Patents

Literature

4088 results about "Bagasse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bagasse (/bəˈɡæs/ bə-GAS-se') is the dry pulpy fibrous residue that remains after sugarcane or sorghum stalks are crushed to extract their juice. It is used as a biofuel for the production of heat, energy, and electricity, and in the manufacture of pulp and building materials.

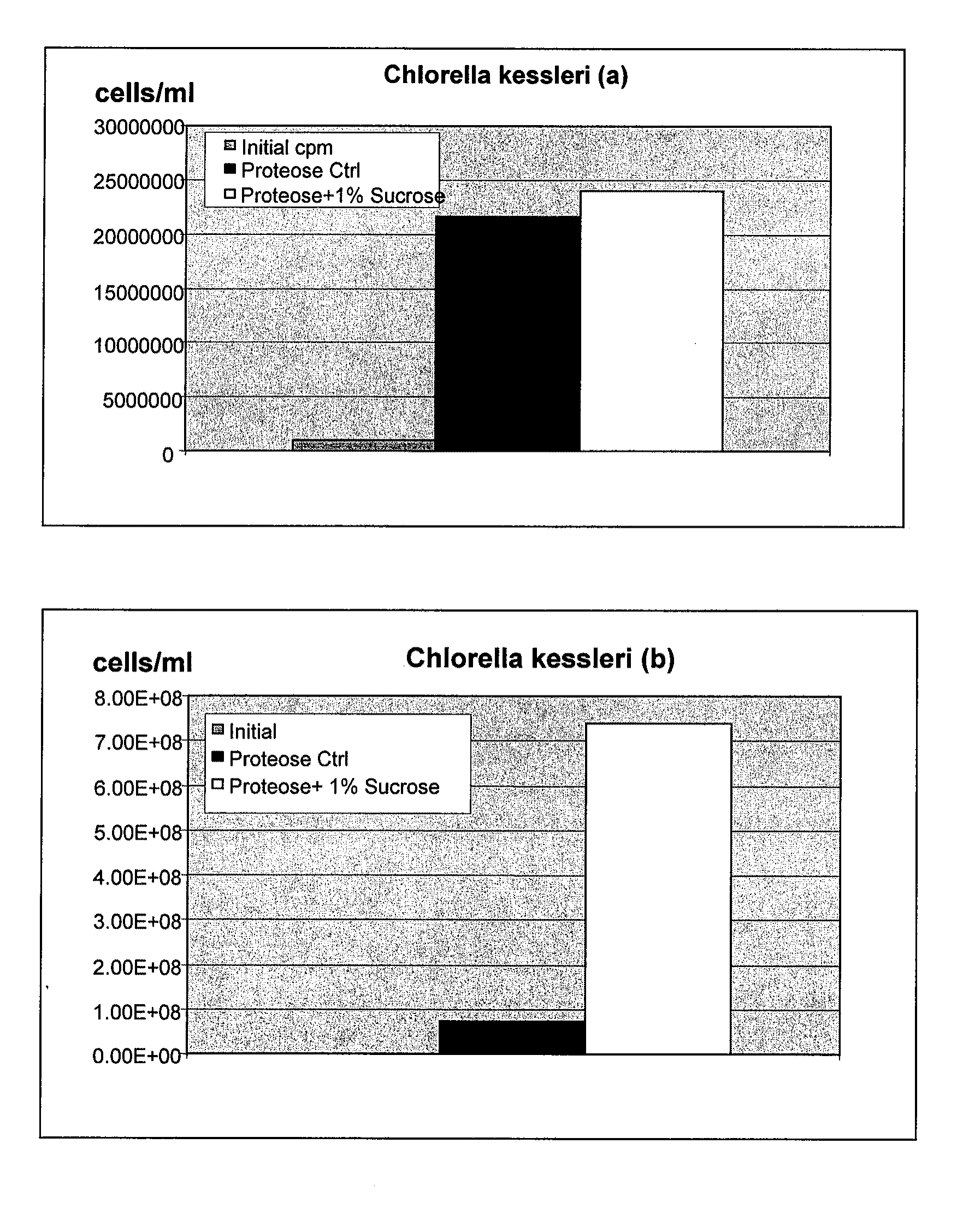

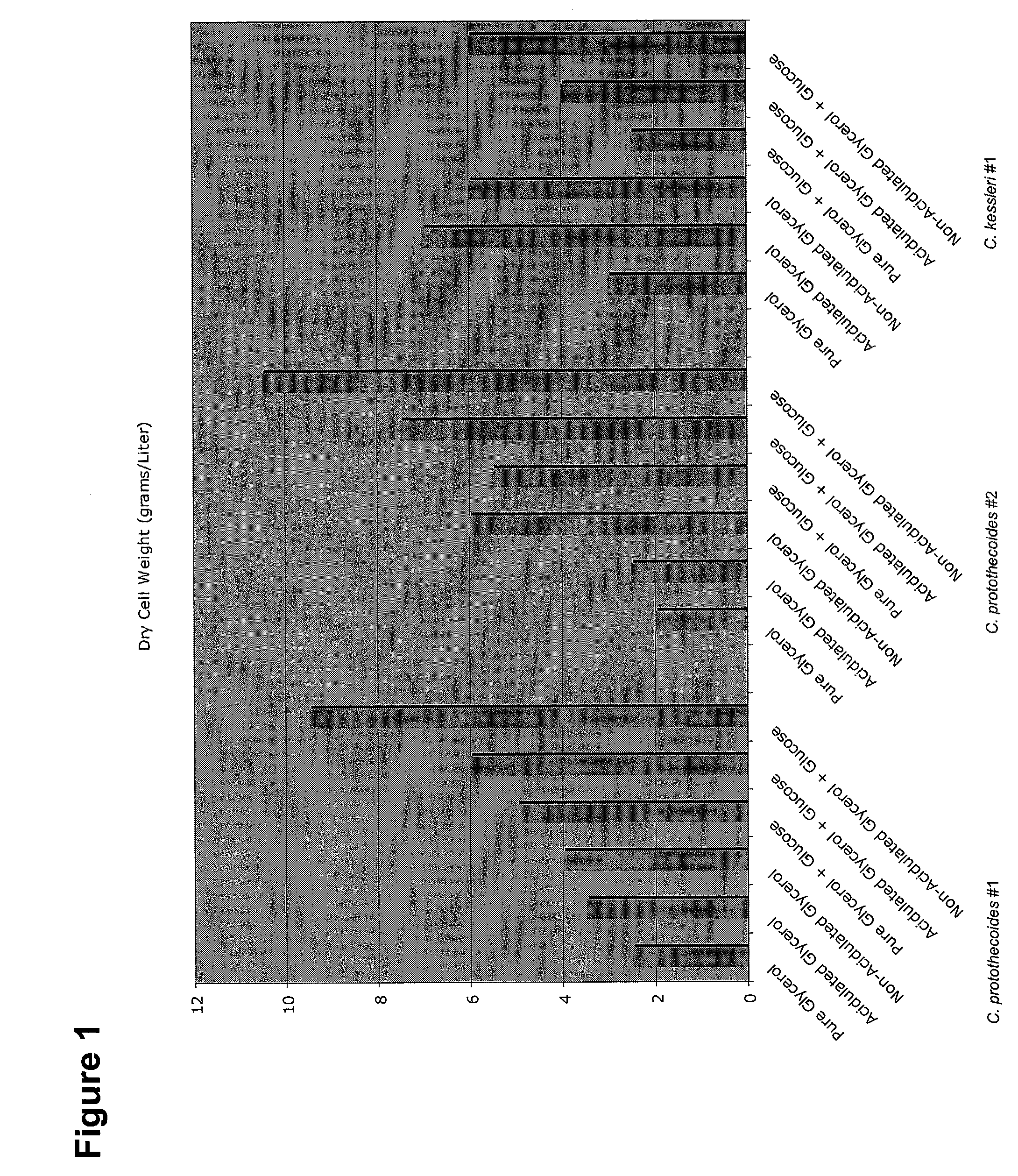

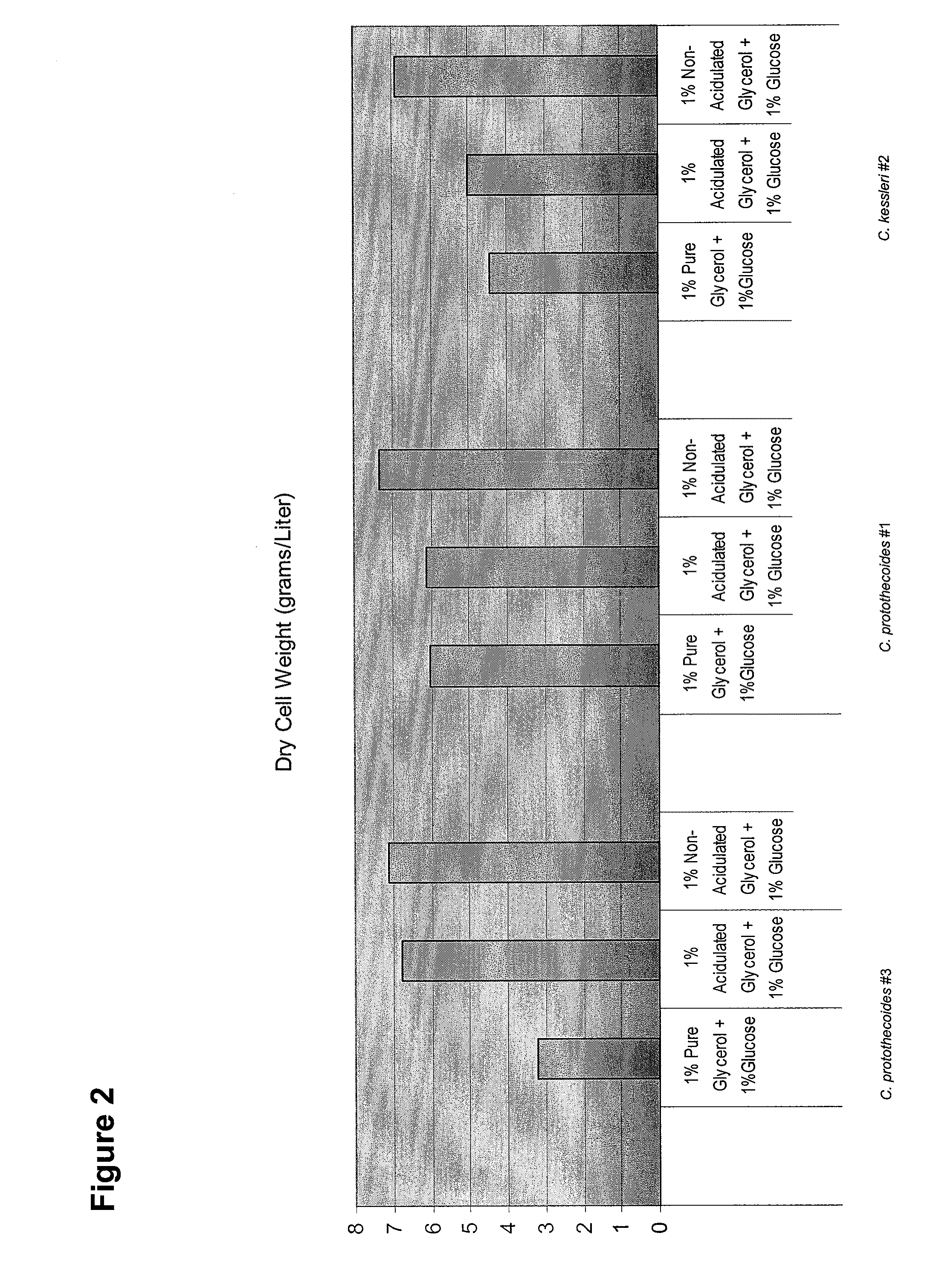

Use of Cellulosic Materials for Cultivation of Microorganisms

Owner:CORBION BIOTECH INC

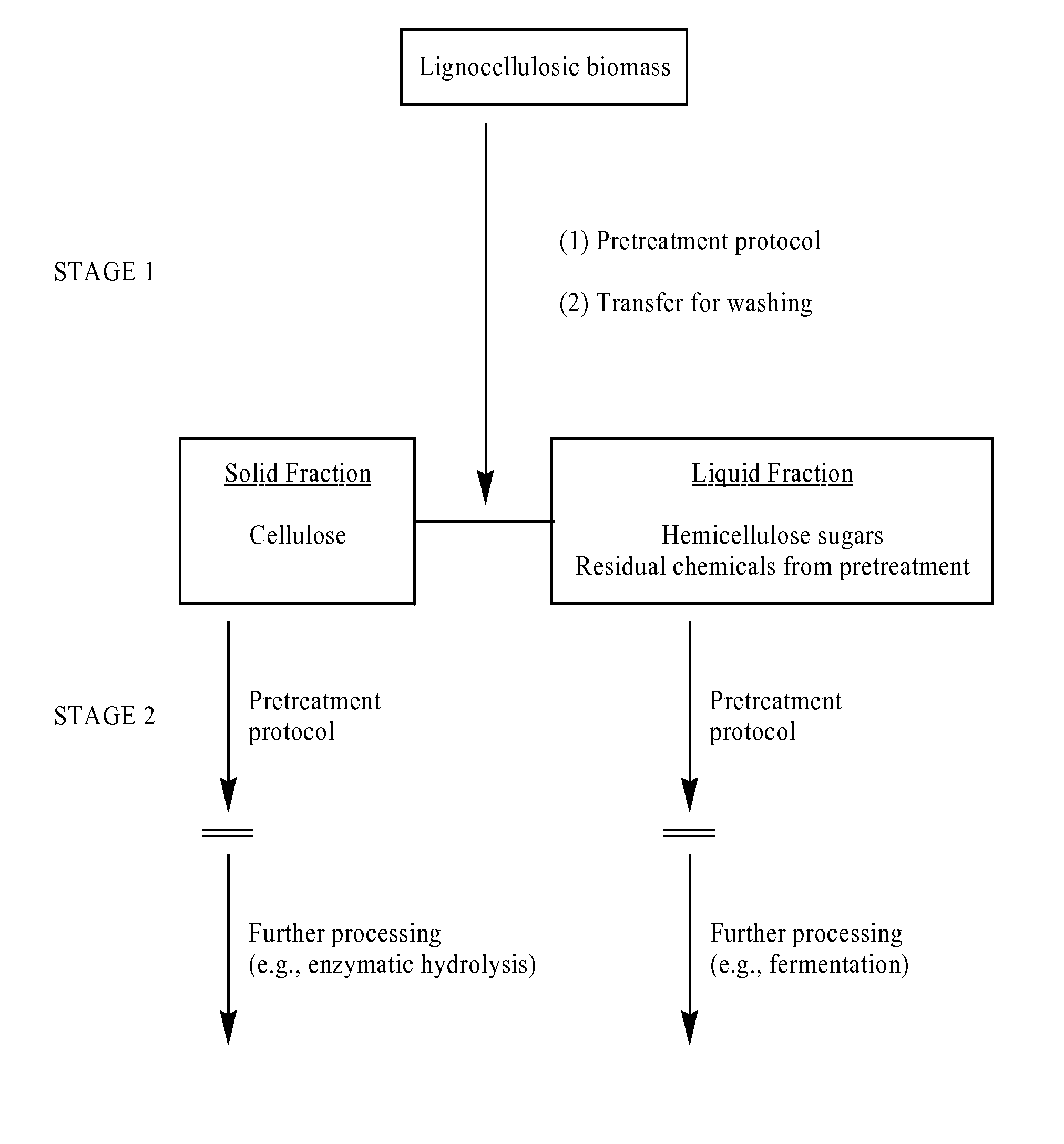

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

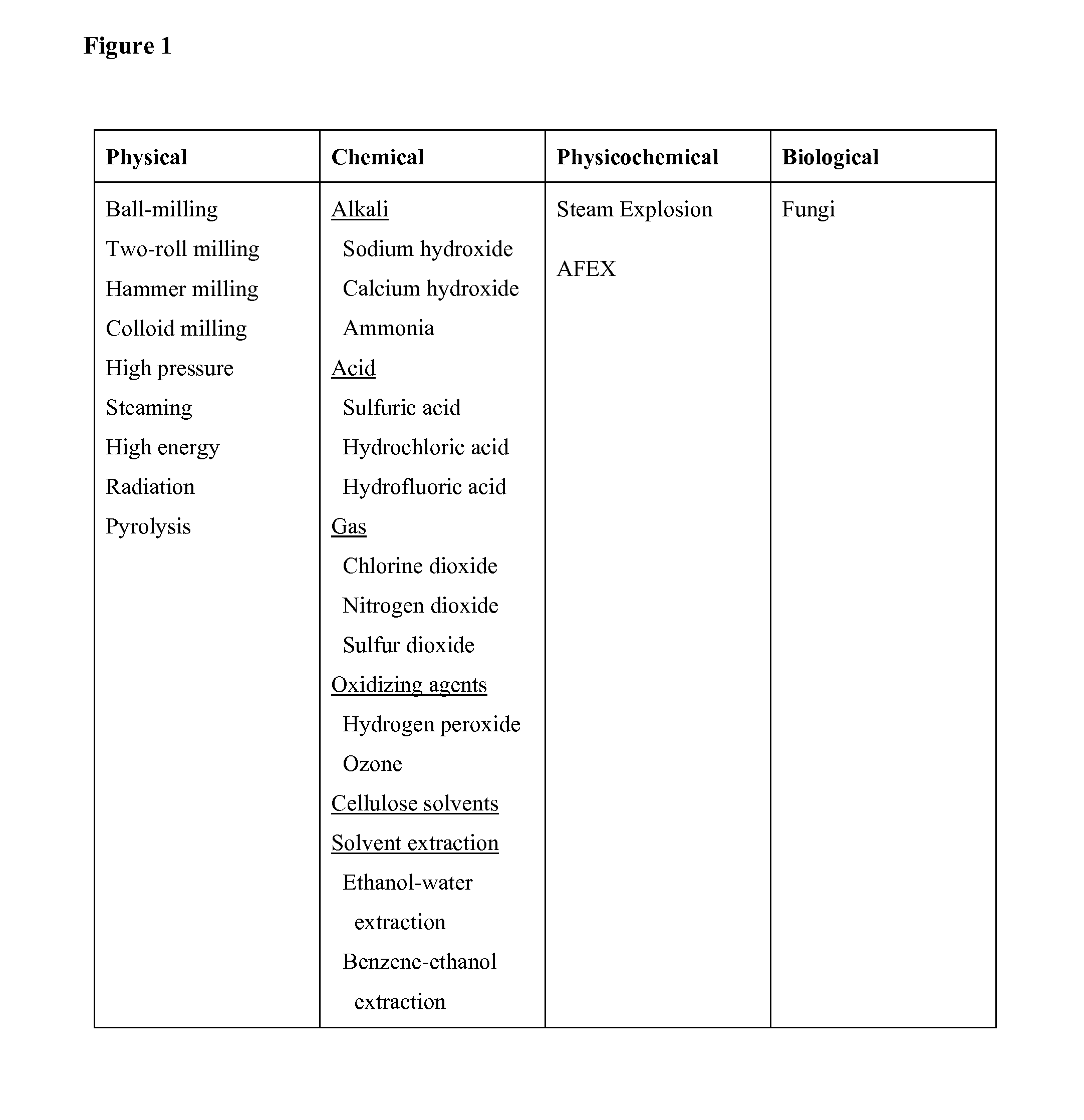

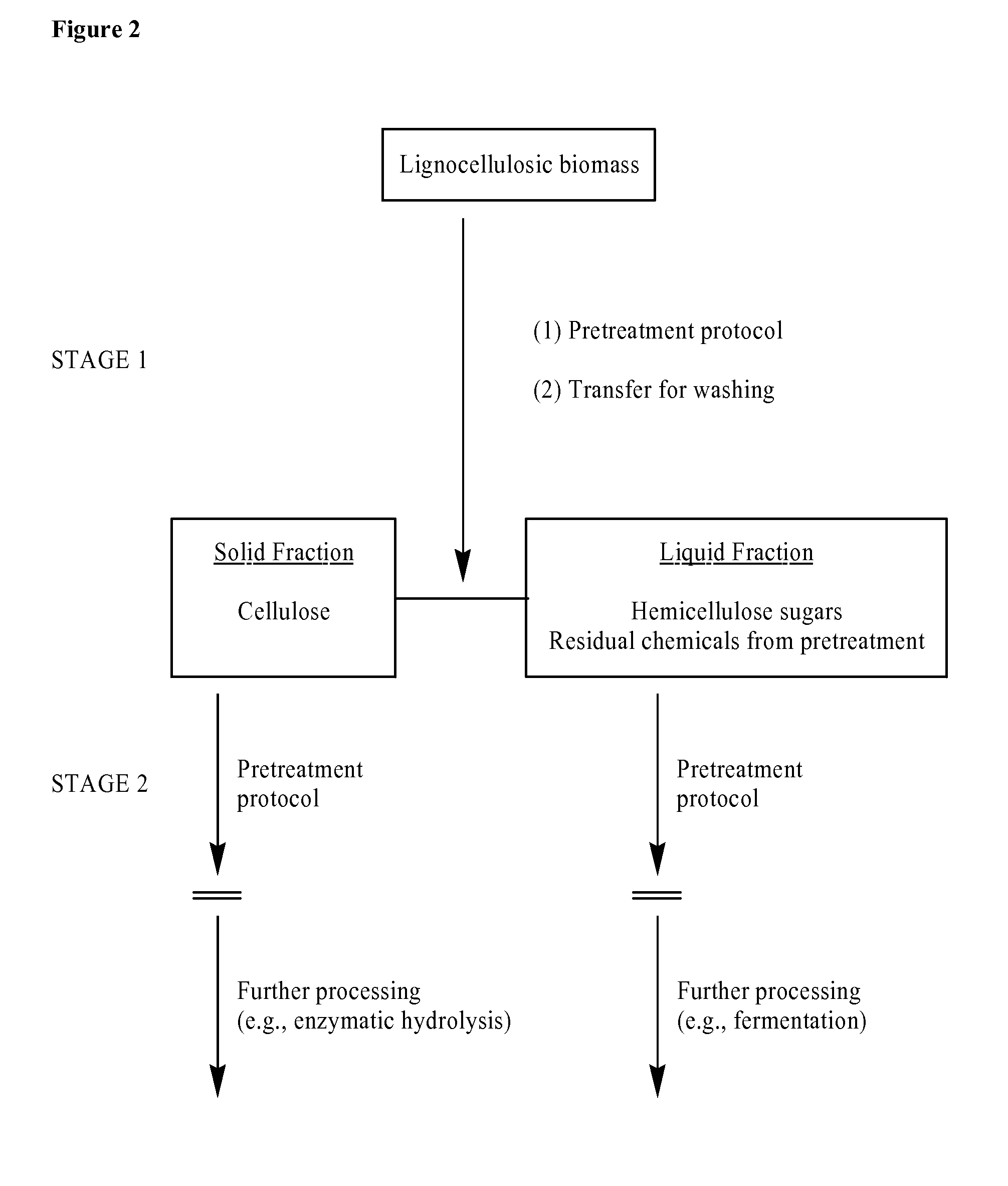

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

Multi-stage blocking pressure-bearing plugging agent

ActiveCN104087274AImprove the blocking effectGood voltage stabilization effectDrilling compositionFiberAdhesive materials

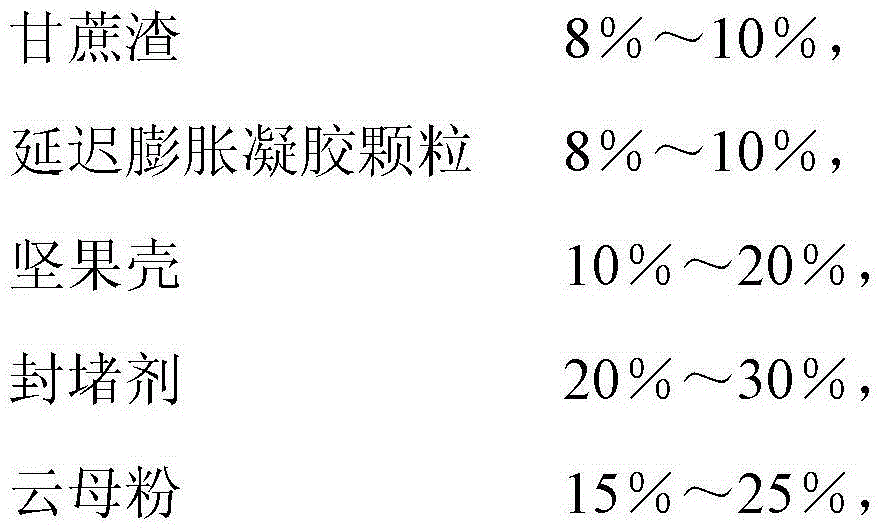

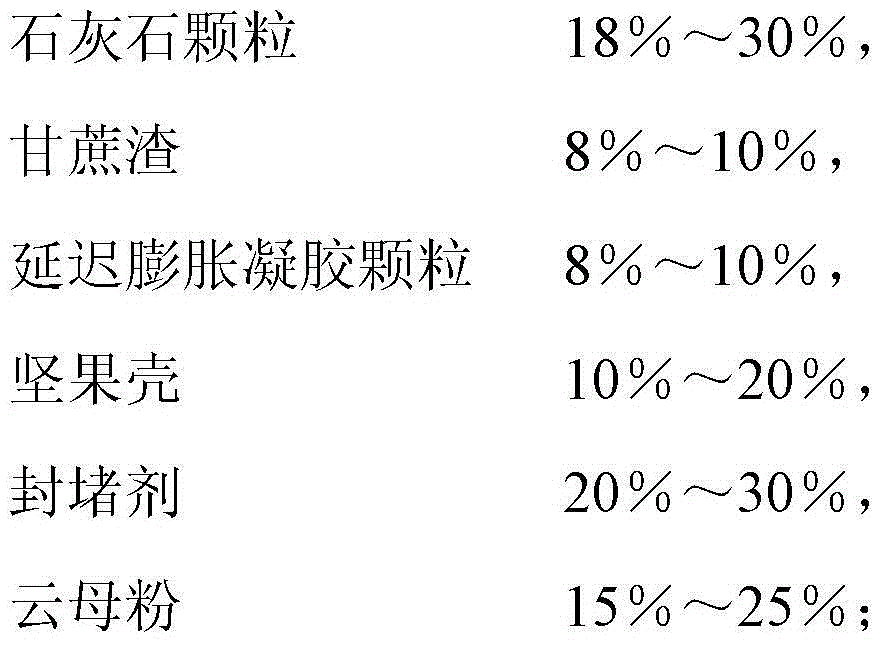

The invention relates to a multi-stage blocking pressure-bearing plugging agent which can be applied to drilling construction of weak pressure-bearing zones of oil and gas fields. The plugging agent comprises the following components in percentage by weight: 18-30% of limestone particle, 8-10% of bagasse, 8-10% of delayed expanding gel granule, 10-20% of nutshell, 20-30% of blocking agent and 15-25% of mica powder, wherein the raw materials are uniformly mixed to prepare the multi-stage blocking pressure-bearing plugging agent. Rigid materials, plant fibers, expandable materials and adhesive materials of different particle grades are mixed according to a certain ratio to prepare the granular, fiber, flaky and expandable plugging material for solving the technical problems of seams, cracks and interlayer fault loss, the once success rate of plugging is high, and the pressure-bearing capability of stratum is effectively improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Special organic-inorganic composite biological pesticide-fertilizer for flowers and preparation method thereof

The invention provides a special organic-inorganic composite biological pesticide-fertilizer for flowers. The special organic-inorganic composite biological pesticide-fertilizer for flowers comprises the following raw materials in parts by weight: 80-90 parts of municipal sludge, 10-20 parts of fruit peel, 10-20 parts of fallen leaves, 10-15 parts of poultry manure, 10-14 parts of bagasse, 20-30 parts of iron ore slag, 10-12 parts of animal feathers, 10-15 parts of tree ash, 10-15 parts of monoammonium phosphate, 20-25 parts of urea, 10-12 parts of ammonia sulfate, 8-10 parts of ammonium hydrogen carbonate, 8-10 parts of potassium chloride, 5-7 parts of carboxymethyl chitosan, 20-30 parts of modified bentonite, 5-8 parts of lignite, 2-4 parts of black dye tree, 9-11 parts of celastrus angulatus, 9-11 parts of common carpesium fruit, 9-11 parts of radix sophorae flavescentis, 4-6 parts of lilac daphne flower bud, 3-5 parts of coptis root, 10-12 parts of powder of root of stellera chamaejasme, 2-4 parts of vegetable oil, 1-3 parts of zinc sulfate, 3-4 parts of ferrous sulfate, 0.8-1.2 parts of borax, 20-26 parts of potassium fulvate and 0.3-0.4 part of EM (effective microorganism) strain. The pesticide-fertilizer disclosed by the invention has the advantages of scientific ratio of nitrogen, phosphorus and potassium, easiness in absorption by crops, obvious yield-increasing benefit and the like. By applying the pesticide-fertilizer, the nutrient absorption of plants can be balanced, the quality of flowers can be effectively improved, plants are green in leaves and bright in flower, and the flowering phase is also prolonged.

Owner:东至县神山化肥有限责任公司 +1

Specialized organic/inorganic composite biological medicine fertilizer for watermelon, and preparation method thereof

The invention provides a specialized organic / inorganic composite biological medicine fertilizer for watermelon, and a preparation method thereof. The weight parts of composition raw materials are as follows: 50-70 parts of sludge produced by sewage treatment, 20-30 parts of tree ash, 30-40 parts of watermelon vines, 20-30 parts of cow manure, 15-20 parts of bagasse, 5-7 parts of fishbone dust, 8-10 parts of oil cakes, 10-15 parts of the tree ash, 10-15 parts of phosphorus slag, 8-10 parts of poultry feather, 8-10 parts of monoammonium phosphate, 10-12 parts of triple superphosphate, 12-15 parts of potassium chloride, 2-4 parts of carboxymethyl chitosan, 20-30 parts of modified bentonite, 10-12 parts of decomposed coal, 2-4 parts of seven leaf clover, 9-11 parts of angled bittersweet, 8-10 parts of capillary artemisia, 5-7 parts of fructus cnidii, 6-8 parts of fructus quisqualis, 3-5 parts of wormwood, 3-5 parts of litsea cubeba, 8-10 parts of daturae flower powder, 3-5 parts of paraffin, 1-1.25 parts of zinc sulfate, 2-3 parts of ferrous sulfate, 0.8-1.2 parts of borax, 10-12 parts of potassium fulvic acid, 3-4 parts of chili oil and 0.2-0.5 part of EM strains. A green organic fertilizer is obtained by mixing a plurality of organic wastes and fermenting the mixture, thereby reducing environment pollutions. The specialized organic / inorganic composite biological medicine fertilizer for the watermelon has the advantages of comprehensive nutrition and enhanced sterilizing effects by mixing the fermented organic materials and inorganic fertilizer and adding medicine juice of the Chinese herbal medicine having insectidical functions. With the application of the fertilizer, watermelon quality can be effectively increased; and the watermelon has green leaves, bright flower, prolonged flowering period and increased output.

Owner:合肥科友生物科技有限公司

High-Purity Xylooligosaccharide Compositions

To provide a high-purity xylooligosaccharide composition while preventing the formation of UV-absorbing substances and coloring matters.A high-pure xylooligosaccharide composition containing reduced UV-absorbing substances and reduced coloring matters and a method of producing the same which comprises alkali-treating or pressure- and heat-treating a plant material such as wood, corn cob, cotton seed hull, bagasse or rice straw, further enzymatically treating the same, and purifying the crude saccharide solution containing the residues thus obtained, wherein the solution is concentrated and then optionally subjected to desalting and active carbon-treatment. According to the method of the invention, the saccharified solution is concentrated followed by the desalting and active-carbon treating so that a high-purity xylooligosaccharide composition can be produced while preventing the formation of UV-absorbing substances and coloring matters.

Owner:SUNTORY HLDG LTD +1

Composite microbial inoculum organic multielement compound fertilizer and production method thereof

ActiveCN102690151AImprove physicsGood biological propertiesFertilizer mixturesThiobacillus ferrooxidansBran

The invention discloses a composite microbial inoculum organic multielement compound fertilizer which is prepared from microbial inoculum, organic component and inorganic fertilizer. The microbial inoculum is a composite microbial inoculum which comprises the following three types of microbial inocula: resource type microbial inoculum, which contains Bacillus megaterium, thiobacillus thiooxidans, Bacillus mucilaginosus and Bacillus circulans; environment-friendly microbial inoculum, which contains Arthrobacter and Alcaligenes; and antibiotic microbial inoculum, which contains Streptomycs micuoflavus and Streptomyces jingyangensis. The organic component is one or more of cereal crop straw, subsidiary agricultural product dreg, sugar mill bagasse, bran coat, municipal and rural domestic waste, and livestock and poultry dung. The inorganic fertilizer is one or more of nitrogen fertilizer, phosphate fertilizer, potash fertilizer and medium / micro-nutrient element fertilizer. The weight proportion of microbial inoculum to organic constituent to inorganic fertilizer is (5-25):(18-28):(47-77).

Owner:赵大伟

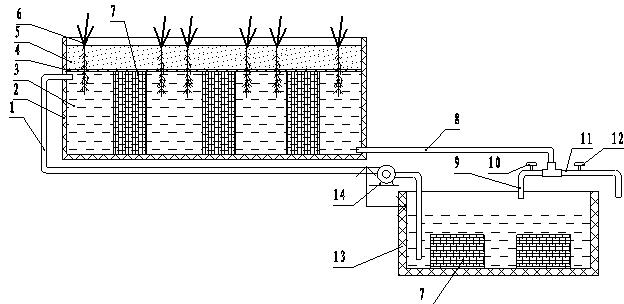

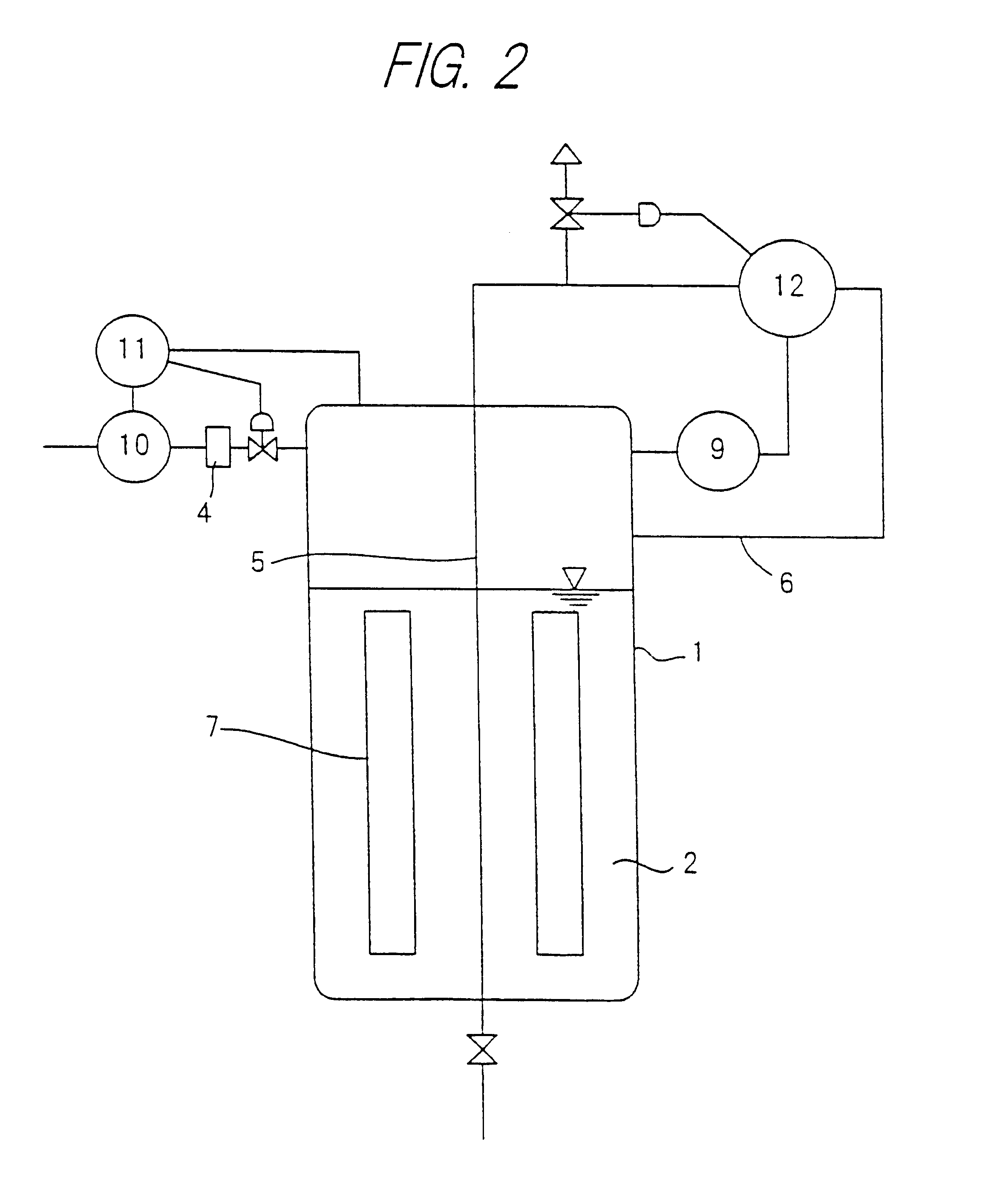

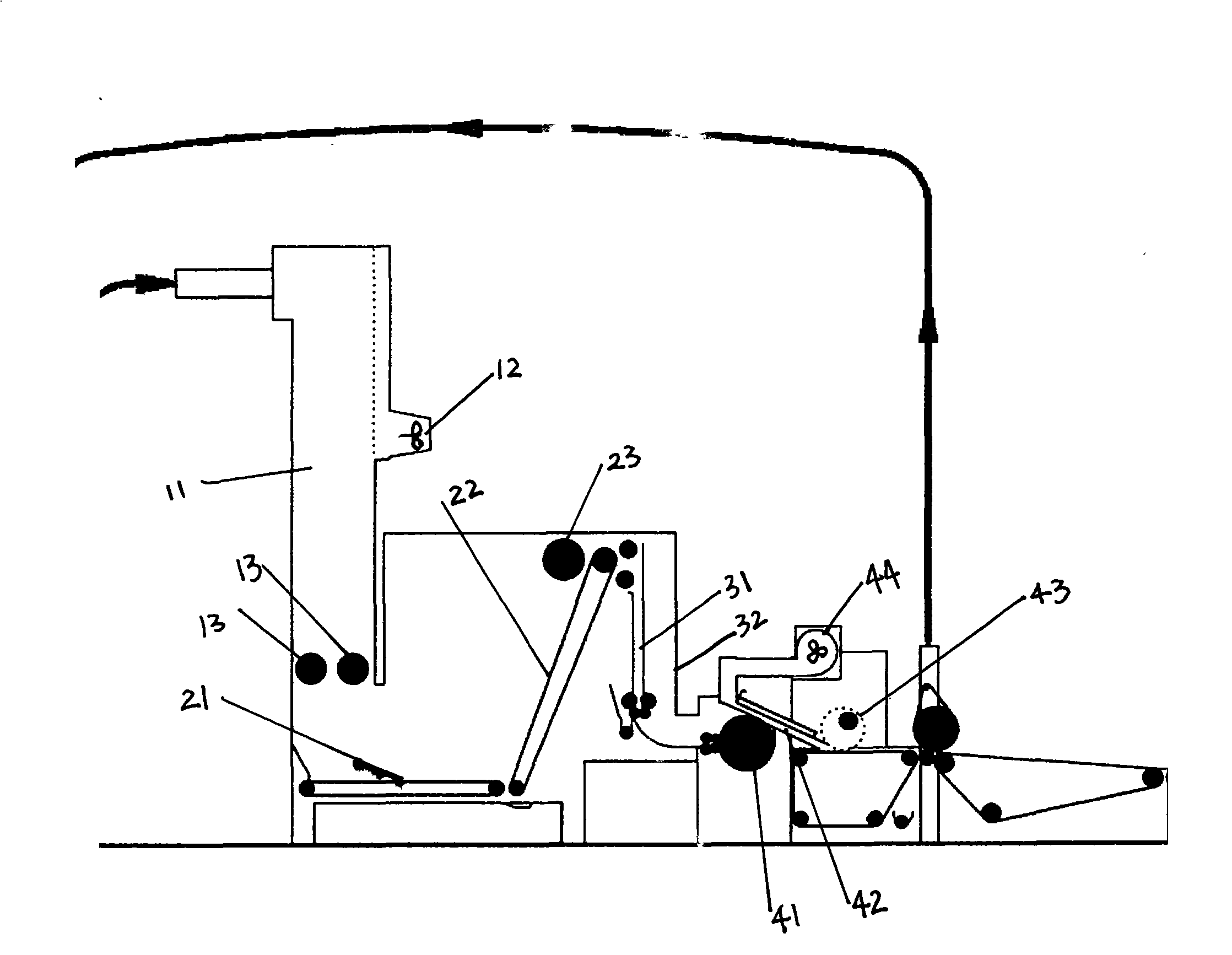

Small soilless culture method and device

ActiveCN102119651AIncrease the concentration of inputFewer deliveriesAgriculture gas emission reductionCultivating equipmentsSlagPeat

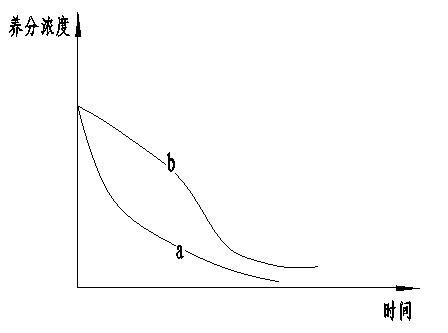

The invention relates to a small soilless culture method and device. A nutrient solution is contained in a culture disk or a nutrient solution storage pool; crops are planted into the nutrient solution; a soil copy material is added into the nutrient solution; the soil copy material comprises the following raw materials in parts by weight: 20-90 parts of organic matter and 2-80 parts of nonmetal mineral substance, wherein the organic matter is one or mixture of peat, fermented straw, fermented bagasse and fermented livestock and poultry manure; the nonmetal mineral substance is one or mixtureof coal ash, steel slag, zeolite, bentonite, opal, attapulgite mineral soil, pearlite, vermiculite, rectorite clay, sepiolite clay and kieselguhr; and the proportion of the nutrient solution to the soil copy material is (5-2):1. By adding the soil copy material into the nutrient solution, the nutrient charge concentration can be improved, the nutrient charge frequency is reduced, and the labor cost is reduced; meanwhile, when the concentration is reduced due to the absorption of the nutrients, the concentration reduction range is slower, and a deficiency symptom caused by lacking nutrients ofplants is lightened; in addition, trace elements needed by plants can be also supplemented.

Owner:杜友萍

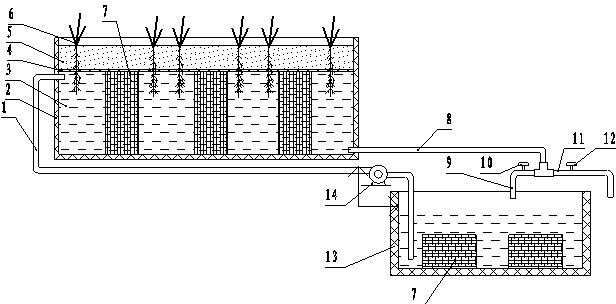

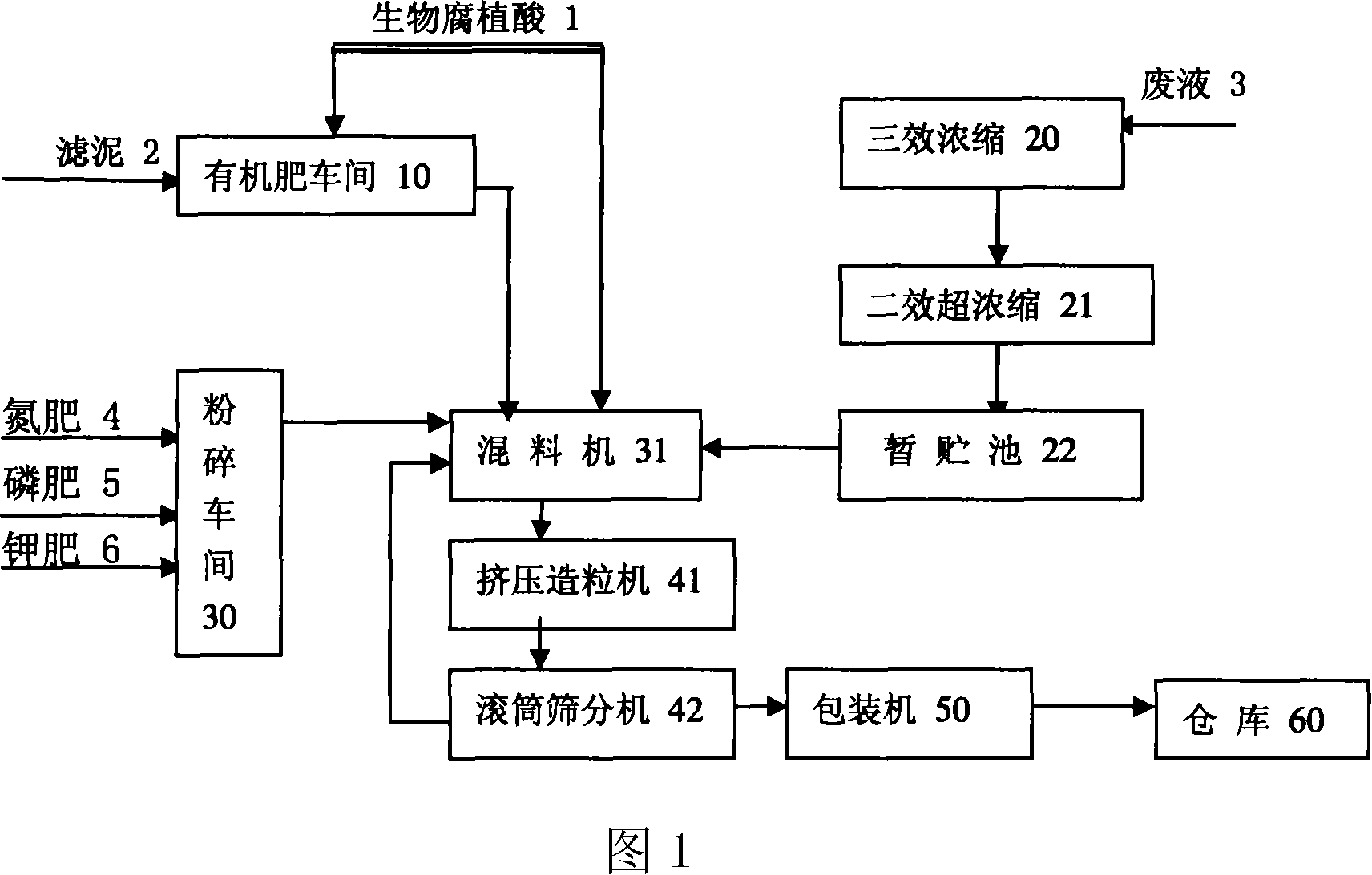

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

Hydrolytic swelling feed and manufacturing method thereof

InactiveCN101461443ALow costSlow release of ammoniaFood processingAnimal feeding stuffFiberDigestion

The invention discloses an hydrolyzed puffing forage and preparation method thereof. The method comprises: choosing the plants with high wood-fiber content such as straw, cereal shell, corn core, coconut cover, palm leaf, wood / bamboo scraps, bagasse, herbage rhizome and weed, performing hydrolysis and puffing treatment for destroying the encapsulation effect of lignin to hemicellulose and cellulose, degrading the hemicellulose and cellulose into small molecule soluble sugar, and continuously extruding and puffing by force. The continuous forced feeding and discharging technology realizes stable transitions between different pressures. The invention increases digestion rate greatly, can substitute part of corn and wheat bran, and can be prepared into complete feeds for different birds or animals in different growth stages by adding protein forage, salt, vitamin, mineral elements and aminating agent. The hydrolyzed puffing forage of the present invention has similar digestion rate with the conventional grain forage and sweeter taste, reduces cost greatly, alleviates the grain shortage difficulty, and is suitable for pig, cattle, sheep, chicken, duck, goose, rabbit and specially raised pets.

Owner:邢志强

High water-absorbing straw cat litter

InactiveCN103348923AReduce manufacturing costWide variety of sourcesAnimal housingRaw materialStarch

The invention discloses straw cat litter clotted after absorbing water. The straw cat litter comprises the following raw materials: 40-50% of plant straw, 10-15% of volcanic, 8-12% of coconut shell, 3-5% of water glass, 4-8% of dry bagasse, 5-10% of high water-absorbing resin and 12-18% of starch. The straw cat litter is prepared through the following steps of taking straw as the main raw material, supplementing with the high water-absorbing dry bagasse, the volcanic and the coconut shell, and compounding to prepare the straw cat litter, has stronger water-absorbing quality, and is quickly clotted after absorbing water, and the raw materials are wide in source, and are low in cost, so that the production cost of the cat litter can be lowered greatly.

Owner:WUHU LEISURELY NURSING SUPPLIES POLYTRON TECH INC

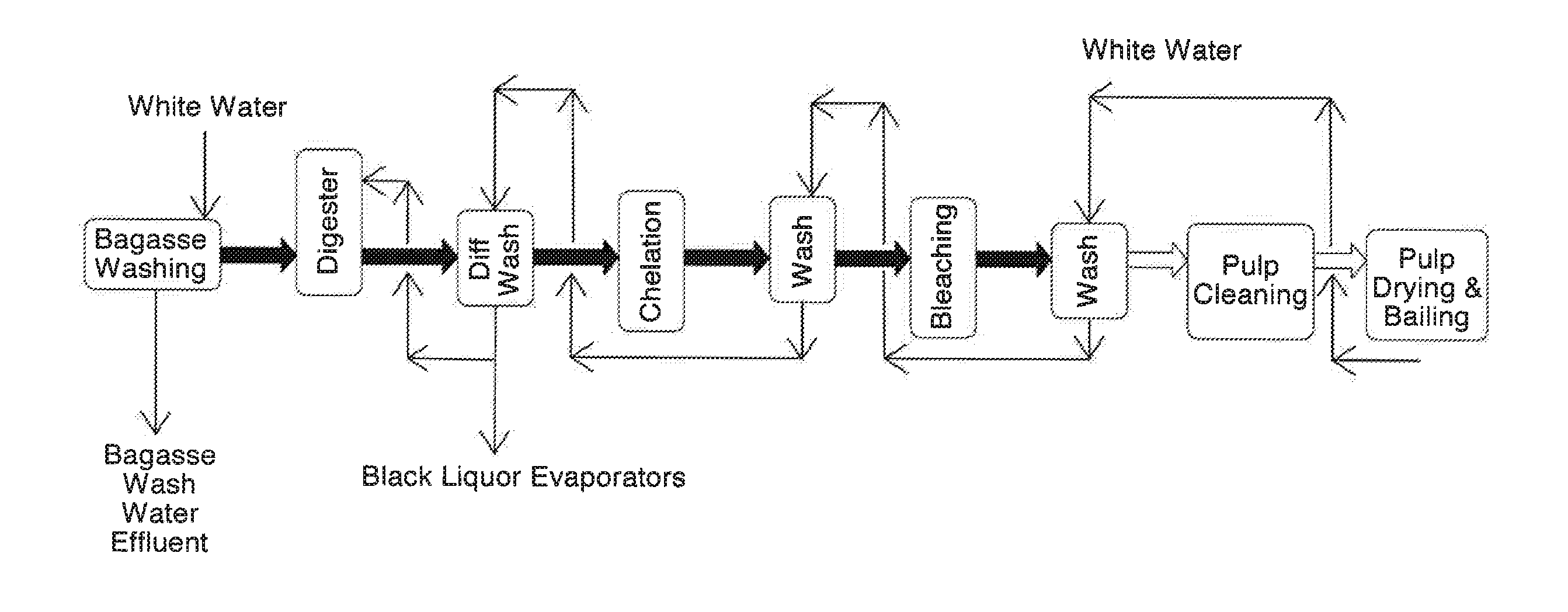

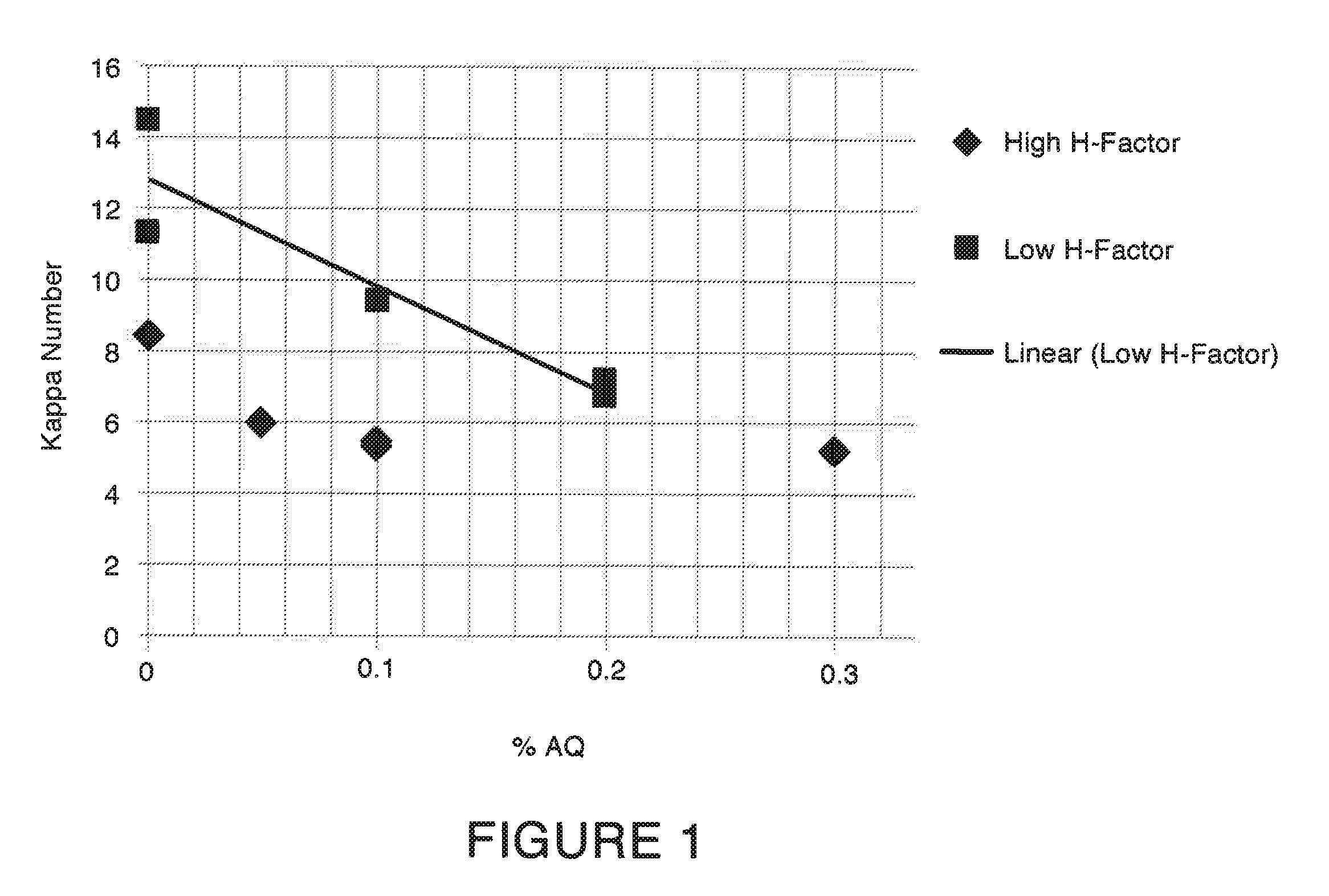

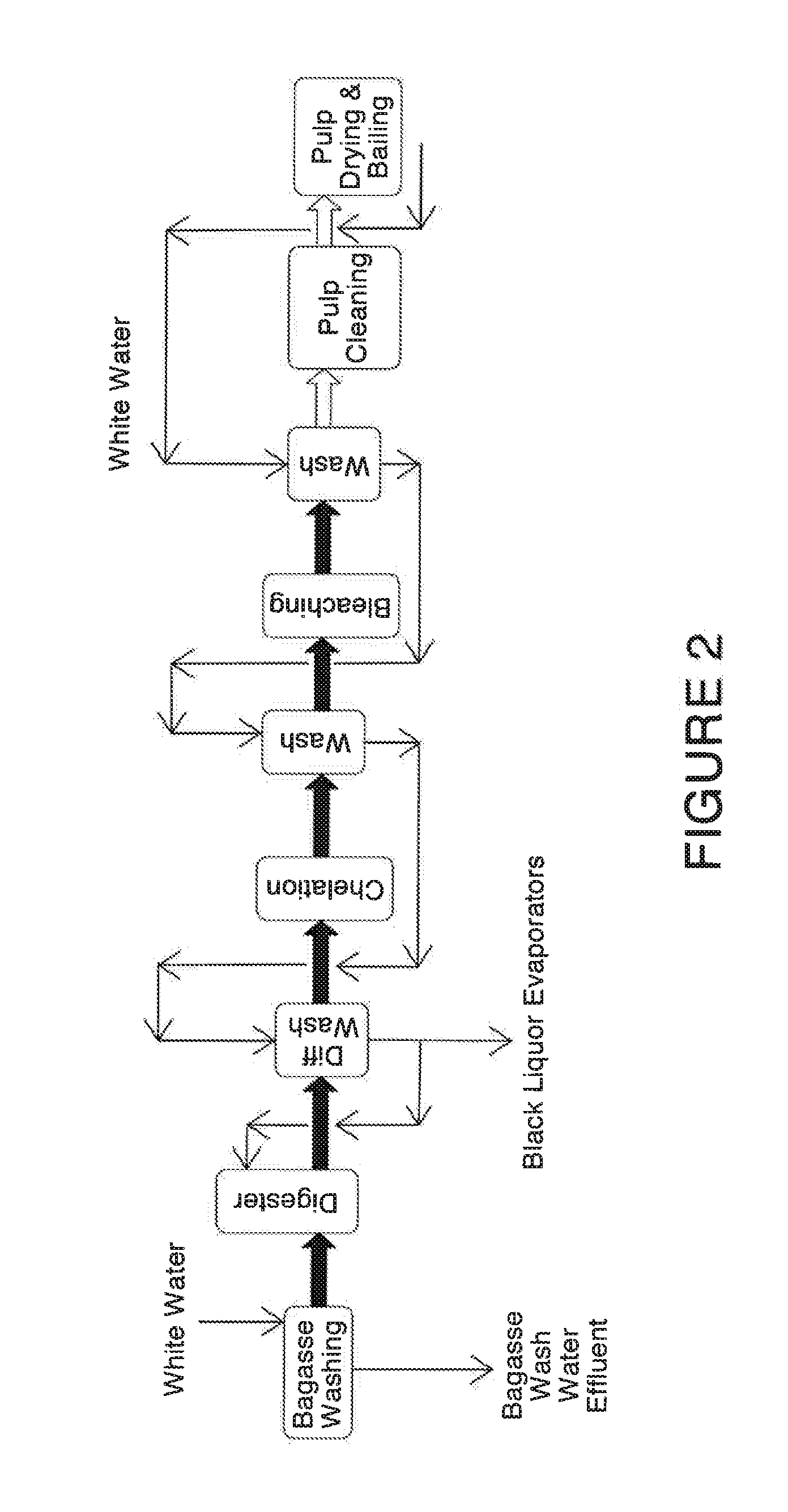

Pulping processes

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

Organic-inorganic compound fertilizer and preparation method thereof

InactiveCN102153413AAlkali solubleSimple structureBio-organic fraction processingOrganic fertiliser preparationPorositySlag

The invention discloses an organic-inorganic compound fertilizer and a preparation method thereof. The organic-inorganic compound fertilizer comprises the following raw materials in parts by weight: 25-30 parts of green algae, 12-17 parts of humic acid, 7-12 parts of bagasse mortar, 8-12 parts of saw dust, 7-15 parts of vermiculite, 5-10 parts of filtration mud, 5-10 parts of yeast organic waste water concentrated liquid, 5-8 parts of cane slag, 2-5 parts of sugarcane top and 2-5 parts of microbial strain liquid. The amount of the compound fertilizer organic matter is large than or equal to 55 weight parts, the total amount of NPK inorganic matters is large than or equal to 12 weight parts, the amount of the moisture is less than or equal to 25 weight parts, the effective viable count is large than or equal to 2 hundred million / gram, and the pH is 5.0-8.5. The preparation method comprises the following steps: fermenting twice by using microbial strains; adding inorganic porosity vermiculite, evenly mixing, and naturally drying so as to obtain the organic-inorganic compound fertilizer. Biodegradable agricultural and industrial production waste water, waste slag and sugarcane top regeneration organic matters are fully utilized as the raw materials, thereby improving the acidity and basicity of soil, improving the cation exchange capability (CEC) of the soil, improving the utilization of fertilizer, promoting the growth of crop and increasing the yield of the crop. The organic-inorganic compound fertilizer has the advantages of good ecological benefits and circular economy benefits and can be used as an additional fertilizer for crops such as sugarcane, watermelon and the like.

Owner:GUANGXI CHONGZUO XIANGGUI SUGAR

Fruit tree special-purpose fertilizer and preparation method thereof

InactiveCN103524270AAvoid pollutionSolve problems such as pollutionFertilizer mixturesPhosphateAgricultural engineering

The invention discloses a fruit tree special-purpose fertilizer which is prepared from the raw materials of, by weight: 300-340 parts of live stock and poultry manure, 200-230 parts of soybean stalk, 100-120 parts of bagasse, 100-120 parts of air-dried sludge, 50-55 parts of beer grains, 30-35 parts of ox blood powder, 20-24 parts of cooked soybean, 60-65 parts of rock phosphate powder, 14-18 parts of bamboo charcoal, 10-12 parts of maifanite powder, 12-15 parts of zeolite powder, 30-35 parts of urea, 50-55 parts of mono-ammonium phosphate, 20-23 parts of ammonium sulfate, 6-9 parts of an EM inoculant, 10-15 parts of a soil conditioner, and proper amount of water. According to the fruit tree special-purpose fertilizer, wastes such as live stock and poultry manure, soybean stalk, bagasse, air-dried sludge, and the like are adopted as main raw materials, such that resource is saved, and problems such as environment pollution are solved. The raw materials are convenient to obtain, and are cheap, such that good environmental and economic benefits are provided. The fertilizer provided by the invention has the advantages that: with the fertilizer, beneficial microbe number and activity are improved, soil physiochemical traits are improved, soil nutrients are increased and balanced, and pesticide and chemical fertilizer residue and other harmful substances in soil can be degraded.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

Method for culturing a basidiomycetous fungus in a liquid culture medium

Disclosed is an efficient method for culturing an edible basidiomycetous fungus such as Mushroom Agaricus Blazei Murill in a liquid culture medium to give fungus aggregates of several centimeter size. Characteristically, the liquid culture medium is formulated with sucrose as a carbon source in the form of crude cane sugar in combination with a water-insoluble growth-supporting material in the form of a fine powder to serve as the core of the fungus aggregates as selected from crushed sugarcane, sugarcane bagasse, pine trees and wheat bran. Further characteristically, the culturing procedure is carried out under an oxygen-enriched condition by blowing oxygen-enriched air of at least 30% by volume oxygen into the culture medium under pressurization at 0.12 to 0.5 MPa (absolute) in a specified blowing rate.

Owner:TSUKUBA BIOSYST

A kind of seedling raising substrate using cassava residue as raw material and preparation method thereof

InactiveCN102276332AFermentation heats up fastDeodorize quicklyBio-organic fraction processingOrganic fertiliser preparationSlagMicrobial agent

The invention relates to a seedling raising substrate using cassava residue as a raw material and a preparation method thereof. The composition and weight percentage of the substrate are: cassava bagasse 40-70%, bagasse 10-30%, peat soil 10-20%, perlite 3-5%, superphosphate 1-2%, potassium chloride 0.2- 0.5%, 0.2-0.5% urea, pH 6-7, 5-10% starter; the starter is the pre-fermented product of cassava bagasse, bagasse, bran and microbial compound bacteria. This substrate is suitable for raising seedlings in nutritional cups and plug trays for vegetables, flowers, etc. It has excellent physical properties, excellent porosity, early, uniform and strong seedlings, suitable particle size composition, and good agglomeration performance. Cassava residue does not need to be crushed and processed, the preparation process is simple, and the cost is low; it can provide a new way for the harmless treatment and resource utilization of cassava residue, and at the same time alleviate the excessive exploitation of non-renewable natural resources such as peat, which is conducive to protecting the ecological environment.

Owner:MICROBIOLOGY RES INST GUANGXI ZHUANG AUTONOMOUS REGION ACADEMY OF AGRI SCI

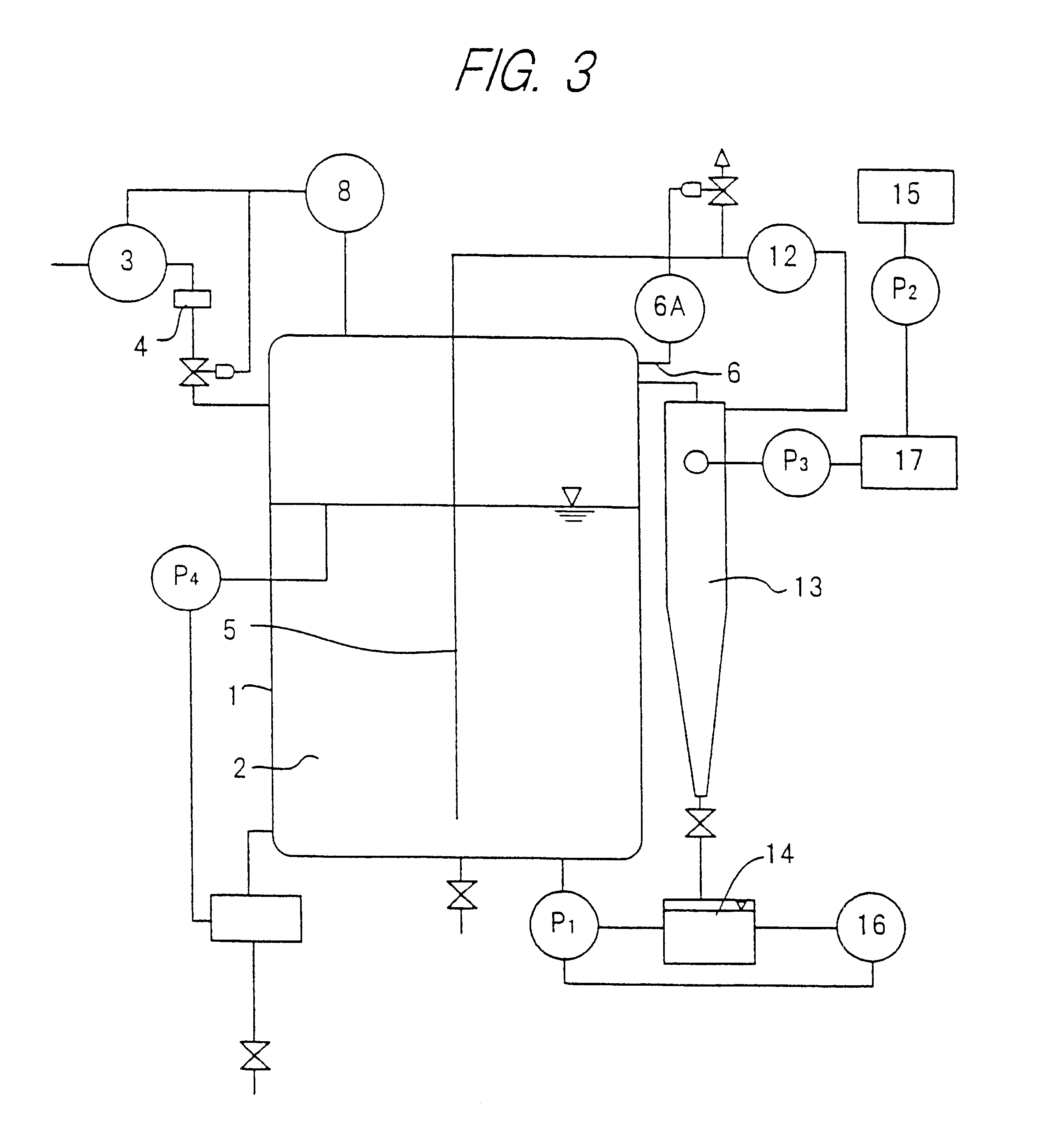

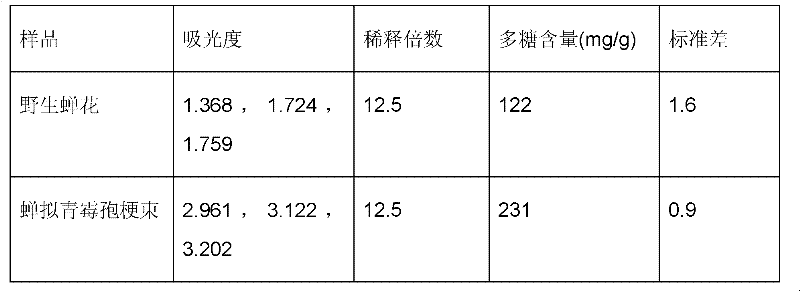

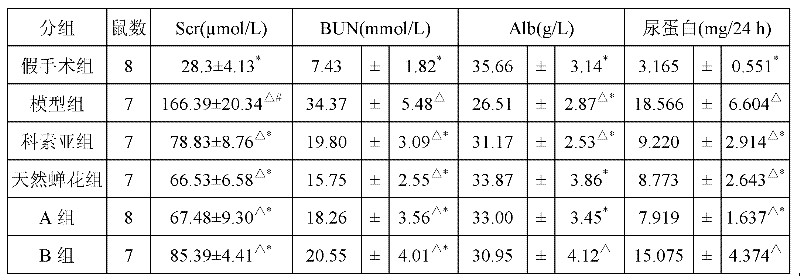

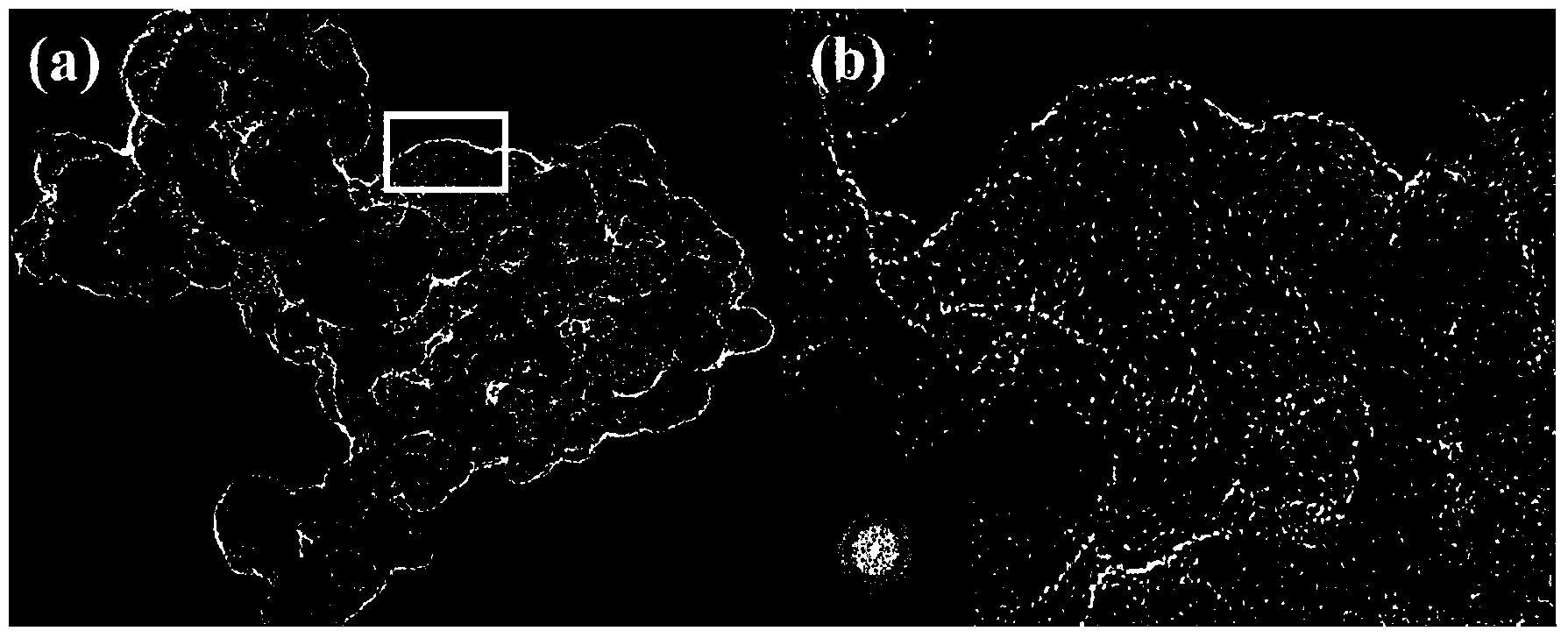

Method for artificially culturing paecilomyces cicadae and application of culturing product thereof

ActiveCN102242070AA Simple Method for Artificially Cultivating Paecilomyces cicadaeReduce manufacturing costCosmetic preparationsSenses disorderSucroseSaccharum

The invention discloses a method for artificially culturing paecilomyces cicadae and application of a culturing product thereof. The method for artificially culturing paecilomyces cicadae in large scales comprises the steps of: preparing strains, dosing and packing into a box, sterilizing, inoculating, solid-fermenting, collecting and the like. The paecilomyces cicadae is cultured by utilizing grains, such as corn flour, bran, wheat, barley, rice, millet, broomcorn and the like and culture mediums of bagasse, cane sugar, shell powder, silkworm chrysalis meal and potassium nitrate. The raw materials are obtained from local resources, a large amount of production cost is saved, the culturing period is shortened, and cordyceps sobolifera obtained by culturing has the advantages of high quality and favorable stability and the like. A culture obtained by the invention can be used for preparing foods, health-care products, drugs and cosmetics with functions of fighting tumor, regulating immunity, reducing blood sugar, blood fat and blood pressure, improving eye sight, resisting radiation, dispelling heat and easing pains, calming and hypnotizing, nourishing and strengthening, improving kidney function and the like.

Owner:ZHEJIANG BIOASIA PHARMA CO LTD

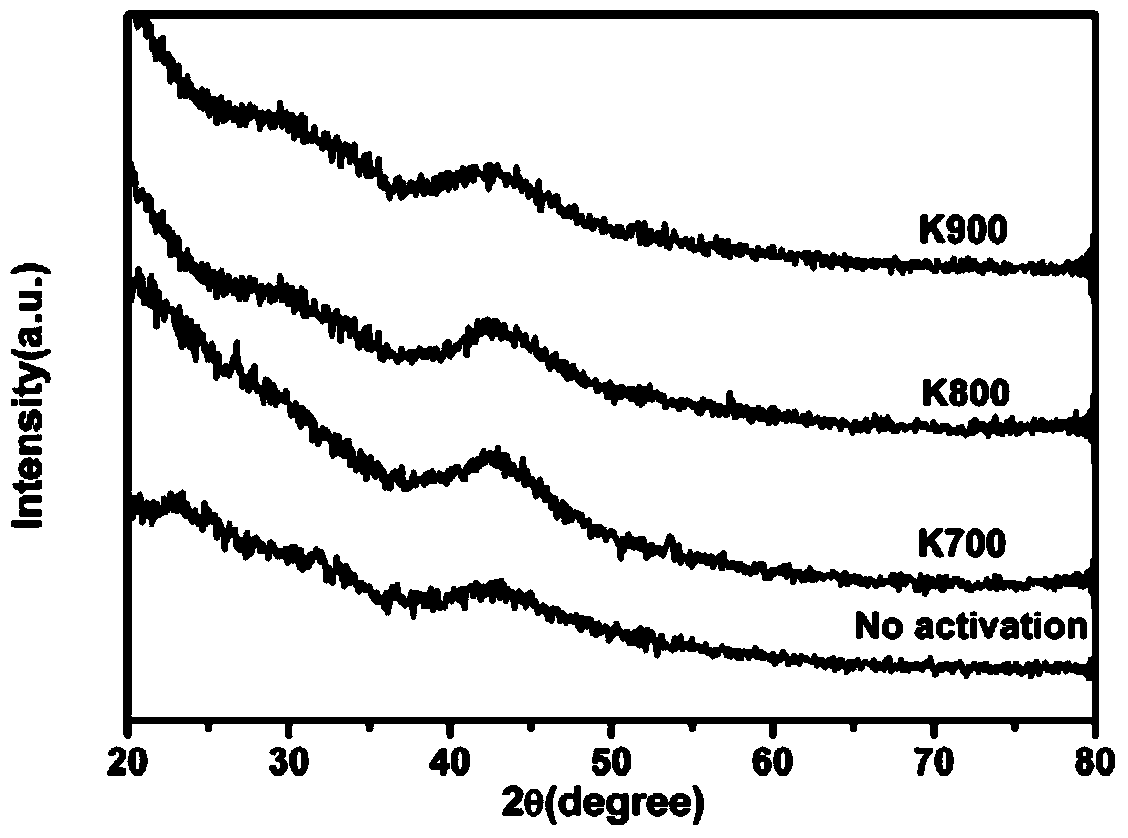

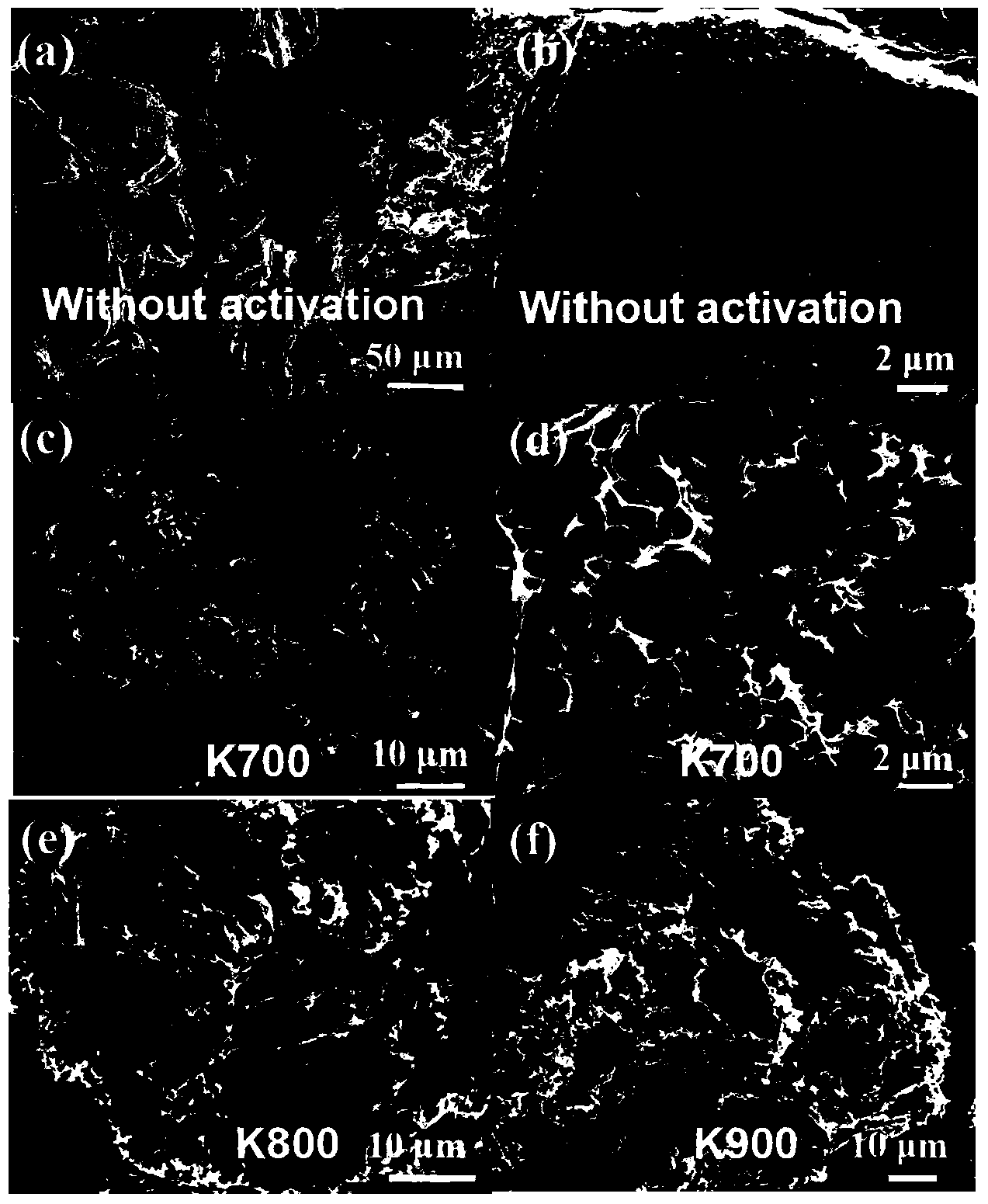

Method for preparing supercapacitor carbon aerogel by utilization of bagasse

ActiveCN103839699AImprove electrochemical performanceLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceToxic industrial waste

The invention discloses a method for preparing supercapacitor carbon aerogel by the utilization of bagasse. The method includes the steps that the bagasse is used for preparing cellulose powder without xylogen and hemicellulose; the cellulose powder is used for preparing cellulose aerogel; the cellulose aerogel is carbonized to obtain carbon aerogel; the carbon aerogel is activated to obtain the supercapacitor carbon aerogel. According to the method, the industrial waste bagasse is used as raw materials, the requirements for sustainable development and environmental protection are met, and the cost of electrode materials is effectively lowered. The product prepared through the method is of a three-dimensional hierarchical pore structure; compared with a product obtained through a conventional method, the product prepared through the method is large in specific area and good in repeatability, and has higher specific capacitance and better cycling stability. The method is more suitable for preparing supercapacitor electrode materials and has wide development prospects.

Owner:SHANDONG UNIV

Method for preparing sodium lignin sulfonate water reducer

The invention relates to a method for preparing sodium lignin sulfonate water reducer. Black liquor which is generated by alkali cooking corncobs, acidolysis residue of the corncobs, bagasse or corn stalks is taken as a raw material, and then the sodium lignin sulfonate water reducer of low water content is prepared after coarse filtration, ultrafiltration membrane concentration, sulfonation and spray drying. Aiming at the characteristics of the raw material, the coarse filtration and ultrafiltration are combined, cellulose, other impurities and the like can be removed by the coarse filtration, lignin can be retained by the ultrafiltration, and the aim of black liquor concentration can be realized at the same time of going through alkali so as to recover and reuse the alkali; the sulfonation method, which can be operated at room temperature and pressure, is adopted, and the sulfonation degree is high. Compared with the existing method, the method for preparing the sodium lignin sulfonate water reducer has no pollution to the environment, the processes are simple and convenient, and the cost is low.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

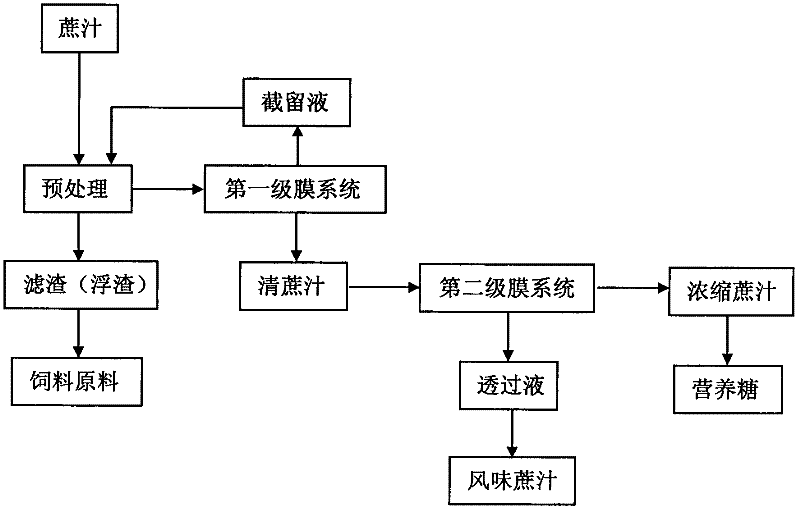

Method for parallel production of nutrient sugar, flavor cane juice and feedstuff by multistage membranes

InactiveCN102489155AReduce the impactPromote optimization and upgradingSemi-permeable membranesFood processingEvaporationChemical agent

The invention relates to a method for parallel production of nutrient sugar, flavor cane juice and a feedstuff by multistage membranes. The method comprises: conducting pretreatment to raw juice for removing bagacillo, bagasse pith and other large granular impurities so as to obtain a filter residue or scum, which can be used as a feedstuff, pumping the obtained cane juice into a first stage membrane separation system so as to obtain clear cane juice, which is then subjected to a second membrane separation system for dehydration and concentration, using a permeated liquid for producing flavor cane juice or low-sugar beverages, and carrying out evaporation and spray drying treatment to a concentrated cane juice so as to obtain nutrient sugar. Based on the integration of membrane process separation, concentration, cold sterilization and other functions, the method of the invention carries out parallel production of nutrient sugar, flavor cane juice and a feedstuff, and has the advantages of no need for adding chemical agents, low production energy consumption, realization of maximum preservation of natural nutrition and flavor of finished sugar, simple and stable operation, basically no discharge of ''three wastes'', and broad adaptability, thus being in favor of optimization and upgrading of sugar products as well as comprehensive utilization of sugar resources.

Owner:GUANGXI UNIV

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

Goat forage and preparation method thereof

ActiveCN103229904AFast growthImprove palatabilityAnimal feeding stuffLolium perenneHelianthus petiolaris

The invention discloses a goat forage and a preparation method thereof. The goat forage is composed of the following raw materials, by weight, 50-60 parts of sorghum straw powder, 25-30 parts of Chenopodium album Linn. powder, 20-30 parts of pine leaf, 10-15 parts of Lolium perenne L., 15-20 parts of bagasse, 8-12 parts of Herba Taraxaci, 15-25 parts of soybean meal, 1-2 parts of a starter, 40-50 parts of corncob, 15-25 parts of rice bran, 10-15 parts of sunflower receptacle, 4-6 parts of a lyophilized powder additive, 3-5 parts of shell powder, 5-10 parts of zeolite powder, 3-5 parts of soybean oil, 2-4 parts of sodium alginate, 0.5-0.8 parts of calcium hydrogen phosphate, 0.01-0.02 parts of potassium iodate and 0.3-0.5 parts of salt. The forage contains all nutrition required by the growth of goats, guarantees the healthy production of the goats, provides healthcare values, and raises the growth speeds of the goats.

Owner:BENGBU DACHENG FOOD

Method for preparing formed fuel by using agriculture castoff

A process for producing molded fuel by using agricultural waste belonging to a solid-fuel technology field and the objective is to resolve the problem of waste utilization. The technical scheme is showed as follows: straw, sawdust, wood chips, rice crust, bagasse and other agricultural waste and liquid waste of paper are used as raw materials to produce molded fuel by drying, grinding, mixing, and so on. The invention produces molded fuel with agriculture waste and liquid waste of paper as raw materials, not only saving raw materials costs, but also reducing pollution emissions. And the adhesion of some materials in liquid waste of paper are used without heating block, thus no heating loss, but also reducing the abrasion of mechanical equipment and heat loss of raw materials caused by heating. In addition, liquid waste of paper contains 3 to 5 percent of alkaline substances, which can enhance the activity of combustion. Molded fuel produced by using the process provided by the invention which is characterized in flammability, high heat value, non-polluting, low cost, and so on.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

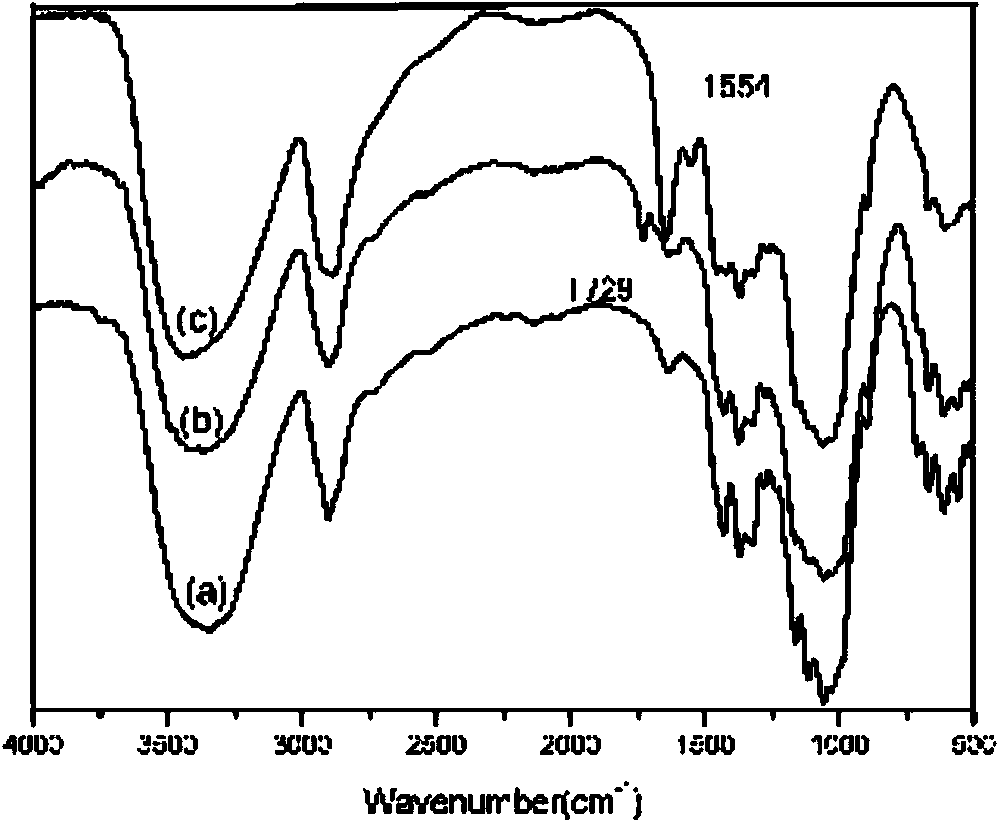

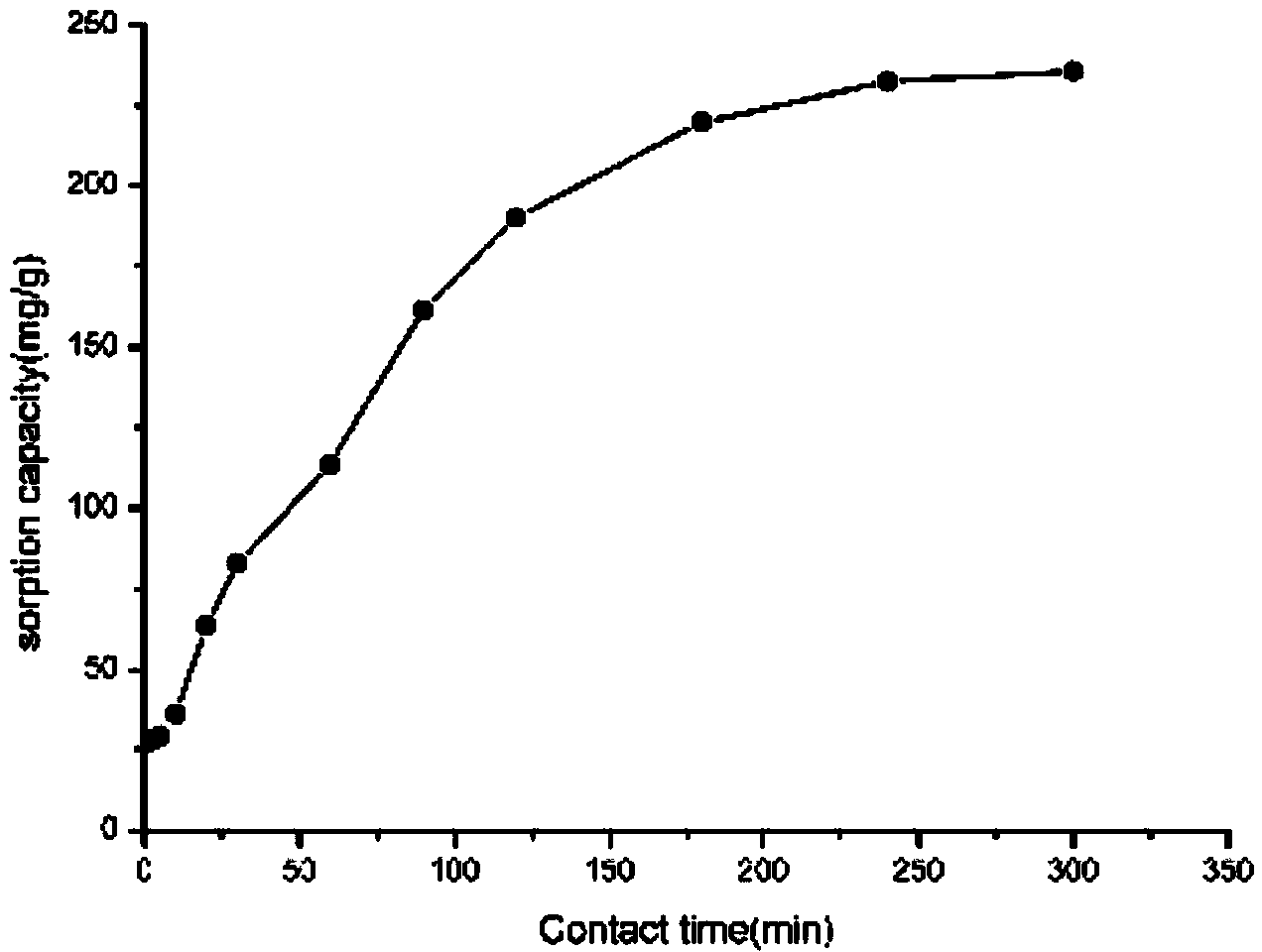

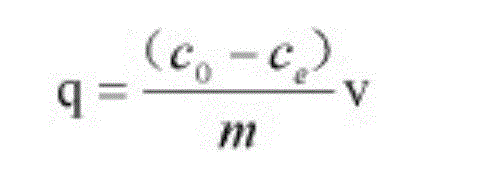

Preparation method for adsorbent for treating dye wastewater

InactiveCN103551124ALow costWide variety of sourcesOther chemical processesWaste water treatment from textile industryFiberCongo red

The invention discloses a preparation method for an adsorbent for treating dye wastewater, and particularly discloses a preparation method for a biomass adsorbent for treating anionic dye wastewater. The adsorbent is prepared by pretreating sugarcane bagasse, performing alkali activation and oxidization treatment, and then grafting a hyperbranched polyamidoamine polymer. The preparation method comprises the following steps: (1) performing pretreatment, alkali activation and oxidization treatment on sugarcane bagasse fiber; (2) grafting the oxidized sugarcane bagasse fiber with the hyperbranched polyamidoamine to obtain the polyamino-modified sugarcane bagasse-based adsorbent. The prepared adsorbent has the characteristics of being good in stability, good in adsorption effect, wide in application range and the like, and can be used for treating the anionic dye wastewater. Taking Congo red dye wastewater for example, the Congo red adsorption capacity and adsorption efficiency of the adsorbent respectively achieve 240mg / g and 97%. The prepared adsorbent is wide in raw material source, low in price and easily available, low in cost, convenient to operate when being applied to wastewater treatment, and simple in technology.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Novel process for preparing xylitol

ActiveCN101823939AIncrease contentImprove qualityIon-exchange process apparatusOrganic compound preparationChromatographic separationDistillation

The invention relates to a novel process for preparing xylitol, which belongs to the technical field of functional sugar alcohol production. Pre-treatment, hydrolysis, neutralization, decoloring, ion exchange, evaporation and concentration and chromatography are carried out to corncob or bagasse and other agricultural waste which contains hemicellulose, high-content xylose solution is collected and distillated, and then continuously hydrogenated, so that the xylose solution is converted into xylitol solution, and finally a xylitol crystal is obtained through refining, concentration, crystallization, centrifugation and drying; the process comprises: corncob-> pre-treatment->hydrolysis->neutralization and decoloring->ion exchange->evaporation and concentration->chromatography->high-content xylose solution collection and distillation-> hydrogenatio->refining->concentration->crystallization->centrifugation->drying->finished crystal xylitol product obtaining. The novel process for preparing xylitol saves a xylose crystallization procedure and a conversion process xylose crystal into sugar, shortens a production procedure, adopts a chromatography technology to improve the content of thexylose solution, facilitates the obtaining of high-content xylitol solution after hydrogenation can prepare the high-grade xylitol product, adopts a continuous hydrogenation process, improves the hydrogenation efficiency, reduces the labor intensity of a worker, and saves the production cost.

Owner:FUTASTE PHARM CO LTD

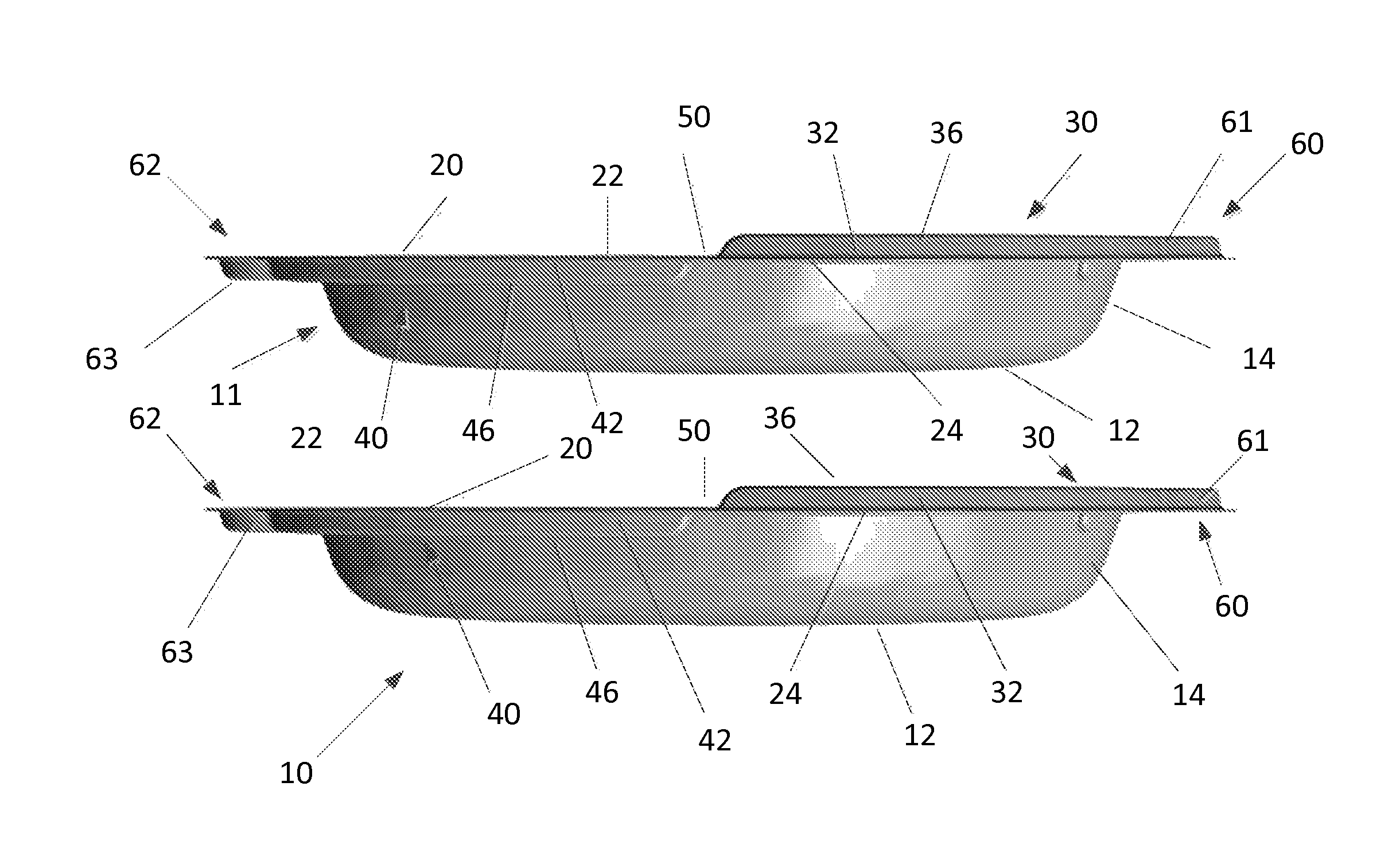

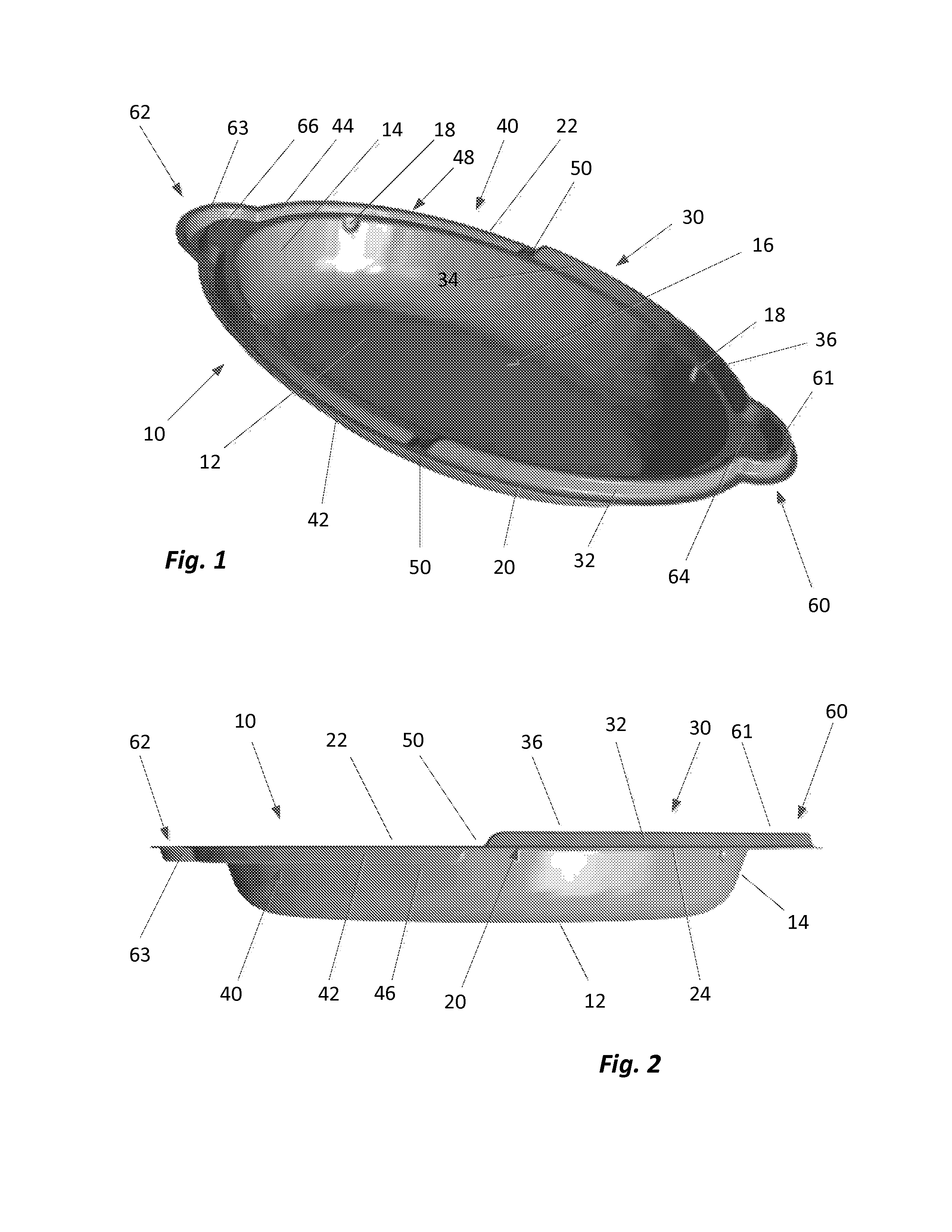

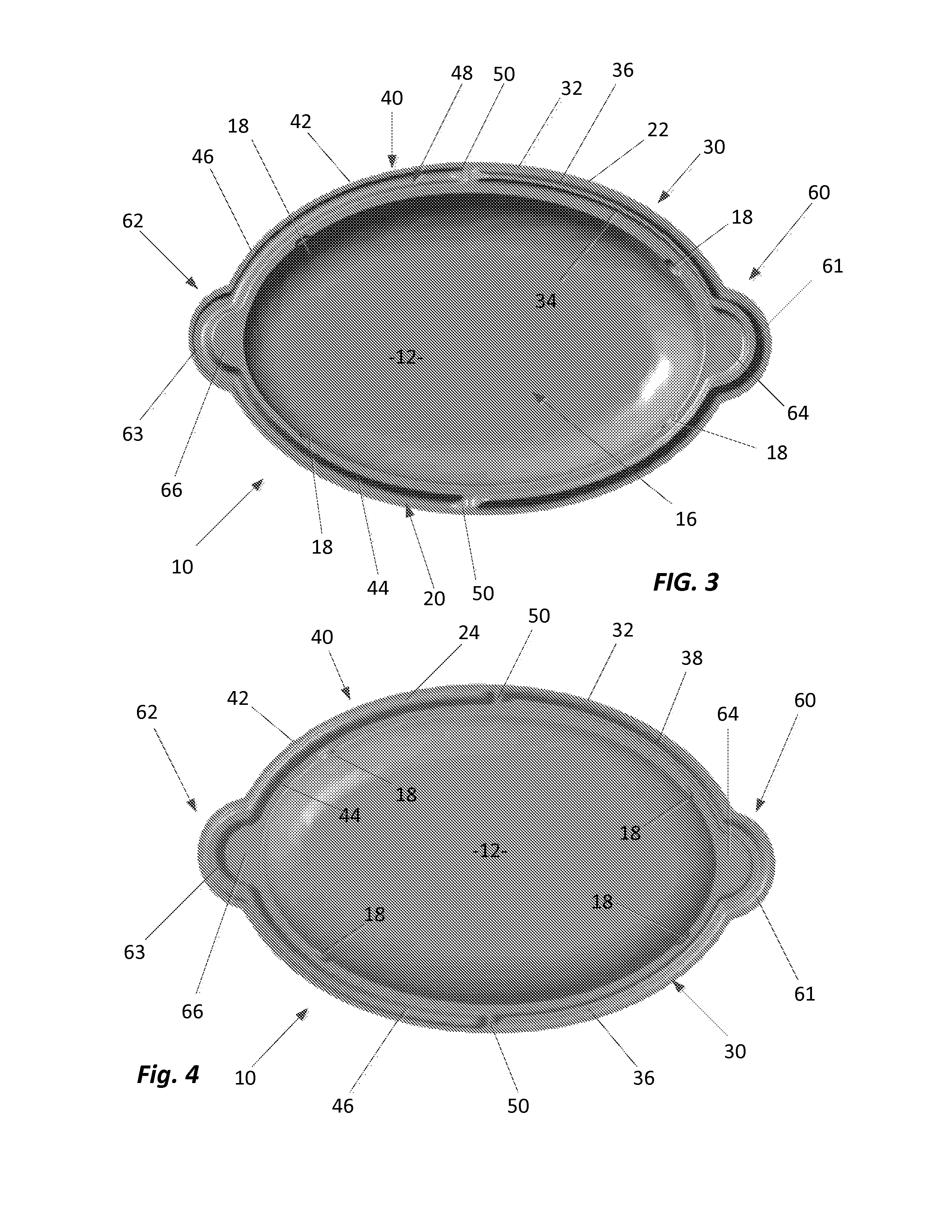

Food service container

ActiveUS8561823B1Low costQuickly biodegradableBio-packagingClimate change adaptationFiberEngineering

Stackable trays for food items are made from fibrous plant material, the source of which may be any fibrous plant or combination of fibrous plants, such as bamboo, wheat straw, bagasse or recycled paper or other paper products. Each tray includes a plurality of locking beads which define recesses. The locking beads and recesses of adjacent identical trays mate with each other when the trays are stacked. Likewise, the locking beads and recesses of two identical trays employed to provide a food container mate with each other to secure the two trays together in a food containment configuration.

Owner:KD DISTRIBUTING L L C

Preparation method of modified bagasse cellulose based heavy metal adsorbent

InactiveCN102716728ASolve the use problemSolve secondary pollutionOther chemical processesWater/sewage treatment by sorptionWater bathsCellulose

The invention relates to a preparation method of a modified bagasse cellulose based heavy metal adsorbent. The preparation method comprises the technological steps of: defibering natural fibers, washing with distilled water and ethanol, stirring and activating in NaOH solution, putting the fibers into dimethyl sulfoxide for water-bath heating and gelatinization, adding deionized water and initiators, feeding in nitrogen for initiation and adding acrylic acid monomers for reaction to obtain graft copolymerization products; adding polyethylene polyamine monomers for reaction, washing and drying to obtain crude cellulose based heavy metal adsorbent; and washing with deionized water, soaking and rinsing in ethanol, rewashing with deionized water, extracting by using acetone and drying to obtain the refined heavy metal adsorbent. The preparation method provided by the invention has the advantages that the method is simple, the cost is low, the environmental friendliness is good, the adsorption effect is excellent, the method is compliant with the concept of circular economy and sustainable development, the problem of secondary pollution caused by bagasse combustion is solved, the water bodies which are polluted by heavy metals are purified and the economic advantage is remarkable.

Owner:GUANGXI UNIV

Mixed feed formula for black goat

InactiveCN103859206ASuitable for growing needsShorten the breeding cycleFood processingAnimal feeding stuffPeanut mealSugarcane tops

The invention provides a mixed feed formula for a black goat. The formula comprises the following components: a green fodder including alfalfa, ryegrass, oat grass, mulberry leaves, locust tree leaves and sugarcane top; a coarse fodder including straw, cornstalk and bagasse; a concentrated feed including corn bran, wheat bran, peanut meal, bean cake and rice bran; an animal feed including fish meal, shrimp meal and mealworms powder; a mineral feed including bone meal, shell powder, urea, salt and aginomoto. The feed formula is low in cost, preferred by the black goat, quick for grow, healthy in physique and high in meat factor.

Owner:罗生芳

Preparation method for bagasse cellulose nanofiber membrane

ActiveCN103422379AConducive to high-value utilizationImprove featuresPulp bleachingPaper-making machinesFiberChemical treatment

The invention discloses a preparation method for a bagasse cellulose nanofiber membrane. The method comprises the main steps of preparing bagasse, preparing bagasse cellulose and preparing the bagasse nano-cellulose membrane. (1) acid-base chemical treatment is carried out; (2) solution is treated through the mechanical methods such as grinding and centrifuging, and uniform biomass cellulose nanofiber is prepared; (3) membrane formation is carried out through vacuum filtration. The preparation method has the advantages that the method is simple, the cost is lower, the popularization is easy, the reclamation and effective recycling of waste are realized, the pollution to the environment is relieved, and the high-value utilization of bagasse is also facilitated.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

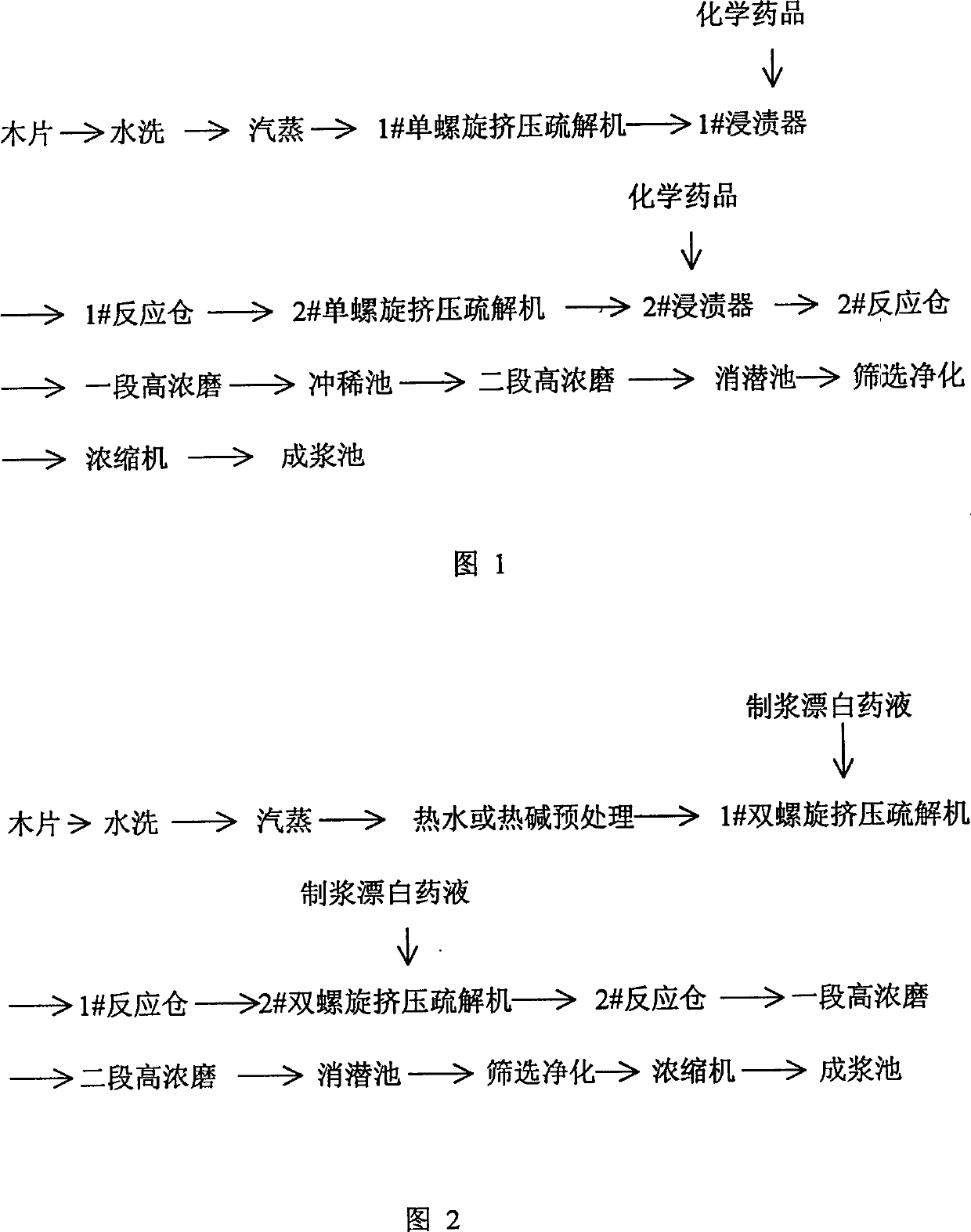

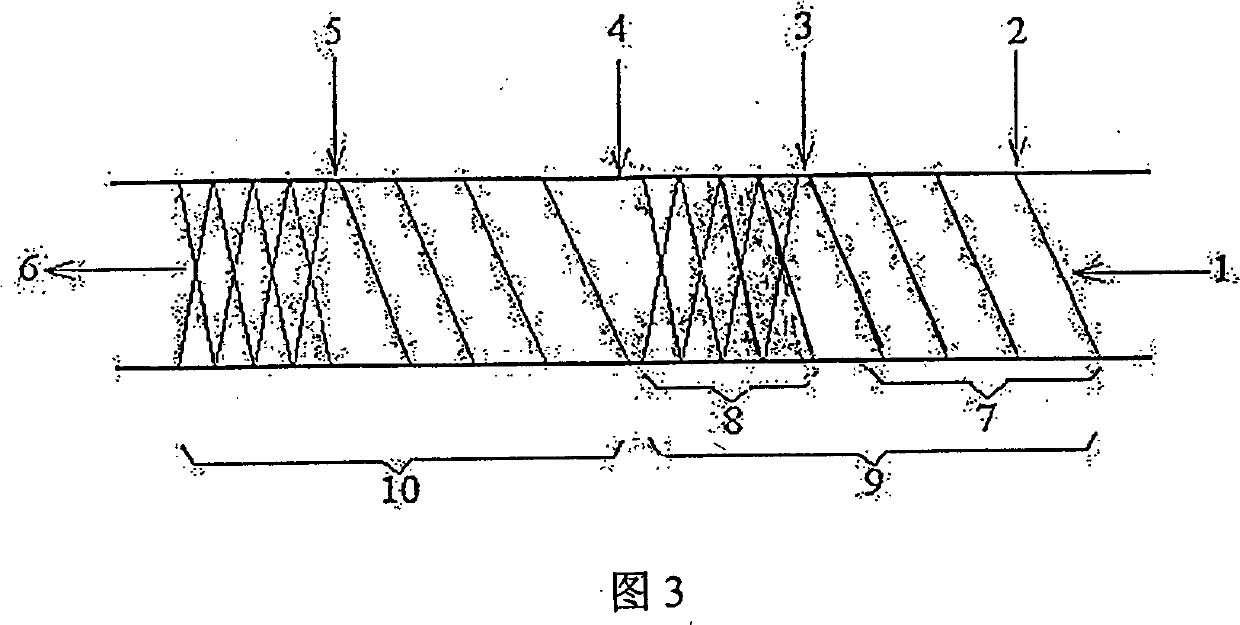

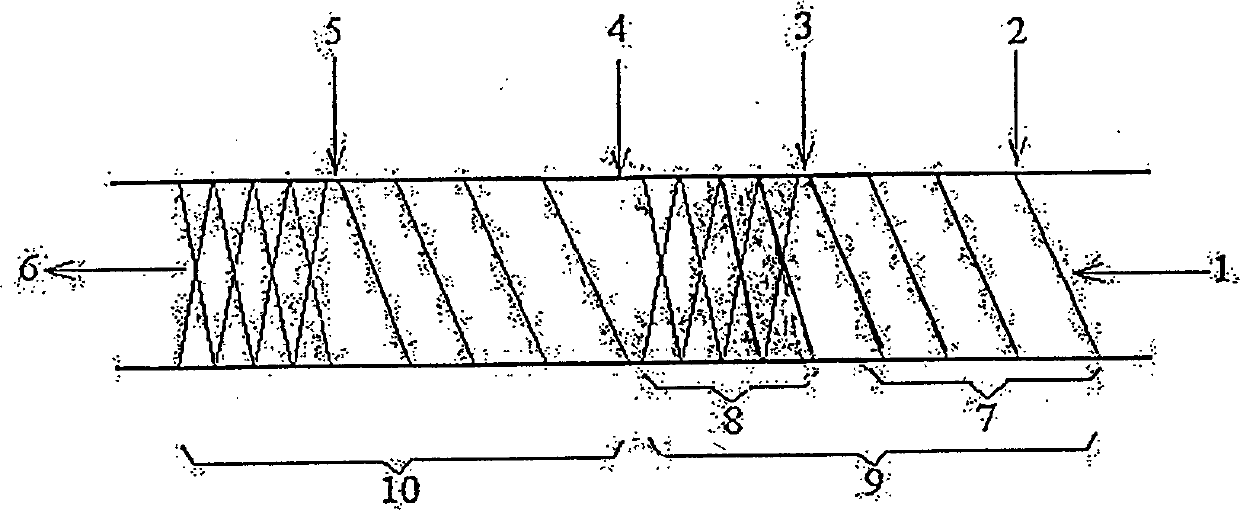

New process for producing alkaline hydrogen peroxide mechanical pulp by double scrwe extruding method

InactiveCN1587502AImprove extrusion tear effectImprove pulping qualityPulp bleachingPulp beating/refining methodsHigh concentrationFiber

The present invention is improved double screw extruding pulp producing process of alkali hydrogen peroxide mechanical pulp (APMP). The technological process includes water washing spill, steam digestion, hot water or hot alkali pre-treatment, treating in the first screw extruding breaker beater, reaction in the first reaction compartment, treating in the second screw extruding breaker beater, reaction in the second reaction compartment, milling in the first high concentration mill, milling in the second high concentration mill, sieving and purification, concentration, pulping pond treatment and other steps. Compared with traditional APMP, the present invention has similar quality and the advantages of simplified technological process, saving in investment and power consumption, less water consumption and lower waste water treating load. The present invention is suitable for producing APMP with different timber material, bagasse, etc.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com