Flame-retardant and antistatic wood-plastic composite material and preparation method thereof

A wood-plastic composite material, flame-retardant and anti-static technology, applied in the field of wood-plastic composite material and its preparation, can solve the problems of high fire hazard, discharge and high cost, reduce the hidden danger of fire safety, improve flame retardant and anti-static Static performance, the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

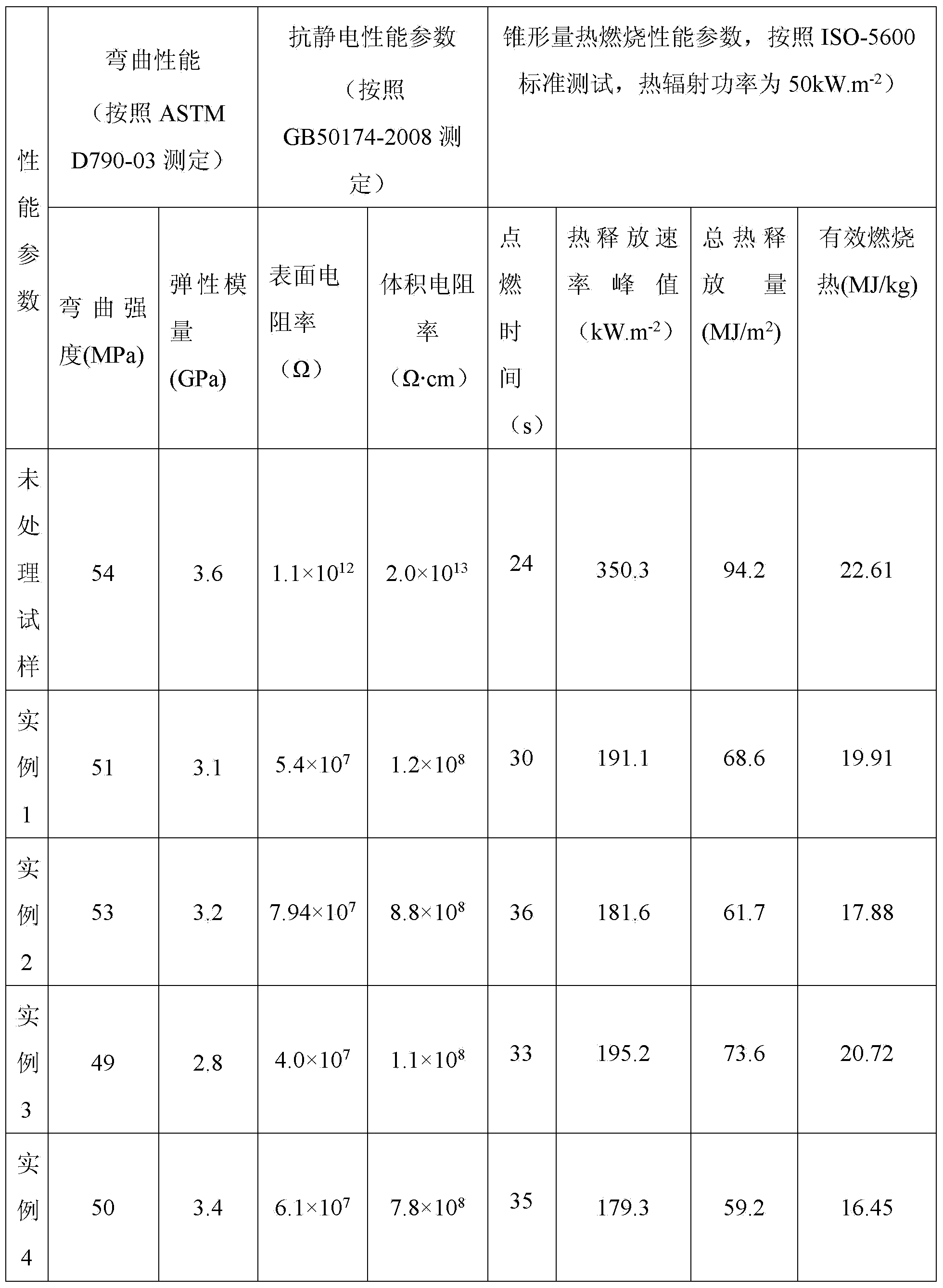

Examples

specific Embodiment approach 1

[0020] Specific implementation mode 1: The flame-retardant and antistatic wood-plastic composite material in this embodiment consists of 20-70 parts by weight of wood fiber materials, 30-80 parts of thermoplastics, 1-3 parts of lubricant, and 2-15 parts of antistatic agent , 5-20 parts of flame retardant, 2-6 parts of coupling agent and 0-5 parts of inorganic filler; wherein the total amount of lignocellulosic materials and thermoplastics is 100 parts, and the antistatic agent is conductive carbon black, A mixture of one or more of nickel powder, copper powder, graphene oxide, and carbon nanotubes in any ratio; the flame retardant is expandable graphite or expandable graphite, ammonium polyphosphate, and microencapsulated red A mixture of one or more of phosphorus, nano aluminum hydroxide, nano magnesium hydroxide, nano organic montmorillonite, and nano zinc borate in any ratio.

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the lignocellulosic material is one of wood powder, bamboo powder, rice husk powder, straw powder, fruit shell powder, bagasse, hemp fiber or Several kinds of mixtures are composed in any ratio, the particle size is 40-160 mesh, and the water content is lower than 2%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the thermoplastic is one or more of polyethylene, polypropylene, recycled polyethylene, recycled polypropylene, and recycled polystyrene. Several mixtures in any ratio. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com