Patents

Literature

44results about How to "High knot strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for making a monofilament-like product

ActiveUS8022171B2Pleasant touchPleasant feelCeramic shaping apparatusMonocomponent polyolefin artificial filamentFiberPolyolefin

The invention relates to a process for making a monofilament-like product from a precursor containing a multitude of continuous polyolefin filaments, comprising exposing the precursor to a temperature within the melting point range of the polyolefin for a time sufficient to at least partly fuse adjacent fibers and simultaneously stretching the precursor at a draw ratio of at least 2.8. With the process according to the invention a monofilament-like product can be made that shows improved tensile properties; making it very suitable for application as e.g. fishing line.

Owner:PURE FISHING

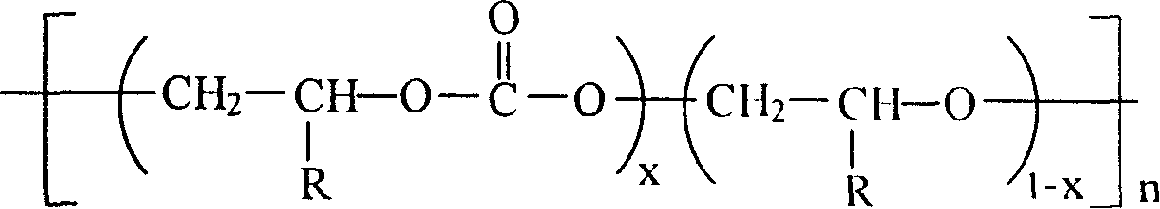

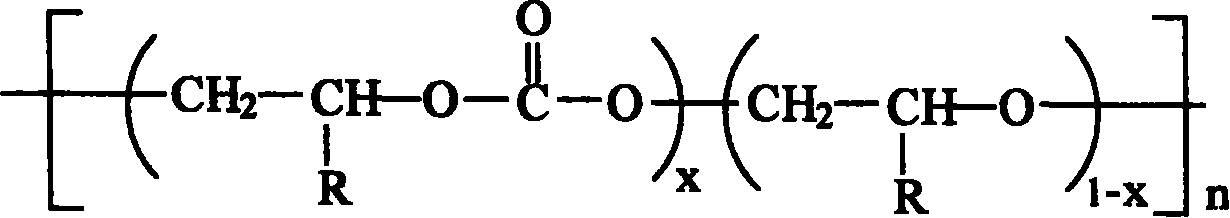

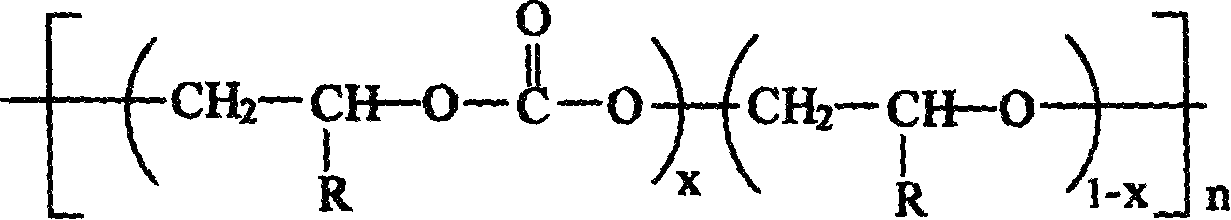

Methods of orienting multifilament yarn and monofilaments of poly-4-hydroxybutyrate and copolymers thereof

ActiveUS9555155B2Improve toughnessGood drapeSuture equipmentsMedical devicesPolymer scienceSoft tissue repair

Resorbable multifilament yarns and monofilament fibers including poly-4-hydroxybutyrate and copolymers thereof with high tenacity or high tensile strength have been developed. The yarns and fibers are produced by cold drawing the multifilament yarns and monofilament fibers before hot drawing the yarns and fibers under tension at temperatures above the melt temperature of the polymer or copolymer. These yarns and fibers have prolonged strength retention in vivo making them suitable for soft tissue repairs where high strength and strength retention is required. The multifilament yarns have tenacities higher than 8.1 grams per denier, and in vivo, retain at least 65% of their initial strength at 2 weeks. The monofilament fibers retain at least 50% of their initial strength at 4 weeks in vivo. The monofilament fibers have tensile strengths higher than 500 MPa. These yarns and fibers may be used to make various medical devices for various applications.

Owner:TEPHA INC

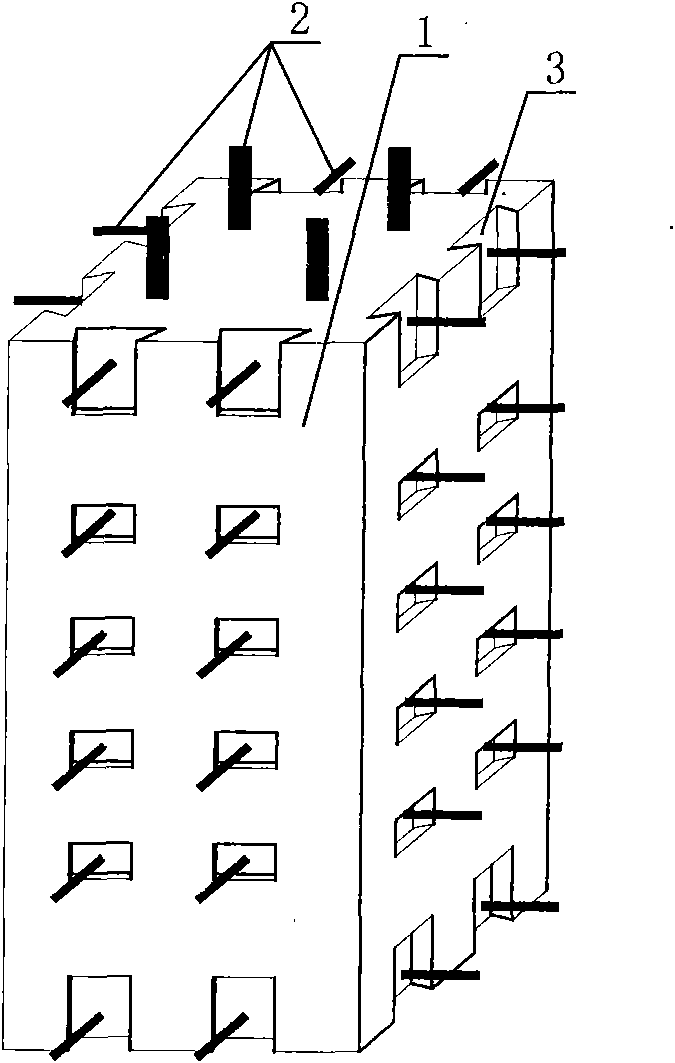

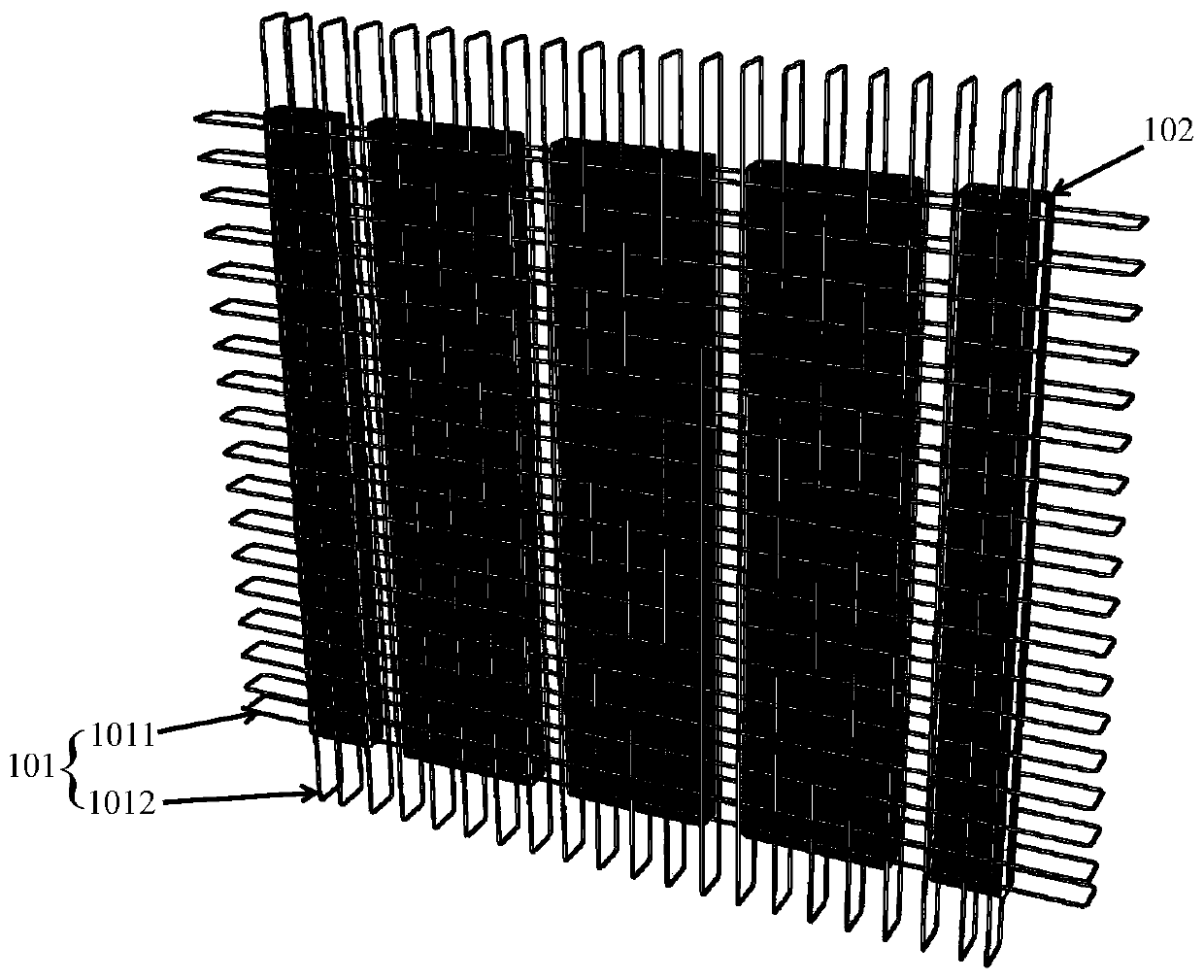

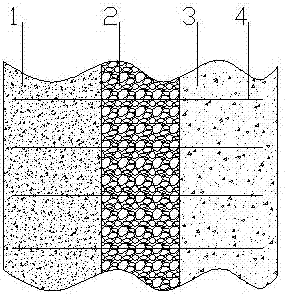

Reinforced concrete prefabricated member

InactiveCN102312481ANot easy to cause tensile stress damageSolve crackingFloorsConvex structureReinforced concrete

The invention discloses a reinforced concrete prefabricated member, which comprises a prefabricated member (1). The reinforced concrete prefabricated member is characterized in that: the prefabricated member (1) is a reinforced concrete structural bearing member; steel bars (2) in the prefabricated member are arranged in a cage shape; the steel bars (2) extend out of at least one end face of the prefabricated member (1) and then are exposed to form connecting steel bars (2) connected with post poured concrete; and a concave structure (3) or / and a convex structure (4) is arranged on the connected end face of the prefabricated member (1) and the post poured concrete. The reinforced concrete prefabricated member is suitable for an assembled wallboard or an assembled house, can be used as a constructional column or a structural column, and has the advantages of stability and reliability in assembly with an adjacent assembled cast-in-place seam and cracking resistance.

Owner:湖南华廷筑邦住宅工业有限公司

Coating method of antibacterial surgical suture made of high molecular absorbable material

The invention discloses a coating method of an antibacterial surgical suture made of a high molecular absorbable material. The method comprises the following steps of: applying a dying process to a coating process; preparing a suture woven by using a warp loom; soaking a primary suture; uniformly spraying a coating liquid onto the suture by adopting a gas-free coating process; and drying and sizing. The suture is reddish violet and fresh in color, is smooth and flexible, is easy for knotting, has high knotting strength, and has the advantages of anti-inflammation, oxidation resistance, high degradability, long tension period and the like; and the safety of a knot is enhanced. The tensile strength is kept by about 70 percent two weeks after clinical suturing; slow absorption starts four weeks later; and the suture is absorbed completely 8-10 weeks later. As proved by clinical application, the antibacterial surgical suture has a wide application range and a good effect, is free from irritability, irritation and inflammatory reactions, and has the advantages of sterilization, anti-inflammation, bacteriostatic action and the like.

Owner:SHANDONG HAIDIKE MEDICAL PROD CO LTD

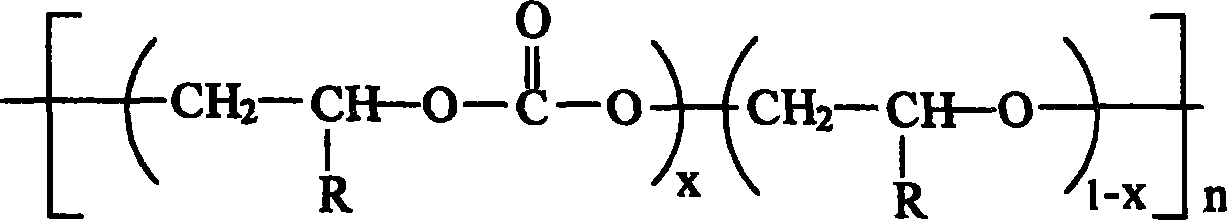

Manufacturing method of medical absorpable suture

InactiveCN1596992ALittle tissue responseWound healing with little scarSuture equipmentsConjugated synthetic polymer artificial filamentsWater bathsAcetic acid

An absorptive medical suture with high strength, toughness, biocompatibility and absorptivity, and abvious body temp memory effect is prepared from CO2 copolymer through fusing, mixing with maleic acid anhydride or acetic acid anhydride, granulating, fusing, mixing with polylactic acid or polyhydroxy butyrate, extruding for granulating, melt spinning and drafting in water bath.

Owner:吉林金源北方科技发展有限公司

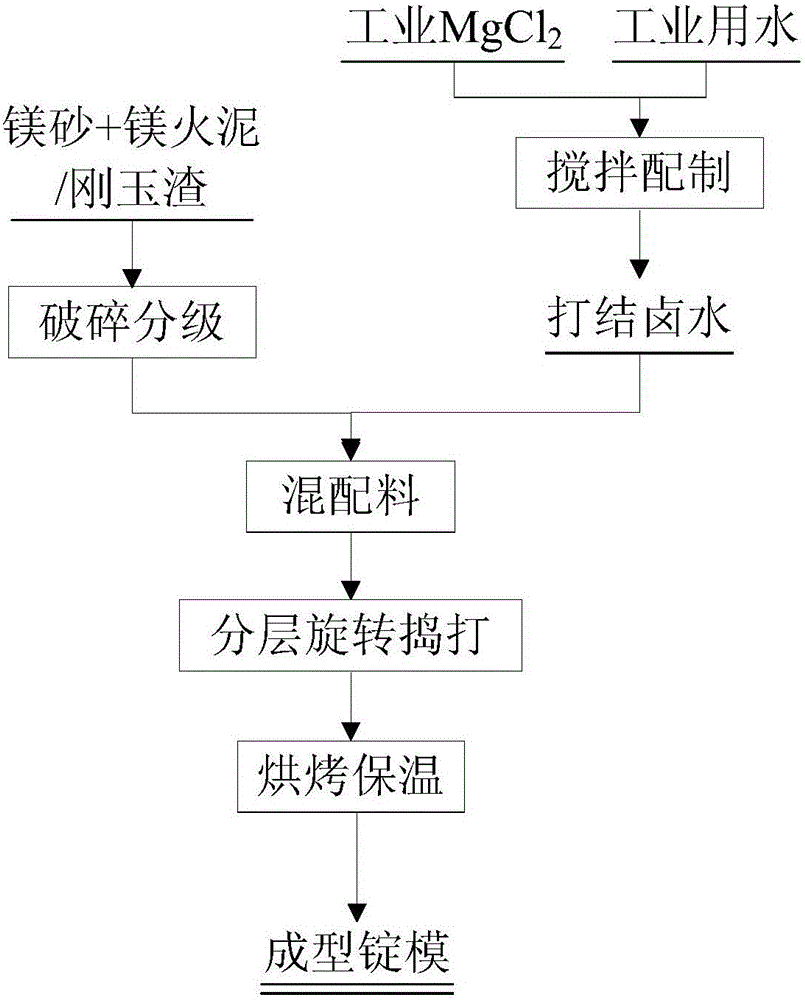

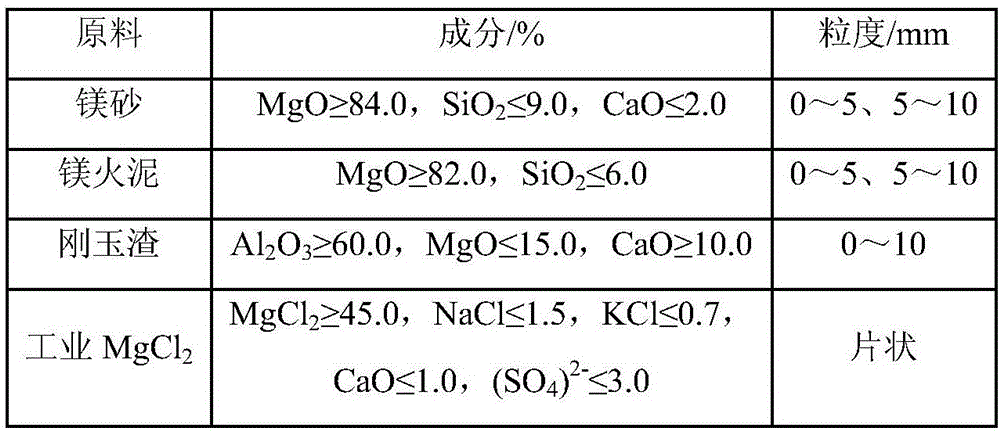

Knotting method of casting ingot mold in preparation process of vanadium-iron alloy

The invention discloses a knotting method of a casting ingot mold in the preparation process of a vanadium-iron alloy, and belongs to the field of metallurgy. The knotting method of the casting ingot mold comprises the following steps of using magnesite and magnesium fire clay with the granularity intervals of 0 to 5mm and 5 to 10mm as knotting main materials; using vanadium-iron smelting corundum slag with the granularity interval of 0 to 10mm as knotting auxiliary materials; mixing the knotting main materials and the knotting auxiliary materials with brine to obtain a knotting mixed material; and performing inner-outer layer knotting on the knotting mixed material according to the proportion requirement. According to the method, the loss amount of vanadium in the vanadium-iron casting process is reduced, and the vanadium-iron smelting corundum slag can be recycled. According to the ingot mold knotted by the method, the permeation thickness of the vanadium-iron alloy is as low as 17.6mm, the vanadium loss in an actual permeated alloy is as low as 3.82kg, and the loss of vanadium in casting of a single furnace is about 0.23 percent.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

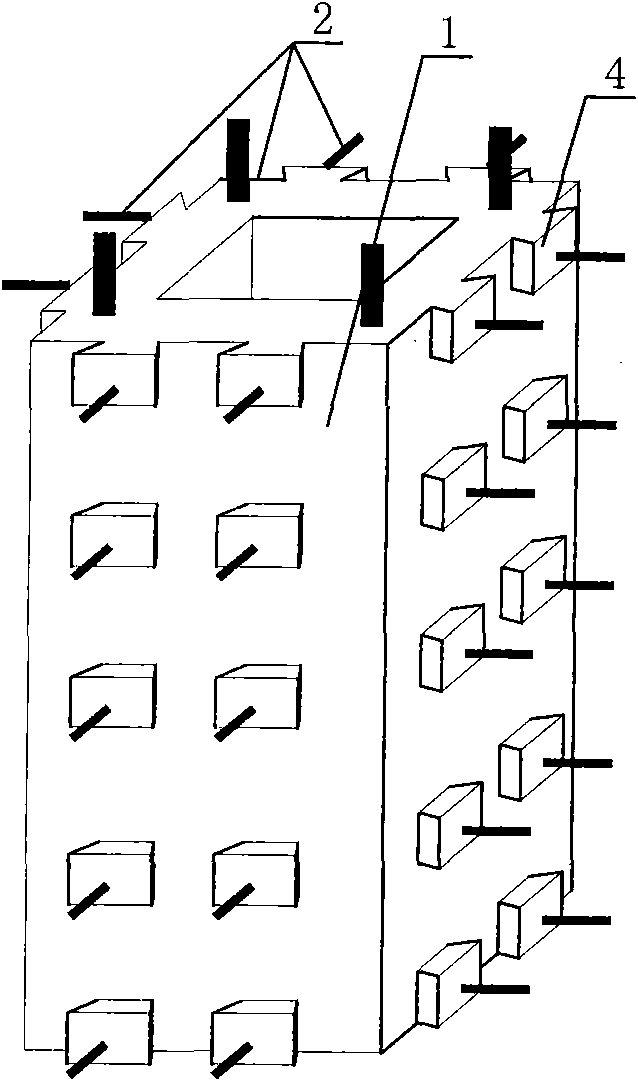

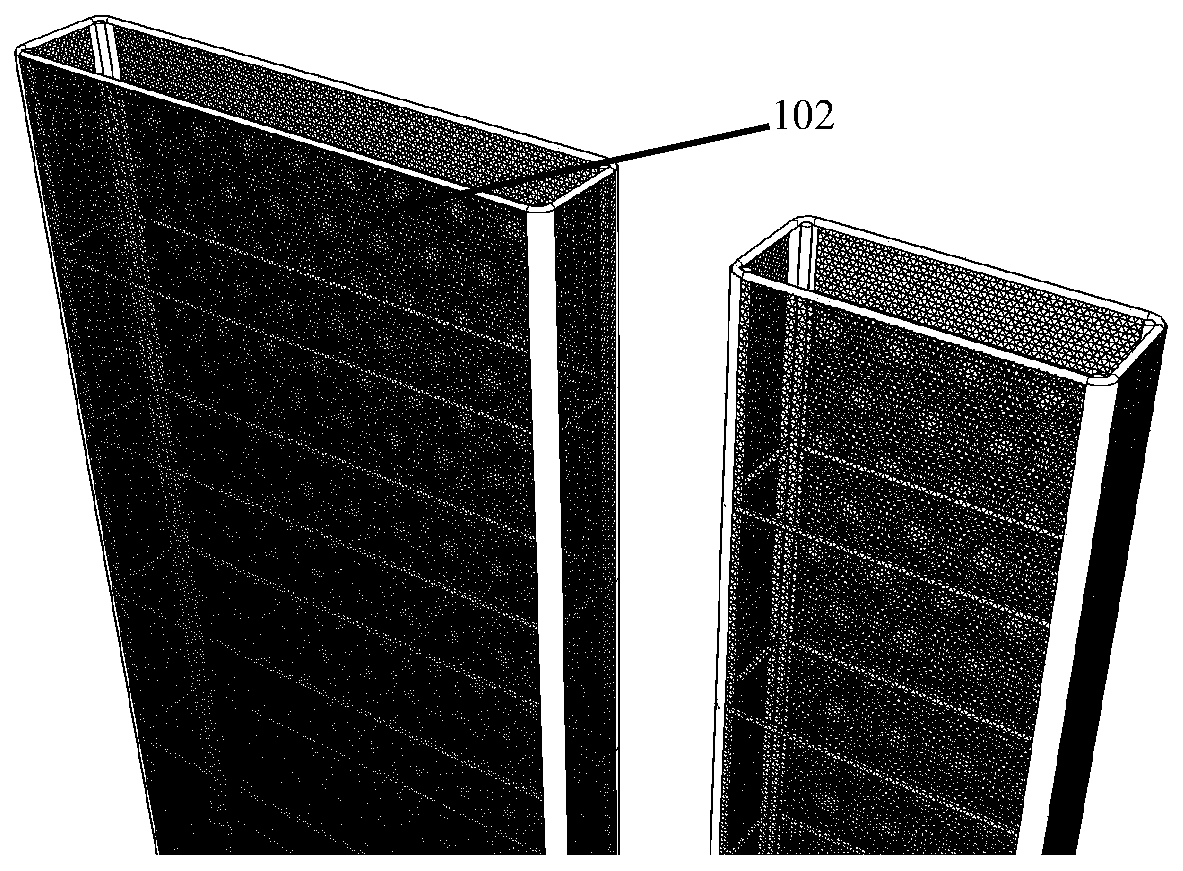

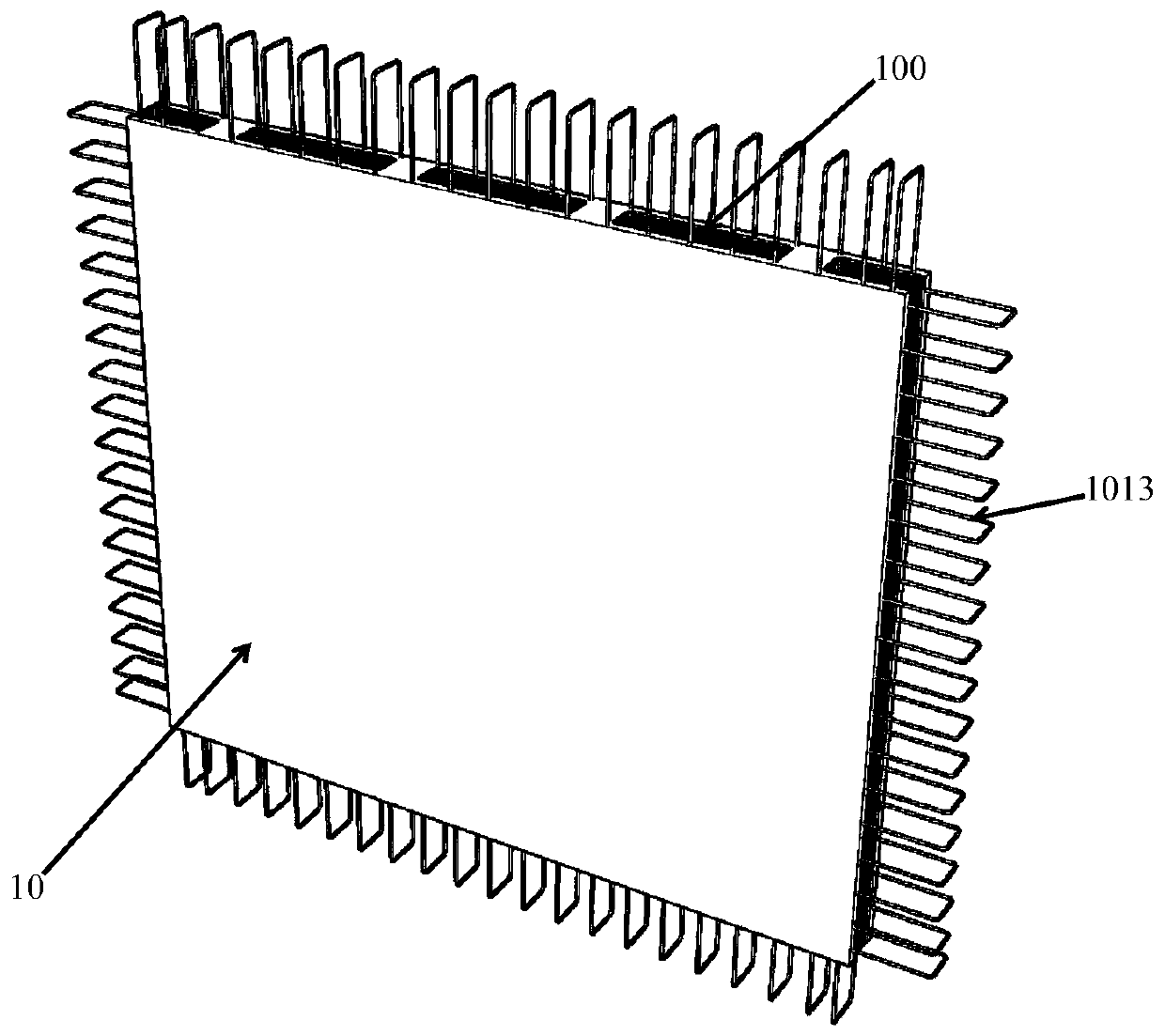

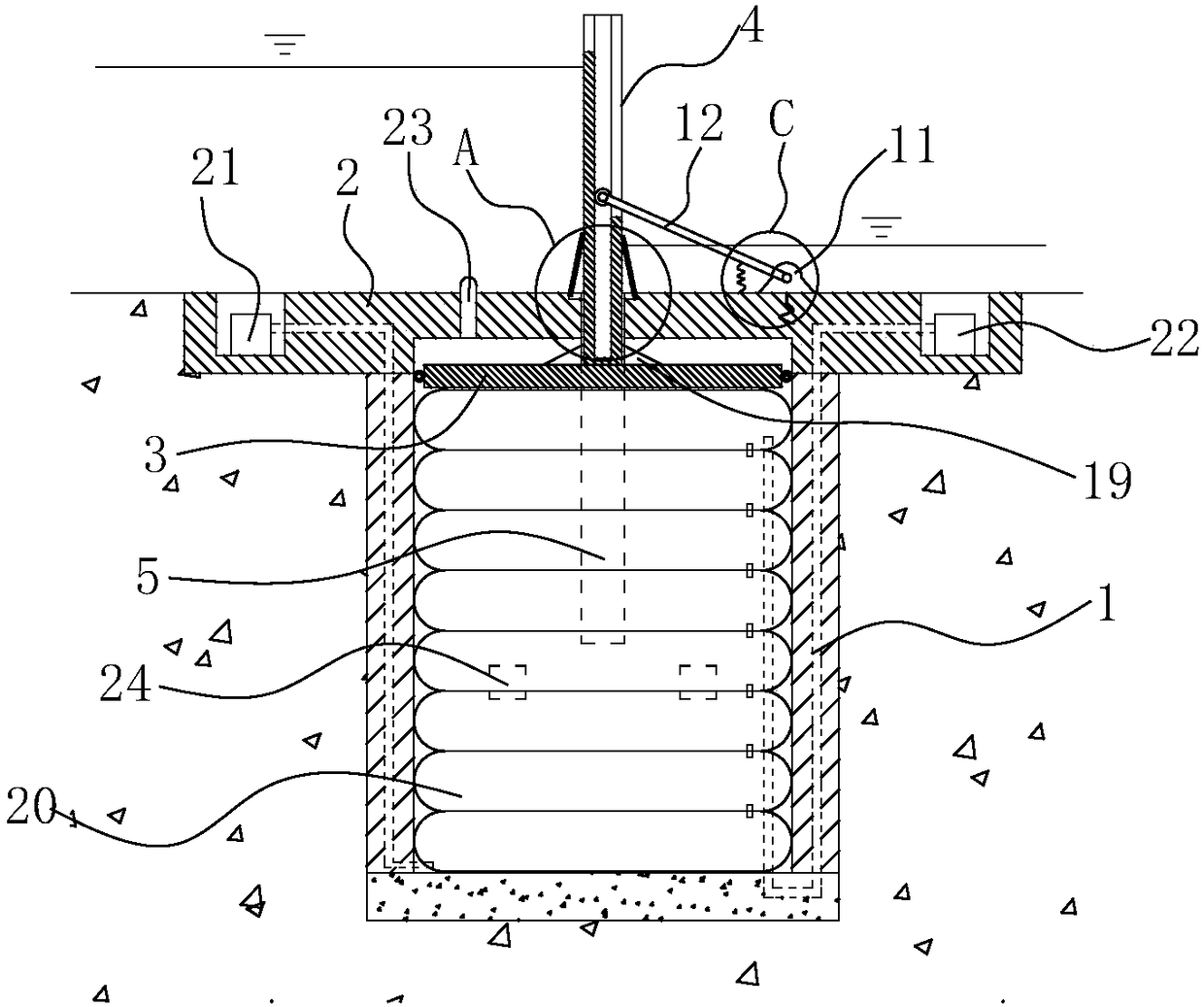

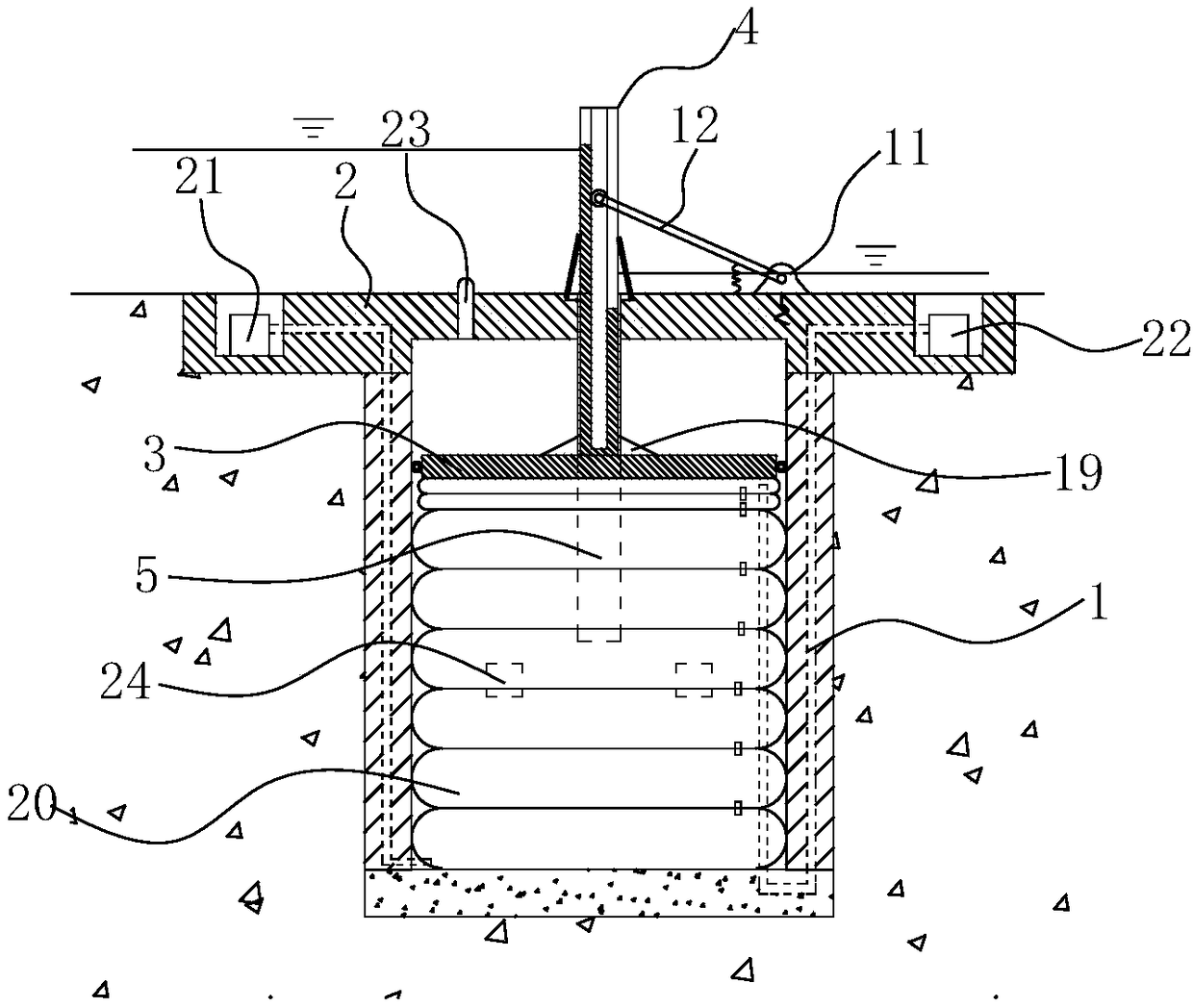

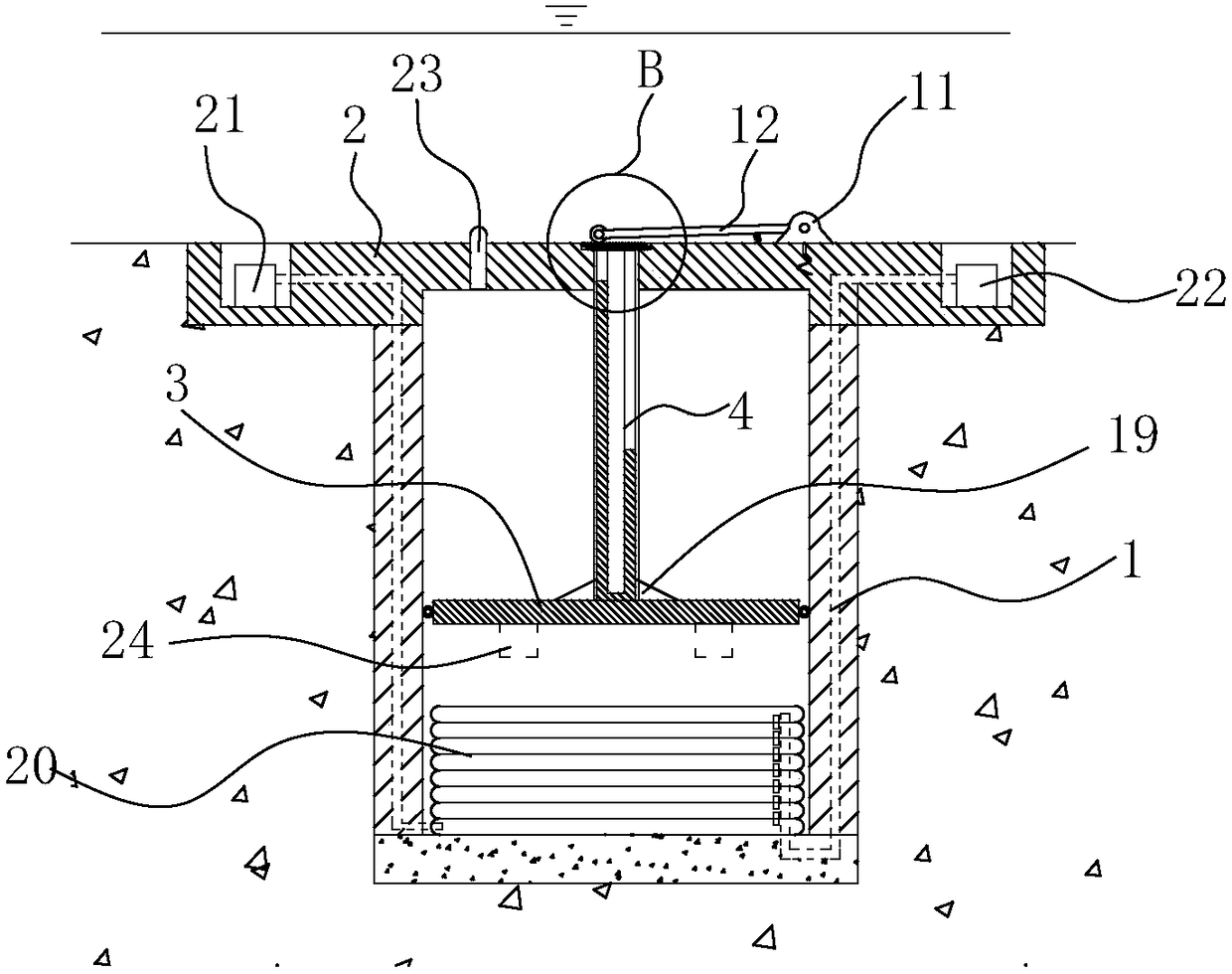

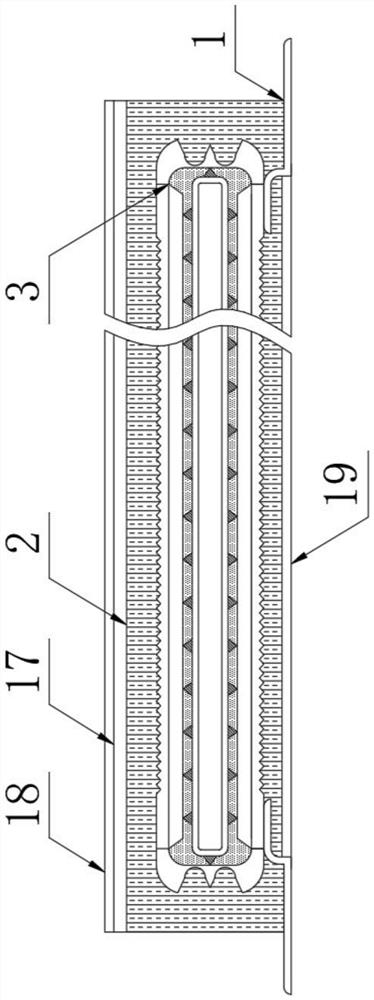

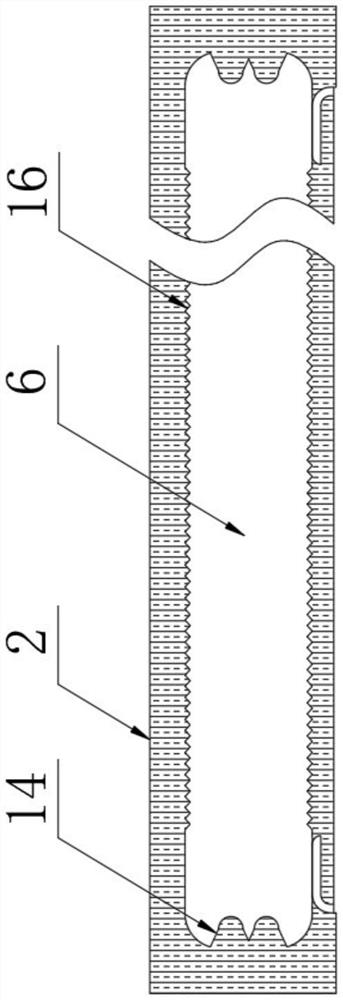

Fabricated core-grouting wall body, construction method of fabricated core-grouting wall body and frame for preparing wall body

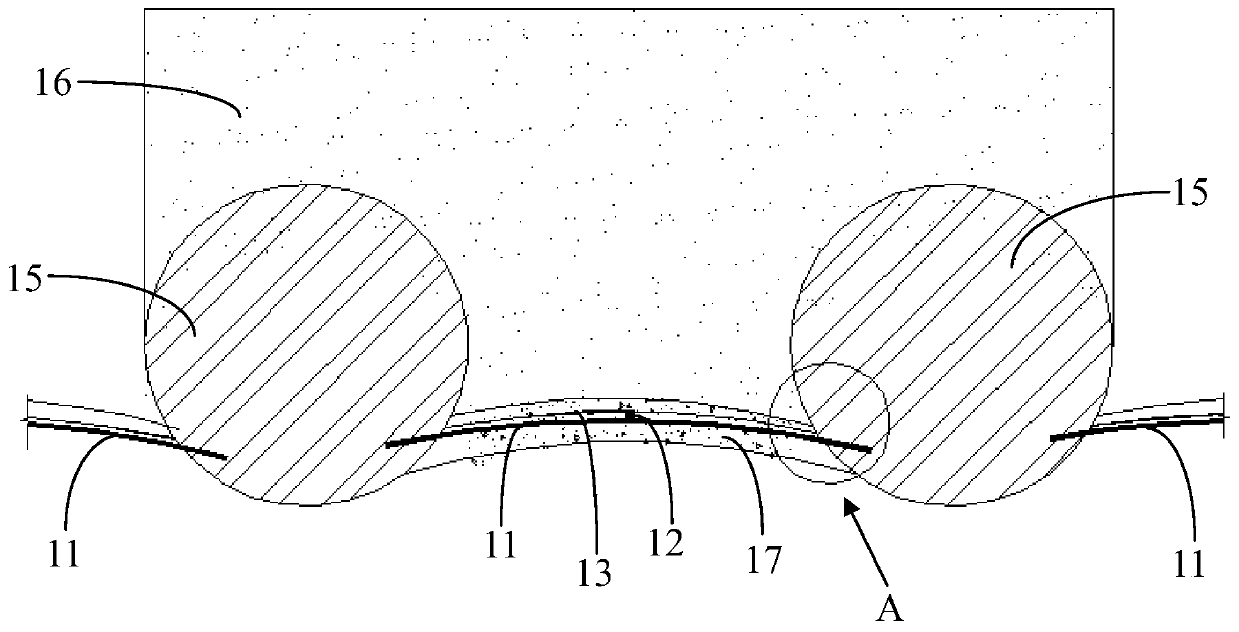

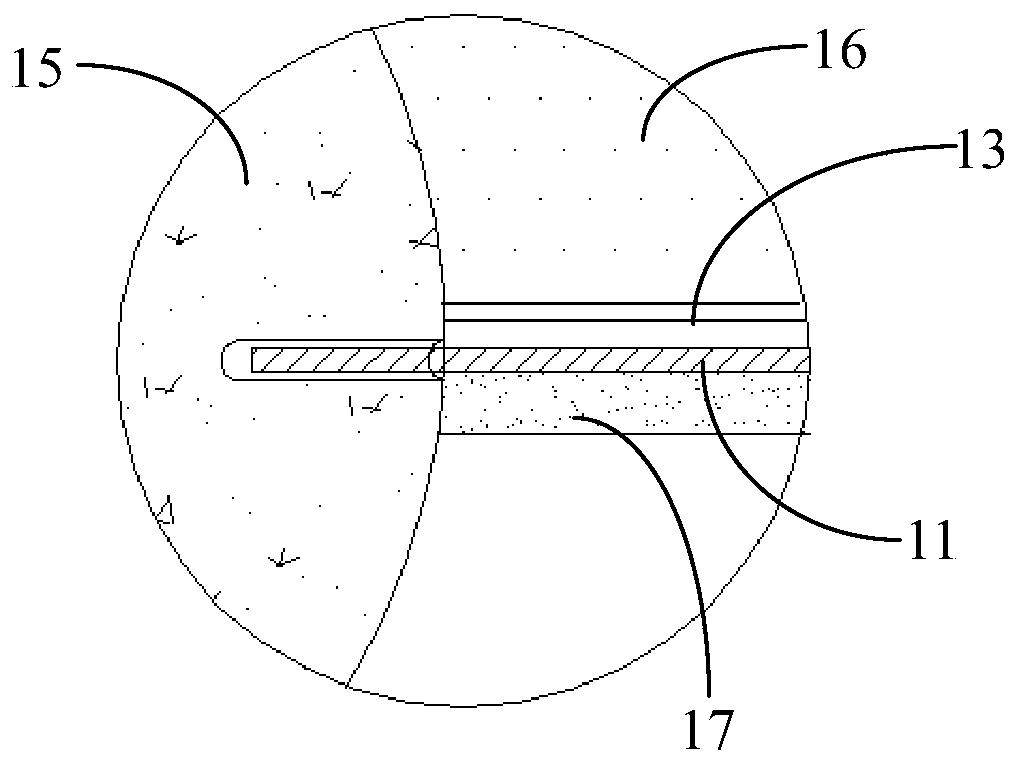

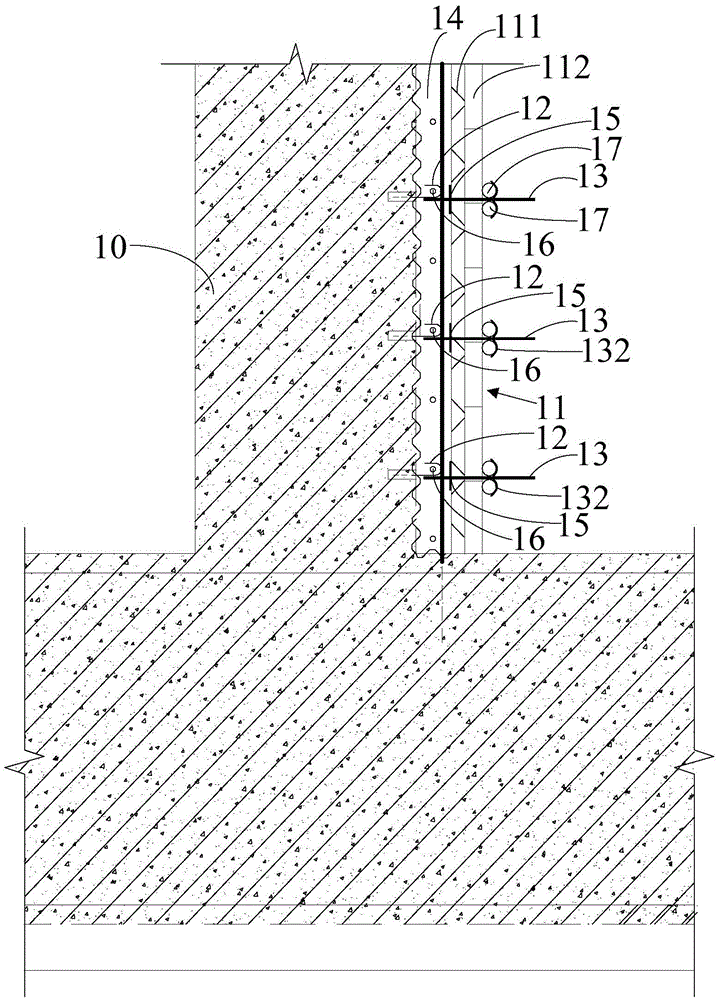

PendingCN110185174ASolve the difficulty of constructionHigh knot strengthConstruction materialWallsDie swellRebar

The invention discloses a fabricated core-grouting wall body, a construction method of the fabricated core-grouting wall body and a frame for preparing the wall body. A longitudinal first cavity is formed in a prefabricated wallboard for grouting concrete at a construction site, and the problem that the construction difficulty of grouting to horizontal seams in the prior art is high is effectivelysolved; the tension intensity between inner and outer leaf wallboards is further effectively enhanced, risks of die expansion of the existing double-side composite wall and die shell shear wall are overcome, so the inner and outer leaf wallboards can be made thinner. A die shell is bounded and fixed in a steel cage in advance, the die shell is not disassembled after completing concrete sproutingbut left in a prefabricated part to form the first cavity, and the problems that the die shell cannot be stressed in the process of using during later periods in the prior art, and due to the fact that a building transforms in the process of using, and hidden cracks are produced between the die shell and internal post-grouting concrete shear wall can be effectively solved; and the die shell is bounded and fixed in the steel cage, the die shell can be stressed in the process of using during the later periods, and the intensity of the prefabricated wallboard is further improved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

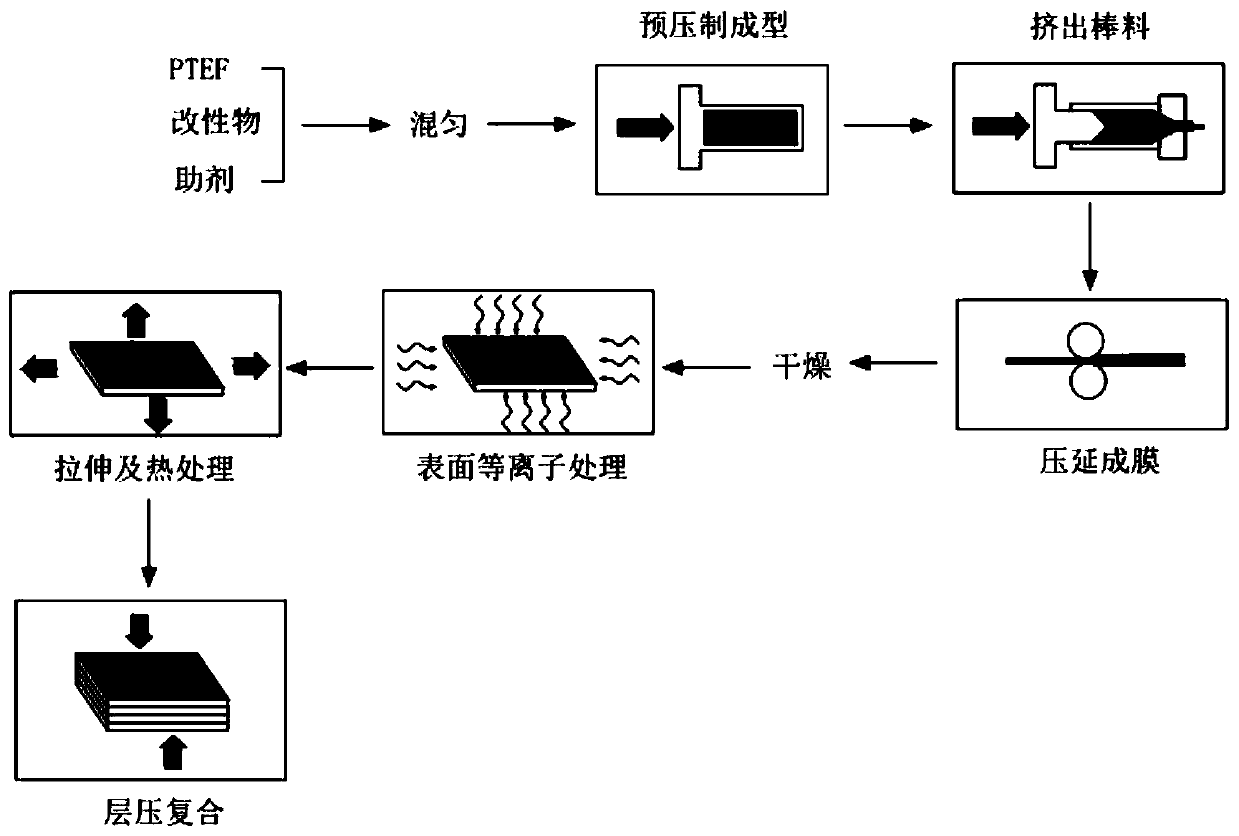

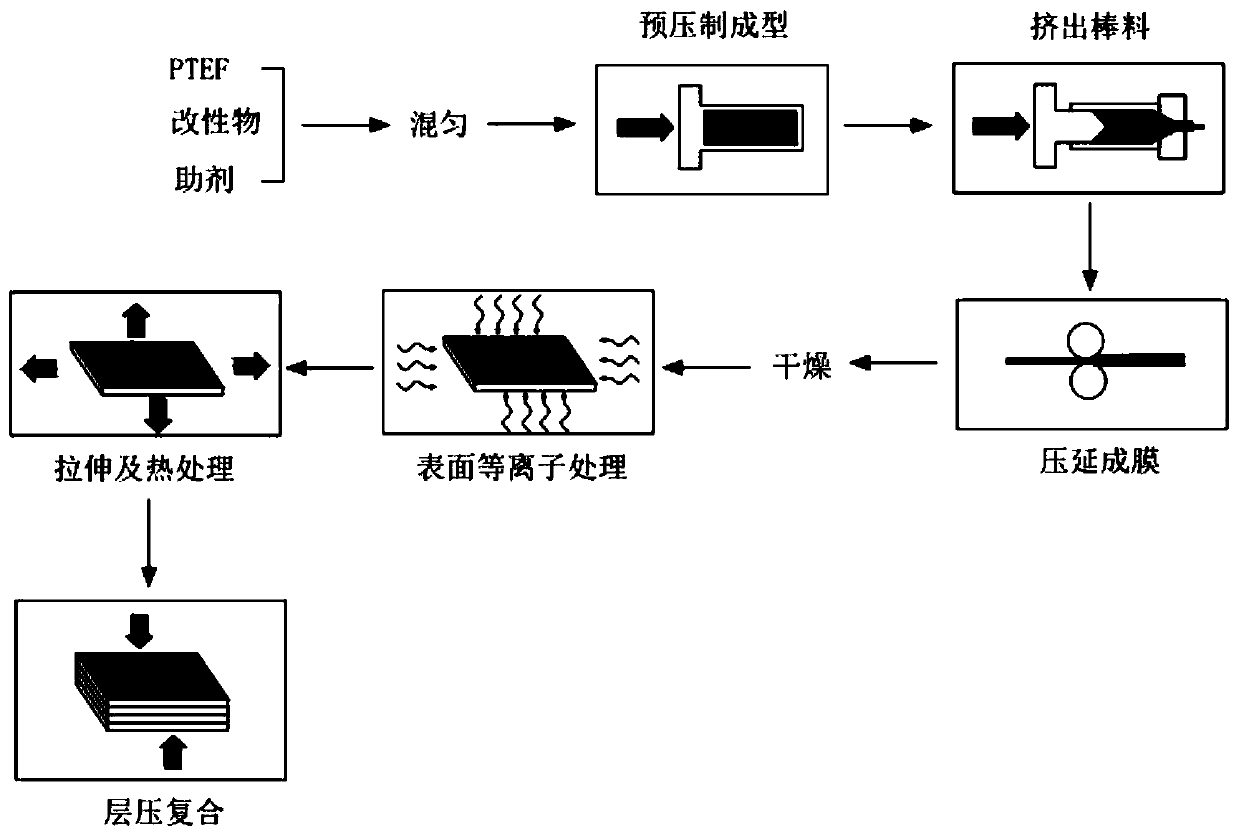

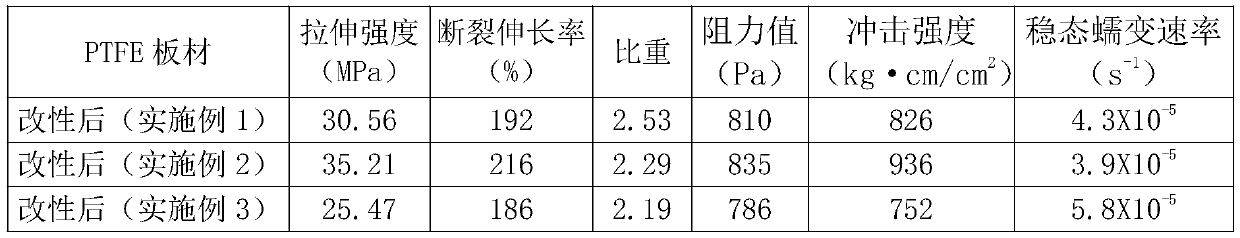

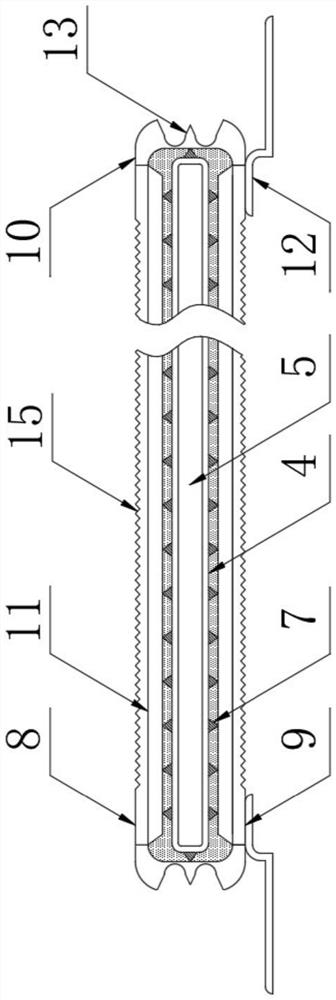

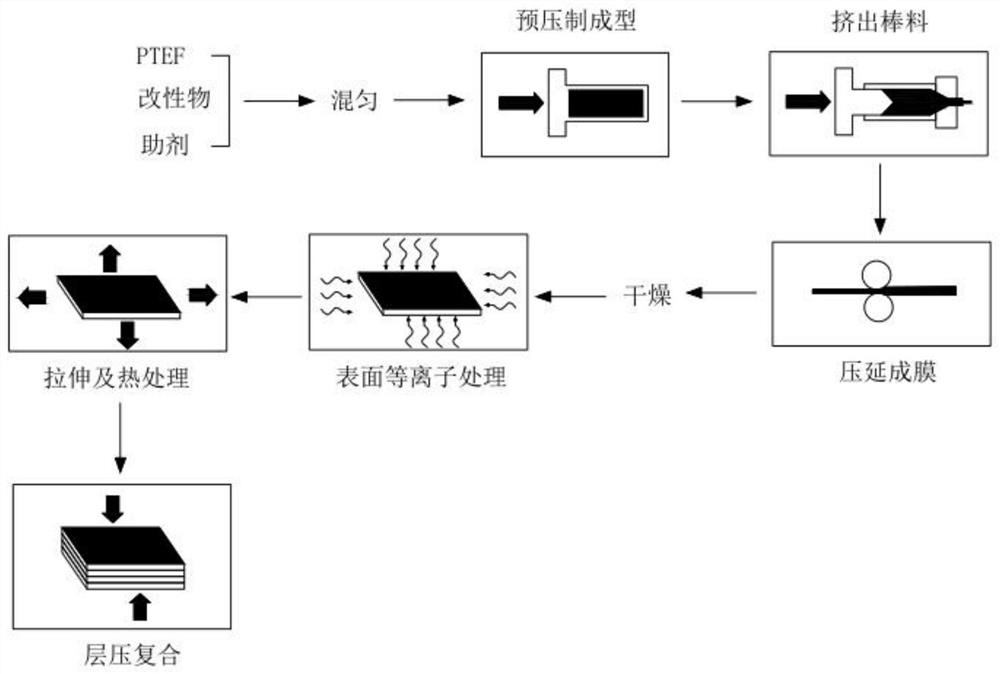

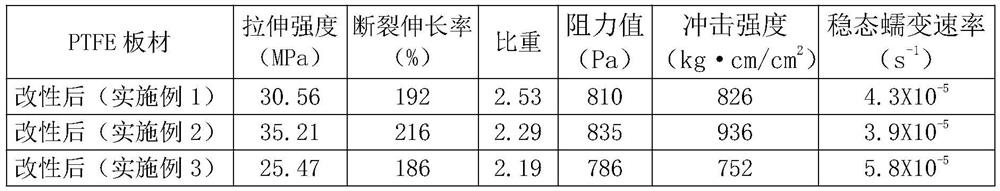

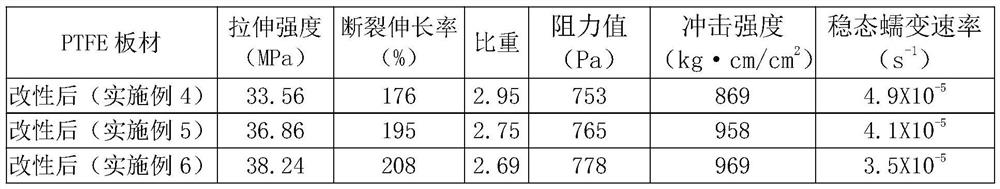

Multifunctional expanded polytetrafluoroethylene plate and laminating-compounding preparation process thereof

ActiveCN111152533AGood sterilization and deodorization effectLubriciousLamination ancillary operationsSynthetic resin layered productsFiberCompression molding

The invention relates to the technical field of polytetrafluoroethylene microporous plates, in particular to a multifunctional expanded polytetrafluoroethylene plate and a laminating-compounding preparation process thereof. The polytetrafluoroethylene plate is prepared by the following steps: uniformly mixing polytetrafluoroethylene, a polytetrafluoroethylene modifier, a fiber material, titanium dioxide and an organic solvent; carrying out pre-compression molding, extruding a bar, carrying out double-screw compression molding to form a film, heating to volatilize the organic solvent, carryingout transverse and longitudinal stretching to obtain a polytetrafluoroethylene microporous film, and carrying out a laminating-compounding process on the polytetrafluoroethylene microporous film to prepare the multifunctional polytetrafluoroethylene plate with high tensile strength. The preparation method is low in preparation cost and simple in preparation process, has a good sealing performance,chemical stability, thermal stability and electrical insulating property, and also has good creep resistance, binding strength and antibacterial property.

Owner:QINGDAO UNIV

Nutria tail collagen surgical suture and preparation method thereof

ActiveCN104587522AMeet surgical requirementsLittle tissue responseSuture equipmentsCross-linkWound healing

The invention discloses a nutria tail collagen surgical suture and a preparation method thereof. The method comprises the following steps: cutting standby nutria tail tendons into thin pieces, performing enzyme treatment by a ficus proteinase solution, preparing extracted natural collagen into a spinning solution, performing forming through a solution wet-spinning technology, and performing cross-linking to prepare the nutria tail collagen surgical suture which is a continuous long filament. The surgical suture has the diameter of 0.118-0.135 mm, the knot strength of 450-510 g and the elongation rate of 10.1-12.3%. The surgical suture meets the requirements of American suture size 6 / 0 and is suitable for clinical suturing. Biological experiments and clinical trials prove that the nutria tail collagen surgical suture has various advantages of mild tissue reaction, naturalness, degradability, non-toxicity, stability and reliability for absorption, high tensile strength, no need of being taken out, capability of being naturally absorbed or naturally falling off, no irritation, no scars after wound healing, and the like.

Owner:HEILONGJIANG LIHAIXIN BIOTECH CO LTD

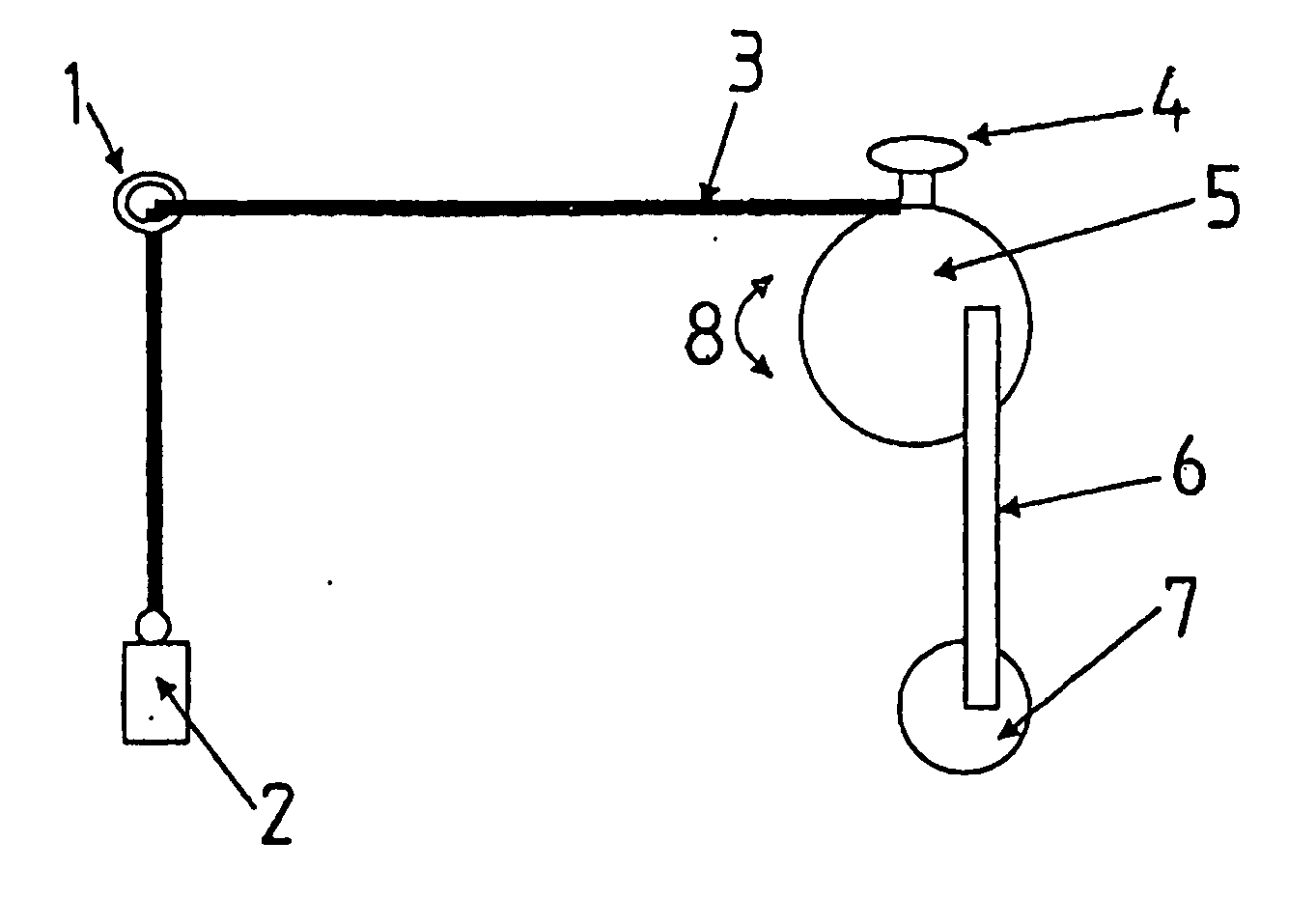

Fishing Line

InactiveUS20080022582A1Improve mechanical propertiesHigh breaking strengthLinesGrip property fibresFiberYarn

A novel, low cost fishing line resolves various problems posed by conventional fishing lines of braided structure, such as breaking strength, knot strength, low breaking elongation, drape insufficiency and producible length. The fishing line is made up of multiple filaments bound and united by means of a water dispersible resin adhesive. This fishing line realizes reduction of yarn damaging though avoidance of knitting and braiding steps, having such a structure that, due to buildup with enhanced linearity, the inherent strength of fiber can be easily exploited and the structure can be made with high productivity.

Owner:TOYOBO CO LTD

Absorbable medical suture line with good mechanical performance

ActiveCN105079869AImprove mechanical propertiesHigh strengthSuture equipmentsLactidePolyethylene glycol

The invention discloses an absorbable medical suture line with good mechanical performance. The absorbable medical suture line comprises, by weight, 100-120 parts of modified polylactic acid, 20-40 parts of polyglycollide, 4-6 parts of sorbitol, 3-5 parts of methyl methacrylate and 5-6 parts of cassia oil. The preparation method of the modified polylactic acid includes: in ice-bath, adding chitosan into perchloric acid, well mixing, dripping sorbic acid chloride, stirring, cooling, preserving heat and purifying to obtain modified chitosan; taking polyethylene glycol, feeding inert gas, heating, preserving heat until the polyethylene glycol melt, adding stannous chloride and lactide, well mixing, heating, preserving heat and stirring, and purifying to obtain intermediate material; dissolving the modified chitosan in mixed solvent, adding triethylamine, well mixing, heating, refluxing, adding the intermediate material, well mixing, continuing refluxing, purifying and drying to obtain the modified polylactic acid.

Owner:安徽省康宁医疗用品有限公司

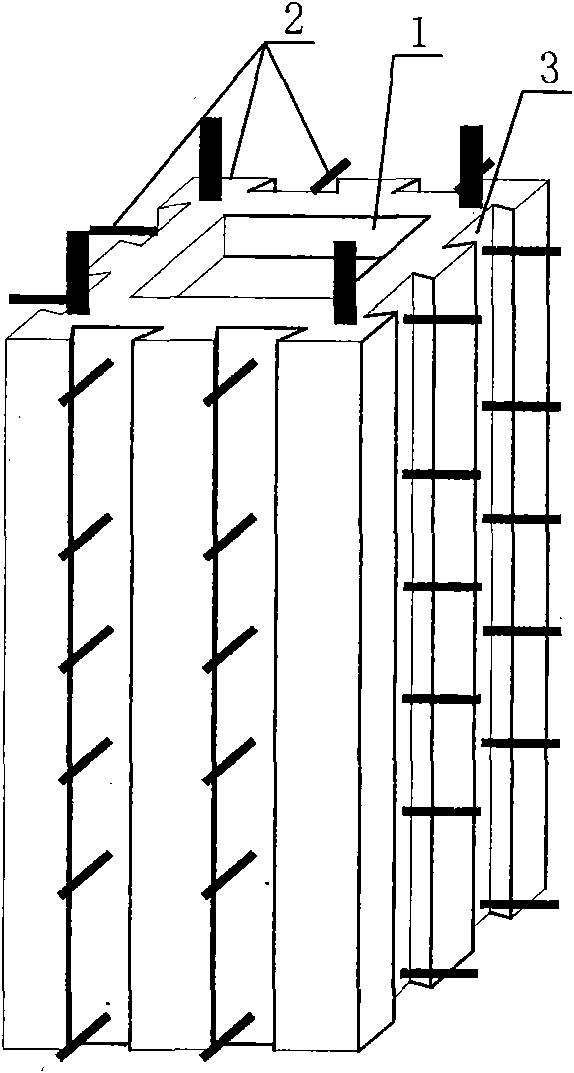

Drilling cast-in-place pile reinforcement mesh fixing structure and method

PendingCN111172999AHigh knot strengthImprove securityExcavationsBulkheads/pilesMesh reinforcementRebar

The invention discloses a drilling cast-in-place pile reinforcing mesh fixing structure and method. The structure comprises a plurality of transverse compression bars, a plurality of longitudinal compression bars, reinforcing mesh sheets, J-shaped anchor bars and fine aggregate concrete. The two ends of the transverse compression bars are implanted into slope protection piles, the plurality of longitudinal compression bars and the transverse compression bars are mutually crossed, welded and fixed, and the reinforcing mesh sheets are internally attached to the sides, facing inter-pile soil, onthe inner sides of the transverse compression bars and the longitudinal compression bars; long straight sections of the J-shaped anchor bars are implanted into the inter-pile soil, bent sections of the J-shaped anchor bars penetrate through the reinforcing mesh sheets and hook the transverse compression bars and the longitudinal compression bars, and implanting holes, where the J-shaped anchor bars are implanted, in the inter-pile soil are filled with mortar fixedly; and the fine aggregate concrete is sprayed to the sides, facing the interior of a foundation pit, on the outer sides of the transverse compression bars, the longitudinal compression bars and the reinforcing mesh sheets. The inter-pile support detailed node treatment can greatly improve the stability and safety of a pile foundation retaining wall, the inter-pile soil can be effectively fixed, and safety of foundation pit support and the overall stability of the foundation pit are ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

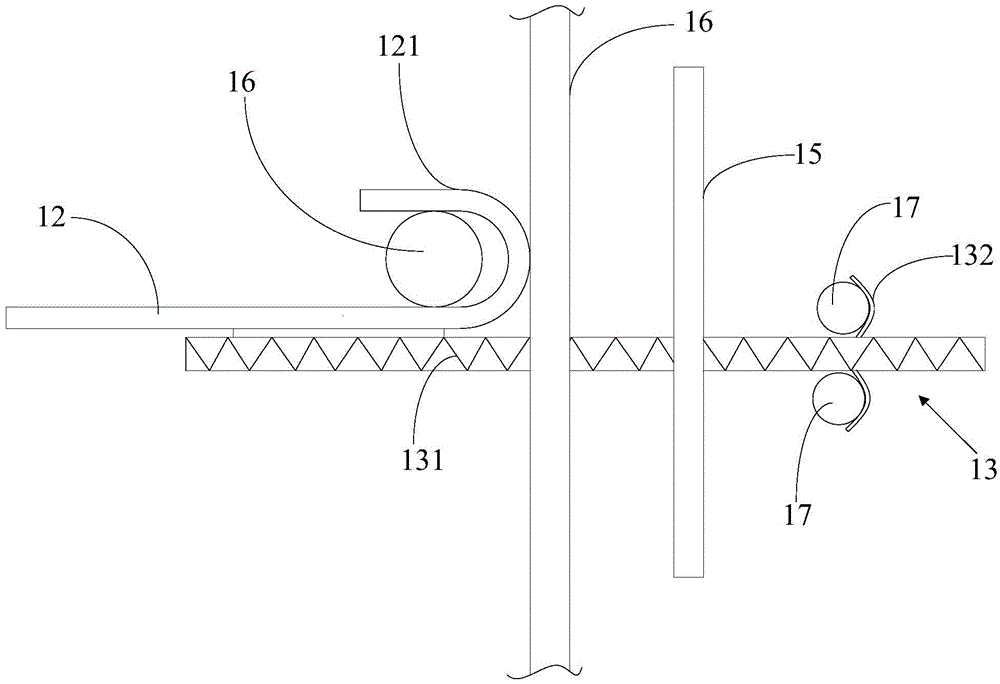

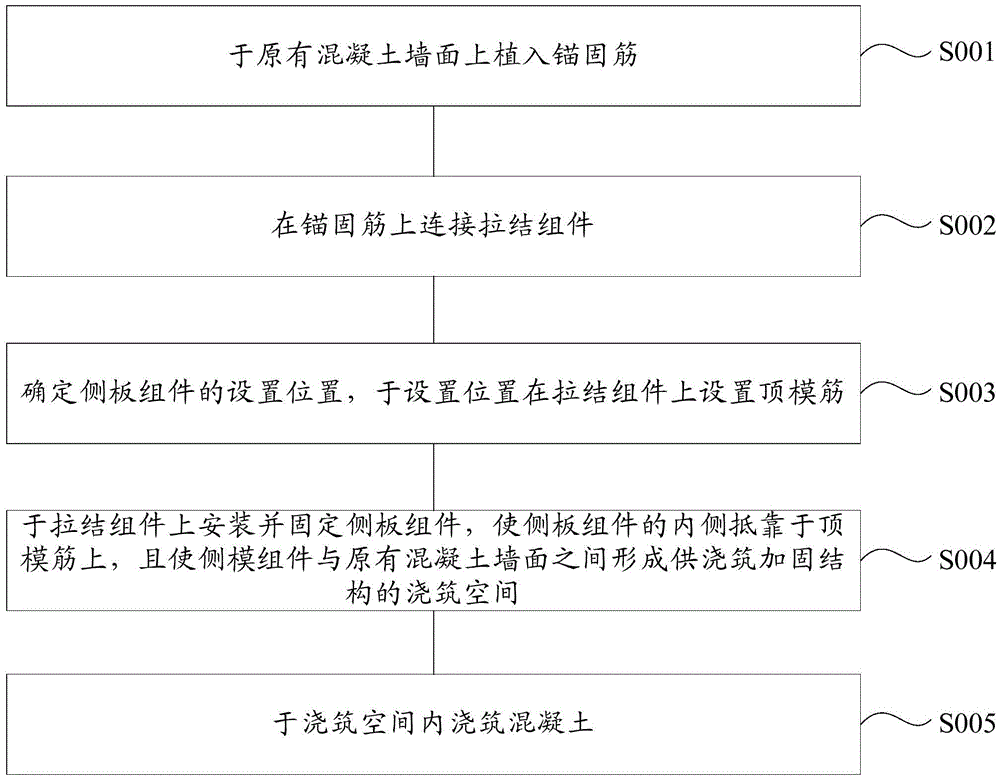

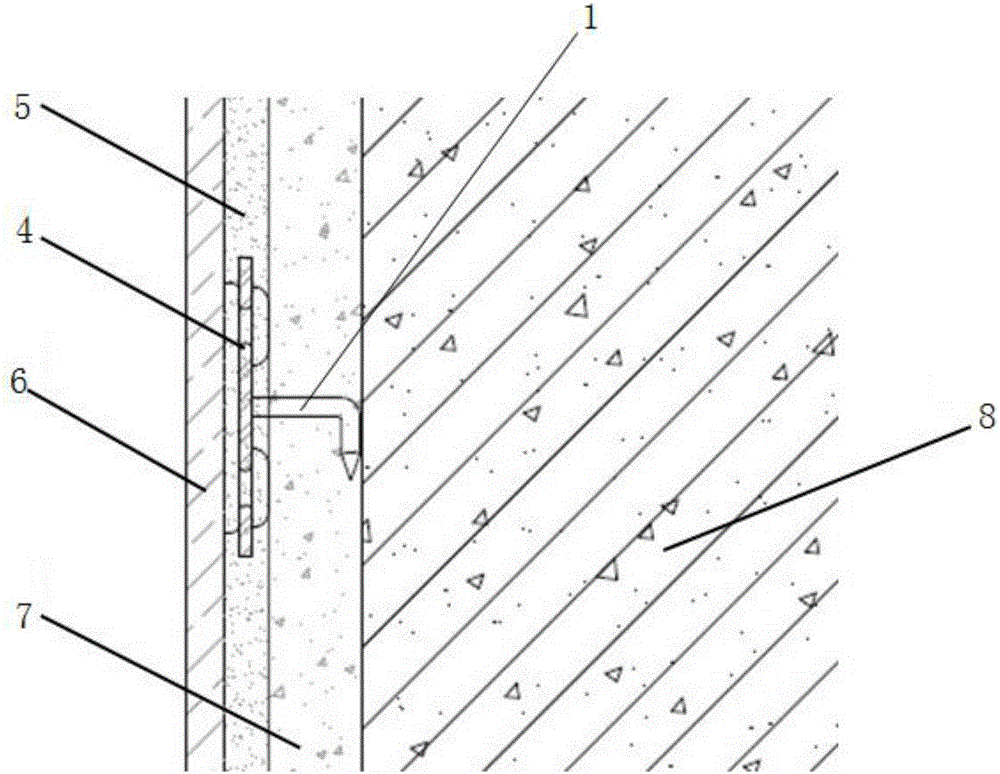

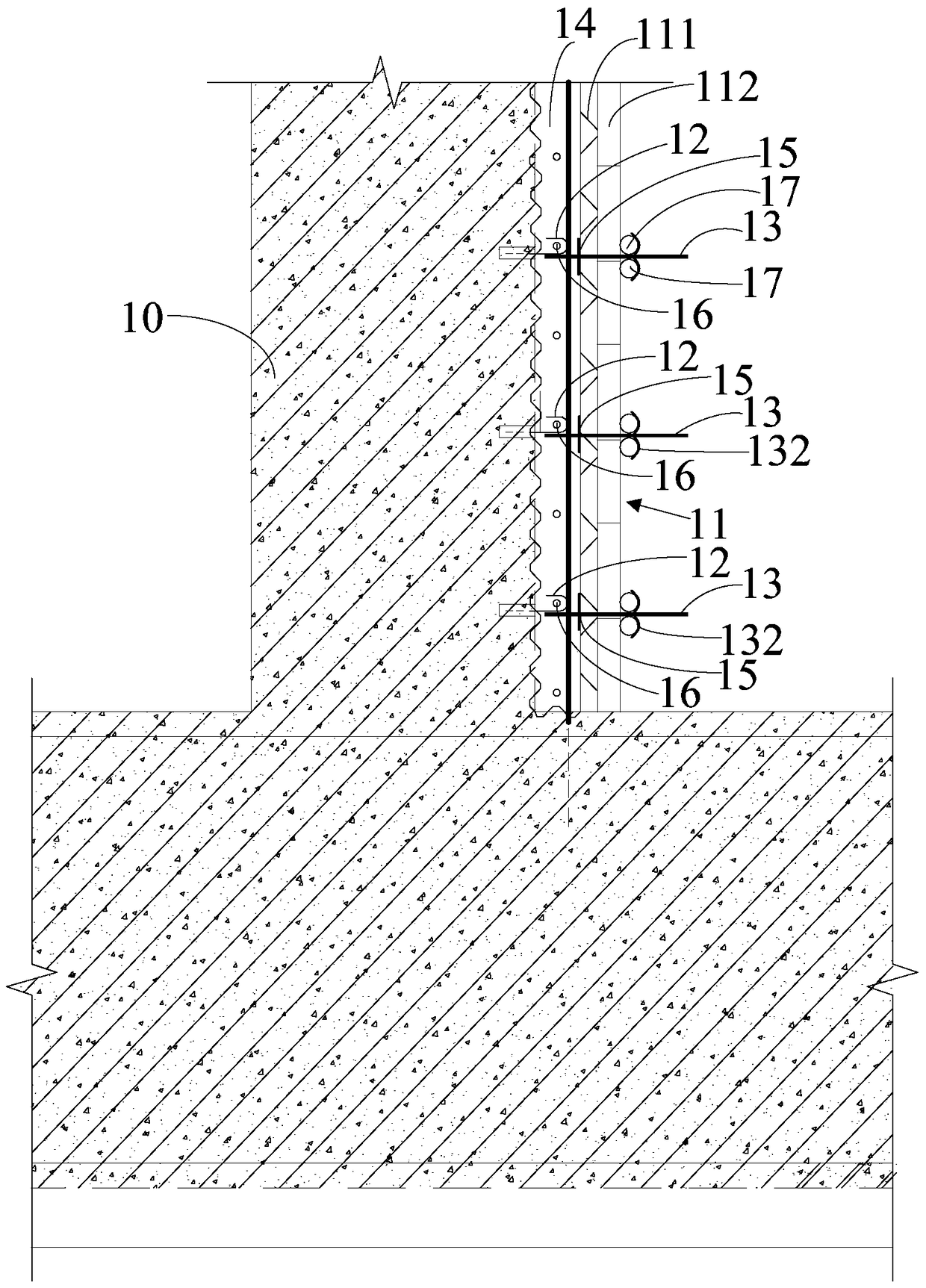

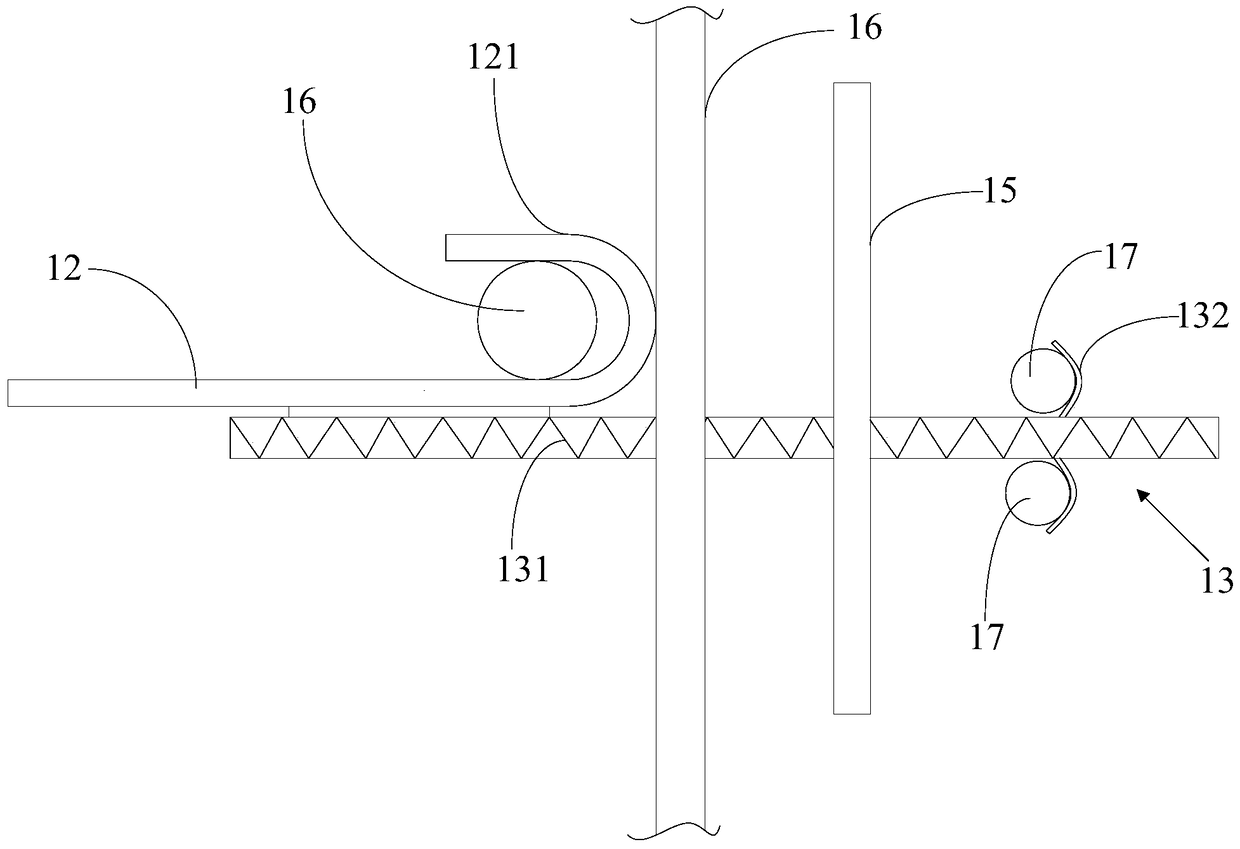

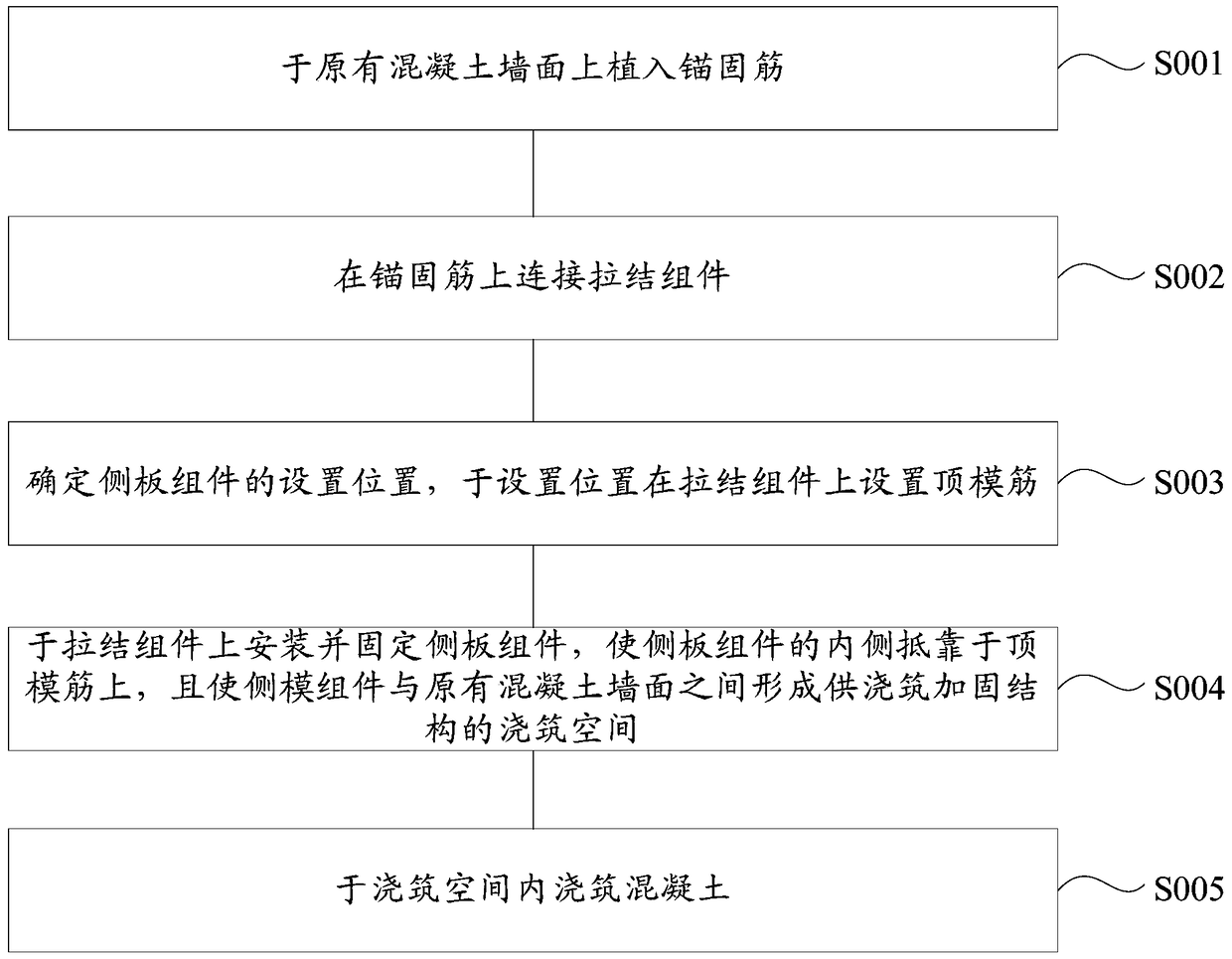

One-side support formwork structure for enlarging section and strengthening construction and construction method

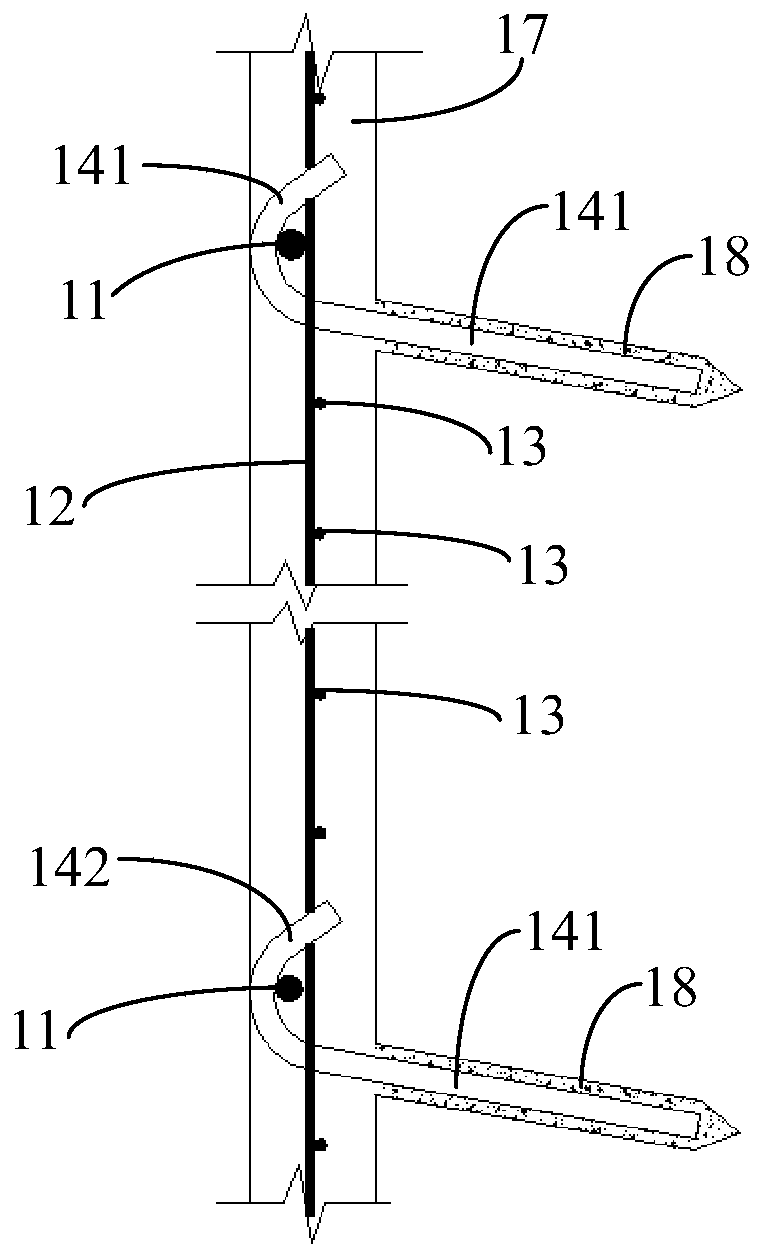

ActiveCN105464401AHigh knot strengthPrevent section neckingBuilding repairsForms/shuttering/falseworksRear quarterBuilding construction

The invention discloses a one-side support formwork structure for enlarging a section and strengthening construction and a construction method. The structure comprises a side formwork assembly, anchor ribs implanted in an original concrete wall surface and pulling and connecting assemblies pulled and connected between the side formwork assembly and the anchor ribs, a pouring space for pouring strengthened structures is formed between the side formwork assembly and the original concrete wall surface, and each pulling and connecting assembly is provided with a top formwork rib which abuts against the inner side of the side formwork assembly. According to the one-side support formwork structure for enlarging the section and strengthening construction and the construction method, due to the fact that the anchor ribs are implanted in the original concrete wall surface, the pulling and connecting assemblies are welded to the anchor ribs, side plate assemblies are pulled and connected to the anchor ribs through the pulling and connecting assemblies, and the pouring space for pouring the strengthened structures is formed between the side formwork assembly and the original concrete wall surface, the difficulty of strengthening of the one-side support formwork structure in the strengthening project can be solved by means of matching of the anchor ribs and the pulling and connecting assemblies, and meanwhile the pulling and connecting strength of the side plate assemblies and the original concrete wall surface is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Saponin-foamed and sisal fiber-enhanced wall body heat preservation mortar

InactiveCN101891436AHigh strengthLow thermal conductivitySolid waste managementCeramicwareThermal insulationPolyvinyl alcohol

The invention discloses a saponin-foamed and sisal fiber-enhanced wall body heat preservation mortar. The mortar is prepared by the steps of raw material selection, processing and preparation of heat preservation mortar. A finished product of the heat preservation mortar is prepared by mixing expanded perlite, volcanic tuff, aluminate early strength cement, polyvinyl formal, a mixture of saponin and short sisal fibers and an organic silicon water repellent in a mass ratio, stirring and performing waterproofing packing. Pores are generated by utilizing a foaming effect of the saponin; the strength of a heat preservation layer is improved by sisal toughening; mechanical strength is improved by utilizing the volcanic tuff; therefore, the heat preservation mortar of the invention has the advantages of low thermal conductivity, high strength, high bending resistance and impact resistance, and convenient production and use, and is applicable to the thermal insulation and the heat preservation of a building wall body.

Owner:HULUDAO DONGFANG IND

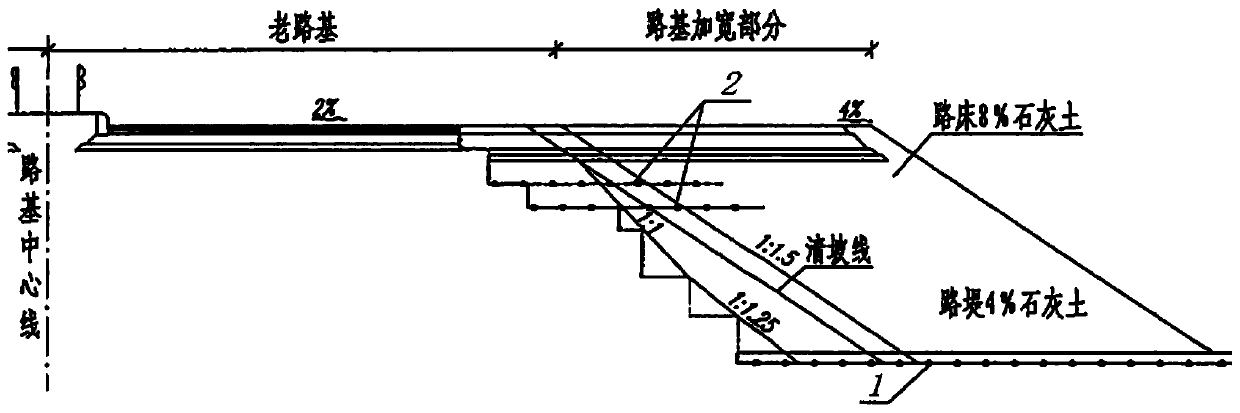

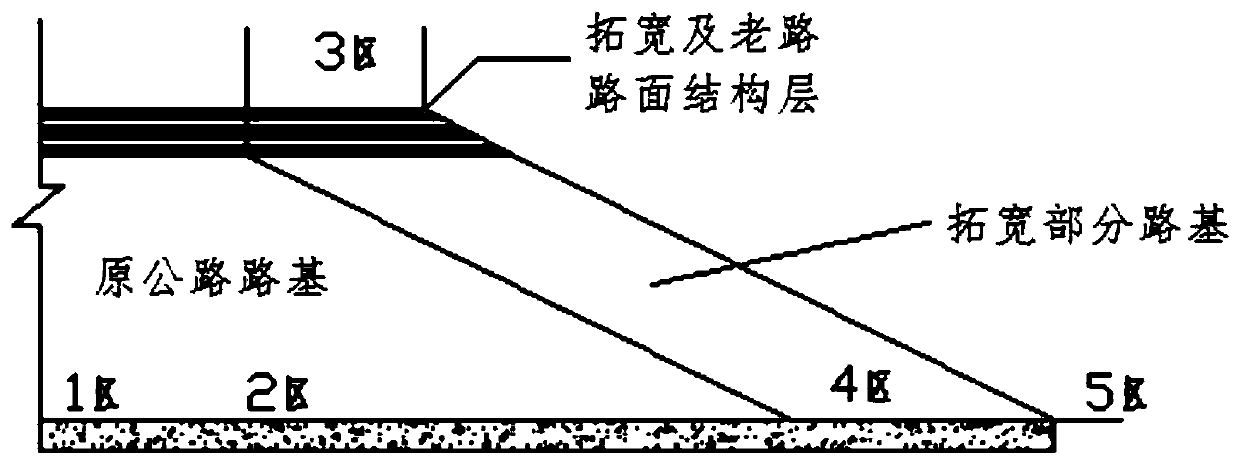

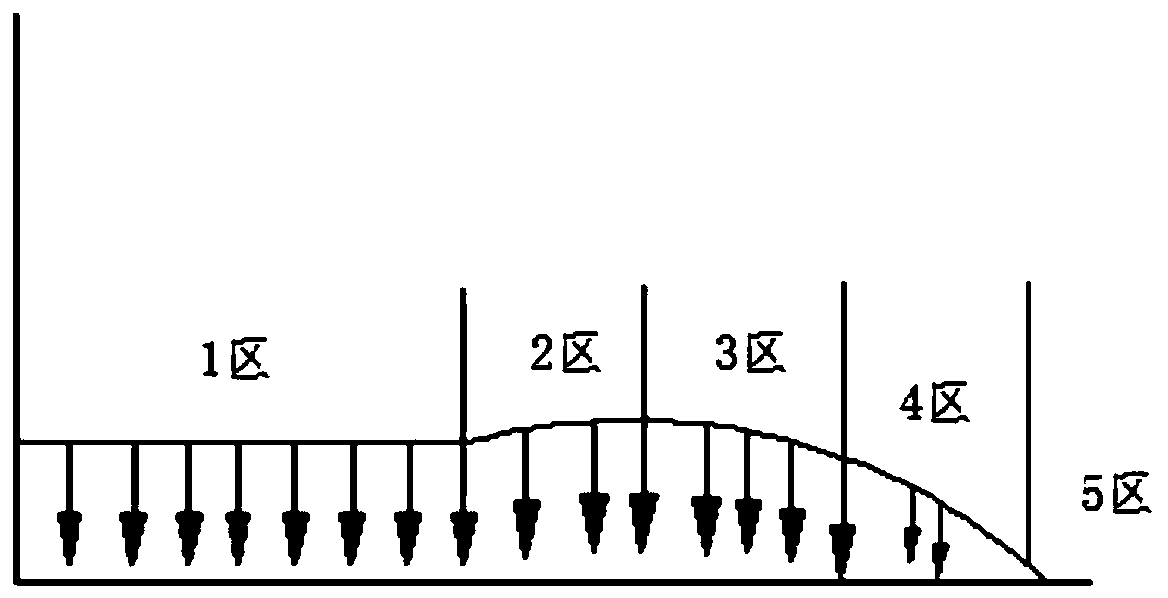

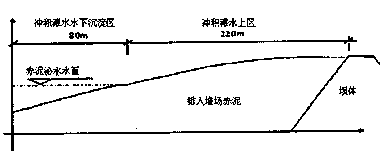

Roadbed splicing construction method in expressway reconstruction and extension

InactiveCN111485463AImprove bindingAvoid uneven settlementRoadwaysObservation pointArchitectural engineering

The invention discloses a roadbed splicing construction method in expressway reconstruction and extension. The method comprises the following steps: 1, removing surface soil of a roadbed substrate tobe widened, and rolling the substrate after the surface soil is removed before filling; 2, laying geocells on the base, and manually scattering gravels in the geocells; 3, performing slope cutting onthe to-be-widened side of the old roadbed, excavating steps at the slope part from top to bottom, and after the steps are excavated, and laying steel-plastic grids at the roadbed along the step surfaces; and 4, performing layered filling on the roadbed to be widened, and arranging settlement observation points and horizontal displacement observation points in the roadbed filling process. With application of the roadbed splicing method, the new roadbed and the old roadbed are well connected, longitudinal cracks caused by differential settlement of the new roadbed and the old roadbed are avoided, and thus the construction quality of highway reconstruction and extension engineering projects is guaranteed, and the highway construction level of China can be improved.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

Vinylidene fluoride resin monofilament and process for producing the same

InactiveUS20070009734A1High knot strengthImprove anti-twist performanceLinesConjugated synthetic polymer artificial filamentsChemistryFluoride salt

A monofilament obtained by smelt-spinning and stretching of a vinylidene fluoride resin is subjected to a high-temperature relaxation treatment for an extremely short period of 0.05-0.5 sec. within a high-temperature heating oil bath at a temperature of 140-175° C., thereby producing a vinylidene fluoride resin monofilament, which comprises a vinylidene fluoride resin having an inherent viscosity of at least 1.40 dl / g, and has a knot strength (JIS L1013) of at least 600 MPa and excellent anti-twist property represented by a twist index of at least 0.90 when measured after the monofilament being subjected to application for 1 minute of a tensile load equal to approximately 50% of a maximum tensile load (JIS K7113), removal of the load, and standing for 3 hours.

Owner:KUREHA KAGAKU KOGYO KK

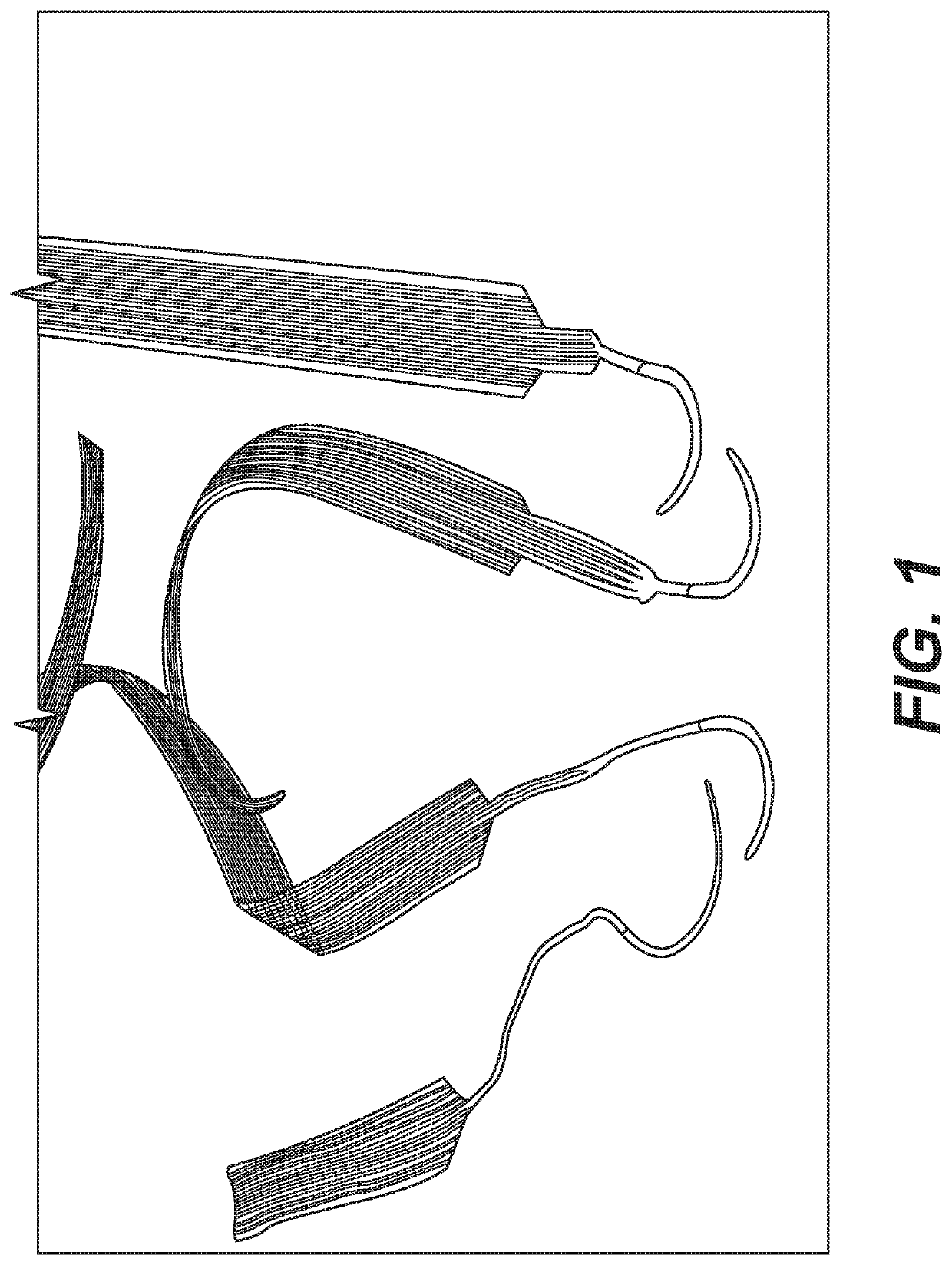

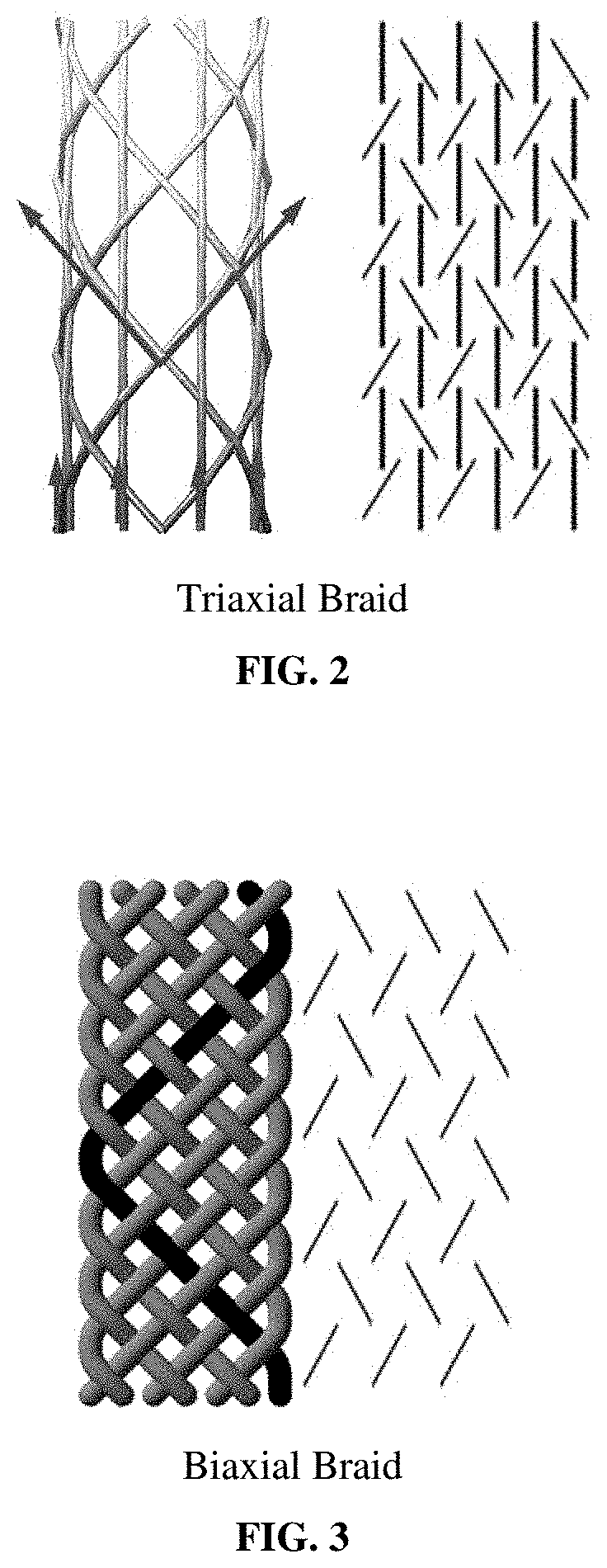

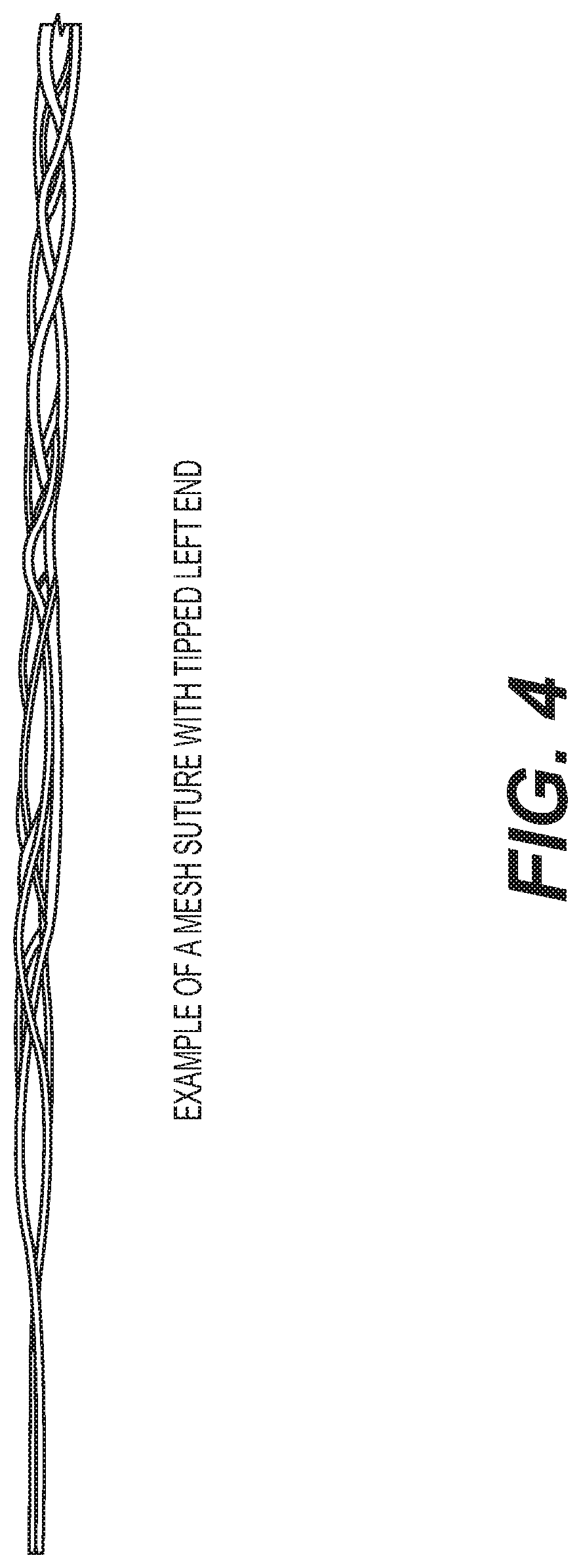

Methods of manufacturing mesh sutures from poly-4-hydroxybutyrate and copolymers thereof

ActiveUS10626521B2Improve toughnessGood drapeSuture equipmentsOrnamental textile articlesPolymer scienceSoft tissue repair

Resorbable multifilament yarns and monofilament fibers including poly-4-hydroxybutyrate and copolymers thereof with high tenacity or high tensile strength have been developed. The yarns and fibers are produced by cold drawing the multifilament yarns and monofilament fibers before hot drawing the yarns and fibers under tension at temperatures above the melt temperature of the polymer or copolymer. These yarns and fibers have prolonged strength retention in vivo making them suitable for soft tissue repairs where high strength and strength retention is required. The multifilament yarns have tenacities higher than 8.1 grams per denier, and in vivo, retain at least 65% of their initial strength at 2 weeks. The monofilament fibers retain at least 50% of their initial strength at 4 weeks in vivo. The monofilament fibers have tensile strengths higher than 500 MPa. These yarns and fibers may be used to make various medical devices for various applications, including mesh sutures.

Owner:TEPHA INC

Carbon fiber bundle and method of producing carbon fiber bundle

ActiveUS20150114262A1High knot strengthLayered productsMonocomponent synthetic polymer artificial filamentFiber bundleCarbon fibers

Provided are carbon fiber bundles which have high knot strength even if the single fiber fineness is large, and which have excellent handling properties and processability. The carbon fiber bundles have a single fiber fineness of 0.8-2.5 dtex, knot strength of 298 N / mm2 or greater. This method of producing carbon fibers having knot strength of 298 N / mm2 or greater involves a heat treatment step for heat treating, for 50-150 minutes, specific polyacrylonitrile-based precursor fiber bundles described in the description in an oxidizing atmosphere rising in temperature in the temperature range of 220-300° C.

Owner:MITSUBISHI CHEM CORP

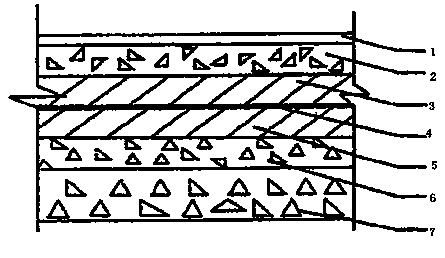

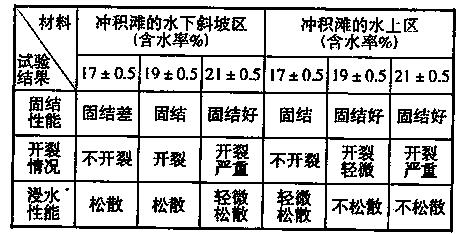

Waste foam plastic sandwich decoration and insulation composite wall and preparation method thereof

The invention relates to a preparation method of a waste foam plastic sandwich decoration and insulation composite wall. The method comprises the following steps that 1, waste foam plastic is crushed into waste foam plastic particles with the particle size small than 3 mm; 2, a bearing inner wall and a non-bearing outer wall with a decorative function are built up, and a connecting pull rod is embedded; 3, the waste foam plastic particles obtained in the step 1 and materials such as cement, chopped fiber, a styrene-acrylic emulsion, a concrete waterproofer, hydrogen peroxide and water are mixed and stirred to be uniform in proportion, after foaming is conducted, the mixture is injected into a cavity between the bearing inner wall and the non-bearing outer wall, and vibration is conducted through a vibrator.

Owner:山东省建设发展研究院

Carbon fiber bundle and method of producing carbon fiber bundle

ActiveUS10837127B2High knot strengthMonocomponent synthetic polymer artificial filamentThin material handlingPolymer scienceCarbon fibers

Provided are carbon fiber bundles which have high knot strength even if the single fiber fineness is large, and which have excellent handling properties and processability. The carbon fiber bundles have a single fiber fineness of 0.8-2.5 dtex, knot strength of 298 N / mm2 or greater. This method of producing carbon fibers having knot strength of 298 N / mm2 or greater involves a heat treatment step for heat treating, for 50-150 minutes, specific polyacrylonitrile-based precursor fiber bundles described in the description in an oxidizing atmosphere rising in temperature in the temperature range of 220-300° C.

Owner:MITSUBISHI CHEM CORP

A graded lift type retaining dam

InactiveCN106968225BReduce weightIncrease stiffnessBarrages/weirsArchitectural engineeringEngineering

The invention relates to the technical field of hydraulic and hydroelectric engineering, and aims to provide a novel grading lifting type water retaining dam which is stable in supporting and does not affect lifting of a gate. According to the technical scheme adopted by the novel grading lifting type water retaining dam, the bulkhead gate is composed of a front steel plate and a rear steel plate, and the front steel plate and the rear steel plate are integrally connected through two side plates. The top of the front steel plate is provided with a plurality of rod recovery openings, the rear steel plate are provided with a plurality of rod penetrating grooves, and the rod recovery openings correspond to the rod penetrating grooves one by one. Each rod penetrating groove is composed of two parallel and vertical strip-shaped groove bodies which extend from the middle of the rear steel plate to the edge of the top of the rear steel plate. A supporting assembly is arranged at each group composed of one rod recovery opening and one rod penetrating groove correspondingly, and comprises supporting rods and hinge supports fixed to a downstream bed. The novel grading lifting type water retaining dam is stable in supporting and does not affect lifting of the gate.

Owner:XIHUA UNIV

Application method for red mud in red mud storage yard impermeable layer

Disclosed is an application method for red mud in a red mud storage yard impermeable layer. The method comprises the steps that a foundation constructed on the flat ground is paved with the red mud with the thickness of 500 mm and then is paved with geomembranes, and the geomembranes are filled with the red mud with the thickness of 500 mm. The red mud layer needs to be ground and dried to be in the solidified state. Clay consumption can be reduced, various negative factors caused when the clay is used as an impermeable layer are avoided, and an effective way is provided for comprehensive utilization and safe storage of the red mud.

Owner:LUOYANG GUANGXIN CONSTR GRP

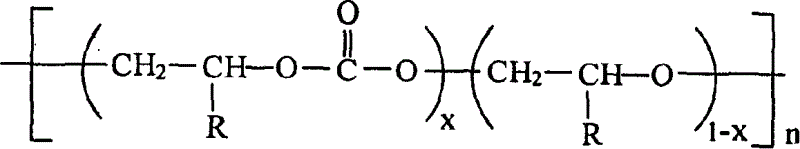

Manufacturing method of medical absorpable suture

InactiveCN100393366CLittle tissue responseWound healing with little scarSuture equipmentsConjugated synthetic polymer artificial filamentsWater bathsPolymer science

An absorptive medical suture with high strength, toughness, biocompatibility and absorptivity, and abvious body temp memory effect is prepared from CO2 copolymer through fusing, mixing with maleic acid anhydride or acetic acid anhydride, granulating, fusing, mixing with polylactic acid or polyhydroxy butyrate, extruding for granulating, melt spinning and drafting in water bath.

Owner:吉林金源北方科技发展有限公司

Composite board special for heat preservation of building external wall

ActiveCN111794394AIncreased longitudinal compression resistanceIncrease lateral compression resistanceClimate change adaptationInsulation improvementInsulation layerArchitectural engineering

The invention discloses a composite board special for heat preservation of a building external wall and particularly relates to the technical field of heat preservation composite boards. The compositeboard comprises a composite board body. The composite board body comprises a rock wool heat preservation layer, and the rock wool heat preservation layer is provided with a reinforcement thermal insulation assembly. The reinforcement thermal insulation assembly comprises a steel plate, a vacuum layer is arranged in the steel plate, a placement groove is formed in the rock wool heat preservation layer, the steel plate is arranged in the placement grove, and first triangular reinforcement strips are fixedly arranged on the outer side of the steel plate. The composite board is extremely high instructural strength and extremely good in pressure resistance capacity and is prevented from being broken and damaged in the transportation and installation process or damaged due to the external force effect after installation. The vacuum layer is arranged in the steel plate, so that heat transfer is reduced. Since the first triangular reinforcement strips and second triangular reinforcement strips are arrayed in a crossed manner, and the contact point is extremely small, the heat transfer efficiency is further lowered, the excellent thermal insulation and heat preservation effect is achieved, and the installation and fixing effect is also good.

Owner:CHONGQING ZHONGHANG SCIENCE AND TECHNOLOGY CO LTD

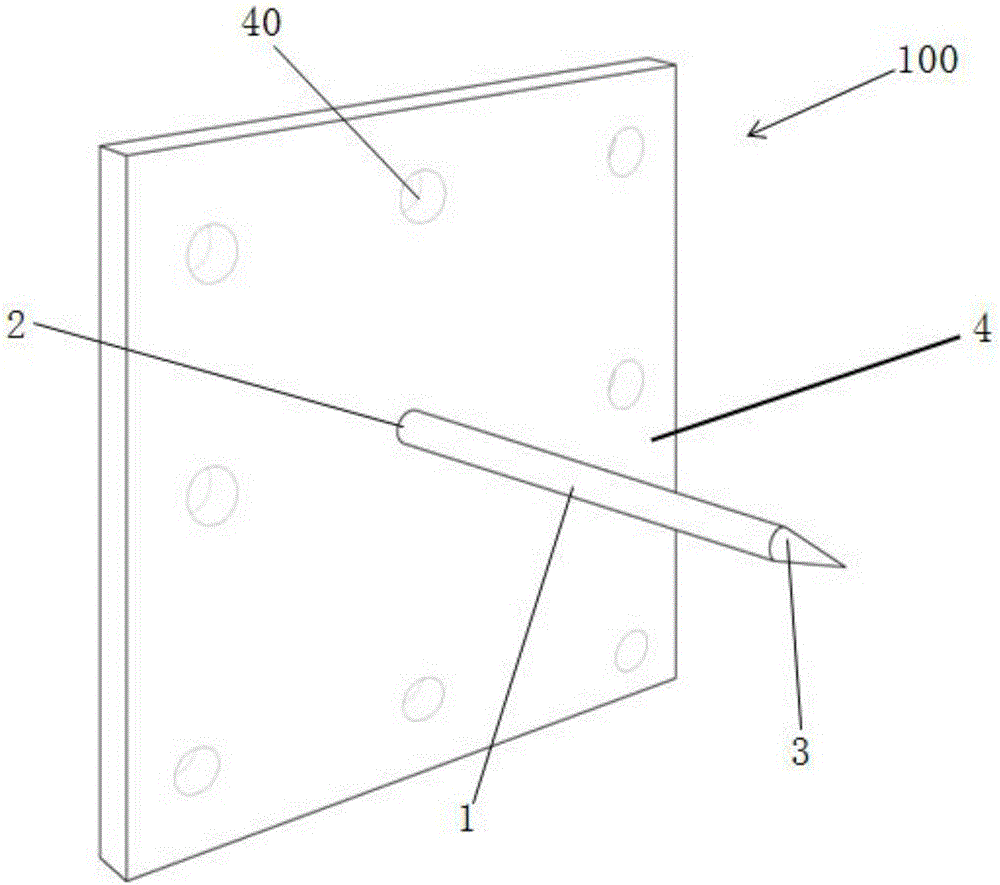

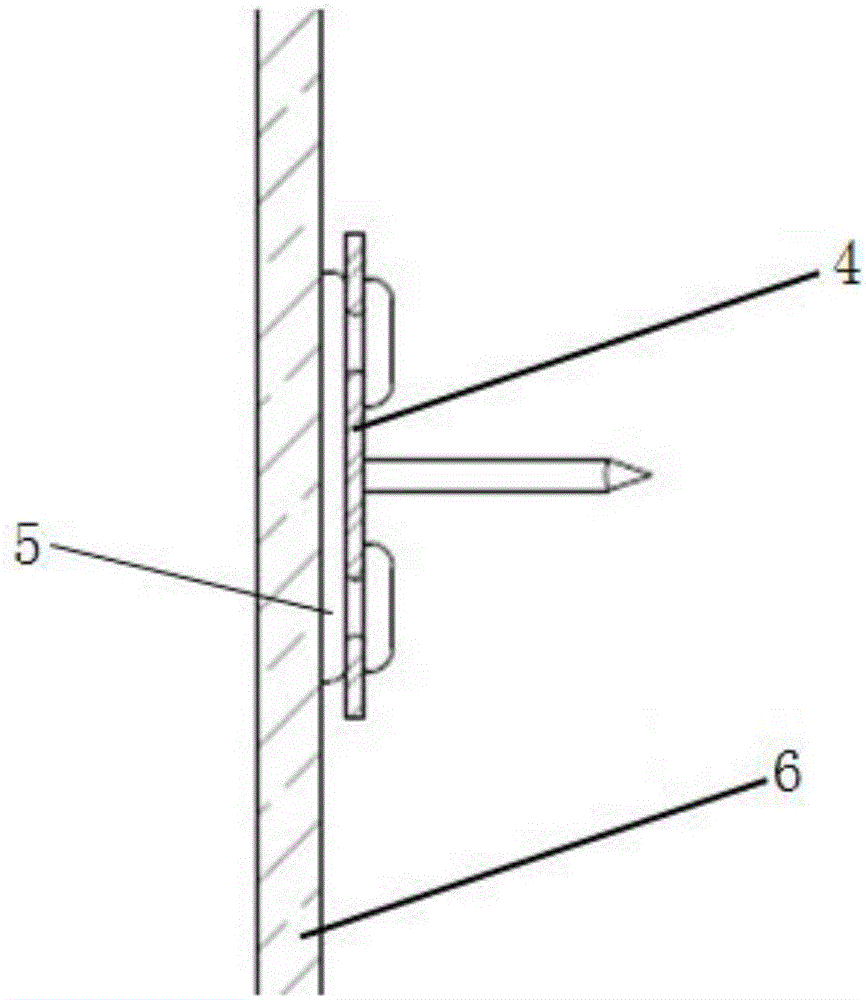

Ceramic tile back-laying structural nail

The invention relates to a ceramic tile back-laying structural nail which comprises a nail body, a nail tail and a nail head, wherein a sheet iron plate is arranged at the nail tail; the nail body is made of an iron wire; a plurality of fixing holes are formed in the sheet iron plate; the sheet iron plate is fixed at the back of a ceramic tile through a structural adhesive; the structural adhesive penetrates through the fixing holes; and the ceramic tile back-laying structural nail is bonded with a wall through a fixing layer. By adoption of the ceramic tile back-laying structural nail provided by the invention, the bonding firmness between the ceramic tile and the wall can be improved; after the ceramic tile is laid, the ceramic tile back-laying structural nail is implanted into a clay layer or a mortar layer, thereby enhancing the tying strength between the ceramic tile and the wall, and effectively controlling the common quality problem that a ceramic tile laid according to the conventional laying technique chips; and the construction principle is reliable, the construction process is concise, and the construction quality of ceramic tile laying on the wall is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Vinylidene fluoride resin monofilament and process for producing the same

InactiveUS20090295038A1High knot strengthImprove anti-twist performanceLinesConjugated synthetic polymer artificial filamentsHeating oilFluoride

A monofilament obtained by smelt-spinning and stretching of a vinylidene fluoride resin is subjected to a high-temperature relaxation treatment for an extremely short period of 0.05-0.5 sec. within a high-temperature heating oil bath at a temperature of 140-175° C., thereby producing a vinylidene fluoride resin monofilament, which comprises a vinylidene fluoride resin having an inherent viscosity of at least 1.40 dl / g, and has a knot strength (JIS L1013) of at least 600 MPa and excellent anti-twist property represented by a twist index of at least 0.90 when measured after the monofilament being subjected to application for 1 minute of a tensile load equal to approximately 50% of a maximum tensile load (JIS K7113), removal of the load, and standing for 3 hours.

Owner:HASHIMOTO +3

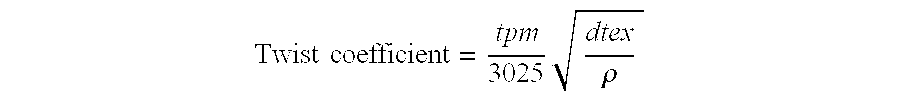

Method for processing modified polypropylene bristle filaments for net mesh

InactiveCN101851799AImproves knot strength and abrasion resistanceGood for knot strengthSpinning head liquid feederFilament manufacturePolypropyleneAirflow

The invention provides a method for processing modified polypropylene bristle filaments for a net mesh, which relates to a method for preparing matrix fibers for a net mesh. The method adopts a stirrer, an extruder, a drawing machine, a filament roller and a filament separator. The method is characterized by comprising the following steps of: mixing PP resin, UHMWPE resin, zinc stearate and auxiliary agent uniformly, stirring the mixture uniformly, extruding and granulating the uniformly stirred mixture through the extruder to obtain mixed granules; melting and extruding the mixed granules through the extruder, pre-drawing the melted and extruded primary filaments, and thermally drawing the pre-drawn filaments twice, wherein a secondary drawing hot oil bath uses ethylene glycol as a drawing heating medium and the total magnification of the pre-drawn filaments is controlled to be between 8.46 and 8.78 through twice thermal drawing; removing oil by adopting high-pressure airflow, then quickly cooling the drawn filaments, and rolling the modified PP bristle filament beams by using the filament roller; and separating the bristle filament beams into the modified PP bristle filaments through the filament separator under the filament separation tension of between 3.2 and 4.0N. The method is used for the production of the modified polypropylene bristle filaments.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Single-side support formwork structure and construction method for reinforcement construction of enlarged section

ActiveCN105464401BPrevent section neckingSolve reinforcement difficultiesBuilding repairsForms/shuttering/falseworksRear quarterBuilding construction

The invention discloses a one-side support formwork structure for enlarging a section and strengthening construction and a construction method. The structure comprises a side formwork assembly, anchor ribs implanted in an original concrete wall surface and pulling and connecting assemblies pulled and connected between the side formwork assembly and the anchor ribs, a pouring space for pouring strengthened structures is formed between the side formwork assembly and the original concrete wall surface, and each pulling and connecting assembly is provided with a top formwork rib which abuts against the inner side of the side formwork assembly. According to the one-side support formwork structure for enlarging the section and strengthening construction and the construction method, due to the fact that the anchor ribs are implanted in the original concrete wall surface, the pulling and connecting assemblies are welded to the anchor ribs, side plate assemblies are pulled and connected to the anchor ribs through the pulling and connecting assemblies, and the pouring space for pouring the strengthened structures is formed between the side formwork assembly and the original concrete wall surface, the difficulty of strengthening of the one-side support formwork structure in the strengthening project can be solved by means of matching of the anchor ribs and the pulling and connecting assemblies, and meanwhile the pulling and connecting strength of the side plate assemblies and the original concrete wall surface is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A multi -functional vertical polytetrafluoroethylene board and its layer pressure composite preparation process

ActiveCN111152533BHigh knot strengthImprove creep resistanceLamination ancillary operationsSynthetic resin layered productsFiberPolymer science

The invention relates to the technical field of polytetrafluoroethylene microporous plates, in particular to a multifunctional expanded polytetrafluoroethylene plate and a lamination composite preparation process thereof. The polytetrafluoroethylene plate is made by mixing polytetrafluoroethylene, polytetrafluoroethylene modified material, fiber material, titanium dioxide and organic solvent evenly, pre-pressing and forming, extruding the bar, and pressing it into a film by twin-screw, then heating and volatilizing. The organic solvent is removed, and the polytetrafluoroethylene microporous film is obtained by horizontal and longitudinal stretching, and the polytetrafluoroethylene microporous film is made into a multifunctional polytetrafluoroethylene plate with high tensile strength through a lamination and composite process. The invention has low preparation cost, simple preparation process, good sealing, chemical stability, thermal stability and electrical insulation, as well as good creep resistance, tensile strength and antibacterial properties.

Owner:QINGDAO UNIV

A kind of nutria tail collagen surgical suture and its preparation method

Owner:HEILONGJIANG LIHAIXIN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com