Graphene oxide ultra-high performance concrete with low cement consumption and preparation method thereof

A low-cement, ultra-high-performance technology, applied in the field of building materials, can solve the problems of large cement consumption, high preparation cost, and reduced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

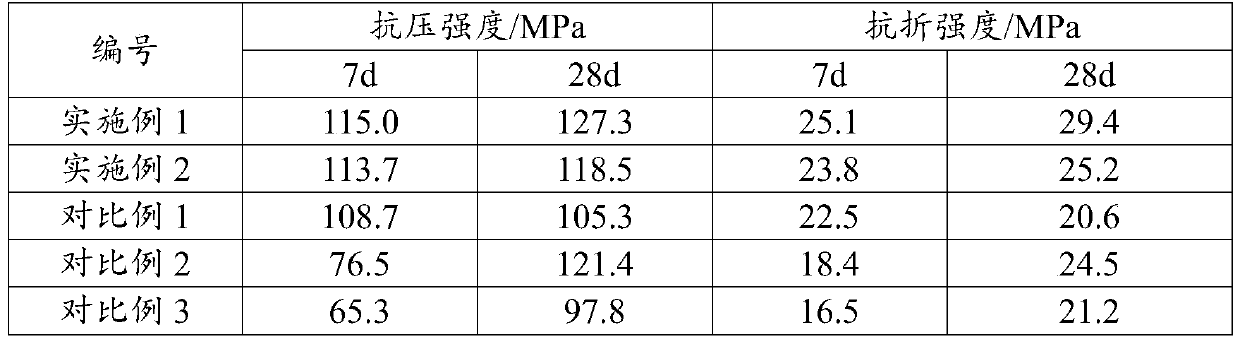

Examples

Embodiment 1

[0025] The raw materials used in this embodiment are as follows:

[0026] Cement: P.O.42.5 Ordinary Portland Cement.

[0027] Silica fume: the appearance is off-white, the average particle size is 100 nanometers, and the specific surface area is greater than 16x10 4 cm 2 / g.

[0028] Fly ash: Class I fly ash;

[0029] Slag powder: S95 grade granulated blast furnace slag powder;

[0030] Quartz sand: close packing density is 1800Kg / m 3 According to the particle size, it can be divided into coarse sand, medium sand and fine sand. The mass ratio of sand: medium sand: fine sand is 1:0.72:0.58;

[0031] Steel fiber: straight copper-plated microwire steel fiber, the length is 14mm, the diameter is 0.2mm, and the tensile strength is 1000Mpa.

[0032] Water reducing agent: polycarboxylate water reducing agent, water reducing rate is 40%;

[0033] Graphene oxide: the in-plane diameter is 1.5 μm, the monolayer ratio is 91%, and the average thickness is 1.1 nm.

[0034] The prep...

Embodiment 2

[0039] The raw materials used in this embodiment are as follows:

[0040] Cement: P.O.42.5 Ordinary Portland Cement.

[0041] Silica fume: the appearance is off-white, the average particle size is 100 nanometers, and the specific surface area is greater than 16x10 4 cm 2 / g.

[0042] Fly ash: Class I fly ash;

[0043] Slag powder: S95 grade granulated blast furnace slag powder;

[0044] Quartz sand: close packing density is 1800Kg / m 3 According to the particle size, it can be divided into coarse sand, medium sand and fine sand. The mass ratio of sand: medium sand: fine sand is 1:0.81:0.75.

[0045] Steel fiber: straight copper-plated microwire steel fiber with a length of 13mm, a diameter of 0.22mm, and a tensile strength of 900Mpa.

[0046] Water reducing agent: polycarboxylate water reducing agent, water reducing rate is 50%.

[0047] Graphene oxide: the in-plane diameter is 2 μm, the monolayer ratio is 91%, and the average thickness is 1.2 nm.

[0048] The preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com