Patents

Literature

456results about "Cellulose/protein filament chemical after-treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene blend regenerated cellulose fiber and preparation method thereof

ActiveCN103046151AImprove conductivityImprove thermal performanceArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentMoisture absorptionCellulose fiber

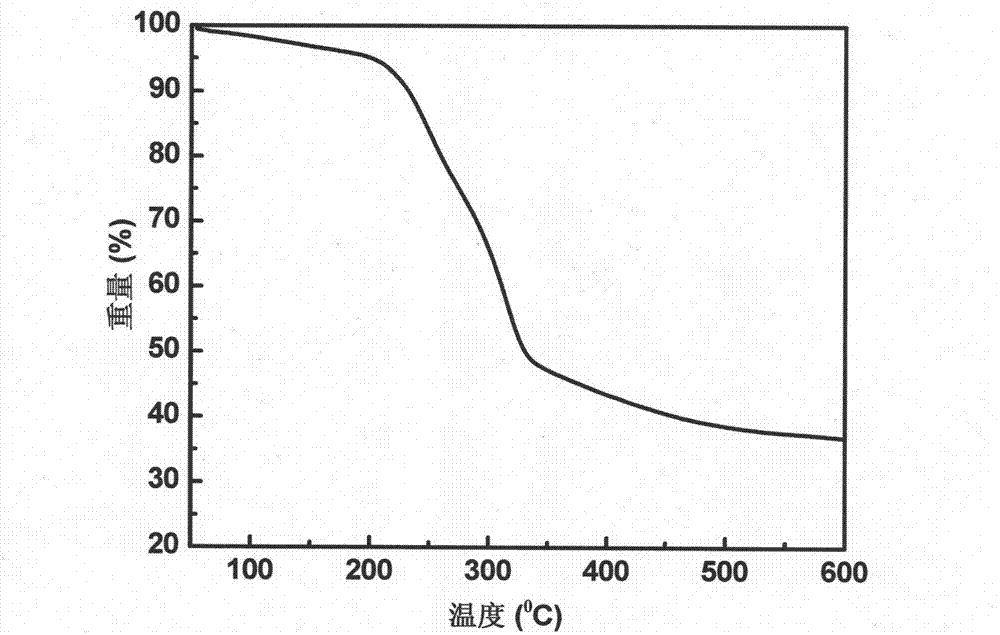

The invention relates to a graphene blend regenerated cellulose fiber. The graphene blend regenerated cellulose fiber is prepared by mixing an oxidized graphene solution and a regenerated cellulose solution, molding a mixture through a viscose wet spinning process and reducing the mixture; the dry breaking strength of the graphene blend regenerated cellulose fiber is not less than 1.8 cN / dtex, the wet breaking strength of the graphene blend regenerated cellulose fiber is not less than 0.9 cN / dtex, the dry breaking elongation of the graphene blend regenerated cellulose fiber is not less than 16%, the mass specific resistance of the fiber is 1-9X106 omega.g / cm2, and the thermal decomposition temperature of the fiber is not lower than 400 DEG C; and with the regenerated cellulose fiber as a matrix, the prepared graphene blend regenerated cellulose fiber has the advantages of good moisture absorption, good air permeability, soft handle and good dyeing performance and has the characteristics of ultrahigh strength, thermal conductivity, electric conductivity, antibacterial property and the like of the graphene; the conductive and thermal properties of the fiber are both improved by being compared with those of the traditional regenerated cellulose fiber; the antibacterial property of the fiber is additionally provided; and the graphene blend regenerated cellulose fiber provided by the invention has the advantages of simple production process, easiness in operation, and higher yield. People estimate that the developed graphene blend regenerated cellulose fiber can be widely applied to the field of costumes, industrial textiles and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG +1

Meltblown process with mechanical attenuation

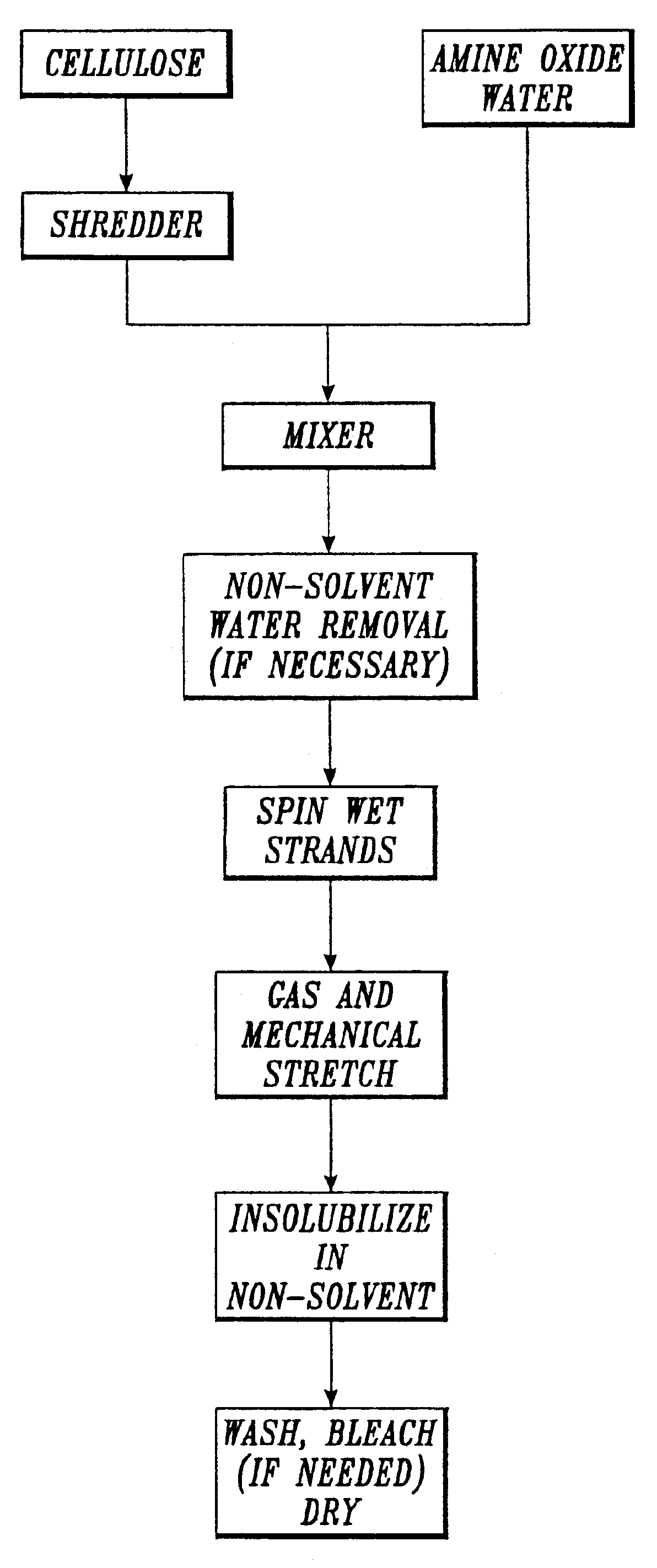

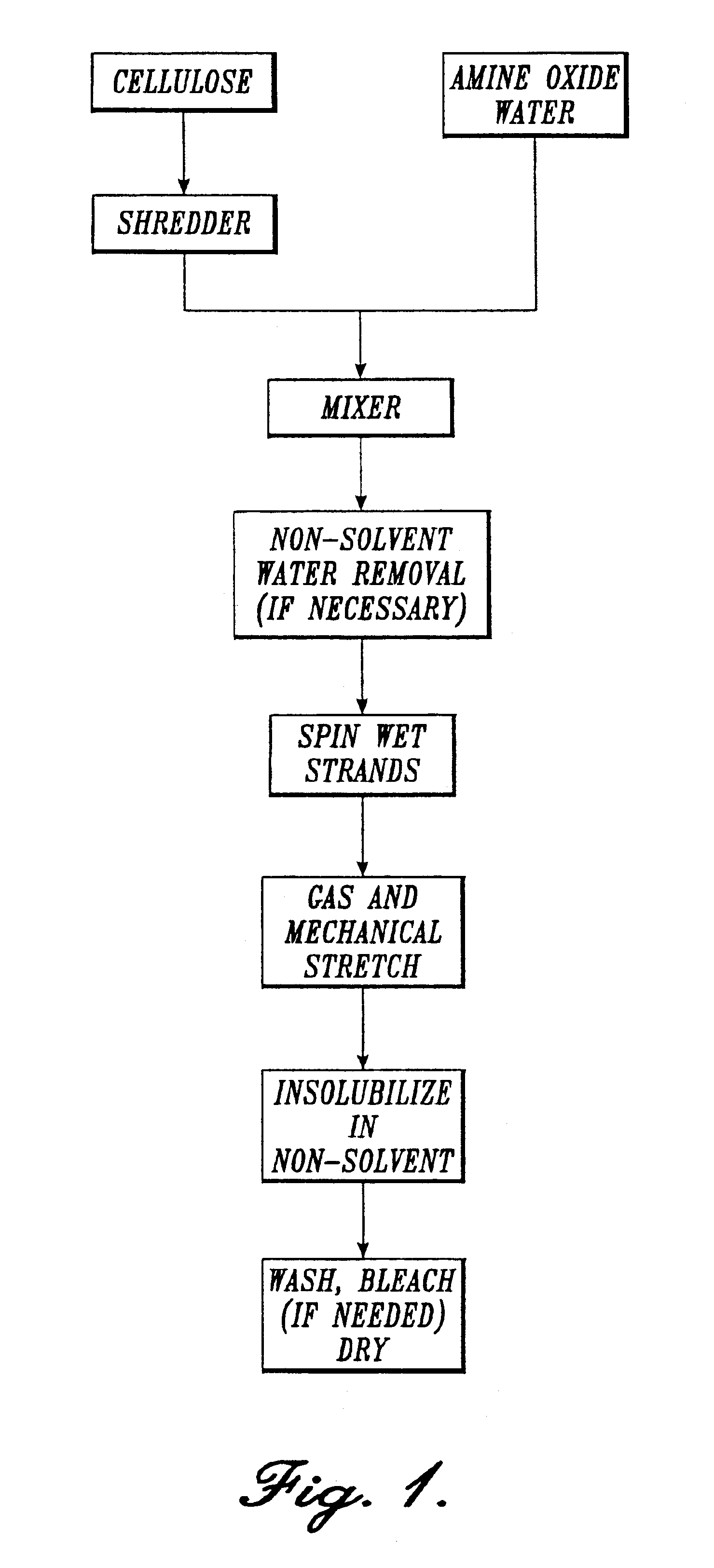

InactiveUS6773648B2High speed spinningImprove productivityPulp properties modificationArtificial filament physical treatmentCelluloseUltrasound attenuation

Owner:WEYERHAEUSER NR CO

Cellulose fiber-supported nano silver antibacterial material and preparation method thereof

InactiveCN102776594ARich sourcesLow priceArtificial filaments from cellulose solutionsCellulose/protein filament chemical after-treatmentControlled releaseWound dressing

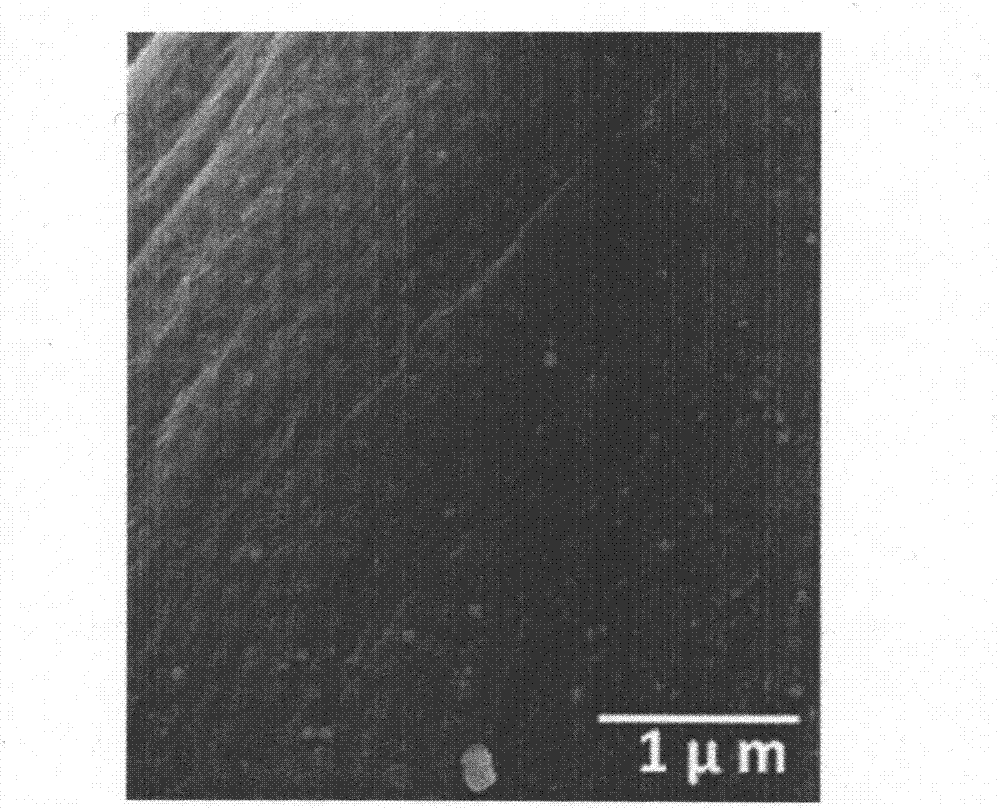

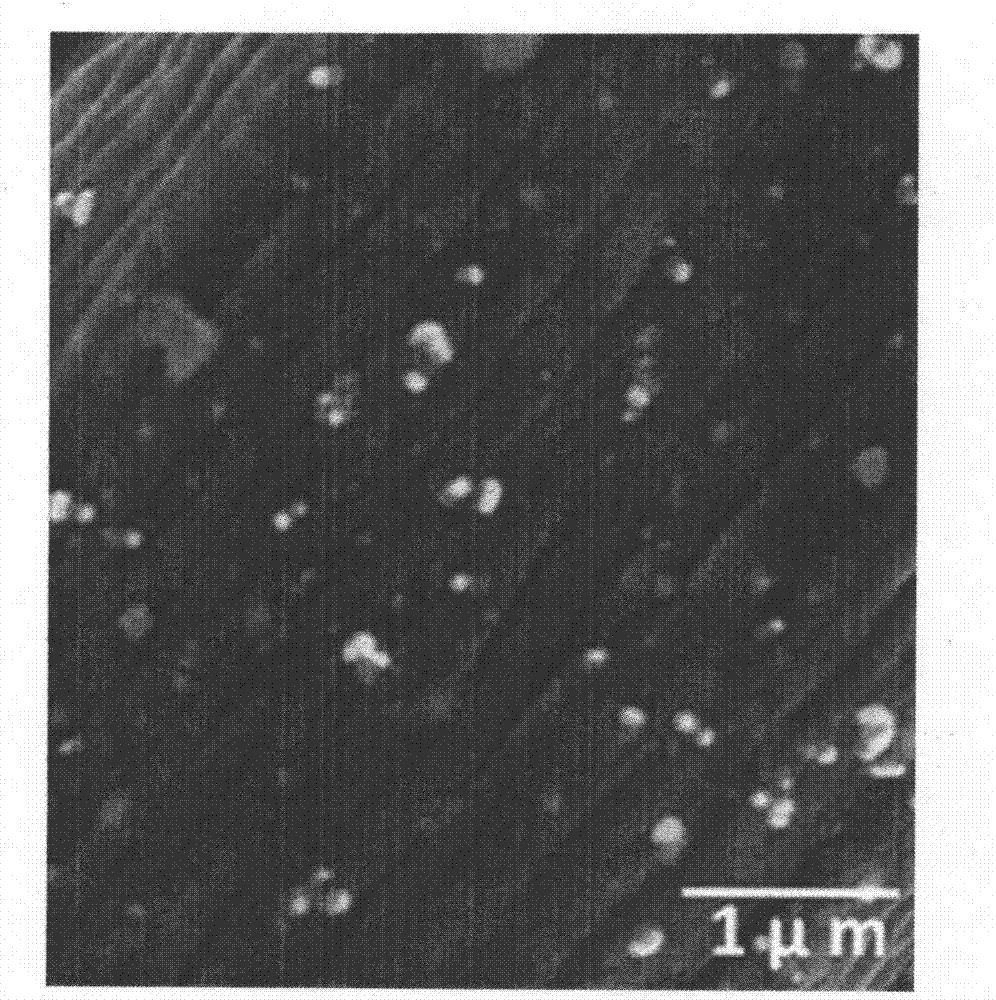

The invention discloses a cellulose fiber-supported nano silver antibacterial material and a preparation method thereof. The preparation method comprises the steps of: conducting chemical pretreatment on cellulose fibers, then conducting TEMPO (2, 2, 6, 6-tetramethylpiperidine-1-oxyl) selective oxidization on the cellulose fibers, and finally on the premise that not any reducing agent is added, enabling the oxidized cellulose fibers to react with silver nitrate in silver nitrate water solution through a short-time microwave heating method to prepare the cellulose fiber-supported nano silver antibacterial material with small-diameter and even-structure nano silver particles. By adopting the preparation method, on the premise that not any reducing agent is added, in-situ reduction and growth of nano silver on carboxylated cellulose fiber supporters are realized. The prepared cellulose fiber-supported nano silver antibacterial material has the advantages of small nano grain size and even size, and can be widely applied to the fields of antibacterial operation clothes, wound dressing, drug controlled release, textile coating and the like.

Owner:DONGHUA UNIV

Chemically-Assisted Alignment of Nanotubes Within Extensible Structures

ActiveUS20090075545A1Smooth connectionImprove thermal conductivityArtificial filament physical treatmentHollow filament manufactureChemical mixturesYarn

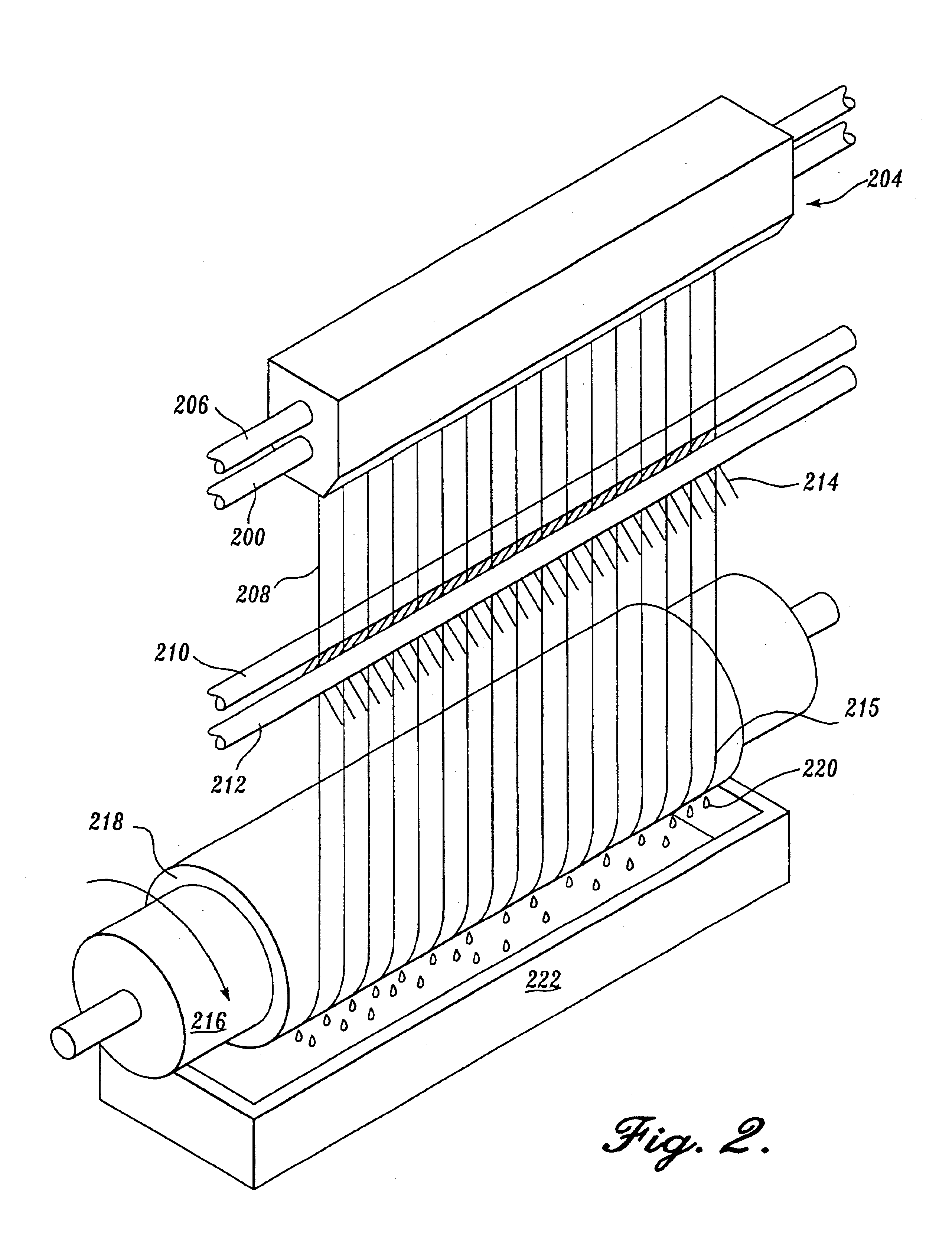

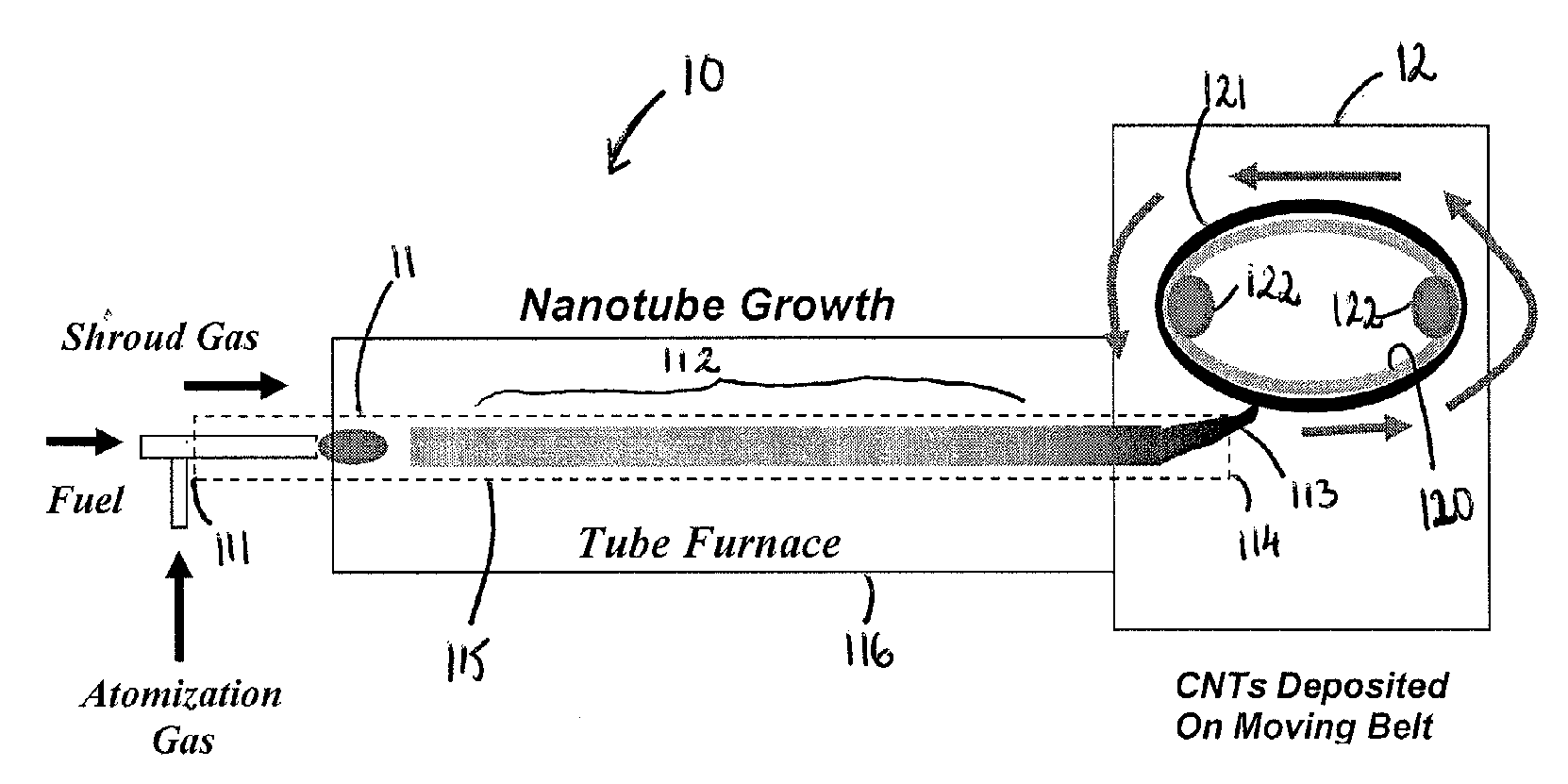

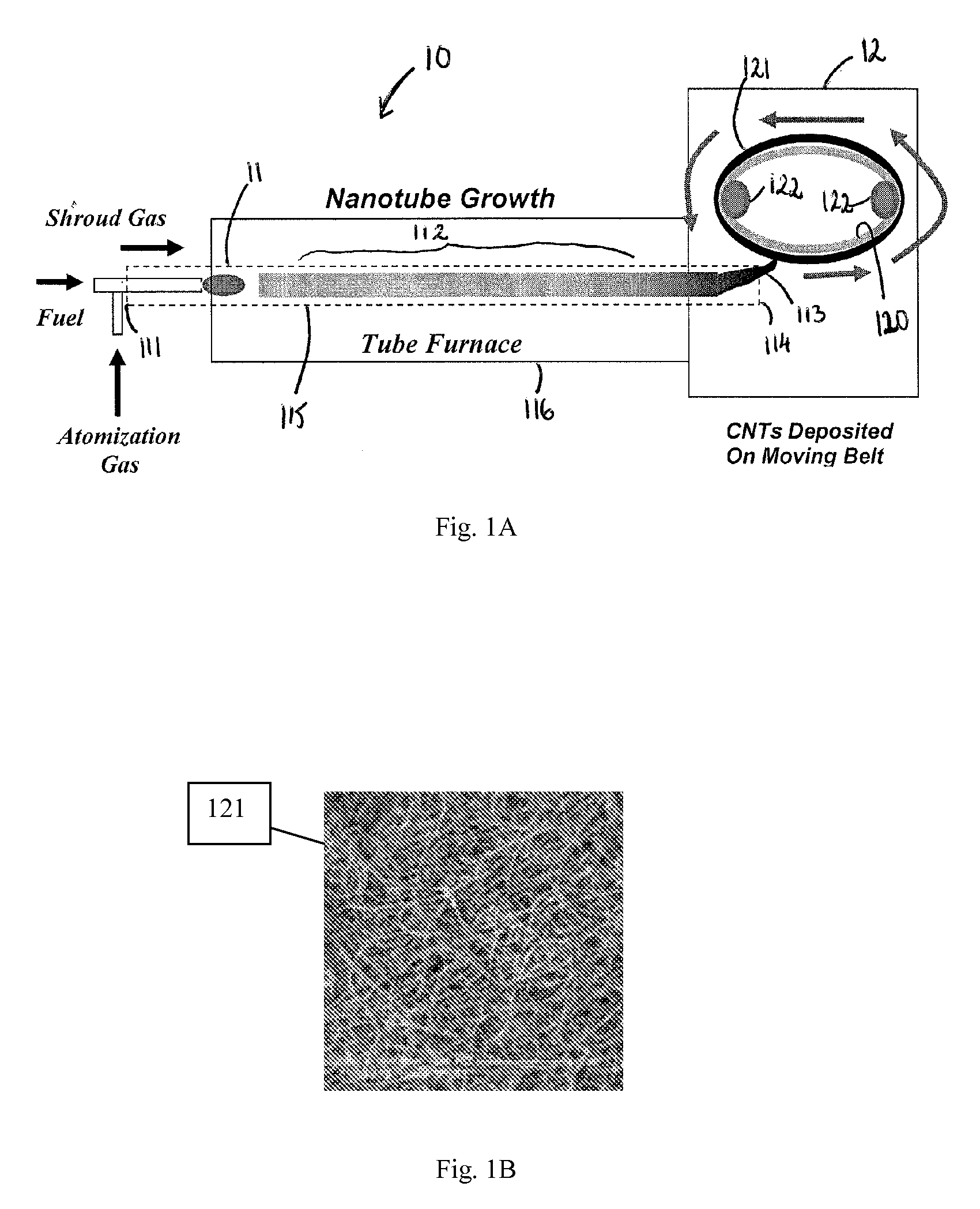

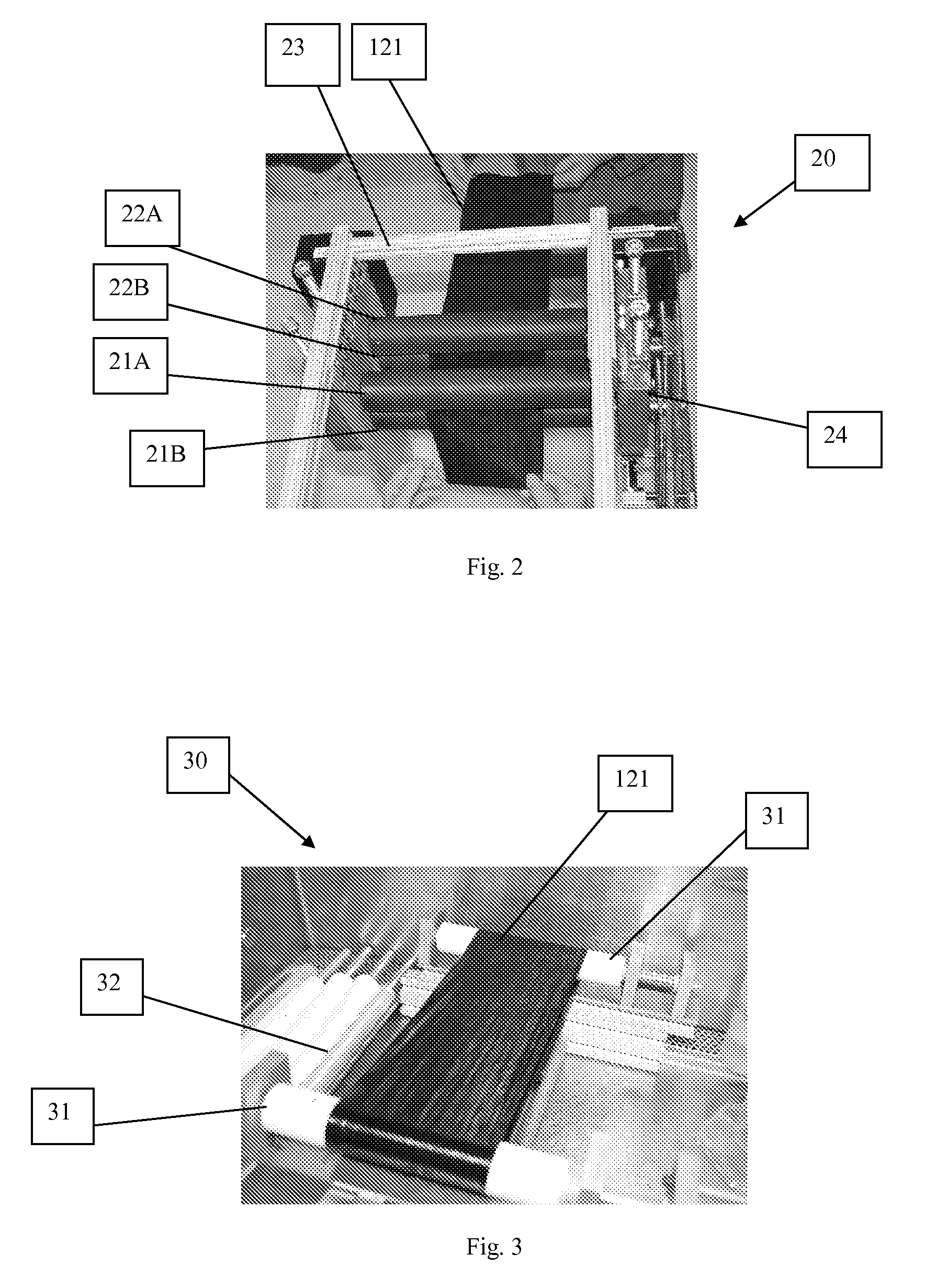

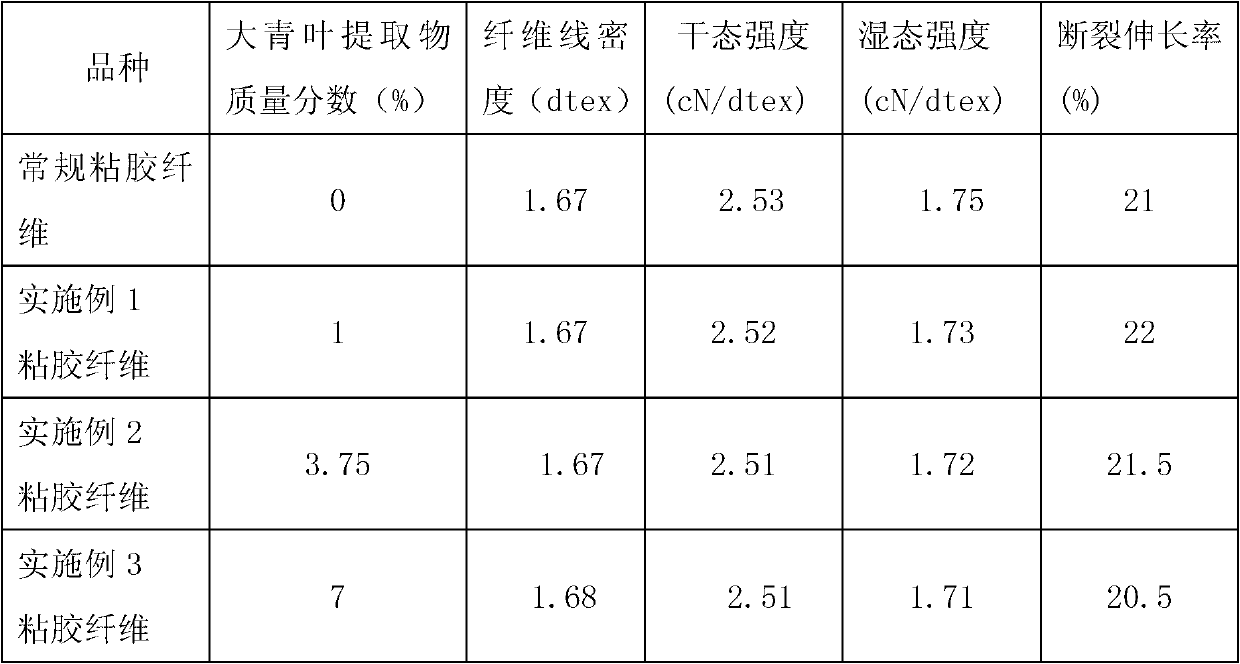

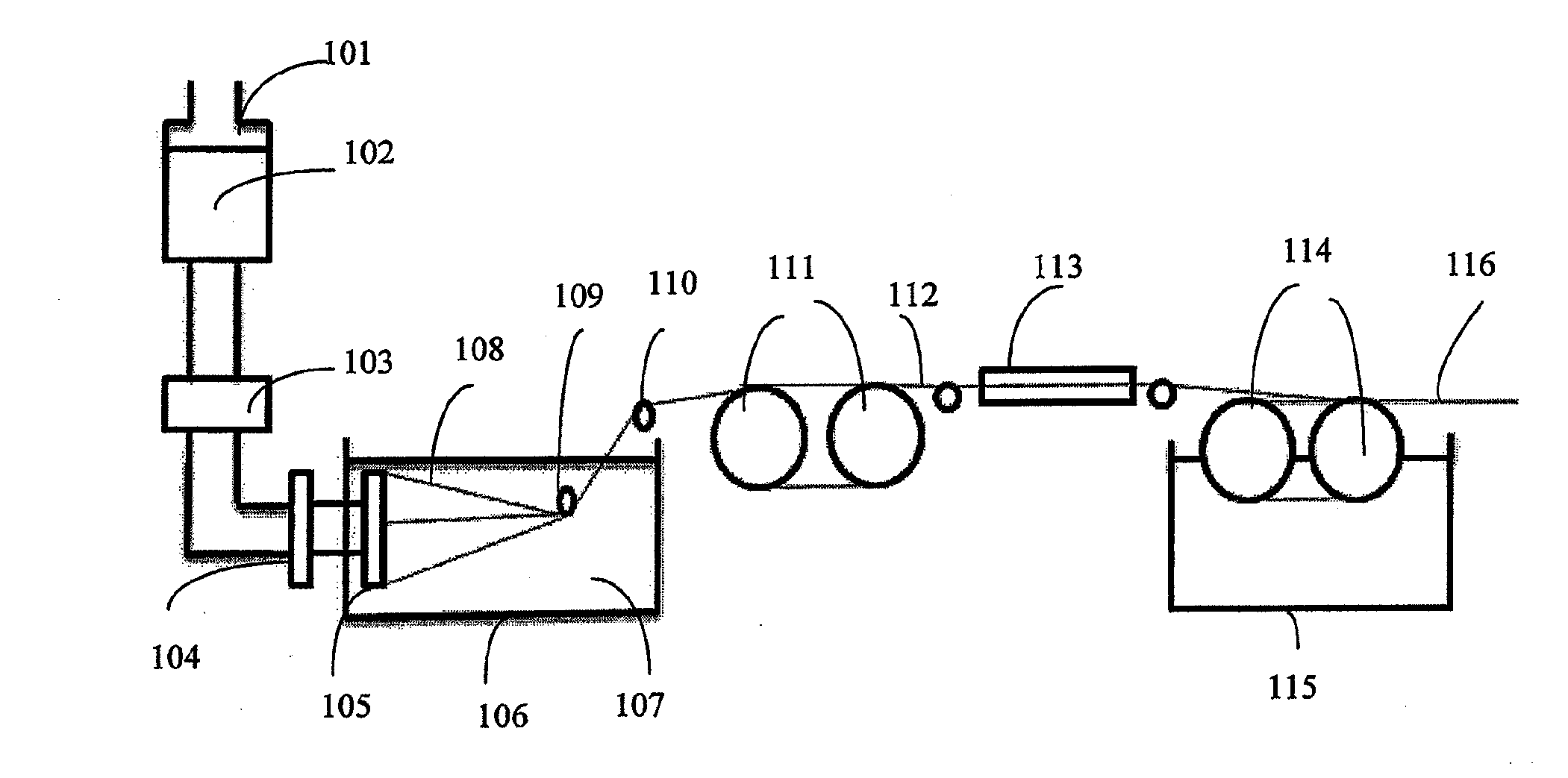

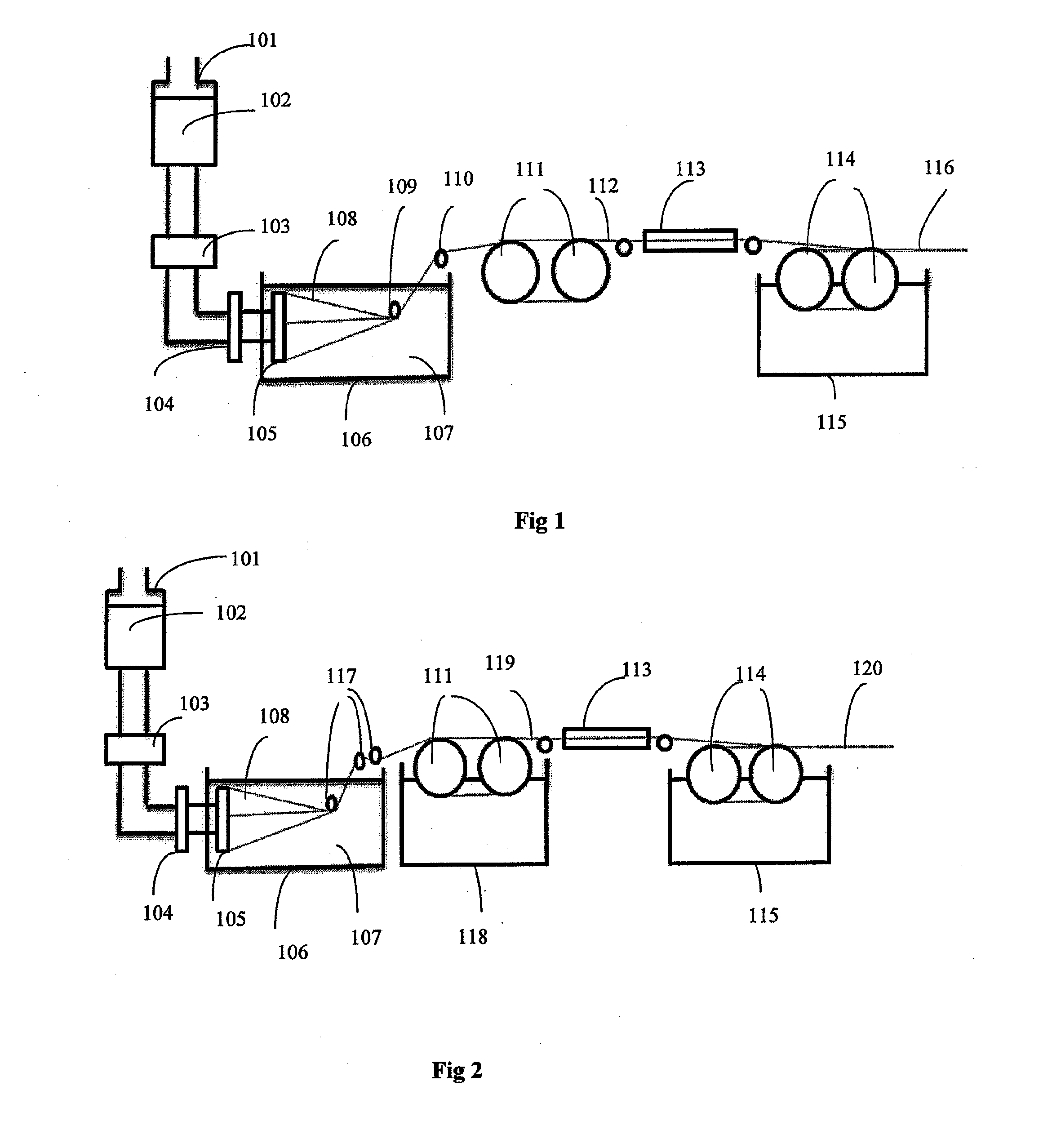

A method and system for aligning nanotubes within an extensible structure such as a yarn or non-woven sheet. The method includes providing an extensible structure having non-aligned nanotubes, adding a chemical mixture to the extensible structure so as to wet the extensible structure, and stretching the extensible structure so as to substantially align the nanotubes within the extensible structure. The system can include opposing rollers around which an extensible structure may be wrapped, mechanisms to rotate the rollers independently or away from one another as they rotate to stretch the extensible structure, and a reservoir from which a chemical mixture may be dispensed to wet the extensible structure to help in the stretching process.

Owner:NANCOMP TECHNOLOGIES INC

Viscose containing natural antimicrobials and preparation method thereof

InactiveCN102926013AImprove antibacterial functionNo side effectsArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentViscose fiberStock solution

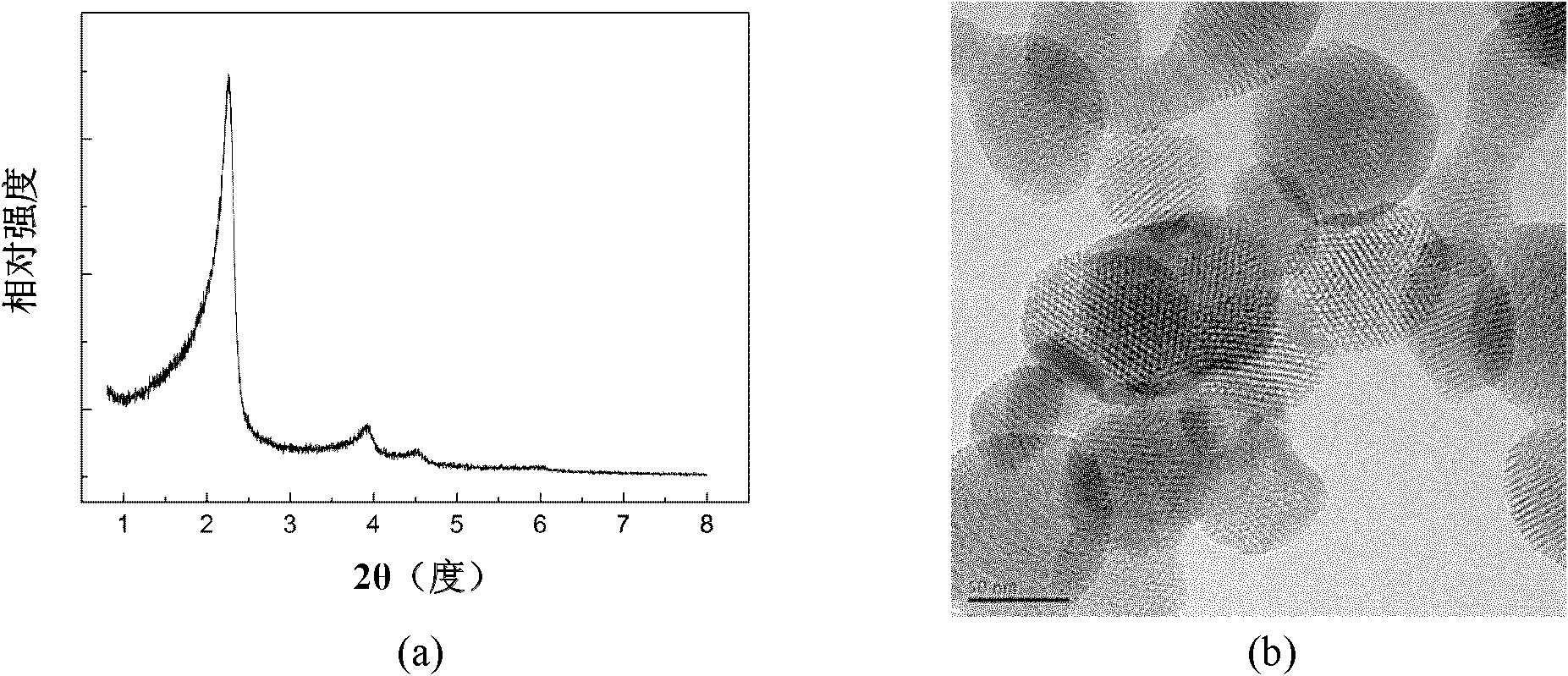

The invention provides viscose containing natural antimicrobials. The viscose containing the natural antimicrobials comprises the viscose and the antimicrobials contained in the viscose. The viscose containing the natural antimicrobials is characterized in that the antimicrobials is natural indigowoad leaf extract powder, a natural indigowoad leaf extract powder solution added with dispersing agent is added into a viscose filature stock solution, the additive amount of the natural indigowoad leaf extract powder is 1%-7% of the quality of the viscose filature stock solution, the additive amount of the dispersing agent in the natural indigowoad leaf extract powder solution is 0.1%-1.0% of the quality of water in the natural indigowoad leaf extract powder solution. The preparation method of the viscose comprises the steps of dissolving the indigowoad leaf extract powder into water and adding the dispersing agent to obtain the indigowoad leaf extract powder solution, adding the indigowoad leaf extract powder solution to the viscose filature stock solution according to a ratio of 10%-14% of the quality of the viscose filature stock solution, and then shaping a obtained solution according to conventional wet spinning jet process to obtain the viscose. The viscose has a durable antibacterial function and has no side effect on human bodies. The preparation method has reasonable and simple technology, and is suitable for industrialized production.

Owner:单修铎

Protein cellulose viscose and preparing method thereof

ActiveCN101298708AGood protein contentImprove spinnabilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentSpinningPROTEIN S HEERLEN

The invention relates to a protein viscose fiber and a preparation method thereof, belonging to the textile field and aiming at solving a technical problem about how to provide a method for adopting different animal and plant proteins as materials to prepare the protein viscose fiber. The preparation method of the protein viscose fiber includes the following steps: 1. the animal and plant proteins are degreased, decolored and deodorized to obtain animal-plant protein powder; 2. alkalization: the animal-plant protein powder is dissolved in alkaline liquor to obtain protein alkaline solution; 3. cross-linker is added into the protein alkaline solution to obtain a protein spinning liquor; 4. the protein spinning liquor is blended with a glue to be spun to obtainprotein filaments; 5. the protein filaments are washed by peroxide solution and are oiled, dried and formed into cylinder form to get the protein viscose fiber. The protein viscose fiber preparation method of the invention does not adopt any acetalation treatments to the protein filaments after spinning so as to avoid the remaining of methanal, etc. harmful matters, the technique steps are simple and can be easily operated and the manufacturing can be realized with the existing viscose fiber preparation equipment.

Owner:YIBIN GRACE GROUP CO LTD

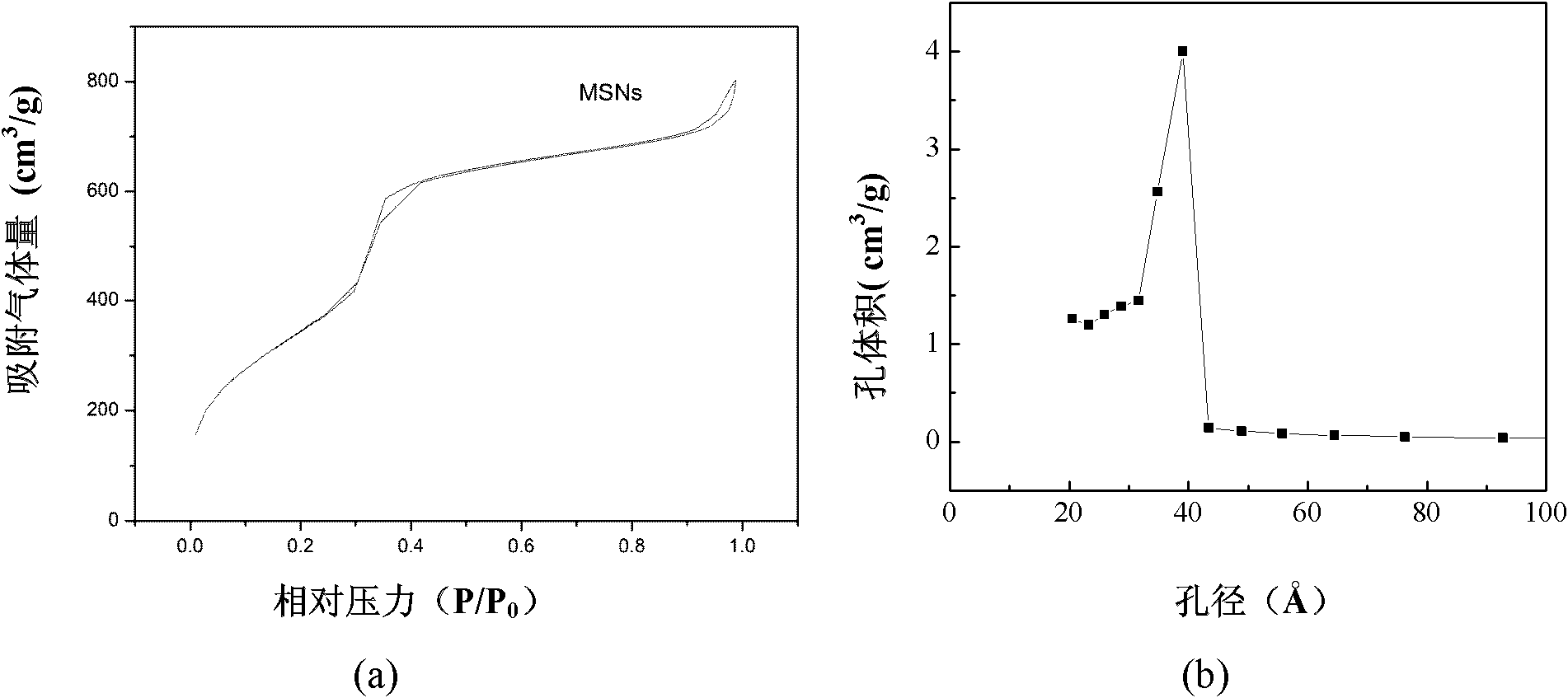

Mesoporous silicon oxide particle/degradable polymer nano composite fiber, preparation method and application thereof

InactiveCN102051702ARetain performanceImprove throughputMonocomponent protein artificial filamentFilament/thread formingFiberElectrospinning

The invention discloses a mesoporous silicon oxide particle / degradable polymer nano composite fiber, a preparation method and application thereof. The method comprises the following steps of: uniformly dispersing mesoporous silicon oxide particles into a solution of degradable polymers; and then preparing nano composite fibers by adopting an electrostatic spinning process, wherein the mesoporous silicon oxide particles are uniformly distributed in the degradable polymer fibers. Compared with traditional polymer fibers, the nano composite fiber can be used for better controlling the release ofdrugs and has quicker biodegradability and higher mechanical strength, and meanwhile, the fiber has better cellular compatibility. The nano composite fiber can be used as a tissue engineering support, a drug release vector, a wound coating material or a functional membrane.

Owner:EAST CHINA UNIV OF SCI & TECH

Environment-friendly type fire retardant as well as preparation method and application thereof

ActiveCN104032401AWon't gelRealize large-scale productionArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentSocial benefitsSpinning

The invention discloses an environment-friendly type fire retardant as well as a preparation method and an application thereof. The fire retardant adopts a preparation method for an environment-friendly type fire retardant matched product, which takes organic silicon hydrolyzing dispersion liquid as a main component of the fire retardant and takes a fixed cross-linking agent as a post-treatment component. The other aim of the invention is to develop the application of the environment-friendly type fire retardant in spinning and post-treat of inflaming retarding viscoses and inflaming retarding synthetic fibers. Raw materials for preparing the environment-friendly type fire retardant are wide in source and low in price; the adverse effects on the environment and the safety, caused by traditional halogen-based and phosphorus based flame retardants, are overcome; the social benefits and the economic benefits are very great.

Owner:SOL FLAME RETARDANT FIBER

Protein and cellulose composite fiber and manufacturing method thereof

InactiveCN101660215AConjugated cellulose/protein artificial filamentsWet spinning methodsCelluloseNatural fiber

The invention discloses a protein and cellulose composite fiber, which is the regenerative protein composite fiber containing 5-50% of natural protein, 50-95% of natural cellulose and 0-30% of alginate, and the fiber is prepared by the technical processes of stock solution preparation, wet spinning, crosslinking finishing and the like. The fiber has the advantages of good hygroscopicity, antistatic property, good dyeing property and complete biodegradability, and the alginate is added in the fiber for leading the fiber to have good flame-retardant performance, thereby being a real green raw material for ecological textiles. The fiber has soft and smooth hand feeling, thereby being applicable to underwear processing, bedroom supplies, sanitary and health care supplies and the like of the textiles.

Owner:陈福库

Production process of wool protein compound viscose fiber

ActiveCN102560735AAvoid joiningReflect the superiority of environmental protectionConjugated cellulose/protein artificial filamentsWet spinning methodsPolymer scienceSpinning

The invention provides a production process of wool protein compound viscose fiber, which belongs to the technical field of viscose fiber. The process comprises the steps of preparing a wool protein spinning solution, blending the wool protein spinning solution with a viscose spinning solution, spinning, solidifying and curing and performing aftertreatment to obtain the wool protein compound viscose fiber. In the invention, the addition of toxic substances is avoided, the obtained finished product is more suitable for manufacturing the textile products with high safety, such as intimate apparels and the like, and shows the advantages in environmental friendliness.

Owner:CHENGDU GRACE FIBER +1

Feather protein fiber and method for preparing same

InactiveCN102733001AImprove wrinkle resistanceImprove toughnessConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentPotassium silicateAqueous solution

The invention discloses a feather protein fiber and a method for preparing the same. The feather protein fiber comprises the following components: 5-40 parts by weight of feather protein and 60-95 parts by weight of chemical fiber. The method for preparing the feather protein fiber comprises the following steps: A, feather protein spinning solution preparing: dissolving feather in an alkaline aqueous solution comprising sodium silicate and potassium silicate with the total mass concentration of 20-35%, and filtering to obtain the feather protein spinning solution, wherein the mass ratio of the sodium silicate to the potassium silicate is 1:(0.5-1); B, blending the feather protein spinning solution and the chemical fiber spinning solution, and spinning; and C, subjecting the feather protein fiber trickle to coagulation-bath treatment, pickling, washing and drying to obtain the feather protein fiber. The method for preparing the feather protein fiber can effectively ensure that the feather protein and the chemical fiber are fully and uniformly blended to achieve the purpose of spinning.

Owner:成都天之蚕生物科技有限公司

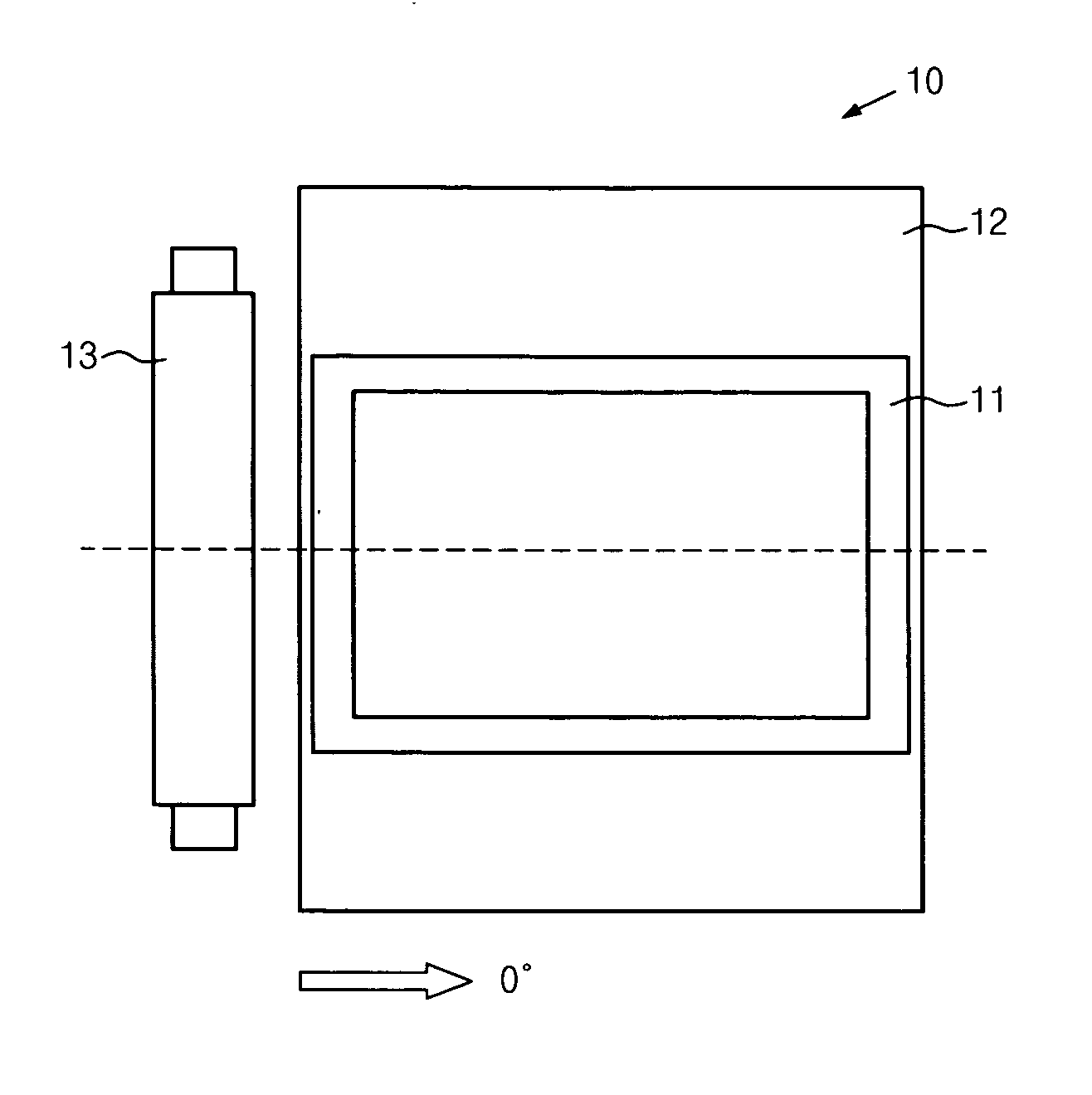

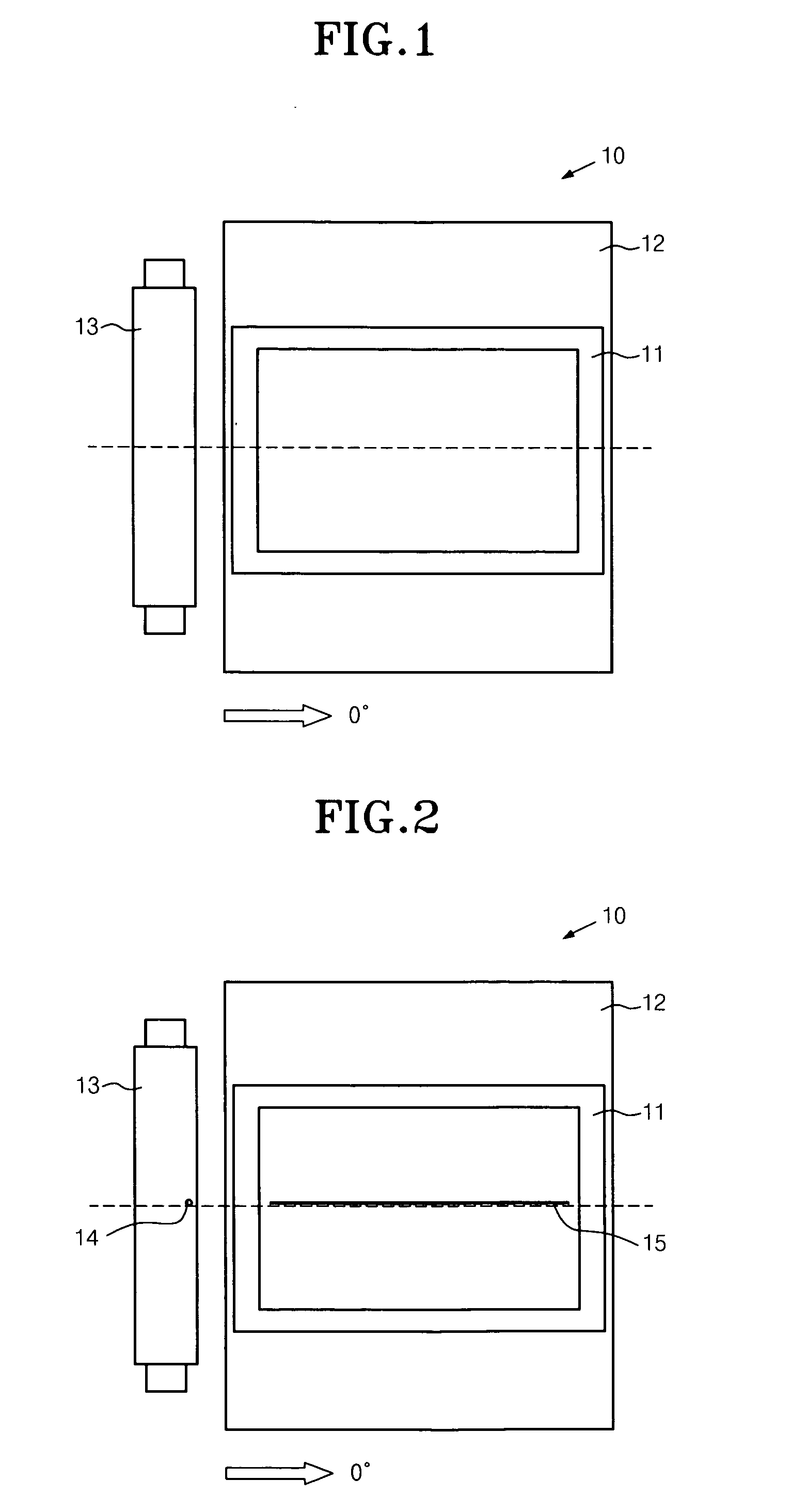

Alignment layer rubbing apparatus

InactiveUS20070132930A1Avoid defectsGrinding feed controlAutomatic grinding controlForeign matterVisibility

Disclosed is an alignment layer rubbing apparatus including a table for seating a glass substrate and a rubbing roller movably positioned on top of the table so as to rub an alignment layer of the glass substrate seated on the table. The table and the rubbing roller are tilted at a predetermined angle, and the rubbing roller is adapted to move at an angle of 0° on the table. Therefore, the damage inflicted on the alignment layer due to poor aligning of rubbing fabric attached to the rubbing roller or due to the existence of an alien substance on a surface of the rubbing roller is not concentrated, but rather spans across a region. This reduces the occurrence of rubbing stains and the visibility of damaged parts.

Owner:BOE HYDIS TECH

Method for producing regenerated cellulose fiber by dual-bath coagulation

InactiveCN101429682ASlow down the curing speedFully curedArtificial filaments from cellulose solutionsFilament manufactureThioureaCellulose fiber

The invention belongs to the material field, and provides a method for preparing a regenerated cellulose fiber by double solidification bath. The method comprises the following steps: precooling cellulose to a temperature of between 8 DEG C below zero and 12 DEG C below zero in a mixed solution which contains the following compositions in weight percentage: 7 to 10 percent of sodium hydroxide, 4.5 to 7 percent of thiourea, 1 to 10 percent of urea, and 73 to 87.5 percent of water to prepare a cellulose solution with concentration of between 2 and 12 percent through filtering and defoaming; spinning the cellulose solution through a spinning machine, and presolidifying and predrafting the cellulose solution in a first solidifying bath; sufficiently solidifying, regenerating, drafting and orientating the cellulose in a second solidifying bath; washing and drying cellulose; and finally, oiling the fiber through a prepared composite oil solution, and winding the fiber to obtain the regenerated cellulose fiber with excellent mechanical performance.

Owner:DONGHUA UNIV

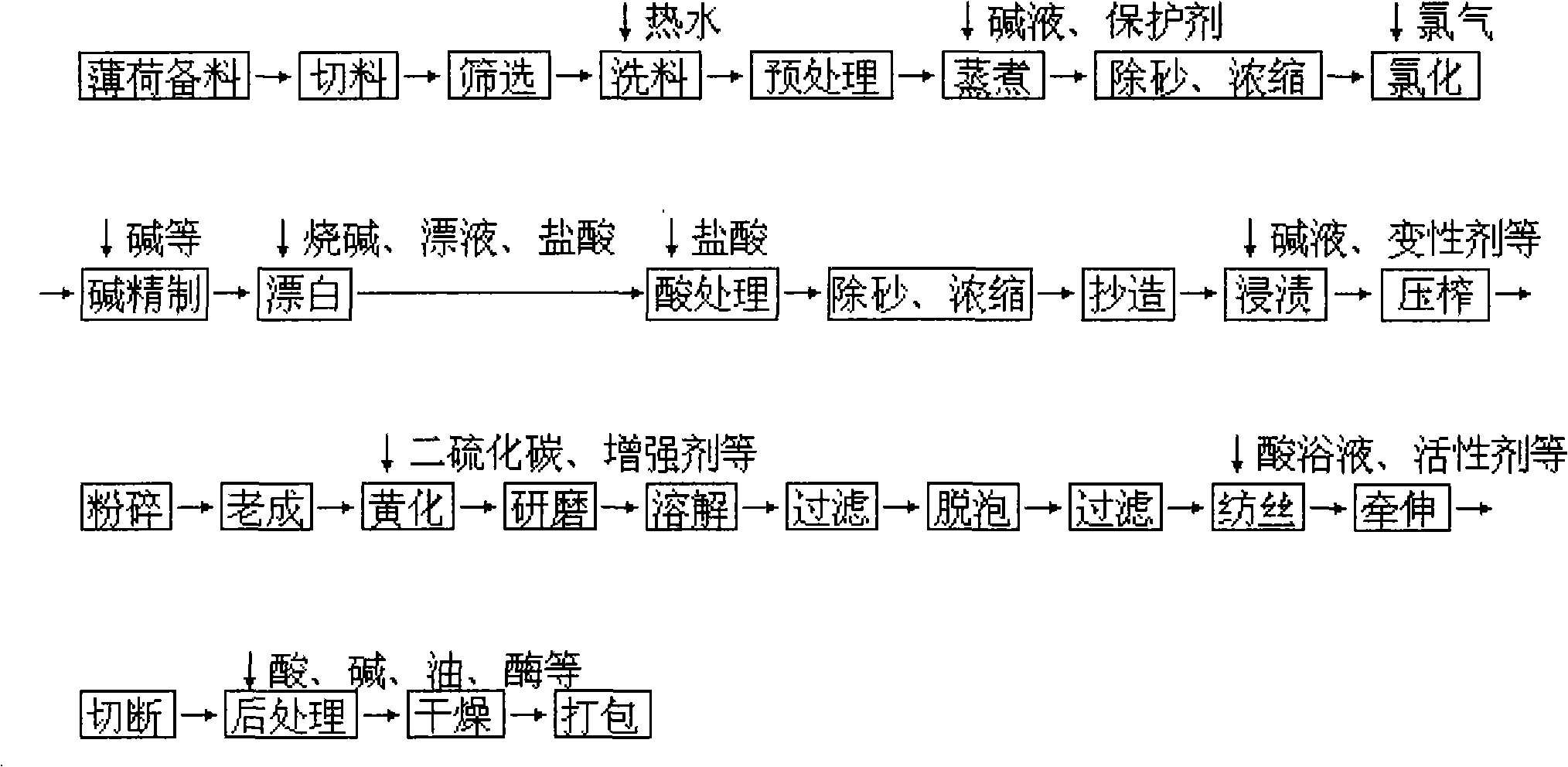

Corn mint cellulose viscose manufacturing technique

InactiveCN101265615AAvoid harmAbundant storageBiochemical fibre treatmentArtificial filaments from viscoseCelluloseMenthone

The invention relates to a viscose fiber produced by utilizing mint and the process engineering thereof. The process includes: mint preparing, cropping, screening, washing, pre-treating, boiling, desanding and concentrating, chloridizing, alkali refining, bleaching, acid treating, desanding and concentrating, papermaking, dipping, pressing, crushing, maturing, yellowing, rubbing, dissolving, filtrating, debubbling, filtrating, spinning, drafting, severing, post-treating, drying, and packing; in the production process, a relaxative pulp technology is adopted, a preservative agent is added, and an enzyme treatment working procedure is added. The invention utilizes mint as the raw material to produce the viscose fiber, which is a creation of applying mint in the textile industry; and the original special matter of the mint, menthol and menthone, are kept, as well as the characteristics of sterilization, balminess, coolness, environmental protection, mosquito repelling, and so on; so that the fiber products thereof have the natural refreshing healthcare function and create a novel field for the development of the viscose fiber and the functional products thereof.

Owner:南京辉恒纺织服装有限公司

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

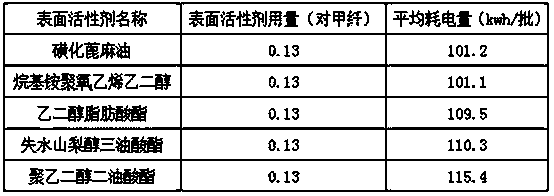

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Compound protein fiber and preparation method thereof

ActiveCN102174720ASoft touchSoft lusterConjugated cellulose/protein artificial filamentsWet spinning methodsMoisture absorptionPVA - Polyvinyl alcohol

The invention relates to a compound protein fiber and a preparation method thereof. The compound protein fiber comprises the following components in percentage by mass: 10 to 45 percent of collagen, 10 to 45 percent of soybean protein and 10 to 80 percent of polyvinyl alcohol. The preparation method of the compound protein fiber comprises the following steps of: dissolving the collagen and the soybean protein in water, adding the polyvinyl alcohol, dissolving, and performing copolymerization modification to obtain spinning solution; and performing processes such as wet spinning, solidification molding, acetalation treatment and the like to obtain the compound protein fiber. The invention has the characteristics that: the compound protein fiber which has a high mechanical property, a high moisture absorption property, high air permeability, a high dyeing property, smooth handfeel, soft luster, skin intimate performance and health-care performance and is comfortably worn is manufactured by performing blending and copolymerization modification on the polyvinyl alcohol by using the collagen and the soybean protein; and the collagen and the soybean protein have wide raw material resources and low prices, a manufacturing process is relatively simple, and production cost is reduced.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

Preparation method for regenerated fibroin fiber

InactiveCN102181957AControl degradationReduce usageMonocomponent fibroin artificial filamentCellulose/protein filament chemical after-treatmentFiberPh regulation

The invention relates to a preparation method for regenerated fibroin fiber, which comprises the following steps: taking regenerated fibroin water solution containing calcium ions as spinning liquid, extruding the spinning liquid out from a spinning nozzle in the temperature range of 5-35 DEG C, then curing the spinning liquid into silk in air directly, taking alcohol-water mixed solution as a finishing agent for post-processing, then taking the silk for drying, and finally obtaining the regenerated fibroin fiber. In the invention, the raw material source is wide, the cost of the raw material is low, and in the whole process, the defects that the traditional wet spinning solvent and the coagulating bath are strong in corrosion, and are toxic; in addition, compared with the other regenerated fibroin fiber dry spinning fiber, the condition of the spinning liquid is optimized, the PH regulation and other complex steps are omitted, and the use of a series of solvent is avoided. Therefore in the method, the cost is saved, and simultaneously the environment is protected. The regenerated fibroin fiber has the advantages of being non-toxic, harmless on human body and the like, is good in biocompatibility, suitable for biological and medical materials, and has good application prospect.

Owner:DONGHUA UNIV

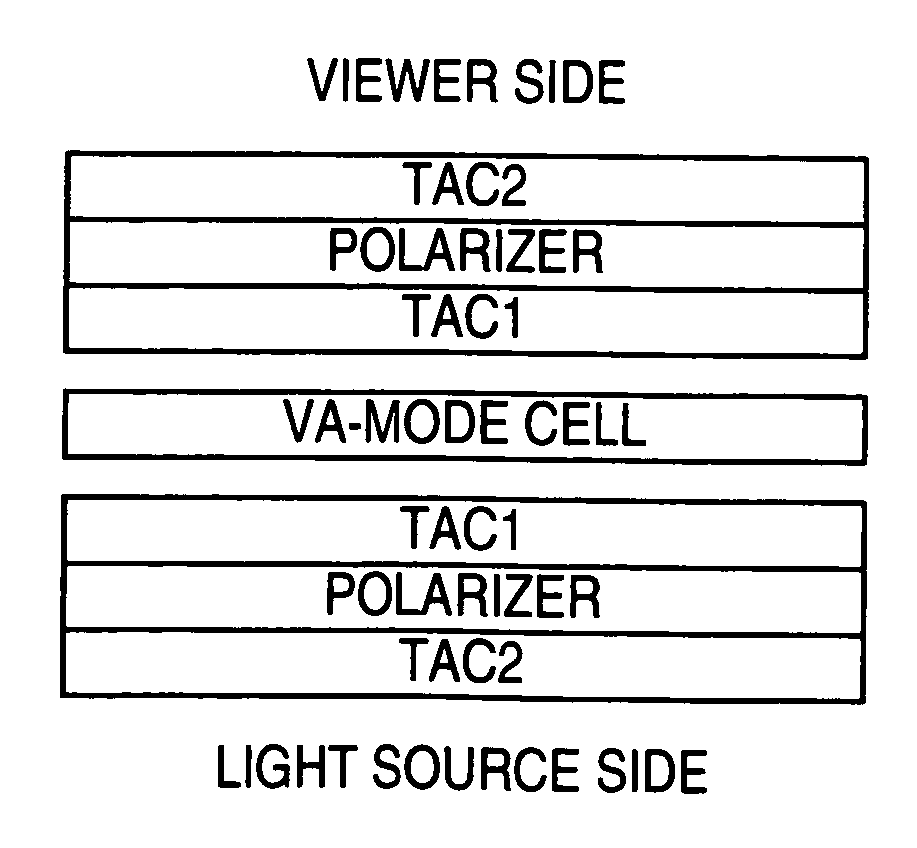

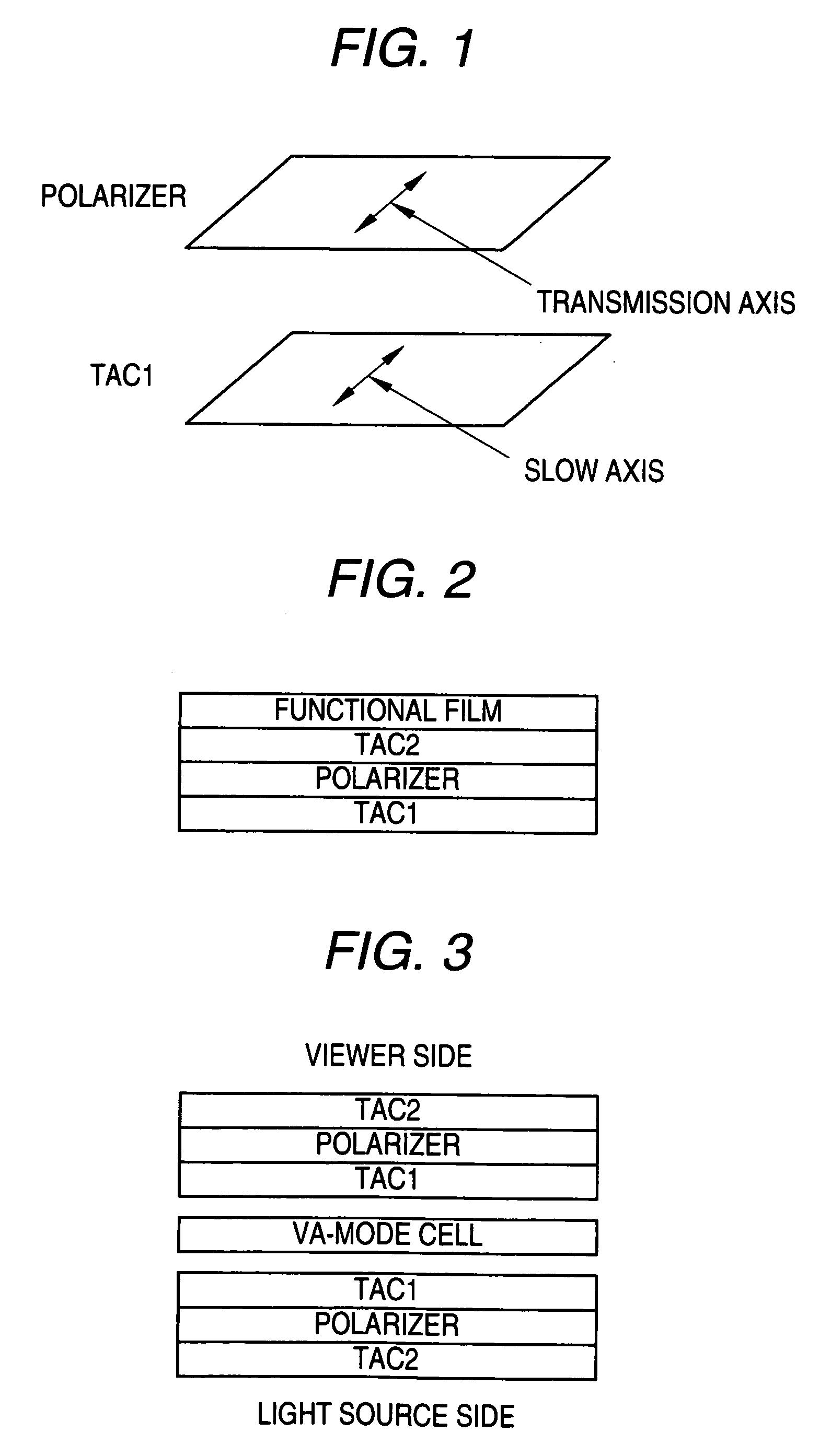

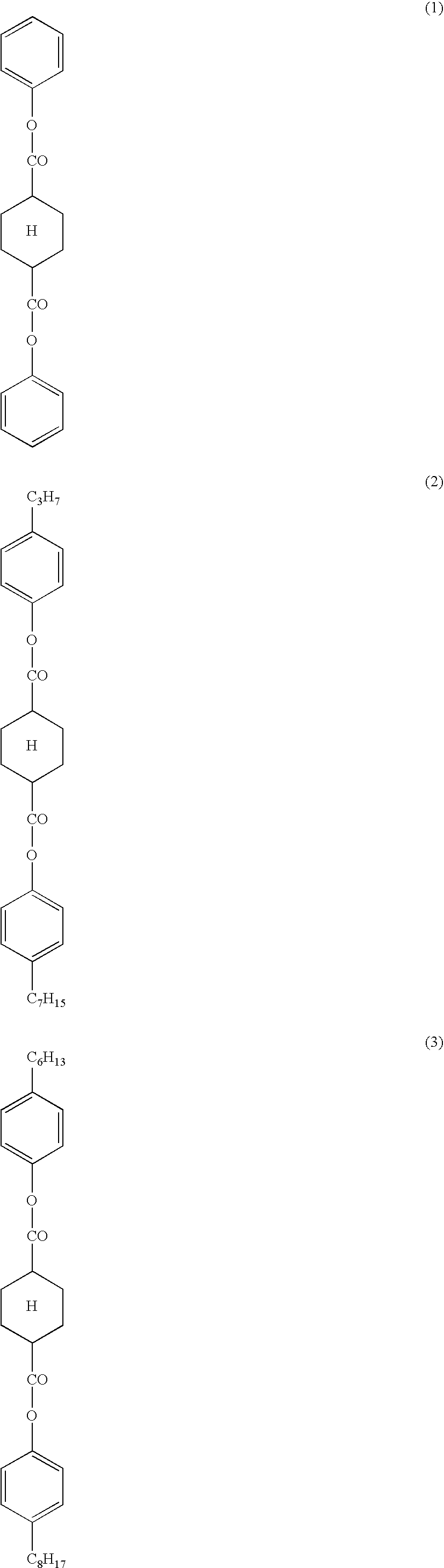

Optical Cellulose Acylate Film, Polarizing Plate and Liquid Crystal Display Device

ActiveUS20080254236A1High expressionLess fluctuationLiquid crystal compositionsSynthetic resin layered productsCelluloseLiquid-crystal display

An optical cellulose acylate film comprising a polymer component which is a cellulose acylate obtained by substituting hydroxyl groups of a cellulose by an acetyl group and an acyl group having 3 or more carbon atoms, wherein a substitution degree A of the acetyl group and a substitution degree B of the acyl group having 3 or more carbon atoms satisfy the following formulae (I) and (II): 2.0≦A+B≦3.0 (I), 0<B (II), and the optical cellulose acylate film comprises a retardation-expressing agent which is at least one of a rod-like compound and a discotic compound or an elastic modulus E(MD) in a casting direction and an elastic modulus E(TD) in a casting width direction satisfy the following formulae (III) and (IV): 1,500 MPa≦E(MD)≦3,400 Mpa (III) and 1,200 MPa≦E(TD)≦3,400 Mpa (IV).

Owner:FUJIFILM CORP

Method for preparing functional polymer material

ActiveCN106283275AIncrease profitImprove efficacyMelt spinning methodsCellulose/protein filament chemical after-treatmentFiberPolymer science

The invention discloses a method for preparing a functional polymer material, and belongs to the field of fiber material and plastic processing. The invention aims at solving the shortcomings of low efficiency and high cost of carrying out functionalization on traditional polymer materials by blending and surface chemical grafting. The method disclosed by the invention comprises the following steps: acting an alternating electric field on functional material particles to be physically embedded on the surface of an extruded base material of the polymer material, carrying out chemical crosslinking and physical blending on a crosslinking group and the surface of the base material of the polymer material, and blowing cold air to the base material of the polymer material for curing or blowing cold air to the base material of the polymer material for curing after stretching to obtain the functional polymer material. The selection range of functional substances in the method disclosed by the invention is very wide, the utilization rate is high, the effect is good, the dosage is small, the preparation procedure of the material is short, and the efficiency is high, so that the method can be widely used in the fields of the textile and garment industry, plastic industry, environmental management, drug extraction and the like.

Owner:WUYI UNIV +1

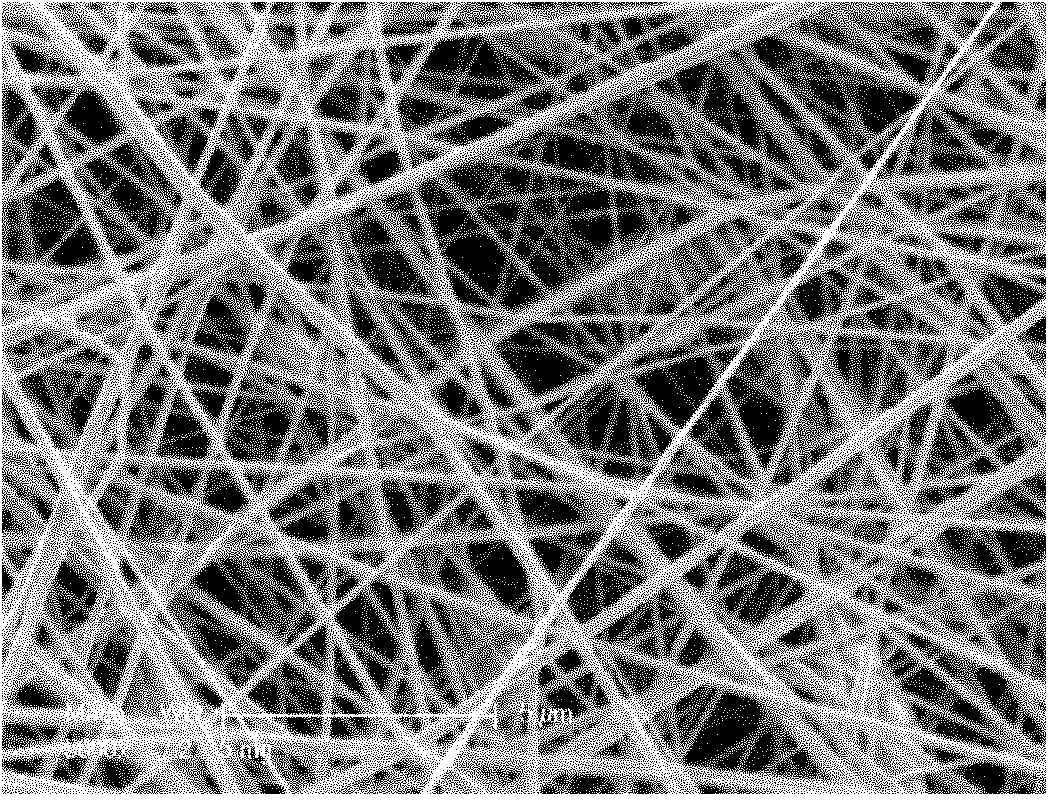

Preparation method of bacterial cellulose composite polymer superfine fiber material

ActiveCN103483606AEasy to manufactureEasy to operateFilament/thread formingCellulose/protein filament chemical after-treatmentPolymer dissolutionFiber

The invention discloses a preparation method of a bacterial cellulose composite polymer superfine fiber material. The method comprises following steps: dissolving polymers in an organic solvent to prepare a homogenous polymer spinning solution, ejecting the polymer spinning solution from a spinning nozzle by adopting an electrostatic spinning method, spraying the ejected polymer solution trickles on bacterial cellulose membranes, which contain absolution ethanol or water, and finally subjecting the processed bacterial cellulose membranes to a post-treatment so as to obtain the bacterial cellulose composite polymer superfine fiber material. The preparation method has the advantages of simple and practicable preparation process, convenient operation, and low cost; is capable of manufacturing a plurality of kinds of bacterial cellulose composite polymer superfine fiber materials, enlarges the application area of bacterial cellulose composite materials, and has a very vast industrial application prospect.

Owner:钟春燕

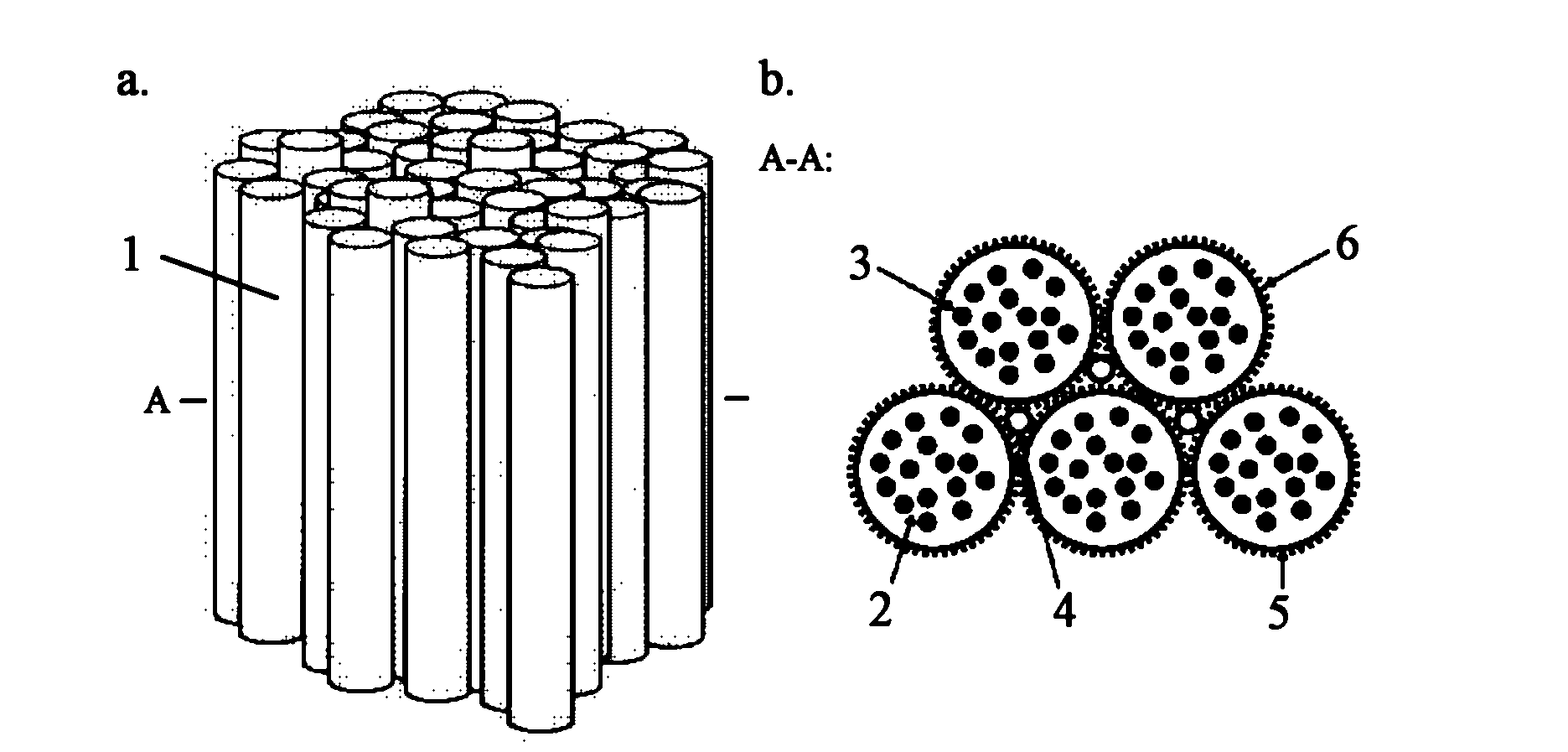

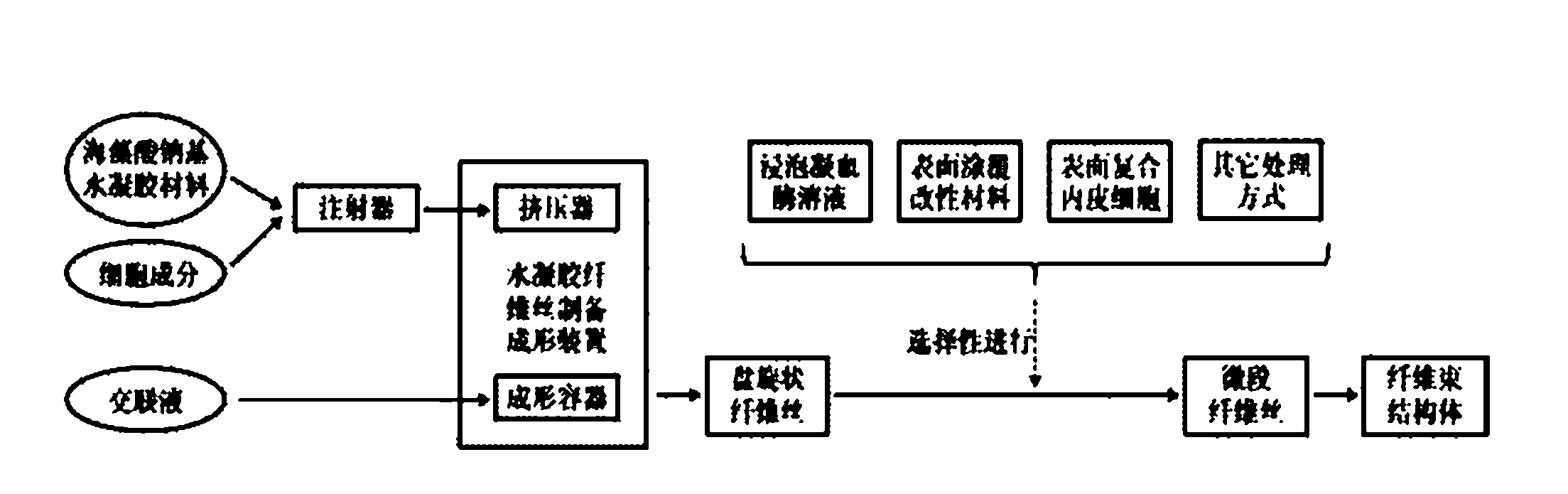

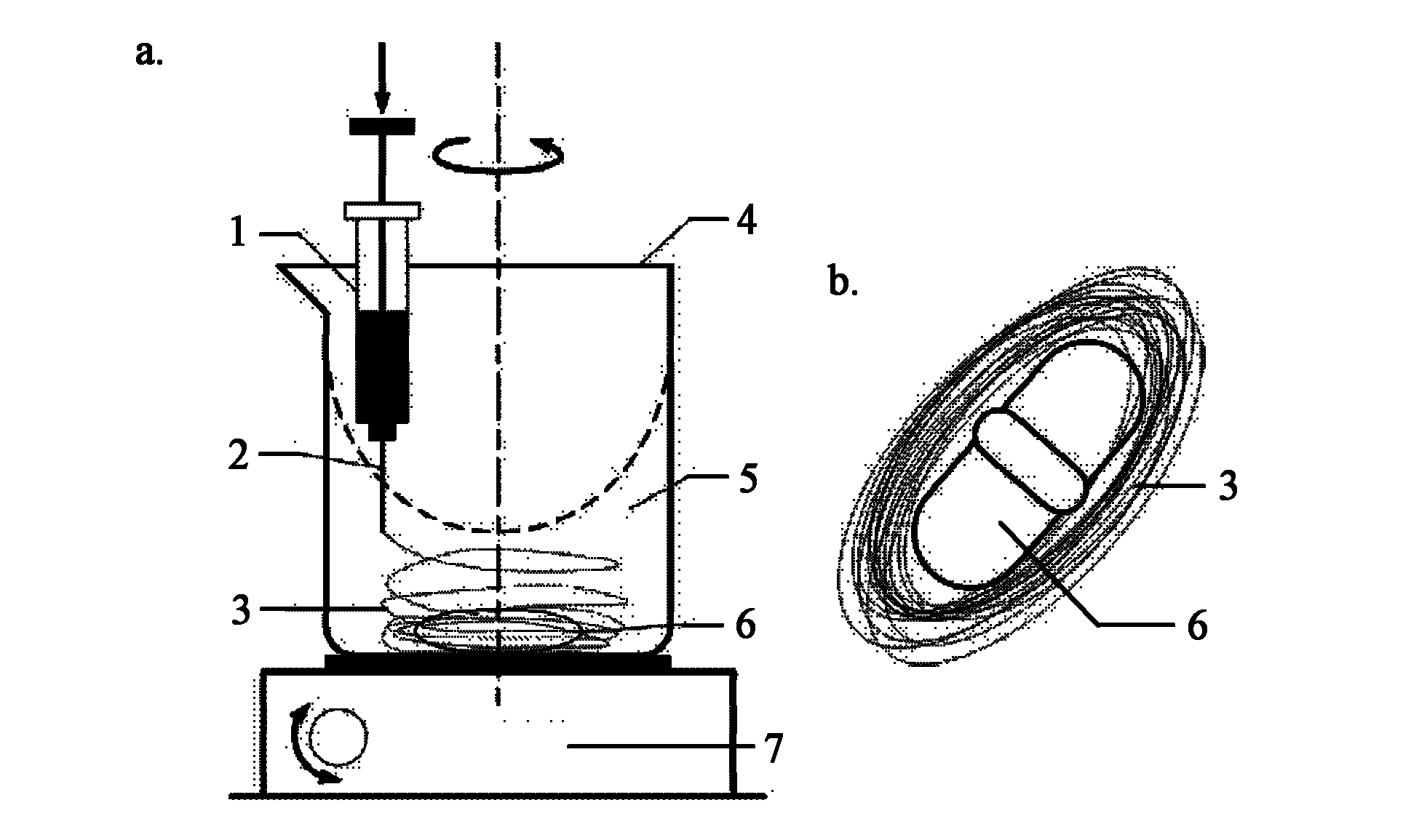

Tissue engineering fiber bundle structure body and preparation method thereof

ActiveCN102505184ABionic effect is goodAdapting to Oxygen Diffusion Distance LimitationsBiochemical fibre treatmentMicrobiological testing/measurementCellular componentHigh density

The invention discloses a tissue engineering fiber bundle structure body and a preparation method thereof. The invention provides a method A or B for preparing hydrogel fiber filaments containing cellular components. The method A comprises the following steps: 1) compositing a hydrogel material utilized as a matrix with cellular components to obtain a mixture containing cellular components; and 2) putting the mixture obtained in the step 1) into crosslinked fluid corresponding to the matrix to undergo crosslinking, thus obtaining the hydrogel fiber filaments containing cellular components. Experiments prove that the design can comprehensively meet the special bionic requirements of high-density cell composition, good vascularization development trend and achievement of directionally ordered structure in tissue engineering, so that the structure body is good in vascularization development prospect and can hopefully break through the development bottleneck that the tissue engineering can not become large and thick at present.

Owner:TSINGHUA UNIV

Method for preparing peanut protein composite fiber by using ionic liquid

InactiveCN102586942ADissolve fastReduce solubilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentHigh concentrationStrong acids

The invention discloses a method for preparing a peanut protein composite fiber by using ionic liquid. The method comprises the following steps of: dissolving peanut protein and polyvinyl alcohol in imidazole ionic liquid respectively to obtain a peanut protein ionic liquid solution and a polyvinyl alcohol ionic liquid solution; mixing the peanut protein ionic liquid solution and the polyvinyl alcohol ionic liquid solution in a mixed ratio of 1:3-1:5; adding an aid to obtain a spinning solution, and entering a coagulating bath; preparing a peanut protein / polyvinyl alcohol composite fiber by awet spinning method in the coagulating bath; and stretching, washing, performing acetal treatment, applying oil, drying, curling, sizing, and thus obtaining the mixed fiber. By the method, the ionic liquid instead of strong acid and strong alkali is used as a solvent in the process of synthesizing a peanut protein fiber, so that the peanut protein and the polyvinyl alcohol can be quickly dissolved at high concentration and a low temperature, and the preparation process is non-toxic and pollution-free at the same time.

Owner:SHANDONG PEANUT RES INST +1

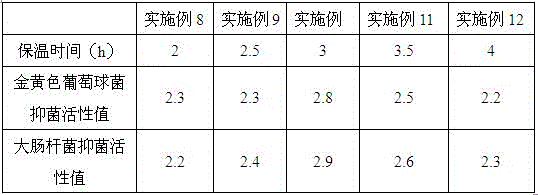

Traditional Chinese medicinal health regenerated cellulose fiber and preparation method thereof

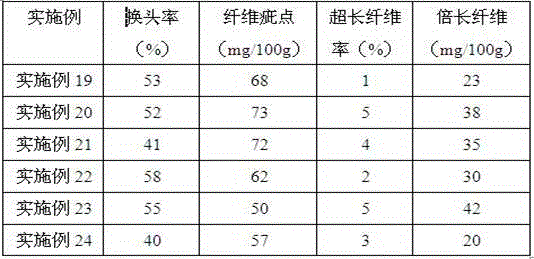

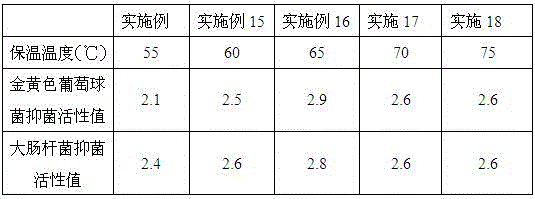

ActiveCN105603557AWill not blockGood antibacterial health effectArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentEscherichia coliViscose

The invention provides a traditional Chinese medicinal health regenerated cellulose fiber, which contains the traditional Chinese medicinal components, wherein the mass fraction of a traditional Chinese medicinal extract in the fiber is 1%-15%. The invention further provides a preparation method of the fiber. The method comprises the following steps: preparing a traditional Chinese medicinal extract assistant, preparing a traditional Chinese medicinal spinning viscose and spinning and molding the traditional Chinese medicinal regenerated cellulose fiber. In the fiber preparation process, a spinning nozzle is not blocked; and the exchange rate is smaller than or equal to 10%. The prepared fiber has a good antibacterial health effect and achieves the natural antibacterial effect. Through detection of the antibacterial property of the prepared traditional Chinese medicinal health regenerated cellulose fiber, the bacteriostatic activity value on staphylococcus aureus and escherichia coli reaches 2.9; and the traditional Chinese medicinal health regenerated cellulose fiber can be widely applied to medical and sanitary products and the like.

Owner:潍坊欣龙生物材料有限公司

Transparent compositions, methods for the preparation thereof, and articles derived therefrom

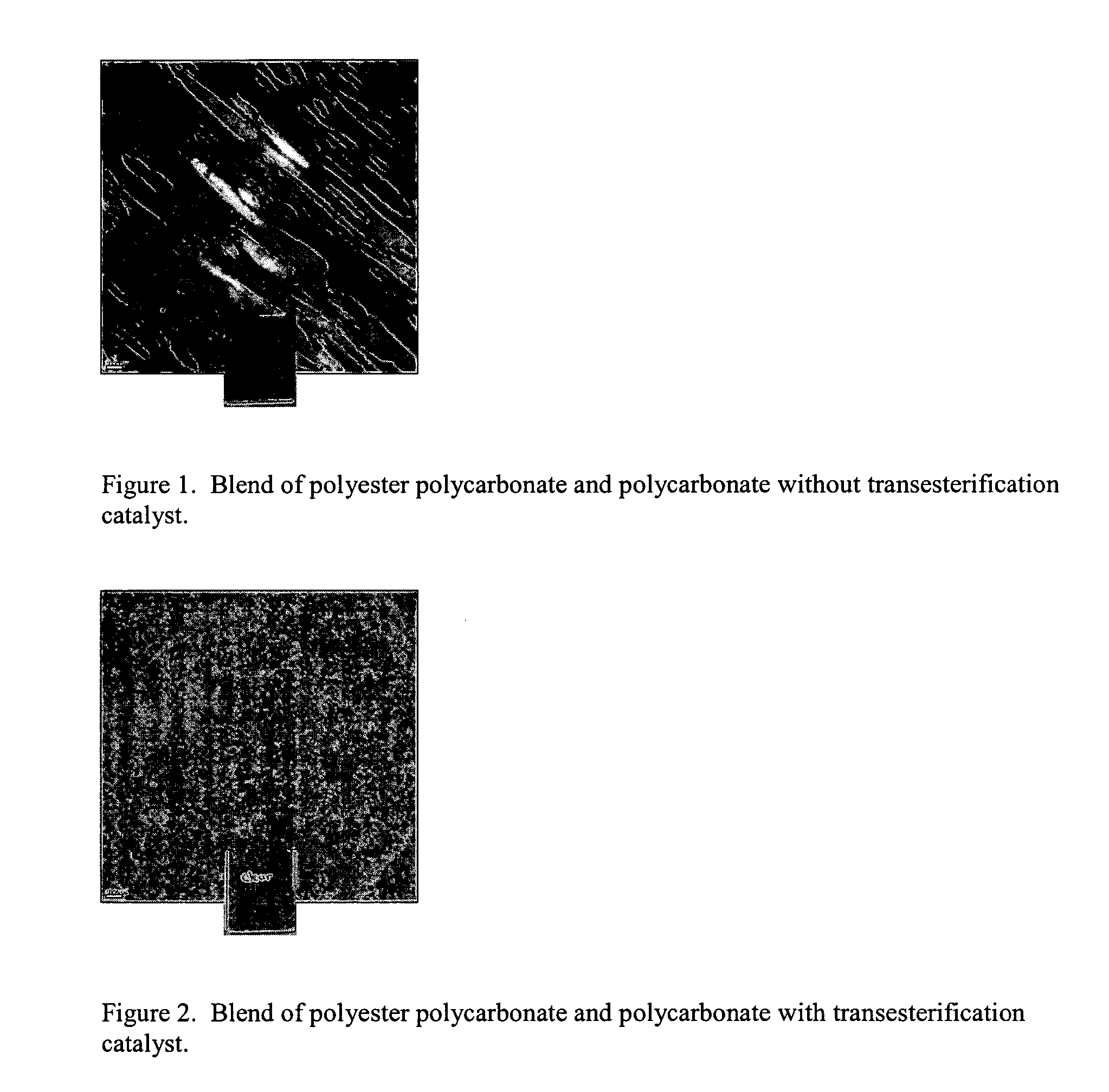

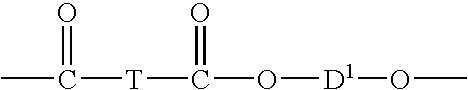

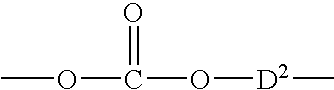

ActiveUS20060264580A1Physical/chemical process catalystsCellulose/protein filament chemical after-treatmentPolyesterTransesterification

A reaction product comprises a polyester-polycarbonate comprising a polyester unit and a polycarbonate unit, a polycarbonate polymer, and a transesterification catalyst. The reaction product has a haze of less than 1.7% as measured at a thickness of 3.2 mm according to ASTM D1003-00. A thermoplastic composition comprising the reaction product and articles formed from therefrom are disclosed. A method of forming the reaction product is also disclosed.

Owner:SHPP GLOBAL TECH BV

Preparation method of dye-absorption fibers and preparation method of dye-absorption non-woven cloth

ActiveCN103938298AAdvantages of preparation methodGrafting is firmCellulose/protein filament chemical after-treatmentNon-woven fabricsCelluloseDye absorption

The invention discloses a preparation method of dye-absorption fibers. The preparation method of the dye-absorption fibers comprises the steps that a cationic cellulose ether aqueous solution with the concentration of 5g / L-100g / L is prepared, an alkali compound is added to the cationic cellulose ether aqueous solution to adjust the pH value to be 11-13, viscose is put into the cationic cellulose ether aqueous solution to be reacted for 15-60 minutes at the temperature of 80-100 DEG C, and poly quaternary ammonium salt viscose is obtained; the poly quaternary ammonium salt viscose is taken out and dried, and then the dye-absorption fibers are obtained. The invention further provides a preparation method of dye-absorption non-woven cloth. The preparation method of the dye-absorption non-woven cloth comprises the steps that the dye-absorption fibers are provided; lapping is carried out on the dye-absorption fibers; net fixation is carried out on the dye-absorption fibers after lapping, and the cloth is obtained. By means of the preparation method of the dye-absorption fibers and the preparation method of the dye-absorption non-woven cloth, dye-absorption non-woven cloth with high absorption force and tearing resistance can be prepared.

Owner:上海希丝无纺布制品有限公司

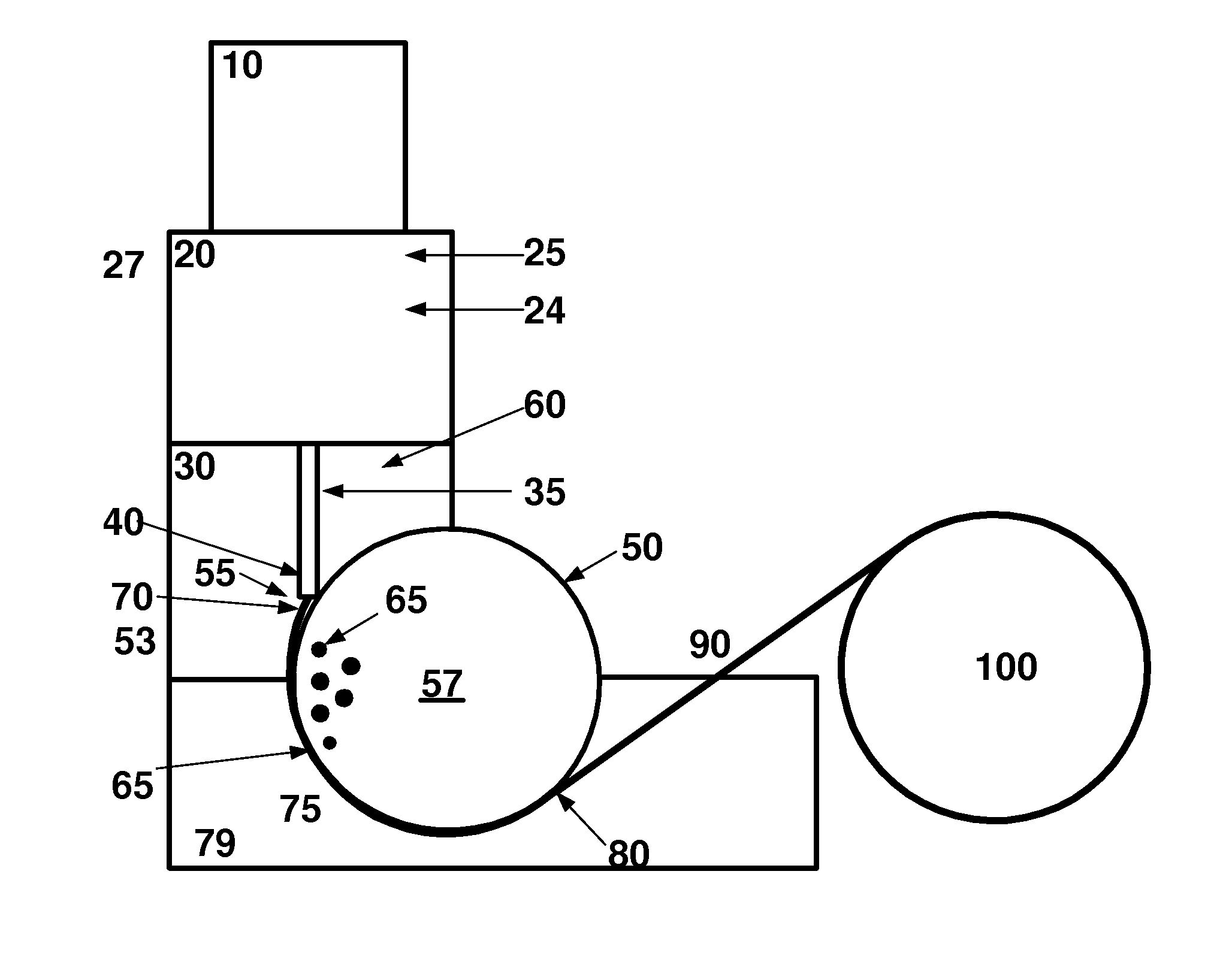

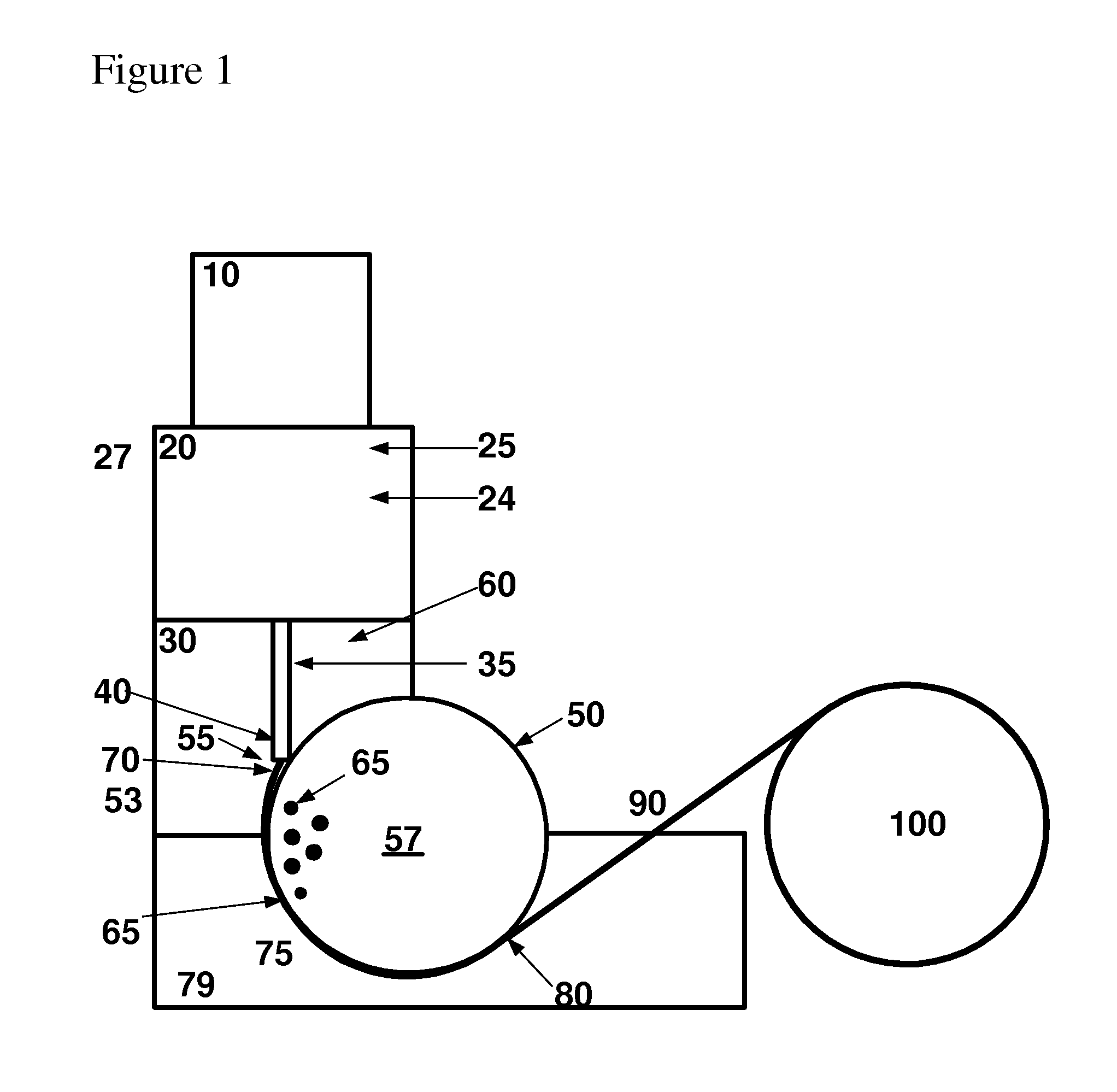

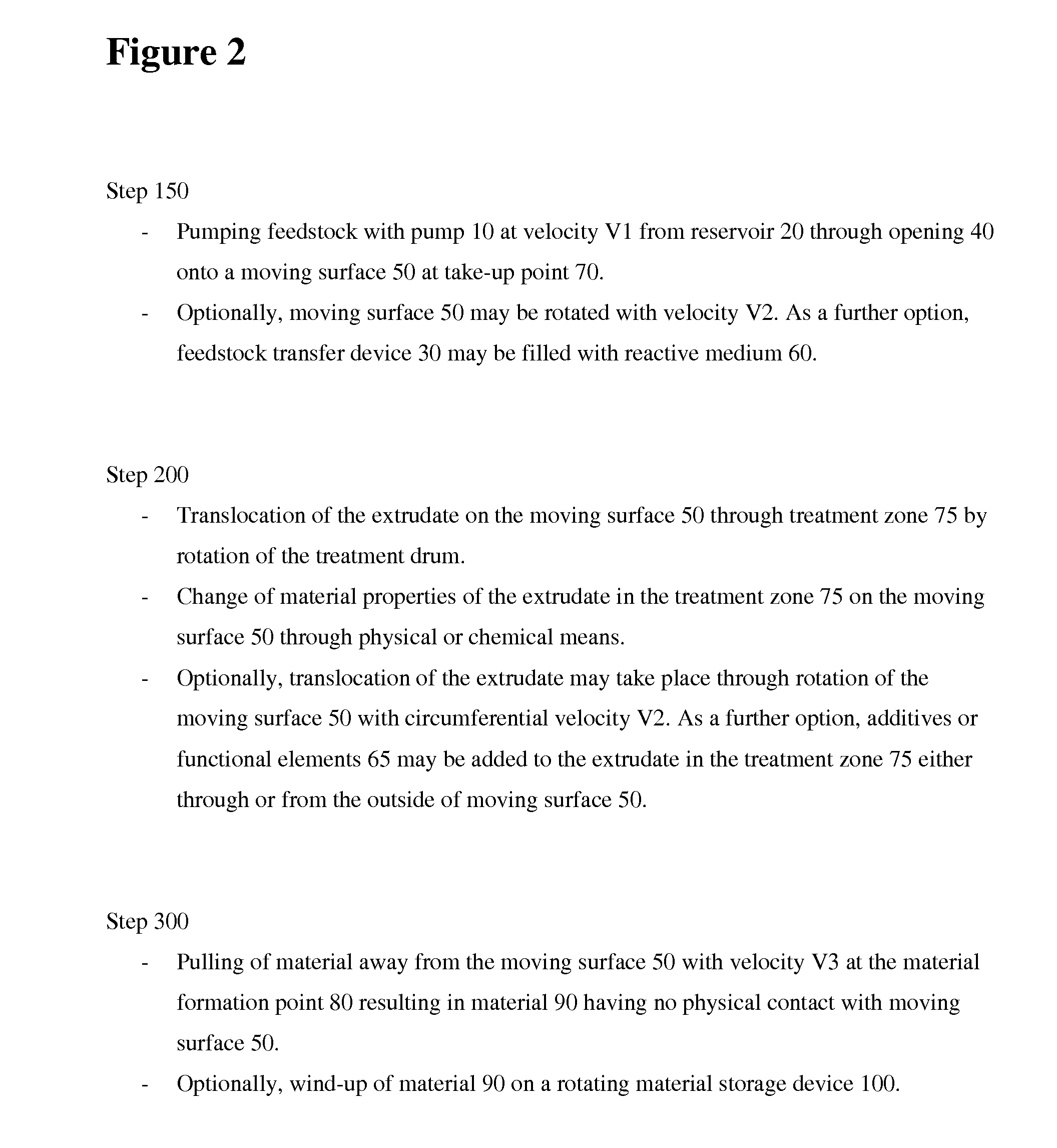

Method and apparatus for the manufacture of a fiber

InactiveUS20110121485A1Monocomponent fibroin artificial filamentArtificial filament heat treatmentFiberWater soluble

A method for the extrusion of a silk fibre from a water-soluble material which comprises providing the water-soluble material (25) in a liquid form, extruding the water-soluble material (25) through an opening (40) to form a precursor of the extruded silk fibre (53) and receiving the precursor on a moving surface (50). The precursor is treated on the moving surface (50) to form the silk fibre.

Owner:SPINTECH ENG

High-wet-modulus and flame-retardant regenerated cellulose fibers and preparation method thereof

ActiveCN102965751AReduce churnImprove flame retardant performanceArtificial filaments from viscoseWet spinning methodsPolymer scienceViscose

The invention provides high-wet-modulus and flame-retardant regenerated cellulose fibers. The high-wet-modulus and flame-retardant regenerated cellulose fibers are prepared by adding 15 to 25wt% of pyrophosphate fire retardant to spinning dope for spinning in a blending way. The preparation method comprises the following steps in sequence: preparing the spinning dope for spinning; compounding and adding the flame retardant; spinning; stretching; and post-processing. The high-wet-modulus and flame-retardant regenerated cellulose fibers remain the hand feel and skin-friendly properties of cellulosic natural fibers, are high in fire resistance, free from risk due to second scalding, high in spinnability and less in loss of fire retardant, the retention rate reaches 98%, resistance to acid and alkali is good, and the fibers can be applied to the spinning industries such as the textile and garment materials industry and the underwears industry.

Owner:唐山三友集团兴达化纤有限公司

Pineapple leaf fiber preparation method

InactiveCN101307502AGood physical and mechanical propertiesImprove dyeing effectCellulose/protein filament chemical after-treatmentMechanical fibre separationHemicelluloseMechanical property

The invention provides a method for preparing arghan, which comprises the following steps that: pineapple leaves are subject to mechanical treatment, acid preimpregnation, washing, basic boiling, alkali cooking, washing, dehydration, loosing and oiling. The method has the advantages that: the provided arghan has high cellulose content, and other compositions such as hemicellulose, lignin and pectin have lower content, so the arghan provided by the method has good physical and mechanical properties, the fiber length of the arghan can reaches between 3 and 38cm, the fiber fineness reaches between 1000 and 5000 metric counts, the strength is between 5 and 6.8cN / dtex, and the softness reaches between 65 and 85 twirl / 25cm. In addition, the arghan provided by the method has good dyeing property as well as anti-ultraviolet performance and sound wave resistant performance.

Owner:DONGHUA UNIV

Method of producing a swellable polymer fibre

ActiveUS20160222548A1Reduce solubilityEnhanced hydrogen bondingBiocideSpinning solution de-aeratingFiberWound dressing

A swellable polymer based fibre and a method of preparing the same optionally comprising glycol, lecithin and optionally an antimicrobial metal species suitable, for example, for medical applications including wound dressings. A method of manufacture may comprise fibre extrusion or spinning involving one or a plurality of in-series coagulation baths to add single or multiple antimicrobial metal species to the as-formed fibre.

Owner:XIROS

Silk hemp cellulose fiber and preparation method thereof

ActiveCN104195663AImprove solubilityGood dispersionArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentEscherichia coliCellulose fiber

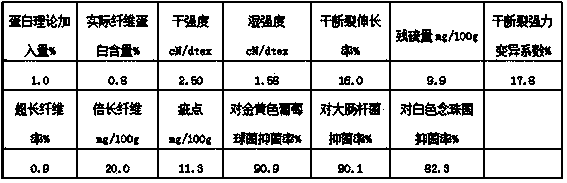

The invention provides a silk hemp cellulose fiber and a preparation method thereof. The cellulose fiber is 1.8-2.5cN / dtex in dry breaking strength, is 0.9-1.6cN / dtex in wet breaking strength, is 16-24% in dry breaking elongation, is less than or equal to 12mg / 100g in residual sulfur content, is more than or equal to 90% in staphylococcus aureus antibacterial rate, is more than or equal to 90.0% in escherichia coli antibacterial rate, and is more than or equal to 80.0% in candida albicans suppression ratio. The preparation method of the silk hemp cellulose fiber comprises the steps of preparing a hemp pulp viscose spinning solution, preparing a protein dispersing emulsion, preparing a hemp pulp protein modified spinning solution, spinning and aftertreatment. The silk hemp cellulose fiber has the smooth and soft hand feeling, feels like hemp, has the smooth zigzagged cross section like the hollow cross section of a natural hemp material, is environmentally-friendly and has the good wearability and textile processability, and besides, a protein material is uniformly dispersed inside the fiber, and therefore, the silk hemp cellulose fiber can resist multiple washing and cannot shed off.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com