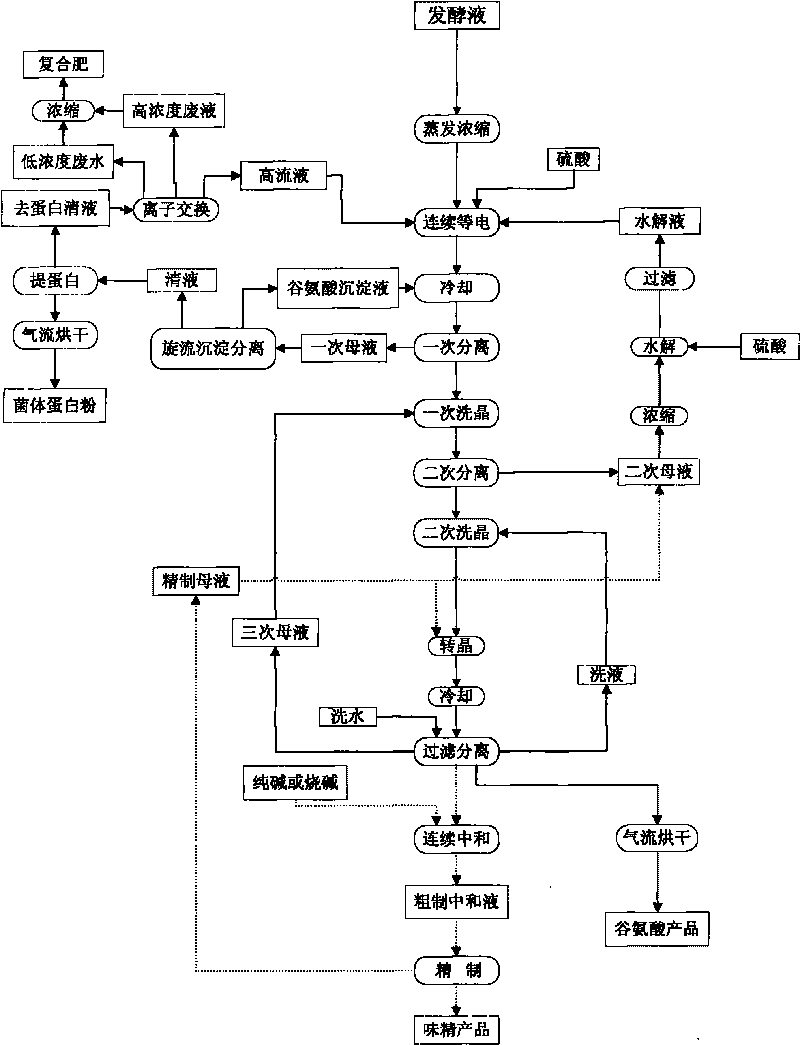

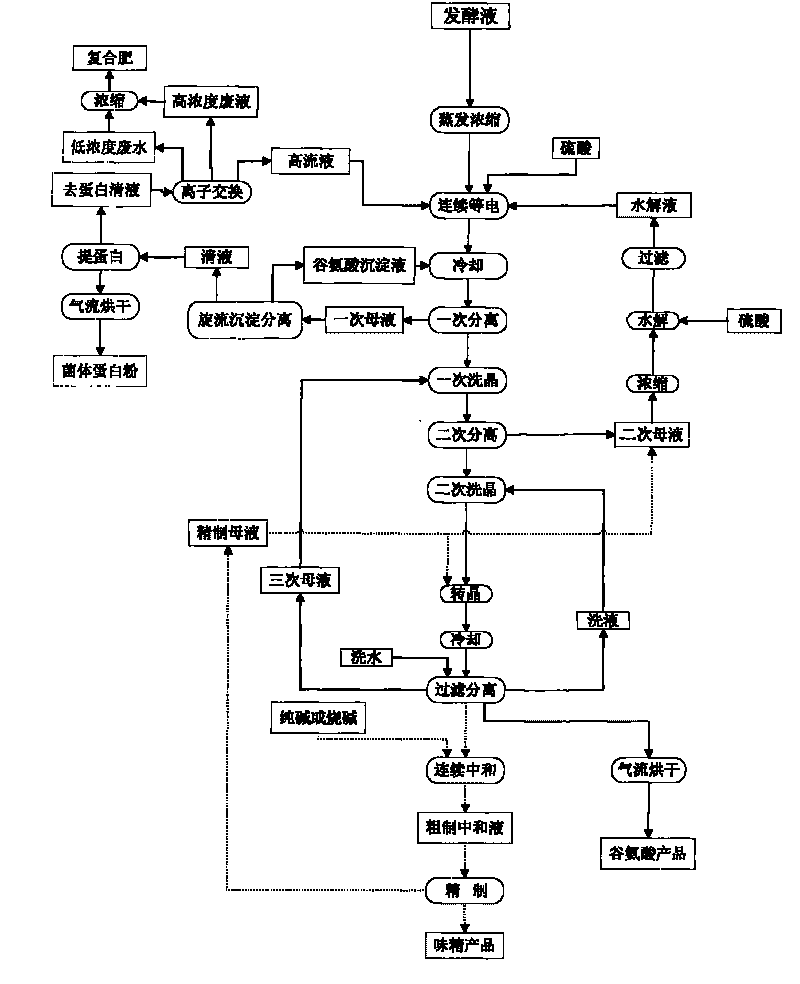

Production process of glutamic acid and monosodium glutamate

A production process and technology of glutamic acid, applied in the field of production technology of glutamic acid and monosodium glutamate, can solve the problems of increasing waste water, bulky liquid, and poor quality of glutamic acid impurities, saving process water and improving total income. rate, the effect of saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] a. Concentration:

[0047] Take the glutamic acid fermentation liquid with a mass percentage concentration of 11% to 12%, enter the four-effect evaporator for concentration, the conditions are: the temperature of the first effect evaporator is 90-95°C, and the glutamic acid concentration after concentration is 17%- 18%, the temperature of the second-effect evaporator is 80-85°C, the concentration of glutamic acid after concentration is 20-22%, the temperature of the third-effect evaporator is 70-75°C, the concentration of glutamic acid after concentration is 25-28% , the temperature of the fourth effect evaporator is 60-65 DEG C, after concentration, a concentrated fermentation broth with a mass percentage concentration of glutamic acid of 30%-32% is obtained, and concentrated condensed water is collected.

[0048] The fermentation broth is first concentrated to reduce the amount of liquid entering the subsequent steps, which can not only reduce the consumption of sulfu...

Embodiment 2

[0073] Steps a~g are the same as embodiment 1.

[0074] h. Crystal transformation, cooling and separation: heating the suspension of glutamic acid crystals containing α-crystal form obtained after the second crystal washing in step d to 80-90° C. to adjust the pH to 4.0-5.0, Cool to 40°C to generate a suspension containing β-crystalline glutamic acid crystals, filter, wash and dehydrate at the same time with a filter separator to obtain β-crystalline glutamic acid crystals, wherein the mother liquor is obtained three times after filtration and returned to step d. In the first crystal washing, add washing water to wash and dehydrate the glutamic acid crystals in the β crystal form, and then return to step d for the second crystal washing.

[0075] i. Neutralization and refining: add soda ash or caustic soda solution to the glutamic acid crystals of β crystal form, neutralize to PH = 7, the obtained crude neutralization solution is refined, and the refined mother liquor and mono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com