Patents

Literature

35results about How to "Improve knot strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

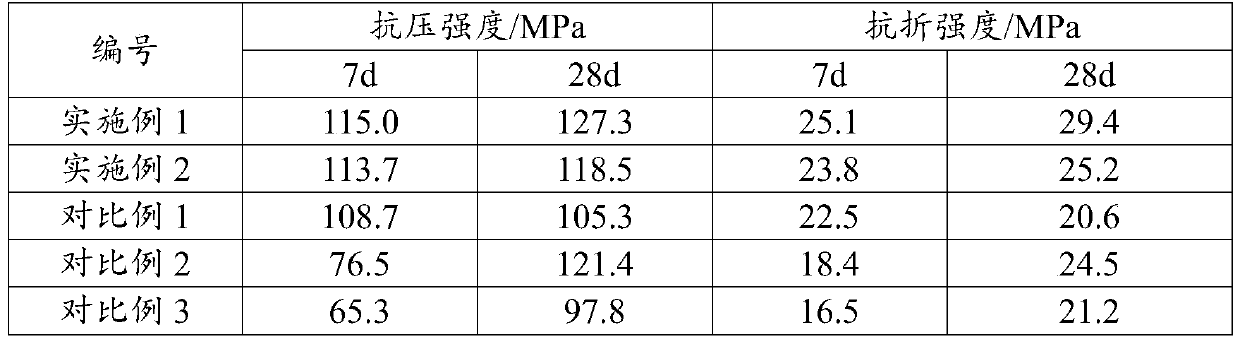

Graphene oxide ultra-high performance concrete with low cement consumption and preparation method thereof

InactiveCN111377687AImprove early strengthIncrease late strengthBreaking strengthUltimate tensile strength

The invention provides graphene oxide ultra-high performance concrete with low cement consumption, which belongs to the technical field of building materials. The concrete comprises the following components in parts by weight: 100 parts of cement, 30-50 parts of silica fume, 60-120 parts of fly ash, 10-50 parts of slag powder, 80-120 parts of quartz sand, 30-50 parts of water, 20-50 parts of steelfiber, 2-10 parts of a water reducing agent and 1-10 parts of graphene oxide. The invention also provides a preparation method of the ultra-high performance concrete. The graphene oxide is compoundedwith the steel fiber concrete doped with the mineral fine powder, and the graphene oxide can promote cement hydration, improve the early and later strength of the concrete, improve the interface conditions of a matrix and steel fibers and improve the binding strength of the matrix and the steel fibers, so that the breaking strength of the concrete is improved. The graphene oxide can improve the pore structure of the concrete, so that the concrete is denser, the strength of the concrete is improved, concrete strength shrinkage caused by steam curing is avoided, and the durability of the concrete is further improved.

Owner:重庆高途新材料科技有限公司

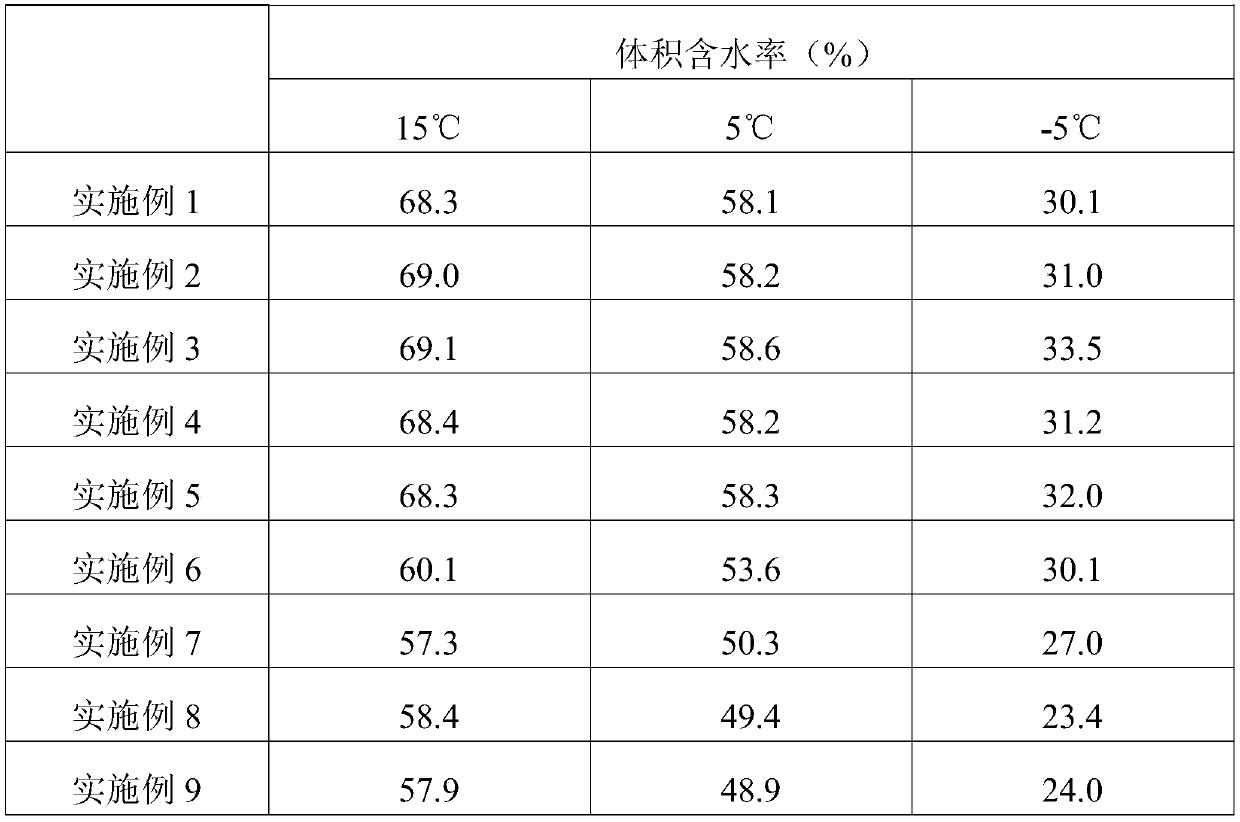

Preparation method of spiced beef with good mouthfeel

InactiveCN105918886AReduce heat and drynessReduce greasy feelingFood ingredient functionsIce waterSoya sauce

The invention discloses a preparation method of spiced beef with good mouthfeel, which comprises the following steps: putting beef in flowing clear water for soaking until no watery blood separates out, and then draining the beef to obtain preprocessed beef; putting the preprocessed beef in an oven for drying, taking the beef out of the drying oven, jetting an injection into the beef, putting the beef in a rolling and rubbing machine for carrying out primary rolling and rubbing, then adding curing seasonings into the rolling and rubbing machine for carrying out secondary rolling and rubbing, taking the beef out of the rolling and rubbing machine, and carrying out low temperature standing to obtain the cured beef; putting blanched cow leg bones, fresh ginger, garlic cloves, fistular onion stalk and water in a boiling container for decocting, and carrying out filtering to obtain soup stock; adding cloves, tea leaves and the like into the soup stock, performing boiling, carrying out filtering, and then adding dark soy sauce, yeast extracts and the like, performing continuous boiling to obtain boiling liquid; and cutting the cured beef into cubes, blanching the beef cubes, then adding the blanched beef cubes into the boiling liquid for boiling to obtain spiced beef cubes, taking the spiced beef cubes out of the boiling liquid, putting the spiced beef cubes in ice water, after the boiling liquid is cooled to room temperature, putting the spiced beef cubes in the boiling liquid again, carrying out low temperature standing, and then putting the spiced beef cubes in the oven for baking to obtain the spiced beef with good mouthfeel.

Owner:FENGYANG COUNTY ZHONGDU FOOD CO LTD

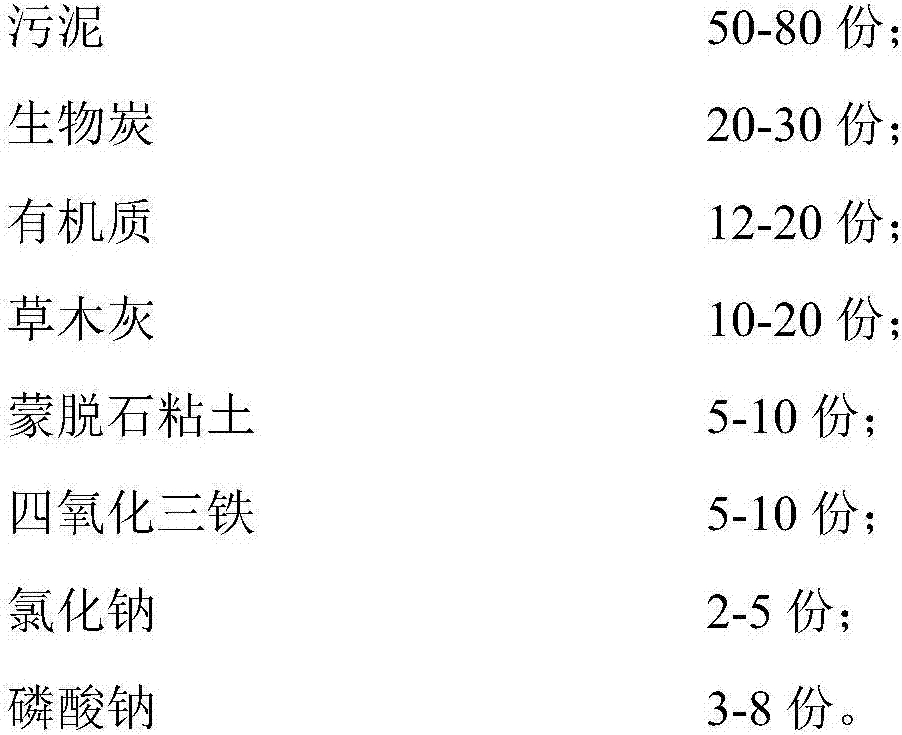

Heavy metal contaminated soil remediation agent, application thereof and contaminated soil remediation method

InactiveCN107282625AImprove fertilityIncrease ionic strengthContaminated soil reclamationSludgeSodium phosphates

The invention relates to a heavy metal contaminated soil remediation agent, application thereof and a contaminated soil remediation method. The heavy metal contaminated soil remediation agent comprises, by weight, 50-80 parts of sludge, 20-30 parts of biochar, 12-20 parts of organic matter, 10-20 parts of plant ash, 5-10 parts of montmorillonite clay, 5-10 parts of ferroferric oxide, 2-5 parts of sodium chloride and 3-8 parts of sodium phosphate, and preferably, the remediation agent further comprises 1-3 parts of humic acid. The invention further provides application of the heavy metal contaminated soil remediation agent and the contaminated soil remediation method. The heavy metal contaminated soil remediation agent avoids secondary pollution generated during heavy metal contaminated soil remediation, the remediation period is shortened, and the remediation effect is good.

Owner:BEIJING GEOENVIRON ENG & TECH

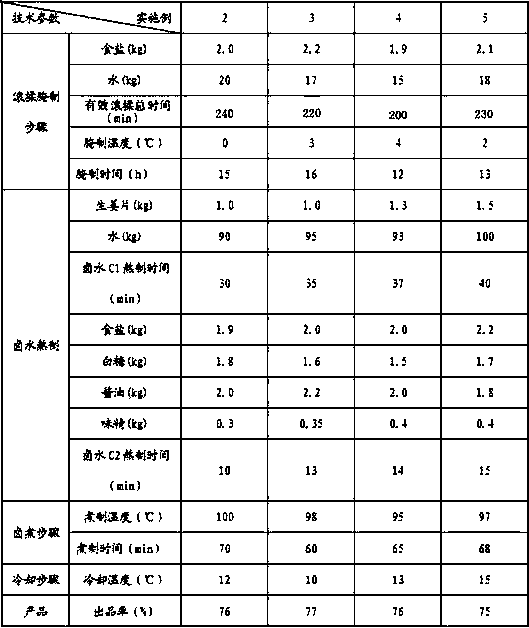

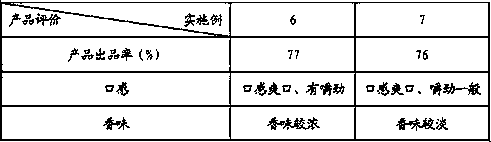

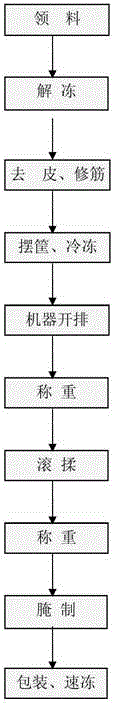

Preparation method of sauce-flavor spiced beef cube

InactiveCN105901529AAccelerated removal of fishy smellImprove fragrance evaporationFood thermal treatmentFood ingredient as flavour affecting agentCooking & bakingFlavor

The invention discloses a preparation method of sauce-flavor spiced beef cubes. The preparation method includes the steps of: 1) cutting beef into cubes, soaking the beef cubes in water, and draining the beef cubes to prepare pre-treated beef cubes; 2) crushing and boiling raw ginger, adding cooking wine with uniform mixing to obtain a soaking liquid; 3) mixing Chinese prickly ash, pericarpium citri reticulatae and the like with salt to prepare a pickling material; 4) drying the pre-treated beef cubes in a baking oven, soaking the beef cubes in the soaking liquid, adding the pickling material, uniformly mixing the mixture, tumbling the beef cubes in a tumbling machine and allowing the beef cubes to stand at low temperature to obtain pickled beef cubes; 5) adding clove, tea and the like to soup stock, adding dark soy sauce, salt and the like and continuously boiling the materials to obtain a boiling solution; 6) blanching the pickled beef cubes in hot water, adding the beef cubes to the boiling solution to obtain spiced beef cubes; 7) placing the spiced beef cubes in ice water, and when the boiling solution is cooled to room temperature, and allowing the spiced beef cubes to stand in the boiling solution at low temperature, baking the beef cubes, and adding the beef cubes into a sauce with uniform stirring, and baking the beef cubes to prepare the sauce-flavor spiced beef cubes.

Owner:FENGYANG COUNTY ZHONGDU FOOD CO LTD

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

Artificial hair and method for production thereof

InactiveUS20040074509A1Improve the coagulation effectHigh glossHair accessoriesToupeesWater basedPolymer science

The present invention provides synthetic hair comprising fiber of 30 to 100 decitex, comprising an acrylic copolymer obtained by copolymerizing acrylonitrile, vinylidene chloride and a vinyl monomer containing a sulfonic acid group and a process for preparing the synthetic hair. The synthetic hair of the present invention has favorable surface gloss and excellent knot strength and hair breaking in the sewing machine steps when preparing the weft and in implanting hair to skin when preparing wigs and toupees is improved. The fiber which becomes the synthetic fiber is prepared by preparing a spinning solution containing, in a polymer solution of an acrylic polymer comprising 40 to 74% by weight of acrylonitrile, 25 to 59% by weight of vinylidene chloride and 1 to 5% by weight of a vinyl monomer containing a sulfonic acid group copolymerizable therewith and a good solvent, 5 to 20 parts by weight of water based on 100 parts by weight of the polymer, forming fiber by wet spinning, conducting drawing treatment so that the total drawing ratio becomes 2.5 to 12 times and conducting relaxing treatment so that the total relaxation ratio becomes at least 15%. By this method, synthetic hair is obtained, in which the gloss contrast is at least 0.88, the knot strength is at least 0.5 cN / decitex and the average fineness of the filament is 30 to 100 decitex.

Owner:KANEKA CORP

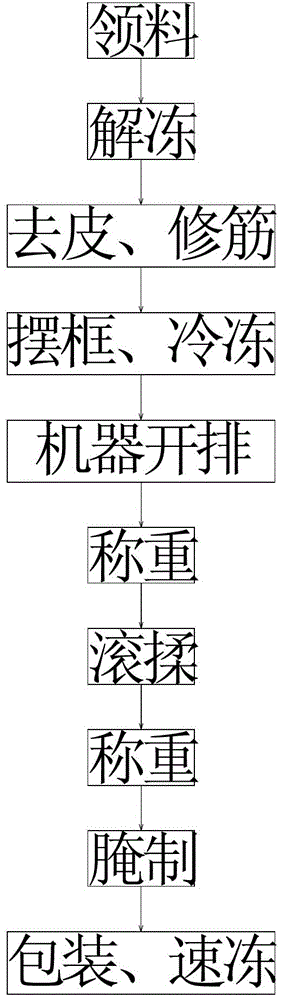

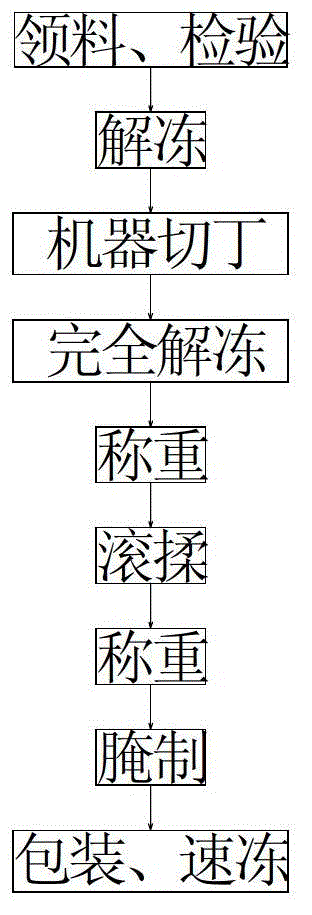

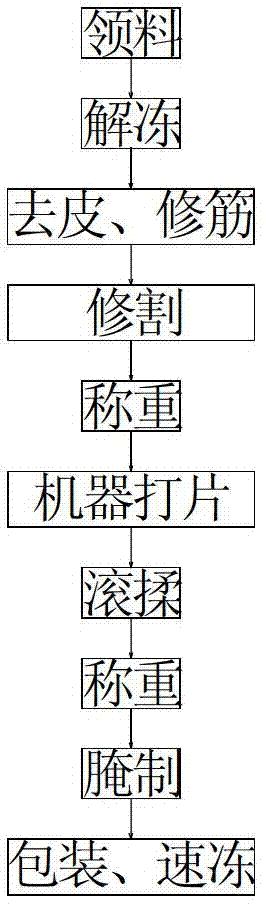

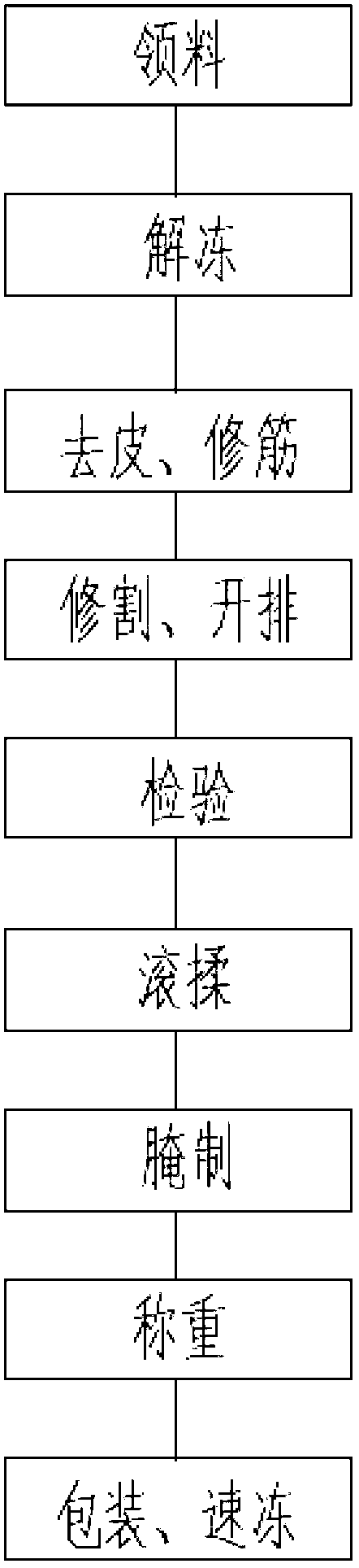

Preparation method for marinated pig knuckle

InactiveCN104082755AImprove knot strengthAvoid frictional heatFood thermal treatmentFood mechanical treatmentProcess engineeringShelf life

A disclosed preparation method for marinated pig knuckle comprises a step of selecting and finishing materials, a step of kneading and preserving, a step of stewing with a master stock, and a step of marinating, and the above steps are successively performed. The prepared product is uniform in internal and external flavor, stable in quality, uniform in color, rich and durable in fragrance, short in preparation period, less in pie knuckle fluid loss and long in shelf life. The yield of the product is 75% or more. The preparation method is applicable to production of marinated pig knuckle.

Owner:SHIJIAZHUANG JINKOU FOOD CO LTD

Water-soluble aluminum alloy drawing oil and preparation method thereof

The invention discloses a water-soluble aluminum alloy drawing oil. The water-soluble aluminum alloy drawing oil comprises, by mass, 20-40% of cycloalkyl base oil, 4.0-15.0% of a composite antirust agent, 9.0-20.0% of a composite alkali retention agent, 0.1-0.5% of a metal deactivator, 10-20% of a lubricant, 0.5-1.5% of a corrosion inhibitor, 2.0-3.0% of an emulsifier, 2.0-3.0% of a bactericide, 0.1-0.3% of an antifoaming agent, and the balance of deionized water. The water-soluble aluminum alloy drawing oil has the advantages of no toxicity, harmlessness, long service life, smooth metal cutting surface, excellent corrosion and rust resistance, applicability under high-pressure and high-speed processing conditions, small and few cutting foams, excellent water solubility, and avoiding of workpiece damages and use performance reduction, caused by cleaning of an aluminum alloy workpiece or generation of residues in the later period of processing.

Owner:浙江渤威能源科技有限公司

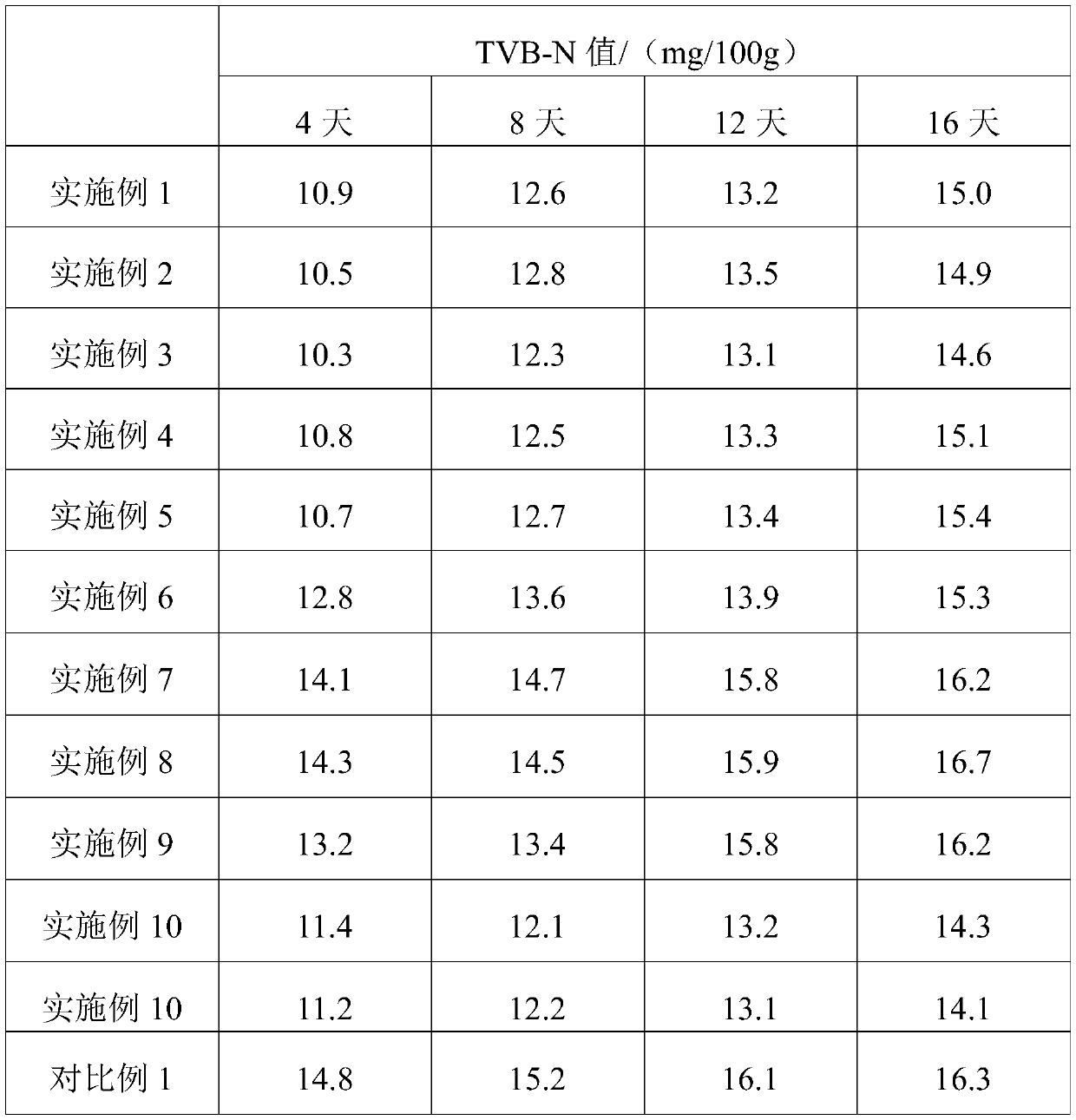

Black pepper beefsteak and preparation method thereof

InactiveCN102715519AImprove knot strengthImprove taste and section effectFood preparationSodium bicarbonateMonosodium glutamate

The invention relates to black pepper beefsteak and a preparation method thereof. The black pepper beefsteak is mainly prepared from the following components in part by weight: 950 to 1,050 parts of main material beef, 40 to 50 parts of starch, 15 to 20 parts of chicken essence, 15 to 20 parts of dark soy sauce, 14 to 16 parts of black pepper powder, 12 to 14 parts of white granulated sugar, 6 to 8 parts of salt, 6 to 8 parts of monosodium glutamate, 1.5 to 2 parts of white pepper powder and 5 to 8 parts of auxiliary material sodium bicarbonate. According to the invention, raw material standardization, product standardization and process standardization of the black pepper beefsteak can be realized.

Owner:SUZHOU HAODELAI FOOD

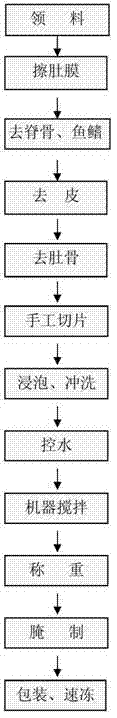

Paste-free fillets and preparation method thereof

PendingCN111567760APrevent oxidationStay nourishedFood mechanical treatmentFood ingredient as taste affecting agentBiotechnologyMonosodium glutamate

The invention provides paste-free fillets and a preparation method thereof. The paste-free fillets comprise the following raw materials in parts by weight: 800-1200 parts of fillets, 1-5 parts of ginger powder, 3-5 parts of salt, 3-5 parts of sugar, 3-5 parts of monosodium glutamate, 5-10 parts of cooking wine, 5-10 parts of starch, 5-10 parts of perilla juice and 1-5 parts of yeast extract. By reasonable proportioning and adding of the raw materials, the nutrition and flavor components of the seasoned fillets are effectively locked, the oxidation of fish fat is avoided, and the nutrition andtaste of seasoned fish kebabs are kept; by adjusting preparation process parameters, fresh and natural fishy smell is guaranteed, fish sections are rich in gloss, and fish muscle tissues are compact and complete, clear in texture, firm and elastic; and the paste-free fillets are a paste-free fillet product which conforms to the taste of the public.

Owner:海南蔚蓝海洋食品有限公司

Diced chicken gristle and preparation method thereof

InactiveCN102715535AImprove knot strengthImprove taste and section effectFood preparationChemistrySodium bicarbonate

The invention provides a diced chicken gristle and a preparation method thereof. The diced chicken gristle mainly comprises the following ingredients: 950 to 1050 parts of chicken, 340 to 360 parts of chicken gristle, 65 to 75 parts of green beans, 20 to 25 parts of spice, 15 to 20 parts of starch, 14 to 16 parts of essence of chicken, 2 to 4 parts of table salt, 8 to 10 parts of spicy pulp covering powder and 5 to 8 parts of sodium bicarbonate. According to the diced chicken gristle, the raw material standardization, the product standardization and the technology standardization of the diced chicken gristle can be achieved.

Owner:SUZHOU HAODELAI FOOD

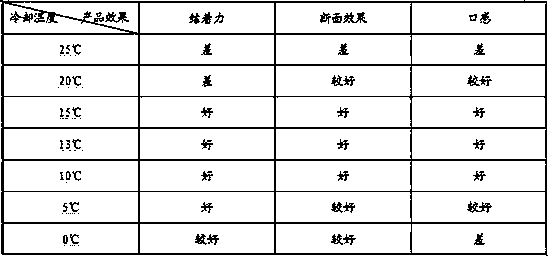

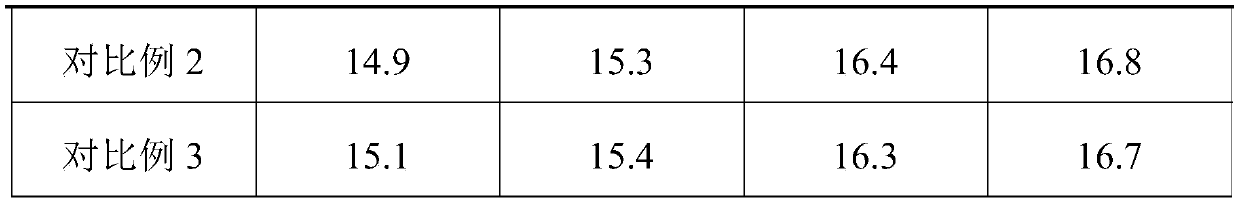

Making method for dried Luchuan port slice

InactiveCN105918896AImprove knot strengthQuality improvementFood ingredient functionsCooking & bakingNational standard

The invention provides a making method for a dried Luchuan port slice. The method comprises the steps of raw material selection, pre-processing, preparation of salting liquor, salting, spreading and screening, baking, roasting, packaging, inspection and the like. According to the making method for the dried Luchuan port slice, a variable temperature drying method is adopted for baking after salting, so that the peroxidation value of a product reaches a standard, and is low, nutritional components of Luchuan pork are completely preserved, the nutritional value of the product is increased, and the quality of the dried Luchuan port slice is improved; physiochemical detection index values are higher than the national standard and the industry standard, and the shelf life is longer; adopted salting materials interact in low-temperature salting, low-temperature baking and roasting processes, so that oil and fat are reduced, oily feel is eliminated, rancidification is inhibited, the acid value is reduced, the shelf life is prolonged, and the prepared dried Luchuan port slice is fragrant, crispy, sweet, delicious and long in aftertaste, and has special healthcare effects, lean pork is dark red, tender and slippery, and after dried Luchuan port slice is eaten, faint fragrance lingers in the mouth.

Owner:罗朝吉

Double-benefit beefsteak and preparation method thereof

The invention relates to double-benefit beefsteak and a preparation method thereof. The double-benefit beefsteak is mainly prepared from the following components in part by weight: 950 to 1,050 parts of main material beef, 15 to 20 parts of starch, 14 to 18 parts of chicken essence, 15 to 20 parts of light soy sauce, 6 to 8 parts of tasty king, 14 to 16 parts of white granulated sugar, 1.5 to 2 parts of salt, 15 to 18 parts of dark soy sauce, 3 to 4 parts of five spice powder, 6 to 8 parts of cumin powder, 1.5 to 2 parts of white pepper powder, 15 to 18 parts of oyster sauce and 5 to 8 parts of auxiliary material sodium bicarbonate. According to the raw material standardization, product standardization and process standardization of the double-benefit beefsteak can be realized.

Owner:SUZHOU HAODELAI FOOD

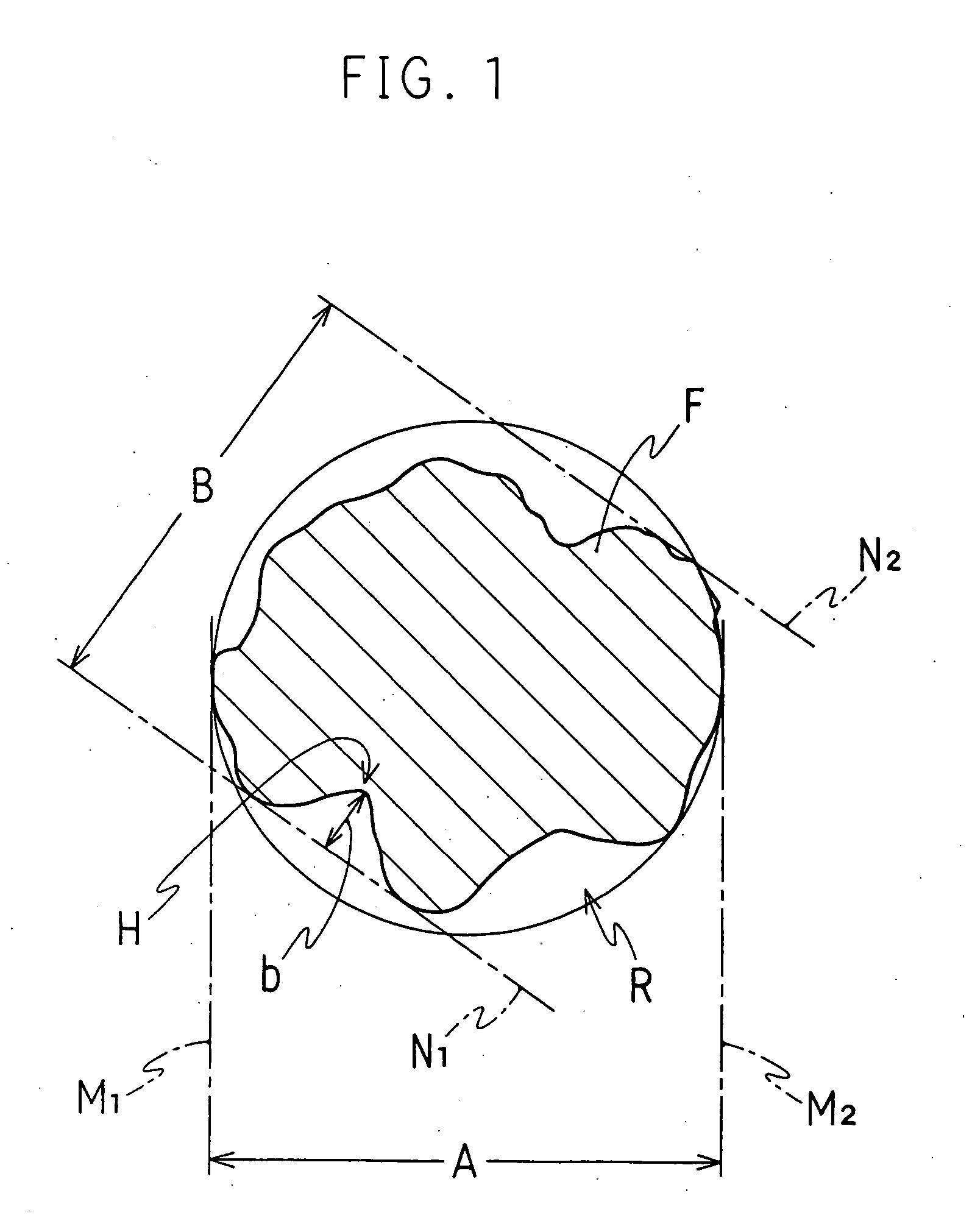

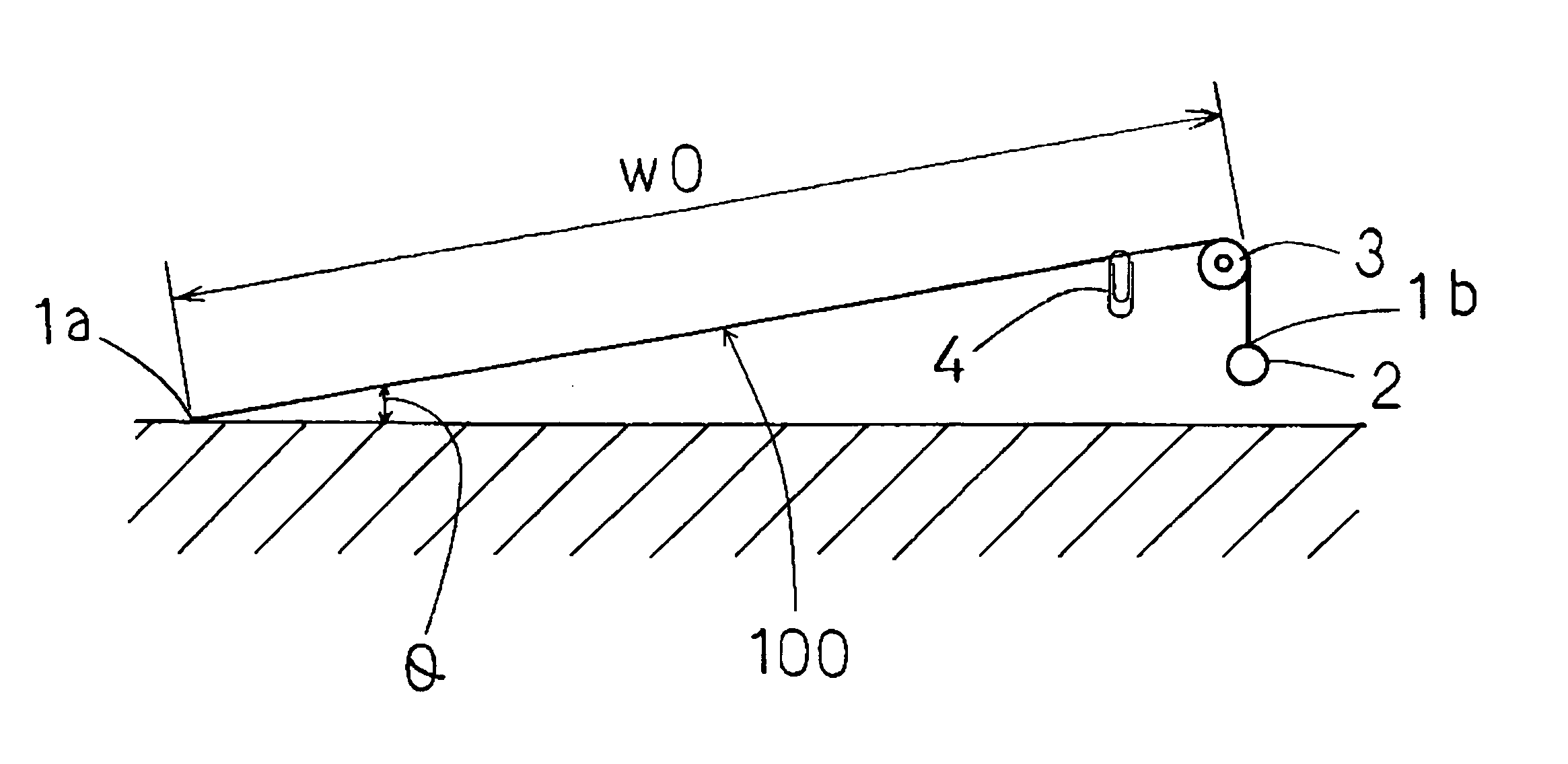

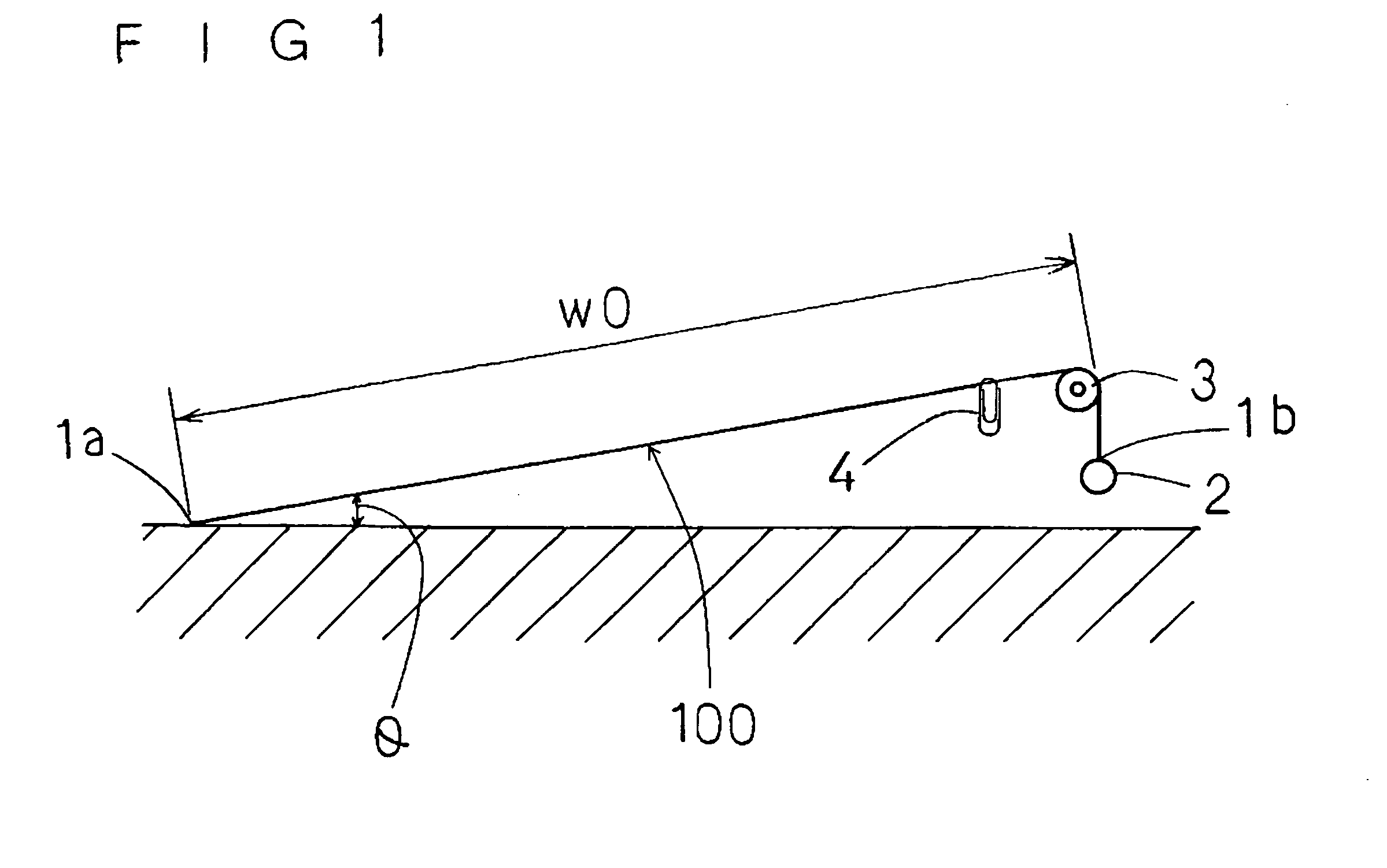

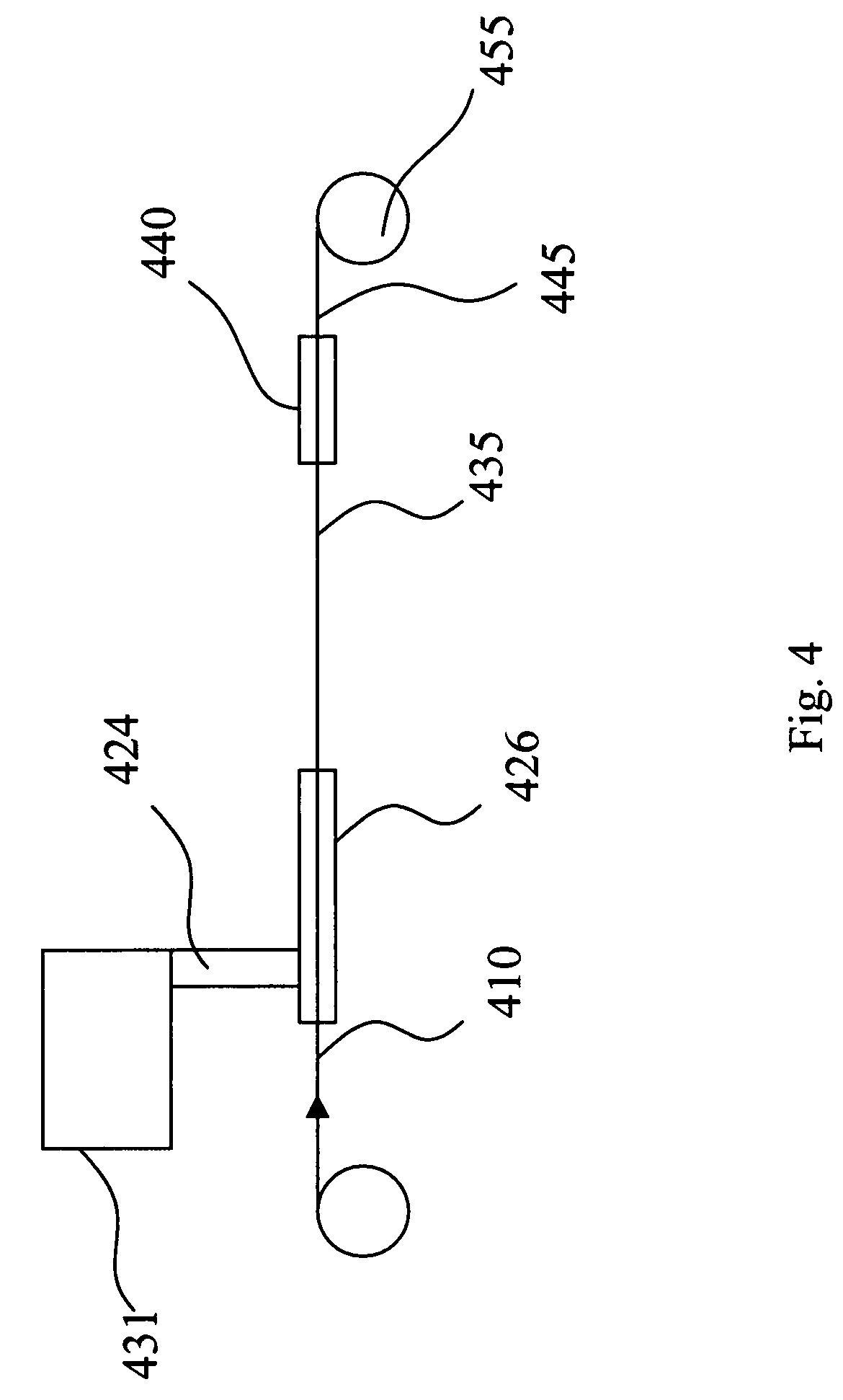

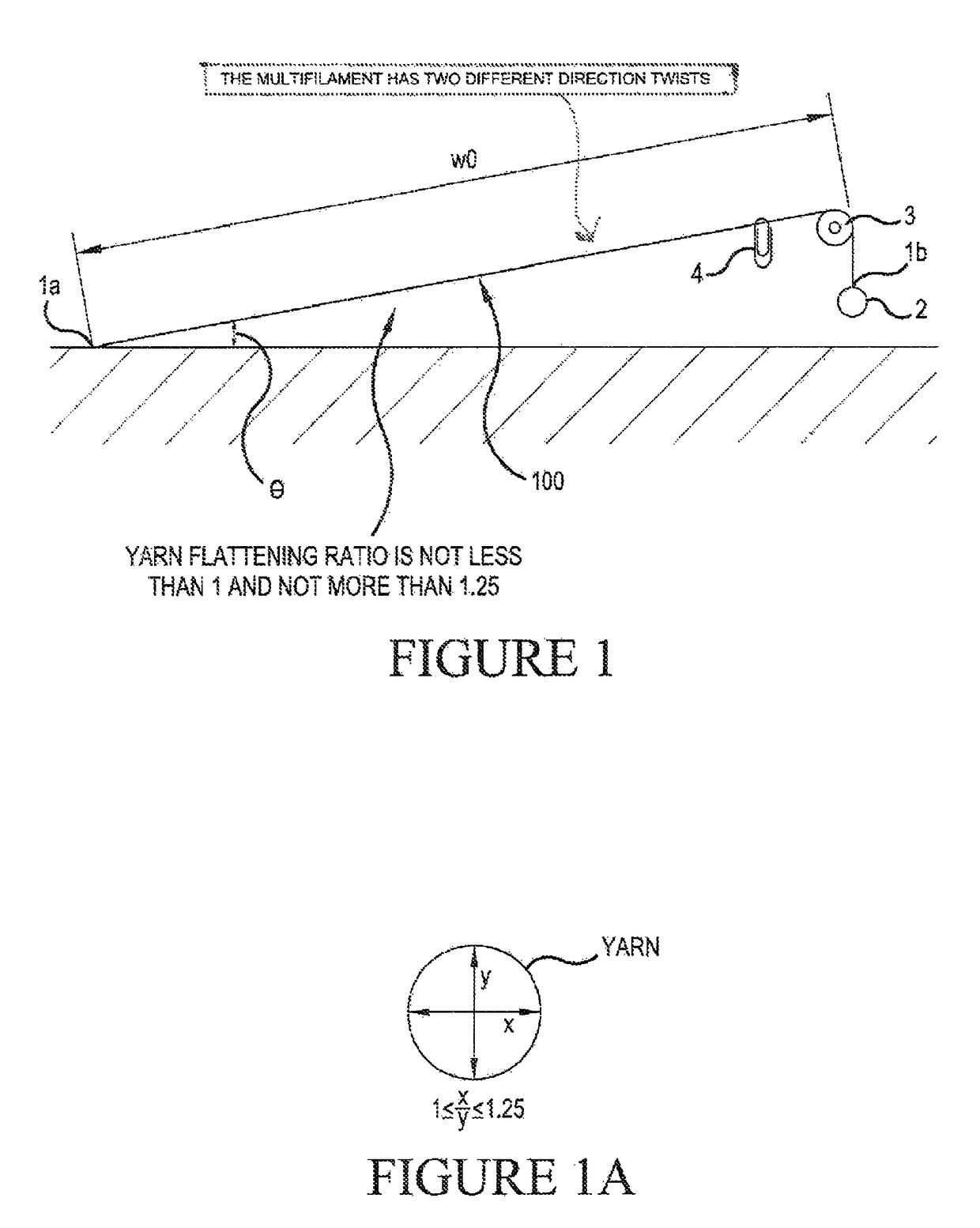

Yarn and Method for Manufacturing the Same

The present application of the invention aims at improving knot strength of a twisted yarn without compromising circularity, with respect to various yarns including a fishing line. For such purpose, the present application of the invention provides a yarn including a multifilament subjected to two twisting processes in different directions, and a coating resin that covers a surface of the multifilament; wherein the multifilament is subjected to a first twist in one direction, and then to a second twist in a direction opposite to that of the first twist, without being doubled with another yarn.

Owner:DUEL

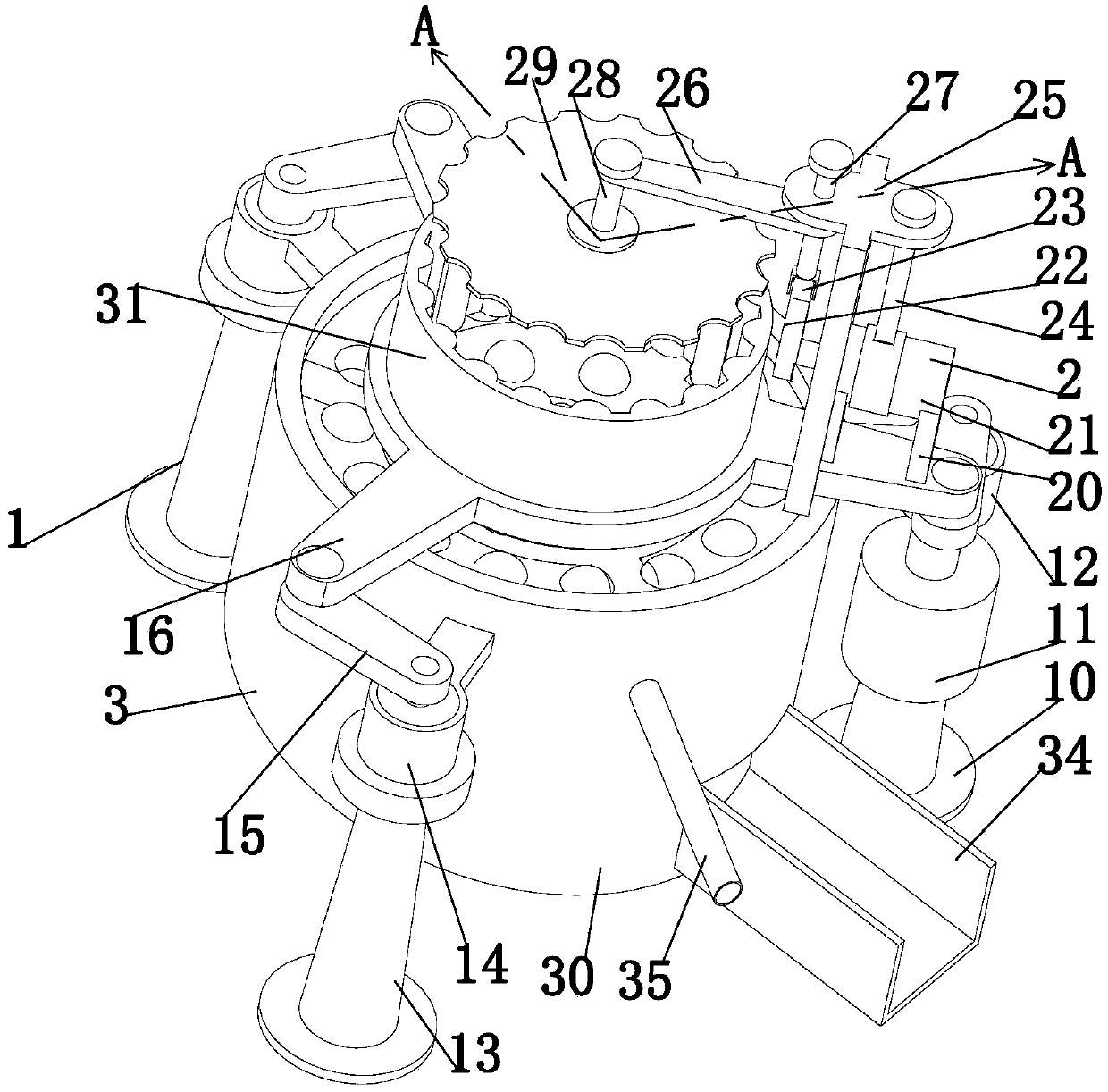

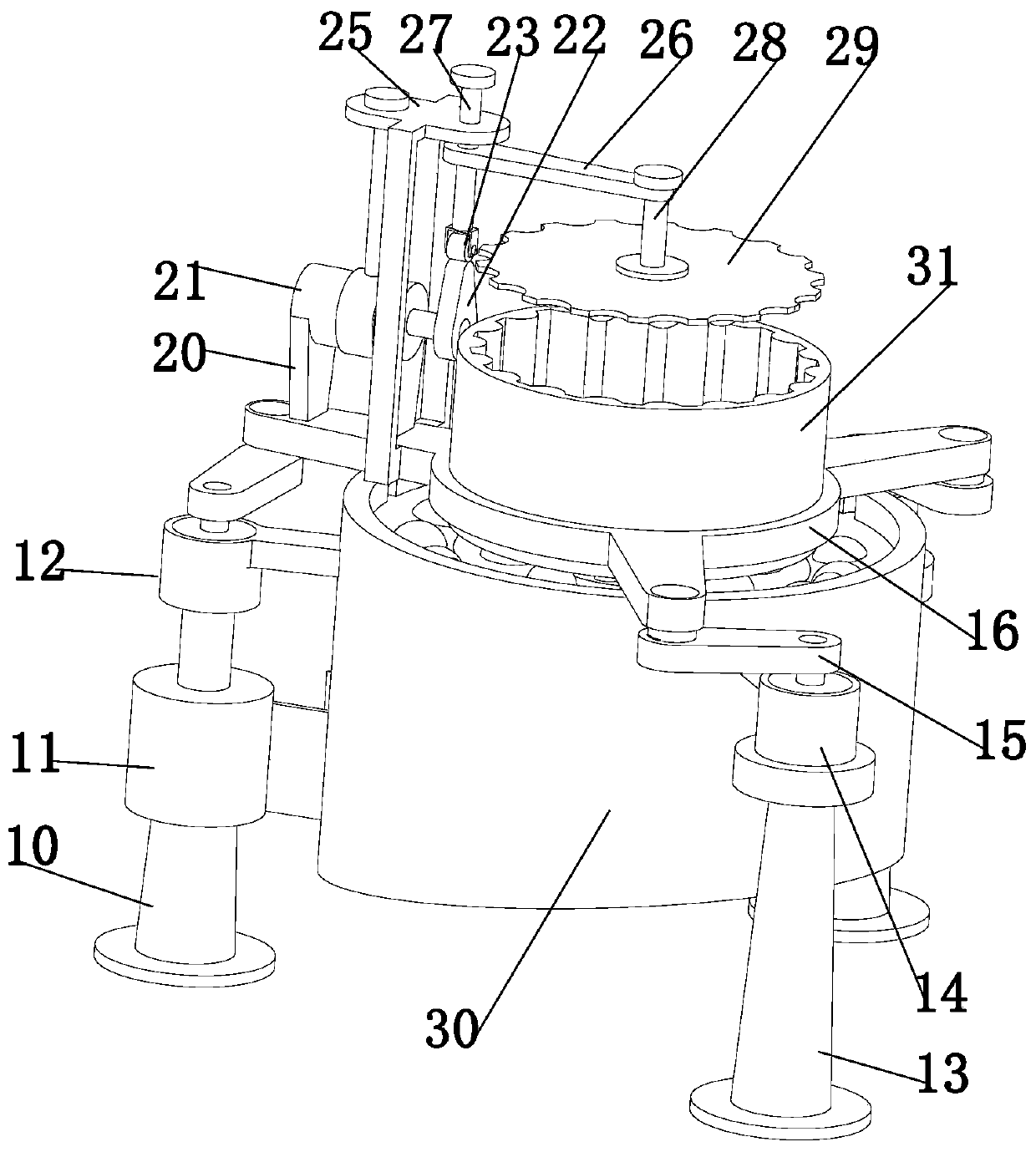

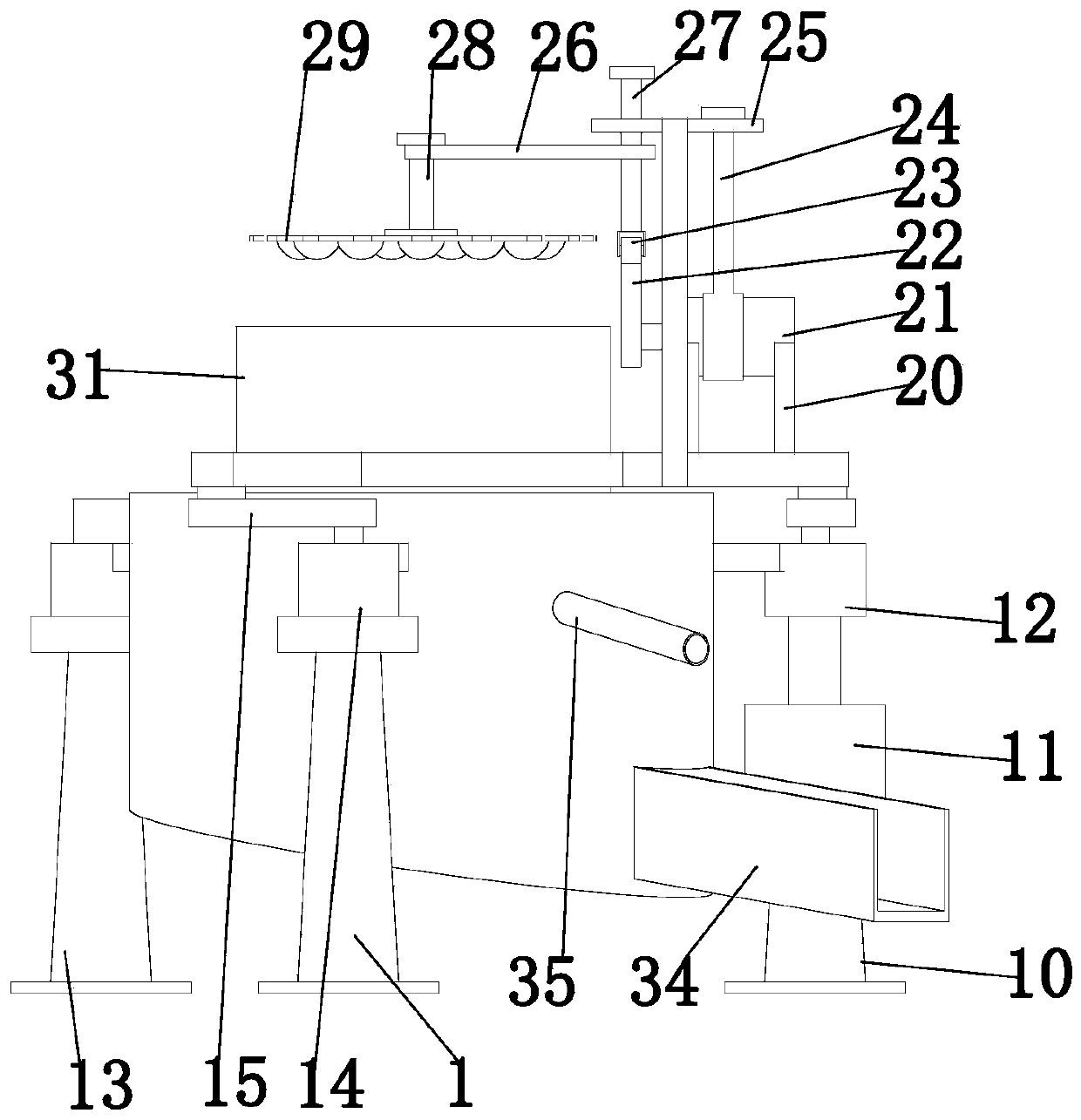

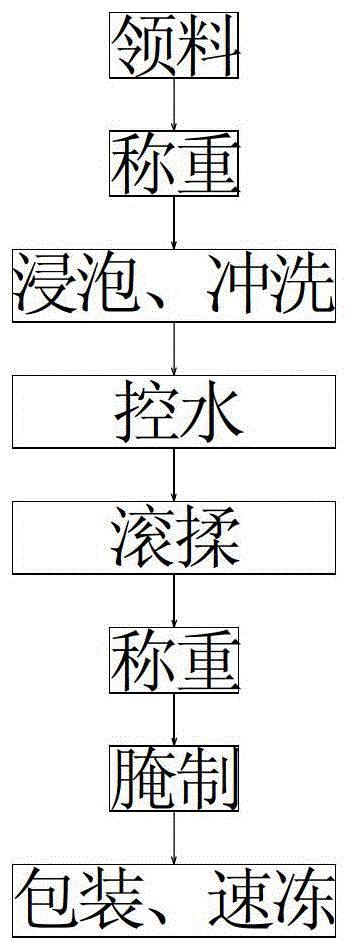

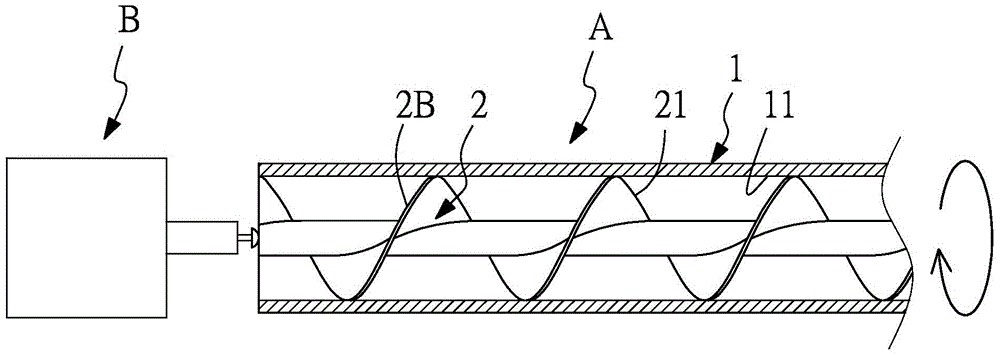

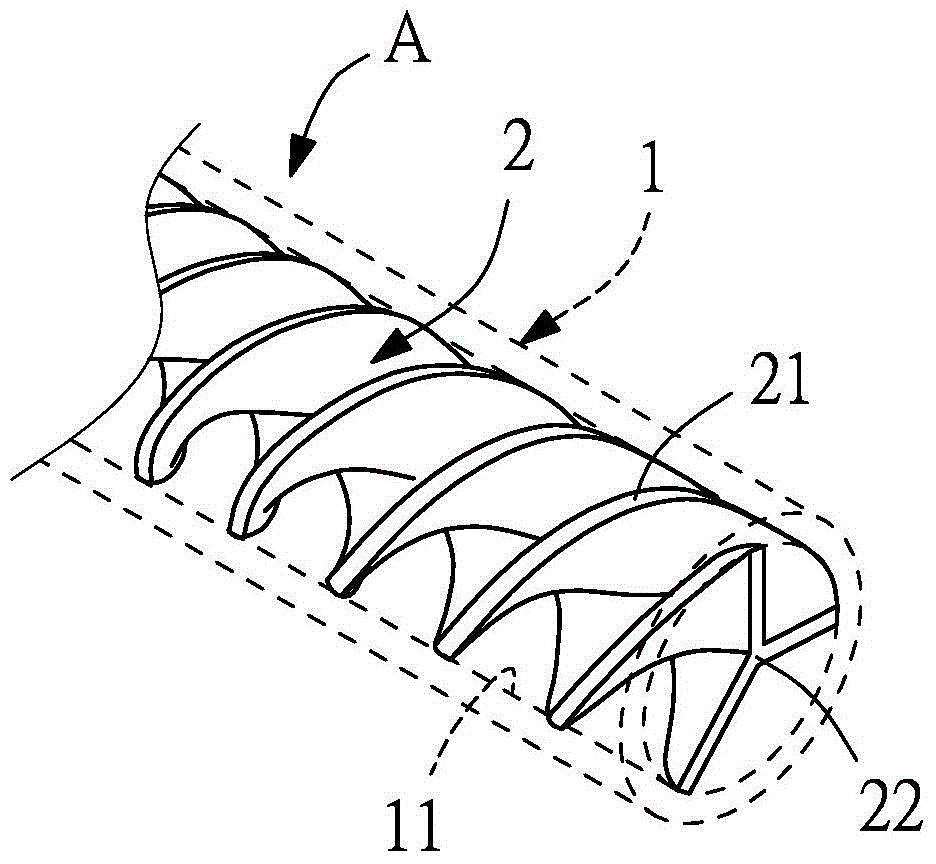

Tumbling device for pickling products

InactiveCN111000158AEvenly absorb pickleImprove knot strengthBeating-based meat tenderisingMassaging-based meat tenderisingIndustrial engineeringFood science

The invention provides a tumbling device for pickling products. The device comprises an actuating mechanism, a cam mechanism and a tumbling mechanism. The cam mechanism is mounted above the actuatingmechanism. The tumbling mechanism is arranged in the middle of the actuating mechanism. The tumbling mechanism is movably connected with the cam mechanism. According to the tumbling device provided by the invention, the problems that in the process of processing a meat product into pickled finished products, the meat product needs to be cleaned and diced firstly, and then beaten and loosened to relax fibers thereof, and more convenience is brought to follow-up flavoring work; a traditional meat beating and loosening process is manually carried out by workers; a large amount of time and a large amount of manpower are consumed in the whole process; the workers often lower the working requirements due to working fatigue; and customer complaints are caused due to the fact that the follow-up flavoring work of the meat product cannot meet expected requirements are solved.

Owner:ANHUI GUANGZHENG FOOD

Black-pepper beef and preparation method thereof

The invention relates to black-pepper beef and a preparation method thereof. The black-pepper beef is mainly prepared from 950-1050 parts by weight of beef as a main material, 20-25 parts of light soy sauce, 14-16 parts of chicken essence, 14-16 parts of starch, 10-12 parts of black-pepper powder, 7-9 parts of salt, 6-8 parts of white granulated sugar, 6-8 parts of flavor enhancer, 3-5 parts of white-pepper powder and 5-8 parts of sodium bicarbonate as auxiliary materials. By adopting the invention, the raw-material standardization, the product standardization and the process standardization of the black-pepper beef can be realized.

Owner:SUZHOU HAODELAI FOOD

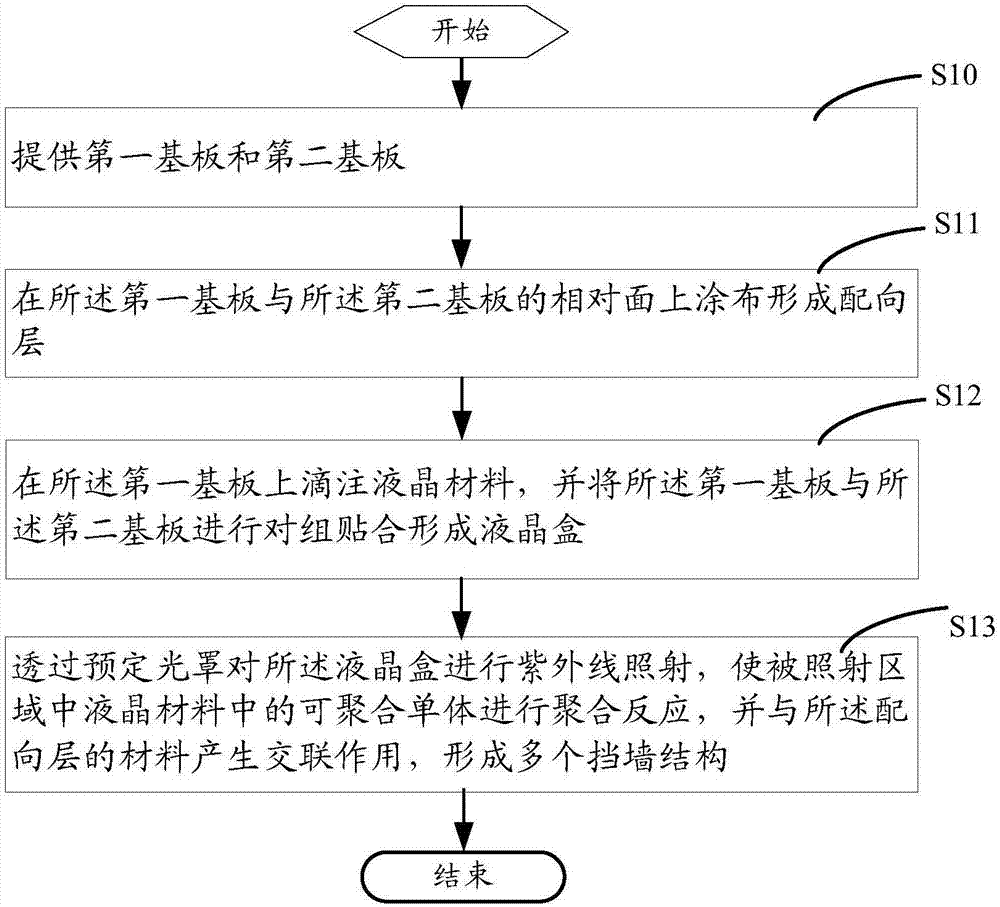

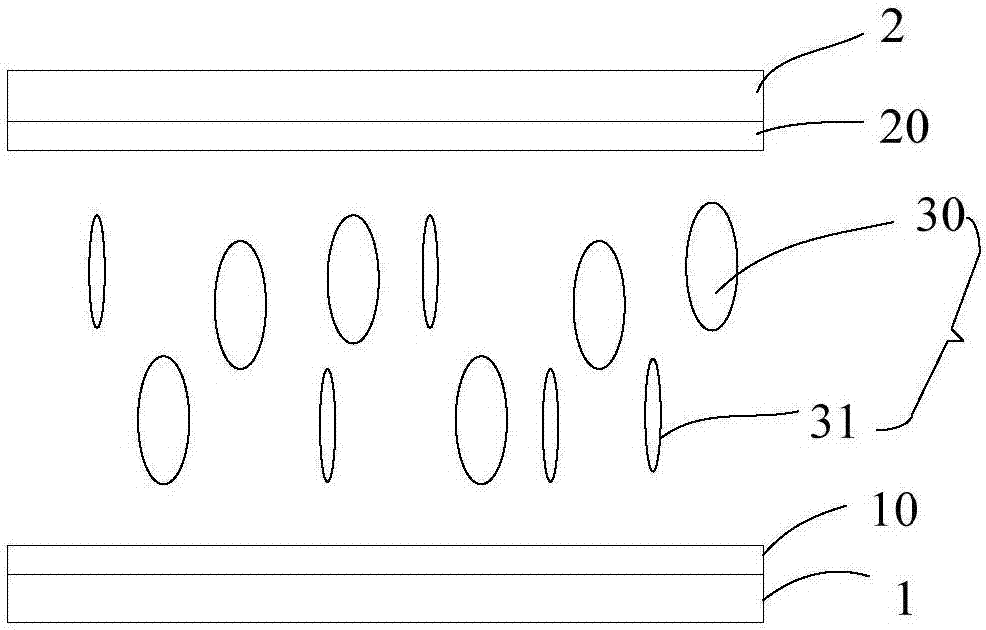

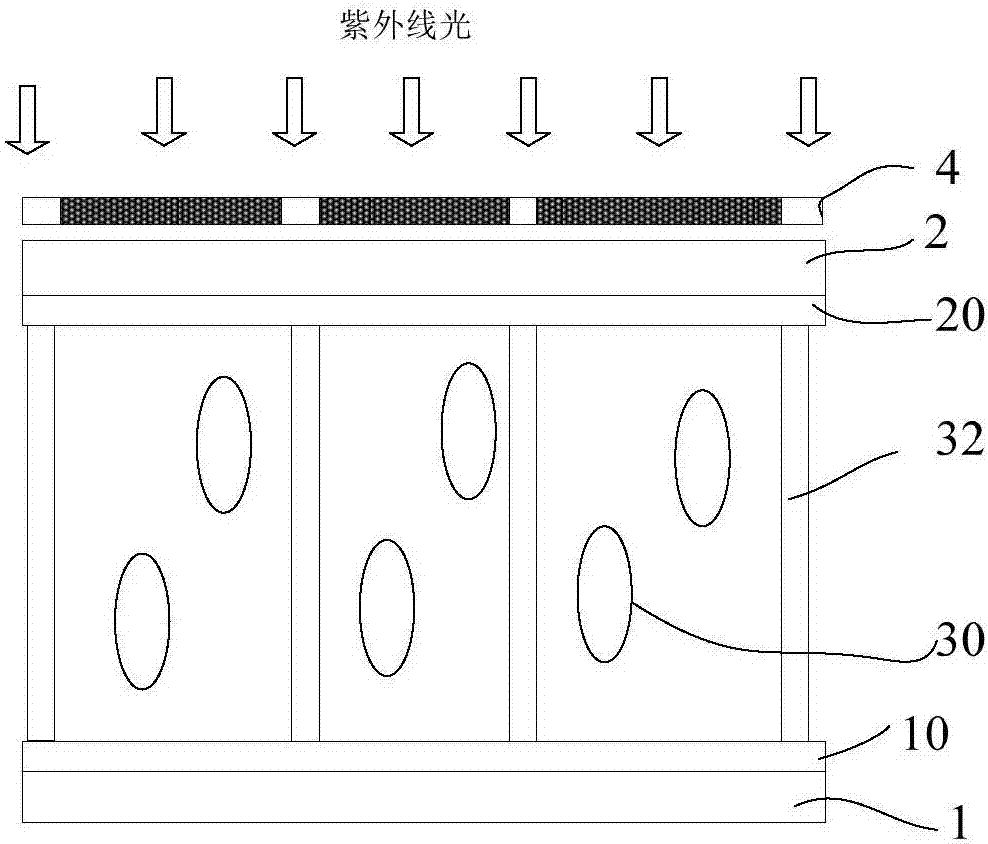

Liquid crystal display panel and production method thereof

An embodiment of the invention discloses a liquid crystal display panel and a production method thereof. The production method includes: providing a first substrate and a second substrate; coating theopposite faces of the first substrate and the second substrate to form alignment layers, wherein the main chain of the material of the alignment layers is provided with a ketone group structure; drilling a liquid crystal material to the first substrate to form a liquid crystal box, wherein the liquid crystal material comprises a plurality of liquid crystal molecules and polymerizable monomers; performing ultraviolet irradiation on the liquid crystal box through a preset photomask to allow the polymerizable monomers in the liquid crystal material in the irradiated area to have polymerization reaction and crosslink with the material of the alignment layers to form a plurality of retaining wall structures connected to the alignment layers. By the production method, the retaining wall structures connected to the alignment layers can be formed, good adhesive power is achieved, and product yield and display effect can be increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Simply fried fillet and making method thereof

The invention provides a simply fried fillet and a making method thereof. The simply fried fillet is mainly prepared from 950 to 1050 parts by weight of the main material fish, 8 to 10 parts of starch, 5 to 7 parts of salt, 14 to 16 parts of chicken's extract and 4 to 6 parts of the accessory of sodium bicarbonate. According to the invention, raw material standardization, product standardization and process standardization of the simply fried fillet can be realized.

Owner:SUZHOU HAODELAI FOOD

Making method of Cantonese cured meat

The invention discloses a making method of Cantonese cured meat. According to the method disclosed by the invention, pork is selected as a main raw material, and table salt accounting for 2-5% of the pork, white sugar accounting for 3-8% of the pork, gourmet powder accounting for 0.5-2% of the pork, a soy sauce accounting for 1.5-3% of the pork, and white wine accounting for 1-3% of the pork are added for use. The Cantonese cured meat is made through the following steps: cutting the raw material, namely the pork, into bar-shaped pork which is 20-70cm in length and 2-20cm in width; under the environment that the temperature is 0-10 DEG C, putting the prepared auxiliary materials and the prepared bar-shaped pork in a vacuum rolling and rubbing machine together, setting the rolling and rubbing temperature to be 2-15 DEG C, and rolling and rubbing the auxiliary materials and the bar-shaped pork in vacuum for 24-100 hours until all the auxiliary materials and the pork are uniformly stirred; and under the environment that the temperature is 2-15 DEG C and the humidity is 20-70%, drying the pork with the auxiliary materials until the moisture content of products is reduced to be equal to or less than 25%. According to the cured meat obtained by the making method disclosed by the invention, meat surfaces present a carmine red color, a peroxide value reaches to the standard, and the nutrient value of the products is greatly increased, so that the quality of the cured meat is improved.

Owner:JINZI HAM CO LTD

Method for preparing fish meat fermented sausage using mixed microbe ferment

InactiveCN100455212CHigh nutritional valueEasy to store and carryClimate change adaptationFood preservationNutritive valuesMicroorganism

Owner:JIANGNAN UNIV

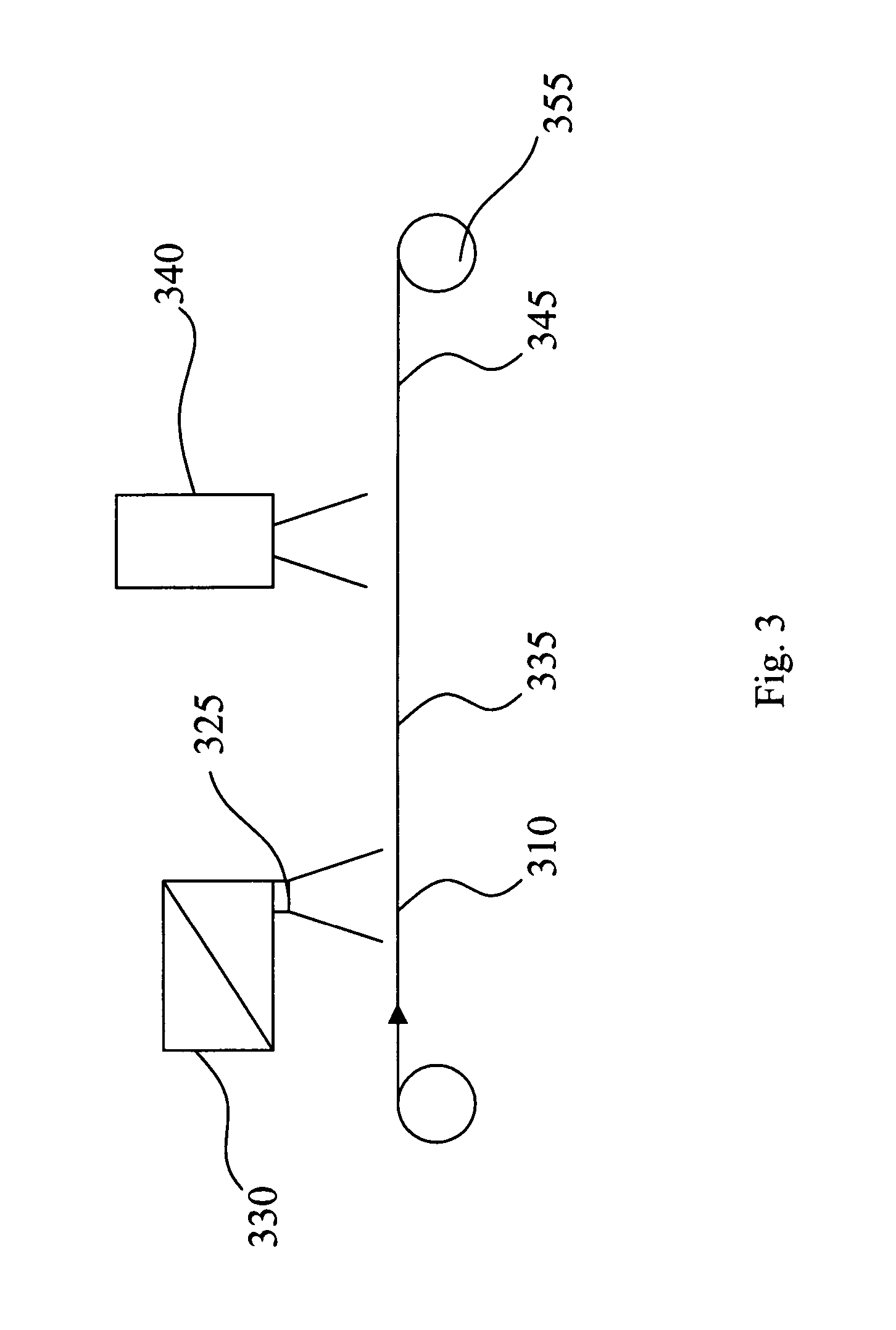

Preparation method of modified polypropylene bristle monofilament for rope of aquaculture net cage or trawl fishing tool

InactiveCN101851793AImprove knot strengthStrong knotFishing netsSpinning head liquid feederFiberBristle

The invention provides a preparation method of a modified polypropylene bristle monofilament for a rope of an aquaculture net cage or a trawl fishing tool, relating to a base fiber for the rope of the aquaculture net cage or the trawl fishing tool and the preparation method of the modified polypropylene bristle monofilament for the rope of the aquaculture net cage or the trawl fishing tool. The method adopts a stirring machine, a screw rod extruding machine, a drawing machine, a bristle monofilament rolling machine and a bristle monofilament dividing machine. The preparation method is characterized by comprising the following steps of: completely and evenly stirring PP resin, PA1010 resin, PP-G-MAH resin, zinc stearate and assistant; extruding and pelleting the evenly-stirred mixture to obtain multi-component mixture granules; fusing and extruding the multi-component mixture granules through a charging barrel of the single-screw rod extruding machine; hot drawing the fused and extruded primary monofilament for twice; removing oil by means of pressure air current after drawing, and fast cooling; and rolling the bristle monofilament with the bristle monofilament rolling machine, and dividing the bristle monofilament with the bristle monofilament dividing machine to obtain the modified PP bristle monofilament. The method is suitable for preparing the modified polypropylene bristle.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

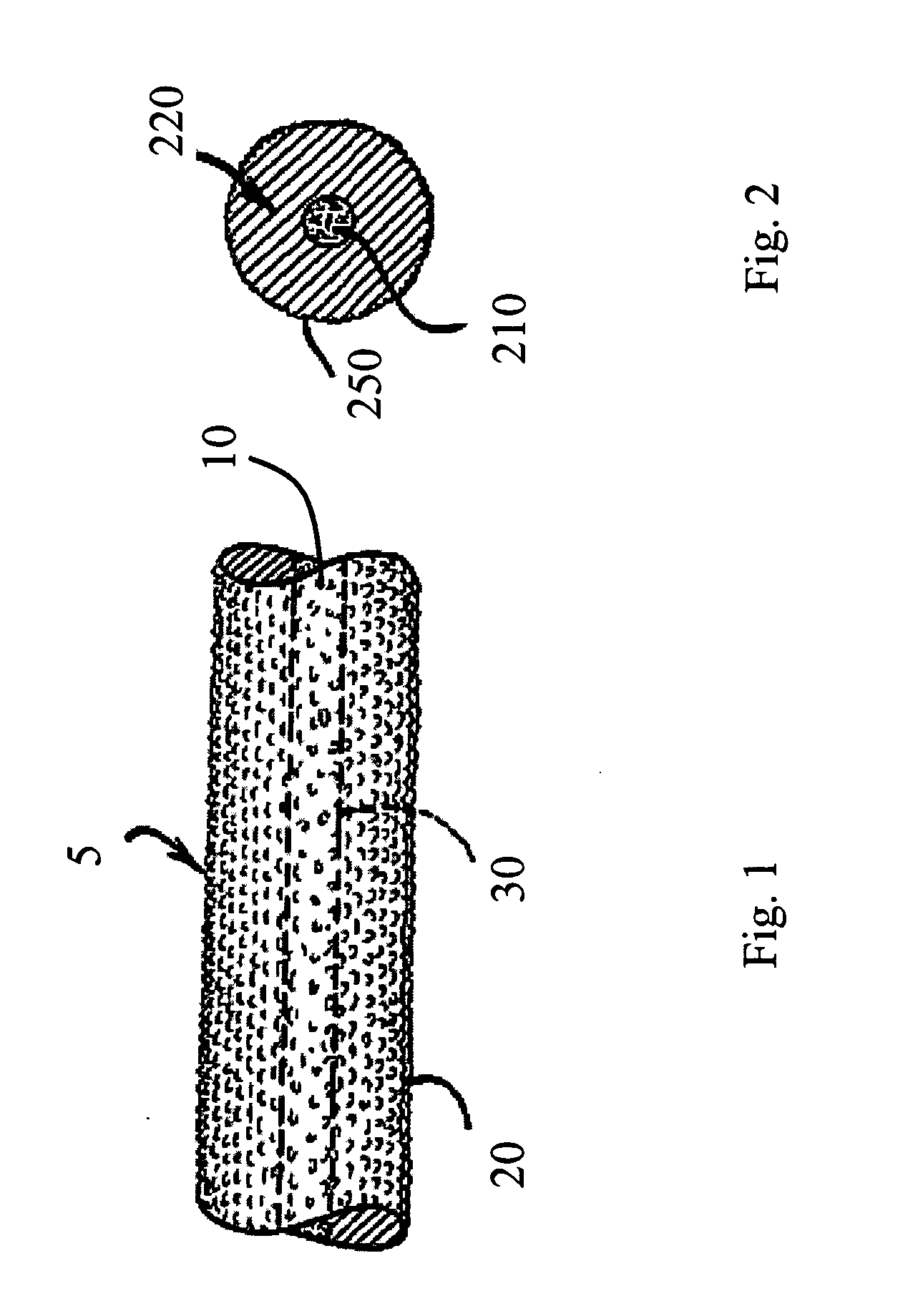

Textured wire tie and methods of making same

InactiveUS20050084674A1Less twistingLess effortFlexible elementsBuilding reinforcementsEngineeringRebar

This invention relates to a textured tie wire product, and more particularly to rebar tying applications, bundling, and packaging applications. The invention also relates to methods of making textured tie wire products.

Owner:AMERICAN WIRE TIE

Snowflake smooth beef and preparation method thereof

InactiveCN102907684AImprove knot strengthImprove taste and section effectFood preparationChemistrySodium bicarbonate

The invention provides a snowflake smooth beef and a preparation method thereof. The snowflake smooth beef mainly comprises the following parts by weight of raw materials: 950 to 1050 parts of beef and 2000 to 2500 parts of eggs as main materials, and 20 to 25 parts of starch, 17 to 20 parts of chicken powder, 17to 20 parts of light soy sauce, 7 to 9 parts of white granulated sugar, 2 to 4 parts of table salt, 8 to 10 parts of black pepper powder, 17to 20 parts of spice and 5 to 8 parts of sodium bicarbonate as auxiliary materials. According to the invention, the raw material standardization, the product standardization and the technology standardization of the snowflake smooth beef are realized.

Owner:SUZHOU HAODELAI FOOD

Orleans roasted steak and preparation method thereof

InactiveCN102715521APicklingEvenly absorb pickleFood preparationSodium bicarbonateMonosodium glutamate

The invention relates to Orleans roasted steak and a preparation method thereof. The Orleans roasted steak is mainly prepared from the following components in part by weight: 950 to 1,050 parts of main material pork steak, 20 to 25 parts of starch, 50 to 60 parts of spice, 20 to 25 parts of flour, 8 to 10 parts of spicy wrapped pulp powder, 4 to 6 parts of soybean protein, 4 to 6 parts of monosodium glutamate and 5 to 8 parts of auxiliary material sodium bicarbonate. According to the invention, raw material standardization, product standardization and process standardization of the Orleans roasted steak can be realized.

Owner:SUZHOU HAODELAI FOOD

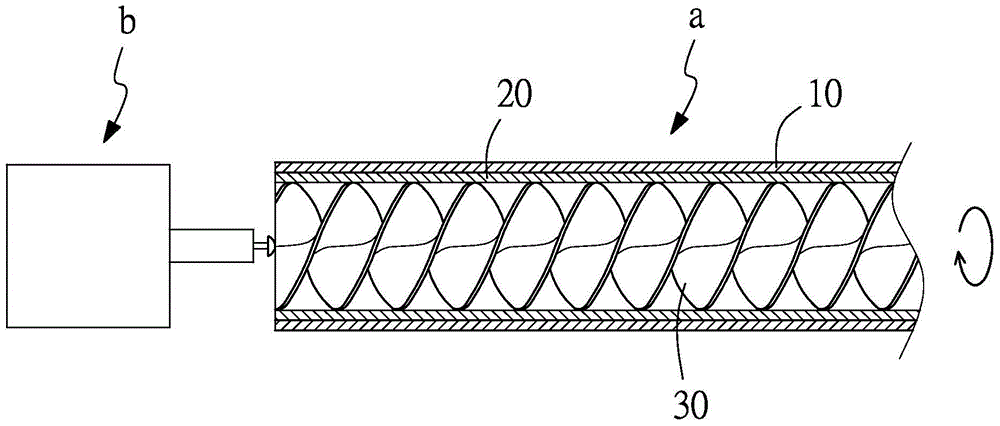

Multifilament and method for manufacturing the same, and yarn and method for manufacturing the same

The present application of the invention aims at improving knot strength of a twisted yarn without compromising circularity, with respect to various yarns including a fishing line. For such purpose, the present application of the invention provides a yarn including a multifilament subjected to two twisting processes in different directions, and a coating resin that covers a surface of the multifilament; wherein the multifilament is subjected to a first twist in one direction, and then to a second twist in a direction opposite to that of the first twist, without being doubled with another yarn.

Owner:DUEL

Inner spiral unit

The invention discloses an inner spiral unit. The inner spiral unit mainly adopts a spiral pipe fitting, and additionally uses a power source for generating power; the spiral pipe fitting has a spiral blade in a hollow pipe body; as the outer side edge of the spiral blade is in seamless fixed connection with the inner wall surface of the hollow pipe body, when the power source drives the hollow pipe body or the spiral blade to rotate, the spiral pipe fitting and the spiral blade can synchronously rotate; and because of the precession driving of the spiral blade in the hollow pipe body, the inner spiral unit can be applied to the conveying of fluids (such as water and oil) or solids (such as corn kernels, grains and plastics), or can be applied to such fields as spiral stirring and fluid power generation so as to achieve such multiple benefits as complete sealing, improvement of structural strength, stable flowing speed and long service life.

Owner:QUAN SIANG TECH DEV

Shredded pork with garlic sauce and preparation method thereof

The invention provides shredded pork with garlic sauce and a preparation method thereof. The shredded pork with garlic sauce is mainly prepared from the main material of 950-1050 parts of pork, and the accessories of 14-16 parts of essence of chicken, 6-8 parts of salt, 6-8 parts of starch, 4-6 parts of Xianweiwang, 1-3 parts of white granulated sugar and 5-8 parts of sodium bicarbonate by weight. The shredded pork with garlic sauce and the preparation method have the following advantage: the raw material standardization, product standardization and process standardization of the shredded pork with garlic sauce can be realized.

Owner:SUZHOU HAODELAI FOOD

Pet food

ActiveCN101584418BPromote absorptionHigh nutritional valueAnimal feeding stuffAccessory food factorsBiotechnologyNutritive values

The invention relates to a pet food, which is prepared from the principal raw material such as seafood protein peptides. the seafood protein peptides are prepared from the seafood by the biofermentation: the strain for the fermentation is inoculated into the culture medium, the culture solution is in the shaking culture, the initial strain solution is obtained after the repeat cultivation, the initial strain solution is in the primary cultivation on a shaking table, the primary seed is added into a seed fermentation cylinder and is in the secondary cultivation to obtain the secondary seed, theprocessed seafood is placed in a cut mixer and crushed, the sugar, salt and the like are added with stirring, the secondary seed is inoculated into the seafood, the fermentation is conducted under the micro-aerobe or anaerobic entironment, after the fermentation is over, the product is obtained and used as the pet food raw material. The seafood protein peptide pet food of the invention is easy tobe absorbed by the pet, and has high nutrition value, special flavor, improved safety and favorable health-care function.

Owner:李达

Red fish line

A fish line having a red color defined by a hue value of a LCH measurement of a colorimeter of between −11.5 and −13.5 is shown to get more strikes than fish line of other colors, thereby providing the user with an opportunity to catch more fish. The red fish line includes a red colorant which provides increased abrasion resistance compared to fish line comprised of the same synthetic or natural materials but a different or no colorant.

Owner:W C BRADLEY ZEBCO HLDG LLC

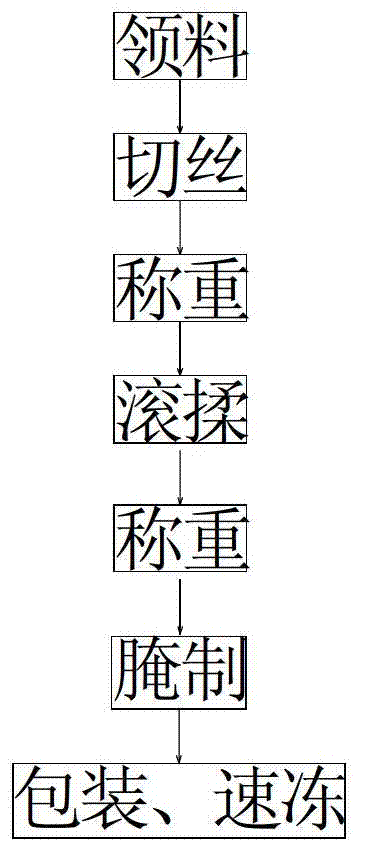

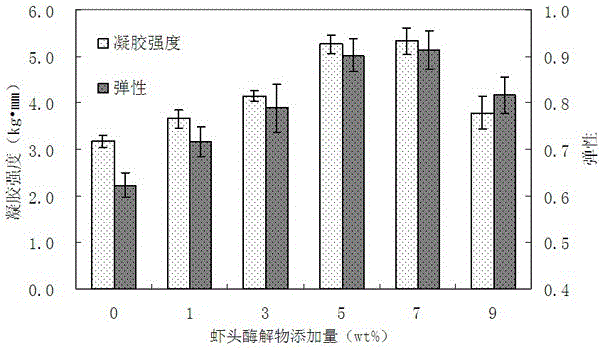

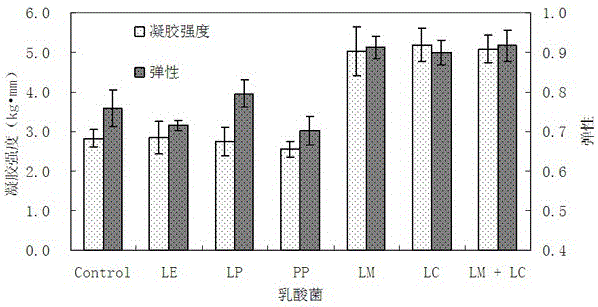

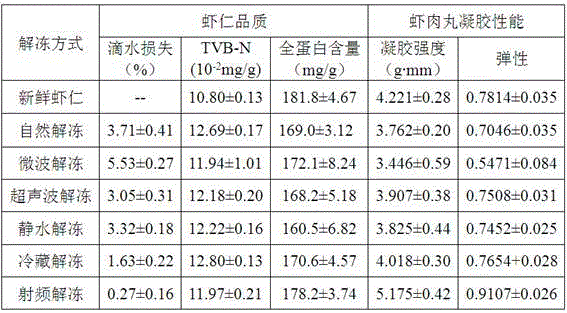

A processing method for improving gel performance of shrimp meatballs

ActiveCN104432228BShorten thawing timeAvoid breedingProtein food ingredientsShrimpProtein hydrolysates

The invention discloses a processing method for improving the gelation ability of shrimp flesh balls, belonging to the technical field of food processing. By directly using frozen peeled shrimps as the raw material, the processing method integrates techniques such as radio frequency unfreezing, addition of shrimp head protein hydrolysate, low-temperature mild fermentation and gelatinization of cold-resistant lactic acid bacteria and the like. According to the processing method disclosed by the invention, the jelly strength and elasticity of a shrimp flesh ball product are greatly enhanced, the gelation ability of the shrimp flesh ball product is improved, and the edible quality of the shrimp flesh ball product is comprehensively enhanced. According to the processing method disclosed by the invention, no exogenous quality improvers are added, so that the product is safe, nutritional and sanitary, and the processing method is simple and convenient to operate, easy to master technical parameters, low in production cost and convenient for industrial processing of shrimp flesh balls.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com