Device for detecting performance of high-speed heavy-load precision roller linear guide rail

A roller linear guide, precise technology, applied in measuring devices, devices using optical methods, measuring acceleration, etc., can solve the problem of lack of roller linear guides, etc., and achieve the effect of simple structure, flexible installation and stable performance

Inactive Publication Date: 2011-09-07

大连高金数控集团有限公司 +1

View PDF2 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is to solve the current situation of lack of detection devices for roller linear guides, to overcome the deficiencies in the prior art, and to invent a device for detecting the performance of high-speed, heavy-duty, precision roller linear guides. The temperature sensor is used as the sensing element to complete the detection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

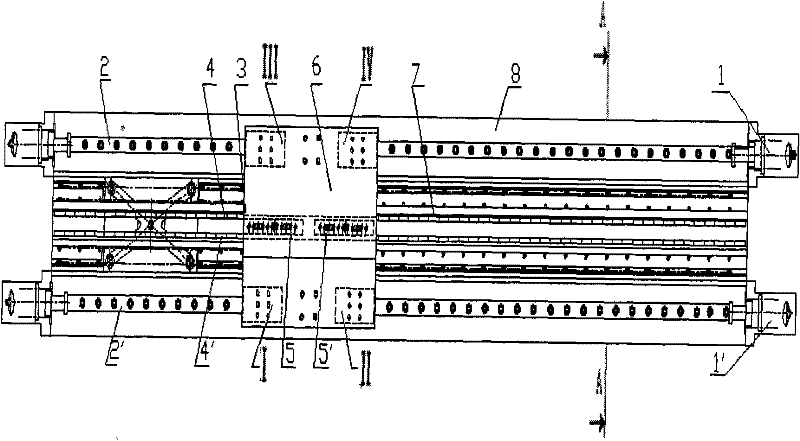

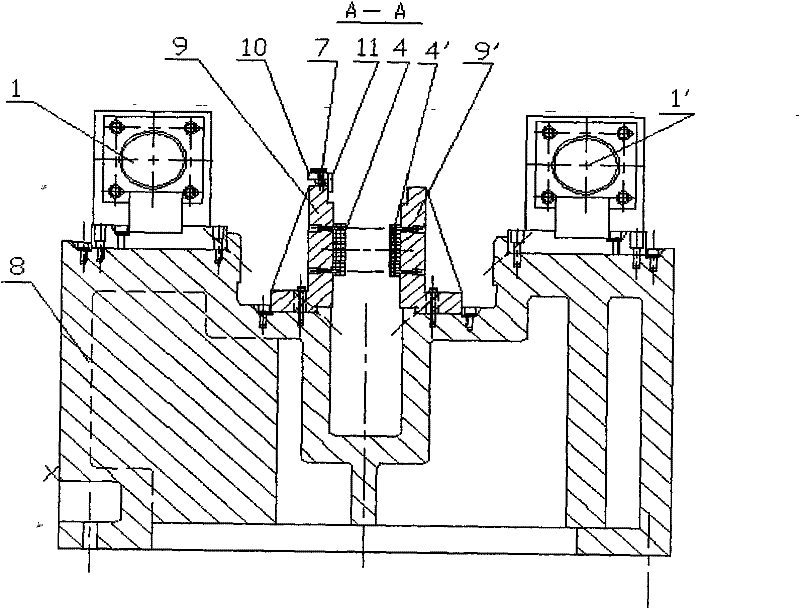

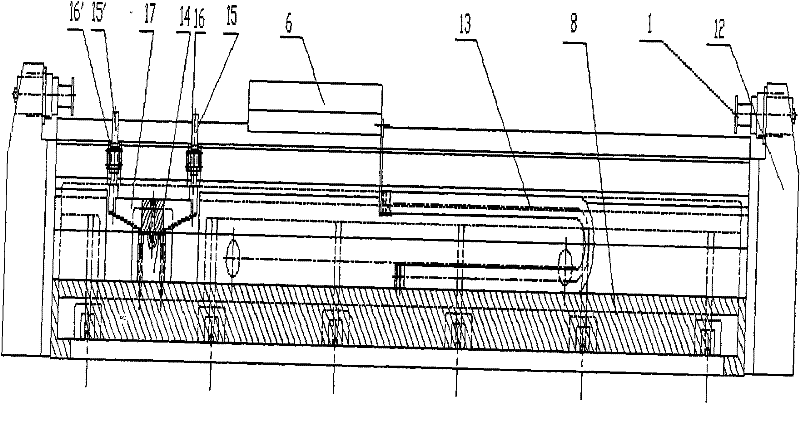

The invention relates to a device for detecting the performance of a high-speed heavy-load precision roller linear guide rail pair, belongs to the technical field relevant to guide rail detection, and particularly relates to a detection device taking temperature sensors, a noise sensor, a vibration sensor and a grating ruler as sensitive elements. In the device, a workbench is arranged on a frontleft slide block, a front right slide block, a rear left slide block and a rear right slide block through connecting screws; the front left slide block, the front right slide block, the rear left slide block and the rear right slide block are arranged on front and rear linear guide rails; the four slide block groups have the totally same structure; four temperature sensors are arranged in a frontleft slide block slipway; the vibration sensor is arranged on the flat surface of the front left slide block through a magnetic seat; and the sensors in the front right slide block, the rear left slide block and the rear right slide block and the magnetic seat are arranged in the totally same way as that in the front left slide block I. The device has the advantages of stable performance, high response speed, simple structure, flexible sensor installation, replacing of roller linear guide rails of different models and wide detection range.

Description

Technical field [0001] The invention belongs to the technical field related to rail detection, and particularly relates to a detection device using a temperature sensor, a noise sensor, a vibration sensor, and a grating ruler as a sensitive element. Background technique [0002] Roller linear guide is a new type of guide assembly that has been widely used internationally only in the 1980s. It has high positioning accuracy, low dynamic and static friction coefficient, can realize high-speed movement of machine tools and mechanical devices, can improve the work efficiency of machine tools and machinery, and save energy , High precision retention, short assembly cycle to machine tools and machinery, etc. At the same time, the rolling linear guide pair plays a role in the bearing and movement guidance of the moving parts in the mechanical transmission pair, and has become one of the key basic components of precision numerical control equipment. With the continuous development of num...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00G01K7/04G01H11/06G01H11/08G01P15/00G01P3/36

Inventor 赵顺利李薇王福吉张雪郑兴民吕祎

Owner 大连高金数控集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com