Patents

Literature

368 results about "Physical change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical changes are changes affecting the form of a chemical substance, but not its chemical composition. Physical changes are used to separate mixtures into their component compounds, but can not usually be used to separate compounds into chemical elements or simpler compounds.

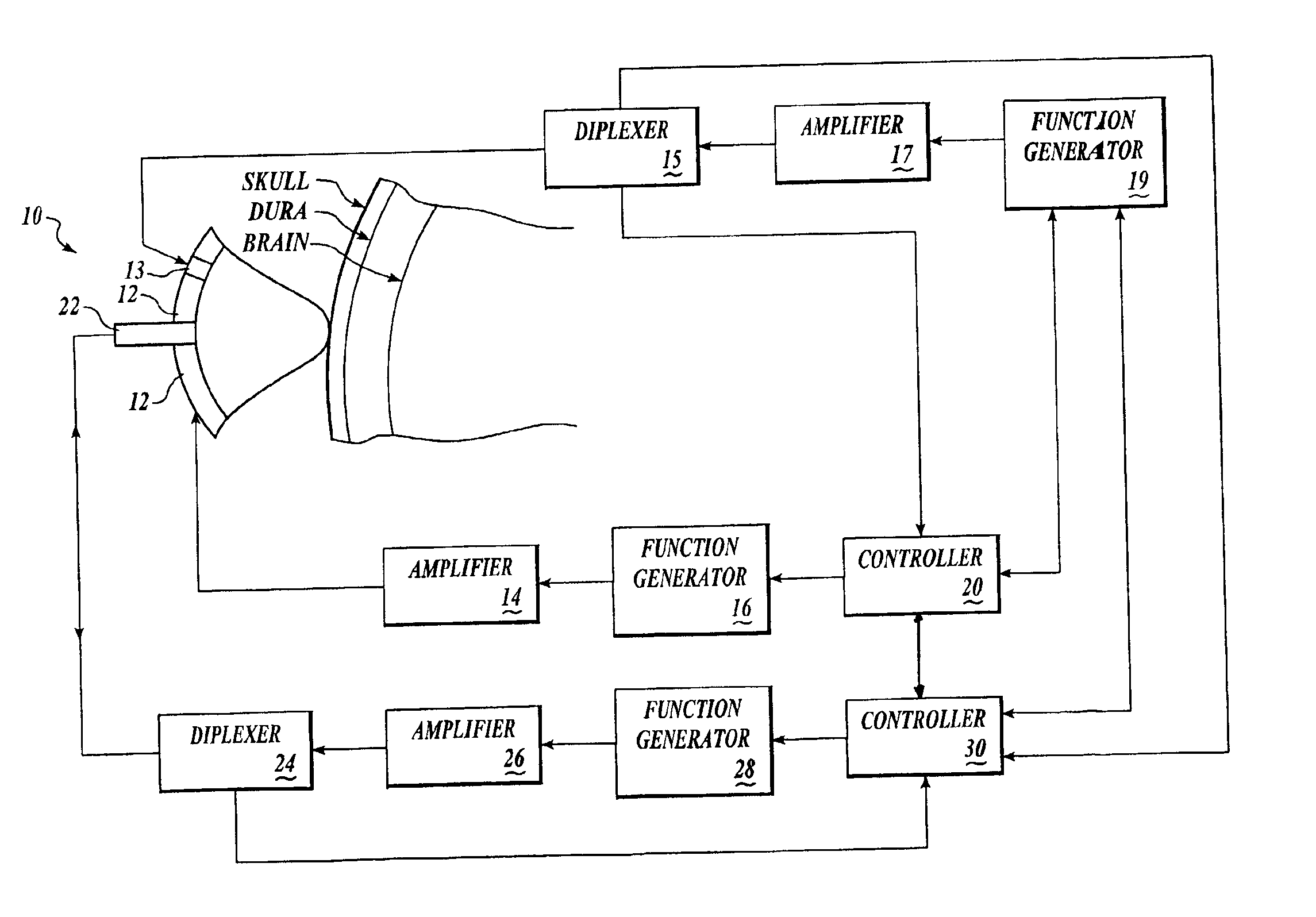

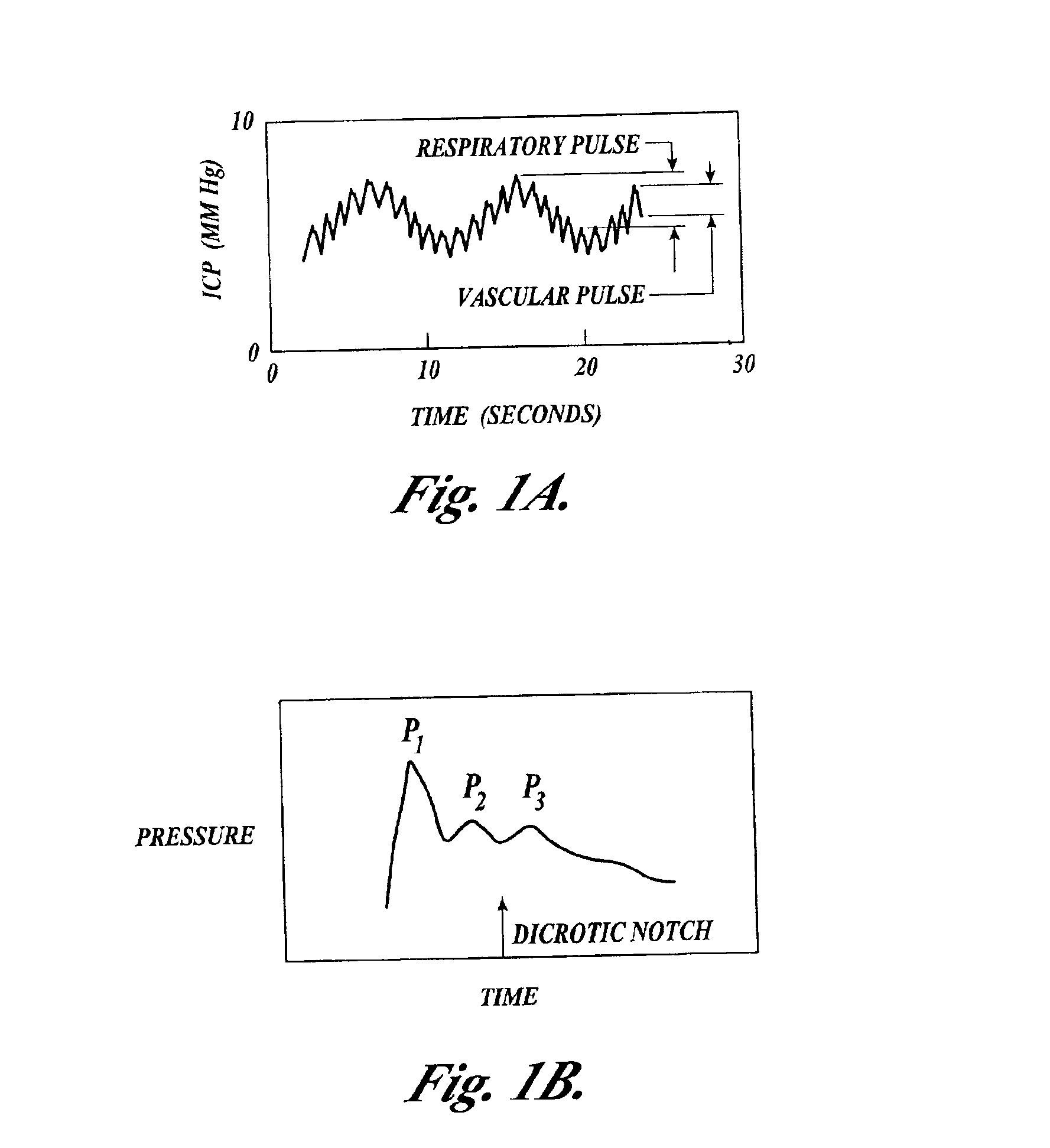

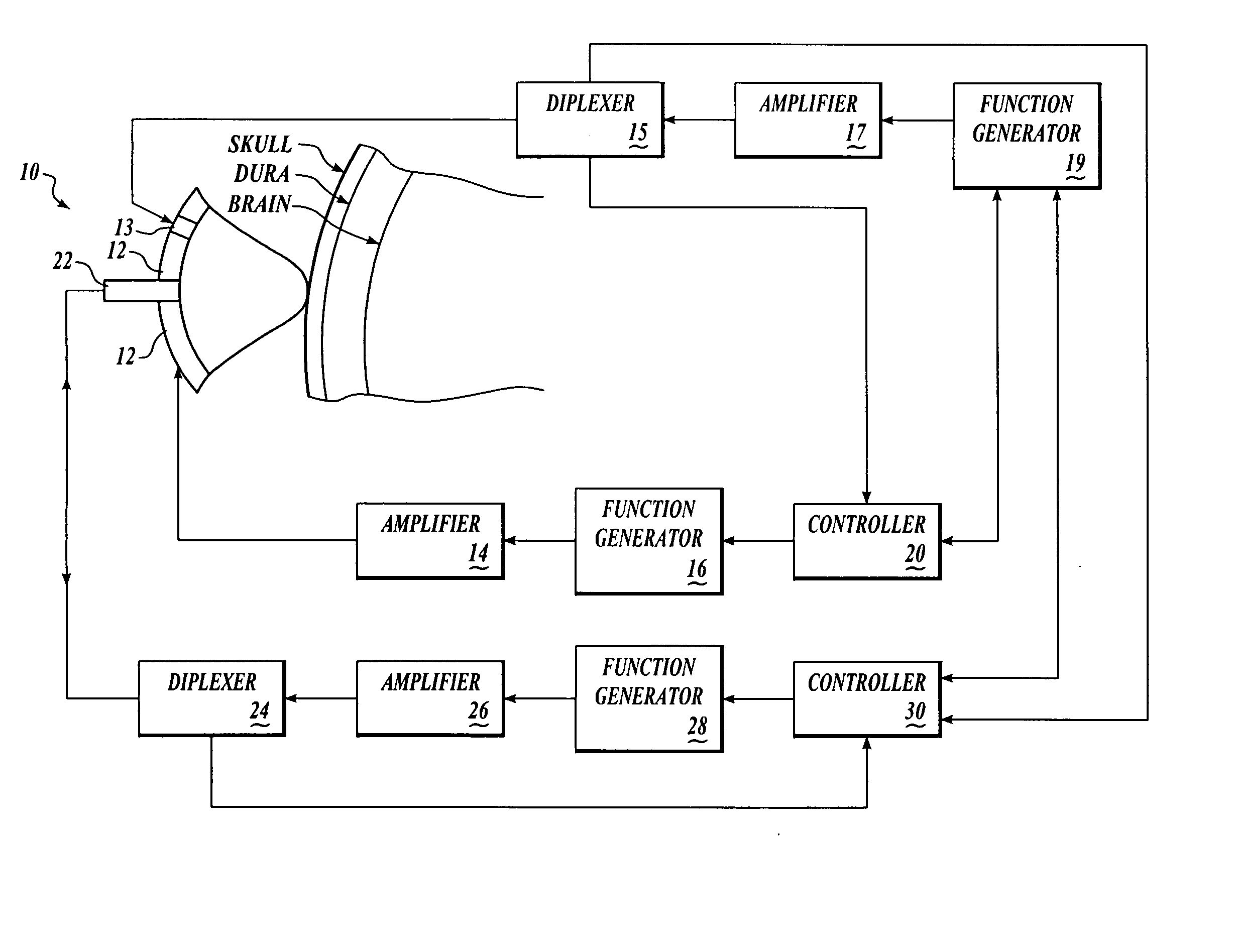

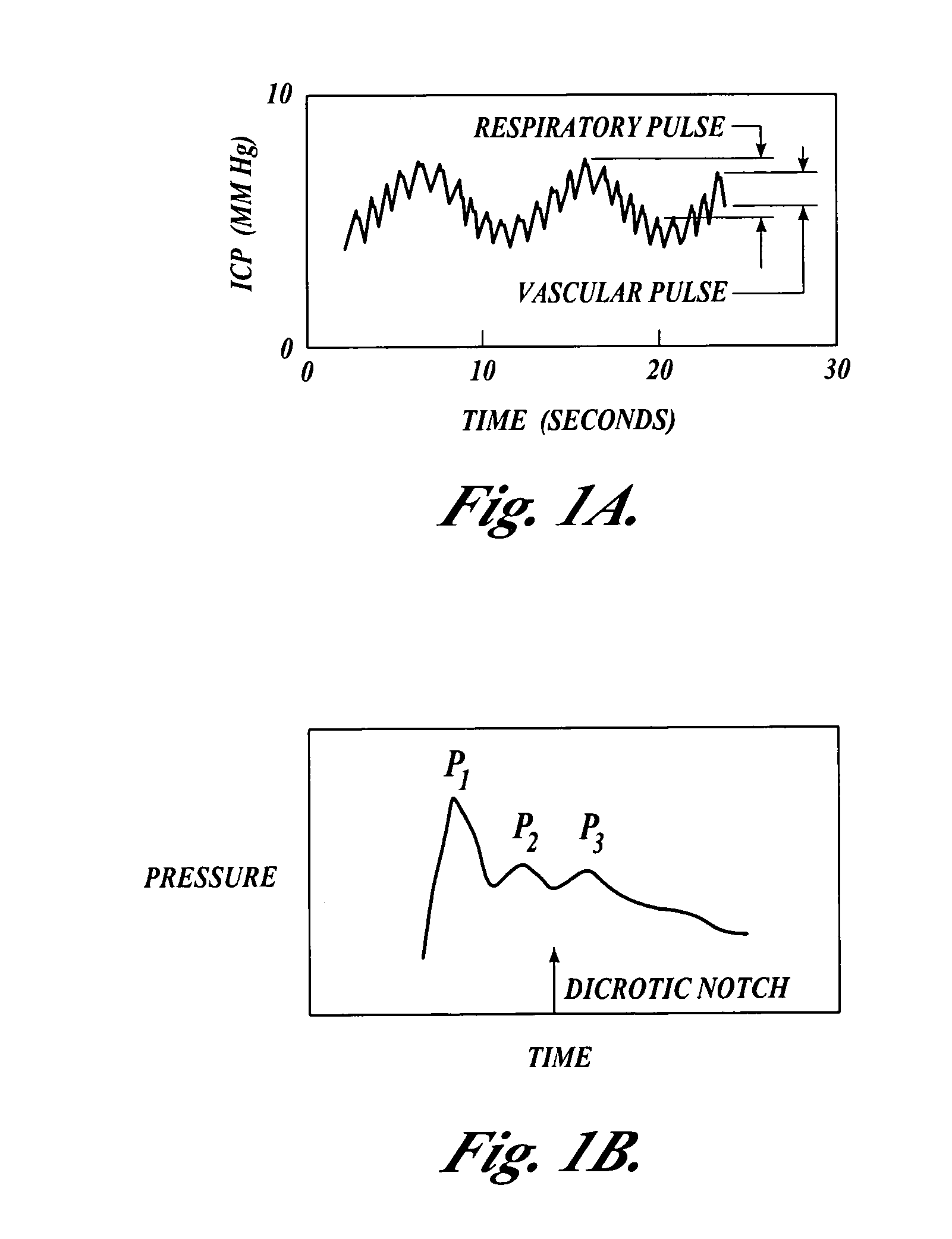

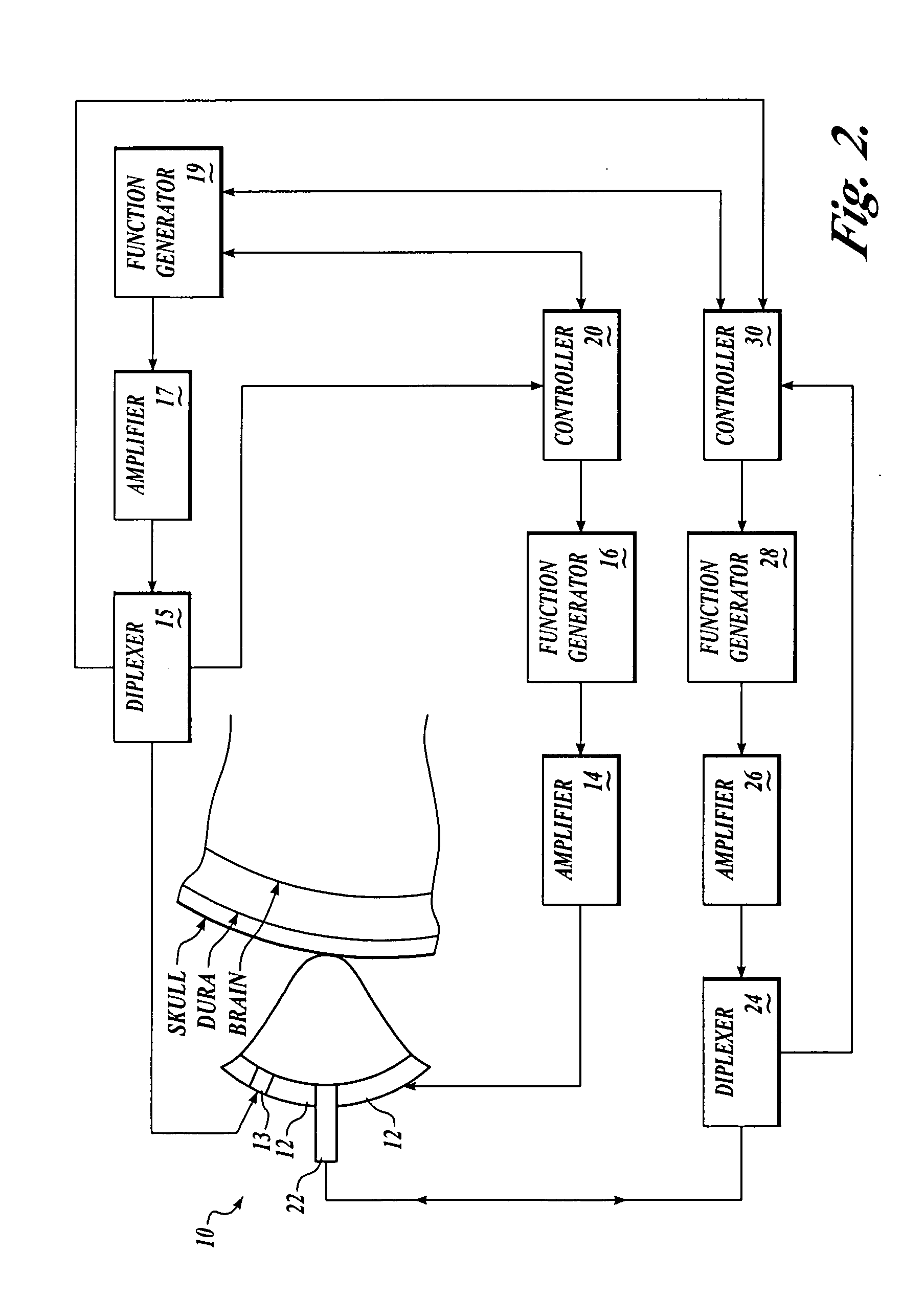

Systems and methods for making noninvasive physiological assessments

InactiveUS6875176B2Improve accuracySensitive highOrgan movement/changes detectionSurgeryDiseaseNon invasive

Systems and methods for assessment of tissue properties, noninvasively, by acquiring data relating to at least one aspect of intrinsic and / or induced tissue displacement, or associated biological responses, are provided. Data relating to tissue displacement and associated biological changes may be acquired by detecting acoustic properties of tissue using ultrasound interrogation pulses, preferably in a scatter or Doppler detection mode. Based on this data, tissue properties are assessed, characterized and monitored. Specific applications for systems and methods of the present invention include non-invasive assessment and monitoring of intracranial pressure (ICP), arterial blood pressure (ABP), CNS autoregulation status, vasospasm, stroke, local edema, infection and vasculitus, as well as diagnosis and monitoring of diseases and conditions that are characterized by physical changes in tissue properties. Methods and systems for localizing physiological condition(s) and / or biological response(s), such as pain, by targeting and selectively probing tissues using the application of focused ultrasound are also provided.

Owner:PHYSIOSONICS

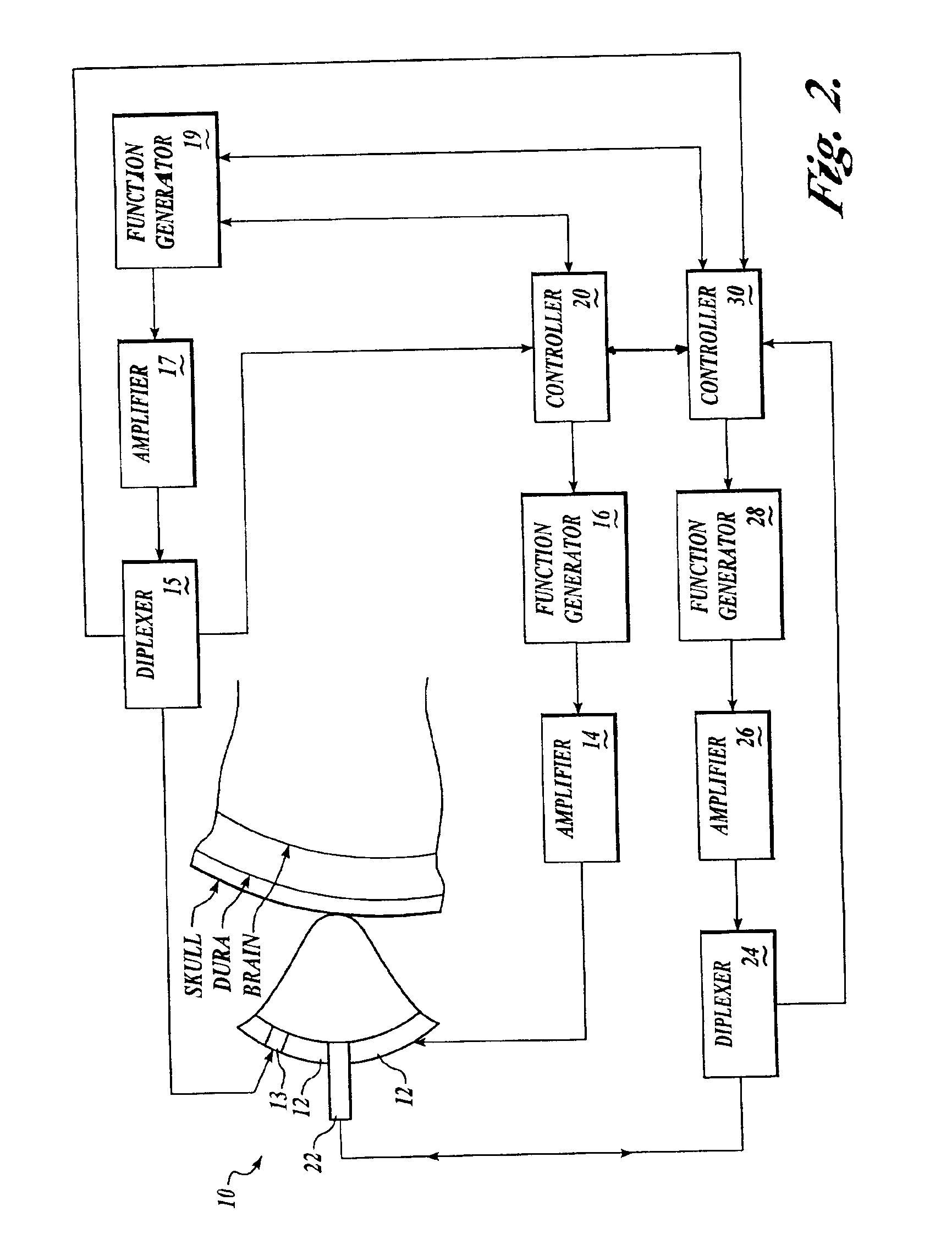

Systems and methods for making non-invasive physiological assessments by detecting induced acoustic emissions

InactiveUS20060079773A1Improve accuracyPositive diagnosisDiagnostics using vibrationsOrgan movement/changes detectionDiseaseNon invasive

Systems and methods for assessing a physiological parameter of a target tissue wherein a pulse of focused ultrasound is applied to a target tissue site thereby inducing oscillation of the target tissue. By these systems and methods, a property of an acoustic signal emitted from the oscillating target tissue is measured and related to a physiological property of the tissue. Specific applications for systems and methods of the present invention include the assessment and monitoring of intracranial pressure (ICP), arterial blood pressure (ABP), CNS autoregulation status, vasospasm, stroke, local edema, infection and vasculitus, as well as diagnosis and monitoring of diseases and conditions that are characterized by physical changes in tissue properties.

Owner:PHYSIOSONICS +1

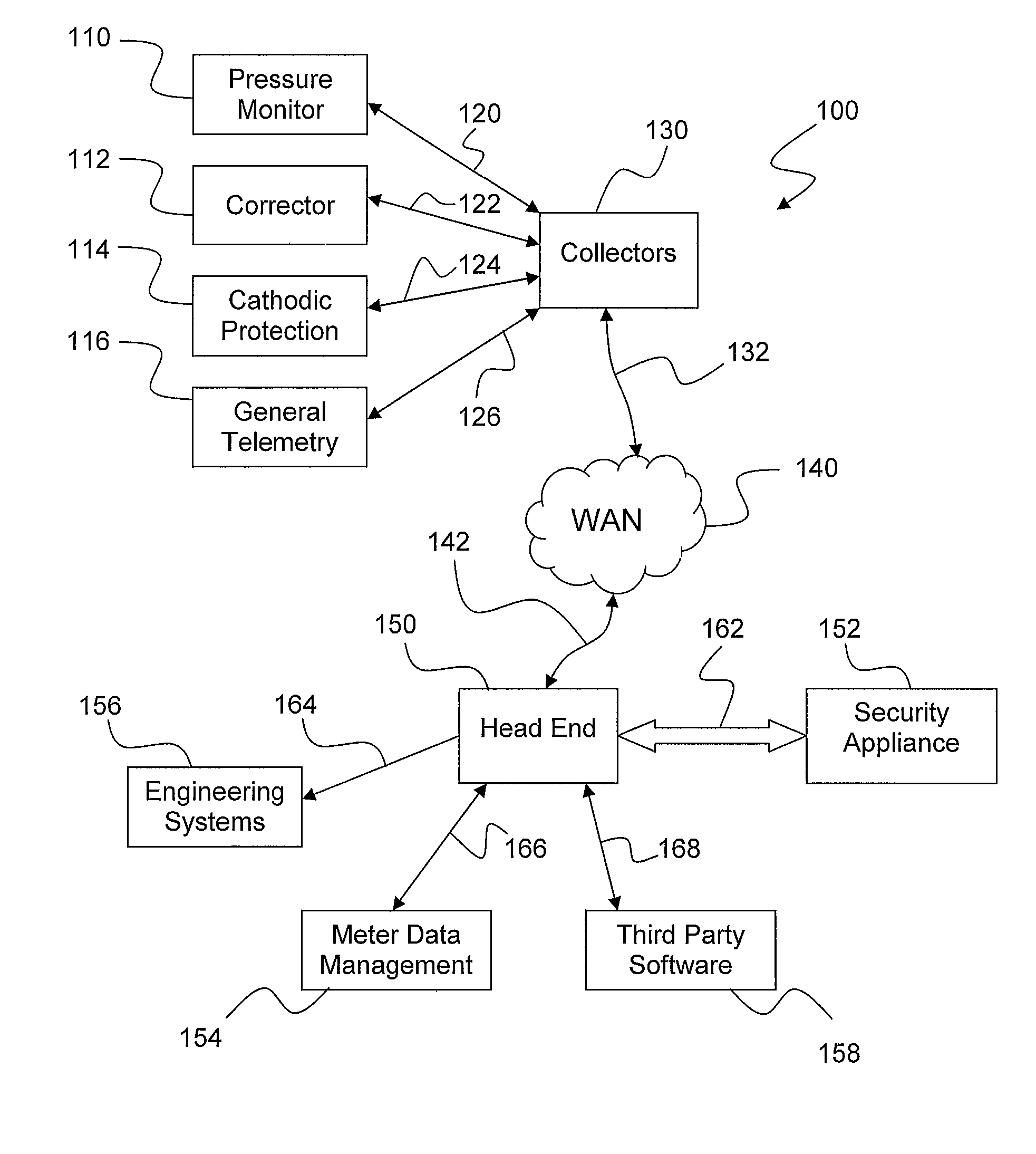

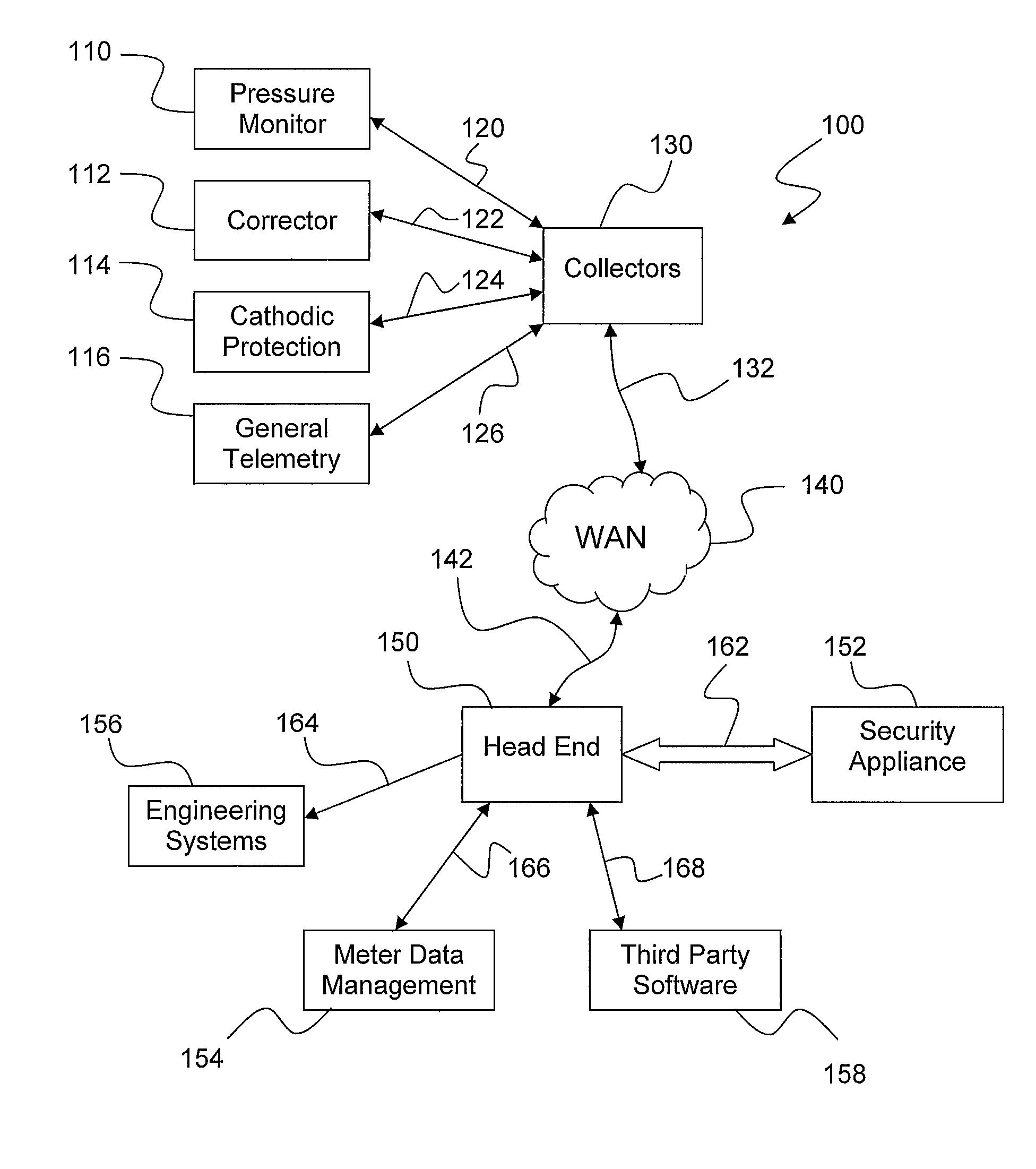

Telemetry system

ActiveUS8484137B2Need for powerReduce monitoring costsElectric signal transmission systemsData processing applicationsElectricityPhysical change

Owner:ITRON

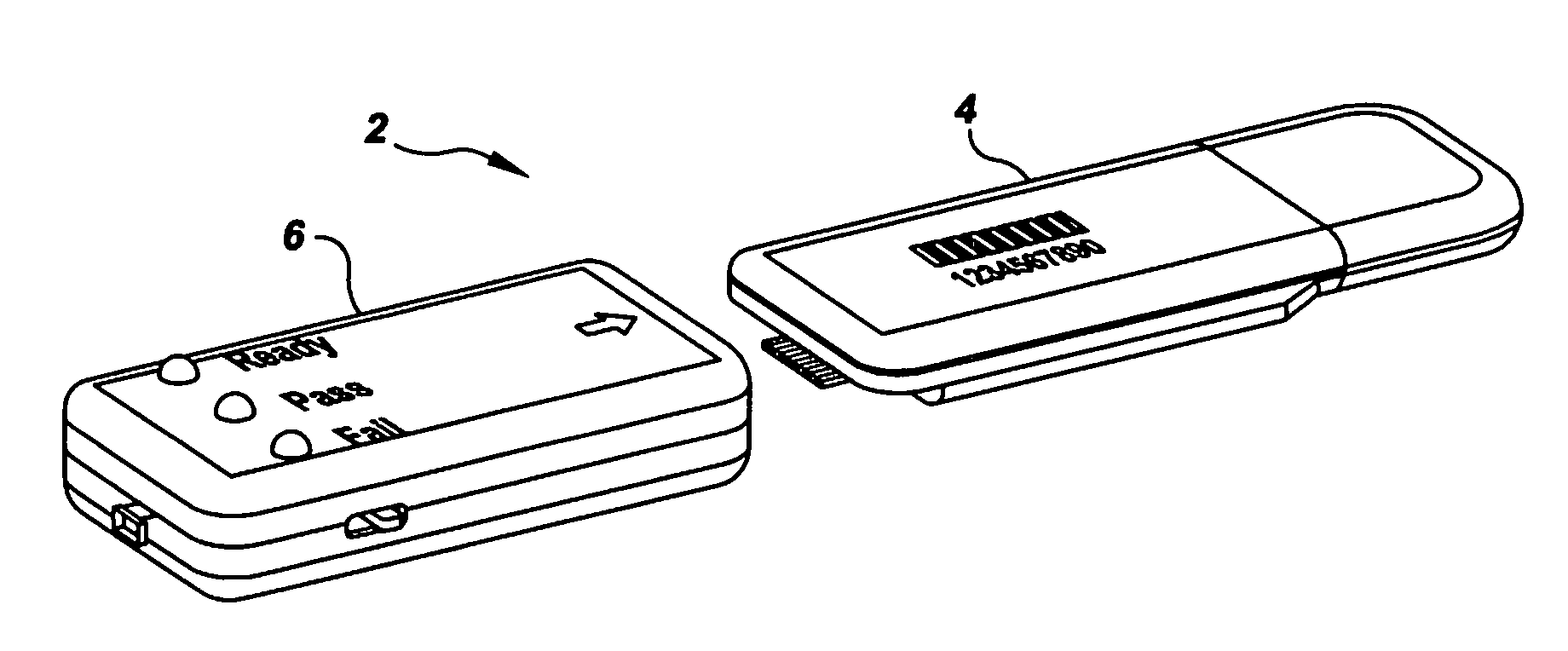

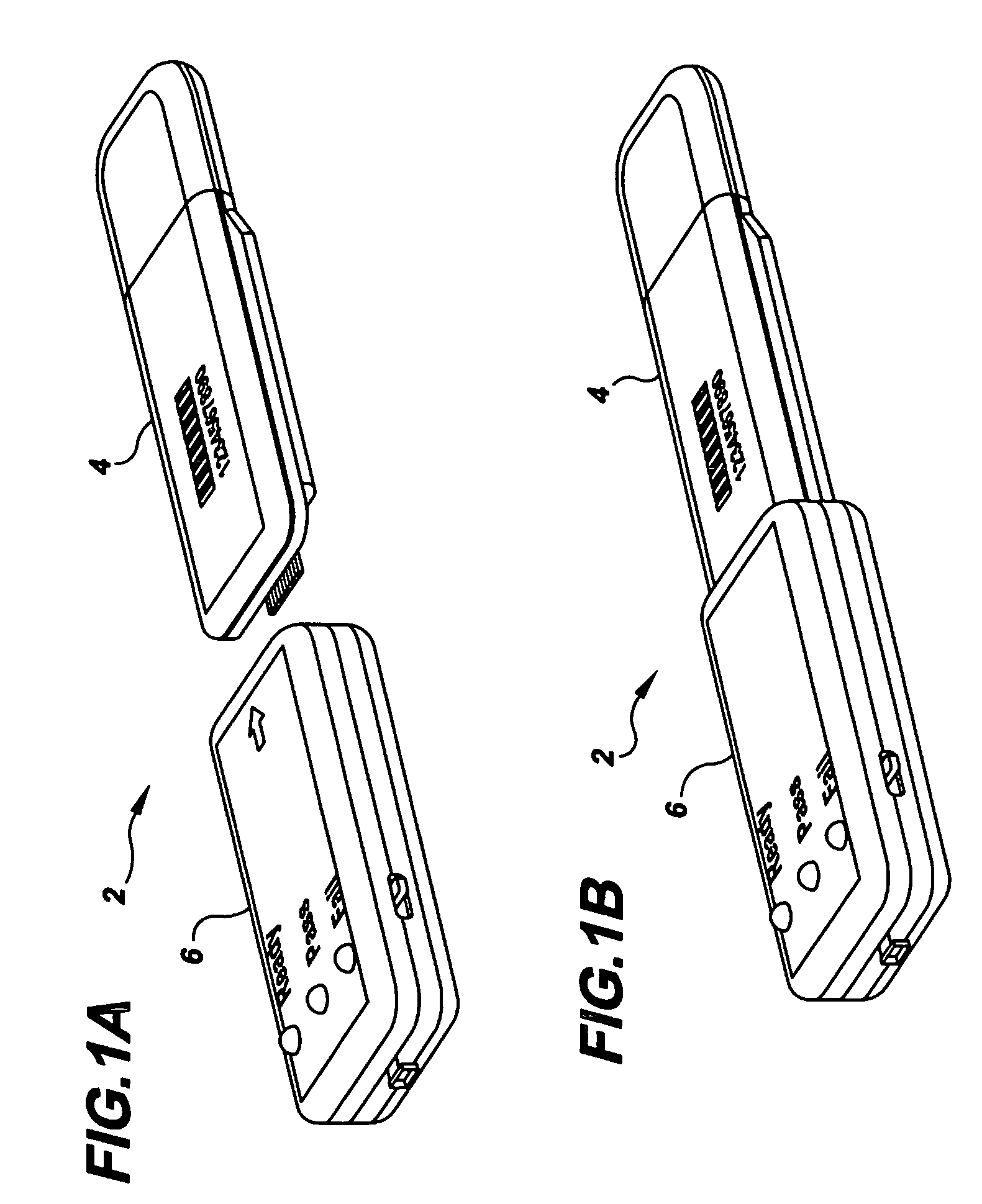

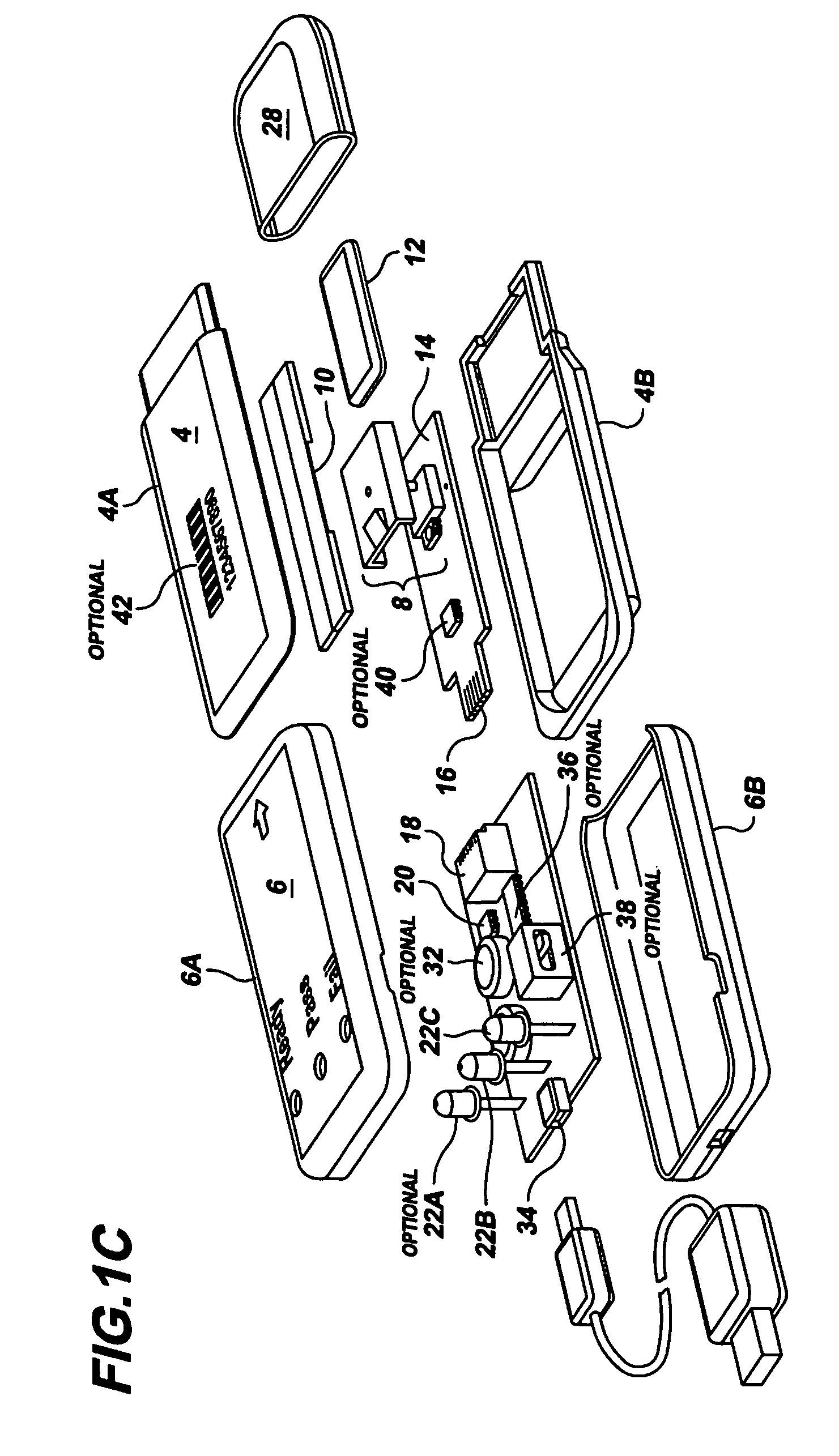

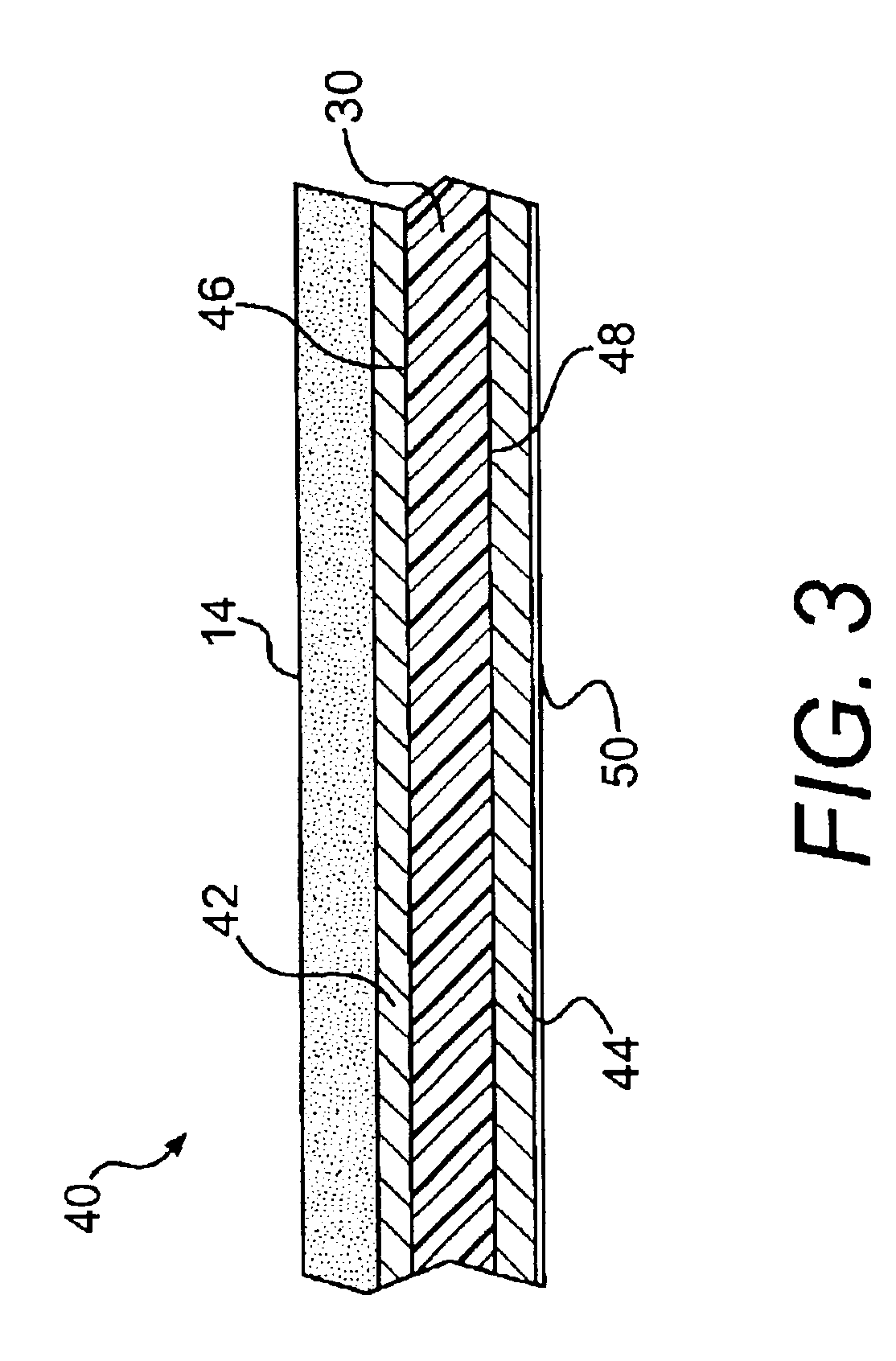

Semi-disposable optoelectronic rapid diagnostic test system

InactiveUS20070081920A1Wide and pointAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionRapid screening testHand held

A hand-held optoelectronic test system comprising a cartridge including at least one light source and sensors prealigned to permit acquisition of electro-optic data from a fluid sample reacted with a reagent, such as upon a test membrane in a reaction zone, and a reader which processes the acquired data to identify a physical change in the fluid sample. The cartridge and reader are operable for separate predetermined or controllable finite numbers of tests before becoming disposable.

Owner:AGILENT TECH INC

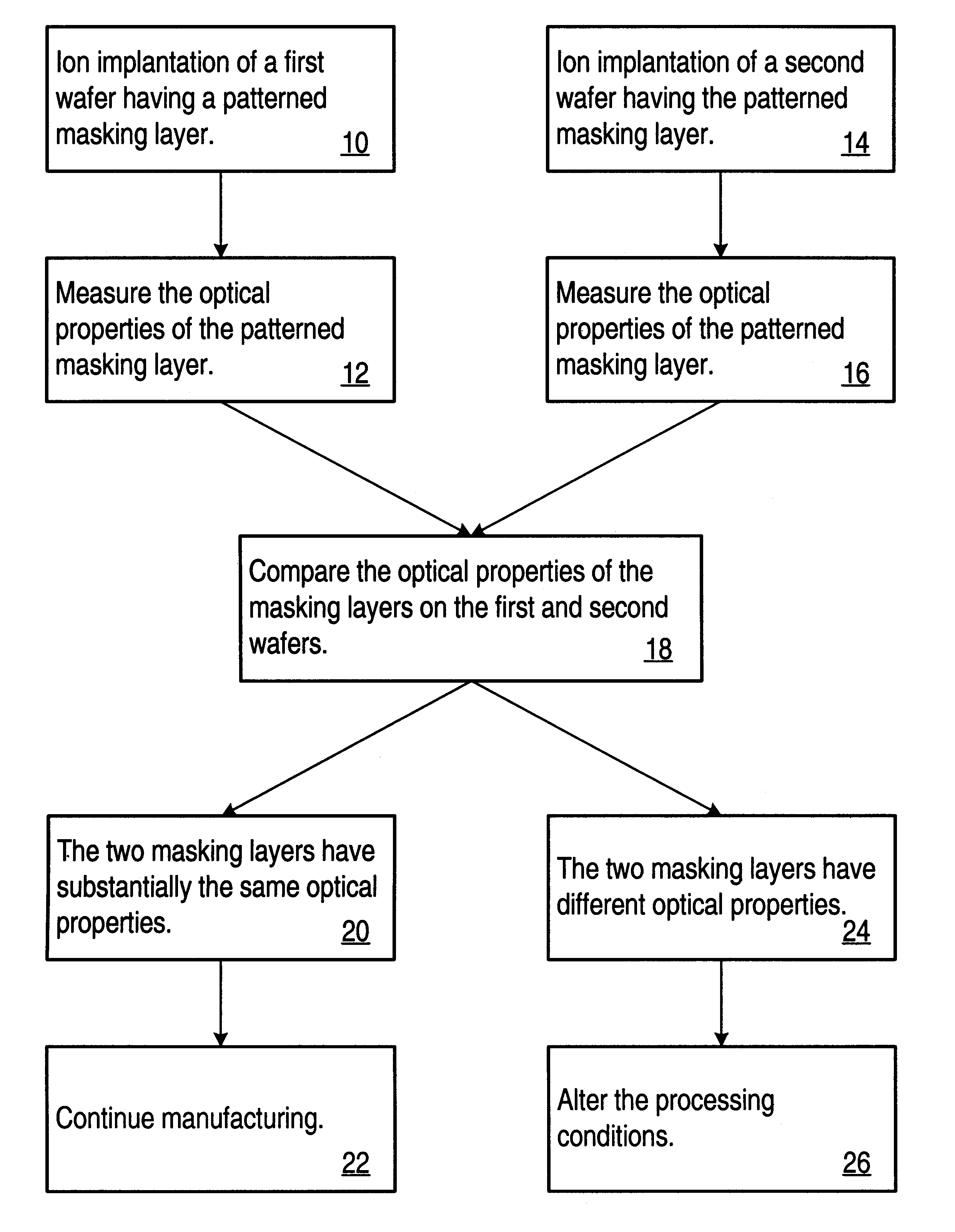

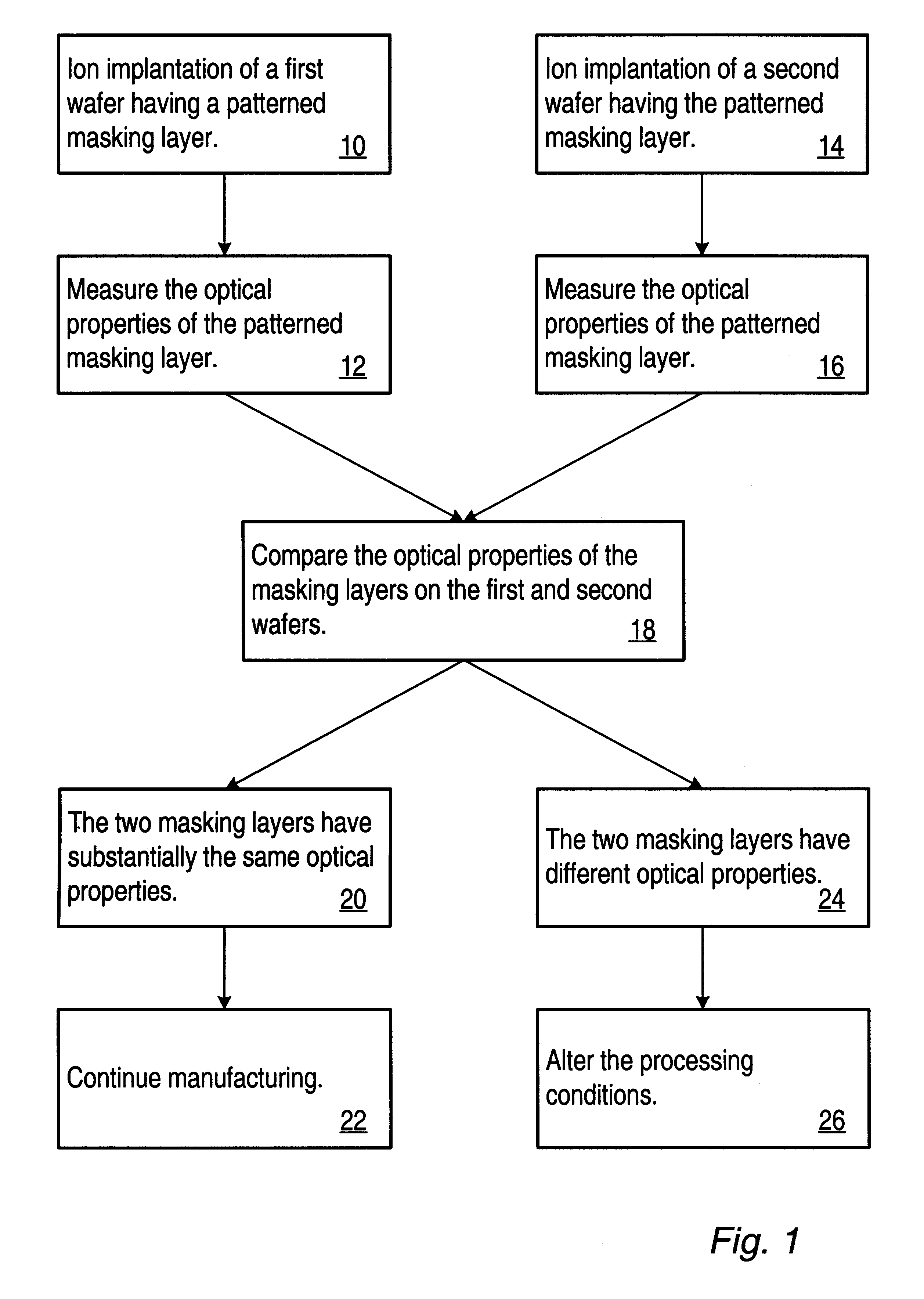

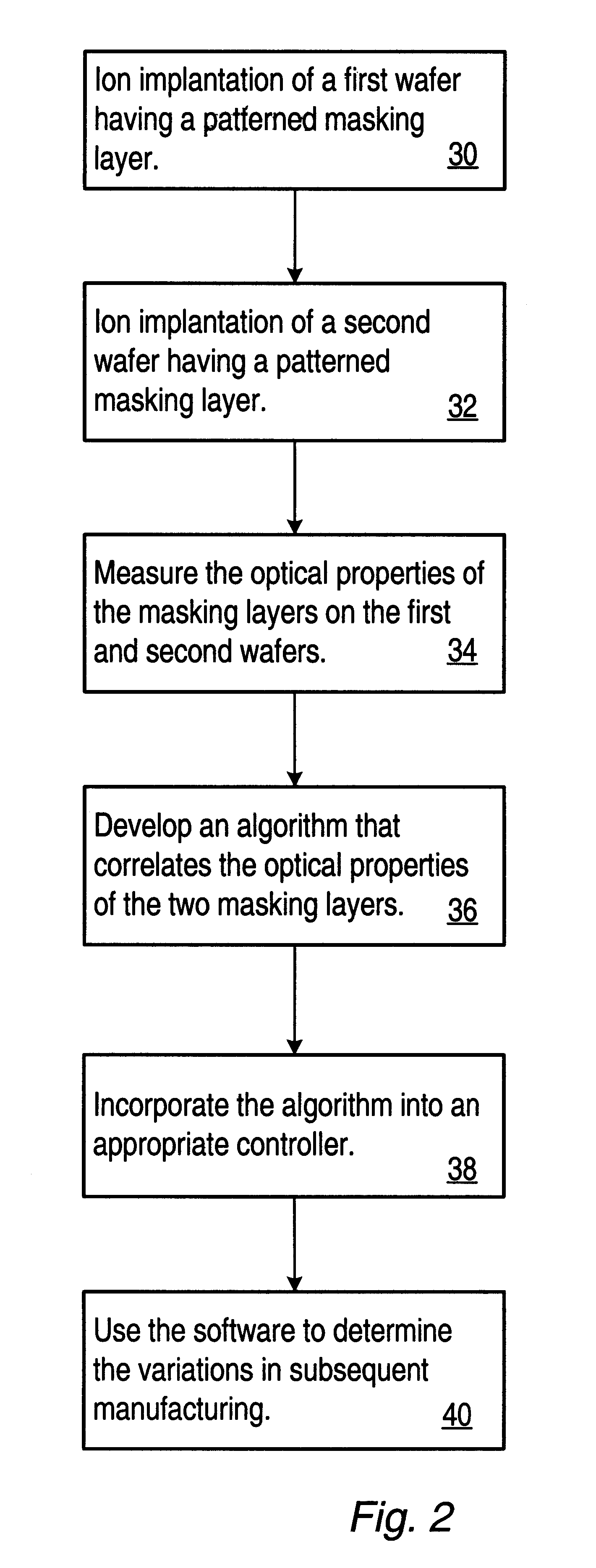

Method of monitoring ion implants by examination of an overlying masking material

InactiveUS6462817B1Semiconductor/solid-state device testing/measurementElectric discharge tubesOptical propertyPhysical change

A process control method to monitor ion implantation process conditions by measuring the optical properties of a masking material is provided. A patterned masking material may protect underlying regions of a semiconductor substrate from undergoing a chemical or physical change during an ion implantation process. The patterned masking material, however, may also undergo a chemical or physical change during processing. The chemical or physical changes to the masking material during such processing may also cause the optical properties of the material to change. The optical properties of the masking material may be used to determine the concentration of ions implanted into the semiconductor substrate.

Owner:KLA TENCOR TECH CORP

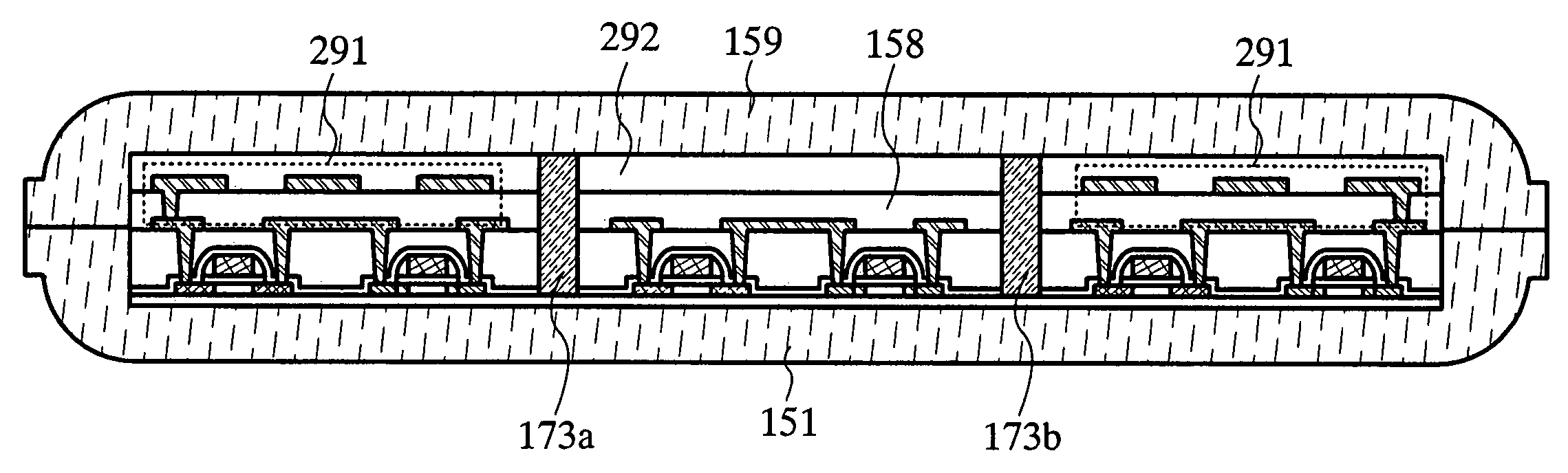

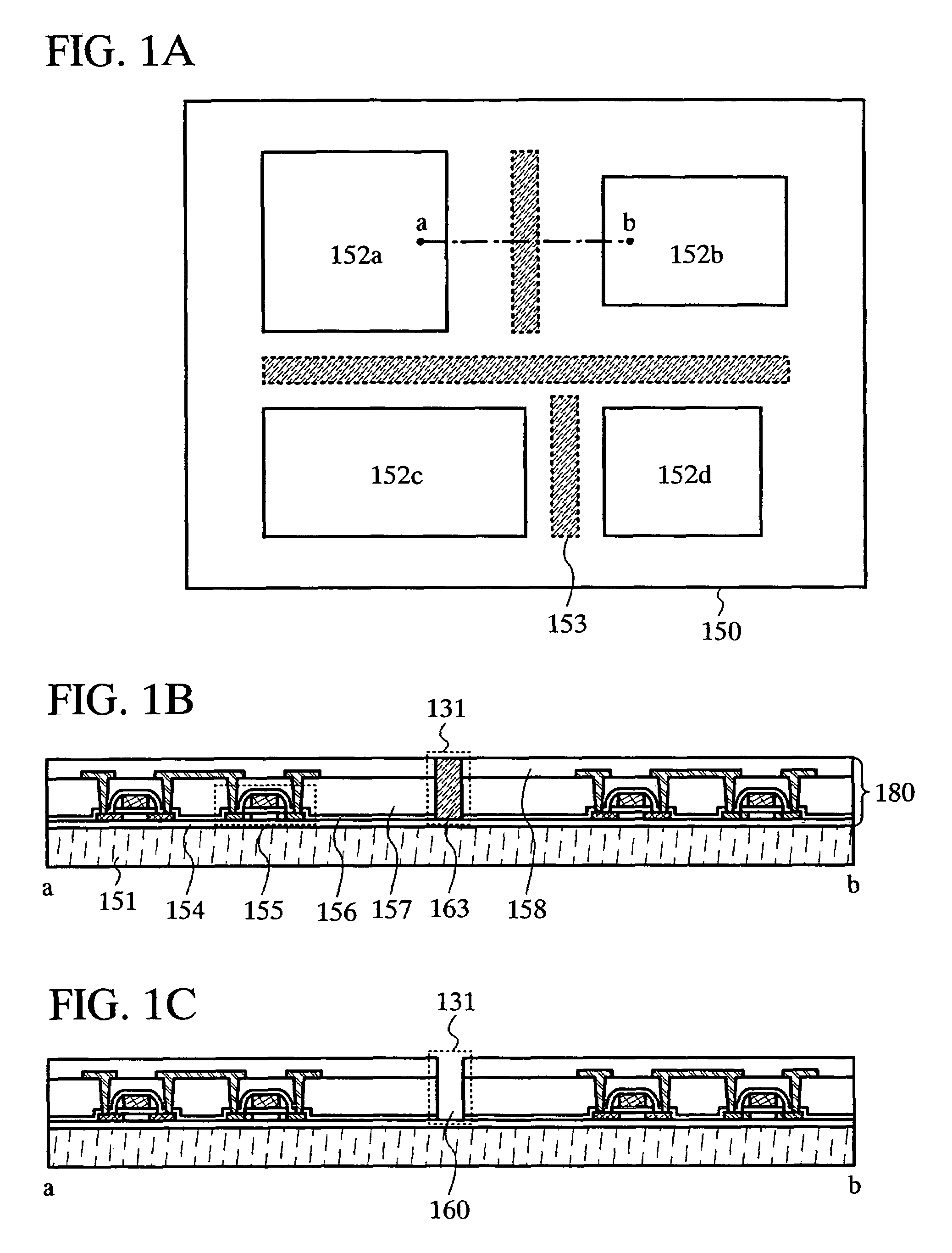

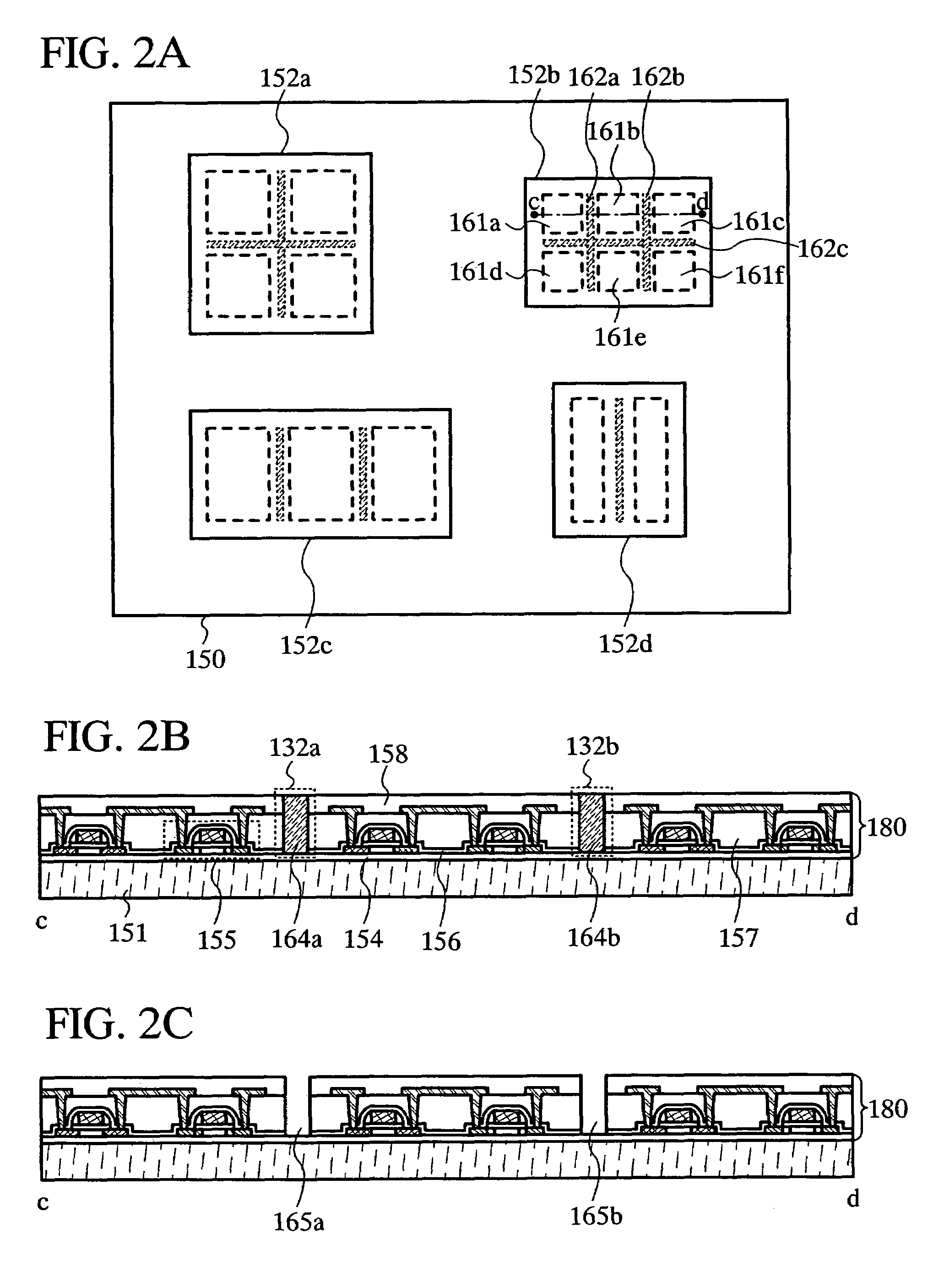

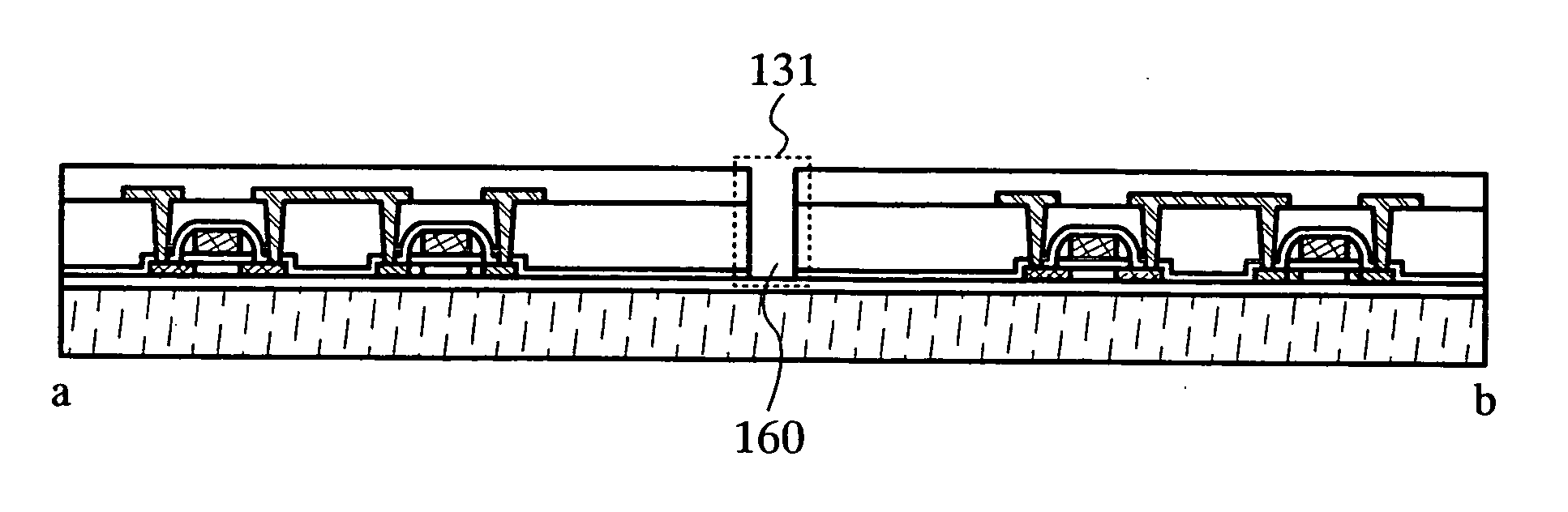

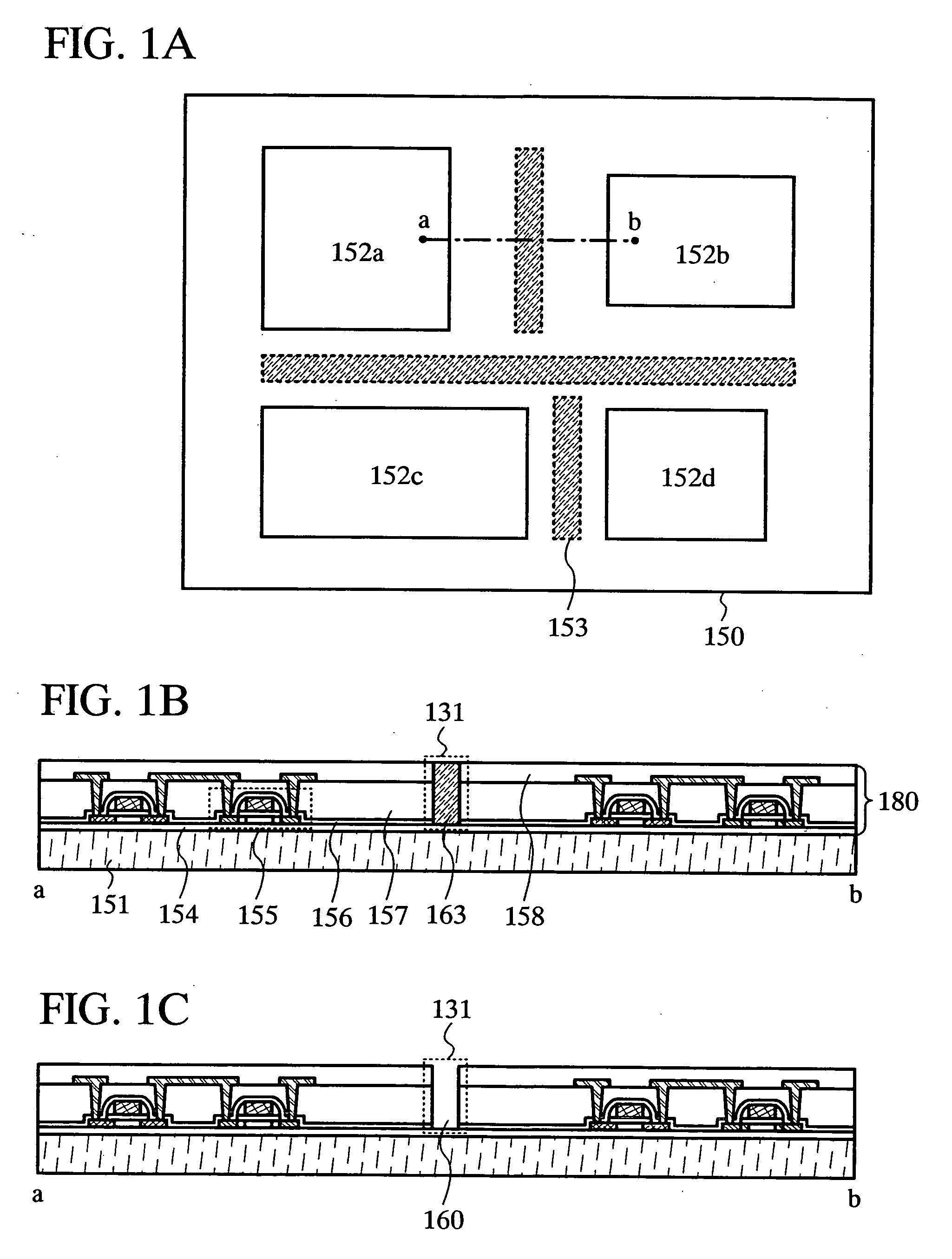

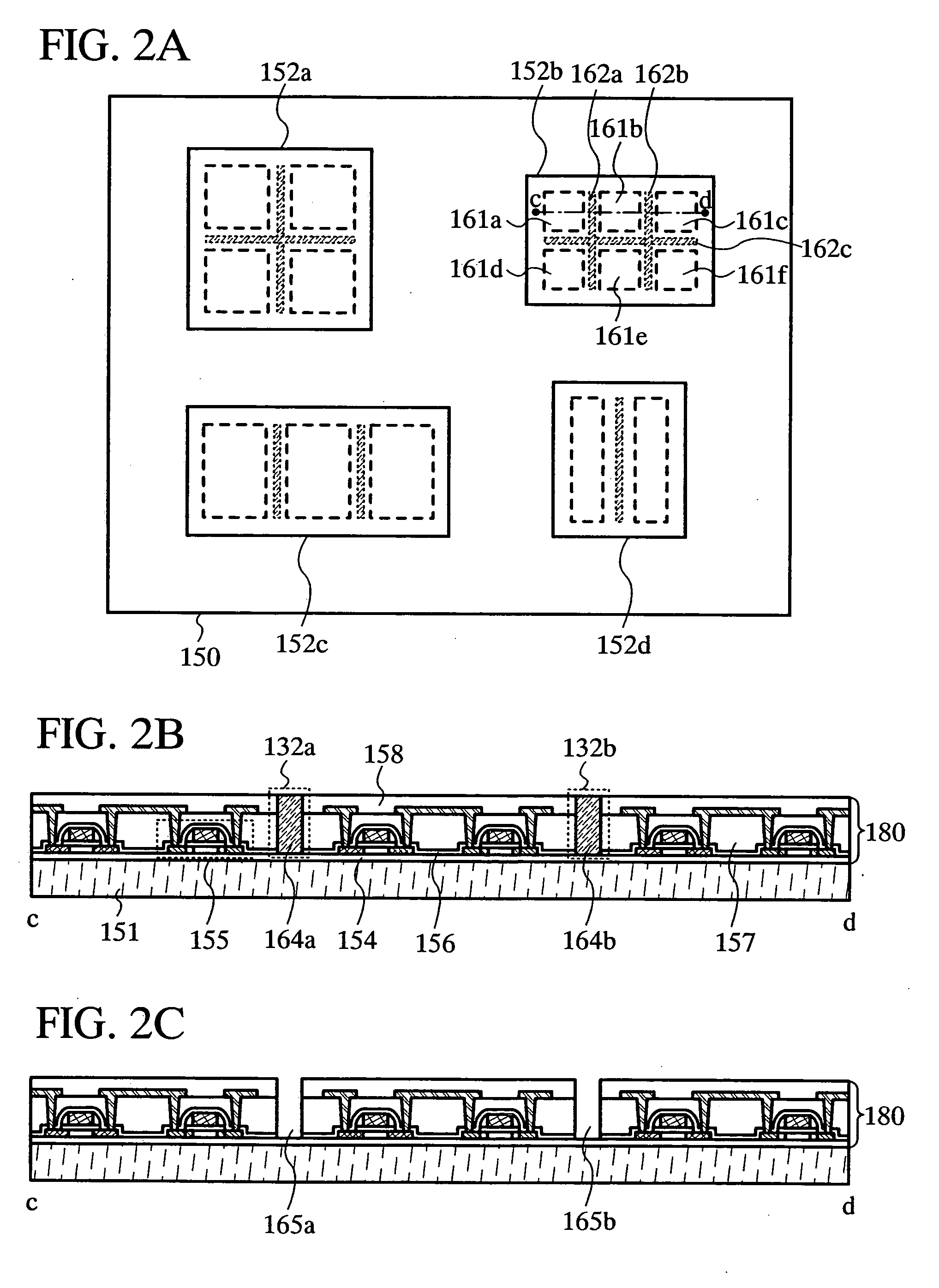

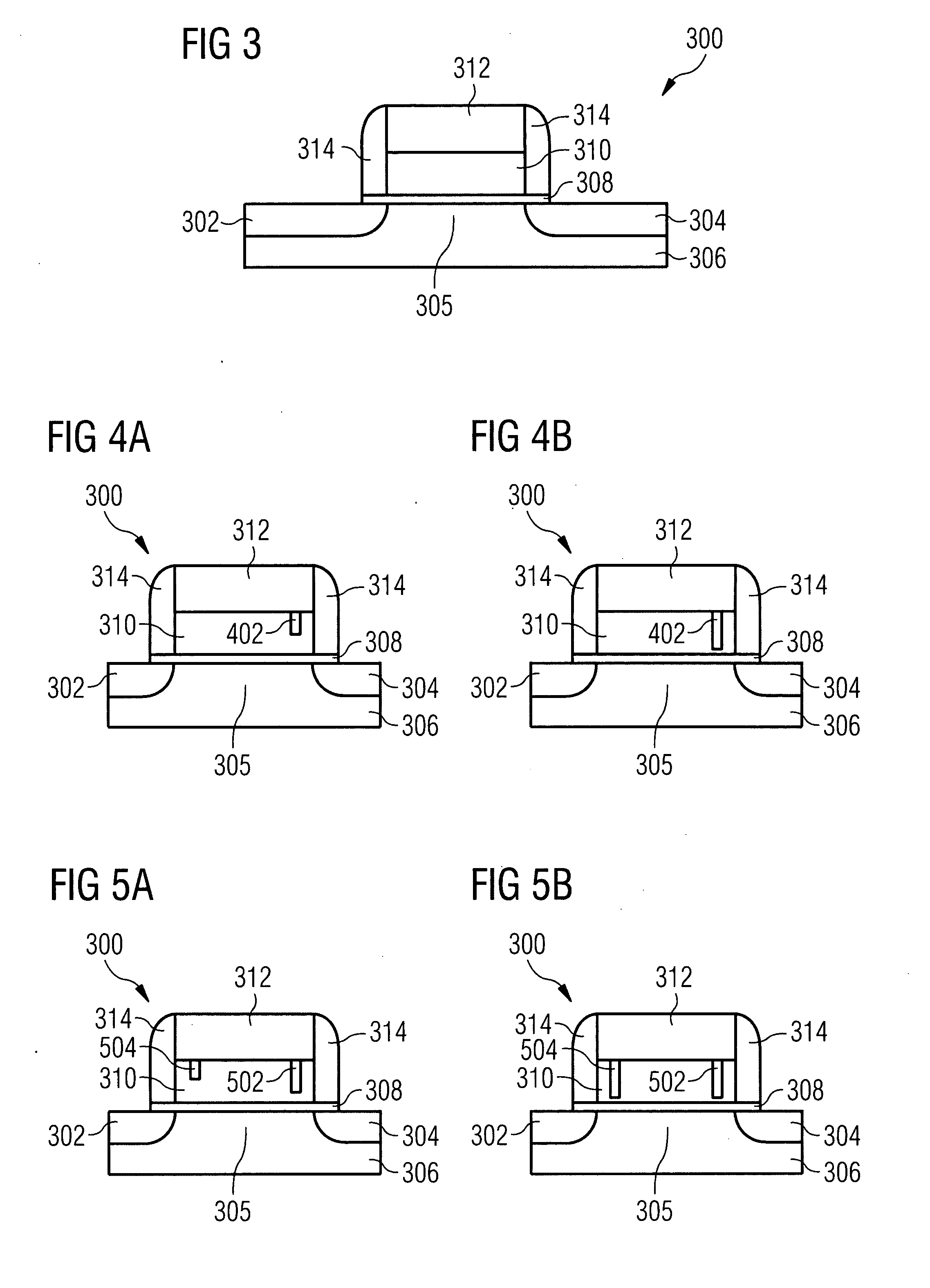

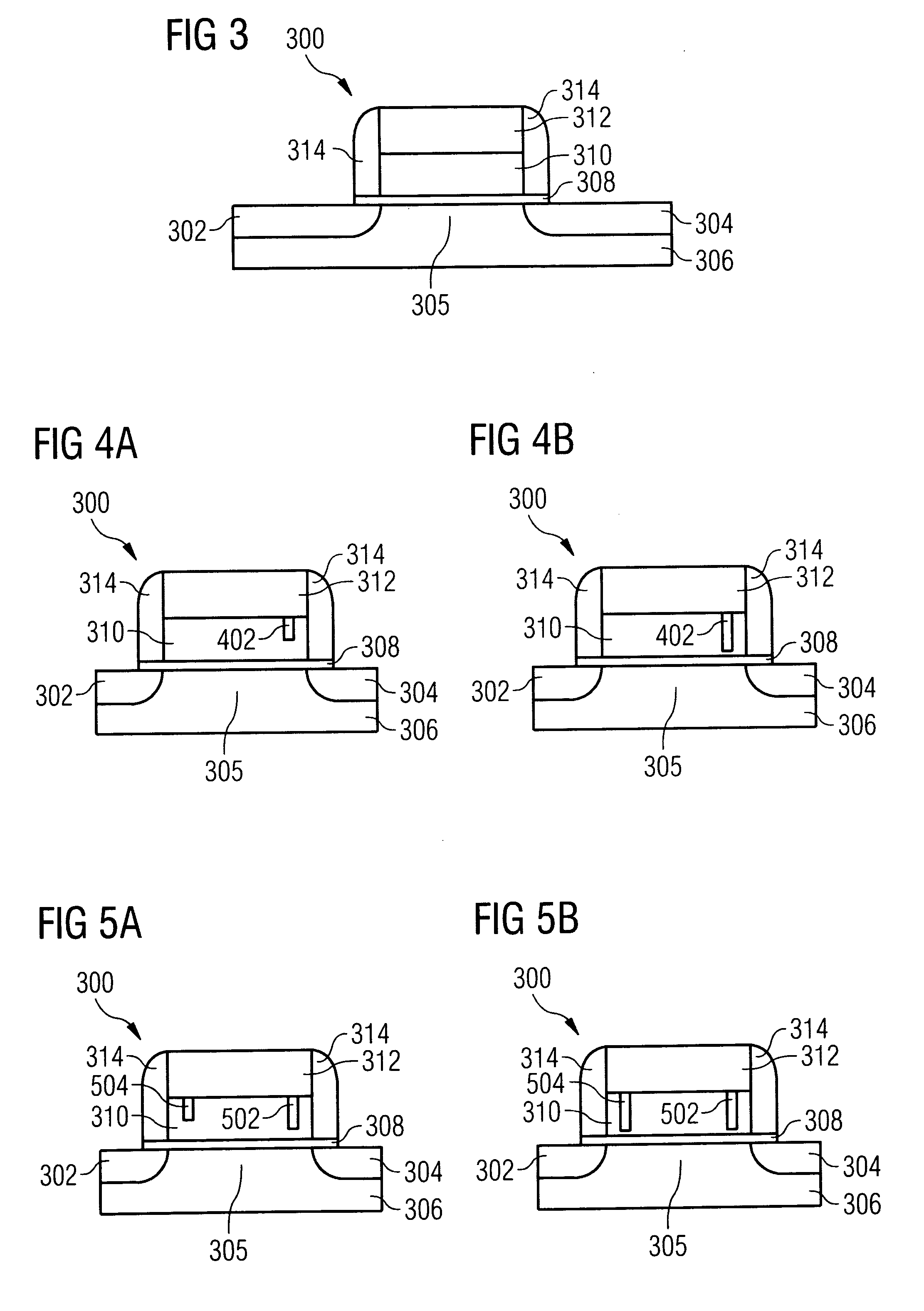

Semiconductor device and method for manufacturing the same

InactiveUS7566633B2Change flexibilityChange resistanceFinal product manufactureSolid-state devicesEngineeringGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

Process for printing images on dark surfaces

InactiveUS20070104899A1Quality improvementImprove adhesionDuplicating/marking methodsTransfer printing processColor imageFiber

Novel processes for printing high quality, high resolution, multi-color images on darkly colored fibrous or porous materials or other ink absorbing materials, is disclosed. The processes are effected by digitally printing a layer of an opaque, lightly colored ink composition, followed by digitally printing the colored image thereon, and optionally further involve applying a wetting composition prior to and / or subsequent to these printings. Processes utilizing wetting compositions and / or liquid ink compositions which can interact therebetween so as to effect a chemical and / or physical change in one or more of these compositions are further disclosed.

Owner:KORNIT DIGITAL LTD

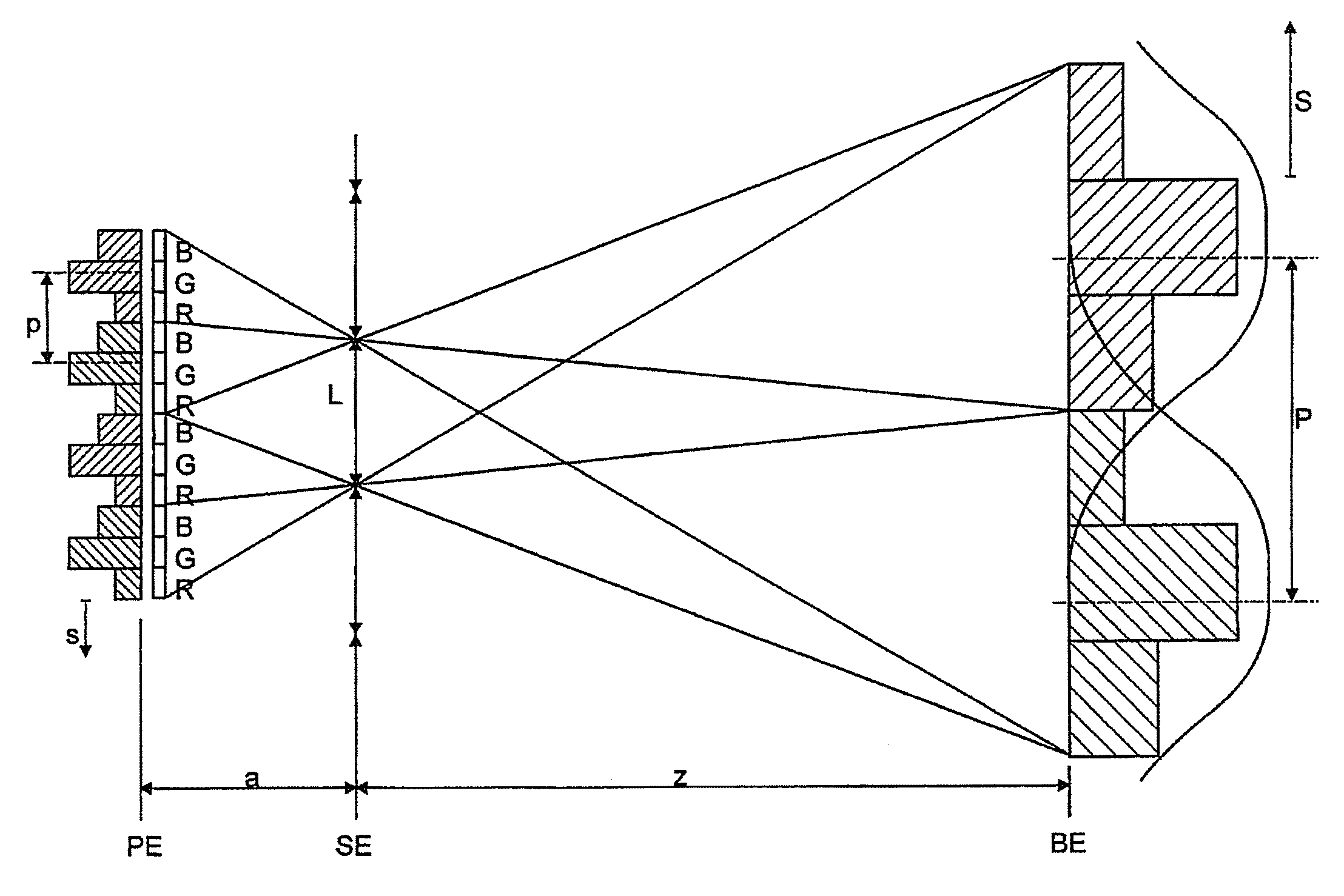

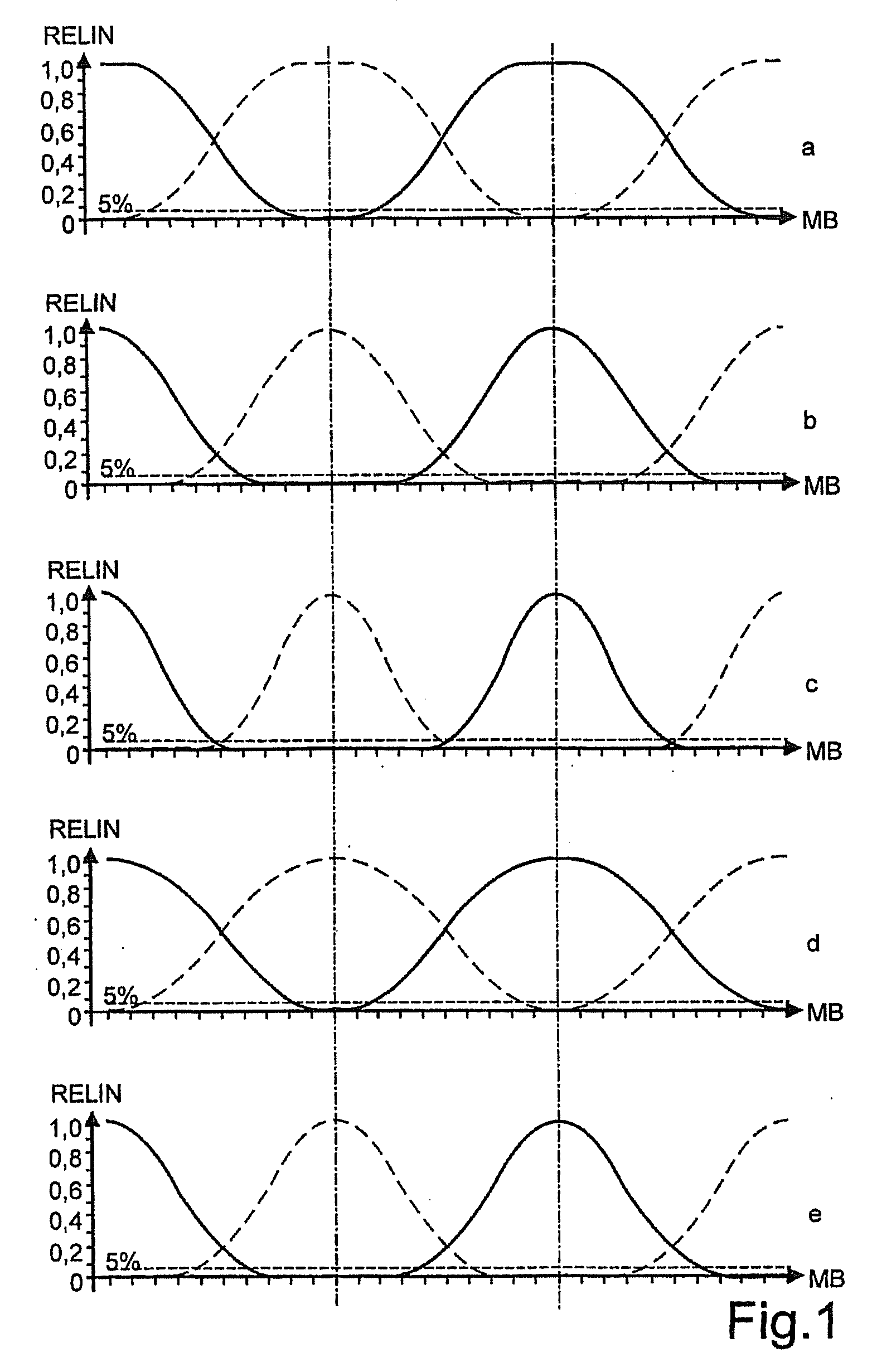

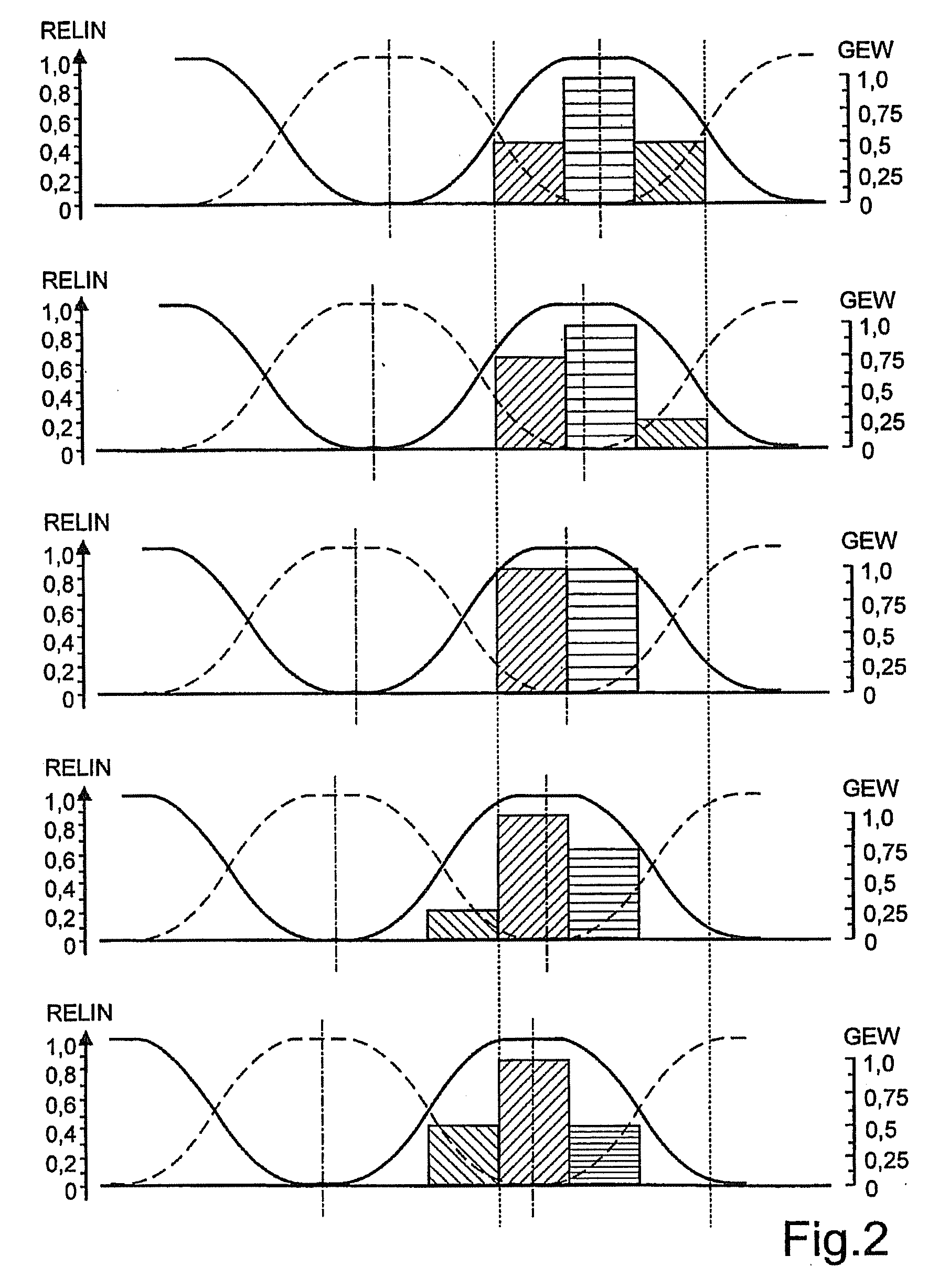

Method For The Autostereoscopic Presentation Of Image Information With Adaptation To Suit Changes In The Head Position Of The Observer

ActiveUS20090123030A1Improve image qualityCharacter and pattern recognitionSteroscopic systemsPhysical changeVariable intensity

For continuous tracking without noticeable skips during physical changes in head position, the intensities of all subpixels of the matrix screen are reduced in order to form intensity focuses for subpixel groups behind barrier elements, which comprise a number n of subpixels, including a subpixel reserve, in the image lines. In the case of parallel alterations, these intensity focuses are then displaced by a constant absolute value continuously through directly adjacent subpixels and also through subpixel group boundaries with different stereo image views. Distance changes involve the intensity focuses being increasingly widened or compressed relative to the screen edges. The intensities of the individual subpixels can be altered by means of simple multiplication by standardized constant or variable intensity factors which can be ascertained as a function of motion.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Semiconductor device and method for manufacturing the same

InactiveUS20060202206A1Less forceReduce stress exertedFinal product manufactureSolid-state devicesDevice materialGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

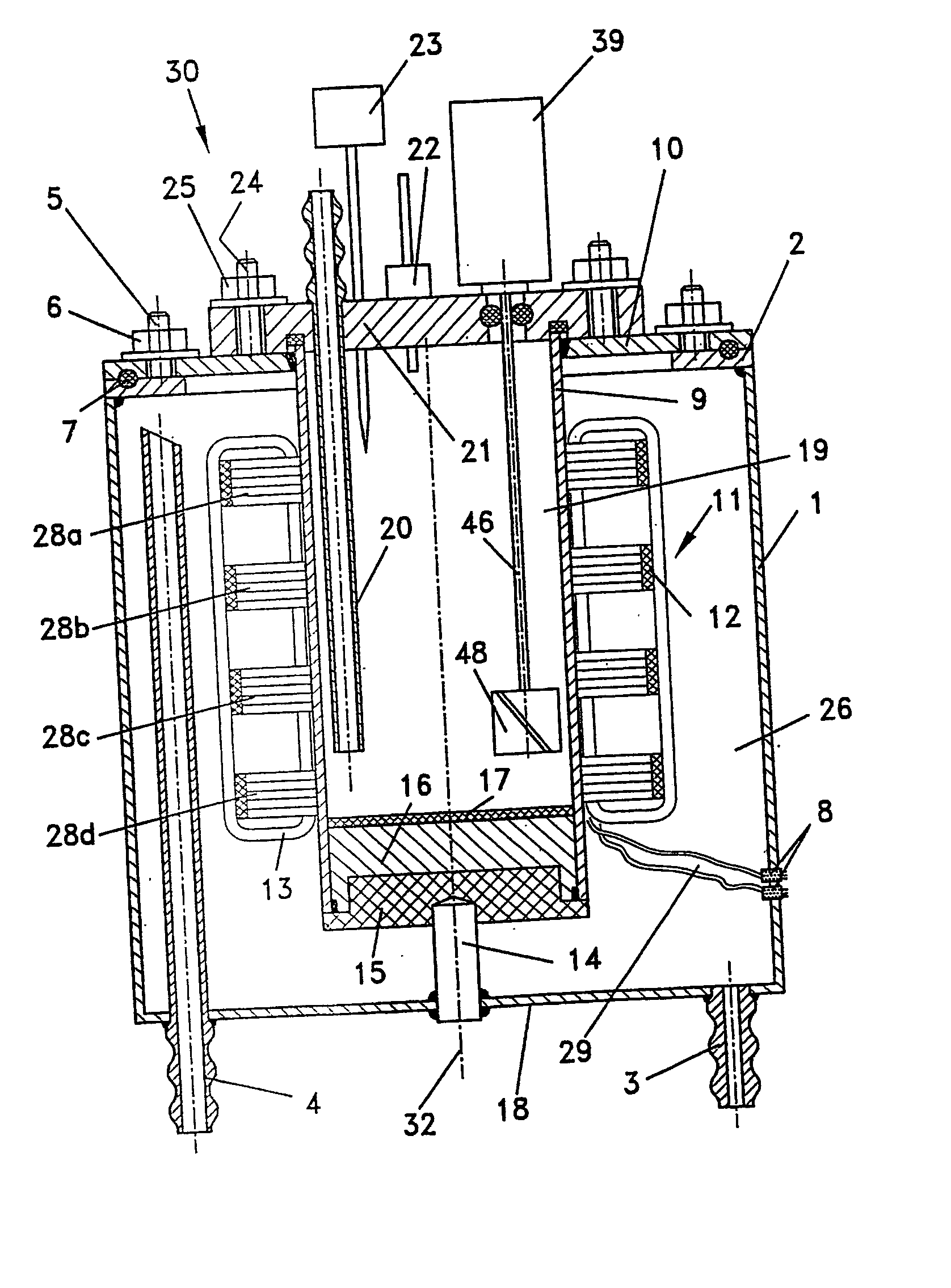

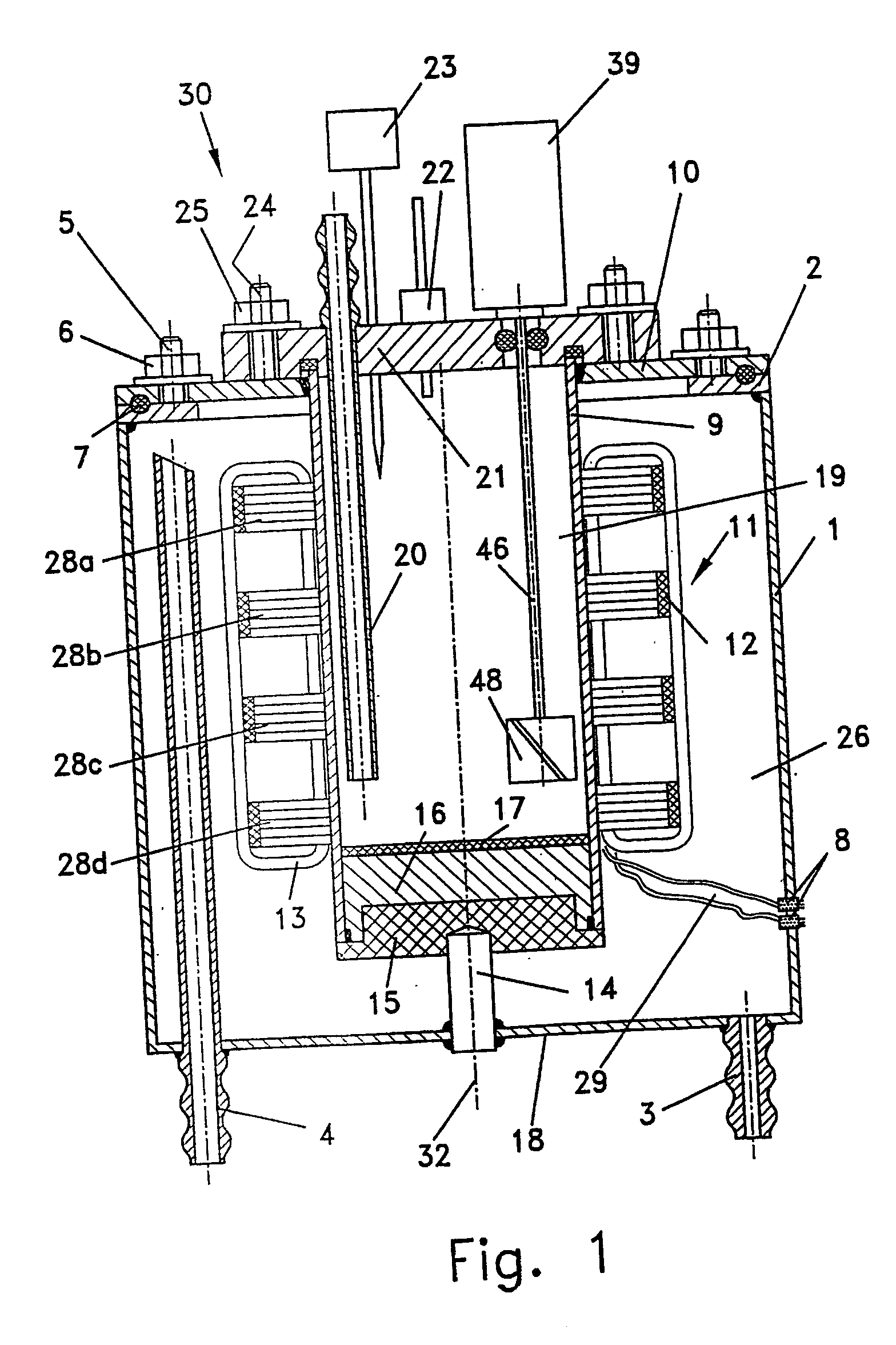

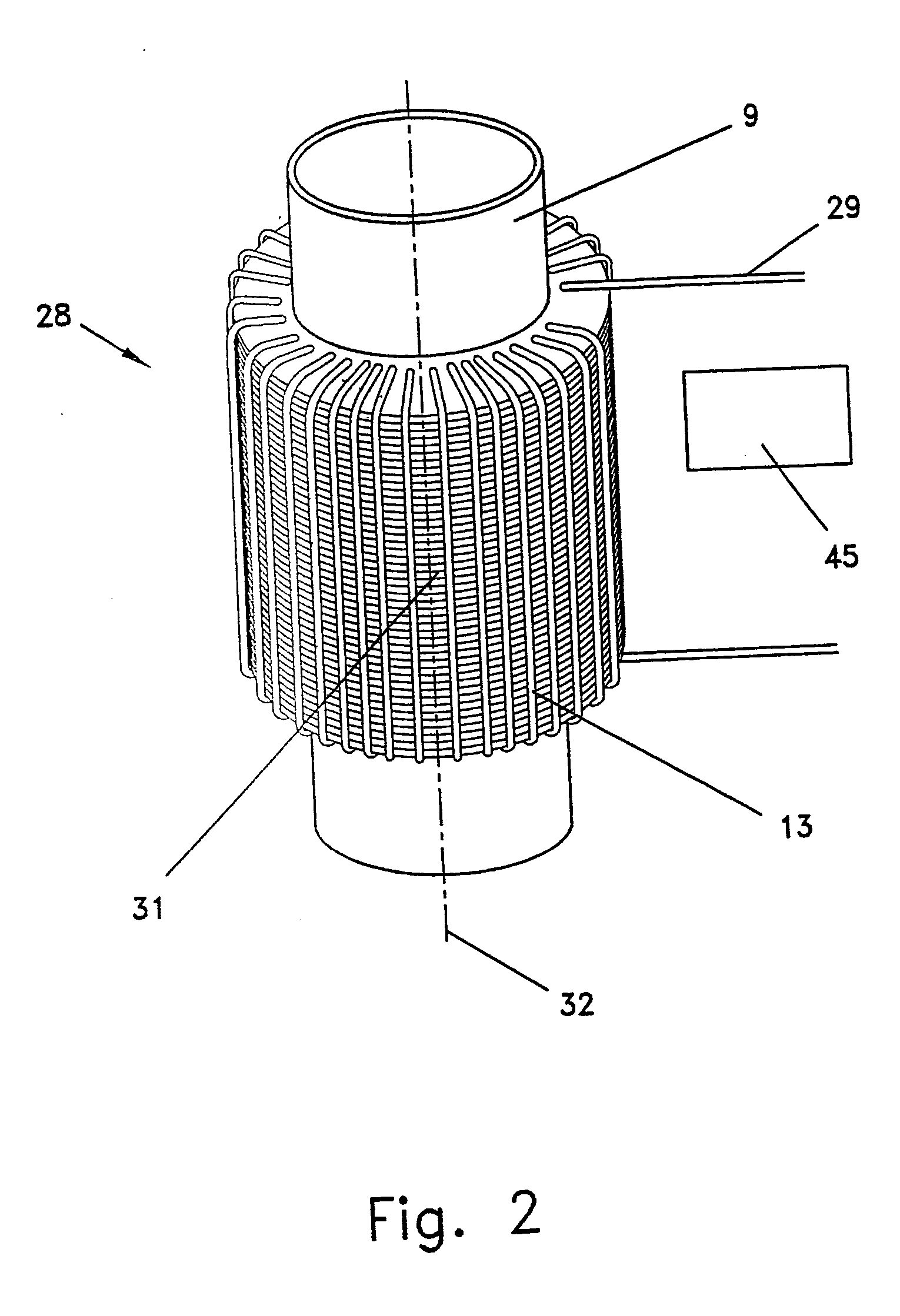

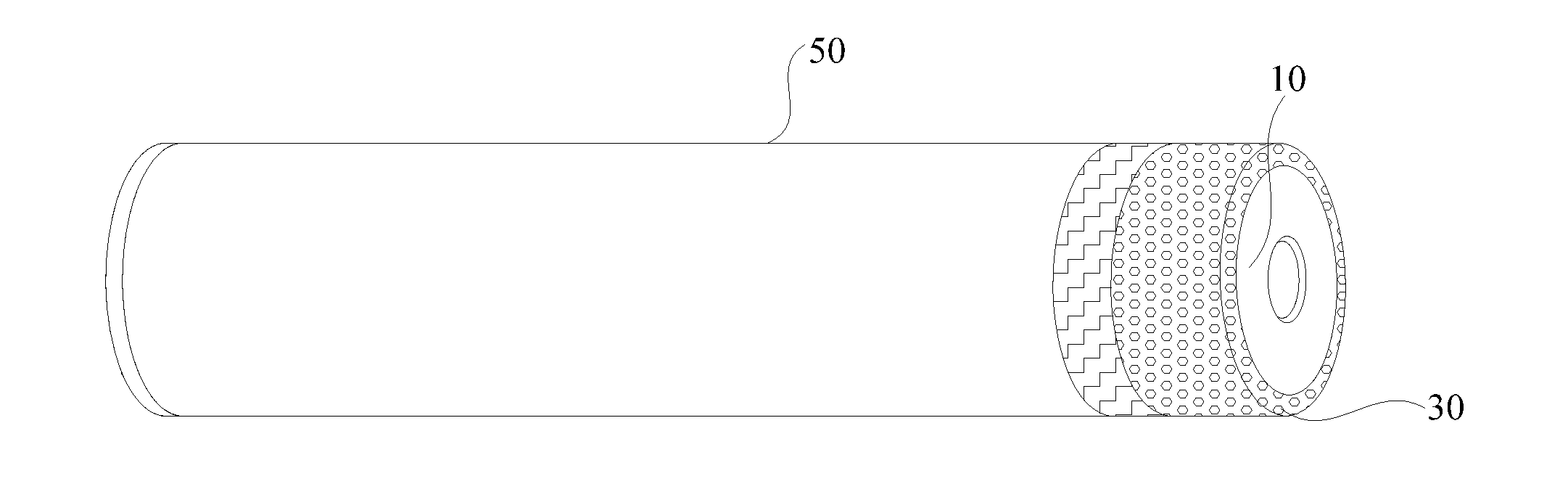

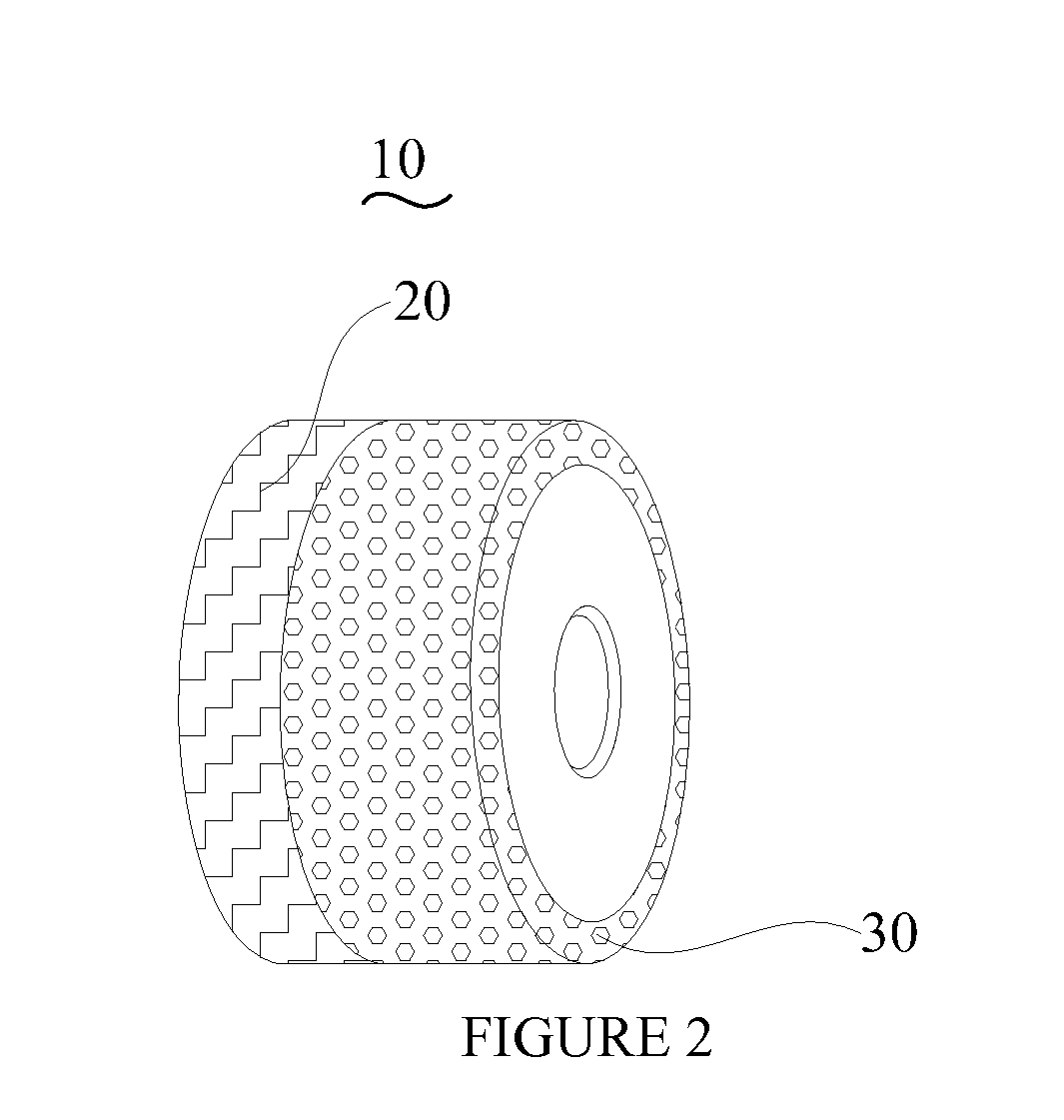

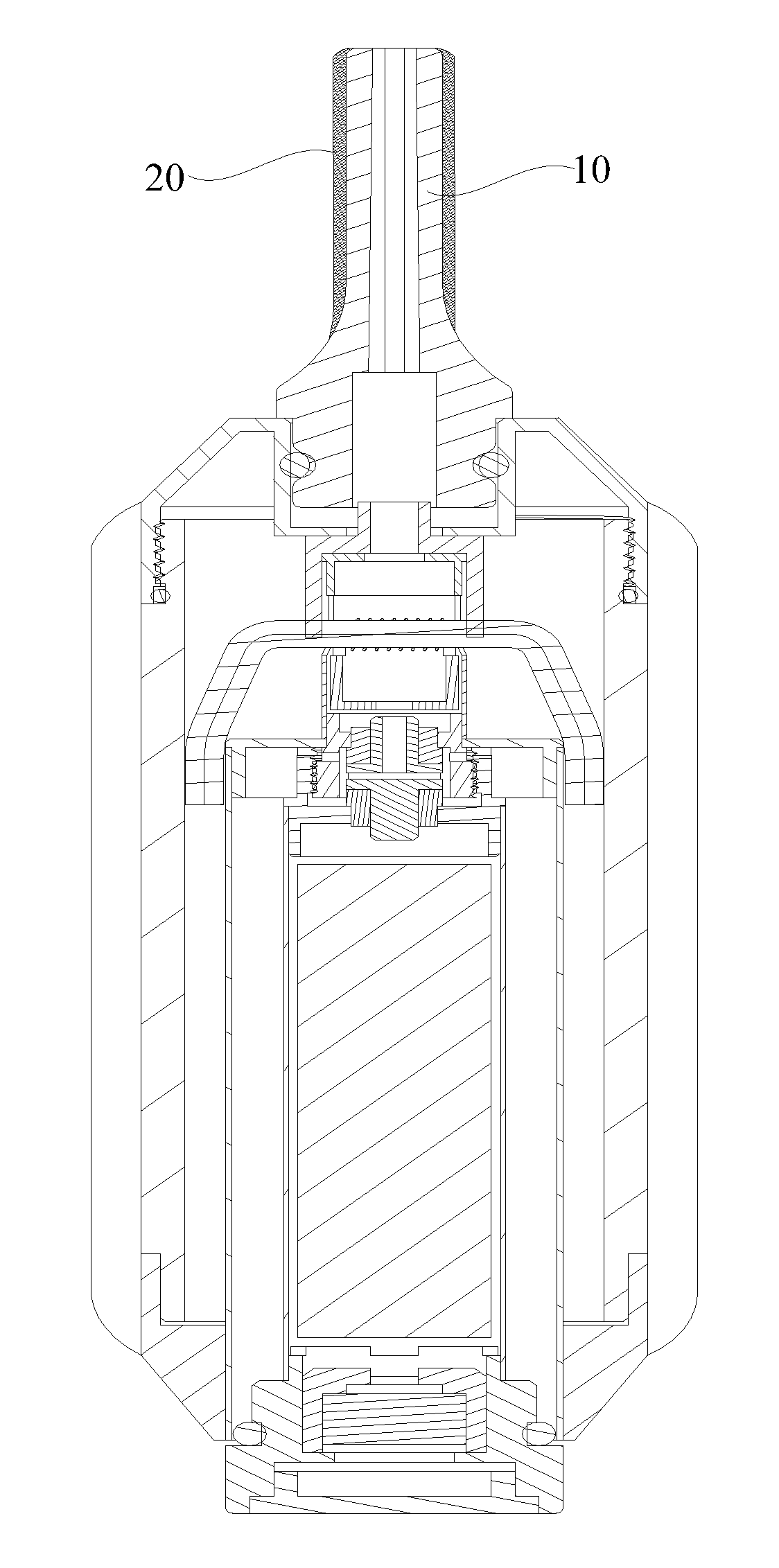

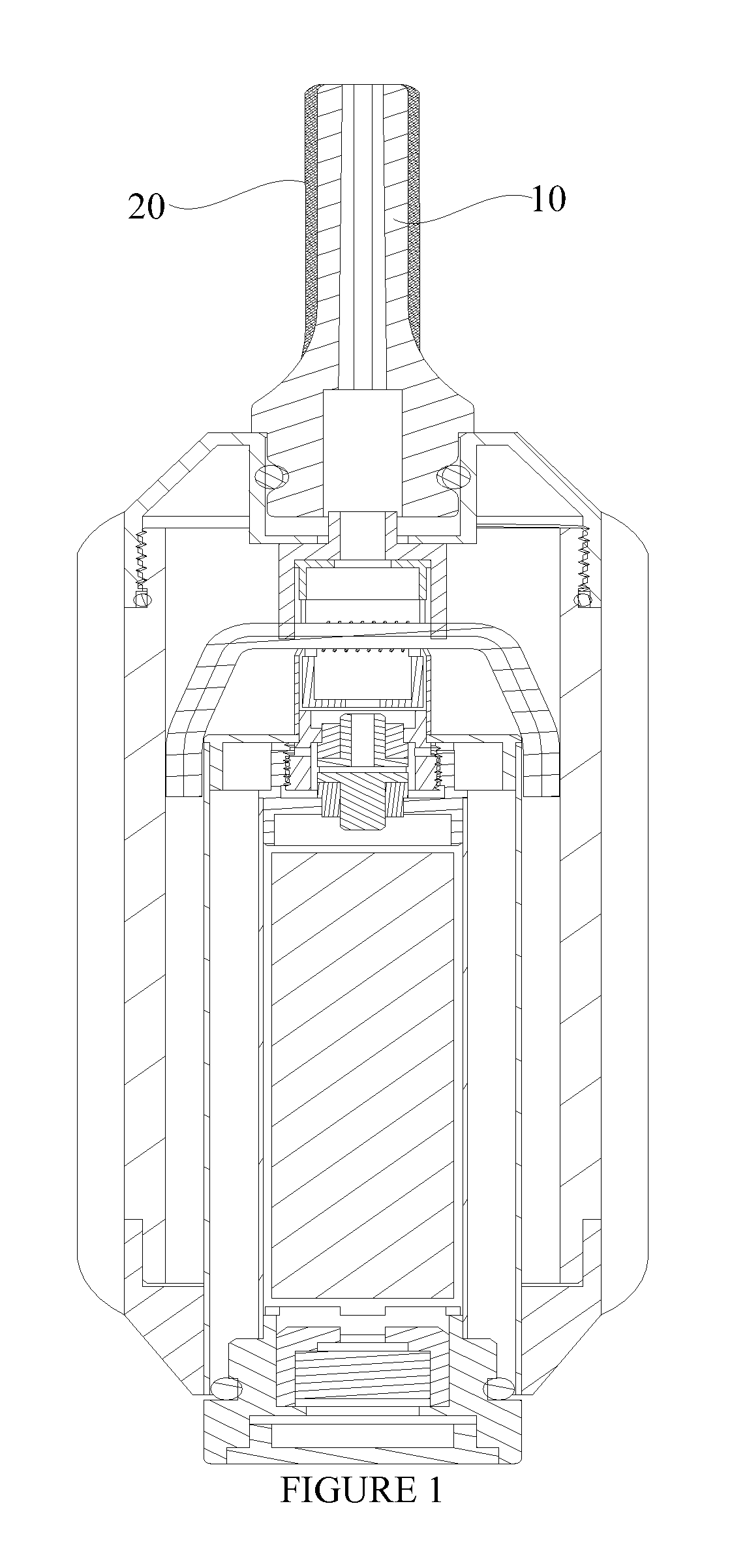

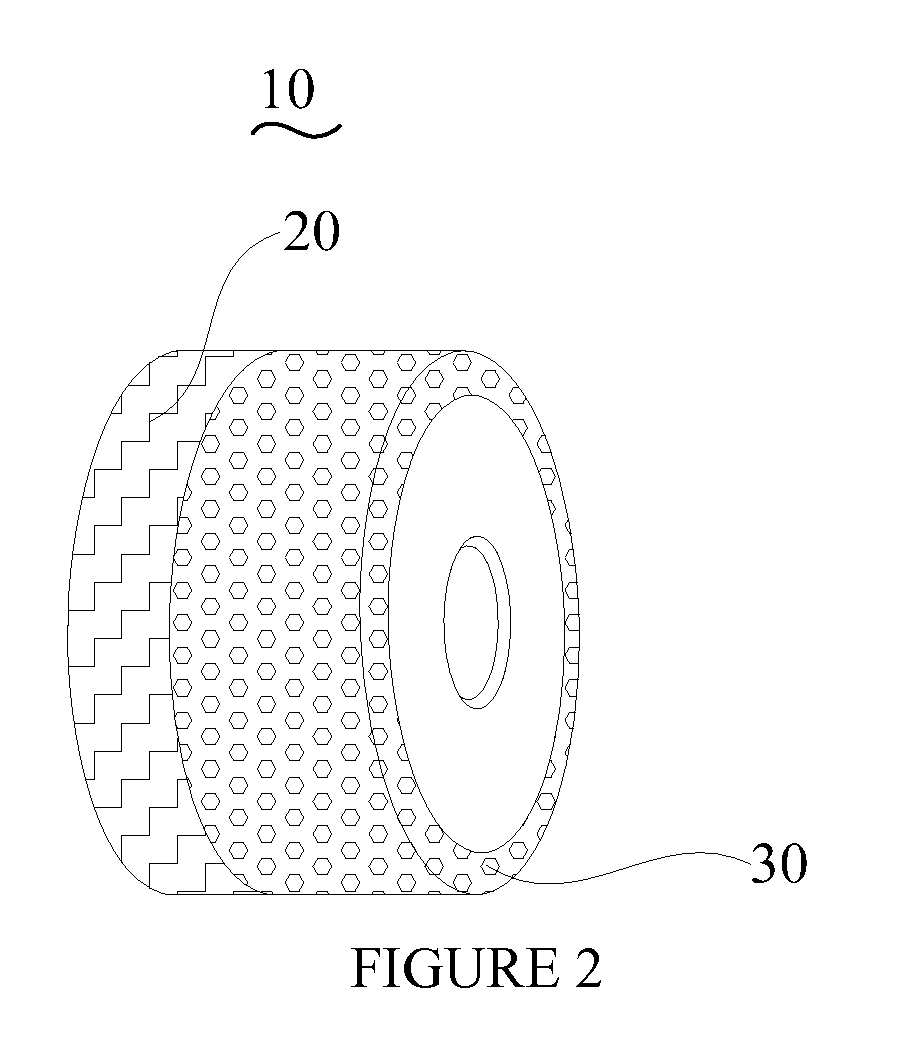

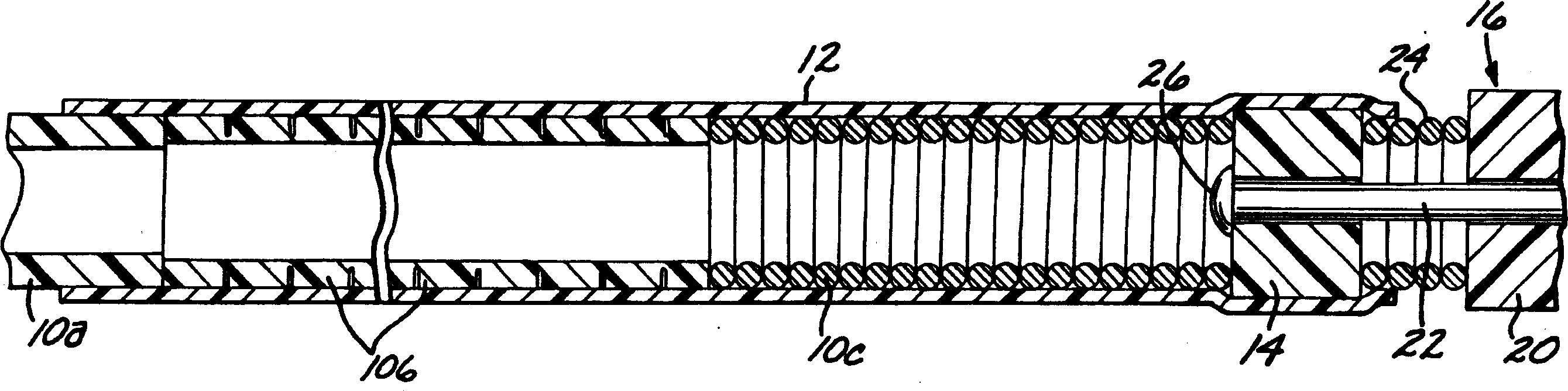

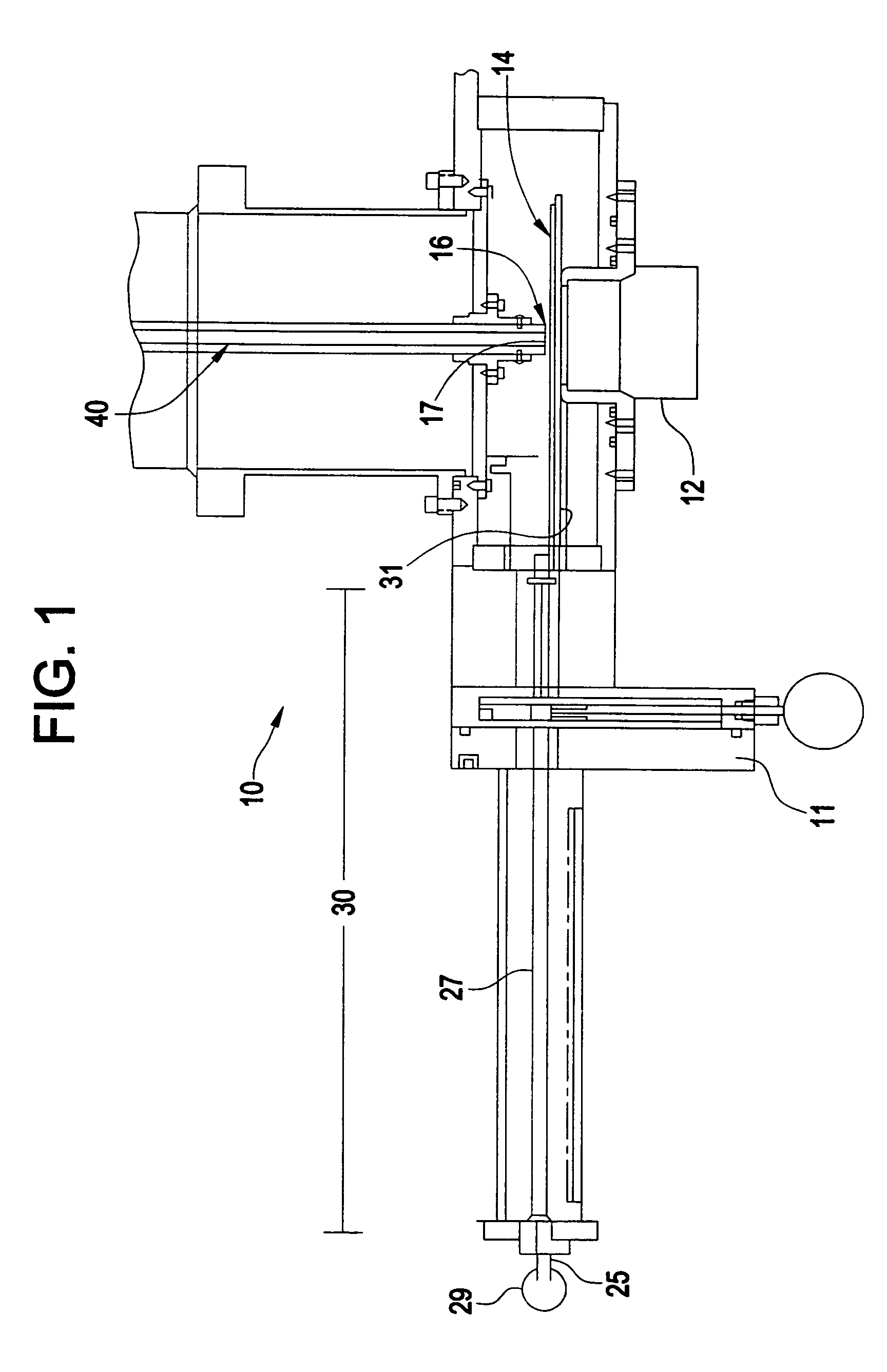

Ultrasonic reactor and process for ultrasonic treatment of materials

InactiveUS20050260106A1Shaking/oscillating/vibrating mixersTransportation and packagingCavitationTransducer

An ultrasound reactor (30) having a reactor body (1), a reactor tube (9) disposed within the reactor body and a magnetostrictor transducer (11) comprising at least one annular element (28a-d) concentric with, and mounted to an external wall of said tube and a process for ultrasonic treatment of a reaction material are disclosed. The transducer is mounted on the reactor tube in such a way so as to transmit ultrasound radiation to the interior of the tube and to induce an upwardly flowing cavitation stream whose longitudinal axis substantially coincides with a longitudinal axis of said tube, causing physical changes to the reaction material.

Owner:NANO SIZE

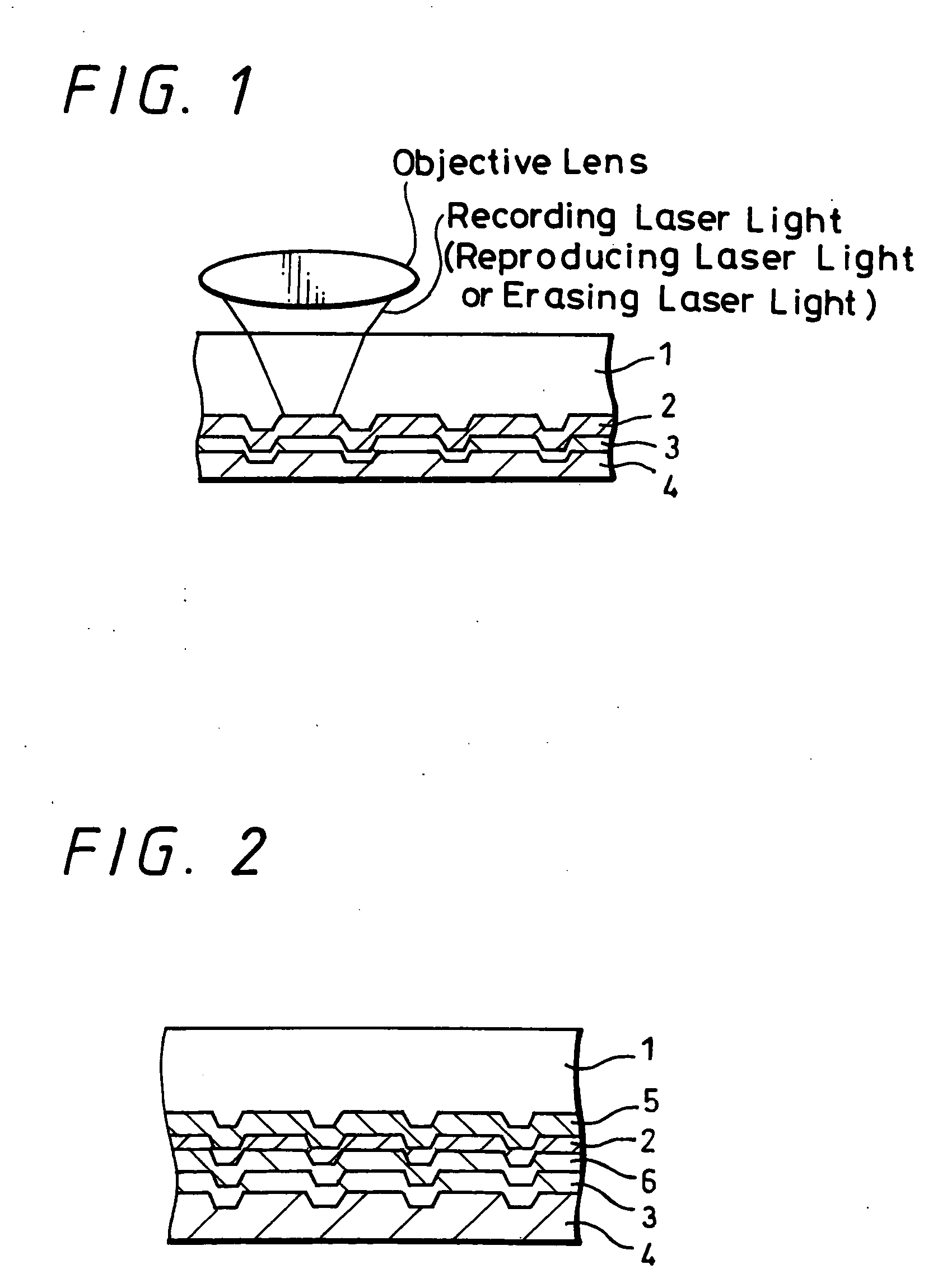

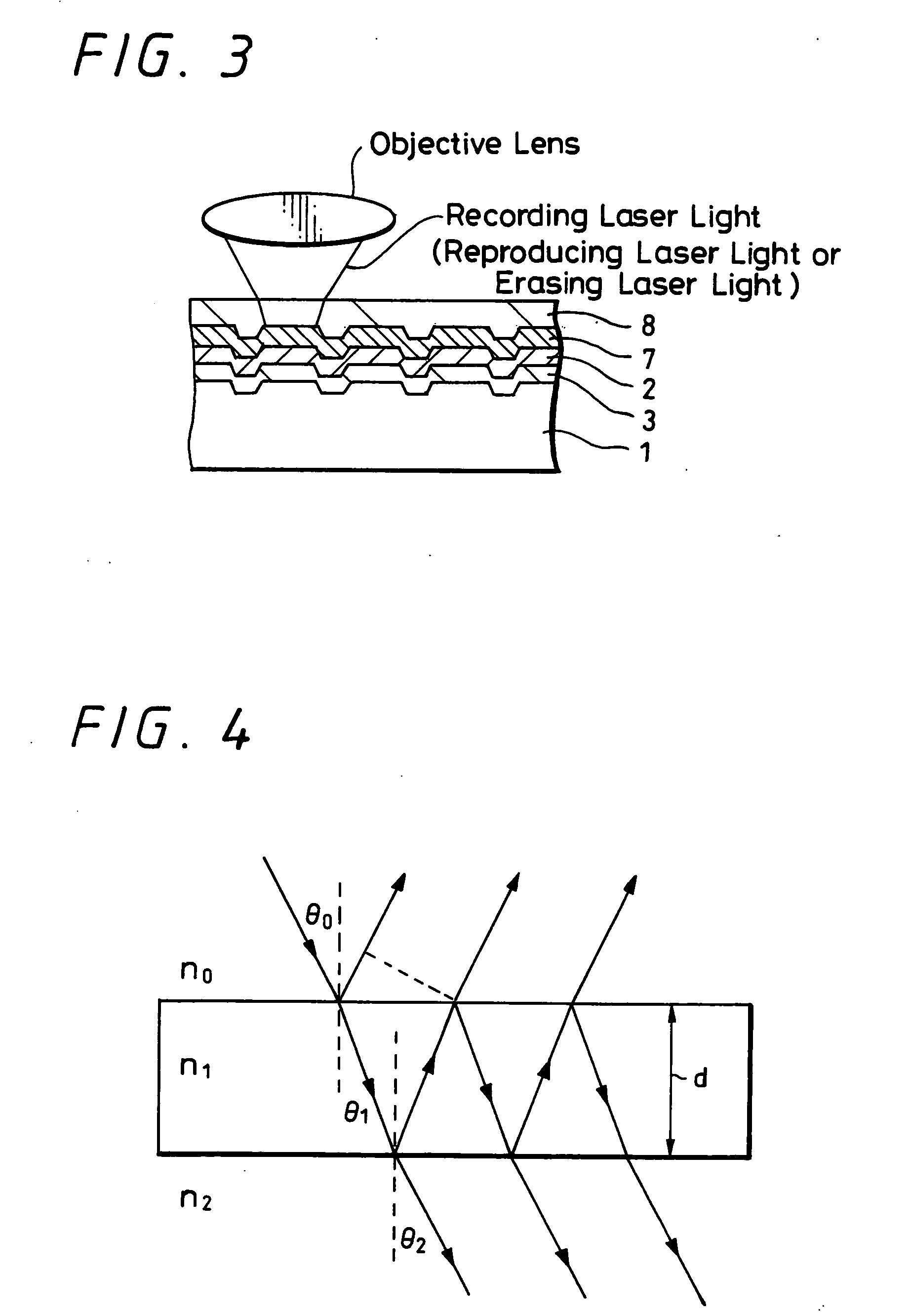

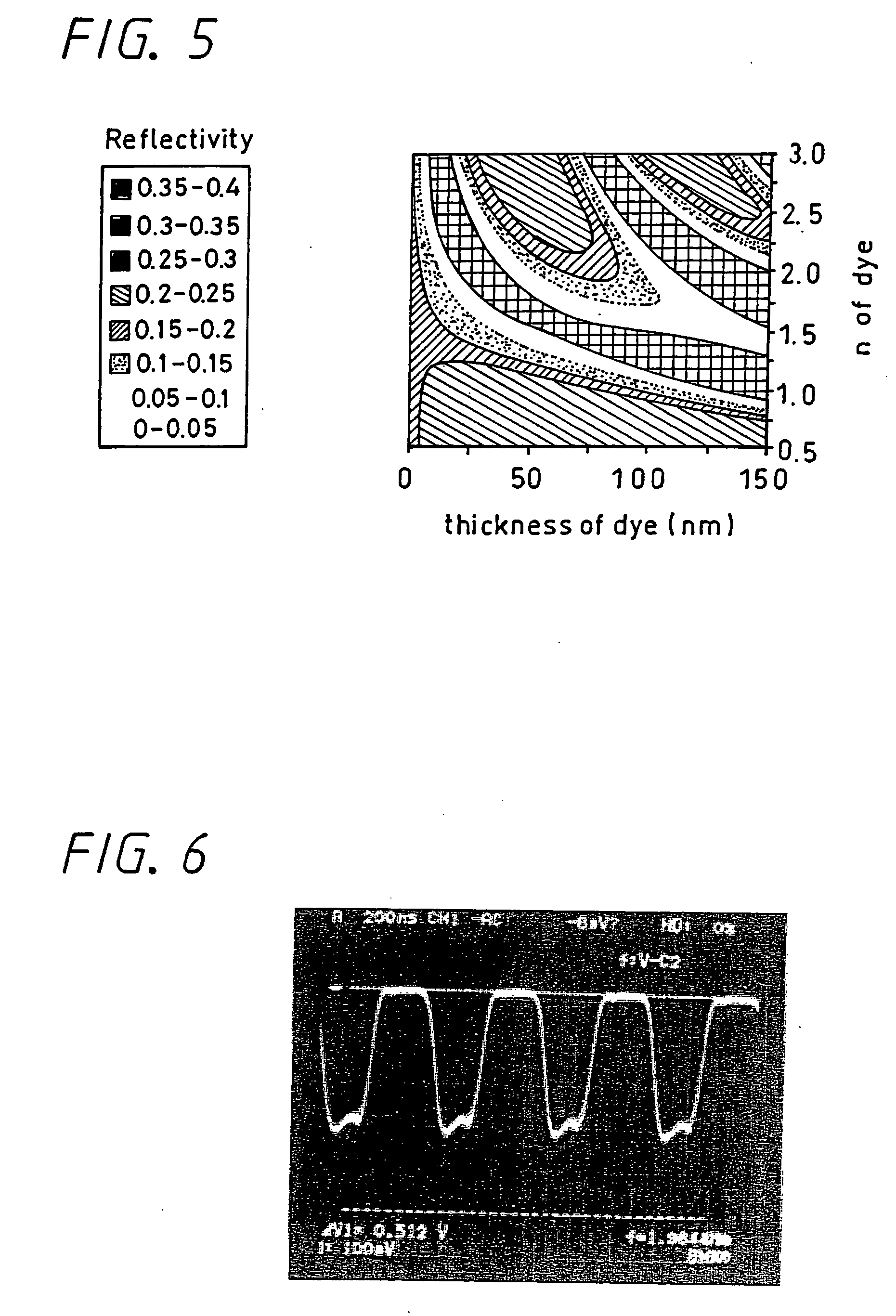

Rewritable optical information recording medium, recording and reproducing methods, as well as recording and reproducing apparatus

InactiveUS20060088786A1More powerLess powerOrganic chemistryReactive dyesContinuous lightOrganic dye

A rewritable optical information recording medium including a recording layer composed of an organic dye film is provided, in which recording and erasing information can be performed reversibly by laser light irradiation. A rewritable optical information recording medium including at least one organic dye film which is substantially made of only at least one kind of organic dye compounds as a recording film is provided. The recording and erasure of information are performed by a reversible physical change of the organic dye film substance caused by laser light irradiation. Specifically, data recording is performed by a physical change locally caused by the irradiation of recording laser light, data reproduction is performed by detecting change in intensity of returned light of reproducing laser light having less power than the recording laser light, and data erasure is performed by applying at least once continuous light or pulse light having laser power more than the reproducing laser light and less than the recording laser light. The physical change is a change in shape.

Owner:SONY CORP +1

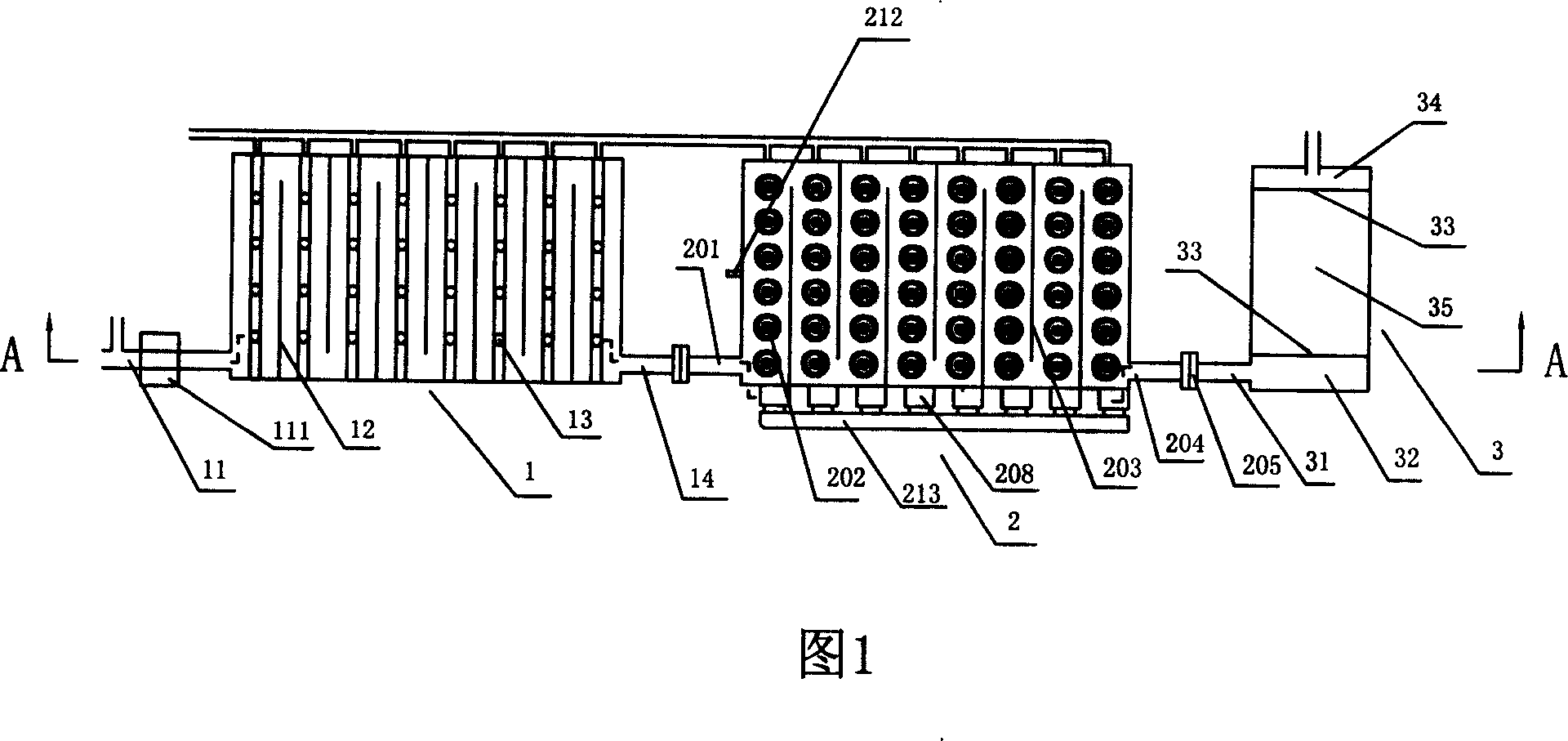

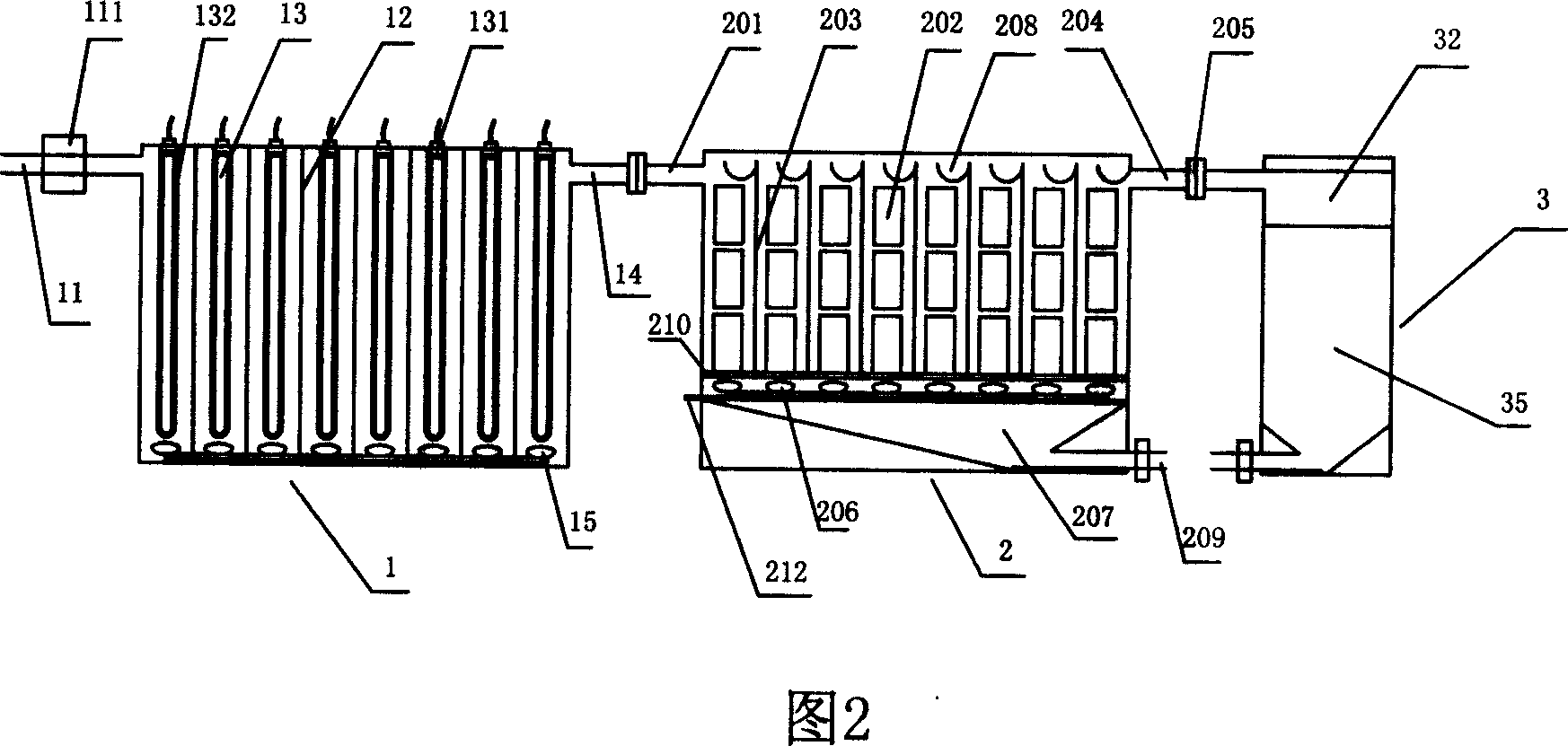

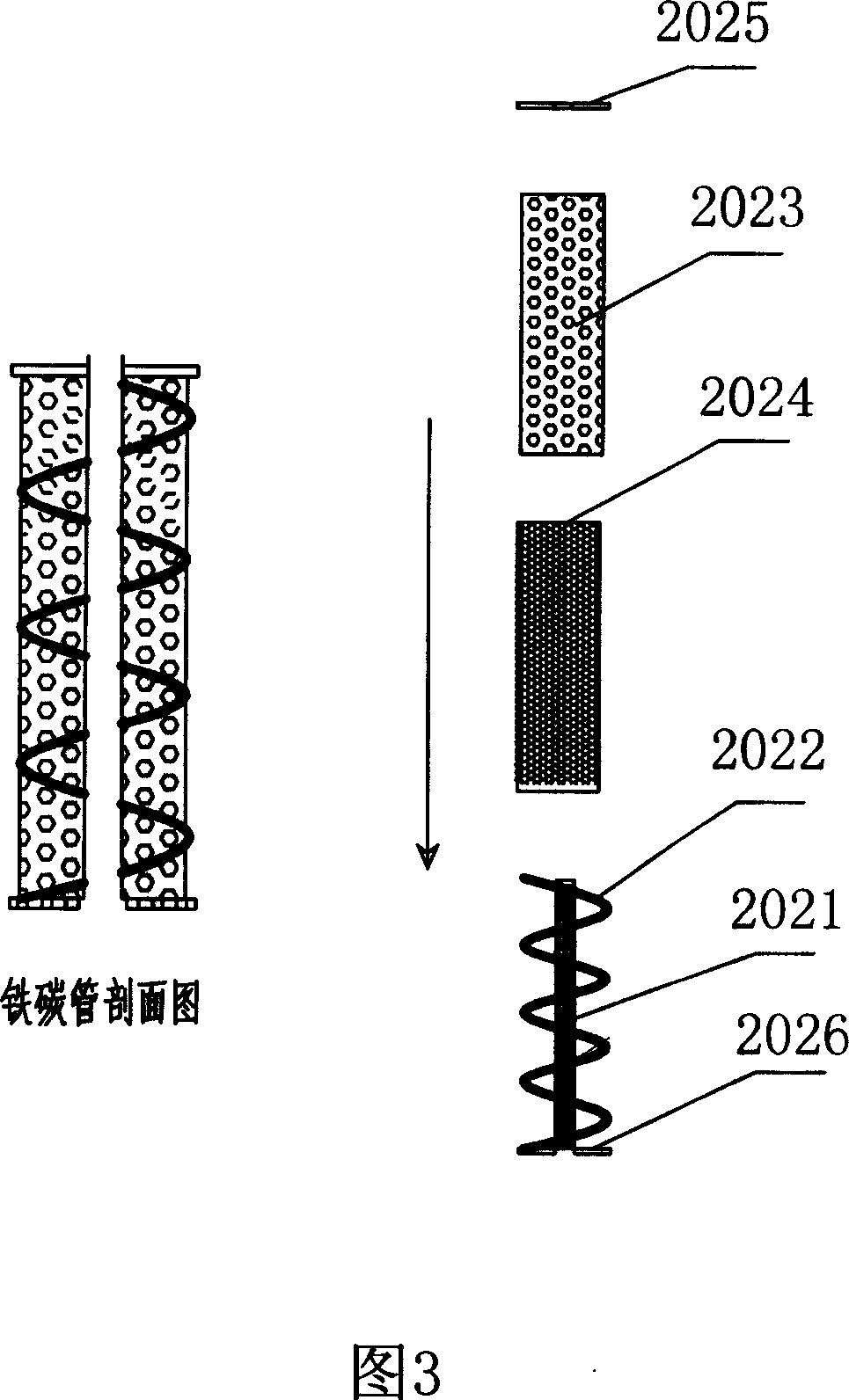

Photoelectromagnetism integrated waste water advanced oxidization method and device thereof

ActiveCN101033105AWide applicabilityGood processing effectWater/sewage treatment by irradiationWater contaminantsUltraviolet lightsWeak current

This invention relates to a photoelectromagnetic integrated advanced oxidation method and its device for waste water, which first of all acidizes the waste water, then strongly magnetizes it to generate energy of physical change and chemical change then enters into a photo-catalyzing box to be oxidated mostly to CO2 and water under the actioin of photo-catalyst, ultraviolet light, ozone and oxydol, in which, molecular chains of some hard-degradated substances are broken, then the waste water is micro-electrolysed to adsorb and recover the hard degraded substances under the action of extra low voltage, weak current and air, ozone and oxydol to get rid of COD, color degree, deodorizatin and disinfectant finall to filter it by diatomite and filter out suspending substances to reach the standard or recover it.

Owner:深圳市华旭半导体科技有限公司 +1

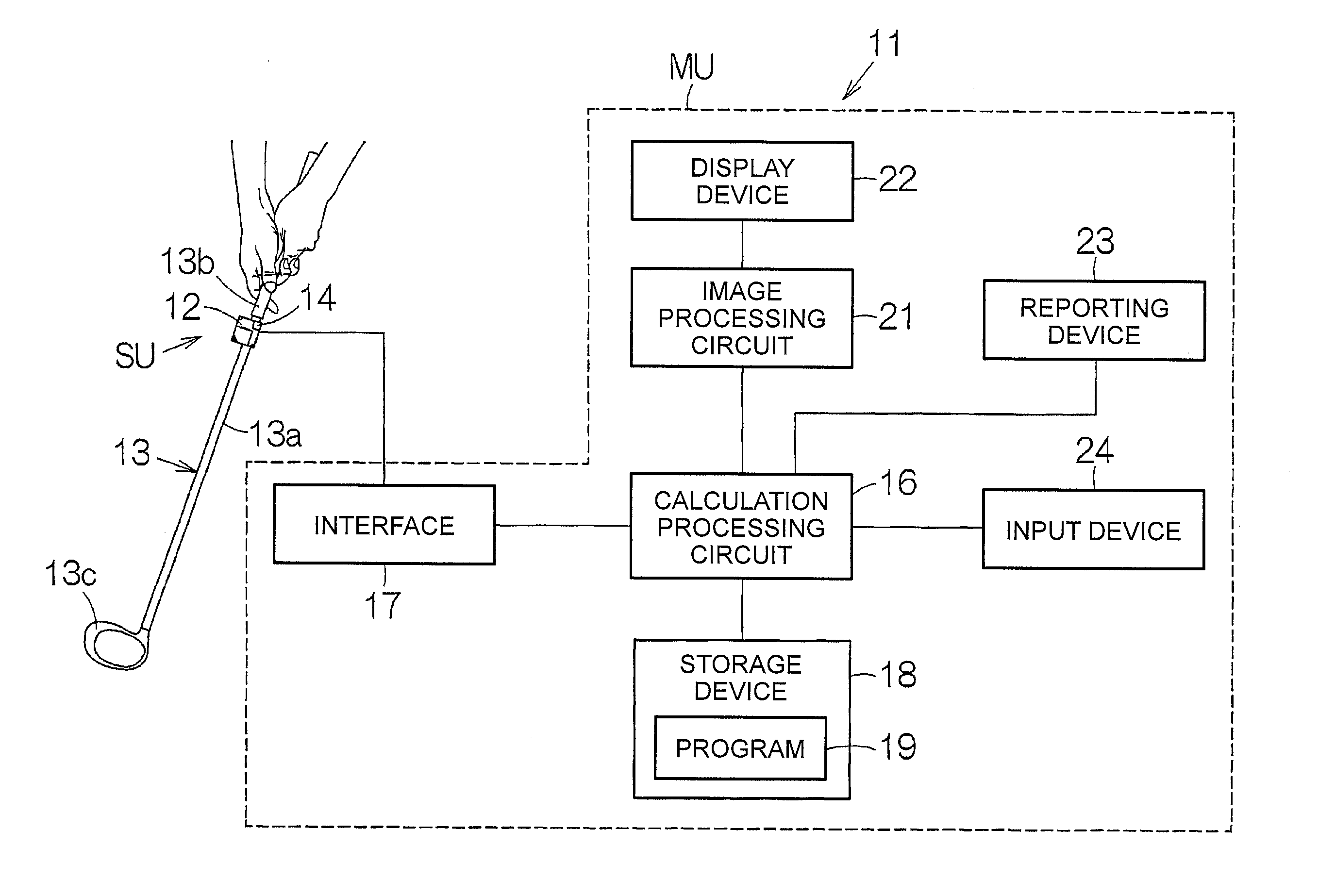

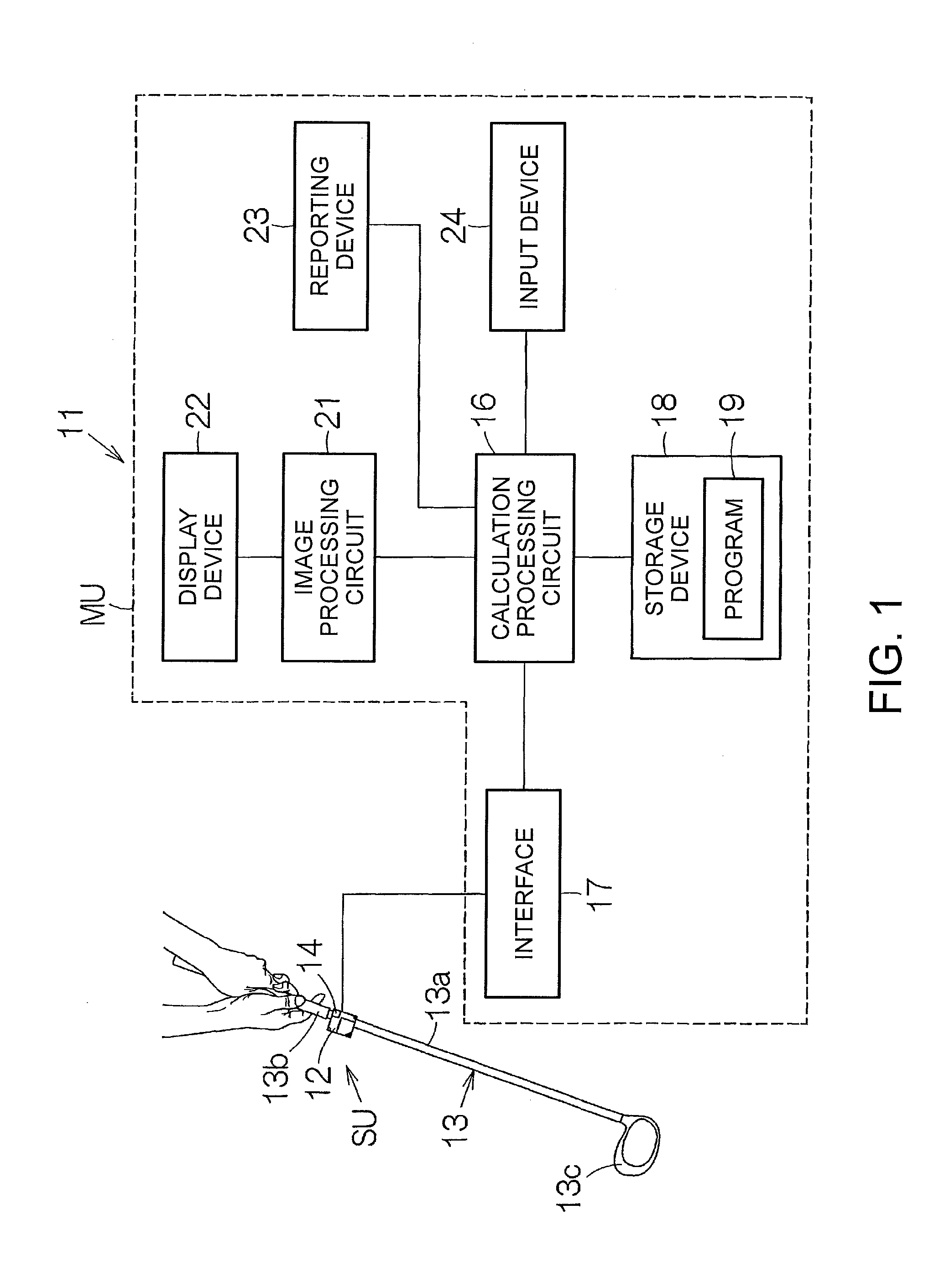

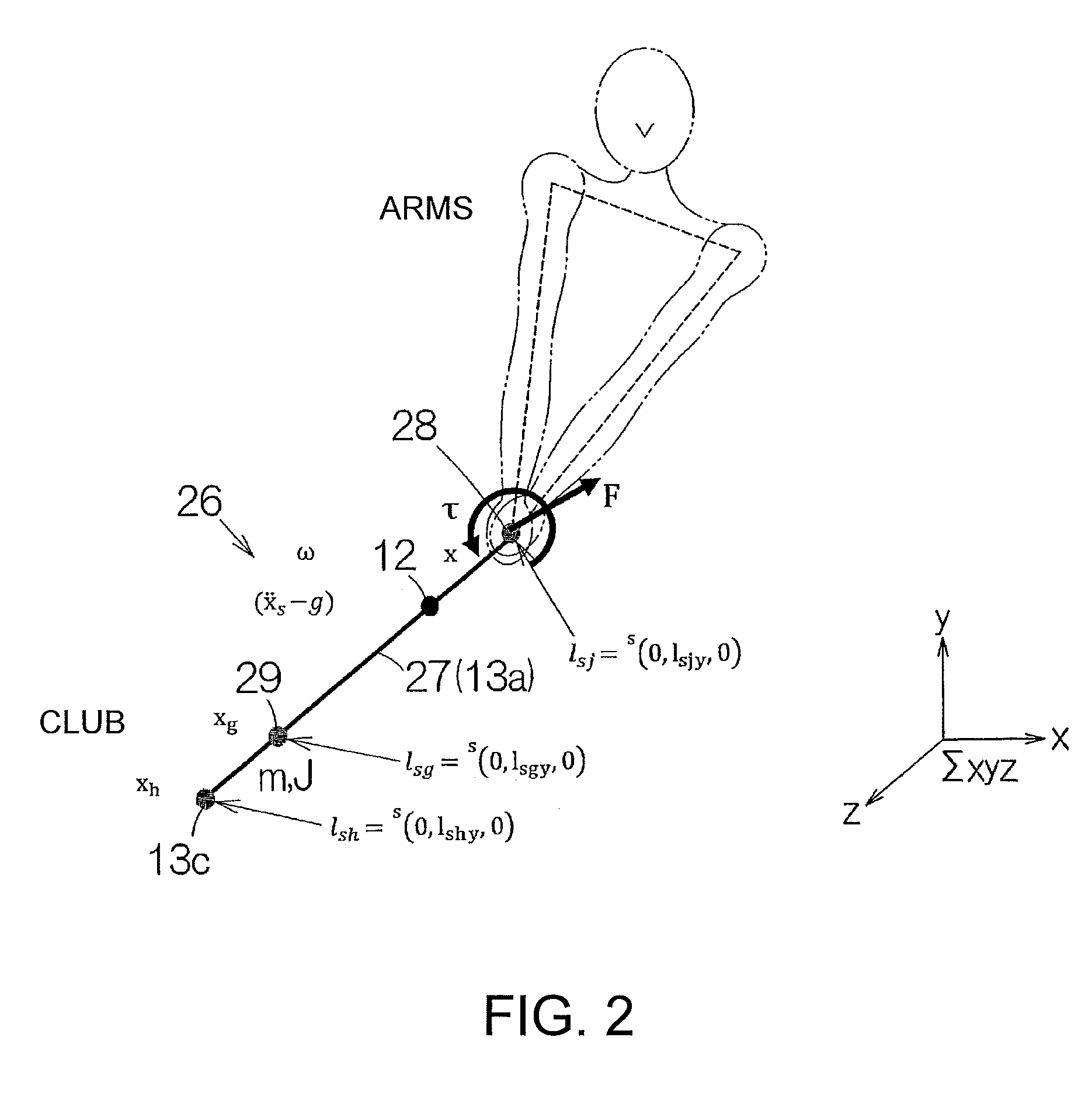

Motion analysis device

InactiveUS20150012240A1Measure securityDistinguish clearlyAcceleration measurement using interia forcesGymnastic exercisingEngineeringPhysical change

An inertial sensor is attached to a sporting gear held by the hand (for example, a golf club). A static state determination unit determines a static state of at least one of the sporting gear and a subject, using an output from the inertial sensor. A notification signal generation unit outputs a static state notification signal according to the static state. The static state notification signal can induce a certain physical change perceived by the subject with the five senses. In response to the physical change, the subject can start a swing movement.

Owner:SEIKO EPSON CORP

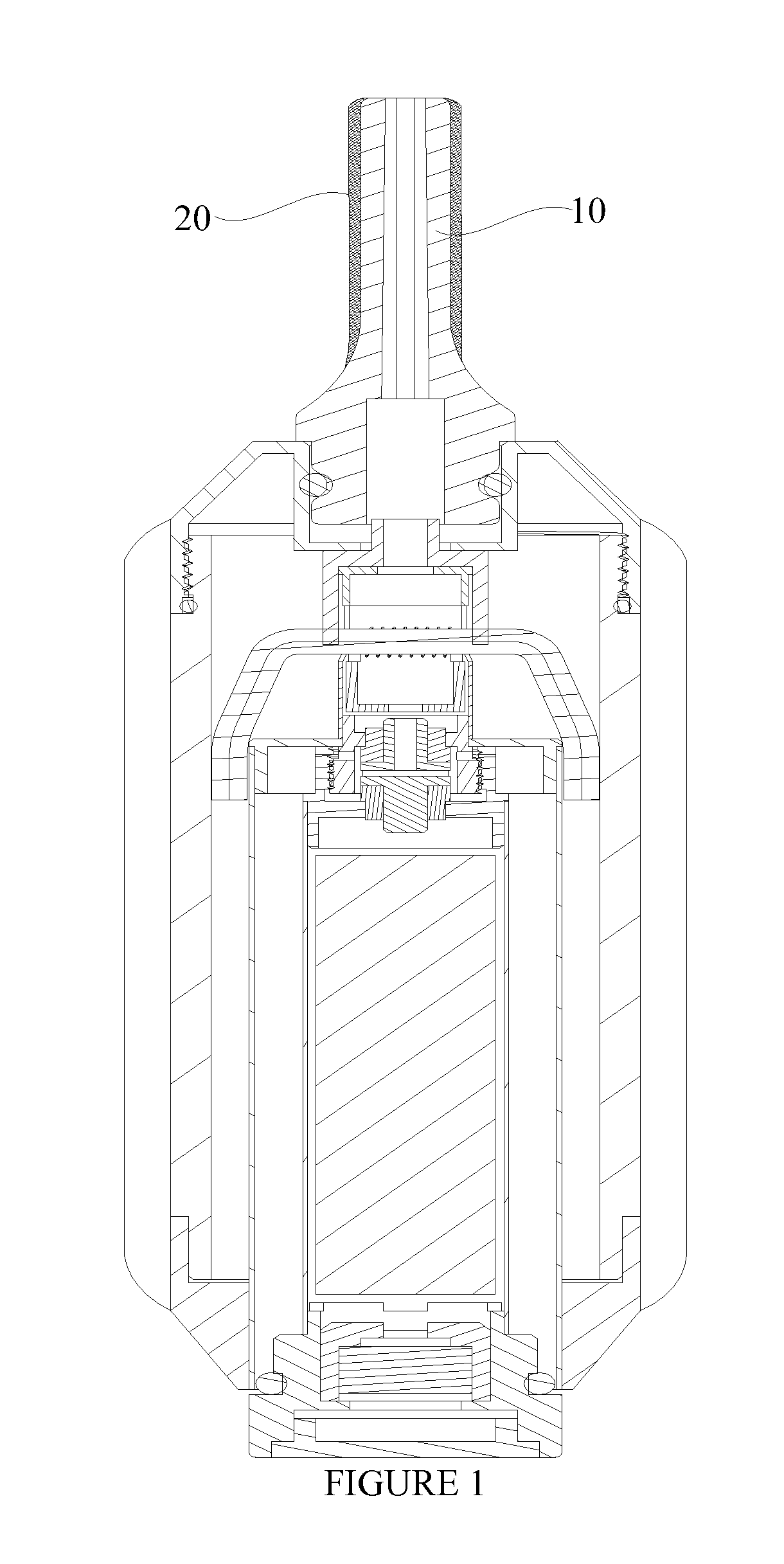

Electronic cigarette, electronic cigarette atomizer, and electronic cigarette-holder

InactiveUS20150000683A1Prevent the spread of diseaseImprove experienceTobacco pipesTobacco devicesChemical reactionElectronic cigarette

An electronic cigarette comprising a cigarette-holder is provided, the cigarette-holder includes a variable color material; and when the electronic cigarette is smoked, the variable color material generates a chemical reaction or a physical change and causes a color of the variable color material to change. Thereby whether the electronic cigarette has been smoked can be determined by observing the color change of the variable color material.

Owner:HUIZHOU KIMREE TECH

Electronic cigarette, electronic cigarette atomizer, and electronic cigarette-holder

InactiveUS9554597B2Prevent the spread of diseaseImprove experienceTobacco pipesTobacco devicesChemical reactionEngineering

An electronic cigarette comprising a cigarette-holder is provided, the cigarette-holder includes a variable color material; and when the electronic cigarette is smoked, the variable color material generates a chemical reaction or a physical change and causes a color of the variable color material to change. Thereby whether the electronic cigarette has been smoked can be determined by observing the color change of the variable color material.

Owner:HUIZHOU KIMREE TECH

Phase-change heat-insulation interior wall coating and preparation method for same

ActiveCN102604500AGuaranteed practicalityImprove reflectivityAntifouling/underwater paintsPaints with biocidesMicrospherePolyethylene glycol

The invention discloses phase-change heat-insulation interior wall coating, which is characterized by comprising elastic emulsion, water, dispersing agent, wetting agent, thickener, antiseptic, hollow polyurethane microspheres, nano titanium dioxide and non-transparent polymers, wherein the hollow polyurethane microspheres wrap polyethylene glycol with the molecular weight ranging from 1000-2000. The temperature can be regulated by making full use that the polyethylene glycol generates phase change at the different temperatures to result in physical changes of heat release and heat absorption, light reflection of the nano titanium dioxide plays a role in radiation and heat insulation, and a conductivity coefficient is decreased in the presence of the hollow swelling microspheres and the non-transparent polymers. The phase-change heat-insulation interior wall coating is particularly suitable for indoor external layers by combining the three heat-insulation mechanisms of phase change, radiation and conductivity.

Owner:SKSHU PAINT

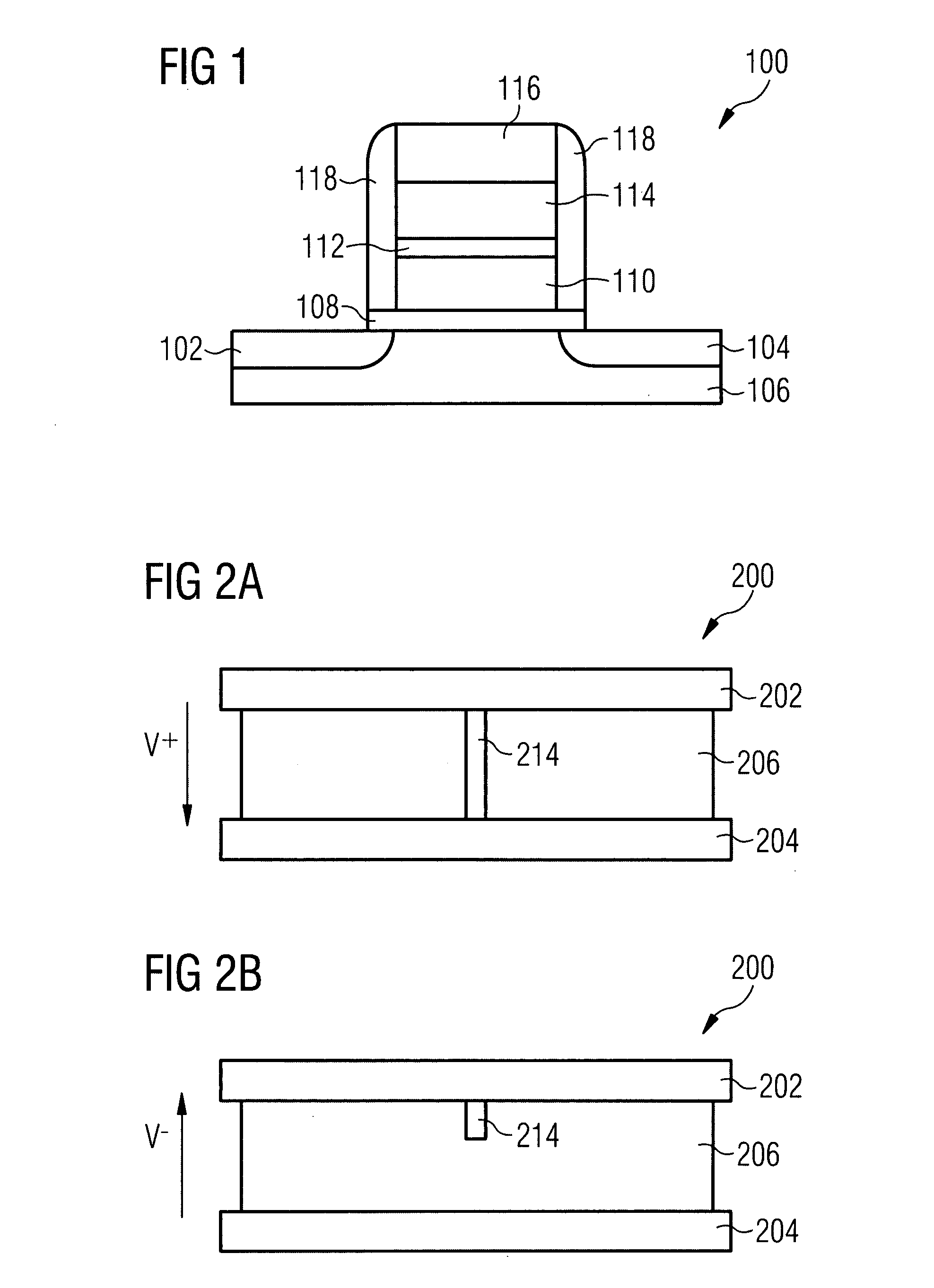

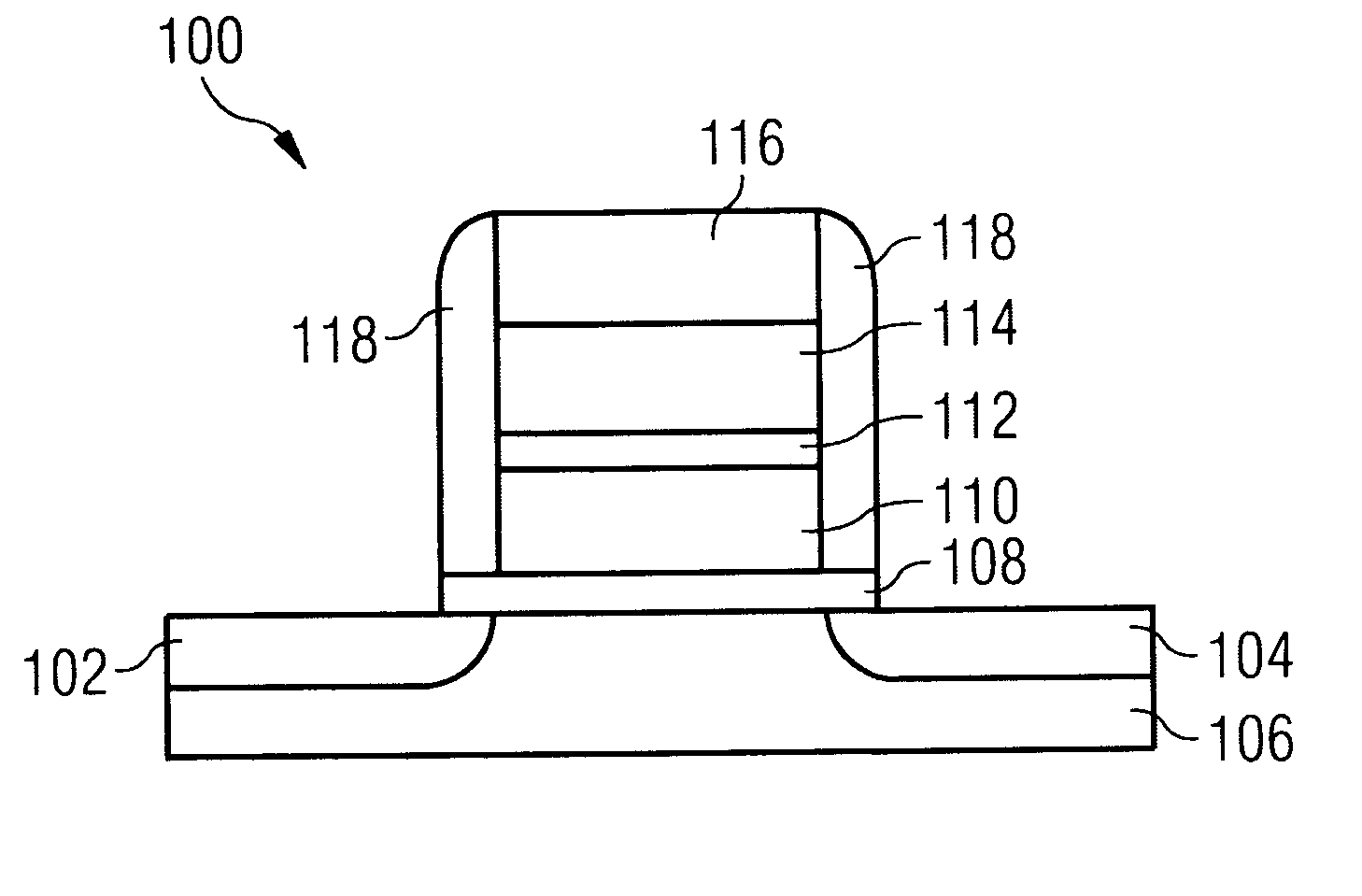

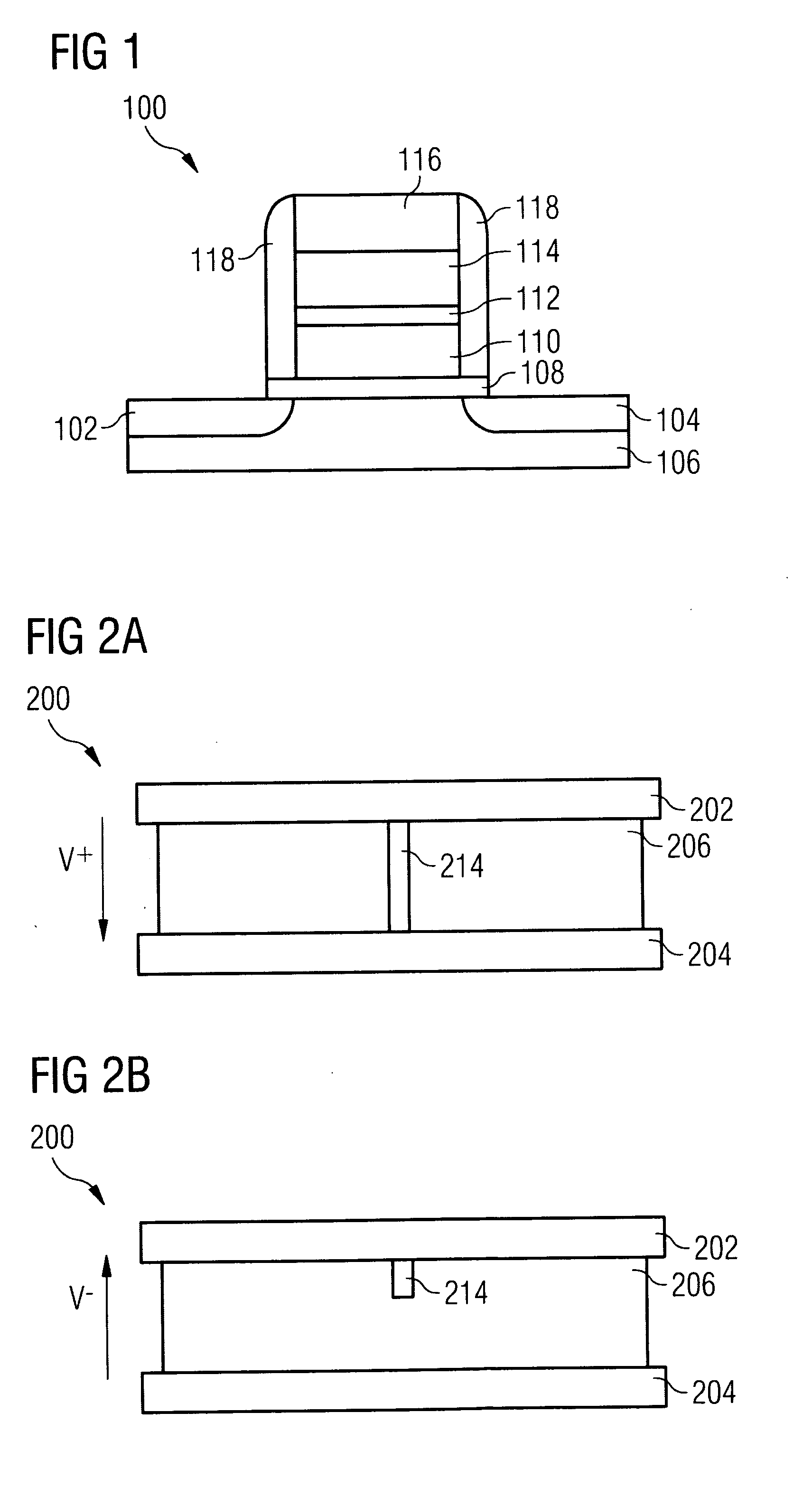

Modifiable gate stack memory element

An apparatus and method for storing information are provided, including using an integrated circuit including a transistor having a channel, a gate oxide layer, a gate electrode, and a modifiable gate stack layer. To store information, the on-resistance of the transistor is changed by causing a non-charge-storage based physical change in the modifiable gate stack layer.

Owner:RISING SILICON

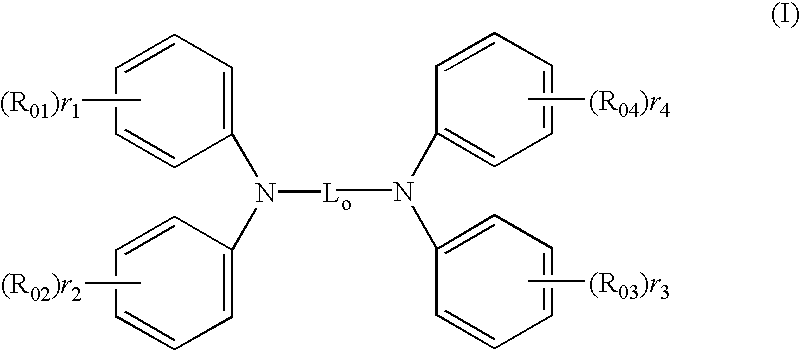

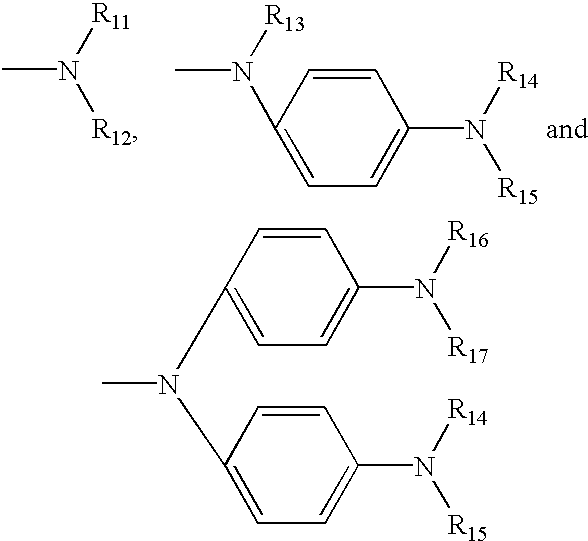

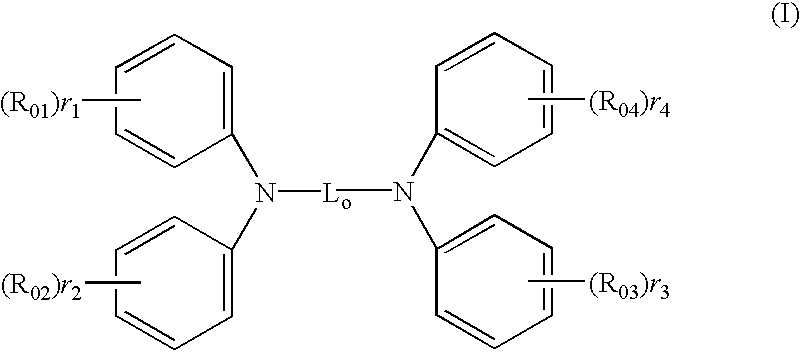

Organic EL device

InactiveUS20020102434A1Discharge tube luminescnet screensElectroluminescent light sourcesHigh current densityEvaporation

Owner:FUTABA CORPORATION

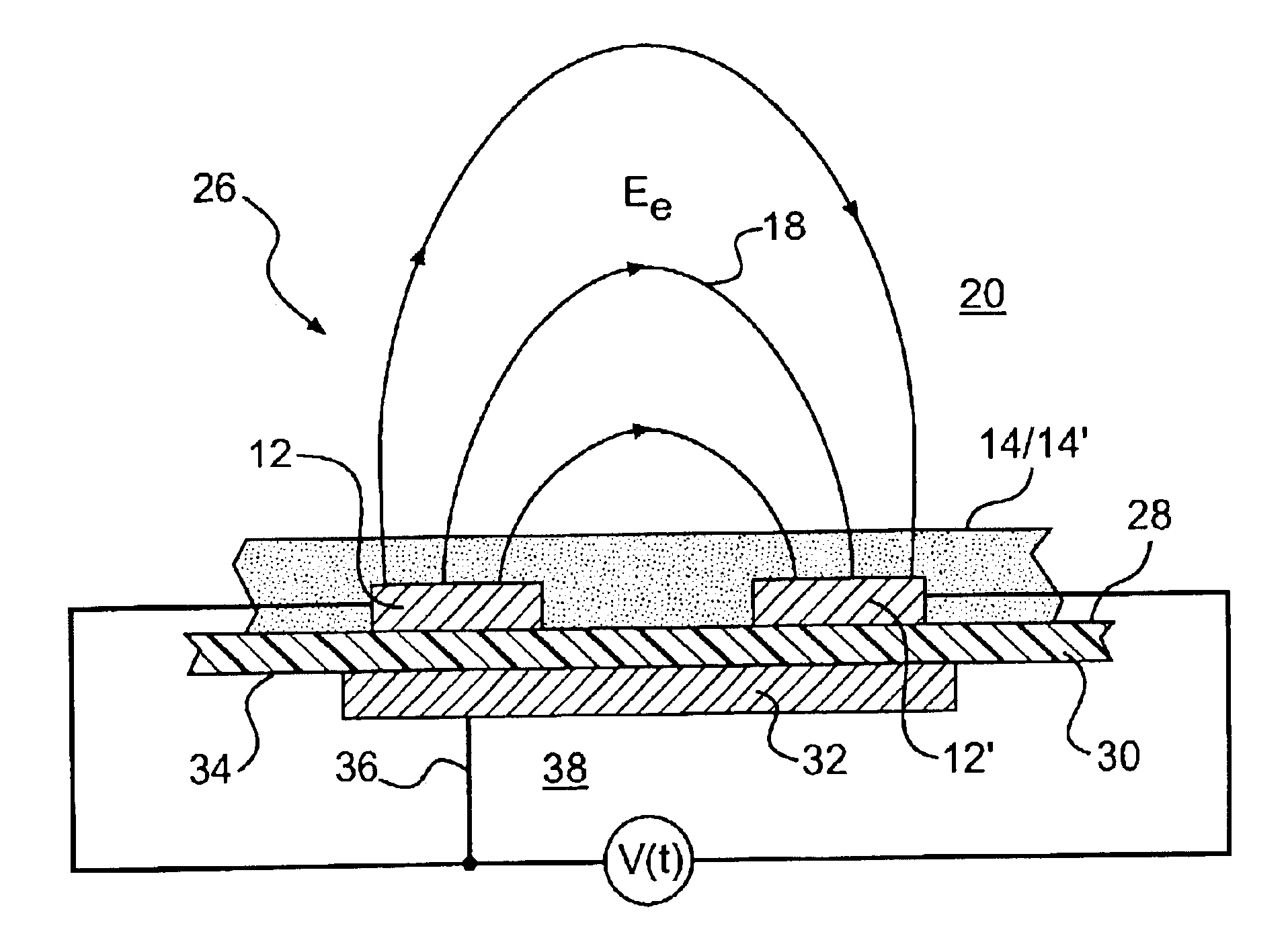

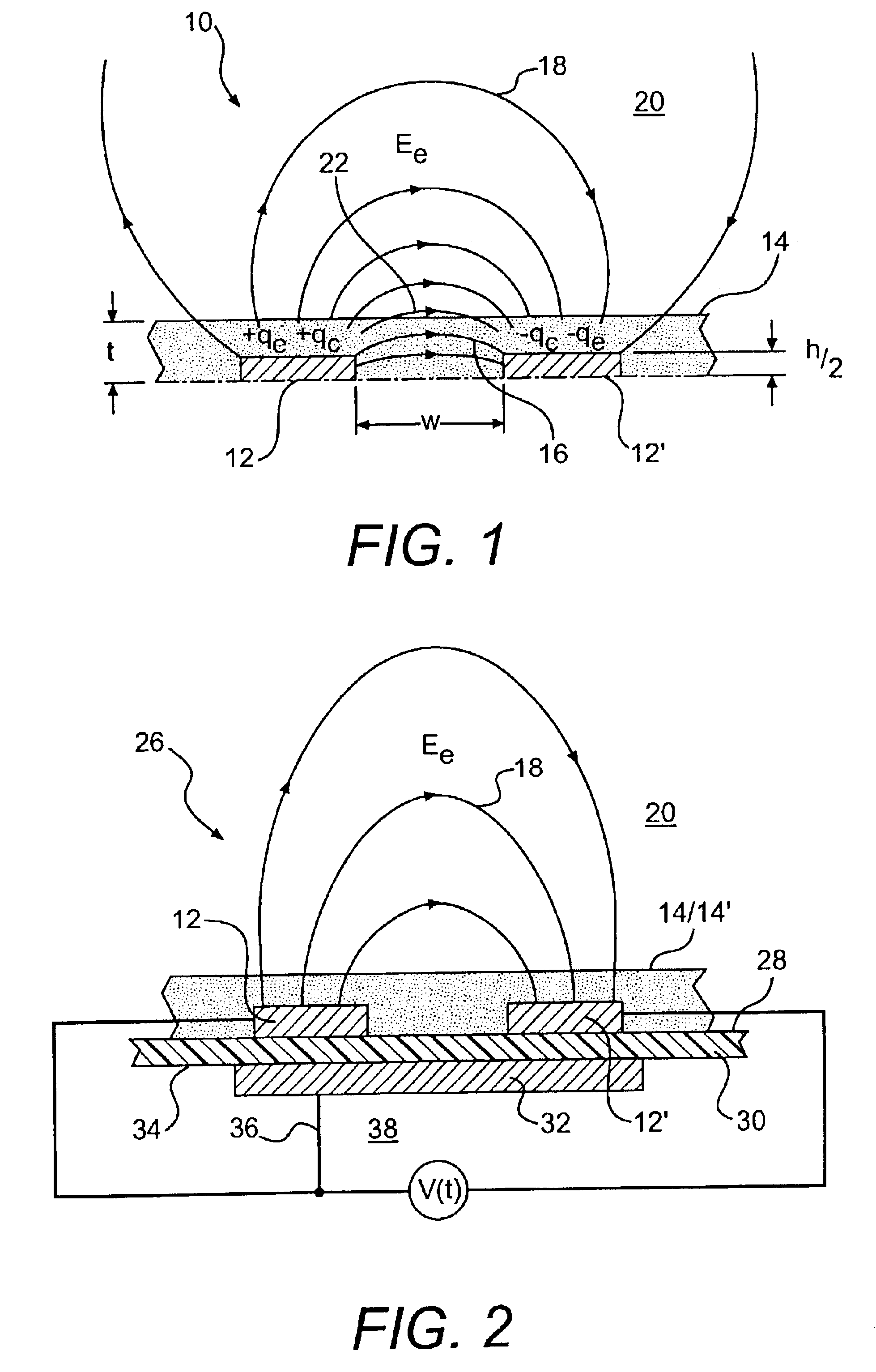

Planar capacitive transducer

InactiveUS6842018B2Increase and decrease surface free energyIncrease moisture contentResistance/reactance/impedenceUsing mechanical meansDesorptionMoisture absorption

A transducer comprising at least one planar capacitor with a thin coverlayer of material selected to maximize electric field coupling between cooperating capacitor electrodes within a region external to a principal surface of the coverlayer. Preferred coverlayer materials have low values of moisture absorption, surface free energy, permittivity, dielectric dissipation, and electrical conductance. According to one embodiment of the invention, a driven shield further enhances electric field coupling over and in a region external to the principal surface. The transducer also can promote a physical change in specific adsorbates and materials and simultaneously detect and measure an effect of the induced change. Applications for the transducer of the invention include the measurement of the moisture content of grain and bulk stored commodities, humidity, a dew point temperature, the onset of condensation and rates of adsorption and desorption.

Owner:MCINTOSH ROBERT B

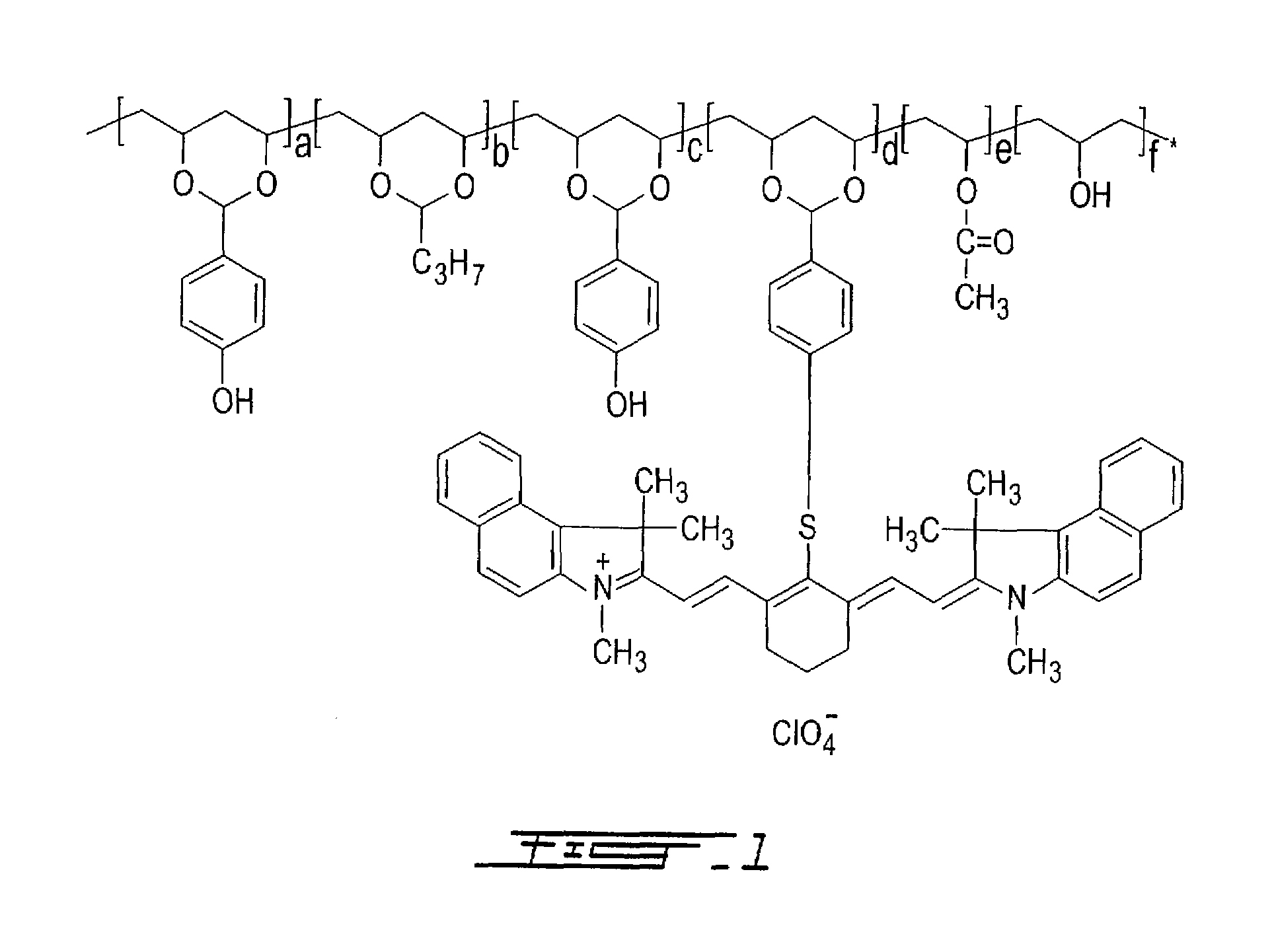

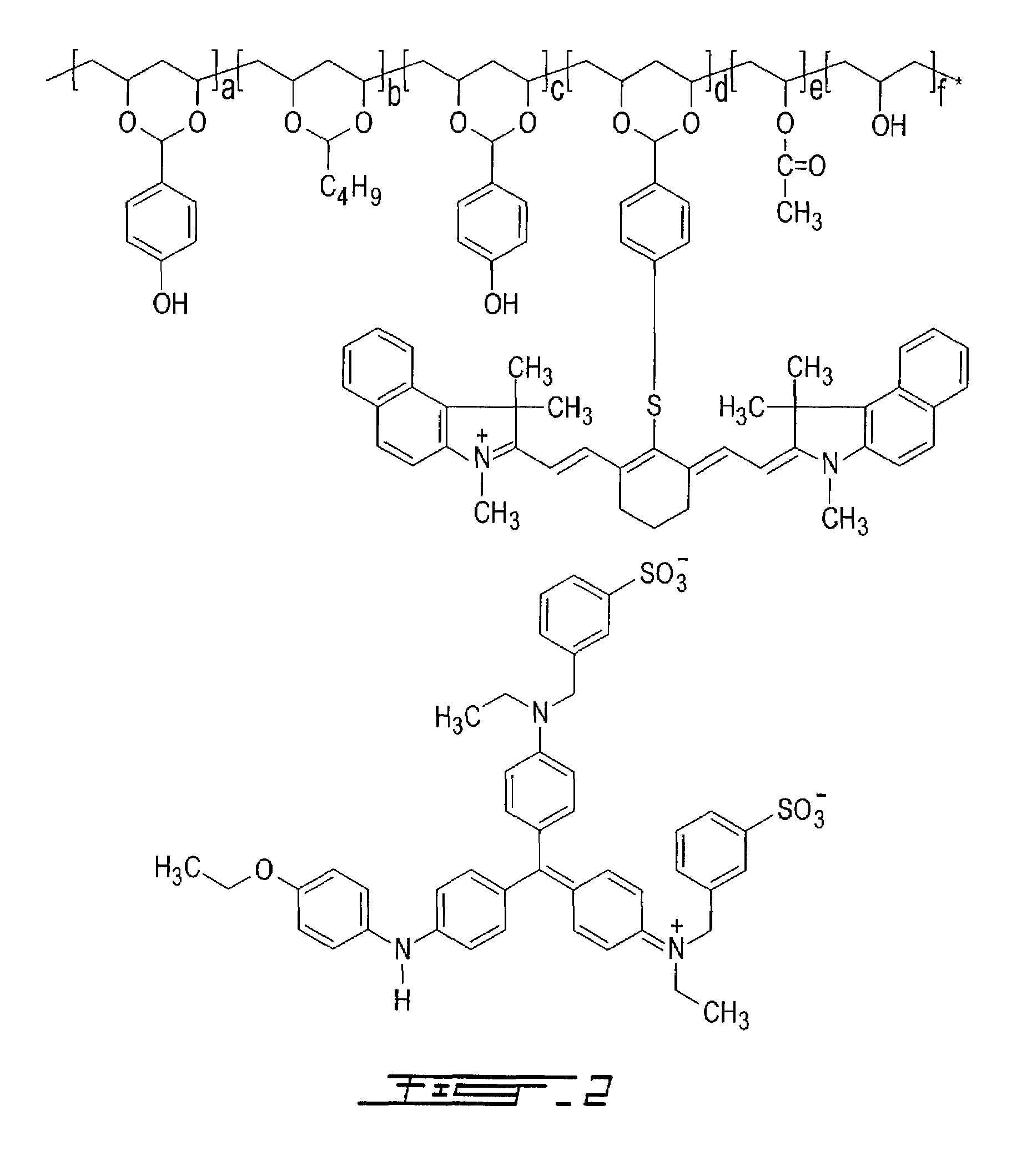

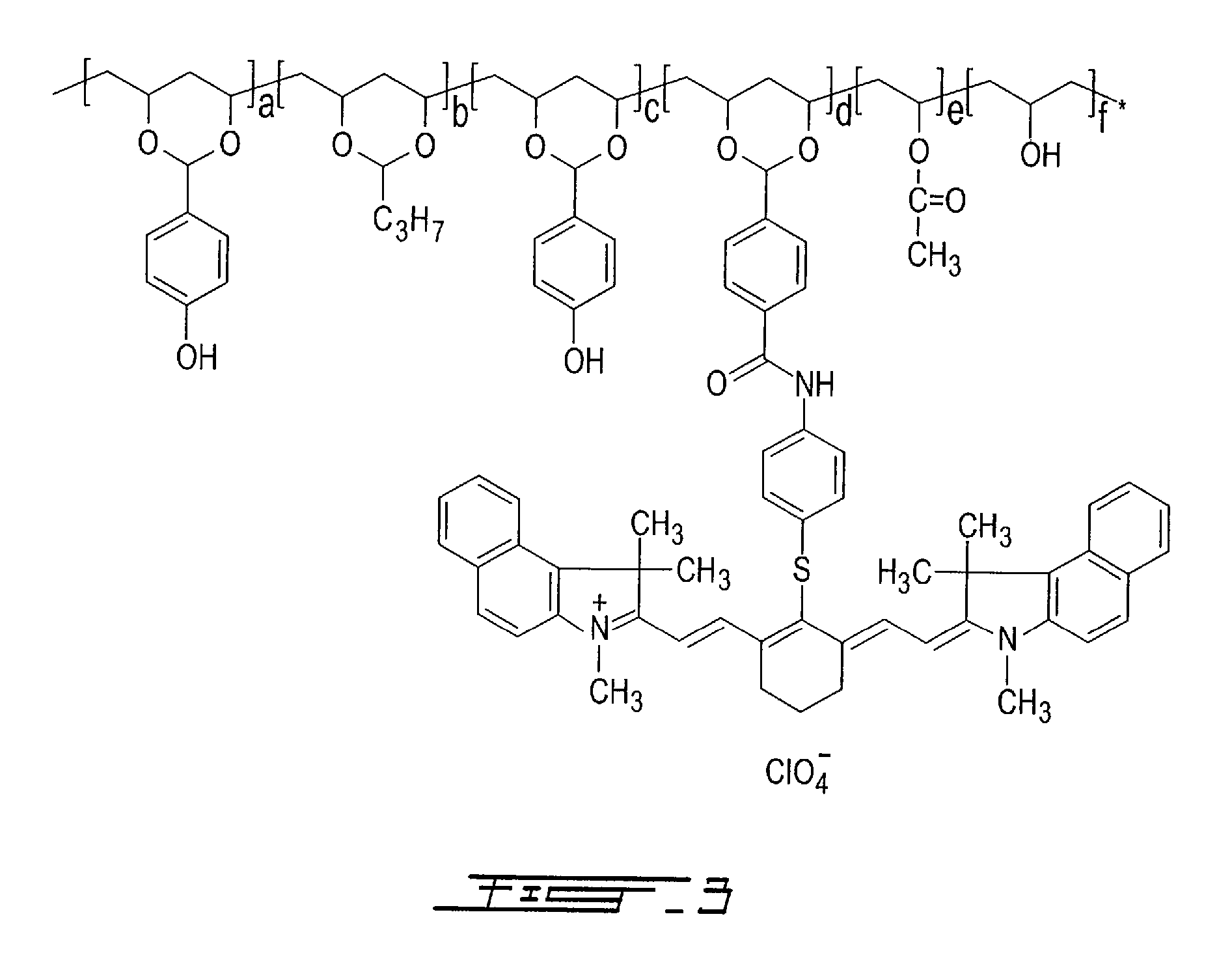

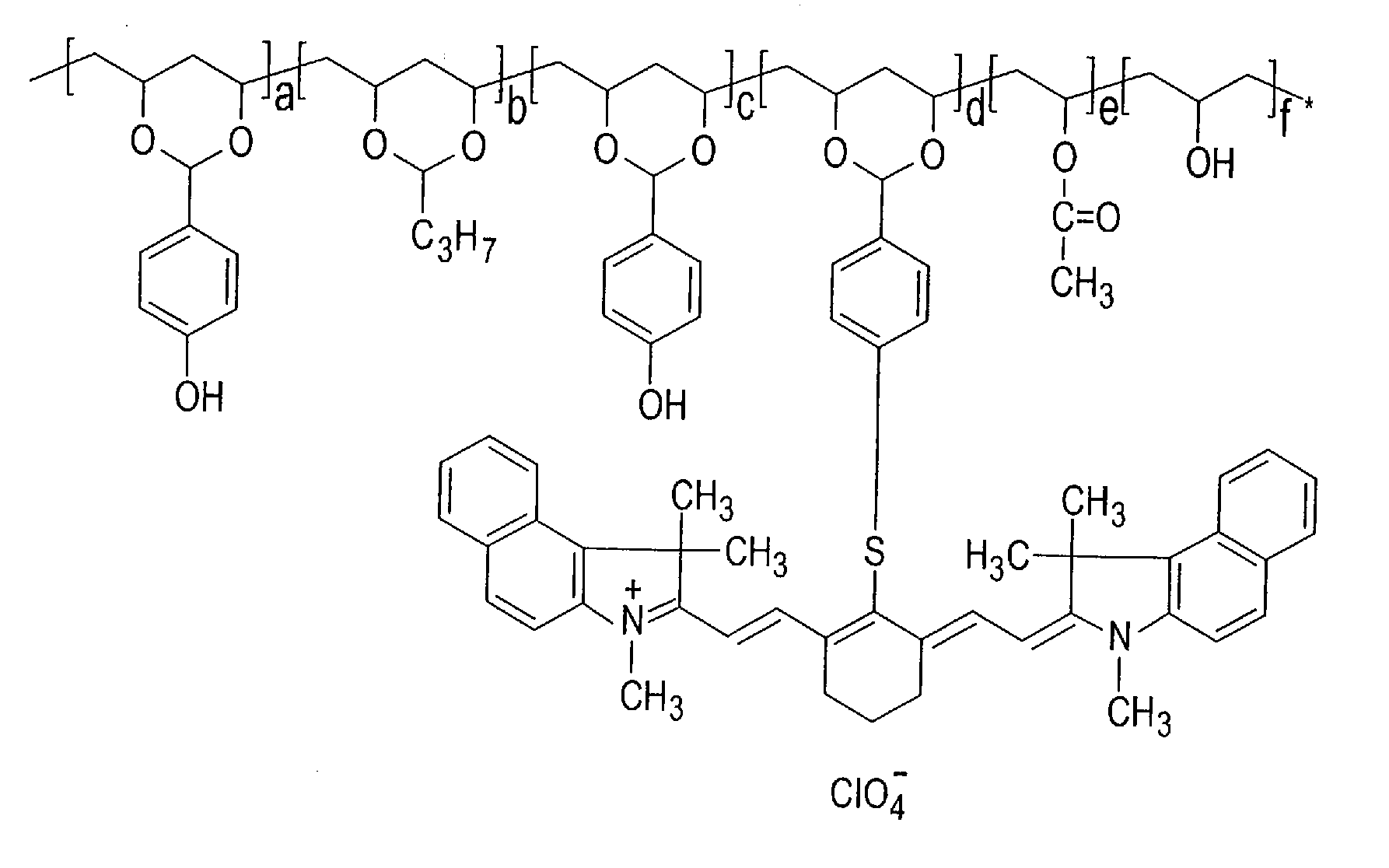

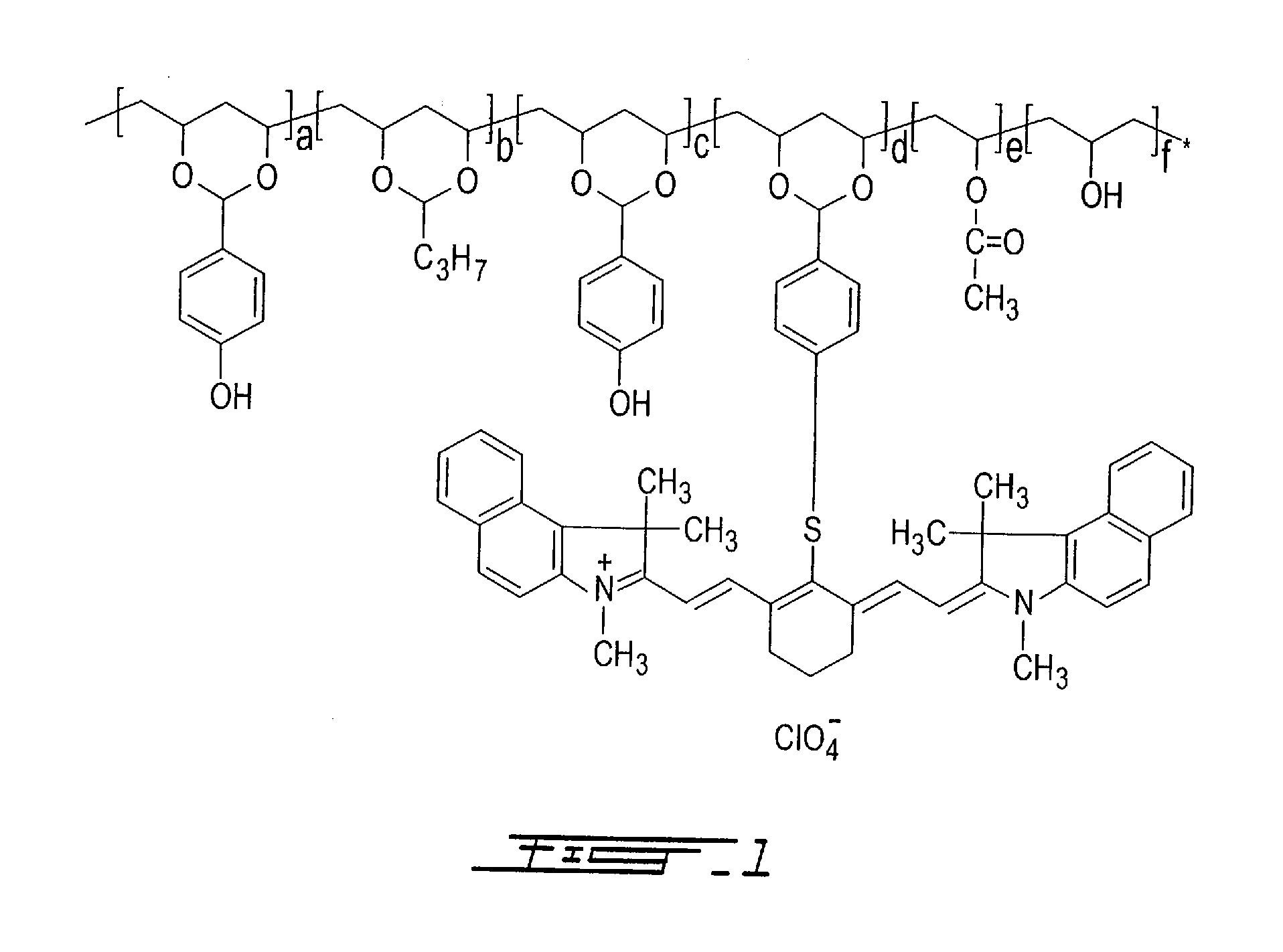

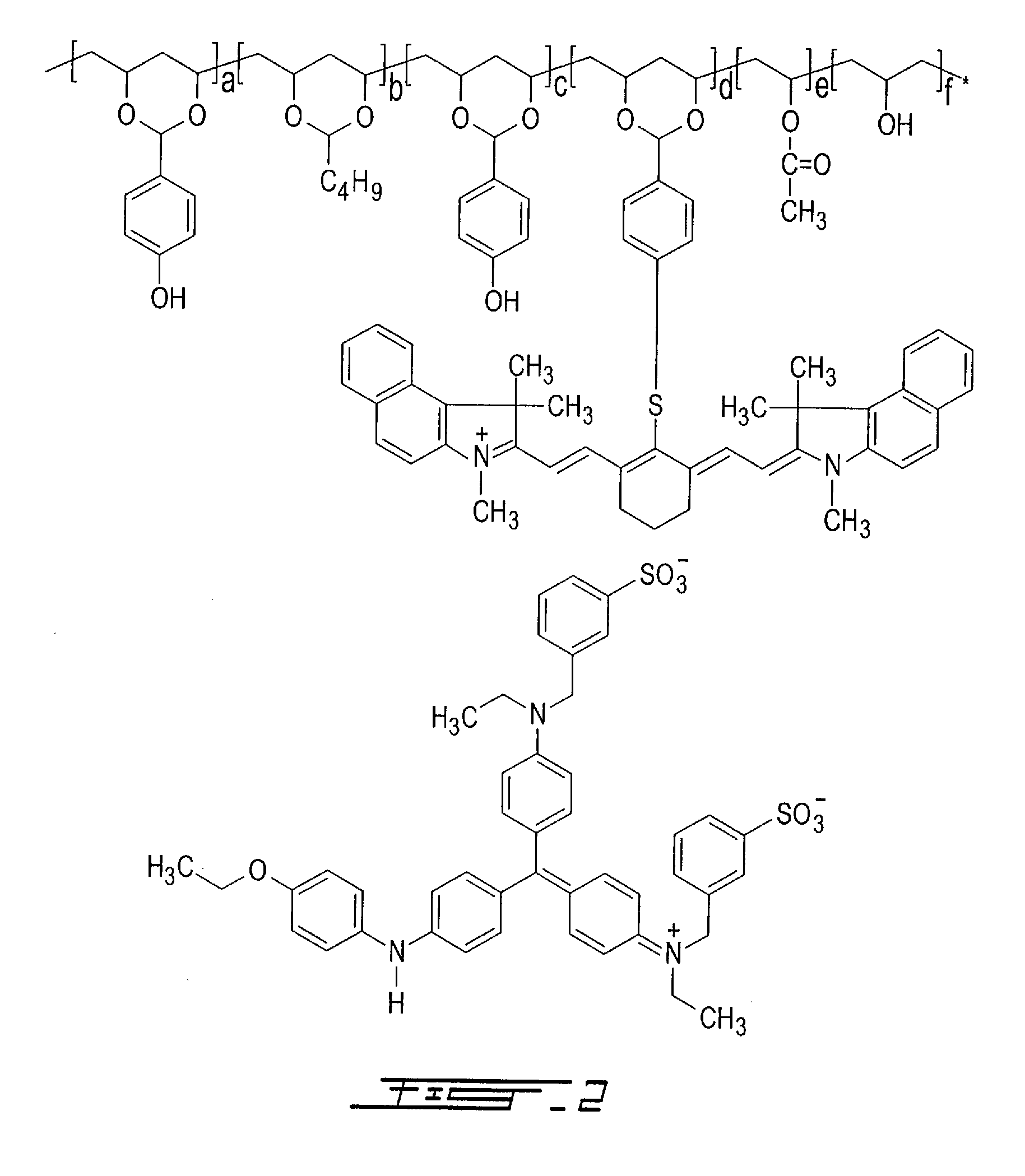

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS7473515B2Photosensitive materialsSemiconductor/solid-state device manufacturingGum printingAcetal copolymer

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

Trafic monitoring system

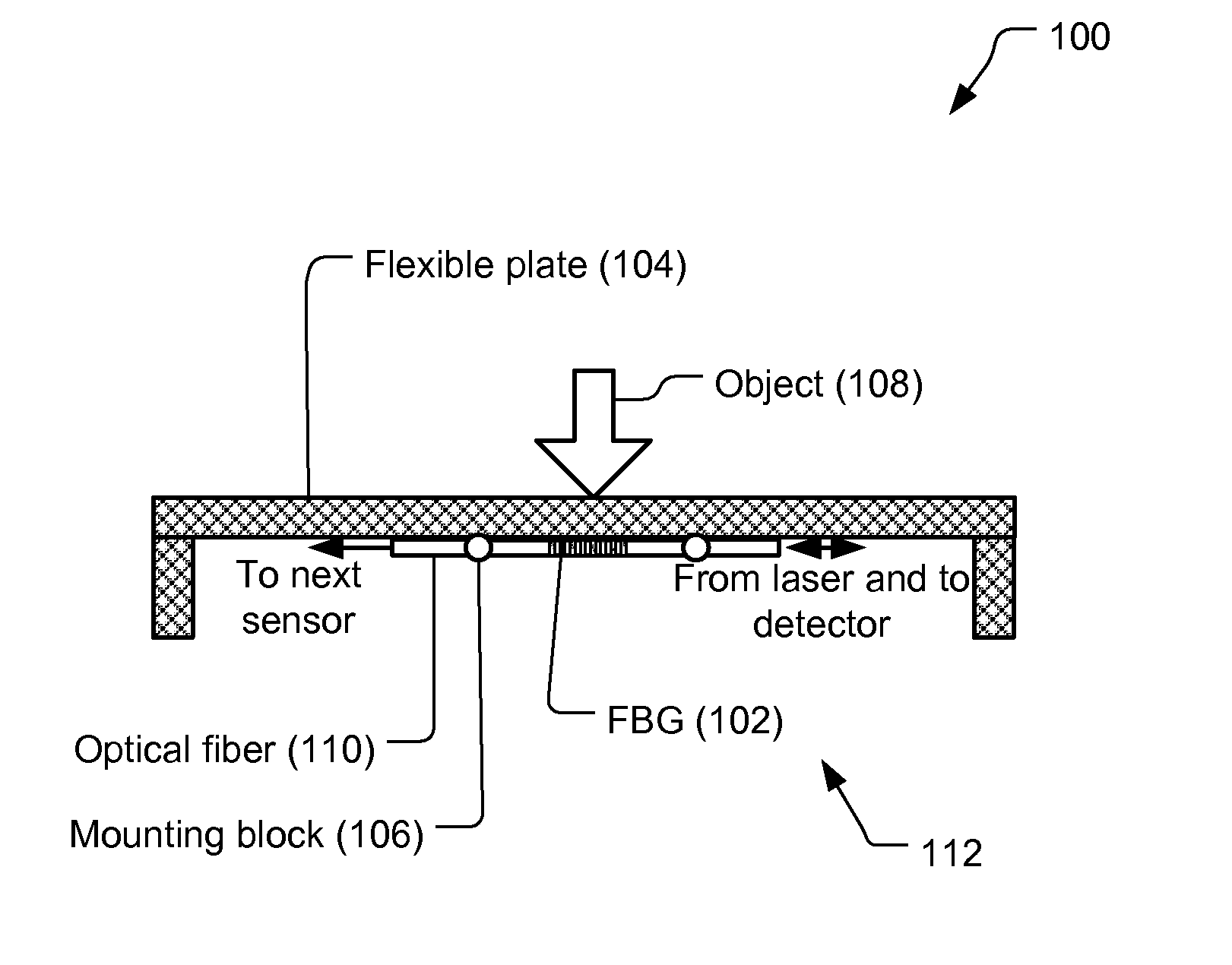

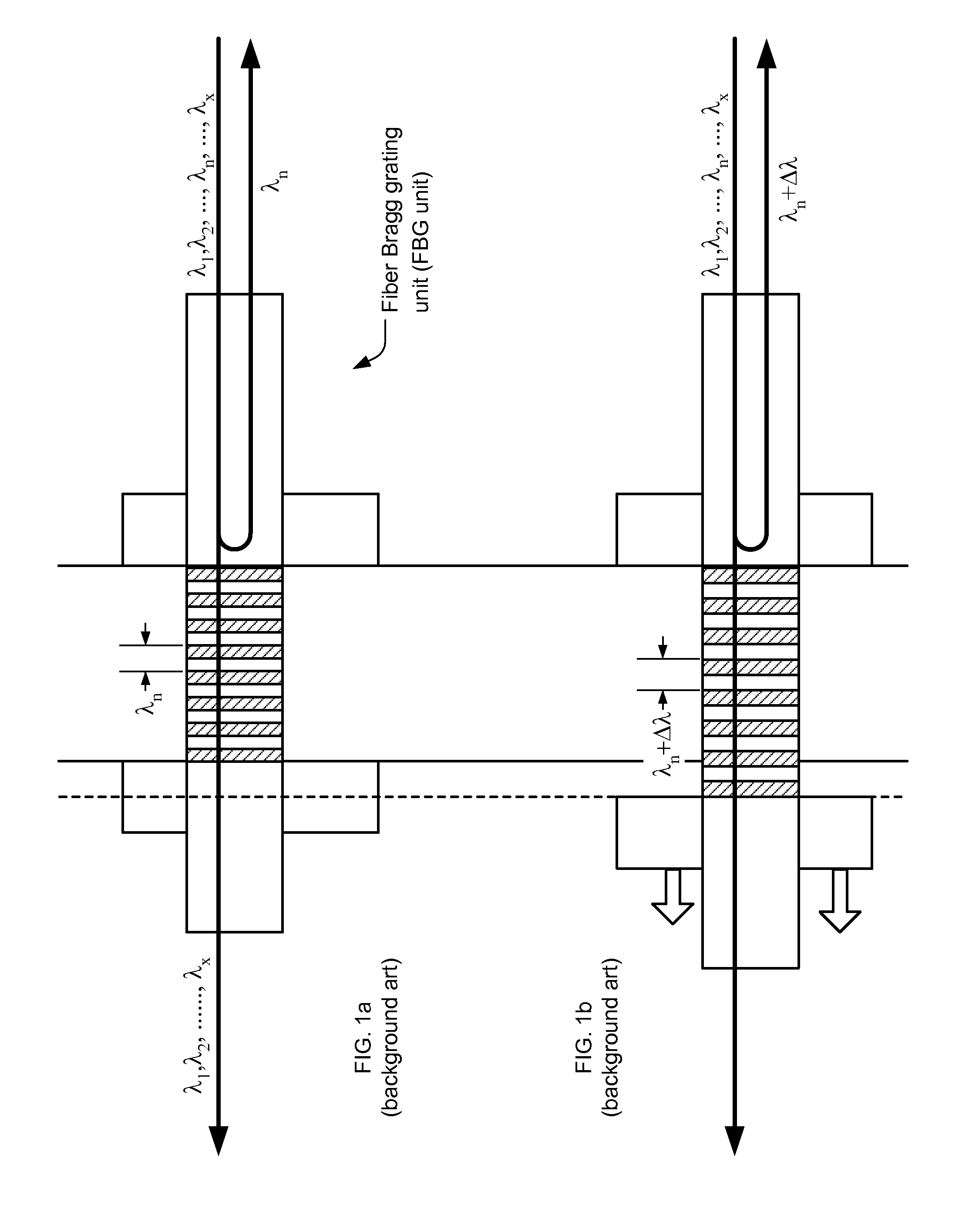

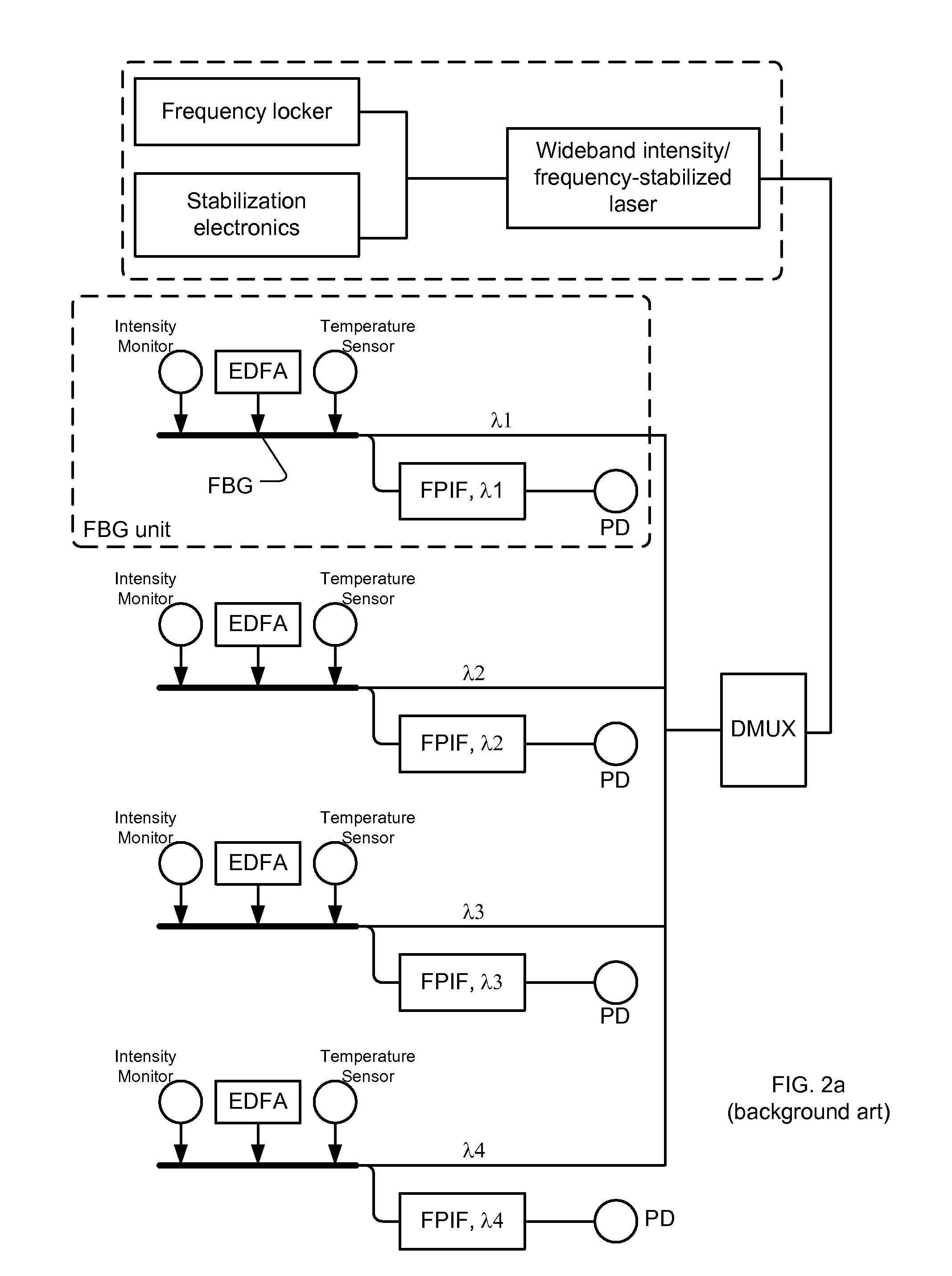

A system for monitoring traffic across a structure. A fiber Bragg grating (FBG) reflects a light wavelength. A mounting mechanism connects the FBG to the structure, such that physical change of the structure changes a stress to the FBG that changes the light wavelength. And optical fiber carries a first light beam to the FBG and carries a second light beam from the FGB. This permits first light beam including the light wavelength to be received from a light source, and permits the first light beam to be altered into the second light beam by passing the light wavelength through the FBG, and permits the second light beam to be provided to a detector to sense the light wavelength present in the second light beam. From this the stress in the structure and information about the traffic across a structure can be inferred.

Owner:FIBERA

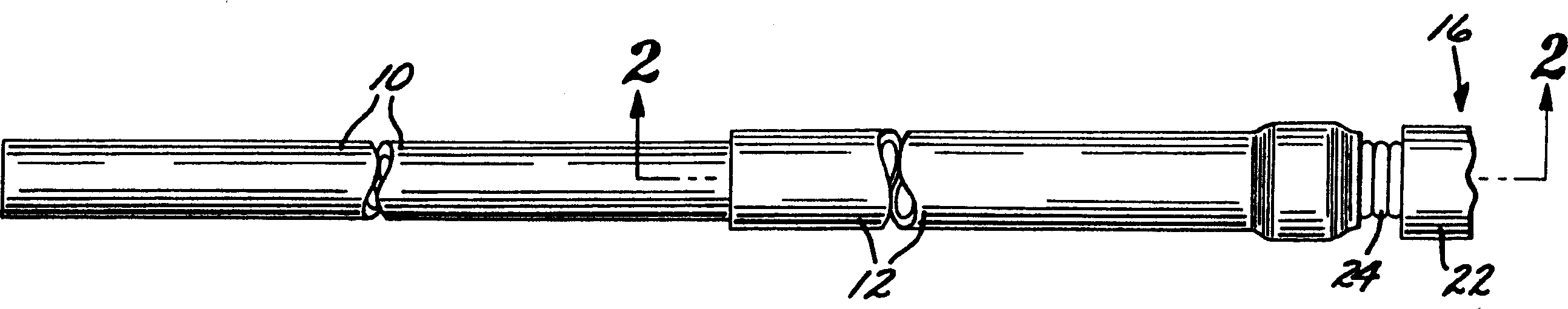

Mechanism for the deployment of endovascular implants

A mechanism for the deployment of a filamentous endovascular device includes an elongate, flexible, hollow deployment tube having an open proximal end, and a coupling element attached to the proximal end of the endovascular device. The deployment tube includes a distal section terminating in an open distal end, with a lumen defined between the proximal and distal ends. A retention sleeve is fixed around the distal section and includes a distal extension extending a short distance past the distal end of the deployment tube. The endovascular device is attached to the distal end of the deployment tube during the manufacturing process by fixing the retention sleeve around the coupling element, so that the coupling element is releasably held within the distal extension of the deployment tube. In use, the deployment tube, with the implant attached to its distal end, is passed through a microcatheter to a target vascular site until the endovascular device is deployed within the site. To detach the endovascular device from the deployment tube, a biocompatible liquid is injected through the lumen of the deployment tube so as to apply pressure to the upstream side of the coupling element, which is thus pushed out of the retention sleeve by the fluid pressure, thereby detaching the endovascular device from the deployment tube. The coupling element may be a solid 'plug' of polymeric material or metal, or it may be formed of a hydrophilic polymer that softens and becomes somewhat lubricious when contacted by the injected liquid. With the latter type of material, the hydration of the hydrophilic material results in physical changes that reduce the adhesion between the coupling element and the sleeve. Alternatively, the coupling element can be made principally of a non-hydrophilic material, with a hydrophilic coating.

Owner:MICROVENTION INC

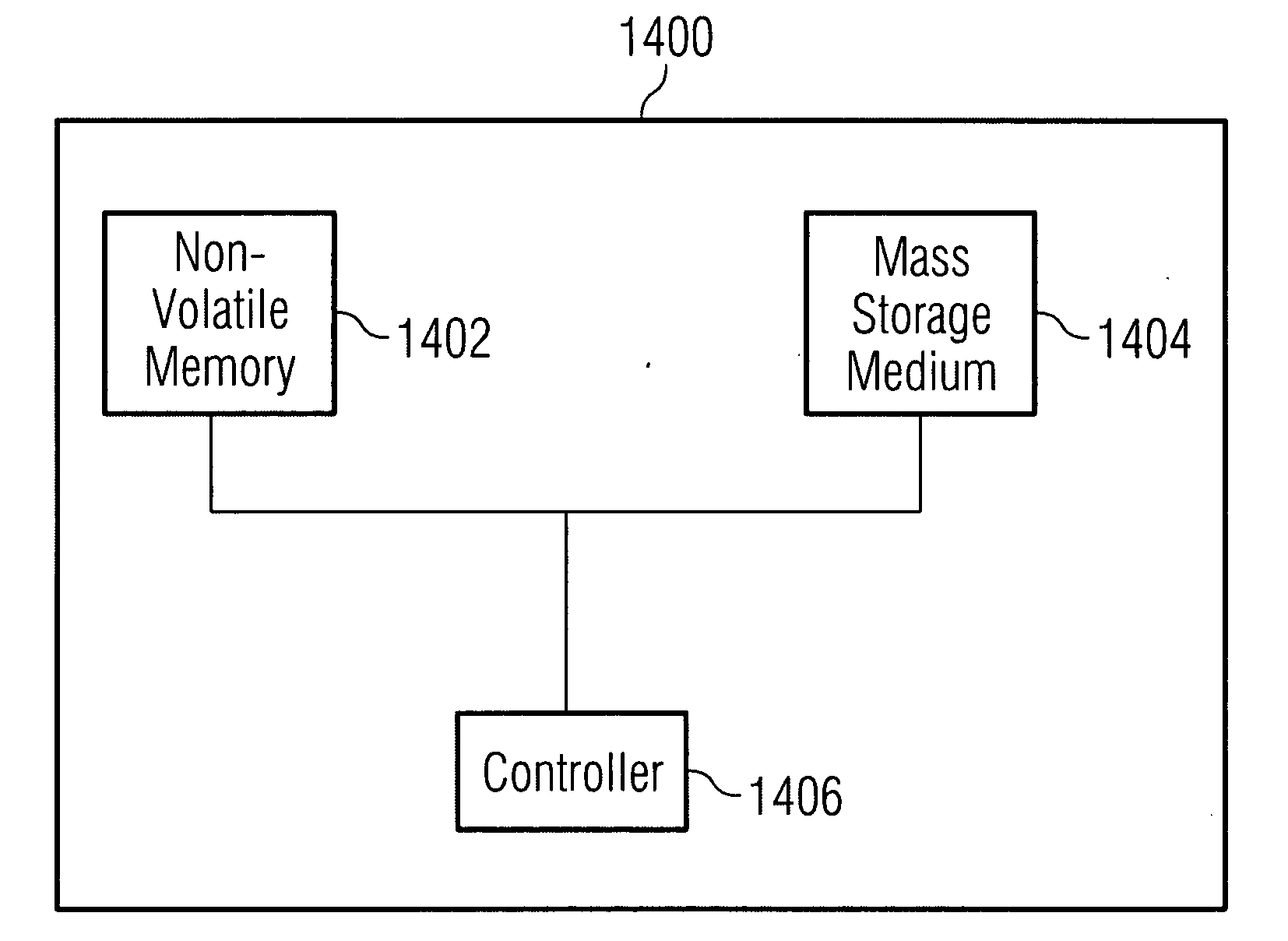

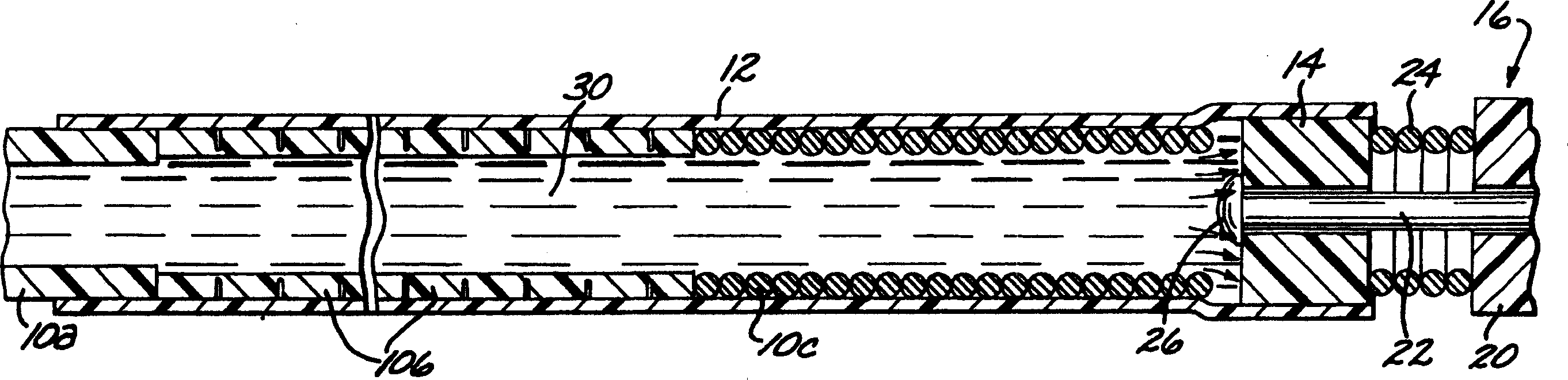

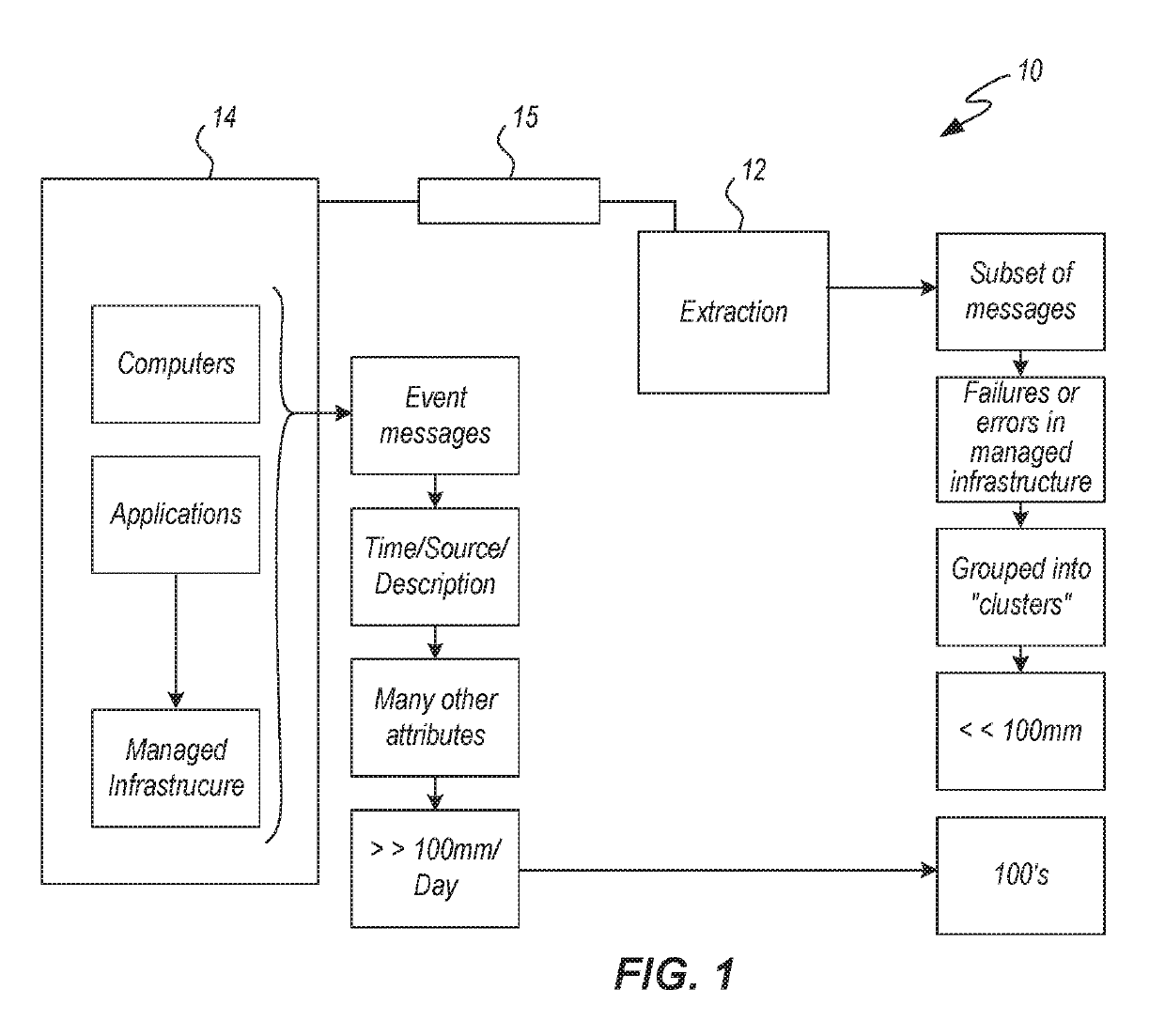

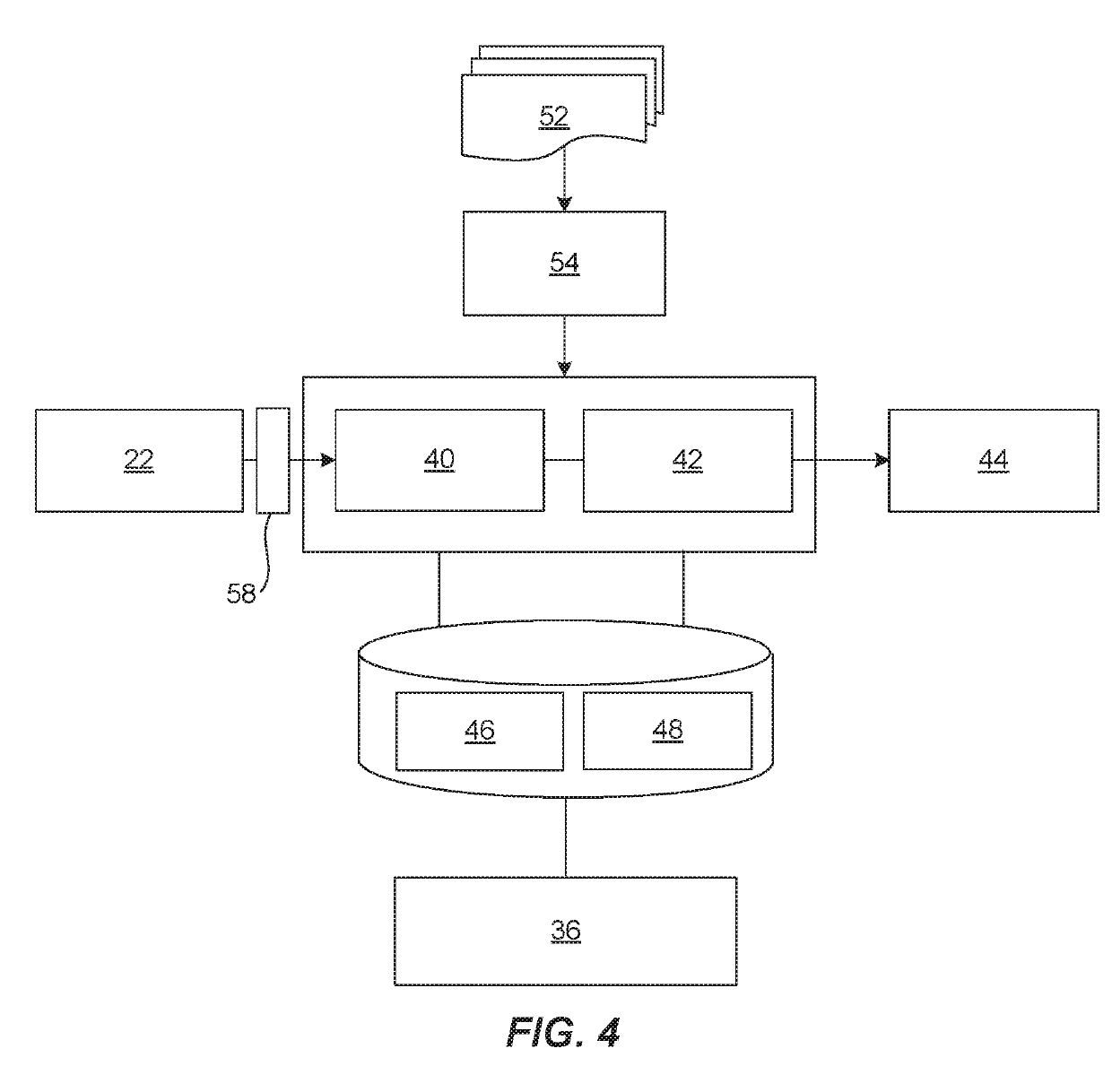

System for managing an instructure with security

PendingUS20190138372A1Maintain securityInterprogram communicationCharacter and pattern recognitionGraphicsDisplay device

A system is provided for managing an infrastructure. An extraction engine is in communication with a managed infrastructure that includes physical hardware. A signalizer engine includes one or more of an NMF engine (Non-negative matrix factorization), a k-means clustering engine (a method of vector quantization), and a topology proximity engine. The signalizer engine determines one or more common characteristics of events and produces clusters of events relating to the failure or errors in the infrastructure. The signalizer engine uses graph coordinates and optionally a subset of attributes assigned to each event to generate one or more clusters to bring together events whose characteristics are similar. One or more interactive displays provide a collaborative interface coupled to the extraction and the signalizer engine with a collaborative interface (UI) for decomposing events from the infrastructure. The events are converted into words and subsets to group the events into clusters that relate to security of the managed infrastructure. In response to grouping the events physical changes are made to at least a portion of the physical hardware. In response to production of the clusters security of the managed infrastructure is maintained.

Owner:MOOGSOFT

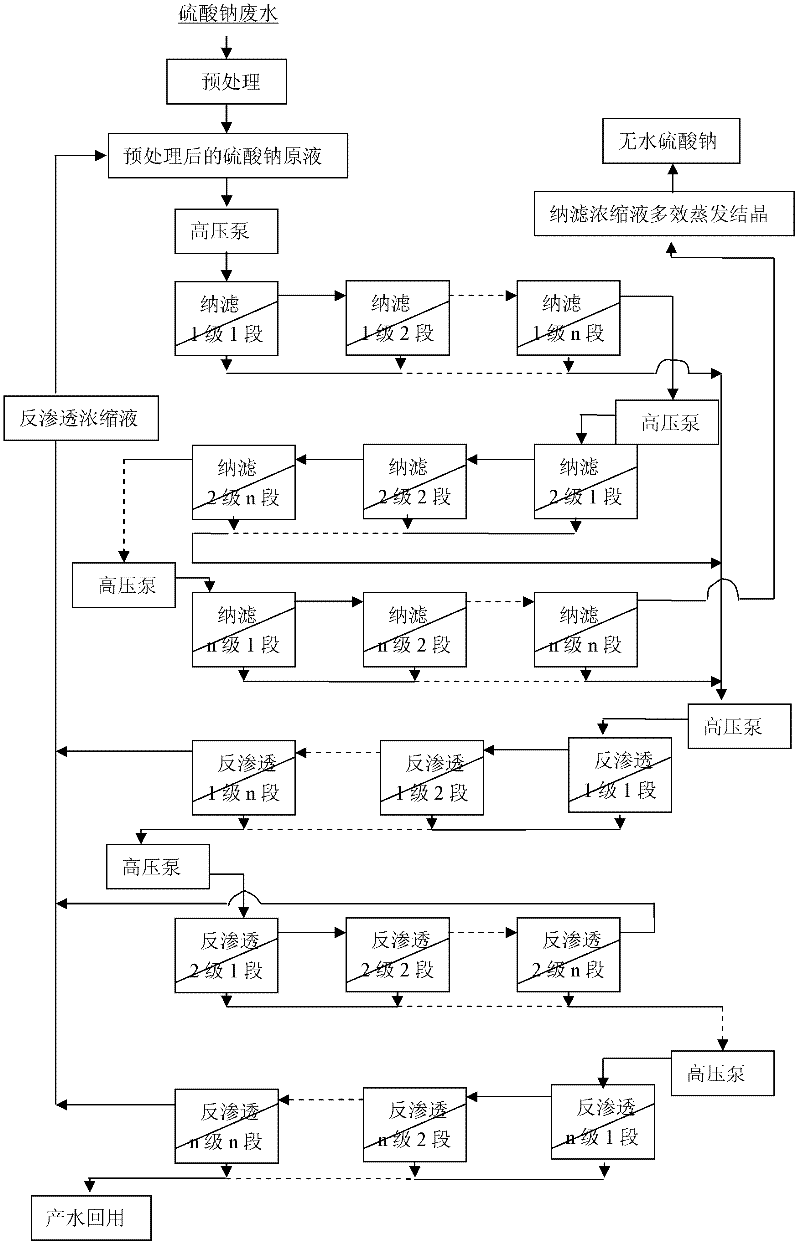

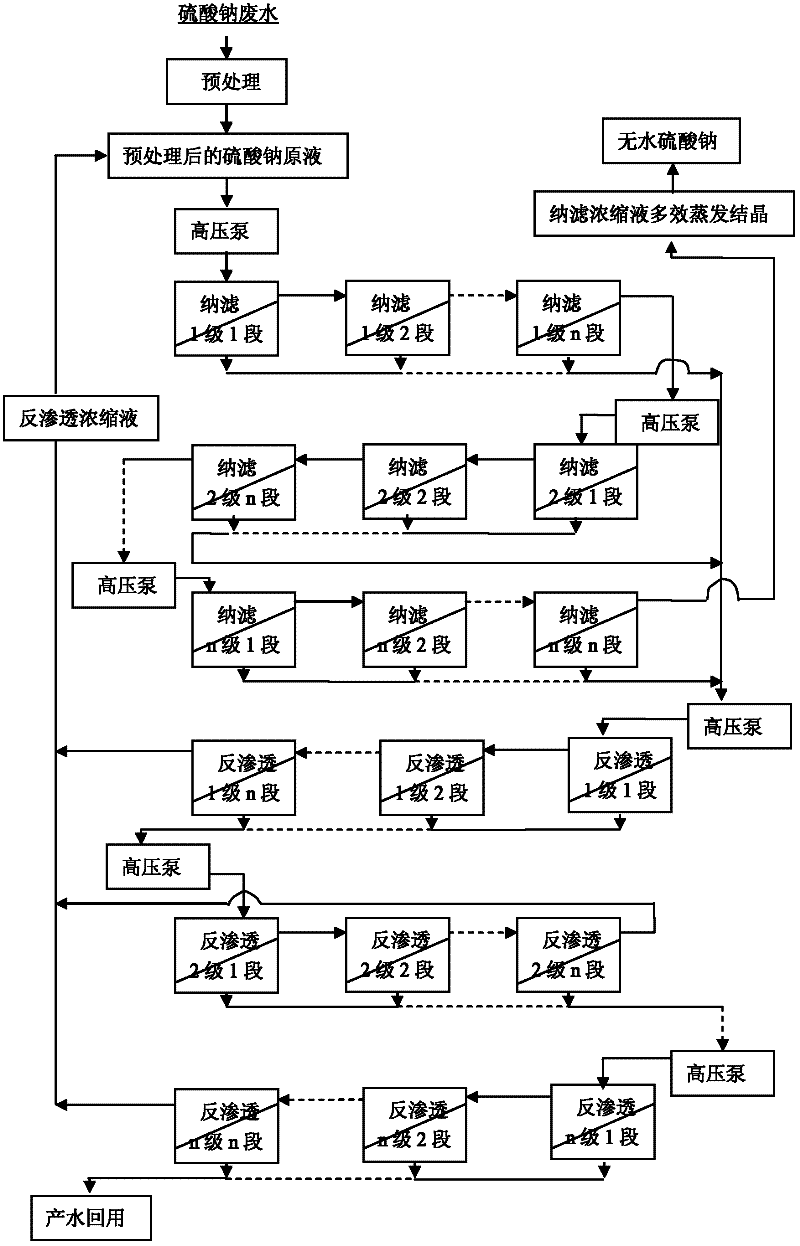

Process for treating sodium sulfate wastewater by using nanofiltration-reverse osmosis combined membrane

InactiveCN102491452AAchieving zero emissionsSmall footprintAlkali metal sulfite/sulfate purificationWater/sewage treatment bu osmosis/dialysisEvaporationReverse osmosis plant

The present invention relates to a process for treating sodium sulfate wastewater by using a nanofiltration-reverse osmosis combined membrane. According to the process, the pretreated sodium sulfate wastewater is conveyed to a nanofiltration membrane stack through a high pressure pump, and the nanofiltered concentrated solution is subjected to multiple effect evaporation crystallization to obtain an anhydrous sodium sulfate product and condensed water, wherein the condensed water is recycled; the nanofiltered producing water is conveyed to a reverse osmosis membrane stack through the high pressure pump, the resulting concentrated solution returns to the pretreated sodium sulfate stock solution to carry out the secondary nanofiltration, and the reverse osmosis producing water is recycled, wherein the concentrated solution is subjected to the reverse osmosis membrane stack. Compared to other pollution control technologies, the process of the present invention has the following advantages that: the equipment is compact, and the land occupation is small; no morphological and chemical influence is generated to the treated object; the process is a continuous process, and the automatic and uninterrupted operating can be achieved; the process has characteristics of low energy consumption, no phase change, no temperature change, easy control and simple operation; the process can be directly circulated on the site; the sodium sulfate is subjected to concentration, evaporation crystallization, and recovery utilization in the absence of chemical and physical changes, such that the zero discharge of the sodium sulfate wastewater is achieved; the reverse osmosis producing water is adopted as the process pure water to use so as to save a large amount of the process water.

Owner:JILIN JIEN NICKEL IND +1

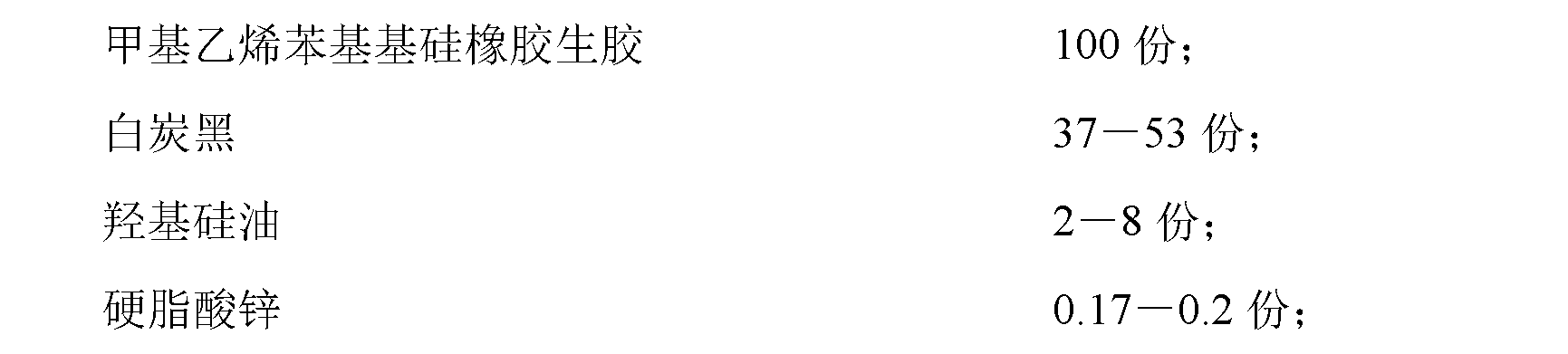

Silicon rubber and preparation method thereof

The invention discloses a silicon rubber and a preparation method thereof, belonging to the technical field of rubber materials. The silicon rubber is prepared from rubber and a reinforced material in a kneading machine through physical change and chemical change by mixing, wherein the reinforced material is white carbon black, the white carbon black is used as the reinforced material so that the strength of vulcanizing silicon rubber can be increased, the rubber is methyl phenyl vinyl silicone rubber so that the cold resistance can be effectively improved; hydroxyl silicone oil is a structure control agent, zinc stearate is a release agent, and 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane without toxicity and pungent smell and with good high-temperature vulcanization effect is selected as a peroxide vulcanization agent. The silicon rubber provided by the invention has low-temperature resistance and high dielectric property, can meet the special requirement of some products on the market, is remarkably unchanged in hardness, tear strength and elongation at break, and thus the application range of the silicon rubber is enlarged.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS20060275698A1Photosensitive materialsSemiconductor/solid-state device manufacturingAcetal copolymerNear infrared radiation

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

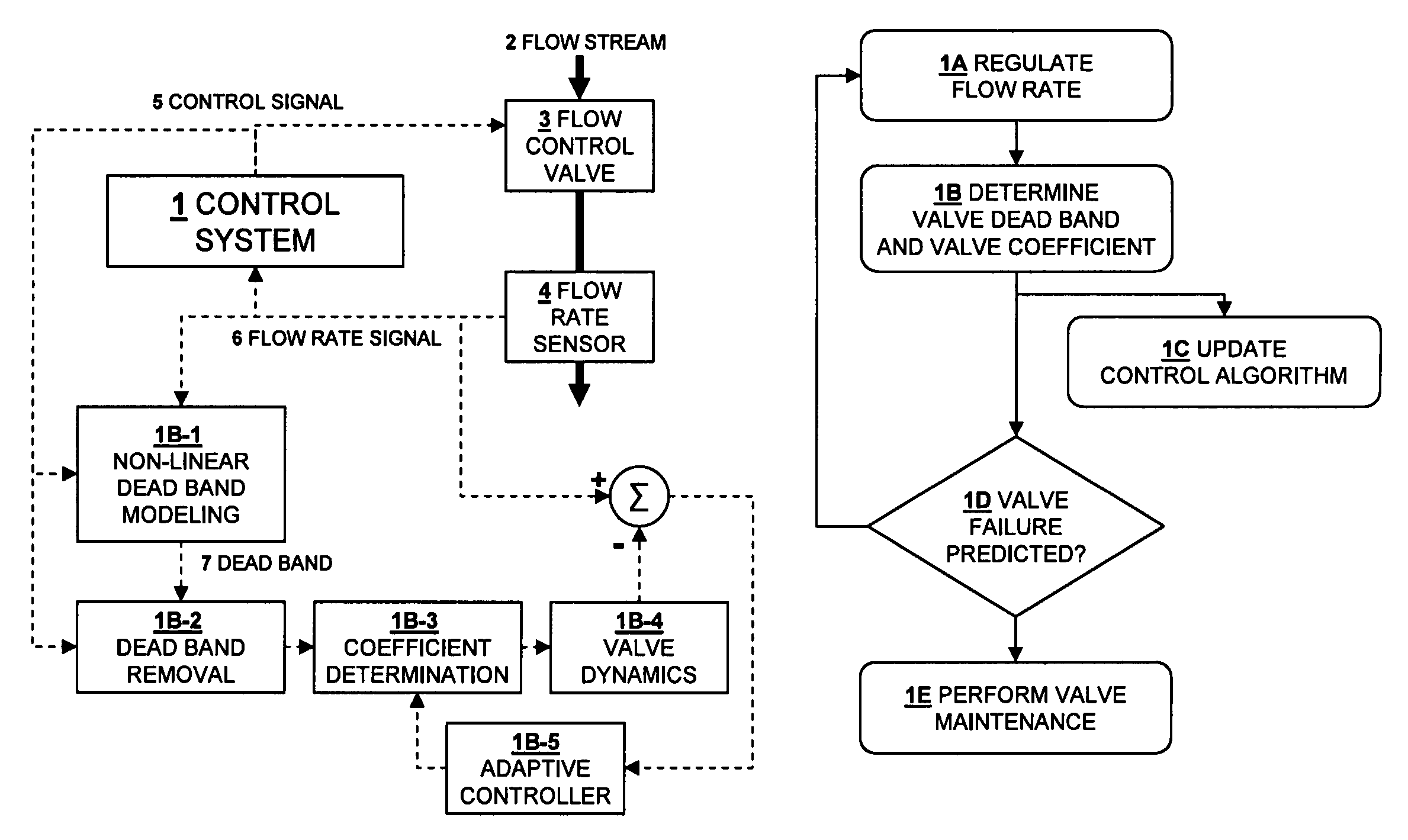

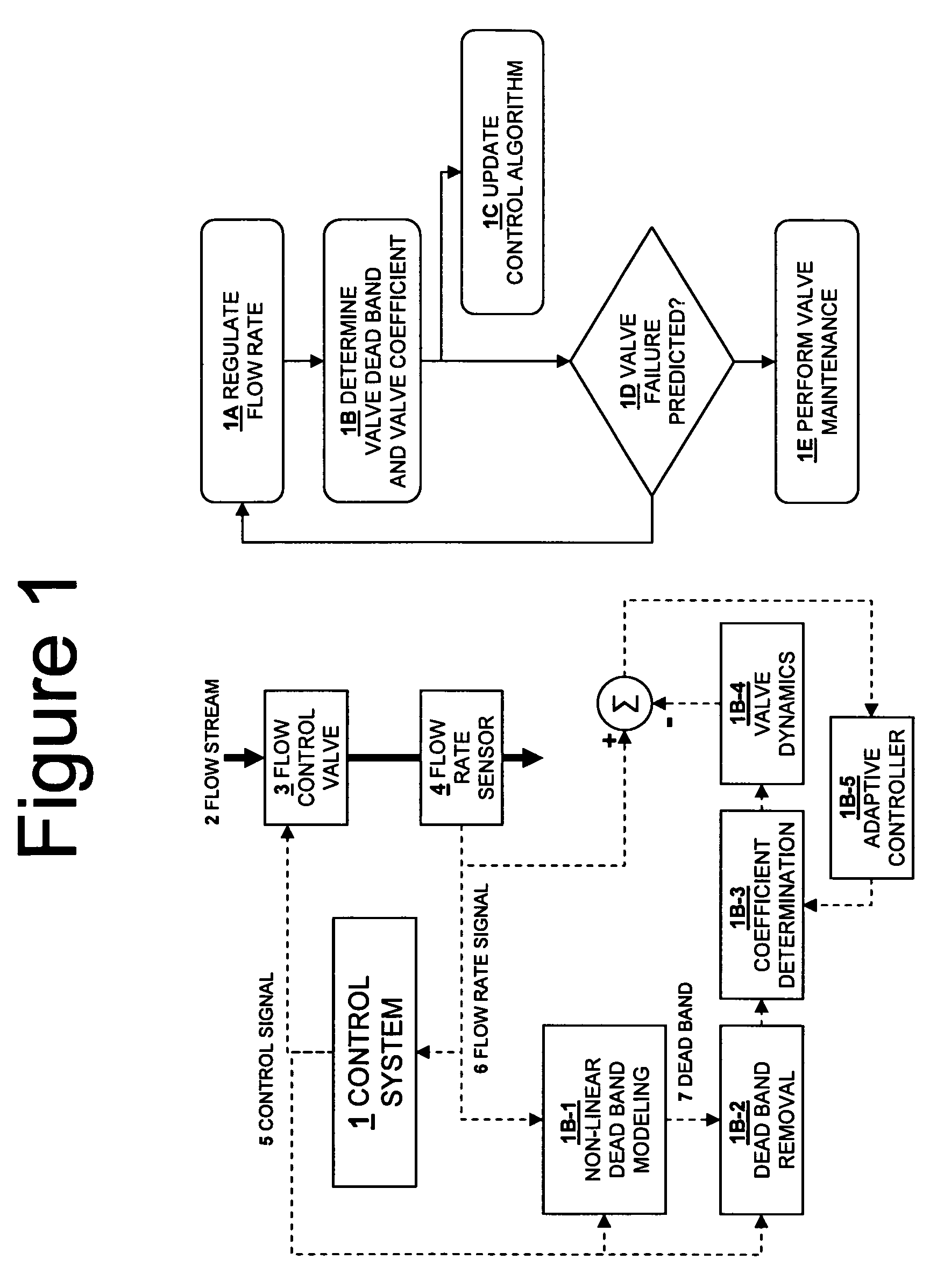

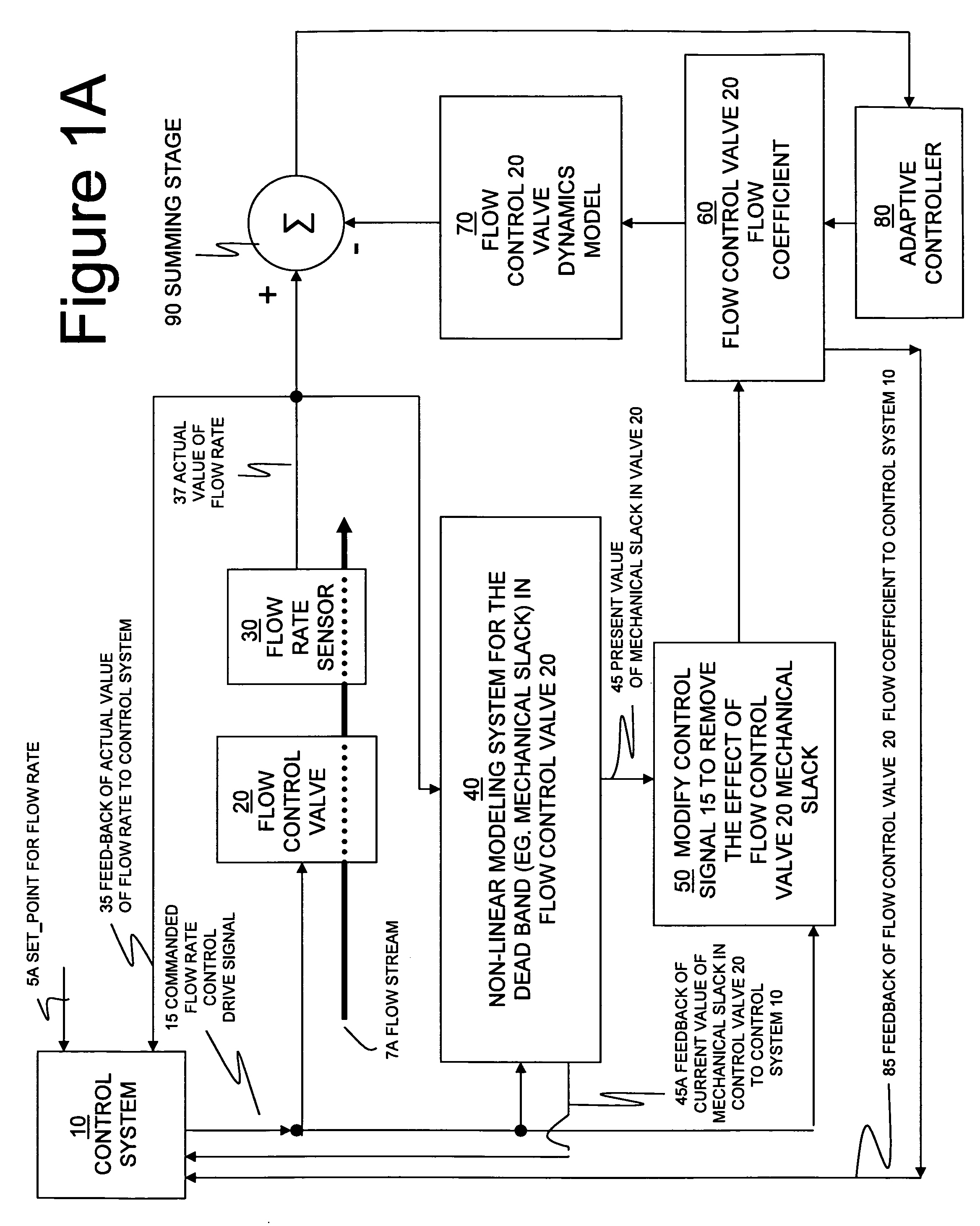

Methods for managing flow control valves in process systems

InactiveUS20080183336A1Amount of signal is lostLose amountTesting/monitoring control systemsRatio controlProcess systemsNon linear dynamic

Methods for managing the operational condition of flow control valves in process systems. As a control valve experiences mechanical wear during operation, the physical changes to the valve can alter its dead band and flow coefficient. A non-linear dynamic model determines the present dead band by modeling the relationship between the actual flow through the valve and the commanded drive signal to the valve. The present valve flow coefficient can be determined by removing the dead band from the drive signal and using that modified signal in a flow rate model for the valve to adaptively find the flow coefficient value which matches the predicted flow from the flow rate model to the present measured flow from a flow rate sensor. The present dead band and flow coefficient can be used to update valve control algorithms and to make valve maintenance decisions.

Owner:HALLIBURTON ENERGY SERVICES INC

Modifiable gate stack memory element

InactiveUS20080099827A1Semiconductor/solid-state device manufacturingDigital storageGate stackPhysical change

An apparatus and method for storing information are provided, including using a transistor having a channel, a gate oxide layer, a gate electrode, and a modifiable gate stack layer. The on-resistance of the transistor is changed by causing a non-charge-storage based physical change in the modifiable gate stack layer, to store information.

Owner:POLARIS INNOVATIONS LTD

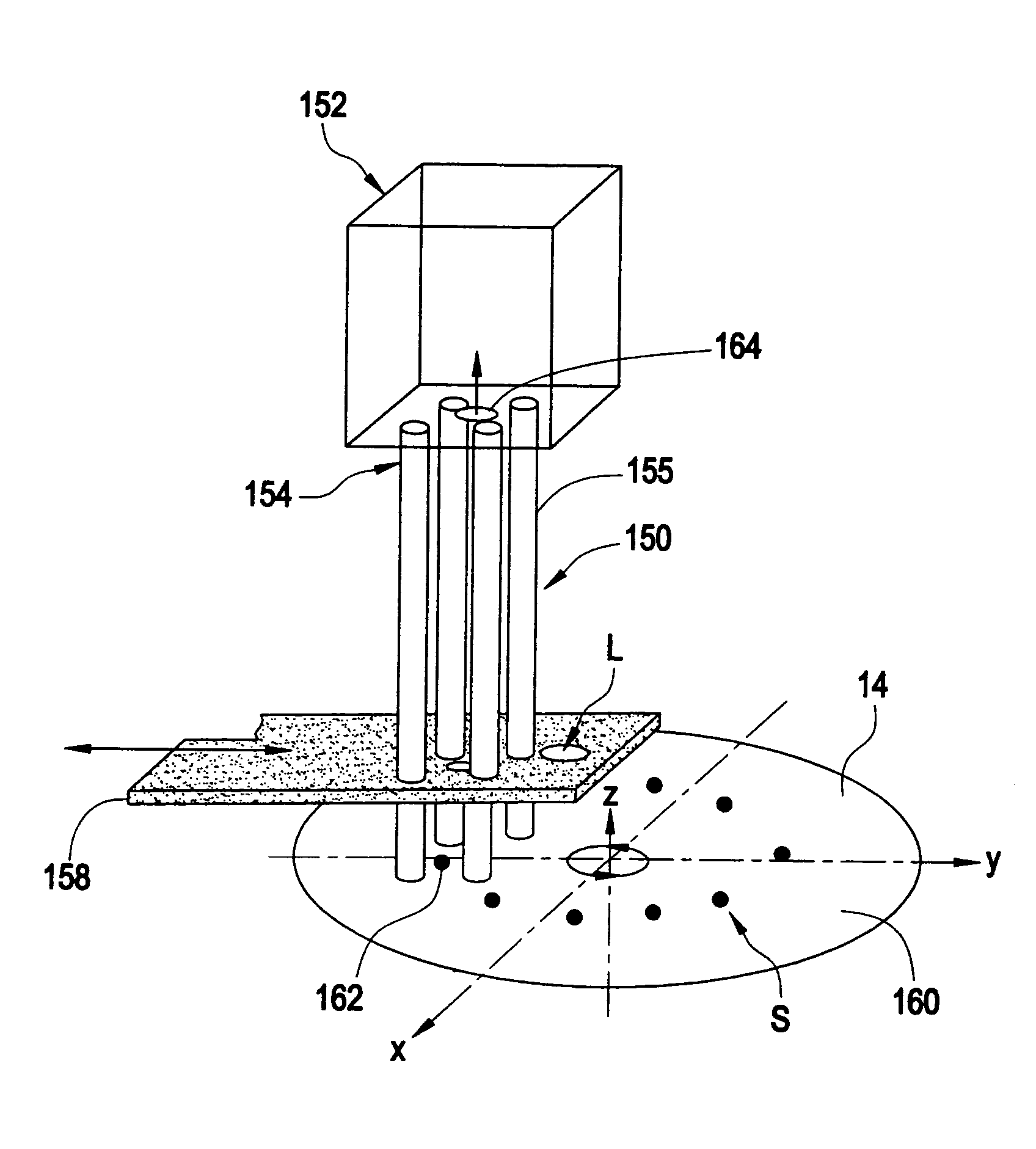

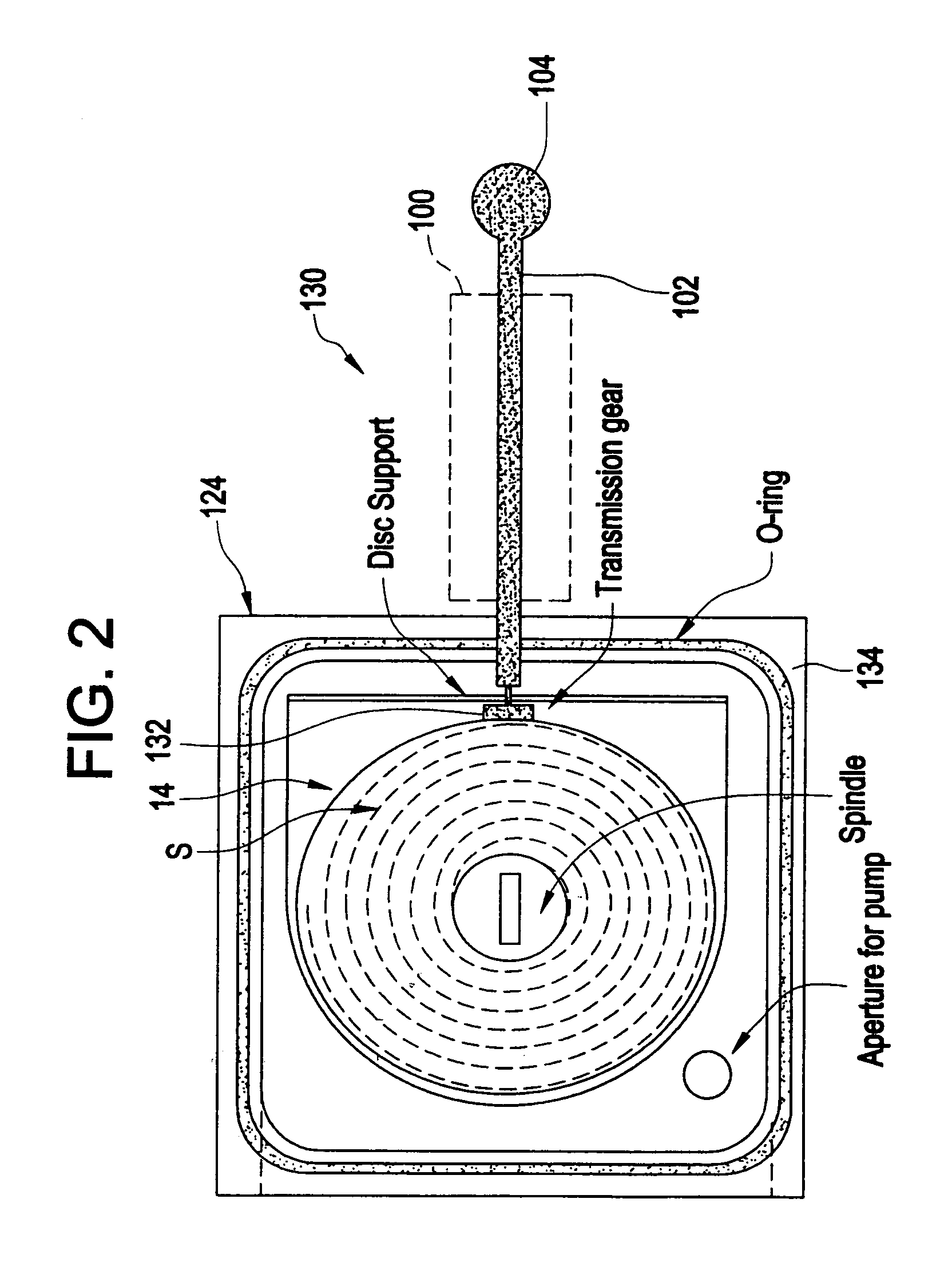

High capacity and scanning speed system for sample handling and analysis

InactiveUS7012249B2Efficient and accurate systemLow costMaterial analysis using wave/particle radiationParticle separator tubesReciprocating motionPhysical change

Disclosed is an apparatus for examining and inspecting at least one sample in order to determine characteristics of the sample having the a support for receiving a compact disc, the compact disc having deposited on a surface thereof at least one sample, inspection means for effecting a physical change in at least one sample, the inspection means positioned for registration with the surface of the compact disc bearing at least one sample; and a traversal mechanism adapted for reciprocating movement, to move the sample in and out of the path of the inspection means.

Owner:THE ROCKEFELLER UNIV

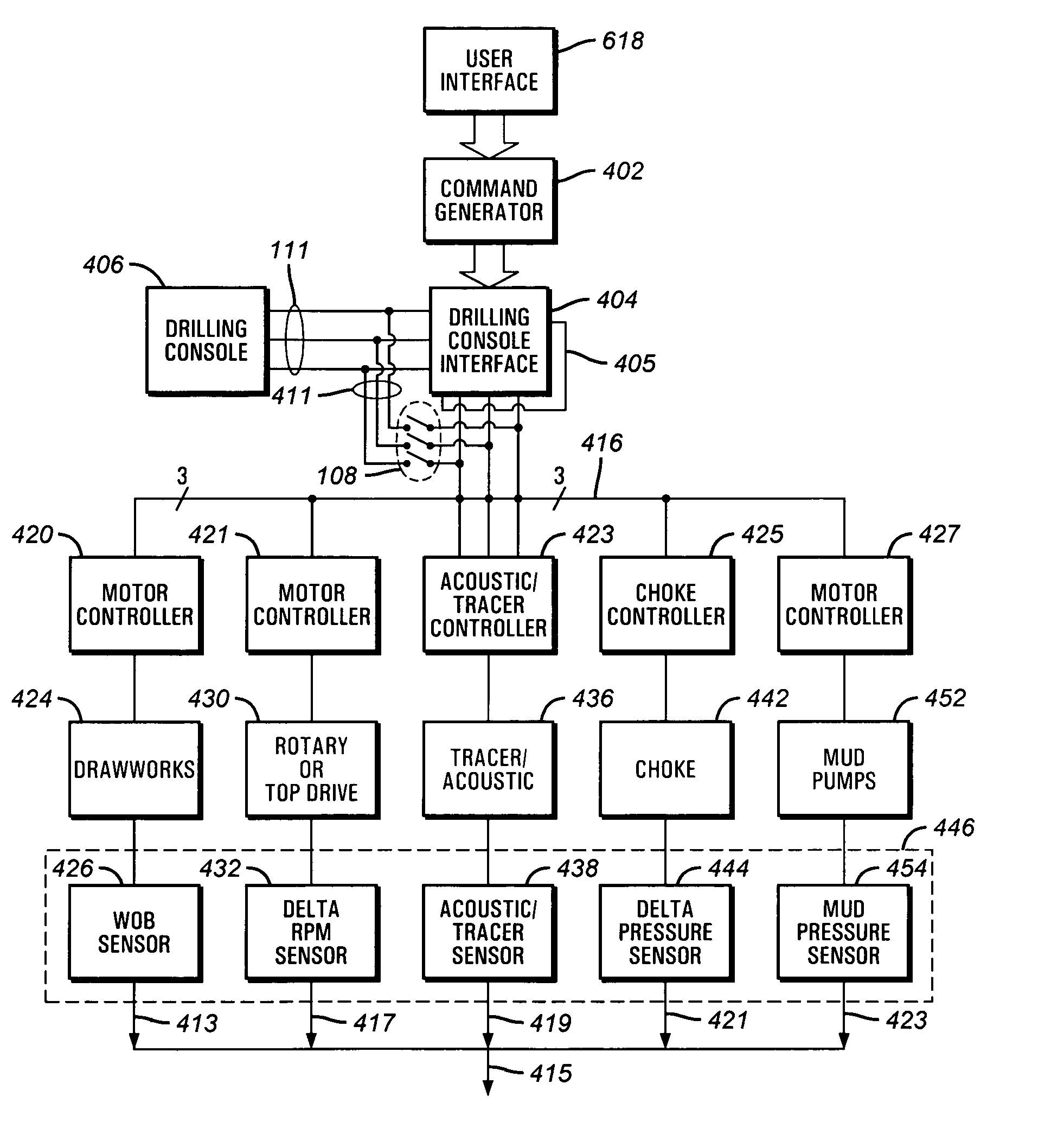

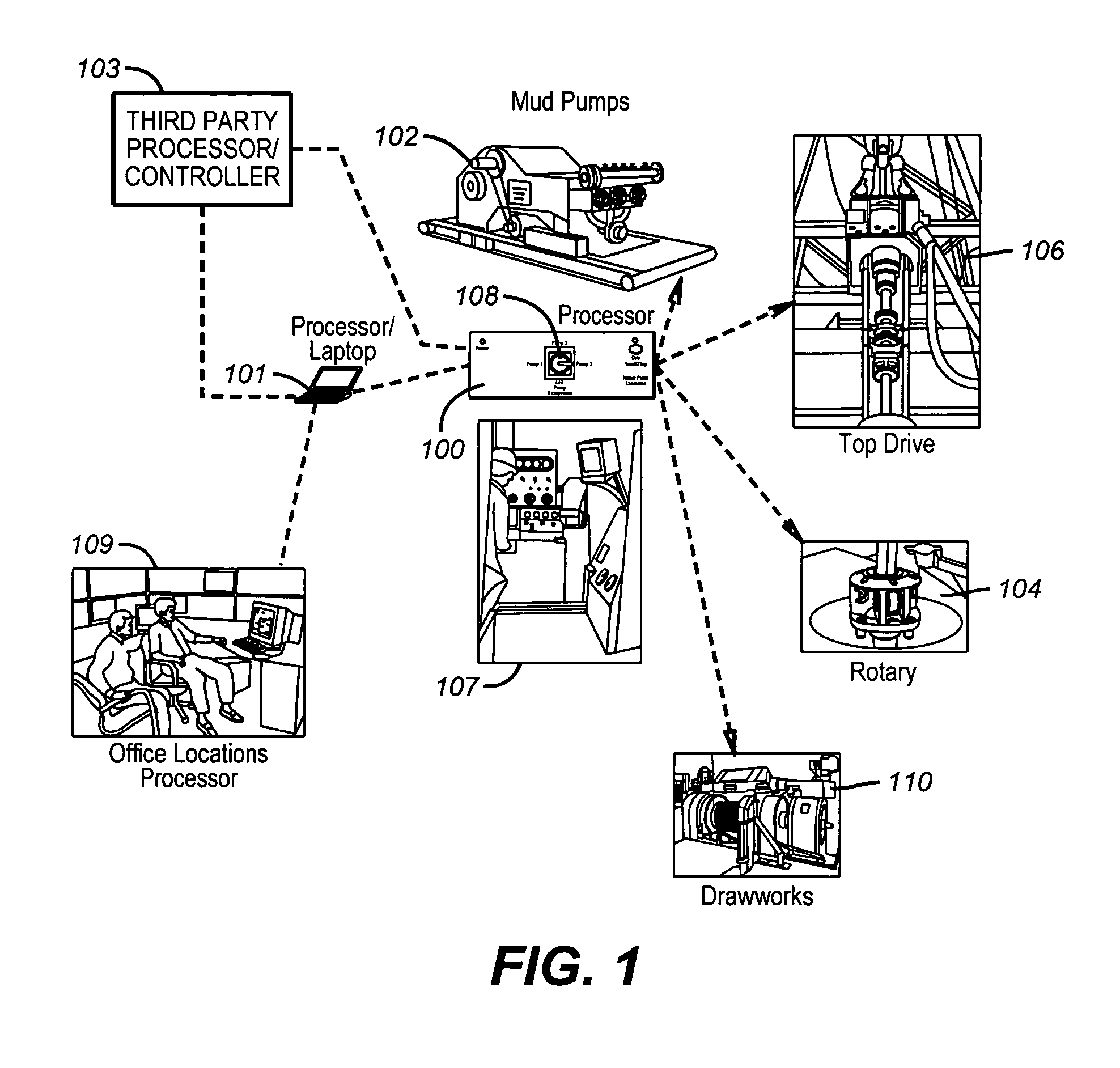

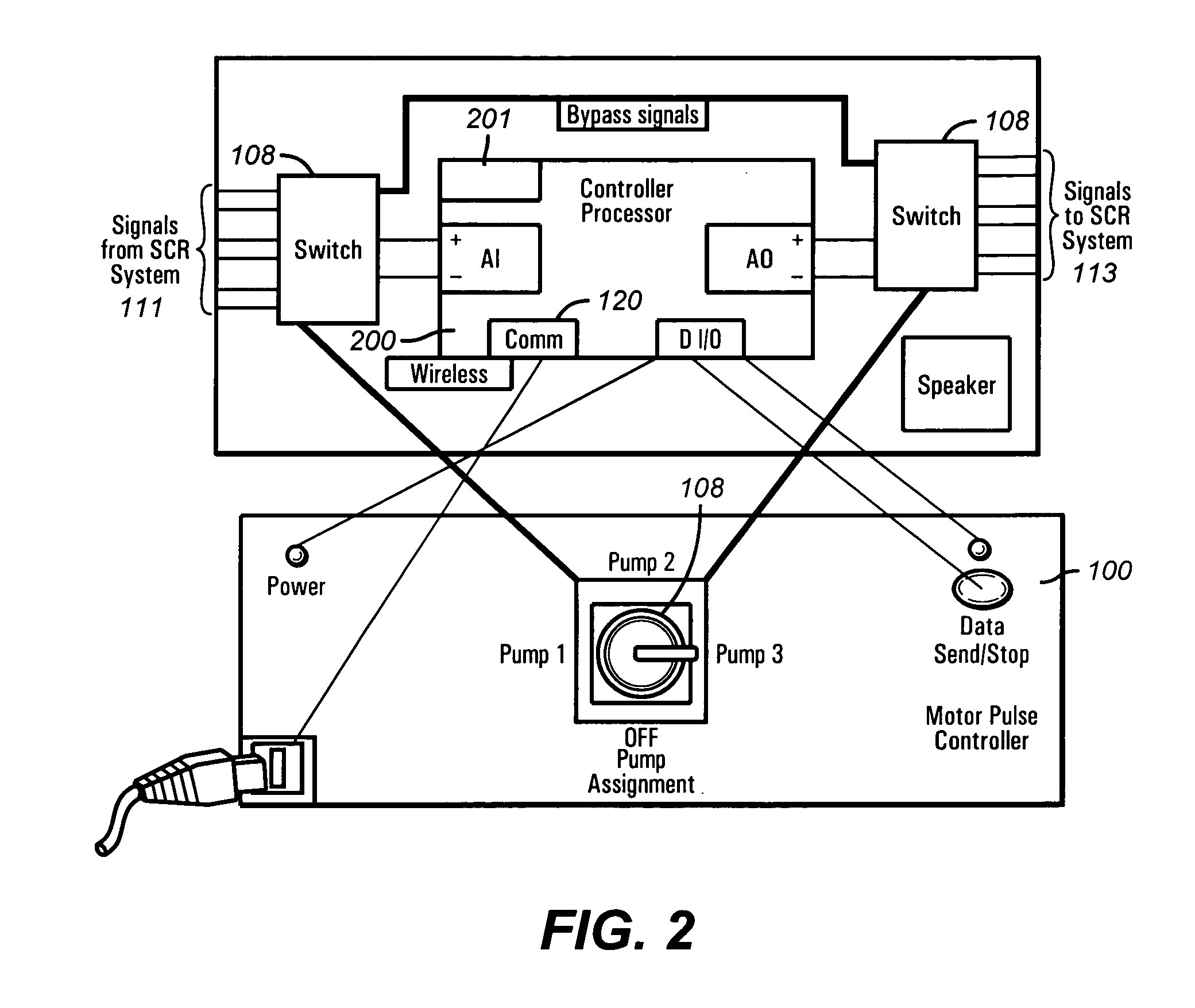

Motor pulse controller

The present invention provides a method and apparatus for generating one or more than one physically detectable physical influence changes to control or manipulate a down hole device. The present invention intercepts existing control signals to various controllers on the rig and superimposes an encoded command on these existing control signals. The controllers comprise of motor drives, choke controllers, acoustic pulse generators, tracer injectors and other controllers that are used to generate a physically detectable changes in the rig environment. The encoded command acting on existing or new controllers generates a perceptible change in a physical parameter such as a variation in drilling mud pressure, a variation in drill string rotation speed, a variation is weight on bit, generation of acoustic pulse, or a variation in tracer injection properties. The physical change is sensed by a down hole device and interpreted as information indicating to the down hole device that it is to execute a command or adjust an operating parameter.

Owner:VARCO I P INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com