Patents

Literature

122 results about "Taking temperatures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal body temperature is about 98.6 degrees Fahrenheit (°F) or 37 degrees Celsius (°C). Your temperature often varies from 1 to 2 °F or ½ to 1 °C. Your temperature is usually lower in the morning and increases during the day.

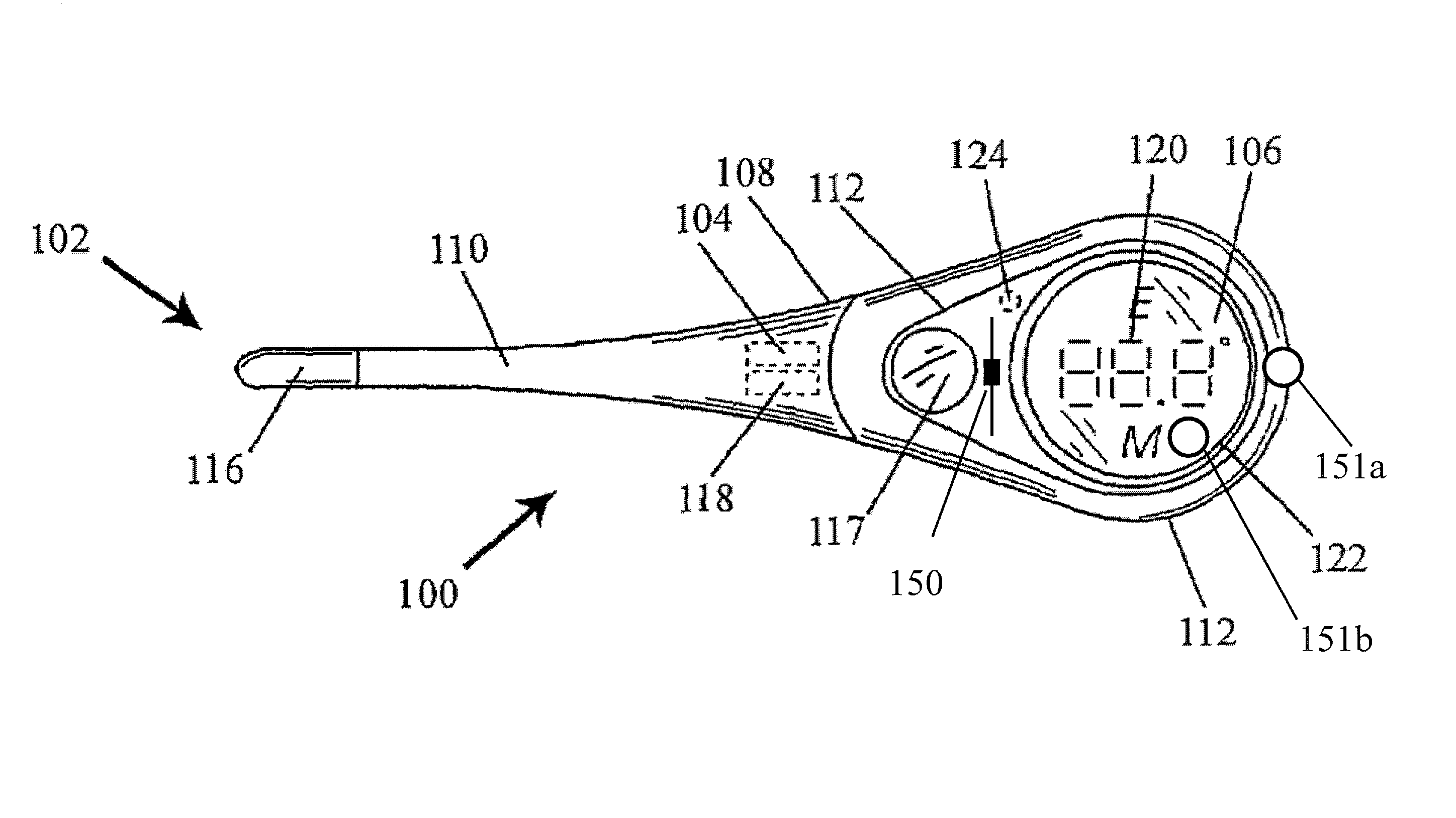

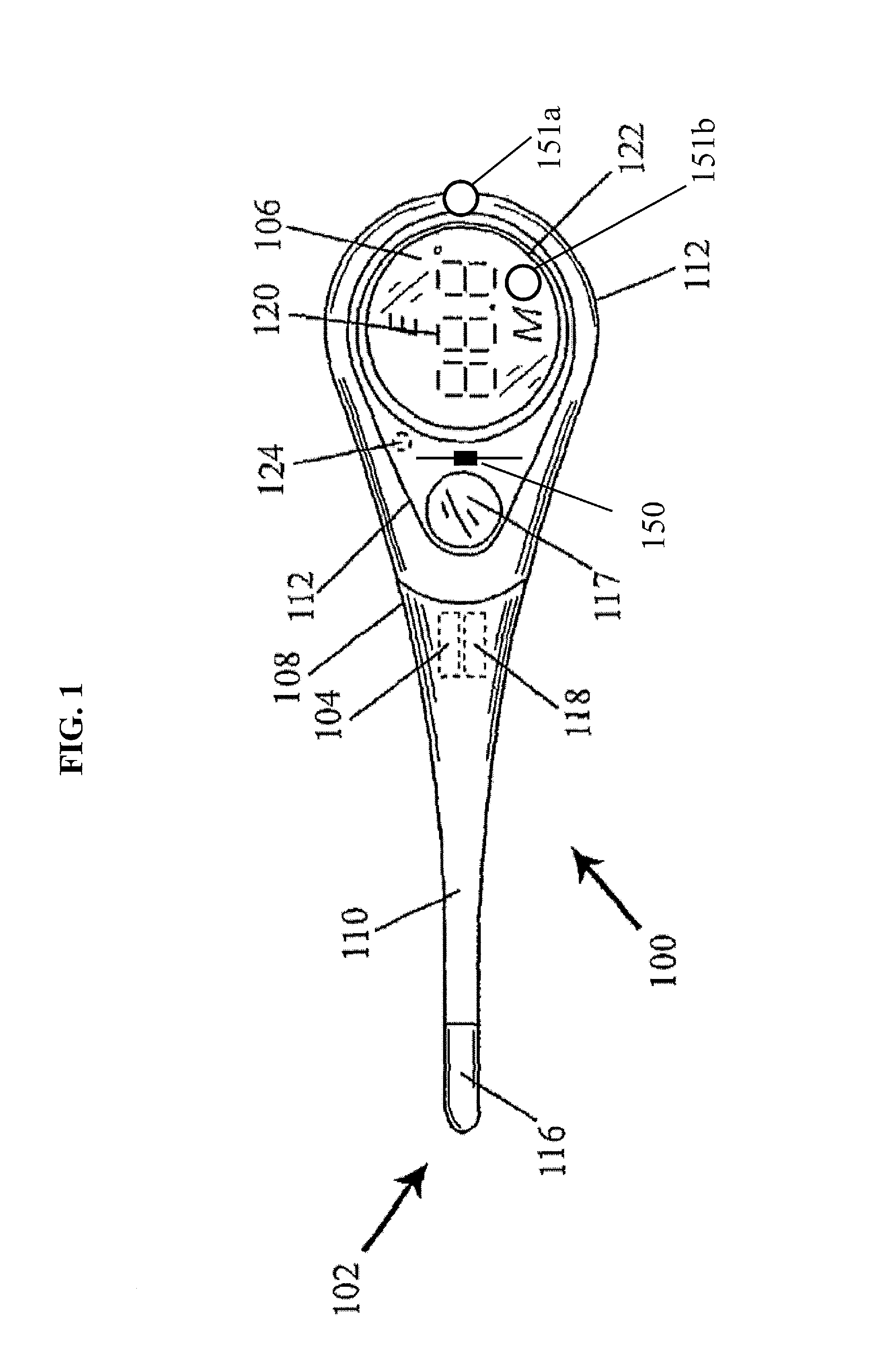

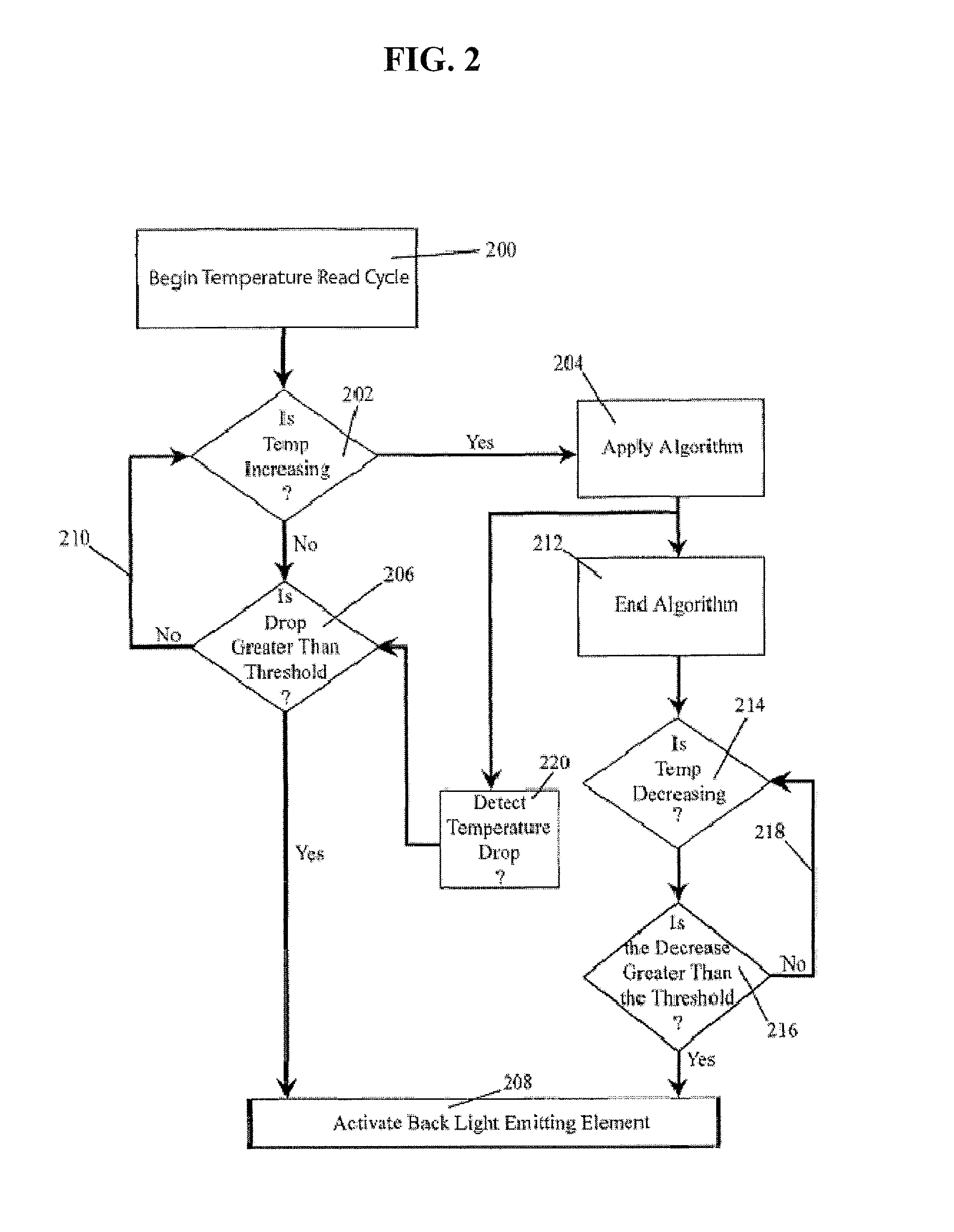

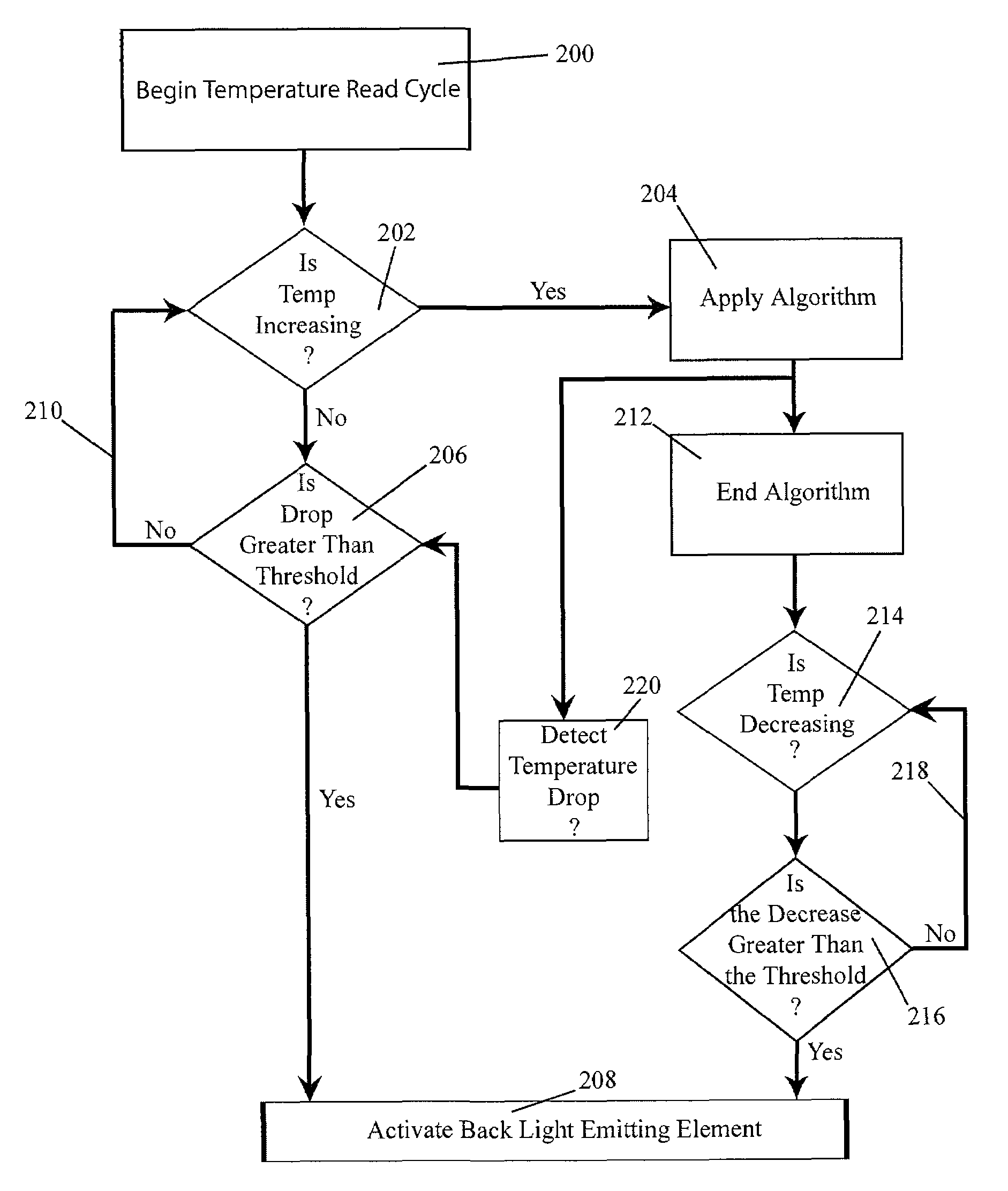

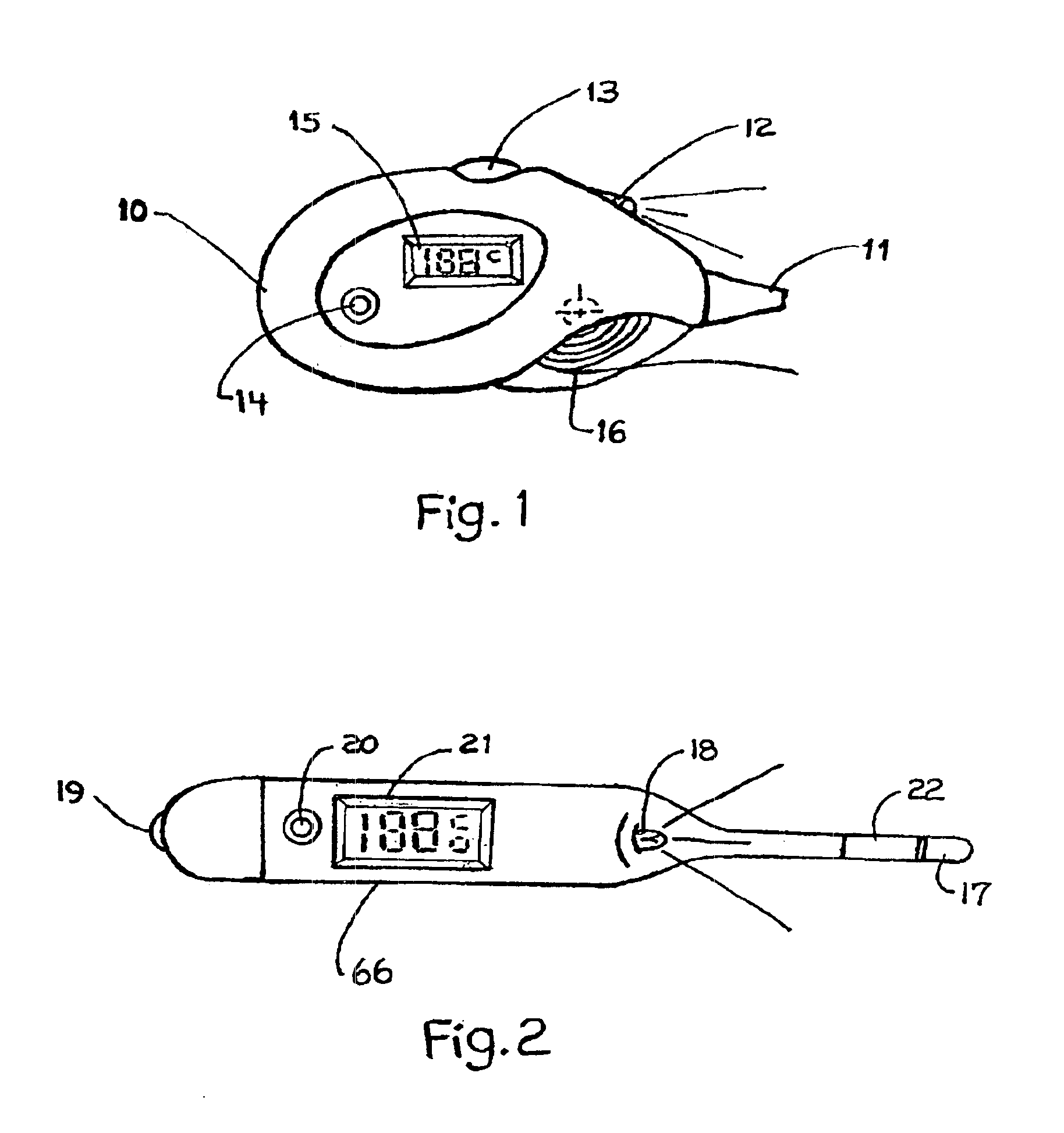

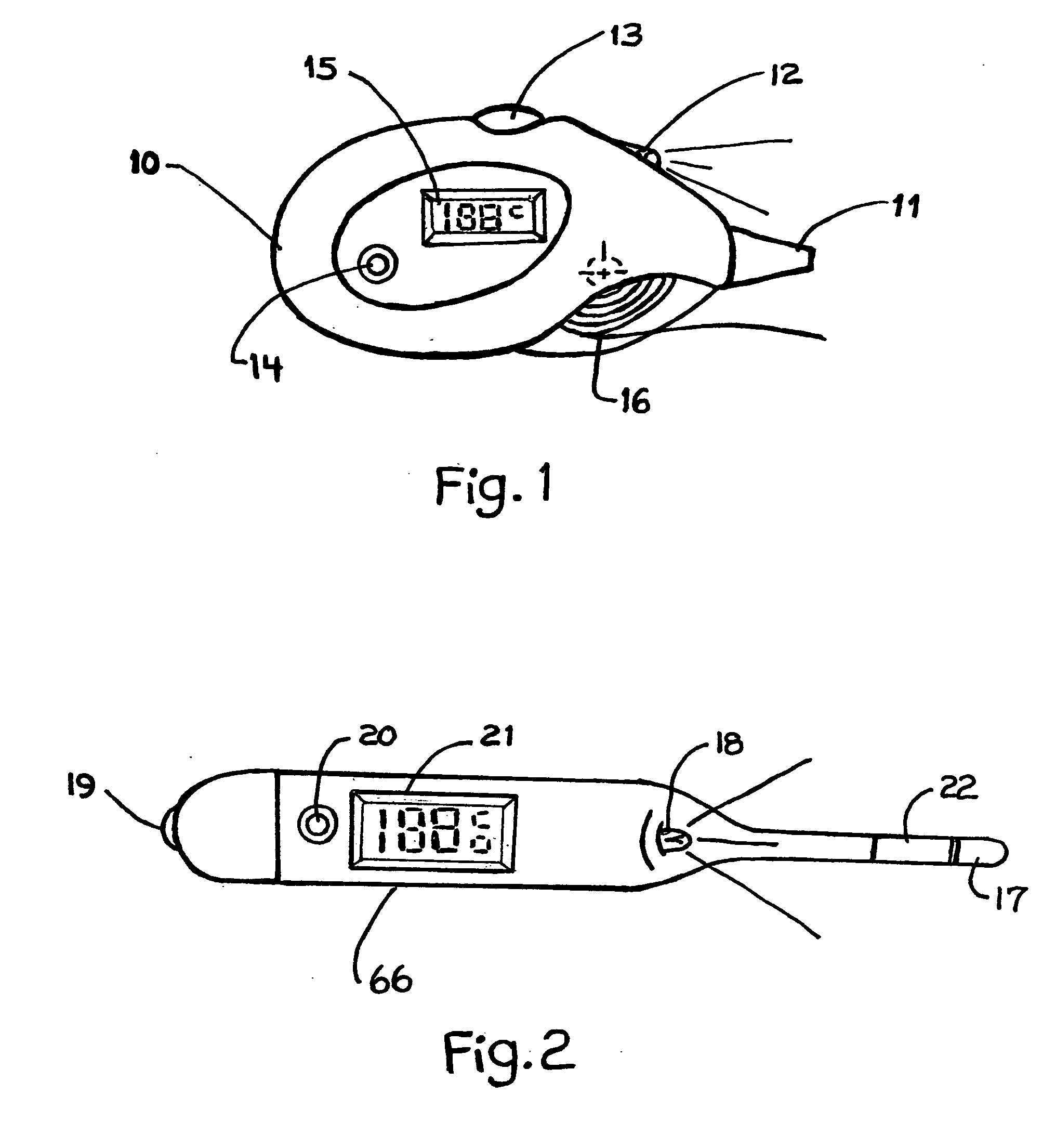

Thermometer with age specific feature selection

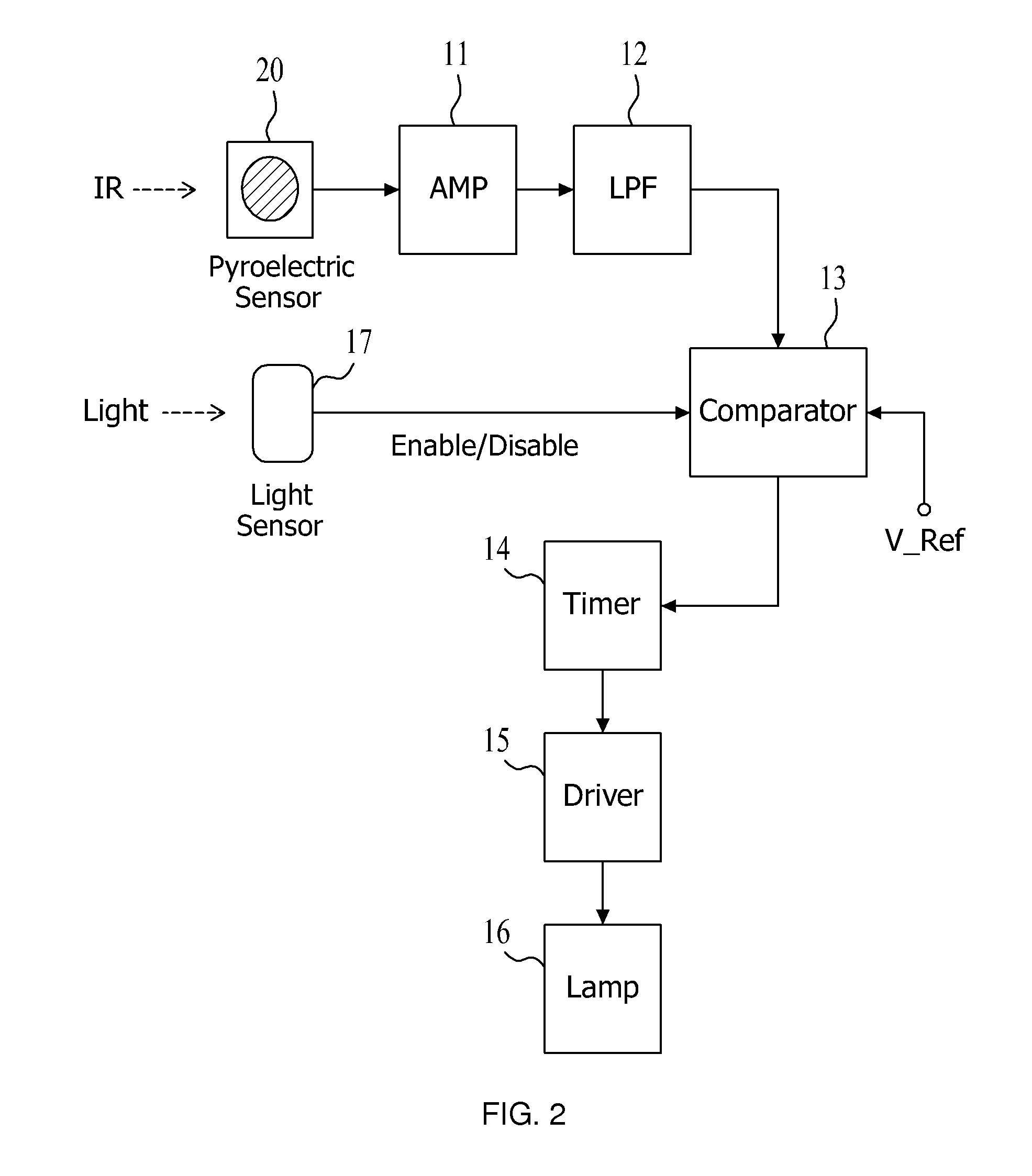

ActiveUS20120150482A1Improve visibilityImprove viewing angleThermometer detailsBody temperature measurementDisplay deviceOperation mode

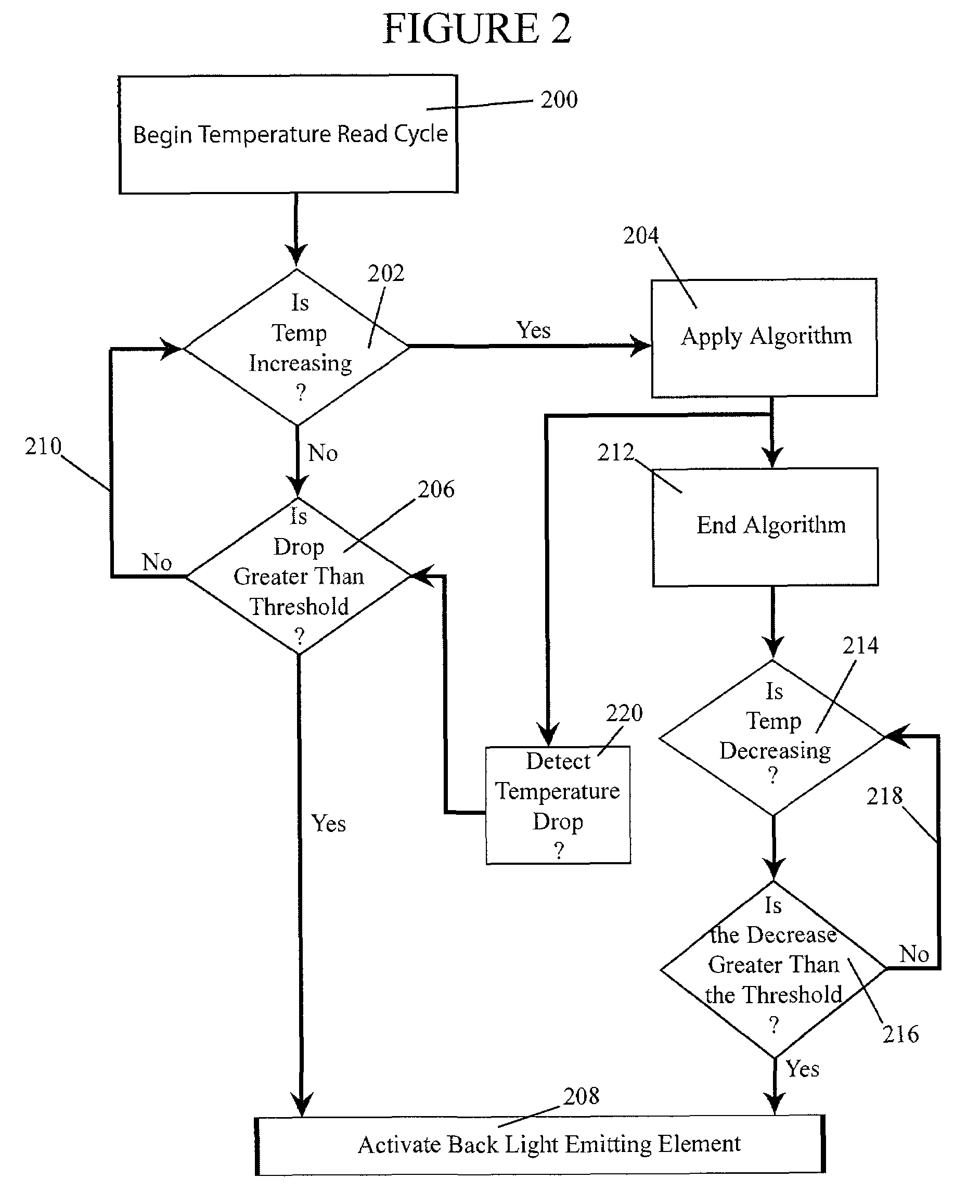

The invention includes a thermometer with a backlight and a method for lighting the backlight. The thermometer has temperature sensing tip, a processor taking temperature readings and determining a sensed temperature reading of the living being from the temperature sensing tip. The thermometer also includes a display and a backlight for lighting the display. The backlight is activated upon a command from the processor and the processor determines whether to activate the backlight based upon the temperature readings. The method embodiment can includes the steps of using the processor to monitor a temperature change indicated by a temperature sensing element. The processor then detects a temperature decrease and activates a first color light emitting element to backlight a display if the temperature decrease exceeds or equals a predetermined threshold. The thermometer is operable in one of a plurality of selectable operating modes, and the predetermined threshold is dependent upon the selected operating mode. For example, operating modes may depend on patient age range or measurement location. Age range may include infant, toddler and adult.

Owner:HELEN OF TROY LIMITED

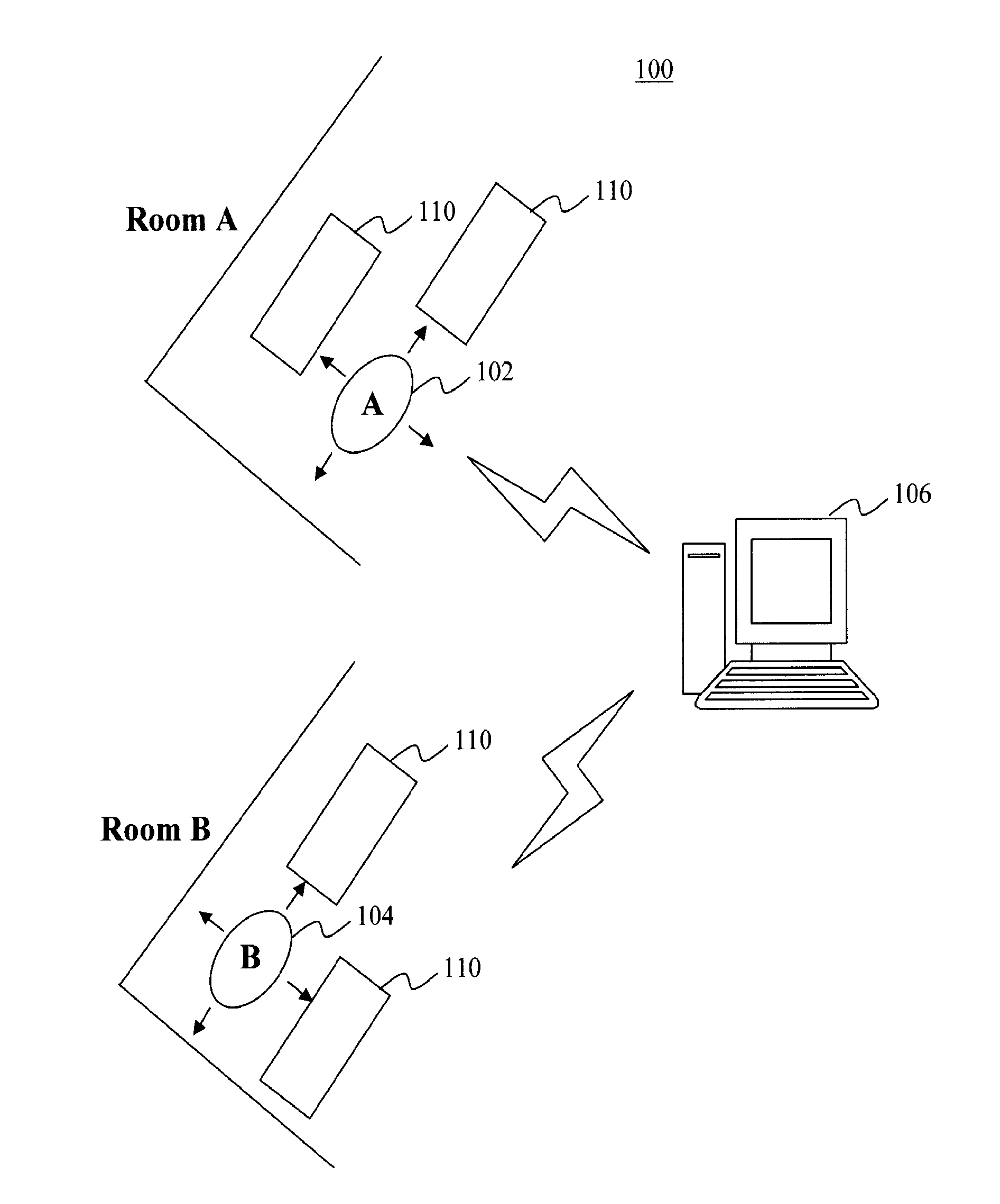

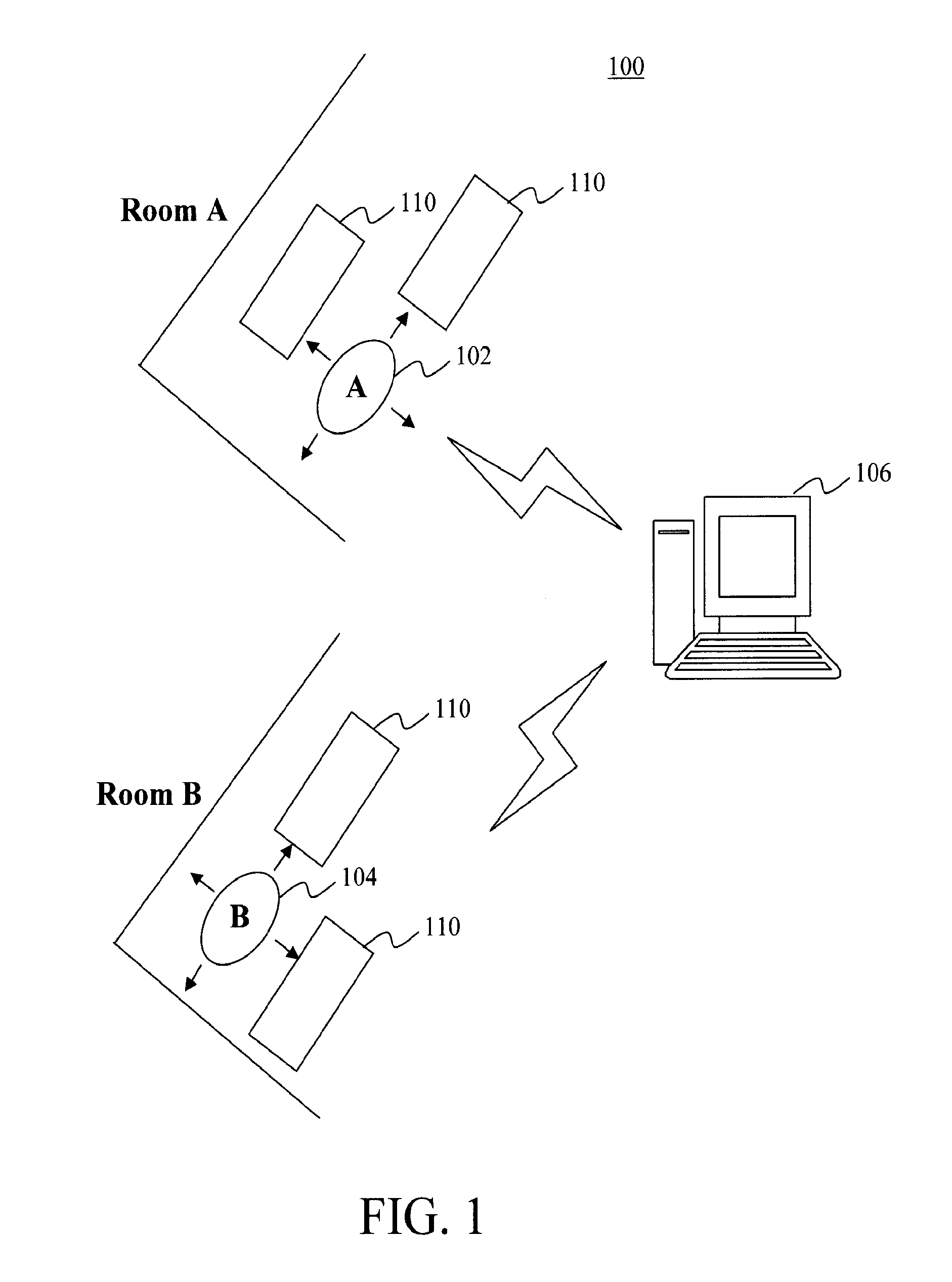

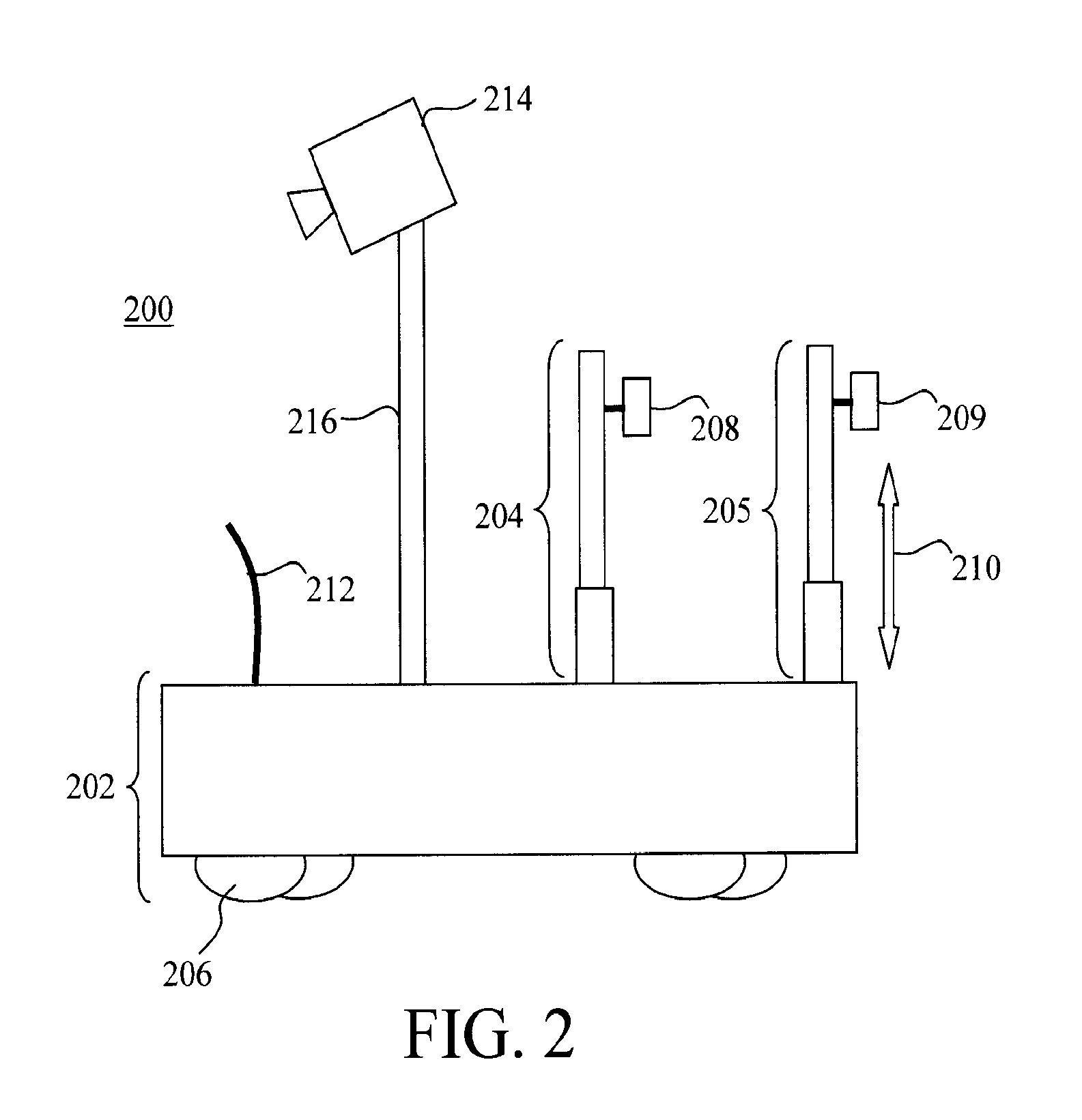

Detecting Energy and Environmental Leaks In Indoor Environments Using a Mobile Robot

InactiveUS20120078417A1Programme-controlled manipulatorThermometers using value differencesEngineeringTaking temperatures

Techniques for energy and environmental leak detection in an indoor environment using one or more mobile robots are provided. An energy leak detection system is provided. The energy leak detection system includes one or more mobile robots configured to move throughout at least a portion of a building and to take temperature and air flow measurements at a plurality of locations within the building. An environmental leak detection system is also provided. The environmental leak detection system includes one or more mobile robots configured to move throughout at least a portion of a building and to take airborne matter measurements at a plurality of locations within the building.

Owner:IBM CORP

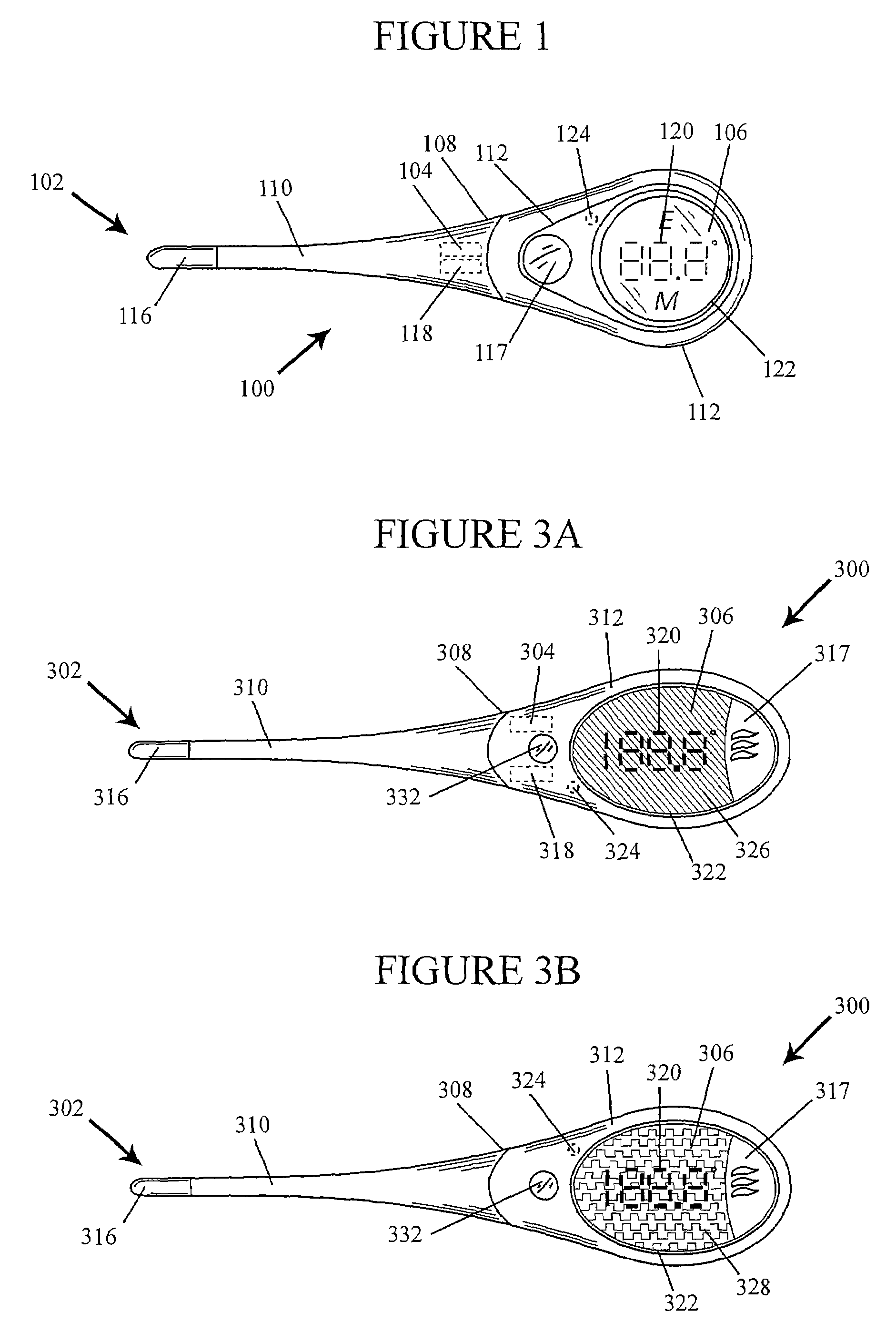

Color changing thermometer

ActiveUS7350973B2Increases visibility and viewing angleThermometer detailsThermometers using electric/magnetic elementsDisplay deviceEngineering

The invention includes a thermometer with a backlight and a method for lighting the backlight. The thermometer has temperature sensing tip, a processor taking temperature readings and determining a sensed temperature reading of the living being from the temperature sensing tip. The thermometer also includes a display and a backlight for lighting the display. The backlight is activated upon a command from the processor and the processor determines whether a decrease in the temperature readings exceeds or is equal to a predetermined threshold in order to activate the backlight. The method embodiment can includes the steps of using the processor to monitor a temperature change indicated by a temperature sensing element. The processor then detects a temperature decrease and activates a first color light emitting element to backlight a display if the temperature decrease exceeds or equals a predetermined threshold.

Owner:HELEN OF TROY LTD

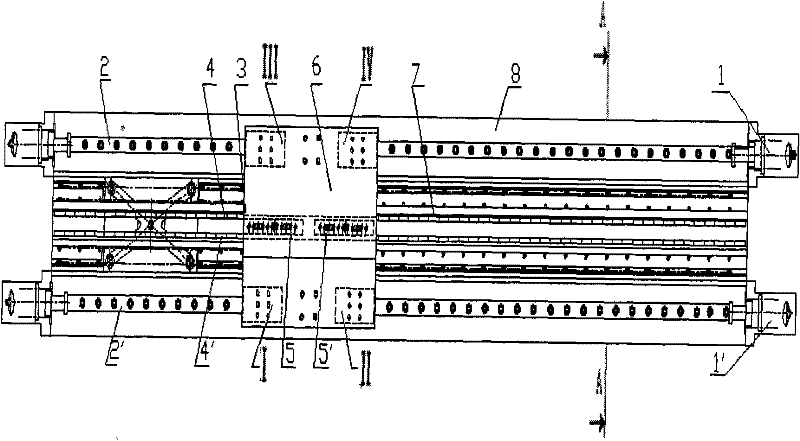

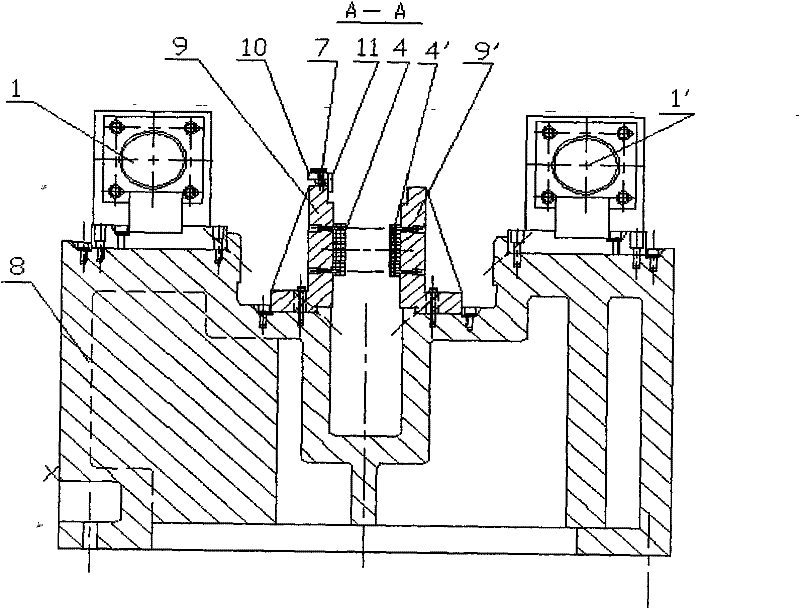

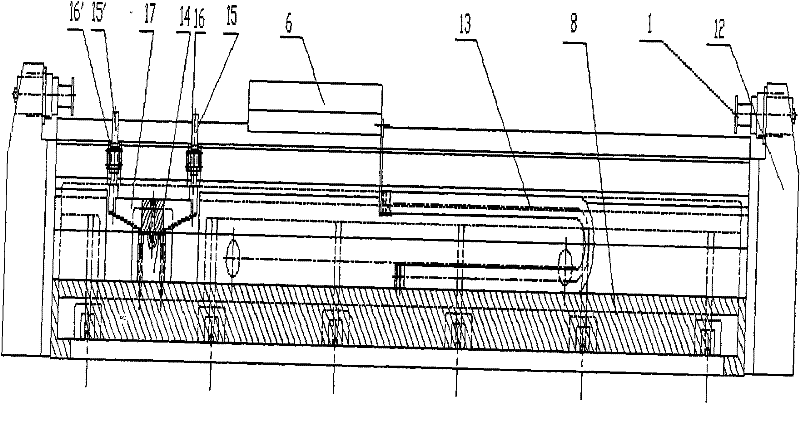

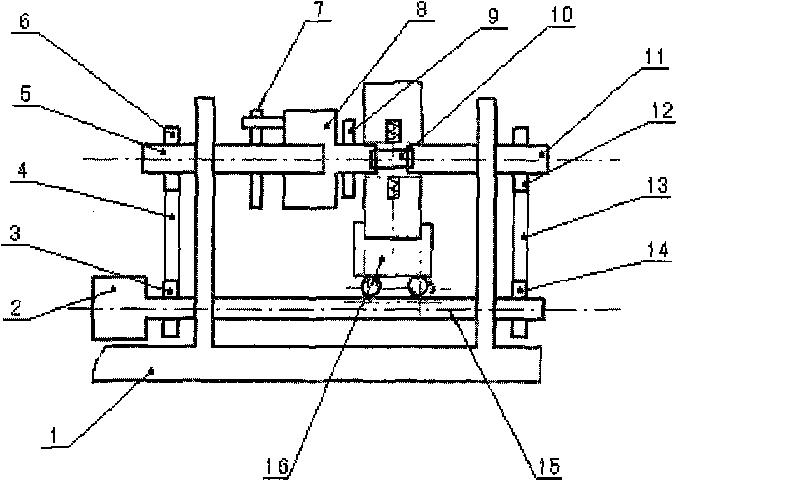

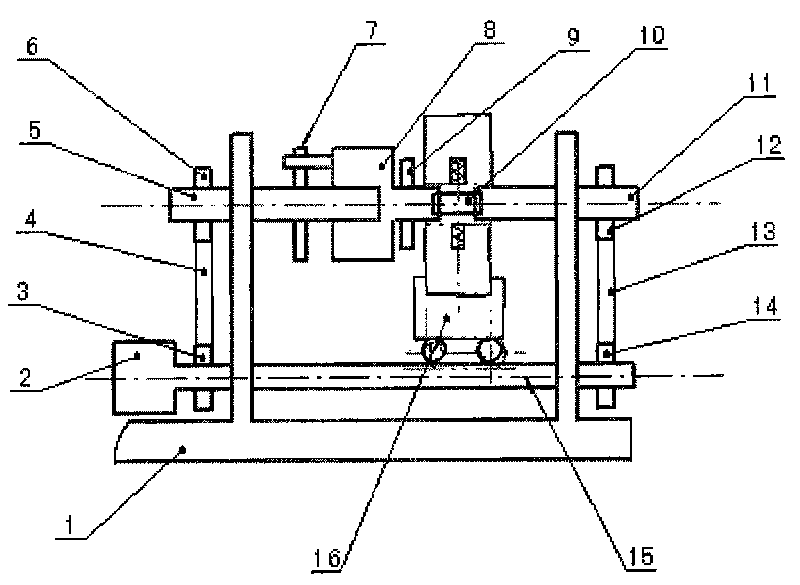

Device for detecting performance of high-speed heavy-load precision roller linear guide rail

InactiveCN102175438AFlexible installationImprove performanceMachine part testingSubsonic/sonic/ultrasonic wave measurementGratingEngineering

Owner:大连高金数控集团有限公司 +1

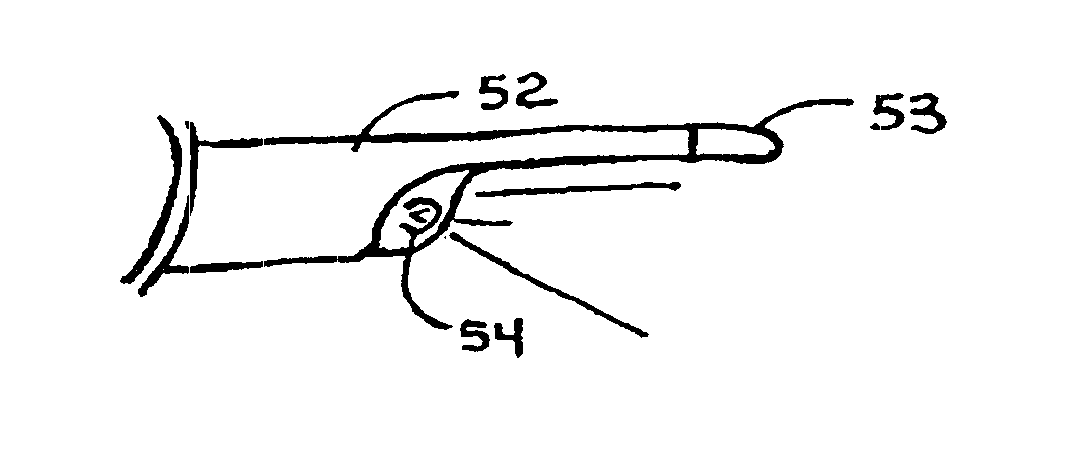

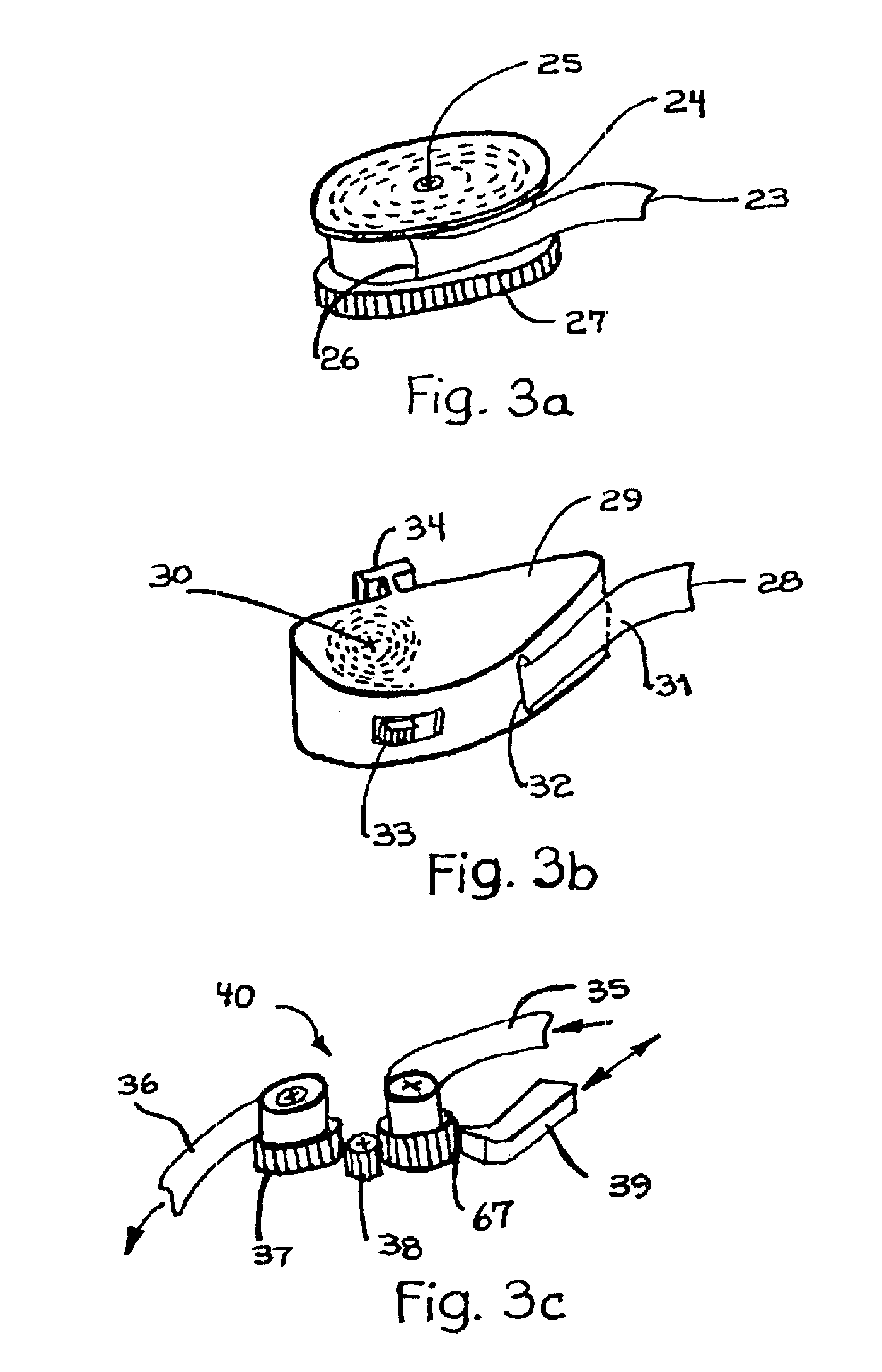

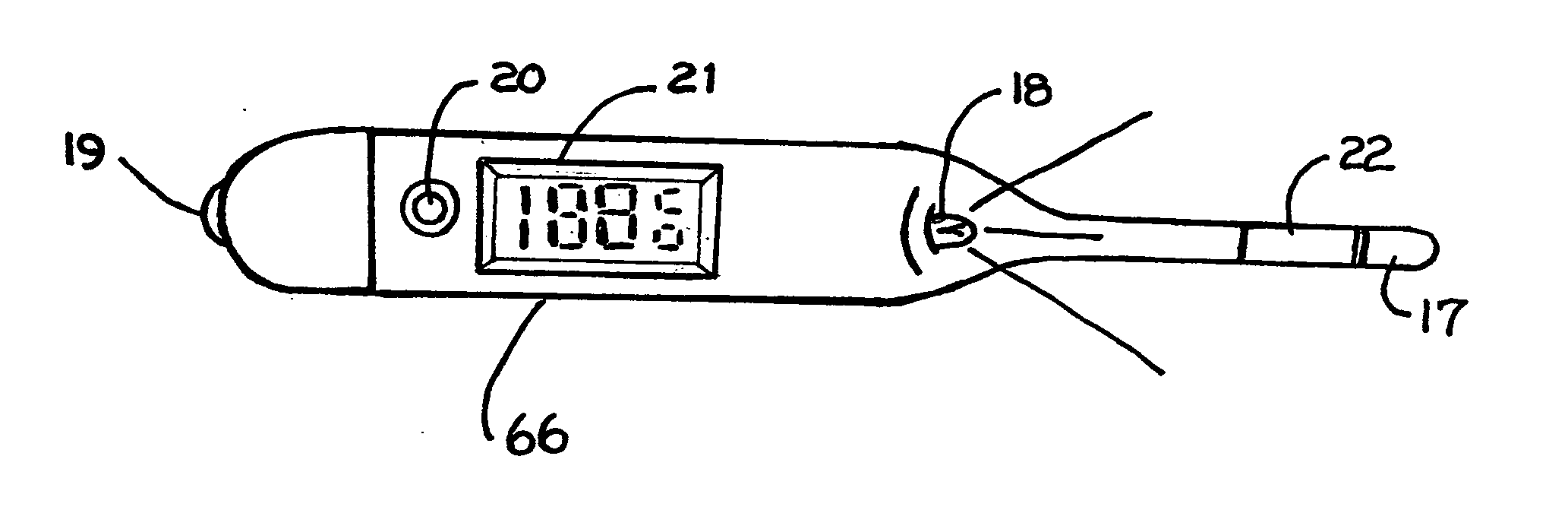

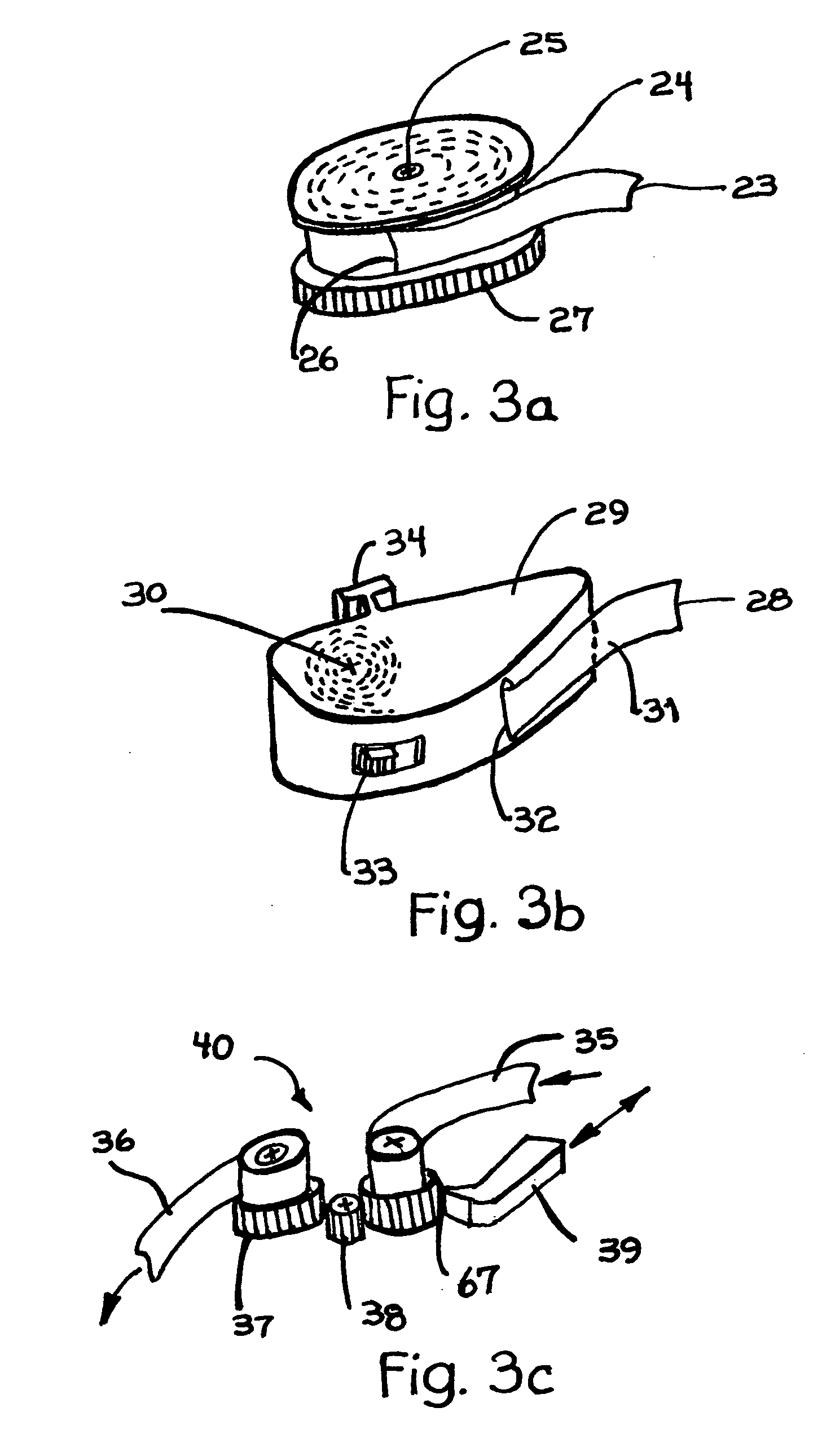

Temperature measure device

InactiveUS6886979B2Good adhesionReduce manufacturing costThermometer detailsThermometers using material expansion/contactionIlluminanceEngineering

A temperature measure device having a light source to provide the user an effective and efficient means to take temperatures in a low-lighted area. A temperature measure device having a cartridge to store, dispense and discard the covers. The covers made of a thin narrow flexible material that is housed by a body and conveniently stored inside or in the proximity of the temperature-measuring device.

Owner:CONFORTI CARL J

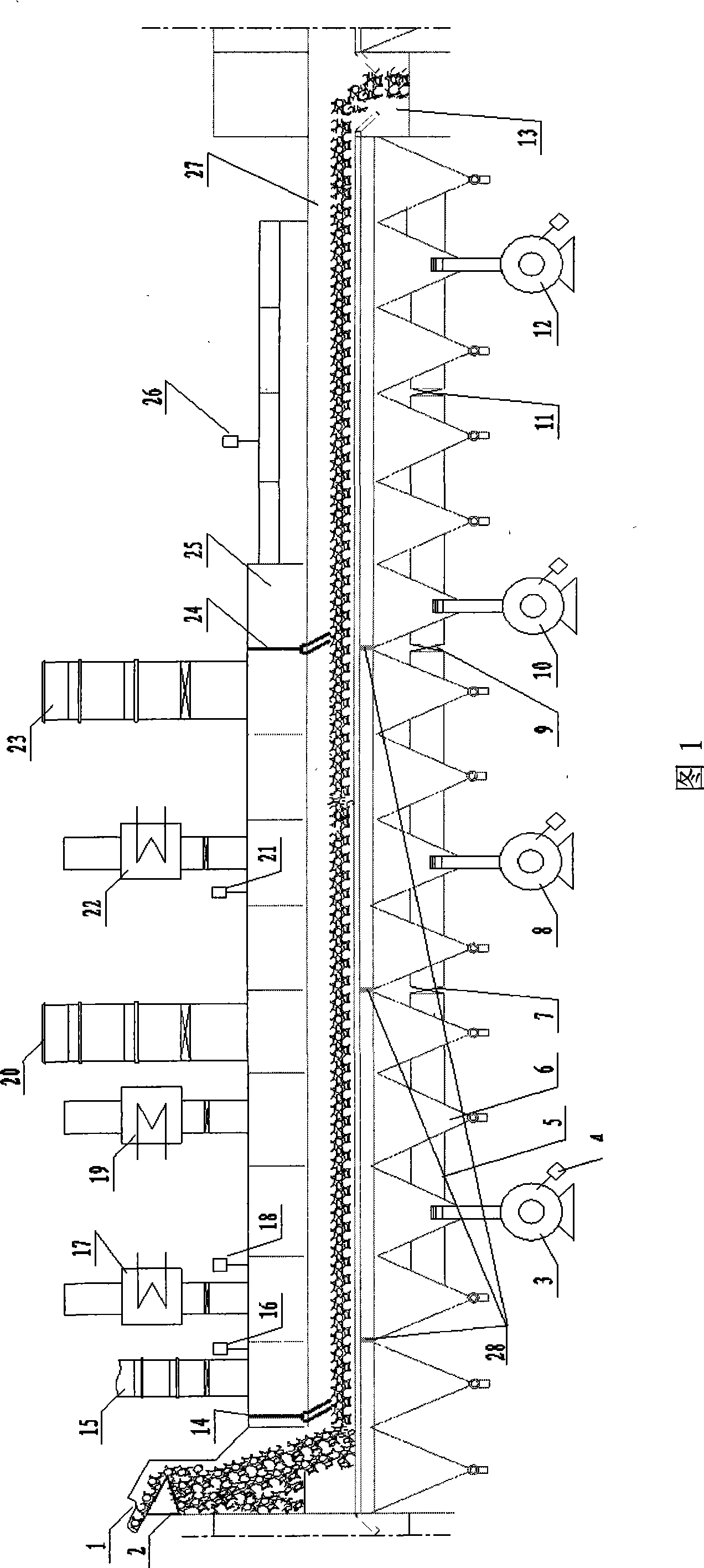

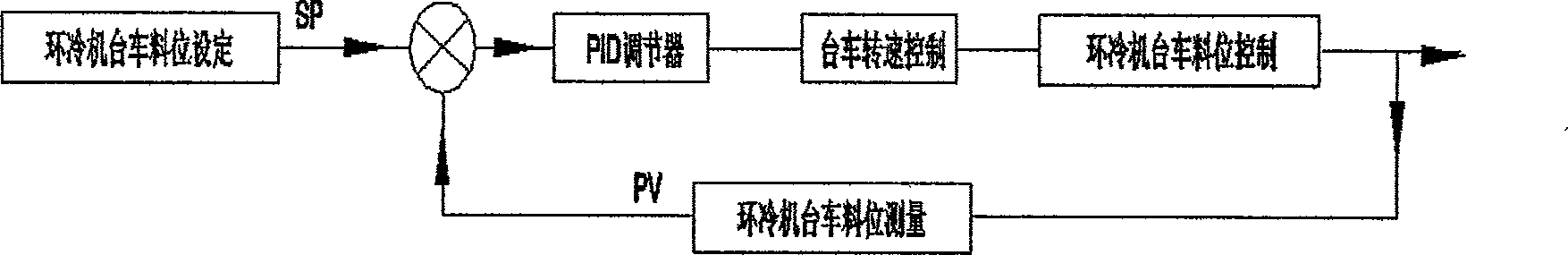

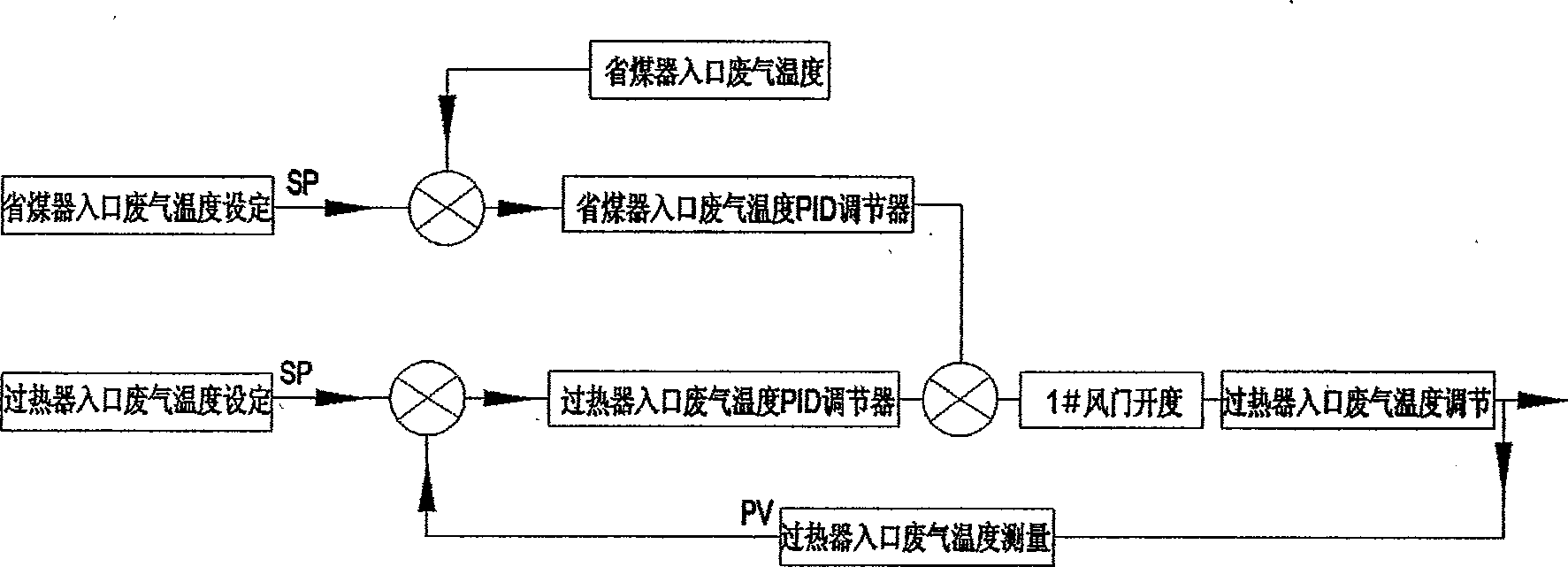

Control method for stabilizing and enhancing sintered ring cooling wind temperature while smelting steel

InactiveCN101424484AEasy to controlGuaranteed uptimeTemperature control with auxillary non-electric powerFurnace typesTaking temperaturesMaterials science

The invention relates to the field of reclaiming of waste gas and waste heat in the steel industry and power generation by the waste gas and the waste heat, in particular to a control method and a device for stabilizing and improving air taking temperature of a sintered ring in steel smelting. The device and the method are characterized in that the device and the technical method can achieve relative stabilization and moderate improvement of the temperature of the waste gas at the upper part of an inner batch layer of a cooling trolley through increasing and adjusting speed and cooled air of a circular cooler and uniformity for transversely feeding at a feed opening; and at the same time, under the premise that the temperature of the waste gas reaches the technical requirement of a waste heat generating technique, flow of the waste gas at the upper part of the batch layer is increased by properly increasing blown air amount at the lower part of the cooling trolley, so as to ensure relative stabilization and moderate improvement of air inlet temperature and flow of a waste heat boiler, and promote stabilization and improvement of vapor yield of the waste heat boiler and generated energy of a generating system.

Owner:昆明阳光基业股份有限公司

Portable device for measuring temperature using infrared array sensor

ActiveUS20130235901A1Accurate measurementImprove reliabilityThermometer detailsSensing radiation from moving bodiesDisplay deviceTaking temperatures

Disclosed is a portable device for measuring temperature with infrared array sensor. This portable device includes: an infrared array sensor module for taking temperature values in a unit of pixel and including a plurality of infrared sensors arranged in an array of pixels; a controller for calculating a resultant temperature value of a subject with reference to the temperature values taken each by the sensors; a display for expressing the resultant temperature value calculated by the controller; and a view finder with an indicator defining a target point to be measured for temperature and having a profile corresponding to the whole or a local shape of the subject. The view finder is formed of a transparent plate on which the subject's shape is reflected. The transparent plate is formed of: a notch representing the indicator; and a lens at least provided in the indicator.

Owner:EASYTEM CO LTD

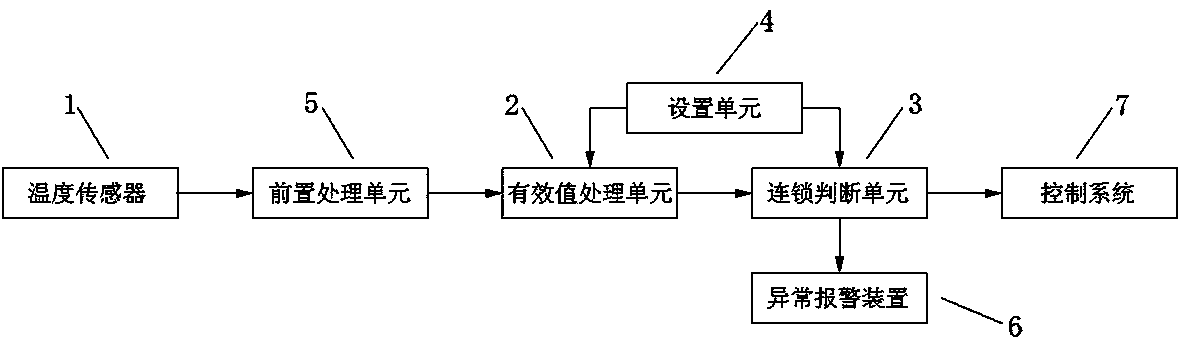

Control system protecting device and protecting method based on temperature measurement

ActiveCN103744316AReliable serviceInterference is effectively eliminatedProgramme control in sequence/logic controllersControl systemProcessing element

The invention discloses a control system protecting device and a control system protecting method based on temperature measurement. The protecting device comprises a temperature sensor, an effective value processing unit and a linkage judgment unit, wherein the temperature sensor is used for measuring the temperature of a control device and outputting the measured temperature, the effective value processing unit is used for calculating the effective value of the measured temperature and outputting the effective value of the temperature, and the linkage judgment unit is used for comparing the effective value of the temperature and the preset effective value and outputting abnormal alarm signals to an alarm device and / or linkage cutting protecting signals to a control system when the effective value of the temperature is not smaller than the preset effective value. The protecting method comprises the steps of temperature measurement, effective value processing and linkage judgment. The control system protecting device and the control system protecting method have the advantages that through the preset effective value, when temperature measuring points generate wire breakage, short circuit and poor contact, collected data are processed and compared in a specified time, data considered to be false signals by a system is isolated in time and processed, the control system linkage protection misoperation caused by false signal input is avoided, and the reliability of the system is improved.

Owner:WUKUN STEEL

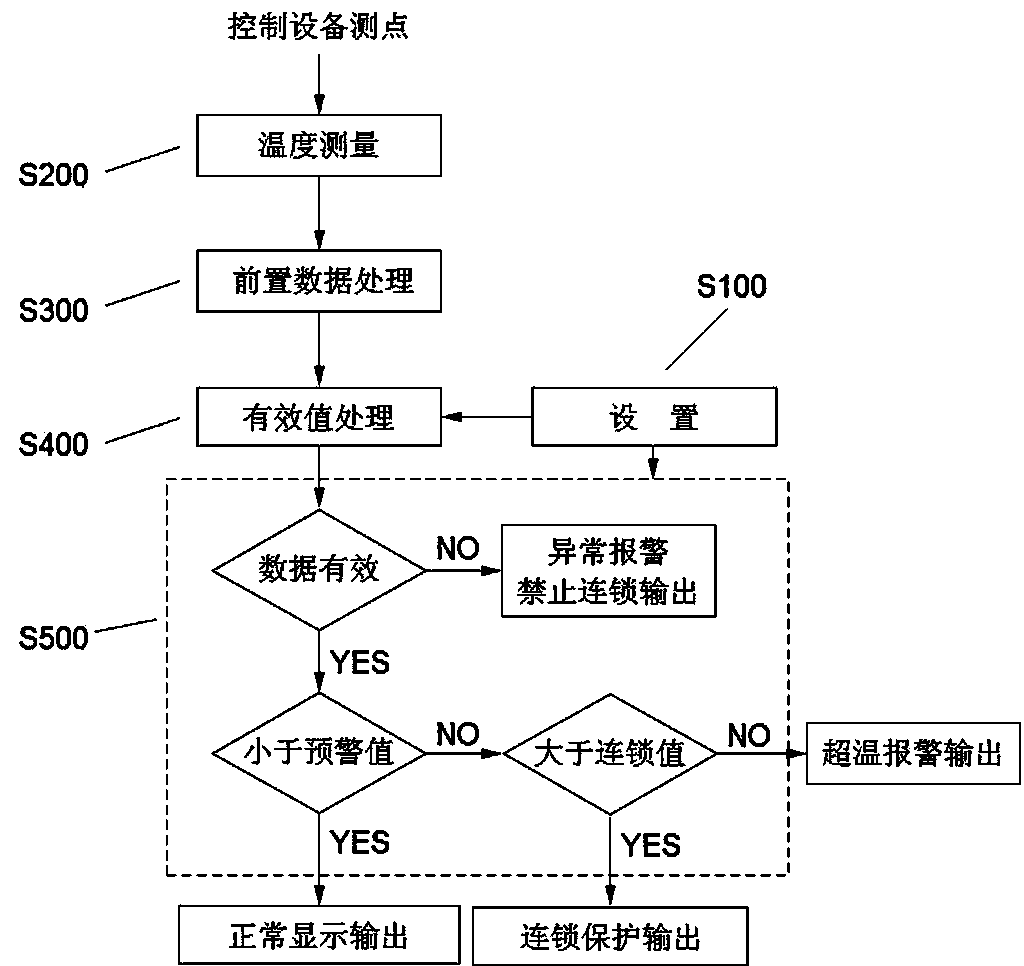

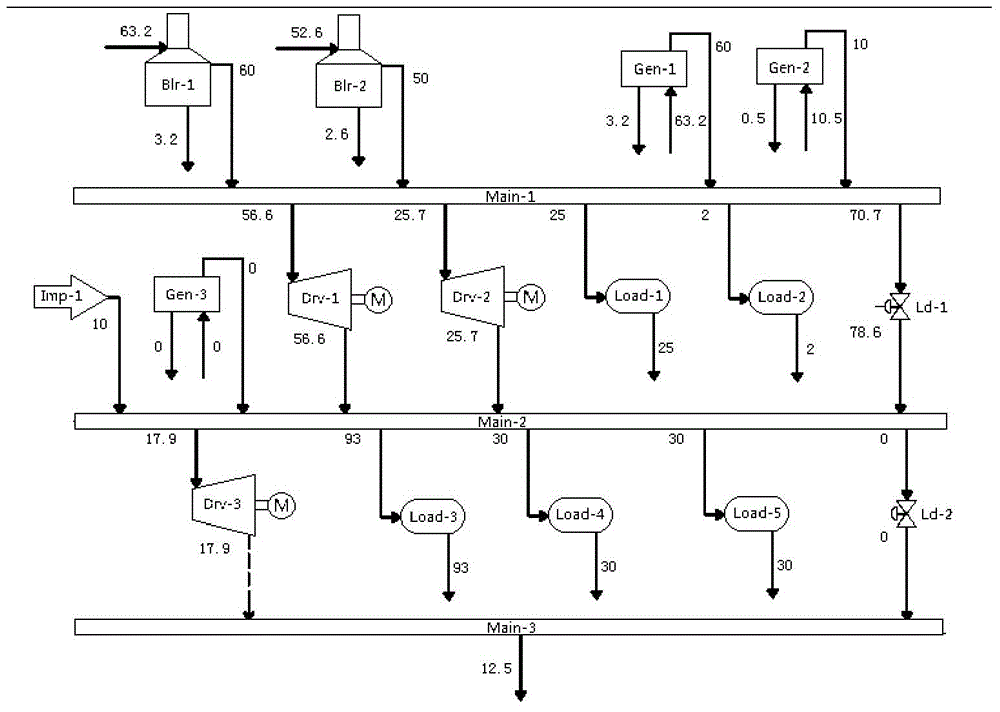

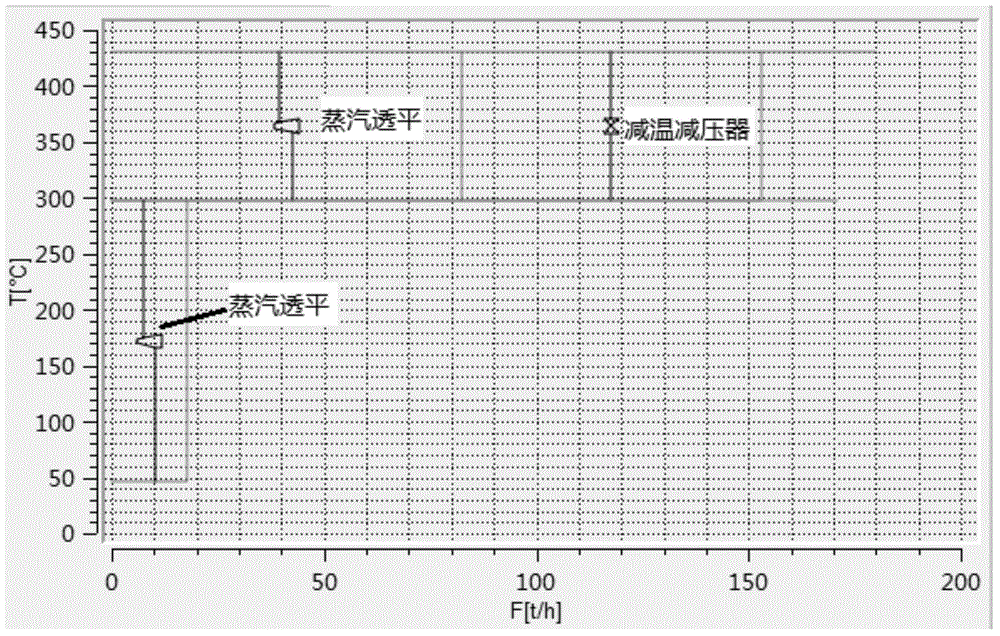

Diagrammatized steam power system analysis and optimization method and device

The invention discloses a diagrammatized steam power system analysis and optimization method and device. The method includes the following steps that process parameters of a first steam power system are collected under different working conditions; a first nonlinear mathematical model is established according to equipment composition and the process parameters of the first steam power system; simulation solution is conducted on the first nonlinear mathematical model, so that first simulation results of all devices and streams in the first steam power system are obtained; according to the first simulation results, steam generation and use data of all grades of steam boilers, steam turbines, turbines and temperature and pressure reducers in the first steam power system are obtained in a statistic mode, a load allocation diagram of the first steam power system is generated, and the load allocation diagram takes temperature as vertical coordinates and takes flow as horizontal coordinates; according to the load allocation diagram and the first simulation results, the running state and structural reasonability of the first steam power system are analyzed, composition of the first steam power system is improved according to the analysis result, and a second steam power system is obtained.

Owner:PROCESS INTEGRATION

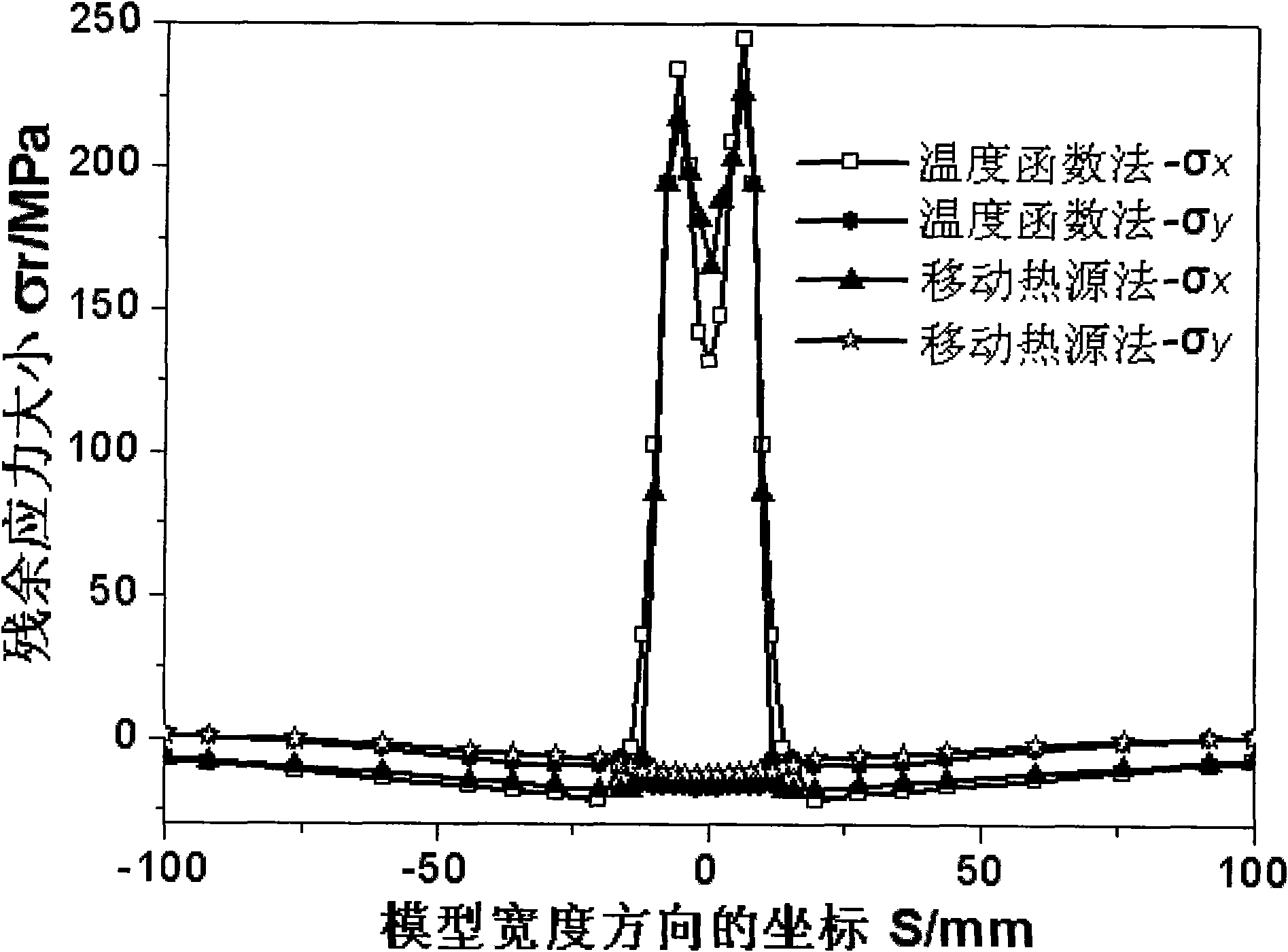

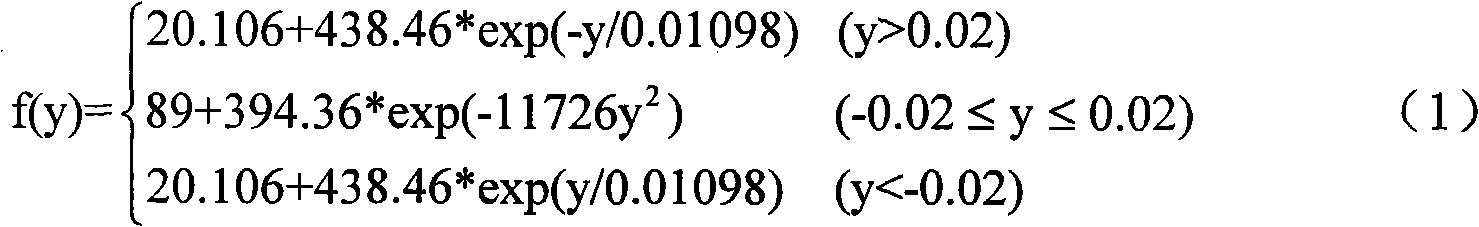

Method for analog calculation of welding value by taking temperature as control variable

ActiveCN101559511AImprove efficiencySolve accurate controlArc welding apparatusProgramme control in sequence/logic controllersResidual deformationWelding residual stress

The invention relates to a method for analog calculation of a welding value by taking temperature as a control variable, which comprises the following steps: 1) arranging welding temperature field distribution into a function of time and space: T(x, y, z,t)=f(x)f(y)f(z)f(t); 2) taking the obtained temperature distribution function T(x, y, z, t)=f(x)f(y)f(z)f(t) as a thermology boundary condition to add into a mechanics analysis model of a welding structure in a subprogram form; and 3) calculating the welding residual stress and the residual deformation of the model. The method converts the control variable in the welding simulation from heat to temperature, adds the proper temperature distribution in a sectional mode onto the mechanical analysis model for the analysis of stress and deformation, and can reduce the mechanical value analyzing time within 10 percent of the time used by a moving heat source method. The method can be widely used for welding welded structures with long welding lines, multiple welding lines and multiple passes, and has very important function on promotion and reference in projects.

Owner:TSINGHUA UNIV

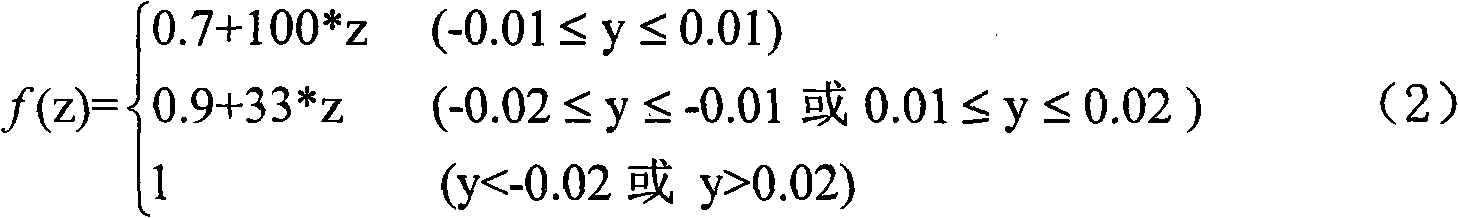

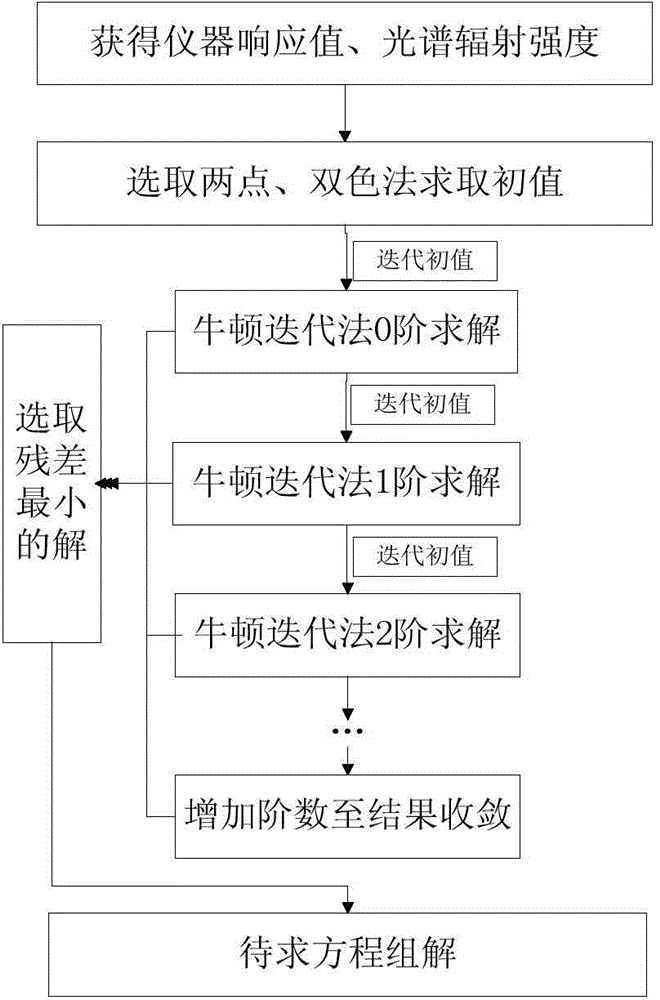

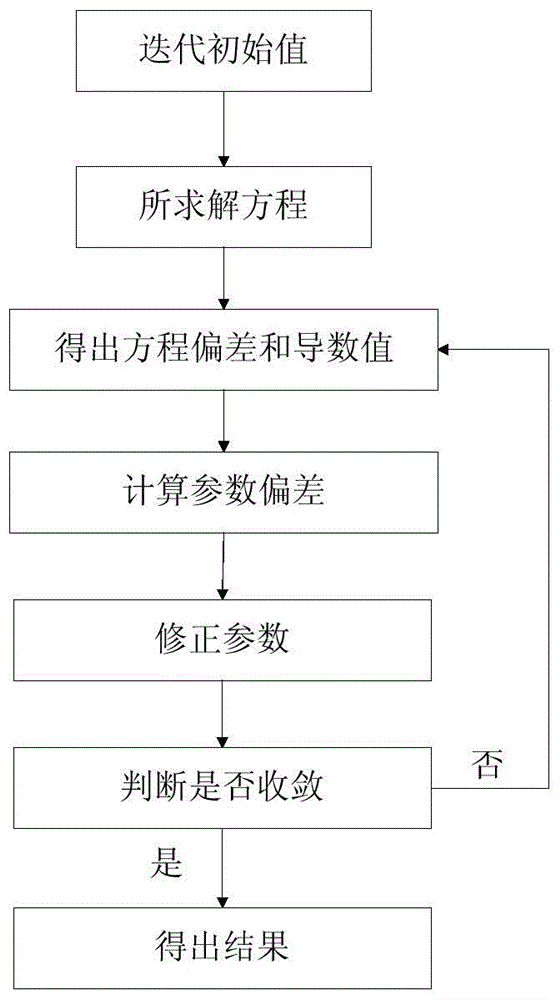

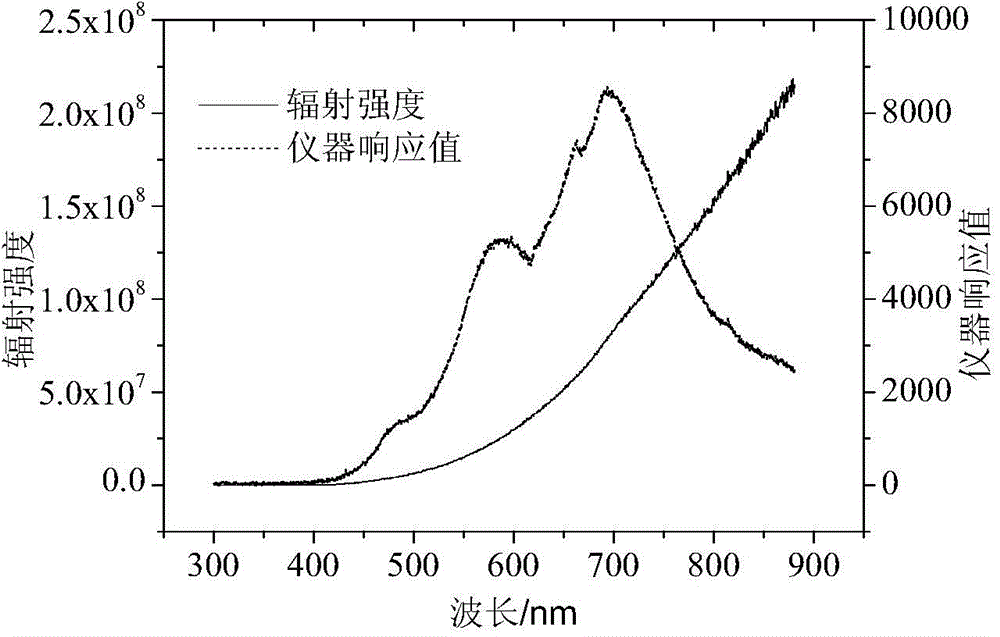

Method for measuring flame temperature and emissivity distribution based on spectral radiance intensity

The invention discloses a method for measuring flame temperature and emissivity distribution based on spectral radiance intensity. The method comprises the following steps: firstly, acquiring the spectral radiance intensity of flame to be measured by using a spectrometer; solving and taking temperature and emissivity as initial values by using a double-color method according to radiance intensity of two middle wavelengths; solving different order coefficients and temperature to be solved in polynomial relationship that the emissivity changes along with the wavelengths by using a Newton iteration method, increasing the orders of the polynomial relationship from zero step by step, solving the coefficients and the temperature of each order, except that the zero order takes the double-color method result as an initial value, taking the result of a previous order as the initial value for other steps; requiring final result when the solving result does not change along with increase of solving orders, that is, the result is converged along with the change of the orders. By adopting the method disclosed by the invention, the temperature of the flame to be measured and the emissivity distribution of the flame along with change of the wavelength can be obtained according to the spectral intensity of the flame to be measured, the measurement does not depend on assumption or priori conditions, and the result is reliable.

Owner:TSINGHUA UNIV +1

Temperature measure device

InactiveUS20060062276A1Good adhesionReduce manufacturing costThermometer detailsThermometers using electric/magnetic elementsEngineeringTaking temperatures

A temperature measure device having a light source to provide the user an effective and efficient means to take temperatures in a low-lighted area. A temperature measure device having a cartridge to store, dispense and discard the covers. The covers made of a thin narrow flexible material that is housed by a body and conveniently stored inside or in the proximity of the temperature-measuring device.

Owner:CONFORTI CARL J

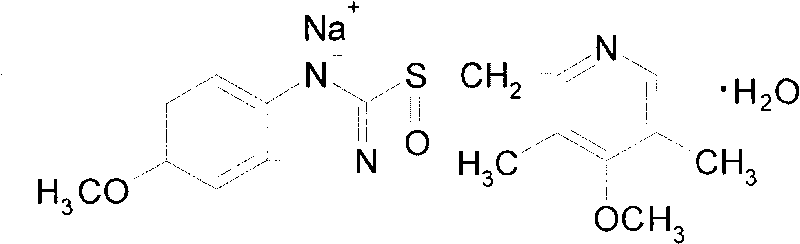

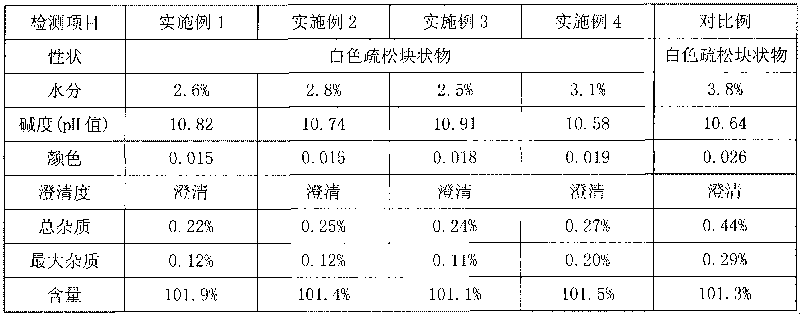

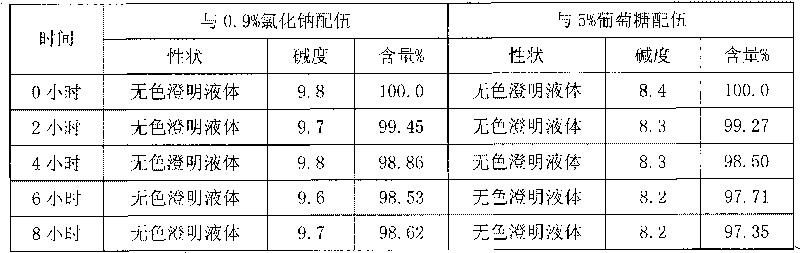

Omeprazole sodium freeze-dried powder injection and preparation method thereof

ActiveCN101703483AReduce the risk of adverse reactionsComply with the requirements of human intravenous injectionPowder deliveryOrganic active ingredientsOmeprazole SodiumFiltration

The invention discloses an omeprazole sodium freeze-dried powder injection and a preparation method thereof. The omeprazole sodium freeze-dried powder injection contains an active ingredient, namely, omeprazole sodium monohydrate, and auxiliary materials, namely, calcium disodium edetate and sodium hydroxide. The preparation method of the omeprazole sodium freeze-dried powder injection is characterized by comprising the following steps: weighing the calcium disodium edetate of prescription amount and dissolving the calcium disodium edetate in water for injection, stirring, dissolving, and regulating pH value to 10.0-12.0 by using 10% of sodium hydroxide solution; weighing omeprazole sodium of the prescription amount and adding the omeprazole sodium in the mixture, stirring at room temperature for dissolution, supplementing and adding the water for injection to full amount; adding active carbon, stirring at room temperature for decoloration and endotoxin removal, conducting rough filtration to remove carbon firstly, and then conducting refining filtration by using a filter membrane of 0.22 Mum; taking refining filtrate to test intermediate, conducting encapsulation after meeting requirements; and freeze-drying and unboxing, thus obtaining the omeprazole sodium freeze-dried powder injection. The freeze-drying technology of the omeprazole sodium freeze-dried powder injection takes temperature below minus 40 DEG C as pre-freezing temperature; after pre-freezing for at least two hours, sublimation is started, wherein the sublimation temperature is 5-12 DEG C, the sublimation time is over 14 hours; and then drying is conducted for over 2 hours at the temperature of 20-35 DEG C. Unboxing is carried out after a stopper is added and a cover is put in place, thus obtaining the finished product of the omeprazole sodium freeze-dried powder injection.

Owner:HAINAN LEVTEC PHARMA

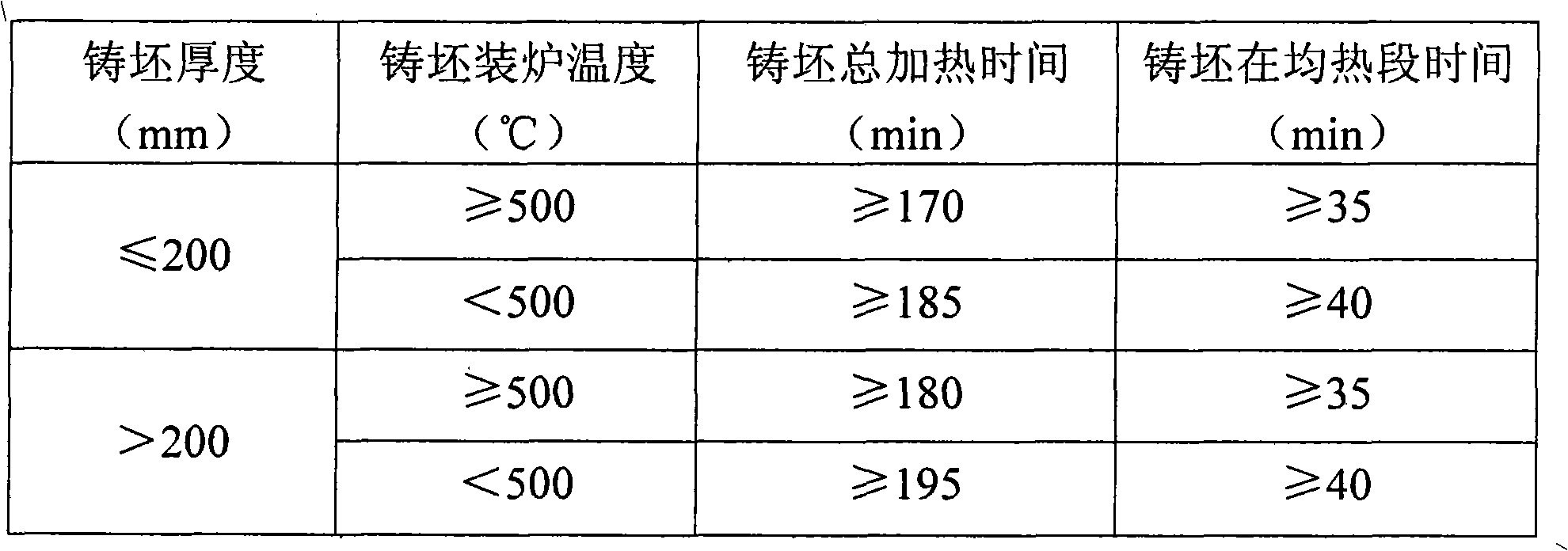

Method for improving rolling stability of container thin material

ActiveCN101927263AImprove stabilityEasy to shapeTemperature control deviceFurnace typesTemperature controlEconomic benefits

The invention relates to a method for improving the rolling stability of a container thin material. By reasonably configuring a rolling plan, optimizing process technical parameters, improving a process schedule, taking temperature control as a principle line and adopting a series of effective technical measures such as strictly controlling a heating mechanism, a rough rolling production process, a finish rolling production process and the like, the rolling stability of the container thin material is improved; head folding, whipping and strip blocking accidents of stripped steel are reduced; punch mark and scratch phenomena of a roller, stripped steel deviation and loop fluctuation in a rolling process are avoided; and the strip shape and the surface quality of the container thin material are improved so that the rolling success ratio is up to 99 percent. Simultaneously, accident processing workload is reduced, rolling mill operating rate and product yield are improved, contract implementation rate is ensured and enterprise goodwill and economic benefit are improved.

Owner:ANGANG STEEL CO LTD

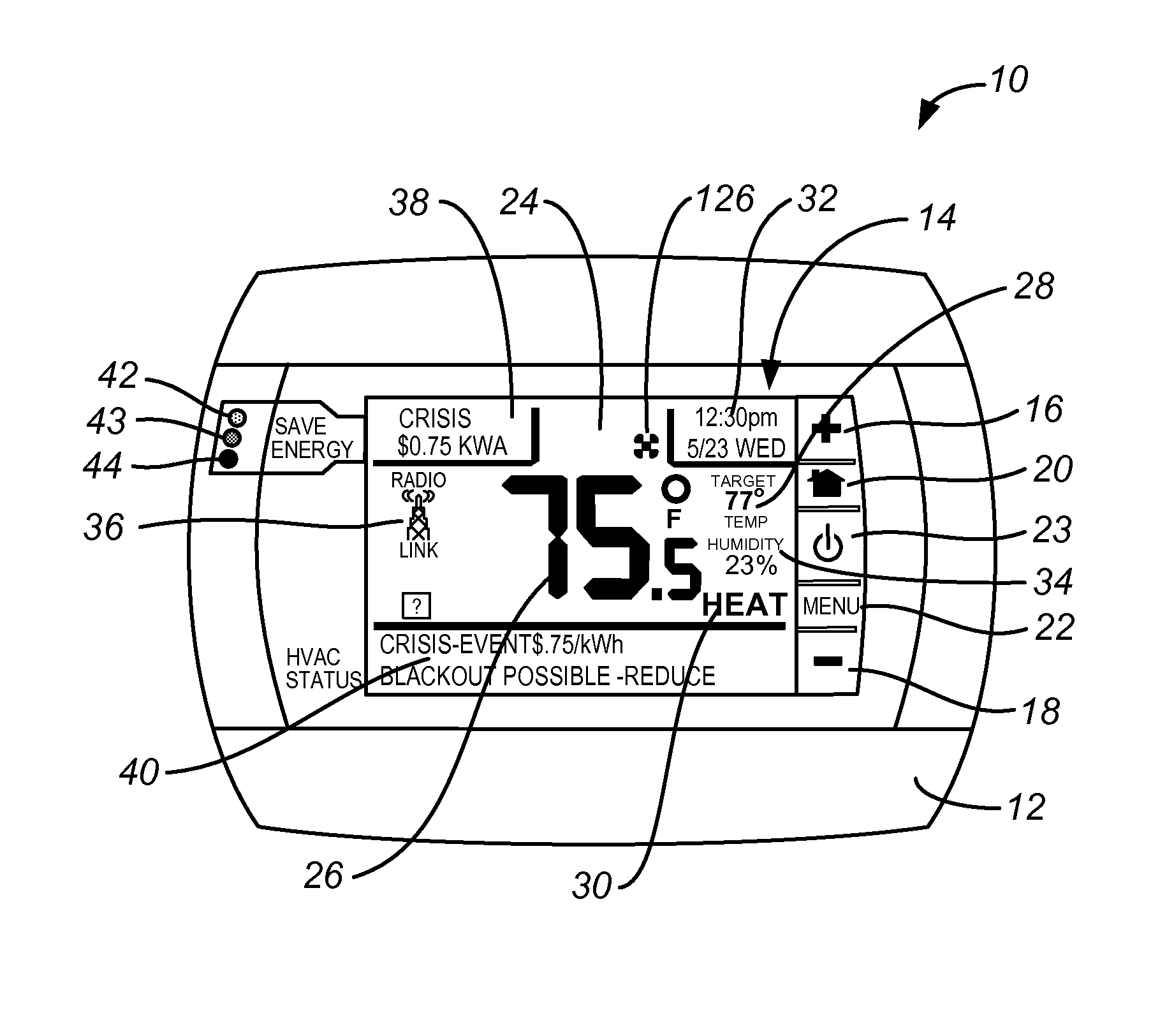

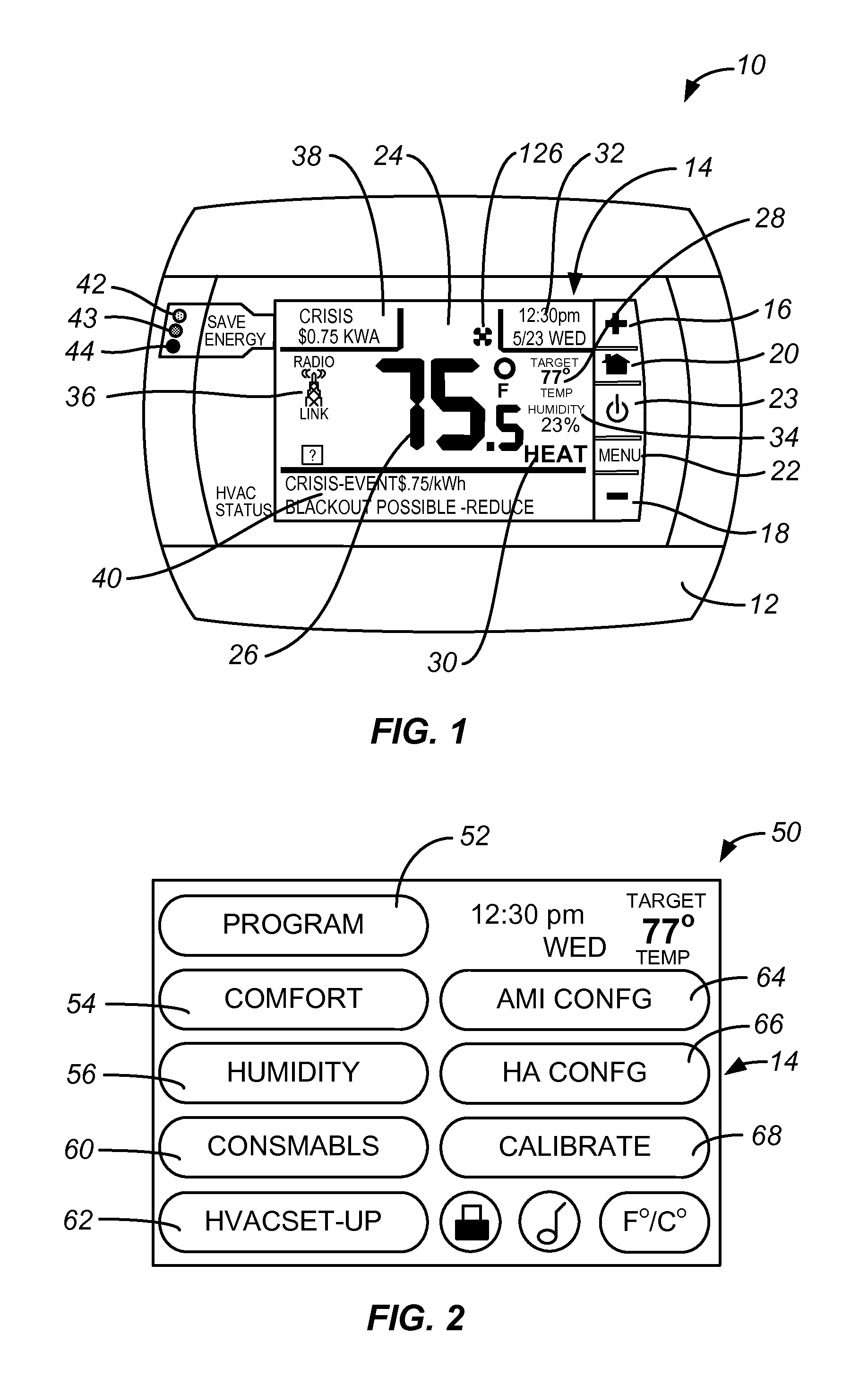

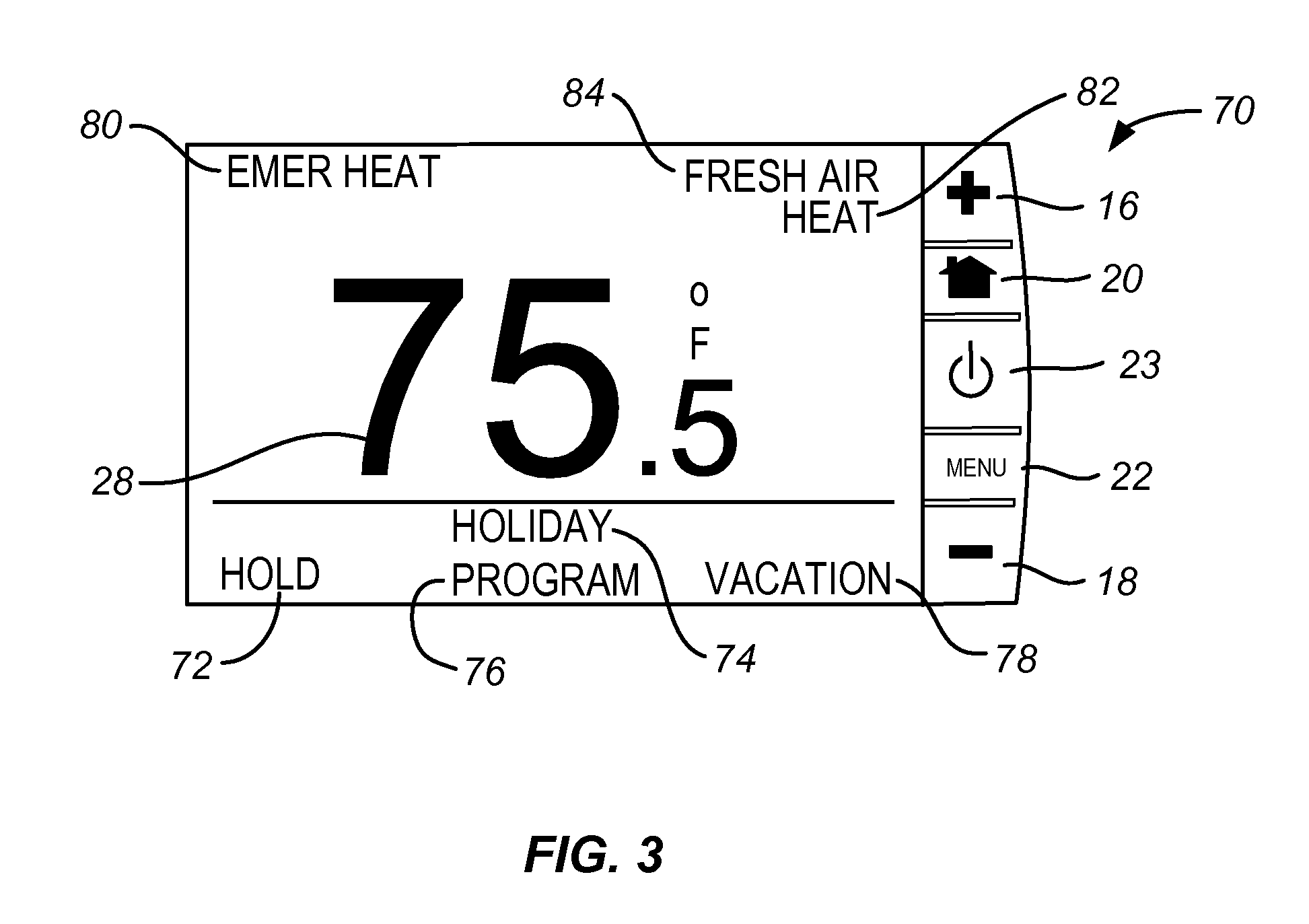

Method for operating a thermostatically controlled heater/cooler with fresh air intake

ActiveUS8306669B1Avoid insufficient heatingMechanical apparatusLevel controlProgram segmentTemperature control

A thermostat-controlled heater / cooler is used to condition air in a temperature-controlled region. A target temperature is obtained and compared to the temperature of the region to determine if heating / cooling is required. If yes, then outside air is directed into the region without operating heater / cooler and updated temperatures of the region are measured. The directing and measuring are continued until (1) the measured temperature equals the target temperature, at which time control returns to the obtaining a target temperature step, or (2) the updated measured temperature differs from the target temperature by a chosen amount, and in some examples, if the updated temperature does not reach the target temperature within a chosen length of time, or the target temperature changes, or the program segment ends, at which time directing outside air into the temperature-controlled region is stopped and the heater / cooler is operated under control of the thermostat.

Owner:TIM SIMON

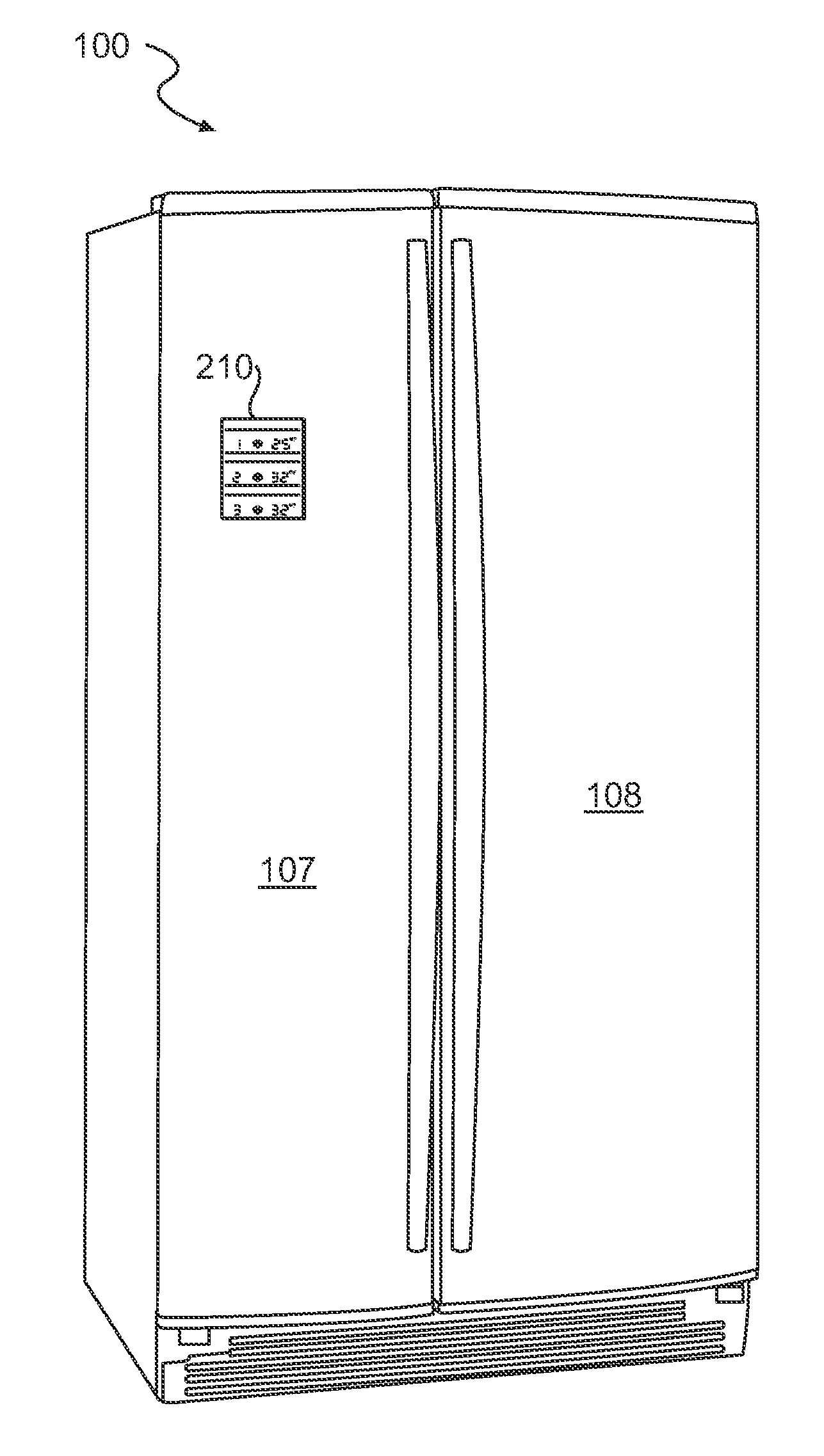

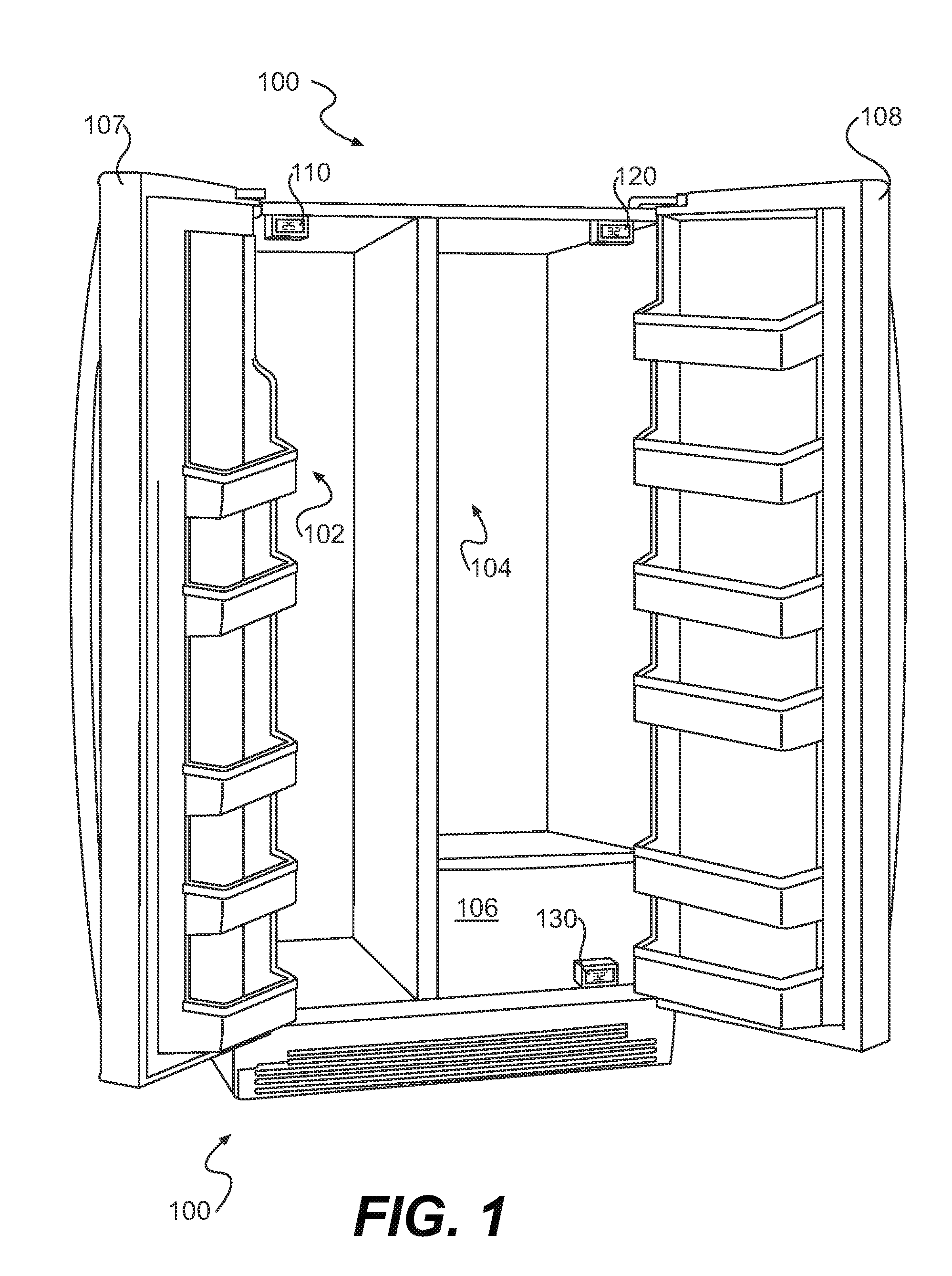

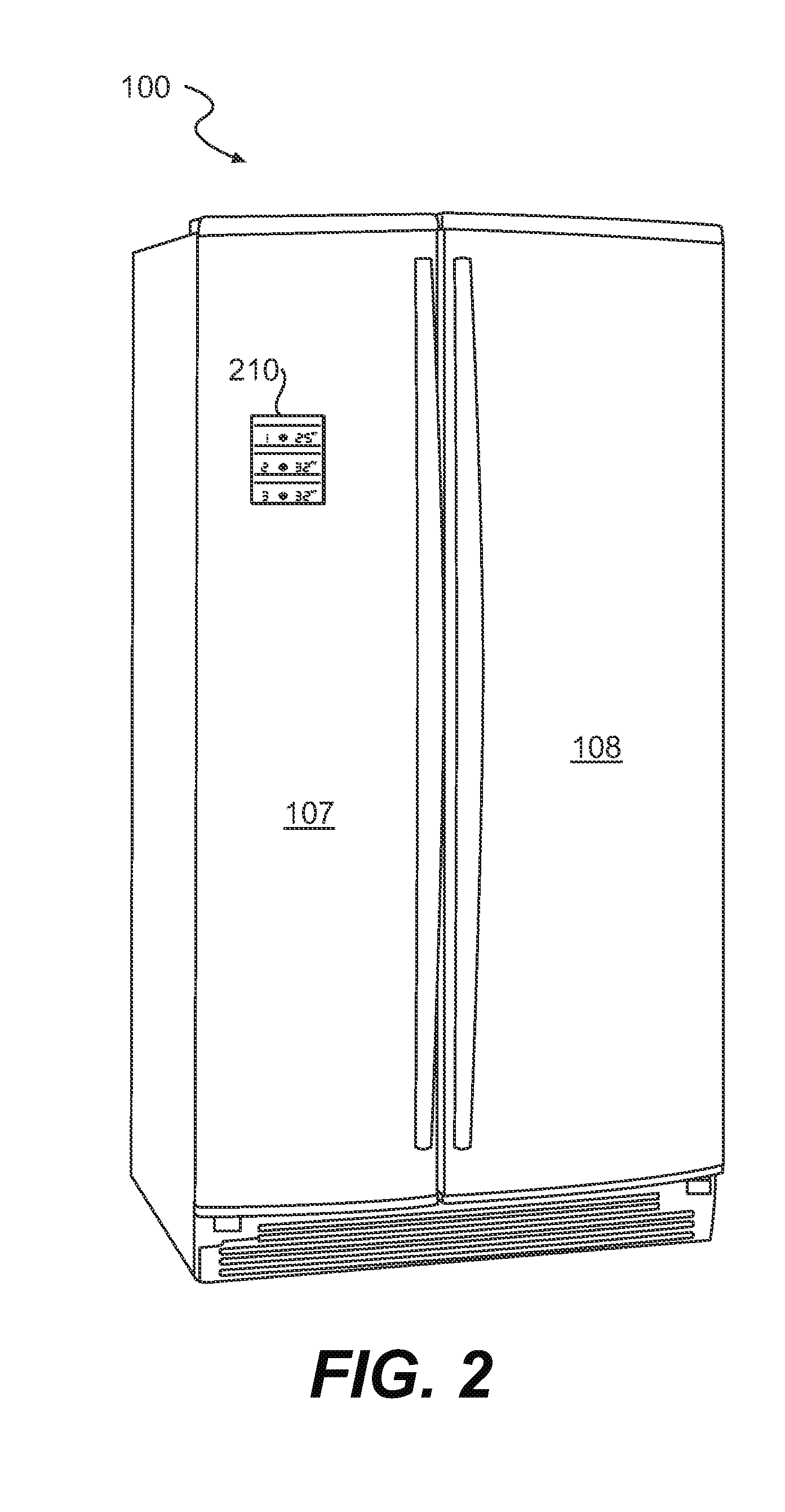

Icebox with external controls and temperature display

An icebox with external controls. The icebox includes an insulated container having one or more compartments. One or more temperature sensors take temperature measurements of the one or more compartments. An externally visible panel displays the temperature measurements and coldness settings corresponding to the temperature measurements. A control mechanism controls a cooling mechanism so as to maintain the temperature of the compartments at a predetermined temperature corresponding to the coldness setting. An externally accessible input allows selective changes of the coldness setting.

Owner:WASSERMAN SAM

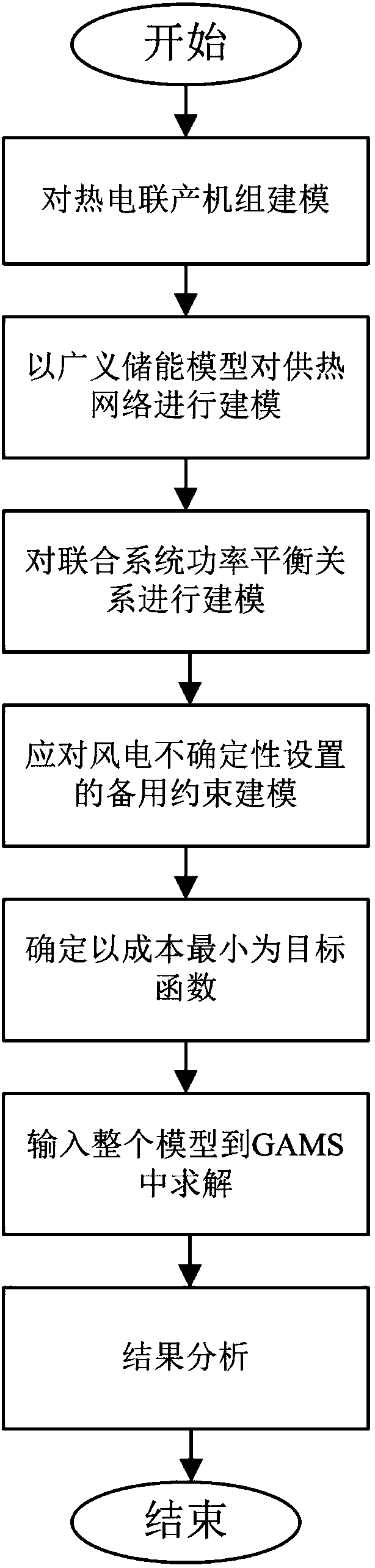

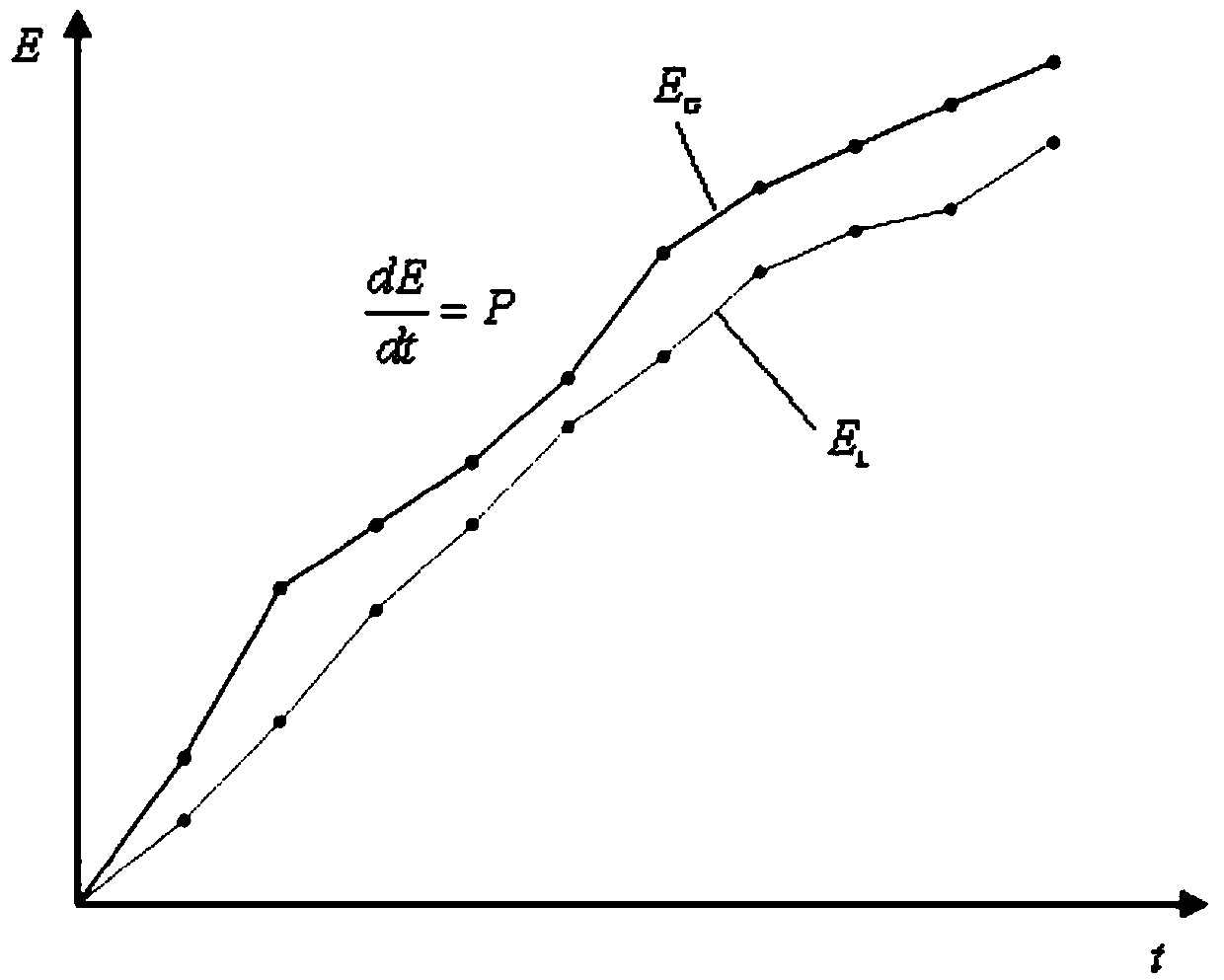

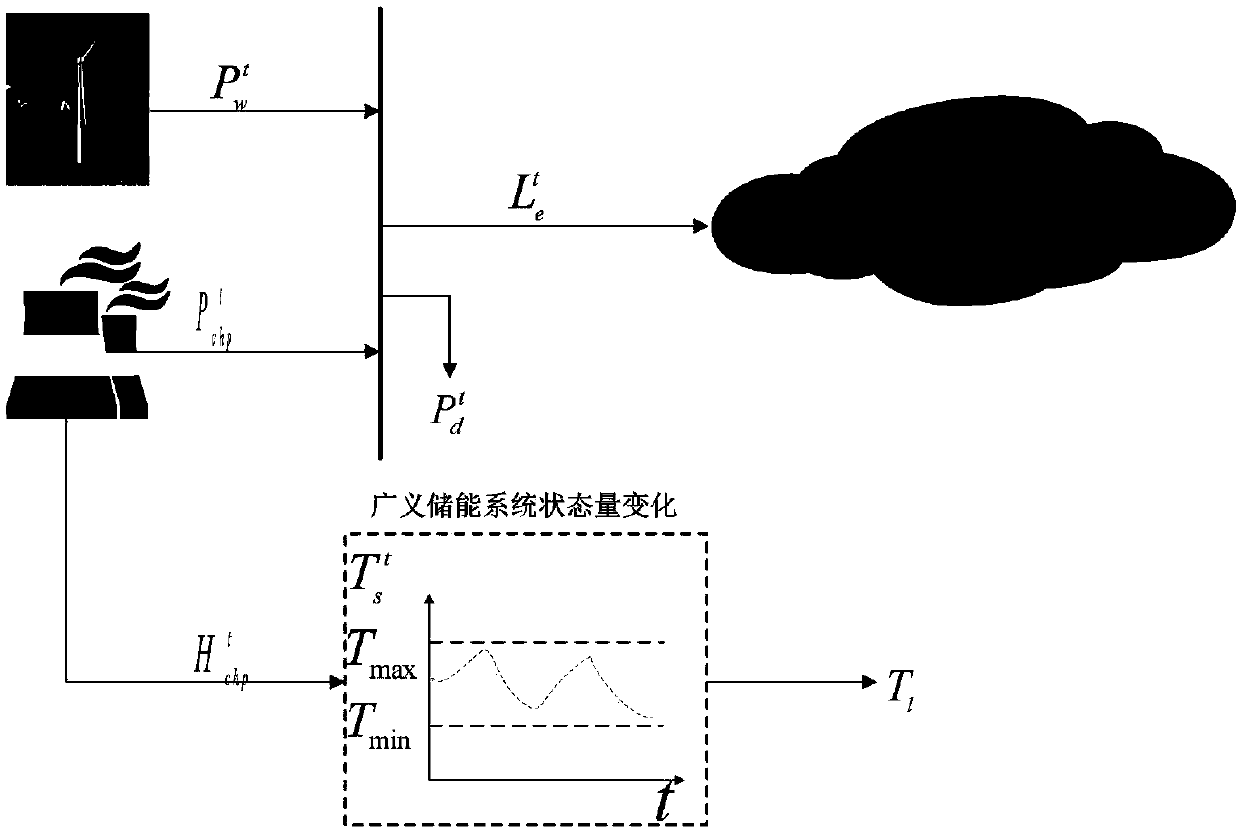

Combined heat-power optimization scheduling method taking account flexibility of heat supply network

ActiveCN108628176AImprove operational flexibilitySimple calculationAdaptive controlLower limitCogeneration

The invention discloses a combined heat-power optimization scheduling method taking account flexibility of a heat supply network. Aiming at digging the source load power non-matching relation betweentwo ends of the heat supply network, through equaling the heat supply network to a generalized energy storage model, making description with a thermodynamic first order differential model and taking temperature as a characteristic quantity, a combined heat and power optimization model is constructed. The method includes steps of obtaining an electric heating operation external characteristic modelaccording to operation characteristics of an air exhaust type heat-power cogeneration unit; equaling the heat supply network as the generalized energy storage model and establishing an upper and lower limit constraint model for the characteristic quantity; according to the structure of the combined heat-power optimization operation system, obtaining a heat-power balance model of the whole system;establishing a standby constrain model; establishing a model taking the minimal cost of the combined heat-power system as a target optimization function; acquiring the minimal cost value of the combined heat-power system and corresponding air exhaust volume through solving the model by utilizing a Cplex algorithm in a GAMS optimization platform; outputting the optimization result and analyzing the result.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

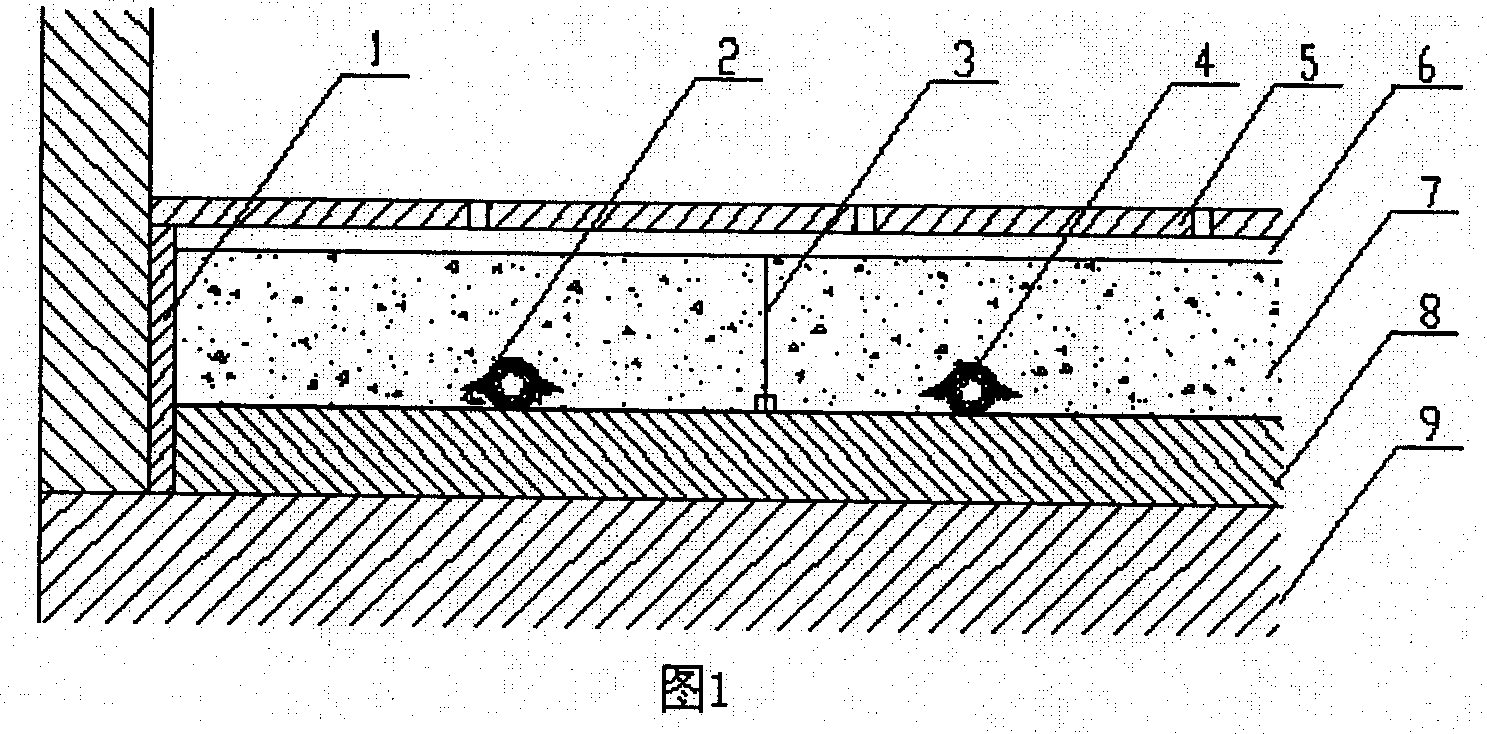

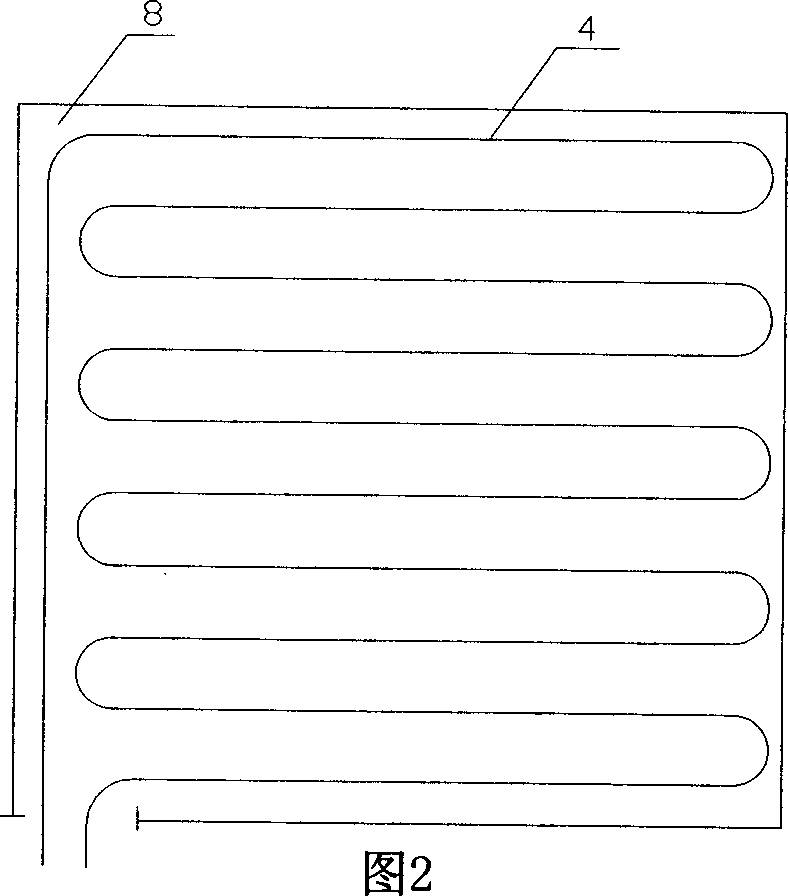

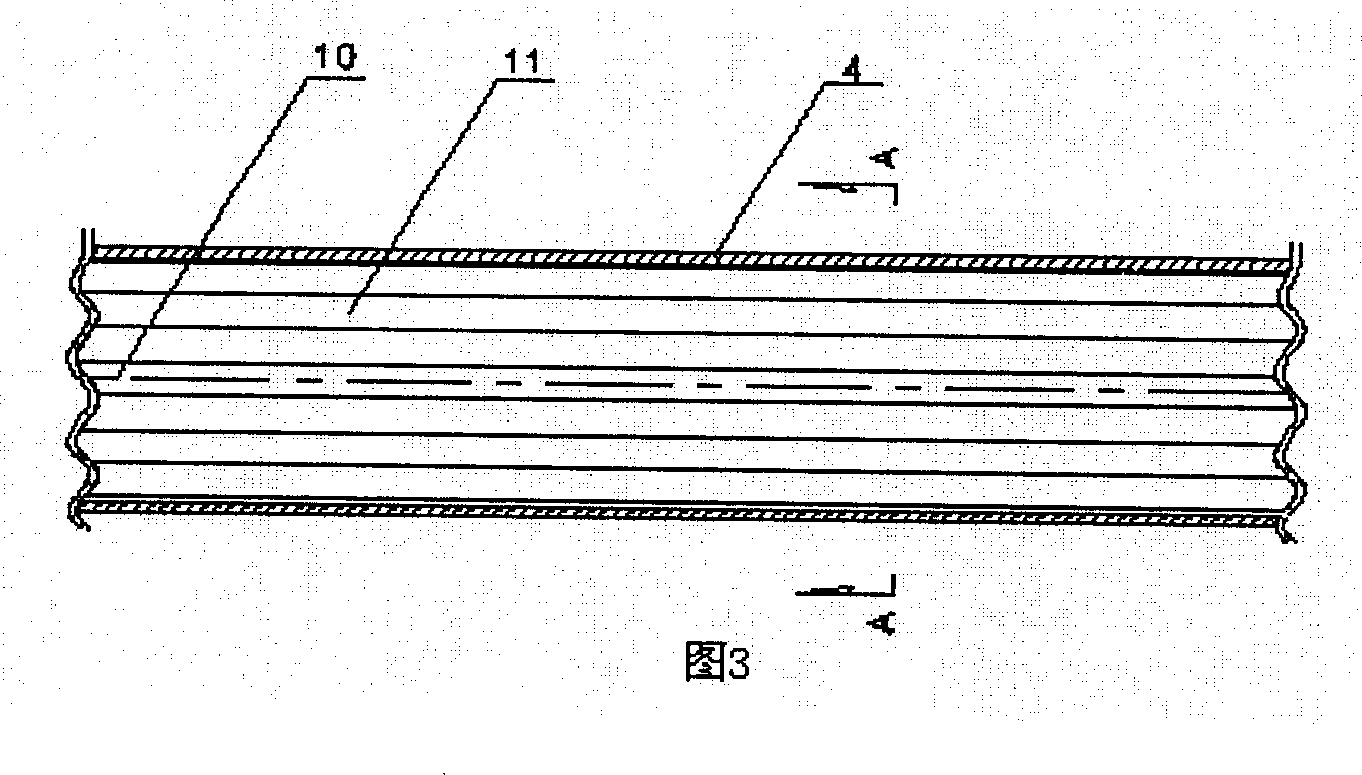

Composite phase-change heat-storage heating method and heating apparatus

InactiveCN1731028AImprove heat storage capacityReduce volumeCentral heating with accumulated heatLighting and heating apparatusElectricityPhase change

The new composite phase changing heat accumulating heating technology includes adding heat accumulating pipe and heat accumulating capsule into traditional electric heating set and filling heat medium in the gaps. The heat accumulating medium takes phase change while being heated and cooled to form one latent heat accumulating process. The heat medium acts as the fluid medium for heat transfer between the heated surface and the heat accumulating medium to strengthen the heat transfer inside the heat accumulating medium on one hand, and takes temperature change as one sensible heat process accompanying the heat accumulating and releasing on the other hand. The technology of the present invention can strengthen the heat transfer process inside heat accumulating medium, raise heat accumulating capacity and decrease size of heat accumulating apparatus.

Owner:BEIJING UNIV OF TECH

Friction welding process heat flow microstructure multi-physical field numerical calculation method

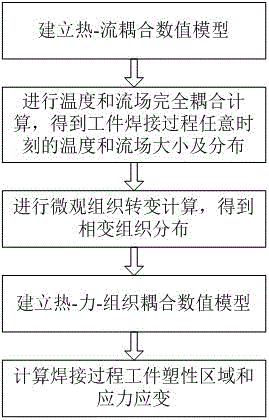

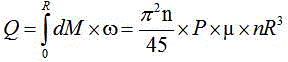

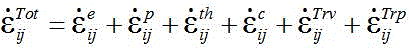

ActiveCN106202803ARealize multi-physics direct coupling numerical simulation calculationAccurate simulation calculation resultsData processing applicationsComputer aided designPhysical fieldNumerical models

The invention discloses a friction welding process heat flow microstructure multi-physical field numerical calculation method, which comprises a first step of building a heat flow coupling numerical model: performing temperature and flow field full coupling calculation by using an Euler method which takes temperature into account so as to obtain the size and distribution ofthe temperature and the flow field at any time during a workpiece welding procedure; a second step of performing microstructure transformation calculation by using a Leblond phase transformation model and algorithm so as to obtain phase transformation tissue distribution; a third step of building a heat flow microstructure coupling numerical model based on the obtained temperature, flow field and the phase transformation distribution, and calculating a workpiece plastic zone and stress-strain during the welding procedure. When the method disclosed by the invention is used for simulating a friction welding process, a simulation result can be obtained efficiently and exactly, and the fit degree to an actual friction welding process can be increased.

Owner:SICHUAN UNIV

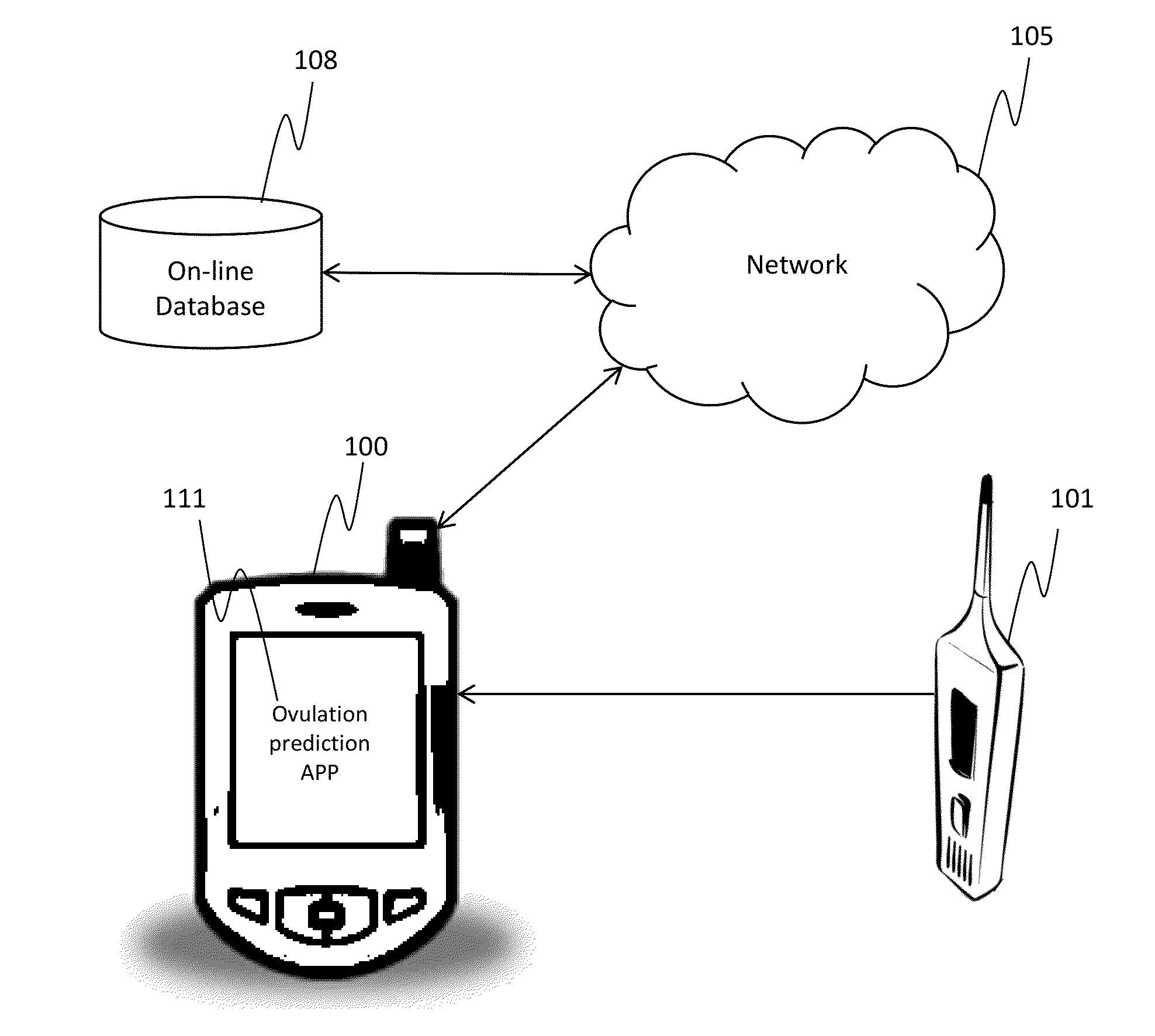

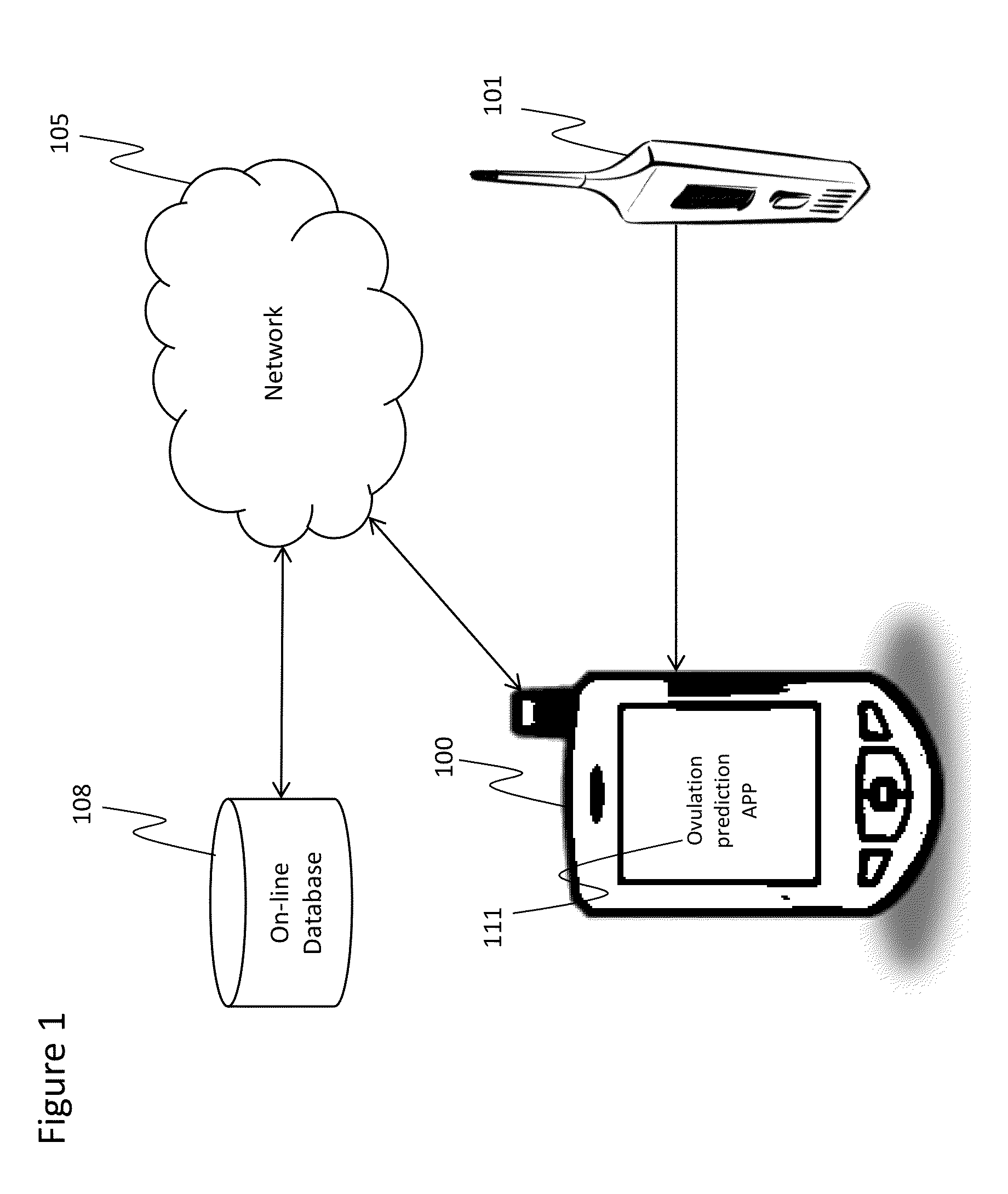

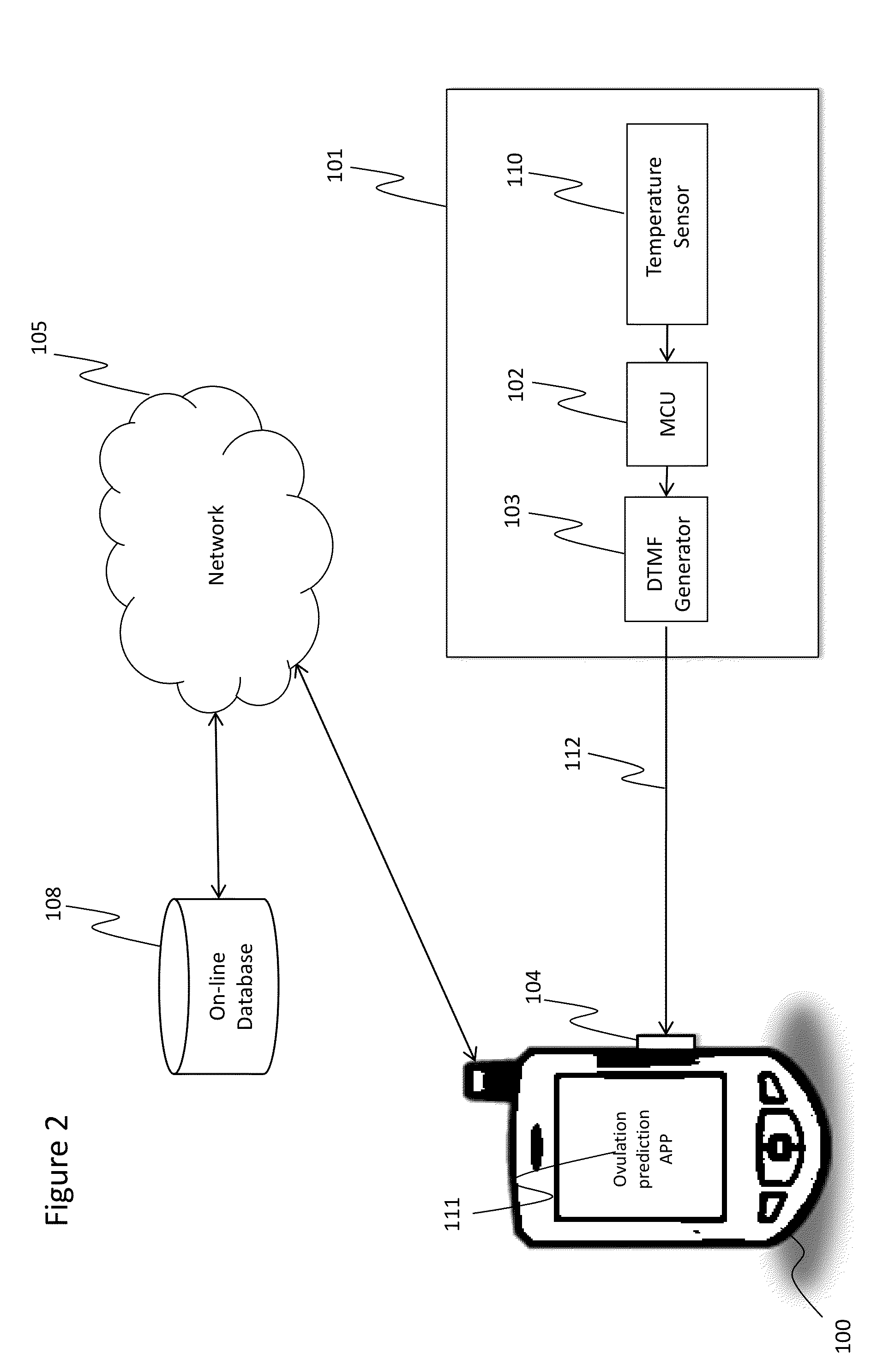

Cell phone app for coupling a cell phone to a basal body temperature thermometer for predicting ovulation

InactiveUS20130131541A1Improve accuracySave a lot of timeSurgeryVaccination/ovulation diagnosticsEngineeringBasal body temperature

A system for predicting ovulation cycles by employing an application running on a mobile communication device such as an iPhone®, a Blackberry™, or an Android-based smartphone is provided. The system includes a basal body temperature thermometer coupled to a mobile communication device. The thermometer takes temperature measurements, encodes the temperature measurements and transmits the encoded temperature measurements to the mobile communication device. The mobile communication device receives and decodes the encoded temperature measurements. The mobile communication device includes an application that analyzes the decoded temperature measurements to determine whether they are satisfactory or unsatisfactory, provides feedback to a user in real-time and provides an ovulation prediction.

Owner:ETERNAL ELECTRONICS

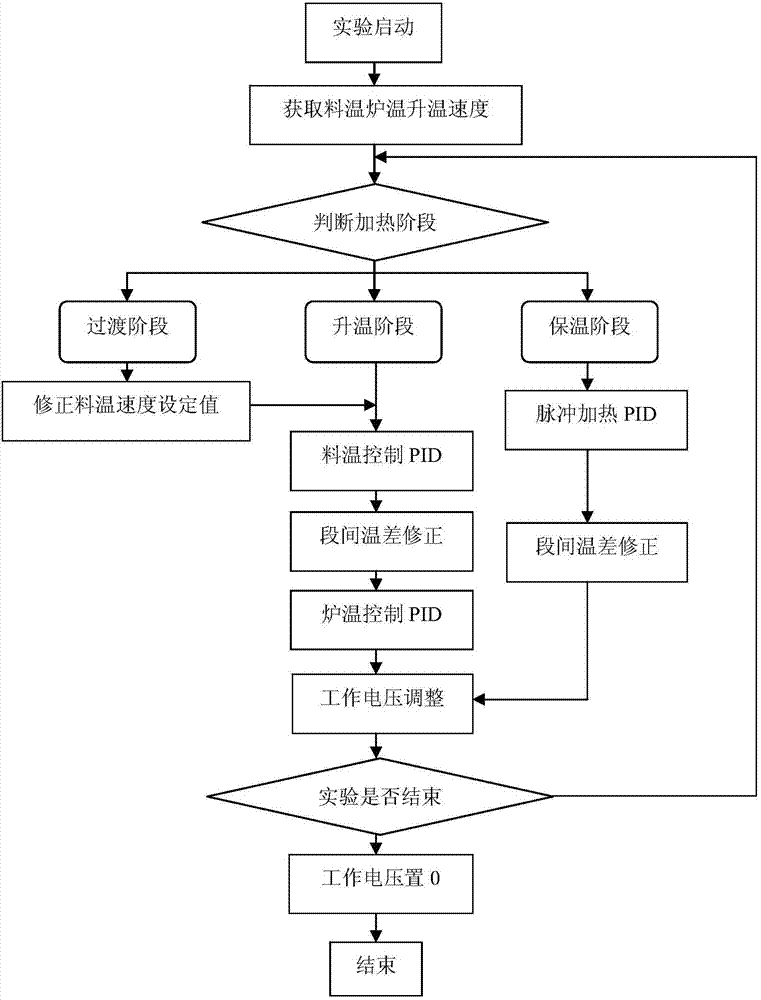

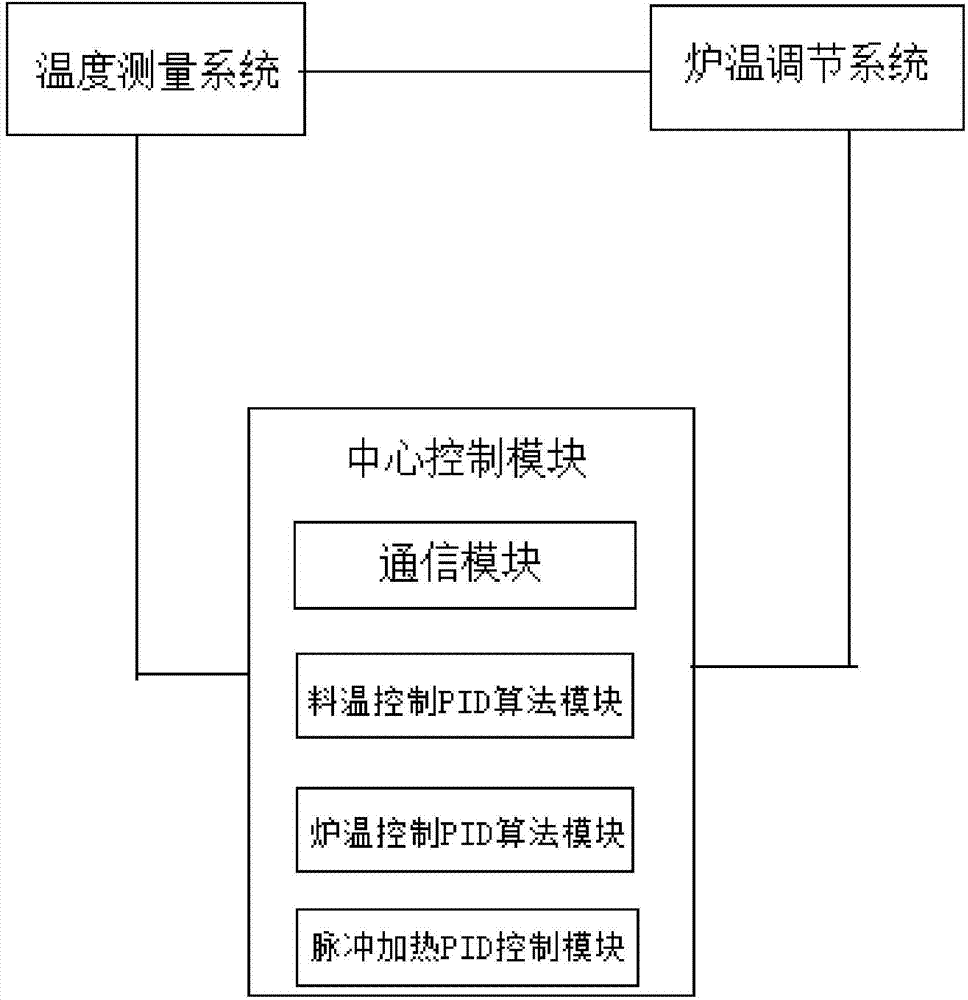

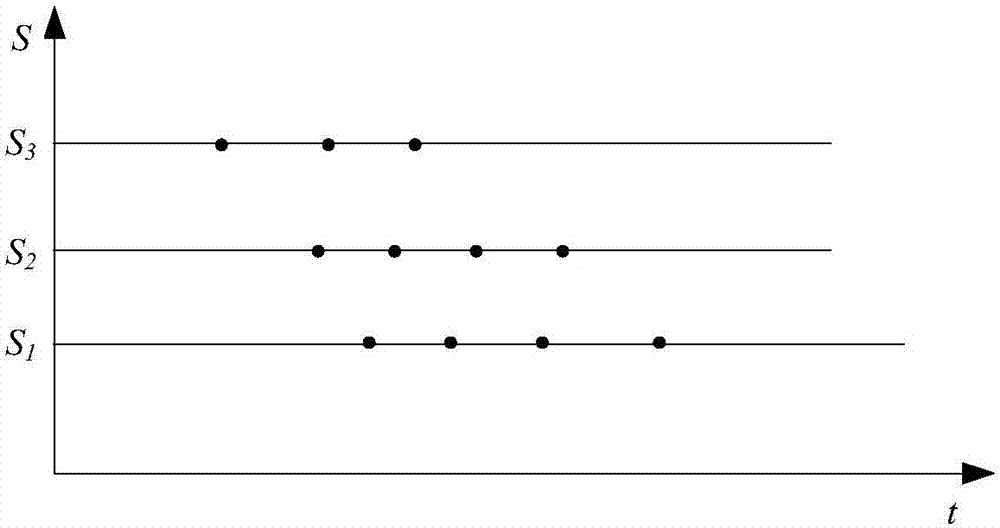

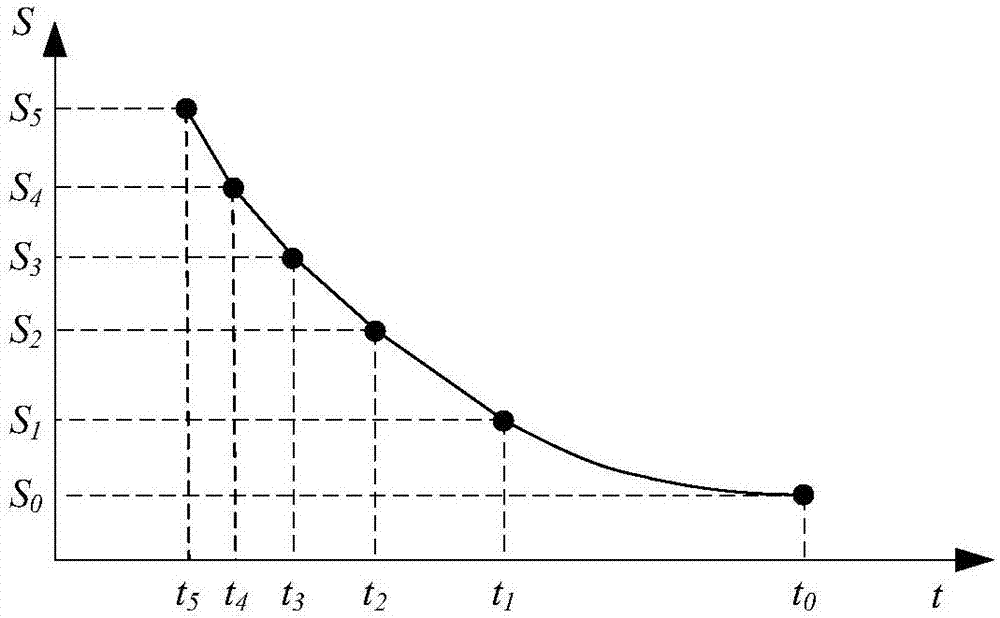

Temperature synchronizing system and method used for metallurgic performance measuring device

ActiveCN104503510AImprove uniformityImprove the efficiency of performance measurementTemperatue controlFurnace temperatureSilicon-controlled rectifier

The invention relates to the field of metallurgy and provides a temperature synchronizing system and method used for a metallurgic performance measuring device. The temperature synchronizing system comprises a temperature measuring system, a furnace temperature adjusting system and a central control module, the temperature measuring system comprises furnace temperature thermocouples and a material temperature thermocouple arranged at the center of an experiment sample in a furnace, the furnace temperature thermocouples are arranged on furnace walls of three heating sections respectively, the furnace temperature adjusting system comprises silicon controlled rectifiers arranged on resistance wires of the heating sections, and the central control module comprises a communication module, a material temperature control PID (proportion, integration and differentiation) algorithm module, a furnace temperature control PID algorithm module and a pulse heating PID control module. Heating processes of the three independent heating sections are unified by adopting an indirect control method and taking temperature increase speed of furnace temperature as a controlled object, so that influence on control accuracy due to difference in heating and cooling capability of each section in a conventional method is eliminated, inter-section temperature difference is reduced greatly, and uniformity in sample temperature is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

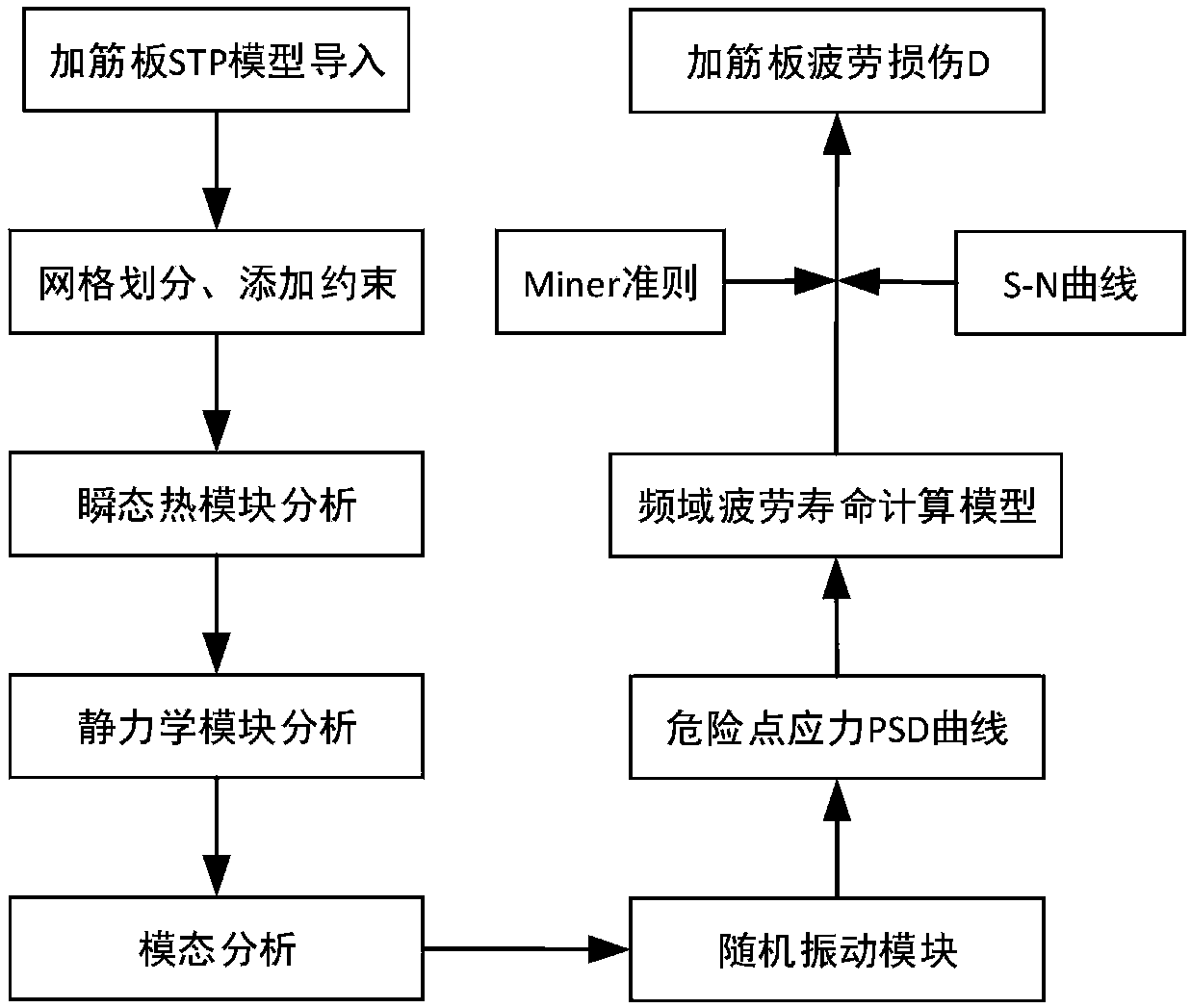

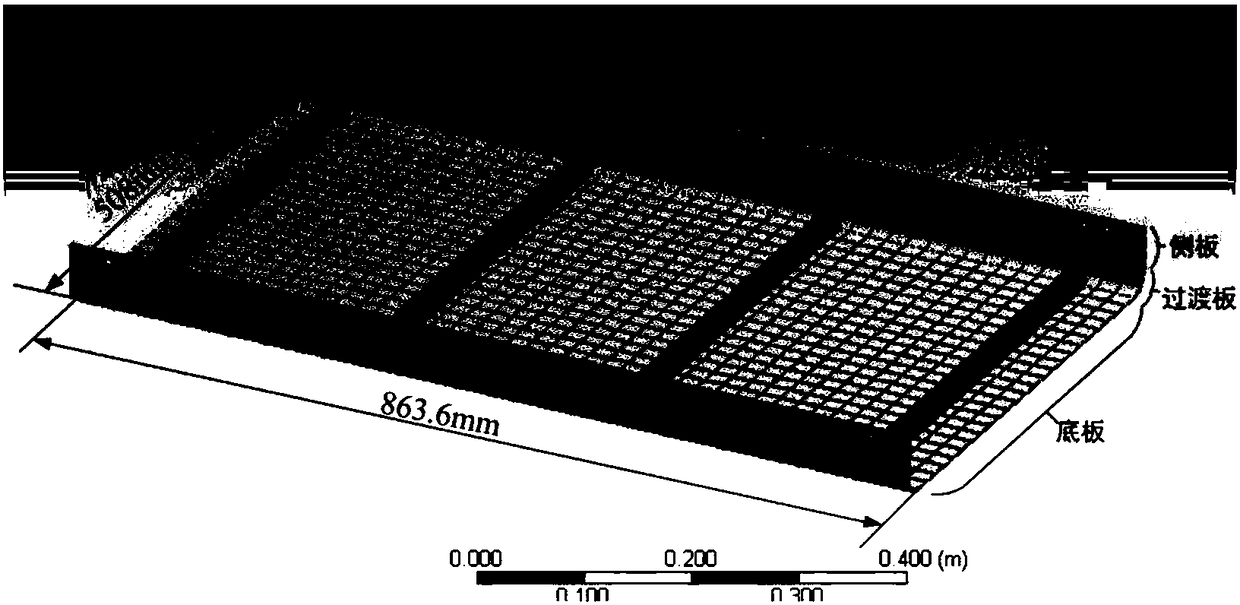

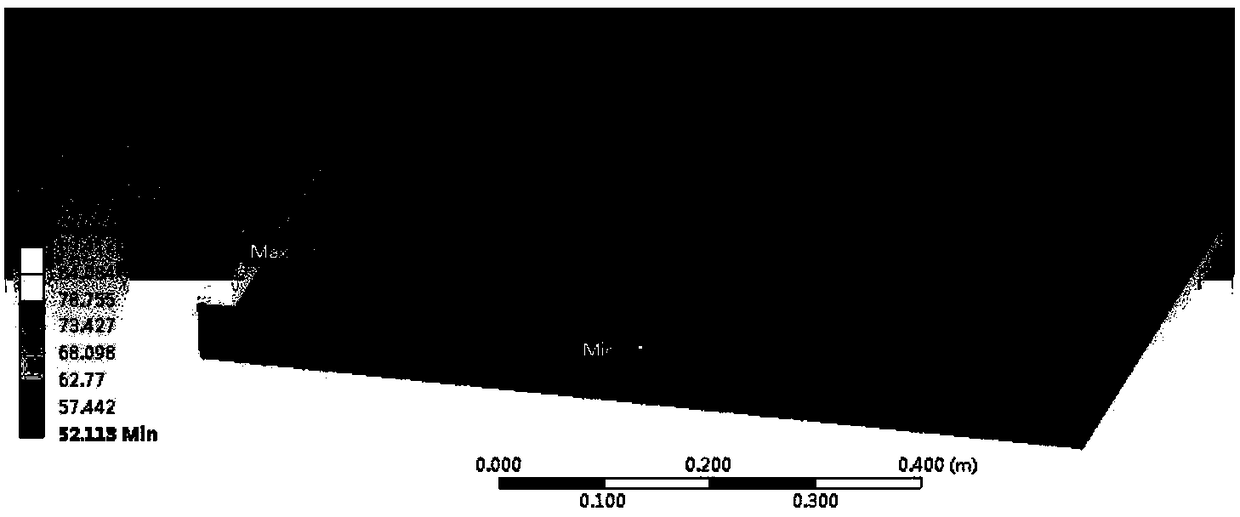

Fatigue life calculation method for stiffened plate structure taking temperature and random vibration load into account

InactiveCN108427844AExtended service lifeImprove fatigue lifeGeometric CADDesign optimisation/simulationFatigue damageModel parameters

The invention discloses a fatigue life calculation method for a stiffened plate structure taking temperature and a random vibration load into account. Pro / E three-dimensional modeling software is adopted to establish a geometric model of a supersonic aircraft stiffened plate; an ANSYS thermal stress analysis module is adopted to calculate a thermal temperature field and thermal stress distributionof the stiffened plate under different surface temperature loads; based on a modal analysis module, the influence law of the temperature load on the first six modes is analyzed; the maximum stress time domain spectrum obtained by ANSYS analysis is imported into matlab software in the form of .txt, and the fatigue damage under set conditions is calculated by combining the Miner linear damage accumulation theory and an S-N curve of the stiffened plate material to obtain service life parameters of the stiffened plate. By establishing geometric model parameters of Proe of the stiffened plate andthermal-vibration coupling parameters of the ANSYS model and integrating frequency domain analysis of matlab and PSD analysis process, the service life of the stiffened plate under certain working conditions, structural parameters and material properties can be optimized.

Owner:BEIJING UNIV OF TECH

Method for measuring temperature correction factor of bridge fatigue life gage

InactiveCN102095597AGood compensationImprove applicabilityStructural/machines measurementMitigation of undesired influencesElectrical resistance and conductanceCurve fitting

The invention discloses a method for measuring the temperature correction factor of a bridge fatigue life gage, comprising the following steps: sticking a test fatigue life gage on a standard fatigue test piece prepared from a material to be measured; arranging in an environmental chamber; at the temperature of miuns 20-60DEG C, adjusting the temperature of the environmental chamber; measuring the real-time resistance value Ri of the test fatigue life gage of each temperature point; taking the resistance value of the fatigue life gage, which is measured at 20DEG C, to serve as a reference resistance value R; setting the rectangular Cartesian coordinate system by taking temperature as the abscissa and the resistance variation rate as the ordinate; obtaining the discrete distribution graph of the resistance variation rate data points of different temperature points; carrying out curve fitting to the discrete data points by a cubic polynomial; calculating the coefficient of each item in the cubic polynomial so as to obtain the generate cubic polynomial phi (Tj) of the corresponding material; according to the temperature correction factor S=phi(Tj)*R of the bridge fatigue life gage, calculating the temperature correction factor S of the corresponding temperature point of the material to be measured; and correcting R obtained in the practical engineering. According to the monitored material, the temperature correction factors of the bridge fatigue life gage are respectively measured with the method, the method is directly applied to the practical engineering, the on-site tests become simple and convenient, and engineering applicability is strong.

Owner:CENT SOUTH UNIV +2

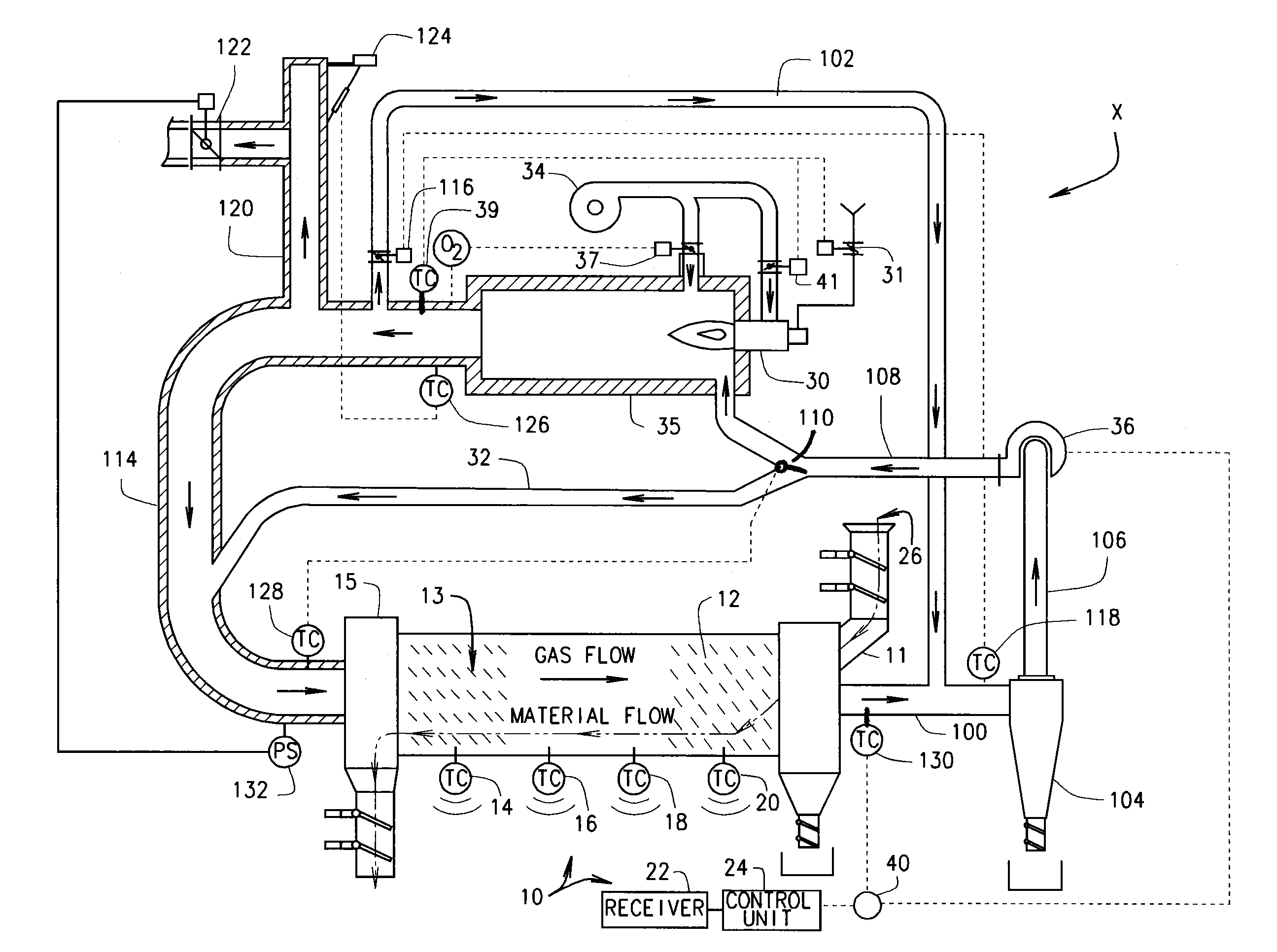

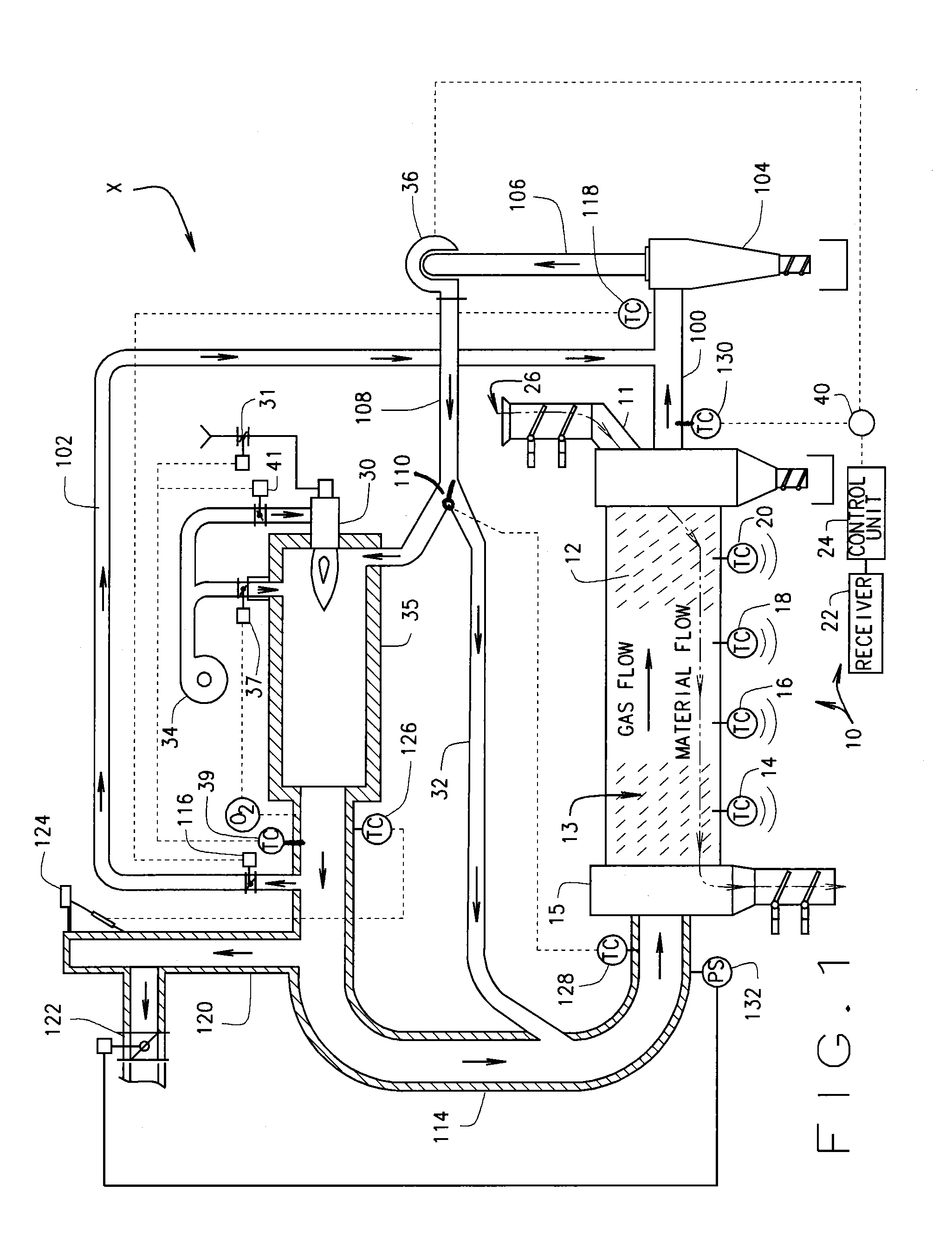

Wireless temperature sensing and control system for metal kiln and method of using the same

A rotary aluminum kiln temperature regulation system comprising a temperature sensing device in the kiln that is configured to take temperature readings in an area of the kiln in proximity to the temperature sensing device. The system including a wireless transmitter operatively associated with the temperature sensing device and a receiver wirelessly associated with the transmitter, such that the transmitter and receiver wirelessly transmit the temperature readings taken by the temperature sensing device from the transmitter to the receiver. The system also including a control unit operatively connected to the receiver that is configured to receive the transmitted temperature readings and determine when the transmitted temperature readings exceed a predefined temperature setpoint. The control unit is operatively connected to a heat flow control device that can adjust heat flow inside the kiln in proximity to the temperature sensing device, such that the control unit regulates the heat flow control device to maintain a desired level of heat flow in the kiln in proximity to the temperature sensing device in response to the temperature readings transmitted from the temperature sensing device.

Owner:GILLESPIE & POWERS INC

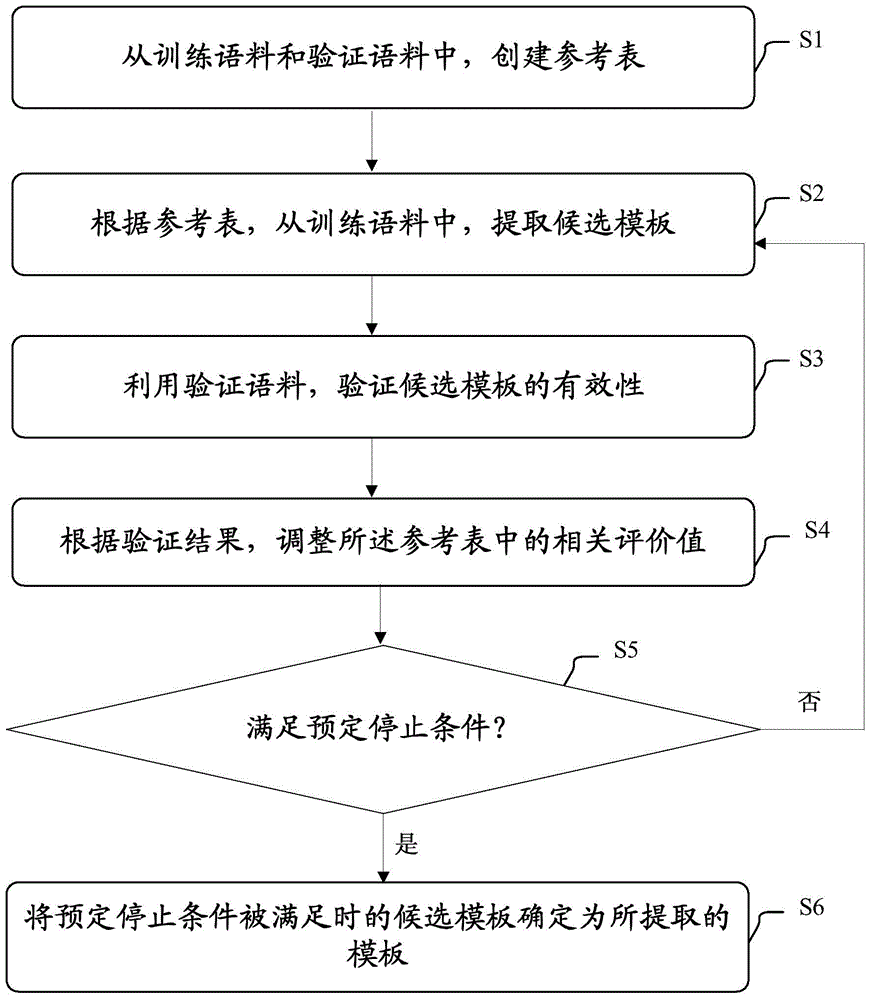

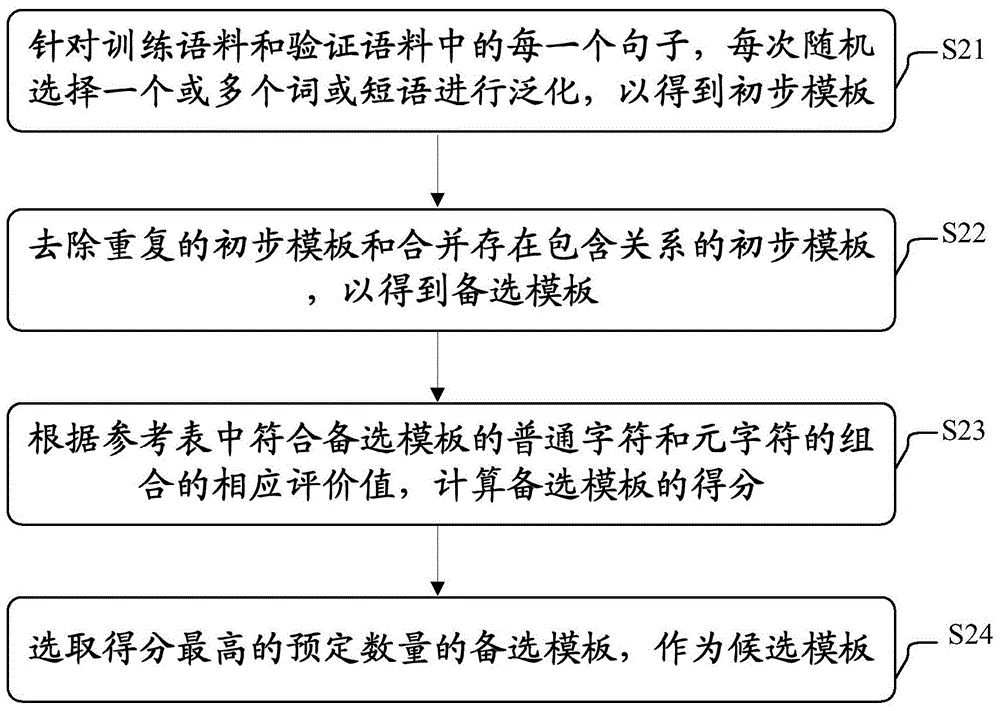

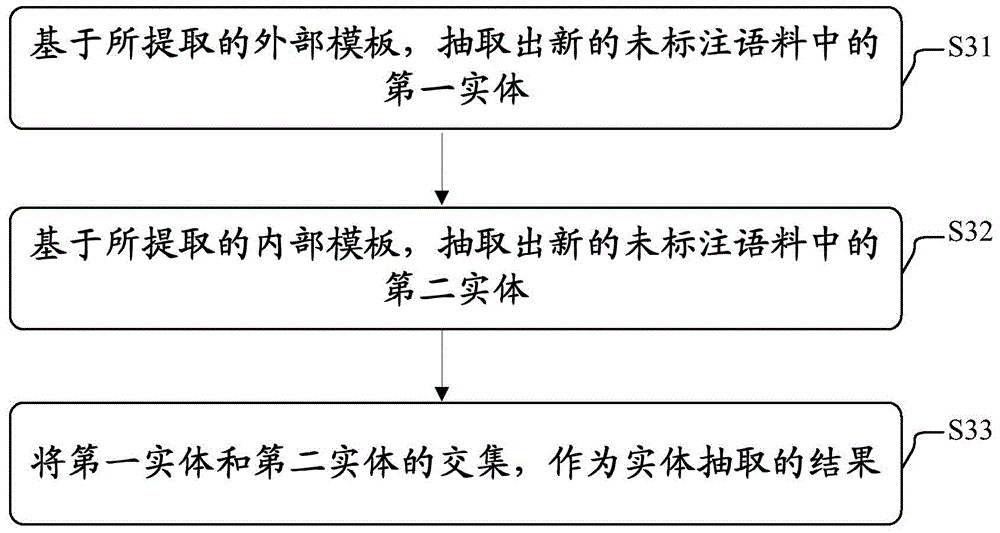

Method and device for taking temperature for extracting entities

The invention discloses a method and device for taking temperature for extracting entities. The method for taking temperature for extracting entities comprises steps of creating reference tables in training corpus; taking candidate templates in training corpus based on reference tables; utilizing certified corpus to certificate the validity of candidate templates; adjusting relevant evaluation values of the reference tables according to the verification result; and determining candidate templates when the second pre-set condition is satisfied as the extracted templates. The reference tables comprise combinations of ordinary characters and meta-characters in accord with a first pre-set condition and corresponding valuation values.

Owner:FUJITSU LTD

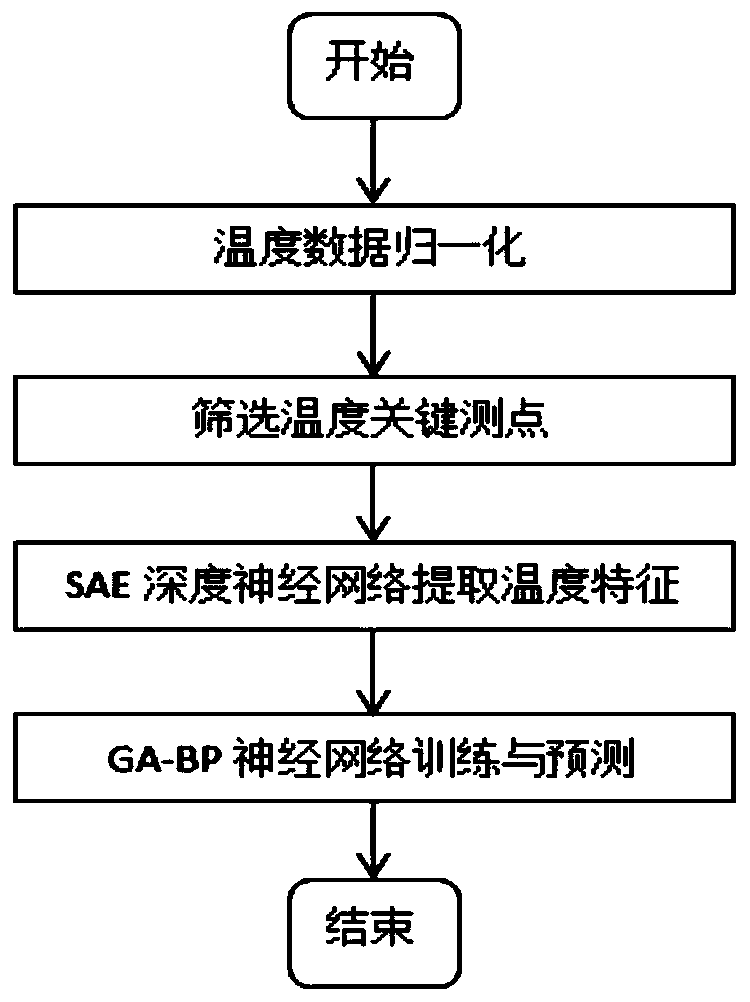

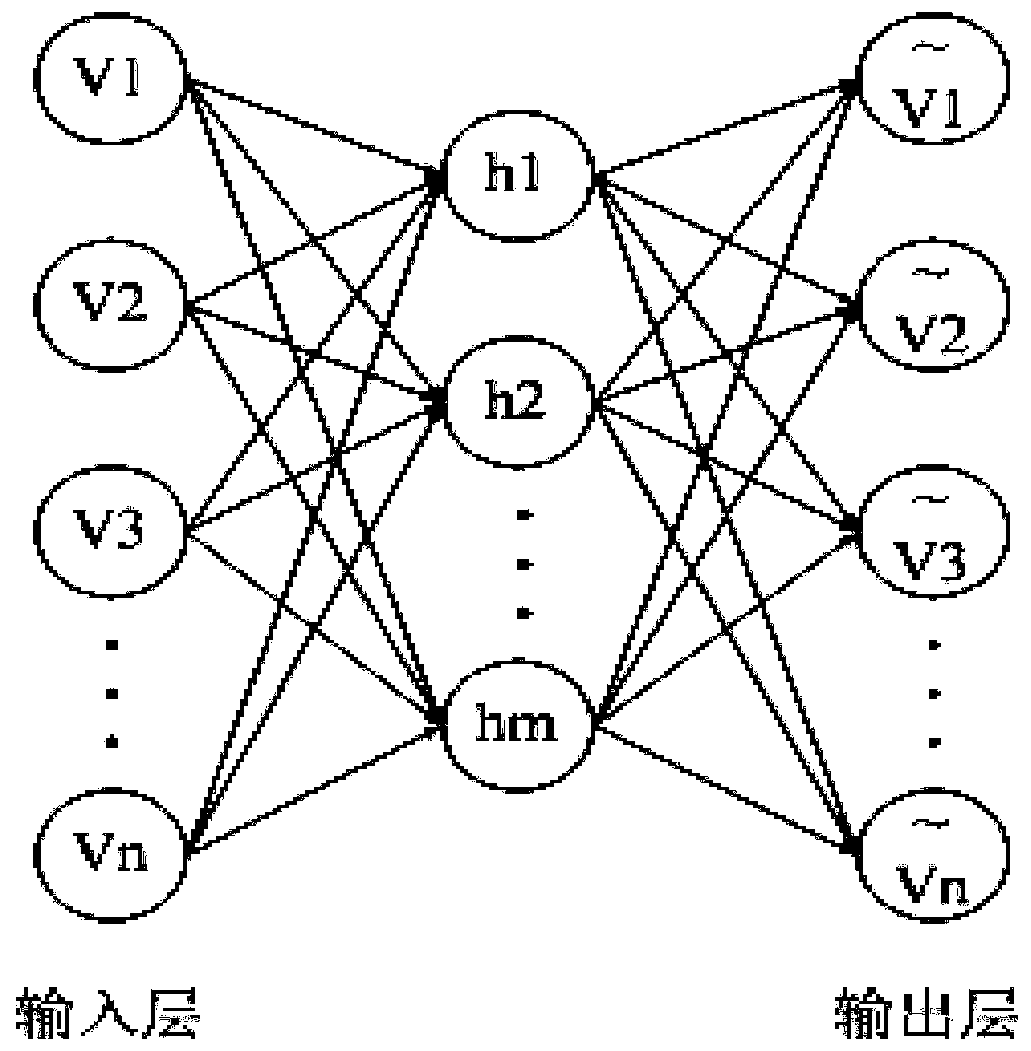

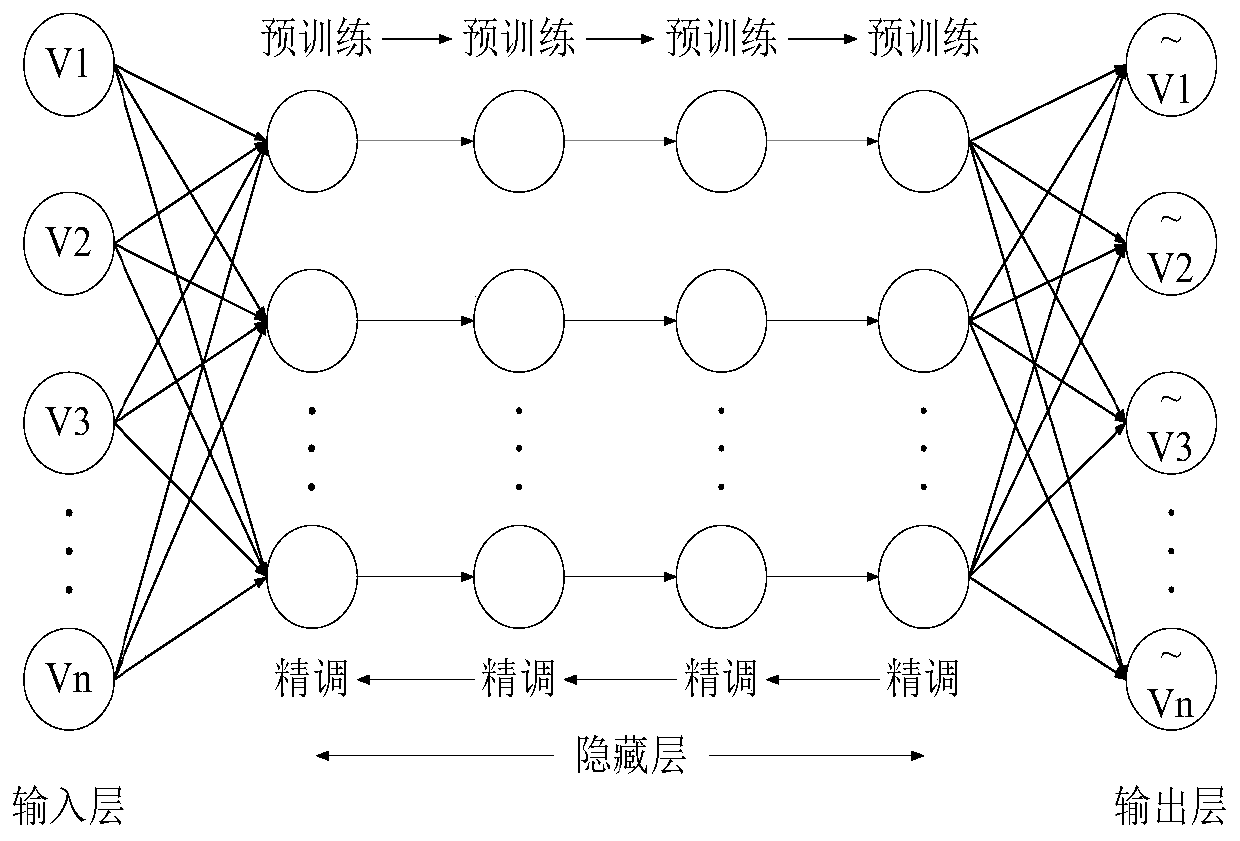

Machine tool thermal error modeling method based on deep learning

ActiveCN110083125AEffective thermal error trendEfficient estimation of thermal error trendProgramme controlComputer controlMachine toolComputer science

The invention discloses a machine tool thermal error modeling method based on deep learning. The method comprises the following steps of obtaining temperature data of a machine tool main shaft and carrying out normalization processing; calculating correlation between each measuring point and thermal errors of a main axis at three directions through a partial correlation coefficient method, and selecting m measuring points with high correlation as temperature critical measuring points; establishing a SAE network and initializing a network parameter, and taking temperature data of the temperature critical measuring points as independent variables and inputting into the SAE network to extract a temperature characteristic of the temperature data; and taking the temperature characteristic as the independent variable, taking corresponding thermal error data as a dependent variable and inputting into a GA-BP neural network to carry out training, and carrying out thermal error prediction. Themethod has advantages that prediction precision is high, robustness is good, a thermal error change trend of the machine tool can be effectively estimated and so on.

Owner:CHONGQING UNIV OF TECH +1

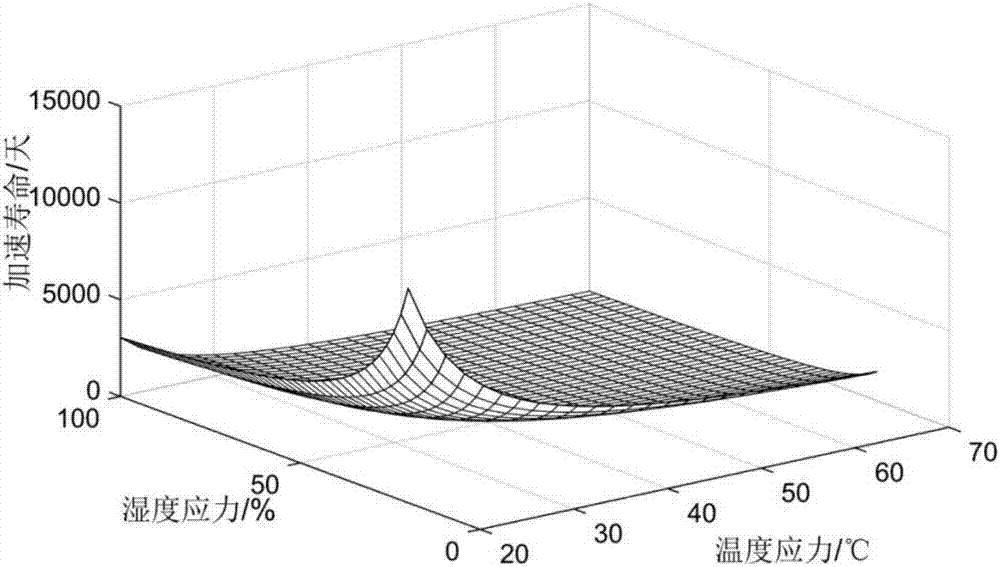

Method for analyzing reliability of explosive logic network based on evaluation of accelerated life

InactiveCN107228926AReduce experimental errorAccelerated shelf life reliabilityFuel testingPair distribution functionDependability

The invention discloses a method for analyzing the reliability of an explosive logic network based on evaluation of accelerated life. According to the method, accelerated stresses in temperature and humidity directions are selected and used; and an acceleration model is introduced into a conventional distribution function for transformation of the distribution function so as to each reliability parameter expression related to temperature-humidity. The method provided by the invention takes the influence of both temperature and humidity on the storage life of the explosive logic network into consideration; and compared with a conventional accelerated-life testing method which only takes temperature into consideration, the method reduces testing errors caused by consideration of the influence of a single environmental stress and better accords with the actual situation of complex storage environments in a battlefield.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

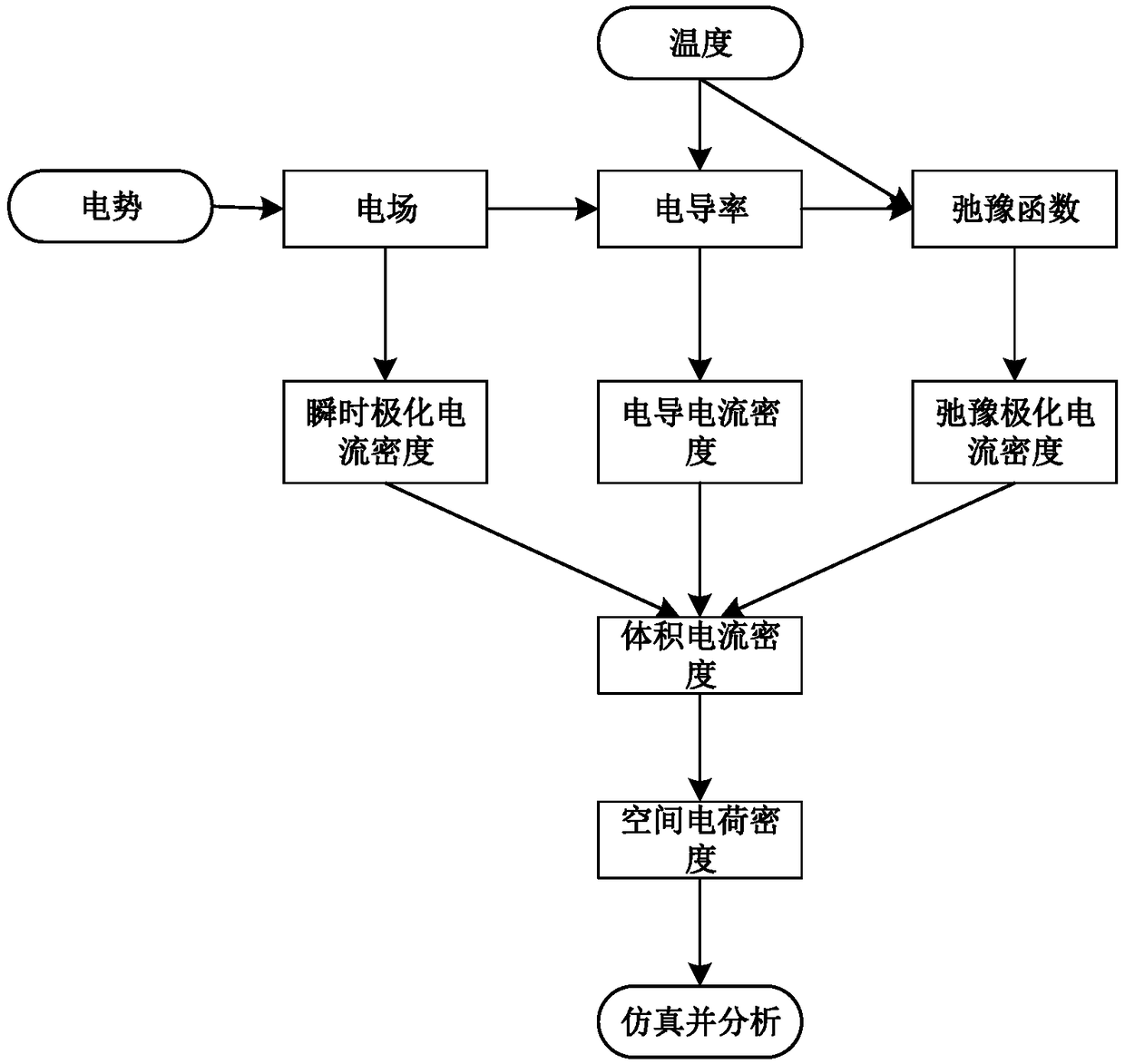

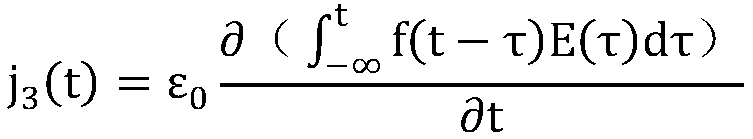

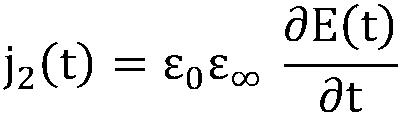

A method for optimizing space charge density model of insulator under high-voltage DC

ActiveCN109408885ASolve ill-considered problemsHigh precisionDesign optimisation/simulationSpecial data processing applicationsMathematical modelTaking temperatures

A method for optimizing space charge density model of insulator under high-voltage DC includes such steps as S1, taking temperature and time-varying electric field as independent variables to obtain conductivity mathematical model and conductivity current density; S2, establishing a dielectric relaxation function and obtaining a relaxation polarization current density; S3, summing that conductivity current density, the relaxation polarization current density and the instantaneous polarization current density to obtain the volume current density; 4, integrate that volume current density to obtain a space charge density data model. Compared with the prior art, the invention comprehensively considers the influence of temperature, electric field and dielectric relaxation on the space charge density, solves the problem that the prior model does not take the environmental factors into consideration, and simulates and analyzes the influence degree of each factor on the space charge density, which can be used as a reference for the material selection and structure design of the high-voltage DC insulator.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

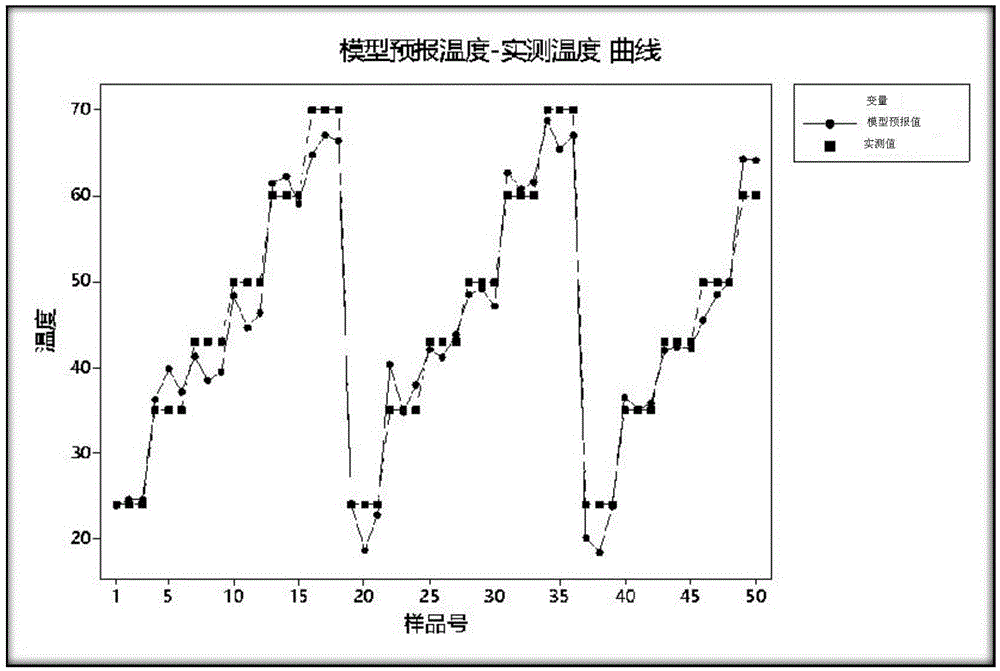

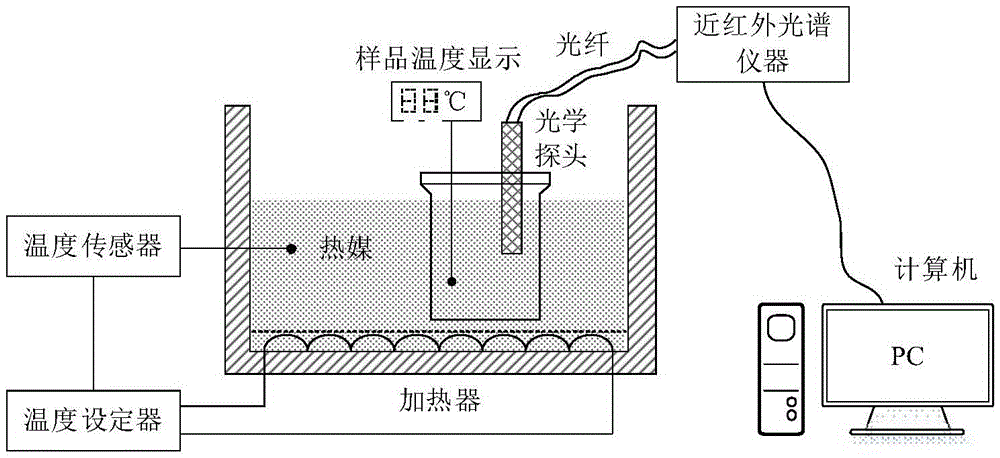

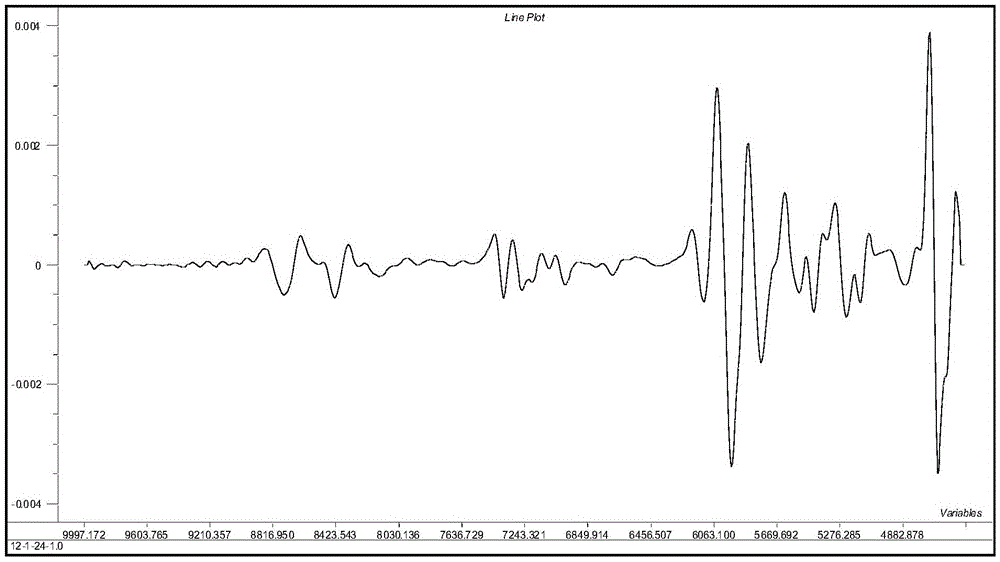

Near-infrared physical property parameter measuring method without measuring point temperature compensation

The invention discloses a near-infrared physical property parameter measuring method without measuring point temperature compensation. The method comprises the following steps: acquiring representative samples, acquiring the near-infrared spectra of all the samples at different temperatures and recording experimental conditions like temperature at the same time; then preprocessing the acquired spectra, establishing a near-infrared prediction model for sample temperatures and separately establishing near-infrared physical property parameter prediction models for low-temperature points and high-temperature points; and carrying out correction computation on different temperatures from the low-temperature points or high-temperature points and constructing a physical property parameter correction model applicable to any temperature. The method provided by the invention takes temperature as an explicit factor variable in construction of a temperature correction model, so physical property measurement at different temperatures can be accomplished in virtue of response of the spectra to temperatures during near-infrared measurement; thus, direct temperature measurement information and related calculation are not needed.

Owner:JIANGNAN UNIV

Optical fiber image inverter rotary torsion processing technology

InactiveCN101702044ASolve heating uniformityReduced Uniformity RequirementsBundled fibre light guideManufacturing technologyDrive shaft

The invention belongs to the technical field of manufacture of optical fiber image transmission devices, in particular to an optical fiber image inverter rotary torsion processing technology. The invention solves the problem of poor optical fiber image inverter quality brought by a simple torsion method of the optical fiber image inverter in the prior art. The technology comprises the following steps of: driving both ends of an optical fiber composite rod blank in a horizontal state to generate synchronous rotation; meanwhile, heating a optical fiber composite rod to a certain temperature and then starting to apply resistance on a driven shaft to enable the driven shaft to gradually form a certain angle difference with a driving shaft; when the difference reaches 180 DEG C, controlling the rotation speed of the driven shaft to be consistent to the rotating speed of the driving shaft so that the two shafts realize the synchronous rotation; when cooling the optical fiber composite rod blank to plate taking temperature during torsion, shutting down and taking a plate to obtain an image transmission device of which both end surfaces are differed by 180 DEG C. Compared with the prior art, by using the technical scheme, the quality and the torsion qualification rate of the optical fiber image inverter can be improved.

Owner:山西长城微光器材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com