Patents

Literature

99results about How to "Less fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

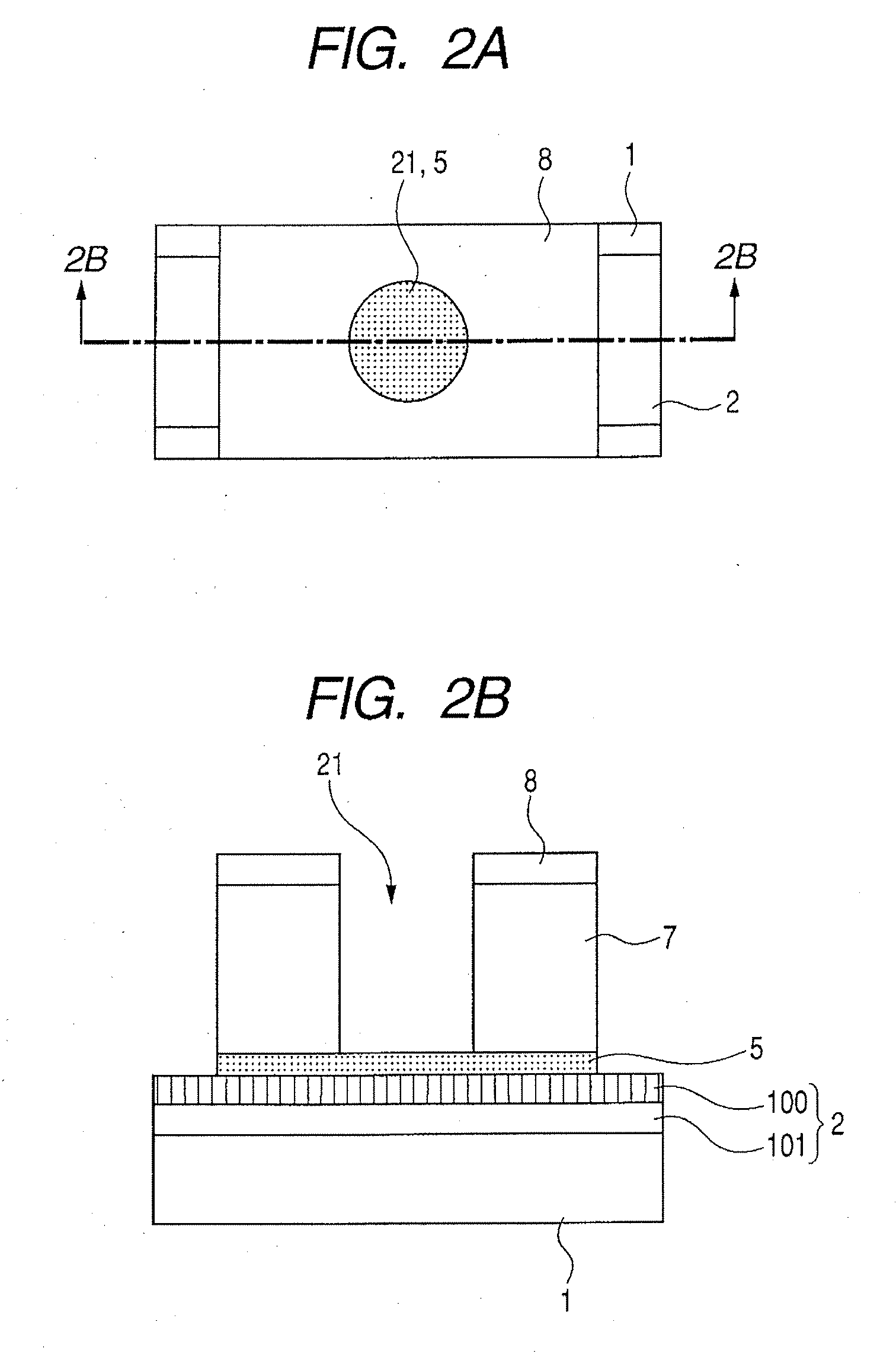

Semiconductor device and method of manufacturing the same

InactiveUS7148092B2Increase speedLess fluctuationTransistorSolid-state devicesEngineeringCrystalline semiconductor

Owner:SEMICON ENERGY LAB CO LTD

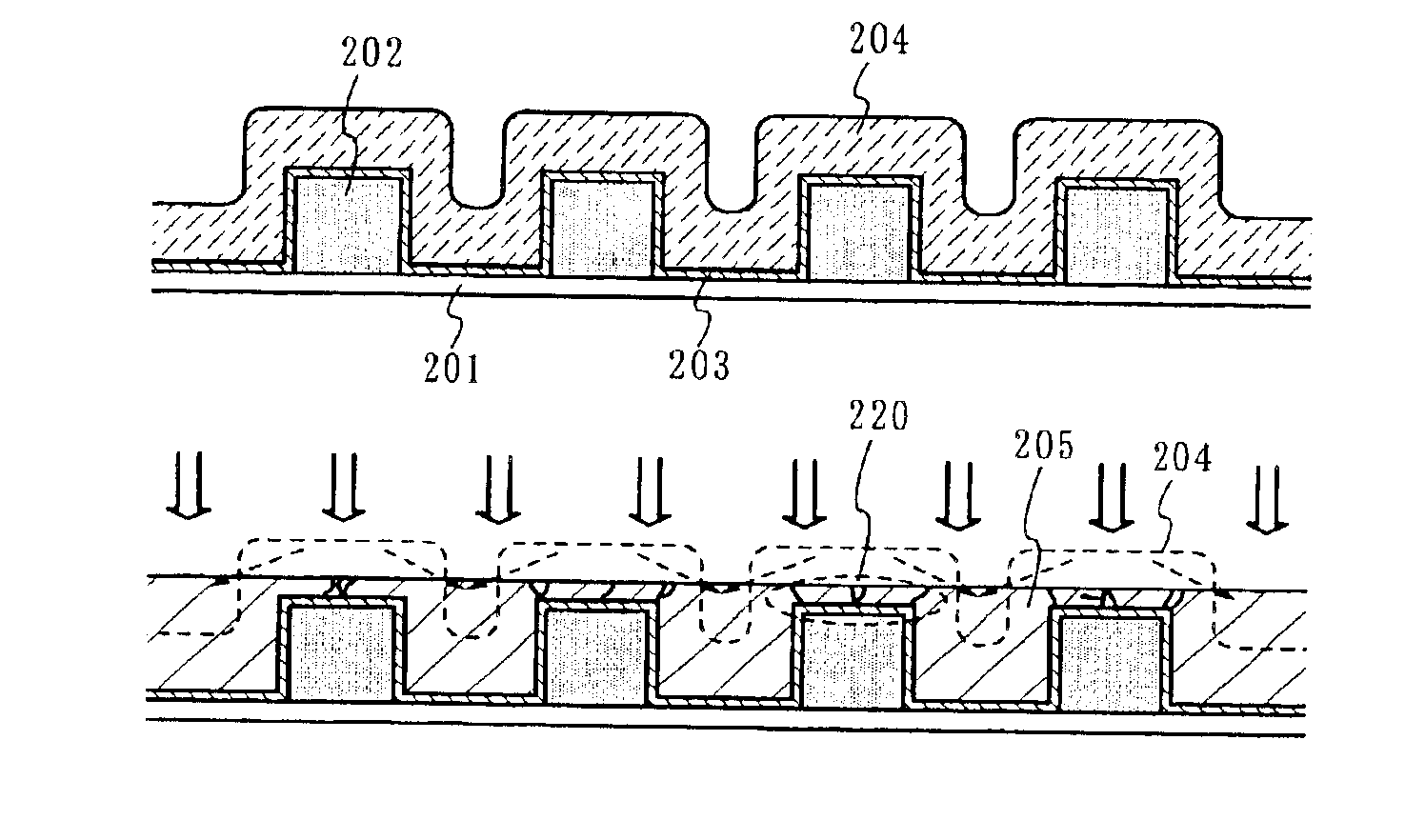

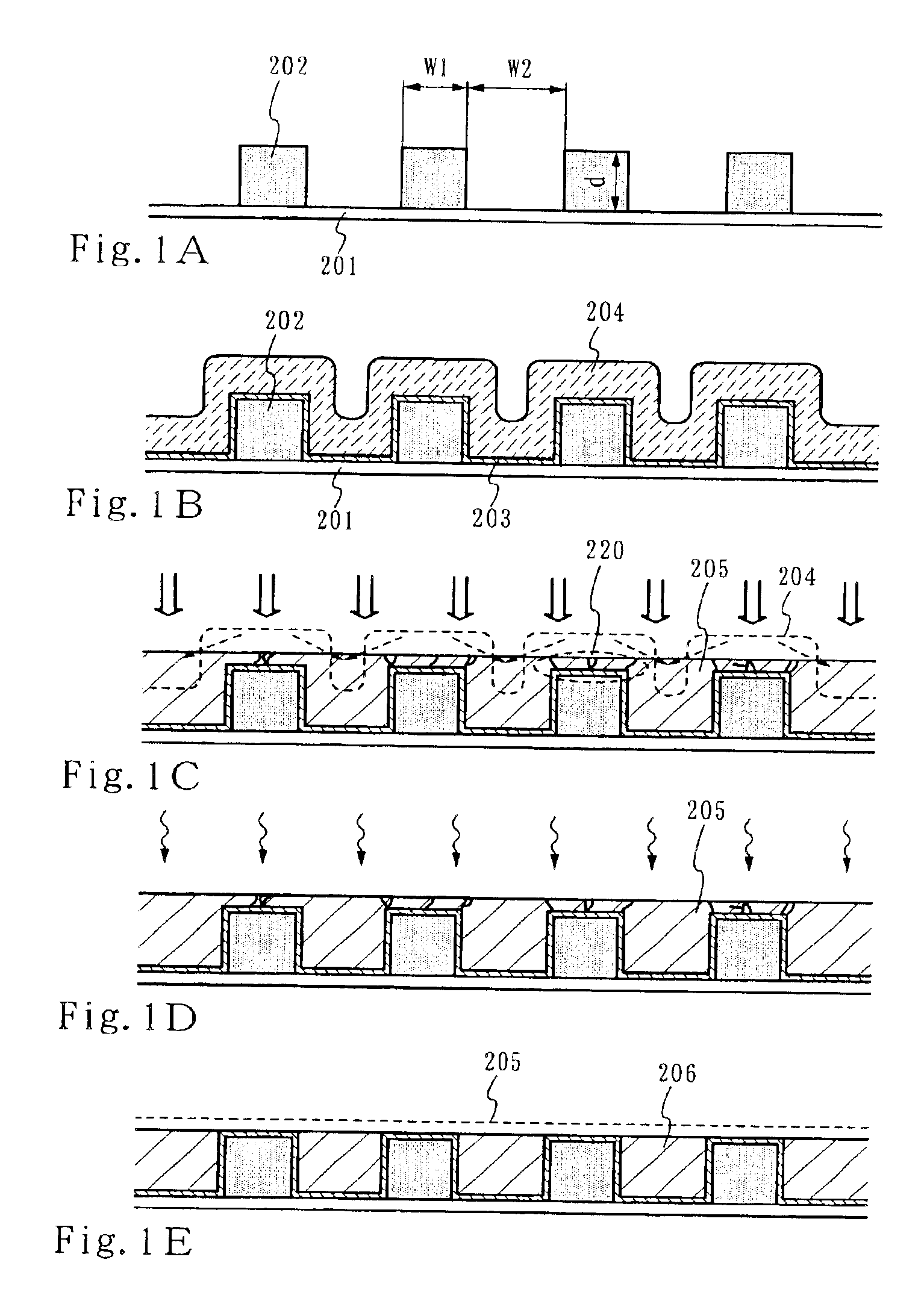

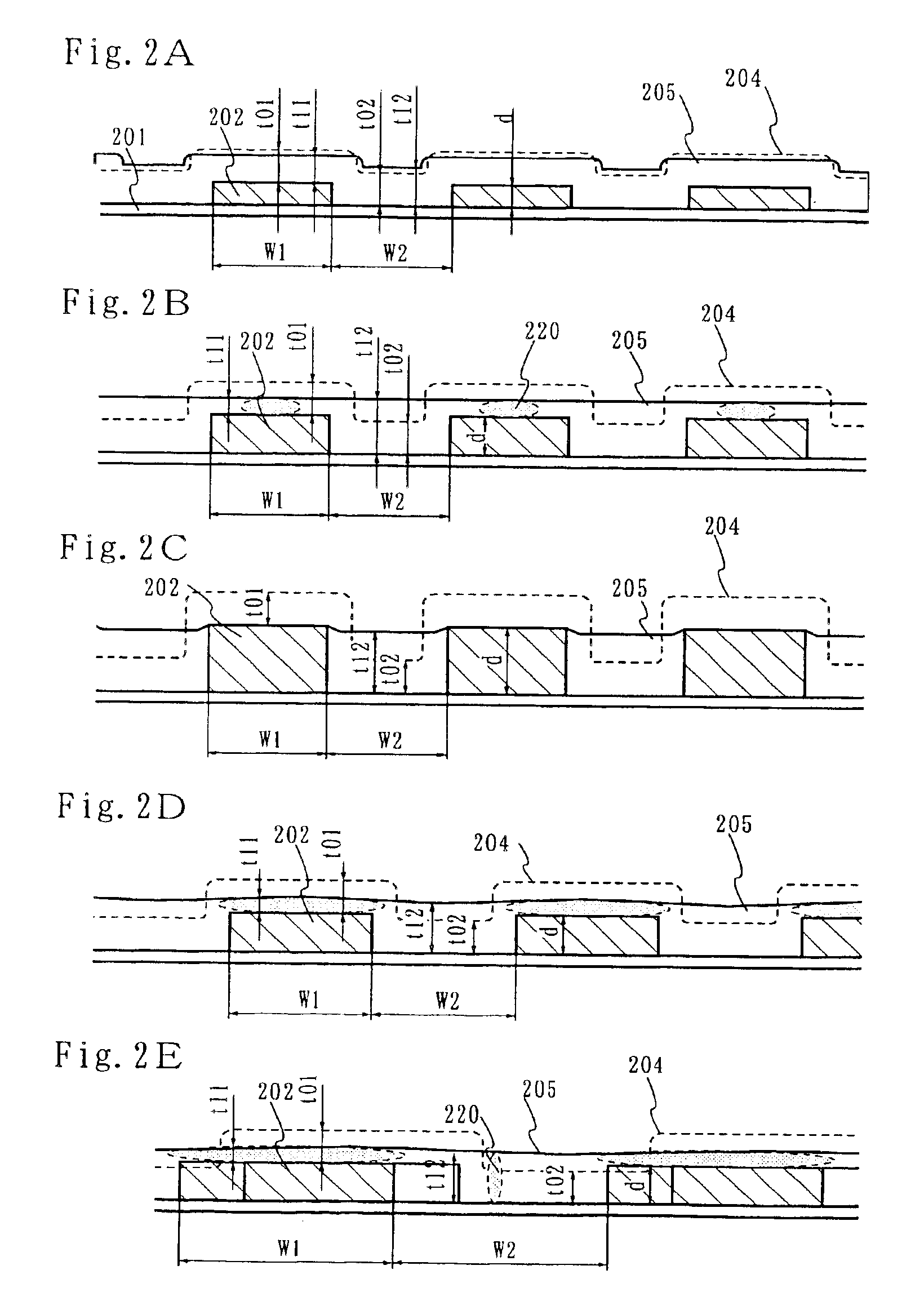

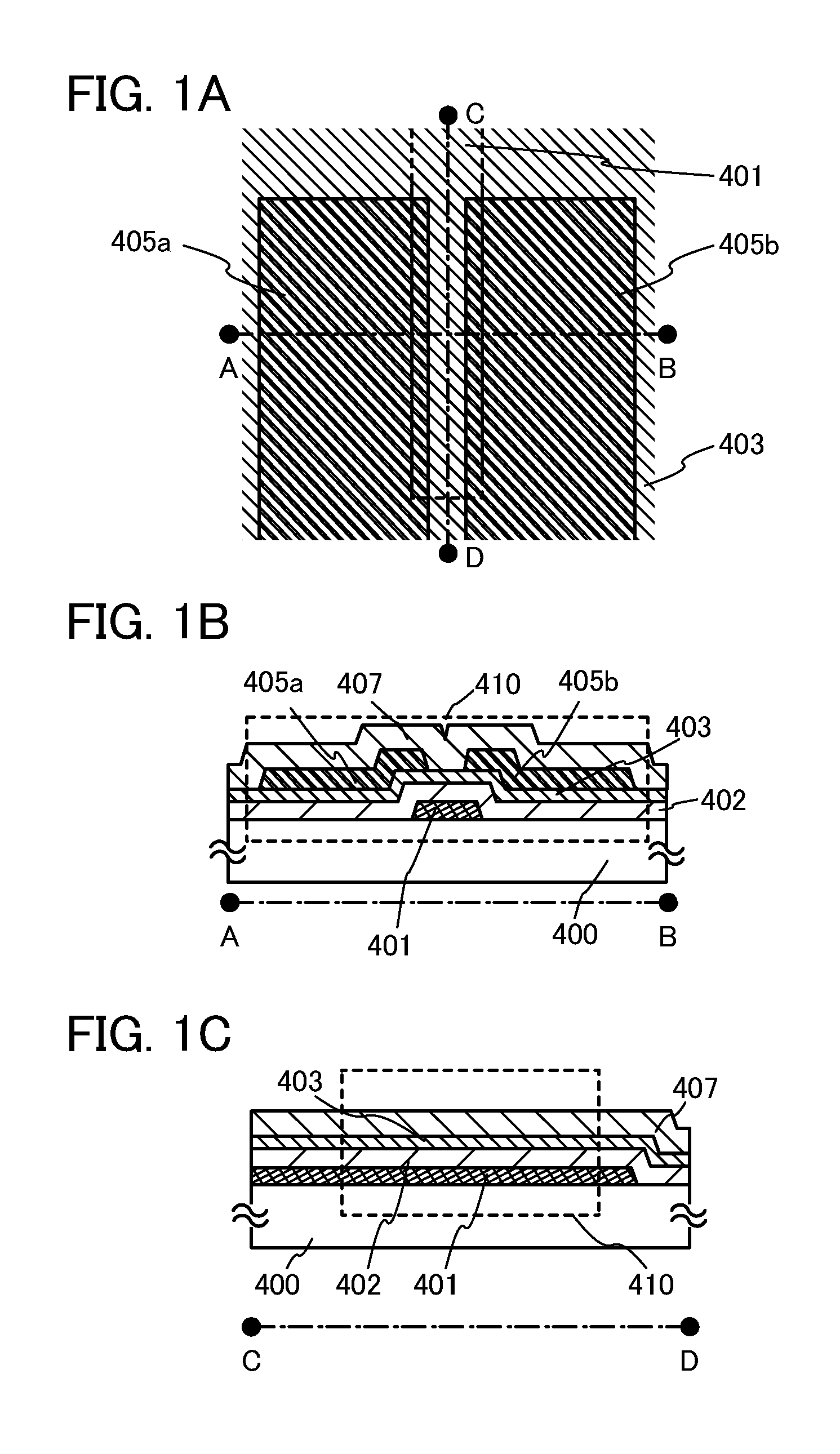

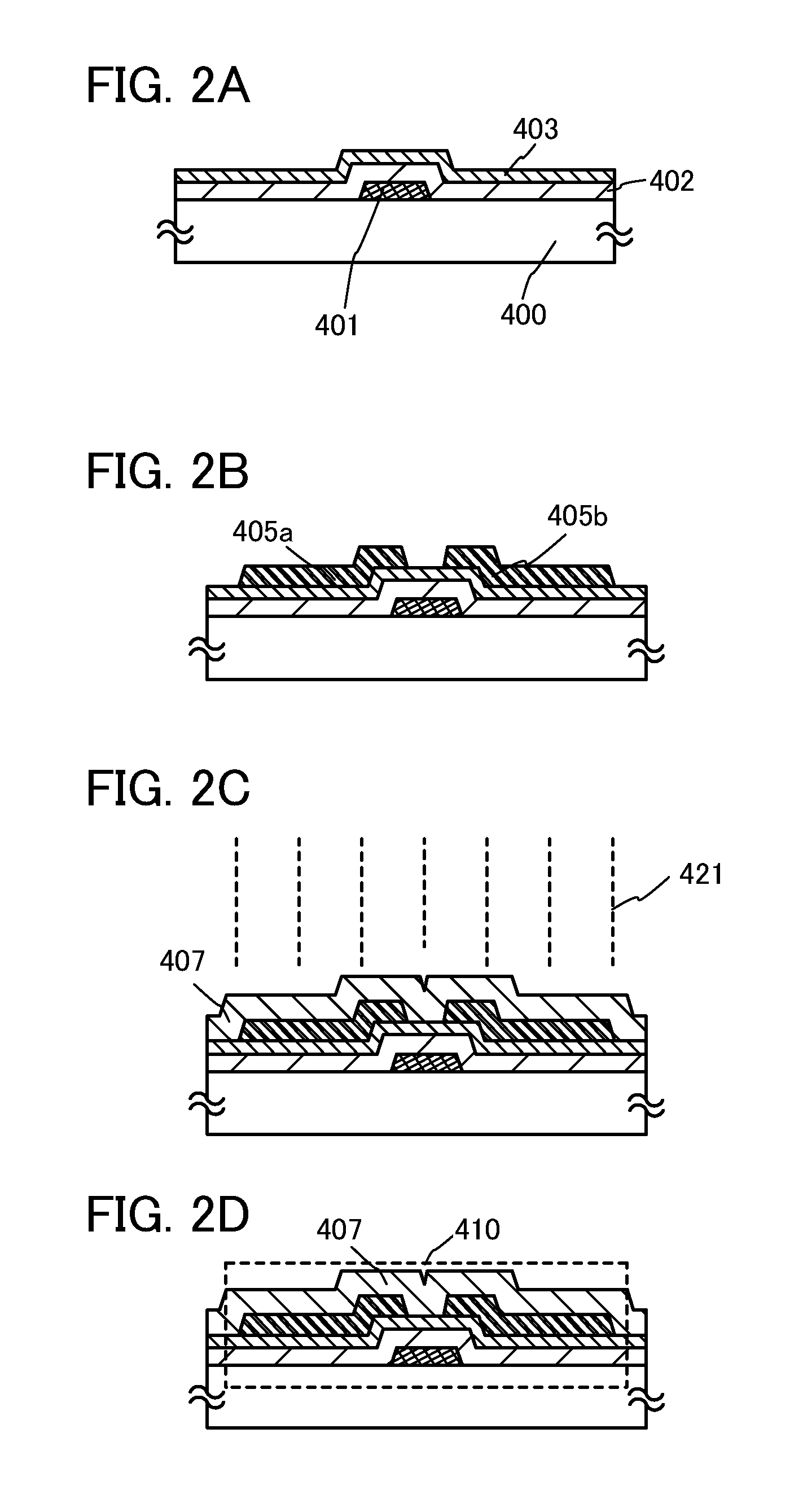

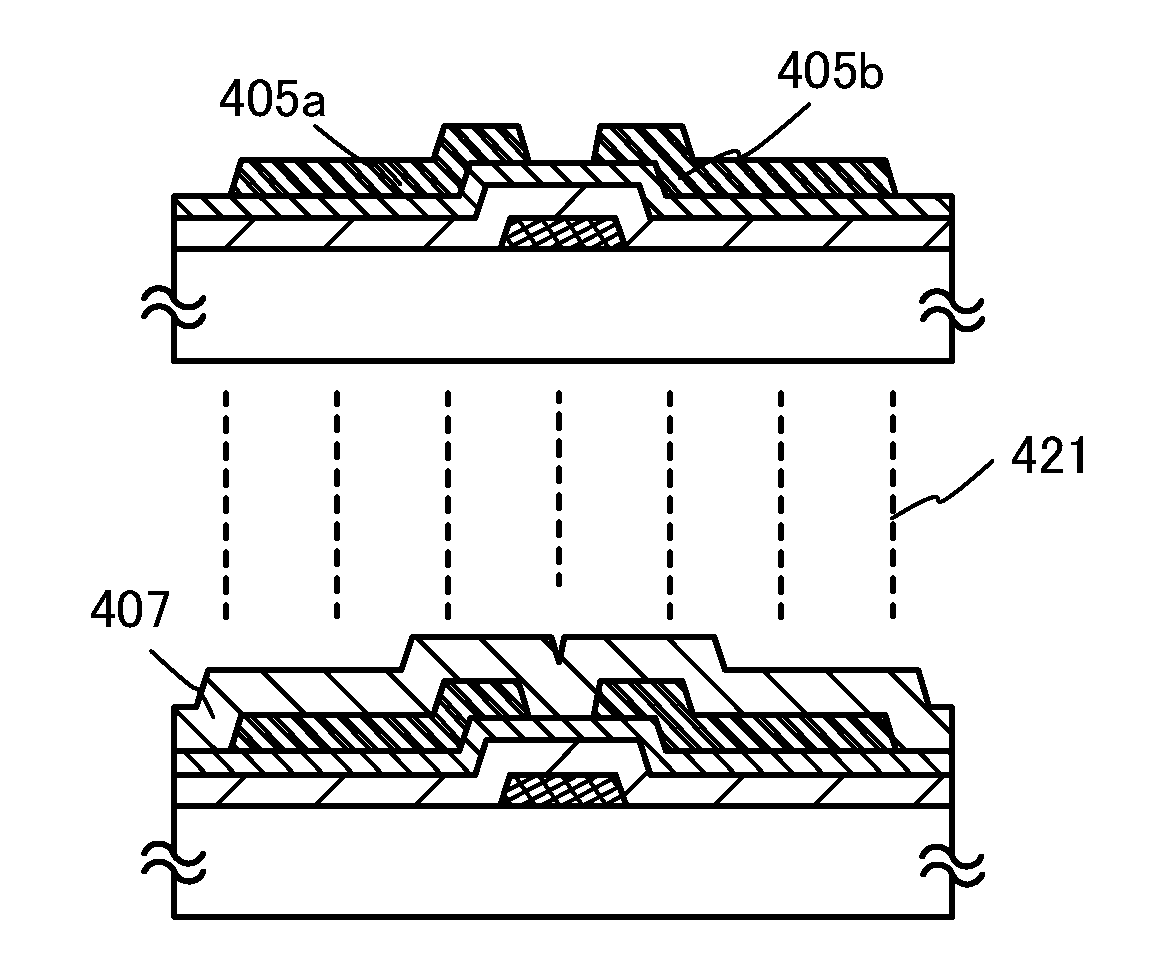

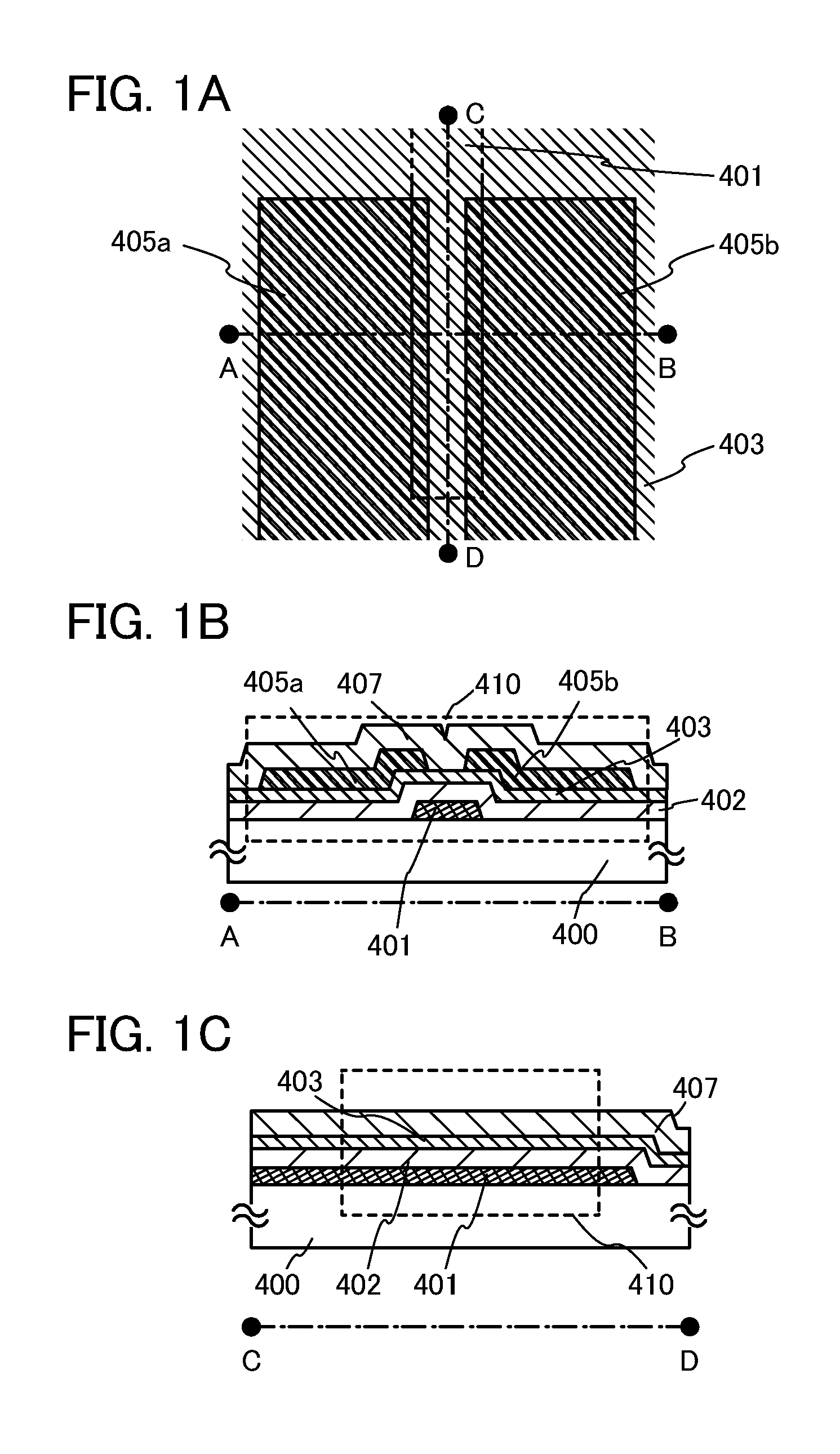

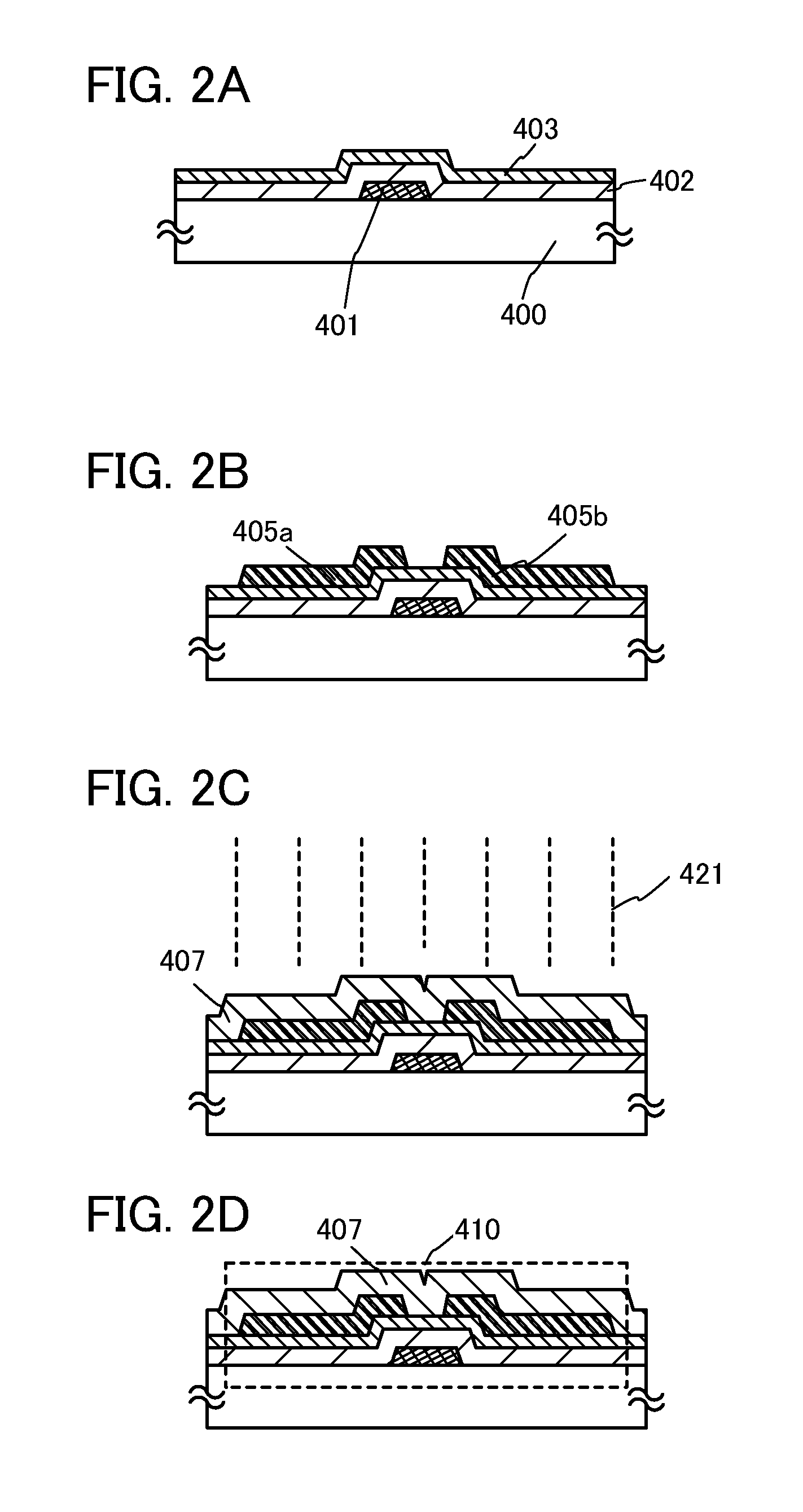

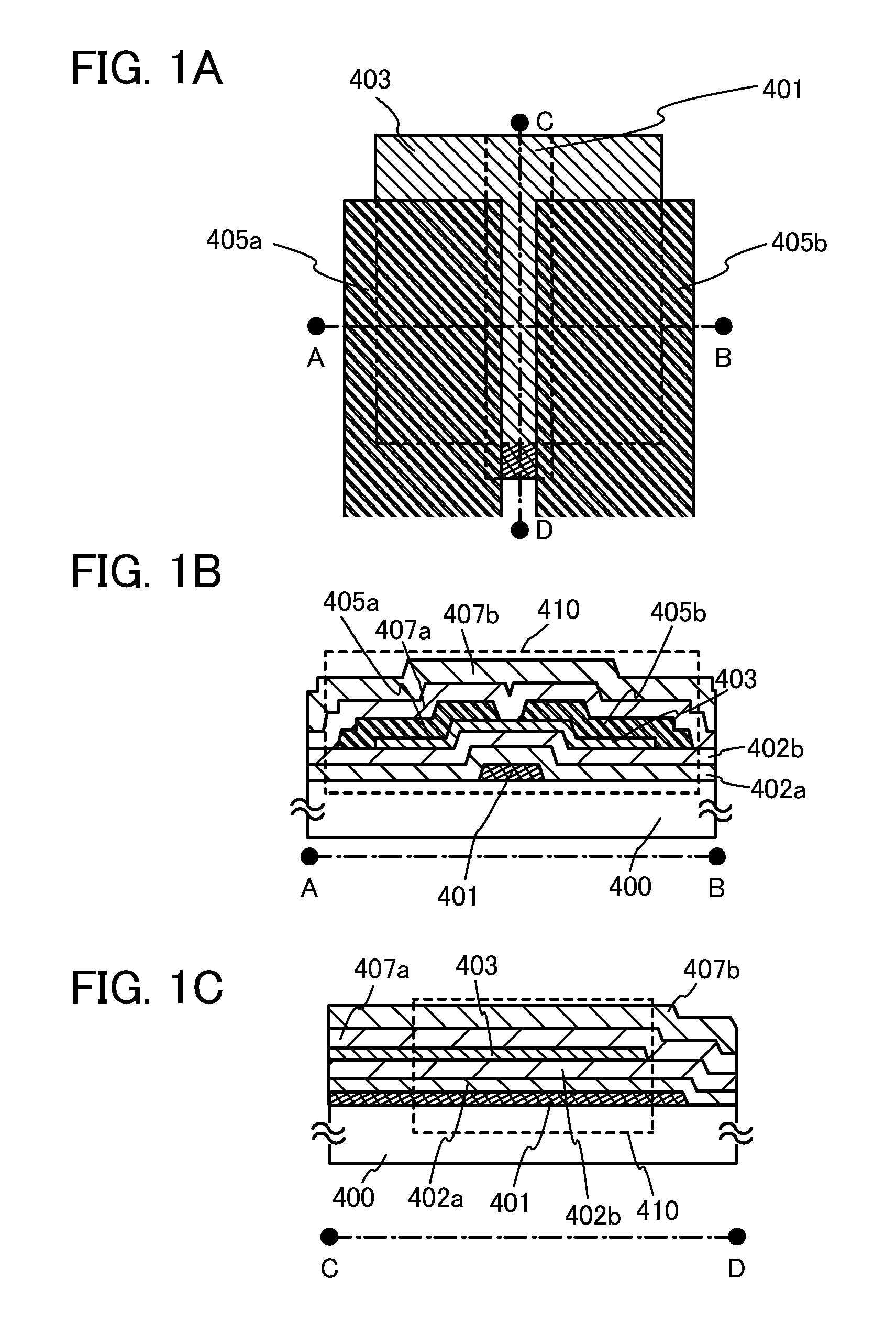

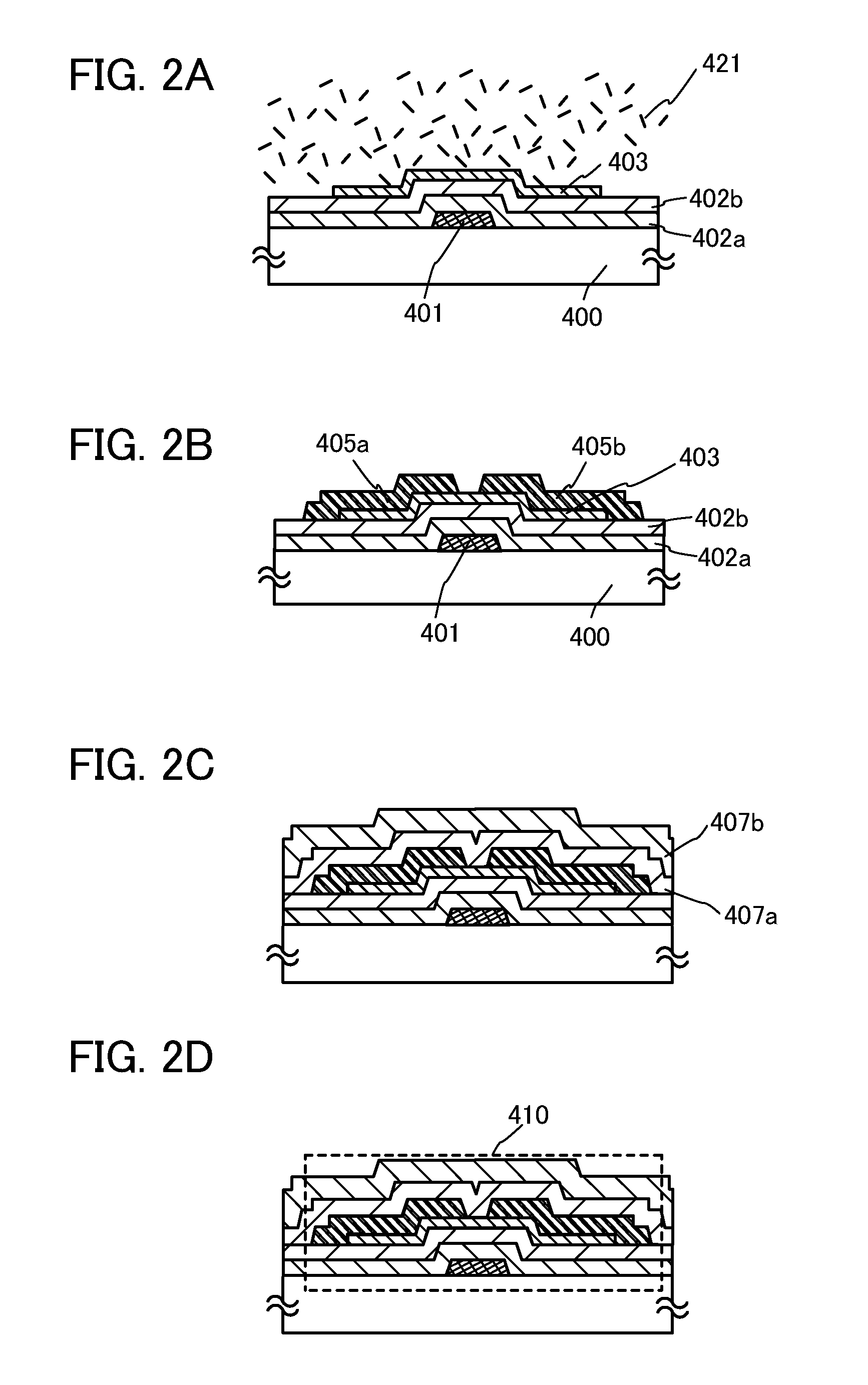

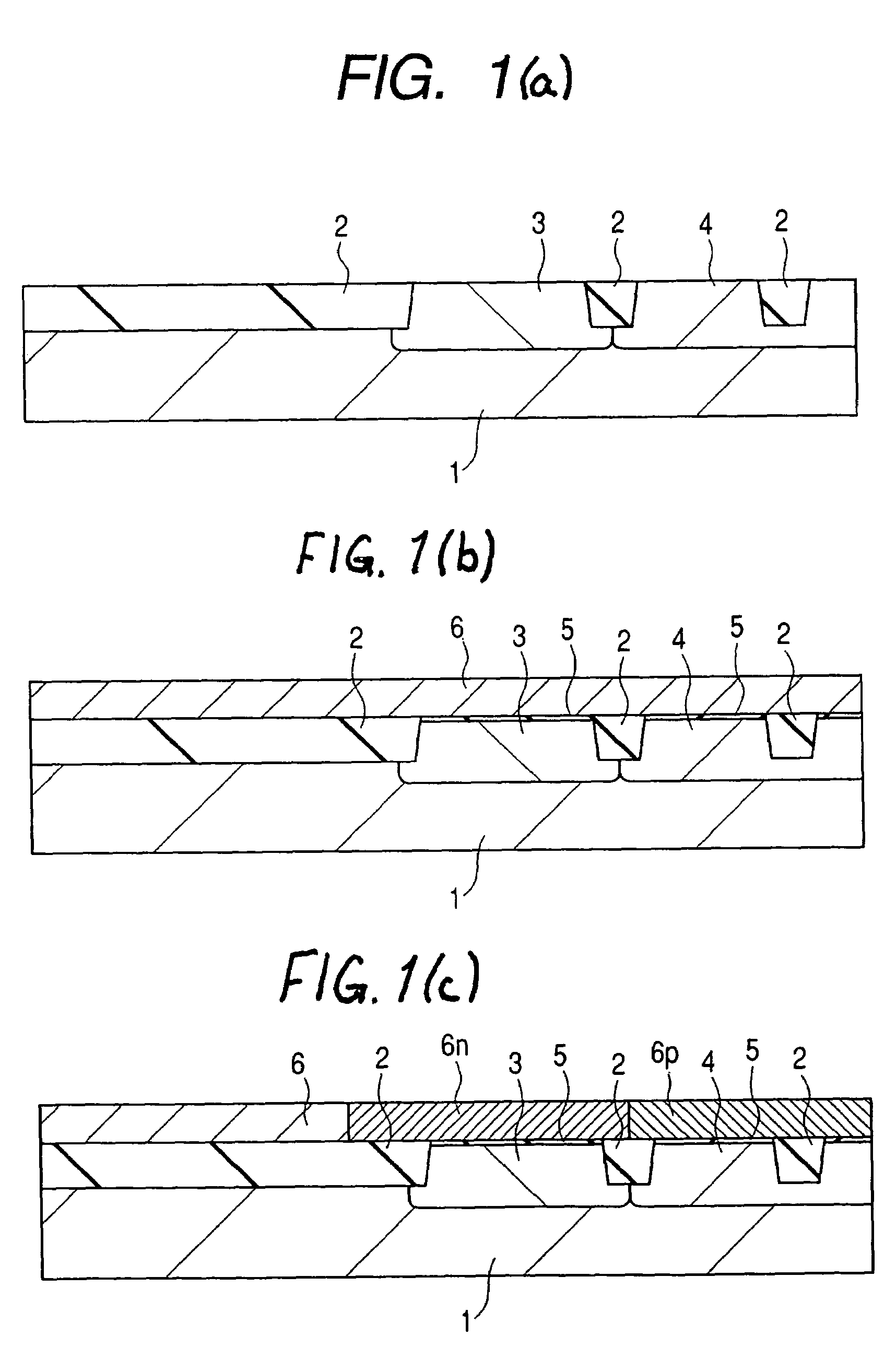

Method of manufacturing semiconductor device

ActiveUS20120231580A1Increasing oxide thicknessLess fluctuationSolid-state devicesSemiconductor/solid-state device manufacturingBias temperature stressSemiconductor

In a manufacturing process of a transistor including an oxide semiconductor film, oxygen doping treatment is performed on the oxide semiconductor film, and then heat treatment is performed on the oxide semiconductor film and an aluminum oxide film provided over the oxide semiconductor film. Consequently, an oxide semiconductor film which includes a region containing more oxygen than a stoichiometric composition is formed. The transistor formed using the oxide semiconductor film can have high reliability because the amount of change in the threshold voltage of the transistor by a bias-temperature stress test (BT test) is reduced.

Owner:SEMICON ENERGY LAB CO LTD

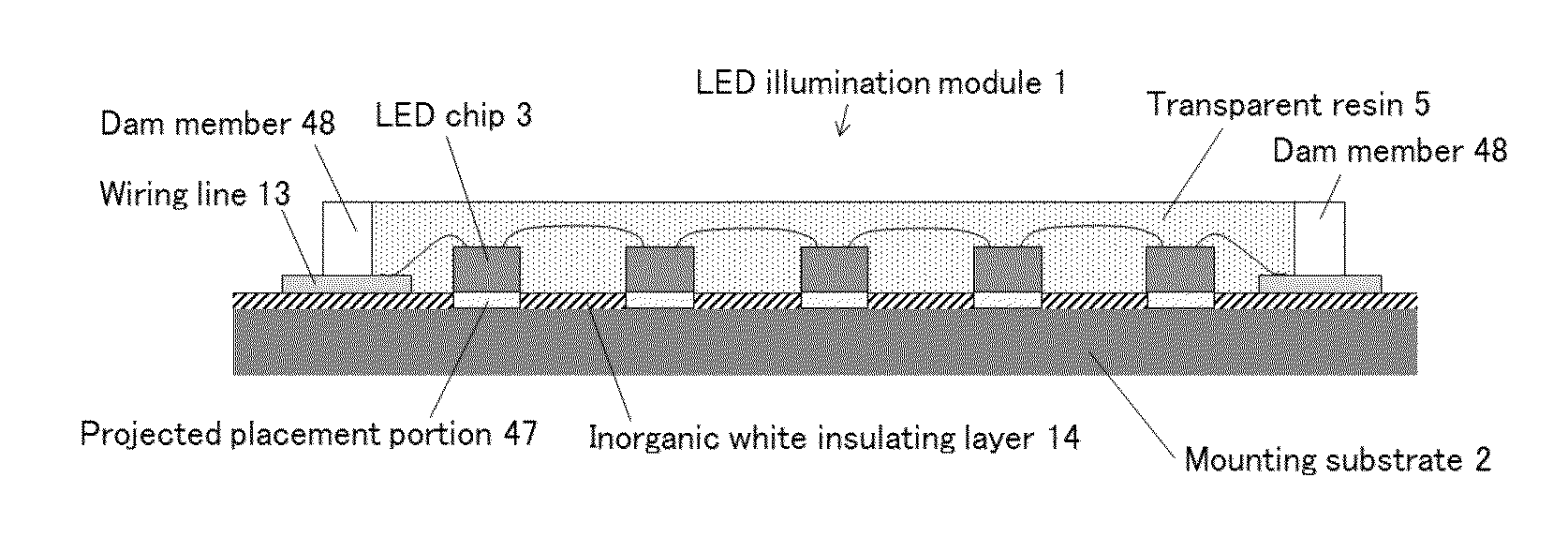

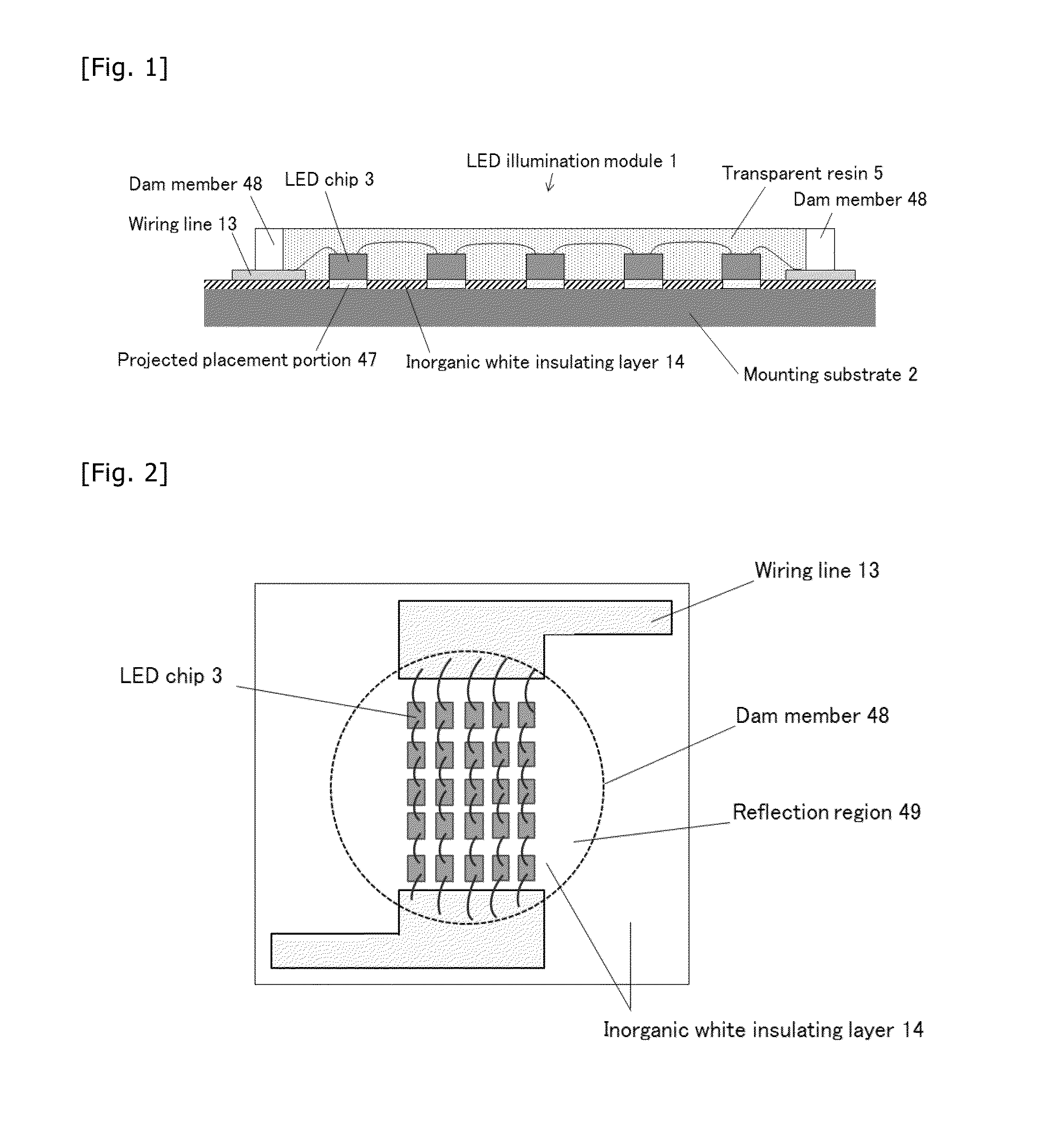

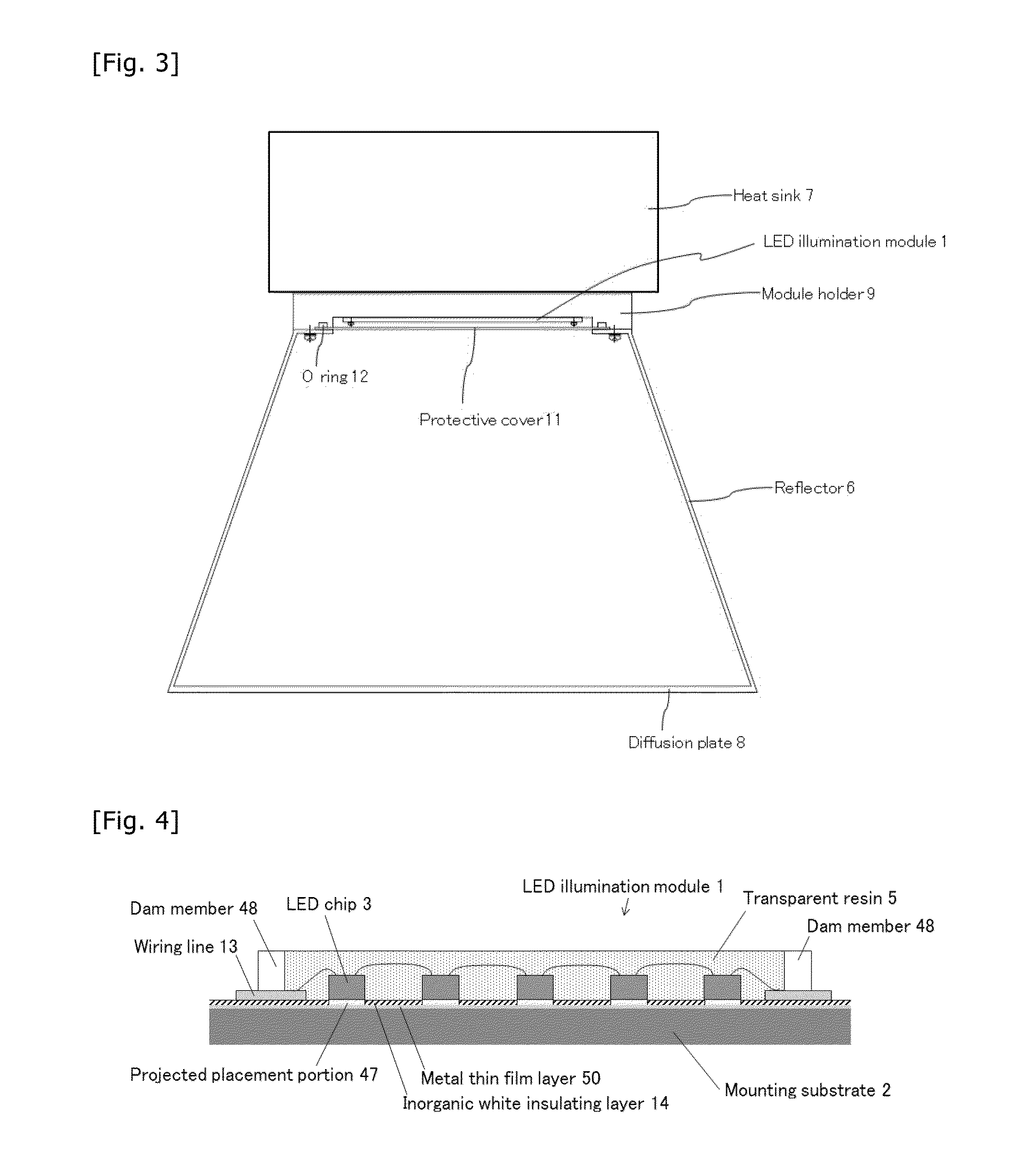

LED illumination module and LED illumination apparatus

ActiveUS20150155459A1Increase brightnessLess fluctuationCircuit optical detailsElectric circuit arrangementsHigh densityLight flux

An LED illumination module in which LED bare chips are mounted on a mounting substrate at a high density, the module comprising many LED bare chips having the same specifications, the mounting substrate at least a surface of which is metal, and a reflection region in which the LED bare chips are sealed off with resin, wherein a surface of the reflection region of the mounting substrate is covered with an inorganic white insulating layer that functions as a reflection member, a unit LED chip group including a plurality of LED bare chips connected in series is disposed plural, the plural unit LED chip groups being connected in parallel, overall light flux is 10,000 lumens or more, and a mounting area density of the LED bare chips in the reflection region is 15 mm2 / cm2 or more. An LED illumination apparatus including the LED illumination module is also provided.

Owner:SHIKOKU INSTR

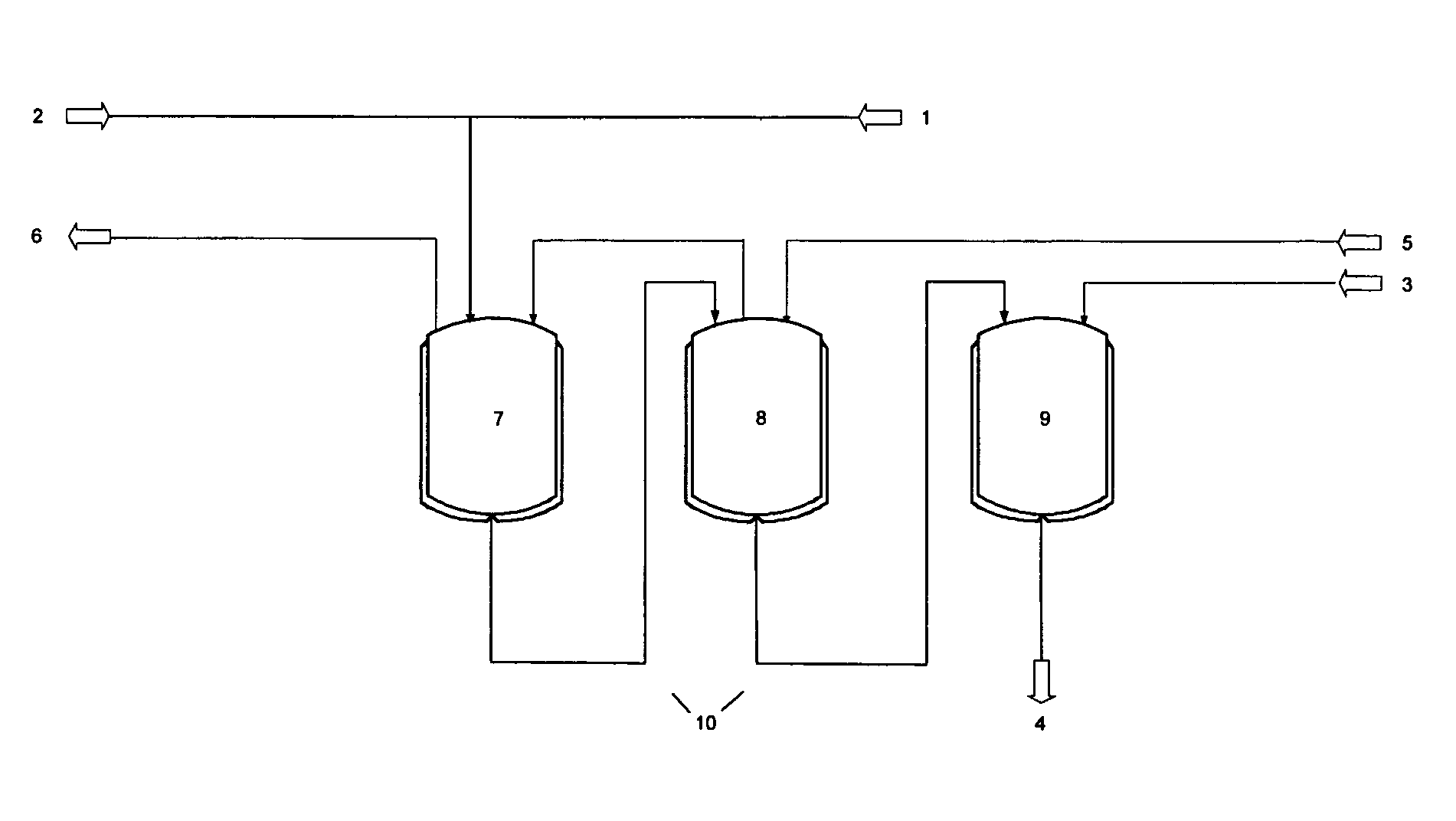

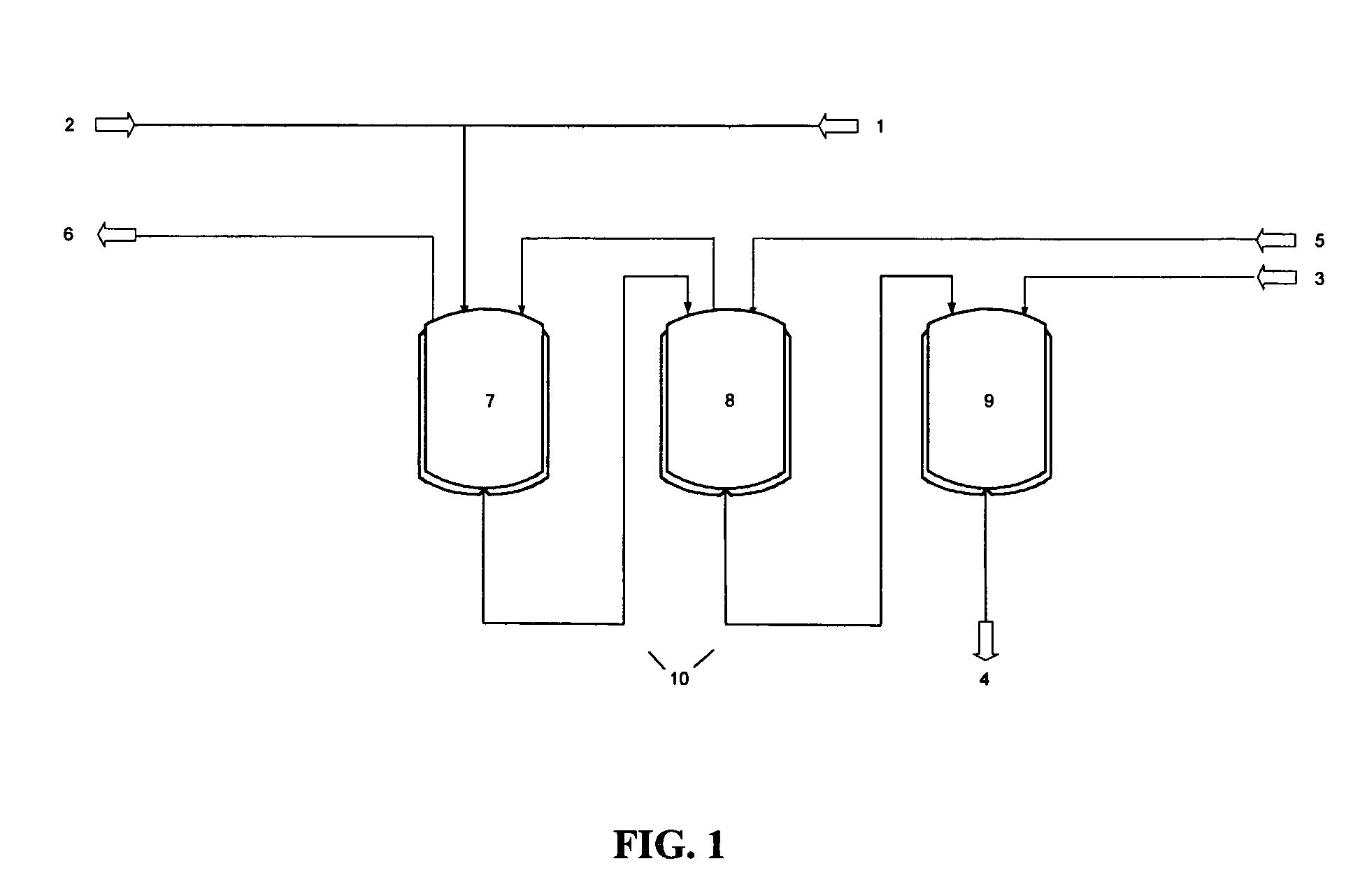

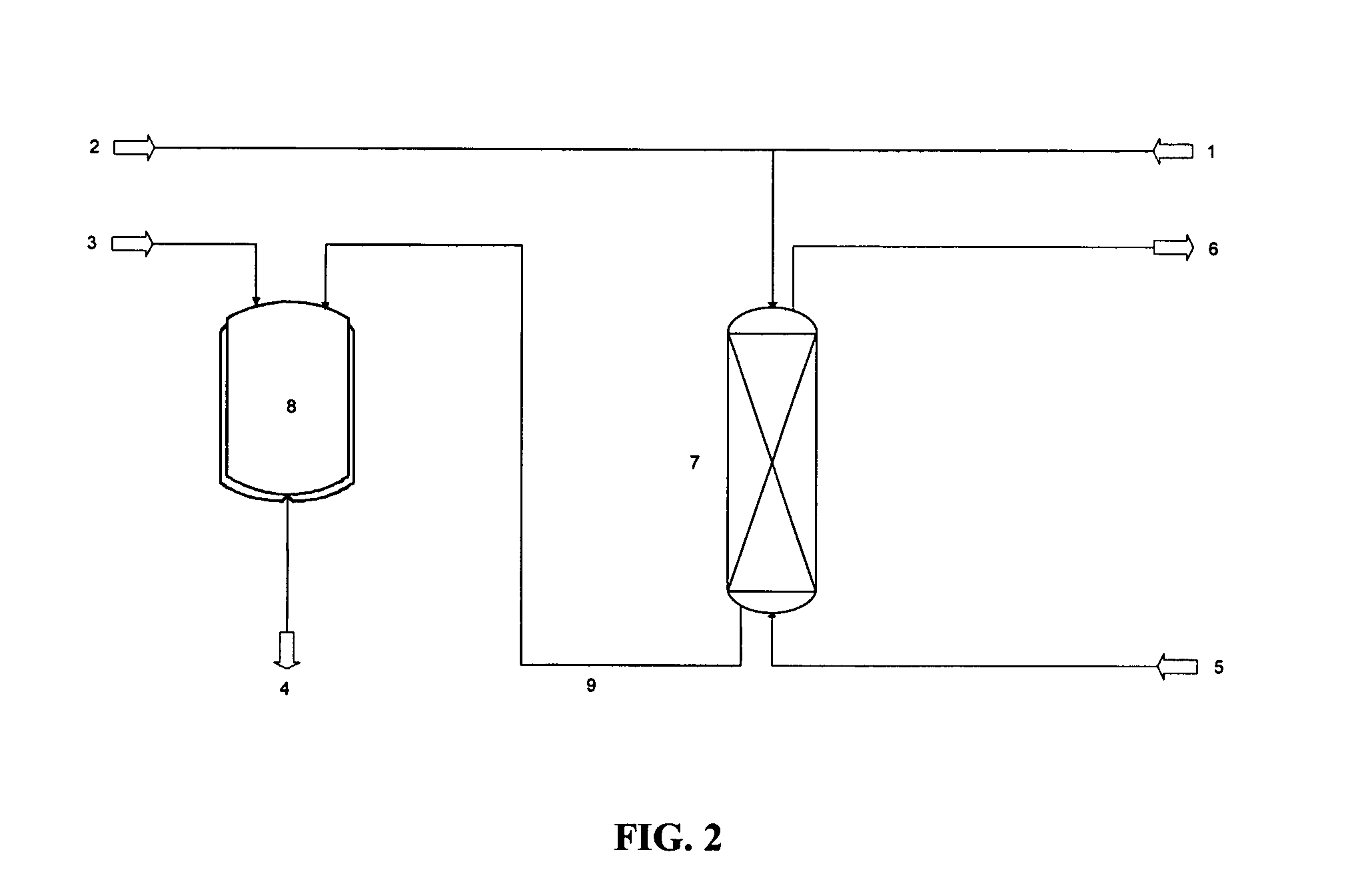

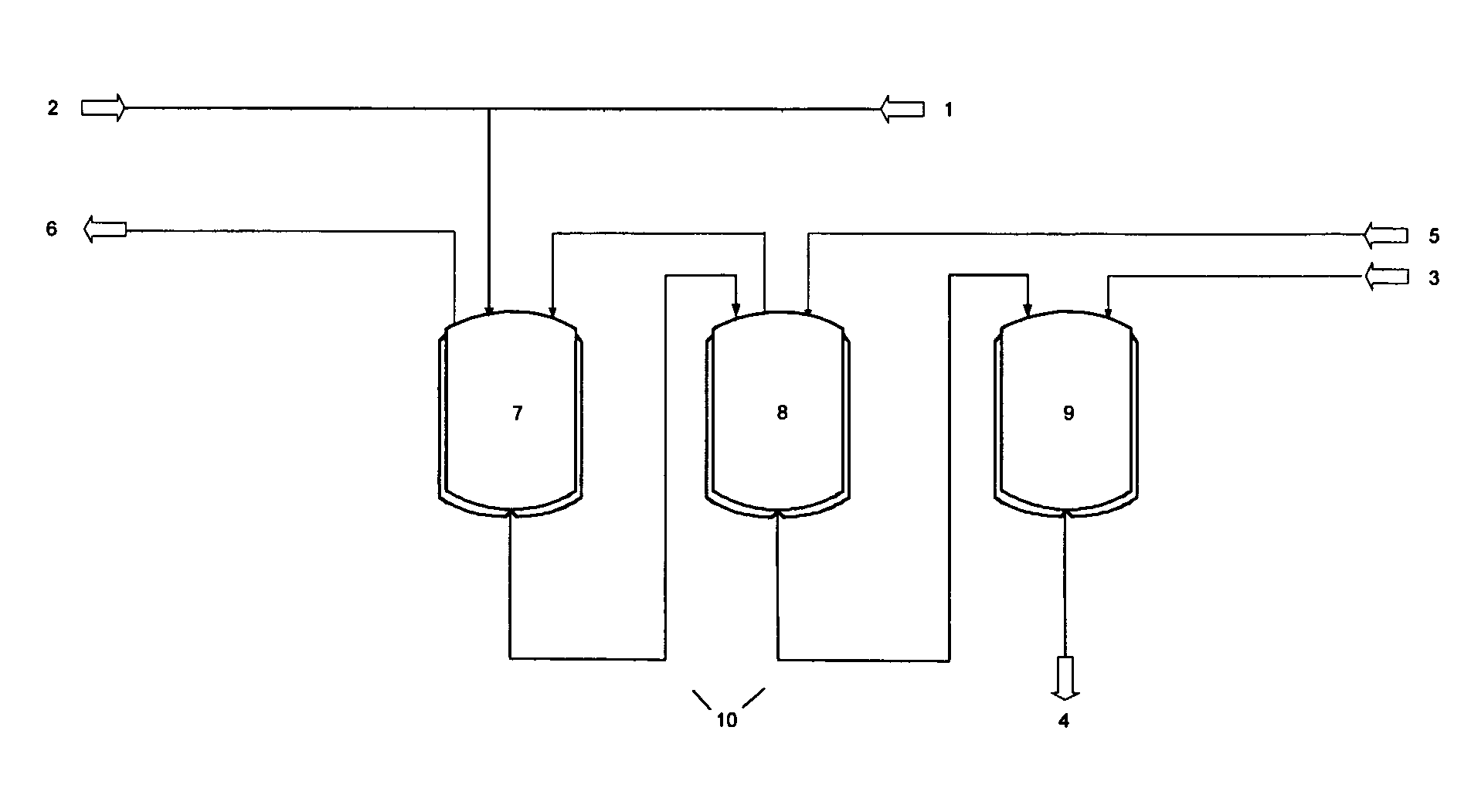

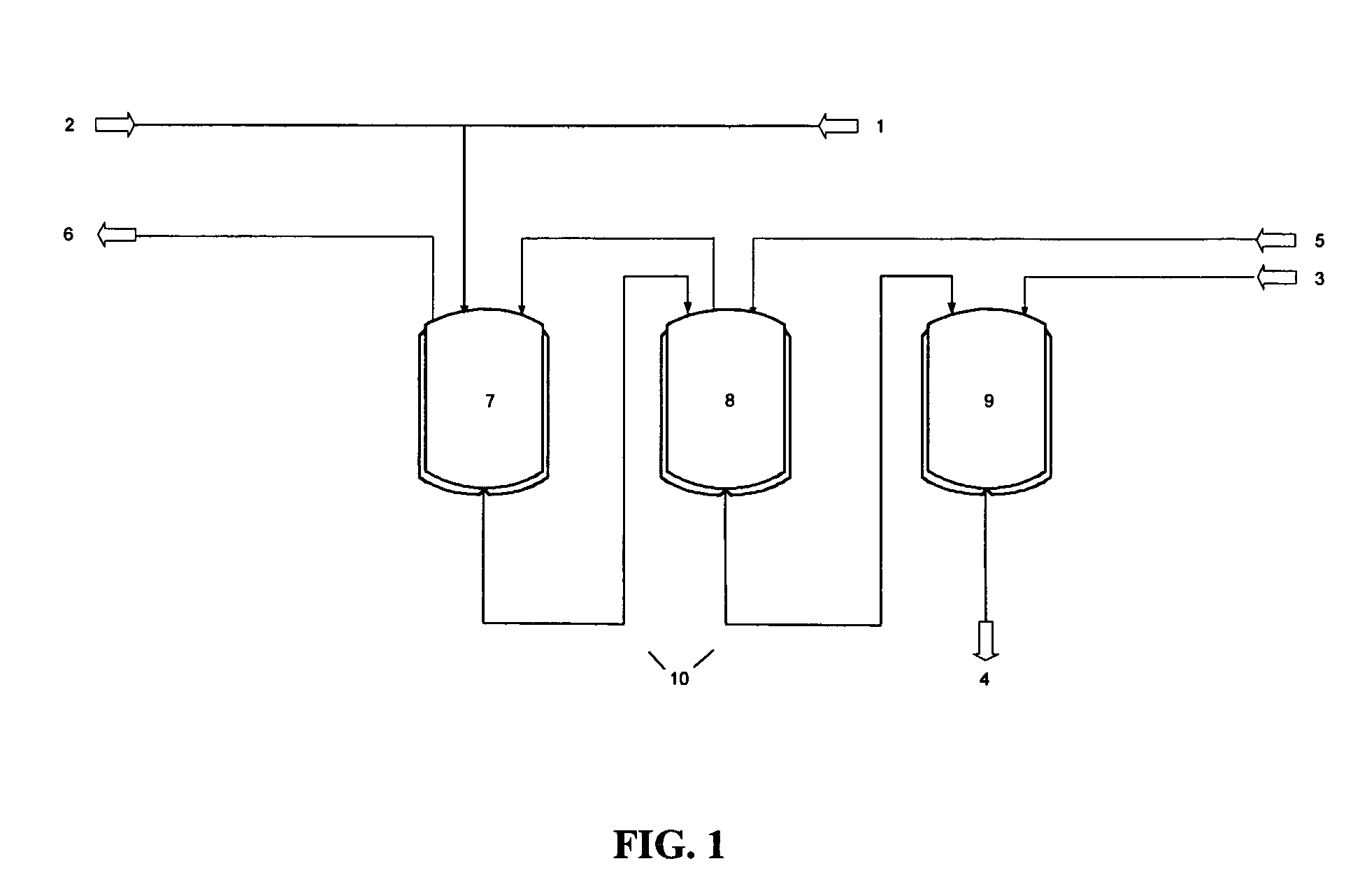

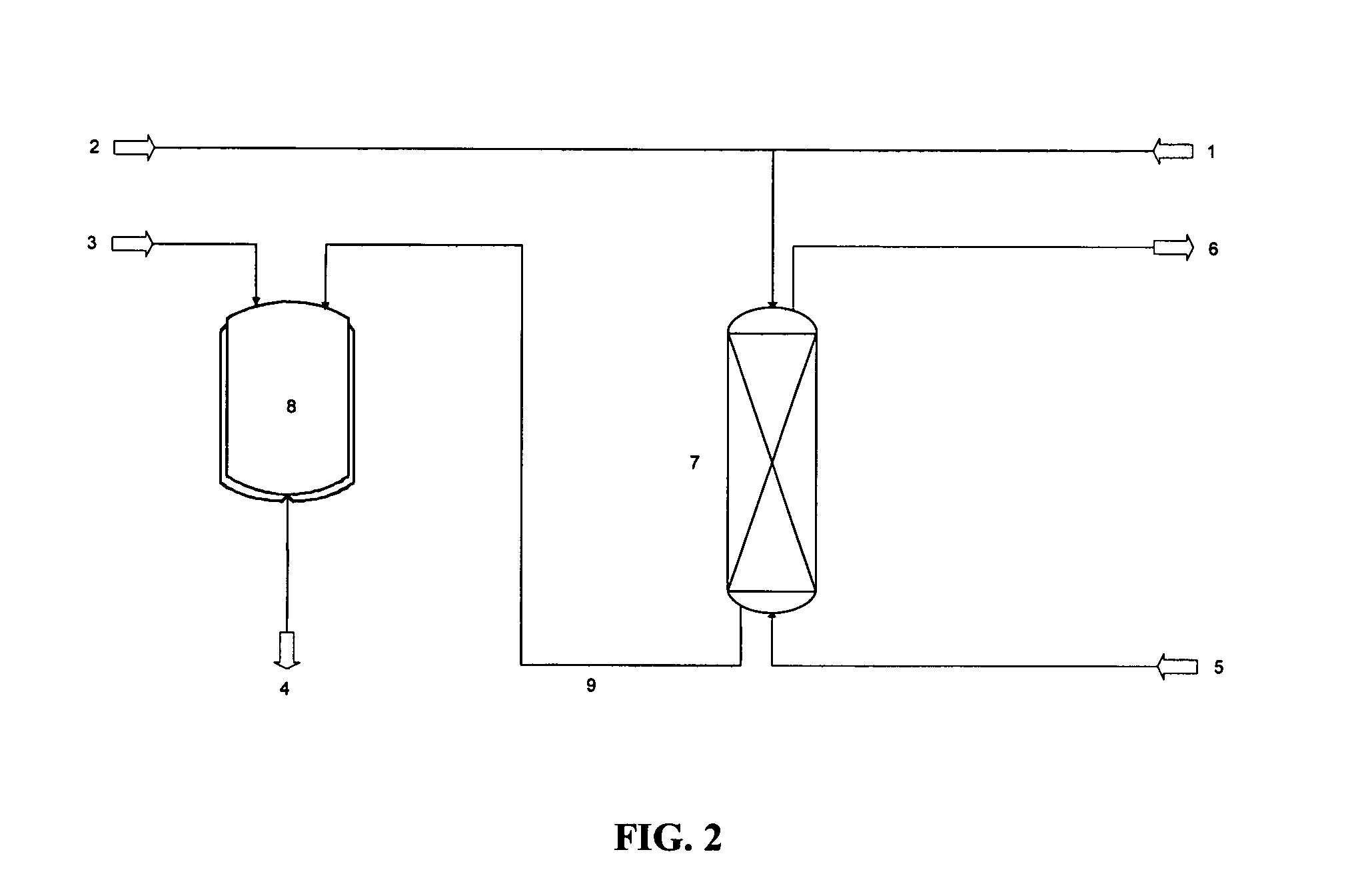

Process for continuous ruthenium-catalysed metathesis

InactiveUS20060009667A1Less fluctuationReduce riskHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryRuthenium catalyst

The invention relates to a process for carrying out metathesis reactions, wherein the process is carried out continuously and a ruthenium-containing catalyst is used.

Owner:BOEHRINGER INGELHEIM INT GMBH

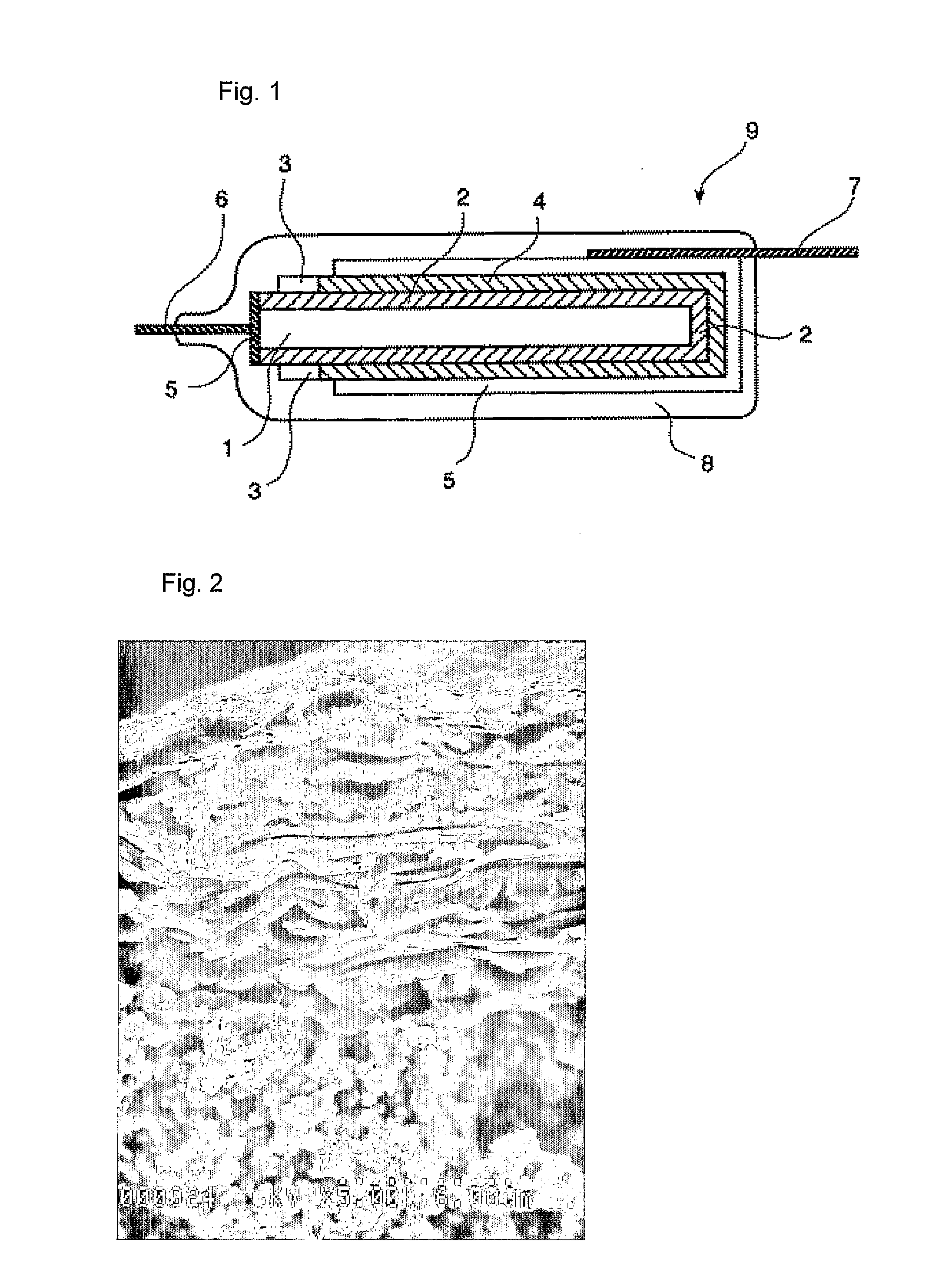

Separator for lithium ion secondary battery, method for manufacture thereof, and lithium ion secondary battery

ActiveUS20110171535A1Less fluctuationUniform densityMaterial nanotechnologyPretreated surfacesLithiumInorganic particle

Disclosed are a separator for lithium ion secondary batteries, having an inorganic layer formed from inorganic particles, characterized in that the inorganic particles have a particle diameter distribution in which the 50% cumulative particle diameter D50 is in the range of 100 nm to 500 nm, the 10% cumulative particle diameter D10 is 0.5D50 or more, and the 90% cumulative particle diameter D90 is 2D50 or less; a method for manufacturing the separator; and a lithium ion secondary battery using the separator. When the separator is used, there can be produced a lithium ion secondary battery in which a short circuit caused by contraction or melting can be definitely prevented, as well as the current density applied to the electrodes during charging and discharging is uniform so that charging and discharging can be efficiently achieved.

Owner:NIPPON BAIRIIN

Epoxy resin composition for encapsulating optical semiconductor element and optical semiconductor device using the same

InactiveUS20050082691A1Small internal stressGood light transmittanceDiffusing elementsSemiconductor/solid-state device detailsChemistryOptical transmittance

Owner:NITTO DENKO CORP

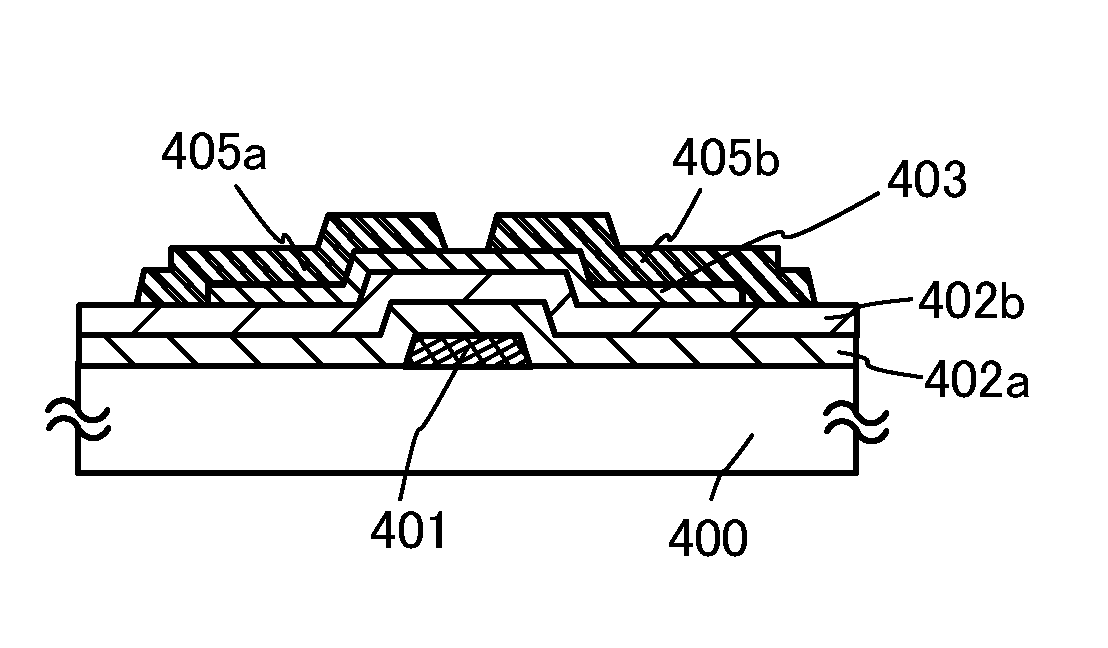

Method of manufacturing semiconductor device

ActiveUS8828794B2Stable electrical characteristicsImprove reliabilityTransistorSolid-state devicesBias temperature stressSemiconductor

In a manufacturing process of a transistor including an oxide semiconductor film, oxygen doping treatment is performed on the oxide semiconductor film, and then heat treatment is performed on the oxide semiconductor film and an aluminum oxide film provided over the oxide semiconductor film. Consequently, an oxide semiconductor film which includes a region containing more oxygen than a stoichiometric composition is formed. The transistor formed using the oxide semiconductor film can have high reliability because the amount of change in the threshold voltage of the transistor by a bias-temperature stress test (BT test) is reduced.

Owner:SEMICON ENERGY LAB CO LTD

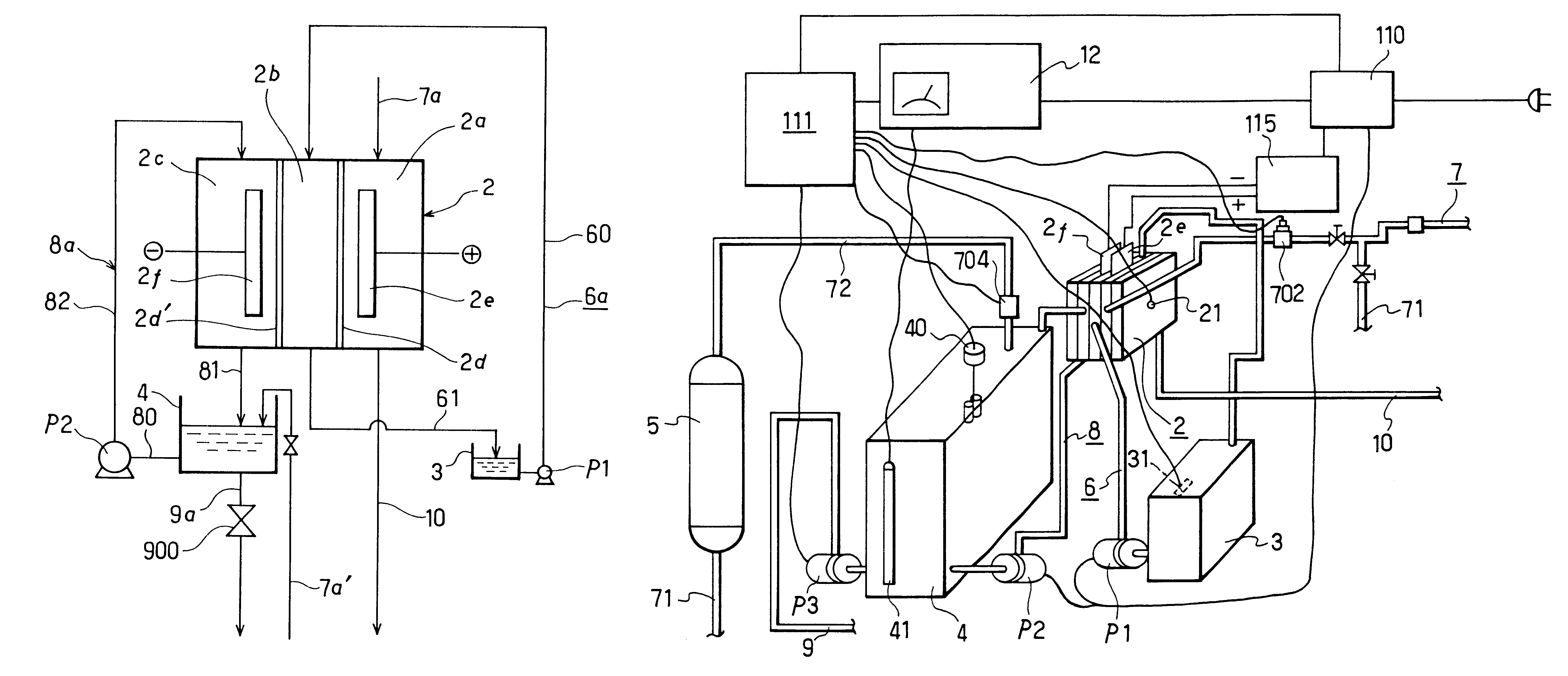

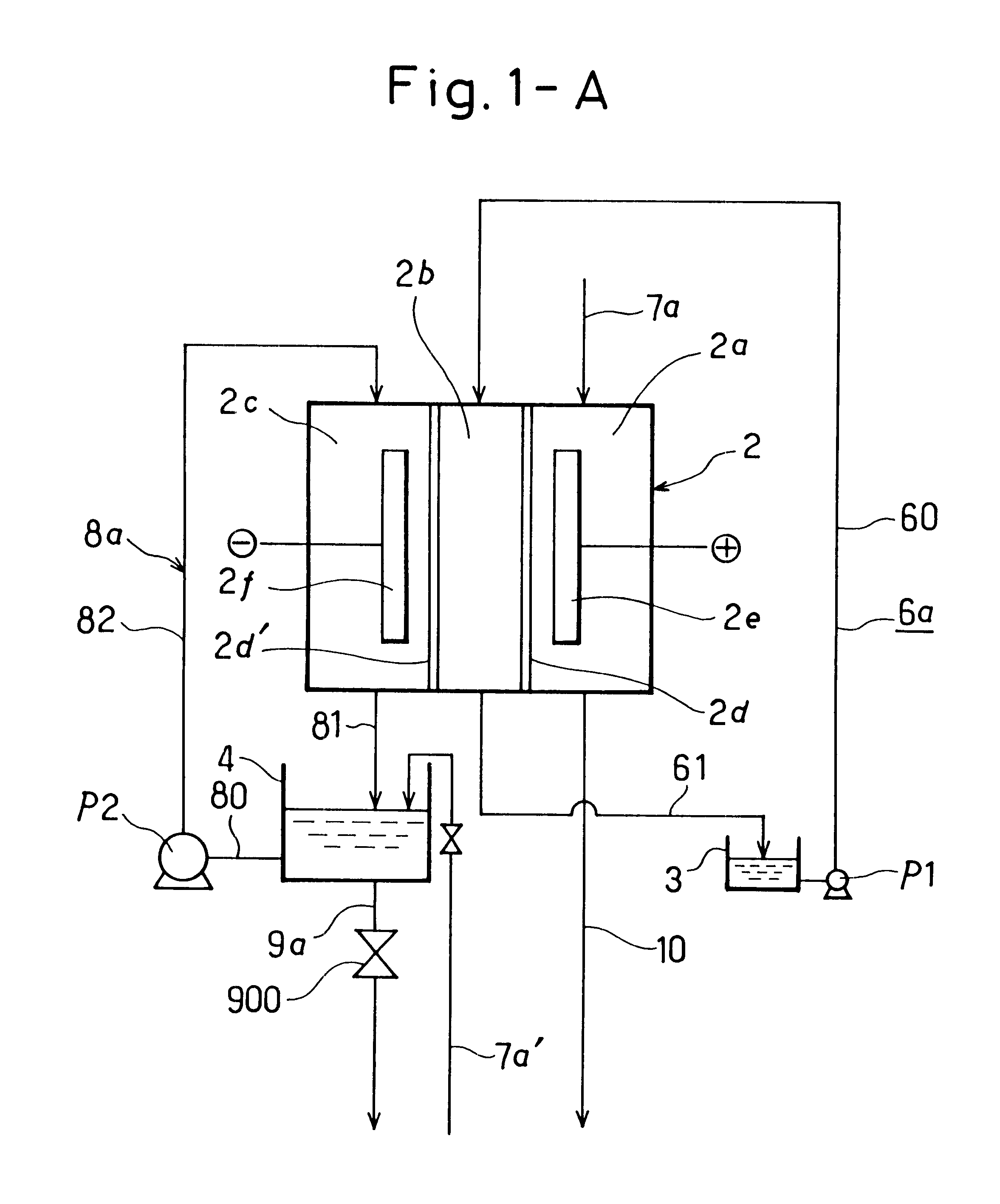

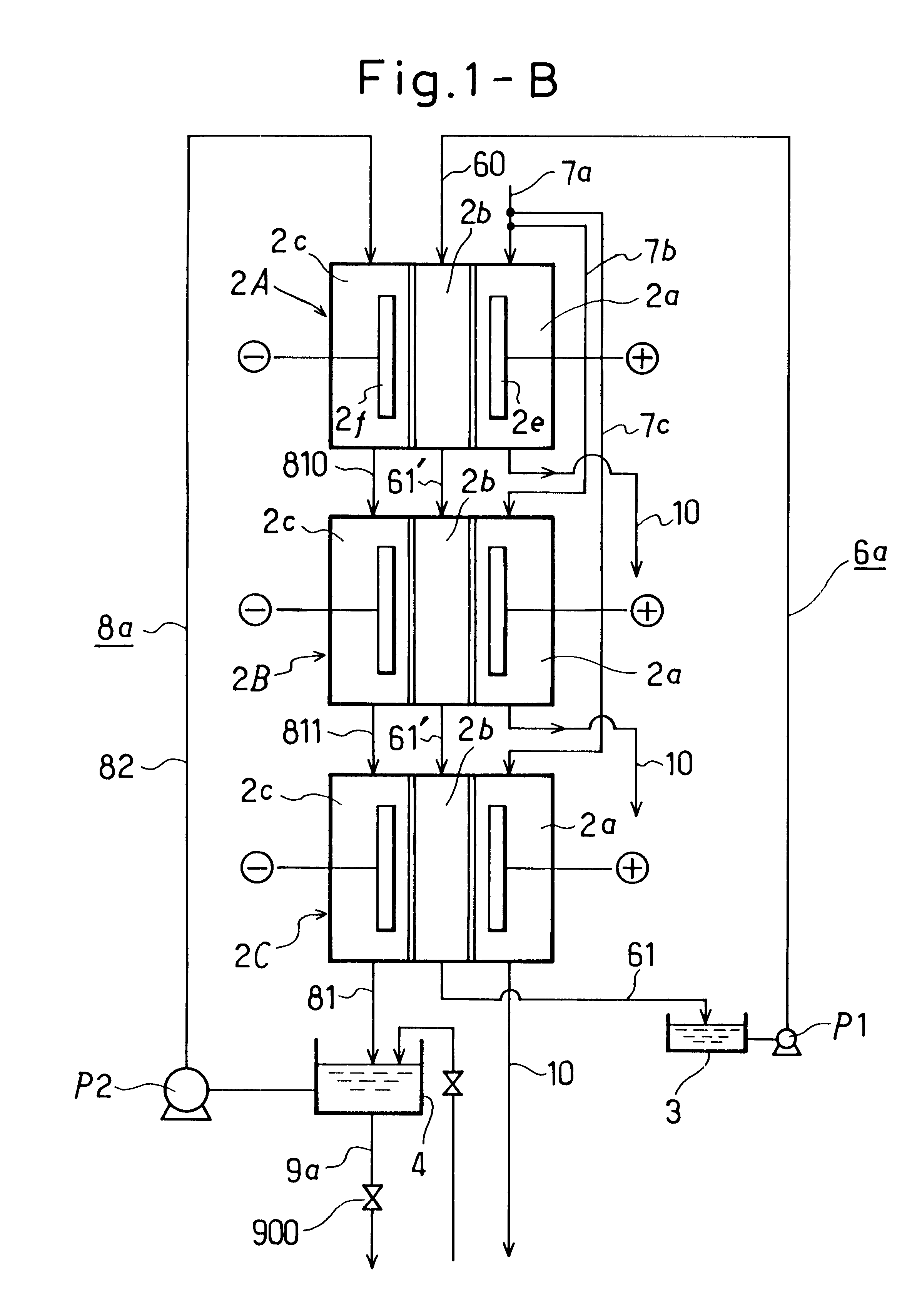

Manufacturing method and apparatus for making alkaline ionized water and acidic water

InactiveUS6464845B2Stably and efficiently mass-produceStrong natureCellsWater treatment parameter controlElectrolysed waterWater cycling

The manufacturing apparatus for producing alkaline ionized water and acidic water by electrolysis of water has an electrolytic bath including a cathode cell, an intermediate cell, and an anode cell, separated by diaphragms; an electrolysis solution bath connected to the intermediate cell via an electrolysis solution circulating line and an electrolysis solution circulating pump; a circulation container bath for alkaline ionized water connected to the cathode cell via an alkaline ionized water circulating line and an alkaline ionized water circulating pump; a supplying line for raw material water for producing acidic water connected to an inlet of the anode cell; a withdrawing line for acidic water connected to an outlet of the anode cell; a supplying system for raw material water for making the alkaline ionized water connected to the circulation container bath and a withdrawing line with a water collecting device for withdrawing alkaline ionized water.

Owner:CHEMICOAT

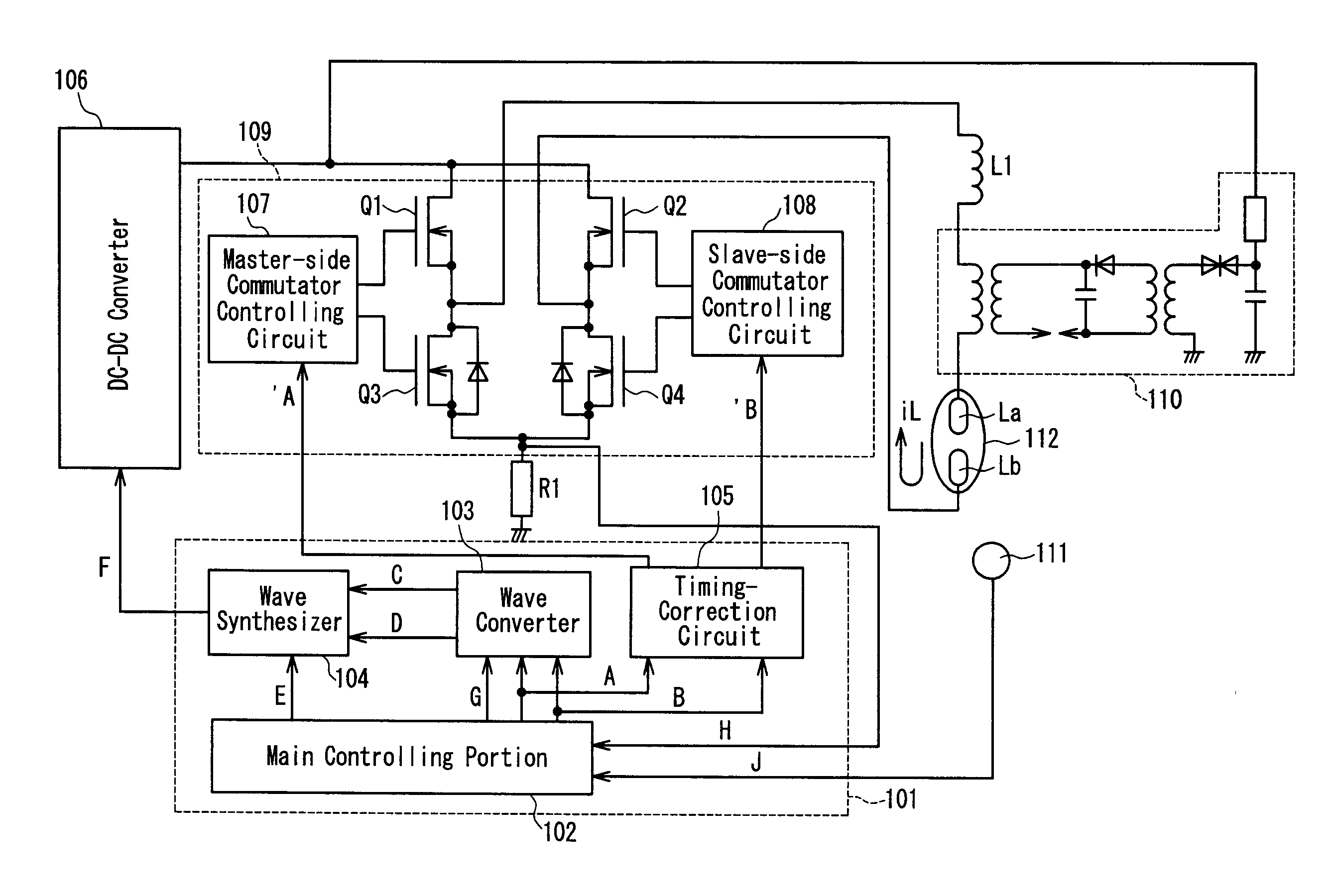

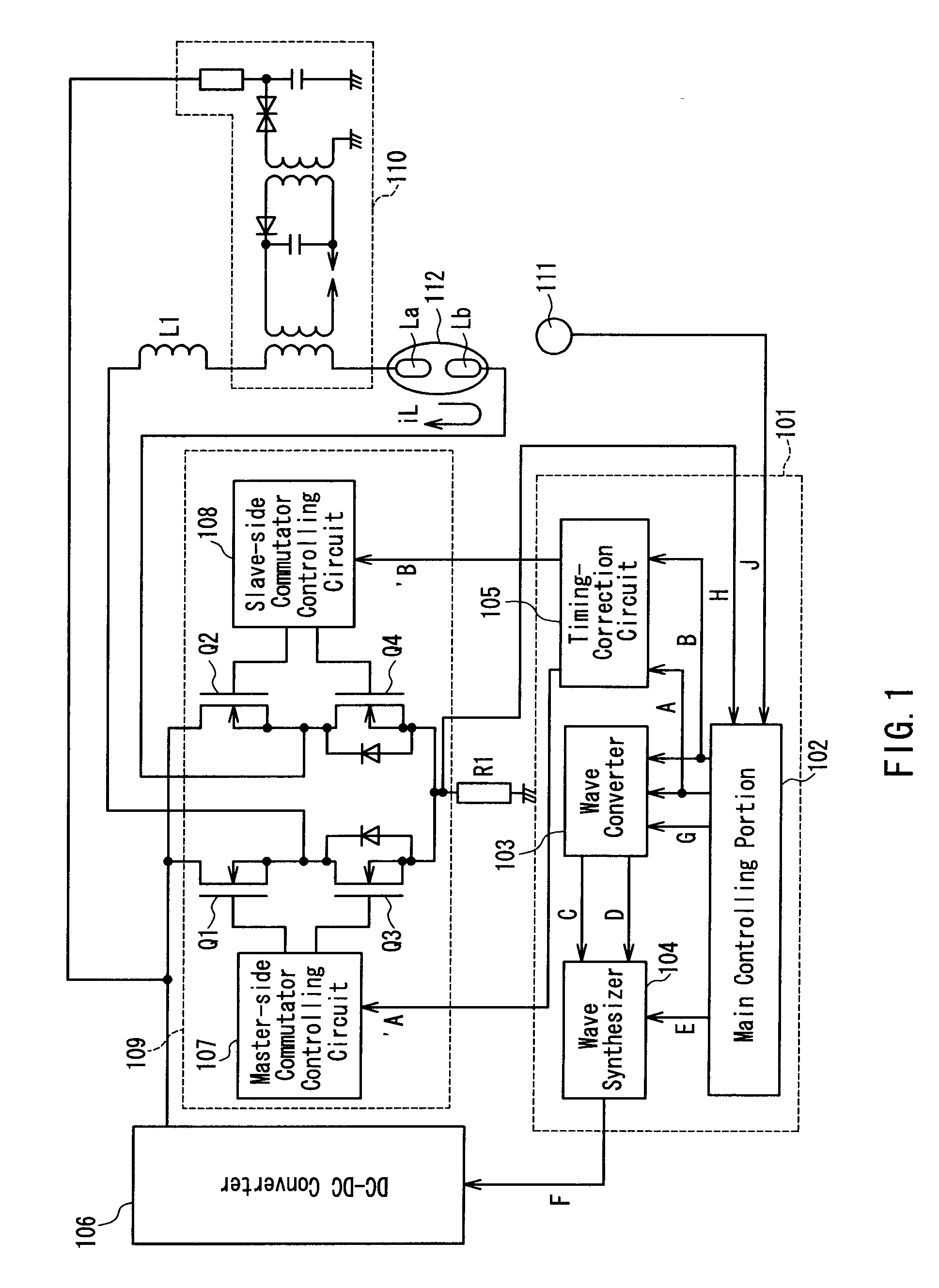

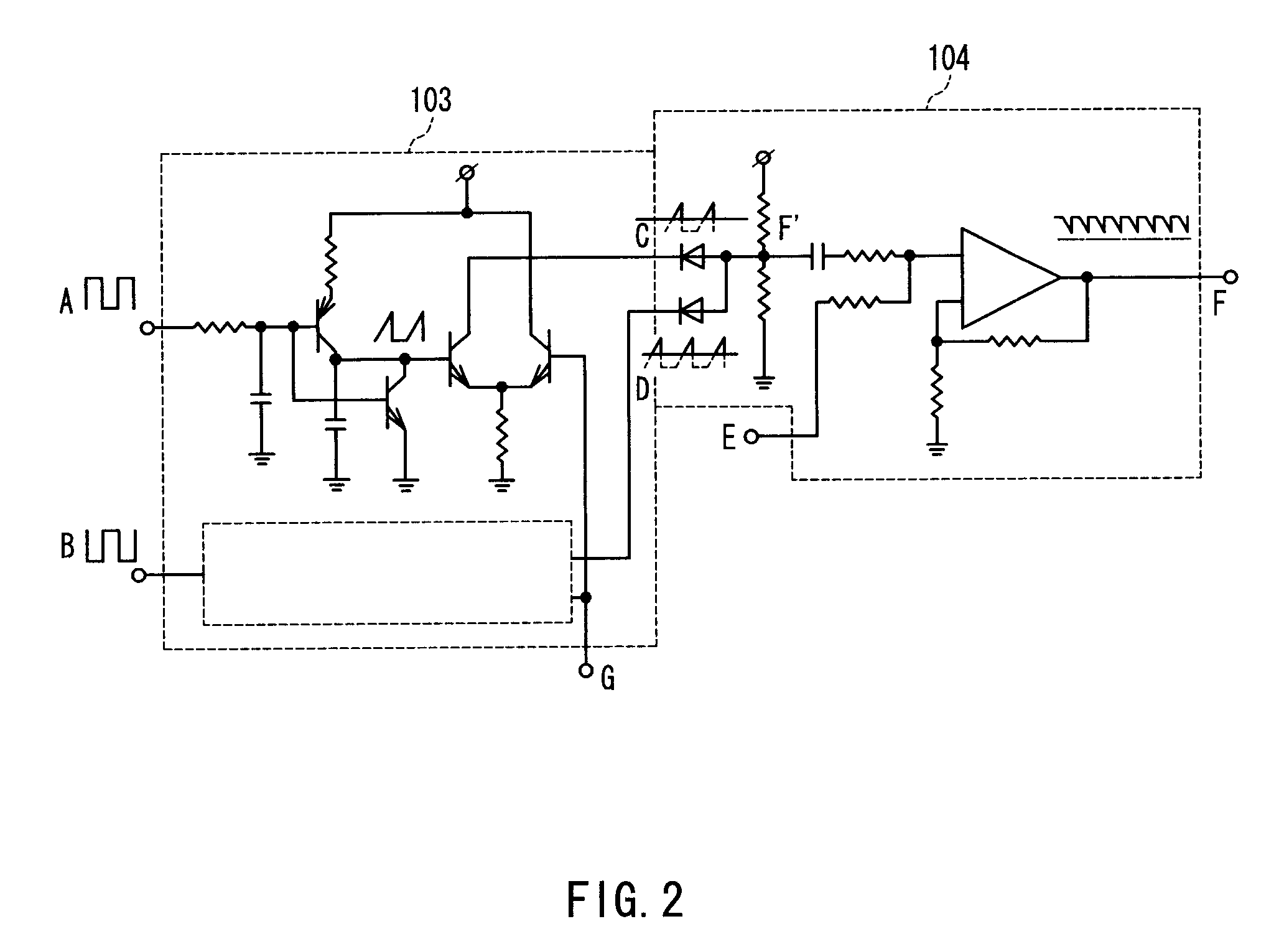

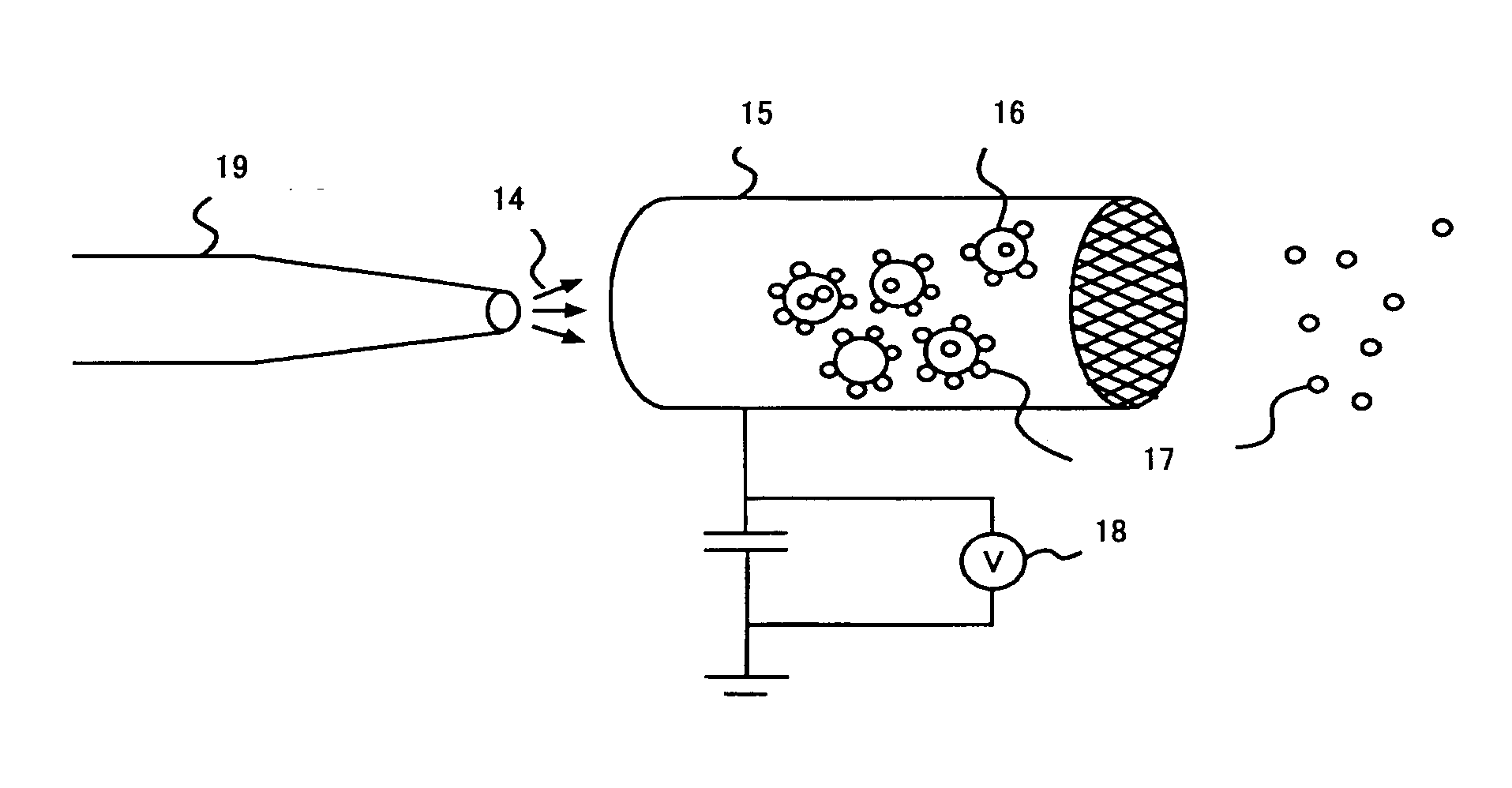

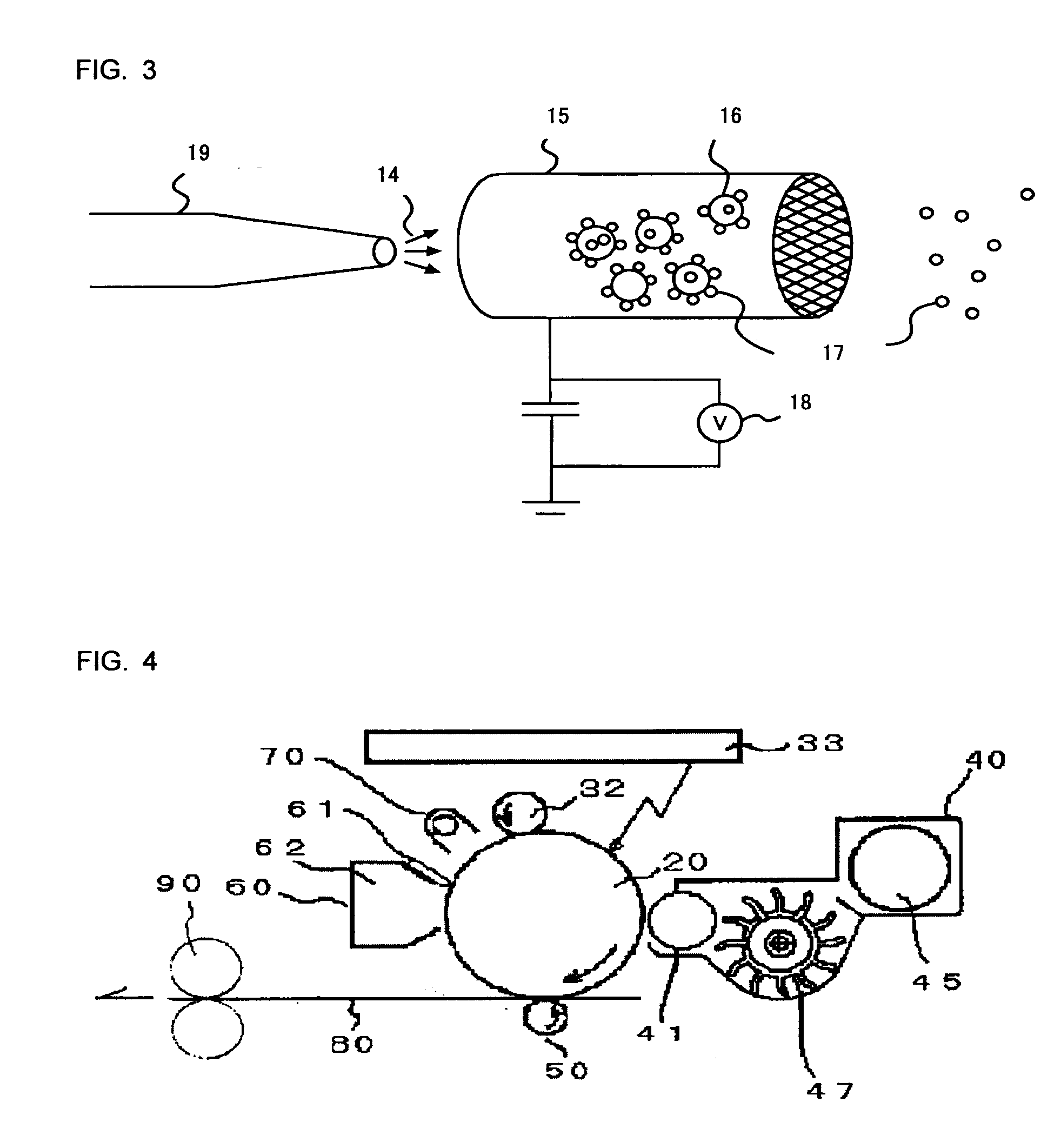

Discharge lamp lighting device and system comprising it

InactiveUS6717375B2Few arc jumpLess fluctuationElectric light circuit arrangementGas discharge lamp usageControl signalEffect light

A discharge-lamp lighting device is provided which decreases arc jumps, suppresses the fluctuation in brightness of the lamp, and prolongs a life of the lamp, by positively accelerating growth of spots even when an inexpensive, small and highly efficient lamp is used. A discharge-lamp controlling portion (101) sets frequencies of drive-controlling signals (A and B) for drive-controlling a commutator (109) within a predetermined frequency range so that spots formed by arc discharge on electrodes composing a high-pressure discharge lamp grow through a cycle of oxidation-reduction of a metal composing the electrodes, and superimposes a triangular wave signal generated on the basis of the drive-controlling signals onto a current-controlling signal (F) over an entire period of the drive-controlling signals so as to make a peak value of the triangular wave constant, thereby adjusting the waveform of current flowing in the high-pressure discharge lamp.

Owner:PANASONIC CORP

Process for continuous ruthenium-catalysed metathesis

InactiveUS7838711B2Less fluctuationReduce riskHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsSalt metathesis reactionChemistry

Owner:BOEHRINGER INGELHEIM INT GMBH

Electrophotographic developer and carrier therefor, core material particle for carrier for electrophotographic developer and production method thereof and image forming method

ActiveUS20070243482A1Minimize toner spentImprove image qualityElectrographic process apparatusDevelopersCost effectivenessEngineering

The present invention can provide small-diameter core material particles for electrophotographic carrier, the particles that can prevent occurrences of carrier adhesions and reduce toner spent, have excellent durability and cause little fluctuations in image density with a narrow particle diameter distribution, and an efficient, cost-effective production method thereof. That is, the core material particles for electrophotographic carrier are particles wherein the weight average particle diameter, Dw, is in the range of 22 μm to 32 μm, the ratio of Dw to the number average particle diameter, Dp, satisfies the condition, 1<Dw / Dp<1.20, the content of particles smaller than 20 μm in diameter is in the range of 0% by mass to 7% by mass and smaller than 36 μm is in the range of 90% by mass to 100% by mass, and the BET specific surface area is in the range of 300 cm2 / g to 900 cm2 / g.

Owner:RICOH KK

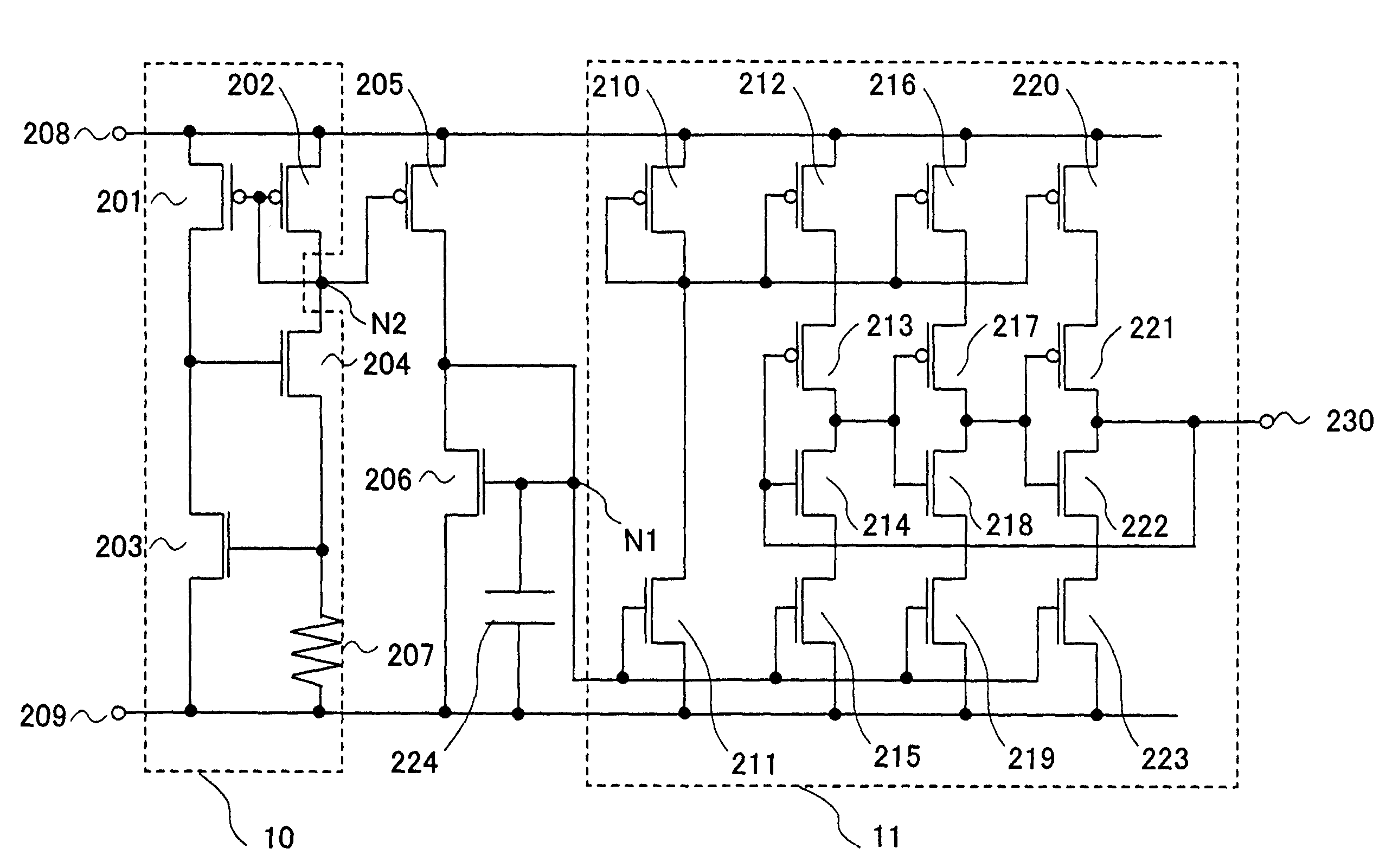

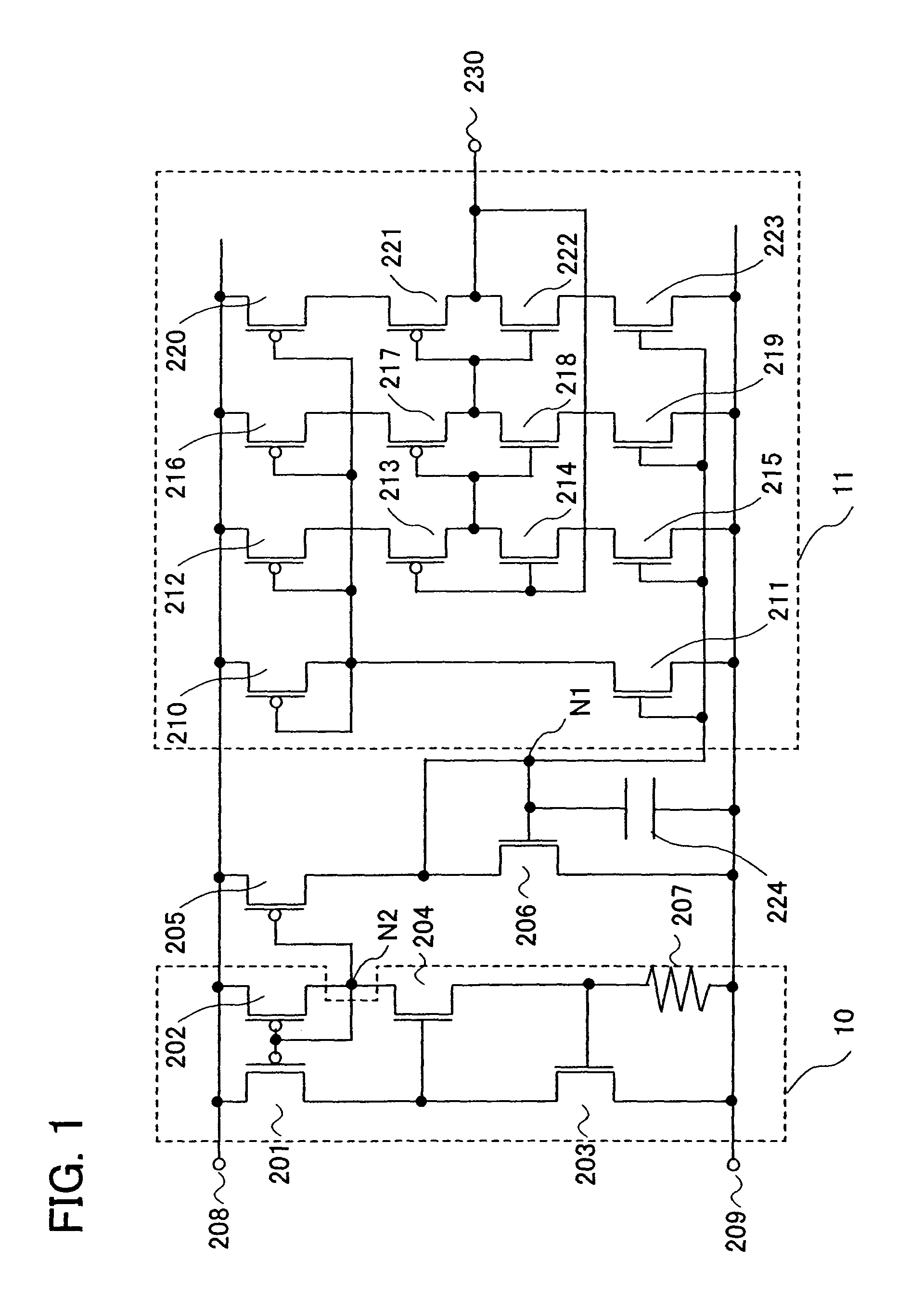

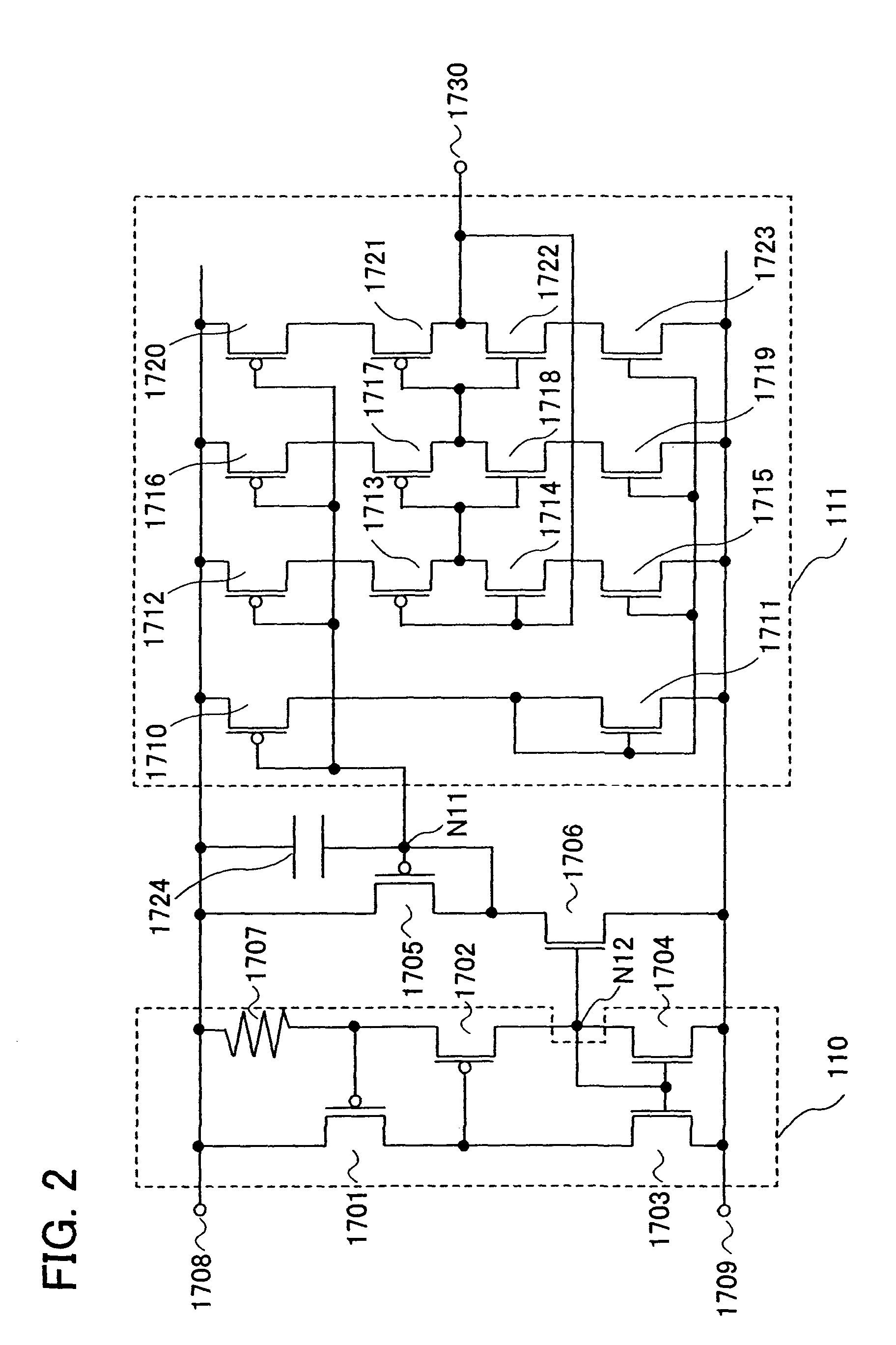

Oscillator circuit having a stable output signal resistant to power supply voltage fluctuation

InactiveUS7663447B2Easily fluctuateSuppress fluctuationsPulse automatic controlSolid-state devicesPotential differenceEngineering

A stable frequency is outputted by an oscillator circuit including a constant current circuit which is electrically connected between a first terminal and a second terminal, a voltage controlled oscillator circuit in which an oscillation frequency fluctuates in accordance with a potential difference between power supply voltage terminals, an n-channel transistor, a p-channel transistor in which a gate-source voltage is set to be constant by the constant current circuit, and a capacitor, in which a source electrode of the p-channel transistor is electrically connected to the first terminal, a drain electrode of the p-channel transistor is electrically connected a drain electrode and a gate electrode of the n-channel transistor, a source electrode of the n-channel transistor is electrically connected to the second terminal, and a gate electrode of the n-channel transistor is electrically connected to the second terminal through the capacitor.

Owner:SEMICON ENERGY LAB CO LTD

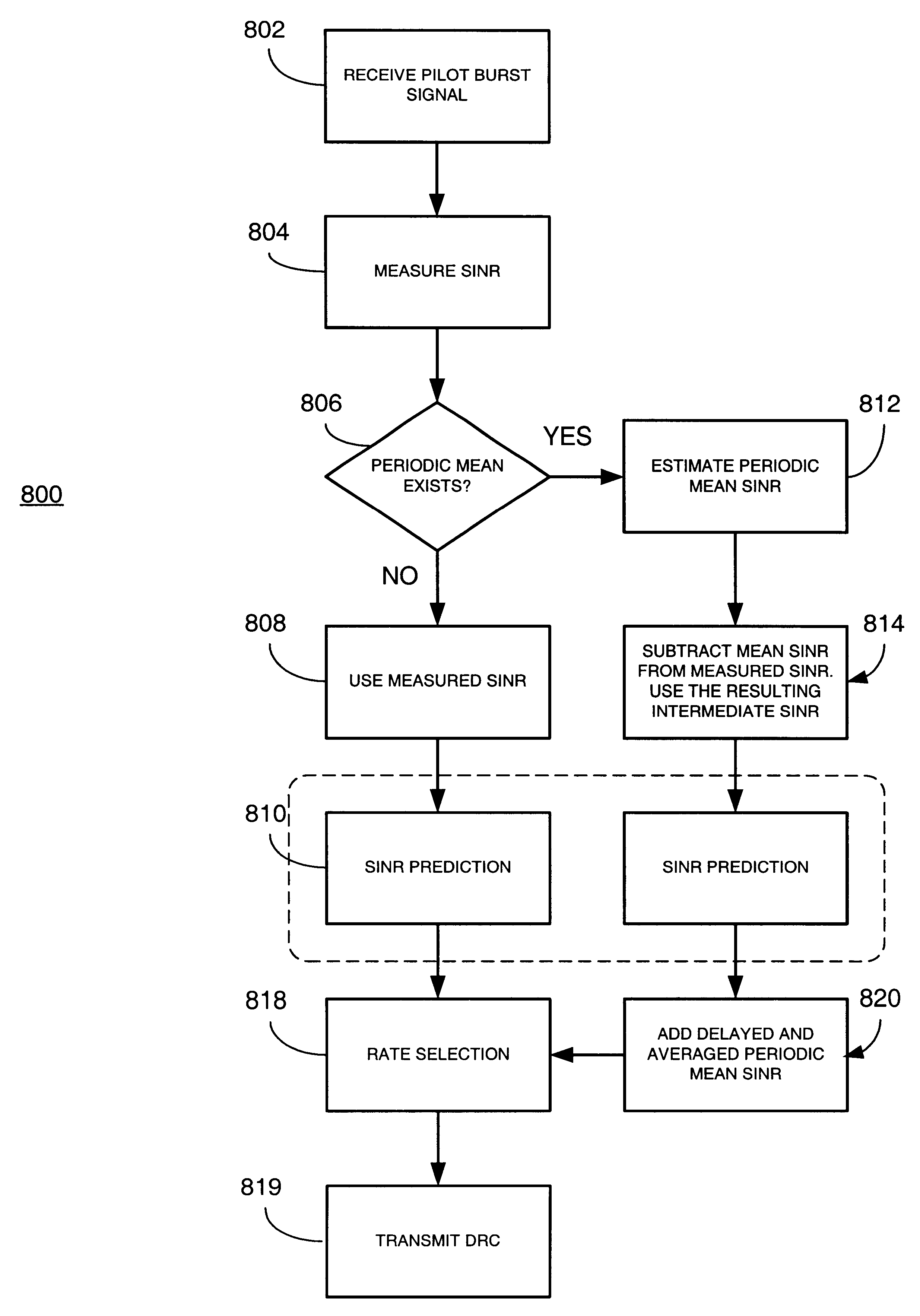

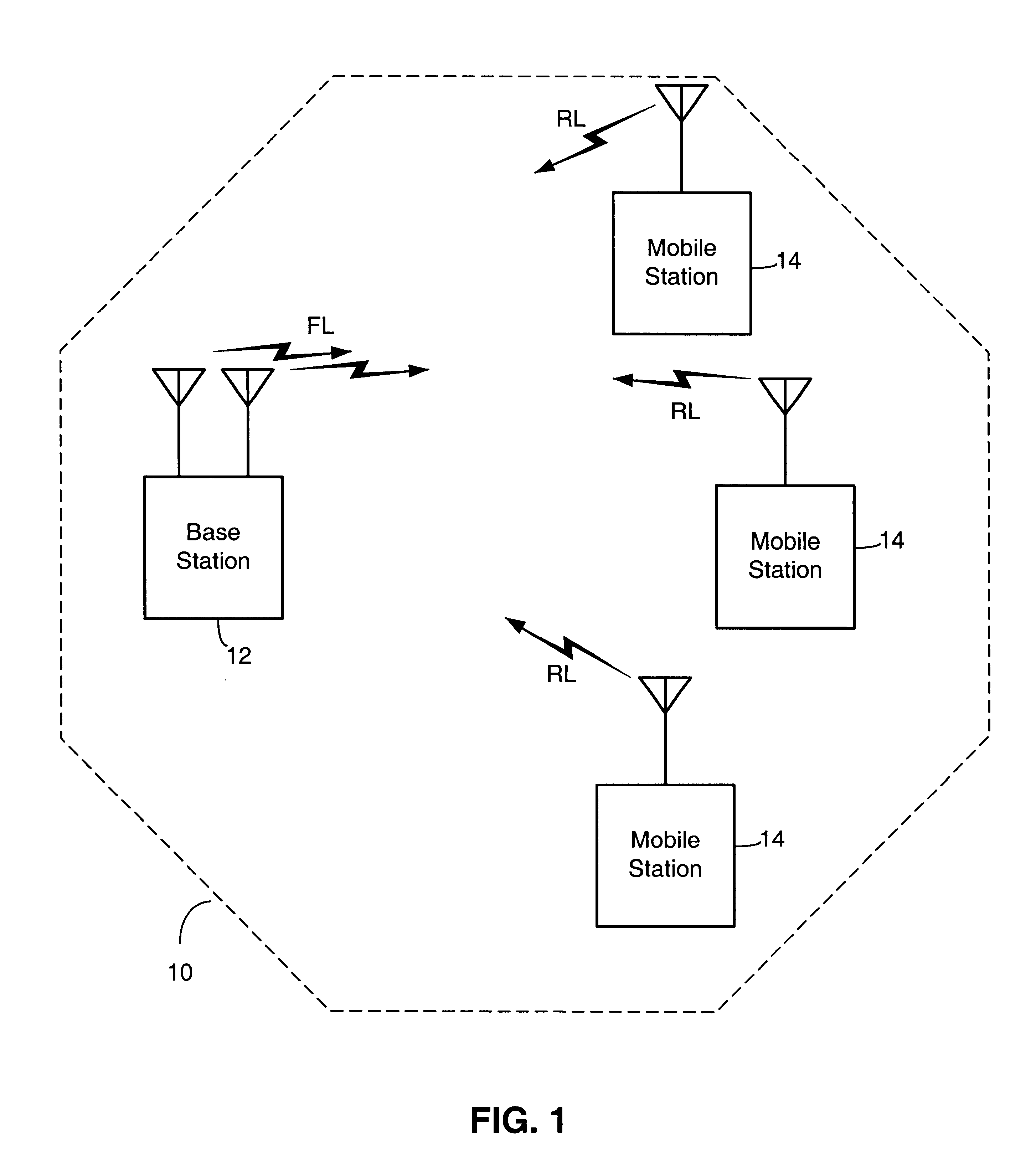

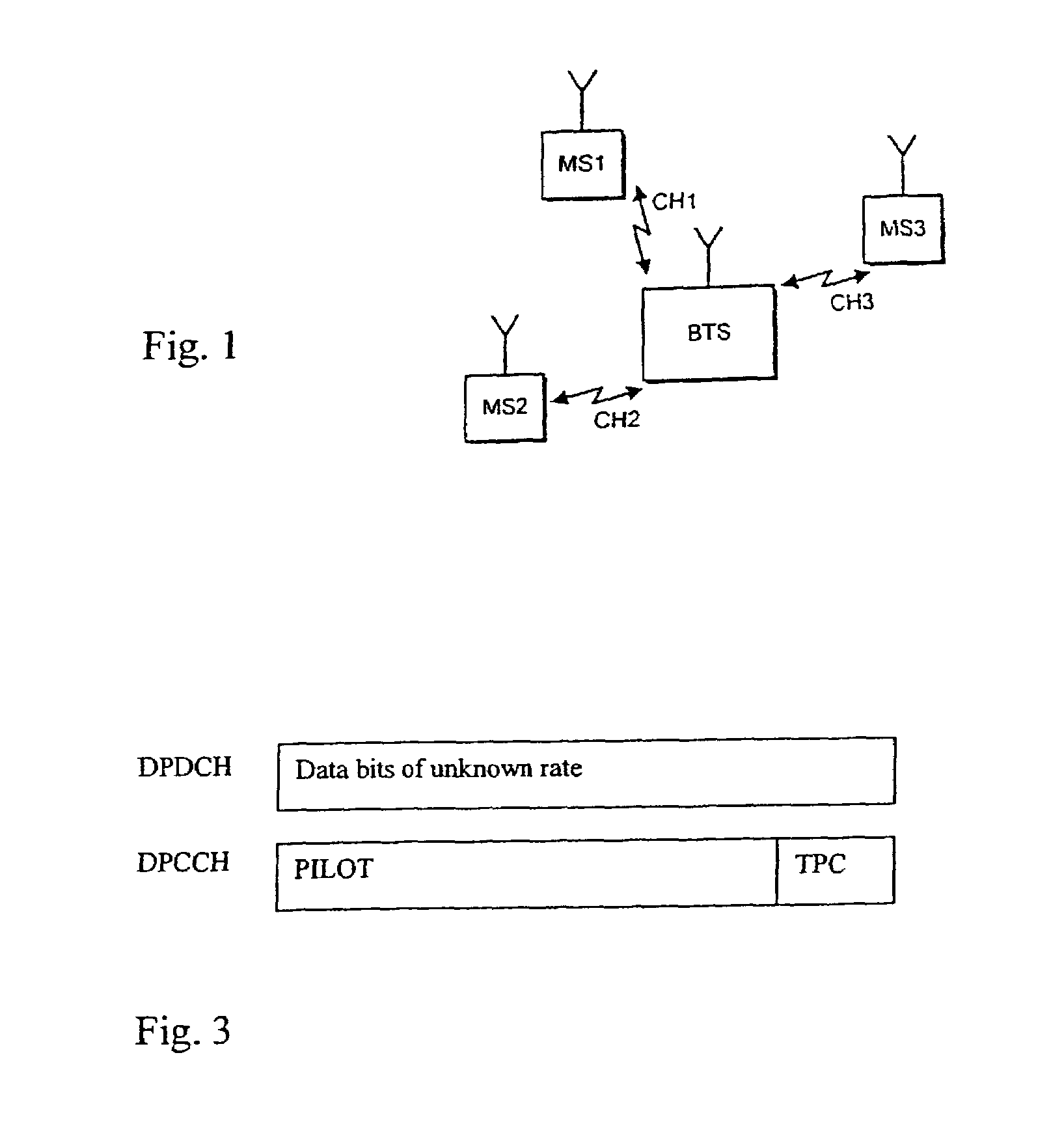

Wireless communication data rate control prediction method and system

InactiveUS6847809B2Improve forecast accuracyLess fluctuationError detection/prevention using signal quality detectorFrequency-division multiplex detailsCommunications systemWireless data

Systems and methods for predicting the signal-to-interference-and-noise ratio (SINR) of the signal to be received by a mobile station transmitted from a base station in a wireless data communications system, for the purpose of forward link data rate control in the presence of partly periodic SINR fluctuations. The invention involves determination of a periodic mean SINR component in the received SINR process, and upon such determination the activation of a method which comprises a periodic mean SINR estimator, a subtractor which subtracts the periodic component from the received SINR process to produce an intermediate SINR process, a generic predictor which may be used to perform predictions on the intermediate SINR process, an adder which adds back an appropriate mean value to the intermediate SINR prediction. The resulting final SINR prediction is then used for rate selection.

Owner:QUALCOMM INC

Face collation apparatus

ActiveUS20090175512A1Efficient and stable face collation detectionEfficient and stable face collationDigital data authenticationBiometric pattern recognitionRejection rateArtificial intelligence

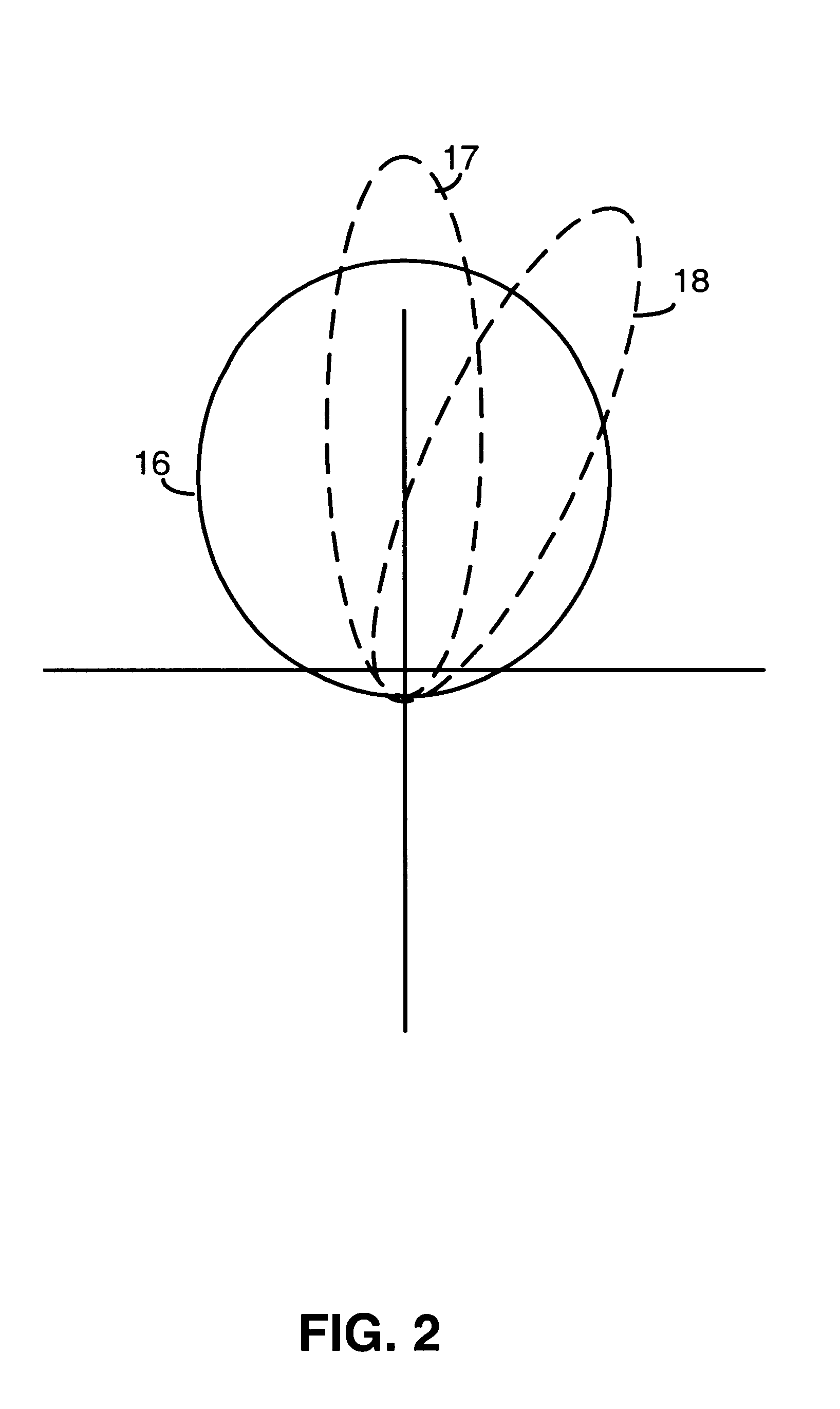

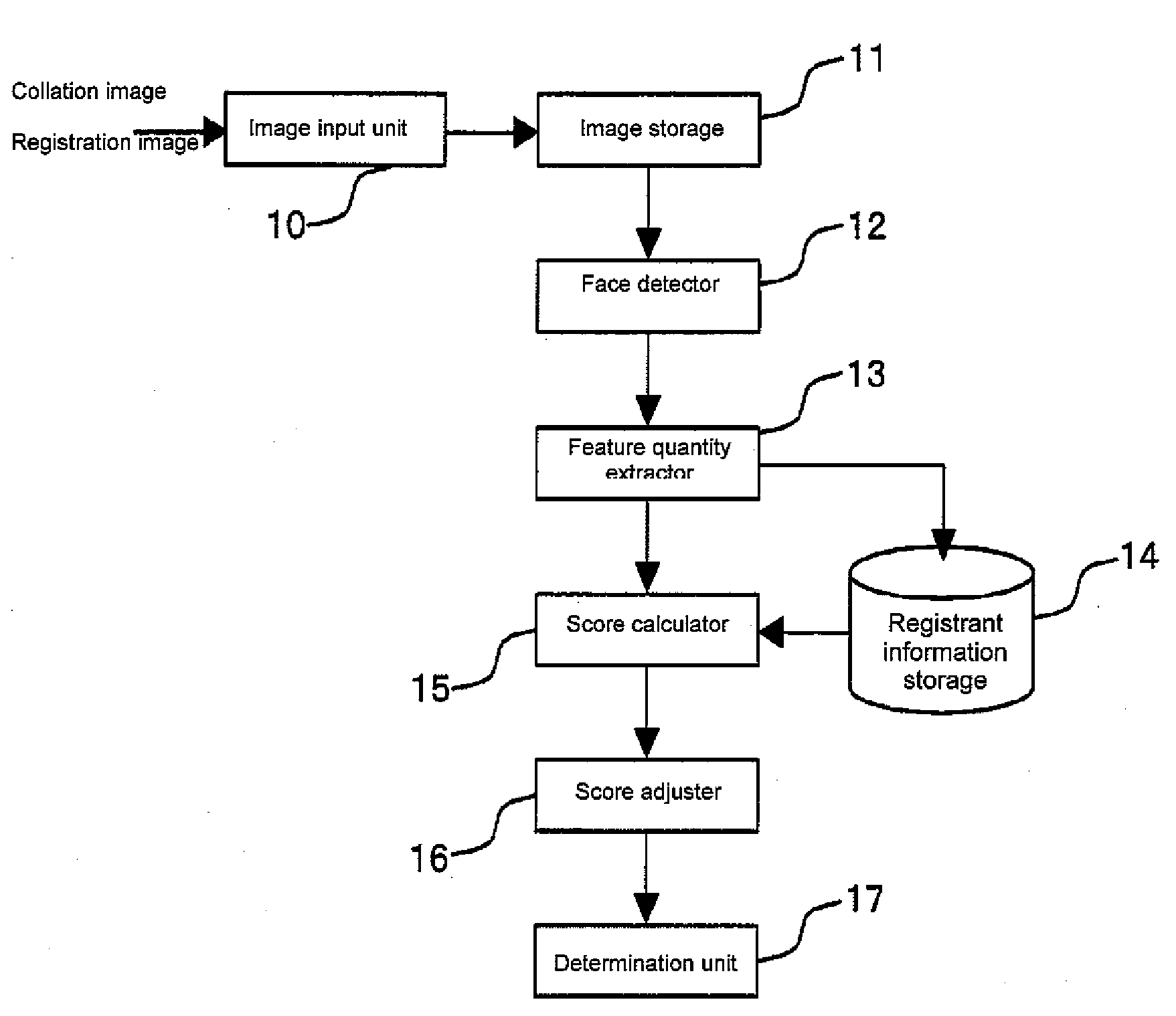

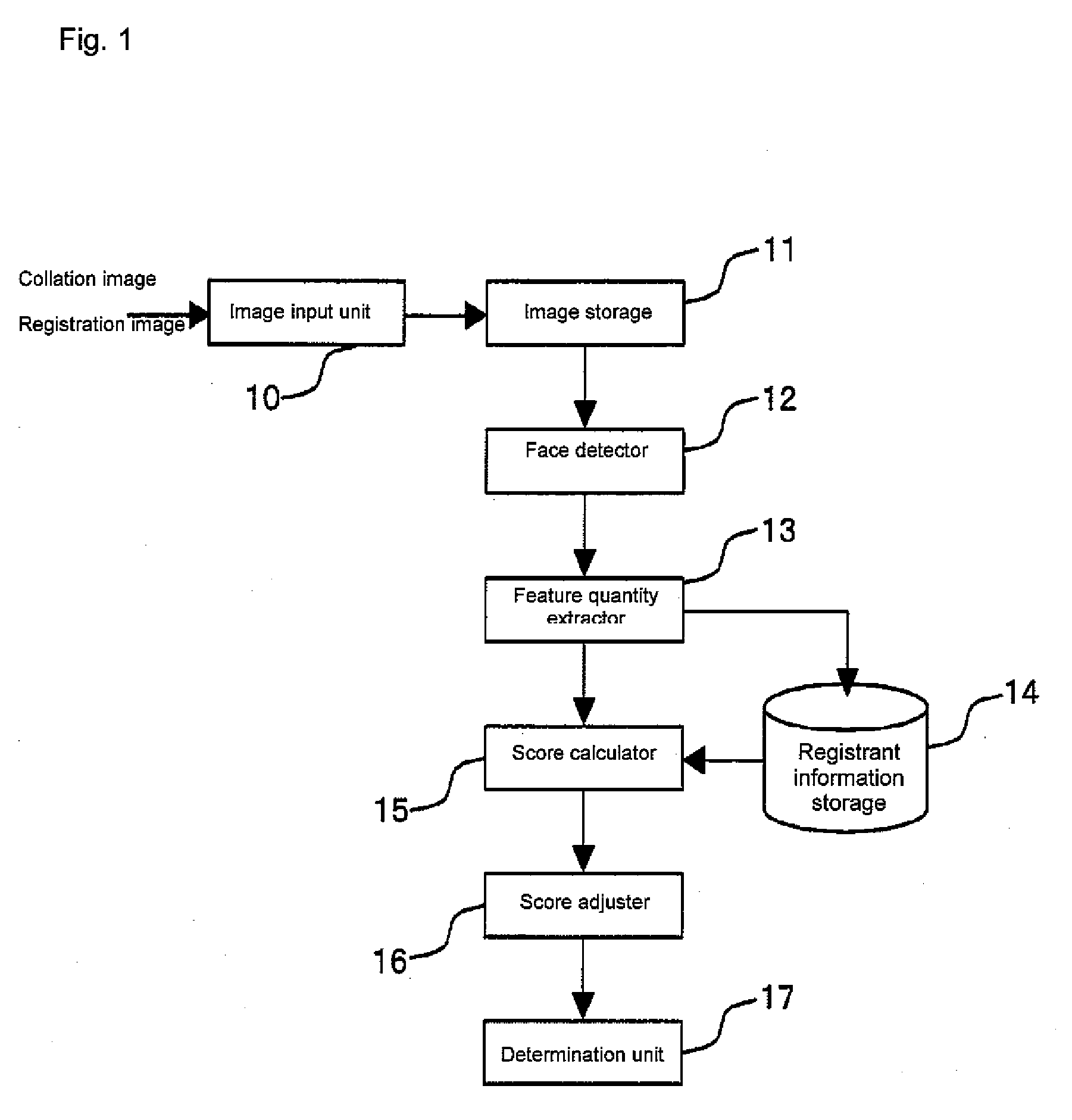

A face collation apparatus has a storage that stores a feature quantity of at least one registrant, the feature quantity being extracted from a registration image of the registrant, a feature quantity extractor that extracts a feature quantity from a collation image of a collation object person, a score calculator that calculates a score indicating an analogy degree between the feature quantity of the registrant and the feature quantity of the collation object person, a score adjuster that adjusts the score using a score adjustment parameter so that any one of a stranger acceptance rate indicating a probability that a stranger is accepted at the time of collation, a principal rejection rate indicating a probability that a principal is rejected at the time of collation, and an equal error rate, which is a probability that the stranger acceptance rate and the principal rejection rate are equal, becomes substantially constant regardless of a registration condition and / or a collation condition, and a determination unit that determines whether the collation object person is the registrant by comparing the adjusted score and a predetermined threshold.

Owner:ORMON CORP

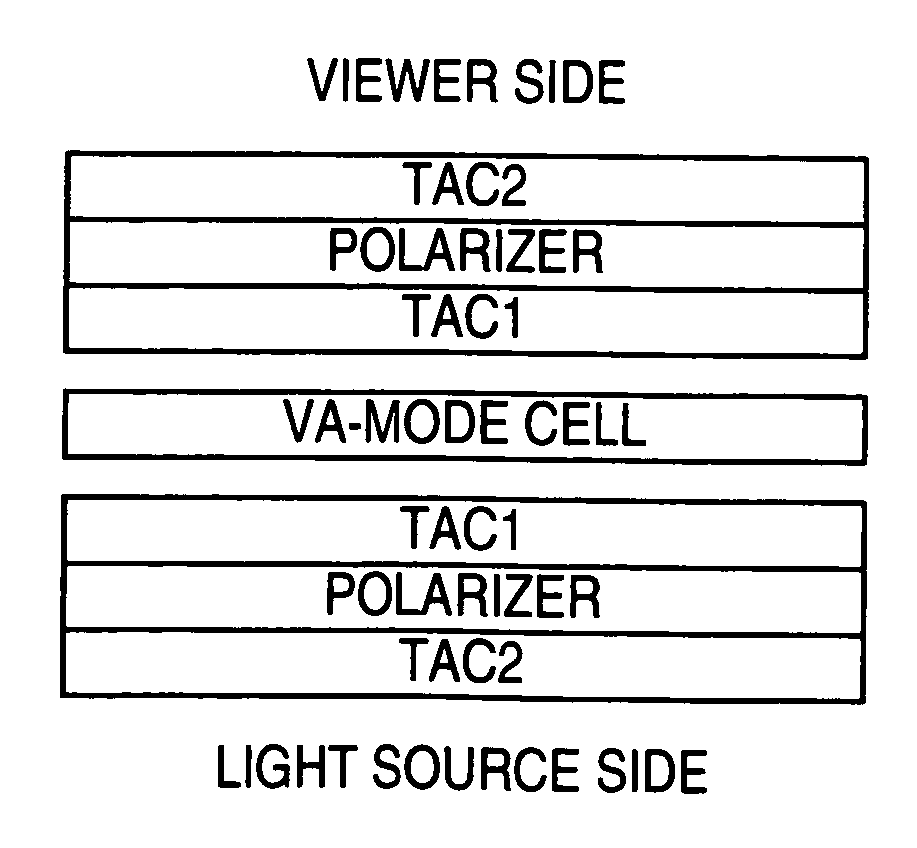

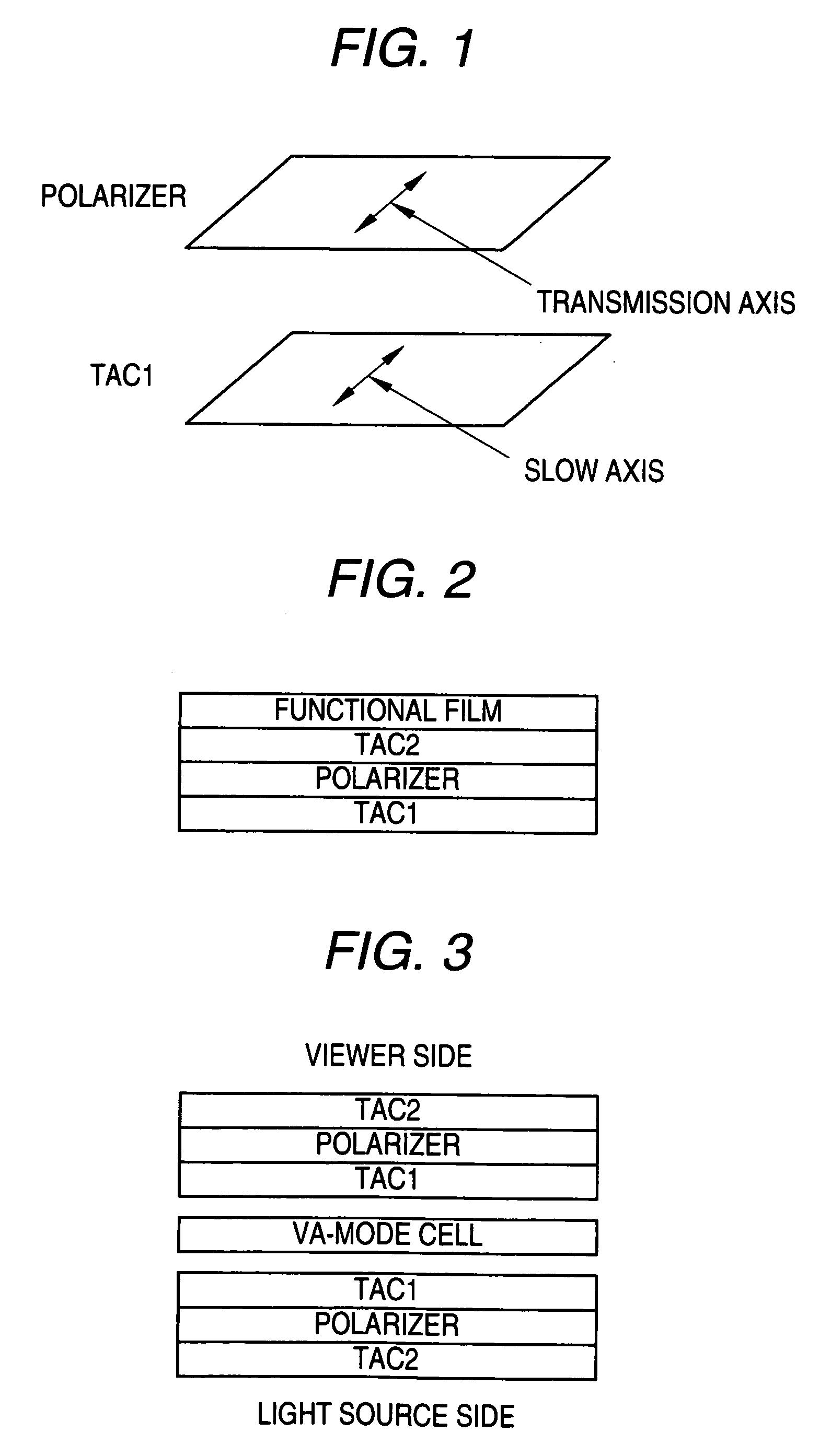

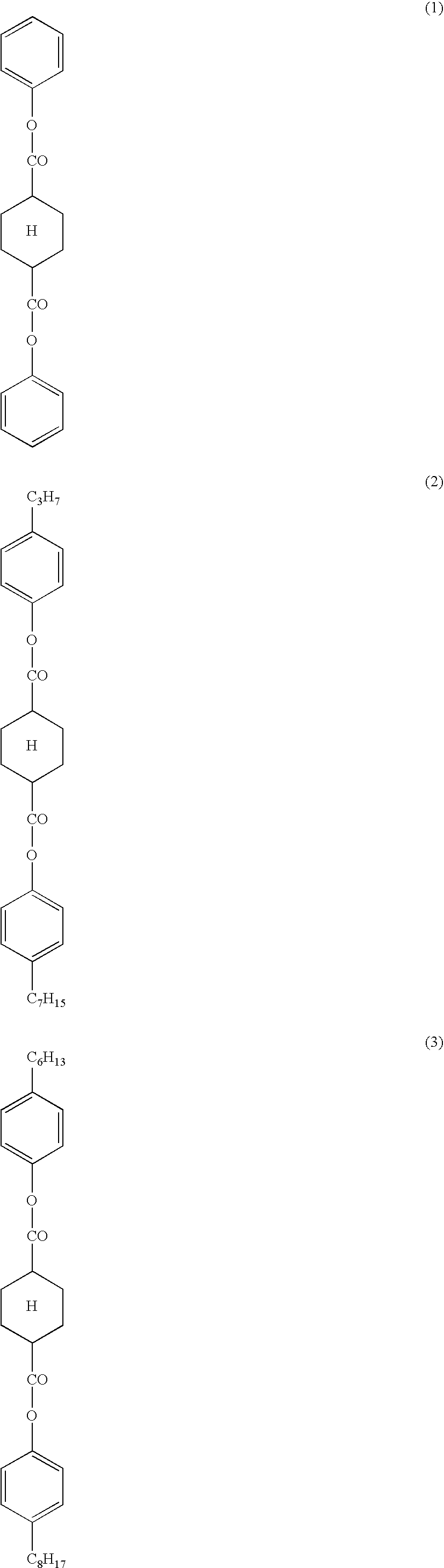

Optical Cellulose Acylate Film, Polarizing Plate and Liquid Crystal Display Device

ActiveUS20080254236A1High expressionLess fluctuationLiquid crystal compositionsSynthetic resin layered productsCelluloseLiquid-crystal display

An optical cellulose acylate film comprising a polymer component which is a cellulose acylate obtained by substituting hydroxyl groups of a cellulose by an acetyl group and an acyl group having 3 or more carbon atoms, wherein a substitution degree A of the acetyl group and a substitution degree B of the acyl group having 3 or more carbon atoms satisfy the following formulae (I) and (II): 2.0≦A+B≦3.0 (I), 0<B (II), and the optical cellulose acylate film comprises a retardation-expressing agent which is at least one of a rod-like compound and a discotic compound or an elastic modulus E(MD) in a casting direction and an elastic modulus E(TD) in a casting width direction satisfy the following formulae (III) and (IV): 1,500 MPa≦E(MD)≦3,400 Mpa (III) and 1,200 MPa≦E(TD)≦3,400 Mpa (IV).

Owner:FUJIFILM CORP

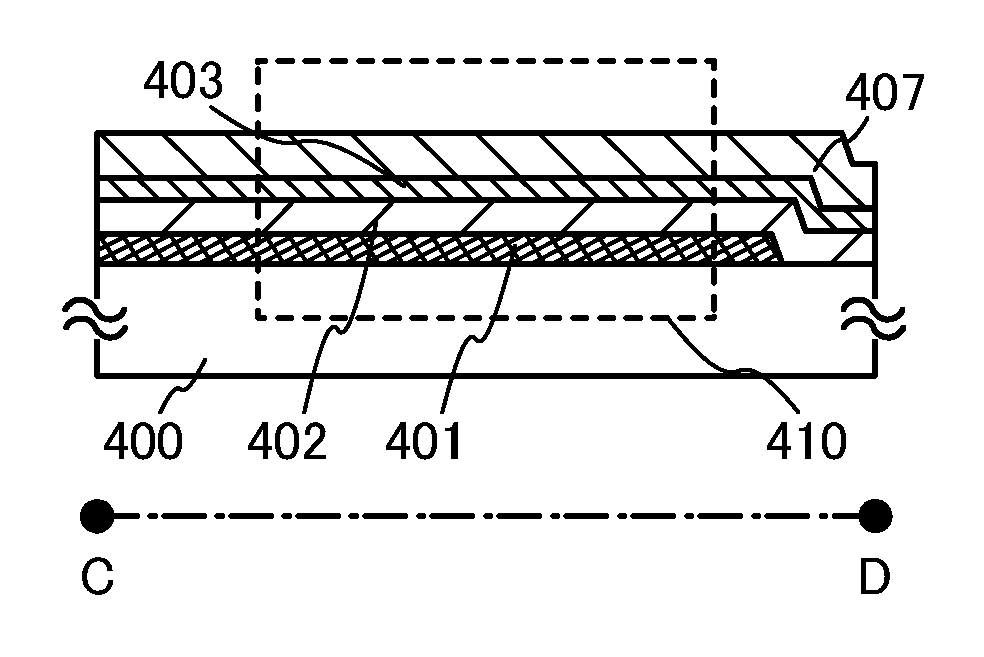

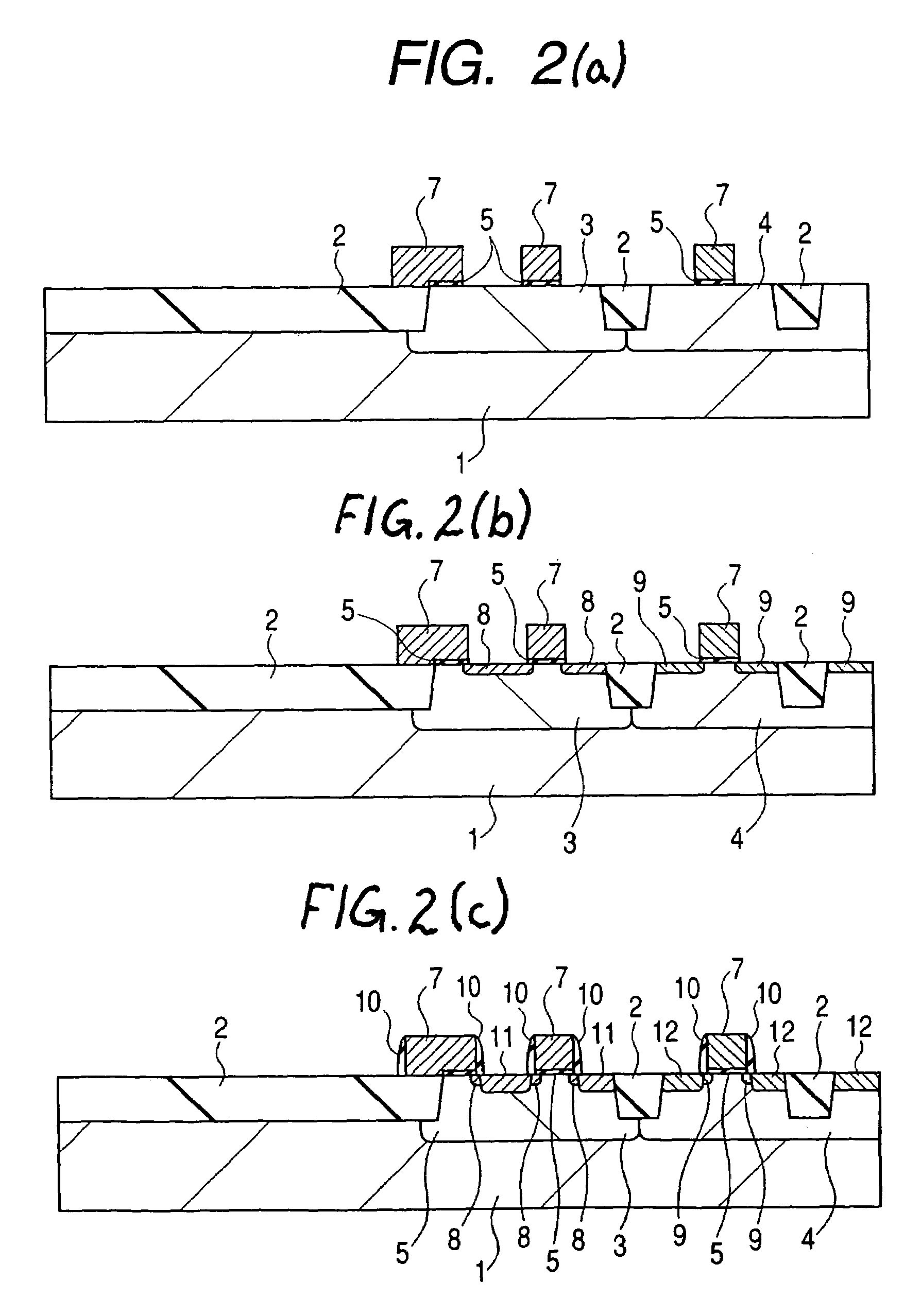

Method for manufacturing semiconductor device

ActiveUS8541266B2Stable electrical characteristicsImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideOxygen

In a method for manufacturing a transistor including an oxide semiconductor layer, a gate electrode is formed and then an aluminum oxide film, a silicon oxide film, and the oxide semiconductor film are successively formed in an in-line apparatus without being exposed to the air and are subjected to heating and oxygen adding treatment in the in-line apparatus. Then, the transistor is covered with another aluminum oxide film and is subjected to heat treatment, so that the oxide semiconductor film from which impurities including hydrogen atoms are removed and including a region containing oxygen at an amount exceeding that in the stoichiometric composition ratio. The transistor including the oxide semiconductor film is a transistor having high reliability in which the amount of change in threshold voltage of the transistor by the bias-temperature stress (BT test) can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

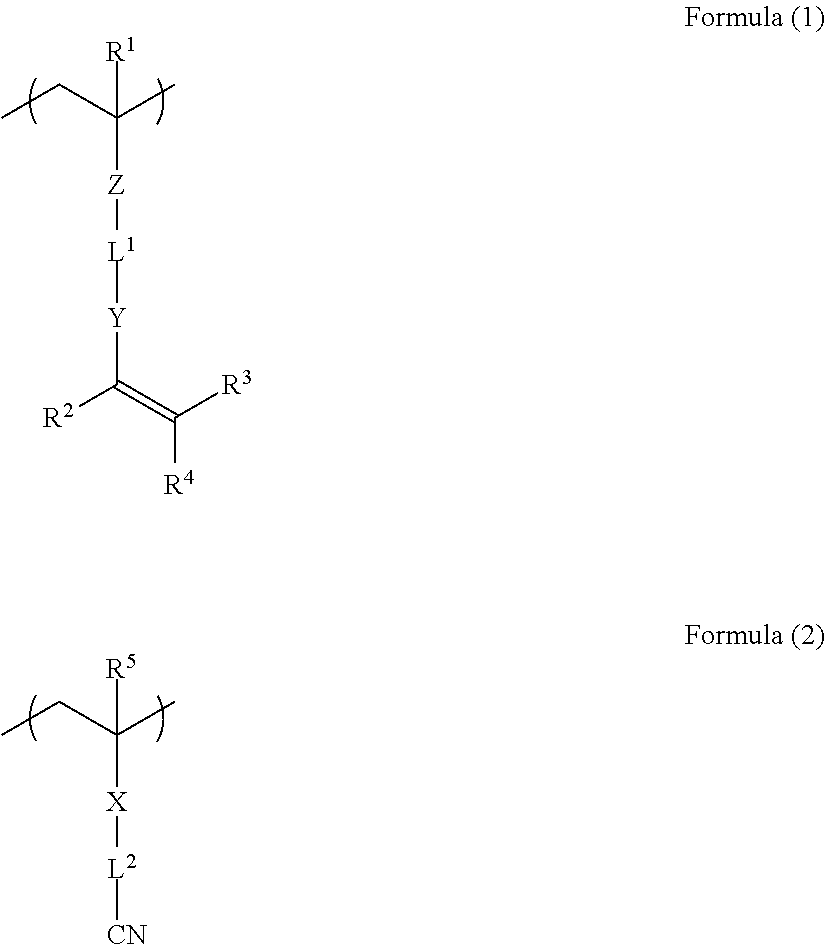

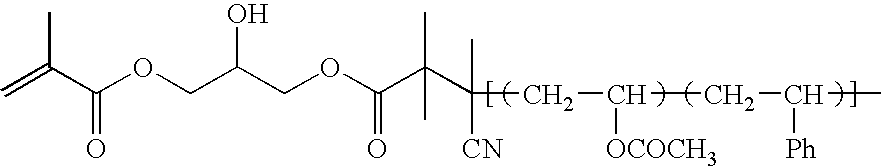

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS8084564B2Improve adhesionLess fluctuationSynthetic resin layered productsLiquid/solution decomposition chemical coatingPolymer scienceEther

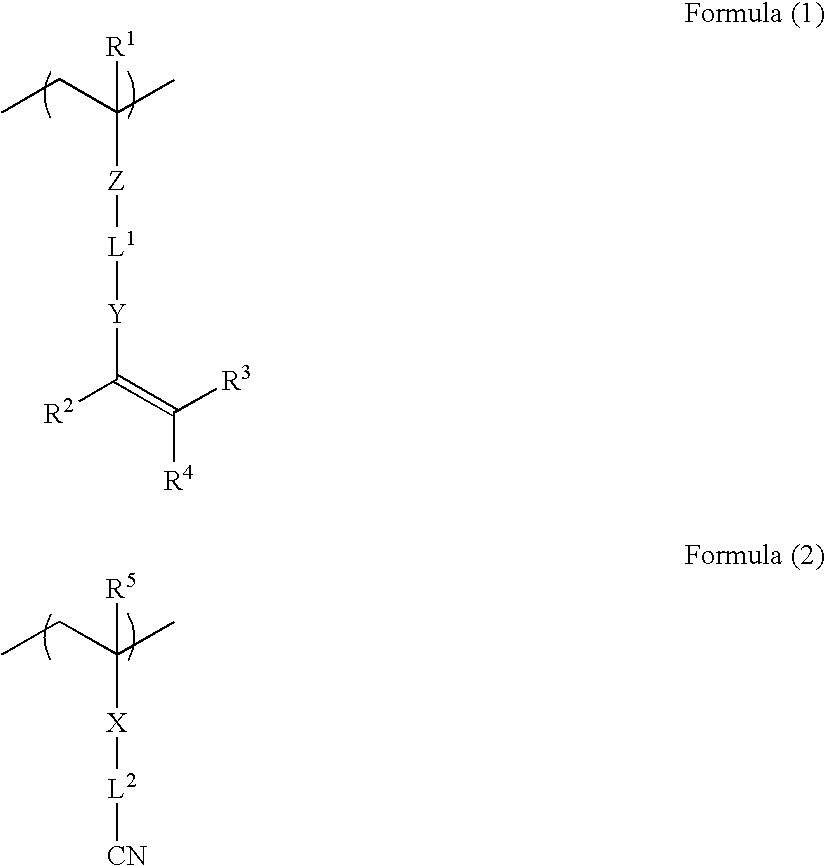

The invention provides a polymer containing at least a unit represented by the following Formula (1) and a unit represented by the following Formula (2). In Formula (1) and Formula (2), R1 to R5 each independently represent a hydrogen atom or a substituted or unsubstituted alkyl group; X, Y and Z each independently represent a single bond, a substituted or unsubstituted divalent organic group, an ester group, an amide group or an ether group; and L1 and L2 each independently represent a substituted or unsubstituted divalent organic group. The invention provides a method of synthesizing embodiments of the polymer, a composition containing the polymer, and a laminate formed by applying the composition on a resin base material.

Owner:FUJIFILM CORP

Method for blowing objects

InactiveUS20060012085A1Shorten cycle timeIncrease productivityHollow articlesEngineeringAtmospheric pressure

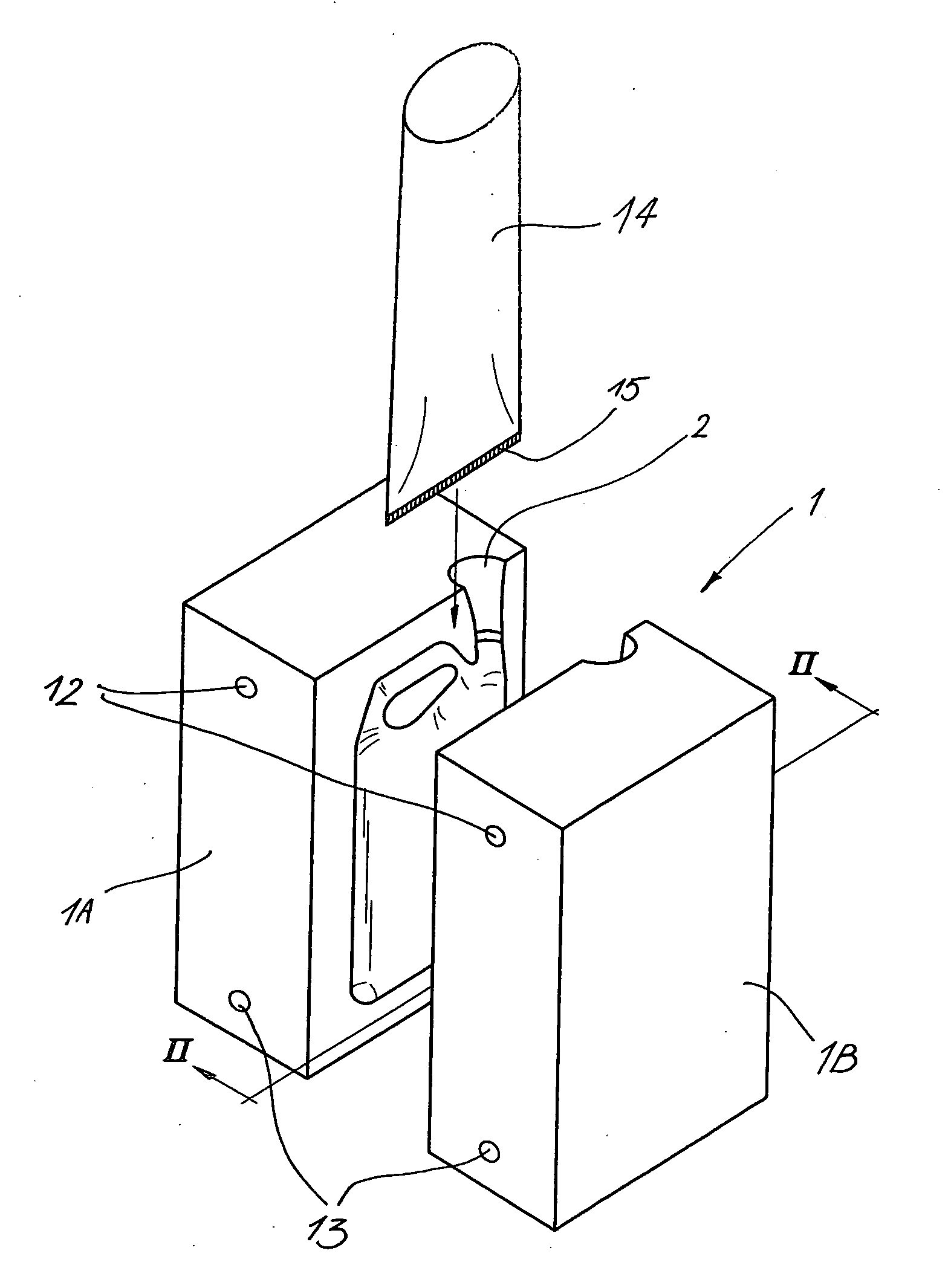

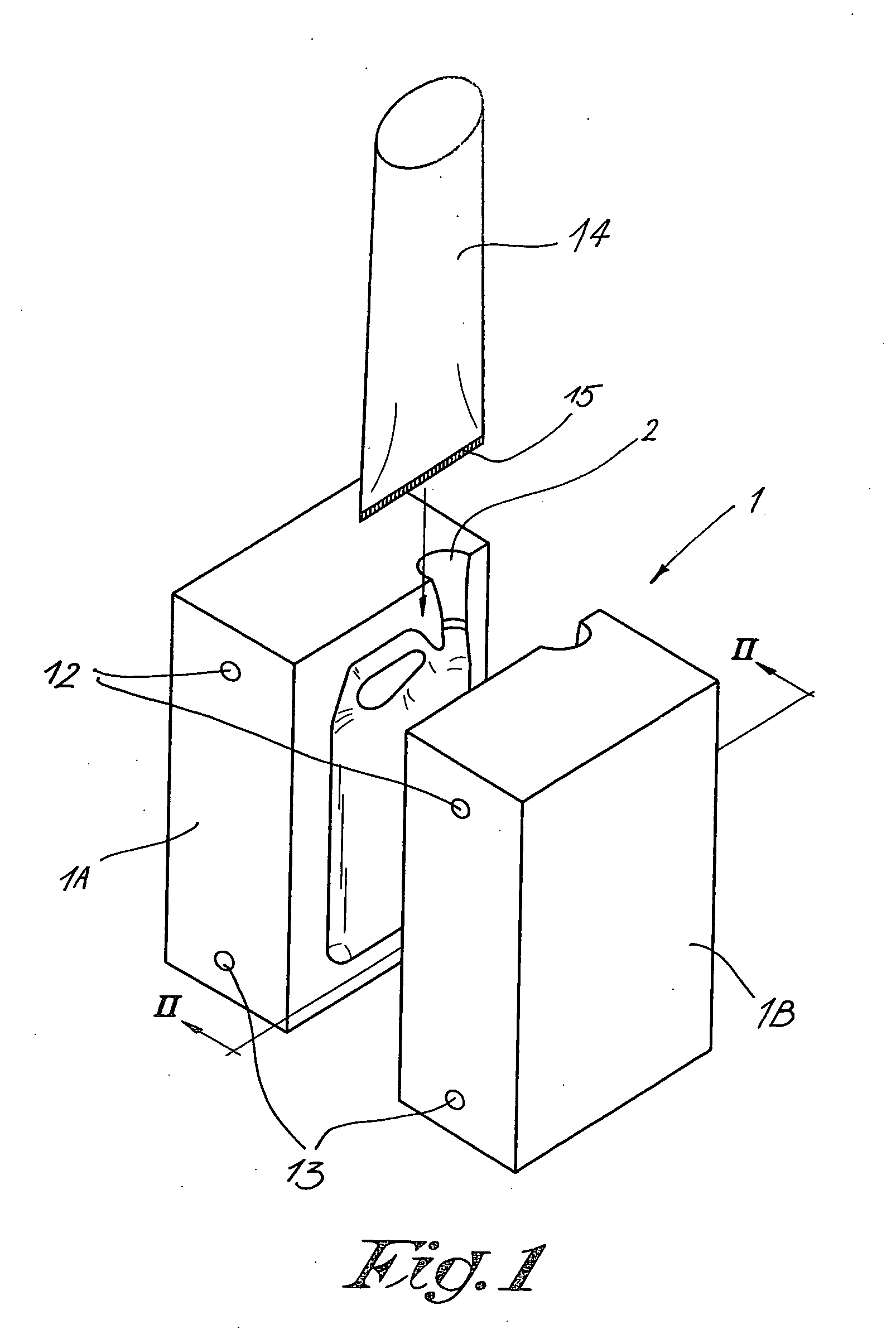

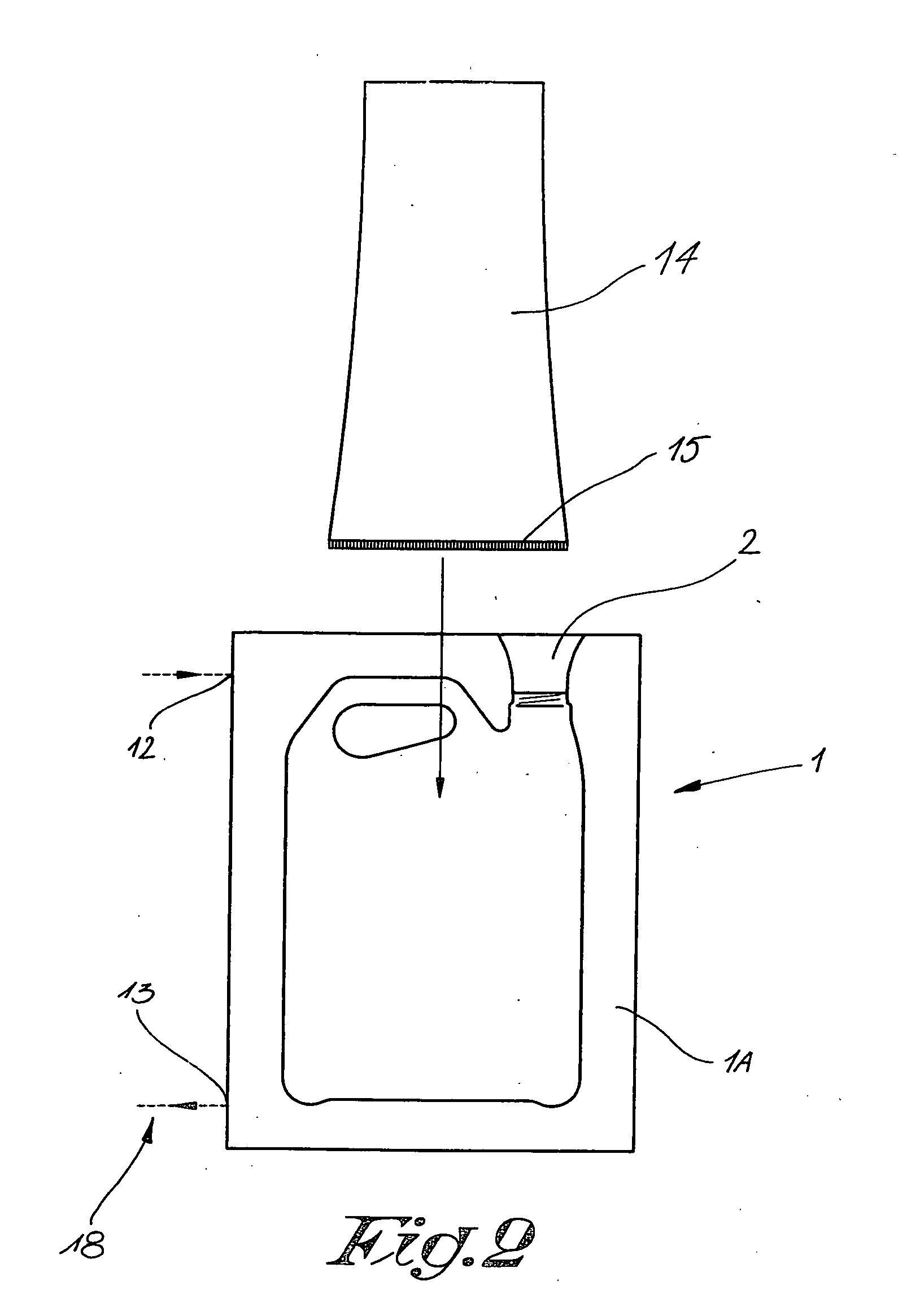

A method for blowing objects, in which the following steps are successively followed: providing a synthetic sleeve (14) in a mould (1); inflating this sleeve (14) by means of compressed air up to a maximum pressure; and scavenging the obtained object (4) by means of a compressed air flow, whereby the air in the object (4) is continuously refreshed, wherein the pressure of the compressed air varies from a start pressure to the atmospheric pressure according to an adjustable course which varies as a function of time.

Owner:DELTA ENG MET

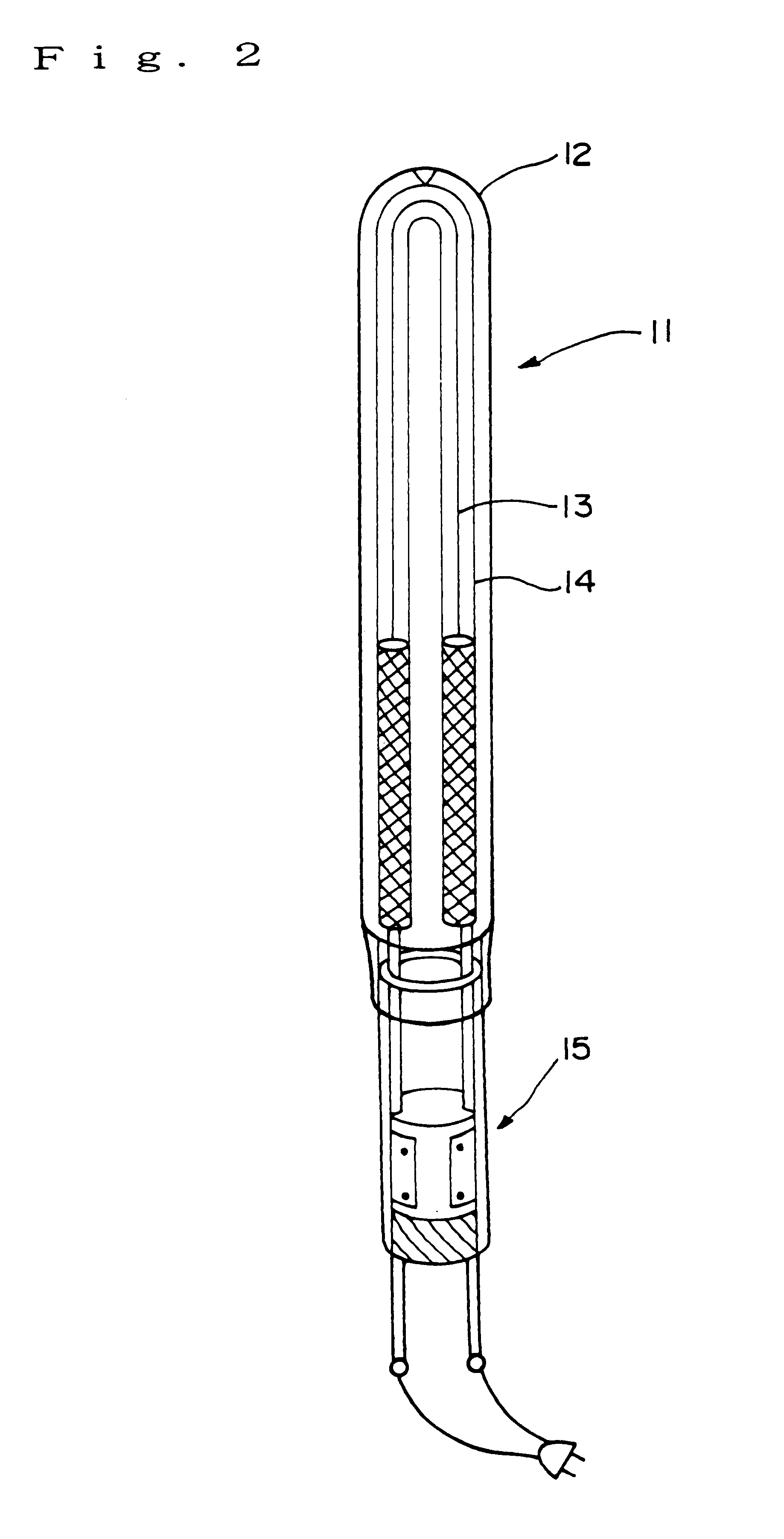

Heater sealed with carbon wire heating element

InactiveUS6584279B2Quality improvementExcellent anti-aging stability of electric resistanceDomestic stoves or rangesIncandescent ignitionSingle fiberCrystal structure

A heater sealed with carbon wire heating element has a carbon wire heating element sealed with a quartz glass member, the carbon wire being prepared by knitting carbon single fibers into a knitted cord of a braid, each wire having a crystal structure with a interlayer spacing d (002) thereof being 0.343 or less and crystallite size Lc (002) thereof being 4.0 nm or more.

Owner:COORSTEK INC +1

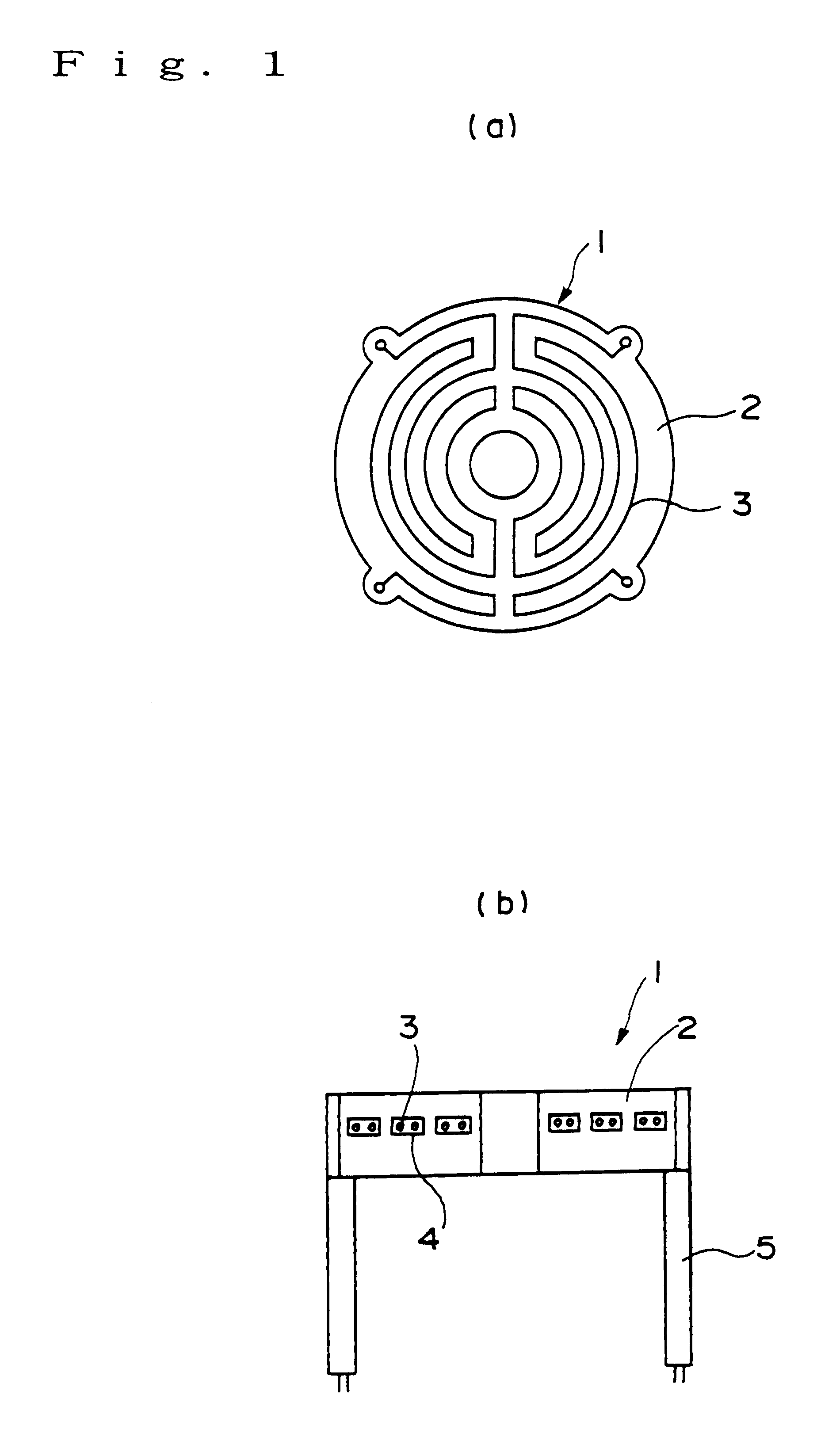

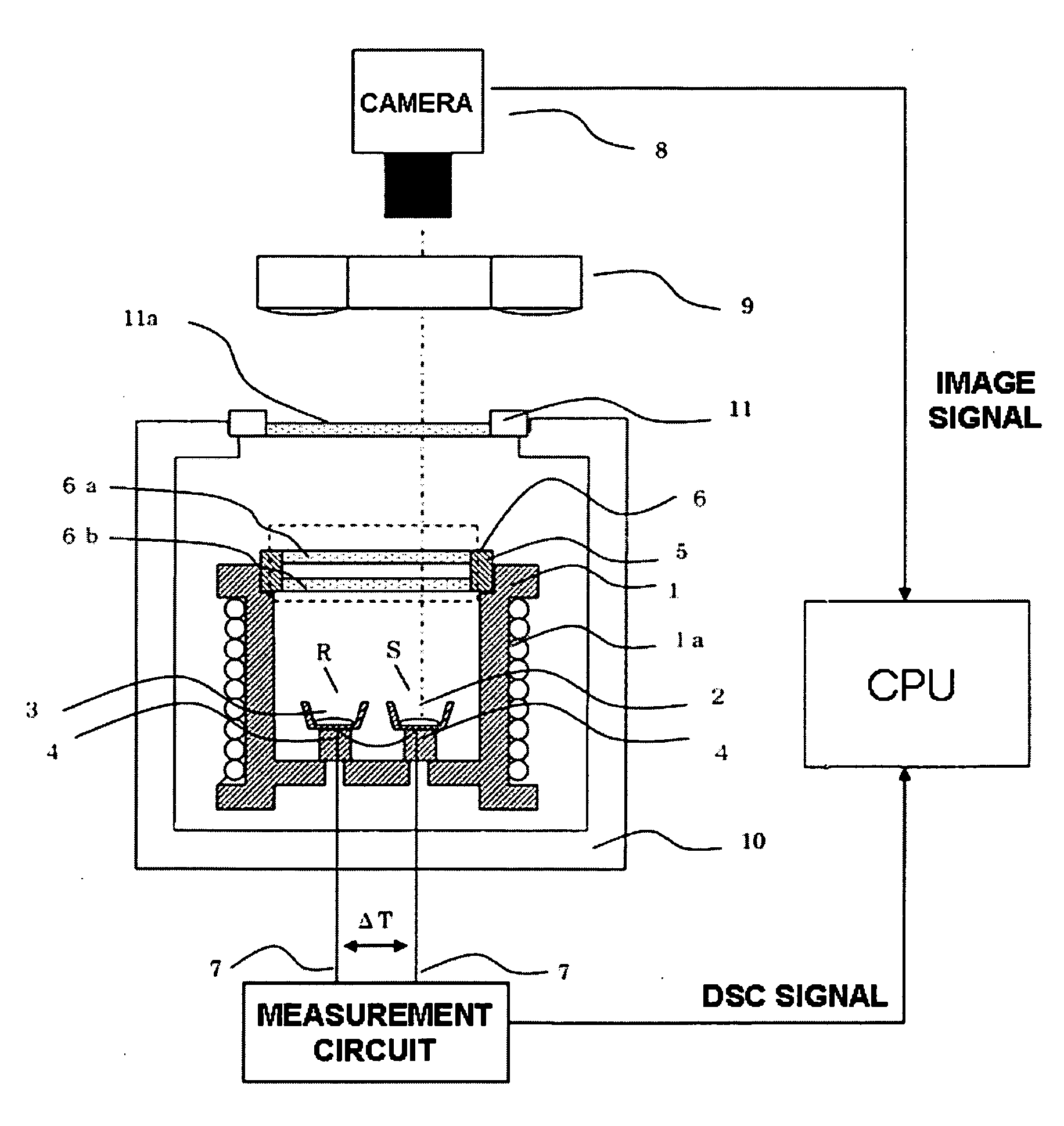

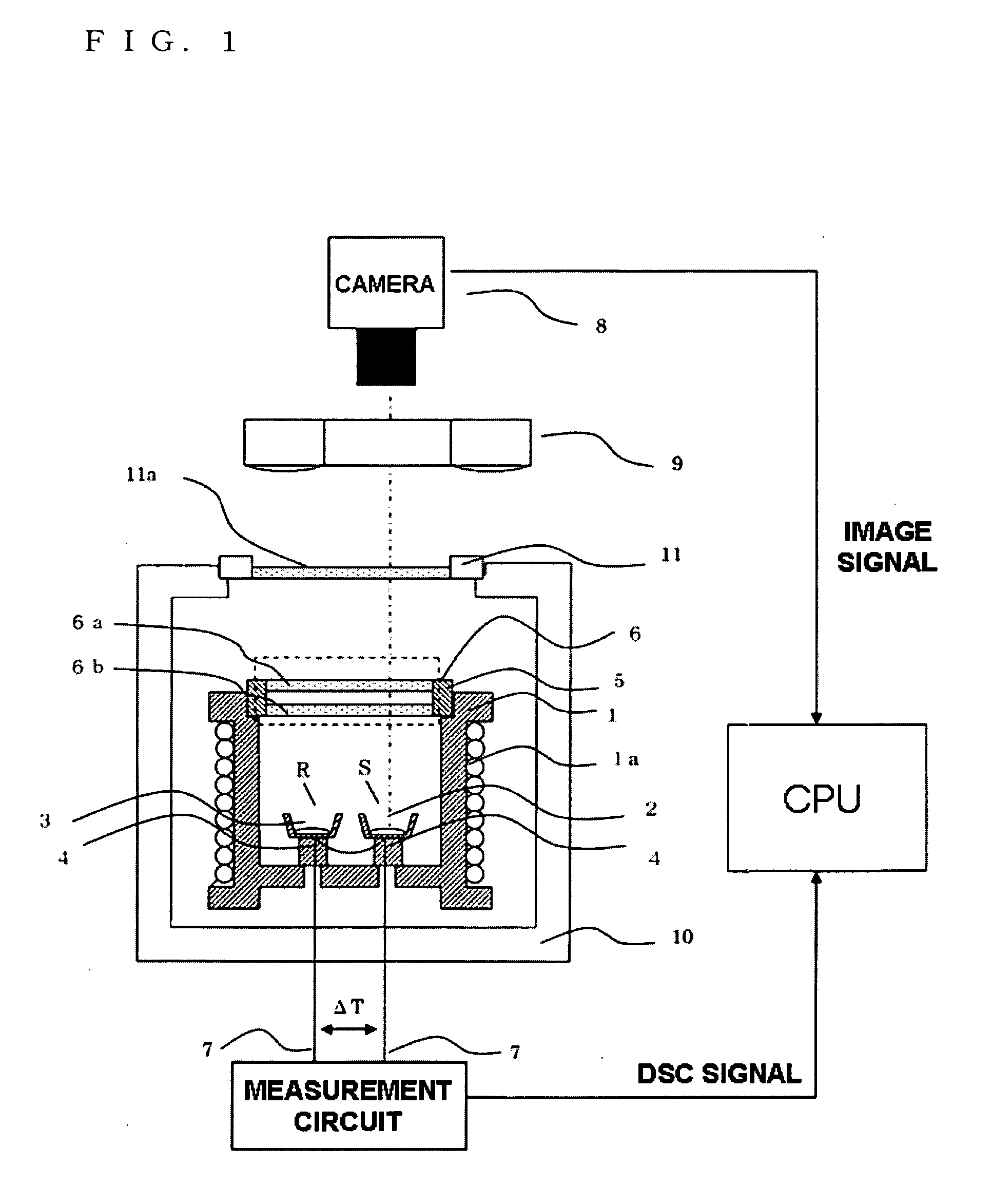

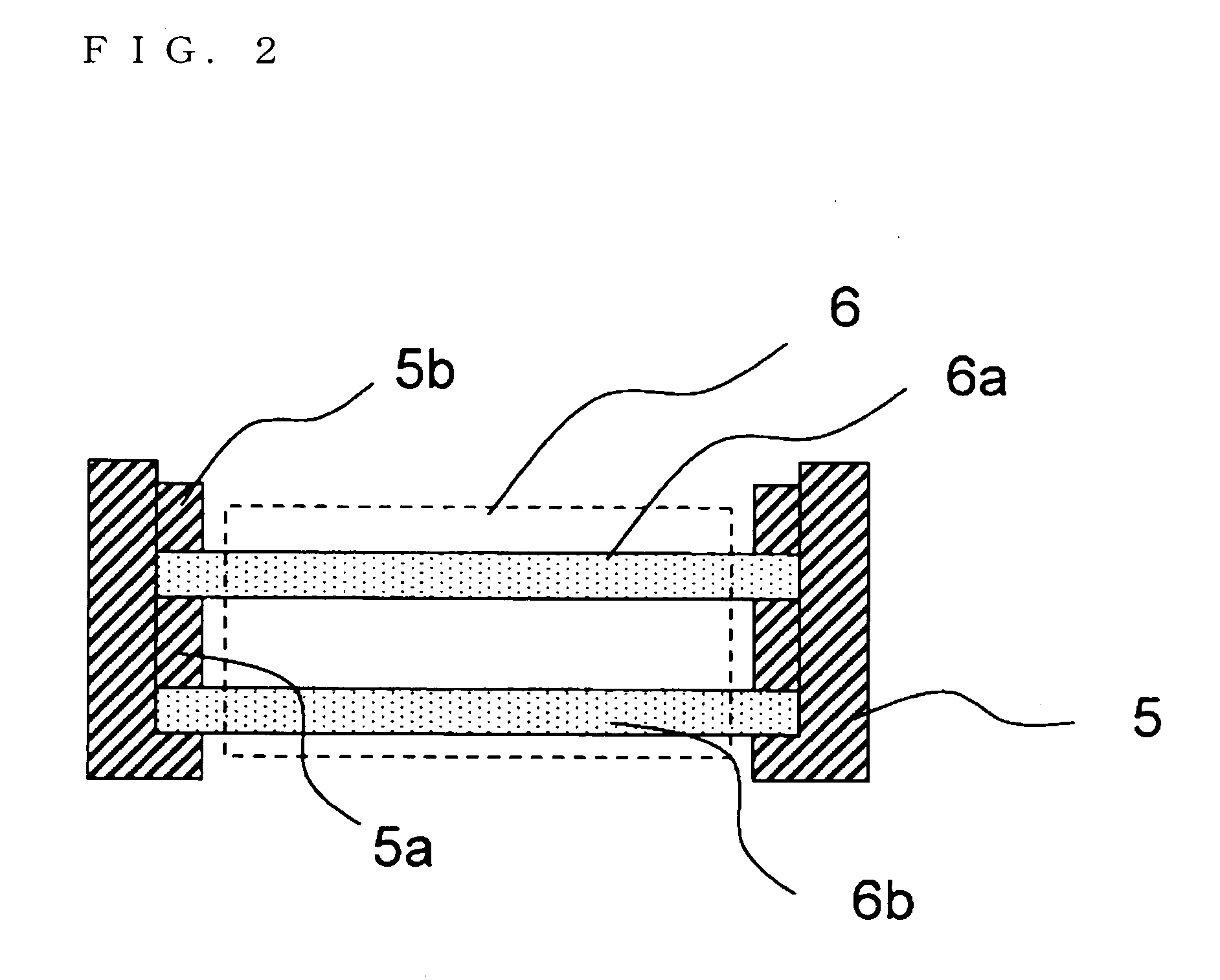

Thermal analysis apparatus

ActiveUS20110054829A1Avoid influenceStable temperature distributionThermometer detailsThermometers using electric/magnetic elementsPhysical changeInstrumentation

To avoid an influence on measurement accuracy in a case where an observation window for a measurement sample is provided to a thermal analysis apparatus, the influence being imposed by thermal conduction through the observation window, the observation window is formed of layers of transparent members, and a gap layer is provided between the layers, to thereby reduce the thermal conduction. Gas or solid having a high heat insulation property is employed for the gap layer to further enhance a heat insulation property of the observation window. Accordingly, a change due to heating of the measurement sample is visually observed in the thermal analysis apparatus, to thereby obtain a thermal change or a physical change with higher accuracy.

Owner:HITACHI HIGH TECH SCI CORP

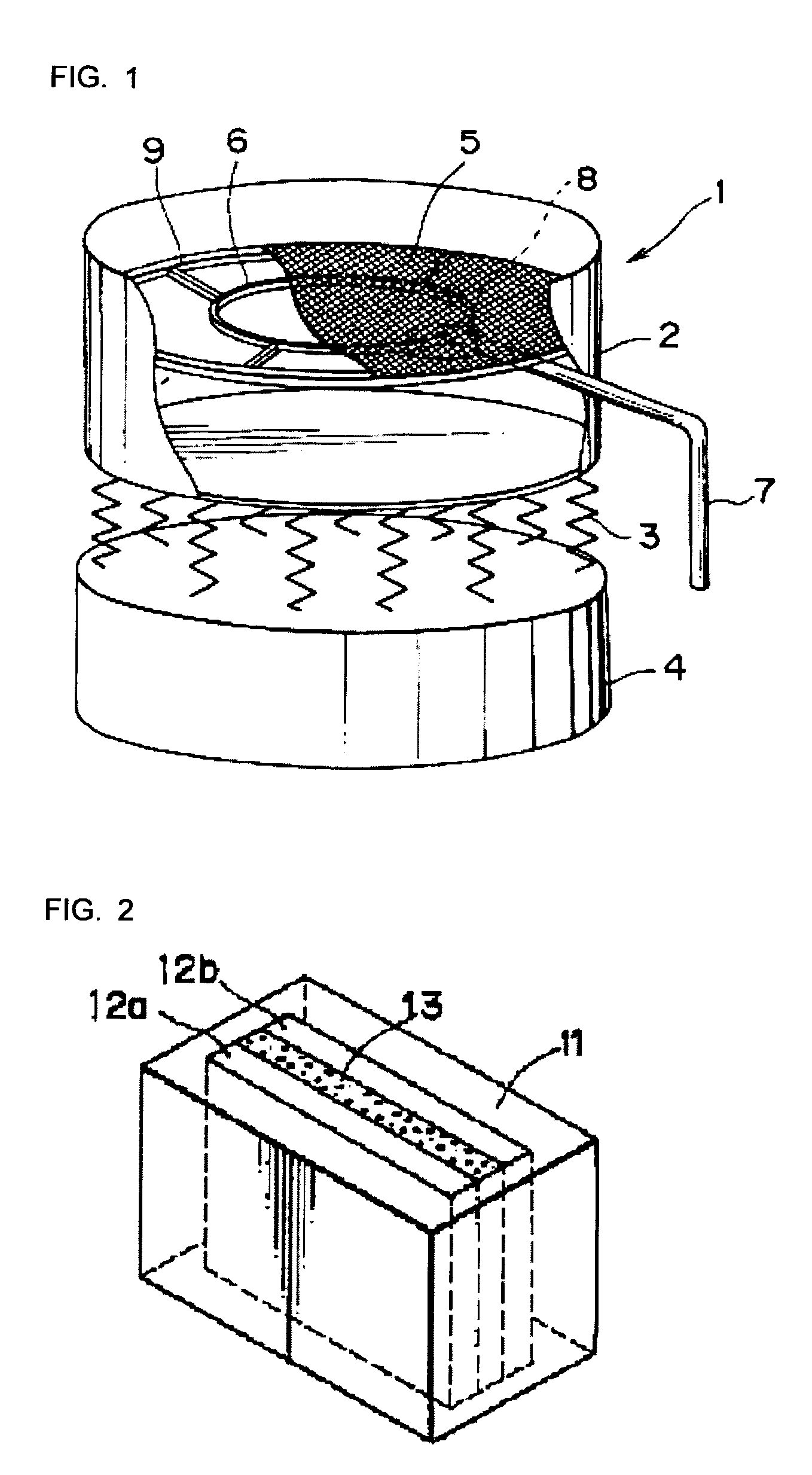

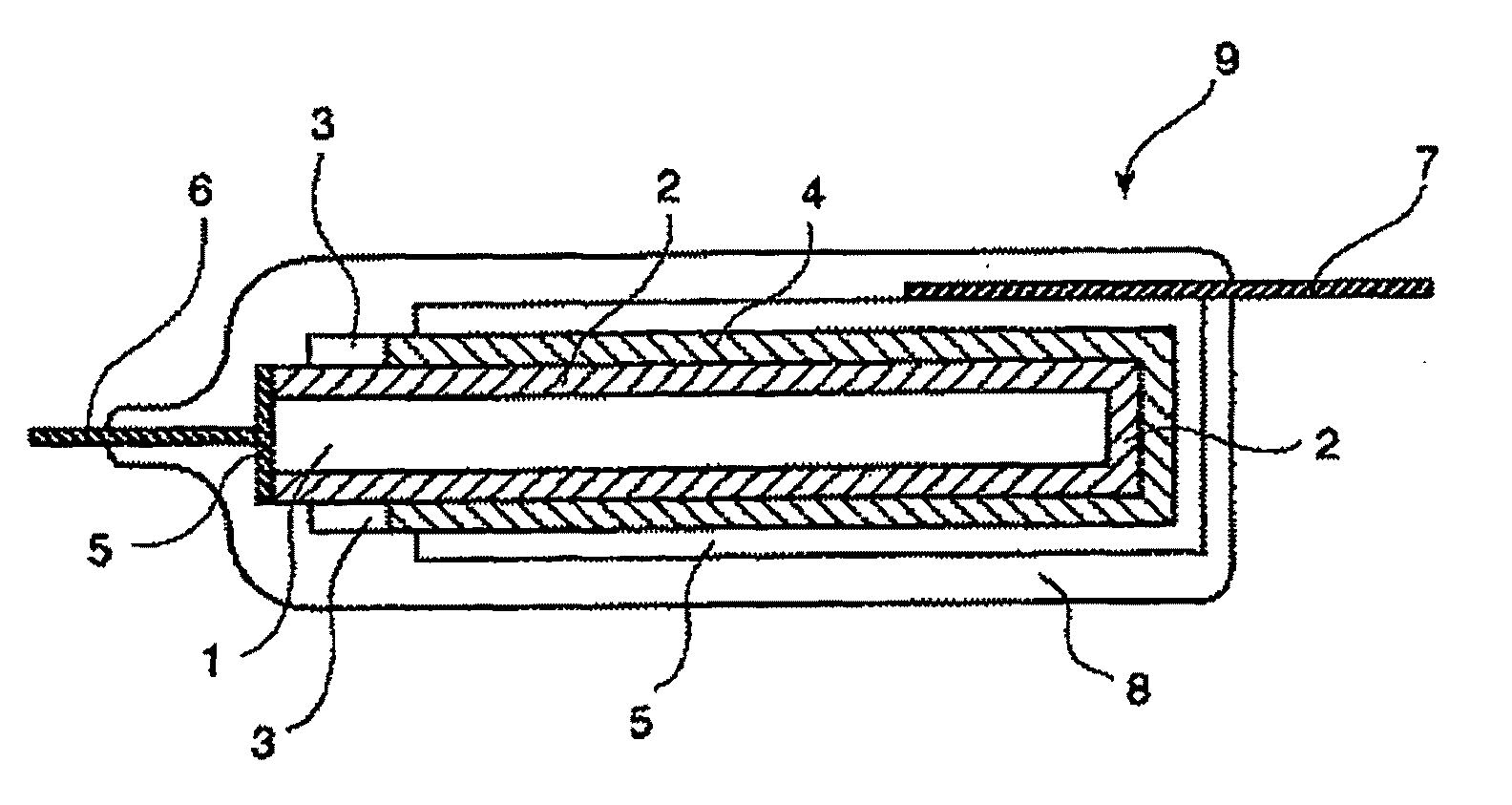

Solid electrolytic capacitor and production method thereof

InactiveUS20100103590A1Less short-circuit failureLarge capacityCapacitor electrolytes/absorbentsCoatingsElectrolysisConductive polymer

The present invention relates to a solid electrolytic capacitor comprising a layer of self-doping type conductive polymer having a crosslink between polymer chains thereof on the dielectric film formed on a valve-acting metal. The present invention enables to stably produce thin capacitor elements suitable for laminated type solid electrolytic capacitors, showing less short-circuit failure and less fluctuation in the shape of element, which allows to increase the number of laminated elements in a solid electrolytic capacitor chip to make a capacitor having a high capacity, and having less fluctuation in equivalent series resistance.

Owner:MURATA MFG CO LTD

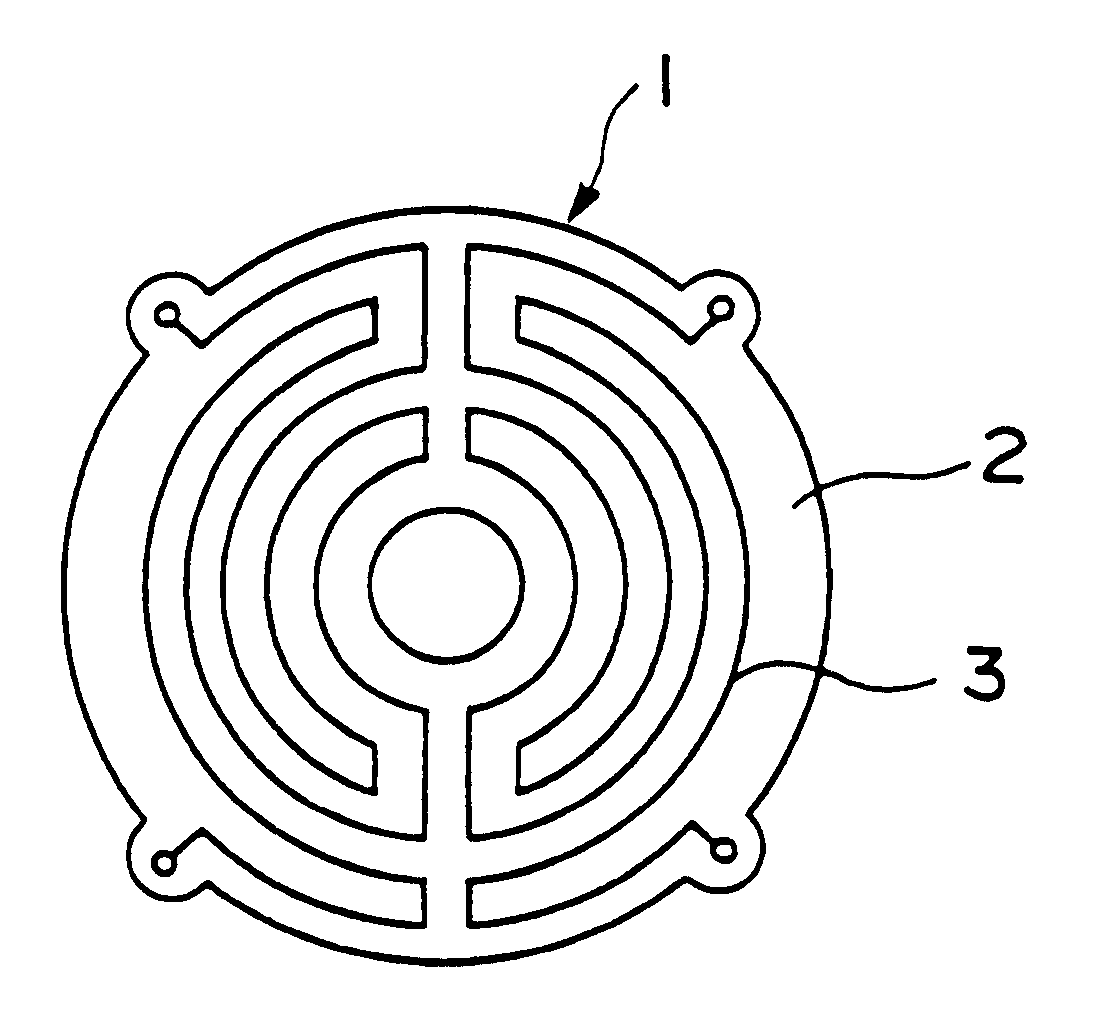

Optical pickup device and diffractive optical element

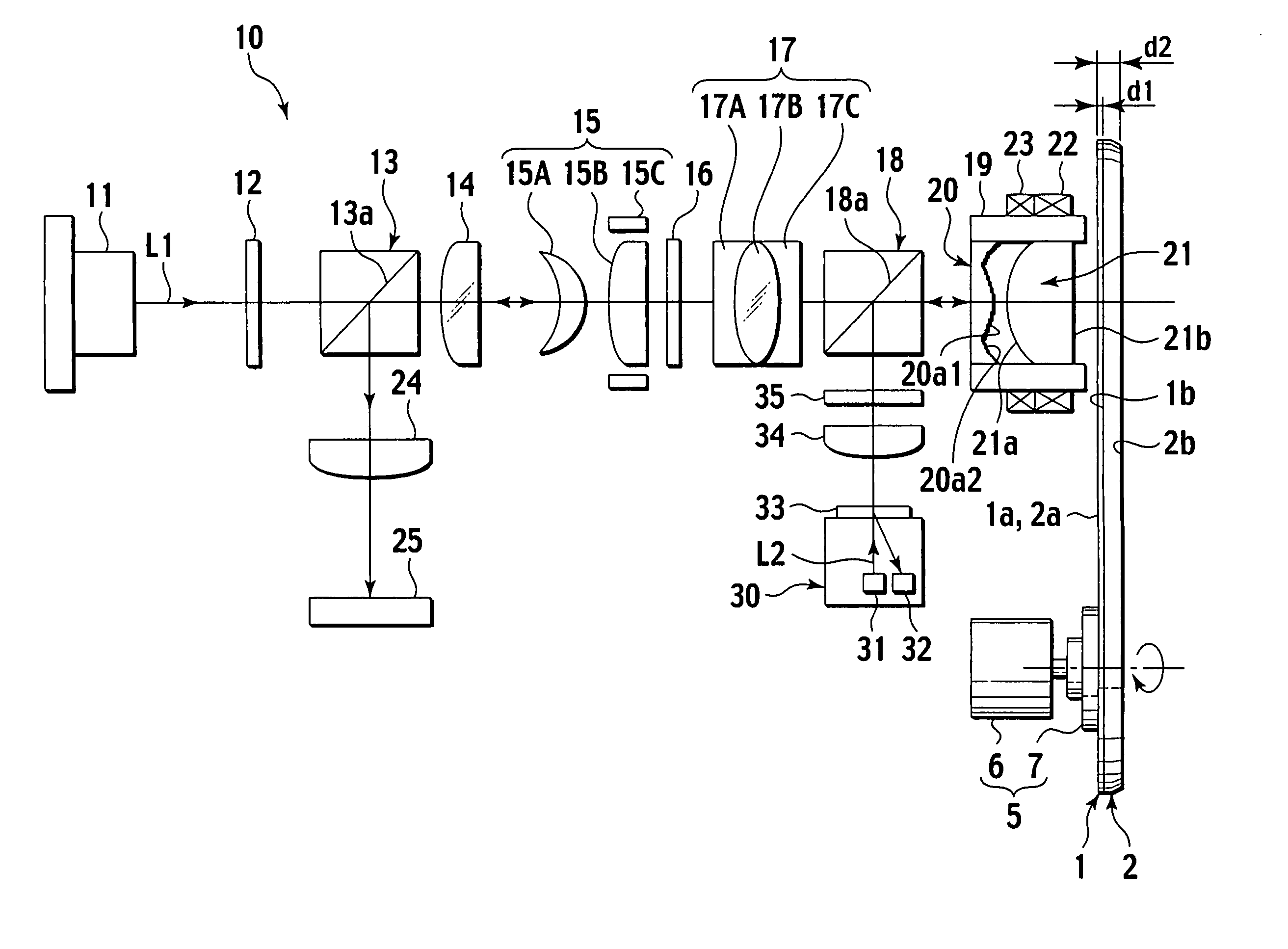

ActiveUS20050157623A1Backward Compatibility GuaranteedLess fluctuationOptical beam sourcesRecord information storageOptical pickupOptical axis

When a wavelength having the same value as a reference wavelength Al of a first laser light is set to a designed wavelength λ, a diffractive optical element has: an inner circular side irregular diffraction pattern portion, in which a plurality of irregular portions in which a height of a convex portion is set to approximately 1λ-fold of the designed wavelength λ with respect to a concave portion are repeated, being formed in an annular shape in an inner circular area having a predetermined diameter for the correction of a spherical aberration generated due to a difference in substrate thickness between first and second optical recording mediums centering on a central point through which an optical axis runs while gradually changing a pitch of the irregular portions in a radial direction toward the outer circular side; and an outer circular side tiered diffraction pattern portion which is intended to improve a chromatic aberration with respect to the first laser light by forming in an annular shape in an outer circular area outside the inner circular side irregular diffraction pattern portion a plurality of tiers by setting a height of each tier to approximately mλ-fold (where m is a natural number which does not include 0) of the designed wavelength λ or by setting the same while changing a value of m for each tier.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS20090214876A1Improve adhesionLess fluctuationSynthetic resin layered productsLiquid/solution decomposition chemical coatingPolymer sciencePtru catalyst

A process for producing a metal film-coated material, the process including: (a1) forming, on a substrate, a polymer layer formed from a polymer which has a functional group capable of interacting with a plating catalyst or a precursor thereof, and is directly chemically bonded to the substrate; (a2) providing a plating catalyst or a precursor thereof to the polymer layer; and (a3) performing plating with respect to the plating catalyst or a precursor thereof. The polymer layer satisfies all of the following requirements (1) to (4): (1) the saturated water absorption coefficient of the polymer layer as measured in an environment of temperature of 25° C. and relative humidity of 50% is 0.01 to 10% by mass; (2) the saturated water absorption coefficient of the polymer layer as measured in an environment of temperature of 25° C. and relative humidity of 95% is 0.05 to 20% by mass; (3) the water absorption coefficient of the polymer layer as measured after 1 hour of immersion in boiling water at 100° C. is 0.1 to 30% by mass; and (4) the surface contact angle of the polymer layer as measured after dropping 5 μL of distilled water thereonto and leaving to stand for 15 seconds in an environment of temperature of 25° C. and relative humidity of 50% is 50 to 150 degrees.

Owner:FUJIFILM CORP

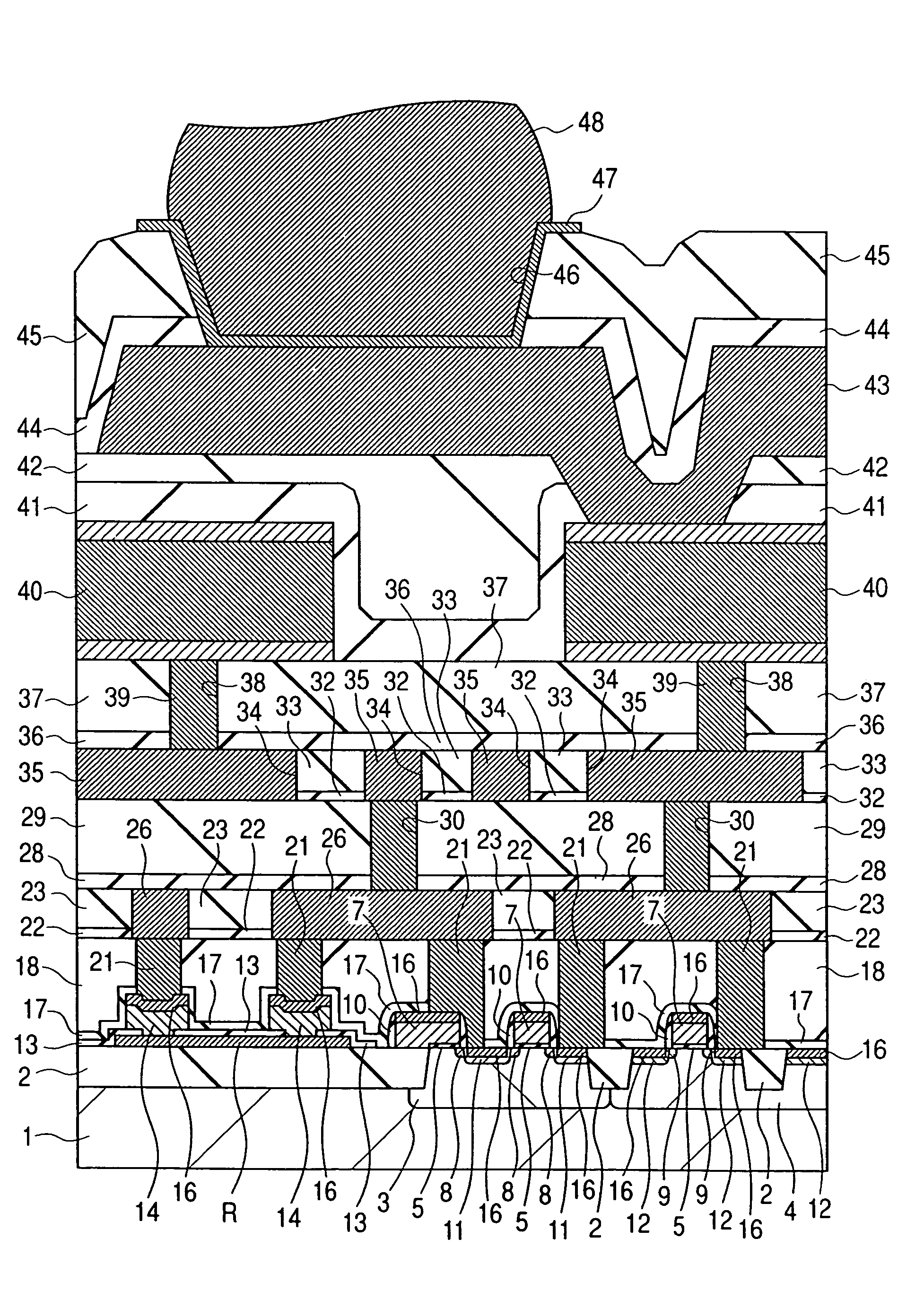

Semiconductor integrated circuit device and process for manufacturing the same

InactiveUS7163886B2Reduce hydrogen contentImprove stress conditionTransistorSolid-state devicesHydrogen contentNitrogen

In the manufacture of a semiconductor device having a high-performance and high-reliability, a silicon nitride film 17 for self alignment, which film is formed to cover the gate electrode of a MISFET, is formed at a substrate temperature of 400° C. or greater by plasma CVD using a raw material gas including monosilane and nitrogen. A silicon nitride film 44 constituting a passivation film is formed at a substrate temperature of about 350° C. by plasma CVD using a raw material gas including monosilane, ammonia and nitrogen. The hydrogen content contained in the silicon nitride film 17 is smaller than that contained in the silicon nitride film 44, making it possible to suppress hydrogen release from the silicon nitride film 17.

Owner:RENESAS ELECTRONICS CORP

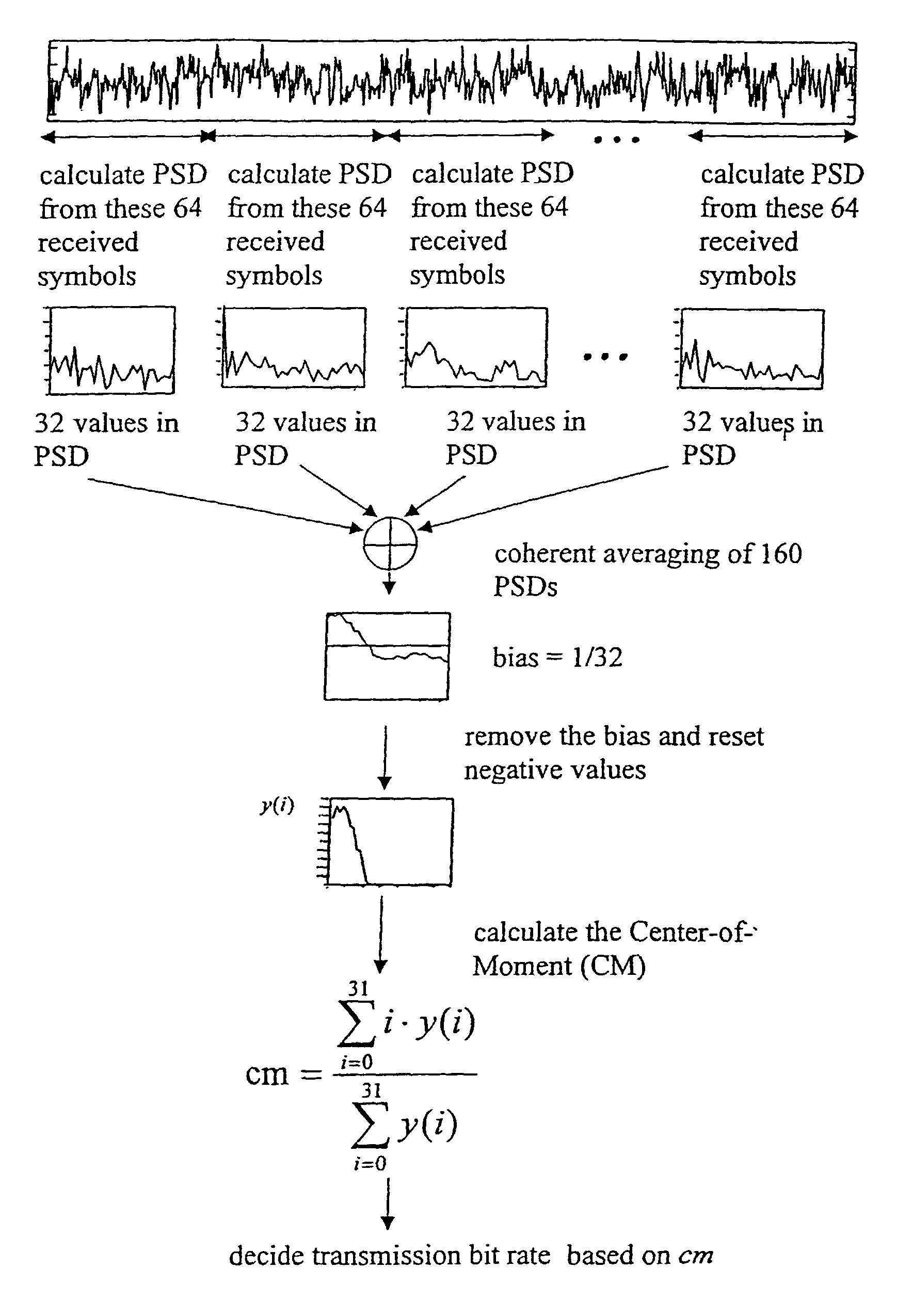

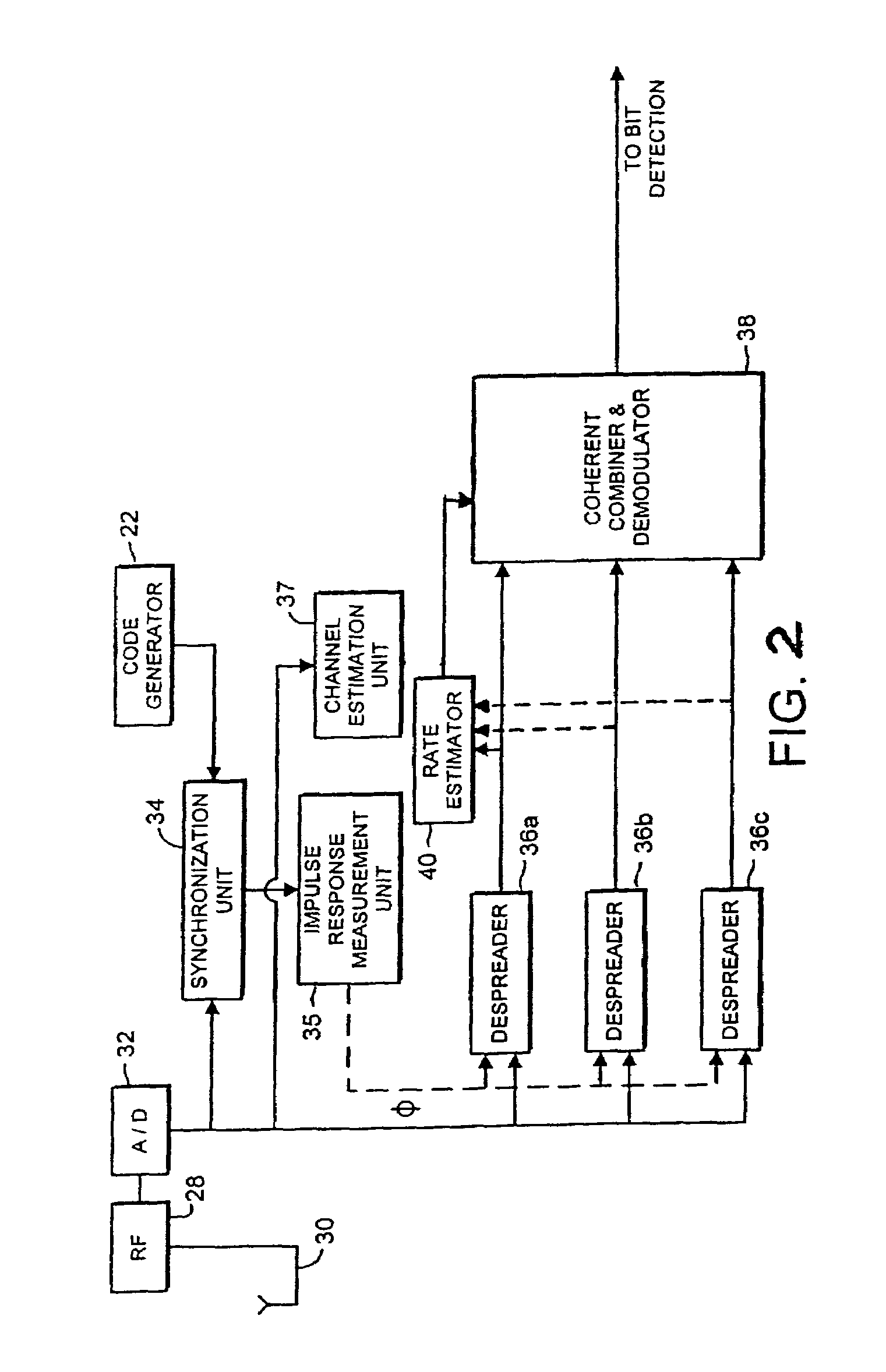

Determination of data rate, based on power spectral density estimates

InactiveUS7170928B1Less fluctuationEarly detectionModulated-carrier systemsCode division multiplexComputer hardwareSpectral density estimation

The present invention relates to a method and a circuitry for estimating data transmission rate in a communication system. The communication system utilizes variable data transmission rates. A transmission signal between two stations of the system includes a plurality of data symbols over a sequence of data frames. A data frame of a received transmission signal is classified in accordance with a predefined classification of the data transmission rates, whereafter the data transmission rate of the received data frame is estimated on basis of said classification.

Owner:NOKIA CORP

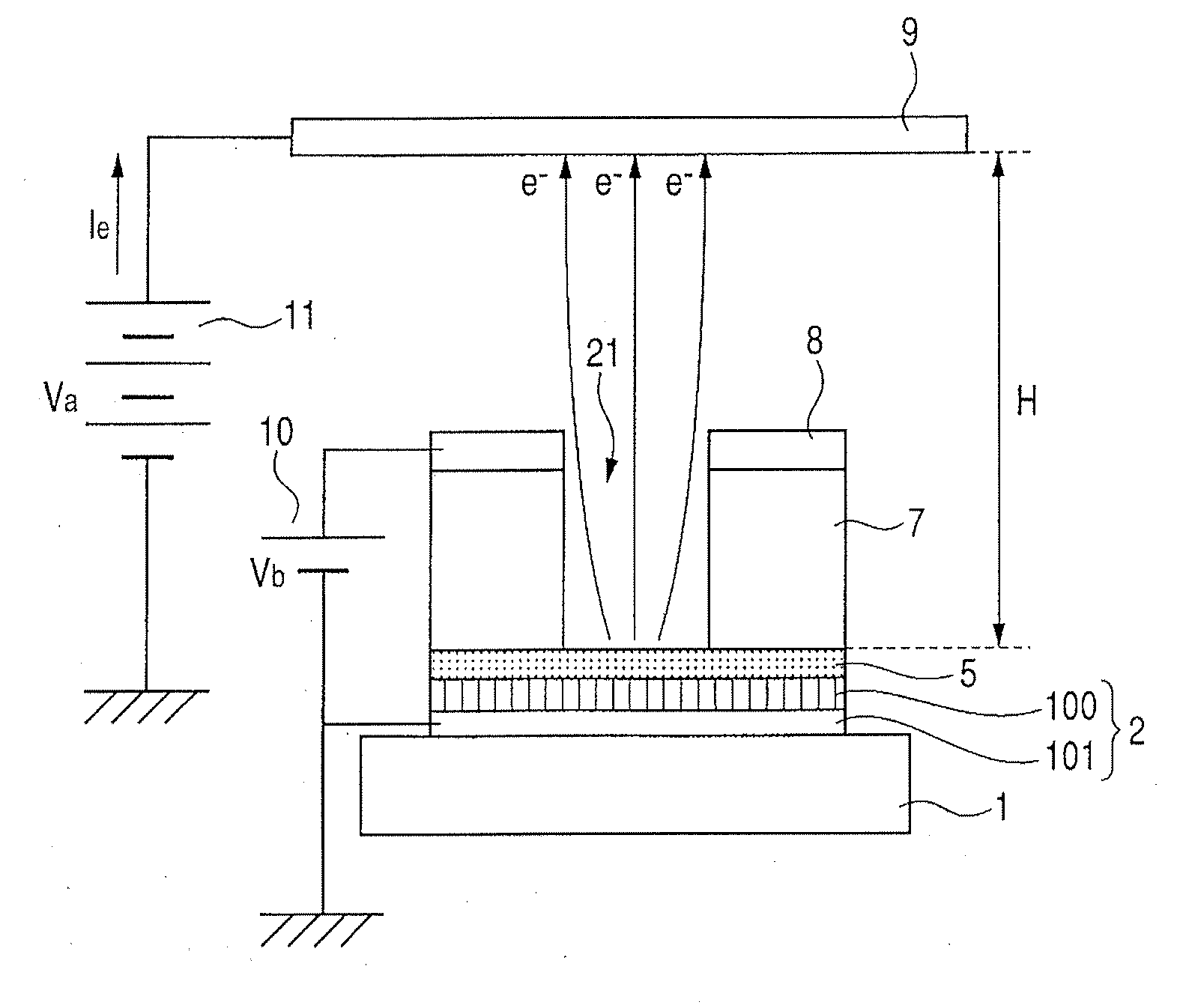

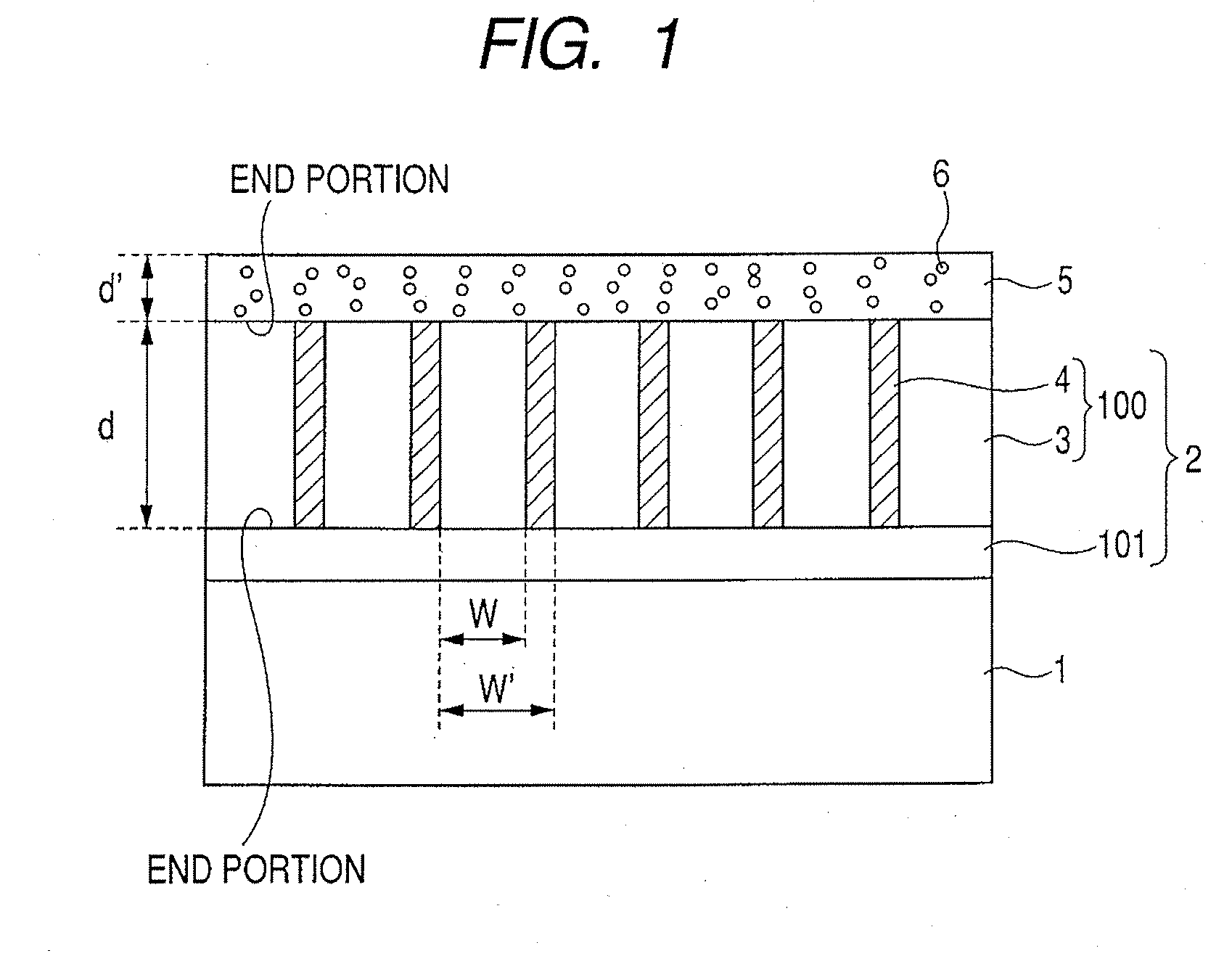

Electron-emitting device, electron source, image display apparatus and method of fabricating electron-emitting device

InactiveUS20070257593A1Fluctuation in electron emission amountLess fluctuation in electron-emitting propertiesDischarge tube luminescnet screensCathode ray tubes/electron beam tubesElectron sourceAtomic physics

There are provided a stable electron-emitting device with less fluctuation in electron-emitting properties and a method of fabricating the electron-emitting device. The electron-emitting device has a substrate; a plurality of columnar first regions respectively orientated substantially perpendicular to the surface of the substrate; a second region provided between the respective first regions higher than the first regions in resistance; and an electron emission layer covering the columnar first regions and the second region.

Owner:CANON KK

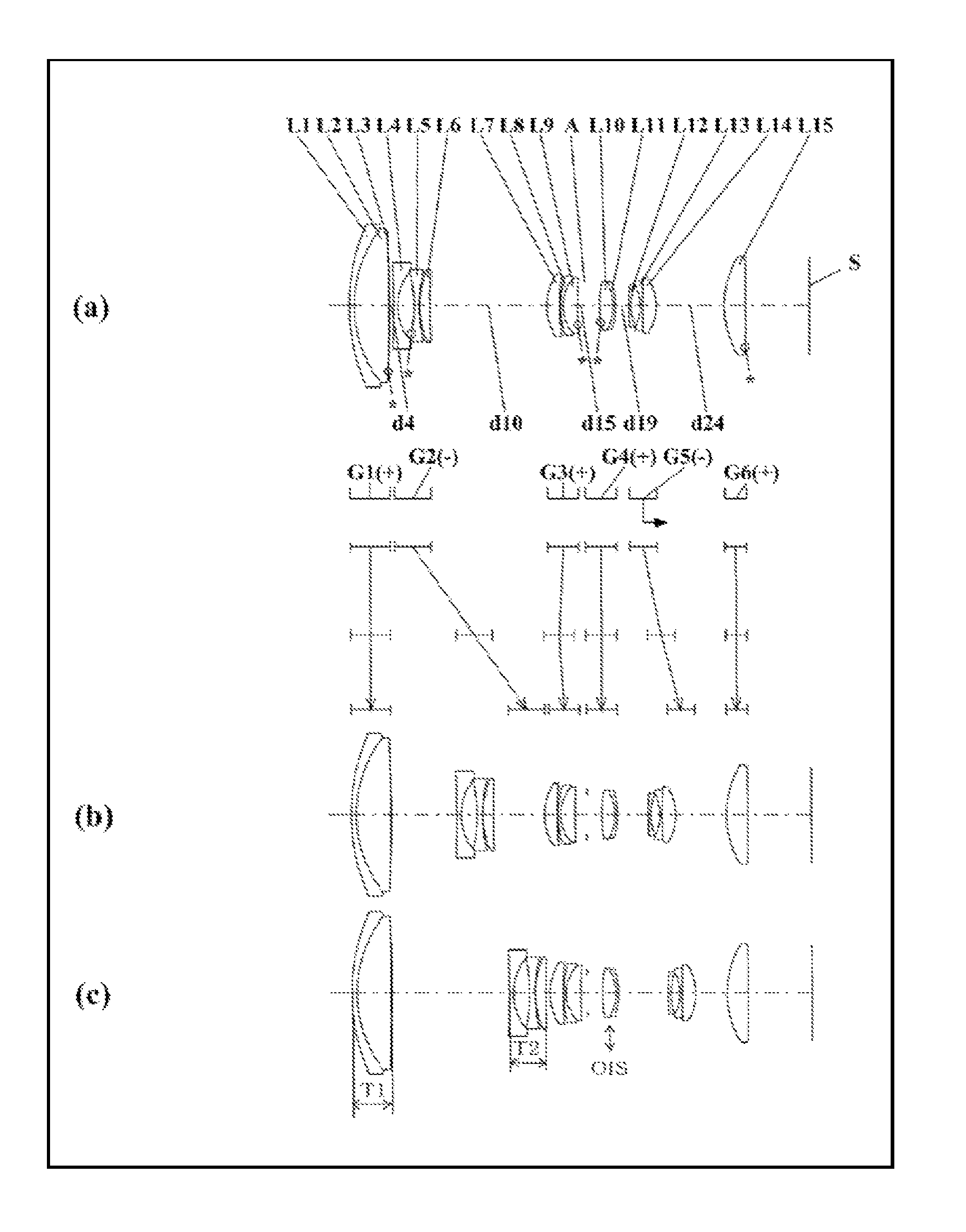

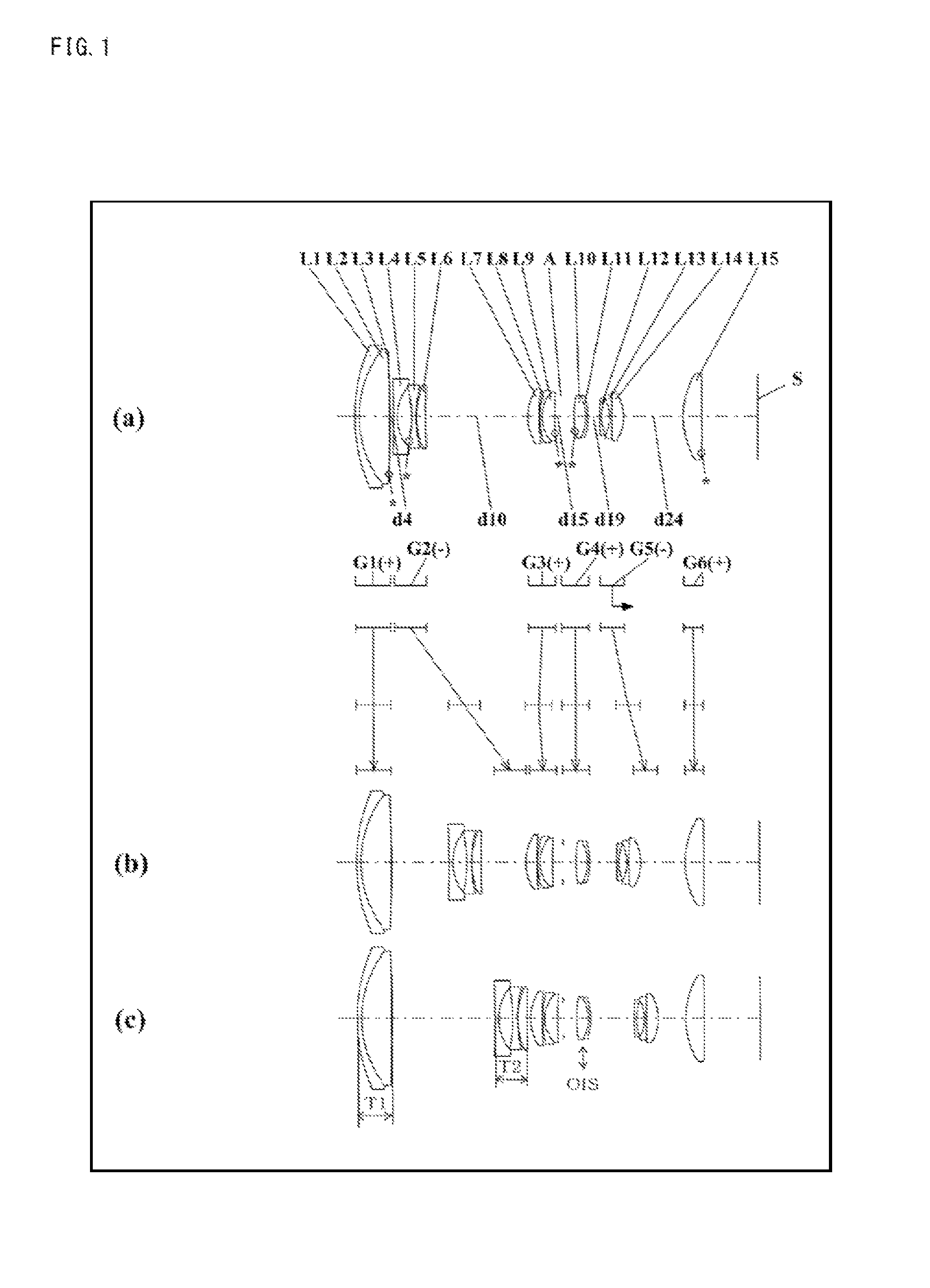

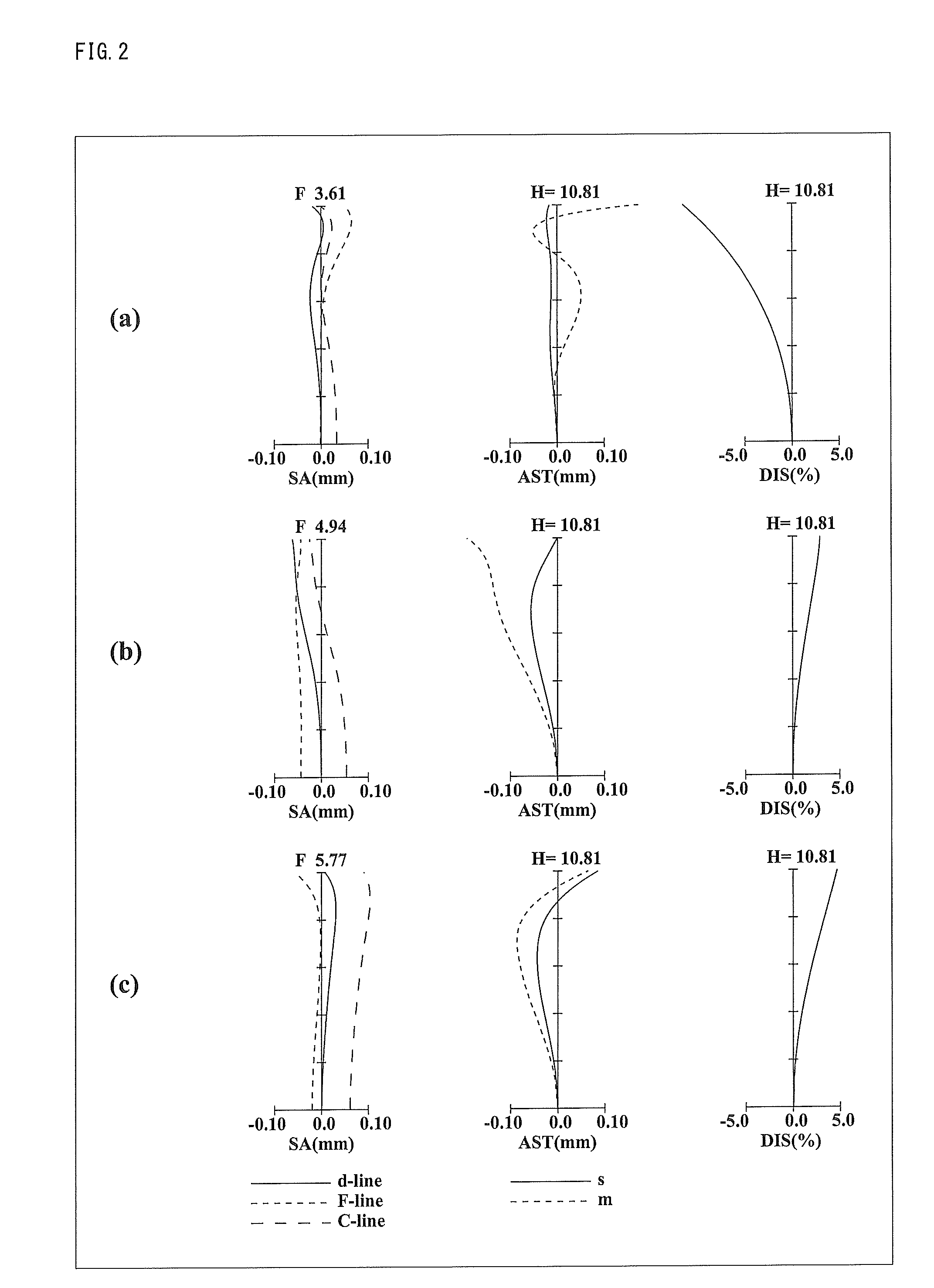

Zoom lens system, interchangeable lens apparatus and camera system

InactiveUS8537249B2High zoom ratioLess fluctuationTelevision system detailsColor television detailsOptical axisOptical power

A zoom lens system of lens units, the system including, in object-side-to-image-side order: a first lens unit having positive optical power; a second lens unit; an aperture diaphragm; one or more additional lens units, with a first of the additional lens units being a first focusing-lens unit having negative optical power and moving along the optical axis in the zoom lens system focusing; an image blur compensating lens unit, adjacent the first focusing-lens unit and movable in a direction perpendicular to the optical axis in order to optically compensate image blur; with the lens system satisfying: 0.1<(T1+T2) / H<2.0 (T1 being the axial thickness of the first lens unit, T2 being the axial thickness of the second lens unit, and H being the height of an image the zoom lens system forms on an image surface on the image-side end of the zoom lens system).

Owner:PANASONIC CORP

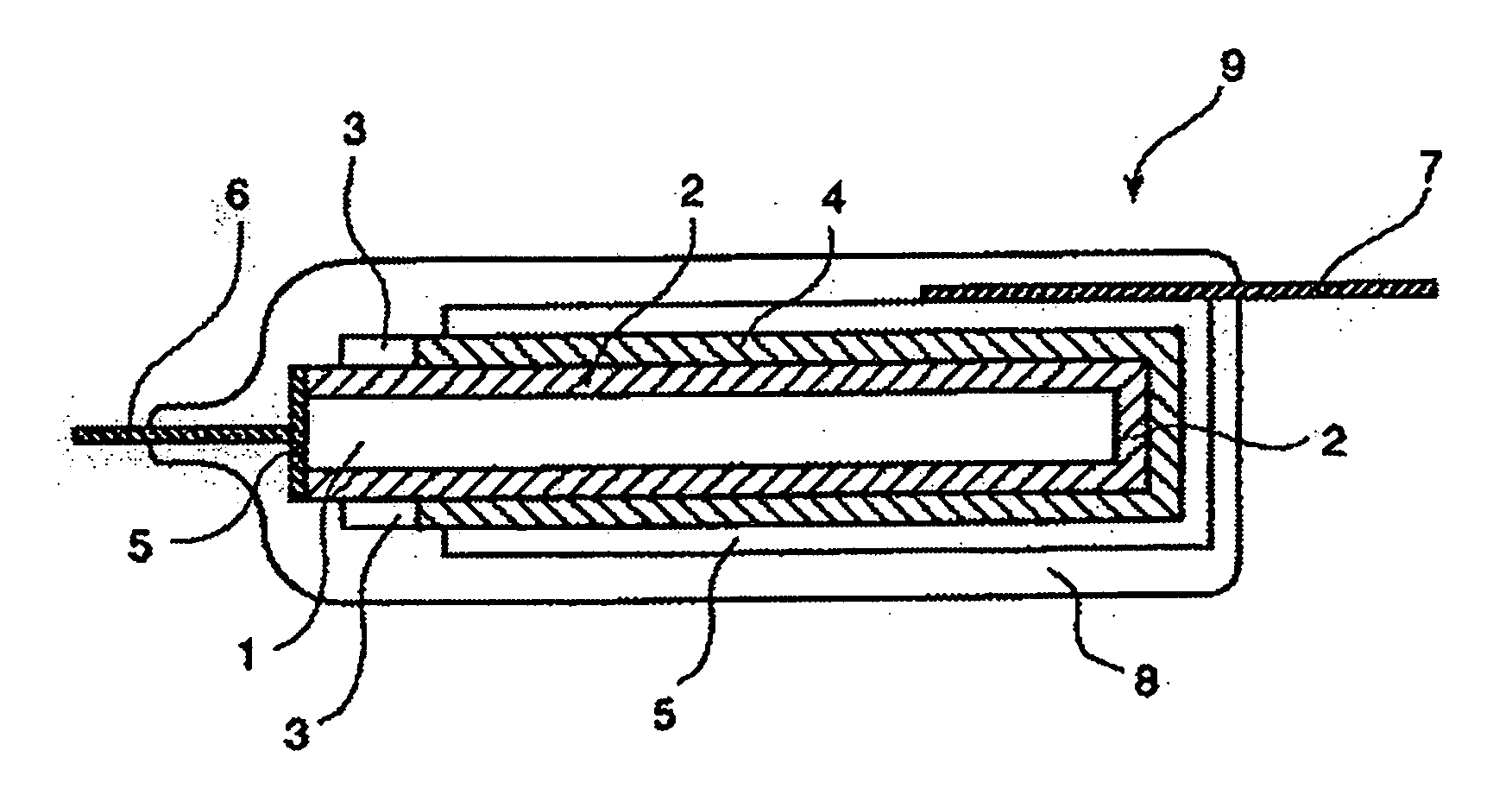

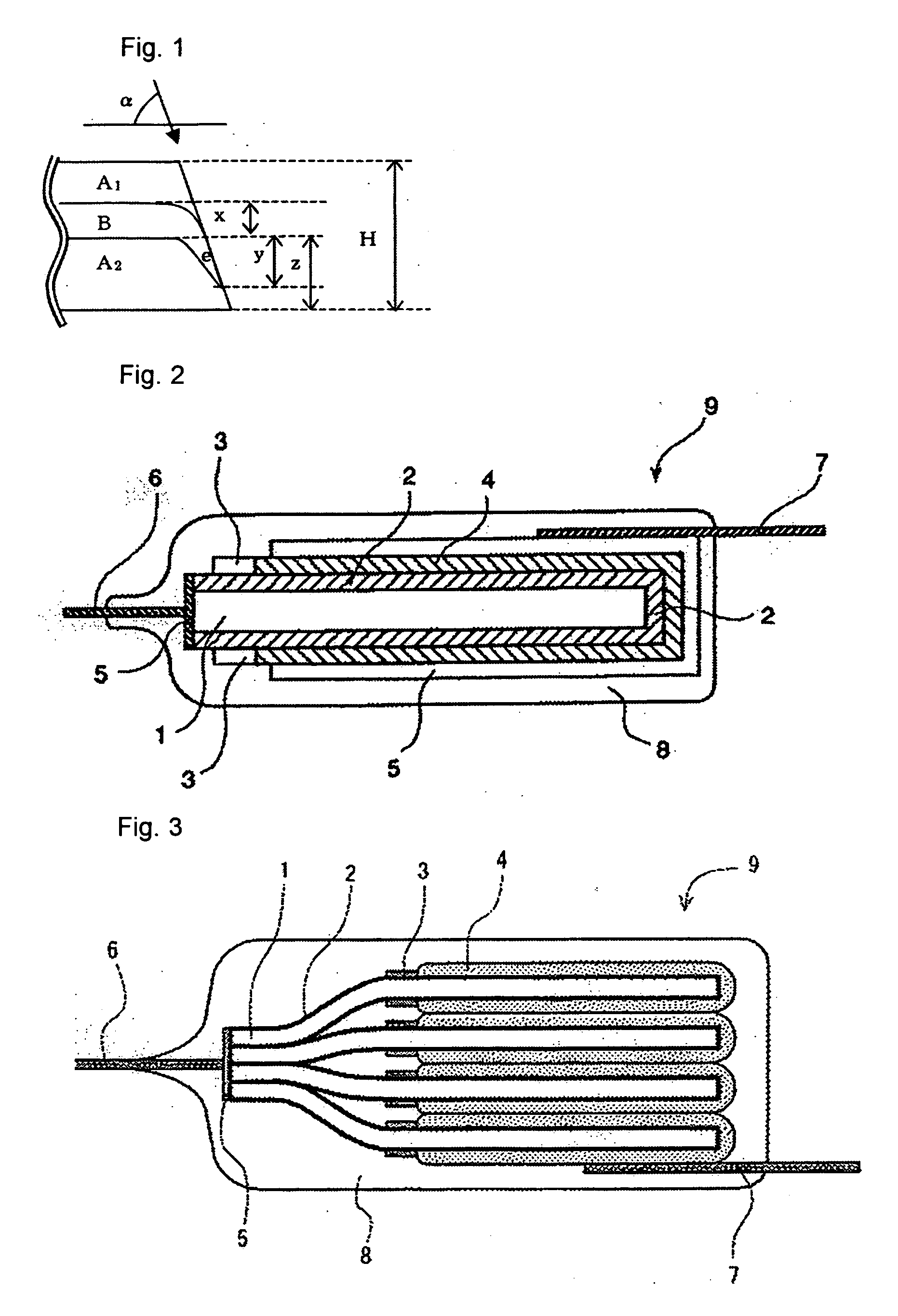

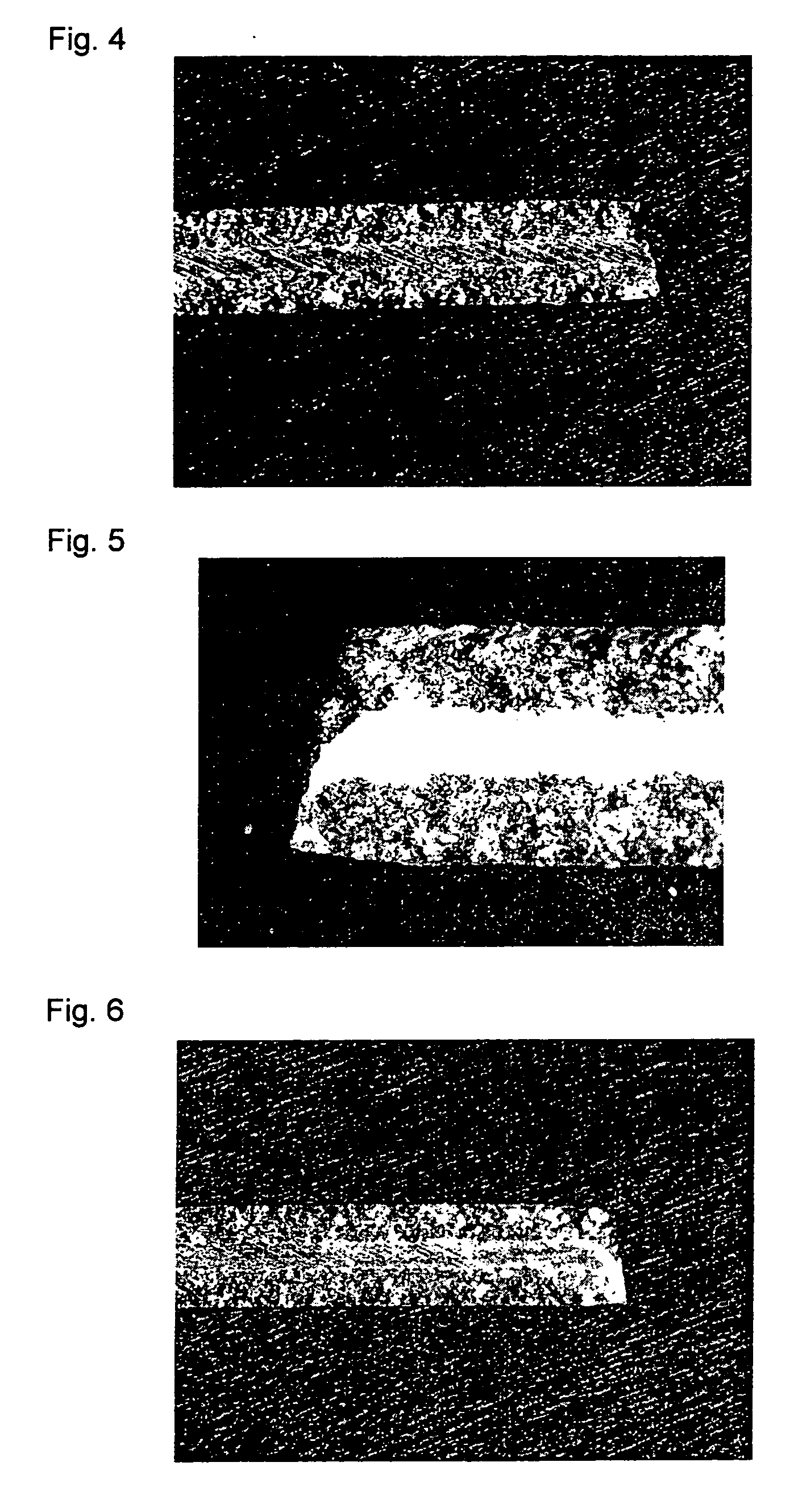

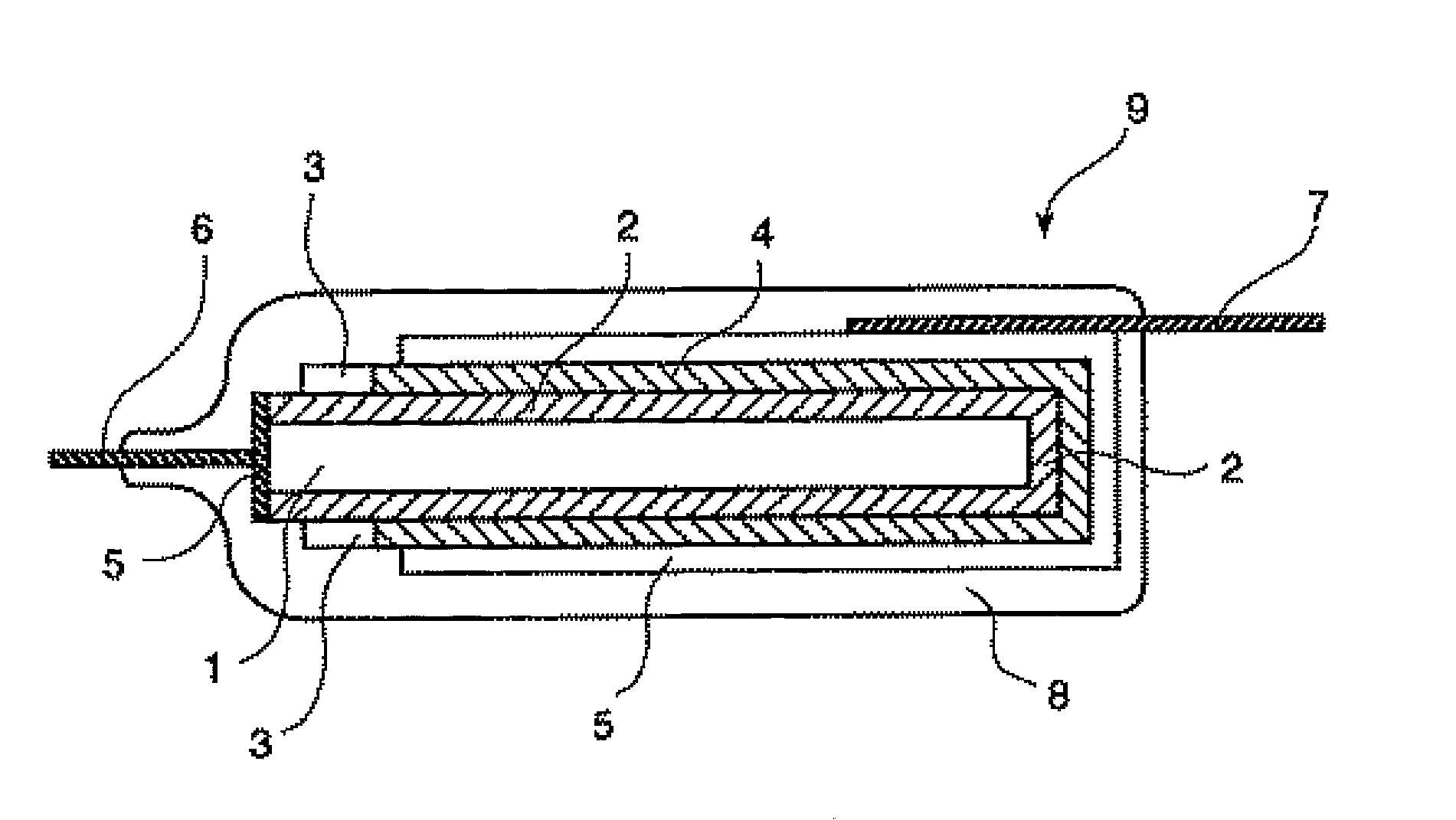

Solid electrolytic capacitor

ActiveUS20070030622A1Uniformly formHigh capacitanceSolid electrolytic capacitorsLiquid electrolytic capacitorsMetal substrateAnode

The present invention relates to an anode substrate for a solid electrolytic capacitor which is produced by cutting obliquely a metal substrate comprising a valve-acting metal layer having fine pores and a valve-acting metal layer without fine pores, and having a cut surface which is formed by elongation of the valve-acting metal layer without fine pores dragged by a cutting blade; particularly to an anode substrate for a solid electrolytic capacitor which is produced by cutting obliquely a metal substrate comprising a valve-acting metal layer having fine pores and a valve-acting metal layer without fine pores, and a layer of the elongated valve-acting metal which is generated by that the valve-acting metal layer without fine pores is elongated being dragged along with a cutting blade and covers the edge part of the valve-acting layer having fine pores meets the requirement represented by the following formula:0≦y / z≦1 [Formula 1]wherein y represents the thickness of the layer of the elongated valve-acting metal in the direction of the thickness of the substrate and z represents the thickness of the valve-acting layer having fine pores which is in contact with the elongated metal layer in the direction of the thickness of the substrate, respectively; and to a solid electrolytic capacitor comprising the above-mentioned anode substrate, an edge of which is chamfered at least partially.

Owner:MURATA MFG CO LTD

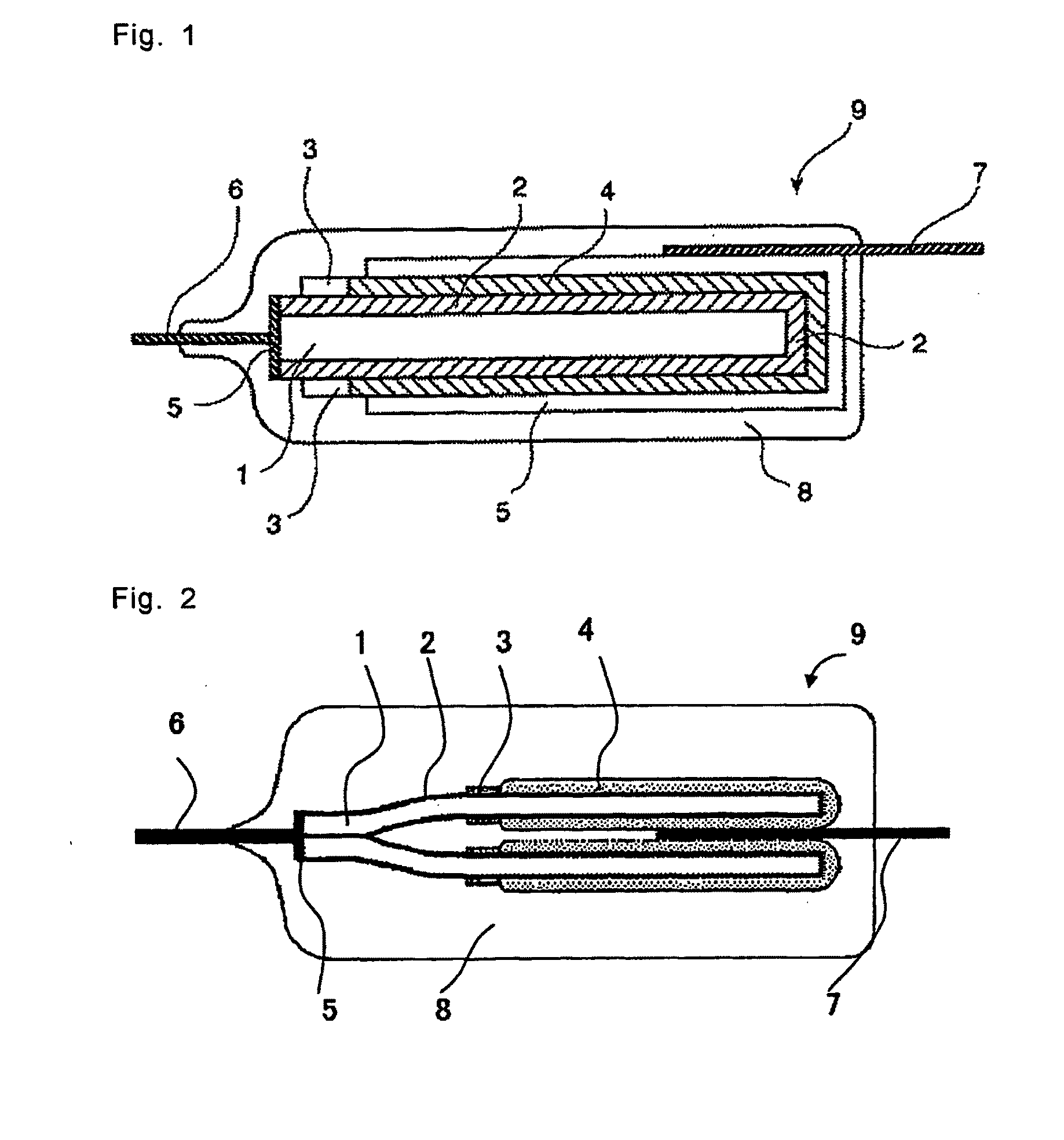

Solid Electrolytic Capacitor and Method for Producing the Same

InactiveUS20080049381A1Less fluctuationIncrease capacitanceHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisFree solution

The present invention relates to a method for producing a solid electrolytic capacitor in which a solid electrolyte layer is provided by a process comprising a step of dipping a valve-acting metal having thereon a dielectric film layer in a monomer-containing solution, followed by drying (Step 1), a step of dipping the valve-acting metal in an oxidizing agent-containing solution, followed by drying (Step 2), and a step of dipping the. valve-acting metal in an oxidizing agent-free solution, followed by drying (Step 3); and to a solid electrolytic capacitor produced thereof. According to the present invention, a thin capacitor element with reduced failure of short circuit and less fluctuation in the element shape can be stably produced, the number of capacitor elements stacked in a solid electrolytic capacitor chip can be increased to realize high capacitance, and a solid electrolytic capacitor element suitable for a solid electrolytic multilayer capacitor with less fluctuation in the equivalent series resistance can be provided.

Owner:MURATA MFG CO LTD

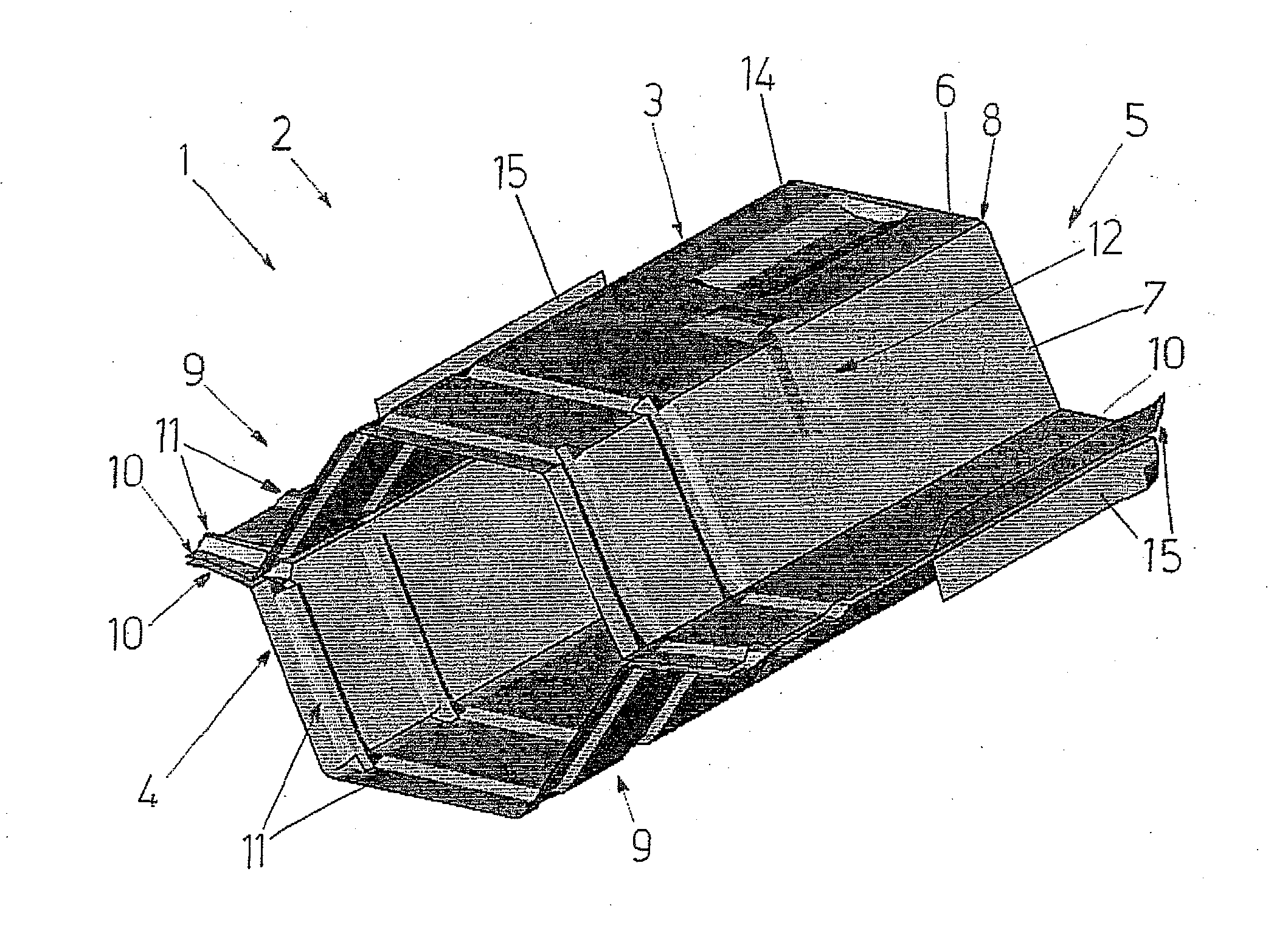

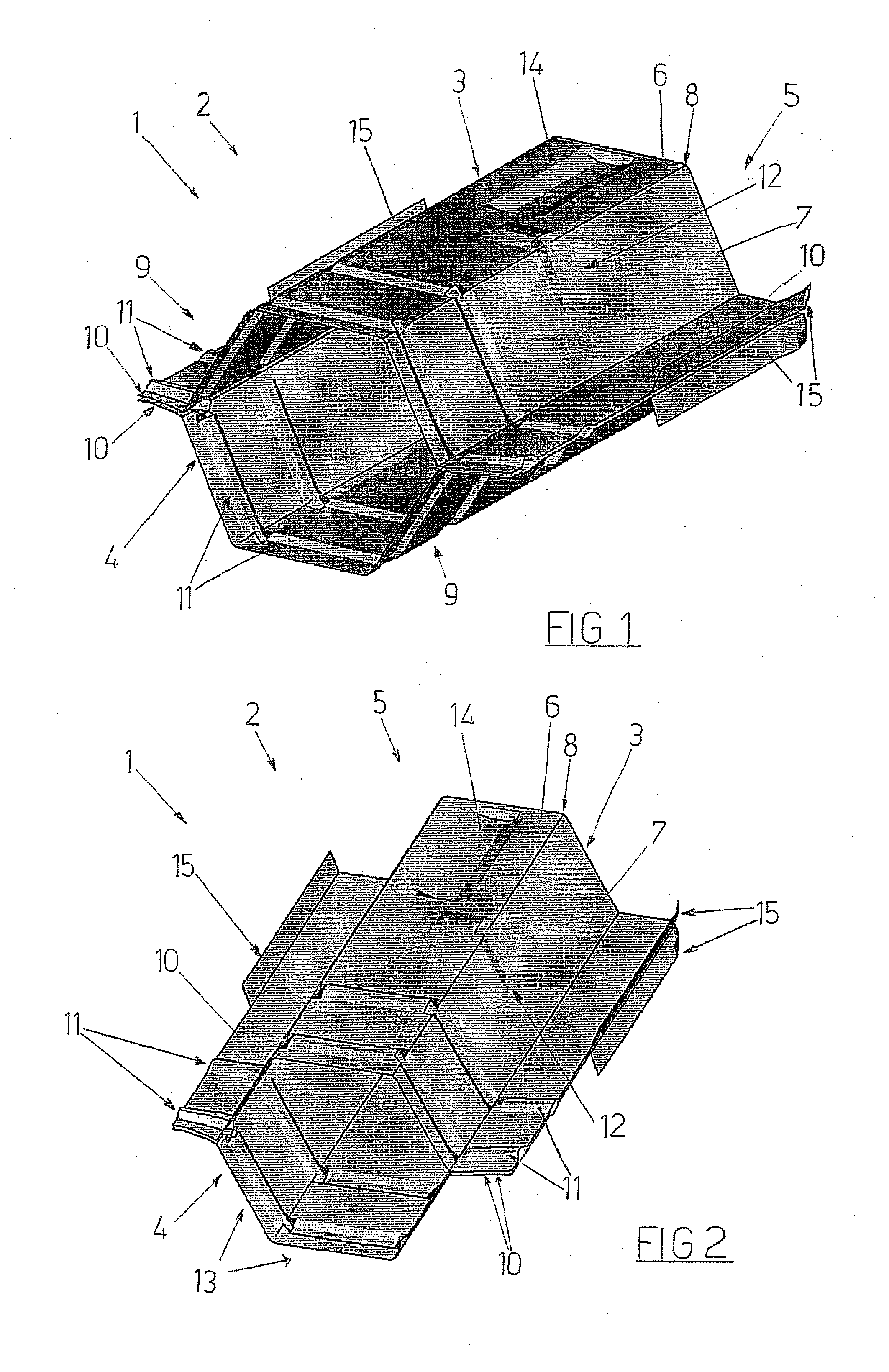

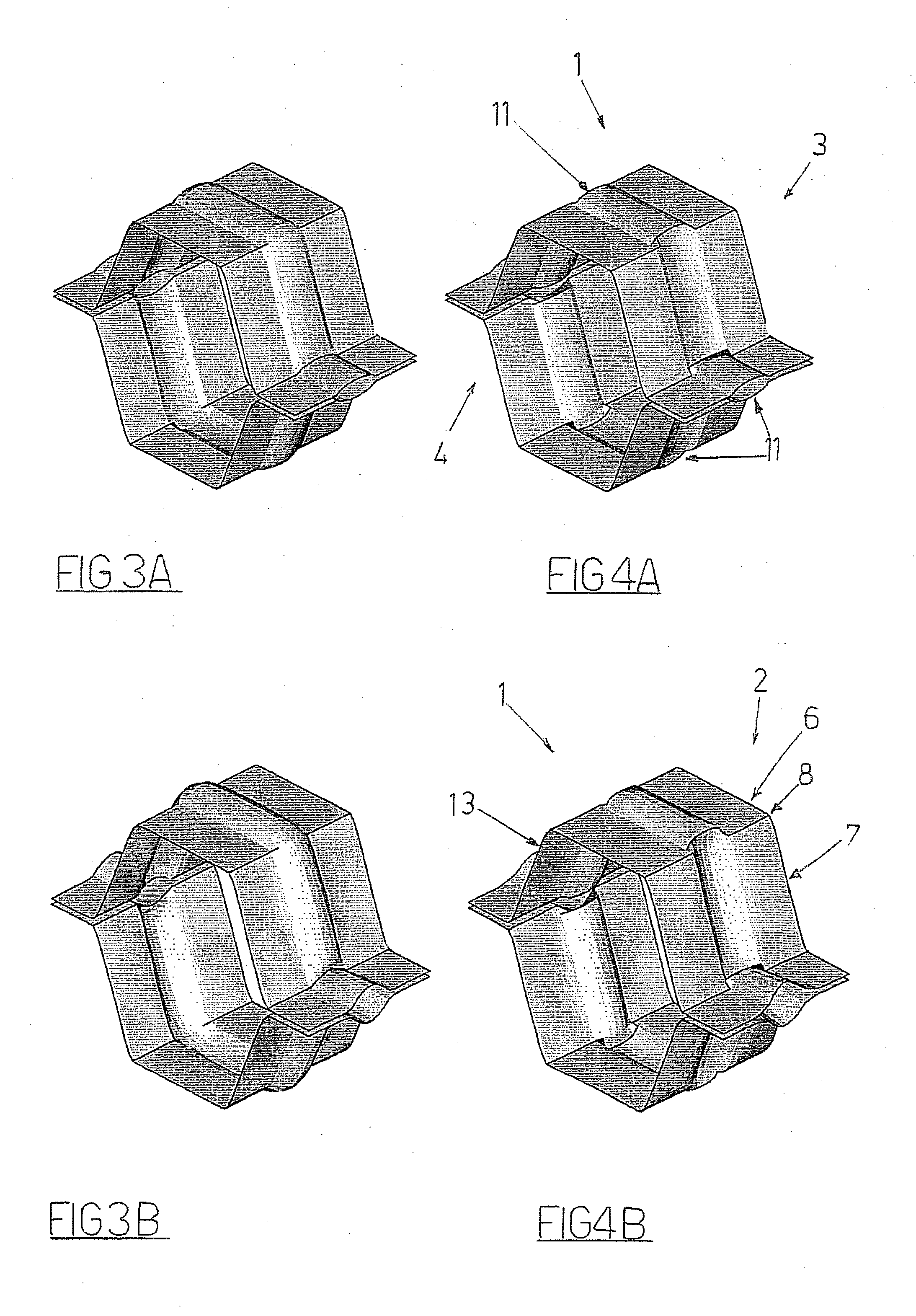

Shock absorber for motor vehicles

InactiveUS20140008925A1Less fluctuationMaximize efficiencyElastic dampersBumpersShock absorberEngineering

A shock absorber for motor vehicles, comprising: a deforming body (2) comprising a first portion (3) and a second portion (4) which are fixed to one another such as to identify a tubular member (5) which has a first axis and comprises a first wall (6) and a second wall (7) adjacent to one another, which intersect to identify an edge (8), each portion (3, 4) comprising a half-shell (9) and two fixing tabs (10) arranged respectively at opposite ends of the half-shell (9), at least a portion (3, 4) comprising at least a bead (11, 12) which develops along a perpendicular development with respect to the first axis. The bead (11, 12) develops continuously at least along a part of the first wall (6) and at least along a part of the second wall (7) of the tubular member (5), following at least the edge (8) identified between the first wall (6) and the second wall (7), the bead (11, 12), when it follows the first wall (6), being orientated projecting with respect to the zone of the external surface of the first wall (6) which surrounds the bead (11, 12), the bead (11, 12), when following the second wall (7), being orientated retracted with respect to the zone of the external surface of the second wall (7) which surrounds the bead (11, 12), the bead (11, 12), at the edge (8), varying orientation thereof between projecting and retracted.

Owner:IMPERO PASQUALE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com