Patents

Literature

1882 results about "Wood-plastic composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic composites (WPCs), also known under the tradename Plastic-Wood® of Covema , are composite materials made of wood fiber/wood flour and thermoplastic(s) such as PE, PP, PVC, or PLA. In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials. WPCs are a subset of a larger category of materials called natural fiber plastic composites (NFPCs), which may contain no cellulose-based fiber fillers such as pulp fibers, peanut hulls, bamboo, straw, digestate, etc.

Wood-plastic composite material and prepration method thereof

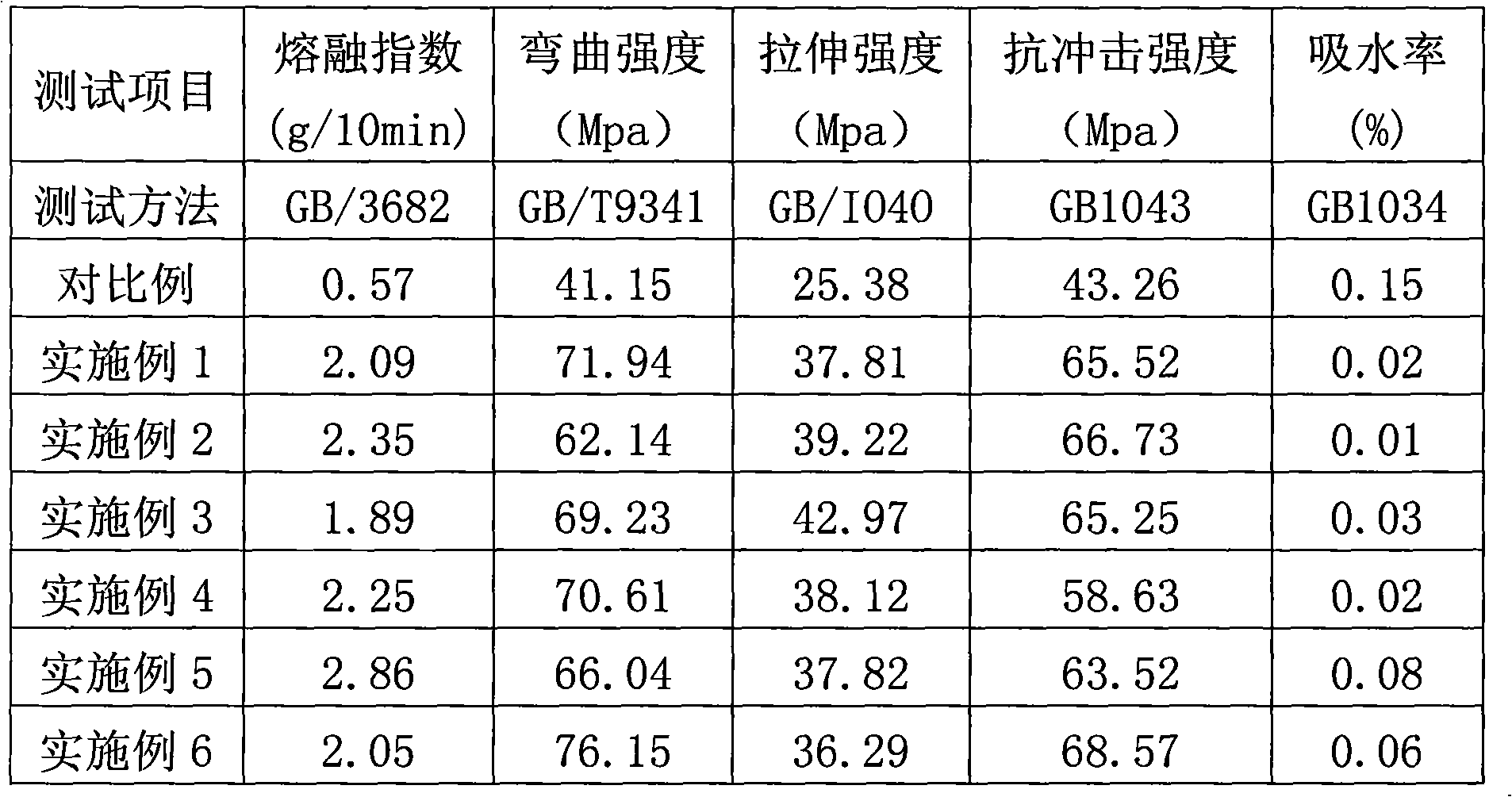

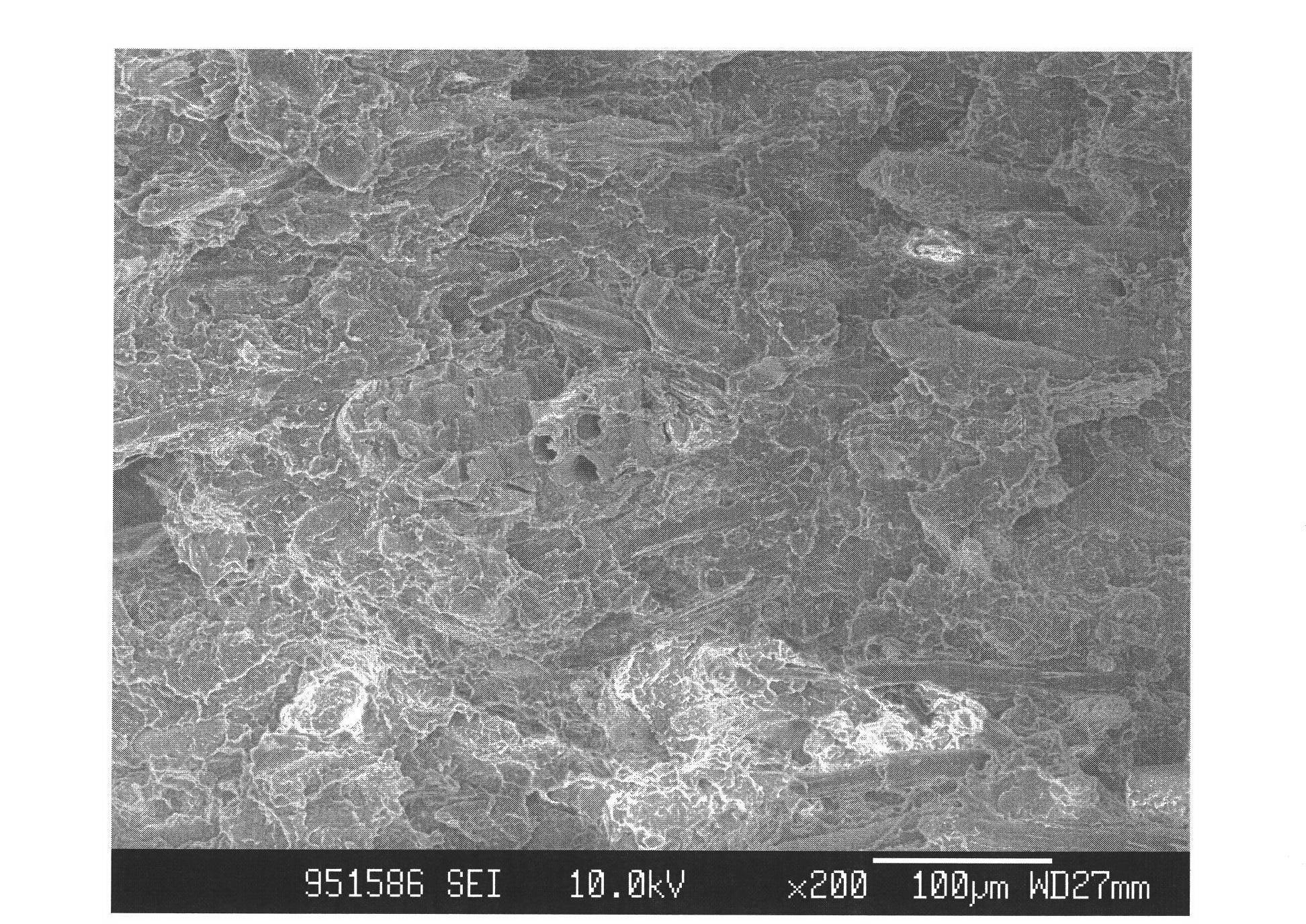

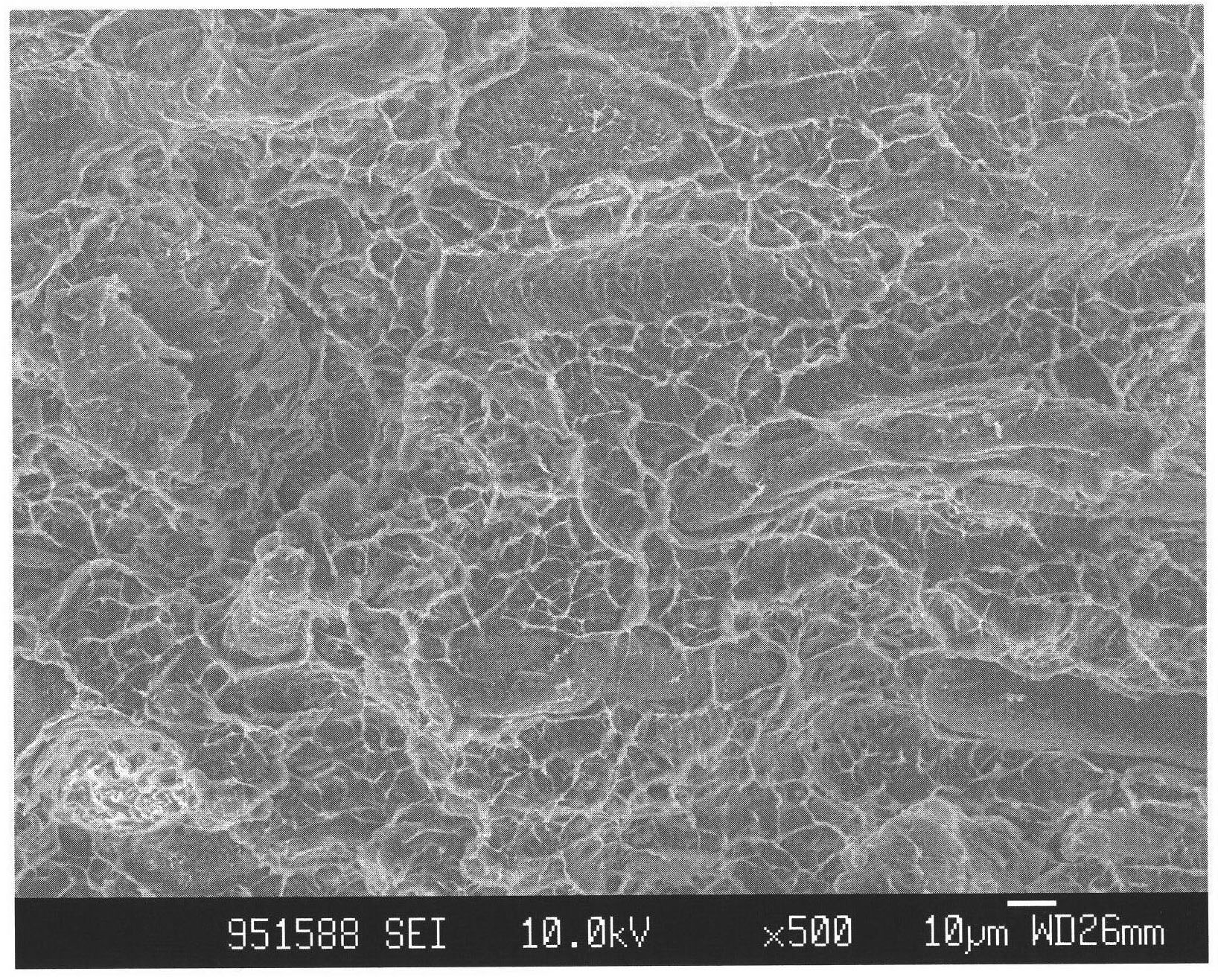

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and a preparation method thereof. The composite material consists of the following components in percentage by mass: 25 to 80 percent of polyolefin resin, 5 to 60 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of flame retardant and flame retardance synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood plastic composite material, the halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material has the characteristics of simple production flow, little using amount of the flame retardant, good halogen-free flame retardant effect, wide range of molding modes and the like and is applicable to various injection molding products, such as electric appliance shells, automobile parts, furniture, buildings and other parts.

Owner:GUANGDONG KINGFA TECH CO LTD

Preparation of multifunctional wood-plastic composite material

The invention relates to a wood-plastic composite material which can be applied to the floor, tableware, daily necessities, Profile, automotive, and other fields. In the invention, it adds the anion additives, nano-photocatalyst, nano-fillers into the composite material to make the wood-plastic composite material achieves the function such as release negative ions, antibacterial bacteriostasis, removing odor, clean air, flame retardant.

Owner:卓玉国

Wood plastic composite material composection and formed board thereof and their preparation process

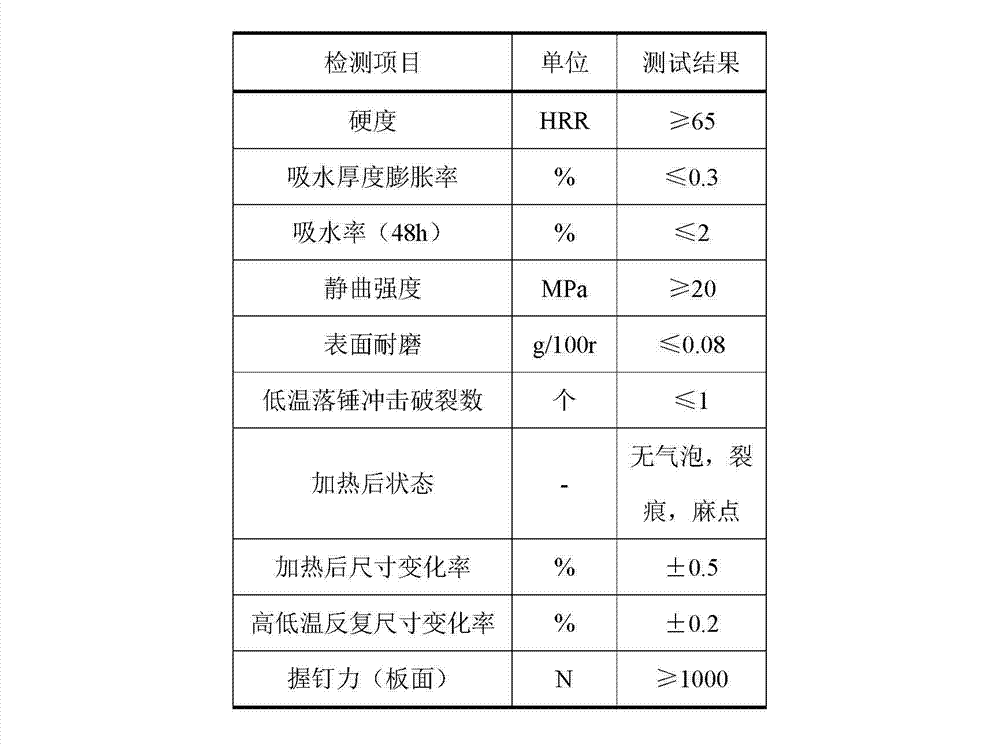

The present invention provides one kind of wood-plastic composition, which contains wood powder and resin as well as nanometer particle of size below 100 nm. The wood-plastic composition with nanometer particle has hardness greater than 56HRR and heat distortion temperature higher than 105 deg.c. It may be produced into plate used widely for building, transportation, packing, household decoration and daily use article.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Plant powder modified thermoplastic wood-plastic composite and preparation method and application

The invention discloses a plant powder modified thermoplastic wood-plastic composite and a preparation method and application thereof. The composite is composed of the following components by weight portion: 100 portions of thermoplastic resin, 1-400 portions of plant powder, 0.1-40 portions of dispersant, 0.5-60 portions of impact modifier, 0-100 portions of inorganic filler and 0-10 portions of antioxidant. Compared with wood, the plant powder modified thermoplastic wood-plastic composite prepared by the method has the advantages of durability, good dimensional stability, easy molding, small water absorption and corrosion resistance. Compared with plastics, the composite has the characteristics of low cost and high rigidity. The composite is suitable for a variety of injection molding parts, such as the shells of electrical equipment including TV, and the like.

Owner:KINGFA SCI & TECH CO LTD +1

Flame-proof smoke-inhibiting wood-plastic composite material

A flame retardant smoke resistant wood plastic composite material relates to a wood plastic composite material, which solves the disadvantages of low flame retardant performance, big smoke mass, large addition of flame retardants, increased cost and decreased mechanical property of existing wood plastic composite materials. The product of the invention is mainly formed by polystyrene and / or polyvinyl chloride fortified with heat stabilizers, lignocellulose, intumescent flame retardant, compatibilizer, lubricant. The flame retardant and smoke-resistant performance of the product of the invention is greatly improved. For wood powder / polystyrene composite material, compared with no addition of flame retardant, the average heat release rate is decreased by 48 percent, the quantity of smoke yield is reduced by 30 percent and the CO yield is decreased by 28 percent during combustion. The product of the invention has high oxygen-index, long ignition time and no droplet, which greatly reduces the fire hazard of the material, and the appearance of the material is similar with wood. The product of the invention also has low cost, wide application range and good creep resistance, forming performance and mechanical property.

Owner:NORTHEAST FORESTRY UNIVERSITY

Completely degraded plant powder modified thermoplastics composite material and preparation method thereof

ActiveCN101760037AHas physical and chemical propertiesEasy to processThermoplastic compositesPolypropylene

The invention discloses a completely degraded plant powder modified thermoplastics composite material and preparation method thereof, which consists of the components with the weight portions as follows: 100 portions of degradable thermoplastics resin, 1-400 portions of plant powder, 0.1-40 portions of dispersing agent, 0.5-60 portions of impact modifier, 0-40 portions of inorganic filler as well as 0.1-10 portions of stabilizing agent. The degraded thermoplastics resin has similar physiochemical performances with universal polyethylene and polypropylene, has excellent processing performances, and can be commixed with plant powder to prepare thermoplastics wood plastic composite materials. The obtained thermoplastics wood plastic composite materials can be completely degraded into carbon dioxide and water in natural environment under the effects of broadly existed microbes like germs, actinomycetes, etc. Compared with wood products, the composite material has the characteristics of good durability and dimensional stability, easy forming, small water absorbability, and corrosion resistance; compared with plastic, the composite material has the characteristics of low cost and high rigidity. The completely degraded plant powder modified thermoplastics composite material can be used for producing the shells of electric apparatuses like TV, sound, copier, printer, etc, and can also be applied on other workpieces used for injection.

Owner:GUANGDONG KINGFA TECH CO LTD +2

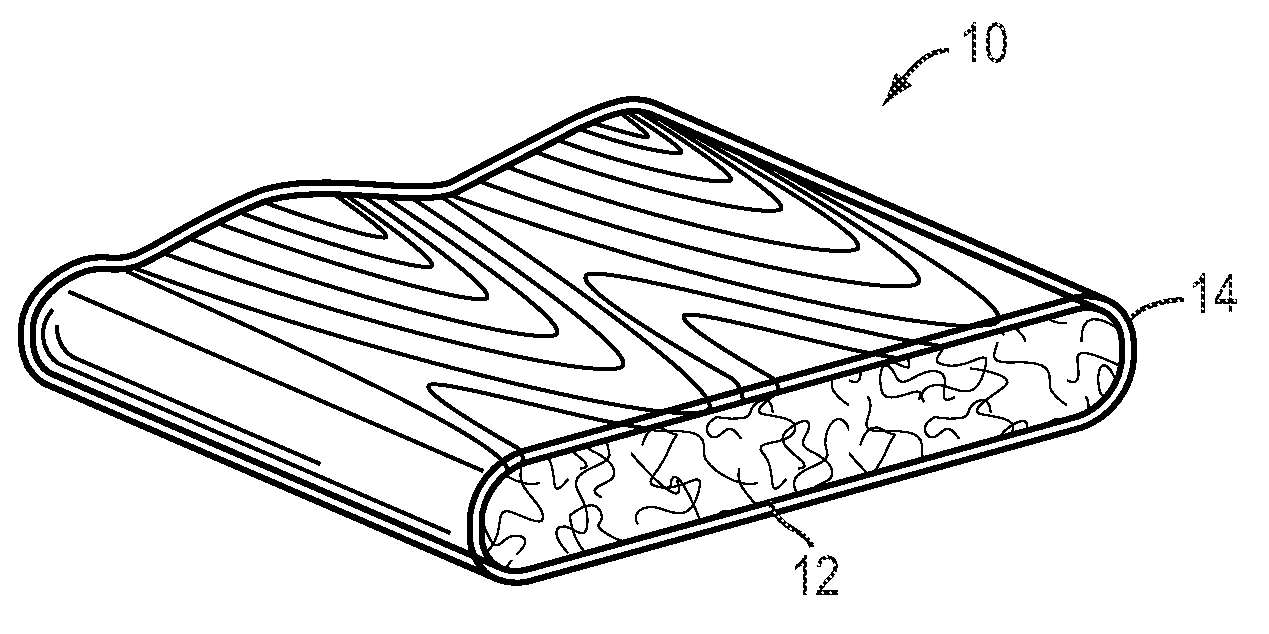

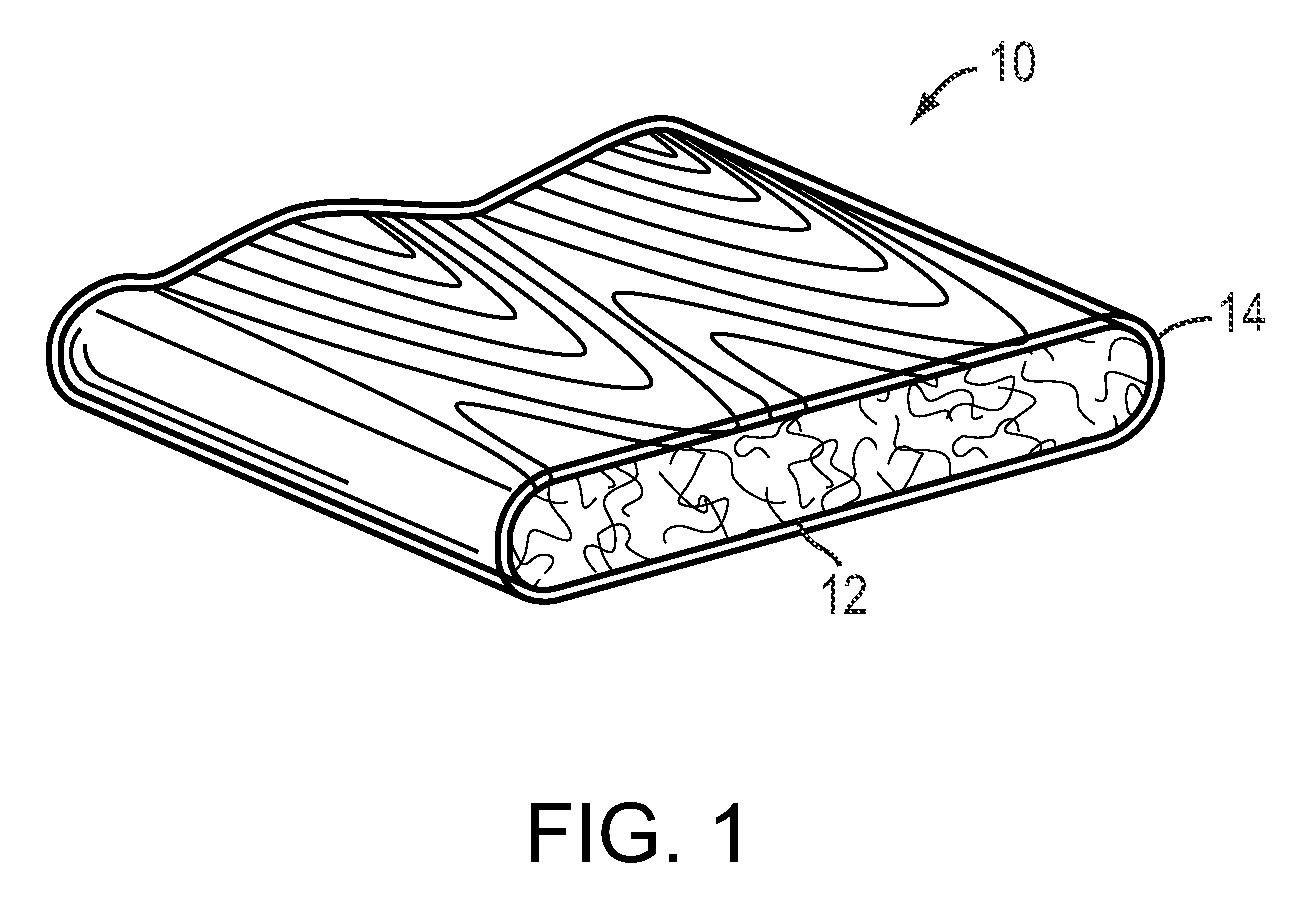

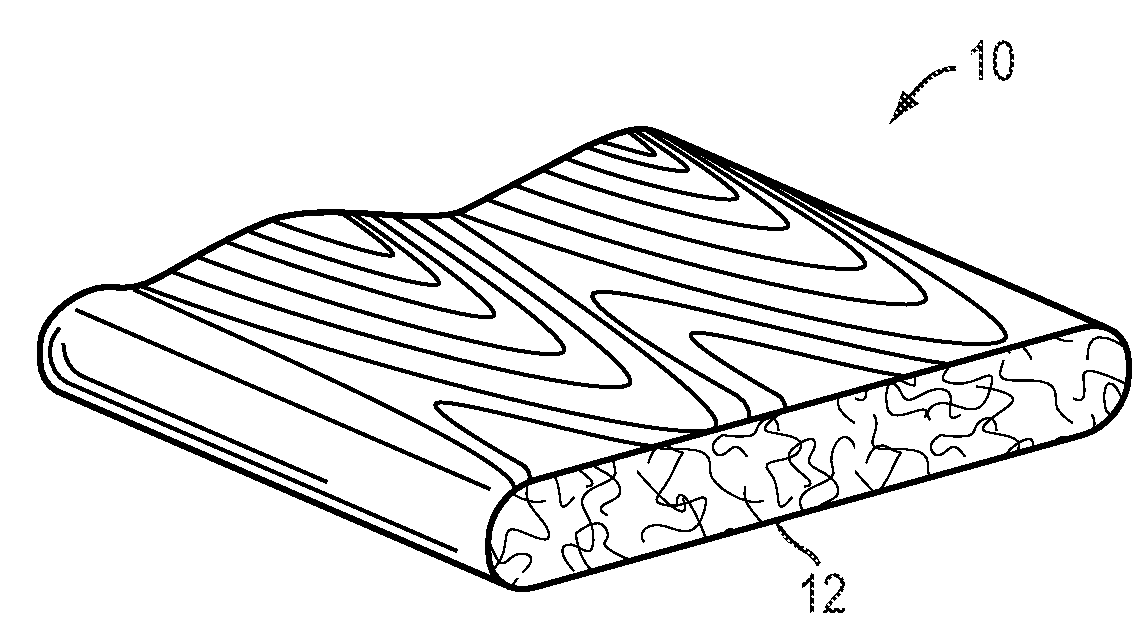

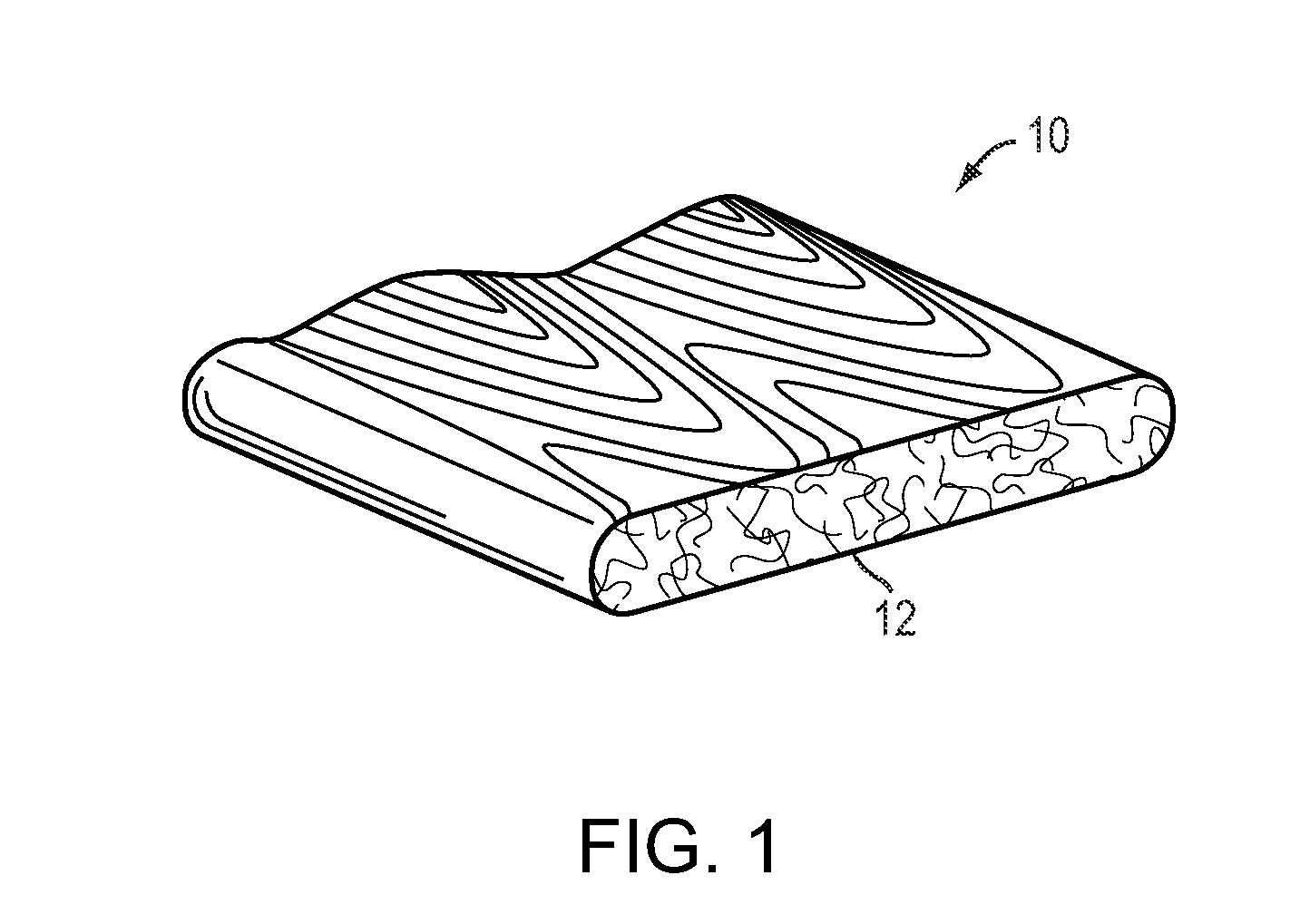

Wood-Plastic Composites Utilizing Ionomer Capstocks and Methods of Manufacture

An extruded composite adapted for use as a building material includes a core having a base polymer and a natural fiber in a substantially homogeneous mixture and an ionomer capstock. To improve adherence of the ionomer to a base polymer, the ionomer can be mixed with a similar or substantially similar base polymer prior to coextrusion with the core. Additionally, various additives may be mixed with the capstock material to improve visual aesthetics of the product and performance of the building material, especially over time.

Owner:FIBER COMPOSITES

Novel wood plastic composite decorative building material and manufacturing method thereof

InactiveCN101955614AImproved performance characteristicsGood environmental characteristicsAntioxidantPolyvinyl chloride

The invention relates to a novel wood plastic composite decorative building material and a manufacturing method thereof. The novel wood plastic composite decorative building material comprises the following components in part by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 30 parts of mixture formed by mixing one or more of wood powder, bamboo powder, rice bran powder and crop straw powder in an arbitrary ratio, 30 parts of calcium powder, 5 to 10 parts of chlorinated polyethylene or MBS resin, 2 to 6 parts of rear earth compound stabilizer, 0.5 to 3 parts of polyethylene wax or oxidized polyethlene wax, 0.5 to 3 parts of stearic acid, 0.5 to 2.0 parts of foaming agent, 5 to 10 parts of blowing promoter, 0.5 to 1 part of antioxidant, 0.5 to 1 part of reinforcing agent, 1 to 3 parts of toner and 0.5 to 1 part of weather resistant agent. PVC plastic is modified by adding the auxiliaries, and the influence of unstable components (such as a vinyl chloride monomer, hydrogen chloride gas and the like) in the PVC on the performance of the building material is eliminated, so that the building material has better performance and environmental protection characteristics on the basis of keeping the original performance.

Owner:CHENGDU AOKINGTH TECH

Wood plastic composite material

The invention relates to a wood plastic composite material comprising the following materials in parts by weight: 100 parts of wood meals, 20-80 parts of waste plastics, 5-50 parts of waste rubbers, 10-60 parts of high-melt index thermoplastic resins, 1-12 parts of surface active agents, 2-8 parts of lubricating agents, 0.1-4 parts of cross-linking agents, 0.1-4 parts of antioxygens and 0.05-1.5 parts of processing agents, wherein the grain diameter of the wood meals ranges from 10 meshes to 325 meshes; the flow velocity of the high-melt index thermoplastic resins is higher than 20 g / 10 minutes; the cross-linking agents are peroxides, thus the invention improves the dispersibility and the flowability of the wood meals contained in the composite and the compatibility of plastics by adding the high-melt index thermoplastic resins, can not only better utilize the resources, but also enhances the mechanical strength (such as tensile strength, bending strength, impact strength, and the like) of the composite material by adding the waste rubbers, has the advantages of good processing property, low water absorption rate, good stability of products, and the like and is suitable for injection moulding and beneficial to market promotion.

Owner:东莞市启原实业有限公司

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

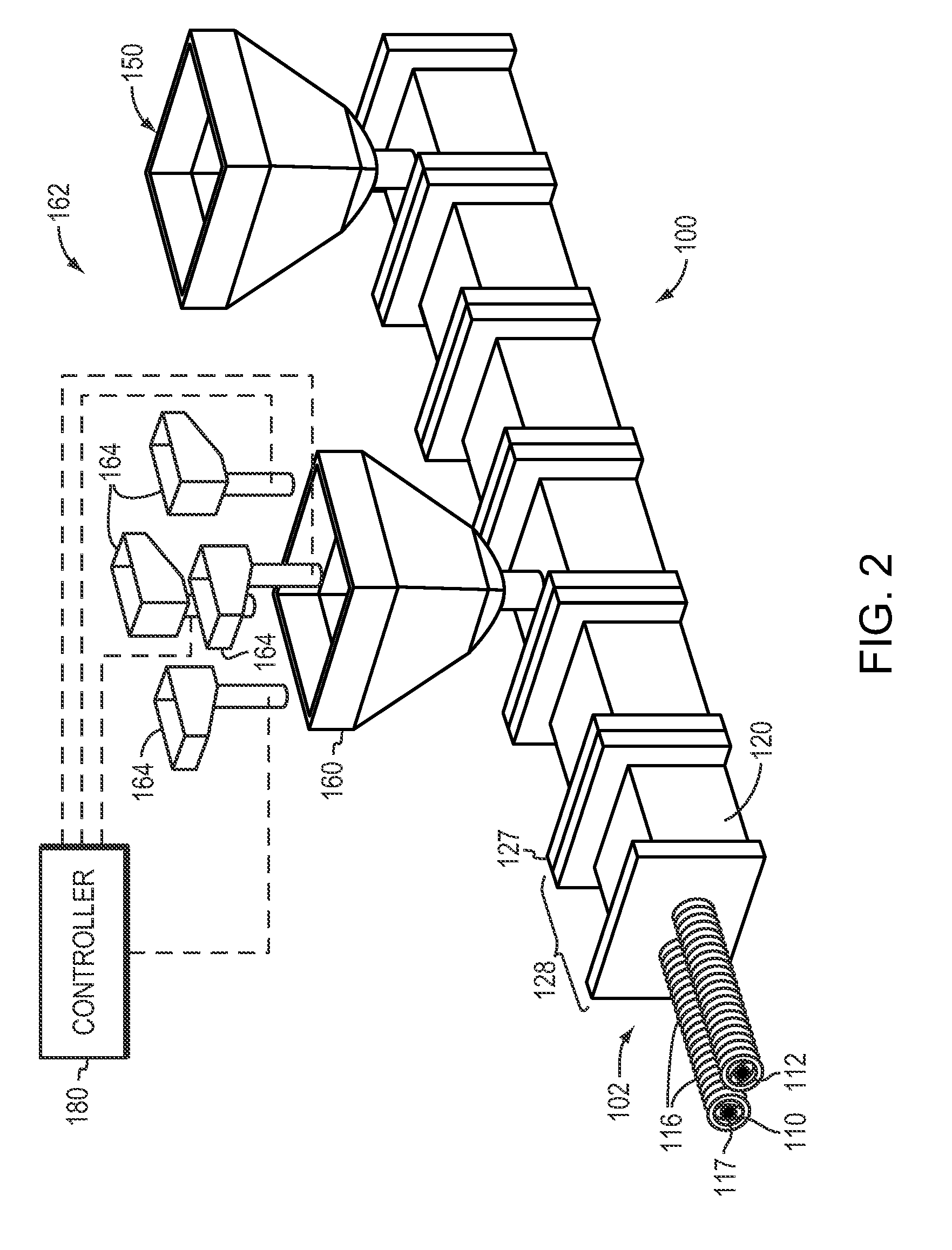

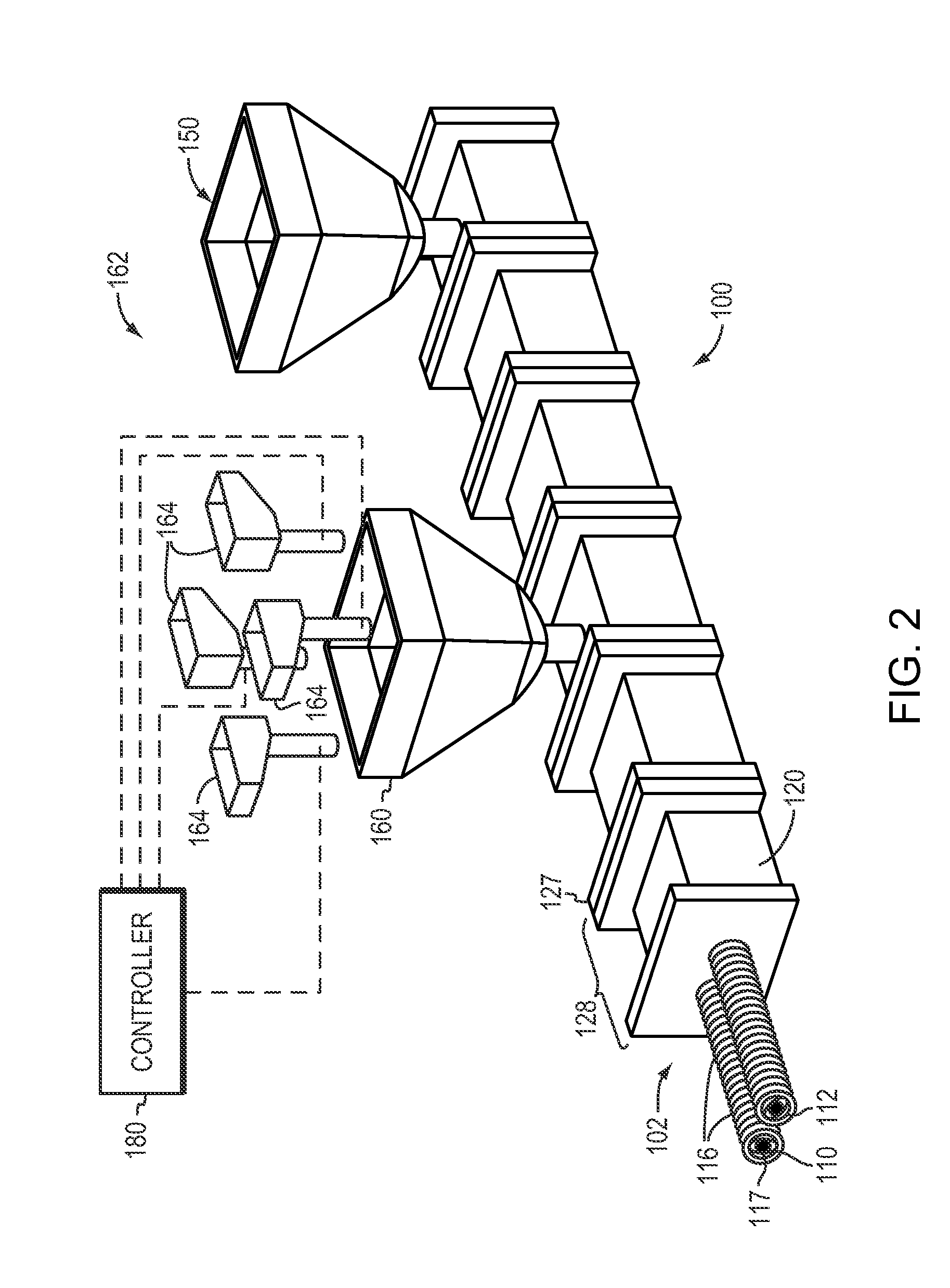

Wood-Plastic Composites Using Recycled Carpet Waste and Systems and Methods of Manufacturing

InactiveUS20080128933A1Reduce material costsPlastic recyclingBuilding constructionsFoaming agentVolumetric Mass Density

An extruded composite utilized as a building material includes a base polymer, unseparated processed recycled carpet waste, and a filler material, which may be a wood filler or other natural fiber. The recycled carpet waste may be used to decrease the amount of both base polymer and wood filler to achieve an equivalent product at lower cost. The extruded composite may also utilize chemical foaming agents to reduce density. Both foamed and non-foamed composites may be capstocked.

Owner:MATERIAL INNOVATIONS LLC

Prepn process of polylactic acid-base thermoplastic wood-plastic composite material

The present invention relates to preparation process of polylactic acid-base thermoplastic wood-plastic composite material, which is prepared with polylactic acid and wood powder as main materials, and through reacting and mixing with compatibilizing agent, brightening agent, plasticizer, nucleater, dispersant, stabilizer and other assistant in a high speed stirrer; extrusion pelletizing the mixture in a double screw extruder; cooling and cutting; and drying in a vacuum drier to obtain the polylactic acid-base thermoplastic wood-plastic composite material. The composite material of the present invention has excellent comprehensive performance, is degradable, and may be used as packing material, environment protecting material and decoration material.

Owner:SHANGHAI JIAO TONG UNIV

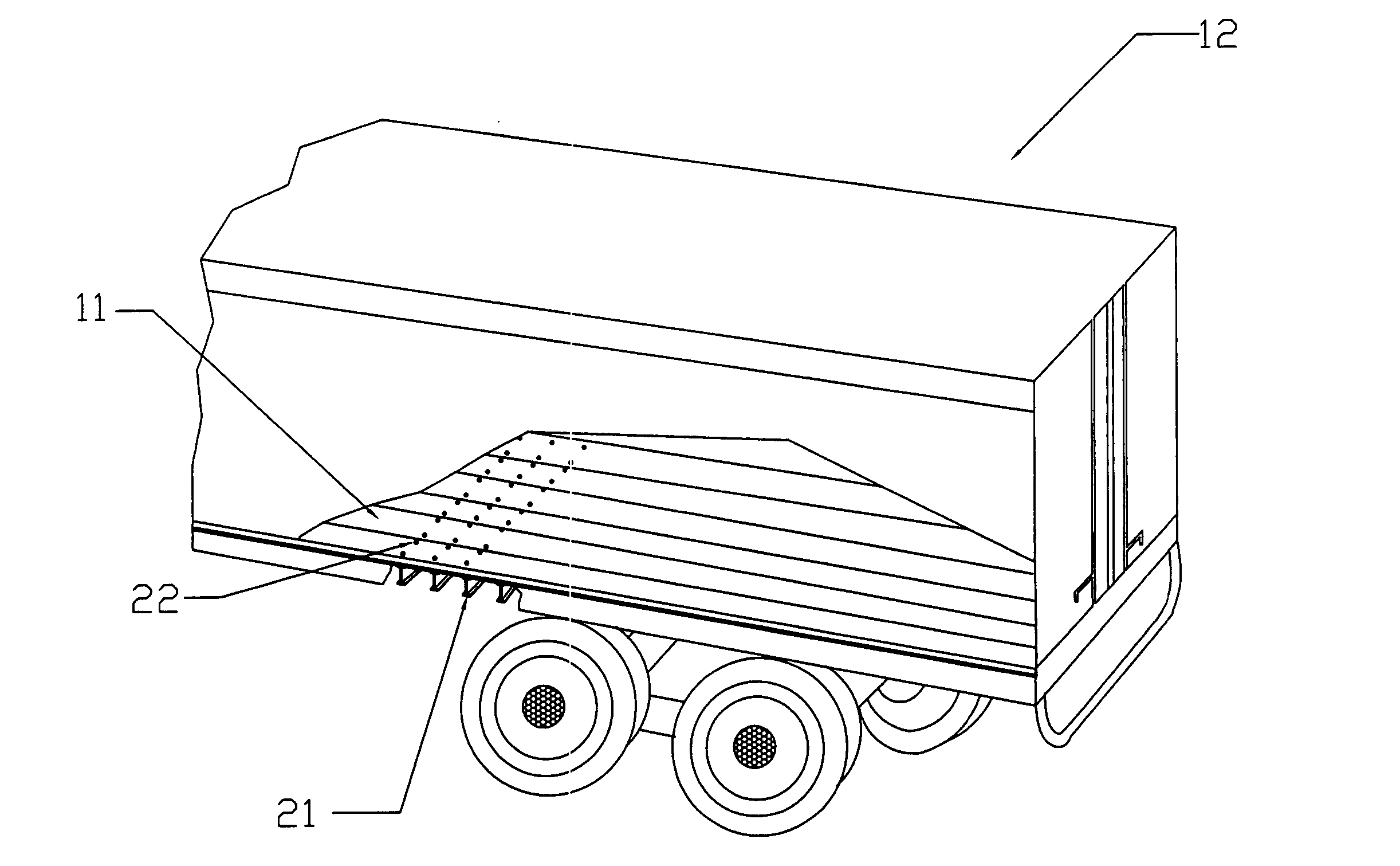

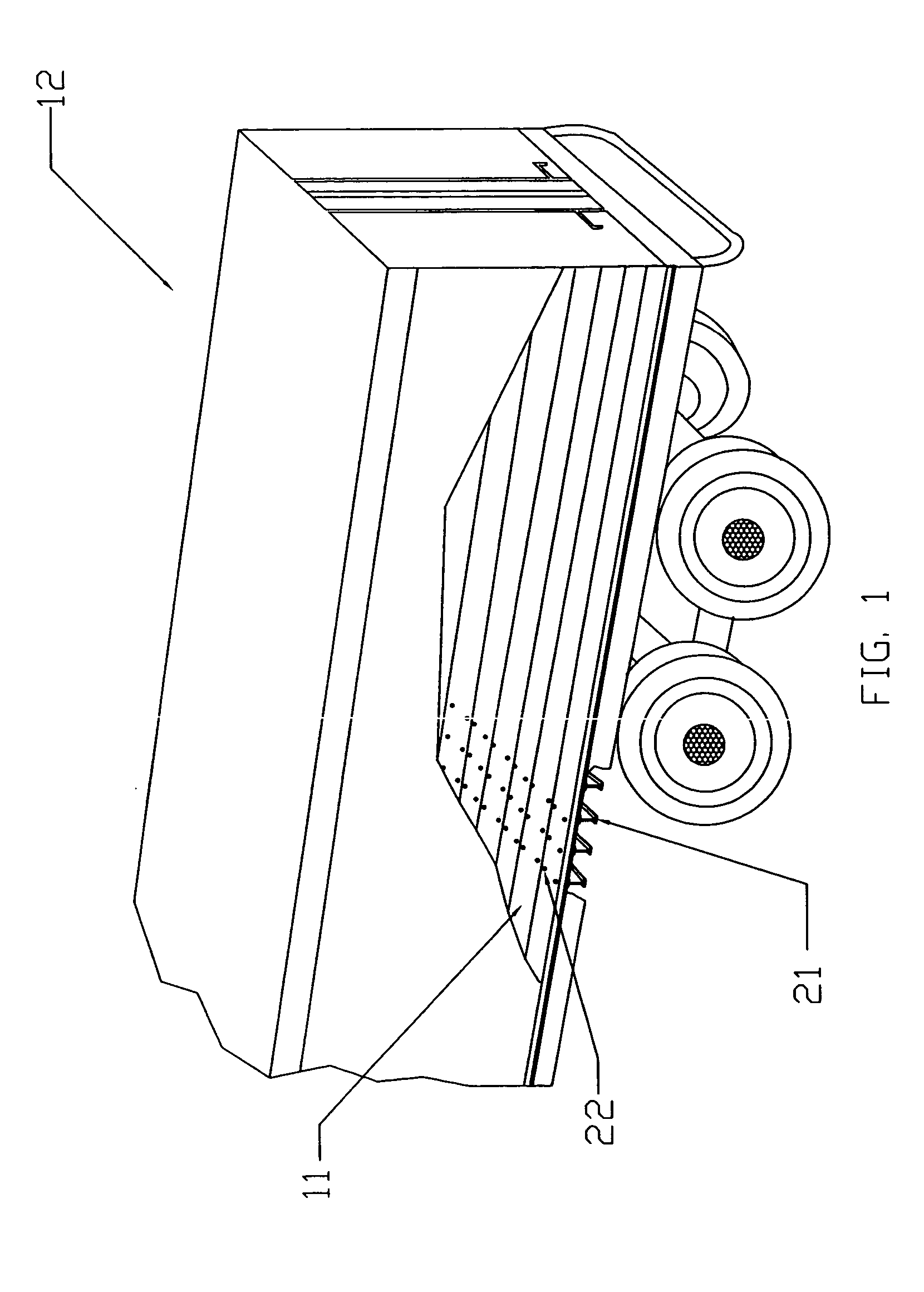

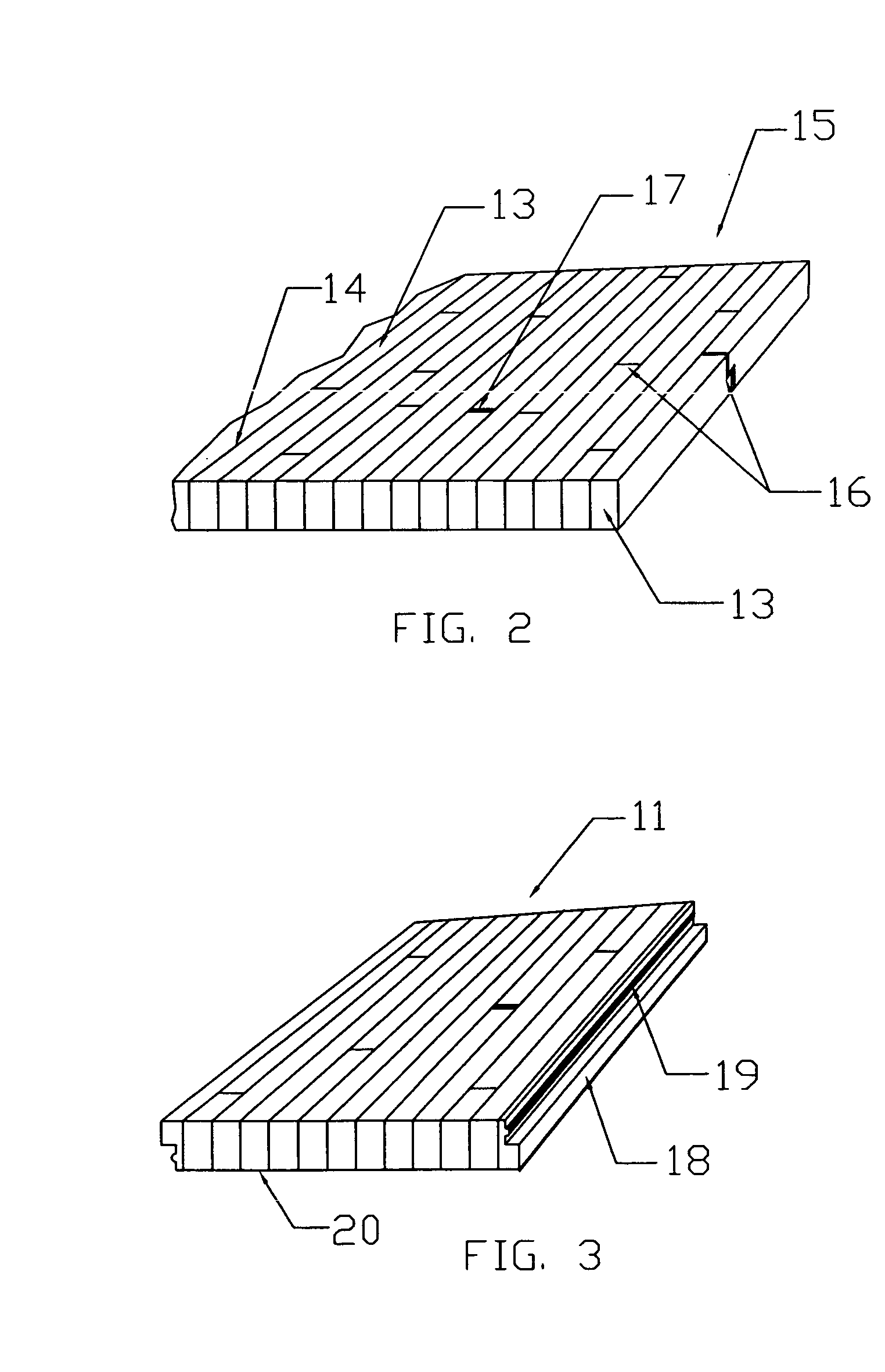

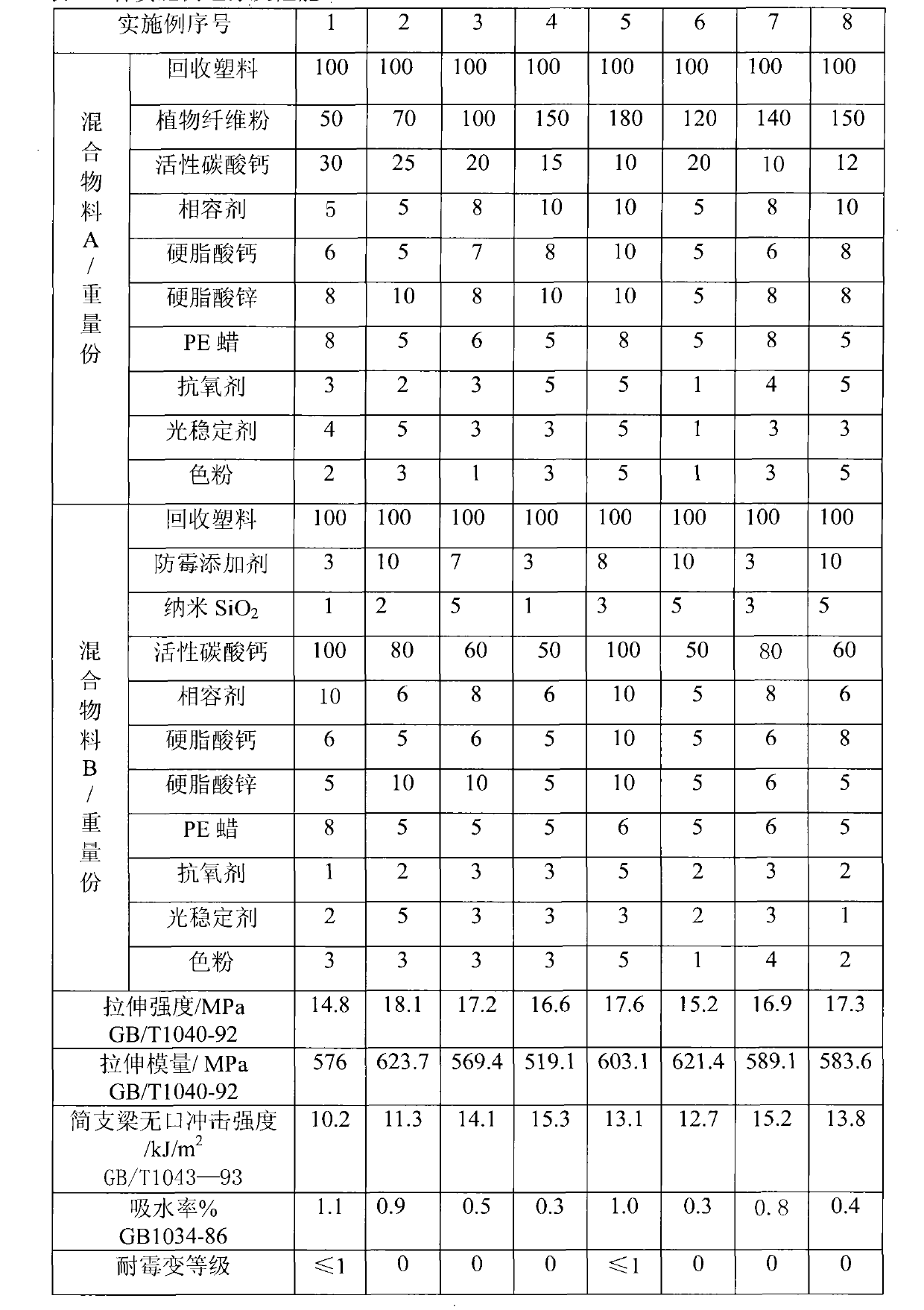

Durable wood-plastic composite flooring for trailers

InactiveUS20060179733A1Little and no structural defectLow costTreadsSynthetic resin layered productsEngineeringThermoplastic composites

A composite wood flooring system for a vehicular trailer floor comprising: a plurality of wood boards, each wood board comprising a top surface and a bottom surface opposite the top surface; and a filled thermoplastic composite layer comprising a thermoplastic polymer and a discontinuous filler, the thermoplastic layer being substantially bonded to the top surface of each wood board.

Owner:HAVCO WOOD PRODS

Halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and preparation method thereof

The invention discloses a halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and a preparation method thereof. The halogen-free flame-retardant polyolefin injection-grade wood-plastic composite comprises the following components in percentage by mass: 25 to 70 percent of polyolefin resin, 5 to 50 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of fire retardant and synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood-plastic composite, the halogen-free flame-retardant polyolefin injection-grade wood-plastic composite prepared by the invention has the characteristics of simple production flow, less fire retardant dosage, good halogen-free flame-retardant effect, wide molding mode range and the like, and is suitable for various injection-molded products such as shells of electrical appliance products, furniture, materials for automobiles, artworks, building products with complex construction and the like.

Owner:KINGFA SCI & TECH CO LTD +1

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

Wood plastic composite material and its preparation method and application

A wood-plastics composition is prepared from used or waste plastics, wooden fibres for modifying plastics, and resin compatibilizer through fusing and proportionally mixing. Said resin compatibilizer is prepared from EVA, acrylic acid or acrylate and polyvinyl chloride through mixing. Its advantages are high strength toughness, and improved machinability.

Owner:CHINA PETROLEUM & CHEM CORP +1

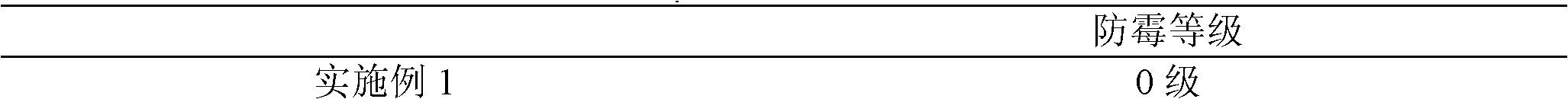

Long-acting mould-proof wood plastic composite material and preparation method thereof

InactiveCN101767362AGood long-term mildew resistanceImprove water absorptionWood working apparatusFlat articlesFiberSurface layer

The invention provides a long-acting mould-proof wood plastic composite material and a preparation method thereof and relates to a double-layer wood plastic composite material which is prepared by mixing surface grafting modified plant fiber power, recycle plastic power and mould-proof functional additive and adopting coextrusion technology, wherein the double-layer wood plastic composite material uses the wood plastic composite material as sandwich layer and the mould-proof functional plastic layer as surface layer. The long-acting mould-proof wood plastic composite material contains 9-29mm of wood plastic sandwich layer and 0.5-1.5mm of mould-proof functional surface layer. The plant fiber power in the sandwich layer is processed through organosilicon surface modification. The mould-proof additive in the surface layer has photocatalysis function and is also processed through organosilicon surface modification. The microcosmic interfacial properties of the entire wood plastic composite material are good. The components are melted, mixed and processed through coextrusion to prepare the long-acting mould-proof wood plastic composite material of the invention. The wood plastic composite material has good long-acting mould-proof function; and as the surface layer is a plastic layer, the wood plastic composite material is ensured to have low water absorption and good mechanical properties. The wood plastic composite material of the invention can be applied in fields such as indoor and outdoor decorations, furniture and packages.

Owner:SOUTH CHINA NORMAL UNIVERSITY

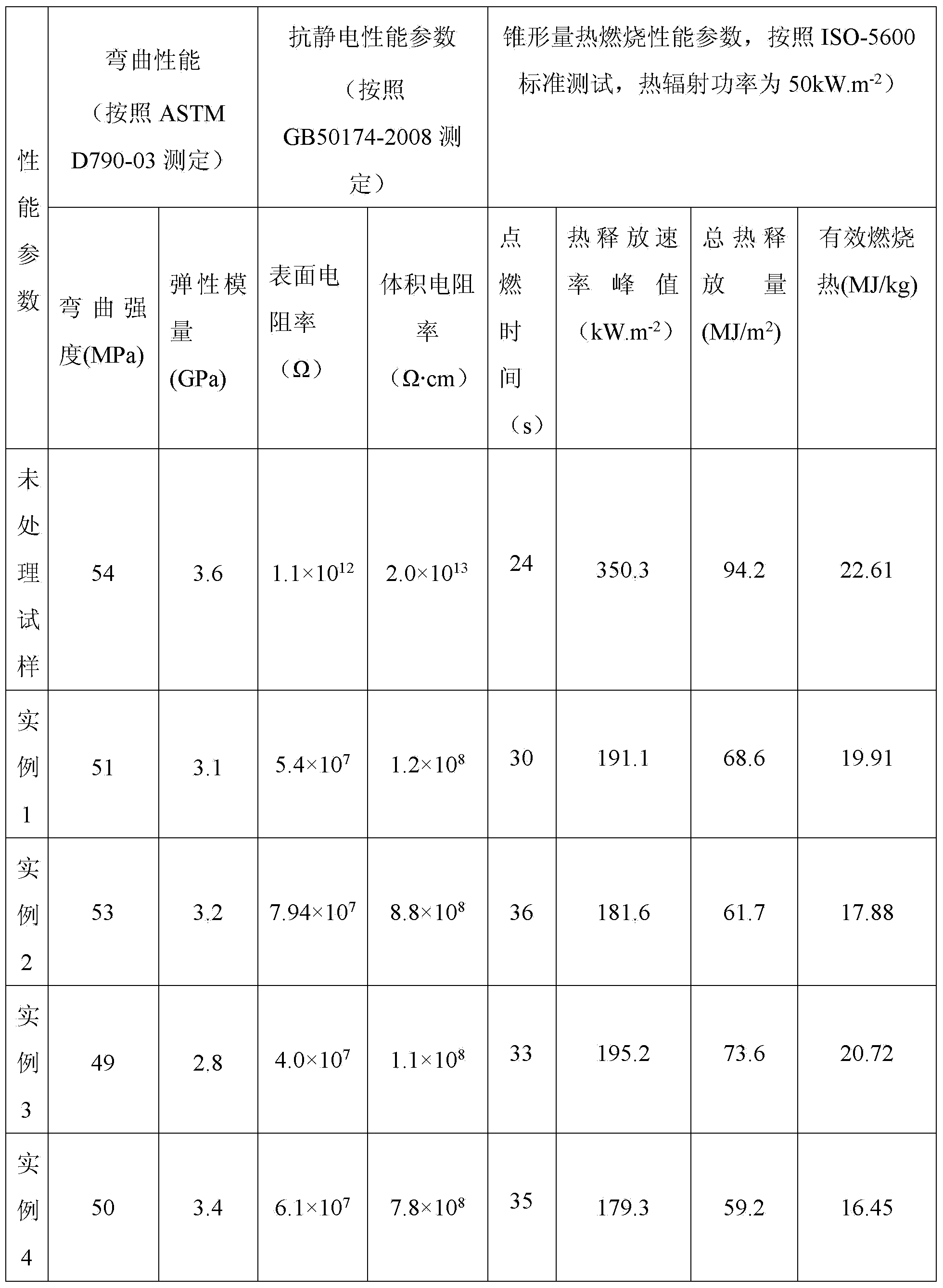

Flame-retardant and antistatic wood-plastic composite material and preparation method thereof

ActiveCN104327530AAchieve flame retardant and antistatic effectImprove flame retardant performanceThermoplasticFiber

The invention discloses a flame-retardant and antistatic wood-plastic composite material and a preparation method thereof and relates to a wood-plastic composite material and a preparation method thereof. The invention aims at solving the problems of relatively poor flame retardance and relatively high cost of the existing antistatic wood-plastic composite material. The wood-plastic composite material is prepared from the following components in parts by weight: a lignocellulosic material, thermoplastic, a lubricant, an antistatic agent, a flame retardant, a coupling agent and an inorganic filler. The method comprises the following steps: 1) performing hot mixing on the lignocellulosic material, the thermoplastic and the lubricant to obtain a hot-mixed material; 2) putting the hot-mixed material into a cold mixing machine for cold mixing, and adding the weighed antistatic agent, the flame retardant, the coupling agent and the inorganic filler into the cold mixing machine for re-mixing when the temperature is lowered to 40-60 DEG C to obtain a premix; 3) putting the premix into a twin-screw extruder to perform melting, mixing and granulation; and 4) performing extrusion molding or thermoforming to prepare the flame-retardant and antistatic wood-plastic composite material. The flame-retardant and antistatic wood-plastic composite material is used in the fields of indoor buildings, decorations, decoration materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Three-layer coextruded PVC (polyvinylchloride) wood-plastic composite foam board and preparation method thereof

ActiveCN102922838AHigh surface hardnessWith processing performanceSynthetic resin layered productsFiberFoaming agent

The invention relates to a three-layer coextruded PVC (polyvinylchloride) wood-plastic composite foam board and a preparation method of the three-layer coextruded PVC wood-plastic composite foam board. The wood-plastic composite foam board is of an ABA structure; an outer layer, namely an A layer, adopts polyvinyl chloride, a filler, an impact modifier, a lubricating agent, a composite stabilizer, a coupling agent, a processing agent and a polyvinyl chloride recycled material as raw materials, and an inner layer, namely a B layer, adopts the polyvinyl chloride, wood fiber powder, the filler, a foaming agent, an enhancer, a foaming regulator, the impact modifier, the lubricating agent, the composite stabilizer and a plate recycled material as raw materials. The three-layer coextruded wood-plastic composite foam board is formed by a main machine and an auxiliary machine in a coextrusion molding manner after mixing at high temperature and cooling. The three-layer coextruded PVC wood-plastic composite foam board has the processing property similar with that of wood, is anti-flaming and does not release formaldehyde, so that the three-layer coextruded PVC wood-plastic composite foam board becomes an ideal material for replacing the wood, can be used as building templates, cabinet boards and the like.

Owner:JIANGSU RUNJU ENVIRONMENTAL TECH CO LTD +1

Anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material and preparation method thereof

The invention discloses an anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material, which comprises the following components in parts by mass: 25-70 parts of plastic resin, 10-50 parts of plant fiber powder, 5-10 parts of camphor wood powder, 0.5-20 parts of a compatibilizer, 0-15 parts of a toughening agent, 10-35 parts of a flame retardant and a synergist, 2-5 parts of a thermal stabilizer, 0-1 part of an antioxidant and 1-4 parts of a lubricating agent. According to a method for preparing the wood-plastic composite material with a two-step fusion method disclosed by the invention, the interfacial compatibility can be improved effectively, and the flame retardance of the wood-plastic composite material is enhanced on the premise of keeping high mechanical property; and moreover, the using amount of ammonium polyphosphate serving as a major flame retardant is reduced. Compared with the conventional wood-plastic composite material, the wood-plastic composite material disclosed by the invention has a simple production flow, has the technical effects of flame retardance, smoke suppression and mildew resistance, and is widely applied to occasions such as indoor and outdoor architectural decoration, and the like.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE +1

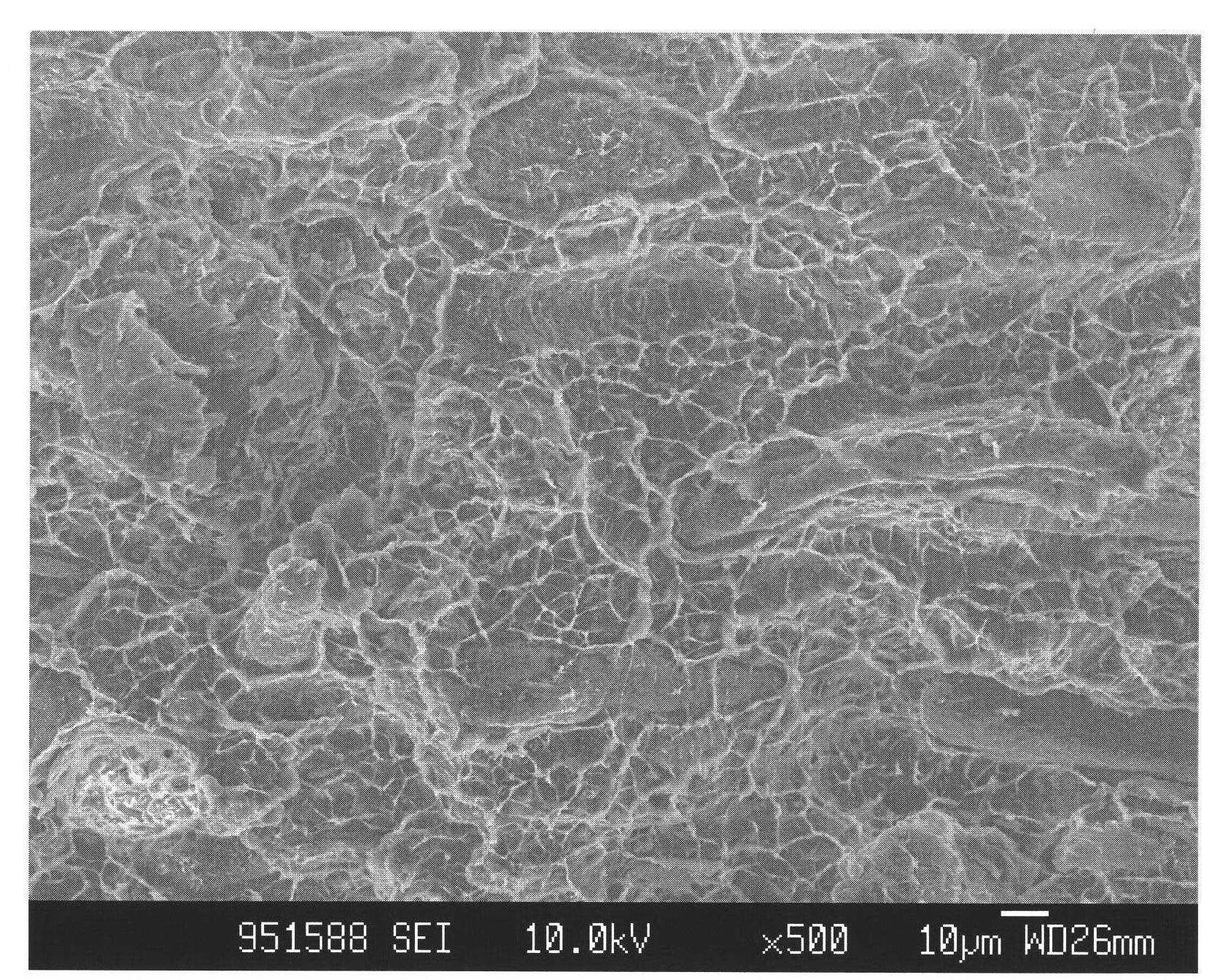

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

Wood plastic composite composition, wood plastic composite and preparation method thereof

ActiveCN101747639AImprove mechanical propertiesImprove toughnessGlass fiberMagnesium Sulfate whiskers

The invention discloses a wood plastic composite composition, wood plastic composite and a preparation method thereof. The wood plastic composite composition comprises wood powder, resin, compatilizer, reinforcing agent and coupling agent, wherein the compatilizer is the copolymer of rubber and maleic anhydride, and the reinforcing agent is basic magneislum crystal whisker and / or glass fiber. Theinvention also discloses a wood plastic composite and a preparation method thereof, comprising the following steps: extruding the wood plastic composite composition to obtain an extruding product, and shaping the extruding product to obtain the wood plastic composite. The wood plastic composite disclosed by the invention has high mechanical property and favourable toughness.

Owner:BYD CO LTD

Method for preparing Wood-plastic composite material by modified wood powder and waste and old plastics

The invention relates to a preparation technique of a wood plastic composite material, in particular to a method for preparing a wood plastic composite material by using modified wood powder and waste plastics. The method is characterized in that: (1) discarded agriculture and forestry wastes are crushed, milled and dried, and three different surface modification agents are added in sequence and mixed with the waste power one after another in a high-speed mixer to produce the modified water powder; and (2) waste plastics are washed and crushed into granules with the grain size of 2mm to 12mm and then dried; the modified waste powder, the waste plastic granules, a lubricant, a vesicant and a blowing promoter are mixed by weight percentage and put into the high-speed mixer for high-speed mixing and then cooled to the temperature lower than 55 DEG C for discharging so as to prepare a special premix. The composite material has super high strength and anti-bending and anti-impact capacity, wherein, the obvious enhancement of the anti-impact strength causes the great enhancement of the processing capacity of the product, thus causing products to meet different demands and ensuring an extremely wide application range.

Owner:FUJIAN NORMAL UNIV

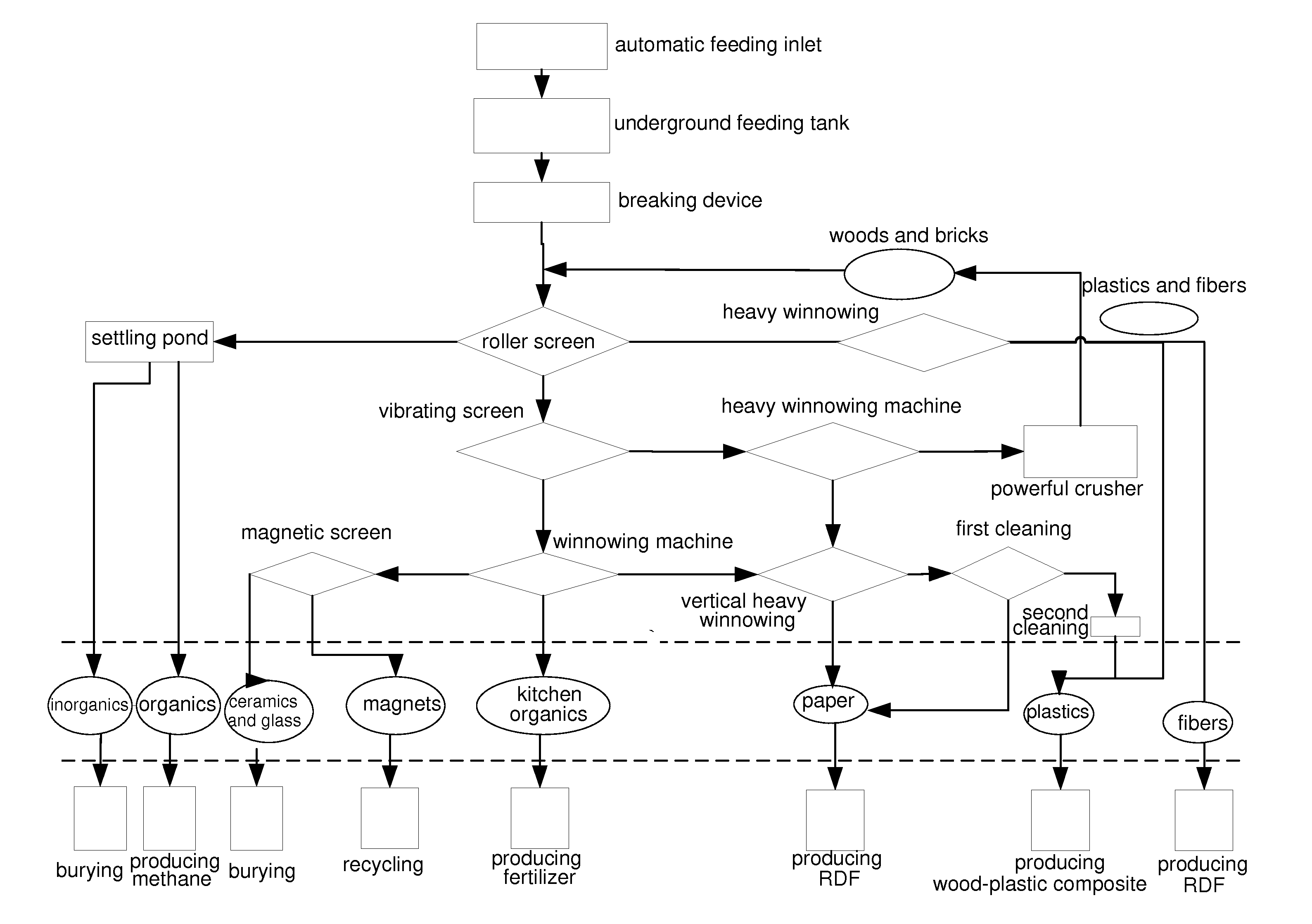

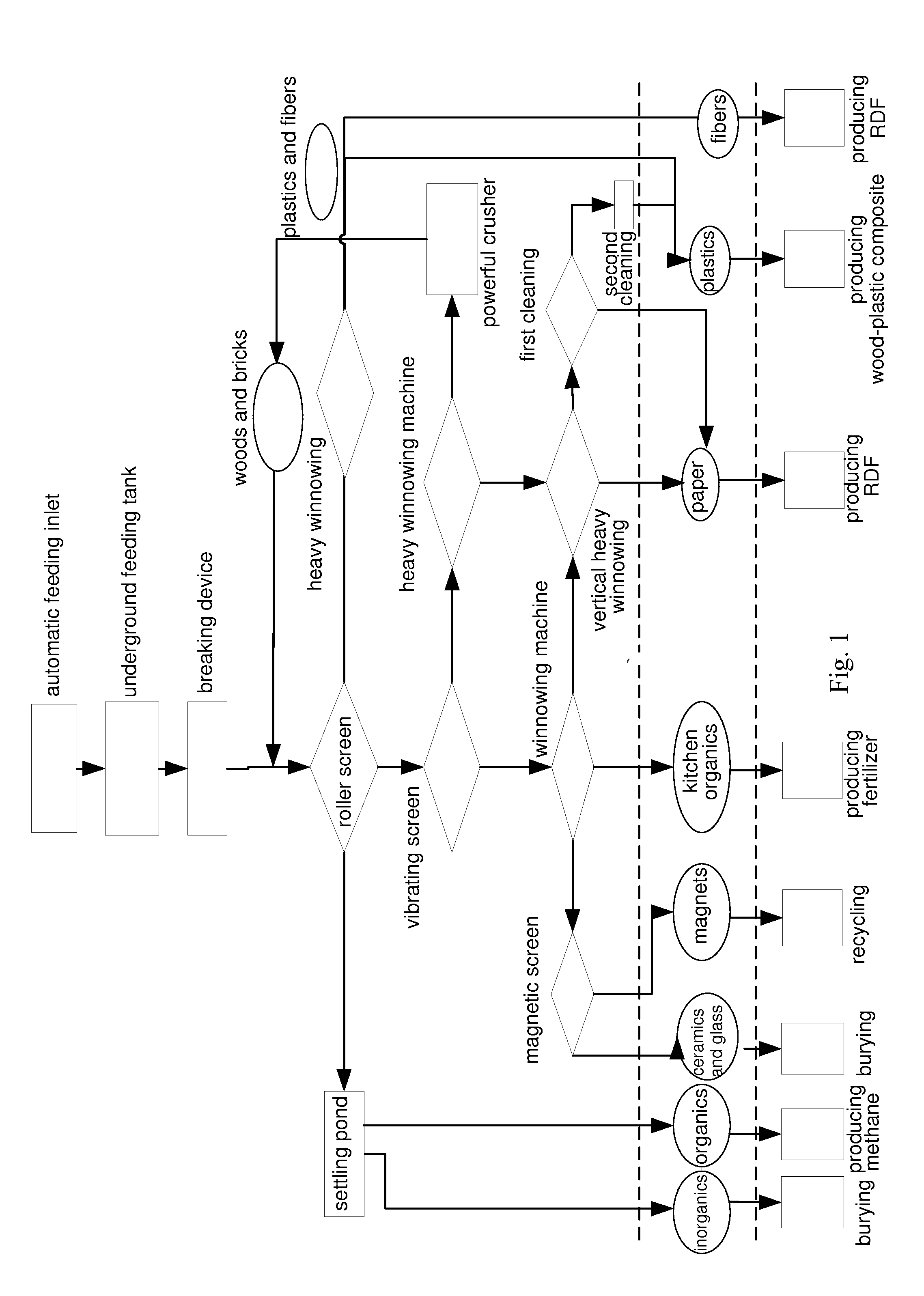

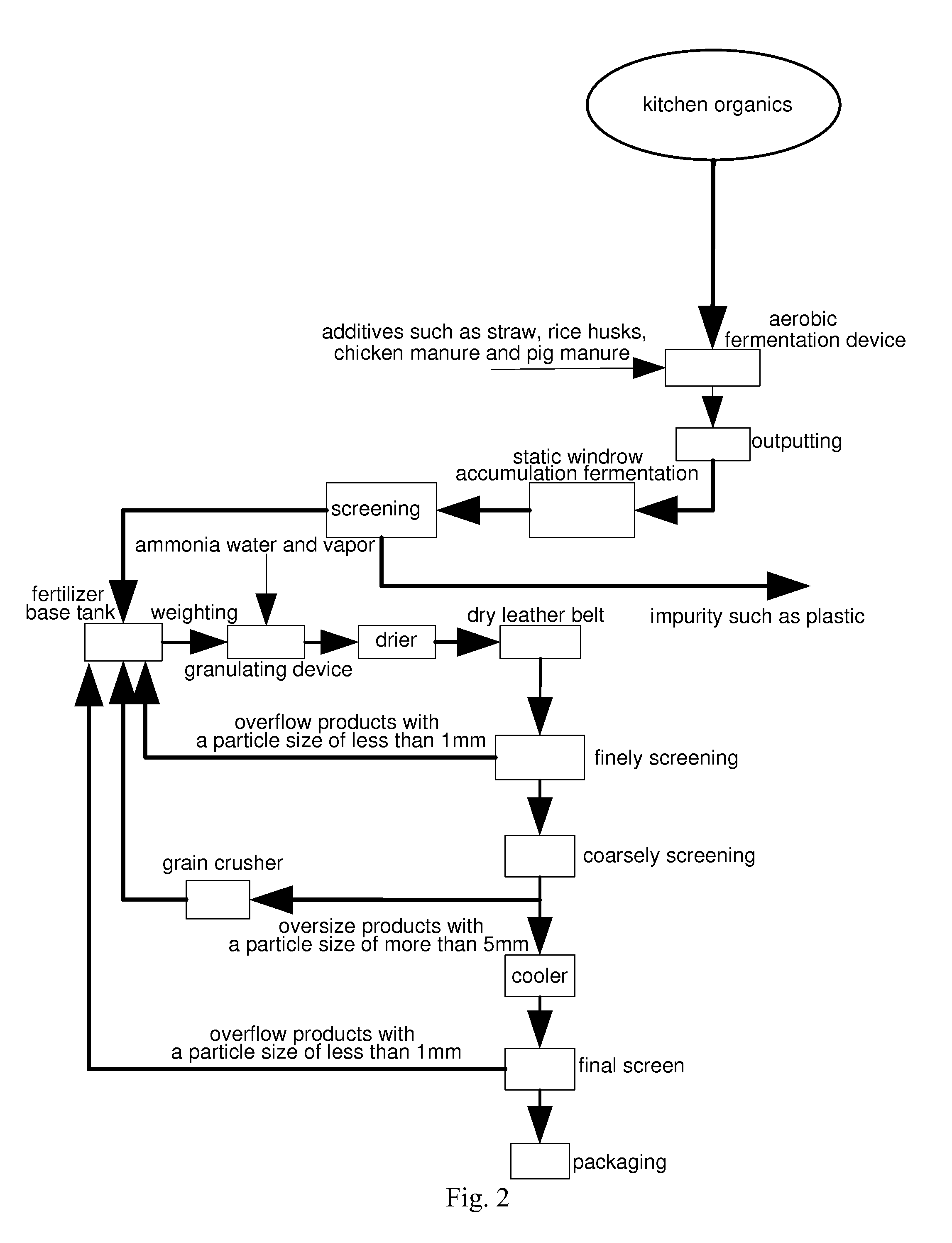

Method for sorting and comprehensively utilizing municipal solid waste

InactiveUS20150135785A1Maximize resource utilizationEfficient combinationBio-organic fraction processingSolid waste disposalRefuse-derived fuelFiber

A method for sorting and comprehensively utilizing municipal solid waste includes steps of: 1) feeding the municipal solid waste into a feeding tank through a feeding inlet, then outputting into a breaking device; 2) breaking refuse bags and large blocks by the breaking device; 3) transporting broken refuse into a two-stage roller screen for screening out dusts with a particle size of less than 3 mm, and hanging strips; and 4) transporting mixed refuse screened by the two-stage screen into a vibrating screen; screening oversize products by a heavy winnowing machine for separating inorganic blocks, large plastics and paper; transporting underflow products into a two-room multi-functional winnowing machine for dividing into heavy materials, light materials and medium materials. By effectively combining sorting devices, effective sorting and reutilization of mixed refuse are achieved. Thereafter, paper, fibers, plastics and kitchen organic refuse are respectively for producing refuse derived fuel, wood-plastic composite and fertilizer.

Owner:XI AN JIAOTONG UNIV

Application of injection molding wood plastic composite in producing electric appliance housing

ActiveCN101754599AGood effectGood dimensional stabilityElectrical apparatus casings/cabinets/drawersAntioxidantInorganic filler

The invention discloses the application of an injection molding wood plastic composite in producing electric appliance housing. The injection molding wood plastic composite is composed of the following components in part by weight: 100 parts of thermoplastic resin; 1-400 parts of plant powder; 0.1-40 parts of dispersing agent; 0.5-60 parts of impact modifier; 0-100 parts of inorganic filler; and 0-10 parts of antioxidant. It is found through long-term research that the injection molding wood plastic composite is extremely great for producing various electric appliance housings, hence, for thefirst time the injection molding wood plastic composite is brought into the production field of electric appliance housing, giving rise to tremendous revolutionary transform of the material for producing electric appliance housing. The injection molding wood plastic composite according to the invention, preferably the plant powder-modified thermoplastic wood plastic composite material, has the characteristics of good durability and dimensional stability, great easiness for molding, small water absorbability and excellent corrosion resistance compared with woods, and has the characteristics oflow cost and high rigidness compared with plastics.

Owner:KINGFA SCI & TECH CO LTD +1

Styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and preparation method thereof

ActiveCN101864118AImprove liquidityGive full play to the flame retardant effectBuilding productHalogen

The invention discloses a styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following components by mass percentage: 25% to 60% of styrene-based resin, 5% to 50% of vegetable fiber, 0.5% to 20% of compatibilizer, 0% to 30% of toughener, 0.5% to 8% of dispersant, 5% to 40% offlame retardant and flame-retardant synergist and 0% to 1% of antioxidant. Compared with the existing wood-plastic composite material, the styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material prepared by the invention has the characteristics of simple production procedure, lower flame-retardant consumption, good non-halogen flame-retardant effect and wide range of forming manners. Therefore, the invention is suitable for various injection-molded parts, such as the housing of electrical products, furnishings, automobile materials, artworks, complex-structured building products and the like.

Owner:KINGFA SCI & TECH CO LTD +2

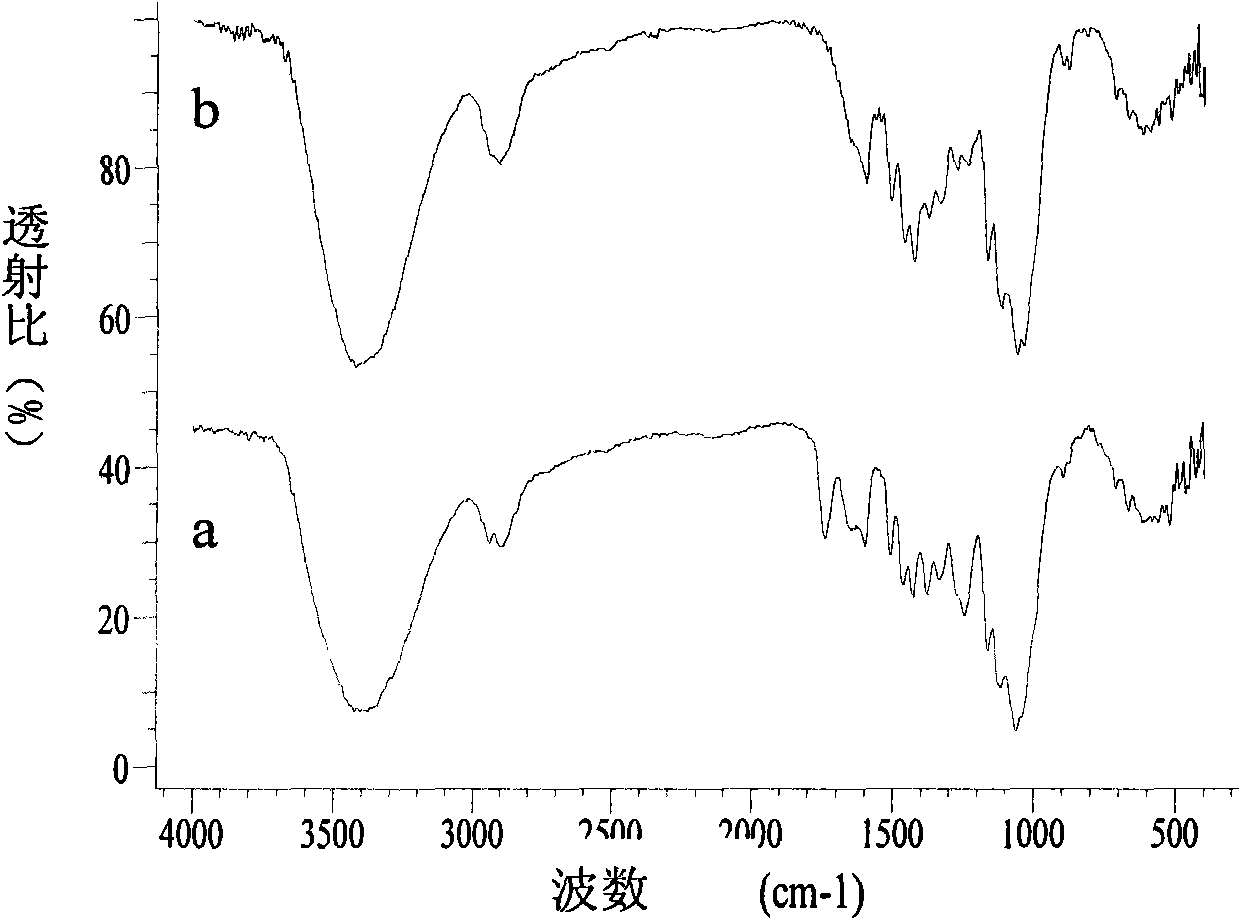

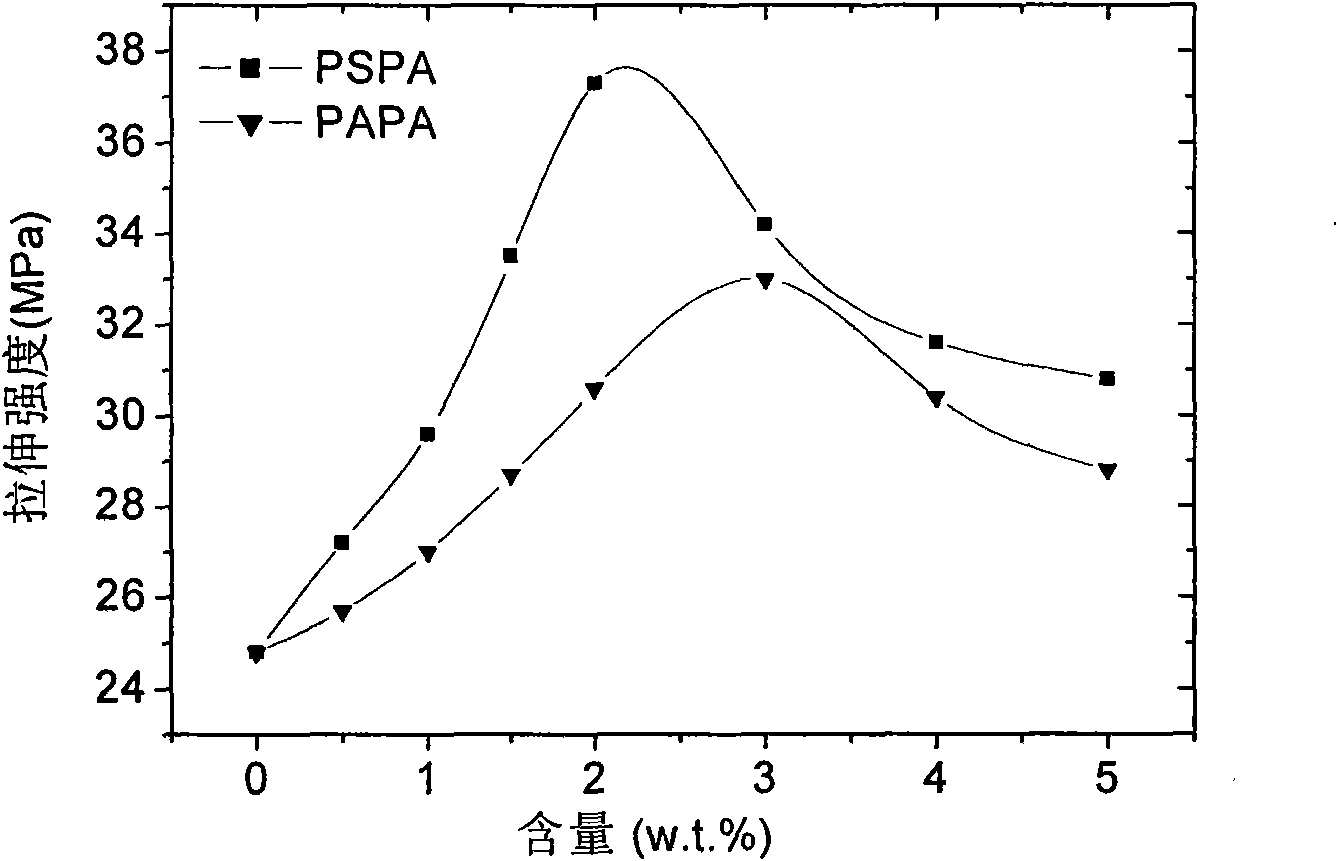

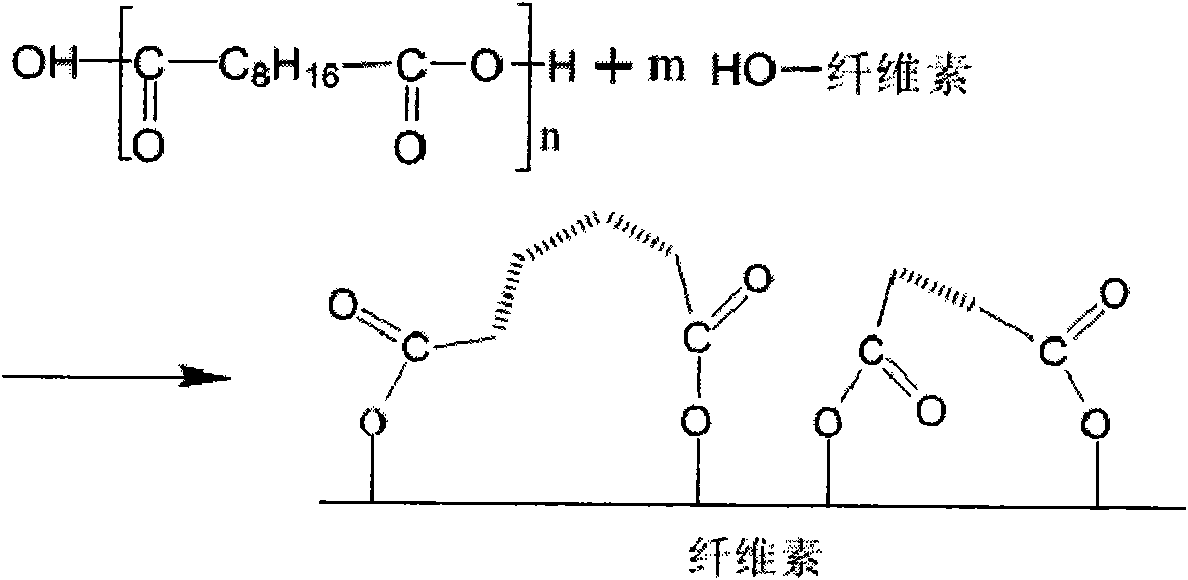

Water-resistant wood-plastic composite material and preparation method thereof

InactiveCN101613503AImprove interface compatibilityImprove composite effectPolyolefinPolymer substrate

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

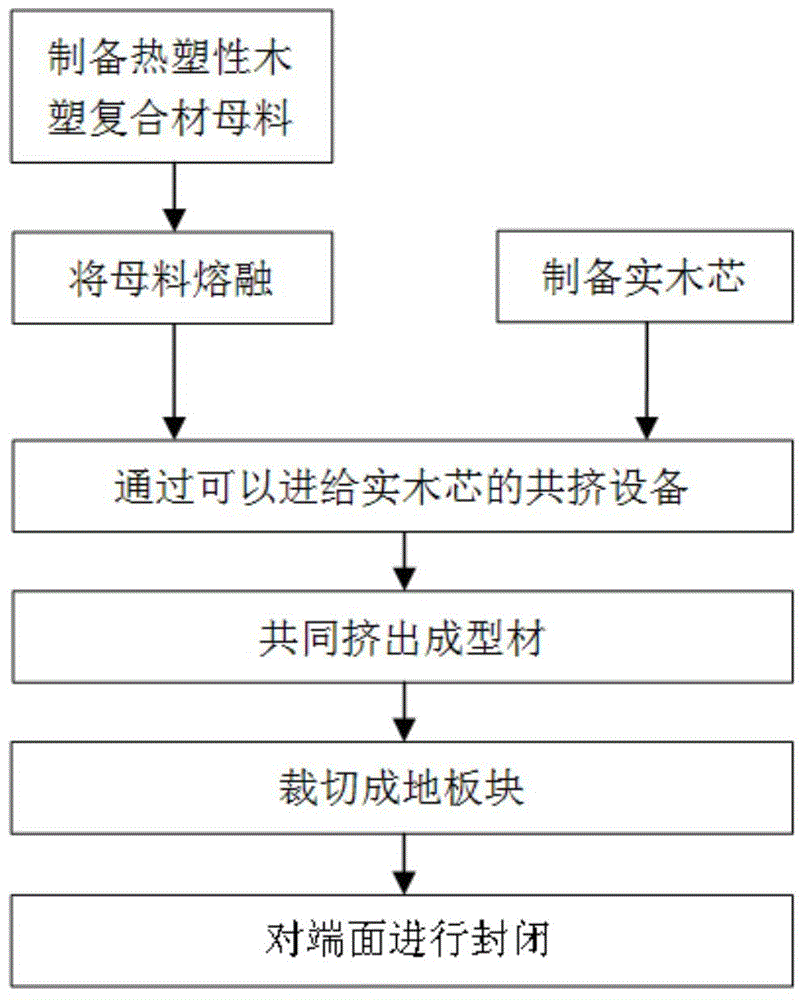

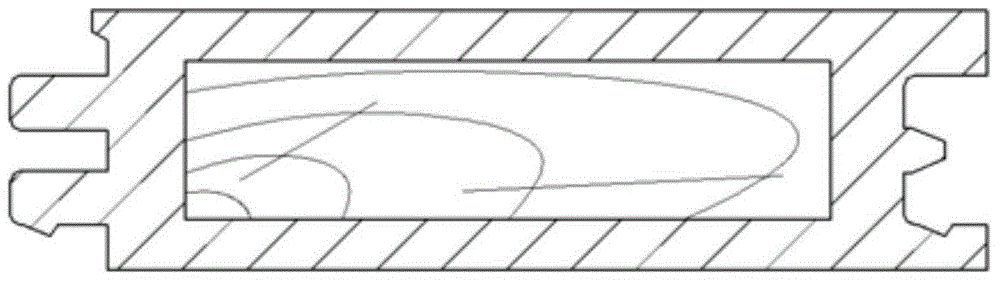

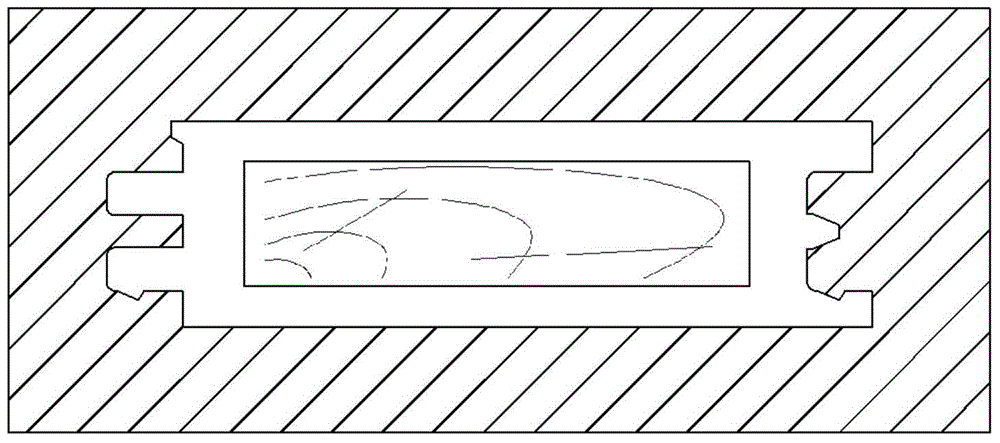

Wood-plastic composite floor and manufacturing method thereof

InactiveCN104631758AHigh strengthImprove water resistanceFlooringHigh intensityUltimate tensile strength

The invention relates to a floor and a manufacturing method thereof, in particular to a wood-plastic composite floor and a manufacturing method thereof. The problem that a wood-plastic floor is low in intensity and high in density, creeping can happen easily, and the wood-plastic floor is not suitable for being used as a large-span floor. The method comprises the steps that a. a wooden core is prepared; b. thermoplasticity wood-plastic composite material parent stock is prepared, the wood-plastic composite material parent stock is subjected to fusion through co-extrusion equipment which can feed the wooden core, the parent stock and the wooden core are subjected to extrusion together to form proximate matter; c. the proximate matter formed in the step b is cut into floor blocks; and d. the end faces of the floor blocks in the step c are sealed. The high-intensity wood-plastic composite floor can be manufactured, the floor cannot crack, warping and deforming are avoided, mildewing rotting is avoided, and pollution is avoided.

Owner:NORTHEAST FORESTRY UNIVERSITY

Styrene series non-halogen flame retardant injection-grade wood plastic composite and preparation method thereof

The invention discloses a styrene series non-halogen flame retardant injection-grade wood plastic composite and a preparation method thereof. The styrene series non-halogen flame retardant injection-grade wood plastic composite is prepared from the following components in percentage by mass: 25-60 percent of styrene series resin, 5-60 percent of plant fiber, 0.5-20 percent of compatilizer, 0-30 percent of flexibilizer, 0.5-8 percent of dispersing agent, 5-40 percent of fire retardant and synergetic fire retardant and 0-1 percent of antioxidant. Compared with the traditional wood plastic composite, the styrene series non-halogen flame retardant injection-grade wood plastic composite prepared by the invention has the characteristics of simple production flow, less consumption amount of fireretardant, good non-halogen flame retardant effect, wide range of moulding ways, and the like, and is suitable for various injection moulded parts such as shells of electric appliances, parts for vehicles, and parts for furniture and buildings, and the like.

Owner:GUANGDONG KINGFA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com