Patents

Literature

1682 results about "Wire breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

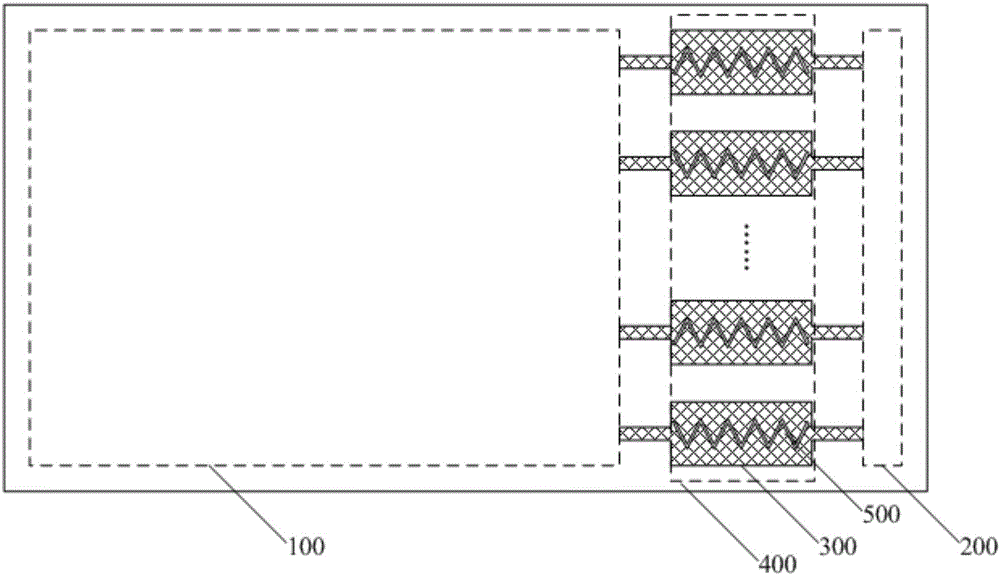

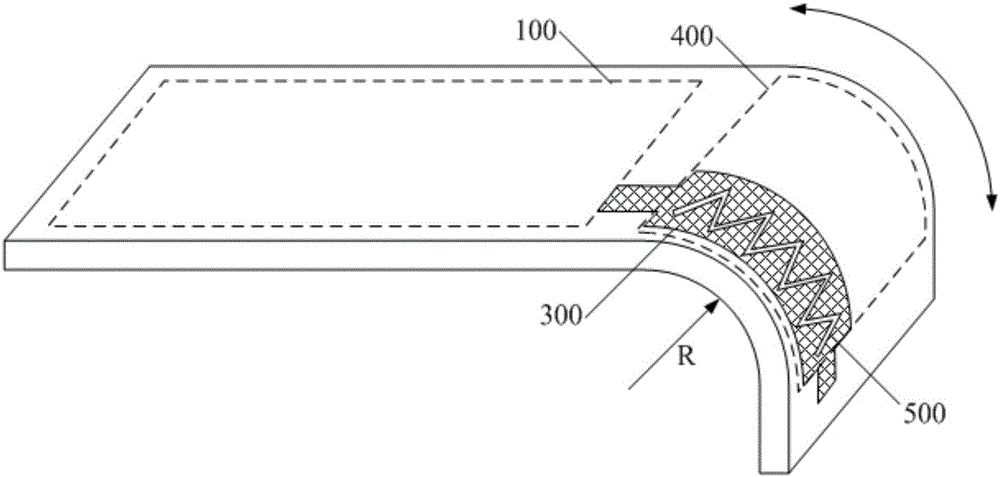

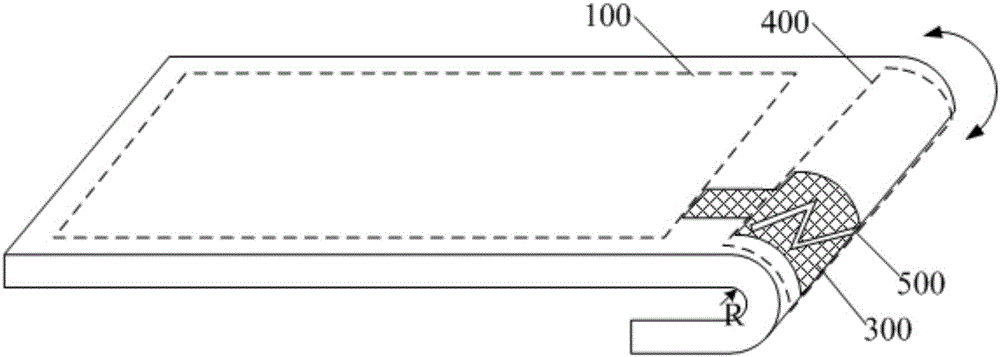

Flexible display panel, display device and manufacture method

ActiveCN106205394AImprove qualityImprove reliabilityPrinted circuit aspectsPrinted circuit manufactureDisplay deviceFlexible display

The invention discloses a flexible display panel, a display device and a manufacture method. Hollow patterns are arranged in bent areas, located between a display area and a binding area, of lead wires, so that the bent areas of the lead wires have the new patterns to dredge stress accumulated on the lead wires in the bending process, the lead wires can be helped to release stress when being bent to prevent lead wire breakage, and then the quality and reliability of the flexible display panel can be improved.

Owner:BOE TECH GRP CO LTD

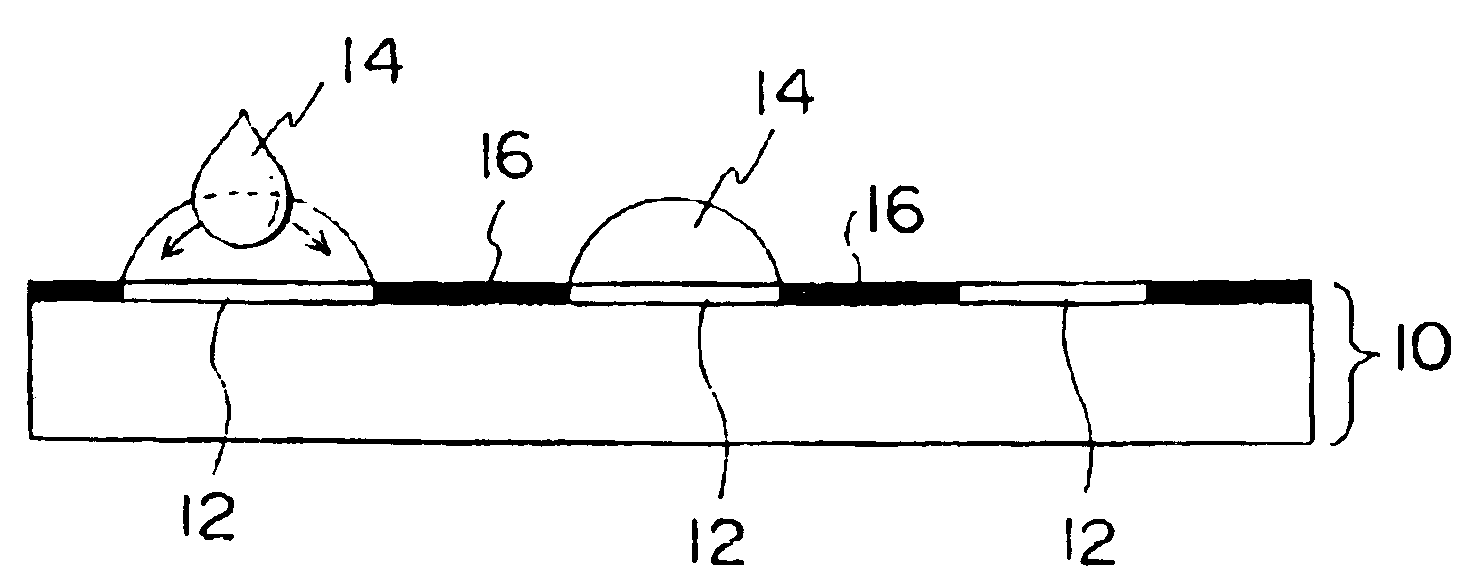

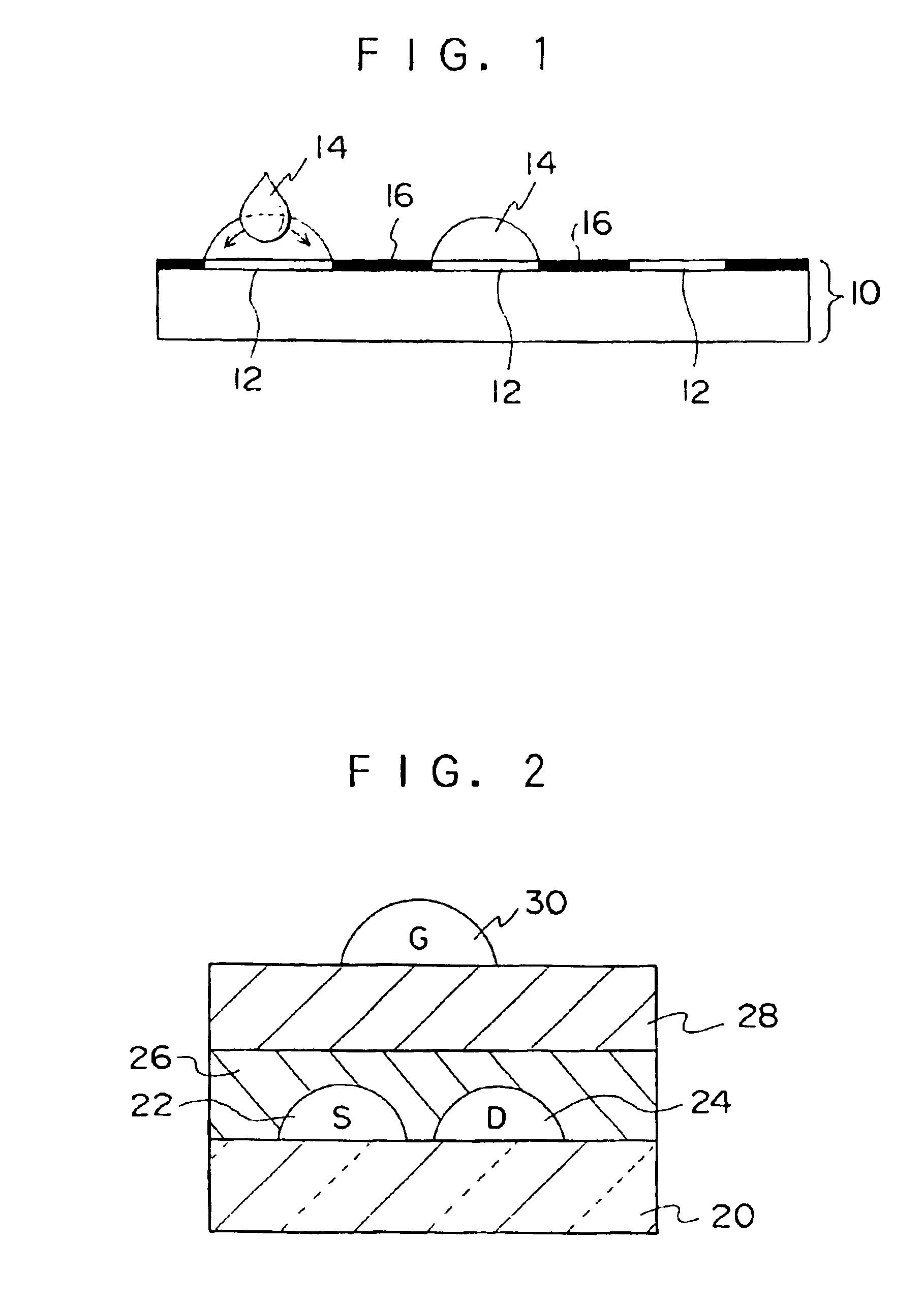

Conductive pattern material and method for forming conductive pattern

InactiveUS6919158B2Wide applicationHigh sensitivityPhotoprinting processesSolid-state devicesConductive materialsSupport surface

There are provided a conductive pattern material and a pattern-forming method by which a fine pattern having a high resolution and no wire breakage is obtained. The conductive pattern material is such that on a support surface a pattern-forming layer is formed which allows the formation of a hydrophilic / hydrophobic region directly bonded to the support surface due to energy imparted. Energy is imparted to the pattern-forming material in an imagewise manner to form the conductive material layer.

Owner:FUJIFILM CORP

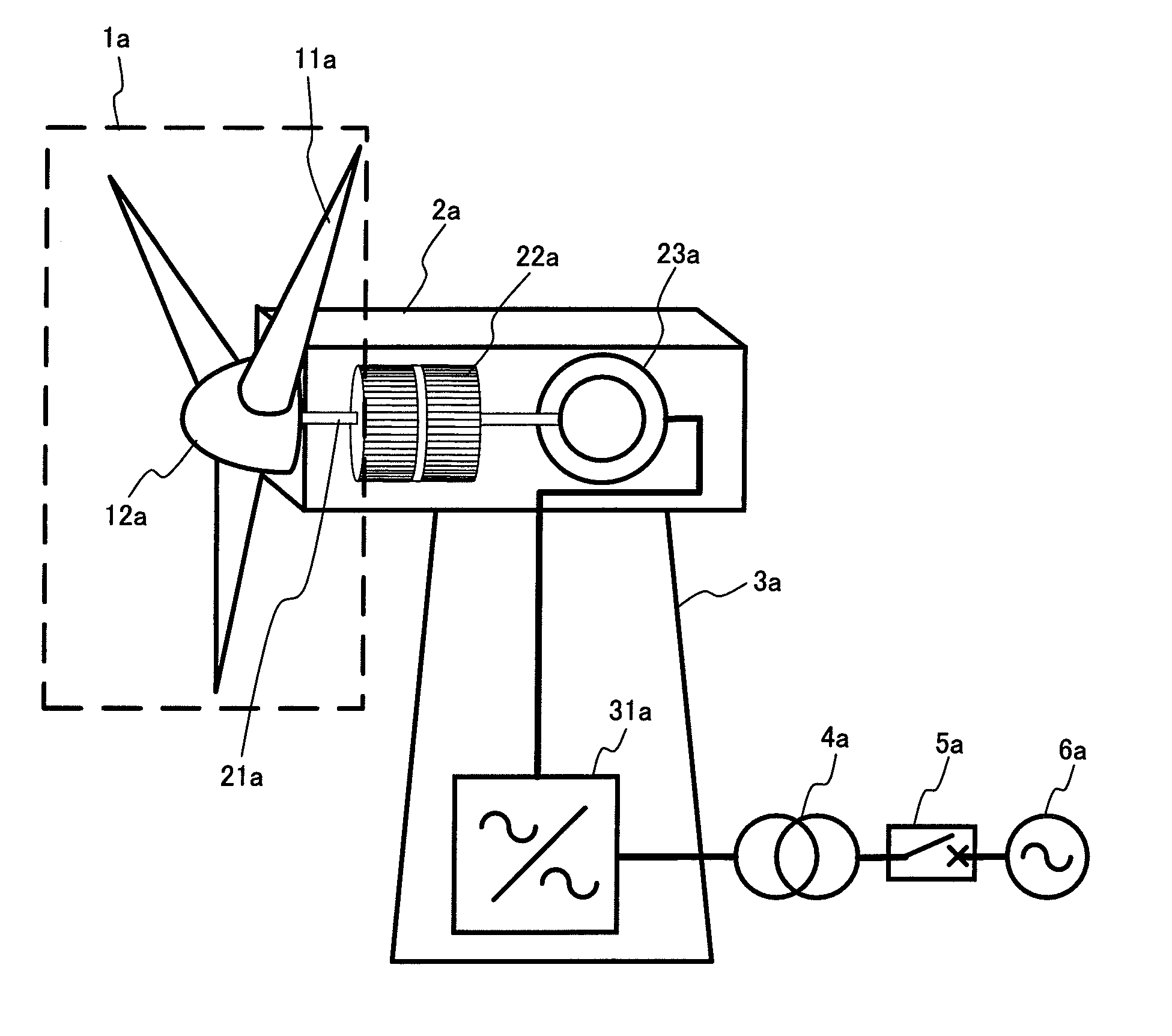

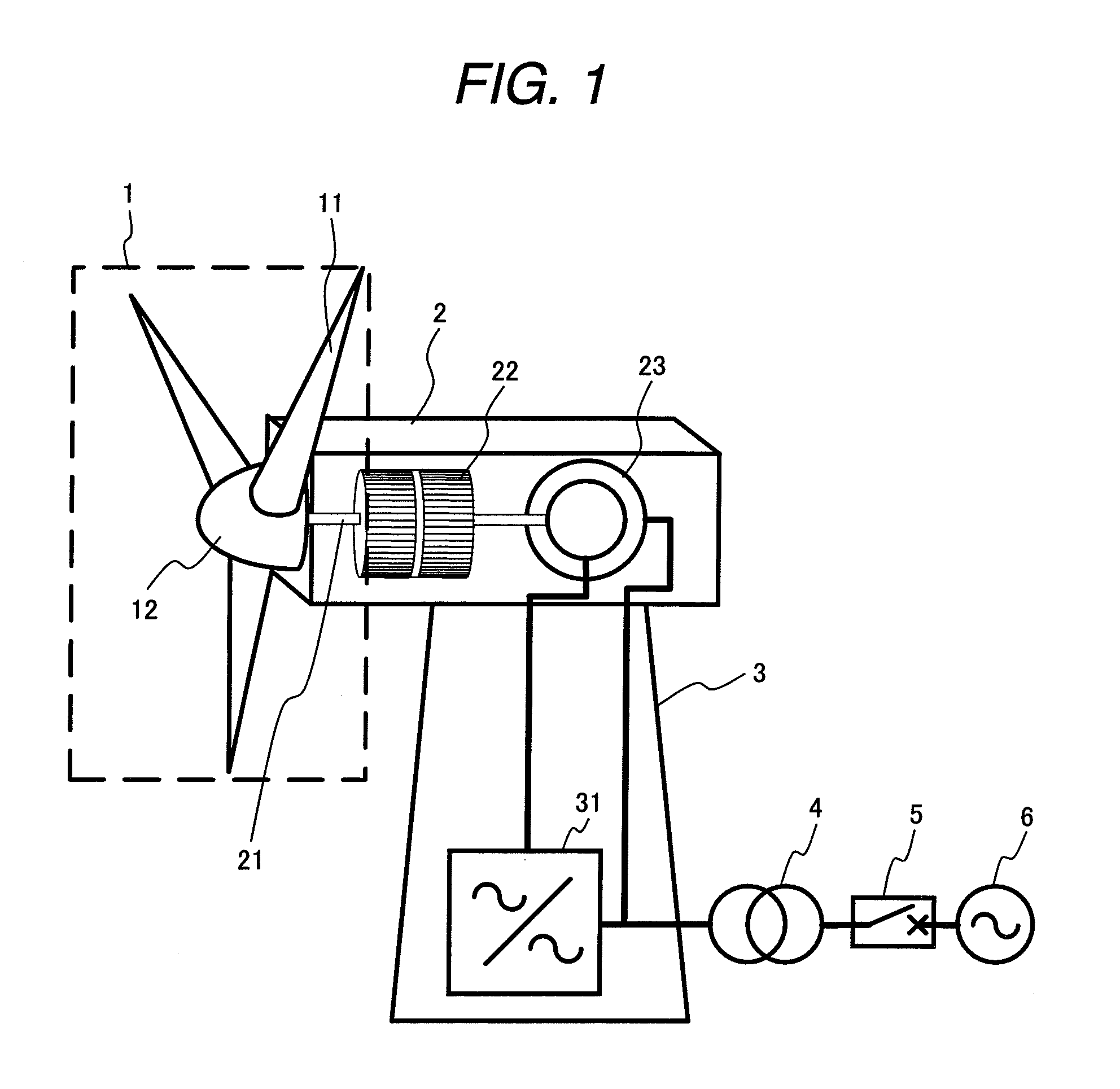

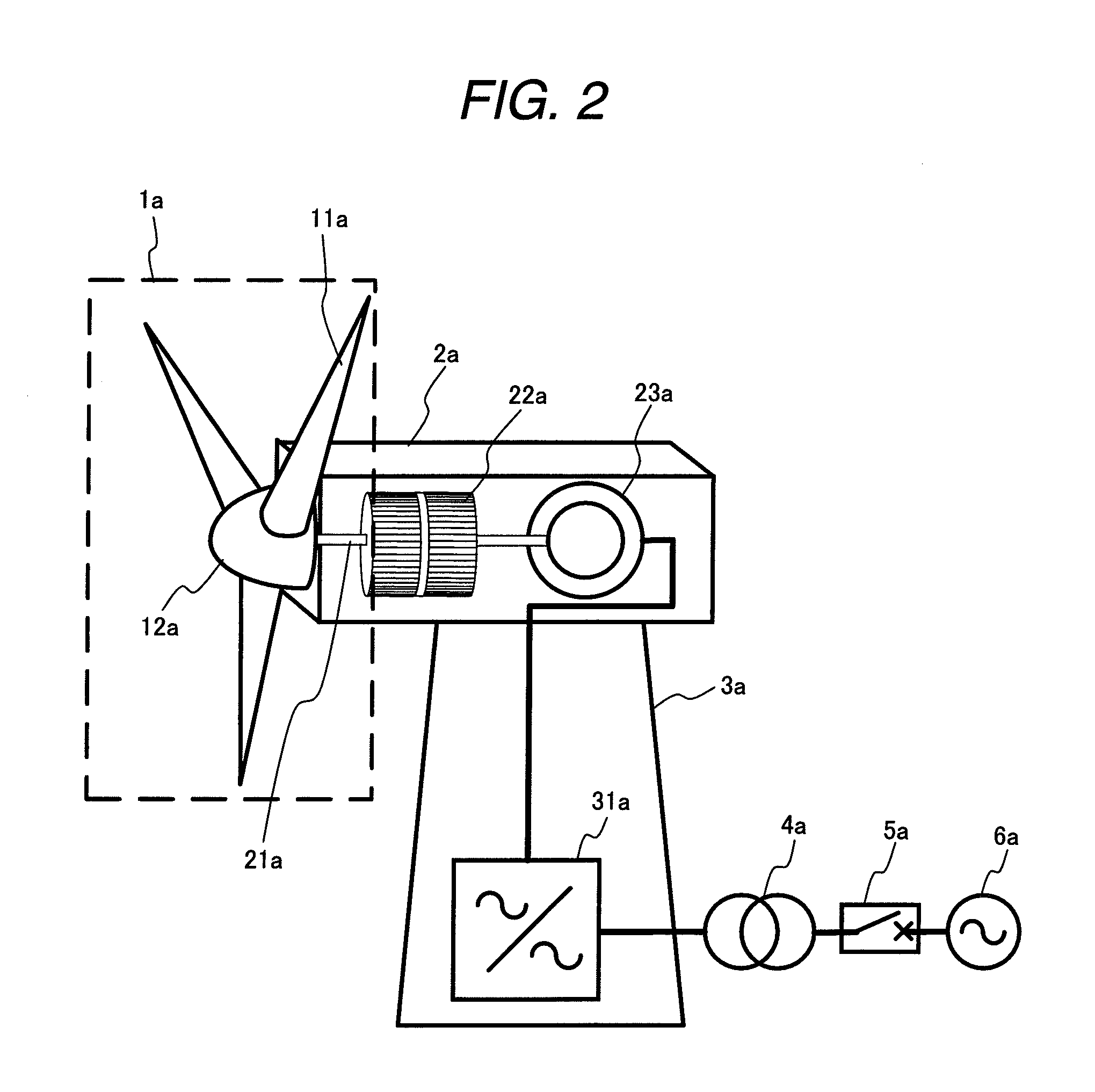

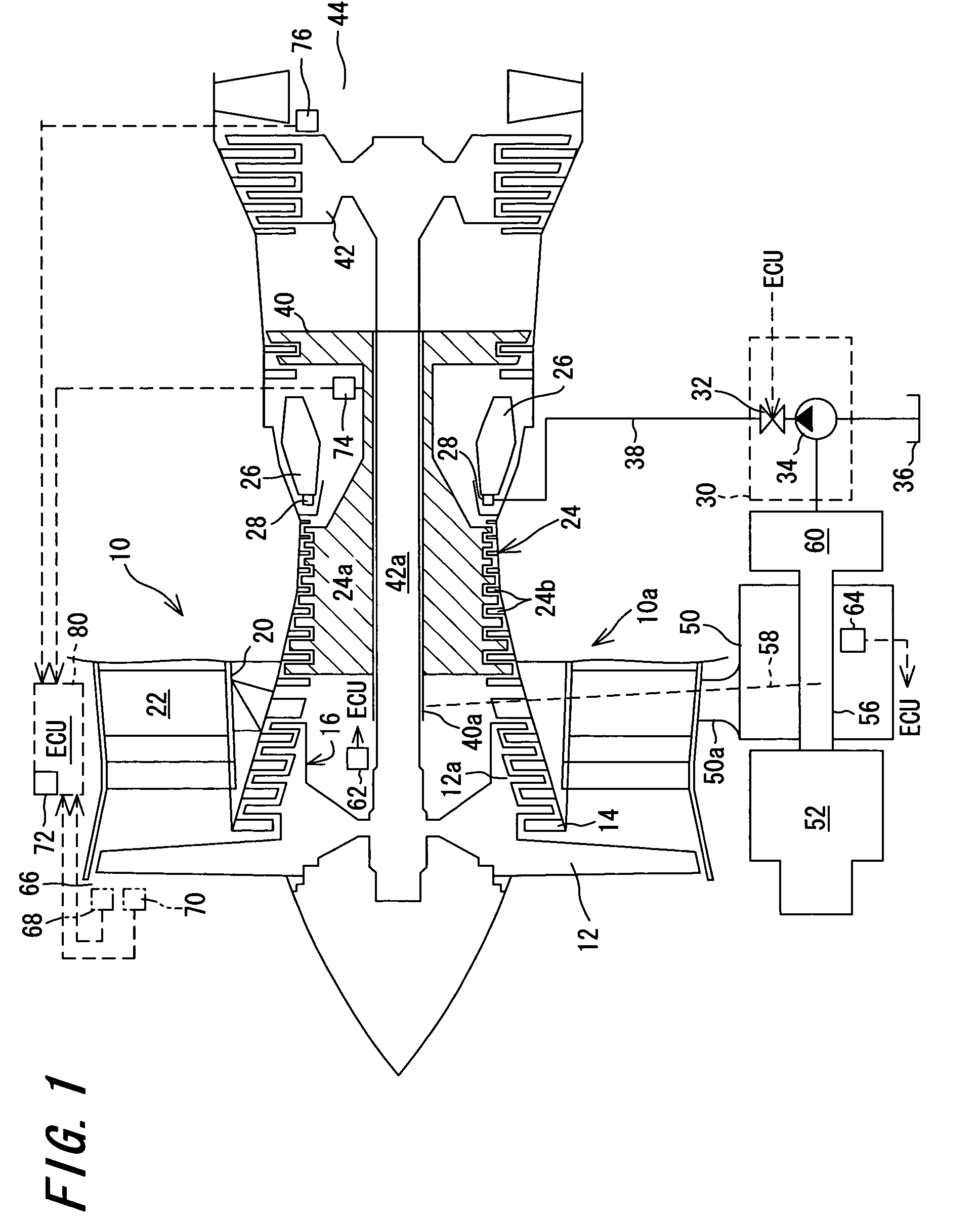

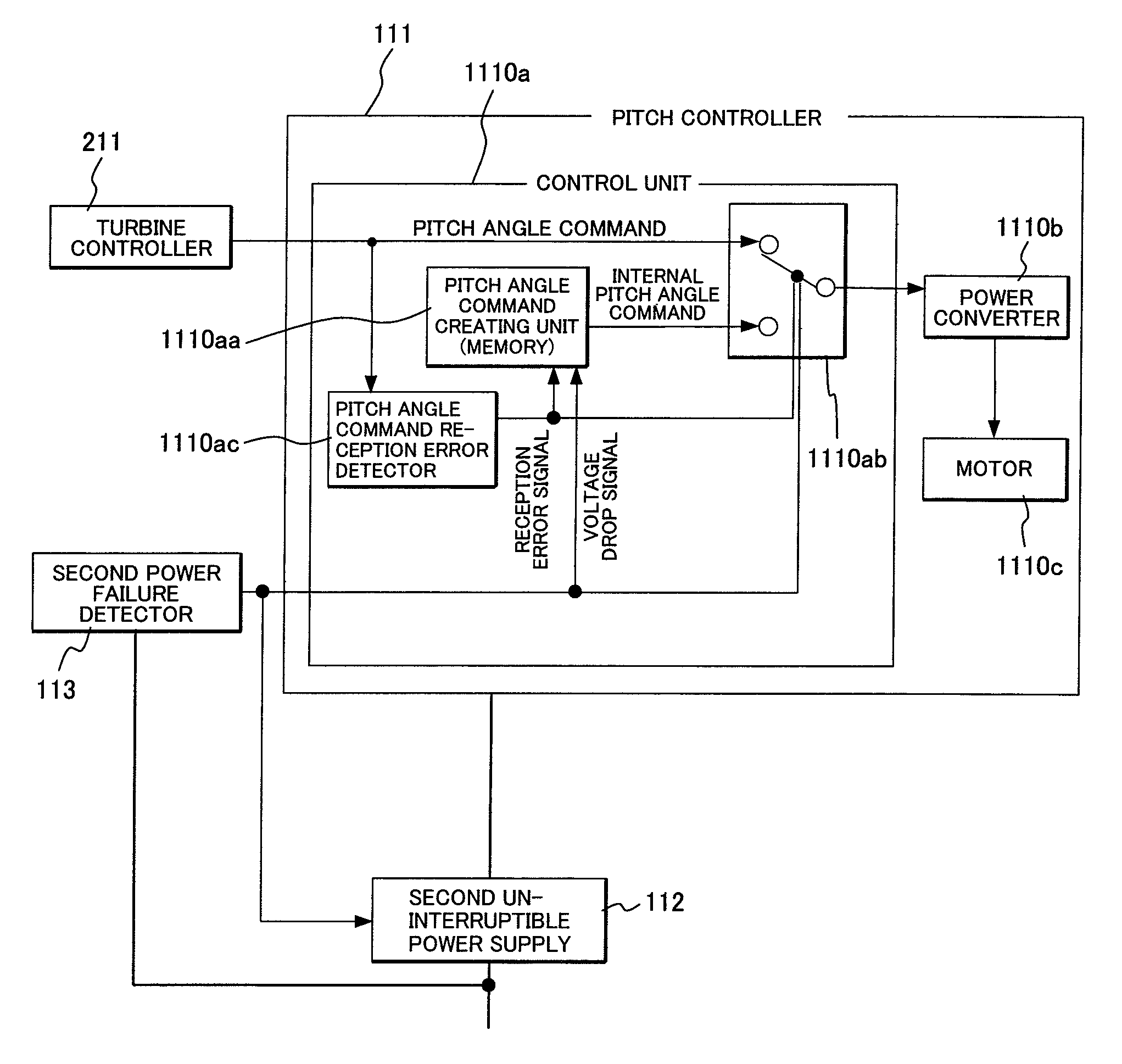

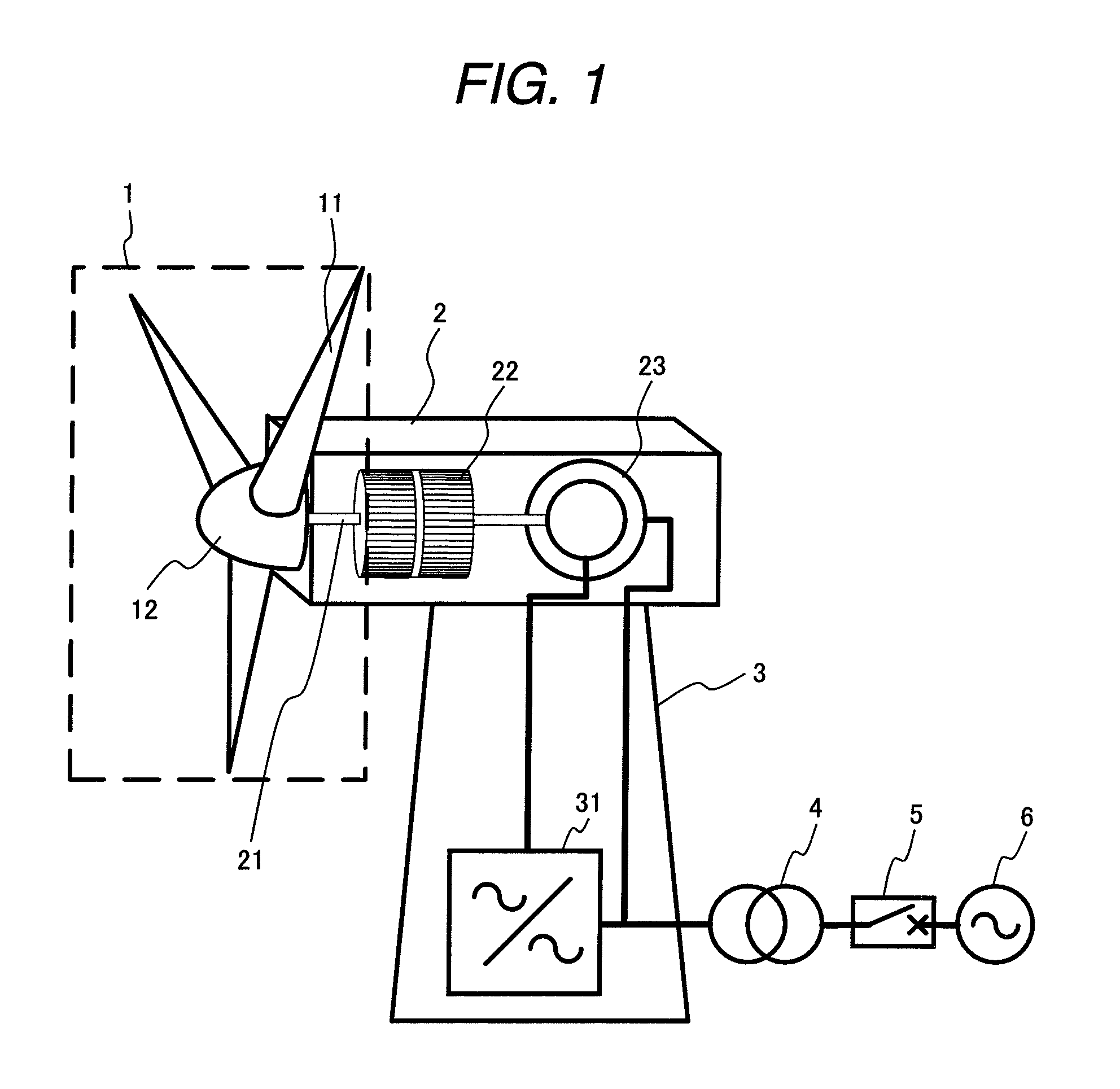

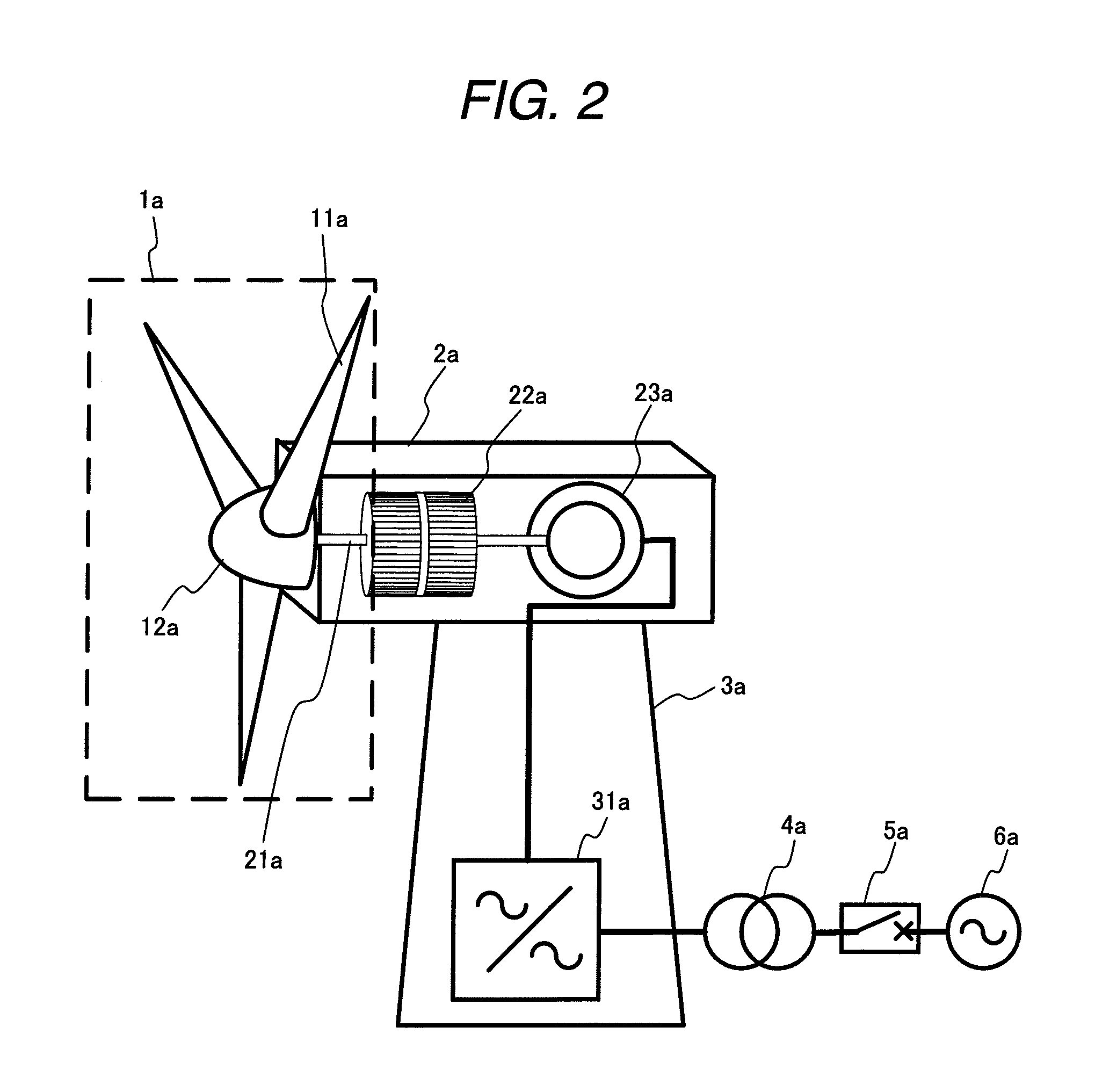

Wind turbine and operating method thereof

InactiveUS20080069692A1Prevent speedingControl moreRotational speed controlLevel controlClassical mechanicsControl theory

A pitch controller, uninterruptible power supply, and rotational speed detector are disposed in the rotor in a wind turbine. When a slip ring failure or wire breakage occurs, the pitch controller internally creates a pitch angle command so as to control the pitch angle.

Owner:HITACHI LTD

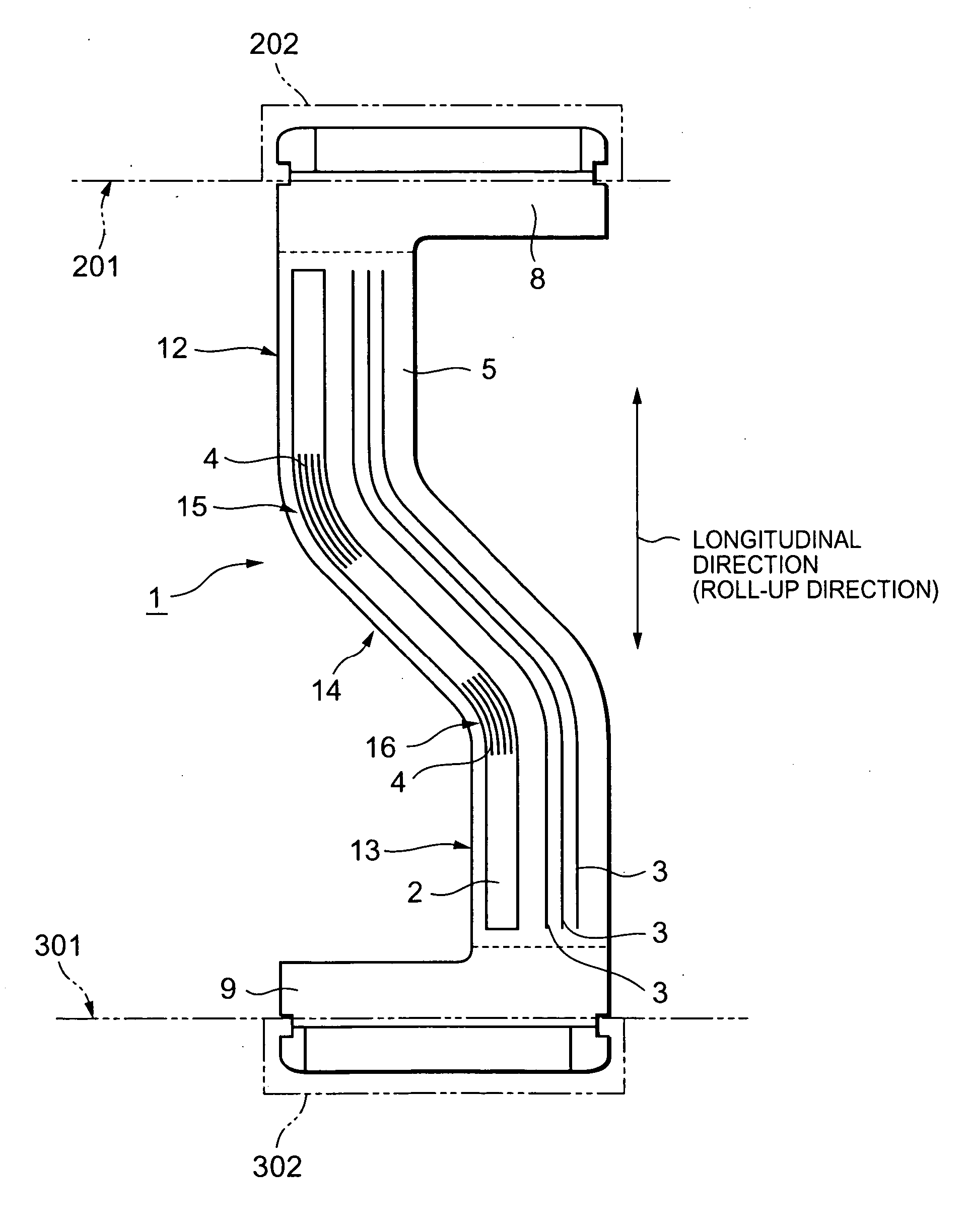

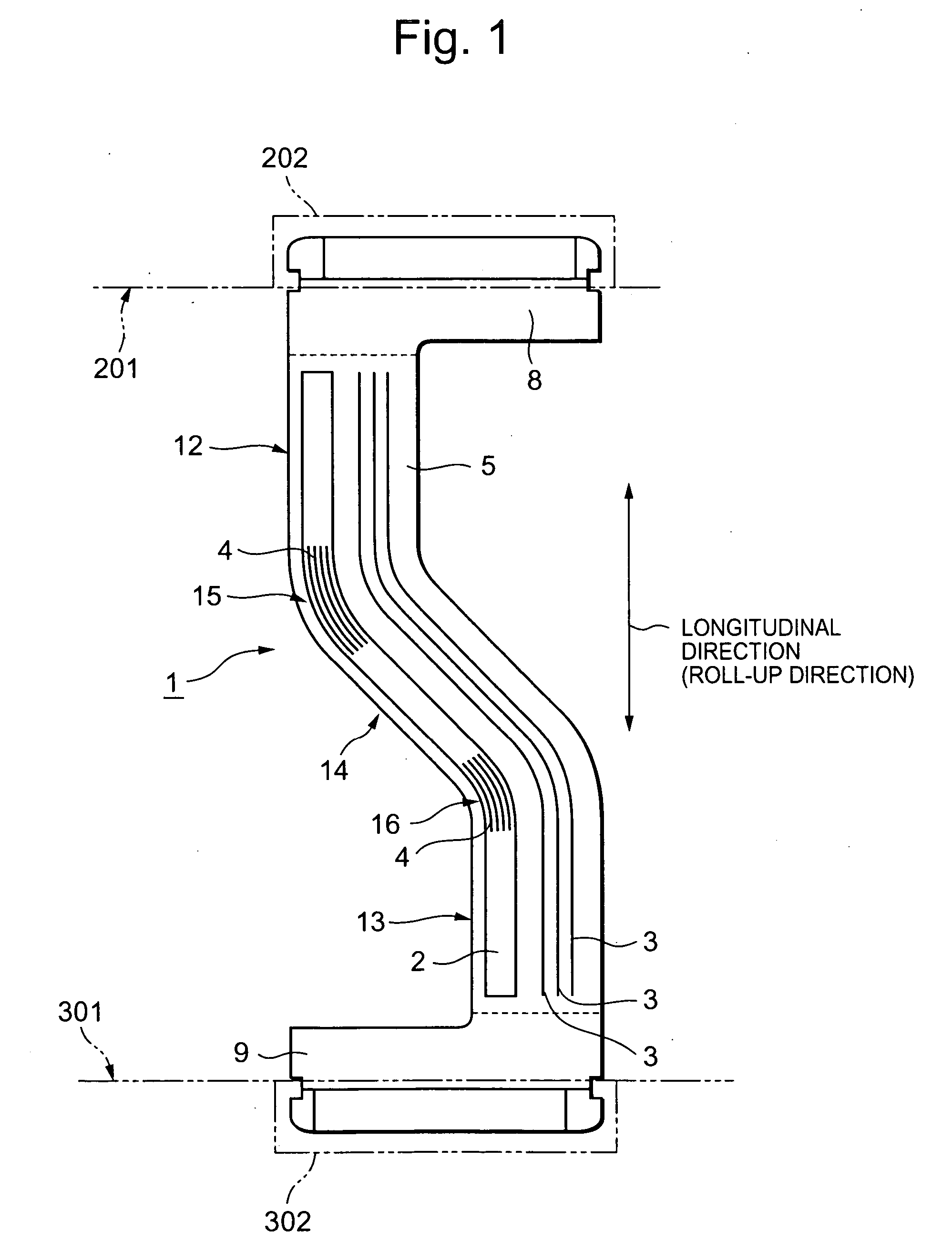

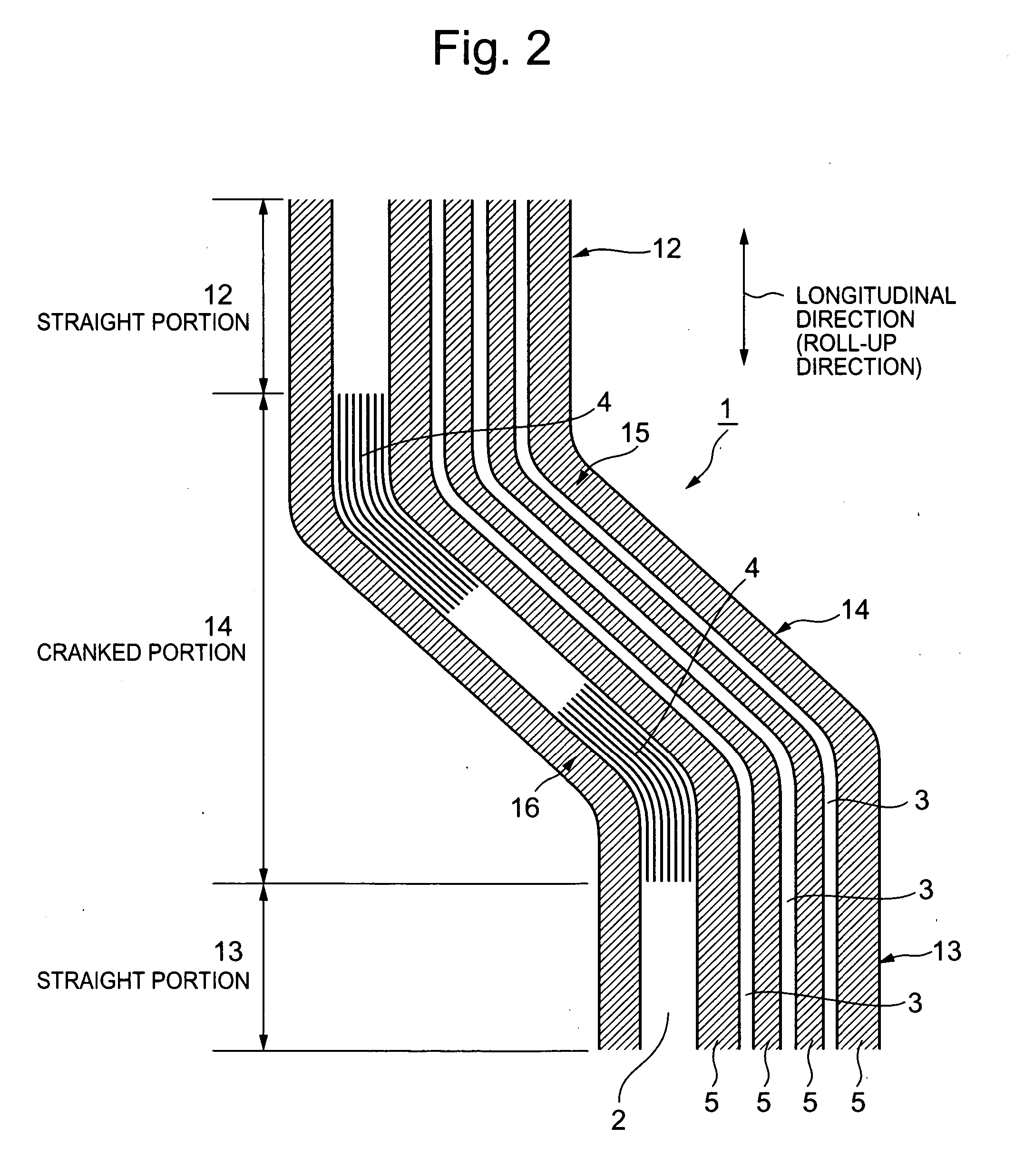

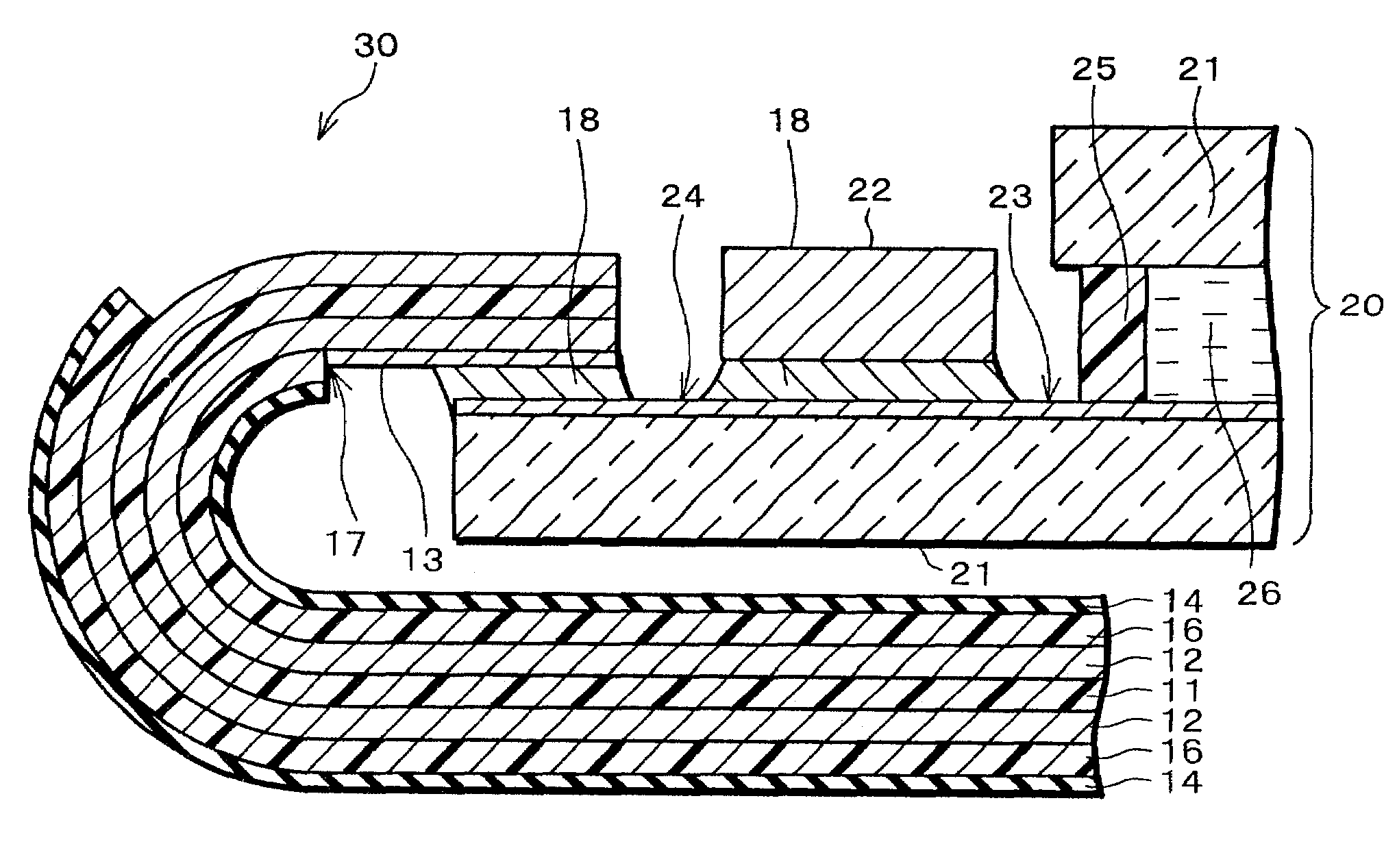

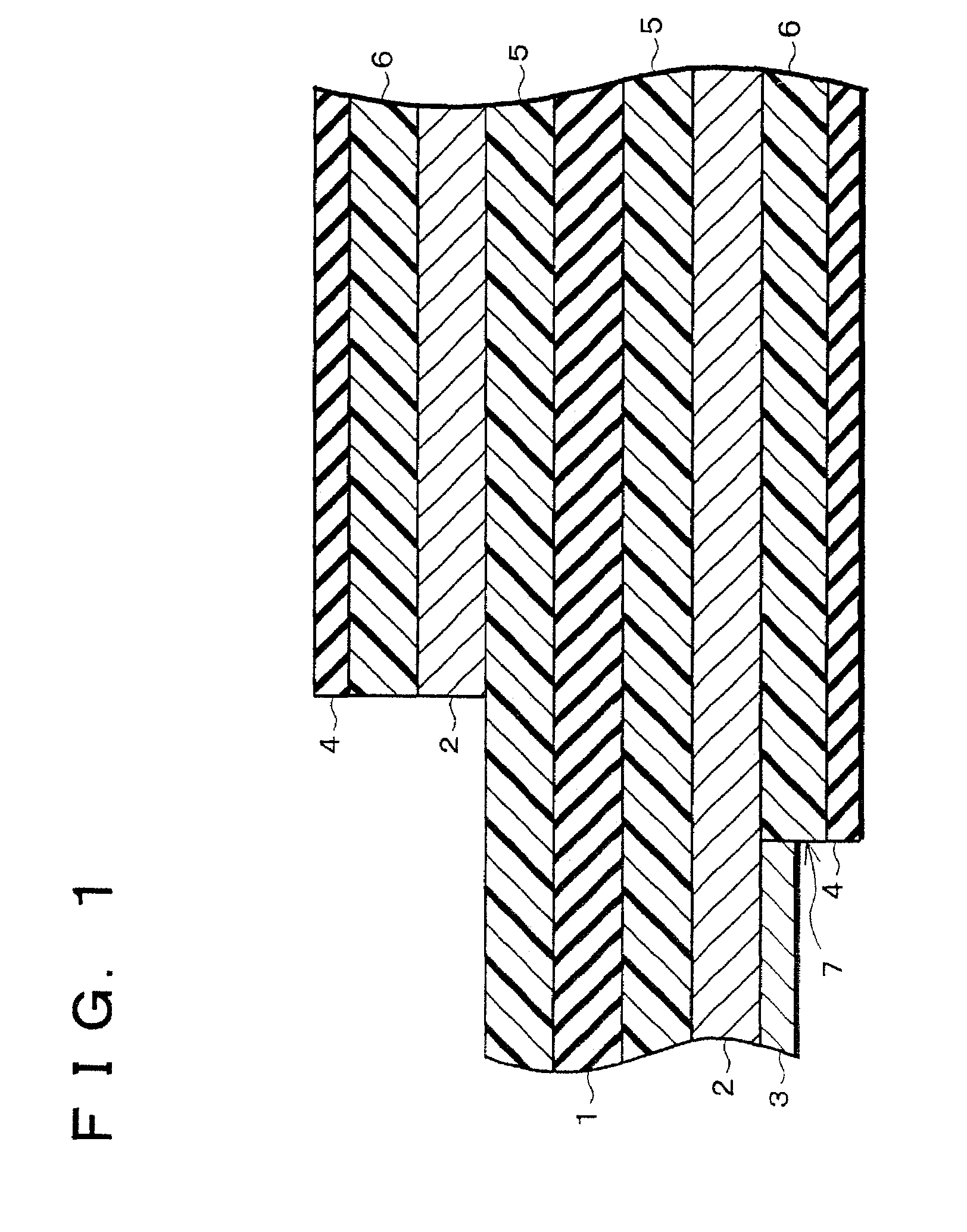

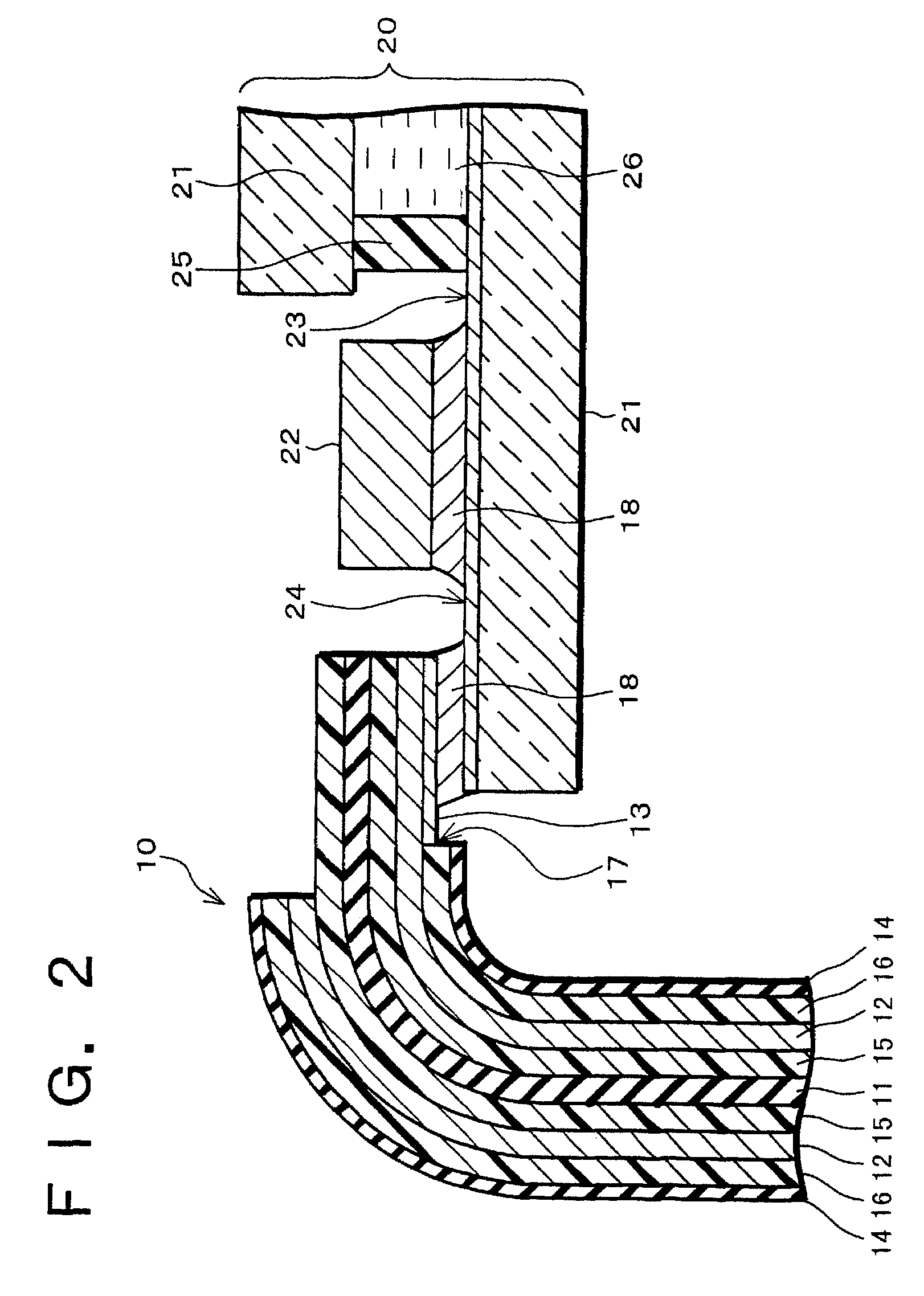

Flexible substrate and electronic device

InactiveUS20050018409A1Increased durabilityAvoid disconnectionPrinted circuit aspectsSupport structure mountingStress concentrationElectricity

A flexible substrate inserted in a hinge electrically connects circuit substrates, which are housed in a first casing and a second casing, respectively, to each other. The substrate has a power supply line and signal lines which are formed from a wiring conductor. Slits are opened in border portions of the power supply line in a cranked portion. The slits opened in the border portions of the power supply line make the rigidity of the border portions lower than in prior art. This means that a base is prevented from squashing the wiring conductor (power supply line) when the substrate is bent and that stress concentration on the border portions can accordingly be avoided. As a result, cracks in the border portions are prevented and the power supply line (wiring conductor) is protected against wire breakage.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Flexible wiring board and electrical device using the same

InactiveUS7348492B1Improve reliabilityAvoid disconnectionSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveCopper foil

A flexible wiring board is obtained as follows. A copper foil pattern is formed on the both surfaces of a base polymer film made of polyimide, etc. The copper foil pattern of the both sides, except for an end portion of the copper foil pattern of one surface, is covered entirely with an insulative protecting film made of polyimide, etc., for protecting the copper foil pattern, and the insulative protecting film and the copper foil pattern are bonded with each other by an insulative protecting film adhesive layer. On the exposed end portion of the copper foil pattern on one surface is formed a plated layer to be connected to an electrical component. The thickness of the insulative protecting film which is bonded with the surface on which the plated layer is formed is set to be thinner than the base polymer film. As a result, it is ensured that insulation failure of the insulative protecting film is prevented, and wire breakage of wiring when bent can easily be prevented.

Owner:SHARP KK

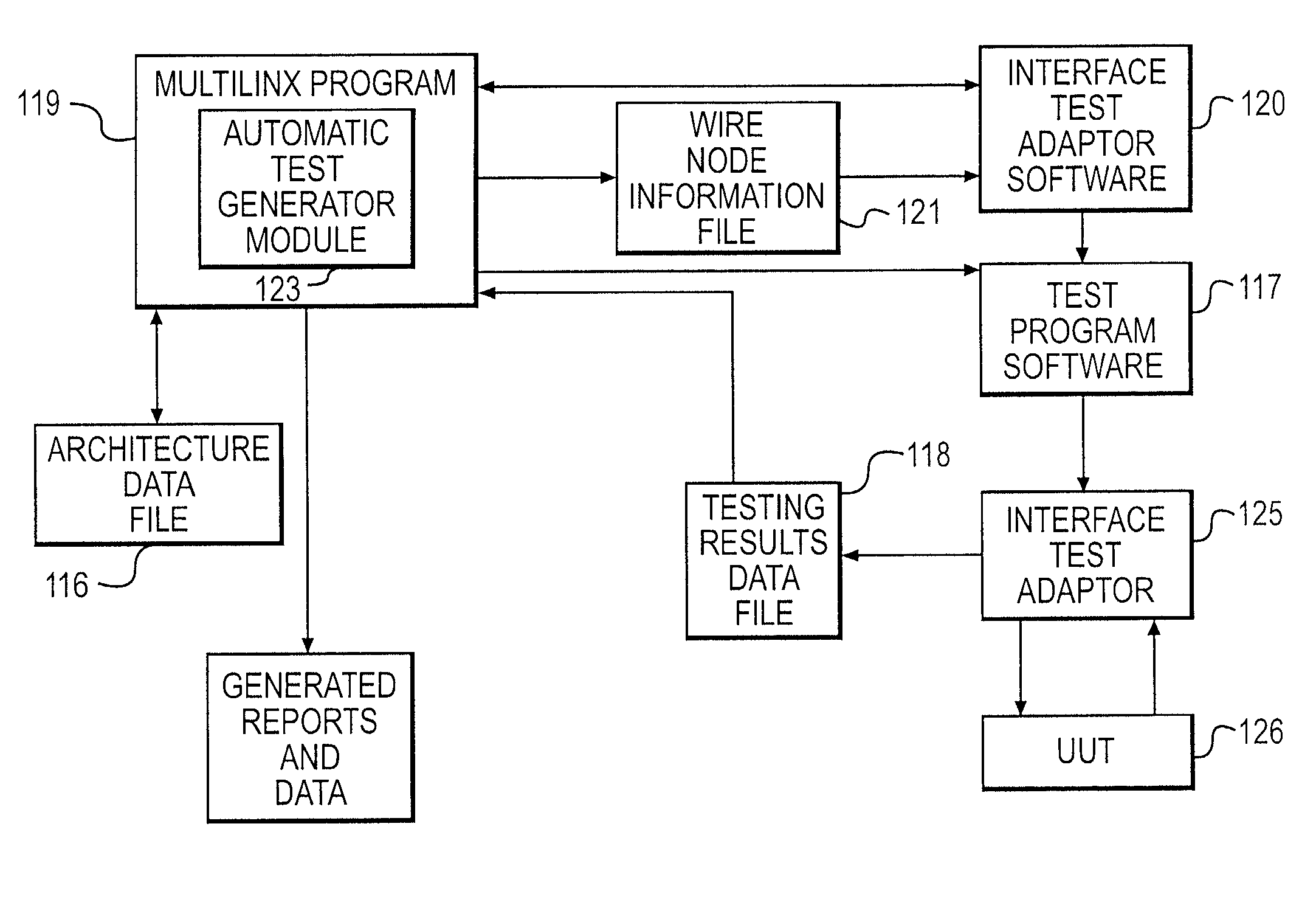

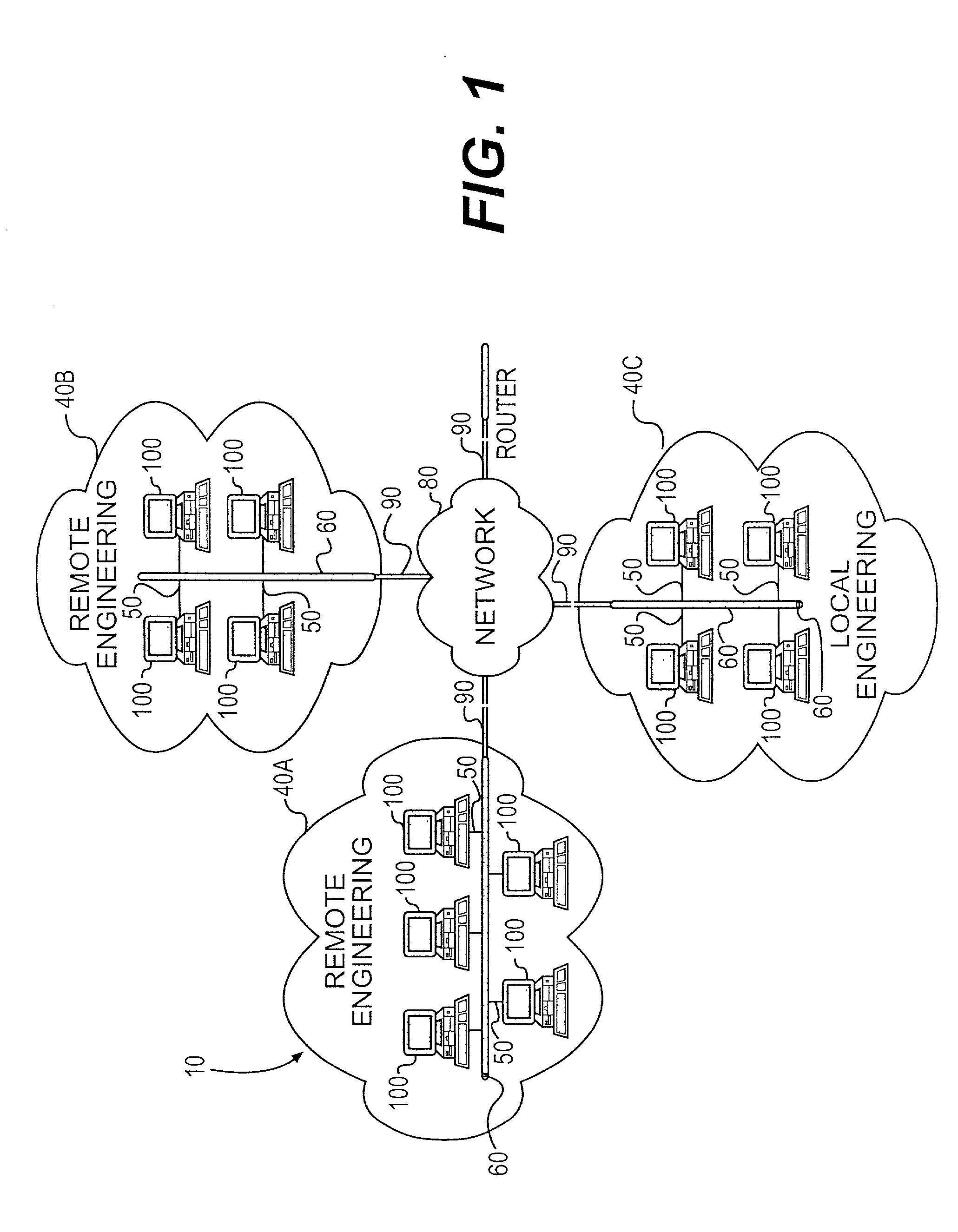

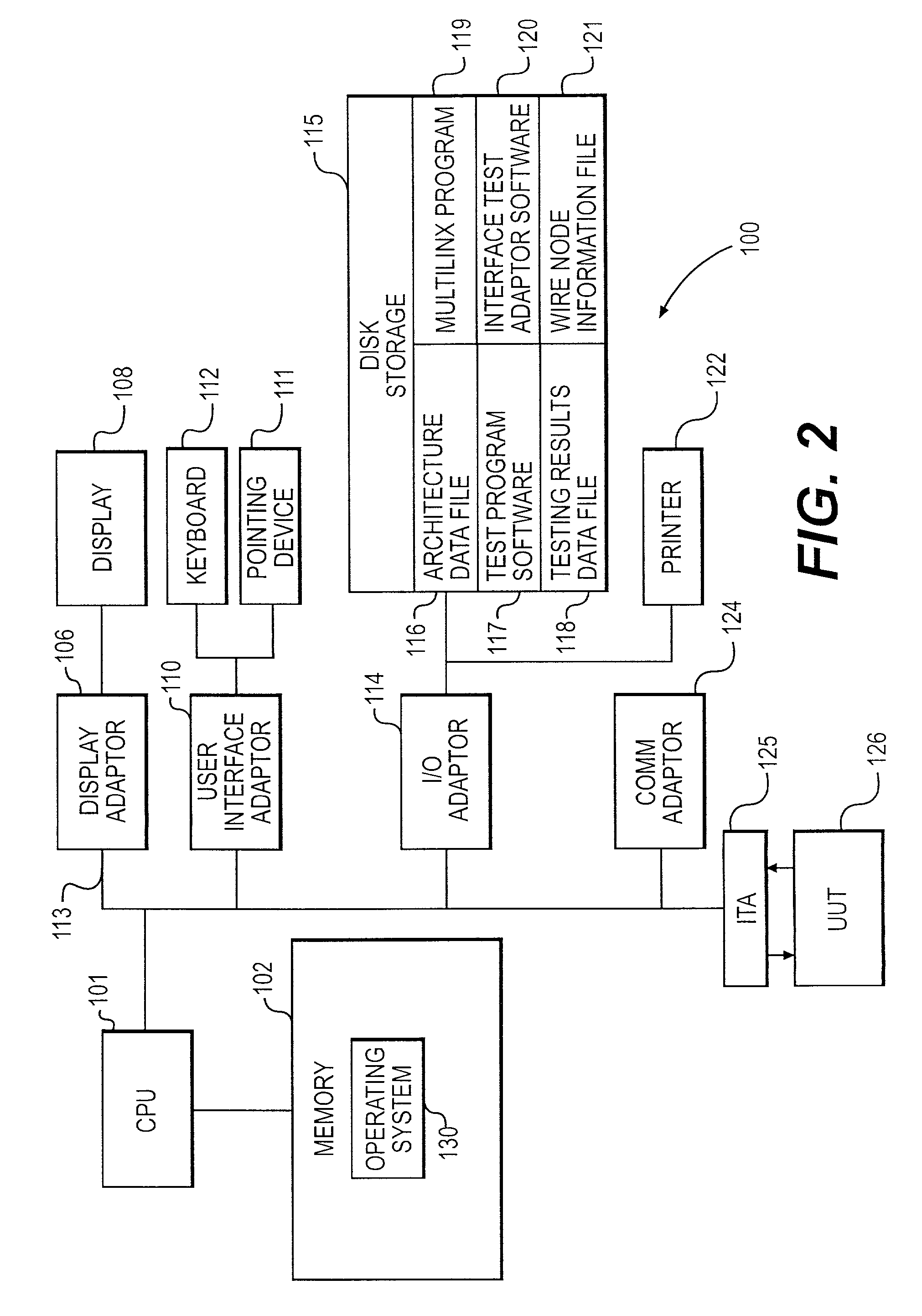

System and method for intelligent wire testing

InactiveUS20020147561A1Resistance/reactance/impedenceTesting circuitsAutomatic test equipmentRelational database

A system and method for providing an intelligent wire testing capability for complex hardware systems. The system is comprised of a software application with a relational database interfacing with an automatic test equipment module. The relational database contains all of a system's architecture information plus all of the text and parametric information associated with the design. During a system test, the subject invention uses the wiring / system architecture as disclosed in the relational database together with an automatically generated test program to identify faults in a unit under test. Using the architecture knowledge, the subject invention is capable of automatically generating a wire harness schematic for printout or display on a CRT. The architecture knowledge also allows a technician to quickly distinguish between a broken wire and an unused pin in a connector. After the test, the observed values are stored in a testing results file for later review and trend analysis. Data from the trend analysis provides the technician with the data necessary to assess the state of the wiring in the UUT. At the completion of testing, the testing results file stays with the UUT thereby ensuring access to a complete testing history of the UUT at any time.

Owner:GRC INT INC

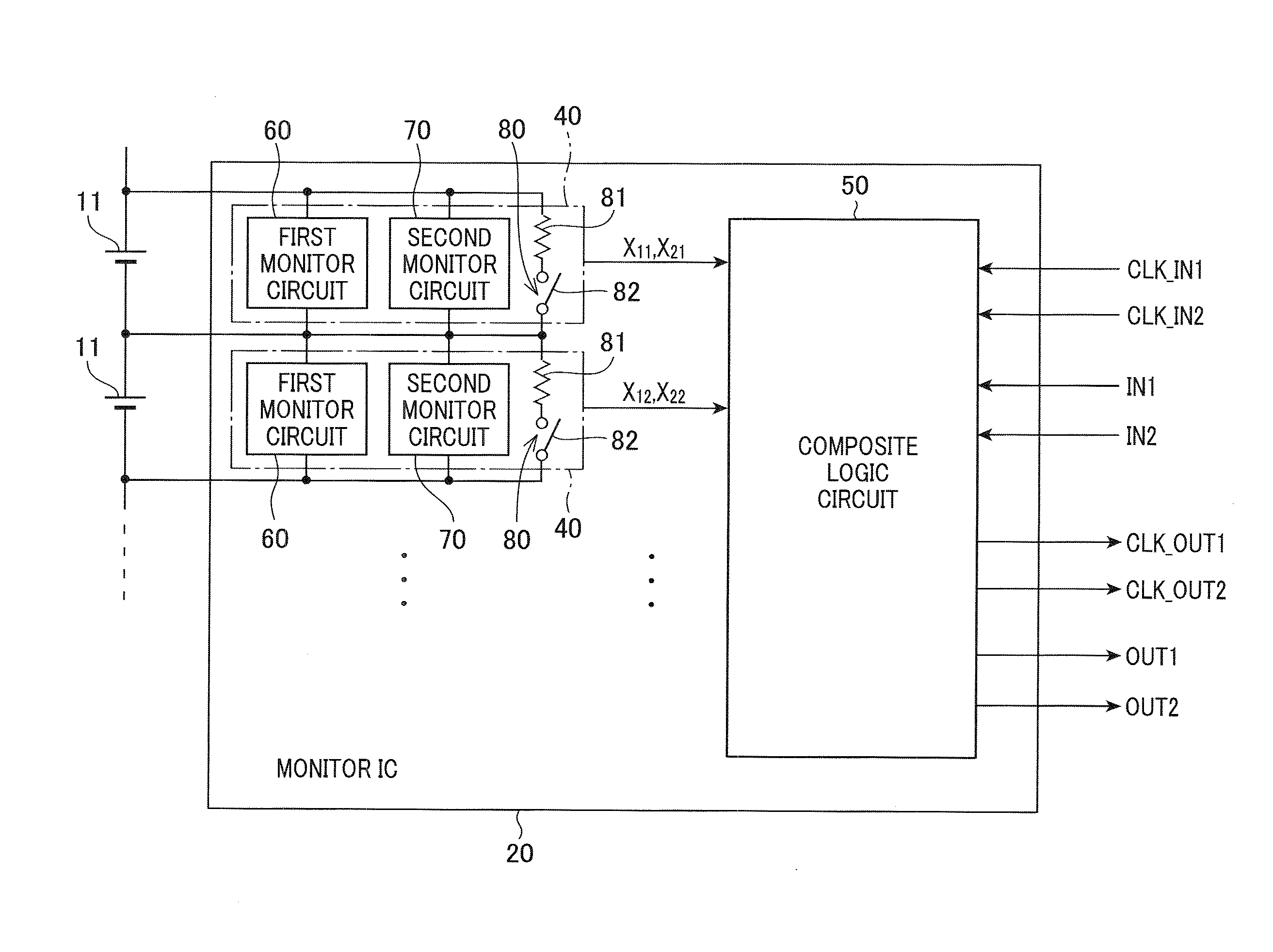

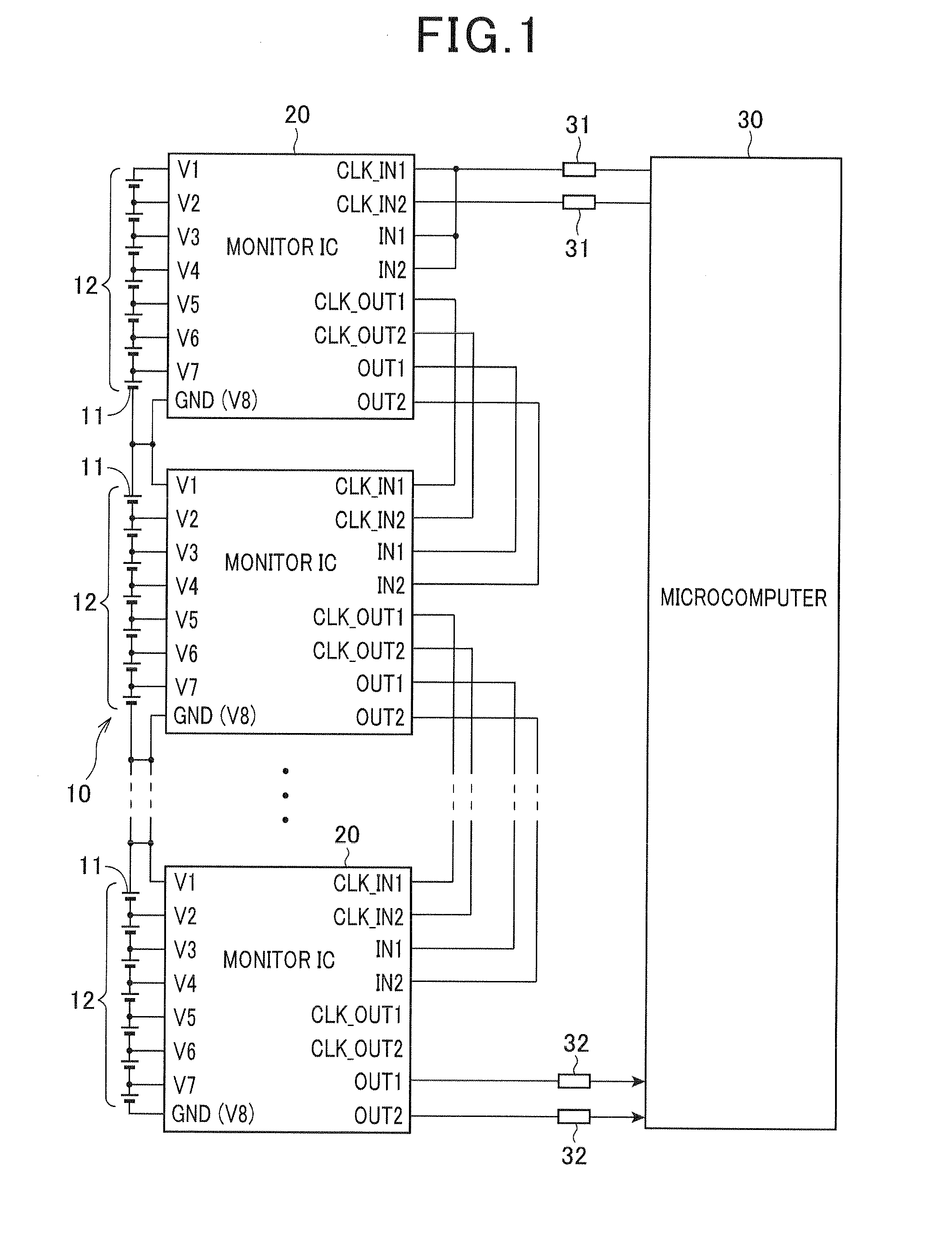

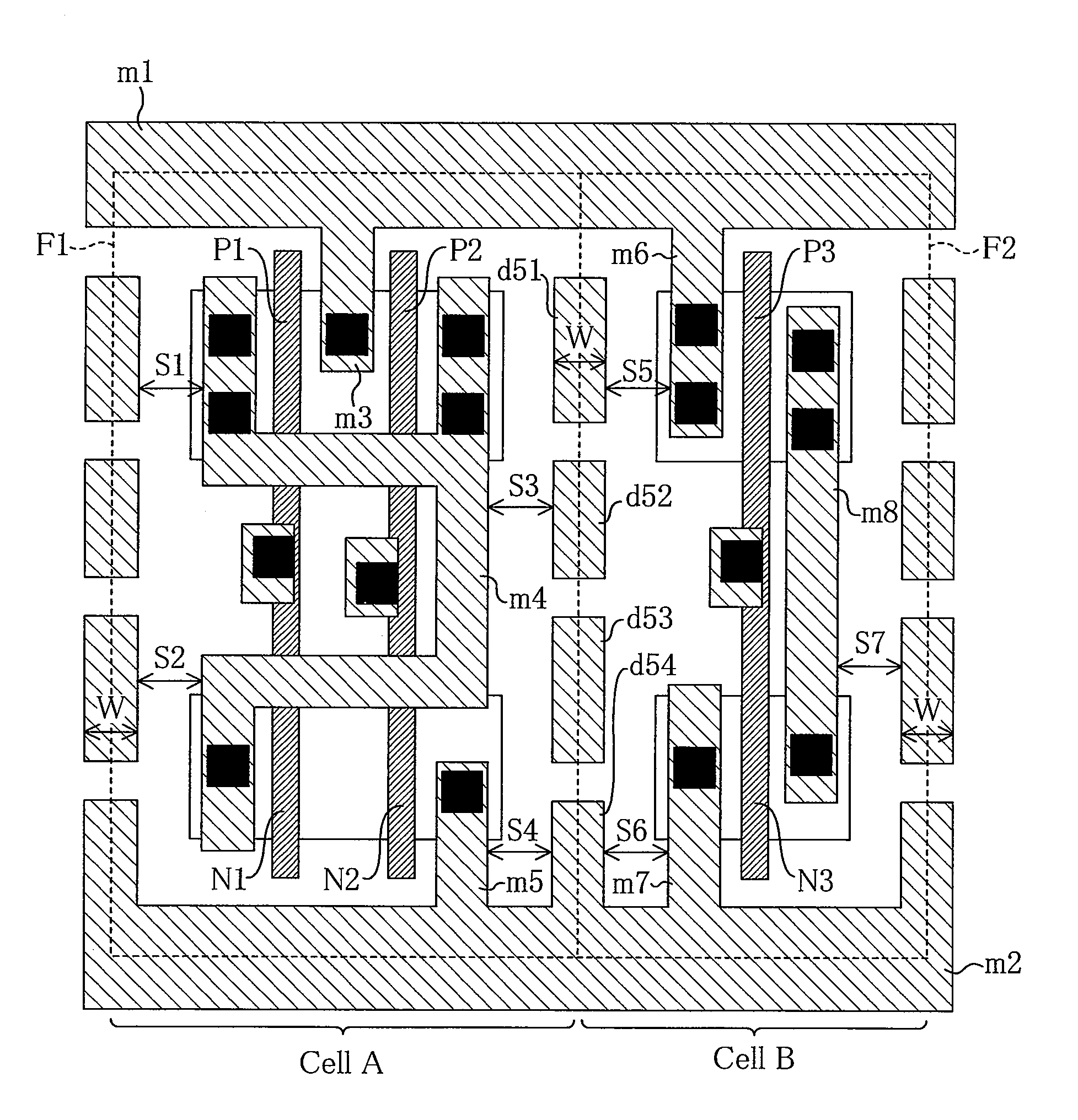

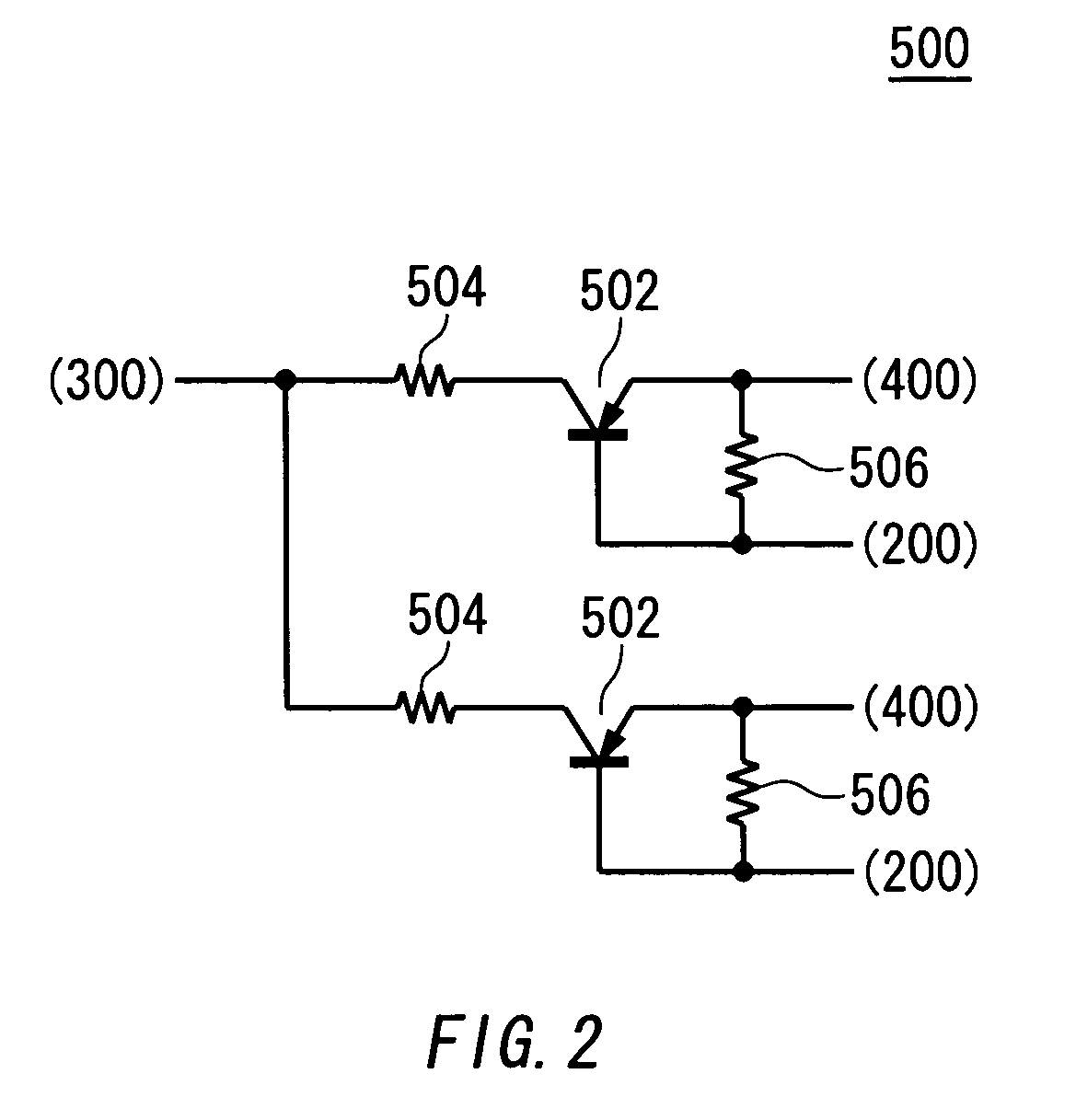

Battery fault detection apparatus

ActiveUS20110156714A1Avoid misjudgmentCircuit monitoring/indicationDifferent batteries chargingControl signalBattery cell

The battery fault determination apparatus includes battery monitor sections connected in a daisy chain, each of which is provided for a corresponding one of unit batteries each including battery cells connected in series to monitor the battery cells and output an output signal indicative of a monitoring result, and a control section configured to output a control signal to the battery monitor sections. The control signal and the output signal are cascaded through the battery monitor sections causing each battery monitor section to perform a state change between a state to monitor overcharge of the battery cells and a state to monitor wire breakage. Each battery monitor section is configured to receive the control signal from the immediately upstream-side battery monitor section, make a detection whether the state change has been performed correctly, and output the output signal including a detection result to the immediately downstream-side battery monitor section.

Owner:DENSO CORP

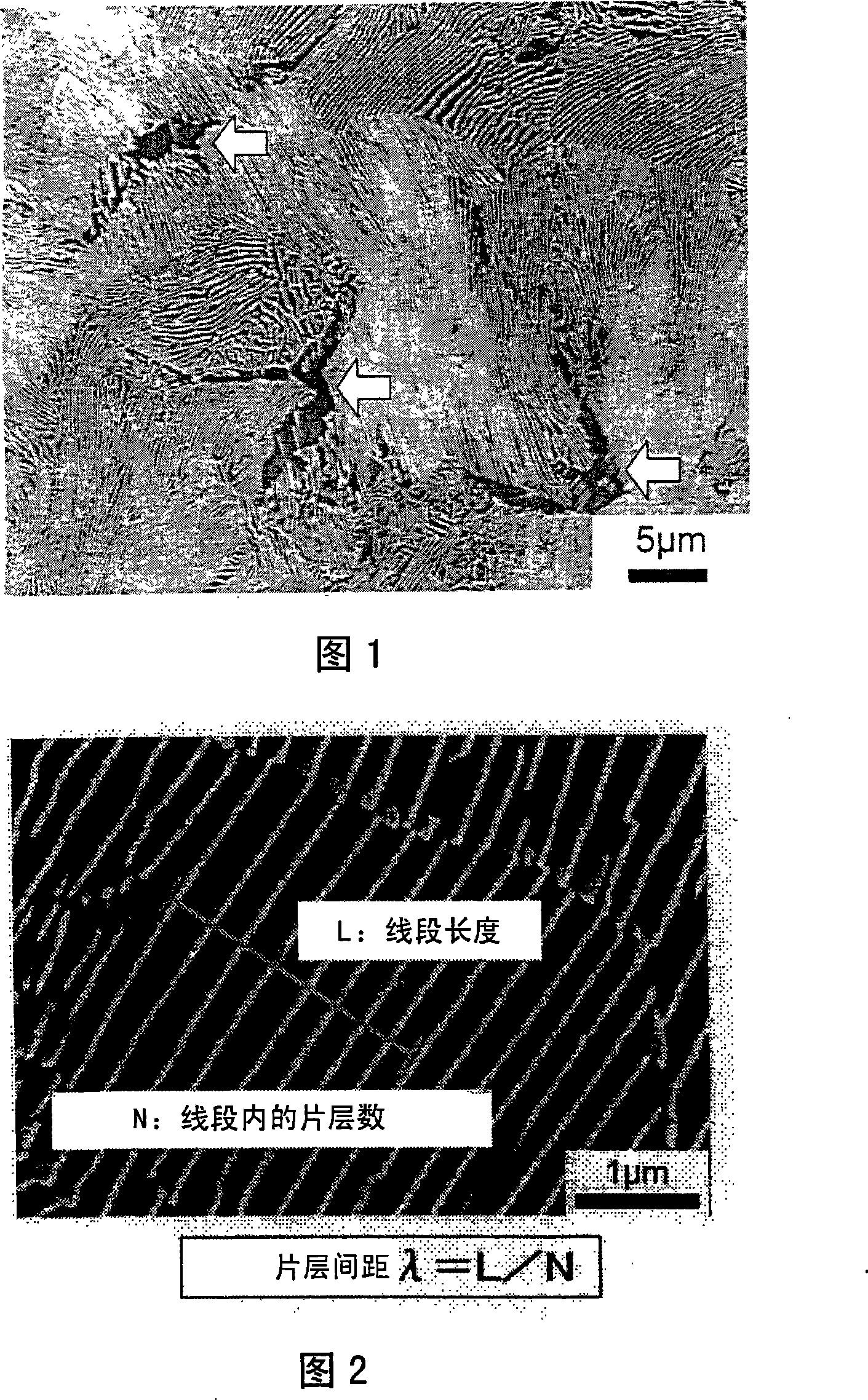

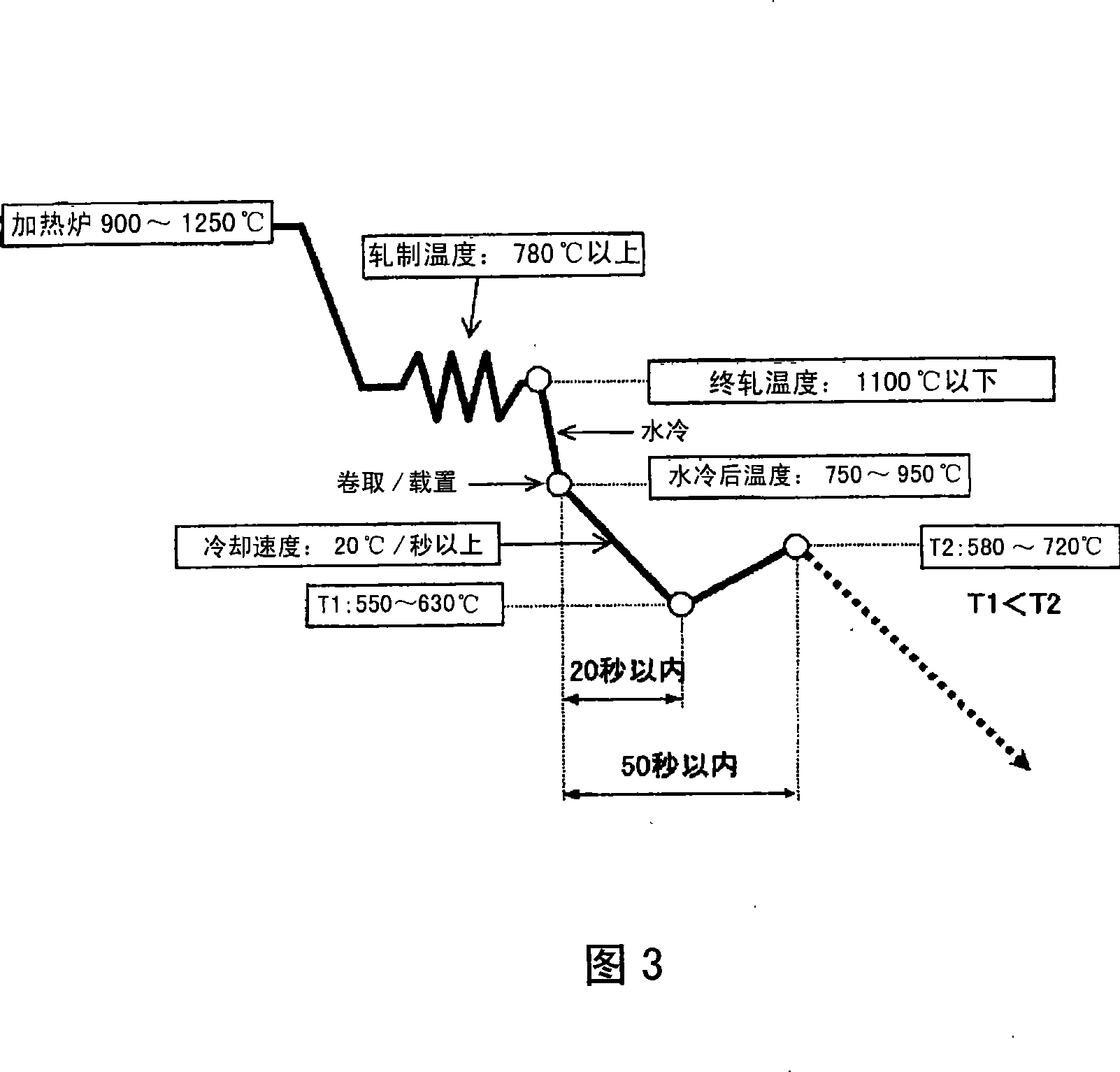

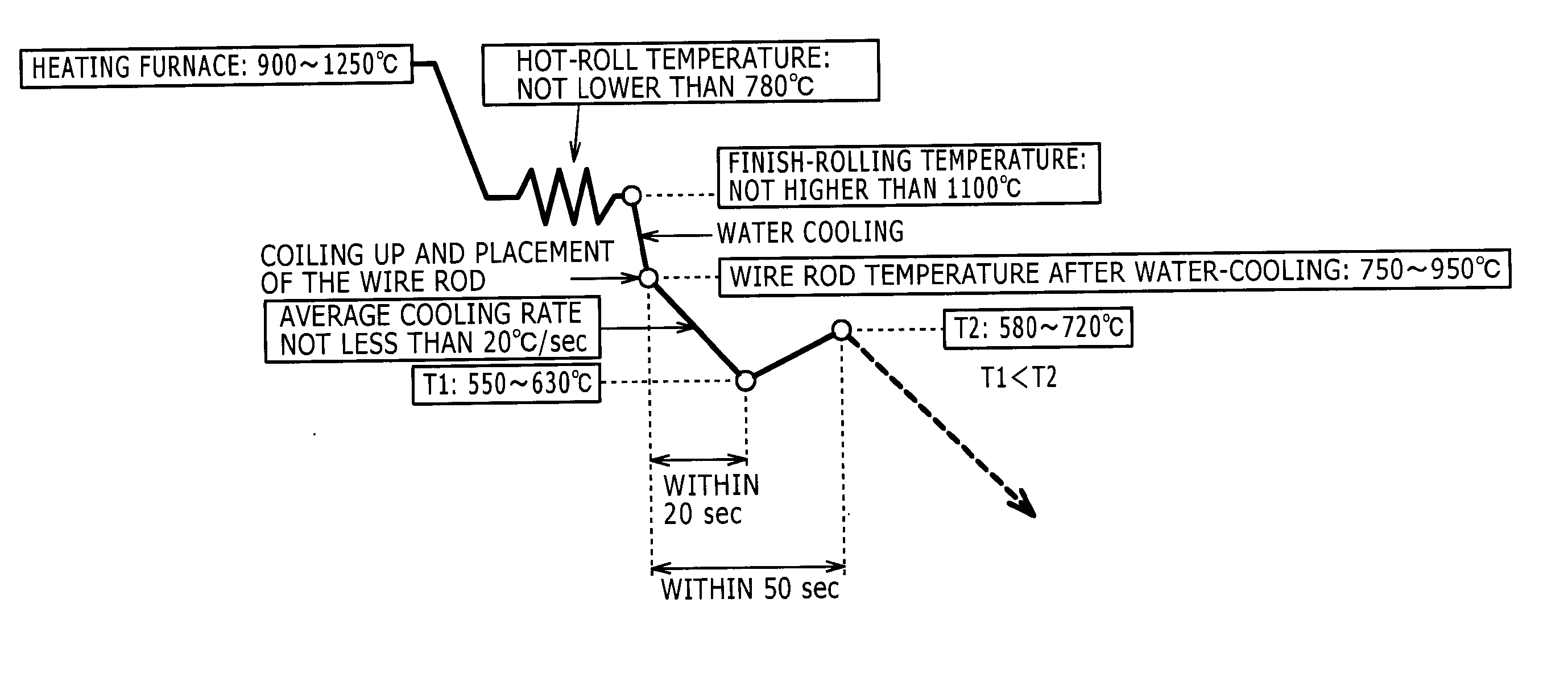

Wire rod excellent in wire-drawing workability and method for producing same

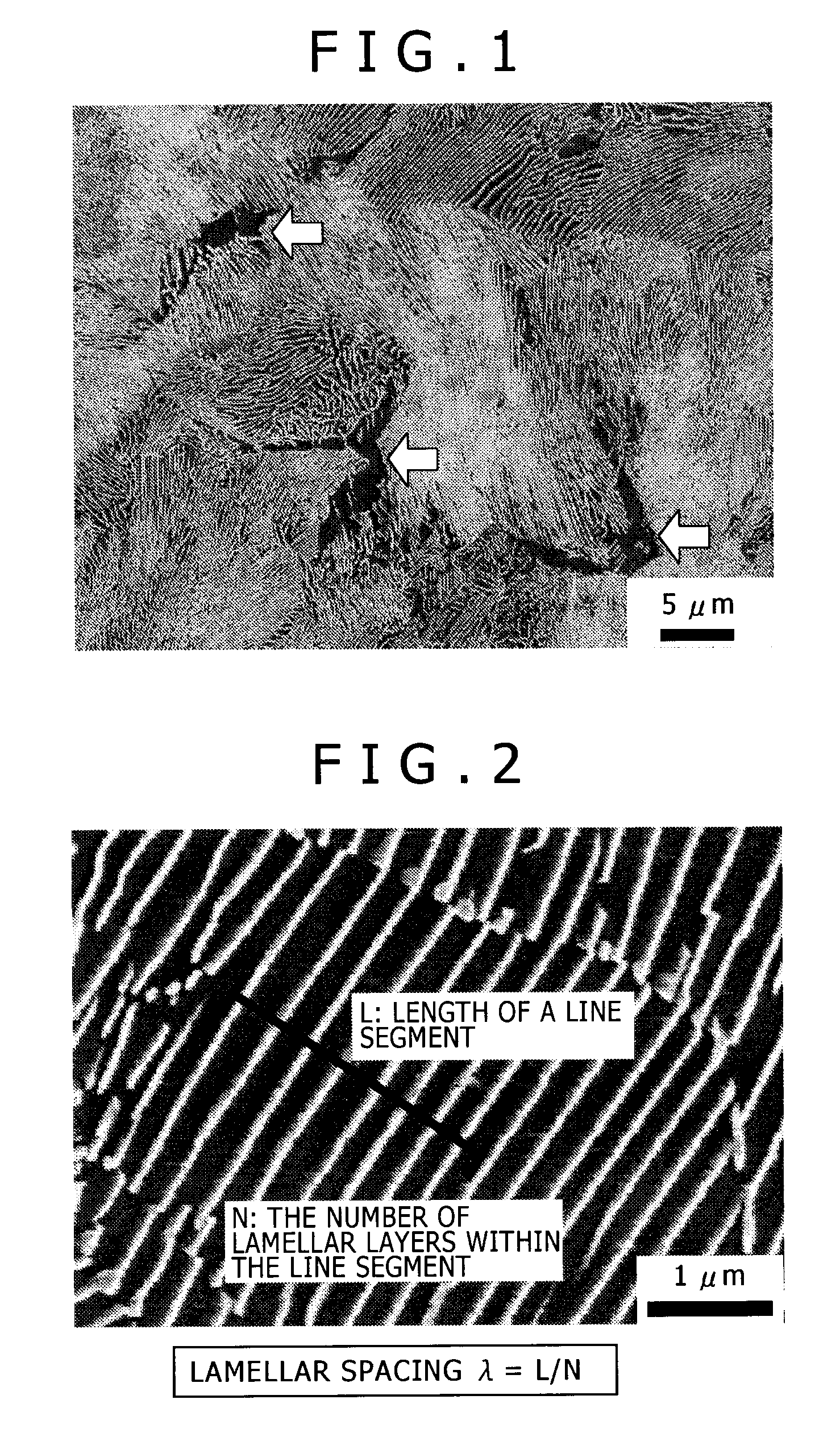

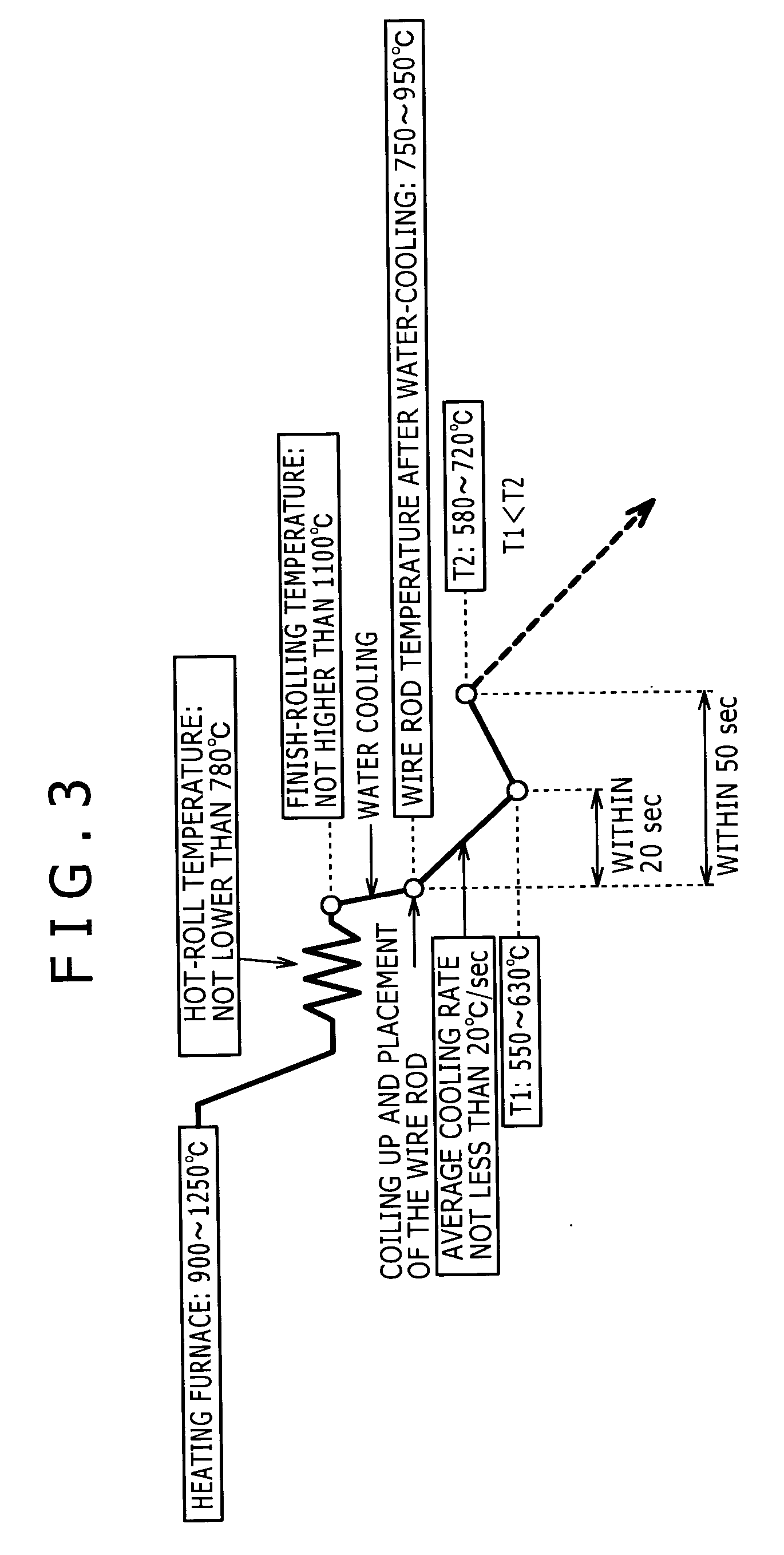

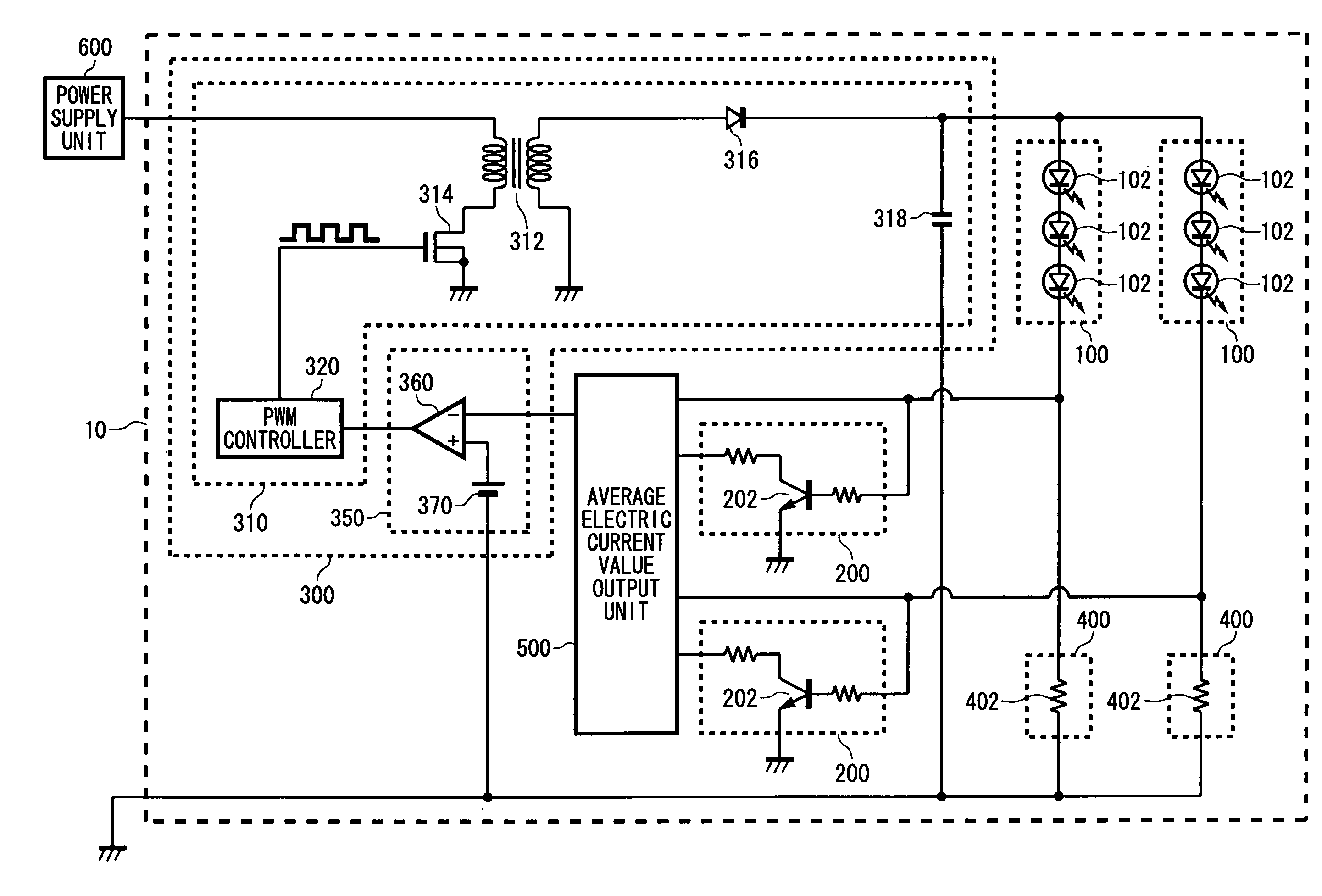

InactiveCN101086052AExcellent drawing processabilityInhibit wearTemperature control deviceHeat treatment process controlWire rodPearlite

Disclosed are a wire rod and a method therefor. The wire rod is excellent in wire-drawing workability, insusceptible to wire break in spite of an increase in wire-drawing rate, and reduction of area, and capable of extending a die life by suppressing die wear. The wire rod is made of steel containing C: 0.6 to 1.1%, Si: 0.1 to 2.0%, Mn: 0.1 to 1%, P: not more than 0.20%, S: not more than 0.20%, N: not more than 0.006%, Al: not more than 0.03%, and O: not more than 0.003%, the balance including Fe, and unavoidable impurities. Further, the wire rod comprises a pearlite structure wherein an area ratio of a second-phase ferrite is not more than 11.0%, and a pearlite lamellar spacing is not less than 120 mum.

Owner:KOBE STEEL LTD

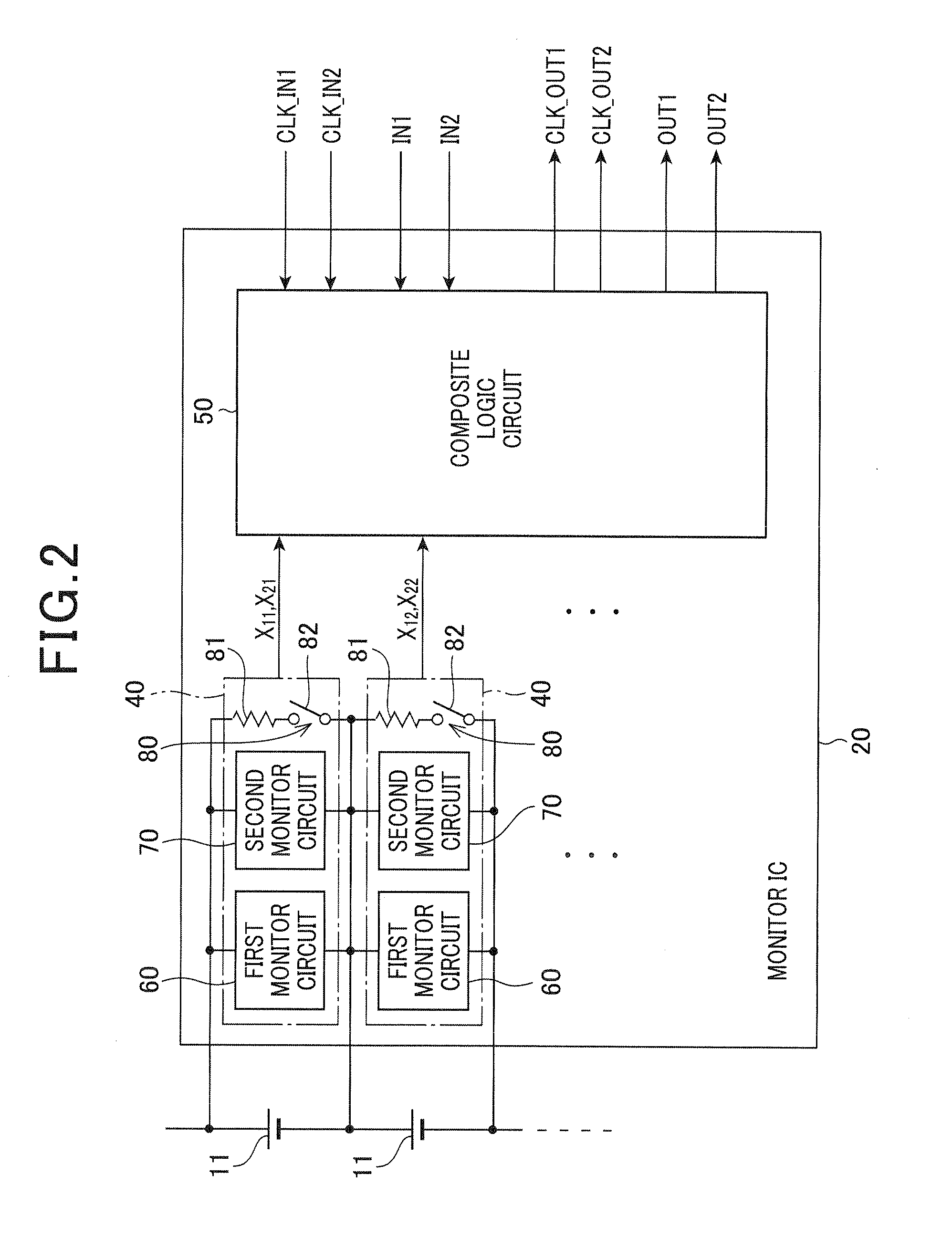

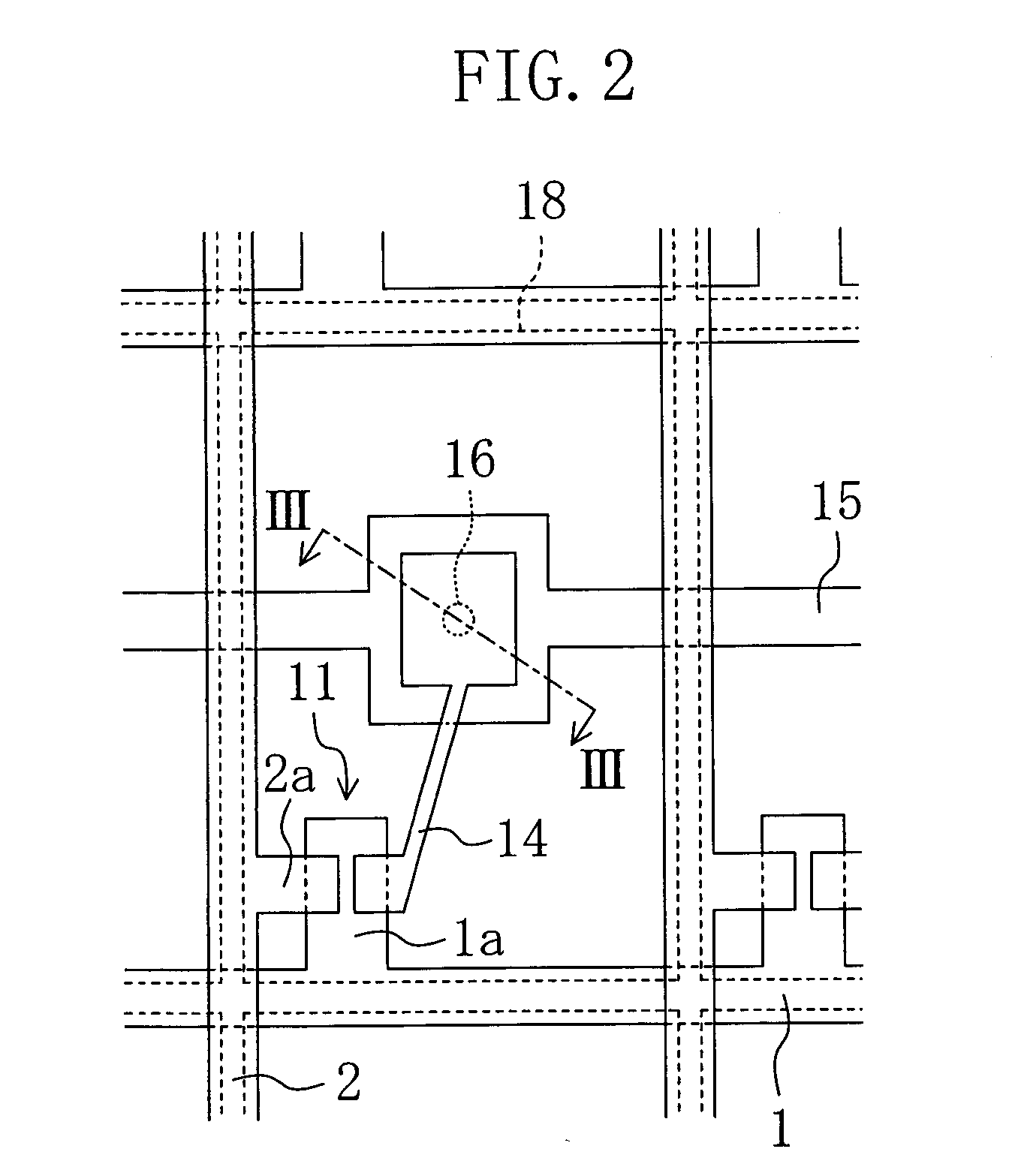

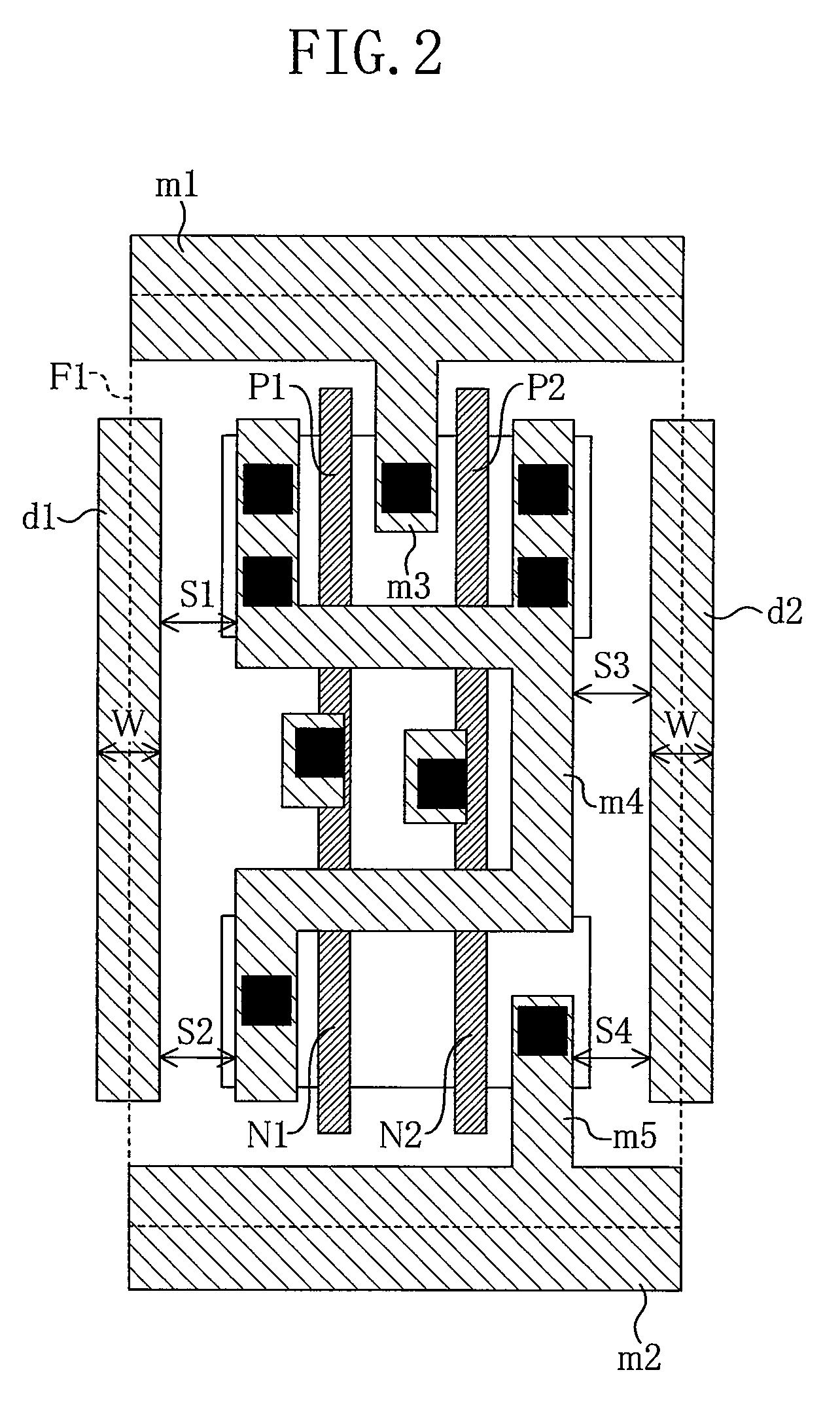

Semiconductor integrated circuit device

ActiveUS20100187699A1Wire breakageReduce amountTransistorSemiconductor/solid-state device detailsThinningSemiconductor

There is provided a layout structure of a semiconductor integrated circuit capable of preventing the thinning of a metal wiring line close to a cell boundary and wire breakage therein without involving increases in the amount of data for OPC correction and OPC process time. In a region interposed between a power supply line and a ground line each placed to extend in a first direction, first and second cells each having a transistor and an intra-cell line each for implementing a circuit function are placed to be adjacent to each other in the first direction. In a boundary portion between the first and second cells, a metal wiring line extending in a second direction orthogonal to the first direction is placed so as not to short-circuit the power supply line and the ground line.

Owner:SOCIONEXT INC

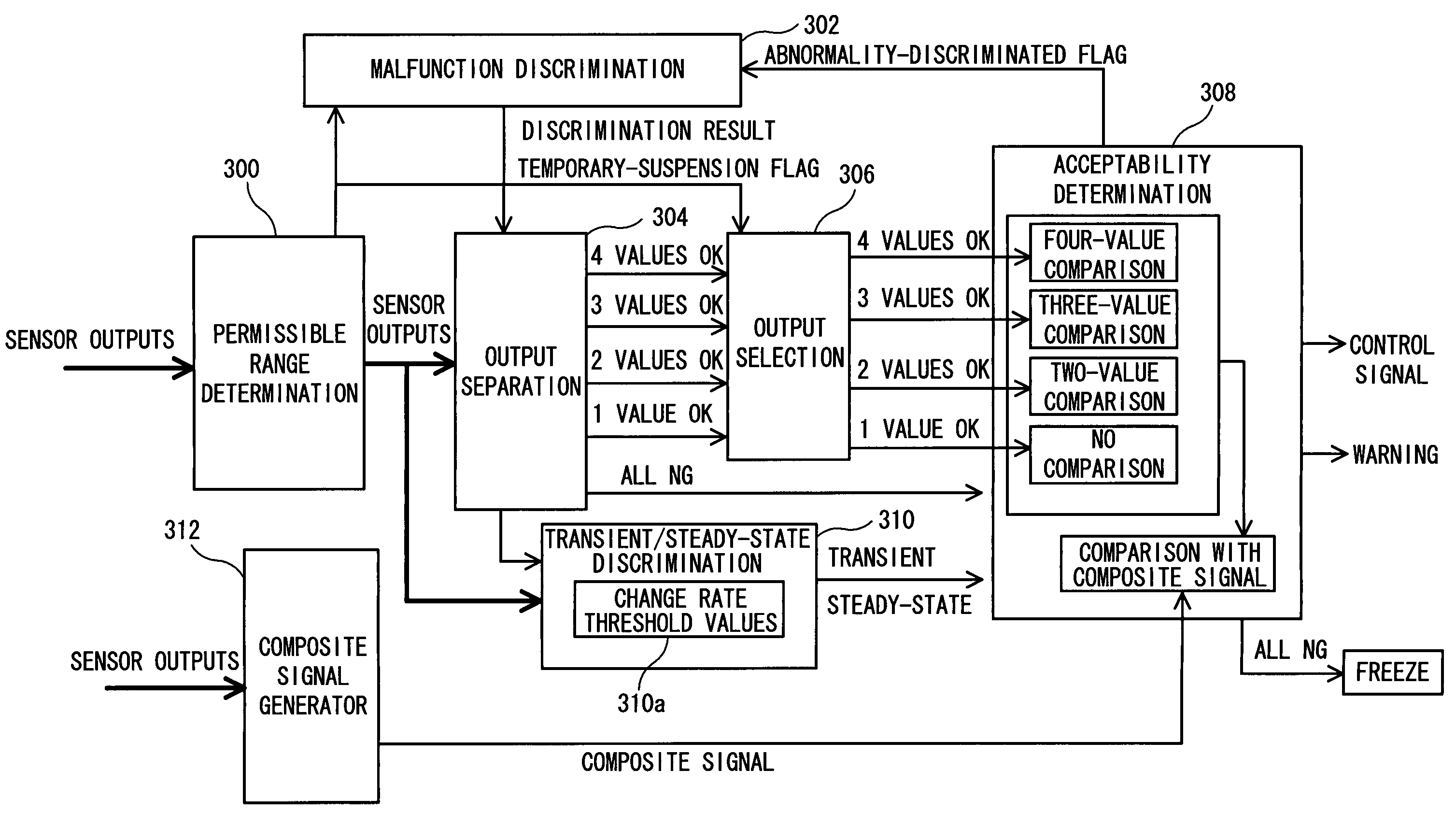

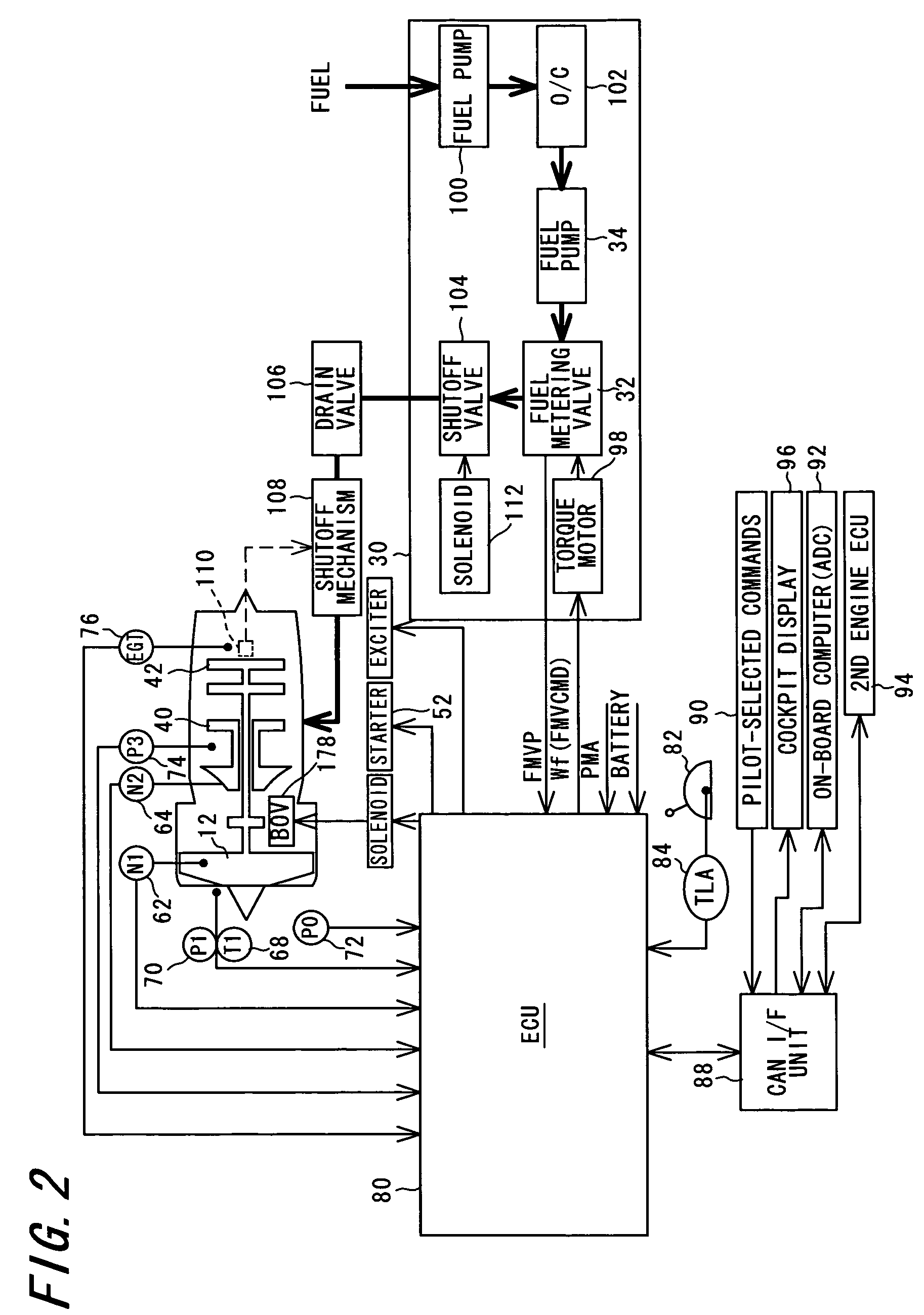

Sensor malfunction detection system for gas-turbine engine

ActiveUS7246024B2Improve accuracySimple configurationVehicle testingGas-turbine engine testingGas turbinesElectrical and Electronics engineering

The sensor malfunction detection system for a gas-turbine engine is configured to determine or check once every first predetermined time period whether the outputted value from the sensor is within a permissible range and determines that the sensor is faulty when the result of the check is at least one result between the case of the number of times the outputted value is found not to be within the permissible range exceeding a first predetermined value and the case of the number of times the outputted value is consecutively found not to be within the permissible range exceeding a second predetermined value. Since the system discriminates whether the total number of times the sensor output is found to be outside the permissible range is fewer than the first predetermined value, it can avoid erroneous detection of transient abnormalities caused by noise or the like as sensor malfunction, and since it discriminates whether the number of times the sensor output is consecutively found not to be within the permissible range is fewer than the second predetermined value, it can promptly detect sensor malfunction owing to wire breakage or the like. The system can therefore detect sensor malfunction with good accuracy using a simple configuration.

Owner:HONDA MOTOR CO LTD

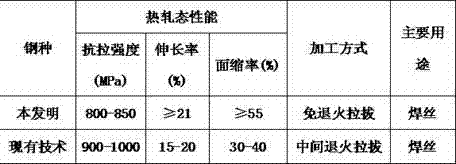

Steel wire rod for annealing-free solder wire and production process thereof

ActiveCN102513725AChemically stableImprove plastic indexWelding/cutting media/materialsSoldering mediaWire rodMechanical property

The invention belongs to the metallurgy field and relates to a production process of a steel wire rod, particularly the steel wire rod for an annealing-free solder wire and a production process of the steel wire rod, wherein the steel wire rod comprises elements in weight percentage as follows: 0.07-0.1% of C, 1.25-1.4% of Mn, 0.4-0.6% of Si, less than or equal to 0.02% of P, less than or equal to 0.02% of S, 0.2-0.55% of Mo, 0.5-1.0% of Ni, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ti and less than or equal to 0.1% of Al with the balance of Fe. The process comprises steps of detecting a blank, heating the steel blank, descaling by high-pressure water, roughly and intermediately rolling, pre-finishing rolling, cooling in a first section by water, finishing rolling bya unit, cooling in a second section by water, diameter reducing and sizing rolling, cooling in a third section by water, spinning, cooling by wind, finishing and delivering to a warehouse. The methodof the invention employs a rolling-controlled and cooling-controlled process to execute process control of the steel wire rod of the solder wire to obtain an F+P tissue appropriate to draw, and has advantages as follows: good comprehensive mechanical property is realized, a solder wire factory can avoid annealing and perform multi-pass drawing without wire breakage, the production efficiency is greatly increased and the production cost is reduced at the same time.

Owner:NANJING IRON & STEEL CO LTD

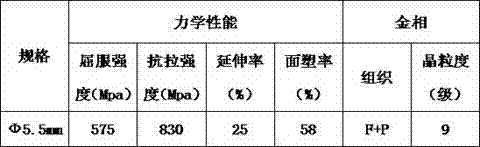

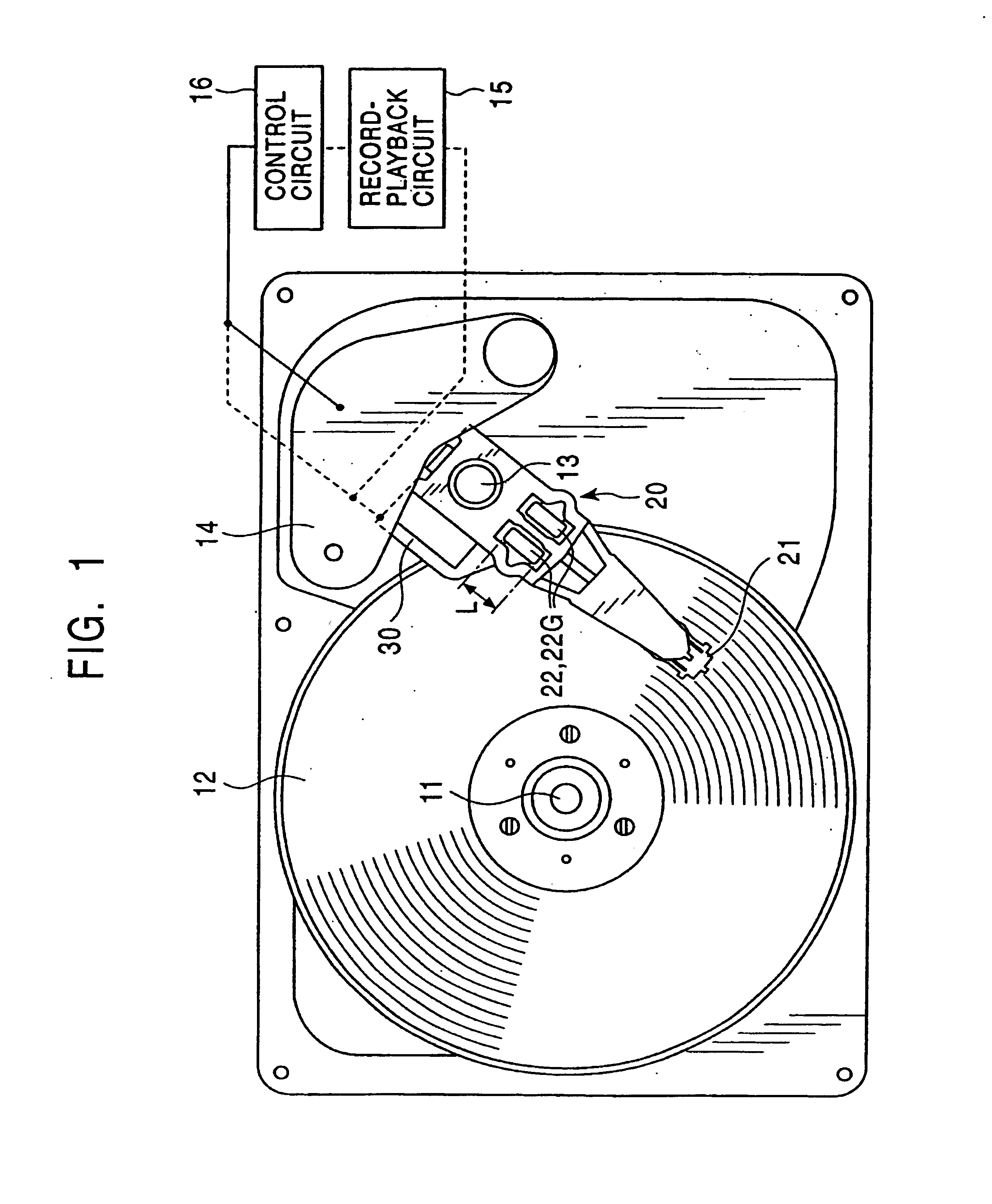

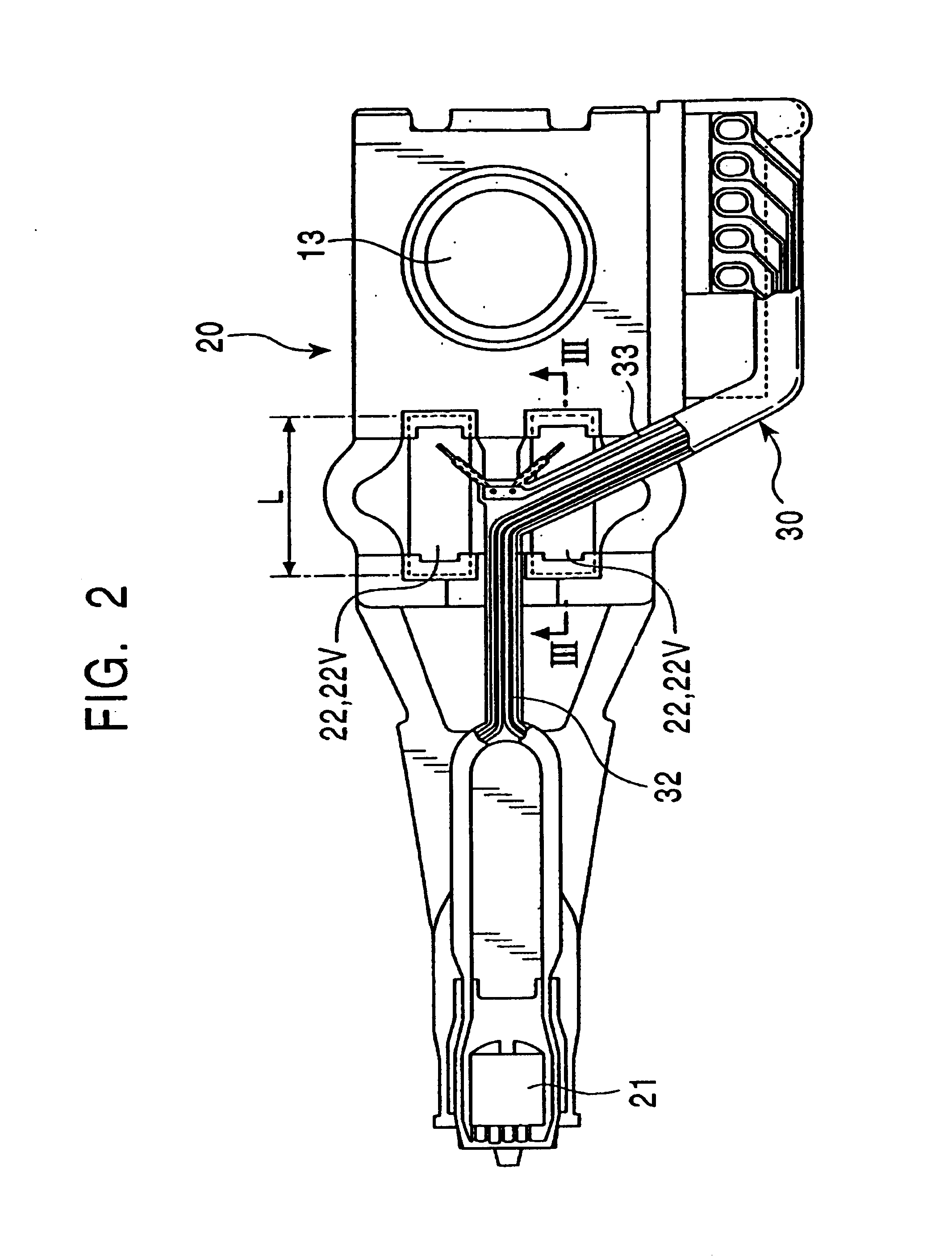

Magnetic head actuator having finely movable tracking device

InactiveUS7167344B2Easy wiringReduce breakagePrinted circuit assemblingTrack finding/aligningEngineeringActuator

A magnetic head actuator provided with a finely movable tracking device having a piezoelectric element is provided for easy wiring to the piezoelectric element and reducing problems such as wire breakage and continuity defects. In the magnetic head actuator, a portion of an FPC board resin base is removed to expose a portion of the feeding line that extends onto a voltage impressing electrode. An electrical and mechanical connection is made between the electrode and the exposed portion of the feeding line by ultrasonic bonding, Au ball bonding, or stud bumping.

Owner:TDK CORPARATION

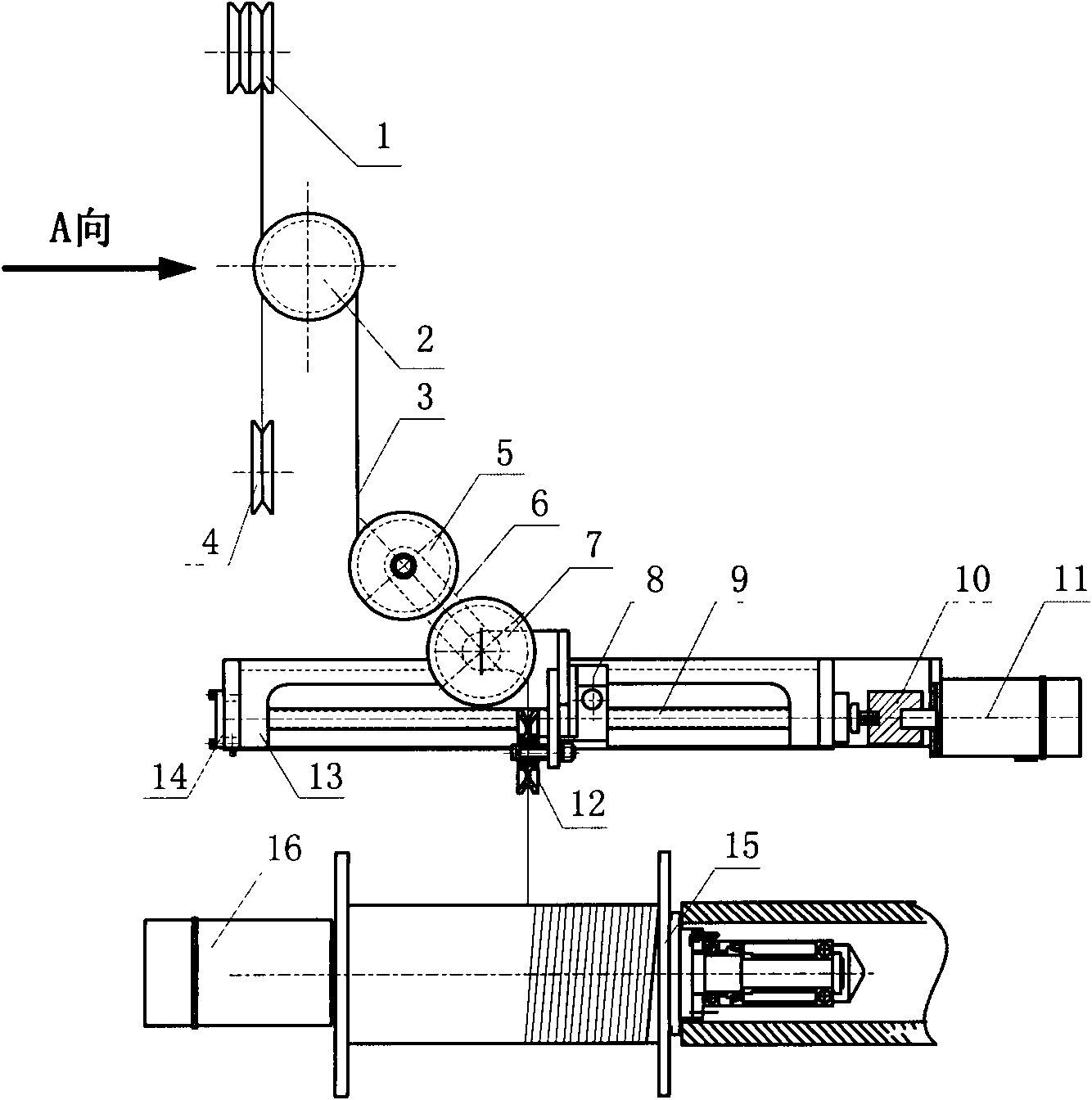

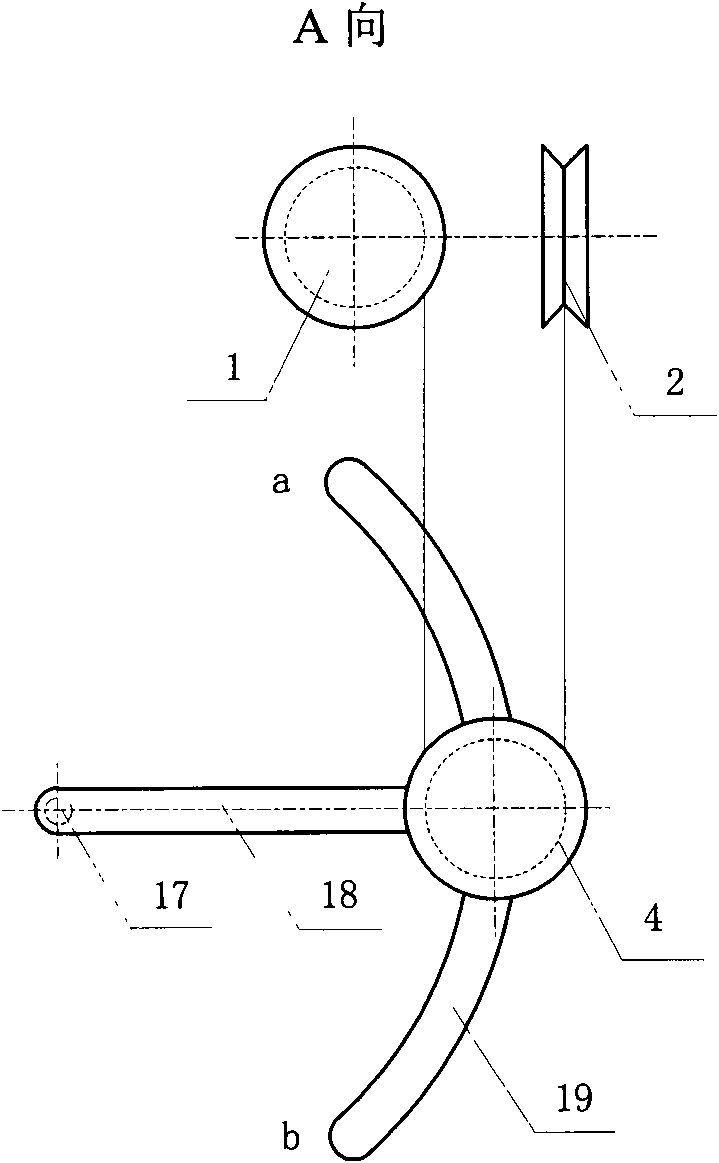

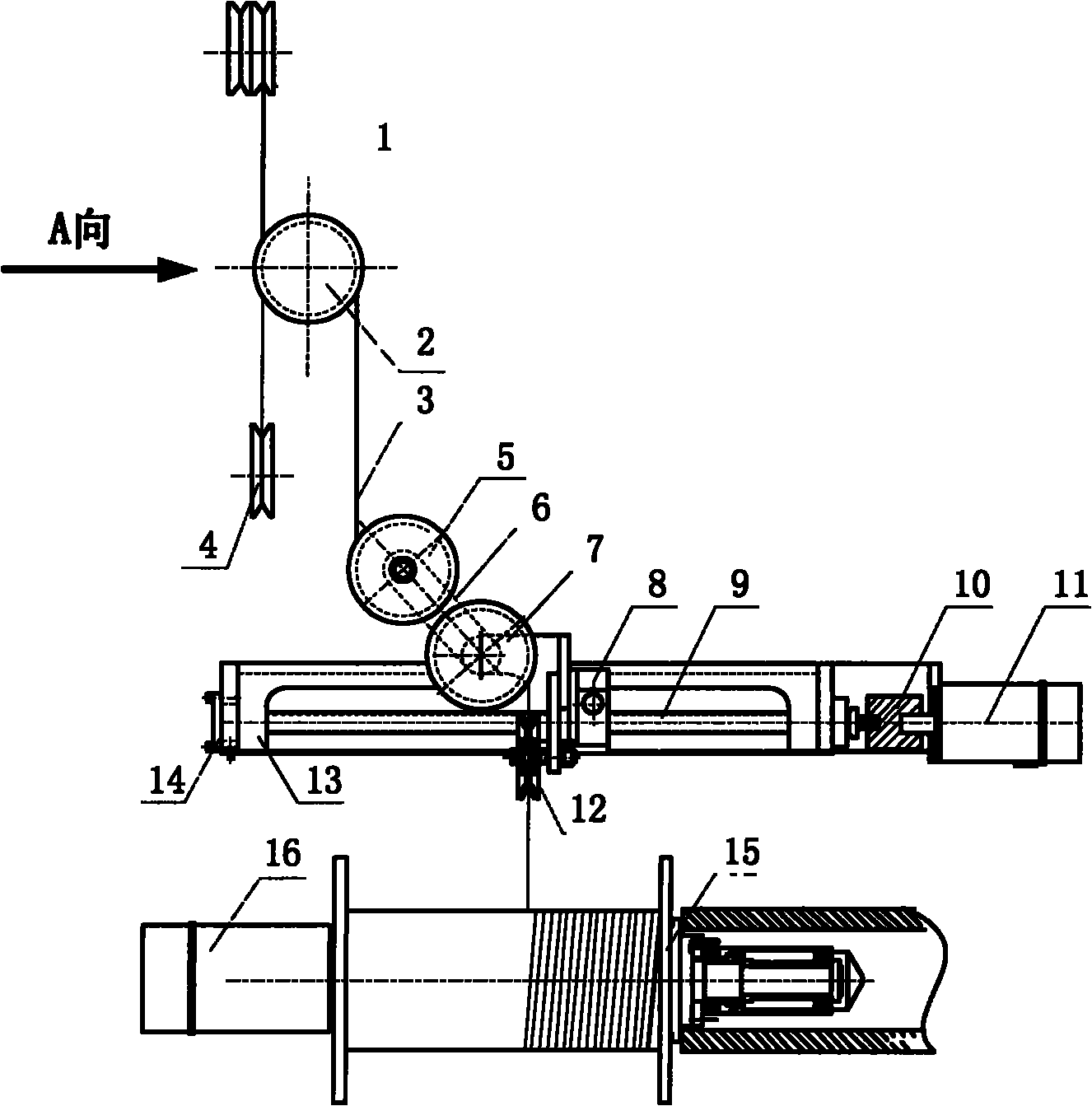

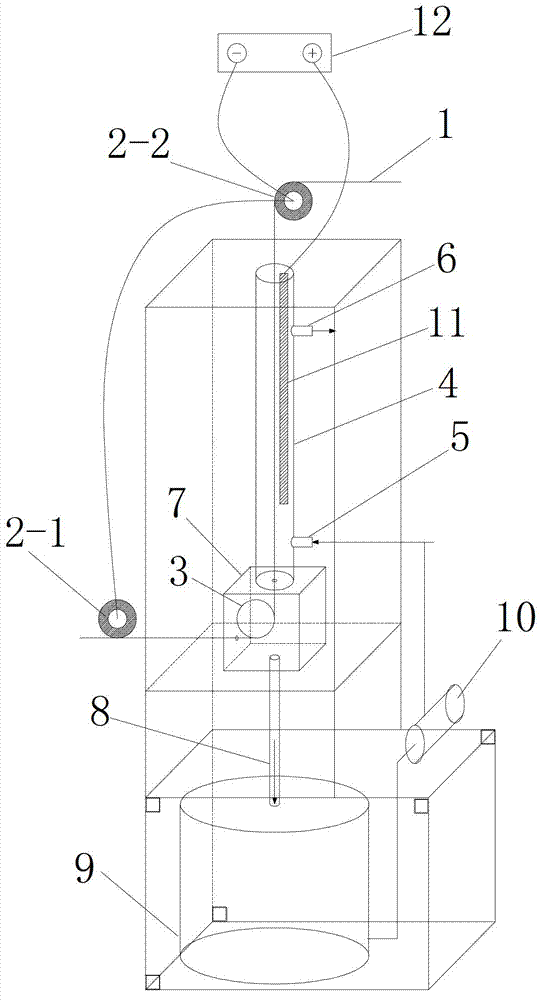

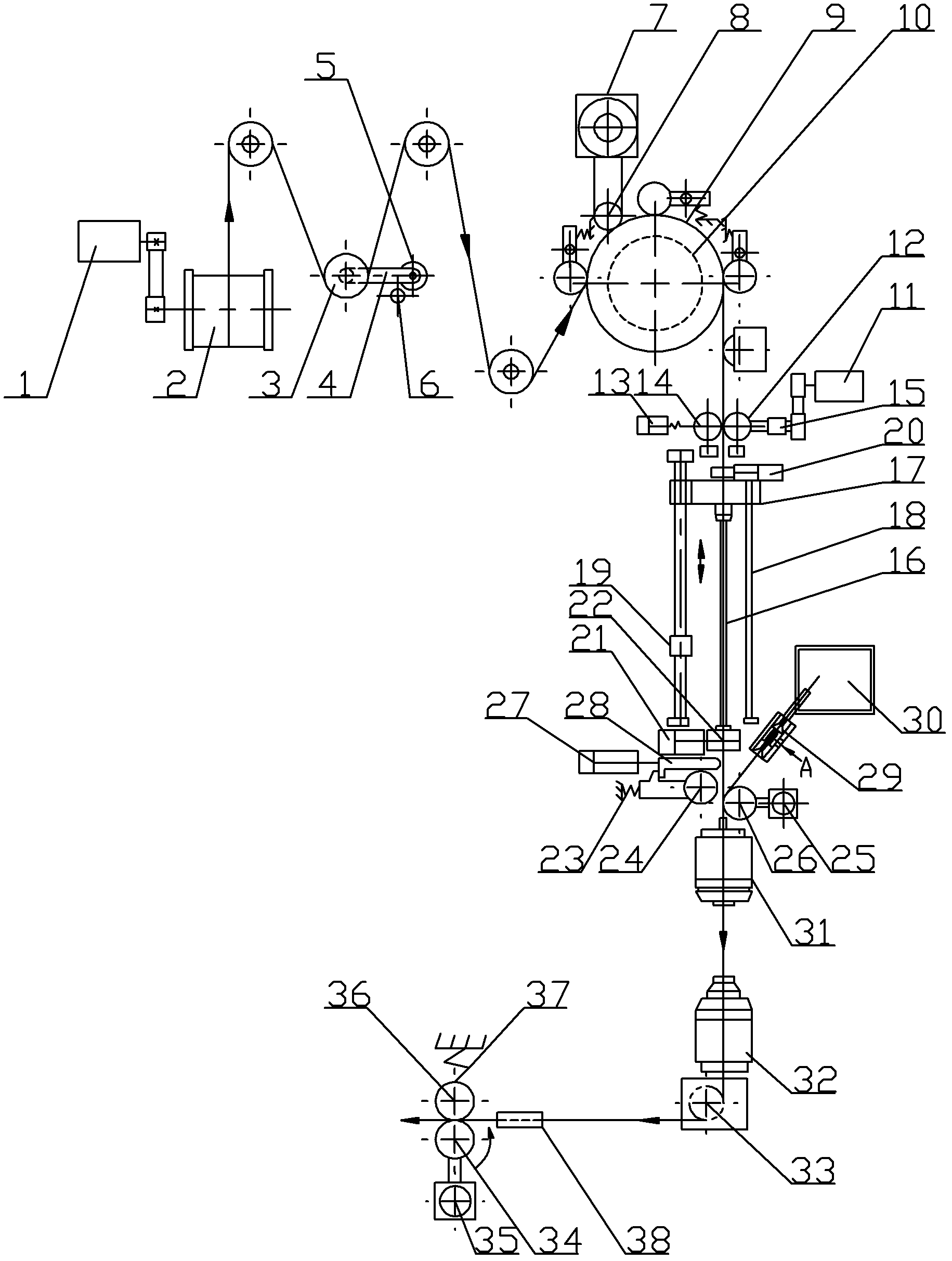

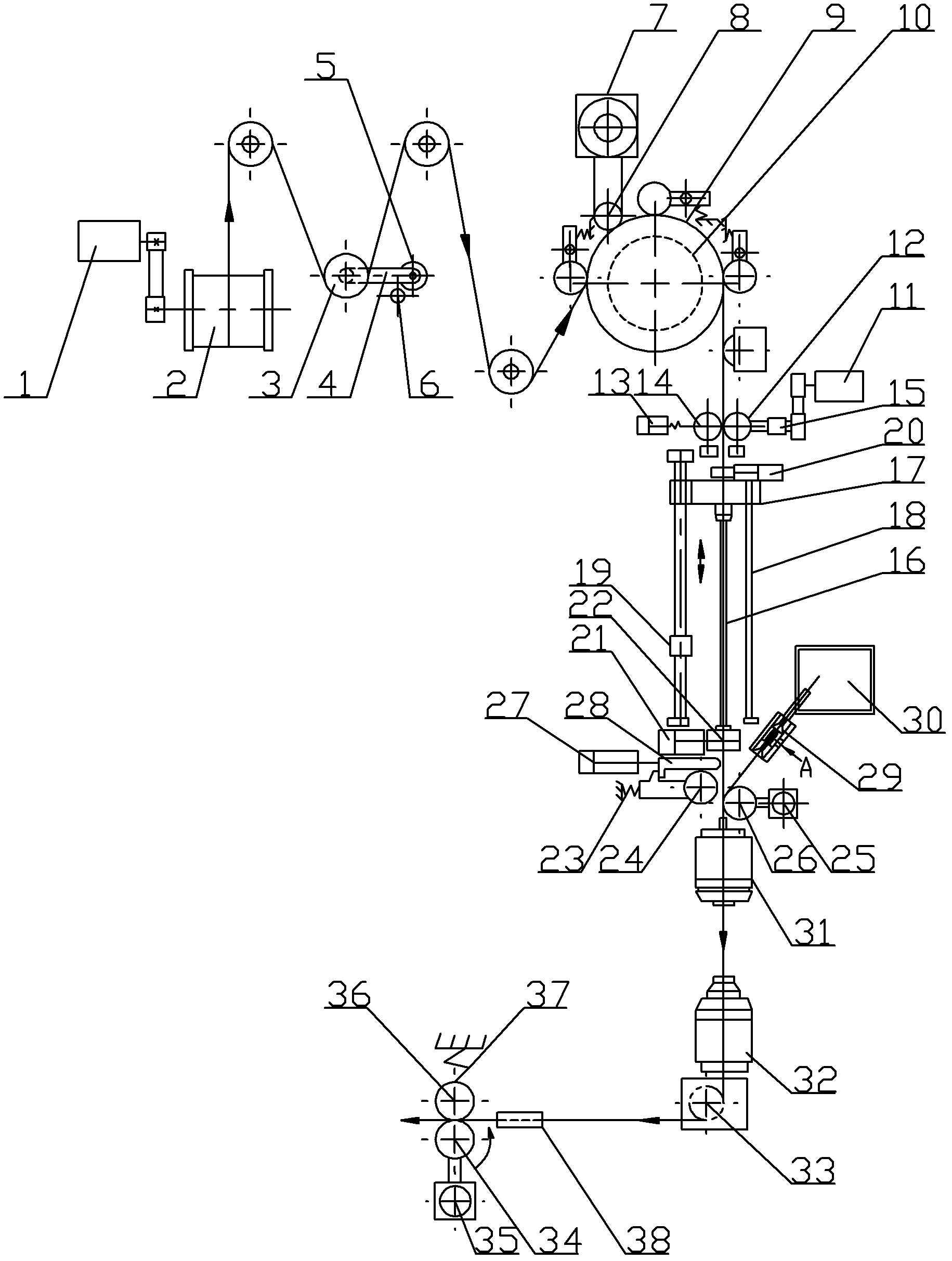

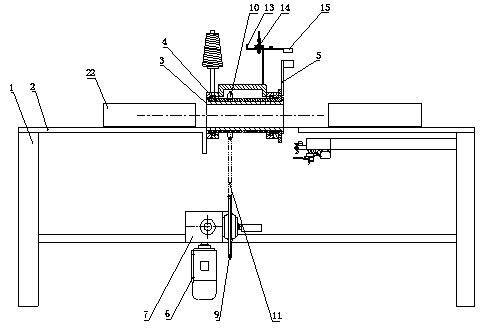

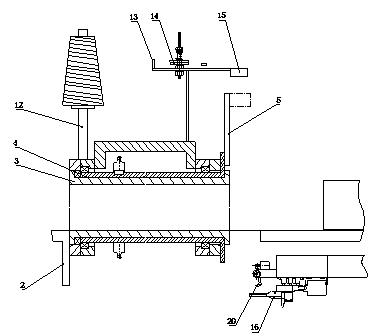

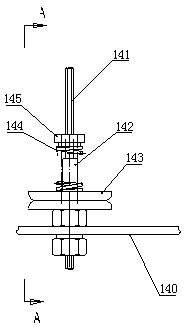

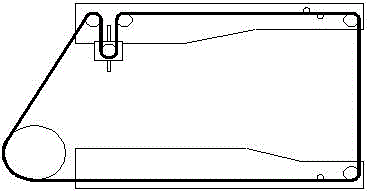

Self-compensating servo wiring device for water tank type wire drawing machine

ActiveCN102172669AWith disconnection alarm functionAvoid the phenomenon of "rising wheel"Metal working apparatusBall screwEngineering

The invention discloses a self-compensating servo wiring device for a water tank type wire drawing machine, which comprises a tension testing unit, a wire distributing device and a wire collecting device, wherein the tension testing unit consists a first wire roller, a second wire roller, a tensioning wire roller, an angular displacement sensor, a tension rod and a guide groove; the wire distributing device consists a third wire roller, a synchronous belt, a fourth wire guide roller, a screw nut, a ball screw, a coupler, a wiring servo motor, a fifth wire roller, a wiring base and an end cover; and the wire collecting device consists of a spool and a wire collecting servo motor. The device adopts the tensioning wire roller for testing the tension of a metal wire, has a simple structure and has a metal wire breakage alarming function for giving an alarm in time incase of breakage of the metal wire.

Owner:JIANGSU HENGLI MACHINE TOOL

Hot rolled wire rod for high-strength cut steel wires and production method of hot rolled wire rod

The invention discloses a hot rolled wire rod for high-strength cut steel wires and a production method of the hot rolled wire rod. The production method of the hot rolled wire rod comprises the work procedures of converter smelting, LF refining, continuous casting and steel rolling. The hot rolled wire rod comprises, by weight percentage, 0.79-0.85% of C, 0.15-0.30% of Si, 0.40-0.60% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.05% of Ni, smaller than or equal to 0.05% of Cu, smaller than or equal to 0.0015% of Alt, smaller than or equal to 0.0008% of Als, smaller than or equal to 0.0010% of Ti, smaller than or equal to 0.0020% of T.O, smaller than or equal to 0.0030% of N, and the balance Fe and inevitable impurity elements. The center segregation of the wire rod obtained through the method is smaller than or equal to the level 2, the grain size is smaller than the level 7, the sorbitizing rate is larger than or equal to 85%, the tensile strength ranges from 1050 MPa to 1250 MPa, the reduction of area is larger than or equal to 38%, and good drawing machining performance is achieved; inclusion has good deformation performance or fragility, the length-width ratio average value of the inclusion is larger than or equal to 6, and the maximum inclusion size is smaller than or equal to 15 microns; and the wire rod is used for a user to produce the 0.11-0.12 mm cut steel wires, and reaches the level that wire breakage is avoided when the length is 10000 km or above.

Owner:XINGTAI IRON & STEEL

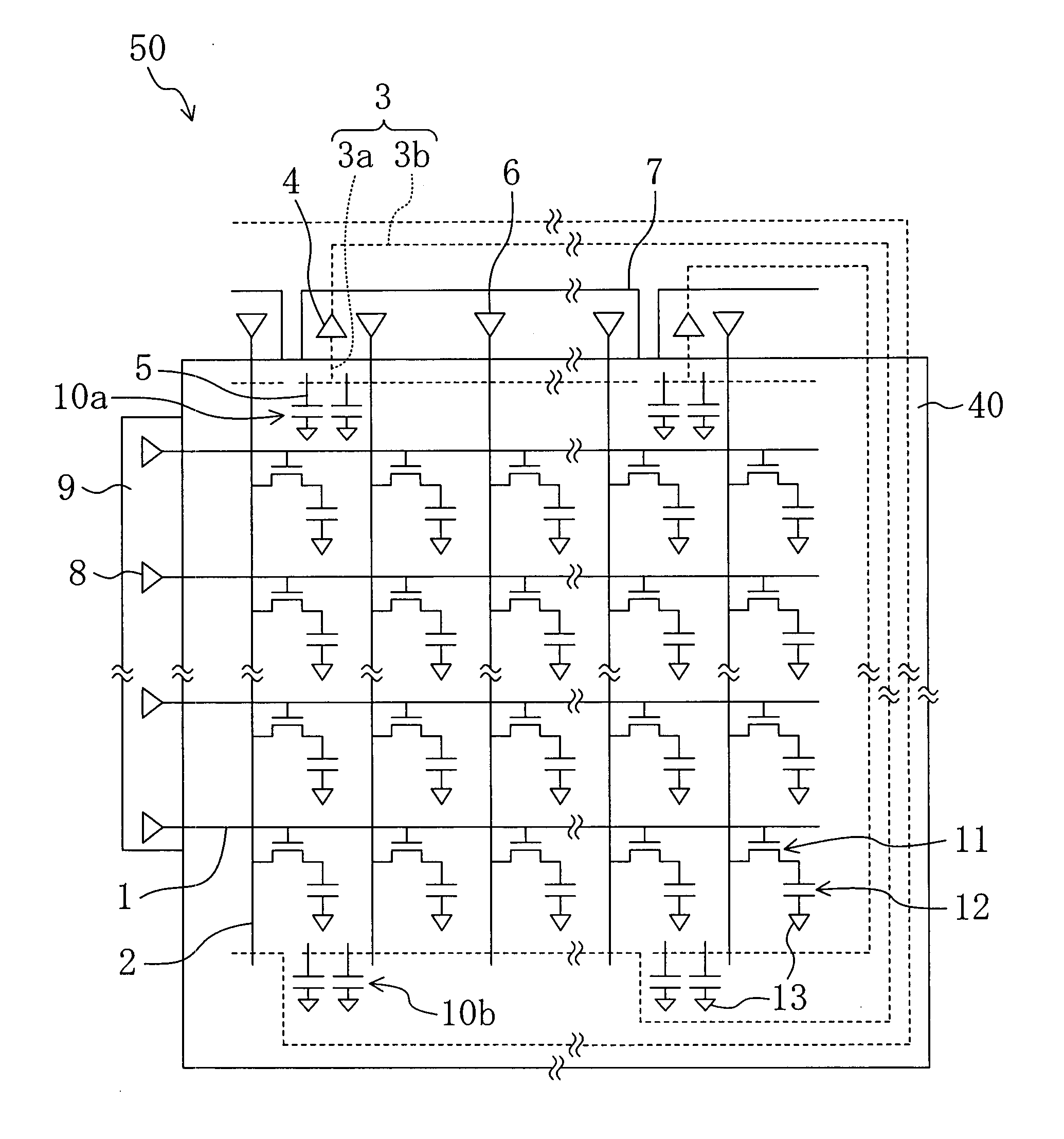

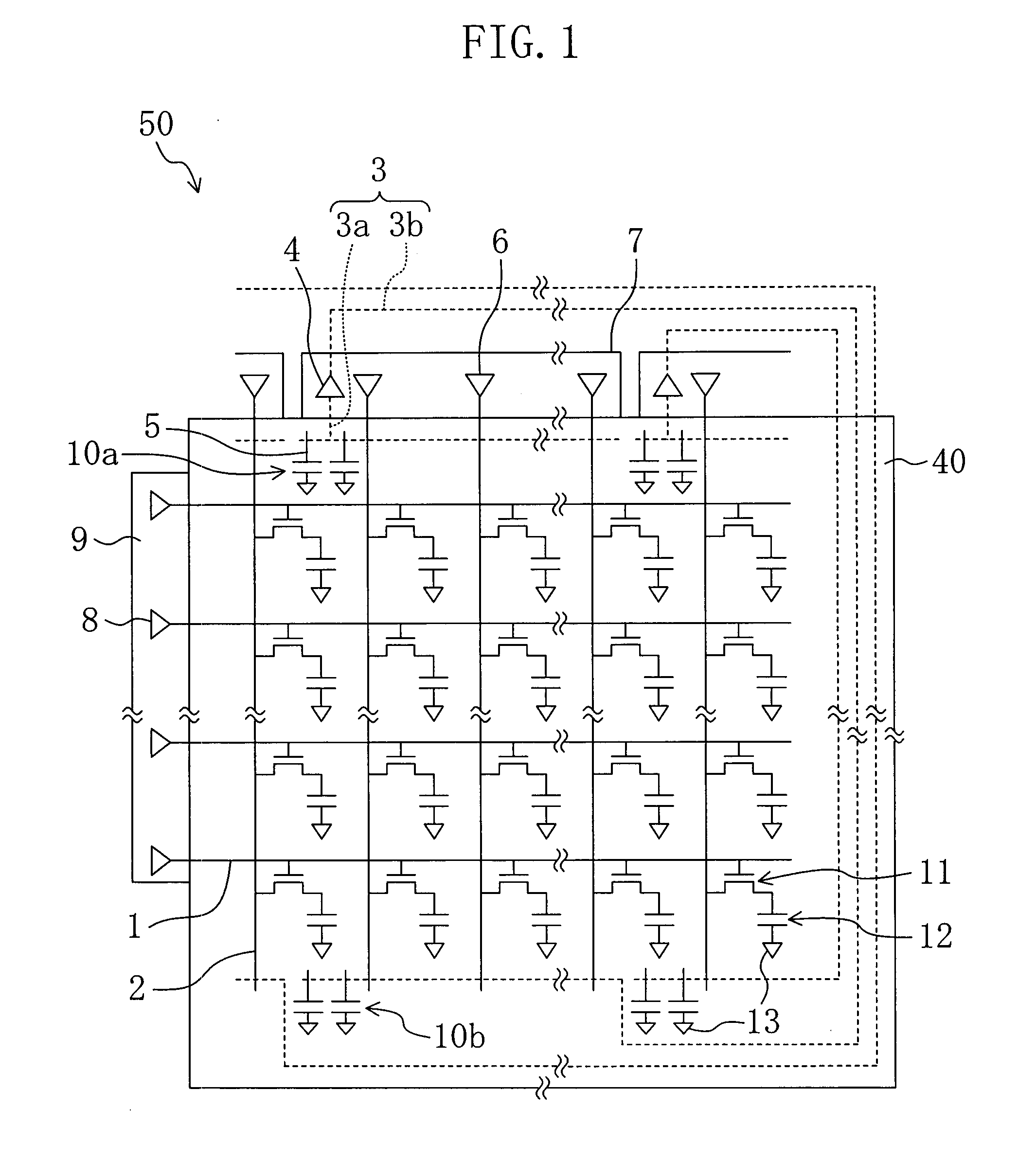

Display Device, Liquid Crystal Display Device, And Method For Producing A Display Device

InactiveUS20070285595A1Suppresses degradation of display qualityCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayDisplay device

A liquid crystal display device includes: a plurality of source lines (2) to which a signal voltage according to a source signal is applied; a first wire (3a) and a second wire (3b) for fixing a wire breakage that are configured so that they can be connected to opposite ends of at least one of the plurality of source lines (2); and a buffer section (4) provided between the first wire (3a) and the second wire (3b) for impedance conversion along the first wire (3a) and the second wire (3b), wherein the liquid crystal display device includes spare capacitors (10a) and (10b) for adjusting a signal waveform according to the source signal applied to the source lines (2a) and (2b) with the first wire (3a) and the second wire (3b) being connected to the source lines (2a) and (2b).

Owner:SHARP KK

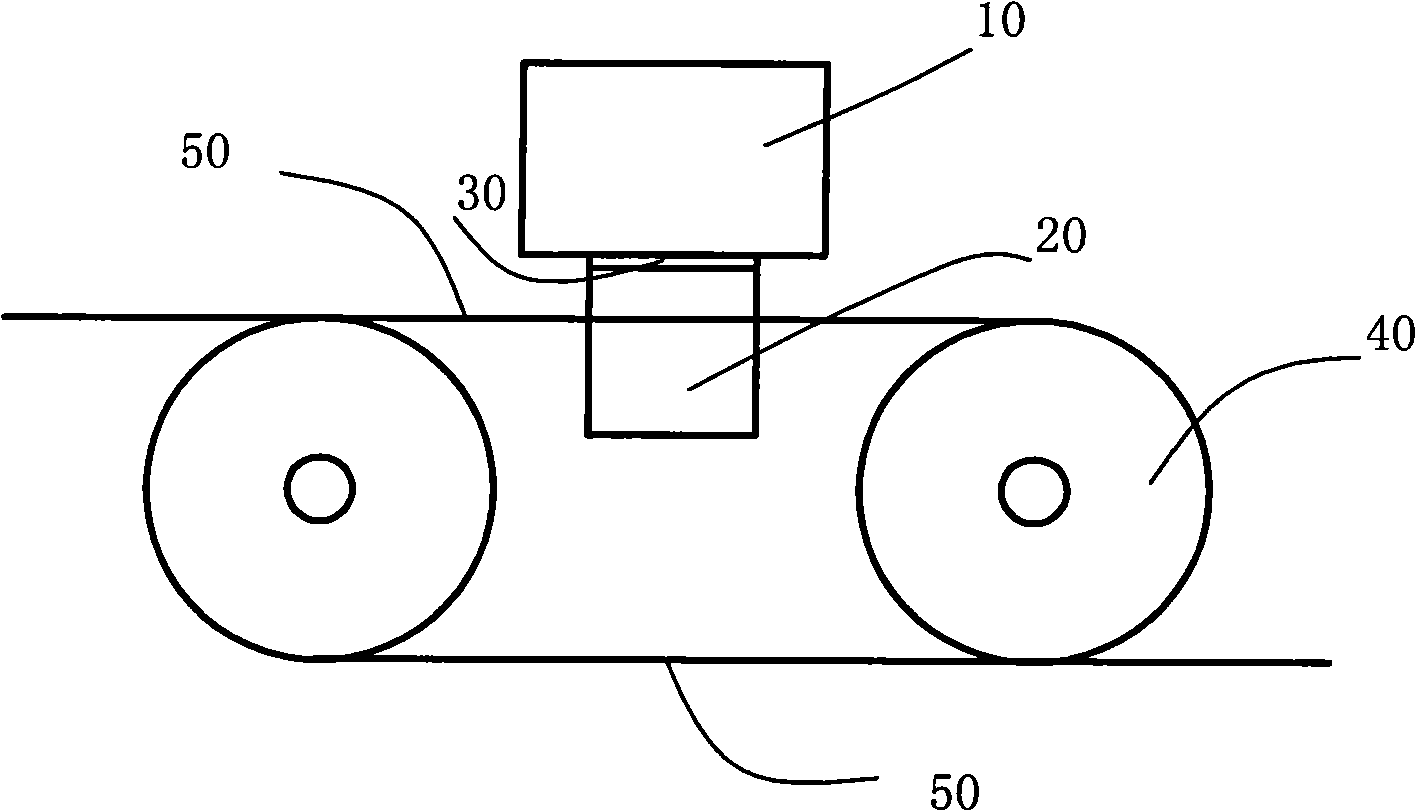

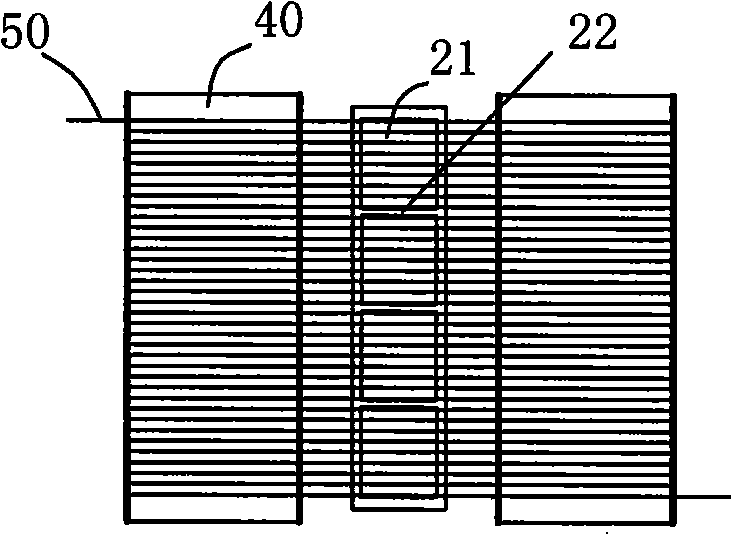

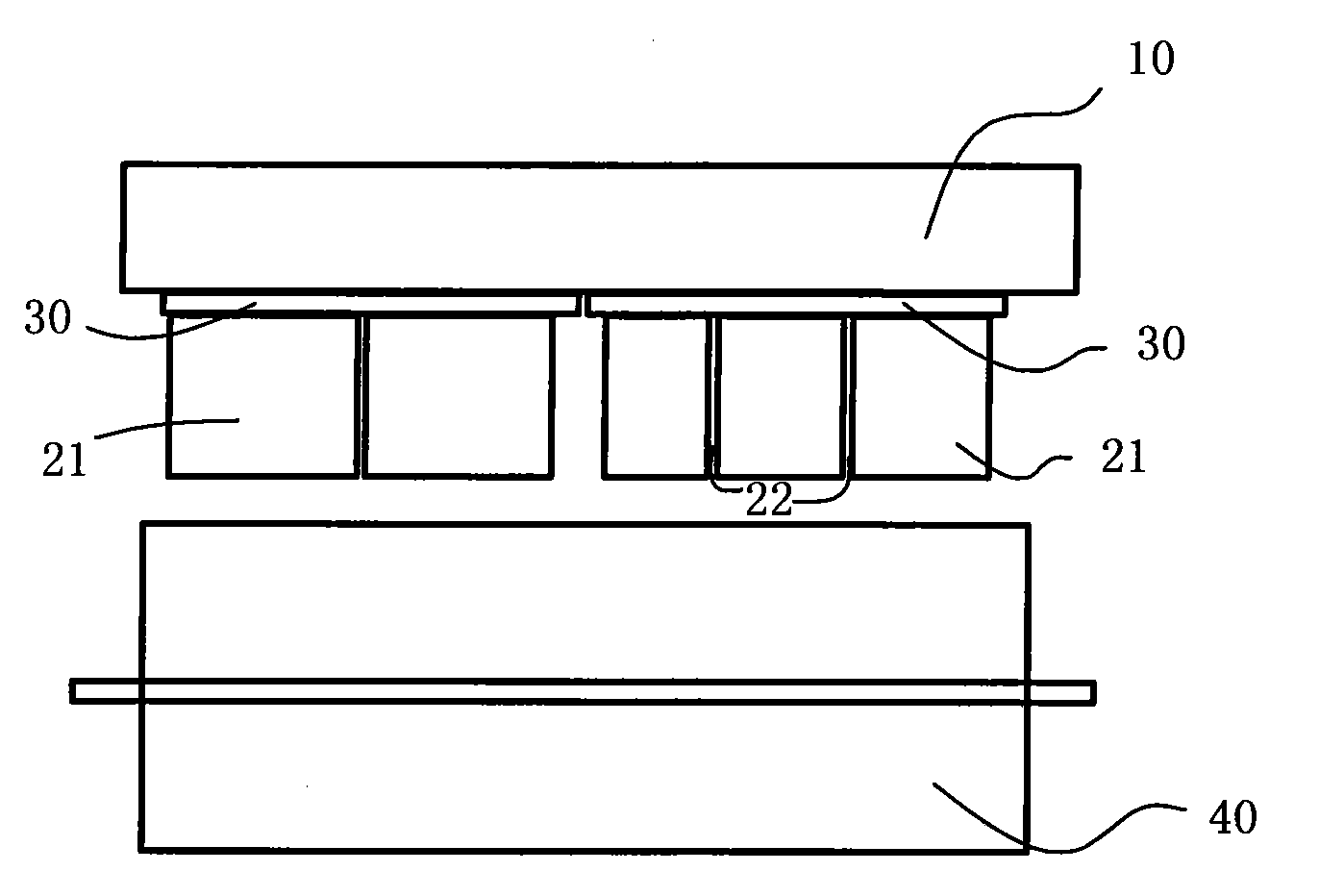

Cutting method of crystalline silicon blocks

InactiveCN101554757AAvoid slope "climbing" phenomenonResolve falling into the wire netFine working devicesPlane surface grinding machinesCrystalline siliconMaterials science

The invention relates to a cutting method of crystalline silicon blocks, a crystalline silicon block to be cut is placed on a section cutter platform, a plurality of line-shaped saws are horizontally distributed and spray mortar so as to cut the crystalline silicon block; and the method is characterized in that: the two end surfaces of the crystalline silicon block are polished to be level before being cut, and the line-shaped saws are parallelly distributed at equal intervals, with the width of shorter than the length of the crystalline silicon block to be cut. The technical proposal improves the 'climbing' phenomenon in the cutting process of the crystalline silicon block, and well solves the problems of wire-break and line-skipping caused by that silicon fragments generated in the cutting process of the crystalline silicon block drop to the line-shaped saw net or an idler pulley.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

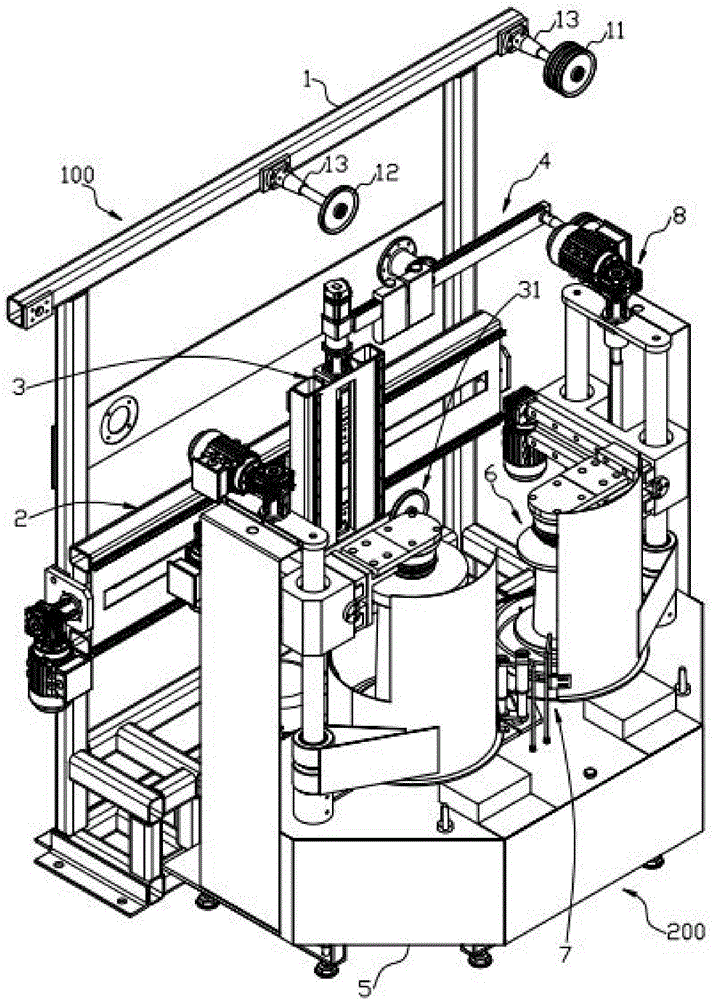

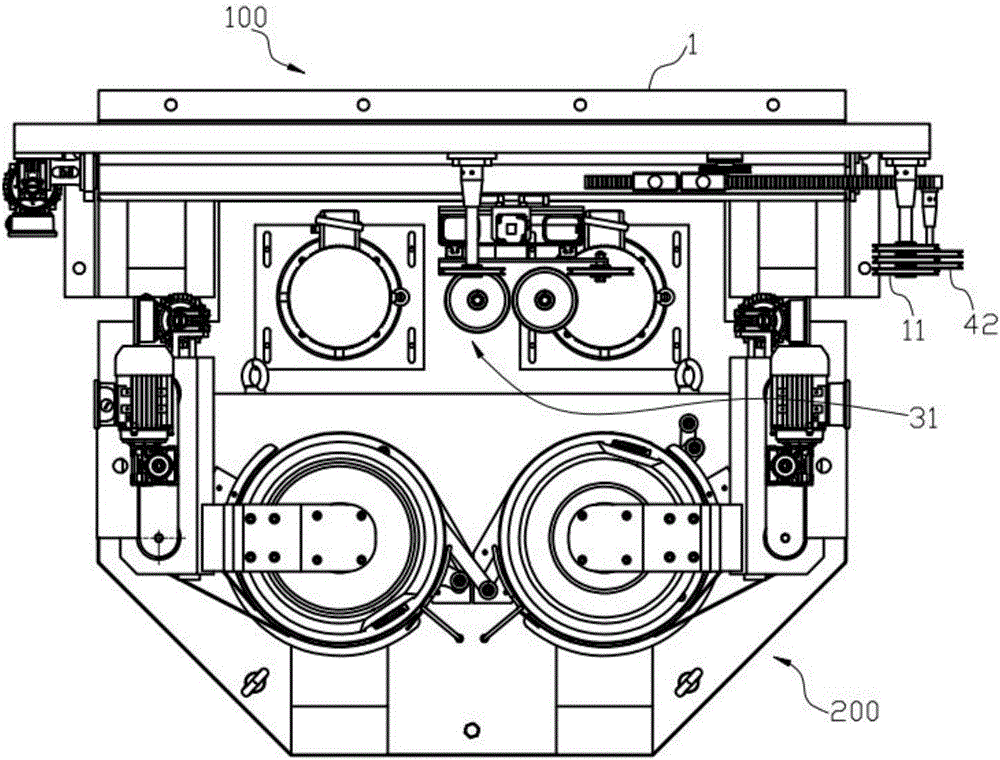

Automatic wire collecting and arranging machine

ActiveCN106276404ARealize automatic switchingAvoid scratchesFilament handlingEngineeringWire breakage

The invention discloses an automatic wire collecting and arranging machine. The machine comprises an XY type wire arranging device and a wire collecting device; the XY type wire arranging device includes a wire arranging frame, a transverse wire arranging frame, a longitudinal wire arranging frame, a first wire passing guide wheel, a second wire passing guide wheel and a wire collecting tension system; the transverse wire arranging frame is mounted on the wire arranging frame; the longitudinal wire arranging frame is movably mounted on the transverse wire arranging frame; the first wire passing guide wheel and the second wire passing guide wheel are both mounted on the wire arranging frame; the wire collecting tension system is horizontally arranged on the wire arranging frame; the longitudinal wire arranging frame is provided with a wire arranging guide wheel device capable of moving up and down; the wire collecting device includes a wire collecting frame, a wire collecting disc device, an automatic disc replacing device and a wire pressing disc device; the automatic disc replacing device is mounted at the bottom of the wire collecting disc device; the automatic disc replacing device is mounted on the wire collecting frame; and the wire collecting disc device is pressed and positioned through the wire pressing disc device in the wire collecting process. The wire arranging guide wheel device can move; and the automatic disc replacing device realizes automatic switching and wire breakage of empty and full discs without scratching product surfaces.

Owner:WUXI JUYI TONGCHUANG TECH CO LTD

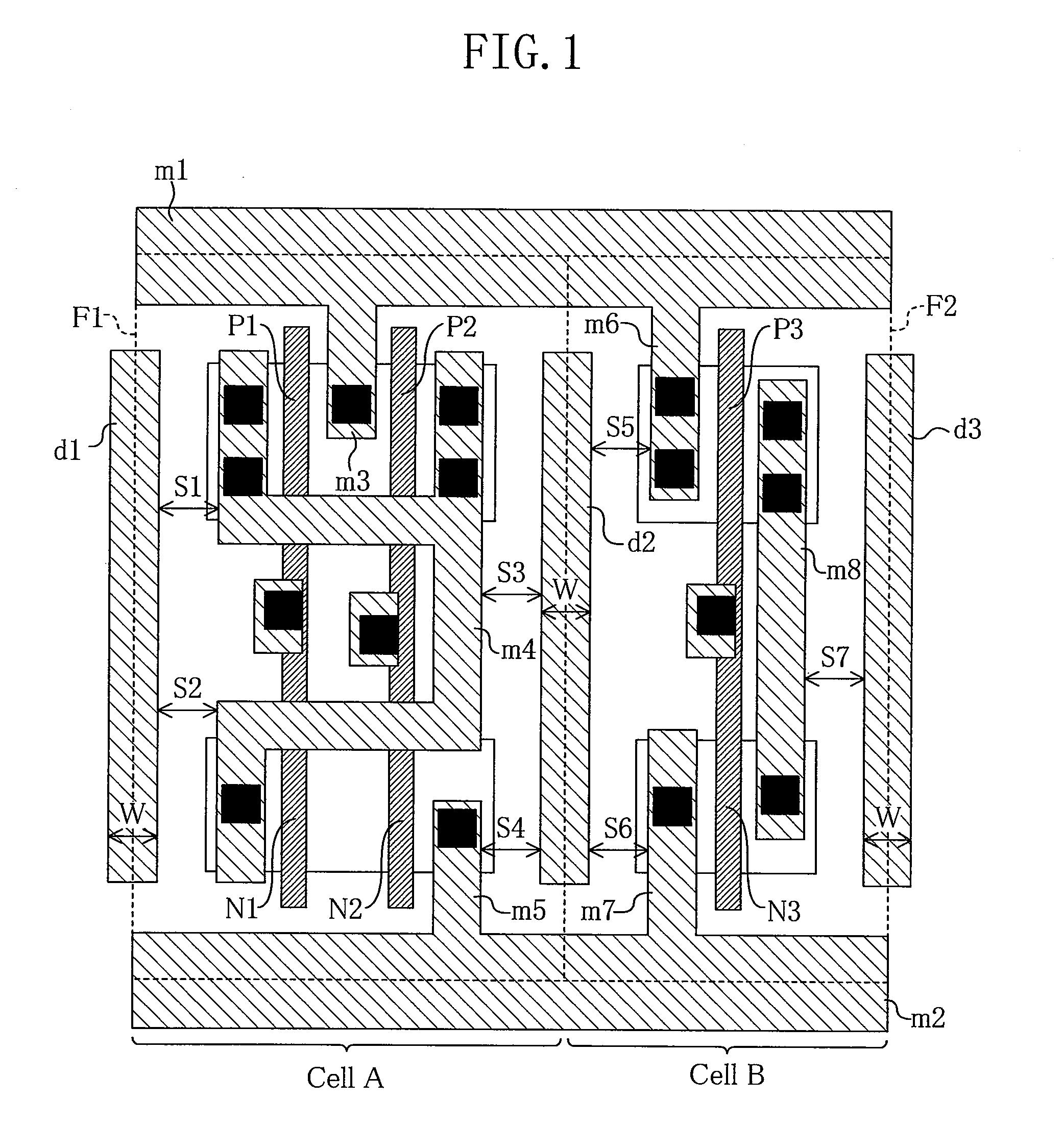

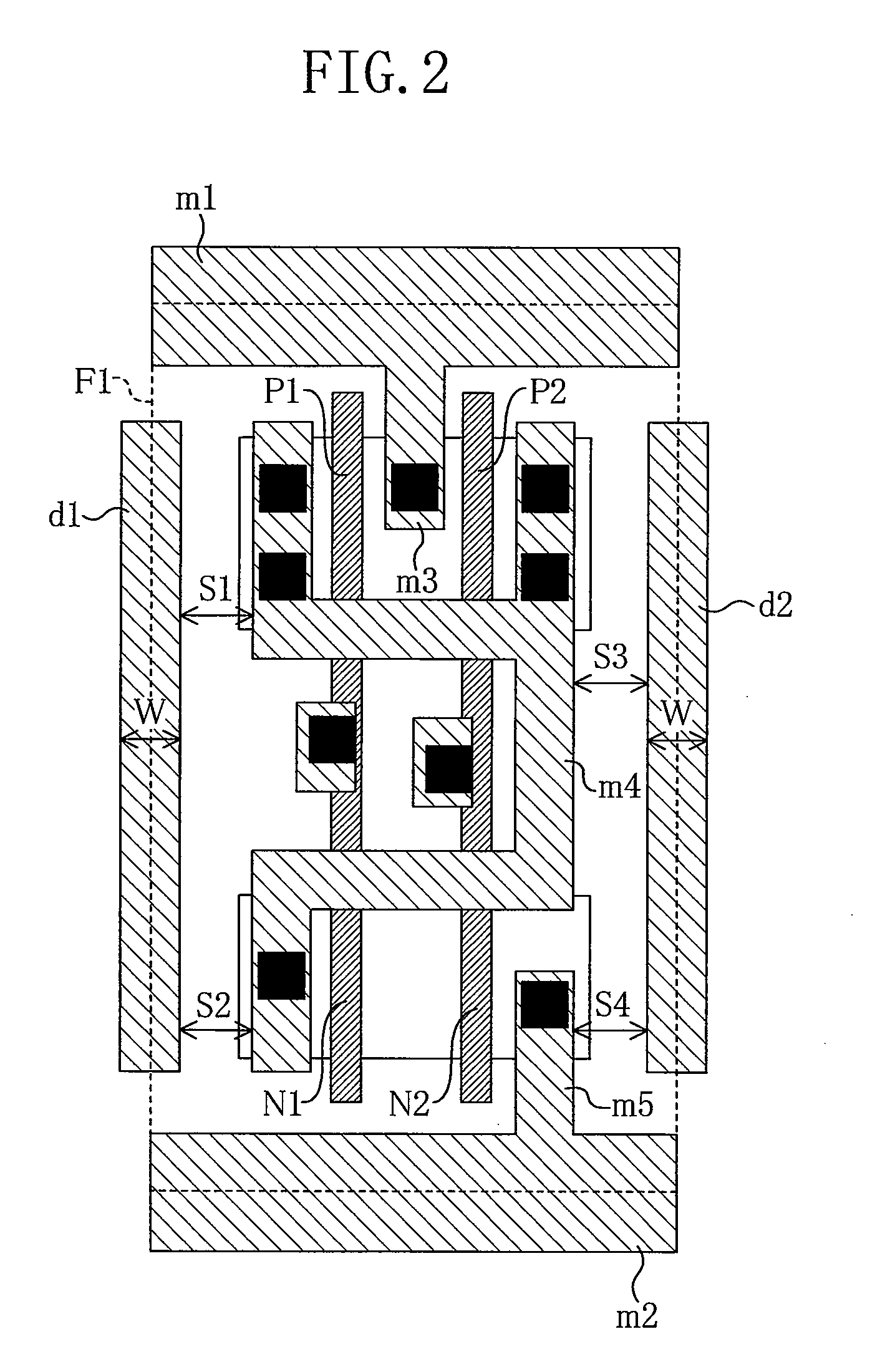

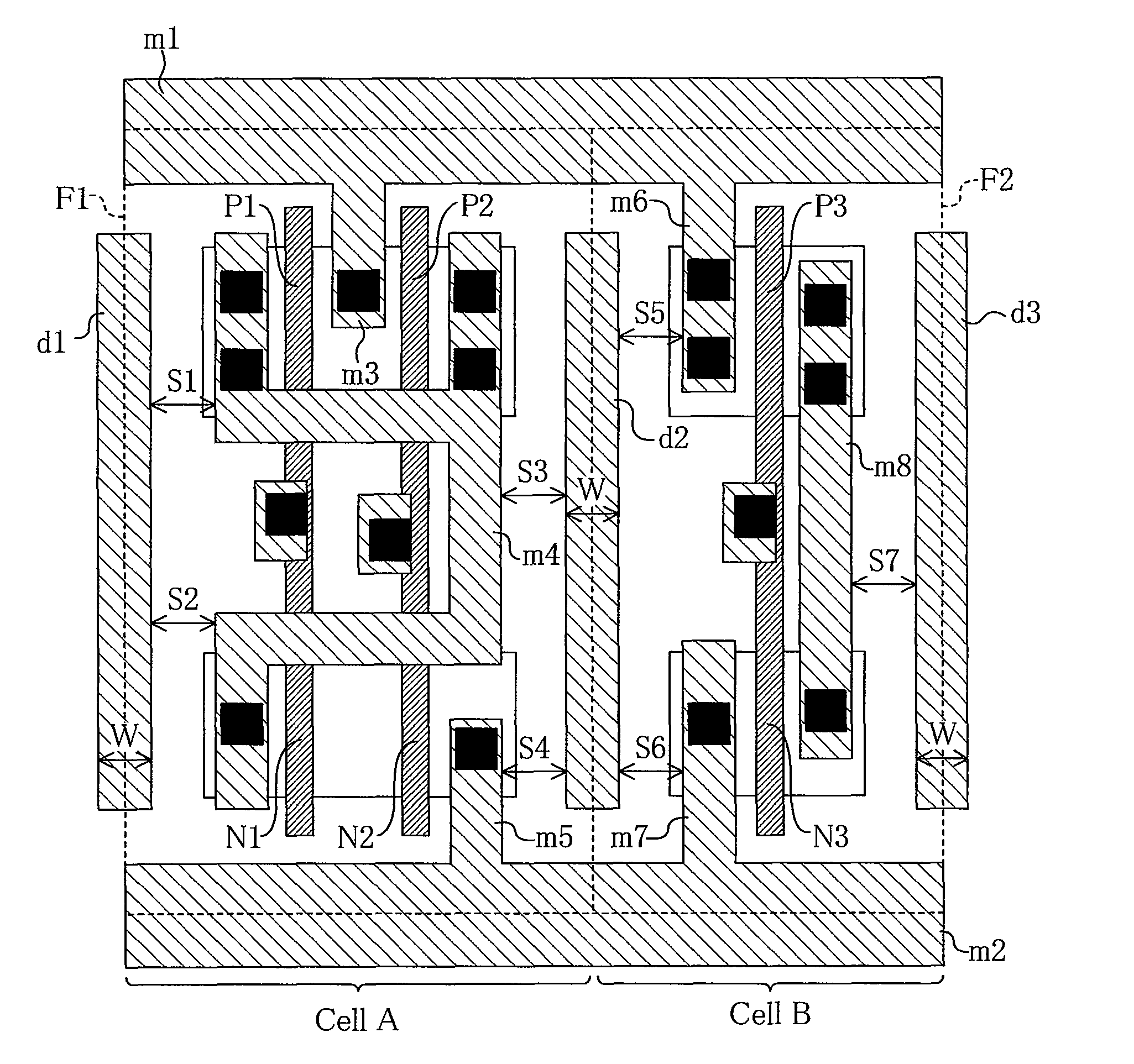

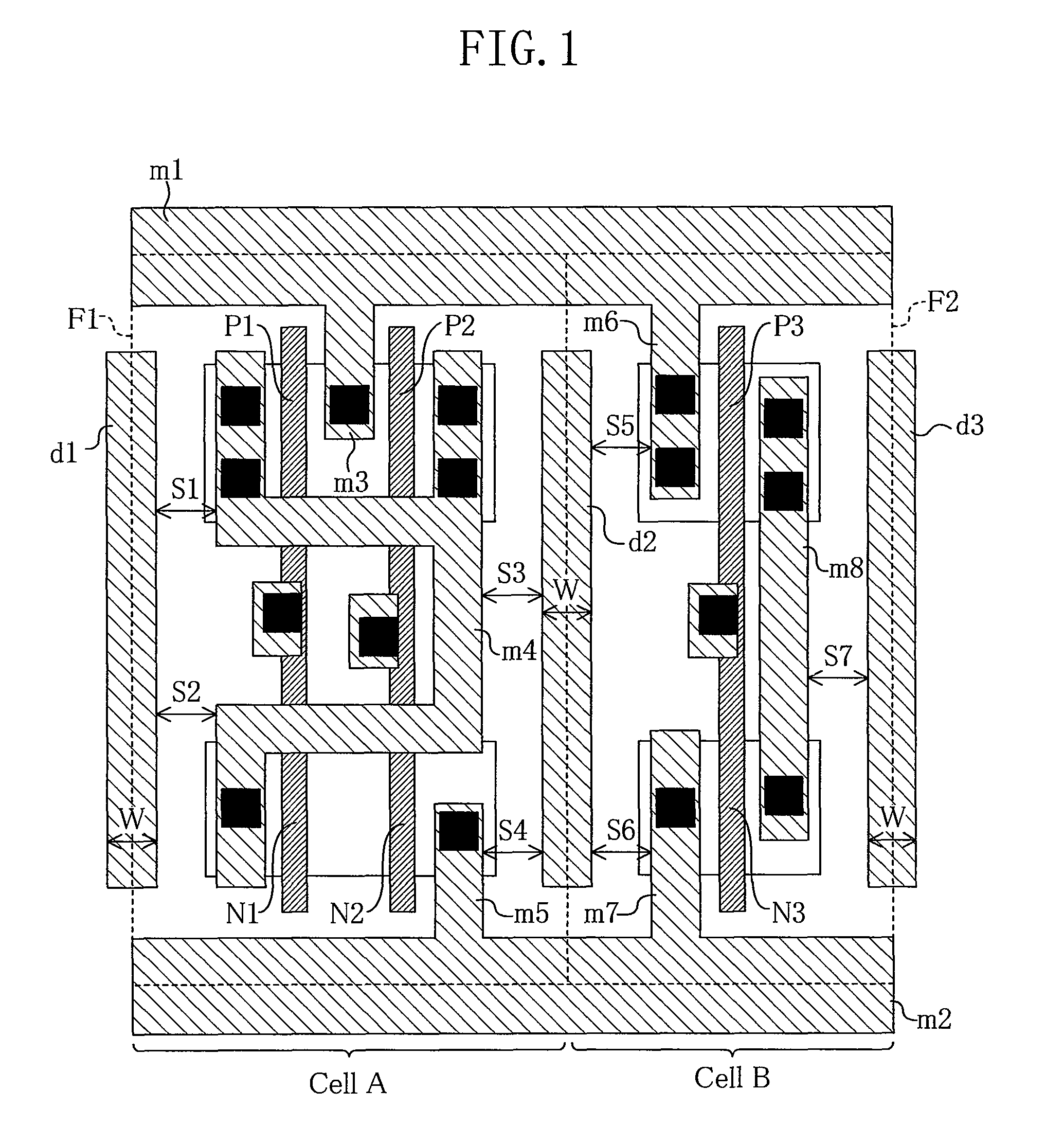

Semiconductor integrated circuit device having a dummy metal wiring line

ActiveUS8159013B2Reduce amountPredict the magnitude of variation in line widthTransistorSemiconductor/solid-state device detailsEngineeringThinning

There is provided a layout structure of a semiconductor integrated circuit capable of preventing the thinning of a metal wiring line close to a cell boundary and wire breakage therein without involving increases in the amount of data for OPC correction and OPC process time. In a region interposed between a power supply line and a ground line each placed to extend in a first direction, first and second cells each having a transistor and an intra-cell line each for implementing a circuit function are placed to be adjacent to each other in the first direction. In a boundary portion between the first and second cells, a metal wiring line extending in a second direction orthogonal to the first direction is placed so as not to short-circuit the power supply line and the ground line.

Owner:SOCIONEXT INC

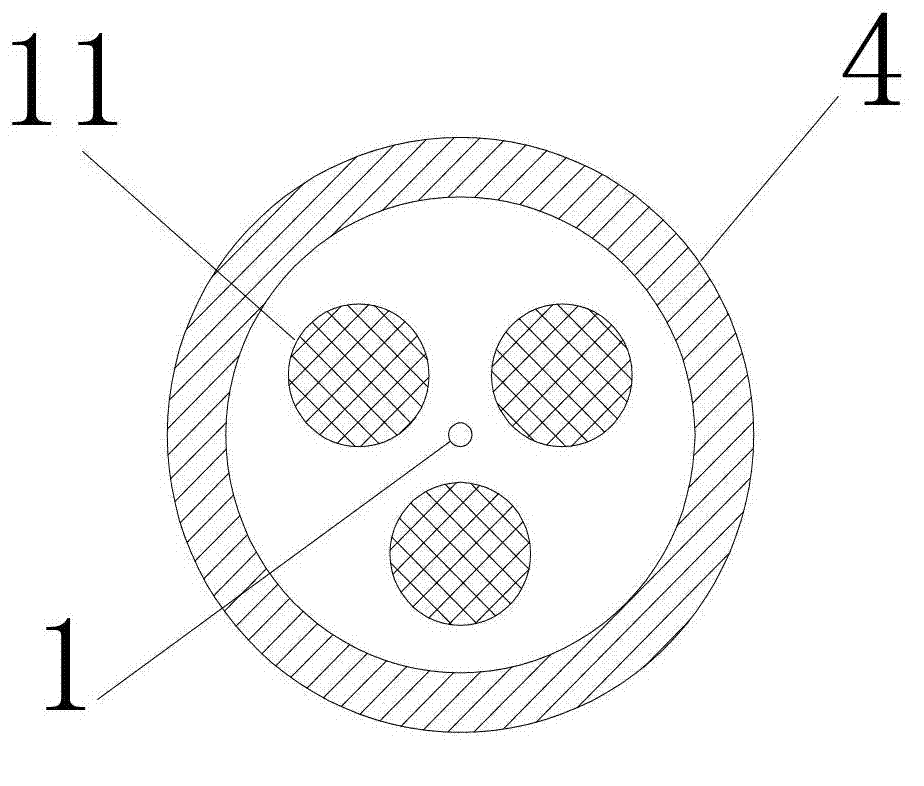

Electroplated diamond wire saw sand-applying device

The invention discloses an electroplated diamond wire saw sand-applying device. The device sequentially comprises the components, from top to bottom: a vertical tubular sand-applying sub tank, a liquid-returning box, and a plating solution master tank. A guide wheel is fixed in the liquid-returning box. A core wire is sequentially wound on a wire-feeding conductive wheel on the bottom of the vertical tubular sand-applying sub tank and the guide wheel. The core wire then penetrates the vertical tubular sand-applying sub tank, and is finally wound on a wire-discharging conductive wheel on the top of the vertical tubular sand-applying sub tank. The wire-feeding conductive wheel and the wire-discharging conductive wheel are connected in parallel, and are then connected to the negative electrode of an electroplating power supply. Metal anodes are arranged around the core wire in the vertical tubular sand-applying sub tank. The metal anodes are connected with positive electrodes of the electroplating power supply. Through a water pump above the plating solution, the plating solution is lifted from the plating solution master tank into the vertical tubular sand-applying sub tank. With the device provided by the invention, sand-application of produced diamond wire is uniform and good. During the production process, current density is high, efficiency is high, internal stresses of the plating and the substrate are small, plating solution application amount is low, and wire breakage probability is low.

Owner:无锡超亚环保设备有限公司

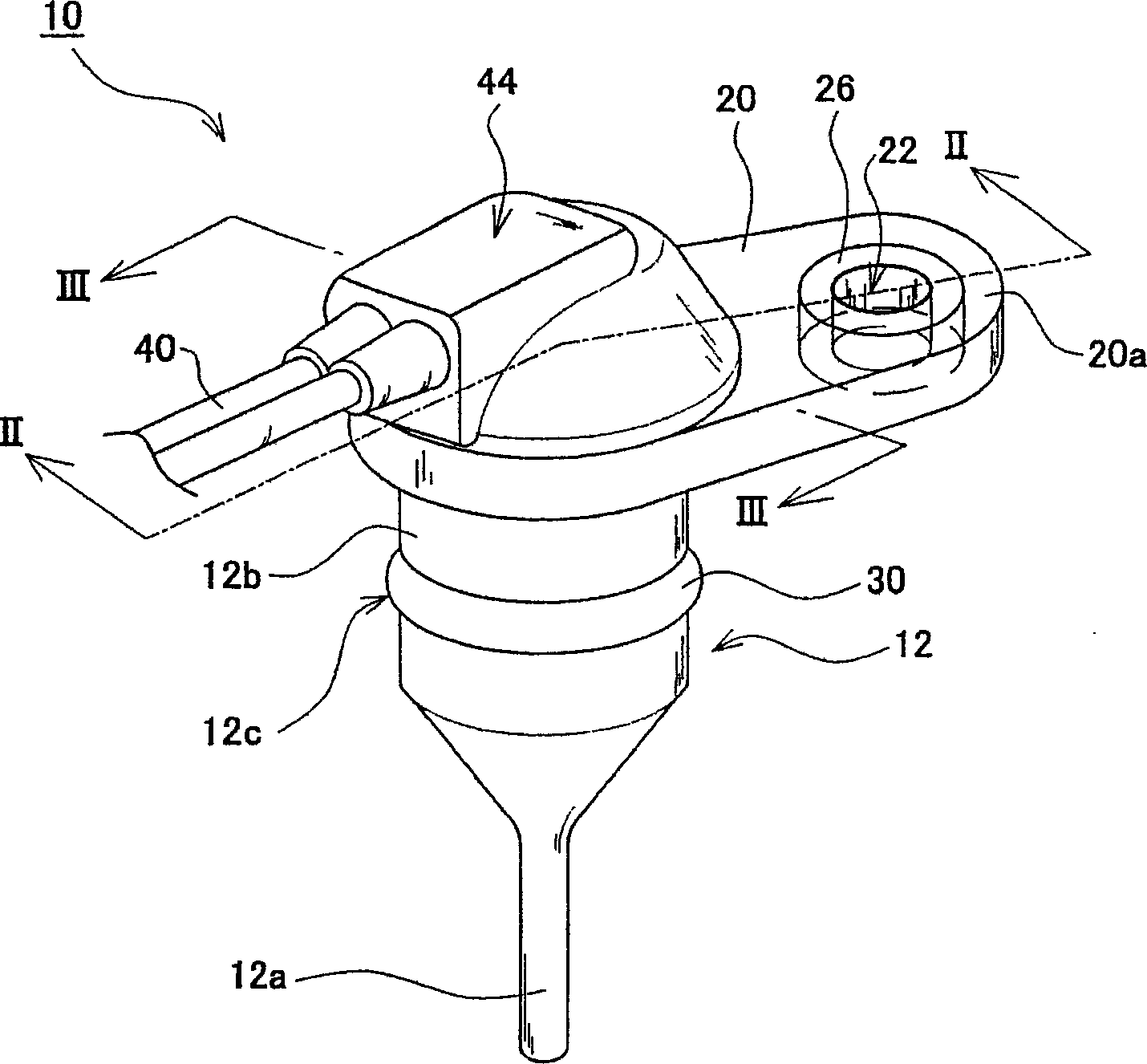

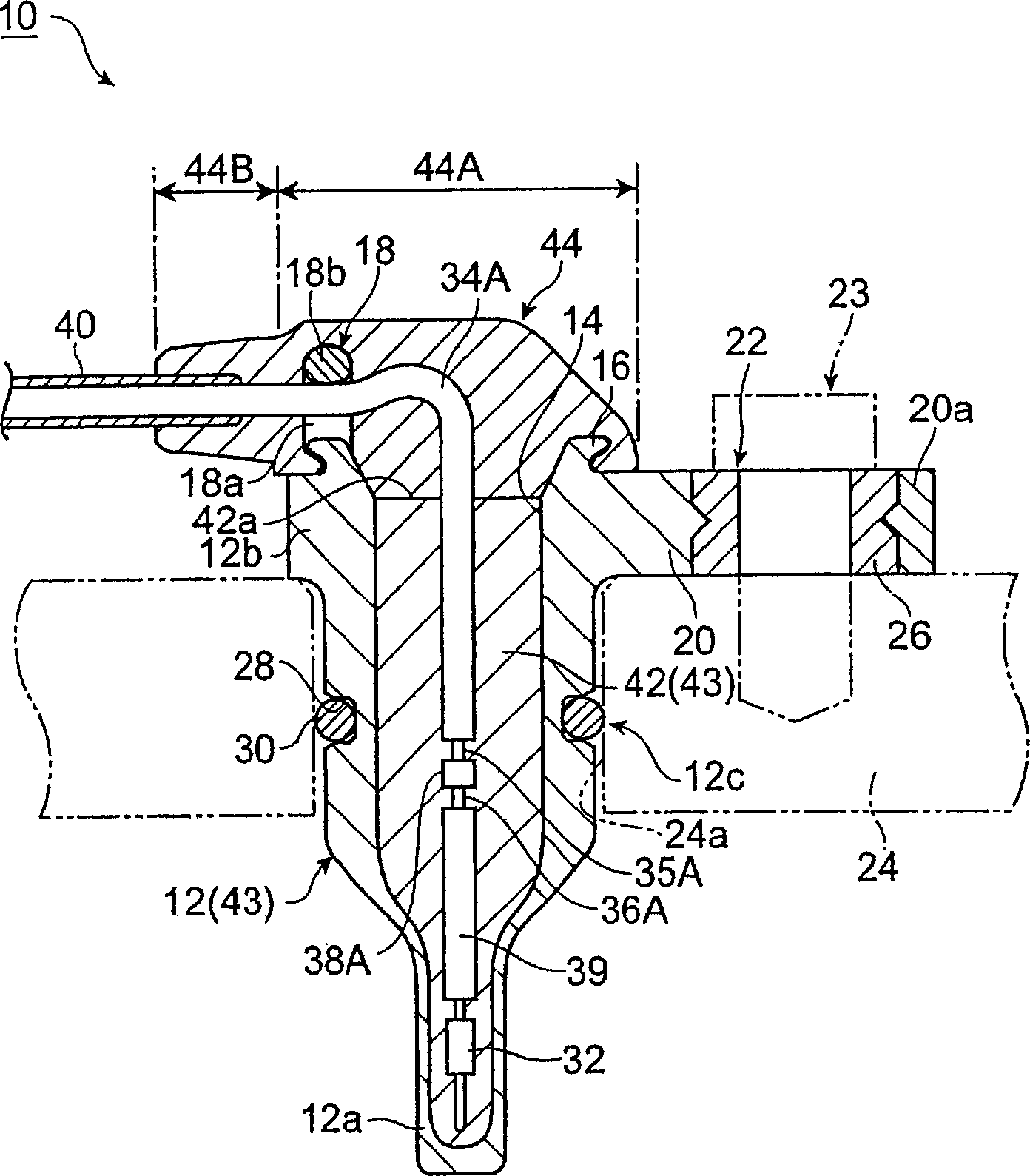

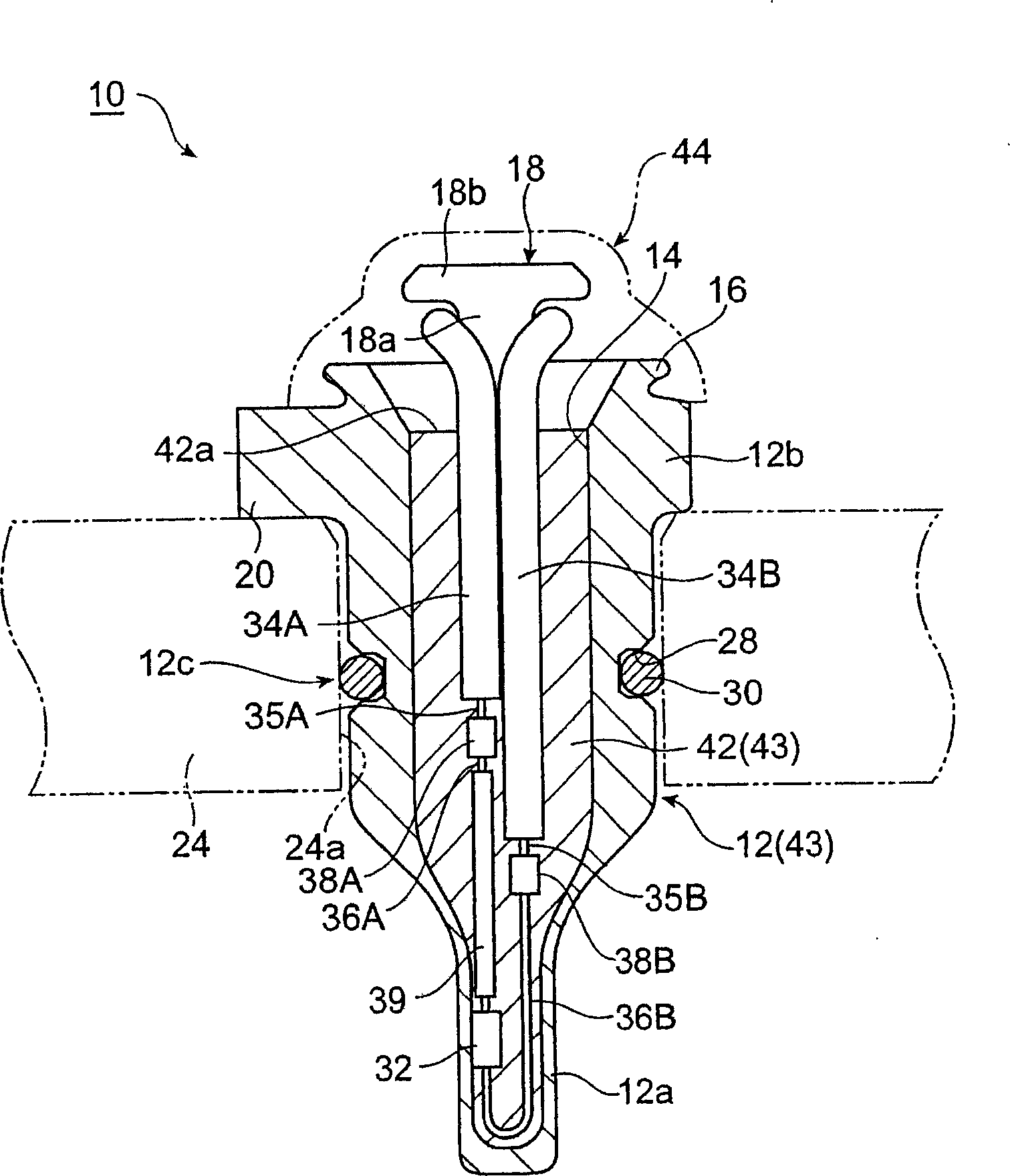

Temperature sensor

ActiveCN1809733AReduce in quantityThermometer detailsThermometers using electric/magnetic elementsEngineeringElectric wire

Owner:TDK CORPARATION

Process for producing ultra-fine copper wire

Owner:浙江力博实业股份有限公司

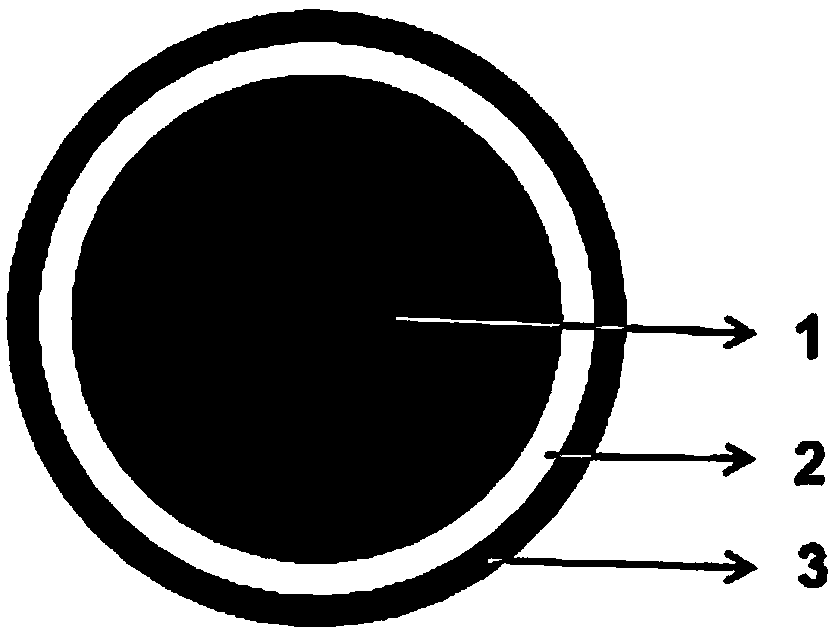

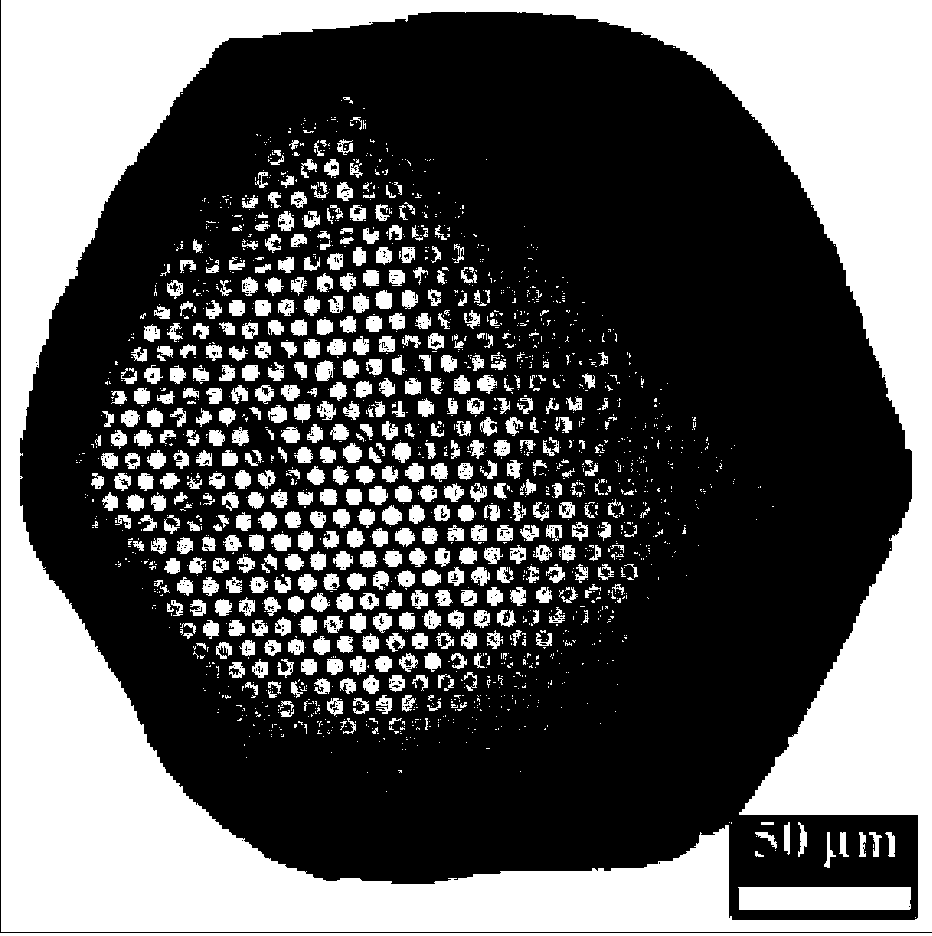

Flexible high-resolution infrared chalcogenide glass optical fiber image transmission bundle and manufacturing method

ActiveCN104181636AHigh mechanical strengthIncreased mechanical toughnessGlass making apparatusBundled fibre light guideFiberImage resolution

The invention discloses a flexible high-resolution infrared chalcogenide glass optical fiber image transmission bundle and a manufacturing method. The optical fiber image transmission bundle is formed by closely stacking optical fiber multifilaments, the optical fiber multifilaments are formed by drawing optical fiber monofilament bundles, the optical fiber monofilament bundles are formed by closely stacking optical fiber monofilaments, the optical fiber monofilaments sequentially comprise chalcogenide glass fiber cores, chalcogenide glass inner coating layers and thermoplastics polymer outer coating layers from inside to outside, and the relation among the refractive index n1 of the chalcogenide glass fiber cores, the refractive index n2 of the chalcogenide glass inner coating layers and the refractive index n3 of the thermoplastics polymer outer coating layers is n1>n2>n3. The manufacturing process is simple and easy to control, the wire breakage rate of the optical fiber bundles is low, and the large-section high-resolution flexible infrared optical fiber image transmission bundle can be manufactured easily.

Owner:XUZHOU NORMAL UNIVERSITY

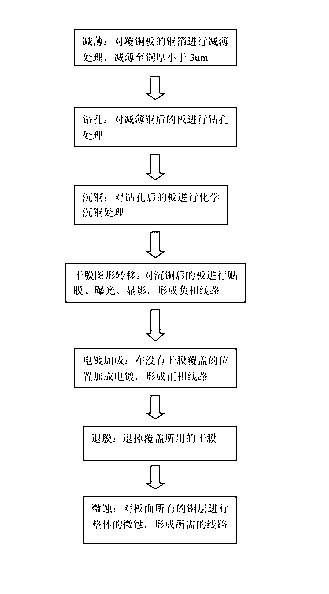

Method for manufacturing circuit board by addition method

The invention provides a method for manufacturing a circuit board by an addition method. The process is as follows: thinning, drilling; precipitating copper; transferring a dry film image; and conducting electroplating addition, film withdrawing and microetching. By adopting the circuit board manufactured by adopting the method, the line width / interval being smaller than 4mil / 4mil can be realized easily, a circuit board with ultra-thick copper can be manufactured, and the quality problems of blocked holes and line breakage can be reduced greatly.

Owner:凯迪思科技股份有限公司 +1

Manufacturing method for fine copper-silver alloy wires

ActiveCN104353696AComposition is stableOrganizational structure is stableSingle bars/rods/wires/strips conductorsWire breakageMaterials science

The invention discloses a manufacturing method for fine copper-silver alloy wires. The method comprises steps as follows: (1) smelting and continuous casting of copper-silver alloy blanks; (2) drawing of copper-silver alloy rods; (3) intermediate heat treatment of copper-silver alloy wires; (4) drawing of the copper-silver alloy wires after intermediate heat treatment into copper-silver alloy wires with diameters in a range of 0.1-0.25 mm by an intermediate wire drawing machine. With the adoption of the manufacturing method for the fine copper-silver alloy wires, components and organization structures of raw copper-silver alloy materials can be stabilized, the texture and the performance of silver are stabilized through control on the distribution form of the silver in the copper-silver alloy wires through heat treatment during wire drawing, wire breakage due to local stress concentration caused by unstable components and organization structures during wire machining is avoided, and manufacturing of the fine copper-silver alloy wires is guaranteed.

Owner:HENAN YOUK ELECTRONICS MATERIALS +2

Constant-tension wire moving mechanism with automatic wire feeding function

ActiveCN102357692AAchieve recyclingImprove machining accuracyElectrical-based machining electrodesProcessing accuracyTension control

The invention discloses a constant-tension wire moving mechanism with an automatic wire feeding function, which comprises a wire release and retract device, a tension regulation device and an automatic wire feeding device. The constant-tension wire moving mechanism is characterized in that: a first-stage tension regulation device and a second-stage tension regulation device are arranged between the wire release and retract device and the automatic wire feeding device; automatic wire breakage and wire feed are realized by setting the automatic wire feed mechanism, automatic retrieving of broken wires and waste wires can be realized, the operation is convenient, time and labor force are saved, the wire feeding efficiency and production efficiency are improved, and the wire feeding quality is increase; two stages of tension control are realized by setting the first-stage tension regulation device and the second-stage tension regulation device, changes of preceding stage wire coil tension are effectively controlled, the constant tension of the metal wire is ensured, and the processing accuracy of parts is improved.

Owner:北京安德建奇数字设备股份有限公司

Wind turbine and operating method thereof

InactiveUS8116914B2Prevent speedingControl moreRotational speed controlLevel controlTurbineUninterruptible power supply

A pitch controller, uninterruptible power supply, and rotational speed detector are disposed in the rotor in a wind turbine. When a slip ring failure or wire breakage occurs, the pitch controller internally creates a pitch angle command so as to control the pitch angle.

Owner:HITACHI LTD

Automatic knotting and wire breaking device for producing sausages

ActiveCN103719224AFully automatedReduce labor intensitySausage skin tying apparatusControl systemRotary encoder

The invention relates to an automatic knotting and wire breaking device for producing sausages. The innovation points are that a sausage guiding sleeve, a wire supplying assembly and a length fixing transmission mechanism are mounted on a working platen; a pneumatic wire clamping assembly and a wire breaking assembly are arranged below the working platen; a shaft sleeve of a wire winding assembly is sleeved with the sausage guiding sleeve, and is driven to rotate through a wire winding driving mechanism; a winder is mounted in the shaft sleeve and at one end near the discharging side. The automatic knotting and wire breaking device has the advantages that the wire winding assembly works together with the pneumatic wire clamping assembly and the wire breaking assembly to bundle the sausages, during the bundling process, the coordination of a control system with rotary encoders and a material sensor is utilized to perform cooperation control, so that actions of bundling and wire breaking are enabled to be performed smoothly without mutual noninterference, manual bundling and wire breaking are not needed, the labor intensity of the operating personnel is reduced, the qualified rate of the bundling and wire breaking is high, the coordination of the length fixing transmission mechanism with the material sensor, the rotary encoders and the like is utilized to convey the sausages in rated length, the distance of each section of bundling wire is ensured to be consistent, and the product specification is enabled to meet the requirement.

Owner:JIANGSU CHANGSHOU GRP CO LTD

Wire rod excellent in wire-drawing workability and method for producing same

InactiveUS20070277913A1Excellent in wire-drawing workabilityImprove mold lifeFurnace typesHeat treatment furnacesWire rodPearlite

Disclosed are a wire rod and a method therefor. The wire rod is excellent in wire-drawing workability, insusceptible to wire break in spite of an increase in wire-drawing rate, and reduction of area, and capable of extending a die life by suppressing die wear. The wire rod is made of steel containing C: 0.6 to 1.1%, Si: 0.1 to 2.0%, Mn: 0.1 to 1%, P: not more than 0.20%, S: not more than 0.20%, N: not more than 0.006%, Al: not more than 0.03%, and O: not more than 0.003%, the balance including Fe, and unavoidable impurities. Further, the wire rod comprises a pearlite structure wherein an area ratio of a second-phase ferrite is not more than 11.0%, and a pearlite lamellar spacing is not less than 120 μm.

Owner:KOBE STEEL LTD

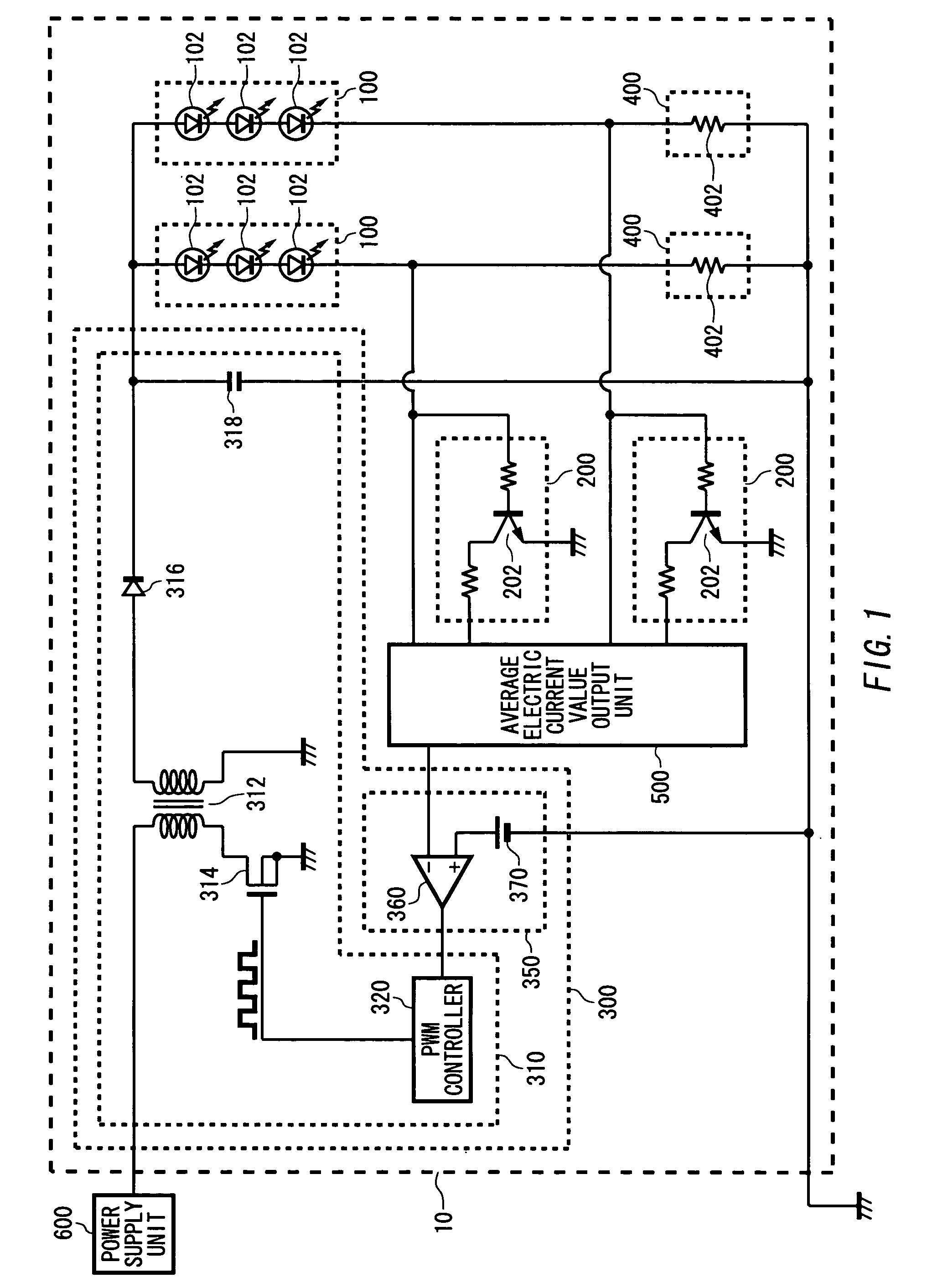

Vehicular lamp

InactiveUS7116052B2Reduce supplyConstant valueElectrical apparatusLighting support devicesEngineeringLight emitting device

Electric current supplied to light source rows of a vehicular lamp is controlled appropriately. The vehicular lamp includes: a plurality of semiconductor light emitting devices connected in parallel; a wire breakage detecting unit detecting wire breakage of each of the plurality of semiconductor light emitting devices; and an electric current supplying unit supplying a predetermined electric current to the plurality of semiconductor light emitting devices. The electric current supplying unit decreases the electric current to be supplied to the plurality of semiconductor light emitting devices when the wire breakage detecting unit detects wire breakage of at least one of the plurality of semiconductor light emitting devices.

Owner:KOITO MFG CO LTD

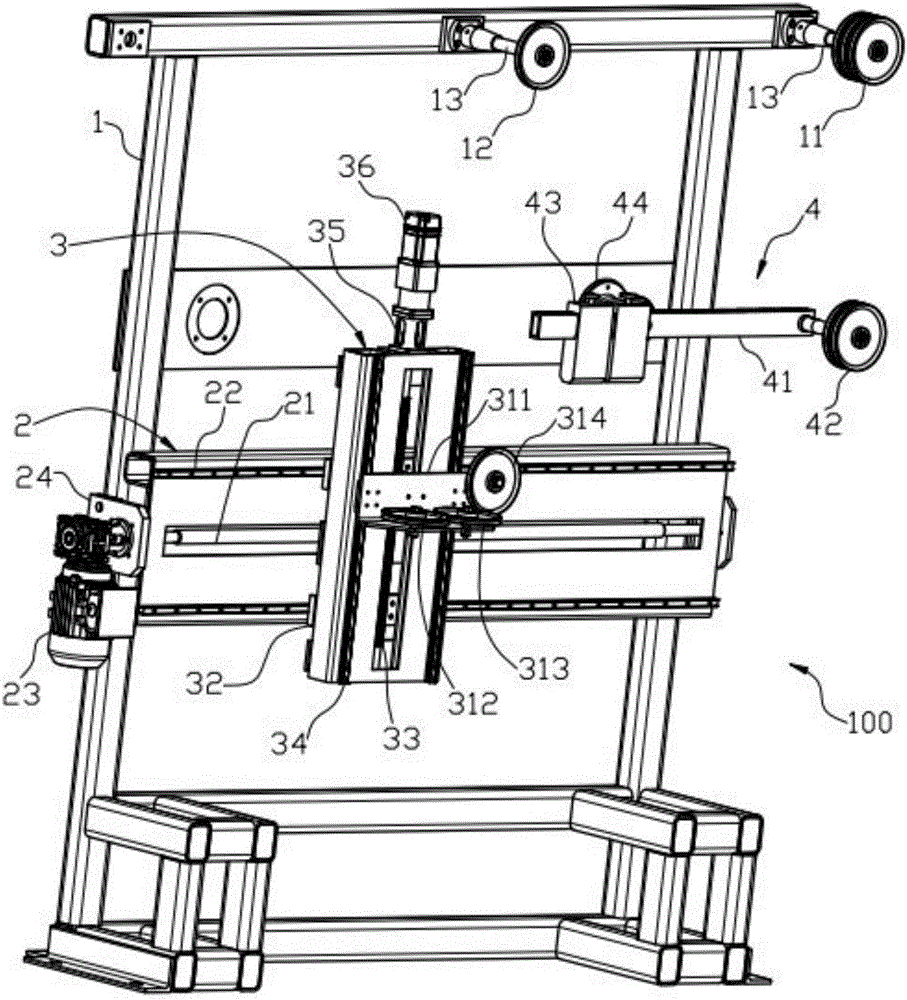

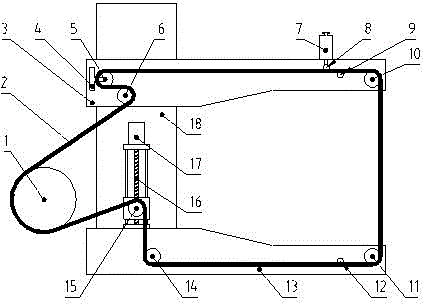

Forward and reverse wiring tension balance control device and method for high-speed reciprocating wiring wire cutting

ActiveCN104607740AReduce vibrationReduce the chance of wire breakageElectrical-based machining electrodesWire cuttingEngineering

A forward and reverse wiring tension balance control device and method for high-speed reciprocating wiring wire cutting are characterized in that the device comprises a stand column (18), wherein an upper wire arm (3) and a lower wire arm (13) are installed on the stand column, the upper wire arm (3) can move up and down on the stand column to adapt to the cutting requirements of workpieces of different thicknesses, an upper fixing wheel (6), a tension wheel (5), a wire breakage protection block (8), an upper current input block (9) and an upper positioning guide wheel (10) are installed on the upper wire arm (3), the wire breakage protection block (8) is controlled by a push rod motor (7), and the tension wheel (5) is connected with a tension sensor (4); a lower positioning wheel (11), a lower current input block (12) and a lower fixing wheel (14) are installed on the lower wire arm (13), and the lower control wheel (15) is controlled by a lead screw sliding table (16) and a stepping motor (17). The forward and reverse wiring tension balance control device and method obviously improve the high-thickness cutting stability and the consistency of workpieces cut in multiple times and can effectively reduce the wire breakage probability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com