Patents

Literature

77 results about "Die swell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die swell, also known as extrudate swell or Barus effect, is a common phenomenon in polymer processing. Die swell occurs in instances of polymer extrusion, in which a stream of polymeric material is forced through a die, a specialized tool in manufacturing to shape or cut polymeric materials. Die swell is an instance where a polymer stream is compressed by entrance into a die, and is followed by a partial recovery or “swell” back to the former shape and volume of the polymer after exiting the die, hence the term die swell.

Enhanced ESCR bimodal HDPE for blow molding applications

Bimodal polyethylene compositions and blow molded bottles made therefrom are provided. In at least one specific embodiment, the composition includes at least one high molecular weight polyethylene component having a molecular weight distribution (MWD) of about 6 to about 9, a short chain branch content of less than about 2 branches per 1,000 main chain carbons, and a Mz of about 1,100,000 or more. The composition also includes at least one low molecular weight polyethylene component where a ratio of weight average molecular weight of the high molecular weight polyethylene component to weight average molecular weight of the low molecular weight polyethylene component is about 20 or less. The polyethylene composition has a density of about 0.94 g / cc or more, an ESCR of about 600 hours or more, a percent die swell of about 70% or more, and may comprise at least 70% ethylene-derived units.

Owner:UNIVATION TECH LLC

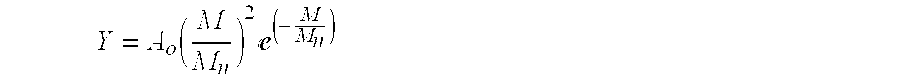

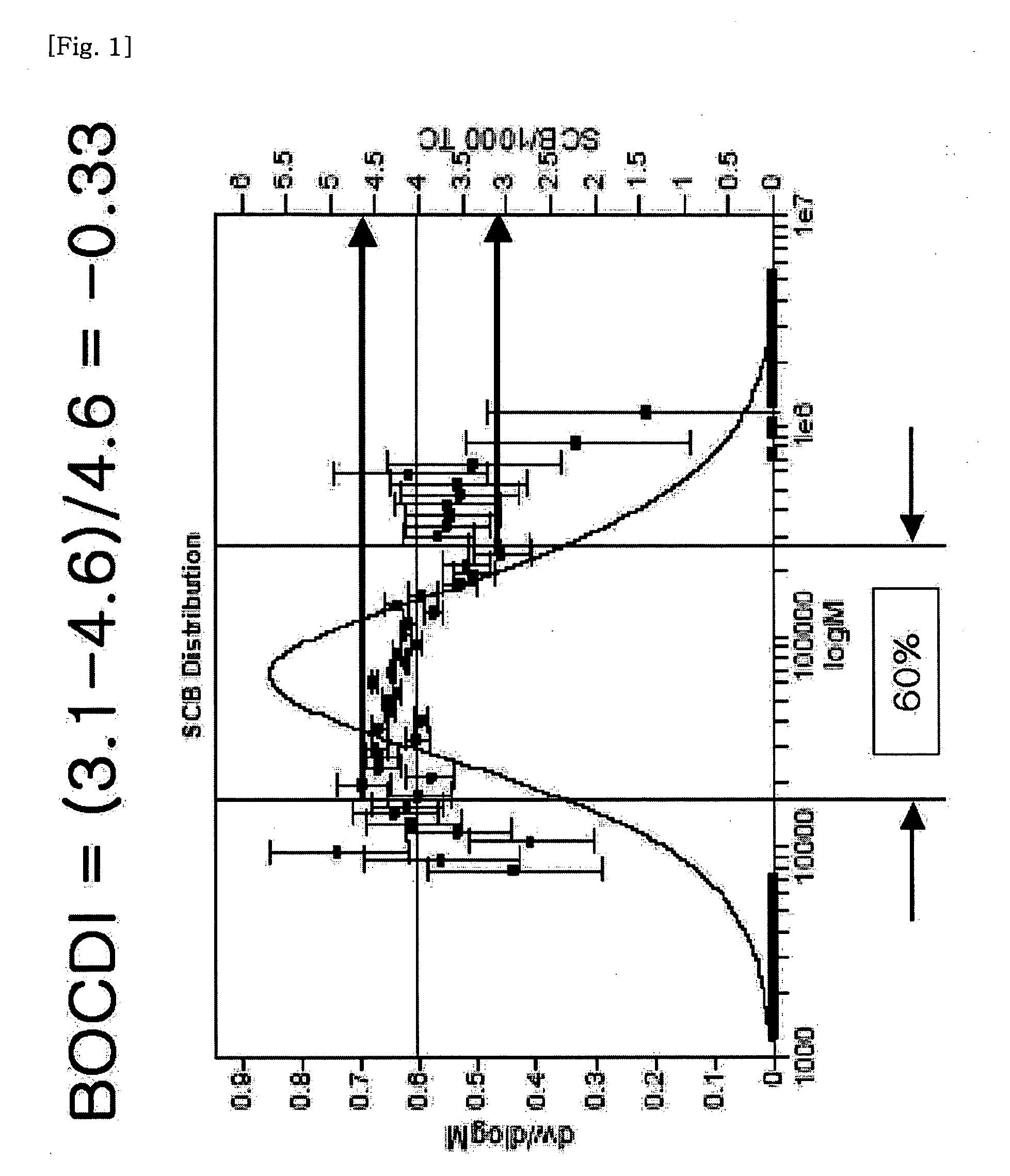

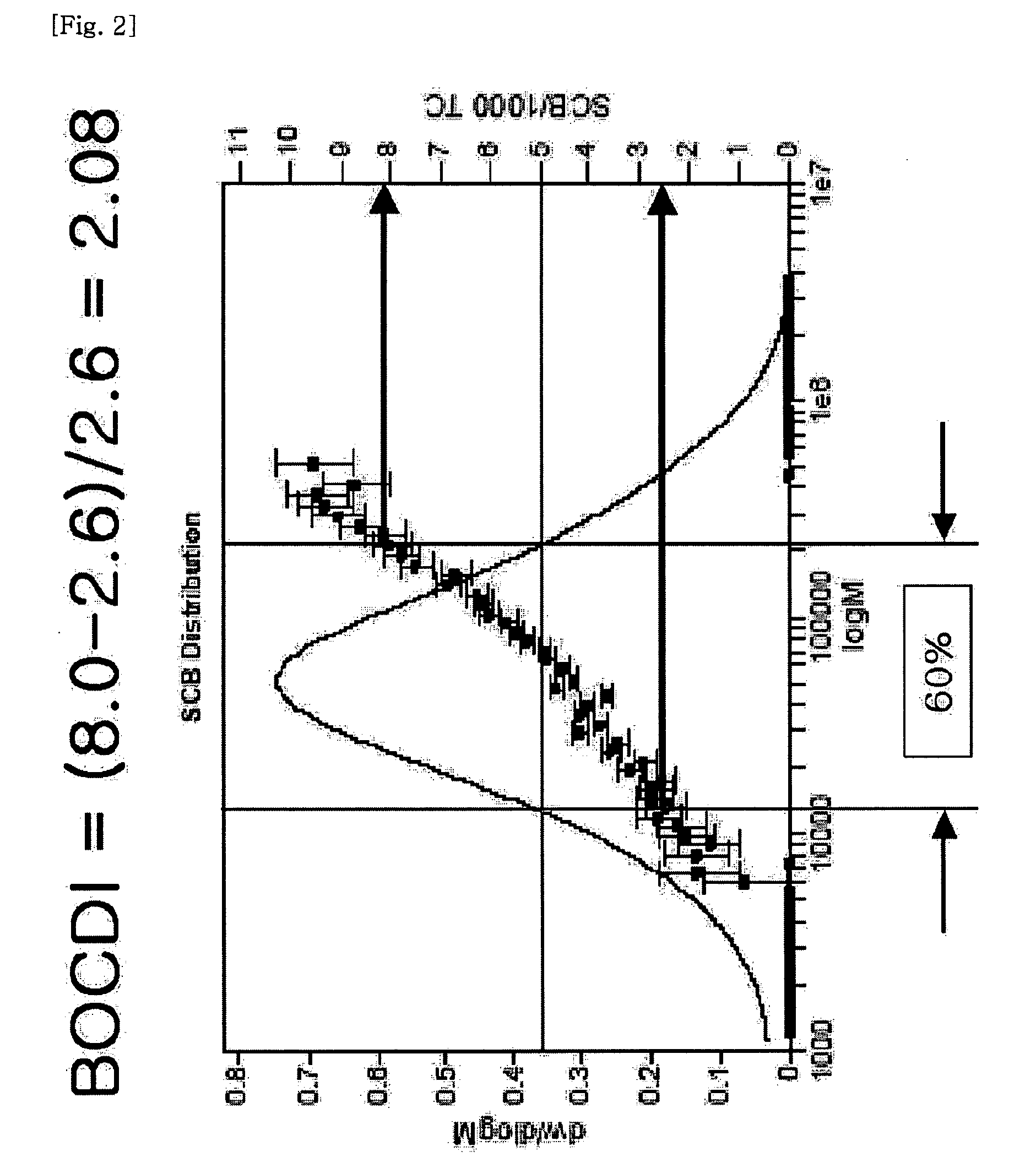

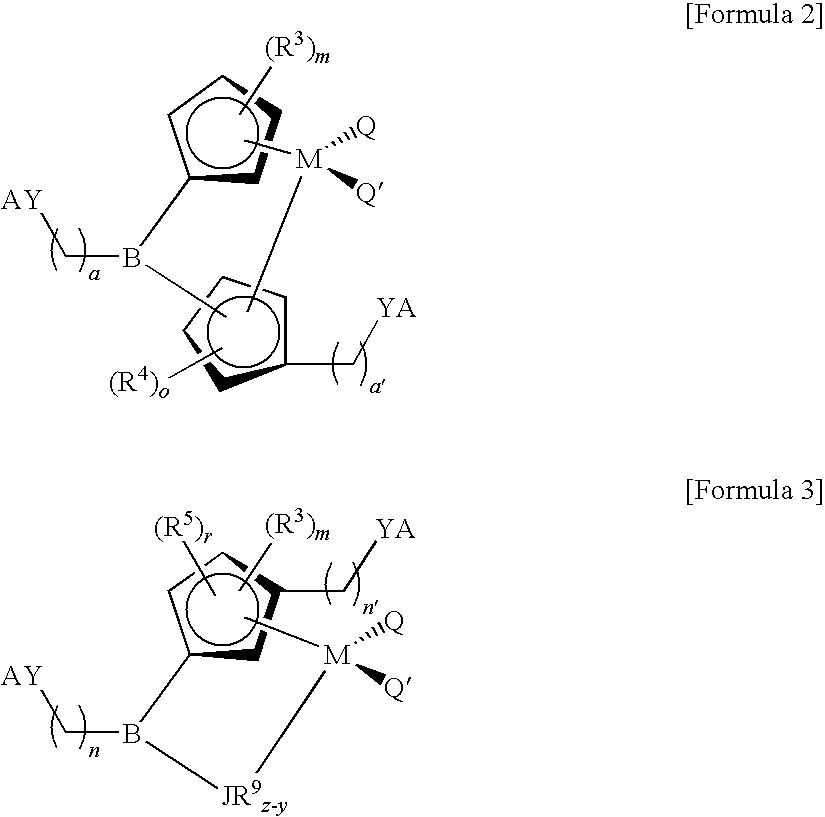

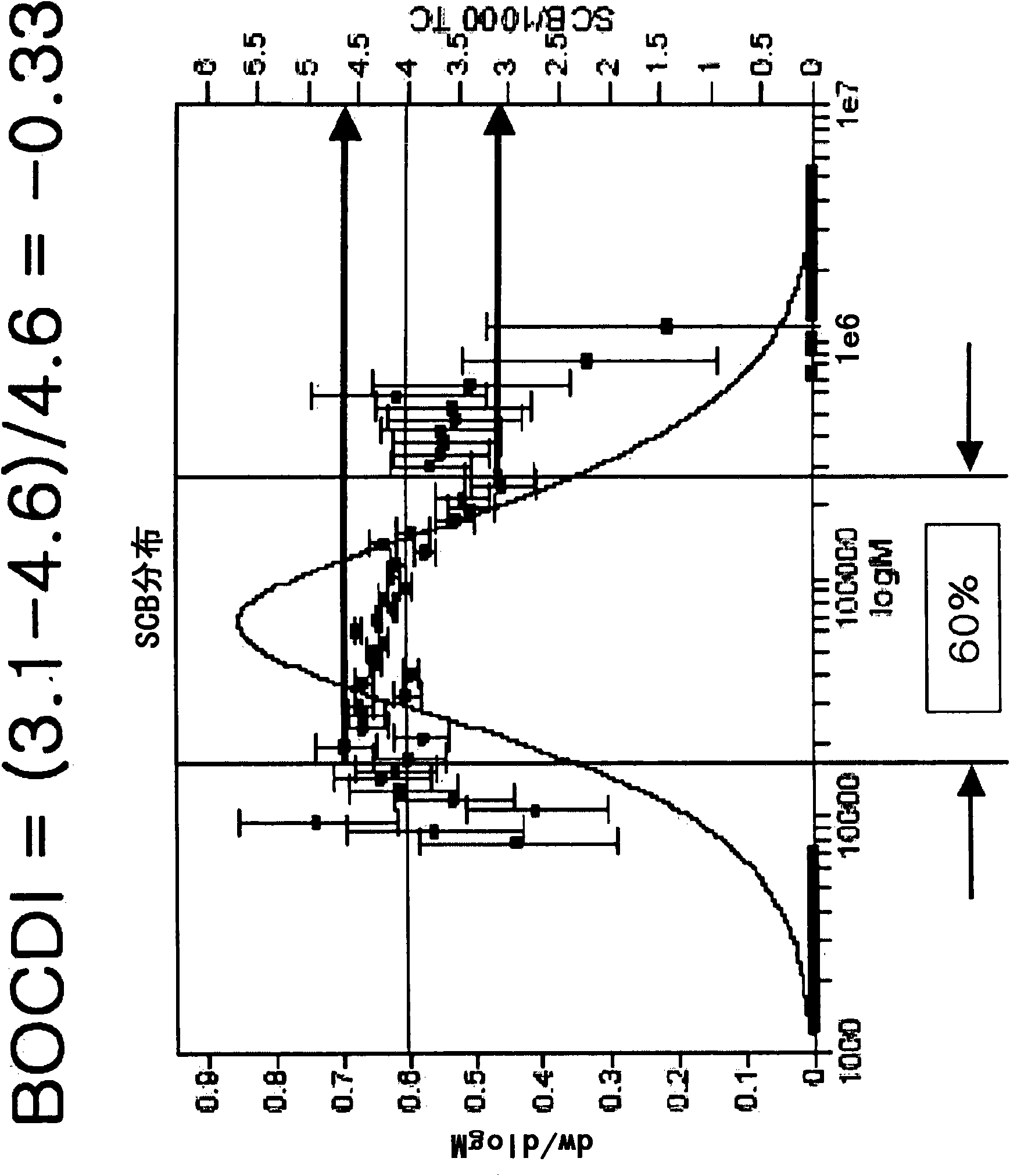

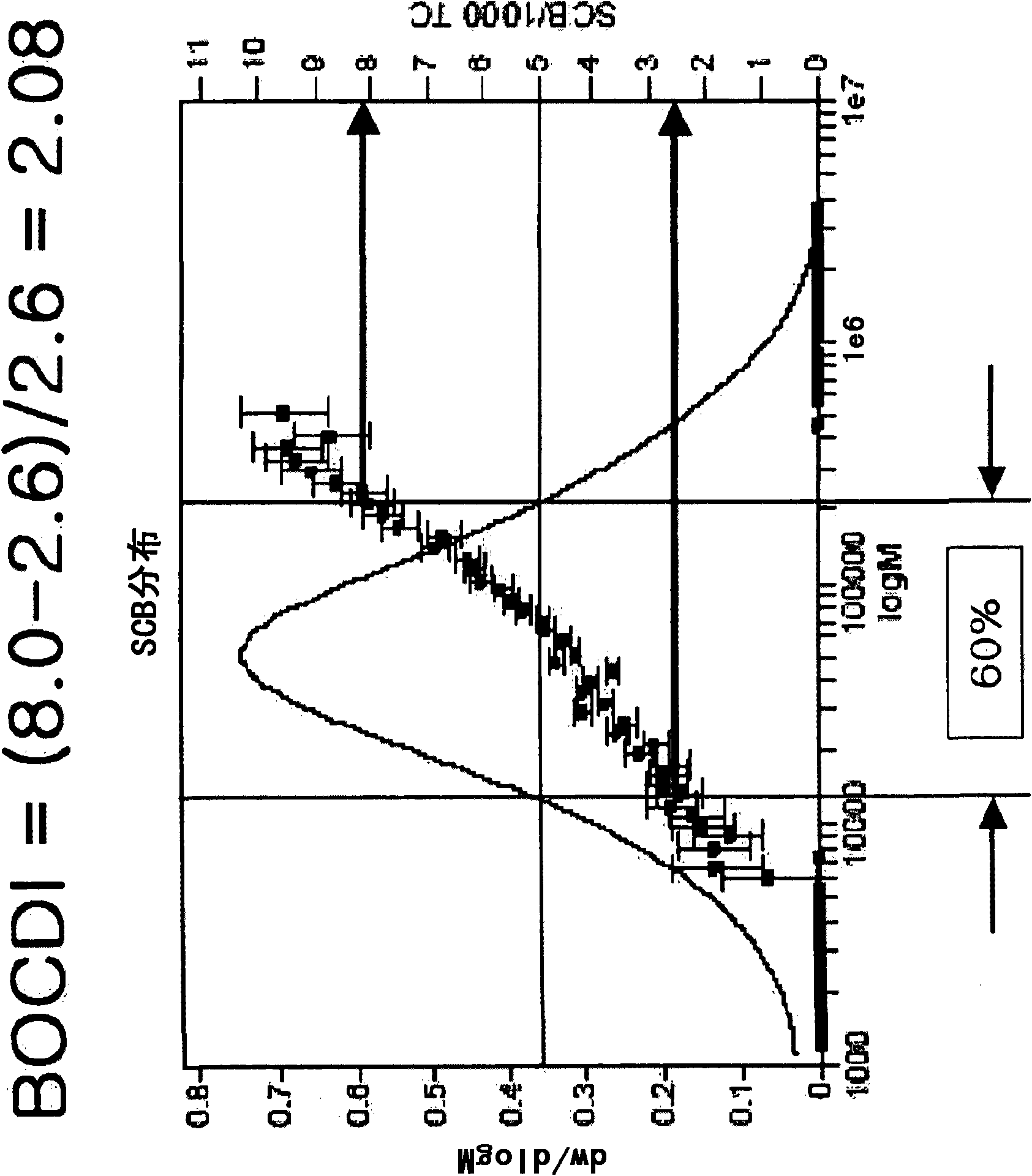

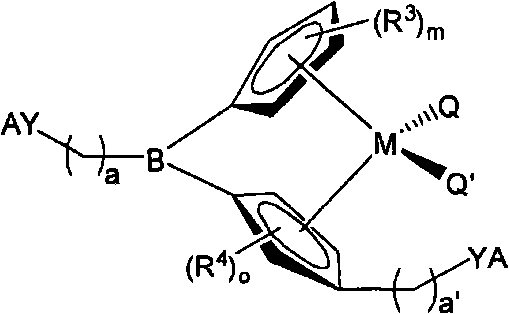

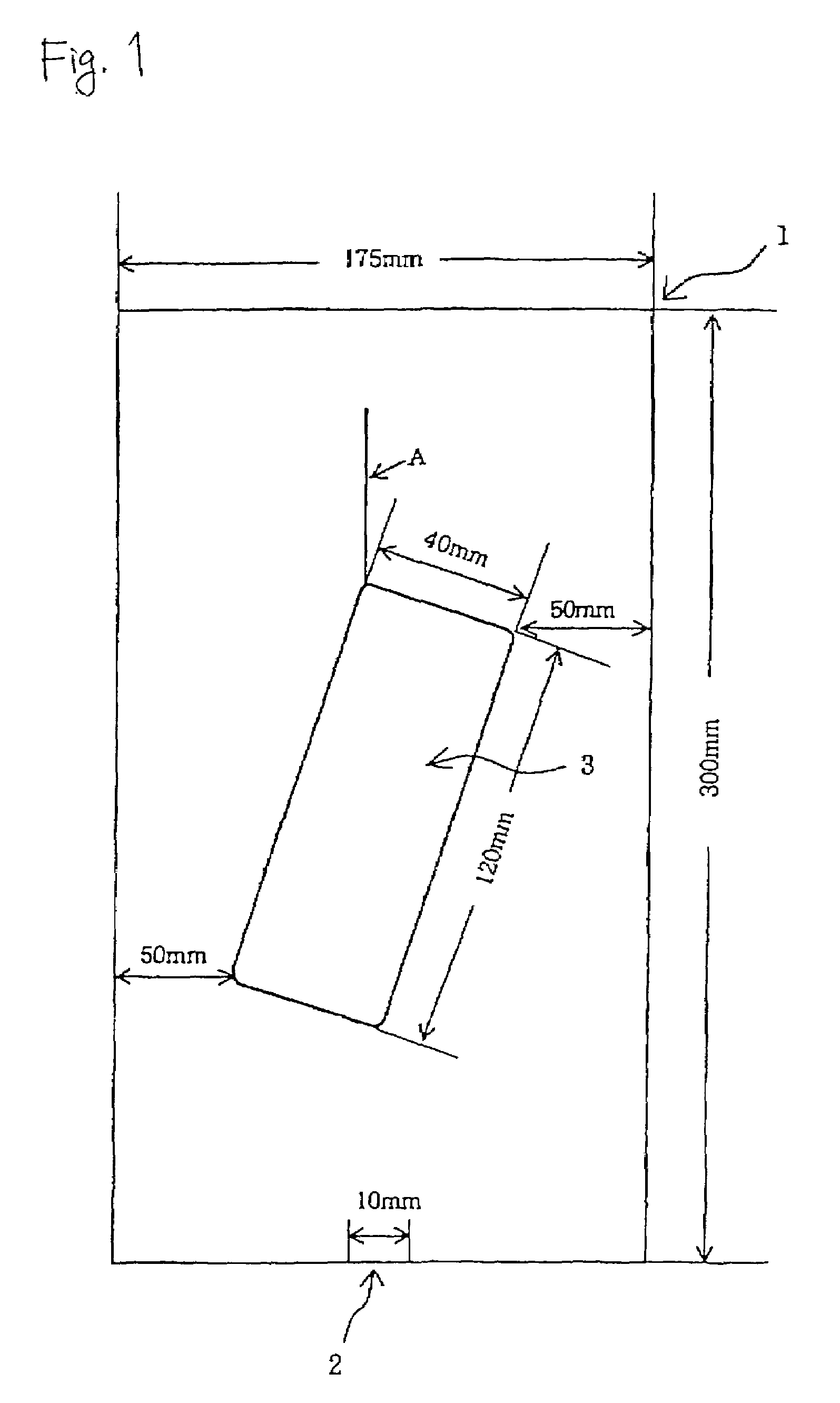

Polyolefin and preparation method thereof

The present invention relates to a polyolefin that has high environmental stress cracking resistance (ESCR), a high impact property, and an excellent die swell property, and a method of preparing the same. According to the method of preparing polyolefin of the present invention, a supported hybrid metallocene catalyst and an alpha olefin comonomer having 4 or more carbon atoms are used to obtain polyolefin having the bimodal or multimodal molecular weight distribution curves during the single reactor polymerization. The polyolefin has excellent processability, a melt flow rate ratio (MFRR) that is useful to processing, excellent shapability, impact strength, tensile strength, in particular, environmental stress cracking resistance (ESCR) and full notch creep test (FNCT), thus being used to manufacture the blow molded product.

Owner:LG CHEM LTD

Bimodal polyethylene compositions for blow molding applications

Bimodal polyethylene compositions and methods for making the same are provided. In at least one specific embodiment, the bimodal polyethylene composition can include a high molecular weight component having a weight average molecular weight (Mw) of from about 400,000 to about 950,000. The bimodal polyethylene composition can also include a low molecular weight component having a weight average molecular weight (Mw) of from about 3,000 to about 100,000. The high molecular weight component can be present in an amount ranging from about 25 wt % to about 40 wt % of the bimodal polyethylene composition. The bimodal polyethylene composition can also have a percent die swell of less than about 80%.

Owner:UNIVATION TECH LLC

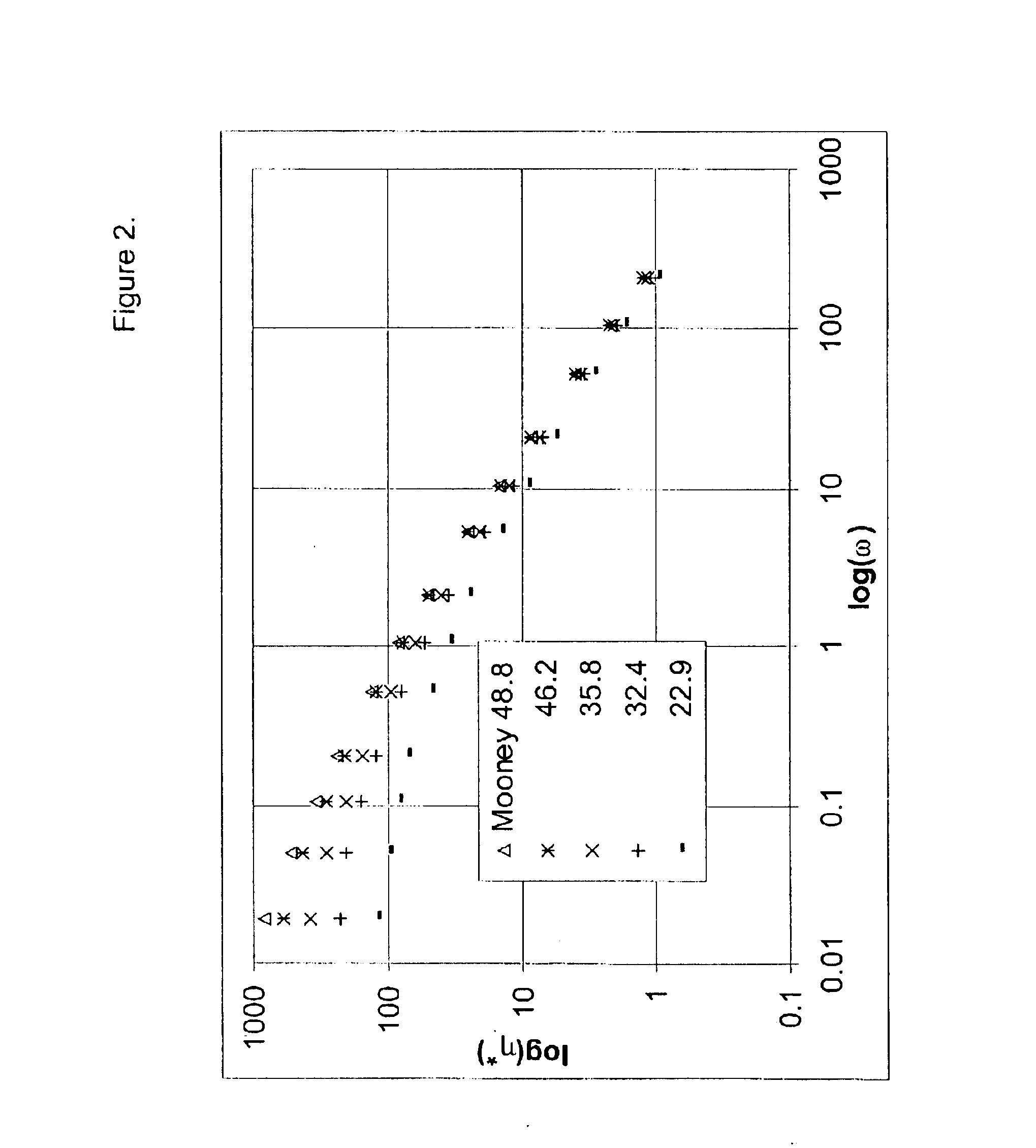

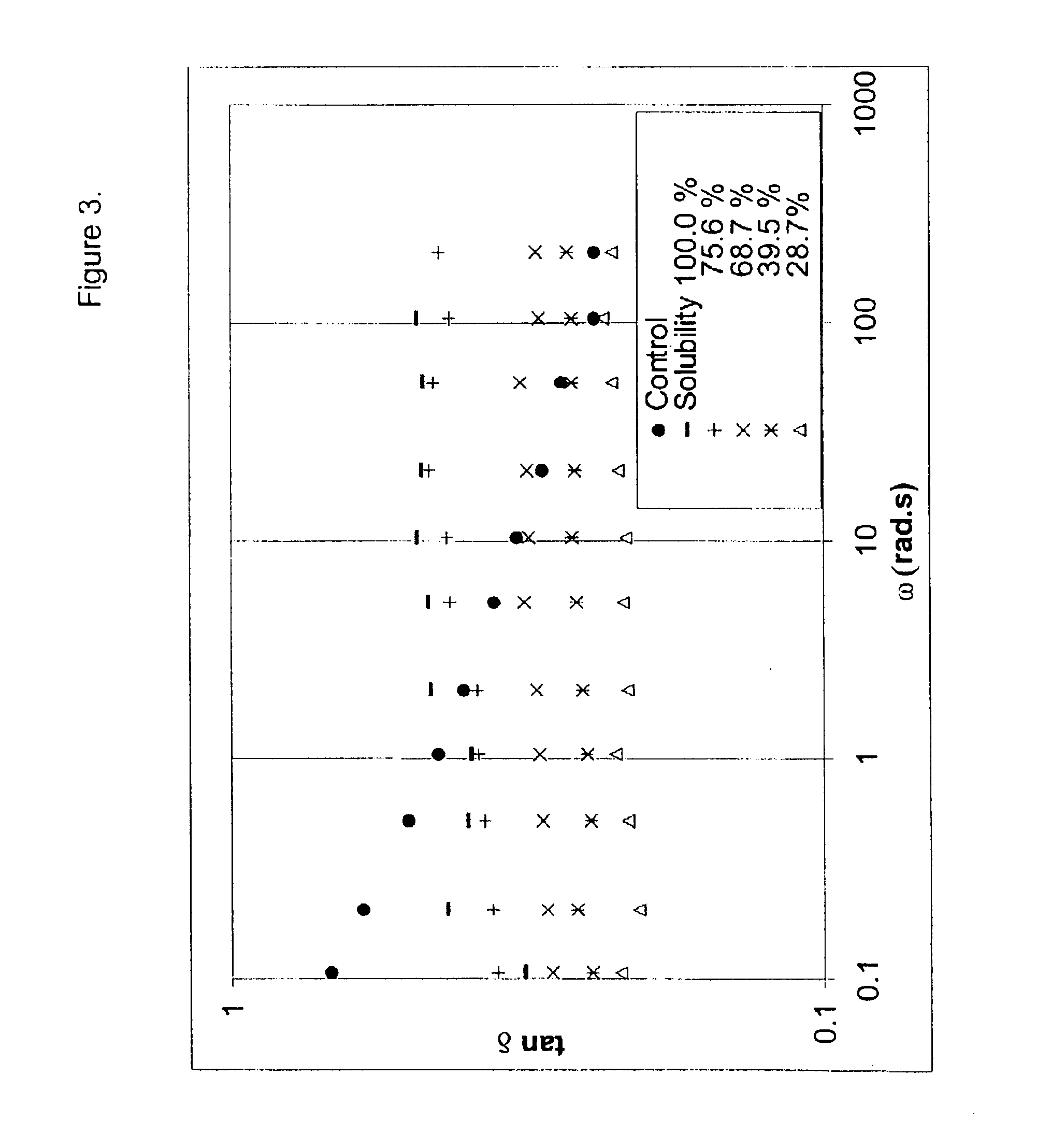

Processability butyl rubber and process for production thereof

A butyl polymer having improved processability is described, together with a process for production thereof. The butyl polymer derived from a reaction mixture which contains: (i) a monomer mixture comprising a C4 to C7 monoolefin monomer (preferably isobutylene) and a C4 to C14 multiolefin monomer (preferably isoprene); (ii) a multiolefin cross-linking agent (preferably divinyl benzene); and (iii) a chain transfer agent (preferably diisobutylene (2,2,4-trimethyl-1-pentene)). The subject butyl polymer has an improved balance of cold flow, filler dispersion, extrusion rate and die swell.

Owner:LANXESS LTD

Enhanced ESCR Bimodal HDPE for blow molding applications

Bimodal polyethylene compositions and blow molded bottles made therefrom are provided. In at least one specific embodiment, the composition includes at least one high molecular weight polyethylene component having a molecular weight distribution (MWD) of about 6 to about 9, a short chain branch content of less than about 2 branches per 1,000 main chain carbons, and a Mz of about 1,100,000 or more. The composition also includes at least one low molecular weight polyethylene component where a ratio of weight average molecular weight of the high molecular weight polyethylene component to weight average molecular weight of the low molecular weight polyethylene component is about 20 or less. The polyethylene composition has a density of about 0.94 g / cc or more, an ESCR of about 600 hours or more, a percent die swell of about 70% or more, and may comprise at least 70% ethylene-derived units.

Owner:UNIVATION TECH LLC

Bimodal polyethylene compositions for blow molding applications

Bimodal polyethylene compositions and methods for making the same are provided. In at least one specific embodiment, the bimodal polyethylene composition can include a high molecular weight component having a weight average molecular weight (Mw) of from about 400,000 to about 950,000. The bimodal polyethylene composition can also include a low molecular weight component having a weight average molecular weight (Mw) of from about 3,000 to about 100,000. The high molecular weight component can be present in an amount ranging from about 25 wt % to about 40 wt % of the bimodal polyethylene composition. The bimodal polyethylene composition can also have a percent die swell of less than about 80%.

Owner:UNIVATION TECH LLC

Enhanced ESCR bimodal HDPE for blow molding applications

Bimodal polyethylene compositions and blow molded bottles made therefrom are provided. In at least one specific embodiment, the composition includes at least one high molecular weight polyethylene component having a molecular weight distribution (MWD) of about 6 to about 9, a short chain branch content of less than about 2 branches per 1,000 main chain carbons, and a Mz of about 1,100,000 or more. The composition also includes at least one low molecular weight polyethylene component where a ratio of weight average molecular weight of the high molecular weight polyethylene component to weight average molecular weight of the low molecular weight polyethylene component is about 20 or less. The composition has a density of about 0.94 g / cc or more, an ESCR of about 600 hours or more, and a percent die swell of about 70% or more.

Owner:UNIVATION TECH LLC

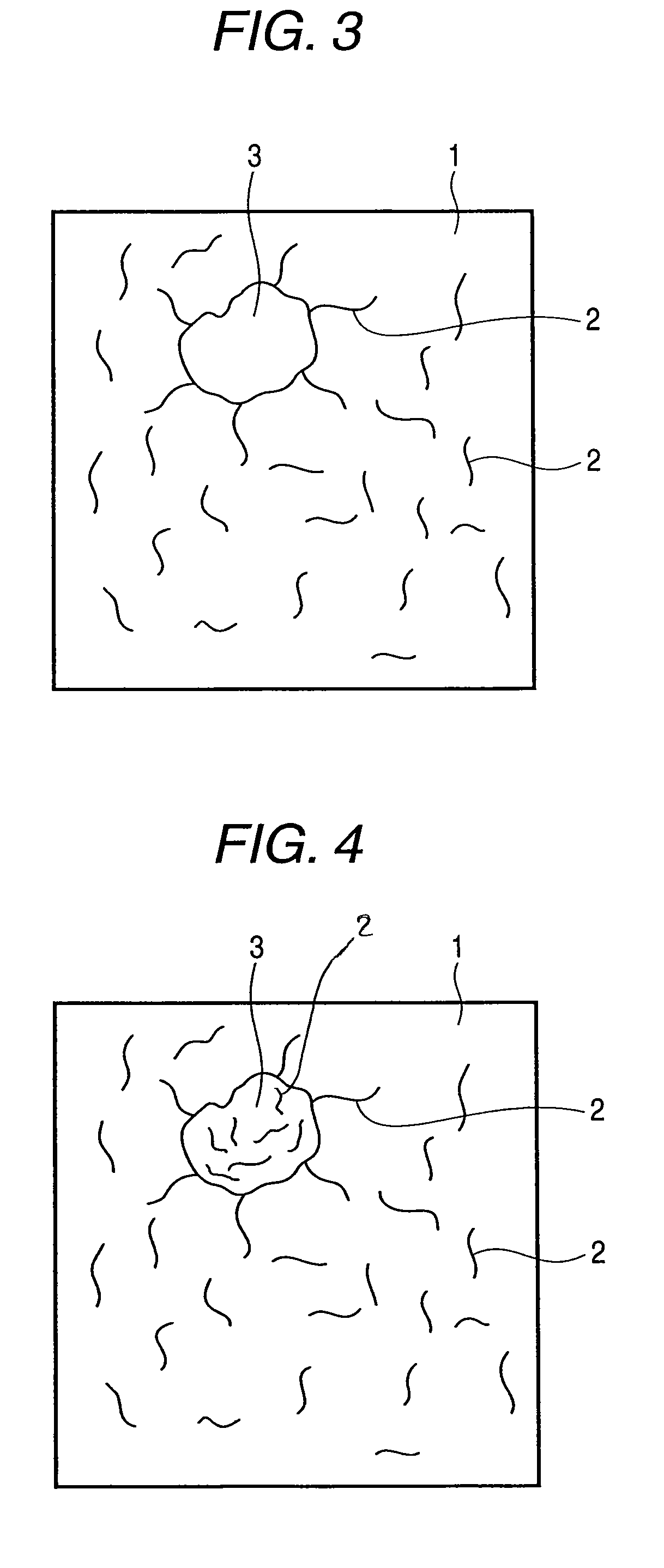

Thermoplastic elastomer composition and molded object thereof

InactiveUS20040097650A1Increase flexibilityEasy to processSynthetic resin layered productsDomestic articlesElastomerPolymer science

A thermoplastic elastomer composition comprising the following components (A) and (B), wherein a weight ratio of the component (A) / the component (B) is from 5 / 95 to 95 / 5: (A): a thermoplastic resin, whose melt flow rate is 0.001 to 100 g / 10 minutes, and whose die swell ratio is 1.7 to 5.0, and (B): a hydrogenated vinyl aromatic compound-conjugated diene-based copolymer satisfied with all the following conditions (i) to (iii): (i) a content of a vinyl aromatic compound unit is not more than 50% by weight, (ii) a ratio of a hydrogenated conjugated diene unit having a side chain of 2 or more carbon atoms contained in the hydrogenated vinyl aromatic compound-conjugated diene-based copolymer to a total hydrogenated conjugated diene unit contained therein is not less than 60%, and (iii) at least 80% of a double bond of a conjugated diene unit contained in the hydrogenated vinyl aromatic compound-conjugated diene-based copolymer is hydrogenated.

Owner:SUMITOMO CHEM CO LTD

Polyolefin and preparation method thereof

The present invention relates to a polyolefin that has high environmental stress cracking resistance (ESCR), a high impact property, and an excellent die swell property, and a method of preparing thesame. According to the method of preparing polyolefin of the present invention, a supported hybrid metallocene catalyst and an alpha olefin comonomer having 4 or more carbon atoms are used to obtain polyolefin having the bimodal or multimodal molecular weight distribution curves during the single reactor polymerization. The polyolefin has excellent processability, a melt flow rate ratio (MFRR) that is useful to processing, excellent shapability, impact strength, tensile strength, in particular, environmental stress cracking resistance (ESCR) and full notch creep test (FNCT), thus being used tomanufacture the blow molded product.

Owner:LG CHEM LTD

Enhanced ESCR bimodal HDPE for blow molding applications

Bimodal polyethylene compositions and blow molded bottles made therefrom are provided. In at least one specific embodiment, the composition includes at least one high molecular weight polyethylene component having a molecular weight distribution (MWD) of about 6 to about 9, a short chain branch content of less than about 2 branches per 1,000 main chain carbons, and a Mz of about 1,100,000 or more. The composition also includes at least one low molecular weight polyethylene component where a ratio of weight average molecular weight of the high molecular weight polyethylene component to weight average molecular weight of the low molecular weight polyethylene component is about 20 or less. The composition has a density of about 0.94 g / cc or more, an ESCR of about 600 hours or more, and a percent die swell of about 70% or more.

Owner:UNIVATION TECH LLC

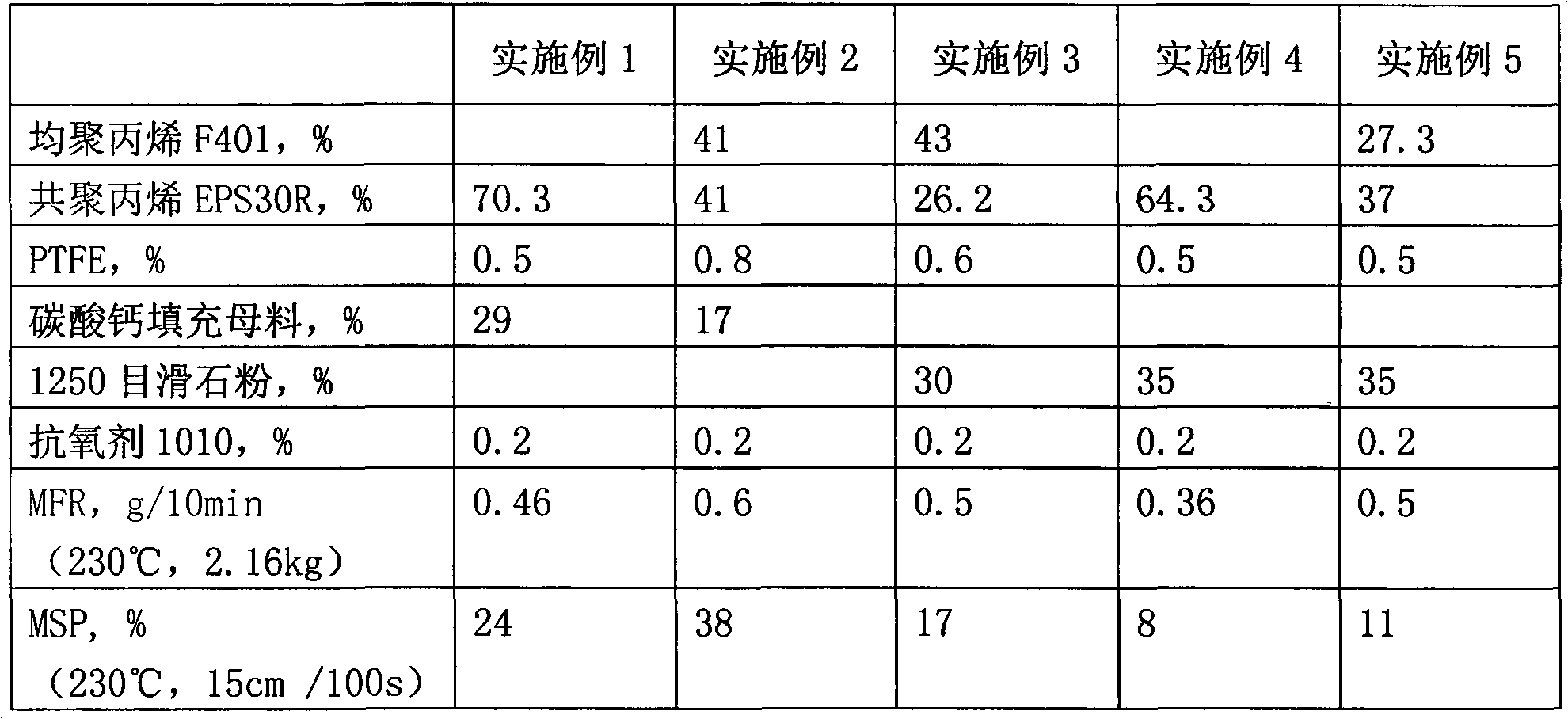

Moldability modifier for polypropylene resin and polypropylene resin composition containing the same

The invention provides a polypropylene based resin composition, which has good moldability on injection molding and which is excellent in its flow mark appearance as well as weld appearance on molding, and suitable for injection-molded articles such as exterior parts of automobiles, and also provides a moldability modifier used for the composition.The invention is a moldability modifier for a polypropylene based resin, which comprises at least one of a propylene homopolymer and a propylene random polymer having die swell ratio of 1.5 to 2.5 and ratio (Q value: Mw / Mn) of 7 to 13 of the weight average molecular weight (Mw) to the number average molecular weight (Mn) measured by gel permeation chromatography (GPC). The moldability modifier is mixed with a propylene-ethylene block copolymer, an ethylenic or styrenic elastomer, an inorganic filler, etc. to prepare a polypropylene based resin composition.

Owner:JAPAN POLYCHEM CORP

Wood plastic composite material veneering plywood and manufacturing method and application thereof

InactiveCN103758339AEasy to separateReduce labor intensityForming/stuttering elementsAdhesiveDie swell

The invention relates to plywood and a manufacturing method of the plywood, and discloses wood plastic composite material veneering plywood and a manufacturing method and application of the wood plastic composite material veneering plywood. The wood plastic composite material veneering plywood aims to solve the problems that when wooden plywood manufactured according to an existing method is used, a die swells easily, the die is released difficultly, the number of turnover using times is small, and the wood plastic composite board cannot be easily used as a building formwork independently. The wood plastic composite material veneering plywood is formed by a wood plastic composite sheet, a non-woven fabric, wood plywood and adhesives in a manufactured mode. The manufacturing method comprises the steps that the wood plastic composite sheet is manufactured; a non-woven fabric cladding wood plastic composite material is manufactured; the plywood is preprocessed; the adhesives are coated; pre-pressing is carried out; hot pressing is carried out. The wood plastic composite material veneering plywood can be used as the building formwork. The wood plastic composite material veneering plywood has the advantages that the formwork and concrete are separated easily, a casting surface is flat and smooth, and labor intensity of die unloading is relieved; the number of turnover using times of the formwork is improved to be 50-70; weight is light and intensity is high.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

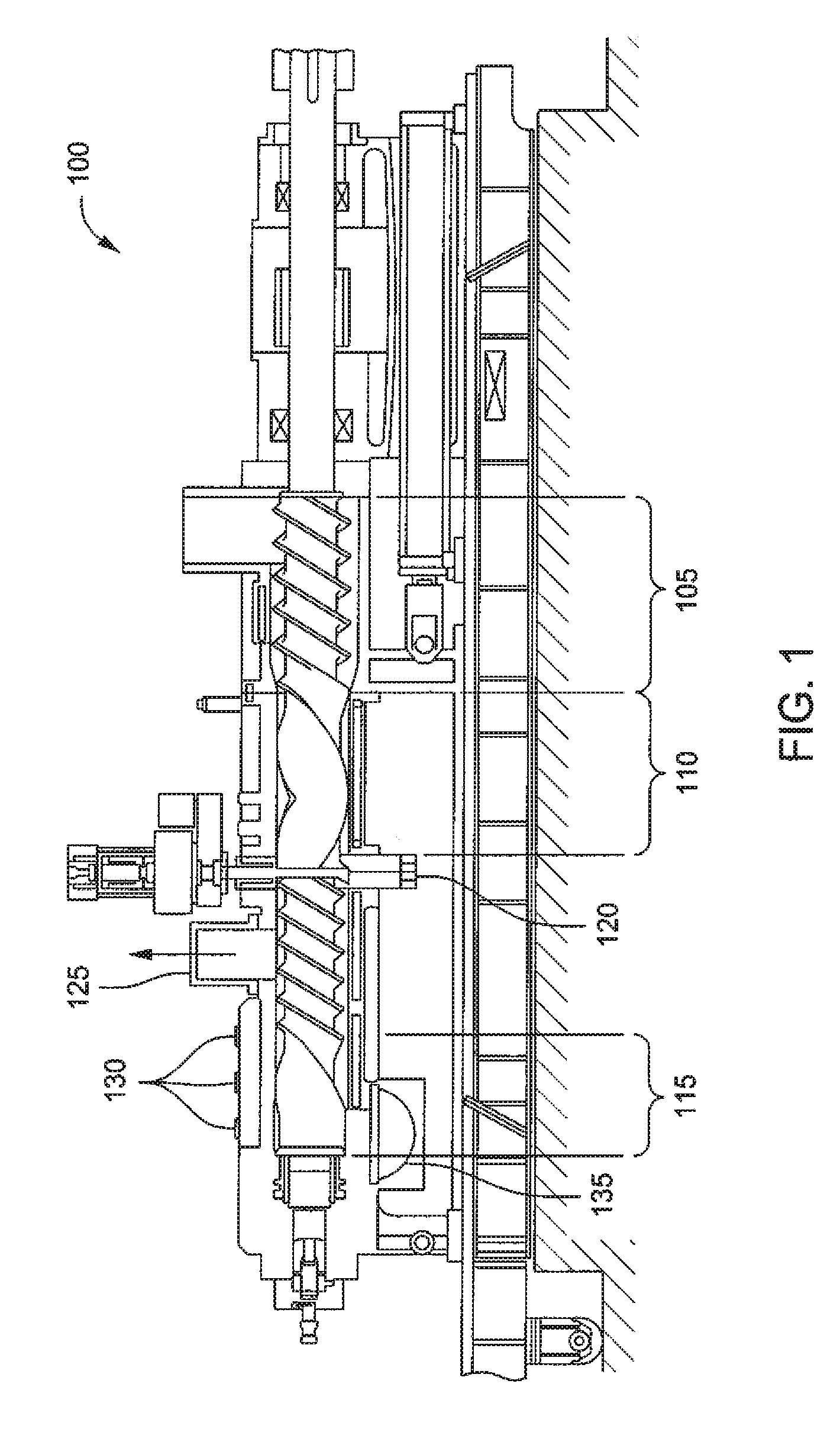

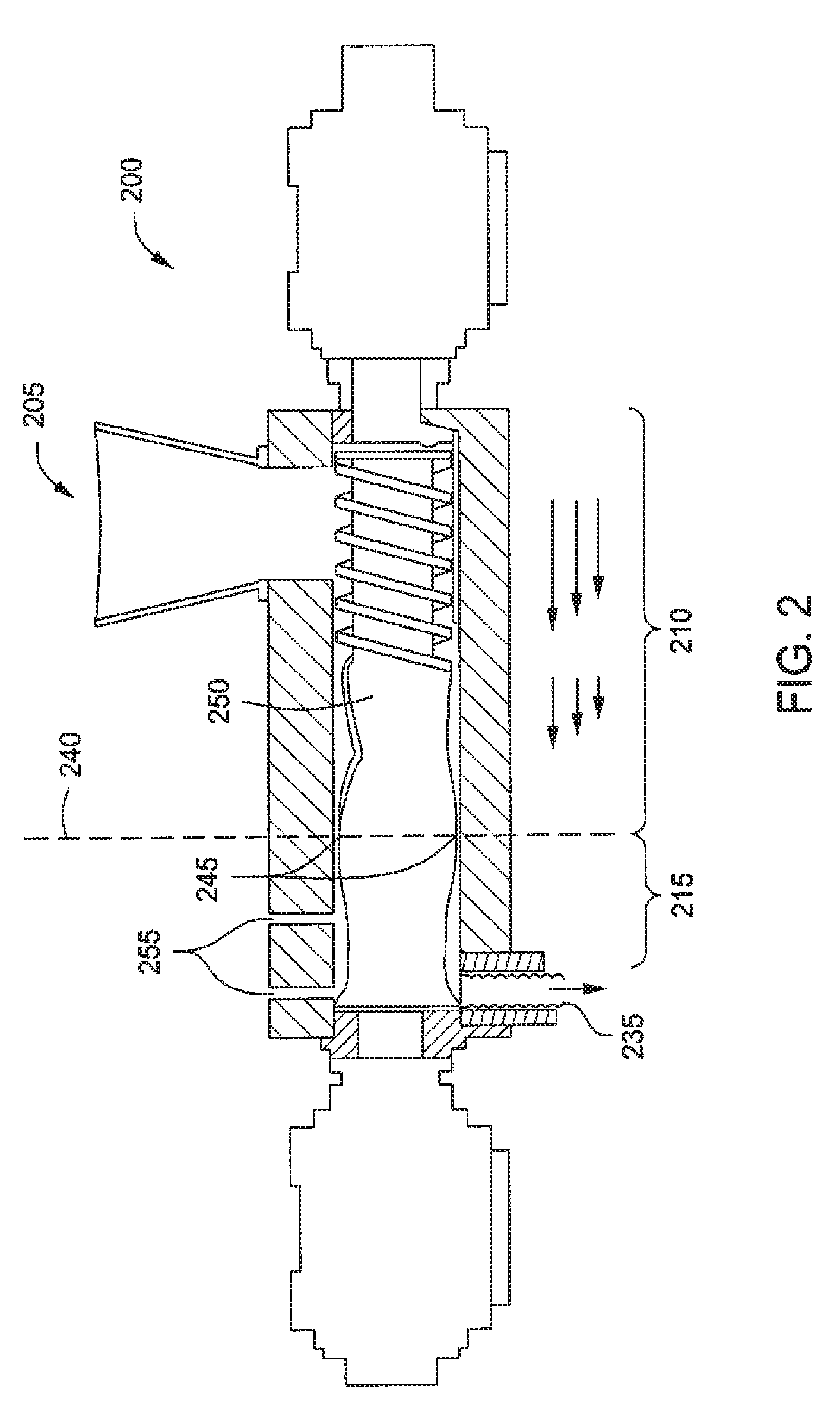

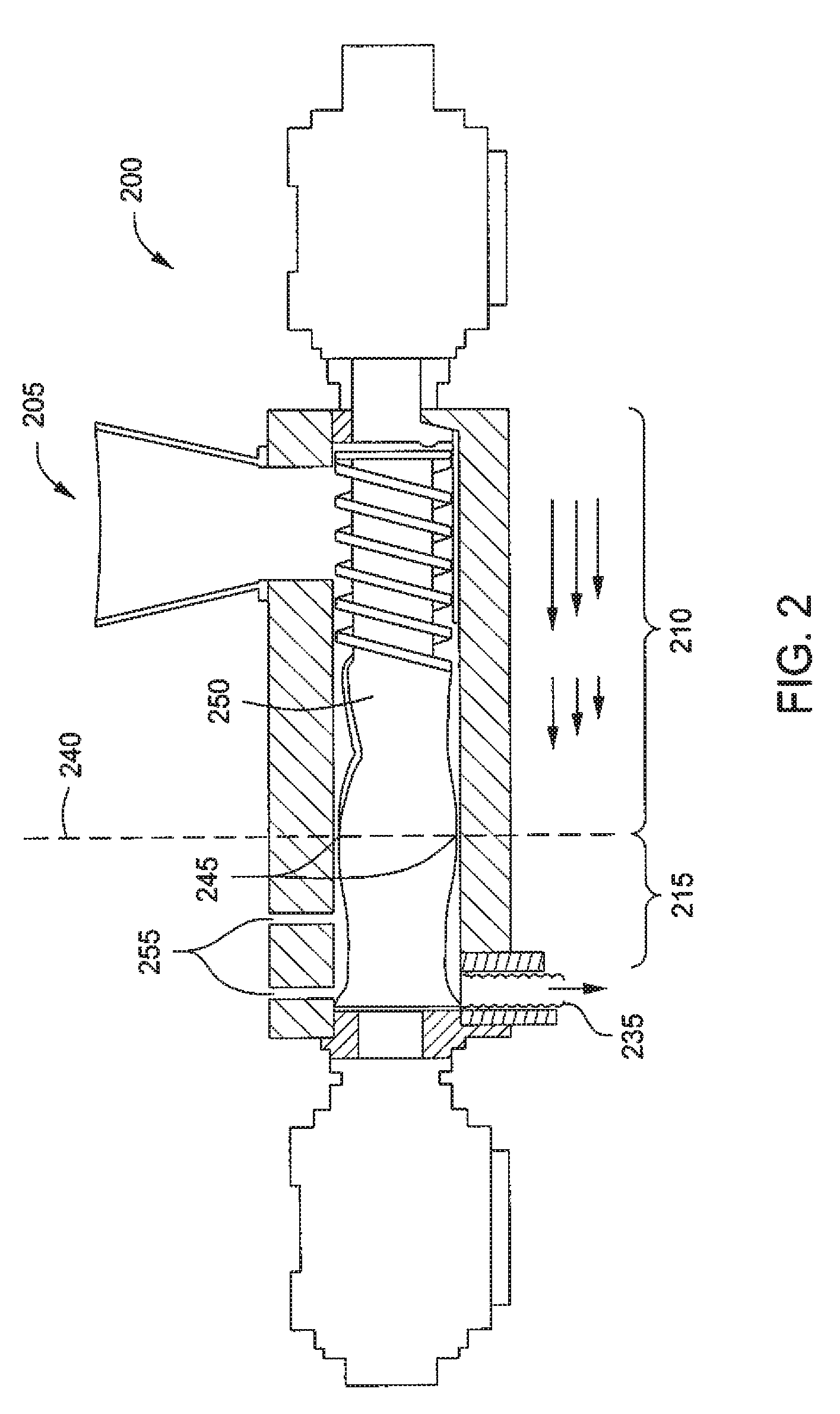

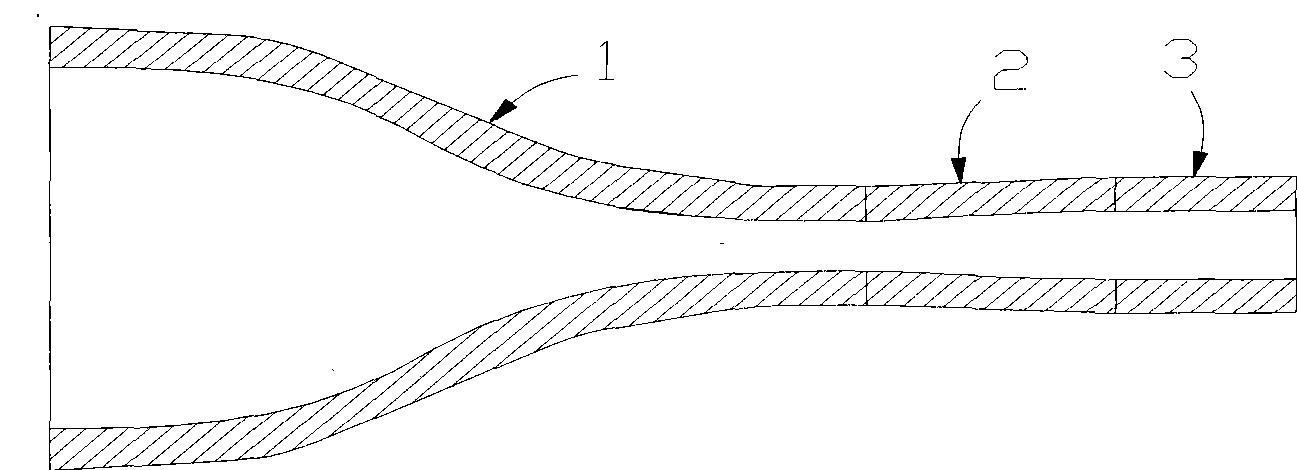

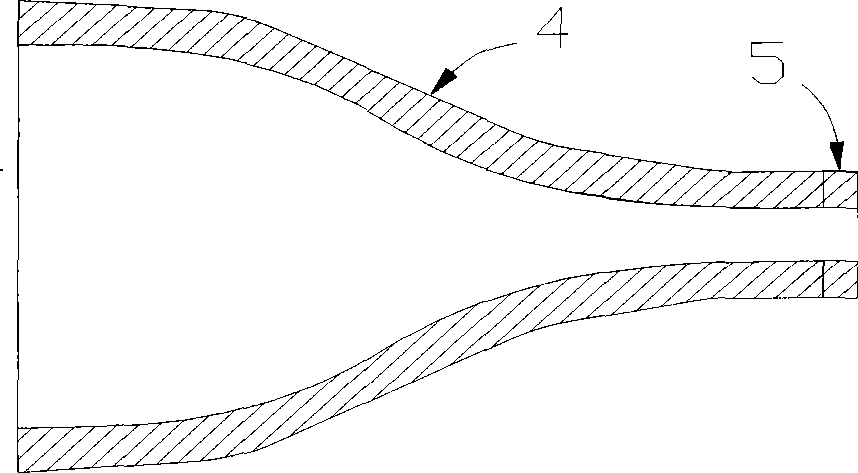

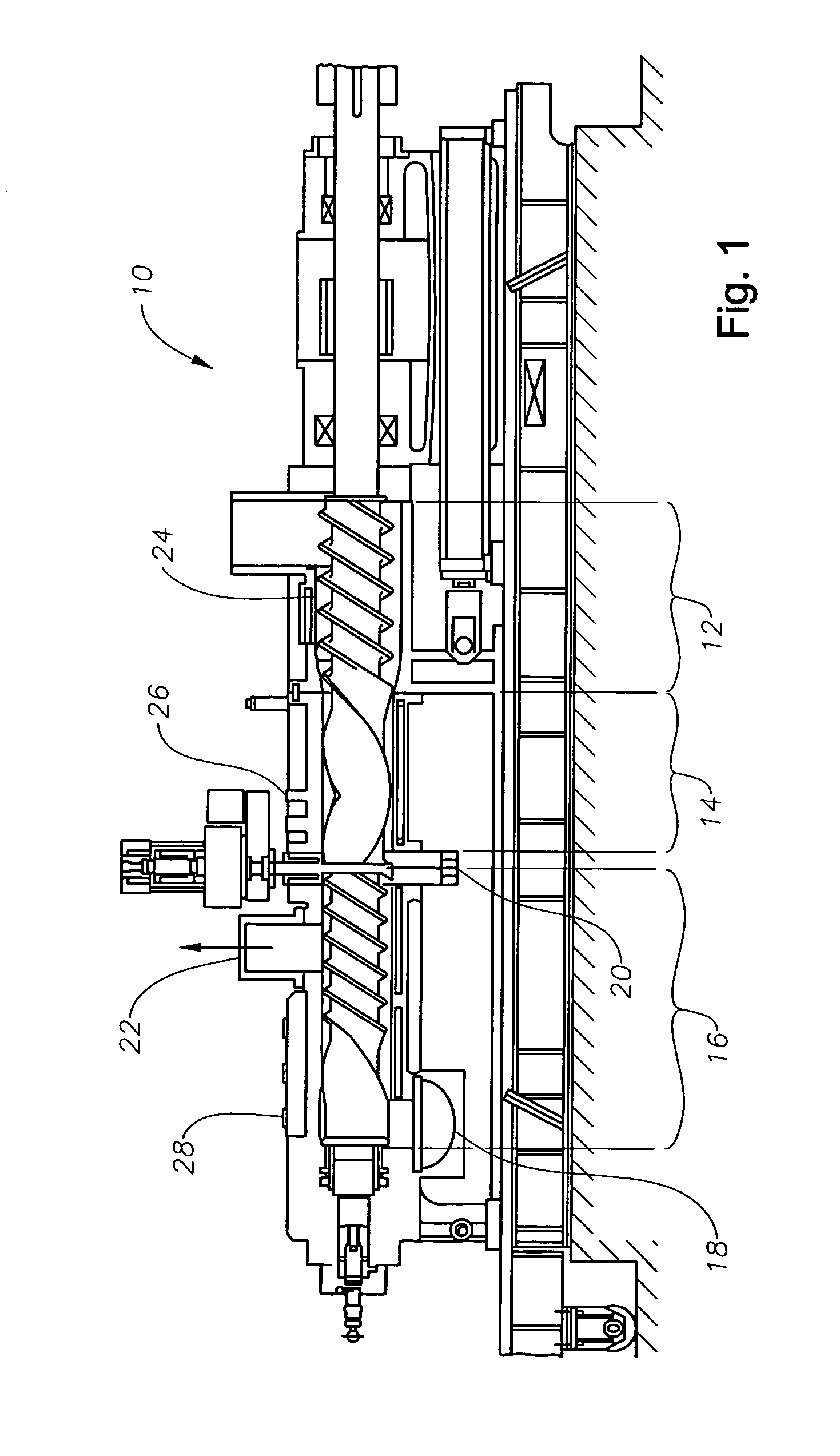

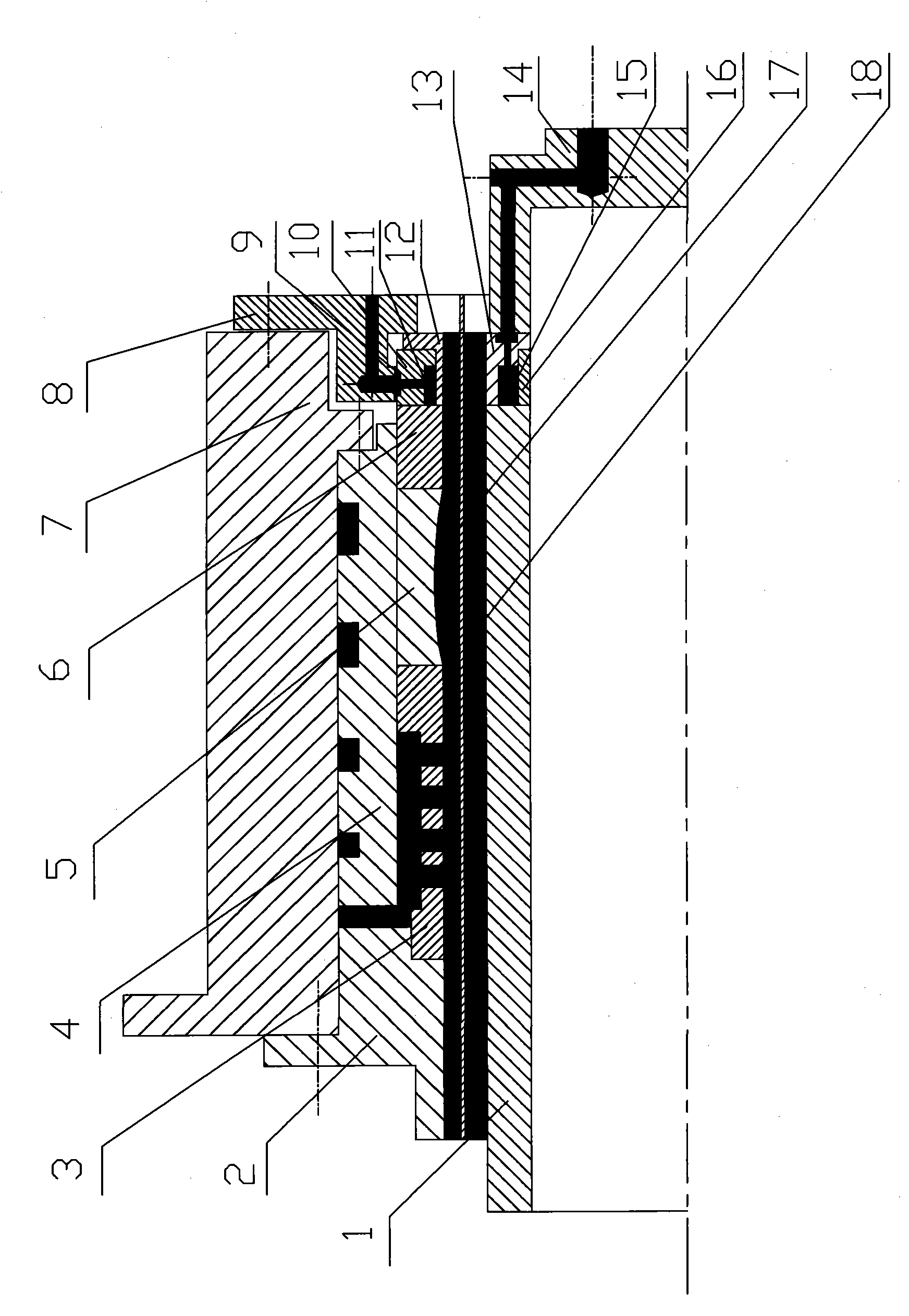

Supersonic nozzle of supersonic speed rotational flow natural gas separator

InactiveCN101387469AAchieve expansion and coolingAchieve separationSolidificationLiquefactionCycloneUltrasonic nozzle

The invention provides a supersonic jet tube used for a supersonic cyclone natural gas separator, which is a key part of the separator, and consists of a contraction tube section, an extension tube section and a rectifying tube section. A moulding surface curve of the contraction tube section is higher-order polynomial, and natural gas airflow is expanded and accelerated in the section to achieve sonic velocity so as to form a straight sonic flow. The moulding surface curve of the extension tube section consists of a plurality of sections of curve, and the sections are smoothly connected to reduce disturbance to the airflow. The moulding surface curve of the supersonic jet tube at inlet and outlet changes flatly, has small curvature change, and has weak influence on the flowing of fluid upstream and downstream without obvious inlet and outlet effect. The extension tube has smooth inlet transition with small disturbance to the fluid. The extension tube section has flat change of moulding surface curve, small airflow expansion rate and good flow speed evenness, thereby helping droplet condensation nucleus grow larger grain diameter for separating. The supersonic jet tube not only evenly accelerates the airflow, improves evenness and stability of flow field, and reduces turbulivity, so that outlet airflow has better airflow quality, and can form droplets with larger grain diameter to improve the separation efficiency of the supersonic cyclone natural gas separator.

Owner:曹学文

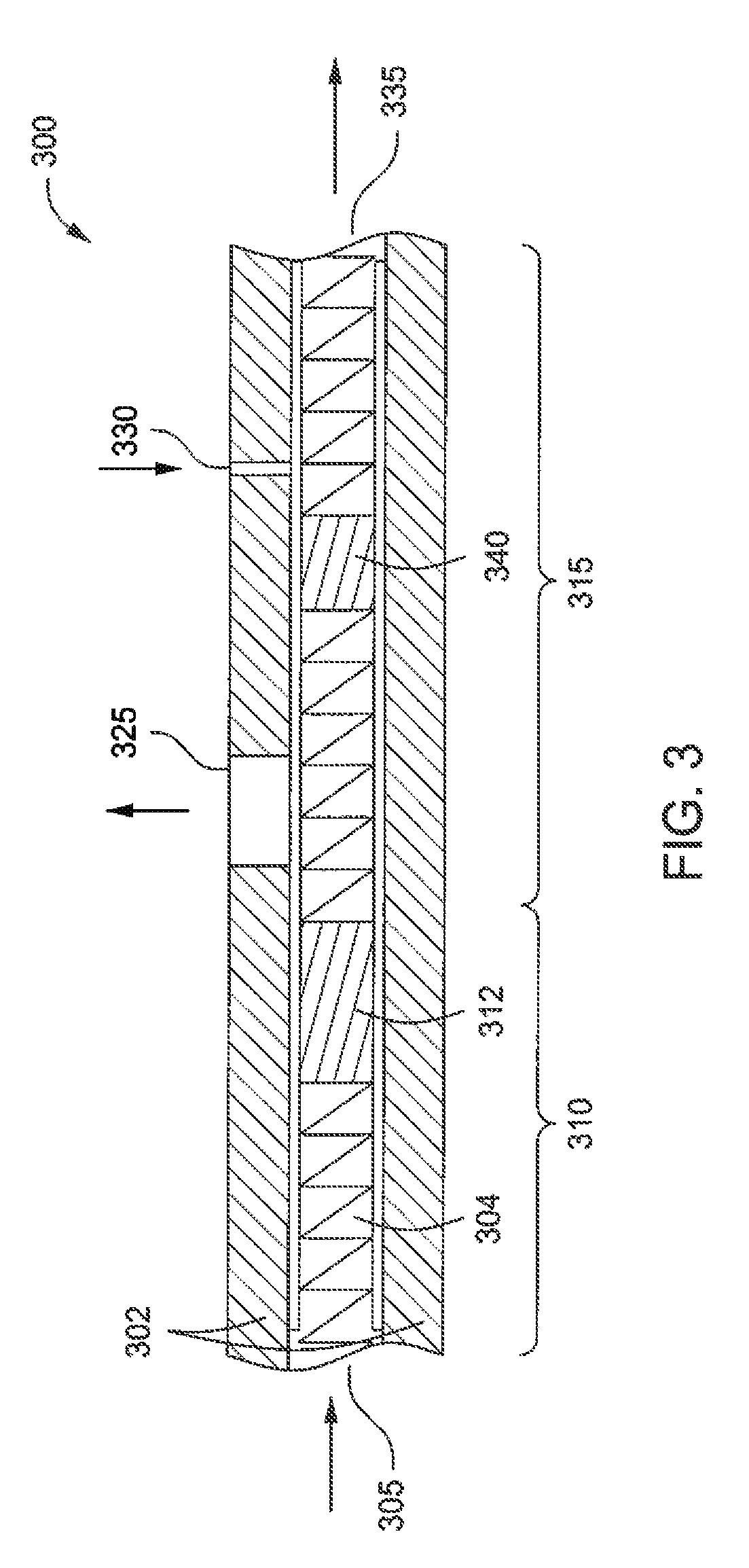

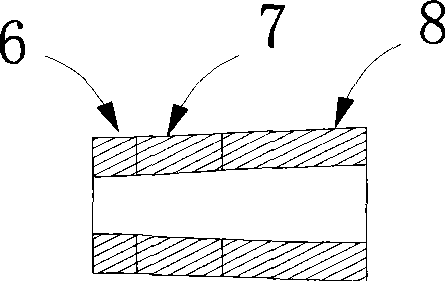

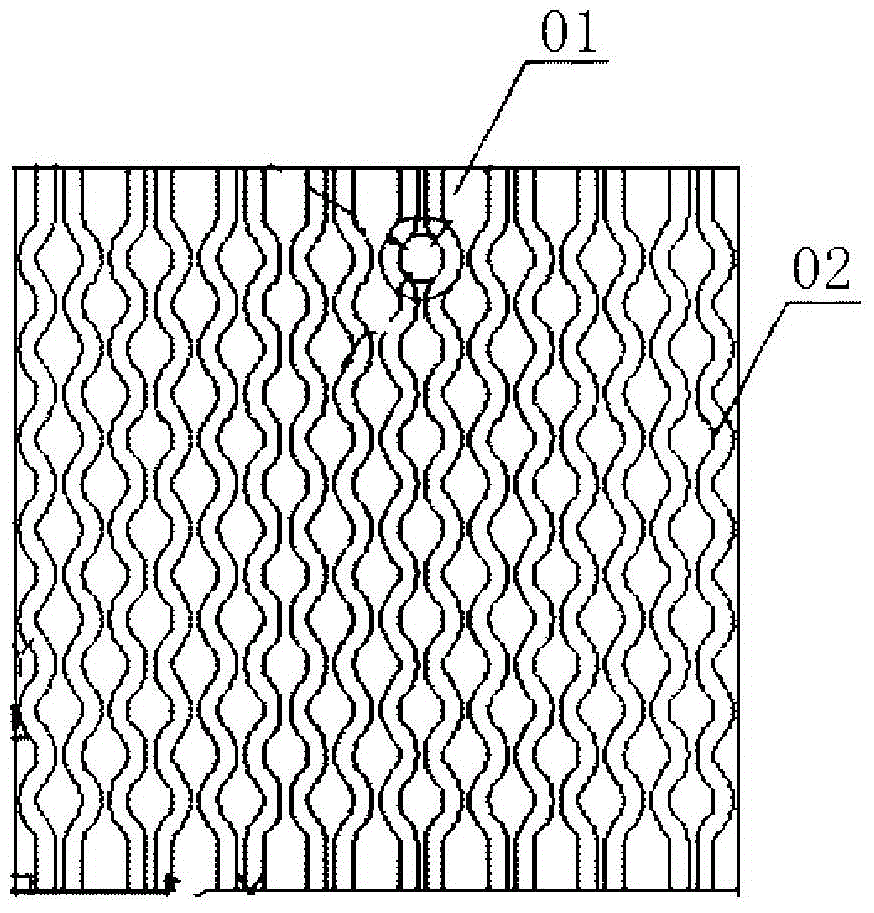

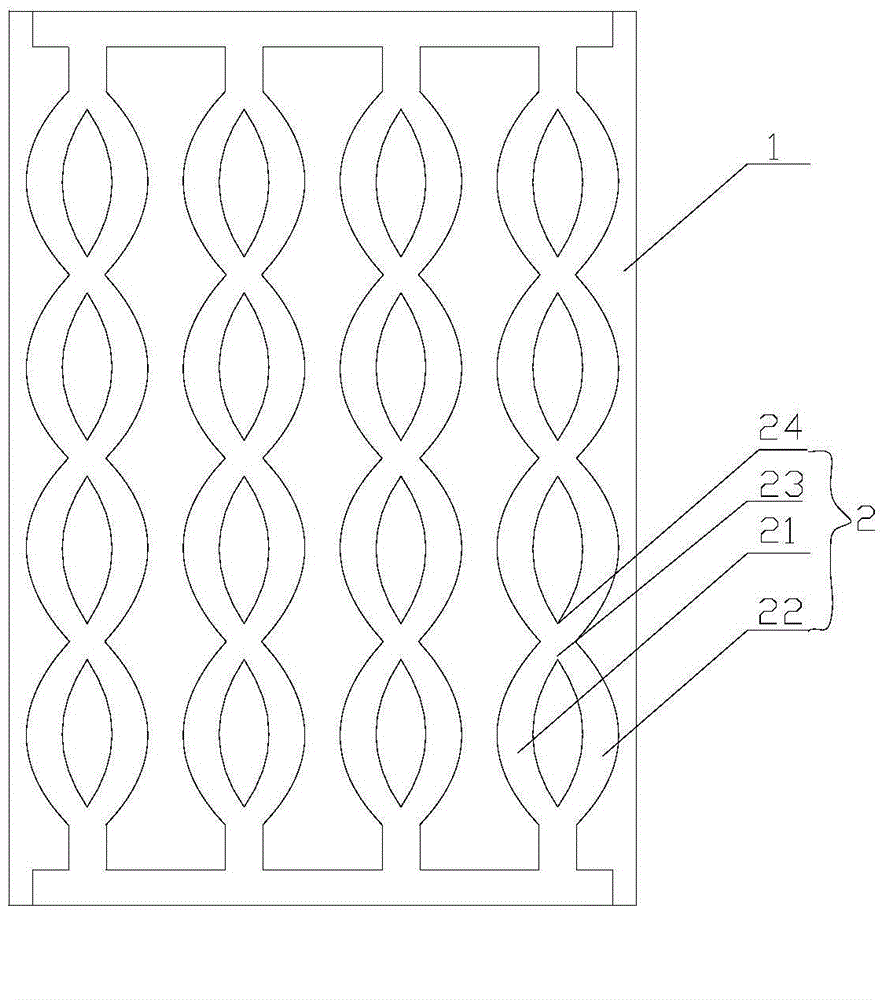

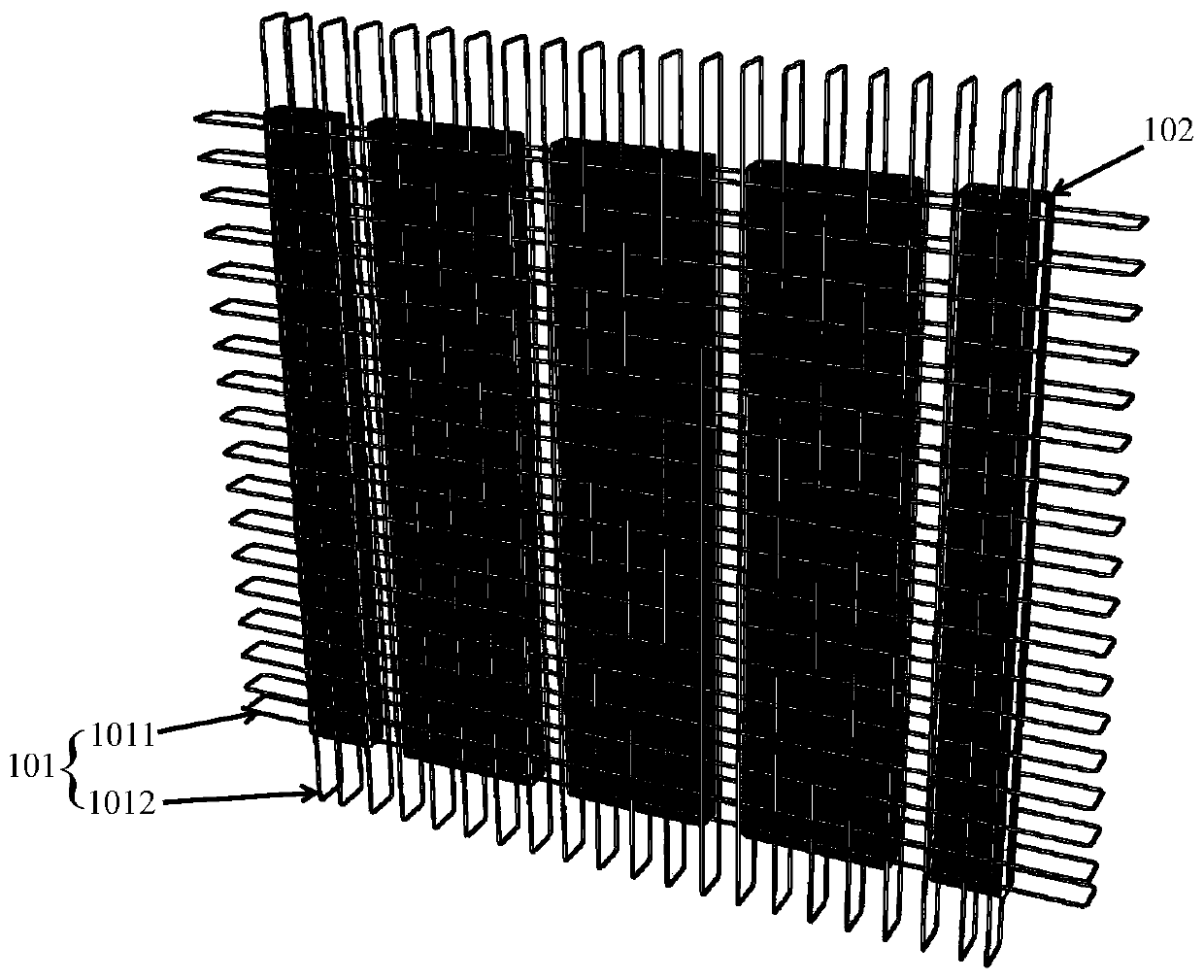

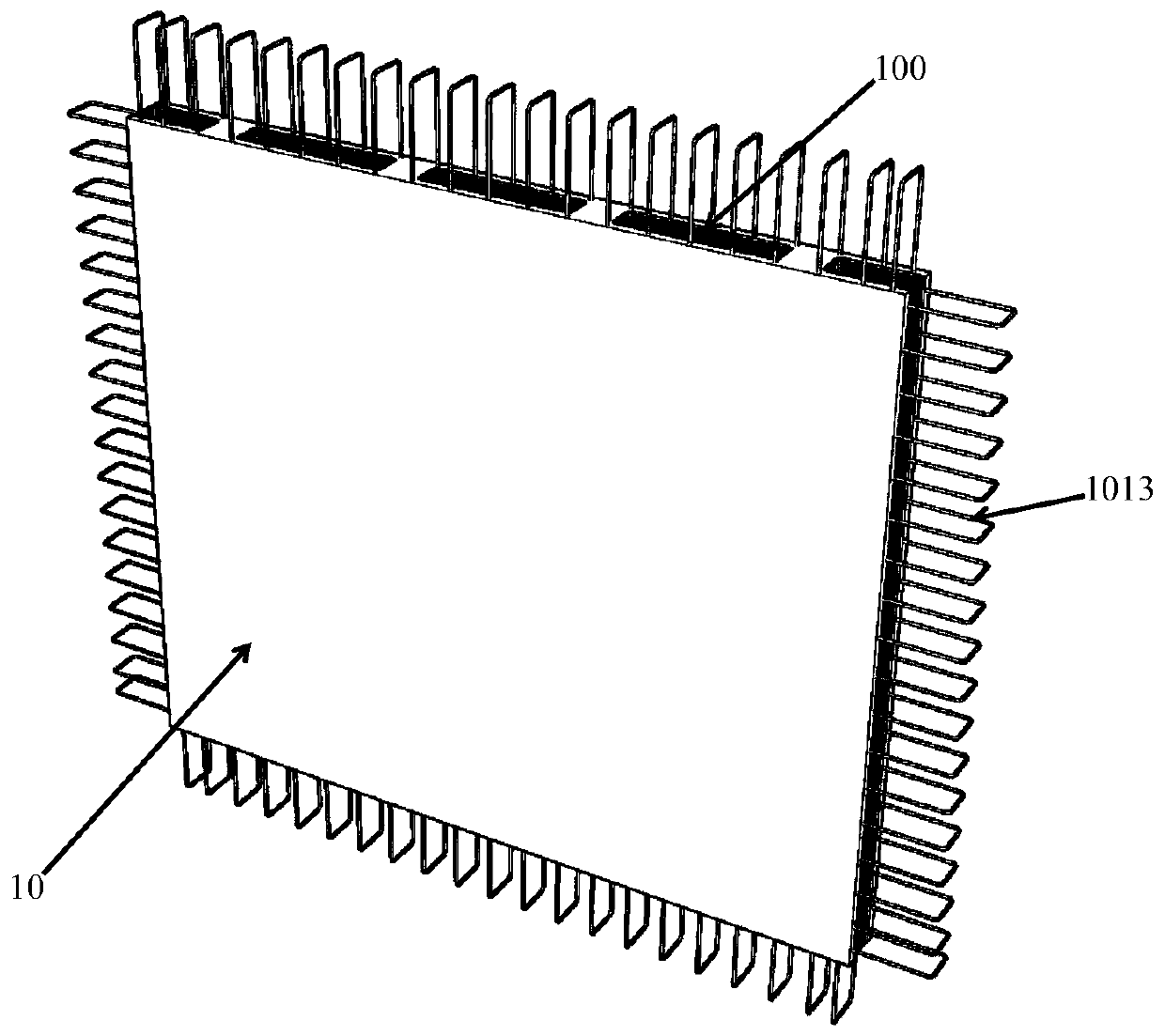

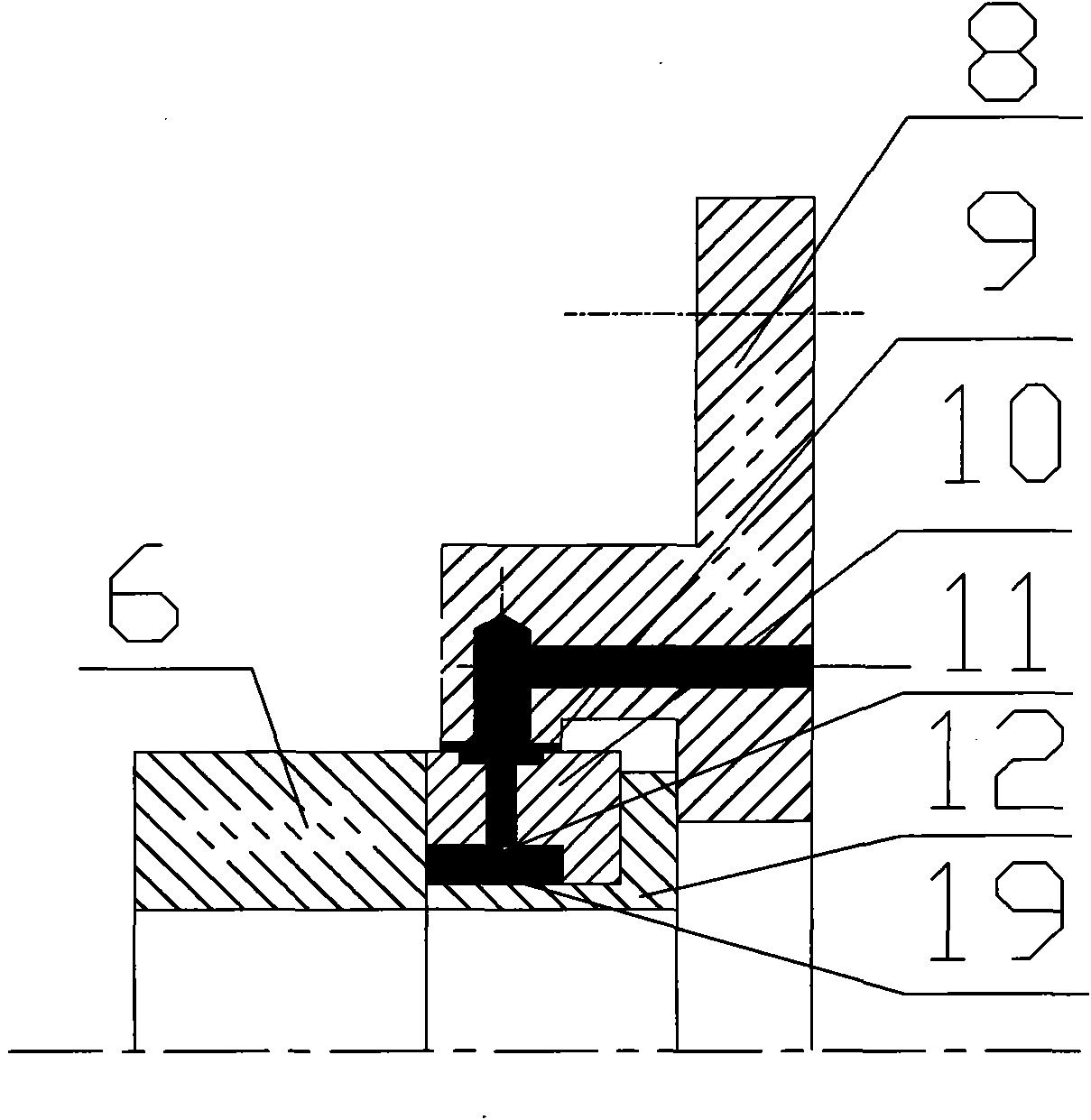

Chain type staggered micro-channel structure

ActiveCN104465562ASpeed up the flowLower coefficient of frictional resistanceSemiconductor/solid-state device detailsSolid-state devicesDie swellEngineering

The invention discloses a chain type staggered micro-channel structure. The chain type staggered micro-channel structure comprises a substrate and micro fluid passageways arranged on the substrate. The chain type staggered micro-channel structure is characterized in that each micro fluid passageway comprises two branch micro fluid passageway bodies which intersect and are separated in a periodic mode, intersections are formed in the positions where the branch micro fluid passageway bodies intersect, and furcation openings are formed in the positions where the branch micro fluid passageway bodies are separated. According to the micro fluid passageways, the bent micro passageways are arc type channels periodically changing and are formed by smoothly connecting different gradients of arcs, and every two adjacent channels are symmetrical, intersect every other distance and are arranged according to arcs after intersecting. A cooling working medium smoothly flows in the channels, and the friction resistance coefficient is small. The two branch micro fluid passageway bodies of each micro fluid passageway are staggered, the redevelopment of the hot boundary layer on the front edge of each channel is caused, the thickness of the boundary layers is reduced, the fluid can be in the developing state all the time through the regenerated entrance effect, and the heat dissipation performance of heat dissipation devices is improved.

Owner:XIDIAN UNIV

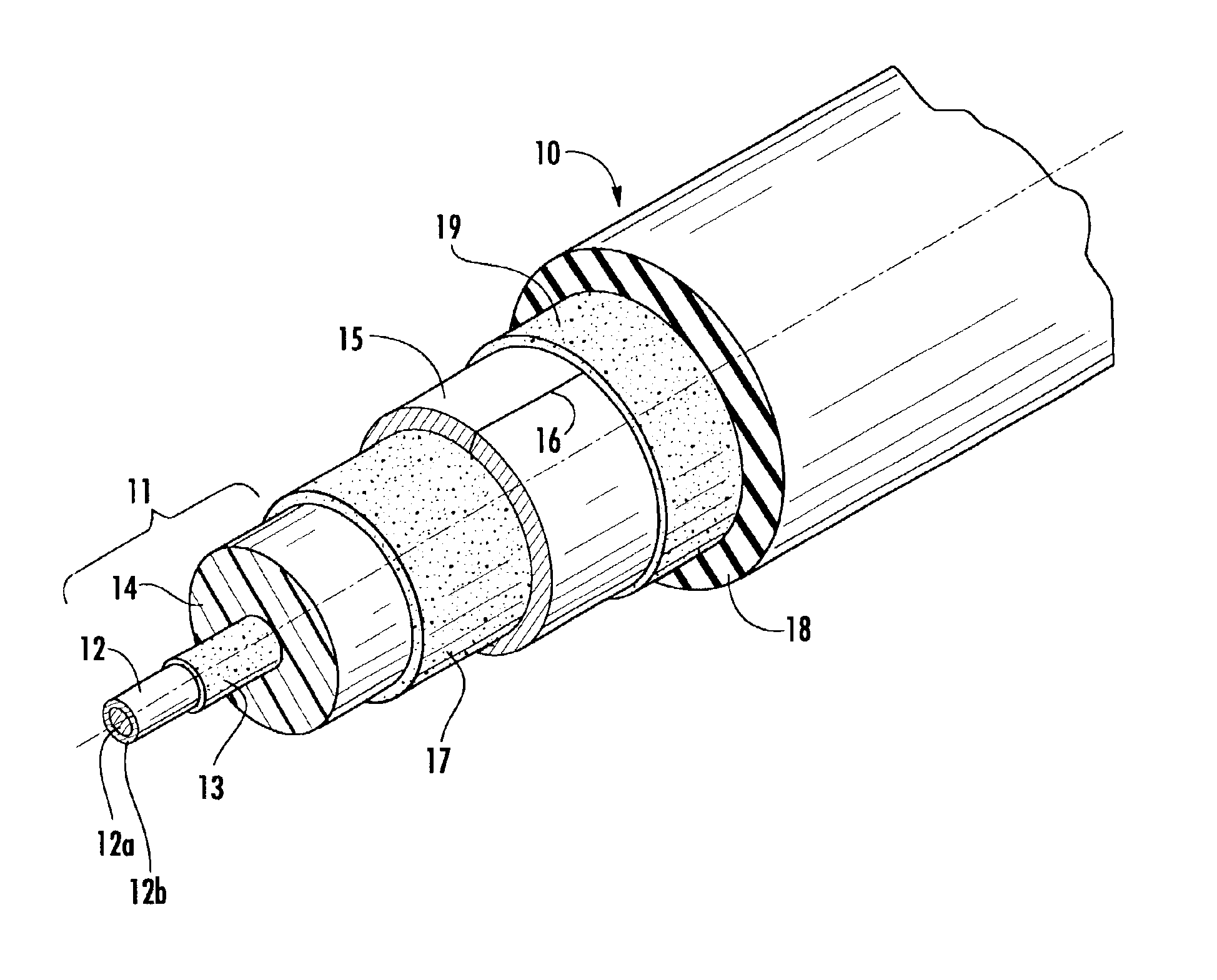

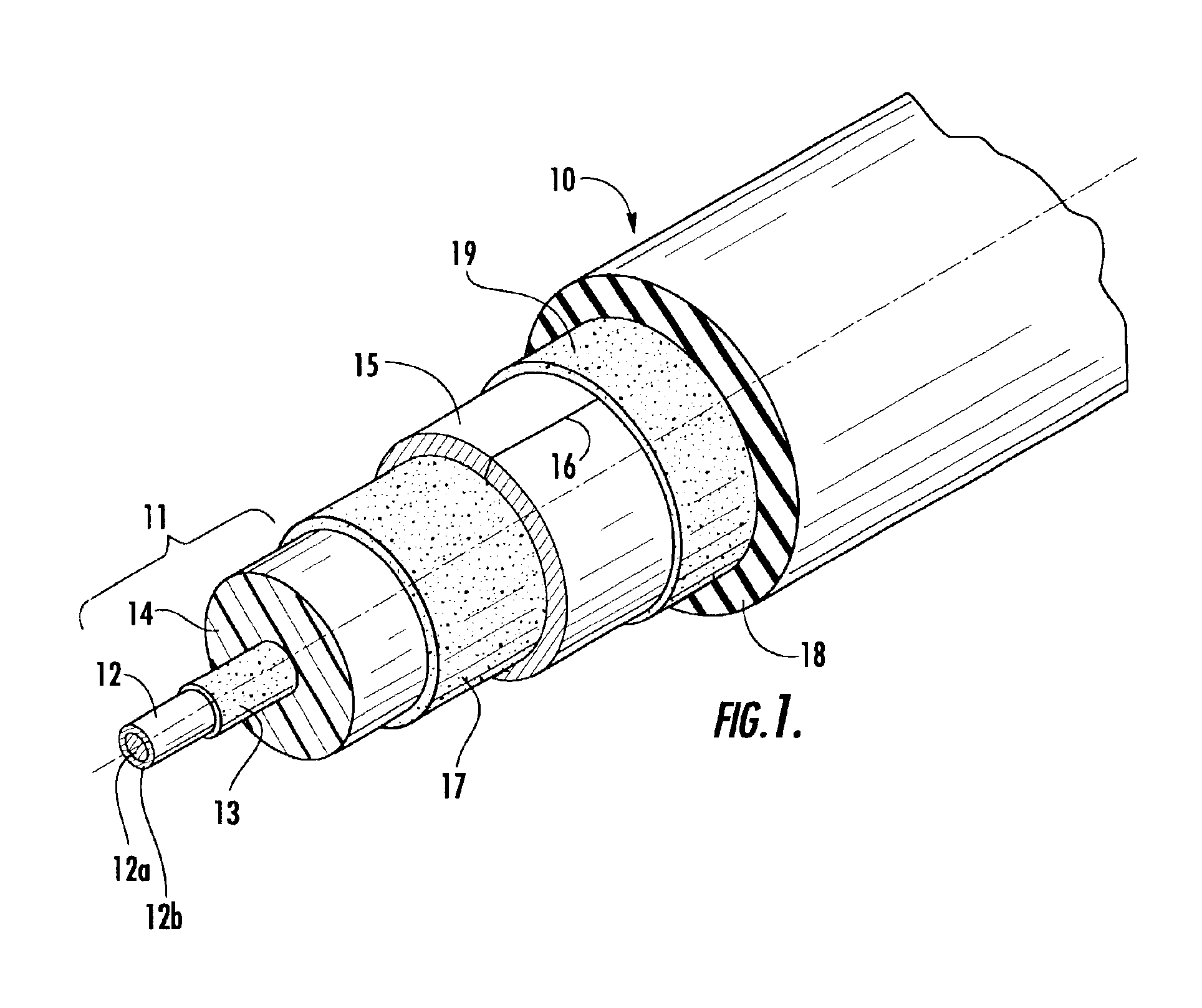

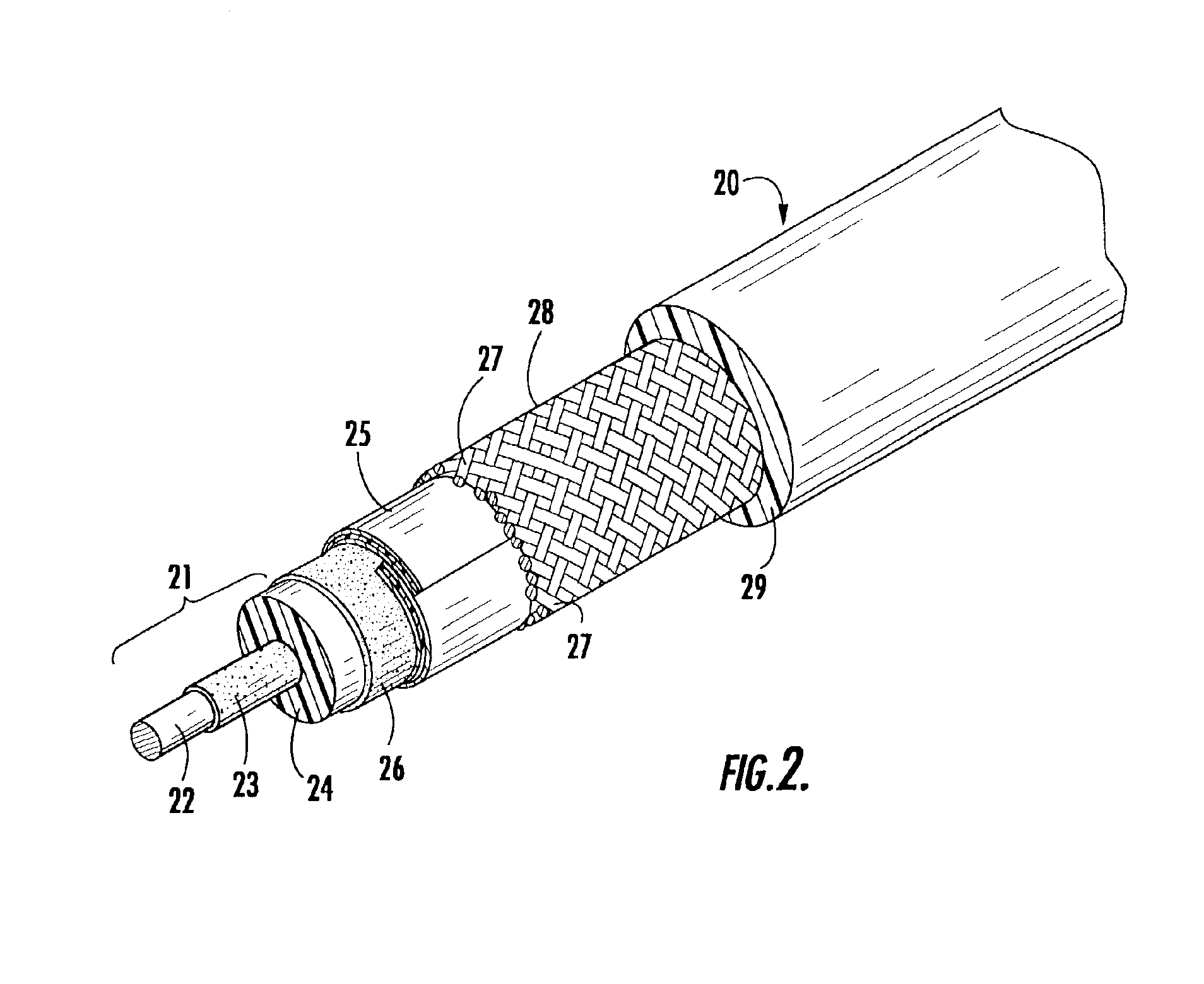

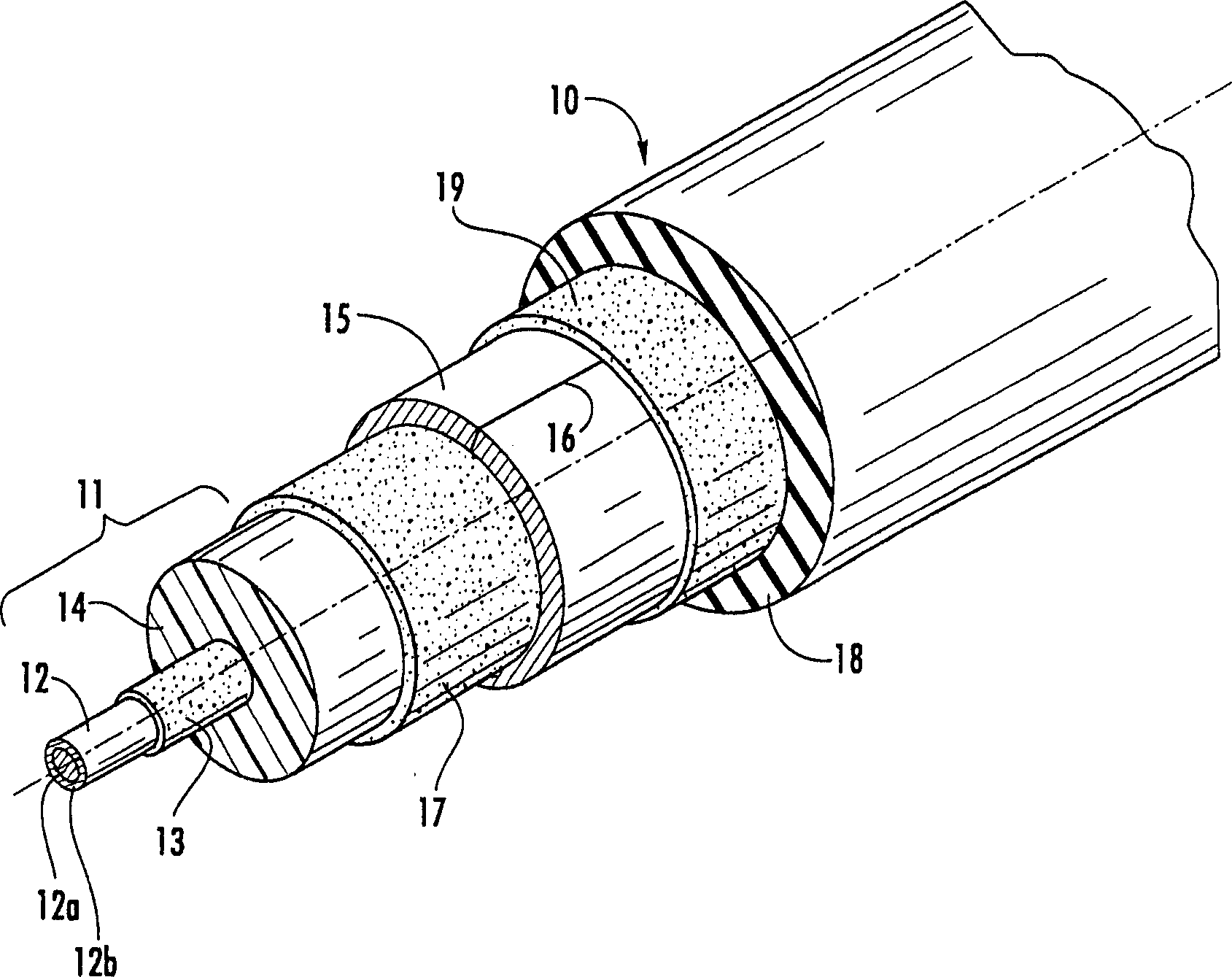

Cable with foamed plastic insulation comprising and ultra-high die swell ratio polymeric material

InactiveUS6858805B2Improve bindingImproved stress crack resistancePlastic/resin/waxes insulatorsCable insulation constructionUltrasound attenuationCrack resistance

An electrical communications element having a foamed plastic insultation extruded about a conductor with said insulation including at least one component with more than 20% by weight of an ultra-high die swell ratio polymer (UHDSRP), preferably around 15% by weight. The UHDSRP is defined as greater than 55% die swell ratio and more preferably greater than 65% die swell ratio. The insulation also preferably includes at least a second component with a high degree of stress crack resistance, such that the combination of (minimally) these polymers will yield an insulation layer that has a unique combination of physical propeties yielding a high degree of foaming, small uniform cell structure, characteristically lower attenuation, and stress crack resistance capable of withstanding greater than 100 hours at 100° C. while coiled at a stress level of 1 times the insulation outside diameter without failure (cracking).

Owner:COMMSCOPE INC

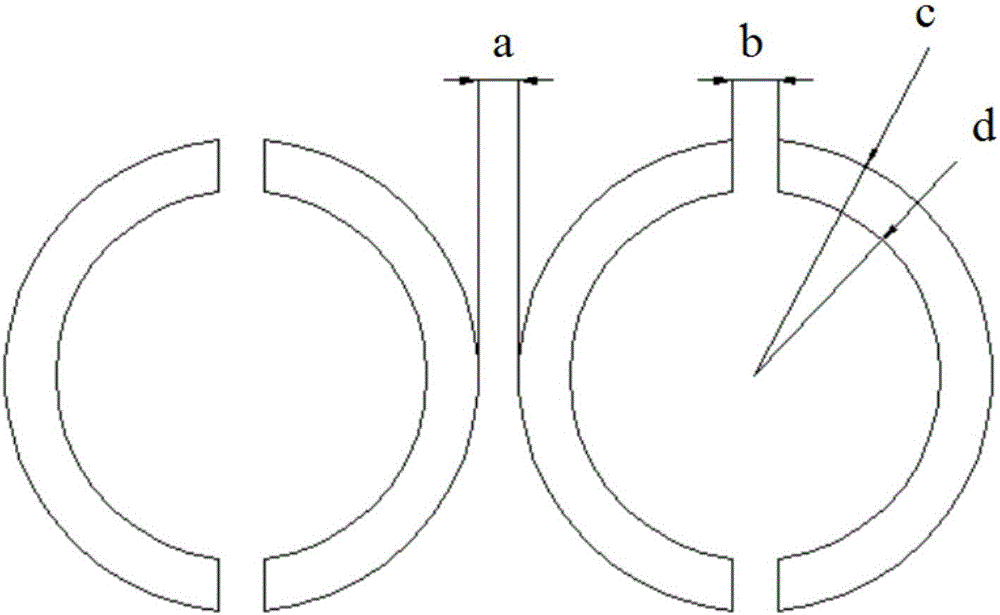

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

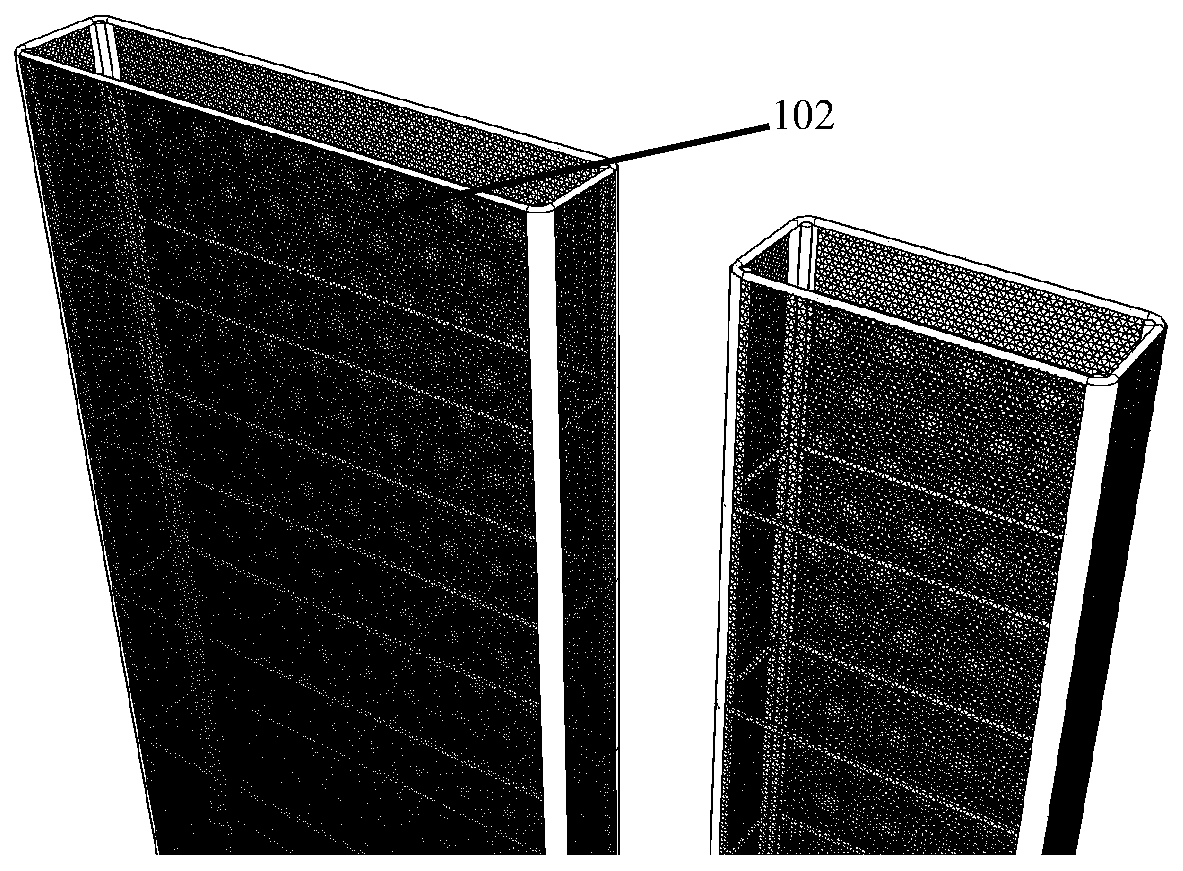

Fabricated core-grouting wall body, construction method of fabricated core-grouting wall body and frame for preparing wall body

PendingCN110185174ASolve the difficulty of constructionHigh knot strengthConstruction materialWallsDie swellRebar

The invention discloses a fabricated core-grouting wall body, a construction method of the fabricated core-grouting wall body and a frame for preparing the wall body. A longitudinal first cavity is formed in a prefabricated wallboard for grouting concrete at a construction site, and the problem that the construction difficulty of grouting to horizontal seams in the prior art is high is effectivelysolved; the tension intensity between inner and outer leaf wallboards is further effectively enhanced, risks of die expansion of the existing double-side composite wall and die shell shear wall are overcome, so the inner and outer leaf wallboards can be made thinner. A die shell is bounded and fixed in a steel cage in advance, the die shell is not disassembled after completing concrete sproutingbut left in a prefabricated part to form the first cavity, and the problems that the die shell cannot be stressed in the process of using during later periods in the prior art, and due to the fact that a building transforms in the process of using, and hidden cracks are produced between the die shell and internal post-grouting concrete shear wall can be effectively solved; and the die shell is bounded and fixed in the steel cage, the die shell can be stressed in the process of using during the later periods, and the intensity of the prefabricated wallboard is further improved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

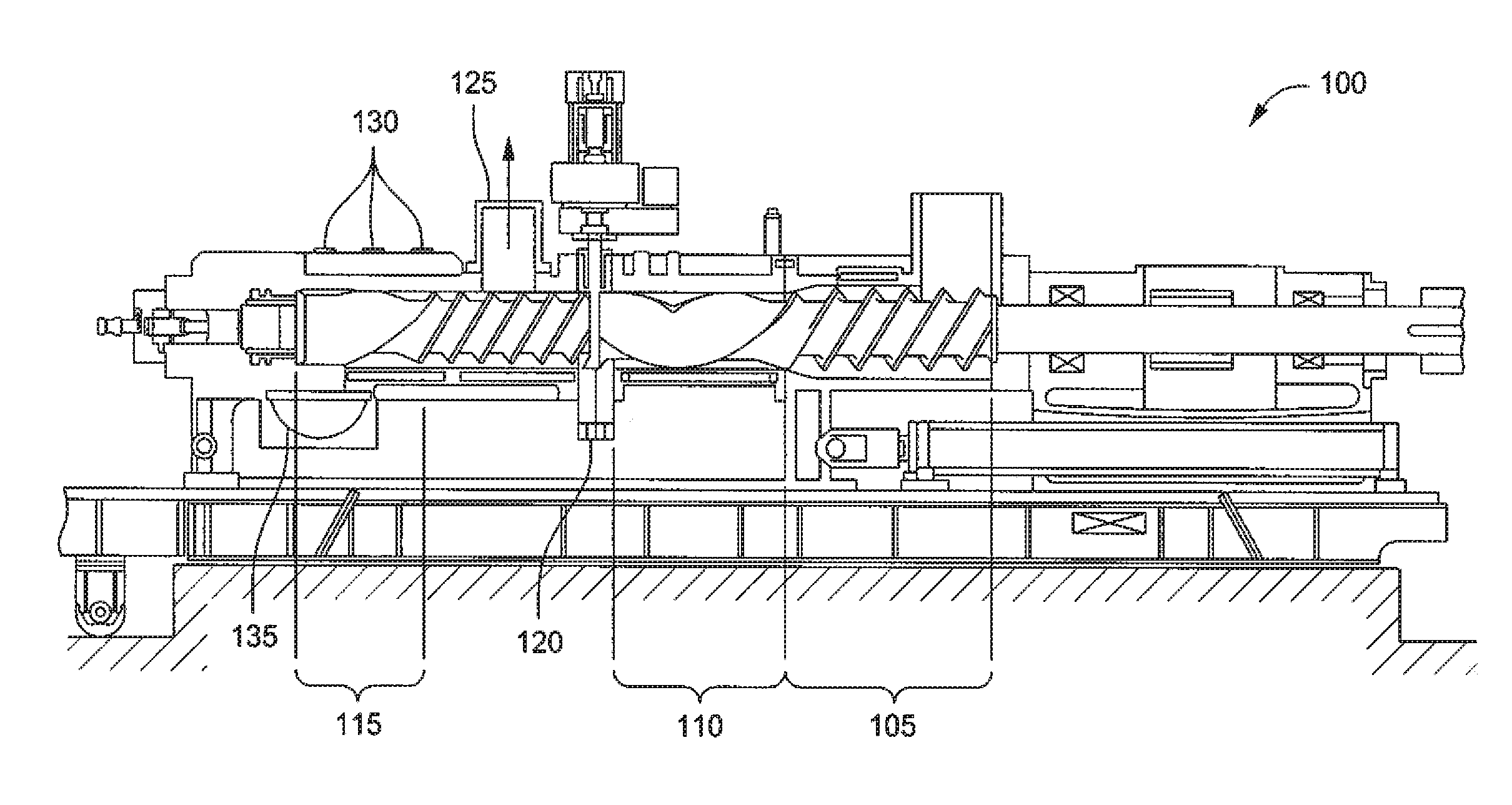

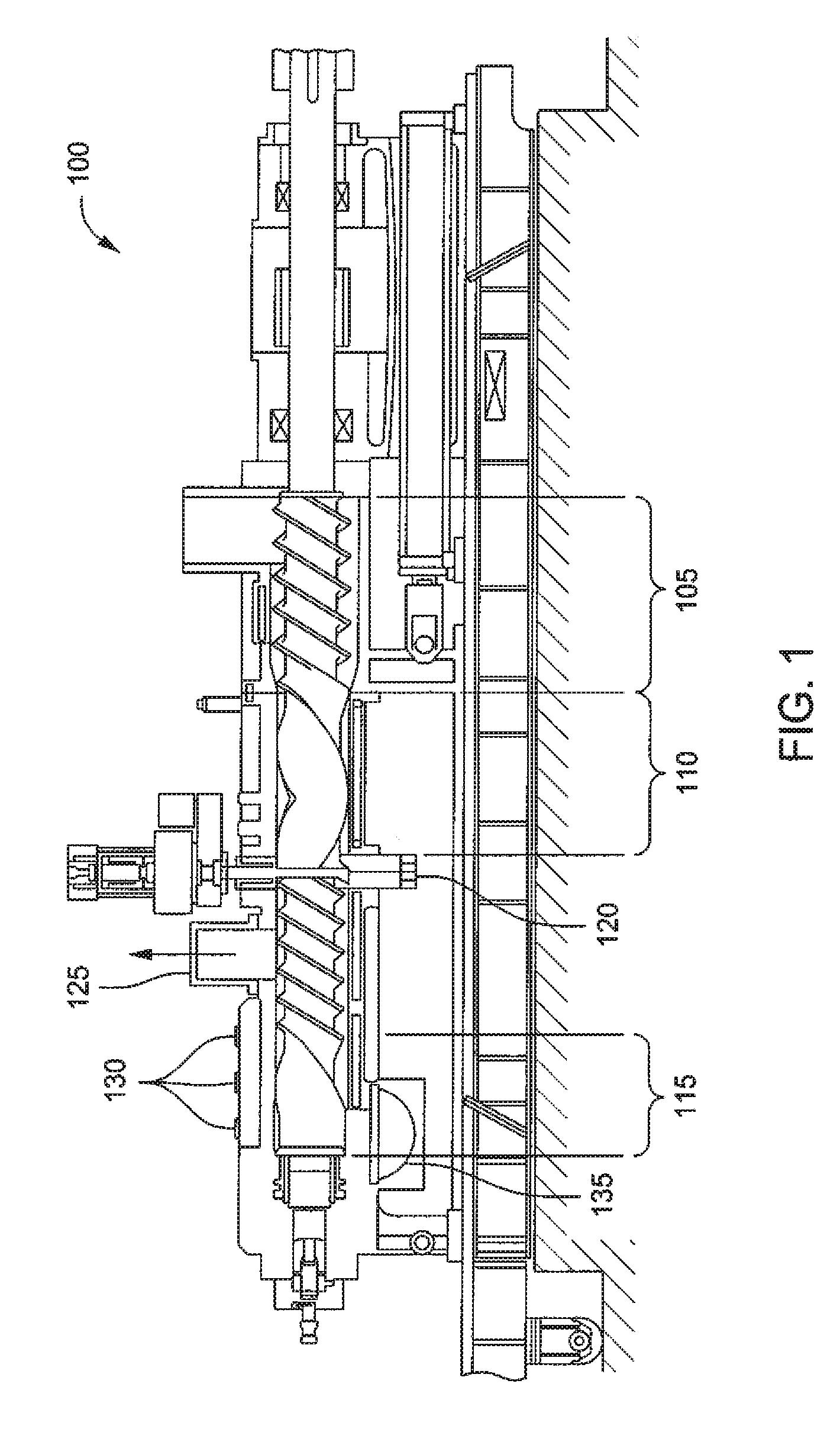

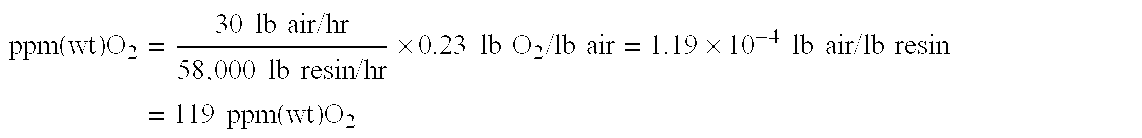

Oxygen tailoring of polyethylene blow molding resins

ActiveUS7285617B2Improve melt strengthReduced die swellWood working apparatusDomestic articlesBlow moldingDie swell

Processes are disclosed for oxygen-tailoring polyethylene blow molding resin. Polyethylene resin is conveyed through a feed zone, a melt-mixing zone and a melt zone, wherein the temperature of the polyethylene resin is from about 216° C. to about 260° C. in the melt zone. The resin is contacted with oxygen in an amount of at least about 20 parts by weight oxygen per million parts by weight resin. The oxygen-treated resin can be used to make polyethylene blow molded articles having improved melt strength, processability, and die swell.

Owner:EXXONMOBIL CHEM PAT INC

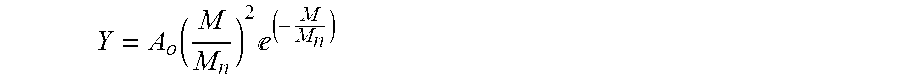

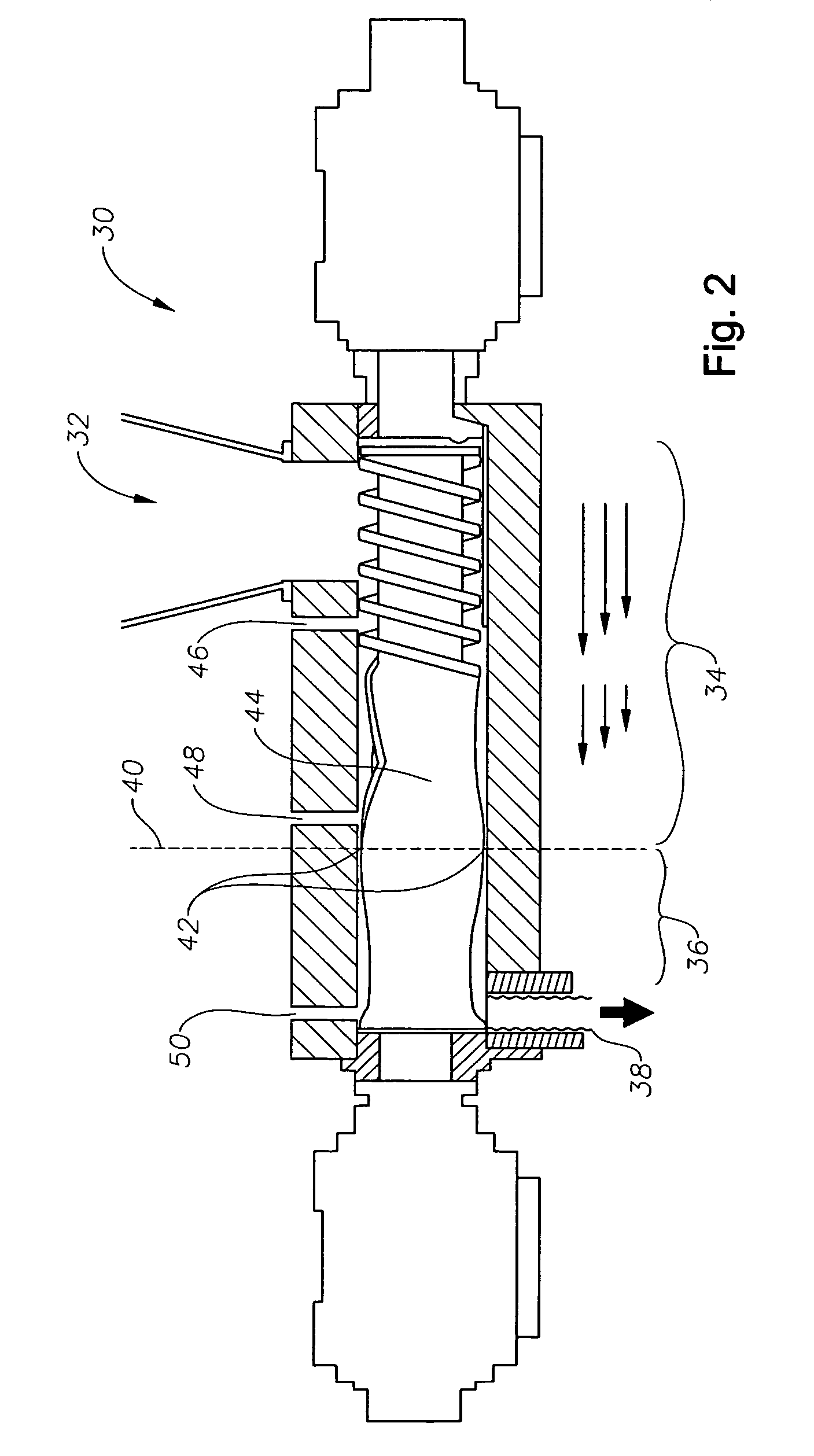

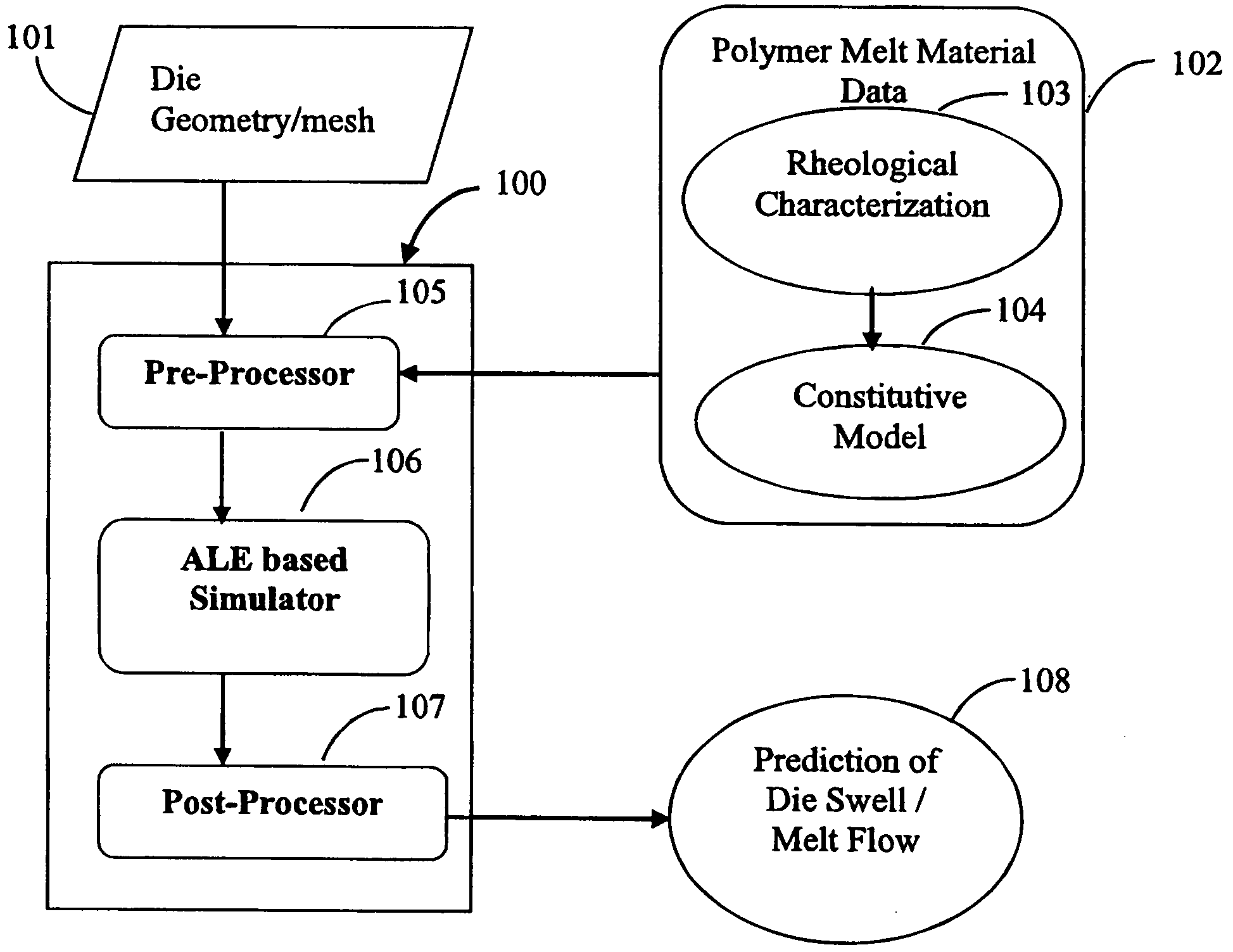

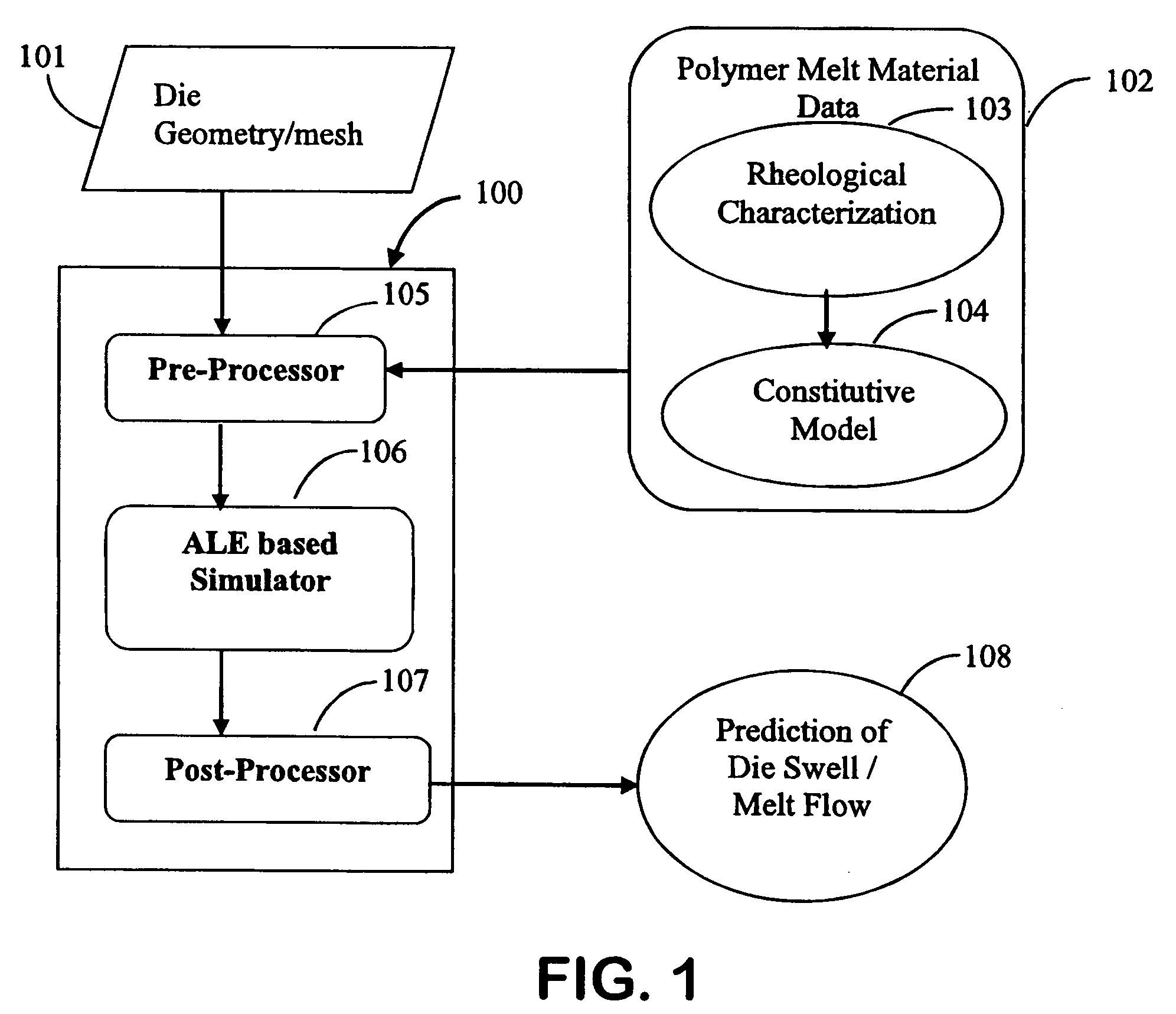

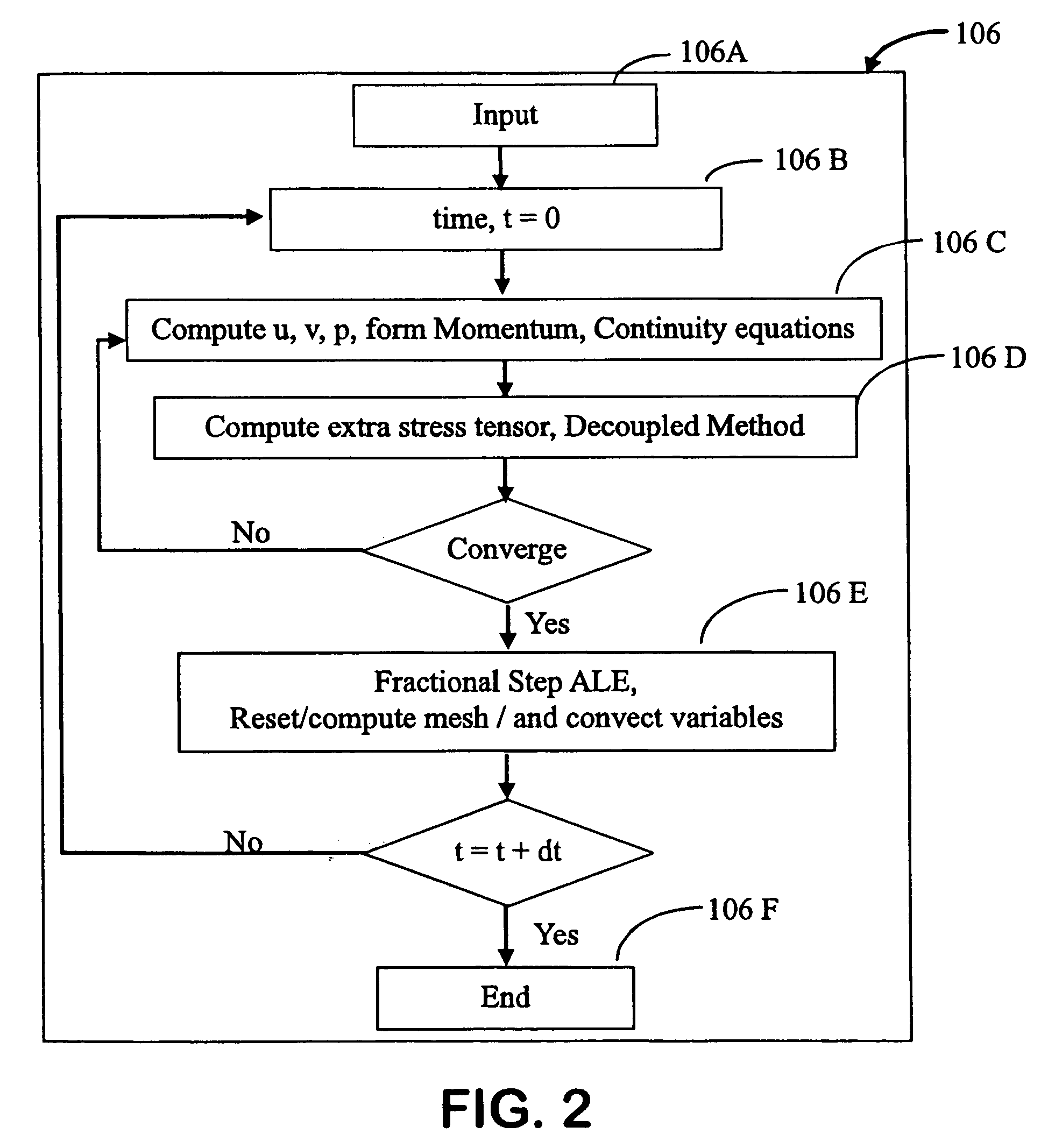

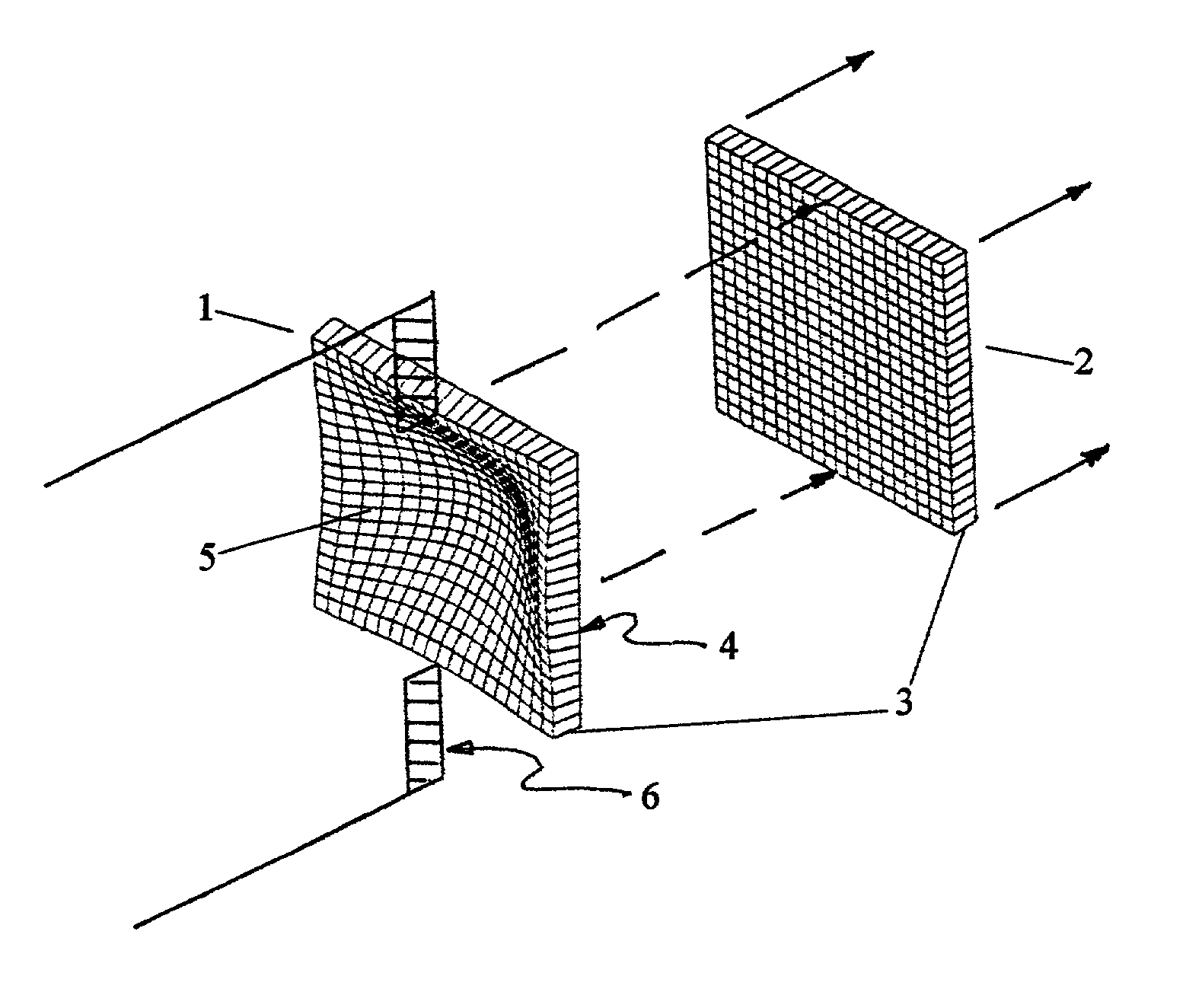

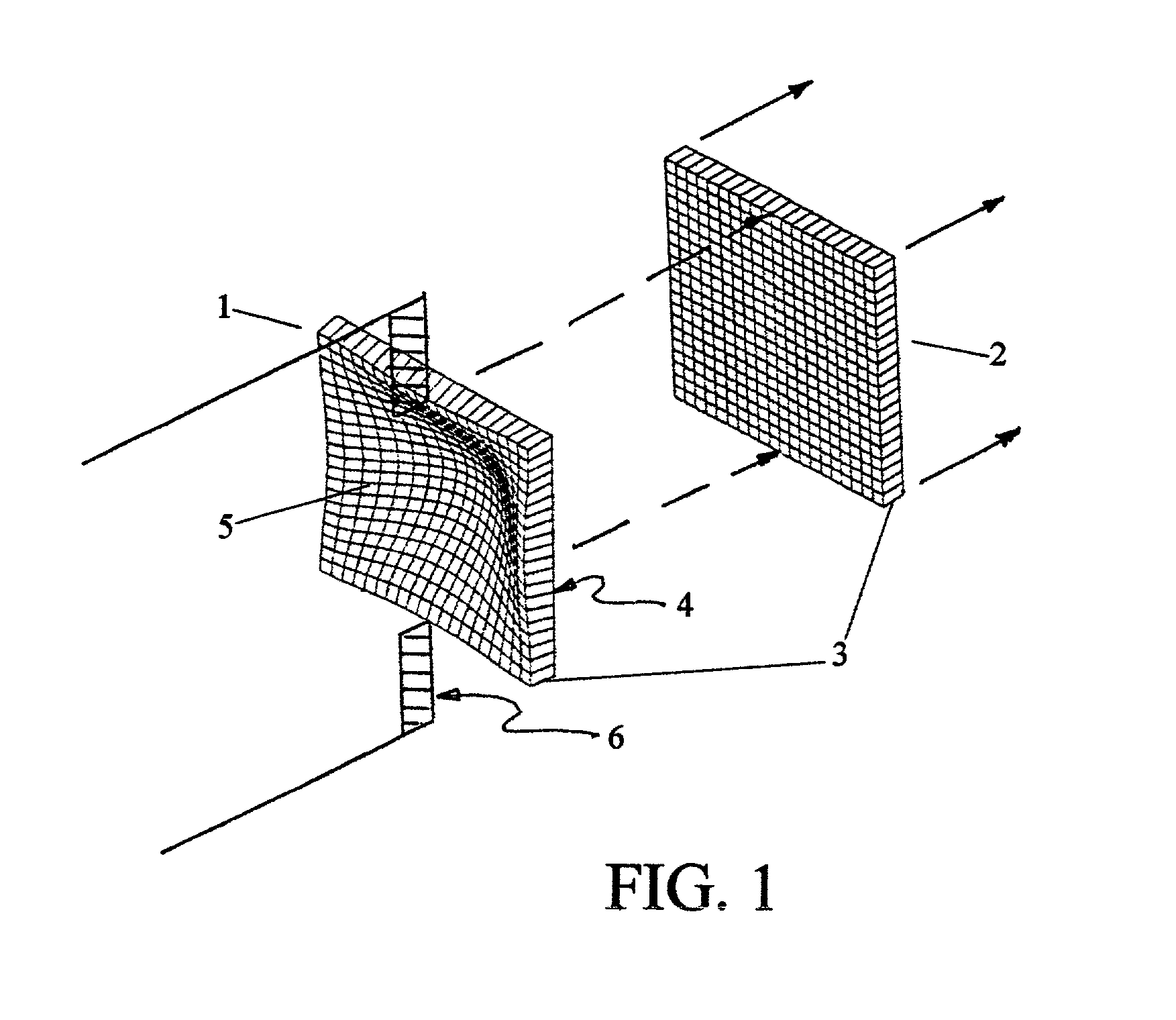

Polymer melt extrusion which has potential use in die design

ActiveUS20090210189A1Improve extrusion rateAccurate calculationDigital computer detailsMeasurement arrangements for variableDie swellPost processor

The present invention discloses a system for analyzing and simulating the die swell and the flow profile in polymer melt extrusion through a die, said system typically comprising a mesh generator adapted to generate a computational mesh; a pre-processor adapted to obtain die parameters, boundary conditions, polymer melt parameters including rheological characterization and constitutive equations and to generate an input file; a simulator adapted to receive the input file from the pre-processor and process the input data to simulate die swell; a mesh corrector means adapted to analyze the die swell obtained from said simulator and to correct the motion of the computational mesh and polymer melt to converge the die swell; a post-processor means adapted to visualize the die swell and flow profiles for the polymer melt; and a database means adapted to store the die swell corresponding to the die, mesh and polymer melt parameters.

Owner:TATA CONSULTANCY SERVICES LTD

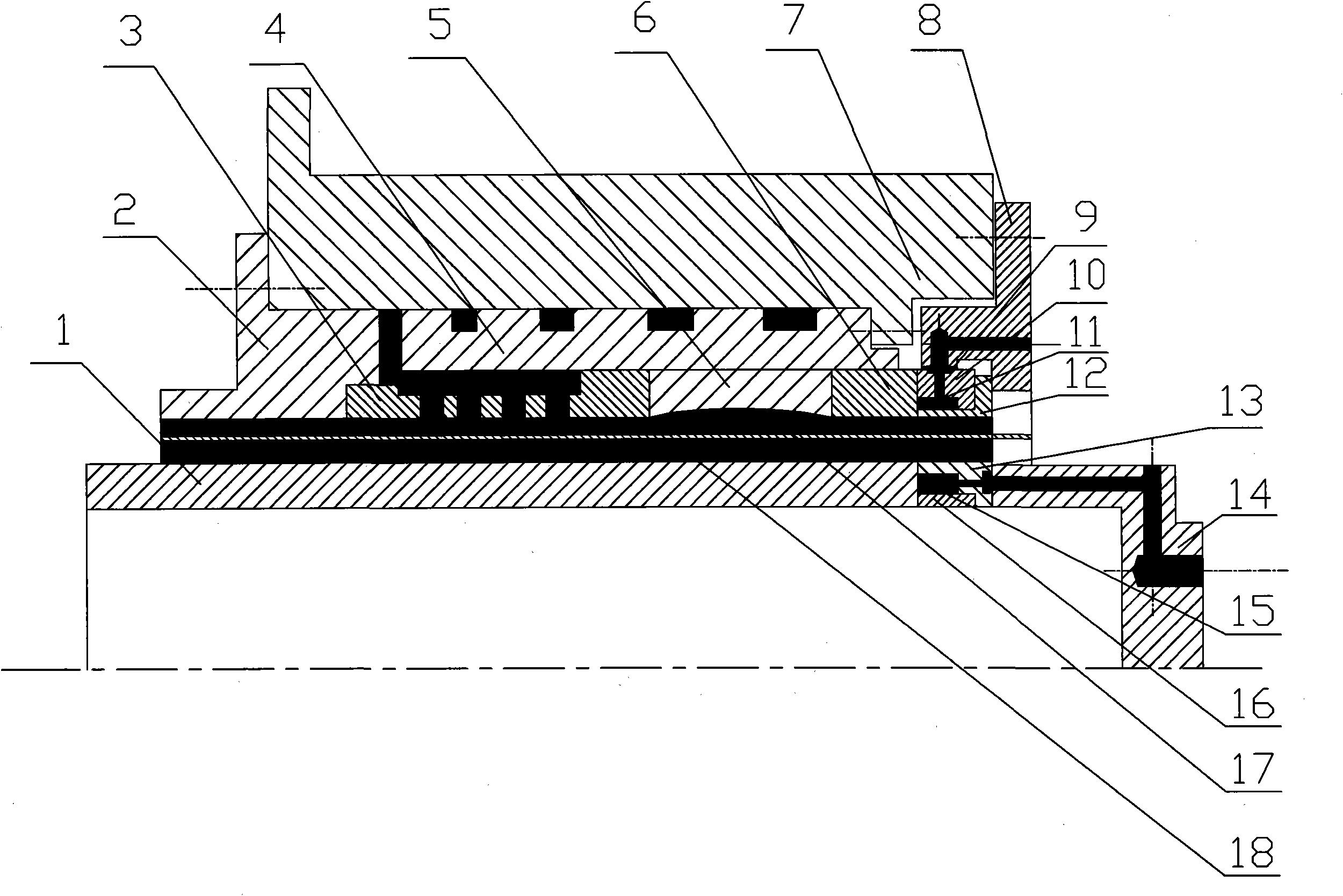

Composite metal plastic pipe extrusion molding device and molding method thereof

The invention discloses a composite metal plastic pipe extrusion molding device and a molding method thereof. The device comprises a sieve mesh cover, a connection flange, a wedging ring, a core rod, a material cover, an airless assisted mold and a connecting outer cover; the right end of the airless assisted mold is connected with an air assisted mold; the outer side of the air assisted mold is provided with an air assisted mold outer cover; the air assisted mold outer cover is connected with a mold air inlet cover plate; the leak tightness of air passage is guaranteed through a sealing ring; the right end of the core rod is connected with the inner cover of the core rod; and the right end is connected with the air inlet cover plate of the core rod. The method comprises that lubrication gas with certain pressure is divided into two paths while entering the air assisted molding passage. Since stable air cushion films are formed between the mold, the core rod and the plastic melt, thereby reducing the extrusion pressure, saving the energy consumption, basically eliminating die swelling, improving precision of products, reducing material waste, shortening molding period, and saving the cost.

Owner:DALIAN MARITIME UNIVERSITY

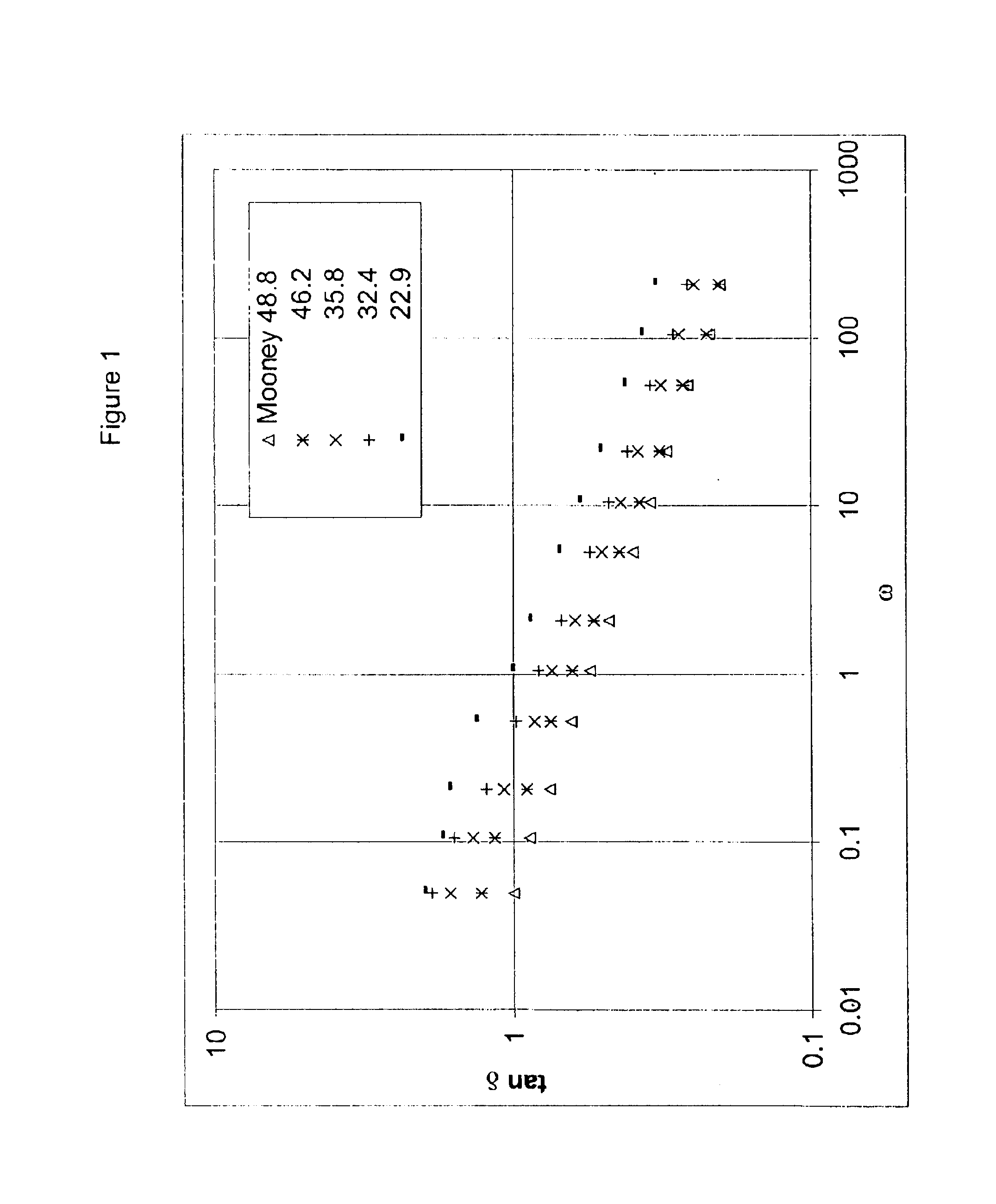

Vinyl-cis-polybutadiene rubber and butadiene rubber composition using the same

InactiveUS7700691B2Low melting pointSynthetic resin layered productsCellulosic plastic layered productsPOLYMER SUBSTANCEPolymer science

Owner:UBE IND LTD

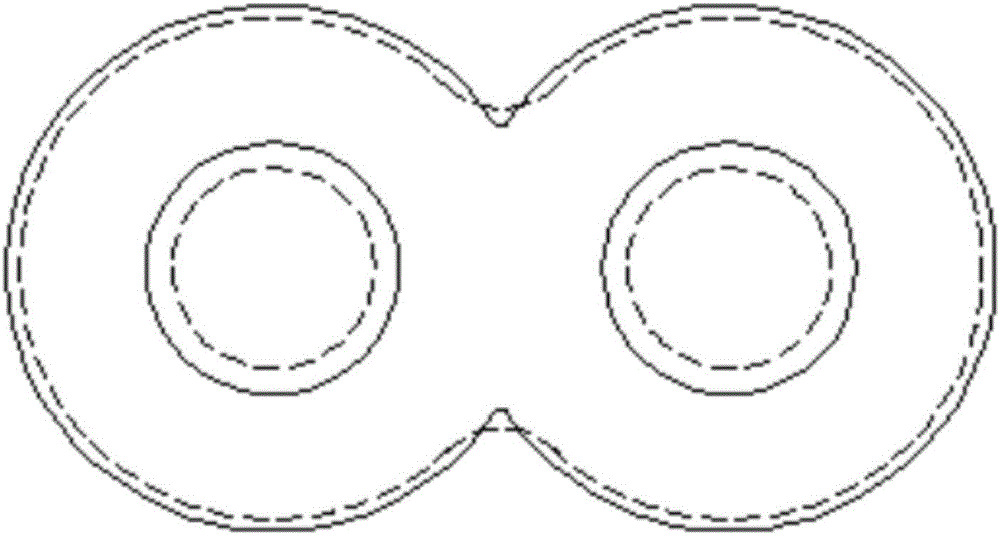

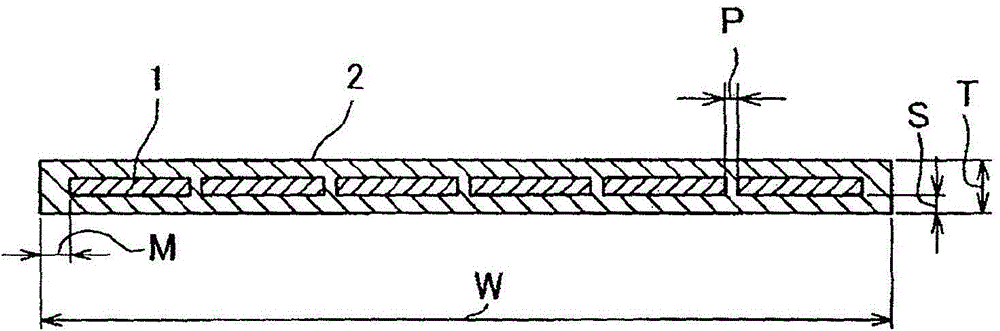

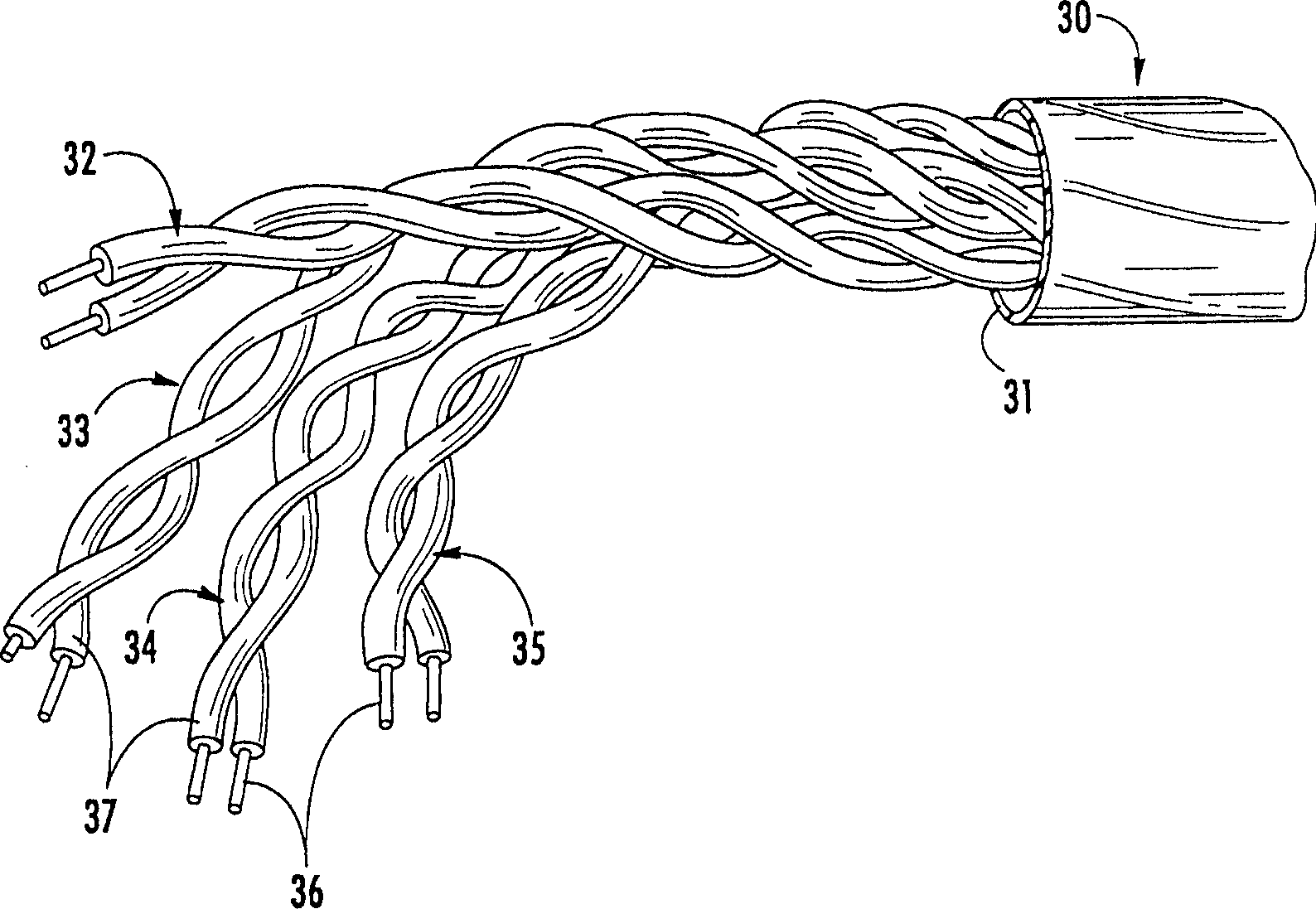

Flexible flat cable and method of manufacturing the same

ActiveCN103959403AGood flexibilityDoes not corrodePlastic/resin/waxes insulatorsFlat/ribbon cablesElectrical conductorDie swell

Owner:YAZAKI CORP

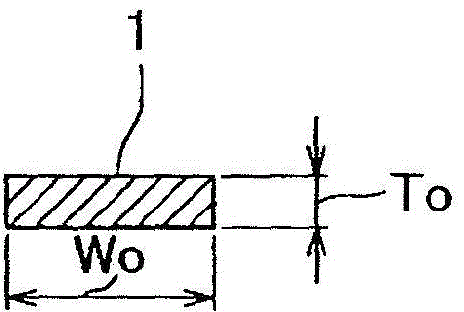

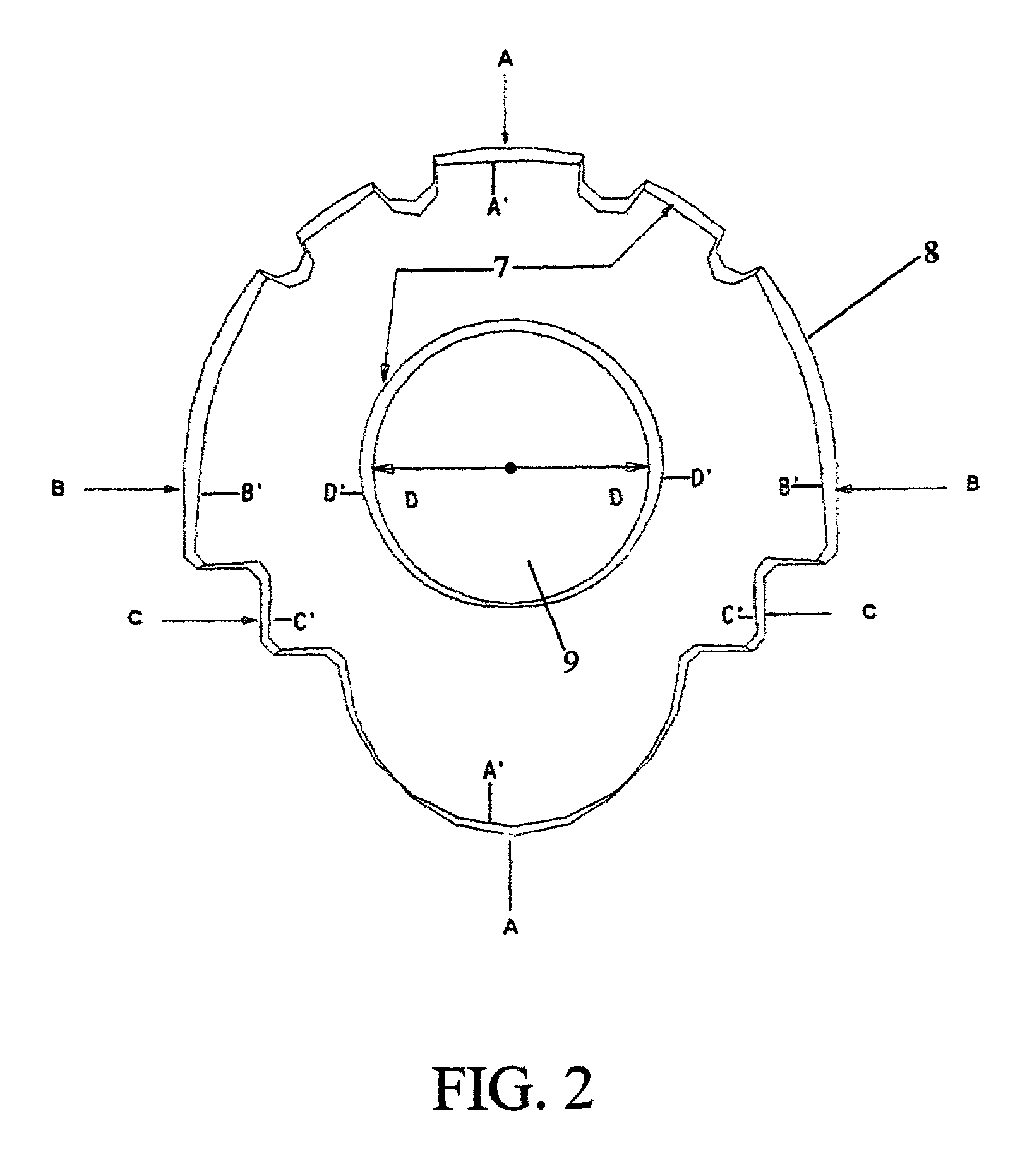

Method for designing a profile die for polymer extrusion

InactiveUS7110921B1Simple designReduces work and cost and cycle timeExtrusion diesLaminationPressure.driveDie swell

A method for designing a profile extrusion die is based on an analogy that exists between membrane deflection under pressure and low Reynolds number pressure driven fluid flow. The analogy is used to predict the relative shape of the die to correct for die swell or die contraction. The application of the analogy takes into consideration the characteristics of the extruder, the operating conditions, and the extrudate composition.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Method for improving stability of polypropylene melt

The invention relates to a principle and a method for improving the stability of a polypropylene melt. The method and the principle are characterized in that: by adding a tetrafluoroethylene polymer with a polypropylene melt strength enhancing function and a flaky component with a melt die swell control function, the melt die swell phenomenon is significantly reduced, and the obtained polypropylene modified material is suitable for thermal forming of various large parts, thus meeting the requirements for extrusion of hollow plates and large-diameter pipes. During extrusion blow molding of large hollow products, the melt dimensional stability can also be ensured. The method and the principle also have the advantages of enhancing the processing speed and reducing the cost.

Owner:文彦飞

Cable with foamed plastic insulation comprising an ultra-high die swell ratio polymeric material

InactiveCN1784751APlastic/resin/waxes insulatorsCable insulation constructionAnti stressElectrical conductor

An electrical communication element having a conductor and a foamed plastic insulation around the conductor, said insulation comprising at most 20% by weight, preferably about 15% by weight, of at least one ultra high die swell polymer (UHDSRP) Element. The UHDSRP is defined as having a die swell greater than 55%, more preferably a die swell greater than 65%. The insulator also preferably comprises at least one second component that is highly resistant to stress cracking, such that combining these polymers (minimum) will produce an insulating layer with a unique combination of physical properties resulting in a high degree of foaming, microscopic , uniform pore structure, and produces characteristic low attenuation and resistance to stress cracking, when crimped at a stress level of 1 times the outer diameter of the insulator at 100 ° C, it will not show defects (cracking) for longer than 100 hours ).

Owner:COMMSCOPE INC

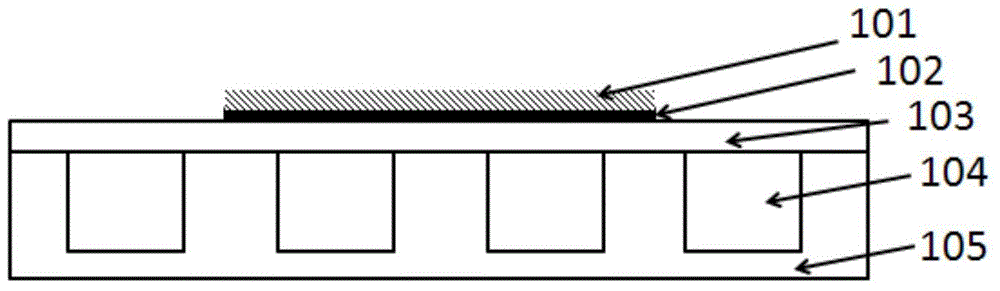

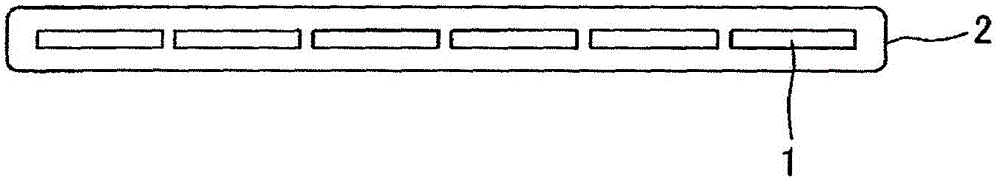

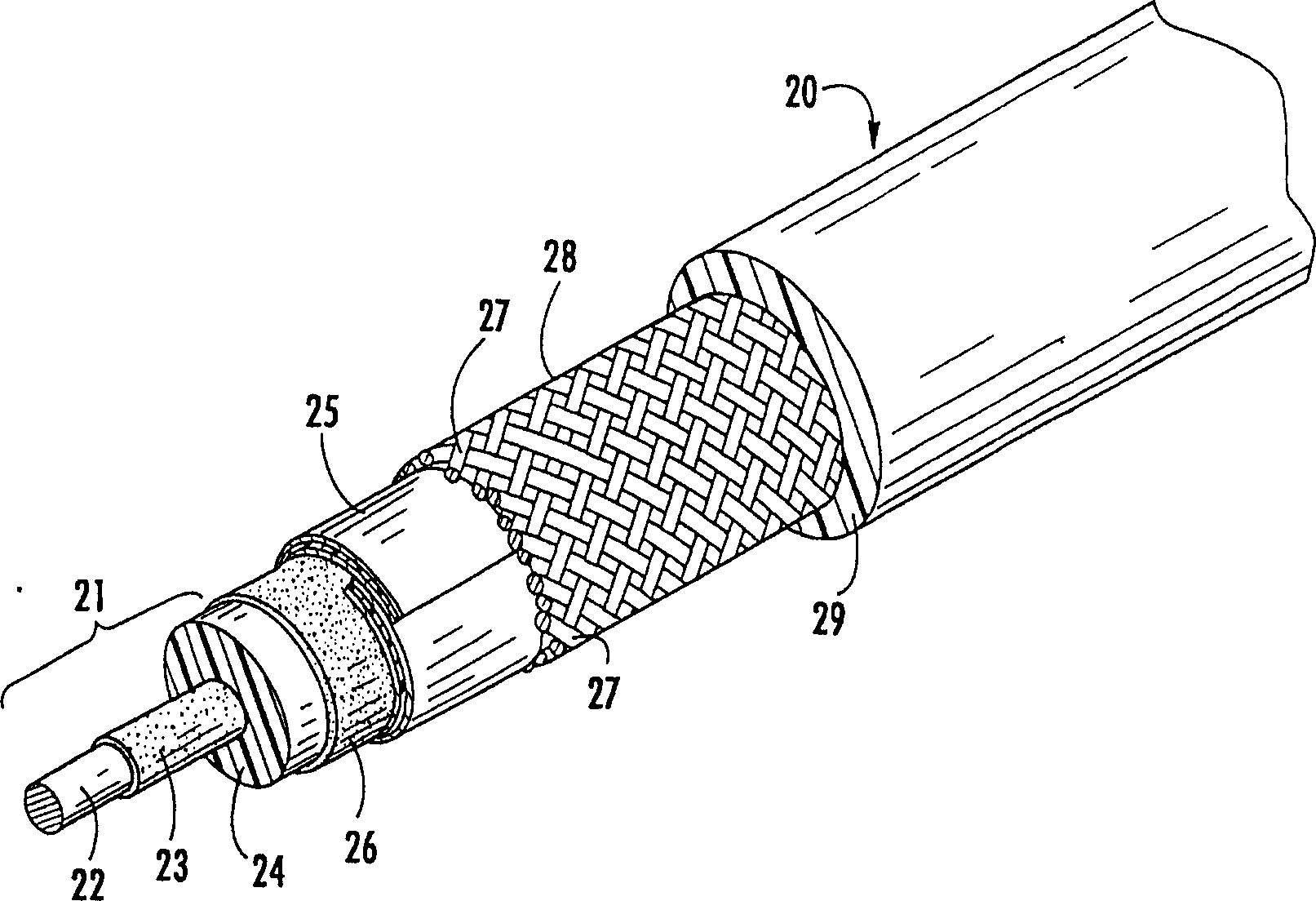

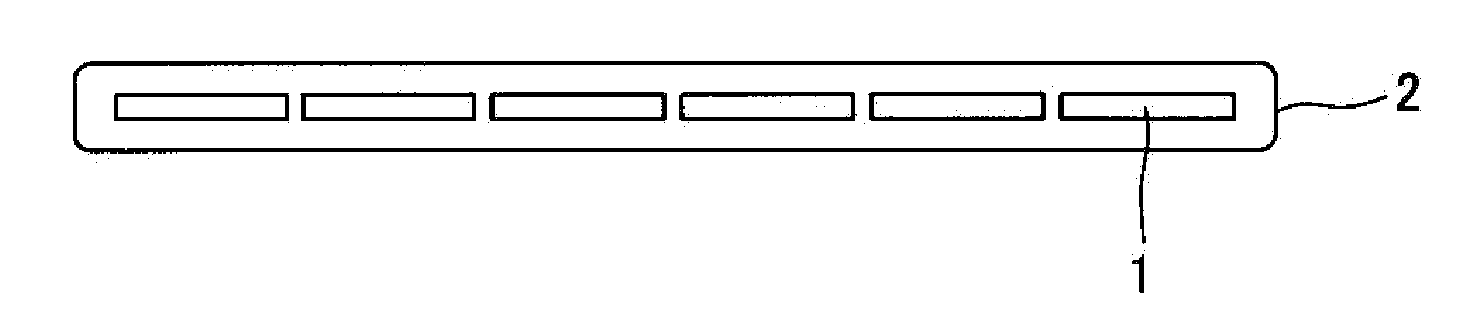

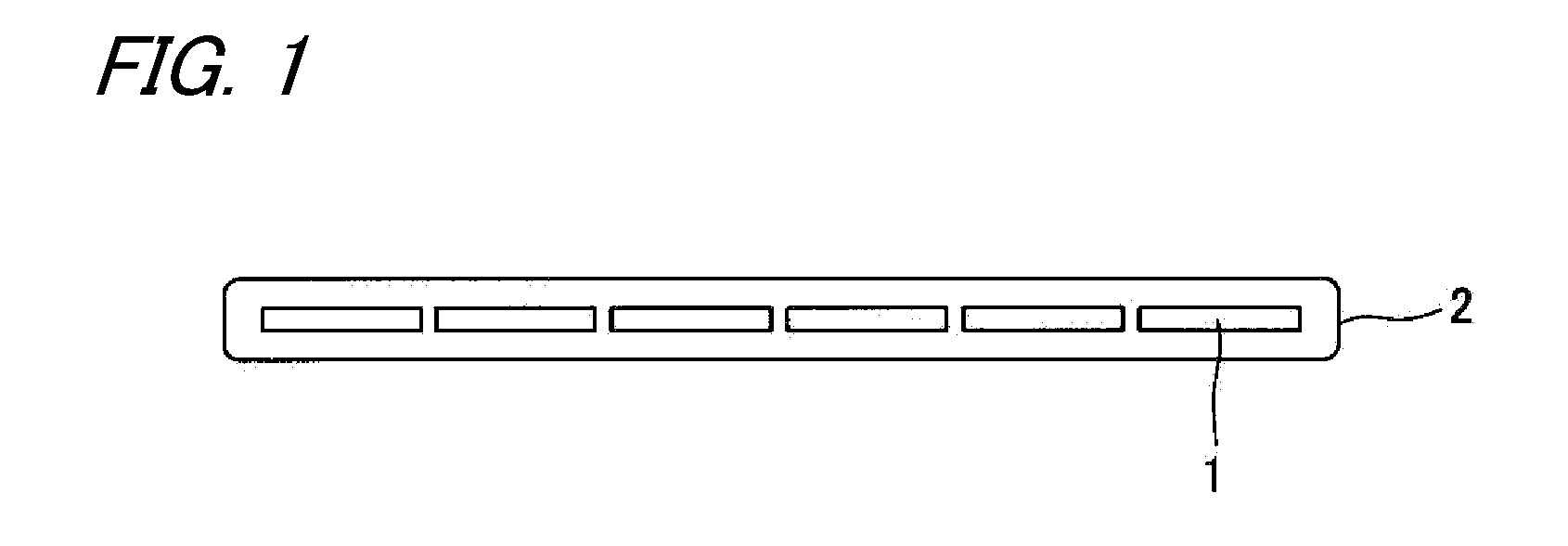

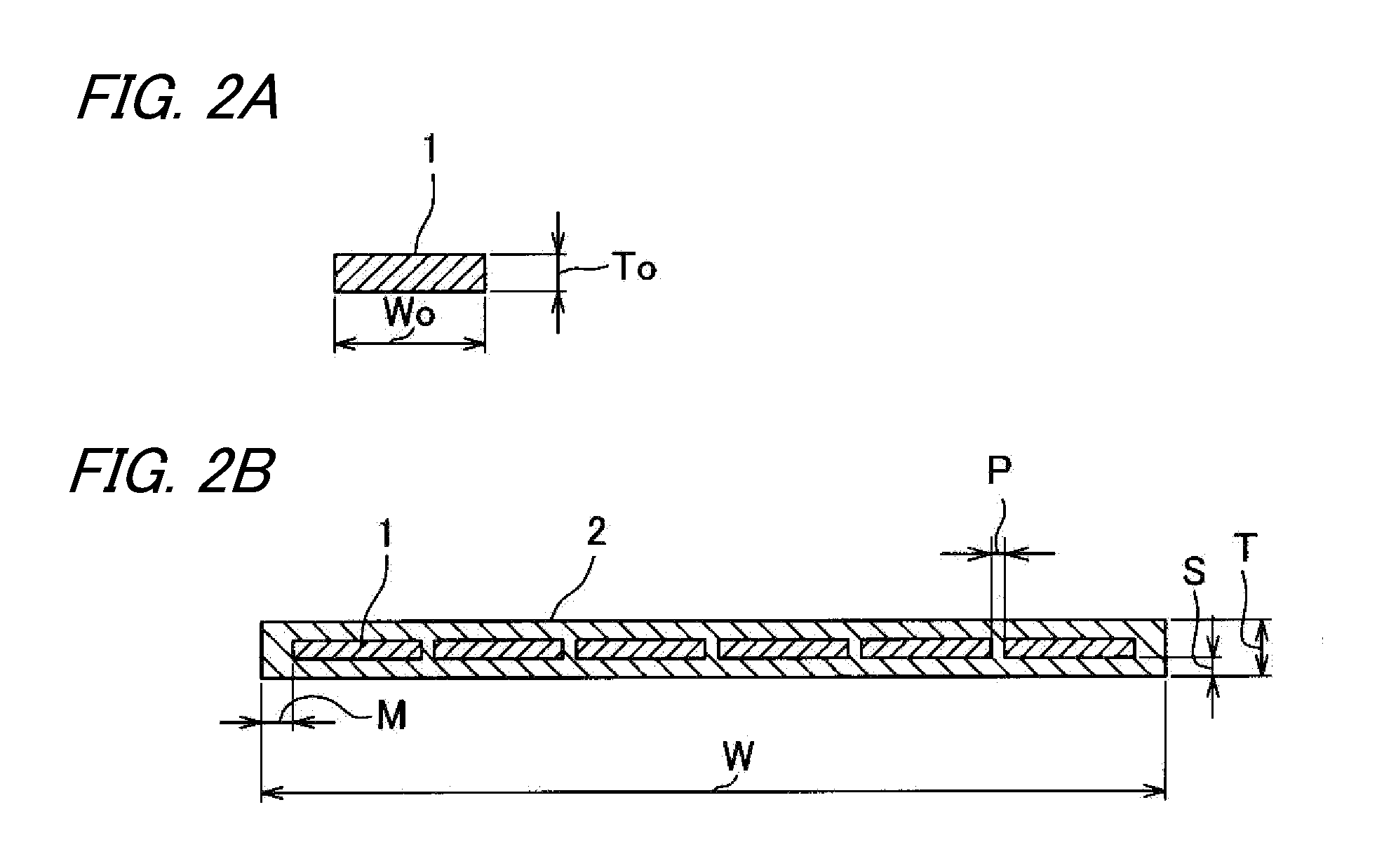

Flexible Flat Cable and Method of Manufacturing the Same

ActiveUS20140262430A1Appropriate useGood flexibilityPlastic/resin/waxes insulatorsLaminationElectrical conductorShell molding

A flexible flat cable includes an insulating layer disposed through extrusion in vicinity of a plurality of conductors arrayed in parallel with each other. The insulating layer is composed of a vinyl chloride-based resin composition having a die swell ratio of 1.1 or more at a molding temperature during the extrusion. The molding temperature is between 150° C. to 200° C. with a linear rate of between 50 m / minute to 200 m / minute. A melt tension of the vinyl chloride-based resin composition is 0.02 N to 0.2 N.

Owner:YAZAKI CORP

Flat polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106835338AReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterYarn

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

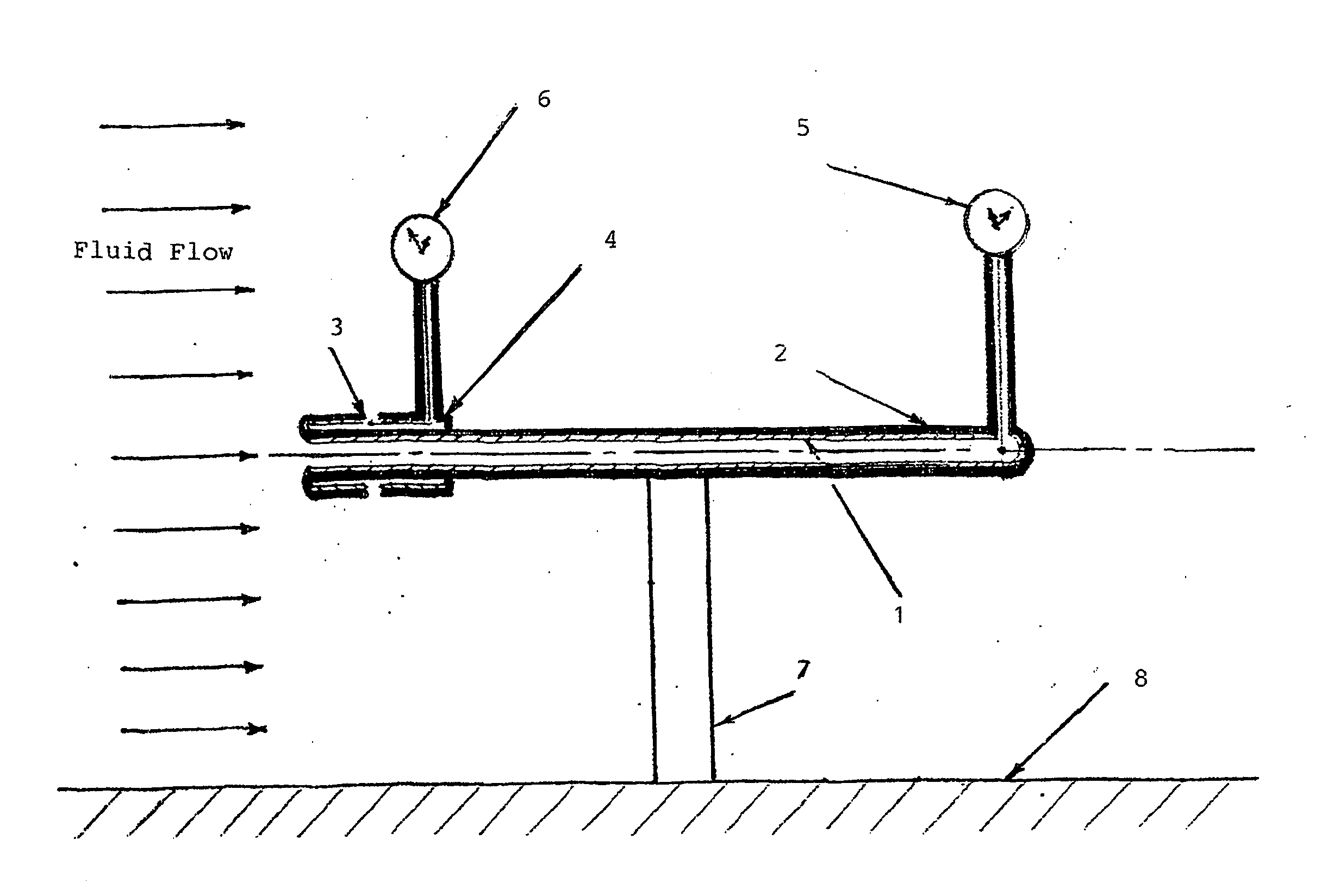

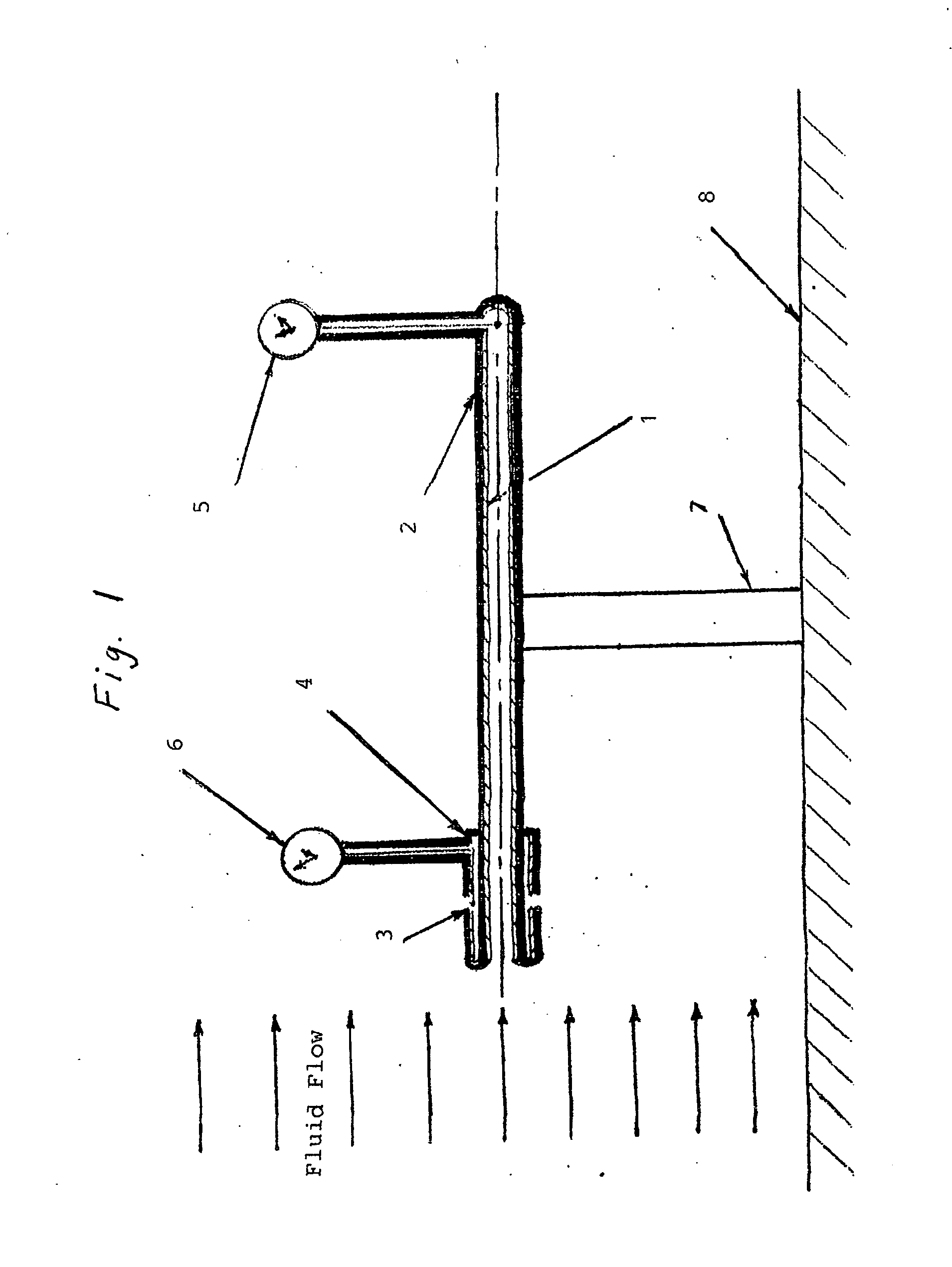

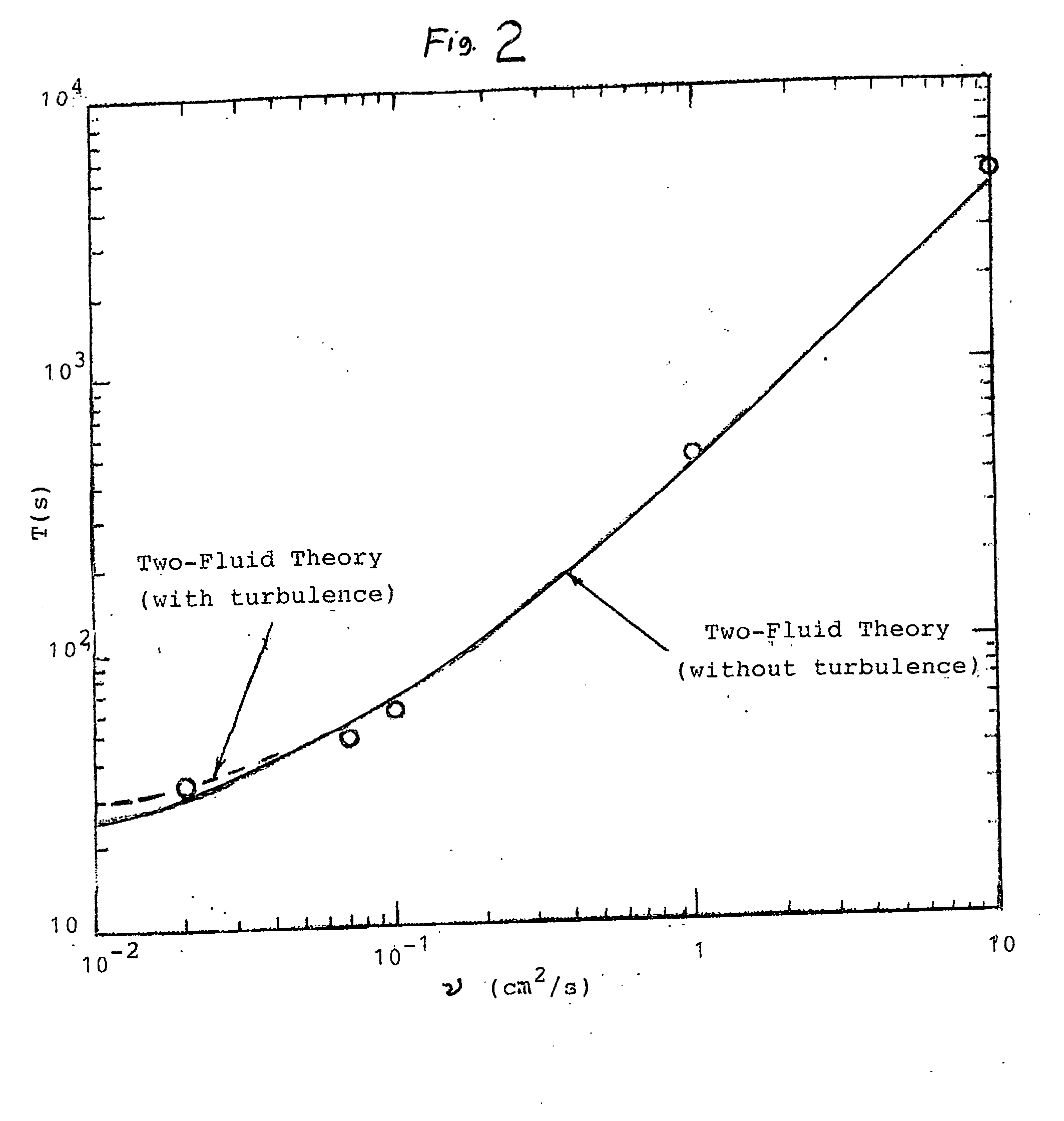

Pitot tube designs for compressible and incompressible fluid flow with viscosity and turbulence

InactiveUS20150122053A1High viscosityAffecting performance of deviceFluid speed measurementVolume/mass flow by differential pressureFully developedDie swell

This invention presents a Pitot tube design and methodology for determining the flow characteristics of fluids in subsonic and supersonic flow, including the effects of viscosity and turbulence. A new methodology, the Two-Fluid Theory, is developed which treats a real fluid as being composed of two ideal fluids: an inviscid fluid and a Poiseuille fluid. The resulting expression for flow velocity is applicable to a real fluid of any viscosity and to pipes of any L / D ratios, including entrance effects.Two designs, comprising annular, smooth-bore tubes, with devices for measuring total and static pressures, are presented: one for incompressible flow; one for compressible, supersonic flow. Allowance is made for the viscous component of the flow to become fully developed, in accordance with the Theory.

Owner:WILLARD JR HAROLD JAMES

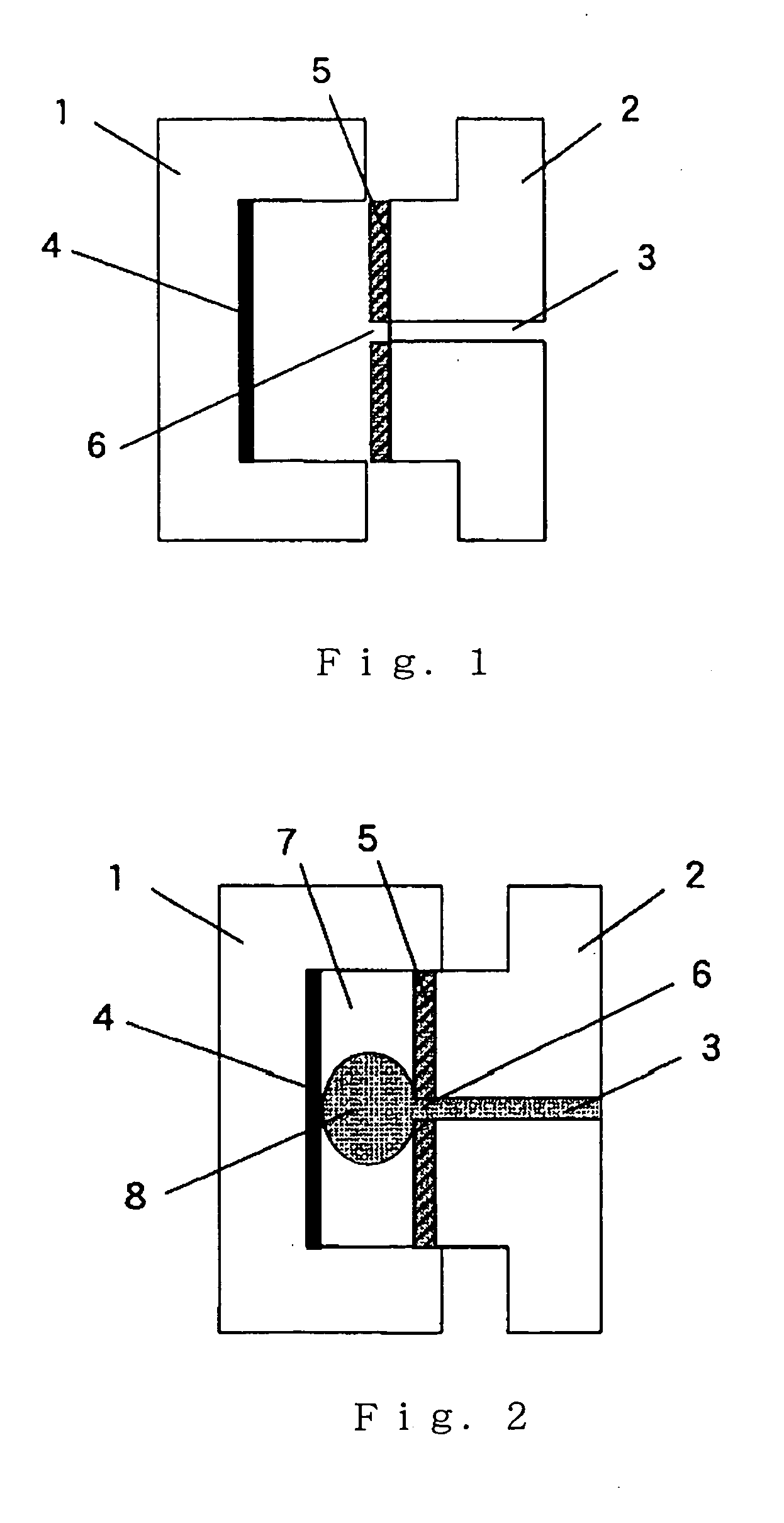

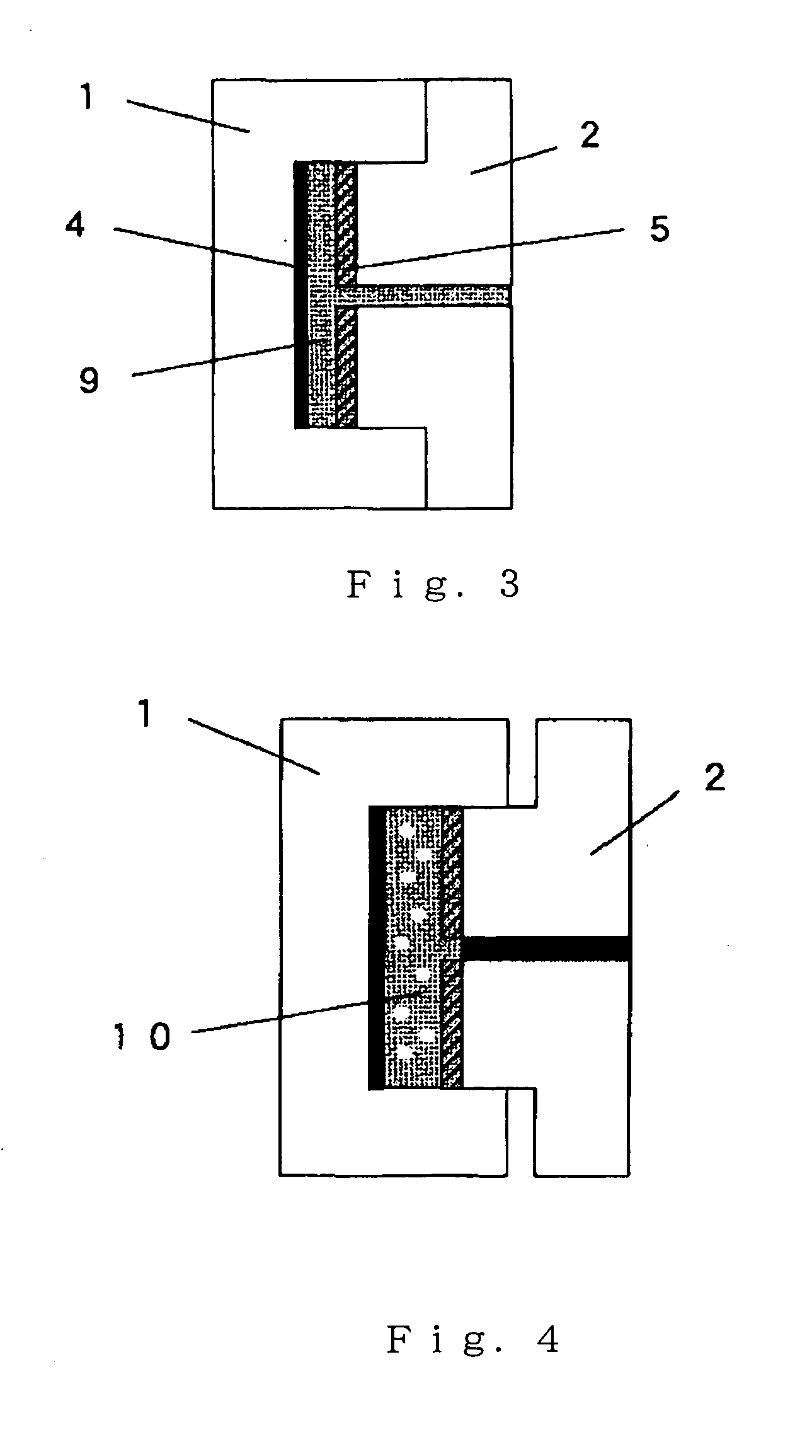

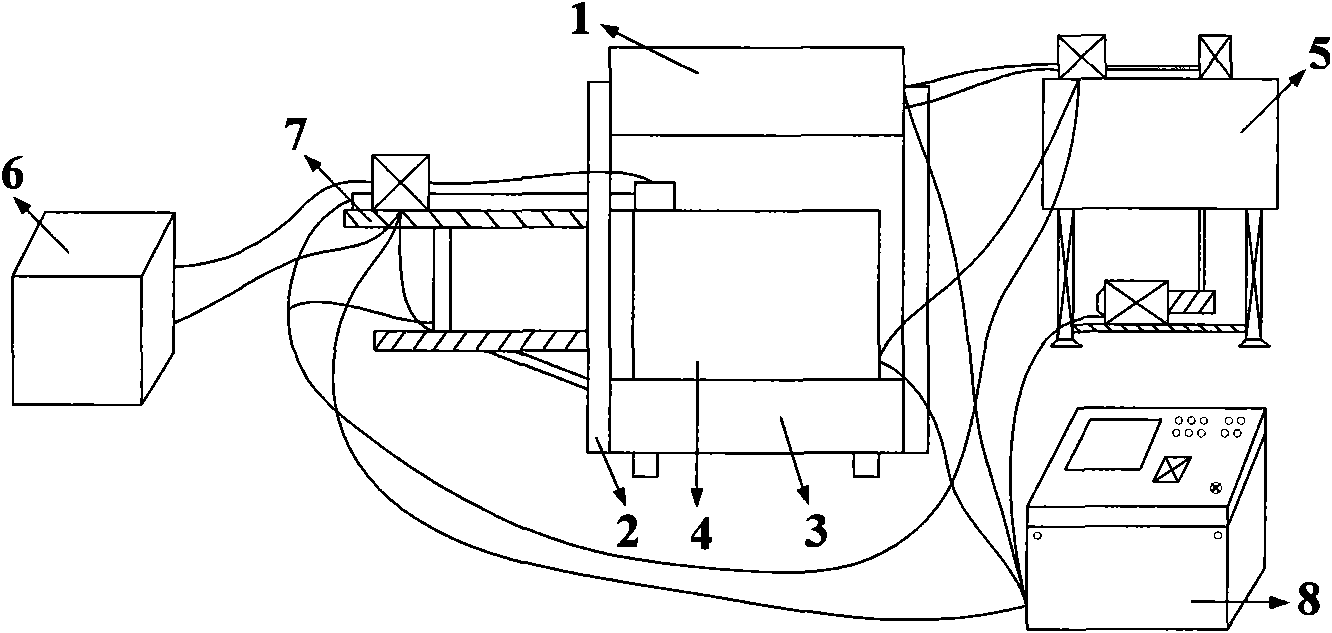

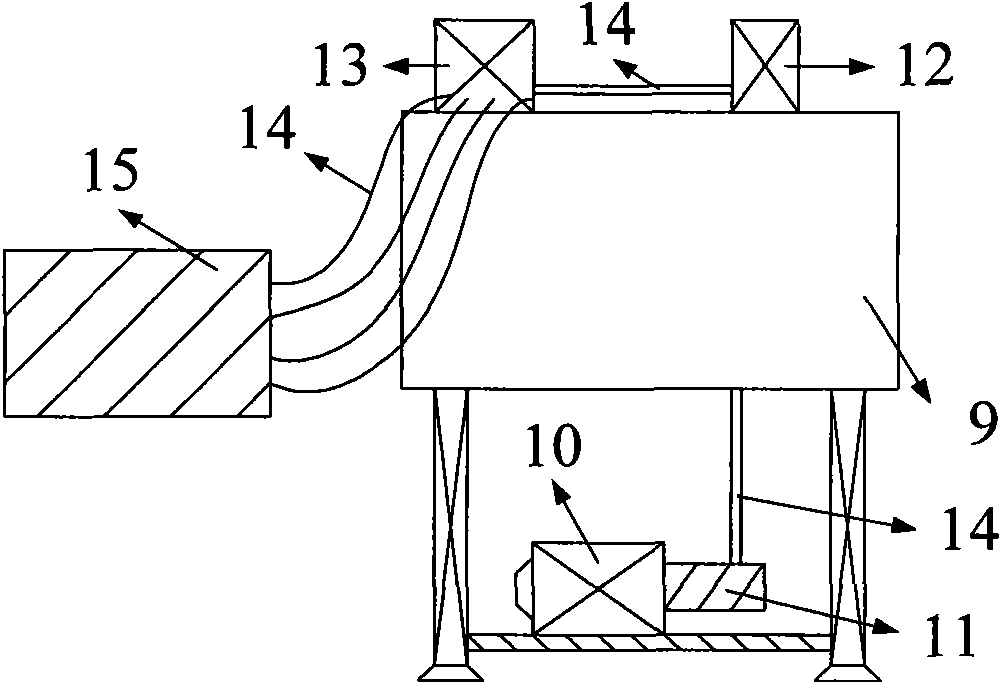

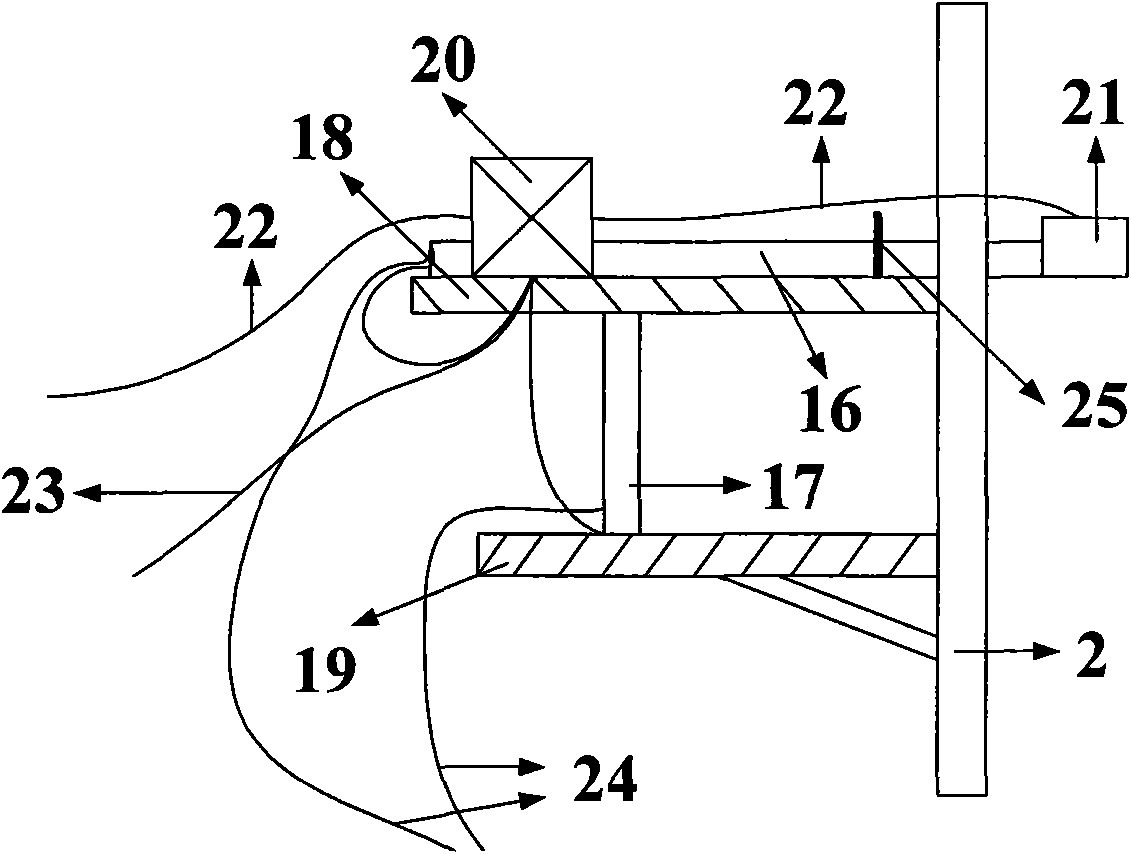

Device used for preparing high-density powder metallurgy parts

The invention discloses a device used for preparing high-density powder metallurgy parts, and belongs to the technical field of powder metallurgy. The device comprises an impact unit (1), a side plate (2), a base (3), a die frame (4), a hydraulic system (5), a die wall lubricating device (6), a die wall lubricating system (7) and a control system (8). The device has the advantages that the combination of a high-speed pressing device and an electrostatic die wall lubricating device realizes the preparation of the high-density powder metallurgy parts (the density is higher than 7.4 g / cm) by carrying out automatic die wall lubrication during high-speed pressing without adding a lubricating agent into the powder, the product precision is ensured, the product shrinkage is reduced, the environment pollution is reduced, and the production cost of the powder metallurgy parts is reduced. Simultaneously, the operation and matching of steps of the device are controlled by a programmable logic controller (PLC), and the automatic production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

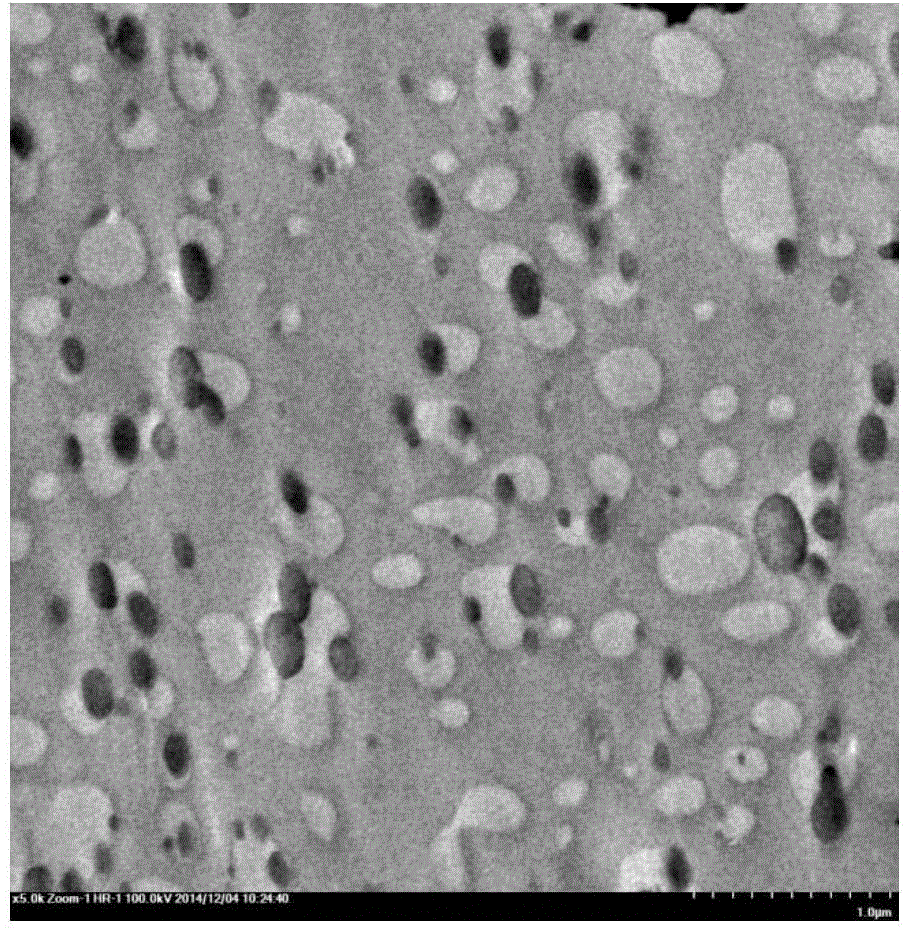

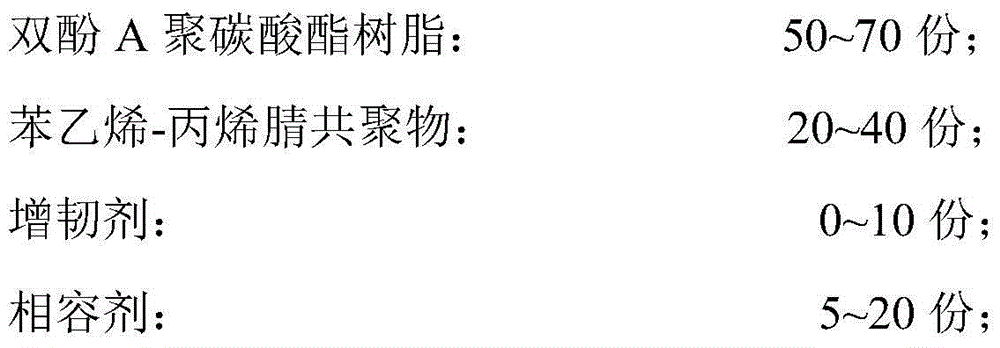

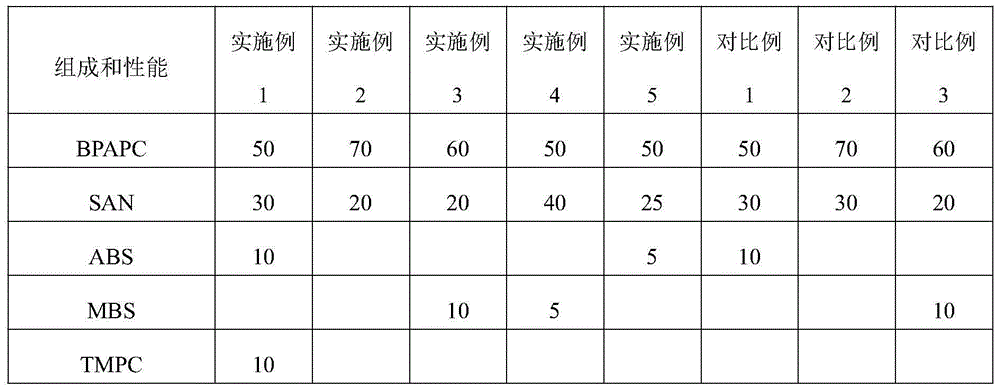

Polycarbonate resin composition with nano-scale dispersed phase state and preparation method therefor

The invention provides a polycarbonate resin composition with a nano-scale dispersed phase state and a preparation method therefor. The composition contains the following ingredients in parts by weight: (a) 50-70 parts of bisphenol A polycarbonate (BPAPC) resin, (b) 20-50 parts of styrene-acrylonitrile (SAN) copolymer, (c) 0-10 parts of toughening agent and (d) 1-10 parts of compatibilizer. The polycarbonate resin composition is prepared through premixing BPAPC, SAN, the toughening agent and the compatibilizer in a medium-speed mixer, and then, feeding the premix to a twin-screw extruder for melt extrusion and granulation. Compared with the prior art, the polycarbonate resin composition with the nano-scale dispersed phase state and the preparation method therefor have the following technical characteristics that the phenomenon of die swelling during the extrusion of PC and SAN is avoided; in a microscopic phase state, SAN is uniformly dispersed in the PC matrix in a nano-scale manner; and the macroscopic mechanical properties of the resin composition are greatly improved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com