Control system protecting device and protecting method based on temperature measurement

A control system and protection device technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as equipment malfunction, malfunction shutdown, and different levels

- Summary

- Abstract

- Description

- Claims

- Application Information

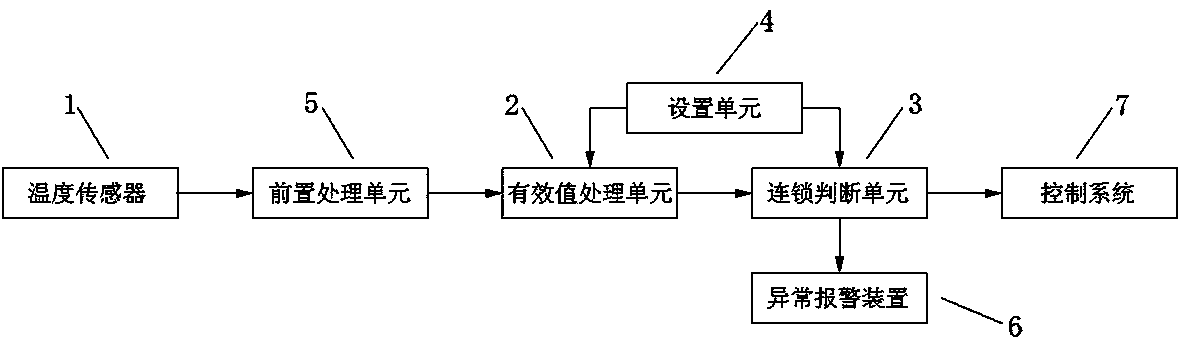

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

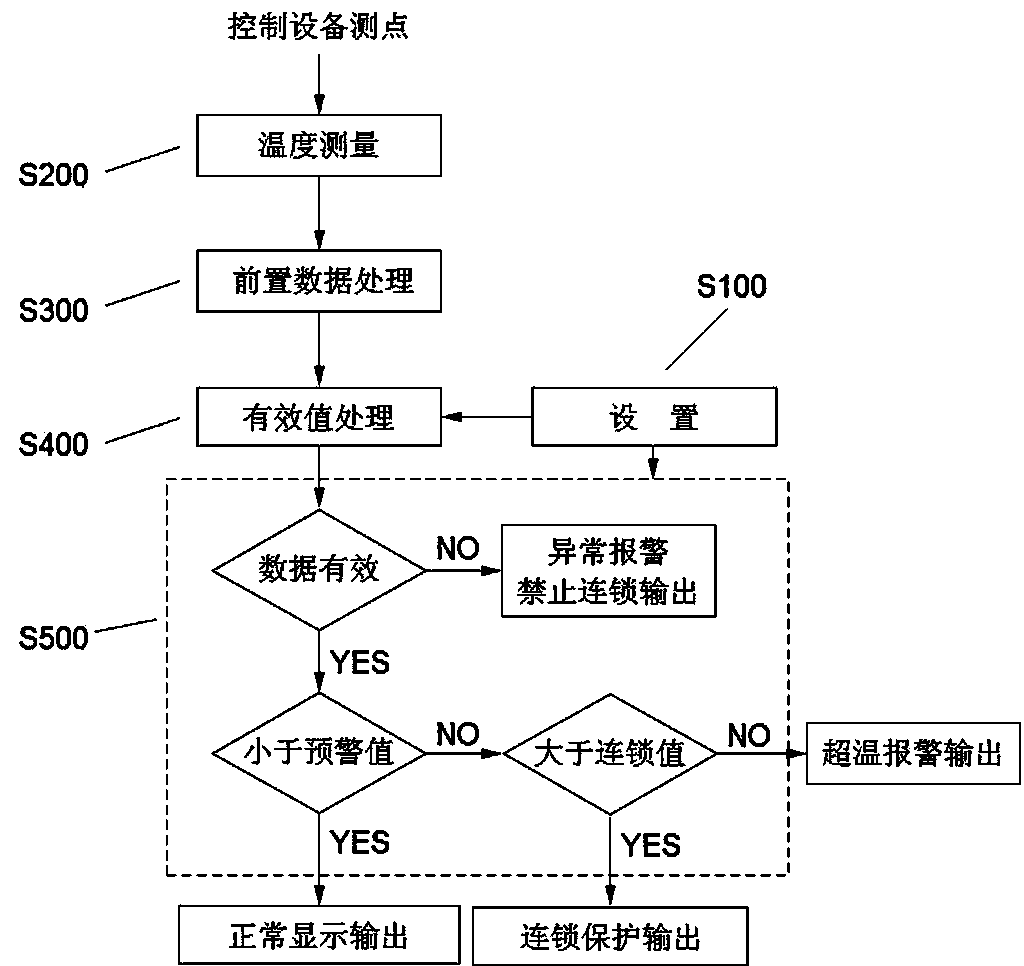

[0040] Such as figure 2 As shown, take the temperature measuring point A as an example to measure the bearing temperature of the blast furnace fan. Since the bearing temperature fluctuation range is 60-80°C under normal circumstances, a PT100 thermal resistance with a range of 0-200°C is used as the temperature measuring probe. ,Proceed as follows:

[0041] S100: Before and after the operation of the control system, set and save the preset filtering time of 1-5s in the effective value processing step S300 and the preset effective value of 20-60°C in the chain judgment step S400, the preset alarm value of 75°C and The preset chain value is 85°C;

[0042] S200: When the system is running, the PT100 thermal resistance probe measures the bearing temperature of the blast furnace fan measuring point A;

[0043] S300: filter the measured temperature signal and / or a modulus device, output and process the temperature signal;

[0044] S400: Obtain the temperature value measured by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com