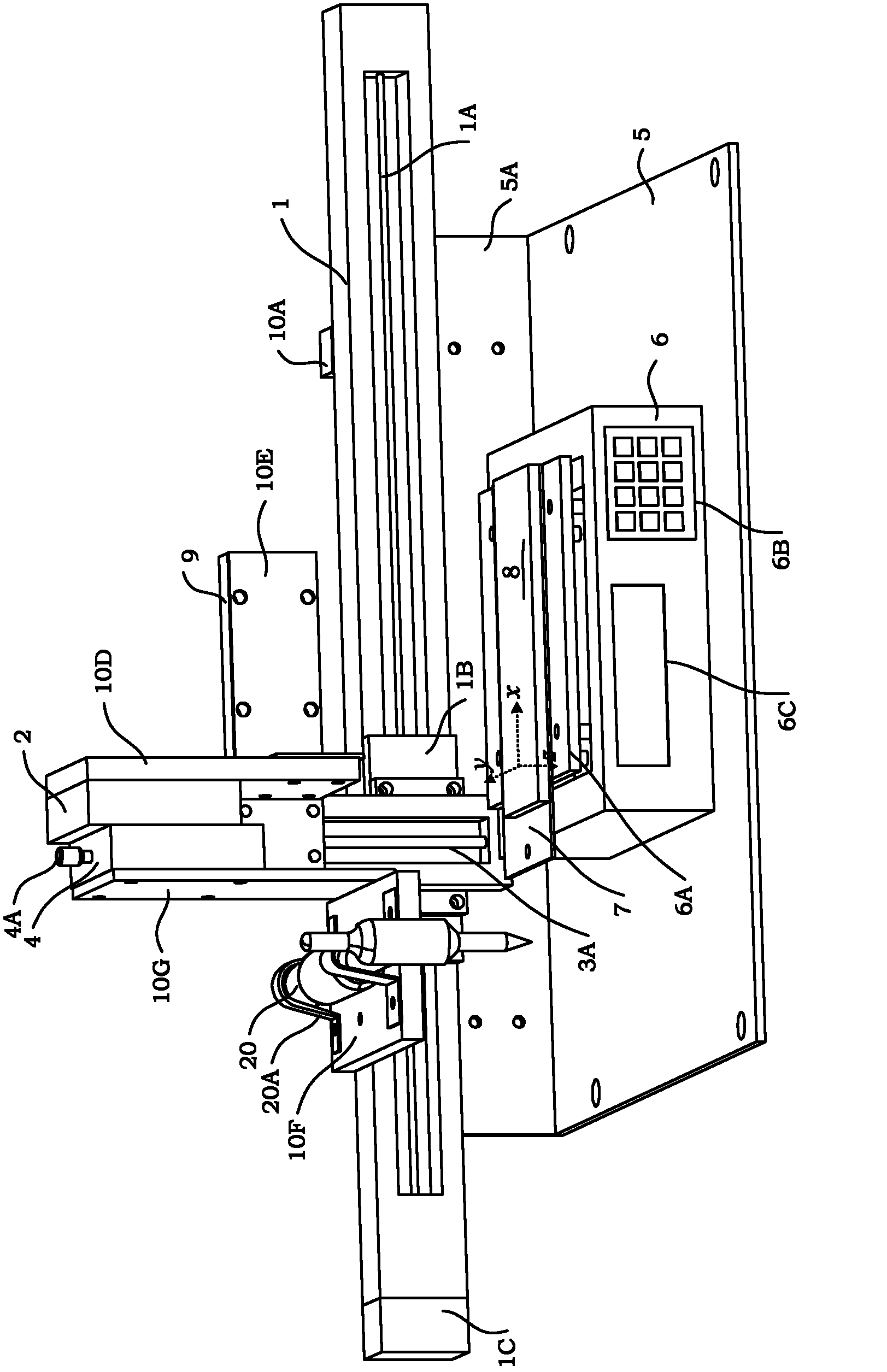

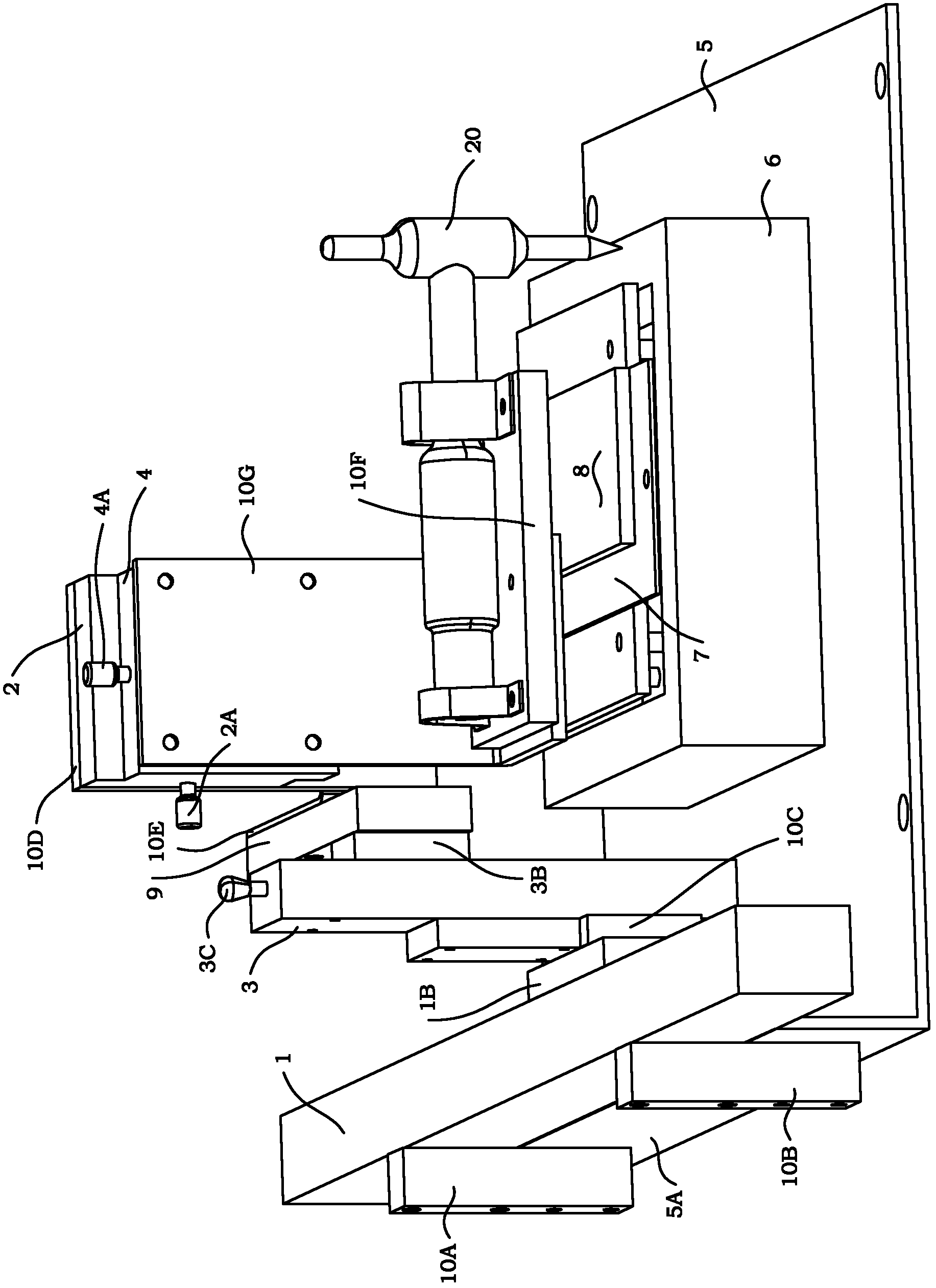

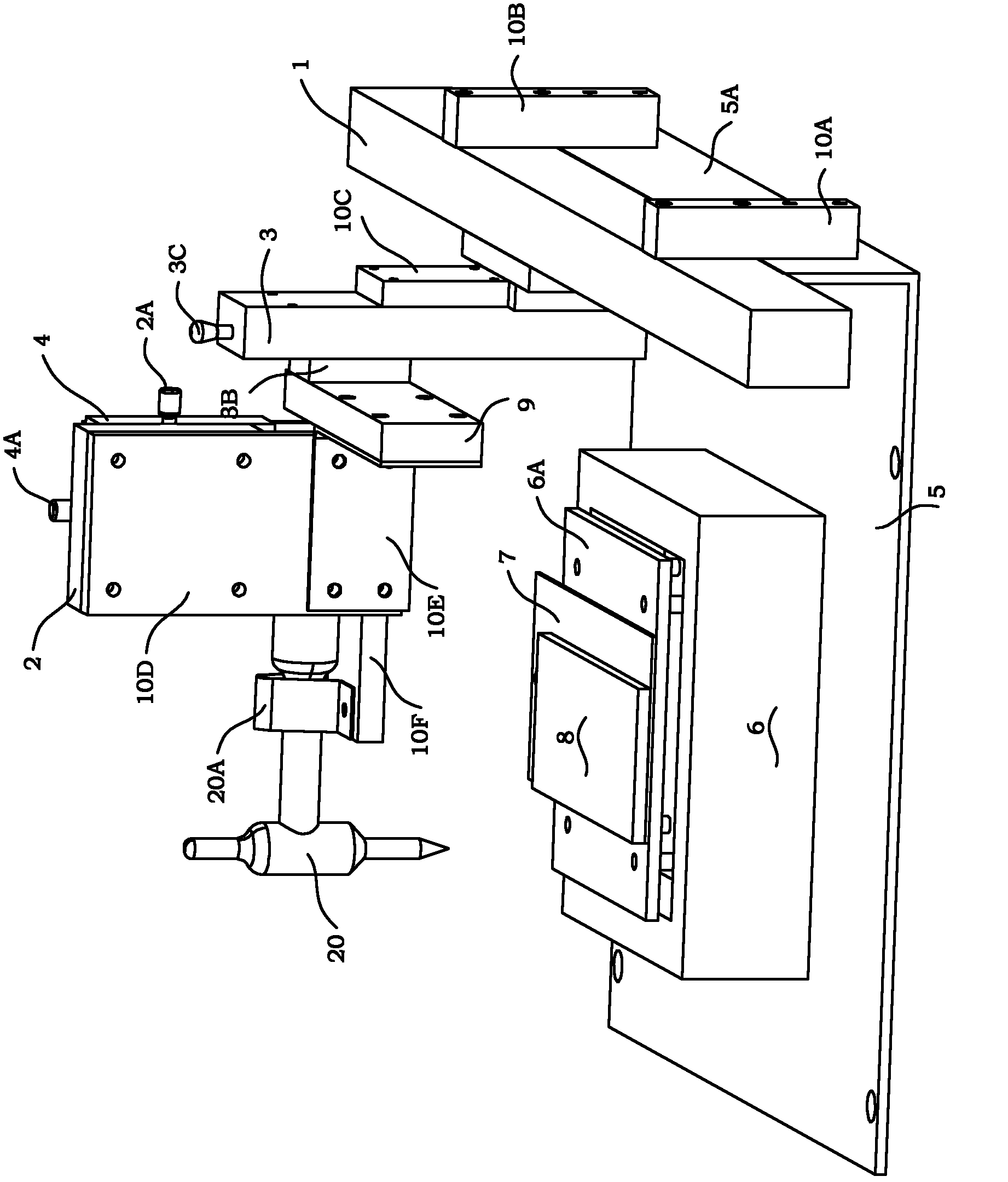

Platform for measuring average arc force of superaudio-frequency pulse TIG (Tungsten Inert Gas) welding

InactiveCN102528228AReal-time monitoring of arc force changesGuaranteed mutual positionArc welding apparatusMetallic materialsEngineering

The invention discloses a platform for measuring average arc force of superaudio-frequency pulse TIG (Tungsten Inert Gas) welding, wherein the measurement platform comprises a welding gun, an X-direction sliding table, a Y-direction sliding table, a Z-direction coarse-tuning sliding table, a Z-direction fine-tuning sliding table, a processing platform, a force measurement sensor, a balance weight and a plurality of support connection plates used for supporting and connecting. The measurement platform disclosed by the invention is mainly used for measuring the arc force of the superaudio-frequency pulse TIG welding, and the arc force measurement of superaudio-frequency pulse welding of common metal materials can be realized; on the basis of the matched movements of the four sliding tables, a three-freedom movement system of the welding gun is designed, the welding gun moves along the direction of a welding joint due to the X-direction sliding table, the top end of a tungsten electrode and the welding joint are subjected to centering control due to the Y-direction sliding table, the distance between the top end of the tungsten electrode and a workpiece is adjusted accurately by the coarse-tuning sliding table and the fine-tuning sliding table in the Z-direction, and the arc is kept to be highly constant during a welding test.

Owner:BEIHANG UNIV

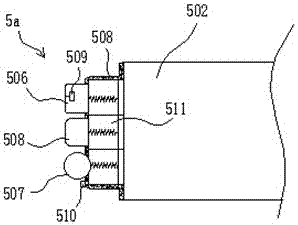

Smart home environment-friendly cleaning robot and working method thereof

ActiveCN107126156AAchieve daily cleaningProtect healthCarpet cleanersCleaning action controlDrive wheelHome environment

The invention discloses a smart home environment-friendly cleaning robot with higher cleaning ability and a working method thereof. The smart home environment-friendly cleaning robot mainly comprises a pedestal, driving wheels, a waist driving motor, a flushing operation arm, a scrubbing operation arm, an oven-drying operation arm, a disinfection operation arm, a core control mechanism, an image collection mechanism, a power supply mechanism and a robot head, wherein the pedestal is mounted on a walking mechanism; the waist driving motor is mounted on the pedestal; the core control mechanism is mounted on the waist driving motor; the flushing operation arm, the scrubbing operation arm, the oven-drying operation arm and the disinfection operation arm are mounted in four sliding chutes in the core control mechanism respectively; the robot head is mounted above the core control mechanism. The smart home environment-friendly cleaning robot can be used for realizing indoor daily cleaning, is used for voluntarily selecting one or the combination of more of cleaning procedures of flushing, scrubbing, oven-drying, disinfection and the like, is good in cleaning effect, is used for protecting the health of a human body, meeting green and environment-friendly requirements, and is further high in intelligentization degree.

Owner:合肥荣事达电子电器集团有限公司

Flexible adaptive under-actuated robot paw

The invention relates to a robot paw, in particular relates to a flexible adaptive under-actuated robot paw. The flexible adaptive under-actuated robot paw comprises a framework, and a left finger and a right finger which are connected to the framework in a movable mode, wherein the left finger is positioned on the left side of the framework and provided with a left side hole; the right finger is positioned on the right side of the framework and provided with a right side hole; the framework is provided with through holes which are coaxial with the left side hole and the right side hole; four sliding shafts are arranged in the left side hole, the right side hole and the through holes; two pressure springs are arranged at two ends of each sliding shaft; and in two end faces of each pressure spring, one end face is pressed on each sliding shaft, and the other end face is pressed on the left finger or the right finger. The paw can automatically adapt to the size of a workpiece, the fingers are opened and closed flexibly, stable and uniform grasping force is generated, and the requirement on a control system is reduced.

Owner:余胜东

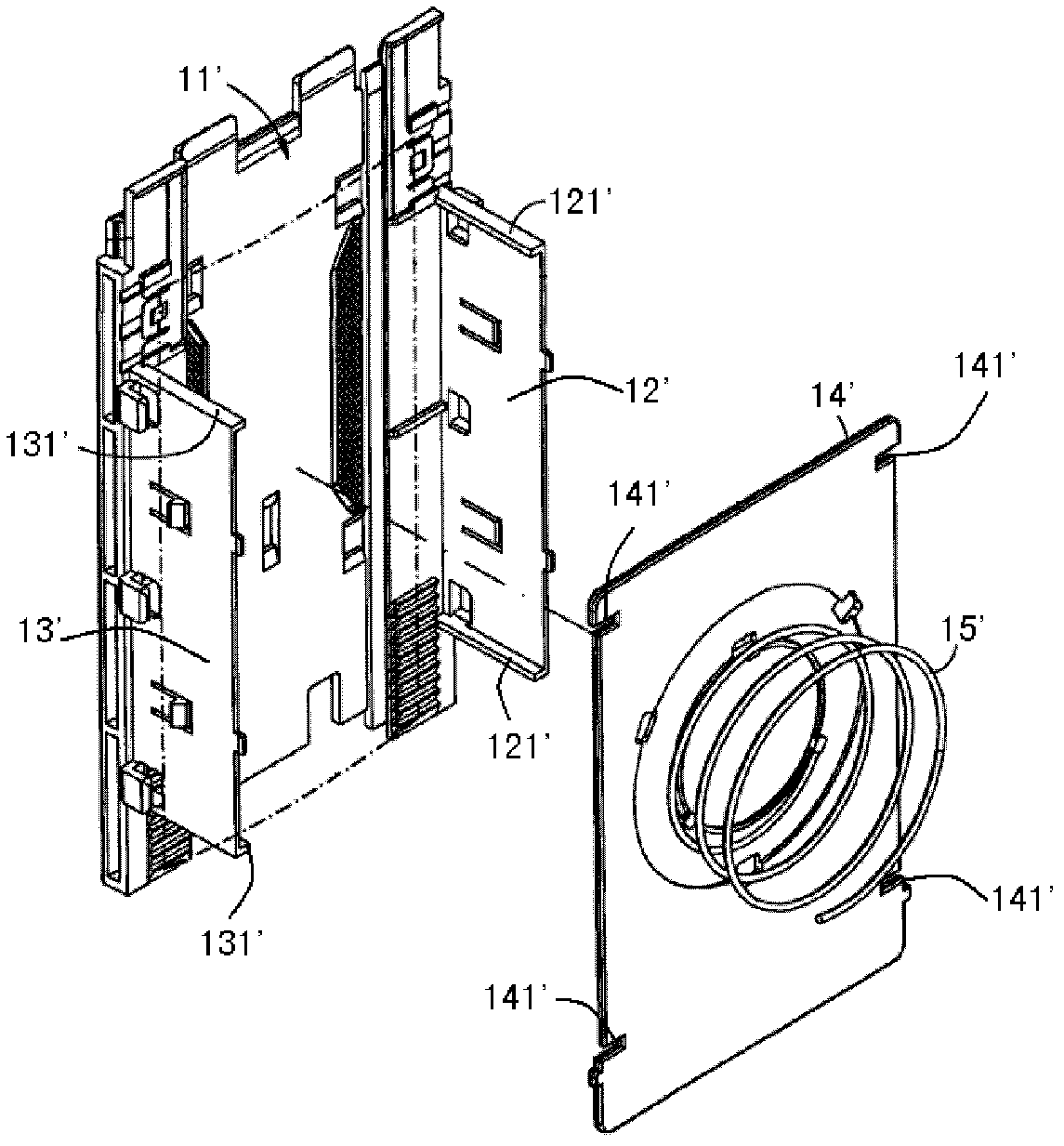

Paper currency box and paper currency recognizer using same

ActiveCN102509388AEasy to withdraw coinsSimple structureCoin testingPaper-money testing devicesPulp and paper industryFour-slide

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

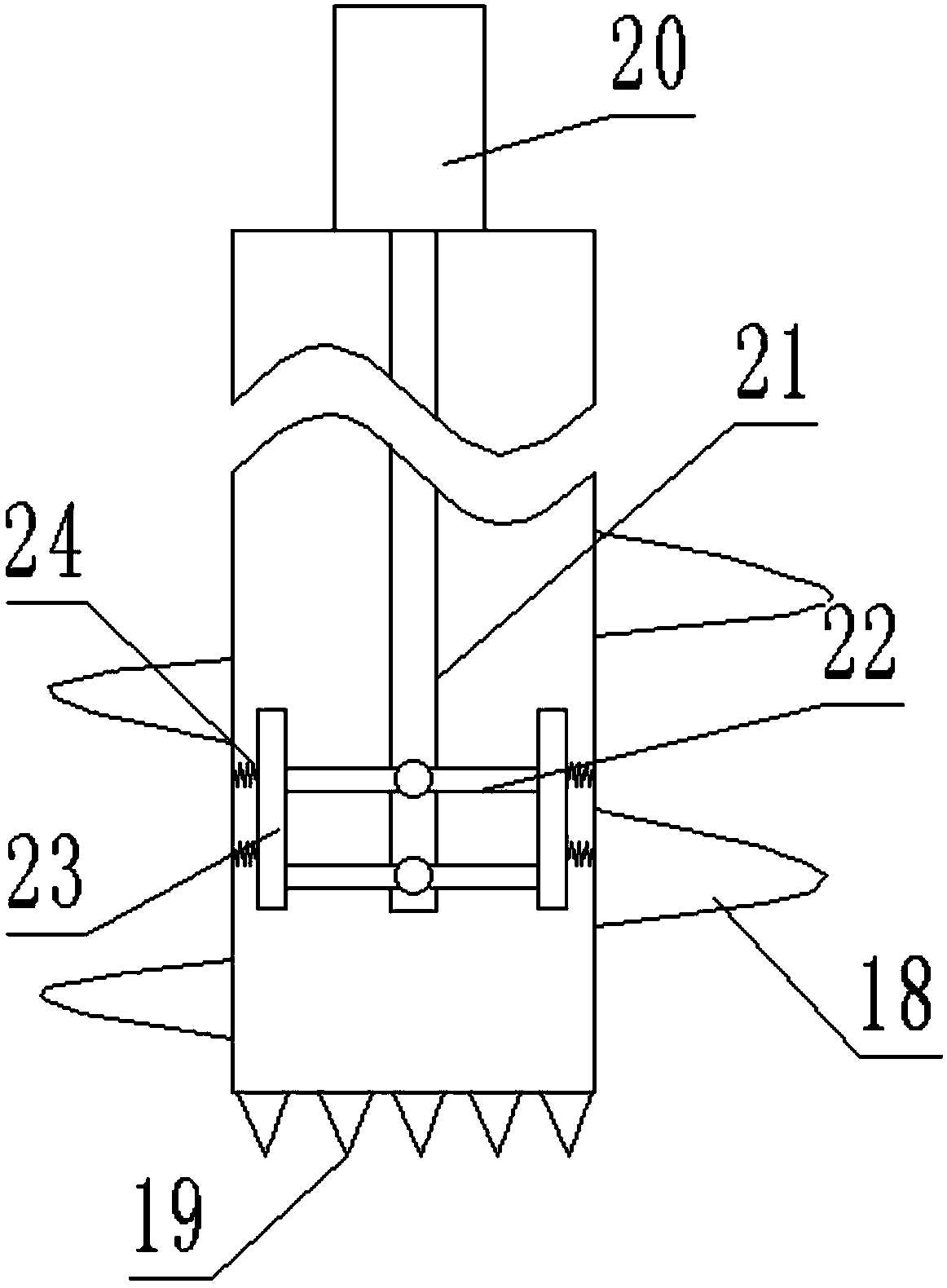

Deep layer soil sampling device for building construction

InactiveCN108871853AIngenious structureSmooth liftWithdrawing sample devicesHydraulic cylinderStructure of the Earth

The invention discloses a deep layer soil sampling device for building construction. The deep layer soil sampling device comprises a fixing frame and an ascending and descending frame, wherein the fixing frame is provided with a square frame plate and four slide rods arranged under the square frame plate; the ascending and descending frame is positioned under the square frame plate, and is glidingly connected with the four slide rods; a controller is arranged on the upper plane of the square frame plate; an ascending and descending device is arranged between the square frame plate and the ascending and descending frame; a first motor is fixed on the bottom surface of the square frame plate; an output shaft of the first motor is connected with a transverse threaded rod; the ascending and descending device comprises a fixing sleeve, a threaded sleeve and a hinging rod. The structure of the ascending and descending device in the device is ingenious; the stable ascending and descending ofa sampling tube can be ensured, so that the taken soil sample can completely maintain the appearance in the soil; the accurate construction exploration work is greatly facilitated; the opening and closing of a pressurization plate are driven through a hydraulic cylinder, so that the smooth taking of the soil is ensured; the occurrence of sampling difficulty under the conditions of soil scatteringand the like can be avoided.

Owner:杜鑫

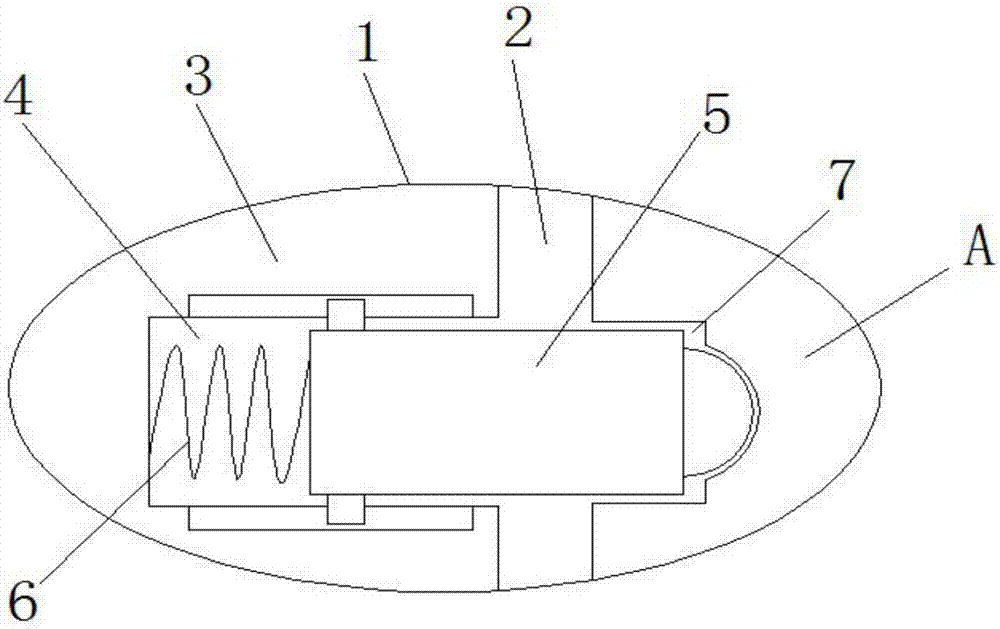

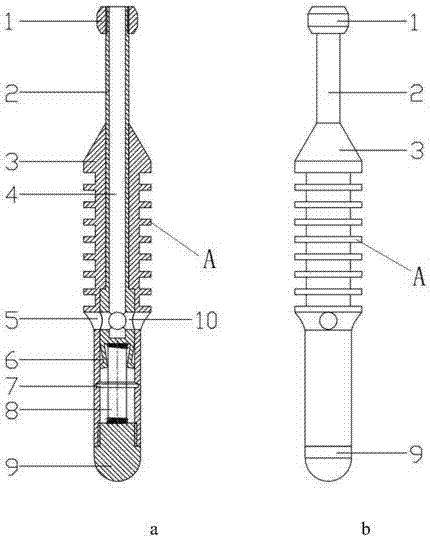

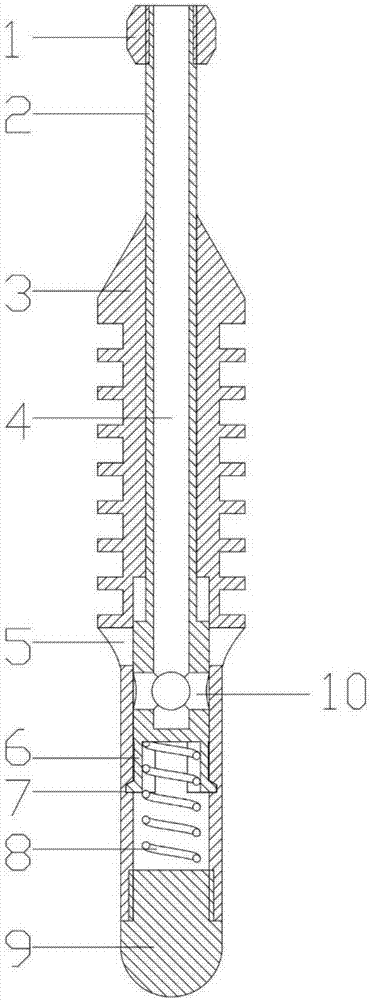

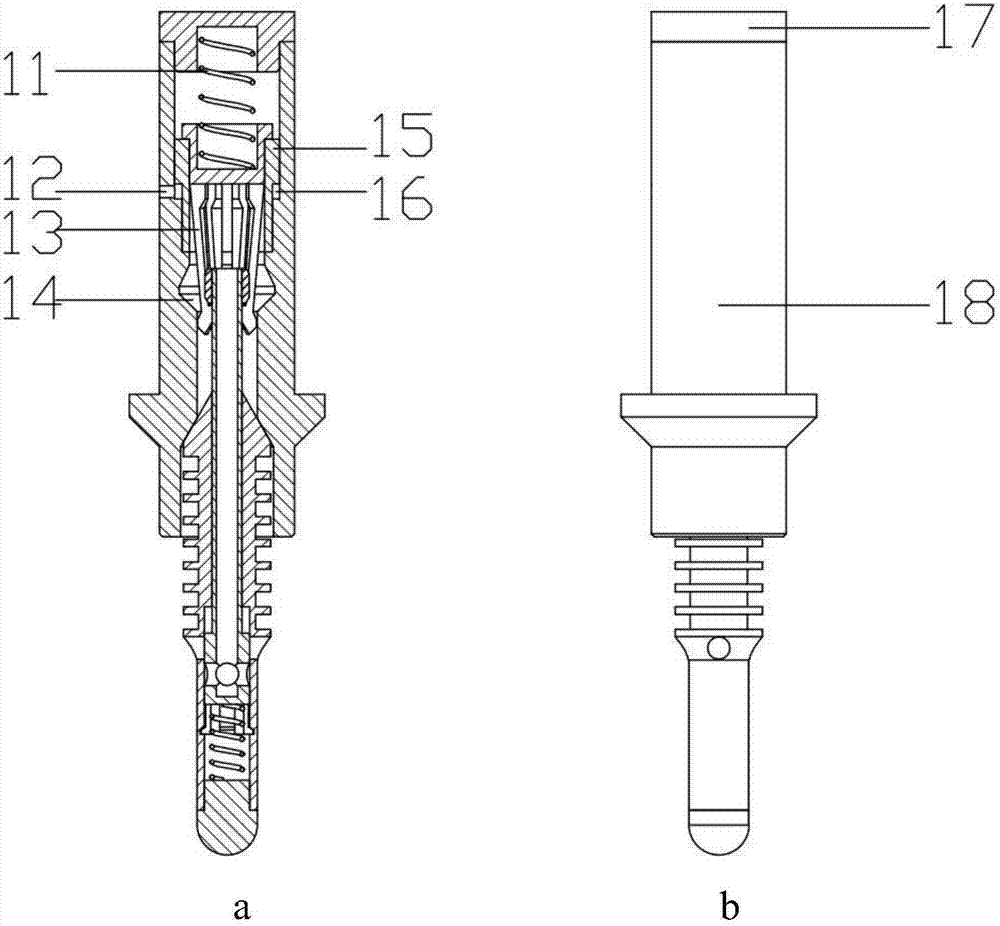

Pressure slide sleeve control type gas well continuous drainage gas production plunger piston

ActiveCN107542433AFast downRealize continuous production without shutting down the wellPositive displacement pump componentsFlexible member pumpsWork periodFishing

The invention relates to a pressure slide sleeve control type gas well continuous drainage gas production plunger piston. Grooves are uniformly distributed in the outer wall of a plunger piston body of a hollow structure; the outer wall of the plunger piston body is also provided with four plunger piston body in uniform distribution in the circumferential direction; the inner wall of the plunger piston body is provided with a groove; a slide sleeve and a spring are sequentially arranged in a hollow inner cavity of the plunger piston body in a sleeved way; the upper part of the slide sleeve isof a hollow structure and is provided with four slide sleeve radial through holes in the uniform distribution in the circumferential direction; the bottom of the slide sleeve is provided with an elastic jack catch; the upper end of the slide sleeve is connected with a fishing head through screw threads; the upper part of the fishing head is connected with the inside of a catcher body; one end of the spring is abutted against the lower end of the slide sleeve; and the other end of the spring is abutted against the upper end of a spring seat and is compressed in the inner cavity of the plunger piston body. The fast descending of the plunger piston in accumulated liquid can be realized through the opening of a passage in the plunger piston; the continuous production without well shut-in of the plunger piston drainage gas production is realized; different springs in the plunger piston can be replaced by aiming at the well status conditions of different wells; the liquid lifting quantity ofeach single work period with different caliber is controlled; the customization aiming at the plunger piston with different well status conditions is realized; and the optimum value of the work efficiency is reached.

Owner:XI'AN PETROLEUM UNIVERSITY

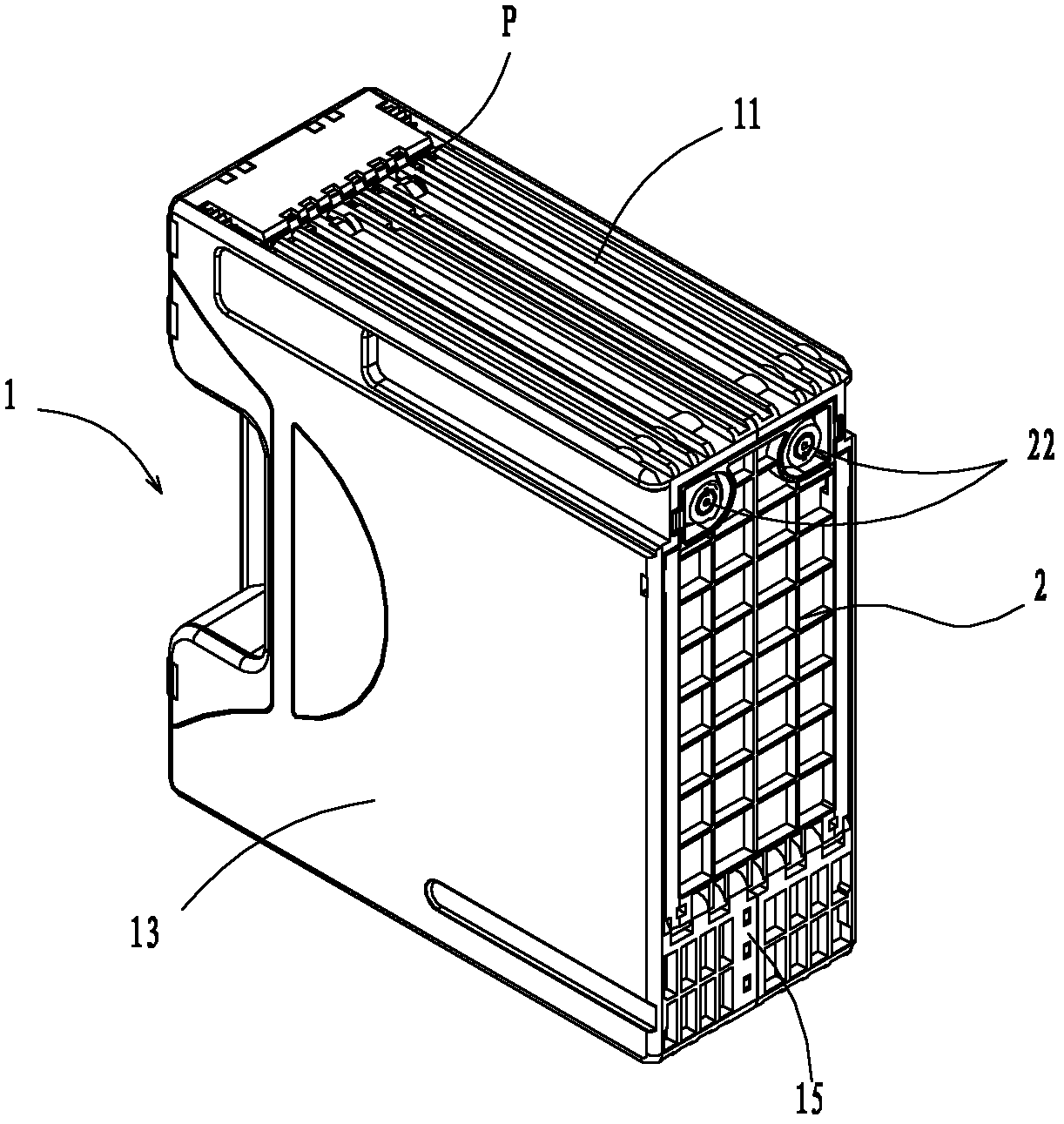

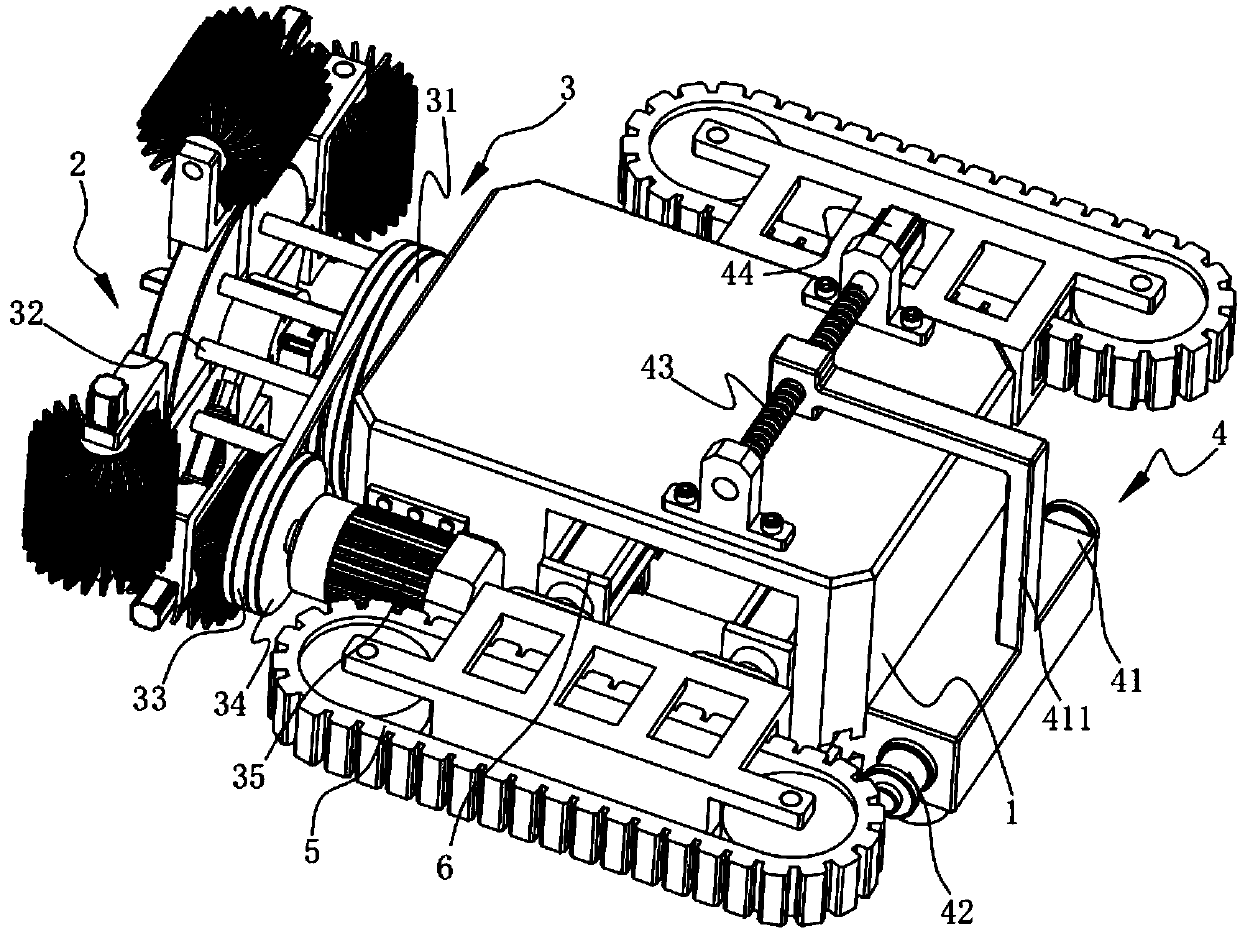

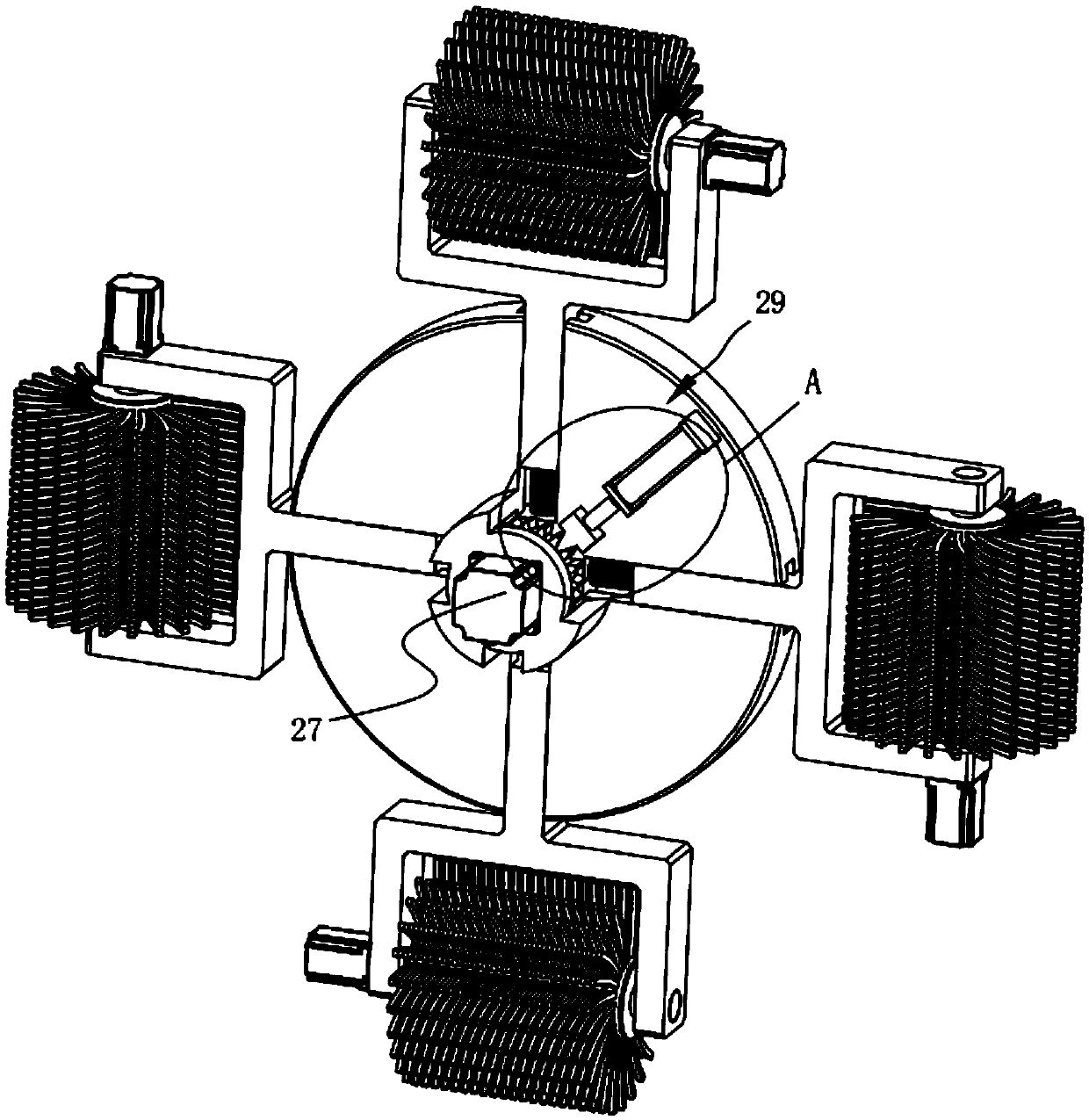

Pipeline cleaning robot

InactiveCN109530351AClean up thoroughlyGuaranteed cleaning effectHollow article cleaningDirt cleaningHydraulic cylinderFour-slide

The invention provides a pipeline cleaning robot. The pipeline cleaning robot comprises a trolley body, a telescopic cleaning device, a driving mechanism, a dust collection device, a crawler belt mechanism and a hydraulic cylinder I, a stirring piece in the telescopic cleaning device is installed on a turntable, four sliding brackets are movably installed on the turntable, and rolling wheels are arranged at the bottoms of the sliding brackets; an arc blocking piece on the stirring piece is separately in contact with the rolling wheels, four hairbrushes are respectively and rotatably installedon the four sliding brackets, and a motor II is installed at the back end of the turntable and fixedly connected with the stirring piece; a limit mechanism is installed on the turntable, the dust collection device is installed on the tail portion of the trolley body, and the driving mechanism is located at the front end of the trolley body and is in transmission connection with the turntable. Theturntable is driven to rotate through self-rotating of the hairbrushes and the driving mechanism, so that the hairbrushes rotate in the two directions to strengthen the cleaning effect, the stirring piece pushes the sliding brackets to stretch out and draw back so that the pipeline cleaning robot can adapt to pipelines of different sizes, and the position of the stirring piece is limited through the limit mechanism to avoid that the sliding brackets extrude the stirring piece and rotate backward.

Owner:CHAOHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com