Process for treating sodium sulfate wastewater by using nanofiltration-reverse osmosis combined membrane

A technology of reverse osmosis membrane and sodium sulfate, which is applied in the direction of osmosis/dialysis water/sewage treatment, alkali metal sulfite/sulfate purification, etc., which can solve the problems of high equipment investment and operating costs, complex physical operation and complicated treatment process and other issues to achieve the effect of compact equipment, simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

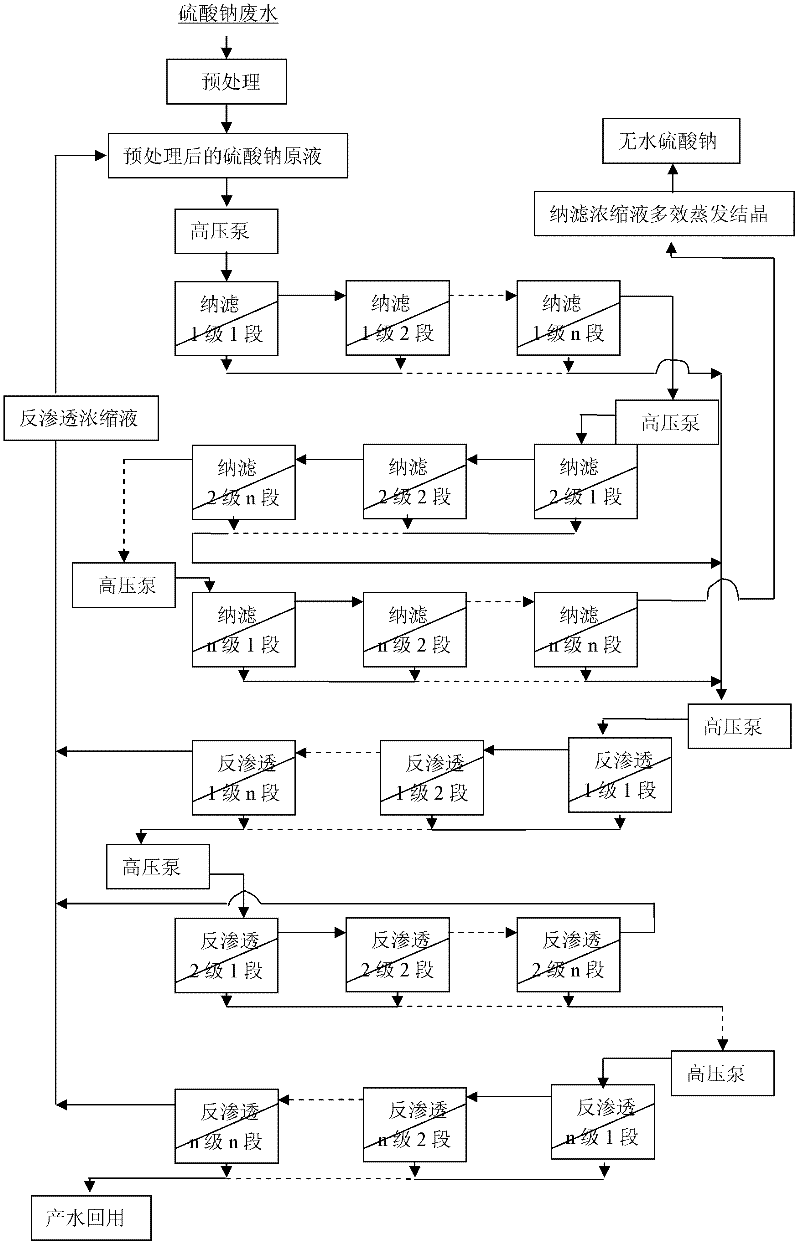

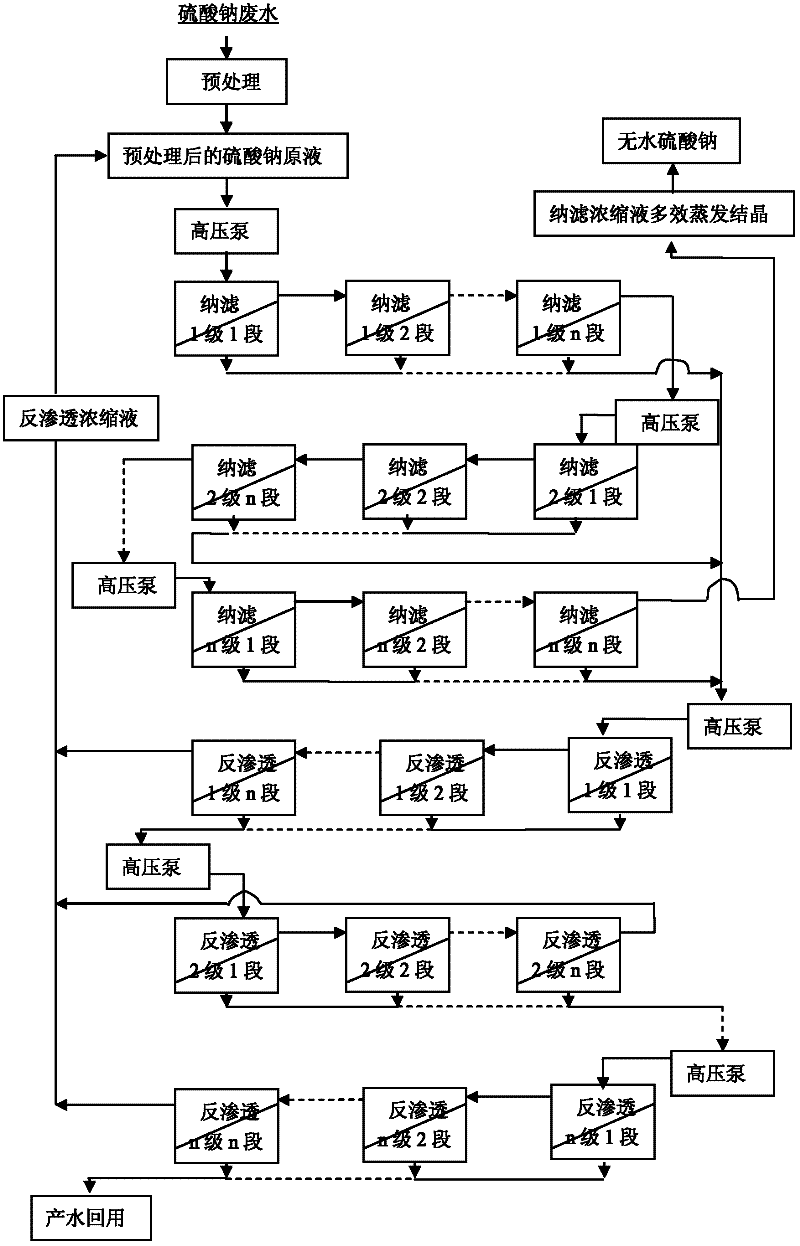

Method used

Image

Examples

Embodiment 1

[0030] The concentration of sodium sulfate wastewater is 500mg / L, the flow rate is 9600t / d, pH=8.2, it is required to be concentrated to 7%, and the TDS of the product water is less than 20ppm.

[0031] a. Send the pretreated sodium sulfate wastewater into the nanofiltration membrane stack through high-pressure pumps, and adopt five stages and ten stages according to the nature of the raw water;

[0032] b. After sodium sulfate wastewater is treated by five-stage and ten-stage nanofiltration membrane stacks, the concentrated solution is directly subjected to four-effect evaporation and crystallization to obtain qualified industrial anhydrous sodium sulfate products and condensed water, and the condensed water is reused;

[0033] c. After the nanofiltration water is pressurized by the high-pressure pump, it is sent to the reverse osmosis membrane stack;

[0034] d. The reverse osmosis concentrated solution enters the nanofiltration stock solution for recycling treatment;

[00...

Embodiment 2

[0037] The concentration of sodium sulfate is 3000mg / L, the flow rate is 2450t / d, and the pH value is 9.8. The concentration of sodium sulfate is required to be concentrated to 8%, and the TDS of the product water is less than 40ppm.

[0038] a. The pretreated sodium sulfate wastewater is sent to the nanofiltration membrane stack through high-pressure pumps, and three stages and five stages are adopted according to the nature of the raw water;

[0039] b. After sodium sulfate wastewater is treated by three-stage five-stage nanofiltration membrane stacks, the concentrated solution is directly subjected to three-effect evaporation and crystallization to obtain qualified industrial anhydrous sodium sulfate products and condensed water, which is reused;

[0040] c. After the nanofiltration water is pressurized by the high-pressure pump, it is sent to the reverse osmosis membrane stack;

[0041] d. The reverse osmosis concentrated solution enters the nanofiltration stock solution ...

Embodiment 3

[0044] The concentration of sodium sulfate wastewater is 5000mg / L, the flow rate is 8000t / d, and the pH value is 6.8. It is required to be concentrated to 8.5%, and the TDS of the product water is less than 50ppm.

[0045] a. Send the pretreated sodium sulfate wastewater into the nanofiltration membrane stack through a high-pressure pump, and adopt the second-stage ten-stage according to the nature of the raw water;

[0046] b. After the sodium sulfate wastewater is treated by the second-stage and ten-stage nanofiltration membrane stack, the concentrated solution is directly subjected to three-effect evaporation and crystallization to obtain qualified industrial anhydrous sodium sulfate products and condensed water, and the condensed water is reused;

[0047] c. After the nanofiltration water is pressurized by the high-pressure pump, it is sent to the reverse osmosis membrane stack;

[0048] d. The reverse osmosis concentrated solution enters the nanofiltration stock solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com