Composite hydrogel material and preparation method thereof

A composite hydrogel and hydrogel technology, applied in the field of biomedical materials, can solve the problems of hydrogel application limitations, achieve superior water absorption, good ventilation, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

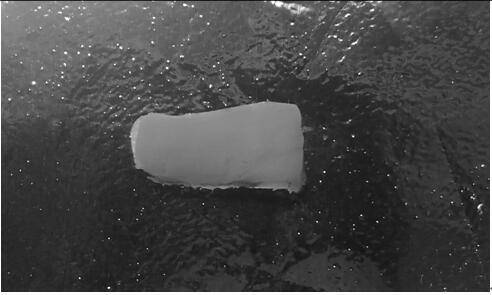

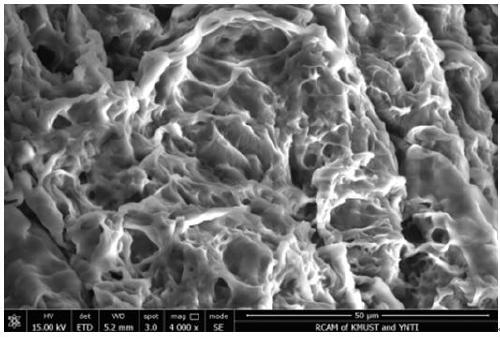

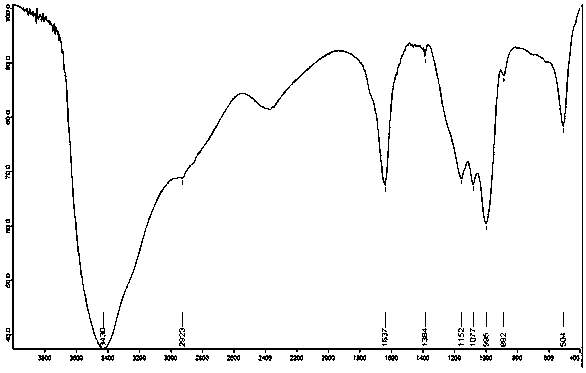

[0031] A composite hydrogel material is a spongy hydrogel material compounded by polyvinyl alcohol, chitosan and sodium hyaluronate.

[0032] The preparation method of this composite hydrogel material, concrete steps are as follows:

[0033] (1) According to chitosan and dilute acetic acid The solid-to-liquid ratio g:mL is the ratio of 1:50, chitosan is added to the dilute acetic acid whose mass percent concentration is 1%, magnetic stirring is mixed evenly, and mixture A is obtained;

[0034] (2) Dissolve sodium hyaluronate in deionized water according to the solid-to-liquid ratio g:mL of sodium hyaluronate and deionized water is 1:50, and mix evenly with magnetic stirring to obtain mixture B;

[0035] (3) According to mixture A and The volume ratio of mixture B is 1:2, and mixture A in step (1) is added to mixture B in step (2) to obtain mixture C;

[0036] (4) Using phosphoric acid with a mass fraction of 5% to adjust the pH value of the mixture C in step (3) to 2, and ...

Embodiment 2

[0042] A composite hydrogel material is a spongy hydrogel material compounded by polyvinyl alcohol, chitosan and sodium hyaluronate.

[0043] The preparation method of this composite hydrogel material, concrete steps are as follows:

[0044] (1) According to chitosan and dilute acetic acid The solid-liquid ratio g:mL is the ratio of 1:80, chitosan is added in the dilute acetic acid that mass percent concentration is 0.5%, magnetic stirring is mixed uniformly, obtains mixture A;

[0045] (2) Dissolve sodium hyaluronate in deionized water according to the solid-to-liquid ratio g:mL of sodium hyaluronate and deionized water is 1:100, and mix evenly with magnetic stirring to obtain mixture B;

[0046] (3) According to mixture A and The volume ratio of mixture B is 1:3, and mixture A in step (1) is added to mixture B in step (2) to obtain mixture C;

[0047] (4) Using phosphoric acid with a mass fraction of 10% to adjust the pH value of the mixture C in step (3) to 1, and magne...

Embodiment 3

[0054] A composite hydrogel material is a spongy hydrogel material compounded by polyvinyl alcohol, chitosan and sodium hyaluronate.

[0055] The preparation method of this composite hydrogel material, concrete steps are as follows:

[0056] (1) According to chitosan and dilute acetic acid The solid-liquid ratio g:mL is the ratio of 1:100, chitosan is added in the dilute acetic acid that mass percent concentration is 3%, magnetic stirring is mixed uniformly, obtains mixture A;

[0057] (2) Dissolve sodium hyaluronate in deionized water according to the solid-to-liquid ratio g:mL of sodium hyaluronate and deionized water is 1:80, and mix evenly with magnetic stirring to obtain mixture B;

[0058] (3) According to mixture A and The volume ratio of mixture B is 1:0.5, and mixture A in step (1) is added to mixture B in step (2) to obtain mixture C;

[0059] (4) Using phosphoric acid with a mass fraction of 8% to adjust the pH value of the mixture C in step (3) to 4, and magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com