Non-cooperative target docking mechanism of forked frame

A technology of non-cooperative target and docking mechanism, which is applied in the field of non-cooperative target docking mechanism to achieve the effect of reasonable design, high compression rate and shortened axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

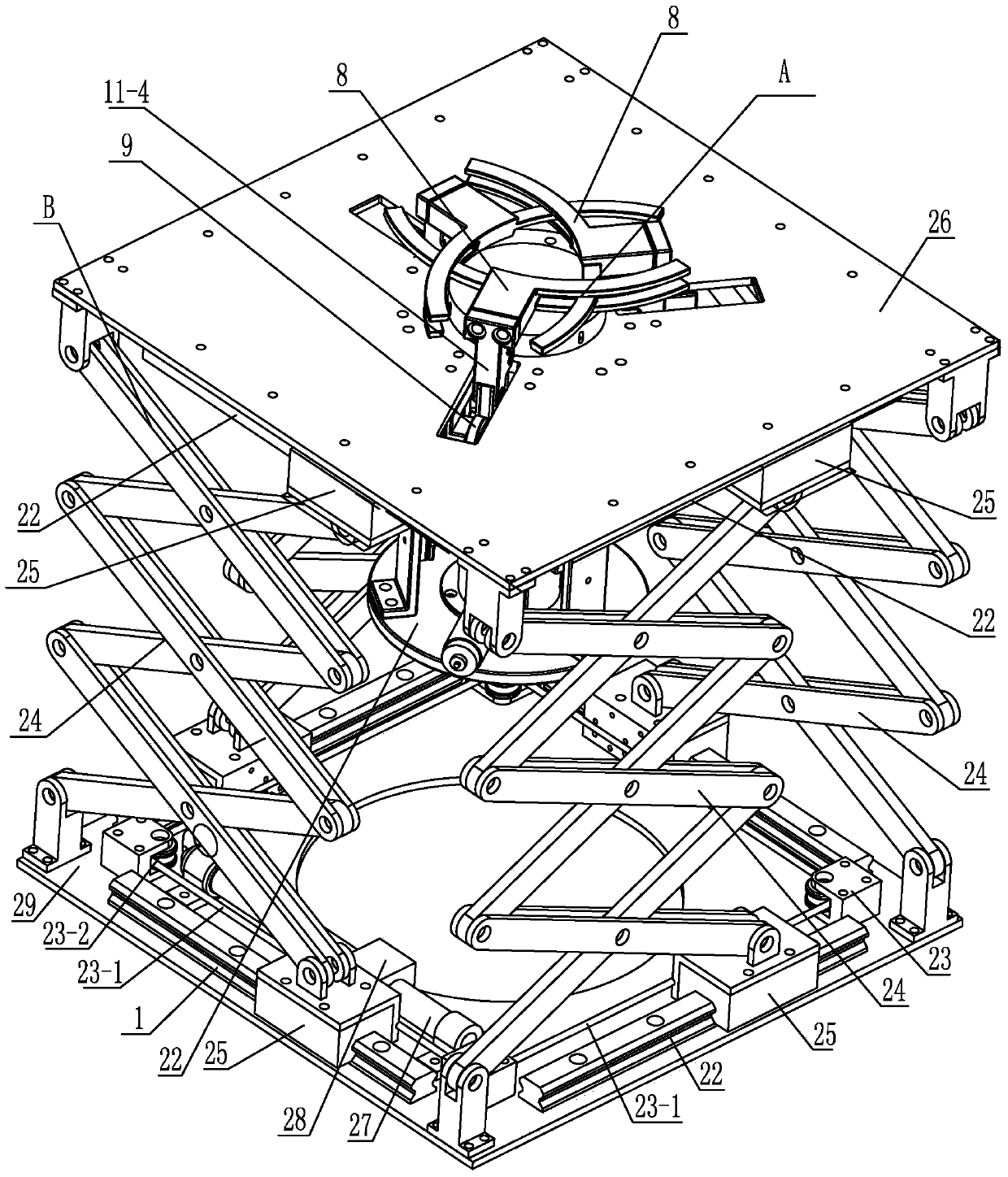

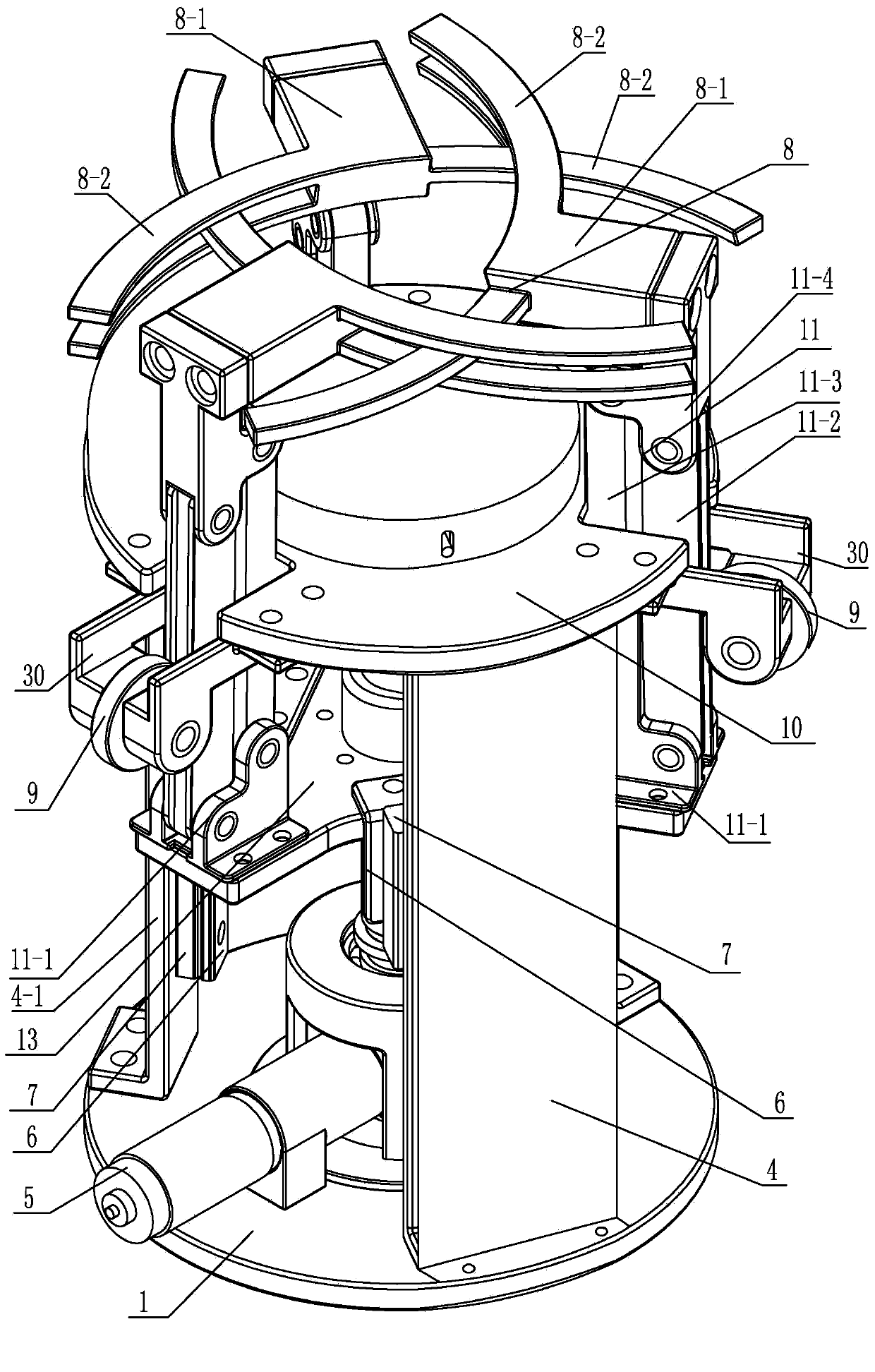

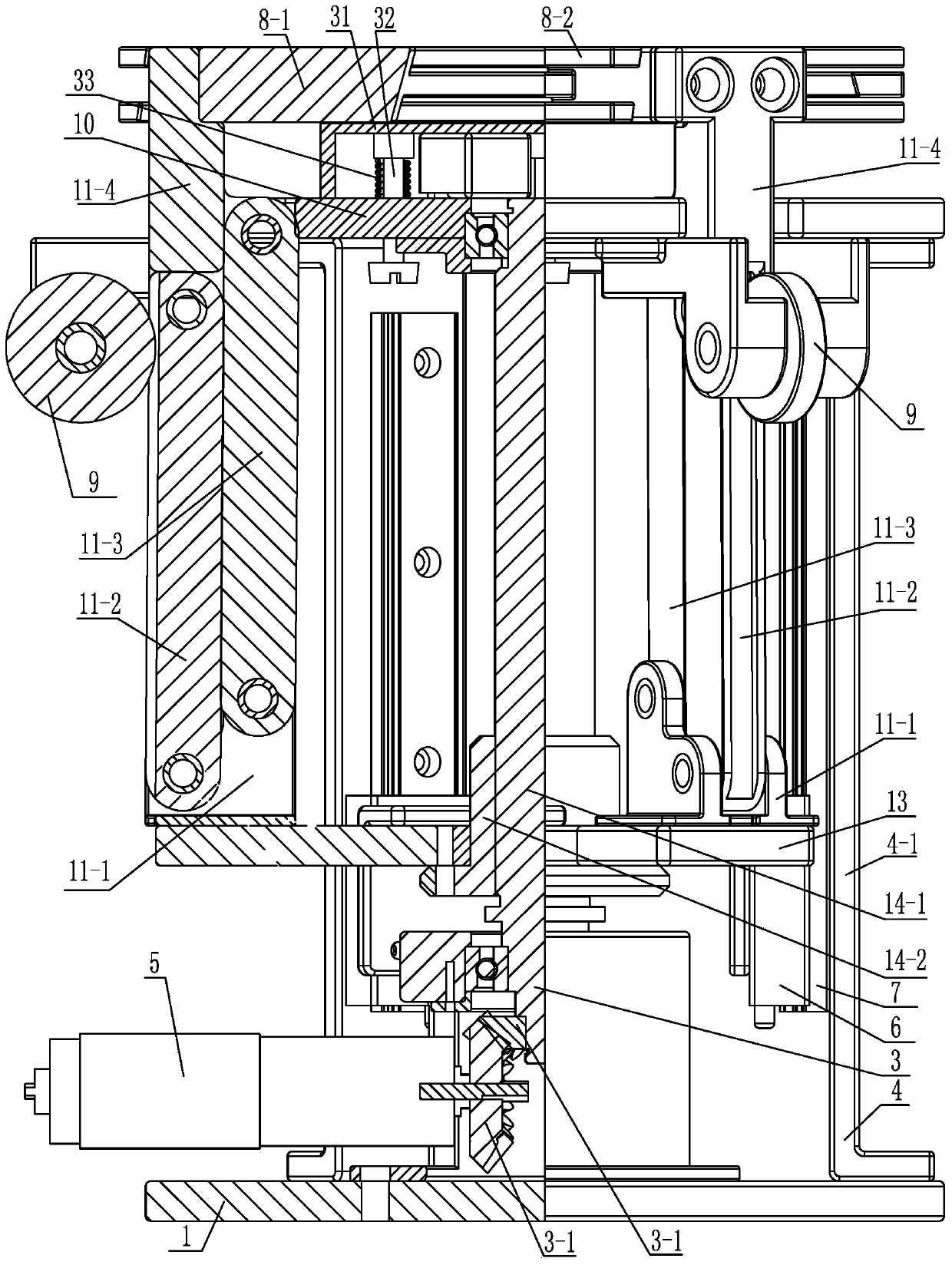

[0012] Specific implementation mode one: combine Figure 1-Figure 3 Explain that the non-cooperative target docking mechanism of the fork frame in this embodiment includes a catch mechanism A and a telescopic mechanism B; the catch mechanism A includes a base 1, a bevel gear pair 3, a slide rail bracket 4, a first motor 5, and an upper cover 10 , a support frame 13, a first lead screw pair 14, three terminal clamping claws 8, three first sliders 6, three first slide rails 7, three rollers 9 and three sets of four-bar linkage mechanisms 11;

[0013] The loam cake 10 is arranged on the top of the base 1, between the loam cake 10 and the base 1, a slide rail support 4 connected with the two is installed, three slide rails 7 are evenly distributed along the circumference of the loam cake 10 on the slide rail support 4, and the base 1 is installed with the first motor 5 axially arranged horizontally, one of the bevel gears 3-1 in the bevel gear pair 3 is arranged axially horizontal...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 2 and image 3 Note that the slide rail bracket 4 in this embodiment includes three support rods 4-1, and the three support rods 4-1 are evenly distributed along the circumference of the upper cover 10, and each support rod 4-1 is equipped with a slide rail 7. The three support rods 4-1 are connected to the upper cover 10 and the base 1 respectively. In this way, an enlarged space is formed between the three support rods, which facilitates the disassembly and assembly of the first lead screw pair, the bevel gear pair and the first motor. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 2 Note that the base 1 and the upper cover 10 in this embodiment are circular. Such arrangement takes up little space and is simple in structure. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com