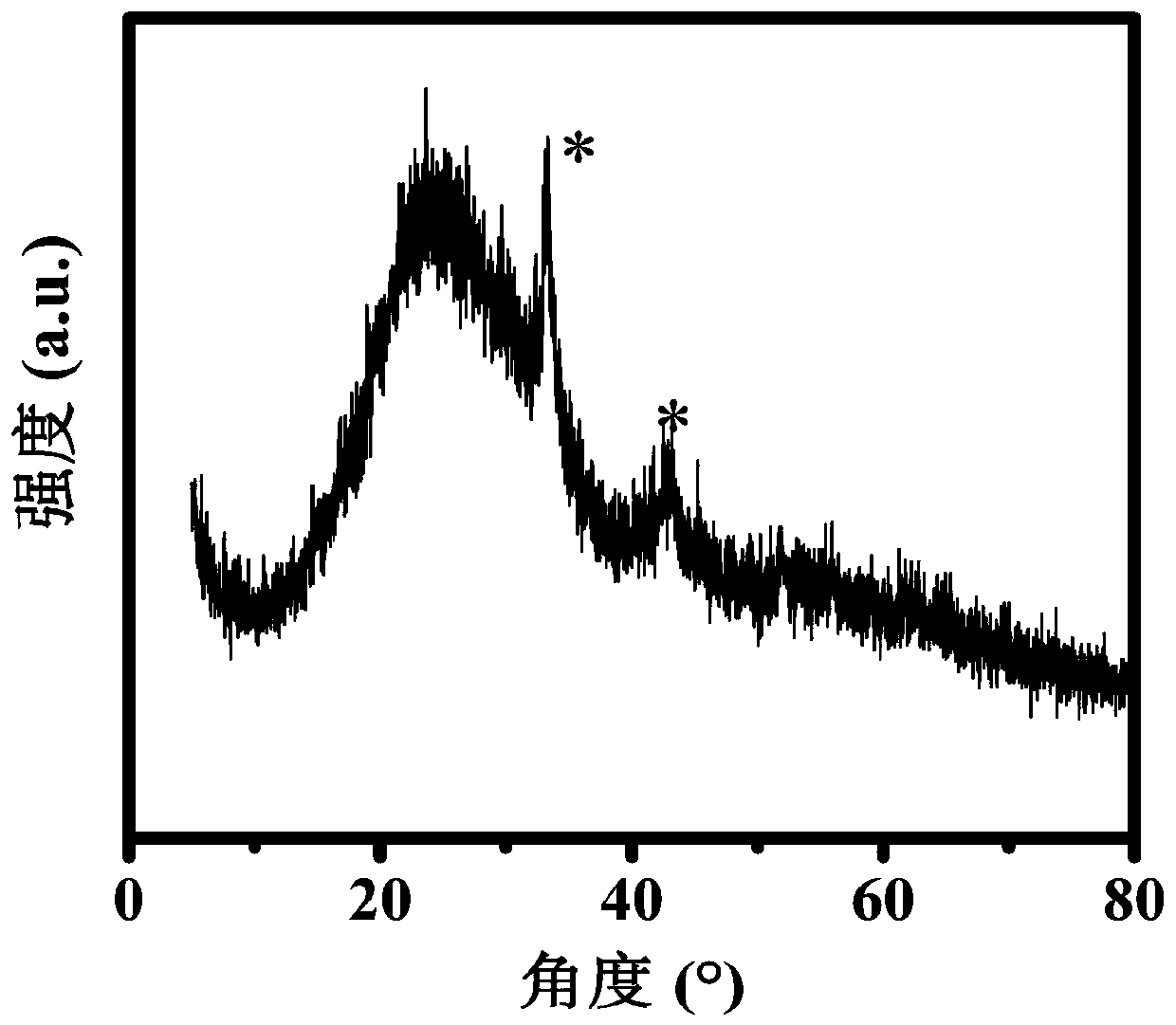

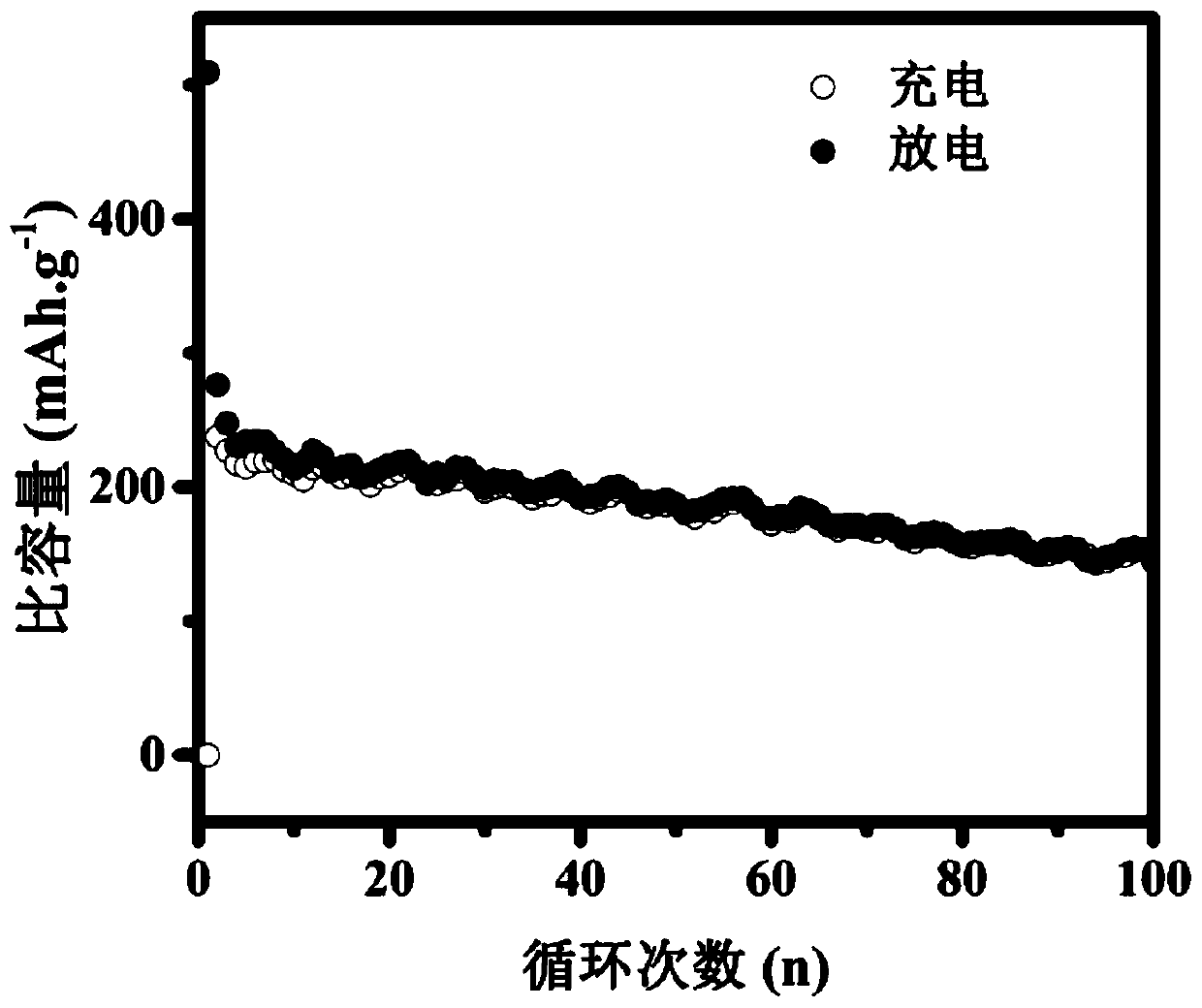

Nitrogen-sulfur co-doped VSe2/CNF potassium ion battery cathode material and preparation method thereof

A nitrogen-sulfur co-doping, battery negative electrode technology, applied in battery electrodes, negative electrodes, secondary batteries and other directions, can solve the problems of slow volume expansion of potassium ion de-intercalation kinetics, restrict development and other problems, achieve excellent electrochemical performance, Inexpensive and highly maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Weigh 5 g of chicken feathers into a beaker, pour 50 ml of acetone into the beaker, and ultrasonicate for 30 min, then put it in 100 o Dried in the oven of C, cut the chicken feathers (about 5 mm) and pulverized to obtain powder. Then it was dissolved with 3wt% NaOH at 90 o C under microwave hydrothermal digestion reaction for 1 hour. The solution obtained by hydrothermal degradation was placed in a lyophilizer at -40 o C After freeze-drying, use a mortar to grind to obtain a solid powdery polypeptide, which is used as a nitrogen-sulfur precursor for future use.

[0033] 2) Take 0.5 g PAN and 0.5 g VO(acac) 2 , dissolved in 10 mL of N,N-dimethylformamide to form a mixed solution. Take 0.2 g nitrogen-sulfur precursor powder and add 60 o C in warm water, stirred for 30 min, slowly added to the above mixed solution, stirred for 24 h to obtain a spinning solution.

[0034]3) Transfer the spinning solution obtained above into a syringe, set the spinning voltage to 2...

Embodiment 2

[0038] 1) Weigh 5 g of pig hair into a beaker, pour 50 ml of acetone into the beaker, and ultrasonicate for 30 min, then put it in 100 o Dry in the oven of C, cut the pig hair into pieces (about 5 mm) and pulverize to obtain powder. Then with 2wt% NaCO 3 which dissolves at 100 o C under microwave hydrothermal digestion reaction for 1 hour. The solution obtained by hydrothermal digestion was placed in a lyophilizer at -40 o C After freeze-drying, use a mortar to grind to obtain a solid powdery polypeptide, which is used as a nitrogen-sulfur precursor for future use.

[0039] 2) Take 0.5 g PAN and 0.5 g VO(acac) 2 , dissolved in 10 mL of N,N-dimethylformamide to form a mixed solution. Take 0.3 g nitrogen-sulfur precursor powder and add 60 o C in warm water, stirred for 30 min, slowly added to the above mixed solution, and stirred for 24 h to obtain a spinning solution.

[0040] 3) Transfer the spinning solution obtained above to a syringe, set the spinning voltage to 22 k...

Embodiment 3

[0044] 1) Weigh 5 g of human hair fiber into a beaker, pour 50 ml of acetone into a beaker and ultrasonicate for 30 min, then put it in 100 o Dry in the oven of C, cut the human hair fiber into pieces (about 5 mm) and pulverize to obtain powder. Then it was dissolved with 1 mL of 20 wt% concentrated ammonia water at 120 o C under microwave hydrothermal digestion reaction for 0.8 hours. The solution obtained by hydrothermal digestion was placed in a lyophilizer at -40 o C After freeze-drying, grind with a mortar to obtain a solid powdery polypeptide, which is used as a nitrogen-sulfur precursor for future use.

[0045] 2) Take 0.5 g PAN and 0.5 g VO(acac) 2 , dissolved in 10 mL of N,N-dimethylformamide to form a mixed solution. Take 0.5 g nitrogen-sulfur precursor powder and add 60 o C in warm water, stirred for 30 min, slowly added to the above mixed solution, and stirred for 24 h to obtain a spinning solution.

[0046] 3) Transfer the spinning solution obtained above to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com