Patents

Literature

428results about How to "Increased mechanical toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

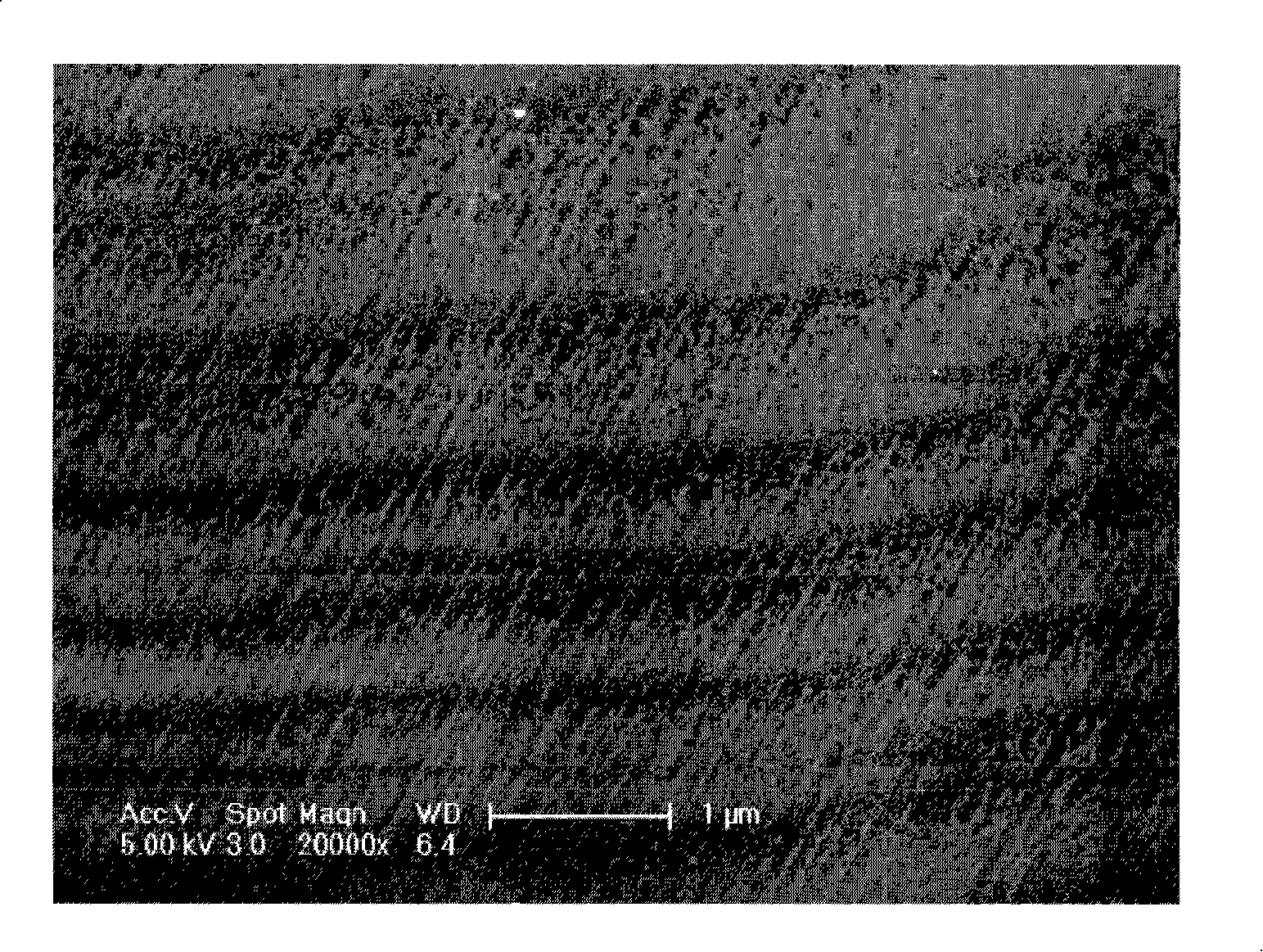

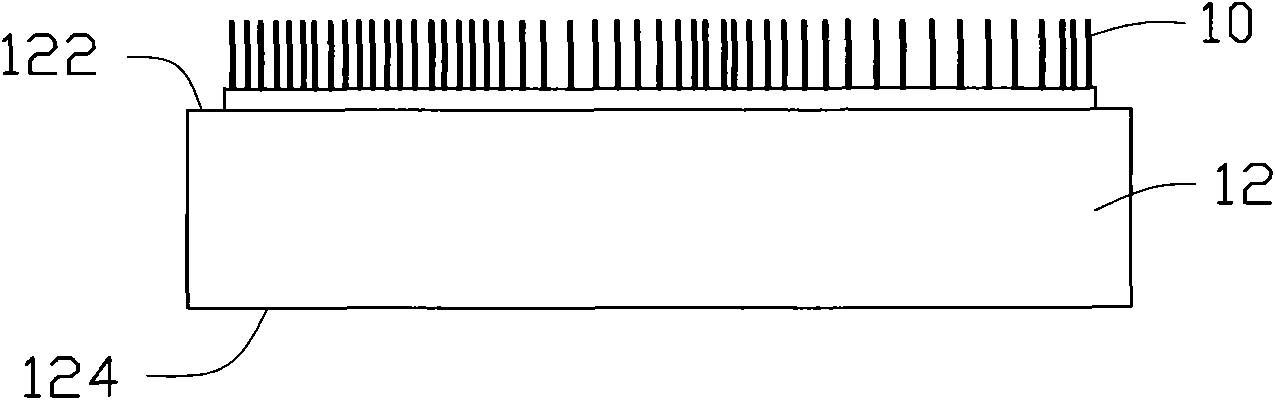

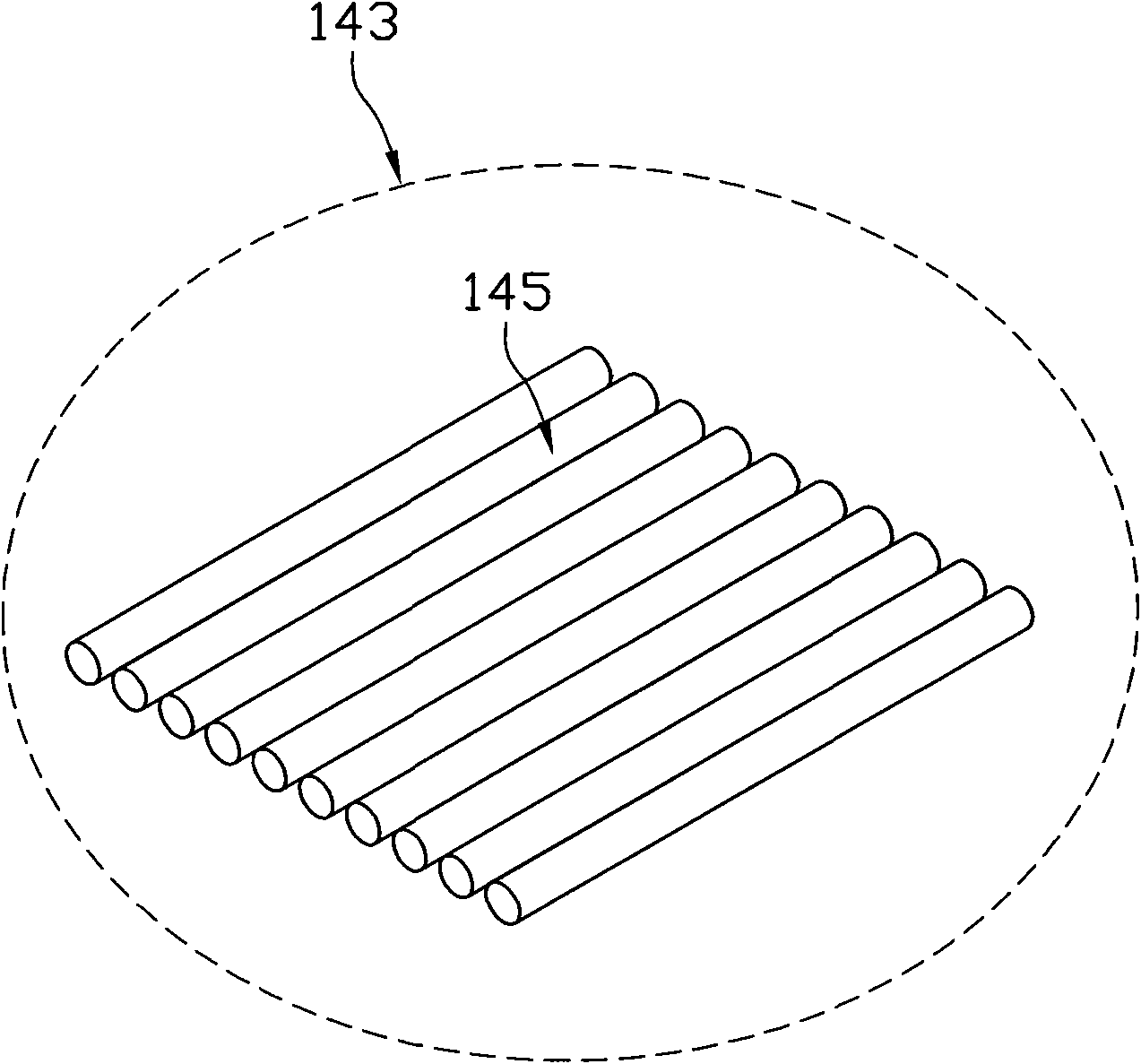

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

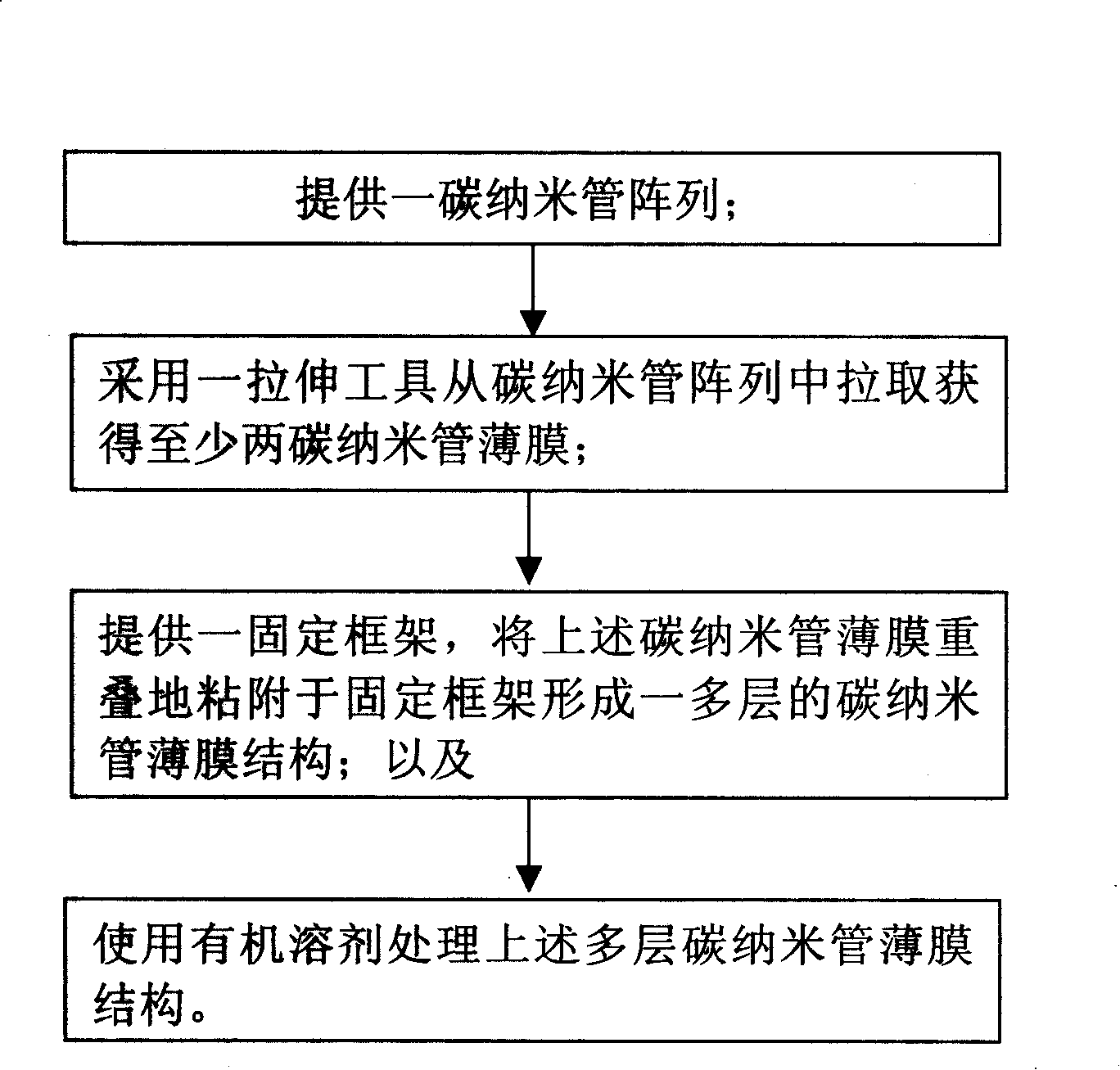

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

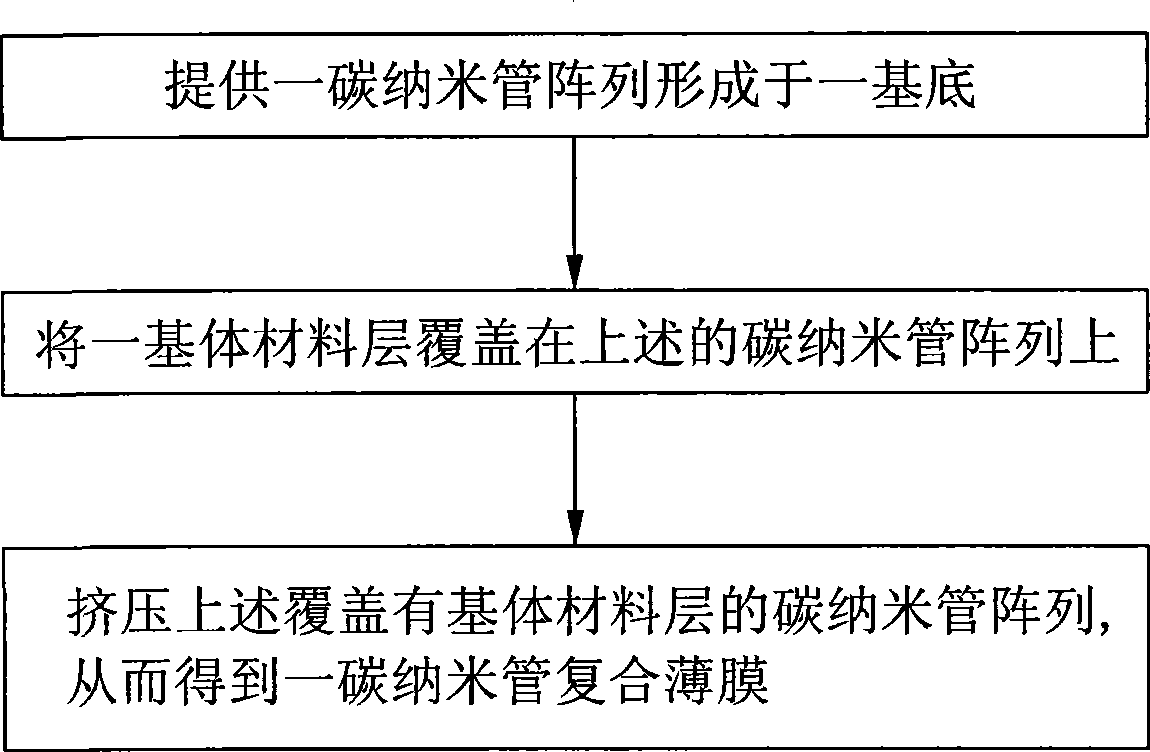

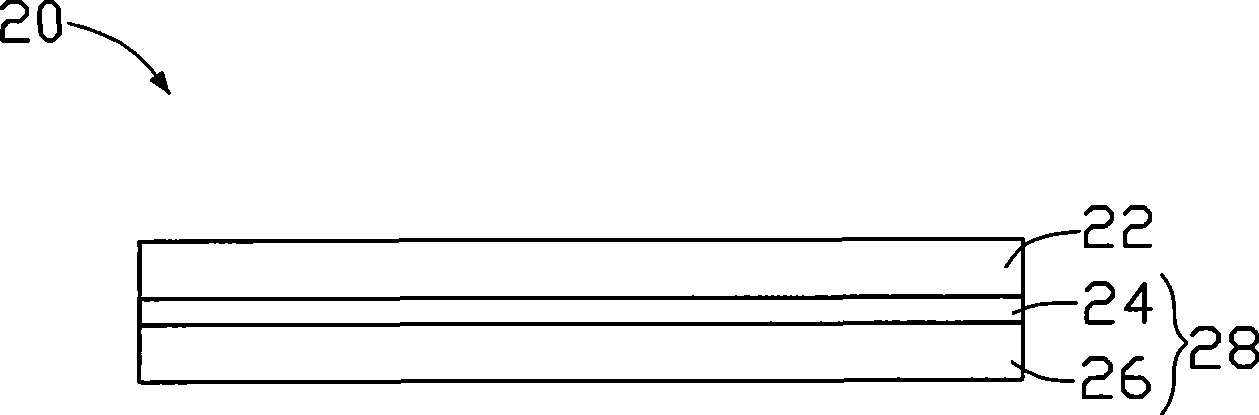

Carbon nanotube compound film and preparation method thereof

ActiveCN101381071AEvenly dispersedHigh mechanical strengthMaterial nanotechnologyIndividual molecule manipulationComposite filmNanometre

The invention relates to a carbon nanotube composite film, which comprises at least one carbon nanotube layer and at least one matrix material layer. The invention also relates to a preparation method for the carbon nanotube composite film, which comprises the following steps: providing a carbon nanotube array formed on a substrate; covering the matrix material layer on the carbon nanotube array to obtain the carbon nanotube array covered with the matrix material layer; and extruding the carbon nanotube array covered with the matrix material layer to obtain the carbon nanotube composite film. The process of extruding the carbon nanotube array covered with the matrix material layer is carried out by a pressure device, so the preparation method is simple. The preparation method can control the carbon nanotubes in the carbon nanotube composite film to be arranged in the same polarity in various directions or along a fixed direction or different directions. Moreover, the carbon nanotubes in the carbon nanotube composite film prepared are distributed uniformly, so that the carbon nanotube composite film has better mechanical strength and roughness.

Owner:TSINGHUA UNIV +1

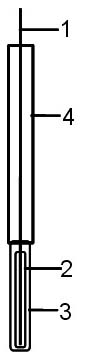

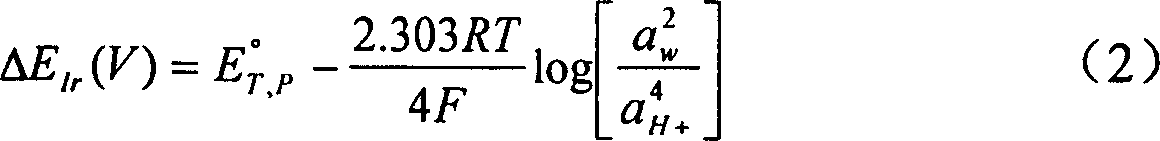

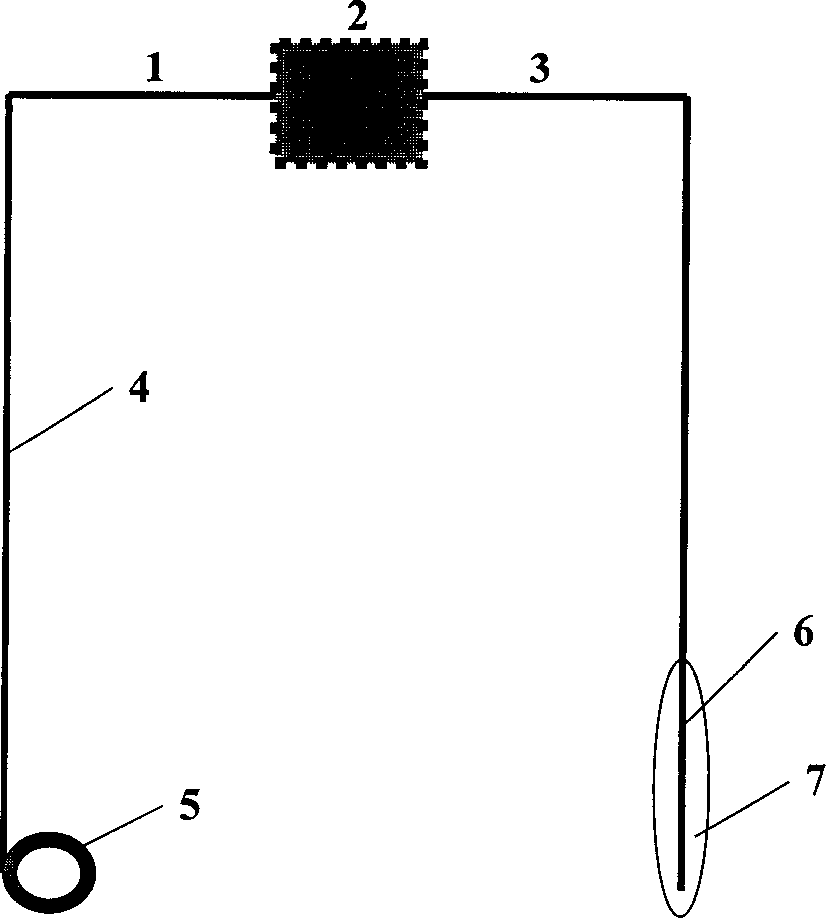

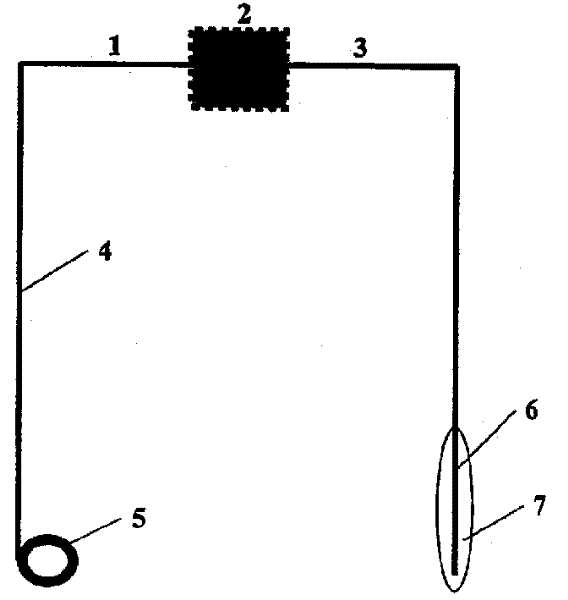

All-solid-state carbonate ion selective electrode and manufacture method of all-solid-state carbonate ion selective electrode

InactiveCN102156157AReduce volumeHigh mechanical strength and toughnessMaterial analysis by electric/magnetic meansMetalIndustrial water

The invention discloses an all-solid-state carbonate ion selective electrode and a manufacture method of the all-solid-state carbonate ion selective electrode. The all-solid-state carbonate ion selective electrode comprises a metal wire, solid electrolyte, a carbonate ion sensitive film and a heat shrinking tube. The solid electrolyte is covered on the metal wire; the carbonate ion sensitive filmis covered on the solid electrolyte layer; and the heat shrinking tube is covered on the part of the metal wire, where is not covered with the carbonate ion sensitive film. The invention also discloses a manufacture method and a calibration method of the all-solid-state carbonate ion selective electrode; the solid electrolyte and the carbonate ion sensitive film are coated on the surface of the metal wire in layers by a coating method; and the concentration of the carbonate ions in the solution can be detected fast and accurately by pairing the selective electrode and an external reference electrode. The exploring electrode provided by the invention has quite high mechanical strength and toughness, has the characteristics of small volume, convenience in carrying and operation, fast response and low manufacture cost, and is suitable for online detecting and long term monitoring the contents of carbonate ions in natural water, chemical and chemical industrial water mediums.

Owner:ZHEJIANG UNIV

Blood compatible biological material and preparation method thereof

InactiveCN1799649AHigh mechanical strengthIncreased mechanical toughnessPharmaceutical containersMedical packagingAnticoagulantMolecular materials

A biological material of blood compatiblility and the preparing method, relating to a biological material of blood compatible used externally or be implanted into body and the preparing method. Dissolving the medical high molecular material of high mechanical property and anticoagulant material with two different solvent and mixing them, fixing the anticoagulant material in the high molecular material uniformly, and preparing the restoring material for tissue organs used externally or be implanted into body with normal process, the invention overcomes the shortcomings existing in traditional technique of not obvious effect or for a short time of the anticoagulant modifying caused by only adsorbing, coating or grafting on the product surface, and makes the material possesses good anticoagulant property and prolongs the anticoagulant durability, and can meet demands of good anticoagulant, biological compatibility, strong mechanical strength and toughness needed by the restoring material for tissue organs used externally or be implanted into body.

Owner:TSINGHUA UNIV

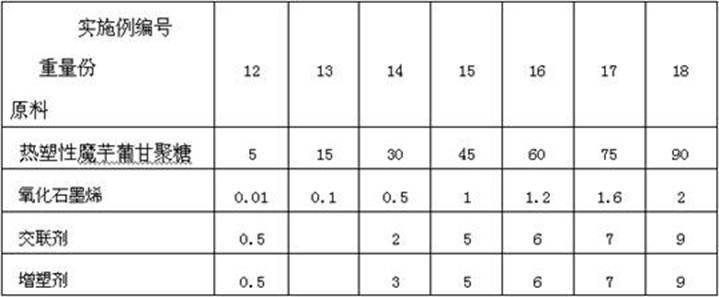

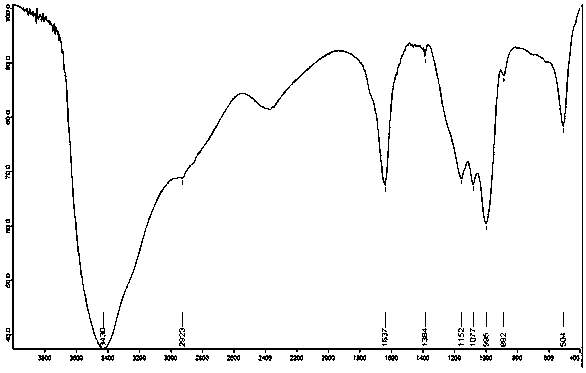

Thermoplastic konjac glucomannan/graphene oxide compound material and preparation method thereof

The invention discloses a thermoplastic konjac glucomannan / graphene oxide compound material and a preparation method thereof. The invention is characterized in that the compound material comprises the following components according to parts by weight: 1 to 99 parts of thermoplastic konjac glucomannan, 0.001 to 2 parts of graphene oxide, 0 to 10 parts of cross-linking agent and 0 to 10 parts of plasticizing agent; and the preparation method comprises the following steps of: proportioning; adding the thermoplastic konjac glucomannan into an ethanol or water solution of the graphene oxide, stirring for 5 to 10 hours, filtering and drying solid substances; then, drying after stirring and mixing with the cross-linking agent and the plasticizing agent in a mixing machine evenly; and afterwards, placing into a double-screw extrusion machine, extruding after carrying out melt blending at the temperature of 100 to 140 DEG C for 5 to 15 minutes, and granulating so as to prepare the compound material. The compound material has favorable processing performance, has excellent adsorbability, thermal stability and mechanical toughness, can be biologically degraded, can be regenerated, has no pollution to the environment and can be widely applied to the fields of chemical engineering, medicine, environmental protection, capital construction and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

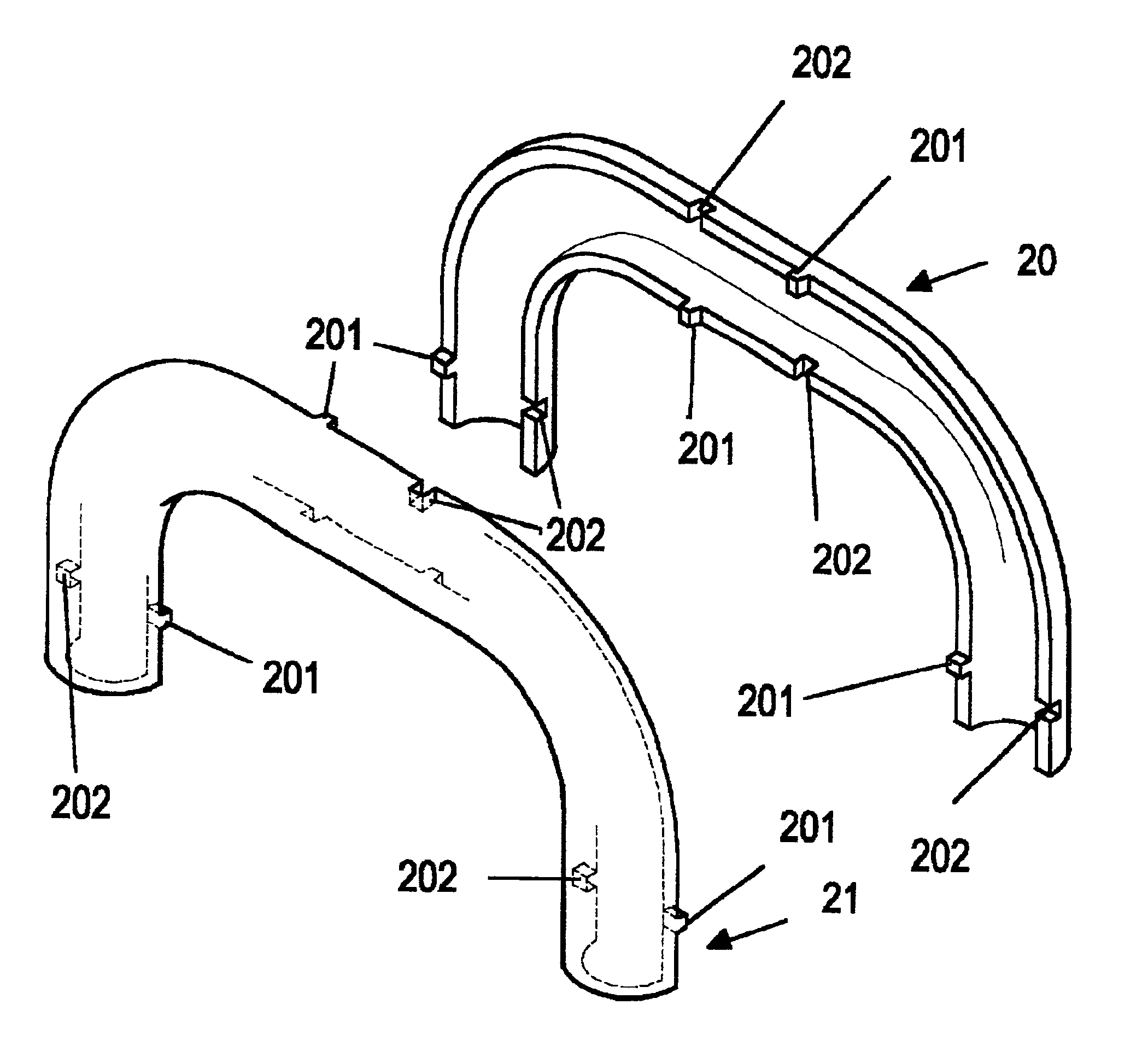

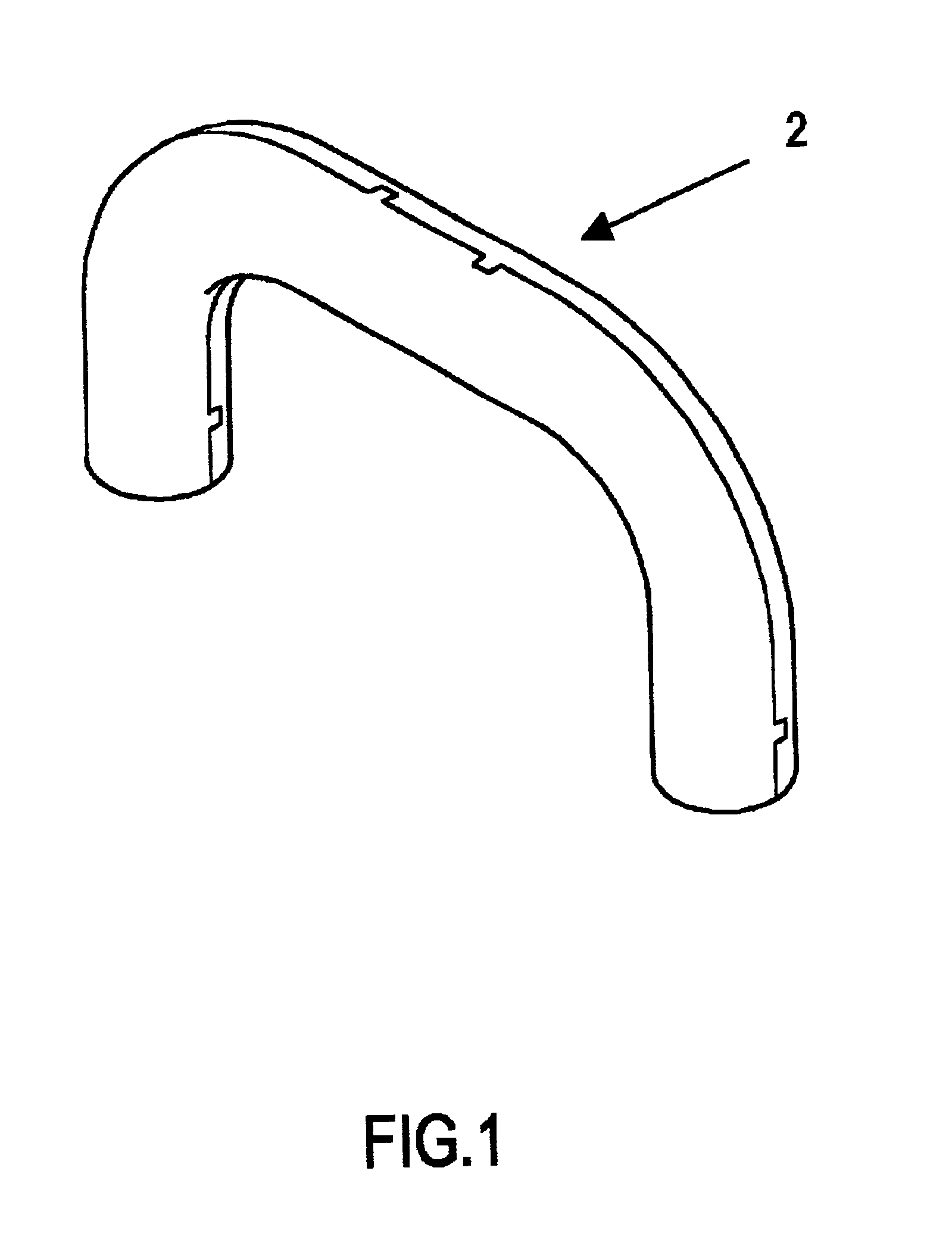

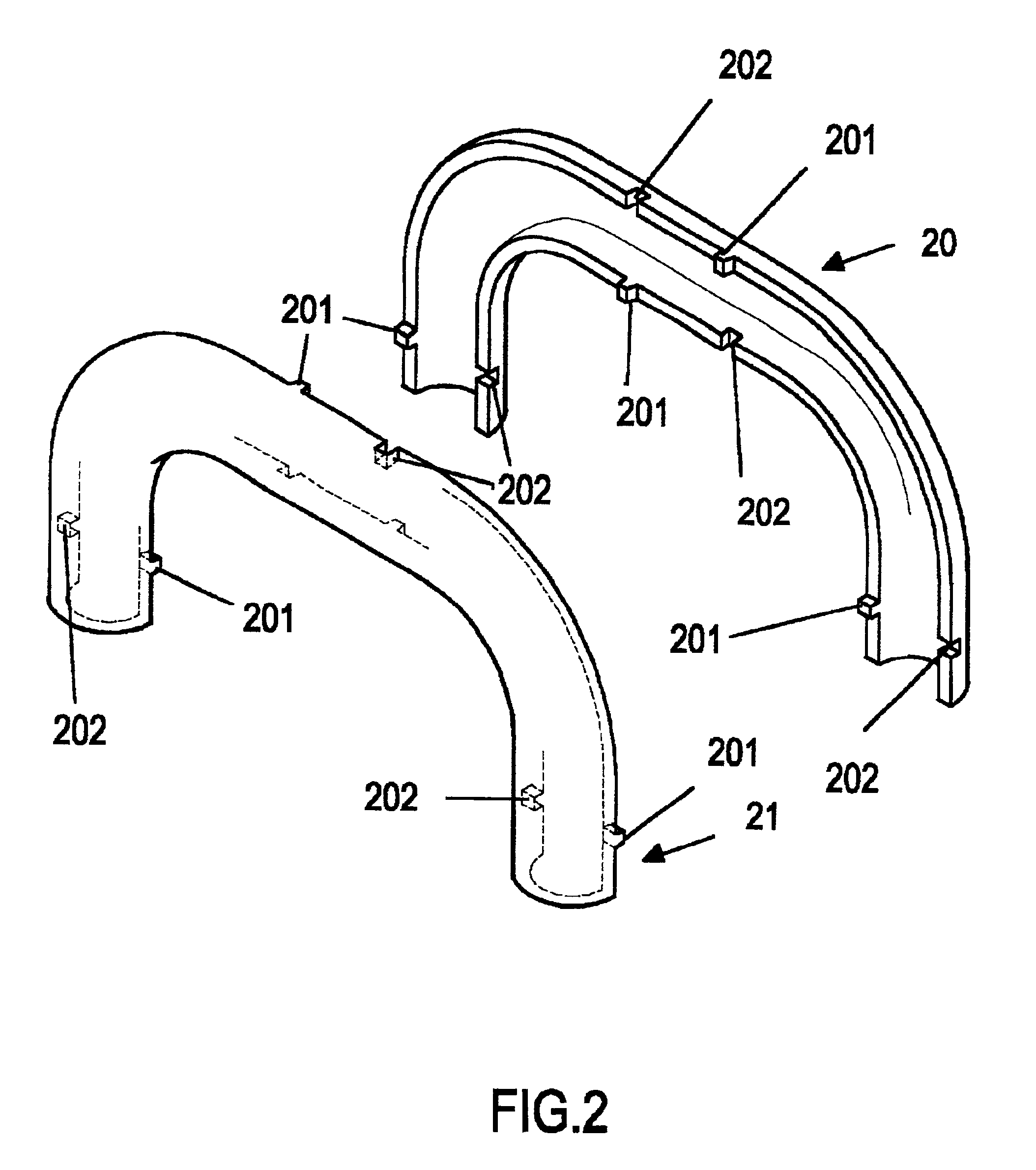

Coupled circulation tube for ball screw unit

InactiveUS6851722B2Easy to manufactureIncreased mechanical toughnessSleeve/socket jointsToothed gearingsBall screwEngineering

A coupled circulation tube for a ball screw unit. The tube is formed on a planar surface at one side of the ball screw bearing, each tube joined to two circulation holes. Each circulation tube is formed by coupling two symmetrical rigid metallic half tubes at recessed grooves and flanges interposedly arrayed one after another longitudinally along the wall of each half tube to form a resultant U shaped arcuate elbow tube for ball circulation such that it is firmly constructed with a desired toughness free from loosening, cracking or deforming by constant collision and abrasion of the rolling balls.

Owner:HIWIN TECH

Environment responding aquogel copolymer and its prepn

The present invention relates to one kind of environment responding aquogel copolymer and its preparation process. The aquogel consists of: N-isopropyl acrylamide 10-90 wt% and methacrylate dextran derivative 10-90 wt%. The preparation process of the environment responding aquogel copolymer includes chemical modification of dextran with GMA to synthesize methacrylate dextran derivative, MA-Dex, with reaction activity; and subsequent copolymerization of MA-Dex and NIPA to obtain the said environment responding aquogel copolymer P(NIPA-co-MA-Dex). The aquogel copolymer has high temperature sensitivity and quick responding speed as well as high strength and excellent biocompatibility. The preparation process is simple, needs no special apparatus and is easy to realize in industry.

Owner:TIANJIN POLYTECHNIC UNIV

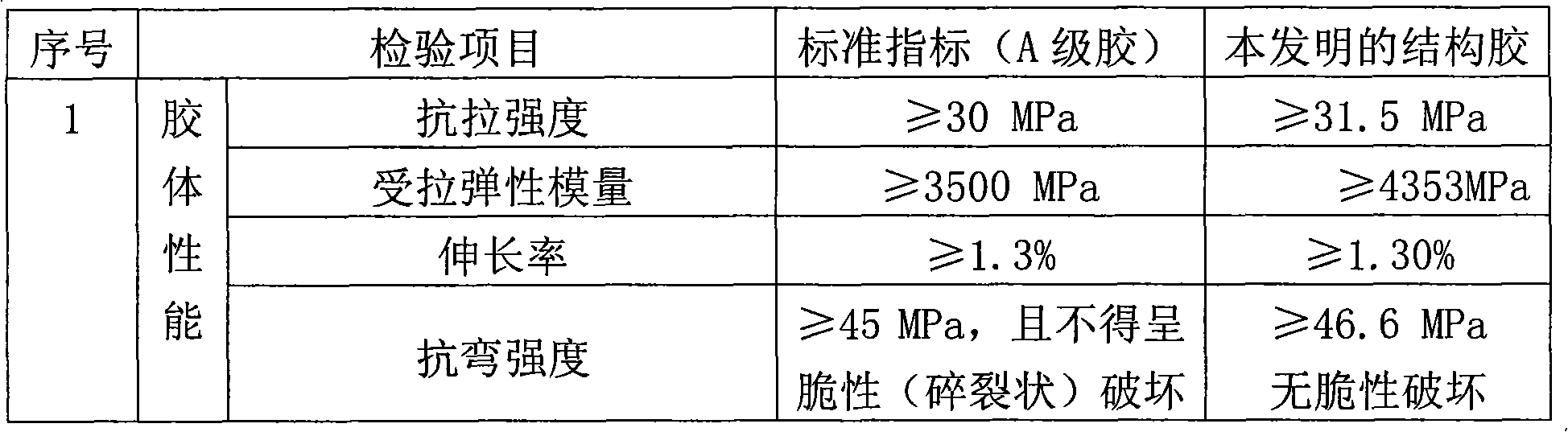

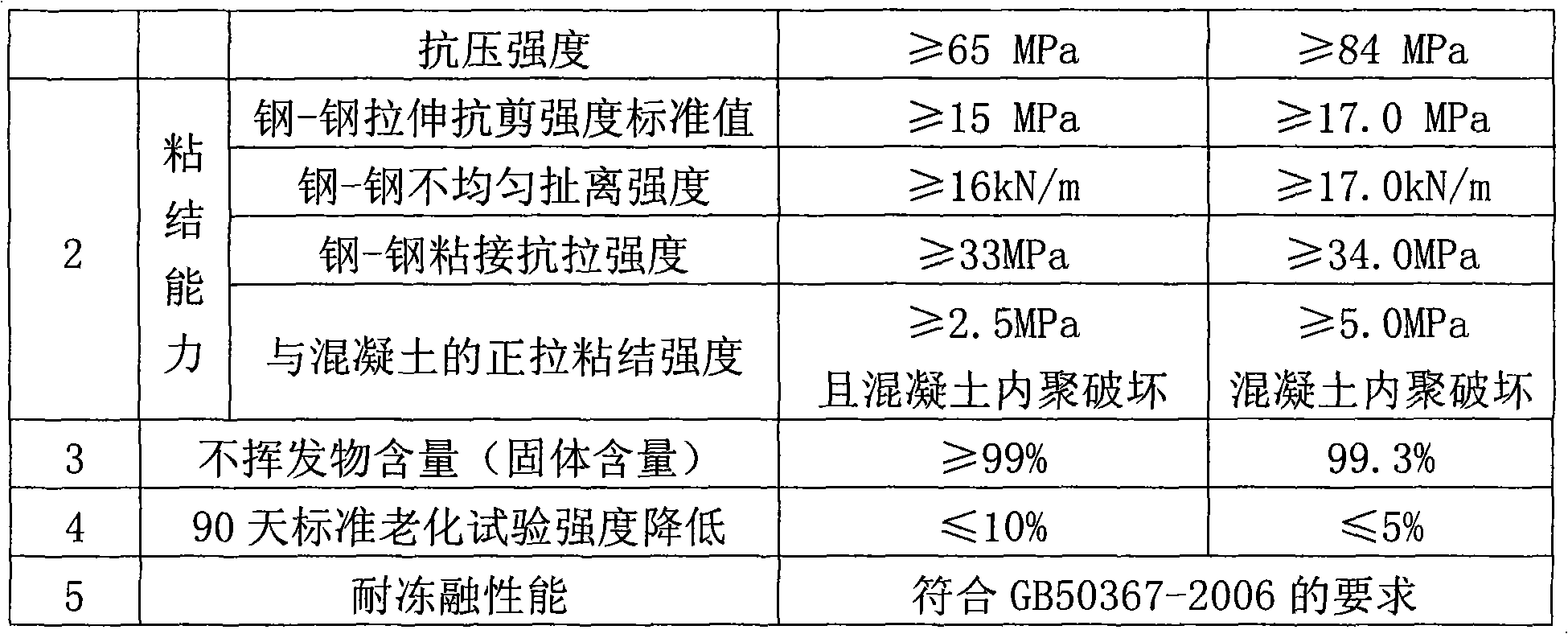

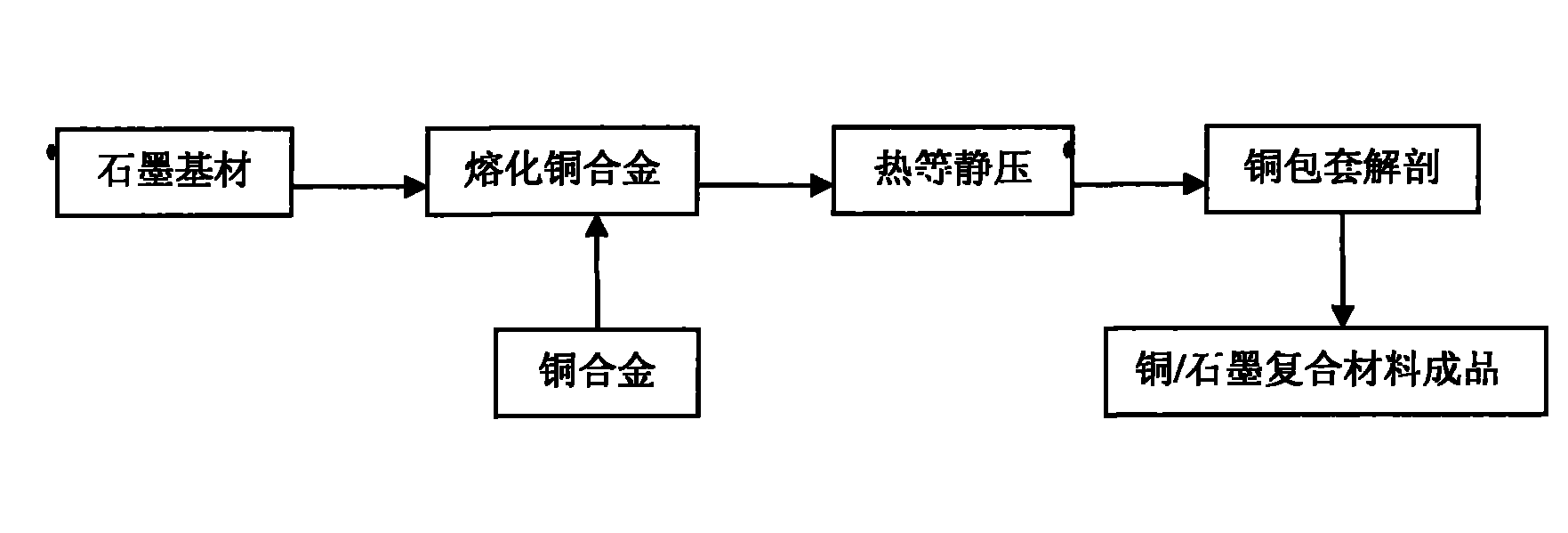

Structural adhesive for steel bonding

InactiveCN101921566AImprove adhesionIncreased mechanical toughnessNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyStress distribution

The invention discloses a structural adhesive for steel bonding, which comprises a component A and a component B of which the quality ratio is 100:(15-65), wherein the component A comprises epoxy resin, diluter, plasticizer, toughener and couplant; and the component B comprises modified polyamide resin, modified fatty amine and amino terminated polyether. The structural adhesive has the advantages of favorable bonding property, uniform stress distribution, high shearing strength and good mechanical toughness, has the characteristics of no flow after plate bonding, large anchorage withdrawal resistance and limit of harmful substances far below the national technical index, has the characteristics of high durability, convenient construction and stable strength, and can well soak the concrete and well bond the concrete and steel plates. The invention has high application and popularization values.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

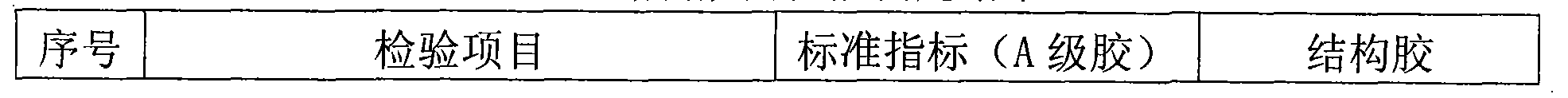

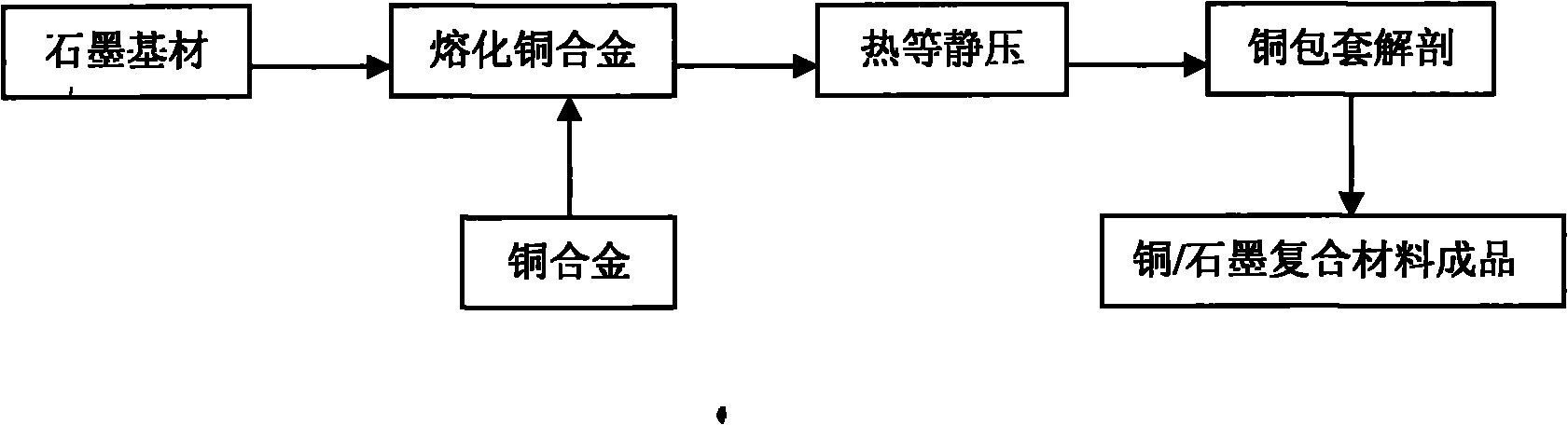

Copper/graphite compound material and preparation method thereof

ActiveCN102146552AHigh mechanical strengthIncreased mechanical toughnessHot-dipping/immersion processesThermal insulationCarbon graphite

The invention relates to a copper / graphite compound material and a preparation method thereof. In the compound material, carbon graphite is used as a substrate material, and a tin bronze alloy is used as a dipping metal. The preparation method comprises the following steps: (1) melting the tin bronze alloy to meltwater in a heat treatment furnace, immersing carbon graphite material blocks, and cooling so as to form a copper clad wrap coated by the graphite material blocks; (2) putting the copper clad wrap obtained in the step (1) in a hot isostatic press for hot isostatic press dipping at the temperature of 1100-1300 DEG C under the pressure of 60-80MPa at the atmosphere of argon, carrying out thermal insulation and pressure preservation for 60-120 minutes, and then carrying out belt pressure cooling; and (3) taking out the copper clad wrap obtained in the step (2) and then dissecting the copper clad wrap by using a machining method. The copper / graphite compound material is applied to machinery motive seal or bearings with high parameters (the temperature changes between minus 253 to 350 DEG C and the rotate speed is over 10000 rpm).

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

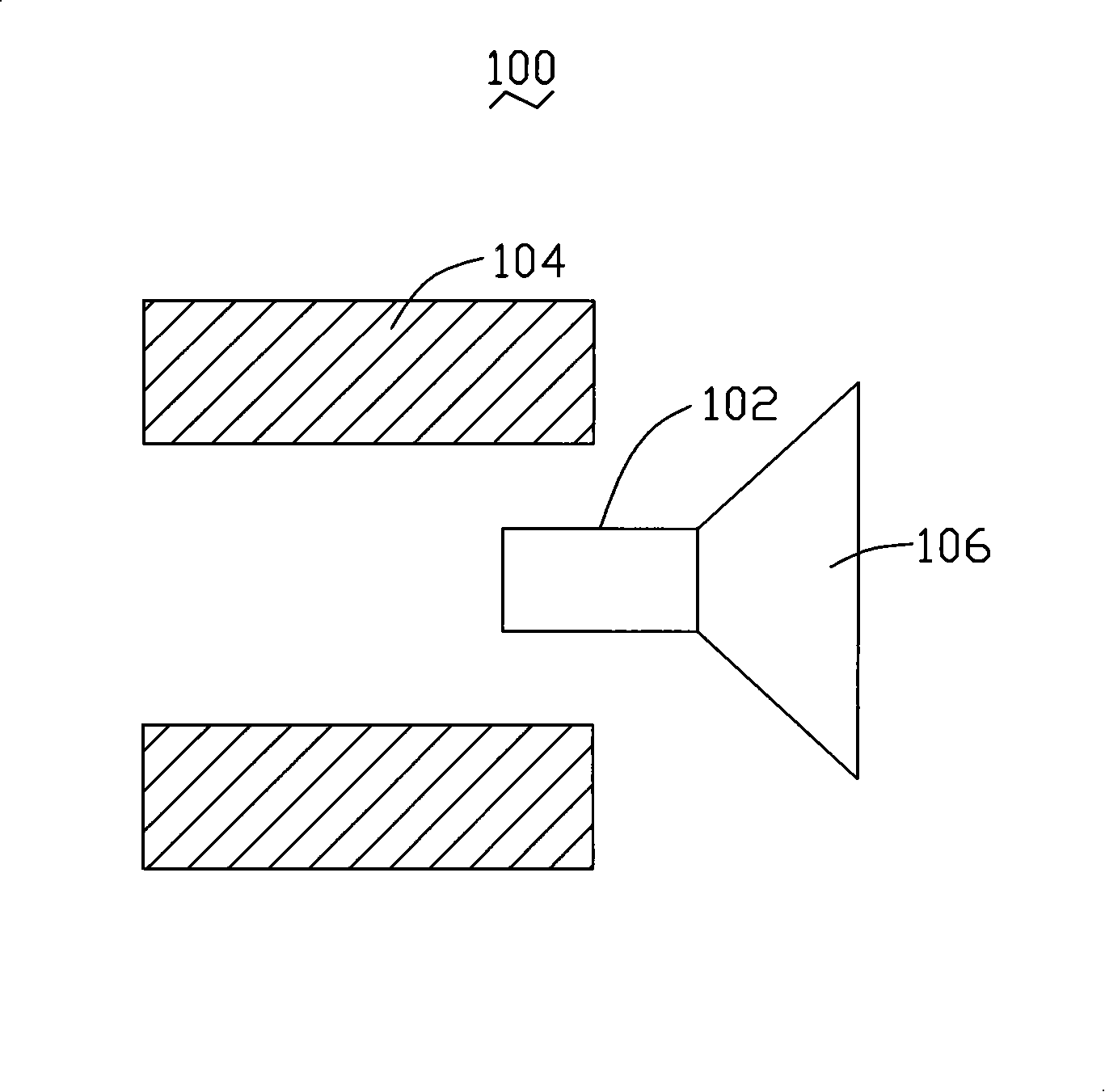

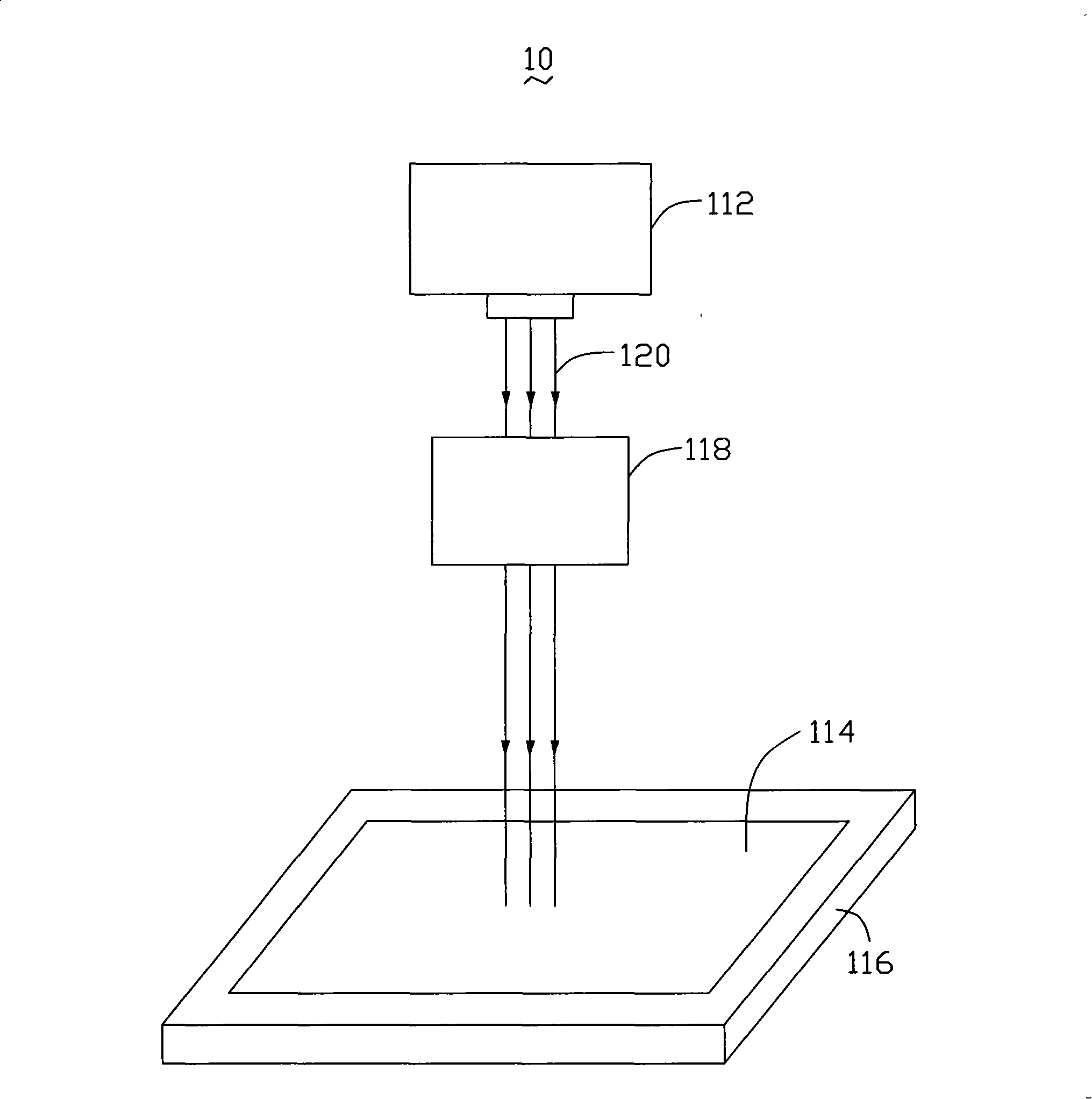

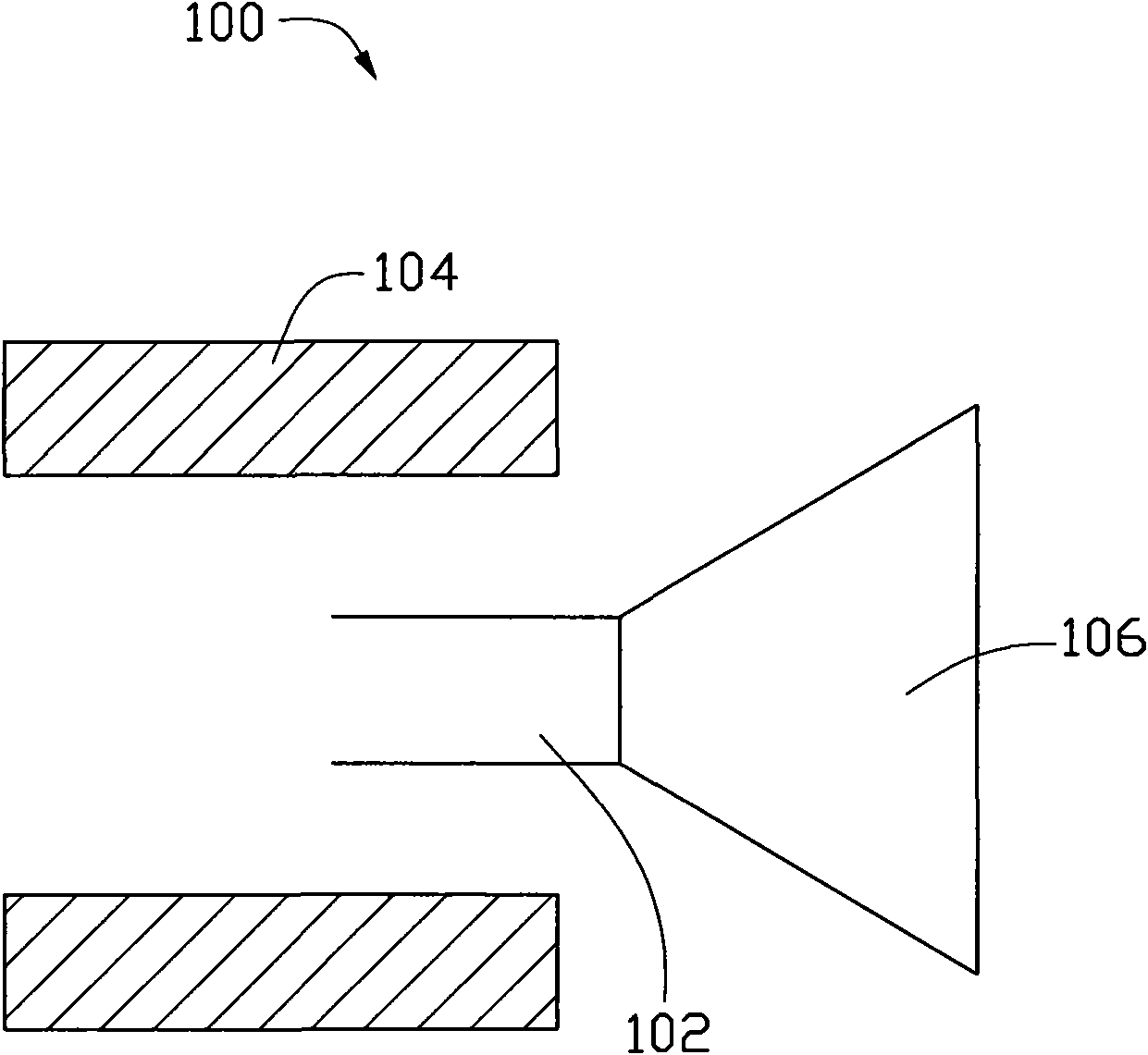

Sounding device

The invention relates to a sounding device comprising an electromagnetic wave signal input device and a sounding element, wherein the sounding element and the electromagnetic wave signal input device are arranged at intervals; the sounding element comprises at least one carbon nano tube film, and the carbon nano tube film includes a plurality of carbon nano tubes which are parallel to each other;and the electromagnetic wave signal input device transmits an electromagnetic wave signal to the carbon nano tube film, thus the carbon nano tube film emits heat by absorbing the electromagnetic wavesignal so as to heat an air medium to send sound waves.

Owner:TSINGHUA UNIV +1

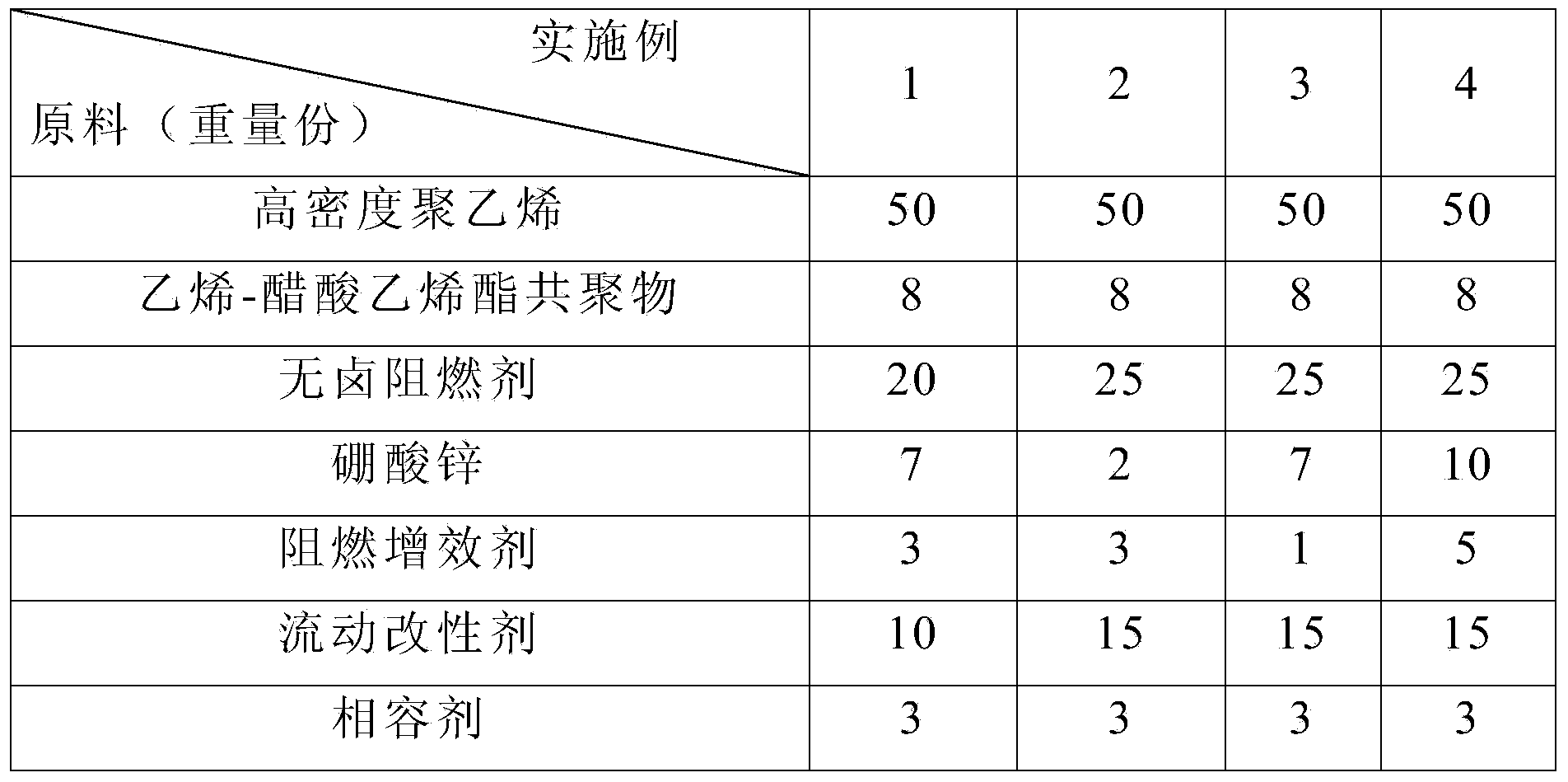

High-fluidity low-smoke zero-halogen flame retardant polyolefin composite and preparation method thereof

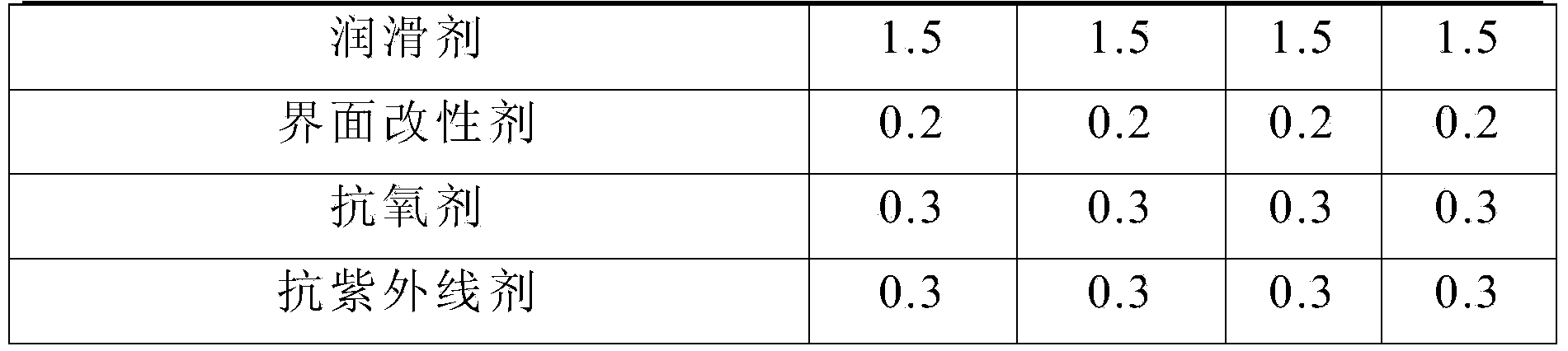

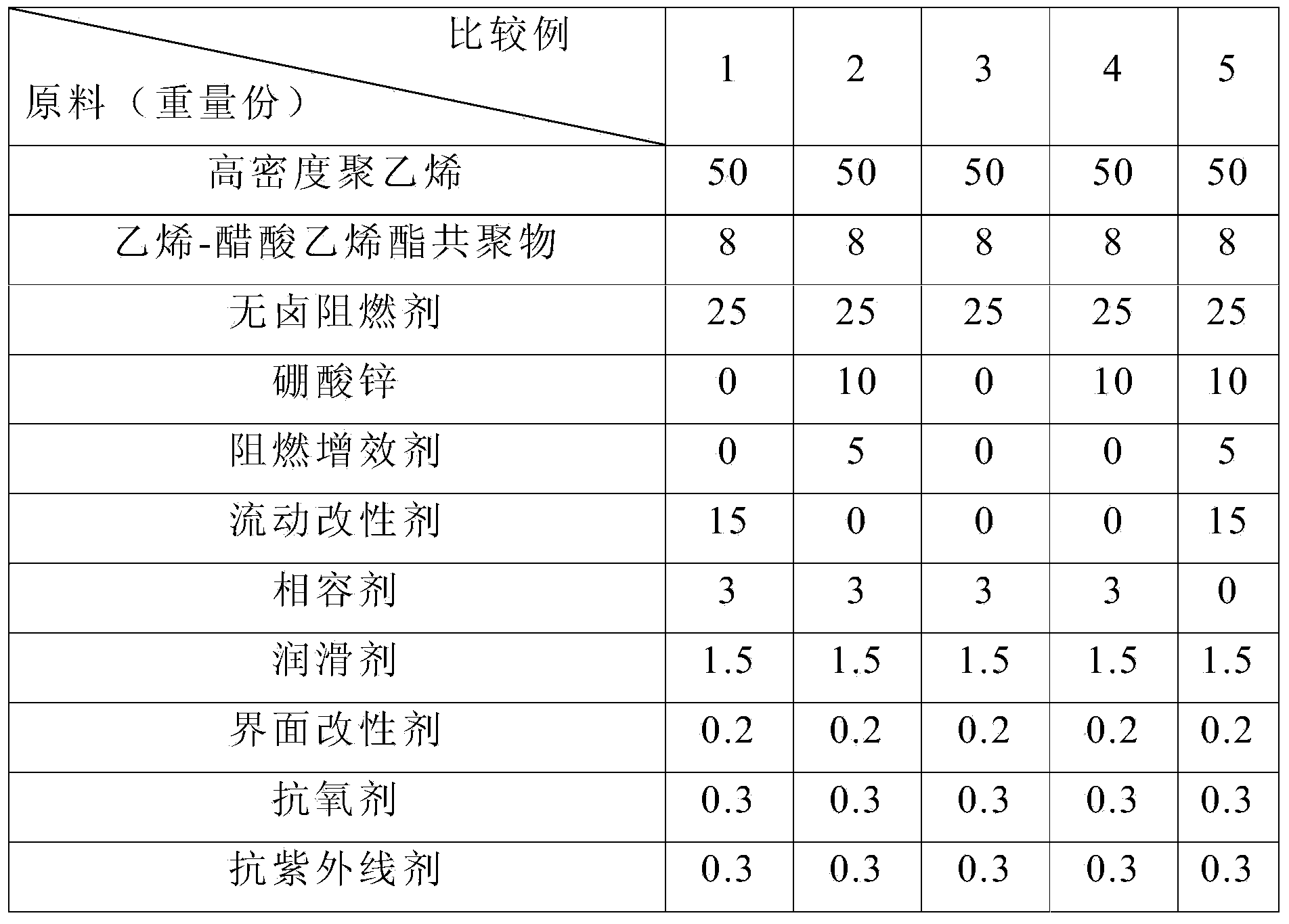

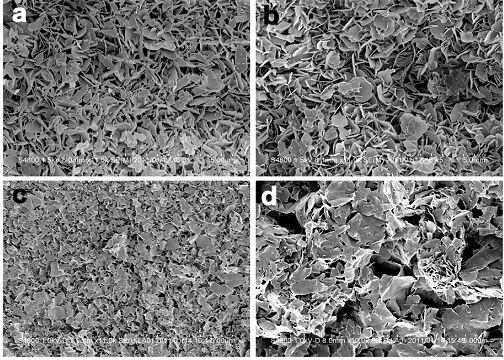

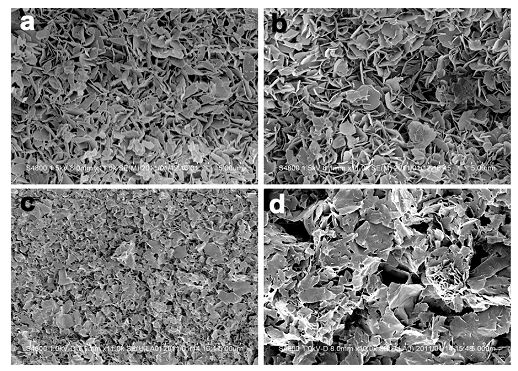

The invention relates to a high-fluidity low-smoke zero-halogen flame retardant polyolefin composite and a preparation method of the high-fluidity low-smoke zero-halogen flame retardant polyolefin composite. The composite comprises the following components by weight: a matrix resin comprising 40-60 parts of high density polyethylene and 5-10 parts of ethylene-vinyl acetate copolymer, a flame retardant comprising 20-30 parts of halogen-free flame retardant, 5-10 parts of zinc borate and 1-5 parts of flaming retardance synergist, 10-15 parts of flow modifier, 1-2 parts of lubricant, 2-5 parts of compatilizer, 0.1-0.5 part of interfacial modifier, 0.3-0.5 part of antioxidant, and 0.3-0.5 part of anti-ultraviolet agent. The preparation method comprises the following steps of preparing and mixing the components, extruding, pelleting, water-cooling, sized-dicing, and drying. Compared with the prior art, the high-fluidity low-smoke zero-halogen flame retardant polyolefin composite has the following characteristics that the material has excellent fluidity (the melt index is up to 9-12 g / 10min) and excellent flame retardant property (the oxygen index is up to 32-34%). The composite further has the advantages of low smoke, zero halogen, excellent dripping resistance, excellent ultraviolet resistance, excellent anti-aging property and good processability.

Owner:NINGBO XIANFENG NEW MATERIAL

Preparation method of cellulose/metal oxide composite aerogel

The invention discloses a preparation method of cellulose / metal oxide composite aerogel. The preparation method comprises the following steps of: (1) preparing a cellulose film; (2) using deionized water to clean the cellulose film obtained in the step (1), and using an organic solvent A to replace moisture in the cellulose; (3) immersing the cellulose film obtained in the step (2) into alcohol solution of inorganic metal salt, simultaneously adding an epoxy compound, standing for reaction, and obtaining the cellulose / metal oxide composite aerogel, wherein the volume of the epoxy compound is 5-20% of the volume of the alcohol solution of the inorganic metal salt; (4) using the deionized water to clean a gel film obtained in the step (3), and then using an organic solvent B to replace the moisture in the gel film; and (5) freezing and drying or drying critically the gel film obtained in the step (4) and obtaining the cellulose / metal oxide composite aerogel. The composite aerogel obtained by the preparation method has higher specific area.

Owner:JIANGNAN UNIV

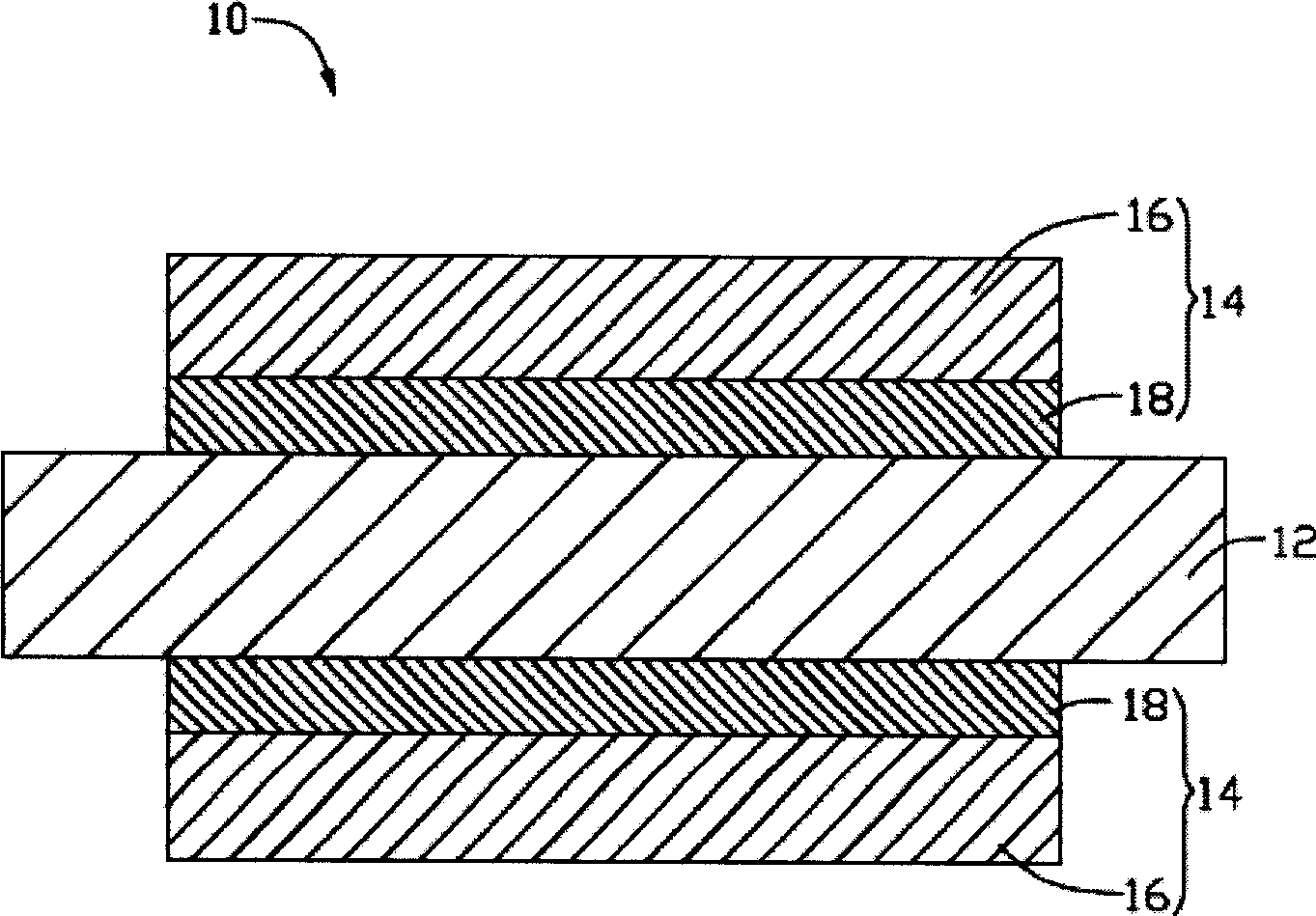

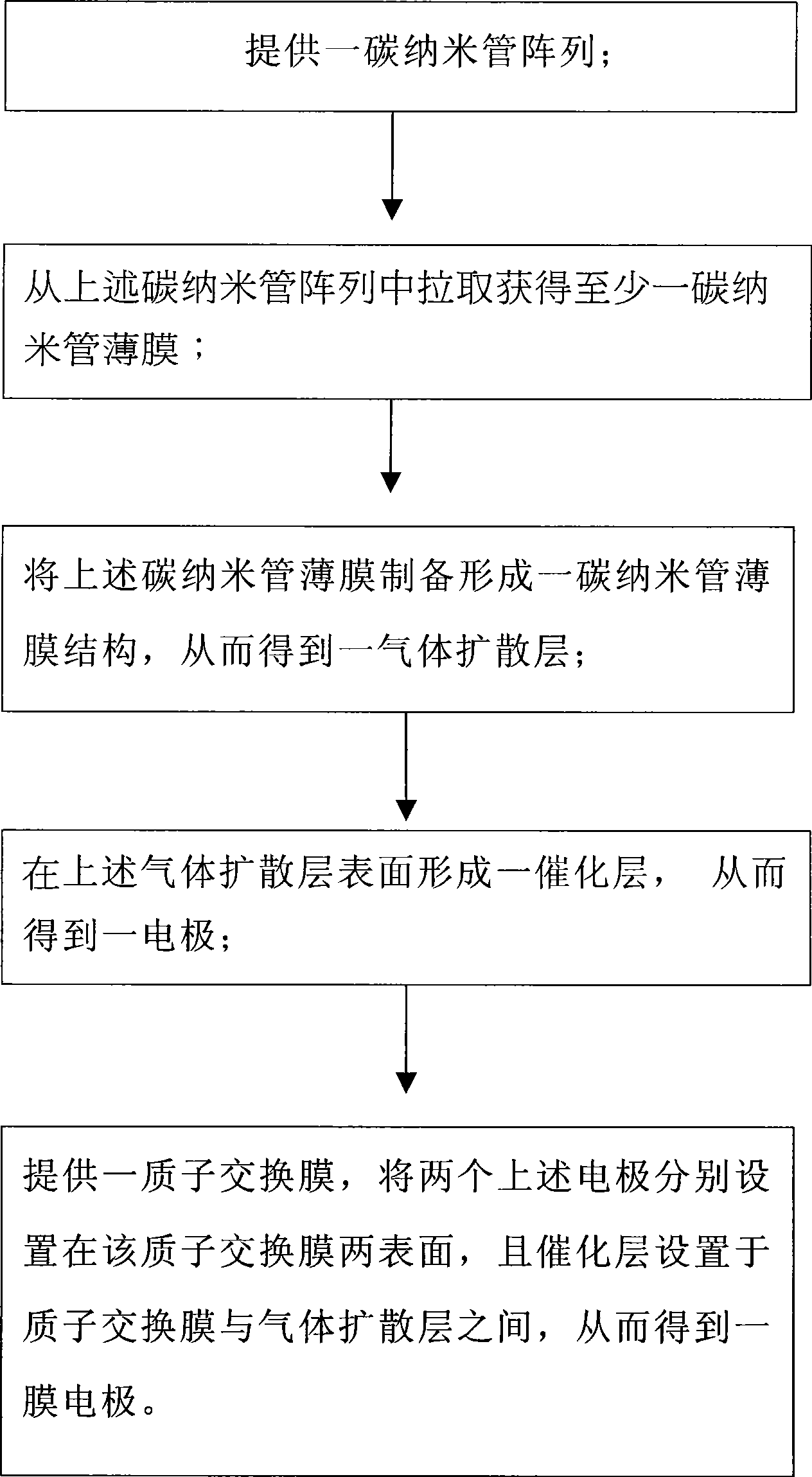

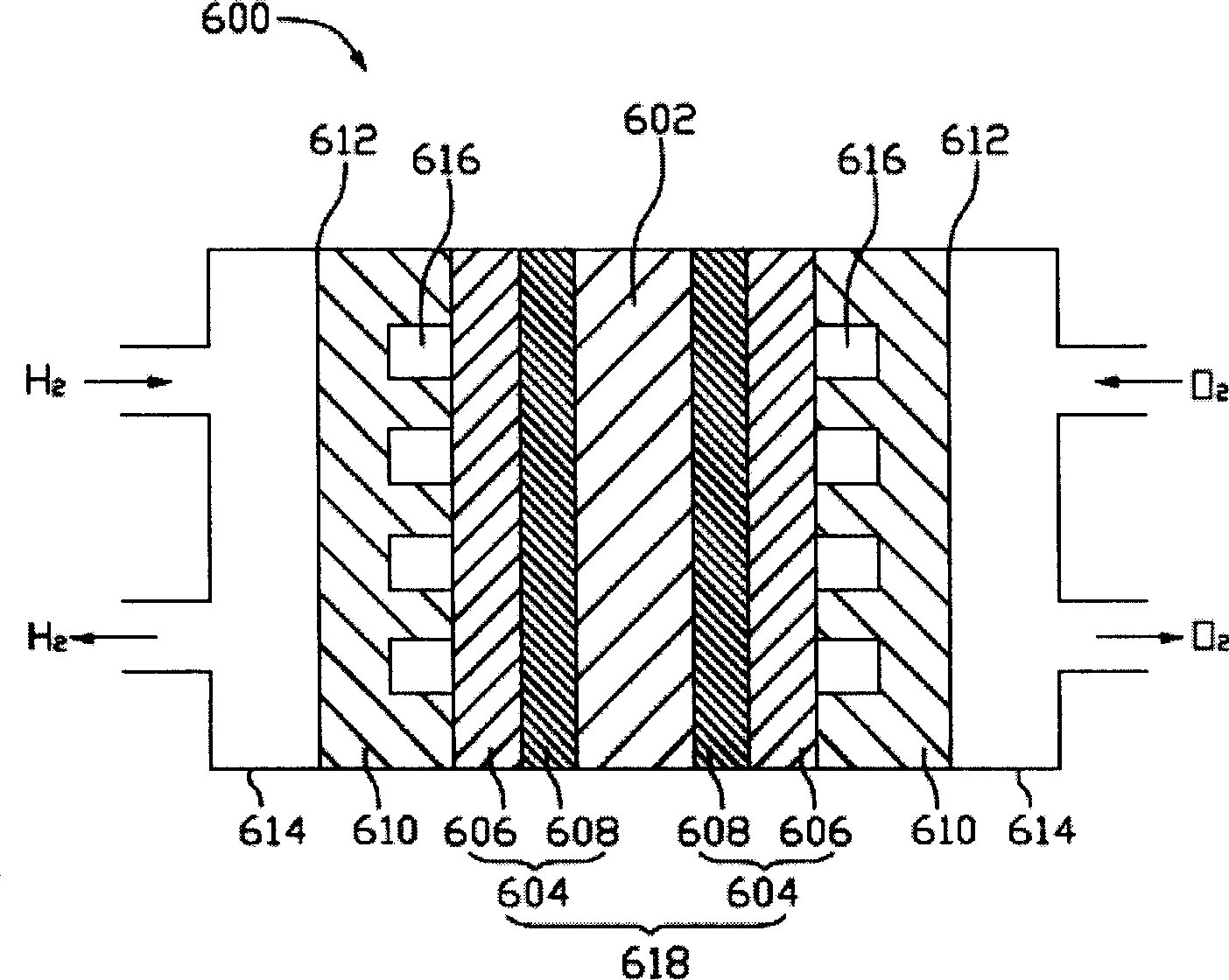

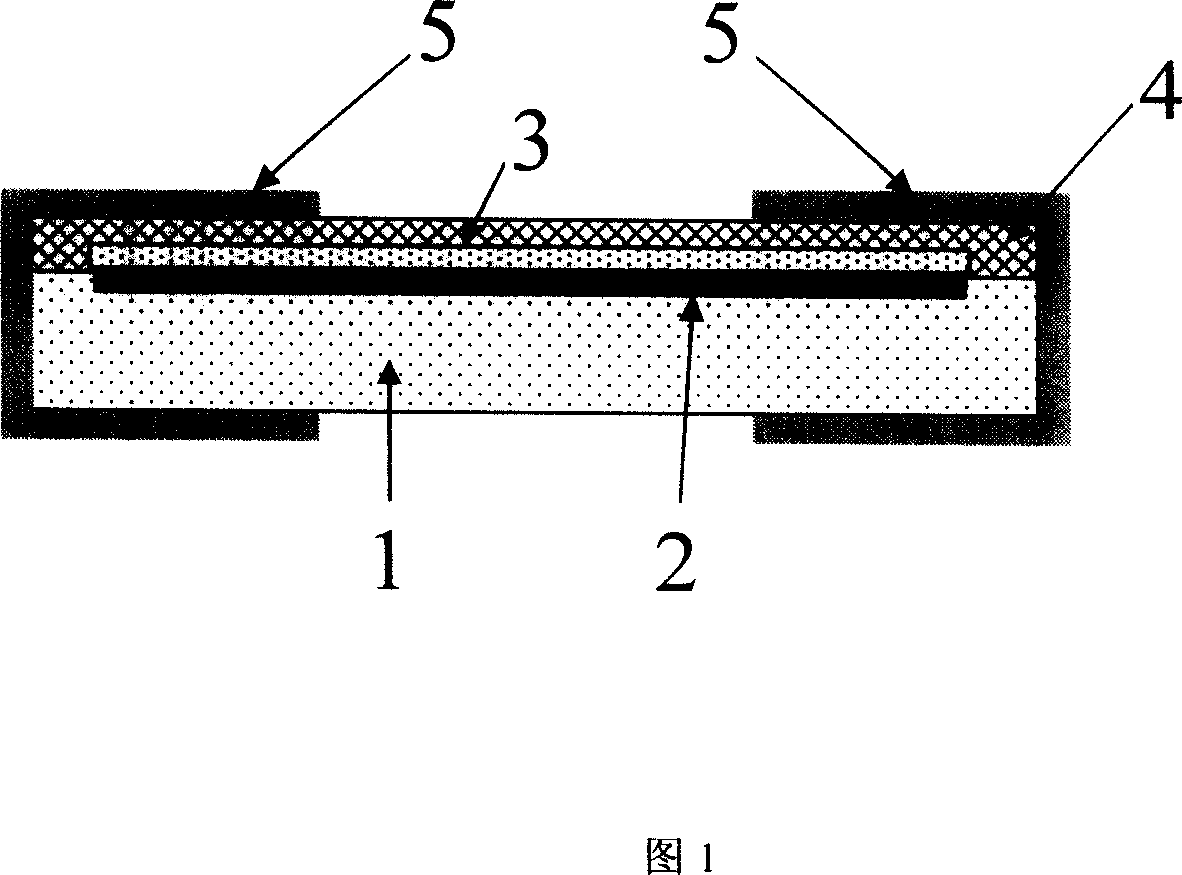

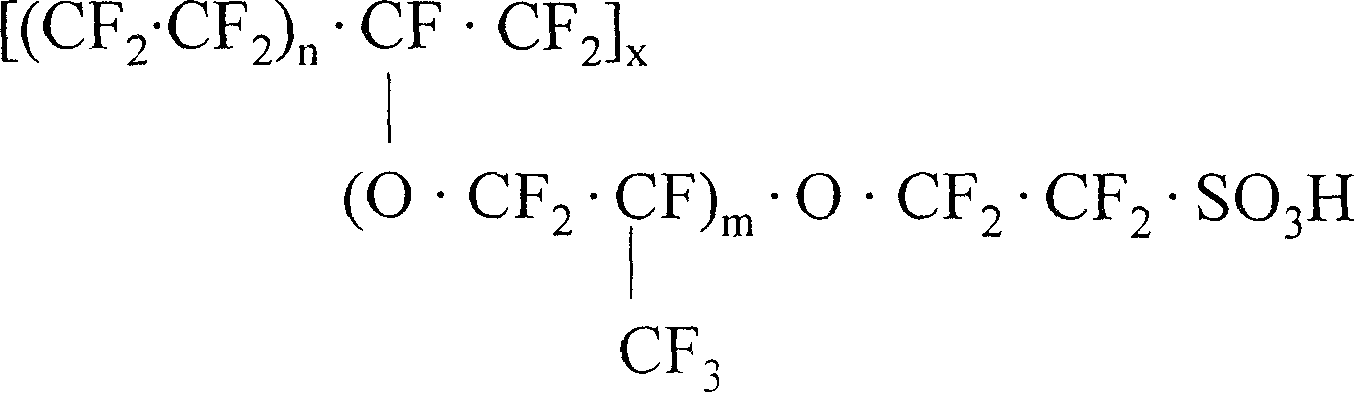

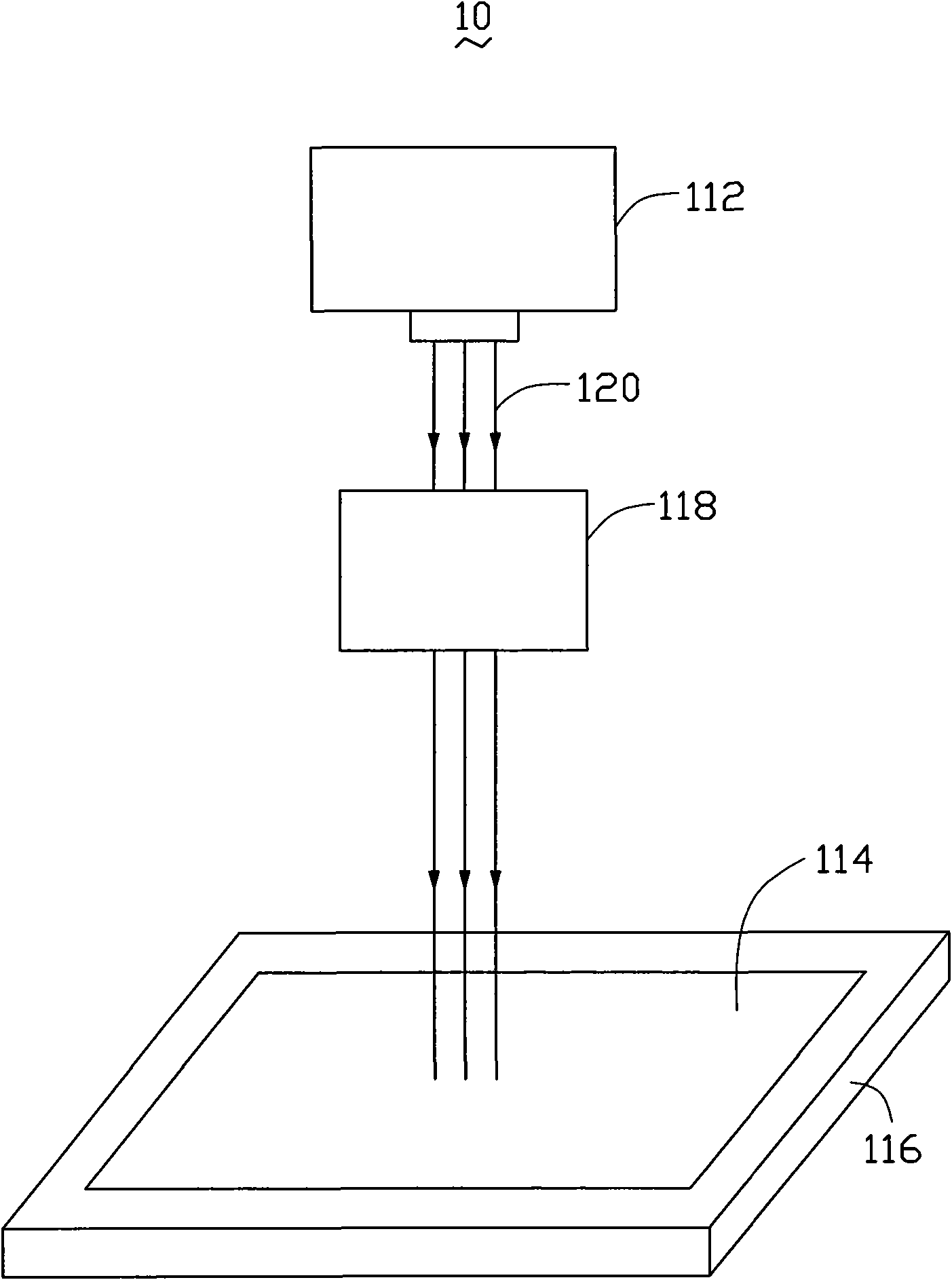

Fuel battery membrane electrode and preparation method thereof

ActiveCN101465434AHigh reactivityHigh mechanical strengthMaterial nanotechnologyFinal product manufactureProtonCarbon nanotube

Owner:TSINGHUA UNIV +1

High-content fiberglass-reinforced halogen-free flame-retardant PC (polycarbonate) composite and preparation method thereof

The invention discloses high-content fiberglass-reinforced halogen-free flame-retardant PC (polycarbonate) composite and a preparation method thereof, comprising the following components according to percent by weight: 50-60% of polycarbonate, 34-45% of fiberglass, 2-5% of a toughener, 8-20% of a flame retardant, 1-3% of a flame-retardant synergist, 0.1-1% of a lubricant, and 0.1-1% of an antioxidant; the polycarbonate is a mixture of common polycarbonate and siloxane copolymer. The polymer is formed of PC (polycarbonate) and siloxane, PC is amorphous resin with good performance, and the siloxane copolymer has the advantages of low temperature resistance, chemical corrosion resistance, good dielectric property and the like; the siloxane-PC copolymer has the advantages of both the siloxane copolymer and PC and has reduced stress cracking performance and gap sensitivity, improved low temperature impact performance, and improved weathering resistance.

Owner:DONGGUAN HONOUR E P

Preparation method of hematopoietic tissue repairing material

InactiveCN1569253AExcellent anticoagulant propertiesGood biocompatibilityProsthesisRepair tissueBiology

The invention relates to a preparation process of repairing materials for tissues and organs, in particular to a preparation process of repairing material for tissues and complex organs. It makes PHBHHx as main materials to prepare film type, single tube, multiple tubes and net tube materials. It uses PLLA, PLGA, PCL, PU, other degradable high molecular materials, drug, growth factor, cell and other components to prepare a material for repairing tissues and organs with favorable anticoagulant property, biological compatibility, comparative highly machinery intensity and toughness, and matching degradation rate with the growth rate of the complex organs.

Owner:TSINGHUA UNIV

A surface paste fuse of nano carborundum-alumina porcelain base and its making method

This invention relates to one nanometer carbon silicon to alumina compound ceramics materials for base slice element surface fuse and its process method, wherein, the nanometer carbon silicon to alumina ceramics base slice surface fuse comprises metal fuse wire, insulation layer, sealing layer and metal terminal; the invention is characterized by the following: the said ceramics base slice is made from nanometer alumina for 70 to 97 percent mole and nanometer carbon silicon for 1 to 30 percent moles.

Owner:NANJING SART SCI & TECH DEV

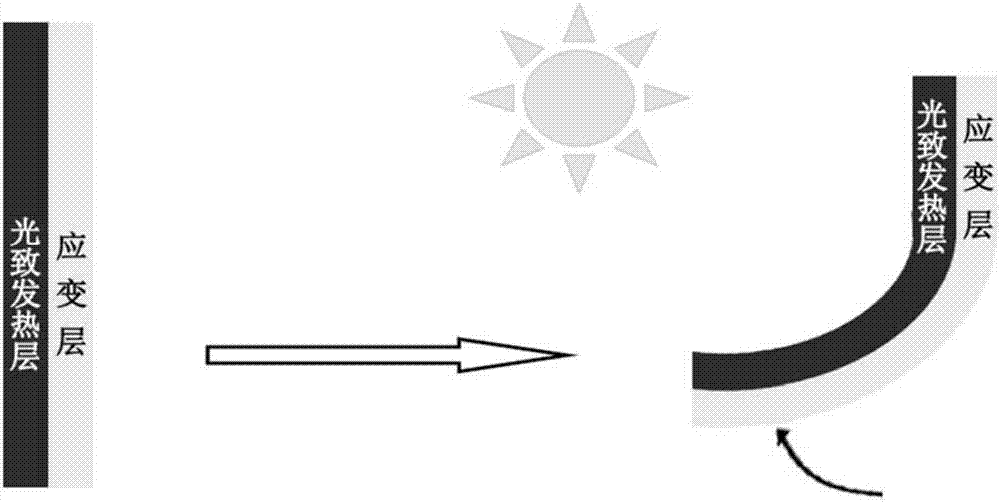

Preparation method of optical-actuated composite film, optical-actuated composite film and optical actuator

ActiveCN107201996AImprove bindingHigh mechanical strengthMachines/enginesMechanical power devicesComposite filmColloid

The invention provides a preparation method of an optical-actuated composite film. The preparation method comprises the following steps that graphite oxide and an optical-actuated heating material are dispersed into a first solvent, and a first colloid is obtained; an organic flexible strained-layer material is dispersed into a second solvent, and a second colloid is obtained; the first colloid is coated on a substrate and dried, and an optical-actuated heating film layer is obtained; and the second colloid is coated on the optical-actuated heating film layer and dried, a strain film layer is formed, the strain film layer is bonded with the optical-actuated heating film layer through chemical bonds, the optical-actuated composite film is formed, and then demolding is conducted on the optical-actuated composite film and the substrate. The invention further provides the optical-actuated composite film prepared through the method. The optical-actuated composite film is composed of the optical-actuated heating film layer and the strain film layer, the optical-actuated heating film layer comprises graphite oxide and the optical-actuated heating material, the strain film layer comprises the organic flexible strained-layer material, and graphite oxide and the organic flexible strained-layer material are combined through the chemical bonds. The invention further provides an optical actuator.

Owner:UNIV OF SCI & TECH OF CHINA

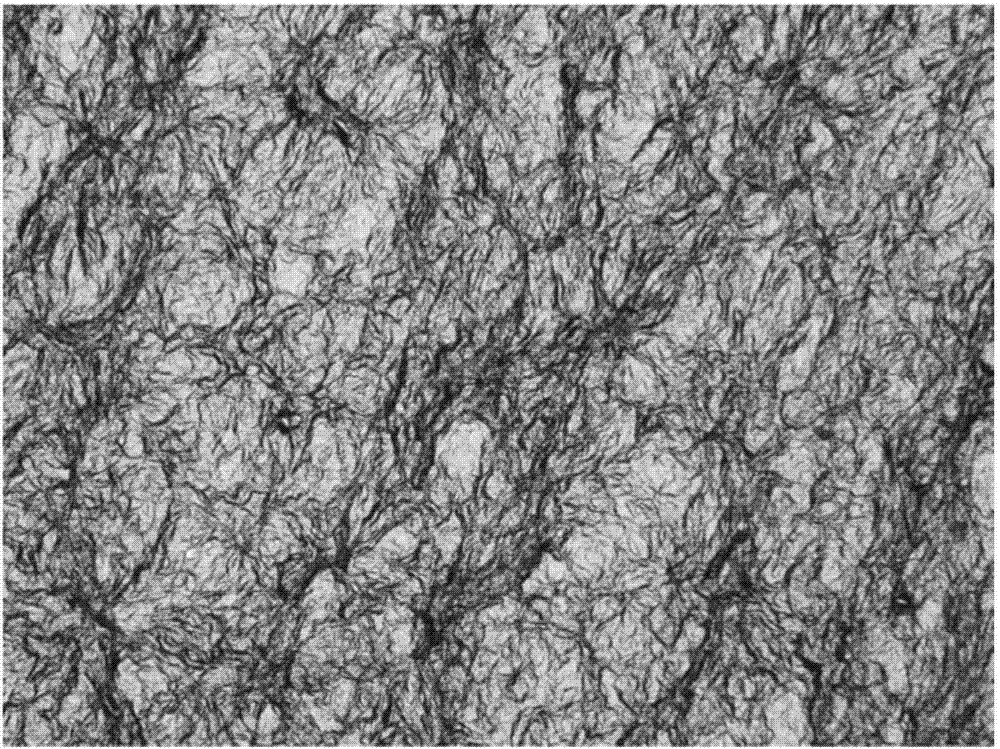

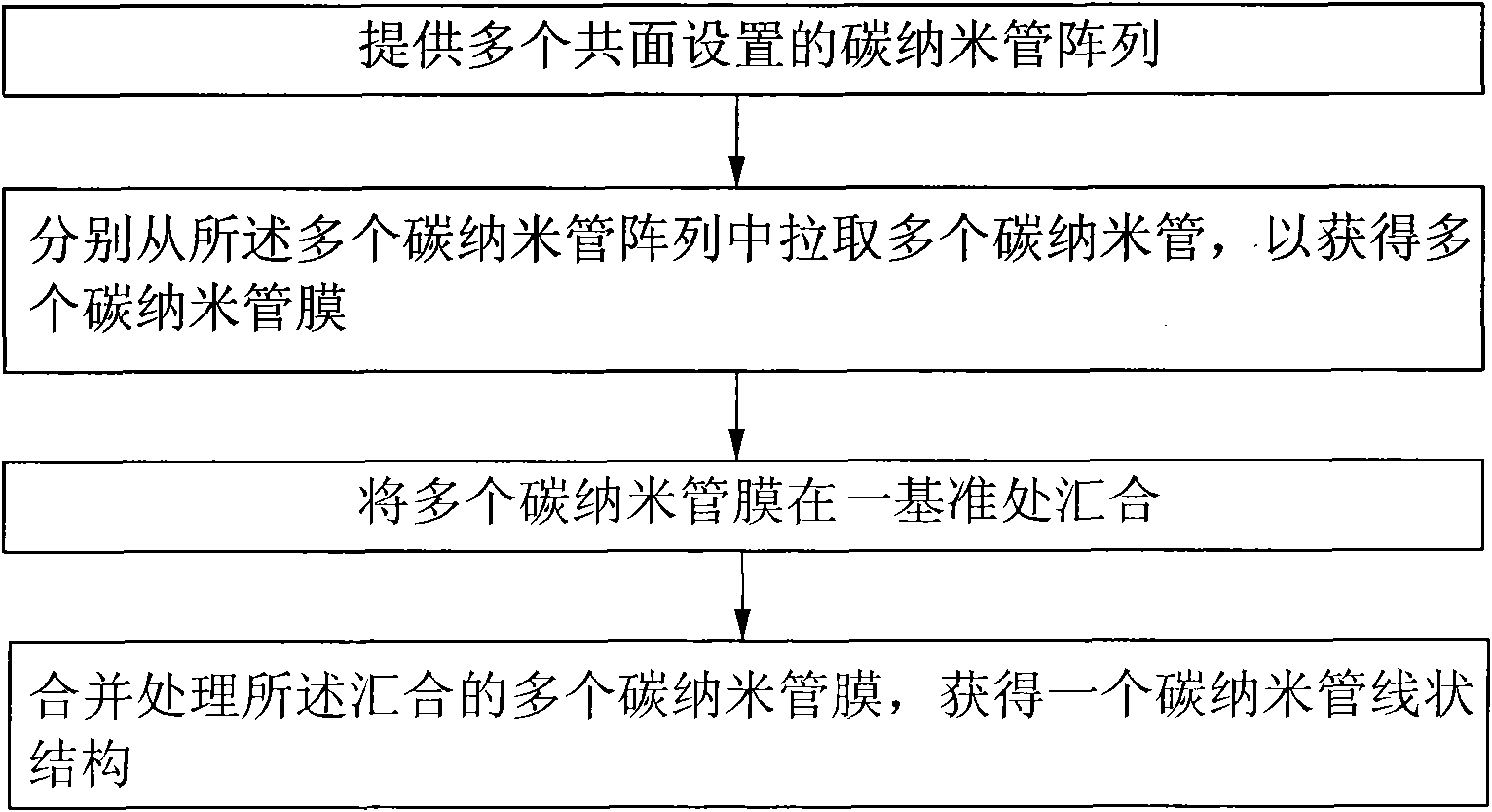

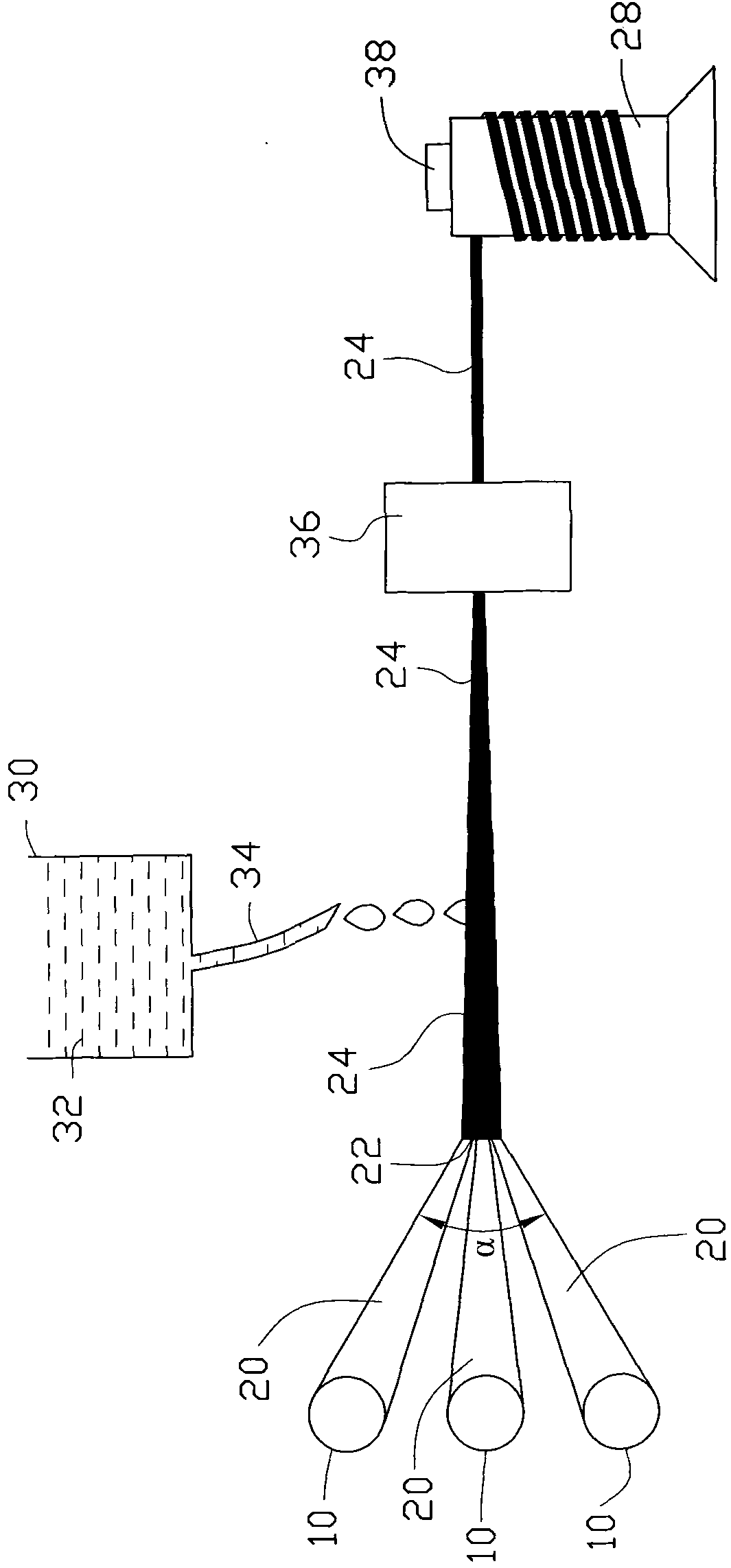

Liner structure of carbon nano tube and preparation method thereof

InactiveCN101905878AHigh mechanical strengthIncreased mechanical toughnessMaterial nanotechnologyNanostructure manufactureCarbon nanotubeToughness

The invention relates to a preparation method of a liner structure of a carbon nano tube. The method comprises the following steps of: providing a plurality of carbon nano tube arrays in coplanar arrangement; respectively drawing a plurality of carbon nano tubes from the plurality of carbon nano tube arrays to obtain a plurality of carbon nano tube films; converging the plurality of carbon nano tube films at a reference point; and merging and processing the plurality of converged carbon nano tube films. The liner structure of the carbon nano tube, which is prepared by using the method, has the diameter that is not limited to the size of a single carbon nano tube array and has favorable mechanical strength and toughness.

Owner:TSINGHUA UNIV +1

MgAlON combined aluminum magenisum permeable brick and preparation method thereof

The invention particularly relates to an MgAlON combined aluminum magenisum permeable brick and a preparation method of the MgAlON combined aluminum magenisum permeable brick. The technical scheme comprises the following steps of: taking 55-65 wt% of sintered corundum grains, 25-35 wt% of aluminum oxide fine powder, 2-10 wt% of metal aluminum powder and 2-10 wt% of fused magnesite fine powder as raw materials; then, additionally adding phenolic resin which is 2-6 wt% of the raw materials and grinding and agitating; carrying out mechanical pressing; drying under the condition of 180-220 DEG C for 12-24 hours; raising the temperature to 1500-1700 DEG C by a temperature-rising speed of 2-5 DEG C / min; and keeping the heat for 3-5 hours to prepare the MgAlON combined aluminum magenisum permeable brick. The prepared MgAlON combined aluminum magenisum permeable brick has the characteristics of high density, larger high-temperature strength, good thermal shock resistance, capability of being not wetted by liquid steel and strong corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH

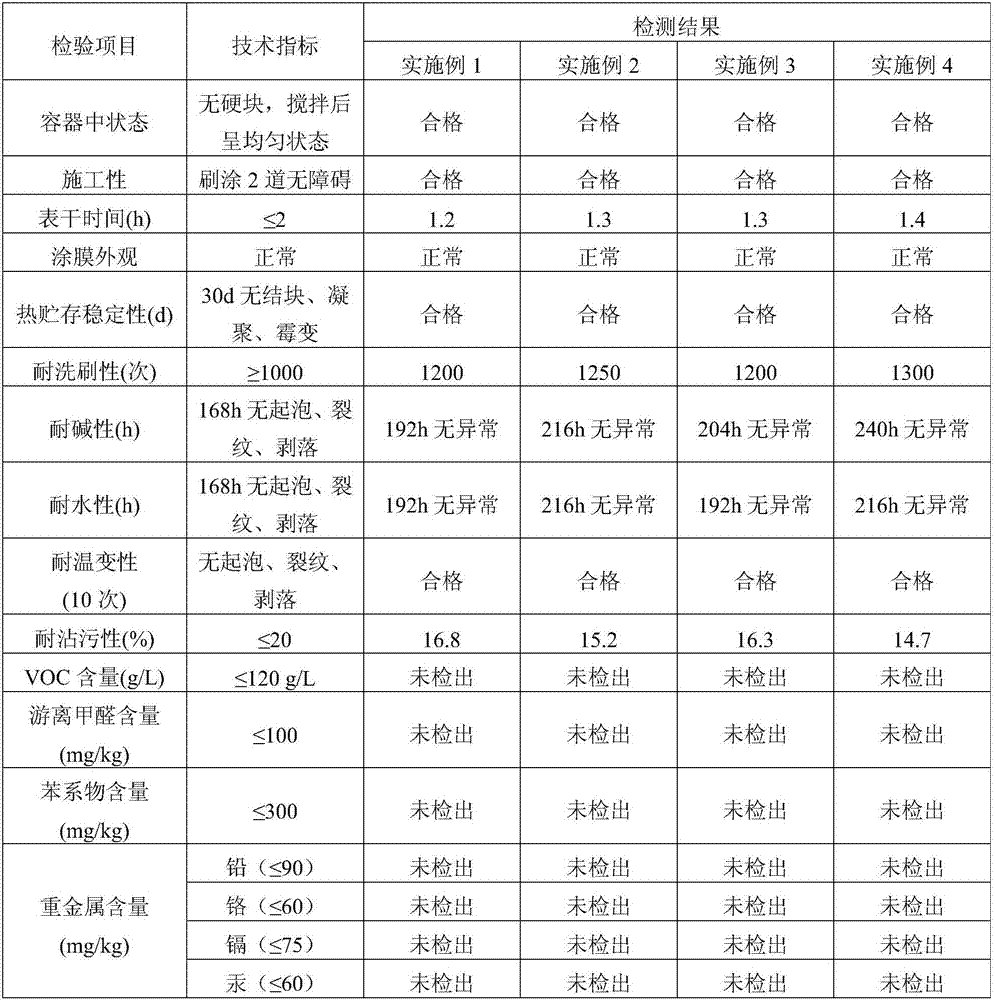

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Filler resin composition for adjusting high backing plate by filling and preparation method

Owner:CHANGSHU JIAFA CHEM

Anti-interference metal/metal oxide pH electrode and preparation method

InactiveCN1869675AReduce volumeHigh mechanical strengthMaterial analysis by electric/magnetic meansChemical synthesisDynamic monitoring

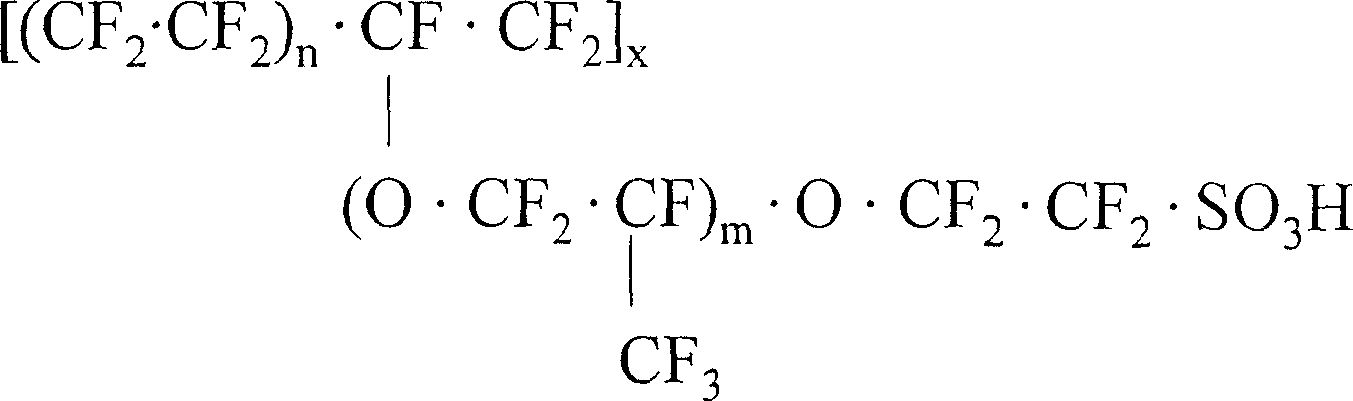

The invention discloses an anti-interference metal / metal oxide pH electrode and the preparing method, adopting metal wire with stable chemical properties as substrate, immersing the metal wire in the melted sodium peroxide for several minutes and forming hydrogen ion-sensitive active oxide film on the surface of the metal wire, then using fluorinated sulfonic acid resin to coat the active oxide film and forming hydrogen ion selective semipermeable membrane, which can transmit protons but stop other anions and cations outside, thus avoiding their interferences to pH electrode and simultaneously largely prolonging pH electrode service life. And the pH electrode has advantages of small bulk, high mechanical strength, and wide application range, etc, and the preparing method has simple process and low cost. And it has application values in the fields, such as chemical synthesis, dynamic monitoring of various power stations and waste management.

Owner:ZHEJIANG UNIV

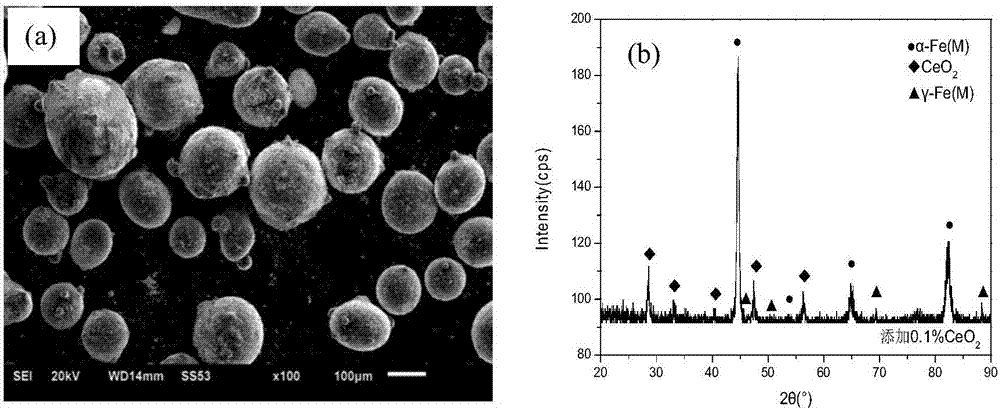

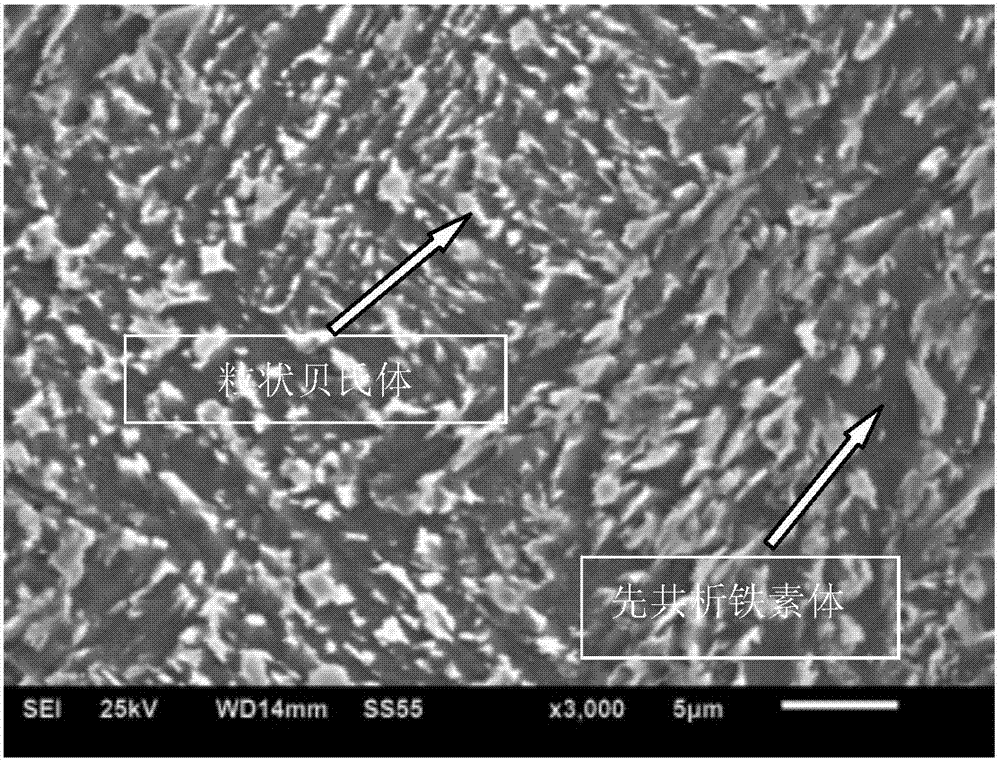

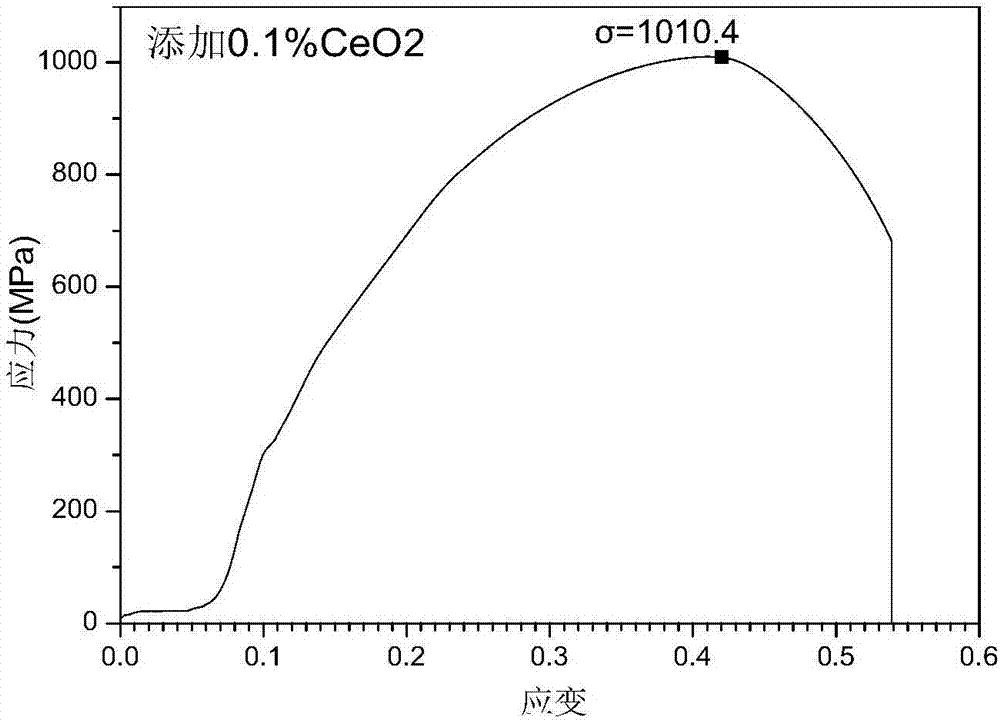

Method for preparing toughened 24 CrNiMo alloy steel through selective laser melting technology

ActiveCN107498054AImprove toughnessImprove mechanical propertiesAdditive manufacturing apparatusBraking discsMelting tankSelective laser melting

The invention relates to a method for preparing toughened 24 CrNiMo alloy steel through a selective laser melting technology. The method is characterized in that 24CrNiMo / CeO2 composite powder with a determined mass ratio and a uniform phase is prepared through mechanical ball-milling; and an alloy steel component is quickly formed layer by layer according to a predetermined selective laser melting path and process parameters. Through actions of refining crystalline grains, purifying a molten pool and the like in the laser molten pool through CeO2, samples which have small structures and are free of obvious defects such as cracks and pores are formed; and a selective laser melting process with large power, a great powder paving thickness and lower scanning speed is adopted, so that the forming rate is increased. A 24CrNiMo alloy steel component has room-temperature tensile strength of 10000 MPa level, and has ductility of 20-26%, so that strength and toughness of 24 CrNiMo alloy steel prepared by the selective laser melting technology are improved. The method is mainly applied to laser additive manufacturing of a 24 CrNiMo alloy steel high-speed railway brake disc.

Owner:NORTHEASTERN UNIV

Photovoltaic modules having reduced weight

InactiveUS20100258183A1Reduce weightIncreased mechanical toughnessPV power plantsGlass/slag layered productsShadowingsThermal expansion

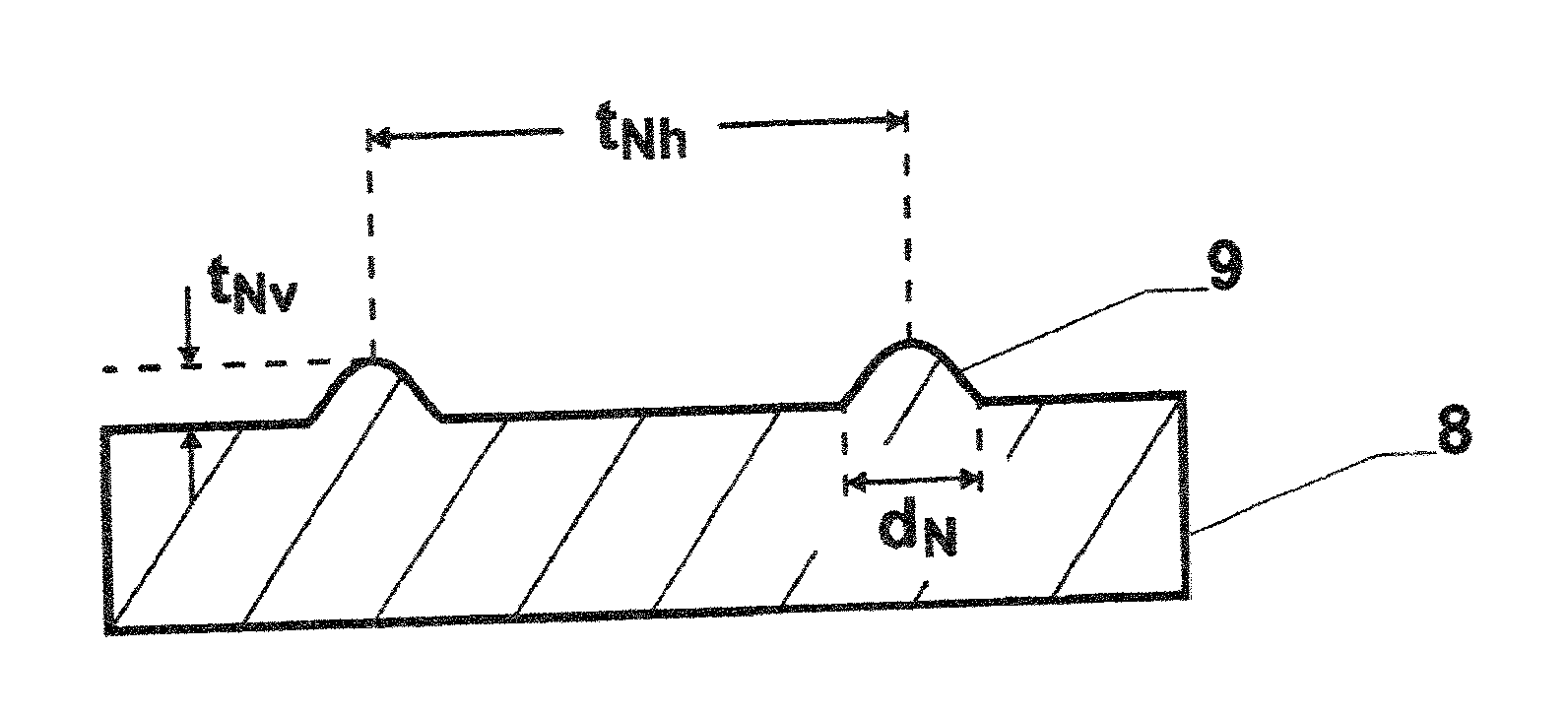

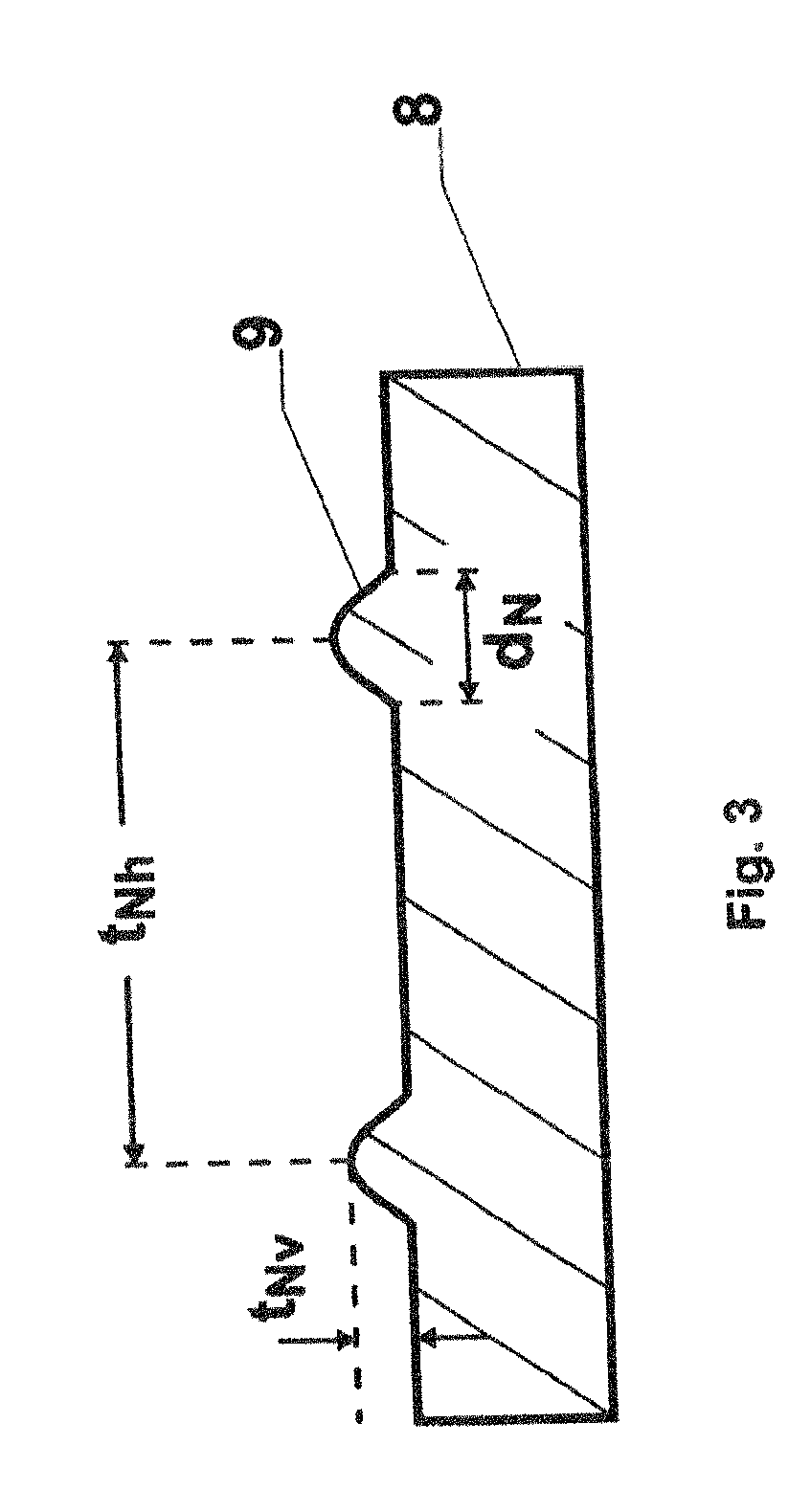

The construction principles according to the present invention make possible large sheet-like solar modules with low weight, which have great mechanical toughness, are inured to rough climatic environment influences and withstand thermal stress due to solar irradiation and shadowing effects. The solar modules have front and back panes, one of which has a thickness of at least 3 mm and the other of which has a thickness of at most 2 mm. The coefficient of thermal expansion of the thicker pane is preferably greater than that of the thinner pane. In preferred embodiments burling or a wavy structure is provided on one side of the front pane and / or the back pane.

Owner:SCHOTT AG

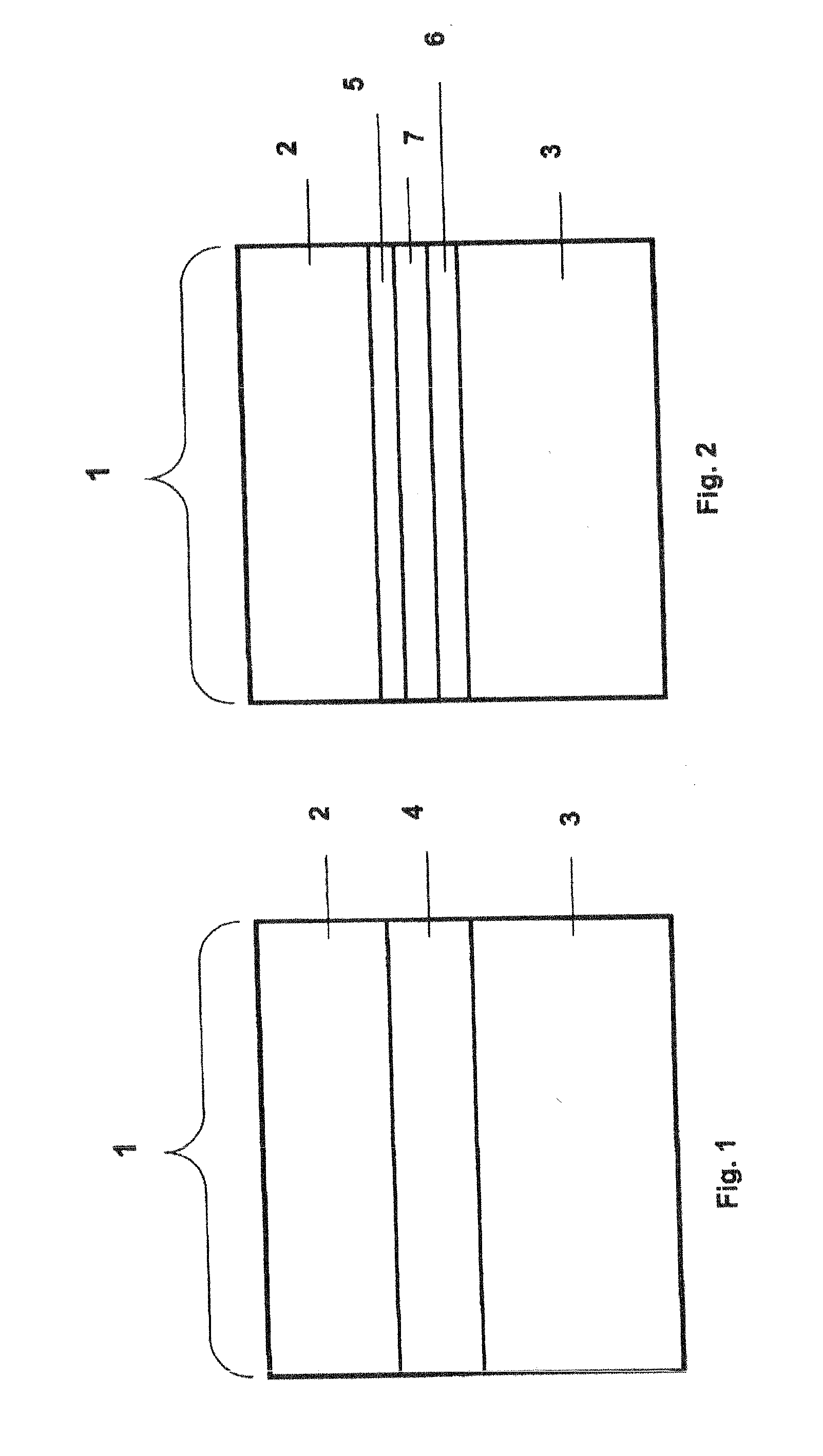

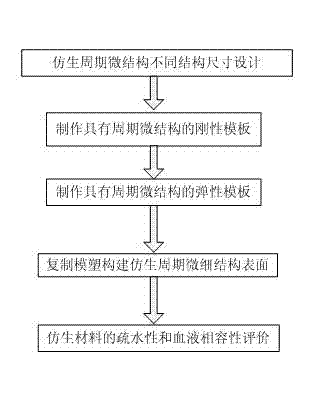

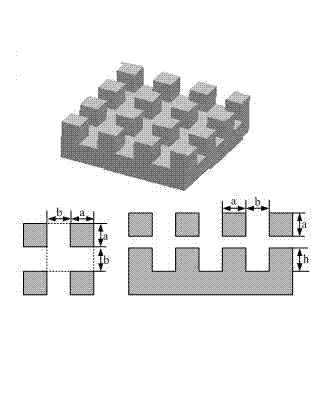

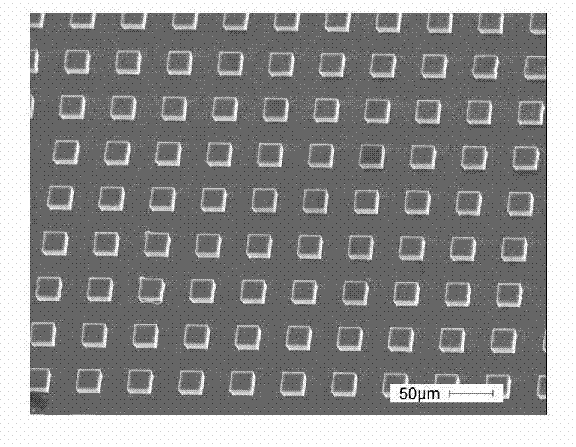

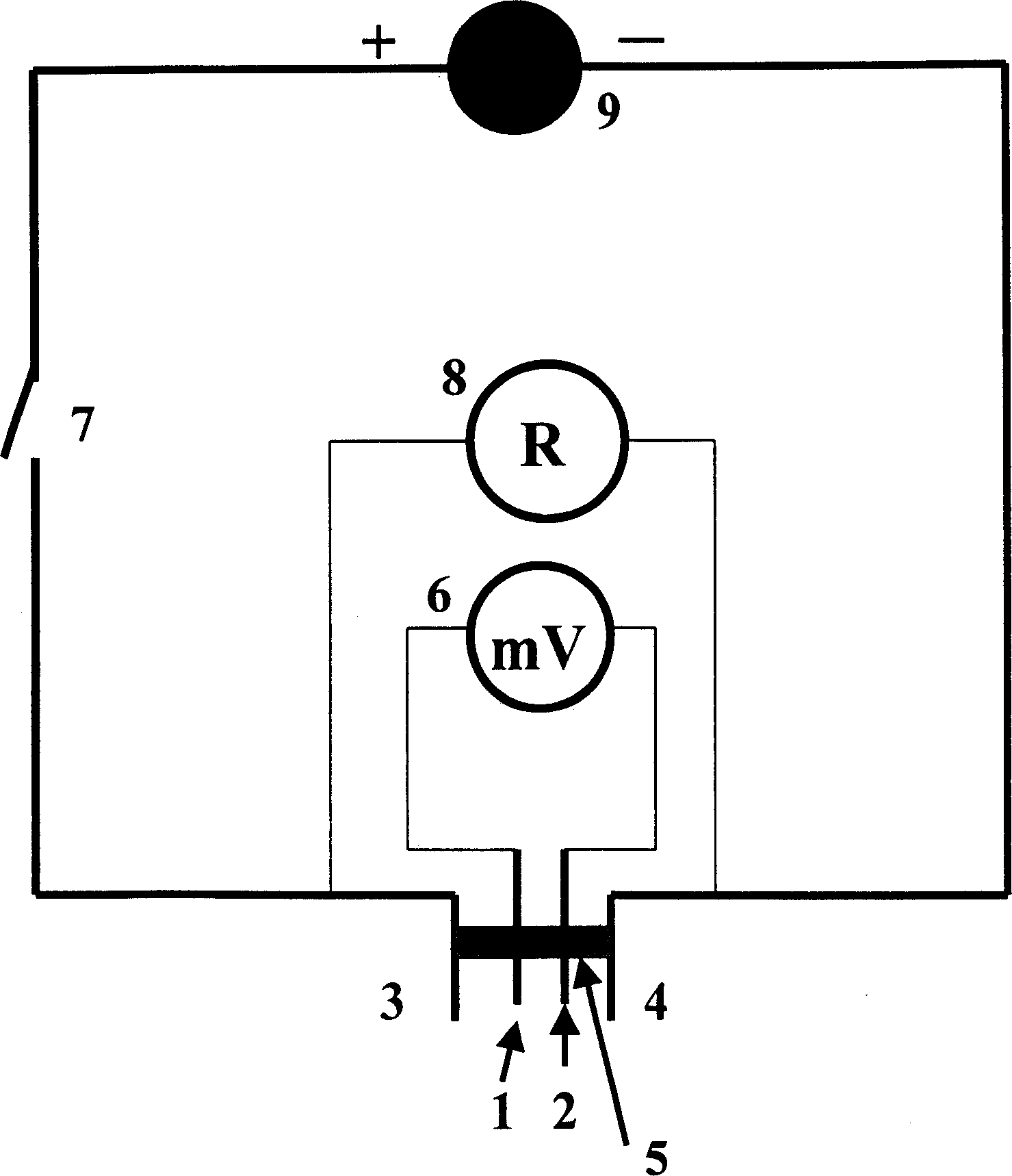

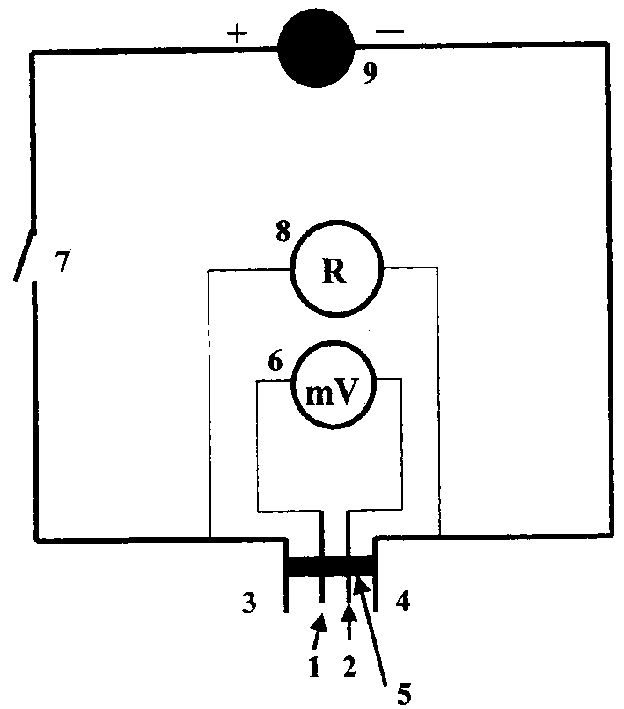

Method for constructing hemocompatible material surface with bionic periodic structure

The invention relates to a method for constructing a hemocompatible material surface with a bionic periodic structure. The method comprises the following steps of: deducing a theoretical prediction formula of surface appearance contact angle of the periodic micro-structure surface according to a micro-pillar surface model, and determining whether the designed micro-structure surface has ideal super-hydrophobicity according to the formula; etching to form a micro-pillar hard template with array structure according to the periodic micro-structure, casting PDMS (polydimethylsiloxane) on the hard template, allowing cross-linking and curing of the PDMS, and stripping off the cured film as an elastic template; and casting a prepolymer on the elastic template, and curing to form a micro-pattern on the polymer surface, which is complementary to the elastic template but similar to the original template. The bionic hemocompatible material constructed by the invention can effectively inhibit adhesion and deformation of platelets, prevent activation of coagulation pathway and increase duration of anticoagulation. Besides, the wetting property of the interface is improved by reasonable regulation of surface geometric dimension, so that the hemocompatibility of the material is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Integrated type dissolved oxygen, PH and salinity sensor and its manufacturing method and use method

InactiveCN1493874AReduce volumeHigh mechanical strengthMaterial electrochemical variablesElectrical resistance and conductancePotential difference

An integrated dissolved oxygen, pH and salinity sensor is composed of working Ir / IrO2 electrode, reference Ag / AgCl electrode, metallic anode and metallic cathode. Its application method features that when external electric field is cut off, the potential difference V1 between said working electrode and reference electrode is relative to the pH value of the solution to be measured, and when an external electric field is applied, the electric resistance of the solution between said anode and cathode is relative to the salinity of said solution while said potential difference is changed from V1 to V2. The V2-V1 is relative to the content of oxygen dissolved in solution.

Owner:ZHEJIANG UNIV

Sounding device and sounding component

The invention relates to a sounding device, which comprises an electromagnetic signal input device and a sounding component, wherein the sounding component comprises at least a carbon nanotube membrane including a plurality of preferred orientation arranged carbon nanotube and contacting with a medium; the electromagnetic signal input device transmits electromagnetic signal to the carbon nanotubemembrane which heats through adsorbing the electromagnetic signal, so as to heat the medium to send out sound wave. The invention also relates to a sounding component.

Owner:TSINGHUA UNIV +1

Super-hydrophobic coating material, a preparation method thereof, a super-hydrophobic coating and preparation method thereof

The invention discloses super-hydrophobic coating material and a preparation method thereof, and discloses a super-hydrophobic coating and a preparation method thereof. The super-hydrophobic coating material is prepared from the following raw material components in parts by mass: 10-30 parts of a curing agent, 10-30 parts of epoxy resin, 80-120 parts of polytetrafluoroethylene powder, 0-10 parts of fluoropolymer, 10-30 parts of zinc oxide and 40-80 parts of a solvent, wherein the curing agent is prepared by carrying out a fluorination reaction on diethylenetriamine and heptafluorobutyric acidin a mass ratio of 1:2. The super-hydrophobic coating is prepared from the super-hydrophobic coating material. The super-hydrophobic coating material has the advantages of excellent super-hydrophobicperformance, strong weather resistance and the like, can be used for preparing the super-hydrophobic coating, and has relatively high use value and a relatively good application prospect. The preparation method of the super-hydrophobic coating has the advantages of being simple in process, convenient to operate and the like, can prepare the super-hydrophobic coating with excellent self-hydrophobicanti-icing performance on a large scale, and facilitates industrial application.

Owner:国家能源集团龙源江永风力发电有限公司

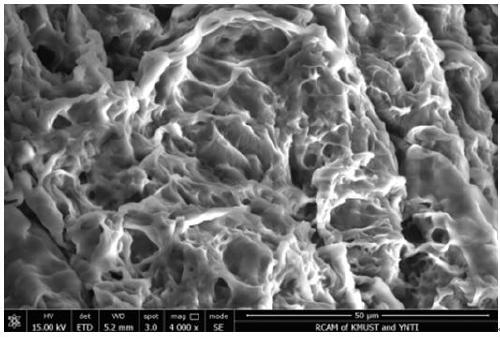

Composite hydrogel material and preparation method thereof

The invention discloses a composite hydrogel material and a preparation method thereof. The composite hydrogel material is a sponge-shaped hydrogel material prepared through the compositing of polyvinyl alcohol, chitosan and sodium hyaluronate. Chitosan and sodium hyaluronate are taken as the raw materials, polyvinyl alcohol is added, and physically cross-linked polyvinyl alcohol / chitosan / sodium hyaluronate composite hydrogel is prepared by virtue of a freezing and thawing cycle method. The preparation process is short in flow, the method is simple and convenient, and the prepared composite hydrogel contains natural polysaccharide chitosan and has active mold resistance; and the hydrogel material has good mechanical properties, tenacity and biocompatibility and can be degraded in a livingbody, and the physically cross-linked hydrogel material has huge application potentials in the fields of artificial skin, skin dressings, medicine carrying, cartilage repair, cancellous bone micro-defects and the like.

Owner:KUNMING UNIV OF SCI & TECH

Electrochemical sensor of hydrogen in extreme environment

InactiveCN1376916AReduce volumeHigh mechanical strengthMaterial electrochemical variablesChemical synthesisHydrogen sensor

An electrochemical hydrogen sensor used in extreme environmental has a metal electrode and a reference metal / metal oxide electrode. Said metal electrode is a metal ring made of Pt, Pd, Ru, Ir, or Au.Said reference electrode has a metal wire with active oxide film on its surface. Its advantages are small size, high mechanical strength, wide application range and low cost.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com