Patents

Literature

123results about How to "Guaranteed precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

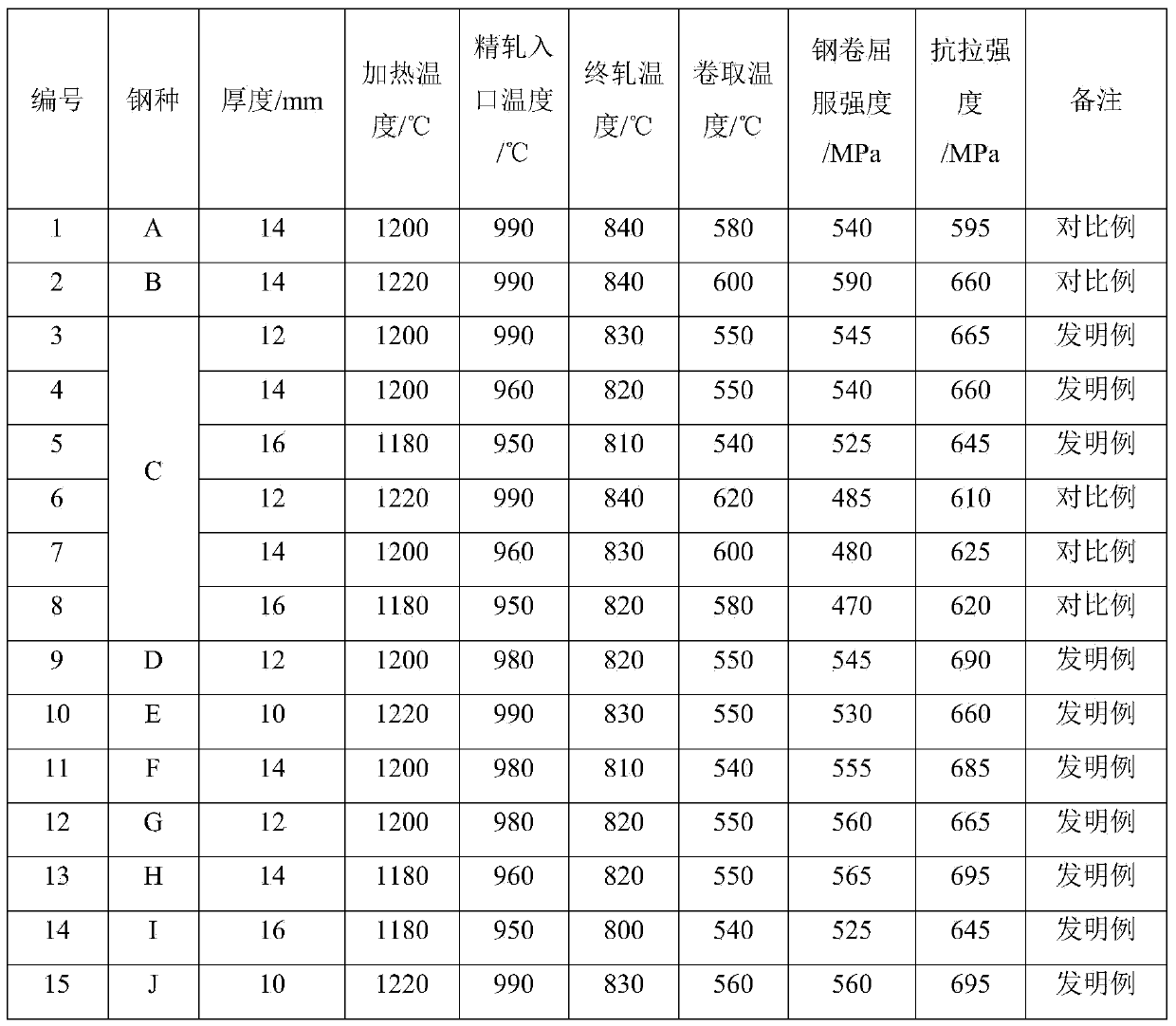

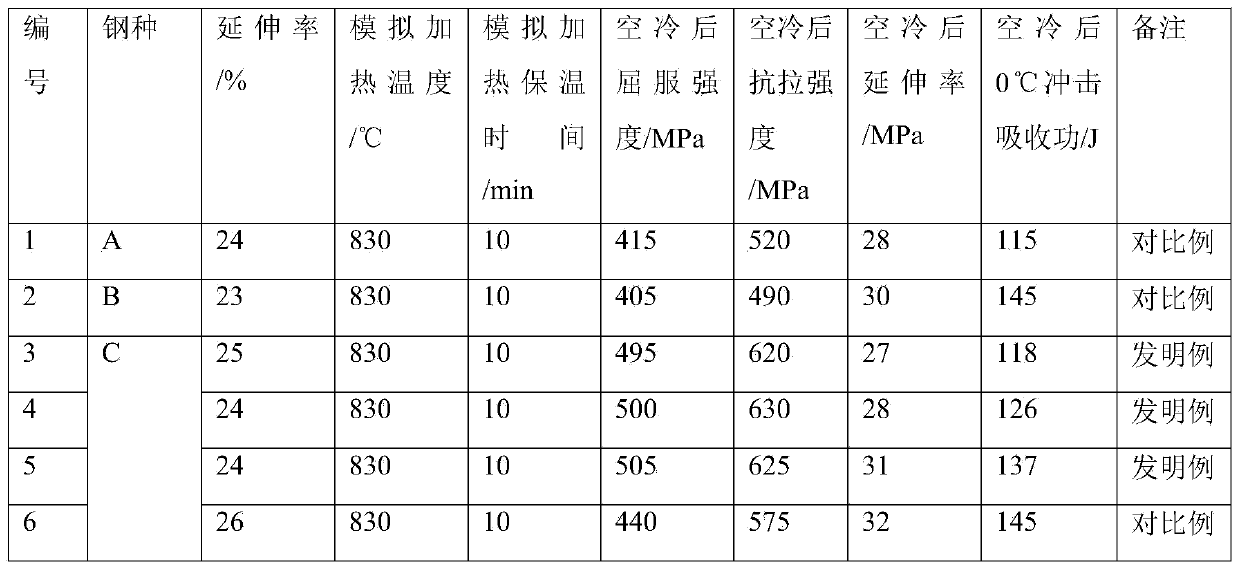

600 MPa level automobile axle housing steel and production method thereof

The invention discloses 600 MPa level automobile axle housing steel and a production method of the 600 MPa level automobile axle housing steel. Compositions of the steel comprise, by weight, 0.21 percent to 0.26 percent of C, 0.51 percent to 0.6 percent of Si, 1.1 percent to 1.5 percent of Mn, 0.01 percent to 0.06 percent of Al, P smaller than or equal to 0.02 percent, S smaller than or equal to 0.01 percent, 0.05 percent to 0.06 percent of V, 0.012 percent to 0.016 percent of N, and the balance Fe and inevitable impurities. The ratio of V to N is smaller than or equal to 5:1. According to the method, the accurate V content, the accurate N content and the controlled rolling and controlled cooling process window are designed, hot rolling strip steel for a 600 MPa level automobile axle housing is produced, the strip steel has the good strength and toughness, and meanwhile various mechanical performance indexes of the axle housing after hot forming at the temperature more than 800 DEG C can be ensured. The method can be applied to automobile axle housing production, the thickness of materials can be effectively reduced, and on the premise that the safety of an automobile is ensured, the lightweight aim can be effectively achieved.

Owner:SHOUGANG CORPORATION

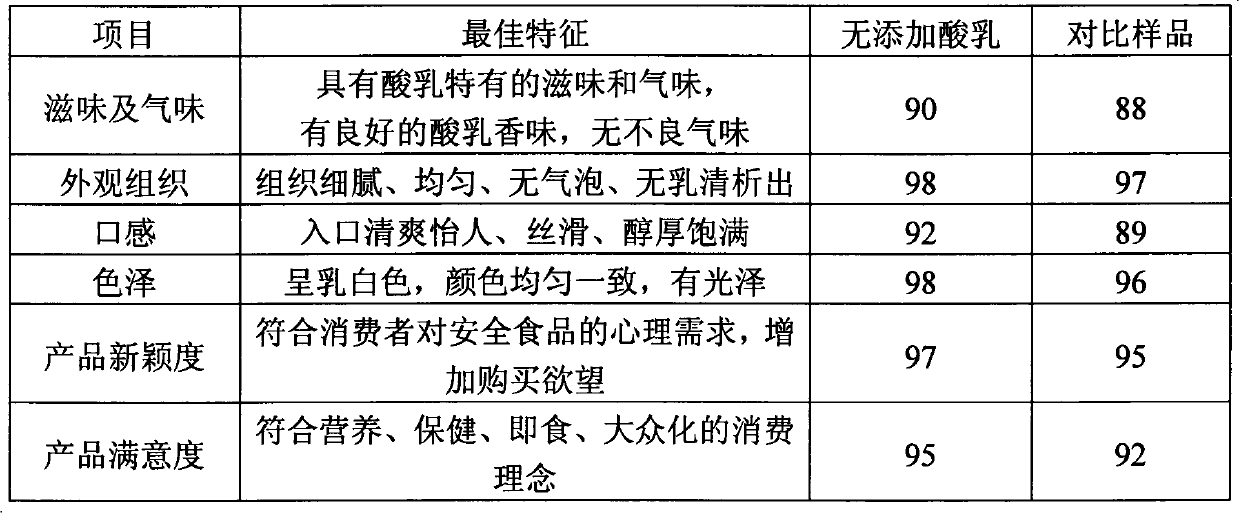

Additive-free yogurt and preparation method thereof

Owner:BRIGHT DAIRY & FOOD

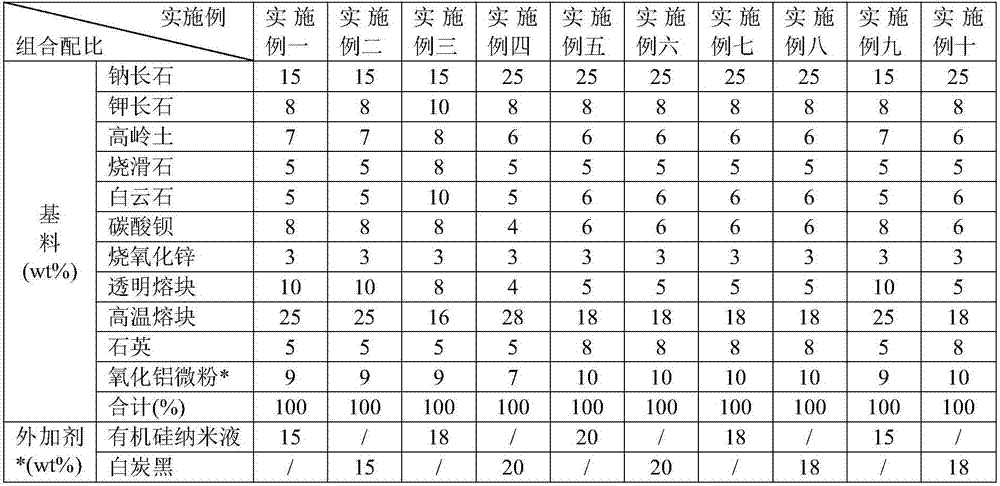

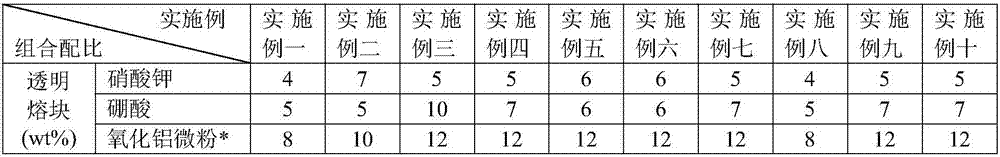

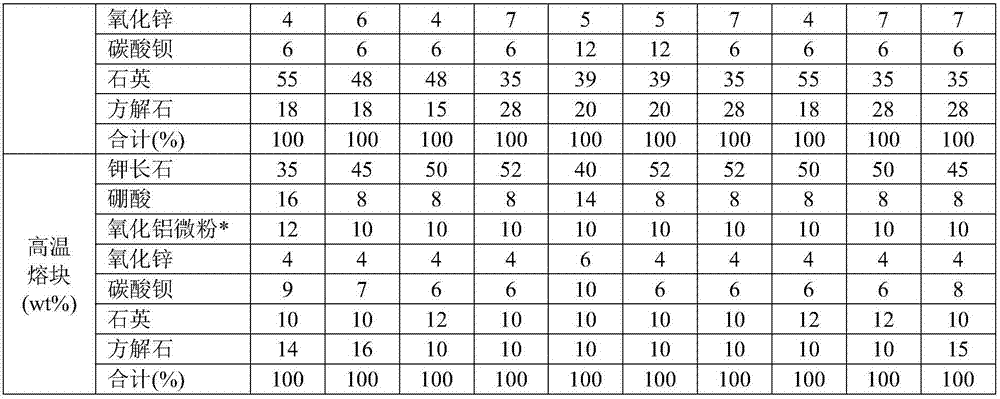

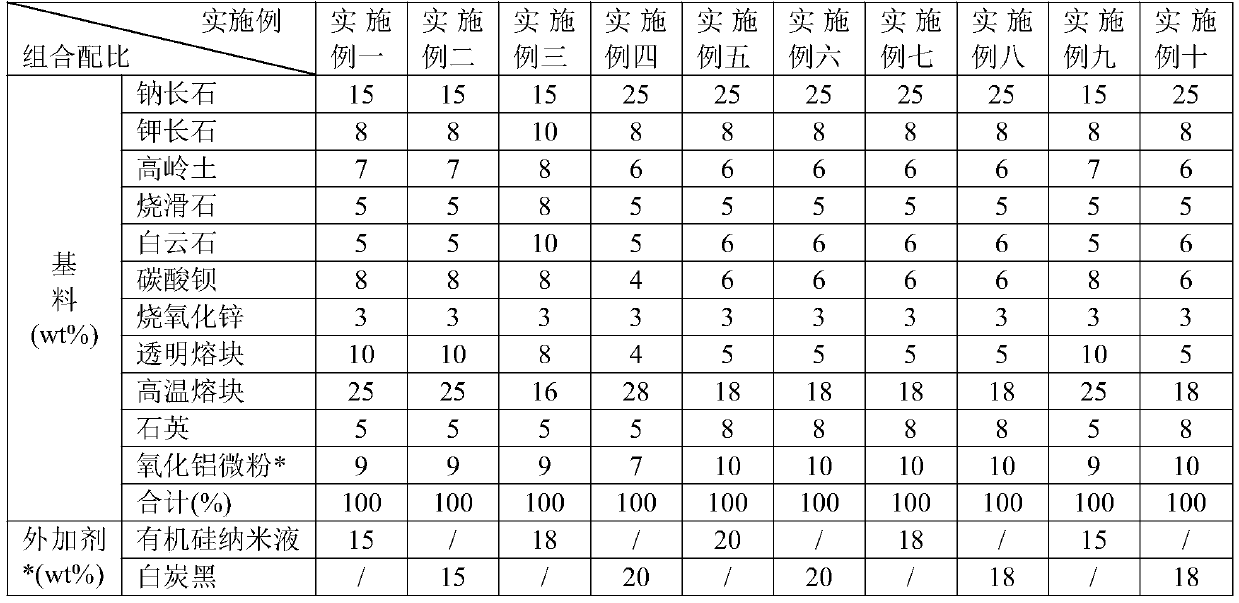

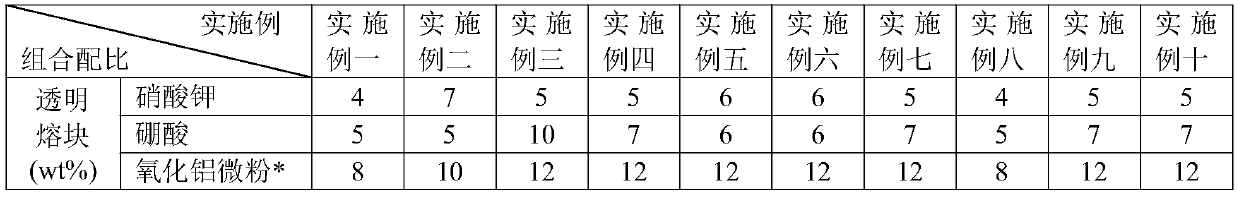

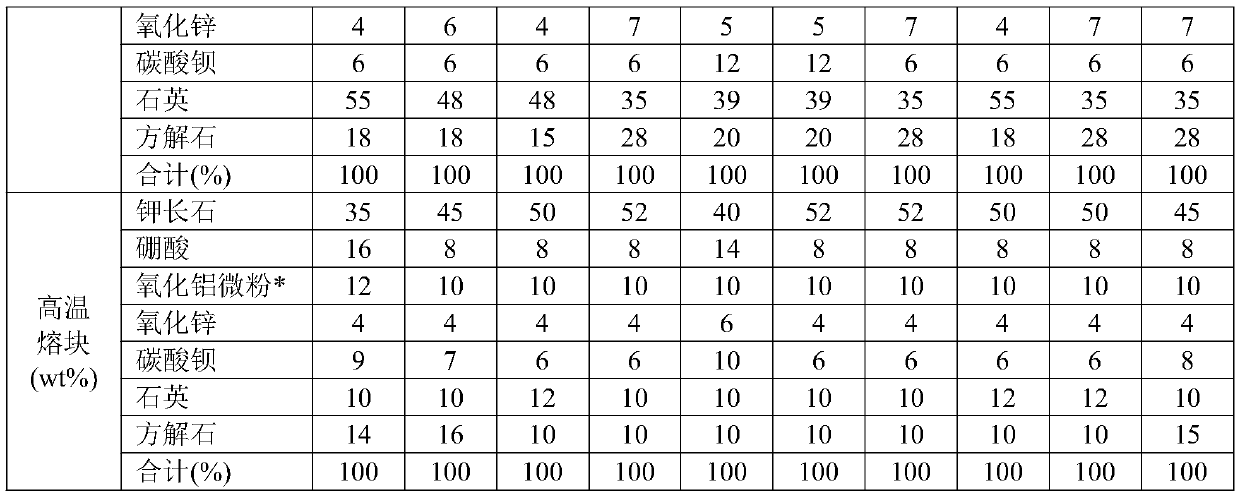

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Glufosinate separation and purification method

ActiveCN104860988ASlow flowFast flowGroup 5/15 element organic compoundsPurification methodsCentrifugation

The invention belongs to the field of pesticide production and particularly relates to a glufosinate separation and purification method. According to the method, the separation and purification is started when a glufosinate hydrochloride reaction solution in the steps of distilling the glufosinate hydrochloride reaction solution under reduced pressure to remove dilute hydrochloric acid, adding ammonia water to adjust the pH to maximally produce ammonium chloride, distilling under reduced pressure to remove water, adding a flotation solvent for dispersion, placing the material into a chute at specific temperature and speed, performing flotation separation according to the difference in the proportion of a principal component and subsidiary salt, removing the solvent, dissolving the material in aqueous methanol to remove trace ammonium chloride, filling ammonia gas to adjust the pH value to 8, performing centrifugation and drying to obtain a final product. The glufosinate separation and purification method uses a flotation method for separating the principal component glufosinate and an intermediate of the principal component from the subsidiary salt ammonium chloride and the aqueous methanol for purification and is high in yield, good in purity, simple in process, low in cost and is suitable for industrial production.

Owner:石家庄瑞凯化工有限公司

Silicon-based ceramic core preparation method

The invention discloses a silicon-based ceramic core preparation method. The method comprises the following steps: powder configuration and mixing, slurry preparation, compression moulding and sintering, wherein the sintering step comprises the following processes: wax melting, gasification, intensified gasification, cristobalite transitional change, cristobalite change and final sintering. The silicon-based ceramic core prepared by using the preparation method is good in creep resistance, low in high temperature deflection, low in shrinking percentage, high in strength, high in porosity, and easy for core leach.

Owner:兴化市兴东铸钢有限公司

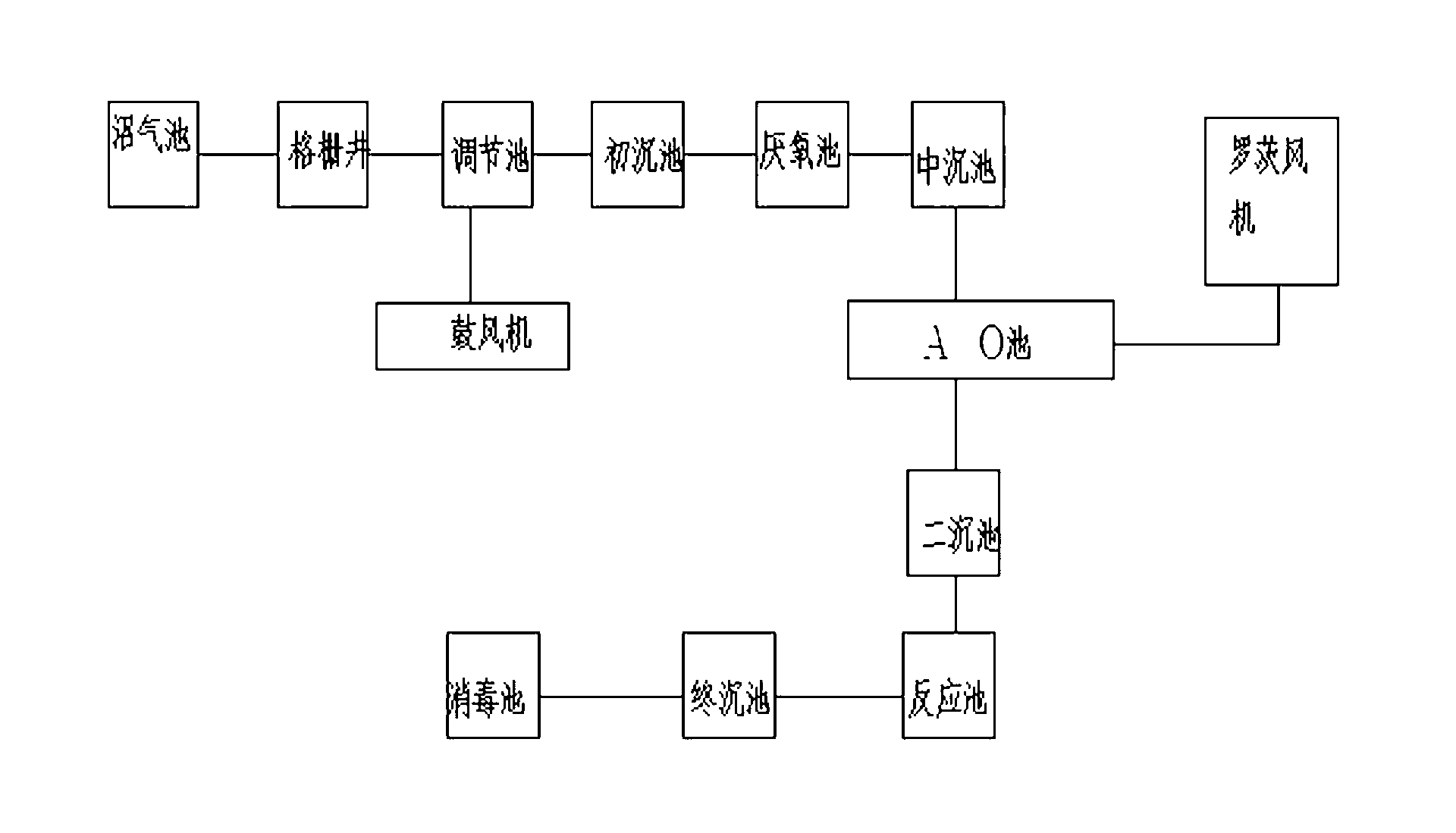

Large-scale pig farm wastewater treatment method

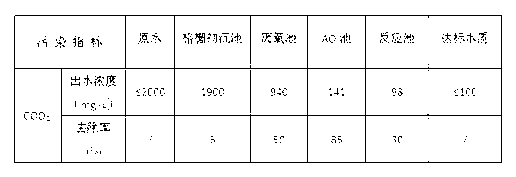

ActiveCN103241908AImprove biodegradabilityAvoid churnMultistage water/sewage treatmentPig farmsMedicine

The invention relates to a large-scale pig farm wastewater treatment method comprising anaerobic fermentation, filtering, regulating pool treatment, primary precipitation, anaerobic pool treatment, secondary precipitation, A / O pool treatment, precipitation of secondary sedimentation tank, flocculent precipitation treatment, final precipitation treatment and disinfecting tank treatment. The treatment method provided by the invention is simple in treatment procedures, low in treatment cost and strong in treatment ability, thereby being suitable for popularization and application of large-scale pig farm wastewater treatment.

Owner:巨星农牧有限公司

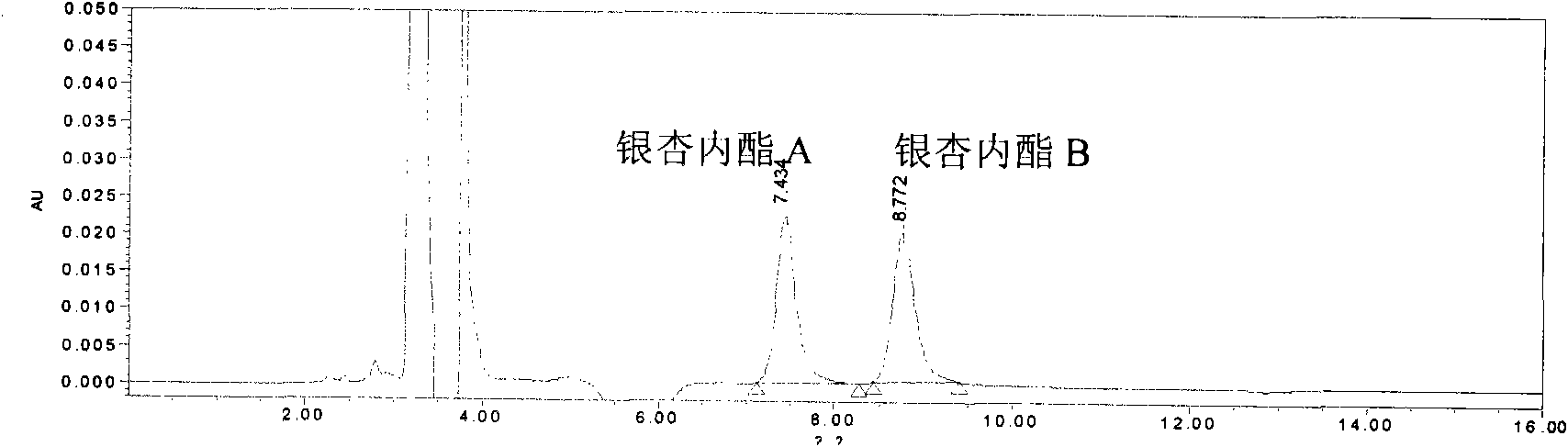

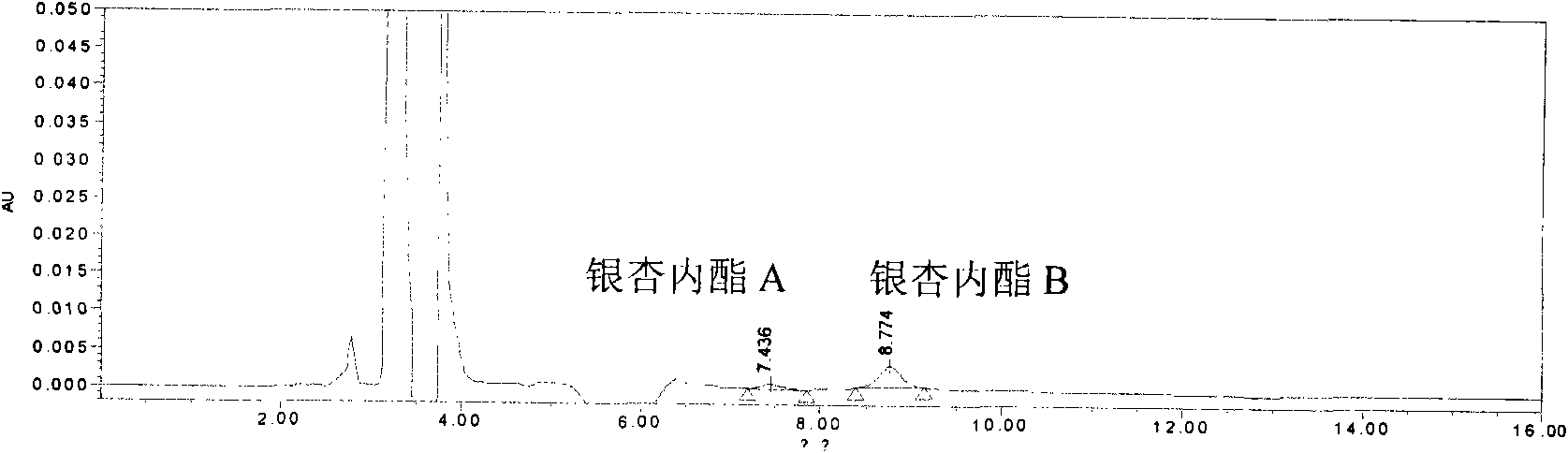

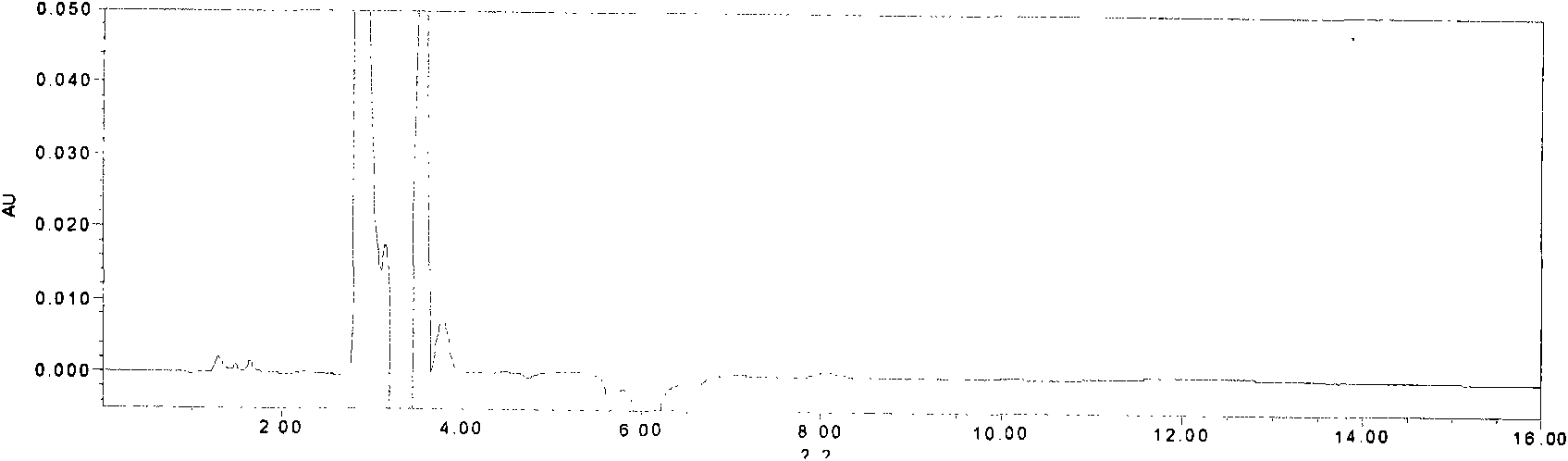

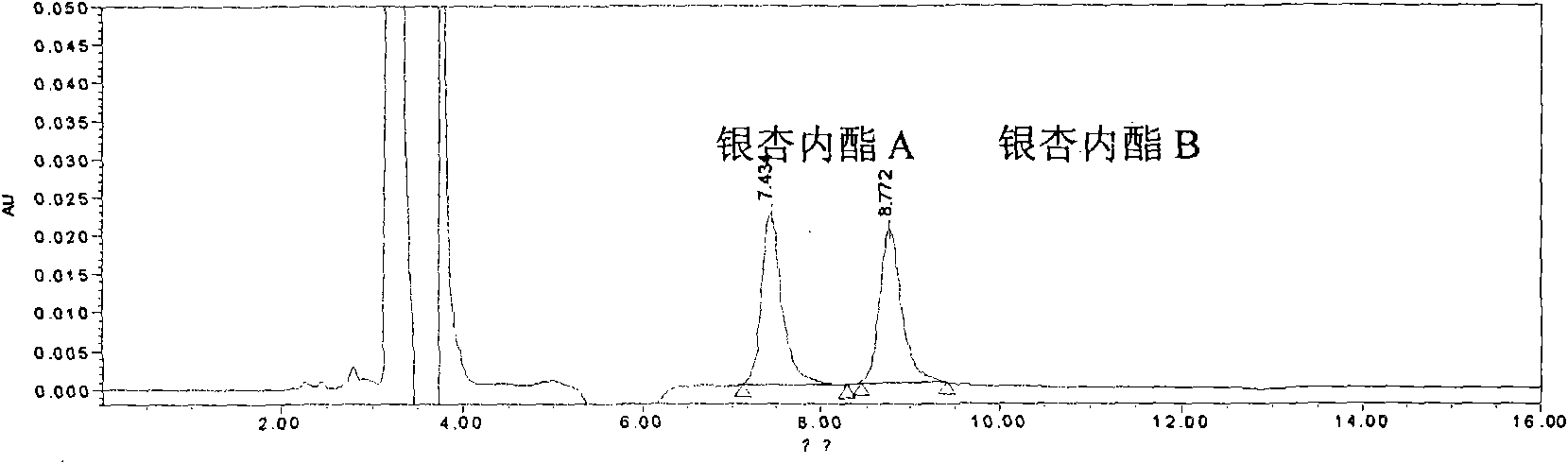

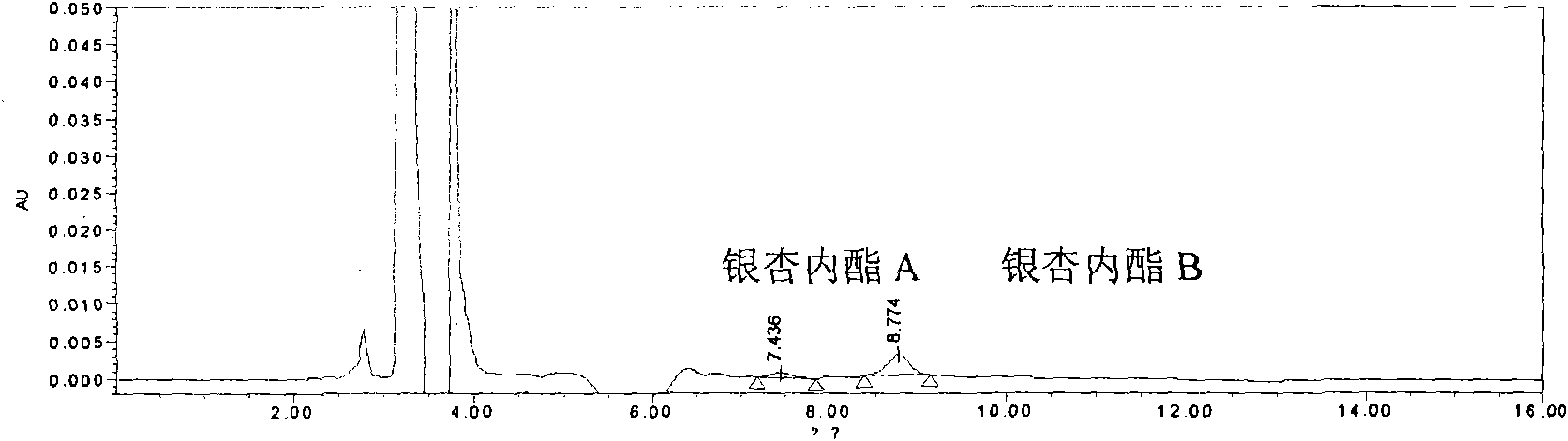

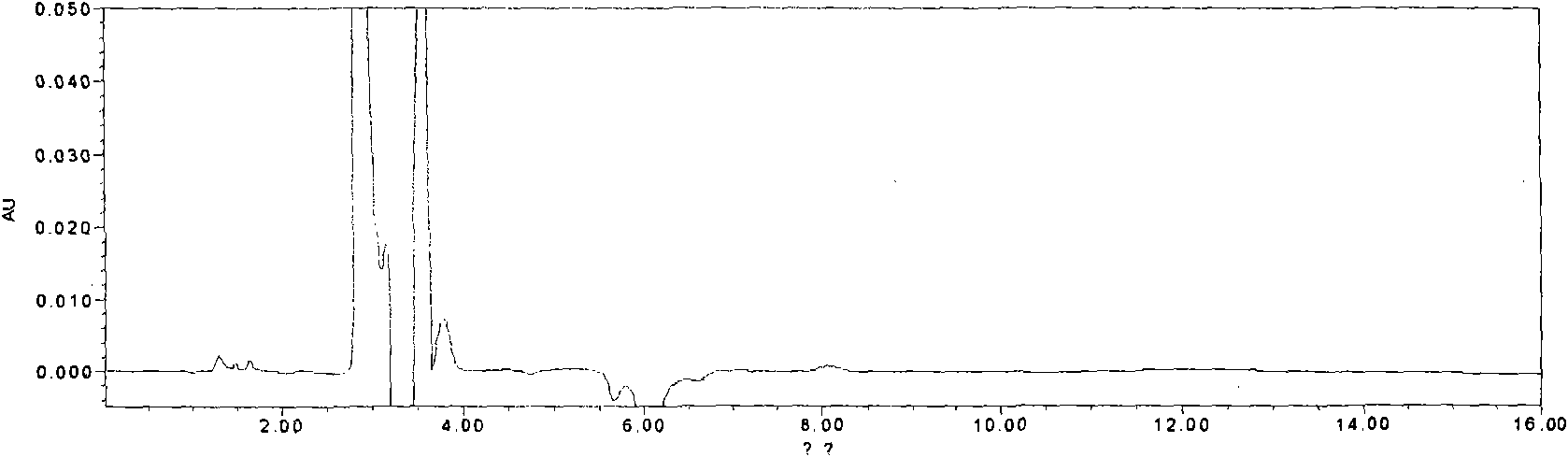

Quality control method of ginkgolide injection

ActiveCN101647829AStrong specificityGood reproducibilityComponent separationGinkgophyta medical ingredientsGinkgolideQuality control

The invention relates to a quality control method of injection, in particular to a quality control method of ginkgolide injection. The invention provides a method for controlling the quality of the ginkgolide injection by adopting high performance liquid chromatography. The method can control the quality of the ginkgolide injection by adopting one or more of a content determination method, a limittest method of dissociation ginkgolide and a chromatographic fingerprint method. The quality control method provided by the invention has the advantages of having high precision, stability and repeatability, and achieving the aim of effectively controlling the quality of the ginkgolide injection in an all-round way.

Owner:JIANGSU KANION PHARMA CO LTD

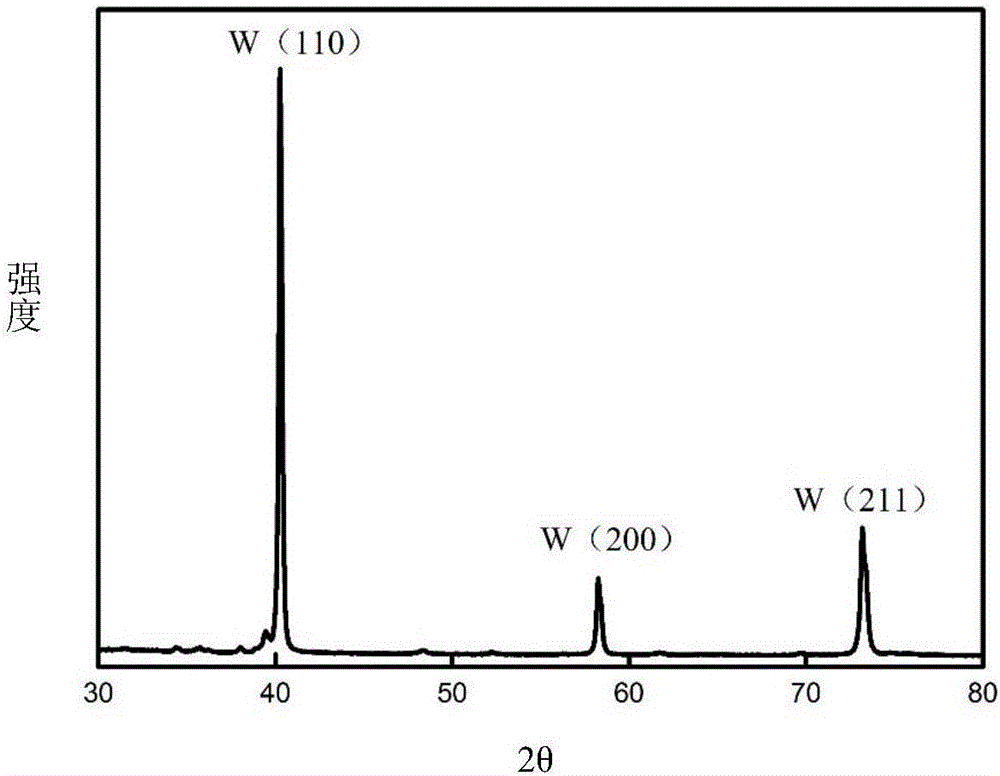

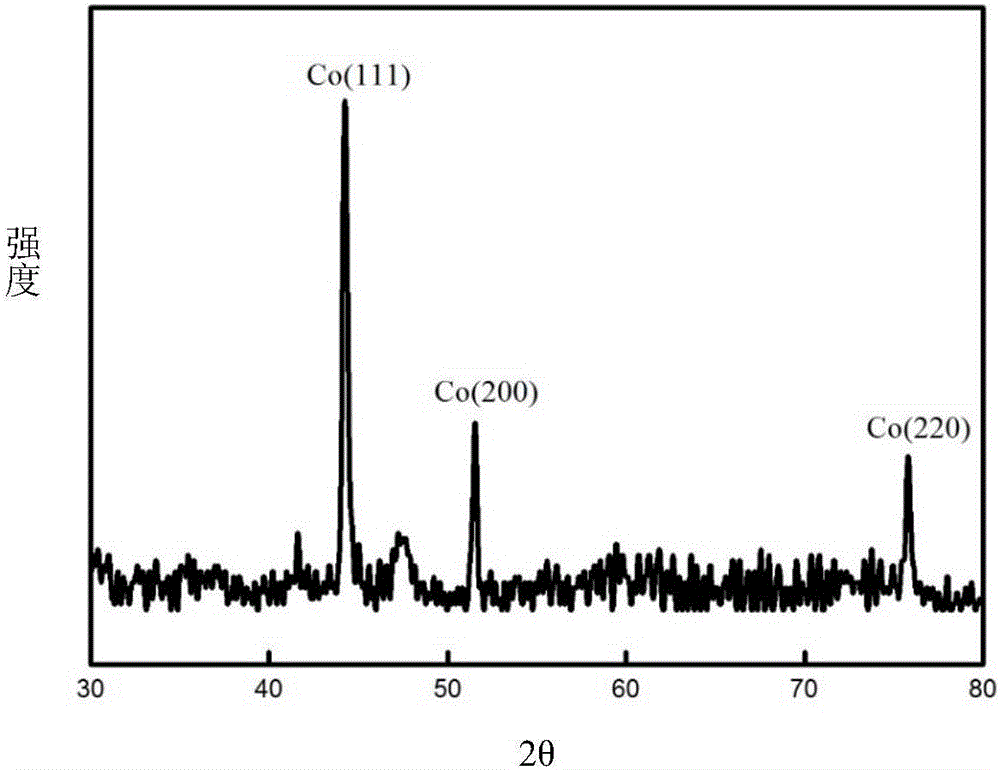

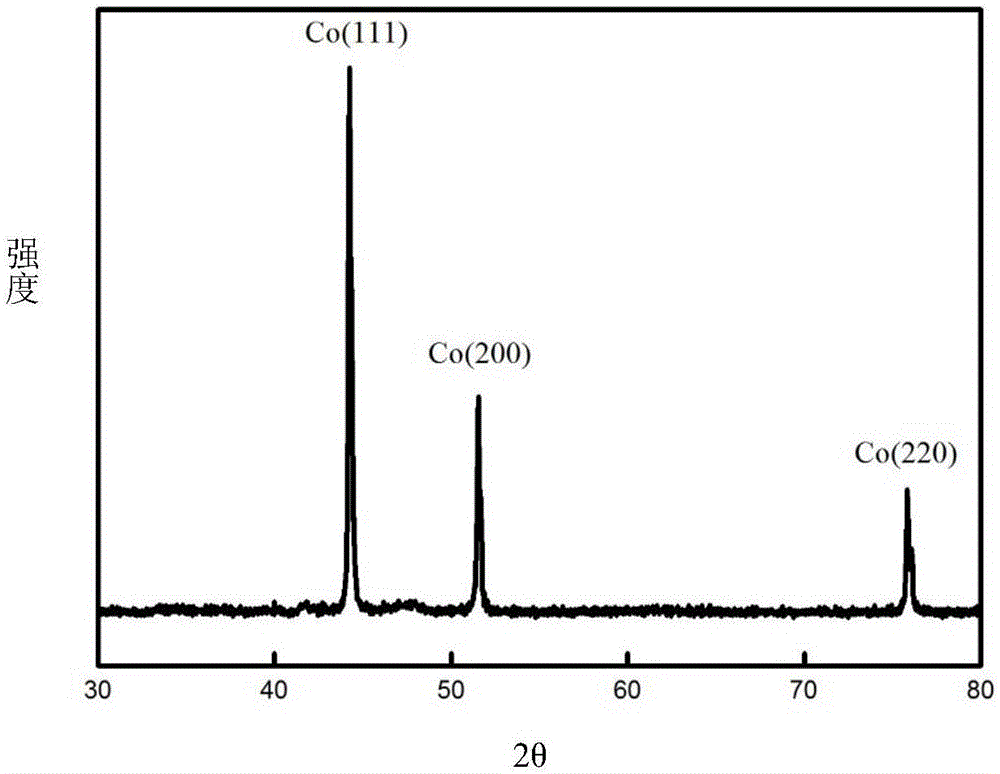

Method for recycling metal in tungsten carbide waste through fluoride electrolysis

ActiveCN106544701AImprove electrochemical activityAccelerate the speed of electrochemical dissolutionLoss rateElectrolysis

The invention provides a method for recycling metal in tungsten carbide waste through fluoride electrolysis. The method is characterized in that the tungsten carbide waste is taken as an anode; high-temperature fluoride is taken as electrolyte; the high-temperature fluoride is one or more of NaF, KF, MgF2, RbF and CaF2; and the tungsten carbide waste is WC alloy waste or WC alloy waste containing Co with mass fraction being 2-20%. According to the method provided by the invention, a fluoride molten salt system has the characteristics of a relatively high electrochemical window at a high temperature, relatively great ionic conductivity, a relatively low molten salt loss rate and relatively strong corrosion; the fluoride molten salt system is taken as a molten salt dielectric medium, so that electrochemical activities, at a high temperature, of WC waste and a waste hard alloy are improved, and therefore, electrochemical dissolution speed of WC waste and the waste hard alloy is quickened.

Owner:BEIJING UNIV OF TECH

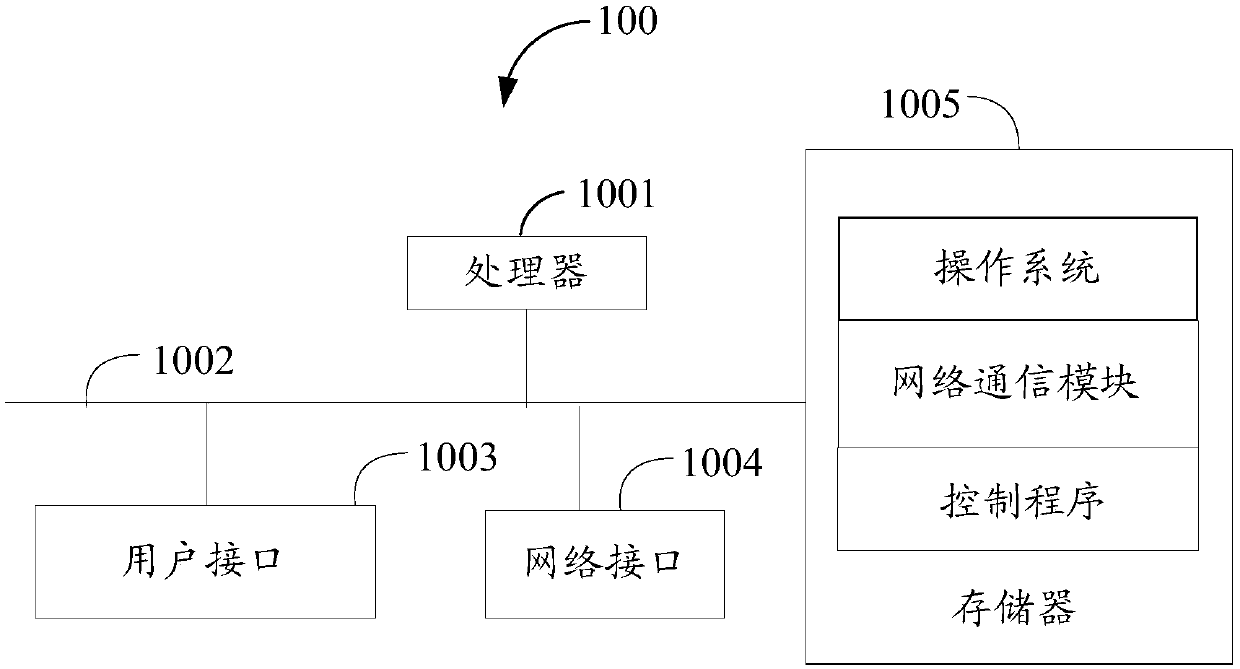

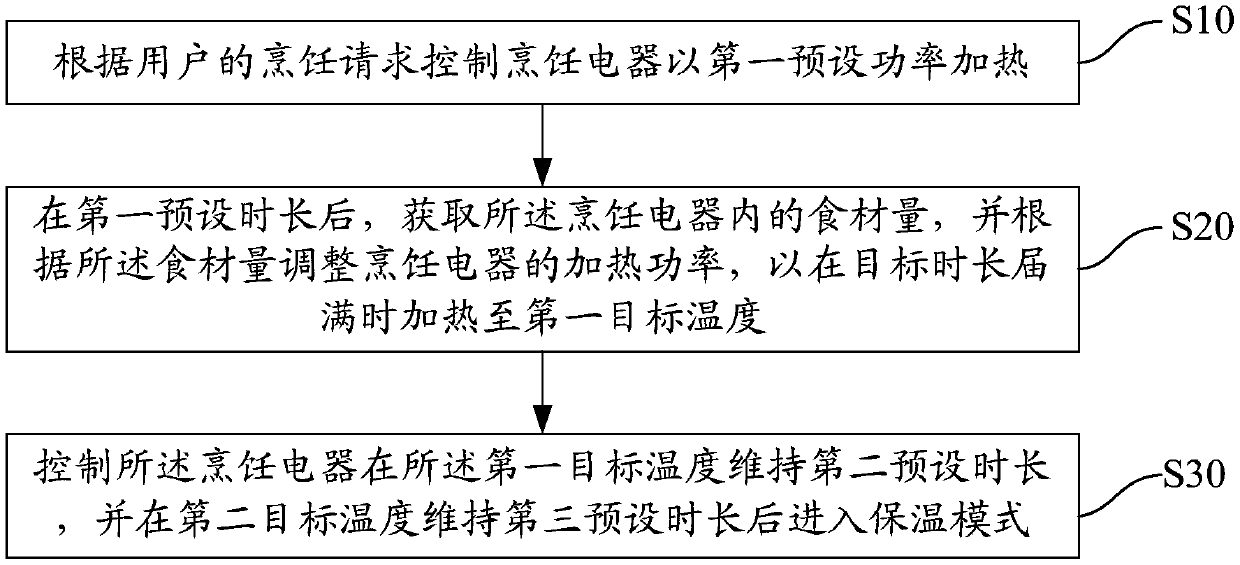

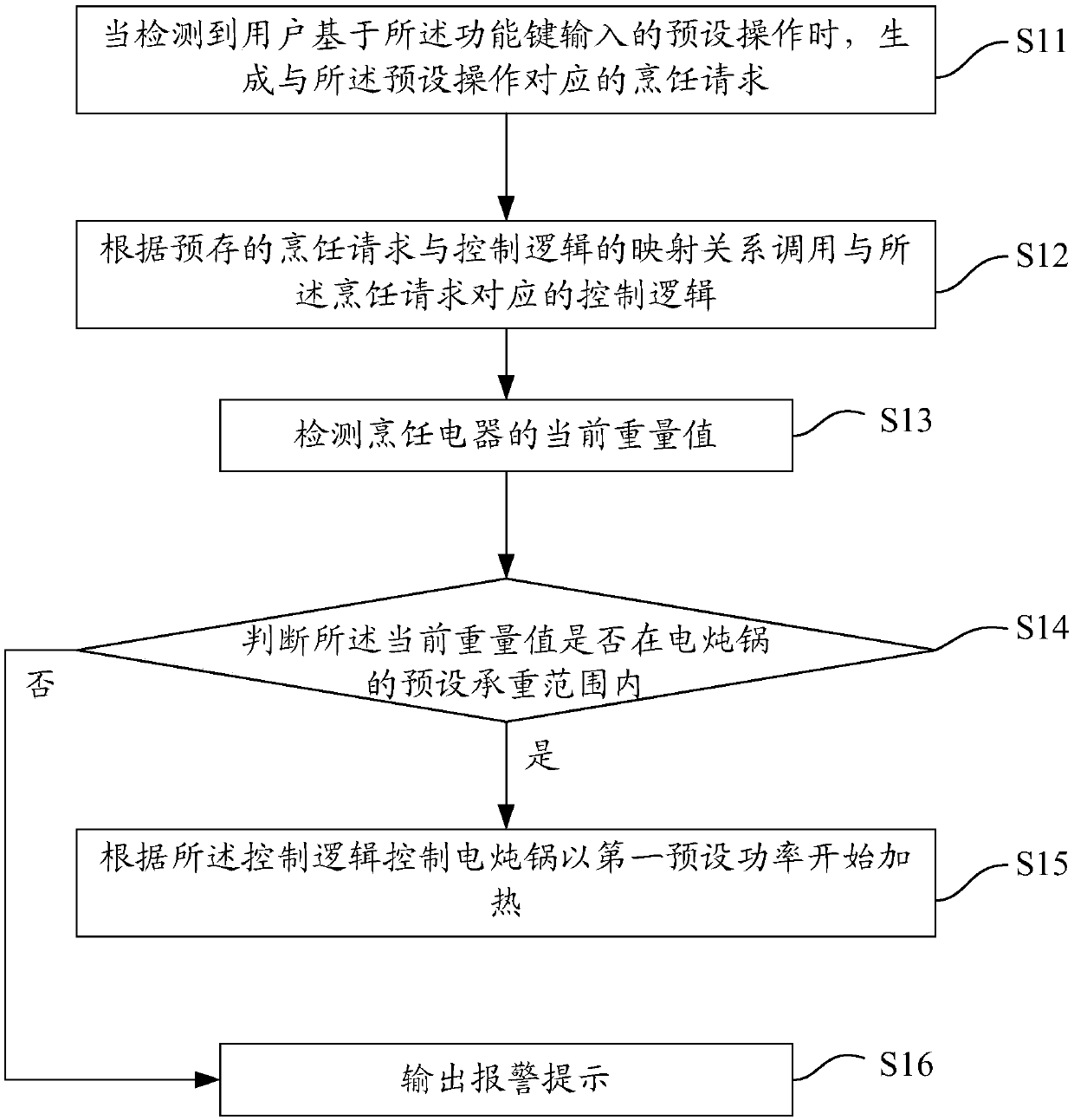

Cooking appliance control method, cooking appliance and storage medium

InactiveCN110623517AImprove cooking resultsEasy to operateVessels with intergral heatingTime-controlled ignitorsProcess engineeringFood material

The invention provides a cooking appliance control method. In the control method, a cooking appliance is controlled to conduct heating with first preset power according to a cooking request of a user,after first preset time, the quantity of food materials in the cooking appliance is acquired, and the heating power of the cooking appliance is adjusted according to the quantity of the food materials, so that the food materials in the cooking appliance are heated to a first target temperature upon expiration of the target time. The invention also provides the cooking appliance and a storage medium. According to the control method, the cooking effect of the cooking appliance is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

610Mpa high-strength steel plate for low-yield-ratio petroleum reserve tank and manufacturing method thereof

InactiveCN104451386ASave the process of quenching + temperingShort production cycleBatch productionSheet steel

The invention belongs to the field of low alloy steel production processes, and specifically relates to a 610Mpa high-strength steel plate for a low-yield-ratio petroleum reserve tank and a manufacturing method thereof. The 610Mpa high-strength steel plate for the low-yield-ratio petroleum reserve tank comprises the following components in percentage by mass: 0.07-0.13% of C, 0.15-0.35% of Si, 1.45-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, less than 0.030% of Nb, 0.03-0.05% of V, 0.010-0.020% of Ti, 0.08-0.18% of Mo, 0.15-0.35% of Ni, less than 0.008% of N and the balance of Fe and inevitable impurities. The method is capable of overcoming the limitation that the yield ratio is difficult to reduce in the traditional production and manufacturing method, simplifying the production process, shortening the production flow and reducing energy consumption, suitable for industrial batch production, and capable of ensuring a low yield ratio while meeting the requirements of strength, toughness and welding performance indexes.

Owner:SHANDONG IRON & STEEL CO LTD

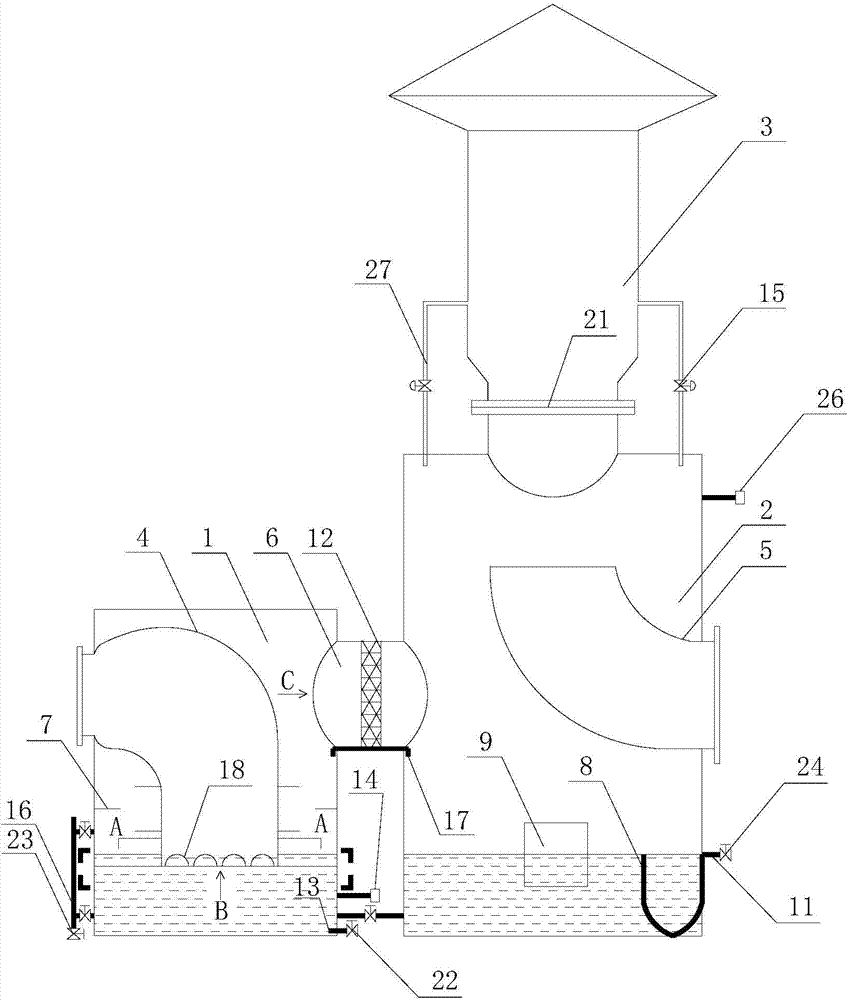

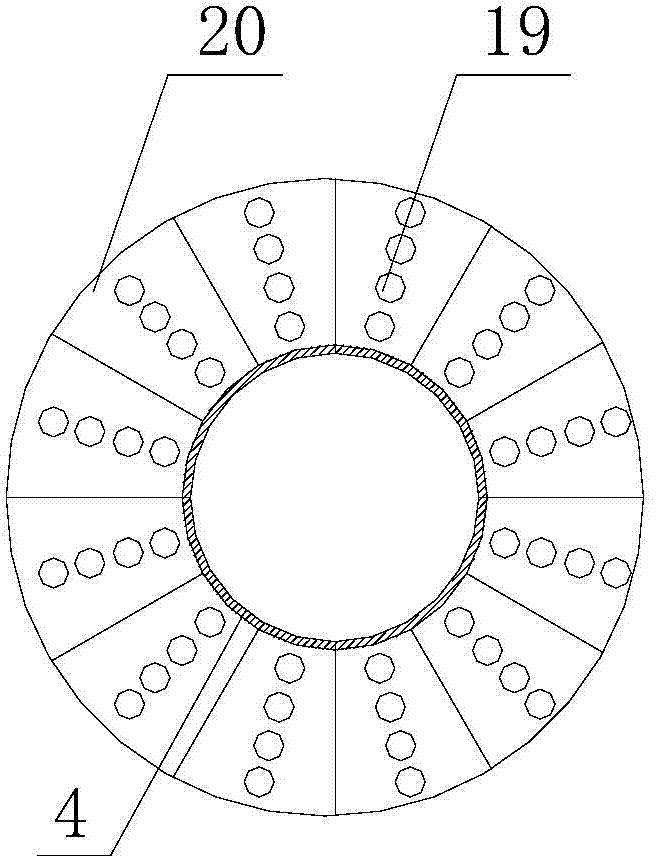

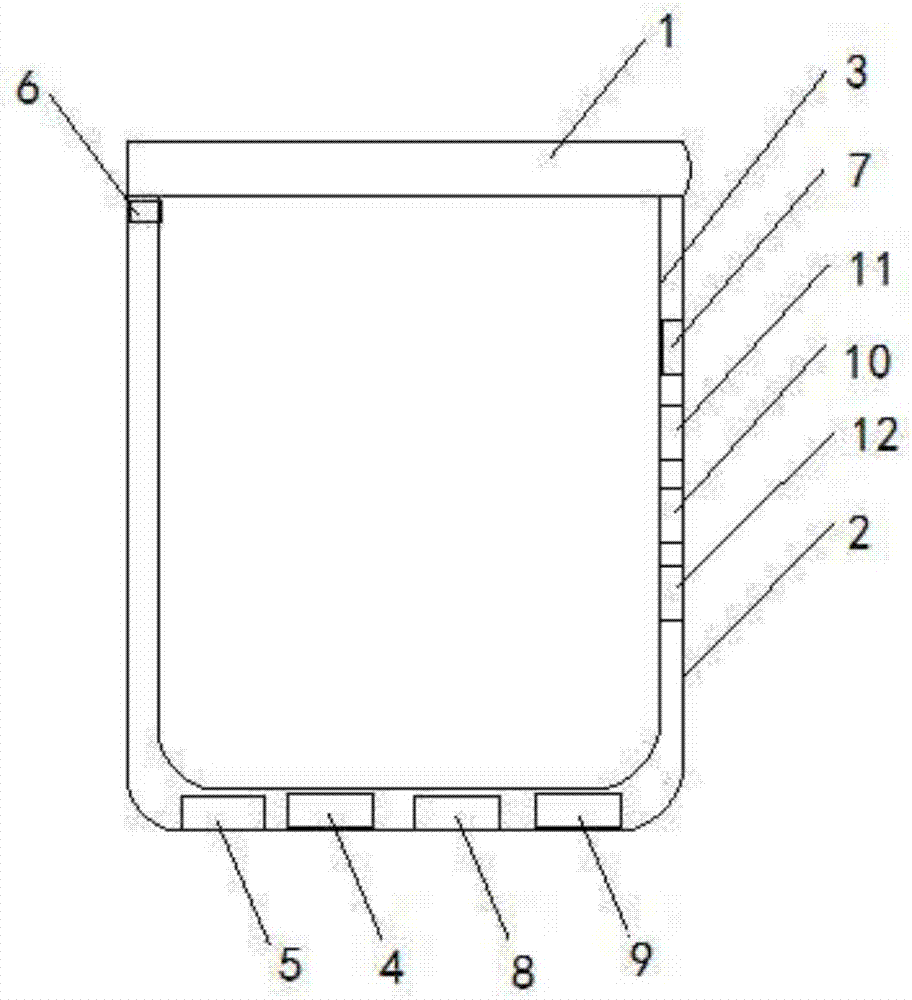

Water sealing fire retardance explosion venting device

The invention discloses a water sealing fire retardance explosion venting device which comprises a fire retardance device and an explosion venting machine. The fire retardance device comprises a fire retardance barrel body, an air inlet pipe, an air outlet pipe and a water filtering metal ring net. One end of the air inlet pipe is placed out of the fire retardance barrel body, the other end of the air inlet pipe extends into the fire retardance barrel body and is inserted to the position below a sealing water liquid level, and the water filtering metal ring net is arranged above the sealing water liquid level and is arranged outside the air inlet pipe in a sleeving mode. The explosion venting machine comprises an explosion venting barrel body, an exhaust pipe and an explosion venting pipe. The exhaust pipe and the explosion venting pipe are communicated with the explosion venting barrel body. The fire retardance barrel body is communicated with the explosion venting barrel body through the air outlet pipe and a communication pipe arranged at the bottom. An explosion piece is arranged in the explosion venting pipe. An air outlet end pipe opening of the air inlet pipe is sealed. An exhaust hole is formed in the side wall, placed below the sealing water liquid level, of the air inlet pipe. The exhaust hole is connected with an air guiding pipe. Air guiding holes for air discharging are distributed in the air guiding pipe. The instability and the acute fluctuation of the liquid level caused when air is discharged from the device exhaust pipe can be avoided, water level control is convenient, and the safety and the reliability of the device are improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

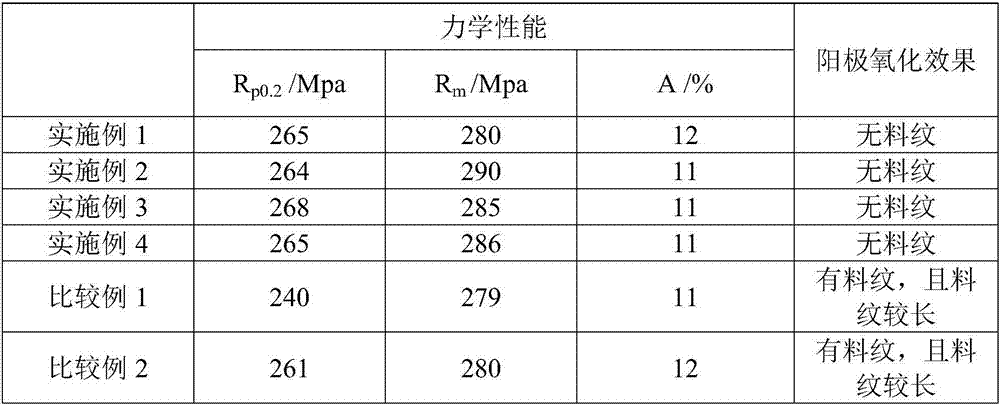

6-series aluminum alloy and machining method thereof

The invention discloses a 6-series aluminum alloy and a processing method thereof. The 6-series aluminum alloy includes: magnesium (Mg): 0.6-1.0 wt%; silicon (Mg): 0.4-0.8 wt%; manganese (Mn): ≤0.04 wt%; Titanium (Ti): ≤0.04 wt%; Iron (Fe): ≤0.10 wt%; Copper (Cu): ≤0.05 wt%; Chromium (Cr): ≤0.01 wt%; ) and unavoidable impurities. The invention optimizes the components of the 6 series aluminum alloy and controls the processing technology, so that the size and distribution of the intermetallic compounds are better controlled, and finally the material has a better anodic oxidation effect.

Owner:杨仲彬

Wide-width, high-strength, high-toughness and thick-wall X80M pipeline steel plate and manufacturing method thereof

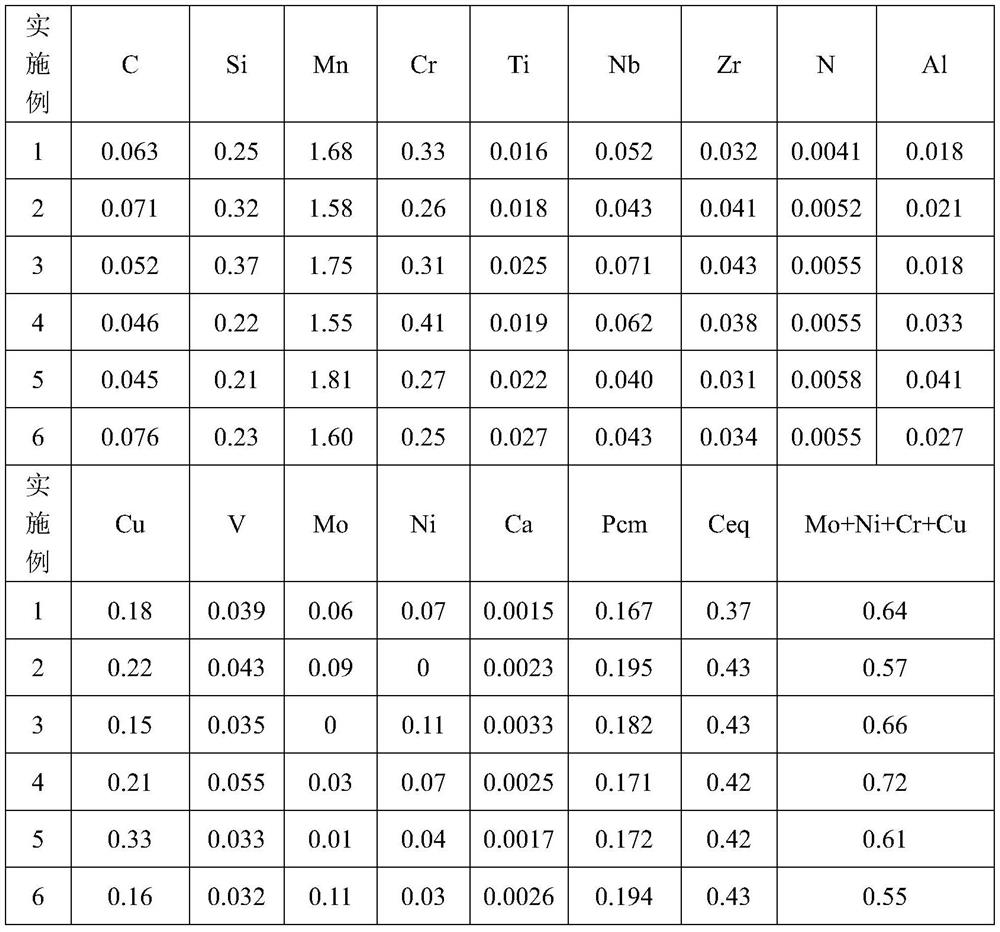

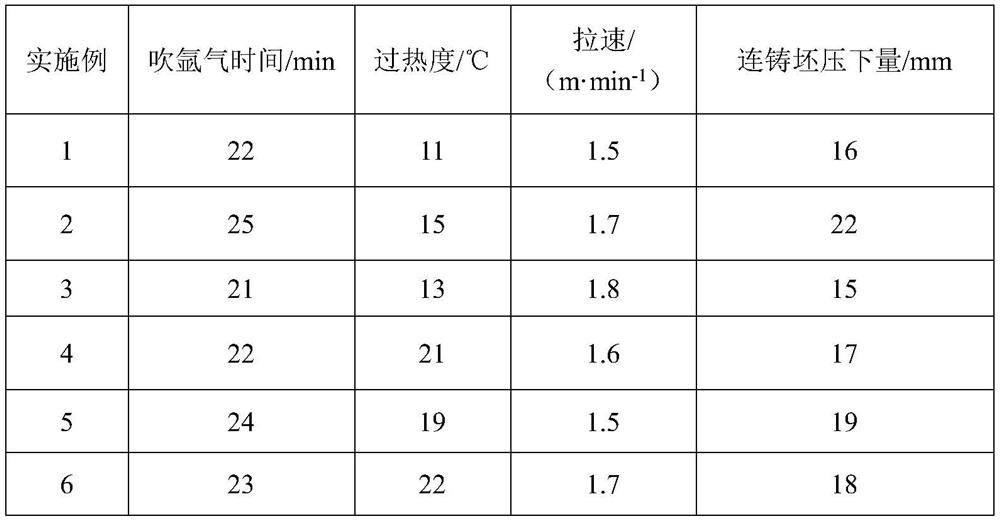

The invention relates to a wide-width, high-strength, high-toughness and thick-wall X80M pipeline steel plate and a manufacturing method thereof. The steel plate is prepared from the chemical components including, by weight, 0.045%-0.08% of C, 0.20%-0.38% of Si, 1.55%-1.85% of Mn, 0.15%-0.35% of Cu, less than or equal to 0.010% of P, less than or equal to 0.015% of S, 0.04%-0.08% of Nb, 0.015%-0.028% of Ti, 0.015%-0.045% of Al, 0.25%-0.5% of Cr, 0.004%-0.006% of N, 0.032%-0.06% of V, 0.03%-0.05% of Zr, less than or equal to 0.15% of Ni, less than or equal to 0.12% of Mo, 0.0012%-0.0035% of Ca and the balance Fe and inevitable impurities. The produced steel plate has the comprehensive performance of high strength and good low-temperature toughness, and can ensure the safety of oil and gas transmission pipelines.

Owner:ANGANG STEEL CO LTD

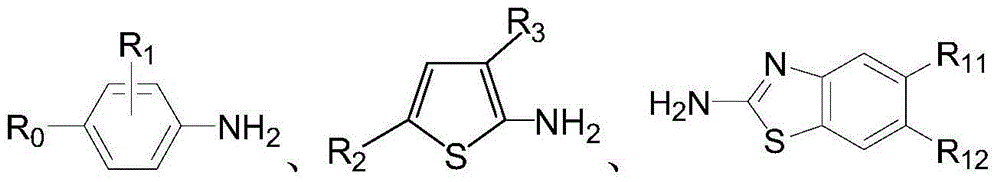

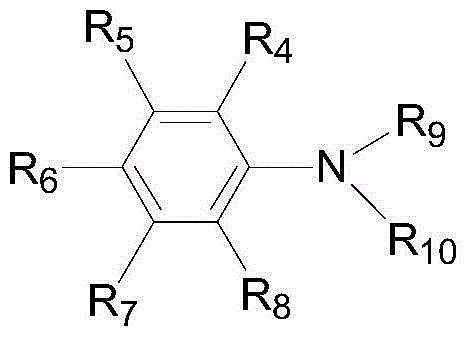

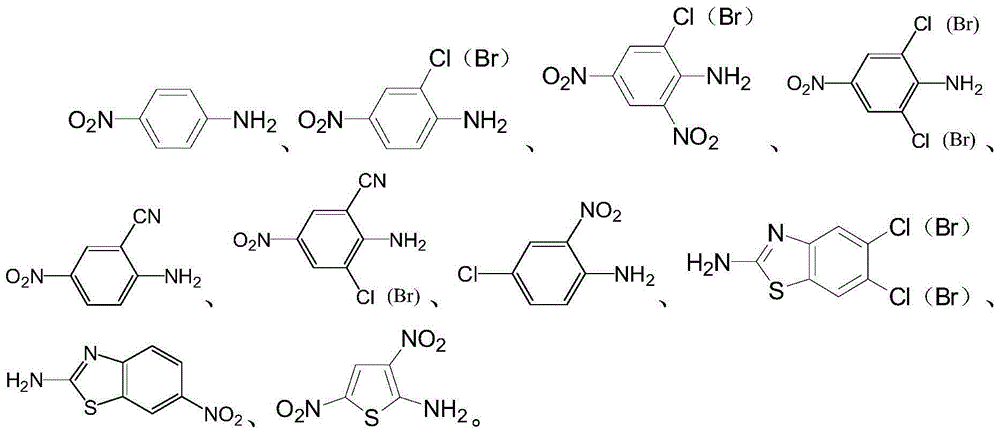

Preparation method of ester group-containing azo disperse dye

The invention discloses a preparation method of an ester group-containing azo disperse dye. The method comprises the following steps: carrying out a coupling reaction on a diazo salt and a coupling component, adding an alkali to the above obtained azo compound material system after the coupling reaction is completed in order to adjust the pH value of the system to 5-7, carrying out heating crystal transformation, and post-processing to obtain a dye filter cake. The pH value of the system is adjusted to 5-7 after the coupling reaction and before the crystal transformation, so hydrolysis of ester groups in the dye product is avoided, the yield of the dye product is improved, and the content of organic matters in wastewater is reduced, thereby the wastewater post-treatment difficulty is reduced.

Owner:ZHEJIANG DIBANG CHEM

Preparation method of trimethyl hydroquinone

ActiveCN102898282ALow costOvercome limitationsOrganic chemistryOrganic compound preparationHydroquinone productsHydroquinone Compound

The invention discloses a preparation method of trimethyl hydroquinone, which comprises the following steps: adding 2,3,5-trimethyl benzoquinone, solvent, and Raney catalyst into a hydrogenation kettle to react, filtering, and drying to obtain the trimethyl hydroquinone product. The invention has the advantages of low raw material cost and simple operating procedure, shortens the period, reduces the solvent recovery loss, and enhances the yield and quality of the product.

Owner:NANTONG BAISHENG CHEM

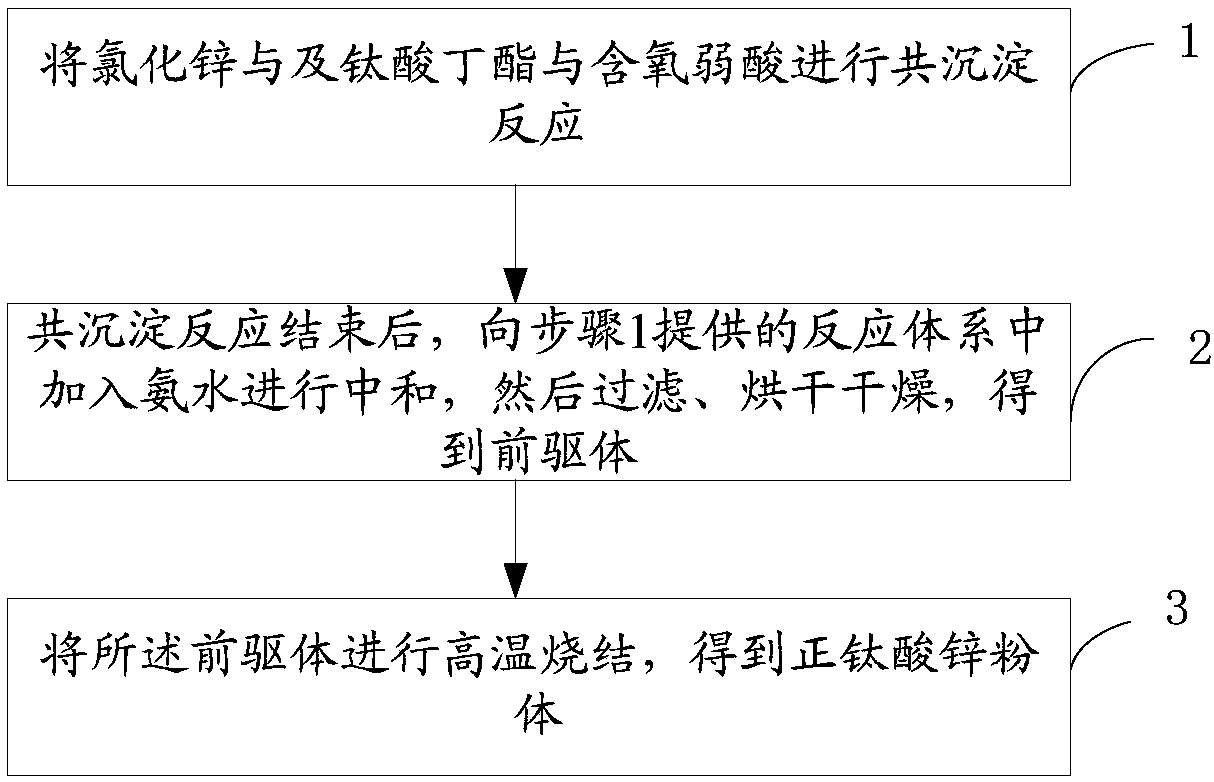

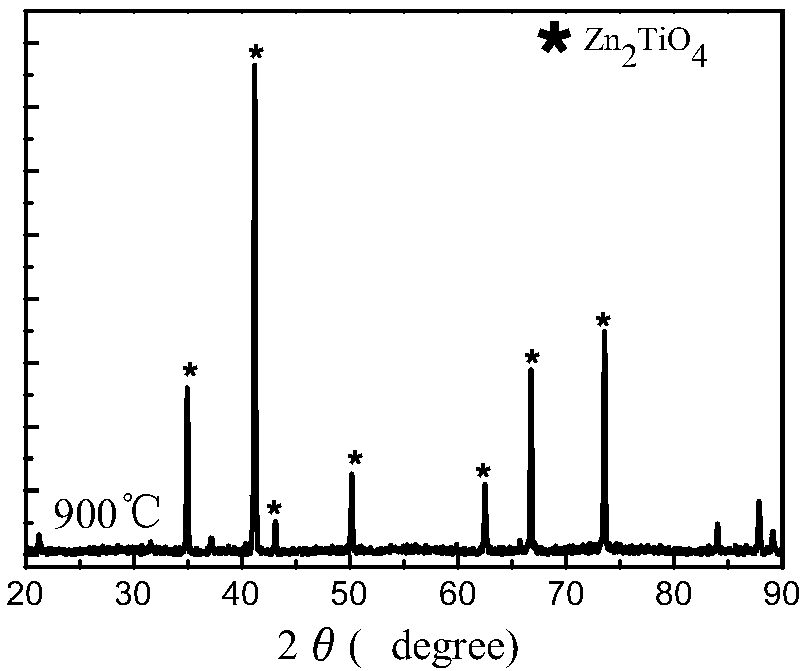

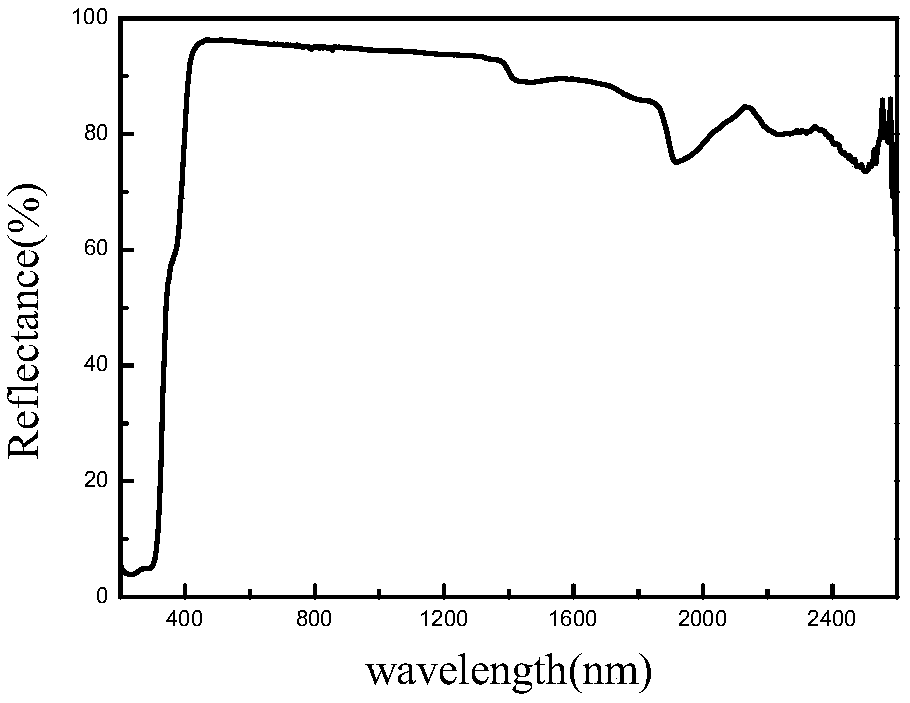

Preparation method of n-zinc titanate powder and application

The invention provides a preparation method of n-zinc titanate powder and application and belongs to the technical field of thermal control coatings of spacecrafts. The preparation method comprises the following steps: performing a co-precipitation reaction on zinc chloride and butyl titanate with a weak acid; after the co-precipitation reaction is completed, putting ammonium hydroxide into the reaction system provided by the step 1, implementing neutralization, filtring, and drying so as to obtain a precursor; performing high-temperature sintering on the precursor, thereby obtaining the n-zinc titanate powder. By adopting the preparation method of the n-zinc titanate powder provided by the embodiment of the invention, butyl titanate is adopted as a titanium source, n-zinc titanate powderwhich is relatively high in purity and small in particle size is prepared, and the powder is relatively low in sunshine absorption rate and good in space environment stability when being used as thermal control packing, and a thermal control coating prepared from the powder is relatively high in hardness and relatively good in stain resistance.

Owner:BEIJING SATELLITE MFG FACTORY

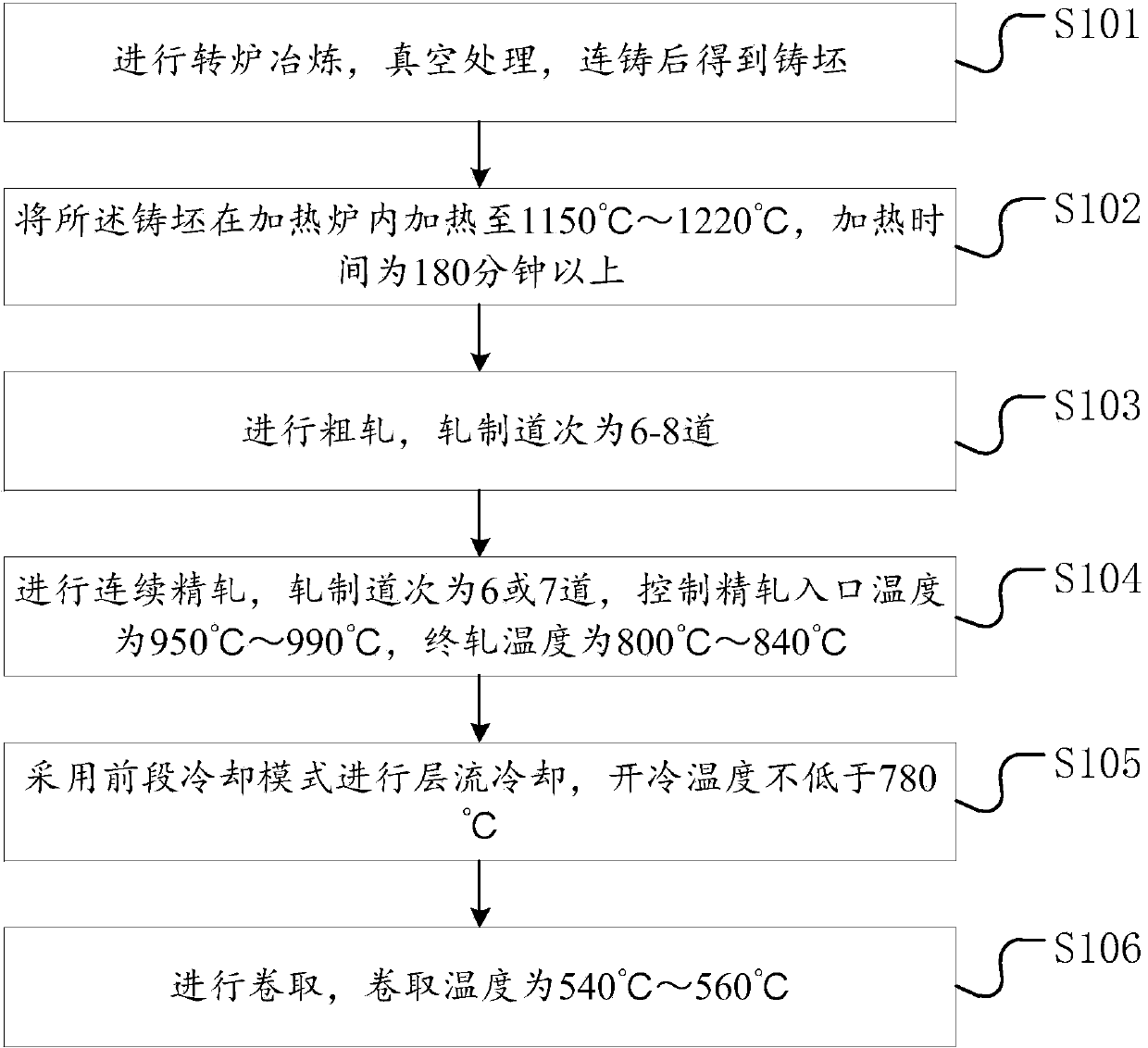

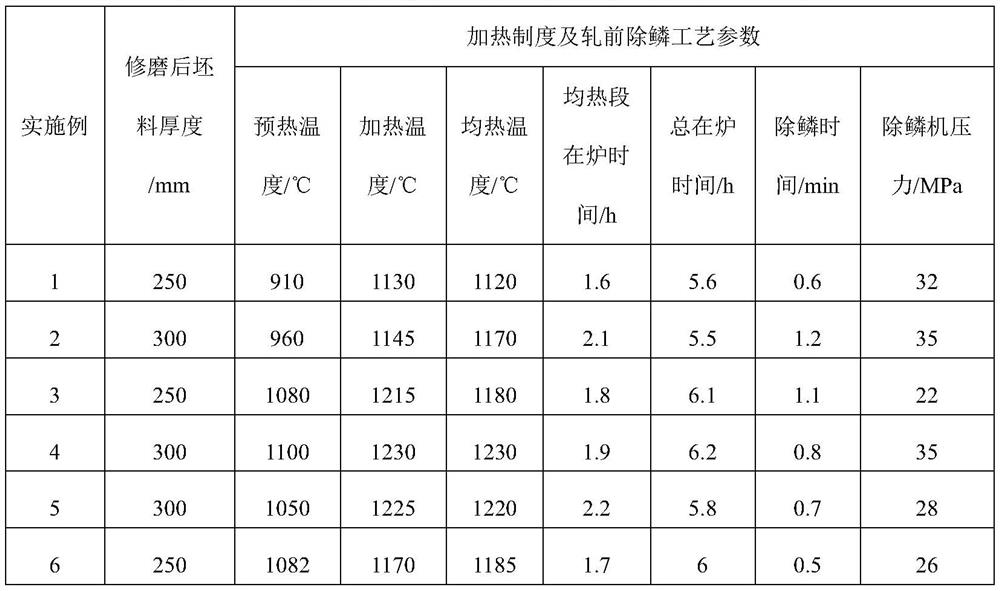

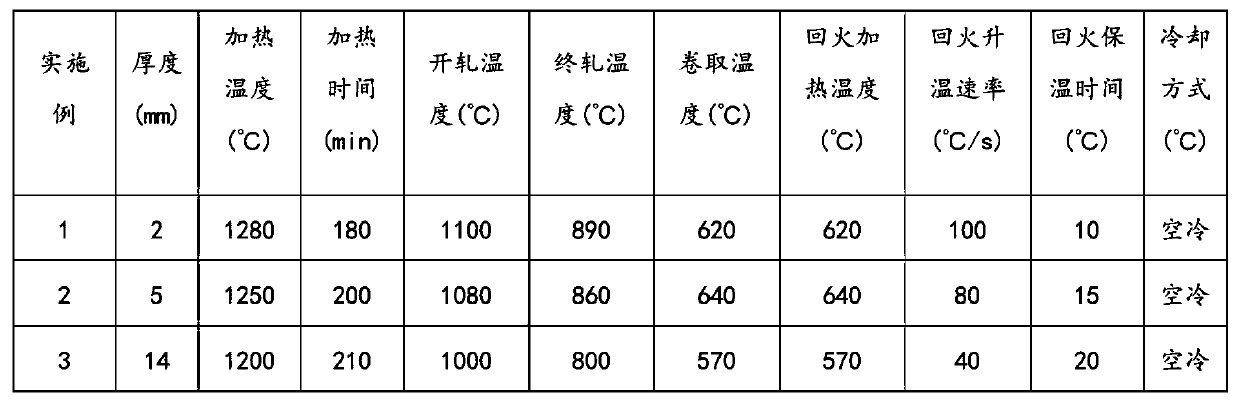

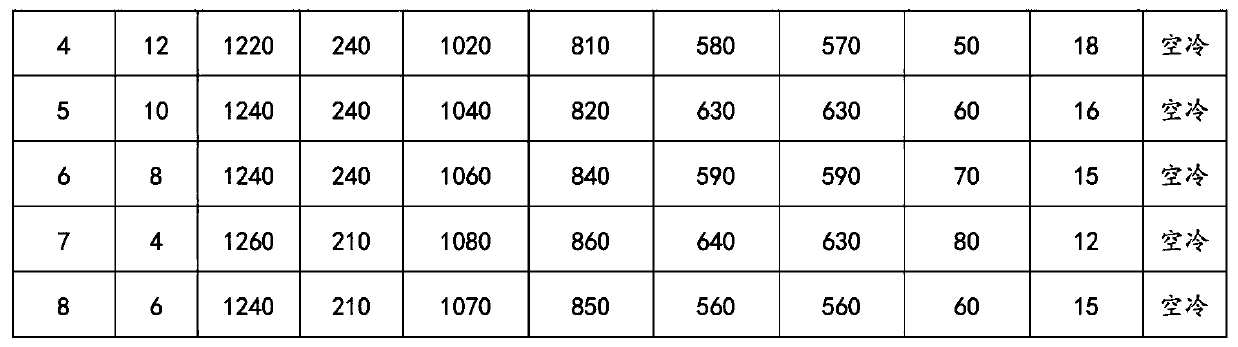

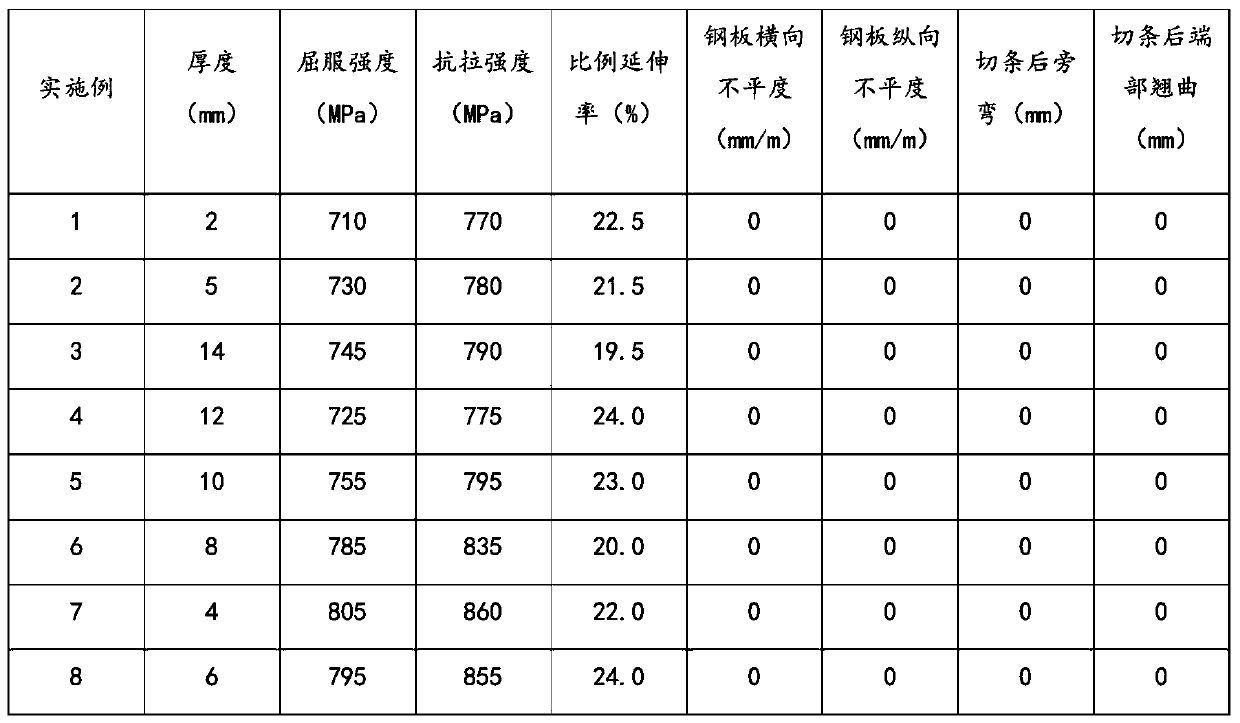

Preparation method of low-alloy high-strength steel plate with low residual stress

InactiveCN110257612AGuaranteed precipitationNo damage to mechanical propertiesProcess efficiency improvementSheet steelChemical composition

The invention relates to a preparation method of a low-alloy high-strength steel plate with low residual stress. The preparation method comprises the following steps: smelting; performing continuous casting; heating; performing rough rolling; performing refined rolling; performing laminar flow cooling; coiling; flattening; straightening; tempering; and performing cross cutting. In the heating step, the heating temperature is more than 1200 DEG C; in the refined rolling step, the final rolling temperature is 800 DEG C to 900 DEG C; in the coiling step, the rolling temperature is 550 DEG C to 650 DEG C; and in the tempering step, the tempering temperature is 550 DEG C to 650 DEG C, and the tempering heat insulation time is 10 minutes to 20 minutes. The method is applied to the steel plate which is prepared from the following chemical components: 0.04 percent to 0.12 percent of C, 0.10 percent to 0.80 percent of Si, 1.3 percent to 2.1 percent of Mn, 0 percent to 0.06 percent of Nb, 0.0 to 0.6 percent of Mo, 0 percent to 0.10 percent of V, 0.02 percent to 0.20 percent of Ti, 0.01 percent to 0.06 percent of Al, less than or equal to 0.003 percent of B, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, less than or equal to 0.008 percent of N, and the balance of Fe and inevitable impurities.

Owner:SHOUGANG CORPORATION +1

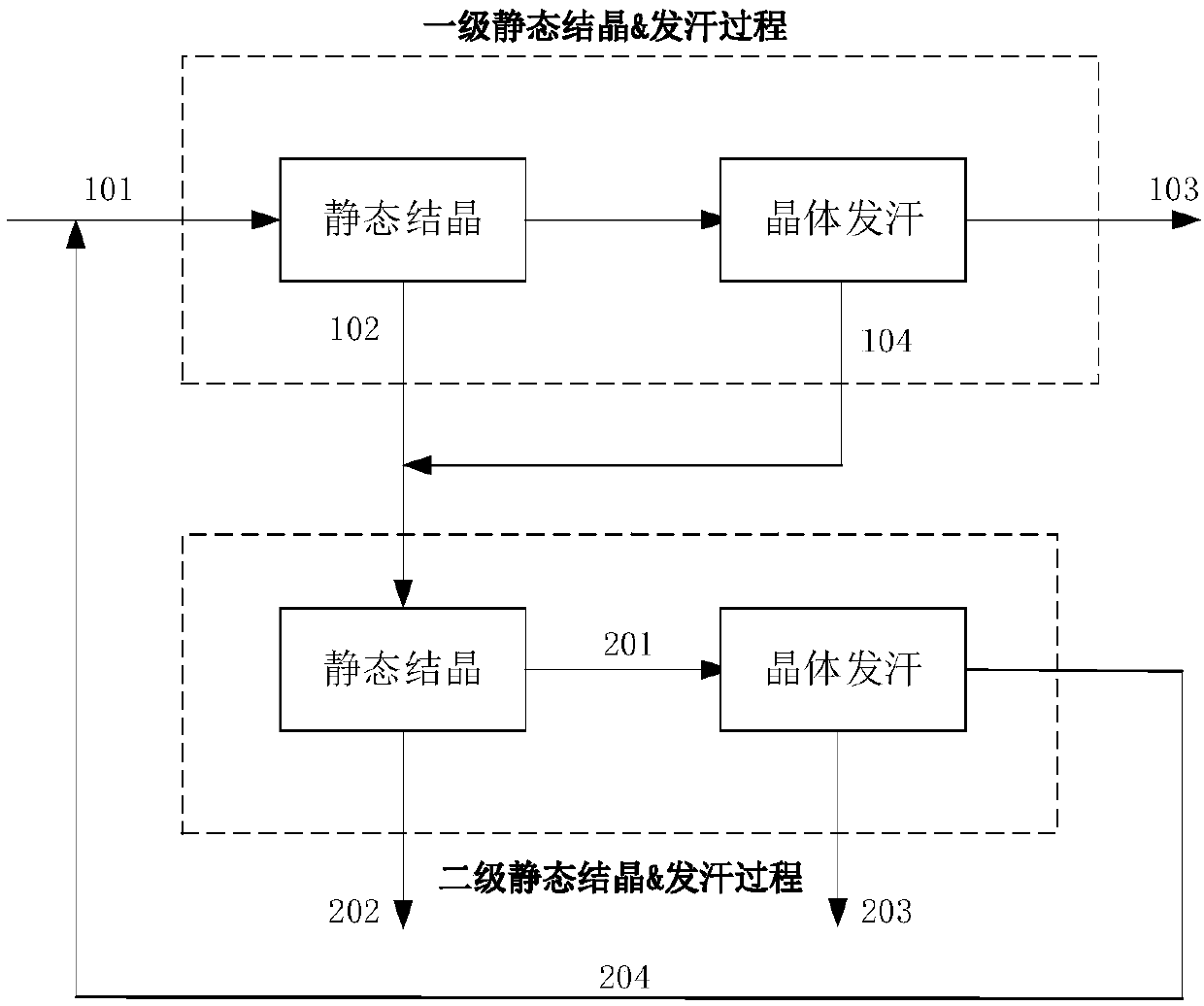

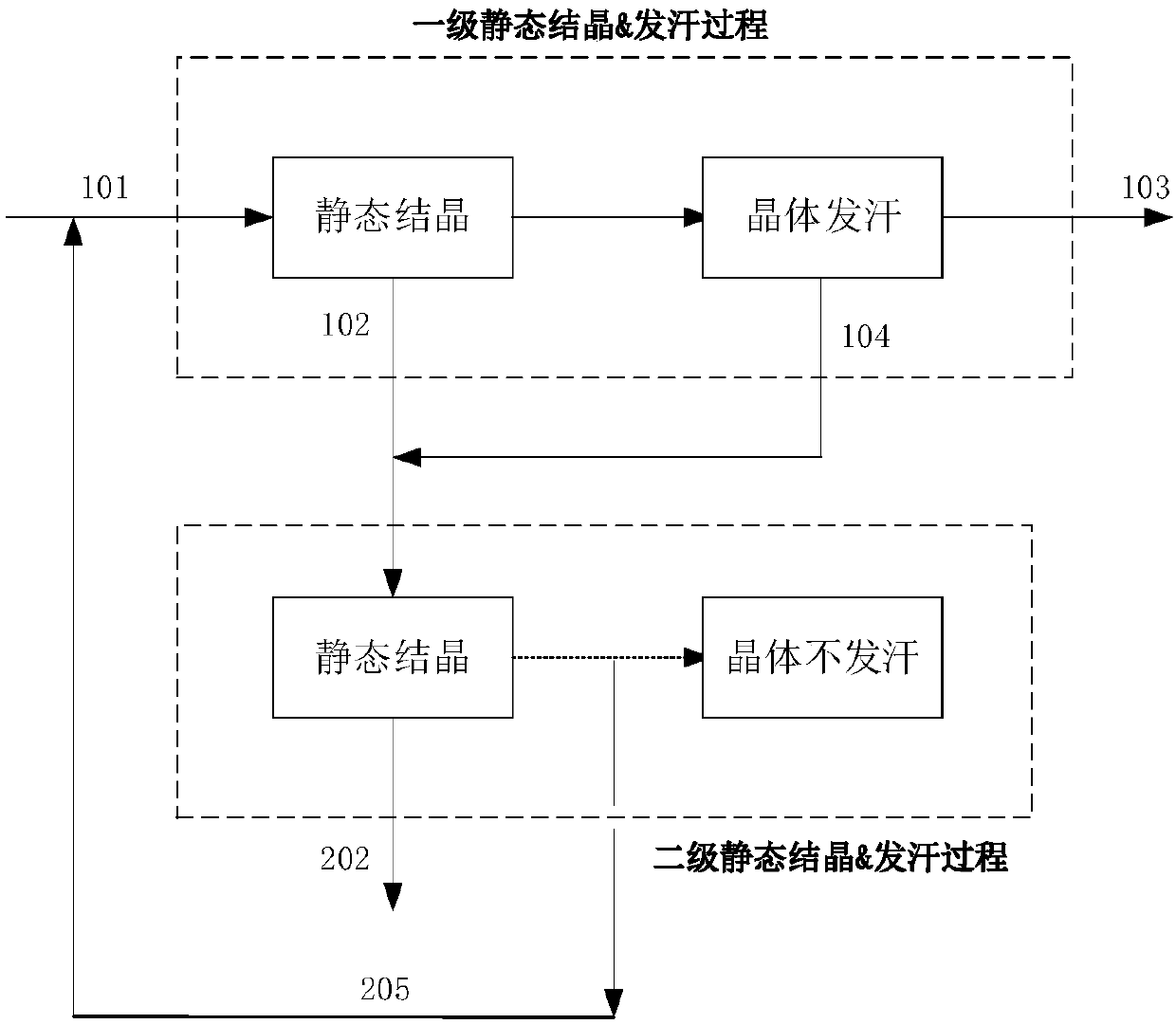

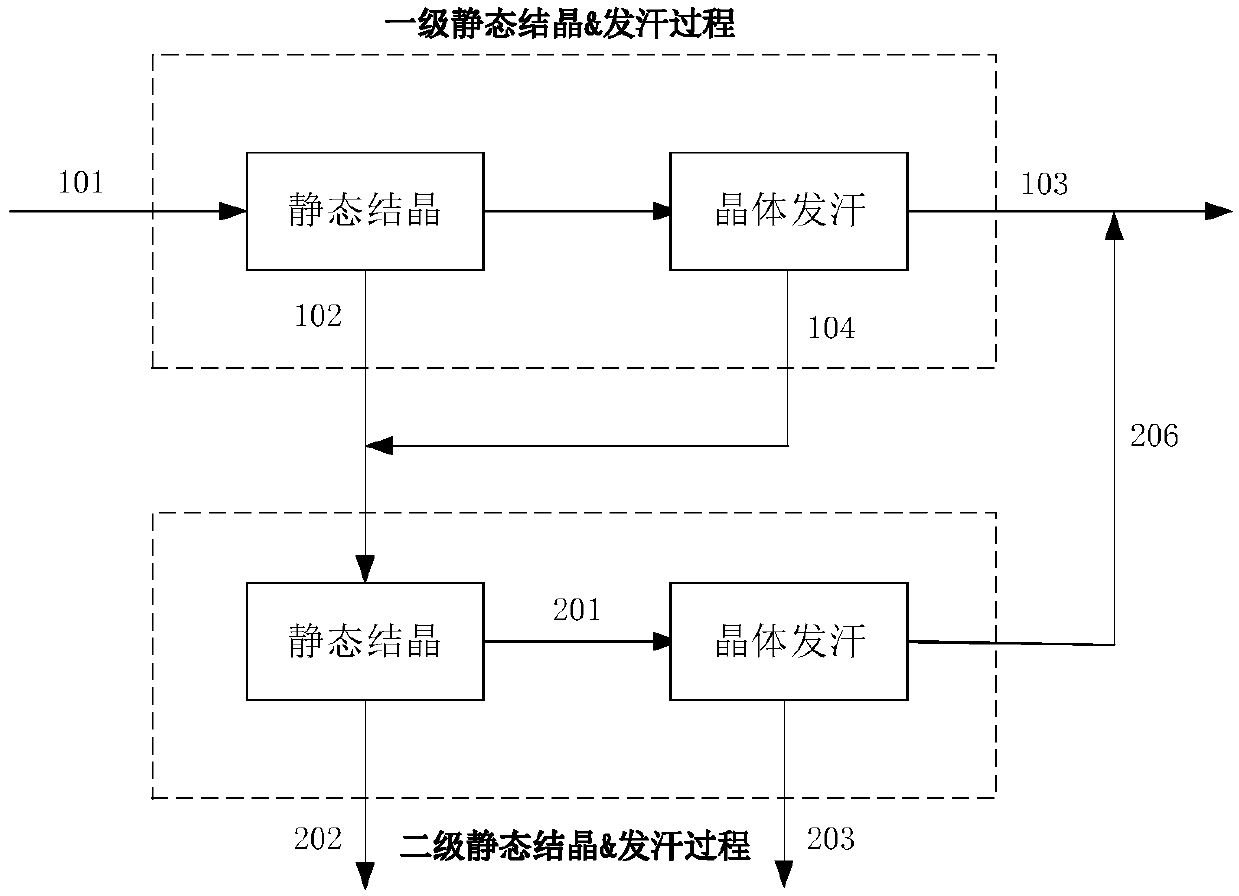

Crystallization and purification process of high-purity ethylene carbonate

ActiveCN111100003AReduce energy consumptionGentle processFinal product manufactureCarbonic/haloformic acid esters purification/separationHigh energyPhysical chemistry

The invention relates to a crystallization and purification process of high-purity ethylene carbonate, and mainly solves the technical problems of high energy consumption, low product purity, low yield and the like when ethylene carbonate is separated and purified in the prior art. According to the technical scheme, the method comprises the following steps: a raw material containing ethylene carbonate is introduced into a static crystallizer for primary static crystallization and sweating; and while a high-purity ethylene carbonate crystal product is obtained, an obtained crystallization mother liquor and a sweating sweat are continuously introduced into a static crystallizer with the same structure to carry out secondary static crystallization and sweating, so that the technical problemsare better solved, and the method can be applied to industrial production of ethylene carbonate, especially power battery grade ethylene carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A low-temperature, high-hardness, high-wear-resistant full-polish glaze and its preparation method

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC UNIV

Quality control method of ginkgolide medicinal preparation

ActiveCN101647830AStrong specificityGood reproducibilityComponent separationGinkgophyta medical ingredientsMedicineQuality control

The invention relates to a quality control method of medicinal preparation, in particular to a quality control method of ginkgolide medicinal preparation. The invention provides a method for controlling the quality of the ginkgolide medicinal preparation by adopting high performance liquid chromatography. The method can control the quality of the ginkgolide medicinal preparation by adopting one ormore of a content determination method, a limit test method of dissociation ginkgolide and a chromatographic fingerprint method. The quality control method provided by the invention has the advantages of having high precision, stability and repeatability, and achieving the aim of effectively controlling the quality of the ginkgolide medicinal preparation in an all-round way.

Owner:JIANGSU KANION PHARMA CO LTD

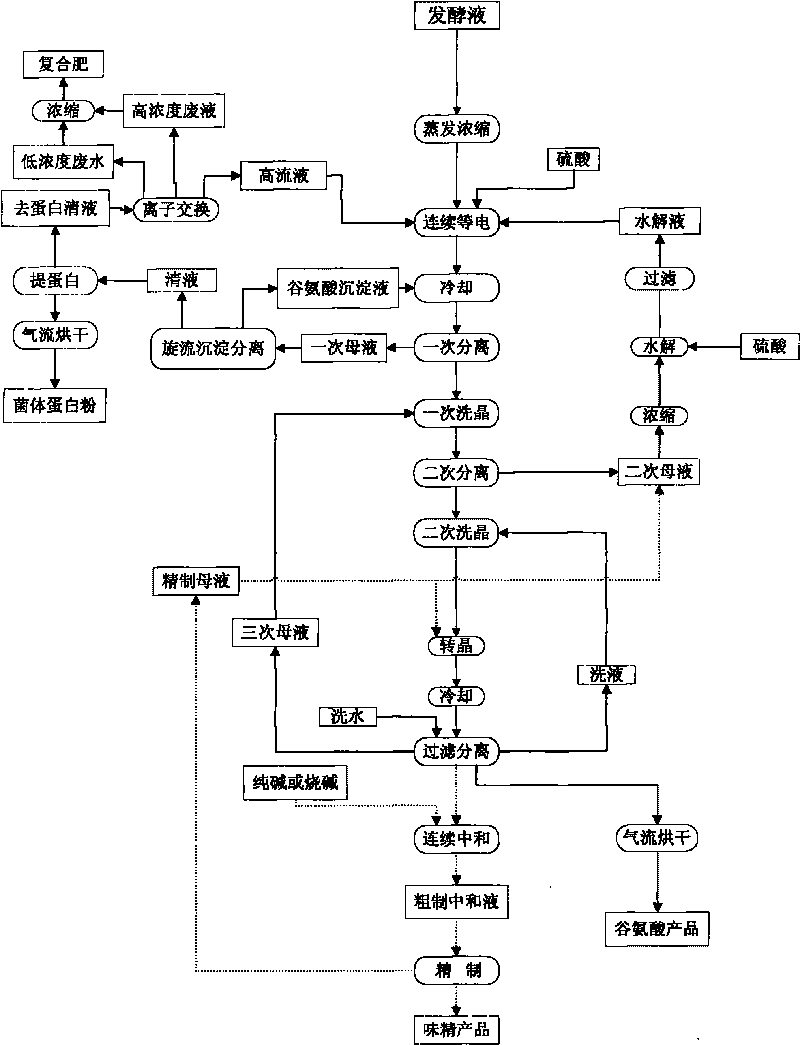

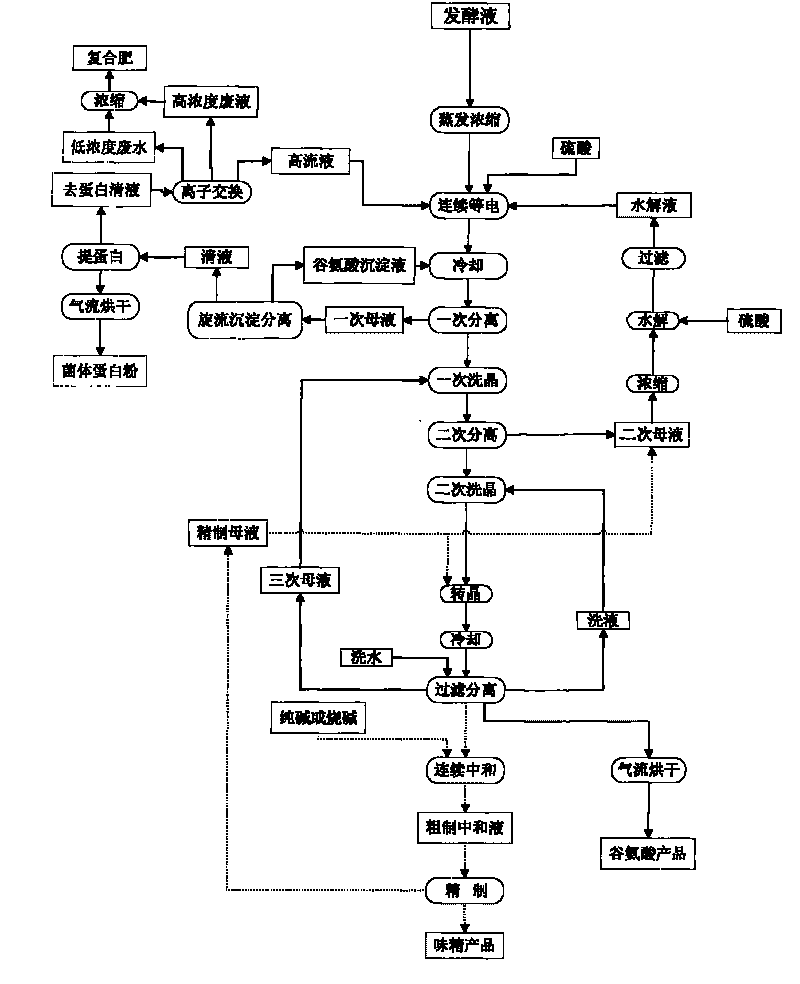

Production process of glutamic acid and monosodium glutamate

InactiveCN101735088AReduce dosageTemperature controlOrganic compound preparationAmino-carboxyl compound preparationMonosodium glutamateFiltration

The invention discloses a production process of glutamic acid and monosodium glutamate, which comprises the following steps: firstly, evaporating and concentrating fermentation liquid; after concentrated sulfuric acid is added for isoelectric operation, cooling to 5-15 DEG C; obtaining an alpha-crystalline glutamic acid crystal suspension after primary separation, primary crystal washing, secondary separation and secondary crystal washing; regulating the pH value to be 4.0-5.0 at 80-90 DEG C, cooling to 35 DEG C, and obtaining a beta-crystalline glutamic acid crystal through filtration and separation, wherein the beta-crystalline glutamic acid crystal can be dried by air flow to obtain glutamic acid products, and the beta-crystalline glutamic acid crystal can be continuously neutralized and refined to obtain monosodium glutamate products; carrying out cyclone precipitation on primary mother liquid after primary separation, removing protein in supernatant liquid by flocculation air flotation process, and drying the protein to obtain bacterial protein powder; and carrying out ion exchange on the deproteinized clear liquid to prepare compound fertilizer. The extraction method of the glutamic acid provided by the invention fundamentally reduces the generation of waste water, improves the extraction yield and the product quality, reduces the amount of water for exchanging ions and washing columns to the minimum, and has higher production efficiency and lower production cost.

Owner:BEIJING PIHUA BIOLOGICAL TECH

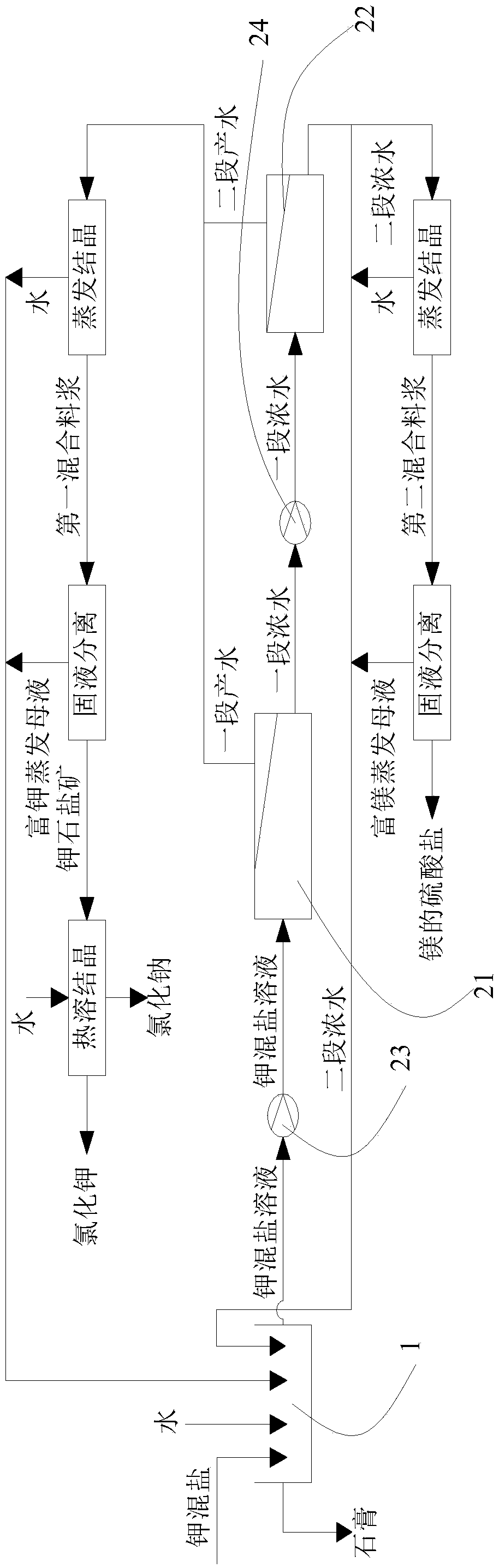

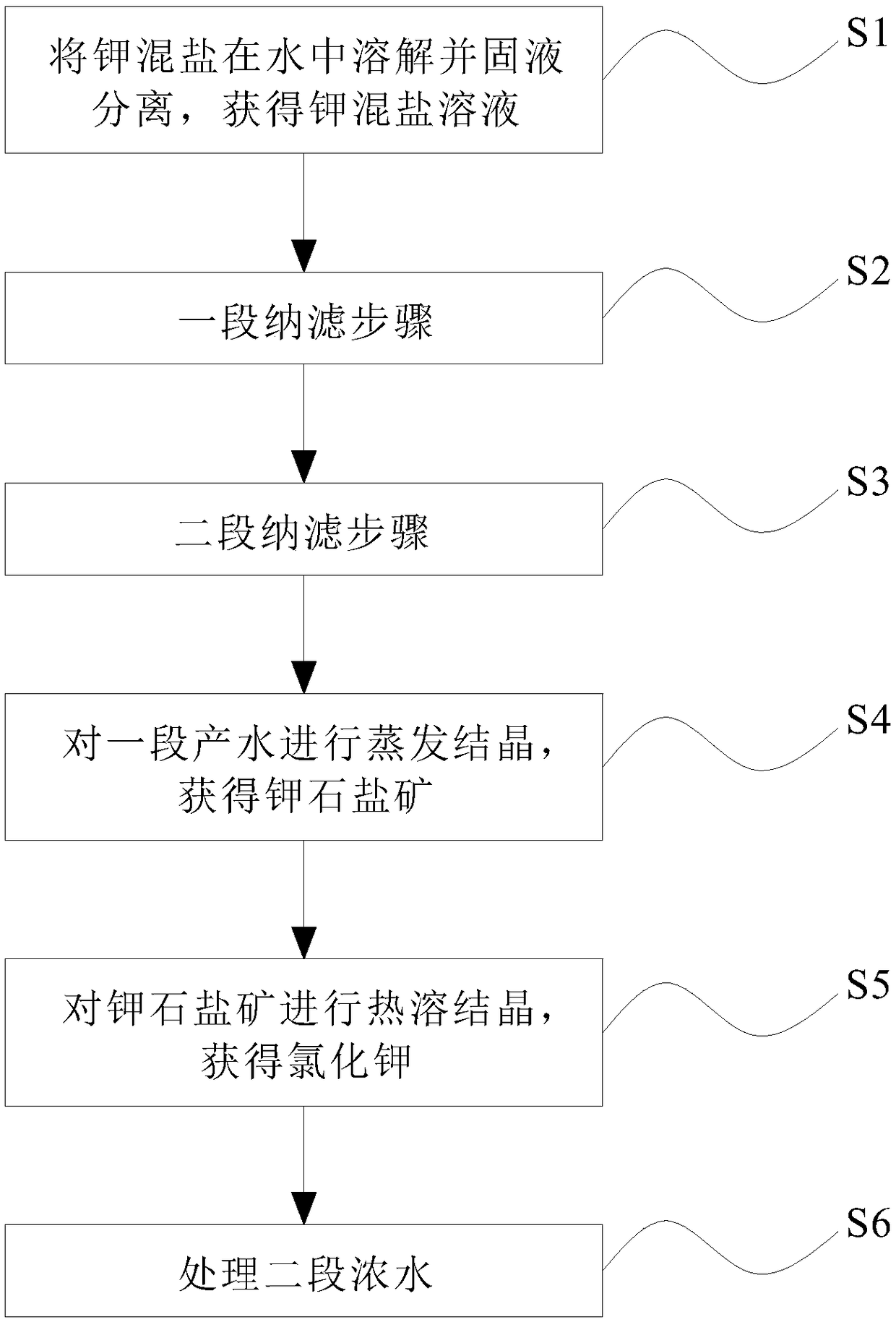

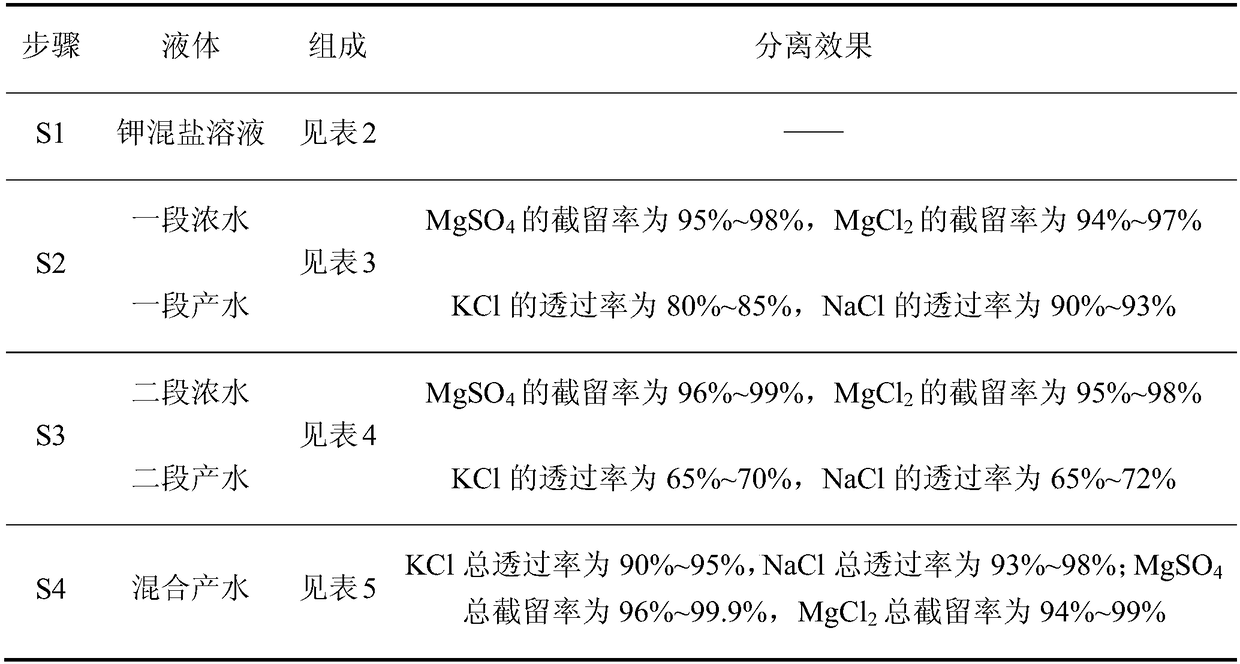

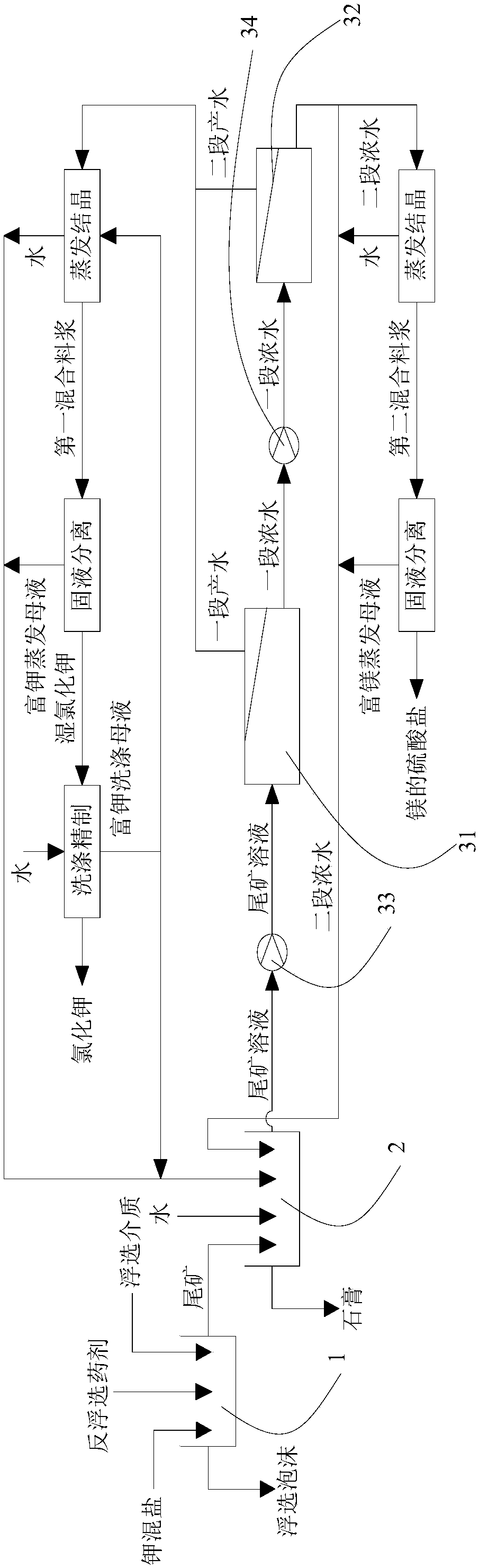

A kind of method utilizing potassium mixed salt to prepare potassium chloride

ActiveCN106517251BHigh purityLarge particlesAlkali metal chloridesAlkali metal halide purificationChloride potassiumChemistry

The invention discloses a method for preparing potassium chloride from potassium mixed salt. The method comprises the steps that the potassium mixed salt is dissolved in water, solid-liquid separation is carried out, and a potassium mixed salt solution is obtained; a first-section nanofiltration step is carried out, wherein a nanofiltration membrane system is adopted for carrying out first-section nanofiltration treatment on the potassium mixed salt solution, first-section concentrated water and first-section produced water are obtained, the nanofiltration system comprises a first nanofiltration membrane assembly, a first concentrated water box and a first produced water box, and the first concentrated water box and the first produced water box are connected to the first nanofiltration membrane assembly; the first-section concentrated water is stored in the first concentrated water box, and the first-section produced water is stored in the first produced water box; the first-section produced water is subjected to evaporative crystallization, and sylvinite ore is obtained; the sylvinite ore is subjected to flash melting crystallization, and potassium chloride is obtained. The novel method is used for producing potassium chloride from the potassium mixed salt and has the advantages of being simple in process, high in product purity, large in particle and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

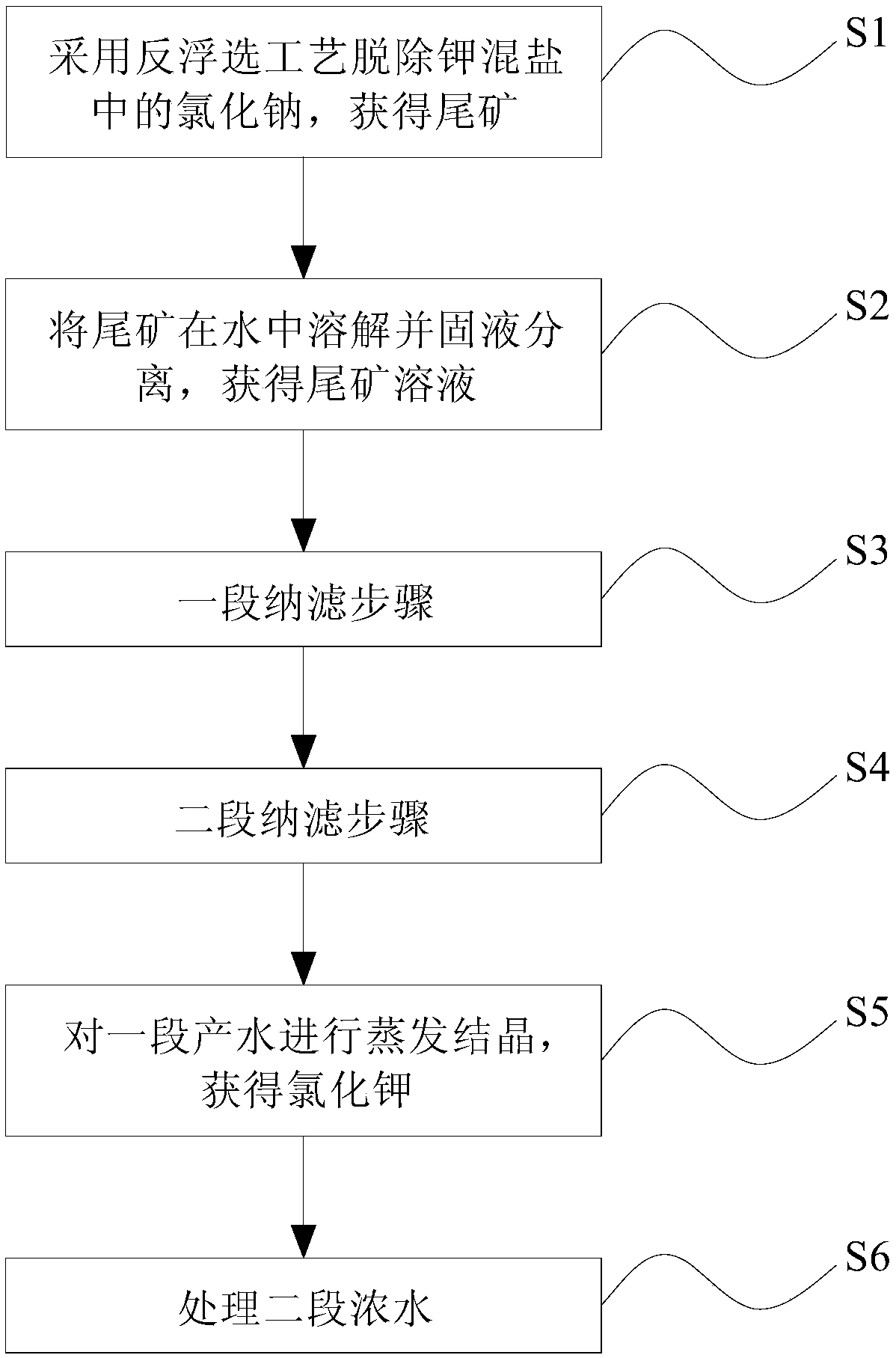

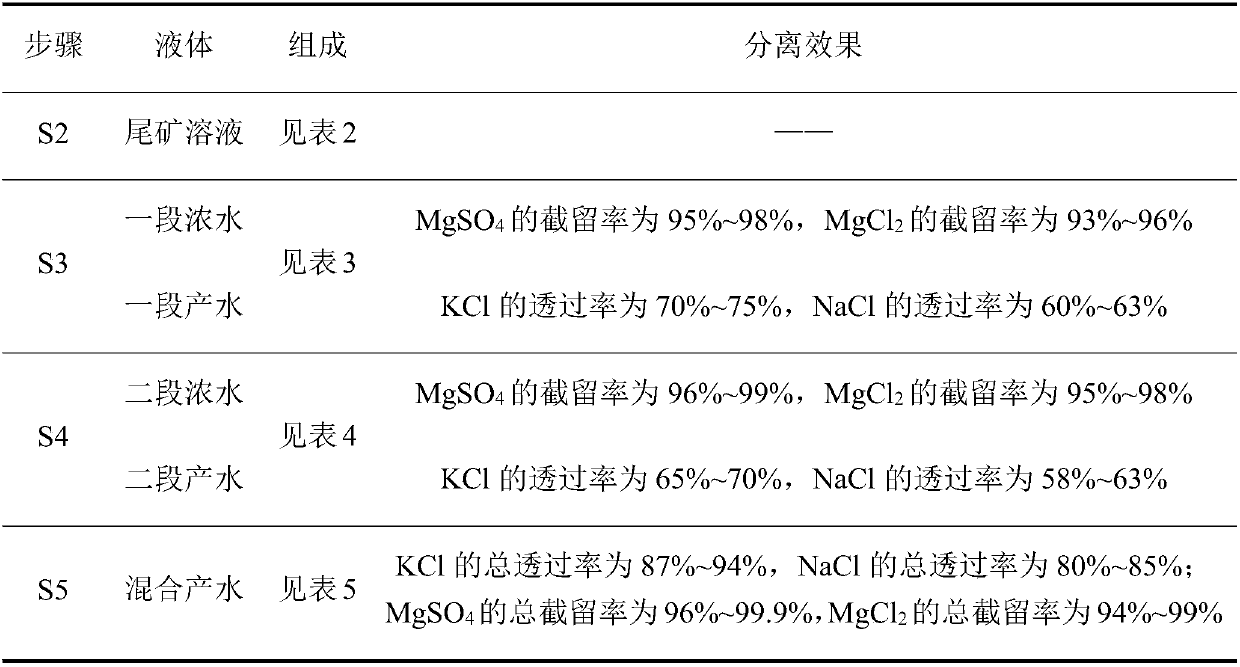

Utilize potassium mixed salt to prepare the method for potassium chloride

ActiveCN106430248BGuaranteed yieldEasy to separateReverse osmosisAlkali metal chloridesNanofiltrationMethods preparation

The invention discloses a method for preparing potassium chloride by utilizing potassium mixed salt. The method comprises the steps that a reverse flotation process is adopted to remove sodium chloride in the potassium mixed salt, and a tailing is obtained; the tailing is dissolved in water, and solid-liquid separation is performed to obtain a tailing solution; a section of nanofiltration step is executed, wherein a nanofiltration membrane system is adopted to conduct a section of nanofiltration treatment on the tailing solution to obtain a section of concentrated water and a section of produced water and comprises a first nanofiltration membrane module and a first concentrated water tank and a first produced water tank connected to the first nanofiltration membrane module, the section of concentrated water is stored in the first concentrated water tank, and the section of produced water is stored in the first produced water tank; evaporative crystallization is conducted on the section of produced water to obtain the potassium chloride. The invention provides a novel method for producing potassium chloride by using potassium mixed salt as a raw material. The method has the advantages of being simple in process, high in product purity and high in yield.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

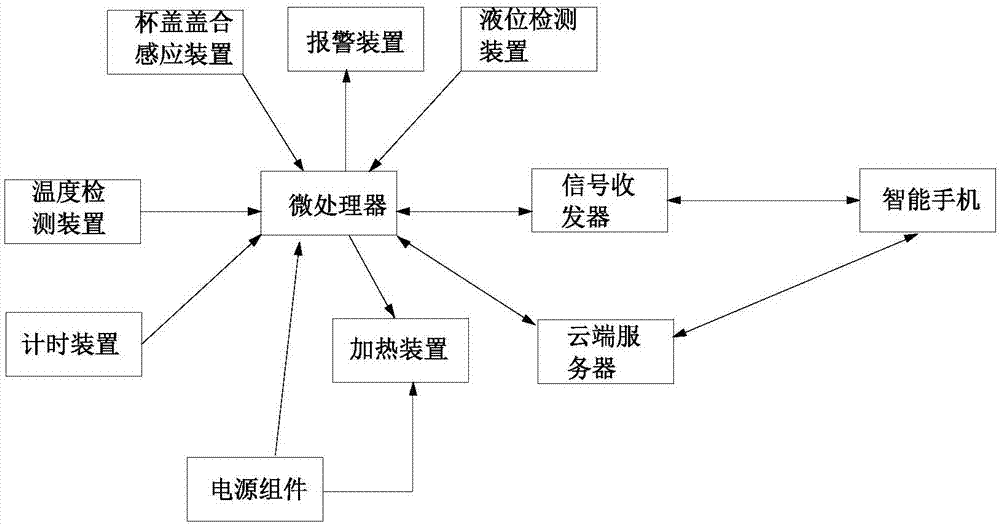

Tea leaf intelligent brewing system

The invention discloses a tea leaf intelligent brewing system. The tea leaf intelligent brewing system comprises a tea leaf brewing device, a cloud side server and a mobile terminal; the tea leaf brewing device comprises a cup body and a cup lid lidding the cup body, a heating device, a temperature detecting device, a cup lid lidding and sensing device, a timekeeping device, a signal transceiver,a microprocessor and a power source assembly are arranged inside the cup body, the microprocessor is connected with the heating device, the temperature detecting device, the cup lid lidding and sensing device, the timekeeping device and the signal transceiver, is connected with the mobile terminal through the signal transceiver, or is connected with the mobile terminal through the cloud side server; the power source assembly is used for providing a power source for the microprocessor and the heating device. By means of the tea leaf intelligent brewing system, the brewing proportion of tea leaves and water and the brewing temperature and time of the tea leaves can be set according to the varieties of the tea leaves, and it is guaranteed that nutrient components like tea polyphenol in the tea leaves of different varieties can be separated out as much as possible to be utilized.

Owner:上海英仲办公家具有限公司

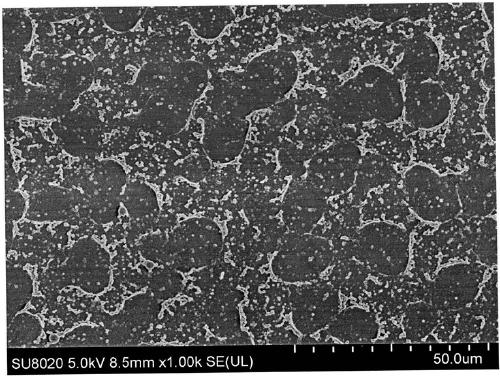

Polymer dispersed liquid crystal material and manufacturing method thereof

ActiveCN109423299AGuaranteed precipitationSufficient precipitationLiquid crystal compositionsNon-linear opticsHandwritingPolymer science

The invention provides a polymer dispersed liquid crystal material and a manufacturing method thereof. The material comprises the following components by weight: 40 to 85% of cholesteric phase liquidcrystal, 7% to 59.75% of a photocuring monomer, 0.05 to 1% of a photoinitiator, 0.05 to 1% of a spacer, 0.1 to 5% of a solvent and 0.05 to 1% of a coupling agent. The invention also discloses the manufacturing method for the material. The polymer dispersed liquid crystal material provided by the invention has the following advantages: the polymer dispersed liquid crystal material can sense pressure to generate handwriting, so the function of handwriting is realized; the handwriting is maintained without the need of continuous power supply, and can be removed by applying of an electric field; and the polymer dispersed liquid crystal material has the characteristics of high brightness, high contrast, moderate handwriting thickness and the like, can be used as a handwriting film, is applied to the industry of liquid crystal handwriting plates, and has huge application space in the fields of writing, painting, teaching, etc.

Owner:SHENZHEN POLICRAL TECH CO LTD

Pabular health tea electuary for preventing osteoporosis

The invention discloses a pabular health tea electuary for preventing osteoporosis, which belongs to the field of nutritious foods and has good effect and rapid effect. The pabular health tea electuary is made from the raw materials such as astragalus mongholicus, fruit of Chinese wolfberry, barley grass, whey calcium, mycose and the like, has the functions of supporting body resistance, reinforcing qi, nourishing blood, nourishing yin and strengthening bone, and has the advantages of good effect and rapid effect.

Owner:BEIJING LVYUAN QIUZHENG SCI & TECH DEV

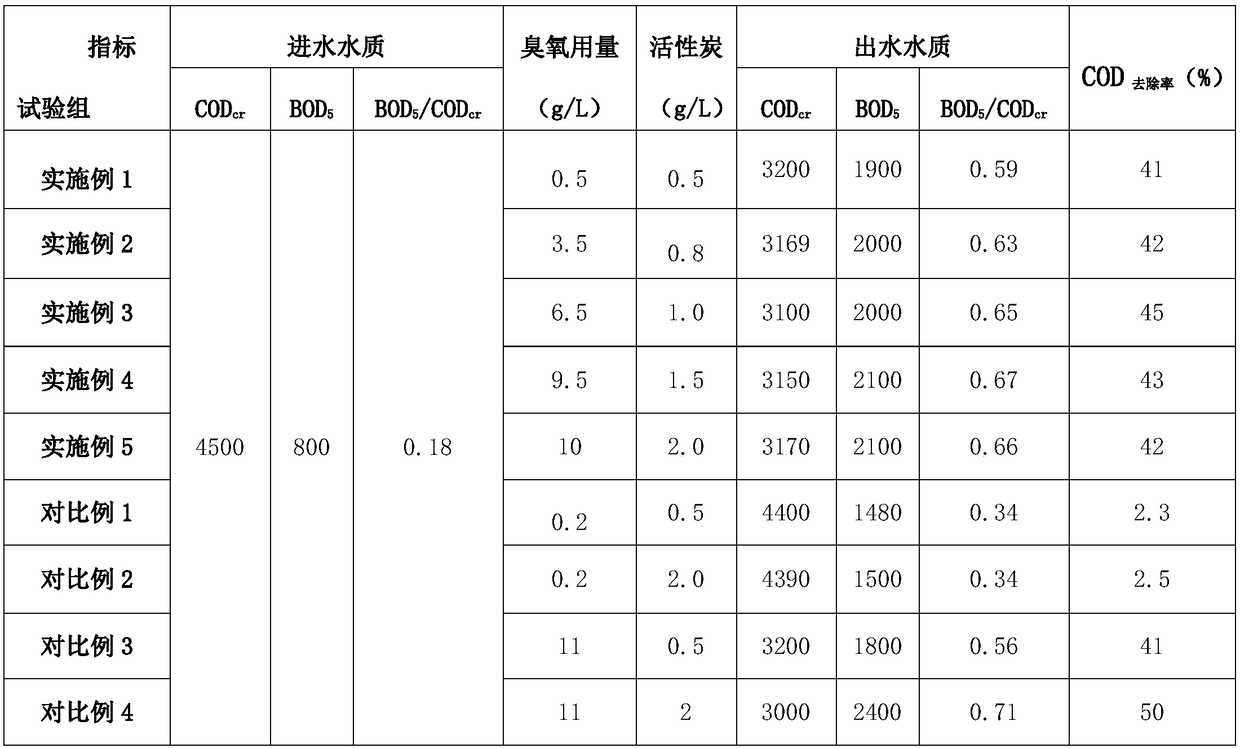

Combined treatment process of synthesis pharmaceutical wastewater

ActiveCN109052783AHigh clarityPhotocatalytic oxidation with high efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationSludgeCatalytic oxidation

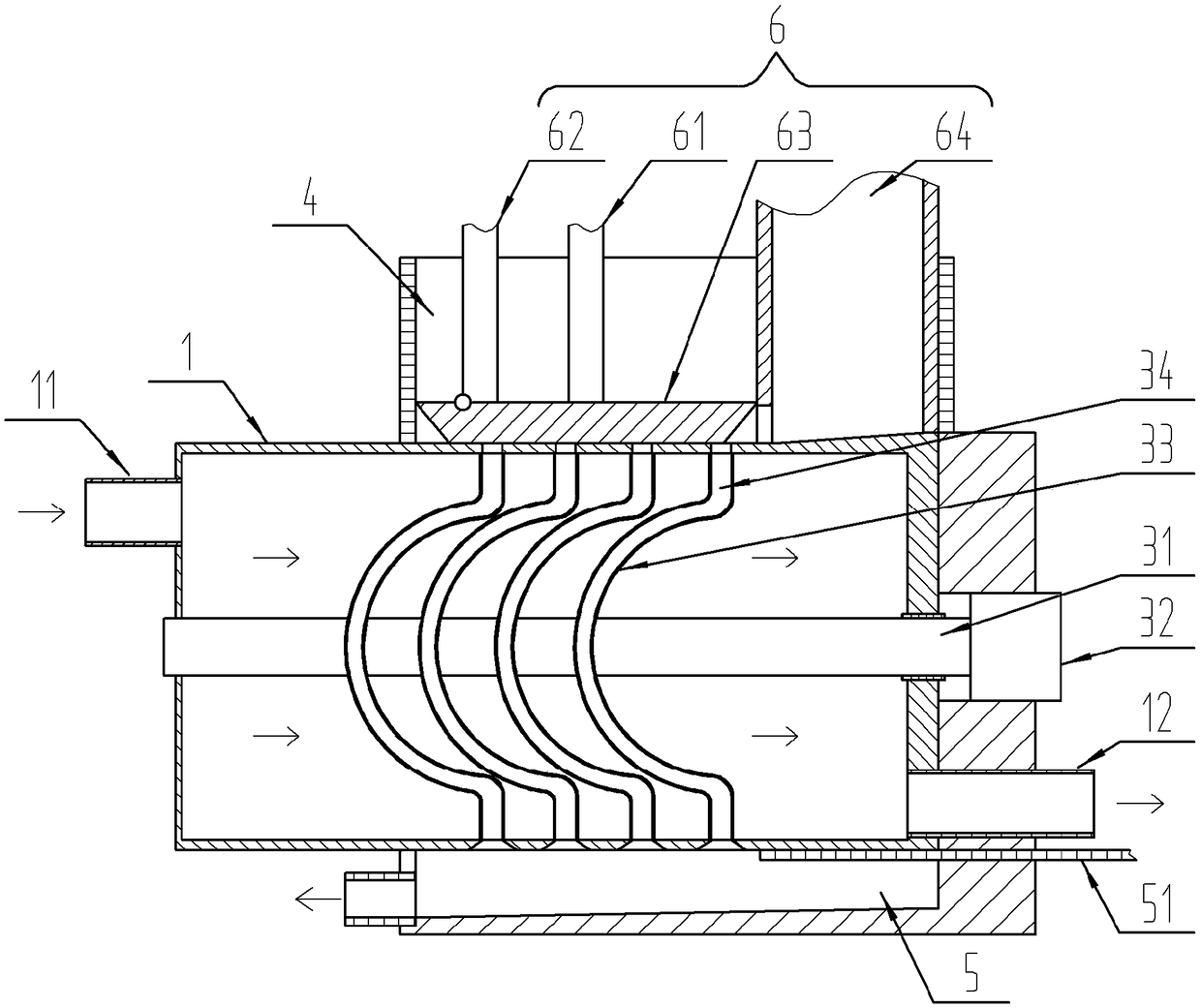

The invention belongs to the technical field of treatment of water, wastewater, sewage, or sludge and particularly discloses a combined treatment process of synthesis pharmaceutical wastewater. The treatment process comprises a pretreatment step and a biochemical treatment step. The pretreatment step comprises the steps that (1) suspended matter is removed through a filter device; (2) the wastewater obtained in the step (1) is recrystallized, and in the cooling process of recrystallization, activated carbon is put into the wastewater; and (3) the wastewater treated in the step (2) is subjectedto ultraviolet radiation and ozone oxidation, wherein the wave length of ultraviolet radiation is 180-200 nm, and the ozone dosage is 0.5-10 g / L. The combined treatment process of the synthesis pharmaceutical wastewater has the better photocatalytic oxidation effect, the biodegradability of the wastewater treated by the pretreatment step is improved, and after treatment, generation of a large amount of the suspended matter is avoided.

Owner:CHONGQING TECH & BUSINESS UNIV

A kind of 610mpa high-strength steel plate for oil reserve tank with low yield ratio and its manufacturing method

The invention belongs to the field of low alloy steel production processes, and specifically relates to a 610Mpa high-strength steel plate for a low-yield-ratio petroleum reserve tank and a manufacturing method thereof. The 610Mpa high-strength steel plate for the low-yield-ratio petroleum reserve tank comprises the following components in percentage by mass: 0.07-0.13% of C, 0.15-0.35% of Si, 1.45-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, less than 0.030% of Nb, 0.03-0.05% of V, 0.010-0.020% of Ti, 0.08-0.18% of Mo, 0.15-0.35% of Ni, less than 0.008% of N and the balance of Fe and inevitable impurities. The method is capable of overcoming the limitation that the yield ratio is difficult to reduce in the traditional production and manufacturing method, simplifying the production process, shortening the production flow and reducing energy consumption, suitable for industrial batch production, and capable of ensuring a low yield ratio while meeting the requirements of strength, toughness and welding performance indexes.

Owner:SHANDONG IRON & STEEL CO LTD

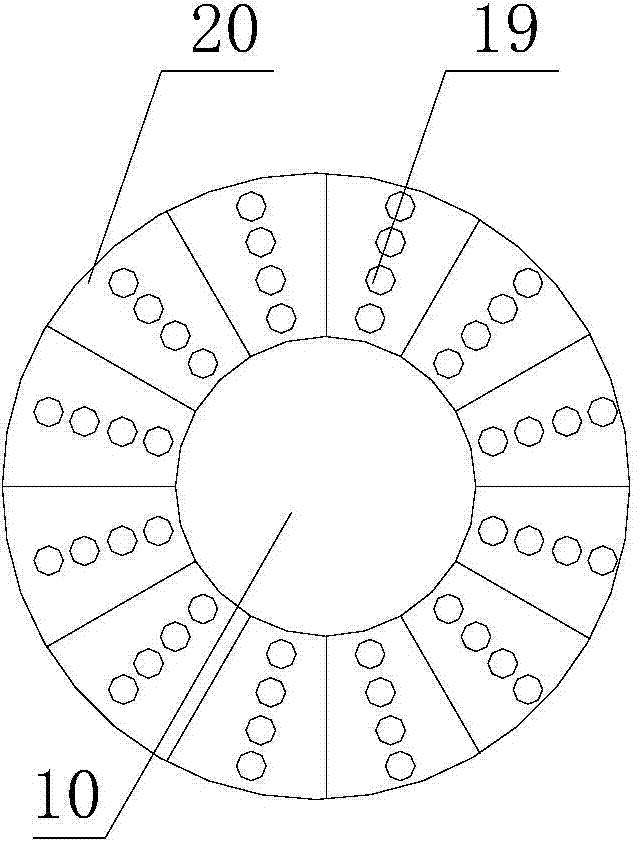

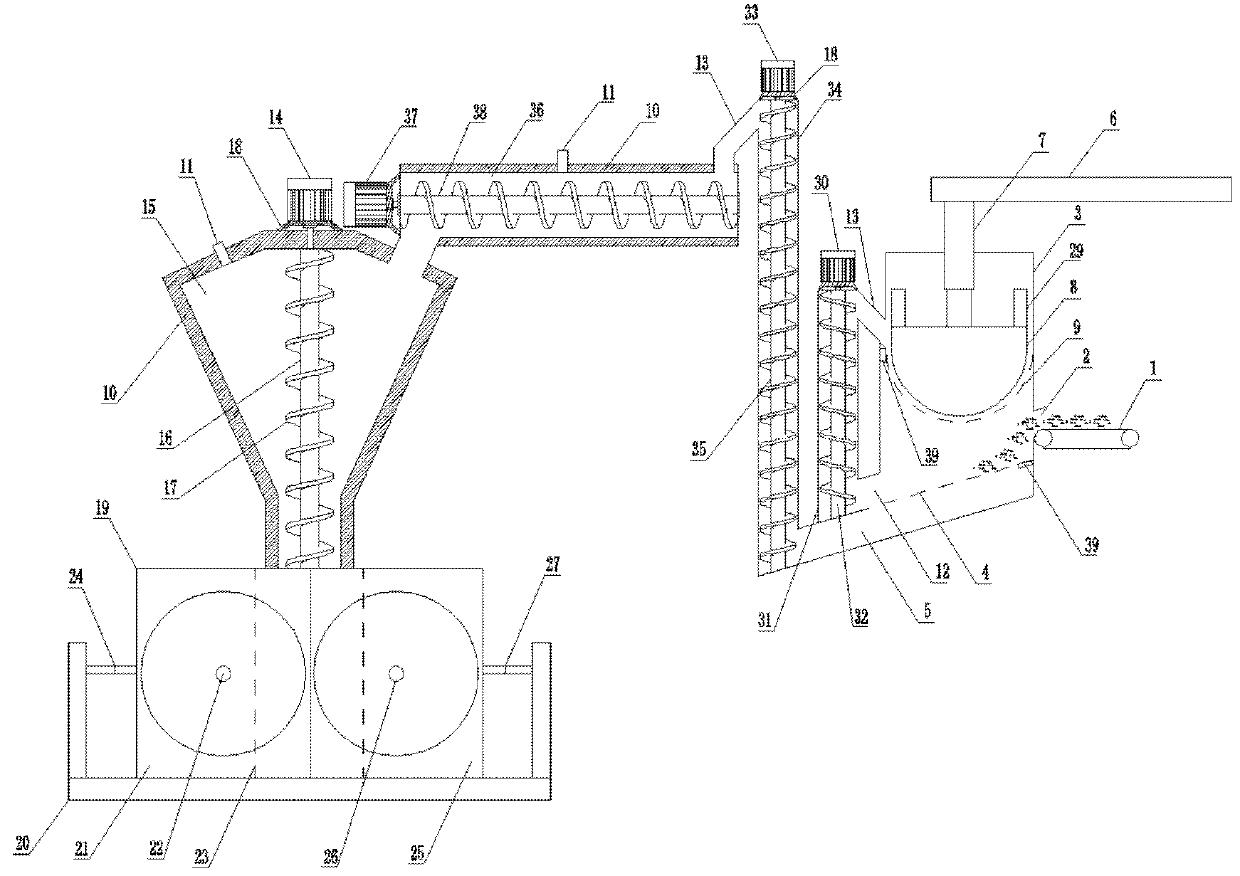

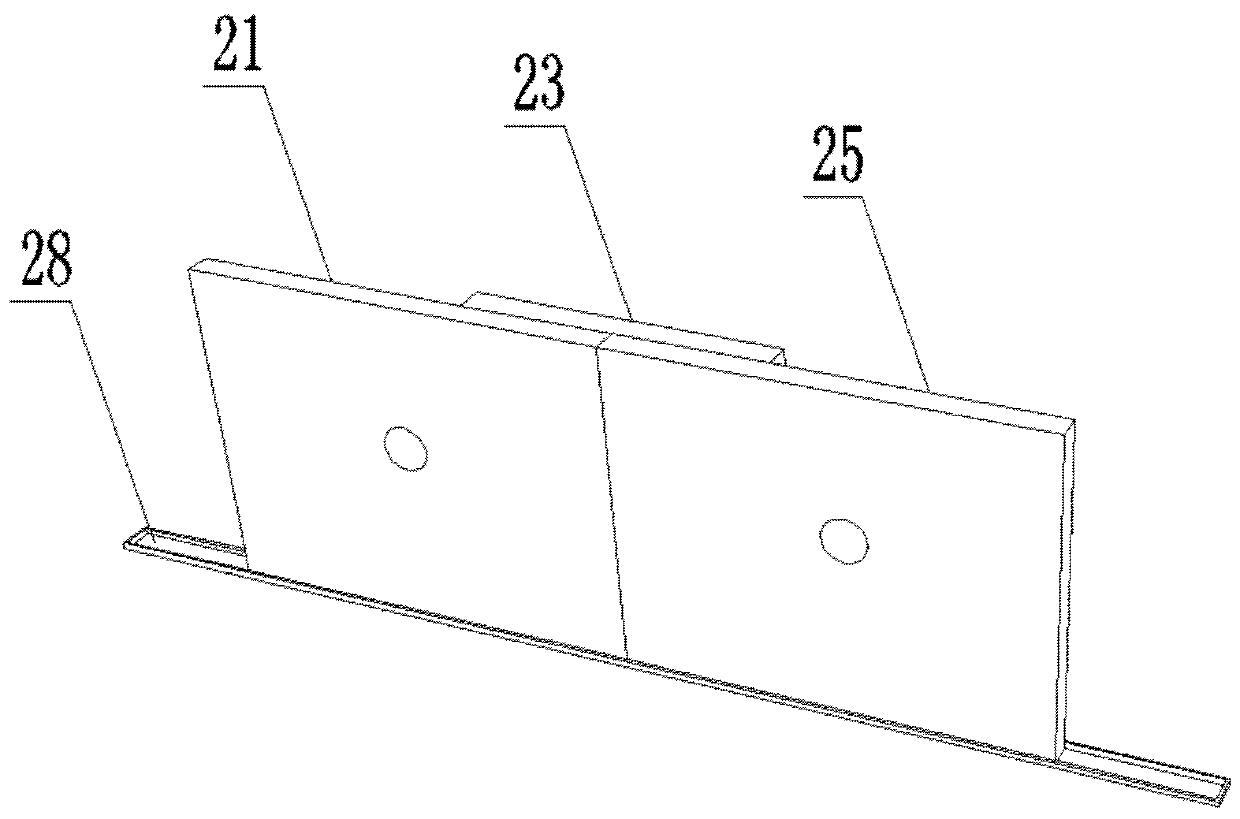

Novel pulverized coal high-pressure forming device

PendingCN110065256AGuaranteed precipitationCompact and reasonable structureGrain treatmentsRotary pressCoal briquetteEngineering

The invention relates to the technical field of a pulverized coal forming device, and discloses a novel pulverized coal high-pressure forming device. The novel pulverized coal high-pressure forming device comprises a first conveying device, a screening box with a feeding port at the lower portion of the right side, a first screen mesh, a conveying channel, a first lifting device, a second liftingdevice, a supporting plate, a pulverizing hydraulic rod, a pulverizing hammer, a second screen mesh, a second conveying device, a screw pressing device, an electric heating layer, a steam exhaust portand a molding device; pulverized coal is screened and smashed through the screening device, when the size of a molded product needs to be changed, a left adjusting hydraulic rod and a right adjustinghydraulic rod are adjusted to move a left adjusting plate and a right adjusting plate in the same or opposite direction, and extrusion molding products in different sizes are achieved; and the novelpulverized coal high-pressure forming device solves the problem that according to an existing pulverized coal forming device, the pulverized coal contains irregular pulverized coal particles or large-volume pulverized coal briquettes, consequently the compactness of the pulverized coal products is insufficient, the strength is not high, and diversified production of the pulverized coal forming products cannot be achieved.

Owner:XINJIANG JIEJING ENERGY TECH RES INST

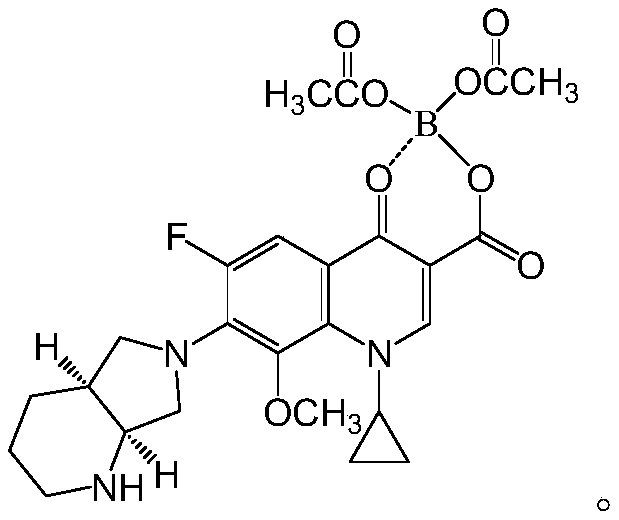

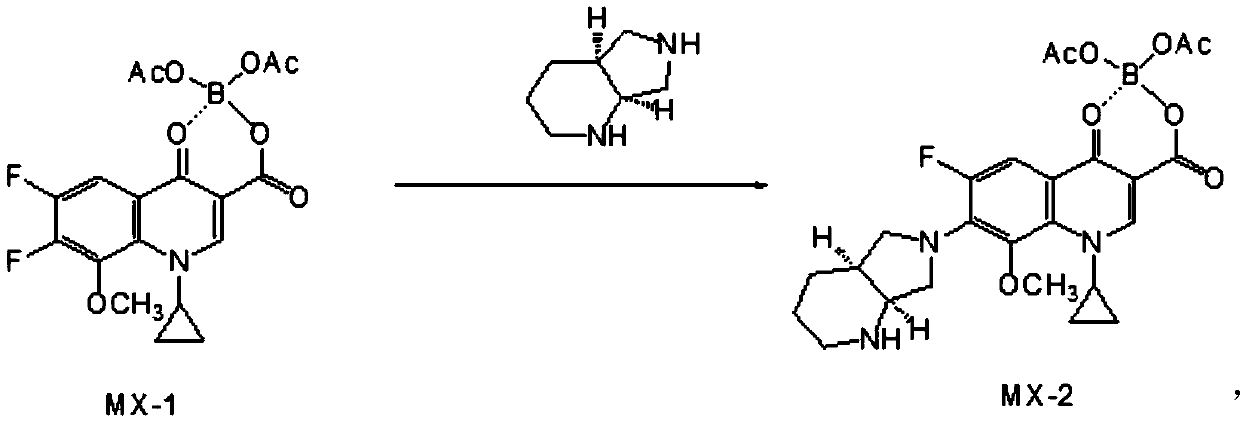

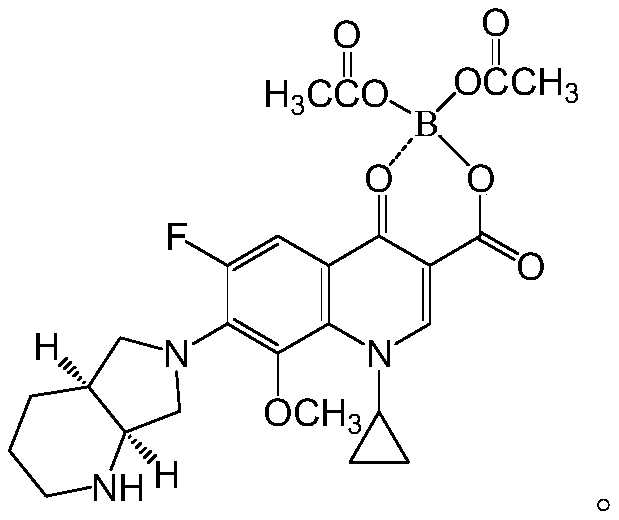

Preparation process of moxifloxacin

The invention relates to the technical field of pharmaceutical engineering, specifically to a preparation process of moxifloxacin. The preparation process comprises the following steps: carrying out ahydrolysis reaction on a moxifloxacin chelate which is chelated with borate so as to form a crude moxifloxacin product containing boric acid; subjecting polyol and the crude moxifloxacin product containing boric acid to a chelation reaction; and then adding a poor solvent for crystallization. The preparation process of the invention can effectively remove elemental boron in the crude moxifloxacinproduct, and the yield and the purity of prepared moxifloxacin are excellent.

Owner:HARBIN ZHENBAO PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com