Patents

Literature

44results about How to "Save process water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

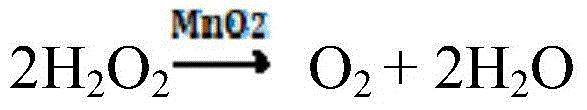

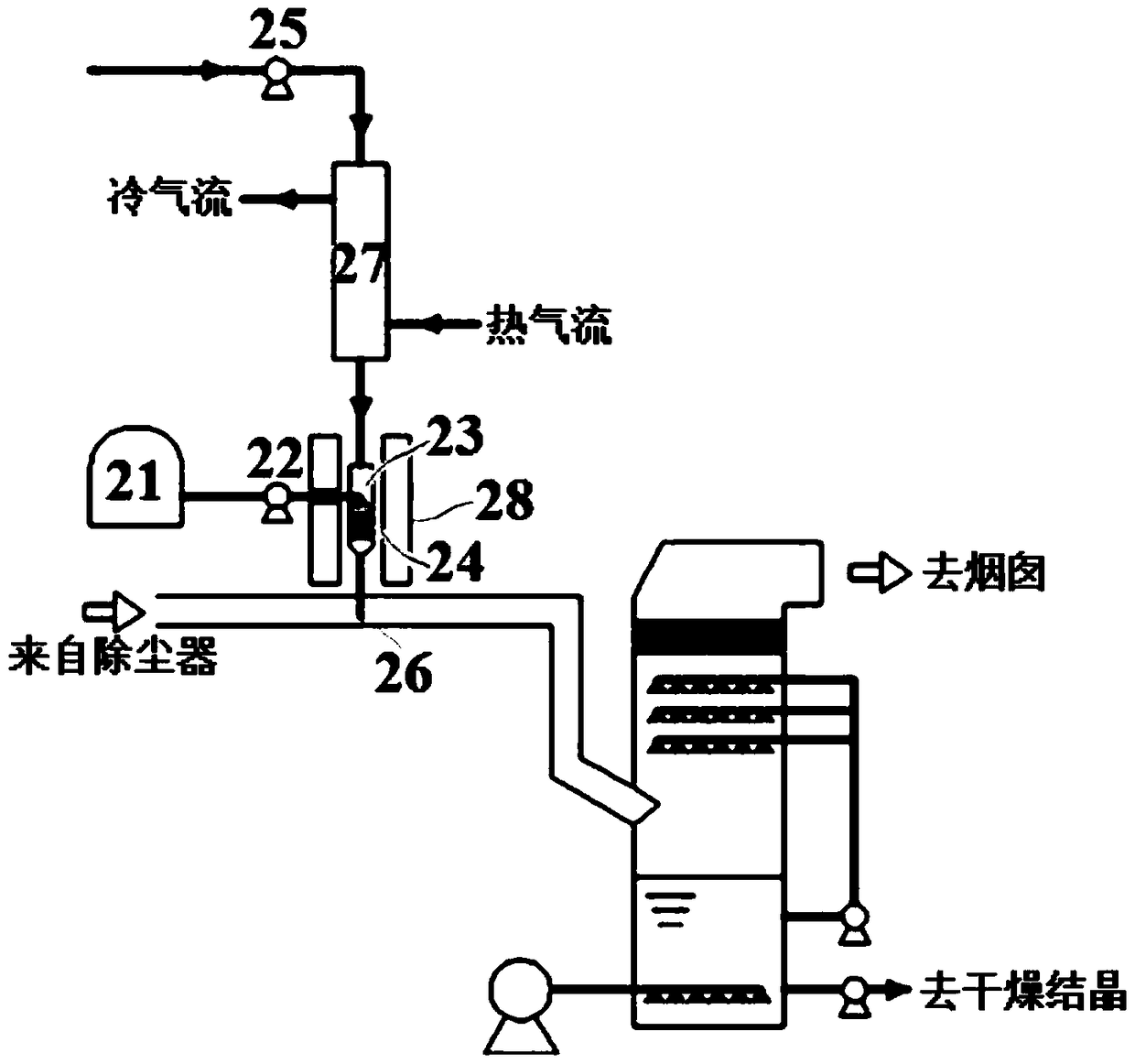

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

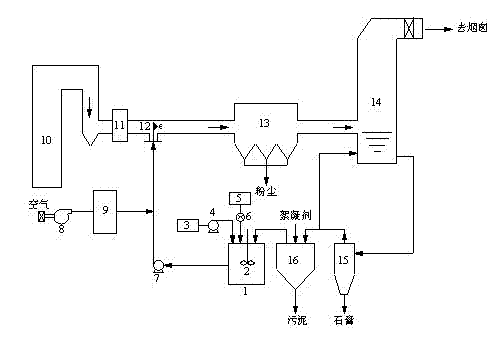

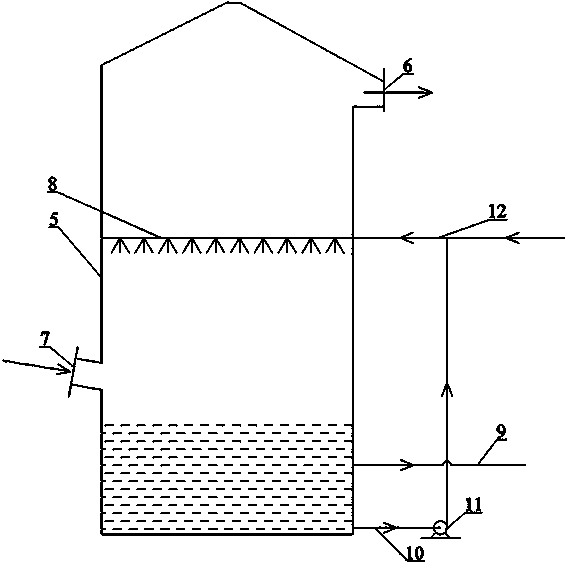

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

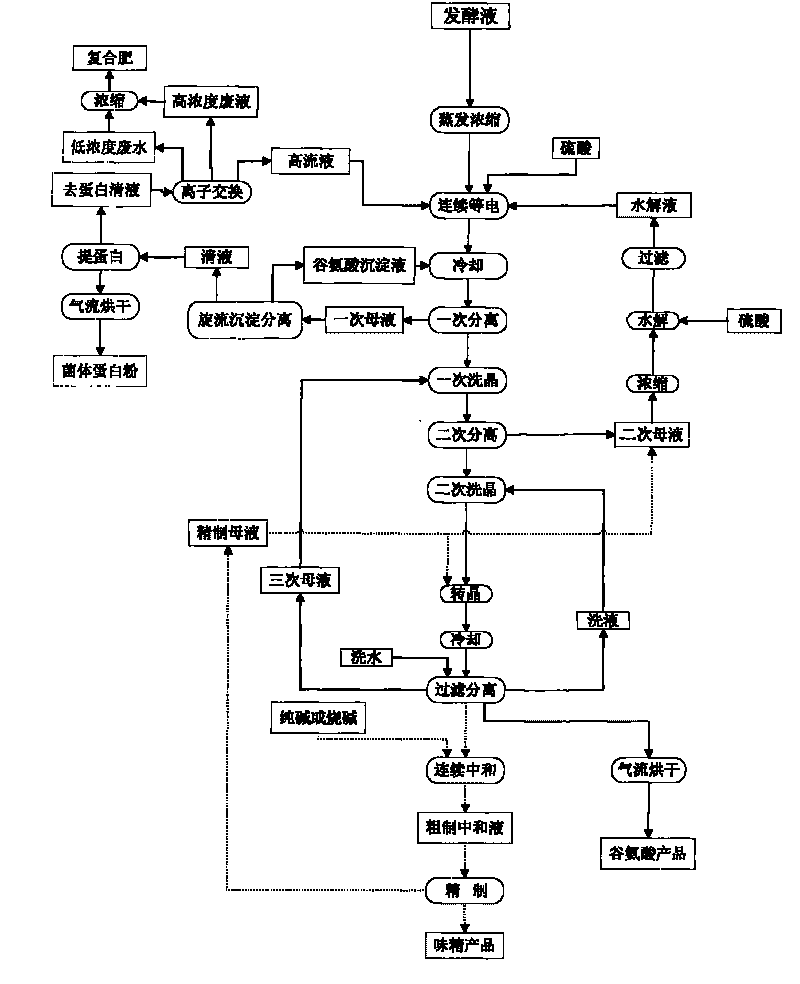

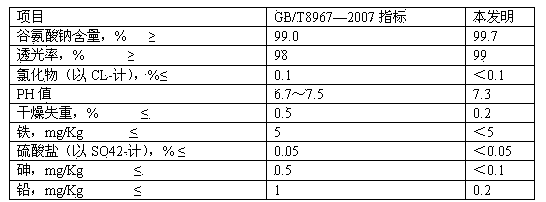

Novel production method for glutamic acid

ActiveCN102703537AReduce lossesLess waste waterOrganic compound preparationMicroorganism based processesHigh concentrationFluidized bed drying

The invention discloses a novel production method for glutamic acid, belonging to the technical field of the production of amino acid. The novel production method for the glutamic acid comprises the following steps of: removing thalli and insolubles by means of high-speed disc separation; evaporating and concentrating separated glutamic acid material liquid through a multi-effect plate type evaporator at low temperature, wherein the generated secondary steam condensed water is used for fermentation ingredients of the glutamic acid; performing continuous isoelectric extraction on the glutamic acid in the evaporated glutamic acid concentrated solution; absorbing the glutamic acid by making supernatant fluid pass through ion exchange columns; performing isoelectric reextraction on the analyzed glutamic acid; inputting high-concentration wastewater into a fertilizer workshop for producing fertilizer; squeezing heavy phase (mycoprotein) through a plate frame, and granulating; and drying through a fluid bed, and thus producing high-protein feed. The novel production method for the glutamic acid has the advantages of low unit consumption of liquid ammonia and sulfuric acid, high extraction yield of the glutamic acid, less ion exchange investment and the like; and meanwhile, the purity of the extracted glutamic acid is high, sodium glutamate can be produced without crystalloblast, resources are fully used in the whole process, the aims of energy conservation and consumption reduction are achieved, and the novel production method for the glutamic acid has a wide application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

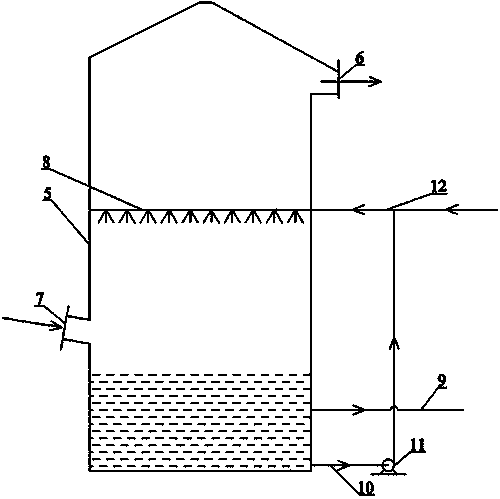

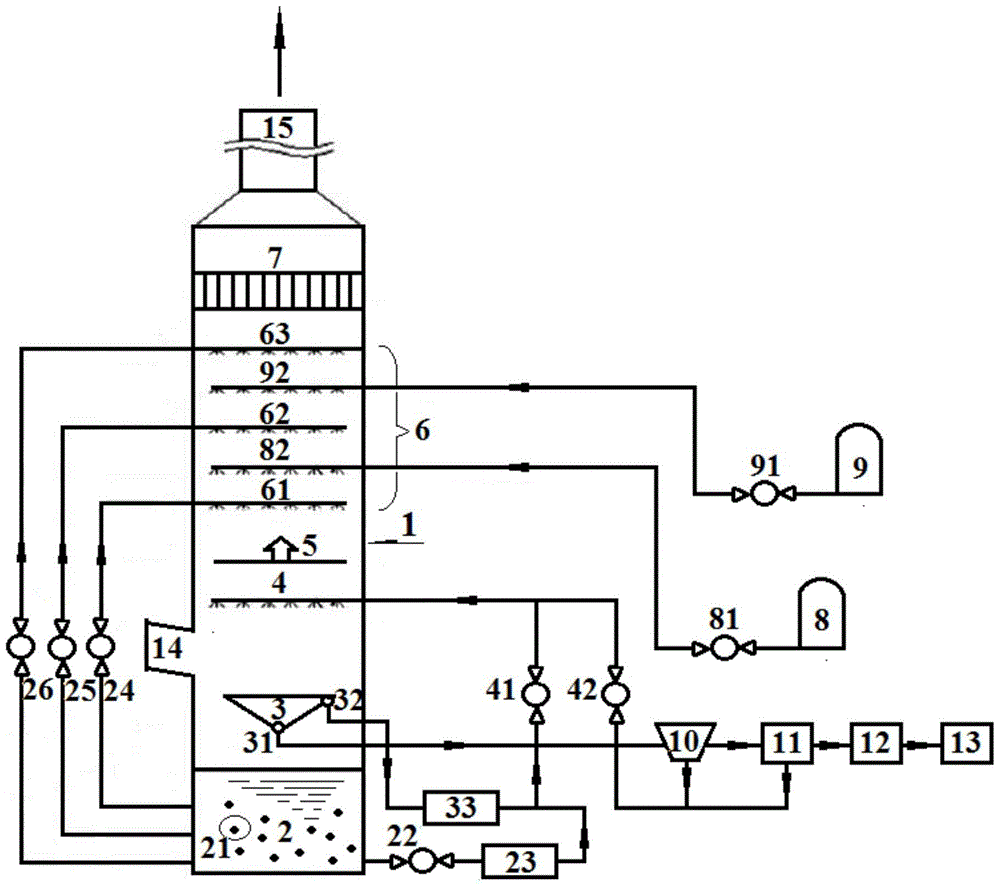

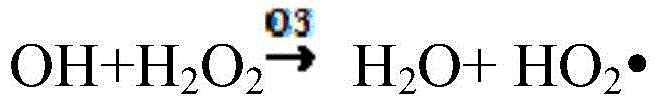

Integrated flue gas treatment device and method

ActiveCN104857835ARealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

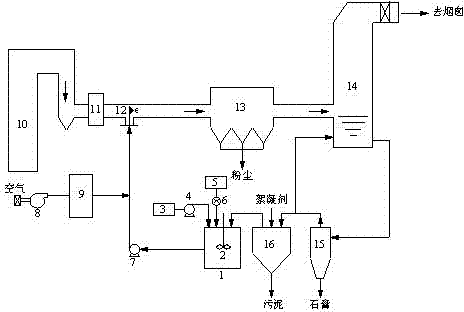

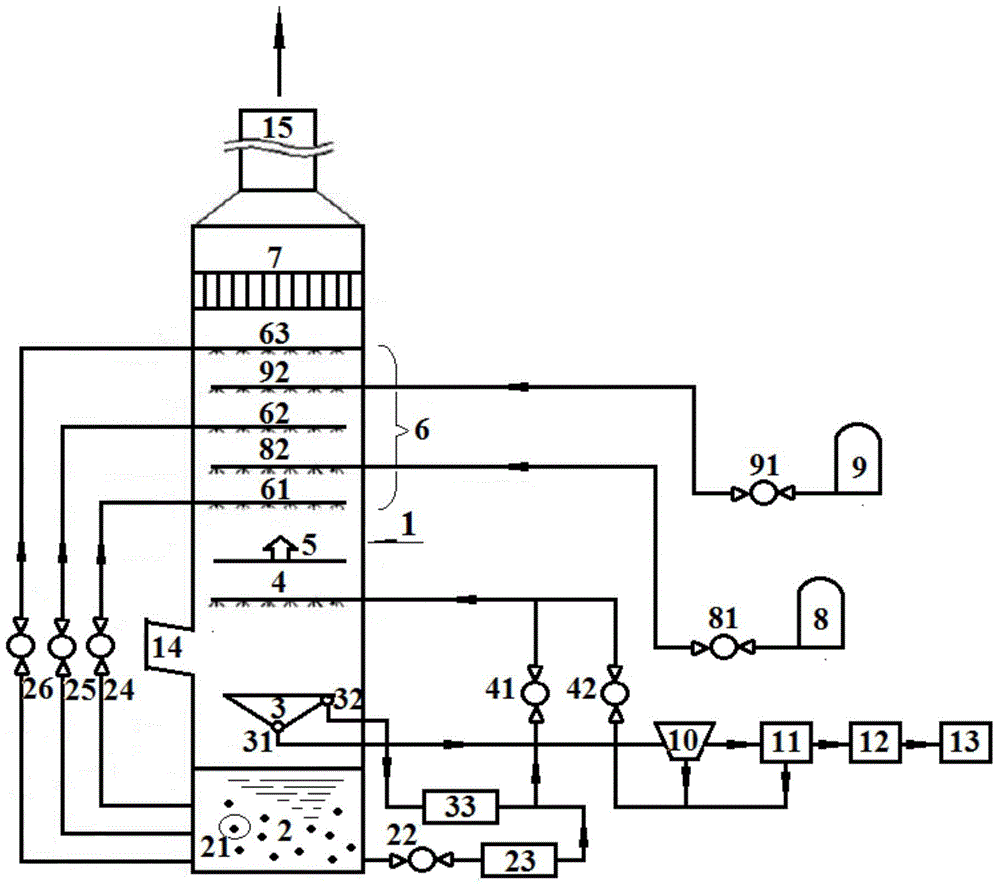

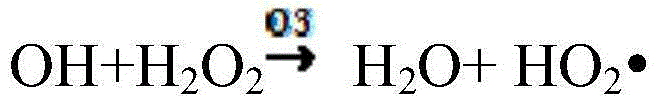

The invention discloses an integrated flue gas treatment device and method. The device comprises flue gas treatment equipment, ozone supply equipment, hydrogen peroxide supply equipment, evaporation and concentration equipment, cyclic sedimentation equipment and the like, wherein the flue gas treatment equipment comprises an ozone spray oxidation reaction layer, a hydrogen peroxide spray oxidation reaction layer, an absorber spray area, a slurry circulation area and a dust and mist removal area; both the ozone spray oxidation reaction layer and the hydrogen peroxide spray oxidation reaction layer are arranged in the absorber spray area; the dust and mist removal area is positioned above the absorber spray area; both the evaporation and concentration equipment and the cyclic sedimentation equipment are arranged in the flue gas treatment equipment. The device and the method disclosed by the invention are suitable for comprehensive treatment of flue gas containing SO2, NOX, Hg and dust and resource utilization of liquid waste in coal fired boilers, iron and steel sintering machines, pellets, industry kiln stoves and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

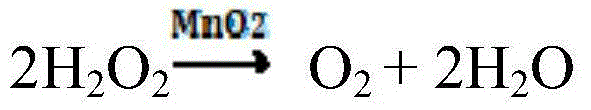

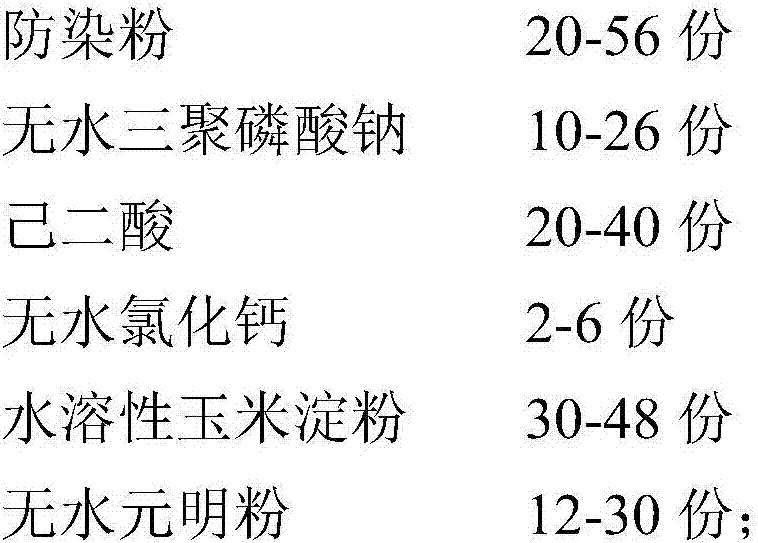

Desizing, enzyme-washing and bleaching integrated one-bath process

InactiveCN107419510AWater saving realizedRealize water savingDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsWorking fluidProcess engineering

The invention discloses a desizing, enzyme-washing and bleaching integrated one-bath process which includes the steps of (1), adding water and denim garments in an industrial washing machine and starting steam-heating; (2), stopping the steam-heating; (3), adding in desizing and enzyme-washing two-in-one enzyme powder for processing; (4), adding in blenching enzymes for processing; (5), discharging working fluid in the industrial washing machine; (6), adding in water to wash denim garments in the industrial washing machine; (7), discharging bath foam in the industrial washing machine, and (8) dewatering and drying the denim garments to obtain the desized, enzyme-washed and bleached denim garments. By the desizing, enzyme-washing and bleaching integrated one-bath process, denim garments are processed with excellent and unique washing effect, while energy saving and environmental protection are achieved during processing. The desizing, enzyme-washing and bleaching integrated one-bath process is a good choice for washing of denim garments.

Owner:JIANGSU NEW REBA TECH CO LTD

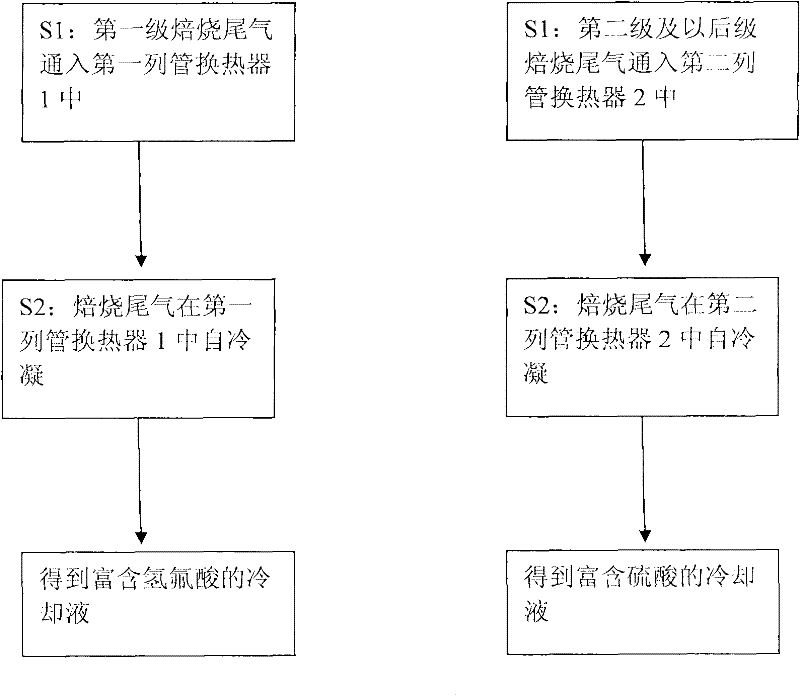

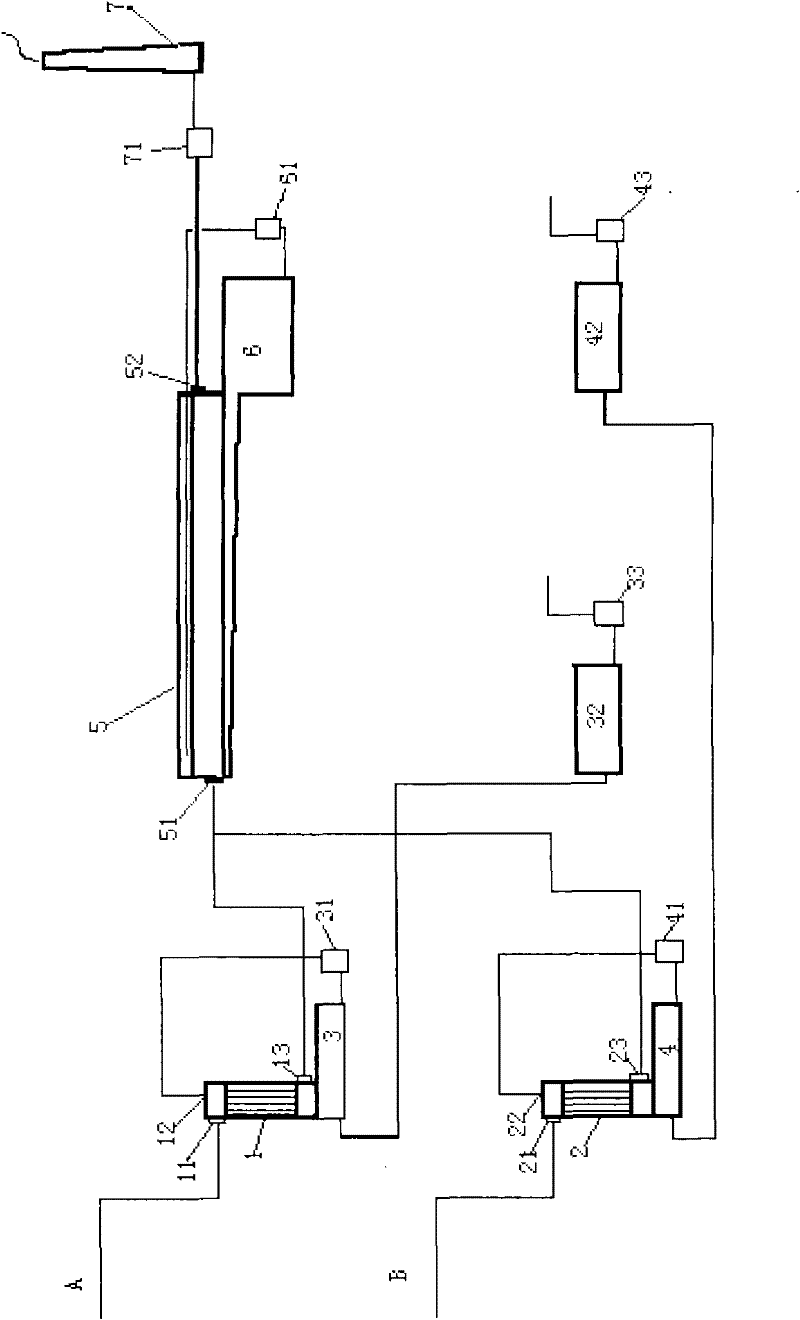

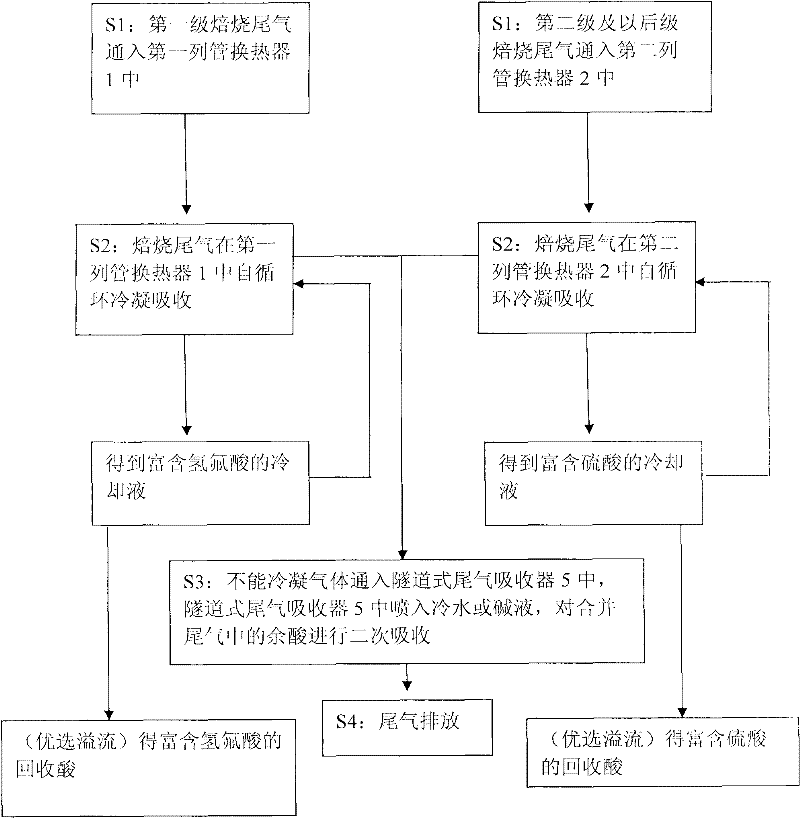

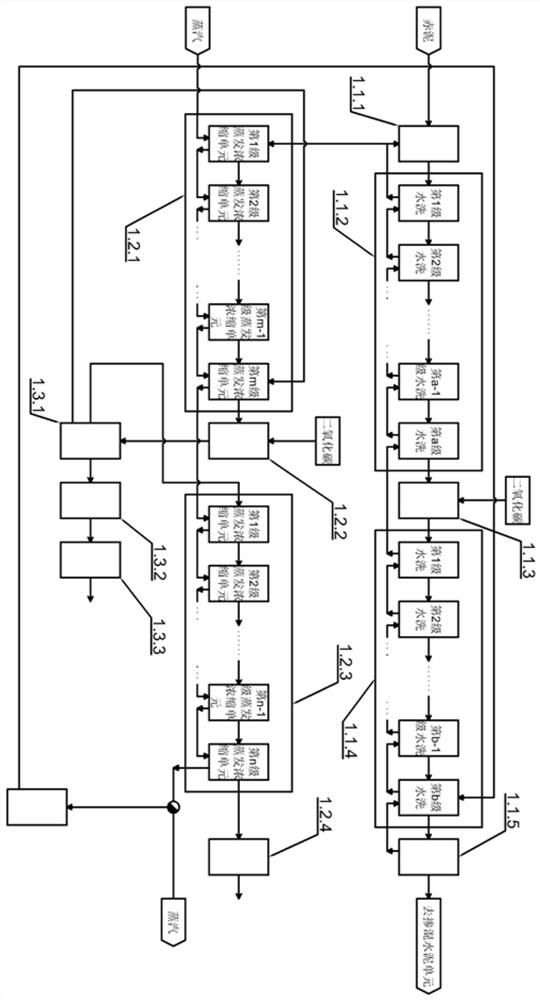

Respective recovery method for rare earth concentrate multi-stage baking tail gases, and device thereof

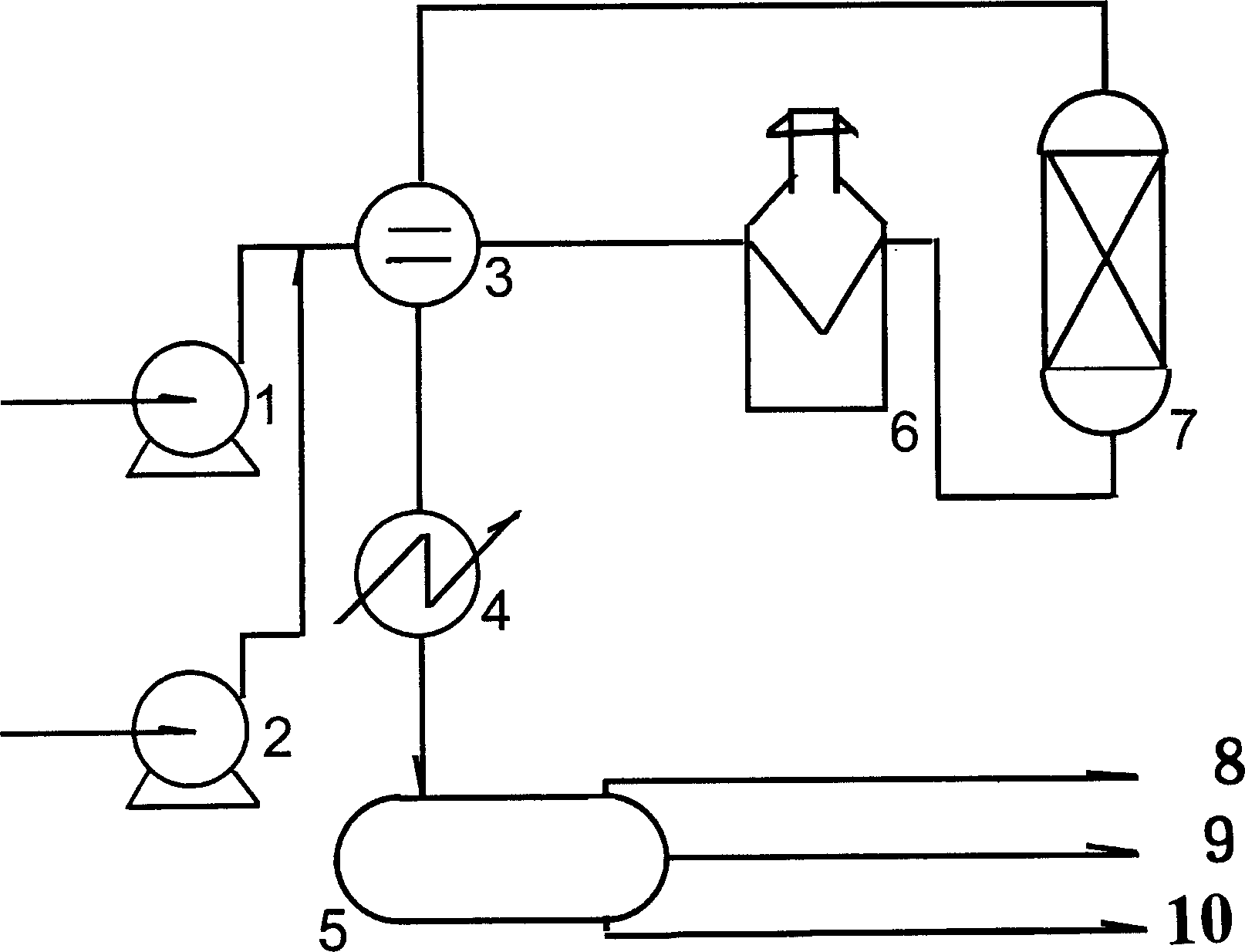

InactiveCN102489034ASimplify the concentration processSave process waterVapor condensationSulfur-trioxide/sulfuric-acidRecovery methodHydrofluoric acid

The present invention provides a respective recovery method for rare earth concentrate multi-stage baking tail gases, and a device thereof. The method comprises the following steps: 1, collecting the tail gases: the tail gas generated from first stage baking is introduced into a first tubular heat exchanger (1), and the tail gas generated from second stage baking and the tail gas generated from later stage baking are mixed and introduced into a second tubular heat exchanger (2); 2, condensing and absorbing: the tail gas generated from the first stage baking is subjected to self-condensation in the first tubular heat exchanger (1) to generate a hydrofluoric acid-rich cooling liquid, and the mixture comprising the tail gases generated from the second stage baking and the later stage baking is subjected to self-condensation in the second tube alignment heat exchanger (2) to generate a sulfuric acid-rich cooling liquid. According to the present invention, the tail gases generated from the first stage baking, the second stage baking and the later stage baking are respectively treated, and the recovery treatments are concurrently performed to obtain the hydrofluoric acid-rich cooling liquid or the sulfuric acid-rich cooling liquid, and the high concentration sulfuric acid can be obtained without the sulfuric acid concentration process.

Owner:BERIS ENG & RES CORP

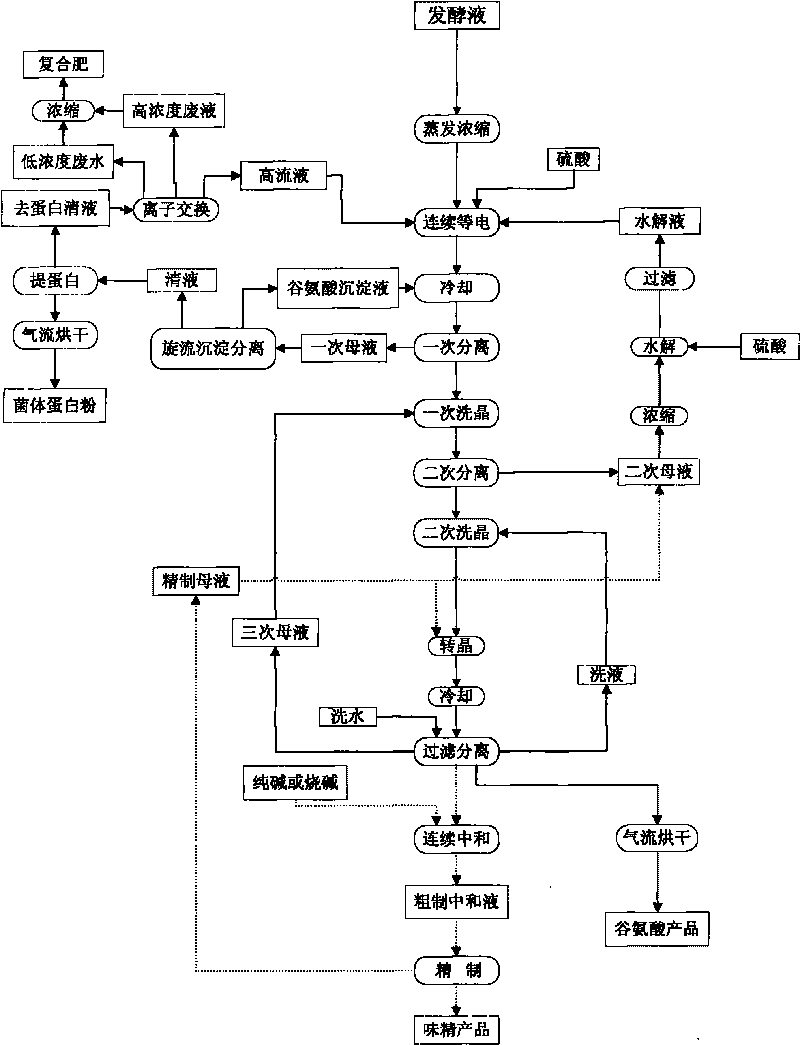

Production process of glutamic acid and monosodium glutamate

InactiveCN101735088AReduce dosageTemperature controlOrganic compound preparationAmino-carboxyl compound preparationMonosodium glutamateFiltration

The invention discloses a production process of glutamic acid and monosodium glutamate, which comprises the following steps: firstly, evaporating and concentrating fermentation liquid; after concentrated sulfuric acid is added for isoelectric operation, cooling to 5-15 DEG C; obtaining an alpha-crystalline glutamic acid crystal suspension after primary separation, primary crystal washing, secondary separation and secondary crystal washing; regulating the pH value to be 4.0-5.0 at 80-90 DEG C, cooling to 35 DEG C, and obtaining a beta-crystalline glutamic acid crystal through filtration and separation, wherein the beta-crystalline glutamic acid crystal can be dried by air flow to obtain glutamic acid products, and the beta-crystalline glutamic acid crystal can be continuously neutralized and refined to obtain monosodium glutamate products; carrying out cyclone precipitation on primary mother liquid after primary separation, removing protein in supernatant liquid by flocculation air flotation process, and drying the protein to obtain bacterial protein powder; and carrying out ion exchange on the deproteinized clear liquid to prepare compound fertilizer. The extraction method of the glutamic acid provided by the invention fundamentally reduces the generation of waste water, improves the extraction yield and the product quality, reduces the amount of water for exchanging ions and washing columns to the minimum, and has higher production efficiency and lower production cost.

Owner:BEIJING PIHUA BIOLOGICAL TECH

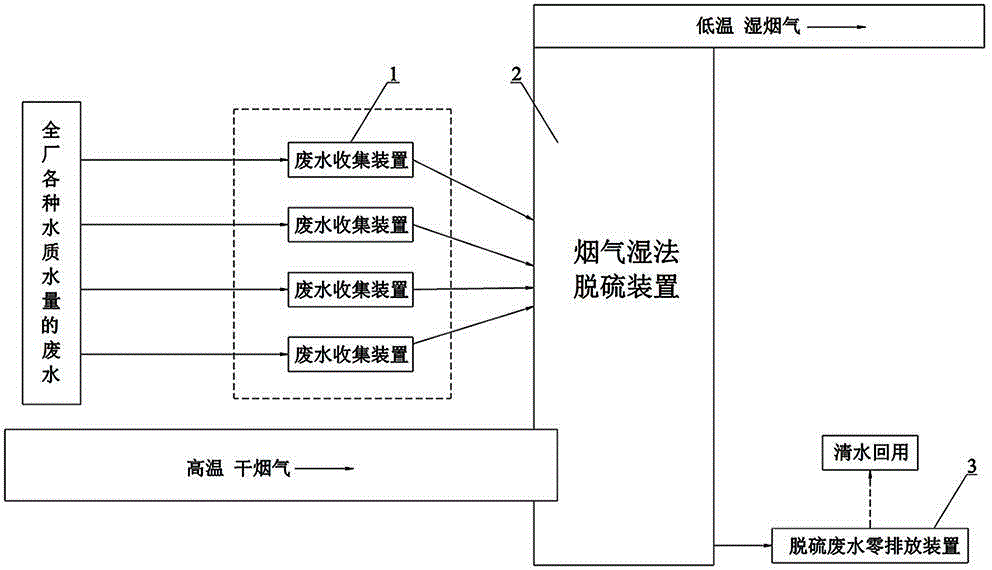

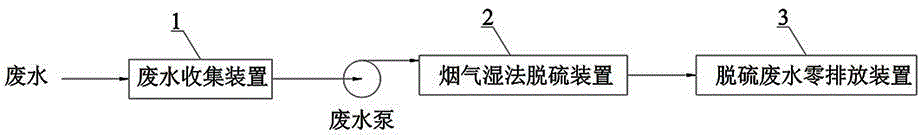

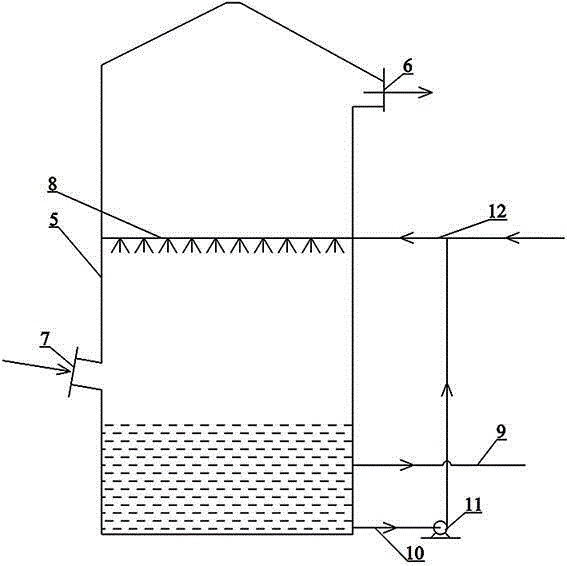

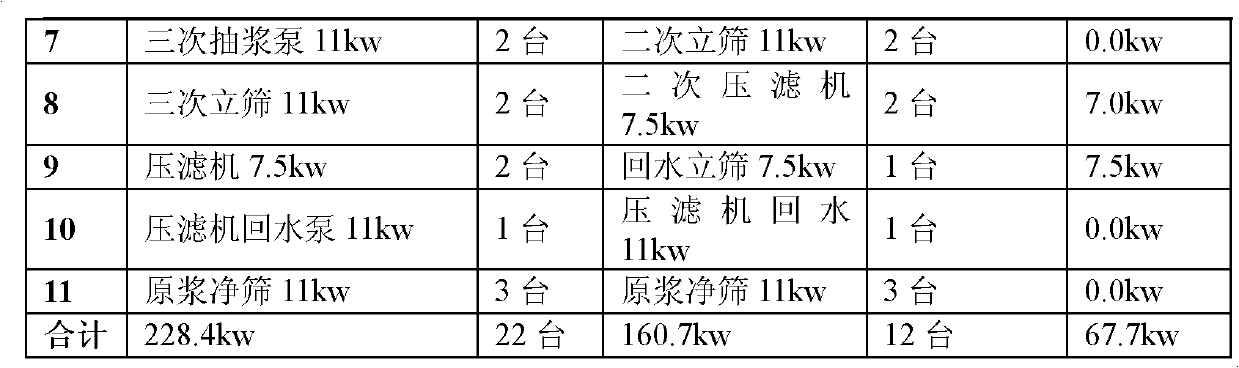

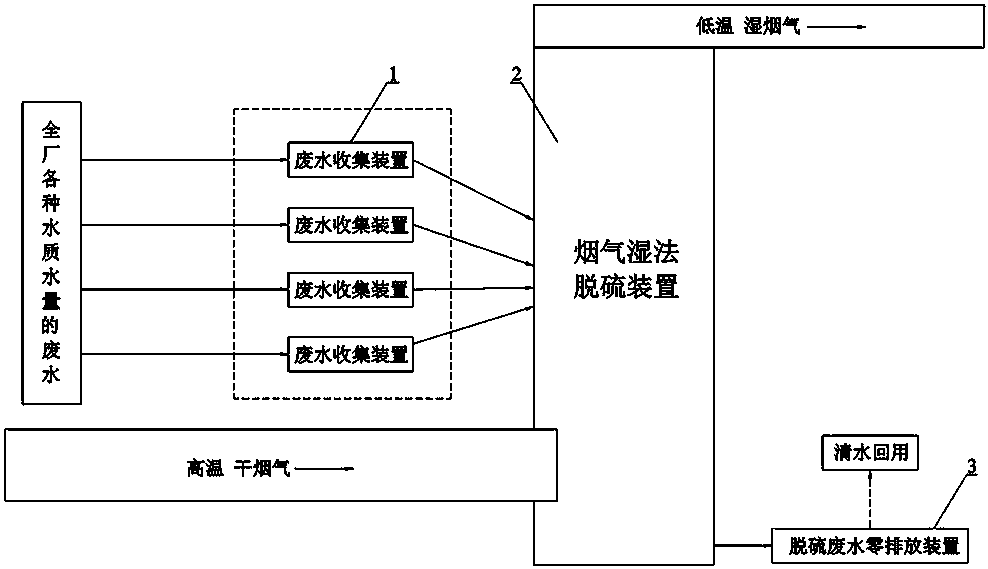

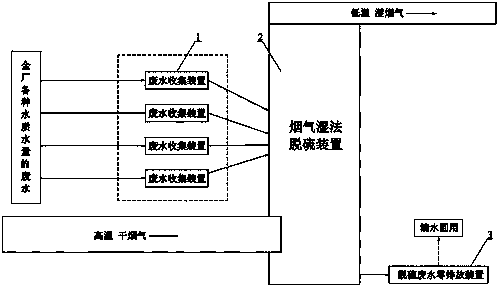

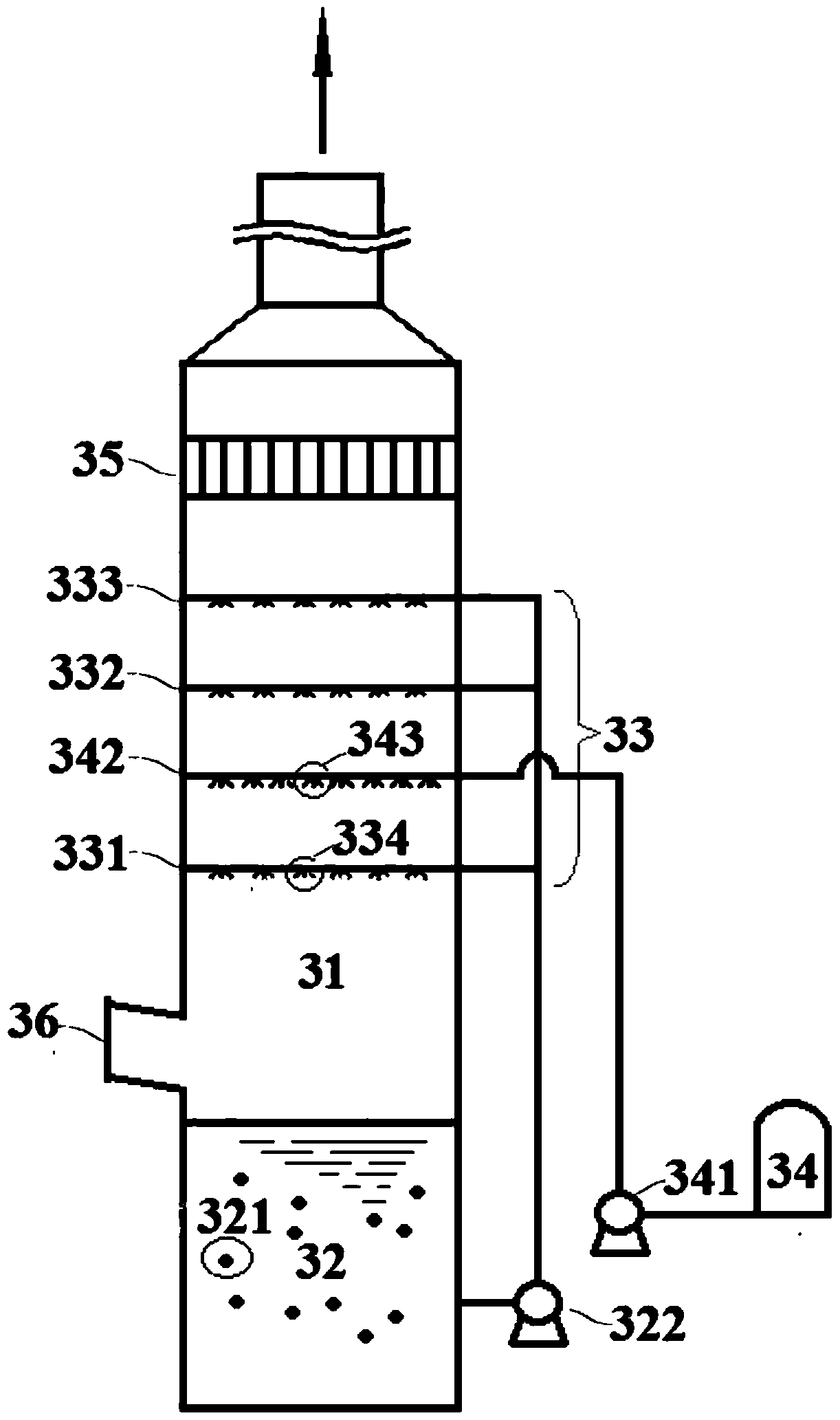

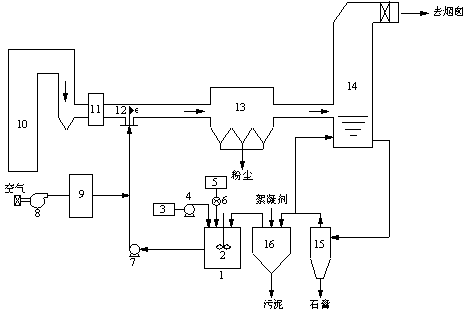

Method and system for realizing zero discharge of whole factory wastewater

ActiveCN104671315AAchieving zero emissionsLess investmentDispersed particle separationWater/sewage treatmentFlue gasEffluent

The invention discloses a method for realizing zero discharge of whole factory wastewater. The method comprises the following steps: collecting the whole factory wastewater by a wastewater collecting device (1), guiding the collected wastewater into a wet flue gas desulfurization device (2), performing heat exchanging and contacting with a high-temperature dry flue gas coming into the wet flue gas desulfurization device (2), humidifying the flue gas by evaporating part of the water in the wastewater and discharging from the top part of the wet flue gas desulfurization device (2); and discharging the concentrated wastewater along with the desulfurization wastewater from the wet flue gas desulfurization device (2). The invention additionally discloses a system adopting the method for realizing zero discharge of the whole factory wastewater, wherein the system comprises the wastewater collecting device (1), the wet flue gas desulfurization device (2) and the desulfurization wastewater zero discharge device (3) which are in turn connected. The method and the system have the following beneficial effects that a large volume of the wastewater is evaporated and decreased through the high-temperature flue gas in the wet flue gas desulfurization device, so that the heat utilization of the waste high-temperature flue gas is realized and the wastewater volume processed by the zero discharge device is reduced, and then the land occupation, the investment and the running cost of the desulfurization wastewater zero discharge device are all reduced.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

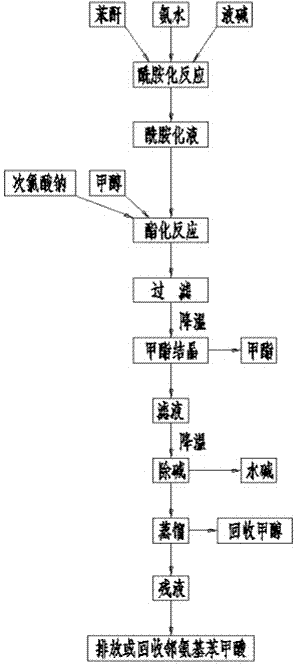

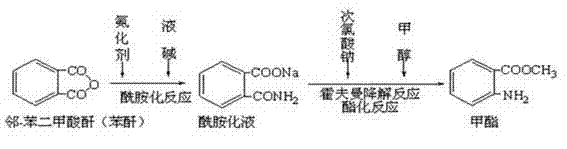

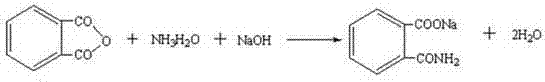

Clean production technology of methyl anthranilate

InactiveCN104844469AReduce saltEmission reductionOrganic compound preparationCarboxylic acid amides preparationSolubilitySolvent

A clean production technology of methyl anthranilate is characterized in that the solubilities of methyl ester, sodium carbonate and sodium chloride in water are different, no other solvents or reagents are introduced, and a solution obtained after esterification and hydrolysis is successively cooled to obtain methyl ester and sodium carbonate decahydrate (called scale for short). The technology shortens the technologic route and reduces impurities in a recovered material, so the quality of the obtained recovered product is high; the technology effectively reduces a large amount of technologic water and recovers reaction byproducts to realize conversion of industrial wastes as a secondary raw material and reinforce recycling of the wastes; the technology realizes comprehensive utilization of energy and reduces total consumption of energy, so the product production cost is greatly reduced; and the technology uses change of physical properties to obtain the methyl ester, and does not use a chemical solvent to extract the methyl ester residual in a mother liquor, so the generation of new pollutants is effectively avoided, and the whole production process is clean and environmentally friendly.

Owner:尹罡煜 +1

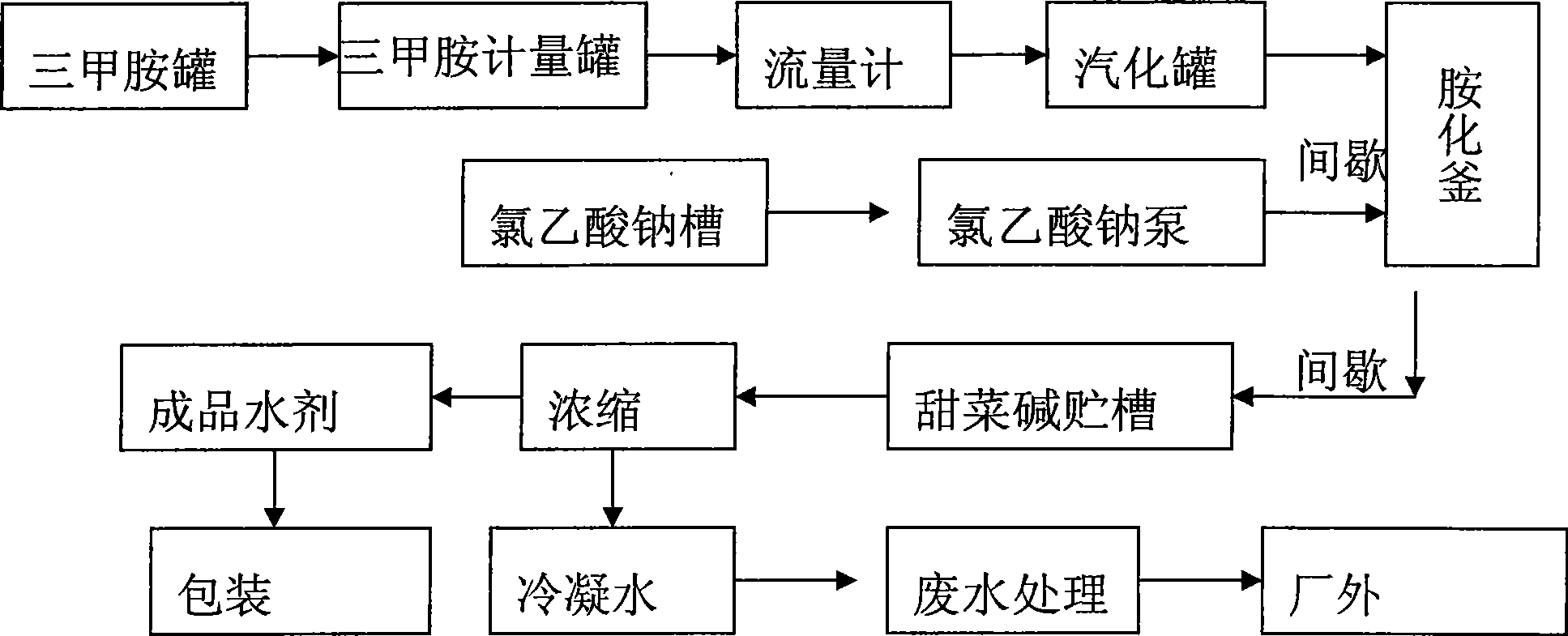

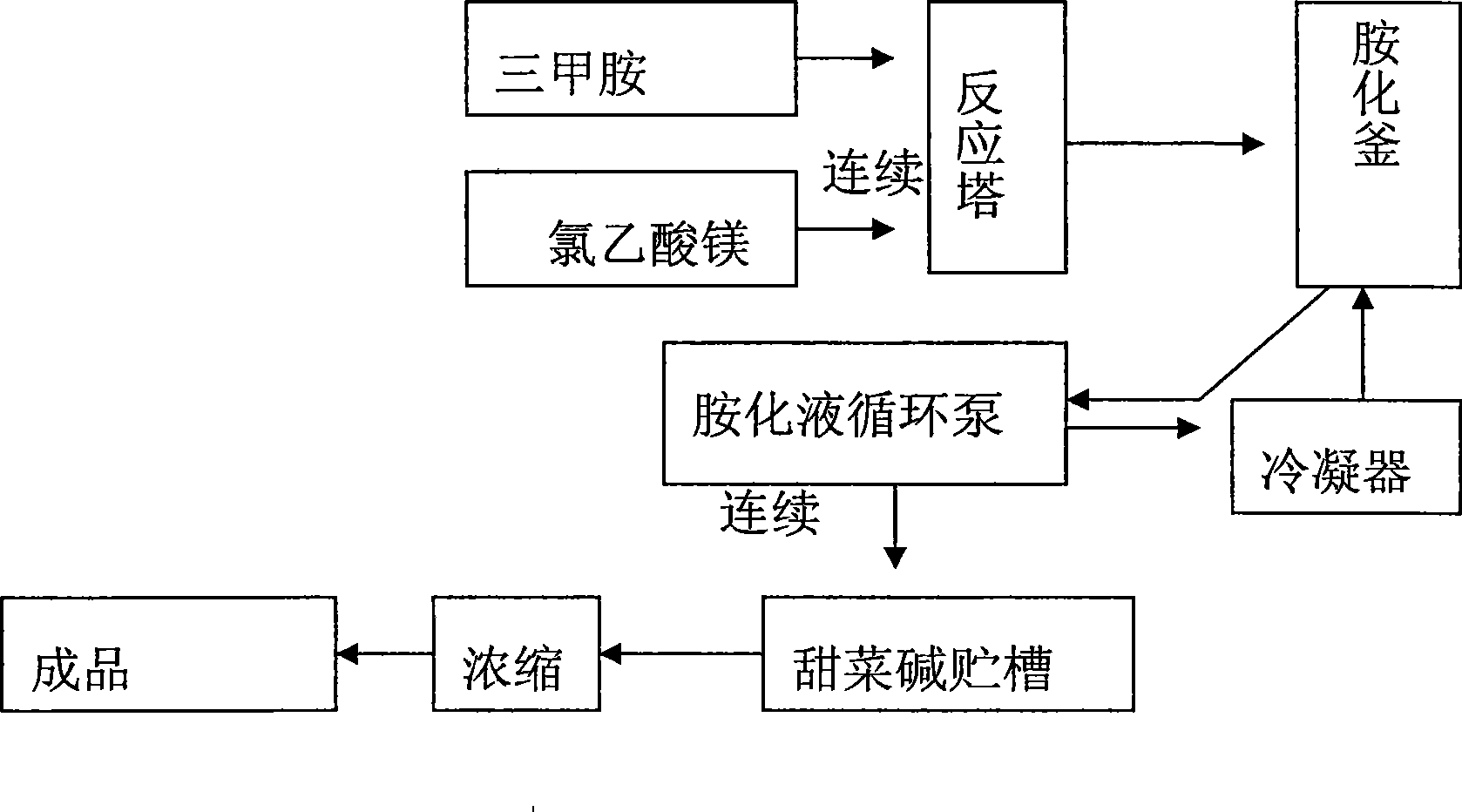

Method for synthesizing betaine

ActiveCN101531604AIncrease profitLow costOrganic compound preparationAmino-carboxyl compound preparationBetaineReaction temperature

The invention relates to a method for synthesizing betaine, which is characterized in that the method uses trimethylamine and chloroacetic magnesium at the molar ratio of 1.02-1.03:1 for amination and synthesis; the reaction temperature of synthesis is controlled between 40 and 60 DEGC; the optimum reaction temperature is controlled between 53 and 55 DEG C; a pH value is controlled to be between 8 and 9; synthesis time is between 2.5 and 5 hours; continuous feeding and continuous discharging are adopted; and the feeding and discharging of reaction are regulated and controlled by use of a pH meter. The method has the advantages of eliminating frequent operation for feeding, synthesis and discharging during batch production, as well as unsafe factors possibly caused by the frequent operation, increasing production yield, treating and recycling water after the concentration of betaine solution and reducing the waste of freshwater resources.

Owner:宜兴市天石饲料有限公司

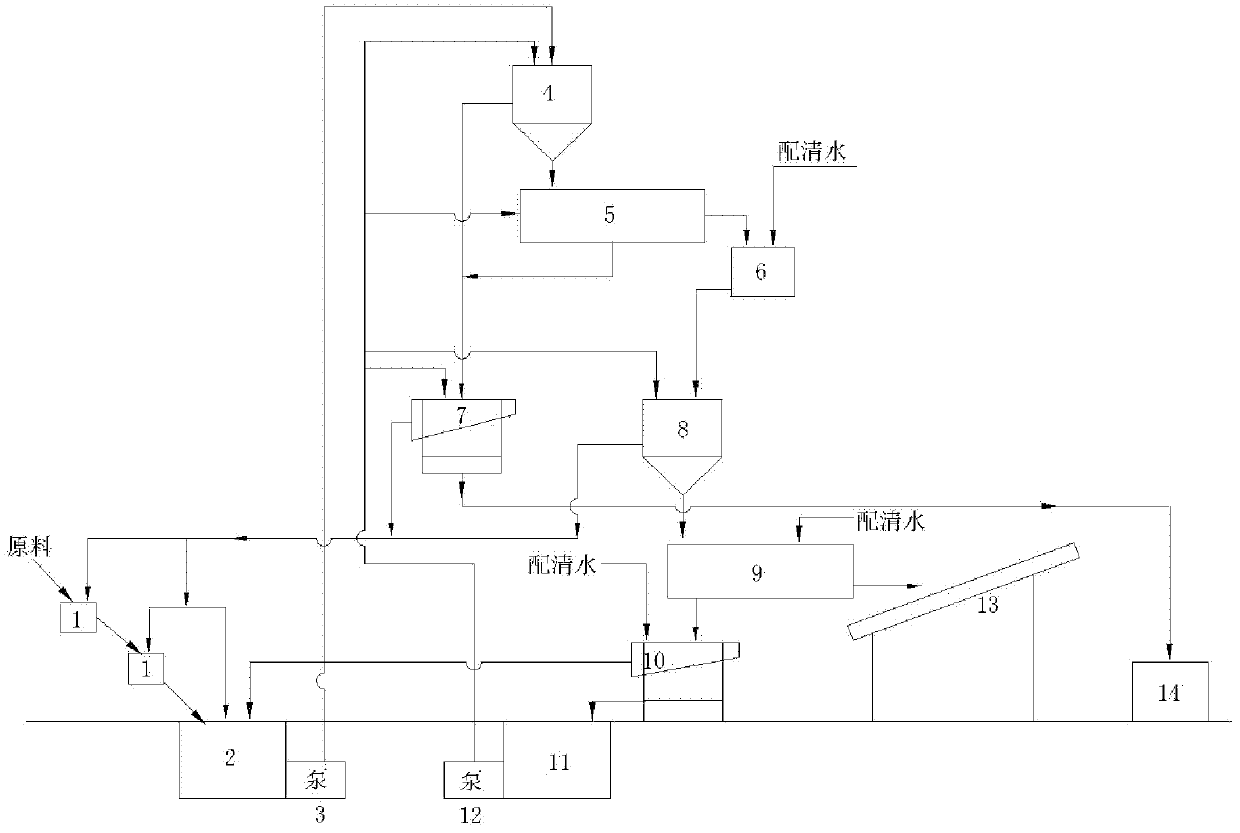

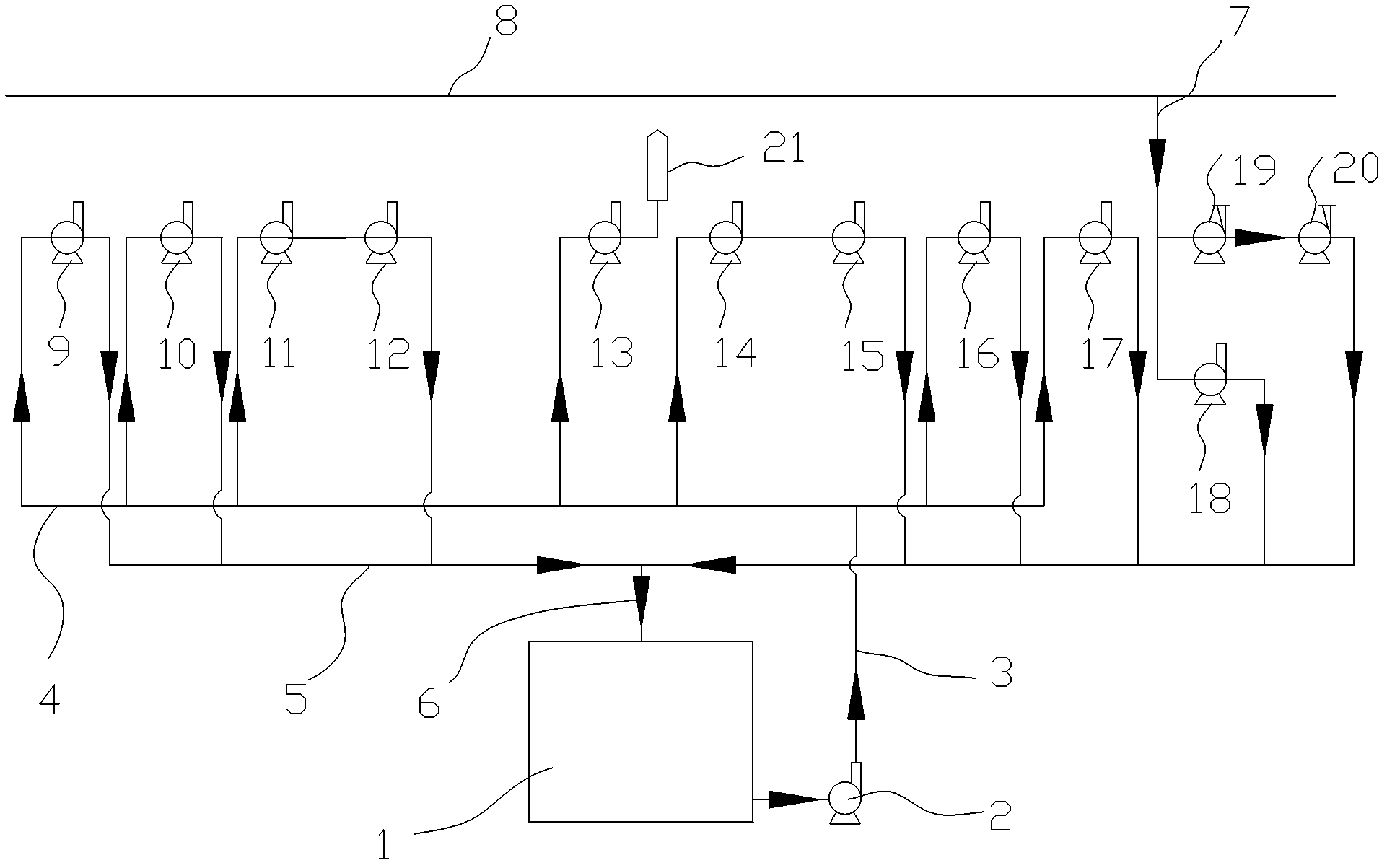

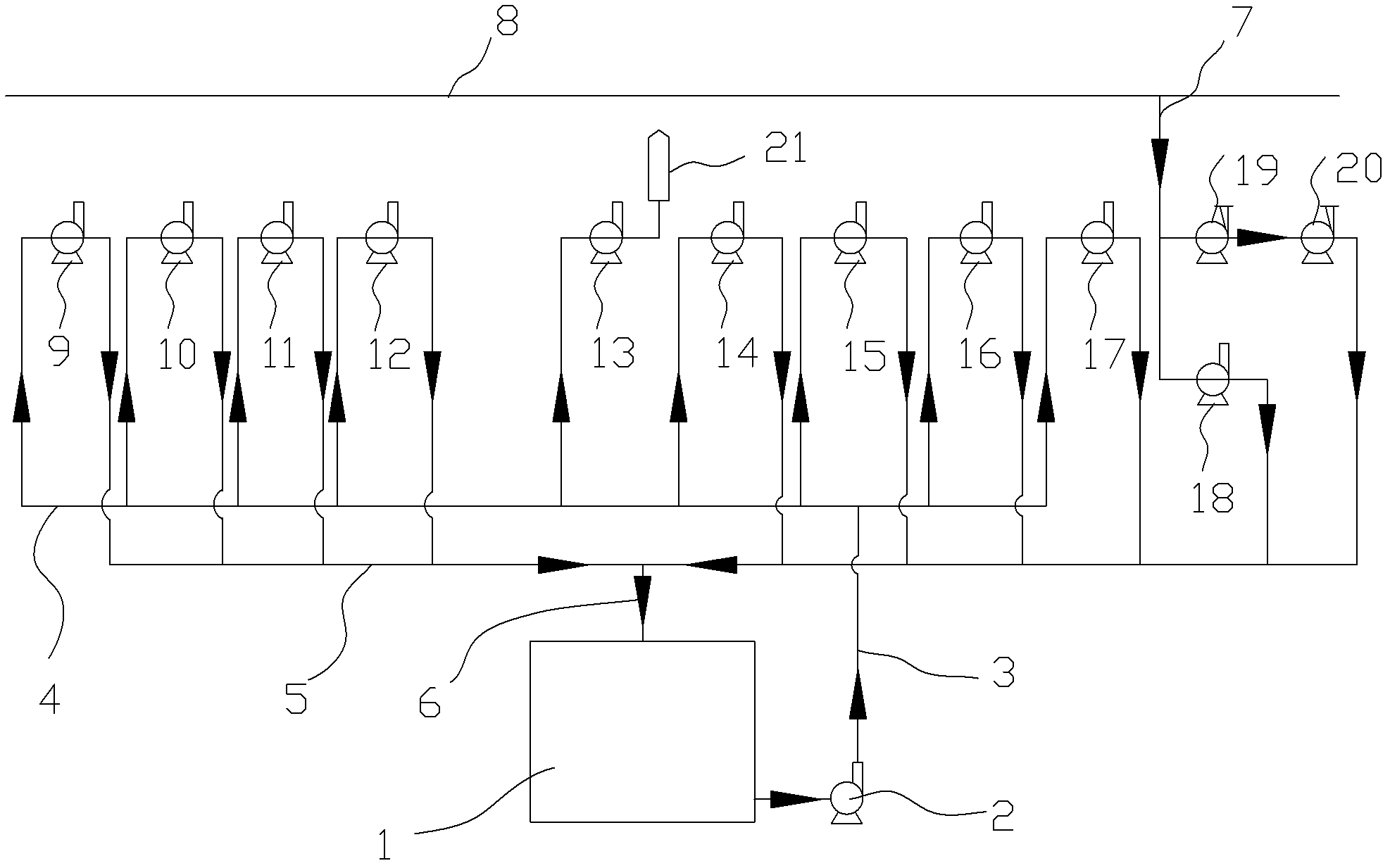

High-potential-difference potato starch-residue separation system

The invention relates to tubers, in particular to a tapioca starch residue separation system, which comprises a raw material cleaning machine, disintegrators, a residue-starch tank, vertical sieves, sieve cleaners, filter presses and the like. Raw materials are cleaned and crushed by a primary disintegrator and a secondary disintegrator to flow into the residue-starch tank, disintegrated residue slurry is sent by a lifting pump from the residue-starch tank to a higher primary vertical sieve, the residue slurry is separated by the primary vertical sieve, dense starch solution passes through a primary sieve cleaner to enter a raw starch tank, the separated tapioca residue is subjected to filter pressing by a primary filter press, dense starch solution and screen washing water after filter pressing pass through the primary sieve cleaner to enter the raw starch tank, fine residue passing through the primary sieve cleaner automatically flows back to the residue-starch tank, the tapioca residue after primary filter pressing enters a stirring tank to be mixed with clear water, and secondary vertical sieving, filter pressing and sieve cleaning are operated as the primary process. Reclaimed water is recyclable, the tapioca residue after secondary filter pressing is dried or directly sold, and the problems that the existing potato starch-residue separation process is complex, large in occupied space and high in operating cost are solved.

Owner:GUANGXI WEIYE STARCH +1

A method and system for zero discharge of waste water in the whole plant

ActiveCN104671315BLess investmentLow running costDispersed particle separationWater/sewage treatmentFlue gasWastewater

The invention discloses a method for zero discharge of waste water in the whole plant. The waste water of the whole plant is collected by a waste water collection device (1) and then introduced into a flue gas wet desulfurization device (2). High-temperature dry smoke heat exchange contact, part of the water in the wastewater evaporates to humidify the flue gas and is discharged from the top of the flue gas wet desulfurization device (2); the concentrated wastewater is discharged from the flue gas wet desulfurization device (2) together with the desulfurization wastewater. Also disclosed is a system adopting the method for zero discharge of waste water in the whole plant, including a waste water collection device (1), a flue gas wet desulfurization device (2) and a desulfurization waste water zero discharge device (3) connected in sequence. The beneficial effects of the present invention are: using the high-temperature flue gas in the flue gas wet desulfurization device to evaporate and reduce the original large amount of wastewater, so as to realize the heat utilization of the waste high-temperature flue gas and reduce the amount of wastewater treated by the zero-emission device, As a result, the land occupation, investment and operating costs of the desulfurization wastewater zero discharge device are all low.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

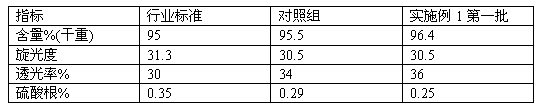

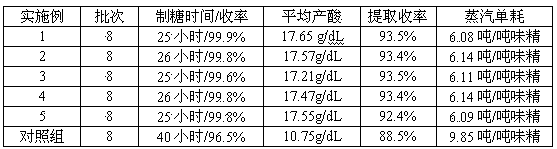

Technology for making aginomoto from rice

The invention provides a technology for making aginomoto from rice. Energy and water are saved, and pollutions and the sewage disposal cost are reduced. According to the technological innovation, the raw material ratio of fermentation liquor is appropriately adjusted, and the extraction and sugar making technology is adjusted. Compared with original technology, the environmental protection pressure is reduced, resources are reasonably utilized, the technology index is improved, and the raw material cost is reduced.

Owner:福建省建阳武夷味精有限公司

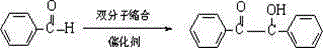

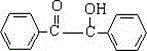

Method for preparing benzoin product in mother liquor recycling manner

ActiveCN103936578AEasy to produceHigh yieldOrganic compound preparationCarbonyl compound preparationInorganic saltsPtru catalyst

The invention relates to a method for preparing a benzoin product in a mother liquor recycling manner, and belongs to the technical field of preparation processes of chemical products. The method comprises the following steps: sequentially and proportionally adding reaction mother liquor, benzaldehyde, water, hydrocyanic acid, a cationic surface active agent, a phase transfer catalyst, a dispersing agent and an inorganic salt which are obtained in a reaction process in the preparation of the benzoin product into a reaction kettle; stirring and heating to 45 DEG C to 65 DEG C; adding the cationic surface active agent and reacting for 1.0 to 2.0 hours in a heat preservation manner; adding the cationic surface active agent, heating to 55 DEG C to 70 DEG C and reacting for 1.5 to 2.5 hours in the heat preservation manner until the finishing of the reaction; separating a crude benzoin solid product, washing with an ethanol solution and drying so as to obtain a white crystalline product, wherein separated filtrate is the reaction mother liquor; and collecting and weighing the reaction mother liquor so as to serve as a reaction solvent for recycling. The method has the characteristics of being simple in production process, high in benzoin product yield, good in benzoin product quality, low in production cost and convenient for industrial production.

Owner:煌途医药(无锡)有限公司

Method for low-pressure continuous hydrolysis preparation of fatty acid

InactiveCN1544595AReduce partial pressureIncrease hydrolysis rateFatty acid chemical modificationIodo fatty acidDecomposition

The invention provides a process for preparing fatty acid through low pressure continuous hydrolytic decomposition, wherein the water-oil weight ratio is 5-30:100, the pump output pressure is controlled between the range of 0.02-0.5MPa, preferably between 0.1-0.4MPa, the raw materials are subjected to heat transfer through heat exchanger and are charged into heating-furnace to be heated to 250-500 deg. C and enter reactor, reacting for 2-30 minutes and the reaction product is led out, the fatty acid is obtained by straight distillation of separated crude fatty acid or fuel gas.

Owner:陈天晓

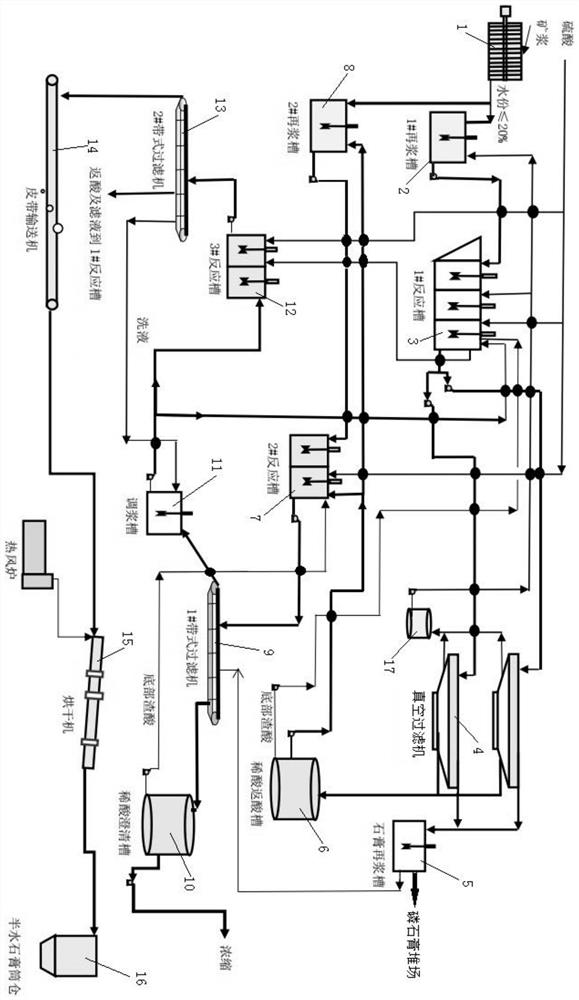

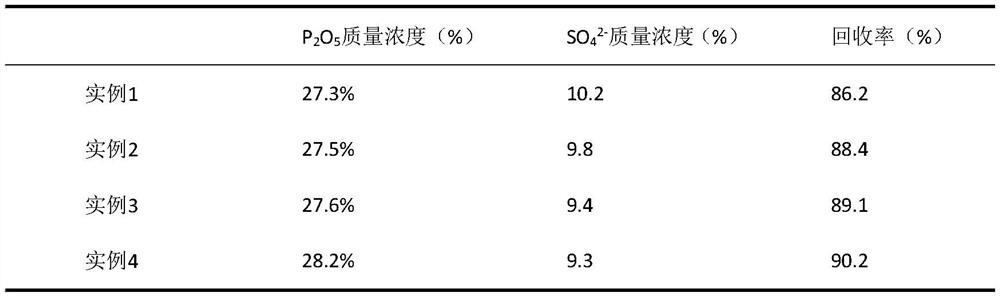

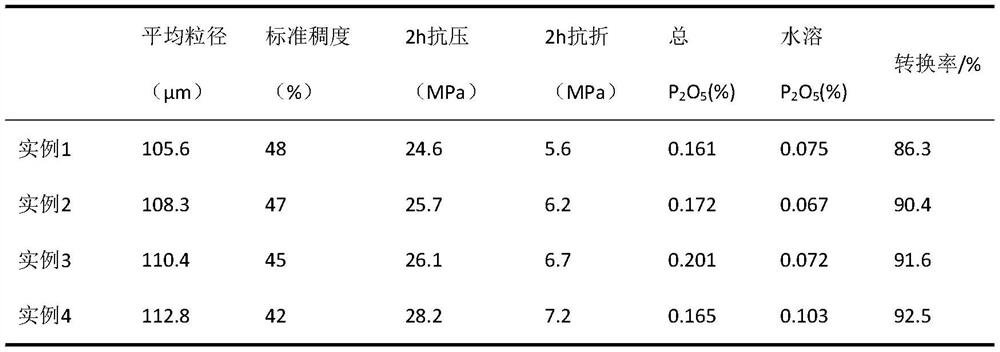

Production device and method for co-production of alpha-semi-hydrated gypsum by two-step wet-process phosphoric acid

ActiveCN112850674AIncrease concentrationIncrease production capacityPhosphorus compoundsO-Phosphoric AcidSludge

The invention discloses a production device and method for co-production of alpha-semi-hydrated gypsum by two-step wet-process phosphoric acid, and relates to the technical field of wet-process phosphoric acid byproduct semi-hydrated gypsum. The device comprises a filter press, a 1 # re-slurry tank, a 1 # reaction tank and a vacuum filter which are sequentially connected; a phosphogypsum outlet of the vacuum filter is connected with a gypsum re-slurry tank, a sludge acid outlet in the bottom of the vacuum filter is connected with the 1 # reaction tank, a filtrate outlet of the vacuum filter is connected with a dilute acid return tank, and a dilute acid outlet of the dilute acid return tank is sequentially connected with a 2 # reaction tank and a 2 # re-slurry tank; the 2 # re-slurry tank is connected with the filter press; a reaction slurry outlet of the 2 # reaction tank is connected with a 1 # belt filter, a filtrate outlet of the 1 # belt filter is connected with a dilute acid clarifying tank, an ardealite outlet of the 1 # belt filter is sequentially connected with a slurry mixing tank, a 3 # reaction tank and the 2 # belt filter, and a filter residue outlet of the 2 # belt filter is sequentially connected with a belt conveyor, a dryer and a semi-hydrated gypsum silo. While high-concentration phosphoric acid is produced, alpha-semi-hydrated gypsum is produced as a byproduct.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

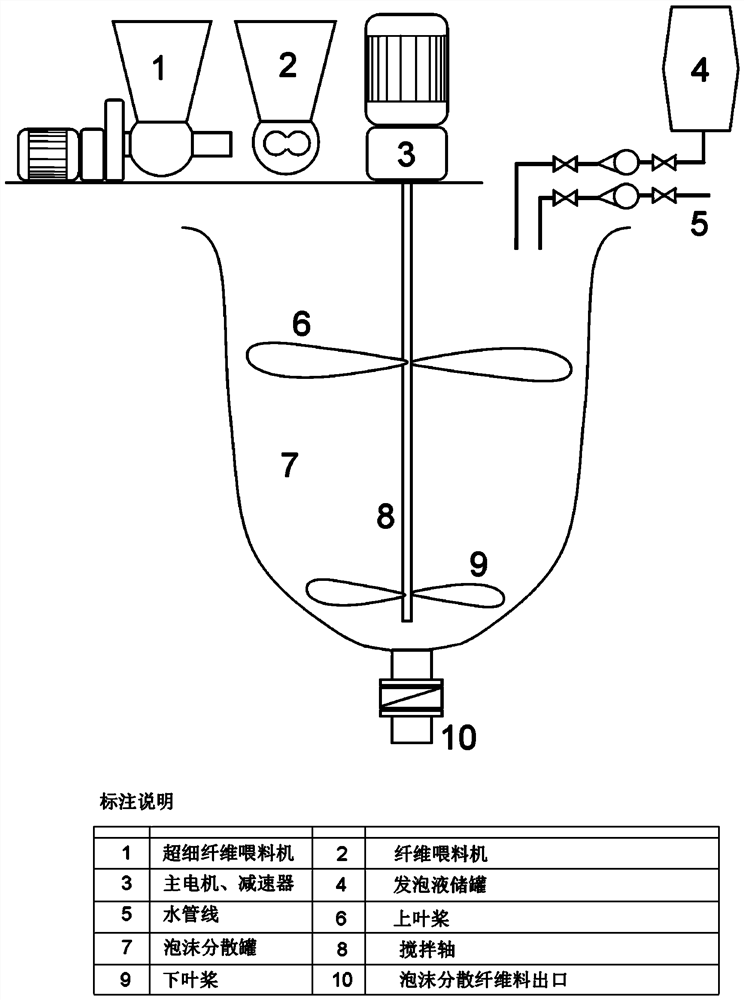

Method for preparing ultra-light thermal insulation material by using foam dispersed fly ash fibers

The invention discloses a process for dispersing fly ash fibers by using foam and a method for preparing an ultra-light fly ash fiber thermal insulation material by using the process. Cement clinker, a foaming agent and a small amount of water are stirred for air entraining to form foam, and fly ash fibers are dispersed by volume formed by the foam to form a light structure. Compared with the traditional fiber pulping, papermaking and filter pressing forming process, the process has the advantage that the water consumption and drying energy consumption are obviously reduced. The fly ash fiber thermal insulation material prepared by the process has good apparent density consistency. The material is waterproof and fireproof, and can work in an environment below 650 DEG C for a long time. The apparent density of the material is between 0.08 g / cm < 3 > and 0.15 g / cm < 3 >, the heat conductivity coefficient of the material is between 0.035 W / (m.K) and 0.043 W / (m.K), and the material has good mechanical strength under dry and wet conditions. And more than 50 times of circulating freezing and thawing can be borne.

Owner:乌鲁木齐胜达天利建材科技有限公司

Whole plant waste water zero-discharge system

InactiveCN107892349AStable post-processingLess investmentDispersed particle separationWater/sewage treatment bu osmosis/dialysisWater dischargeFlue gas

The invention discloses a system for zero discharge of waste water in the whole plant, comprising a waste water collection device (1) for collecting waste water in the whole plant, a flue gas wet desulfurization device (2) and a desulfurization waste water zero discharge device (3). The discharge pipe of the device (1) is connected to the flue gas wet desulfurization device (2) through a pipeline, and the liquid discharge pipe of the flue gas wet desulfurization device (2) used to discharge the desulfurization wastewater is connected to the desulfurization wastewater zero through the pipeline. discharge device (3). The beneficial effects of the present invention are: using the high-temperature flue gas in the flue gas wet desulfurization device to evaporate and reduce the original large amount of wastewater, so as to realize the heat utilization of the waste high-temperature flue gas and reduce the amount of wastewater treated by the zero-emission device, As a result, the land occupation, investment and operating costs of the desulfurization wastewater zero discharge device are all low.

Owner:马中亮

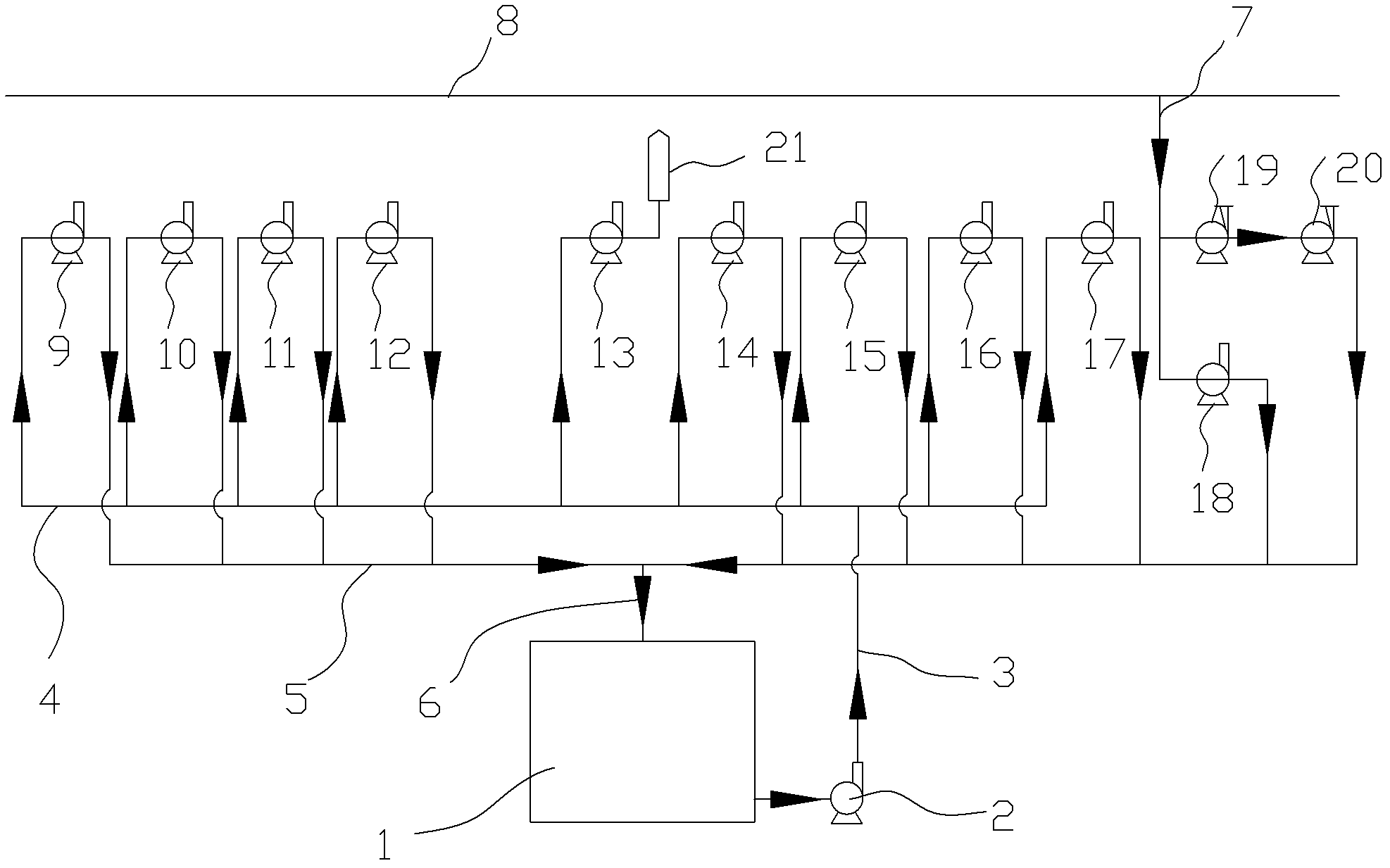

Method for recovering and using machine sealing water during monoammonium phosphate production

InactiveCN102491296AReduce water temperatureReduce one-time input costsPhosphatesWater dischargePhosphate

The invention discloses a method for recovering and using machine sealing water during the monoammonium phosphate production, which comprises a cycle water tank and a bench of circulating pump used for collecting and supplying machine sealing water; the machine sealing water discharged by one or more pumps from a dilute acid transfer pump, a reaction circulating pump, a double-effect circulating pump, a first-effect circulating pump, a tail gas washing pump, a washing displacement pump, a double-effect condensed water circulating pump and a first-effect condensed water transfer pump; water in the cycle water tank is taken as machine sealing water and returned by the circulating pump to the above pumps, the investment is small, a lot of process water can be saved, processing amount of sewage can be also minimized and the production cost can be reduced.

Owner:ANHUI LIUGUO CHEM CO LTD

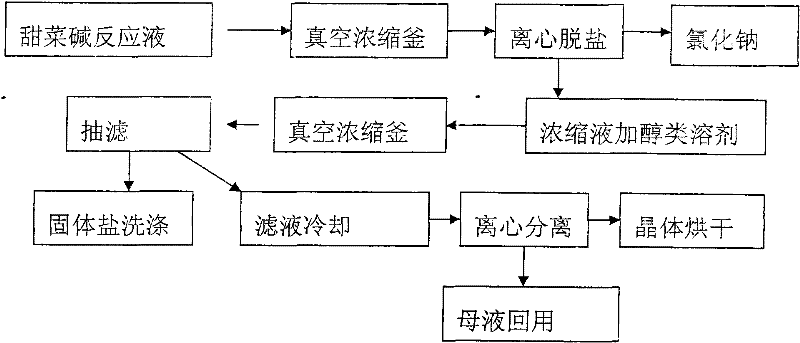

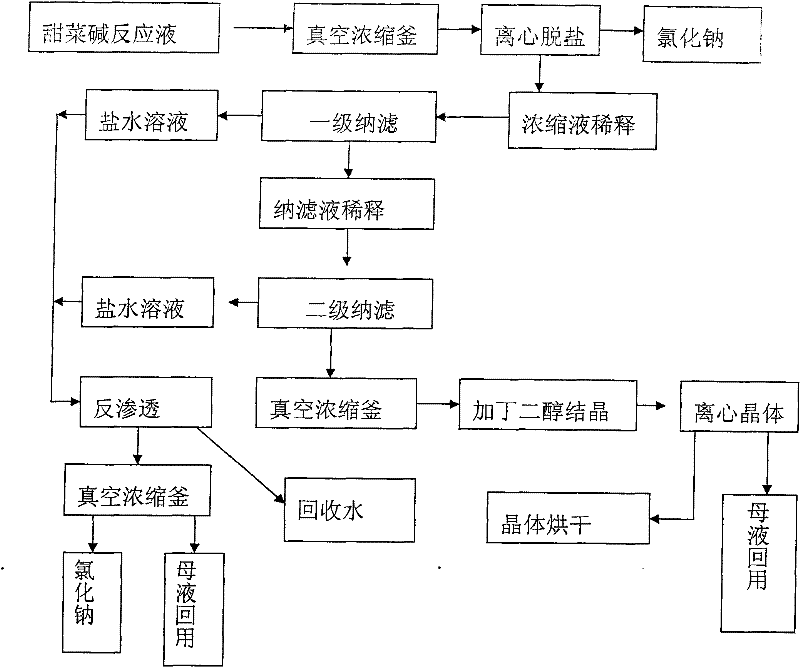

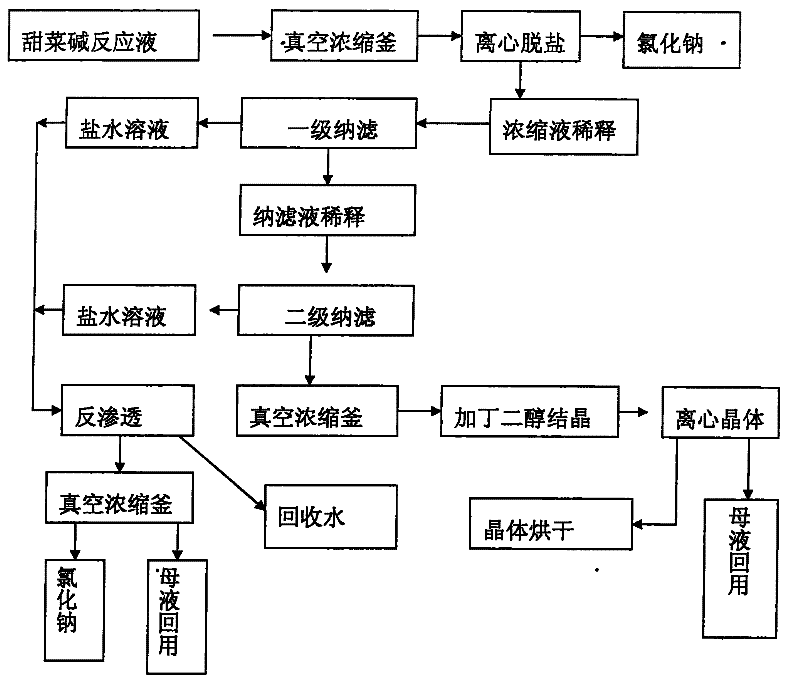

Method for removing salt in betaine solution

ActiveCN101591254BIncrease profitSmall footprintOrganic compound preparationUltrafiltrationBetaineEthyl Chloride

The invention discloses a method for removing salt in betaine solution, which comprises the followings steps: firstly removing 70 weight percent of salt in the betaine solution synthesized by taking chloroactic acid, sodium carbonate and trimethylamine as raw materials through concentration; then diluting with water until the mass concentration of the betaine is between 10 and 15 percent; performing a first-stage semi-transparent film nanofiltration on the solution at a temperature of between 60 and 70 DEG C; when the conductivity of the betaine solution reaches between 7,000 and 8,000mu s / cm, diluting the betaine solution again until the mass percentage concentration of the betaine is between 10 and 15 percent; performing a second-stage semi-transparent film nanofiltration on the solution at a temperature of between 50 and 60 DEG C; when the conductivity of the betaine solution reaches between 700 and 800 mu s / cm, finishing the treatment, desalting by a two-stage nanofiltration membrane, and achieving the effect of completely removing the salt, which cannot be achieved in a common concentration process; and performing thickening crystallization to produce betaine crystal containing less than 0.5 percent of salt. The method ensures the production of pure betaine products, saves electricity, and reduces the phenomenon of raw material waste.

Owner:宜兴市天石饲料有限公司

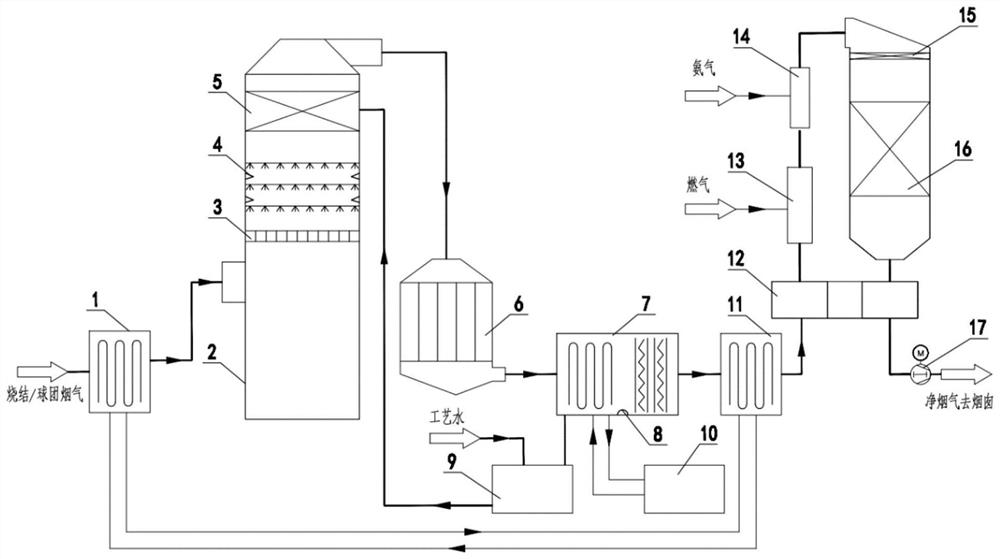

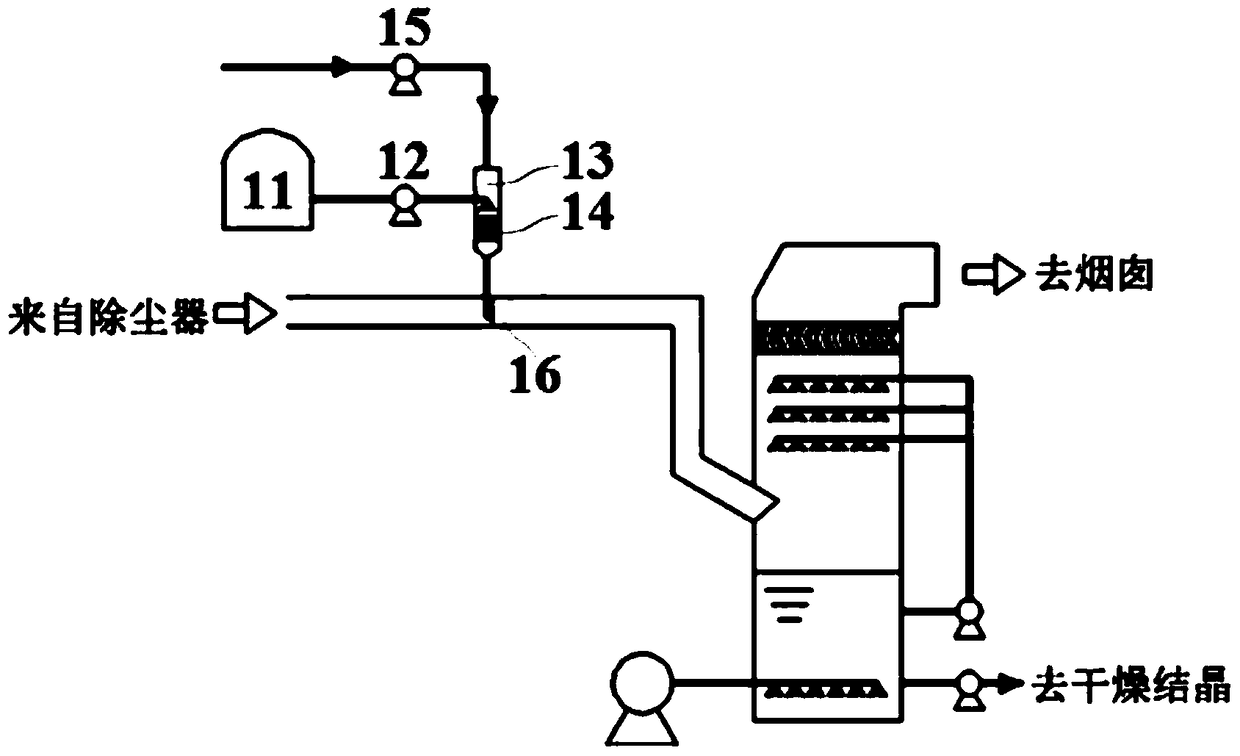

Ultra-low emission device and method for sintering and pelletizing flue gas

PendingCN114177755AReduce consumptionReduce heat lossGas treatmentElectrostatic separationSulfur dioxideDust collector

The invention relates to a sintering and pelletizing flue gas ultralow emission device and method. The technology of an MGGH heat collector, a limestone-gypsum method desulfurization tower, a wet type electrostatic dust collector, a flue gas condensation deacidification device, an MGGH heater, a GGH, a direct combustion type combustor and SCR denitration is adopted. The tray and the flow guide ring are arranged in the desulfurization tower, so that flue gas is uniformly distributed, the desulfurization efficiency is improved, and sulfur dioxide and dust are greatly removed; a set of flue gas deacidification demister system is arranged at an outlet section of the wet-type electric precipitator, the temperature of flue gas is reduced by more than 4 DEG C, sulfuric acid mist in the flue gas is condensed and separated out, a large amount of sulfuric acid mist and other salt substances are removed, and system equipment blockage caused by substances such as acid mist and the like of subsequent equipment is prevented; according to the denitration system disclosed by the invention, the built-in combustors are uniformly arranged in the flue, the heating is uniform, the coal gas consumption is reduced, and the static mixer is arranged at the inlet of the denitration reactor, so that the uniformity of an ammonia-flue gas flow field is ensured, and the denitration efficiency is improved.

Owner:武汉华德环保工程技术有限公司

A kind of method for preparing benzoin product by circulation of mother liquor

ActiveCN103936578BEasy to produceHigh yieldOrganic compound preparationCarbonyl compound preparationPtru catalystBenzaldehyde

The present invention is a method of preparing a scent product for a mother liquid circulation, which is the field of chemical products preparation technology.In the proportion, the reaction parent, phenyldehyde, water, hydrochloric acid, cationic surface active agent, phase transfer catalyst, dispersant, and inorganic salt are obtained during the reaction of the reaction of the incense product reaction process.Stir, heat up to 45-65 ° C, add cation surfactant agent, and thermal insulation reaction is 1.0-2.0h; add cation surface active agent to 55-70 ° C, the insulation reaction is 1.5-2.5h, until the reaction is over;Rough products, washed with ethanol solution, dry, and white crystal products; separated filtrates reflect the mother liquid, collect, weigh, and use it as a reaction solvent cycle.The present invention has the characteristics of simple production process, high product revenue, good quality, low production cost, and facilitating industrial production.

Owner:煌途医药(无锡)有限公司

A kind of preparation method of microcrystalline cellulose

The invention relates to a preparation method of a high-molecular compound, and in particular relates to a preparation method of microcrystalline cellulose. The method sequentially comprises the following steps: (1) in a step of acidolysis, plant fibers are mixed with concentrated hydrochloric acid in a rotary reactor in a mass ratio of 1:1-1.5, a mixture is subjected to acidolysis for 0.8-1.5 hours at the temperature of 70-100 DEG C to obtain an acidolysis liquid, and the mass fraction of the concentrated hydrochloric acid is more than or equal to 28 percent; (2) in a neutralizing step, ammonia water of which the weight is 0.01-0.05 times that of the plant fibers is added into the acidolysis liquid, pulping water is added until a pH value is 6-7, and raising the temperature to be between 70 and 100 DEG C to obtain a neutralizing liquid; the pulping water is reverse osmosis water; (3) in a filter pressing and washing step, the neutralizing liquid is pumped into a plate-and-frame filter press and washed by using the pulping water until chloride is less than 35 mg / L to obtain a wet material; and (4) in a drying step, the wet material is put into a flash distillation dryer to be dried, an air inlet temperature is controlled to be between 130 and 140 DEG C, an air outlet temperature is controlled to be between 70 and 80 DEG C, and then, the wet material is pulverized and screened to obtain the microcrystalline cellulose. The method is energy-saving, environmental-friendly, and low in production cost.

Owner:湖州展望天明药业有限公司

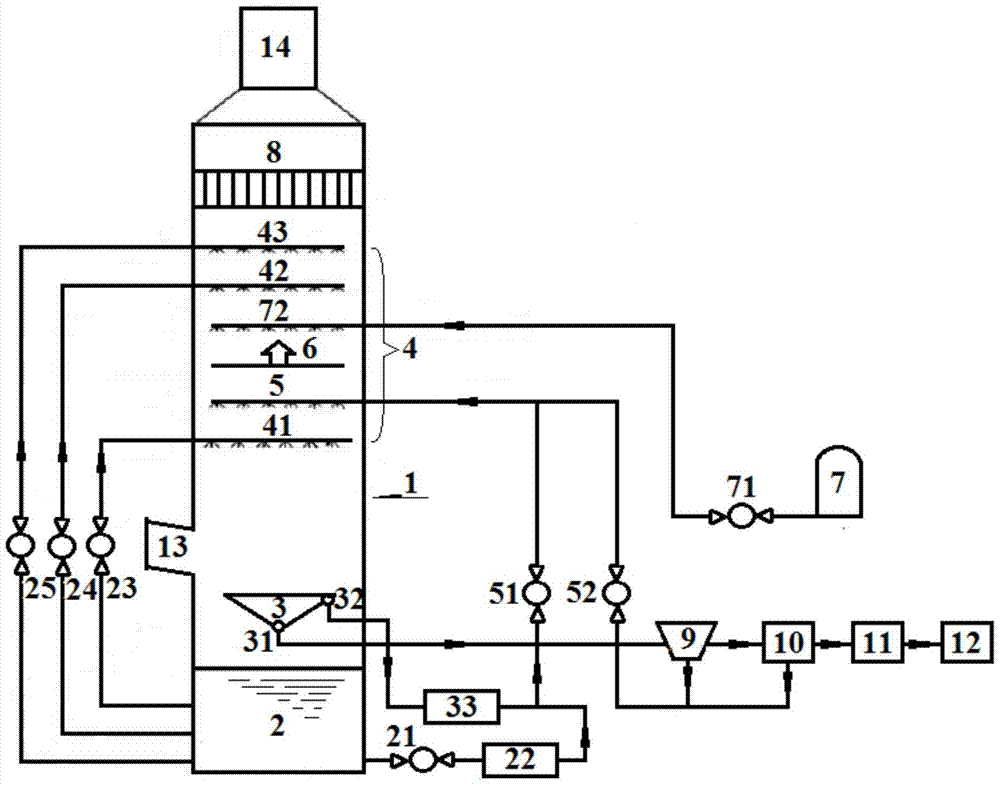

Flue gas integrated treatment device and method

ActiveCN104857835BRealize resource utilizationReduce wateringCombination devicesMagnesium nitratesLiquid wasteReaction layer

An integrated flue gas treatment device and method. The device comprises a flue gas treatment device, an ozone supply device, a hydrogen peroxide supply device, an evaporation and concentration device, a circulating sedimentation device, etc., wherein the flue gas treatment device comprises an ozone spray oxidation reaction layer (82), a hydrogen peroxide spray oxidation reaction layer (92), an absorption spraying area (6), a slurry circulation area and a dedusting and demisting area, both of the ozone spray oxidation reaction layer (82) and the hydrogen peroxide spray oxidation reaction layer (92) being arranged in the absorption spraying area (6); the dedusting and demisting area is located above the absorption spraying area (6); and both of the evaporation and concentration device and the circulating sedimentation device are arranged in the flue gas treatment device.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Method for comprehensively utilizing supernatant of calcium carbide slurry and dilute brine generated by electrolysis

ActiveCN102259961BChlorine savingLow costWater/sewage treatment by flocculation/precipitationPhysical chemistryMaterials science

The invention relates to a method for comprehensively utilizing supernatant of calcium carbide slurry and dilute brine generated by electrolysis. The method comprises: carrying out sedimentation, aeration and layering on the calcium carbide slurry to obtain the supernatant for later use; and carrying out vacuum dechlorination on the dilute brine generated by electrolysis during an ionic membrane caustic soda production process, and then mixing with the supernatant for reacting, wherein wastewater obtained by reaction is used as water for dissolving salts and melting salts. In the method provided by the invention, two wastewaters with different physical properties are used as mutual neutralizers for each other to carry out acid-base neutralization and redox reactions, and the treated wastewater is used for dissolving salts and melting salts, so that the method is a comprehensive utilization method which is economic and beneficial and can effectively treat two wastewaters at the same time.

Owner:JIANTAO HENGYANG IND

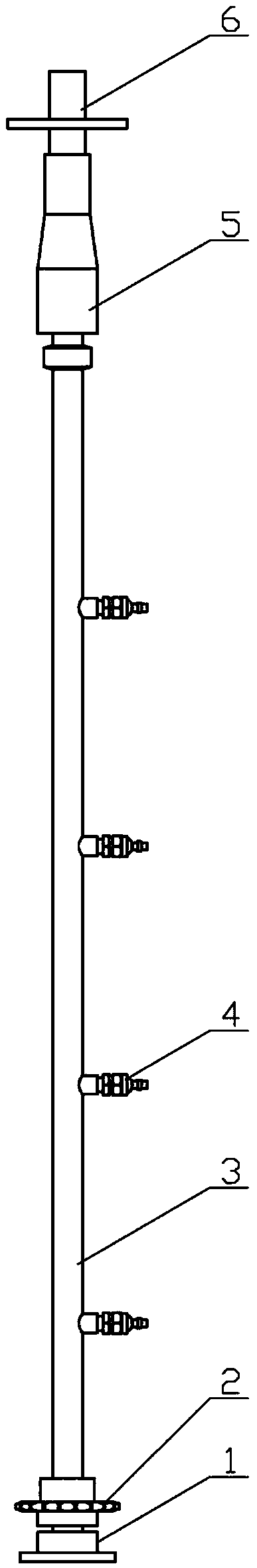

Flue gas treatment system and method thereof

ActiveCN104941415BIncrease productionImprove removal efficiencyCombination devicesAir quality improvementReaction layerFlue gas

The invention discloses a flue gas treatment system and method. The system comprises flue gas treatment equipment, hydrogen peroxide supply equipment, dedusting and defogging equipment and the like, wherein the flue gas treatment equipment comprises a hydrogen peroxide spray oxidation reaction layer, an absorbing sprinkling area and a slurry circulating area; the hydrogen peroxide spray oxidation reaction layer is arranged in the absorbing sprinkling area; the dedusting and defogging equipment is positioned above the absorbing sprinkling area. The system and the method provided by the invention are suitable for comprehensive treatment of flue gas which contains SO2, NOX, Hg<0> and dust, and is produced by coal burning boilers, steel sintering machines, pellets, industrial furnaces and the like.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

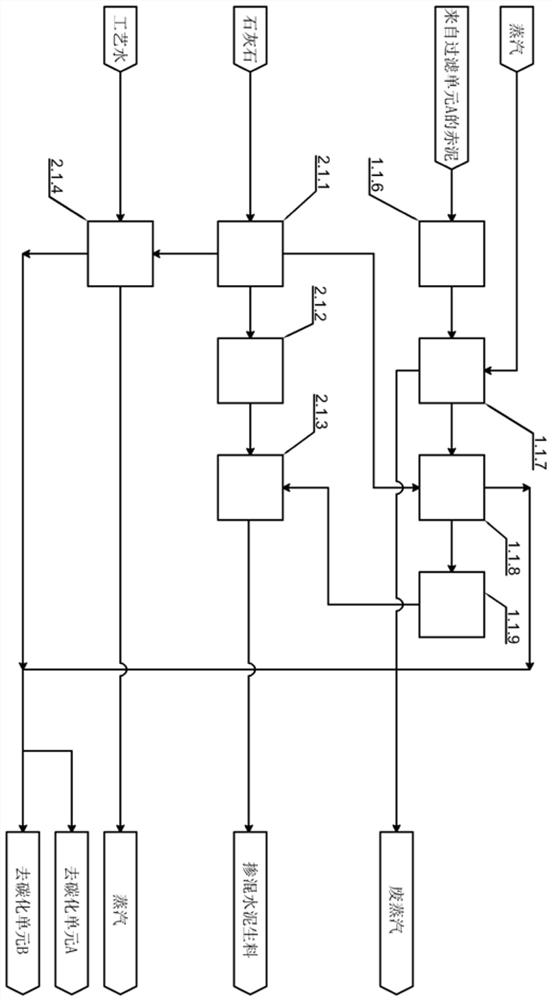

Process for producing sodium carbonate, aluminum oxide and blended cement from red mud

PendingCN111960451ASave process waterEasy to operateEnergy inputCement productionSodium carbonateEnvironmental chemistry

The invention discloses a process for producing sodium carbonate, aluminum oxide and blended cement from red mud. The process comprises the following steps: diluting red mud to obtain diluted red mud,feeding the diluted red mud into an a-stage washing unit, feeding the diluted red mud into a carbonization unit A for reaction, feeding the reacted diluted red mud into a b-stage washing unit for washing, feeding the diluted red mud into a filtering unit, filtering to obtain low-sodium red mud, and mixing and grinding the low-sodium red mud and lime to obtain blended cement; in the process, collecting washing water that is used for washing red mud in the b-stage washing unit, feeding the washing water into the a-stage washing unit for a-stage washing; collecting the washing water that is usedfor washing the red mud in the a-stage washing unit; delivering one part of the washing water to an m-stage evaporation and concentration unit, then sending the washing water to a carbonization unitB, introducing the washing water to a filtering and washing unit, separating out aluminum hydroxide and liquid sodium carbonate in the filtering and washing unit, drying and burning aluminum hydroxideto obtain aluminum oxide, and making liquid sodium carbonate pass through n evaporation and concentration units and an evaporation and drying unit to obtain sodium carbonate.

Owner:陶予敏

Smoke treatment device and method

ActiveCN105032138BRealize resource utilizationIncrease productionCombination devicesAir quality improvementLiquid wasteReaction layer

A flue gas treatment device and method. The device comprises a flue gas treatment device, a hydrogen peroxide supply device, a dedusting and demisting device, an evaporation and concentration device, a circulating sedimentation device, etc., wherein the flue gas treatment device comprises a hydrogen peroxide spray oxidation reaction layer (72), an absorption spraying area (4) and a slurry circulation area, the hydrogen peroxide spray oxidation reaction layer (72) being arranged in the absorption spraying area (4); the dedusting and demisting device is located above the absorption spraying area (4); and both of the evaporation and concentration device and the circulating sedimentation device are arranged in the flue gas treatment device. The method uses the device to treat flue gas.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278BLow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

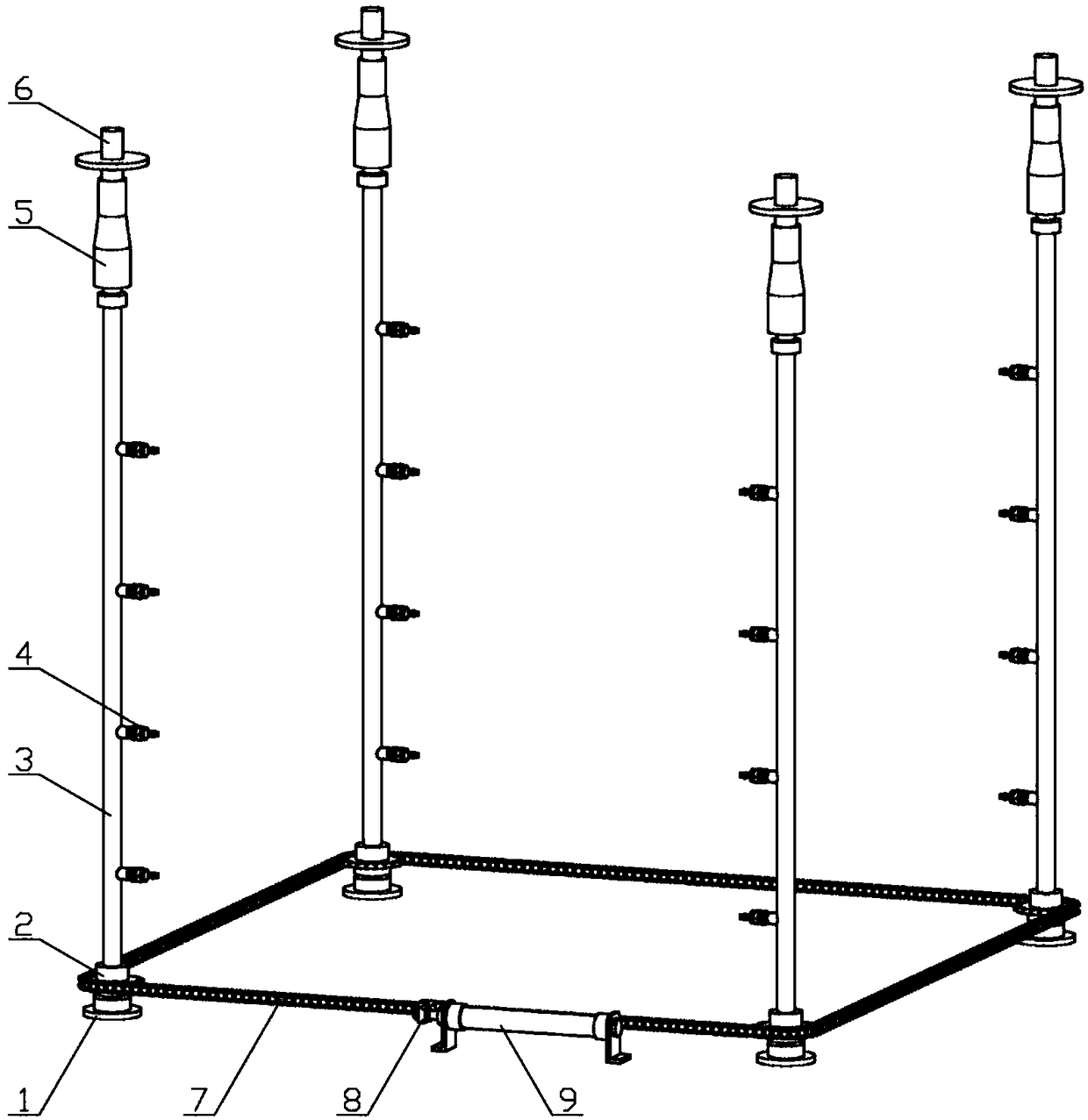

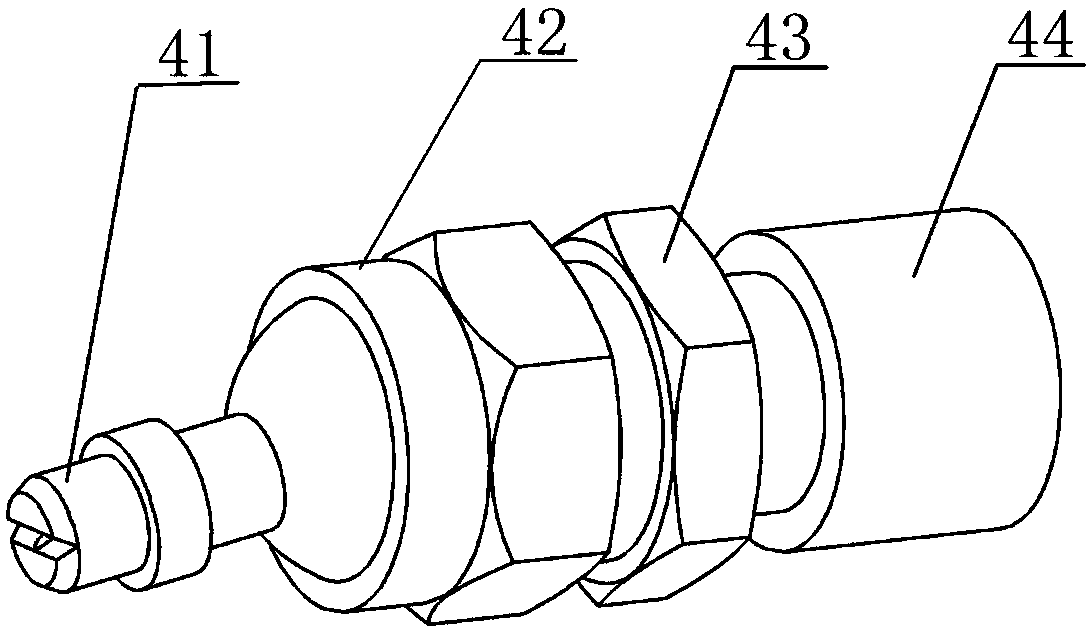

An all-round automatic cleaning system and its application

ActiveCN106179801BSolve manufacturing defects that are not cleanReduced activityMovable spraying apparatusCleaning using liquidsFreeze-dryingUltimate tensile strength

The invention discloses an omnidirectional automatic cleaning system and an application thereof. The omnidirectional automatic cleaning system comprises a power transmission assembly, a spraying water pipe, a connecting assembly and a power assembly, wherein the power transmission assembly comprises a chain wheel and a chain; the connecting assembly comprises a bearing pedestal, a rotary sealing assembly and a connecting component; the power assembly is connected to the chain by the connecting component; the chain is meshed with the chain wheel to form a closed ring; the bearing pedestal is arranged below the chain wheel; the upper end of the chain wheel is connected to one end of the spraying water pipe; and a water inlet at the other end of the spraying water pipe is connected to the spraying water pipe by the rotary sealing assembly. The omnidirectional automatic cleaning system has the beneficial effects that the omnidirectional automatic cleaning system is capable of cleaning the right side and reverse side of a charging tray of a turnover plate type freeze-drying machine, a plate layer support, a tank and a mushroom valve channel of the turnover plate type freeze-drying machine in an omnidirectional and three-dimensional manner without cleaning dead angles, meets the cleaning requirements of a food freeze-drying production technology, can save 80% of process water and 60% of cleaning time and has the characteristics of no cleaning dead angles and automatic operation; and the omnidirectional automatic cleaning system greatly reduces the labor intensity of operating personnel, improves the working efficiency and has wide practicability.

Owner:新疆玉昆仑天然食品工程有限公司

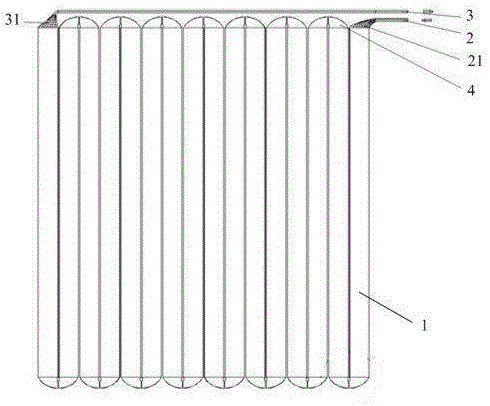

A non-cleaning anode plate and wet electrostatic precipitator

ActiveCN104368448BReduce corrosionSufficient flow rateExternal electric electrostatic seperatorElectrode constructionsAlkaline waterGypsum

The invention discloses a rinse-free anode plate and a wet electrostatic precipitator. The rinse-free anode plate comprises an anode plate module which comprises a or a plurality of anode plate rows; each anode plate row comprises a plurality of anode plate units which are in series connection with each other; the anode plate units are of hollow structures and used for allowing cooling water to pass through; each anode plate row comprises a water inlet and a water outlet; an anode plate row is a loop or a plurality of the anode plate rows are a loop. The wet electrostatic precipitator comprises a shell of an empty cavity inside; an anode plate and a cathode system and the like are disposed in the shell, wherein the anode plate is a rinse-free anode plate, and an electric field is formed between the cathode system and the anode plate. With the rinse-free anode plate and the wet electrostatic precipitator provided by the invention, rinsing process of the anode plate is eliminated, use of process and alkaline water is saved, various bad effects brought by rinsing are avoided, removal efficiency of the wet electrostatic precipitator to droplets, gypsum rain, dust and the like is improved at the same time.

Owner:SHANGHAI DEFOG ENVIRONMENTAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com