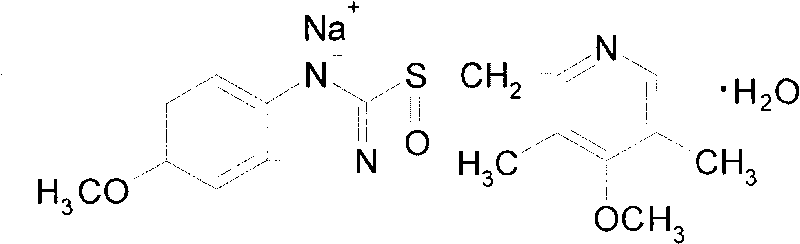

Omeprazole sodium freeze-dried powder injection and preparation method thereof

A technology of omeprazole sodium and freeze-dried powder injection, which is applied in the field of pharmaceutical preparations, can solve the problems of increasing the risk of adverse reactions, increasing the production cost of preparations, unfavorable clinical use, etc., and achieves the reduction of adverse reaction risks, good stability, and prescription simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

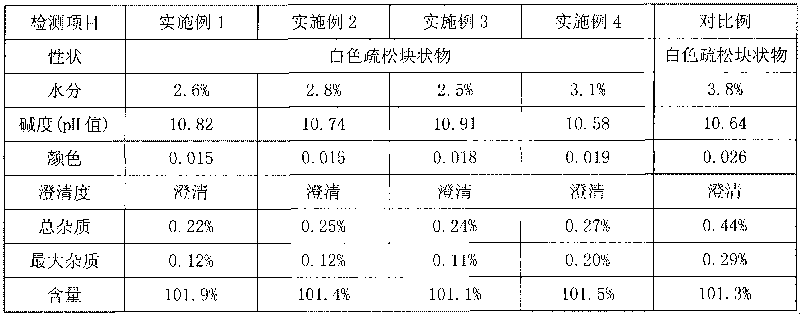

Examples

Embodiment 1

[0028] Omeprazole sodium 40g (calculated as omeprazole)

[0029] Edetate Calcium Sodium 1.5g

[0030] Appropriate amount of sodium hydroxide

[0031] Add water for injection to 1000ml

[0032]

[0033] Made 1000 pieces

Embodiment 2

[0035] Omeprazole sodium 40g (calculated as omeprazole)

[0036] Calcium Edetate Sodium 3.0g

[0037] Appropriate amount of sodium hydroxide

[0038] Add water for injection to 1000ml

[0039]

[0040] Made 1000 pieces

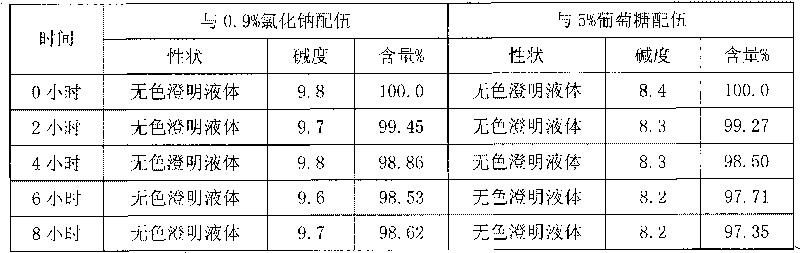

[0041] Embodiment 1 and 2 preparation technology: in the clean area, the calcium sodium edetate that takes prescription quantity is dissolved in 800ml water for injection, stirs, dissolves, and the pH value of solution is 11.6 with 10% sodium hydroxide aqueous solution adjustment (implementation Example 1) and 11.0 (embodiment 2); The Omeprazole Sodium that takes prescription quantity adds in the above-mentioned solution, stirs at room temperature and makes it dissolve, adds water for injection to full amount; Then adds liquid amount 0.1% (W / V ) activated carbon, stirring and decolorizing at room temperature for 20 minutes, recirculating and stirring for 10 minutes, filtering with a titanium filter stick, and then fine filtering with a 0.22 μm filter mem...

Embodiment 3

[0043] Omeprazole sodium 40g (calculated as omeprazole)

[0044] Edetate Calcium Sodium 4.0g

[0045] Appropriate amount of sodium hydroxide

[0046] Add water for injection to 1000ml

[0047]

[0048] Made 1000 pieces

[0049] Preparation process: In a clean area, weigh the prescribed amount of edetate calcium sodium and dissolve it in 800ml of water for injection, stir and dissolve, and adjust the pH of the solution to 12.0 with sodium hydroxide; then weigh the prescribed amount of Omela Add azole sodium into it, stir at room temperature to dissolve it, add water for injection to the full amount; then add activated carbon with a liquid volume of 0.2% (W / V), stir at room temperature for 30 minutes and then circulate and stir for 15 minutes. Filtrate, and then fine filter through a 0.22μm membrane; take the fine filtrate for content, density, endotoxin, alkalinity, clarity, etc., and fill it after passing the test; put the subpackaged sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com