Patents

Literature

209 results about "Poultry feather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

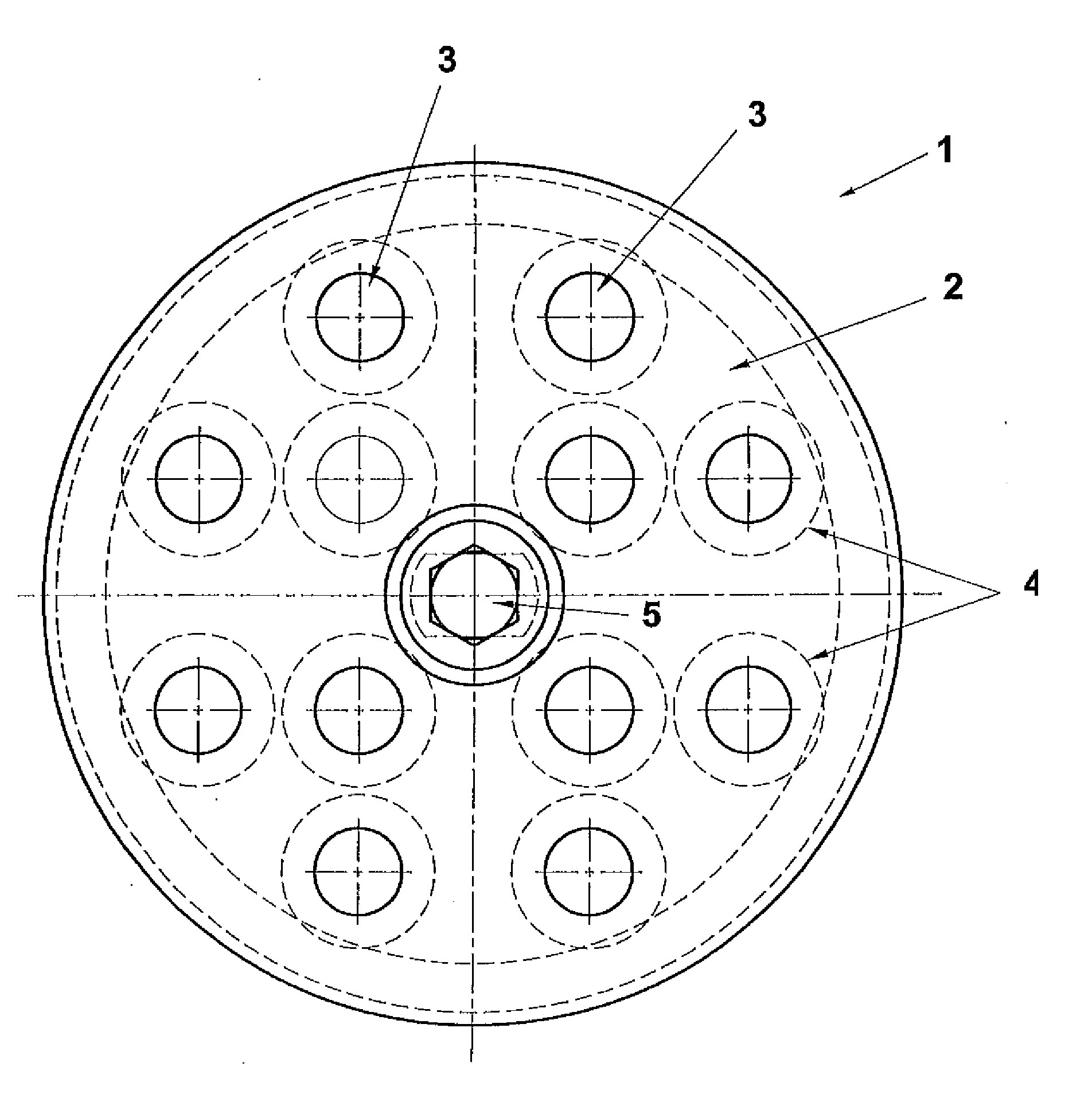

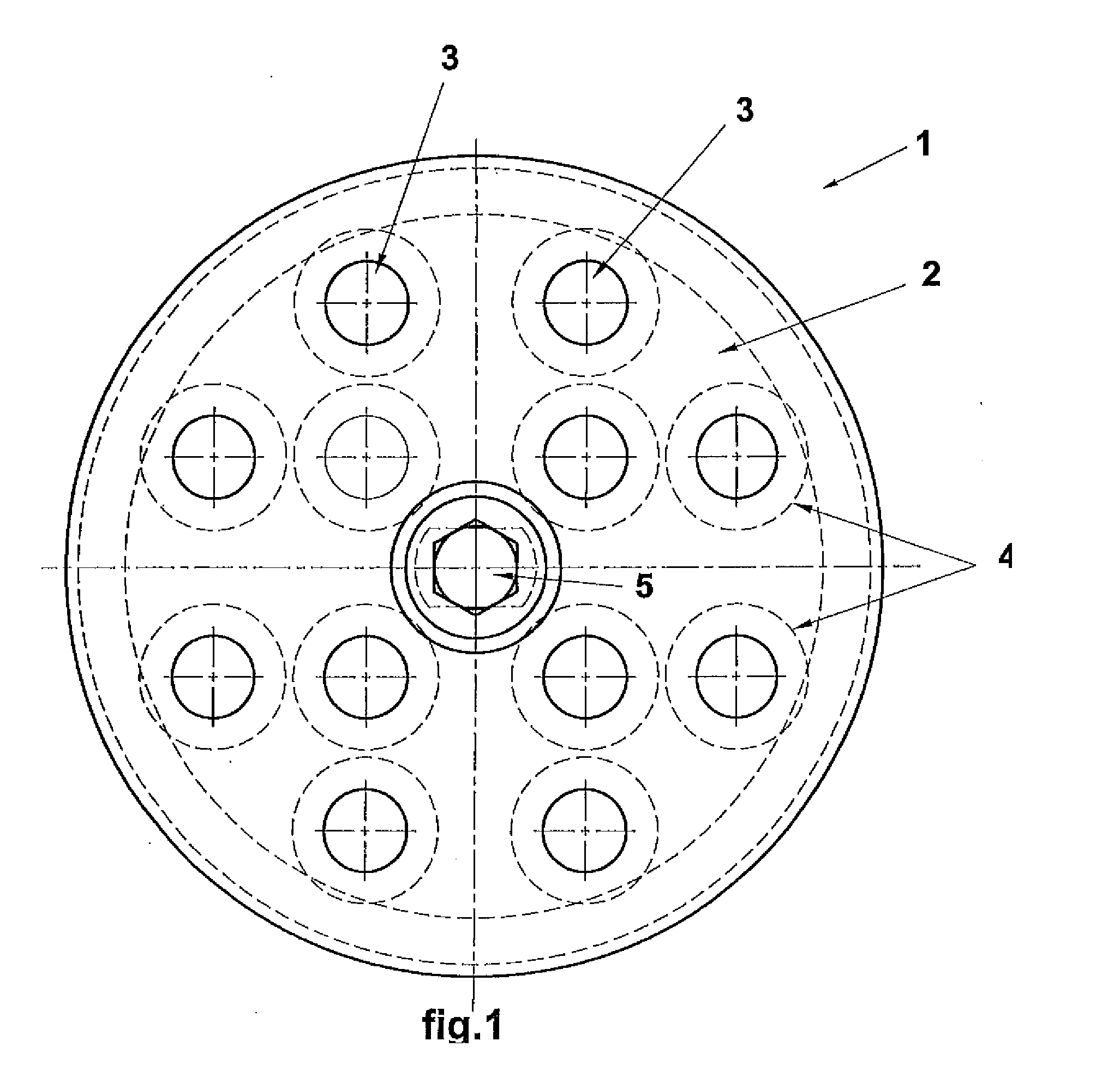

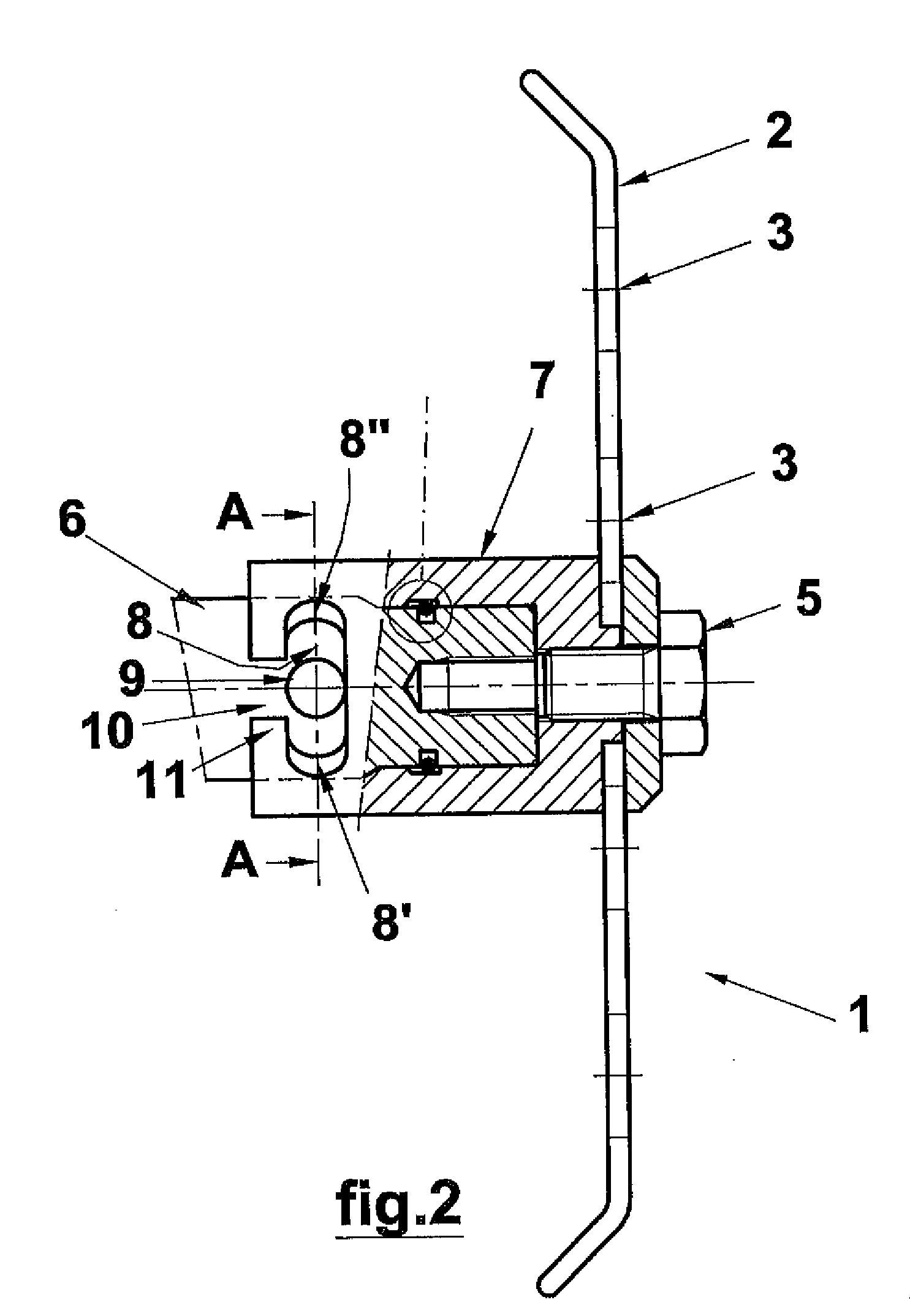

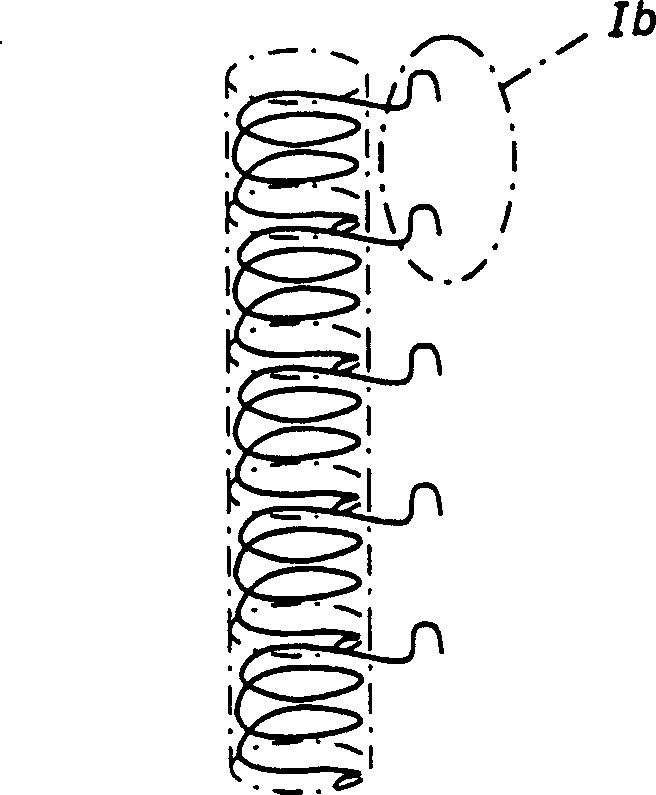

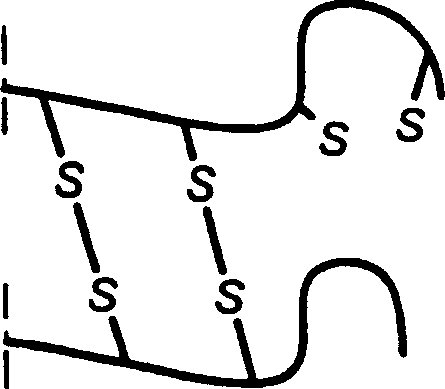

Device for picking or plucking poultry-feathers and an apparatus for driving such a device

InactiveUS20100075584A1Easily dismountingImproves secure mountingFish washing/descalingPoultry plucking mechanismsDrive shaftEngineering

A device for picking or plucking poultry feathers is provided that includes a sleeve-coupling and, connected or connectable thereto, a plucking plate with receptacles for plucking fingers, which sleeve-coupling is mountable on a drive-shaft for the plucking plate. The sleeve-coupling is provided with a circumferentially extending slot for receipt of a radially extending pin that is provided on the drive-shaft, and the circumferentially extending slot has an opening between the slot-extremities to allow the pin to enter and to exit the slot so as to securely mount the sleeve coupling on the drive shaft with the pin being located at one of the slot extremities.

Owner:MEYN FOOD PROCESSING TECH

Thermoplastics from poultry feathers

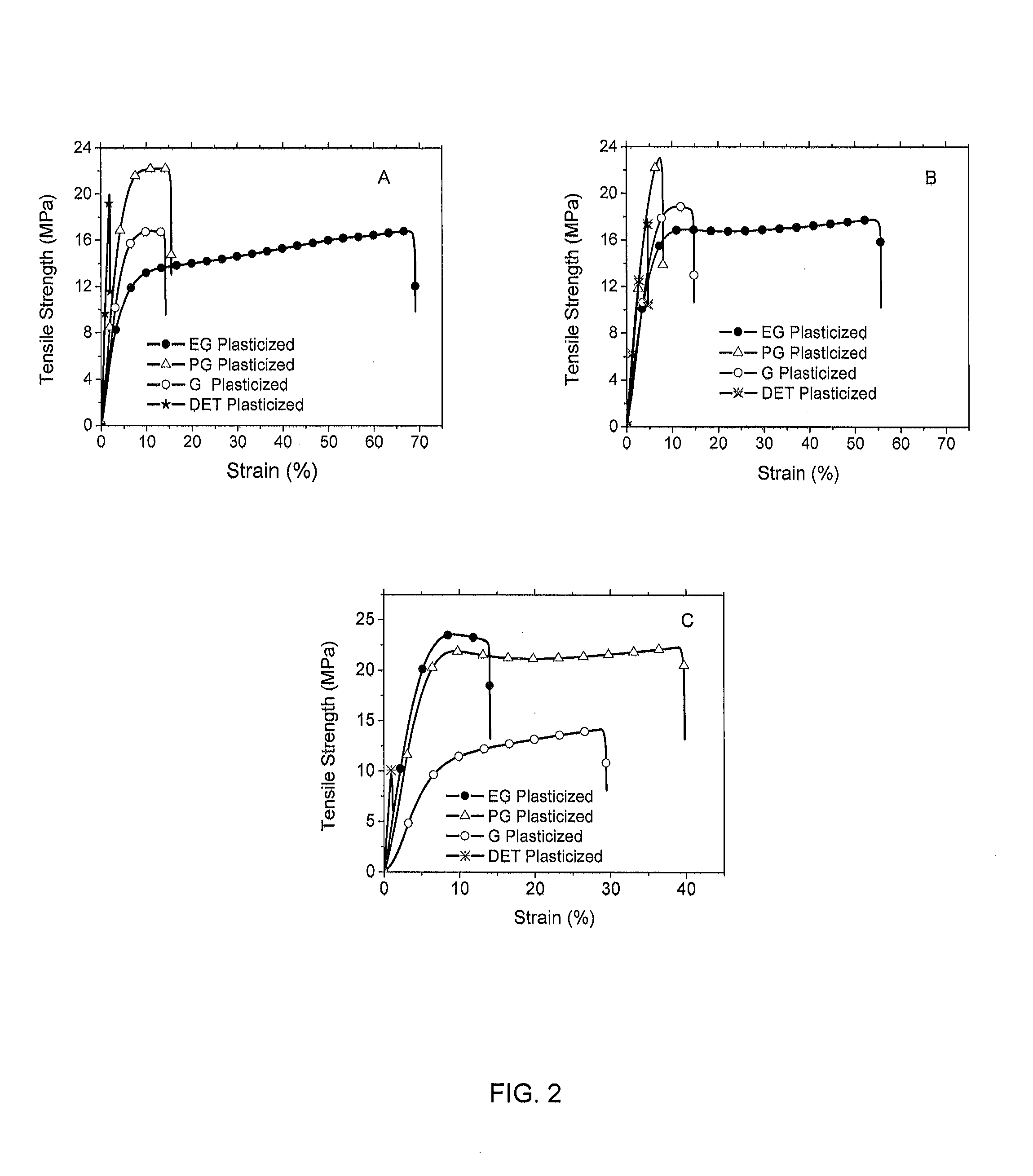

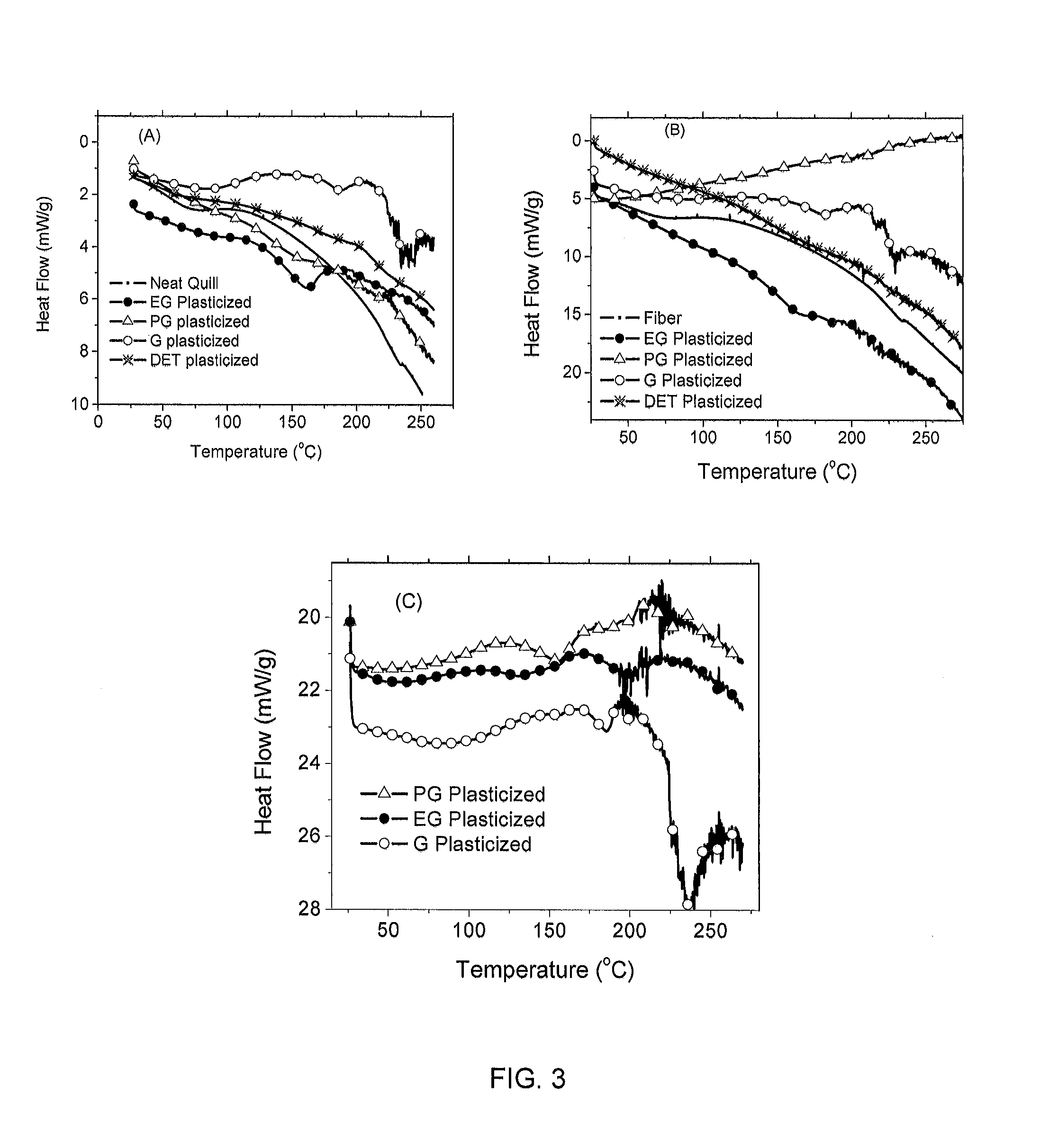

The invention is directed to thermoplastics derived from feathers. The thermoplastics are prepared by blending whole feathers or portions thereof with a plasticizer in an amount ranging from about 20 wt to about 40 wt % and a reducing agent in an amount ranging from about 1 wt % to about 5 wt % to form a mixture; and either extruding the mixture to form an article, or pressing the mixture into a film at an elevated temperature.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

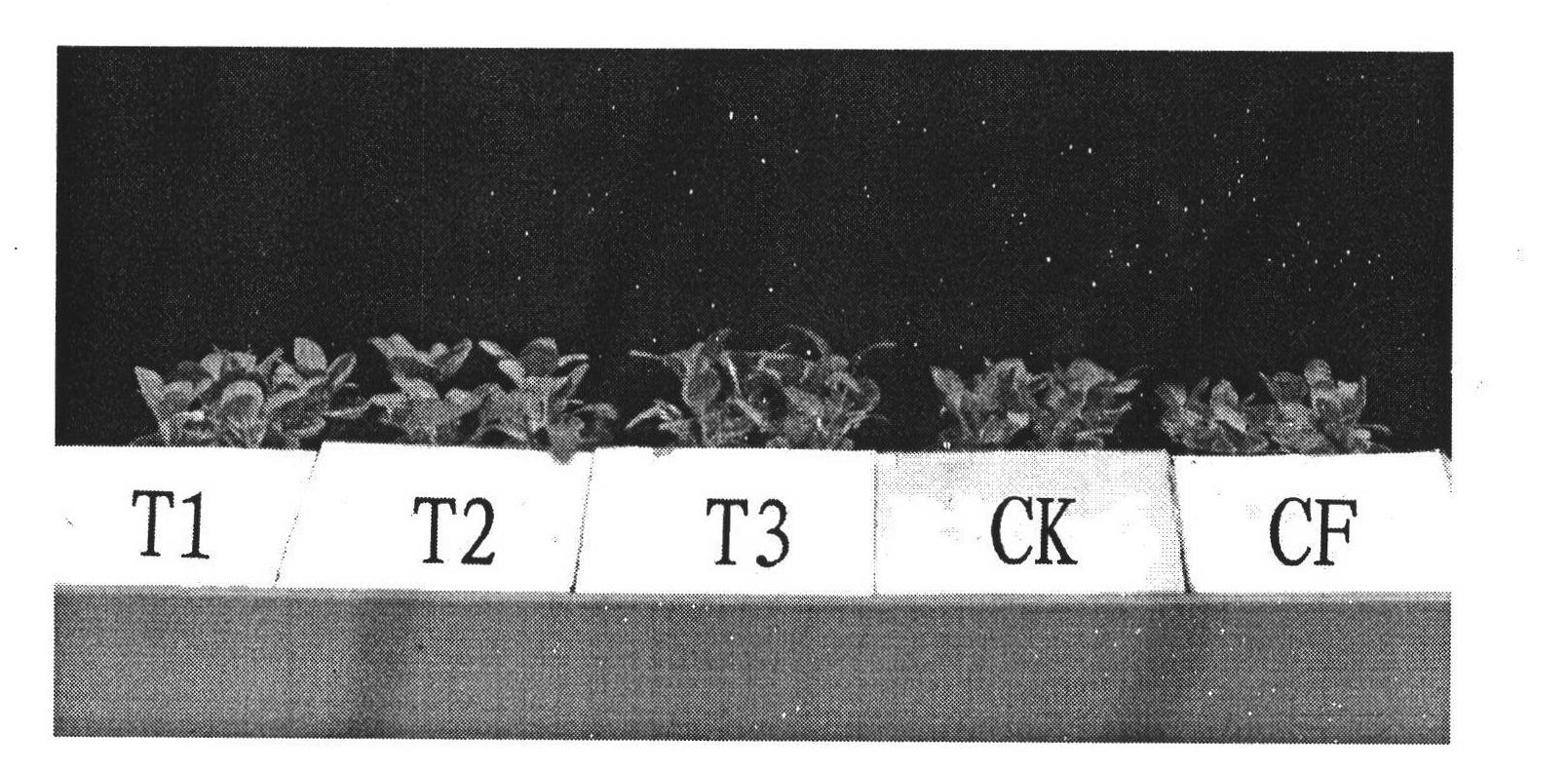

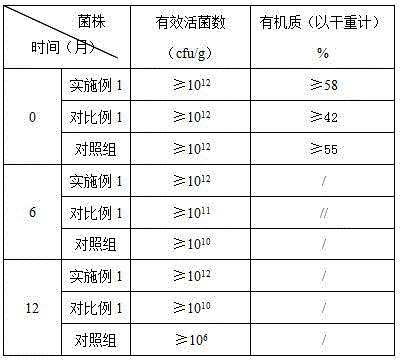

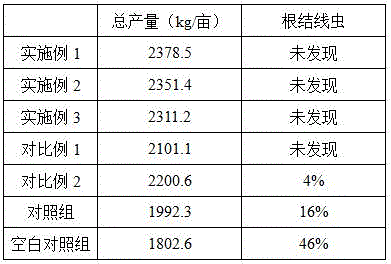

Bio-organic fertilizer of poultry feather amino acid and preparation method of same

InactiveCN105000923AImprove biological activityReduce pollutionBio-organic fraction processingOrganic fertiliser preparationDiseaseBiotechnology

The present invention discloses a bio-organic fertilizer of a poultry feather amino acid and a preparation method of the same. According to the present invention, bacillus amyloliquefaciens, moist cellulomonas cartae and trichoderma viride that can efficiently secrete keratinase are used to perform fermentation and enzymatic hydrolysis on a mixture of poultry feathers and edible fungi residues; then anti-disease bacteria and solubilizing and potassium bacteria are added in an aging phase to perform secondary fermentation; mature materials are milled and sieved; and the bio-organic fertilizer of the poultry feather amino acid is prepared and obtained. The bio-organic fertilizer not only has a high content of organic matter and a high content of humic acid that are capable of soil amelioration, but also has a high content and various types of amino acids that are capable of crop production increasing and quality improving; the added functional microorganisms are capable of disease resisting, and further capable of releasing poorly soluble potassium and phosphorus in the soil to an absorbable and usable form; and applying the bio-organic fertilizer to the production can reduce the quantity of applied pesticides and fertilizers and produce safe and healthy agricultural products, and has a very wide application prospect.

Owner:GUANGDONG INST OF MICROORGANISM +1

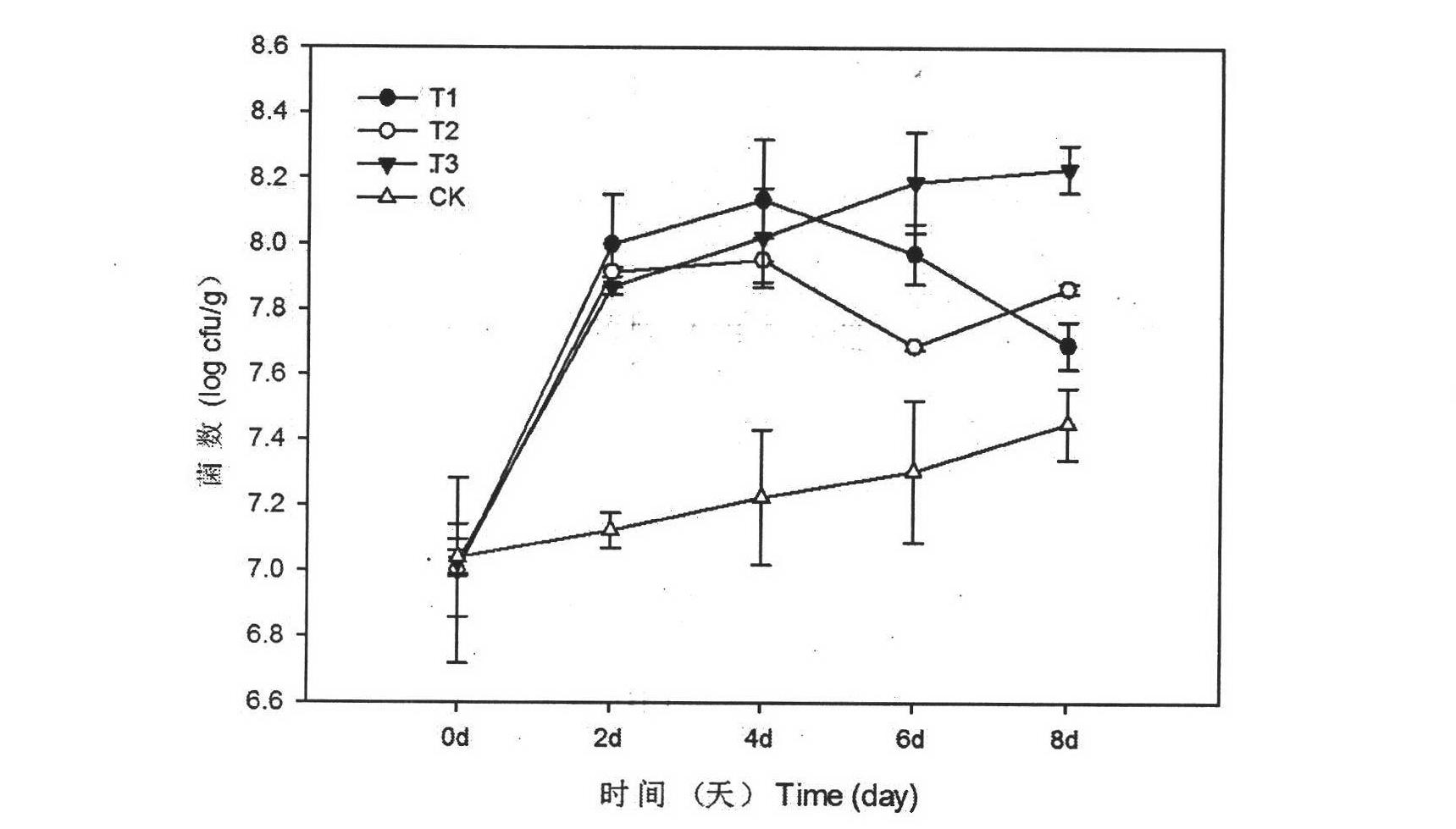

Method for producing microbial organic fertilizer by utilizing poultry feathers and product thereof

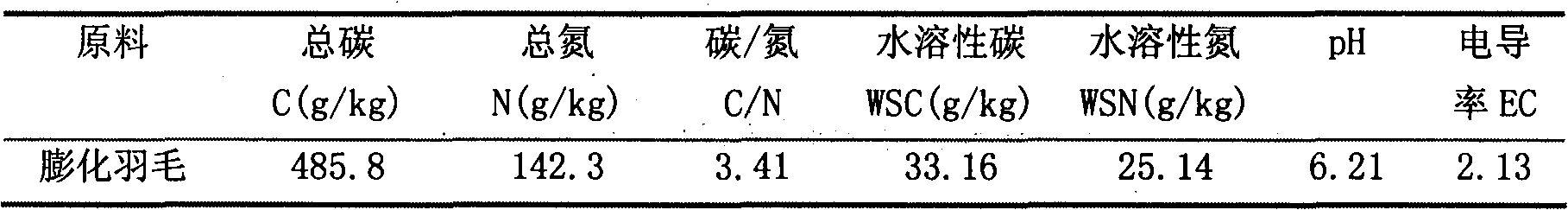

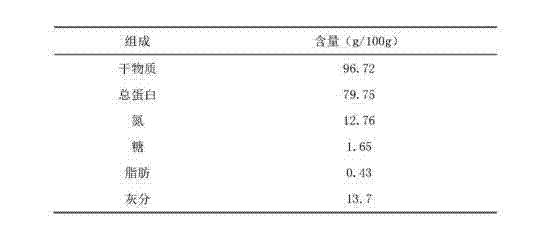

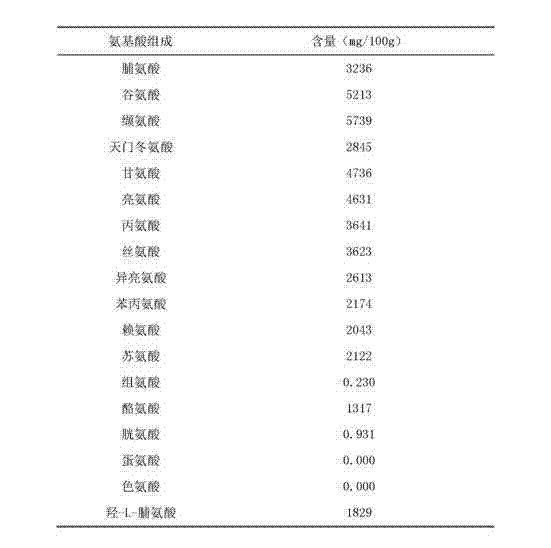

ActiveCN102617203APromote growthSuitable for growthBio-organic fraction processingOrganic fertiliser preparationPotassiumTotal nitrogen

The invention relates to a method for producing a microbial organic fertilizer by utilizing poultry feathers and a product thereof, and belongs to an agricultural intensive production technology. According to the method disclosed by the invention, the puffed feathers are taken as amino acid source carriers, mature pig manure compost and microbes of rapeseed meal are mixed for decomposing a mixture, and solid fermentation is performed for preparing the microbial organic fertilizer. The fertilizer contains more than 1 multiplied by 10<8> / g of functional bacterial, 2-4% of total nitrogen (organic nitrogen accounts for more than 90%), 3-5% of total nitrogen, phosphorus and potassium and 25-35% of organic matters. Test results show that the waste feathers are puffed and then mixed with the pig manure compost, secondary fermentation is performed for producing the biological organic fertilizer, and the total effects are better.

Owner:NANJING AGRICULTURAL UNIVERSITY

Organic peanut planting controlled-release functional fertilizer and preparation method thereof

InactiveCN104311344AStable structureNo pollutionCalcareous fertilisersBio-organic fraction processingSodium bicarbonatePotassium

Animal hair in life is a waste energy, the protein structure of the animal hair is stable and difficult to decompose under the natural condition, poultry feather and pig hair are used as raw materials to be mixed with alkaline substance slaked lime and sodium bicarbonate, the mixture is firstly soaked and then boiled, after the structure of the poultry feather and pig hair is destructed, the poultry feather and pig hair are ground and fermented to be used for preparing organic matters of the fertilizer, so that waste is utilized, the environment pollution is avoided, the resource is saved, the inner layer contains NPK (Nitrogen, Phosphorus and Potassium) element and trace minerals which are necessary for the high yield of crops, the NPK element and trace minerals are wrapped by a coating agent prepared by utilizing the resin so as to be used as a core of the organic fermented material, a film material is slowly decomposed, an effect for controlling the release of internal nutrients can be achieved, the waste caused by frequent application of fertilizer can be avoided, the cost is reduced, and the economic benefit is increased.

Owner:肥东县花生原种场

Polymer composites containing keratin

Polymer composites containing keratin and at least one polymer (e.g., polyurethane, polyethylene, polypropylene, polyamide, polyesters, polyvinyl chloride, polylactic acid, polyvinyl alcohol, polycaprolactone, polyhydroxy esther ether, polyhydroxybutyrate, polyhydroxyalkanoates, polystyrene, polycarbonate, polymethyl methacrylate, polybutadiene, polyisoprene, polyurethane, epoxies, or mixtures thereof; wherein polypropylene is not atactic polypropylene). Methods for producing the polymer composites are also provided. The properties of polymers are improved by the dispersion of cleaned, processed keratin material, preferably derived from poultry feathers, in the polymeric material. The keratin material can be in the form of fibers, particles, or large pieces from animal hair, nail, hoof, horn, or avian (e.g., poultry) feathers.

Owner:US SEC AGRI

Method for producing peptone by taking poultry feather as raw material

The invention discloses a method for producing peptone by taking poultry feather as a raw material. The method comprises the following steps: performing pretreatment on the poultry feather raw material, and then sending into a microwave puffing machine for treatment; adding keratinase for performing enzymolysis reaction and heating for enzyme deactivation; adding activated carbon to perform deodorization, peculiar smell removal, decolorization and other treatment, and filtering; and performing evaporation concentration and high-speed centrifugal spray-drying, and getting the peptone after drying. According to the method disclosed by the invention, the combination of microwave puffing and keratinase enzymolysis technologies is adopted for producing the peptone by taking the poultry feather as the raw material, a new way is opened for resource utilization and development of the waste feather, and the resource utilization is performed on the poultry feather produced during cultivation, so that environmental pollution and the waste of resources are reduced, social benefits are increased, the cost of the raw material is low, process equipment is simple, the process flow is simple and strong in operability, and the industrial production can be realized; the peptone produced by the method disclosed by the invention has good quality and high yield; and the method disclosed by the invention can fill in the technical blank in preparation of the peptone by taking the feather as the raw material.

Owner:安徽华强羽绒有限公司

Regenerated eiderdown filament fiber and method of manufacture

InactiveCN1632194AWide variety of sourcesImprove wrinkle resistanceMonocomponent polyesters artificial filamentWrinkle skinAcrylonitrile

The invention relates to a regenerated down filament fiber and a manufacturing method thereof. The ultra-fine powder made of poultry feathers in the fiber is evenly distributed in polyacrylonitrile, and is combined with polyacrylonitrile macromolecules by covalent bonds. The content of down components is 20-40%, and the polyacrylonitrile group Mineral content is 60-80%. The steps of the present invention to produce the regenerated down filament fiber are as follows: using poultry feathers as raw materials to prepare ultra-fine powder, and acrylonitrile in redox system through graft copolymerization to make polyacrylonitrile spinning stock solution, and then through traditional Wet or dry spinning process route is processed into regenerated down filament fiber. The regenerated down filament fiber of the invention has the excellent properties of natural down, such as warmth retention, water resistance, good wrinkle resistance, softness, smoothness, lightness and the like. The source of processing raw materials is wide and the price is low; the processing route of down powder is simple and pollution-free; the spinning process does not change the processing route of traditional polyacrylonitrile fiber, which is easy for industrial production.

Owner:WUHAN TEXTILE UNIV

Method for producing organic fertilizers by using microbial fermentation of fungi dregs and poultry feather

ActiveCN103804038ALess investmentEasy to operateBio-organic fraction processingOrganic fertiliser preparationBiotechnologyFermentation

The invention discloses a method for producing organic fertilizers by using microbial fermentation of fungi dregs and poultry feather. According to the method, the production of organic fertilizers are implemented based on a series of steps including pretreatment of raw materials, preparation of a microbial fermentation zymophyte agent, treatment of edible fungi residues and poultry feather. The method is not only simple and convenient in operation, easily popularized, and requires small energy consumption and low treatment cost, but also edible fungi residues and poultry feather are changed into values, the obtained organic fertilizer is a high-efficient environment-friendly green fertilizer, and the technical indexes of the organic fertilizer meet the regulations of the professional standard of Agriculture Ministry NY525-2012 Organic Fertilizers.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

Washable wrinkle-proof compound silk floss material

InactiveCN105088404AAdd new usesGood antibacterialFibre treatmentConjugated cellulose/protein artificial filamentsFiberWrinkle skin

The invention discloses a washable wrinkle-proof compound silk floss material. The washable wrinkle-proof compound silk floss material is characterized by being prepared by, by weight, 40-60 parts of poultry feathers, 14-17 parts of down feathers, 1-3 parts of silane coupling agents KH550, 1-2 parts of nano silica, 1-2 parts of nano-silver, 14-20 parts of chitosan, 30-50 parts of polypropylene, 4-6 parts of soybean protein fibers, 2-5 parts of waterborne polyurethane and an appropriate amount of water. The soybean protein fibers and the waterborne polyurethane interact with each other to improve strength and elongation and the properties of good acid and alkali resistance, good moisture absorption and moisture conductivity and others of the compound silk floss material, and the compound silk floss material is free of washing, achieves a good wrinkle-proof effect, brings noble and comfortable feeling and is high in cost performance, abandoned feathers are utilized, the number of effective utilization paths is increased, and the compound silk floss material saves energy, is environmentally friendly and has broad application prospects.

Owner:安徽咏鹅家纺股份有限公司

Poultry feather protein viscose silk and manufacturing method thereof

InactiveCN102230237AReliable strengthImprove dyeing effectConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentFiberAdditional values

The invention provides poultry feather protein viscose silk and a manufacturing method thereof. The poultry feather protein viscose silk is characterized by being prepared from the following raw materials in percentage by weight: 5 to 15 percent of poultry feather protein and 85 to 95 percent of organic fibers. The poultry feather protein viscose silk is reliable in strength, high in chromaticity, wide in application range and high in economic additional value, can improve the comfortableness with skin, has a certain function of ultraviolet absorption and radiation protection, can be manufactured into functional textile shell fabrics of the new generation and has the great commercial value.

Owner:张很文

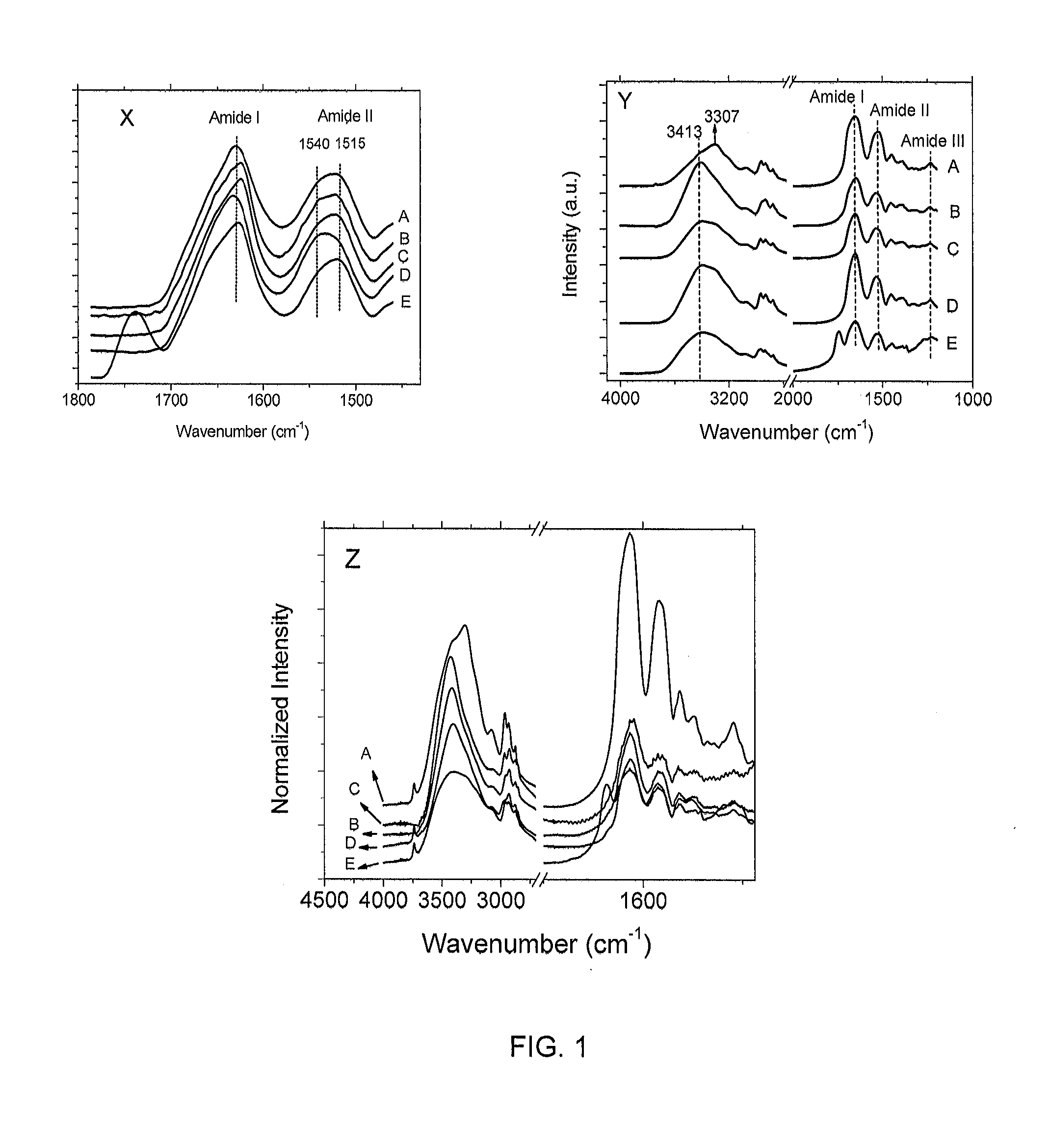

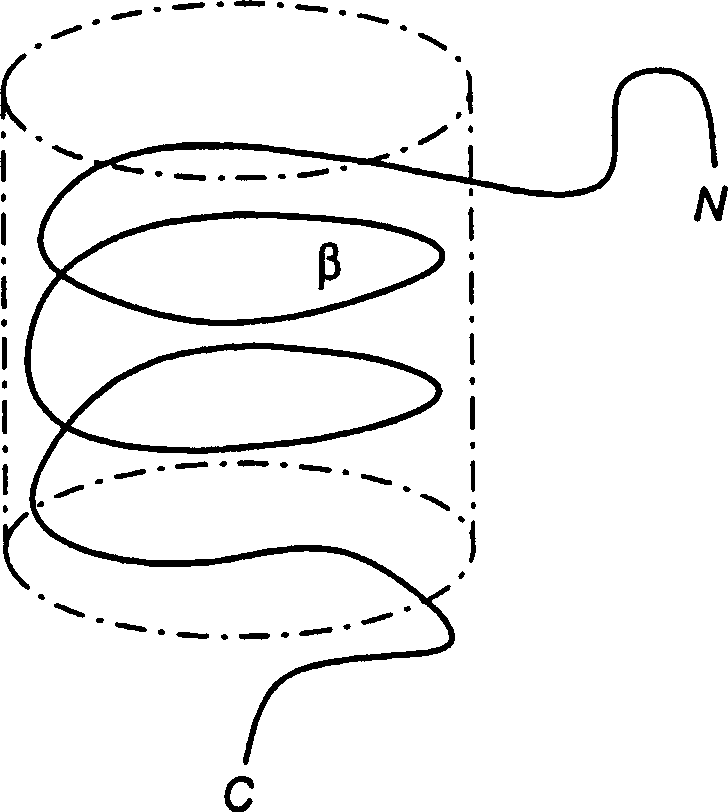

Keratin-based products and methods for their production

The present invention relates to a process for solubilising keratins from a keratin containing starting material such as poultry feathers. The keratins are may be solubilised using a sulphide under alkaline conditions. In the process the cysteine residues of solubilized keratins are partially modified, e.g. by alkylation. The conditions of solubilisation and partial modification are chosen such that the keratins are also partially hydrolysed. The partially modified and partially hydrolysed keratin may be used as stable dispersions e.g. for the production of films and coatings by casting.

Owner:STICHTING NEDERLANDS INST VOOR ZUIVELONDERZOEK (NIZO)

Method for producing compound amino acid with poultry feathers as raw material

The invention discloses a method for producing a compound amino acid with poultry feathers as a raw material. The method comprises the steps: firstly, washing and drying the poultry feathers, carrying out shearing smashing pretreatment, after shearing smashing, adopting a microwave puffing and protease enzymolysis combined method, then carrying out deodorization, peculiar smell-removal and decoloration treatment by adopting activated carbon, filtering, concentrating, carrying out high speed centrifugal spray drying, and finally producing the compound amino acid. The method adopts the waste feathers as the raw material, has wide sources of the raw material, develops a new way for resource utilization and development of waste materials, reduces environmental pollution and resource waste, increases social benefits, besides, has the advantages of simple equipment, simple technological process and strong operability, and can realize industrialized production; and the produced compound amino acid has good quality, the compound amino acid conversion efficiency of the feathers reaches 68.4%, the production yield is high and reaches 85.7%, and resource utilization on the poultry feathers produced by breeding is performed.

Owner:陈后前

Special biofertilizer for cucumbers and preparation method thereof

InactiveCN103524228AObvious benefits of increasing productionHas insecticidal effectFertiliser formsFertilizer mixturesAgaricusEcological environment

The invention discloses a special biofertilizer for cucumbers. The biofertilizer comprises the following raw materials in parts by weight: 40-55 parts of cucumber stems, 30-35 parts of pig manure, 20-25 parts of phosphogypsum, 20-32 parts of spent mushroom compost, 8-10 parts of peat soil, 6-10 parts of plant ash, 15-20 parts of poultry feather, 8-12 parts of borax and 0.5-1.2 parts of microbial fermented matters. The invention also discloses a preparation method of the special biofertilizer for cucumbers. Compared with the prior art, the biofertilizer has the advantages that the biofertilizer can protect the ecological environment and the farmland soil, is easily absorbed by crops, has obvious yield increase benefit, integrates double functions of fertilization and sterilization, is low in cost and is environment-friendly and pollution-free.

Owner:合肥科友生物科技有限公司

Hair keratin composite fiber and spinning method thereof

ActiveCN102817101AReduce manufacturing costImprove performanceConjugated cellulose/protein artificial filamentsWet spinning methodsFiberBristle

The invention relates to a hair keratin composite fiber and a spinning method thereof. The hair keratin composite fiber comprises: by weight, 1 to 60 parts of hair keratin and 40 to 99 parts of polyvinyl alcohol. Hair keratin raw materials of the hair keratin composite fiber comprise low-value and low-price short pig hairs separated from bristles, short hair wastes, poultry feathers and wool residues from a woolen mill. A hair keratin and polyvinyl alcohol extracted from pig hairs, hair wastes, wastes of a woolen mill and poultry feathers are used as main raw materials and are processed into the hair keratin composite fiber. The hair keratin composite fiber greatly reduces a production cost, improves product performances and has a good application prospect. The hair keratin composite fiber satisfies green ecological textile requirements.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

Liquid fertilizer capable of preventing soil-borne diseases and preparation method therefor

InactiveCN105110879AReduce dosageMake up for the lossFertilizer mixturesEcological environmentSodium potassium tartrate tetrahydrate

The invention discloses a liquid fertilizer capable of preventing soil-borne diseases. The liquid fertilizer is prepared from the following raw materials, by weight, 36-40 parts of biogas residue mud, 5-7 parts of sodium potassium tartrate tetrahydrate, 6-8 parts of citric acid, 40-50 parts of corn germ meal, 15-19 parts of urea, 55-65 parts of dry chicken manure, 120-140 parts of waste livestock and poultry feathers, 6-7 parts of copper sulphate, 4-6 parts of ferrous sulphate, 4-5 parts of GM microbial preparations and a proper amount of water. Biogas residue mud, chicken manure and the like are employed in the raw materials of the liquid fertilizer and contain a lot of microbes with various kinds, the GM microbial preparations are added to raise the beneficial bacterium content, thus the liquid fertilizer becomes a microbe resource base, the soil microbial community structure can be adjusted after drip irrigation and spraying of the liquid fertilizer, the soil microbial diversity is raised, the soil micro-ecological environment is improved, the survival scope of plant pathogens is narrowed, and therefore the purpose of preventing soil-borne diseases is achieved.

Owner:HEFEI ZHONGYUE HEALTH TECH

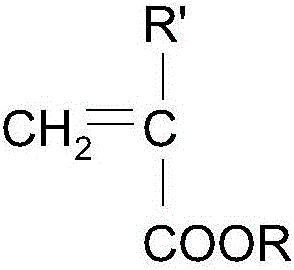

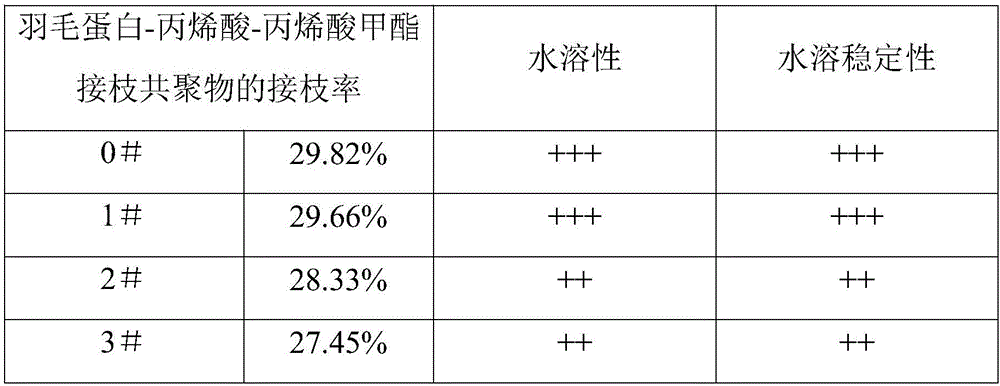

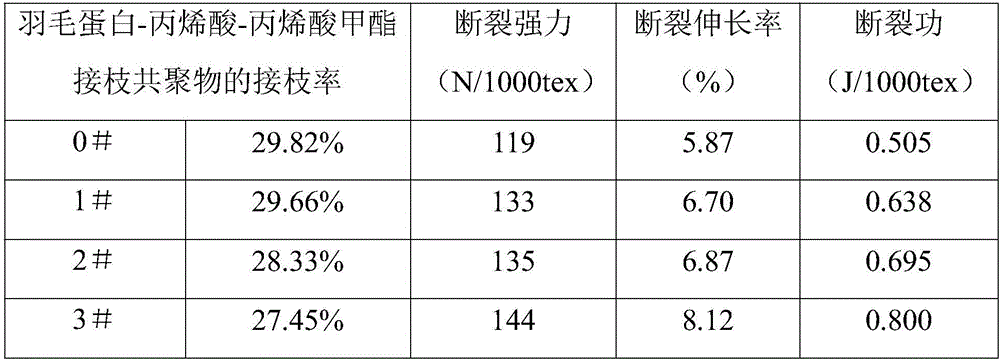

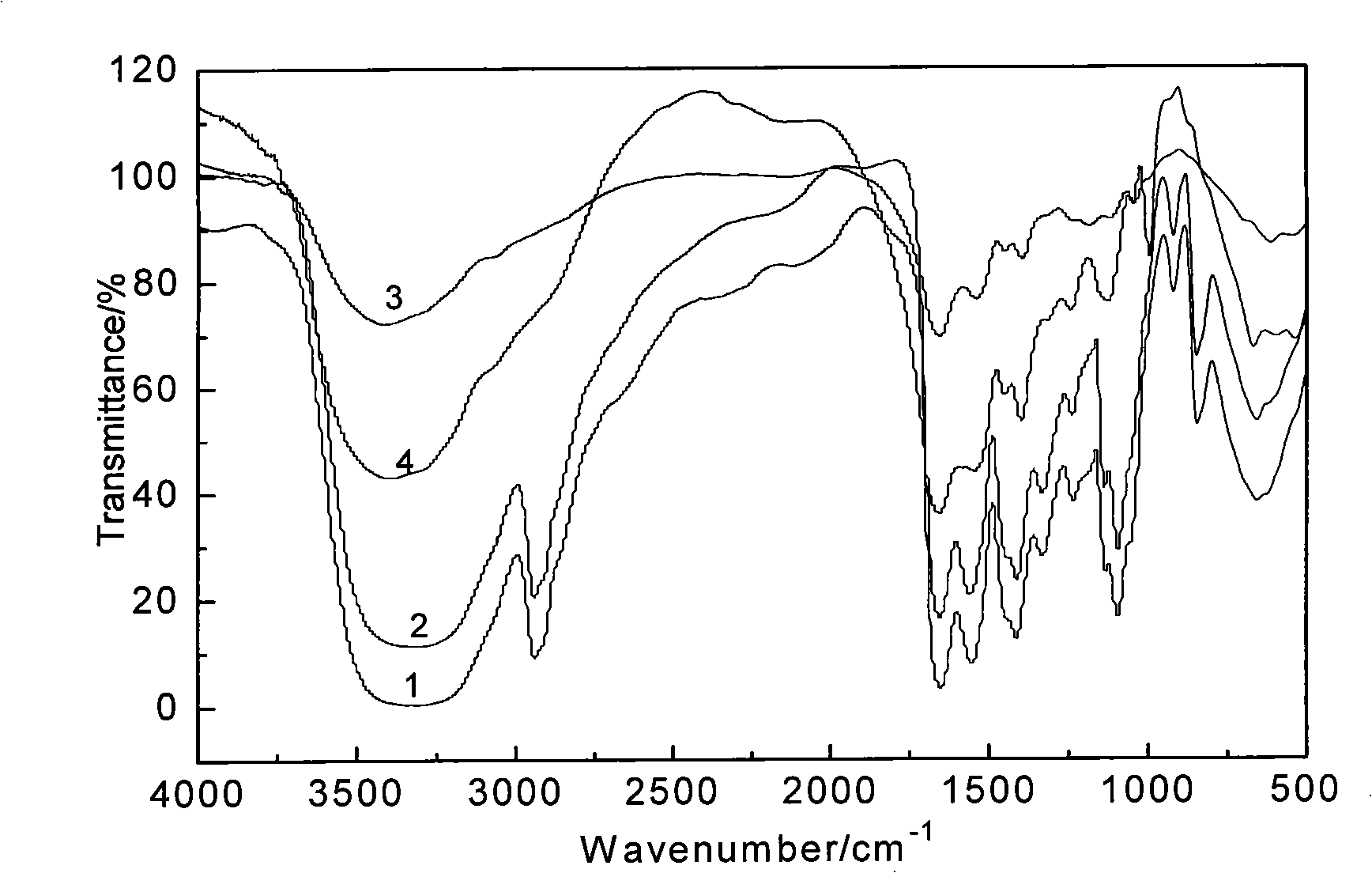

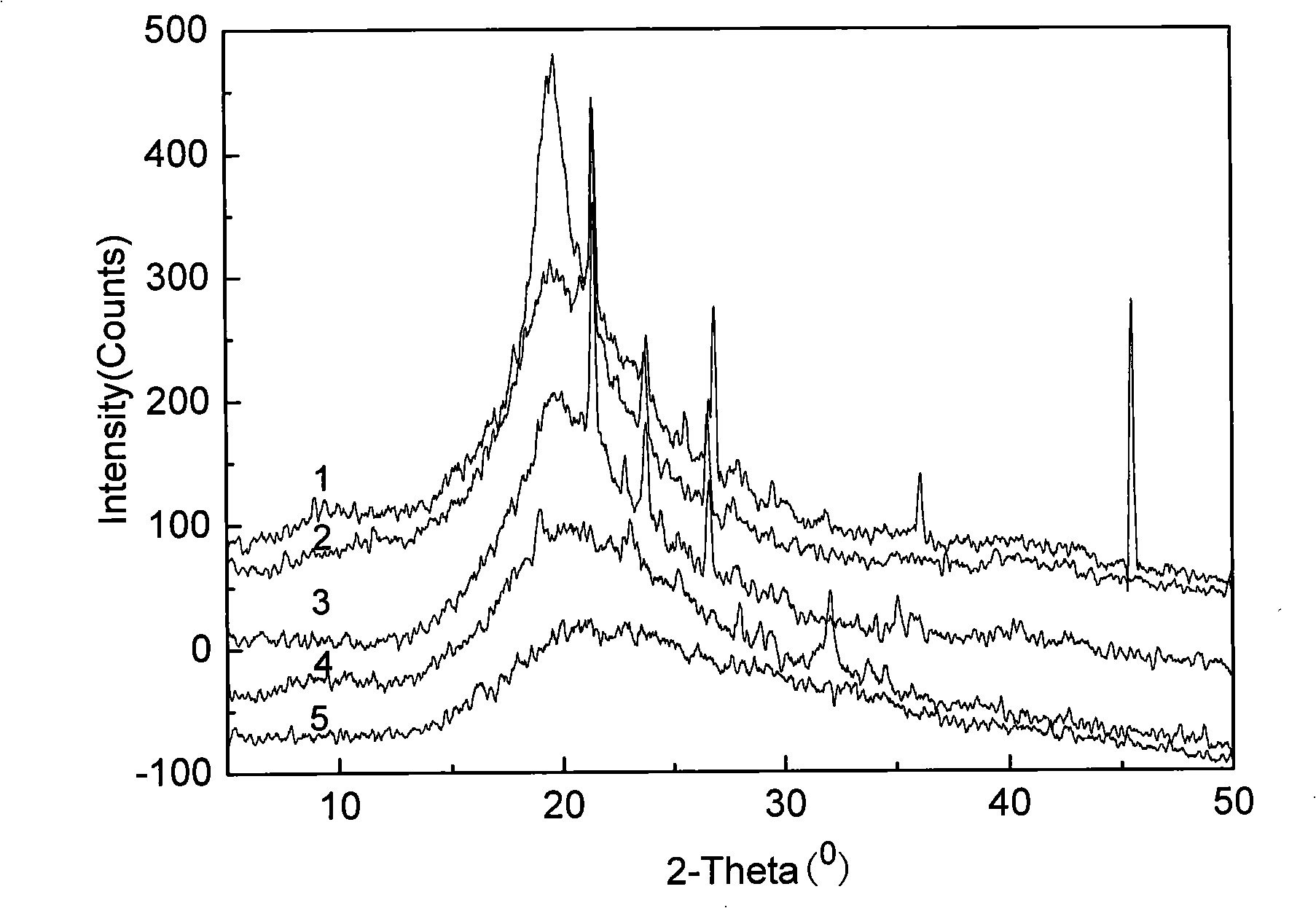

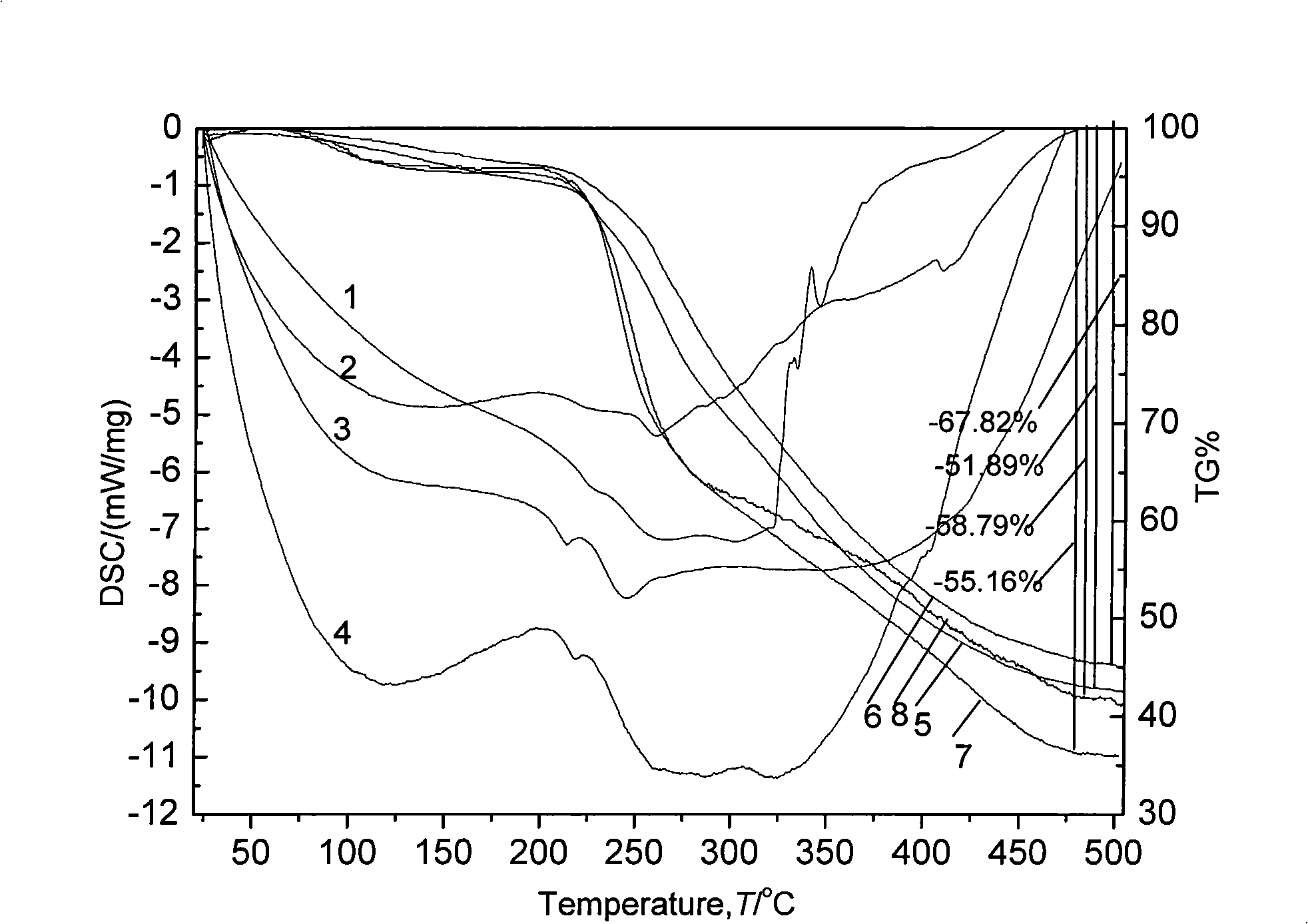

Feather protein grafted copolymer sizing material and preparation method thereof

InactiveCN106750043AGuaranteed water solubilityGood water solubilityVegetal fibresHydrophilic monomerYarn

The invention belongs to the technical field of modified protein sizing materials used for spinning warp sizing, and discloses a feather protein grafted copolymer sizing material and a preparation method thereof. The preparation method is characterized by after mixing a hydrophilic monomer-acrylic acid with a hydrophobic monomer-acrylate according to a certain molar ratio under the trigger action of a redox system, commonly grafting the hydrophilic monomer-acrylic acid with the hydrophobic monomer-acrylate to a molecular chain of protein extracted from poultry feathers which are subjected to reduction pretreatment, thus preparing a feather protein-acrylic acid-acrylate grafted copolymer sizing material which has good sizing performance on pure polyester and high-proportion polyester cotton blended yarn. According to the feather protein grafted copolymer sizing material prepared by the preparation method disclosed by the invention, the application field of a modified feather protein sizing material is expanded to synthetic fiber yarn sizing on the basis that the feather protein grafted copolymer sizing material is still enabled to be dissolved into water when in a neutral condition, and the limitation of a current feather protein sizing material is just suitable for natural fiber yarn sizing is broken.

Owner:SHAOXING UNIVERSITY

Livestock and poultry feather keratin based coextruded film and method for preparing same

The invention relates to an animal wool keratin based composite membrane. The compositions by weight portion of the animal wool keratin based composite membrane are: 10 to 29 portions of animal wool keratin solution, 1 portion of filmerformer, 0 to 1 portion of cross linker and 0 to 0.5 portion of plasticizer. The preparation method comprises the following processing steps of: preparation of keratin stock solution by utilization of animal feathers through the reduction hydrolytic method or the oxydrolysis method, ultrasonic treatment of the keratin stock solution, preparation of composite solution and preparation of the membrane. The method uses abandoned animal feathers as raw materials and adopts ultrasonic hydrolyzation to prepare the keratin stock solution to prepare the keratin composite membrane after mixing of the keratin stock solution and polyvinyl alcohol. The preparation method has the advantages of simple technique, simple and convenient operation and so on; the keratin composite membrane prepared by adoption of the preparation method has high tensile strength and low elongation at break, can be degraded and can be used as materials for manufacturing a package; the package is buried underground, can be degraded and converted into organic fertilizer and then absorbed by crops and solve the problem of environmental pollution of plastic bags.

Owner:SHAANXI NORMAL UNIV

Natural feather plugging fiber used for drilling of oil and gas wells in oil fields and preparation method thereof

InactiveCN101638577ANo pollutionImprove hydrophilicityFibre treatmentDrilling compositionFiberWell drilling

The invention provides a natural feather plugging fiber used for drilling of oil and gas wells in oil fields and a preparation method thereof. The fiber comprises 100-120 parts of poultry feathers (with water content less than 25%), 0.2-0.4 part of surfactant, 0.0-0.8 part of washing agent, 1.0-3.0 parts of alkaline defatting agents and 120 parts of clear water. The preparation method comprises the following steps: firstly, pouring 120 parts of tap water into a liquid mixing tank; secondly, under normal temperature and normal pressure, adding 0.0-0.8 part of washing agent and 1.0-3.0 parts ofalkaline defatting agents respectively and stirring the mixture for 0.5h to prepare treatment liquid; thirdly, placing the poultry feathers into the treatment liquid to be stirred and then standing for 24h; fourthly, cleaning the treated poultry feathers with clear water and filtering and drying the poultry feathers, placing the poultry feathers into surfactant solution to be stirred for 0.5h andthen soaked, taking out the poultry feathers to be baked and ground, and sieving 95% of the products by a 10-mesh sieve. The fiber has the characteristics of good dispersibility, good plugging effect,low manufacturing cost and no environmental pollution.

Owner:XI'AN PETROLEUM UNIVERSITY

Liquid fertilizer adjusting soil acid-base value and preparation method thereof

A disclosed liquid fertilizer adjusting soil acid-base value is prepared from the following raw materials in parts by weight: 50-70 parts of rice chaff ash, 4-6 parts of boric acid, 10-14 parts of ammonium calcium nitrate, 1-3 parts of isoflavones, 28-36 parts of hoof horn powder, 45-55 parts of edible fungus residue, 115-130 parts of waste livestock and poultry feathers, 5-8 parts of copper sulphate, 6-7 parts of ferrous sulphate, 4-6 parts of GM microbial preparation, and proper amount of water. according to the liquid fertilizer, through hydrolysis and composting, a large amount of production organic waste residue difficult to utilize is converted into nutrients easily absorbed by crops, also the liquid fertilizer with alkalescence can be used as a natural chelating agent for promoting absorption on trace metal ions by crops, improves and optimizes the absorption conditions of nutrients and water by crops, is capable of adjusting soil pH value and improving soil buffering capability, and possesses extremely good resistant effect on acidic soil, acid rain and other unfavorable plantation conditions.

Owner:HEFEI ZHONGYUE HEALTH TECH

Method for preparing organic/inorganic humate foliar fertilizer

InactiveCN101712581AGood moisturizing effectImprove stress resistanceOrganic fertilisersFertilizer mixturesSludgePlant growth

The invention discloses a method for preparing an organic / inorganic humate foliar fertilizer, which comprises the following steps: firstly, preparing humate serving as a first component by activating peat; then, preparing mixed solution of polypeptide, amino acid and intermediate products thereof from poultry feather by cleaning, degreasing, hydrolyzing, filtering to remove impurities and adjusting the pH value, and obtaining solution of amino acid with certain viscosity serving as a second component through moderate chemical crosslinking; acidifying boric sludge to form a boric magnesium fertilizer containing magnesium sulfate or magnesium nitrate and boric acid to be used as a third component; and finally, mixing the three components according to a certain proportion, and diluting the mixture with water to obtain the organic / inorganic humate foliar fertilizer. The method selects and uses the waste resources such as peat, poultry feather, boric sludge and the like to prepare the foliar fertilizer which is favorable for the growth of plants and the improvement of farm product quality; and because various wastes are adopted as the main raw materials, the method can have good social benefit and economic benefit in the aspect of environmental protection.

Owner:SHAANXI UNIV OF SCI & TECH

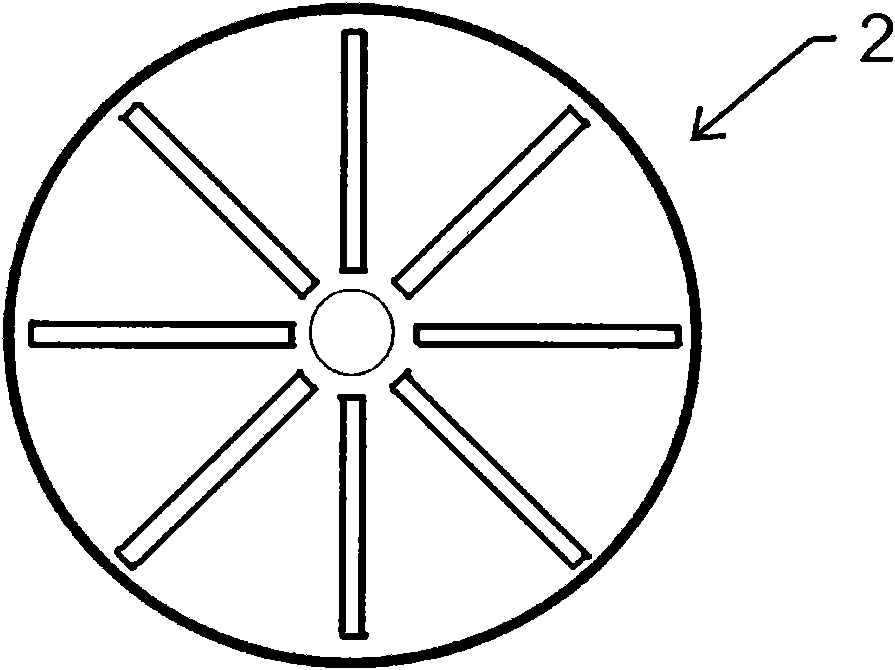

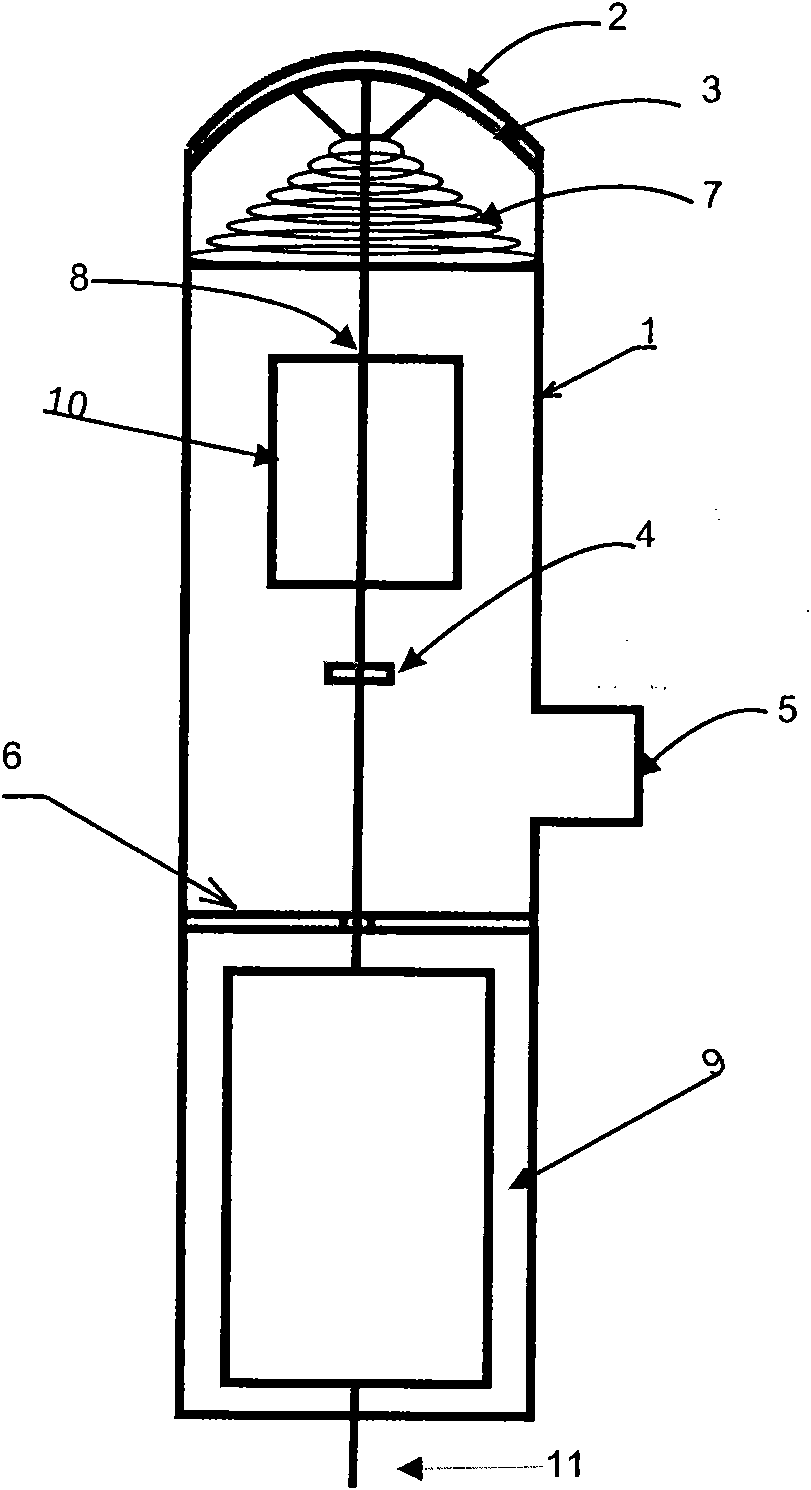

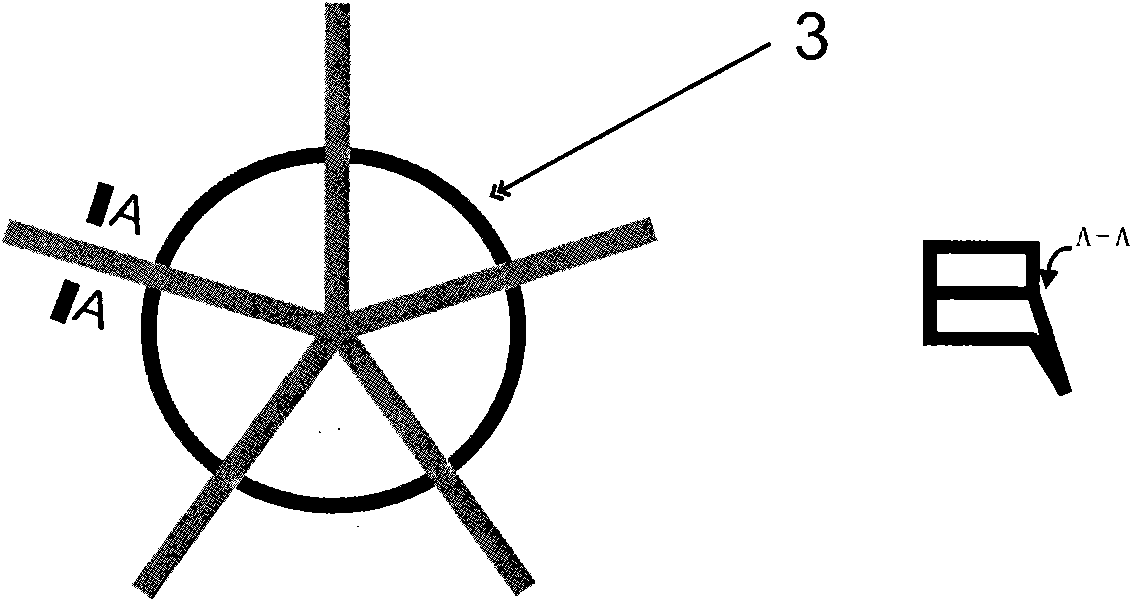

Poultry feather plucker

InactiveCN101946819AFast and clean pluckingImprove ergonomicsPoultry plucking mechanismsPluckerMicromotor

The invention provides a rapid feather plucker which plucks small or infant feathers of the killed poultry after the big feathers of the poultry is removed. The poultry feather plucker comprises a cylindrical shell, wherein one end of the cylindrical shell is fixed with a semi-circular stainless steel cap; the top end of the semi-circular stainless steel cap is provided with a round hole and eight suction sumps for sucking the small feathers of the poultry; an inner end of the cylindrical shell is provided with a micromotor; the middle of a lengthening shaft of the micromotor is provided with a suction pump blading; the other end of the operating shaft of the micromotor is provided with a semi-circular feather clipping five-claw blade tallying with the semi-circular stainless steel cap of the shell; and a drain outlet is arranged in the middle of the cylindrical shell. The plucker is simple to operate and efficient and clean and can improve the existing manual plucking efficiency by over 5 times.

Owner:陈志中

High-permeability liquid fertilizer and preparing method thereof

InactiveCN105000993AReduce dosageMake up for the lossFertilizer mixturesAdditive ingredientCell membrane

The invention discloses high-permeability liquid fertilizer. The high-permeability liquid fertilizer is prepared from, by weight, 40-50 parts of fishbone meal, 10-13 parts of calcium nitrate, 5-6 parts of saponin, 25-30 parts of black pepper, 80-90 parts of marine product leftovers, 14-16 parts of potassium nitrate, 100-120 parts of waste livestock and poultry feather, 4-7 parts of copper sulfate, 8-10 parts of ferrous sulfate, 4-6 parts of GM microorganism preparations and appropriate amount of water. The liquid fertilizer contains a great deal of nitrogen, phosphorus and potassium which are necessary elements for crop growth, the liquid fertilizer is rich in various medium trace elements such as calcium and magnesium after the added fishbone meal, the black pepper and the like are composted and extracted, and tetrahydropiperine extracted from the black pepper and the saponin take effect together, and can improve the permeability of cell membranes of crops, promote absorption of effective ingredients in the liquid fertilizer by the crops and improve the permeability of the liquid fertilizer; the adopted raw materials are natural substances and have no adverse effect on the crops or the environment, so that the liquid fertilizer is wide in application range and suitable for long-time use.

Owner:HEFEI ZHONGYUE HEALTH TECH

Method for extracting poultry feather keratin by using water insoluble ionic liquid and relative poultry feather keratin solution

InactiveCN102229665AEasy to recycleEasy to separatePeptide preparation methodsDepsipeptidesDisulfide bond reductionWater insoluble

The invention provides a method for extracting a poultry feather keratin by using water insoluble ionic liquid, comprising the follow steps: 1) washing, drying and crushing a poultry feather; 2) adding a water insoluble ionic liquid with stirring for 3-6h at the temperature of 70-100 DEG C; and 3) after the reaction, adding water, carrying out centrifugation to form a three-phase system of water insoluble ionic liquid / undissolved poultry feather / water, so as to obtain a crude keratin solution. In a preferred step 2), a disulfide bond reducing agent is added, and a little water is added to dissolve the disulfide bond reducing agent. The invention also provides a poultry feather keratin solution extracted by the method. The method for extracting the poultry feather keratin by using the water insoluble ionic liquid, has the advantage of simple separation of keratin, is convenient recovery of ionic liquid and friendly to environmental protection, and can be widely applied.

Owner:EAST CHINA UNIV OF SCI & TECH

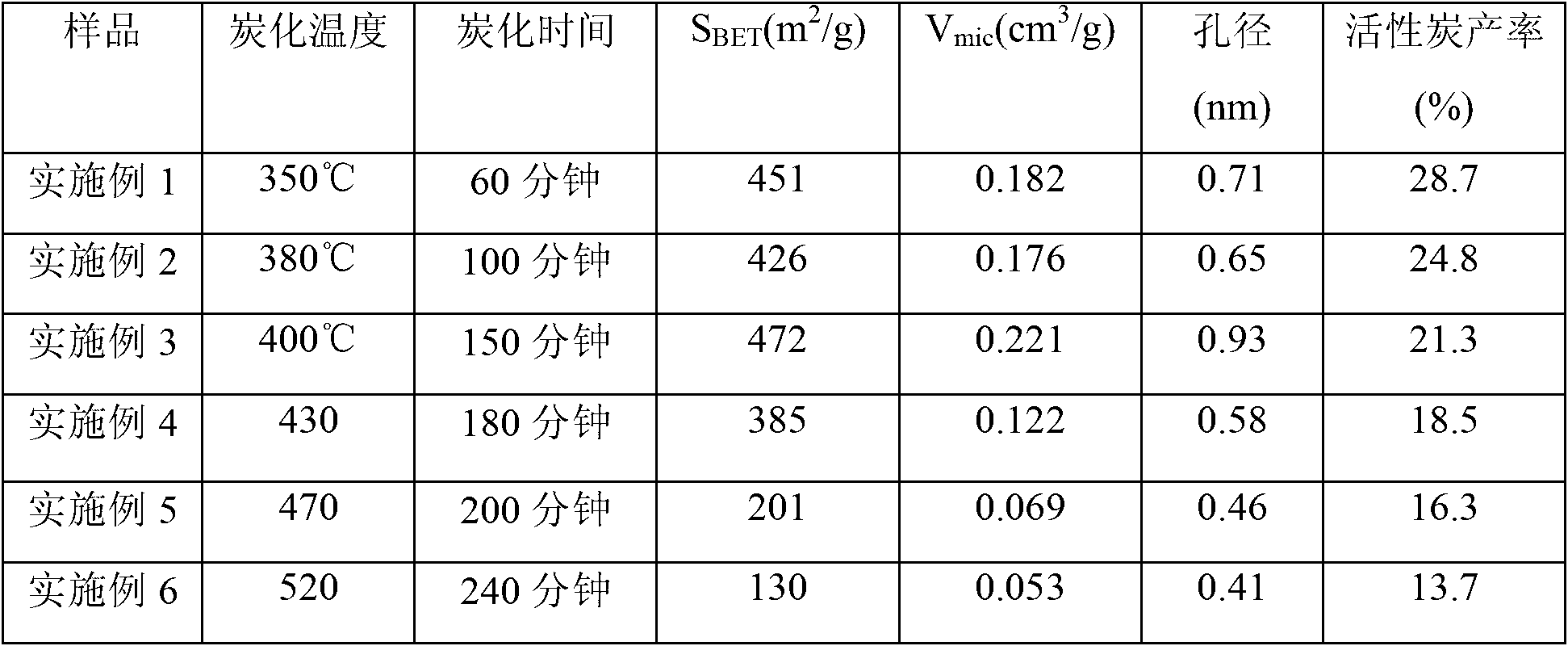

Preparation method of activated carbon

InactiveCN102838112AReduce the temperatureReduce energy consumptionCarbon compoundsSocial benefitsActivated carbon

The invention discloses a preparation method of activated carbon, which comprises pretreatment and carbonization processes of raw materials so as to obtain microporous activated carbon finally. The carbonization process is carried out at normal pressure and at 350-520 DEG C; and the temperature rising rate of carbonization is 1-10 DEG C / min. The preparation method uses waste poultry feathers as raw materials, and is a new method for preparing microporous carbon materials; on the one hand, the environmental pollution resulted from poultry feathers is relieved, and renewable resources are fully used; on the other hand, the manufacturing cost of the microporous carbon materials is lowered, the carbonization temperature is low, the energy consumption of the carbonization process is reduced, the environmental pollution resulted from activation using chemical reagents is further avoided, and the preparation method has good economic and social benefits and comprehensive utilization value.

Owner:XIANGTAN UNIV

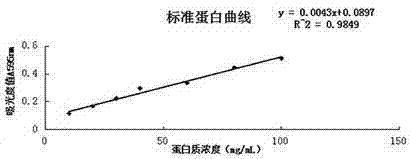

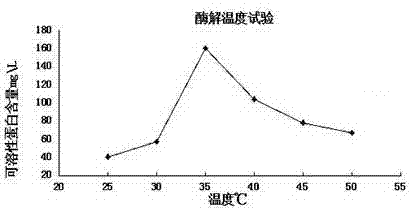

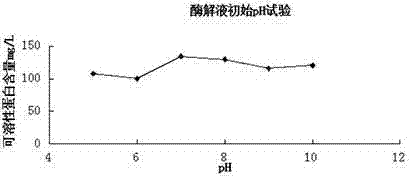

Method of preparing feather protein powder from keratinase

InactiveCN104770574AIncreased soluble protein contentSimple processAnimal feeding stuffFermentationPROTEIN S HEERLENPhenylalanine

The invention relates to the technical field of animal fodder processing, and especially relates to a method of preparing feather protein powder from keratinase. The method takes poultry feathers as the raw material and is characterized by comprising the following steps: (1) preparing feather powder; (2) performing enzymatic hydrolysis; (3) filtering and drying. The technology is simple, the suitable field of the technology is enlarged, the temperature of enzymatic hydrolysis is low, the pH range is wide, the cost of enzymatic hydrolysis is low, and the efficiency of enzymatic hydrolysis is high. The content of soluble protein in the supernate of enzymatic hydrolysis is high, the supernate contains 8 amino acids with a high content, wherein phenylalanine, isoleucine, leucine and valine are essential amino acids; the protein powder can be used to produce amino acid products and added into the feed, thus the production cost is reduced, and the comprehensive economic benefit is increased.

Owner:QILU UNIV OF TECH

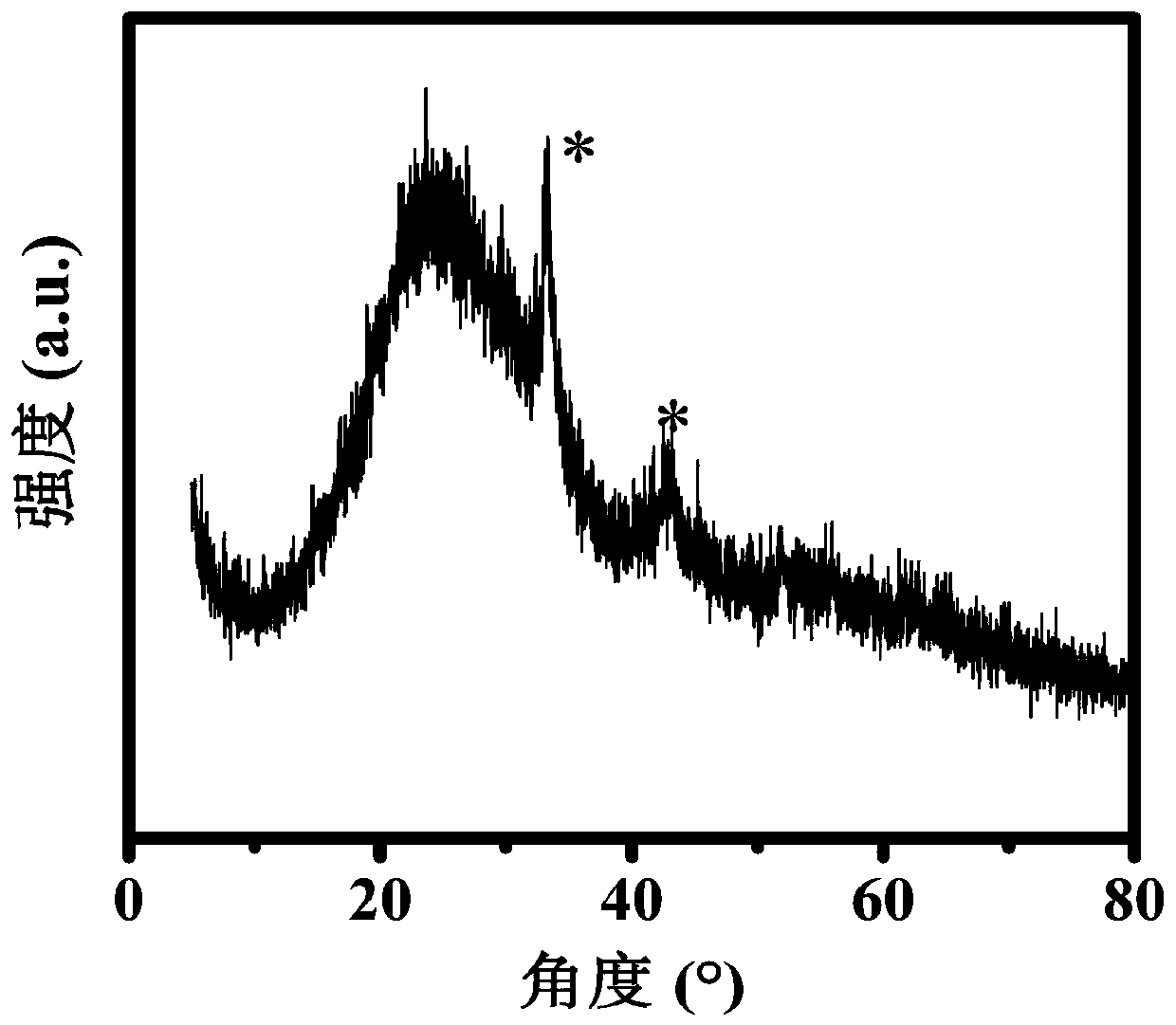

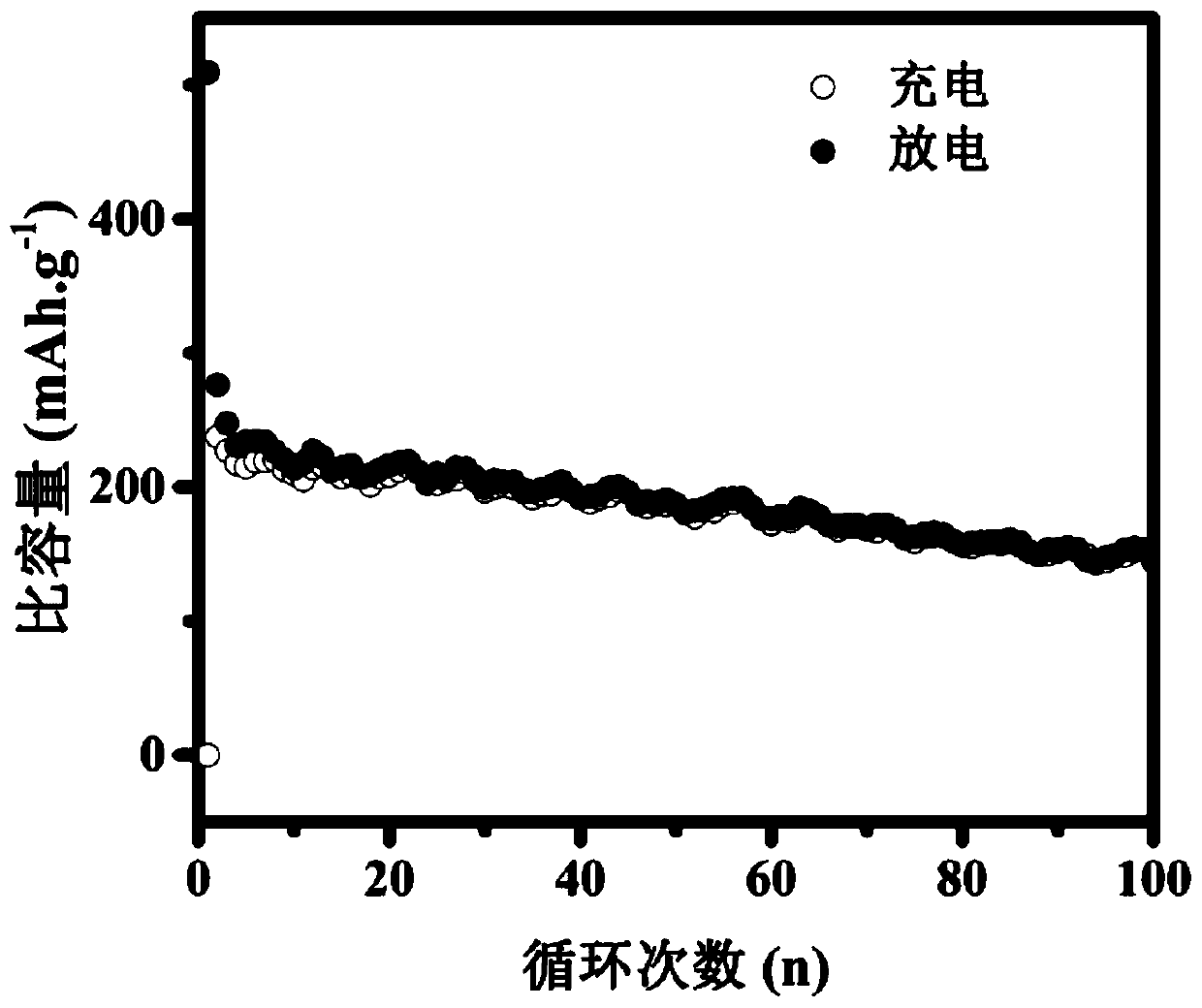

Nitrogen-sulfur co-doped VSe2/CNF potassium ion battery cathode material and preparation method thereof

ActiveCN110190255AEasy transferPlay the role of functional modificationSecondary cellsNegative electrodesFiberCarbon composites

The invention discloses a nitrogen-sulfur co-doped VSe2 / CNF potassium ion battery cathode material and a preparation method thereof. The method is characterized in that keratin is extracted from pig hair, cow hair, wool, poultry feathers or human hair fiber and is doped into PAN / VO(acac)2 compound as a main source of nitrogen and sulfur, and the nitrogen-sulfur co-doped VSe2 / CNF potassium ion battery cathode material is produced through spinning and selenization. The result shows that the potassium ion battery cathode material exhibits superior potassium storage performance. The method is advantaged in that the operation process is simple, conditions are controllable, excellent structural properties of the VSe2 / CNF carbon composites facilitate deintercalation of the potassium ion battery,the animal hairs and the like are utilized as raw materials, green and environmental protection and resource cycle are achieved, high value utilization of waste resources is achieved, co-doping of nitrogen and sulfur provides more active sites for the electrode material itself, the transport of ions and electrons is facilitated, and thereby electrochemical performance is improved.

Owner:FUJIAN NORMAL UNIV

Method for producing liquid organic fertilizer by fermentation of poultry feathers with microbes

InactiveCN106116765ARich in nutrientsRich in amino acidsBio-organic fraction processingMagnesium fertilisersKeratinChemistry

The invention discloses a method for preparing liquid organic fertilizer with an efficient feather degrading bacterium stenotrophomonas maltophilia (Microbacterium sp. TSMC-99). The method is realized by a series of steps: pretreatment of raw materials, preparation of fermenting bacteria of organic fertilizer, optimization of fermenting conditions and production of liquid organic fertilizer. The method makes the most of the poultry feather protein source to produce the liquid organic fertilizer by fermentation, can relieve the insufficiency of organic fertilizer in China, and also can solve the environmental problem caused by a large backlog of feathers. The liquid organic fertilizer produced by microbial fermentative degradation of feather keratin contains rich amino acid and polypeptide and is efficient and environment-friendly green fertilizer; the method has the advantages of mild production conditions, environment friendliness, simple operation, easy popularization and low cost and makes waste profitable; and the technical indexes of the prepared liquid organic fertilizer conform to specifications in the industry standard 'NY525-2012 Organic Fertilizer' of the Department of Agriculture.

Owner:TAISHAN MEDICAL UNIV

Compound biofertilizer and preparation method thereof

InactiveCN105646109ASlow down fermentationImprove solubilityBio-organic fraction processingAnimal corpse fertilisersContinuous croppingBacillus licheniformis

The invention belongs to the technical field of fertilizer, in particular to compound biofertilizer and a preparation method thereof. The compound biofertilizer is prepared by taking apple pomace, crap straw, poultry feather, and urea as fermentation primers, cane sugar and carboxymethylcellulose as encapsulating agents, streptomyces microflavus, paecilomyces lilacinus, bacillus subtilis and bacillus licheniformis as zymophyte, and fermenting; according to the compound biofertilizer provided by the invention, through synergistic interaction of various microbial strains, the requirement on soil is greatly reduced, the physical property of soil and quality of crops are improved, the disease-resistant and continuous cropping resistant capacities are improved, the cane sugar and the carboxymethylcellulose are taken as the encapsulating agents, the nutrient needing by microbial action in later period is provided, meanwhile, the water and nutrient retention capacity of the soil is improved, and the crop yield can be improved by about 30 percent.

Owner:SHANDONG LVHENG BIOLOGICAL ENG

Method for preparing feather protein powder from alkaline protease/keratinase

InactiveCN104798981ASimple processBroaden the field of application of the processProtein foodstuffs working-upAlkaline proteinaseFeed additive

The invention relates to the technical field of animal feed processing, in particular to a method for preparing feather protein powder from alkaline protease / keratinase. Poultry feathers are taken as raw materials, and the method for preparing the feather protein powder from the alkaline protease / keratinase is characterized by comprising steps as follows: (1) preparation of feather powder; (2) enzymolysis; (3) filtration and drying. The technology is simple, the technology application field is broadened, the enzymolysis temperature is low, the pH action range is wide, the enzymolysis cost is low, the enzymolysis efficiency is high, the content of soluble protein of an enzymolysis supernatant is higher, meanwhile, 11 amino acid components with higher content are contained, phenylalanine, isoleucine, leucine and valine are amino acids essential to human bodies, amino acid products and feed additive protein can be processed, the production cost is reduced, and the comprehensive economic benefit is increased.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com