One-side support formwork structure for enlarging section and strengthening construction and construction method

A technology of single-side formwork and enlarged cross-section, which is applied to the connection of formwork/formwork/work frame, building structure, and processing of building materials. It can solve the difficulty of single-side formwork reinforcement and the quality of concrete molding. Control and other issues, to achieve the effect of good concrete forming quality, solving reinforcement difficulties, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

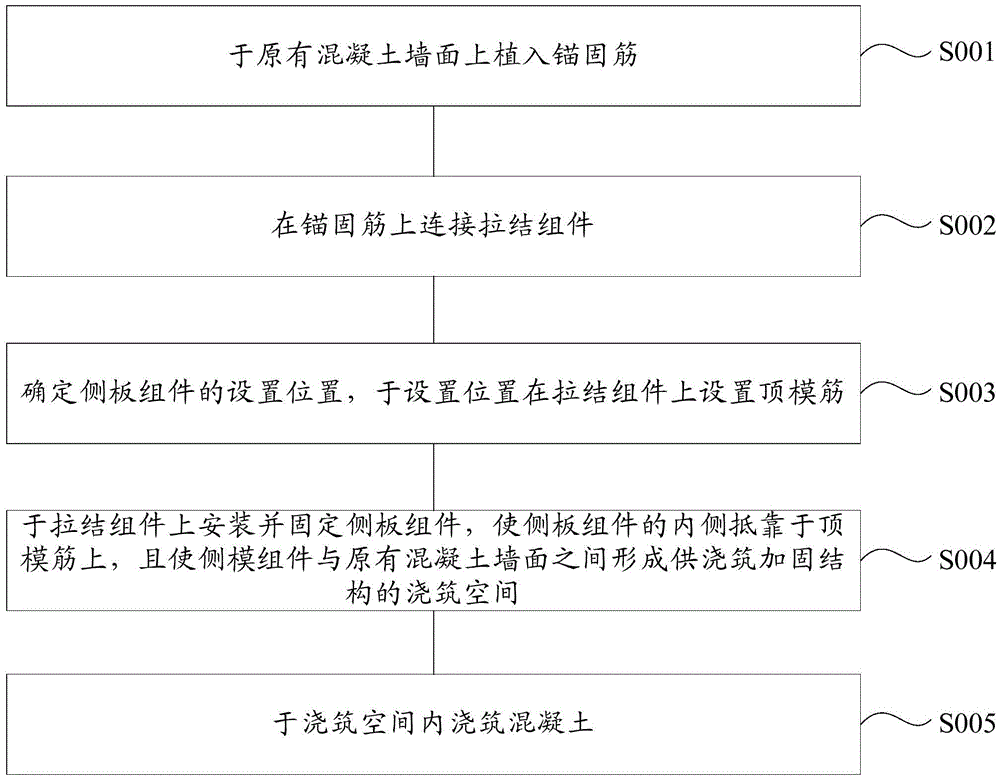

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

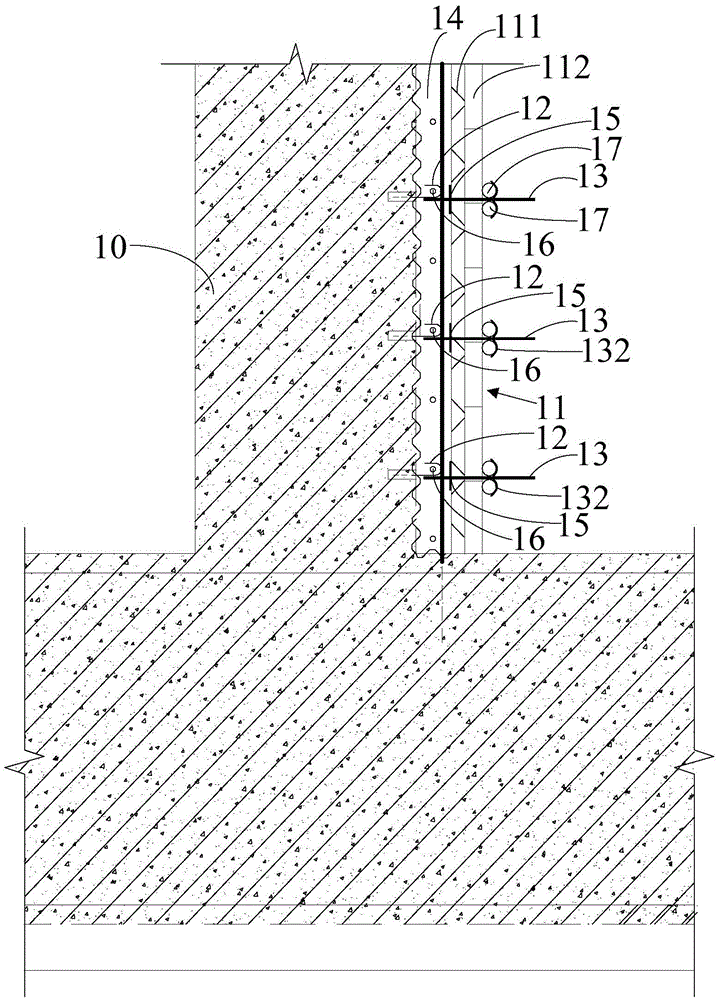

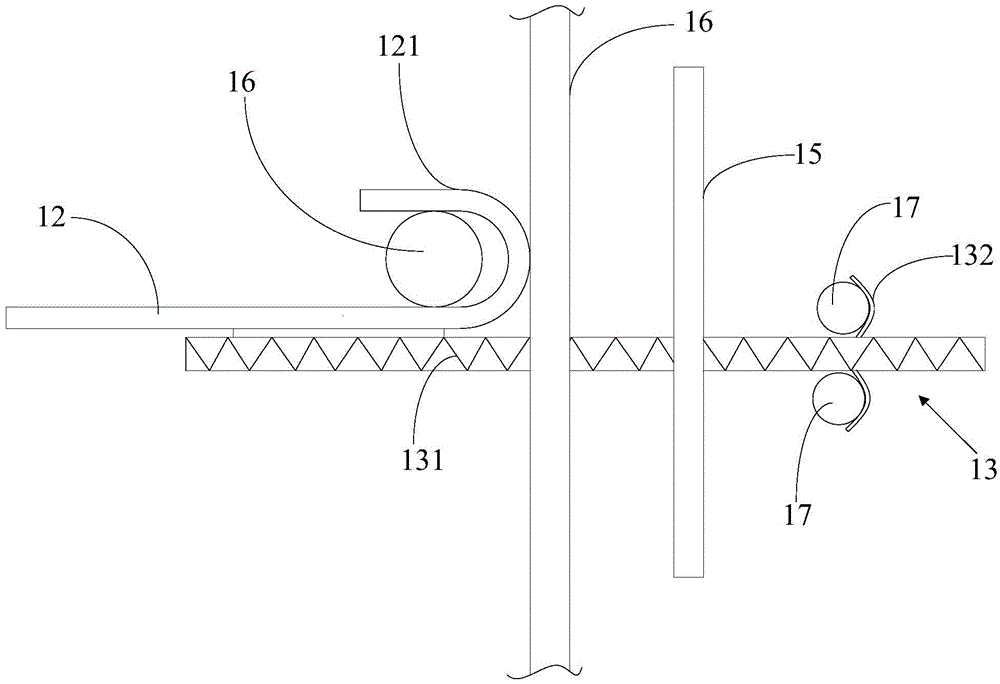

[0028] First, see figure 1 and figure 2 As shown, a single-side formwork structure for enlarging cross-section reinforcement construction of the present invention is mainly composed of side formwork components 11, anchor bars 12 implanted on the original concrete wall surface 10, and tied to the side formwork group. The tie assembly 13 between the piece 11 and the anchor bar 12, the pouring space 14 for pouring the reinforcement structure is formed between the side form assembly 11 and the original concrete wall 10, and the tie assembly 13 is provided with a The top mold rib 15 on the inner side of the assembly 11. Wherein, the side form assembly further 11 comprises formwork 111 and the wooden side 112 that is arranged on the outside of formwork 111, and formwork 111 is the thick wooden formwork of 15mm, and wooden side 112 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com